Patents

Literature

269results about How to "Friction-resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

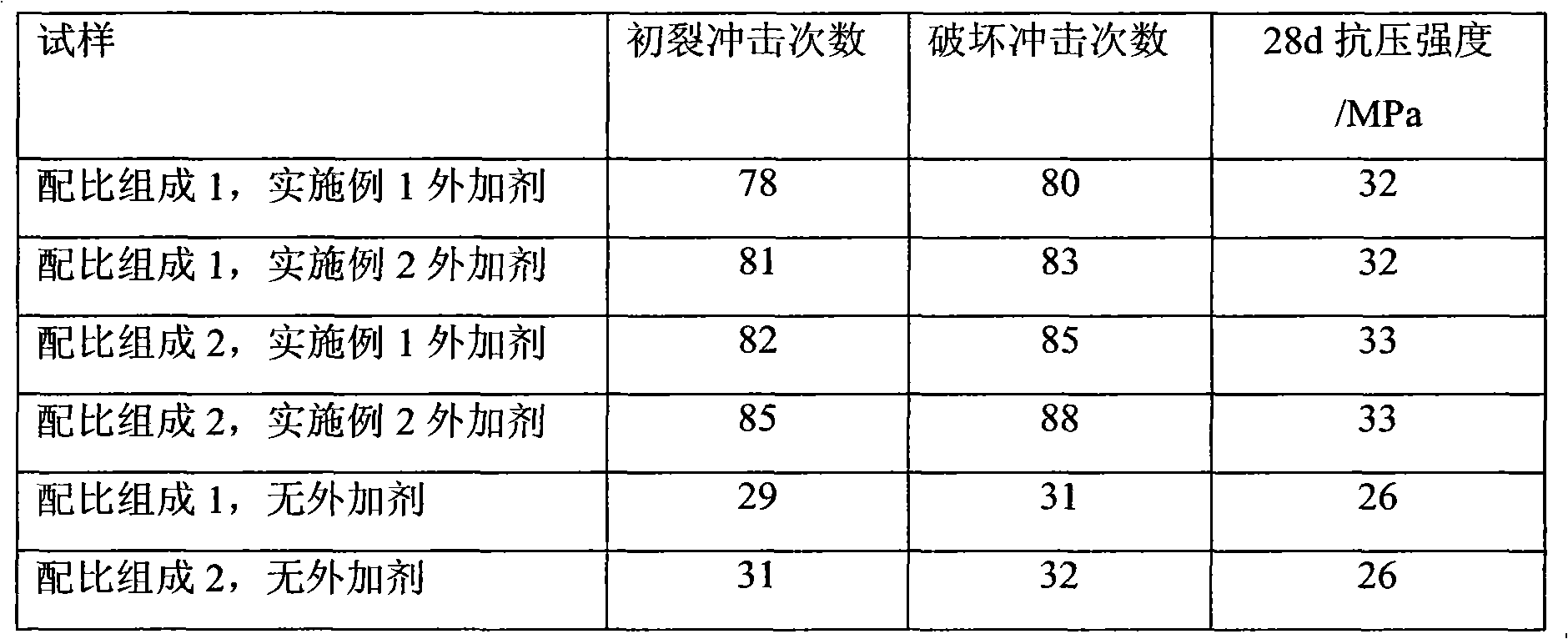

Concrete complex additive

The invention provides a concrete complex additive which comprises the following components by weight percent: 17.5-58.0% of efficient water reducing agent, 0.5-5.5% of organosilicon waterproofing agent, 0.2-2.5% of organosilicon reinforcing agent, 3.5-25% of polyacrylamide, 1.2-2.8% of triethanolamine, 3.2-6.3% of sodium nitrite, 0.3-1.2% of glycol, 0.6-1.3% of glycerol, 2.8-5.5% of sodium gluconate and the balance of water. The impact resistance, crocking resistance, impermeability and waterproofness of the concrete material can be obviously improved by using the complex additive provided by the application in the preparation process of the concrete, thus the concrete complex additives is especially suitable for the requirement on high-performance concrete for construction of airfield runways or highway bridges.

Owner:JIANGSU FENGTAI TOOLS

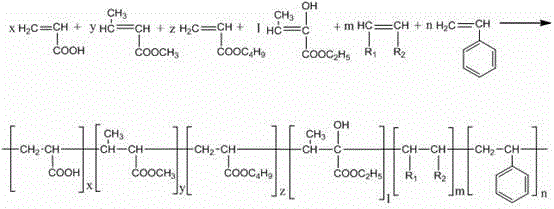

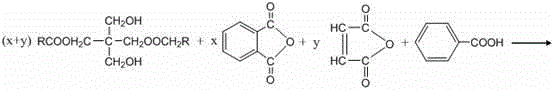

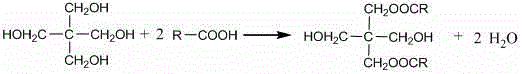

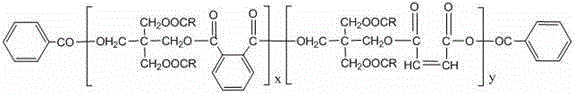

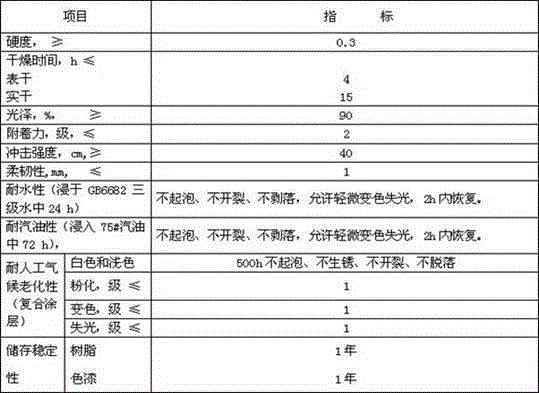

Aqueous alkyd acrylic resin paint and preparation method thereof

The invention relates to an aqueous alkyd acrylic resin paint and a preparation method thereof. According to the invention, high-molecular alkyd resin with main chain containing unsaturated double bond is synthesized through molecular design. Alkyd resin is subjected to free radical graft copolymerization with acrylic monomer. A reaction system is neutralized by using an amine compound, such that water-reducible alkyd acrylic resin is synthesized. Molecular chains of alkyd and acrylic resins are connected through chemical bond, such that the compatibility of the two resins is improved. In a material curing and shaping process, phase separation of the resin is avoided. Deionized water, a pigment, a filling material, an antifoaming agent, a dispersing agent, a siccative, and alkyd acrylic hybrid emulsion are uniformly dispersed, such that the aqueous alkyd acrylic resin paint is obtained. The aqueous alkyd acrylic resin paint comprises the components of: aqueous alkyd acrylic resin 65%-80%, the pigment 3%-4%, the filling material 6-10%, deionized water 10%-20%, the dispersing agent 0.05%-0.5%, the antifoaming agent 0.10%-0.30%, and the siccative 0.9%-3.5%.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

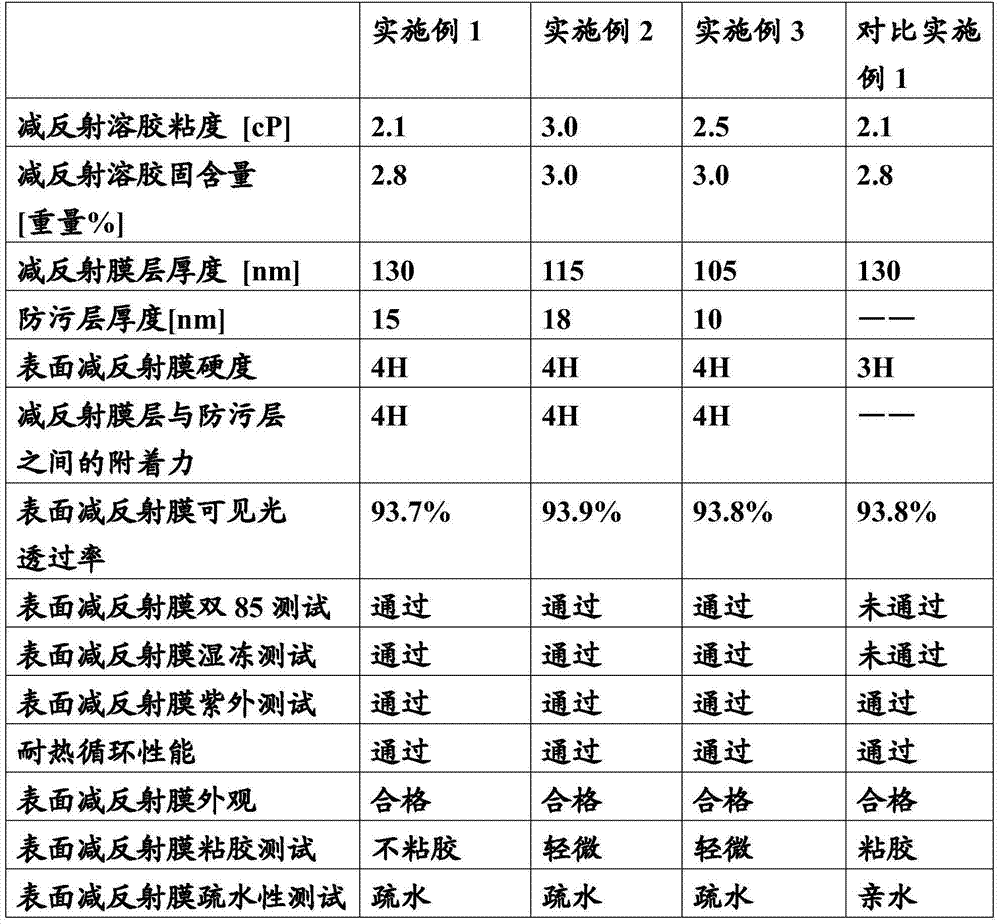

Anti-reflection glass substrate as well as preparation method and application thereof

The invention relates to a preparation method of an anti-reflection glass substrate. The preparation method comprises the following steps: a, preparing an anti-reflection sol, namely, acidizing silica sol, adding orthosilicate to react with deionized water to form sol, then adding an organic solvent, stirring, sealing and ageing; adding a coalescing agent in the aged sol and controlling a dry chemical additive, and stirring to obtain the anti-reflection sol; b, coating, namely, applying the anti-reflection sol in the step a on the surface of a glass substrate to form a glass substrate with an anti-reflection coating; c, tempering, namely, tempering the glass substrate prepared by the step b to form an anti-reflection film layer; and d, spreading an anti-fouling solution, namely, applying the anti-fouling solution above the film layer of the glass substrate treated in the step c to form an anti-fouling layer. The invention further relates to an anti-reflection glass substrate prepared by adopting the method disclosed by the invention, and an application of the anti-reflection glass substrate.

Owner:HENAN ANCAI HI-TECH

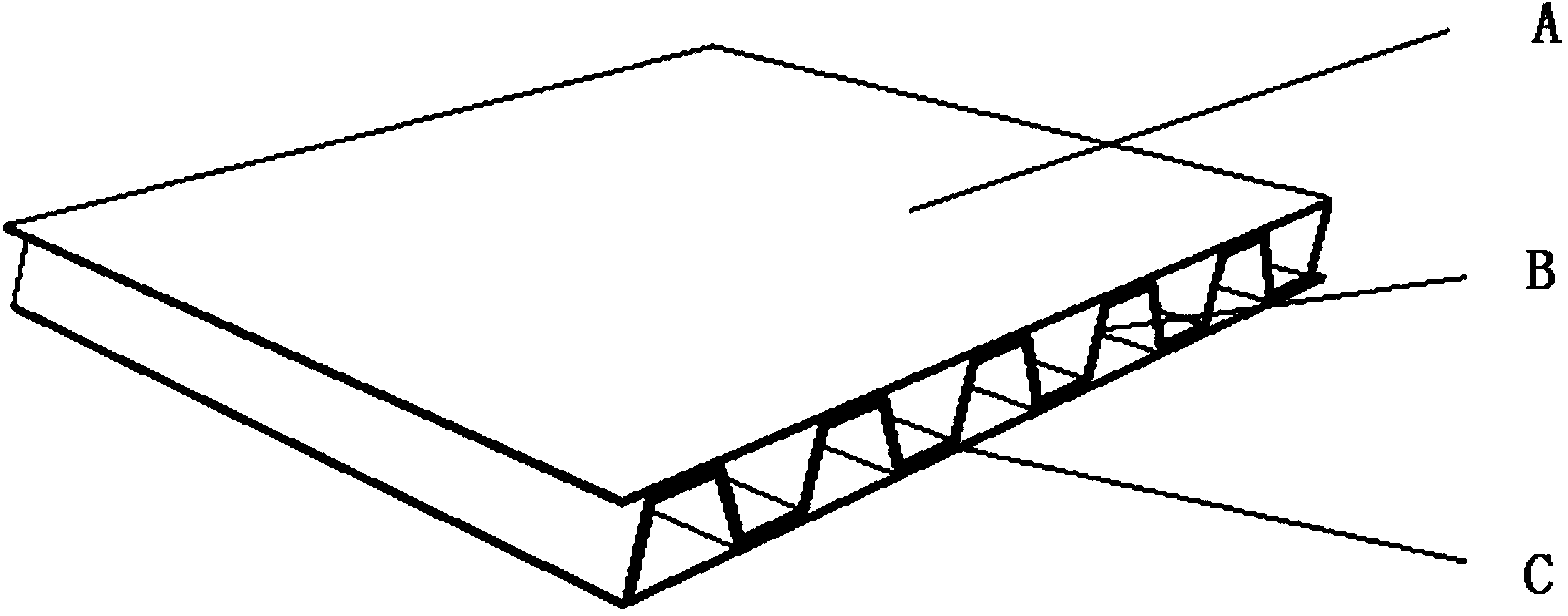

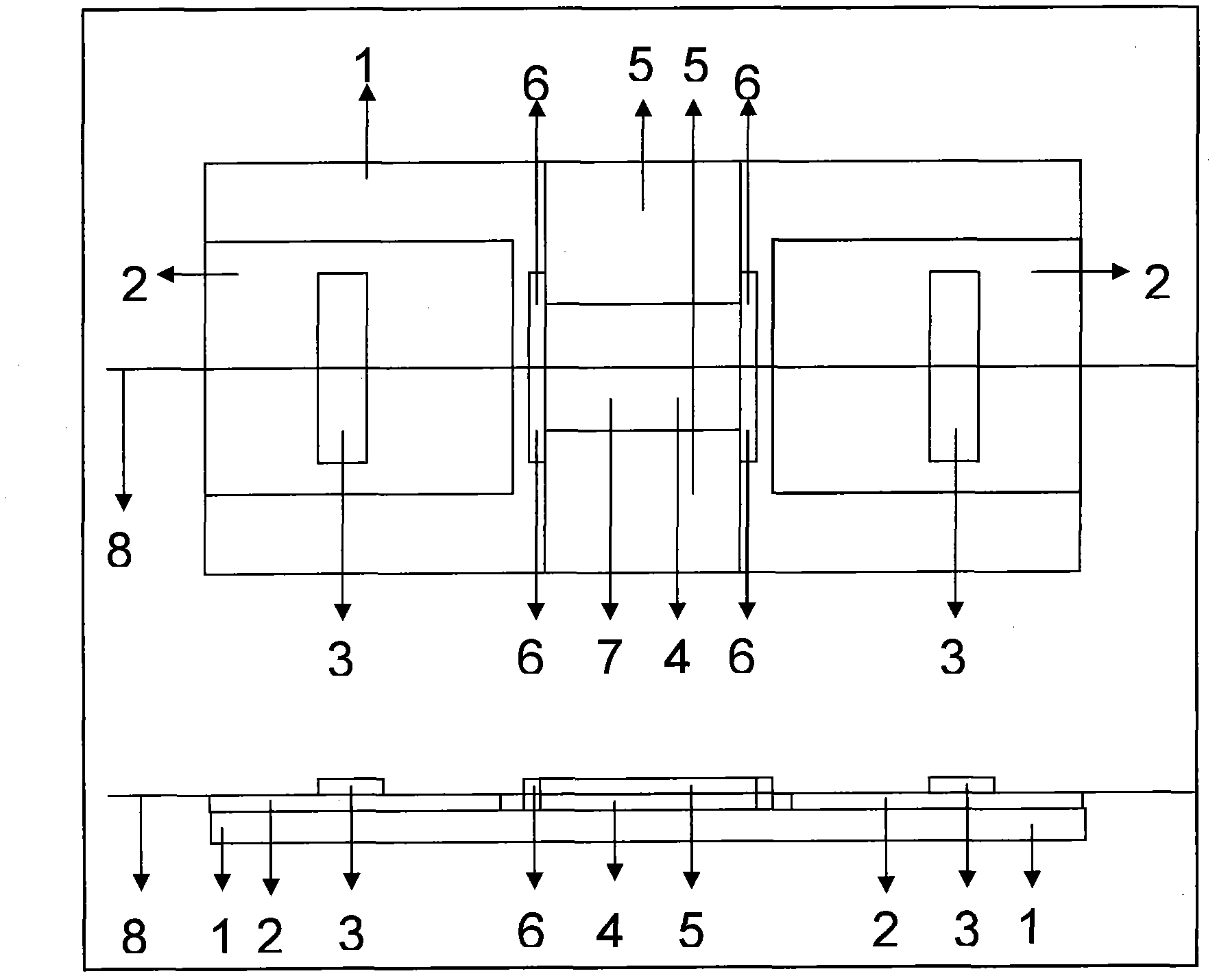

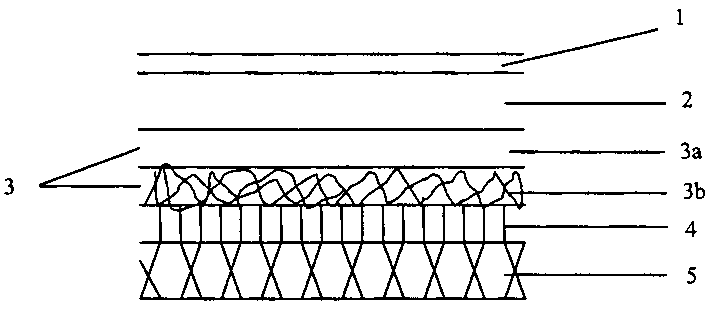

Preparation method for corrugated ceramic-based composite material flat plate

InactiveCN104177110AEasy to design and implementWide range of applicationsTemperature resistanceCorrosion

