Patents

Literature

671results about How to "Prevent extension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique for protecting against failure of a network element using Multi-Topology Repair Routing (MTRR)

ActiveUS20080049622A1Prevent extensionReduce needError preventionTransmission systemsTopological routingDistributed computing

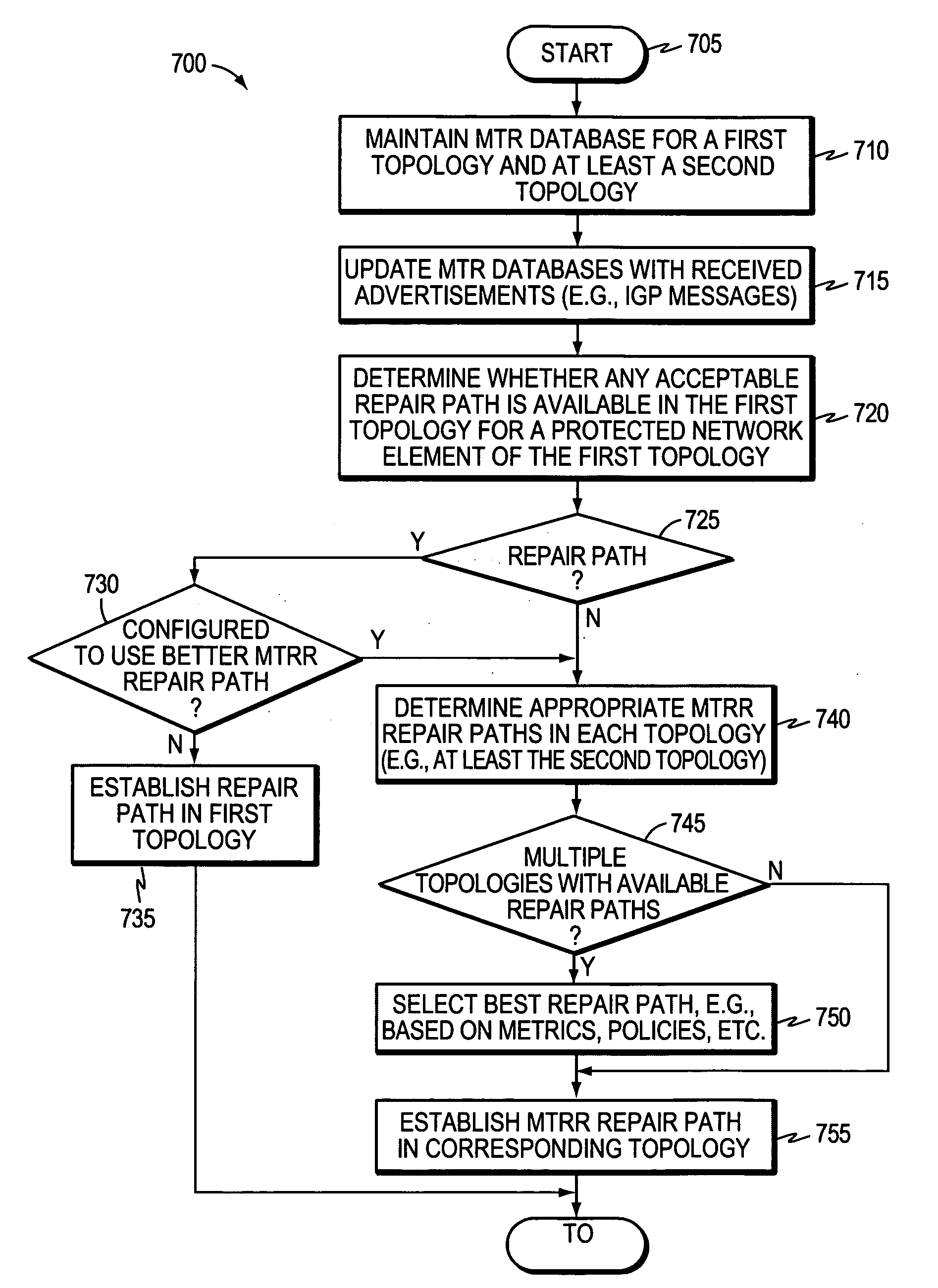

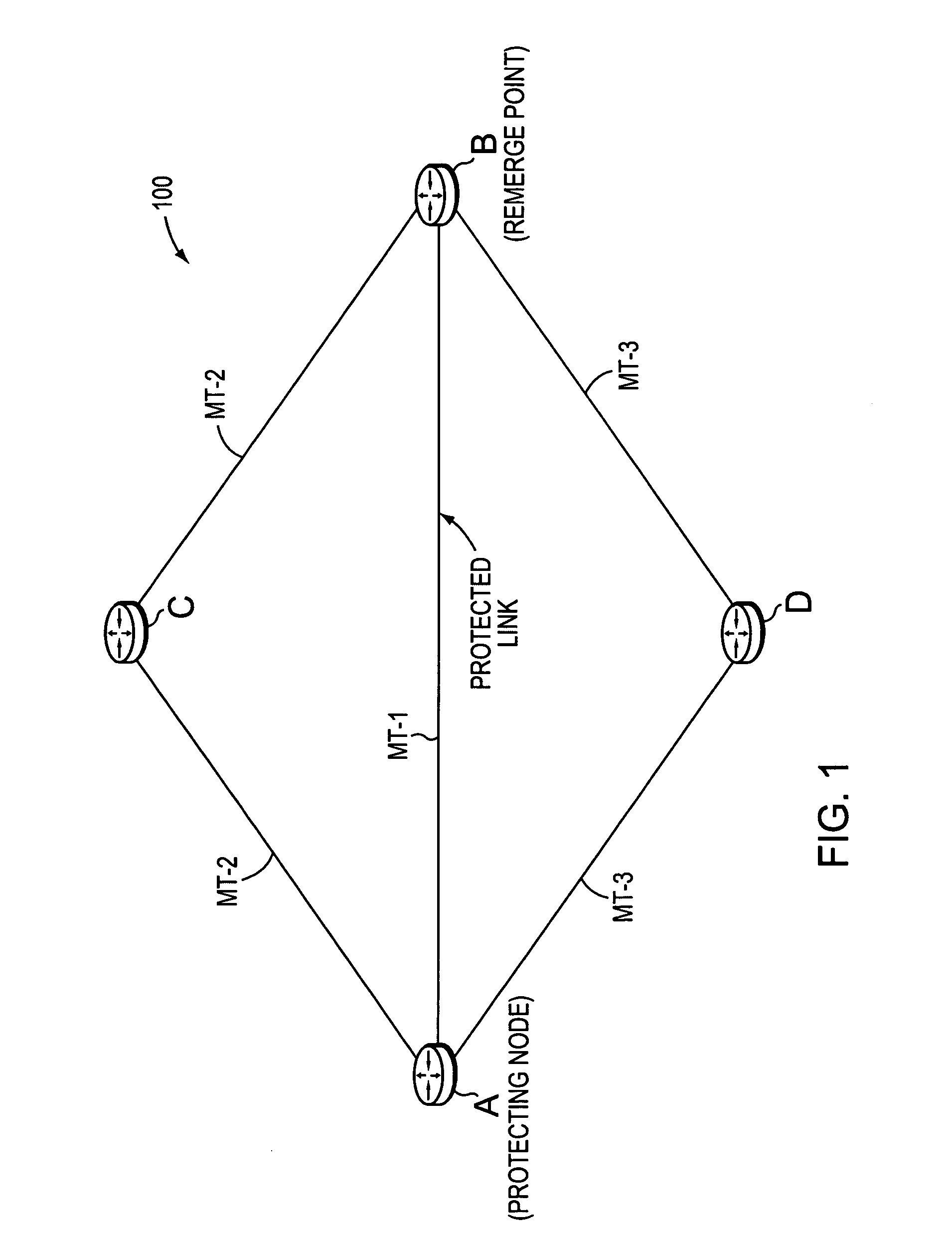

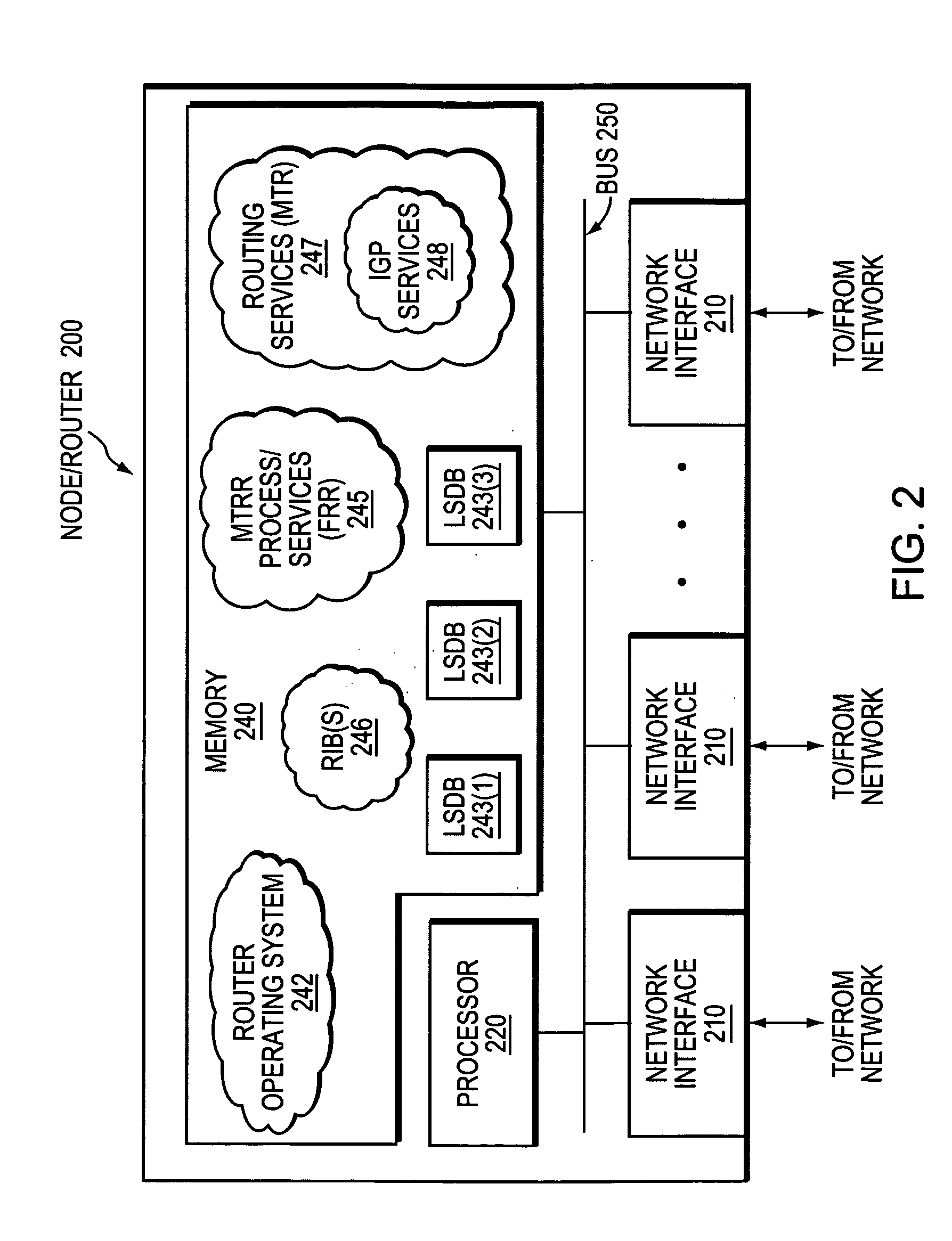

A technique protects against failure of a network element using Multi-Topology Repair Routing (MTRR) in a computer network. According to the novel technique, a protecting node (e.g., a router) maintains Multi-Topology Routing (MTR) databases for a first topology and at least a second topology. The protecting node determines whether any acceptable repair paths are available in the first topology for a protected network element (e.g., node, link, etc.) of the first topology. If not, the protecting node may establish a repair path (e.g., for Fast ReRoute, FRR) in the second topology for the protected network element.

Owner:CISCO TECH INC

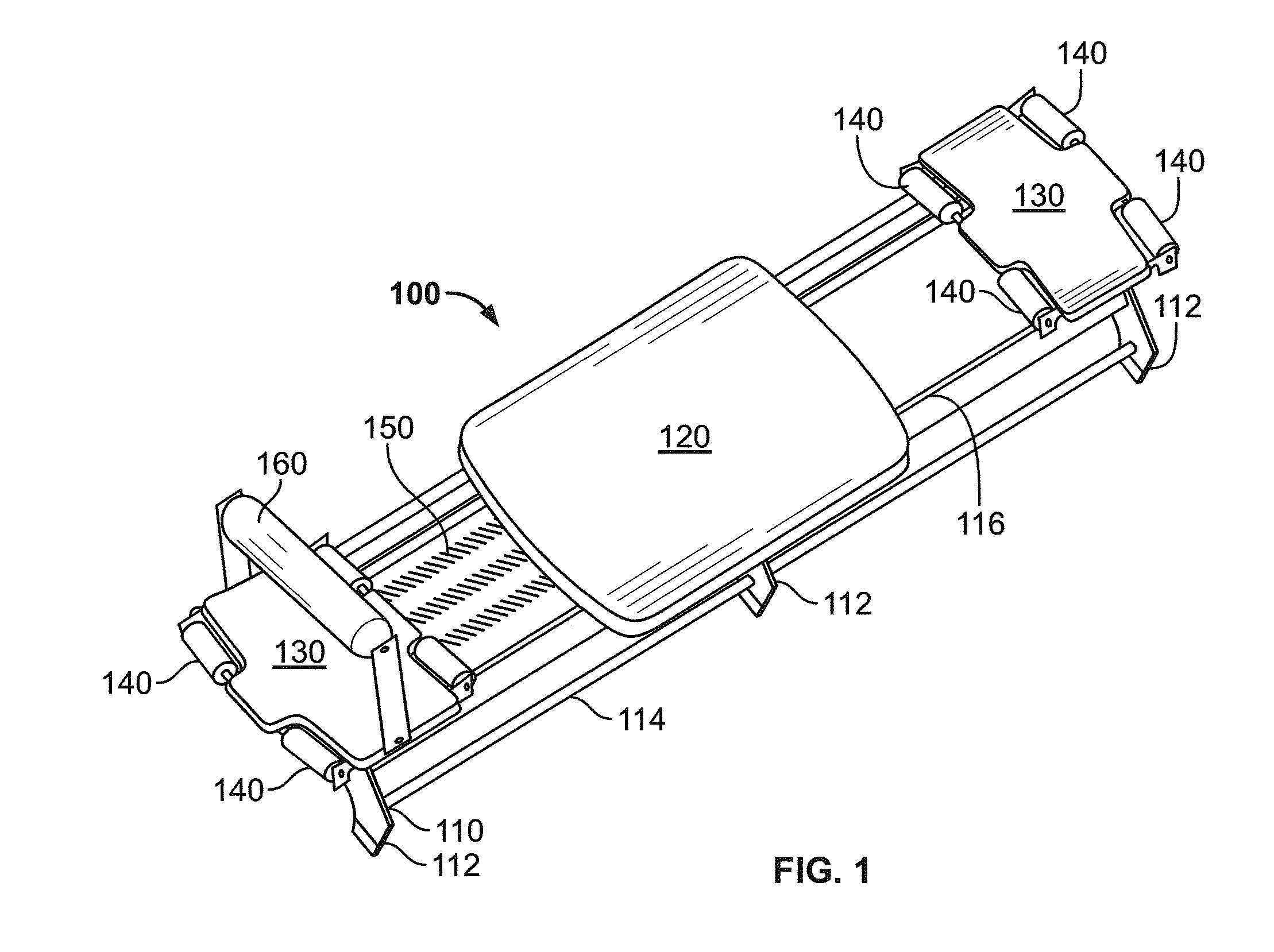

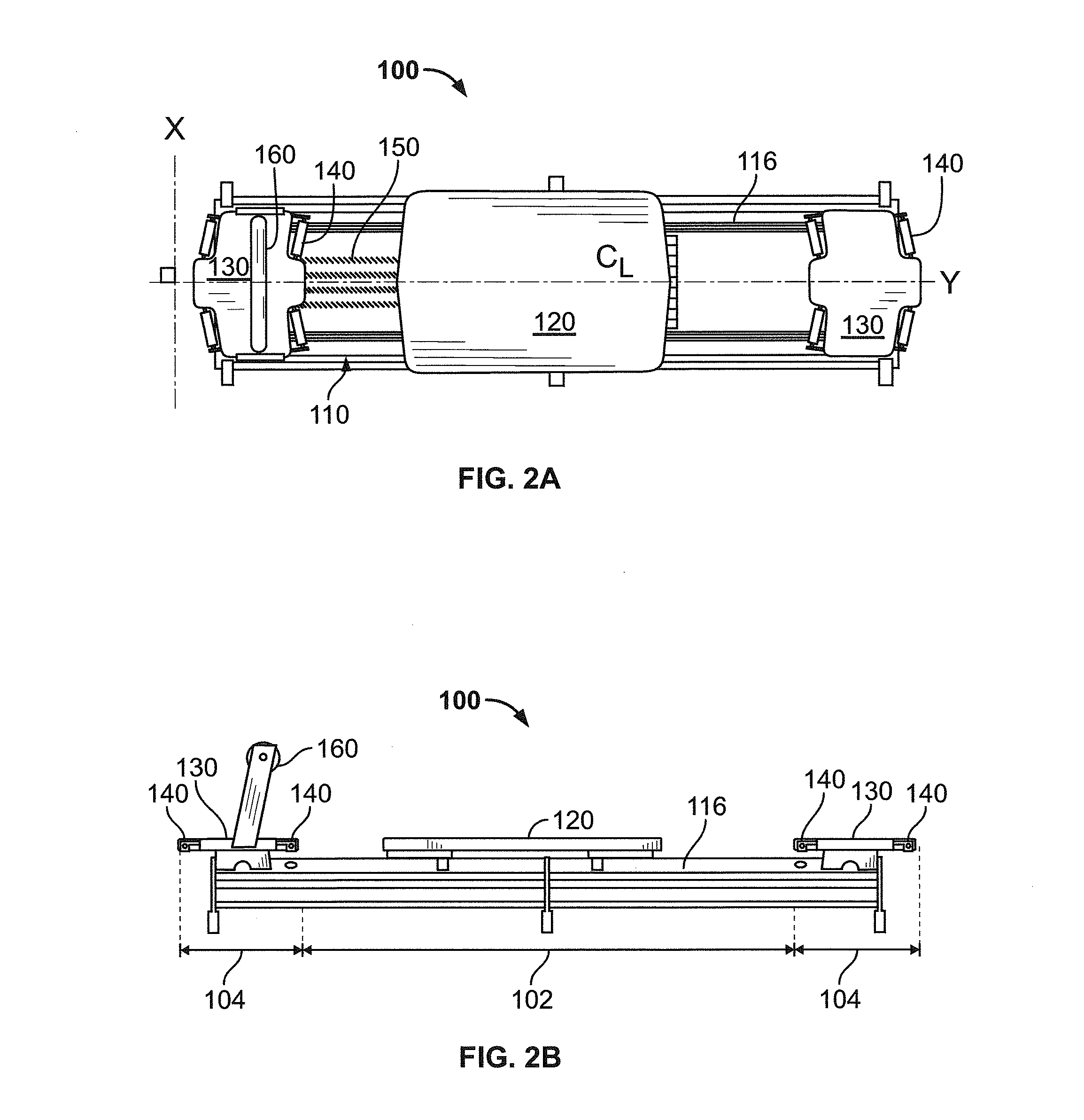

Exercise Machine Ergonomic Handle System

ActiveUS20150065318A1Improve ergonomicsFlexible cuttingStiltsMuscle exercising devicesHand heldEngineering

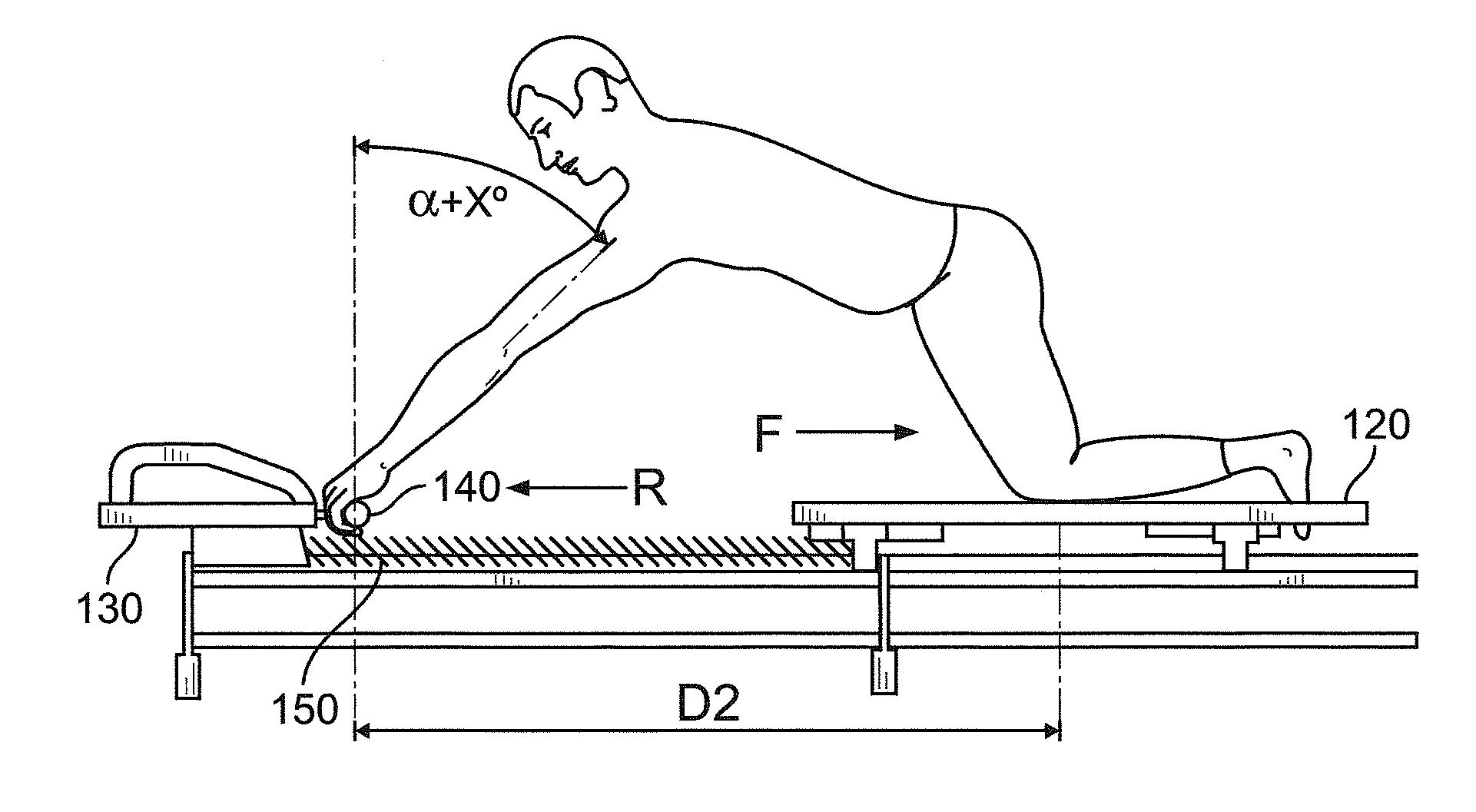

An exercise machine ergonomic handle system for providing hand-holds for the performance of exercises with reduced flexion and / or extension of the hand and wrist and reduced ulnar and / or radial deviation so as to reduce injury and allow application of full strength to the exercise machine. The exercise machine ergonomic handle system generally includes a longitudinally extending frame, a carriage that moves upon a first longitudinal portion of the frame, and at least one pair of ergonomic handles positioned on a second longitudinal portion of the frame. The ergonomic handles rotate about an axis to prevent flexion and / or extension, and can be positioned at a width and / or angle that reduces ulnar and / or radial deviation.

