Patents

Literature

242 results about "Ammonium molybdate tetrahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soiless culture nutrient solution

InactiveCN103172438AInhibition of reproductionIncrease resistanceFertilizer mixturesCalcium nitrate tetrahydrateManganese

The invention relates to the soiless culture field and in particular relates to a soiless culture nutrient solution; every liter of water comprises the following components by weight: major constituents consisting of 900mg-2200mg of much EM (Effective Microorganisms) probiotics liquid, 900mg-2200mg of brown sugar, 900mg-1000mg of calcium nitrate tetrahydrate, 700mg-900mg of potassium nitrate, 150mg-220mg of ammonium dihydrogen phosphate and 300mg-500mg of magnesium sulfate heptahydrate; micro constituents consisting of 20mg-25mg of EDTA (Ethylene Diamine Tetraacetic Acid) chelated iron, 2mg-3mg of boric acid, 2mg-3mg of manganese sulfate monohydrate, 0.1mg-0.5mg of zinc sulfate heptahydrate, 0.01mg-0.1mg of copper sulfate and 0.01mg-0.08mg of ammonium molybdate tetrahydrate. The soiless culture nutrient solution provided by the invention can be used for improvising the immunity of the soiless culture nutrient solution for resisting plant diseases and insect pests of the crops.

Owner:北京天食和谷农业科技有限公司

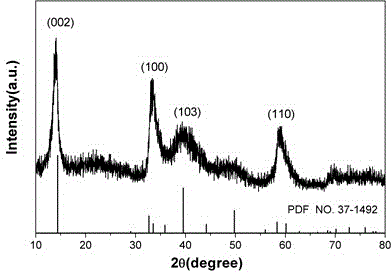

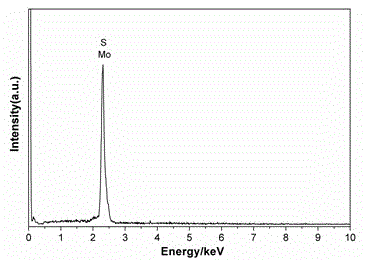

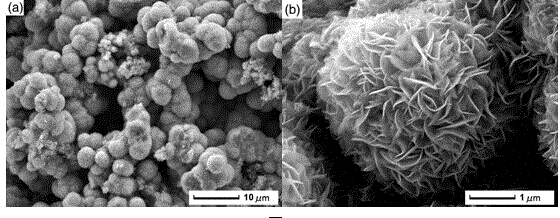

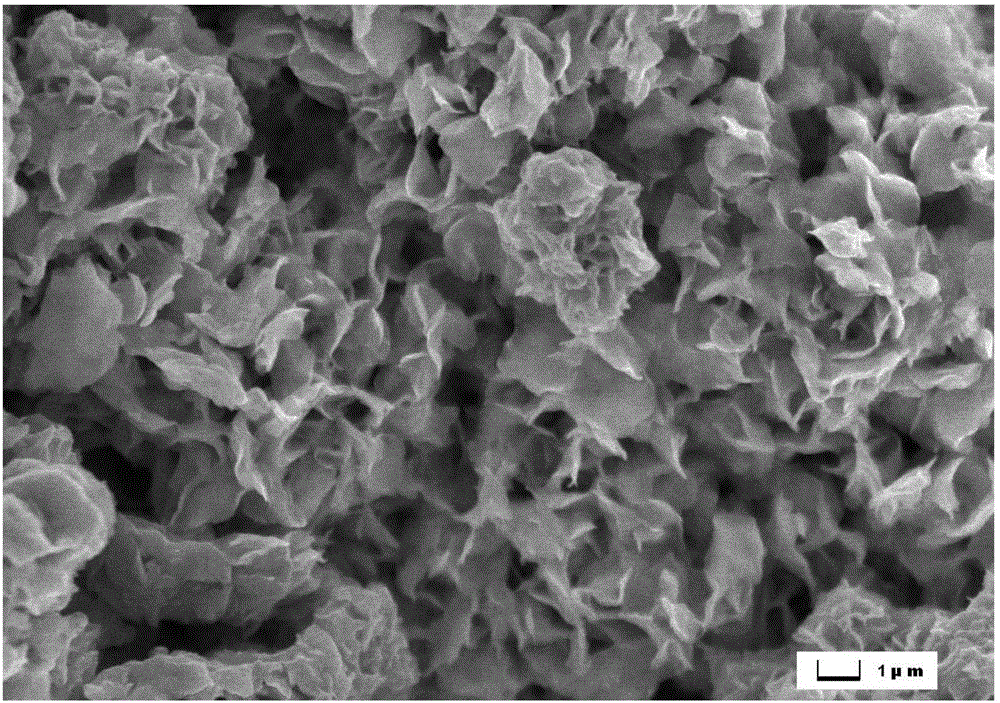

Preparation method of flower-shaped molybdenum disulfide microspheres

InactiveCN104393294AUniform shapeIncrease productivityCell electrodesMolybdenum sulfidesAlcoholThiourea

The invention discloses a preparation method of flower-shaped molybdenum disulfide microspheres. The preparation method comprises the steps of dissolving ammonium molybdate tetrahydrate in deionized water to prepare a solution of 0.02-0.05 mol / L; adding thiourea to the solution, and stirring the mixture for 20-30 min by using a magnetic stirrer so that the solution is mixed uniformly, wherein the mol ratio of ammonium molybdate tetrahydrate to thiourea is (1 : 20) to (1 : 30); transferring the solution to a hydrothermal reaction kettle, performing hydrothermal reaction for 4-8 hours at 220-240 DEG, naturally cooling, centrifuging, washing by deionized water and ethyl alcohol, and drying again to obtain molybdenum disulfide microspheres. The preparation method of the flower-shaped molybdenum disulfide microspheres has the advantages that the cost is low, the process is simple and is easy to control, the appearances of the prepared microspheres are even, and the product output is high; the preparation method is applied to large-scale industrial production.

Owner:JIANGSU UNIV OF TECH

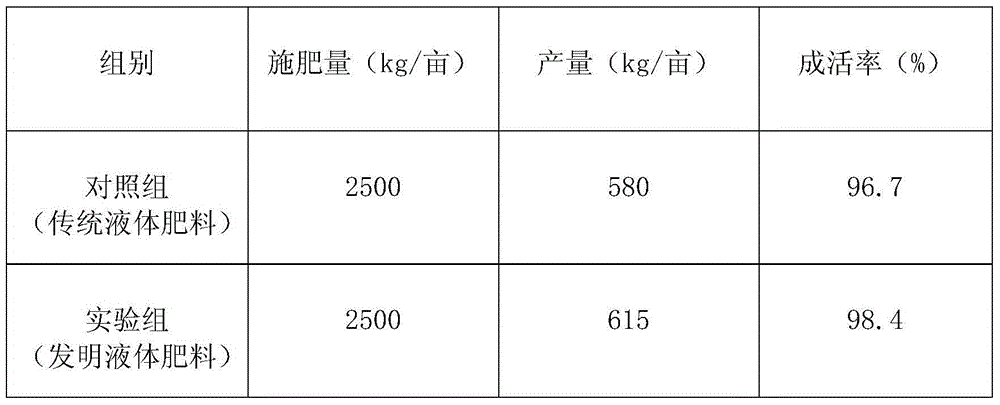

Root-promoting liquid fertilizer and preparation method thereof

The invention discloses a root-promoting liquid fertilizer, which is prepared from the following raw materials in parts by weight: 2-4 parts of ferrous sulfate, 2-3 parts of ammonium molybdate tetrahydrate, 1-3 parts of potassium pyrophosphate, 5-7 parts of short rhizome of spathiphyllum, 6-9 parts of castor cake, 15-20 parts of bran, 5-8 parts of potassium sulfate, 7-10 parts of urea, 2-4 parts of matrine, 2-3 parts of zinc sulphate heptahydrate, 0.1-0.2 part of 6-benzylaminopurine, 0.1-0.2 part of triiodobenzoic acid, 4-8 parts of rose, 10-14 parts of brewer's grains and 8-12 parts of an ingredient. Due to the addition of the 6-benzylaminopurine, the triiodobenzoic acid and the like, the liquid fertilizer disclosed by the invention has the function of adjusting the raw materials with a crop growth function, and is capable of effectively promoting rooting and formation of flower buds of the crops; the nutrient components of a microelement fertilizer can be increased by extract liquids such as chaff and brewer's grains; and the root-promoting liquid fertilizer is convenient to use, and obvious in yield-increasing effect, and has a good application prospect.

Owner:周作艳

Water culture nutrient solution of blueberry and preparation method thereof

InactiveCN102101803APromote absorptionReturn to normal growthFertilizer mixturesBiotechnologyCalcium nitrate tetrahydrate

The invention belongs to the technical field of fruit tree culture, in particular to a water culture nutrient solution prescription of a blueberry and a preparation method thereof. In the technology, the water culture nutrient solution of a blueberry comprises the following elements: 95-110mg / L of N, 10-15mg / L of P, 125-135mg / L of K, 80-90mg / L of Ca, 20-28mg / L of Mg, 4-6mg / L of Fe, 0.3-0.6mg / L of B, 0.4-0.6mg / L of Mn, 0.04-0.06mg / L of Zn, 0.02-0.04mg / L of Cu and 0.002-0.004mg / L of Mo. A pH value of the water culture nutrient solution is 4.8 to 5.5. The preparation method of the nutrient solution comprises the following steps of: weighing EDTA (Ethylene Diamine Tetraacetic Acid) ferrisodium, boric acid, manganese sulfate tetrahydrate, zinc sulphate heptahydrate, copper sulfate pentahydrate and ammonium molybdate tetrahydrate for dissolving into water and blending into 100 times of trace element mother liquor for storage and later use; additionally weighing calcium nitrate tetrahydrate, potassium nitrate, monopotassium phosphate and magnesium sulfate heptahydrate for dissolving into water; absorbing the trace element mother liquor into the solution according to the consumption; adding water for quantifying to needed volume; uniformly stirring; and adjusting the pH value of the solution to be 4.8 to 5.5 with 0.1mg / L dilute H2SO4 or dilute NaOH. By utilizing the technology, the water culture aims of growing a plurality of aquatic roots in 20 days after a blueberry seedling is transplanted and having the plant survival rate of more than 90 percent can be achieved.

