Patents

Literature

73results about How to "Fireproof has" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of ecological fire preventing and heat insulating building material

InactiveCN101618567AImprove insulation effectImprove insulation performanceMixing operation control apparatusCeramic shaping apparatusFiberExpanded clay aggregate

Owner:王建国

Fireproof foaming compound insulation board and preparation method thereof

InactiveCN102850024AImproved dimensional stability and crack resistanceCost-effectiveCeramicwareLower faceFiberglass mesh

The invention discloses a fireproof foaming compound insulation board and a preparation method thereof. The insulation board is made from the following raw materials: portland cement, special cement, coal ash, water-retaining agent, water repellent, retarder, fiber, water, polyphenyl granules and foaming agent. The preparation method comprises the following steps of pouring the portland cement, the special cement, the coal ash, the water-retaining agent, the water repellent, the retarder and the fiber into a mixer to be mixed evenly, and adding water to form a mixture; pouring the polyphenyl granules into the mixture, and mixing to obtain a paste; adding the foaming agent to form a foam paste; injecting the foam paste into a mould for moulding; cutting into boards after maintenance; laying a layer of glass fiber grid cloth on each upper and lower face of the boards, scraping and pressing a cement paste layer on the surface of each grid cloth, and maintaining to obtain the insulation board. By the preparation method disclosed by the invention, the size stability and anti-cracking performance of the insulation board can be obviously improved, and the insulation board has the characteristics of light weight, heat insulation, durability, fire resistance, environment protection and high cost performance.

Owner:JIANGSU NIGAO SCI & TECH +1

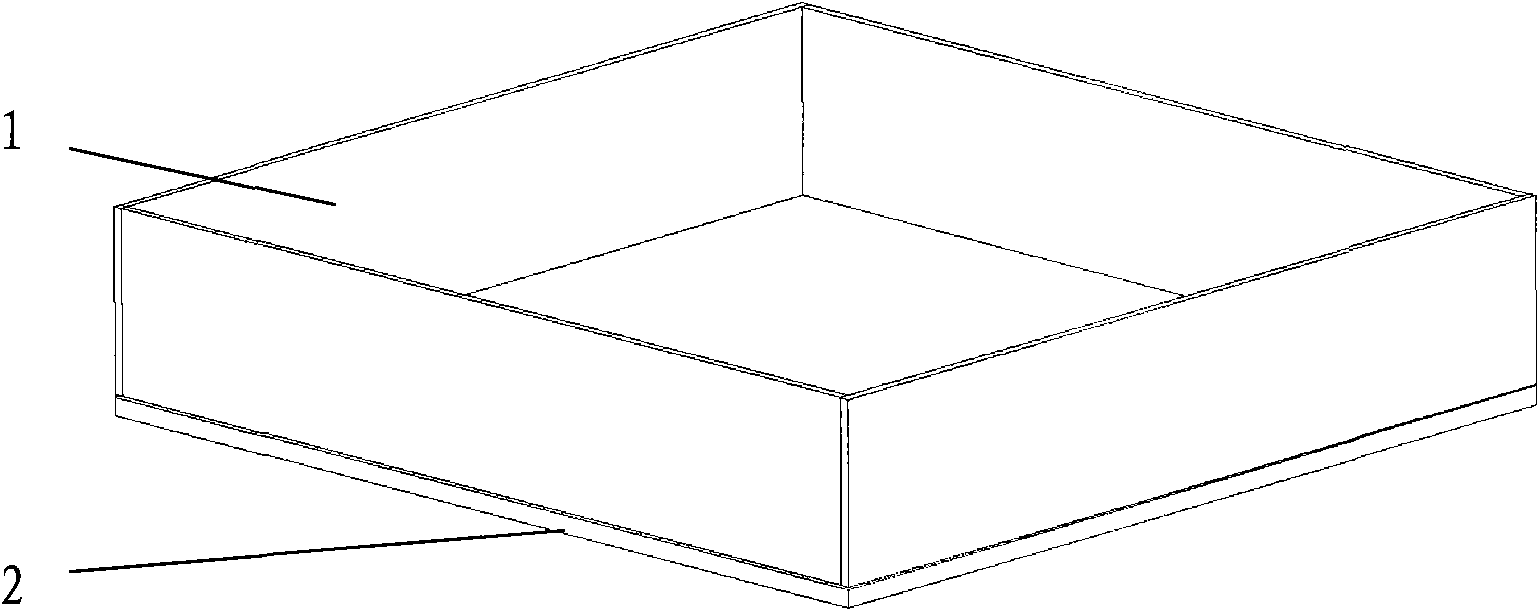

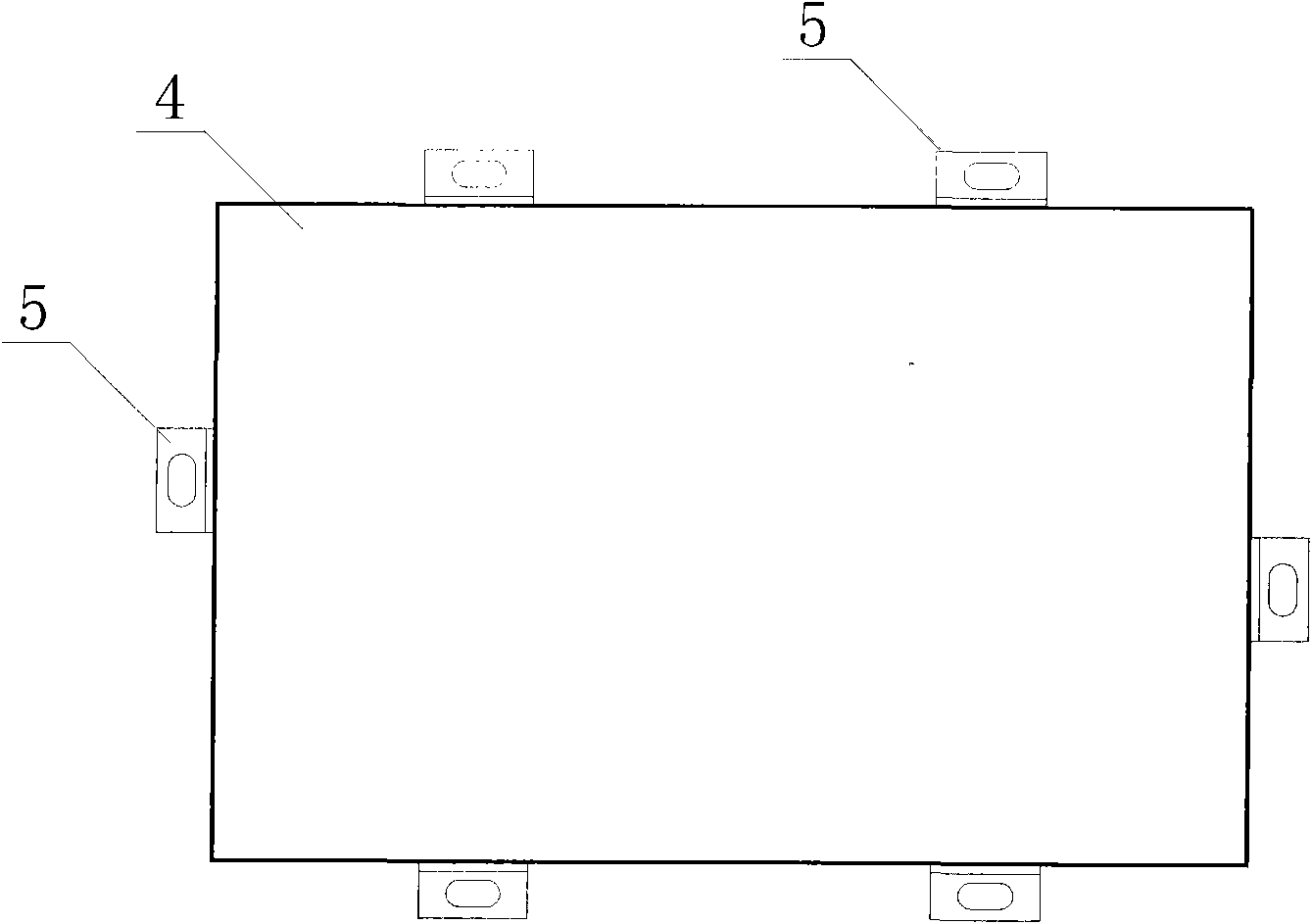

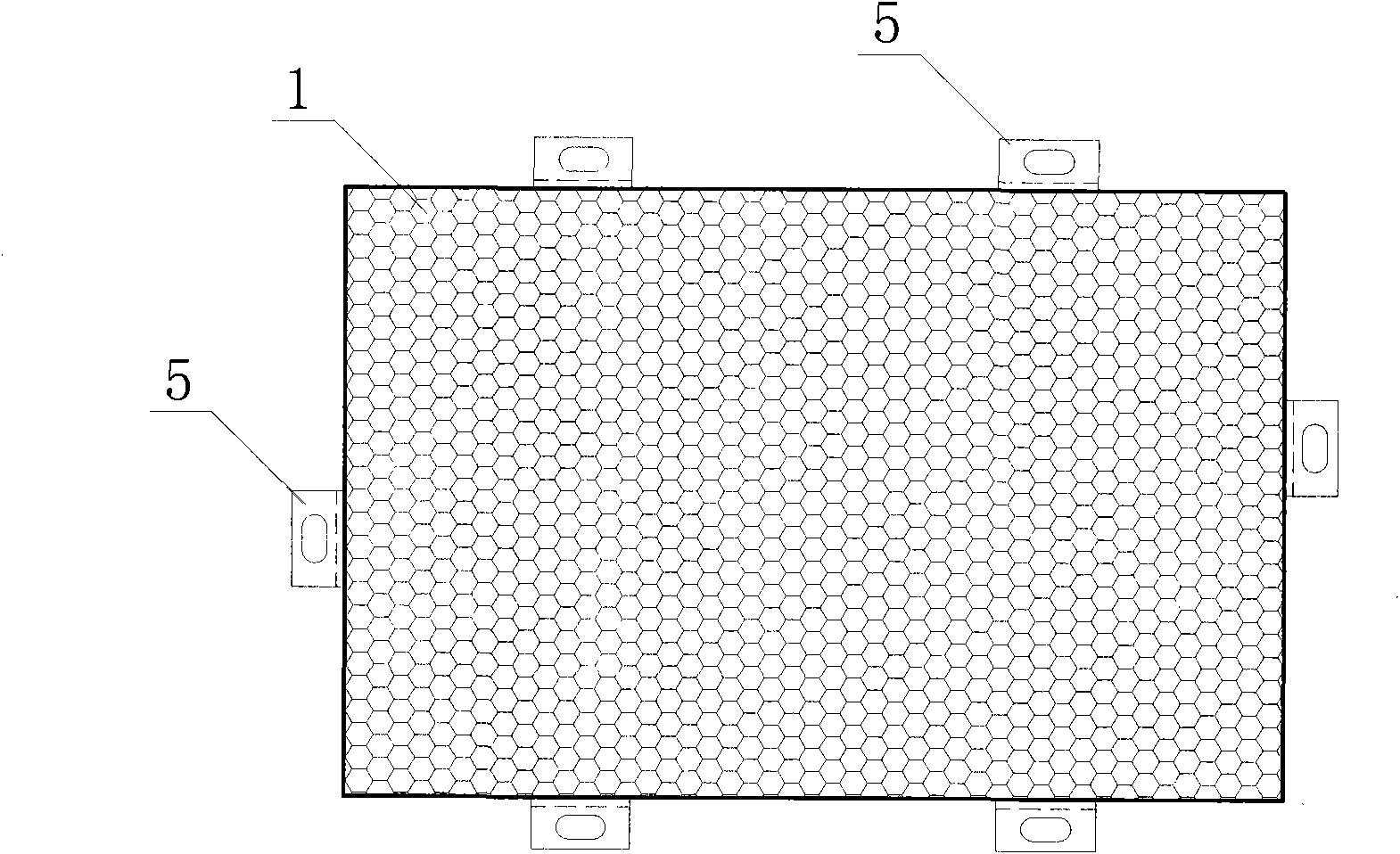

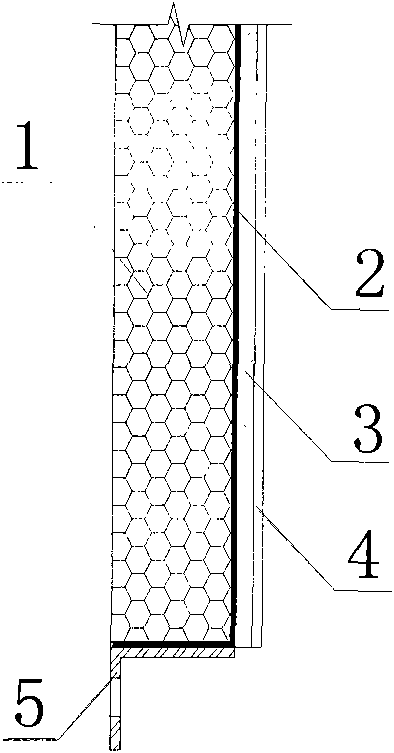

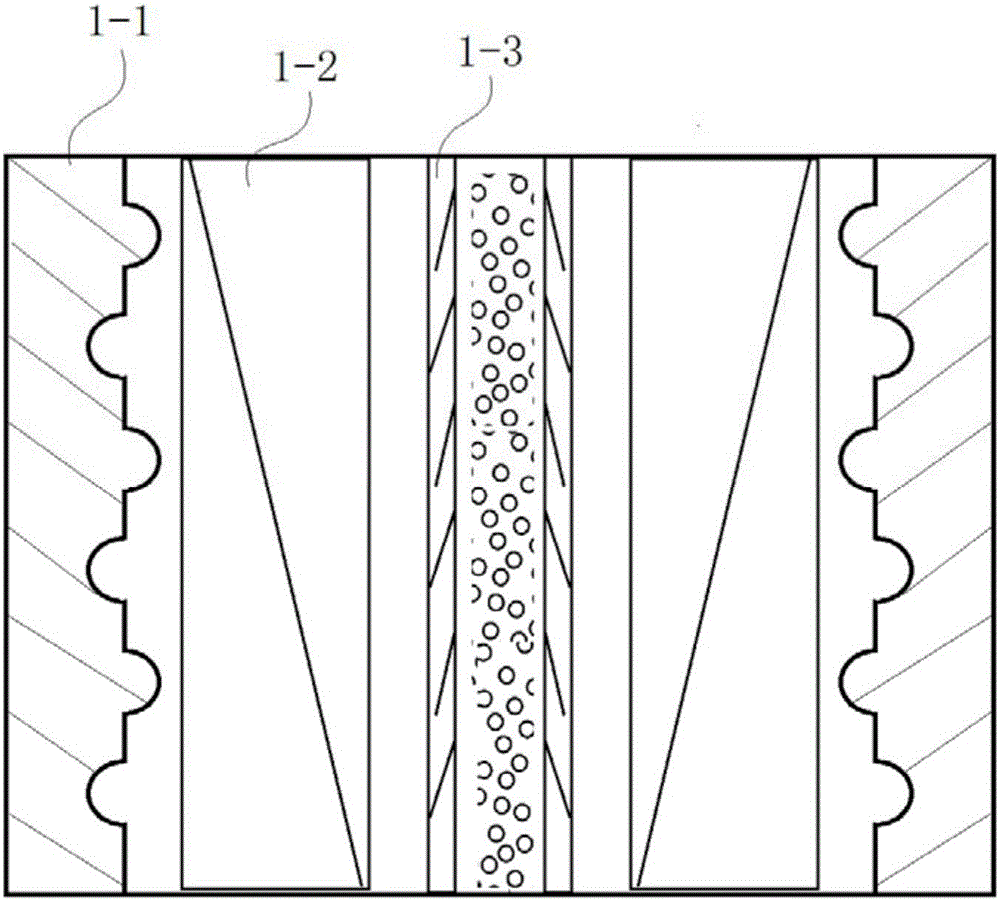

Heat-insulating decorative fireproof partition board for exterior wall of building and construction method thereof