The invention discloses a preparation method for a corrugated ceramic-based composite material flat plate and relates to a preparation method for a composite material flat plate. The preparation method disclosed by the invention aims at solving the problem that forming is difficult in the prior art during the preparation of a ceramic-based corrugation sandwich structural plate. The preparation method comprises the following steps: I, mixing to prepare an impregnation liquid; II, preparing carbon fiber cloth into an upper panel, a lower panel and a core panel; III, filling into a corrugated plate to prepare a mould; IV, preparing an initial forming body; V, preparing a corrugated SiC composite material initial product; VI, preparing a corrugated SiC composite material intermediate; and VII, repeating the step VI to prepare the corrugated ceramic-based composite material flat plate. The corrugated ceramic-based composite material flat plate prepared by the preparation method disclosed by the invention not only has the goodness of the structure of the corrugated material, but also has the characteristics of high temperature resistance, corrosion resistance, oxidization resistance and friction resistance of the SiC ceramic. The preparation method disclosed by the invention is used for preparing the corrugated ceramic-based composite material flat plate.

Owner:HARBIN UNIV OF SCI & TECH

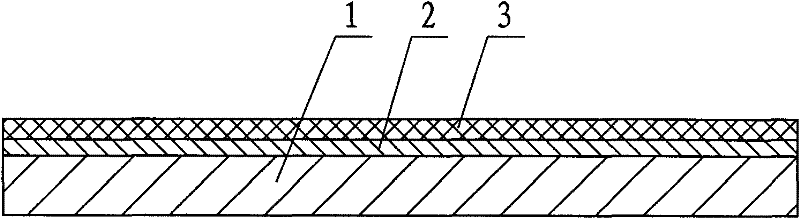

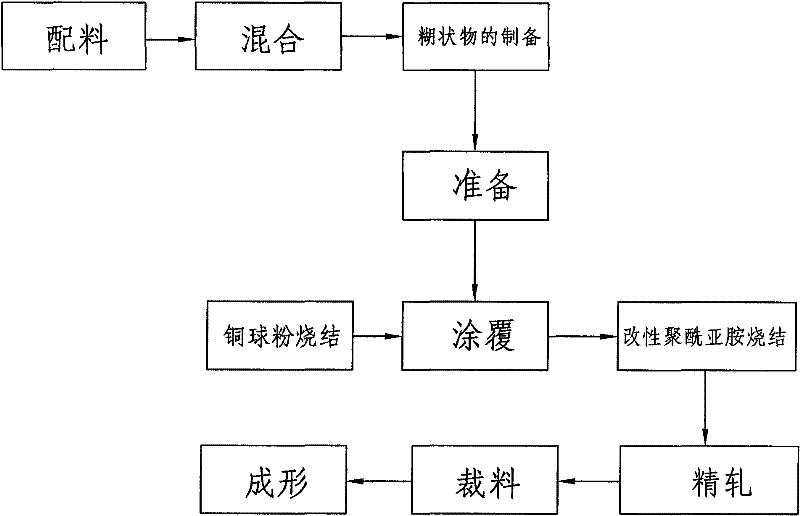

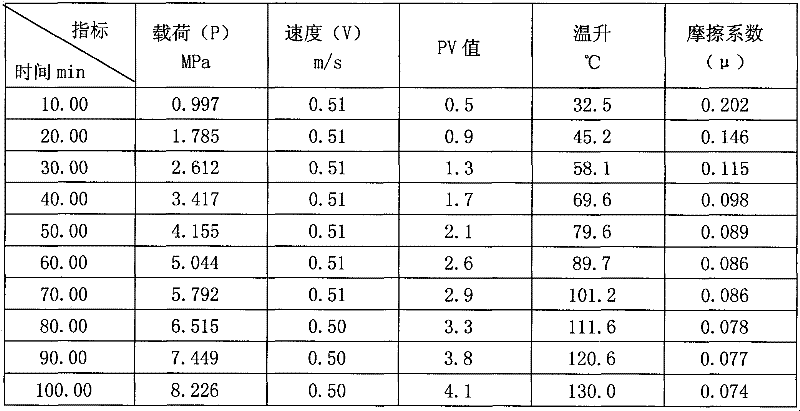

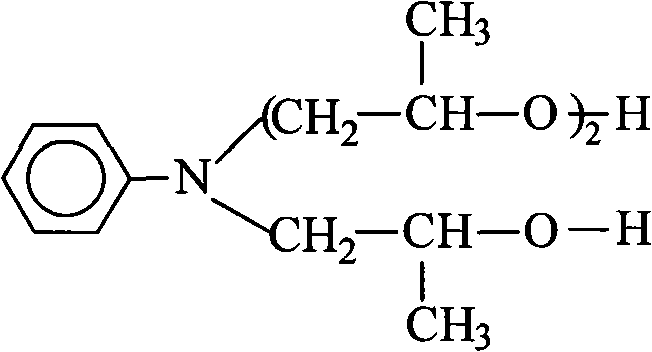

Three layer composite self-lubricating sliding bearing with modified polyimide wear layer and preparation method thereof

The invention discloses a three layer composite self-lubricating sliding bearing with a modified polyimide wear layer and a preparation method thereof. A layer of porous spherical bronze powder is sintered on a layer of a steel plate; a layer of modified polyimide wear resistant material is covered on the porous spherical bronze powder layer to prepare a sheet material of the self-lubricating sliding bearing; and the sheet material of the self-lubricating sliding bearing is prepared into products of a sliding bearing in a spindle sleeve shape or a thrust washer or a slide plate or a friction disc sheet or ball seat structural member. A production technology comprises steps of: preparing modified polyimide mash, sintering the spherical bronze powder, preparing, coating, sintering the modified polyimide, finishing rolling, cutting material and forming. The three layer composite self-lubricating sliding bearing with the modified polyimide wear layer of the invention has excellent performances of good rigidity, high strength, high temperature resistance, friction resistance and no lead, and is especially suitable for heavy load, variable load and high PV value sliding bearing.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

Vehicle finish with polymer/inorganic composite nano-powder and preparing method thereof

InactiveCN1456618AImprove anti-aging propertiesImprove mechanical propertiesLiquid surface applicatorsPolyester coatingsPolymer sciencePolymer resin

A surface paint for car is prepared through diluting part of polymer resin with diluent while stirring, sequentially adding nano-class composite inorganic powder, titanium white powder and assistant while stirring, grinding, filtering, adding the rest of polymer resin, and high-speed stirring while adding solidifying agent and diluent. Its advantages are high anti-ageing performance and high hardness.

Owner:SICHUAN UNIV +1

Method for preparing high performance urethane elastomer for thermal barrier coating

ActiveCN101358030AIncrease elasticityFriction-resistantPolyurea/polyurethane coatingsPolymer scienceThermal insulation

The invention provides a preparation method of a thermal insulation coating high-performance polyurethane elastomer. After the reaction of terminal hydroxyl polybutadiene liquid rubber and polyisocyanate, polyurethane is added for reaction for 3 to 4.5 hours at 85 to 90 DEG C to produce isocyanate-terminated prepolymer; a certain amount of heat insulating filler is added in the prepolymer and is mixed evenly to produce component A; chain extender, antioxidant, curing agent and solvent are mixed evenly according to a certain portion to produce component B; the component A and the component B with the weight portion of 3: 1 to 6: 1 are mixed, stirred evenly, cured at room temperature to produce the thermal insulation coating high-performance polyurethane elastomer. The process of the invention used to synthesize the thermal insulation coating high-performance polyurethane elastomer is more reasonable, the product has higher quality and better comprehensive properties. The test date shows that the tensile strength is 3.50 to 5.80MPa, the elongation at break is more than 220 percent, the bond strength is more than 10.0MPa, the glass transition temperature is less than 60 DEG C below zero, the solidification shrinkage rate is less than 0.1 percent. The product is mainly applicable to aerospace industry.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

Manufacturing method for composite aluminium plastic decorative buckles

InactiveCN1456436AImprove flatnessFriction-resistantMetal layered productsTectorial membraneSurface oxidation

A decorative fastening aluminium-plastic plate is prepared through preparing plastic substrate from engineering plastics, filler, stabilizer, plasticizer, lubricant and assistant through mixing, granulating, extruding out, fixing shape, and cutting, preparing the coated aluminium foil through washing, removing oil, oxidizing surface, baking, painting, baking and coiling, combining said plastic substrate with aluminium foil, covering adhesive protecting film on the surface of aluminium foil, and cutting. Its advantages are high abrasion compression, fire and water resistance, good thermal and acoustic insulation, no poison and beautiful appearance.

Owner:无锡市中德装饰新材料有限公司

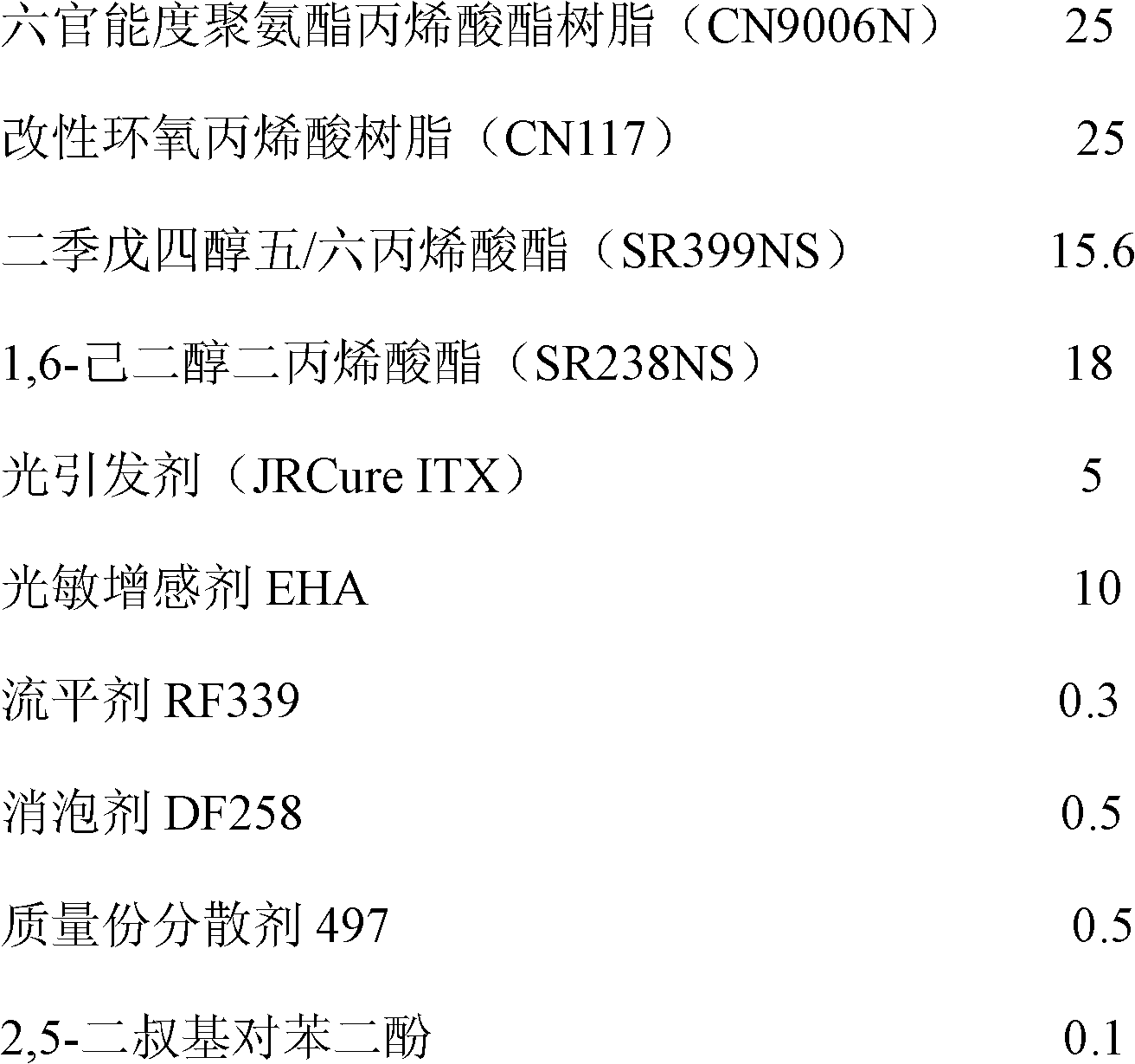

High-gloss abrasion-resisting ultraviolet (UV) gold-stamping gloss oil for the field of cigarette packet printing and preparation method thereof

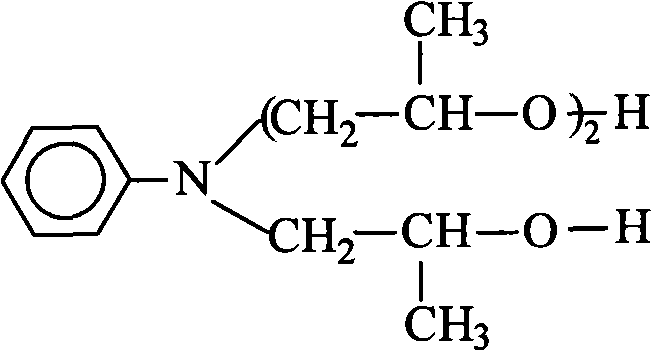

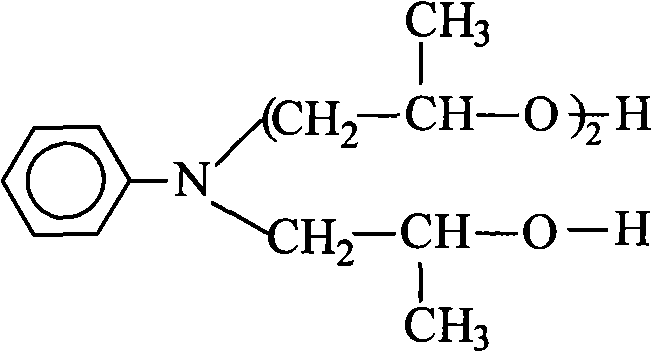

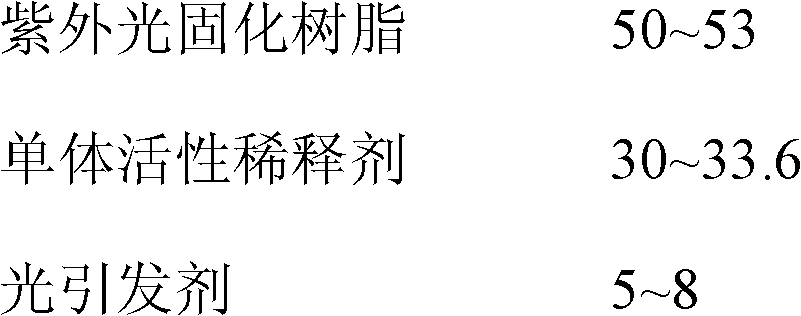

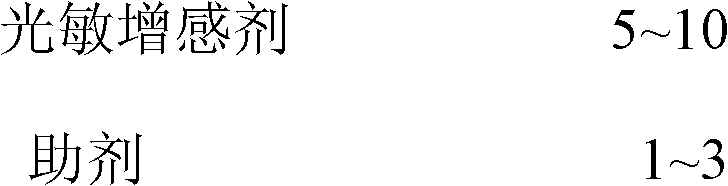

The invention provides high-gloss abrasion-resisting ultraviolet (UV) gold-stamping gloss oil for the field of cigarette packet printing and a preparation method thereof. The high-gloss abrasion-resisting UV gold-stamping gloss oil is gold-stamping gloss oil with the viscosity of 130-150 cps / 25 DEG C and is prepared by mixing and stirring, by mass, 20-25 parts of CN9006 N six-functionality polyurethane acrylate, 25-30 parts of CN117 modified epoxy acrylate, 15-15.6 parts of SR399NS dipentaerythritol senary acrylic ester, 15-18 parts of SR238NS 1,6- hexylene glycol diacrylate, 5-8 parts of photoinitiator, 5-10 parts of photosensitivity sensitizer and1-3 parts of auxiliaries. The high-gloss abrasion-resisting UV gold-stamping gloss oil adopts monomers and resin with small acid value and corrosivity, has the advantages of being high in glossiness, good in adhesive force, friction-resisting, quick in drying speed and the like and has good gold-stamping effect when used for the cigarette packet printing.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

