Patents

Literature

269results about How to "Good anti aging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

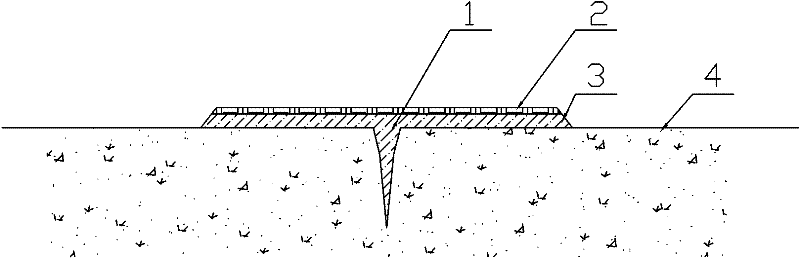

Asphalt pavement crack pouring process and pavement crack repair agent

InactiveCN102251464AThe method steps are simpleSimple stepsRoads maintainenceBuilding insulationsFiberRoad surface

The invention provides an asphalt pavement crack pouring process and a pavement crack repair agent. The process is mainly characterized by adopting a composite structure repair mode of bonding a composite fiber cloth on the upper surface of a repair agent layer. The used repair agent is prepared from the following raw materials in percentage by mass: 65-90% of substrate asphalt, 3-10% of modifying agent, 3-20% of solvent oil and 1-5% of plasticizing agent. The process is applicable to the crack repair of an asphalt pavement at (-16)-15 DEG C in autumn and winter, reduces the damage of snowmelt to the pavement in winter, prolongs the service life of the pavement, improves the pavement quality and lowers the maintenance cost.

Owner:淄博恒信路面材料有限公司

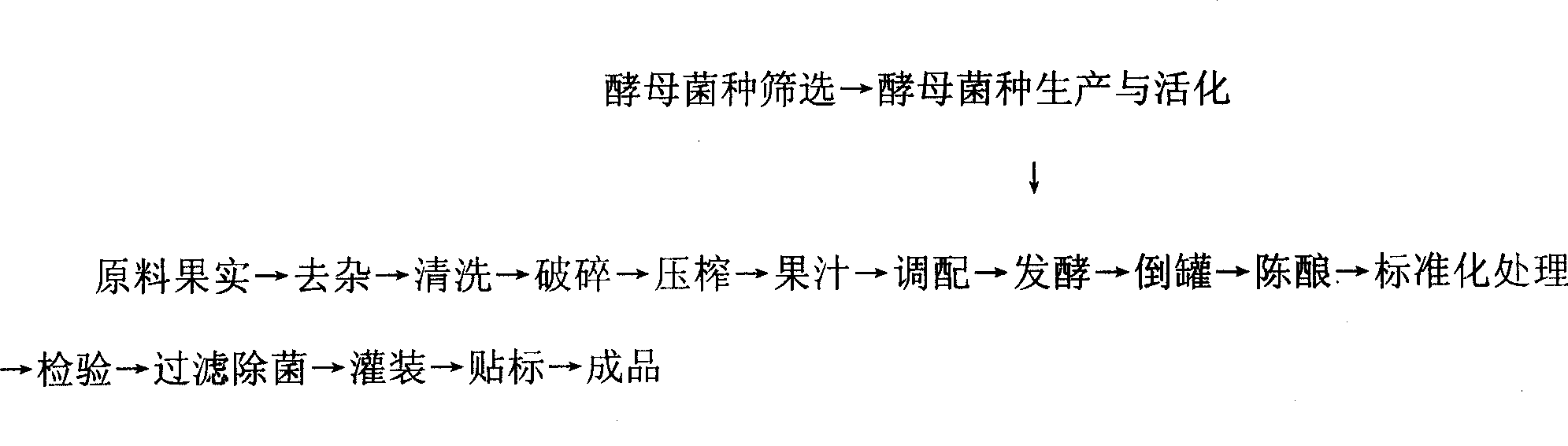

Aroniamelanocarpa fruit wine and brewing method thereof

InactiveCN101481643ARaw materials are uniqueFull of nutritionAlcoholic beverage preparationFruit juiceAntioxidant

The invention relates to an aroniamelanocarpa fruit wine and a brewing method thereof. The fruit of aroniamelanocarpa is taken as raw material and is made into fruit juice, fruit wine microzyme is selected for use and put into the fruit juice according to the proportion being 5-10% of the weight of the fruit juice, and the aroniamelanocarpa fruit wine is brewed with the alcohol content of 5-13% (v / v) and the total sugar content of 4.0-80.0g / L. The brewing technique of the invention comprises preparing the fruit juice, inoculation and fermentation, aging and store maturity, purifying wine body as well as filtration and sterilization, and the most advanced fermenting and purifying technique can be adopted by the production. The product of the invention has unique flavor, slightly acerbic and fresh taste, mellow mouthfeel, pleasing aroma and wide applicable people. The fruit wine contains multiple nutritional functional components such as anthocyanin, flavone, polyphenol active substance, vitamins antioxidant, mineral composition, polyoses, organic acid and the like which are rich in the fruit of aroniamelanocarpa, and has good effects of oxidation resistance, ageing prevention, blood pressure regulation, vessel relaxing, blood-fat reduction, anti-inflammation and detoxification, radiation resistance, etc.

Owner:辽宁省干旱地区造林研究所

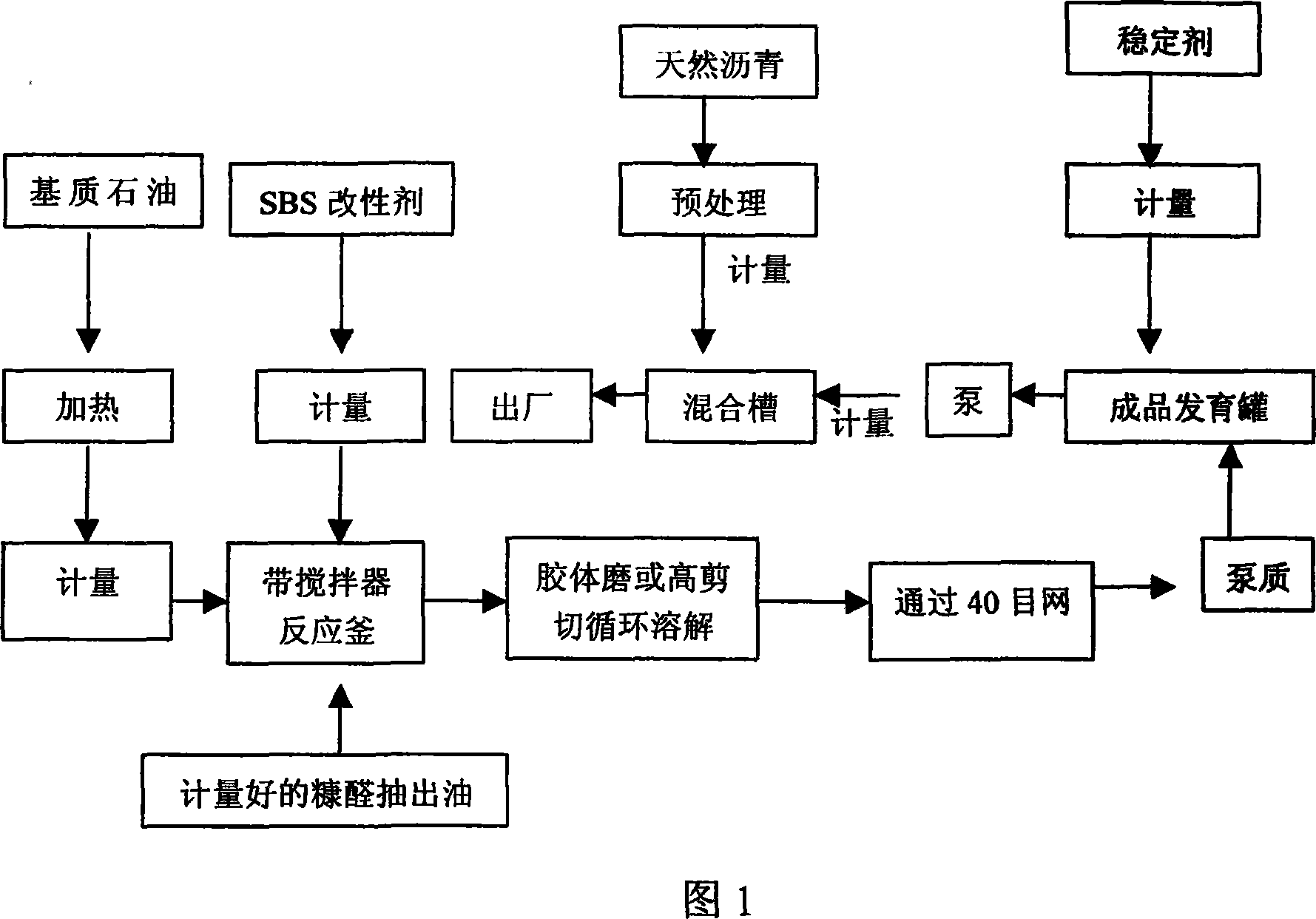

Method for producing compound modified bitumen

ActiveCN101130635AImprove anti-agingImprove antioxidant capacityBuilding insulationsPetroleumMaterials science

The invention discloses a preparing method of composite modified pitch, which comprises the following steps: adding base material mineral oil pitch into stirred autoclave; building up closed-circuit system with colloidal mill and stirrer; adding SBS modifier and furfural extract oil into stirred autoclave; getting miscible liquids I; adding into end product growth pot; adding into stabilizator; getting miscible liquids II; sending into heated mixed tank with jacket; adding into natural pitch; stirring; getting the product. This product combines the advantages of SBS modified pitch and natural pitch, which possesses good stability and durability.

Owner:JIANGSU BAOLI INT INVESTMENT CO LTD

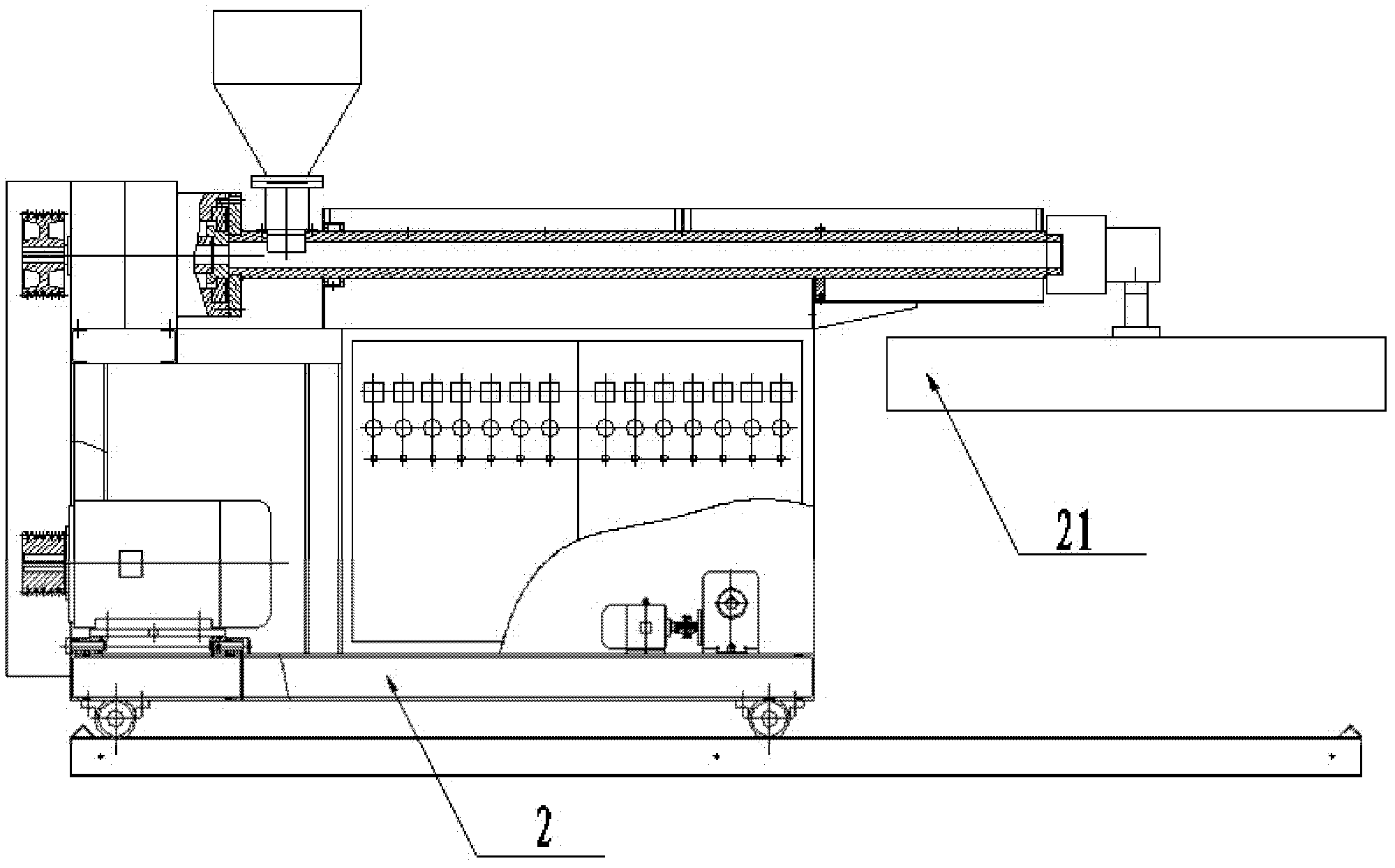

Catalyst for catalytic combustion of VOCs and preparation method thereof

PendingCN110614101AHigh activityGood mass and heat transferHeterogenous catalyst chemical elementsDispersed particle separationAlkaline earth metalRare earth

