Patents

Literature

206results about How to "Does not increase thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

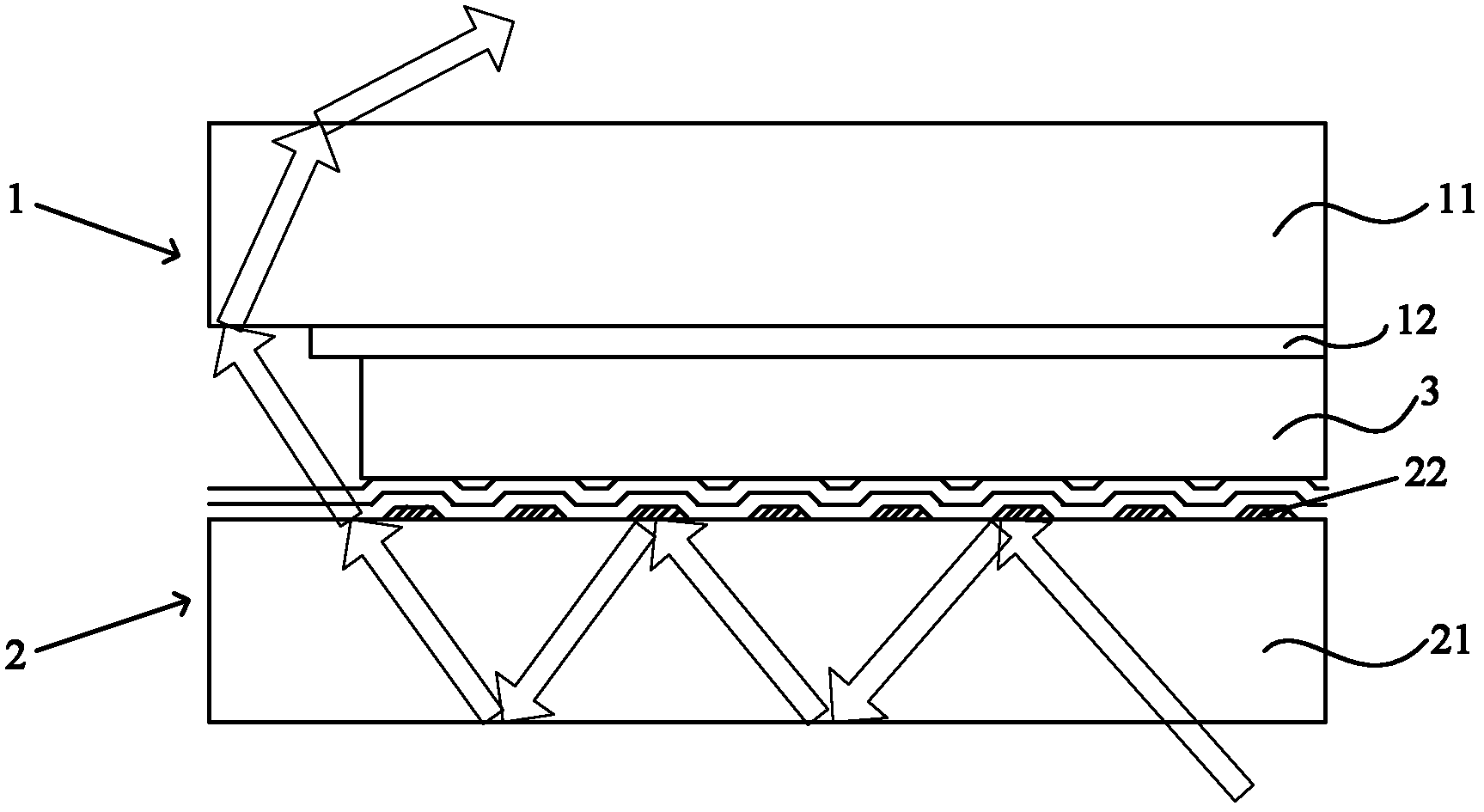

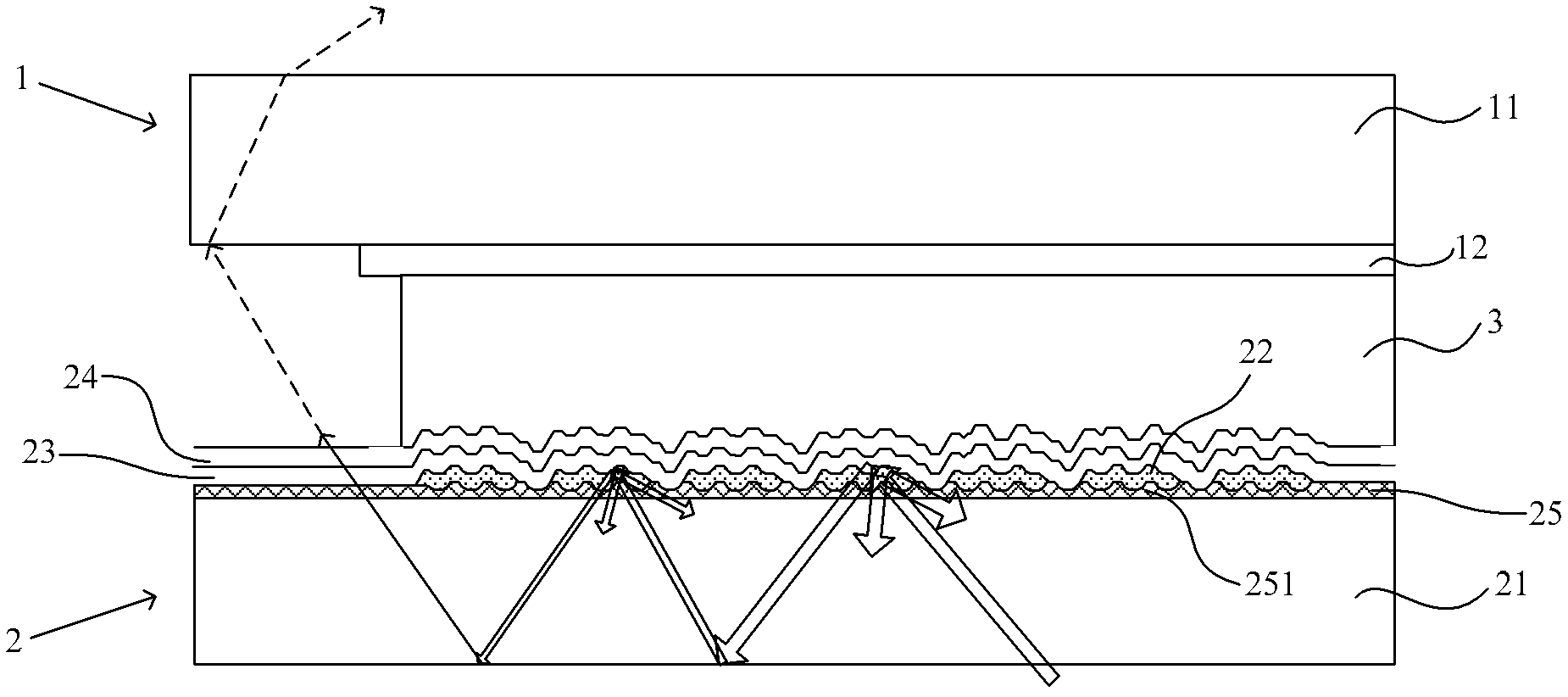

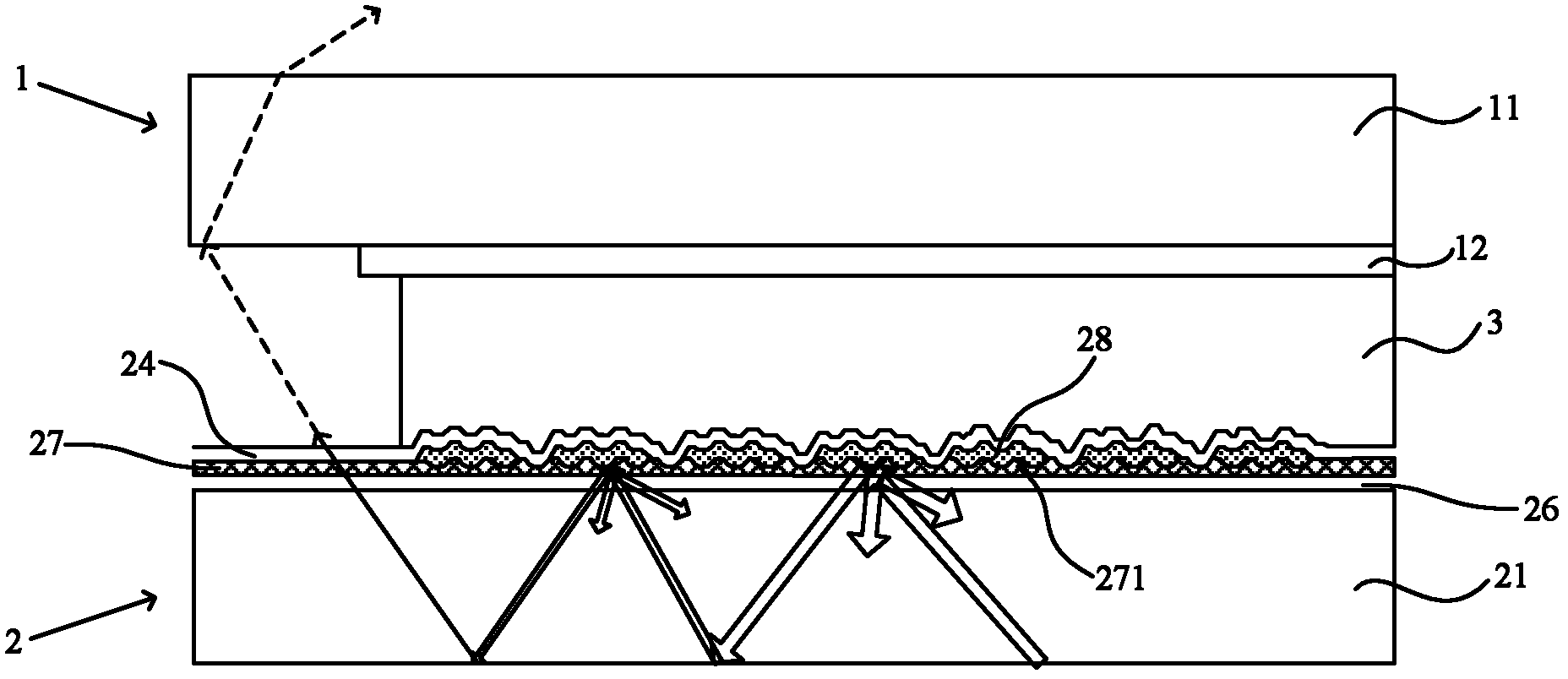

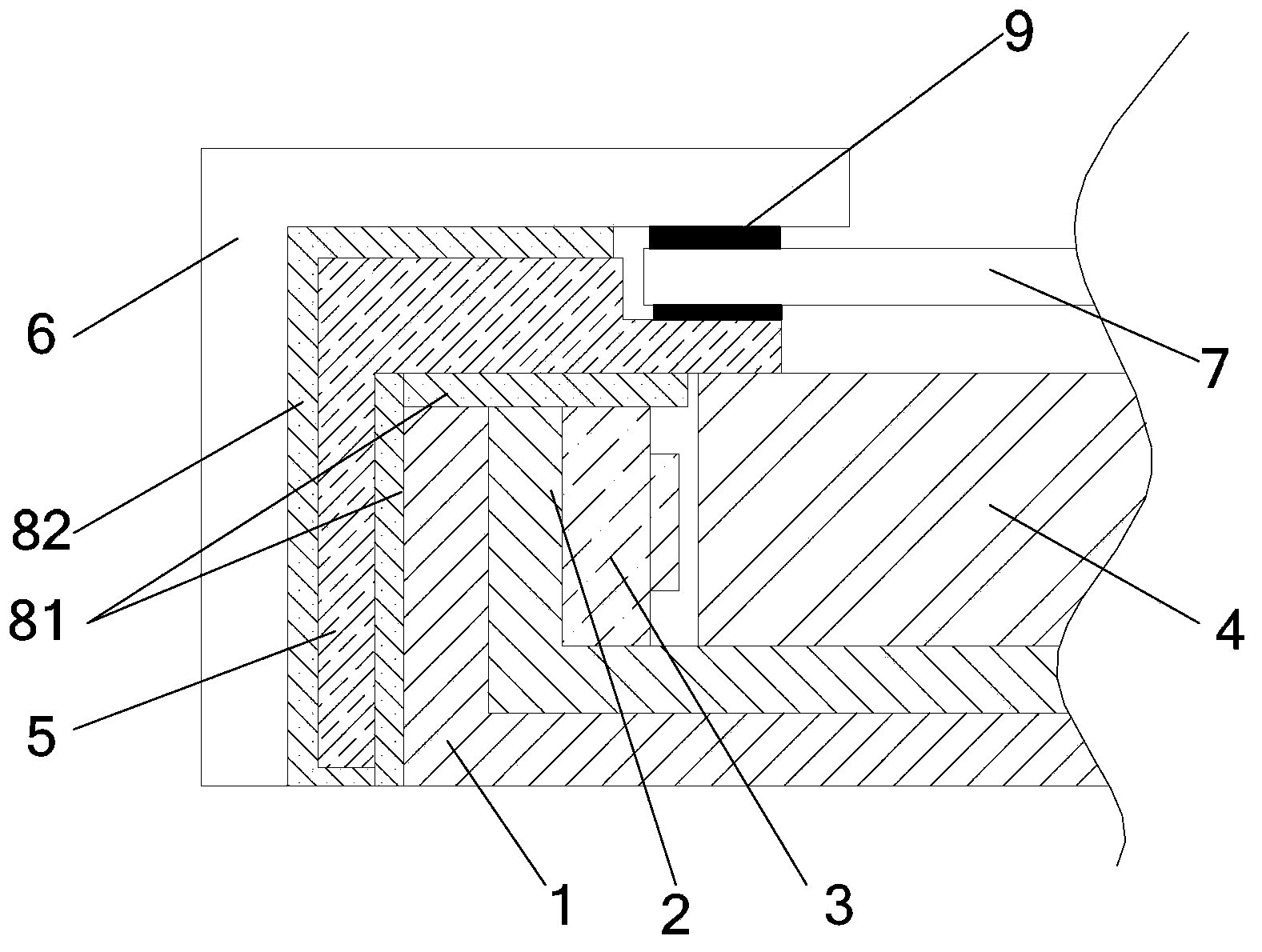

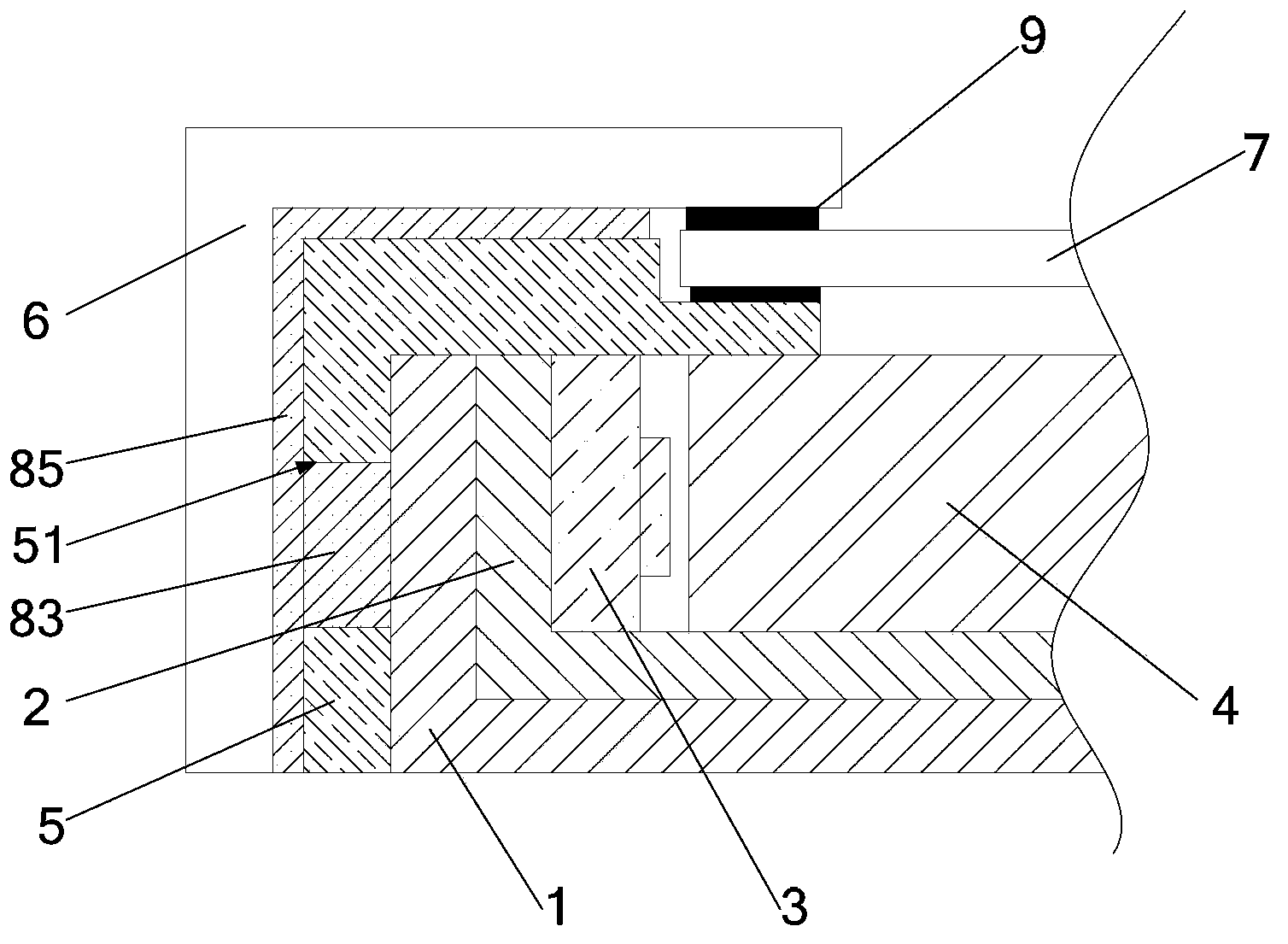

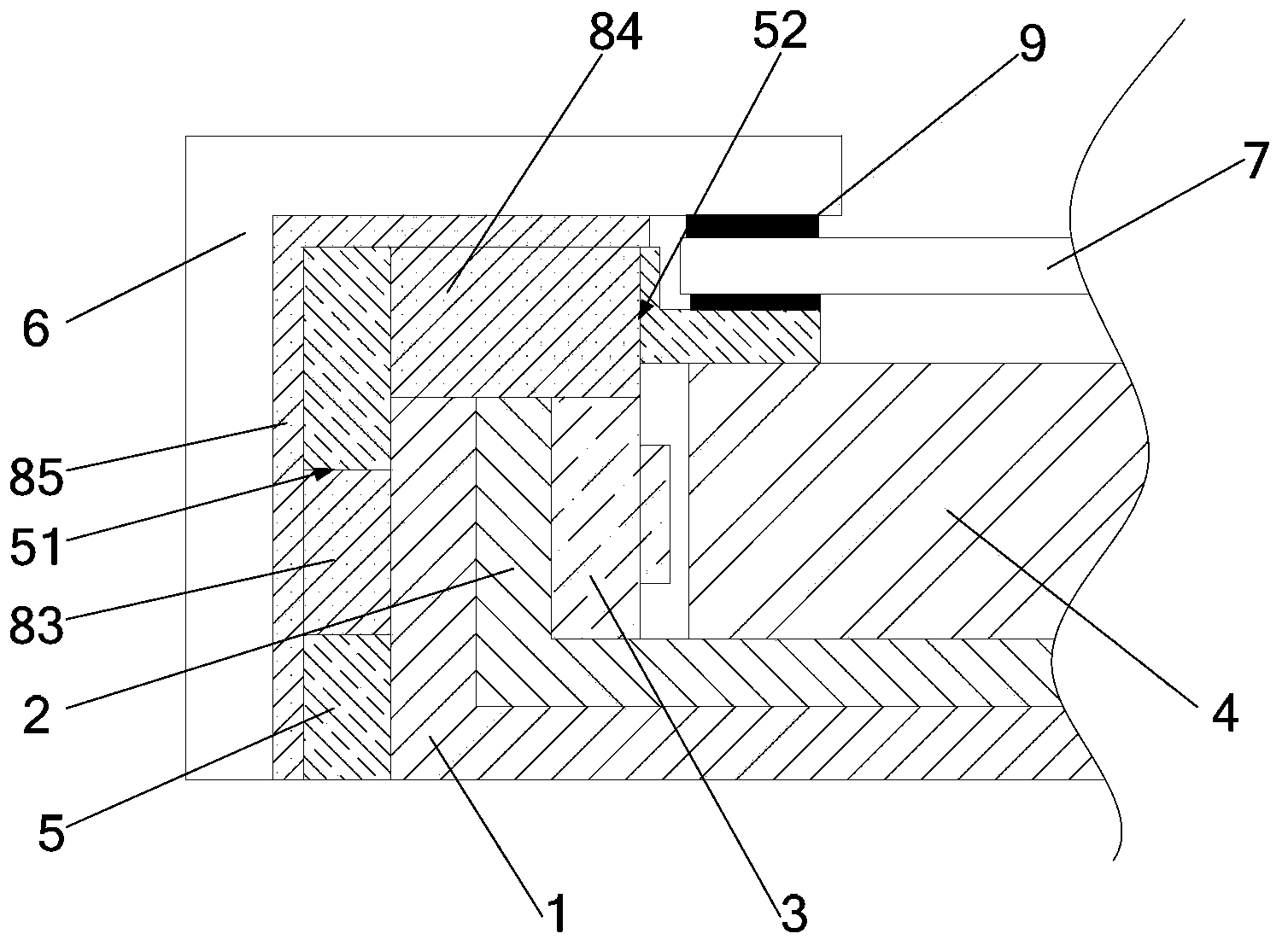

Narrow frame display panel and display device

InactiveCN107728365ADoes not increase thicknessAvoid reflectionsNon-linear opticsDisplay deviceColor film

