Self-healing environment-friendly type steel normal-temperature blackening agent

An environmentally friendly, blackening agent technology, which is applied in the coating process of metal materials, etc., can solve problems such as poor stability, difficult solution maintenance, and poor gloss of the blackened film, achieving excellent adhesion and corrosion resistance, and avoiding excessive Or less black, the effect of uniform film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

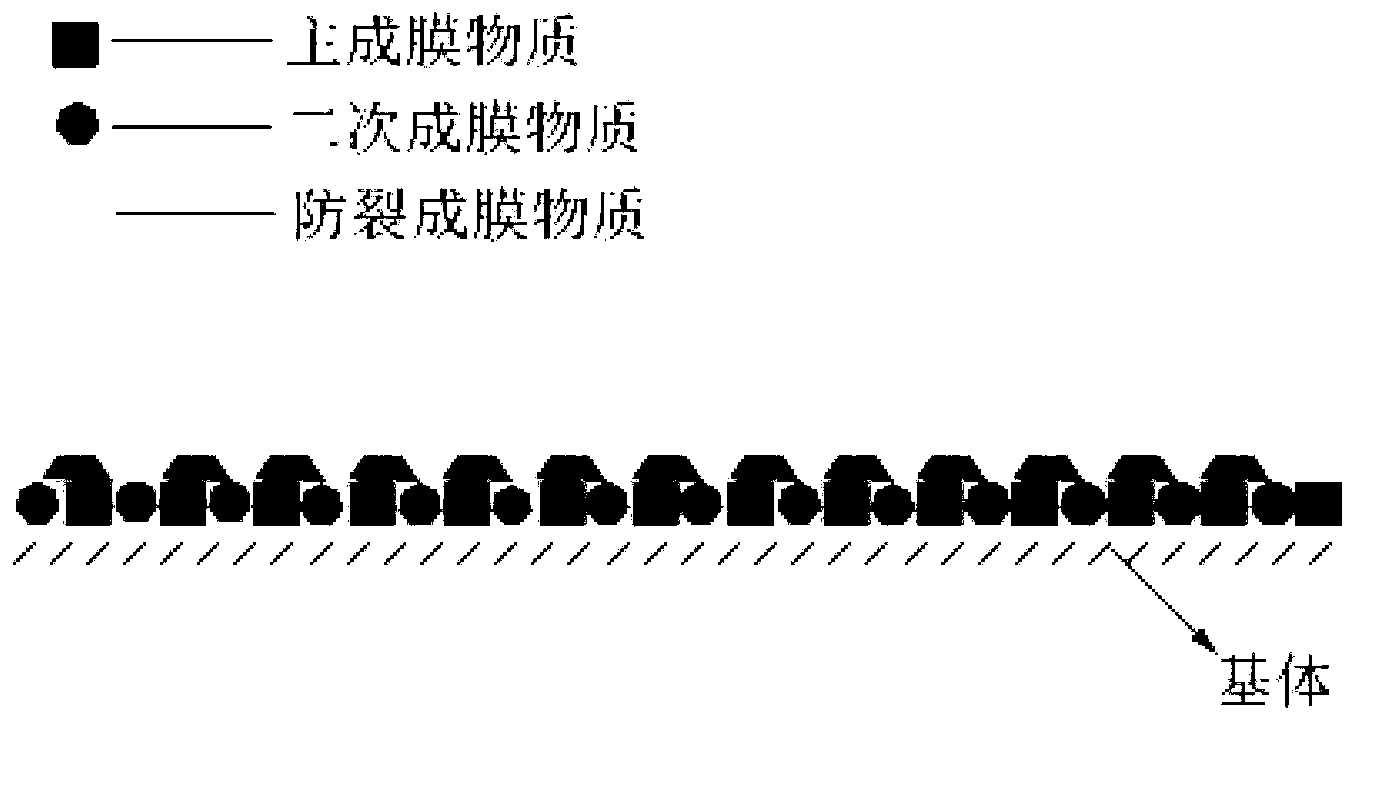

Method used

Image

Examples

Embodiment 1

[0036] 1) Weigh each raw material and its content in the following table (calculated based on 1L of solution):

[0037]

[0038] 2) Measure 958.5mL of water and weigh 1g of alkyl glycoside.

[0039]3) Dissolve the components of the blackening stabilizer in 2 / 3 of the water, stir evenly to form a stable solution, then add the main film-forming agent and secondary film-forming agent in sequence, and add the remaining 1 / 3 of the solvent water, then add surfactant, and form a blackened mother liquor after fully stirring at room temperature; then add the mixed film anti-cracking agent into the mother liquor under ultrasonic dispersion, finally, add alkyl glucoside, stir well, and statically After 24 hours, the self-healing and environment-friendly blackening agent for steel at room temperature was prepared, and the measured pH was 1.9.

