Patents

Literature

1662results about "Power plant air intake arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

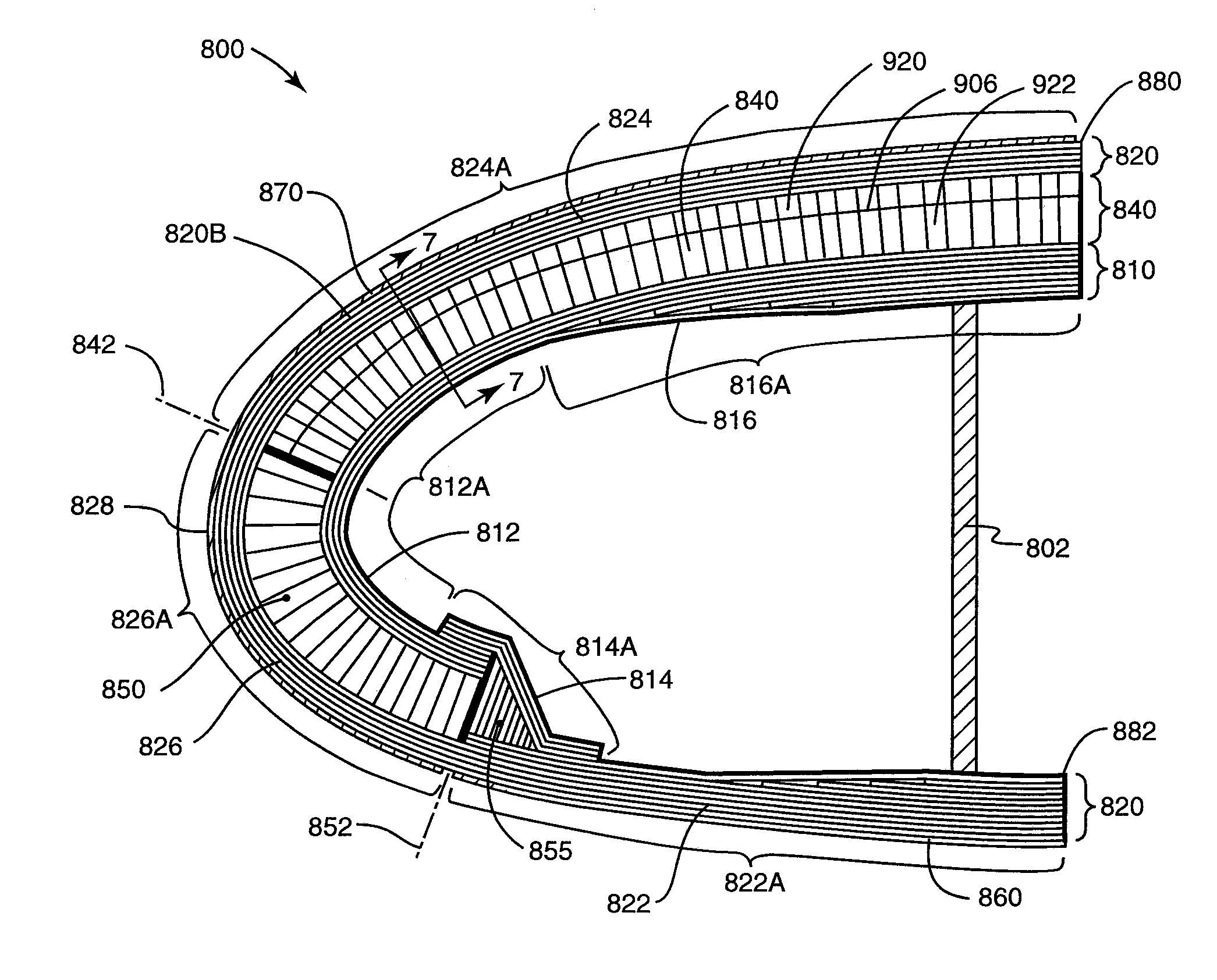

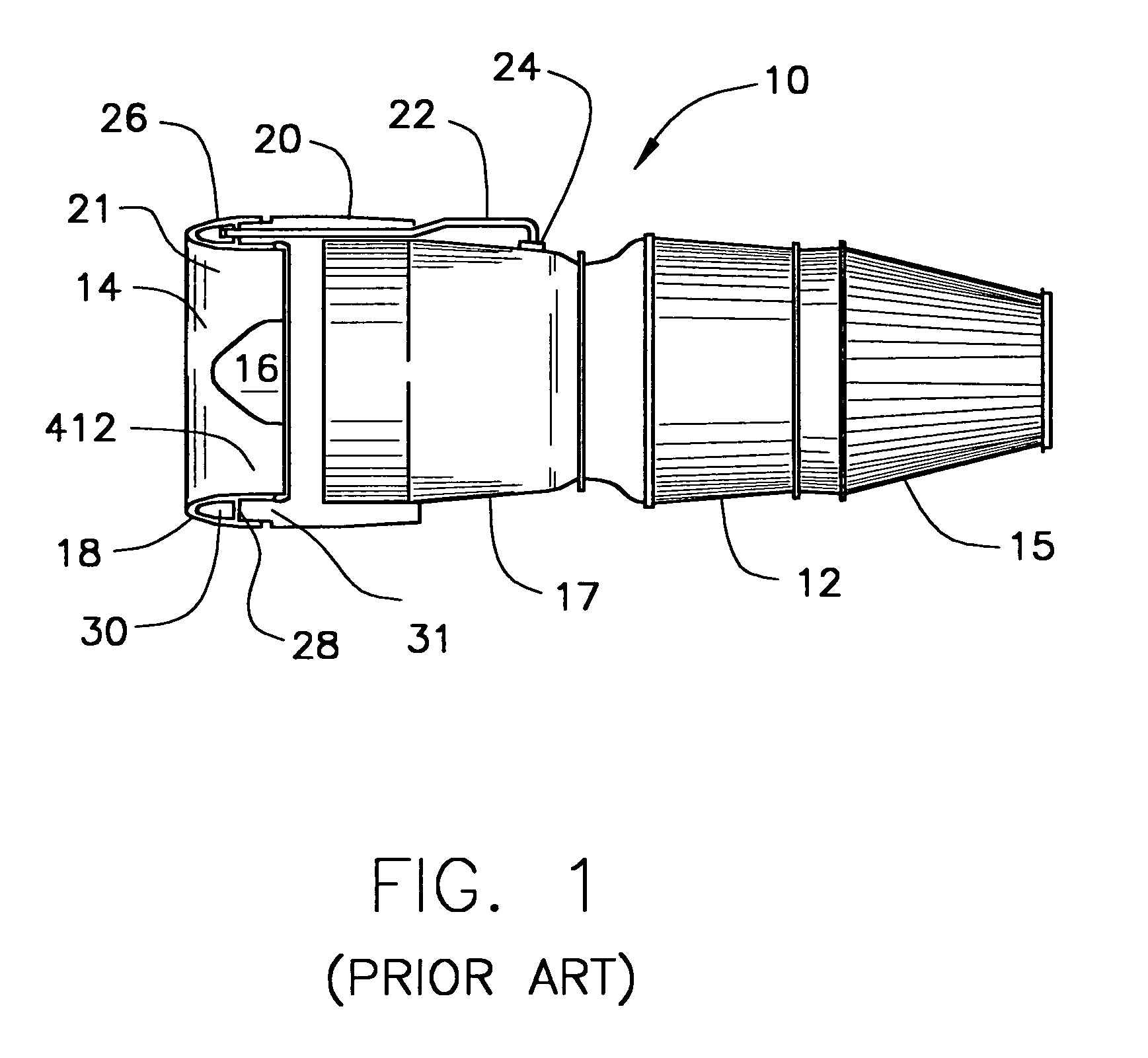