Owner:JINLING INST OF TECH

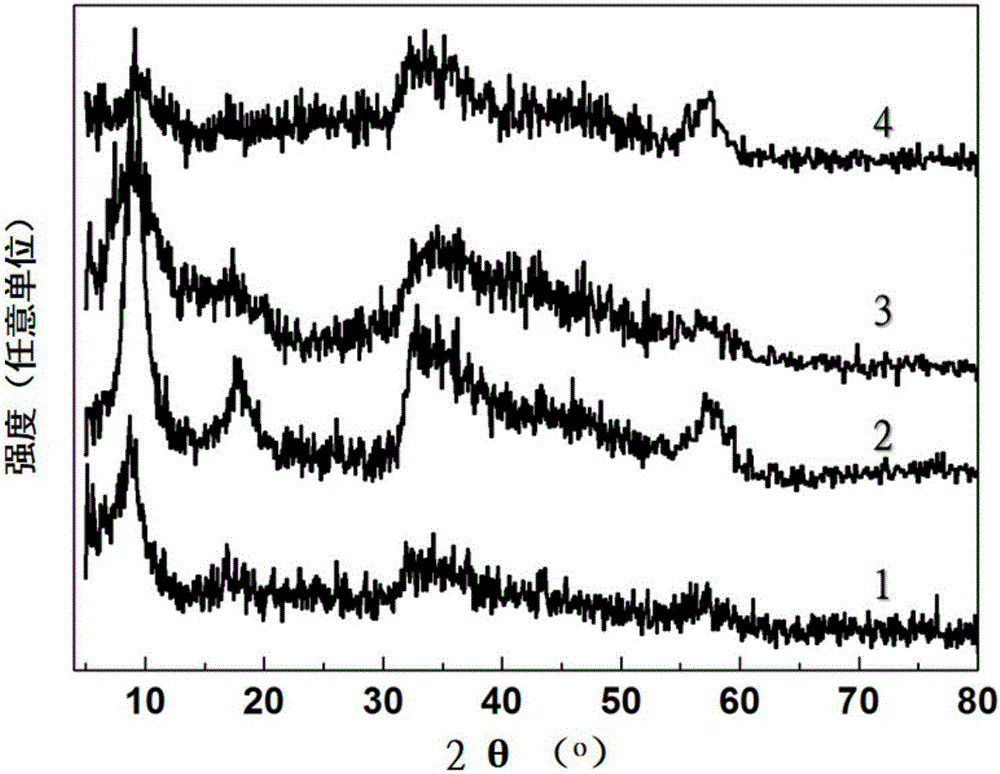

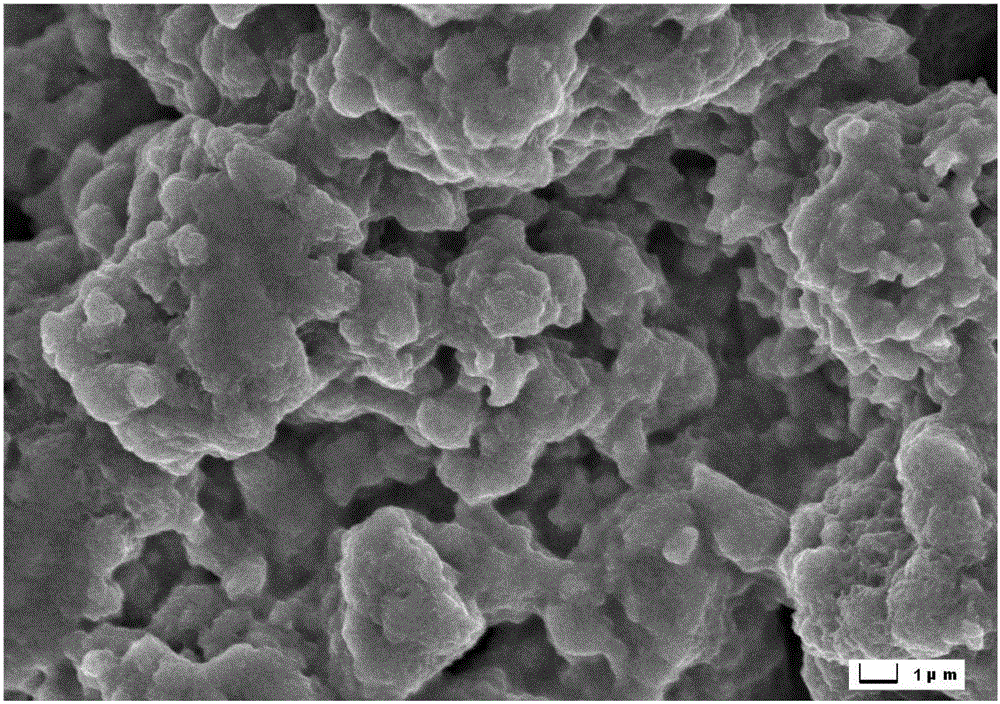

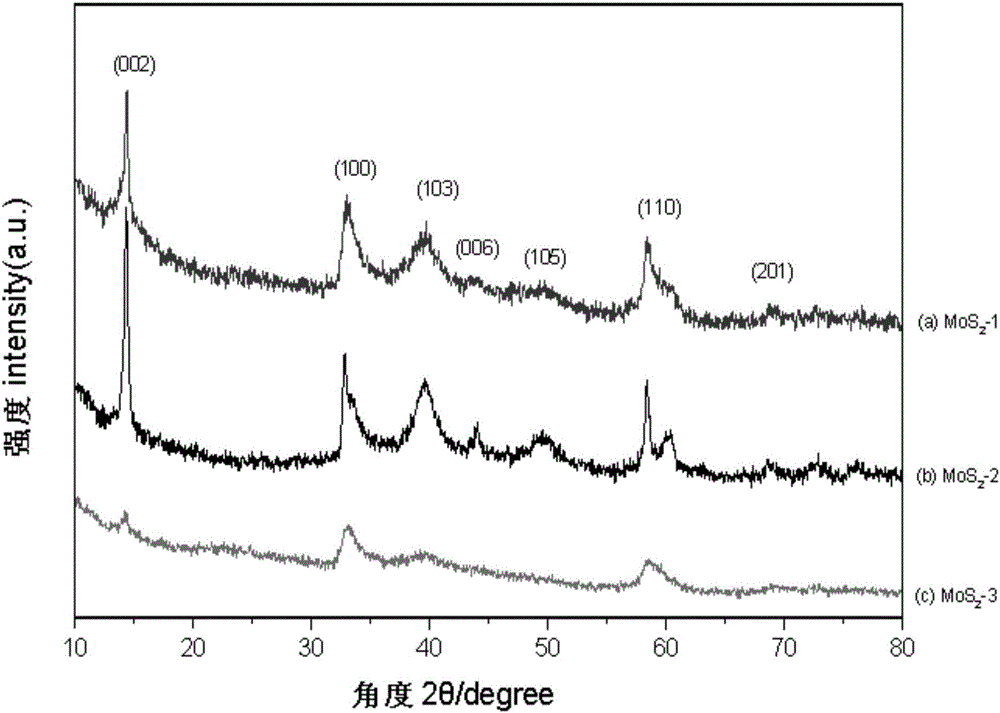

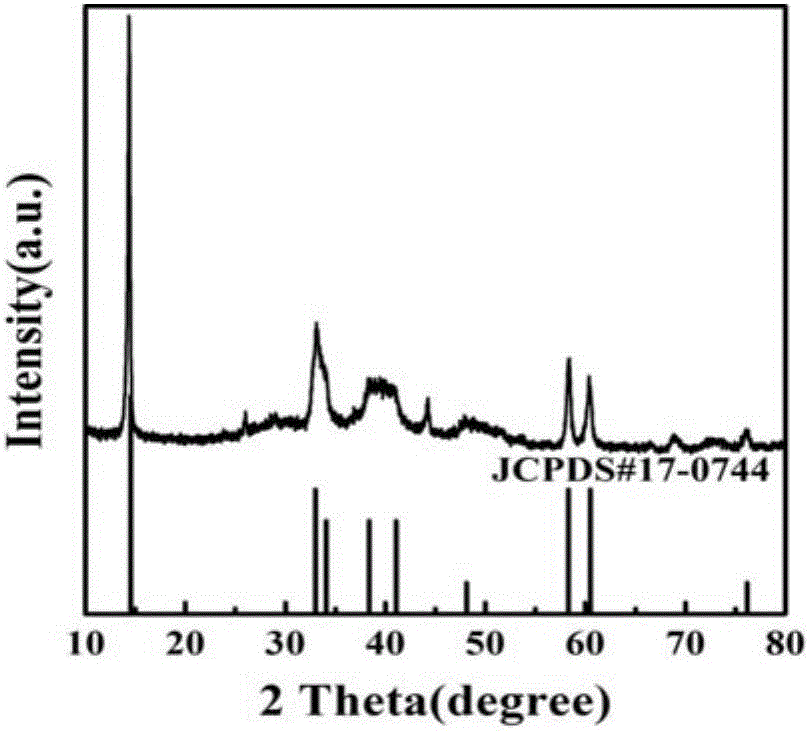

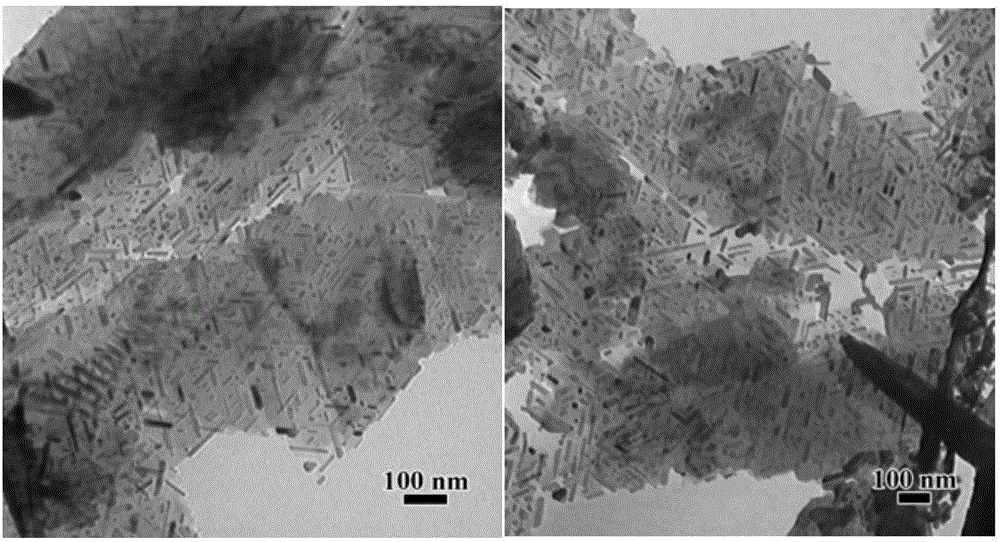

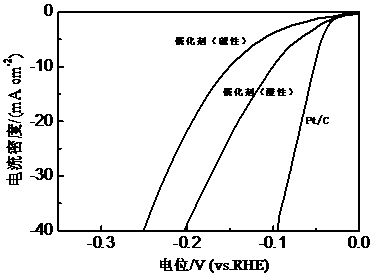

Micron molybdenum disulfide hydrogen evolution electro-catalytic material, preparation method and application of micron molybdenum disulfide hydrogen evolution electro-catalytic material

InactiveCN106040264ASize is easy to controlAchieving controllable synthesisPhysical/chemical process catalystsElectrodesHydrogenThiourea

The invention discloses a micron molybdenum disulfide hydrogen evolution electro-catalytic material, a preparation method and an application of the micron molybdenum disulfide hydrogen evolution electro-catalytic material in hydrogen evolution electro-catalysis, and belongs to the technical field of catalytic materials. The preparation method comprises the following steps of dissolving ammonium molybdate tetrahydrate (H24Mo7N6O24 4H2O) in a solvent so as to prepare a 0.025-0.05 mol / L of solution; adding thiocarbamide (CH4N2S), wherein the molar ratio of the ammonium molybdate tetrahydrate to the thiocarbamide 1:30 to 1:40; stirring to mix the solution evenly; performing hydrothermal reaction; reducing the temperature to room temperature after the hydrothermal reaction is completed; centrifuging, washing and drying to obtain the micron-grade molybdenum disulfide hydrogen evolution electro-catalytic material. The preparation method disclosed by the invention is low in cost, simple and easily controlled in production process, high in yield, and suitable for industrial production; and the prepared micron sheets are uniform in shape.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Antitoxic regeneration solution of deactivated SCR denitration catalyst, and preparation method thereof

ActiveCN102935388ATo achieve the effect of picklingNitrogen removal efficiency recoveryCatalyst regeneration/reactivationCerium nitrateAdhesive

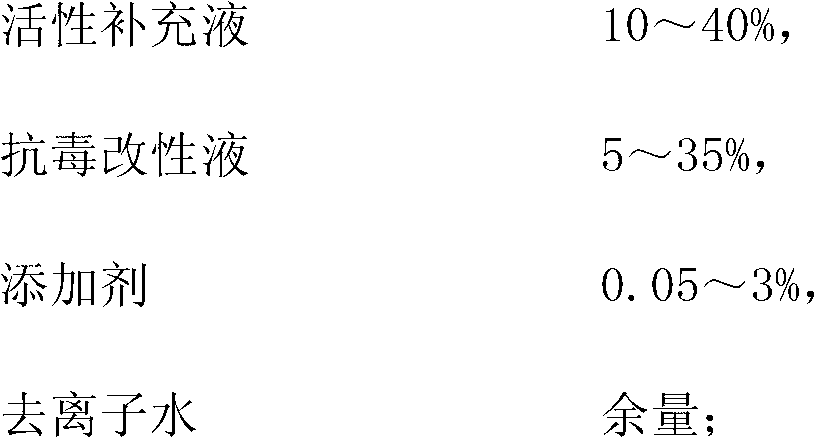

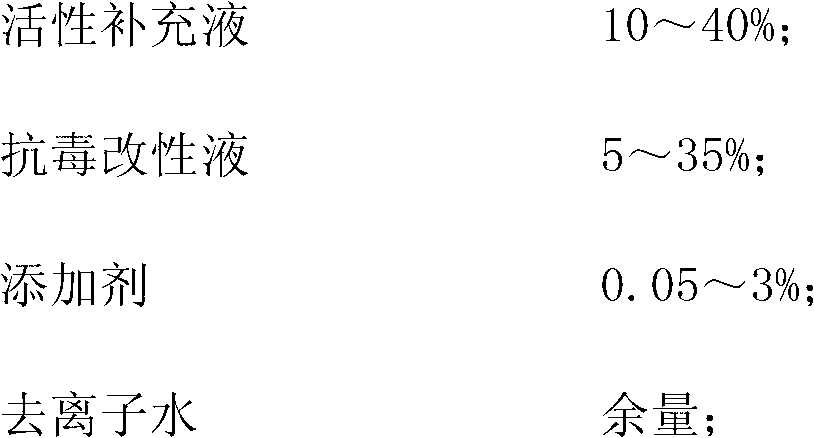

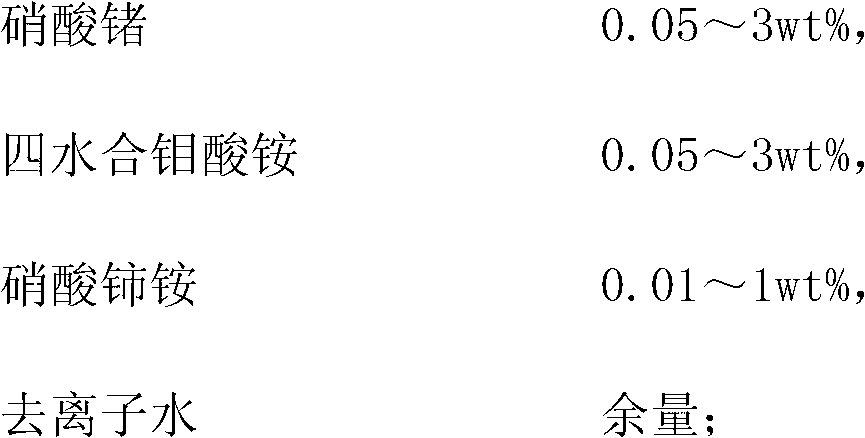

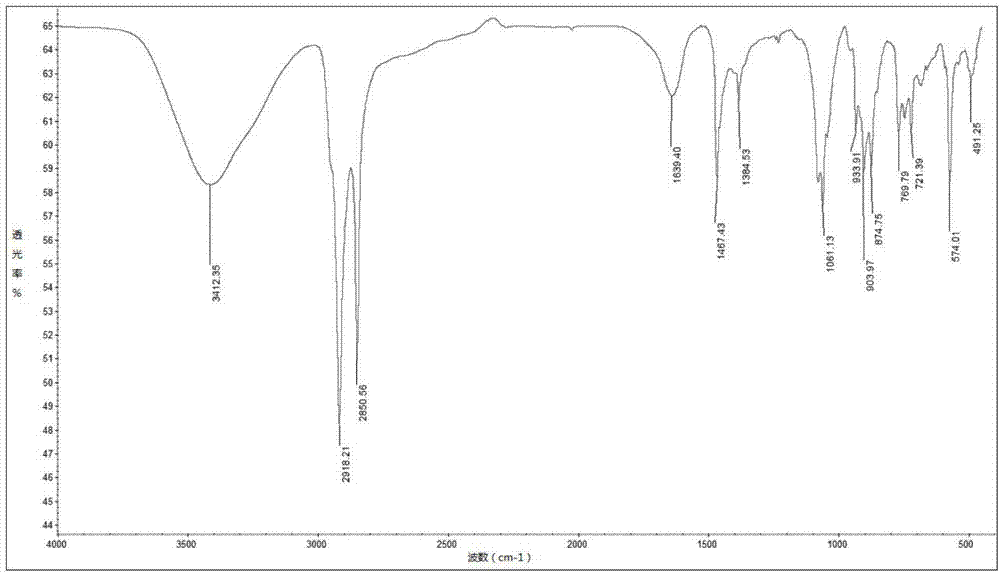

The invention relates to an antitoxic regeneration solution of a deactivated SCR denitration catalyst, and a preparation method thereof. The antitoxic regeneration solution comprises an active replenisher, an antitoxic modification liquid, and an additive component. The active replenisher comprises ammonium metavanadate, ammonium tungstate, and acid liquid. The antitoxic modification liquid comprises germanium nitrate, ammonium molybdate tetrahydrate, and ammonium cerium nitrate. The additive component comprises a penetrating agent, a dispersing agent, and an adhesive. According to the invention, the prepared active replenisher, antitoxic modification liquid, and additive component are well mixed according to a certain weight ratio, such that an antitoxic regeneration solution is obtained. The solution and the preparation method provided by the invention have the advantages that: the deactivated catalyst is pickled, and active components are simultaneously replenished, such that catalyst denitrification efficiency is recovered to above 90%. With the existence of the antitoxic component, the antitoxic performance of the catalyst is substantially improved, such that catalyst arsenic, sulfur and alkali metal toxic effects can be effectively relieved, and service life of the catalyst after regeneration is prolonged.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Non-sulfur and non-phosphorus organic molybdenum compound and preparation method and application thereof

InactiveCN104844656AImprove thermal stabilityImprove tribological propertiesAdditivesGroup 6/16 organic compounds without C-metal linkagesOrganic solventSulfur

The invention provides a non-sulfur and non-phosphorus organic molybdenum compound and preparation method and application thereof. The structural formula is shown in the formula, wherein R is a C1-C30 linear or branched alkyl or cycloalkyl. The preparation method comprises the step of reacting hydroxyalkyl amine with ammonium molybdate tetrahydrate in the presence of an organic solvent and a catalyst. The organic molybdenum compound provided by the present invention can be used as a lubricating oil additive and has good antiwear and extreme-pressure properties.