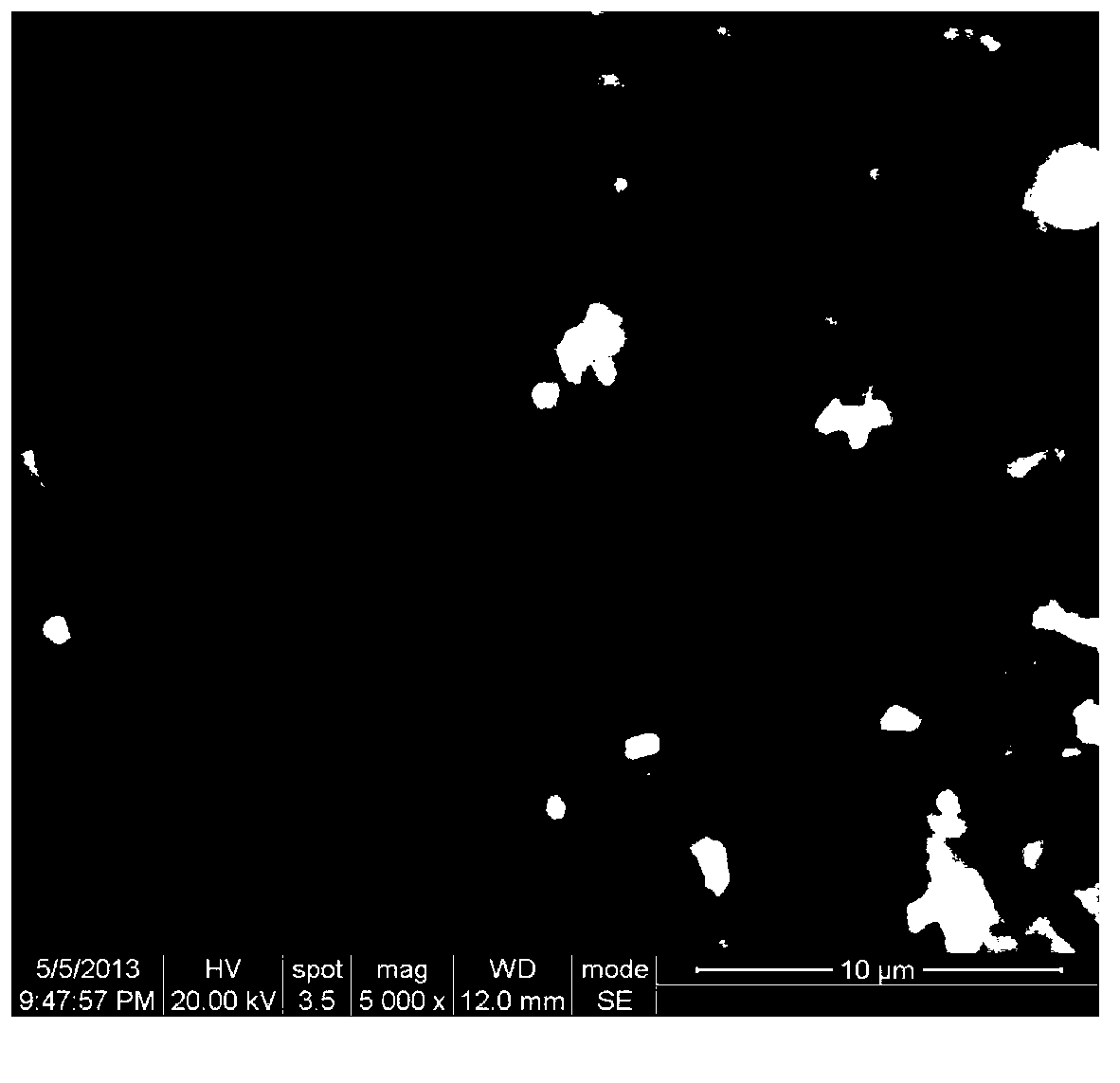

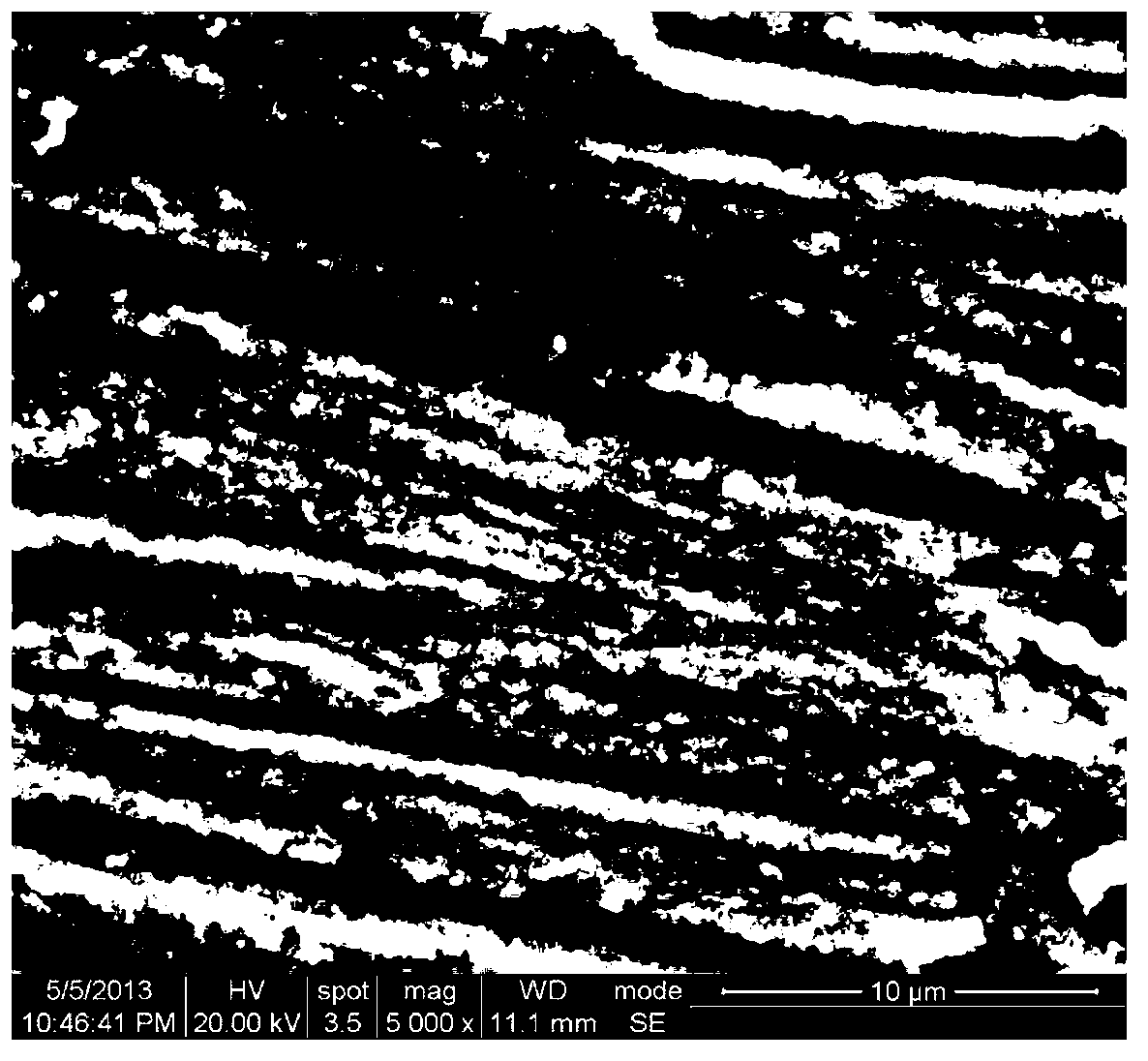

[0040] 4) After the 45 steel has been degreased and derusted, it is put into the configured self-healing and environment-friendly steel blacke...

Embodiment 2

[0043] 1) Weigh each raw material and its content in the following table (calculated based on 1L of solution):

[0044]

[0045] 2) Measure 926.2mL of water and weigh 1.5g of alkyl glycoside.

[0046] 3) According to the method described in Example 1, a self-healing and environment-friendly iron and steel room temperature blackening agent was prepared, and the measured pH was 1.7.

[0047] 4) After the 45 steel has been degreased and derusted, it is put into the configured self-healing and environment-friendly steel blackening agent at room temperature for blackening experiments, and the performance of the blackened film is tested. The results are as follows:

[0048] project

Embodiment 3

[0050] 1) Weigh each raw material and its content in the following table (calculated based on 1L of solution):

[0051]

[0052] 2) Measure 892mL of water and weigh 2g of alkyl glycoside.

[0053] 3) According to the method described in Example 1, a self-healing and environment-friendly steel room temperature blackening agent was prepared, and the measured pH was 1.6.

[0054] 4) After the 45 steel has been degreased and derusted, it is put into the configured self-healing and environment-friendly steel blackening agent at room temperature for blackening experiments, and the performance of the blackened film is tested. The results are as follows:

[0055] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com