Owner:LAGREE TECH INC

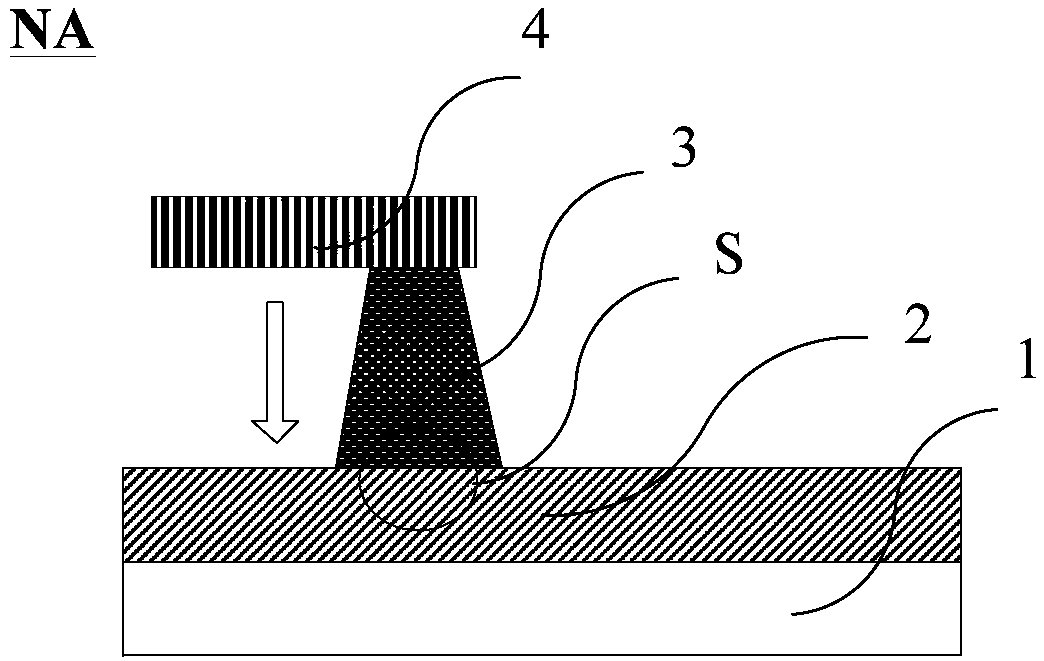

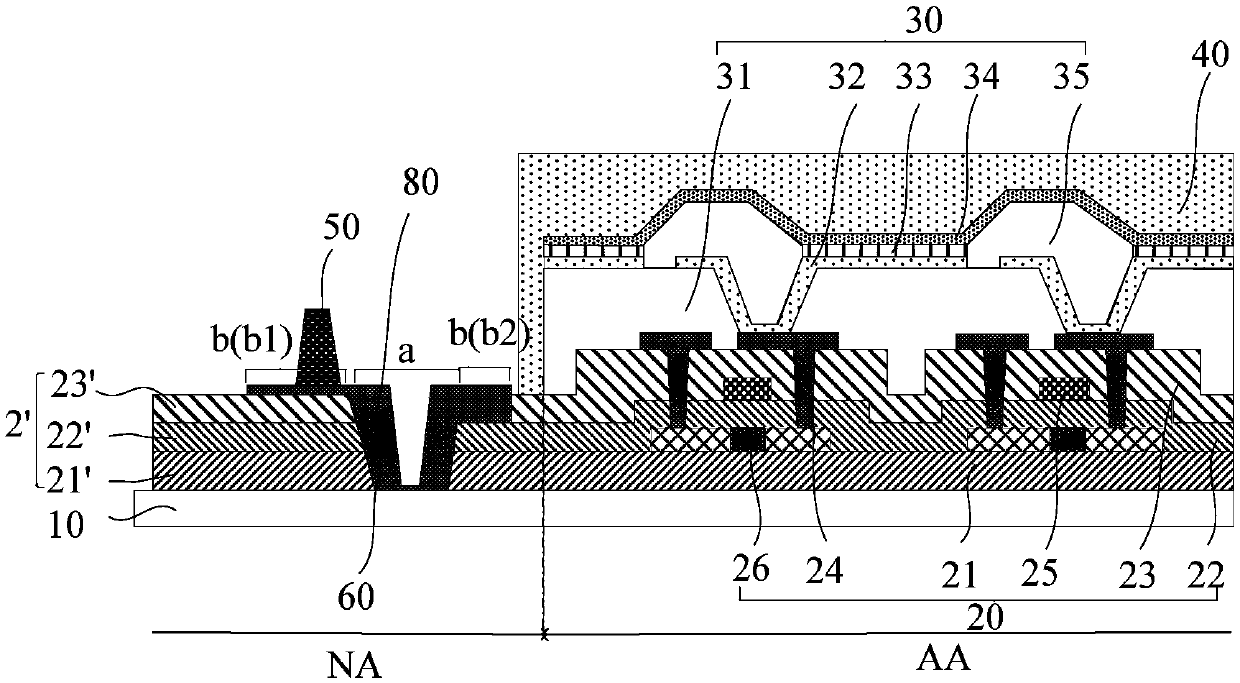

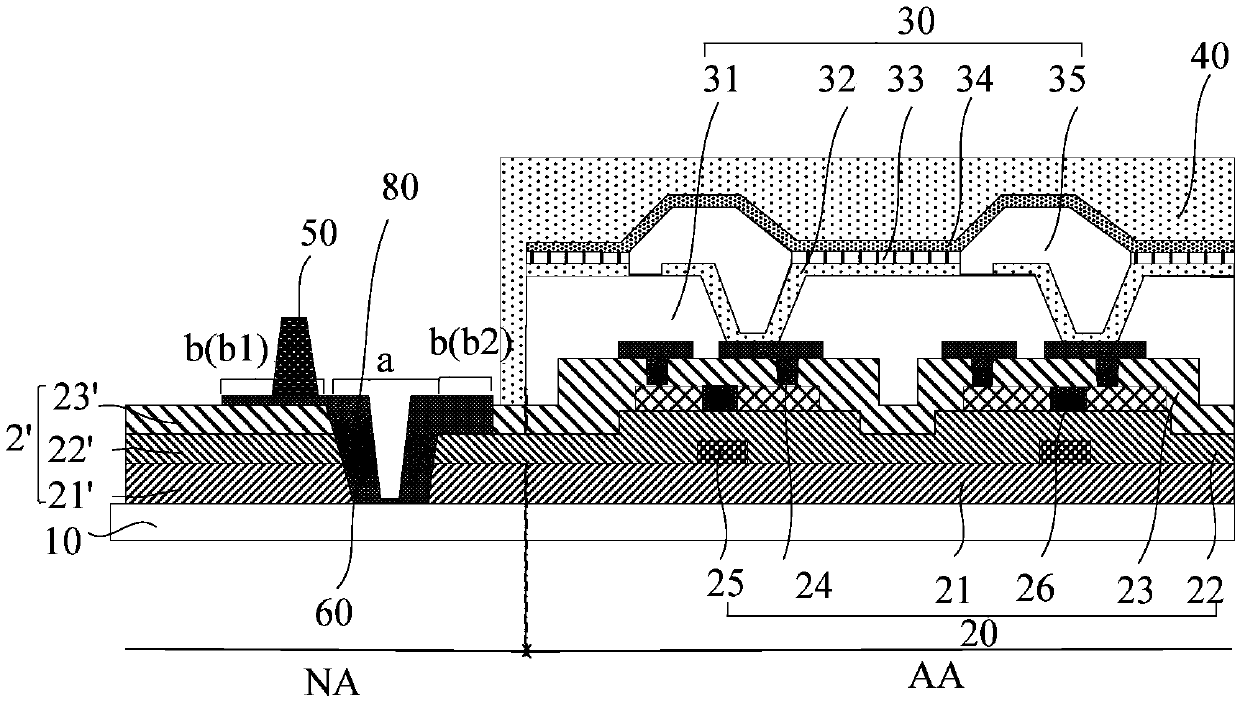

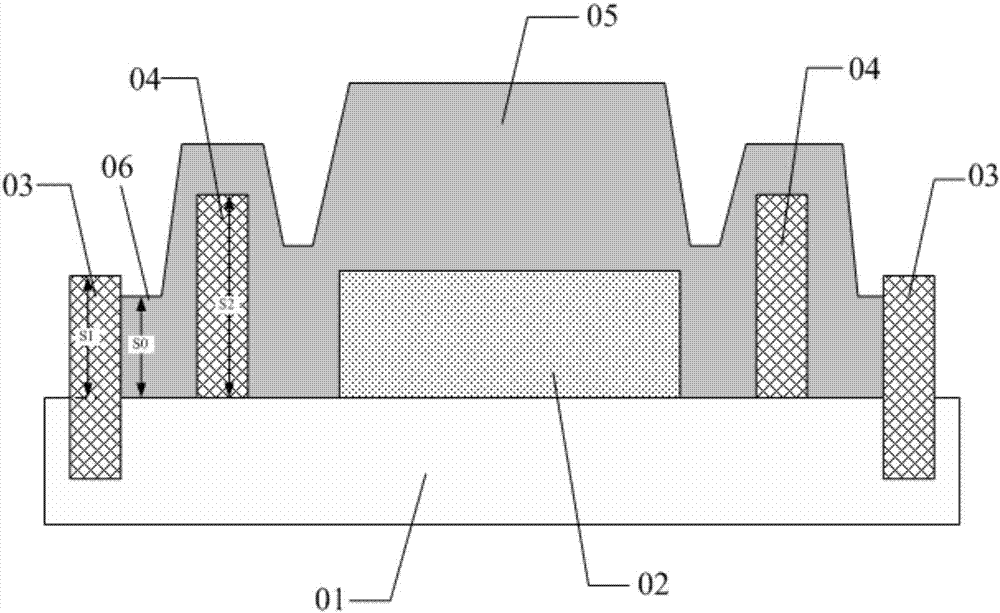

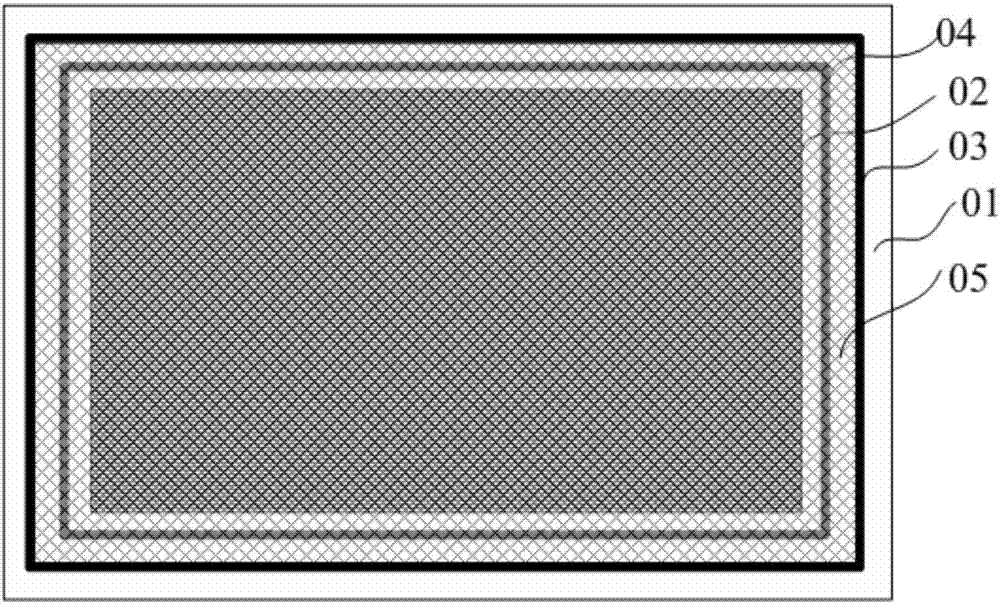

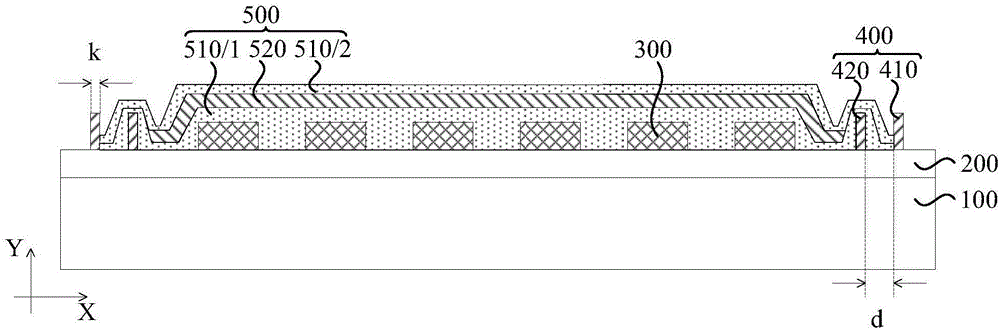

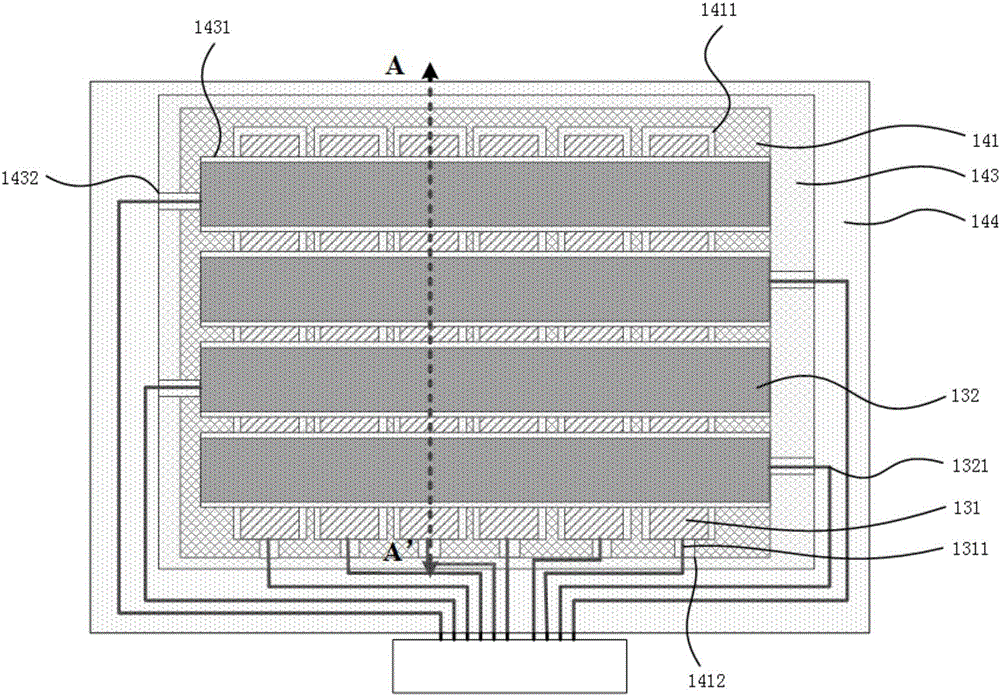

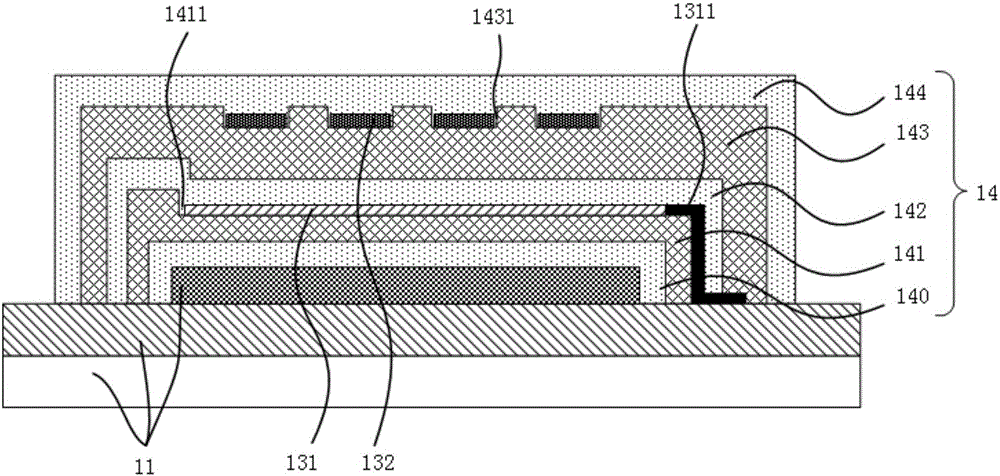

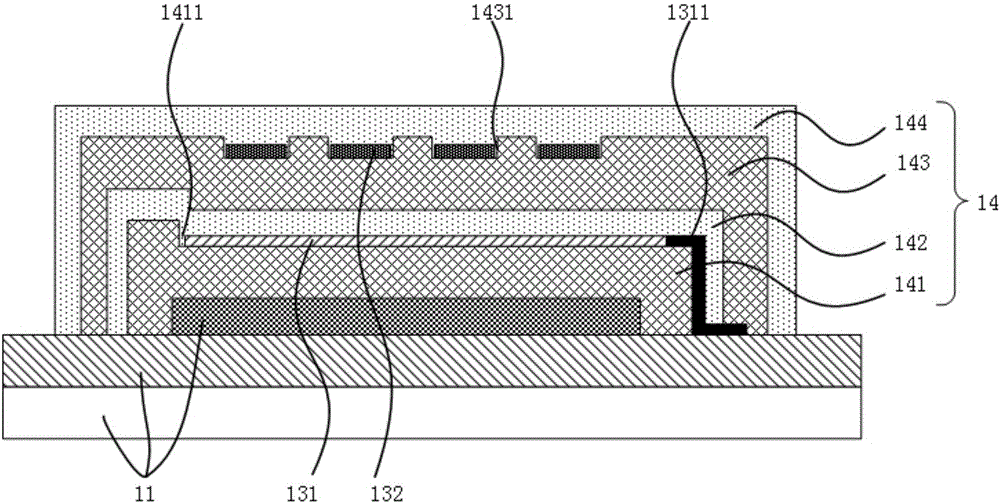

Organic light-emitting display panel, organic light-emitting display device, and method for preparing organic light-emitting display panel

ActiveCN107068715AImprove bindingPrevent extensionSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceDisplay device

The invention provides an organic light-emitting display panel comprising a substrate including a display region and a non-display region, wherein the non-display region comprises: an insulating layer disposed on the same side of a array layer and provided with at least one groove exposing the substrate; a metal layer comprising a first portion covering the groove and in contact with the substrate, and a second portion covering the outer side of the groove and in contact with the insulating layer; at least one shielding wall disposed on a side, away from the substrate, of the second portion and in contact with the second portion, wherein the material of the shielding wall comprises an organic substance. The organic light-emitting display panel can increase the bonding ability of the shielding wall and the substrate, reduce a peeling risk when being in contact with a mask plate, and prevent the expansion of cracks, increases a side wrapping effect in order that little water enters to corrode an organic light emitting device from the side.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

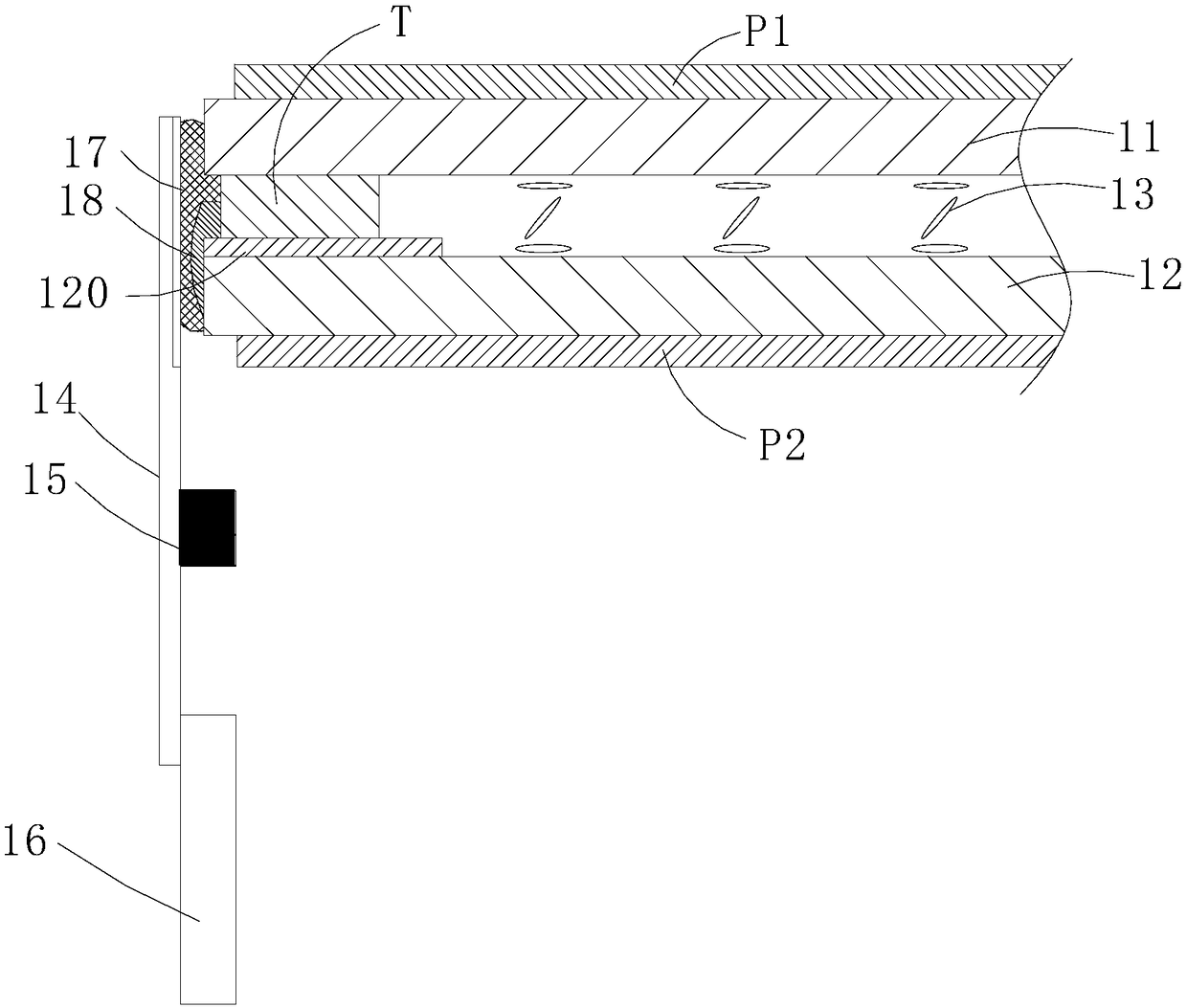

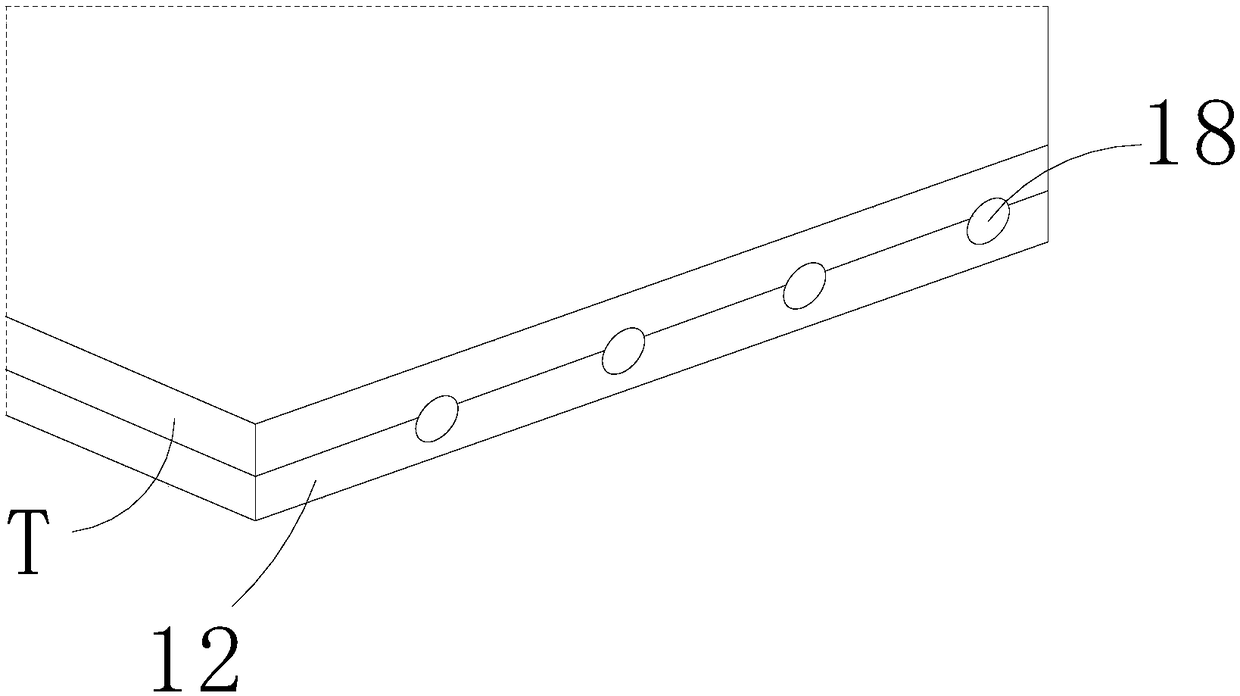

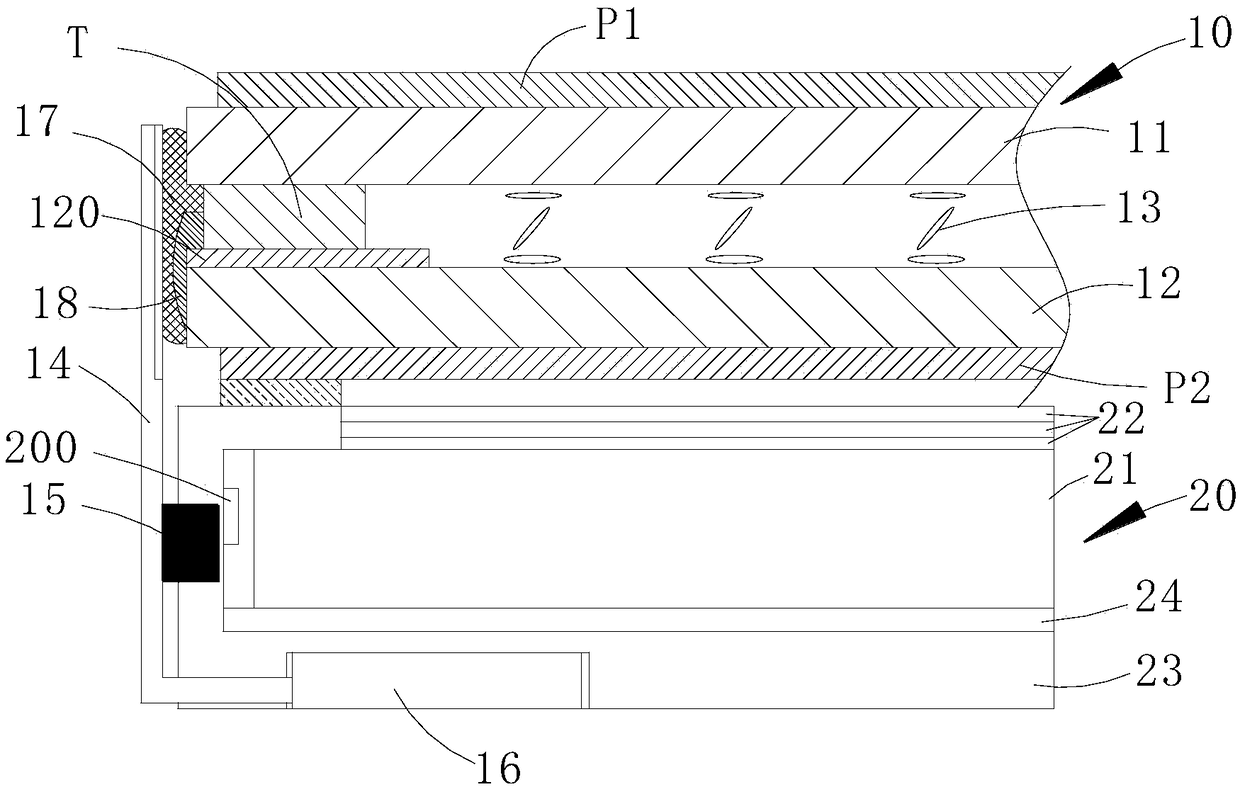

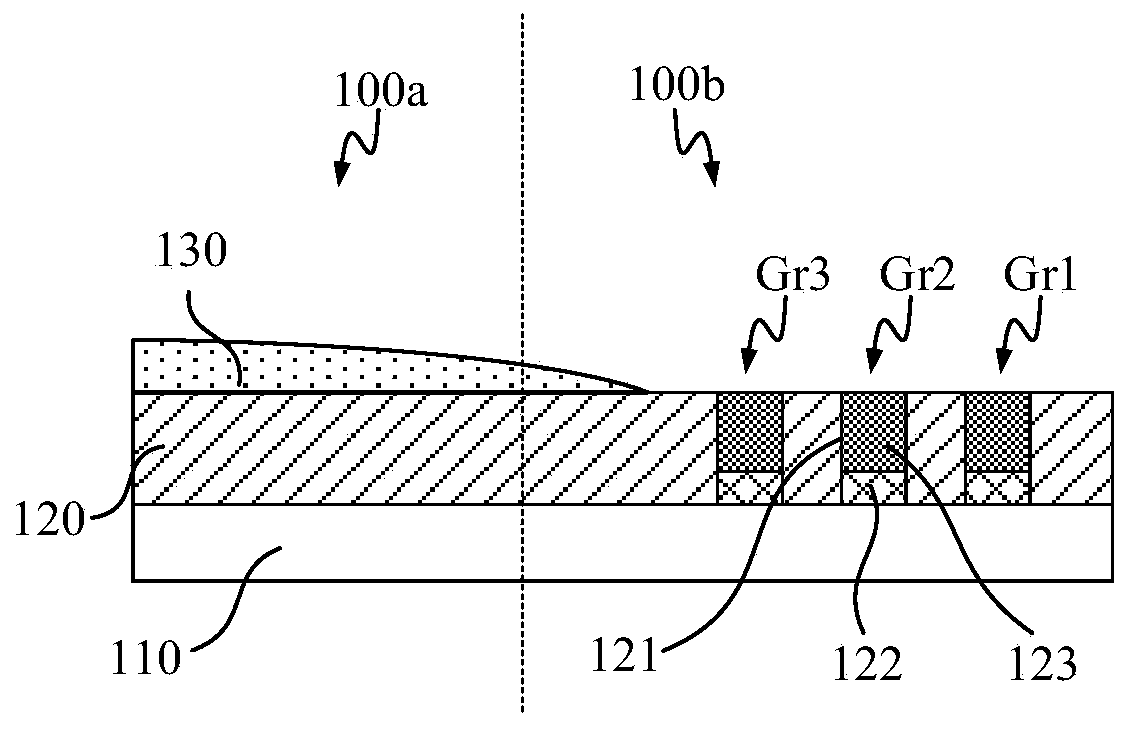

Liquid crystal panel, manufacturing method thereof and display device

InactiveCN108153070AAchieve conductionAchieve ultra-narrow bezelNon-linear opticsLiquid-crystal displayColor film

The invention discloses a liquid crystal panel, which comprises a color film substrate, an array substrate, a liquid crystal between the color film substrate and the array substrate, a crystal coatingthin film, a driving chip arranged on the crystal coating thin film and a circuit board; one end of the crystal coating thin film is bonded to the end face of the array substrate, and electrically connected with a metal conductor array in the array substrate; the other end of the crystal coating thin film is bounded with the circuit board. The invention further discloses a manufacturing method ofthe liquid crystal panel, and the display device. When the liquid crystal panel is accessed with signal, the crystal coating thin film is laminated on the end face of the array substrate by the method of end face binding, thus the conduction of the metal conductor array in the array substrate is realized, a long binding zone extended from the TFT substrate side can be avoided; the liquid crystalpanel is good for realizing an ultra-narrow side frame or a frame-free display device.