Owner:SHANGHAI JIAO TONG UNIV

FUNCTIONALIZED HYBRID NANOTUBE C@MoS2/SnS2 AND PREPARATION METHOD AND APPLICATION THEREOF

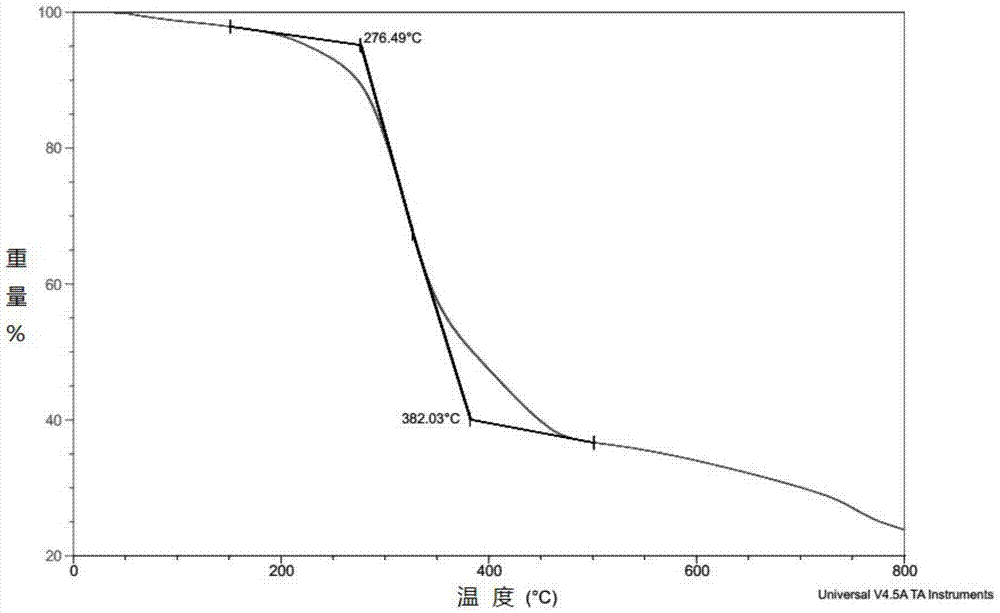

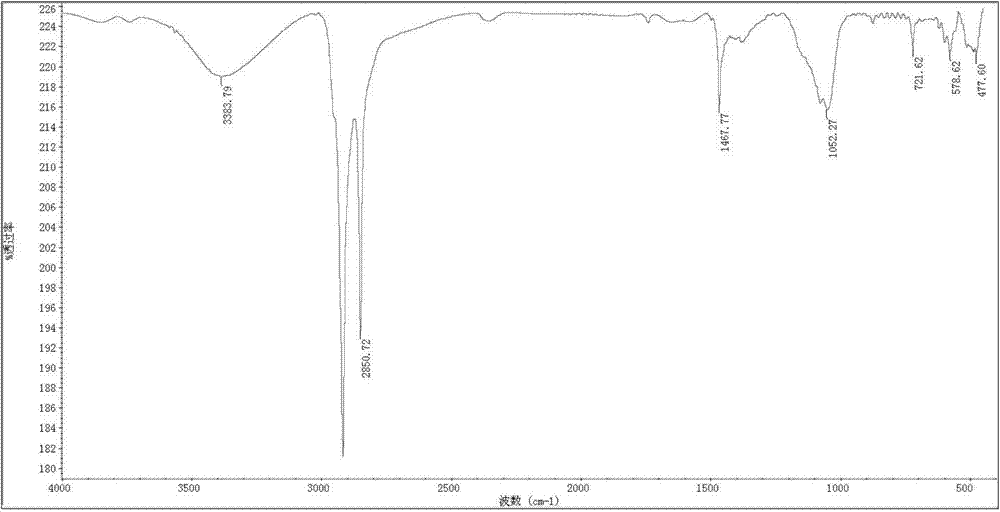

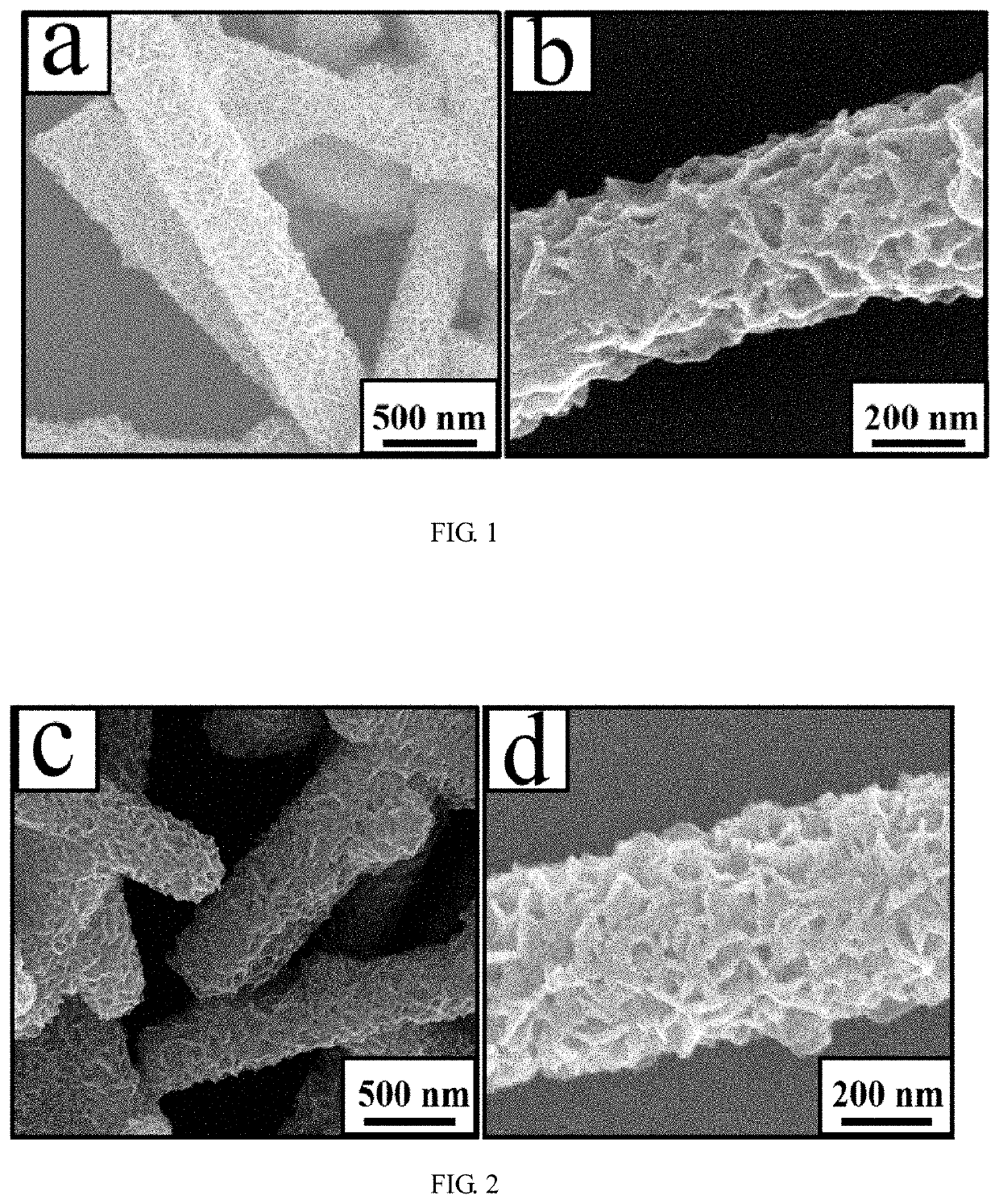

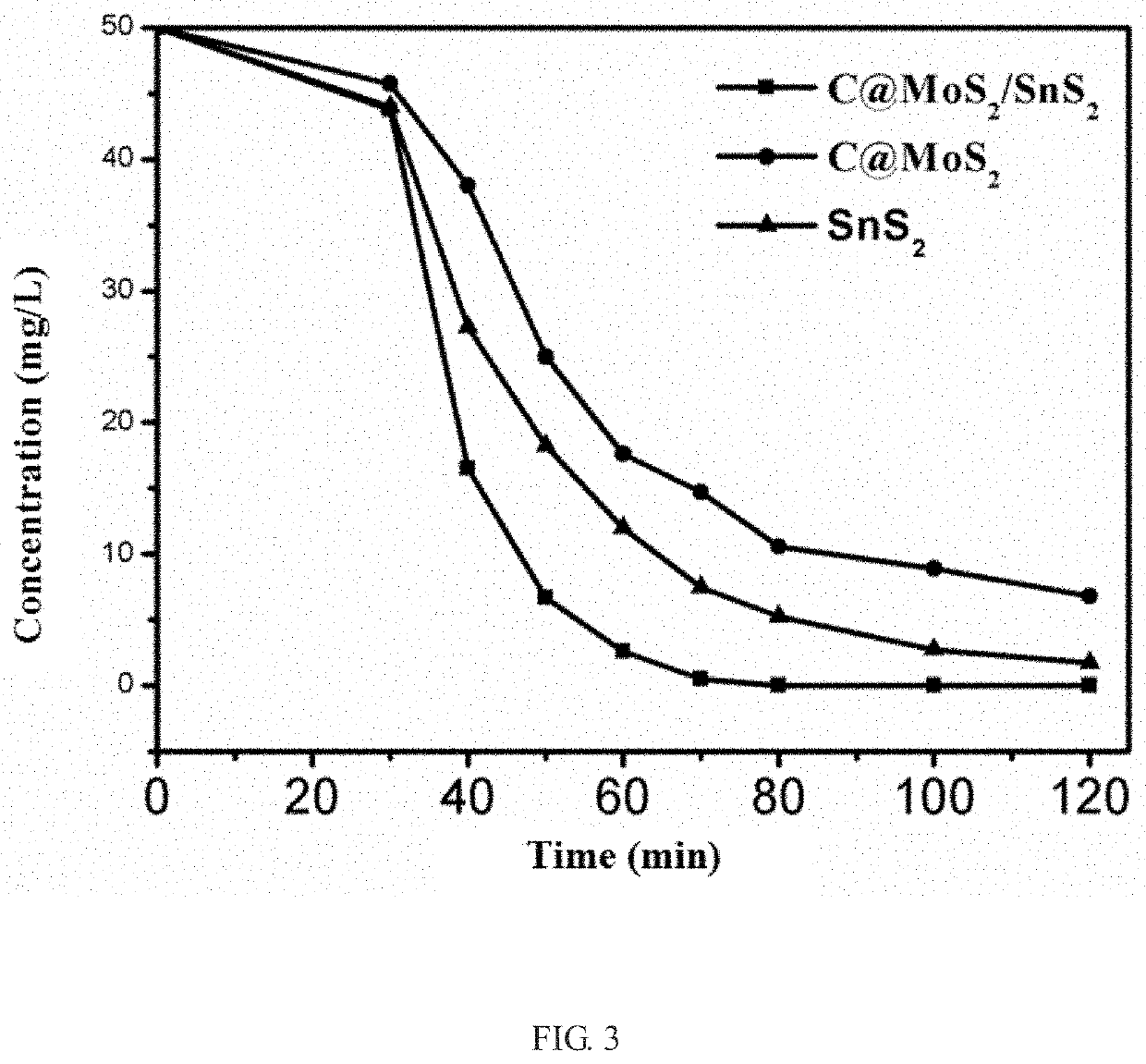

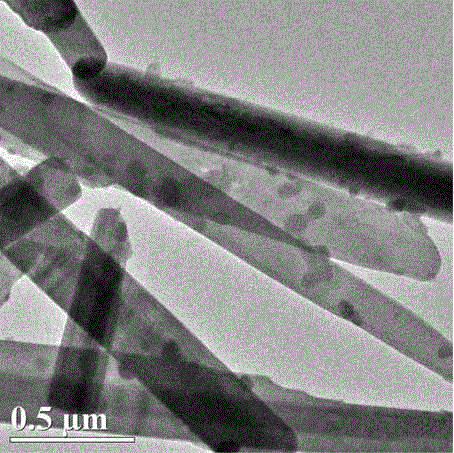

ActiveUS20190366309A1Low costEasy to getWater/sewage treatment by irradiationWater treatment compoundsEthylenediamineNanowire

The invention discloses a functionalized hybrid nanotube C@MoS2 / SnS2 and preparation method and application thereof. Dissolving ammonium molybdate tetrahydrate in water under ultrasound, adding ethylenediamine with stirring, and then adding dilute hydrochloric acid dropwise to react to obtain MoO3-EDA nanowires; adding L-cysteine and glucose into water containing MoO3-EDA nanowires, and obtaining a dispersion by ultrasonication; heating the dispersion and then centrifuging, then drying the solid matter and then calcining to obtain C@MoS2 nanotubes; adding C@MoS2 nanotubes into water containing SnCl4.5H2O and KSCN, and hydrothermally reacting to obtain functionalized hybrid nanotubes C@MoS2 / SnS2. The invention realizes photocatalytic reduction of heavy metal ions to achieve treatment of heavy metal ion solution.

Owner:SUZHOU UNIV

Preparation method of phosphorus doped cobalt molybdate hydrogen evolution electrocatalyst and product thereof