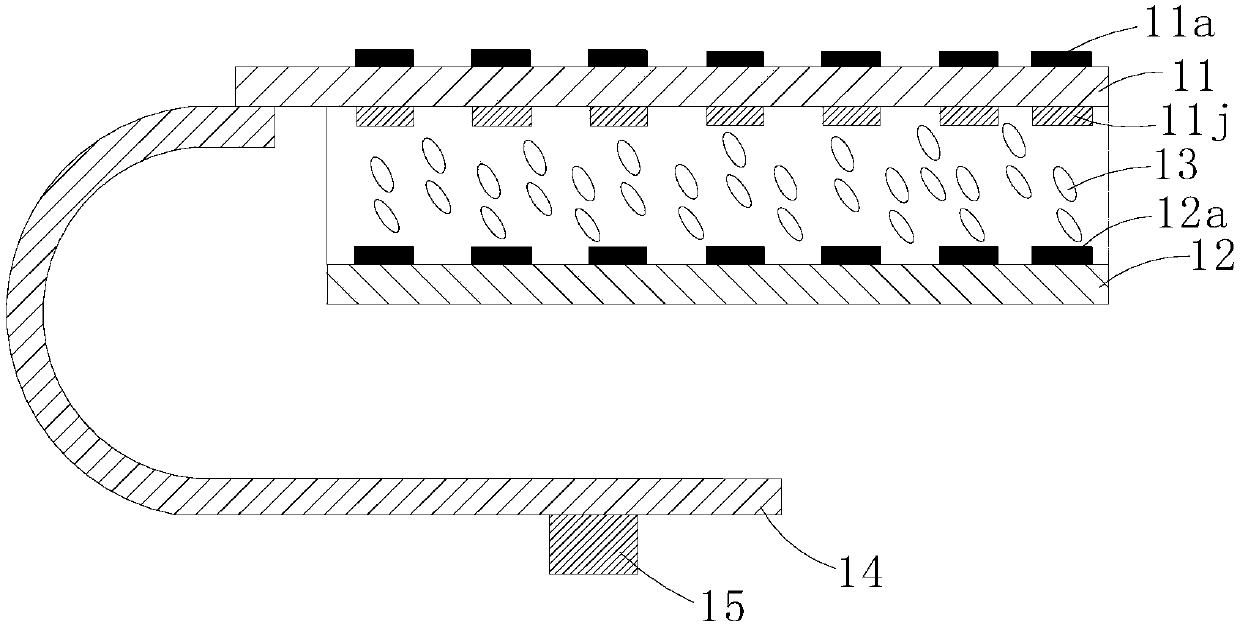

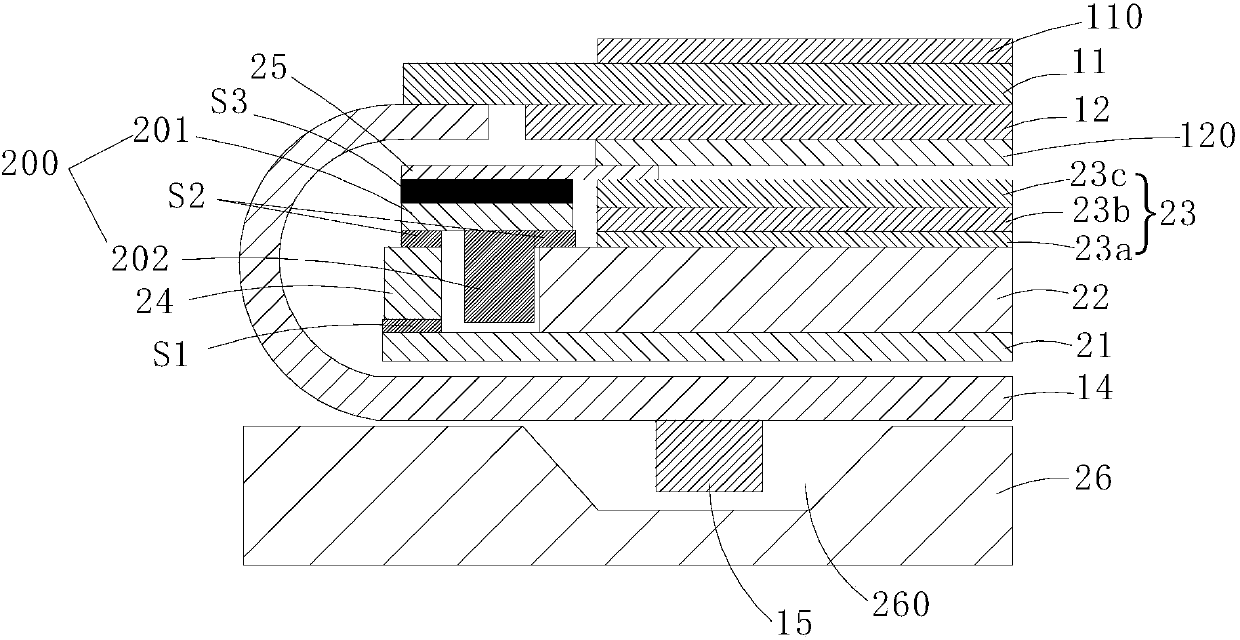

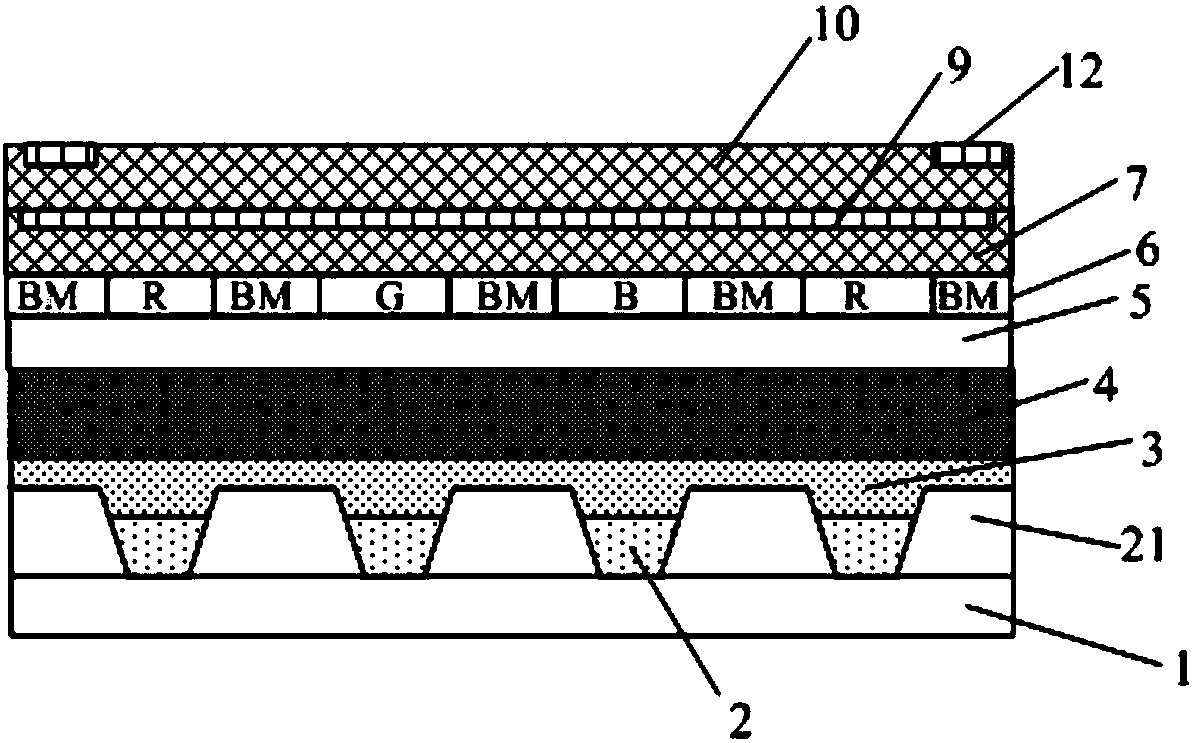

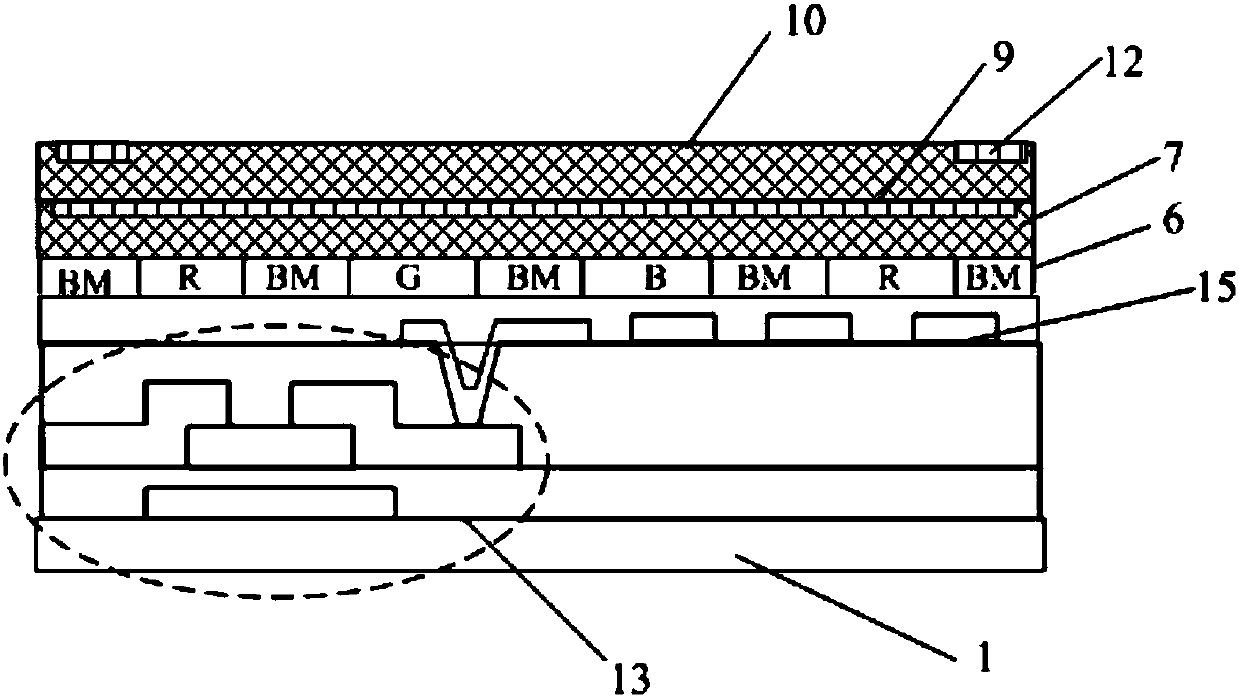

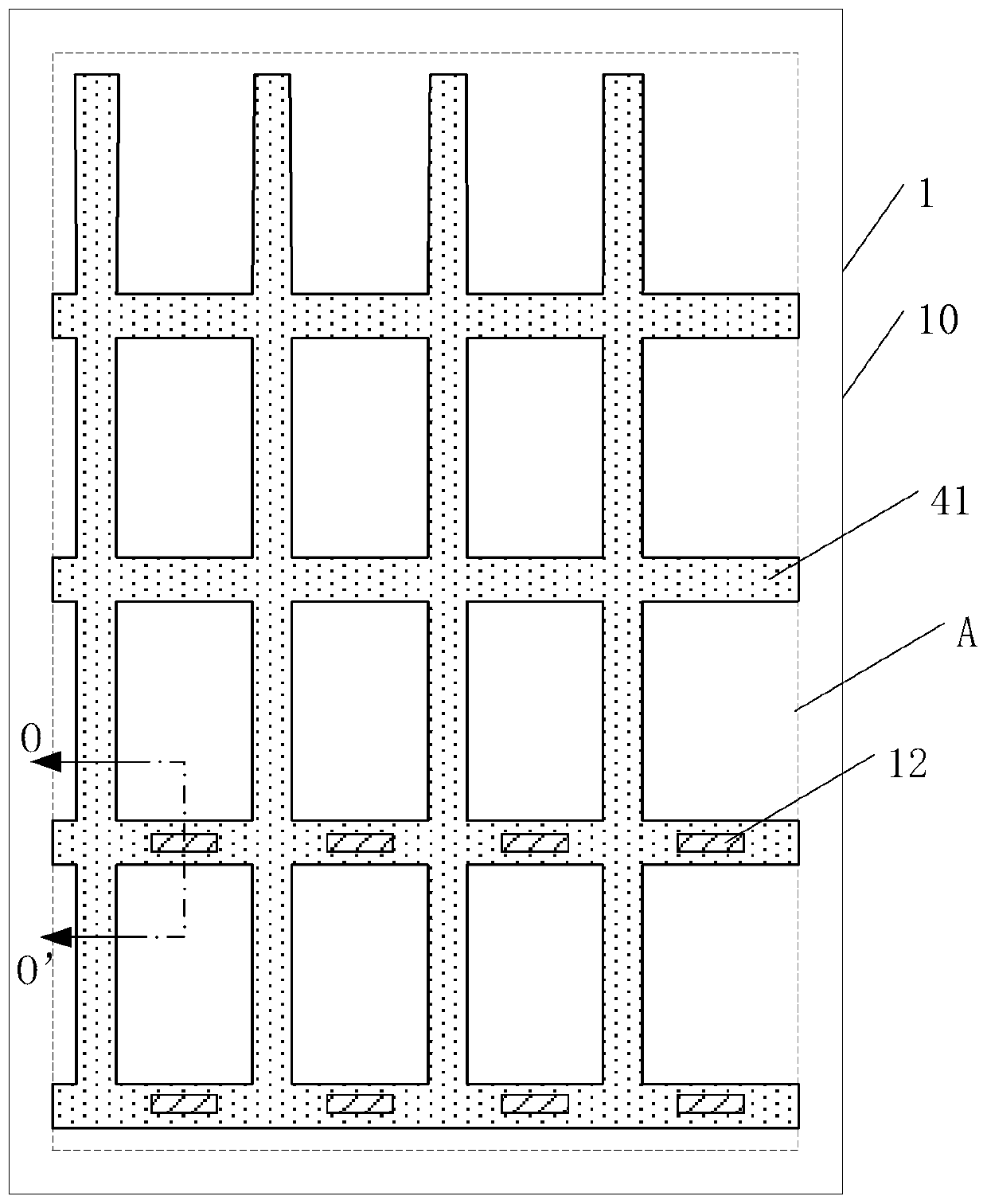

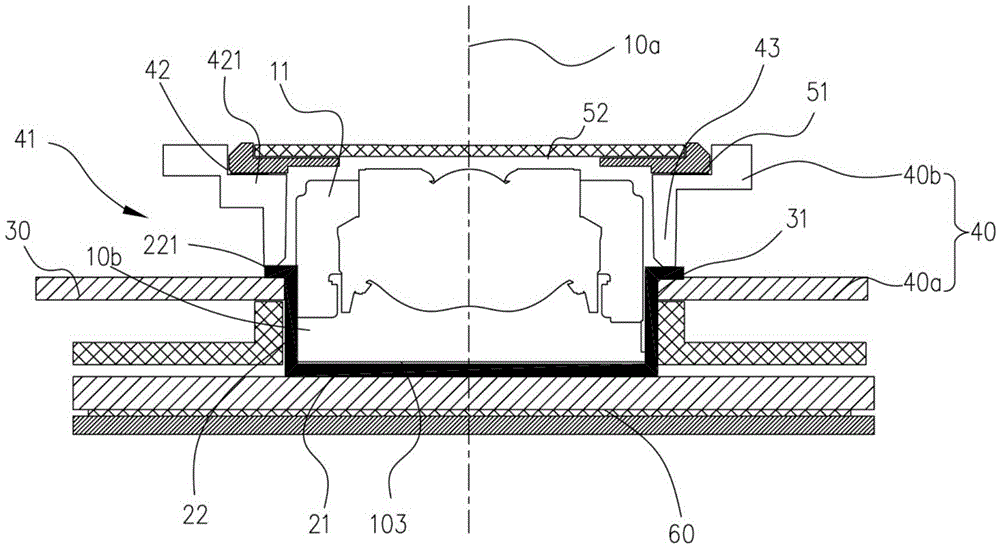

The invention discloses a narrow frame display panel. The narrow frame display panel comprises an array substrate, a color film substrate, a liquid crystal filled between the color film substrate andthe array substrate, a flexible printed circuit board and a driving chip. The side where the array substrate is positioned is a light-emitting surface; one end of the array substrate is a binding end;one end of the flexible printed circuit board is bound on the surface, facing the color film substrate, of the binding end; the driving chip is bound at the other end of the flexible printed circuitboard; after the flexible printed circuit board is bent back to the light-emitting surface, the flexible printed circuit board is arranged opposite to the color film substrate; the driving chip is positioned on one surface, deviating from the color film substrate, on the flexible printed circuit board. The invention also discloses a display device. By binding one end of the flexible printed circuit board on the surface, facing the color film substrate, of the binding end and binding the other end of the flexible printed circuit board with the driving chip, the width of the frame can be reduced; the driving chip is far from a reflector plate of a backlight module, so that the optical quality is ensured and the thickness of the display device cannot be increased; meanwhile, a black shieldinglayer on the outer surface of the array substrate also can prevent specular reflection.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

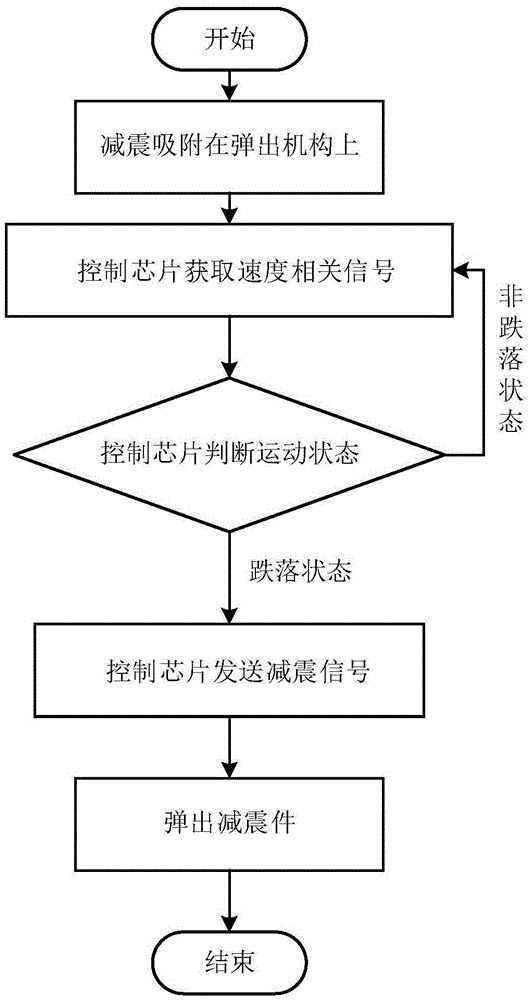

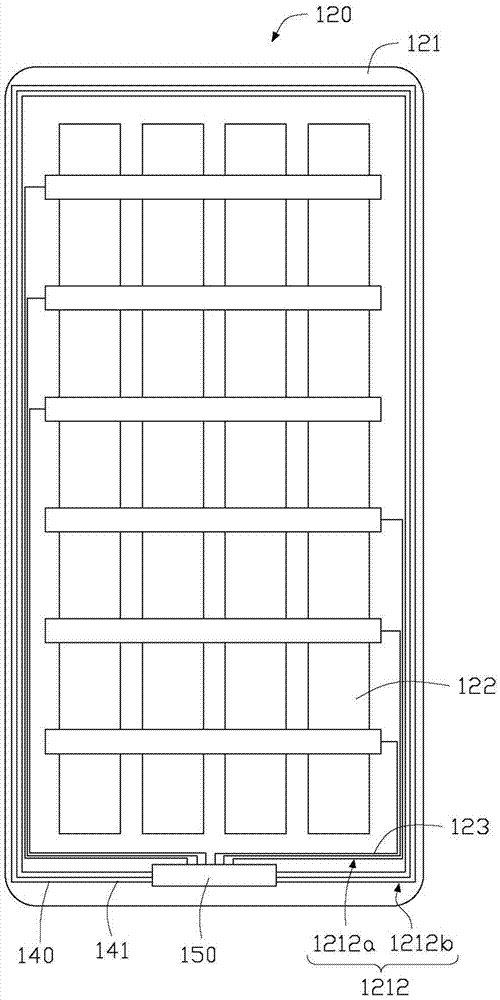

Anti-fall device and mobile terminal anti-fall method

ActiveCN105472069ARealize active anti-drop functionDoes not increase thicknessTelephone set constructionsControl signalHand held

The invention relates to the field of electronic technology, discloses an anti-fall device arranged on a mobile terminal and a mobile terminal anti-fall method based on the device. The anti-fall device comprises a sensor, a control chip and a damping module which is arranged on a mobile terminal shell and is electrically connected with the control chip, and the damping module comprises a pop-up mechanism and a damping part adsorbed on the pop-up mechanism through a magnetic force. Wherein, the senor collects a real-time speed correlation signal and sends the real-time speed correlation signal to the control chip, and the control chip generates a control signal according to the speed signal and sends the control signal to the damping module for controlling the pop-up mechanism to pop up the damping part. By adopting the anti-fall device and the mobile terminal anti-fall method, damage caused by fall can be not only prevented, and no influence is generated on the appearance or the hand holding feeling of the mobile terminal basically.

Owner:SHANGHAI CHUANGGONG COMM TECH

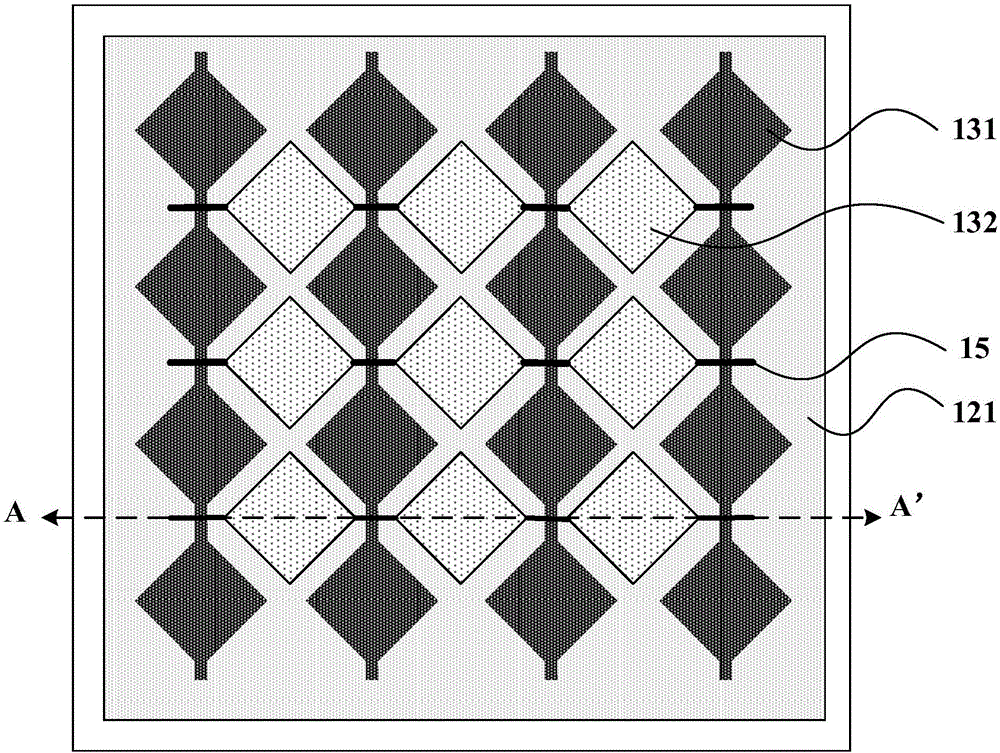

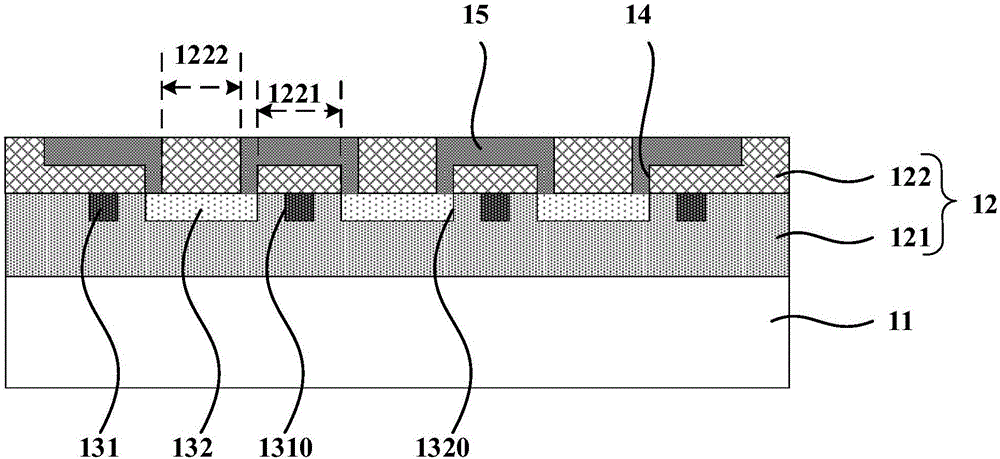

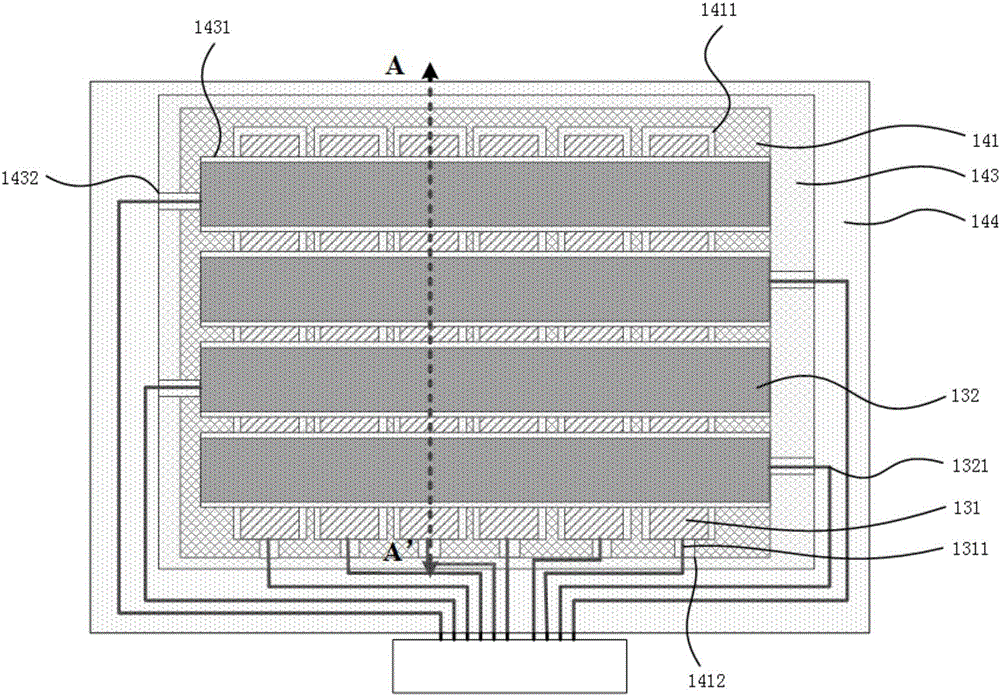

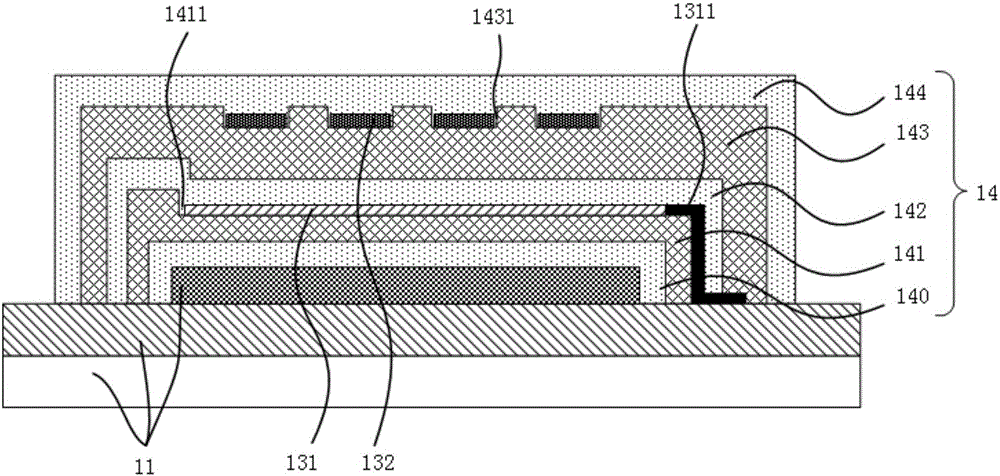

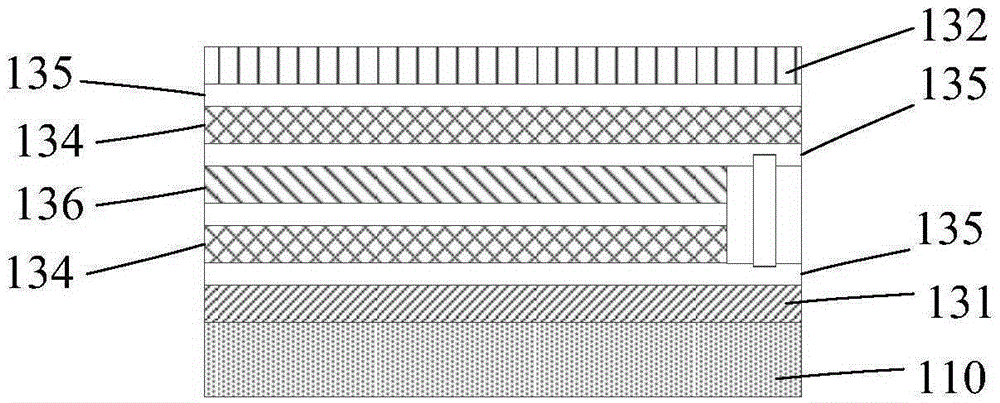

Organic light emitting display panel and device, and manufacturing method

ActiveCN106547405ADoes not increase thicknessIncreasing the thicknessSolid-state devicesSemiconductor/solid-state device manufacturingOrganic layerOptoelectronics

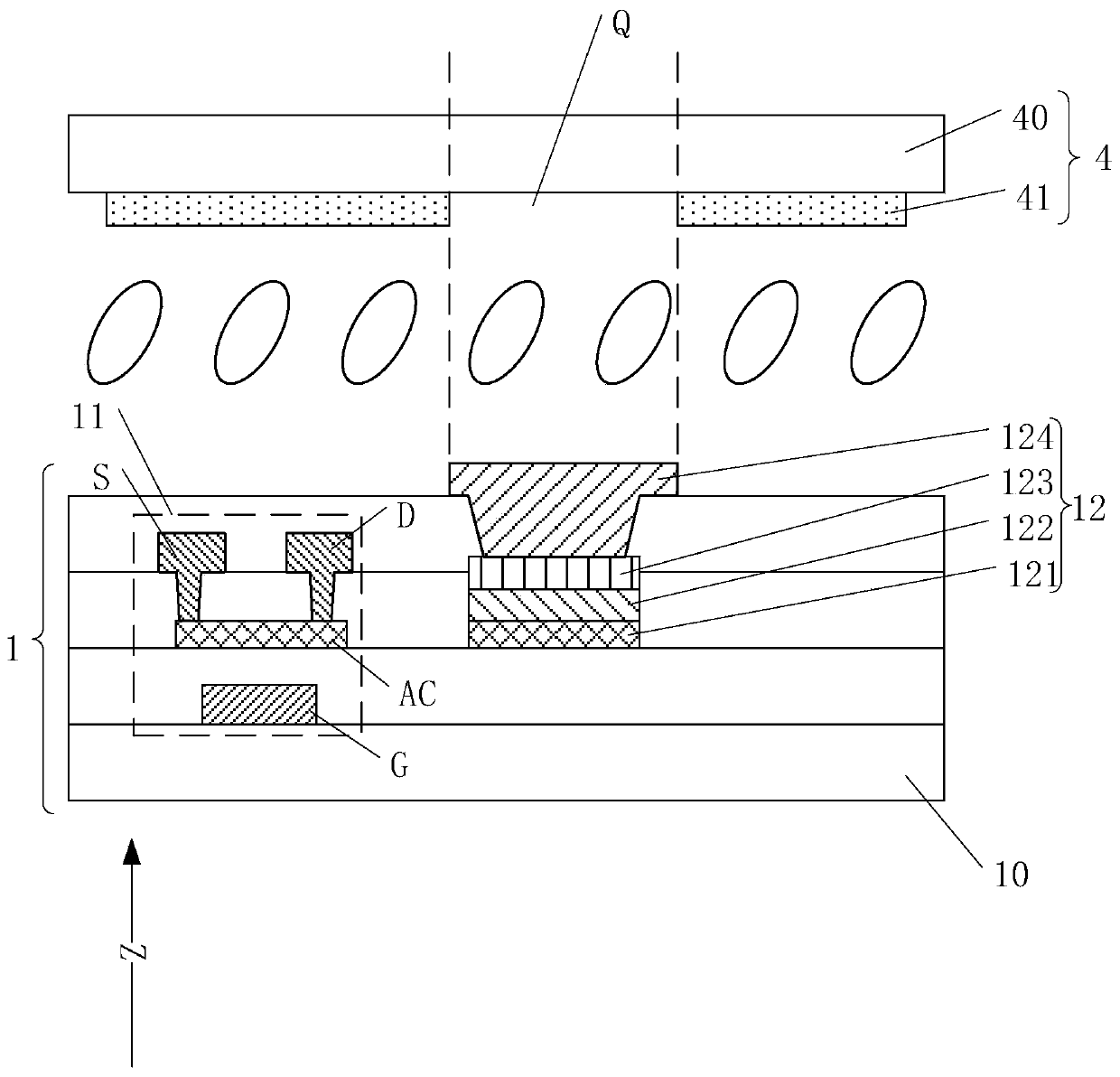

The invention discloses an organic light emitting display panel and device, and a manufacturing method. The organic light emitting display panel comprises: an organic light emitting array substrate; a thin film package layer covering the organic light emitting array substrate; a plurality of first touch electrodes and a plurality of second touch electrodes arranged on the same layer; adjacent first touch electrodes in the same column are connected; adjacent second touch electrodes in the same column are disconnected with each other; the thin film package layer comprises a first organic layer and a second organic layer, the first organic layer is provided with a plurality of first groove structures and a plurality of second groove structures; the first touch electrodes are located in the first groove structures, and the second touch electrodes are located in the second groove structures. By adoption of the organic light emitting display panel disclosed by the invention, the smoothness of the thin film package layer is improved, and the reliability of the organic light emitting display panel is improved on the premise of ensuring the thinness and light weight of the organic display panel.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