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

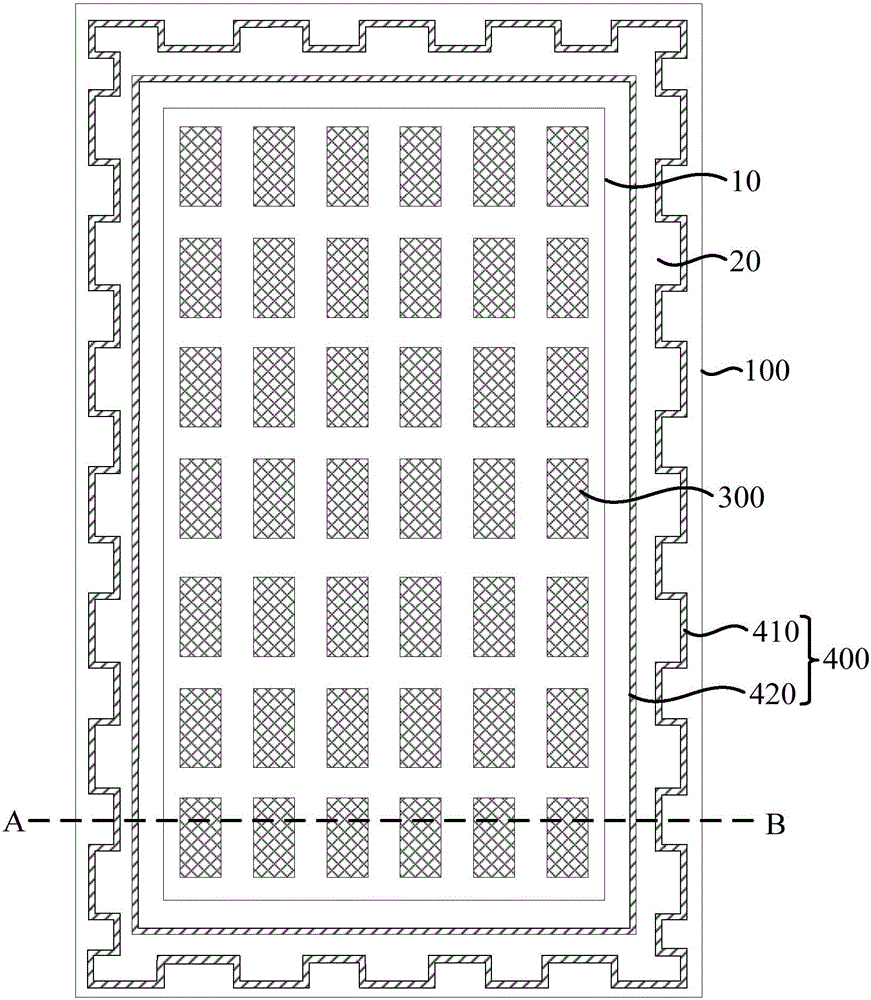

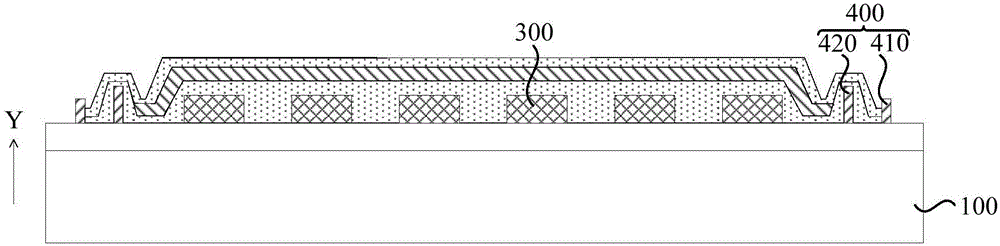

Flexible display panel and manufacturing method thereof, and display device

ActiveCN106876428AExtended service lifeReduce the impactFinal product manufactureSolid-state devicesDisplay deviceEngineering

The invention discloses a flexible display panel and a manufacturing method thereof, and a display device. A groove is formed in a non-display region of a flexible substrate; the bottom of a first barrier dam is embedded into the first groove; and a packaging membrane layer covering a plurality of organic electroluminescent structures and a second barrier dam is arranged in a region limited by the first barrier dam. Therefore, interfaces in different directions are increased by using the first barrier dam so as to block an extension direction of a crack, so that extension of the crack caused at the edge of the flexible display panel to the display region can be prevented. Moreover, the bottom of the first barrier dam is embedded into the first groove of the flexible substrate and the first barrier dam in the first groove and the flexible substrate form interfaces in different directions, so that the extending direction of the crack can be blocked based on the interfaces; and thus extending of the crack to the display region can be prevented, so that an objective of reducing the opportunity of entrance of water and oxygen into the display region can be achieved and thus the influence on the organic electroluminescent structure by water and oxygen can be reduced. Therefore, the service life of the flexible display panel can be prolonged.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

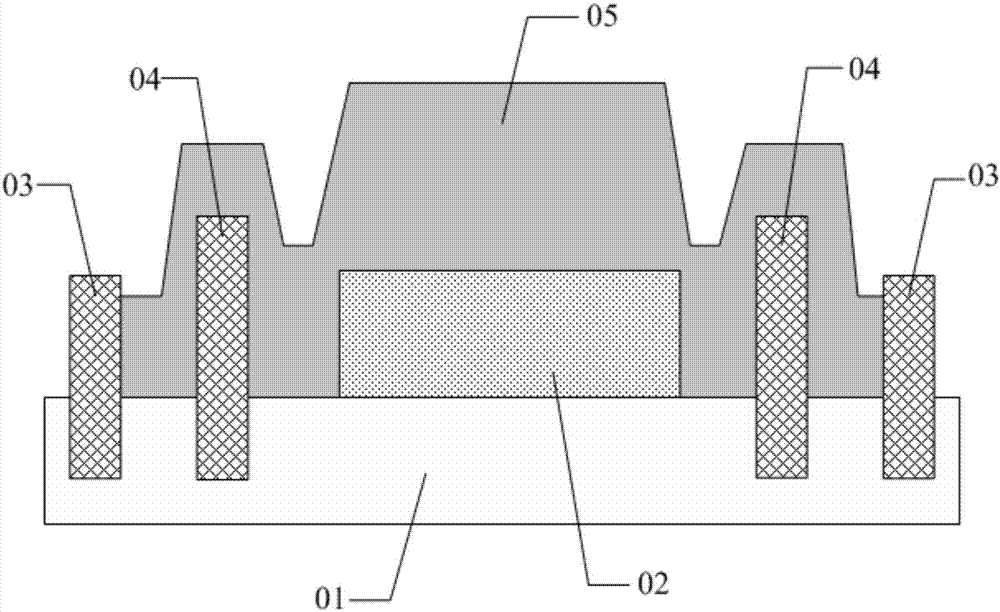

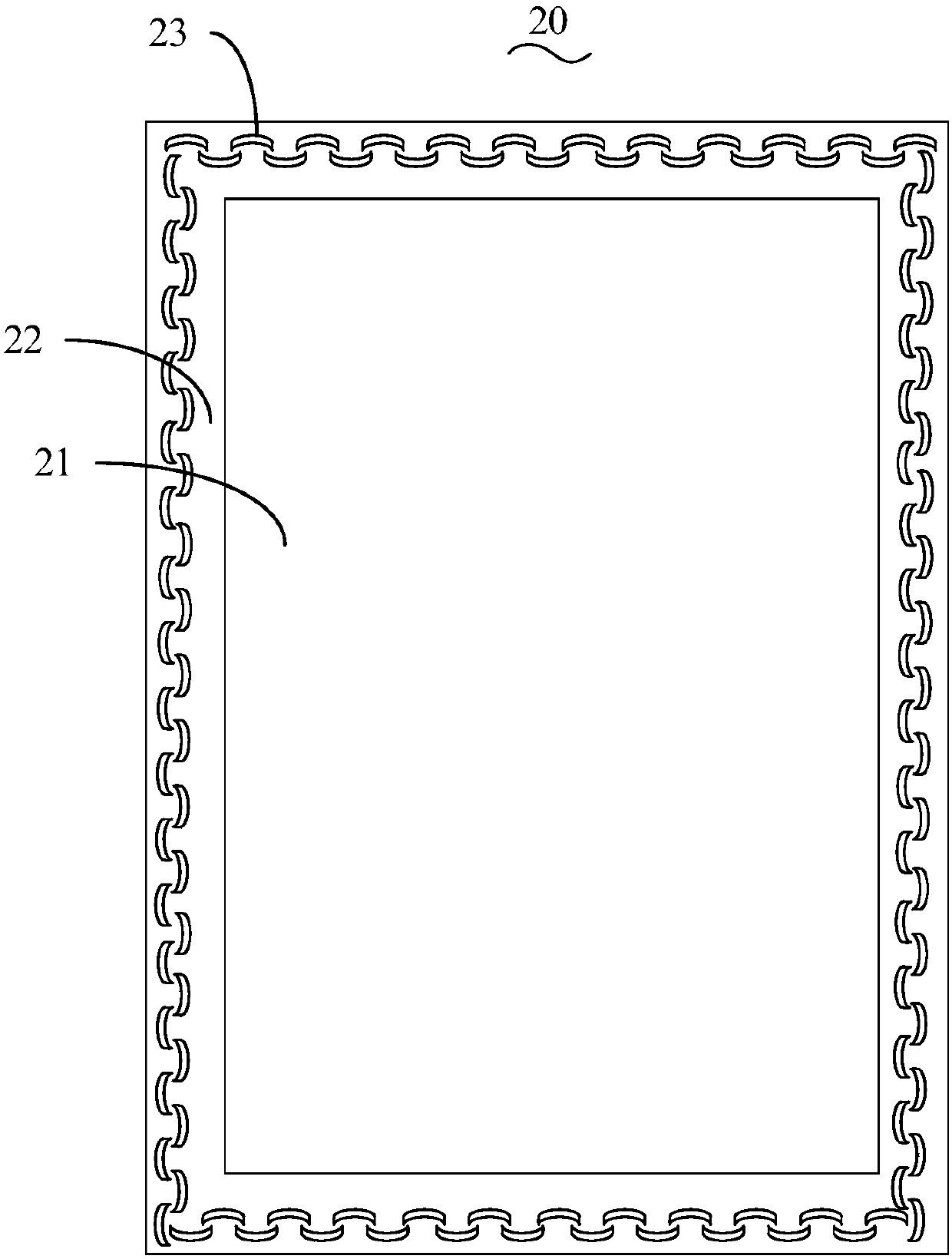

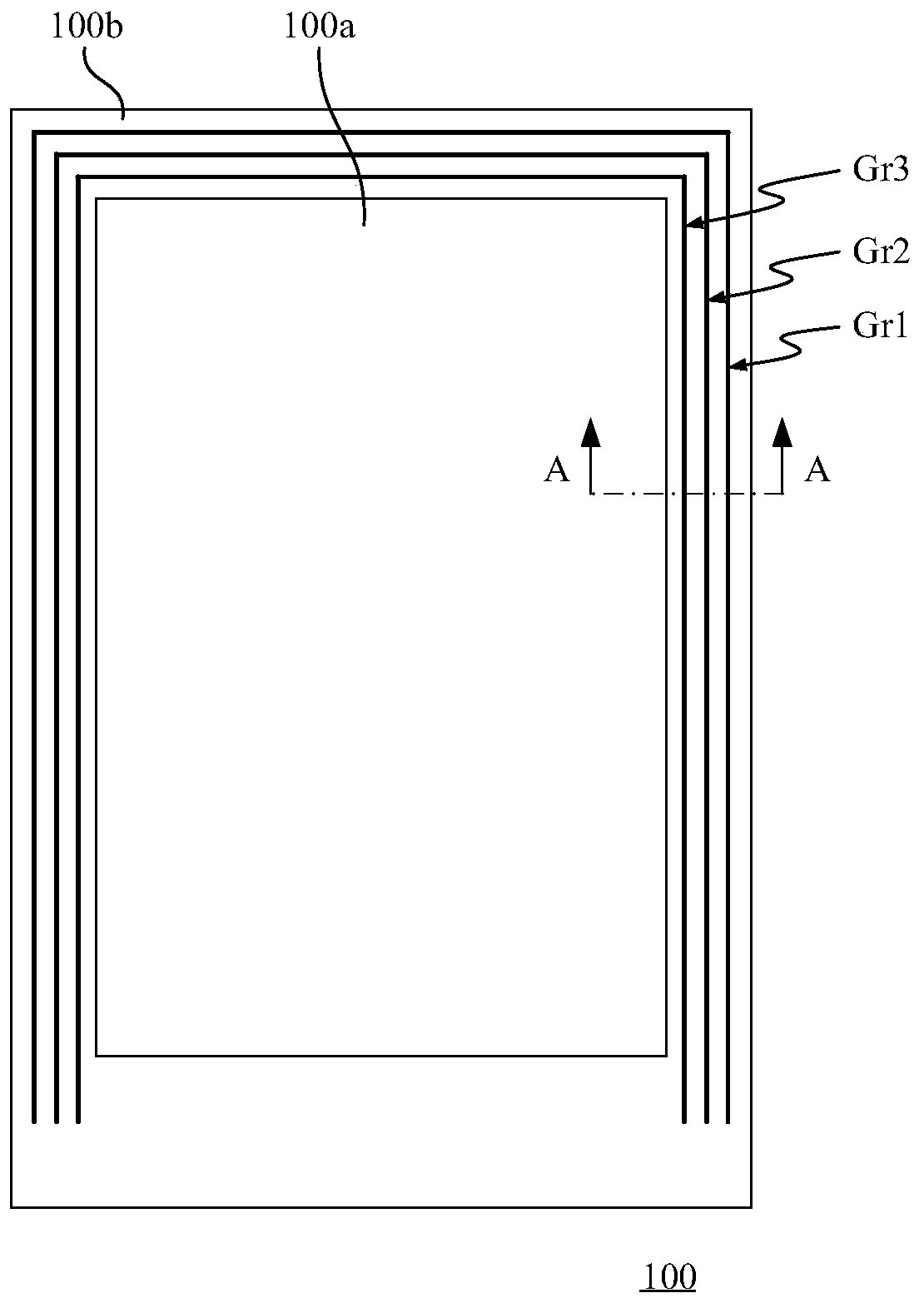

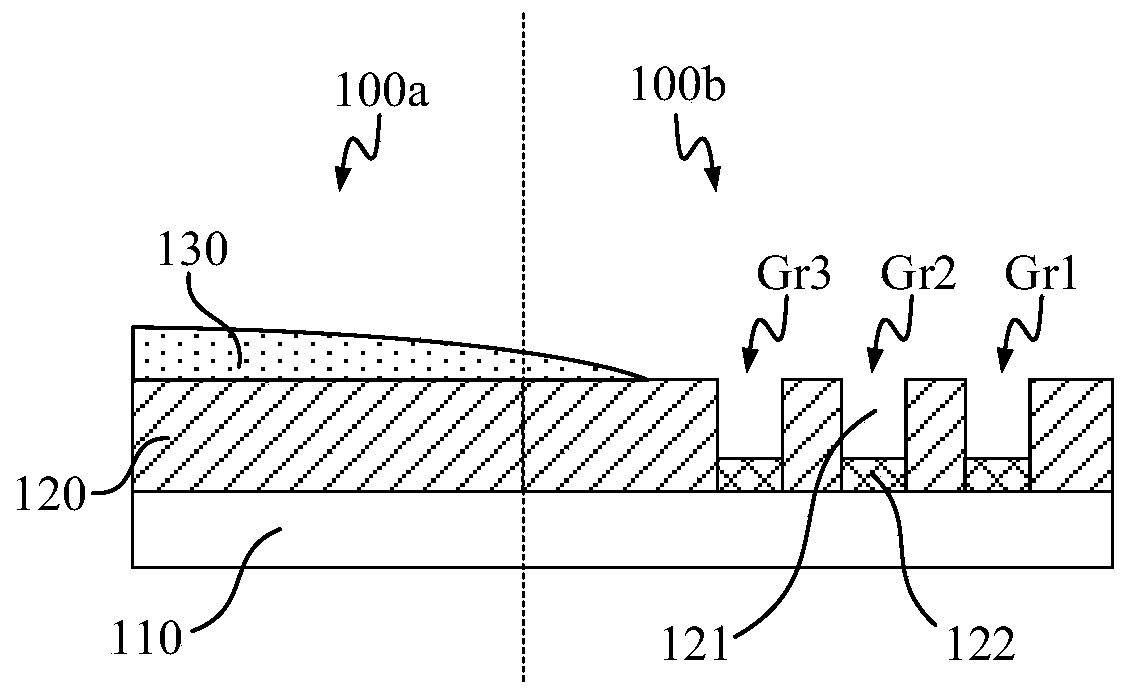

Organic light-emitting display panel and organic light-emitting display device

InactiveCN106848107AIncreased stress surfacePrevent extensionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses an organic light-emitting display panel and an organic light-emitting display device. The organic light-emitting display panel comprises a substrate, an organic light-emitting structure and at least one barricade, wherein the barricades surround the organic light-emitting structure and point to the edge along the geometric center of the substrate, and the barricades are sequentially arranged. In the direction perpendicular to the stacking direction of the substrate and the organic light-emitting structure, the barricade closest to the edge of the substrate is the first barricade, and the first barricade is formed by connecting one or more nonlinear sub barricades, so that the stress area of the first barricade is increased, the effect of dispersing stress generated on the edge when the organic light-emitting display device is bent is achieved, and then the phenomenon that cracks generated by the stress effect stretches to a display region is avoided.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

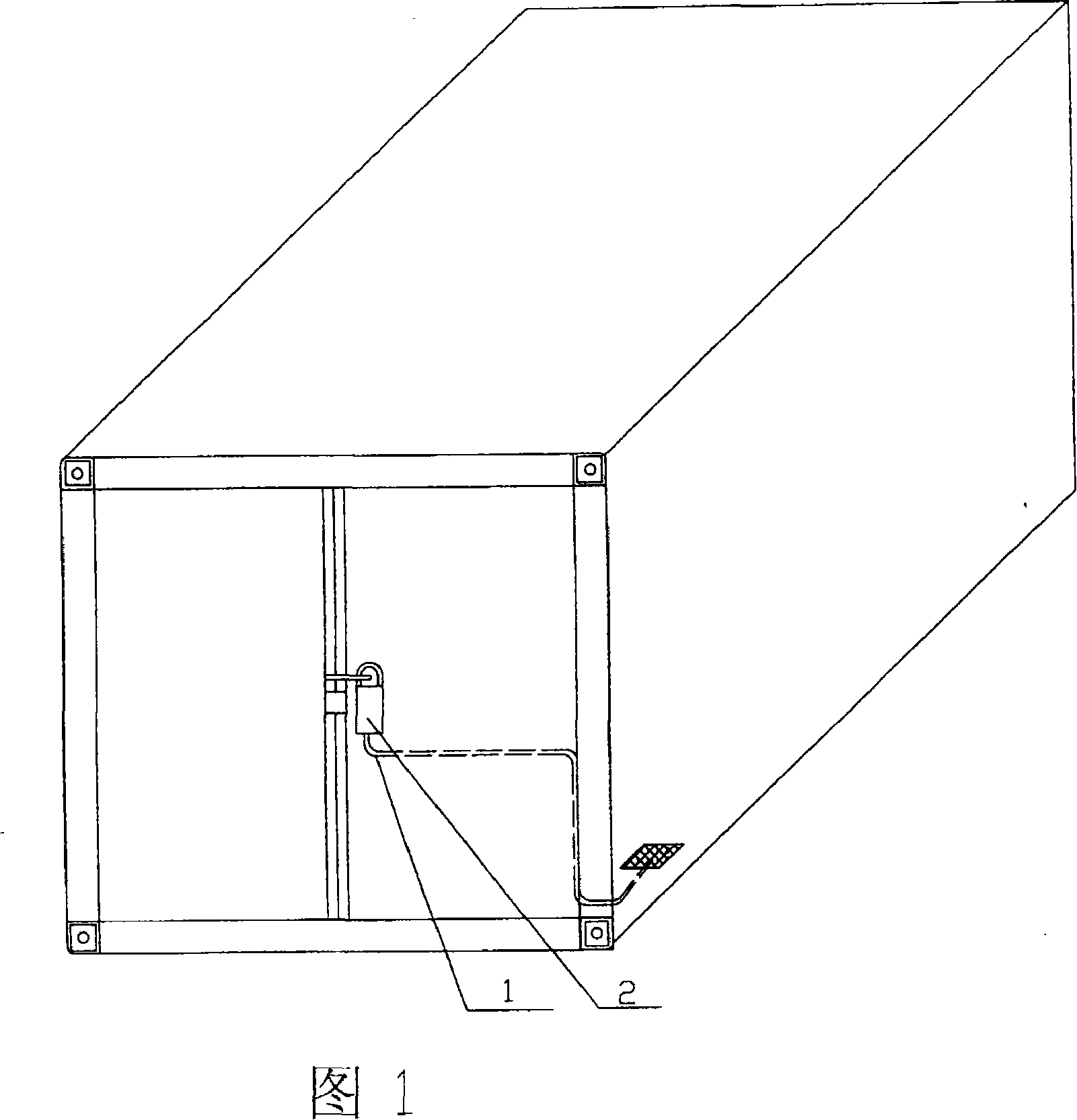

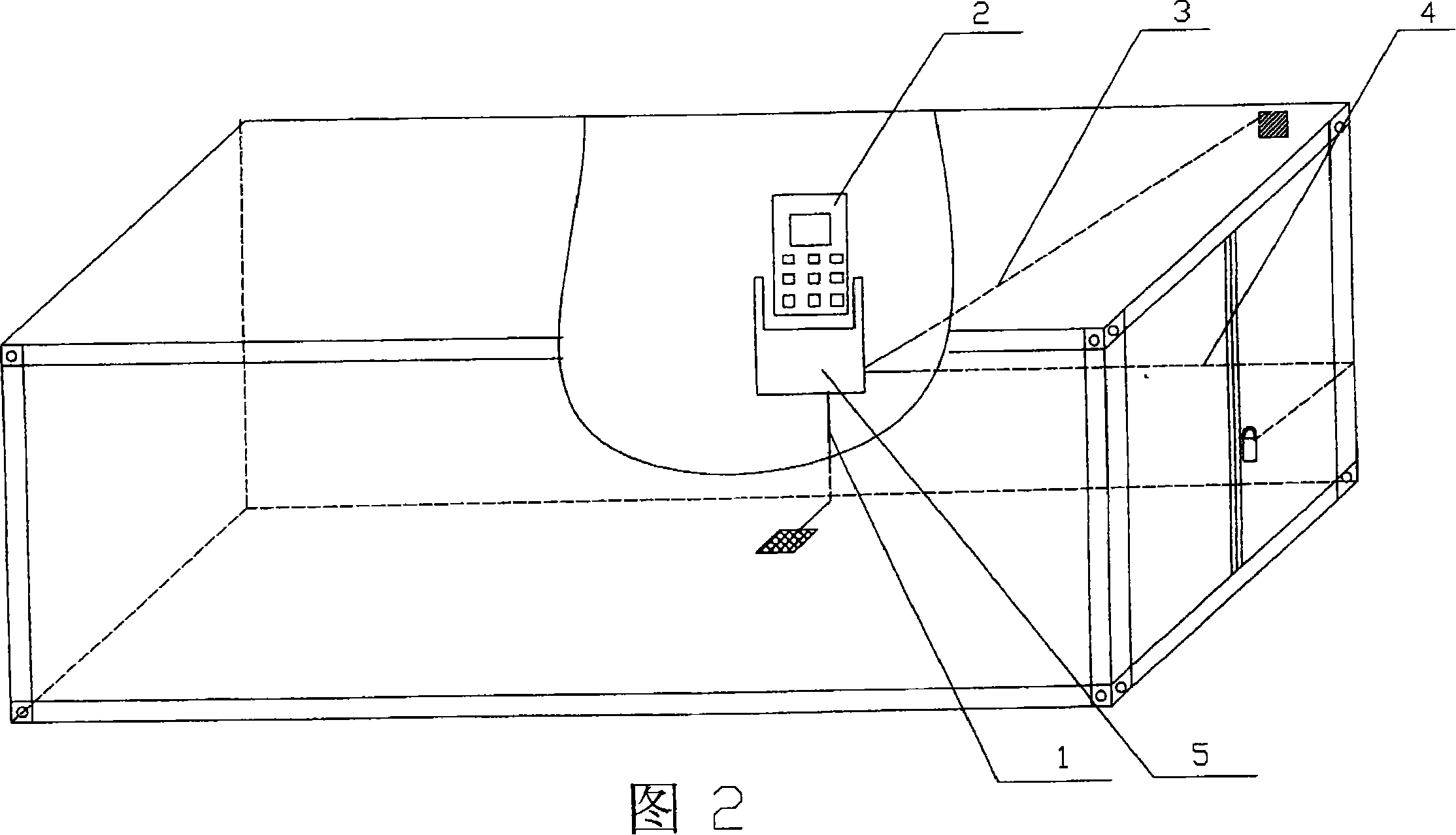

Intelligent container or the like and use thereof

InactiveCN101229869AIncrease useReduce volumeTemperatue controlLarge containersIntelligent NetworkLogistics management

The invention relates to an intelligent container or the analogs thereof, which is technologically characterized in that the invention consists of two parts of the installation power and an intelligent terminal with an entrance guard and an electronic lock (an intelligent lock) which is built-in arranged in an antenna integration; by combining with a lifting device, the invention is provided with an intelligent container with a function of lifting self-loading and unloading or the analogs. By integrated application of the technology such as the intelligent terminal combining with satellite positioning, the wireless communication, the RFID radio frequency identification, the network and the computer calculation, the real-time performance, the controllability and the security of freight transportation in the container can be solved and extend to a client as a temporary warehouse, which saves the automobile resources and waiting time and realizes the freight path information management which is a highest level of logistics business that anyone loads or unloads the freight anywhere and at anytime, the freight is in any location and in any status, the recording and monitoring of the freight environmental status in transporting the freight and the freight information and flow business can be inquired, traded and stowage planned on the network.