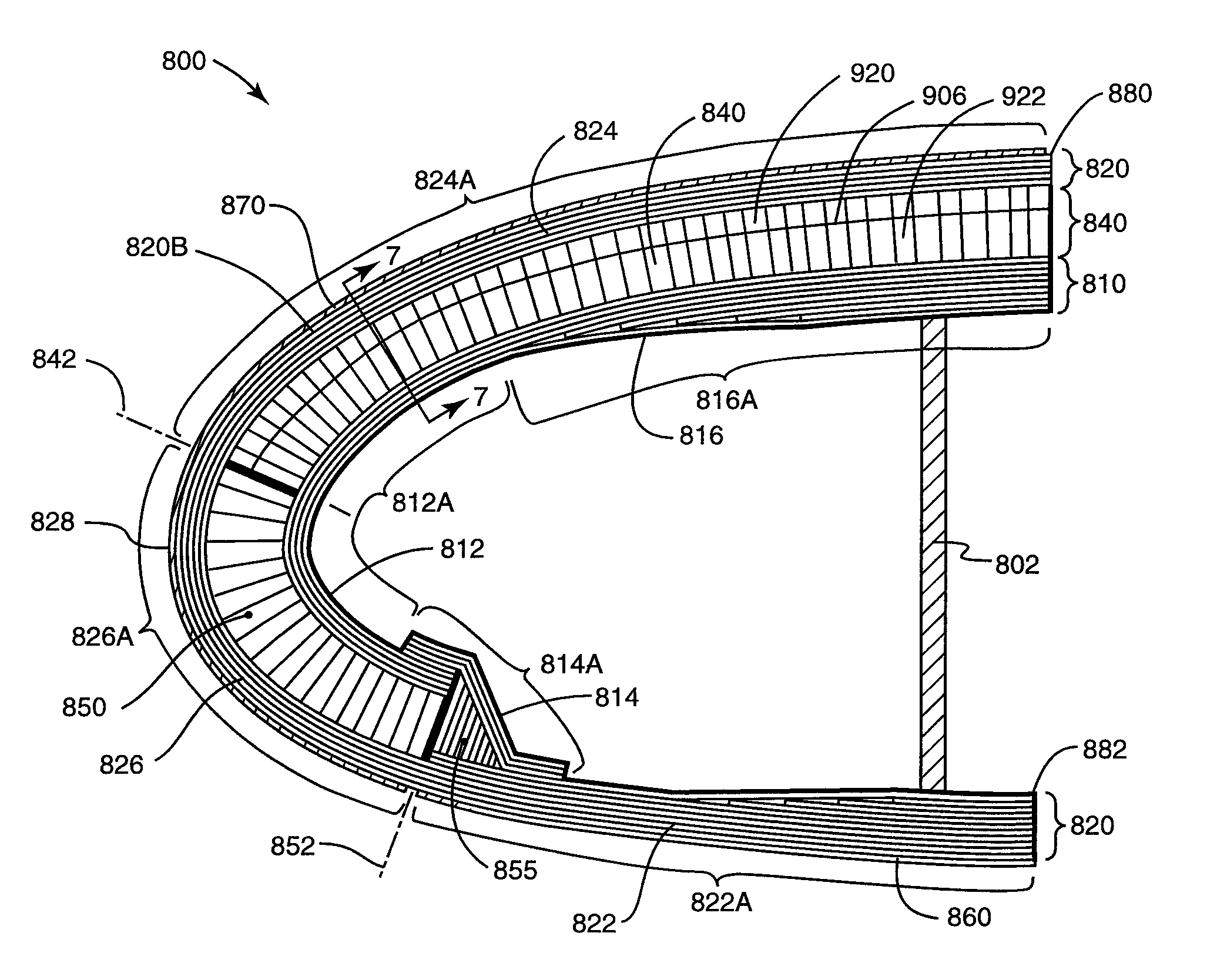

Acoustic nacelle inlet lip having composite construction and an integral electric ice protection heater disposed therein