The invention discloses a catalyst for catalytic combustion of VOCs and a preparation method of the catalyst. Cordierite honeycomb ceramic or a porous metal material is used as a carrier, the carrieris coated with a nano coating material, precious metal compound transition metal is used as an active component, compound rare earth oxide is used as a catalyst aid, and a solid solution prepared froman alkaline earth metal compound and main group metal oxide is used as a carrier modifier; the carrier and the active component are coated through an automatic production line; the catalyst has advantages of high substrate bonding force, high adhesive force between the active component and the carrier after high-temperature roasting, difficult shedding, high activity, good thermal stability, goodsulfur resistance and long service lifetime, is a broad-spectrum VOC oxidation catalyst, can be used for catalytic combustion treatment of VOCs in the industries of spraying, printing, electronics and the like, and is suitable for CO and RCO catalytic combustion devices.

Owner:ZHENJIANG EAST CHINA ELECTRIC POWER EQUIP FACTORY CO LTD

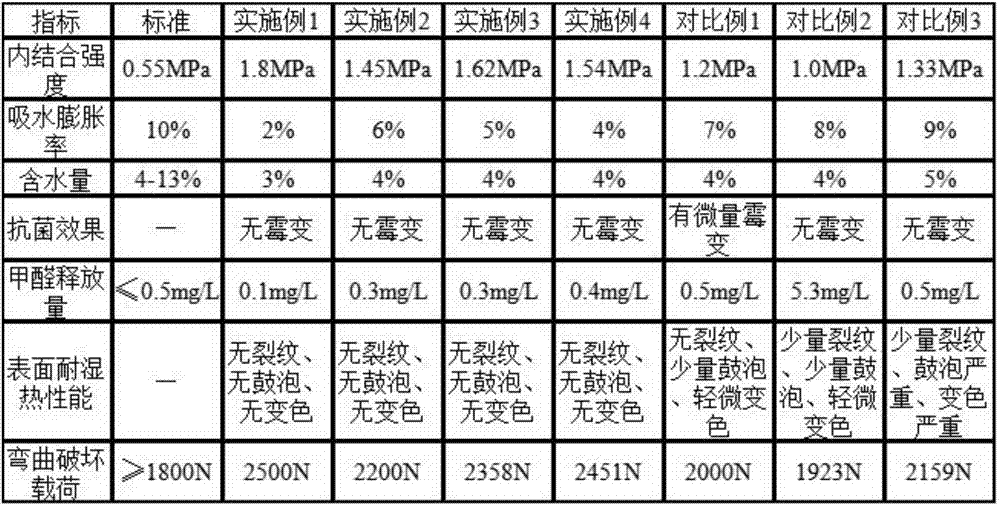

Method for making artificial board with wood leftover materials and straw

ActiveCN107030840AEnvironmentally friendlyHigh modulusFlat articlesDomestic articlesAnti bacterialCorrosion

The invention discloses a method for making an artificial board with wood leftover materials and straw. According to the method, the wood leftover materials and the straw are used as raw materials to make the artificial board. Compared with a common artificial board, the artificial board is more environment-friendly, the ageing resistance, anti-bacterial property, corrosion resistance, flame retardant property and water resistance are more excellent, and the service life is longer. Moreover, the wood leftover materials and crop straw can achieve waste recovery, so that production cost of the artificial board is reduced, and social benefits and economic benefits are remarkable.

Owner:湖北中能木业有限公司

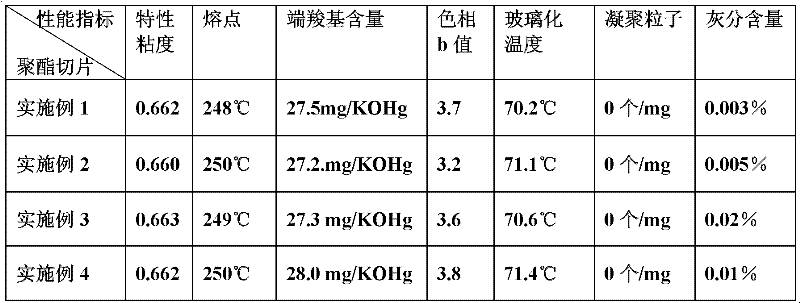

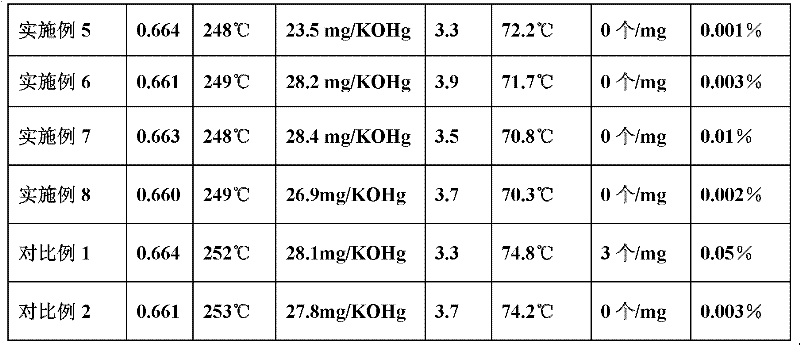

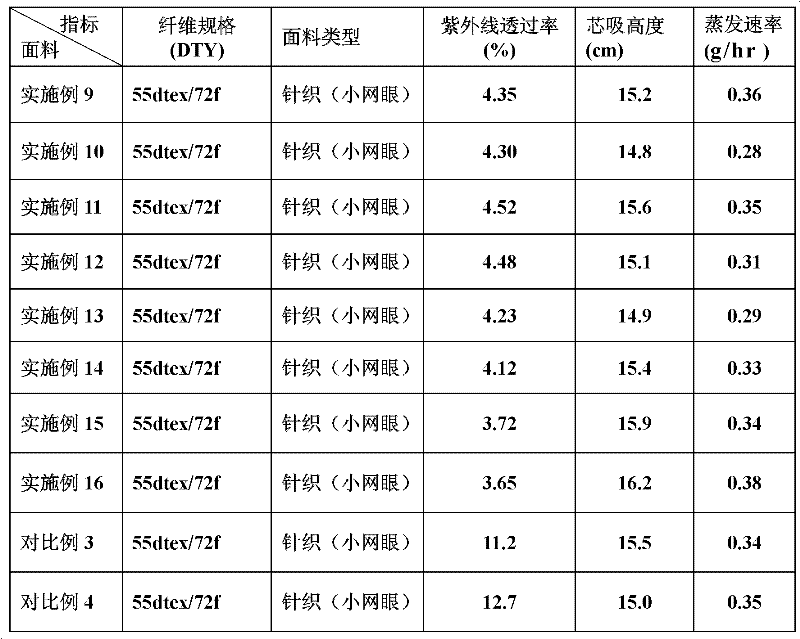

Preparation method for polyester fiber with compound ultraviolet ray resisting, aging resisting, moisture absorbing and quick drying functions

ActiveCN102443876AImproves UV resistanceReduce permeationMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a preparation method for a polyester fiber with compound ultraviolet ray resisting, aging resisting, moisture absorbing and quick drying functions. The method comprises an esterification reaction process, a polymerization reaction process and a spinning process in sequence, and comprises the following specific steps of: in an esterification reaction, introducing a third monomer with relatively large steric hindrance; after the esterification reaction and before a pre-polymerization reaction, adding titanium dioxide serving as a high-content delustering agent, a hindered amine light stabilizer and a hindered phenol antioxidant; after the pre-polymerization of polymerization reaction process and before final polymerization, adding an ultraviolet absorber; and beforethe spinning process, pre-crystallizing and drying polyester slices obtained in the polymerization reaction process, and designing a special-shaped section for the fiber. The polyester fiber obtainedby using the method has superior ultraviolet ray resisting, aging resisting, moisture absorbing and quick drying functions. As provided by testing, relevant technical indexes are that: the ultraviolet transmission is less than or equal to 5.0 percent, the wicking height is more than or equal to 120 millimeters, and the evaporation rate is more than or equal to 0.20g / hr after the polyester fiber is woven into a knitted fabric and a woven fabric.