ActiveCN102071754AGood decorative effectAdvanced technologyCovering/liningsHeat proofingCeramicFluorocarbon

The invention discloses a heat-insulating decorative fireproof partition board for an exterior wall of a building and a construction method thereof. The heat-insulating fireproof decorative board adopts a heat-insulating foaming ceramic board made of fireproof materials as a fireproof partition and heat-insulating material; the heat-insulating foaming ceramic board, an enhanced panel and veneer materials form an integrated board with the functions of fire prevention, heat insulation and decoration; integrated boards are arranged along the horizontal direction of the building at intervals of certain height in a heat-insulating system for the exterior wall of the building or arranged on upper edges of window and door openings of the building to form a fire barrier, so that the flame propagation can be effectively prevented and the fire damage can be reduced; the heat-insulating fireproof decorative board is bonded with a base course wall of the building through cement mortar at first and then anchored and supported through a machine; and exterior finishes can be painted with fluorocarbon paint, fluorocarbon metallic paint, stone-like paint and the like and be matched with a conventional heat-insulating decorative board for the exterior wall of the building for use. The heat-insulating decorative fireproof partition board disclosed by the invention can be used as a fireproof construction measure to be widely applied to heat-insulating projects of exterior walls of the building industry, and has the advantages of fire prevention, heat insulation, durability, impact resistance, good decorative effect and the like. The construction method disclosed by the invention has the advantages of advanced technology, economy and rationality, convenience for assembly, low energy consumption for construction, and conformity with the national requirements of environmental protection and energy saving.

Owner:江苏建科土木工程技术有限公司

Manufacturing method for composite aluminium plastic decorative buckles

InactiveCN1456436AImprove flatnessFriction-resistantMetal layered productsTectorial membraneSurface oxidation

A decorative fastening aluminium-plastic plate is prepared through preparing plastic substrate from engineering plastics, filler, stabilizer, plasticizer, lubricant and assistant through mixing, granulating, extruding out, fixing shape, and cutting, preparing the coated aluminium foil through washing, removing oil, oxidizing surface, baking, painting, baking and coiling, combining said plastic substrate with aluminium foil, covering adhesive protecting film on the surface of aluminium foil, and cutting. Its advantages are high abrasion compression, fire and water resistance, good thermal and acoustic insulation, no poison and beautiful appearance.

Owner:无锡市中德装饰新材料有限公司

Formula of carbonized solid-wood high-density fiber composite board and producing and recycling process

ActiveCN104308947AFireproof hasFire retardant withConstruction materialWood working apparatusFiberSolid wood

The invention discloses a formula of a carbonized solid-wood high-density fiber composite board and a producing and recycling process. The raw materials are carbonized wood fiber powder and highly dehydrated carbonized materials, the characters of plastic fusion has been improved, hydrophilic factors in the carbonized wood are recombined, the balance point (commonly known as moisture line) of moisture absorption of the wood is lowered and is not easy to be affected by the surrounding, and quality of the products can be guaranteed. The formula thoroughly overcomes the defects of similar products in the market and has the advantages of water resistance, insect prevention, corrosion prevention, flame retarding and the like. Meanwhile, the formula can be used for decorations such as sculpture, veneering and spraying, is free of formaldehyde and can be recycled and reused completely.

Owner:GUANGDONG HUANGTIAN ENVIRONMENTAL PROTECTION TECH CO LTD

Manufacturing method for reinforced fiber magnesium fireproof board

InactiveCN106738201AFireproof hasThe fireproof board is environmentally friendlyCeramic shaping apparatusFire proofingFiberTemperature control

The invention relates to a manufacturing method for a reinforced fiber magnesium fireproof board. The method includes the following steps that three tons of magnesium sulfate and 1.6 tons of hydrated slurry are placed in a pulping tank, then a mixture is pumped into a stirring tank, and 120kg of magnesium oxide, 25kg of saw dust powder, 80kg of magnesium sulfate and 25kg of bamboo fibers are added; after uniform stirring, a mixture is placed into the upper layer of a hopper, uniformly stirred raw materials flow into a template of a grid cloth at the lower layer of the hopper, and a semi-finished product of the reinforced fiber magnesium fireproof board is primarily formed through pressing forming of a rolling barrel; the semi-finished product of the reinforced fiber magnesium fireproof board is fed into a curing chamber, the temperature in the curing chamber is constant at of 40 DEG C, temperature-controlled drying and curing forming is conducted for 12 hours, and the reinforced fiber magnesium fireproof board which is subjected to curing forming is demolded uniformly; and finally the finished board is sent into a finished product warehouse to be cured for one week, and then cutting, forming and packaging are carried out. The method has the beneficial effects that the reinforced fiber magnesium fireproof board is environmentally friendly, fireproof, waterproof, capable of preserving heat, not prone to deformation and resistant to corrosion, and can be used as a ventilation pipeline, a decoration plate, an outer wall insulation board and the like.

Owner:桐庐朝发装饰材料厂

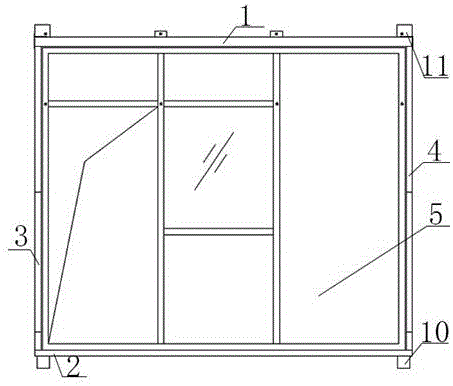

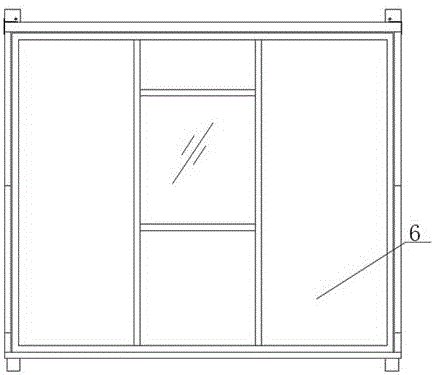

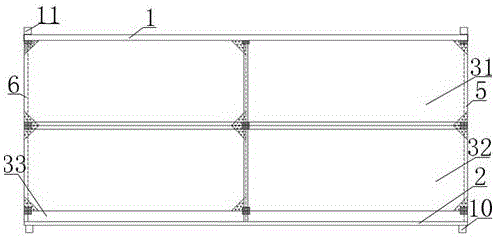

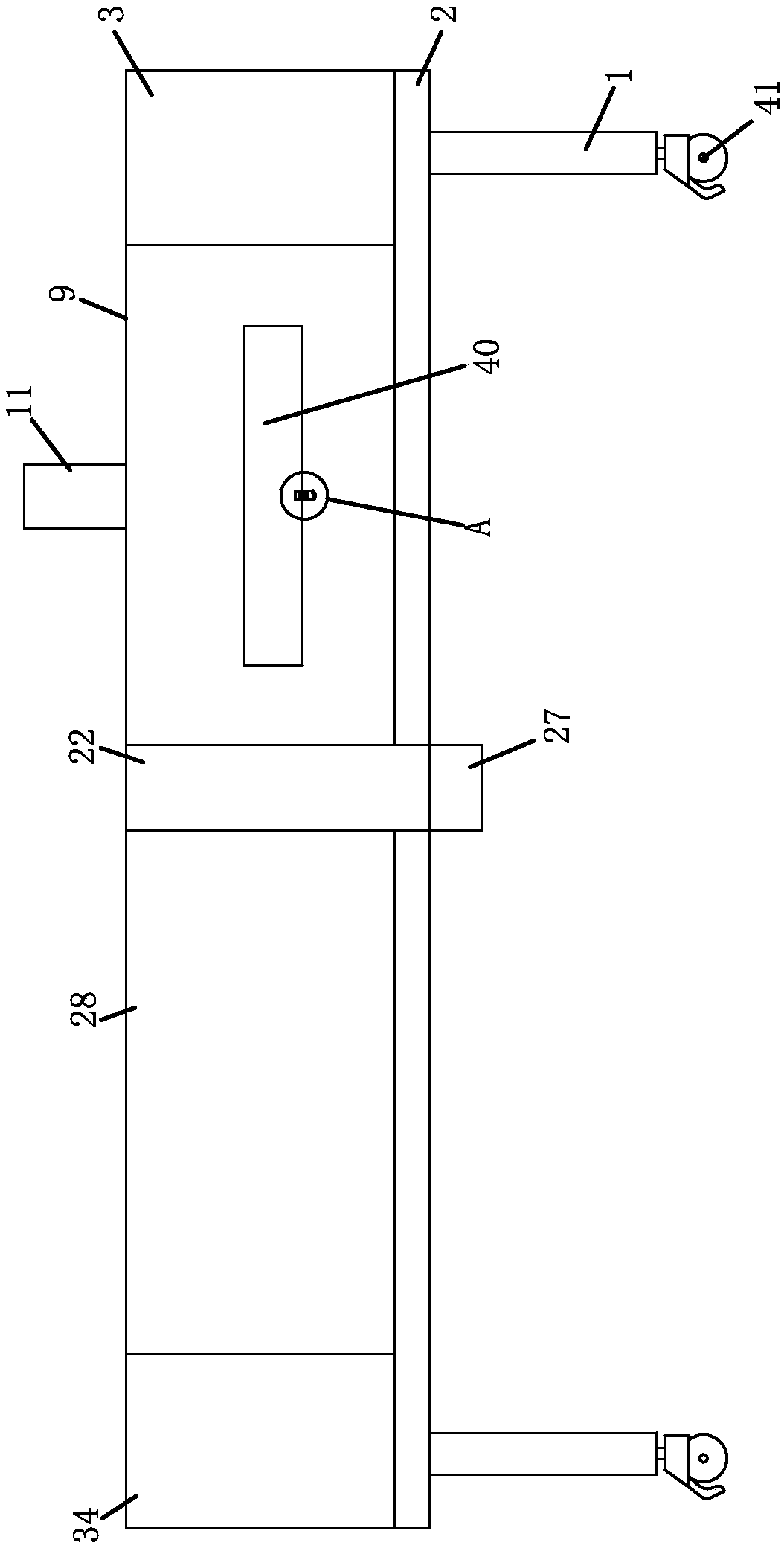

Folding box-type board room capable of being overlapped

InactiveCN105971122AIngenious designCompact and reasonable structureHeat proofingOn boardEngineering

Owner:JIANGSU BIAOLONG CONSTR GRP CO LTD

Heat preservation wallboard and manufacturing method thereof

ActiveCN106088461AIncreased durabilityImprove flame retardant performanceClimate change adaptationBuilding componentsWall materialWall plate

Owner:马鞍山华亿工程技术有限公司

Method for manufacturing wood skin decorated fire-proofing board

ActiveCN1528583AFireproof hasHeat resistantPaper/cardboard layered productsCoatingsHeat resistancePulp and paper industry

The invention is a real wood skin decorating fireproof board making method, including the steps: dipping multiple layer paper with resin, where the multiple layer paper dipped has resin content of 25-60%, and then making heat pressing on the multiple layer paper at 90-200 deg.C at 50-100x10,0000Pa to form fireproof substrate; grinding the surface of the fireproof substrate and pasting the real wood skin onto the grinded surface of the fireproof substrate; coating fireproof resin on the surface of the real wood skin. It has senses of beauty and nature of natural timber and also advantages of fire safety, heat resistance, water resistance, etc.

Owner:WEIDA WOOD IND SUZHOU

AEPS (class-A expandable polystyrene) zinc-magnesium steel plate fireproof insulation decorative integrated board and construction process thereof

InactiveCN105298054AMeet fire protection requirementsImprove stain resistanceCovering/liningsLaminationMaximum dimensionPolystyrene

The invention discloses an AEPS (class-A expandable polystyrene) zinc-magnesium steel plate fireproof insulation decorative integrated board, comprising an AEPS polystyrene board and a zinc-magnesium steel plate composited together. The zinc-magnesium steel plate is 0.5-1.5 mm in thickness. The minimum dimensions of a rectangular plate of the zinc-magnesium steel plate are 100*200 mm. The maximum dimensions of the rectangular plate of the zinc-magnesium steel plate are 1250*12000 mm; two sides of the AEPS polystyrene board are provided with grooves; the zinc-magnesium steel plate has a planarity deviation, is not less than 2 mm in thickness and not greater than 0.2% in long side allowable deviation, and is less than 2 mm in thickness and not greater than 0.5% in long side allowable deviation.

