Air inlet duct for a turbojet nacelle

A technology of engine nacelle and turbojet, which is applied in the aviation field, can solve the problems of increasing materials and achieve the effect of preventing insufficient aerodynamic force and improving aerodynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

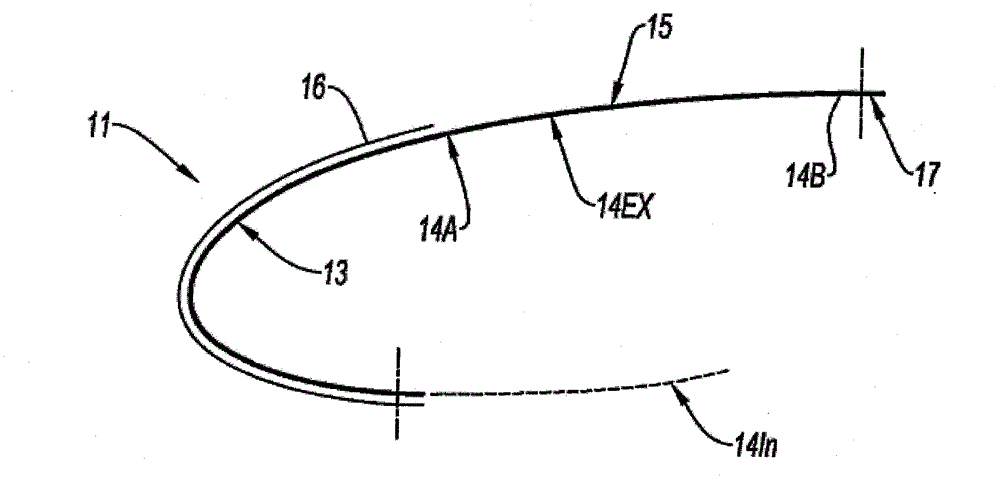

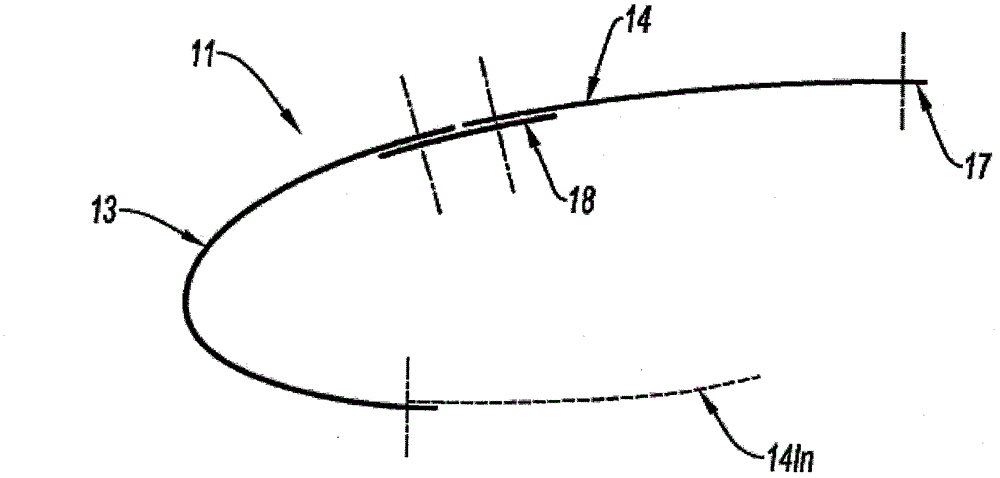

[0035] For a better understanding of the figures, the same reference numerals are used to designate the same technical parts.

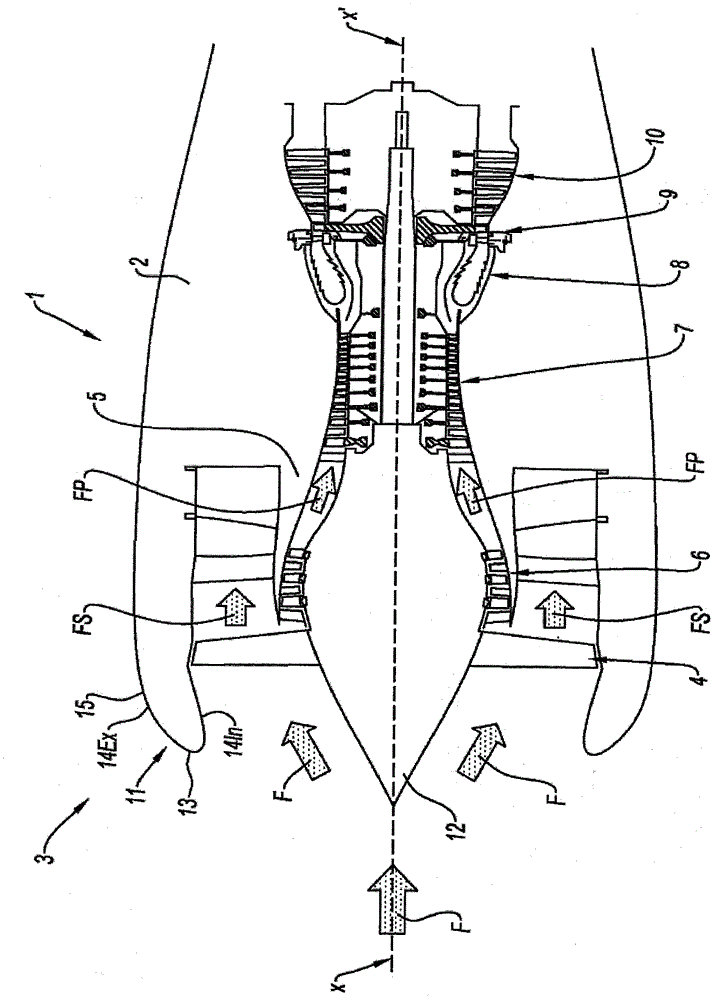

[0036] figure 1 The turbojet engine 1 in is a two-flow path and two-body engine, which is axisymmetric around the axis X-X'. In a known manner, within the nacelle 2 that is the housing of its different devices, this turbojet 1 comprises an air intake 3 through which the inflow air F can enter in order to then flow through an intake fan 4 . This air flow F is then divided into two flow paths, the primary flow path FP and the secondary flow path FS, via the intermediate casing 5, the end of which constitutes the separator nozzle.

[0037] In the following description, the terms "upstream" and "downstream" both refer to an axial position along the longitudinal axis X-X' in the direction of air flow inside the turbojet engine 1 .

[0038] The secondary flow path FS flows through the rectification stage and is discharged downstream of the turbojet. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com