Transparent energy-saving hydrophobic film used for civil aircraft porthole glass and preparation method thereof

A technology for porthole glass and civil aircraft, which is applied in the field of energy-saving hydrophobic transparent film for civil aircraft porthole glass and its preparation, can solve problems such as improvement, lack of hydrophobicity on the outer surface of the glass, and achieves improved stability and life, excellent energy-saving effect, The effect of improving the energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

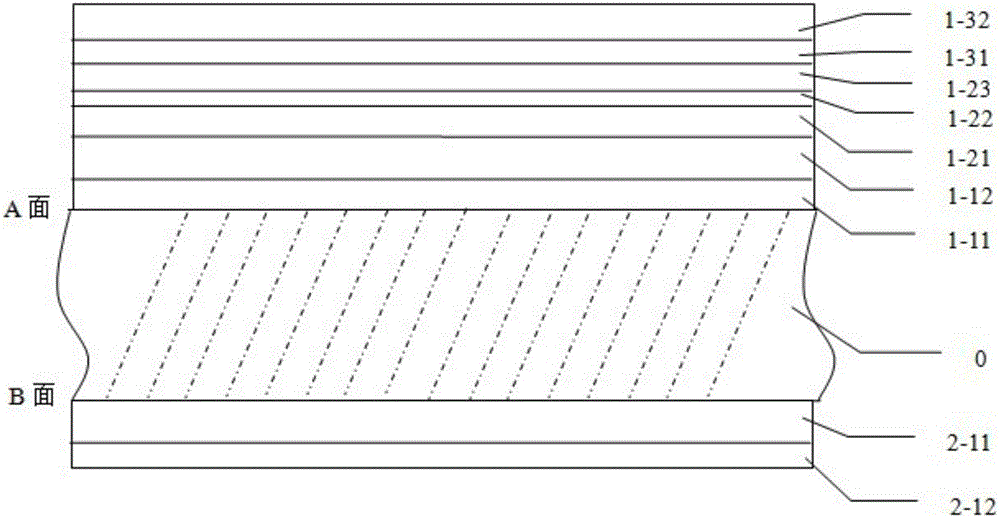

[0030] A kind of energy-saving and hydrophobic transparent film for civil aircraft porthole glass of the present invention, the plexiglass substrate O of the energy-saving and hydrophobic transparent film for civil aircraft porthole glass includes A surface and B surface, and the A surface and B surface Different transparent films are provided respectively, the A side is an energy-saving transparent conductive film system, and the B side is a hydrophobic transparent film system;

[0031] The energy-saving film system includes an isolation layer, an energy-saving functional layer and a protective layer from the organic glass substrate 0 to the outside; the hydrophobic film system consists of an adhesion layer and a hydrophobic functional layer from the organic glass substrate 0 from the inside to the outside.

[0032] The separation layer and the adhesion layer are used to prevent impurity ion elements such as sodium calcium from entering the functional layer to affect the effec...

Embodiment 2

[0050] The difference between embodiment 2 and embodiment 1 is: a kind of energy-saving and hydrophobic transparent film for civil aircraft porthole glass of the present invention, the isolation layer is the first silicon oxide layer 1-11 and titanium oxide layer 1 in sequence from the inside to the outside -12, the film thickness of the first silicon oxide layer 1-11 is 20 nm, and the film thickness of the titanium oxide layer 1-12 is 20 nm.

[0051] The energy-saving functional layer is sequentially composed of a first zirconia layer 1-21, a metal titanium layer 1-22 and an indium tin oxide layer 1-23 from the inside to the outside, and the film thickness of the first zirconia layer 1-21 is 20nm , the film thickness of the metal titanium layer 1-22 is 7nm, and the film thickness of the indium tin oxide layer 1-23 is 80nm.

[0052] The protective layer consists of a niobium oxide layer 1-31 and a second silicon oxide layer 1-32 from the inside to the outside, the film thickne...

Embodiment 3

[0061] The difference between Embodiment 3 and Embodiment 1 is that in the energy-saving and hydrophobic transparent film used for civil aircraft porthole glass of the present invention, the isolation layer is sequentially composed of the first silicon oxide layer 1-11 and the titanium oxide layer 1 from the inside to the outside. -12, the film thickness of the first silicon oxide layer 1-11 is 35 nm, and the film thickness of the titanium oxide layer 1-12 is 25 nm.

[0062] The film color can be adjusted by adjusting the thickness of the two through the process;

[0063] The energy-saving functional layer is sequentially composed of a first zirconia layer 1-21, a metal titanium layer 1-22 and an indium tin oxide layer 1-23 from the inside to the outside, and the film thickness of the first zirconia layer 1-21 is 26nm , the film thickness of the metal titanium layer 1-22 is 14nm, and the film thickness of the indium tin oxide layer 1-23 is 95nm.

[0064] The protective layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com