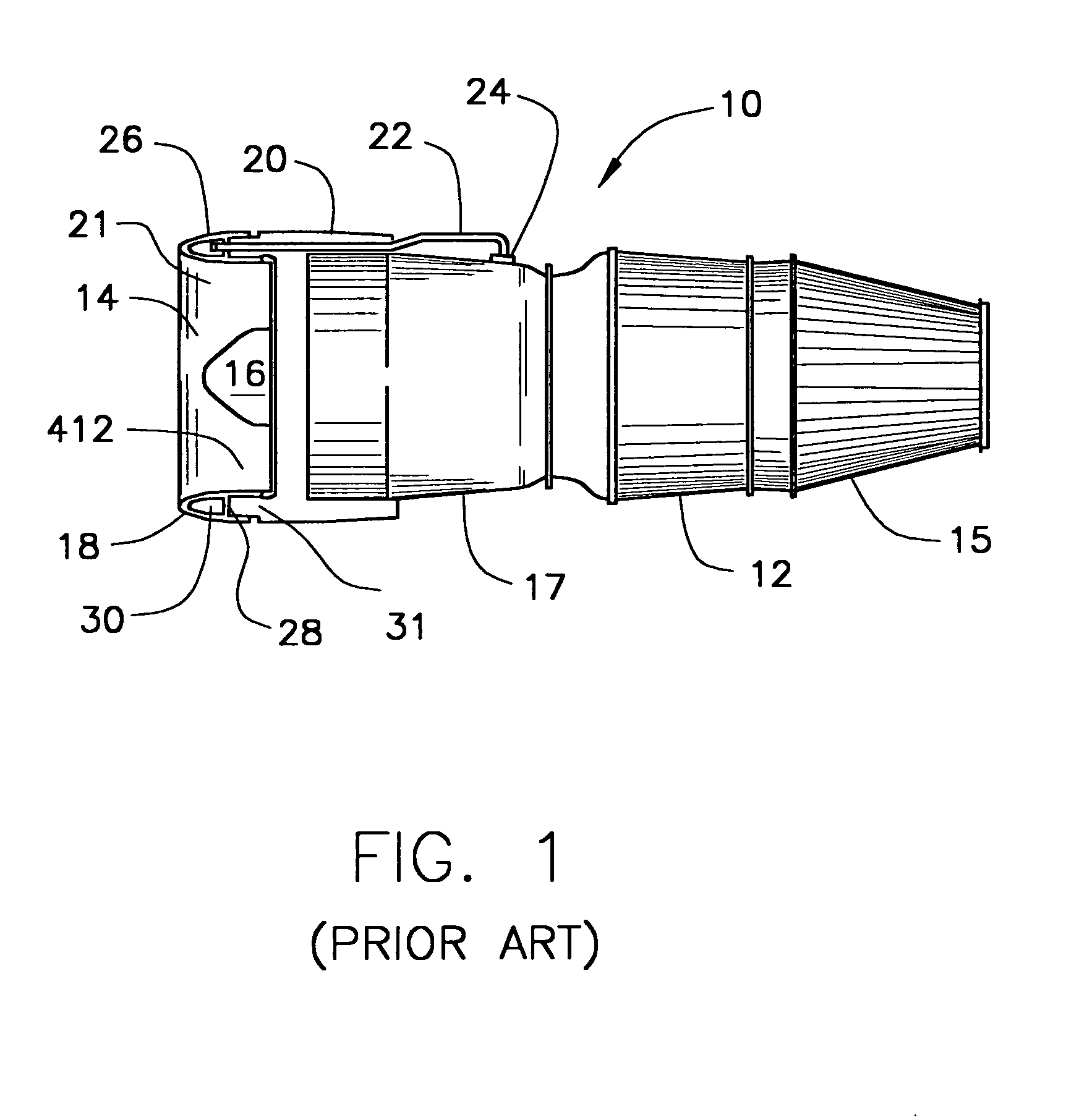

An engine nacelle inlet lip includes both acoustic treatment and electric heating for ice protection. The inlet lip has a composite outer skin and a composite inner skin, with the composite outer skin having at least one integrated heater element embedded in the composite material. An acoustic cellular core positioned between the outer and inner skin acts to attenuate fan noise from the engine. Covering the outer skin and overlying the acoustic core is a perforated erosion shield having a first set of openings that pass entirely thorough its thickness. The composite outer skin includes a second set of openings such that sound waves can pass from an inner barrel portion of the inlet lip through the erosion shield, outer skin, and heater element to the underlying acoustic cellular core.

Owner:THE BF GOODRICH CO +1

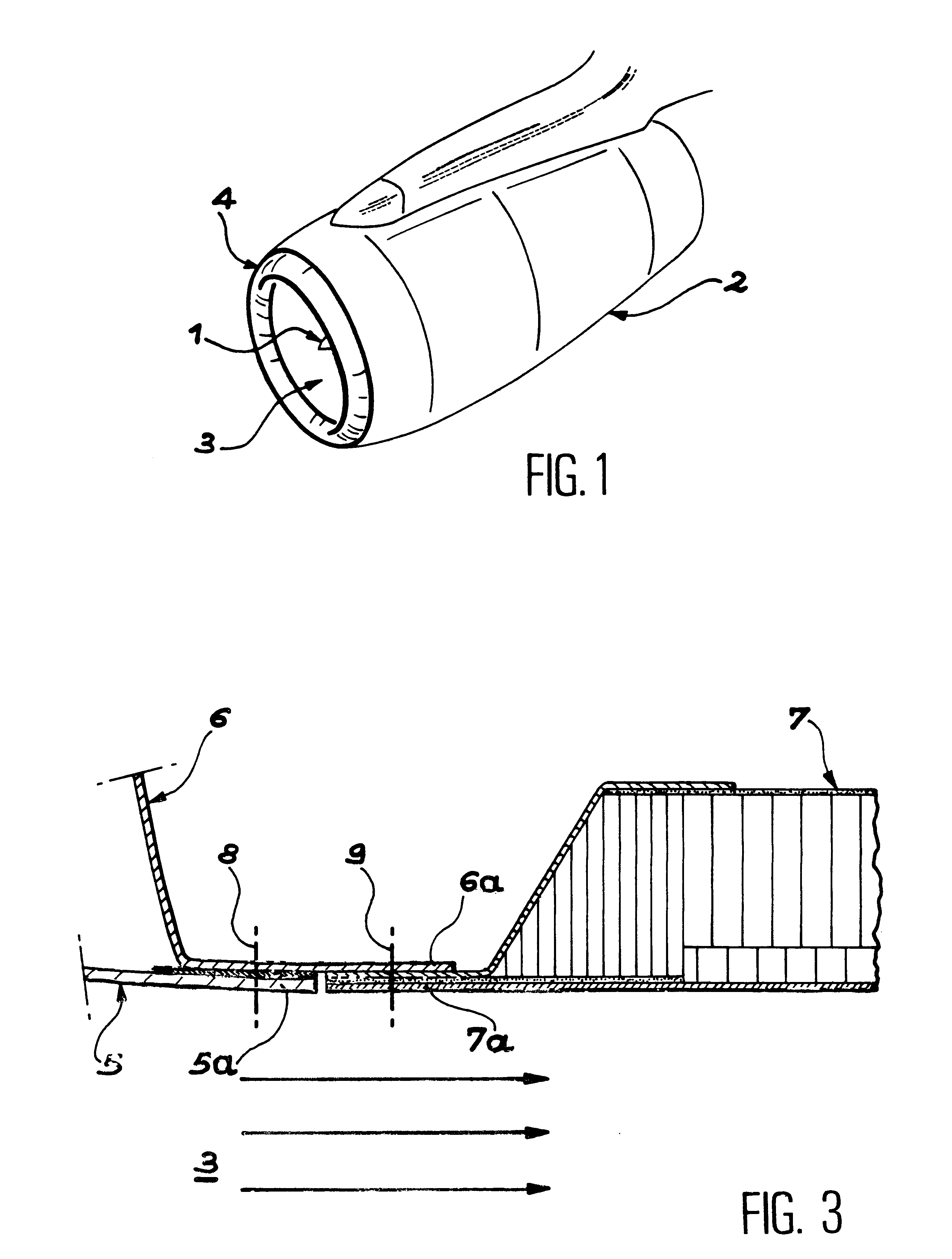

Air intake structure for aircraft engine

InactiveUS6328258B1Aircraft power plant componentsEfficient propulsion technologiesAirplaneEngine room