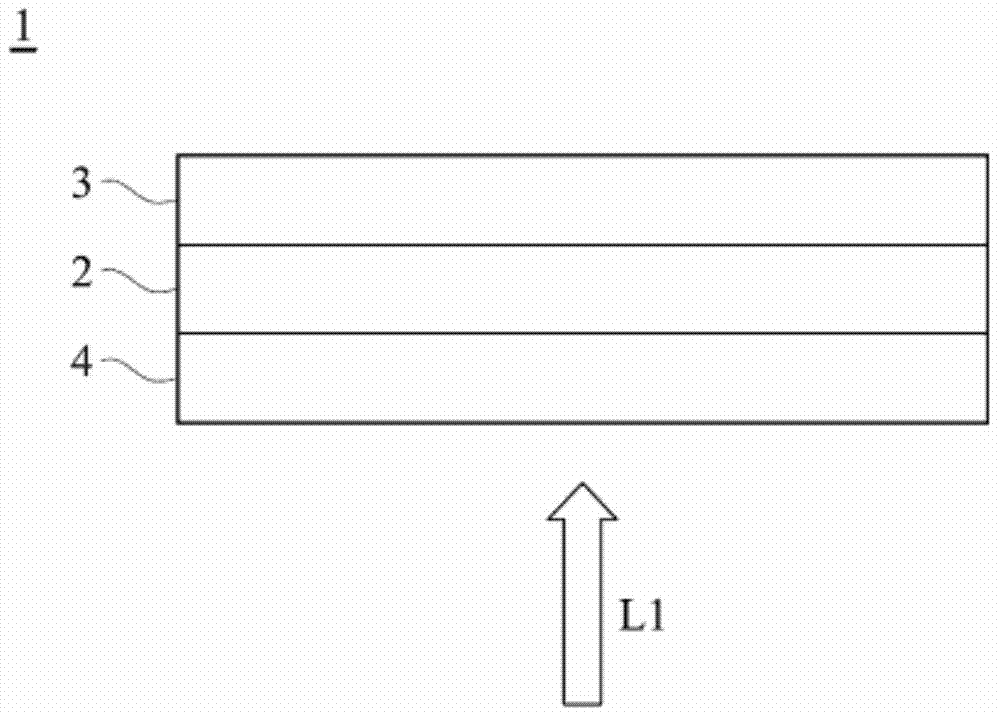

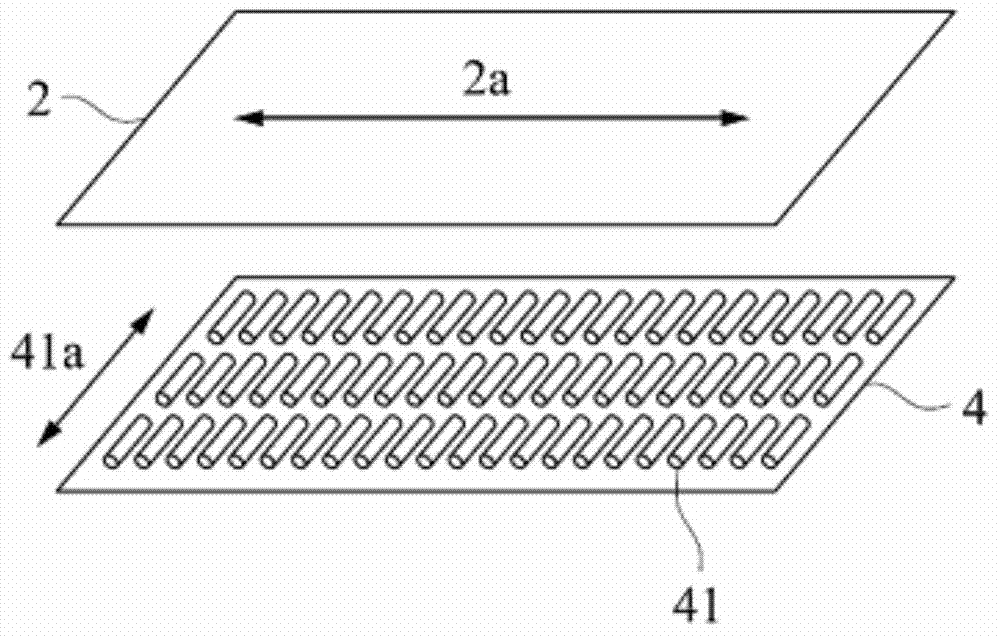

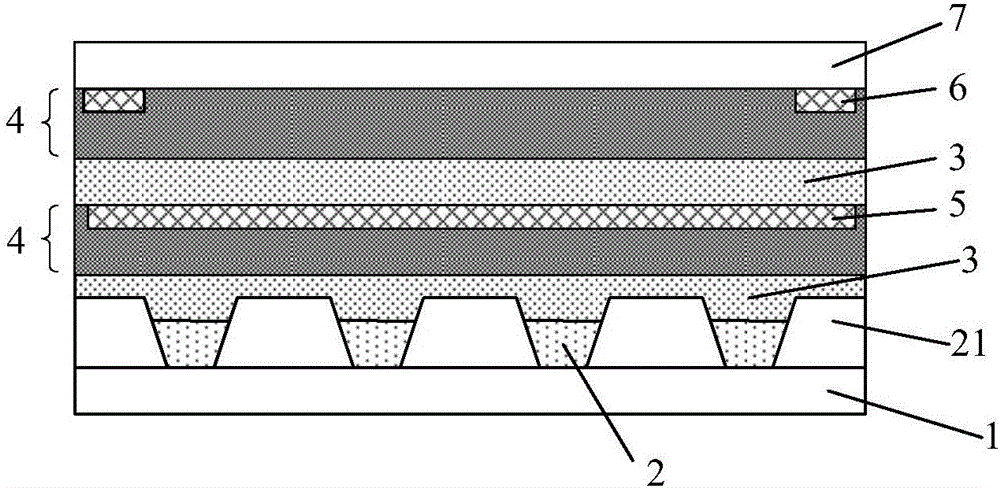

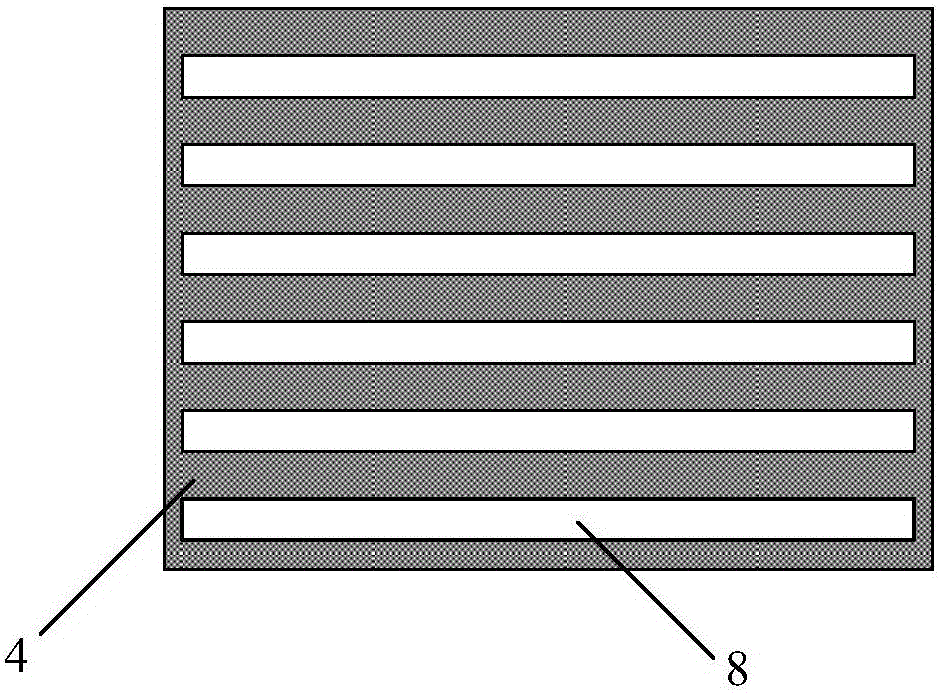

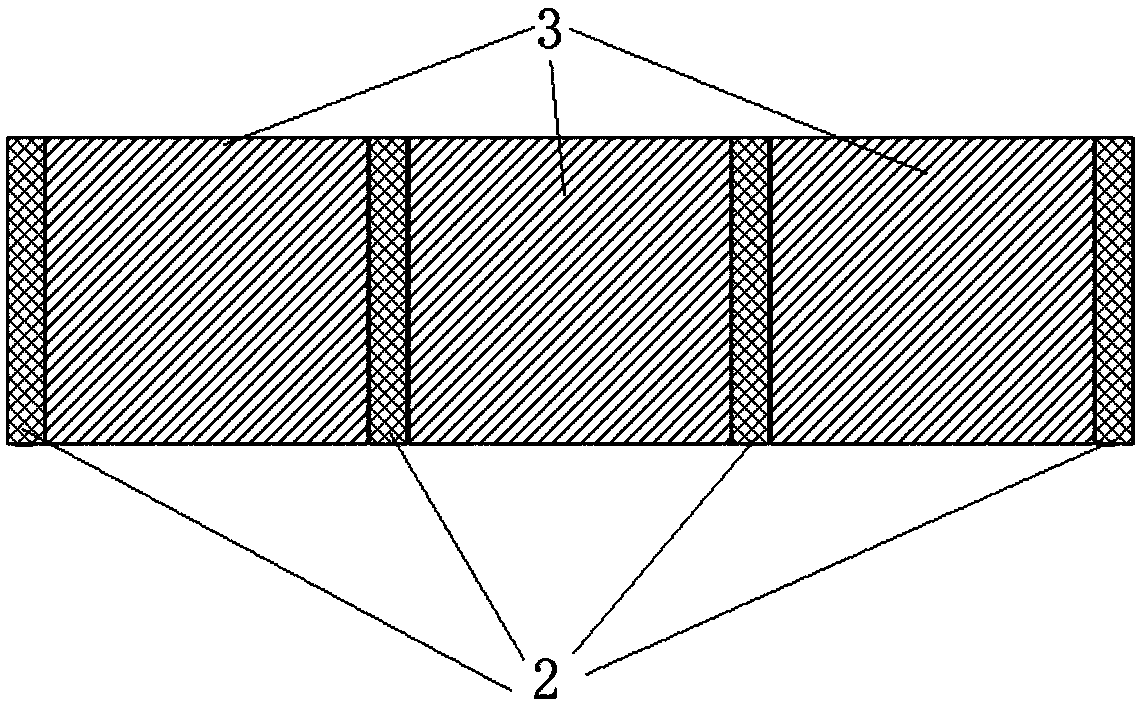

Polarizing plate

InactiveCN104749680ADoes not increase thicknessNot easily affected by heatPolarising elementsNon-linear opticsLiquid-crystal displayQuantum rods

The invention relates to a polarizing plate applied to a liquid crystal display. The polarizing plate comprises a polarizing layer, a first protecting layer and a second protecting layer, wherein the first protecting layer is arranged on one surface of the polarizing layer; the second protecting layer is arranged on the other surface of the polarizing layer; a plurality of quantum rods are arranged in the protecting layer, and long shafts of the plurality of quantum rods are vertical to an absorbing shaft of the polarizing plate. According to the polarizing plate, unpolarized incident light emitted by a backlight source enters the polarizing plate and is converted by the quantum rods into polarized light and then directly flows through the polarizing layer, and therefore, the utilization rate of the backlight source can be increased.

Owner:BENQ MATERIALS +1

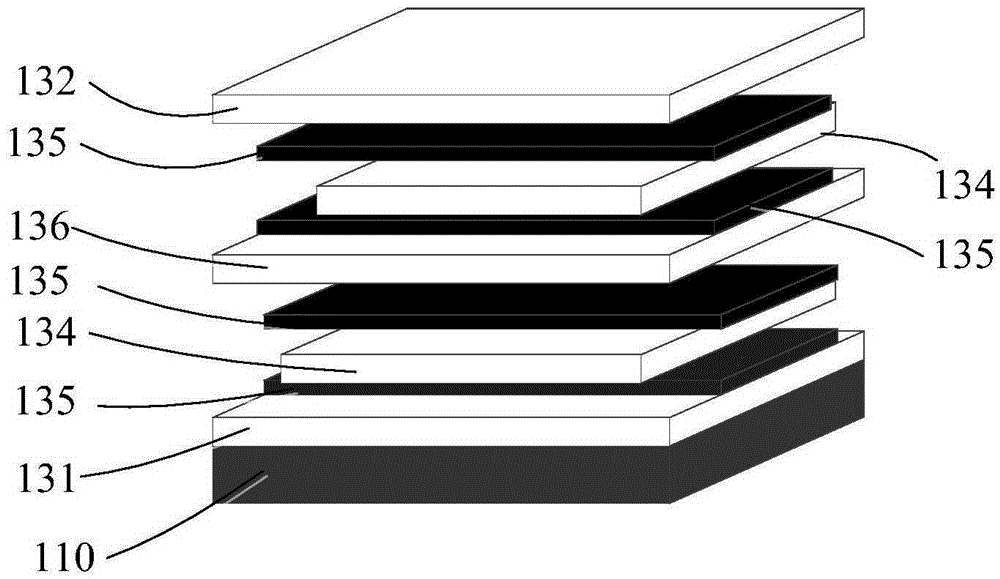

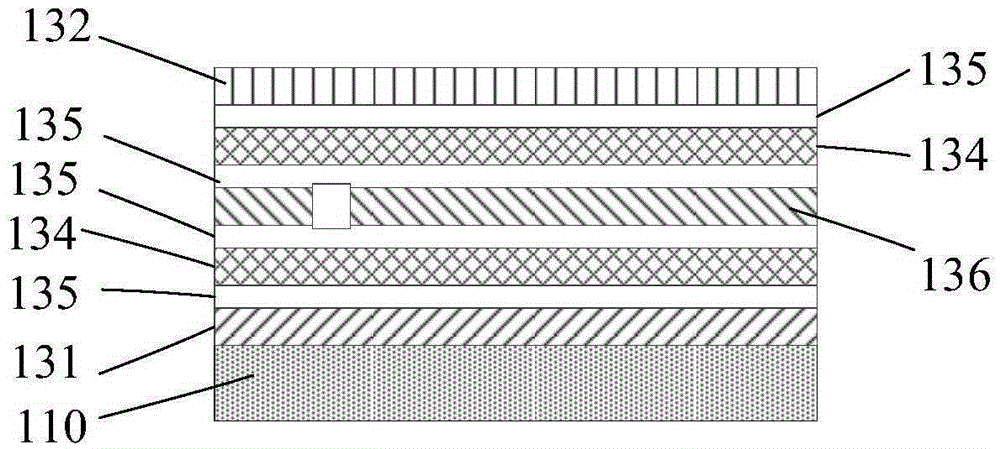

Organic electroluminescence diode substrate and preparation method and display apparatus thereof

ActiveCN105977279AHigh degree of integrationIncrease added valueSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmOrganic electroluminescence

The invention provides an organic electroluminescence diode substrate and a preparation method and a display apparatus thereof, and belongs to the field of display technology. The organic electroluminescence diode substrate includes a substrate, an organic electroluminescence unit arranged on the substrate, and N groups of film sets which are arranged on the organic electroluminescence unit. N is an integer which is equal to or greater than 2. Each group of film set includes an inorganic film layer and an organic film layer which are successively arranged away from the direction of the organic electroluminescence unit, and one layer of the organic film layers is provided with a plurality of first grooves, and the other layer of the organic film layers is provided with a plurality of second grooves. The plurality of first grooves and the plurality of second grooves are intersected in orthographic projection on the substrate. Each first groove is filled with a first lead. Each second groove is filled with a second lead. According to the invention, the organic electroluminescence diode substrate is suitable for flexible display panels.

Owner:BOE TECH GRP CO LTD

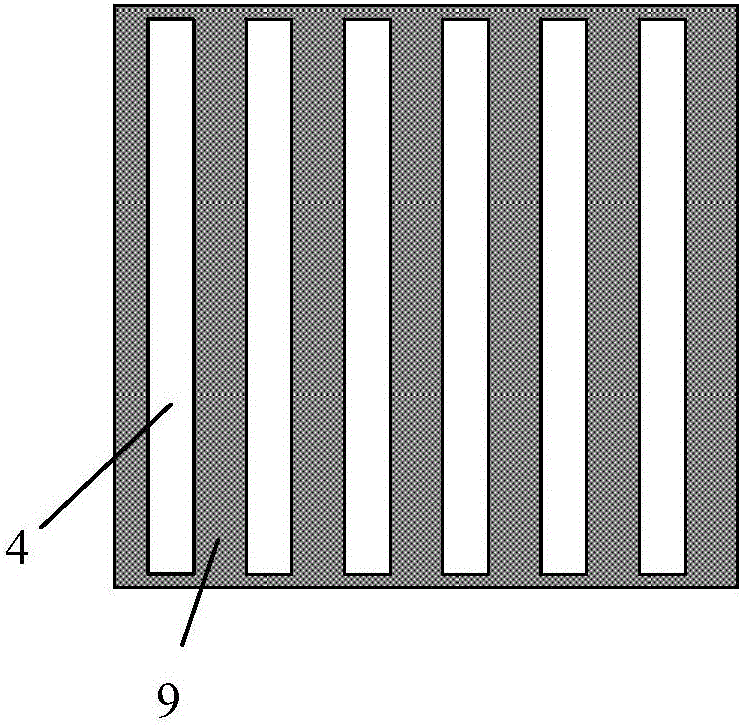

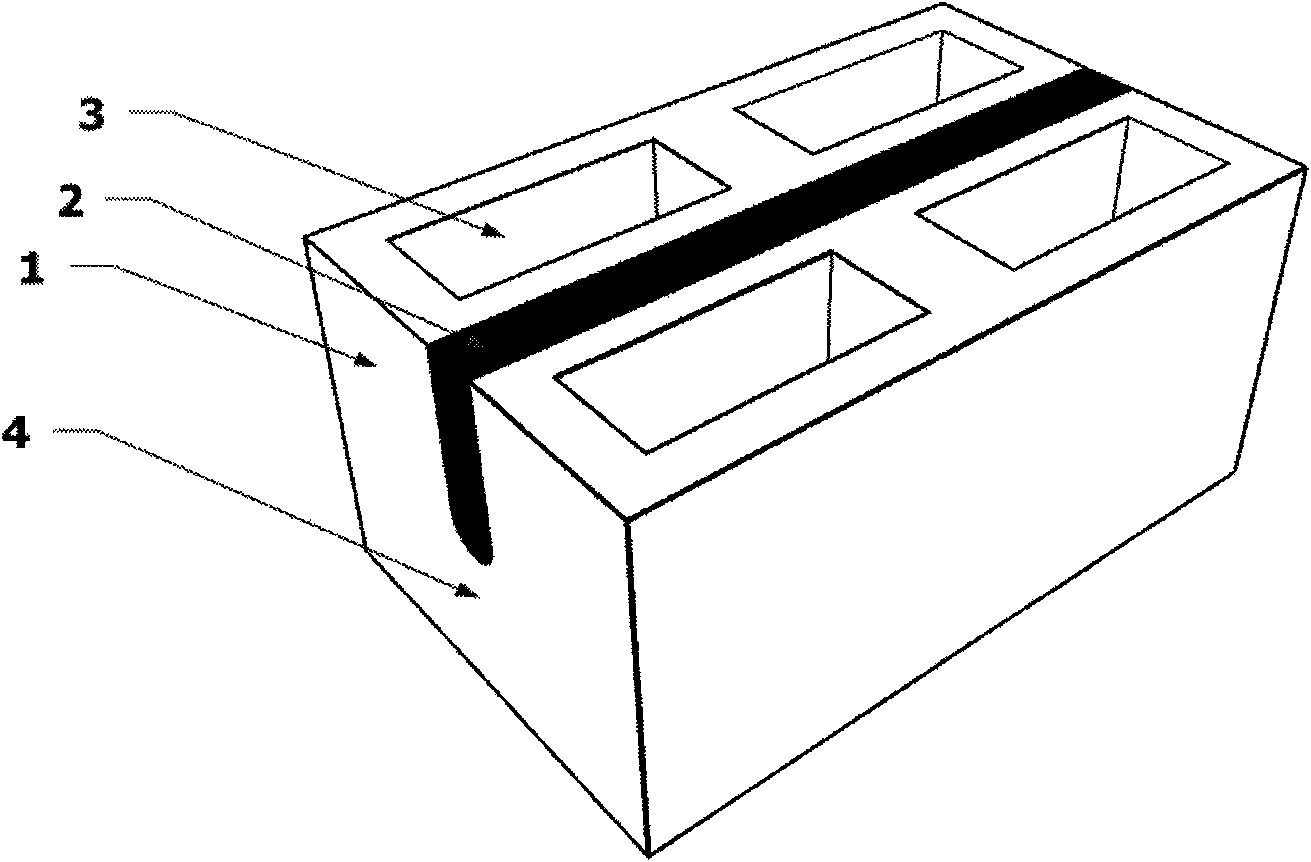

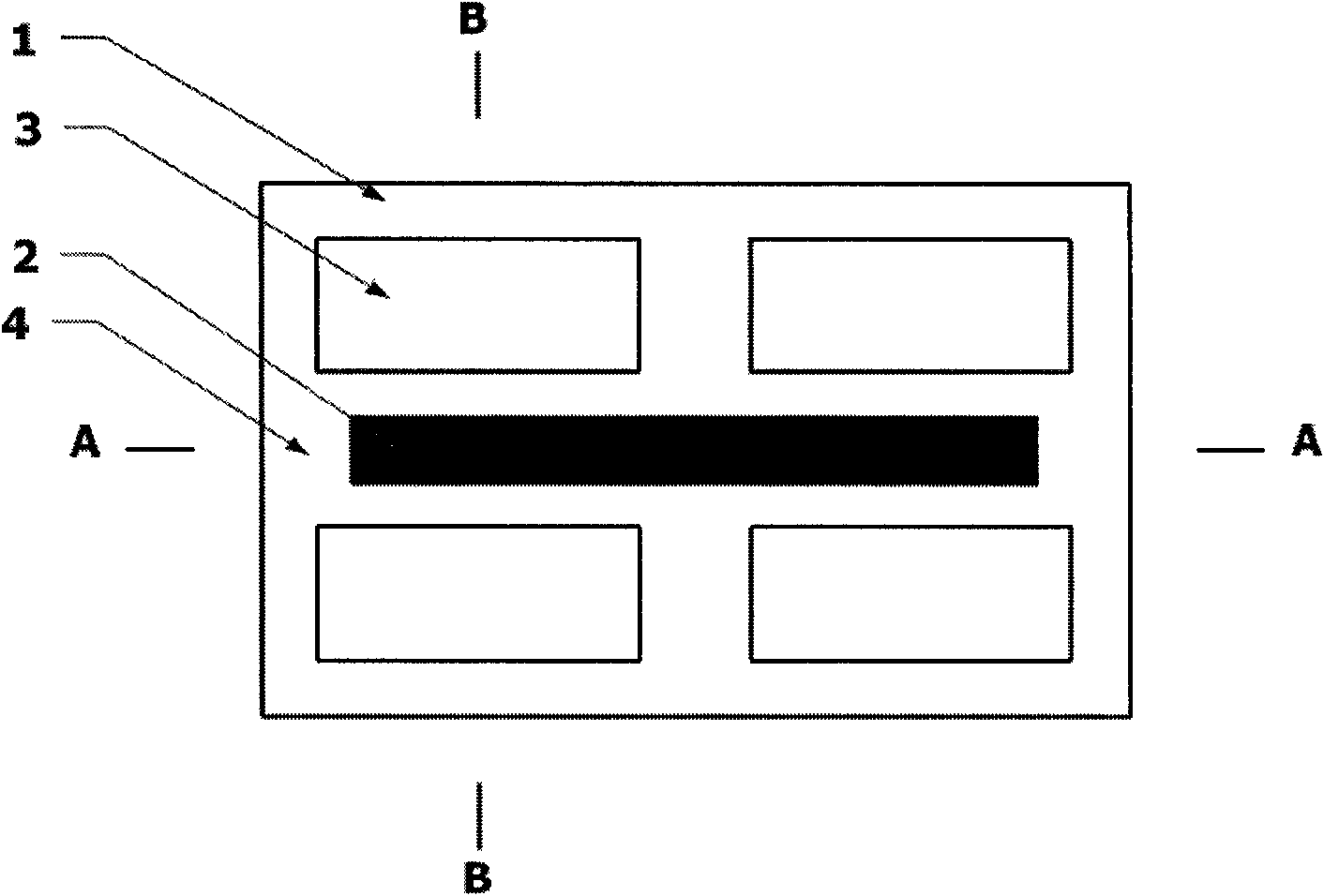

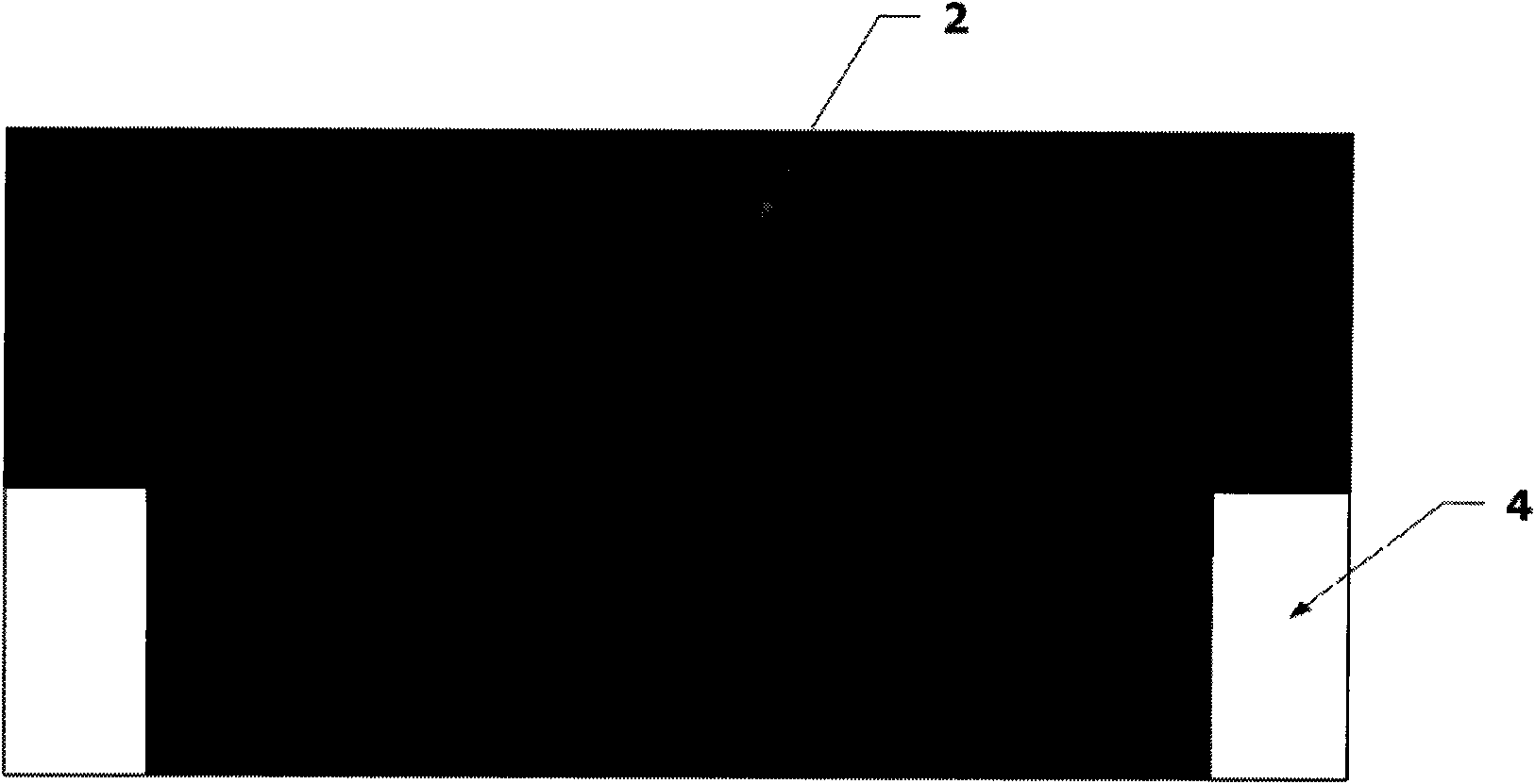

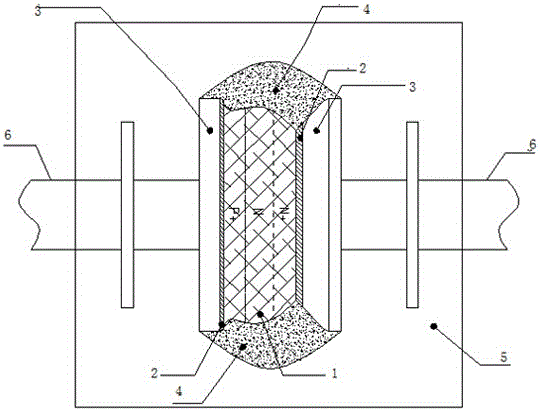

A composite self-insulating block

InactiveCN102261155ASimple structureReduce weightConstruction materialThermal insulationAgricultural engineering

The invention discloses a composite self-insulating block, which is composed of a block body and heat-insulating material. The block body is on both sides of the heat-insulating material, and there are connecting pieces at the bottom of both ends of the block body to connect the block bodies on both sides. The block has good thermal insulation effect, simple structure, convenient construction and does not increase the thickness of the wall body.