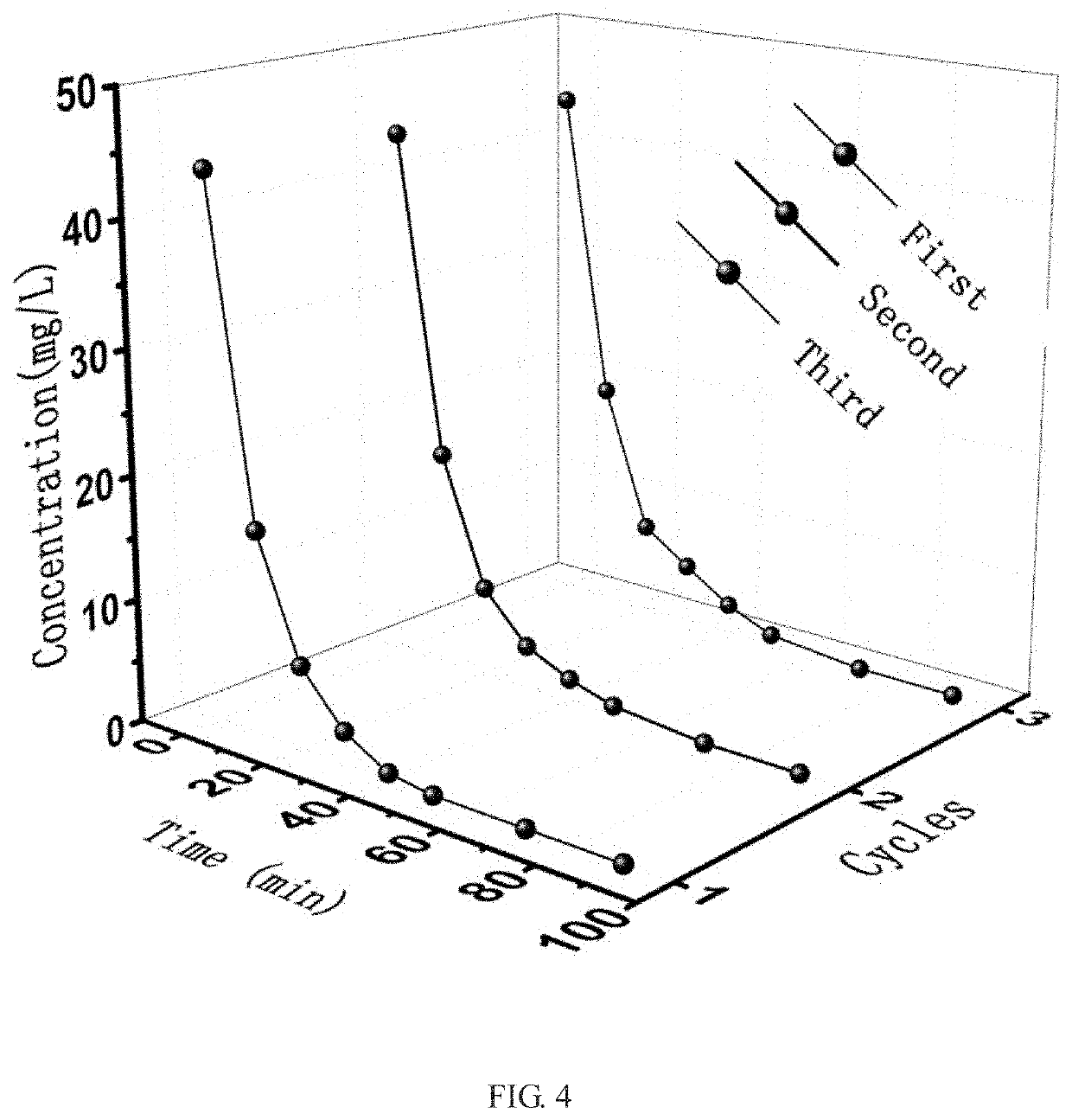

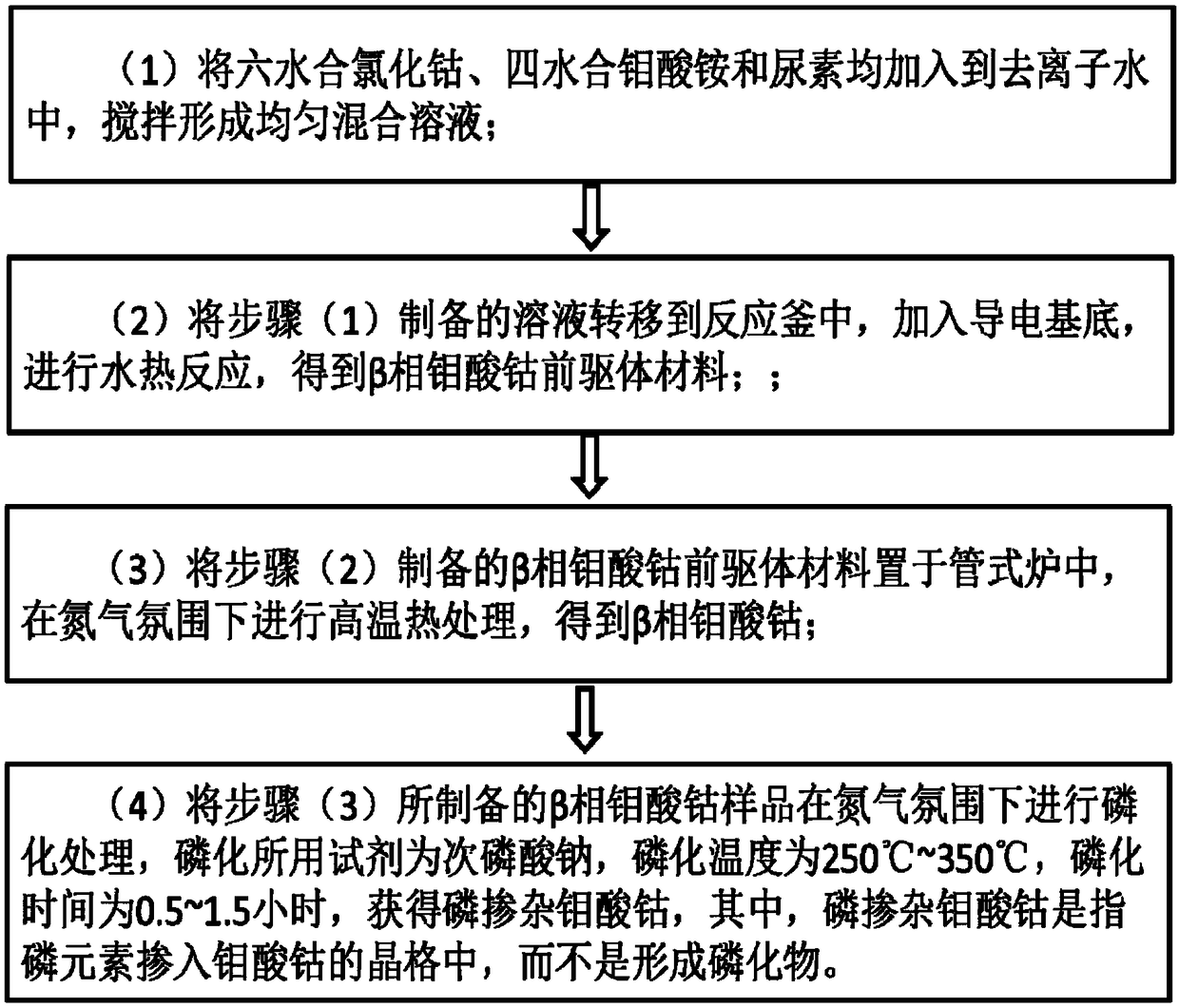

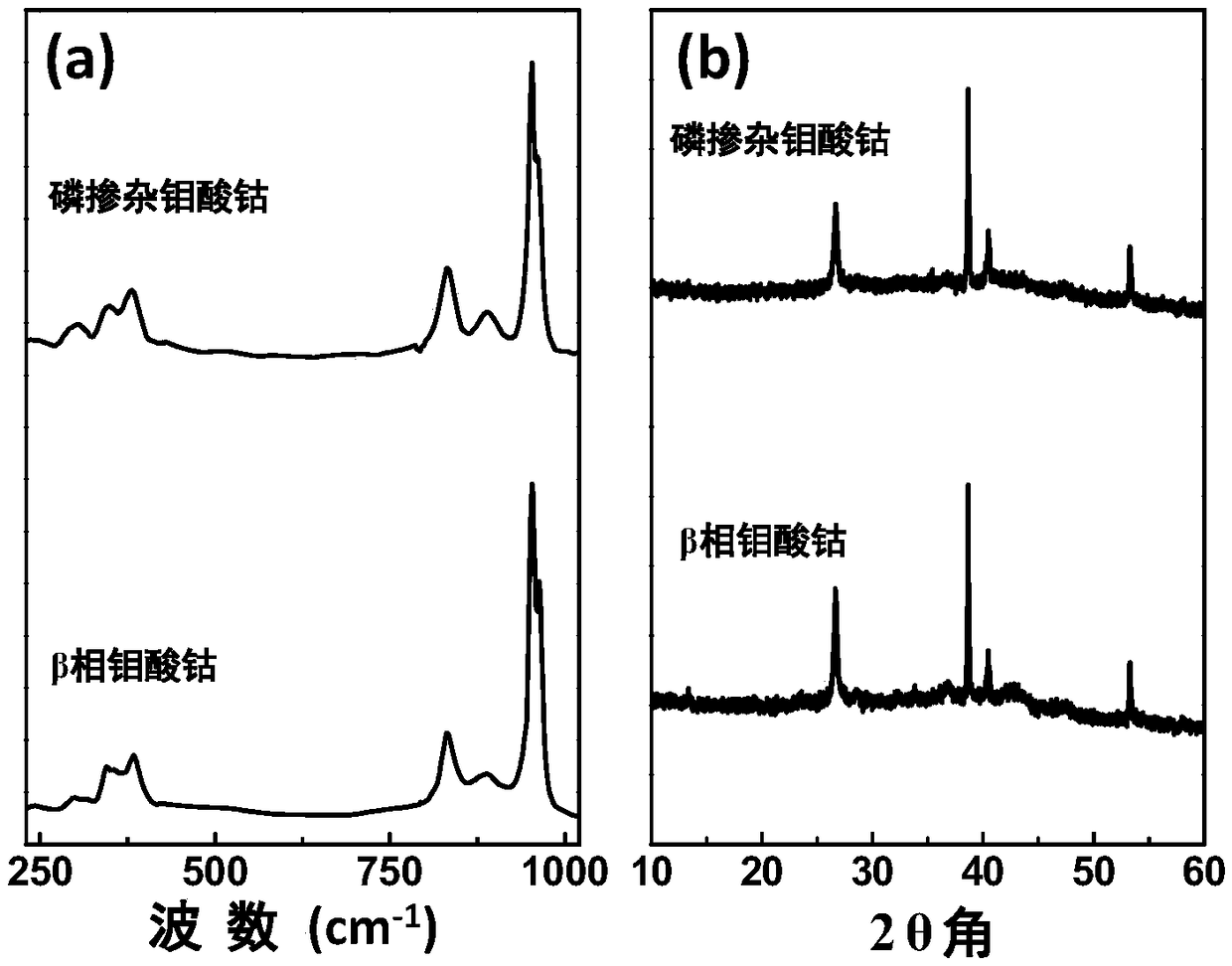

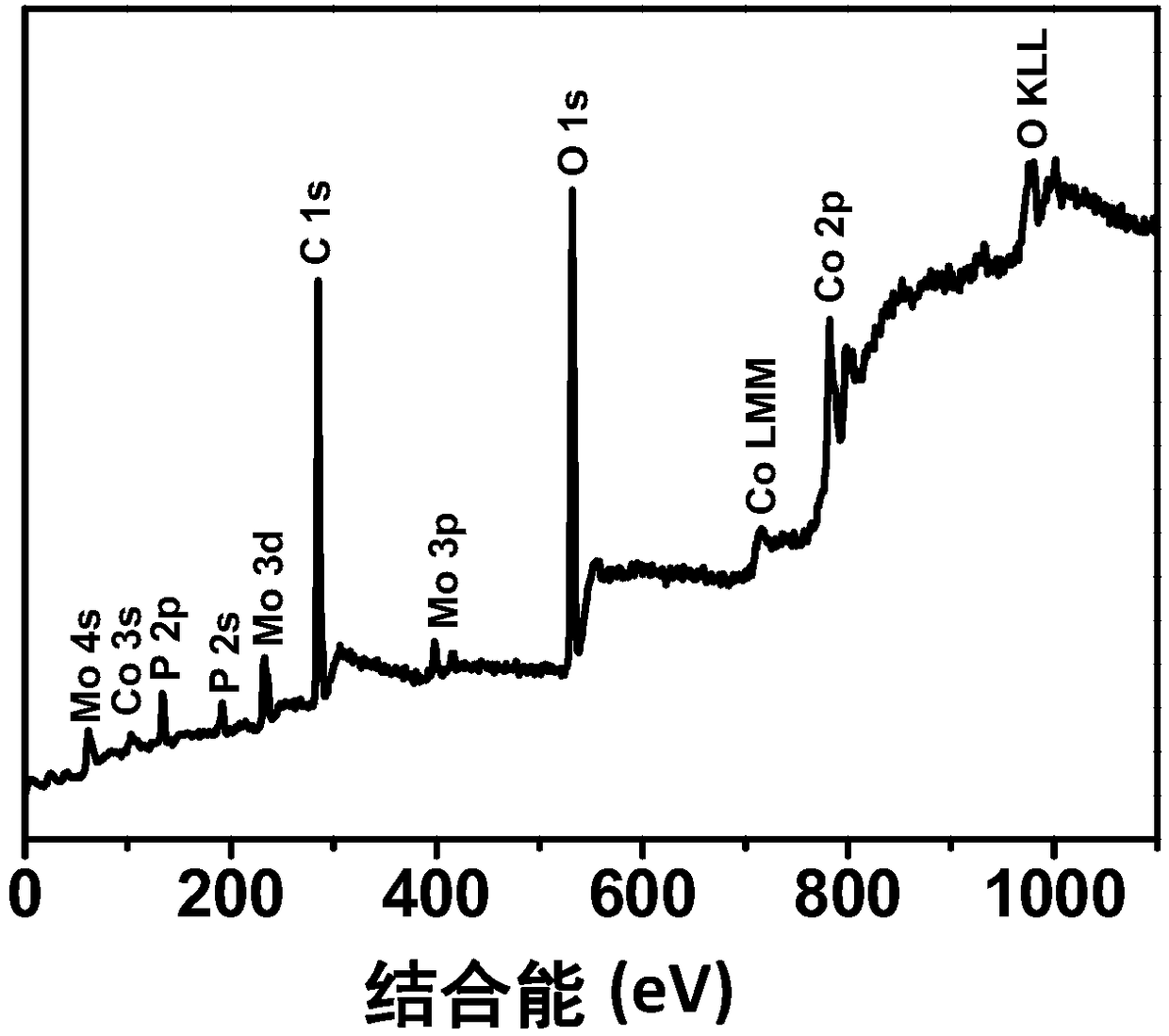

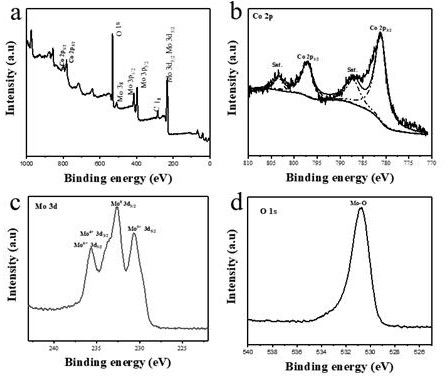

InactiveCN108380229AEffective control of electronic structureChange conductivityPhysical/chemical process catalystsHydrogen productionBeta phaseNitrogen gas

The invention discloses a preparation method of a phosphorus doped cobalt molybdate hydrogen evolution electrocatalyst and a product, and belongs to the technical field of electro-catalysis hydrogen evolution. The method comprises the following steps: (1) separately adding cobalt chloride hexahydrate, ammonium molybdate tetrahydrate and urea in deionized water, and stirring to form a uniform mixedsolution; (2) transferring the solution prepared in step (1) in a reaction kettle, adding a conductive substrate, and carrying out hydrothermal reaction to obtain beta-phase cobalt molybdate precursor material; (3) placing a sample prepared in step (2) in a tube furnace, and carrying out high-temperature thermal treatment in a nitrogen atmosphere to obtain beta-phase cobalt molybdate; and (4) carrying out phosphating on the sample prepared in step (3) in a nitrogen atmosphere to obtain phosphorus doped cobalt molybdate, wherein a reagent for phosphating is sodium hypophosphite. According to the method, by control over the amount of the sodium hypophosphite and the pyrolysis time, phosphorus is successively blended in crystal lattices of cobalt molybdate, and the prepared catalyst has efficient hydrogen evolution capability in an alkaline solution.

Owner:HUAZHONG AGRI UNIV

Selenium-containing trace element foliar fertilizer for selenium enriched cultivation of crops and use method thereof

InactiveCN105175179APromote absorptionPromote vegetative growthFertilizer mixturesTrace elementPotassium

The invention discloses a selenium-containing trace element foliar fertilizer for selenium enriched cultivation of crops and a use method thereof. The foliar fertilizer is obtained by mixing of borax, ammonium molybdate tetrahydrate, chelated iron, sodium selenite, potassium fulvate and a selenium yeast extract. The use method includes: mixing the raw materials in proportion, then dissolving the fertilizer in a certain amount of water, conducting adding under stirring till the fertilizer is completely dissolved, then adding organic silicon, and finally adding a proper amount of water to perform spray application on leaf surfaces uniformly. The selenium-containing trace element foliar fertilizer provided by the invention can be used cooperatively with other bulk drugs to promote absorption of selenium-containing fertilizer by crop leaves so as to enhance the content of selenium element in crops, thereby improving the content of selenium element in crop products.

Owner:HUBEI HENO BIOLOGICAL ENG CO LTD

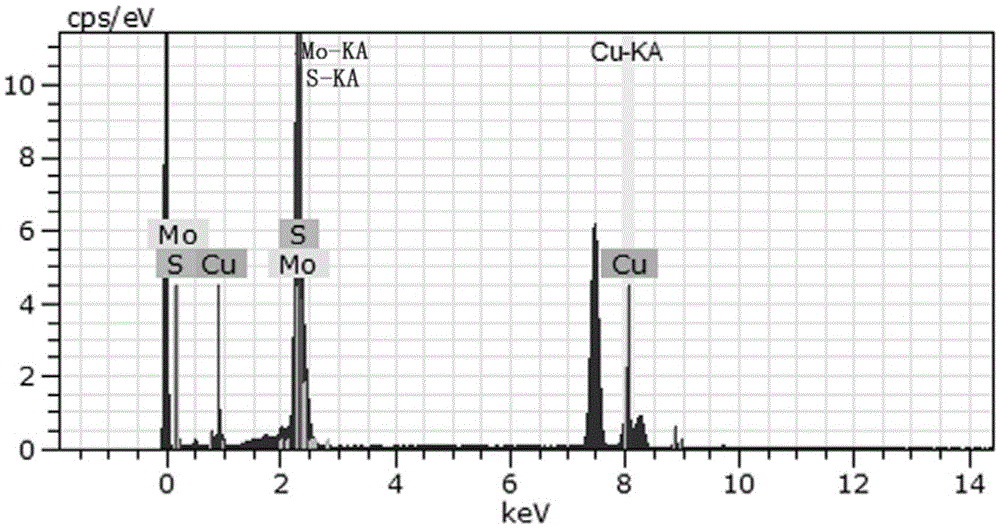

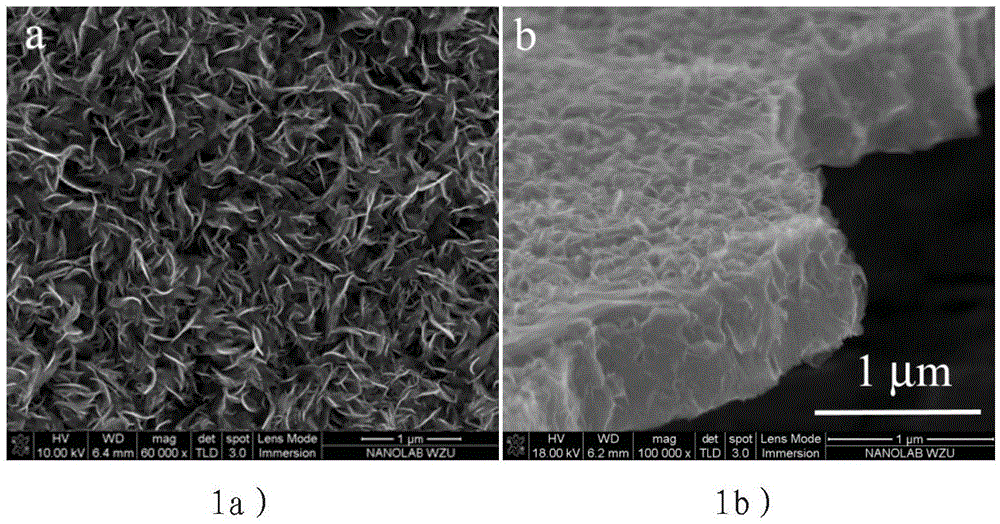

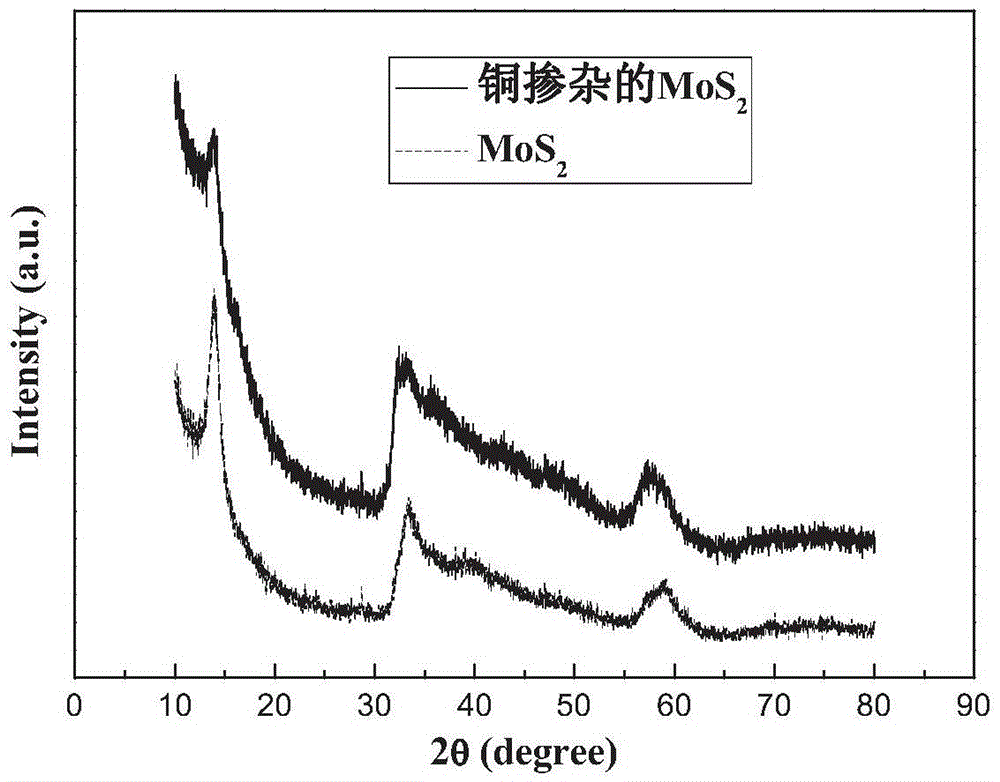

Method for preparing efficient copper-doped MoS2 nano-sheet array electrocatalyst

ActiveCN105597785AEasy to operateGood repeatabilityElectrolysis componentsPhysical/chemical process catalystsHydrogenDecomposition

The invention discloses a method for preparing an efficient copper-doped MoS2 nano-sheet array electrocatalyst. The preparing method includes the steps that a 2,300-mesh stainless wire mesh serves as a substrate material, Mo7O24.6 (NH4).4(H2O) and CH4N2S serve as raw materials, and a material is synthesized at the certain synthesis temperature and the certain synthesis time in a water phase system; the efficient electrocatalytic activity of the obtained MoS2 nano-sheet array material is further obtained by doping copper. By means of the method, the product is environmentally friendly, can be prepared in a large-scale mode and has the efficient water electrocatalytic decomposition hydrogen generation performance.

Owner:WENZHOU UNIVERSITY

Molybdenum sulfide-based catalyst for preparing low-carbon alcohol from synthesis gas and preparation method thereof

ActiveCN108325548ASimple preparation processMild conditionsOrganic compound preparationHydroxy compound preparationAlcoholThiourea

The invention relates to a preparation method of a molybdenum sulfide-based catalyst for preparing low-carbon alcohol from synthesis gas. The method comprises the following steps that (1) ammonium molybdate tetrahydrate and thiourea are added into water according to the mole ratio of Mo:S being 1:(2 to 4); after dissolution, a solution A is prepared; (2) the solution A is added into a hydrothermalreaction kettle; reaction is performed at 220 DEG C; products are washed and dried to obtain a precipitate A, i.e., petaloid MoS2; (3) the precipitate A and potassium carbonate are subjected to mechanical grinding according to a mole ratio of Mo:K being 1:(0.5 to 1) to obtain the catalyst for preparing low-carbon alcohol from the synthesis gas. The catalyst has the advantages that the preparationmethod is simple; the sulfur-resistant performance is good; the product total alcohol and C<2+> alcohol selectivity is high, and the like. Good industrial application prospects are realized.

Owner:INNER MONGOLIA UNIVERSITY

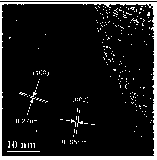

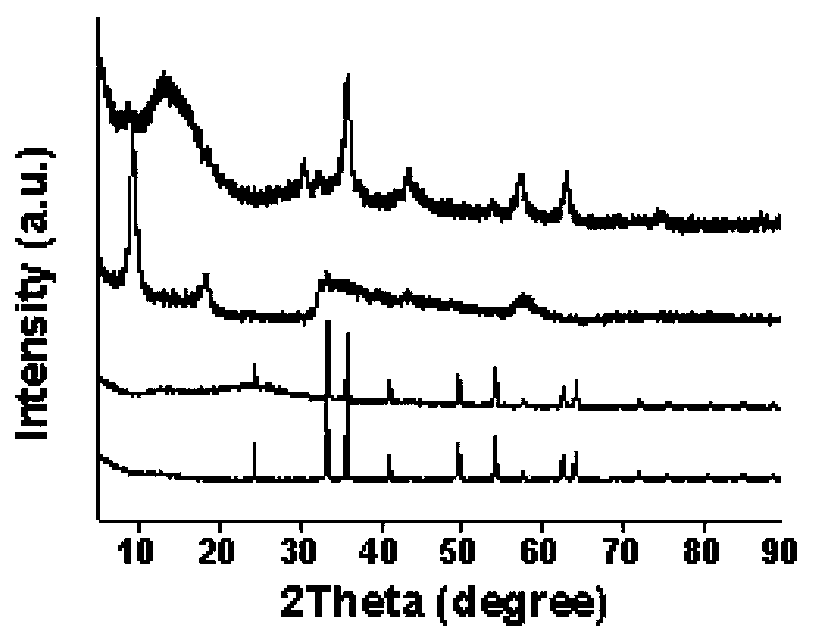

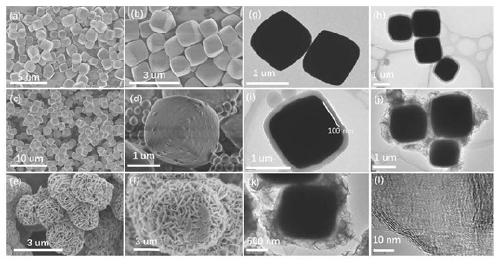

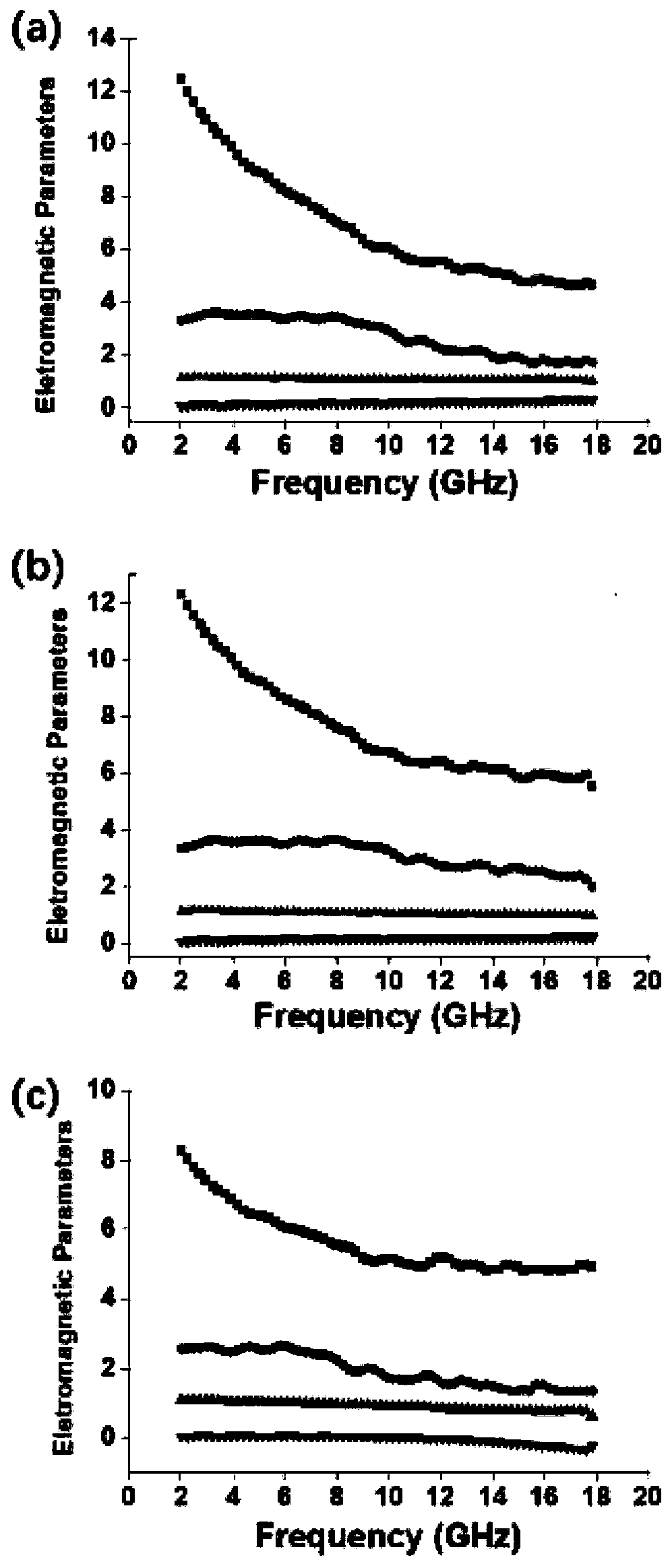

Preparation and application of Fe3O4@C@MoS2 composite material with core-shell structure

ActiveCN109825252AImprove microwave absorption performanceOther chemical processesMagnetic/electric field screeningThioureaAutoclave

The invention discloses a preparation and an application of an Fe3O4@C@MoS2 composite material with a core-shell structure. The preparation method includes the following steps: S1. adding FeCl3 and NaOH into water, uniformly mixing, loading the mixed solution into a polytetrafluoroethylene stainless steel autoclave, and reacting to obtain uniform cubic Fe2O3 particles; S2, adding the Fe2O3 particles prepared in S1 and dopamine hydrochloride into a trimethylolaminomethane buffer solution, stirring and reacting at room temperature with a magnetic stirrer, then washing the reaction product, and collecting an Fe2O3@PDA composite with a core-shell structure through a centrifugal method; S3. adding the Fe2O3@PDA prepared in S2, ammonium molybdate tetrahydrate and thiourea into water in sequenceand stirring uniformly, washing the product after the reaction is finished, and collecting Fe2O3@PDA@MoS2 composite through the centrifugal method; and S4. calcining the Fe2O3@PDA@MoS2 composite underthe flow of hydrogen and argon to finally obtain the Fe3O4@C@MoS2 composite. The Fe3O4@C@MoS2 composite material prepared by the method has excellent microwave absorption performance.