Aqueous alkyd acrylic resin printing ink and preparation method thereof

The invention relates to an aqueous alkyd acrylic resin printing ink and a preparation method thereof. According to the invention, high-molecular alkyd resin with main chain containing unsaturated double bond is synthesized through molecular design. Alkyd resin is subjected to free radical graft copolymerization with acrylic monomer. A reaction system is neutralized by using an amine compound, such that water-reducible alkyd acrylic resin is synthesized. Molecular chains of alkyd and acrylic resins are connected through chemical bond, such that the compatibility of the two resins is improved. In a material curing and shaping process, phase separation of the resin is avoided. Deionized water, a pigment, a filling material, an antifoaming agent, a dispersing agent, a siccative, and alkyd acrylic hybrid emulsion are uniformly dispersed, such that the aqueous alkyd acrylic resin printing ink is obtained.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

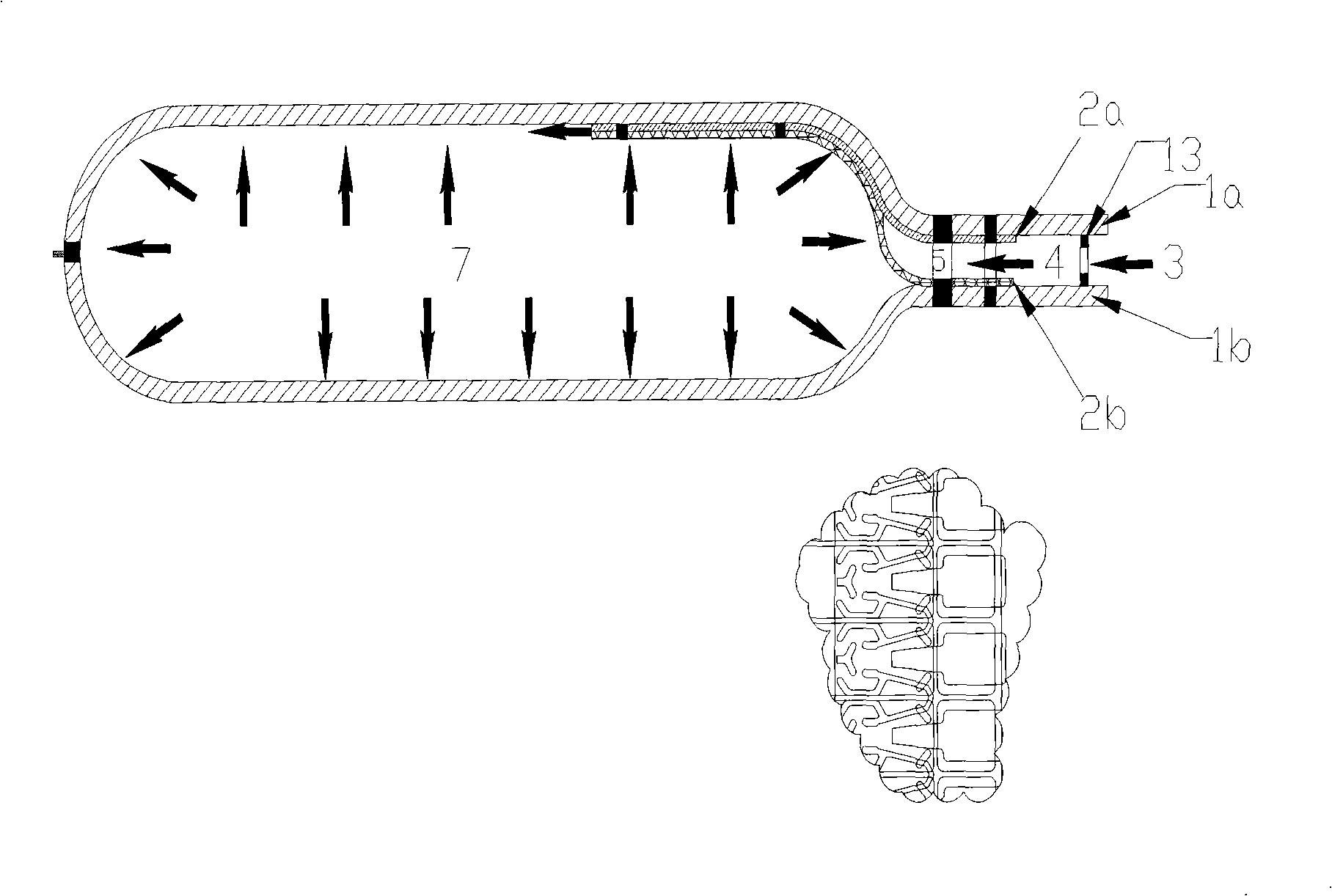

Reusable multifunctional three-dimension sealing and packing material and method for preparing same

ActiveCN101513952ACorrosion resistanceUse light materialEnvelopes/bags making machineryPackage recyclingEngineeringPack material

The invention provides an environmentally-friendly three-dimension sealing and packing material which is developed by using the characteristics of different film products, has different functions, can be formed quickly on use sites and has recycling value. The three-dimension packing material is combined with a plurality of layers of functional resin films without any extra supporting device. The films are sealed by heat and folded to form a space capable of storing gas media including the air for a long time, and the air and the films jointly form the functional three-dimension packing material by using a self-adhesive film preventing and air blocking technology. The three-dimension packing material is completely flat before use, is quickly formed in three dimensions by using a gas such as the air when to be used by a user and forms an air bag protective structure around an product to be protected. The three-dimension packing material has excellent comprehensive protective functions such as extrusion resistance, shock resistance, falling resistance and impact resistance and functions such as light shielding, moisture prevention, electrostatic prevention, conductivity, wear resistance, corrosion resistance, rust resistance, and printability.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

Sheet laminating preparation method for sisal fiber reinforced polypropylene composite material

The present invention adopts the sisal hemp fiber as fiber raw material, and uses the nonwoven fabric of thermoplastic resin PP, film, powder material and its fiber as resin base body, and adopts thefollowing steps: pretreating sisal hemp fiber and making it into fiber felt, hot-pressing and forming, selecting and using a certain number of fiber felts, delaminating and sand wiching pp nonwoven fabric or film, under the condition of a certain temp. and pressure hot-pressing and forming or mixing PP fiber (PP powder) directly with sisal hemp fibre, making them into fiber felt and then hot-pressing and forming so as to obtain the invented sisal hemp fiber reinforced polypropylene composite material.

Owner:SUN YAT SEN UNIV

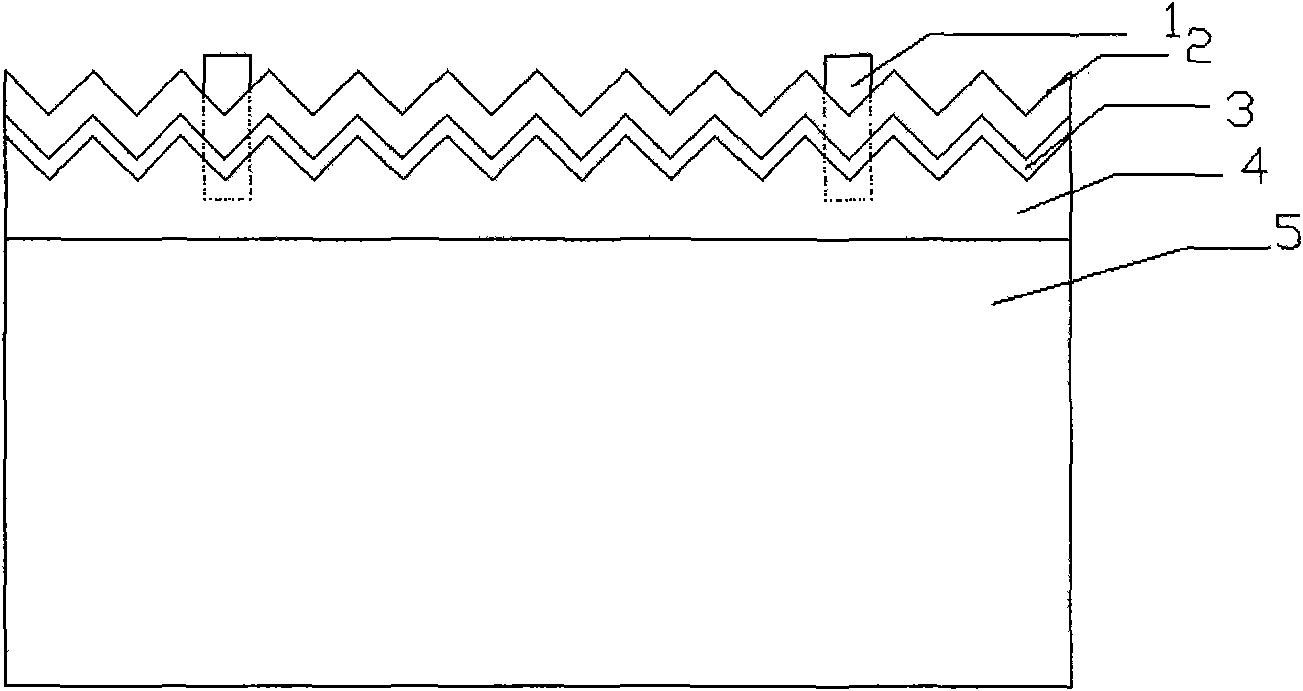

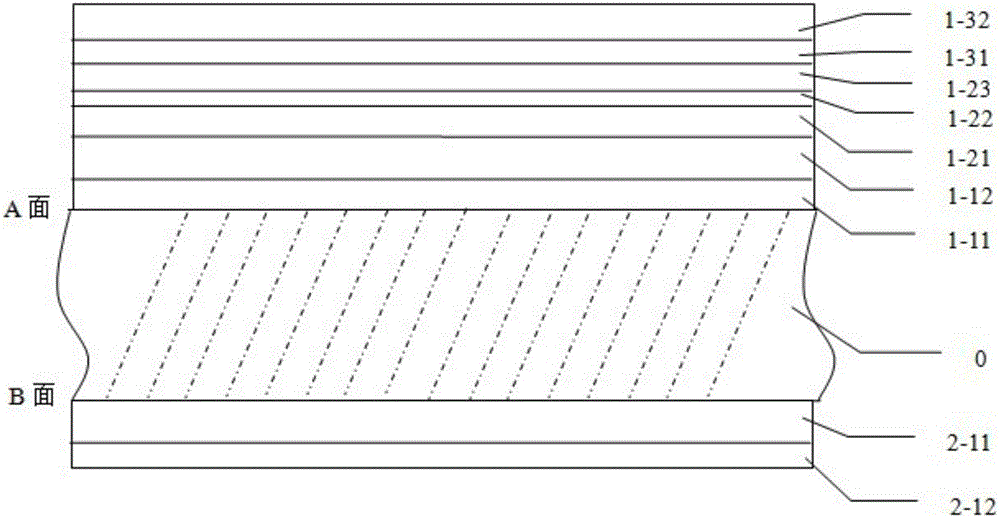

Preparation method of double-layer antireflection coating of crystalline silicon solar battery

InactiveCN101609859AEasy to prepareLow costFinal product manufactureSemiconductor devicesBack surface fieldHYDROSOL

The invention relates to a preparation method of a double-layer antireflection coating of a crystalline silicon solar battery, comprising following concrete steps: firstly, mixing tetraethyl orthosilicate and ethanol, stirring and heating; adding attenuant hydrochloric acid solution into the mixed solution; after cooling, adding organic superaddition into the solution, stirring and dissolving, sealing and maturing to obtain acid catalysis colloidal sol; mixing tetraethyl orthosilicate and ethanol, stirring and heating, adding aattenuant aqua ammonia into the mixed solution; after cooling, adding organic superaddition into the solution, stirring and dissolving, sealing and maturing to obtain base catalysis colloidal sol; mixing the prepared acid catalysis SiO2 colloidal sol and the base catalysis SiO2 colloidal sol, evenly stirring the solution, sealing, standing and maturing for one day to obtain new colloidal sol; preparing a crystalline silicon solar battery substrate, forming a silicon nitride film, spraying the prepared colloidal sol on the silicon nitride film to prepare a silicon dioxide film, hot processing the obtained silicon dioxide film, printing the front back electrodes and back surface fields, drying and sintering.

Owner:上海泰阳绿色能源有限公司

In-situ remediation method for water in black and odorous river

InactiveCN105399209AHigh temperature resistantFriction-resistantBiological water/sewage treatmentFiberCarbon fibers

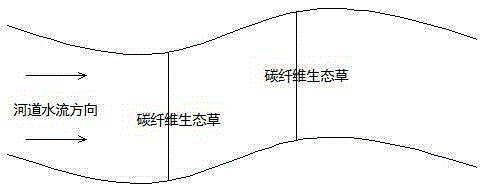

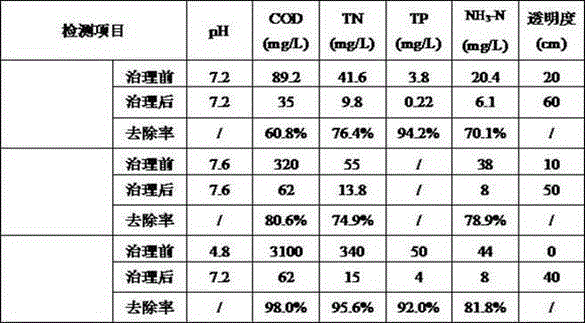

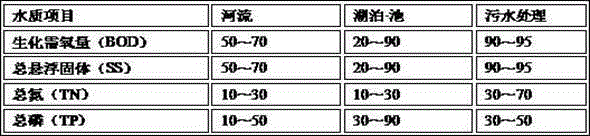

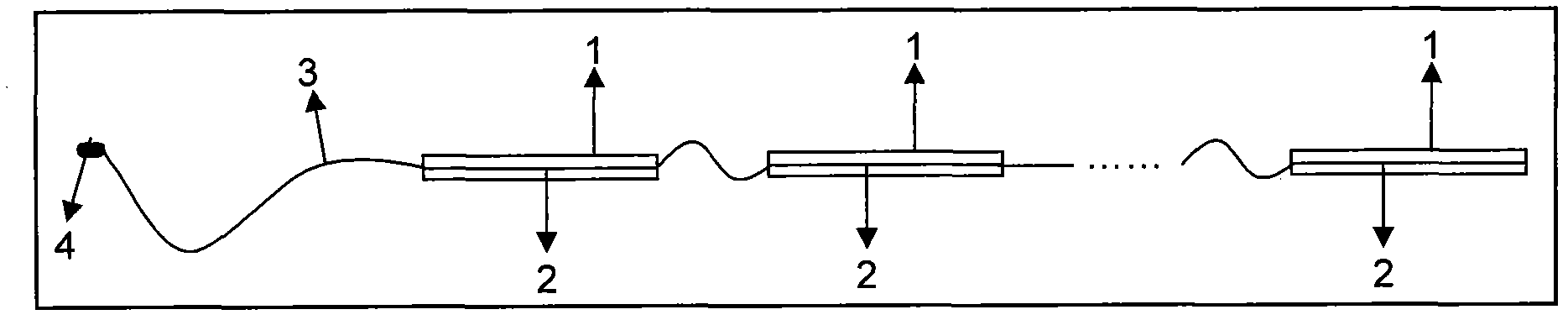

An in-situ remediation method for water in a black and odorous river comprises steps as follows: (1), pollution indexes of the water in the river are detected; (2), the river is pre-treated, the water in the black and odorous river is oxygenized in a biological oxygen enrichment method, and the concentration of dissolved oxygen in a river aquatic system is kept between 2 mg / L and 8 mg / l; (3), carbon fiber ecological grass is laid in the black and odorous river in the downstream direction, one end of the carbon fiber ecological grass is fixed on an iron framework, the iron framework is fixed at the bottom of the river through a weight or an anchor, and the laying density of the carbon fiber ecological grass is 40 cm<2> / L after biofilm formation; (4), after primary biofilm formation of the carbon fiber ecological grass in 3-5 days, cultured indigenous microorganisms are sprayed to starting ends of different water area sections of the black and odorous river in a liquid water-surface spraying manner, the microorganism feeding area accounts for 41% of the water area, and the ratio of fed microorganisms to water amount in areas with different water quality is (2-5):104. The in-situ remediation method solves the increasingly serious blackening and odor problem of the river, and the water remediation method is low in development cost and operation expense and safe.

