Preparation method of phosphorus doped cobalt molybdate hydrogen evolution electrocatalyst and product thereof

An electrocatalyst, cobalt molybdate technology, applied in the field of electrocatalytic hydrogen evolution, can solve problems such as low catalytic activity, weak adsorption capacity, failure, etc., achieve high-efficiency hydrogen evolution performance, reduce hydrogen production costs, and improve catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

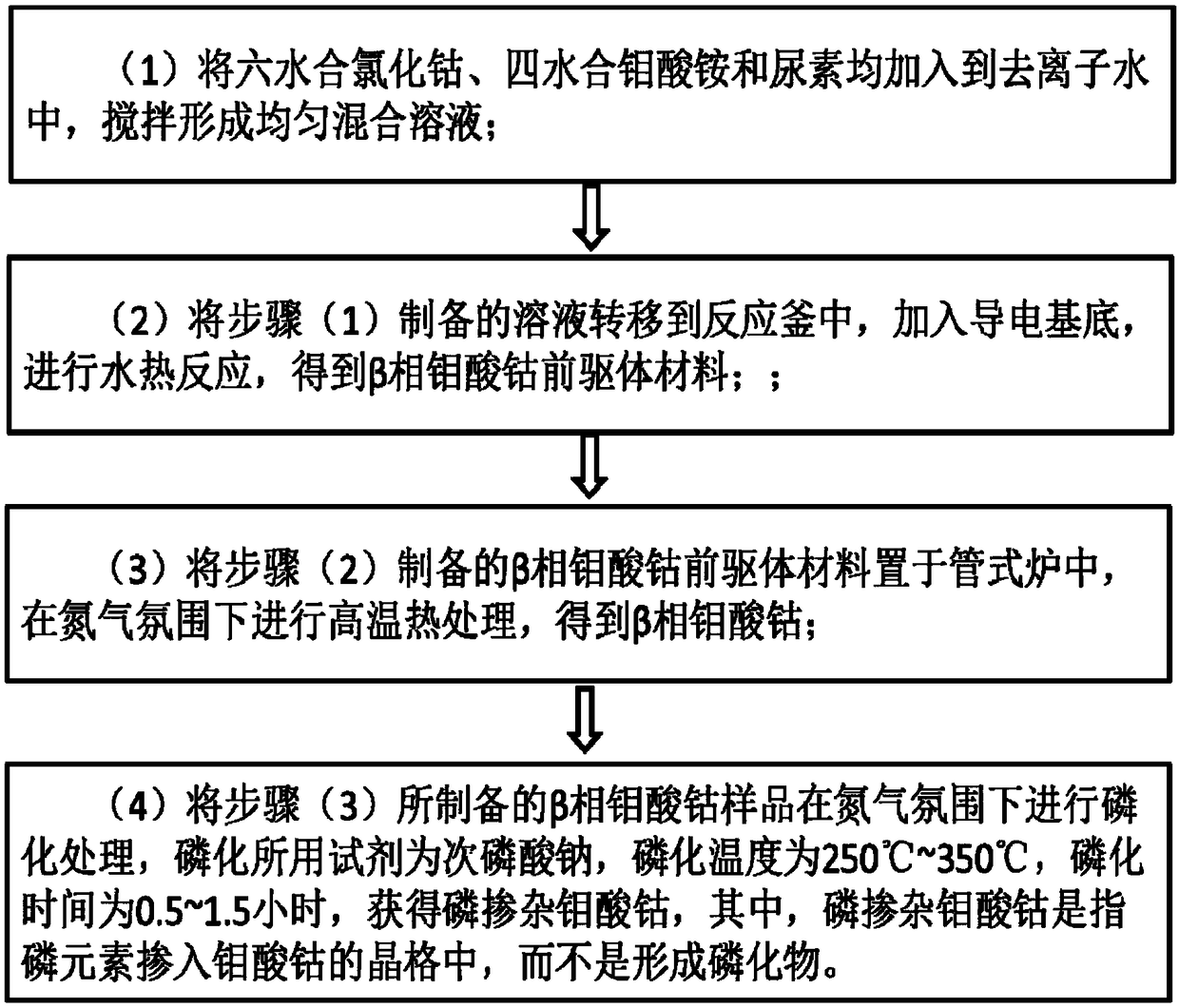

[0021] figure 1 It is a flow chart of the preparation method of phosphorus-doped cobalt molybdate hydrogen evolution electrocatalyst of the present invention, as can be seen from the figure, a kind of preparation method of phosphorus-doped cobalt molybdate hydrogen evolution electrocatalyst of the present invention comprises the following steps:

[0022] (1) Cobalt chloride hexahydrate, ammonium molybdate tetrahydrate and urea are added to deionized water respectively, and stirred to form a uniform mixed solution;

[0023] (2) Transfer the solution prepared in step (1) to a reaction kettle, add a conductive substrate, and perform a hydrothermal reaction to obtain a β-phase cobalt molybdate precursor material;

[0024] (3) Place the sample prepared in step (2) in a tube furnace, and carry out high-temperature heat treatment under a nitrogen atmosphere to obtain β-phase cobalt molybdate;

[0025] (4) The sample prepared in step (3) is subjected to phosphating treatment under a ...

Embodiment 1

[0034] The preparation method of a phosphorus-doped cobalt molybdate hydrogen evolution electrocatalyst of the present embodiment comprises the following steps:

[0035](1) 476mg cobalt chloride hexahydrate, 706.4mg ammonium molybdate tetrahydrate and 600mg urea are added to 72ml deionized water, stirred to form a uniform mixed solution, wherein the cobalt chloride hexahydrate and the urea are mixed in the The mass concentration in the uniformly mixed solution is 6.6mg / ml and 8.3mg / ml respectively, and the molar ratio of the cobalt element in the described cobalt chloride hexahydrate to the molybdenum element of the described ammonium molybdate tetrahydrate is 1:2;

[0036] (2) Transfer the solution prepared in step (1) to a reaction kettle, add a titanium sheet, and conduct a hydrothermal reaction at 120° C. for 8 hours to obtain β-phase cobalt molybdate;

[0037] (3) Place the sample prepared in step (2) in a tube furnace, and perform high-temperature heat treatment under a ...

Embodiment 2

[0044] The preparation method of a phosphorus-doped cobalt molybdate hydrogen evolution electrocatalyst of the present embodiment comprises the following steps:

[0045] (1) 432mg cobalt chloride hexahydrate, 641.1mg ammonium molybdate tetrahydrate and 576mg urea are added to 72ml deionized water, stirred to form a uniform mixed solution; the cobalt chloride hexahydrate and the urea are uniformly mixed The mass concentration in the solution is respectively 6mg / ml and 8mg / ml, and the molar ratio of the cobalt element in the described cobalt chloride hexahydrate and the molybdenum element of the described ammonium molybdate tetrahydrate is 1:2;

[0046] (2) Transfer the solution prepared in step (1) to a reaction kettle, add a titanium sheet, and conduct a hydrothermal reaction at 140° C. for 9 hours to obtain β-phase cobalt molybdate;

[0047] (3) Place the sample prepared in step (2) in a tube furnace, and perform high-temperature heat treatment in a nitrogen atmosphere, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com