Owner:ANHUI UNIV OF SCI & TECH

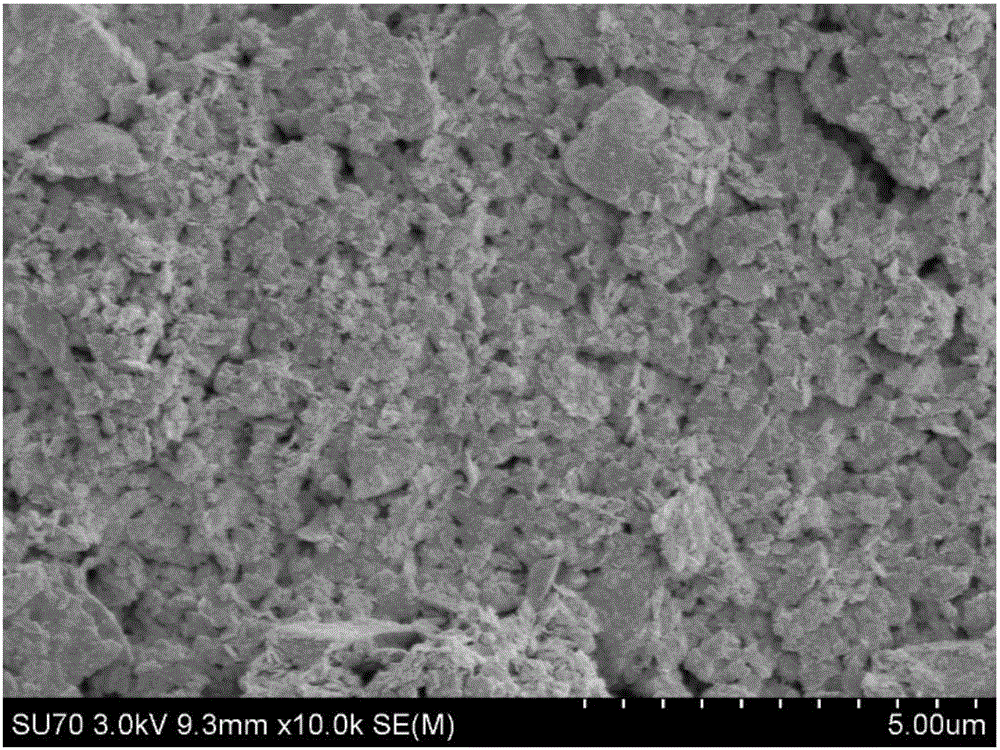

Ultrathin molybdenum disulfide nanosheet/polyimide self-lubricating composite material and preparation method thereof

InactiveCN106893323AImprove radiation resistanceGood chemical resistanceThioureaUltrasonic dispersion

The invention provides an ultrathin molybdenum disulfide nanosheet / polyimide self-lubricating composite material and a preparation method thereof. The preparation method comprises the following preparation steps that ammonium molybdate tetrahydrate is dissolved in deionized water and is prepared into an ammonium molybdate solution, thiourea is added, ultrasonic dispersion and even magnetic stirring are performed, the mixture is transferred to a reaction kettle, and hydrothermal reaction is performed; then, natural cooling, centrifugation, washing and drying are performed to obtain ultrathin disulfide molybdenum nanosheets; the ultrathin disulfide molybdenum nanosheets and polyimide resin are mixed evenly to obtain the mixture of the disulfide molybdenum nanosheets and the polyimide resin, the mixture is poured into a mold, hot pressed sintering is performed in a gradient heating mode, natural cooling is performed, and mold release is performed to obtain the ultrathin molybdenum disulfide nanosheet / polyimide self-lubricating composite material. The ultrathin molybdenum disulfide nanosheet / polyimide self-lubricating composite material has the advantages of being short in frictional 'running-in' period, small in friction coefficient, low in abrasion rate and the like and can be used in aviation, aerospace, machinery, electrons and other national defense and civil fields.

Owner:JIANGSU UNIV

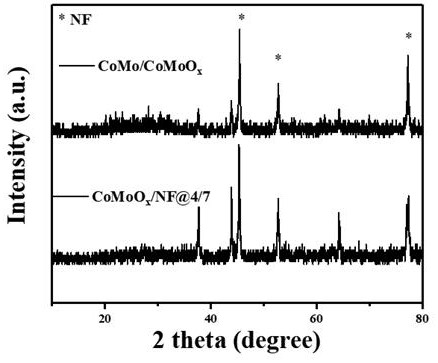

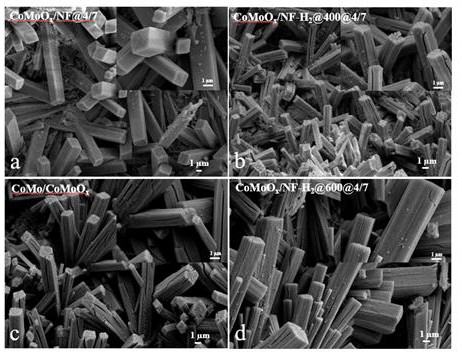

Preparation method of electrocatalytic material, corresponding material and use method

PendingCN112108149AImprove conductivityIncrease the areaMetal/metal-oxides/metal-hydroxide catalystsElectrodesHydration reactionCobalt

The invention discloses a preparation method of an electrocatalytic material. The method comprises the following steps: by using foamed nickel as a substrate, sequentially carrying out continuous ultrasonic cleaning with HCl, acetone, ethanol and deionized water, and blow-drying the foamed nickel at room temperature; ultrasonically dispersing a mixed solution of ammonium molybdate tetrahydrate, cobalt nitrate hexahydrate and deionized water into a reaction kettle, keeping the temperature, performing cooling to room temperature, performing cleaning, and blow-drying a sample to obtain a CoMoOx precursor; transferring the cobalt-molybdenum-oxygen precursor sample into a porcelain boat, transferring the porcelain boat into a programmed heating tubular furnace, performing calcining under protective gas, performing cooling to room temperature, and taking out the product to obtain a CoMo / CoMoOx hydrogen evolution electro-catalytic material; according to the method disclosed by the invention,the electro-catalytic hydrogen evolution performance is improved, and the stability is improved; the invention further provides the cobalt-molybdenum oxide hydrogen evolution electro-catalytic material obtained based on the method and a using method of the material.

Owner:KUSN INNOVATION INST OF NANJING UNIV

Liquid fertilizer containing humic acid and preparation method thereof

ActiveCN103804073AHigh content of active ingredientsAvoid easy cloggingFertilizer mixturesActive agentPotassium hydroxide

The invention provides a liquid fertilizer containing a humic acid. The liquid fertilizer containing the humic acid comprises the following components in parts by mass: 45-50 parts of water, 30-40 parts of monopotassium phosphate, 8-9 parts of potassium hydroxide, 20-35 parts of urea, 1-5 parts of heptahydrate, 2-5 parts of borate decahydrate, 0.5-1 part of ammonium molybdate tetrahydrate, 5-10 parts of potassium fulvate, 0.1-0.5 part of growth modifier, and 0.1-0.5 part of surfactants. The nitrogen, phosphorus and potassium content in each liter of the liquid fertilizer obtained by using the method disclosed by the invention is increased to 460g, the content of the humic acid can be up to 45g, no sediment is generated, the pipe is not easily blocked, the content of effective ingredients of the liquid fertilizer is greatly increased, and crop growth is facilitated.

Owner:黑龙江省禾森农业科技开发有限公司

Preparation method of multilayer molybdenum disulfide material

ActiveCN106629852ALow process conditionsReduce processing costsMolybdenum sulfidesSulfurTube furnace

The invention discloses a preparation method of a multilayer molybdenum disulfide material. The method comprises the following steps: pouring ammonium molybdate tetrahydrate used as a molybdenum source and thioacetamide used as a sulfur source into deionized water, and sufficiently stirring until the ammonium molybdate tetrahydrate and thioacetamide are completely dissolved; adding a chelator, and uniformly stirring; standing the obtained sol in a 60+ / -5 DEG C drying oven for 12-36 hours; continuing drying the obtained gel at 60+ / -5 DEG C for 2-6 days; and carrying out heat treatment on the obtained dried gel at 600-1000 DEG C in a pipe furnace in an argon protective atmosphere for 2-6 hours to obtain the multilayer molybdenum disulfide material.

