A kind of fluorine-containing polymer-based dielectric composite film and preparation method thereof

A composite film and polymer technology, applied in the field of dielectric composite materials, can solve the problems of high dielectric loss of composite materials and difficult processing of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

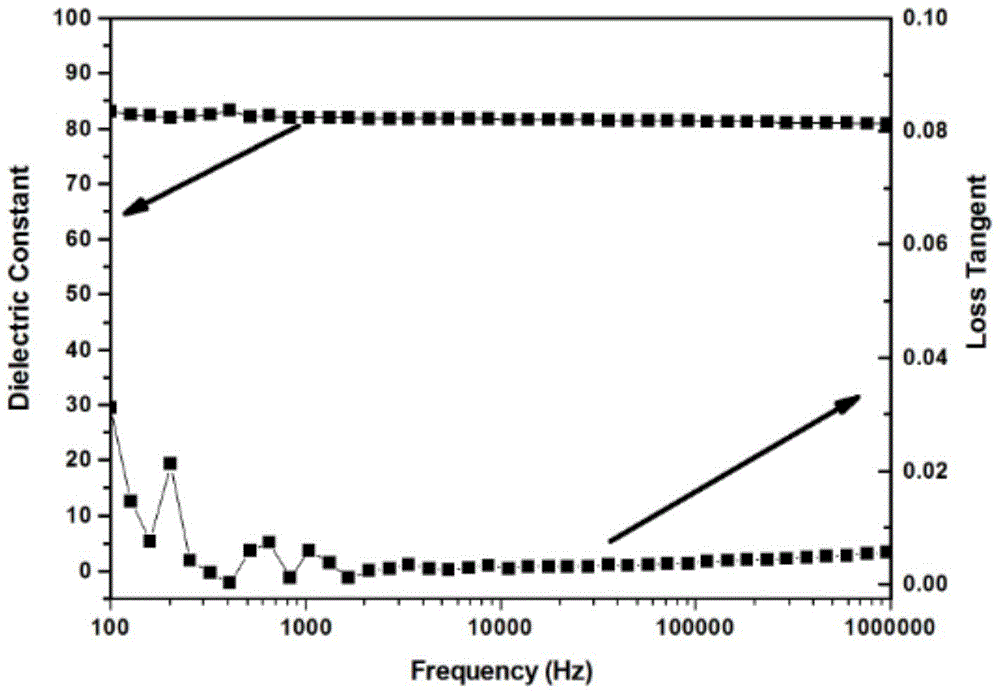

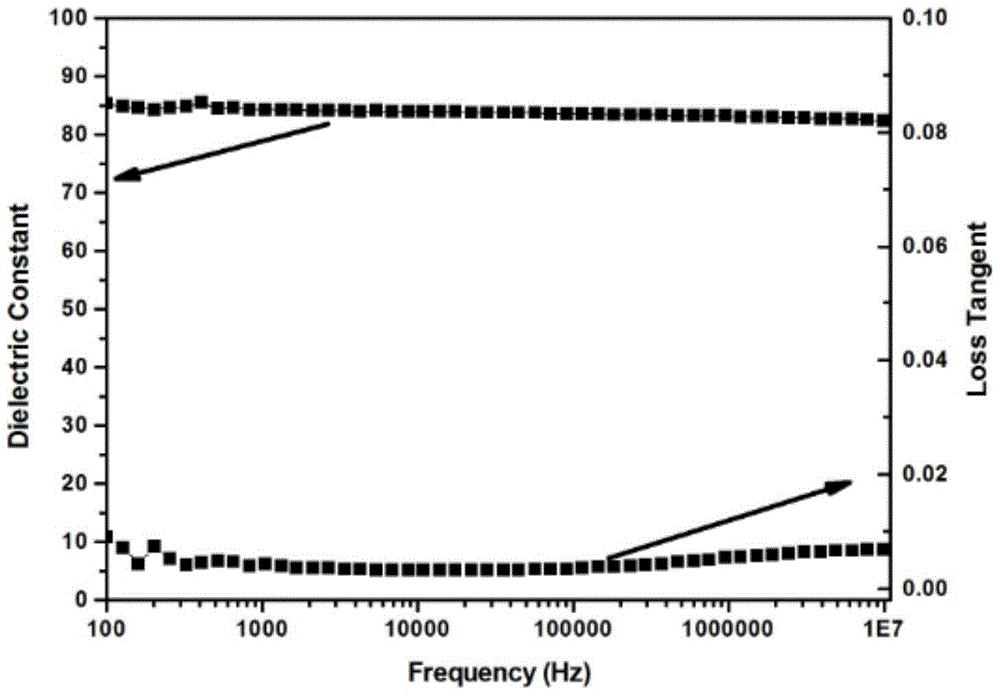

Examples

Embodiment Construction

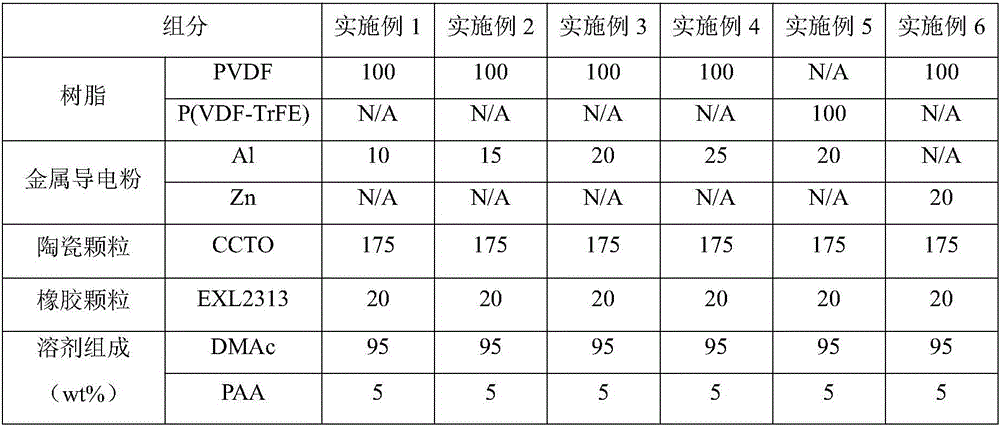

[0009] In some embodiments of the present invention, the metal conductive powder is selected from aluminum powder or zinc powder;

[0010] In some embodiments of the present invention, the fluoropolymer is polyvinylidene fluoride, polyvinylidene fluoride-trifluoroethylene, polyvinylidene fluoride-trifluoroethylene-chlorotrifluoroethylene, polyvinylidene fluoride- Any of hexafluoropropylene;

[0011] In some embodiments of the present invention, the core of the rubber particles is acrylic rubber, and the shell is polymethyl methacrylate core-shell rubber.

[0012] In some embodiments of the present invention, the mass ratio of metal conductive powder, copper calcium titanate, rubber particles, and fluoropolymer is 1-2.5:17.5:2:10.

[0013] In some embodiments of the present invention, the mass ratio of metal conductive powder, copper calcium titanate, rubber particles, and fluoropolymer is 2:17.5:2:10.

[0014] In some embodiments of the present invention, the mass ratio of N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com