Owner:黄靓

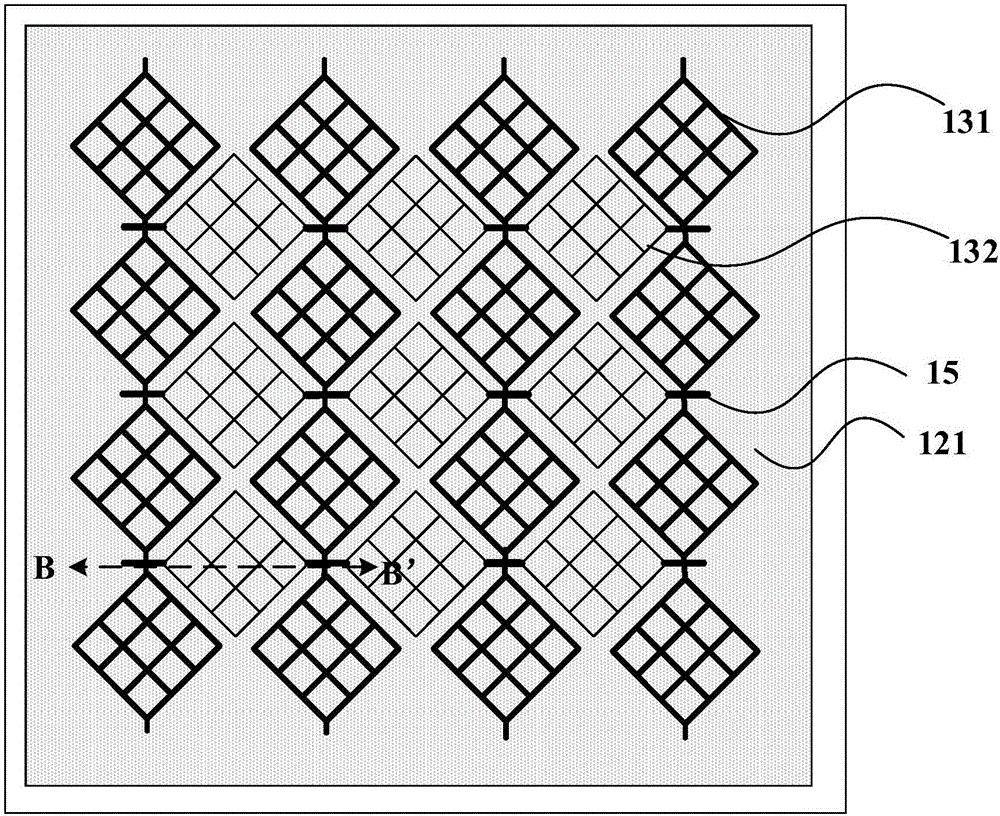

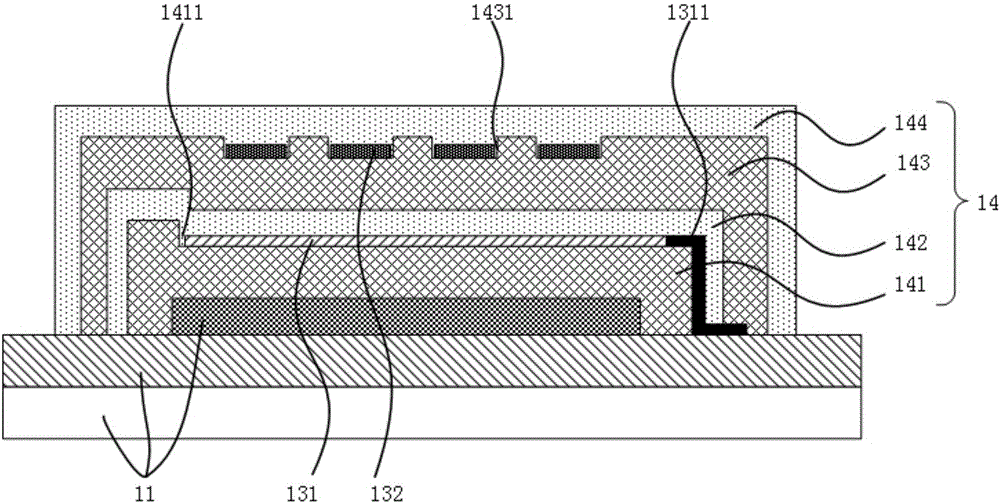

Organic light-emitting display panel

ActiveCN106293258AAvoid corrosionDoes not increase thicknessSolid-state devicesInput/output processes for data processingOrganic layerEngineering

The invention discloses an organic light-emitting display panel. The organic light-emitting display panel comprises an organic light-emitting element array substrate, a thin-film encapsulation layer covering the organic light-emitting element array substrate, a plurality of touch-control driving electrodes, a plurality of touch-control sensing electrodes, a plurality of first touch-control routing lines, and a plurality of second touch-control routing lines, wherein the first touch-control routing lines are electrically connected with the corresponding touch-control driving electrodes; the second touch-control routing lines are electrically connected with the corresponding touch-control sensing electrodes; the thin-film encapsulation layer comprises a first organic layer and a second organic layer; a plurality of first grooves and a plurality of second grooves are formed in the first organic layer, and a plurality of third grooves and a plurality of fourth grooves are formed in the second organic layer; the touch-control driving electrodes are located in the first grooves, and the first touch-control routing lines are located in the second grooves; the touch-control sensing electrodes are located in the third grooves, and the second touch-control routing lines are located in the fourth grooves; the first touch-control routing lines and the second touch-control routing lines are located in the thin-film encapsulation layer. The organic light-emitting display panel provided by the invention is used for meeting the requirement that the touch-control routing lines are not easy to corrode.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

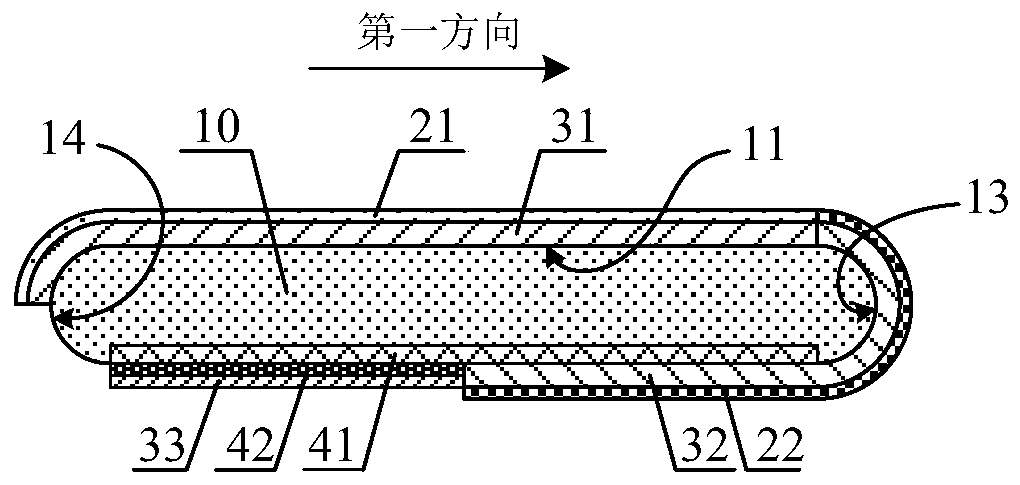

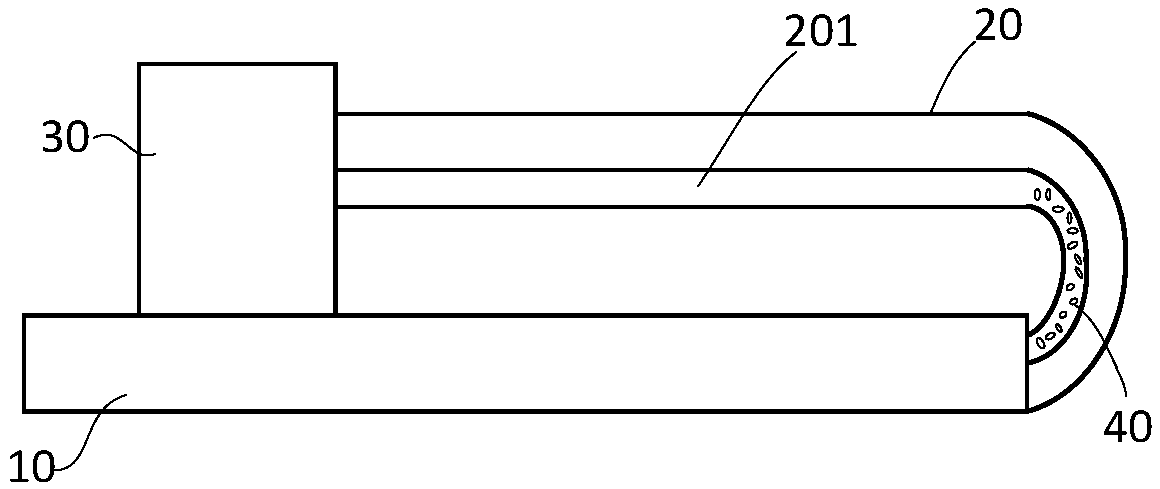

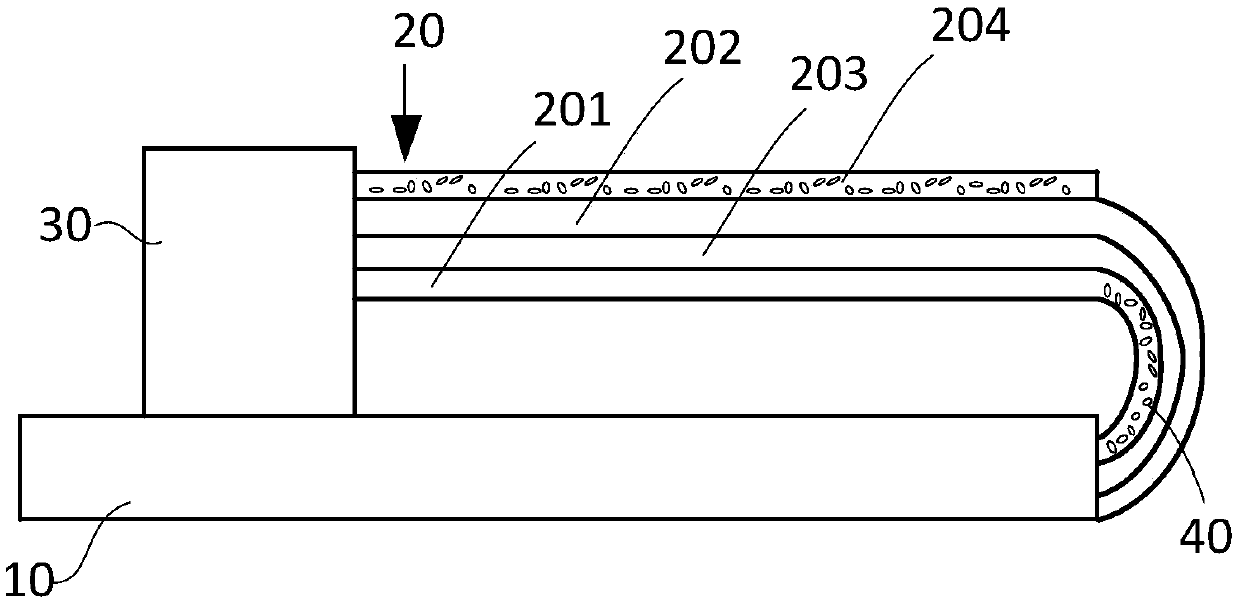

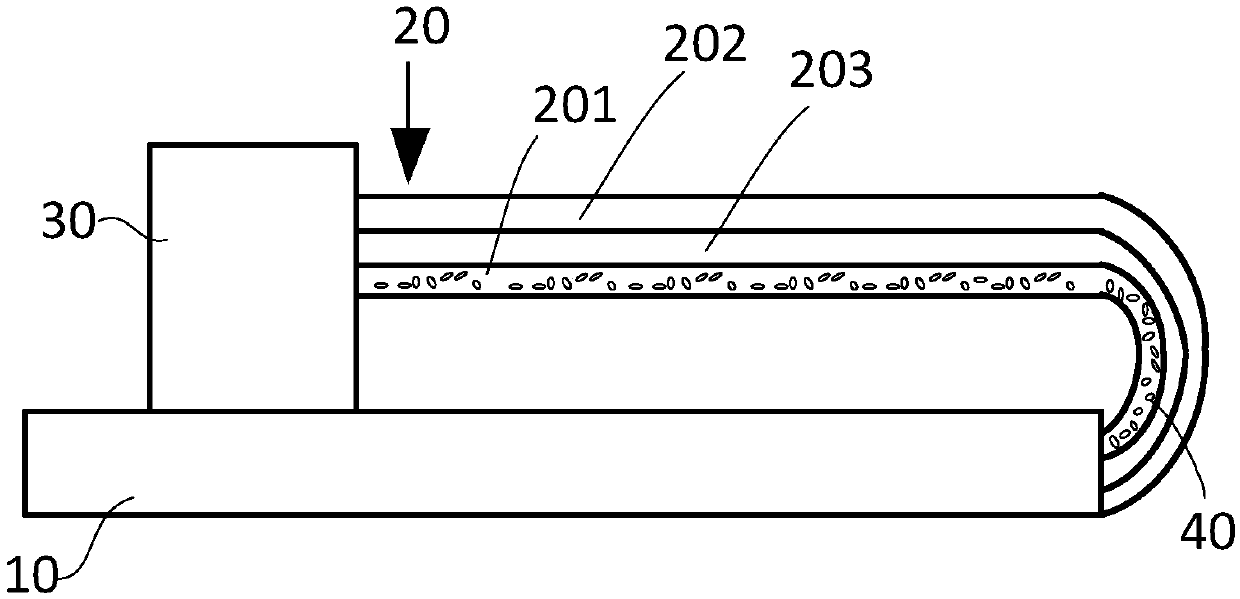

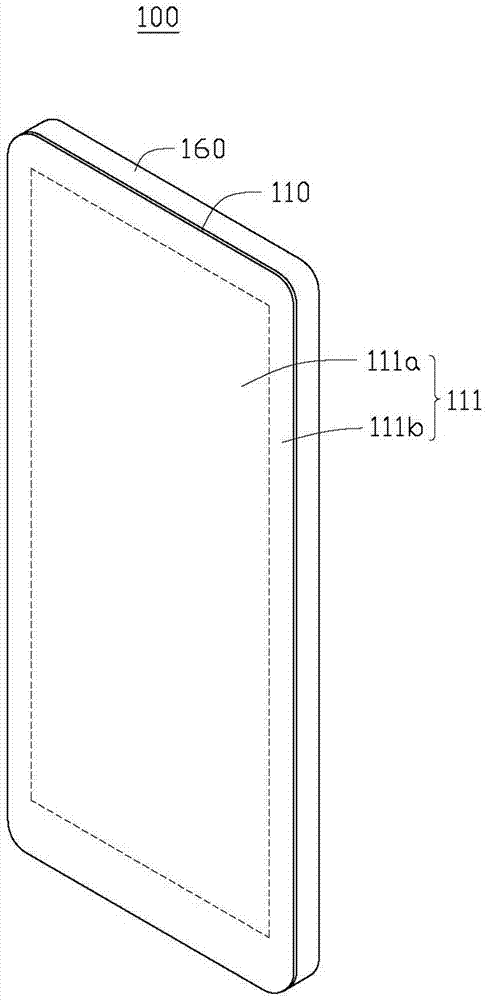

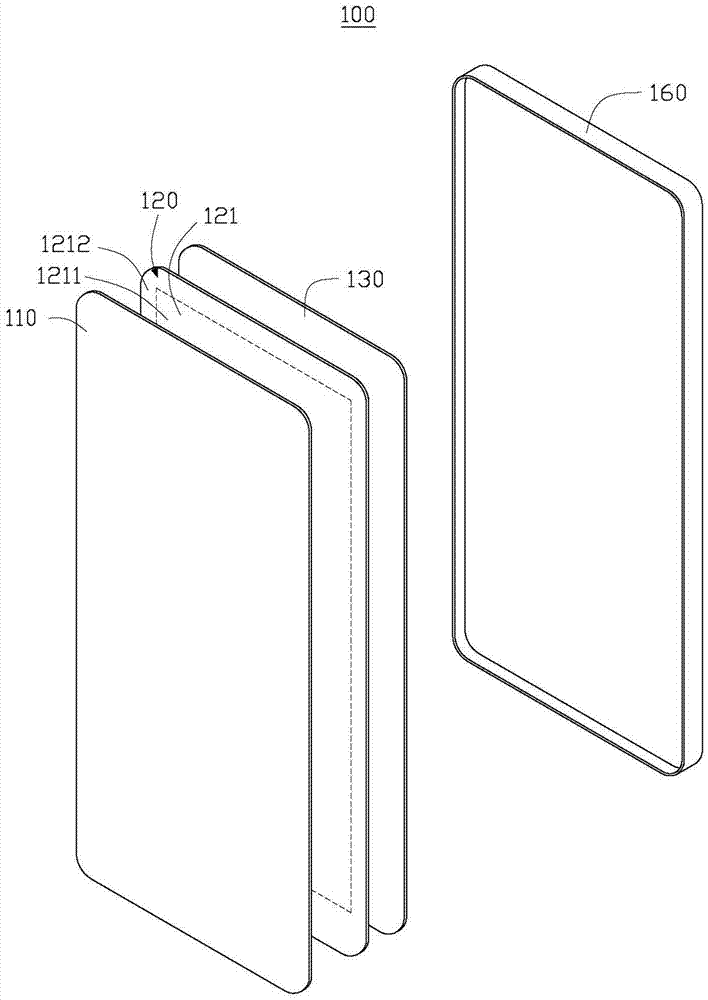

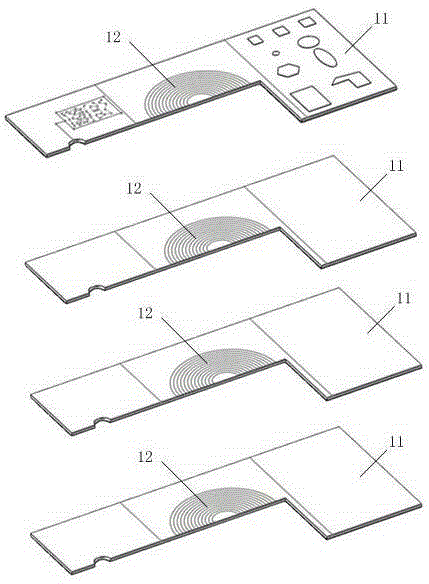

Display device and using method thereof

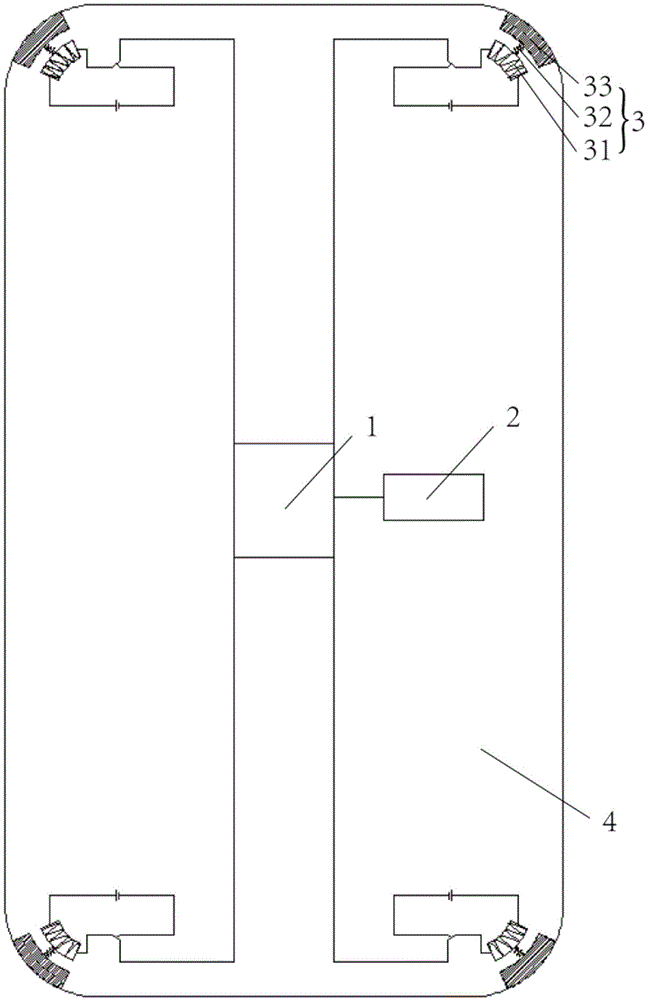

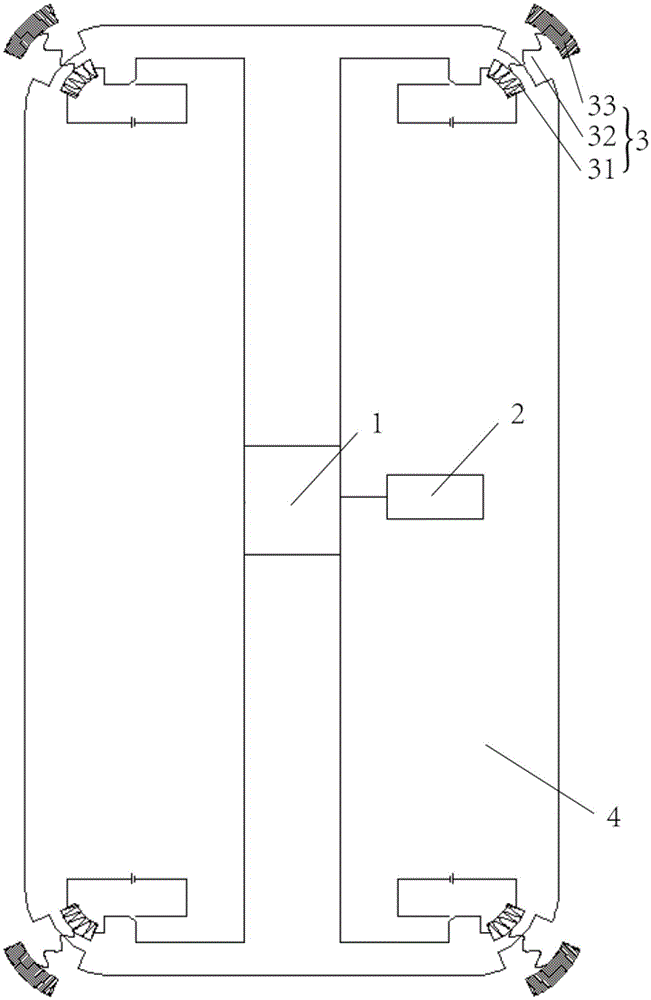

ActiveCN110868486AIncrease the display area towards the frontDisplay area adjustment towards the frontDevices with multiple display unitsTelephone set constructionsComputer hardwareComputer graphics (images)

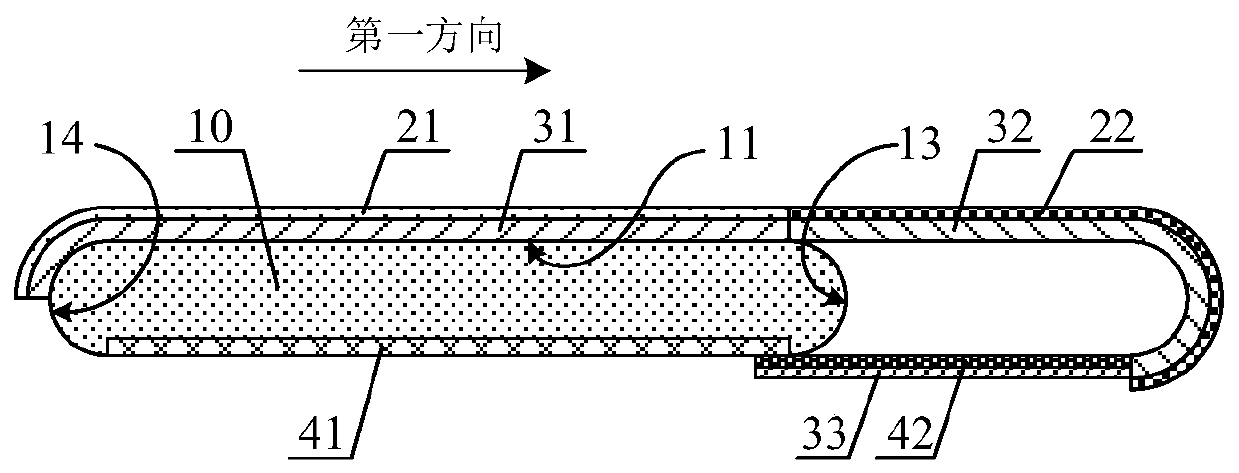

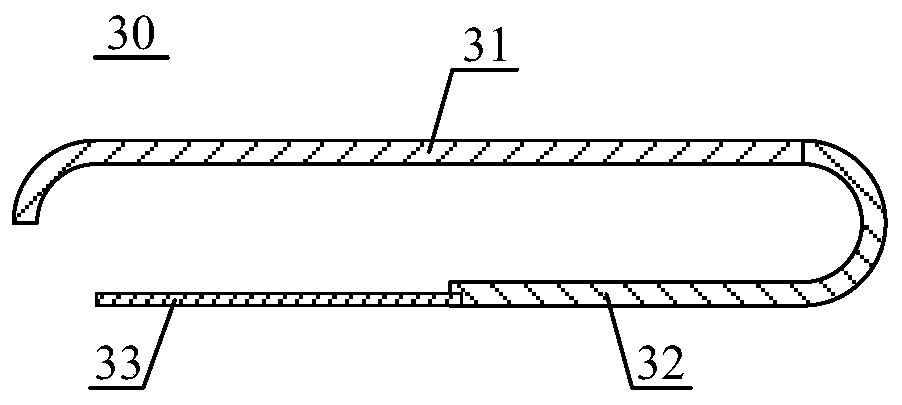

The invention discloses a display device and a using method thereof. The display device comprises a main body, and a first display screen and a flexible second display screen which are arranged alonga first direction; the main body comprises a front surface facing one side of a user and a back surface opposite to the front surface; the first display screen is arranged on the front surface; one end, close to the first display screen, of the second display screen is arranged on the front surface; the end, away from the first display screen, of the second display screen is arranged on the back face through a first sliding mechanism and slides in the first direction through the first sliding mechanism, so that the area of the side, facing the front face, of the second display screen is increased or decreased. According to the display device, the second display screen is driven by the first sliding mechanism to slide, so that the display area of the display device in the front direction isexpanded, the thickness of the display device is not increased, and the display device is convenient to store and carry.

Owner:BOE TECH GRP CO LTD

Display base board, preparation method thereof, and display apparatus

InactiveCN105957878AHigh degree of integrationIncrease added valueSolid-state devicesSemiconductor/solid-state device manufacturingComputer scienceMembrane layer

The present invention provides a display base board, a preparation method thereof, and a display apparatus, belonging to the technical field of display. The present invention solves the problem that an existing display base board has a low integration degree and is thick, thereby making a display panel thick and heavy. The display base board includes a base, a display unit, a color membrane layer, a first flat layer and a second flat layer. The display unit is disposed above the base. The color membrane layer is disposed above the display unit. The first flat layer and the second flat layer are sequentially disposed above the color membrane layer. A plurality of first grooves is disposed on the first flat layer. A plurality of second grooves is disposed on the second flat layer. Orthographic projections of the plurality of first grooves and the plurality of second grooves on the base are cross. The first grooves are filled with first leads. The second grooves are filled with second leads.

