Outdoor MDF powder coating and application thereof

A powder coating, outdoor technology, used in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of single variety and difficult to meet requirements, and achieve the effects of high utilization rate, excellent anti-aging and strong adaptability

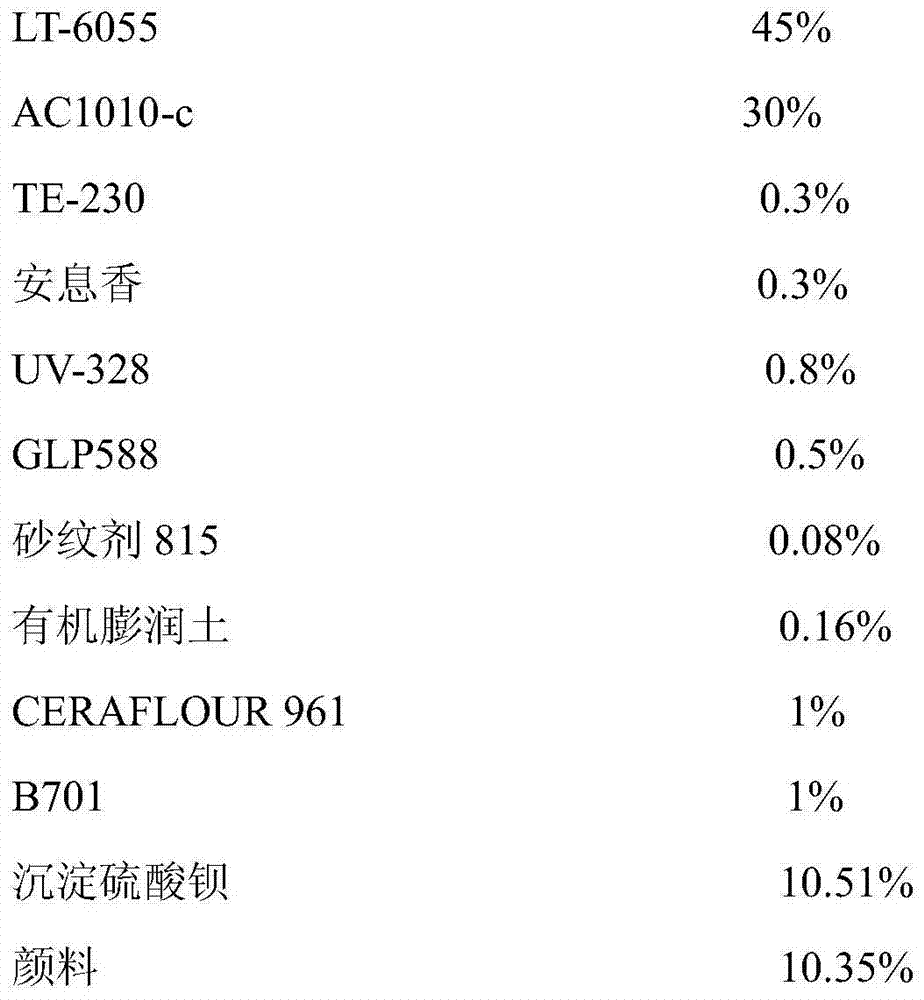

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

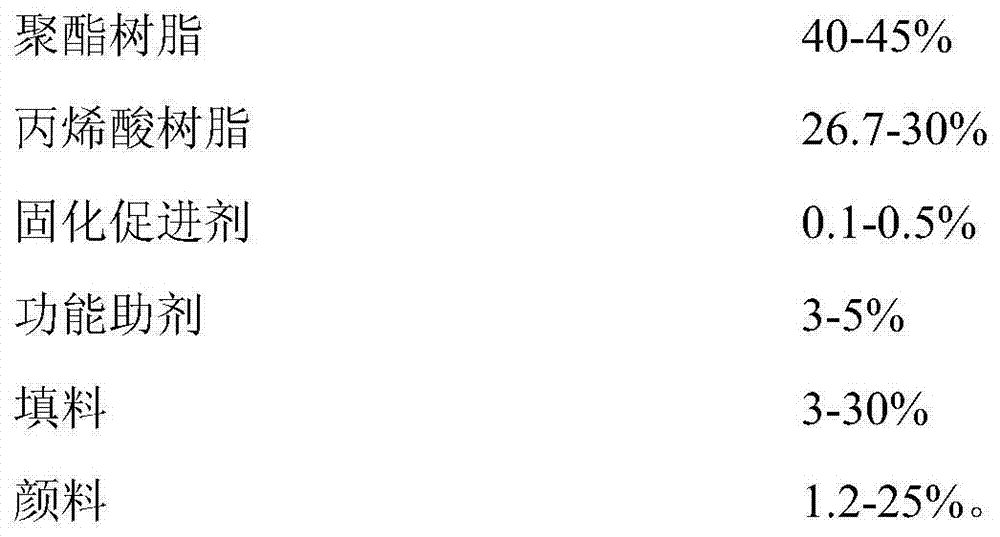

[0050] The outdoor MDF powder coating is made of the following mass percentage raw materials:

[0051]

[0052] The whole process steps are:

[0053] (1) Weigh, extrude, crush and grind according to the formula;

[0054] (2) Electrostatic powder spraying is performed on the MDF that has undergone surface pretreatment, and the thermosetting coating is obtained by curing. The curing method adopts medium-wave infrared pulse radiation heating, the curing temperature is set to 130°C, and the curing time is 10 minutes.

Embodiment 2

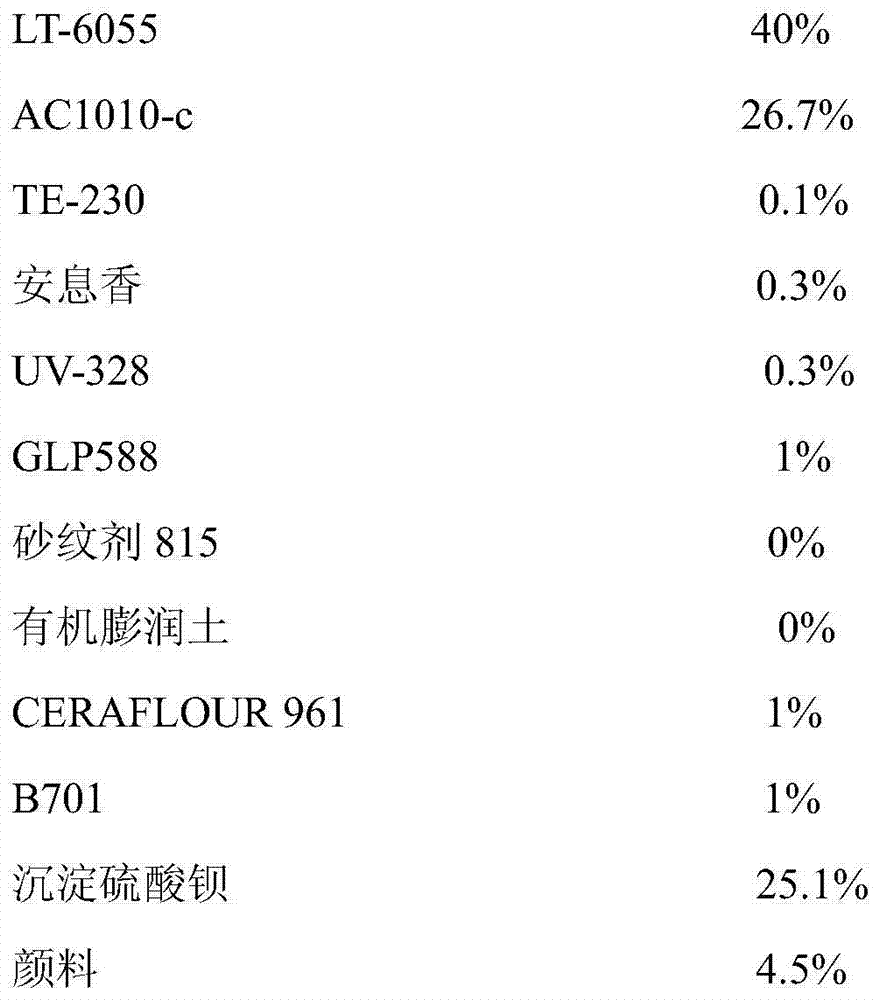

[0056] The difference from Example 1 is the outdoor MDF powder coating formula and the setting of thermosetting conditions. The rest is the same as Example 1. The outdoor MDF powder coating formula in Example 2 is made of the following mass percentages of raw materials:

[0057]

[0058] The later thermosetting conditions are: curing temperature is 140°C, curing time is 8min.

Embodiment 3

[0060] The difference from Example 1 is the outdoor MDF powder coating formula and the setting of the thermosetting conditions. The rest is the same as Example 1. The outdoor MDF powder coating formula in Example 3 is made of the following mass percentage of raw materials:

[0061]

[0062] The later thermosetting conditions are: curing temperature is 150℃, curing time is 5min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com