Patents

Literature

30results about How to "Uniform film layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

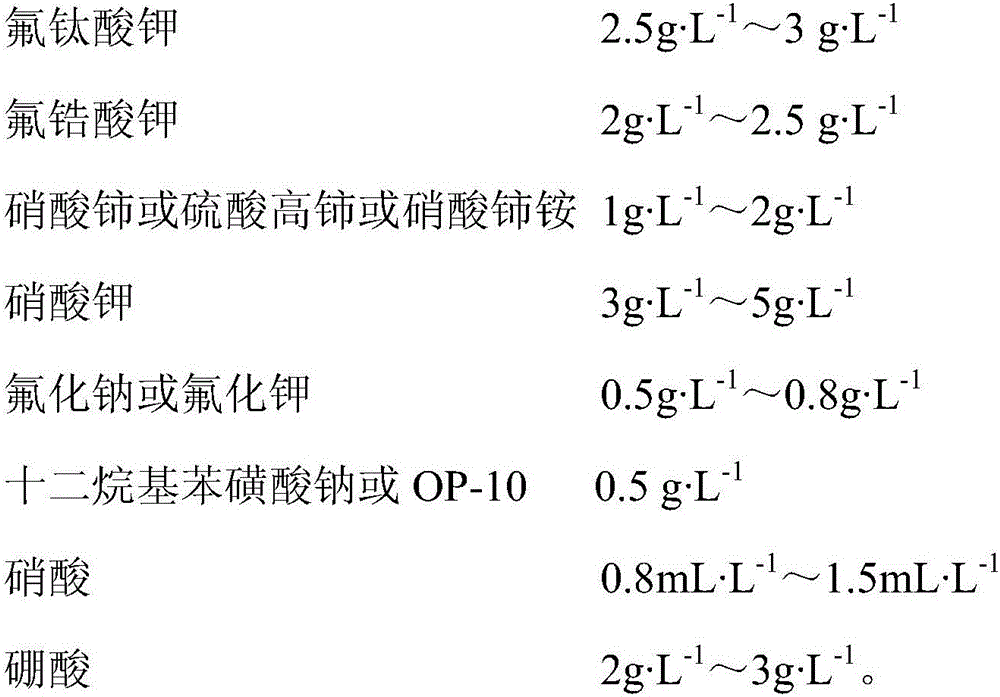

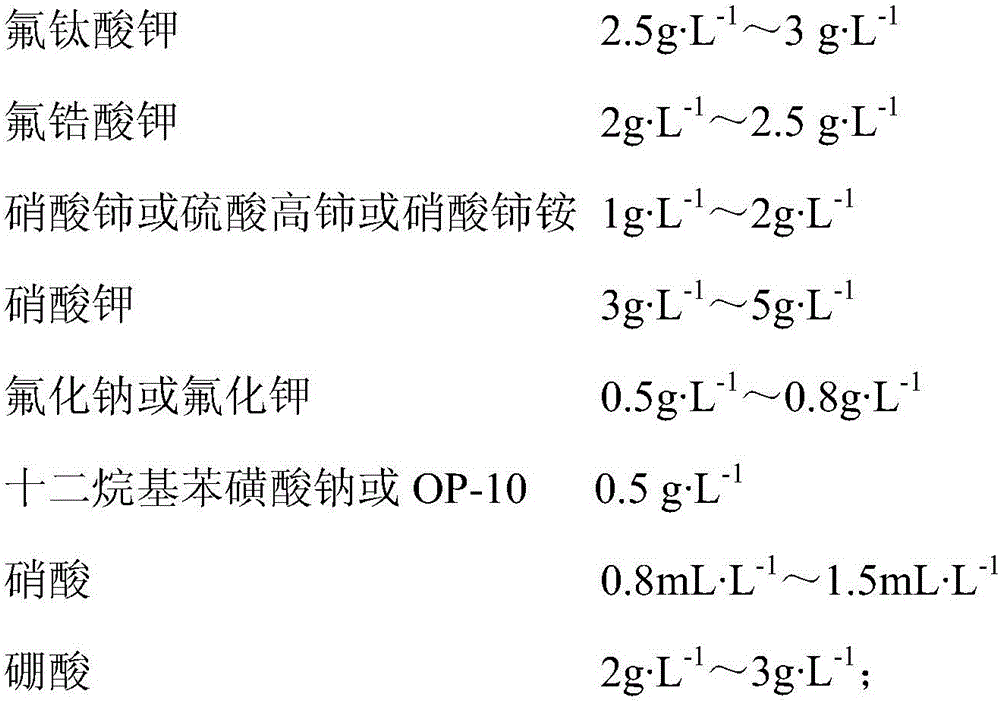

Rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and using method of rare-earth modified Ti-Zr chemical passivation solution

ActiveCN103103512AImprove compactnessImprove performanceMetallic material coating processesCerium nitratePotassium fluoride

The invention discloses a rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and a using method of the rare-earth modified Ti-Zr chemical passivation solution. The rare-earth modified Ti-Zr chemical passivation solution is characterized in that the passivation solution is a main salt for auxiliary film-formation, which takes rare-earth compounds as a Ti-Zr passivation treatment solution, and a passivation film is light yellow in appearance and has field judgement property on the quality of a formed film. A formula of the rare-earth modified Ti-Zr chemical passivation solution is as follows: each litre of solution contains 0.5g.L<-1>-10g.L<-1> of potassium fluotitanate (hexafluorotitanic acid), 0.5g.L<-1>-10g.L<-1> of potassium fluozirconate (fluozirconic acid), 0.5g.L<-1>-5g.L<-1> of cerium nitrate (ceric sulfate and ammonium ceric nitrate), 2g.L<-1>-10g.L<-1> of potassium nitrate, 0.5g.L<-1>-3g.L<-1> of sodium fluoride (potassium fluoride), 0.5g.L<-1>-1g.L<-1> of sodium dodecyl benzene sulfonate or OP-10, 0.2mL-5mL.L<-1> of nitric acid and 1g.L<-1>-5g.L<-1> of boric acid. The using method of the rare-earth modified Ti-Zr chemical passivation solution comprises the following steps of: (1) clearing dirt, such as dirt attached to an aluminium alloy; (2) pretreating the surface of the aluminium alloy; (3) carrying out passivating treatment on the surface of the aluminium alloy by using the rare-earth modified Ti-Zr chemical passivation solution; and (4) washing the aluminium alloy by using water and drying the aluminium alloy. The rare-earth modified Ti-Zr chemical passivation solution disclosed by the invention has the advantages of light yellow appearance, high film formation speed, simple process, uniformity in film layer, strong corrosion resistance, low environment pollution and the like.

