Method for micro-arc depositing ceramic layer onto positive and negative bipolarities on magnesium alloy

A technology of micro-arc electrodeposition and magnesium alloy, which is applied in the direction of anodic oxidation, electrolytic inorganic material coating, etc., can solve the problems of high production cost and large power consumption, achieve high production efficiency, reduce power consumption, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Using a bidirectional full-wave pulsed micro-arc oxidation power supply, connect the magnesium alloy specimen to the positive and negative poles of the power supply respectively. The entire technological process is: sample grinding, cleaning, degreasing, connecting wires electrified, micro-arc oxidation, cleaning the sample, and drying.

[0023] Taking AZ91D cast magnesium alloy as an example, the optimal scheme of cathode and anode bipolar micro-arc electrodeposition on the surface of magnesium alloy obtained by orthogonal optimization of electrolyte parameters and electrical parameters is as follows:

[0024] Na 2 SiO 3 9H 2 O 15g / L

[0025] NaOH 5g / L

[0026] h 3 BO 3 3g / L

[0027] CeF 4 ·H 2 O 1g / L

[0028] pH 12~13

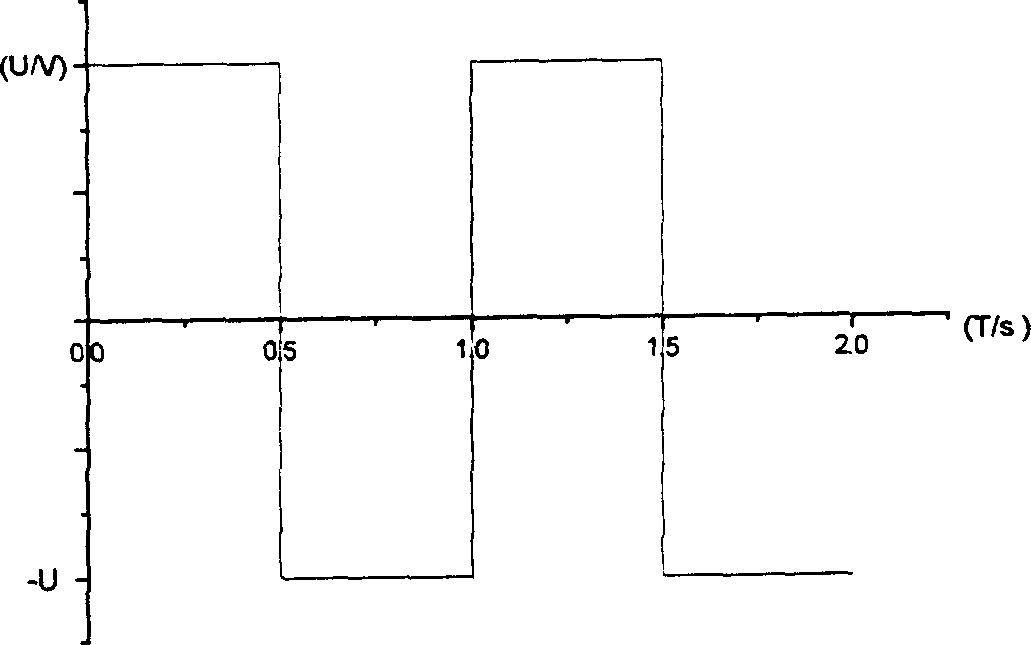

[0029] Frequency 50Hz

[0030] Duty cycle 0.5

[0031] Time 60min

[0032] Voltage 220V

[0033] figure 2 and image 3 The structure and morphology of the cathode and anode AZ91D cast magnesium alloy micro-arc ceramic lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com