Owner:沈军

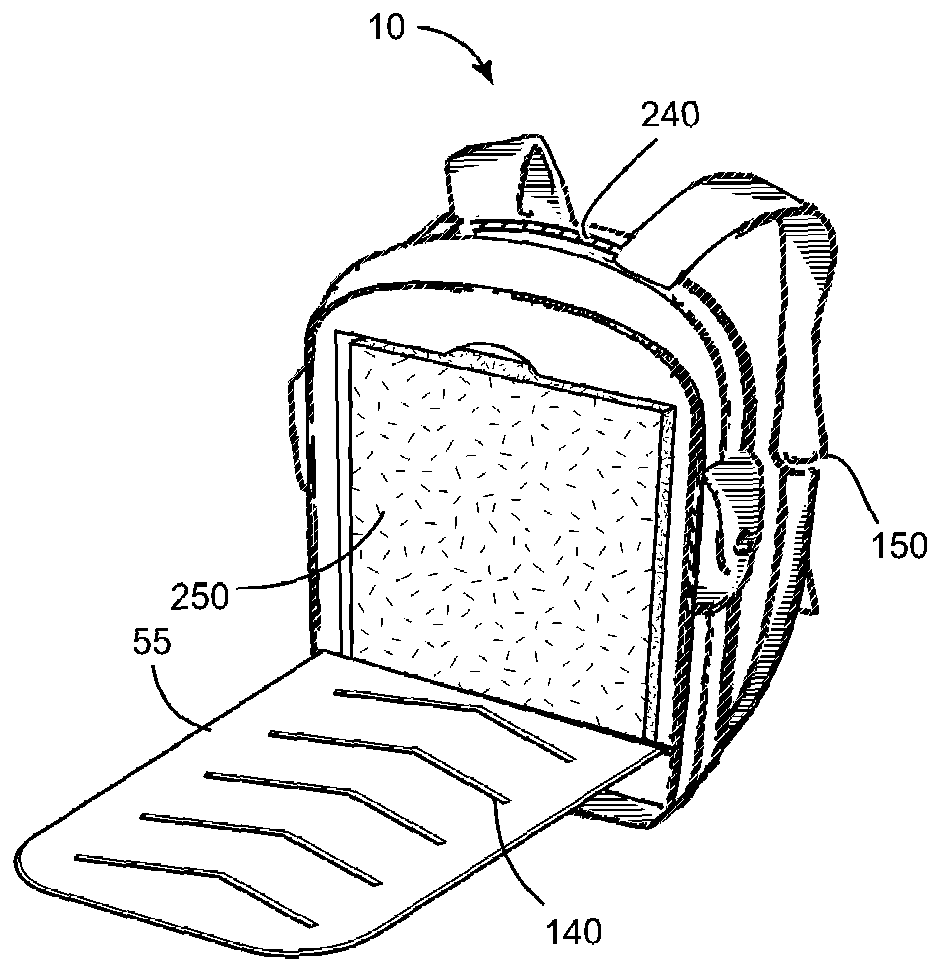

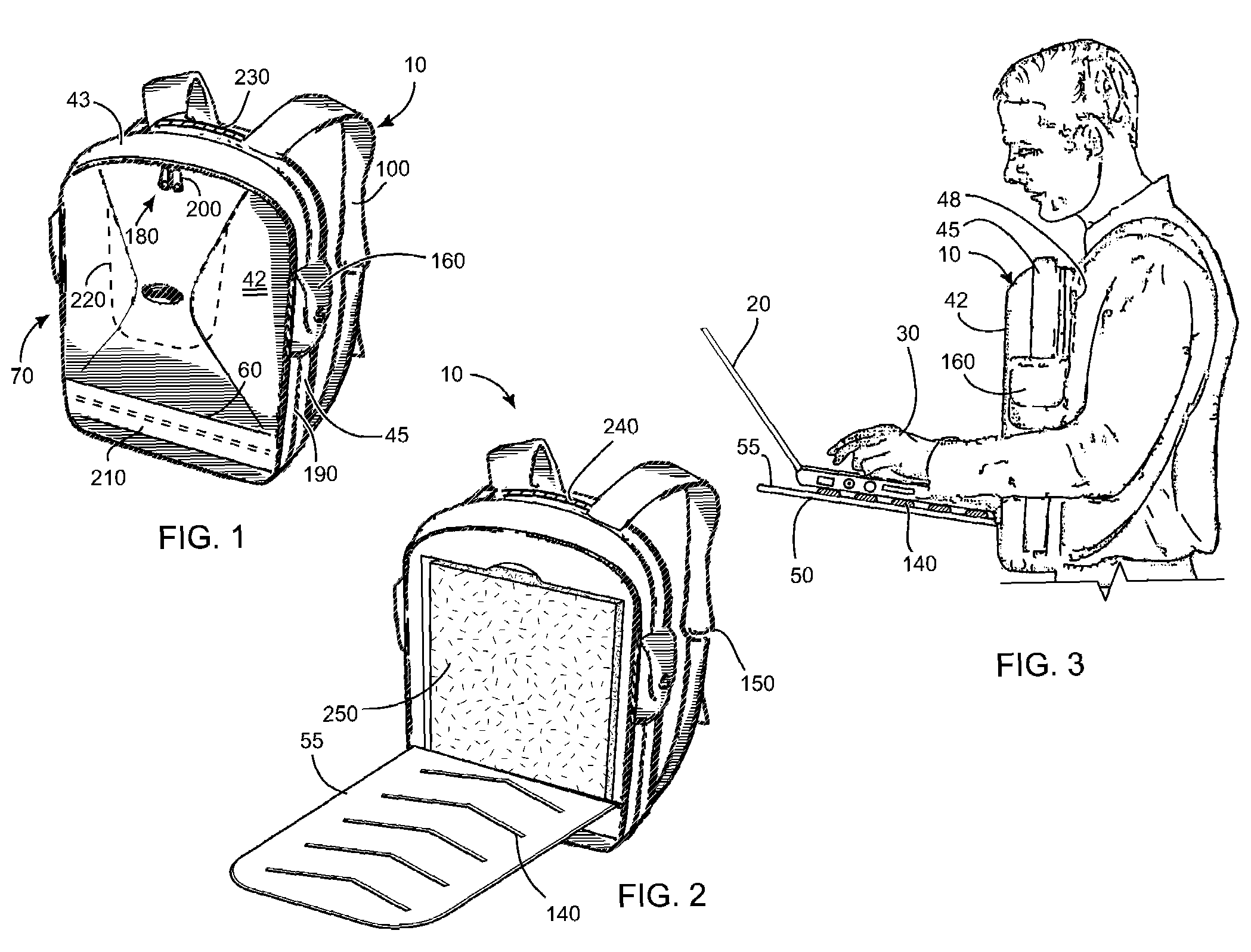

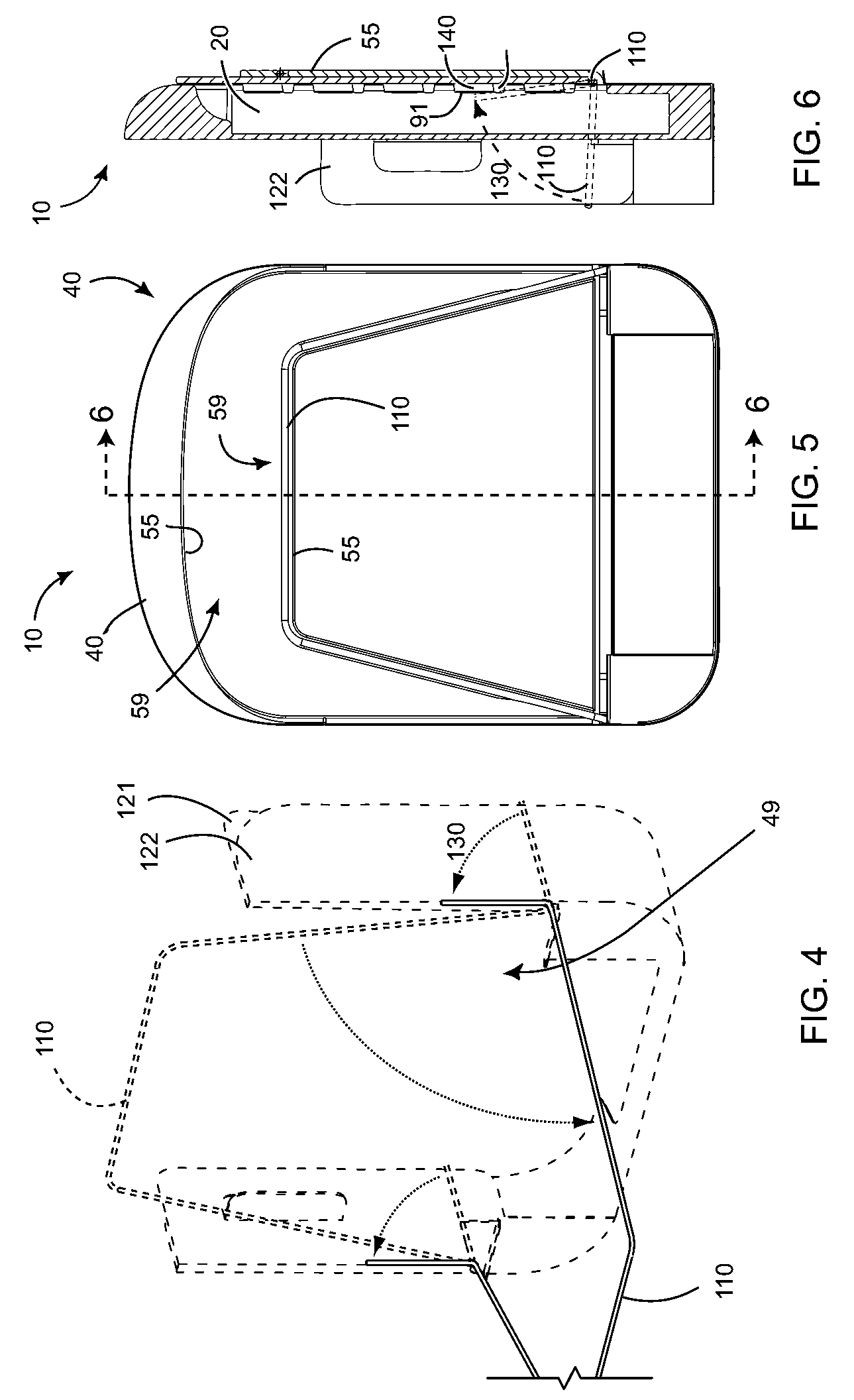

Backpack Laptop Tray

InactiveUS20100116860A1Easy to usePrevent extensionTravelling sacksTravelling carriersComputer caseLaptop

A backpack for storing and facilitating the use of a laptop computer by a user is disclosed. The backpack includes an enclosure having a front side, a back side, and at least one peripheral edge. The front side includes a laptop compartment flap that is hinged across a horizontal fold line and pivotable between a closed and an open position. The laptop compartment flap also includes a stop means preventing the laptop compartment flap from extending past the open position. With the laptop stored in the laptop compartment of the enclosure, the user may support the backpack in front of the user by the shoulders using shoulder straps, open the laptop compartment flap, remove the laptop and supported the laptop on an inside surface of the laptop compartment flap, with the weight of the laptop being supported by the flap and the stop means.

Owner:TELLO RICARDO

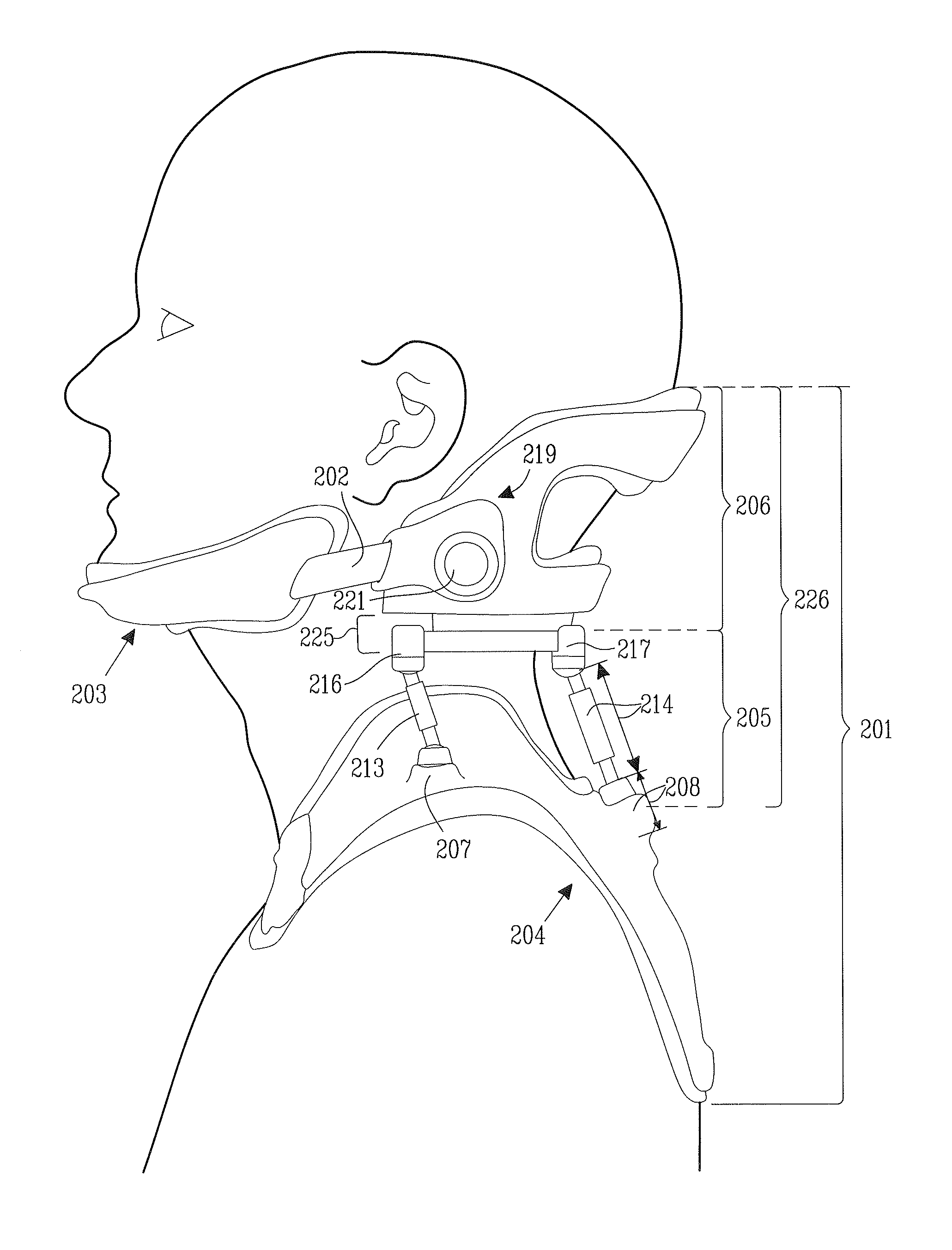

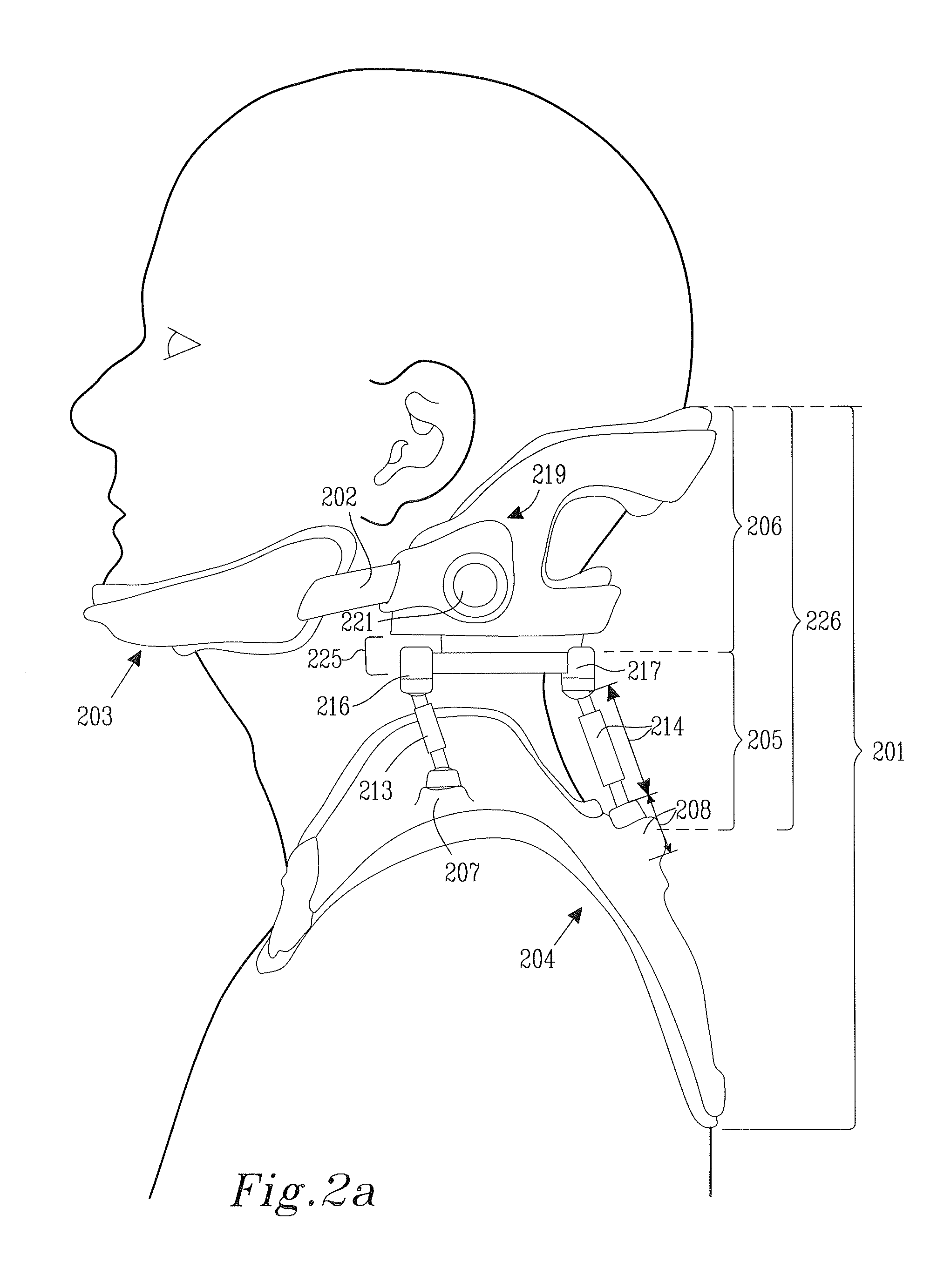

Mobilizing neck support device

InactiveUS20100298748A1Comfortable supportComfortable safetyFractureChinPhysical medicine and rehabilitation

The invention discloses a cervical collar which provides support, safety and stability to the neck of the wearer, and is arranged to prevent cervical flexion, extension and bilateral lateral flexion while allowing cervical rotation. The cervical collar comprises two parts; one back piece including a shoulder and back support piece attached to an adjustable neck piece and a chin support piece. The chin support piece can be lowered, raised and / or removed by the wearer of the collar in order to allow opening of the mouth sufficiently for eating or performing personal hygiene without unwanted extension of the neck.

Owner:CERVRITE

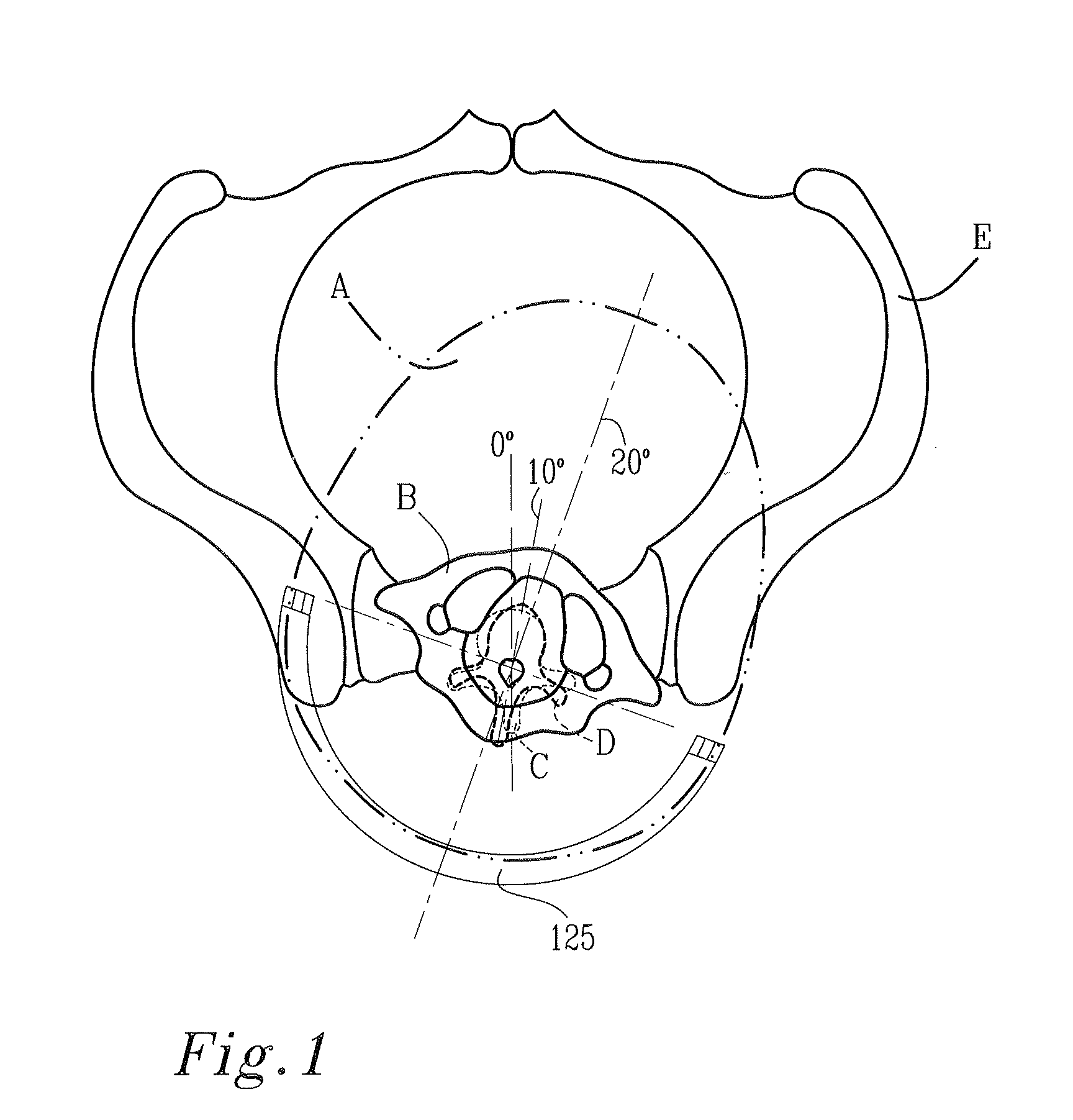

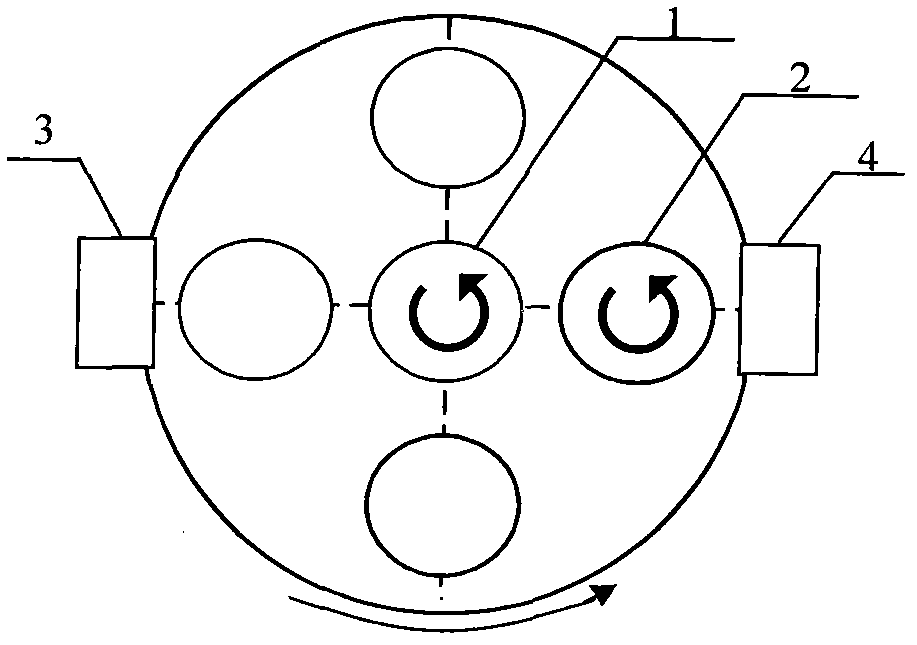

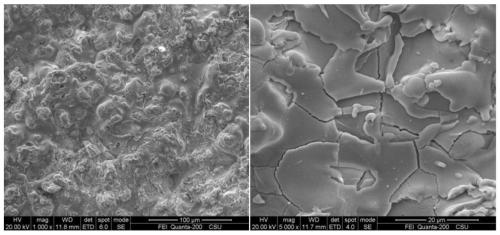

TiAlN/TiAlCN multilayer coating of substrate surface and preparing method thereof

ActiveCN102011090AMitigate defectsAlleviate dislocationVacuum evaporation coatingSputtering coatingSputteringHardness