Owner:AEROSPATIALE MATRA

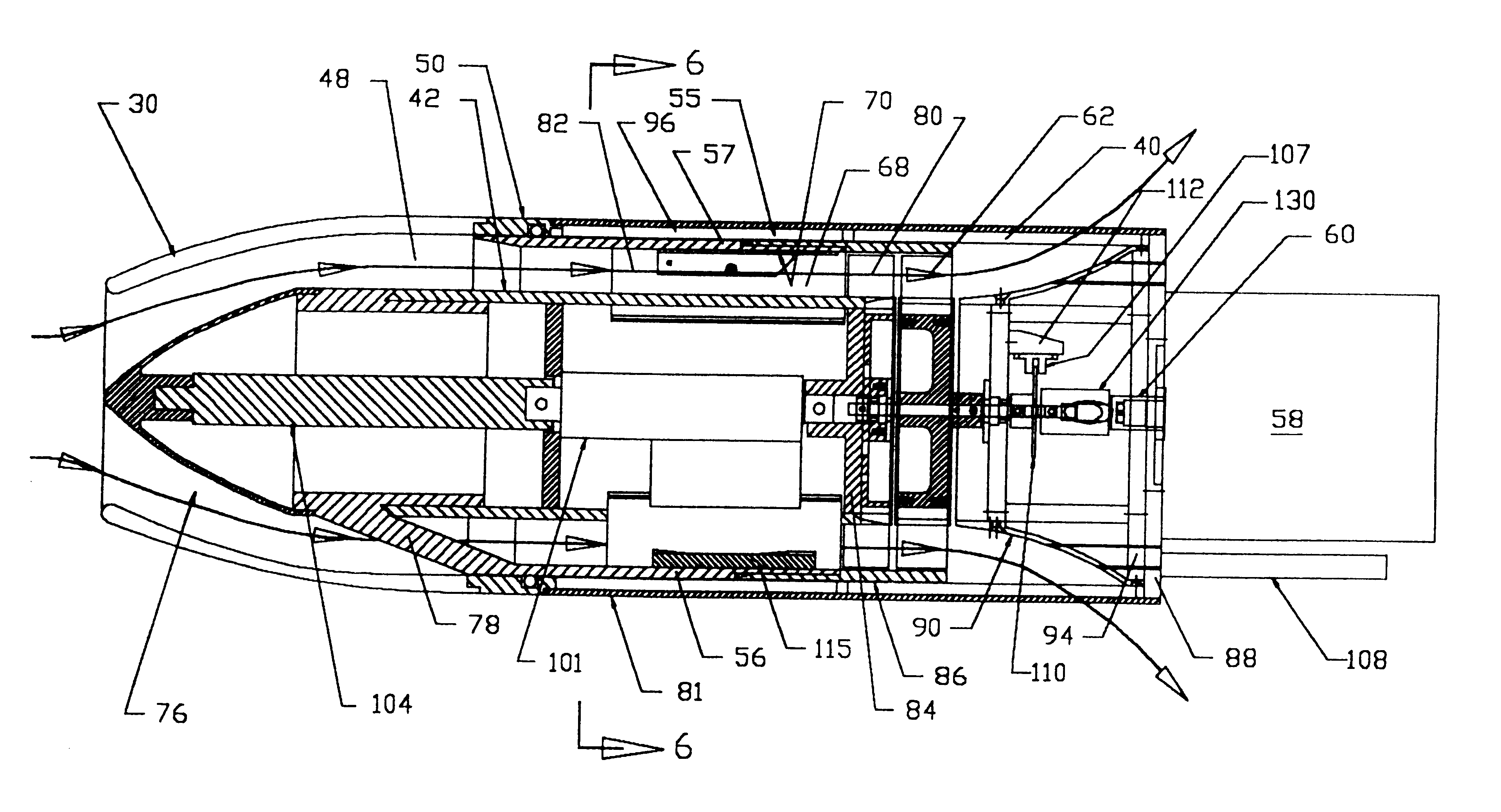

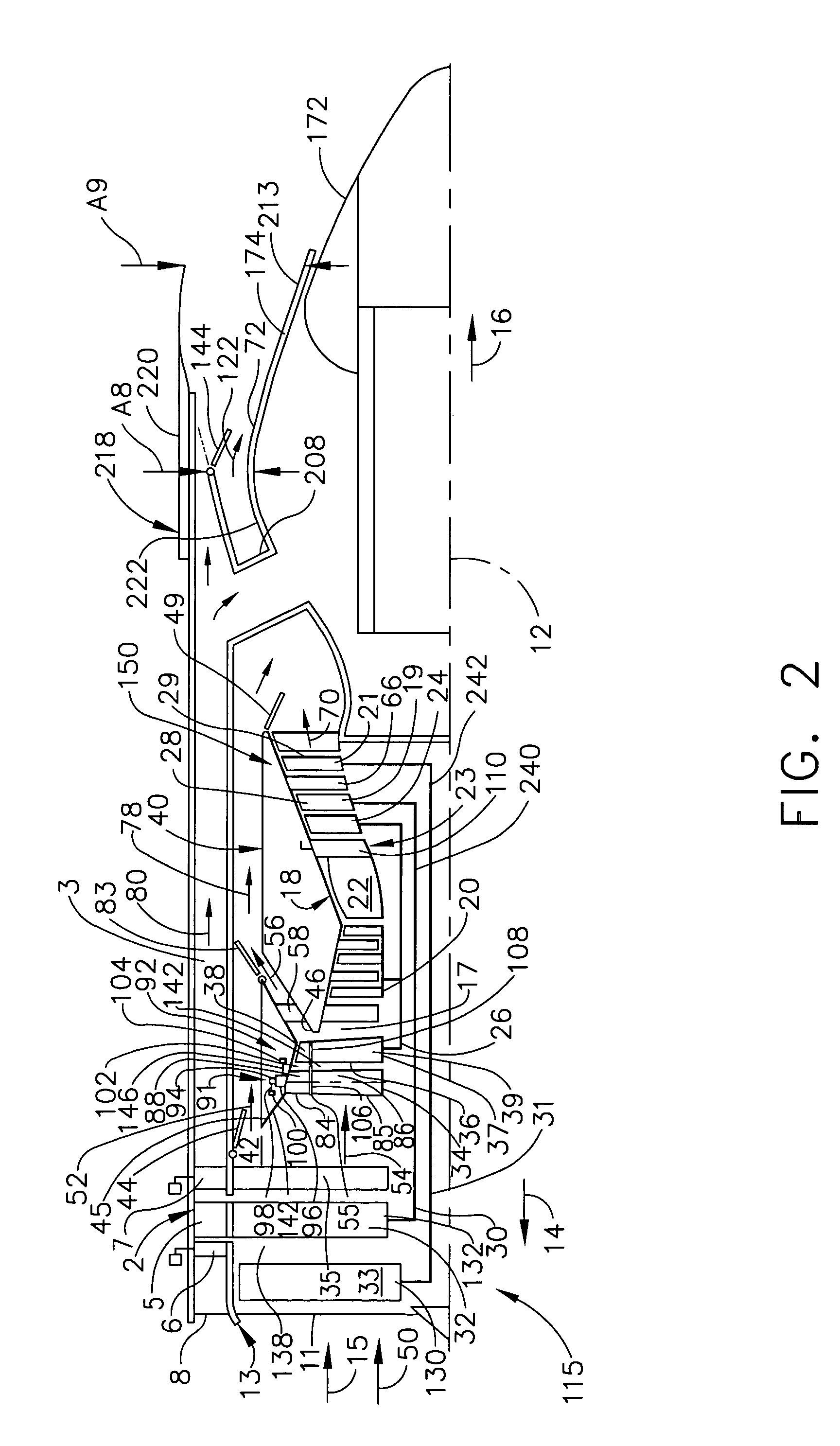

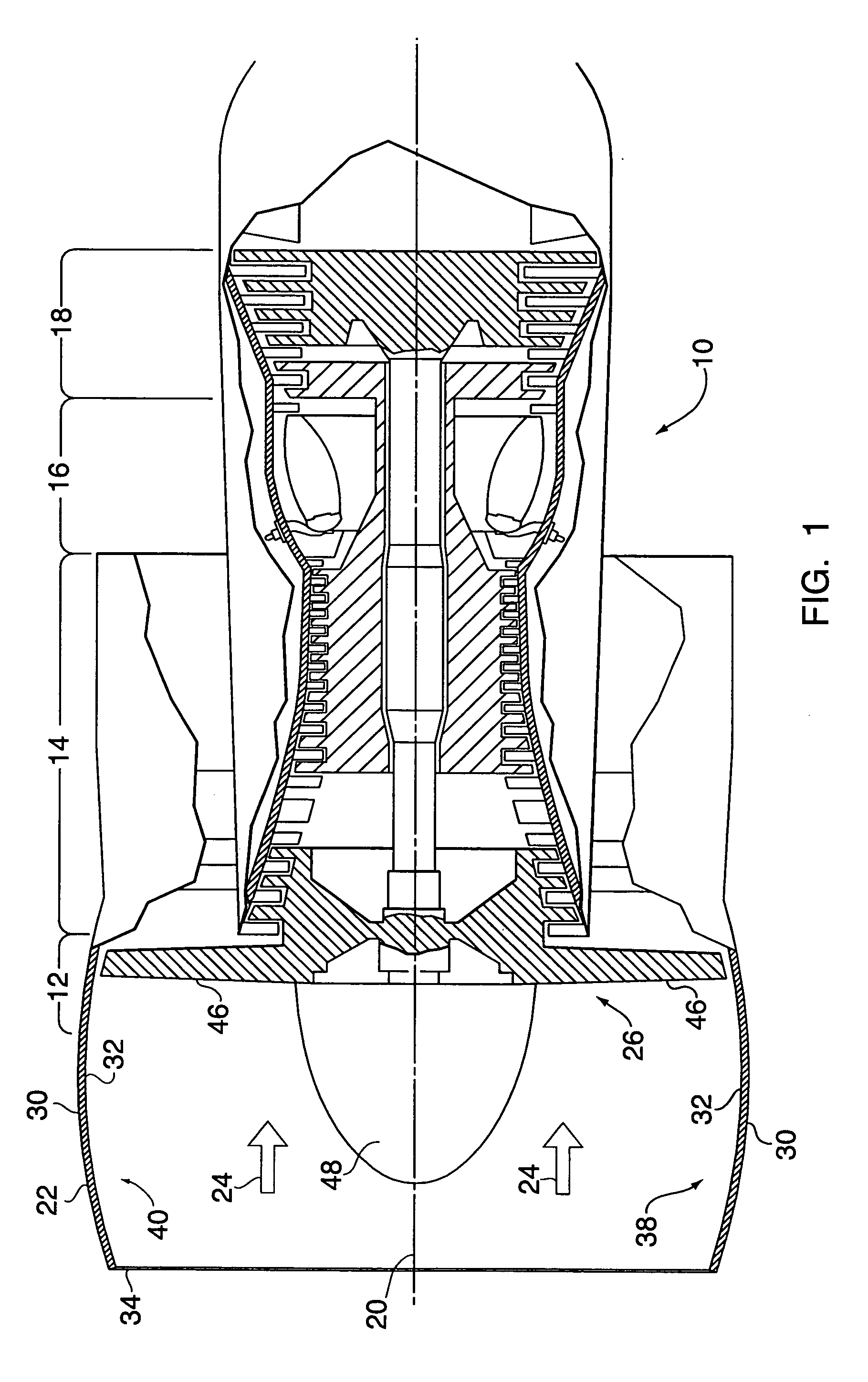

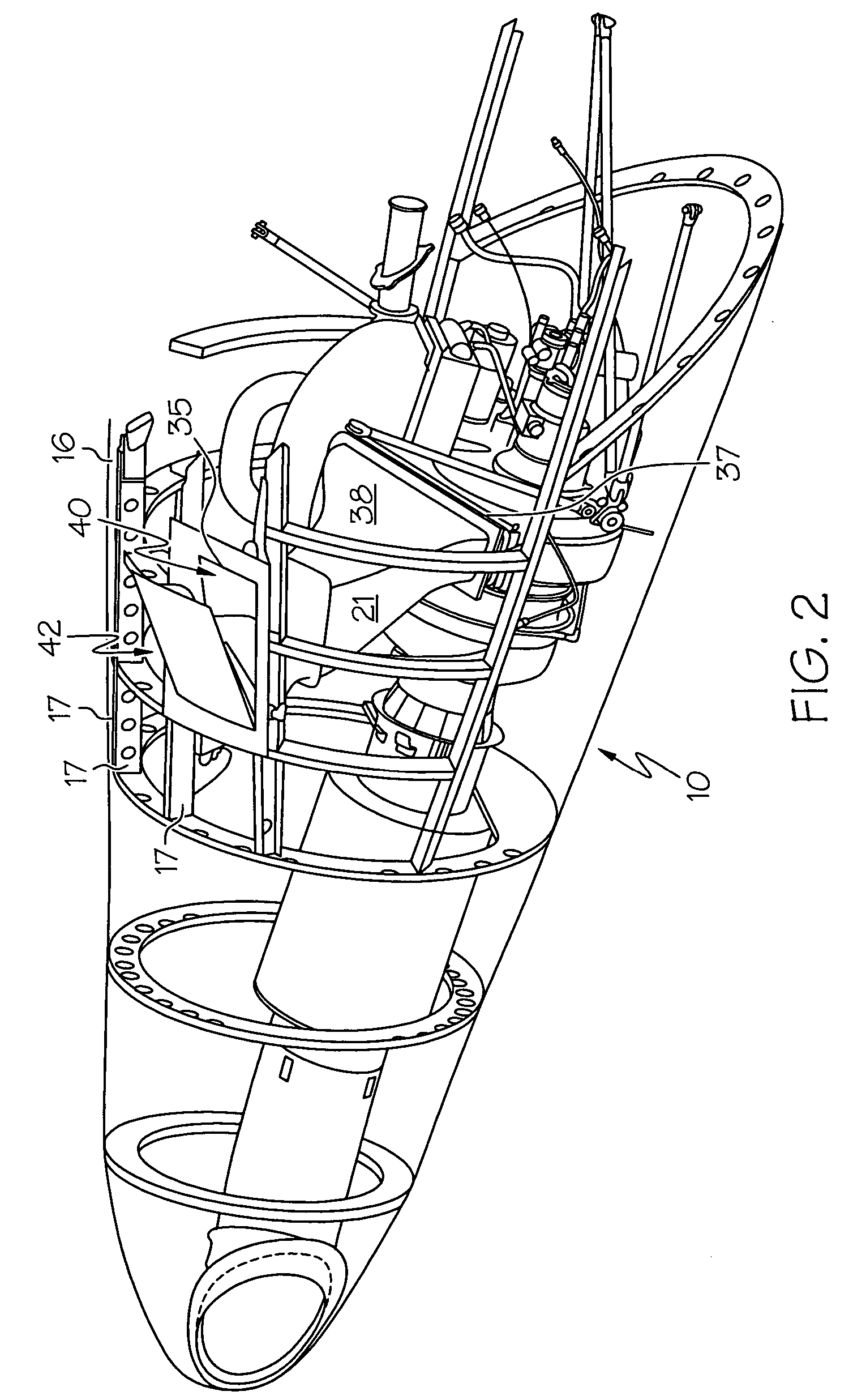

Low drag ducted Ram air turbine generator and cooling system

InactiveUS6270309B1Efficient extractionEnergy efficiencyPump componentsWind motor controlRam air turbineElectric generator