Owner:山东雅达节能建材科技有限公司

Composite plate and preparation method thereof

InactiveCN103331964ALow costImprove fire performanceLaminationLamination apparatusComposite plateAdhesive materials

The invention provides a composite plate, which comprises a base plate, a metal surface plate and a metal bottom plate, wherein the metal surface plate is arranged at one side of the base plate, the metal bottom plate is arranged at the other side of the base plate, high-polymer films are respectively arranged between the base plate and the metal surface plate as well as between the base plate and the metal bottom plate, and the base plate is made of 70wt% to 80wt% of fireproof hard material and 20wt% to 30wt% of adhesive material. A preparation method comprises the following steps of carrying out ball milling on the waterproof hard material into powder, and mixing with the adhesive material to obtain a mixture; stirring and dissolving the mixture, extruding and forming, and drying to obtain the base plate; carrying out waterproof treatment on the metal surface plate and the metal bottom plate, heating, and respectively laminating with the high-polymer films; and respectively laminating the two sides of the base plate with the metal surface plate and the metal bottom plate. The composite plate has the advantages that by adopting the base plate with fireproof and high temperature-proof performances and low cost, after the base plate is laminated with the metal bottom plate and the metal surface plate, the fireproof, environment-friendly, anti-aging and high temperature-proof effects are better.

Owner:朱孟领

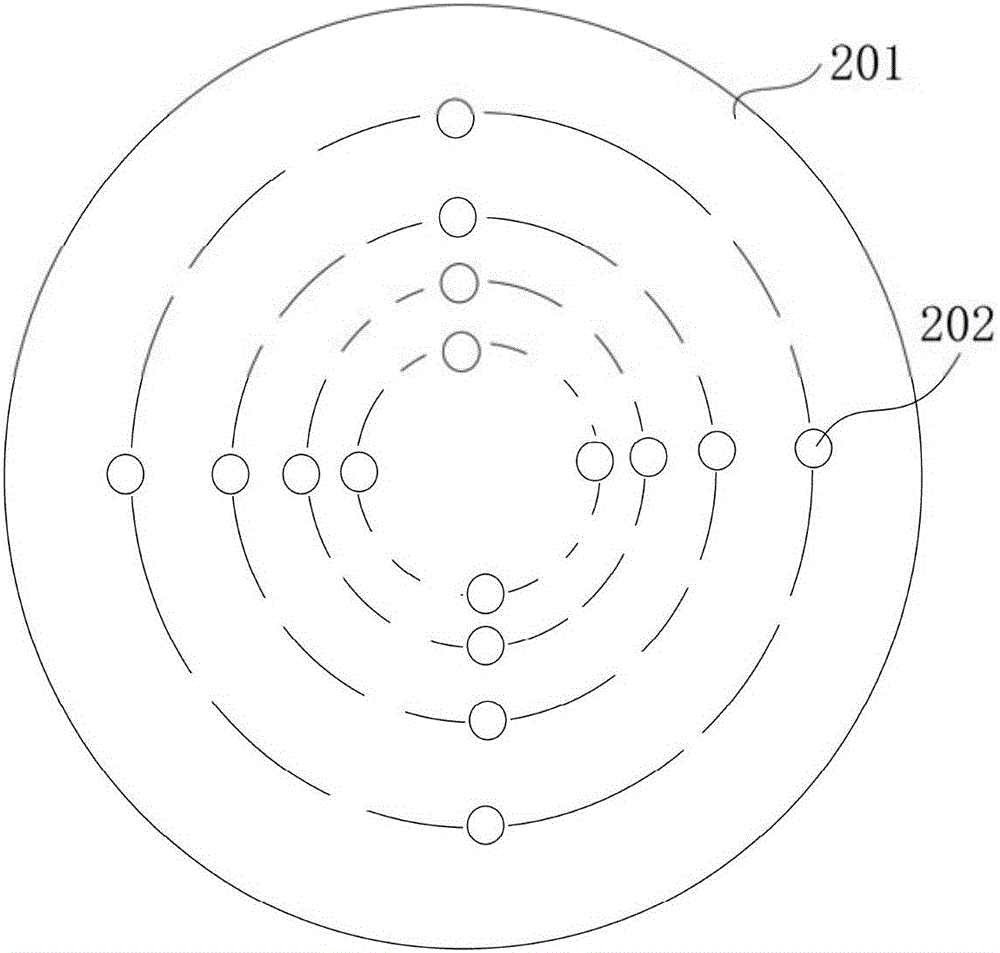

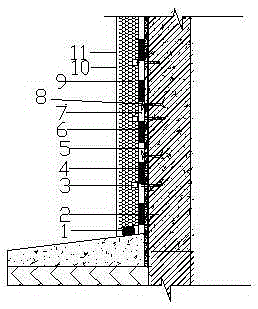

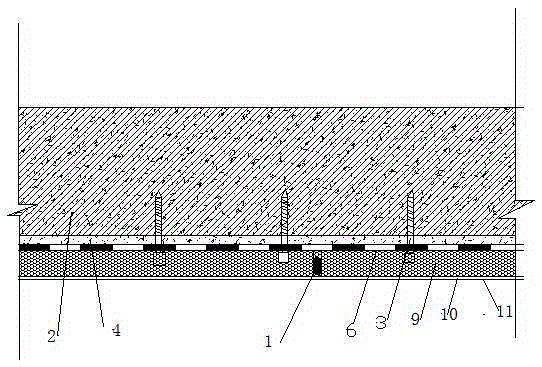

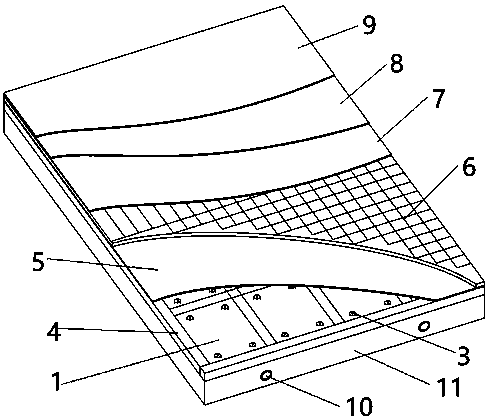

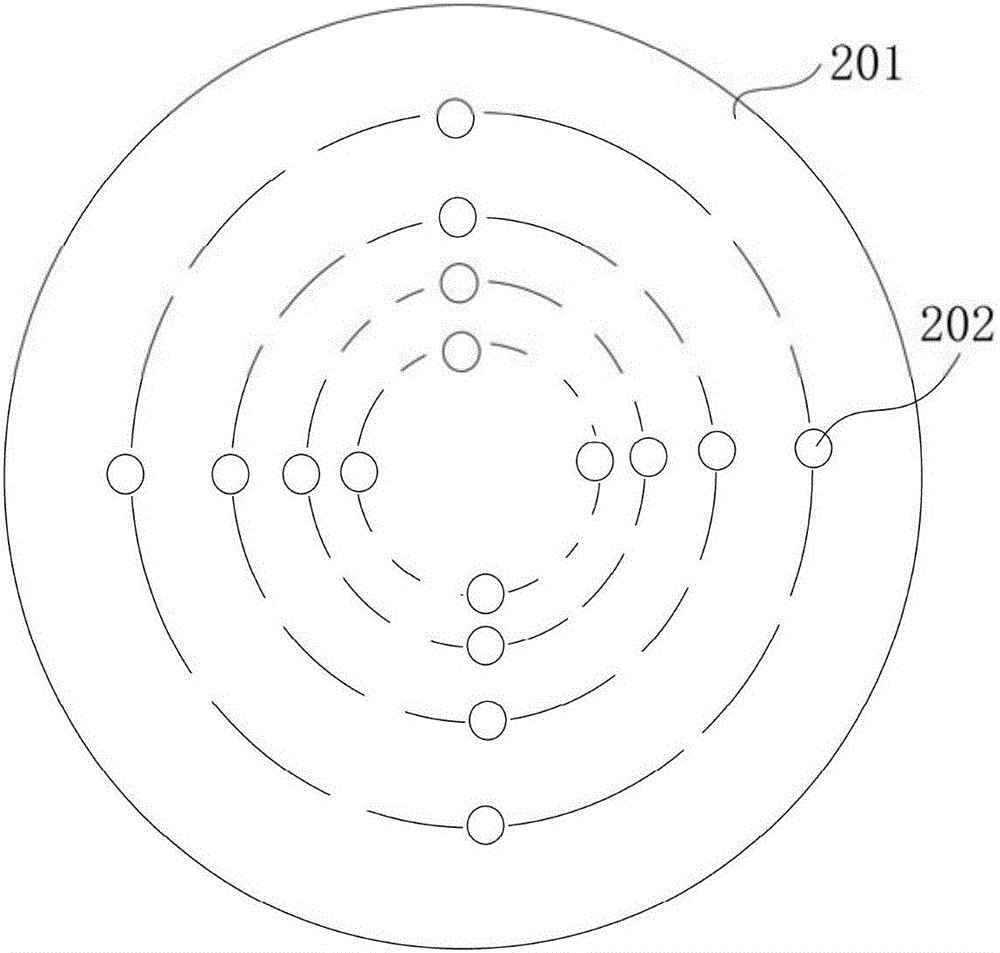

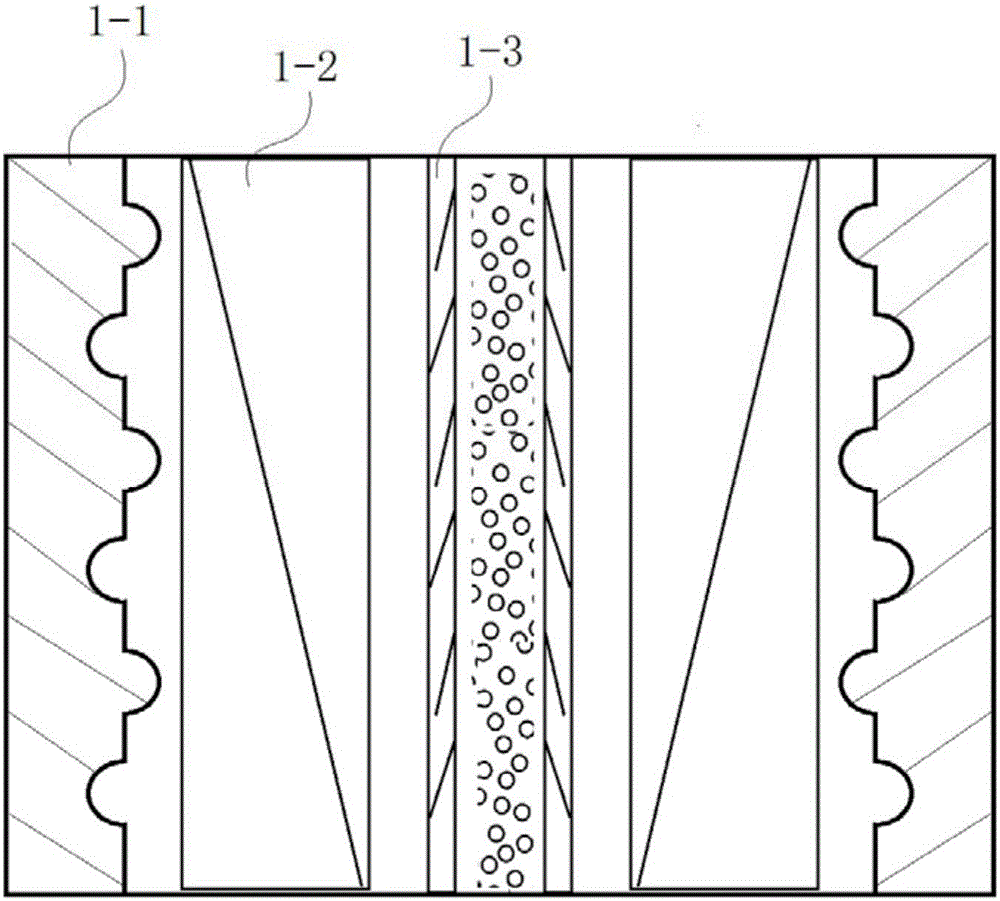

Six-in-one prefabricated concrete outer wall panel and production method thereof

PendingCN109356319AIncrease adhesive frictionTo achieve the purpose of fire preventionCeramic shaping apparatusBuilding componentsThermal insulationEngineering

The invention provides a six-in-one prefabricated concrete outer wall panel and a production method thereof. The six-in-one prefabricated concrete outer wall panel comprises a hydrophobic self-cleaning coating layer, a flexible board, a crack-resistant mortar layer, a gridding cloth, a fireproof dry mixed mortar layer, a heat insulation board and a concrete board which are fixedly connected from outside to inside in sequence. Heat insulation nails are uniformly distributed on the heat insulation board, the end parts of one ends of the heat insulation nails are located in the heat insulation board, and the end parts of the other ends of the heat insulation nails are located in the concrete board. A plurality of strip-shaped through grooves with isosceles trapezoidal cross sections are formed in the lower surface of the heat insulation board, and the strip-shaped through grooves are arranged side by side and evenly distributed. Clamping blocks with isosceles trapezoidal cross sections are integrally arranged at the position, corresponding to the strip-shaped through grooves, on the upper surface of the concrete board, and the clamping blocks are embedded in the strip-shaped through grooves. The six-in-one prefabricated concrete outer wall panel adopts the closed design and has good fireproof performance; the strip-shaped through grooves and the heat insulation nails can increasethe bonding friction force between the heat insulation board and the concrete board after pouring concrete; and the six-in-one prefabricated concrete outer wall panel has the effects of load bearing,heat insulation, fireproof, waterproof, decoration and self cleaning.