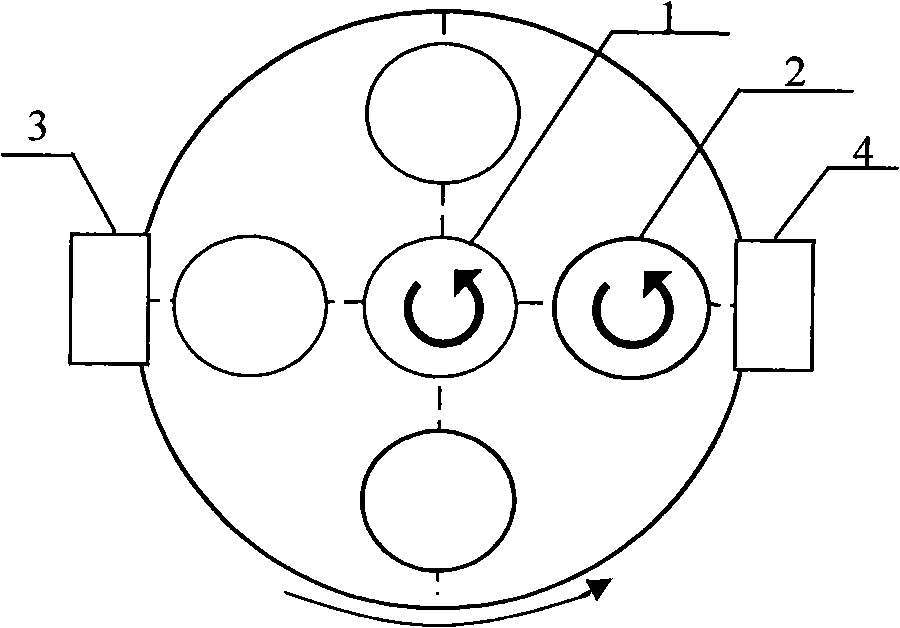

The present invention discloses a TiAlN / TiAlCN multilayer coating of substrate surface and preparing method thereof, wherein a transitional layer is between a substrate and a TiAlN / TiAlCN multilayer coating; the multilayer coating is formed by alternating periodic arrangement of TiAlN films and TiAlCN films; in a period, the thickness sum of the TiAlN films and the TiAlCN films is 1-20 nano; the percentage by weight of C atom in the TiAlCN films is 0.1-5%. The multilayer coating of the present invention has the advantages of high hardness, low internal stress and high tenacity; the cutting efficiency and corrosion resistance of the substrate can be improved, and the service life of the substrate can be prolonged. In the present invention, the multilayer coating is deposited by high power pulse magnetron sputtering technique; the problems that cathode arc ion plating and depositing speed is too fast to prepare a nano epitaxial film and that target poisoning is caused during the procedure for preparing films by DC magnetron sputtering are solved; the nano modulation period is controlled via adjusting the autorotation and revolution speeds of the substrate and adjusting the quantity of targets.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Elastic plugging agent

ActiveCN104559973AGood deformabilityImprove the blocking effectDrilling compositionSolid particleMonomer

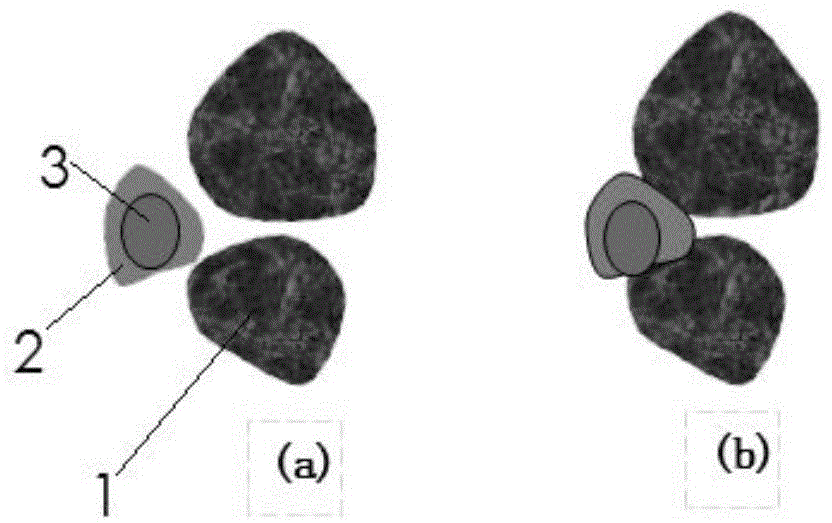

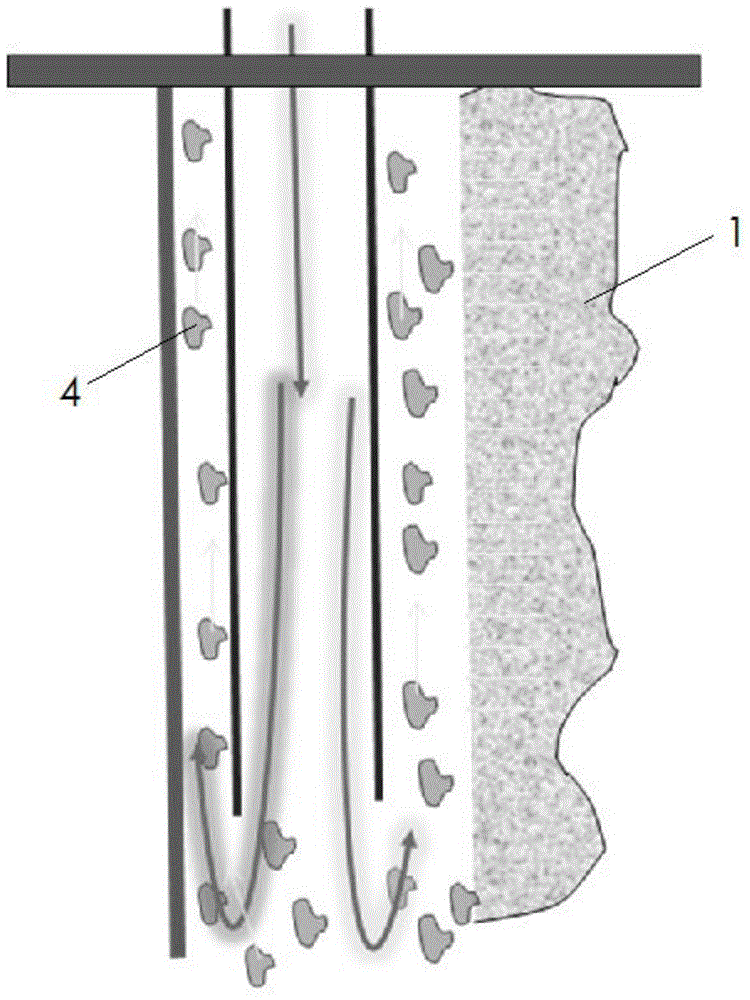

The invention relates to an elastic plugging agent which comprises the following components in parts by weight: 1 part of elastic temporary plugging particles and 0.1-10 parts of a bridging agent, wherein the elastic temporary plugging particles are prepared in such a way that a monomer, an initiating agent, a dispersing agent, rigid solid particles and elastic gel are added into water, stirred uniformly, heated to 60-150 DEG C, and dried after reaction is finished. The elastic plugging agent provided by the invention plays a unidirectional plugging effect, and has favorable adaptability to holes with inlets in different shapes owing to the characteristic of variable elasticity.

Owner:东营市大用石油助剂有限责任公司

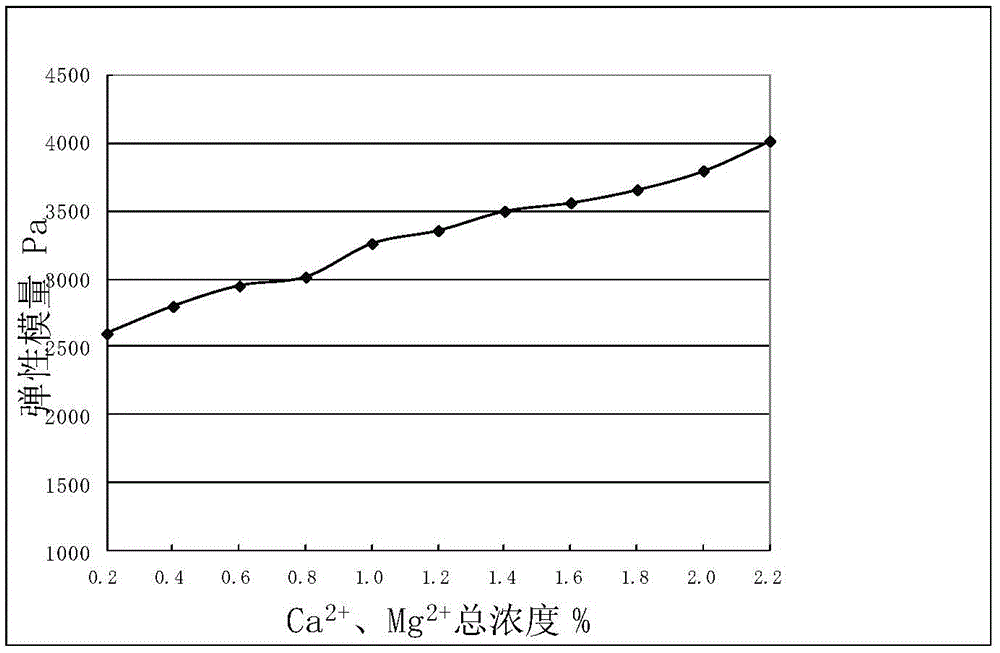

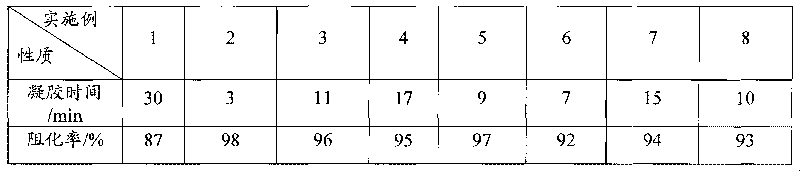

Composite gel inhibitor for preventing and controlling spontaneous combustion of coal in coal mine and preparation method thereof

InactiveCN101713296AReduced oxygen uptakeEasy to isolate and contactOther chemical processesDust removalSpontaneous combustionWater soluble

The invention relates to a composite gel inhibitor for preventing and controlling spontaneous combustion of coal in a coal mine and a preparation method thereof. The composite gel inhibitor provided by the invention comprises the following components in percentage by weight: 10 to 65.0 percent of graft copolymer, 0 to 4.00 percent of flame retardant, 20 to 60.0 percent of water glass, and the balance of water. The graft copolymer containing a -COOH functional group is obtained by adopting a water soluble polymer and unsaturated carboxylic acid monomers to perform graft copolymerization, and the composite gel inhibitor for preventing and controlling the spontaneous combustion of the coal in the coal mine is obtained by adding the flame retardant and the water glass into the graft copolymer. The flame retardant provided by the invention has the advantages of excellent retarding effect, environmental friendliness and the like.

Owner:府谷能源投资集团五一矿业有限公司

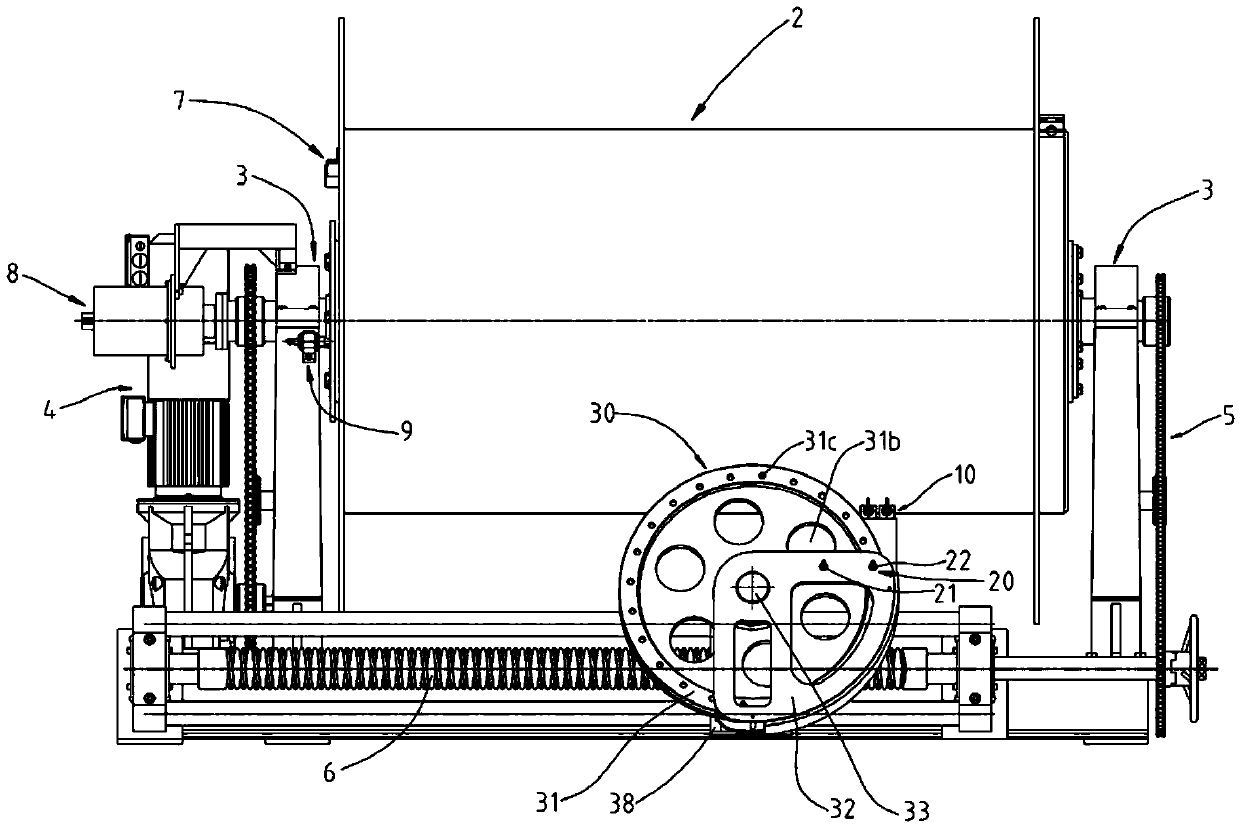

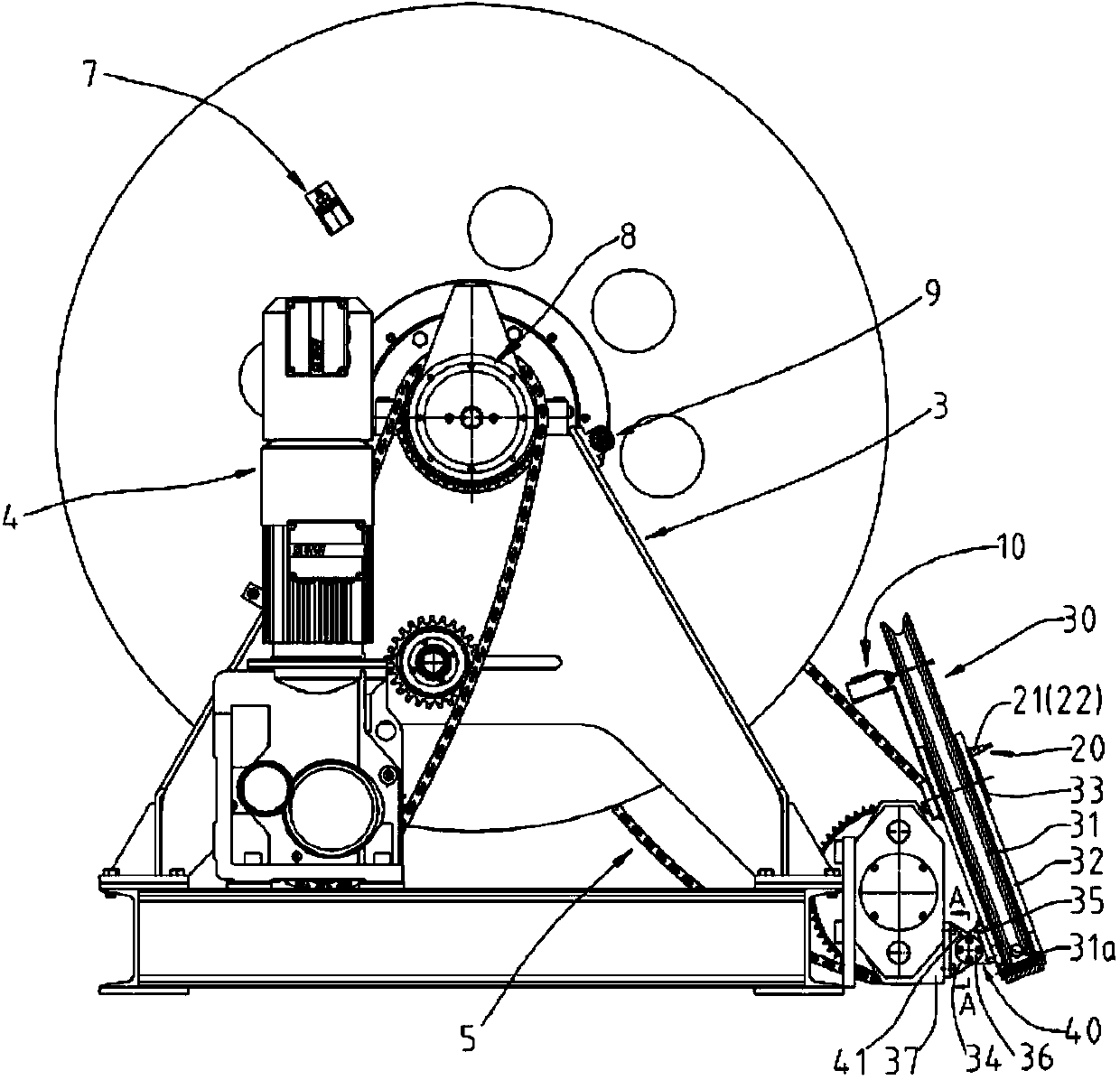

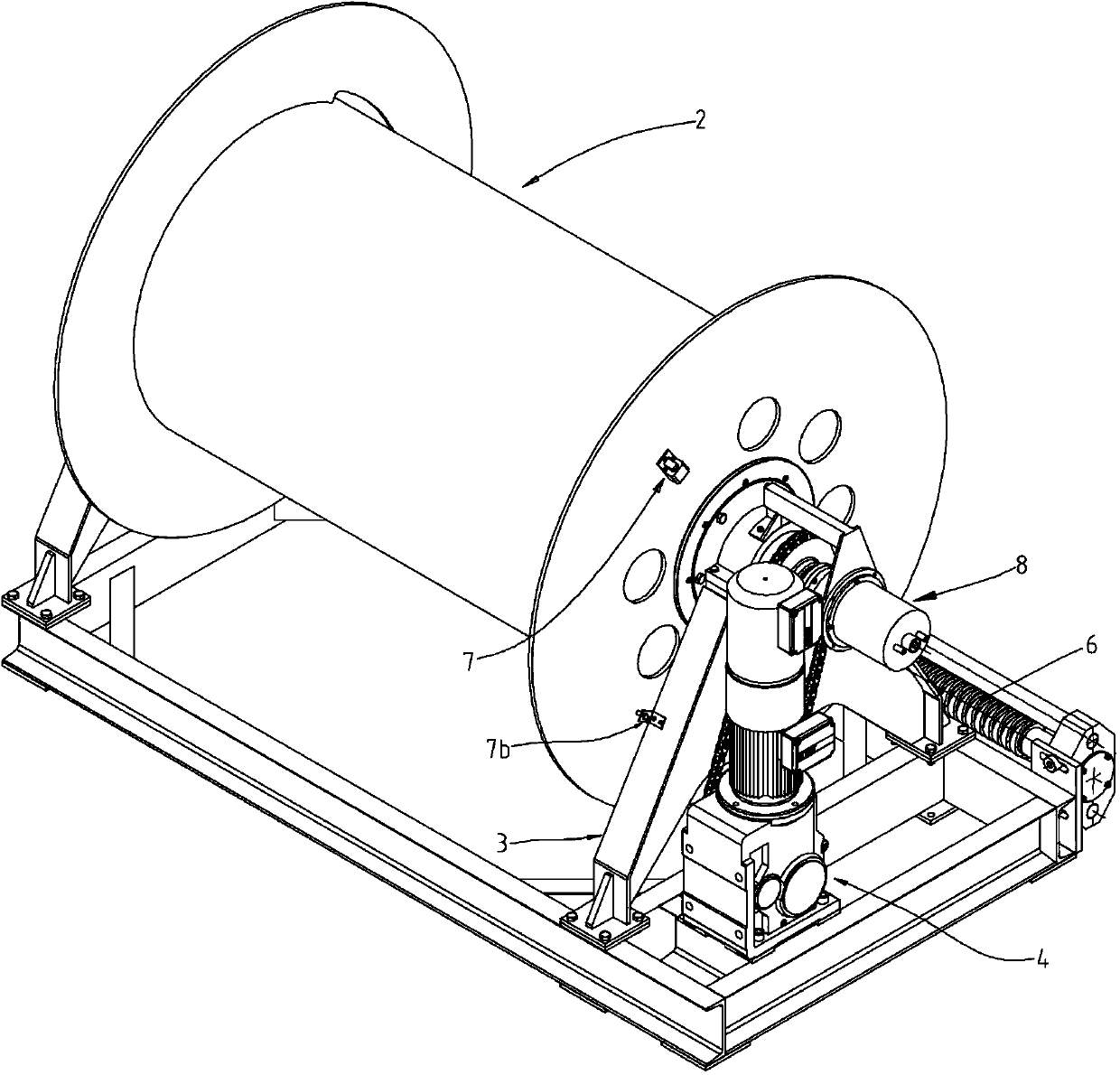

Storage winch with function of measuring tension and length of cable

InactiveCN103616048APrevent extensionPrevent slippageMeasurement devicesWinding mechanismsEngineeringLength measurement

The invention discloses a storage winch with a function of measuring tension and length of a cable. The storage winch comprises a cable storage cylinder, a support device, a cable guide device, a driving component, a cable arranging mechanism, a warning device, a power transmission communication interface connection device, a lightning attractor, a cable tension measuring device and a cable length measuring device. For cable length measurement, two lines of independent but related proximity switches are adopted for improving work reliability and measurement accuracy; for tension measurement, a pressure sensor is adopted, and force application pin rolls at two pin joint support seats between a cable guide support and a cable arranging sliding block are used for transmitting tension of the cable. The storage winch can be matched with a friction drive winch, is applicable to storage of a large volume of cables and arrangement of cables in order based on special support cables, has functions of measuring tension and laying length of the cable, protecting the cable and guaranteeing the operation safety, and meets special task requirements on large load, good safety, reliable operation, long cable laying distance, and the like.