Owner:江苏青禾环境修复有限公司

Far infrared ceramic material and preparation method thereof

The invention relates to a far infrared ceramic material. The material is multi-element mixed superfine powder which is prepared by mixing the following components in part by weight: 5 to 15 parts of zirconium oxide, 10 to 30 parts of zirconium silicate, 5 to 15 parts of feldspar, 10 to 20 parts of alpha-alumina, 5 to 15 parts of manganese oxide and 1 to 3 parts of boron nitride, wherein the average particle size of the multi-element mixed superfine powder is less than or equal to 1 micron. The zirconium oxide, the alpha-alumina and the manganese oxide in the raw materials adopted by the far infrared ceramic material have high far infrared emission performance; a coating which is formed by the zirconium silicate and the feldspar has compactness and high-temperature resistance; and the boron nitride has lubricity and adhesion resistance. The far infrared ceramic material is suitable to be applied to boiler water wall tubes, heating tube walls, high-temperature drying rooms and the like.

Owner:中国石化集团胜利石油管理局有限公司 +1

High-temperature resistant FBG (fiber bragg grating) sheet type strain sensor and manufacturing method thereof

InactiveCN102645176AHigh temperature resistantCorrosion resistantCladded optical fibreUsing optical meansGratingFiber Bragg grating

The invention discloses a high-temperature resistant FBG (fiber bragg grating) sheet type strain sensor and a manufacturing method thereof. The strain sensor consists of an FBG, a polyimide film, an armored cable and an optical fiber connector, wherein the FBG is connected with the polyimide film; the armored cable is connected with the FBG; the optical fiber connector is connected with the armored cable; and when the strain of a structural component is monitored, the surface of the monitored object needs to be milled by abrasive paper, and the polyimide and FBG composite sheet is stuck on the monitored object with adhesives. The method adopts a polyimide curing technology and comprises the following steps of: sealing the FBG and polyimide into a mould, and organically combining through heating, curing and cooling to form a polyimide and FBG composite sheet; leading out the armored cable from the end part of the polyimide and FBG composite sheet; and sticking the polyimide and FBG composite sheet on the surface of the structural component to be monitored by use of high-temperature resistant adhesives. The strain sensor disclosed by the invention resists high temperature, has good durability and high measurement accuracy, and is in quasi-distributed arrangement, free from electromagnetic interference and convenient to construct.

Owner:HARBIN INST OF TECH

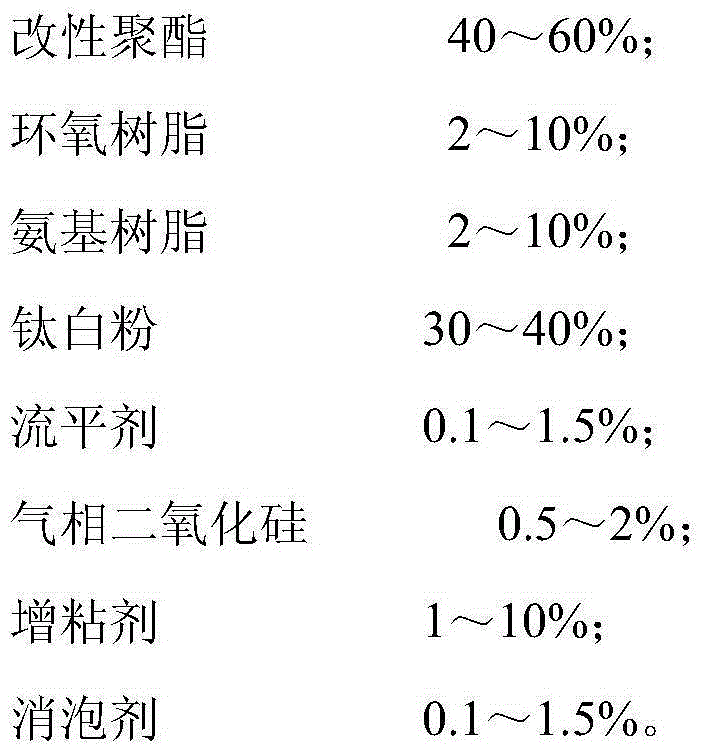

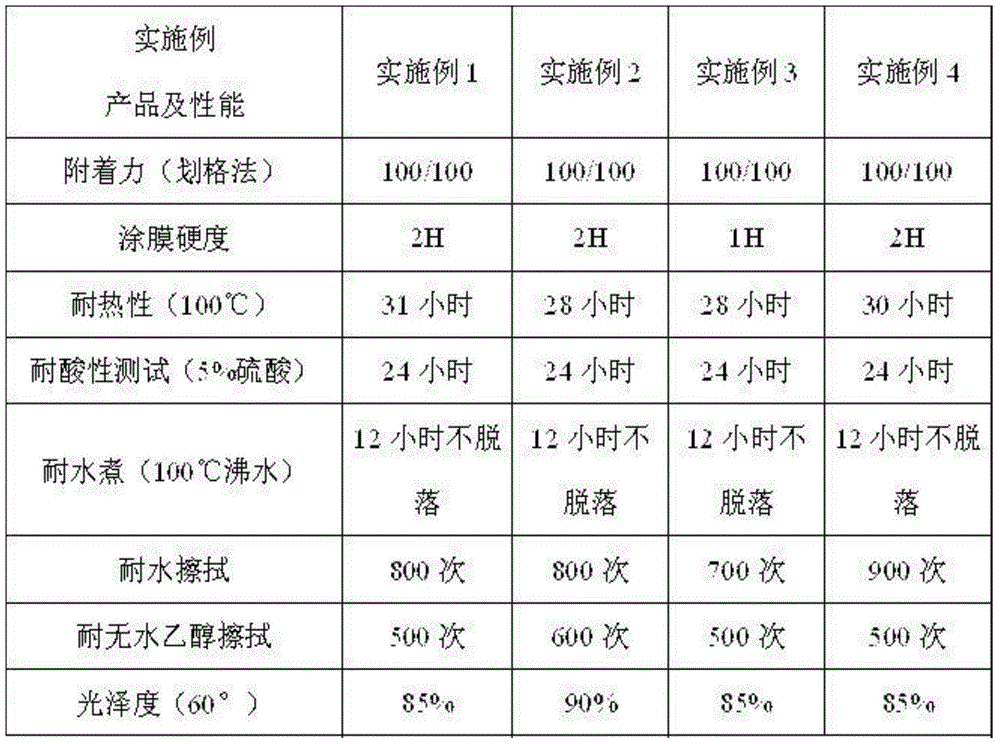

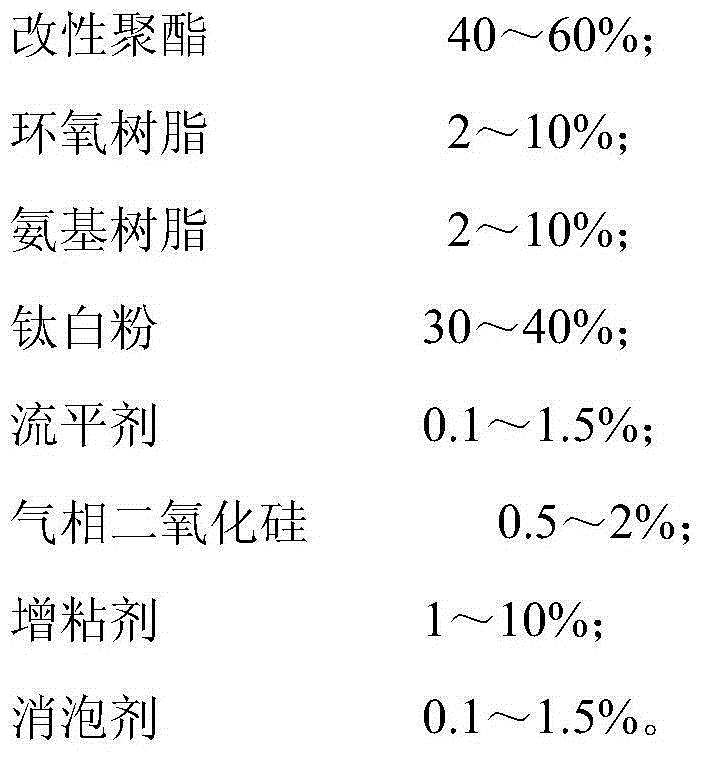

Waterproof single-component glass printing ink and preparation method thereof

The invention provides waterproof single-component glass printing ink. A raw material formula of the waterproof single-component glass printing ink comprises, by weight percentage, 40-60% of modified polyester, 2-10% of epoxy resin, 2-10% of amino resin, 30-40% of titanium dioxide, 0.1-1.5% of flatting agent, 0.5-2% of fumed silica, 1-10% of tackifier and 0.1-1.5% of antifoaming agent, wherein the modified polyester is organic silicone modified polyester. The epoxy resin is heat-resistant epoxy resin, and the heat-resistance temperature is 185-205 DEG C. The amino resin is etherified amino resin with a solid content of 45%. The grain size of the titanium dioxide is 100 nanometers or below. Correspondingly, the invention further provides a method for preparing the waterproof single-component glass printing ink. The prepared glass printing ink has the advantages of being good in water resistance, high in gloss and weather resistance, good in interlayer adhesion and resistant to friction.

Owner:BAUHINIA VARIEGATA INK & CHEM (ZHONGSHAN) LTD

Method for manufacturing double-layer film of crystalline silicon solar cell

InactiveCN101814548AEasy to prepareLow costFinal product manufacturePhotovoltaic energy generationGas phaseOptoelectronics

The invention relates to a method for manufacturing a double-layer film of a crystalline silicon solar cell. The method is characterized by comprising the following specific steps of: mixing tetraethyl orthosilicate and ethanol, stirring and heating, adding dilute solution of hydrochloric acid into the solution, cooling, adding an organic additive into the solution, stirring and dissolving, and closing and aging to obtain a sol; and preparing a substrate of the crystalline silicon solar cell by a routine method, forming a silicon nitride film by a plasma enhanced chemical vapor deposition method, spraying the prepared sol on the silicon nitride film to prepare a silicon dioxide film, performing heat treatment on the obtained silicon dioxide film at the temperature of between 200 and 600 DEG C, printing positive and negative electrodes and a back field, drying, and sintering. The method has the advantages that: the light reflectivity of the surface of the solar cell is lower; the power of a solar cell plate is higher; and the short-wave and long-wave absorption of the double-layer film cell is further improved.

Owner:上海泰阳绿色能源有限公司

Insulation glue for lithium metal batteries and preparation method thereof

InactiveCN105885753AImprove insulation performanceInsulation has no effectNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterAntioxidant

The invention discloses insulation glue for lithium metal batteries and a preparation method thereof. The insulation glue for the lithium metal batteries are prepared from epoxy resin, organic silicon resin, nitrile rubber, polyvinyl butyral resin, an epoxy reactive diluent, anhydride, an inorganic filler, an antioxidant, a curing agent, a bifunctional reactive diluent, a plasticizer, a solvent, a coupling agent, a phosphorus-containing flame retardant, a nitrogen-containing flame retardant, acrylic acid, polyvinyl alcohol and sodium dodecyl benzene sulfonate. The plasticizer is prepared from dibutyl phthalate, tributyl phosphate, tri(2-chloroethyl)phosphate, polyester and polyether. The insulation glue has good electric insulation performance, thermal conductivity, high heat resistance and low cost, can be easily sprayed, brushed or dipped, has moisture-proof, acid-proof, friction-resisting, corrosion-resisting properties and other properties, have the good sealing and insulating performance effects on coated positions, is suitable for the insulation precaution of exposed parts of lithium-ion metal batteries, has no effect on the properties of the lithium-ion metal batteries completely and is safe and reliable.