Owner:ZHEJIANG UNIV

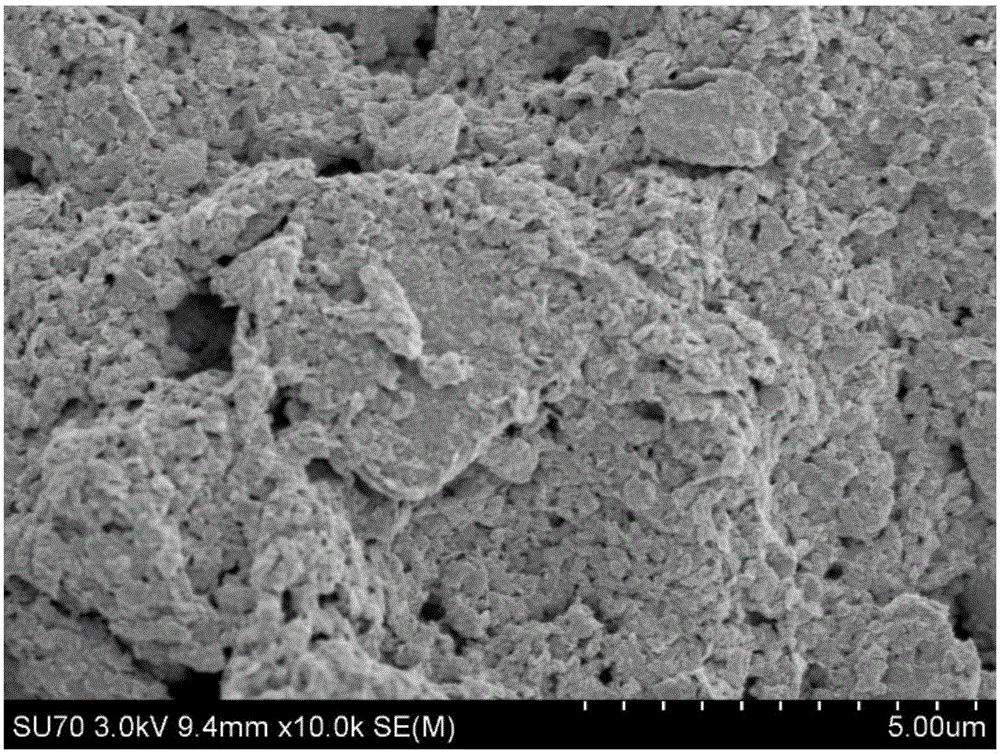

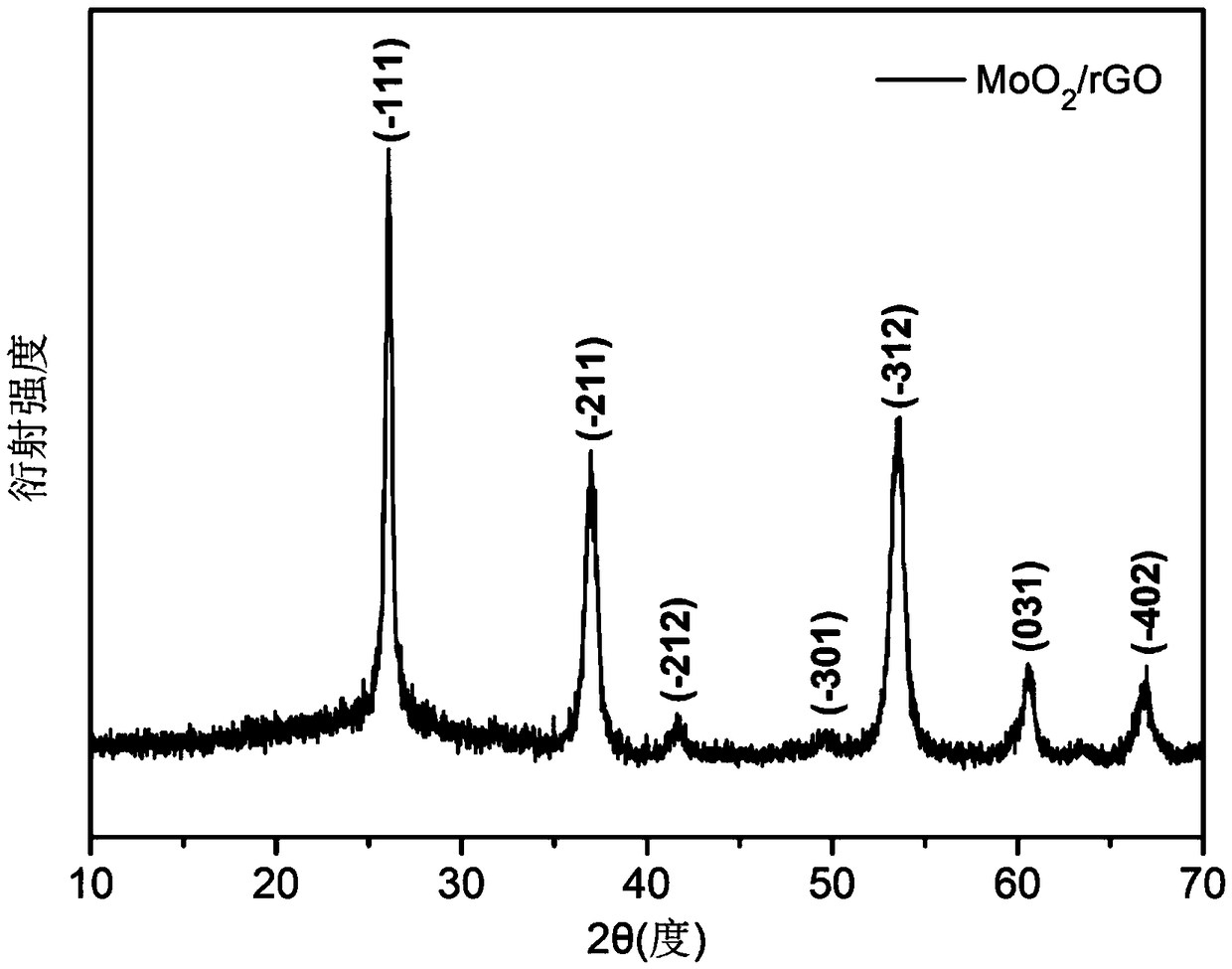

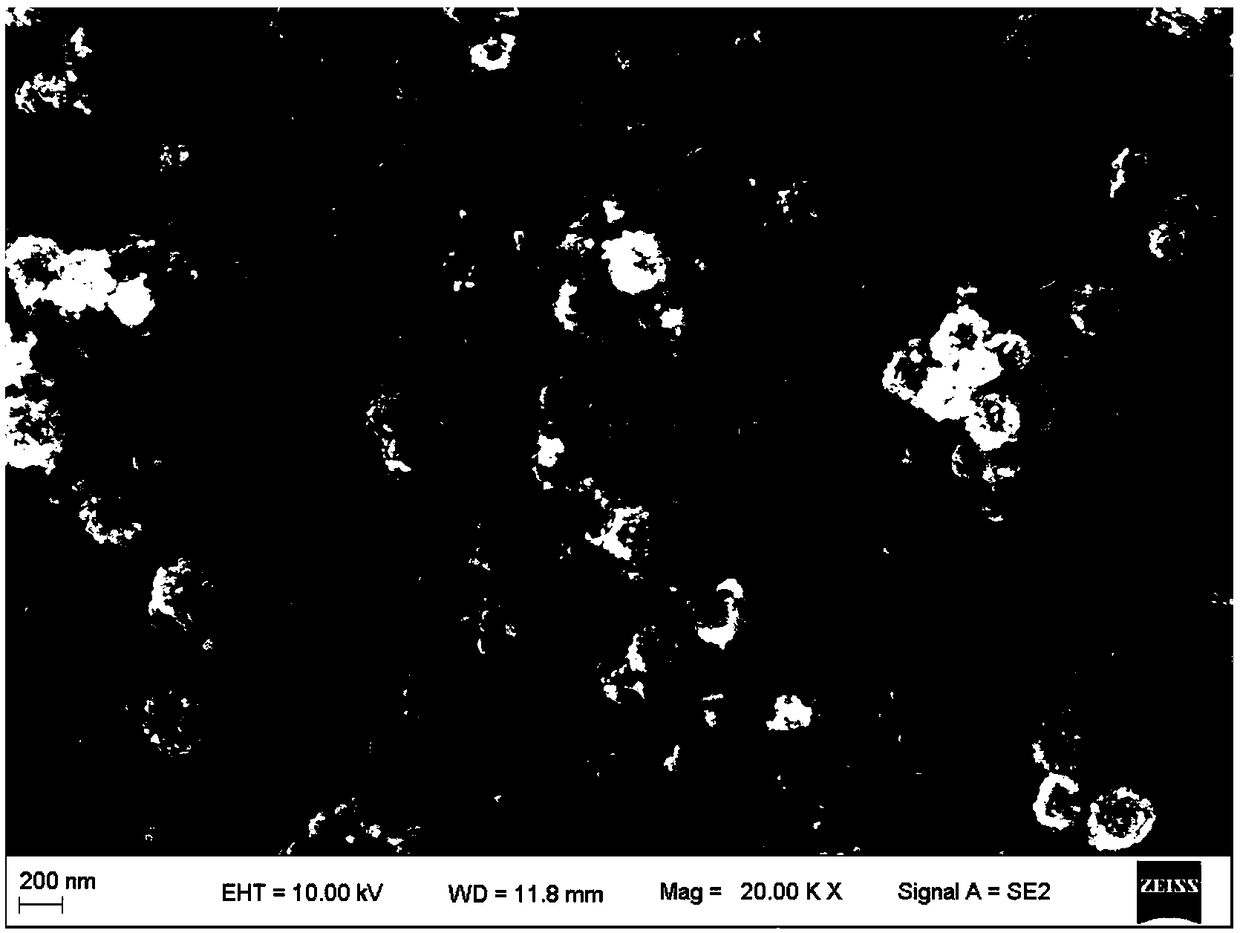

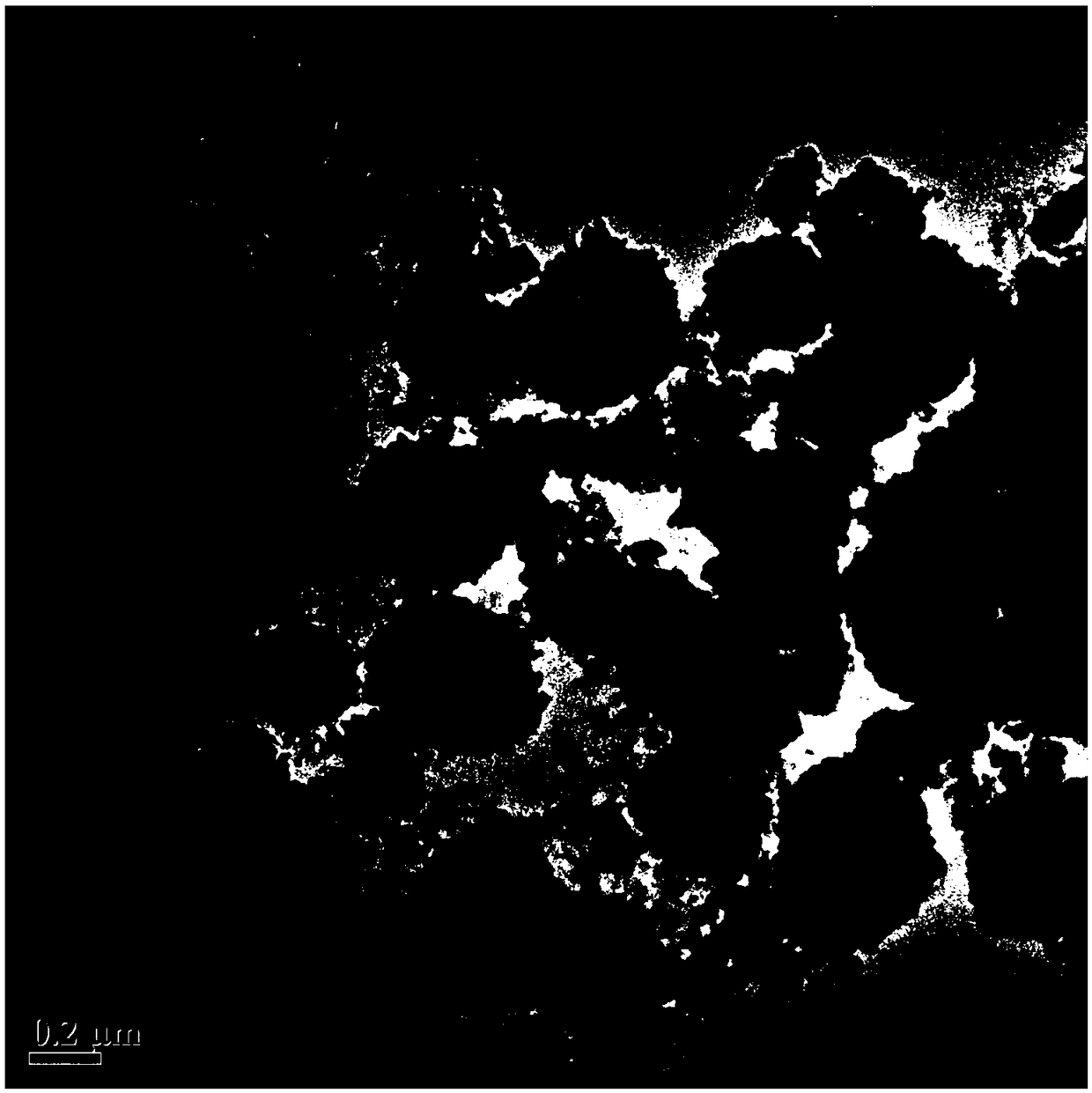

MoO2/rGO composite material, and preparation method and application thereof

ActiveCN109473650AHigh specific capacityImprove cycle stabilityCell electrodesSecondary cellsCvd grapheneControllability

The invention provides a MoO2 / rGO composite material, and a preparation method and application thereof. The method comprises the following steps: (1) adding ammonium molybdate tetrahydrate and ascorbic acid to a graphene oxide dispersion for magnetic stirring; (2) transferring the mixed liquid obtained in the step (1) to an autoclave for heating to grow a MoO2 / rGO composite precursor; (3) washing,drying and calcining the MoO2 / rGO composite precursor obtained in the step (2) to obtain the MoO2 / rGO composite material, wherein the pH of the graphene oxide dispersion in the step (1) is 1.5 to 3.The MoO2 / rGO composite material provided by the invention is simple in preparation method and steps, low in cost and strong in controllability. In the prepared MoO2 / rGO composite material, the hollowspherical MoO2s are uniformly distributed on the surface of the grapheme, with uniform particles, large specific surface area, rich pore structures, stable structure, and excellent cycle performance and rate performance, thereby having broad application prospects.