Owner:JIANGSU GUOWANG HIGH TECH FIBER CO LTD

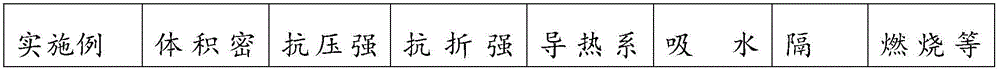

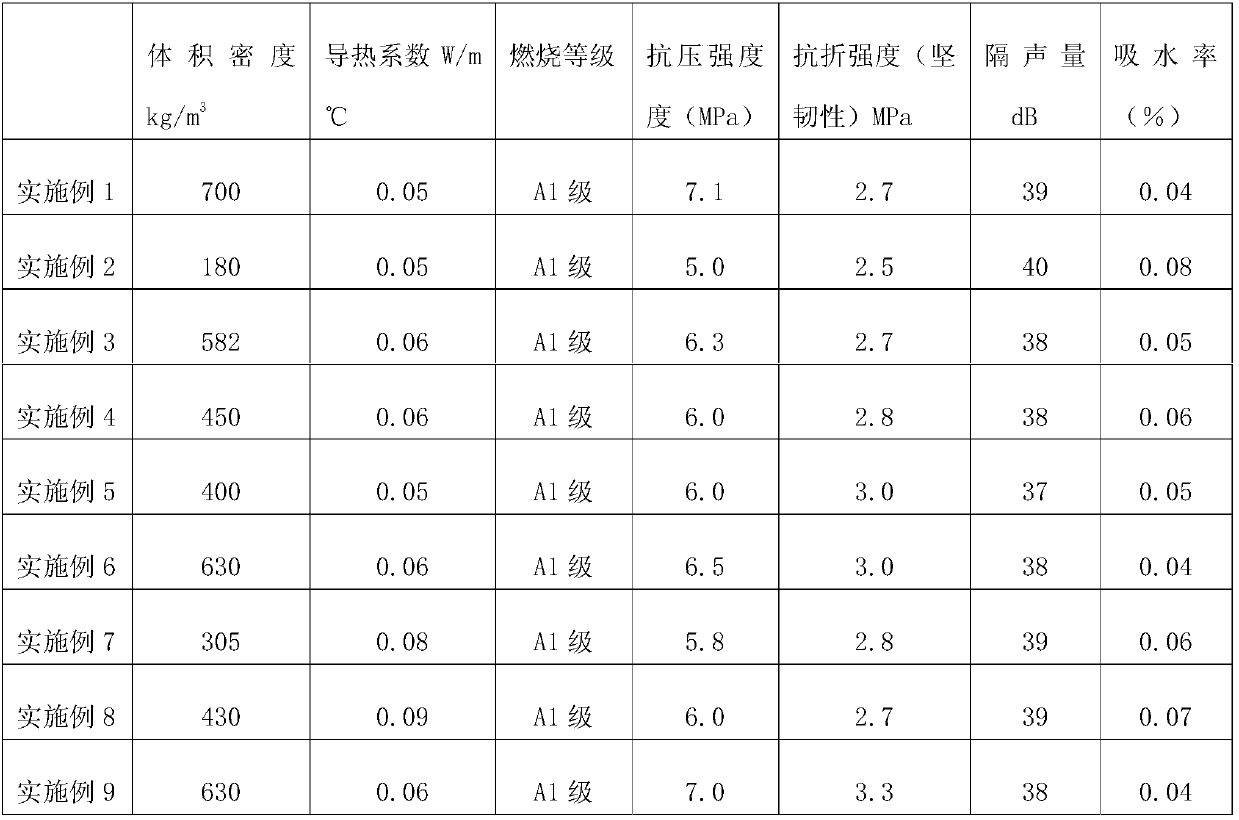

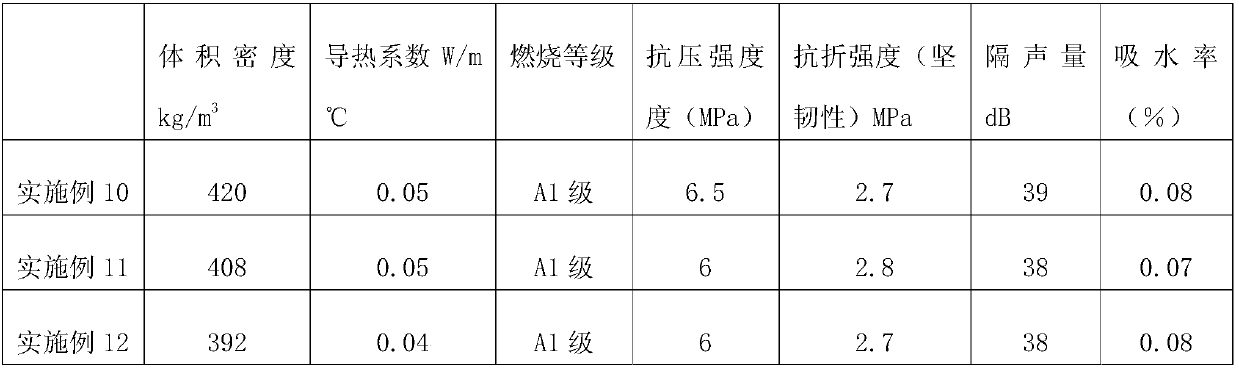

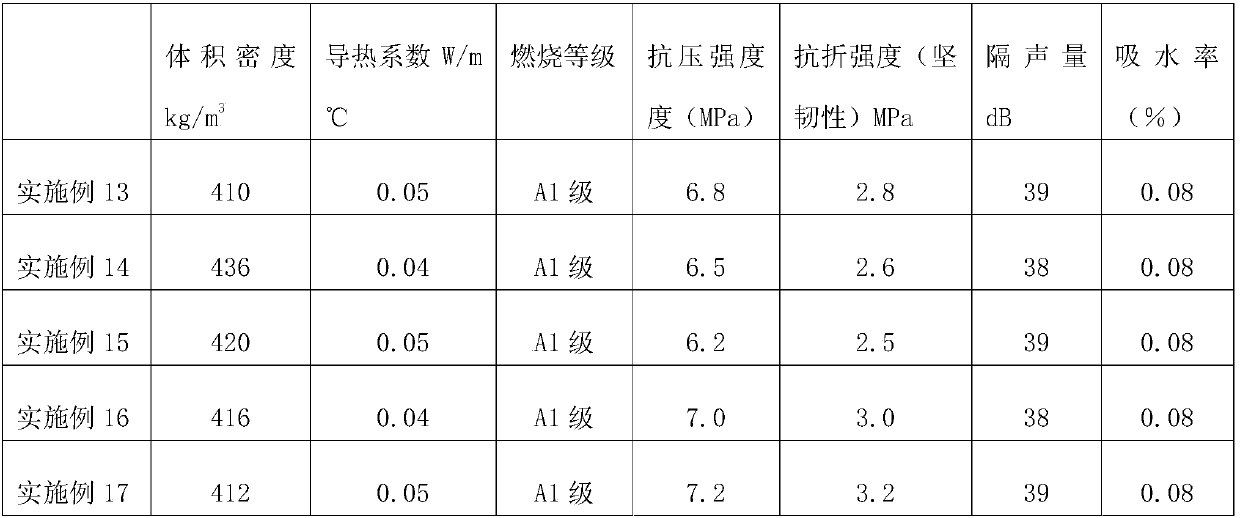

Light foaming wall material based on granite and preparation method thereof

The invention discloses a light foaming wall material based on granite and a preparation method thereof. The light foaming wall material is prepared from, by weight, 75-90% of granite, 5-20% of clay, 0-10% of fluxing agent, 0.05-5% of foaming agent, 0.05-5% of stabilizer and 0.05-5% of dispergator. The preparation method includes the steps of raw material mixing and ball-milling, spraying, drying and granulation, distribution, melting and foaming, cooling and cutting and the like. The light foaming wall material based on granite remarkably integrates ageing resistance, corrosion resistance, heat insulation, heat preservation, sound isolation, waterproof and fireproof performance, low weight, high strength and environmental friendliness. The light foaming wall material based on granite can directly serve as a building wall material for integrated construction and installation, various kinds of decoration fish treatment can be directly conducted on the granite light foaming wall material, manpower and manufacturing cost are saved, and the material is safe, environmentally friendly and attractive.

Owner:深圳超超科技控股有限公司

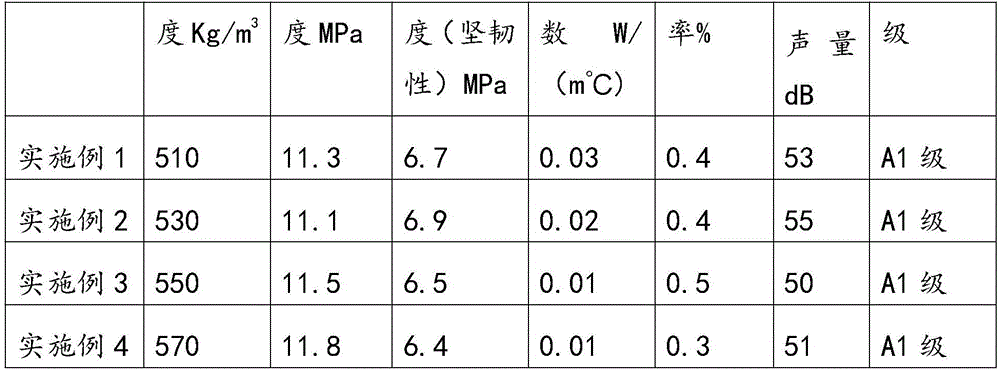

Method for preparing no-yellowing polyurethane sponge capable of being foamed at normal temperature

The invention discloses a method for preparing no-yellowing polyurethane sponge capable of being foamed at normal temperature. 4,4'-dicyclohexylmethane diisocyanate or a prepolymer thereof and polyether polyol serve as main raw materials; an environment-friendly catalyst and other auxiliary materials are added, the reaction and foaming are performed through a conventional polyurethane sponge production line at normal temperature, and the no-yellowing polyurethane sponge is obtained through a curing stage. The no-yellowing sponge can be obtained through the conventional polyurethane sponge production line at normal temperature, the raw materials do not need to be heated, existing equipment does not need to be modified, and the method has the advantages of small equipment investment and low energy consumption. In addition, since 4,4'-dicyclohexylmethane diisocyanate does not contain a benzene ring structure, obtained polyurethane sponge does not yellow, is excellent in aging resistance, oxidization resistance and illumination resistance and can be widely applied to the fields of shoe materials, furniture, electronics, printing supplies, aviation, automobiles, medical beauty, packaging, sports goods and articles for daily use.

Owner:CHANGZHOU SHUNXIANG NEW MATERIAL TECH CO LTD

Preparation method of fabric having anti-aging function

The invention relates to a preparation method of a fabric having an anti-aging function. The preparation method comprises the following steps: (A) soaking; and (B) spin-drying and curing. A treatment agent used in the steps (A) and (B) comprises the following raw materials in parts by weight: 32g to 48g of squalane, 23g to 37g of tocopheryl acetate, 18g to 34g of large-leaved gentian extract, 8g to 25g of centella extract liquid, 5g to 17g of epimedium extract liquid, 10g to 22g of arbutin, 13g to 18g of glossy privet fruit extract liquid, 9g to 26g of calendula extract liquid, 7g to 16g of wild chrysanthemum flower extract liquid, and 3g to 14g of gynostemma pentaphylla extract liquid, and the treatment agent also comprises 1g to 3g of antistatic agent, 3g to 8g of softening agent, 5g to 9g of adhesive and 4g to 10g of curing agent. The preparation method is simple in process and low in raw material cost; the fabric is treated in the anti-aging treatment agent and is then used for preparing various textiles, when people contact the fabric for a long time, the senescence can be effectively slowed down, and a purpose of resisting the aging can be achieved.

Owner:JIANGSU TEVEL

Foaming ceramic heat-insulating wallboard based on graphene and preparation method thereof

InactiveCN107602106AImprove fire insulation and weather resistanceImprove fire performanceCeramicwarePore distributionEnvironmental resistance

The invention provides a graphene-based foamed ceramic insulation wallboard, which is made of the following components: potassium sodium feldspar, ceramic waste residue, graphene, vermiculite, high-temperature co-solvent, expanded graphite, zirconia, clay, stable agent and debonding agent. Using potassium sodium feldspar and ceramic waste slag as the base material, adding graphene and vermiculite to make the board more lightweight, high-strength, thermal insulation, and improve the performance of the board such as fire resistance, insulation and weather resistance, using expanded graphite as a foaming agent, using high temperature The foaming process can better control the density, pore distribution and pore size of the board, achieve better heat preservation and light weight effects, and make a board with remarkable anti-aging, corrosion resistance, heat insulation, sound insulation, waterproof and impervious, fireproof and fireproof. , lightweight, high-strength, non-cracking, green and environmental protection and other comprehensive performance in one foam lightweight wallboard.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

Flame-retardant water-based polyurethane paint

InactiveCN105505180AHigh glossHigh hardnessFireproof paintsPolyurea/polyurethane coatingsWater basedHeat resistance

The invention discloses flame-retardant water-based polyurethane paint which is prepared from 85-88 parts of modified polyurethane resin, 12-15 parts of resol resin, 7-10 parts of waterborne acrylic resin, 3-6 parts of bentonite, 15-18 parts of zeolite powder, 13-16 parts of diatomite, 12-15 parts of talcum powder, 2-4 parts of a thickening agent, 3-5 parts of a flatting agent, 1-2 parts of a defoaming agent, 1-2 parts of an anti-corrosion agent and 2-3 parts of pigment. The flame-retardant water-based polyurethane paint has excellent heat resistance, fireproof performance and flame retardancy, excellent in water resistance, high in adhesive force, high in hardness and high in drying speed.