Owner:何凤英

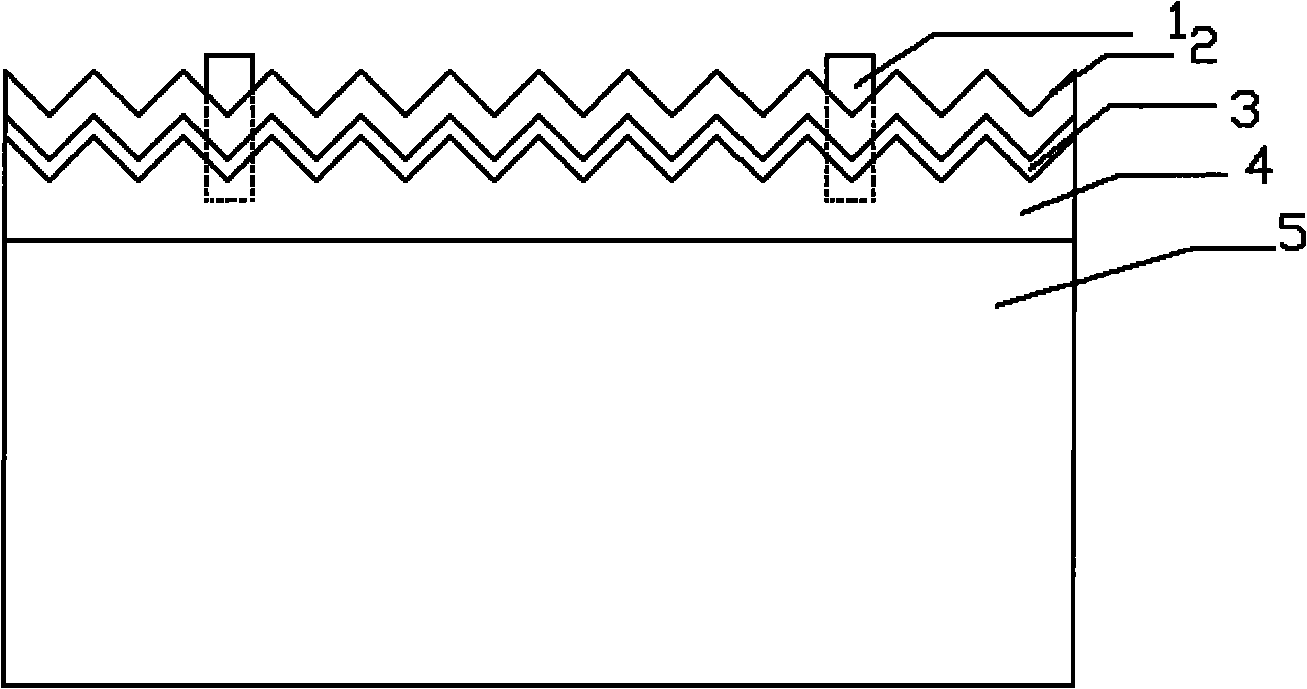

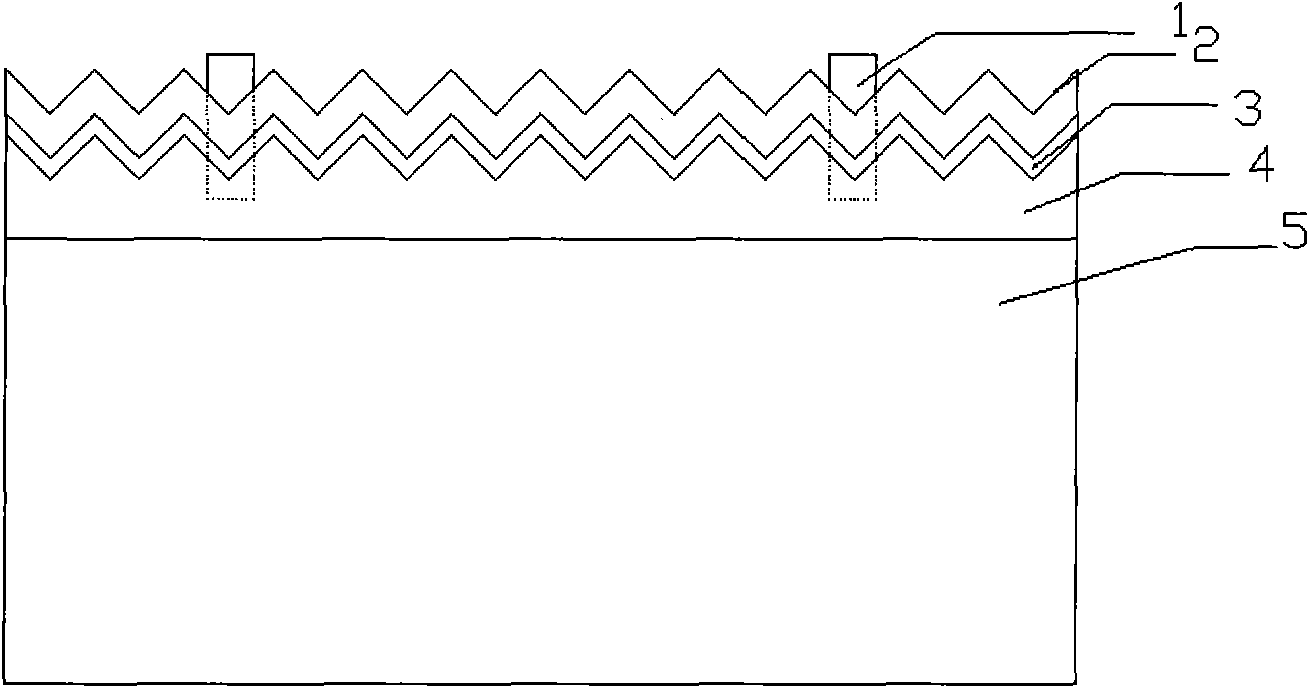

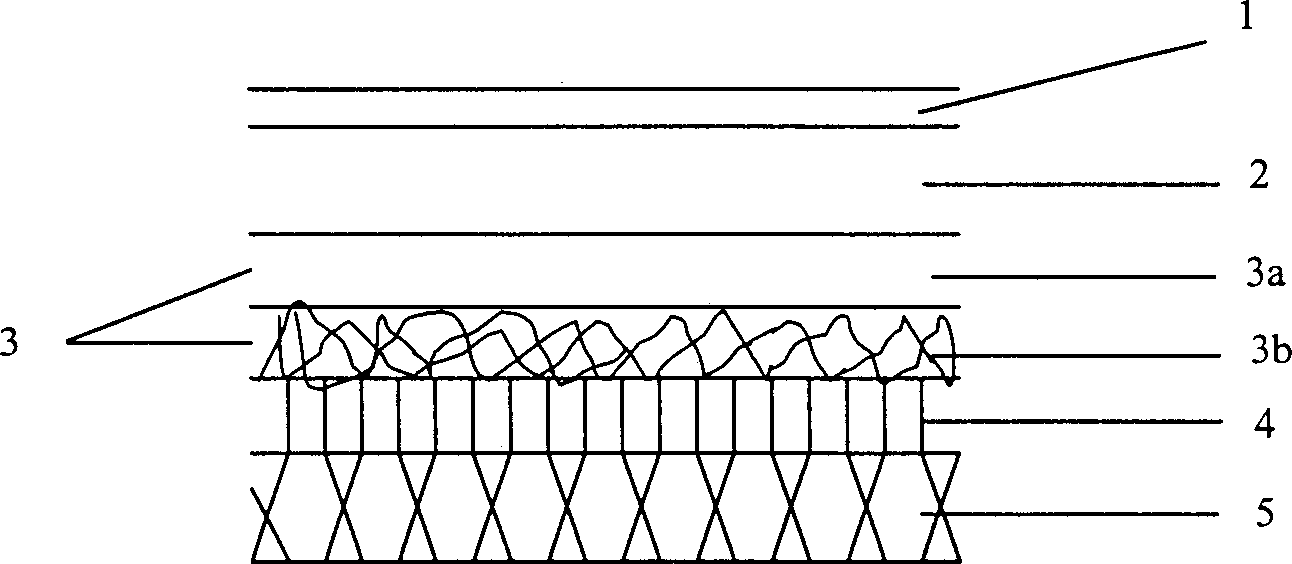

Transparent energy-saving hydrophobic film used for civil aircraft porthole glass and preparation method thereof

InactiveCN106222612AImprove corrosion resistanceGood weather resistanceVacuum evaporation coatingSputtering coatingInfraredWeather resistance

The invention discloses a transparent energy-saving lyophobic film used for civil aircraft porthole glass and a preparation method thereof. An organic glass substrate involved in the transparent energy-saving hydrophobic film used for the civil aircraft porthole glass comprises a surface A and a surface B. Different transparent film bodies are arranged on the surface A and the surface B. A transparent energy-saving conductive film system is arranged on the surface A, and a transparent hydrophobic film system is arranged on the surface B. The energy-saving film system comprises an isolation layer, an energy-saving functional layer and a protective layer sequentially from inside to outside in the organic glass substrate. The hydrophobic film system comprises an attaching layer and a hydrophobic functional layer sequentially from inside to outside in the organic glass substrate. The inner side of the transparent energy-saving hydrophobic film can achieve the infrared reflecting and energy saving function, the outer side of the transparent energy-saving hydrophobic film can achieve the hydrophobic, oleophobic and anti-dirt functions, the film layers on the two sides are coordinated in function, the effects of high light transparency and excellent energy conservation are achieved, the film layers are high in corrosion resistance and weather resistance, the production process is simple and can be autonomously controlled, and the technological process can be adjusted according to performance parameter requirements.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

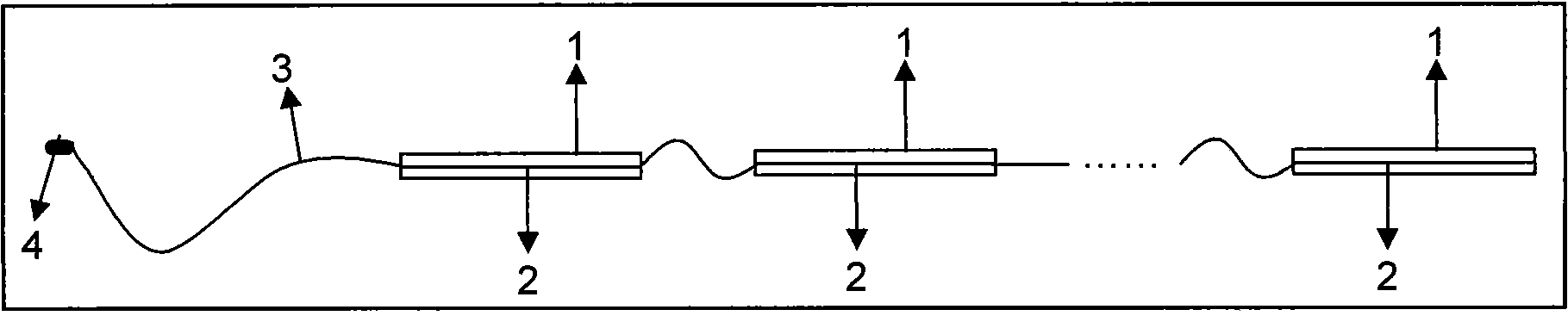

Heavy cable and zero float cable mixed type photoelectric composite tow

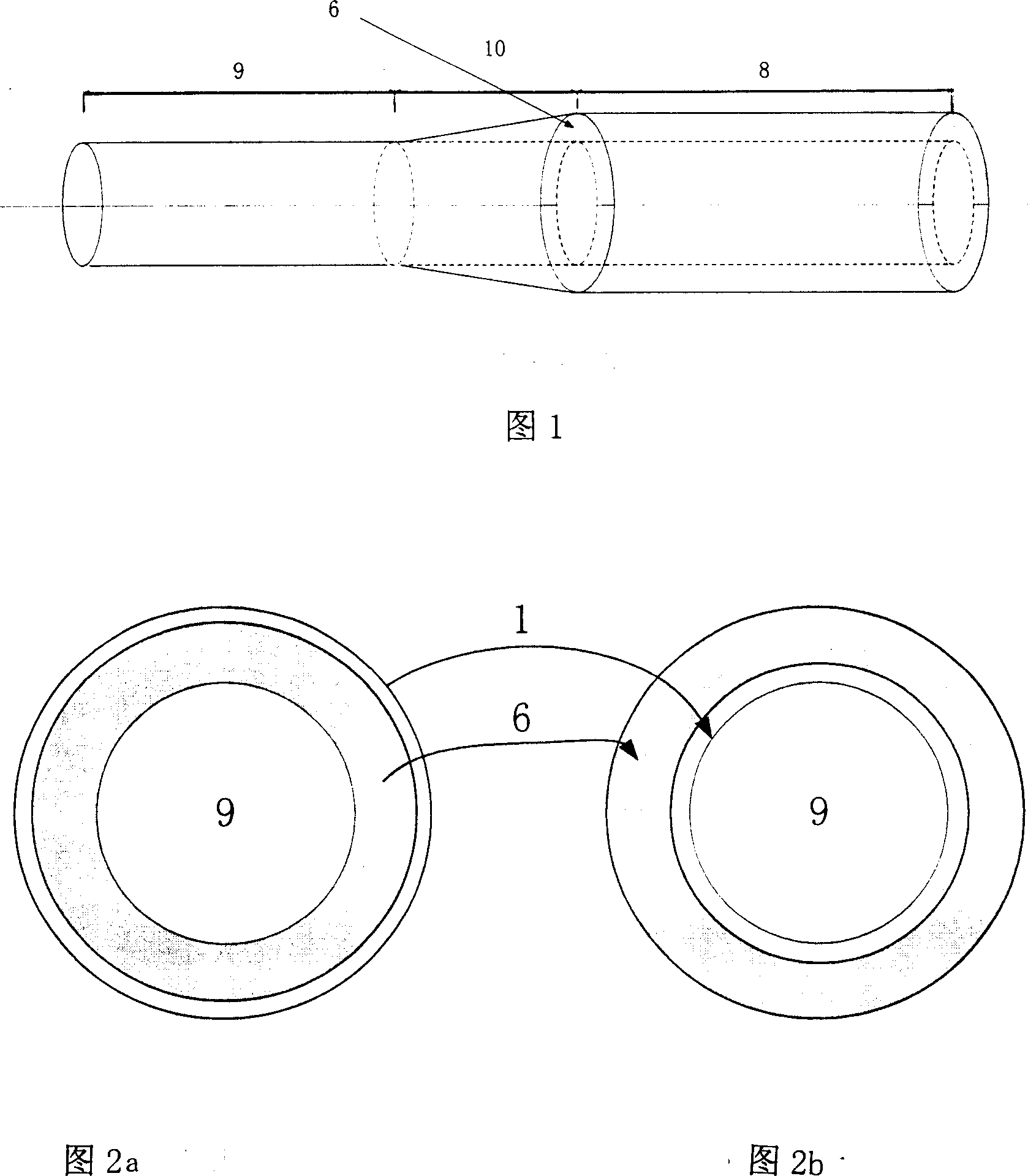

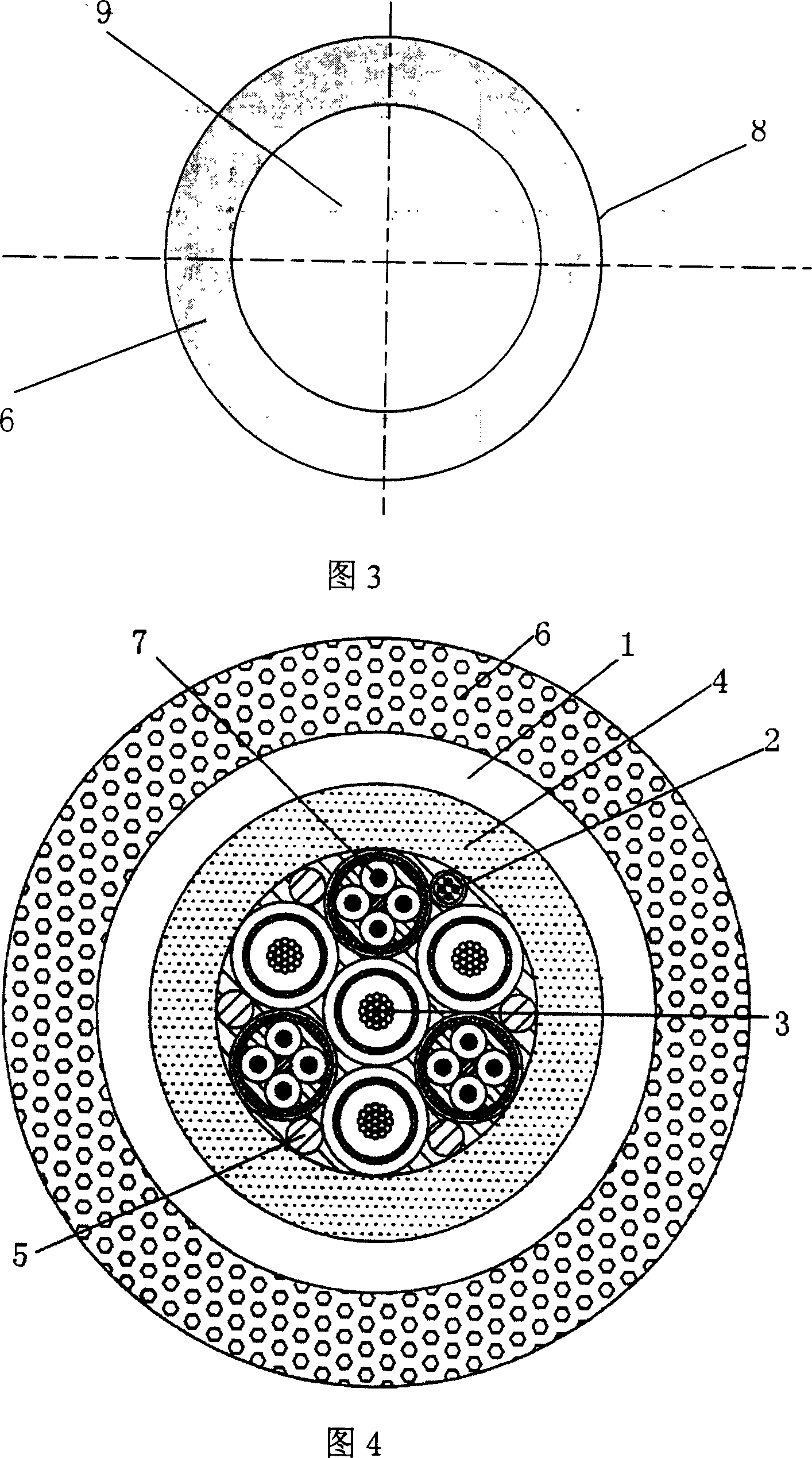

InactiveCN101000815ASimple structureHigh system stabilityPlastic/resin/waxes insulatorsInsulated cablesMulti-mode optical fiberMixed type

A photoelectric composite tow of heavy cable and zero-buoyancy cable mixed type is prepared as forming heavy cable by heavy cable section and transition section as well as zero-buoyancy section, setting heavy cable section at one end of heavy cable and zero-buoyancy section at the other end of heavy cable, covering a polyimine resin protection sheath on tensile outer layer of heavy cable, preparing zero-buoyancy cable section on said sheath, setting said transition section between two said sections for making foamed protection sheath there be from thick to thin to form transition section of tow.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

