Camera component and terminal

A technology of camera assembly and camera module, which is applied in the directions of electrical components, image communication, color TV components, etc., can solve the problems of large tolerance accumulation, large volume, occupation of the overall structure of the camera assembly, etc., and achieves compact structure and improved structure. The effect of stability and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

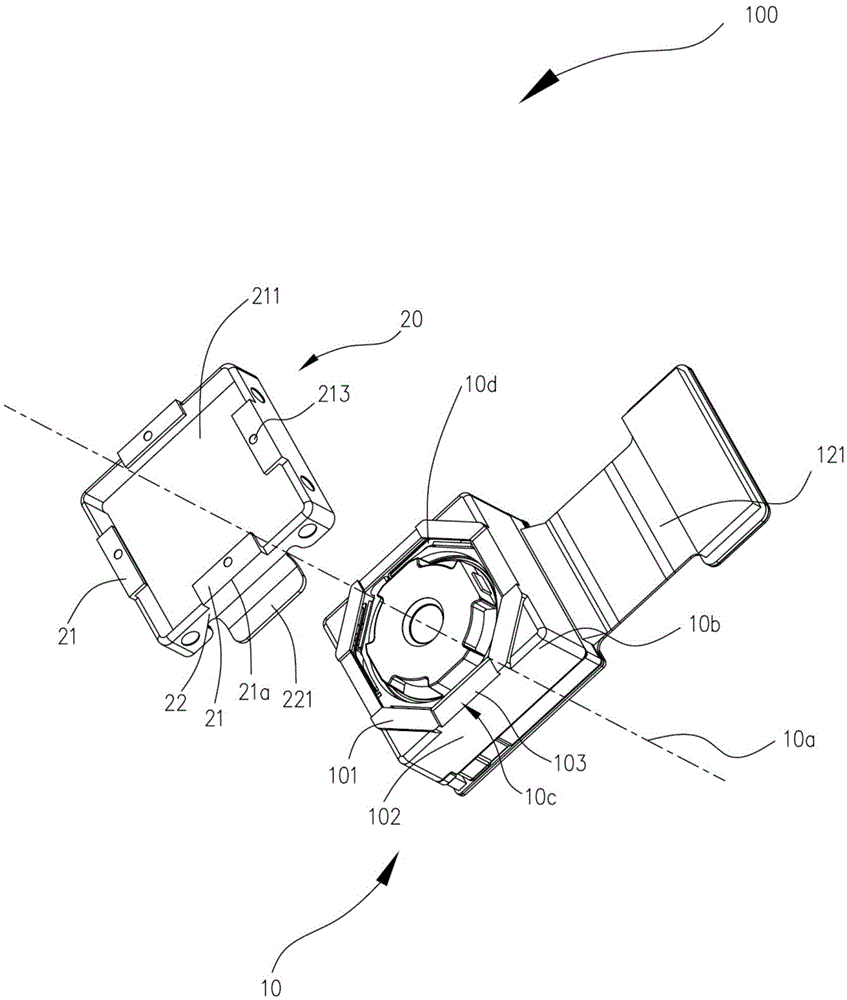

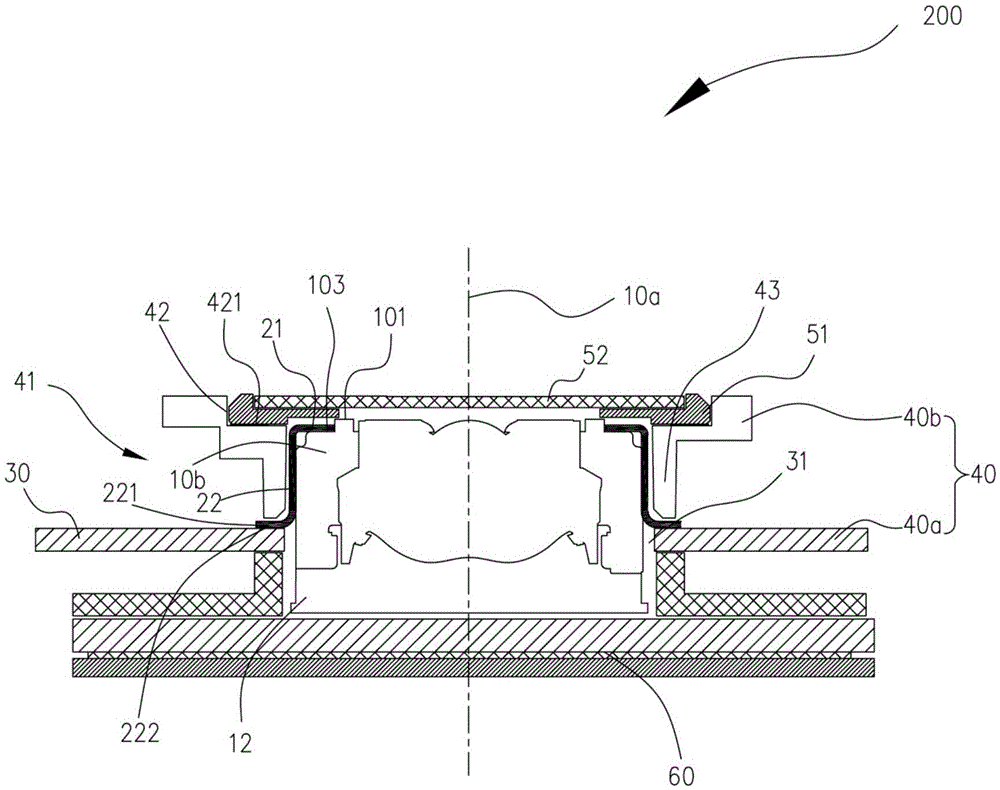

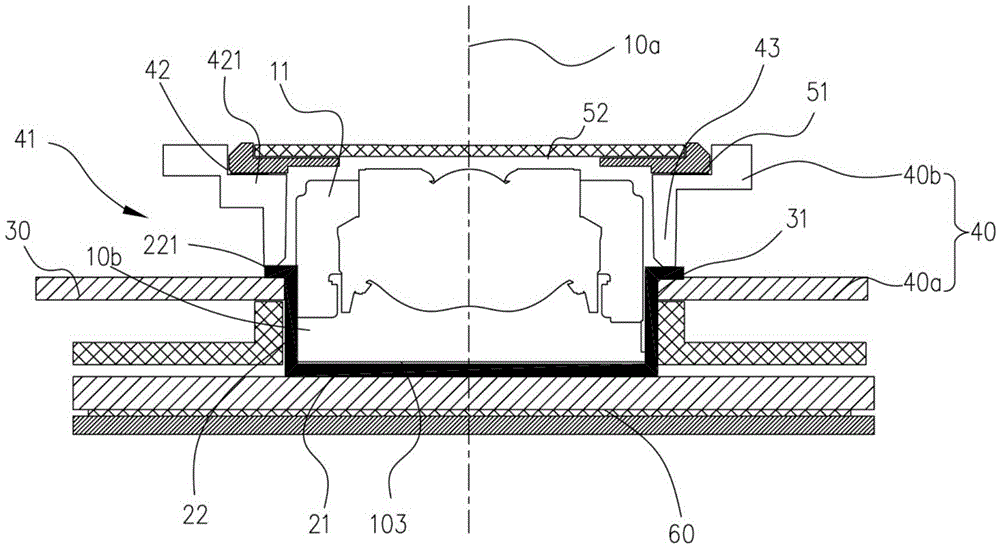

[0024] In the first embodiment, the camera module 10 is in the shape of a rectangular block. The end 10b is the top of the camera module 10, and the camera module also includes a bottom 12 opposite to the end 10b. The camera module 10 is provided with four sides 102 surrounding the end surface 101 . Four grooves 10 c are defined on the end surface 101 , and the four grooves 10 c are respectively arranged at four angles between the four side surfaces 102 and the end surface 101 . The end surface 101 is also provided with a lens hole 10d communicating with the groove 10c. The lens hole 10d is used to penetrate the scene light into the camera module 10, so that the camera module 10 can take pictures. The shooting main optical axis 10a coincides with the geometrical central axis of the lens hole 10c. The bottom end 12 may be connected with a flexible circuit board 121 , and the flexible circuit board 121 is used to electrically connect with the circuit board 30 . In other embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com