Owner:ANHUI ANDA HUATAI NEW MATERIALS CO LTD

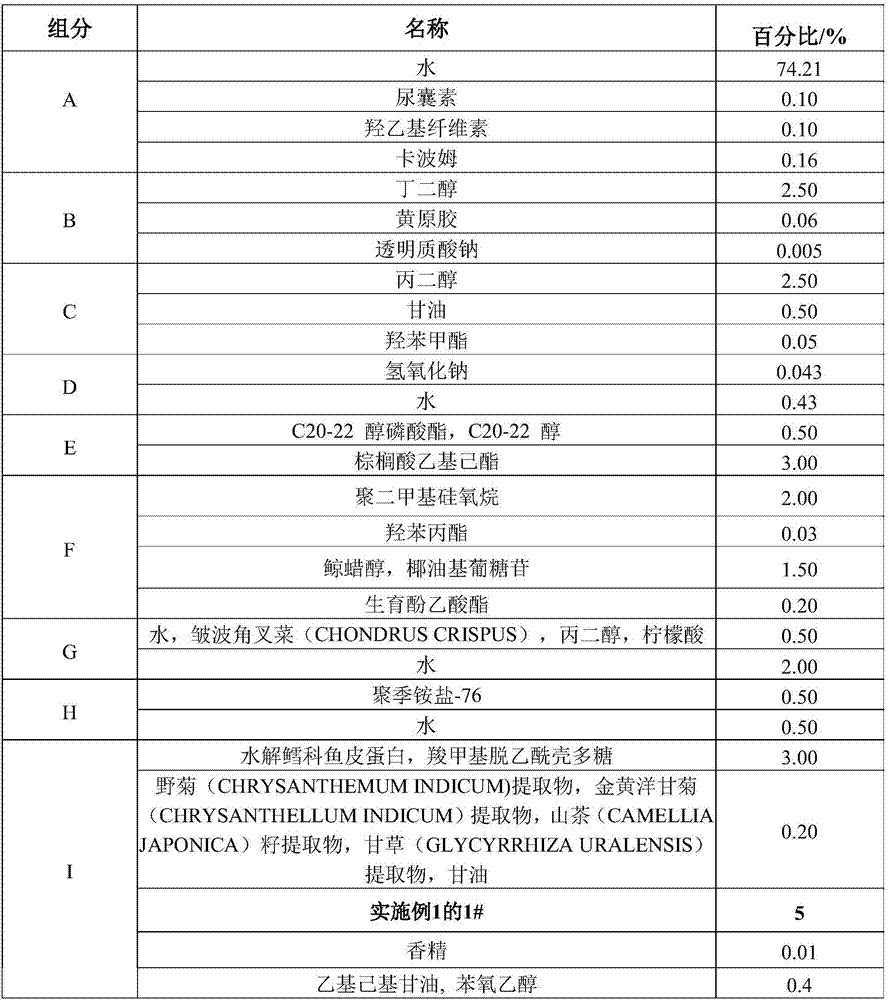

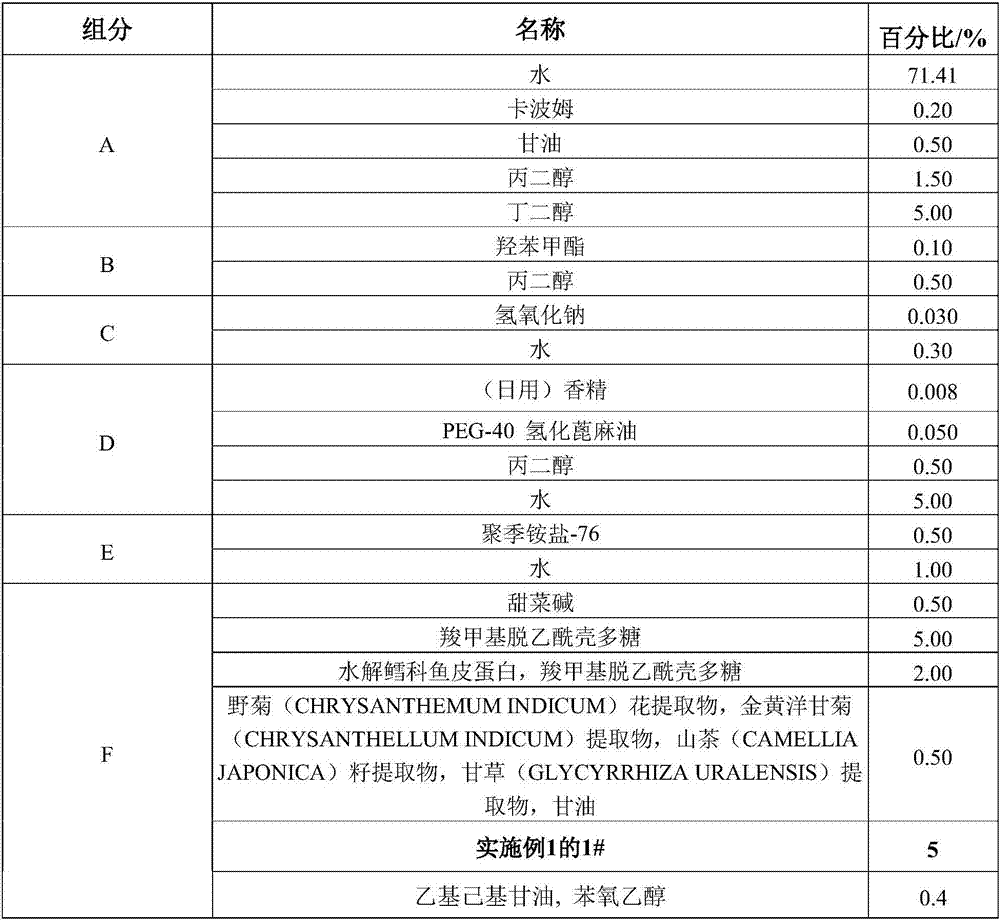

Composite black plant fermentation composition with whitening effect as well as preparation method and application in facial mask product

ActiveCN107184464AIncrease contentEfficacy material balanceCosmetic preparationsToilet preparationsActive componentPolyphenol

The invention provides a composite black plant fermentation composition which is prepared from blackcurrant and blackberry as raw materials via enzymolysis and fermentation. The composite black plant fermentation composition is rich in active components such as polyphenols, polysaccharides and flavonoid substances, has very good effects of preventing oxidation, preventing aging and whitening skin, and is applicable to cosmetics, in particular to facial mask products.

Owner:SHANGHAI YUEMU COSMETICS

Wear-resisting corrosion-resistant antibacterial aqueous coating

InactiveCN104403504AGood chemical resistanceImproves Strength and ToughnessShellac coatingsAntifouling/underwater paintsSodium carboxymethylcelluloseChemistry

The invention discloses a wear-resisting corrosion-resistant antibacterial aqueous coating which comprises the following raw materials in parts by weight: 50-55 parts of epoxy resin emulsion, 25-30 parts of acrylic emulsion, 20-28 parts of polystyrene emulsion, 10-15 parts of shell-lac tablet, 40-45 parts of natural latex, 3-6 parts of hydroxyethyl cellulose, 2-5 parts of carboxymethyl cellulose, 1-3 parts of fumed silica, 15-20 parts of styrene-butadiene thermoplastic elastomer, 10-15 parts of polyamide emulsion, 15-20 parts of sodium dodecylbenzene sulfonate, 10-15 parts of lauryl silver sulfate, 5-10 parts of nano-silver, 5-10 parts of titanium nitride, 5-10 parts of aluminum nitride, 10-15 parts of sepiolite powder, 10-15 parts of blast furnace slag powder, 2-4 parts of cerium oxide, 10-14 parts of a defoaming agent, 25-28 parts of a leveling agent, 2-4 parts of an aluminum-zirconium coupling agent TL-3, 3-4 parts of a filming cosolvent. 5-10 parts of a curing agent and 90-105 parts of water.

Owner:ANHUI JINDUN PAINT

Strong-acid-resistant high-strength anticorrosive paint and preparation method thereof

InactiveCN104629588APlay the role of anti-corrosion protectionStrong scrub resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsDiacetone alcoholEpoxy

The invention discloses a strong-acid-resistant high-strength anticorrosive paint which comprises the following components in parts by mass: 25-28 parts of epoxy resin, 22-26 parts of polyurethane, 9-13 parts of silicon dioxide, 5-7 parts of titanium dioxide, 3-6 parts of zinc powder, 2-5 parts of barium sulfate, 4-6 parts of graphite, 7-9 parts of diacetone alcohol, 5-9 parts of polytetrafluoroethylene, 7-11 parts of polydimethylsiloxane, 4-8 parts of carboxymethyl cellulose, 1-3 parts of tributyl phenol polyethenoxy ether and 33-45 parts of deionized water. The invention also discloses a preparation method of the strong-acid-resistant high-strength anticorrosive paint. The product can resist corrosion of strong acid and strong alkali, performs the protective and anticorrosive functions on equipment in extreme weather, and has the advantages of excellent mechanical properties, high scrub resistance, high aging resistance, high powdering resistance, higher weather resistance, higher wear resistance, better high-temperature resistance, high safety and environment friendliness.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Marine high-performance rubber material

The invention discloses a marine high-performance rubber material which is prepared from the following raw materials in parts by weight: 50-65 parts of chlorinated polyethylene 135B, 25-30 parts of styrene-butadiene rubber, 20-30 parts of ethylene propylene diene monomer, 0.5-1.2 parts of metal oxide vulcanization system, 1.2-1.8 parts of bismaleimide, 1-3 parts of vulcanizing agent BIBP, 2-5 parts of magnesium oxide, 1-3 parts of calcium stearate, 1-3 parts of barium stearate, 30-40 parts of white carbon black, 15-20 parts of nano calcium carbonate, 13-24 parts of talcum powder, 35-45 parts of calcined argil, 1-3 parts of phenyl alkyl sulfonate, 1-3 parts of dioctyl phthalate, 0.8-1.3 parts of anti-aging agent RD, 1-1.65 parts of anti-aging agent 4040NA, 1-1.3 parts of tetramethyl-thiuram disulfide and 1.5-2 parts of N-cyclohexyl-2-benzothiazolyl sulfenamide.

Owner:天长市远洋船舶设备股份有限公司

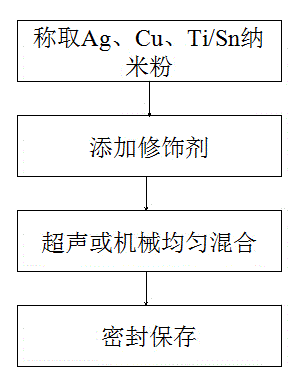

Ag-Cu-Ti/Sn nano-particle soldering paste and preparation method thereof

InactiveCN104588905AGood dispersionMass percentage controllableWelding/cutting media/materialsSoldering mediaSolid componentOrganic solvent

The invention discloses Ag-Cu-Ti / Sn nano-particle soldering paste and a preparation method thereof. The soldering paste is prepared from, by mass, 80-90% of nano-particle solid components and 10-20% of modifying agent, wherein the modifying agent comprises, by mass, 2-8 parts of dispersing agent, 2-8 parts of binding agent, 2-10 parts of diluent and 2-10 parts of soldering flux; the nano-particle solid components are formed by mixing Ag, Cu and Ti or Sn, the Cu accounts for 20-50% of the total mass of the nano-particle solid components, and the Ti or Sn accounts for 0-20% of the nano-particle solid components. The method comprises the following preparation steps: 1, weighing the nano-particle solid components; 2, adding the modifying agent sequentially; 3, evenly and uniformly mixing the system in an organic solvent, then evaporating the excessive solvent out, and forming the Ag-Cu-Ti / Sn nano-particle soldering paste; 4, placing the Ag-Cu-Ti / Sn nano-particle soldering paste obtained through preparation into a needle tube to be sealed and stored. The Ag-Cu-Ti / Sn nano-particle soldering paste has the advantages that the ratios of any components are controllable, the process is simple, and the cost is low.