Owner:JIANGSU UNIV OF SCI & TECH

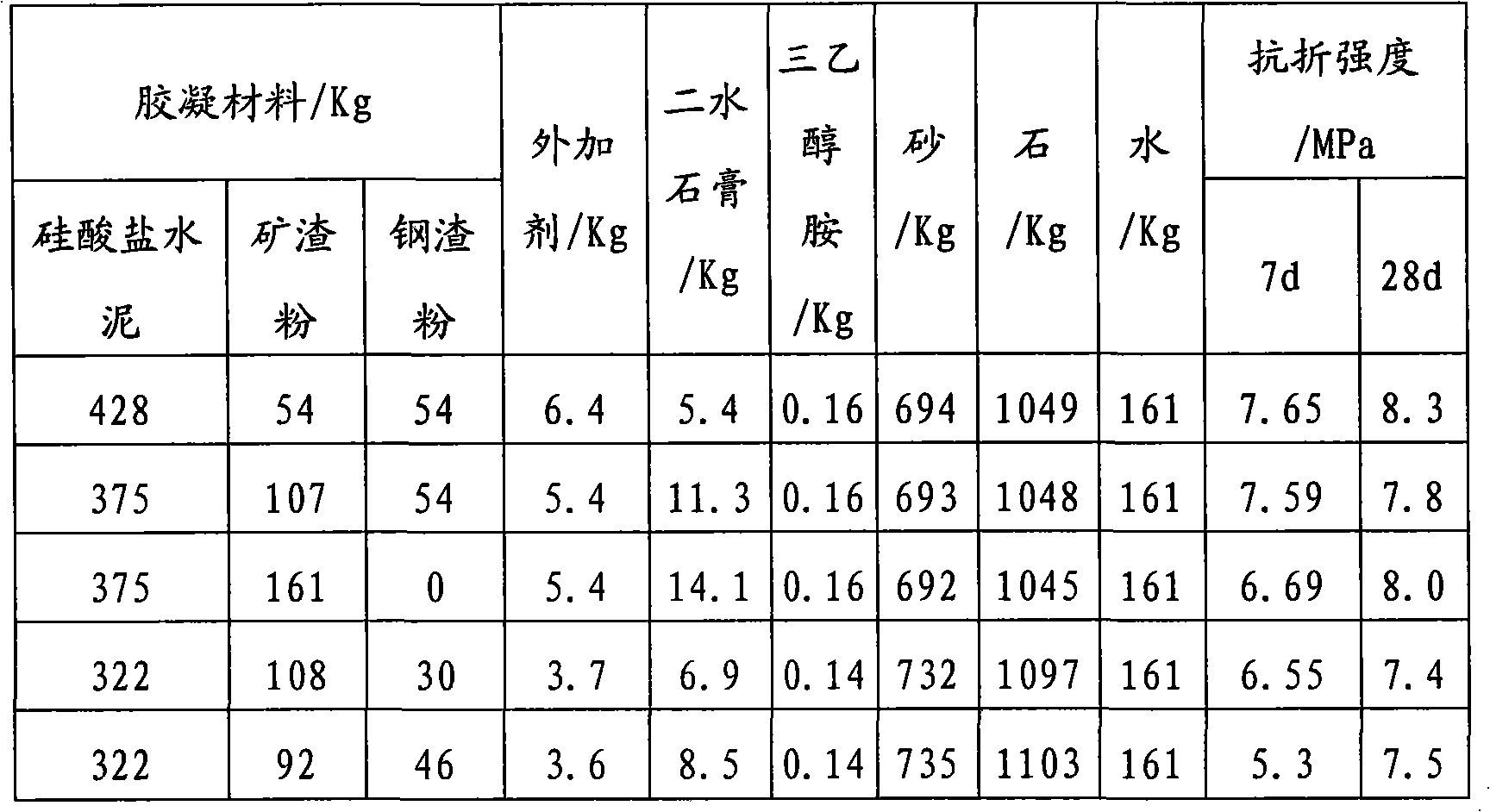

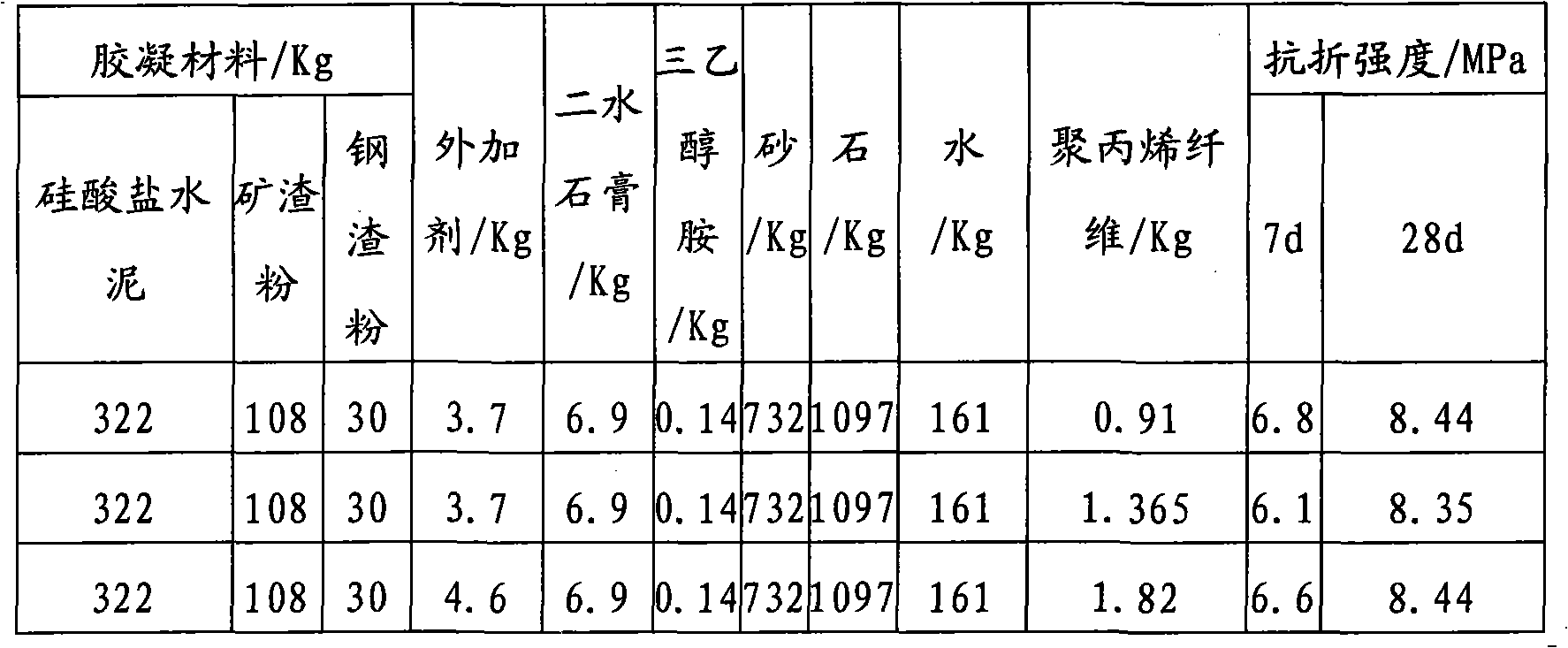

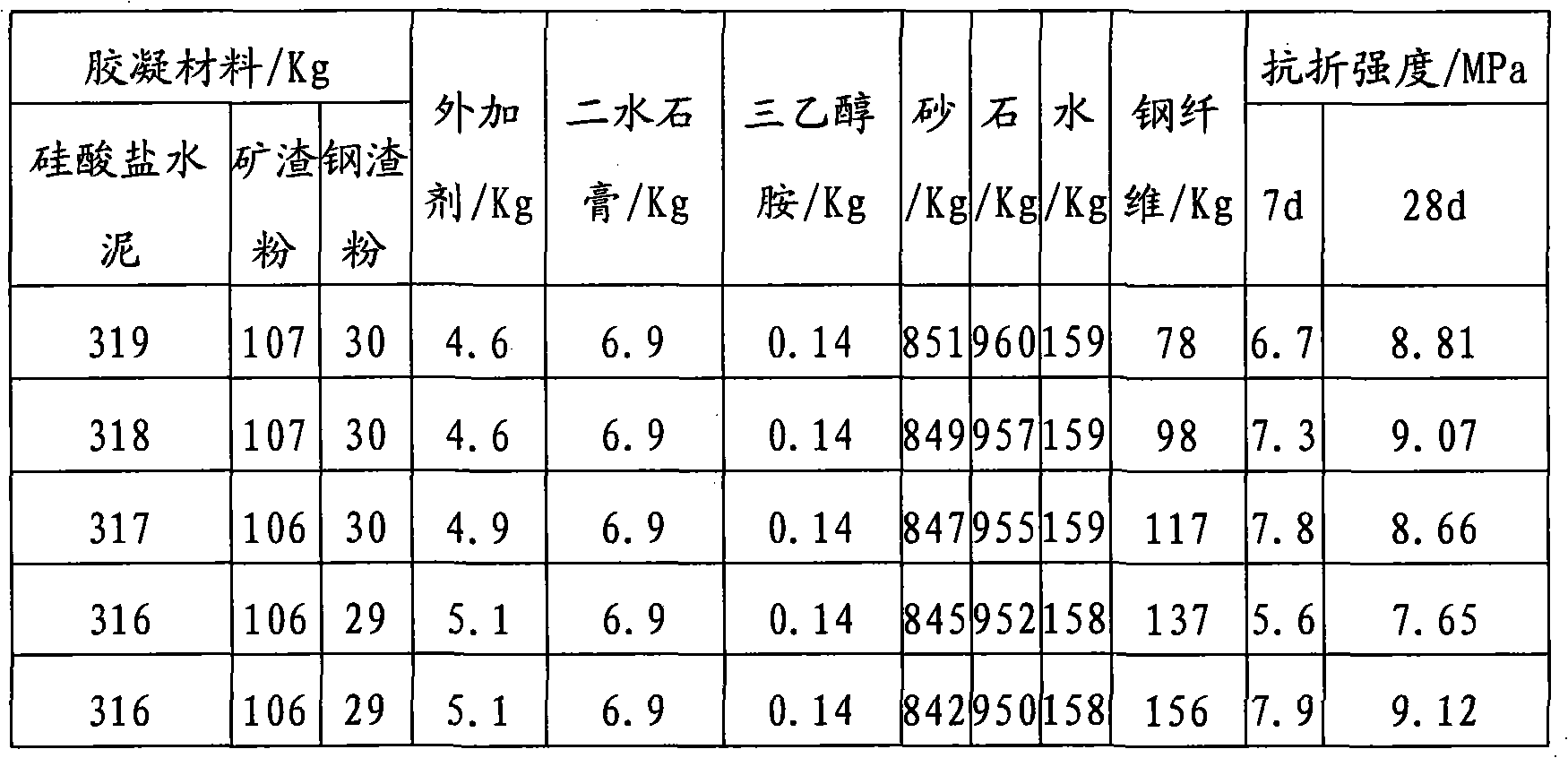

High folding resistance road concrete material and preparing method thereof

InactiveCN101265066AImprove compactnessImprove flexural strengthSolid waste managementSlagSodium fluoride

The invention discloses a road concrete material with high folding strength and a production method thereof. The road concrete material with high folding strength mainly contains binding agent, sand stone aggregate, mixing water, concrete admixture and excitant. The binding agent is composed of common silicate cement, ore slag powder and steel slag powder. The mass percentages of the components are as follows: 60-70% of common silicate cement, 20-30 % of ore slag powder and 0-10% of steel slag powder. The additional amount of the excitant is 5.0-10.0% of the total mass of the ore slag powder and the steel slag powder. The excitant is selected from gypsum, sodium sulfate, sodium fluoride, triethanolamine or a mixture thereof. By adding the excitant, the latent activity of the ore slag and the steel slag is excited, so that the compactness of concrete is improved and the folding strength of the road concrete is greatly improved.

Owner:SHENZHEN UNIV

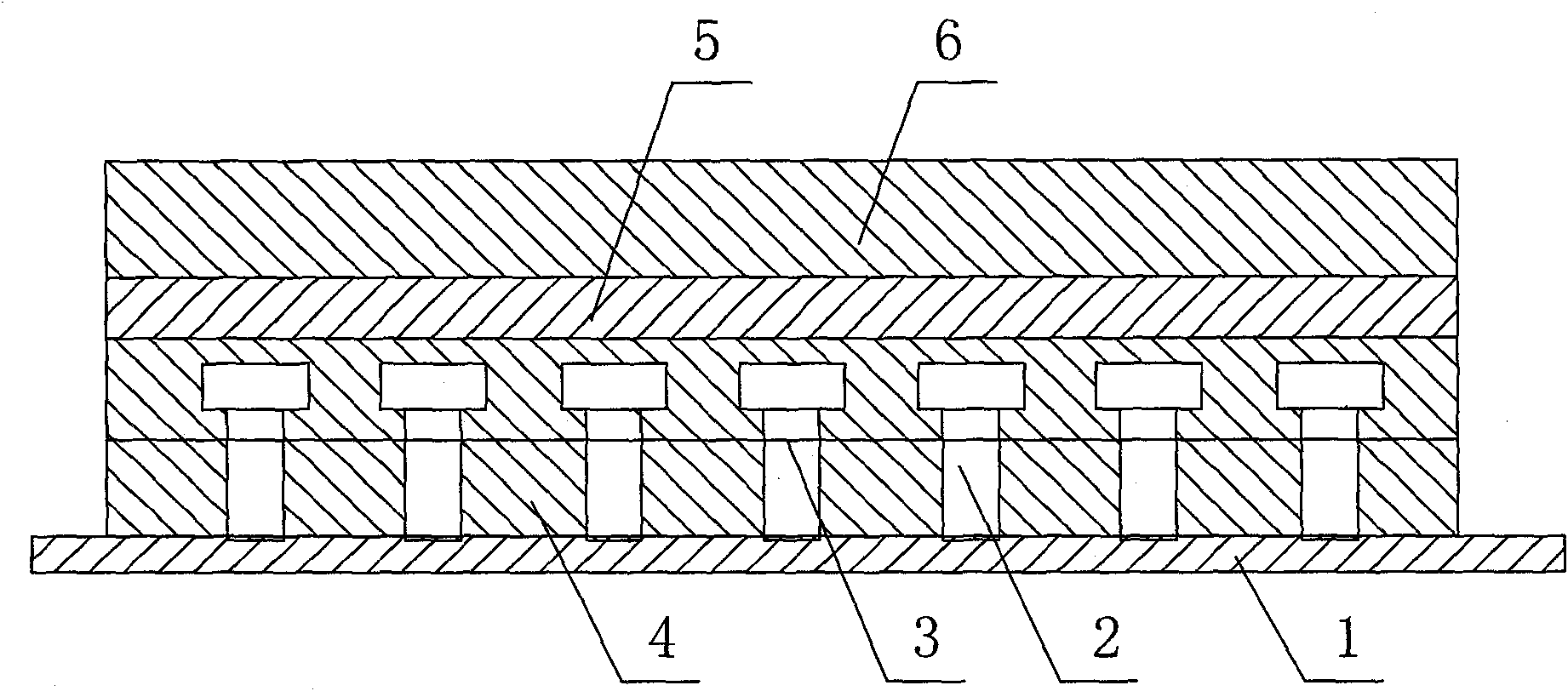

Paving method of steel box girder bridge deck payment layer

ActiveCN101660293AReduce tensile stressReduce shear stressSolid waste managementBridge structural detailsBridge deckEngineering

The invention belongs to the field of building materials, in particular to a paying method of a steel box girder bridge deck payment layer. The paying method of the steel box girder bridge deck payment layer is characterized by comprising the following steps: (1) bridge deck pre-cleaning; (2) welding of shearing rivets; (3) binding of reinforcing mats; (4) payment of a high-toughness high-strengthlight aggregation concrete layer: paying high-toughness high-strength light aggregation concrete on steel plates of a steel box girder bridge deck and forming the high-toughness high-strength light aggregation concrete layer, wherein the high-toughness high-strength light aggregation concrete is higher than the shearing rivets by 1-2 cm and the thickness of the high-toughness high-strength lightaggregation concrete is 5-8 cm; (5) payment of a waterproof bonding stress absorbing layer, wherein the thickness of the waterproof bonding stress absorbing layer is 1-2 cm; and (6) payment of a payment layer for resisting slipping, reducing noise and draining: preparing the payment layer for resisting slipping, reducing noise and draining, wherein the thickness of the pavement layer is 3-5 cm. The payment layer has the characteristics of stress absorption, lightness and excellent slipping resistance.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Low-smoke flame-retarding ceramizable PVC material, preparation method, and application thereof

The invention relates to the technical field of PVC materials and particularly relates to a low-smoke flame-retarding ceramizable PVC material, a preparation method and an application thereof. The PVC material includes, by weight, 20-80 parts of PVC resin, 20-60 parts of a plasticizer, 10-30 parts of a flame retardant, 1-10 parts of a smoke inhibitor, 20-80 parts of a ceramization powder, 0.5-5 parts of a compatilizer, 0.02-0.1 parts of an anti-ultraviolet agent, and 0.02-0.1 parts of an antioxidant. The PVC material has excellent flame-retarding effect, low smoke density, high strength, good flexibility and high break elongation, can form a compact ceramized product at the temperature range of 600-1000 DEG C, is low in ceramization temperature and can form compact ceramic. The formed ceramized product has high high-temperature strength and anti-heat-flow-impact capability.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Organic light-emitting display panel

ActiveCN106293258AAvoid corrosionDoes not increase thicknessSolid-state devicesInput/output processes for data processingOrganic layerEngineering

The invention discloses an organic light-emitting display panel. The organic light-emitting display panel comprises an organic light-emitting element array substrate, a thin-film encapsulation layer covering the organic light-emitting element array substrate, a plurality of touch-control driving electrodes, a plurality of touch-control sensing electrodes, a plurality of first touch-control routing lines, and a plurality of second touch-control routing lines, wherein the first touch-control routing lines are electrically connected with the corresponding touch-control driving electrodes; the second touch-control routing lines are electrically connected with the corresponding touch-control sensing electrodes; the thin-film encapsulation layer comprises a first organic layer and a second organic layer; a plurality of first grooves and a plurality of second grooves are formed in the first organic layer, and a plurality of third grooves and a plurality of fourth grooves are formed in the second organic layer; the touch-control driving electrodes are located in the first grooves, and the first touch-control routing lines are located in the second grooves; the touch-control sensing electrodes are located in the third grooves, and the second touch-control routing lines are located in the fourth grooves; the first touch-control routing lines and the second touch-control routing lines are located in the thin-film encapsulation layer. The organic light-emitting display panel provided by the invention is used for meeting the requirement that the touch-control routing lines are not easy to corrode.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

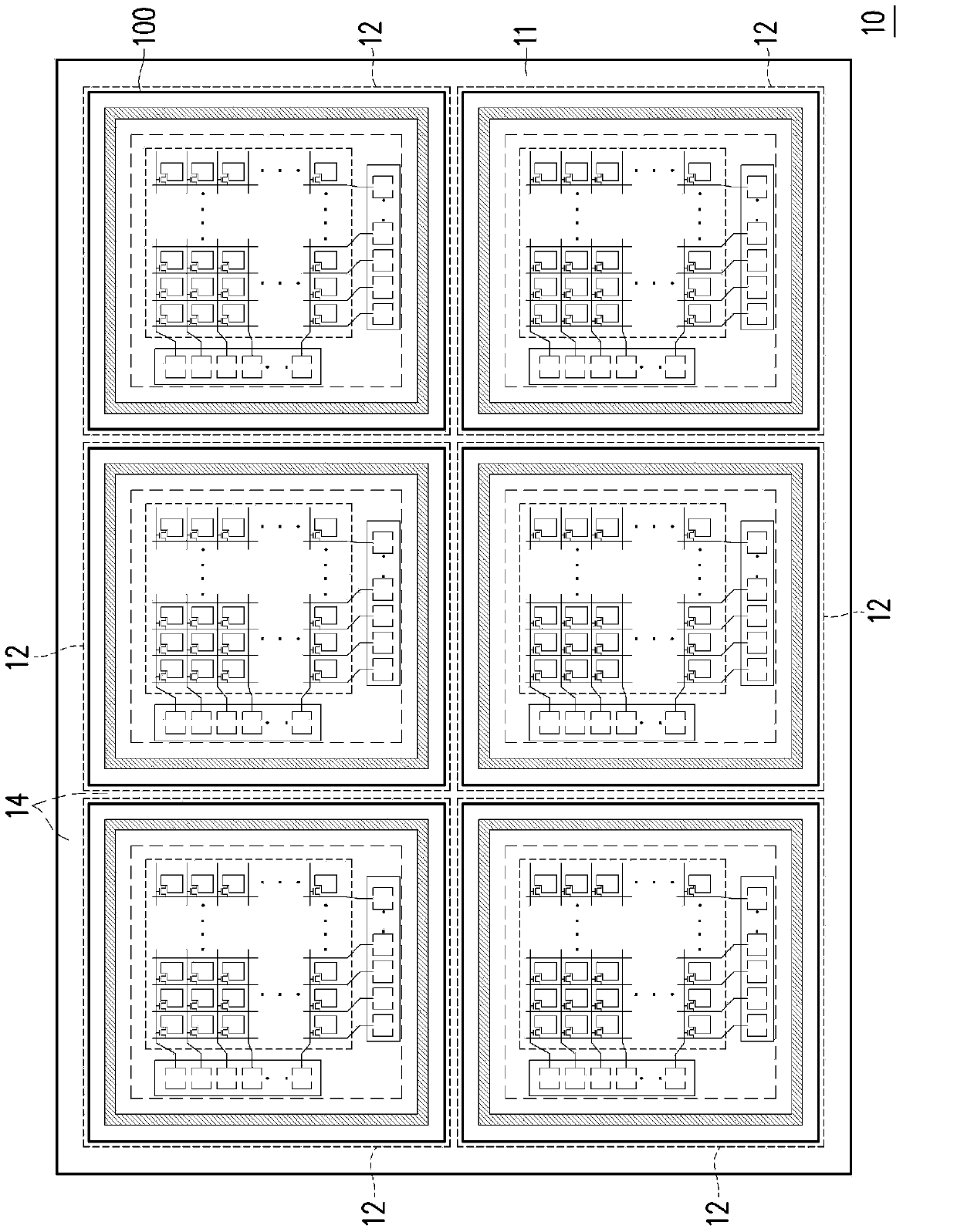

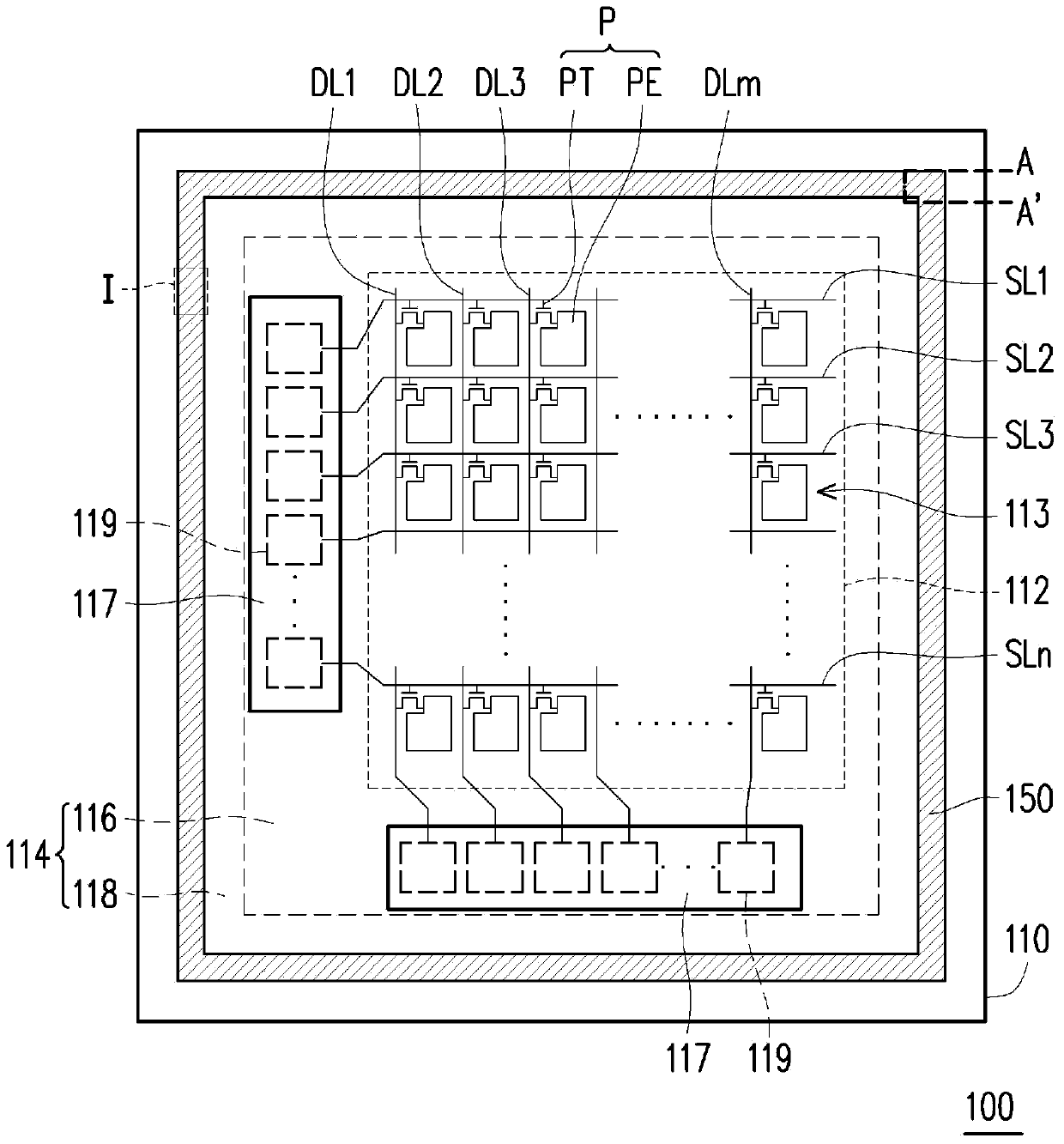

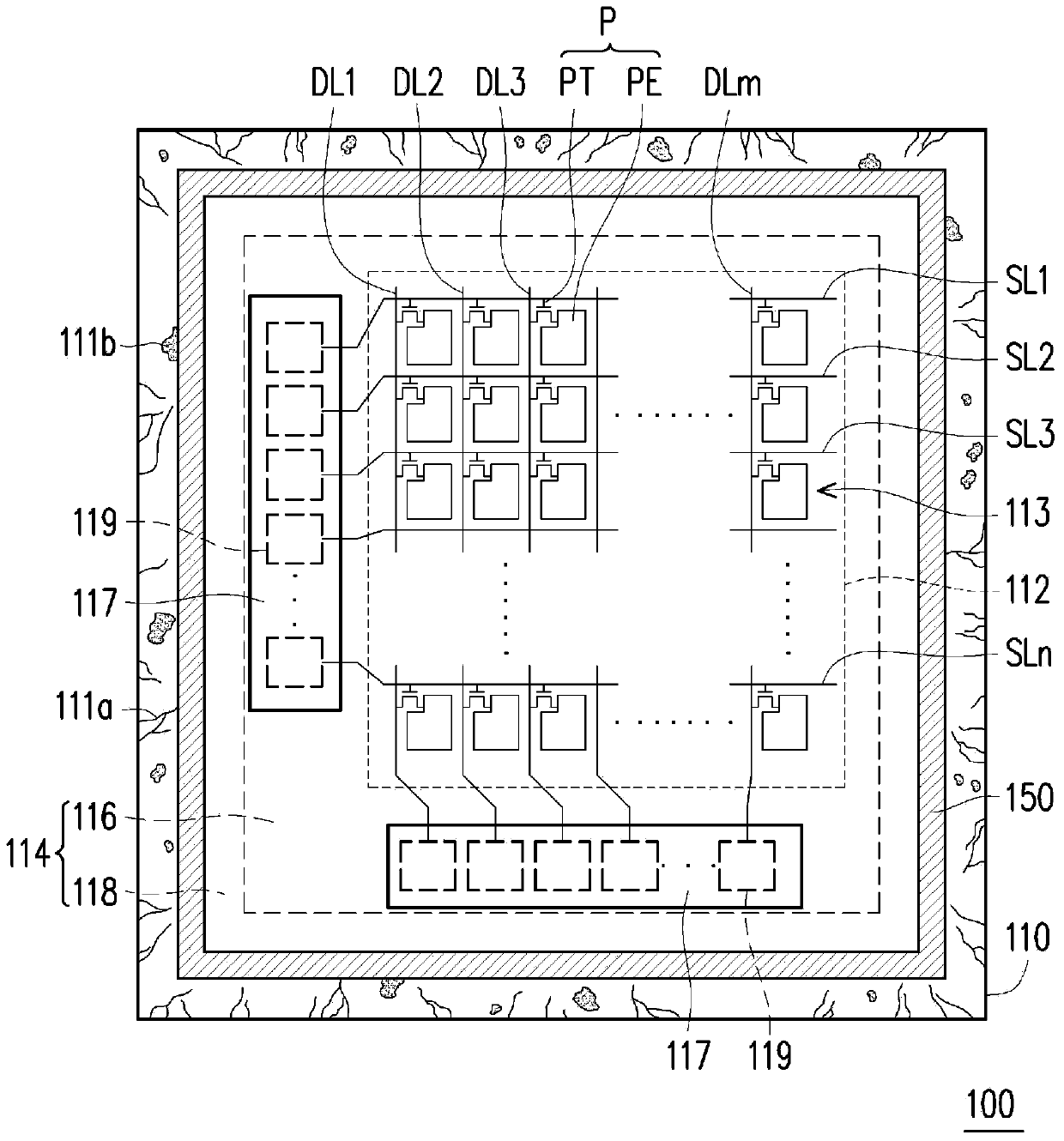

Display panel and mother board thereof

ActiveCN104216153AImprove tensile propertiesImprove reliabilityStatic indicating devicesNon-linear opticsHemt circuitsMechanical engineering

The invention provides a display panel and a mother board thereof. The display panel comprises a substrate, a pixel array, at least a driving circuit, insulating layers and metal walls, the substrate comprises a display area and a non-display area, the non-display area comprises a driving circuit area and an outside area positioned at the outside of the driving circuit area, the pixel array and the driving circuit are respectively positioned in the display area and the driving circuit area, the insulating layers configured on the substrate and positioned in the non-display area, the metal walls are positioned on the insulating layer and positioned in the outside area, and the Poisson of the metal walls is larger than or equal to 0.32.