Owner:河南省第二建设集团有限公司

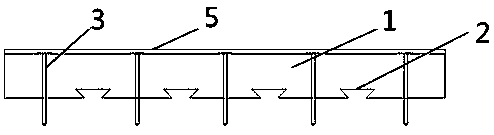

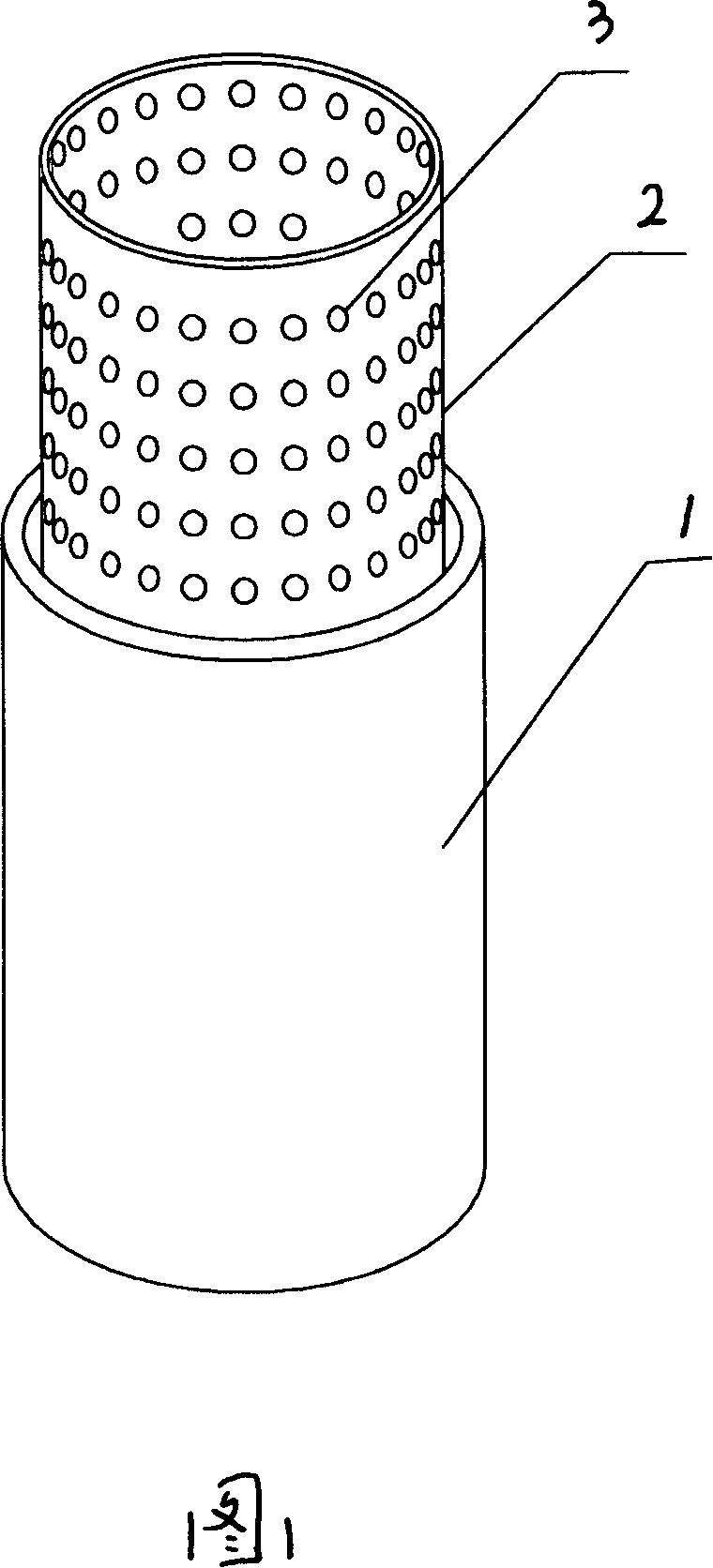

Web frame for concrete organization

InactiveCN101117837AImprove bearing strengthAvoid instabilityBuilding reinforcementsEngineeringHigh torque

The present invention relates to a reinforced frame for concrete structure, and belongs to the construction engineering technology. The present invention is characterized in that a steel tube is arranged and small holes are provided on the tube wall of the steel tube. During the process of pouring concrete column, the concrete is combined with the concrete column via small holes on the tube wall to form an integrated body, therefore, the structure has the functions of high pressure resistance, high shearing resistance, and high torque and vibration resistance, and the present invention has the advantages of simple structure, acceleration of construction progress, saving raw materials and labor forces, being not affected by climate and temperature, being fireproof, being aging and corrosion resistant, and extending service life.

Owner:王加多

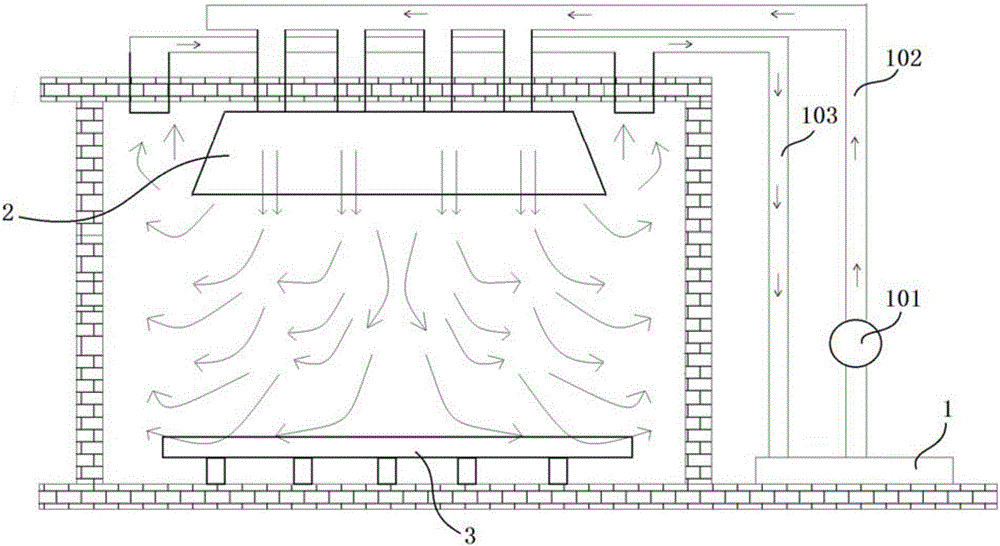

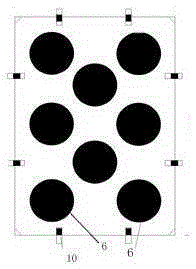

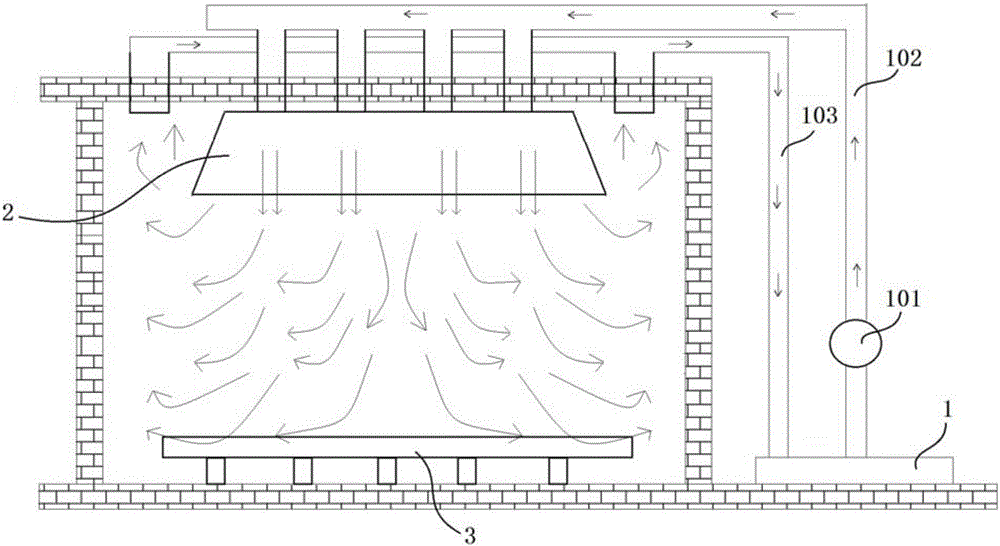

Dustless room and construction method thereof

ActiveCN106150148AImprove insulation effectEffective insulationMechanical apparatusSpace heating and ventilation safety systemsClosed spaceArchitectural engineering

The invention discloses a dustless room and a construction method thereof, belonging to the field of civil construction engineering. The dustless room comprises an air conditioning unit and a closed space formed by enclosing of insulating wallboards, wherein a horizontal supporting platform is arranged at the bottom of the closed space, an air inlet hood is arranged at the top of the closed space and is communicated with the air conditioning unit through an air inlet pipe; and the circumference of the air inlet hood is communicated with the air conditioning unit through an air outlet pipe. The construction method of the dustless room comprises the following steps: A. constructing the dustless room; B. collecting dust; C. purifying air; and D. paving a floor. The temperature uniformness inside the dustless room can be promoted, and the effective heat insulation of the dustless room can be realized.

Owner:马鞍山华亿工程技术有限公司

Fireproof A1 level inorganic interior and exterior wall heat insulation board and production method thereof

InactiveCN104692735AFireproof hasWith compressive strengthSolid waste managementCeramicwareCelluloseFiber

The invention discloses a fireproof A1 level inorganic interior and exterior wall heat insulation board and a production method thereof. The heat insulation board comprises 60-80wt% of Portland cement, 0-21wt% of slag powder, 10-35wt% of fly ash, 1.4-2wt% of a waterproof agent, 1-2wt% of iron oxide black, 0.1-0.34wt% of fiber, 0.01-0.8wt% of cellulose, 0.3-1.2wt% of an early strength agent, and 7-12wt% of a foaming agent. The invention also provides a production method of the fireproof A1 level inorganic interior and exterior wall heat insulation board. The heat insulation board is produced by adopting inorganic materials, so the heat insulation board has the advantages of certain compressive strength and tensile strength, light weight, water and fire proofing, corrosion proofing, sound insulation, heat insulation, non-toxicity, no peculiar smell, small heat conduction coefficient, freeze and thaw resistance, and good weather ability, has same life with a unit building, and is a most rational exterior heat insulation material. Repeated construction, repeated investment and repeated pollution are avoided in the invention. The heat insulation board and the production method have good economic, social and environmentally friendly benefits.

Owner:金海龙

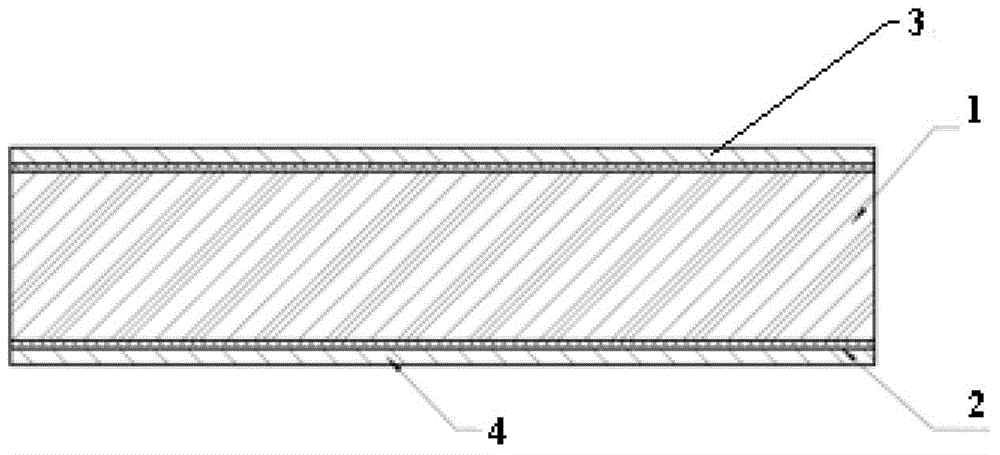

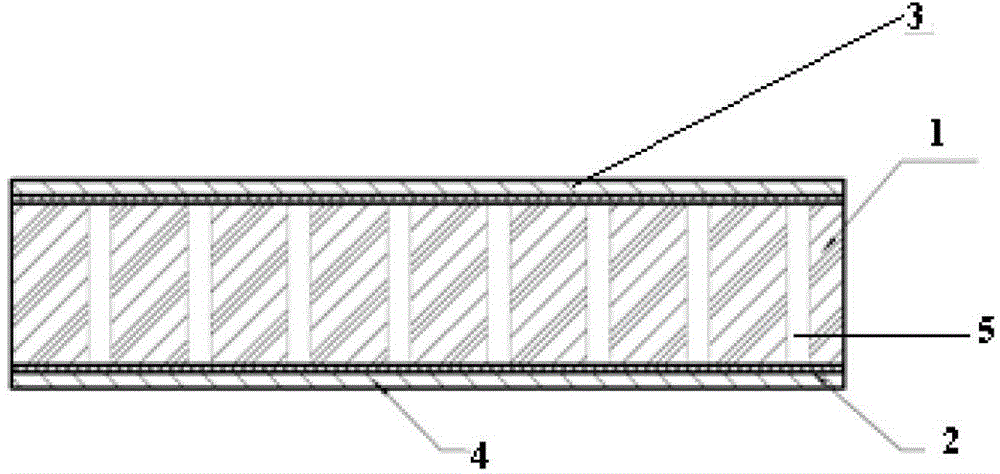

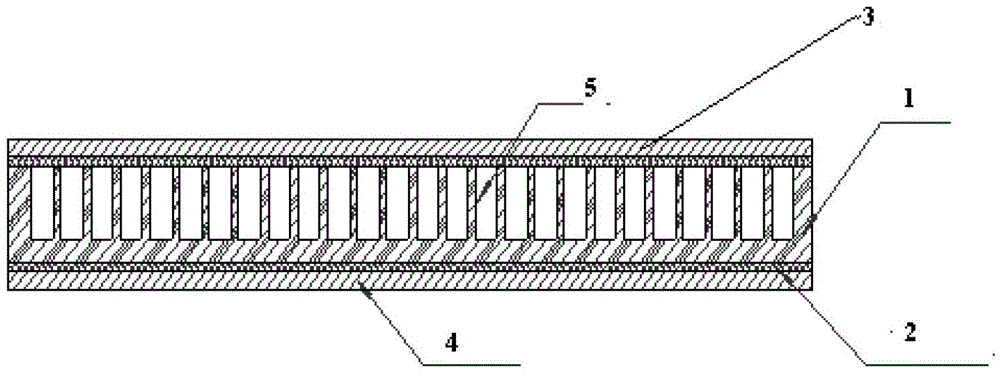

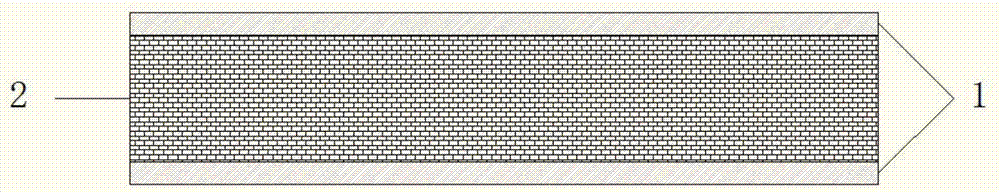

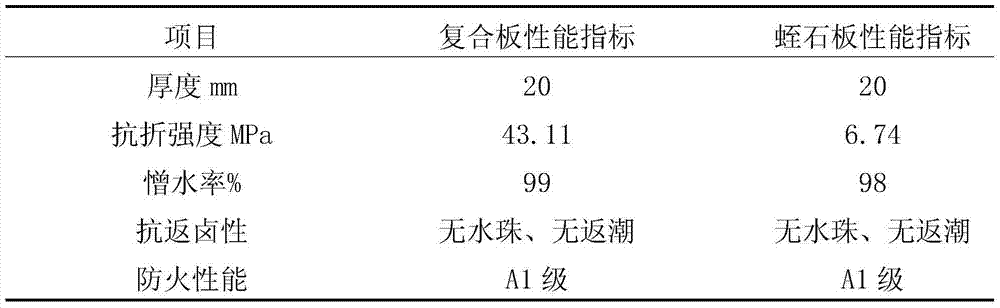

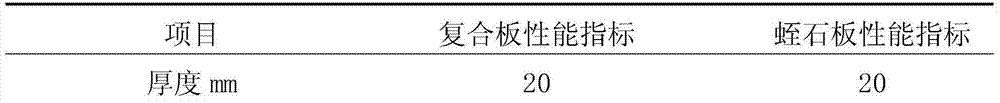

Vermiculite-based sandwich structure type non-combustible plate and preparation method of the plate