Owner:HARBIN INST OF TECH

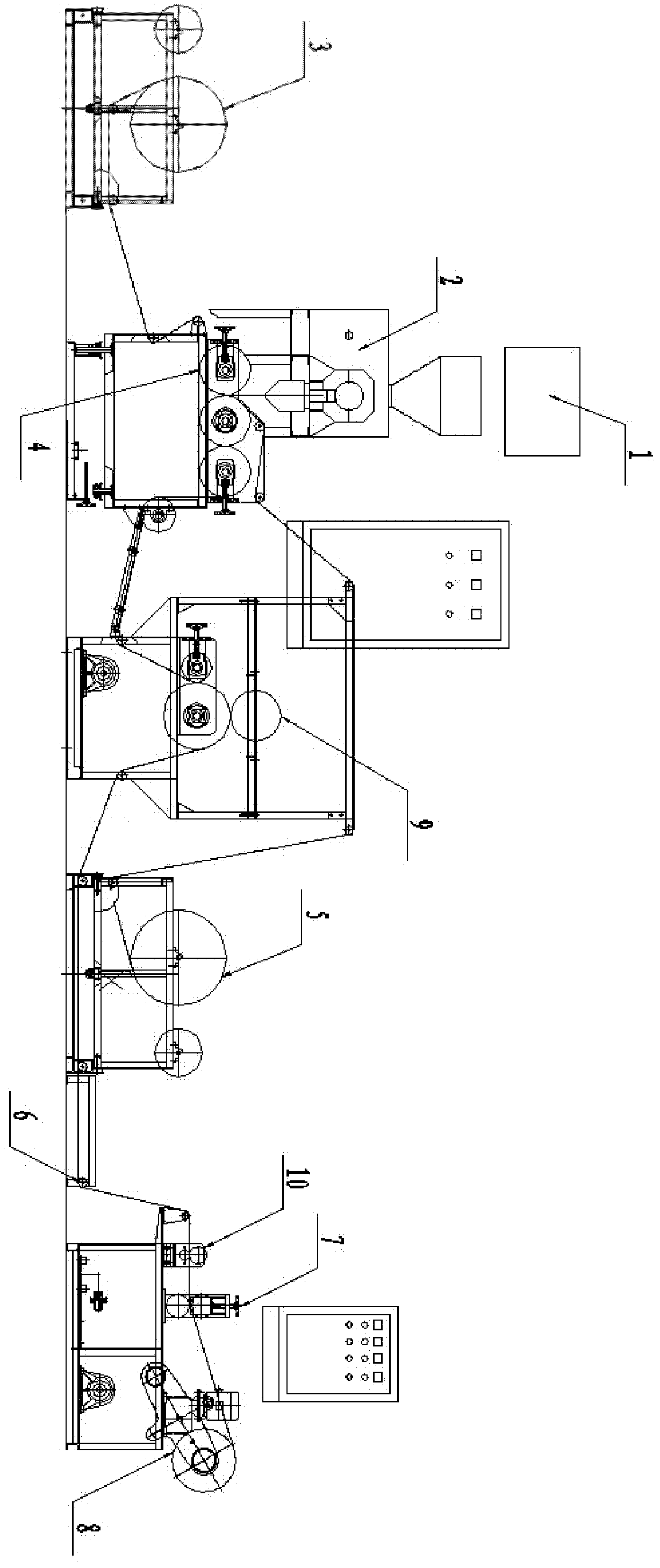

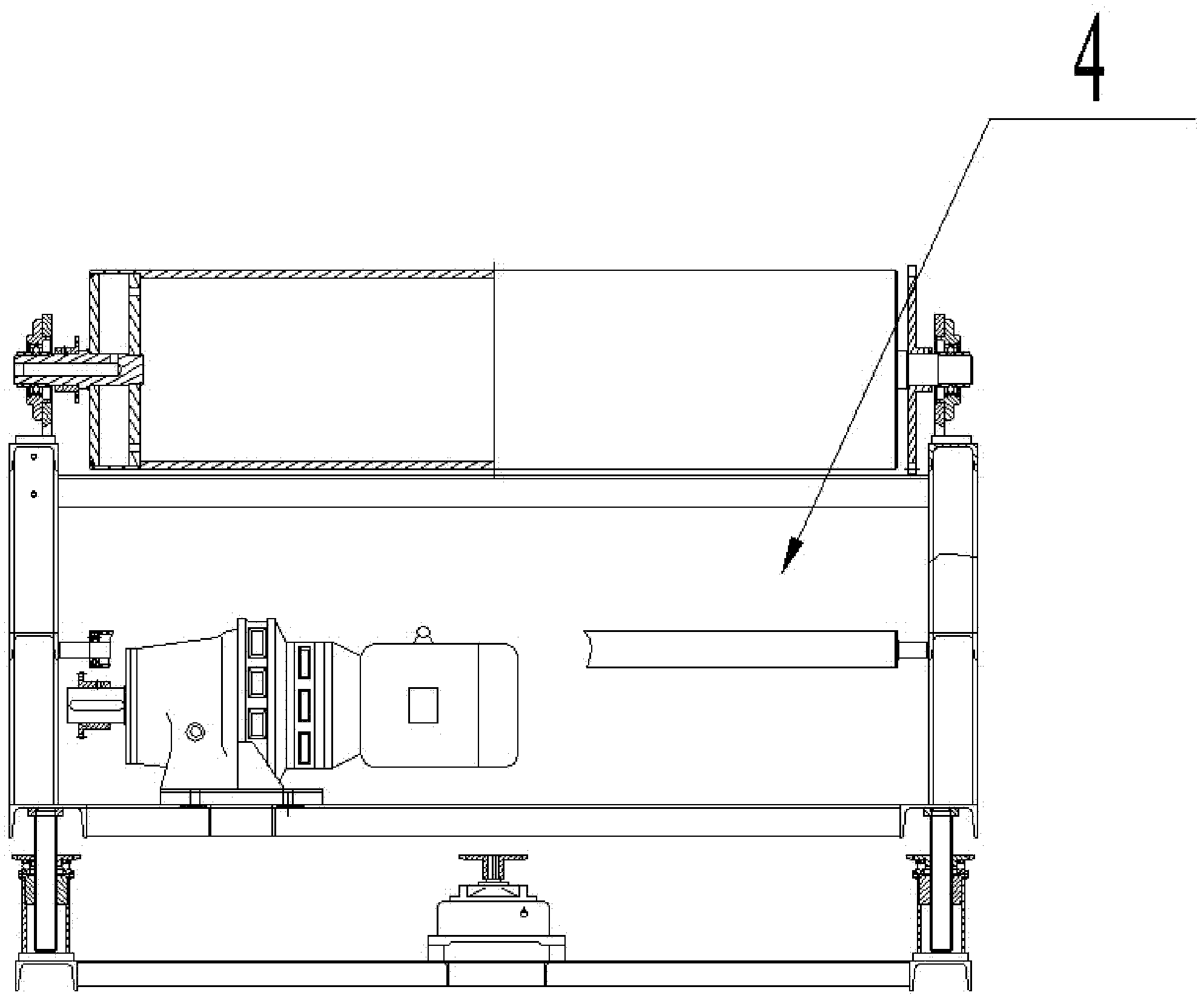

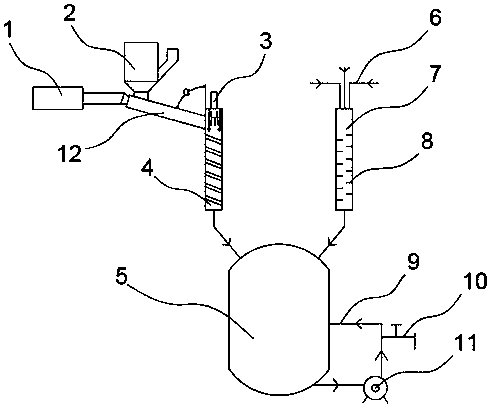

Production method and device of waterproof rolled material

InactiveCN102423952AImprove structural performanceSimple structureSynthetic resin layered productsLaminationAging resistanceNonwoven fabric

The invention relates to a production method of a waterproof rolled material for construction engineering and a device for producing the material. The production method comprises the following steps: mixing polyethylene with calcium carbonate and plastic antifoaming agent, extruding a film through plasticizing and fusion, then laminating the film with two layers of non-woven fabrics, compacting and bonding by a laminating device and cooling to obtain a composite material, drawing the composite material through a guide roller and a draw gear, conveying the drawn composite material to a double station center reeling machine for reeling to obtain the rolled material. The produced waterproof rolled material has the advantages of good structural behavior, and excellent peel strength, tensile strength, fracture resistance, percentage elongation, aging resistance and other comprehensive properties. The device for producing the material comprises a raw material proportioning and blending unit, a first unreeling unit, the laminating device, the draw gear and the double station center reeling machine, and also comprises an extrusion unit arranged at one side of the laminating device and a second unreeling unit for sending the rolled material to the laminating device, and a printing device and a clipping device which are successively arranged at the back of the laminating device and at the front of the draw gear. The device has the advantages of simple structure and convenient operation.

Owner:CHANGZHOU RIYUE MACHINERY

Health-care moringa seed product

InactiveCN105054007APromote detoxificationBody EnhancementFood ingredient functionsFood preparationMoringaDisease

The invention relates to a health-care product, in particular to a health-care moringa seed product. The health-care moringa seed product is characterized by consisting of the following ingredients in parts by weight: 20-60 parts of moringa seeds, 5-25 parts of black Chinese wolfberries, and 2-20 parts of dendrobium. The composition is complementary, and has the synergy effects of preventing diseases, improving immunity, delaying the senescence of human bodies, and resisting tumors.

