Vermiculite-based sandwich structure type non-combustible plate and preparation method of the plate

A sandwich structure, vermiculite-based technology, applied in the direction of chemical instruments and methods, manufacturing tools, building structures, etc., can solve the problem of poor quality and environmental protection of sandwich panels, low strength of fireproof insulation boards, unsuitable for wide use, etc. problems, to achieve the effect of good construction and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

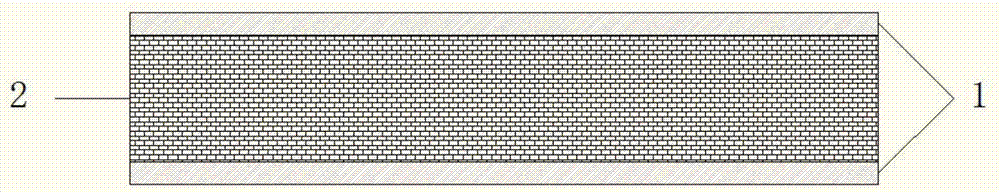

Image

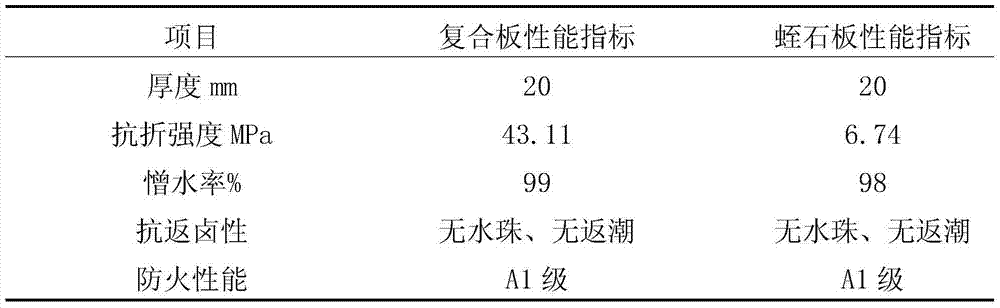

Examples

Embodiment 1

[0026] Step 1. Preparation of ultra-thin vermiculite-based fireproof board

[0027] Fully stir 6.0kg magnesium oxide, 4.5kg magnesium chloride, 0.5kg magnesium sulfate, 11.0kg water, 0.7kg aluminum dihydrogen phosphate, 1.0kg trisodium phosphate, 3.0kg vermiculite powder, 0.15kg fly ash and 30g glass fiber silk , forming a slurry. Then the slurry and the glass fiber mesh cloth are machine rolled and cured to obtain a finished 4mm thick ultra-thin vermiculite-based fireproof board.

[0028] Step 2. Preparation of expanded vermiculite fireproof insulation board

[0029] Mix 10.0kg of water glass solution and 1.7kg of lithium silicate solution evenly, heat to 65°C, add 1.5kg of silica sol to it while stirring, stir well to mix evenly, continue heating for 0.5-1h, stop heating, and cool to room temperature . Then add 150g of methyl hydrogen-containing silicone oil emulsion and 150g of methyl hydroxy silicone oil emulsion therein, and stir evenly. Add 50g of potassium dihydroge...

Embodiment 2

[0035] Step 1. Preparation of ultra-thin vermiculite-based fireproof board

[0036] Fully stir 6.2kg magnesium oxide, 4.3kg magnesium chloride, 0.8kg magnesium sulfate, 11.5kg water, 0.9kg aluminum dihydrogen phosphate, 1.0kg trisodium phosphate, 3.3kg vermiculite powder, 0.15kg fly ash and 35g glass fiber silk , forming a slurry. Then the slurry and the glass fiber mesh cloth are machine rolled and cured to obtain a finished 4mm thick ultra-thin vermiculite-based fireproof board.

[0037] Step 2. Preparation of expanded vermiculite fireproof insulation board

[0038] Mix 10.0kg of water glass solution and 1.7kg of lithium silicate solution evenly, heat to 65°C, add 1.5kg of silica sol to it while stirring, stir well to mix evenly, continue heating for 0.5-1h, stop heating, and cool to room temperature . Then add 150g of methyl hydrogen-containing silicone oil emulsion and 150g of methyl hydroxy silicone oil emulsion therein, and stir evenly. Add 50g of potassium dihydroge...

Embodiment 3

[0045] Step 1. Preparation of ultra-thin vermiculite-based fireproof board

[0046] Fully stir 6.3kg magnesium oxide, 4.1kg magnesium chloride, 1.1kg magnesium sulfate, 11.3kg water, 0.7kg aluminum dihydrogen phosphate, 1.0kg trisodium phosphate, 3.0kg vermiculite powder, 0.15kg fly ash and 35g glass fiber silk , forming a slurry. Then the slurry and the glass fiber mesh cloth are machine rolled and cured to obtain a finished 4mm thick ultra-thin vermiculite-based fireproof board.

[0047]Step 2. Preparation of expanded vermiculite fireproof insulation board

[0048] Mix 10.5kg of water glass solution and 1.8kg of lithium silicate solution evenly, heat to 65°C, add 1.6kg of silica sol to it while stirring, stir well to mix evenly, continue heating for 0.5-1h, stop heating, and cool to room temperature . Then add 150g of methyl hydrogen-containing silicone oil emulsion and 150g of methyl hydroxy silicone oil emulsion therein, and stir evenly. Add 55g of potassium dihydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com