Owner:东北大学秦皇岛分校

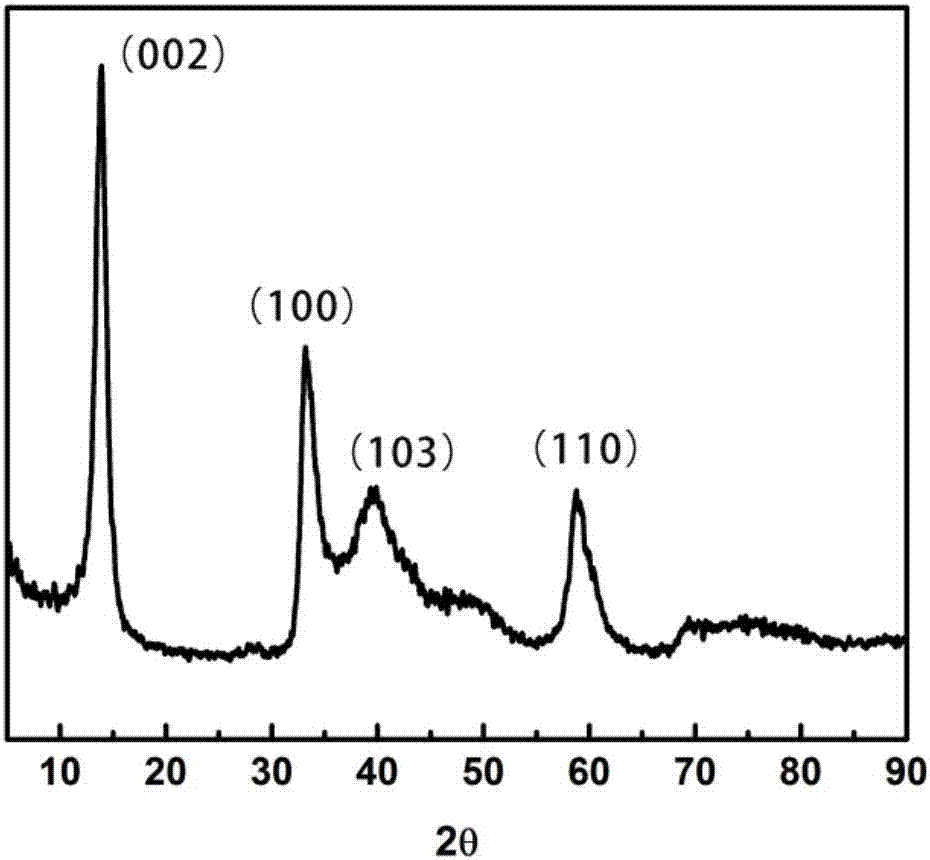

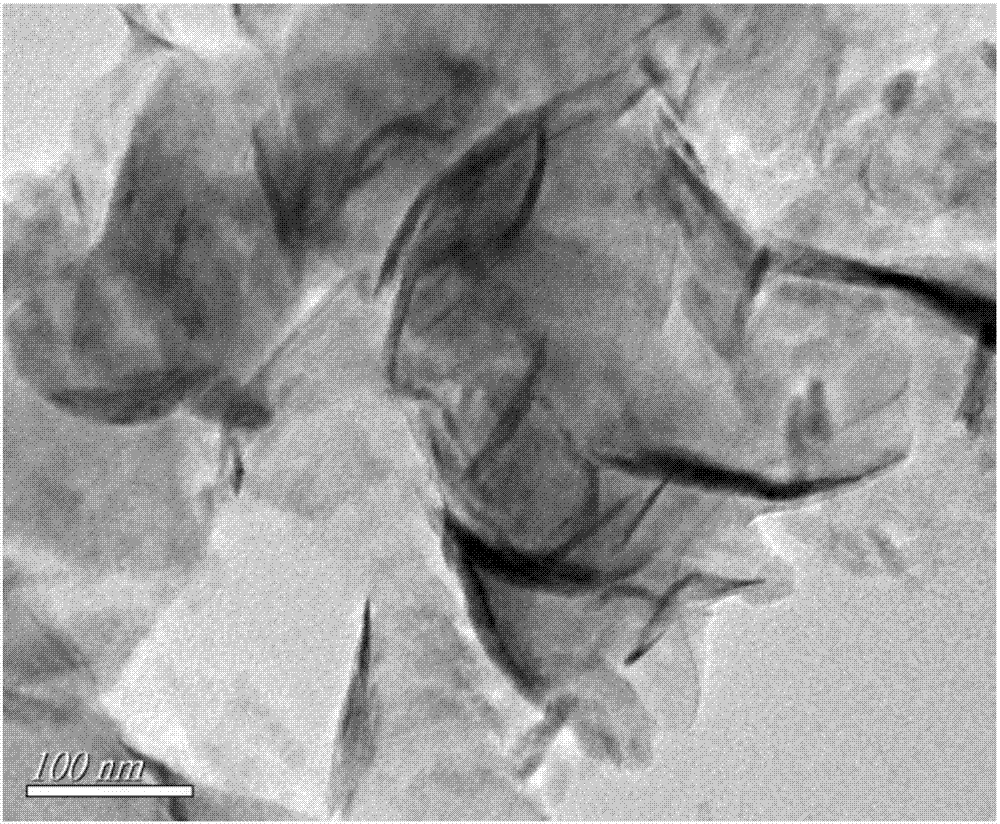

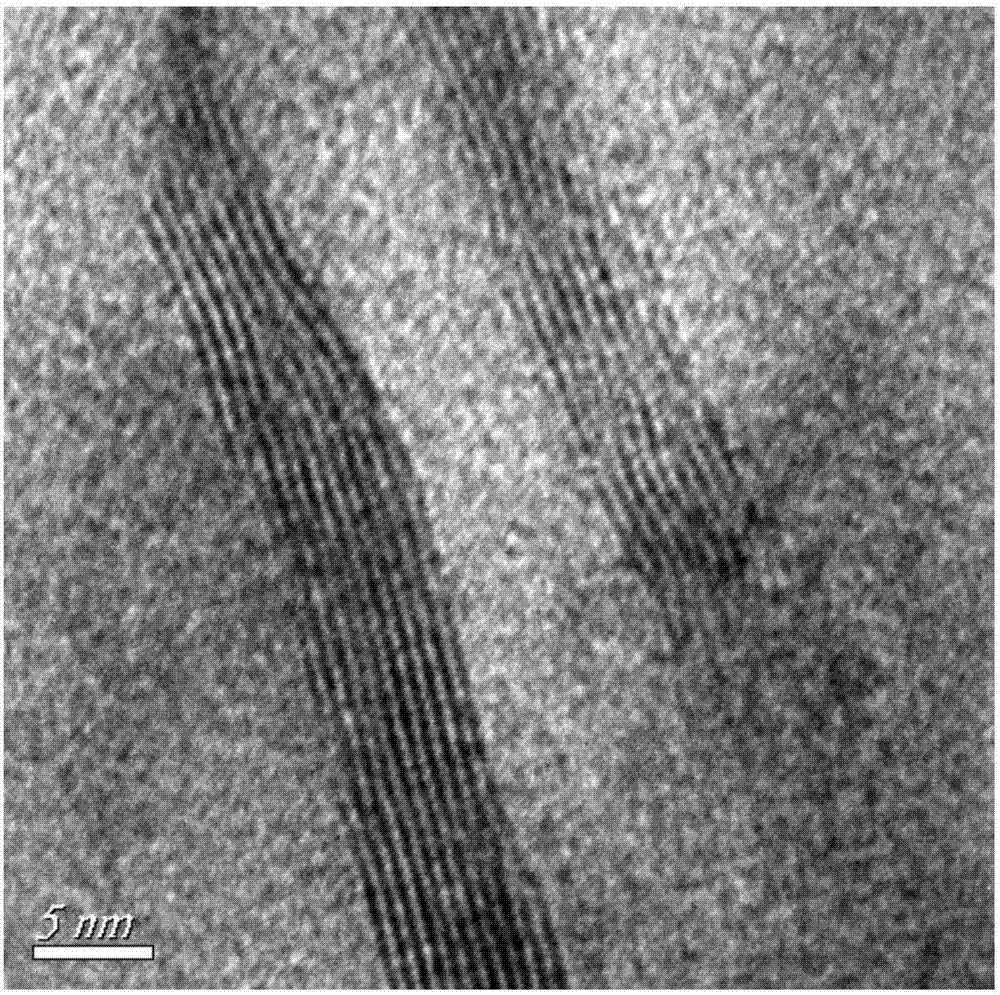

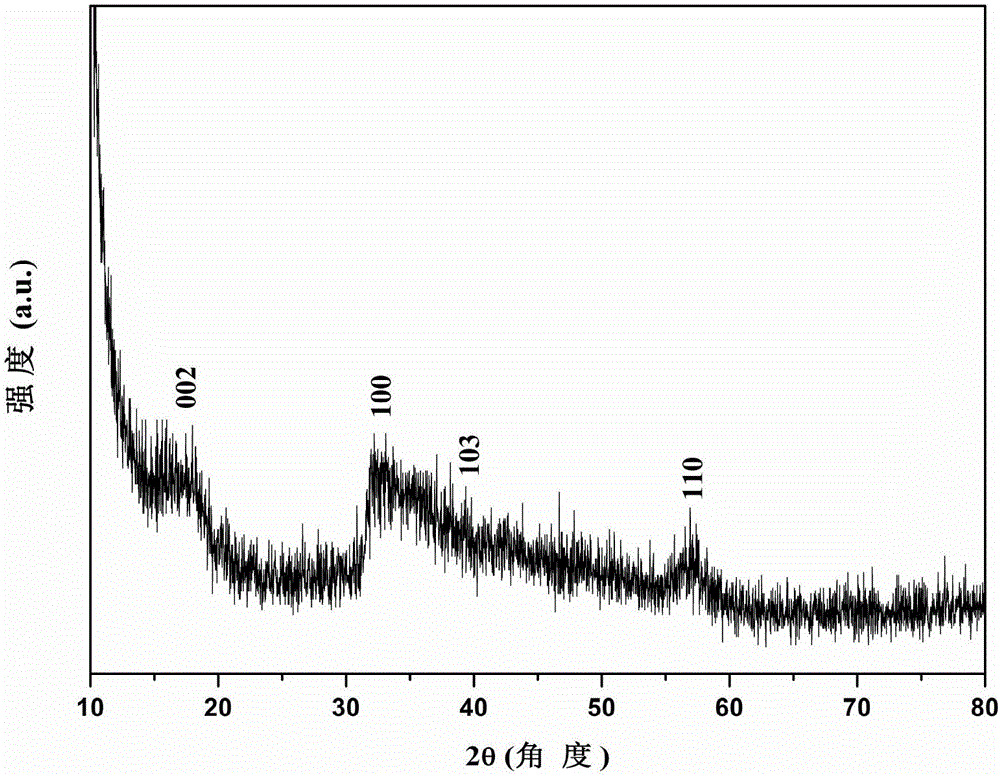

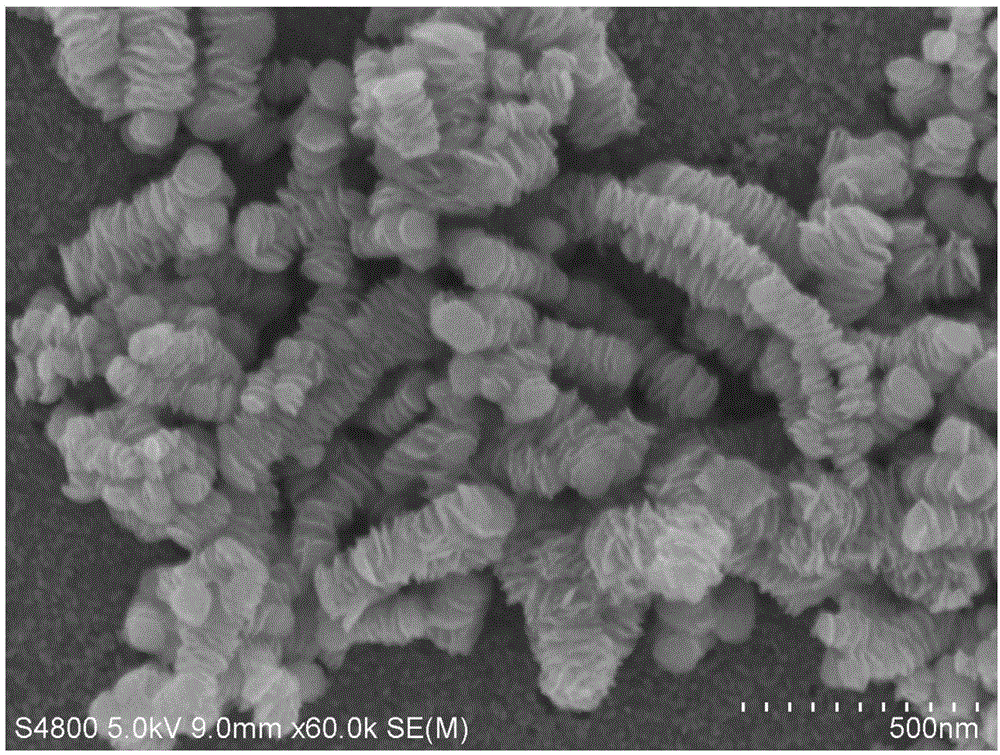

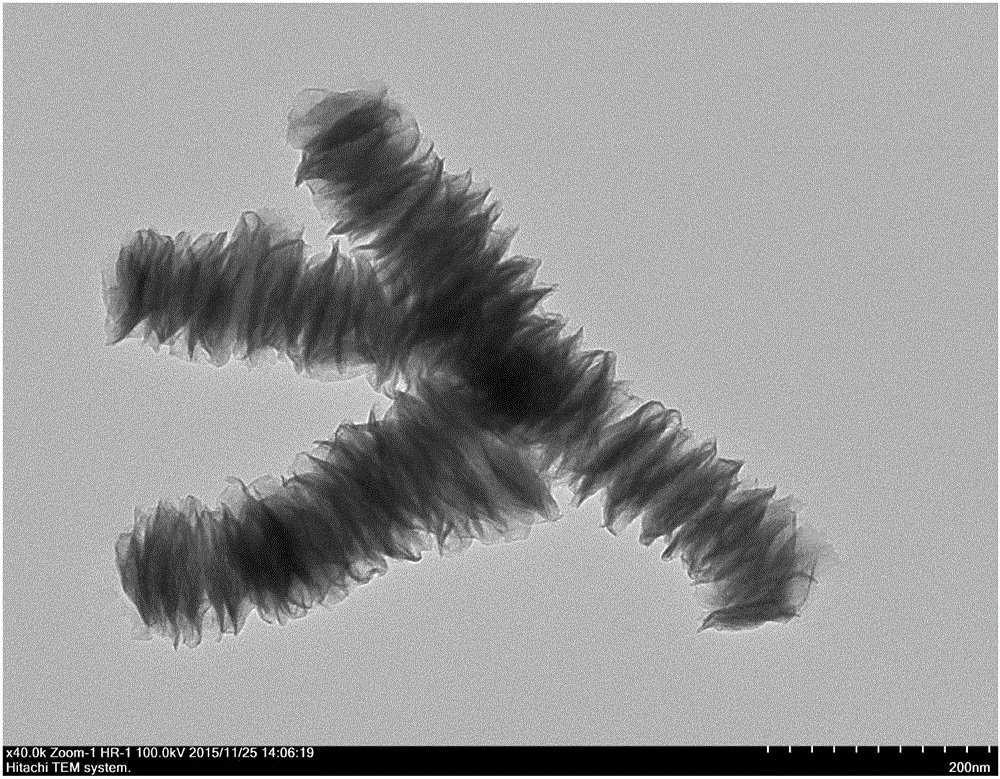

Lamella accumulated one-dimensional molybdenum disulfide nanometer material and preparation method thereof

ActiveCN106277055AImprove electrocatalytic activitySimple ingredientsPhysical/chemical process catalystsElectrolysis componentsSodium molybdateElectrolysis

The invention provides a lamella accumulated one-dimensional molybdenum disulfide nanometer material and a preparation method thereof. The molybdenum disulfide catalyst material is prepared by adopting a sodium molybdate crystal or an ammonium molybdate tetrahydrate crystal and a mercaptoacetic acid solution to react. Compared with the prior art, the lamella accumulated one-dimensional molybdenum disulfide nanometer material obtained by the invention is used as a catalyst in an electrolysis water hydrogen evolution process, shows excellent catalytic activity, and has a giant potential application value in the field of electrolysis water hydrogen production. In addition, according to the lamella accumulated one-dimensional molybdenum disulfide nanometer material and the preparation method thereof provided by the invention, the controllable preparation of morphology of the catalyst can be realized, the reaction is moderate, and the product yield is high.

Owner:ANHUI NORMAL UNIV

Selenium-containing trace element corn leaf fertilizer and cultivation technique thereof for selenium-rich corn

InactiveCN104355740AIncrease productionIncrease selenium contentAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersMonopotassium phosphateChelating iron

The invention discloses a selenium-containing trace element corn leaf fertilizer and a cultivation technique thereof for selenium-rich corn. The selenium-containing trace element corn leaf fertilizer comprises the following raw materials in percentage by mass: 24-26% of chelate zinc, 3.5-4% of ammonium molybdate tetrahydrate, 24-26% of chelate iron, 12-13% of borax, 8.5-9% of sodium selenite and 24-26% of monopotassium phosphate. The cultivation technique comprises the following steps: preparing before seeding, selecting good seeds, seeding, densely planting reasonably, preventing diseases and removing insects, weeding, dressing the fertilizer, performing water-saving irrigation, and harvesting and storing. By adopting the selenium-containing trace element corn leaf fertilizer, the yield of corn is greatly increased, the content of the selenium element in corn is increased, the nutrition of corn self is maintained, and the content of the selenium element needed by human bodies can be met, therefore, the immunity is improved, and cancer can be prevented. As the fertilizer is completely absorbed by the crop, the cultivation technique is relatively safe and reliable.

Owner:ENSHI MAOHE FOOD

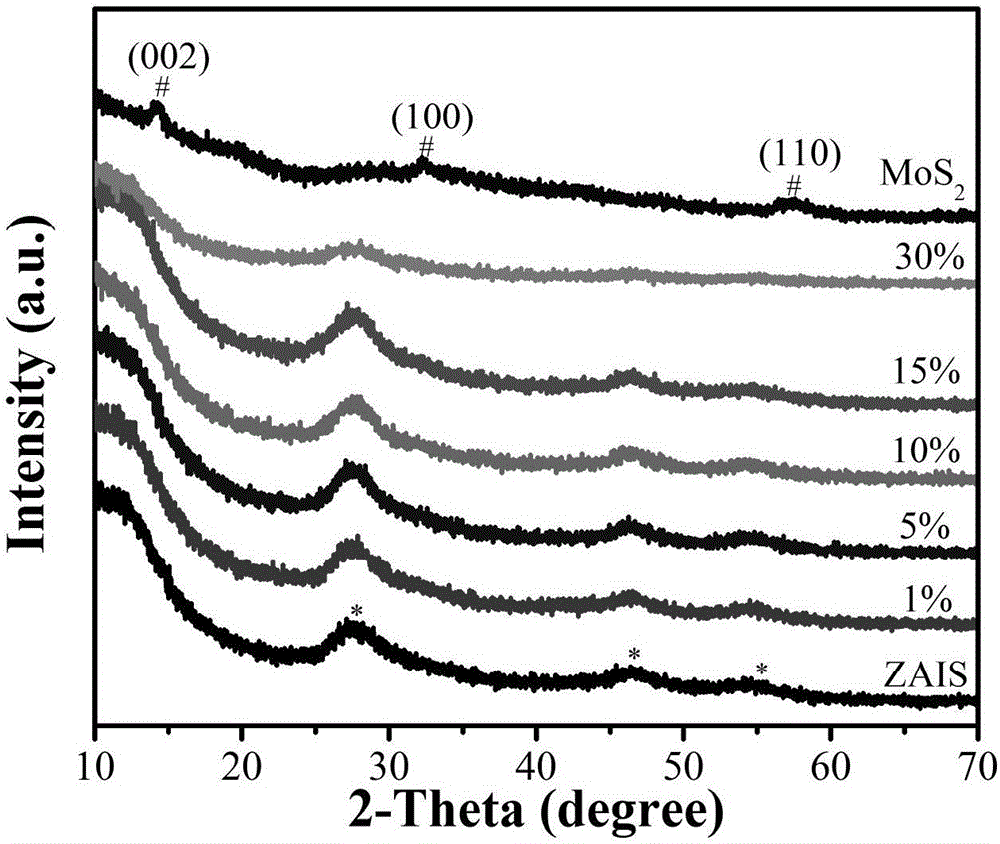

Method for preparing quaternary sulfide quantum dot based heterojunction efficient photocatalyst

ActiveCN105727999AFully crystallizedGood dispersionPhysical/chemical process catalystsHeterojunctionThiourea

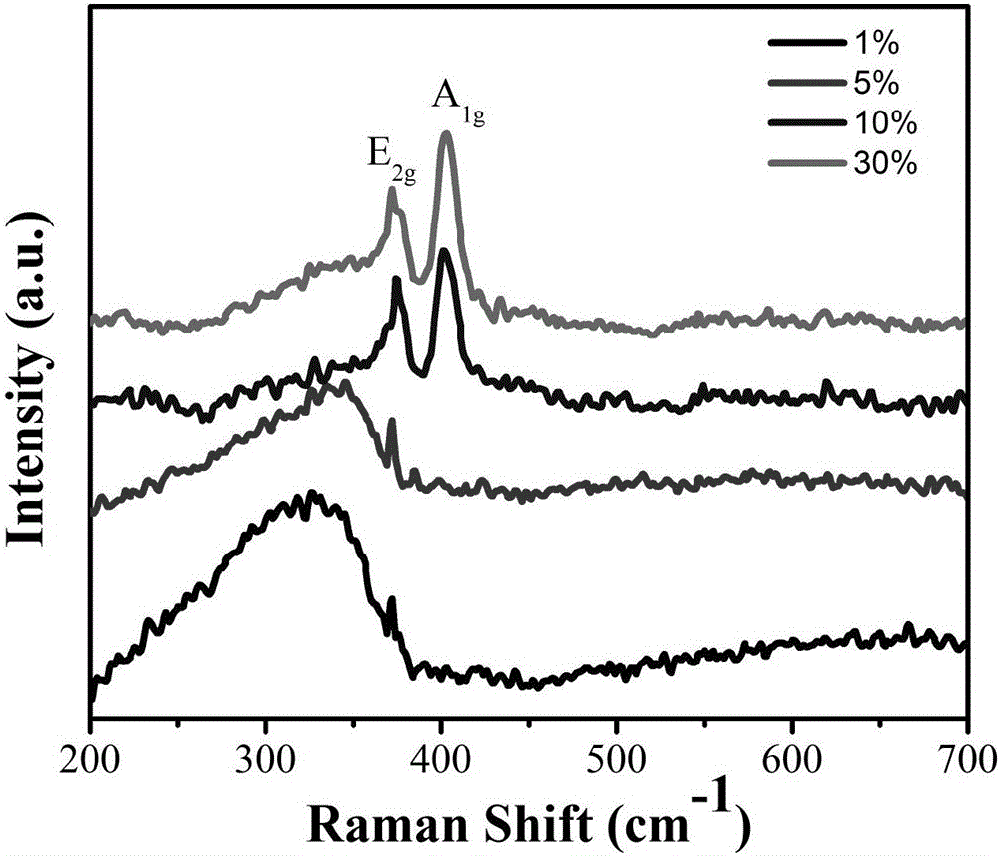

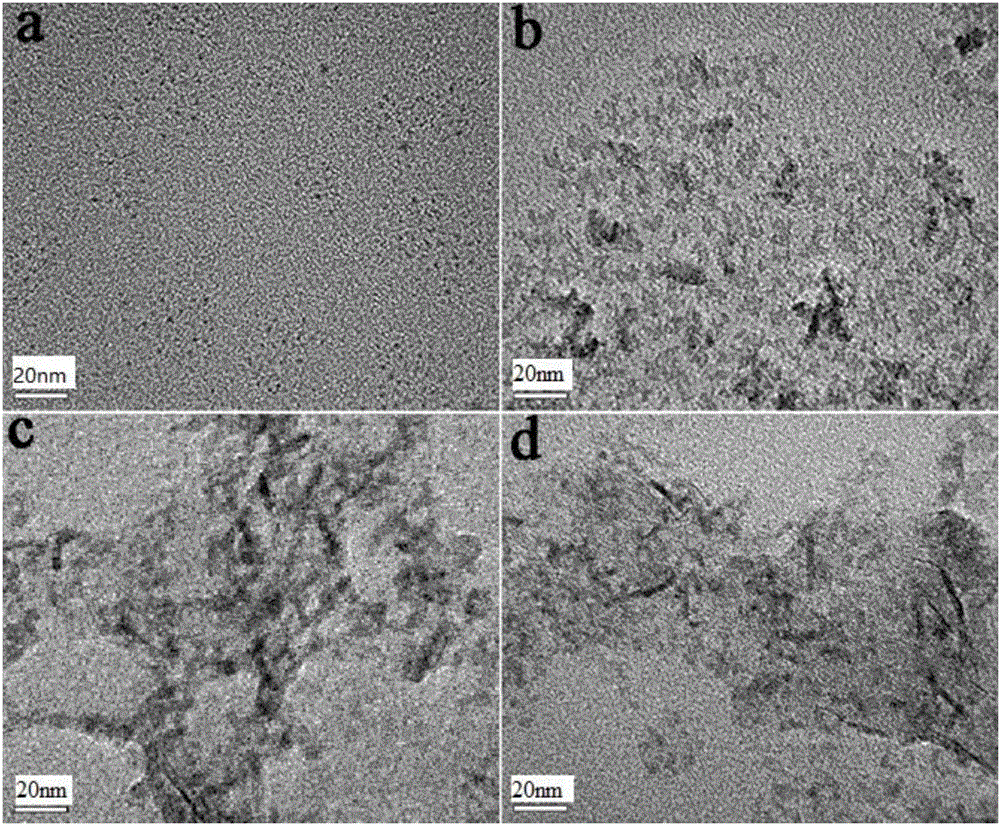

The invention relates to I-III-VI group 2 sulfide and particularly relates to an AgIn5S8-ZnS / MoS2 heterojunction composite photocatalyst prepared by utilizing a simple and rapid hydrothermal method. The AgIn5S8-ZnS / MoS2 heterojunction composite photocatalyst can be used for degrading a rhodamine B dye under visible light. The AgIn5S8-ZnS / MoS2 heterojunction composite photocatalyst is prepared by mixing and stirring AgIn5S8-ZnS nano crystals, ammonium molybdate tetrahydrate and thiourea, carrying out a hydrothermal reaction for 8 hours at 200 DEG C, and filtering, washing and drying after the reaction is finished, wherein the mass ratio of the MoS2 to the AgIn5S8-ZnS nano crystals is 1%-30%, and the optimal mass ratio of the photocatalytic performance is 5%. An experiment of degrading rhodamine B (RhB) under the visible light shows that the prepared composite photocatalyst has good photocatalytic activity.

Owner:JIANGSU UNIV

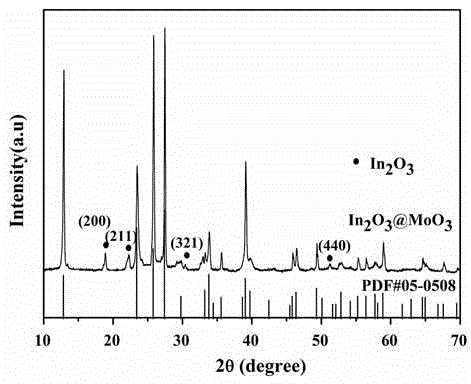

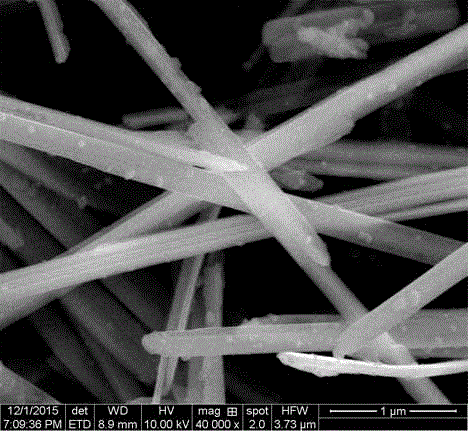

Preparation method of In2O3 nanoparticles/MoO3 nanorod composite materials

InactiveCN105540670ANo pollution in the processHigh sensitivityMaterial nanotechnologyMaterial resistanceSensor fieldHydrogen peroxide

The invention provides a preparation method of In2O3 nanoparticles / MoO3 nanorod composite materials. The preparation method concretely comprises the following steps that ammonium molybdate tetrahydrate, hydrogen peroxide and concentrated nitric acid are used as raw materials; after calcining treatment and hydrothermal reaction, rodlike molybdena gas sensitive materials are obtained; further, indium nitrate is used as raw materials; granular indium oxide is loaded on the surface of rodlike molybdena; finally, In2O3 nanoparticles / MoO3 nanorod composite gas sensitive materials are obtained. The method has the advantages that the production process is simple; the obtained gas sensitive materials have a heterogeneous structure formed by indium oxide and molybdenum oxide; higher sensitivity and fast response and recovery on trimethylamine are shown; the method can be used in the field of a trimethylamine gas sensor, so that the novel gas sensitive material with high sensitivity is obtained.