Owner:苏州阿拉丁生物科技有限公司

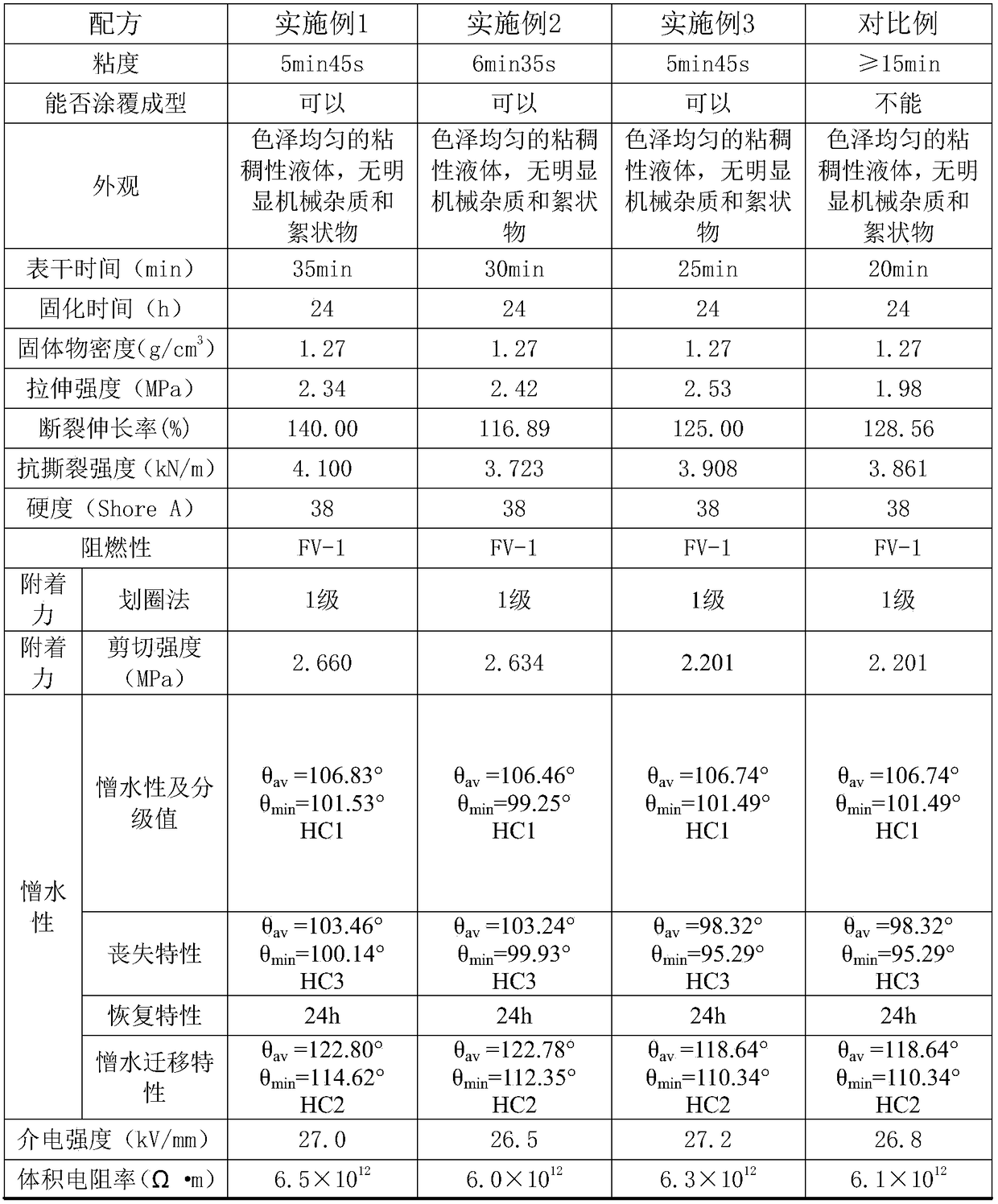

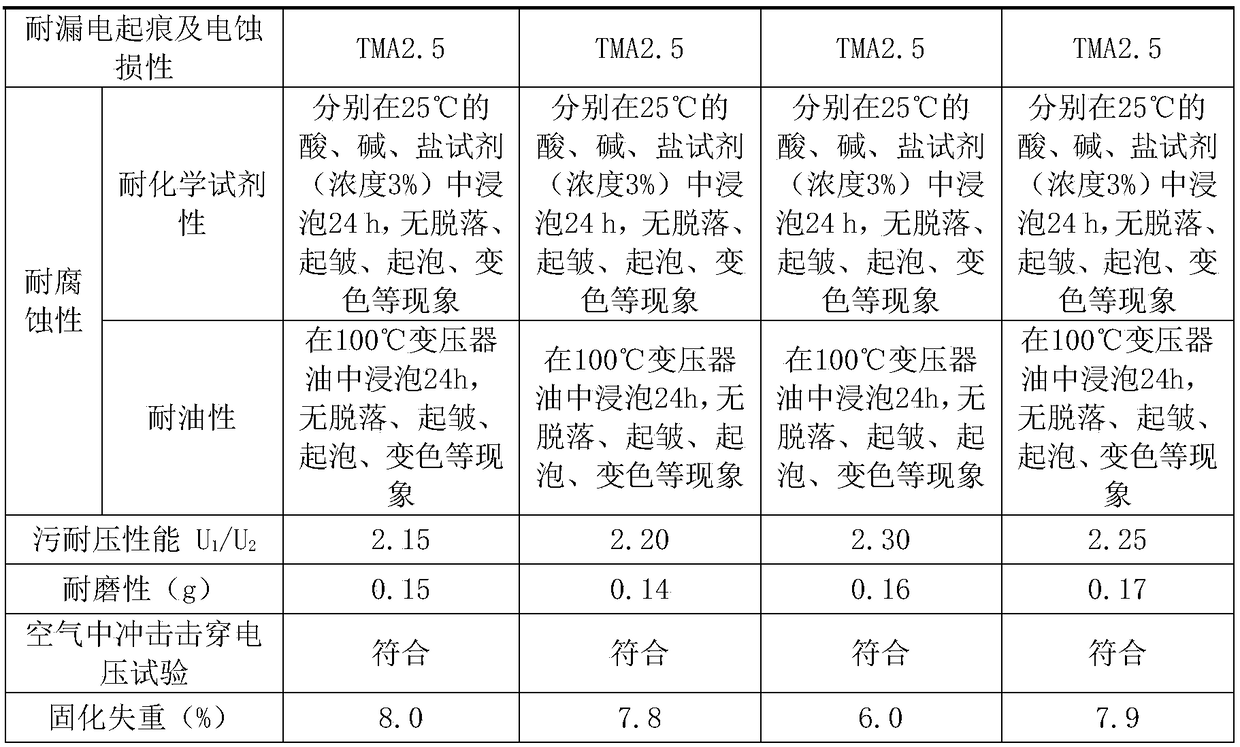

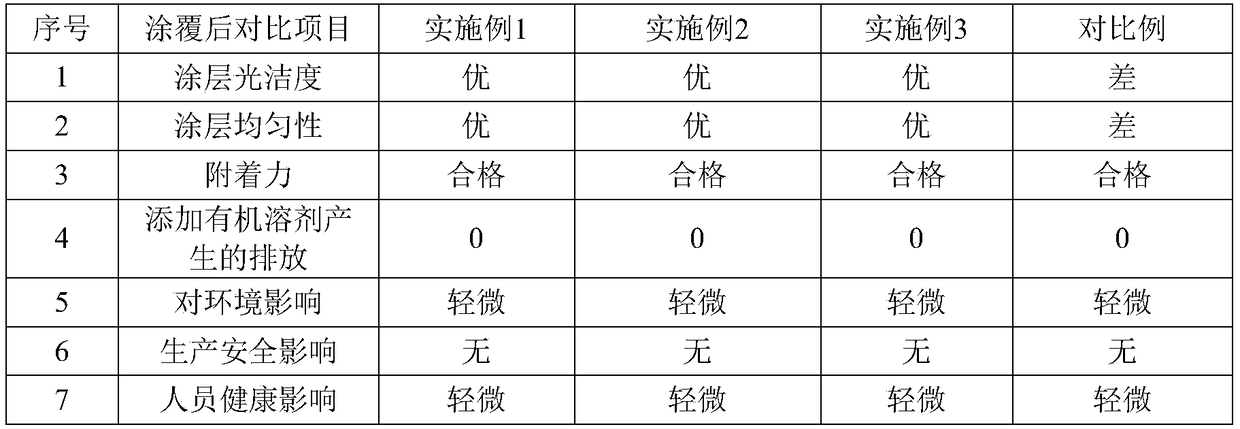

Organic solvent-free RTV anti-pollution flashover coating and preparation method thereof

ActiveCN109233620AGood hydrophobicityStrong maneuverabilityAntifouling/underwater paintsPaints with biocidesWeather resistanceChemistry

The invention discloses organic solvent-free RTV anti-pollution flashover coating and a preparation method thereof. The RTV anti-pollution flashover coating comprises the following components in partsby weight: 30-60 parts of polydimethylsiloxane, 5-10 parts of a hydrophobic auxiliary agent, 5-15 parts of silicone resin, 20-40 parts of a a flame-retardant filler, 1-10 parts of a crosslinking agent, 0.5-5 parts of a tackifier, 0.01-1 part of a catalyst and 0.1-10 parts of a pigment. The RTV anti-pollution flashover coating does not contain any organic solvent, and performance indexes thereof can meet performance requirements of the power industry on insulation, hydrophobicity, weather resistance, construction and the like of the anti-pollution flashover coating; the problems of environmentpollution and the like caused by high VOC emission from the organic solvent in the existing RTV anti-pollution flashover coating are essentially solved.

Owner:CHENGDU TALY TECH CO LTD

Anti-crack thermal insulating mortar

The invention discloses anti-crack thermal insulating mortar. The anti-crack thermal insulating mortar is composed of the following raw materials in parts by weight: 40-60 parts of ordinary Portland cement, 20-30 parts of mullite sand, 1.5-2.5 parts of polypropylene chopped fiber, 4-6 parts of ground steel slag, 10-15 parts of polystyrene foam particles, 5-10 parts of expanded perlite, 0.5-1 part of hydroxypropyl methyl cellulose, 3-5 parts of re-dispersible emulsion powder, 4-6 parts of polyvinyl alcohol, 3-7 parts of asbestos powder, 4-8 parts of diatomite, 2.5-4.5 parts of corncob powder, 3-6 parts of neopentyl glycol, 2-3 parts of sodium lignin sulfonate and 4-6 parts of composite filler. The thermal insulating mortar is relatively high in bonding strength and compressive strength and excellent in anti-cracking ability, and the defects of easy hollowing and cracking of the traditional thermal insulating mortar are overcome; meanwhile, the thermal insulating mortar has excellent properties such as thermal insulation property, waterproofness, weather fastness, acid-alkali corrosion resistance, freeze thawing resistance, aging resistance, mildew resistance and fire resistance, and has good construction performance, is green and environment-friendly, and safe and reliable, and has extremely large market space and development prospect.

Owner:安徽阜阳富龙建筑材料有限责任公司

Iron hoop

InactiveCN105295662AImprove wear resistanceExcellent anti-foulingAnti-corrosive paintsEpoxy resin coatingsEpoxyTetrafluoroborate

The invention discloses an iron hoop. A protective film is adhered to the surface of a main body of the iron hoop, and the protective film comprises the following components in parts by weight: 1-2 parts of Mo2B, 10.2 parts of modified epoxide resin, 2.3 parts of tetraethylammonium tetrafluoroborate, 1.2 parts of vinyl trimethoxysilane, 0.7 part of gamma-epoxypropylether trimethoxysilane, 0.9 part of pentaerythritol, 2.8 parts of pentaerythritol and 1.9 parts of xylene. The iron hoop disclosed by the invention has good wear resistance, scale prevention, ageing resistance, oxidation resistance, corrosion resistance and weather resistance as the protective film is adhered to the surface of the main body of the iron hoop.

Owner:CHANGSHU FUDA METAL PROD CO LTD

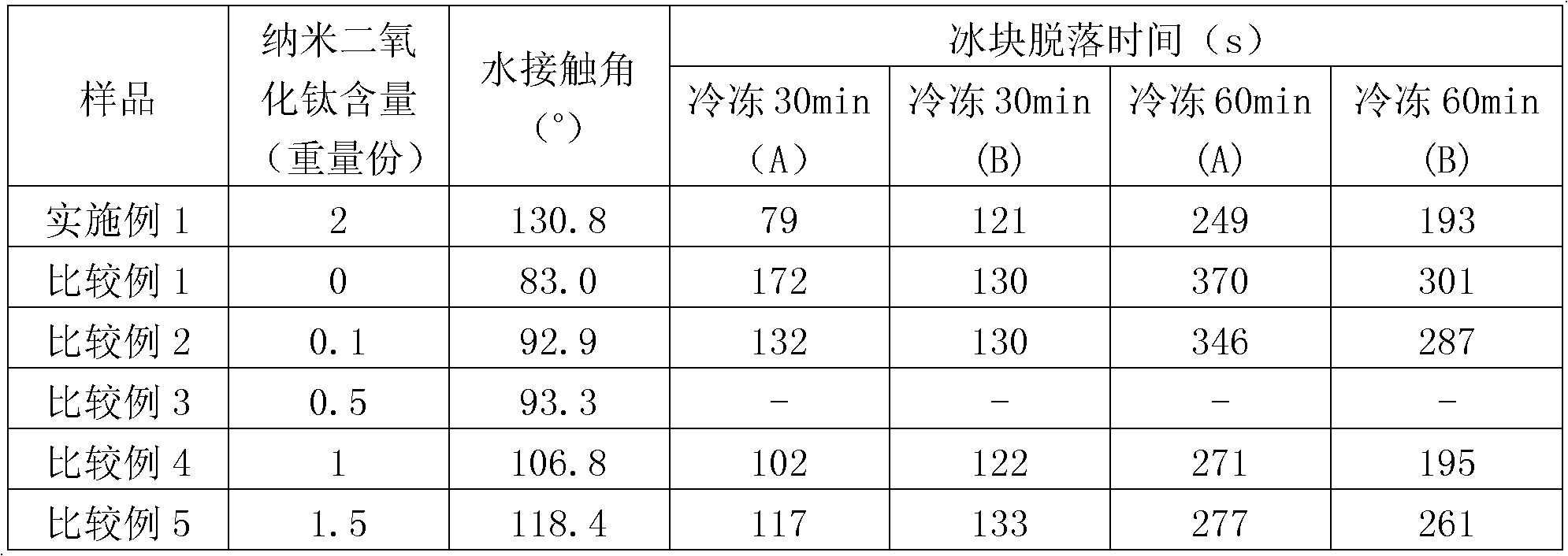

Anti-freeze nanometer titanium dioxide composite material and application thereof

The invention discloses an anti-freeze nanometer titanium dioxide composite material, comprising the following components based on parts by weight: 1-10 parts of nanometer titanium dioxide, 0.1-20 parts of copolymer, 0.1-10 parts of epoxy resin curing agent and 10-90 parts of organic solvent. The composite material is prepared as follows: dissolving the copolymer and the curing agent into a certain amount of mixed solvent of toluene and acetone to obtain polymer bonder, and dispersing the nanometer titanium dioxide into a certain amount of mixed solvent of toluene and acetone at the same time, and uniformly mixing and stirring them to obtain. The nanometer titanium dioxide composite material is advantaged by strong anti-freeze ability, aging resistance, abrasion resistance, low production cost and so on. The composite material can be used as anti-freeze coating material to be coated on the substrate surface such that the substrate surface has obvious anti-freeze ability, and can be widely used in industries like aviation, electricity and traffic.

