Preparation method of TiO2/SnO2 semiconductor two-layer composite film photo anode

A double-layer composite and semiconductor technology, which is applied in coating, metal material coating technology, ion implantation plating, etc., can solve the problems of inability to effectively exert the metal photogenerated cathodic protection effect, unstable film bonding, and low photoelectric efficiency of the film, etc. problem, to achieve the effect of improving photogenerated cathodic protection effect, novel method and uniform film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

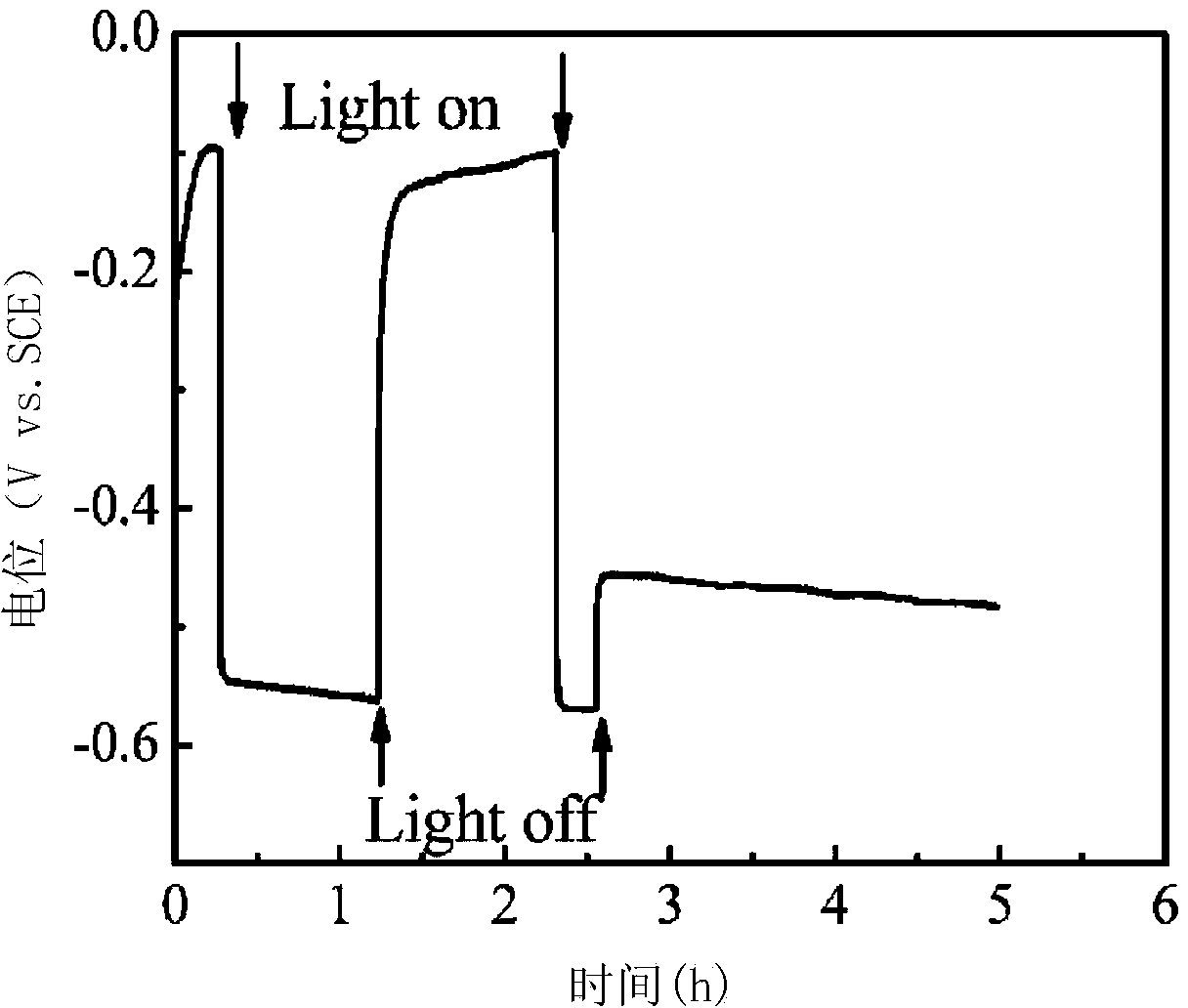

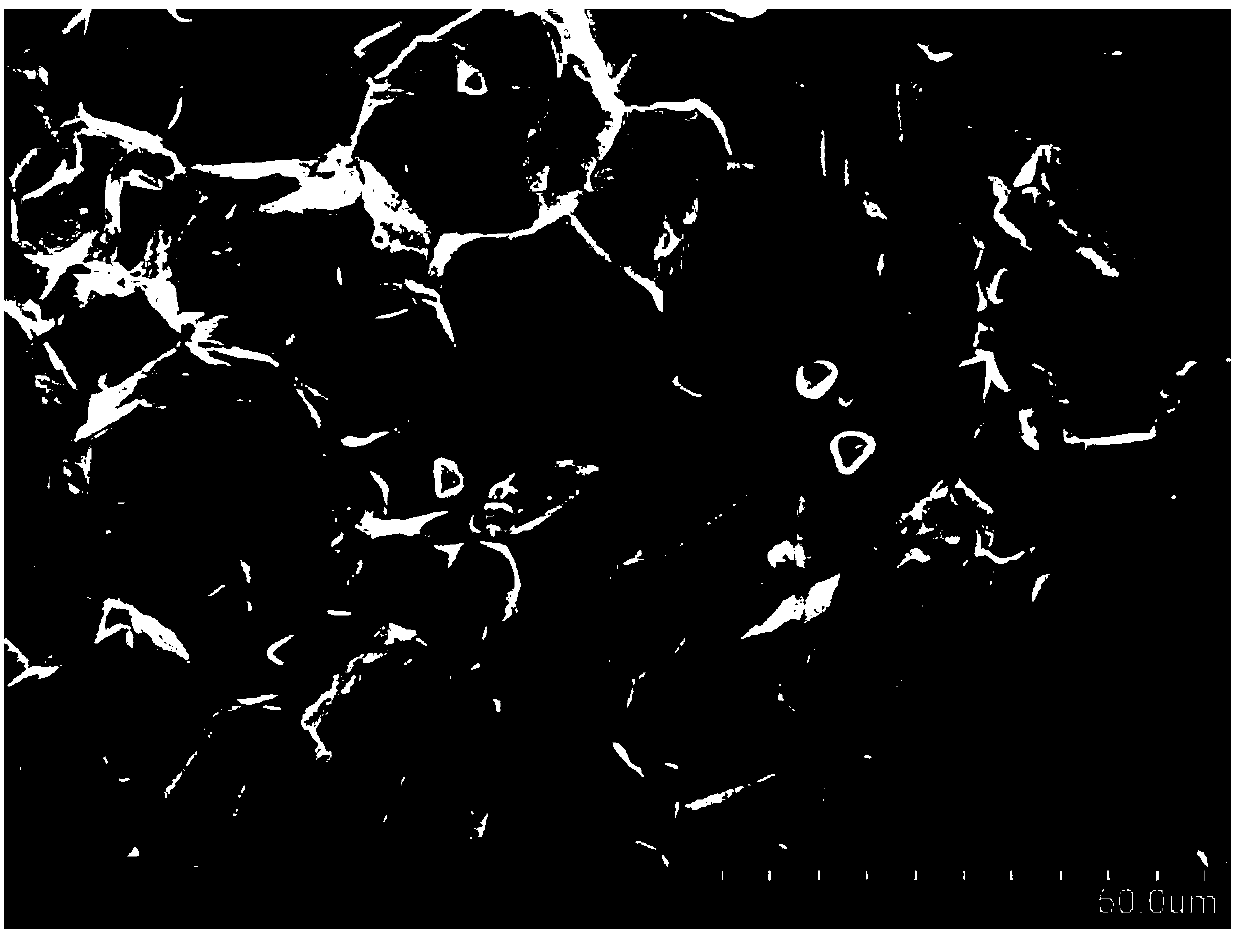

[0039] According to the above technical scheme, nano-TiO was prepared on the surface of 304 stainless steel 2 / SnO 2 Semiconductor double-layer composite film, and test the photogenerated cathodic protection effect of the film as a photoanode on 304 stainless steel.

[0040] A rectangular 304 stainless steel with a thickness of 0.2 mm is used as a sample, which is 1.5 cm long and 1.0 cm wide. The surface of the sample was polished with 800-1500 water-grinding paper and Al 2 o 3 After the polishing powder is polished, it is ultrasonically cleaned in acetone, absolute ethanol and deionized water for 10 min respectively.