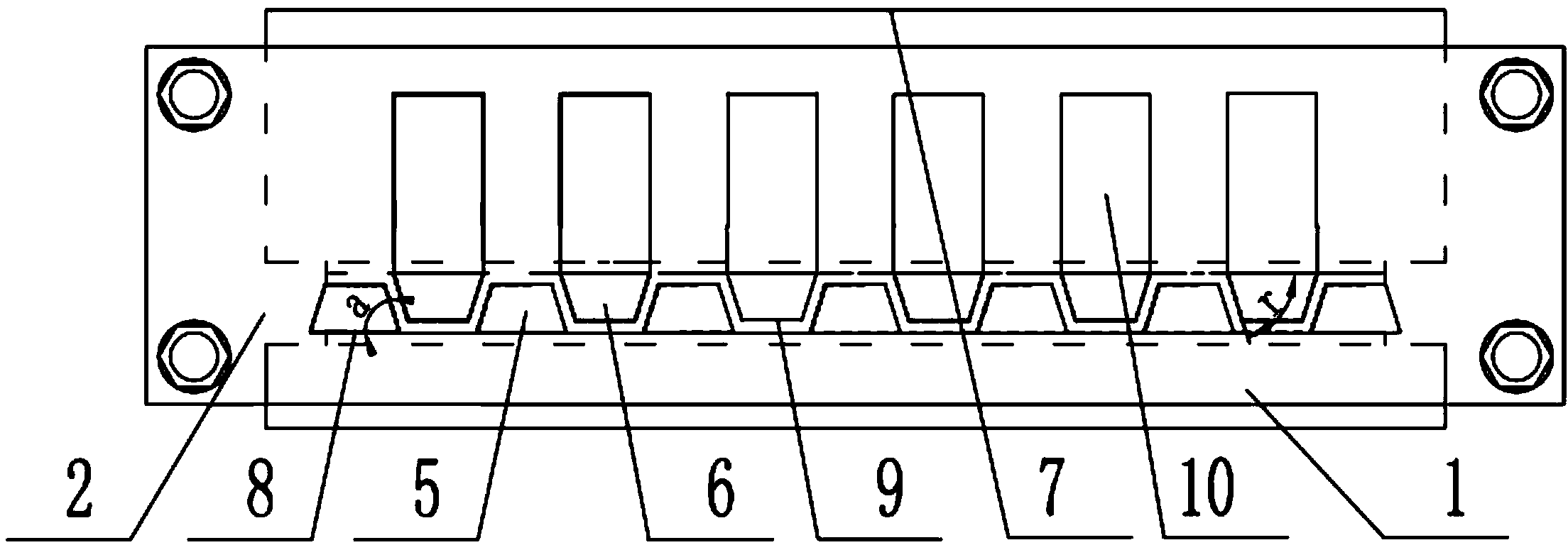

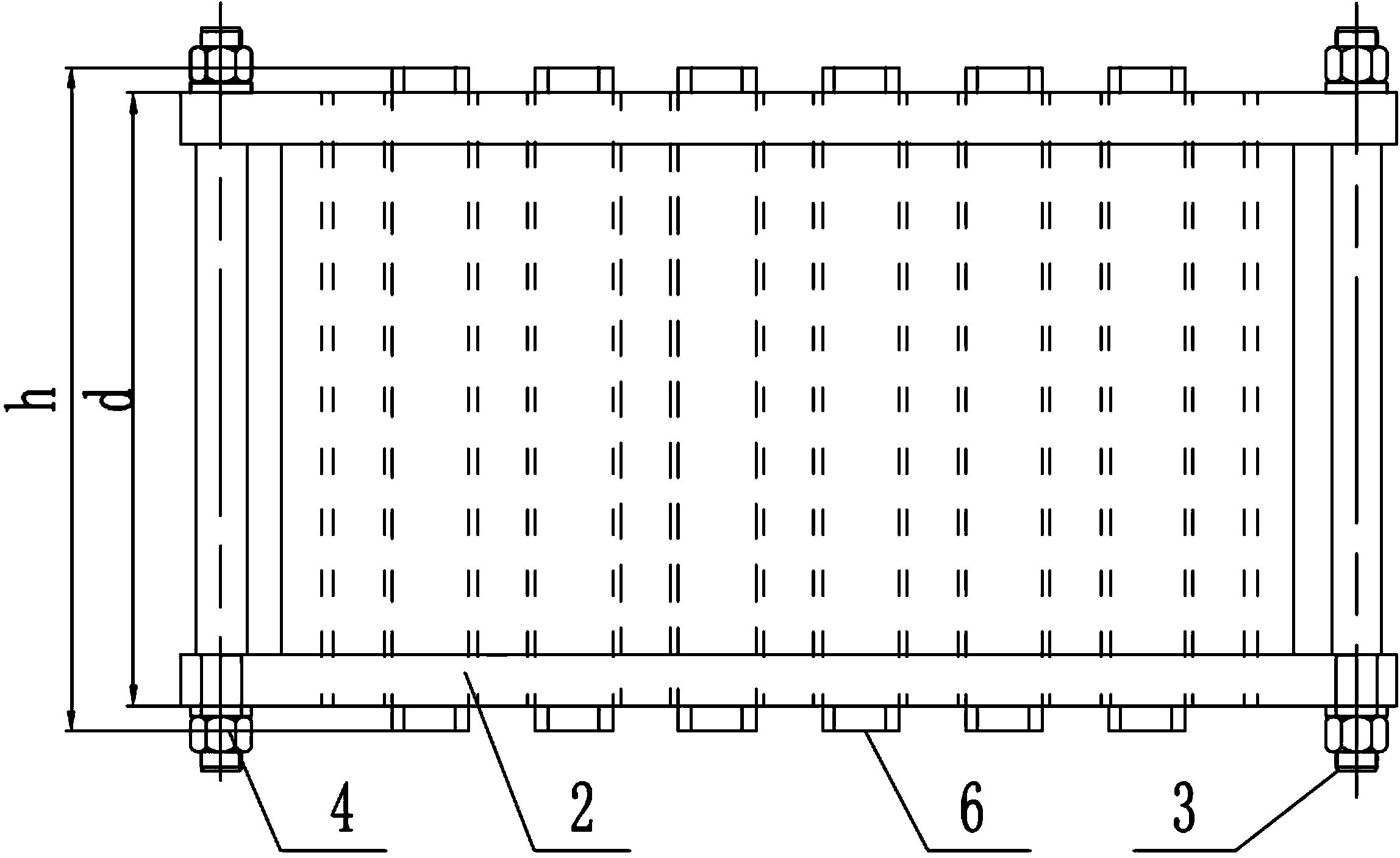

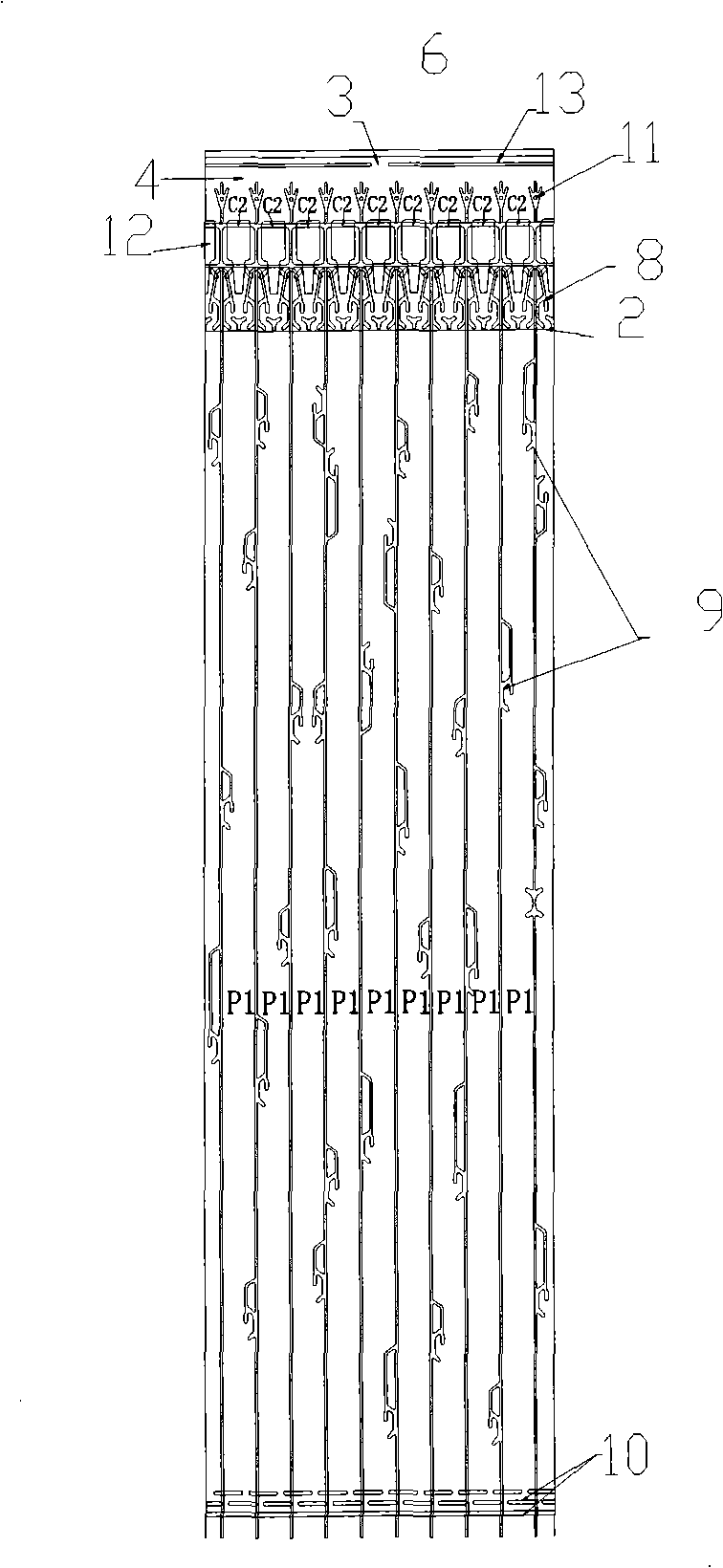

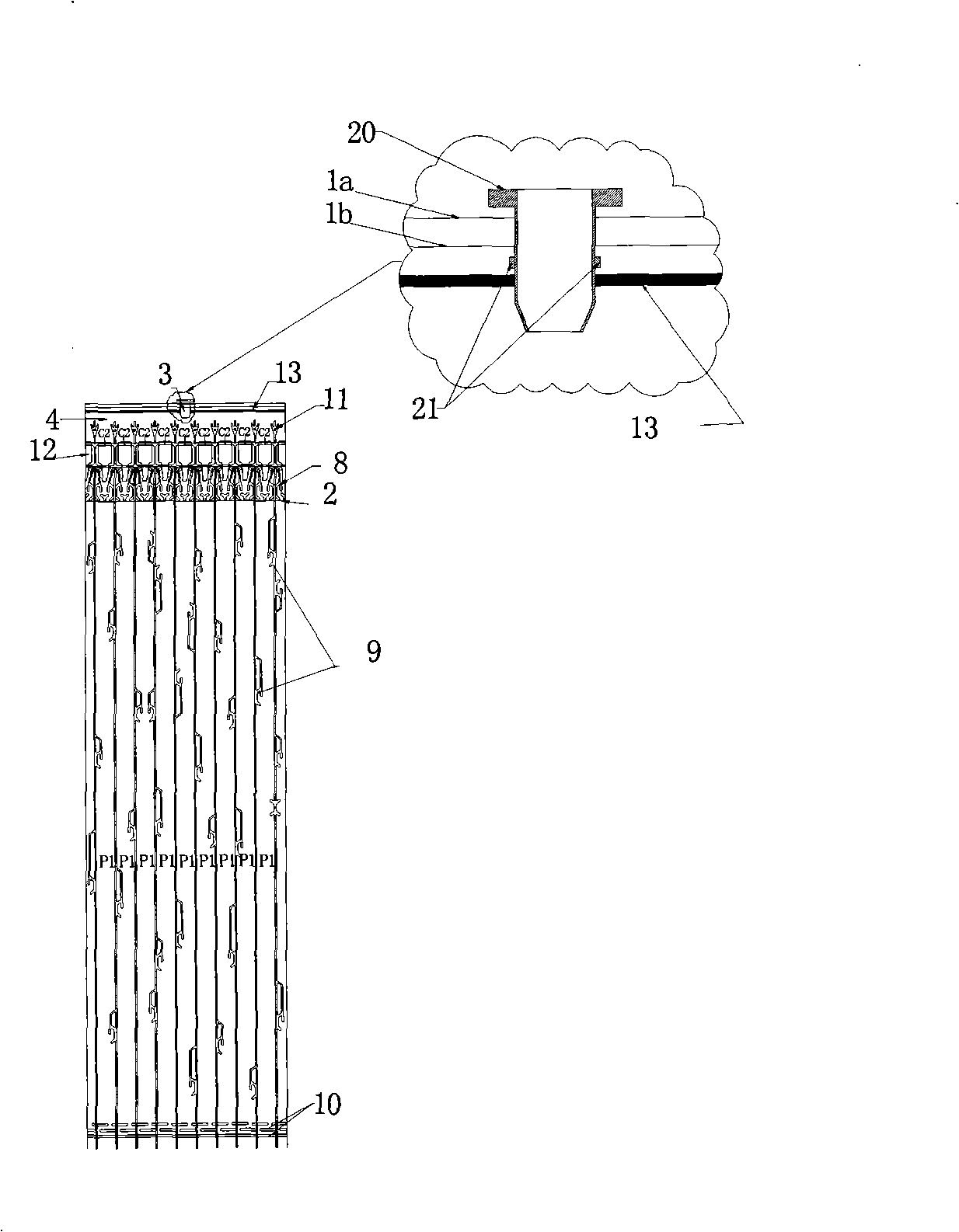

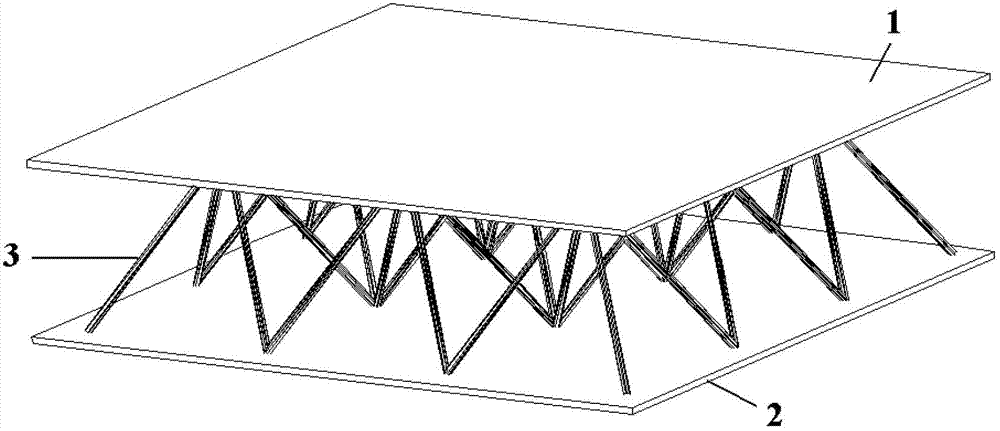

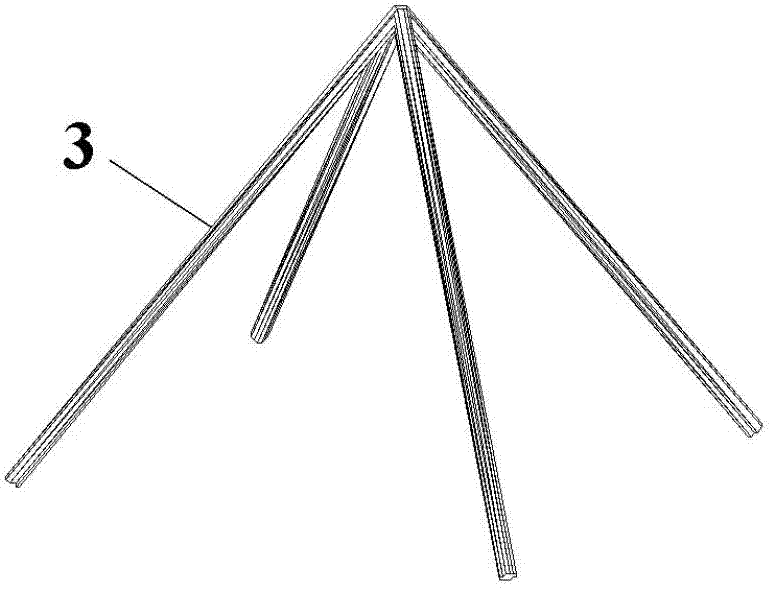

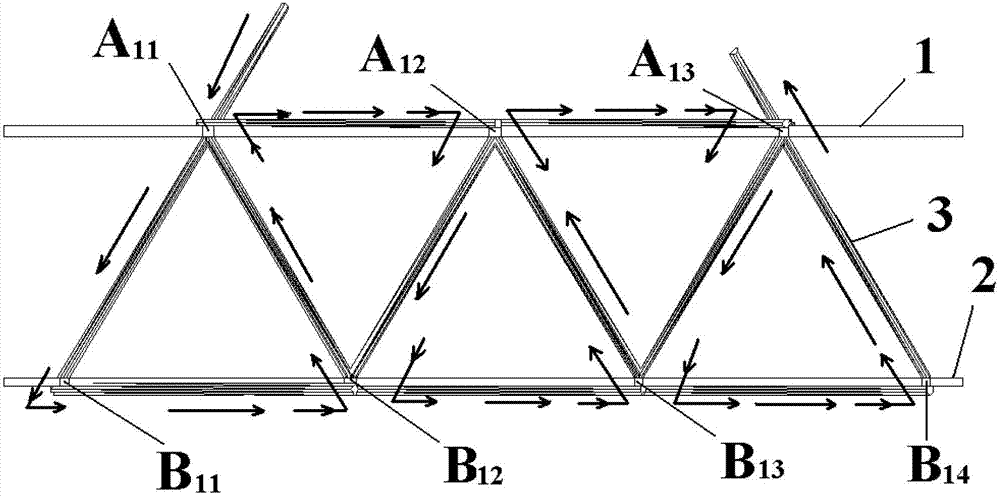

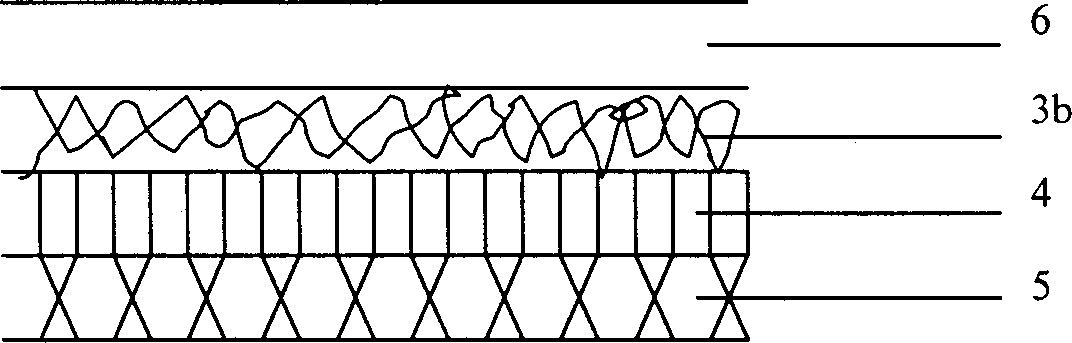

Cf/SiC dot matrix composite flat plate with rectangular pyramid structure and preparation method for flat plate

The invention discloses a Cf / SiC dot matrix composite flat plate with a rectangular pyramid structure and a preparation method for the flat plate, and relates to the field of dot matrix composite materials and preparation methods thereof. The Cf / SiC dot matrix composite flat plate mainly solves the problems that the conventional metal-based and resin-based dot matrix materials cannot meet the requirement and a ceramic-based dot matrix composite material is difficult to prepare in the prior art. The Cf / SiC dot matrix composite flat plate with the rectangular pyramid structure consists of an upper panel, a lower panel, and rectangular pyramid cells positioned between the upper and lower panels and arranged periodically in a dot matrix core form. The preparation method comprises the following steps of: preparing a skeleton of the Cf / SiC dot matrix composite flat plate with the rectangular pyramid structure by adopting a process of inserting polycarbosilane soaked carbon fibers into polycarbosilane soaked carbon fiber cloth, soaking the skeleton into polycarbosilane, curing, cracking, and thus obtaining the Cf / SiC dot matrix composite flat plate with the rectangular pyramid structure. The flat plate is applied in the fields of noise reduction, electromagnetic radiation shielding, impact resistance, heat insulation and heat conduction reduction.

Owner:HARBIN UNIV OF SCI & TECH +1

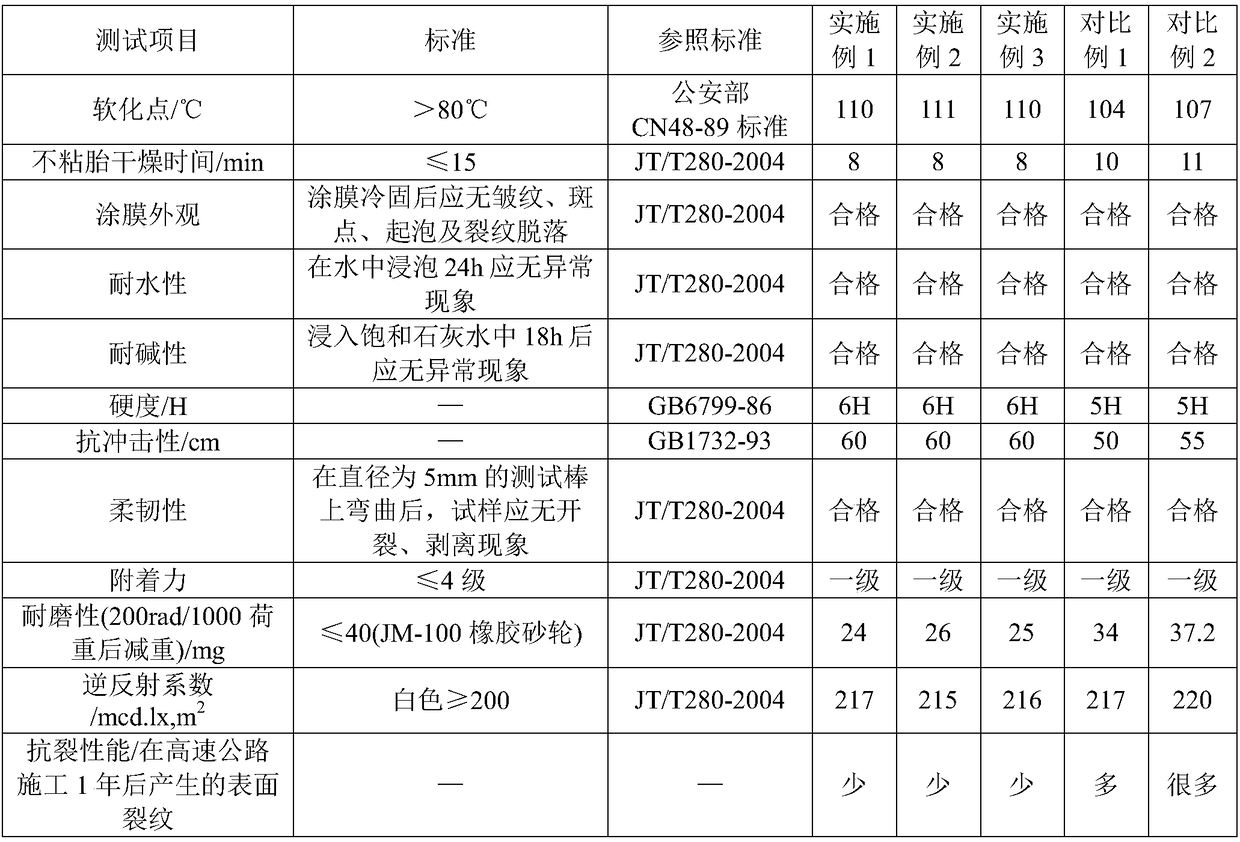

Hot melting reflective type road reticule coating

ActiveCN108659686AGood reflectiveShort drying timeAntifouling/underwater paintsPaints with biocidesRosinCorrosion