Owner:BOE TECH GRP CO LTD

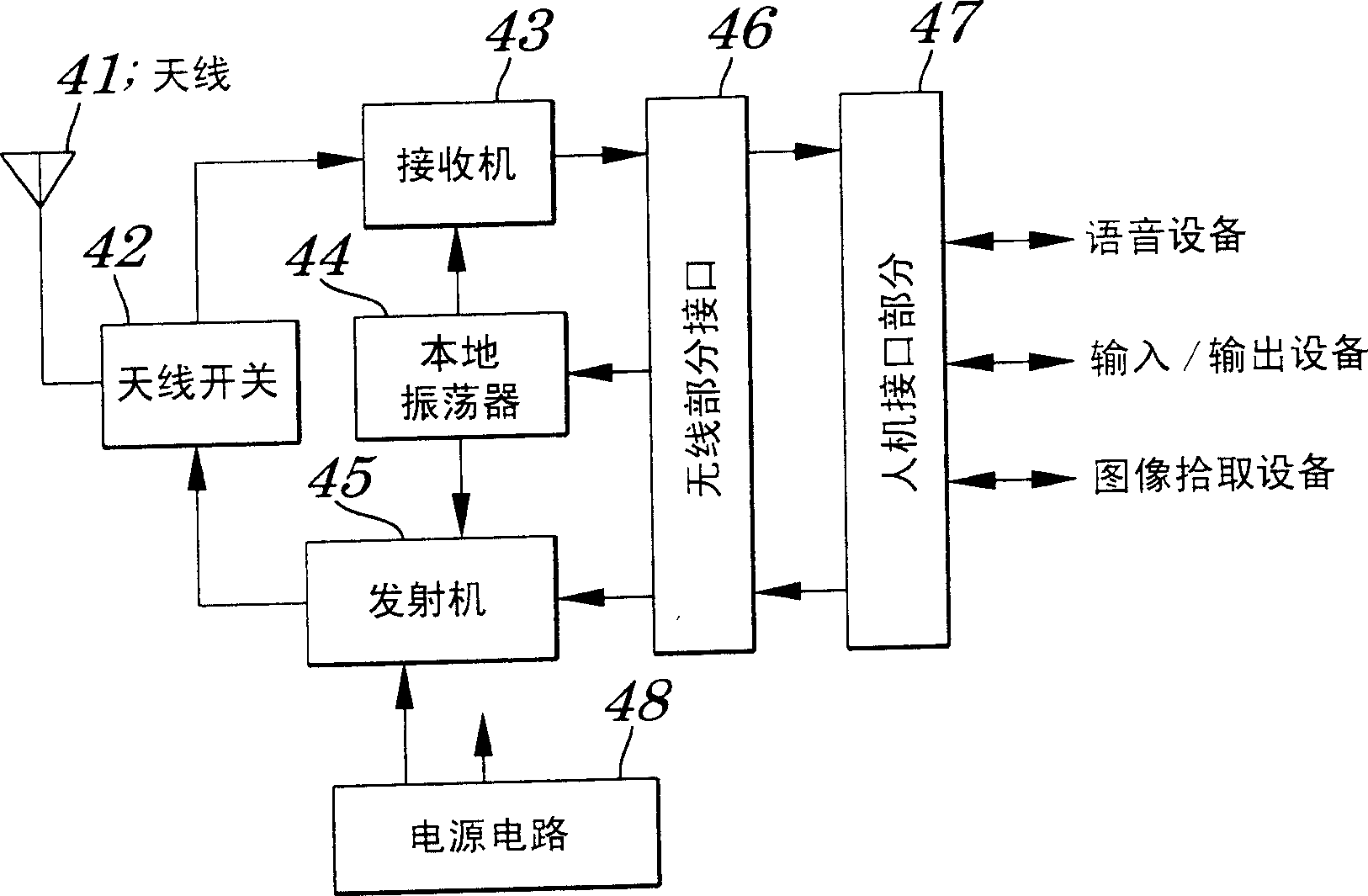

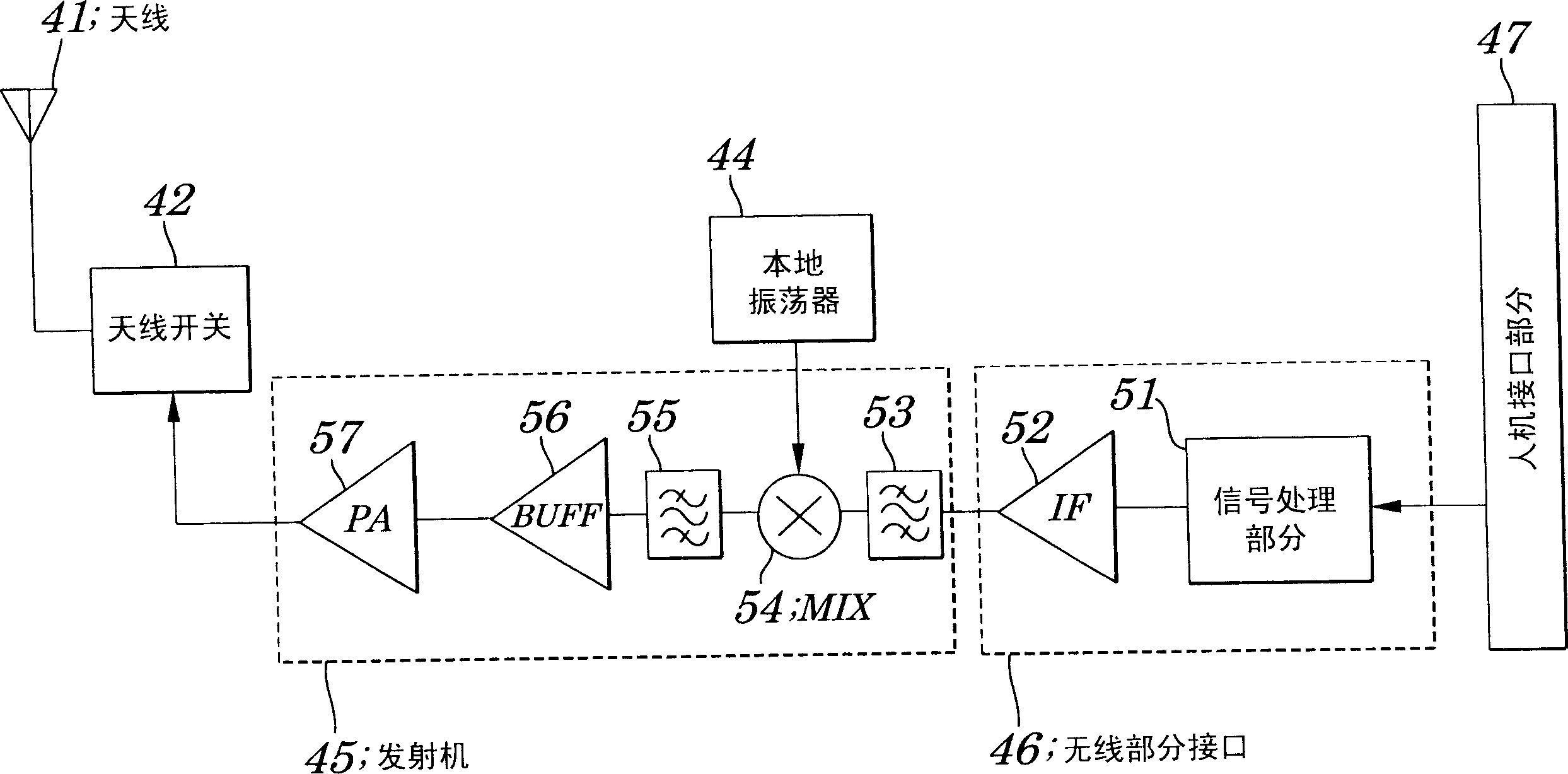

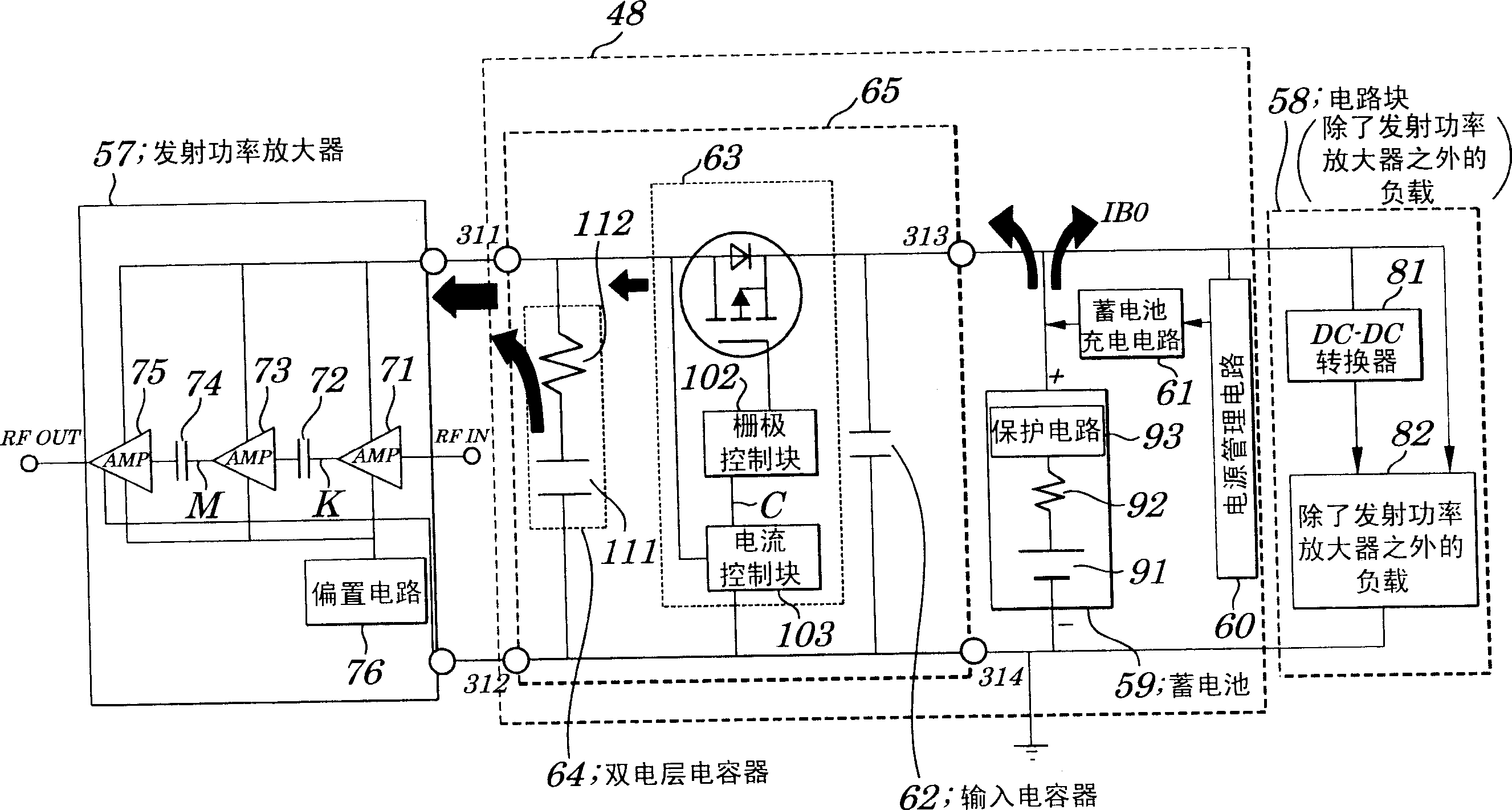

Power source circuit and communication appts. having same

InactiveCN1520072AShort lifeIncreasing the thicknessPower managementBatteries circuit arrangementsInternal resistanceCommunication device

A power circuit is provided which is capable of lengthening use time of a battery in a portable communication terminal of a TDMA (Time Division Multiple Access) or TDD (Time Division Duplex) type portable communication devices, and of making them compact and lightweight. Since, by using a control circuit, an output current having been limited to become a pre-set current value is supplied from the battery to a transmission power amplifier and an electrical double layer capacitor is charged so that power is accumulated therein and since power is applied from the electrical double layer capacitor to both the control circuit and the transmission power amplifier, even if power consumption of the transmission power amplifier increases during a burst period, a drop of the output voltage from the battery is small. Therefore, time required for the output voltage to reach a terminating voltage in the battery is made longer and a life of the battery can be lengthened. Also, even if the battery is put under a low-temperature circumstance and its internal resistance increases, shortening of the life of the battery can be avoided.

Owner:ENVISION AESC ENERGY DEVICES LTD

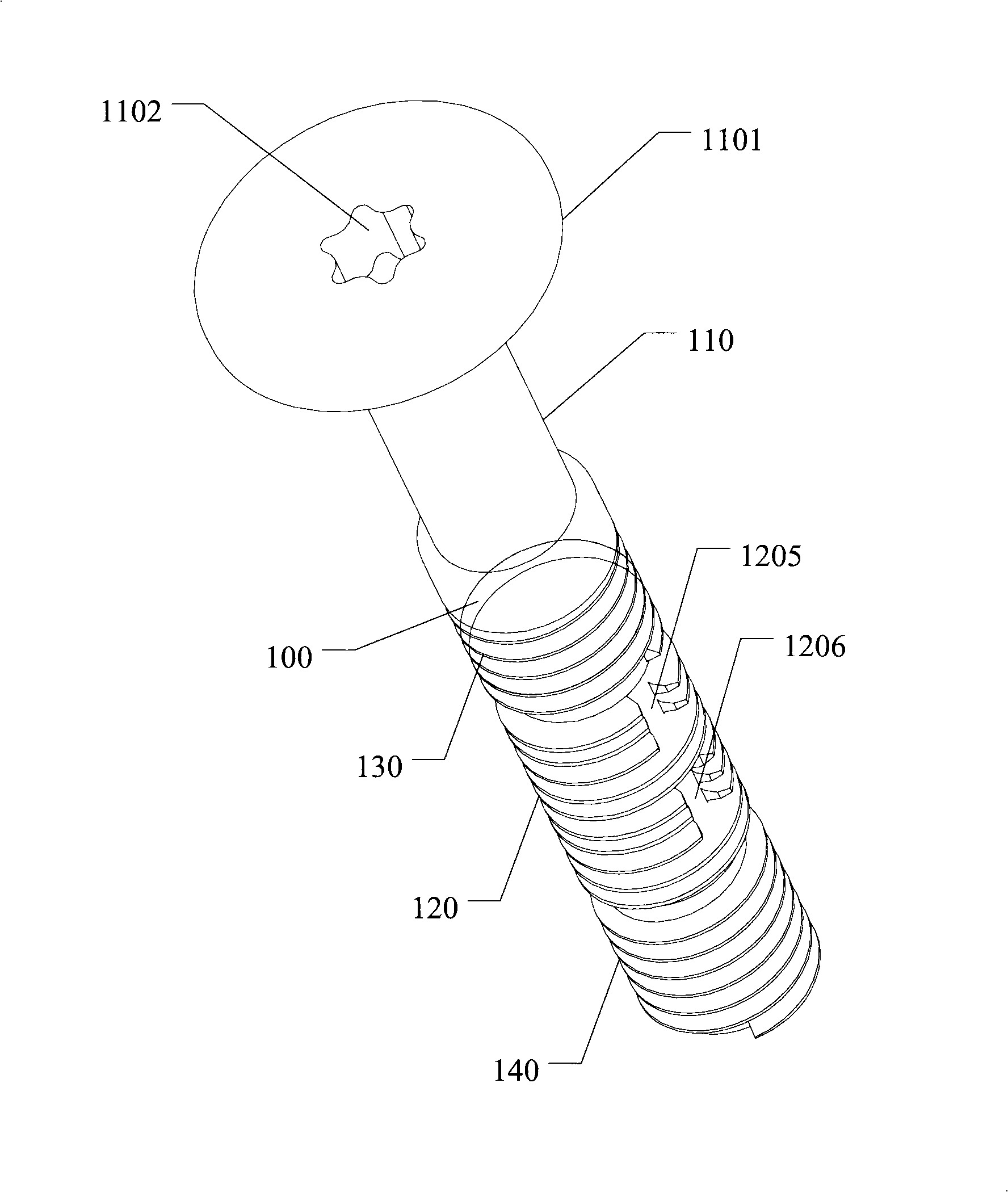

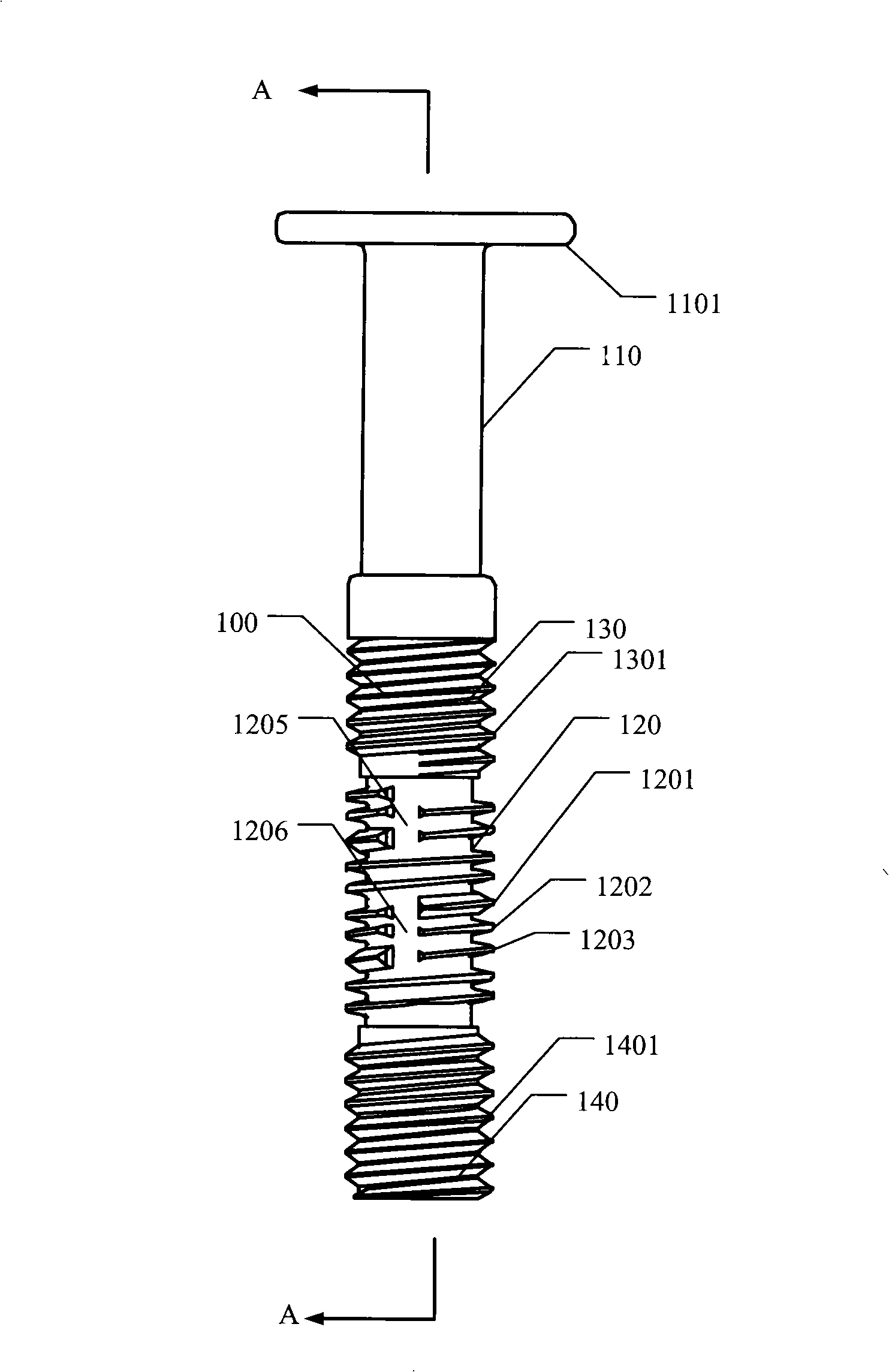

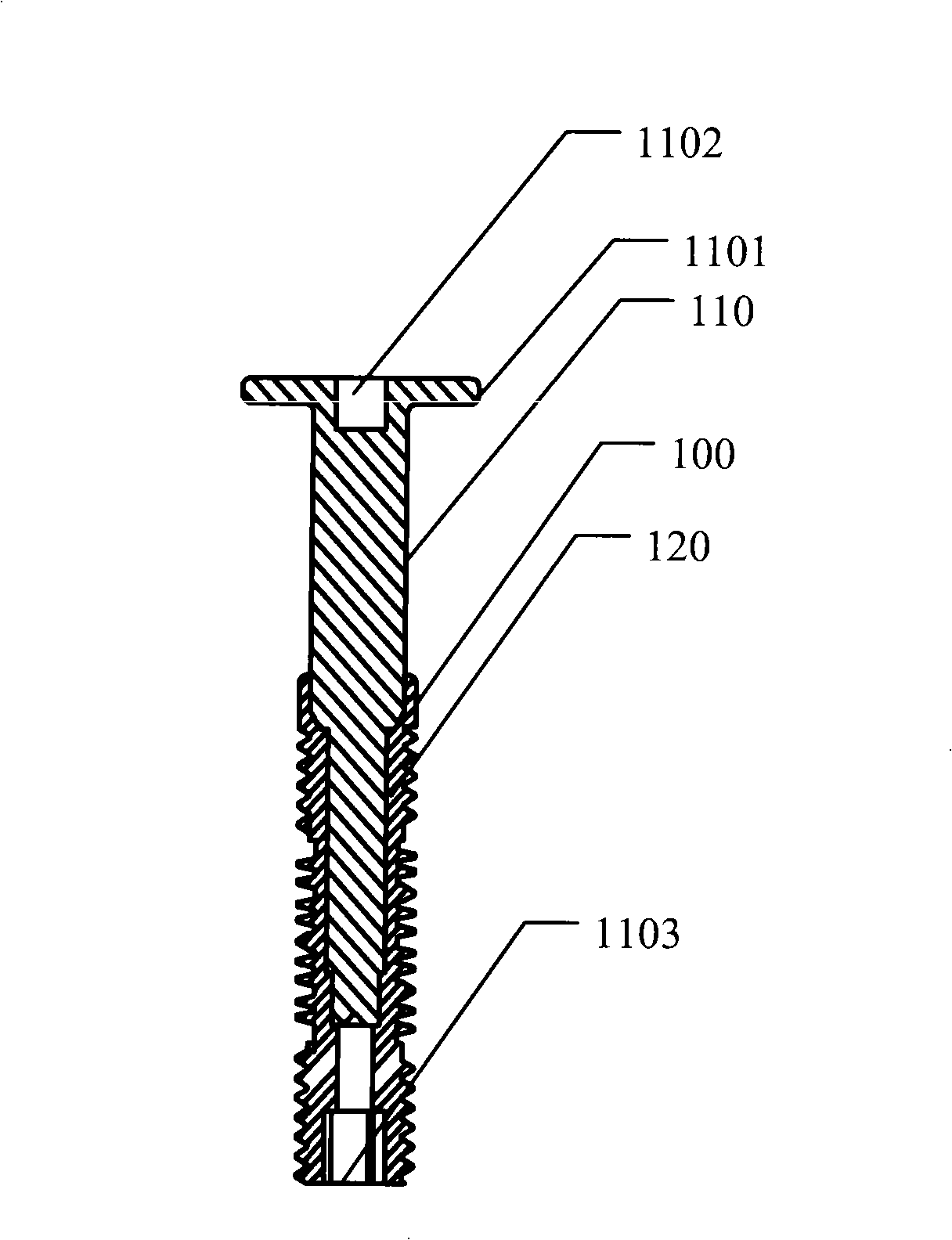

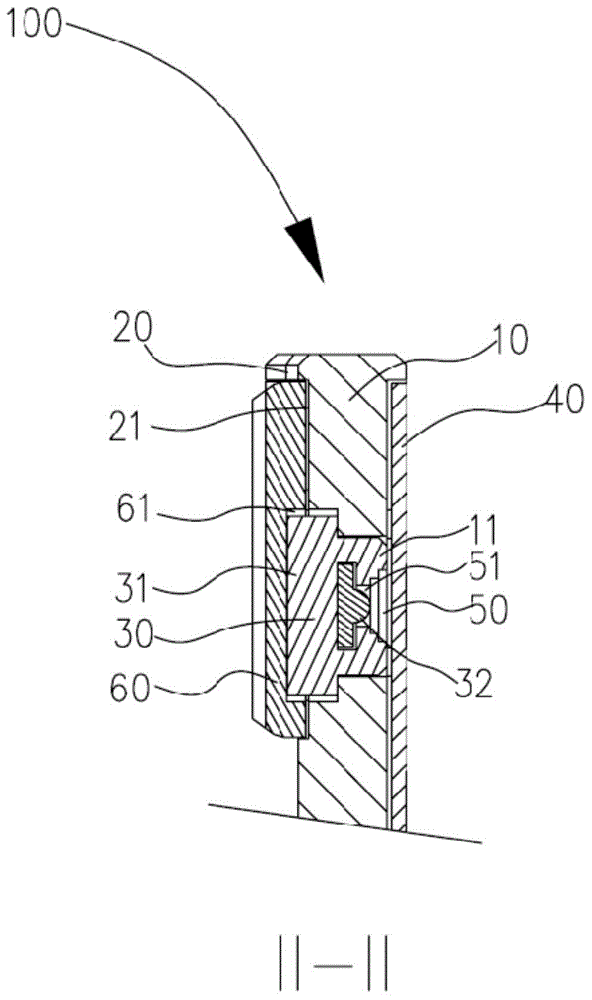

Screw device and cavity filter using the same

ActiveCN101315999ADoes not increase thicknessTo achieve the purpose of self-lockingNutsBoltsEngineeringSelf locking