The invention relates to a compound plate and a preparation method of the plate, particularly relates to a vermiculite-based sandwich structure type non-combustible plate and a preparation method of the plate, and belongs to the crossing field of fire science and building and ornament materials. The vermiculite-based sandwich structure type non-combustible plate comprises an expanded fireproof heat-insulation vermiculite plate and an ultrathin fireproof vermiculite-based plate, and the ultrathin fireproof vermiculite-based plate is compounded on the surface layer of the fireproof heat-insulation expanded vermiculite plate. The preparation method of the vermiculite-based sandwich structure type non-combustible plate comprises the steps: compounding the expanded fireproof heat-insulation vermiculite plate and the ultrathin fireproof vermiculite-based plate through an adhesive, and compounding in a single layer manner or in an upper-lower surface layer manner according to the demand. According to the preparation method of the vermiculite-based sandwich structure type non-combustible plate, provided by the invention, the expanded fireproof heat-insulation vermiculite plate and the ultrathin fireproof vermiculite-based plate are compound, the thickness of the ultrathin fireproof vermiculite-based plate is 4mm, and the thickness of the expanded fireproof heat-insulation vermiculite plate is 12mm, and thus a sandwich structure is formed. The vermiculite-based sandwich structure type non-combustible plate has multiple functions of high strength, fireproof performance, moisture prevention, water resistance, heat insulation, sound insulation and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

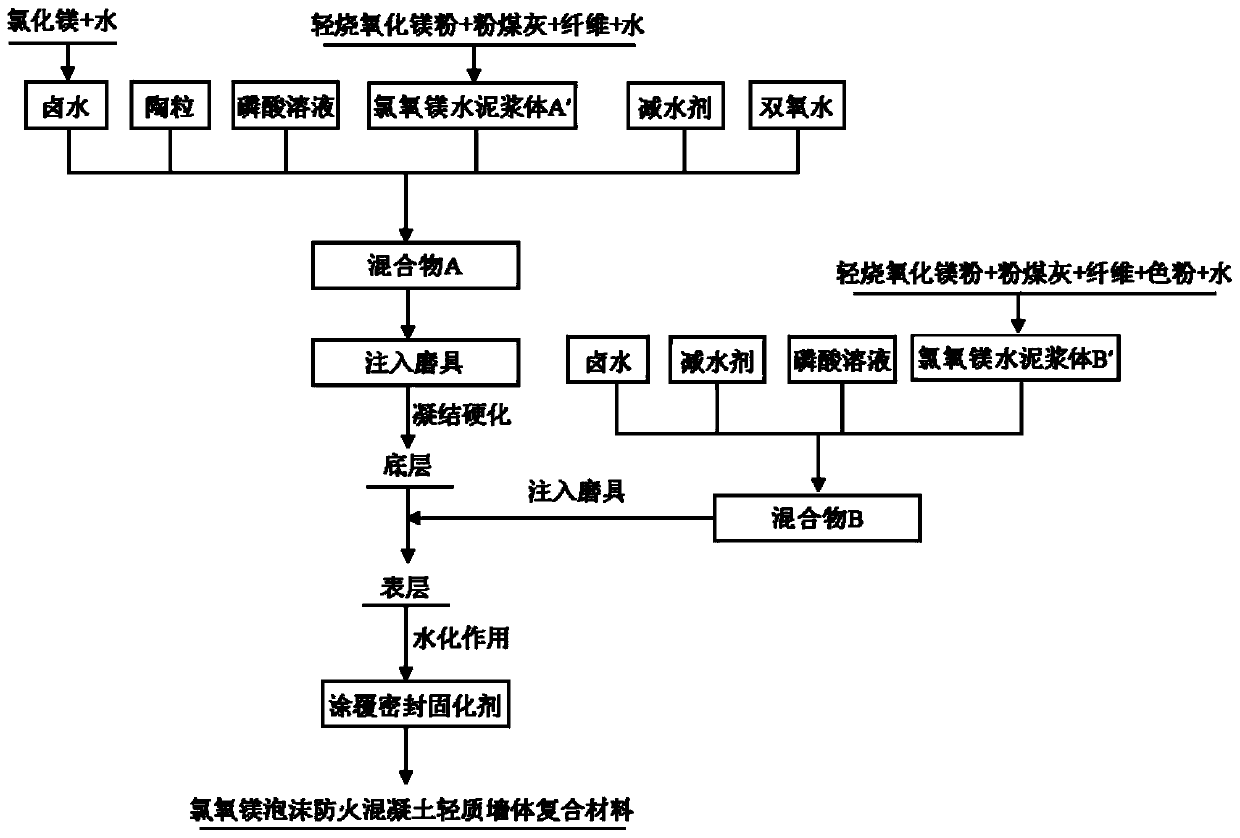

Magnesium oxychloride foam fireproof concrete lightweight wall composite material and preparation method thereof

ActiveCN110407555ALight in massHigh strengthRoof covering using slabs/sheetsCeramic shaping apparatusMagnesiumOxide

The invention discloses a magnesium oxychloride foam fireproof concrete lightweight wall composite material and a preparation method thereof, and belongs to the field of building materials. The composite material comprises a bottom layer and a surface layer; the bottom layer is prepared from, by weight, 10-20 parts of magnesium chloride, 4-6 parts of magnesium oxide, 2-8 parts of water, 0.1-0.2 part of phosphoric acid, 4-8 parts of ceramsite, 3-8 parts of a filler, 0.1-0.2 part of inorganic glass reinforced plastic fibers, 0.1-0.2 part of a liquid polycarboxylate-type water reducing agent and0.1-0.2 part of hydrogen peroxide; the surface layer is prepared from, by weight, 10-20 parts of magnesium chloride, 4-6 parts of magnesium oxide, 2-8 parts of water, 0.1-0.2 part of phosphoric acid,3-8 parts of a filler, 0.1-0.2 part of inorganic glass reinforced plastic fibers, 0.1-0.2 part of a liquid polycarboxylate-type water reducing agent and 0-0.2 part of a toner. The magnesium oxychloride cement foam ceramsite fireproof sound-insulation concrete lightweight wall composite material has the advantages of light weight, high strength, fireproof performance, heat preservation, sound insulation and the like and is an environment-friendly sound absorbing and insulating material; the preparation method of the sound absorbing ceramic material is low in cost, short in consumed time and easy to implement.

Owner:STATE GRID HUNAN ELECTRIC POWER +3

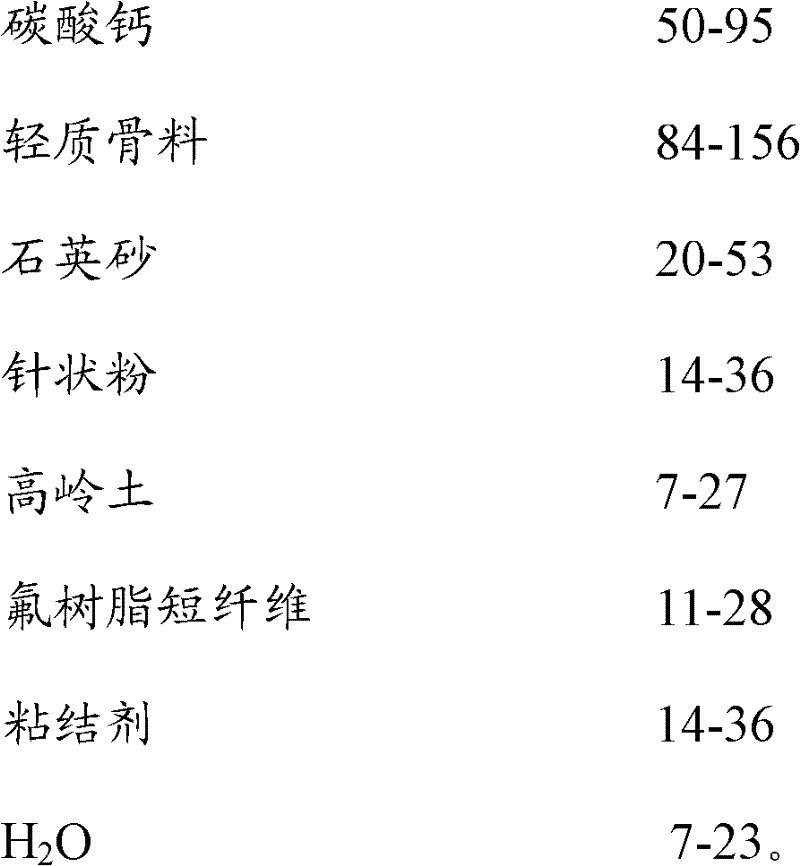

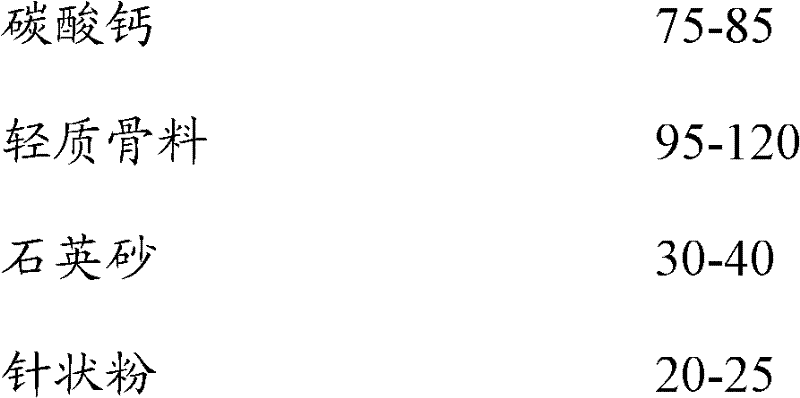

Fire-proof aluminum composite board

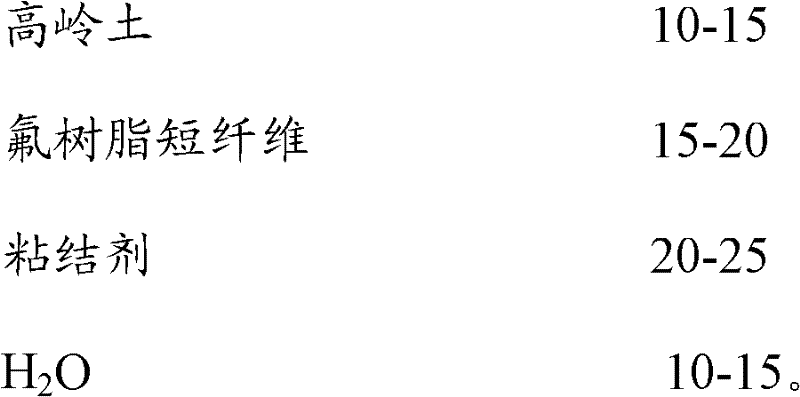

The invention relates to a fire-proof aluminum composite board which is manufactured by a conventional process from calcium carbonate, lightweight aggregate, needle-shaped powder, kaolin, fluororesin short fiber, quartz sand, a binder and the like. The aluminum composite board manufactured by the ingredients above has obviously improved toughness and workability of core materials and the fire-proof performance can be up to the standard of A2 level.

