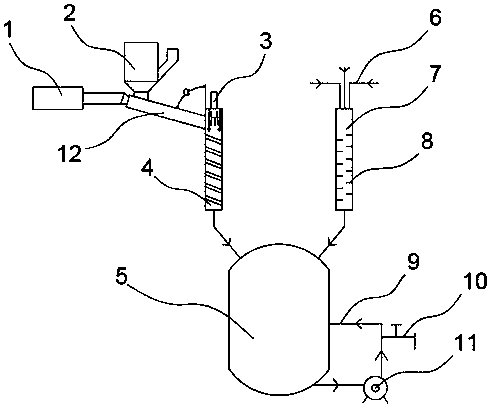

Antibacterial and anti-mildew aqueous shell powder and nano-silver coating and production device thereof

A nano-silver antibacterial and water-based coating technology, applied in the field of coatings, can solve the problems of poor air permeability, inability to adjust humidity and remove harmful odors, unsustainable development of productivity, and easy agglomeration of coatings. Excellent mildew effect and enhanced antibacterial and antifungal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

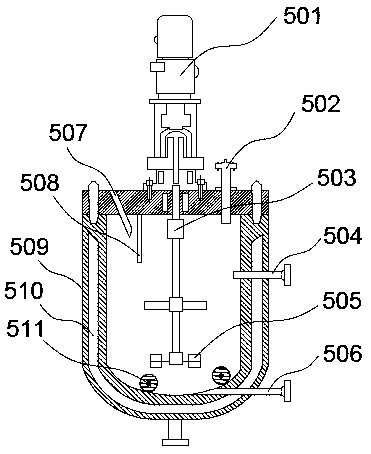

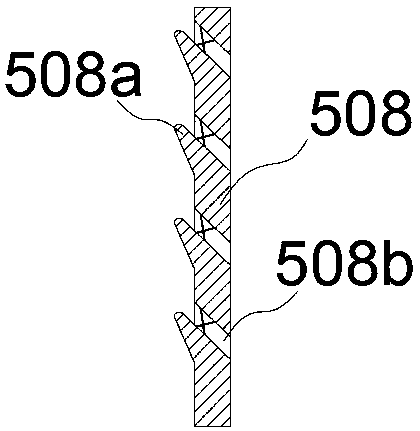

Method used

Image

Examples

Embodiment 1

[0030] A shell powder nano-silver antibacterial and mildew-proof water-based paint, the water-based paint is composed of the following components and preferred parts by weight: 27 parts of modified shell powder, 6 parts of titanium dioxide, 10 parts of nano-silver, 4 parts of adhesive, 34 parts of water, The adhesive is composed of the following components and parts by weight: 32 parts of polyurethane prepolymer, 2 parts of E03, 2 parts of butanone, 0.35 parts of polyglycerin fatty acid ester, and 14 parts of cyclohexanone. The polyurethane prepolymer is composed of the following polyε- 98 parts of caprolactone diol, 33 parts of 2,4-toluene diisocyanate, 0.7 part of dibutyltin dilaurate, 2 parts of xylene, and the epoxy resin is E03 brand bisphenol A epoxy resin.

[0031] The preparation steps of the modified shell powder are as follows: take 100 mesh mussel shell powder and add it into the mixed solution of 4wt% citric acid solution and 2wt% N-1-naphthylethylenediamine dihydro...

Embodiment 2

[0035] A shell powder nano-silver antibacterial and mildew-proof water-based coating, the water-based paint is composed of the following components and parts by weight: 38 parts of modified shell powder, 7 parts of titanium dioxide, 10 parts of nano-silver, 4 parts of adhesive, 30 parts of water, adhesive The adhesive is composed of the following components and parts by weight: 32 parts of polyurethane prepolymer, 4 parts of E03, 2 parts of methyl ethyl ketone, 0.35 parts of polyglycerin fatty acid ester, 14 parts of cyclohexanone, and the polyurethane prepolymer is composed of the following polyε-hexyl 100 parts of lactone diol, 31 parts of 2,4-toluene diisocyanate, 0.62 parts of dibutyltin dilaurate, 3 parts of xylene, and the epoxy resin is E03 brand bisphenol A epoxy resin.

[0036] The preparation steps of the modified shell powder are as follows: take 120 mesh mussel shell powder and add it into the mixed solution of 3wt% citric acid solution and 1wt% N-1-naphthylethylene...

Embodiment 3

[0039] The test of the shell powder nano-silver antibacterial and mildew-proof water-based paint of the present invention: the water-based paint prepared by the present invention is compared with the antibacterial and mildew-proof paint (control group) in the supermarket randomly selected in Zhoushan, and the paint of the present invention and the contrast The groups of coatings were tested on the walls respectively, and the experimental results are as follows:

[0040] 1) Bacteriostasis and mildew, the coatings of Examples 1 and 2 of the present invention and the control group are coated on the walls of the room, the coating area is the same, the doors and windows of the room are opened, and the wall is tested after 2 months coli and staphylococcus aureus on the surface and the moldy area (the moldy area accounts for the coating area of the paint), the situation is as follows:

[0041]

[0042] 2) Adhesion, flexibility, drying time and impact resistance, according to GB1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com