A kind of inorganic composite orange pigment and preparation method thereof

An orange pigment and inorganic composite technology, applied in the field of inorganic pigments, can solve the problems of poor weather resistance, temperature resistance and chemical stability, poor thermal stability and weather resistance, and affect the color performance of pigments, etc., to achieve good dispersion, thermal stability, etc. Good stability and weather resistance, strong hiding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

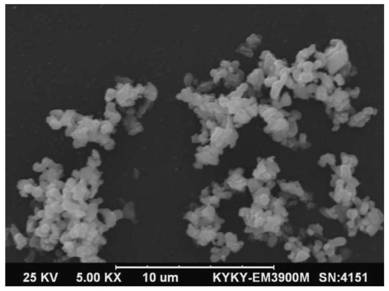

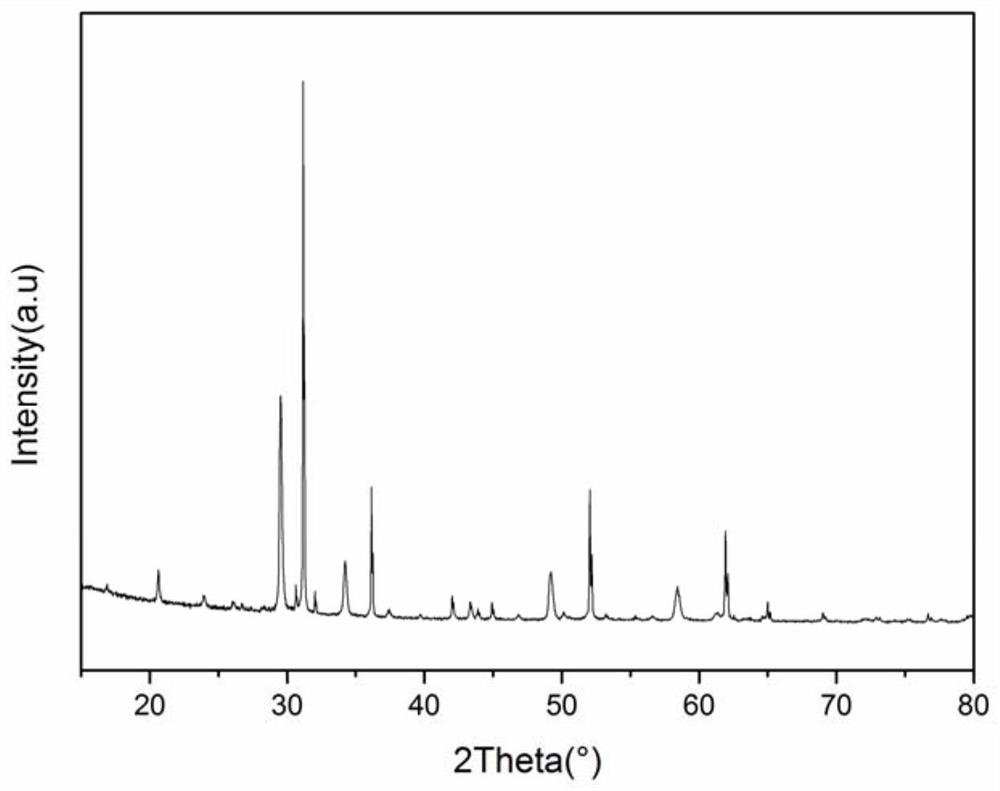

[0028] A kind of inorganic composite orange pigment of present embodiment, its chemical composition is Sn 1.3 Zn 0.7 Ti 1.5 Nb 0.5 o 7-δ , prepared by solid-phase method, the steps are as follows:

[0029] (1) with SnO, ZnO, TiO 2 , Nb 2 o 5 as raw materials, according to the chemical composition, mix evenly by wet ball milling with ethanol as the dispersion medium, the ball milling speed is 450r / min, and the ball milling time is 6h, to obtain the mixed material;

[0030] (2) The above mixed material is dried at a temperature of 75° C. to obtain a powder;

[0031] (3) The above-mentioned powder is packed in a corundum crucible, put into a tube furnace, and argon is introduced as a protective atmosphere, and the flow rate is 40mL / min; then the temperature is raised to 850°C at 5°C / min for firing, and the holding time is After 5 hours of firing, it was naturally cooled to room temperature, and a brightly colored inorganic composite orange pigment was obtained.

[0032] ...

Embodiment 2

[0034]A kind of inorganic composite orange pigment and preparation method thereof of the present embodiment, differs from embodiment one in that:

[0035] 1. Step (3) of the preparation method: heat up to 800° C. for firing.

[0036] 2. The inorganic composite orange pigment prepared in this example has L*, a*, and b* values of 67.2, 29.1, and 47.7, respectively.

Embodiment 3

[0038] A kind of inorganic composite orange pigment and preparation method thereof of the present embodiment, differs from embodiment one in that:

[0039] 1. The chemical composition of the inorganic composite orange pigment is SnZnTi 1.2 Nb 0.8 o 7-δ .

[0040] 2. Step (3) of the preparation method: heat up to 850° C. for firing.

[0041] 3. The inorganic composite orange pigment obtained in this example has L*, a*, and b* values of 71.4, 27.8, and 58.6, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com