Owner:GUANGDONG XINGFA ALUMINUM

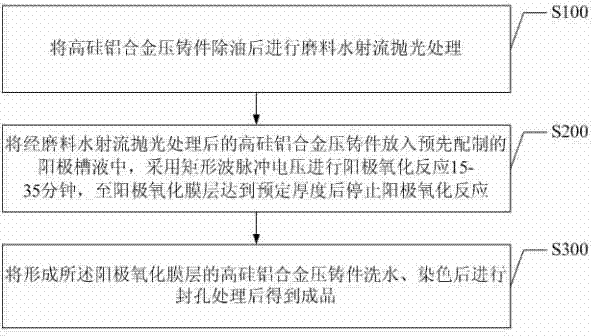

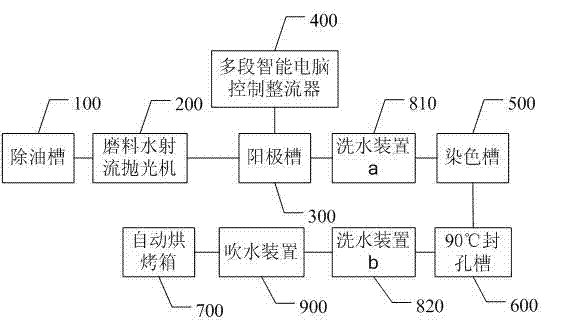

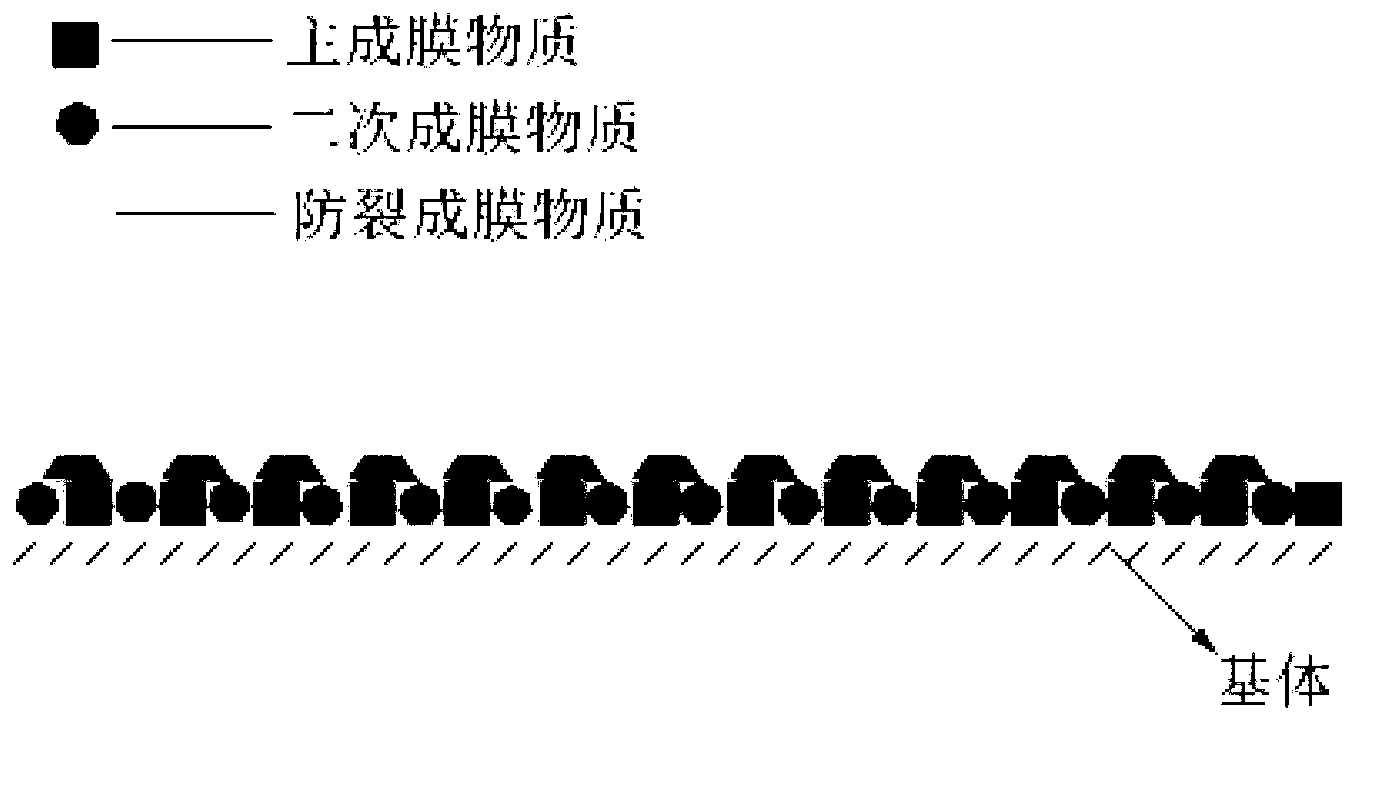

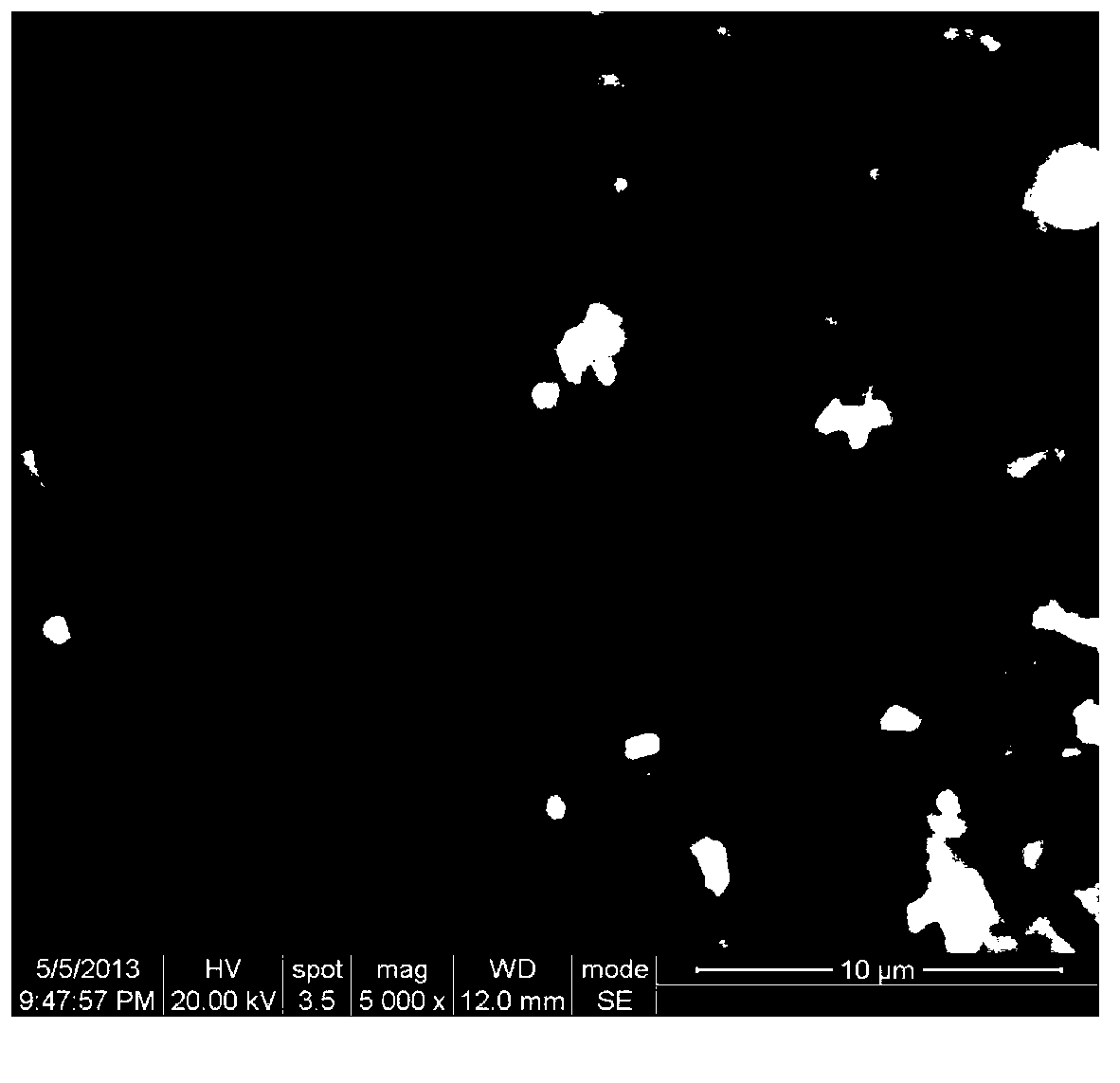

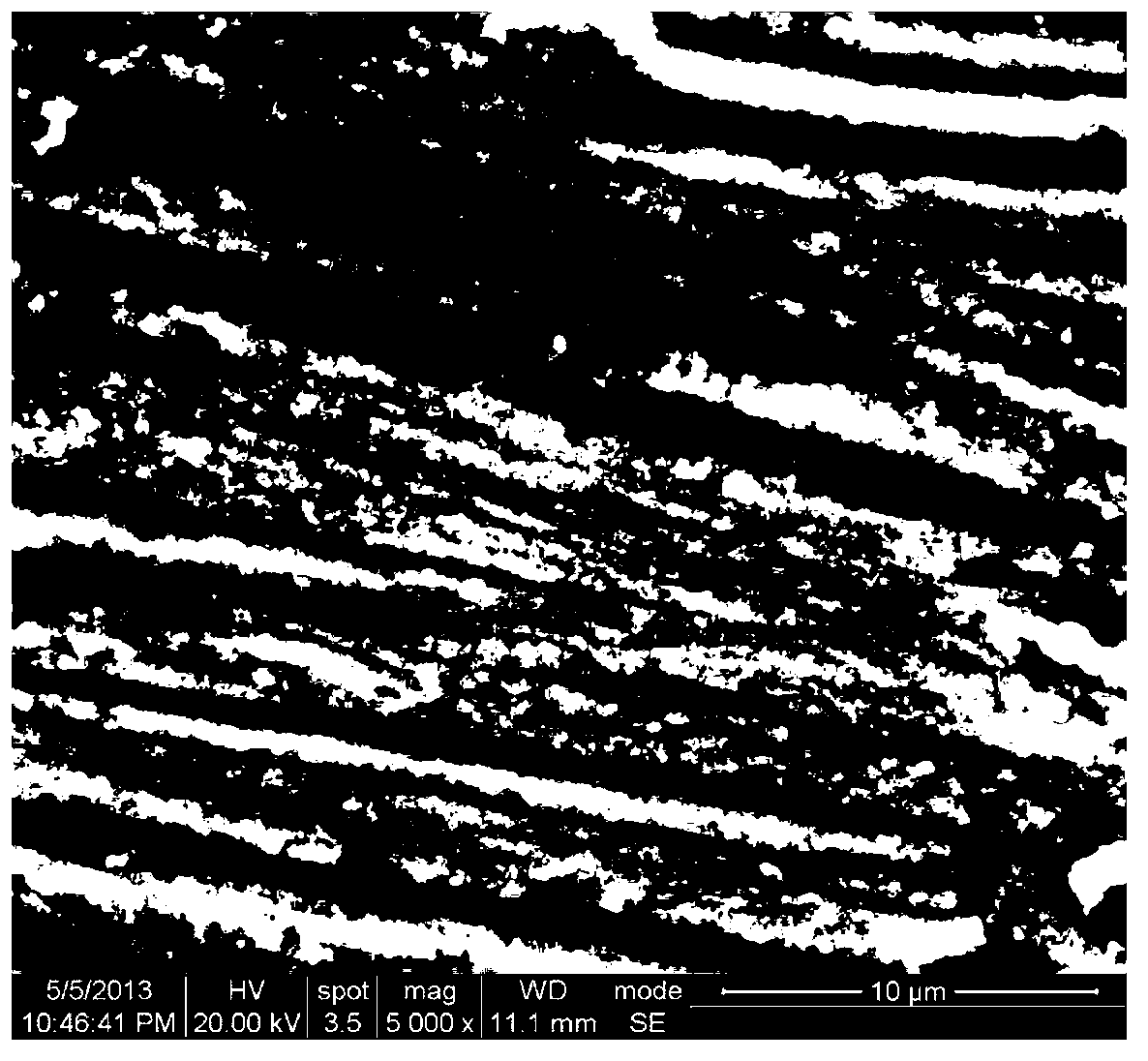

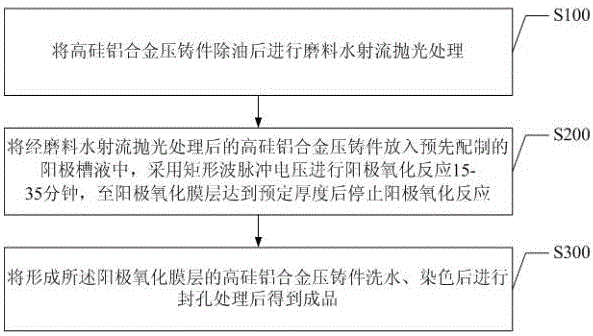

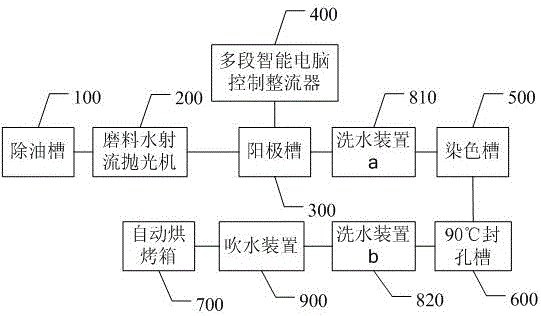

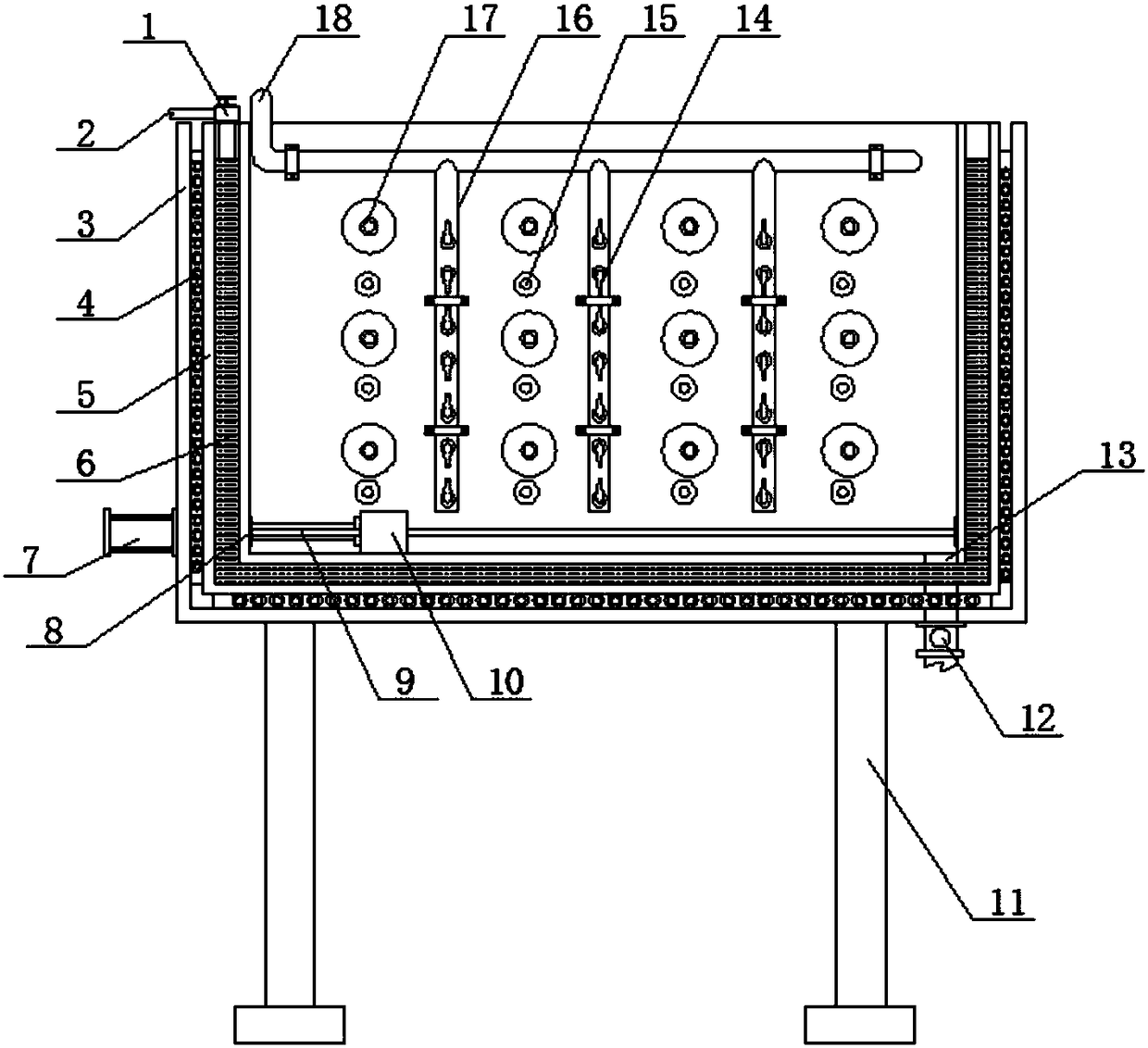

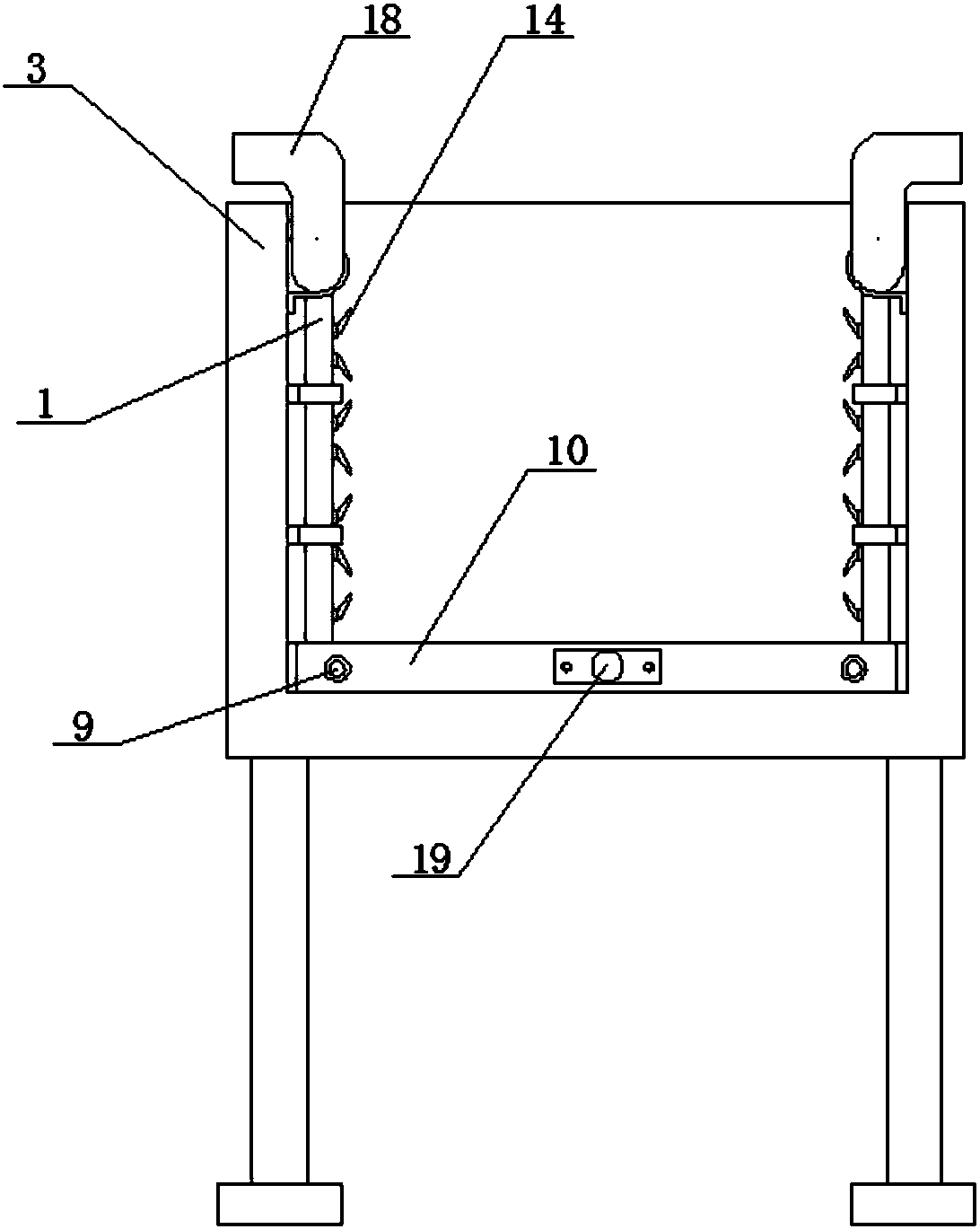

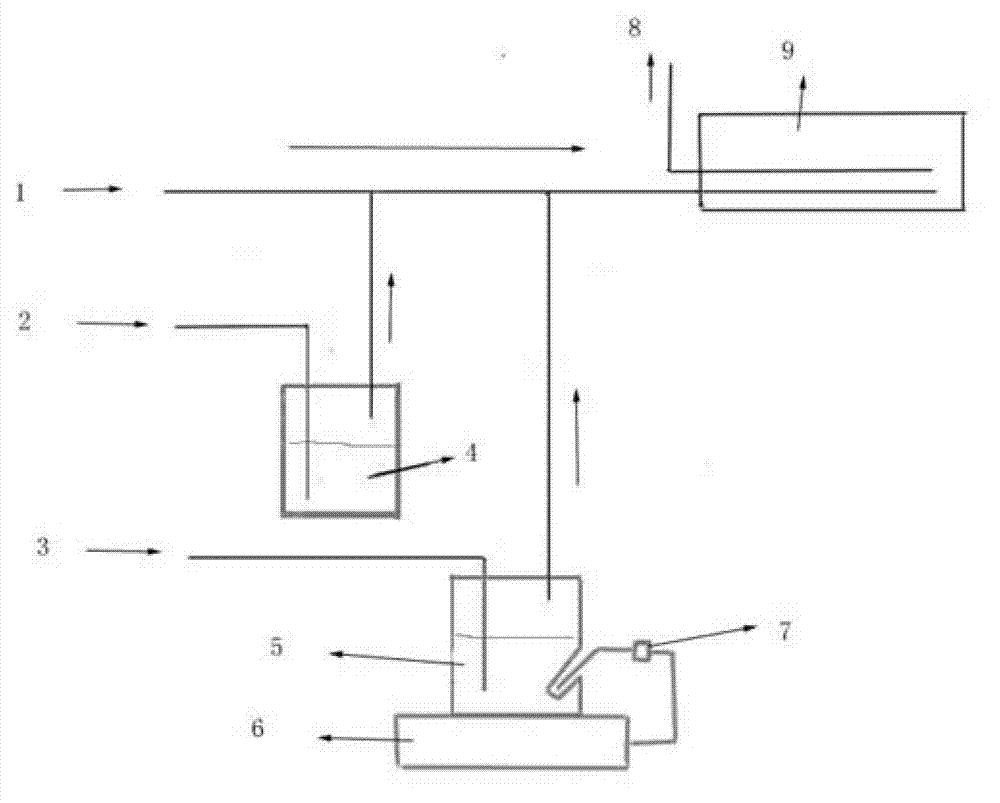

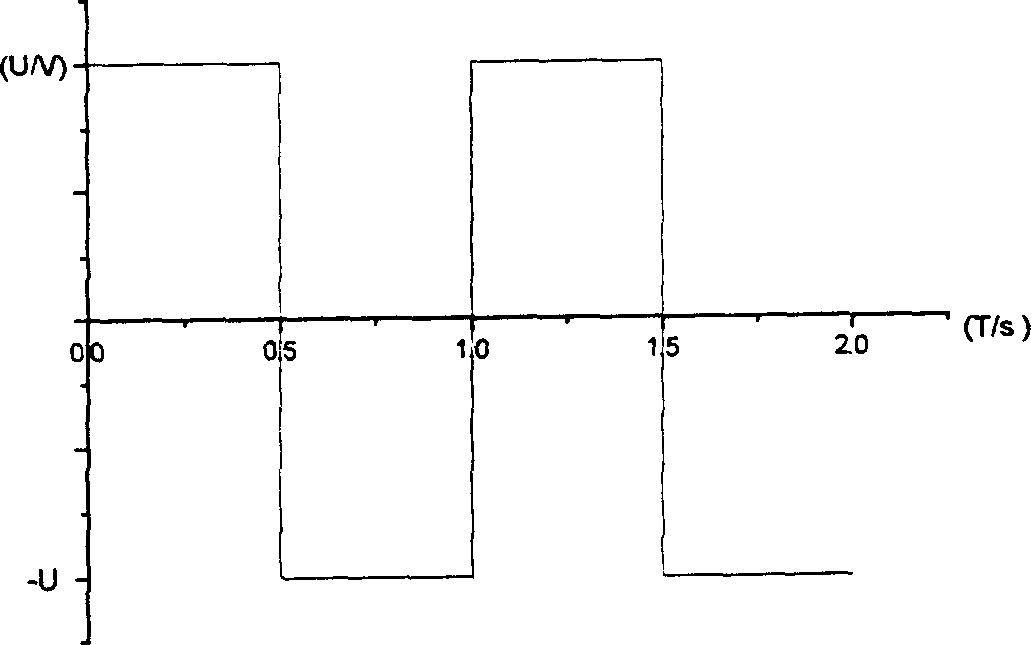

High silicon aluminum alloy anodic oxidation method and equipment thereof

ActiveCN103484914AHigh dimensional accuracyUniform film layerSurface reaction electrolytic coatingDie castingPulse voltage

The invention discloses a high silicon aluminum alloy anodic oxidation method and equipment thereof. The method comprises the steps as follows: A, after a high silicon aluminum alloy die casting is subjected to oil removing, abrasive water jet polishing treatment is performed; B, the polished high silicon aluminum alloy die casting is placed in a prepared anodic bath solution, rectangular wave pulse voltage is used for performing an anodic oxidation reaction, and the anodic oxidation reaction is stopped after an anodic oxidation film layer reaches a preset thickness; and C, after the high silicon aluminum alloy die casting with the anodic oxidation film layer is subjected to water washing and dyeing, hole sealing treatment is performed, so that a finished product is obtained. According to the method, pretreatment, anodic oxidation reaction and post treatment technologies of the anodic oxidation reaction of the high silicon aluminum alloy die casting are modified, so that the oxidation layer which is uniform, high in dimensional accuracy, compact and attractive is formed on the surface of the prepared high silicon aluminum alloy die casting; and compared with a conventional technology, the processing technology is more environment-friendly, the processing cost is lower, and large-scale industrial production can be realized more easily.