The invention relates to hot melting reflective type road reticule coating and belongs to the technical field of road reticule coating. The hot melting reflective type road reticule coating is prepared by mixing the following components in parts by mass: 110 to 120 parts of fillers, 20 to 25 parts of modified rosin-alkyd resin, 5 to 10 parts of EVA resin, 7 to 8 parts of pigment, 2.0 to 2.4 partsof a plasticizer and 40 to 50 parts of glass microbead. The hot melting reflective type road reticule coating provided by the invention is simple and convenient to construct, only needs to be paved with one layer, and has a remarkable anti-cracking property, wear resistance, corrosion resistance, anti-fouling property and insusceptibility to fall off.

Owner:北京路桥方舟交通科技发展有限公司

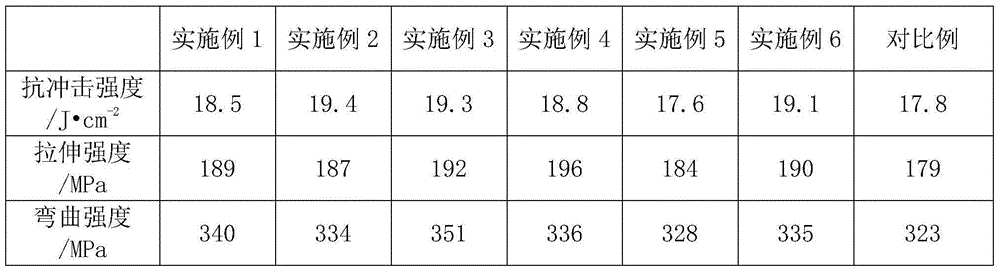

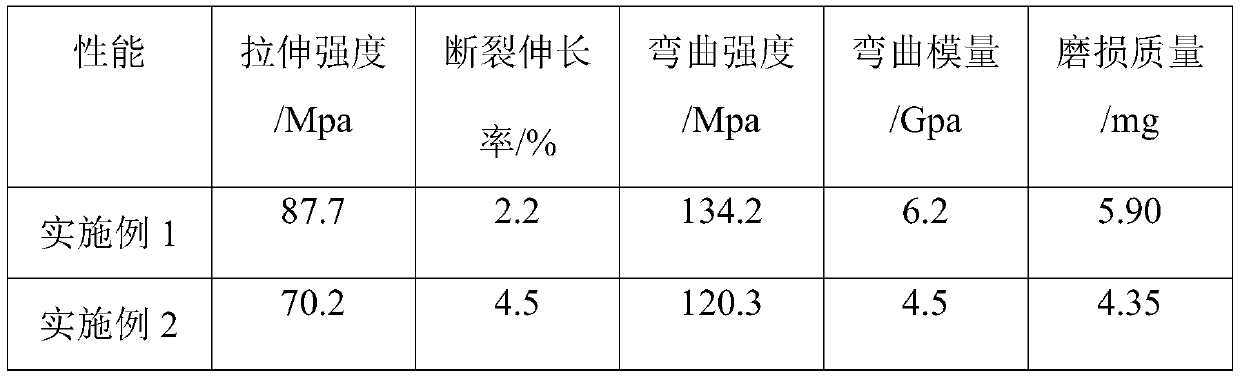

Preparation method for polyimide composite material for automobile

The invention provides a preparation method for a polyimide composite material for an automobile. The method comprises the following steps that 1, impurities in sisal fiber are removed, the sisal fiber is dried and added into a sodium hydroxide solution to be soaked, the sisal fiber is taken out to be washed to obtain alkalified sisal fiber, a silane coupling agent is dissolved into an acetic acid solution, the PH value is adjusted to be 7 through ammonium hydroxide, conditioning fluid is obtained after standing, and the alkalified sisal fiber is added into the conditioning fluid for ultrasonic dispersion and taken out for drying, taking, dispersion and smashing to obtain modified sisal fiber; 2, talcum powder is added into a mixing machine to be stirred, then a titanate coupling agent is added, and modified talcum powder is obtained after taking out and drying are performed; 3, polyimide, the modified sisal fiber and the modified talcum powder are added into a stirring machine for stirring and mixing and then taken out to be put into a mold for compression molding forming, and mold stripping is performed to obtain the polyimide composite material for the automobile. According to the preparation method, raw materials are cheap and easy to obtain, the production cost is saved, and the obtained composite material has the good mechanical performance, has the certain degradability and is environmentally friendly.