Owner:WUXI SUNDA INTELLIGENT AUTOMATION & ENG COMPANY

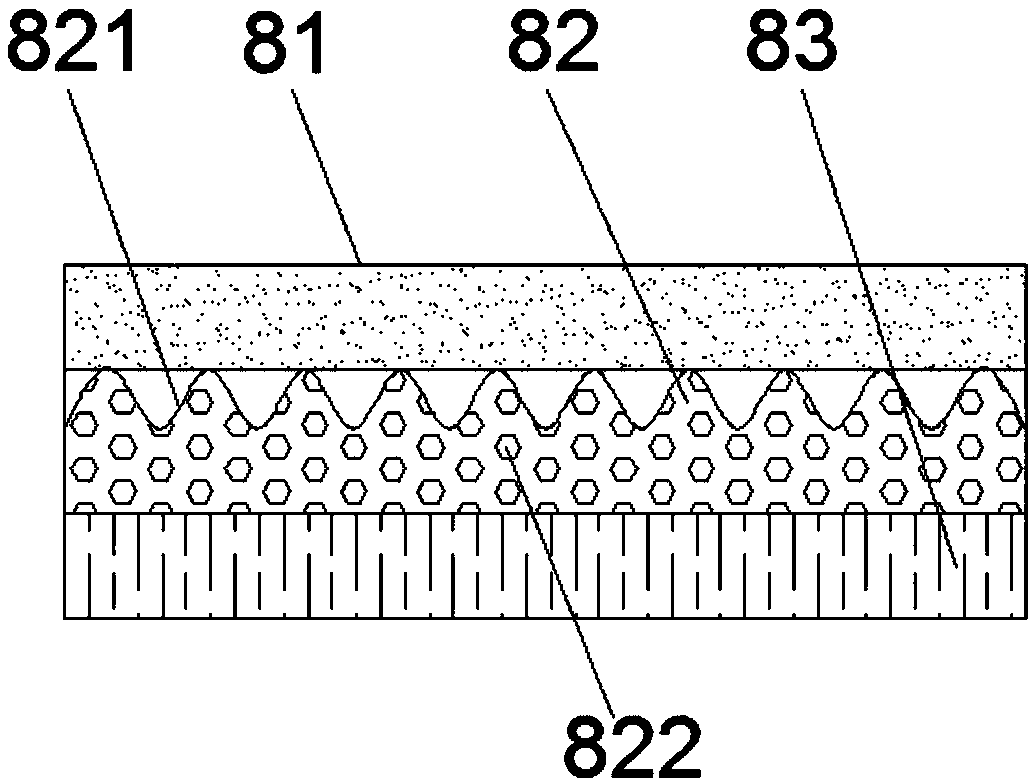

Waterproof and fireproof thermal insulation composite board

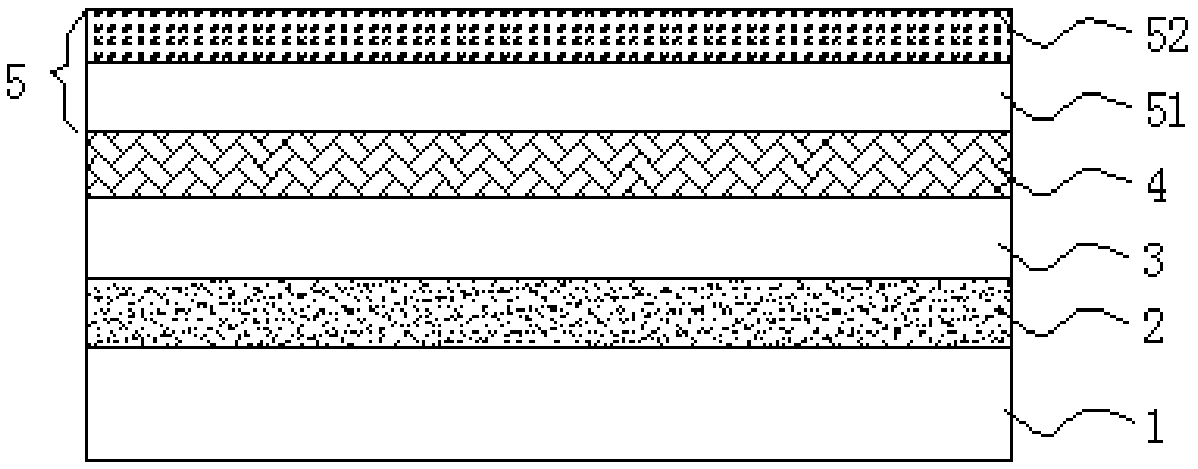

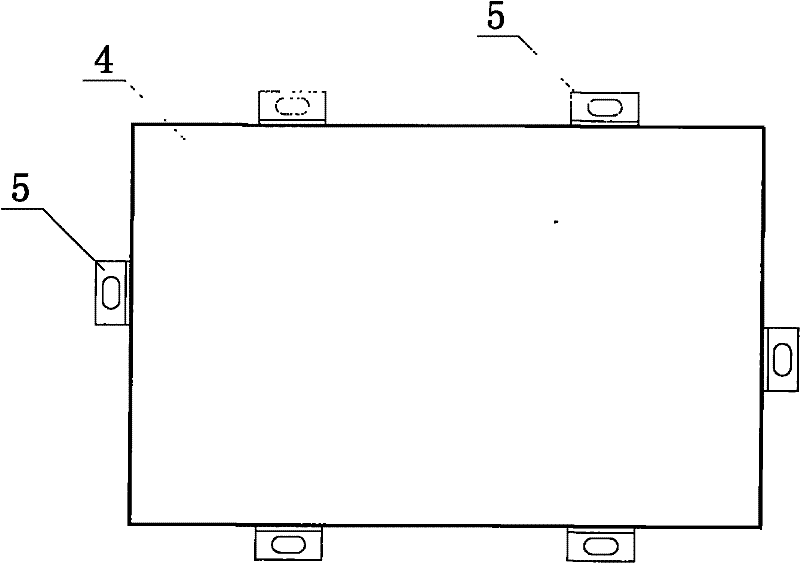

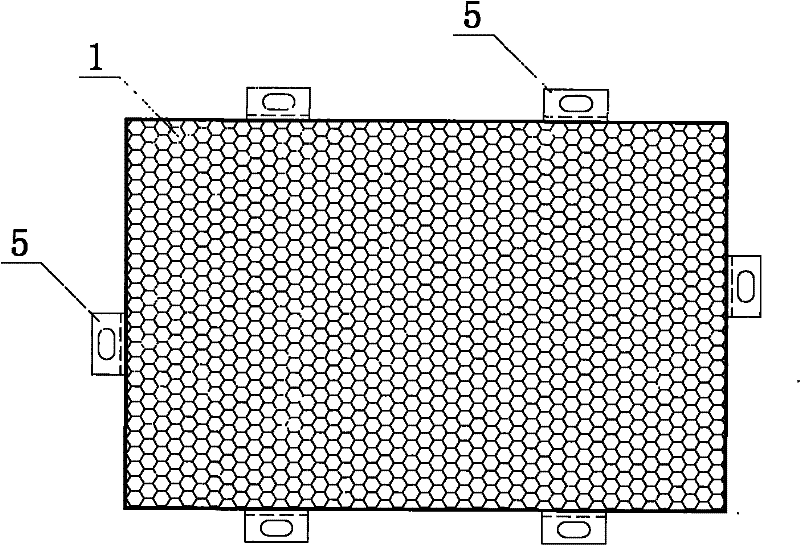

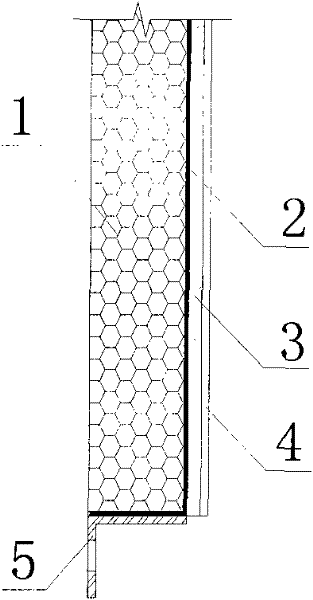

InactiveCN108035446AReasonable structureFireproof hasHeat proofingGlass/slag layered productsTemperature controlThermal insulation

The invention discloses a waterproof and fireproof thermal insulation composite board which comprises a temperature control fireproof layer, a reinforcing layer, a waterproof anti-cracking layer, a temperature regulating layer and a thermal insulation composite layer; the reinforcing layer is located above the temperature control fireproof layer, the waterproof anti-cracking layer is located abovethe reinforcing layer, the temperature regulating layer is located above the thermal insulation composite layer, the thermal insulation composite layer comprises a thermal insulating layer and a reflecting layer, and the reflecting layer comprises an aluminum foil layer and a TiO2 coating which coats the aluminum foil layer; the thickness of the TiO2 coating is 8-14 micrometers. The waterproof and fireproof thermal insulation composite board has the good heat preservation performance, waterproofness, thermal insulating performance and working performance, can solve the problem bothering people for a long time in thermal insulating material application, is suitable for large-scale application and popularization and has the remarkable economic benefits.

Owner:新沂市申美达食品有限公司

Novel environment-friendly fireproof sealing gypsum

The invention discloses an environment-friendly fireproof sealing gypsum, which comprises the following components in percentage by weight: 0.2 to 8 percent of non-metallic mineral fireproof material, 0.1 to 5 percent of modifier, 0.01 to 0.8 percent of water retention thickening agent, 0.01 to 0.2 percent of bonding agent, 0.01 to 0.5 percent of retarder, 0.1 to 2 percent of intensifier, and the balance of construction gypsum. Because the non-metallic mineral fireproof materials such as mica powder or vermiculite and the like are added, and the modifier, the intensifier and the like are also added, the environment-friendly fireproof sealing gypsum can ensure the basic performances of the sealing gypsum and simultaneously has the characteristics of fire resistance, crack resistance, environmental protection, no toxin, no irritation, and the like.

Owner:北新建材(苏州)有限公司

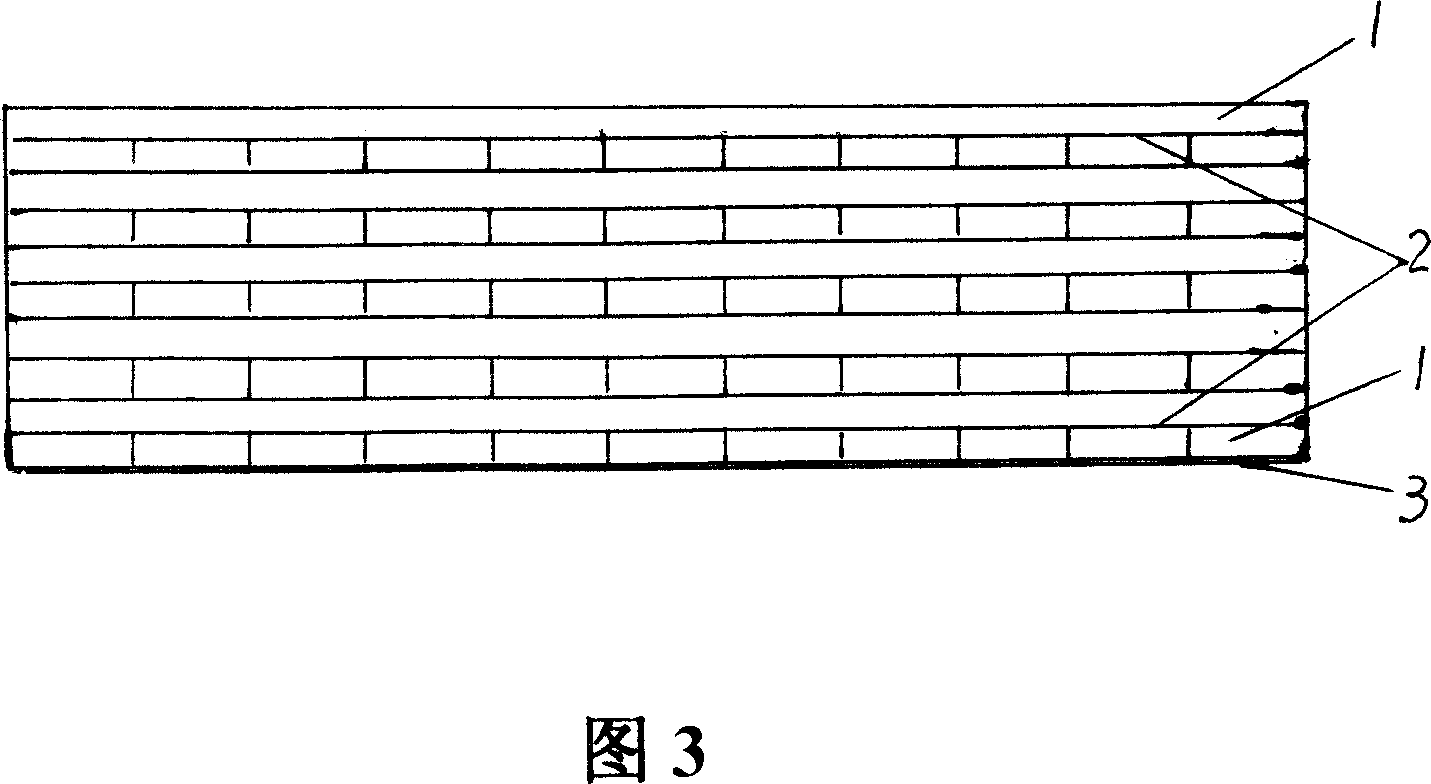

Method for fabricating bricks, planks, and strips by using outer skin of straw of corn or kaoliang

InactiveCN101049710AExtensive resourcesEasy to prepareOsier rod peelingDomestic articlesBrickAdhesive

A technology for manufacturing brick, board, or bar with the stalks of corn and sorghum includes such steps as cutting short by needed length, removing leaves and pitch, spreading a paper on the bench, spraying adhesive, spreading the pre-treated stalks and spraying adhesive layer by layer, pressing, solidifying and cutting by required sizes.