Owner:东莞市容邦尚电子科技有限公司

Self-healing environment-friendly type steel normal-temperature blackening agent

ActiveCN103290400AAvoid over or under blackUniform film layerMetallic material coating processesChemistrySelf-healing

The invention discloses a self-healing environment-friendly type steel normal-temperature blackening agent which takes a molybdate / sulfur-copper system as a main membrane component and which consists of 12-22g / L of copper nitrate, 14-24g / L of ammonium molybdate tetrahydrate, 8-12g / L of sodium thiosulfate, 18-28g / L of monosodium phosphate, 3-5g / L of oxalic acid, 6-13g / L of nickel sulfate, 3-5g / L of dimethylformamide, 0.5-1g / L of lanthanum oxide, 30-40g / L of aluminum potassium sulfate, 4-10g / L of sodium chloride, 2-6g / L of citric acid, and a surfactant. The blackening agent is high in blackening capability, free of selenium, environment-friendly, low in production cost and simple in process; a steel normal-temperature blackening film layer obtained through blackening has the characteristics that the corrosion resistance and the healing capability are good, a blacking film is free of crack, the film layer is uniform and dark and bright in color, and the adhesion capability and the corrosion resistance are excellent; and the technical indexes of the blackening film layer are that the 3% copper sulfate drop test lasts for 65 seconds (the blackening film layer is not dipped into anti-rust oil), the 3% sodium chloride soaking test lasts for 8 hours, and the binding force is greater than 187 times.

Owner:HUNAN UNIV

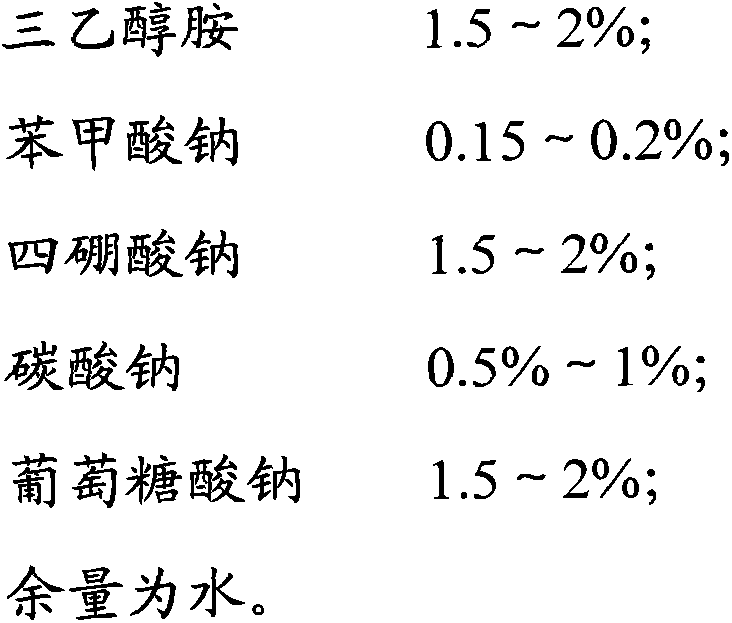

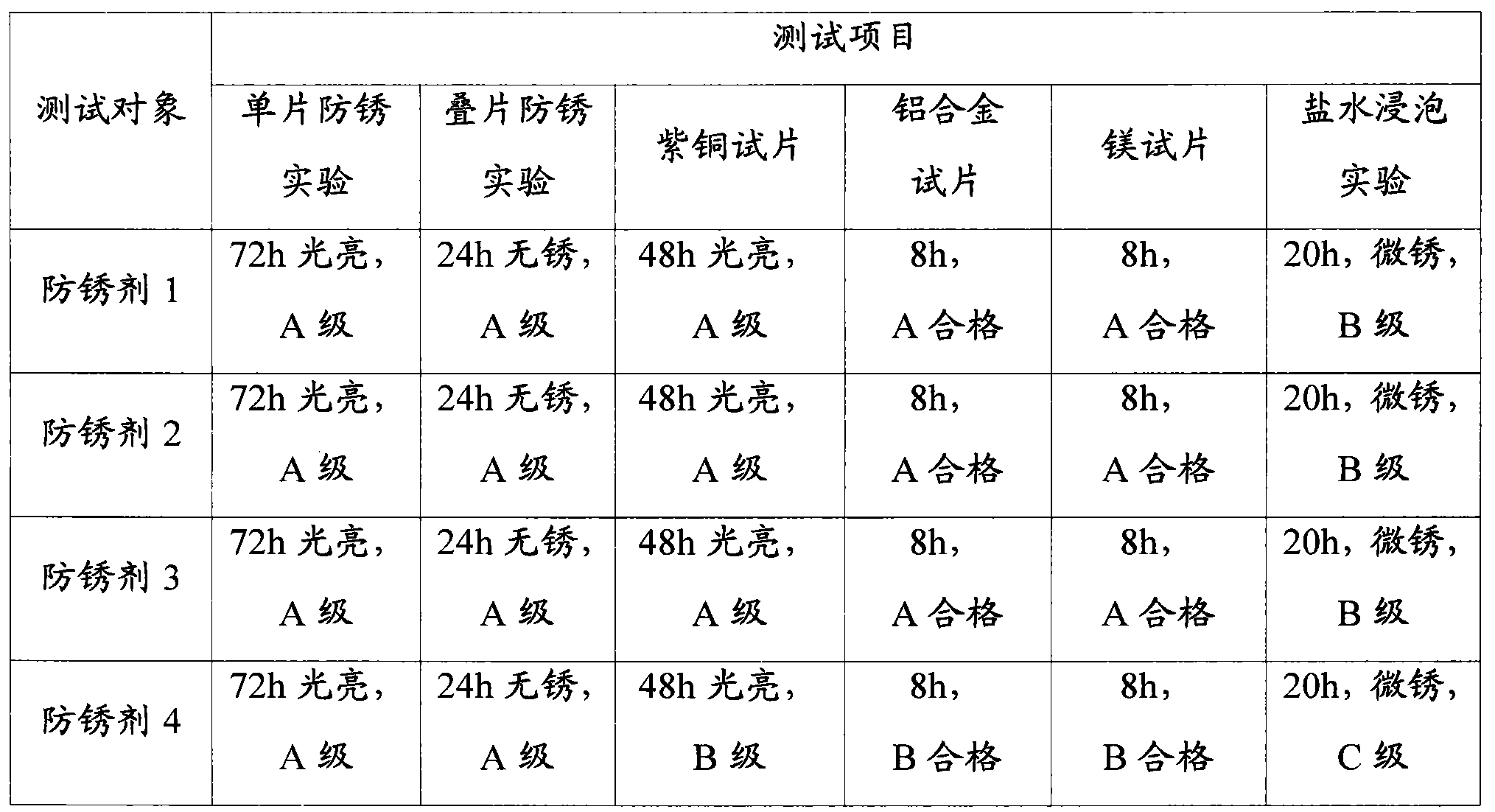

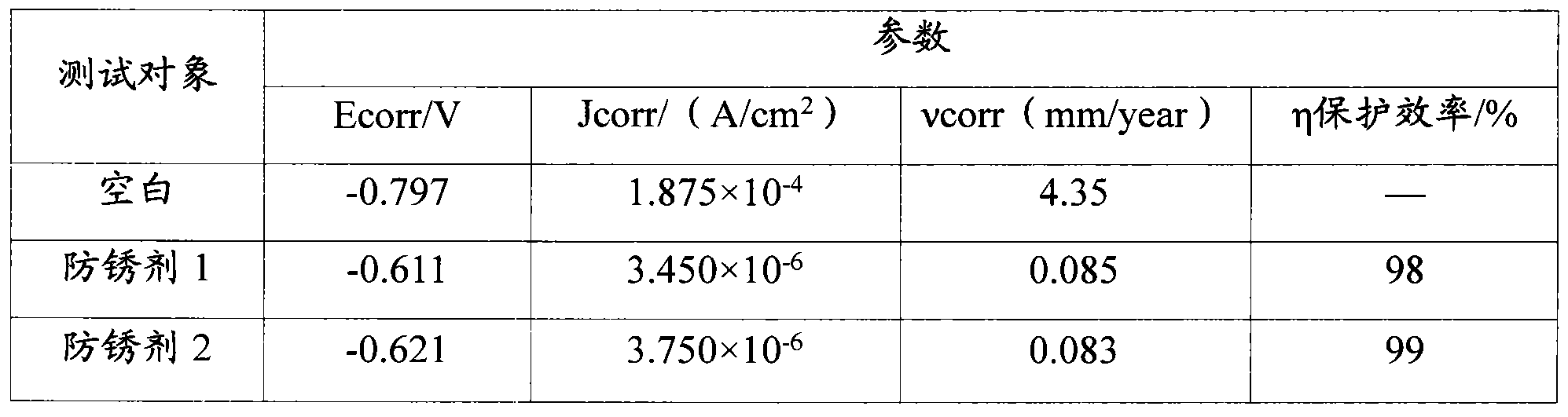

Water-soluble environment-friendly anti-rusting agent, and preparation method and application thereof

The invention provides a water-soluble environment-friendly anti-rusting agent, and a preparation method and application thereof. The water-soluble environment-friendly anti-rusting agent comprises the following components in percentage by mass: 1.5 to 2 percent triethanolamine, 0.15 to 0.2 percent of sodium benzoate, 1.5 to 2 percent of sodium tetraborate, 0.5 to 1 percent of sodium carbonate, 1.5 to 2 percent of sodium gluconate and the balance of water. The anti-rusting agent is prepared by mixing and uniformly stirring the components, and the pH value of the anti-rusting agent is adjusted to be 8 to 10 by adjusting the amount of each component in a mixing and stirring process. The water-soluble environment-friendly anti-rusting agent can be used for the anti-rusting protection of ferrous metal such as cast iron and steel and nonferrous metal such as copper, aluminum and magnesium, is free of environmental pollution, harmless to a human body, low in cost and easy to prepare, has superior anti-rusting effects, and is applied to the anti-rusting of various kinds of metal, and the required components are simple and easily available.

Owner:SOUTHWEST UNIVERSITY

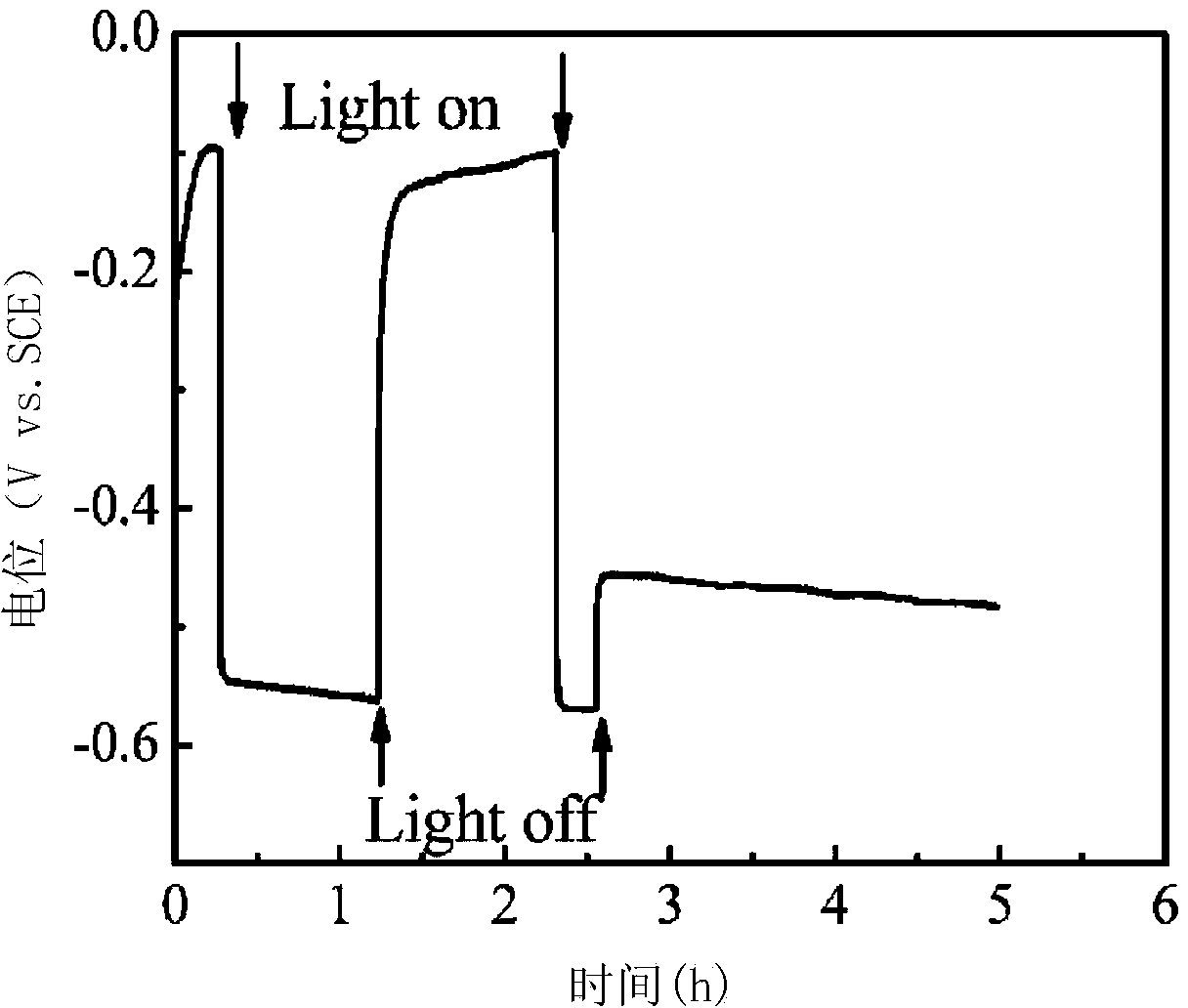

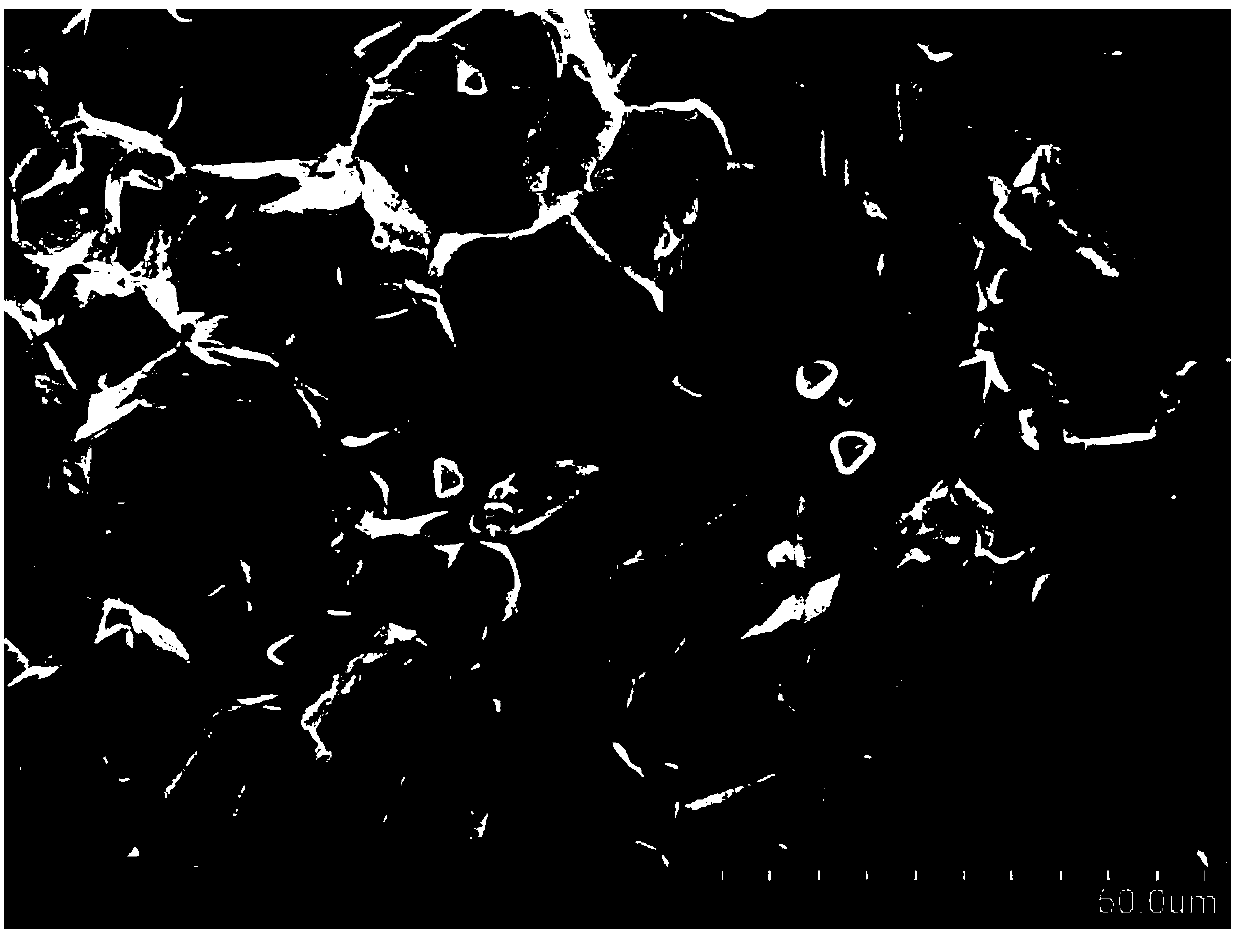

Preparation method of TiO2/SnO2 semiconductor two-layer composite film photo anode