Owner:HUAWEI TECH CO LTD

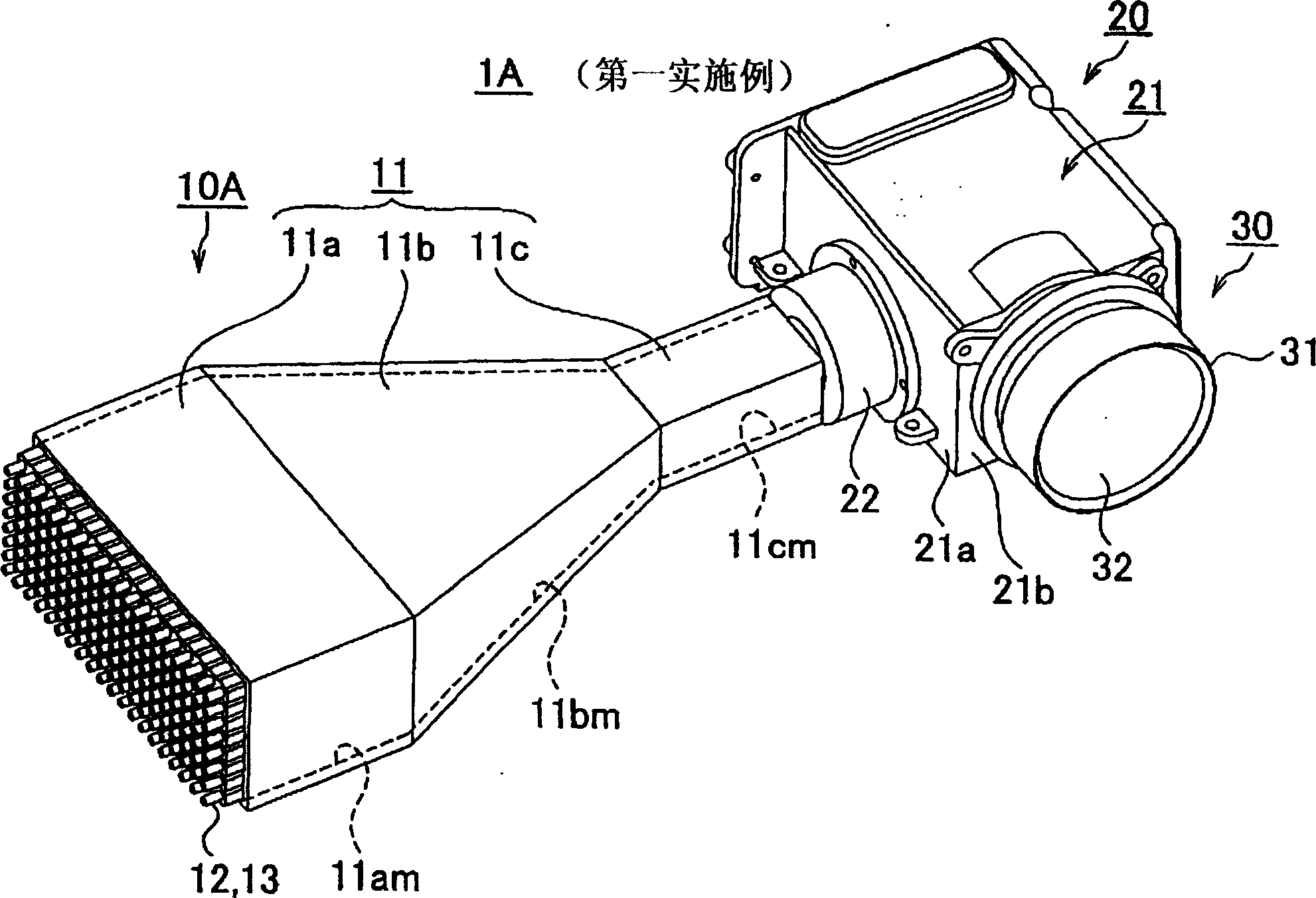

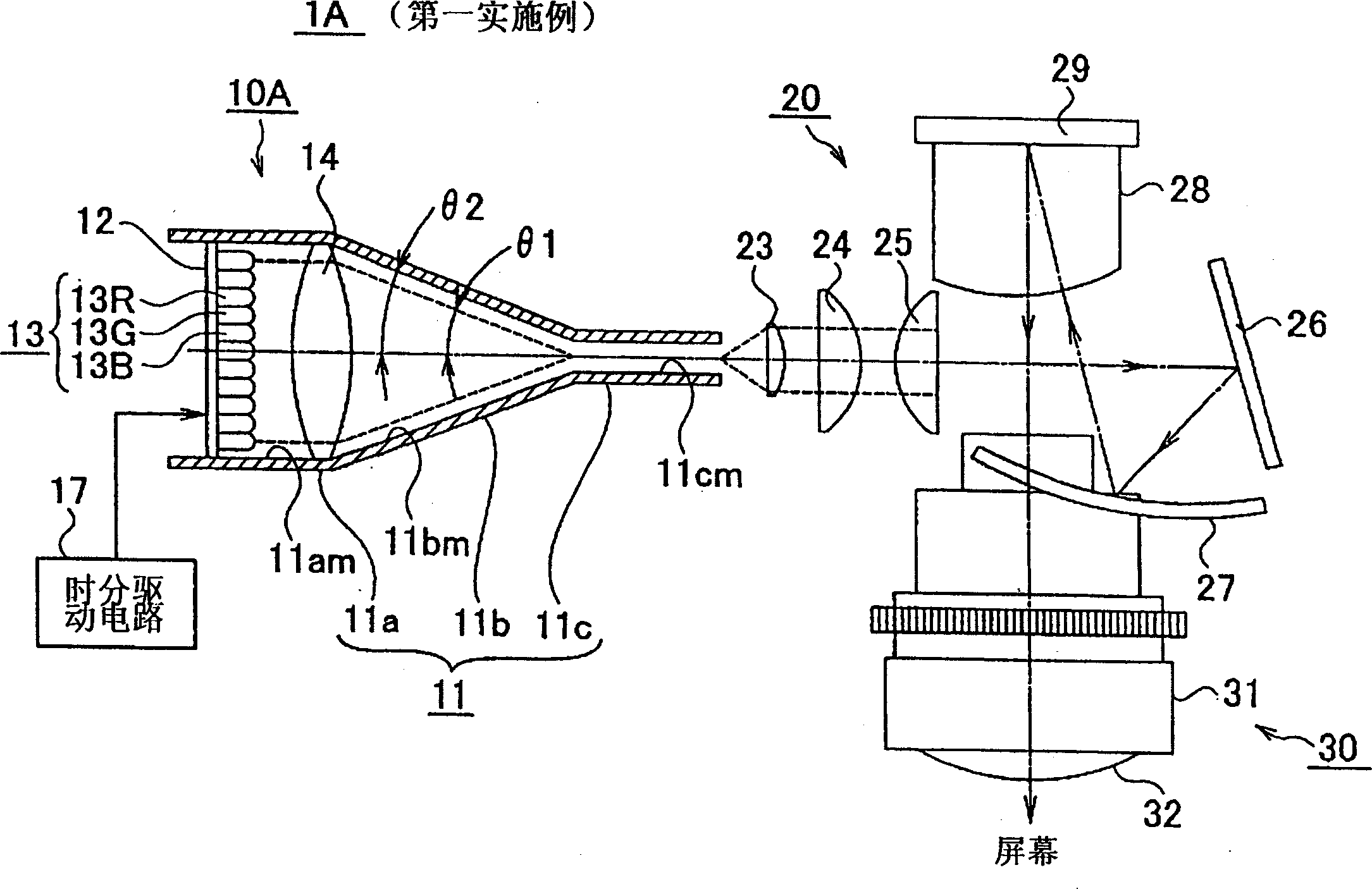

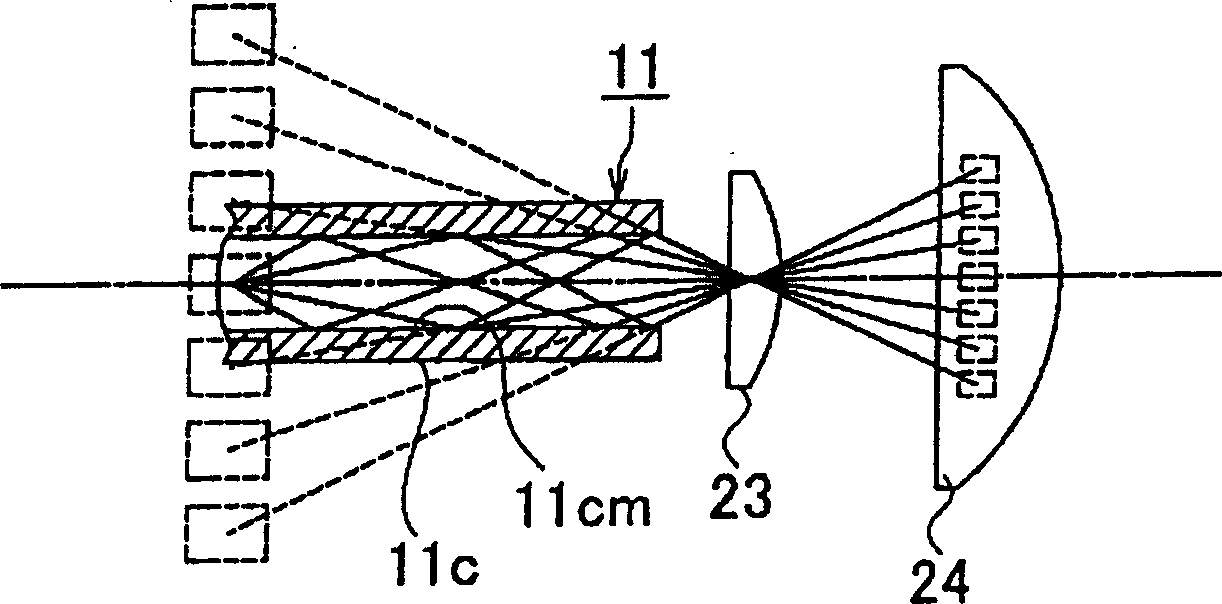

Light source device and projecton type display deivce using the light source device

InactiveCN1538235AConvergence efficientConvergence emits high-efficiency light from an array of semiconductor light-emitting elementsProjectorsOptical light guidesLight guideLight emitting device

Owner:VICTOR CO OF JAPAN LTD

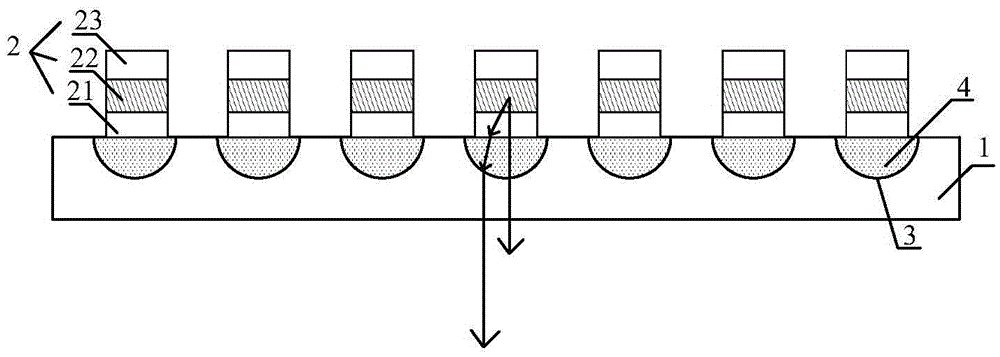

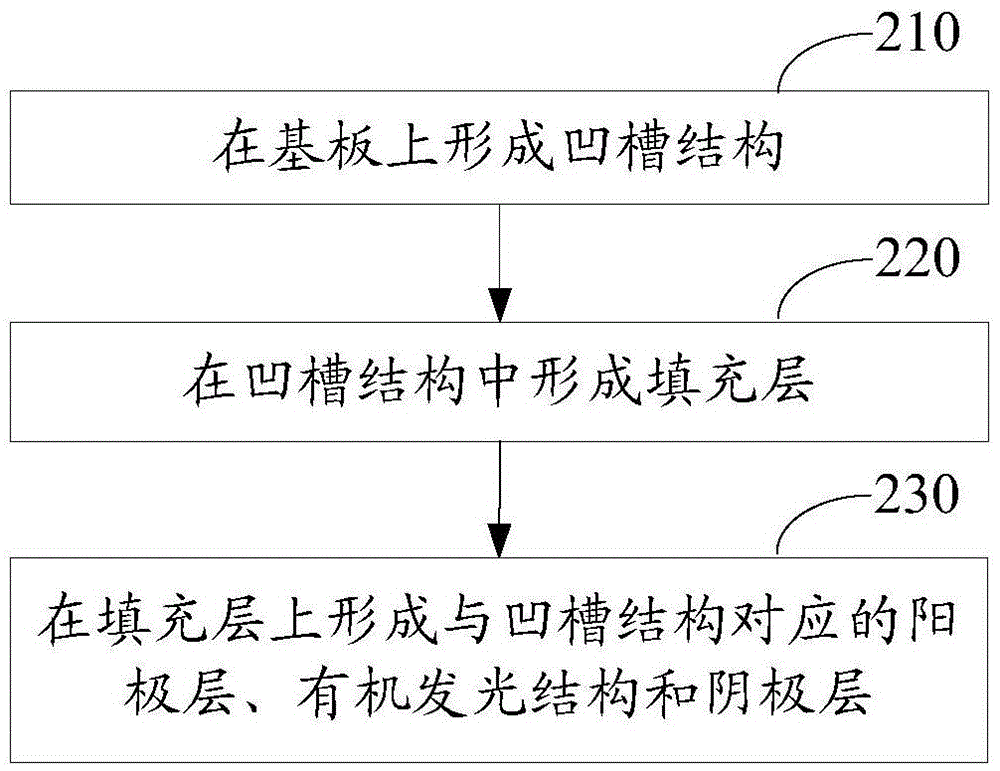

Electroluminescent display panel, manufacturing method therefor, and display apparatus

ActiveCN105633121ADoes not reduce flexibilityImprove removal efficiencySolid-state devicesSemiconductor/solid-state device manufacturingRefractive indexReflective layer

Embodiments of the invention disclose an electroluminescent display panel, a manufacturing method therefor, and a display apparatus. The electroluminescent display panel comprises a substrate and multiple OLEDs positioned on the substrate, wherein each OLED comprises a transparent positive electrode layer positioned on the substrate, an organic light emitting structure positioned on the positive electrode layer, and a negative electrode layer positioned on the organic light emitting structure; the negative electrode layer is a reflecting layer; a groove structure corresponding to the organic light emitting structure is arranged on the contact surface between the substrate and the positive electrode layer; a transparent filling layer is arranged in the groove structure; the upper surfaces of the filling layer and the substrate are on the same horizontal plane; and the refractive index of the filling layer is greater than that of the positive electrode layer, and is different from that of the substrate. Under the refraction of the groove structures, the incident angle of the light from each organic light emitting structure to the substrate is reduced, so that the probability of total reflection of the light entering the substrate from the positive electrode layer is lowered, and the extraction efficiency of the light from each organic light emitting structure is improved; and in addition, the flexibility of the display panel is not lowered.

Owner:BOE TECH GRP CO LTD

Liquid crystal panel and manufacturing method thereof

ActiveCN103185978AReduce light leakageAvoid uneven thicknessSemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayDiffuse reflection

The invention discloses a liquid crystal panel and a manufacturing method thereof. The liquid crystal panel comprises an active element array substrate and a color filtering substrate which are connected with each other through frame sealing glue, wherein the active element array substrate comprises a substrate, a public electrode wire and a plurality of thin film transistors; the color filtering substrate comprises a black matrix; the liquid crystal panel is provided with a display area and a border area surrounding the display area; the active element array substrate further comprises a light absorbing layer having a light absorbing property; the light absorbing layer is positioned in the border area, and is positioned between the substrate and a metal structure which is closest to the substrate in the border area; the metal structure is provided with a first diffused reflection structure; and the first diffused reflection structure is used for making light coming from a backlight source enter the first diffused reflection structure to generate diffused reflection. Due to the adoption of the liquid crystal panel, the border light leakage of the liquid crystal panel can be reduced greatly on the premise of not elongating the black matrix till the edge of the black matrix is aligned with the edge of the substrate.

Owner:BEIHAI HKC OPTOELECTRONICS TECH CO LTD

Display module, manufacturing method thereof, and display device

InactiveCN109559640AEasy to bendAvoid damageCross-talk/noise/interference reductionIdentification meansSolder maskFlexible circuits

The invention discloses a display module, a manufacturing method of the display module, and a display device. A flexible circuit board is filled with a wave-absorbing material, thus an isolating electromagnetic material does not need to attach to a COF, so that the COF is thin, and thus the possibility of causing damage to the circuit is reduced. The display module comprises a display panel and the flexible circuit board connected with the display panel, and the flexible circuit board is provided with a bent area bent towards the back of the display panel; and the flexible circuit board is provided with a solder mask protection layer, and the wave-absorbing material is at least arranged in the solder mask protection layer of the bent area.

Owner:BOE TECH GRP CO LTD +1

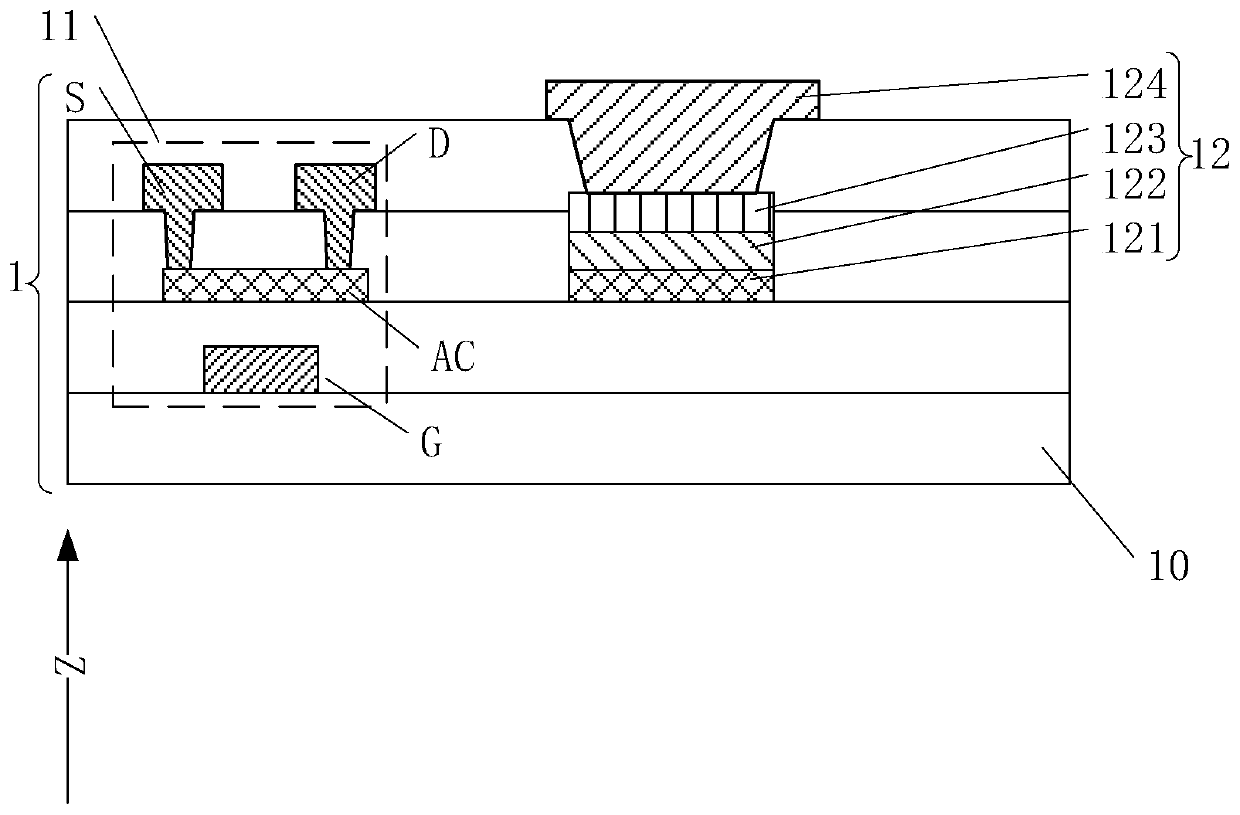

Display panel, display device and manufacturing method of display panel

ActiveCN109858443AThe production process is simpleReduce manufacturing costSolid-state devicesCharacter and pattern recognitionDisplay deviceAmorphous silicon

The invention discloses a display panel, a display device and a manufacturing method of the display panel, and the display panel comprises a plurality of thin film transistors, and a plurality of fingerprint recognition elements, and each thin film transistor comprises a grid electrode, a source electrode, a drain electrode and an active layer; each fingerprint identification element comprises a first semiconductor part, a second semiconductor part, an insulating part and an electrode part. The first semiconductor part and the active layer are arranged on the same layer, the second semiconductor part is located on the side, away from the substrate, of the first semiconductor part, the insulating part is located on the side, away from the substrate, of the second semiconductor part, the electrode part is located on the side, away from the substrate, of the insulating part, the first semiconductor part is made of polycrystalline silicon, and the second semiconductor part is made of amorphous silicon. By constructing the fingerprint identification elements of the MIS structure, the photosensitivity of the fingerprint identification element is improved, the manufacturing cost of the display panel is reduced, the fingerprint identification precision is improved, and the manufacturing process of the display panel is reduced.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

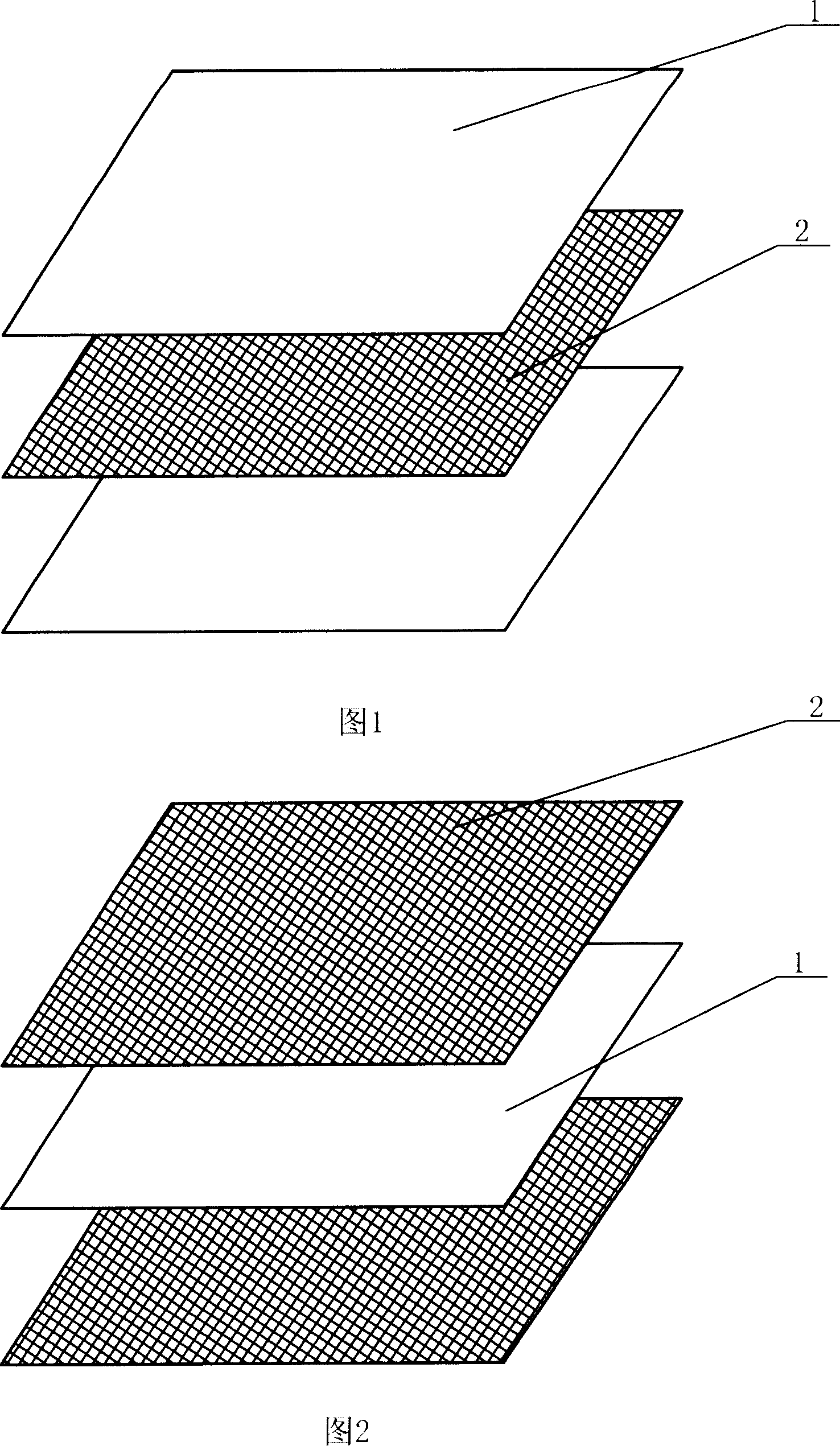

Heterogeneous ion-exchange membrane reinforced by ion conductible screen cloth

InactiveCN1762557ADoes not increase thicknessImproved ion transport performanceSemi-permeable membranesIon-exchange membranesMembrane configuration

The invention relates to out-phase ion exchange membrane reinforced by conductive ion screen cloth comprises: a cation exchange membrane, an anion exchange membrane, at least one layer of reinforced screen cloth arranged on membrane surface or between membrane space. This invention overcomes problems in prior art, has reasonable design, reduces membrane surface resistance, and high ion exchange efficiency.

Owner:ZHEJIANG OMEX ENVIRONMENTAL ENG CO LTD

Sidelight type liquid crystal module, direct type liquid crystal module and television

InactiveCN103439831ASimple structureImprove cooling effectTelevision system detailsLighting heating/cooling arrangementsLuminosityEngineering

The invention provides a sidelight type liquid crystal module, a direct type liquid crystal module and a television. The sidelight type liquid crystal module comprises a back plate, a heat radiation plate, a lamp strip, a rubber frame and a surface frame, wherein the heat radiation plate is mounted on the back plate; the lamp strip is mounted on the side face of the heat radiation plate; the rubber frame and the back plate are fixedly connected; the surface frame and the rubber frame are fixedly connected; the sidelight type liquid crystal module further comprises a heat-conduction sheet; one side of the heat-conduction sheet is connected with the lamp strip, the heat radiation plate and / or the back plate and the other side of the heat-conduction sheet is connected with the rubber frame and / or the surface frame; the heat generated by the lamp strip can be transmitted to the surface frame. The liquid crystal module provided by the invention is simple in structure; the liquid crystal module is internally provided with the heat-conduction sheet so that the heat generated by the lamp strip can be simultaneously dissipated from the back plate and the surface frame; the heat radiation effect is effectively enhanced, the luminosity of the lamp strip is improved and the service life of the lamp strip is prolonged; the quality of a picture displayed by the liquid crystal module is ensured; and furthermore, the picture quality of the television is ensured.

Owner:HISENSE VISUAL TECH CO LTD

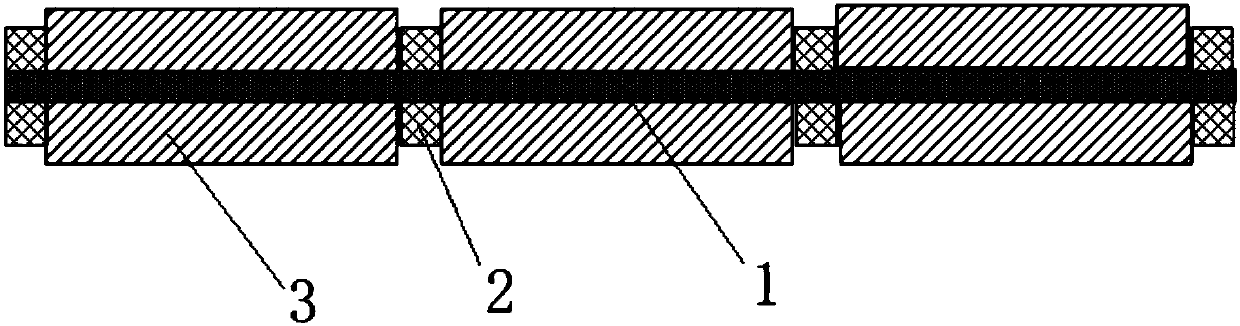

Battery pole piece, preparation method of battery pole piece, and battery

PendingCN107768597AIncrease internal resistanceImprove securitySecondary cellsElectrode collector coatingElectrical batteryEngineering

The invention relates to a battery pole piece, a preparation method of the battery pole piece, and a battery, and relates to the technical field of batteries. The mainly adopted technical scheme is asfollows: the battery pole piece comprises a current collector, an active material coating and a PTC (positive temperature coefficient) material coating, wherein the surface of the current collector comprises a first area and a second area, the active material coating is coated on the first area, and the PTC material coating is coated on the second area. The preparation method of the battery polepiece comprises the following steps: preparing a PTC material slurry, coating the PTC material slurry on the second area of the current collector, preparing an active material slurry, and coating theactive material slurry on the first area of the current collector. The battery comprises the above battery pole piece. The battery pole piece is mainly used to reduce the probability of thermal runaway occurring when the battery is short-circuited or the temperature is too high, and the safety of the battery is improved.

