Organic light-emitting display panel

A technology of light-emitting display and organic light-emitting elements, which is applied in instruments, semiconductor devices, computing, etc., and can solve the problem of failure of touch function, high requirements for the production of protective film layer, polarizer and cover plate, and the inability to realize touch-sensitive flexible display Panel thinning and other issues to achieve the effect of avoiding breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below with reference to the drawings and embodiments. It can be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for ease of description, the drawings only show a part but not all of the structure related to the present invention.

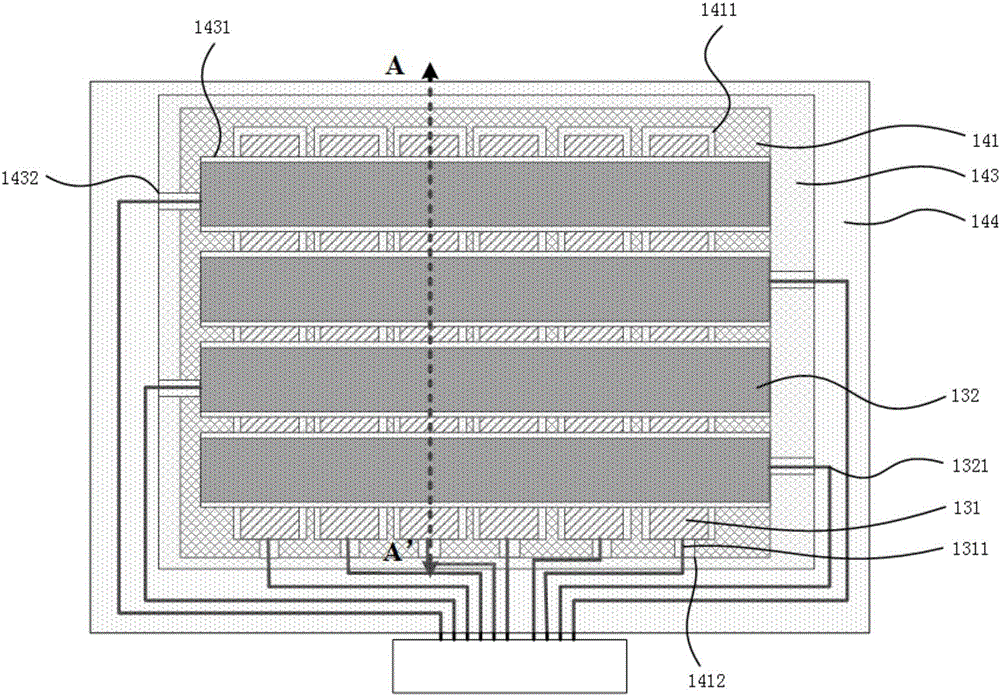

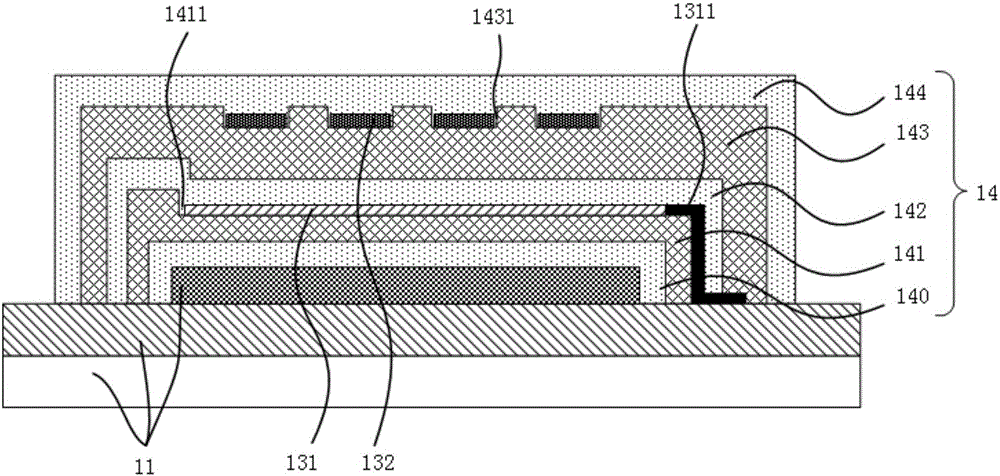

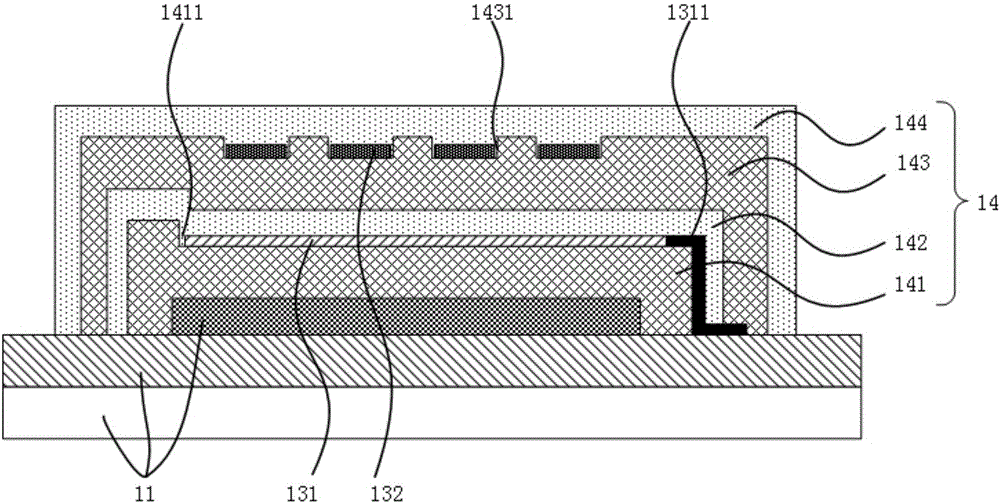

[0026] Figure 1a It is a schematic top view of an organic light emitting display panel provided by an embodiment of the present invention. Figure 1b For the edge Figure 1a Schematic diagram of the cross-sectional structure in the AA' direction. Combine Figure 1a with Figure 1b As shown, the organic light-emitting display panel provided by this embodiment includes an organic light-emitting element array substrate 11, a thin-film encapsulation layer 14 covering the organic light-emitting element array substrate 11, a plurality of touch drive electrodes 131,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com