ActiveCN104047043AUniform film layerLower electrode potentialElectrolytic coatingsVacuum evaporation coatingComposite filmPellicle membrane

The invention relates to a preparation method of a TiO2 / SnO2 semiconductor two-layer composite film photo anode and relates to a semiconductor photo anode. The invention provides the preparation method of the TiO2 / SnO2 semiconductor two-layer composite film photo anode with an efficient photo-induced cathodic protection effect. The preparation method comprises the following steps: 1) by using stainless steel as a matrix sample, grinding the surface of the matrix sample to a mirror surface, and then cleaning; 2) dissolving SnCl2.2H2O in water, then adding NaNO3 and nitric acid to prepare an electrolyte solution, and then adding water to fix the volume to 1000mL; by using platinum as a counter electrode and saturated mercurous chloride as a reference electrode and the matrix sample as a working electrode, in the electrolyte solution, electro-depositing and drying, namely electro-depositing a SnO2 film layer on the surface of the matrix sample; and 3) sputtering a TiO2 film on the surface of the SnO2 film layer obtained in the step 2), and then thermally treating to obtain the TiO2 / SnO2 semiconductor two-layer composite film photo anode. The photo-induced cathodic protection effect on metals by a TiO2 nano thin film in dark state is improved.

Owner:XIAMEN UNIV

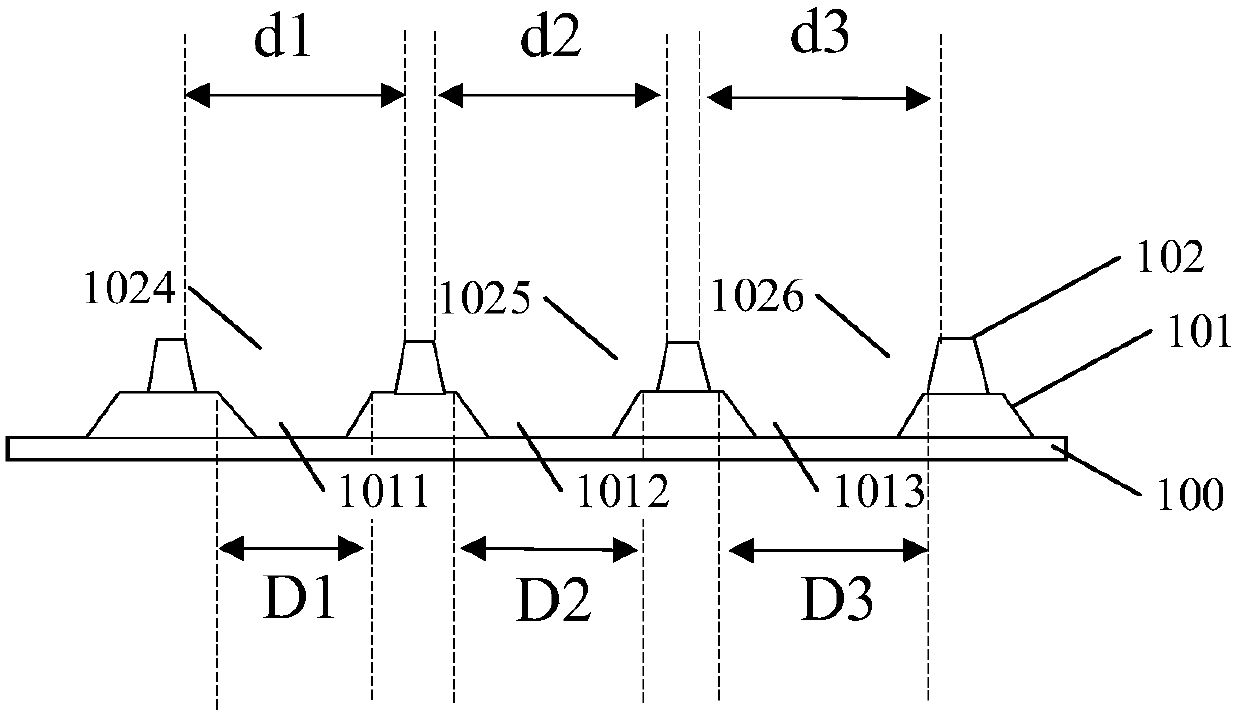

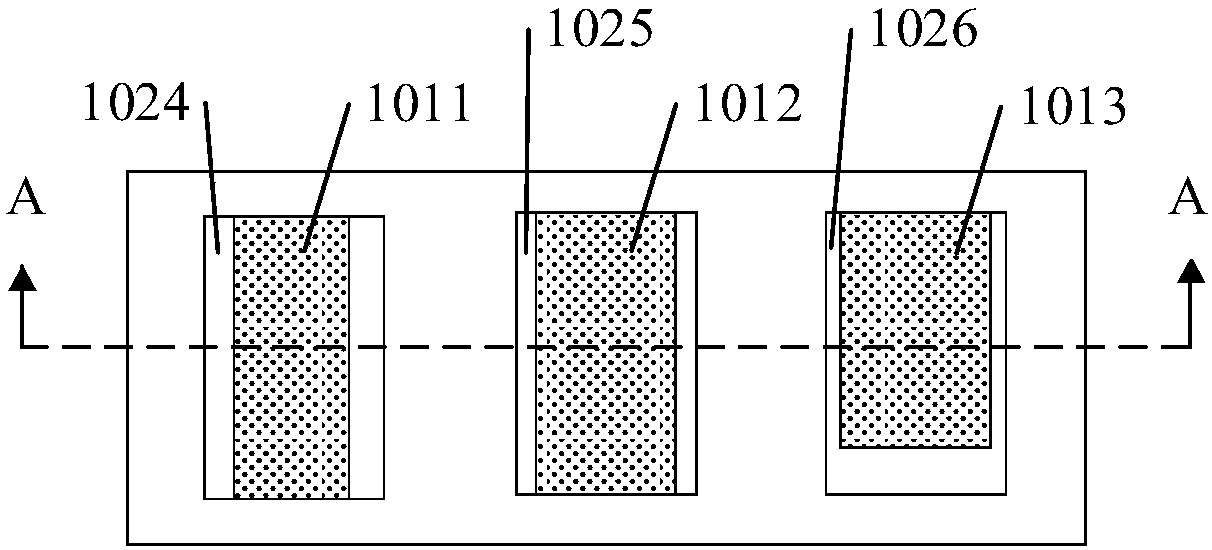

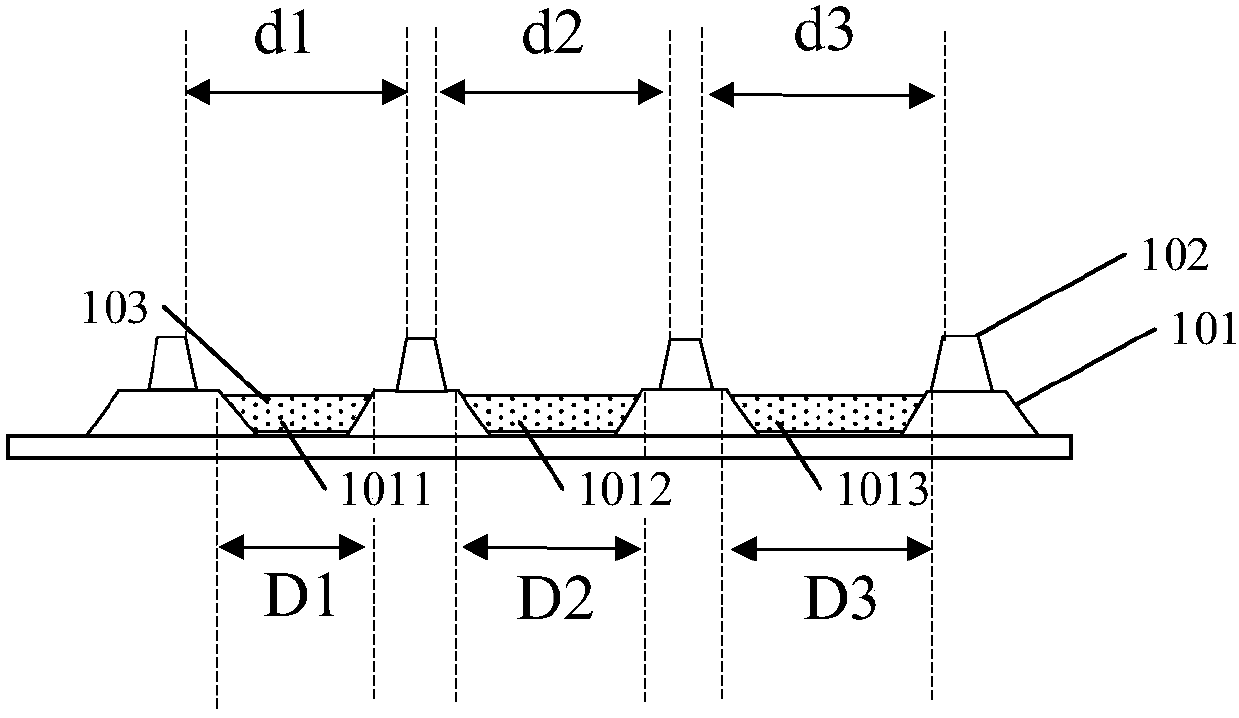

Pixel defining layer, display substrate, display device, and inkjet printing method

ActiveCN109860223AConsistent drying speedUniform film layerSolid-state devicesSemiconductor/solid-state device manufacturingInkjet printingComputer graphics (images)

The present invention provides a pixel defining layer, a display substrate, a display device and an inkjet printing method. The pixel defining layer comprises: a first pixel defining layer having a first opening, wherein the first opening comprises a first sub pixel opening and a second sub pixel opening which correspond to different sub pixels, and the size of the opening of the second sub pixelopening is larger than the size of the opening of the first sub pixel opening; and a second pixel defining layer located on the first pixel defining layer, wherein the second pixel defining layer hasa second opening, the second opening has a fourth sub pixel opening corresponding to and communicating with the first sub pixel opening and a fifth sub pixel opening corresponding to and communicatingwith the second sub pixel opening, and the difference of the opening size of the fourth sub pixel opening and the opening size of the first sub pixel opening is larger than the difference of the opening size of the fifth sub pixel opening and the second sub pixel opening. The pixel defining layer is employed for ink jet printing to allow the film layer obtained after ink is dried to be more uniform.