Owner:GREE ELECTRIC APPLIANCES INC

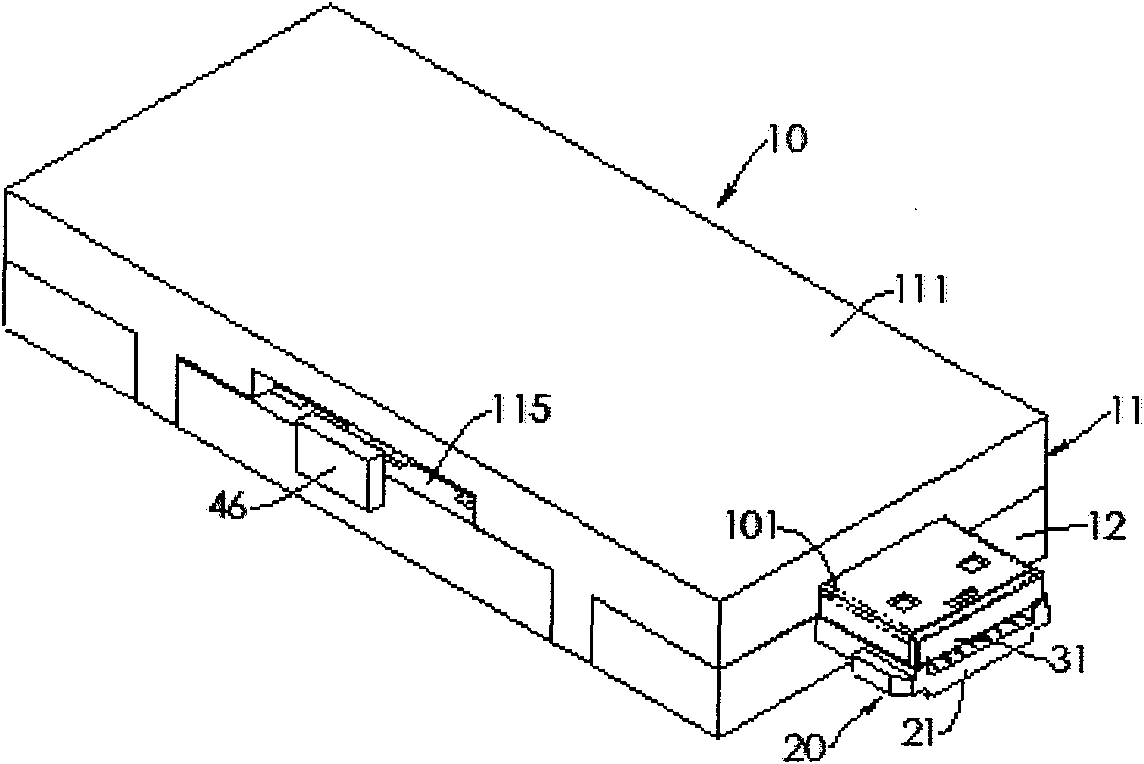

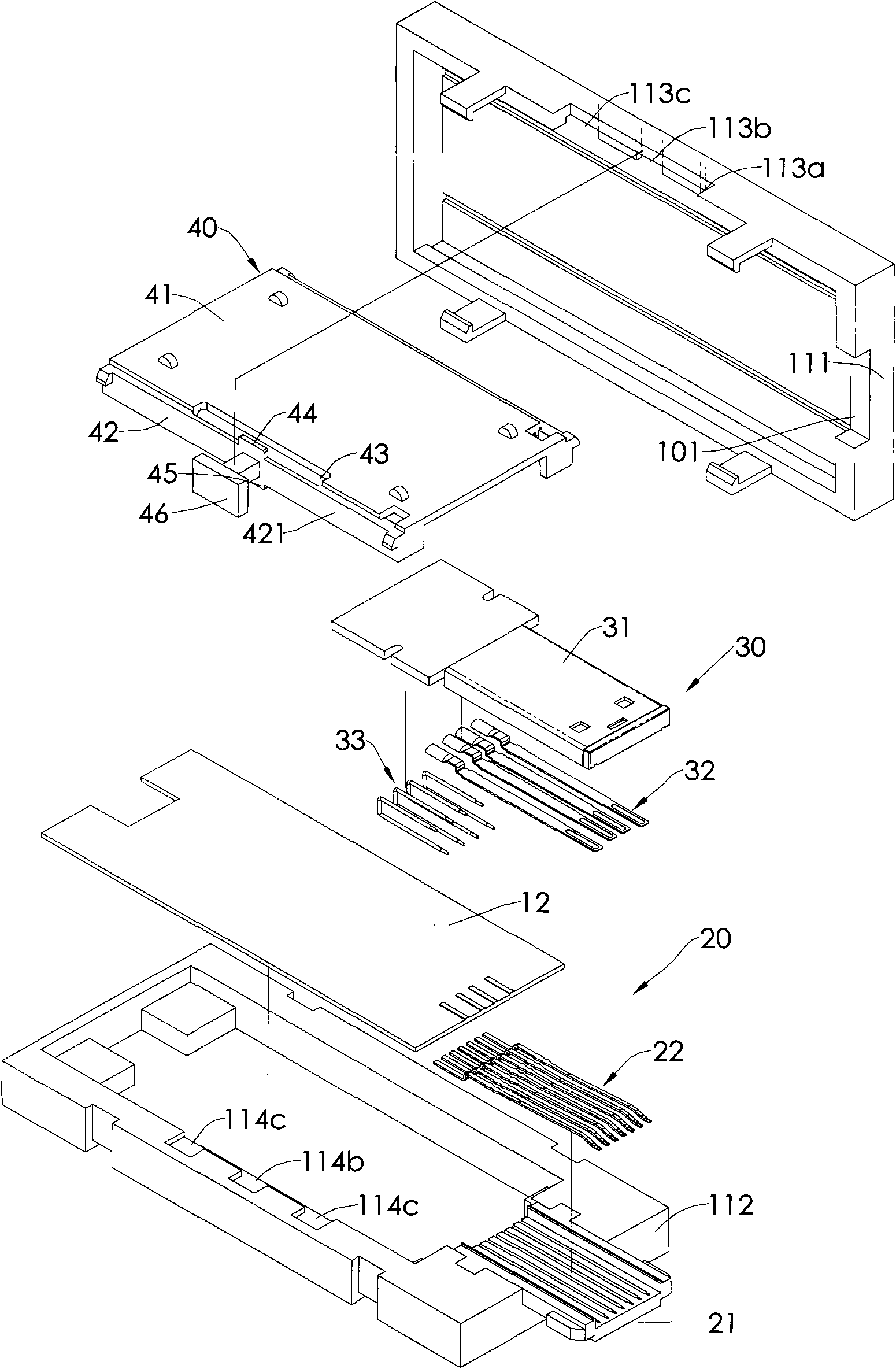

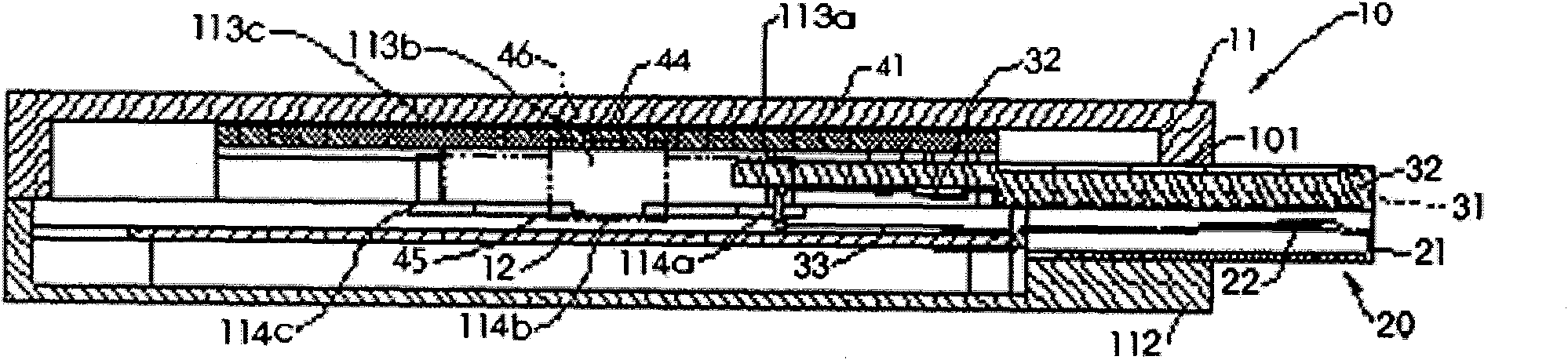

Telescopic all-in-one connector plug

InactiveCN101867099ADoes not increase thicknessHas the effect of thinningCouplings bases/casesEngineering

The invention relates to a telescopic all-in-one connector plug, which comprises a shell, an all-in-one adapter part, a signal circuit board and a moving component, wherein the all-in-one adapter part is arranged in the shell, and is exposed outside a front opening of the shell; the all-in-one adapter part comprises two separated adapter components which are laminated and is electrically connected with the signal circuit board; and the moving component is arranged in the shell, passes through one side wall of the shell after being connected with one of the adapter components of the all-in-one adapter part so as to be pushed to control the adapter component connected with the moving component, and retracts inwards or extends outwards from the front opening of the shell. The all-in-one adapter part of the invention can be inserted into an all-in-one socket, also can be compatible in different single-interface sockets and has the thinning effect.

Owner:TAIWAN ELECTRONICS

Shell and mobile terminal

InactiveCN106101339ADoes not increase thicknessImprove portabilityBatteries circuit arrangementsElectric powerComputer terminalElectrical and Electronics engineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

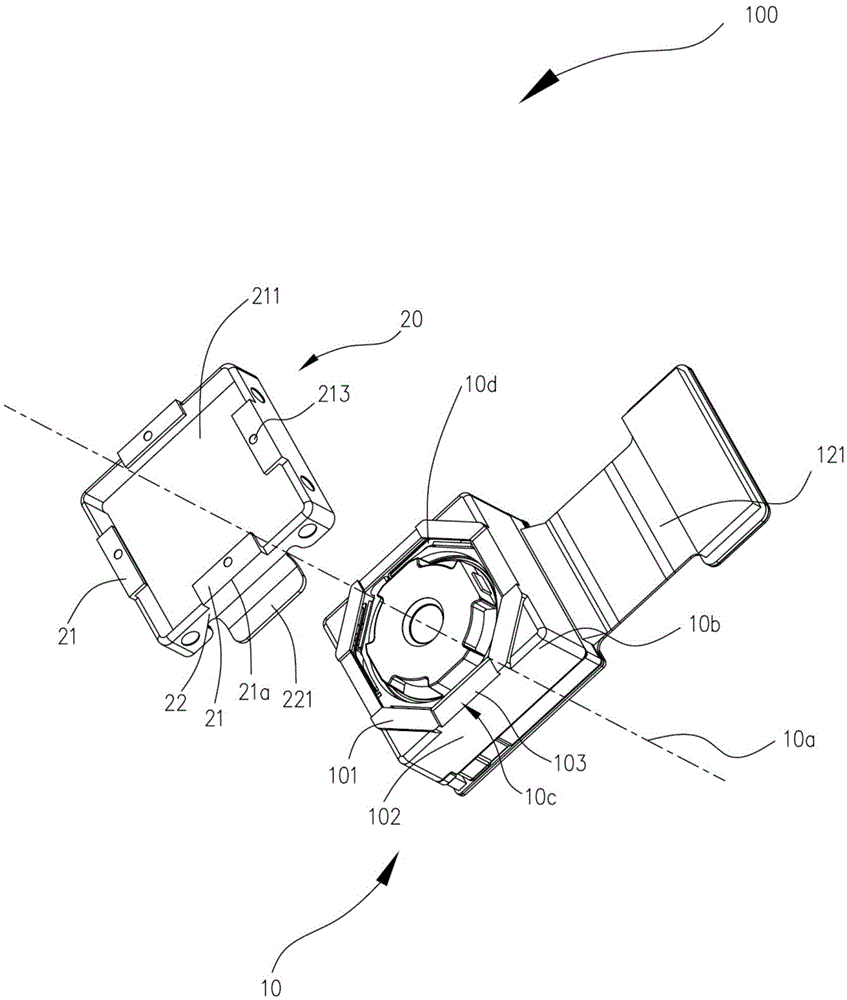

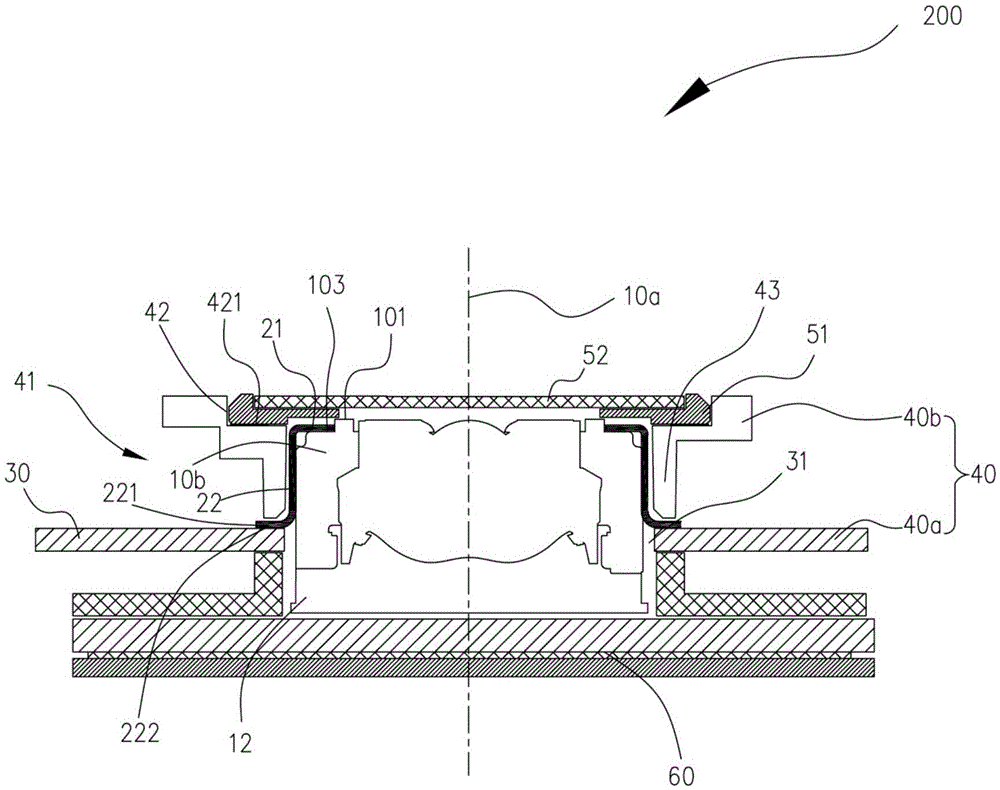

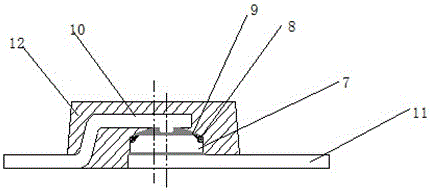

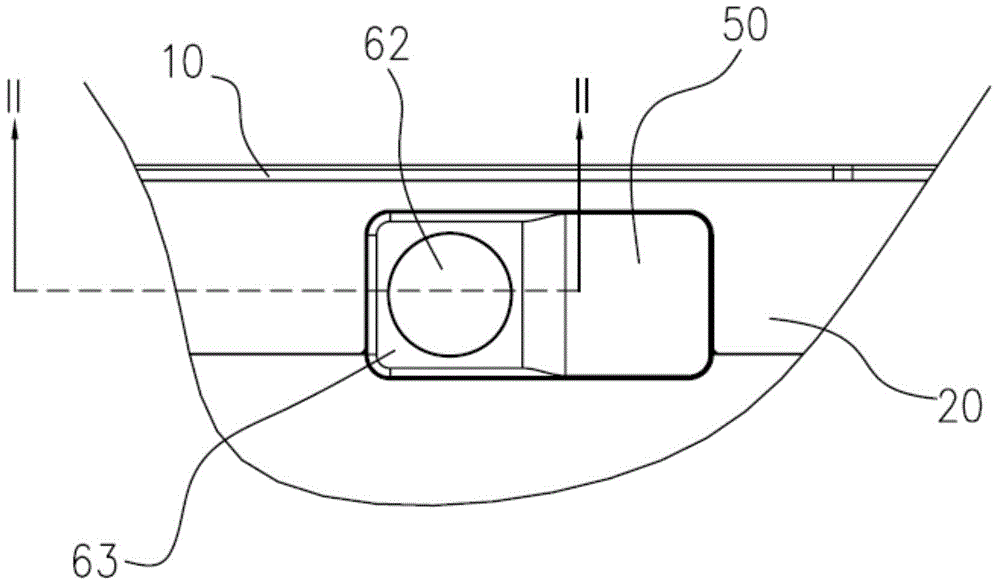

Camera component and terminal

ActiveCN105635535AStable structureCompact structureTelevision system detailsColor television detailsOptical axisComputer terminal

The invention discloses a camera component and a terminal. The camera component comprises a camera module group and a fixing support. The camera module group is provided with a photographing primary optic axis and an end part which is arranged in the direction of the photographing primary optic axis. The end part comprises grooves which comprise a bottom surface perpendicular to the photographing primary optic axis. The fixing support comprises a top plate and at least two side plates. The top plate is accommodated in the grooves. The top plate comprises at least two edges which stretch out of the side surfaces. The at least two side plates are arranged at the circumferential side of the camera module group and are symmetrically arranged around the photographing primary optic axis. Each side plate is provided with a folding side which extends in a way of being parallel to the bottom surface. The folding sides are used for being carried on a circuit board. The top plate of the fixing support is fixed in the grooves of the end part so that the fixing support can be fixed on the camera module group, the fixing support is enabled to be structurally stable relative to the camera module group, and the overall thickness of the camera module group is not increased by the top plate.

Owner:MEIZU TECH CO LTD

Air inlet duct for a turbojet nacelle

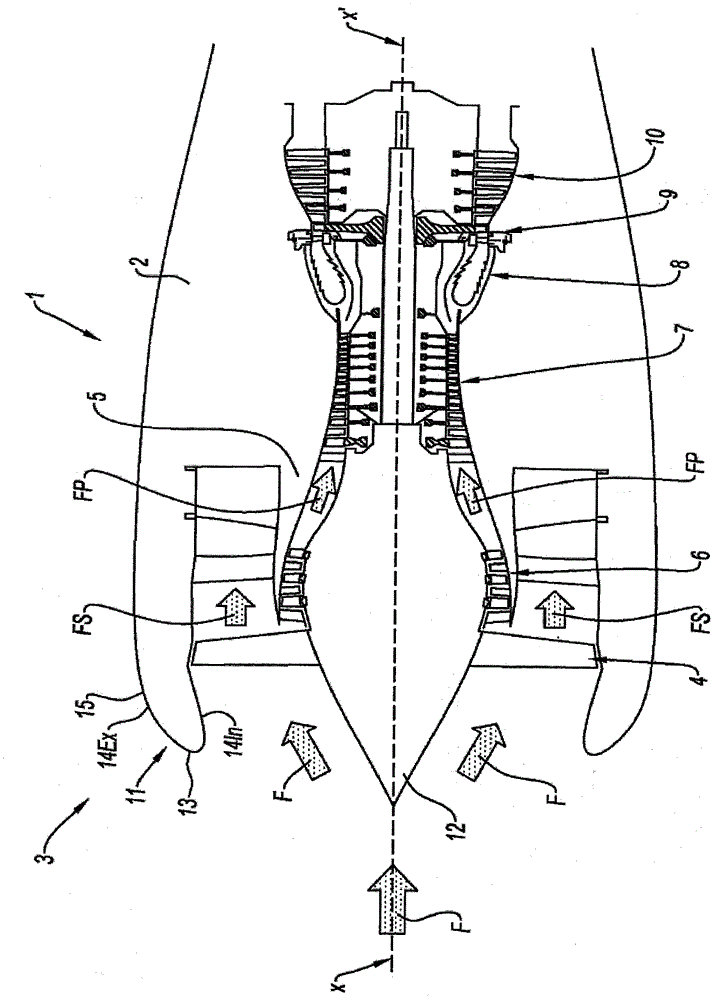

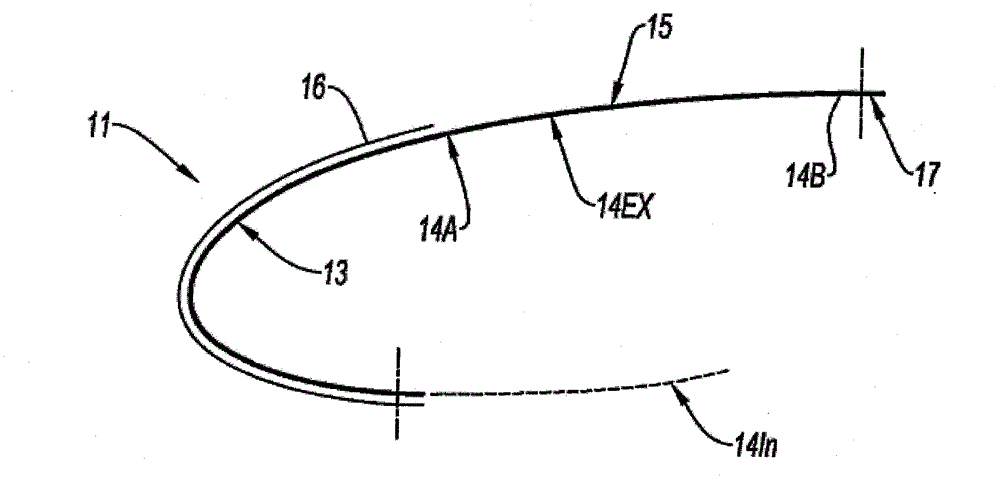

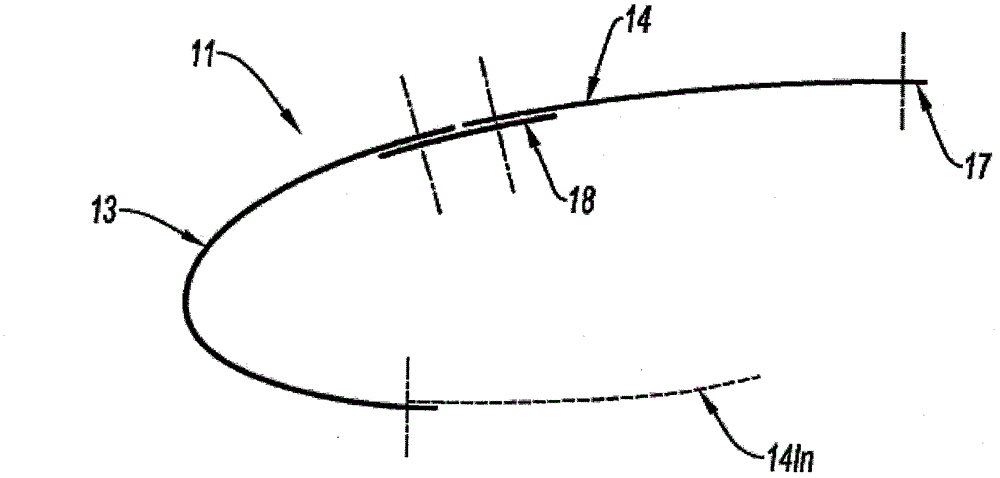

InactiveCN102947182AImprove corrosion resistanceImprove impact resistanceAircraft power plant componentsPower plant air intake arrangementsNacelleEngineering

The invention relates to an air inlet duct (11) for a turbojet nacelle, comprising an upstream annular lip (13) and a downstream outer annular structure (14Ex). The invention is characterised in that the upstream annular lip (13) and the downstream outer annular structure (14Ex) are formed as a one-piece part (15) made from composite material and in that the upstream lip (13) is covered with a metal layer (16) formed, in particular, by electrodeposition or plastic forming. The invention also relates to a turbofan engine having an air inlet duct (11) thus formed, and to a method for producing one such air inlet duct (11).

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

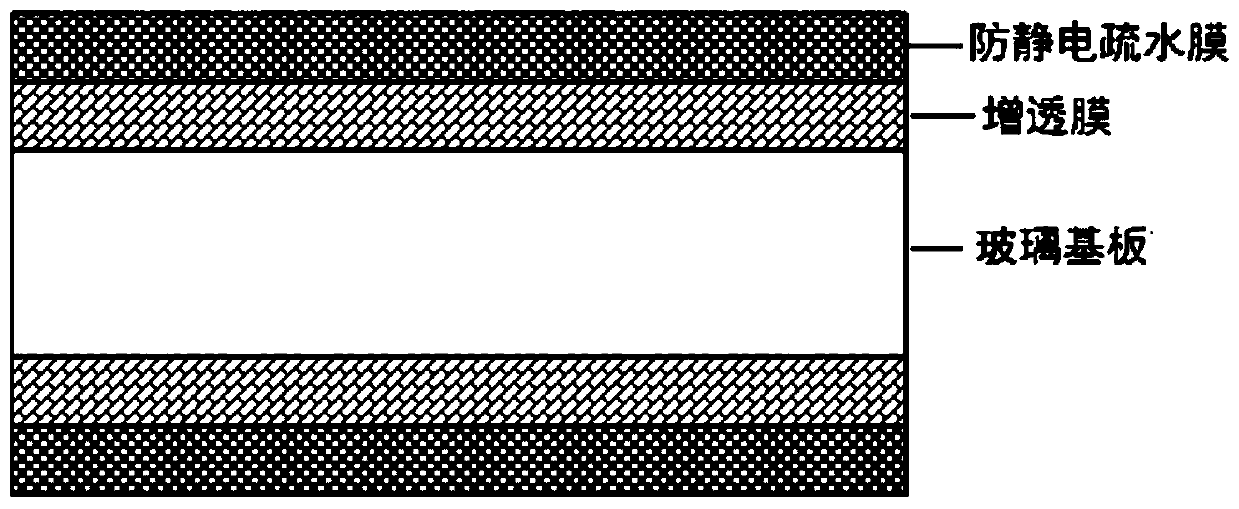

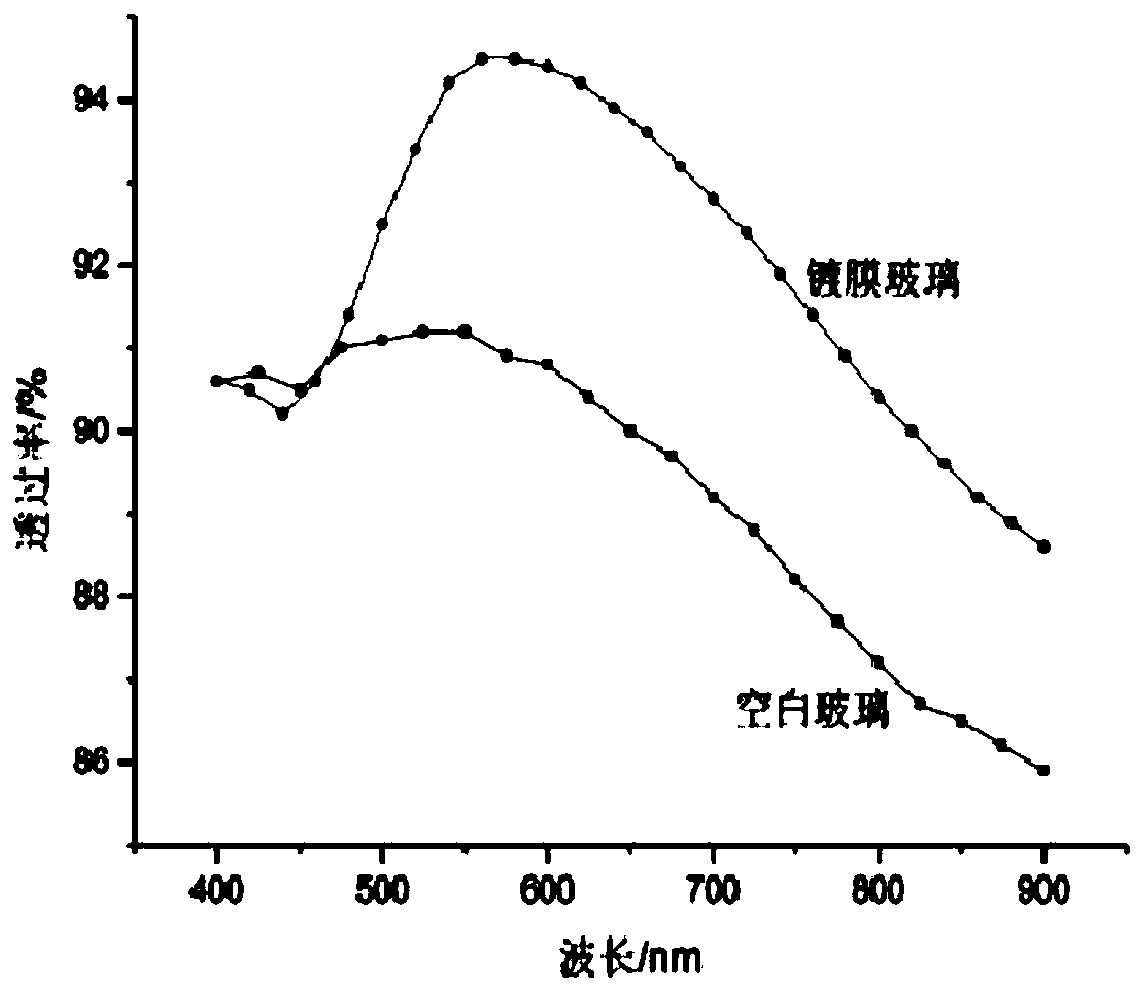

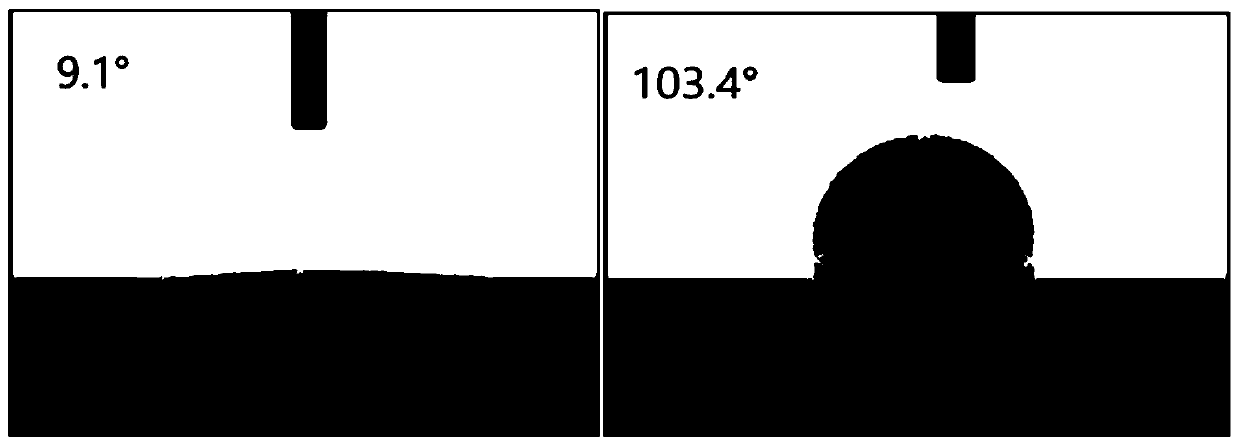

Glass with antistatic, hydrophobic and anti-reflection functions and preparation method of glass

The invention relates to glass with antistatic, hydrophobic and anti-reflection functions and a preparation method of the glass. The preparation method comprises the steps of firstly, respectively preparing anti-reflection sol and anti-static hydrophobic sol by adopting a sol-gel method, and then plating a certain layer and number of anti-reflection films and anti-static hydrophobic films on the surface of the glass by using a lifting coating method. In the process, the thickness of the films, the dosage of a modifier and a heat treatment system are controlled, performance indexes such as therefractive index, the transmittance and the reflectivity of the films can be regulated and controlled, and the prepared glass has multiple functions of static electricity prevention, hydrophobizationand anti-reflection, is particularly suitable for being used as a solar cell cover plate without cleaning and maintenance and is applied to arid and dusty areas.

