A kind of method for preparing vanadium pentoxide nano film at low temperature

A technology of vanadium pentoxide nanometer and vanadium pentoxide, which is applied in the field of low-temperature preparation of vanadium pentoxide nanometer film, to achieve the effect of uniform film layer, flexible method and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of vanadium pentoxide film at 300°C for 12 hours

[0032] The specific preparation method is as follows:

[0033] The first step is to clean the glass sheet: use piranha reagent (concentrated sulfuric acid and hydrogen peroxide at a volume ratio of 7 to 3) to soak the glass substrate for 1 hour; the soaked glass sheet is ultrasonicated for 20 minutes with acetone, methanol, and ultrapure water in sequence, and then dried for later use ;

[0034] The second step, sol preparation: pour the vanadium pentoxide sol of 5g molten state into 200ml ultrapure water, after stirring at 1000 revolutions per minute for 1 hour, add PVP in the vanadium pentoxide sol by 6% mass ratio, continue Stir at 1600 rpm for 1 hour, set aside;

[0035] The third step, film forming process: use the constant temperature pulling machine of Shenyang Kejing, with the pulling speed of 500μm / s, the infiltration speed of 500μm / s, the infiltration time of 10s and the drying time of ...

Embodiment 2

[0038] Example 2 Preparation of vanadium pentoxide film at 180°C for 36 hours

[0039] The specific preparation method is as follows:

[0040] The first step is to clean the glass sheet: use piranha reagent (concentrated sulfuric acid and hydrogen peroxide at a volume ratio of 7 to 3) to soak the glass substrate for 1 hour; the soaked glass sheet is ultrasonicated for 20 minutes with acetone, methanol, and ultrapure water in sequence, and then dried for later use ;

[0041] The second step, sol preparation: pour the vanadium pentoxide sol of 5g molten state into 200ml ultrapure water, after stirring at 1000 revolutions per minute for 1 hour, add PVP in the vanadium pentoxide sol by 6% mass ratio, continue Stir at 1600 rpm for 1 hour, set aside;

[0042] The third step, film forming process: use the constant temperature pulling machine of Shenyang Kejing, with the pulling speed of 500μm / s, the infiltration speed of 500μm / s, the infiltration time of 10s and the drying time of ...

Embodiment 3 to 7

[0046] Except for the contents shown in Table 1, the vanadium pentoxide thin film was prepared in the same manner as in Example 1, and its parameters are shown in Table 1 below.