Owner:BOE TECH GRP CO LTD +1

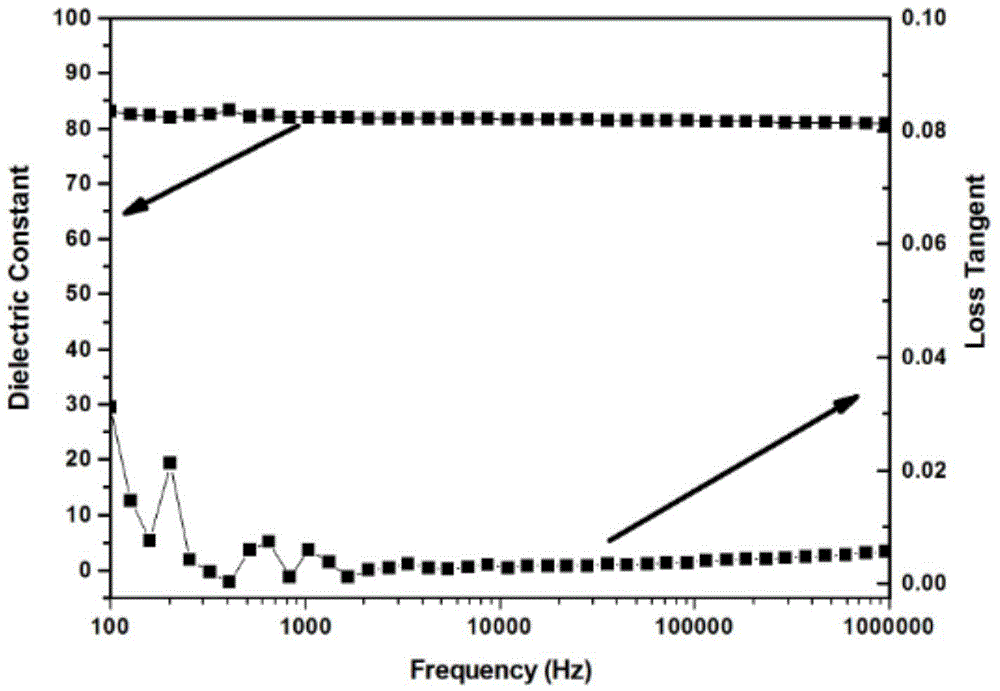

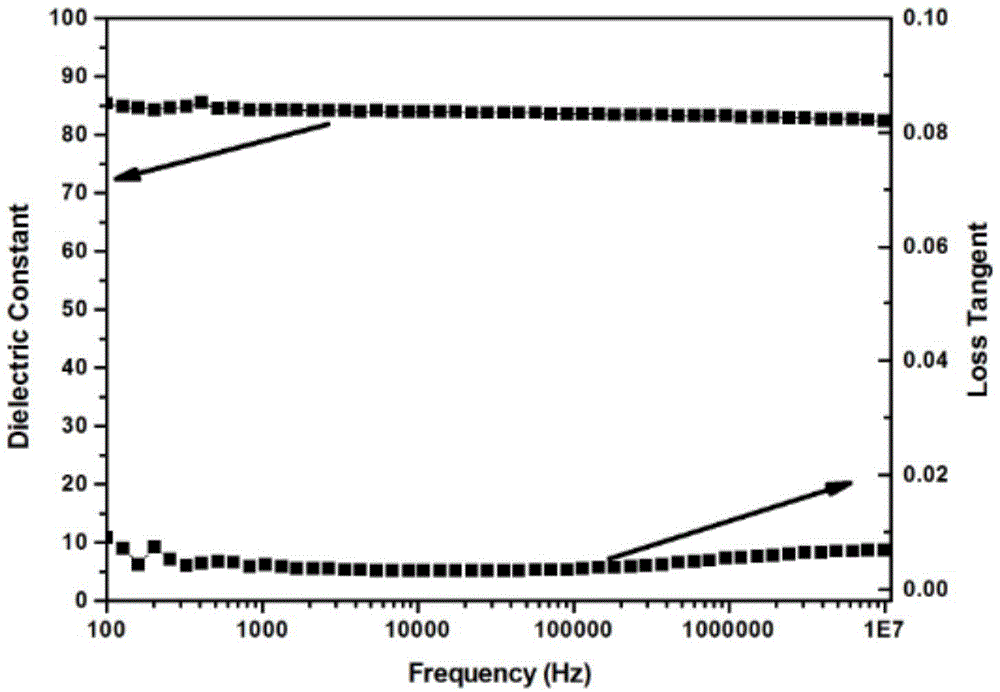

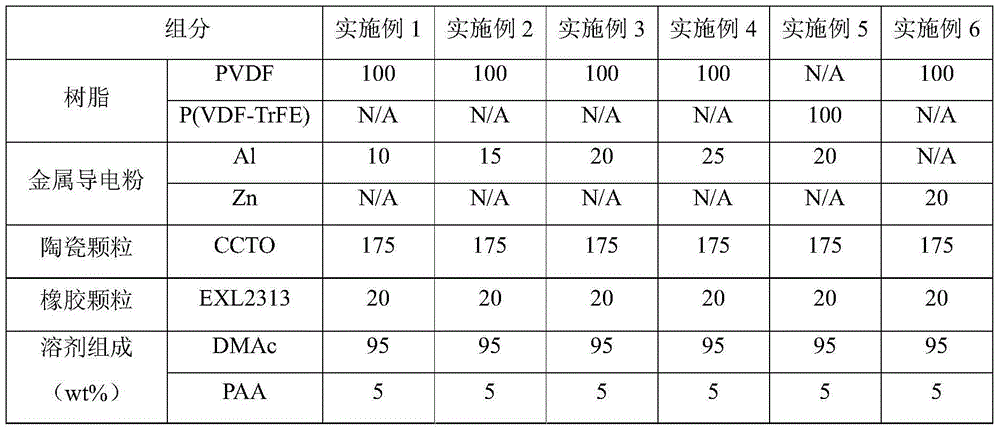

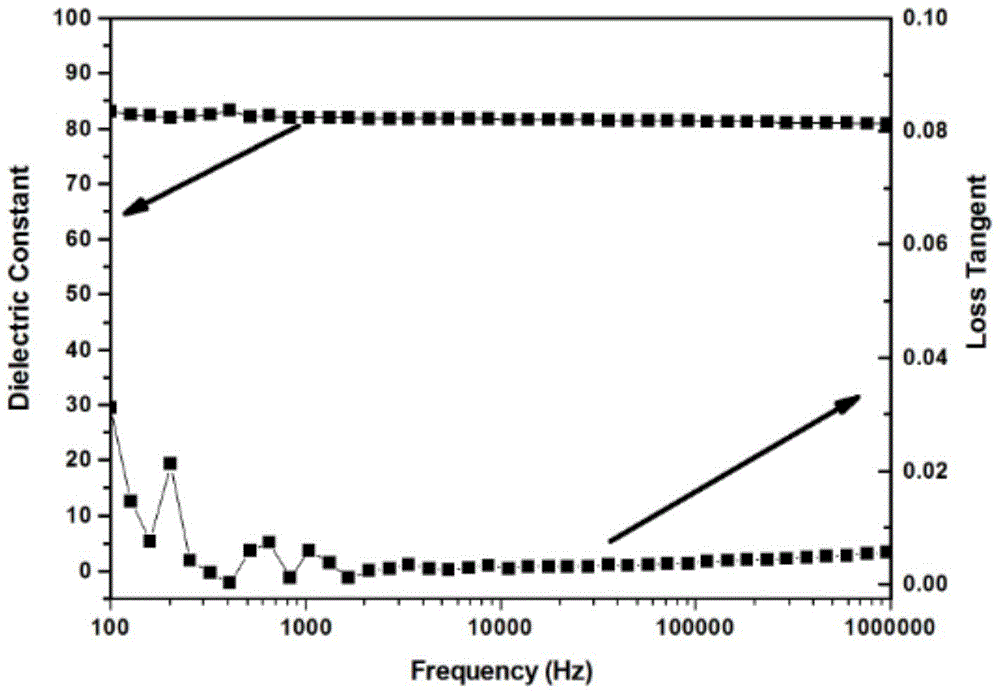

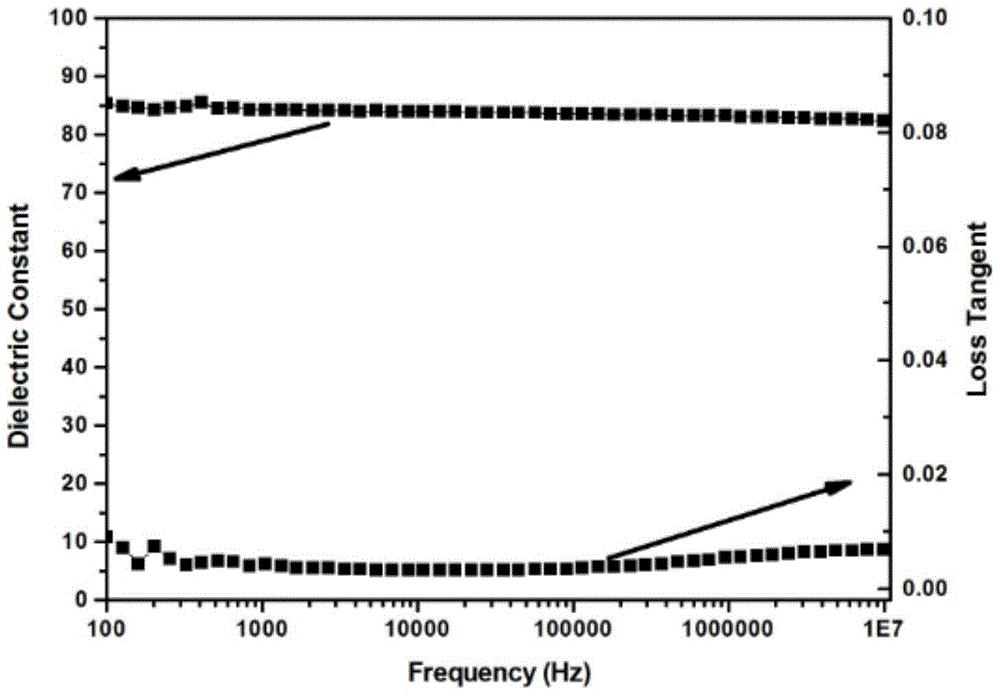

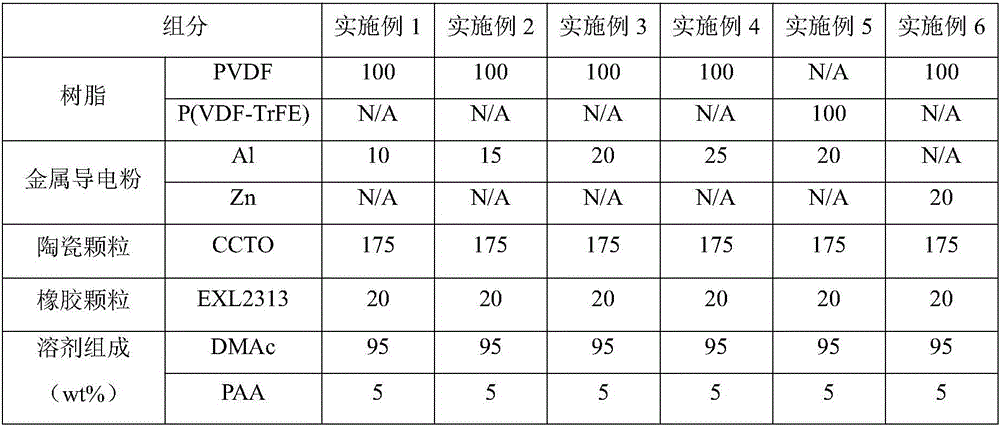

Fluorine-containing polymer-based dielectric composite film and preparation method thereof

The invention discloses a fluorine-containing polymer-based dielectric composite film. The dielectric composite film is prepared from conductive metal powder, calcium copper titanate, rubber particles and fluorine-containing polymer as raw materials in the presence of a compound liquid of N, N-dimethyl acetamide and polyacrylic acid as a solvent, wherein the mass ratio of components is (0-2.5): (10-30): (0-3): 10. The invention also discloses a preparation method of the composite film. The fluorine-containing polymer-based dielectric composite film is a dielectric composite film which has the advantages of high dielectric constant, high compressive strength, low dielectric loss and excellent elongation and controllable thickness.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

Electrochemical synthesis method for cobalt oxide/polyaniline composite material

An electrochemical synthesis method for a cobalt oxide / polyaniline composite material includes the following processing steps of mixing a mixed solution containing 0.1mol / L of aniline and 0.5mol / L of sulfuric acids and another mixed solution containing 0.1mol / L of cobalt sulfate and 0.5mol / L of sulfuric acids based on the proportion of 1:2, adjusting the potential of hydrogen (pH) value of the mixed solution by the sulfuric acids until the pH value reaches to 1.0 to 2.0, adding 0.3g / L of cetyl trimethyl ammonium bromide, stirring with a magnetic stirrer, and performing an electropolymerization at the constant potential of 1.5V to 5.0V and at the temperature of 10 DEG C to 25 DEG C for 3 to 15 minutes to obtain the cobalt oxide / polyaniline composite material. According to the electrochemical synthesis method for the cobalt oxide / polyaniline composite material, the cobalt oxide / polyaniline composite material which is uniform, compact and good in corrosion resistance can be obtained on surfaces of conducting glass and stainless steel.

Owner:广州和力表面处理技术有限公司

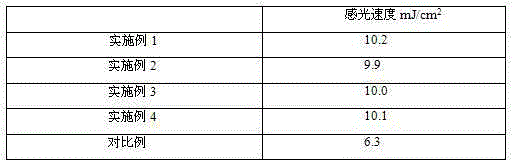

Positive photoresist composition

InactiveCN105301907AUniform film layerHigh precisionPhotosensitive materials for photomechanical apparatusMethoxypropanePhotoresist

The invention discloses a positive photoresist composition. The composition comprises 0.4-0.55 parts of an organosilicon flatting agent, 23-25 parts of a solvent, 2-3 parts of an optical active substance and 16-18 parts of resin. The solvent contains tetrahydrofuran, 2-acetoxy-1-methoxypropane and dimethyl acetamide. The prepared positive photoresist has a higher photosensitive speed, and is suitable for large scale popularization and application.

Owner:BEIJING ZHONGKEZIXIN TECH

Ocean blue colored glass online film coating method and online film coating equipment

ActiveCN103819096AUniform film layerHigh acid and alkali resistanceFilm coatingContinuous production

The invention provides an ocean blue colored glass online film coating method. Mixed gas of silicane and ethylene is introduced in a molten tin bath for floating glass production, and a nanometer film layer is deposited on the surface of ocean blue glass with a chemical vapor deposition method so as to obtain ocean blue film coated glass. The ocean blue glass prepared with the method provided by the invention is uniform in film layer, and has extremely high acid and alkali resistance and extremely high abrasive resistance. According to the preparation method, no atmosphere disturbance of the molten tin bath exists, and meanwhile the preparation method fully utilizes the temperature and owned heat of the molten tin bath, so that integral continuous production of the film layer and glass is realized, the production efficiency is improved, the production cost is reduced, the resources are saved, and the ocean blue film coated glass has unique secondary processing performance that the glass can be tempered and thermally bent.

Owner:株洲醴陵旗滨玻璃有限公司 +1

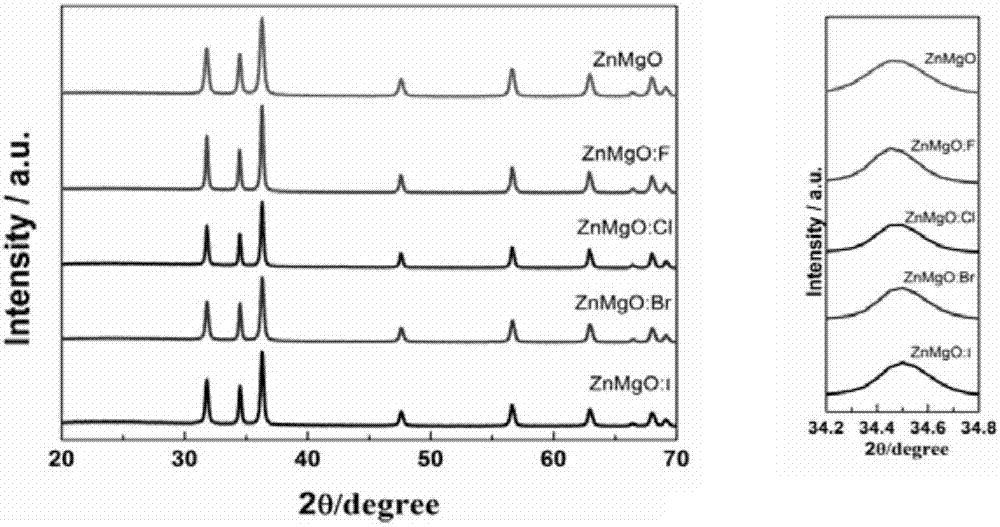

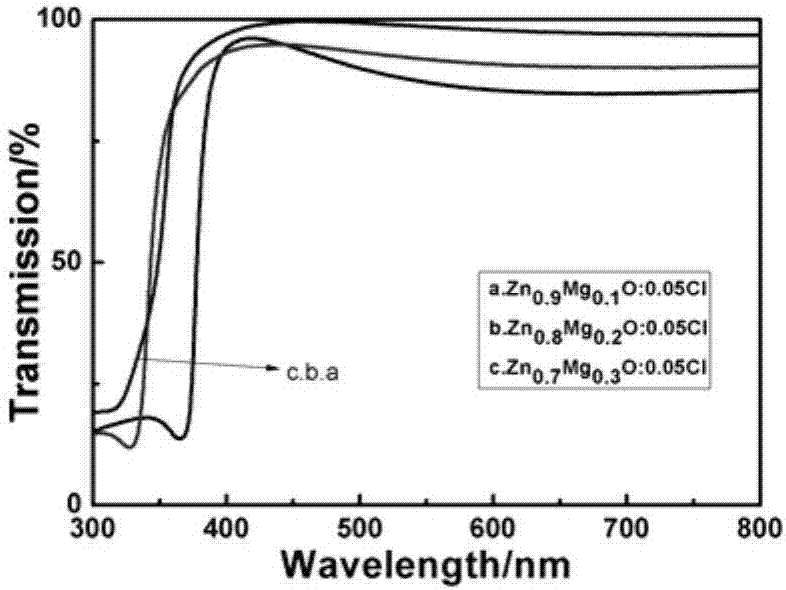

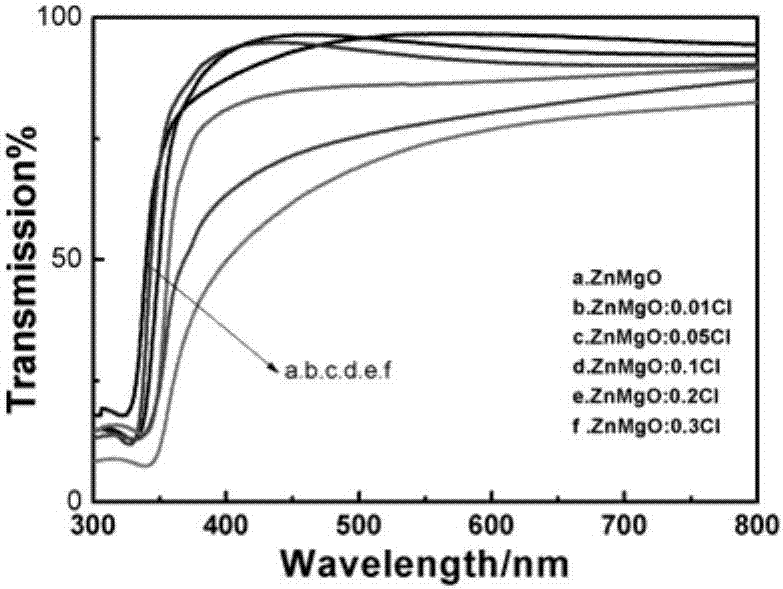

Halogen-doped ZnMgO film and preparation method thereof

InactiveCN106927688AUniform film layerGood compactnessPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionZinc Acetate DihydrateFilm material

The invention belongs to the fields of low-dimensional nanometer material and nanometer technique and provides a halogen-doped ZnMgO film and a preparation method thereof. The preparation method comprises the following steps: cleaning and drying a substrate; adding zinc acetate and a magnesium source into a solvent, wherein ethylene glycol monomethyl ether or normal propyl alcohol is taken as the solvent and ethanol amine is taken as a stabilizer; stirring for 1-2h at 55-80 DEG C, thereby acquiring a solution; adding NH4X or NaX into the solution, wherein X represents halogen; stirring for 2-3h at 55-80 DEG C, thereby acquiring a uniform and stable solution; utilizing a spinning method to prepare the film on the substrate and repeating for several times; putting the substrate with the film into a thermal treatment furnace and annealing, wherein the annealing temperature is at 400-700 DEG C and the heat insulating time is 0.5-3h; and cooling to room temperature, thereby acquiring the halogen-doped ZnMgO film. The preparation method for the halogen-doped ZnMgO film provided by the invention is characterized by mild preparation environment, low cost, high reliability and simple process. The method is expected to be used for preparing a film material with a piezoelectric property.