Owner:SUZHOU ZHENZHAN TECHCAL MATERIAL CO LTD

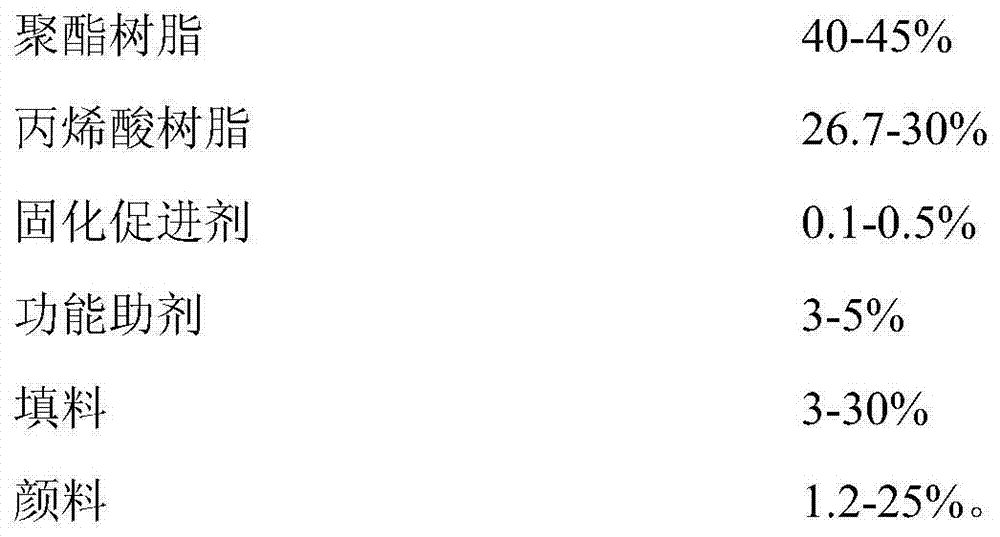

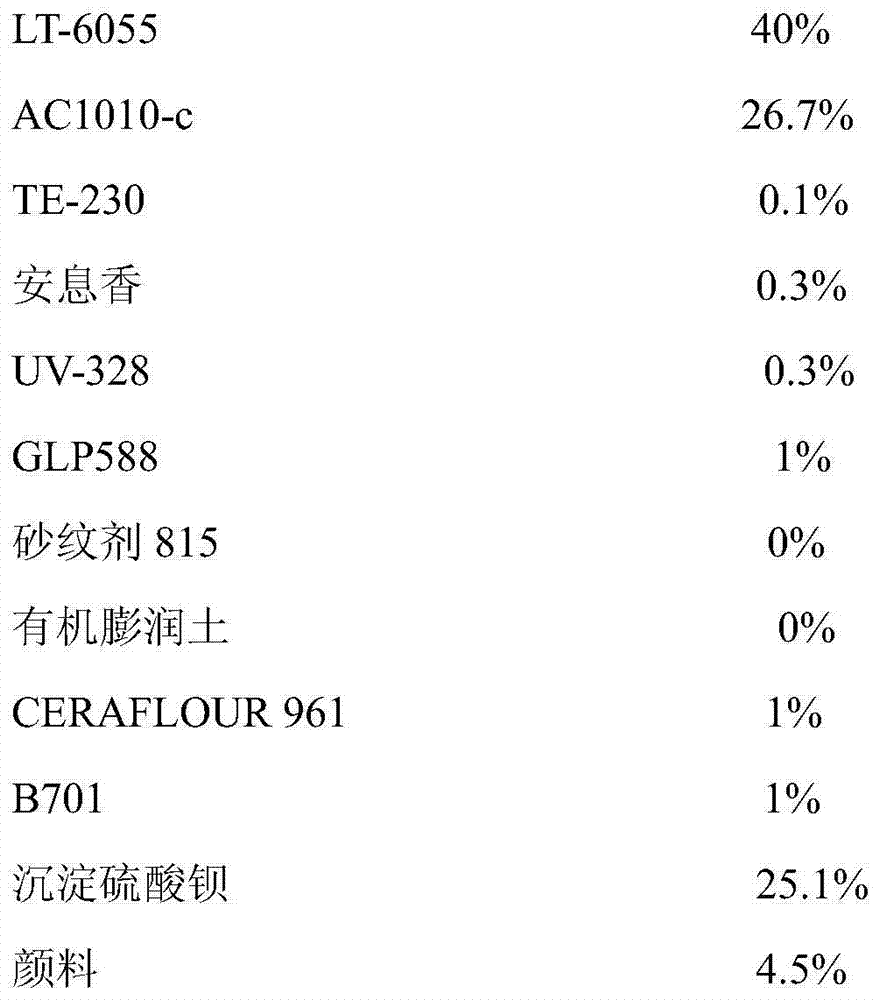

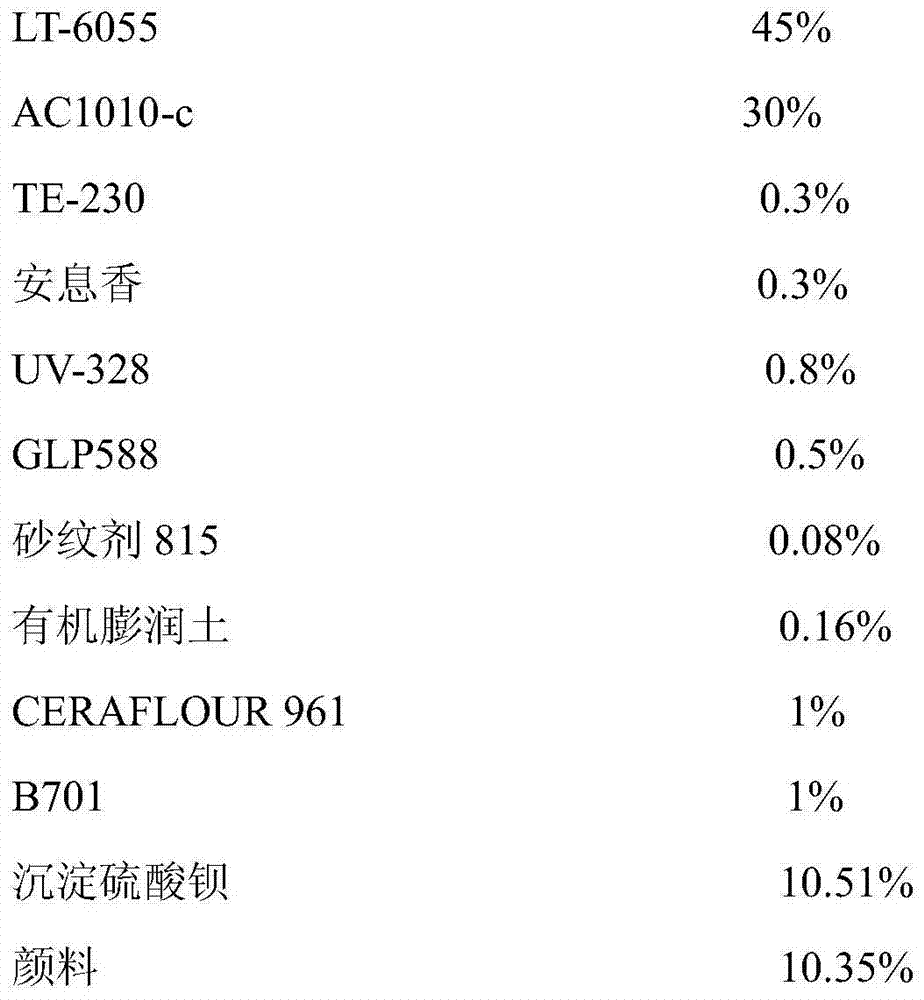

Outdoor MDF powder coating and application thereof

InactiveCN104497810ALow gloss lossIncrease profitPretreated surfacesAnti-corrosive paintsAcrylic resinUltraviolet lights

The invention belongs to the technical field of powder coating, and particularly relates to an outdoor MDF powder coating and application thereof. The outdoor MDF powder coating is prepared from the following raw materials in percentage by weight: 40-45 percent of polyester resin, 26.7-30 percent of acrylic resin, 0.1-0.5 percent of a curing accelerator, 3-5 percent of a functional additive, 3-30 percent of filler and 1.2-25 percent of a pigment. The powder coating disclosed by the invention is high in strength and toughness, resistant to friction and corrosion, high in dielectric coefficient, resistant to ultraviolet light and good in radiation resistance. The powder coating is high in utilization rate in construction and free of three wastes and satisfies the environmental protection requirements; in comparison with traditional paint spraying and film pressing processes, the powder coating disclosed by the invention is lower in cost and higher than the film pressing process in product shape adaptability, can be produced by adopting a large-scale industrial production way and is excellent in physical performances such as ageing resistance and weather resistance during coating.

Owner:山东朗法博粉末涂装科技有限公司

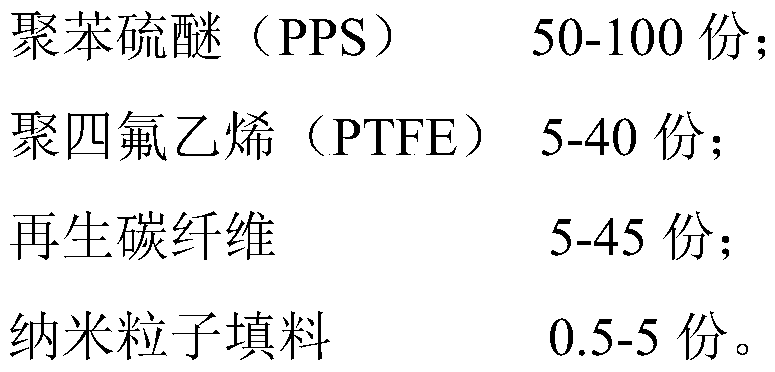

High-wear-resistance polyphenylene sulfide/regenerated carbon fiber composite material and preparation thereof

The invention relates to a high-wear-resistance polyphenylene sulfide / regenerated carbon fiber composite material and a preparation method thereof. The high-wear-resistance polyphenylene sulfide / regenerated carbon fiber composite material comprises the following components in parts by mass: 50-100 parts of polyphenylene sulfide (PPS); 5 to 40 parts of polytetrafluoroethylene (PTFE); 5-45 parts ofregenerated carbon fibers; and 0.5 to 5 parts of a nanoparticle filler. The preparation method comprises the following steps of: weighing 50-100 parts of the PPS, 5-40 parts of the PTFE and 0.5-2 parts of the nanoparticle filler according to proportions and placing the components in a high-speed mixer, and uniformly mixing the components; and adding the completely prepared raw materials into a main feeding port and an auxiliary feeding port of a double-screw extruder, and carrying out melt blending, extrusion, water drawing, bracing and dicing so as to obtain the polyphenylene sulfide / regenerated carbon fiber composite material. Compared with the prior art, the polyphenylene sulfide / regenerated carbon fiber composite material has the characteristics of high temperature resistance, frictionresistance and excellent mechanical properties. And meanwhile, the recycling of the carbon fibers also has the advantages of energy conservation, environmental protection and low cost.

Owner:SHANGHAI JIAO TONG UNIV +1

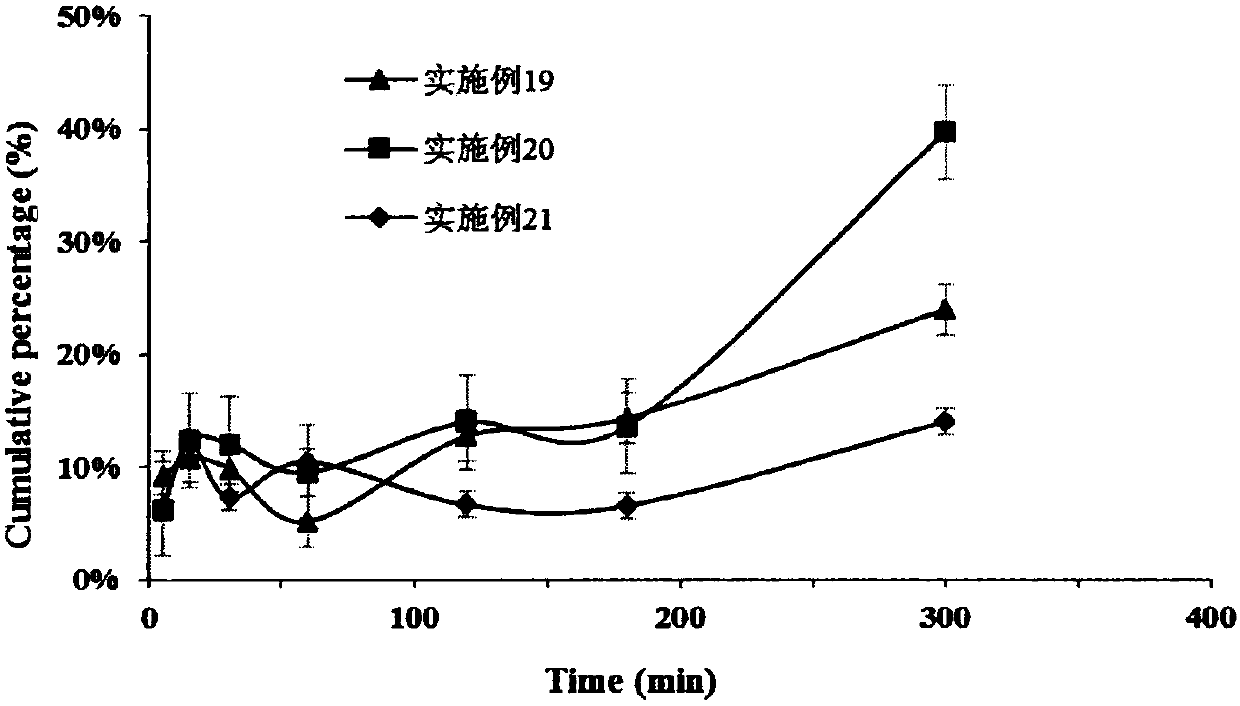

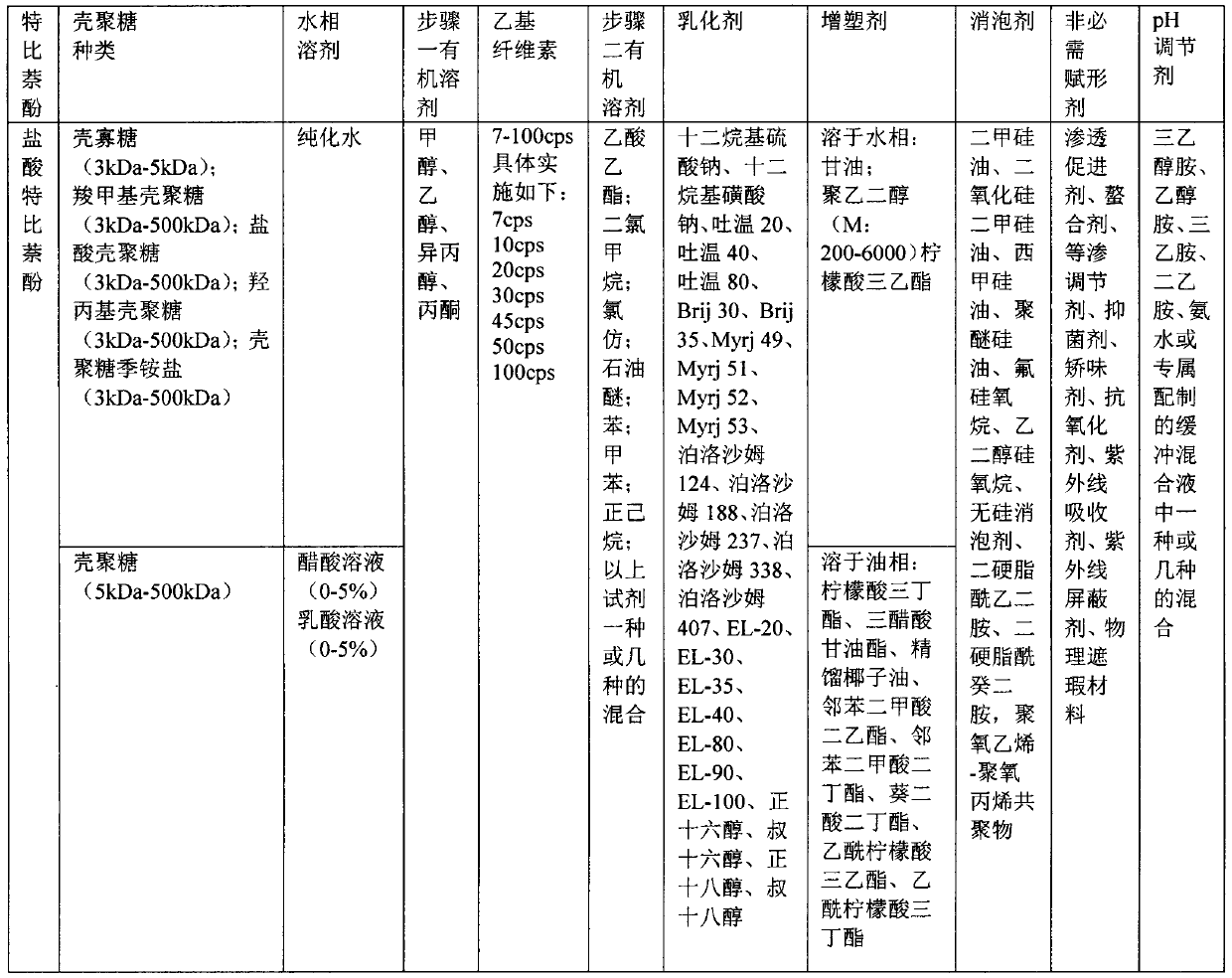

Transdermal delivery system of terbinafine hydrochloride long-acting spraying agent

ActiveCN107638423AWaterproofFriction-resistantOrganic active ingredientsAntimycoticsPharmaceutical drugMedicinal chemistry

The present invention belongs to the technical field of pharmaceutical preparations, discloses a transdermal delivery system for long-acting treatment of fungal skin infections, ie., a terbinafine hydrochloride long-acting spraying agent, and particularly provides a terbinafine hydrochloride water-soluble stable system preparation method, wherein the terbinafine hydrochloride long-acting sprayingagent can form a true film layer after the terbinafine hydrochloride long-acting spraying agent is sprayed onto the skin surface, such that the maintenance time of the preparation on the skin can be prolonged, the drug can be slowly released on the skin, and can act and be stored at lesions, and the long-acting treatment of fungal skin infections can be achieved.

Owner:CHINA PHARM UNIV

Building wall tile modified by superhydrophobic nanotechnology and preparation method thereof

The invention relates to the technical field of ceramic materials and particularly relates to a building wall tile modified by a superhydrophobic nanotechnology and a preparation method thereof. The wall tile comprises a green tile substrate and ceramic glaze coating the surface of the green tile substrate. The ceramic glaze is prepared from 70-80 parts by weight of glass frit, 7-15 parts by weight of metal copper microparticles, 2-8 parts by weight of Fe2O3 microparticles, and 5-10 parts by weight of kaolin. Through a spray-coating method, the prepared suspension liquid coats the surface of the green tile substrate. The building wall tile has strong super hydrophobic performances, antibacterial effects and friction resistance.

Owner:ZHEJIANG OCEAN UNIV

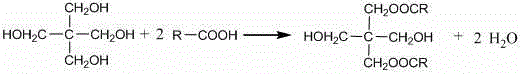

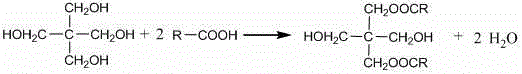

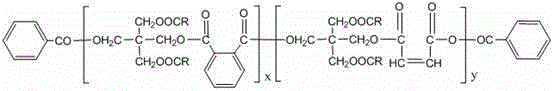

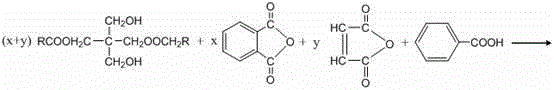

Alkyd acrylic graft copolymer and preparation method thereof

The invention relates to an alkyd acrylic graft copolymer and a preparation method thereof. According to the invention, high-molecular alkyd resin with main chain containing unsaturated double bond is synthesized through molecular design. The copolymer comprises the components of: soybean oil acid 55%-65%, pentaerythritol 17%-19%, maleic anhydride 1.07%-1.24%, phthalic anhydride 15.54%-17.92%, xylene 7.5%, and benzoic acid 1.55%-1.79%. Synthesized alkyd resin is subjected to free radical graft copolymerization with acrylic monomer, such that the alkyd acrylic graft copolymer is obtained. The copolymer monomer comprises the components of: acrylic acid 0.2%-0.9%, methyl methacrylate 2.7%-10.1%, styrene 2.6%-9.5%, butyl acrylate 4.0%-14.8%, alkyd resin 9.0%-35.0%, an initiator 0.15%-0.30%, and xylene 60.0%.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Adherable and peelable plastic printing ink and comprehensive antiforge mark made of said printing ink

An ink able to be adhered to and torn from plastic film is disclosed, which can be used to prepare antiforge marker by gravure printing on plastic film. It features that its antiforge pattern can be torn from plastic film, but not produce, so having high antiforge effect.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com