Owner:张俊峰

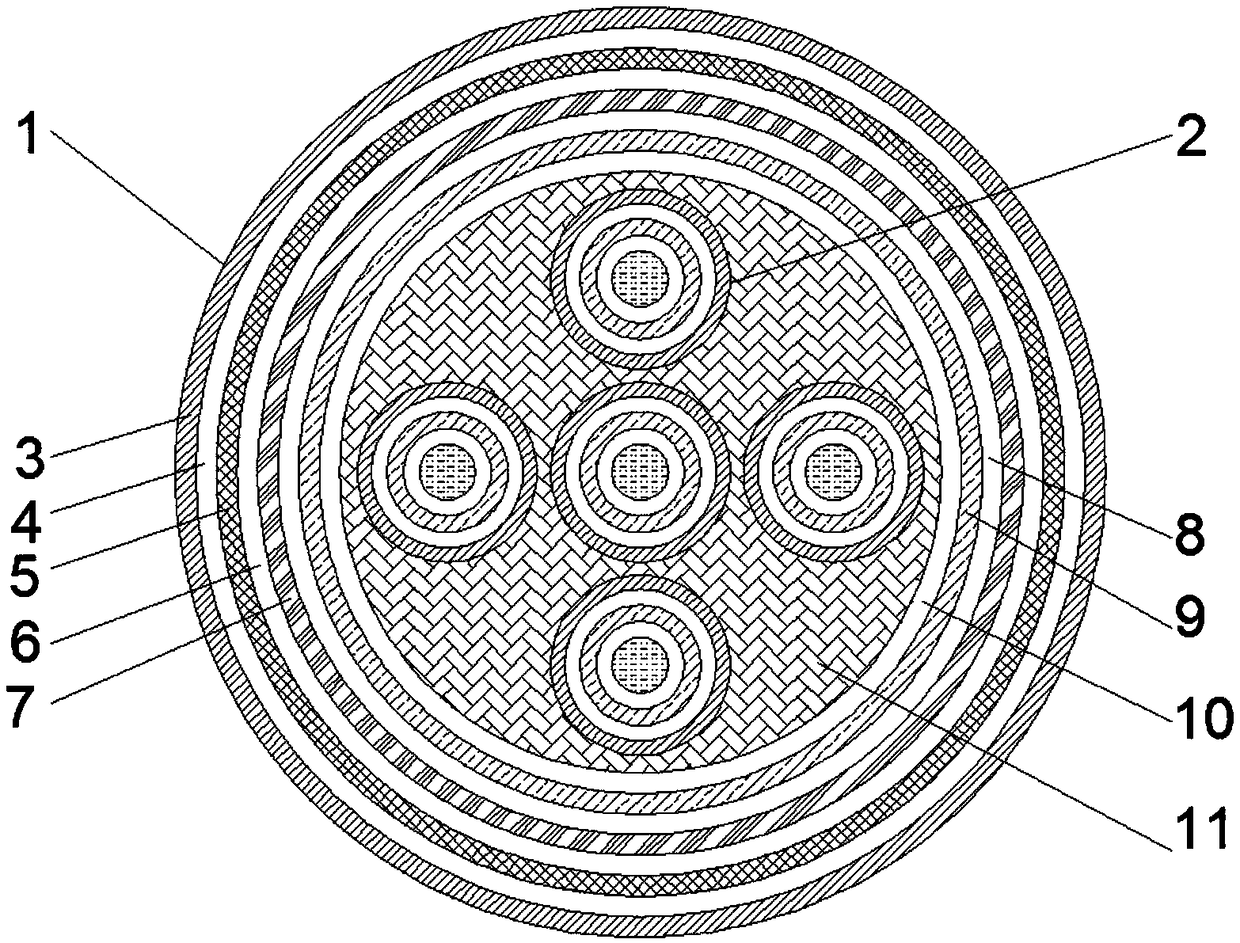

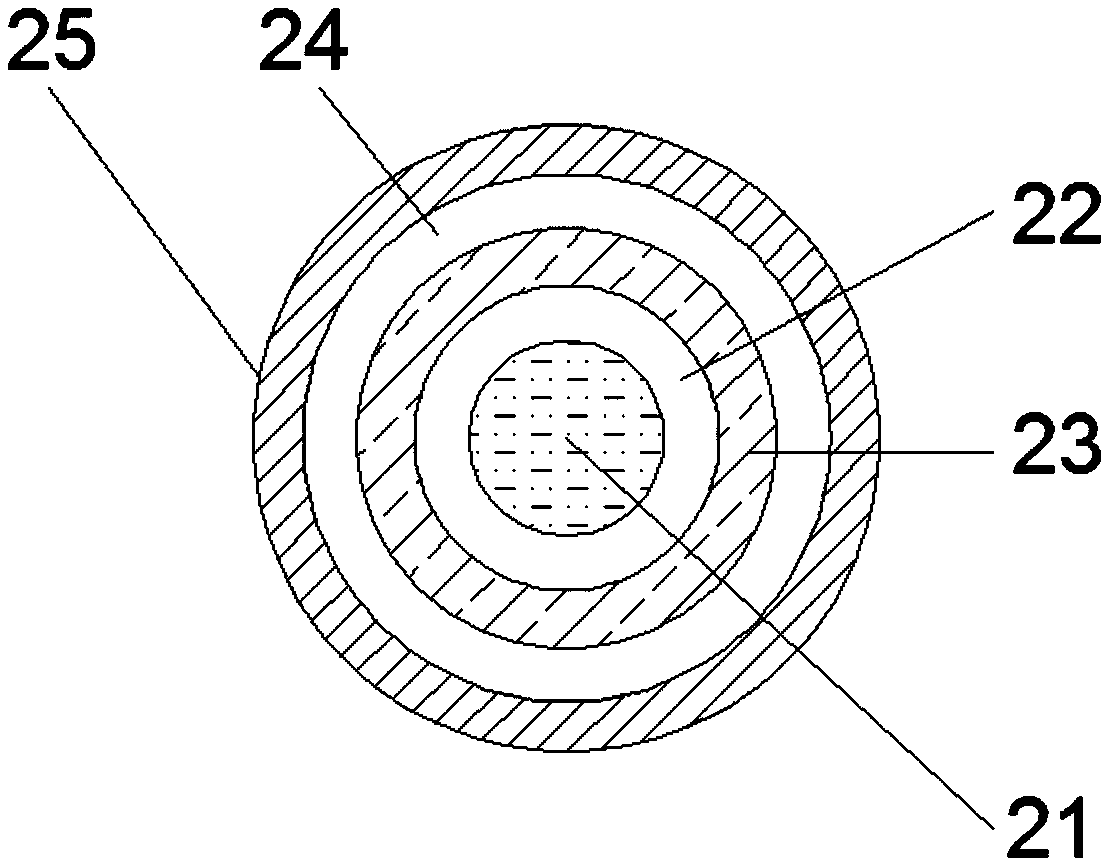

An anti-interference high-voltage cable in a new energy vehicle

InactiveCN109036699AExtended service lifeImprove anti-interference abilityPower cables with screens/conductive layersInsulated cablesNew energyCopper wire

The invention discloses an anti-interference high-voltage cable in a new energy vehicle, includes a cable body and a core, At that outermost side of the cable body is provide with a first protective sleeve, A corrosion resistant layer is arranged on the inner side of the first protective sleeve, a high-temperature resistant layer is arranged on the inner side of the corrosion resistant layer, a fire-proof layer is arranged on the inner side of the high-temperature resistant layer, a water-proof layer is arranged on the inner side of the fire-proof layer, a shield layer is arranged on the innerside of the water-proof layer, a first insulating layer is arranged on the inner side of the shield layer, and a first high-voltage resistant layer is arranged on the inner side of the first insulating layer. The shielding layer arranged in the invention can absorb the interference electromagnetic wave through the copper wire layer, At the same time, through holes in aluminum foil layer can alsoreflect and absorb the interference electromagnetic wave, further strengthen the anti-interference ability of the cable, and finally, the interference electromagnetic wave can be completely eliminatedthrough stainless steel wire layer.

Owner:ANHUI SPECIAL CABLE GRP

Heat-insulating decorative fireproof partition board for exterior wall of building and construction method thereof

ActiveCN102071754BInsulation hasInsulation decoration fireproofCovering/liningsHeat proofingFlame propagationRefractory

The invention discloses a heat-insulating decorative fireproof partition board for an exterior wall of a building and a construction method thereof. The heat-insulating fireproof decorative board adopts a heat-insulating foaming ceramic board made of fireproof materials as a fireproof partition and heat-insulating material; the heat-insulating foaming ceramic board, an enhanced panel and veneer materials form an integrated board with the functions of fire prevention, heat insulation and decoration; integrated boards are arranged along the horizontal direction of the building at intervals of certain height in a heat-insulating system for the exterior wall of the building or arranged on upper edges of window and door openings of the building to form a fire barrier, so that the flame propagation can be effectively prevented and the fire damage can be reduced; the heat-insulating fireproof decorative board is bonded with a base course wall of the building through cement mortar at first and then anchored and supported through a machine; and exterior finishes can be painted with fluorocarbon paint, fluorocarbon metallic paint, stone-like paint and the like and be matched with a conventional heat-insulating decorative board for the exterior wall of the building for use. The heat-insulating decorative fireproof partition board disclosed by the invention can be used as a fireproof construction measure to be widely applied to heat-insulating projects of exterior walls of the building industry, and has the advantages of fire prevention, heat insulation, durability, impact resistance,good decorative effect and the like. The construction method disclosed by the invention has the advantages of advanced technology, economy and rationality, convenience for assembly, low energy consumption for construction, and conformity with the national requirements of environmental protection and energy saving.

Owner:江苏建科土木工程技术有限公司

Sound-insulation fireproof building material

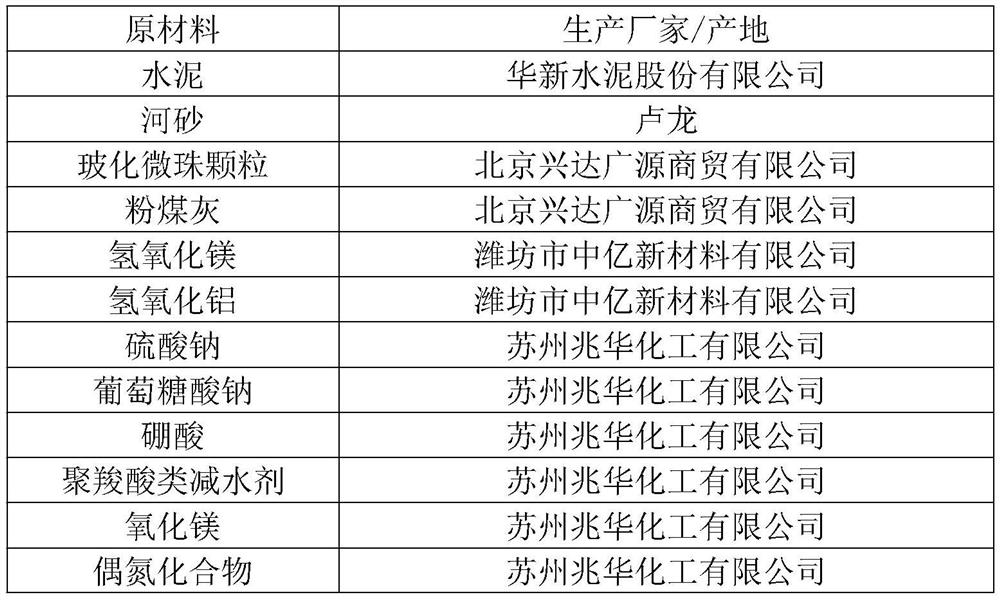

ActiveCN111807866AIncreased hydration rateImprove setting timeSolid waste managementCeramicwareAggregate (composite)Fire prevention

The invention relates to the technical field of building materials, and in particular, relates to a sound-insulation fireproof building material comprising the following raw materials in parts by weight: 45-60 parts of composite cement, 30-35 parts of graded aggregate, 15-20 parts of a sound insulation component, 3-5 parts of a fireproof component, 1-2 parts of a water reducing agent, 0.5-1.8 parts of a thickening time control component, 2-4 parts of an expansion component, 0.1-0.2 part of a foaming agent, 0.2-0.4 part of a defoaming agent and 0.02-0.04 part of a water retaining agent, whereinthe thickening time control component consists of sodium sulfate, sodium gluconate and boric acid in a mass ratio of (2-4):(0.5-1):(0.6-0.8). The composite cement, the graded aggregate, the sound insulation component, the fireproof component, the water reducing agent, the thickening time control component, the expansion component, the foaming agent, the defoaming agent and the water retaining agent are reasonably proportioned, and all the raw materials are matched with one another, so that the sound-insulation fireproof building material has the advantages of fire prevention, sound insulation, high mechanical strength and short setting time, and has important significance for development of the concrete industry.

Owner:广东潮威建设工程有限公司

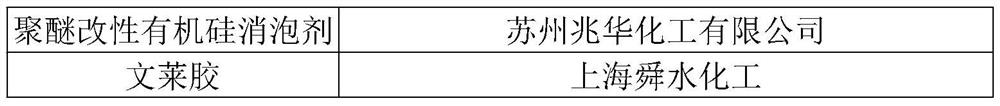

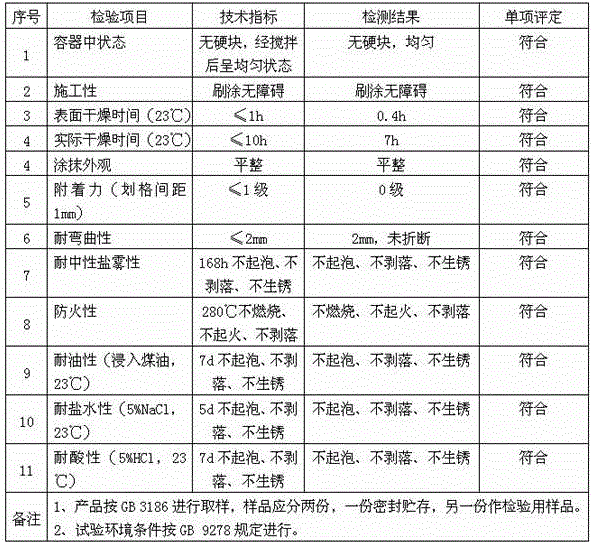

Polyurethane fireproof building exterior wall coating and production method thereof

InactiveCN106590397AGloss retention hasHigh glossFireproof paintsAntifouling/underwater paintsAcrylic resinFire retardant

The invention discloses a polyurethane fireproof building exterior wall coating and a production method thereof. The polyurethane fireproof building exterior wall coating comprises the main components of water-setting type polyurethane, waterborne acrylic resin and a fire retardant namely polytetrafluoroethylene, overcomes some defects of single polyurethane or single polyacrylic resin, such as poor stability, white thickening property and gloss retention of a film, high solid content, narrow application range and the like, and achieves a complementary effect in nature. The composite coating has the advantages of the two, has the characteristics of good fireproof property, wear resistance, corrosion resistance, brightness, softness, elasticity, water resistance and mechanical properties, good weathering resistance, good fire proof property and the like, and also has high glossiness, high elasticity and excellent weathering resistance. Compared with conventional other polyurethane coatings, the polyurethane fireproof building exterior wall coating has the advantages of being convenient in construction, being fireproof, nontoxic, pollution-free, environment-friendly, and the like.

Owner:广西宾阳县荣良农业科技有限公司

Texture coating and preparation method thereof

The invention discloses a texture coating and a preparation method thereof and aims to solve the problems that the existing texture coatings are produced by using artificial color sand and are bad in weather resistance. The texture coating disclosed by the invention is made from aggregate, emulsion and other auxiliaries. The preparation method comprises the following steps: uniformly mixing cement, lime, gypsum, fine sand, waterborne color paste and biomass adhesive, and granulating to obtain the aggregate; and adding softened water, a thickener and a dispersing agent, uniformly stirring and dispersing in a dispersion machine, sequentially adding the emulsion, a film forming auxiliary, the aggregate, propylene glycol, a defoamer and preservative, uniformly stirring and dispersing to obtain the texture coating. The texture coating is friendly to environment and free of formaldehyde and has the characteristics of fire prevention, damp prevention, sound insulation, high strength, good weather resistance and the like.