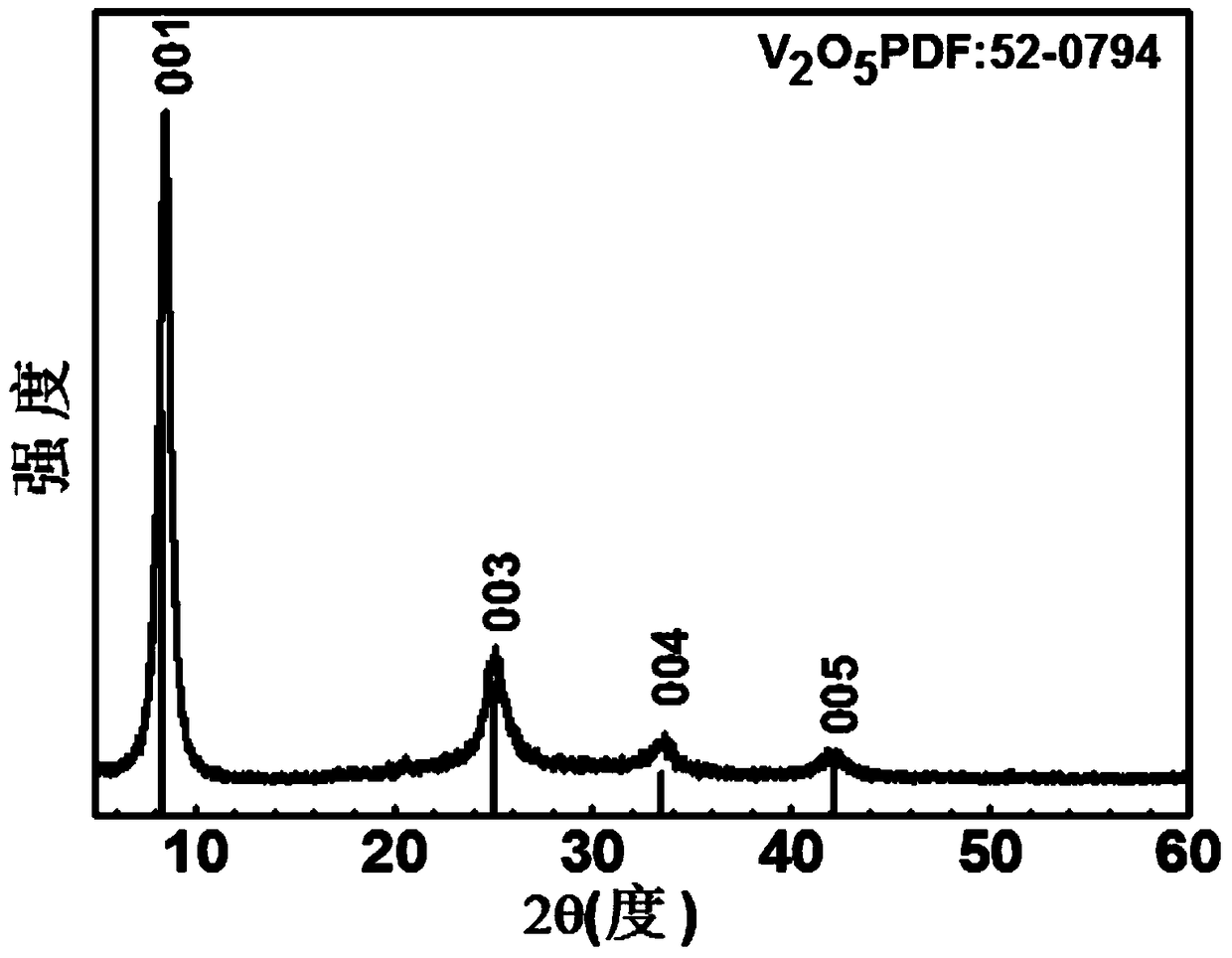

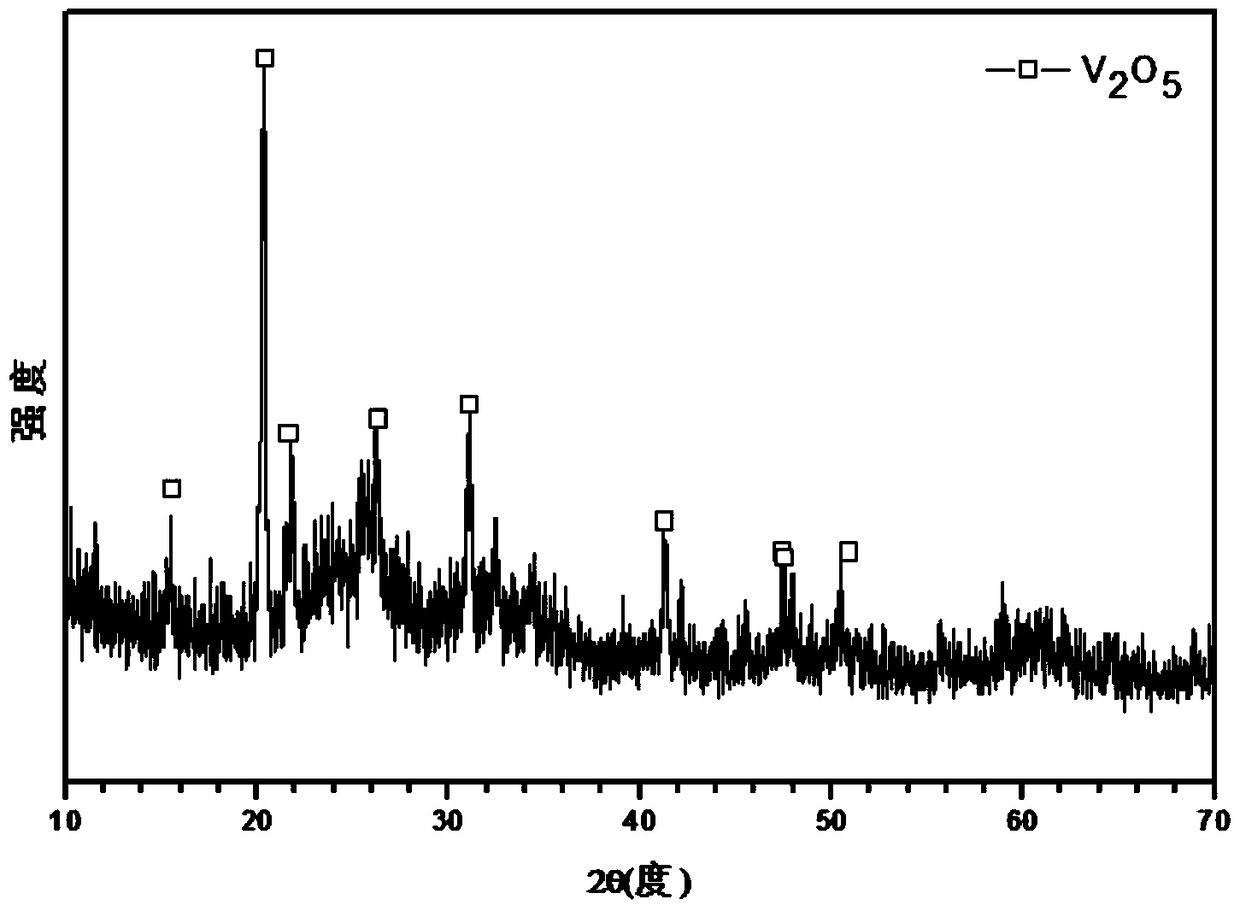

[0047] Adopt SEM method known in the art to observe the uniformity of thin film and adopt the Japanese D / max-rb type X-ray diffractometer that can be purchased commercially, carry out scanning test to thin film with the speed of 1 degree / min, test result shows that also all Similar results were obtained. In comparison, Figures 1 to 2 effect is particularly pronounced.

[0048] The parameters adopted when each embodiment of table 1 prepares vanadium pentoxide thin film

[0049] Example number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com