Owner:SHANDONG JIAOTONG UNIV

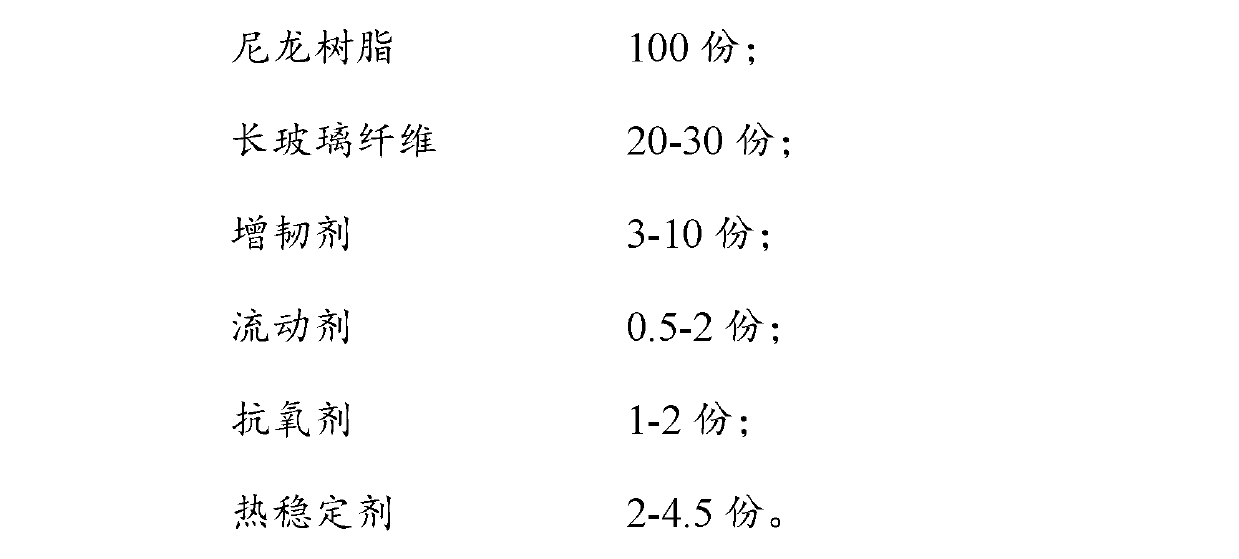

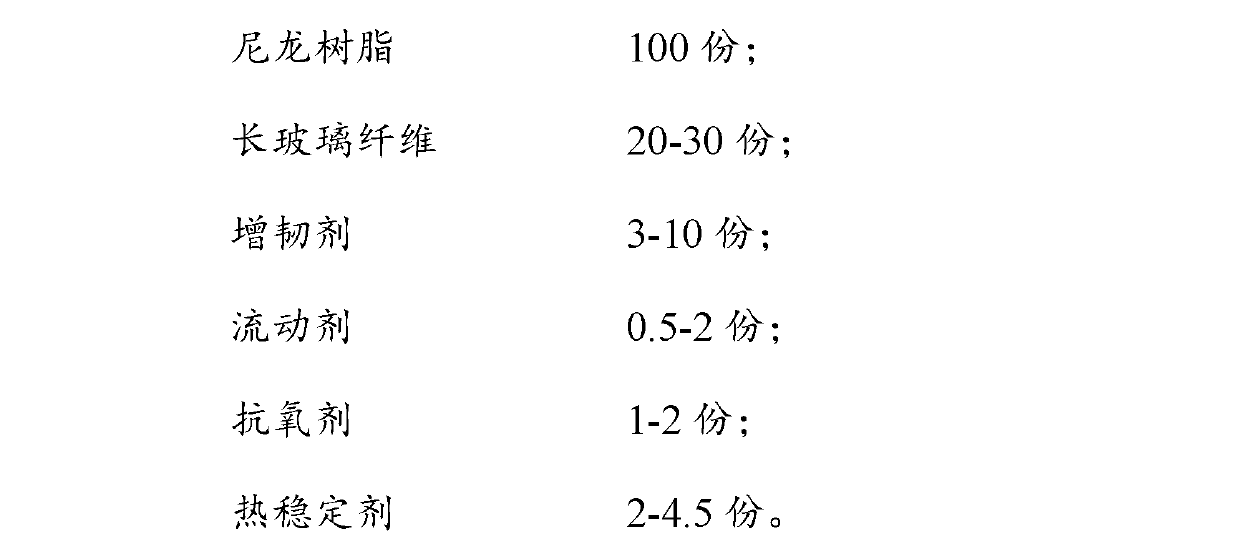

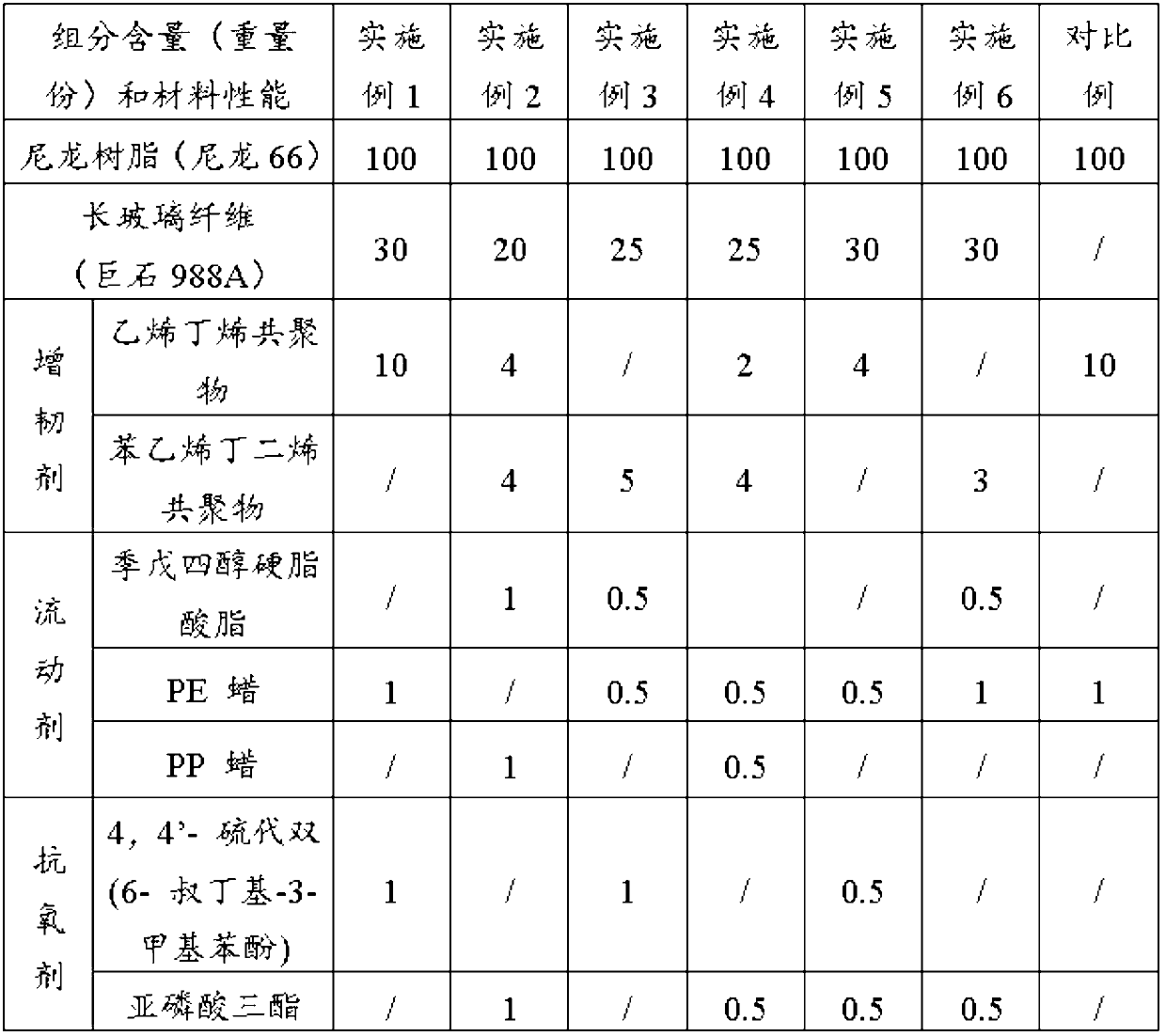

Long glass fiber-nylon resin composition and preparation method thereof

The invention discloses a long glass fiber-nylon resin composition and a preparation method thereof. The long glass fiber-nylon resin composition comprises, by weight, 100 parts of nylon resin, 20 to 30 parts of long glass fibers, 3 to 10 parts of a flexibilizer, 0.5 to 2 parts of a flowable agent, 1 to 2 parts of an anti-oxidant and 2 to 4.5 parts of a heat stabilizer. The preparation method has a simple principle, a low cost, and low equipment requirements. The long glass fiber-nylon resin composition has the advantages of good rigidity, good impact resistance, alkali and acid resistance, aging resistance, oxidation resistance, and weatherability.

Owner:SHENZHEN XINGSHENGDI NEW MATERIALS

Flame retardant modified polyurethane metallic paint

InactiveCN105482671AImprove lipophilicityImprove crosslink strengthFireproof paintsPolyurea/polyurethane coatingsPhosphoric Acid EstersPolymer science

The present invention discloses a flame retardant modified polyurethane metallic paint, which comprises raw materials of organic phosphorus-modified polyurethane, water-based phenolic resin, water-based alkyd resin, sodium carboxymethyl cellulose, montmorillonite, calcined kaolin, nanometer nitride aluminum, melamine polyphosphate, nano magnesium hydroxide, a defoamer, a levelling agent and a pigment. The preparation method of the organic phosphorus-modified polyurethane is as follows: heating tung oil polyol and N,N-diethyl bis(2-hydroxyethyl)aminomethylphosphonate, insulating, conducting vacuum dehydration, adding dicyclohexylmethylmethane-4,4'-diisocyanate, introducing N2 protection, heating, insulating, cooling, adding 1,5-pentanediol, dimethylolpropionic acid, pentaerythritol and acetone, and then adding zinc naphthenate, heating, insulating, cooling, dropwise adding a mixed solution containing dimethylethanolamine and triethanolamine, heating, insulating, neutralizing, adding water for emulsified dispersion, and conducting vacuum distillation to obtain organic phosphorus-modified polyurethane. The flame retardant modified polyurethane metallic paint has excellence flame retardant property.

Owner:NINGGUO LONGSHI METAL PROD CO LTD

Calcium carbonate enhanced PVC composite board and processing method thereof

InactiveCN108864590AImprove flame retardant performanceImprove stabilityPhytic acidPolydimethyl siloxane

The invention discloses a calcium carbonate enhanced PVC composite board and a processing method thereof. The composite board comprises the following raw materials in parts by weight: 100 parts of PVCresin, 10-20 parts of calcium lignosulphonate, 40-80 parts of wood flour, 40-60 parts of modified calcium carbonate, 3-5 parts of aramid fiber, 3-5 parts of sepiolite fiber, 1-3 parts of polyether modified polydimethylsiloxane, 2-4 parts of polyoxyethylene glycerol ether monostearate, 1-3 parts of composite foaming agent, 2-4 parts of coupling agent, 1-2 parts of stabilizing agent, 2-4 parts of lubricating agent, 1-2 parts of antioxidant and 3-5 parts of processing agent. The modified calcium carbonate adopted by the invention is subjected to surface modification with ceraphyl RMT and polyoxypropylene polyoxyethylene propylene glycol ether and then is subjected to secondary surface modification with aminopropyl Poly(methylsilsesquioxane) and phytic acid. The PVC composite board prepared by the invention has the advantages of high strength, high toughness, high impact resistance, excellent fire resistance, wear resistance, heat resistance, difficulty in deformation, high stability, andthe like, and can be widely applied to the construction fields of wood floors, ceilings, wallboards, and the like.

Owner:贺州钟山县双文碳酸钙新材料有限公司

Preparation method of anti-aging and anti-bacterial PE pipe

The invention discloses a preparation method of an anti-aging and anti-bacterial PE pipe. The preparation method comprises the following steps: adding 3-8% of nano-modified bamboo charcoal plastic particles into PE resin, uniformly mixing, heating to 170-210 DEG C, then extruding by a twin-screw extruder, cooling and performing vacuum shaping to obtain the anti-aging and anti-bacterial PE pipe. The core of the invention is that the nano-modified bamboo charcoal plastic particles are adopted to replace carbon black and an inorganic metal antibacterial agent, so that the PE pipe has good anti-aging and anti-bacterial performances. The preparation method disclosed by the invention has the advantages of strong practicality, low cost, greenness and environmental friendliness, the nano-modified bamboo charcoal plastic particles have good dispersibility and stable natures, and the obtained PE pipe has excellent anti-aging and anti-bacterial performances, as well as relatively strong actual application value and market development prospects.

