Bending-resistant and tensile elevator or lift travelling flexible fireproof cable

A technology for fireproof cables and elevators, which is applied in the direction of bendable cables, insulated cables, cables, etc., to achieve the effects of improving flexural resistance, flexibility, and tensile resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

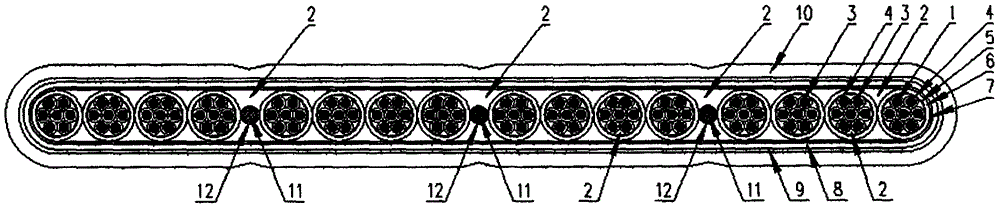

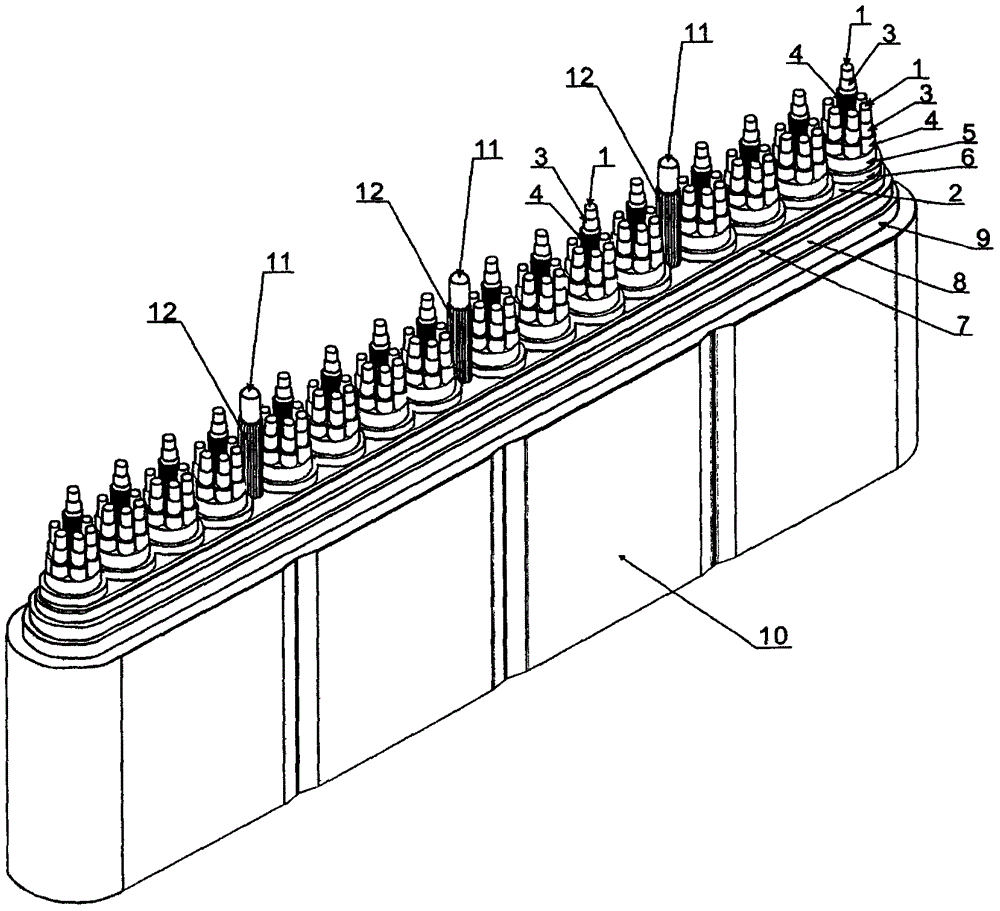

[0019] see figure 1 , figure 2 , a kind of flexure-resistant and tension-resistant elevator or elevator accompanying flexible fireproof cable, which includes a multi-strand annealed copper wire conductor 1 formed by twisting a plurality of annealed copper wires, the surface of the multi-strand annealed copper wire conductor 1 is wound with the first synthetic mica Tape layer 3, the surface of the first synthetic mica tape layer 3 is extruded with a ceramicized silicone rubber insulating layer 4, and the multi-strand annealed copper wire conductor 1, the first synthetic mica tape layer 3, and the ceramicized silicone rubber insulating layer constitute a fireproof insulating core A number of fire-proof insulated wire cores are twisted, and after twisting, the third fire-resistant layer 5 and the second synthetic mica tape layer 6 are wrapped outside to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com