Owner:UNIV OF JINAN

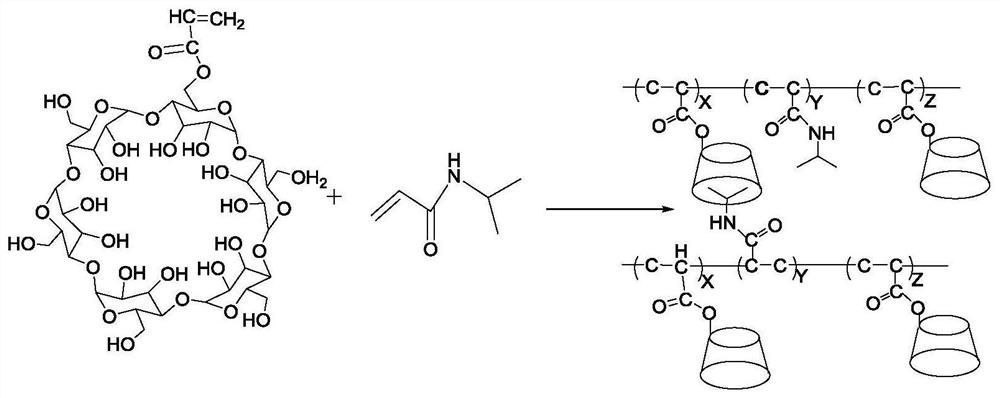

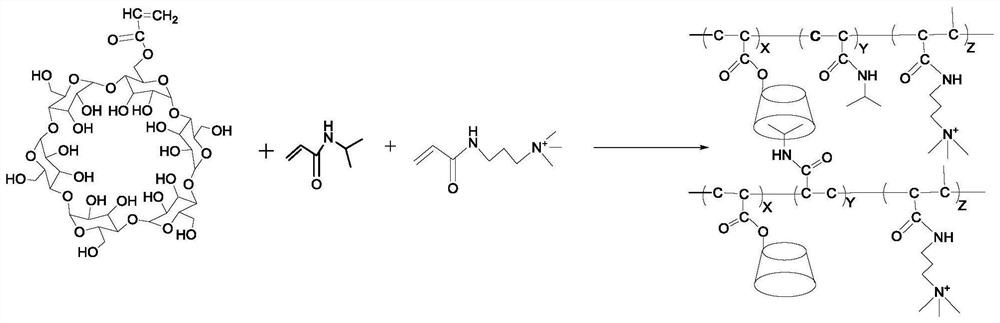

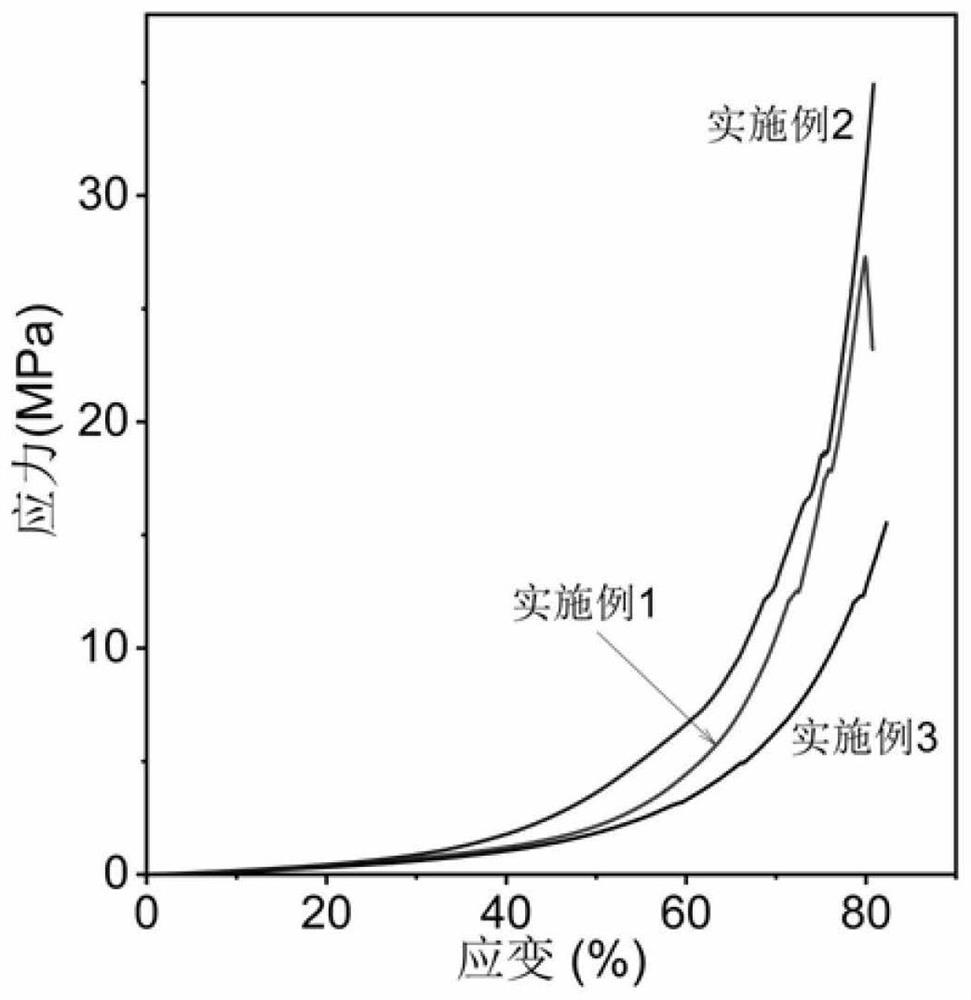

Self-repairing multi-photoresponse double-layer supramolecular hydrogel as well as preparation method and application thereof

ActiveCN112126082AClosely connectedHigh bonding strengthRecord carriers used with machinesMeth-Isopropyl

The invention relates to the technical field of supramolecular chemistry, and discloses a preparation method of self-repairing multi-photoresponse double-layer supramolecular hydrogel, which comprisesthe following steps: (1) reacting N-isopropylacrylamide, cyclodextrin monomer and graphene oxide aqueous dispersion to obtain a hydrogel layer 1; (2) carrying out a reaction on N-isopropylacrylamide,a cyclodextrin monomer and acryloyloxyethyl trimethyl ammonium chloride to obtain a prepolymer solution of the hydrogel layer 2; and (3) injecting the prepolymer solution into a mold to obtain double-layer hydrogel, and soaking the double-layer hydrogel in an ammonium molybdate tetrahydrate solution to finally obtain the double-layer supramolecular hydrogel. According to the hydrogel, physical crosslinking is realized by utilizing host-guest interaction between cyclodextrin and N-isopropylacrylamide isopropyl, tight connection between double-layer hydrogel is also realized through host-guestinteraction, the double-layer bonding strength is high, and the hydrogel has good self-repairing performance, multiple photoresponse deformation discoloration performance and injectable performance.

Owner:QUZHOU RES INST OF ZHEJIANG UNIV +1

Synthesis method of molybdenum disulfide/carbon nano composite material

InactiveCN106423218AReach protectionMaterial nanotechnologyPhysical/chemical process catalystsCarbon filmCarbon composites

The invention discloses a synthesis method of a molybdenum disulfide / carbon composite material for preparing potassium humate, belonging to the field of inorganic non-metal materials. The method comprises the following steps: dissolving a soluble molybdenum salt ammonium molybdate tetrahydrate in water, adding potassium humate into the solution, reversely dropping the mixed solution into nitric acid, and regulating the pH value to 1-3 to prepare a precipitate; and roasting in argon or any other inert atmosphere by a fused salt roasting process to generate carbon thermal reaction, thereby obtaining the composite structure on which nanorods with the length of 100nm or so are carried on the carbon film. The method has the advantages of simple technique and low cost. The biomass material potassium humate is used as the carbon source to directly synthesize the loaded nano composite structure.

Owner:XINJIANG UNIVERSITY

Mung bean foliar fertilizer containing trace element selenium and technique for cultivating selenium-enriched mung beans by utilizing mung bean foliar fertilizer

ActiveCN104355739AIncrease productionIncrease selenium contentAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersMonopotassium phosphateZINC SULFATE HEPTAHYDRATE

The invention discloses a mung bean foliar fertilizer containing the trace element selenium and a technique for cultivating selenium-enriched mung beans by utilizing the mung bean foliar fertilizer. The mung bean foliar fertilizer comprises the following raw materials in mass percent: 14-16% of boric acid, 4.5-5.5% of manganese sulfate monohydrate, 12-13% of zinc sulfate heptahydrate, 3.5-4% of ammonium molybdate tetrahydrate, 4.5-5.5% of copper sulfate pentahydrate, 24-26% of chelated iron, 8.5-9% of sodium selenite and 24-26% of monopotassium phosphate. Through the cultivation steps of variety selection, seed treatment, seed sowing, fertilization, weeding by means of intertillage, pest control and the like, the selenium-enriched mung beans can be harvested. The technique for cultivating the selenium-enriched mung beans by utilizing the mung bean foliar fertilizer has the advantages that the yield of mung beans is improved, the content of selenium in the mung beans is increased, and the cultivated mung beans not only have the own nutritions but also contain a high content of selenium which can meet the content needs of human bodies, so that immunity can be improved and cancers can be prevented. The mung bean foliar fertilizer can be completely absorbed by crops with no physical process, so that compared with the processing step of producing selenium-enriched rice through seed soaking, the technique is safer, more reliable, and low in cost.

Owner:ENSHI MAOHE FOOD

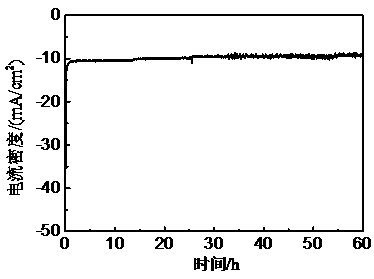

High-efficiency hydrogen evolution catalyst and preparation method thereof

InactiveCN110433835AHigh catalytic activityLow hydrogen evolution overpotentialCatalyst activation/preparationEthylenediamineElectrolysis

The invention discloses a high-efficiency hydrogen evolution catalyst and a preparation method thereof. The preparation method is characterized by comprising the following steps: with chitosan as a carbon source, trimesic acid as an organic ligand, ethylenediamine as a nitrogen source, ammonium molybdate tetrahydrate as a molybdenum source and an iron-based metal (iron, cobalt or nickel) salt as adoping metal source, carrying out uniform mixing and a sufficient reaction; and then performing one-step high-temperature pyrolysis to realize nitridation and carbonization so as to prepare the high-nitrogen-doped carbon-coated iron-based metal element-doped Mo2C catalyst for water electrolysis. The electrocatalyst prepared by using the method has excellent water electrolysis performance, low hydrogen evolution overpotential in acidic and alkaline aqueous solutions, and good stability, and can work stably for at least 60 hours. The catalyst can be widely used in the field of electrochemical hydrogen production, and lays a technical foundation for large-scale preparation of hydrogen.

Owner:CHANGZHOU UNIV

Dedicated fertilizer for soybean and preparation method thereof

InactiveCN104262018AExtended release timeReduce the amount of applicationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSoil scienceDiammonium phosphate

The invention discloses a dedicated fertilizer for a soybean. The dedicated fertilizer is prepared by coating outer layer membranes which are made from a degradable material on inner layer fertilizer grains, wherein the inner layer fertilizer grains are prepared from the following raw materials in parts by weight: 43-45 parts of ammonium bicarbonate, 10-17 parts of potassium sulphate, 37-42 parts of monopotassium phosphate, 21-26 parts of diammonium hydrogen phosphate, 3-7 parts of boric acid, 8-12 parts of ammonium molybdate tetrahydrate, 1-3 parts of bean dregs and 2-4 parts of vinasse. In the dedicated fertilizer for the soybean and the preparation method of the fertilizer, provided by the invention, the dedicated fertilizer for the soybean can be released in long acting with gradual degradation of the external release control layer, so that the fertilizer decomposition and release time is prolonged, the application amount of the fertilizer can be lowered, the utilization rate of the fertilizer is increased, the fertilizer application time is reduced as one-time application can meet the requirement of whole growth period on the fertilizer, the waste can be avoided, the stress on the environment is reduced in the meantime, the eutrophication phenomenon due to over dosage of fertilizer application to the environment can be avoided; the preparation method is less in steps, simple to operate, good in coating effect between the release control layer and the inner layer fertilizer, and capable of increasing the release control efficiency.

Owner:WENZHOU UNIVERSITY

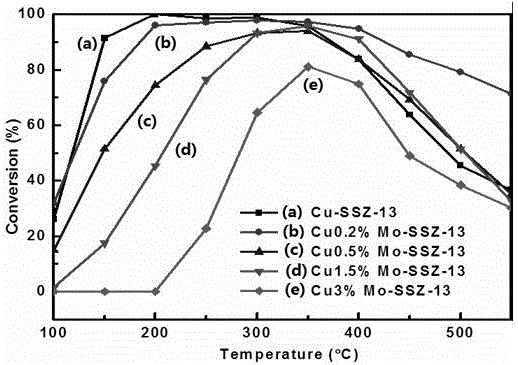

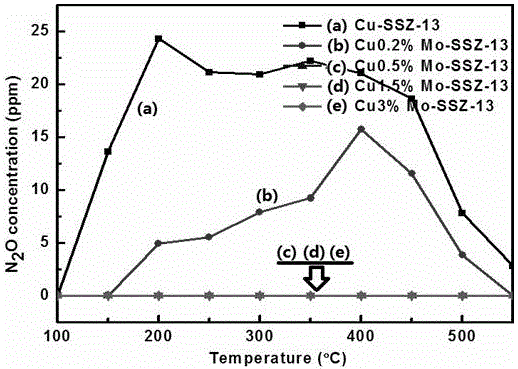

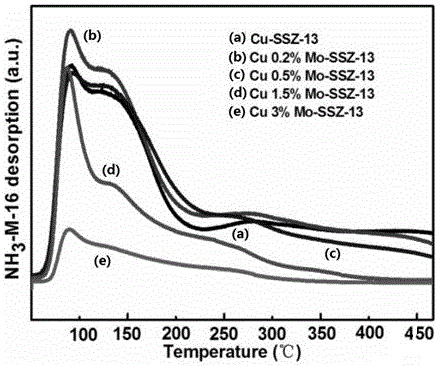

Preparation method of Mo modified Cu-SSZ-13 catalyst

InactiveCN106334577AEasy to prepareEasy to operateNitrous oxide captureGas treatmentActive componentCopper nitrate

The invention discloses a preparation method of a Mo modified Cu-SSZ-13 catalyst. Ammonium molybdate tetrahydrate and copper nitrate are taken as precursors and are directly dipped and loaded to an H-SSZ-13 (SiO2:Al2O3=10:1) molecular sieve. In the Mo modified Cu-SSZ-13 catalyst, the mass percent of Cu is 4 percent, and the mass percent of Mo is 0.2 to 3 percent. Active components are transition metal Cu<2+>, a Bronsted acidic locus and a Lewis acidic locus. The transition metal catalyzes the NO oxidation, and all the acidic loci take charge of ammonia activation. When the addition of Mo is 0.2 percent, a NO conversion rate temperature window is widened; when the addition of Mo is 0.5 percent or more, a NOx conversion rate temperature window is reduced. Through the adoption of the Mo modified Cu-SSZ-13 catalyst, the discharge of NOx can be reduced, and meanwhile the generation of a by-product N2O can be reduced.

Owner:NANCHANG UNIV

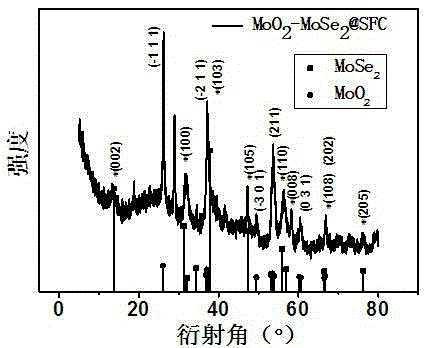

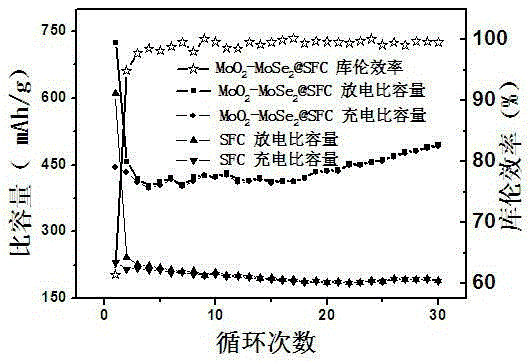

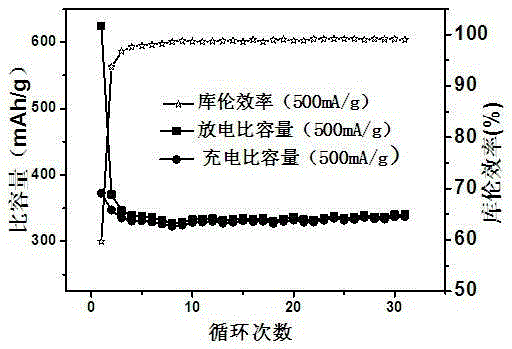

Nano MoO2-MoSe2@SFC lithium ion battery negative electrode material and preparation method therefor

ActiveCN105428612AGood electrochemical propertiesHigh discharge specific capacityMaterial nanotechnologyCell electrodesFiberPolyethylene glycol

The invention discloses a nano MoO2-MoSe2@SFC lithium ion battery negative electrode material and a preparation method therefor. A nano MoO2-MoSe2@SFC composite material takes sisal fiber carbon (SFC) with a hierarchical pore-shaped structure as a substrate material, and MoO2 and MoSe2 are uniformly dispersed in the surface and pores of the SFC. Ammonium molybdate tetrahydrate, ammonium molybdate dehydrate or molybdenum dioxide is taken as a molybdenum source; selenium dioxide, sodium selenite or selenium powder is taken as a selenium source; carbonized, ball-milled and sieved SFC is taken as a substrate material; hydrazine hydrate and polyethylene glycol 400 are used as a reductant and a dispersant respectively; a hydrothermal reaction is performed by utilizing a high-pressure reaction kettle; and dispersoid materials with different particle sizes can be obtained by changing different reaction conditions. The obtained nano MoO2-MoSe2@SFC composite powder is relatively high in reversible capacity, relatively stable in cyclic performance and relatively high in charging / discharging rate performance when being used as the lithium ion battery negative electrode material, so that the nano MoO2-MoSe2@SFC composite powder has relatively good application prospects.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Selenium-rich radish traditional Chinese medicine leaf fertilizer

ActiveCN103351255APromote absorptionGuaranteed outputFertilizer mixturesAdditive ingredientZINC SULFATE HEPTAHYDRATE

The invention discloses a selenium-rich radish traditional Chinese medicine leaf fertilizer. The leaf fertilizer comprises the following ingredients in parts by weight: 20-26 parts of potassium nitrate, 10-15 parts of diammonium phosphate, 8-12 parts of ammonium molybdate tetrahydrate, 10-13 parts of zinc sulphate, 10-15 parts of ammonium sulfate, 12-14 parts of anhydrous boric acid, 20-23 parts of sodium selenite, 15-20 parts of potassium sulfate, 2-5 parts of fulvic acid and the like. According to the invention, the sodium selenite solution and other fertilizers are organically combined, so that radish obtains lots of nutrition to ensure vigorous growth, and selenium absorption is improved; when the selenium-rich radish traditional Chinese medicine leaf fertilizer is used a lot, the yield of radish is guaranteed and the quality of yield is improved.

Owner:西安皓通农林科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com