Owner:WUHAN UNIV OF TECH

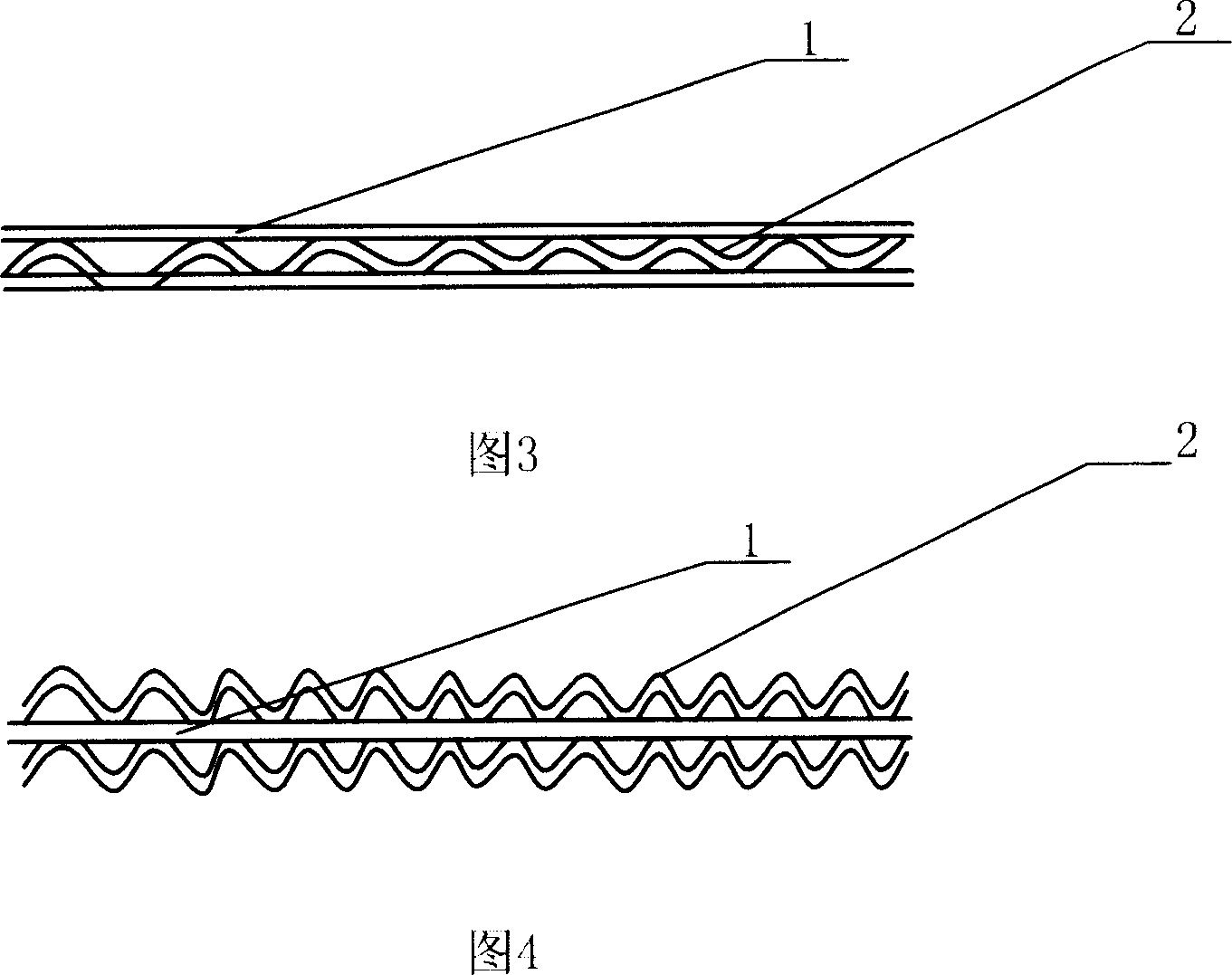

Piezoelectric thin film package structure and self-power-generating flexible display screen

ActiveCN105405958ACapable of generating electricitySolve power problemsPiezoelectric/electrostrictive/magnetostrictive devicesElectricityComposite film

The invention relates to a piezoelectric thin film package structure and a self-power-generating flexible display screen using the piezoelectric thin film package structure. The package structure comprises a flexible substrate and a luminous layer arranged on the flexible substrate; the package structure also comprises a composite thin film layer deposited on the flexible substrate and covers the luminous layer; the composite thin film layer comprises a blocked layer close to the flexible substrate and a protective layer far from the flexible substrate; a piezoelectric thin film power-generating structure is arranged between the blocked layer and the protective layer; the piezoelectric thin film power-generating structure comprises electrode layers arranged on the upper and lower sides of the piezoelectric thin film power-generating structure, and a piezoelectric thin film layer arranged between the electrode layers. The piezoelectric thin film package structures combines the piezoelectric power generation with the thin film package to endow the luminous element package layer with a power generation capacity based on bending of the luminous element package layer, so that the power supply for the flexible display screen can be well realized without increasing the thickness of the flexible display screen.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

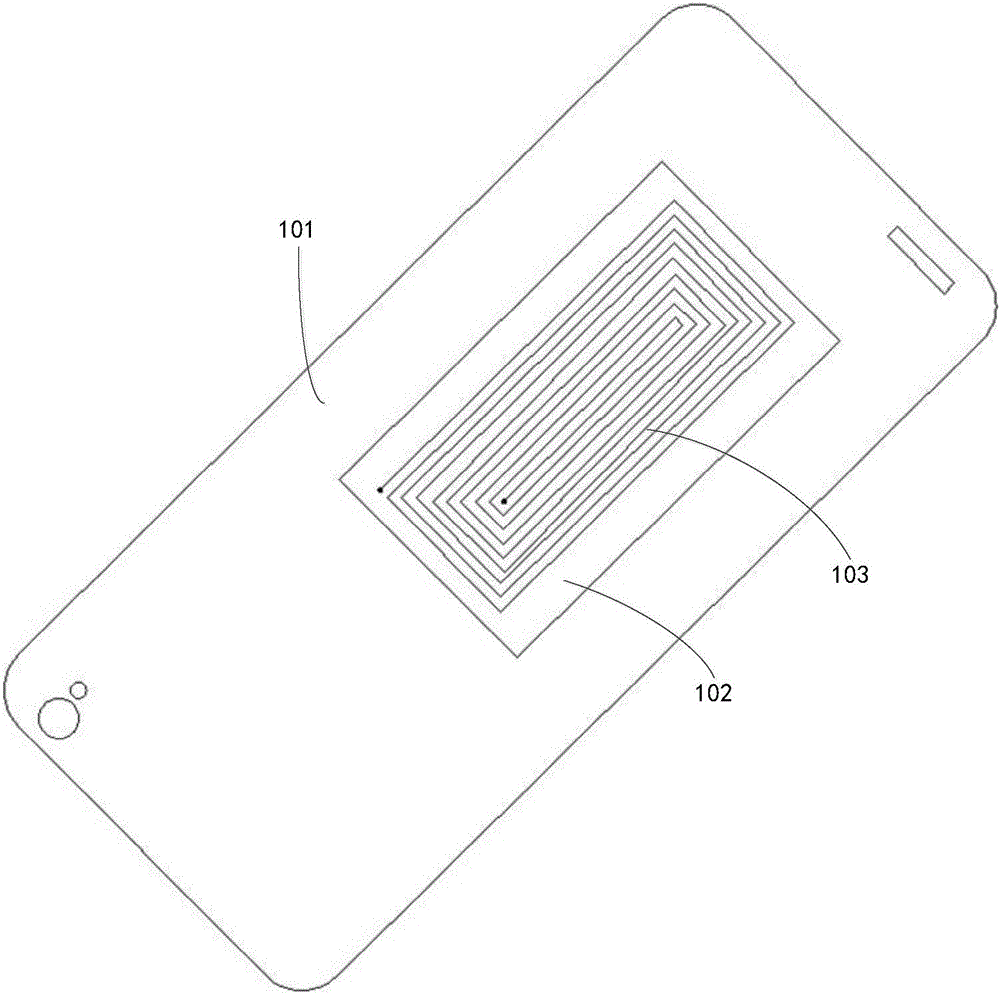

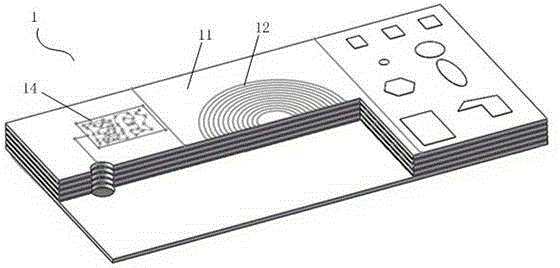

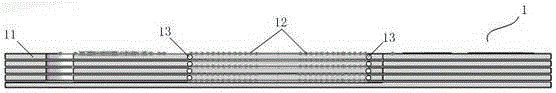

Touch panel, short-range wireless communications technology terminal, and production method thereof

InactiveCN105446526ADoes not increase thicknessConducive to the development of thinInput/output processes for data processingSensing by electromagnetic radiationMiniaturizationTouch panel

Provided is a short-range wireless communications technology terminal, comprising: a touch panel and an NFC antenna. The touch panel comprises a substrate, a sensing electrode structure, and a plurality of signal lines. The substrate has a touch area and a line area that surrounds the touch area. The line area comprises a first line area and a second line area that surrounds the first line area. The first line area is closer to a display area than the second line area. The sensing electrode structure is formed on a touch area. The plurality of signal lines is formed on the first line area and is separately connected to the sensing electrode structure, and the NFC antenna is formed on the second line area. The NFC antenna is formed on the substrate inside of the touch panel. Compared with formation on a back cover, the NFC antenna takes advantage of extra space on the substrate, which will not increase an overall thickness of the touch panel, thereby facilitating thinness development of the NFC terminal and following a miniaturization trend of miniaturization NFC terminal products.

Owner:INTERFACE OPTOELECTRONICS SHENZHEN +1

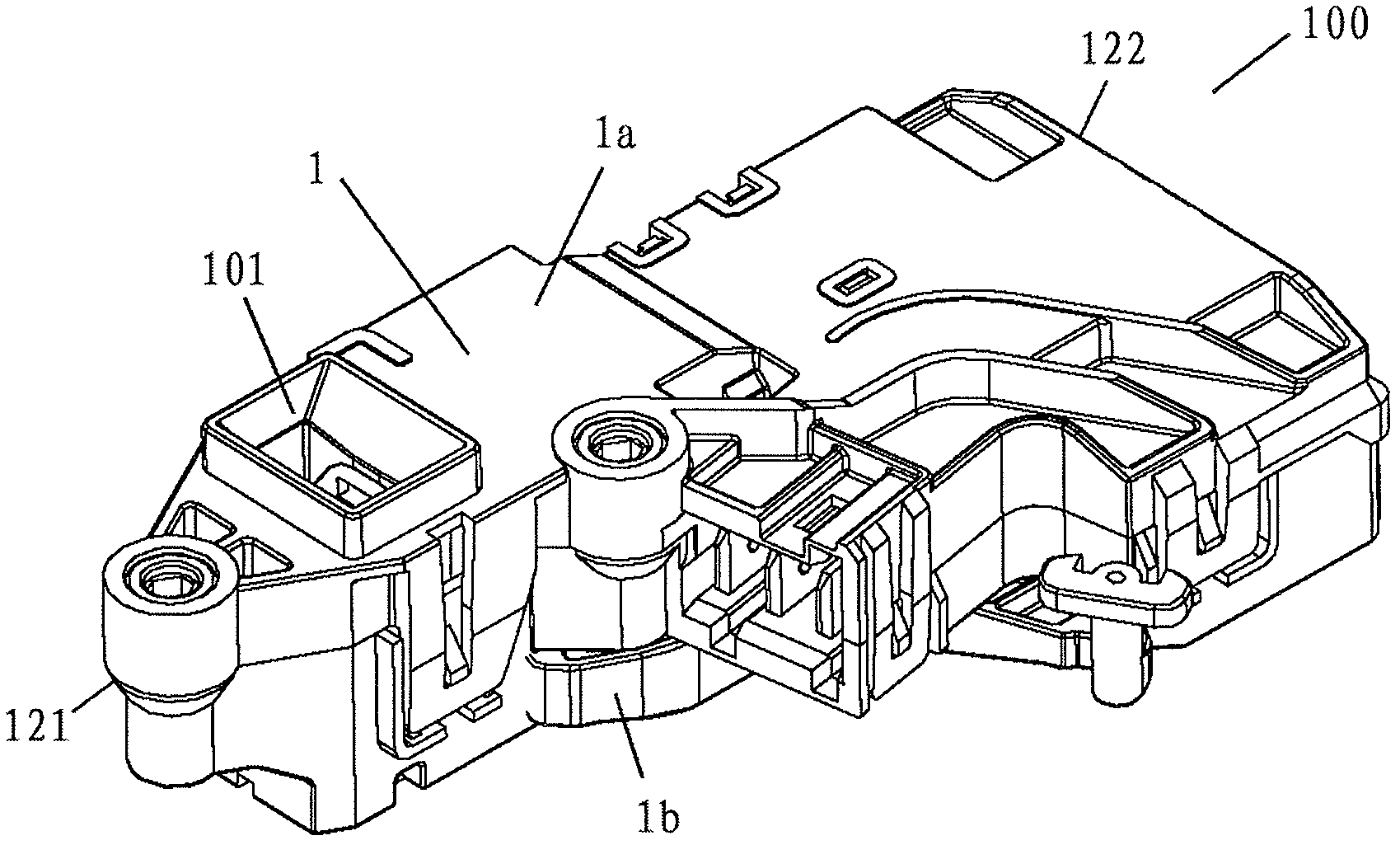

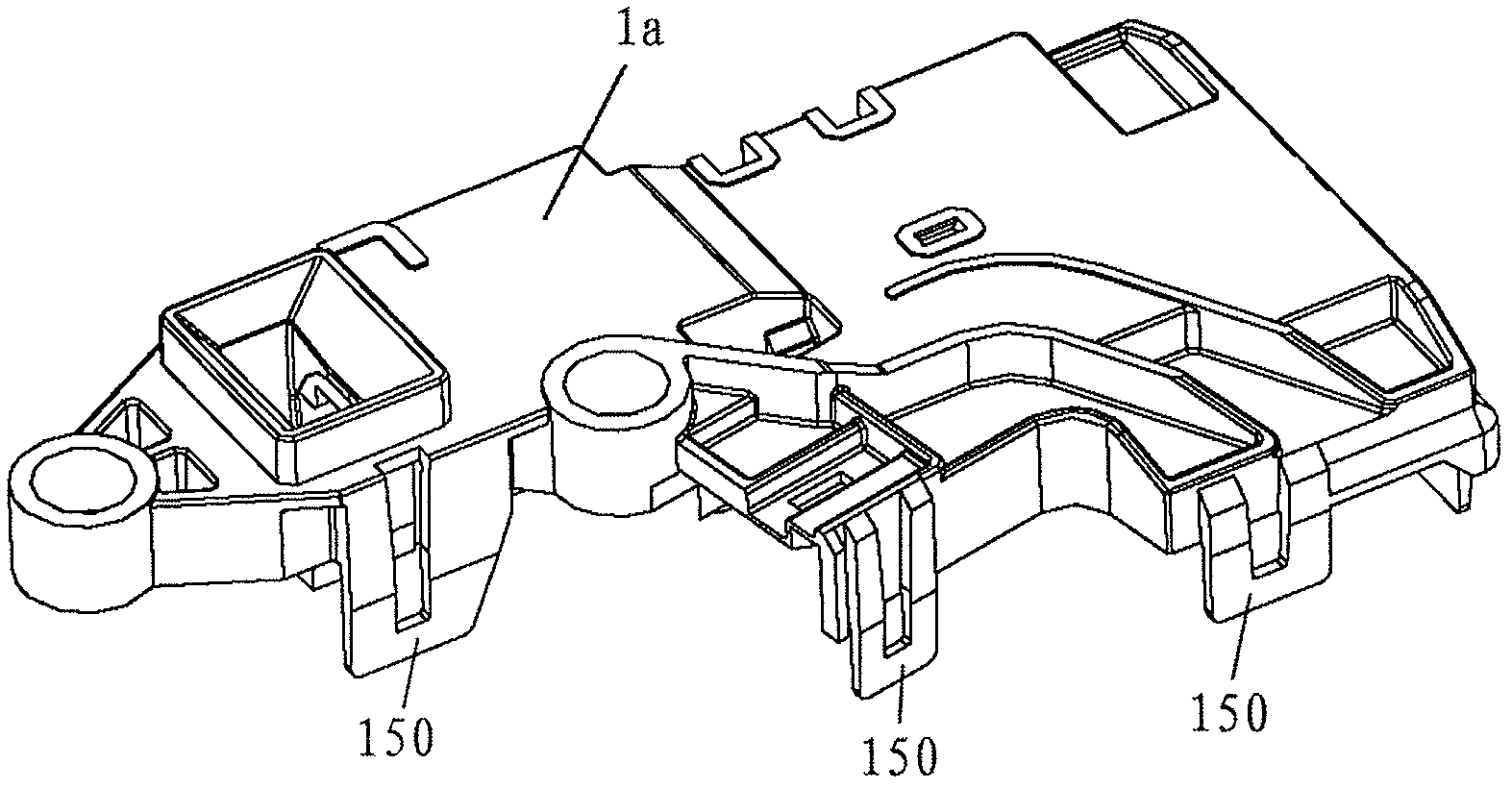

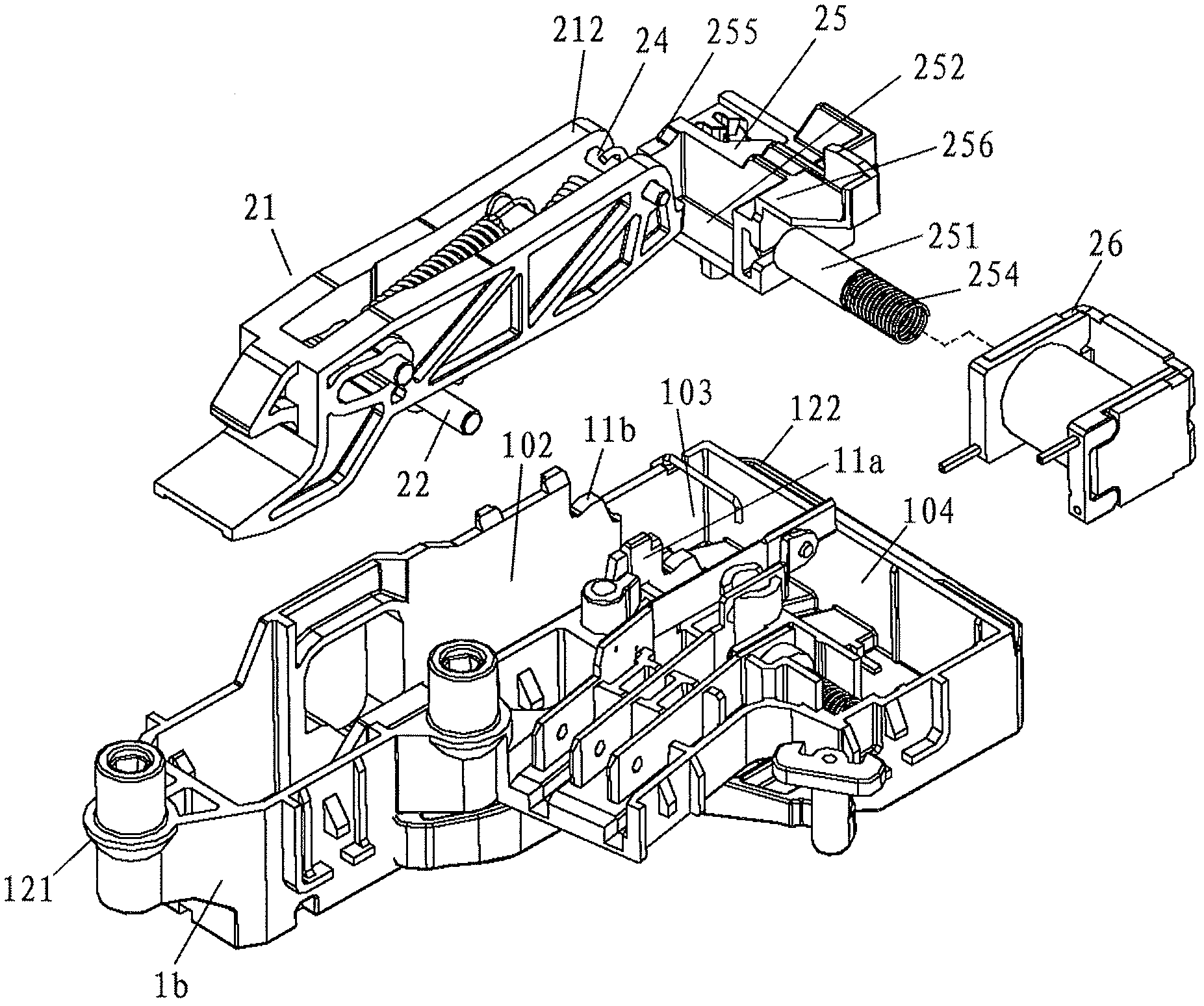

Door lock and equipment with same

InactiveCN103015810APromote recoveryCompact structureNon-mechanical controlsOther washing machinesEngineeringNormal state

The invention relates to a door lock, which has an open state and a closed state, and comprises a shell, a lock arm, a rocker and a guide pin, wherein an opening for allowing a door hook to go in or out of the shell is arranged in the shell, and the lock arm is arranged in the shell; the front part of the lock arm is provided with a lock groove, and a long hole is arranged between the two ends of the lock arm; a lock tongue is arranged at the upper part of the lock groove, and when the door lock is in the closed state, the lock tongue is inserted into a lock hole in the door hook, and a slope or radian is arranged above the lock tongue; the rocker is arranged in the shell and is provided with a fixed end and a movable end, and the fixed end is rotatably and fixedly arranged in the shell; and the movable end is arranged in the long hole in a sliding way, and the guide pin is arranged at the back part of the lock arm, and moves up, down, back and forth on the guide surface to allow the lock arm to move up, down, back and forth. The door lock can conveniently restore to the normal state in the abnormal closed state. The invention also relates to equipment with the door lock.

Owner:ILLINOIS TOOL WORKS INC

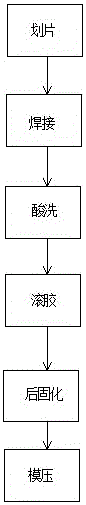

SMD diode preparation technology

ActiveCN105789045AGuaranteed performanceAvoid influenceSemiconductor/solid-state device manufacturingSemiconductor devicesPlastic packagingMiniaturization

The invention relates to an SMD diode preparation technology, and the technology sequentially comprises the steps: scribing, acid pickling, welding, alkaline cleaning, glue pouring, glue curing, plastic packaging, post curing, electroplating, and testing. The technology is advantageous in that the technology employs O / J jacketing for an SMD diode through the adjustment of a conventional diode preparation process; from the technological aspect, the technology, compared with the GPP jacketing technology, saves a plurality of processes with higher requirements: light resistance, development and yellow light; on the basis of meeting the small-size and thinning packaging requirements, the technology is simpler in manufacturing process, is cheap in material, and is lower in cost; meanwhile, the SMD diode is designed into a unique construction, so as to facilitate the successful gluing.

Owner:王志敏

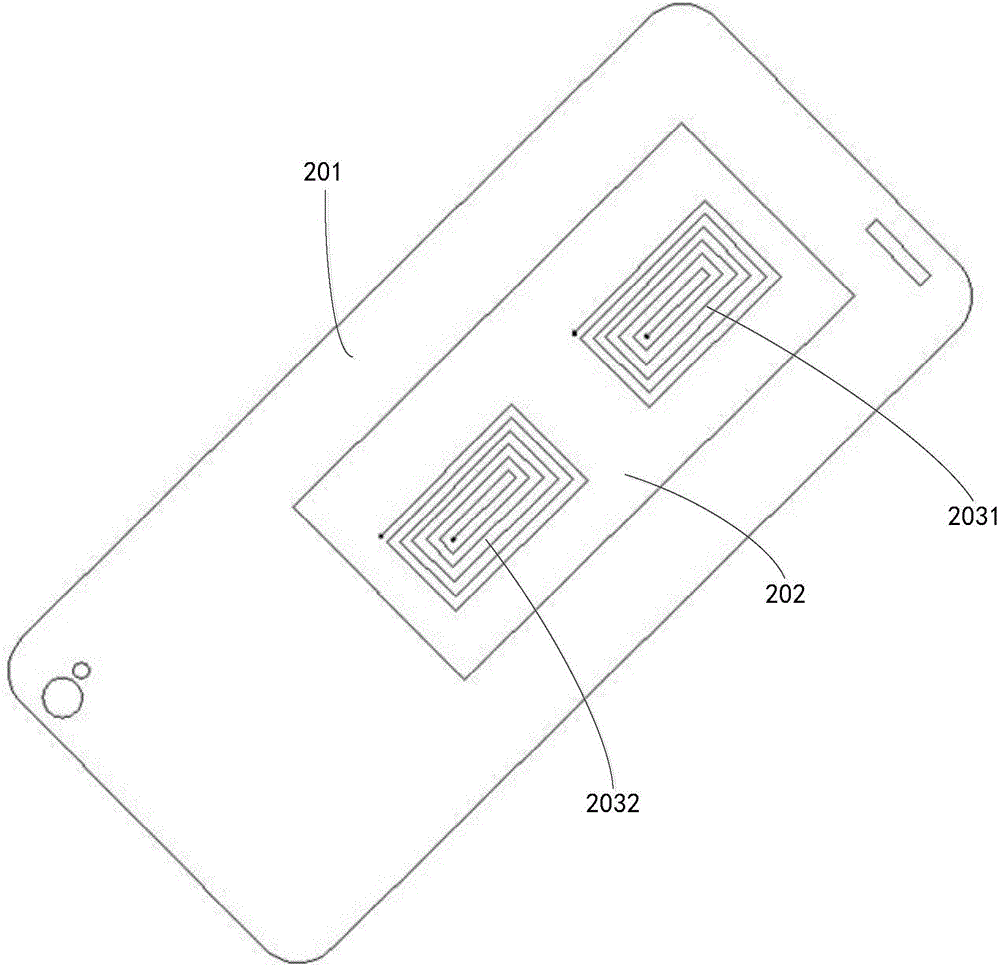

Mobile phone back housing capable of realizing wireless charging and preparation method thereof

InactiveCN105162908AImprove wireless charging efficiencyDoes not increase thicknessBatteries circuit arrangementsElectromagnetic wave systemElectricityM.2

The invention discloses a mobile phone back housing capable of realizing wireless charging. The mobile phone back housing is composed of at least two layers of ceramic sheets, a coil is printed on each layer of ceramic sheet, and electric connection between the ceramic sheets is realized through through holes. The thickness of each ceramic sheet is 20 [mu]m-1000 [mu]m, and the total thickness of the mobile phone back housing is 0.2 [mu]m-2 [mu]m. Correspondingly, the invention further provides a method for preparing the mobile phone back housing capable of realizing wireless charging. According to the invention, the wireless charging efficiency of a mobile phone is improved, the wireless charging speed is substantially increased to 2-3 times of the speed of common wireless charging, the thickness of the mobile phone is not increased but decreased, the lightening and thinning requirements of a user to the mobile phone are met, and the market competitiveness is improved.

Owner:广东百工新材料科技有限公司

Terminal

ActiveCN105120017AGuaranteed photo effectImprove user experienceTelephone set constructionsEngineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com