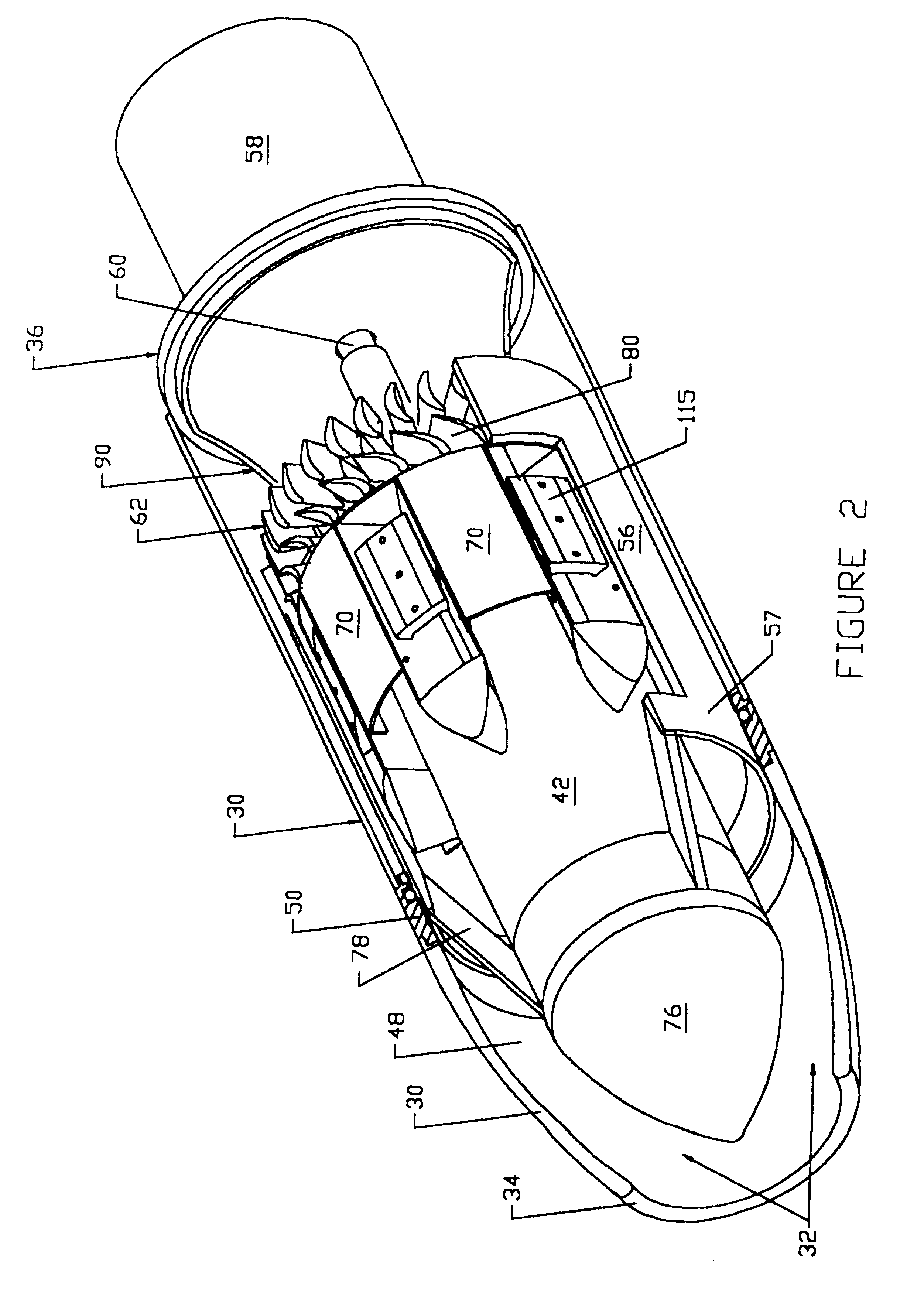

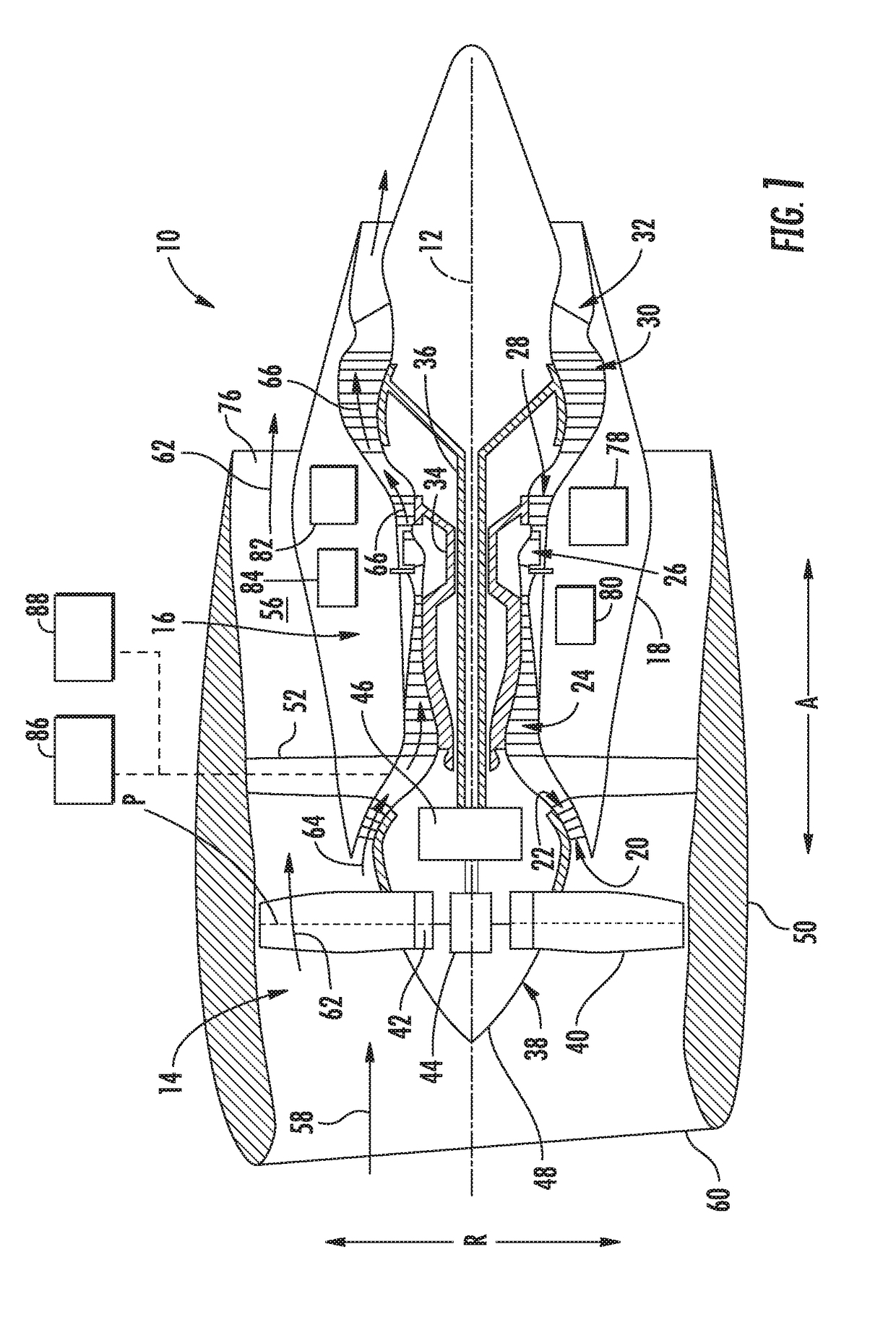

A low drag ducted ram air turbine generator and cooling system is provided. The ducted ram air turbine generator and cooling system has reduced drag while extracting dynamic energy from the air stream during the complete range of intended flight operating regimes. A centerbody / valve tube having an aerodynamically shaped nose is slidably received in a fairing and primary structure to provide a variable inlet area. An internal nozzle control mechanism attached to the valve tube positions nozzle control doors to provide variable area nozzles directing air flow to the turbine stator and rotor blades to maintain optimum generator efficiency. An alternate embodiment includes an annular internal nozzle having interleaved panels to modulate the air flow to the turbine.