Owner:WUHAN UNIV OF TECH

Preparation method of glass loaded copper/chromium ion double doped nano titanium dioxide photocatalysis film

InactiveCN103007948AImprove photocatalytic performanceImprove degradation rateWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsCopperTitanium dioxide

The invention discloses a preparation method of a glass loaded copper / chromium ion double doped nano titanium dioxide photocatalysis film. The preparation method comprises the following steps: firstly, plating an SiO2 film on a glass substrate by using a sol-gel method; further dipping the glass substrate plated with the SiO2 film into copper / chromium ion double doped titanium dioxide sol; and lifting, drying and roasting so as to prepare the film. Compared with a pure nano titanium dioxide photocatalysis film, the glass loaded copper / chromium ion double doped nano titanium dioxide photocatalysis film has the advantages that the SiO2 film plated on the glass substrate increases the degradation rate of methylene blue dye by two fold.

Owner:HUBEI UNIV OF TECH

Treating solution for preparing Al-Mo-Mn-Re quaternary composite passivation film on aluminum profile surface and its application method

ActiveCN102732870BImprove compactnessImprove performanceMetallic material coating processesCerium nitrateCeric sulfate

The invention discloses a treating solution for preparing a corrosion resistant Al-Mo-Mn-Re quaternary composite passivation film on an aluminum alloy surface and its application method. The passivation solution is characterized by being a passivation treatment solution which is used for preparing a passivation film on an aluminum alloy surface by utilizing a molybdate, a rare earth salt and a permanganate oxidant. Per liter of the treating solution consists of: 8g.L<-1>-25g.L<-1> of sodium molybdate (or ammonium molybdate), 5g.L<-1>-10g.L<-1> of potassium permanganate, 0.5g.L<-1>-3g.L<-1> of sodium fluoride (or potassium fluoride), 0.5g.L<-1>-5g.L<-1> of cerium nitrate (or ceric sulfate, lanthanum nitrate), 1g.L<-1>-5g.L<-1> of acetic acid, 0.5g.L<-1>-1g.L<-1> of sodium dodecyl benzene sulfonate (or OP-10) . The application method includes: (1) removing adhered dust and other dirt from the aluminum alloy; (2) then conducting pretreatment on the aluminum alloy surface; (3) using the treating solution for passivation treatment; and (4) carrying out water washing and drying. The treating solution of the invention has the advantages of fast film formation speed, simple process, uniform film, strong corrosion resistance, and less environmental pollution, etc.

Owner:GUANGDONG XINGFA ALUMINUM JIANGXI

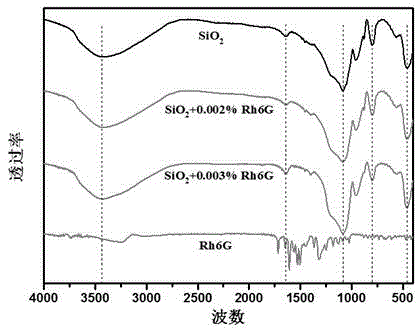

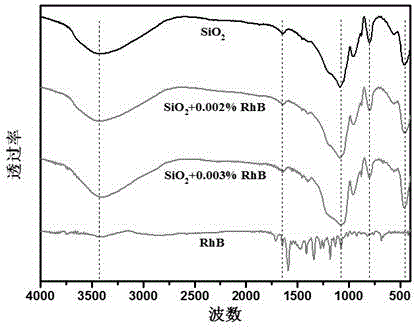

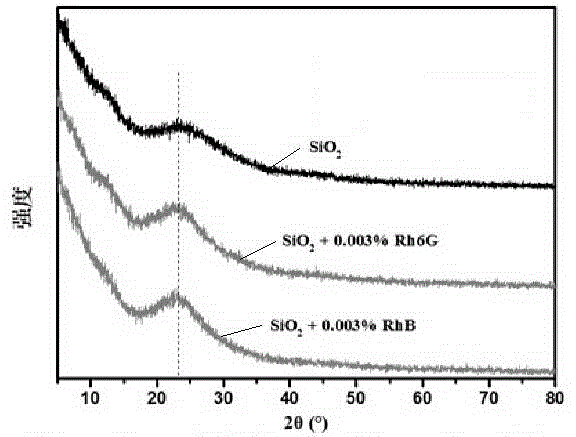

Preparation method of fluorescent-response silica aerogel thin film

InactiveCN104977285AReduce photodegradationGood fluorescence responseFluorescence/phosphorescenceOXALIC ACID DIHYDRATESilicic acid

The invention discloses a preparation method of a fluorescent-response silica aerogel thin film, and belongs to the functional material technical field. The preparation method comprises the steps: dipping a clean glass substrate in a fluorescent silica sol, then lifting from the glass substrate to obtain a wet gel thin film, and then carrying out ordinary pressure drying on the wet gel thin film in an atmosphere of ethanol, to obtain the silica aerogel fluorescent thin film. The silica fluorescent sol is characterized by being prepared by the steps: firstly, mixing evenly tetraethyl orthosilicate with ethanol, then adding an oxalic acid solution, after a hydrolysis reaction is finished, adding ammonia water and an ethanol solution of a dye, and evenly stirring, to obtain the silica fluorescent sol. The method is simple and convenient, simple in used equipment, good in dispersibility, low in running cost, and suitable for preparation of the silica aerogel thin films doped with different functional molecules.

Owner:YANGZHOU TIANCHEN FINE CHEM +2

Stable and high-efficient room-temperature black phosphating presoak

InactiveCN107245712AAdapt to wideHigh blacknessMetallic material coating processesChromate conversion coatingNitrite

The invention discloses a stable and high-efficient room-temperature black phosphating presoak. Each liter of the presoak comprises the following raw materials by weight: 1-10 g of a blackening agent, 0.1-1 g of a blackening assistant, 0.5-5 g of a stabilizer, 1-5 g of an accelerant and the balance of water. The presoak can be applied on the surface of steel, so that blackness is high; a film layer binding force is firm; and the appearance is uniform. Besides, a conversion film is of a compact crystalline structure, so that the corrosion resistance of the phosphating conversion film can be greatly improved by the presoak; and besides, the presoak is extremely stable and high in treatment capacity, does not contain nickel, nitrites and other toxic or harmful substance and thus is low-pollution to the environment.

Owner:ANHUI JIANGNAN MACHINERY

A kind of high-silicon aluminum alloy anodic oxidation method and its equipment

ActiveCN103484914BHigh dimensional accuracyUniform film layerSurface reaction electrolytic coatingAnodizingDie casting

The invention discloses a high silicon aluminum alloy anodic oxidation method and equipment thereof. The method comprises the steps as follows: A, after a high silicon aluminum alloy die casting is subjected to oil removing, abrasive water jet polishing treatment is performed; B, the polished high silicon aluminum alloy die casting is placed in a prepared anodic bath solution, rectangular wave pulse voltage is used for performing an anodic oxidation reaction, and the anodic oxidation reaction is stopped after an anodic oxidation film layer reaches a preset thickness; and C, after the high silicon aluminum alloy die casting with the anodic oxidation film layer is subjected to water washing and dyeing, hole sealing treatment is performed, so that a finished product is obtained. According to the method, pretreatment, anodic oxidation reaction and post treatment technologies of the anodic oxidation reaction of the high silicon aluminum alloy die casting are modified, so that the oxidation layer which is uniform, high in dimensional accuracy, compact and attractive is formed on the surface of the prepared high silicon aluminum alloy die casting; and compared with a conventional technology, the processing technology is more environment-friendly, the processing cost is lower, and large-scale industrial production can be realized more easily.

Owner:东莞市容邦尚电子科技有限公司

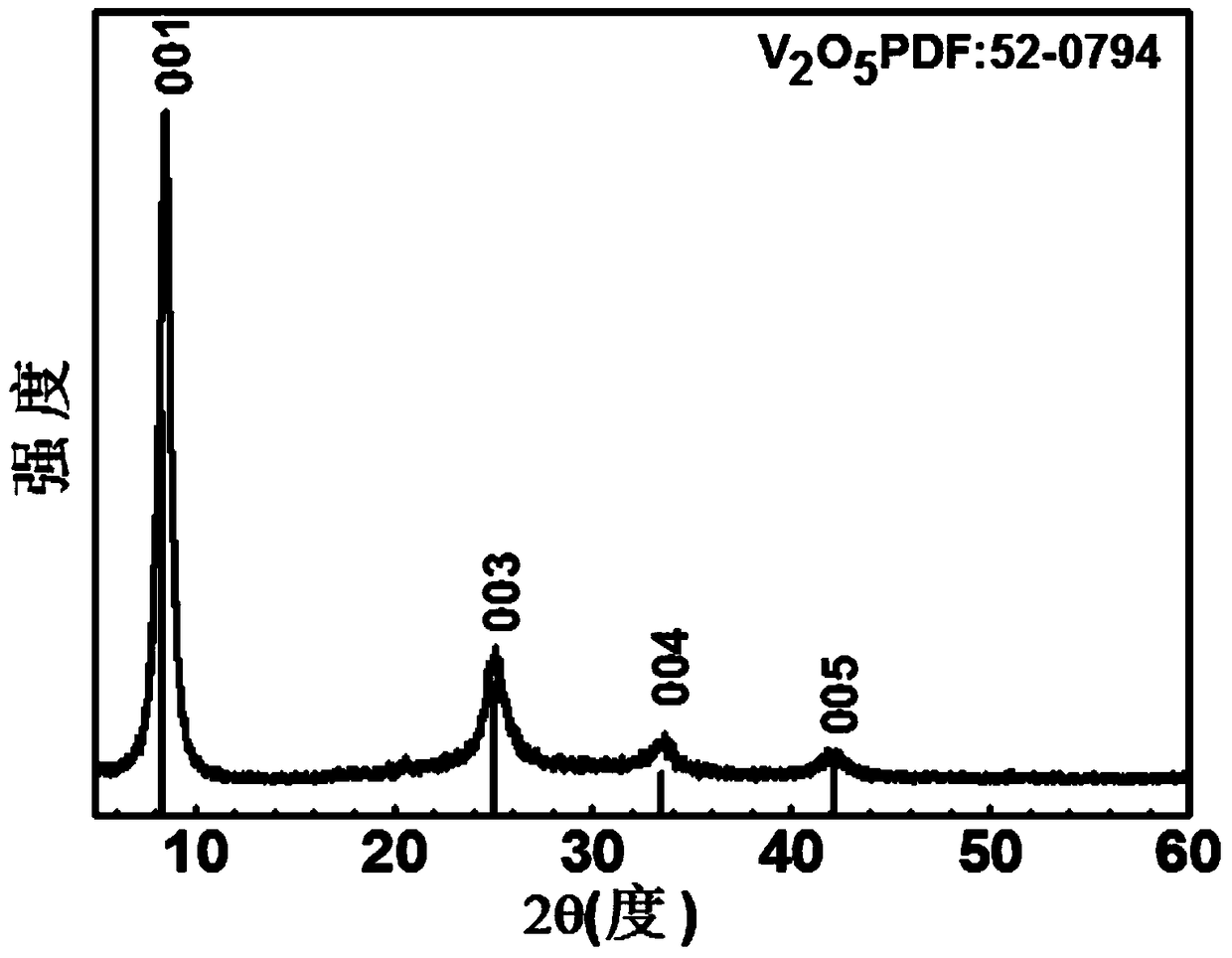

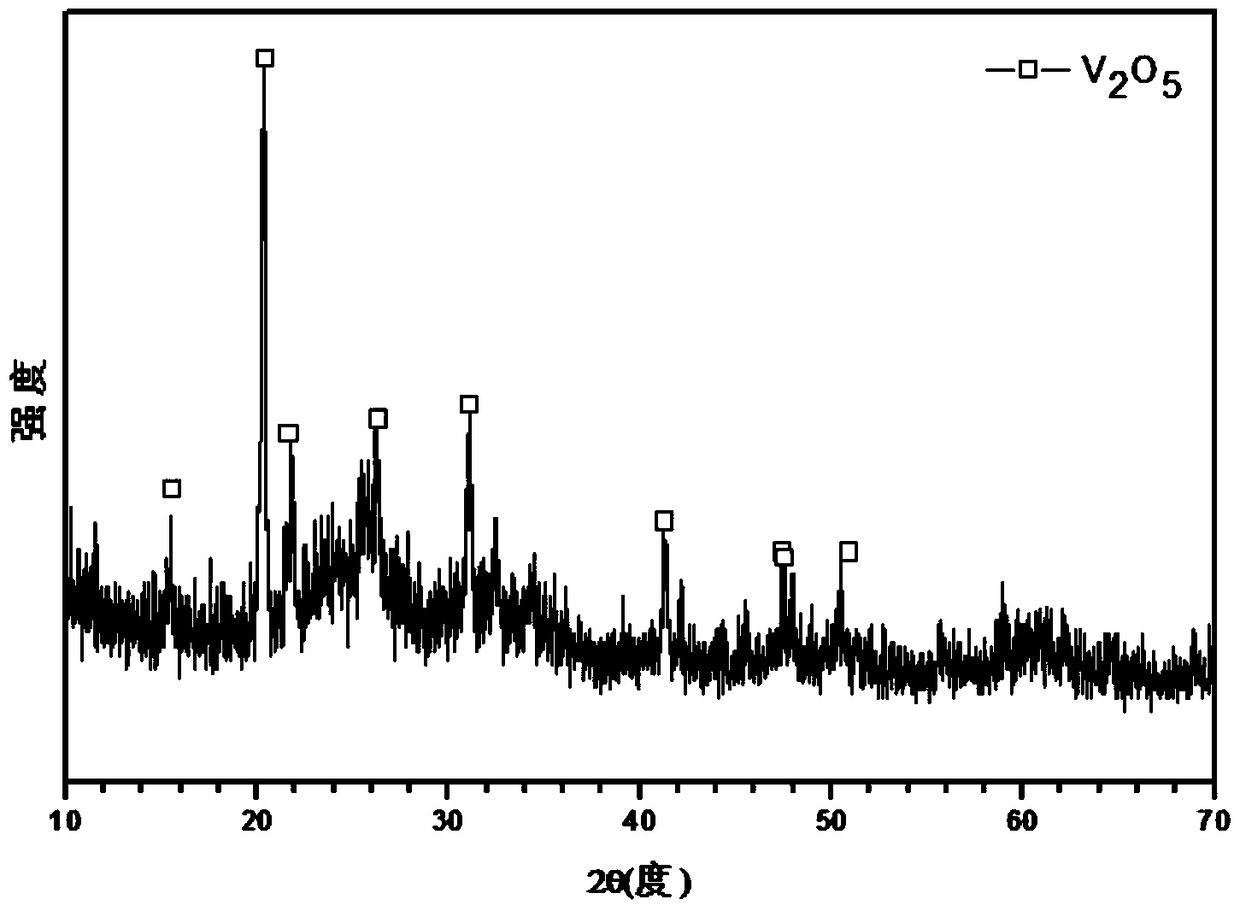

A kind of method for preparing vanadium pentoxide nano film at low temperature

The invention relates to a method of preparing vanadium pentoxide nano-films at a low temperature. The method is characterized by comprising the following steps of carrying out substrate cleaning, sol preparing, film forming, film aftertreatment and the like. The invention also relates to the vanadium pentoxide nano-films prepared by the method and application of the vanadium pentoxide nano-films in thermal-induced phase transition devices, electrochromic devices, or gas-sensitive devices and the like. The method provided by the invention has the advantages of being simple in film forming, low in cost, capable of being applied to large-area preparation, and the like; according to the method, heat treatment is carried out in a closed environment, so that the temperature for preparation is remarkably lowered, and the energy consumption and cost required for preparation are greatly reduced, and environmental pollution is reduced; the prepared vanadium pentoxide films are nano-films, thereby having relatively good crystallinity.