Owner:GANSU GLDARK NEW MATERIAL

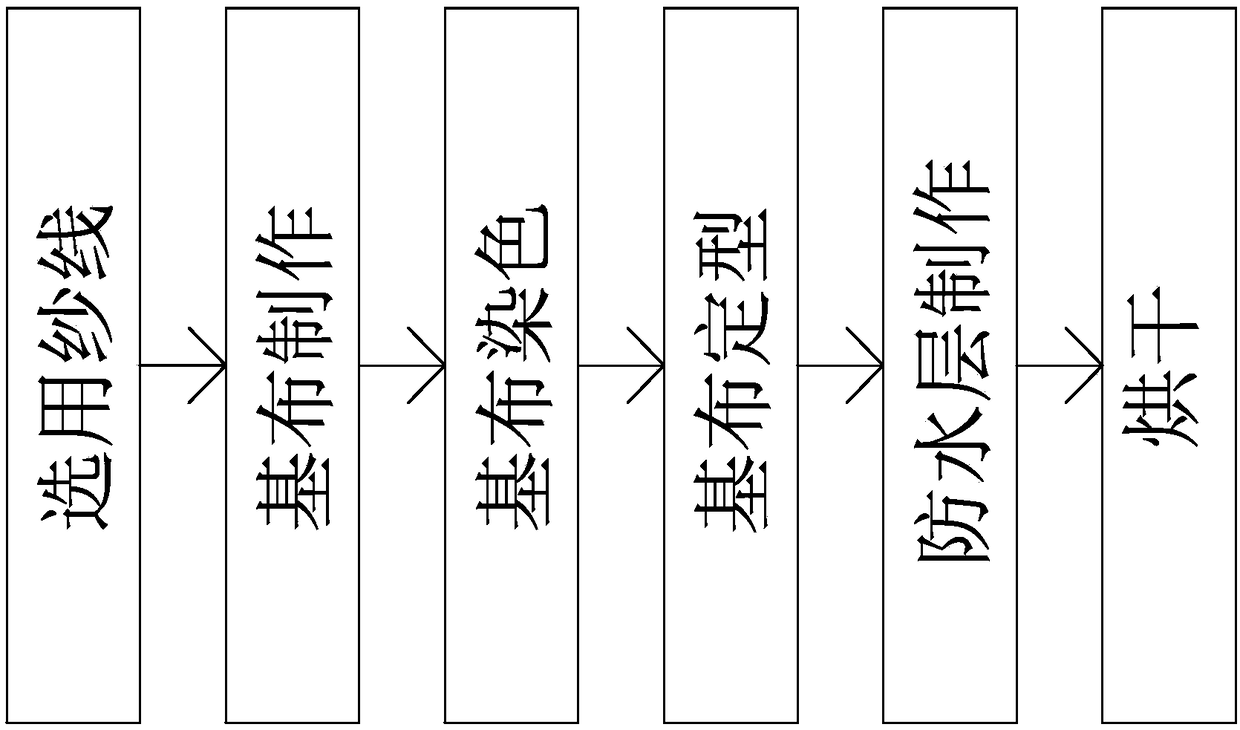

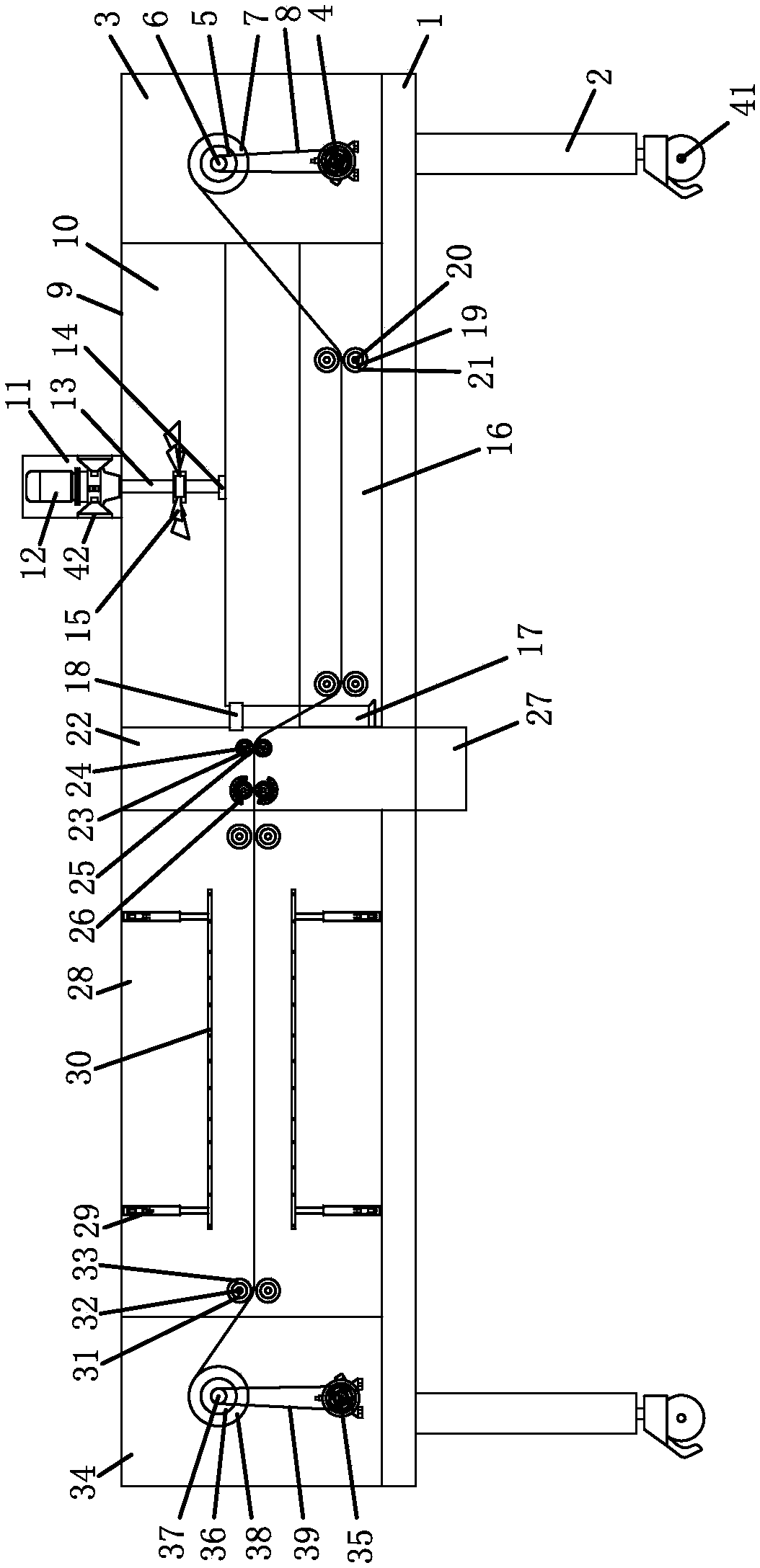

Manufacturing process of waterproof and fireproof fabric

InactiveCN108086004AWith waterproof functionWith warm functionLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsEngineeringFire retardant

The invention provides a manufacturing process of a waterproof and fireproof fabric, and belongs to the technical field of a fabric. The manufacturing process solves the problem of low manufacturing efficiency in the prior art. The manufacturing process of the waterproof and fireproof fabric comprises the following steps of S1, selecting yarns: selecting dacron yarns; soaking the yarns in a soaking cylinder; putting a fire retardant into the soaking cylinder to prepare fire-retardant yarns; S2, making base cloth: weaving the base cloth by warp yarns and weft yarns, wherein both the warp yarnsand the weft yarns use fire-retardant yarns in the S1; S3, dyeing the base cloth: using a spinning soaking dyeing device for performing dyeing treatment on the base cloth in the S2; S4, shaping the base cloth: using a shaping machine for performing shaping treatment on the base cloth in the S3; S5, manufacturing a waterproof layer; covering waterproof paint onto the base cloth to obtain a waterproof layer; S6, performing drying: drying the fabric in the S5 to obtain the waterproof and fireproof fabric. The manufacturing process has the advantage that the manufacturing efficiency is improved.

Owner:海宁市金义服饰有限公司

Manufacturing method for composite aluminium plastic decorative buckles

InactiveCN1221381CImprove flatnessFriction-resistantMetal layered productsTectorial membraneSurface oxidation

A decorative fastening aluminium-plastic plate is prepared through preparing plastic substrate from engineering plastics, filler, stabilizer, plasticizer, lubricant and assistant through mixing, granulating, extruding out, fixing shape, and cutting, preparing the coated aluminium foil through washing, removing oil, oxidizing surface, baking, painting, baking and coiling, combining said plastic substrate with aluminium foil, covering adhesive protecting film on the surface of aluminium foil, and cutting. Its advantages are high abrasion compression, fire and water resistance, good thermal and acoustic insulation, no poison and beautiful appearance.

Owner:无锡市中德装饰新材料有限公司

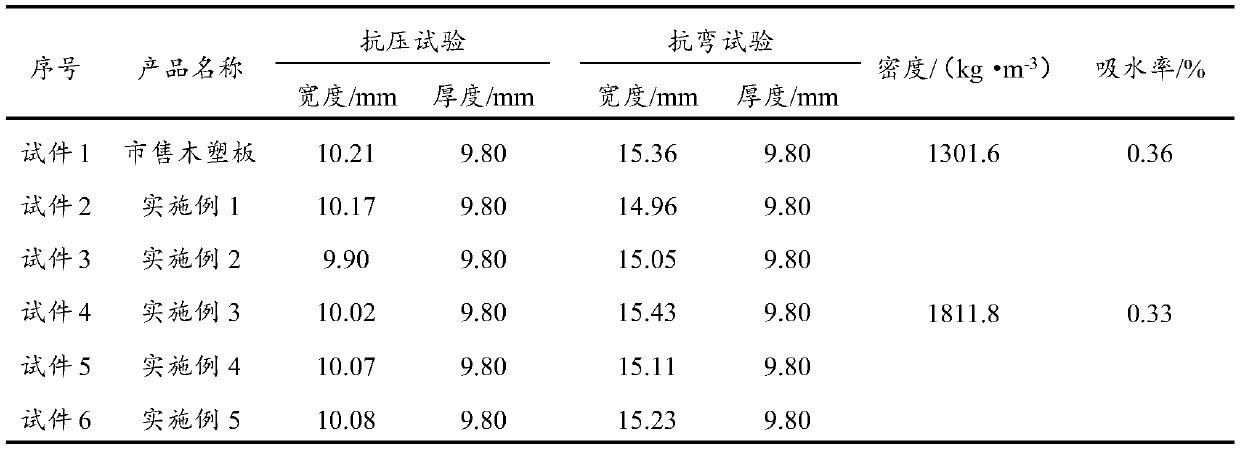

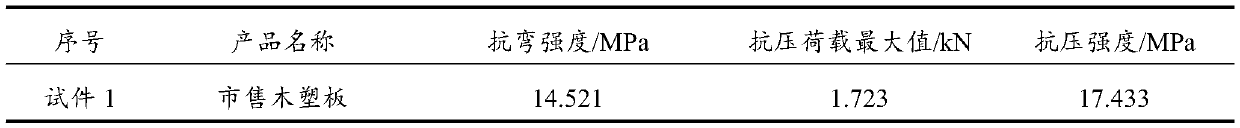

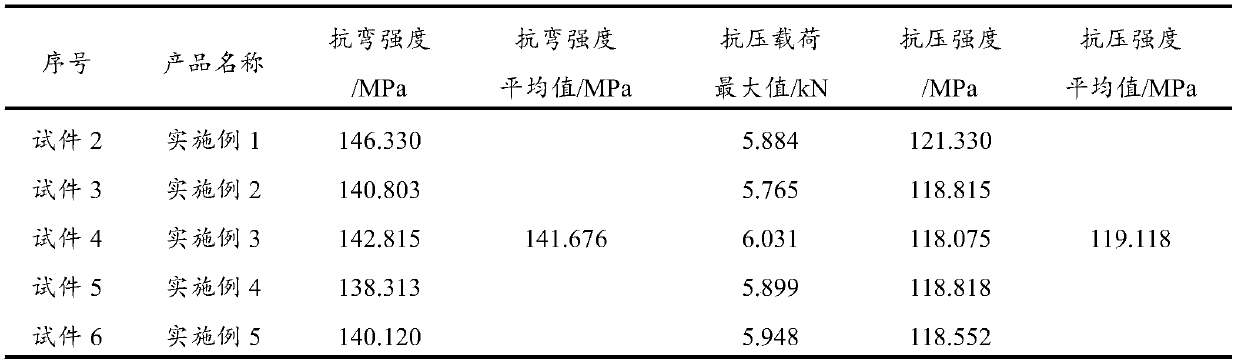

Preparation method and application of improved wood-plastic composite material

The invention discloses a preparation method of an improved wood-plastic composite material. The preparation method comprises the following steps: high-density polyethylene melting, dyeing, mixing andmolding. The wood-plastic composite material comprises 50-70 wt% of high-density polyethylene, 10-20 wt% of nylon plastic powder and 20-30 wt% of wood fiber powder. The wood-plastic composite material is prepared by uniformly mixing the above components. The high-density polyethylene is used as a main raw material, and is mixed with nylon plastic and wood fiber powder, and the addition of the wood fiber powder makes the wood fiber powder completely coated with a high-density polyethylene melt, so the hygroscopicity of the wood fiber powder is greatly reduced, and the dispersibility, the oxidation resistance and the flame retardancy are greatly improved, thereby the strength of the wood-plastic composite material is increased; and the addition of the nylon plastic further improves the strength, and products manufactured from the wood-plastic composite material have excellent oxidation resistance, flexural resistance and bending resistance, and can meet the needs of use.

Owner:GUANGDONG HUANGTIAN ENVIRONMENTAL PROTECTION TECH CO LTD

Expandable graphite nanometer fire-proof coating, preparation and use thereof

InactiveCN1296447CImprove fire performanceGood weather resistanceFireproof paintsGlass fiberPentaerythritol

The invention opened a process to product the inflatable graphite nano fire resisting paint. The composition is : acrylic resin20-25; amine resin 3-4; pentanol1-4; inflatable graphite 18-22; organic siliconresin2-4; melocol ammonia polyphosphate12-16; nano-compound fire retardant 2-6; intensify spun glass4-6; rutile titanium white3-5; elasticizer2-4; smoke abatementer2-4; antifoam agent0.3-0.6; flow promoter0.3-0.6; mixing solvent15-20. The product has the good mechanical character, weather resisting property and rotproofness.

Owner:中科纳米涂料技术(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com