Owner:GUANGXI JIALI IND & TRADE

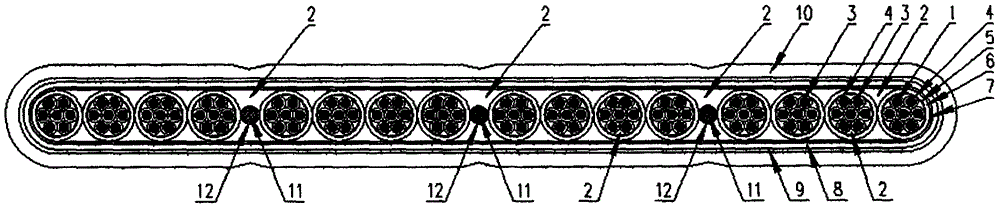

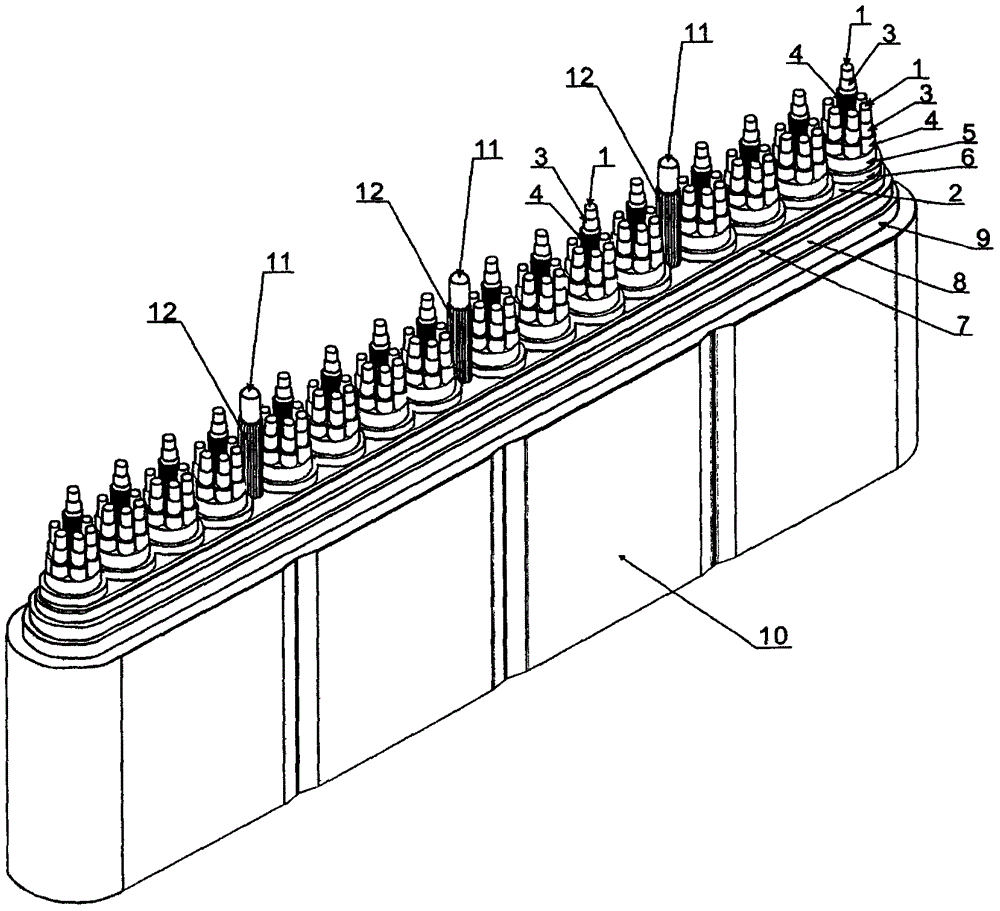

Bending-resistant and tensile elevator or lift travelling flexible fireproof cable

InactiveCN106057290AImprove flexibilityImprove flex resistanceNon-insulated conductorsClimate change adaptationGlass fiberElectrical conductor

Owner:兴乐电缆有限公司

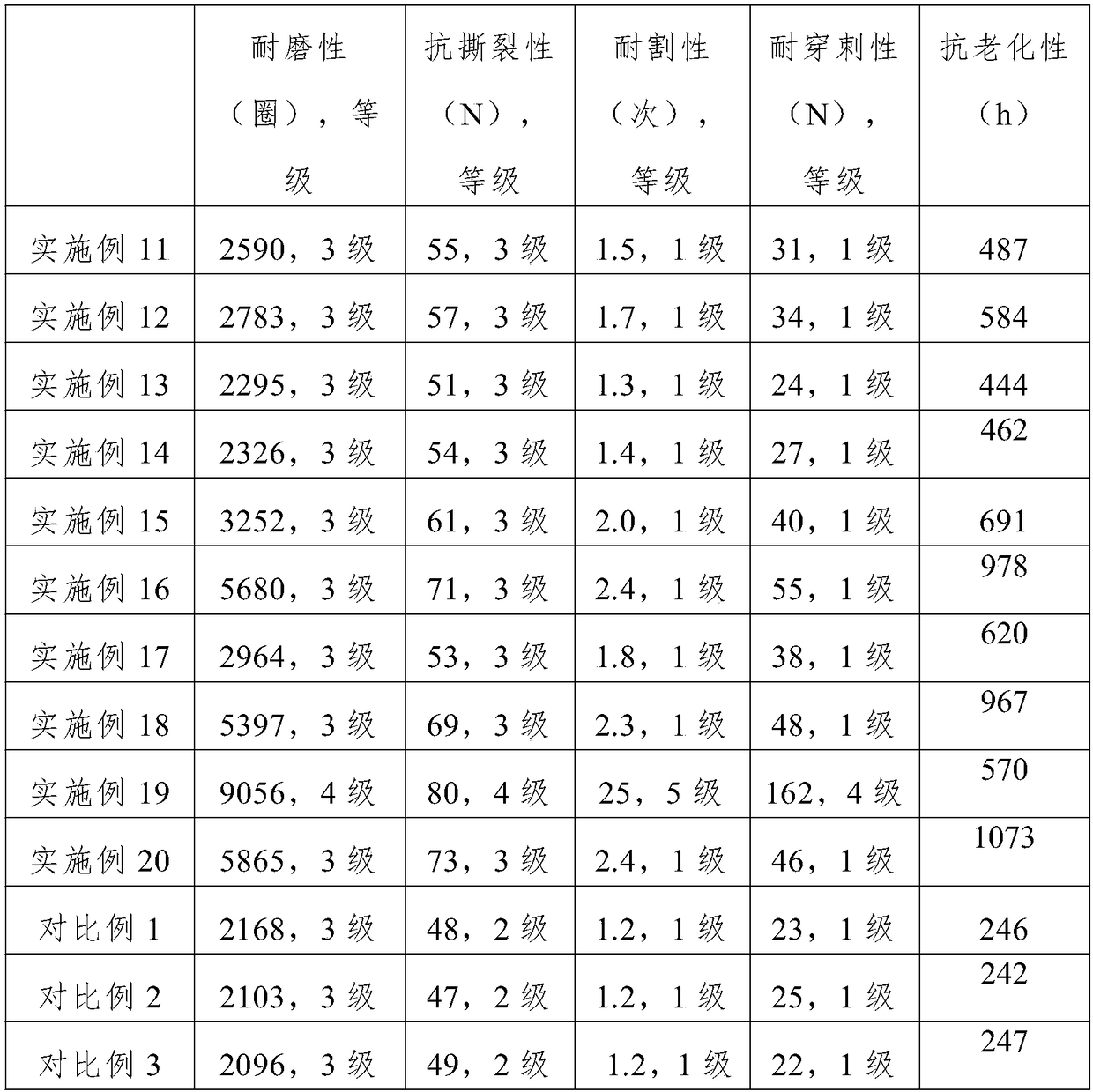

Natural emulsion composite slurry and preparation method thereof, protection gloves and preparation method thereof

ActiveCN108299689ASave materialReduce manufacturing costGlovesDomestic articlesEmulsionPolypropylene glycol

The invention relates to natural emulsion composite slurry. The natural emulsion composite slurry is prepared from natural emulsion and a heat sensitizing agent, wherein the natural emulsion is subjected to pre-sulfurization, and the heat sensitizing agent is diluted by cold water and is a composition comprising one or more of polyvinylmethyl ether, polyether polyformaldehyde dimethyl acetal and polypropylene glycol. The invention further relates to natural emulsion thermosensitive embossed protection gloves prepared from the natural emulsion composite slurry. The natural emulsion composite slurry can not only prevent the gloves from glue penetration during impregnation, avoid damage to the human body, save energy and protect the environment but also prevent liquid from entering the gloves, so that the prepared gloves are soft in texture, light, sensitive and good in breathability, people does not easily feel tired when wearing the gloves for a long time, and therefore the prepared gloves are particularly suitable for mechanical operation; besides, the prepared gloves can have good composite performance of abrasion resistance, cutting resistance, tearing resistance, stabbing resistance, aging resistance and the like, so that influence on the latter aging resistance performance of glove products and blooming are avoided.

Owner:SHANDONG XINGYU GLOVES

Heat insulating body and manufacturing method thereof

ActiveCN101054277AGood anti agingImprove impact resistanceOther chemical processesSodium BentoniteAdhesive

The invention provides a thermal insulator for preventing heat exchange in heat working field and preparation method thereof. A pasty slurry is mixed by rockwool, sepiolite, polyvinyl alcohol, rare earth compound adhesive, bentonite and mixture of hollow ceramic powder and porous ceramics microparticles. The pasty slurry is laid between fibrous layers to form a thermal insulator. The thermal insulator of the invention has advantages of excellent ageing resistance, impact resistance, high temperature resistant and high heat insulation, can be applied widely in heat preservation environment such as boilers, kilns, heat exchangers, cold-heat transition pipeline, air-condition and refrigerated warehouse etc.

Owner:ZHONGHAI RUNDA NEW MATERIAL TECH CO LTD

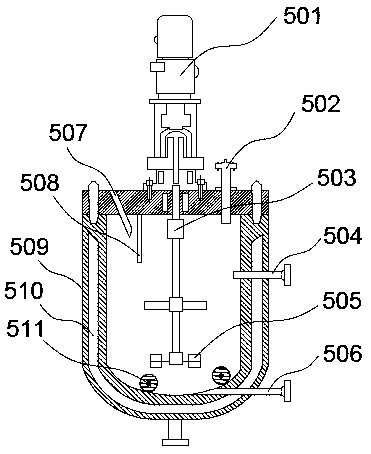

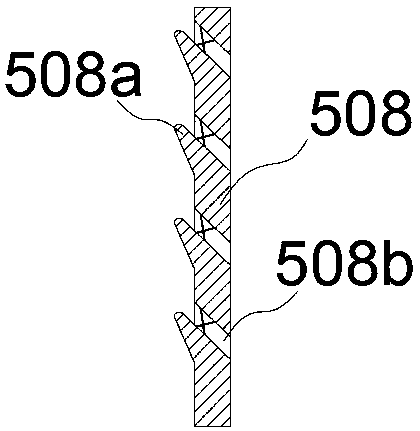

Antibacterial and anti-mildew aqueous shell powder and nano-silver coating and production device thereof

ActiveCN107722698AFree from pollutionPrevent mining damageAntifouling/underwater paintsTransportation and packagingNon toxicityAdhesive

The invention discloses an antibacterial and anti-mildew aqueous shell powder and nano-silver coating and a production device thereof, and belongs to the technical field of coatings. The aqueous coating comprises modified shell powder, titanium dioxide, nano-silver, an adhesive and water. The production device comprises a reactor, the upper end of the reactor is respectively connected with a solidmixing cylinder and a liquid mixing cylinder, the upper end of the solid mixing cylinder is connected with a feeding bin through a feeding tube, the tail end of the feeding tube is connected with a blowing pump, the bottom and the side surface middle part of the reactor are connected with a circulation pump through communicating pipelines, and the communicating pipeline connected to the top of the circulation pump is provided with a discharge port. The coating has the advantages of low cost, small energy consumption, non-toxicity, good adhesion, good water resistance, good antibacterial property, good mildew resistance and good other comprehensive mechanical properties.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com