Owner:HARBIN INST OF TECH

High-adhesion selenium-free normal temperature blackening liquid

ActiveCN107365987APromote generationAvoid obstructionMetallic material coating processesEnvironmental resistanceCopper plating

The invention relates to a high-adhesion selenium-free normal temperature blackening liquid, and belongs to the technical field of steel treatment. First of all, an effective component which has a specific chelation effect on iron ions is extracted from a Chinese medicine, and used for chelating and shielding ferrous ions replaced from the surface of steel so as to avoid the ferrous ions to hinder copper plating on the surface of the steel; and then a soy saponine extracting solution is utilized to wash the surface of the steel so as to improve the wettability of the surface of the steel, in this way, liquid is easy to wet and be spread on the surface of the steel, so that forming of even blackening films is facilitated; and finally Arabidopsis thaliana and an egg yolk fermentation material are utilized to supply the elements of nitrogen, sulfur and phosphorus, a layer of chemical protection film is formed through reoxidation on a copper oxide layer of the surface of the steel and used for filling holes between the blackening films, so that the glossiness of the blackening films is enhanced; and meanwhile, combination between the blackening films and a steel substrate can further be firmer, and the adhesion performance of the blackening films is improved. The prepared blackening liquid has the characteristics of being even in film layer, the blackening films are good in glossiness, adhesion and corrosion resistance, the component is nontoxic and environmentally friendly, and the application prospects are wide.

Owner:平湖瑞星金属工艺有限公司

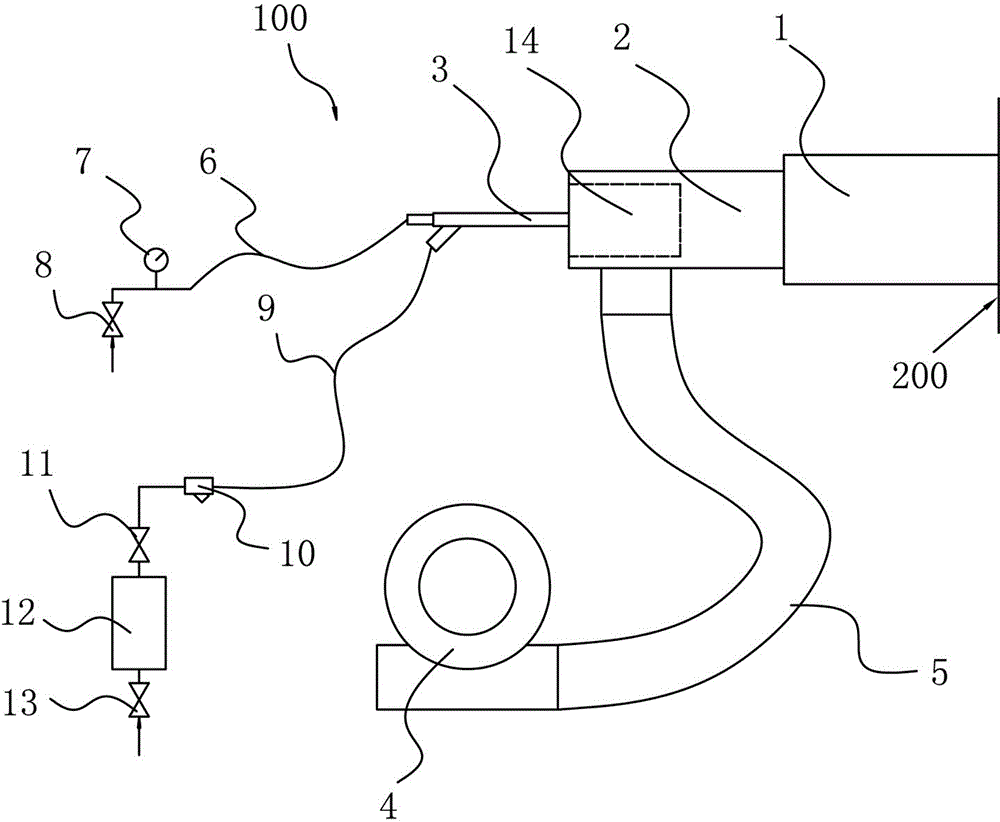

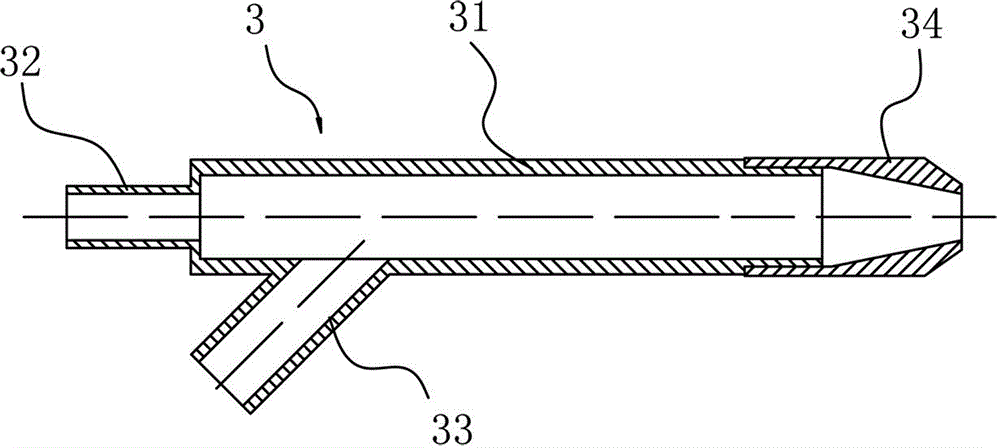

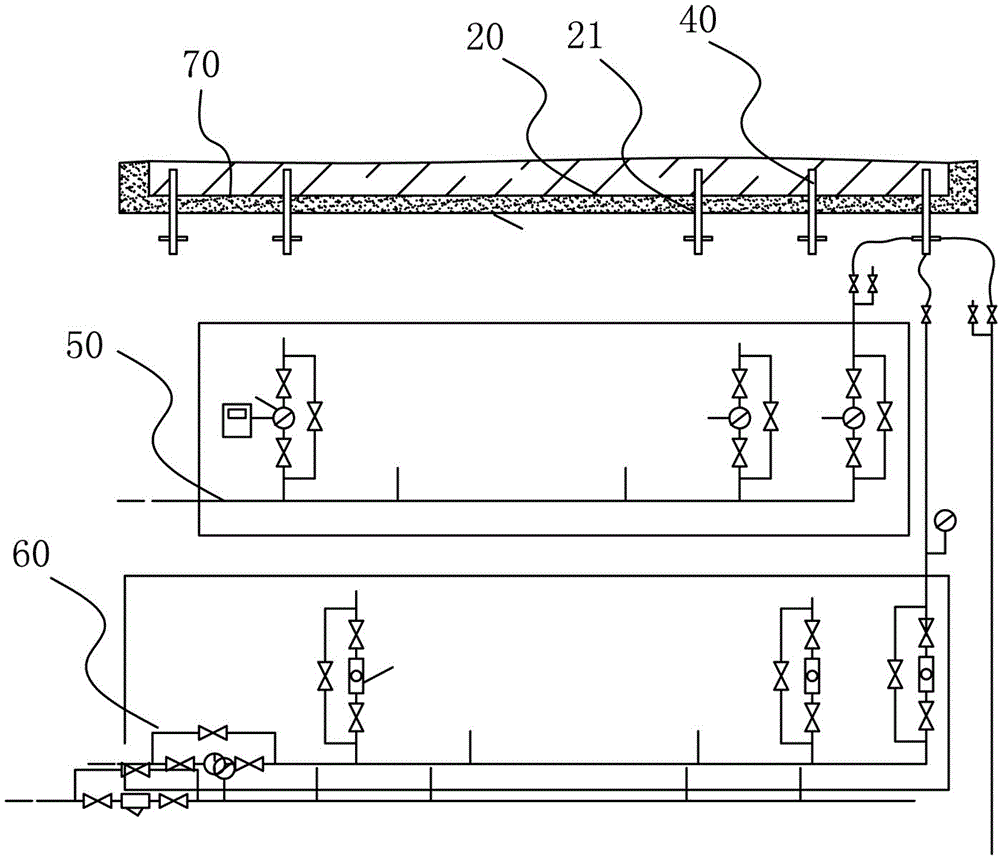

Ultrasonic phosphorizing device

PendingCN108425111ASolve problems such as rustImprove the quality of subsequent processingMetallic material coating processesUltrasonic sensorHeat conducting

The invention discloses an ultrasonic phosphorizing device for goods shelf production. The ultrasonic phosphorizing device comprises an outer jacket and a phosphorizing tank, supporting feet are arranged at the bottom of the phosphorizing tank, the outer jacket is nested outside the phosphorizing tank, an electric heating resistance wire is paved on the outer surface of the phosphorizing tank andarranged between the phosphorizing tank and the outer jacket, and an ultrasonic transducer and a temperature sensor are mounted on the side wall of the phosphorizing tank in an embedded manner and arranged in an up-down staggered manner. Ultrasonic phosphorizing technology is adopted, so that easiness in adjustment and control is realized; a phosphorized film obtained by the method is uniform, thin, compact and high in phosphorizing speed and corrosion resistance, and subsequent processing quality of workpieces is improved; heat conducting liquid is utilized to uniformly heat the phosphorizingtank, so that the problem that the phosphorizing tank is too high in temperature locally caused by the electric heating resistance wire is avoided; a nozzle enables tank liquid to be quickly stirredwell, so that heating efficiency is improved; an automatic deslagging device is arranged, so that labor intensity of workers is lowered.

Owner:浙江剑麟金属制品有限公司

Crystalline silicon solar cell mask manufacturing device

ActiveCN102931279ACompact structureUniform film layerFinal product manufactureSemiconductor devicesIonDamp environment

The invention discloses a crystalline silicon solar cell mask manufacturing device. The crystalline silicon solar cell mask manufacturing device comprises a reaction cavity, a phosphorus source output device and a constant temperature heating device and is characterized by further comprising a deionized water device, wherein the deionized water device is arranged above the constant temperature heating device. The crystalline silicon solar cell mask manufacturing device has the advantages that the deionized water device is arranged above the constant temperature heating device, the internal temperature of the deionized water device is controlled by a temperature controller, phosphorus diffusion and surface oxidation can be carried out on silicon wafers under moist environment by means of the crystalline silicon solar cell mask manufacturing device, and therefore a silica mask layer formed on surfaces is structurally compact and uniform and can effectively prevent secondary diffusion of a phosphorus source. Waste gas after reaction is exhausted through an exhaust pipeline.

Owner:DONGFANG HUANSHENG PHOTOVOLTAIC (JIANGSU) CO LTD

Method for micro-arc depositing ceramic layer onto positive and negative bipolarities on magnesium alloy

InactiveCN1226467CShorten the timeReduce consumptionAnodisationElectrolytic inorganic material coatingPlasma electrolytic oxidationMicro arc oxidation

A technology for electrically depositing a ceramic layer on the surface of Mg alloy with the microarc between cathode and anode is disclosed. The pretreated Mg-alloy workpiece is connected respectively to the positive and negative electrodes of a high-power full-wave pulse power supply and then put in the alkaline electrolyte prepared from deionized water and sodium silicate. The cathode and anode of the electrolyzer are Mg-alloy workpiece. The symmetrical AC pulse voltage is used for the microarc depositing on the surface of Mg-alloy workpiece. The output voltage of power supply is continuously raised up with the progress of microarc oxidizing. Its advantages are less heat and energy consumption, low cost, and high effect and productivity.

Owner:UNIV OF SCI & TECH BEIJING

A kind of nickel-free one-component high corrosion resistance environmental protection black phosphating liquid

InactiveCN104032293BImprove corrosion resistanceHigh blacknessMetallic material coating processesNitriteHazardous substance

The invention discloses highly corrosion-resistant environment-friendly black phosphatizing liquid without nickel single component. Each liter of the treatment liquid consists of the following raw materials: 25-50g of main film forming agent, 5-25g of film forming aid, 0.1-3g of accelerant, 60-80g of grain refiner, 0.5-2g of stabilizer, 0.05-1g of blackening agent and 0.1-0.5g of blackening aid. The phosphatizing liquid disclosed by the invention can form a black phosphatized film on a steel surface by a one-step process. The phosphatized film has high blackness and high corrosion resistance, is uniform and avoids stripping; a copper sulfate spot test can reach 40min which is much longer than the national standard (2min); the phosphatizing liquid does not contain toxic and harmful substances such as nickel, nitrite and the like and causes little environmental pollution.

Owner:ANHUI JIANGNAN MACHINERY

Preparation and using method of magnesium oxide film coating liquid

InactiveCN109055920AUniform film layerUniform colorLiquid/solution decomposition chemical coatingEmulsionMagnesium

The invention belongs to the technical field of surface treatment and relates to the preparation and a using method of magnesium oxide film coating liquid, and particularly relates to a preparing process method of 1J22 material punching sheet magnesium oxide film coating liquid and the use of magnesium oxide coating liquid. The invention solves the problems of the preparation of the 1J22 materialpunching sheet magnesium oxide film coating liquid and the use of the thermal coating method of the coating liquid. The prepared coating liquid is subjected to high-speed grinding refining and high-speed stirring treatment, so that the magnesium oxide in the mixed liquid is completely refined, uniformly, and dispersed into the mixed liquid to form an off-white to milky white emulsion. Before coating, the magnesium oxide film coating liquid is pre-heated, and the surface of the part is also pre-heated to above 120 DEG C, so that the moisture in the coating liquid is quickly dried and vaporizedduring coating, and a uniform magnesium oxide coating film is formed on the surface of the part. According to the preparation and using method of magnesium oxide film coating liquid, no baking is required before coating, the film layer and the color are uniform, the number of stacked sheets is not affected, and since the concentration of the mixed liquid is low and the emulsion mixed liquid is formed by grinding and stirring, the emulsion mixed liquid can form a more uniform film layer during thermal coating.