Owner:AU OPTRONICS CORP

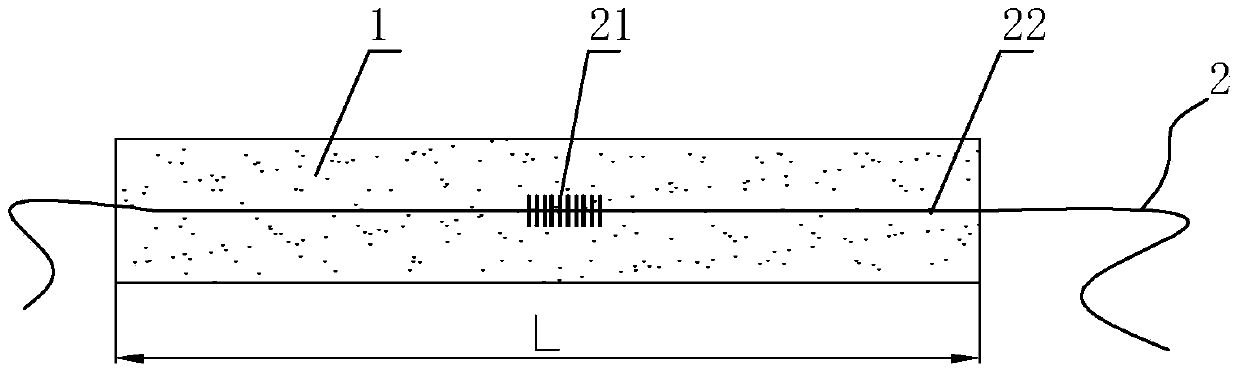

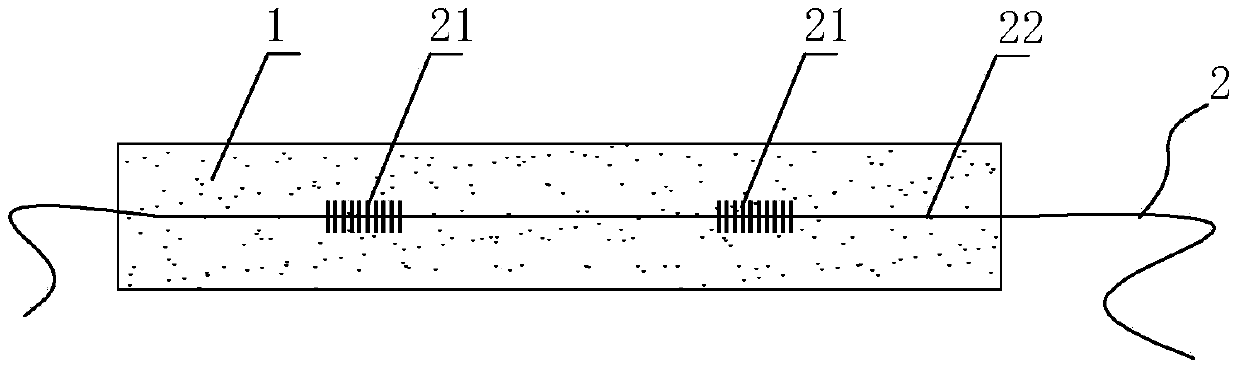

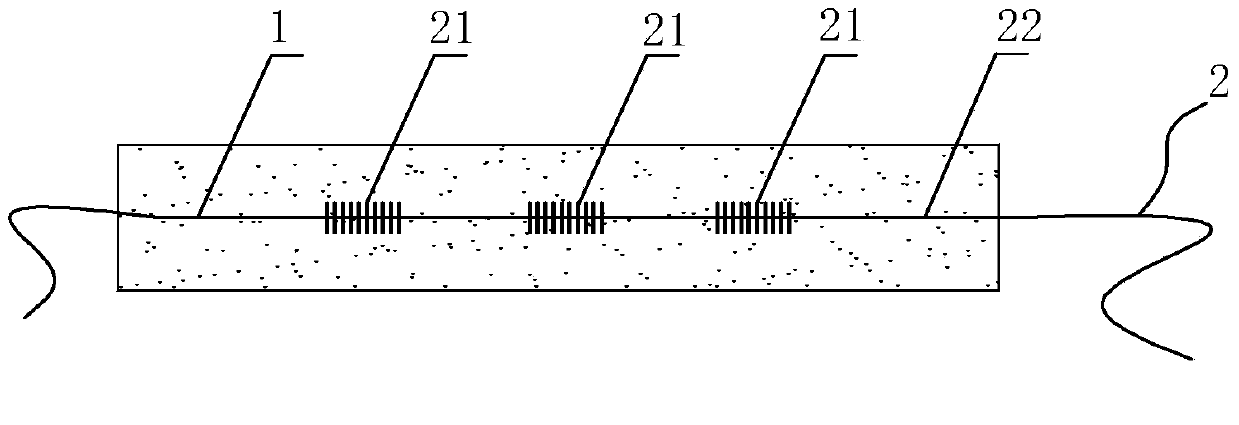

Fiber grating intelligent plate made of fiber reinforced polymer in pulling extrusion and continuous forming mode and manufacturing method thereof

InactiveCN103628697AAchieve securityRealize health diagnosisBuilding repairsBuilding componentsGratingFiber orientation

The invention relates to a fiber grating intelligent plate made of fiber reinforced polymer in a pulling extrusion and continuous forming mode and a manufacturing method thereof. The intelligent plate has civil engineering structural stress and self-monitoring double functions. The intelligent plate comprises a plate body composed of fiber grey yarns and matrix resin, wherein the plate body is filled with sensor fibers containing fiber grating sensors and transmission fibers in the fiber direction, the number of the sensor fibers is m, m is an integer larger than or equal to one, each sensor fiber is provided with n fiber grating sensors, and n is an integer larger than or equal to one. The intelligent plate is manufactured in a pulling extrusion and continuous forming process, the fiber volume content of the intelligent plate is no less than 60%, and the intelligent plate facilitates accurate control of tension control stress of fiber plates, compensation of lost prestress and real-time monitoring of reinforced structures when the fiber plates, especially prestress fiber plates are used for reinforcing and repairing concrete structures and steel structures.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Light-weight corundum-magnesium aluminate spinel castable and preparation method thereof

The invention relates to a light-weight corundum-magnesium aluminate spinel castable and a preparation method thereof. The technical scheme of the invention is taking nano-aperture porous corundum-magnesium aluminate spinel ceramic particles with the partical sizes successively being 3-5mm, 1-2.5mm and 0.1-0.5mm as aggregates, taking nano-aperture porous corundum-magnesium aluminate spinel ceramic fine powder with the partical size being smaller than 0.074mm, magnesium aluminate spinel fine powder, corundum fine powder, magnesia fine powder and alpha-Al2O3 micro powder as matrixes and taking aluminate cement as a binding agent; the preparation method comprises the following steps: mixing the matrixes, the binding agent and sodium hexametaphosphate firstly, then adding the aggregates, uniformly mixing, then adding water, uniformly stirring, moulding by casting, carrying out maintenance, demoulding and drying, and keeping the temperature for 2-6h at the condition with the temperature being 1450-1600 DEG C to obtain the light-weight corundum-magnesium aluminate spinel castable. By adopting the light-weight corundum-magnesium aluminate spinel castable and the preparation method, the process is simple, and a prepared product has the average pore size in a nanoscale, is low in heat conductivity coefficient, good in medium erosion and penetrability resistance and high in thermal shock resistance, and is suitable for parts, including bottoms, walls and the like, of steel ladles.

Owner:WUHAN UNIV OF SCI & TECH

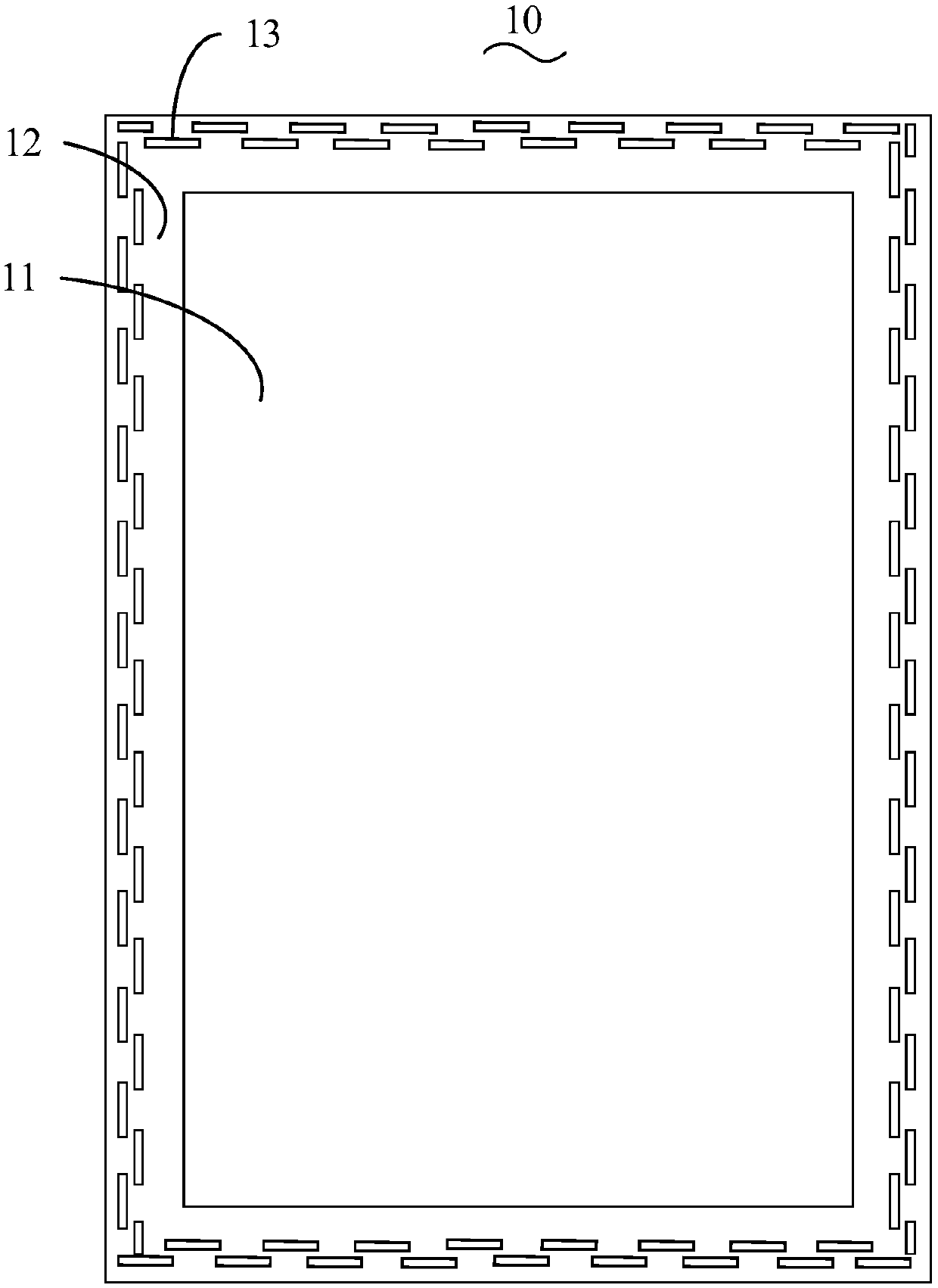

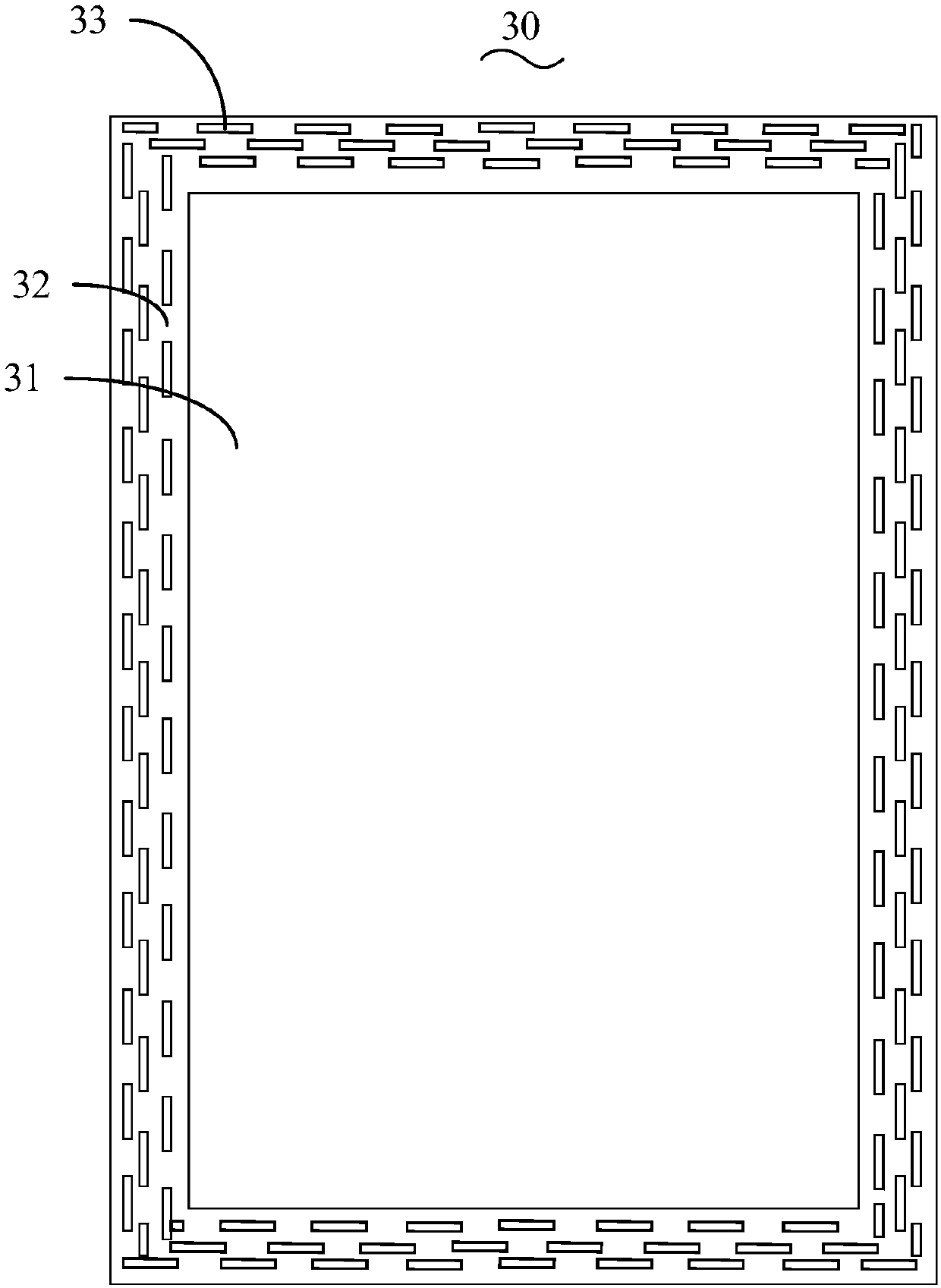

Displaying device and displaying substrate

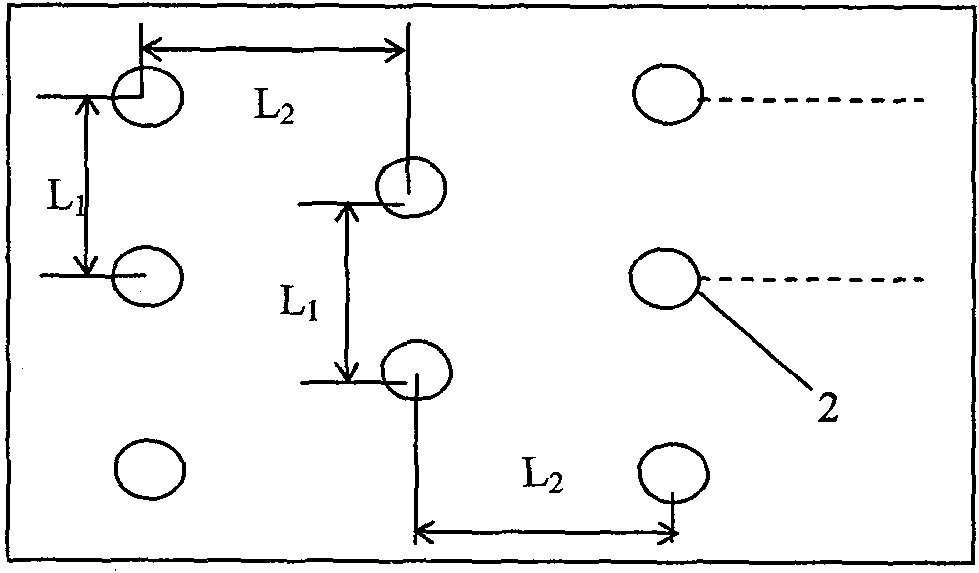

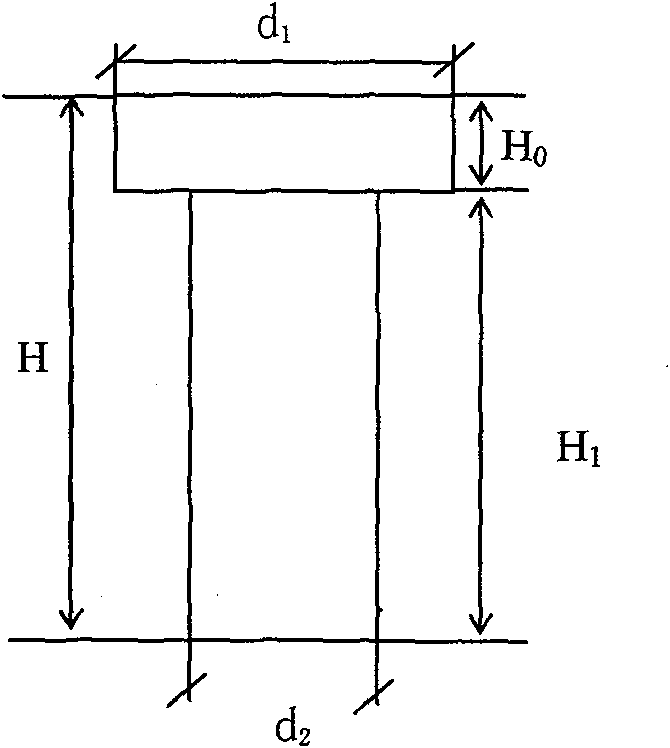

The invention discloses a displaying device and a displaying substrate. The displaying substrate comprises a displaying area located inside the displaying substrate and a barrier layer located betweenthe displaying area and the substrate edge of the displaying substrate, wherein the barrier layer is provided with at least two rows of first hole sections in the direction from the displaying area to the substrate edge in a spaced mode, each row of first hole section comprises at least two first hole section bodies in the extending direction of the substrate edge in a spaced mode, and adjacent rows of first hole section bodies are overlapped with one another on the projection in the extending direction of the substrate edge. Through the mode, a crack can be effectively prevented from expanding, and the product yield is increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

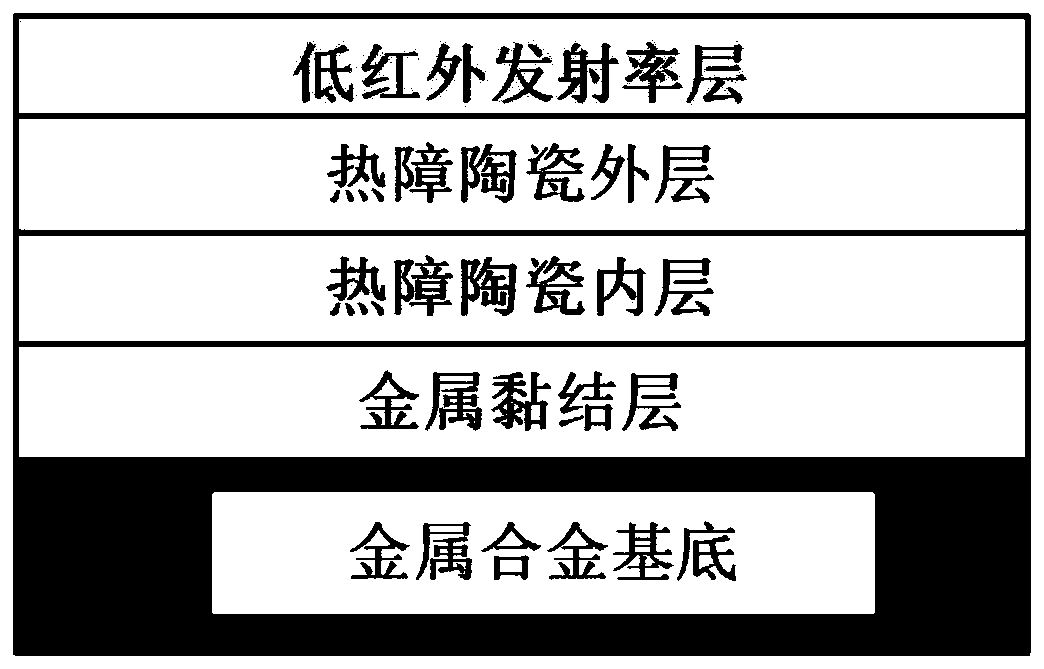

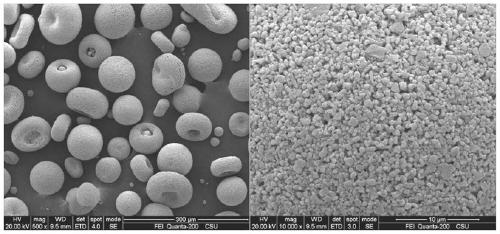

Double-layer thermal barrier/high-temperature low-infrared emissivity integrated coating, metal composite material with coating and preparation method thereof

ActiveCN110055486AGood oxygen barrier effectStop the spreadMolten spray coatingSuperimposed coating processEmissivityAlloy

The invention discloses a double-layer thermal barrier / high-temperature low-infrared emissivity integrated coating which is of a multilayer superposition structure. The multilayer superposition structure sequentially comprises a metal bonding layer, a thermal barrier ceramic inner layer, a thermal barrier ceramic outer layer and a low-infrared emissivity layer from inside to outside, and the thermal barrier ceramic inner layer is La2Zr2O7-8YSZ mixture layer, wherein the mass fraction of La2Zr2O7 powder in the mixture is not more than 45%, the thermal barrier ceramic outer layer is a rare earthzirconate layer, and the low-infrared emissivity layer is a Bi2O3-Al2O3-ZrO2-CaO-SiO2 glass coating comprising conductive phase AuPt alloy powder. The invention also provides a metal composite material with the coating and a preparation method thereof. The integrated coating has the characteristics of heat insulation performance, high-temperature low infrared emissivity, excellent thermal shock resistance and the like.

Owner:NAT UNIV OF DEFENSE TECH

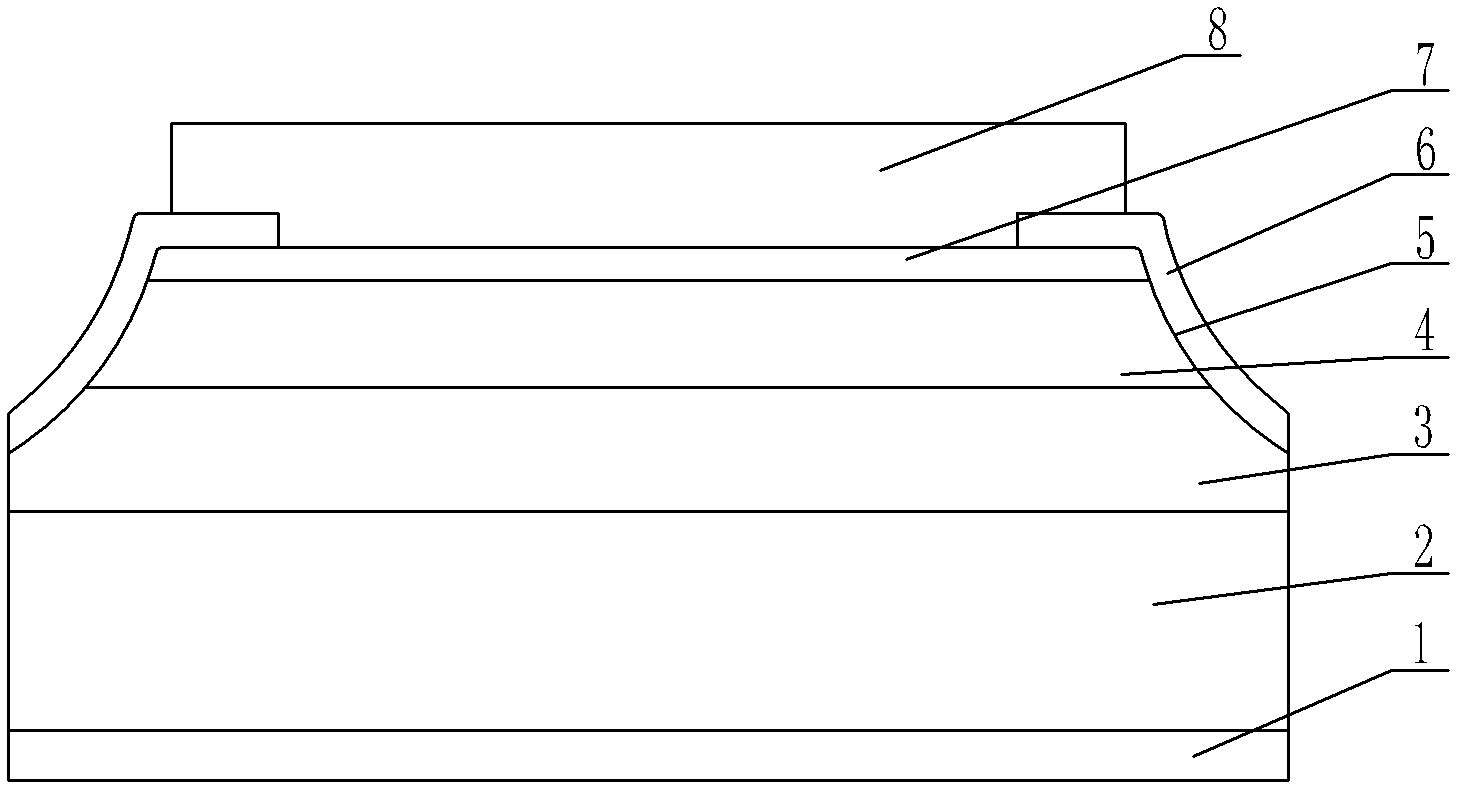

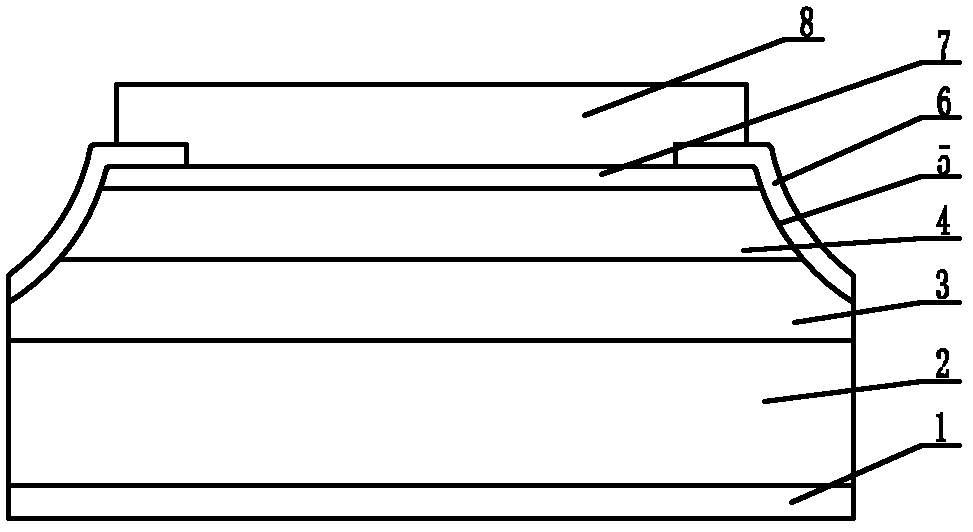

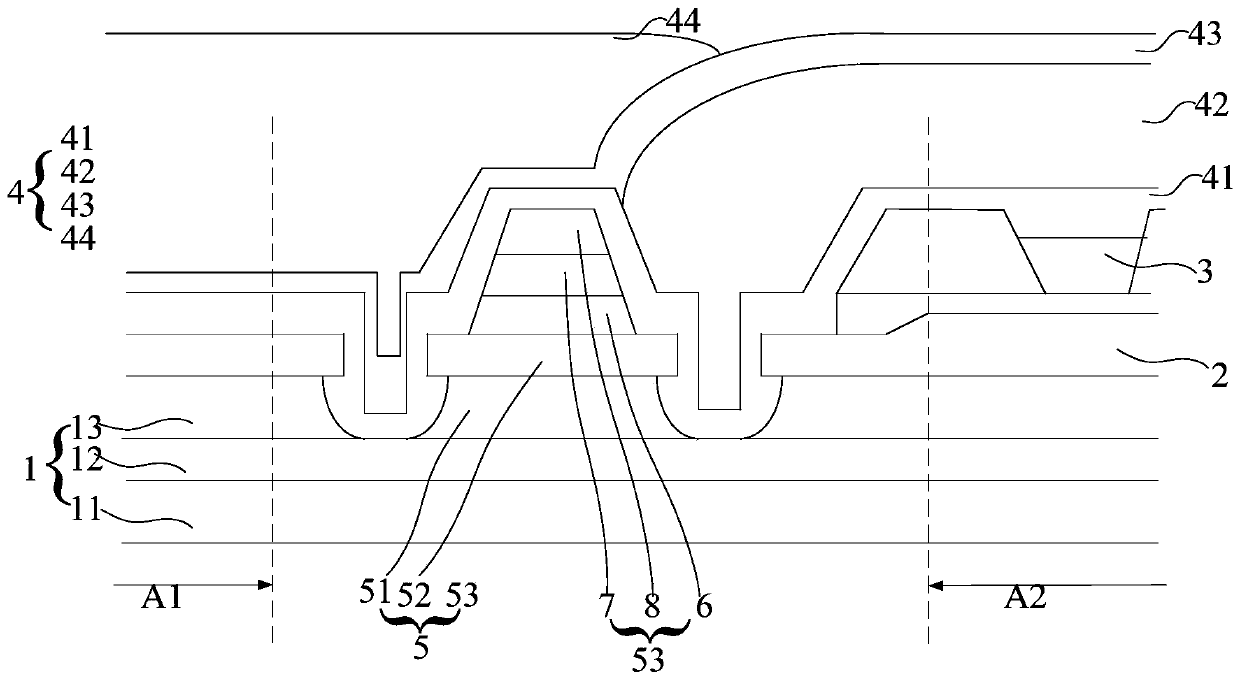

Fast recovery epitaxial diode and preparation method thereof

InactiveCN102496572AGood ohmic contactPrevent extensionSemiconductor/solid-state device manufacturingSemiconductor devicesVoltage dropSilicon chip

The invention relates to a fast recovery epitaxial diode comprising a metal cathode layer, an N + substrate silicon chip, a first epitaxial layer, a second epitaxial layer, a third epitaxial layer, wherein the above-mentioned parts are successively connected. A mesa silicon groove penetrates the third epitaxial layer and is extended into the second epitaxial layer; a glass passivation layer that is arranged inside the mesa silicon groove and is provided with a window is extended to the top surface of the third epitaxial layer; and a metal anode layer that is arranged at the upper portion of the glass passivation layer passes through the window that is arranged on the glass passivation layer and then is connected with the third epitaxial layer. According to the invention, an epitaxial technology is used to accurately control impurity concentration and thickness of all the epitaxial layers; and a mesa channeling technology and a glass passiviation technology are utilized to manufacture a terminal structure, thereby substantially reducing a technology flow. Besides, the fast recovery epitaxial diode has good consistency and repeatability; high quality characteristics including low forward direction voltage drop, super speediness, and soft recovery characteristic and the like of the fast recovery epitaxial diode can be easily realized.