[0041] Weigh 4.152g SnCl 2 2H 2 O, add 400mL ion water, dissolve and then add 4.248g NaNO 3 and 30 mL of concentrated HNO 3 Solution, after stirring, add deionized water to make the volume to 1000mL. That is to prepare a certain concentration of electrodeposition solution for use. Use DJS-292C potentiostat at room temperature, use platinum as auxiliary...

Embodiment 2

[0046] According to the above technical scheme, nano-TiO was prepared on the surface of 304 stainless steel 2 / SnO 2 Semiconductor double-layer composite film, and test the photogenerated cathodic protection effect of the film as a photoanode on 304 stainless steel.

[0047] A rectangular 304 stainless steel with a thickness of 0.2 mm is used as a sample, which is 1.5 cm long and 1.0 cm wide. After the surface of the sample was polished by No. 800-1500 water abrasive paper, it was ultrasonically cleaned in acetone, absolute ethanol and deionized water for 10 minutes respectively.

[0048] Weigh 4.152g SnCl 2 2H 2 O, add 400mL ion water, dissolve and then add 4.248g NaNO 3 and 30 mL of concentrated HNO 3 Solution, after stirring, add deionized water to make the volume to 1000mL. That is to prepare a certain concentration of electrodeposition solution for use. Use DJS-292C potentiostat at room temperature, use platinum as auxiliary electrode, calomel electrode as referenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com