Owner:BEIJING SHUGUANG AERO ELECTRICAL

Ti-Mg-B surface conditioner for zinc-phosphating and preparation method thereof

ActiveCN101974743BImprove refinementCrystal fineMetallic material coating processesSodium bicarbonatePyrophosphate

Owner:DALIAN SANDAAOKE CHEM

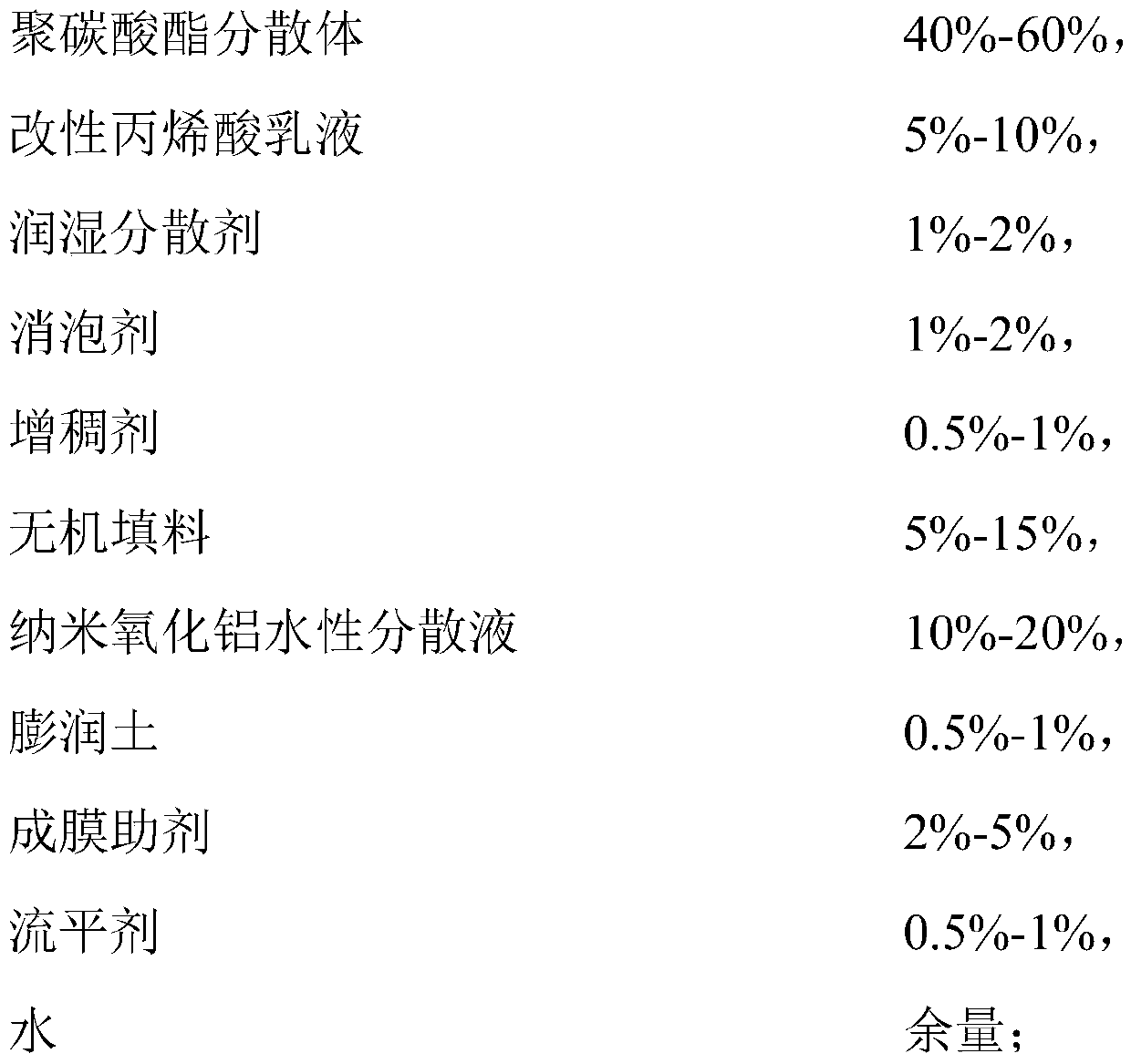

Waterborne flame-retardant coating and use method thereof

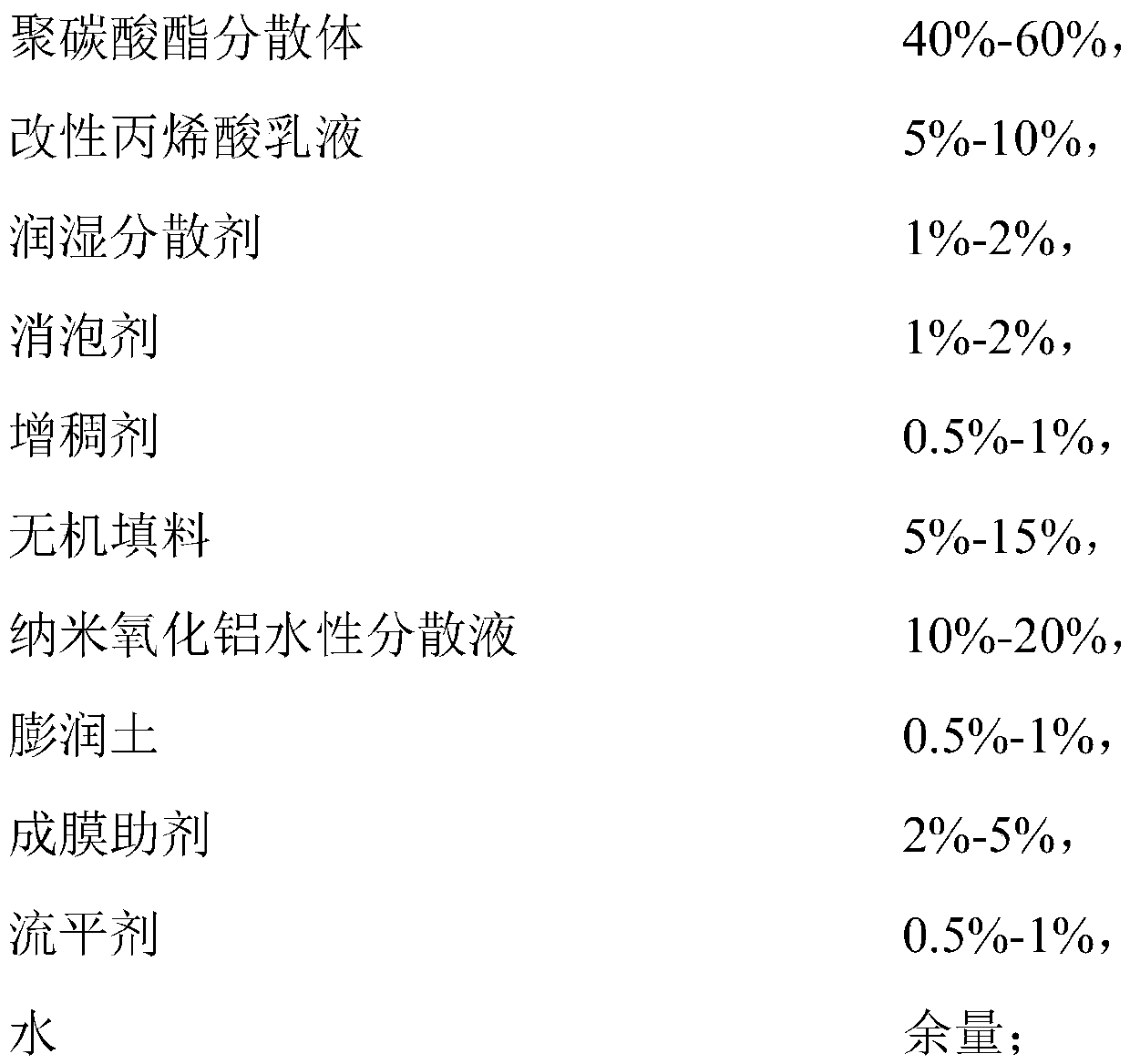

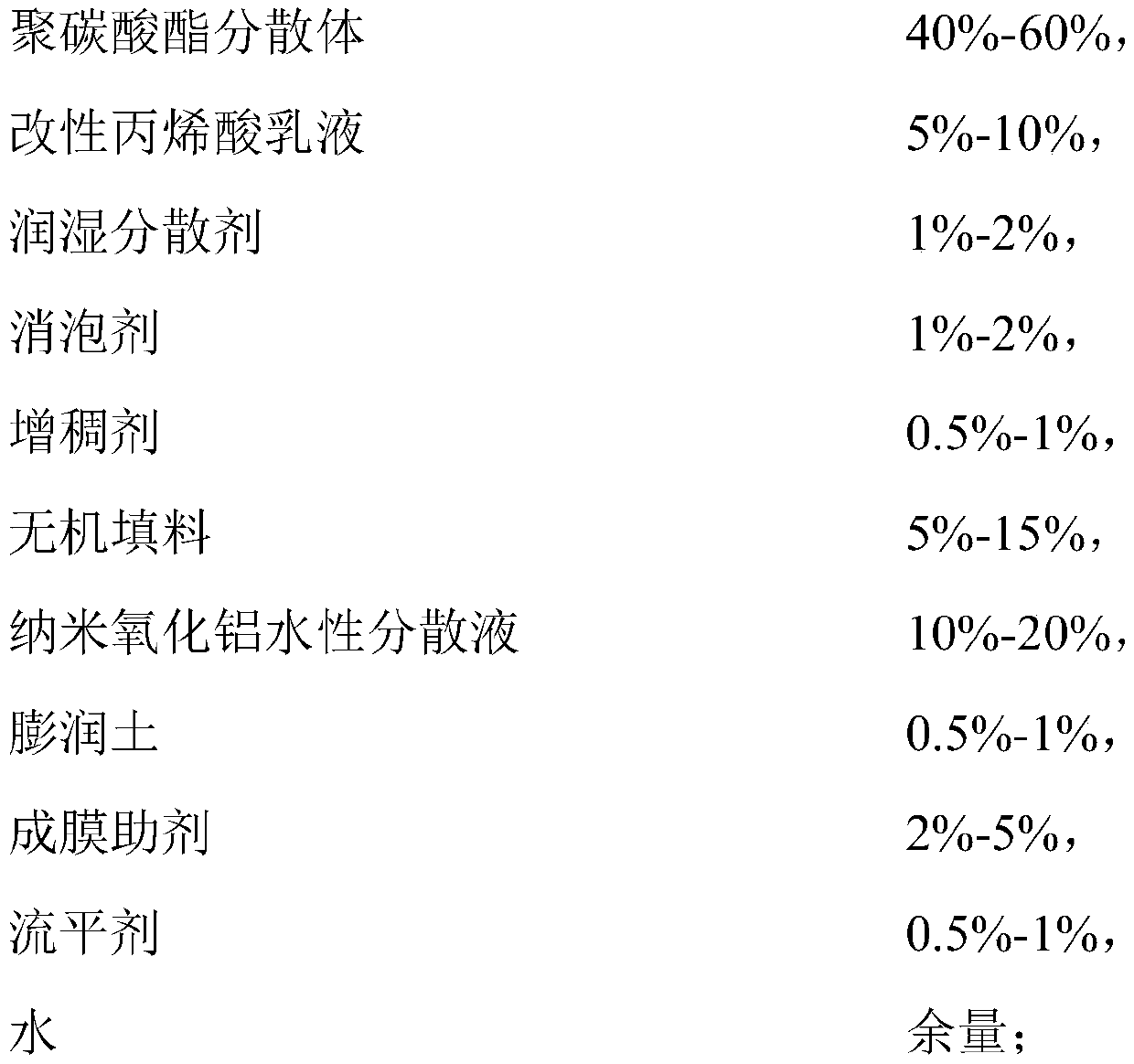

InactiveCN111471379AUniform film layerImprove flame retardant performanceFireproof paintsLiquid surface applicatorsPolymer scienceMeth-

The invention belongs to the technical field of coating, in particular to waterborne flame-retardant coating. The coating comprises a component A and a component B. With the total mass of the component A being 100%, the component A comprises 40%-60% of polycarbonate dispersion, 5%-10% of modified acrylic emulsion, 1%-2% of a wetting dispersant, 1%-2% of a defoamer, 0.5%-1% of a thickener, 5%-15% of an inorganic filler, 10%-20% of a dispersant, 0.5%-1% of bentonite, 2%-5% of a coalescing agent, and 0.5%-1% of a leveling agent, with the balance being water. The component B comprises hexamethylene diisocyanate. Through the combined action of the component A and the component B, a coating film formed by the waterborne flame-retardant coating has excellent flame-retardant and heat-insulating properties, has good adhesion on a base material, and can well delay material combustion; and meanwhile, when the flame-retardant coating is coated in a conventional wood product, furniture can obtain good flame retardance, and the product universality is relatively wide.

Owner:中华制漆(新丰)有限公司

Rare-earth modified titanium-zirconium series chemical passivation solution for surface treatment of aluminum profiles and usage method

ActiveCN103103512BImprove compactnessImprove performanceMetallic material coating processesCerium nitrateTitanium zirconium

The invention discloses a rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and a using method of the rare-earth modified Ti-Zr chemical passivation solution. The rare-earth modified Ti-Zr chemical passivation solution is characterized in that the passivation solution is a main salt for auxiliary film-formation, which takes rare-earth compounds as a Ti-Zr passivation treatment solution, and a passivation film is light yellow in appearance and has field judgement property on the quality of a formed film. A formula of the rare-earth modified Ti-Zr chemical passivation solution is as follows: each litre of solution contains 0.5g.L<-1>-10g.L<-1> of potassium fluotitanate (hexafluorotitanic acid), 0.5g.L<-1>-10g.L<-1> of potassium fluozirconate (fluozirconic acid), 0.5g.L<-1>-5g.L<-1> of cerium nitrate (ceric sulfate and ammonium ceric nitrate), 2g.L<-1>-10g.L<-1> of potassium nitrate, 0.5g.L<-1>-3g.L<-1> of sodium fluoride (potassium fluoride), 0.5g.L<-1>-1g.L<-1> of sodium dodecyl benzene sulfonate or OP-10, 0.2mL-5mL.L<-1> of nitric acid and 1g.L<-1>-5g.L<-1> of boric acid. The using method of the rare-earth modified Ti-Zr chemical passivation solution comprises the following steps of: (1) clearing dirt, such as dirt attached to an aluminium alloy; (2) pretreating the surface of the aluminium alloy; (3) carrying out passivating treatment on the surface of the aluminium alloy by using the rare-earth modified Ti-Zr chemical passivation solution; and (4) washing the aluminium alloy by using water and drying the aluminium alloy. The rare-earth modified Ti-Zr chemical passivation solution disclosed by the invention has the advantages of light yellow appearance, high film formation speed, simple process, uniformity in film layer, strong corrosion resistance, low environment pollution and the like.

Owner:GUANGDONG XINGFA ALUMINUM

A kind of fluorine-containing polymer-based dielectric composite film and preparation method thereof

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

Method for preparing nanostructure using photo-activation nano active water

InactiveCN101357748AFine and even textureUniform colorNanostructure manufactureUltravioletCurrent technology

The invention discloses a method for producing nanometer structure with nano-photocatalytic active water. Templates and nanometer materials to be processed are immerged in the nano-photocatalytic active water; under irradiation of ultraviolet, the nanometer materials are deposited on the templates to generate the nanometer structure. Nanometer atom in the active water can be deposited on the templates or a work piece to crank out a nanometer product, thus replacing methods of high temperature, microvacuum, electron beam, laser, and vapor phase, and the like, for producing the nanometer structure. The nanometer structure prepared by the method is compact, well distributed, and is provided with strong bonding force, and is characterized by distinct properties of mechanics, optics, heat exchange, electromagnetic, superconduct, electricity, physics, and chemistry, and the like, particularly, the nanometer structure can be applied to important fields of national defense, military affairs, medical treatment, epidemic situation, industry and agriculture, and has important significance, can be capable of being applied to key technology which can not be solved by current technology. The technical craft is simple and is suitable for industrialized production; the cost is low; the technique can become a technical revolution.

Owner:张金龙

A high adhesion selenium-free room temperature blackening solution

ActiveCN107365987BPromote generationAvoid obstructionMetallic material coating processesEnvironmental resistanceCopper plating

The invention relates to a high-adhesion selenium-free normal temperature blackening liquid, and belongs to the technical field of steel treatment. First of all, an effective component which has a specific chelation effect on iron ions is extracted from a Chinese medicine, and used for chelating and shielding ferrous ions replaced from the surface of steel so as to avoid the ferrous ions to hinder copper plating on the surface of the steel; and then a soy saponine extracting solution is utilized to wash the surface of the steel so as to improve the wettability of the surface of the steel, in this way, liquid is easy to wet and be spread on the surface of the steel, so that forming of even blackening films is facilitated; and finally Arabidopsis thaliana and an egg yolk fermentation material are utilized to supply the elements of nitrogen, sulfur and phosphorus, a layer of chemical protection film is formed through reoxidation on a copper oxide layer of the surface of the steel and used for filling holes between the blackening films, so that the glossiness of the blackening films is enhanced; and meanwhile, combination between the blackening films and a steel substrate can further be firmer, and the adhesion performance of the blackening films is improved. The prepared blackening liquid has the characteristics of being even in film layer, the blackening films are good in glossiness, adhesion and corrosion resistance, the component is nontoxic and environmentally friendly, and the application prospects are wide.

Owner:平湖瑞星金属工艺有限公司

Method for plating X-ray parabolic reflector surface with high-reflective film

The invention discloses a method for plating an X-ray parabolic reflector surface with high-reflective film. The method comprises the steps of, firstly, cleaning a glass substrate; secondly, clamping the glass substrate with a specific clamp and baking the glass substrate; thirdly, coating the glass substrate with Cr film; fourthly, coating the Cr film with Ir film. The method has the advantages that reflectivity and the target use rate are high, film coatings are uniform and film adsorption capacity is high.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com