Owner:MACMIC SCIENCE & TECHNOLOGY CO LTD

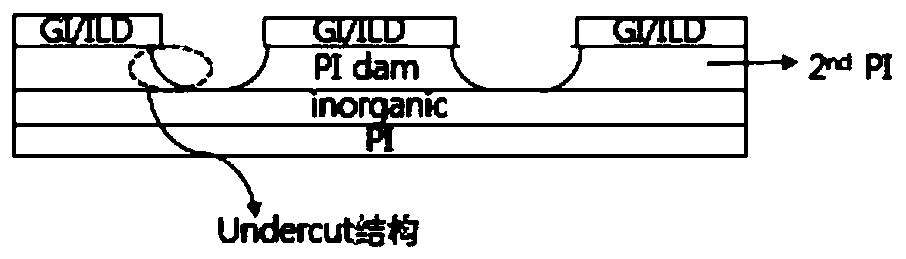

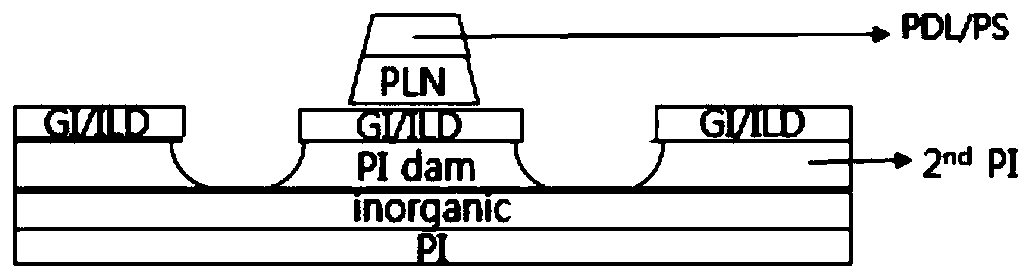

OLED display panel and display device

PendingCN111430566AExtended flow pathBlock the flowSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides an OLED display panel and a display device. A retaining wall of the OLED display panel comprises a substrate retaining wall layer, an inorganic retaining wall layer and an organic retaining wall layer which are stacked, an inorganic retaining wall film and the cross section of the substrate retaining wall layer form an undercut shape, and the substrate retaining wall layer comprises a second flexible substrate. The inorganic retaining wall layer comprises an inorganic layer in the driving circuit layer, and the organic retaining wall layer comprises at least one of a planarization layer, a pixel definition layer and a supporting column. Based on the retaining wall structure, the retaining wall height is increased, the organic materials can be better prevented from flowing, and the distance between the retaining wall and the display area is reduced. Meanwhile, the undercut shape between the retaining wall and the display area can also increase the flow path of theorganic materials, so that the distance between the retaining wall and the display area can be further reduced. Moreover, the cutting cracks can be prevented from extending to the display area alongthe inorganic layer and the substrate, so that the size of a frame can be further reduced to a greater extent.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Display panel, fabrication method thereof and display device

ActiveCN110048014AImprove production yieldImprove production yield and service lifeSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringDisplay device

The invention discloses a display panel, a fabrication method thereof and a display device. The display panel is provided with a display region and a non-display region, wherein the non-display regionis arranged around the display region, a groove structure is arranged at a part, corresponding to the non-display region, of the display panel, and a cooling layer is arranged in at least one part ofthe groove structure. In the display panel disclosed by the embodiment of the invention, the groove structure is arranged at the part, corresponding to the non-display region, of the display panel, the transfer of mechanical stress at the non-display region can be reduced, so that a crack generated by cutting of the display panel is prevented from extending to the display region in the display panel; and by arranging the cooling layer in the groove structure, heat generated by a cutting line is absorbed and dissipated by the cooling layer during cutting of the display panel, separation of aninorganic layer and an organic layer in the display panel caused by factors such as thermal diffusion, thermal expansion and thermal stress generated by the cutting line is prevented, the fabricationyield of the display panel is improved, and the service lifetime of the display panel is prolonged.

Owner:YUNGU GUAN TECH CO LTD

Ultrahigh-toughness concrete and production method thereof

The invention discloses an ultrahigh-toughness concrete and a production method thereof. The ultrahigh-toughness concrete is produced by proportionally mixing Portland cement, slag aggregate, steel fiber, silicon powder, flyash beads, lithium salt residue, latex, rubber powder, a nano waterborne binder, graphene-modified glass fiber, trimethylolpropane, sulfoaluminate clinker, a defoaming agent, polyoxyethylene alkyl ether, p-toluenesulfonic acid, nano silicon particles, nano calcium carbonate, elastic silicone acrylic emulsion, methyl N,N-dihydroxyethyl-3-aminopropanoate, water and a polycarboxylate superplasticizer. The ultrahigh-toughness concrete produced herein has high compressive strength, high tensile strength and lasting ultrahigh ductility and has good energy-dissipating capacityand elastic modulus.

Owner:TANGSHAN COLLEGE

Low-smoke, halogen-free and flame-retardant thermoplastic polyolefin elastomer composite with ceramization function as well as preparation method and application thereof

ActiveCN107383576AImprove flame retardant performanceGood low smoke performancePlastic/resin/waxes insulatorsThermoplasticPolymer science

The invention relates to the technical field of polyolefin elastomers, in particular to a low-smoke, halogen-free and flame-retardant thermoplastic polyolefin elastomer composite with a ceramization function as well as a preparation method and an application thereof. The low-smoke, halogen-free and flame-retardant ceramic thermoplastic polyolefin elastomer composite is prepared from raw materials in parts by weight as follows: 20-80 parts of thermoplastic polyolefin, 2-10 parts of EVA (ethylene-vinyl acetate) resin, 2-10 parts of ethylene propylene rubber, 20-70 parts of a halogen-free flame retardant, 1-10 parts of a smoke suppressant, 20-80 parts of ceramization powder, 0.5-5 parts of a compatilizer and 0.02-0.1 parts of an antioxidant. The low-smoke, halogen-free and flame-retardant ceramic thermoplastic polyolefin elastomer composite has a good flame retardant effect and is low in smoke density, high in strength, good in flexibility and high in elongation at break; a compact ceramization product can be formed at the temperature of 600-1,000 DEG C, the ceramization temperature is low, ceramization is compact, and the formed ceramization product has good high-temperature strength and heat flow impact resistance.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

High copolymer pulp components for composite inorganic nanoparticles

The invention discloses a component of copolymer using in complex inorganic nanoparticles and relates to the pulp and sizing production and process technology of spinning warp sizing and paper-making glue processes. The said copolymer is a kind of ionic acrylic polymers and it is made of ionic monomers, hydrophilic monomers, acrylate monomers and few other monomers by free radical copolymerization reaction, or is made of polyacrylamide as the raw material by macromolecular chemical reaction. The said copolymer is used to prepare a new slurry component which substantial replaces PVA in the spinning warp sizing and paper-making glue processes. The said slurry contains of the mixture in a proportion of 0.1-50 % of copolymer, 0.1-50 % inorganic nanoparticles and residual water.

Owner:XUZHOU CITY ZHONGHENG FINE CHEM TECH

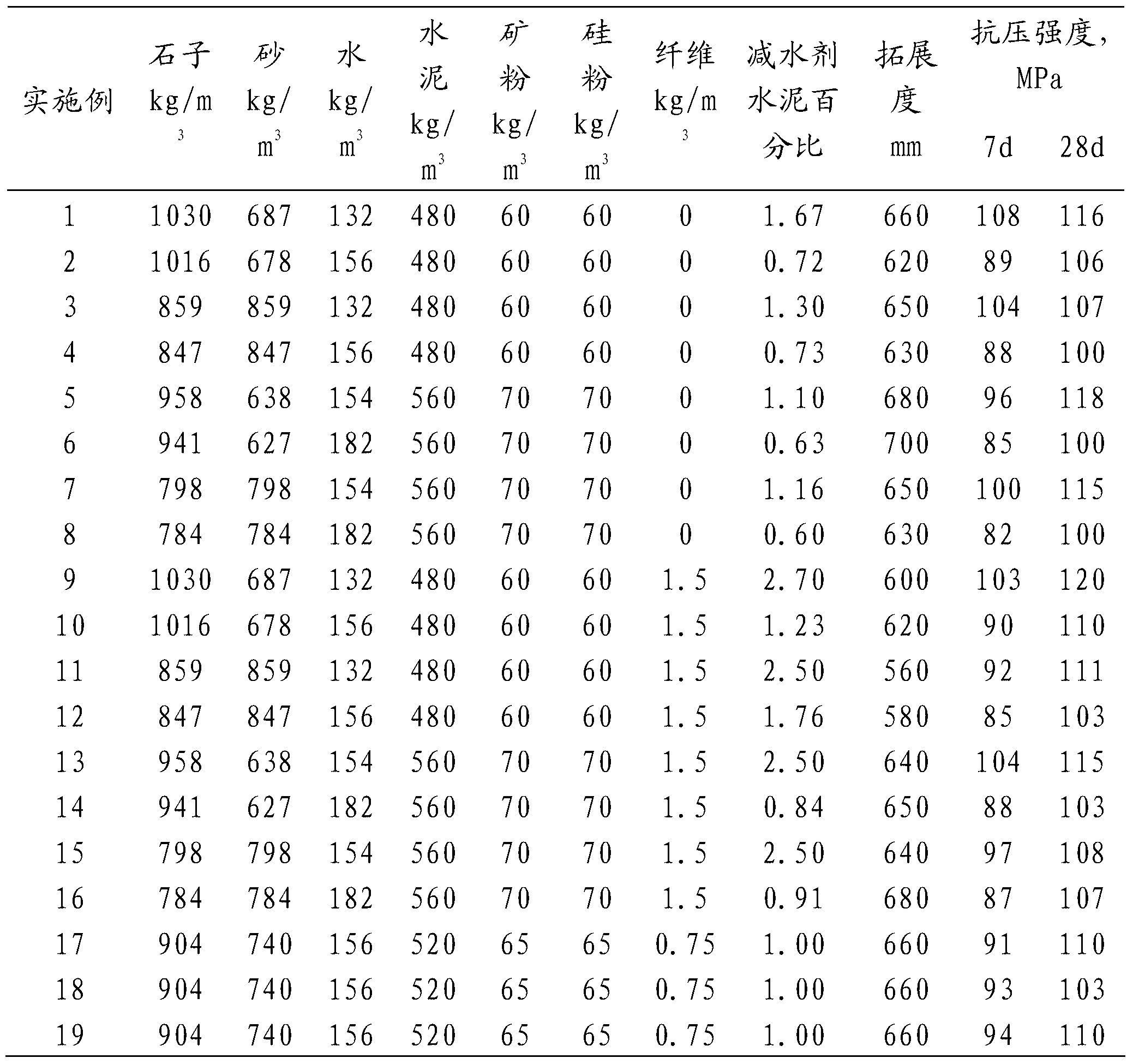

Ultrahigh-strength self-compacting concrete and preparation method thereof

InactiveCN103304206AImprove microscopic propertiesImprove the interface transition areaFiberPolyvinyl alcohol

The invention discloses an ultrahigh-strength self-compacting concrete and a preparation method thereof. The ultrahigh strength self-compacting concrete is mainly composed of a cementing material, an efficient water reducer, a fine aggregate, a coarse aggregate, water and PVA (Polyvinyl Alcohol) fibers, wherein the cementing material is composed of 70%-80% of common silicate cement, 10%-20% of mineral slag and 5%-10% of silicon powder by weight percentage; the fine aggregate is medium sand; the coarse aggregate is granite macadam. The ultrahigh-strength self-compacting concrete has the beneficial effects that the advanced techniques of the ultrahigh-strength concrete and the self-compacting concrete in the field of the concrete materials at present are studied, the advantages of the two concrete techniques are combined so that the dosage of the cement is reduced while ultrahigh performance of the concrete is realized, and furthermore, the purposes of emission reduction of CO2, materials saving and environmental protection as well as green construction are achieved.

Owner:SHENZHEN UNIV

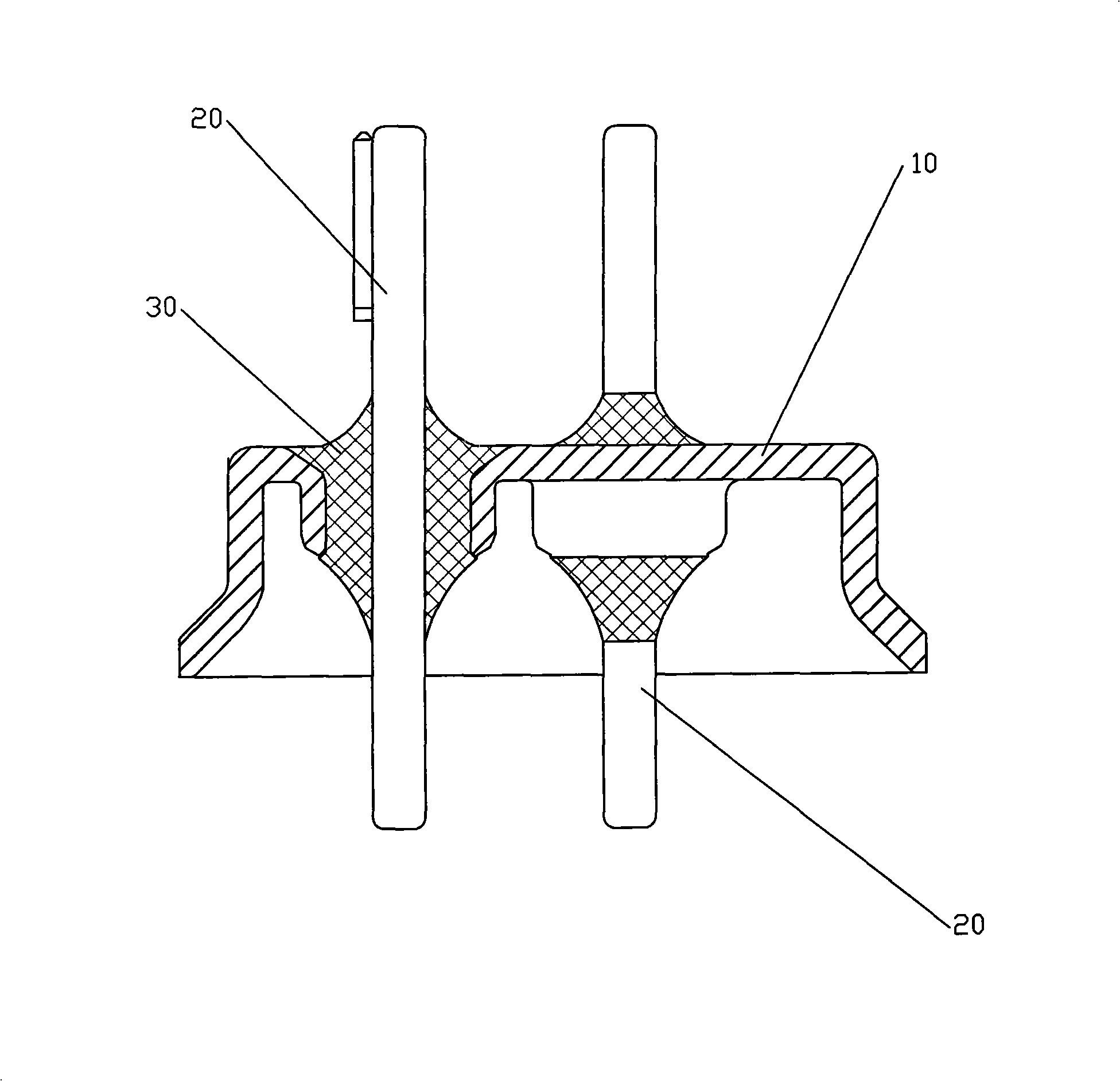

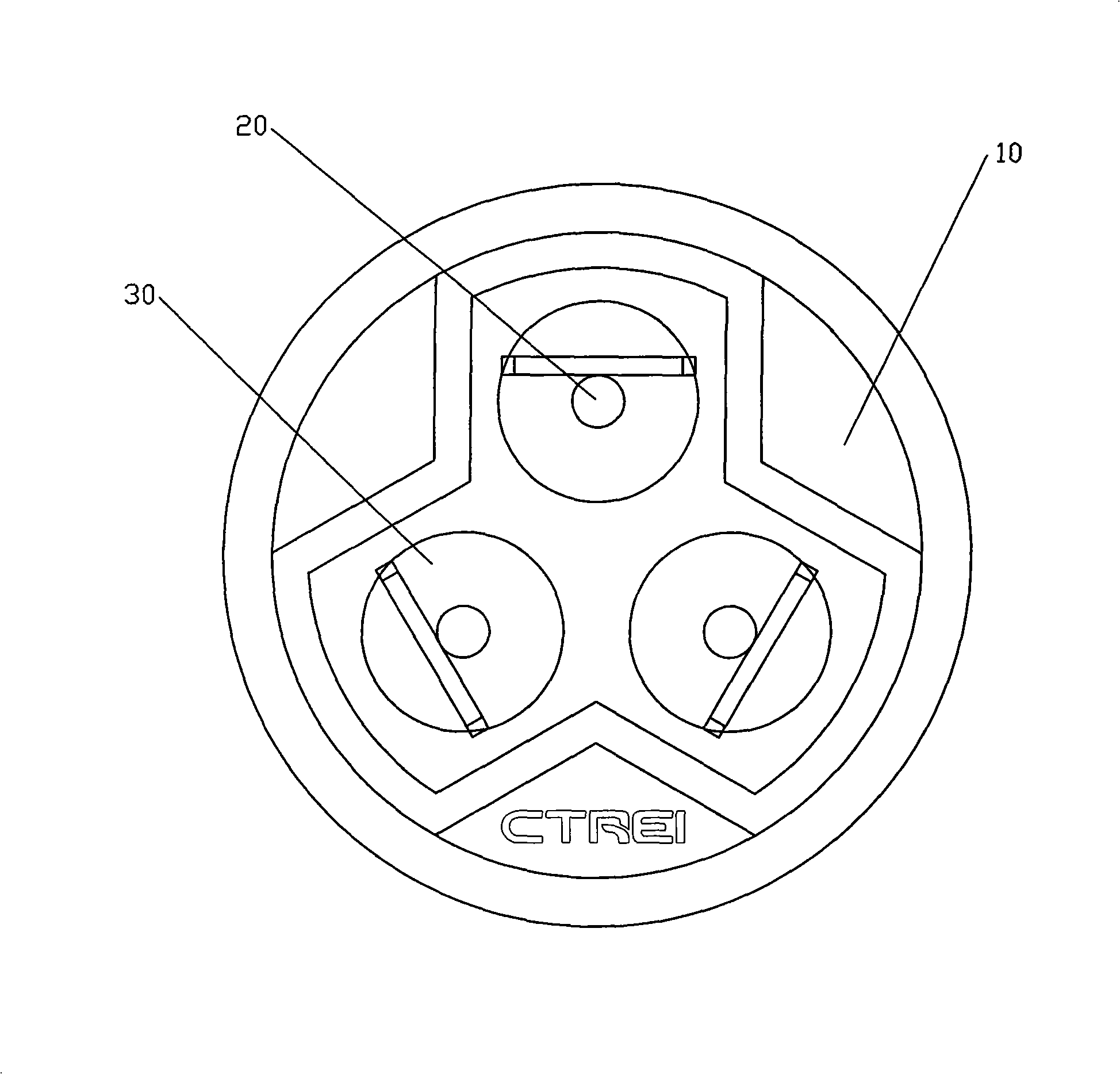

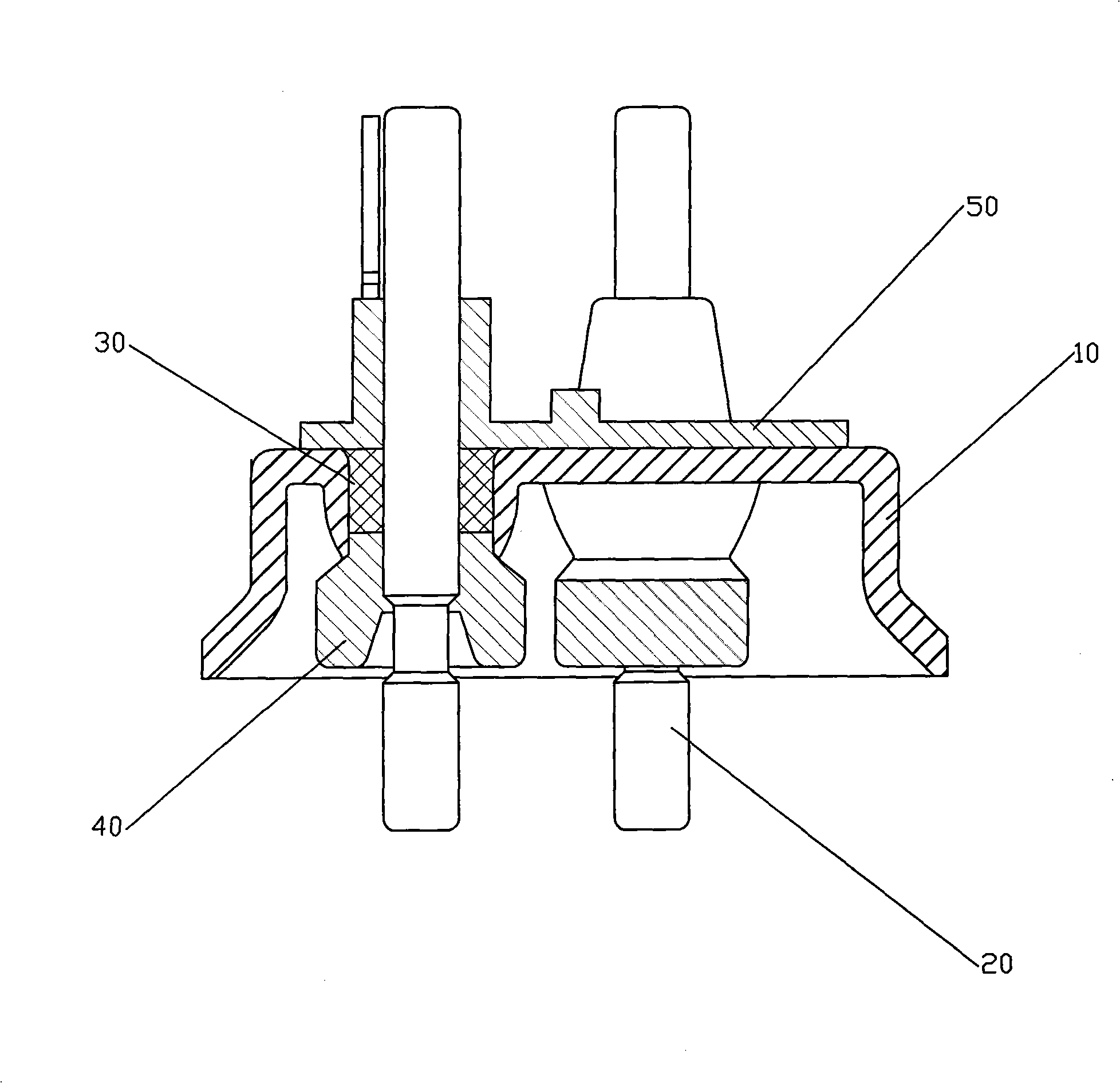

Connector post of refrigeration compressor

ActiveCN101404360AEasy to sinterPorcelain forming temperature rangeElectrically conductive connectionsCeramicsRefrigeration compressorSilicon oxide

The invention relates to a terminal part of a compressor, in particular to a binding post of a cold compressor of highly reliable ceramic insulation medium connection. The binding post comprises an end cover which is welded with a shell of the compressor, and a conductive pillar that is sealed and connected with the end cover by glass; wherein, the glass is used for playing the role of insulation and sealing, the conductive pillar is provided with an insulator separating the surface of the glass from the air, and the insulator is made of the following materials: 92-96% of aluminium oxide, 2-3% of silicon oxide, 1-3% of calcium oxide, 0.5-1.0% of bismuth oxide and 0.5-1.0% of antimony oxide. The binding post has the advantages that specially prepared aluminum oxide ceramics is adopted to replace steatite ceramics (or forsterite) to be taken as the insulator, so that the creep age distance is prolonged, and the phenomenon of overflash is avoided in the low vacuum environment, thereby effectively avoiding the serious result of compressor explosion. At the same time, the expansion of microcrack is prevented, and the probability of air leakage is effectively reduced, so that good connecting effect is formed.

Owner:CHAOZHOU THREE CIRCLE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com