Owner:GHETZLER AERO POWER CORP

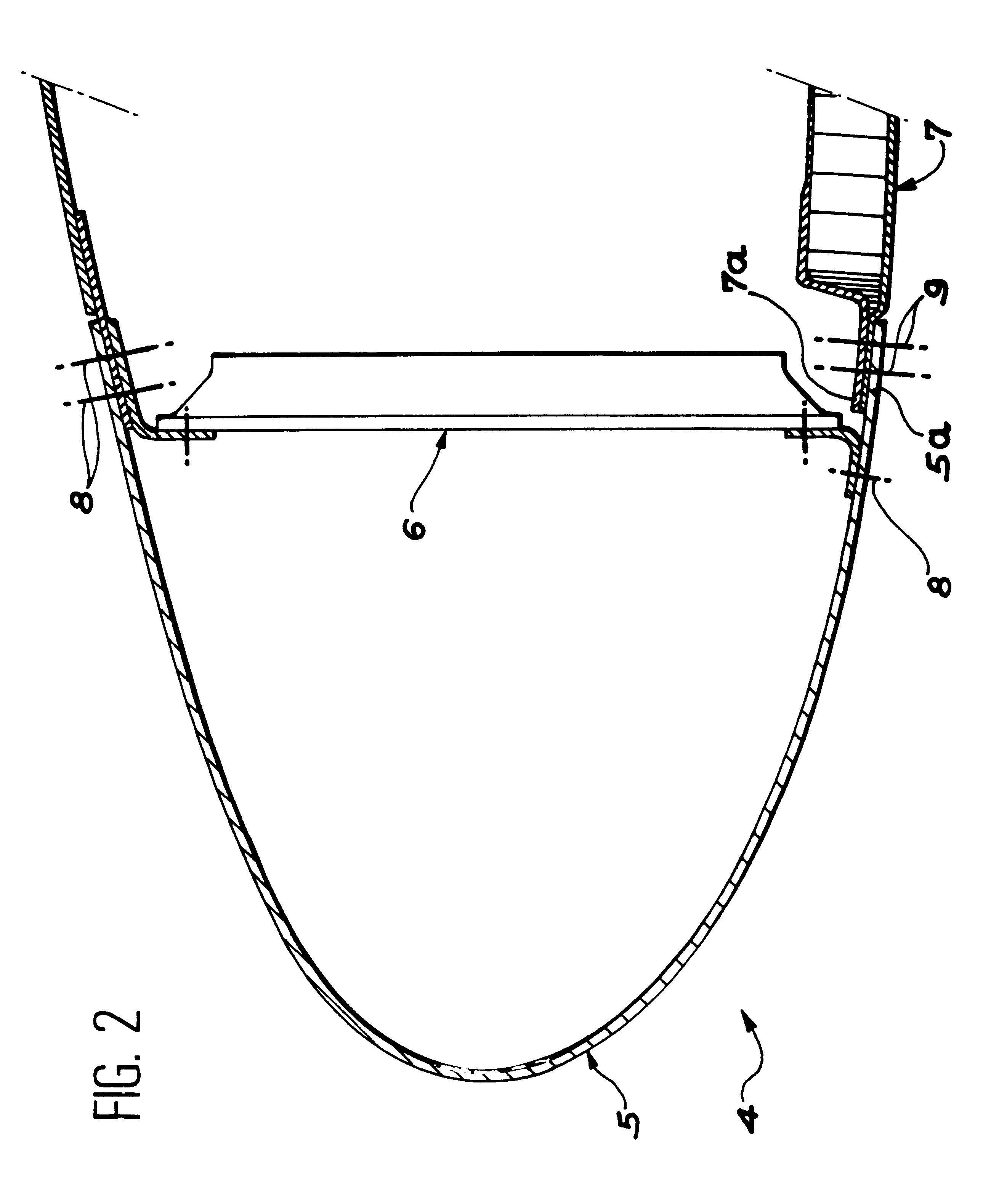

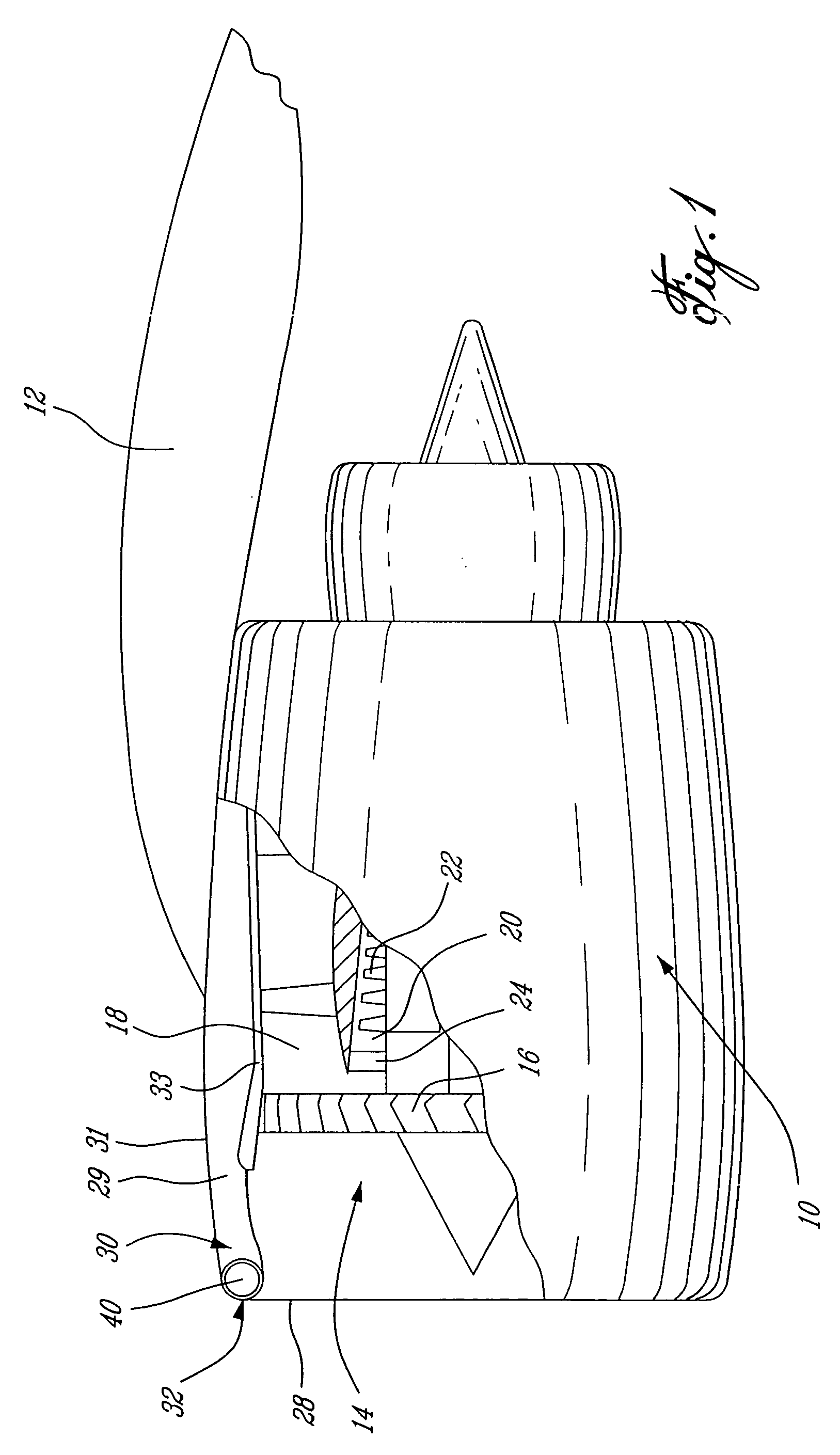

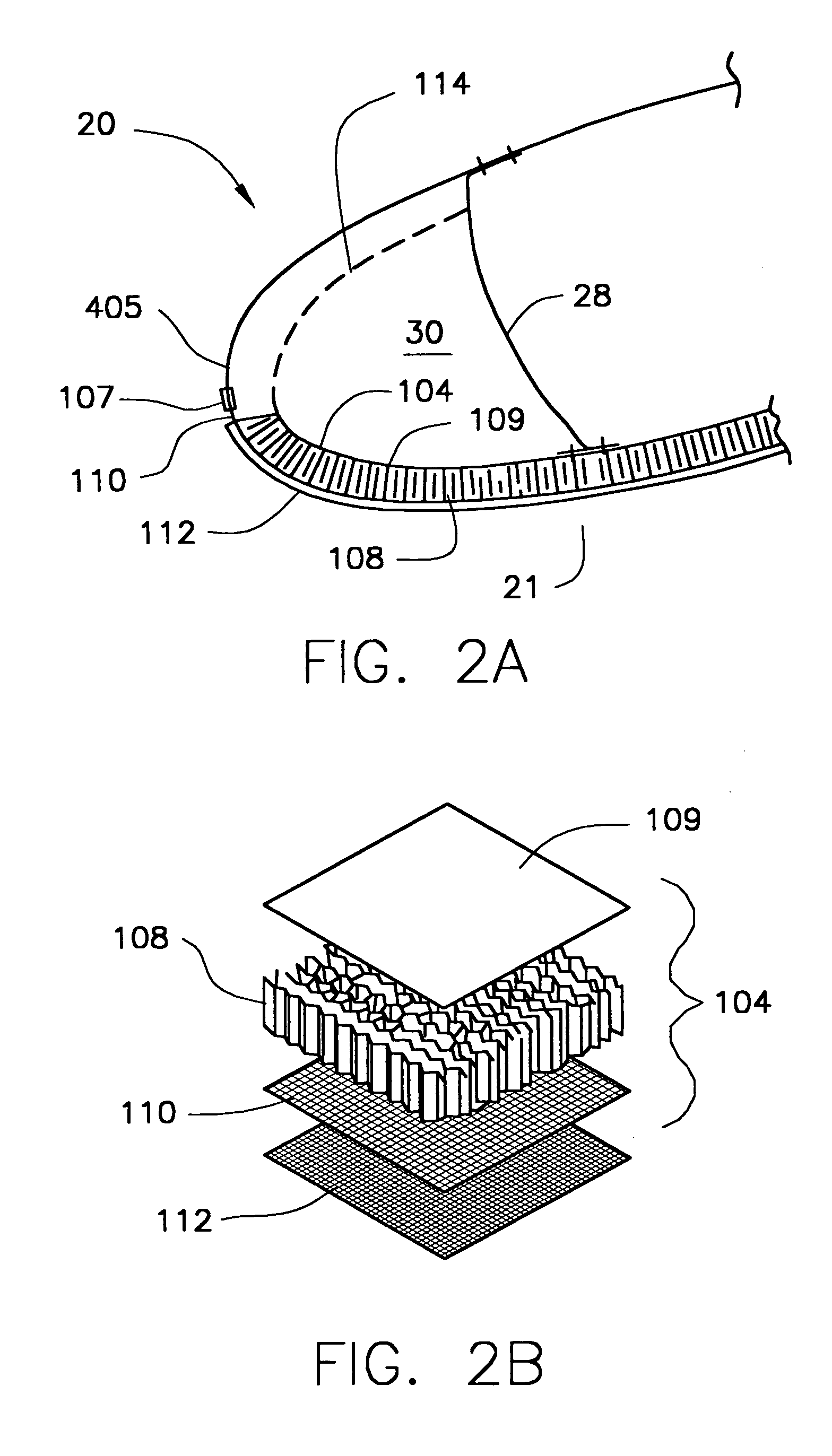

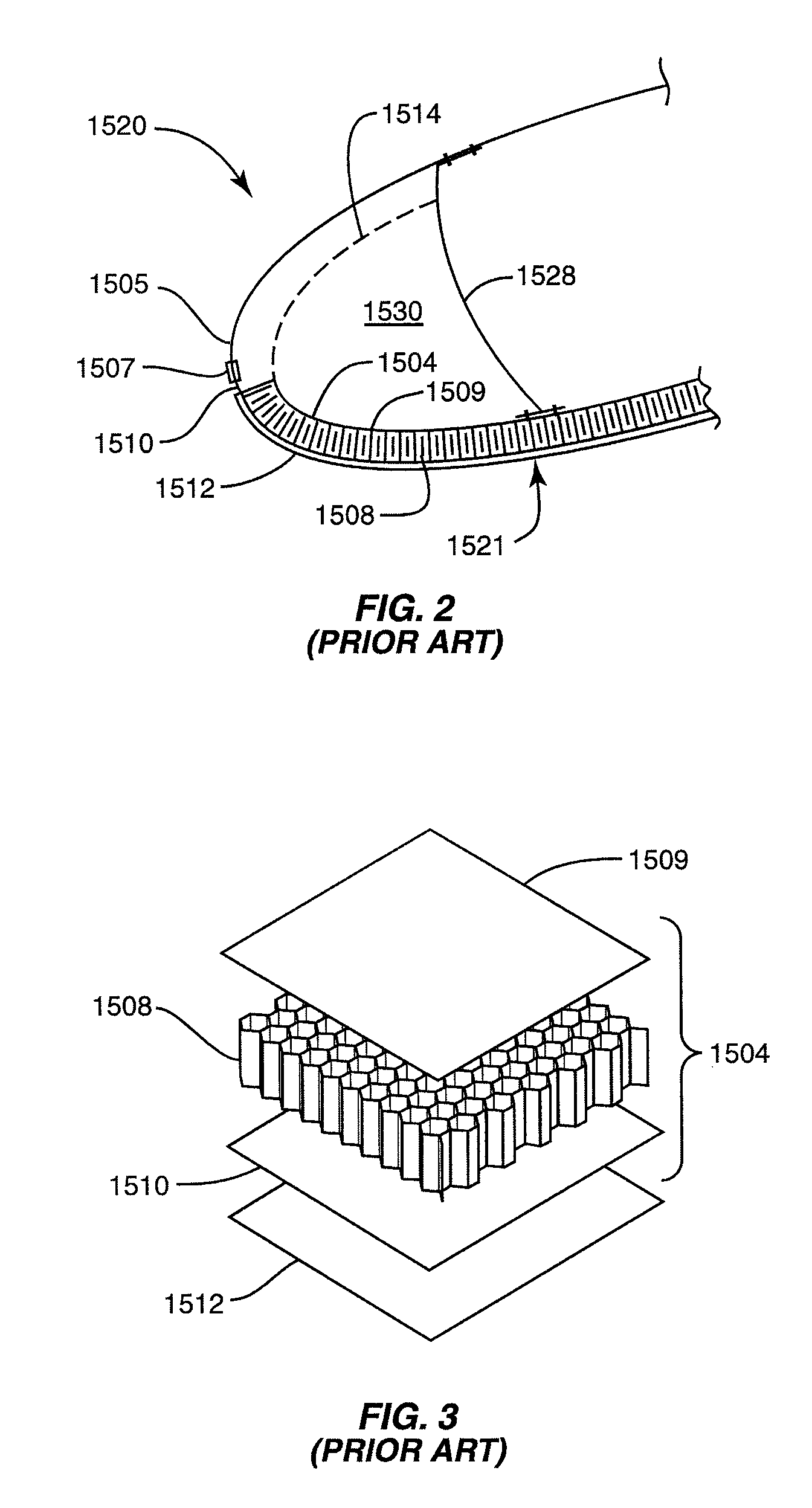

Method and apparatus for noise abatement and ice protection of an aircraft engine nacelle inlet lip

InactiveUS20050006529A1Avoid temperatureCost penaltyDe-icing equipmentsFuselage insulationNacelleAcoustic noise reduction

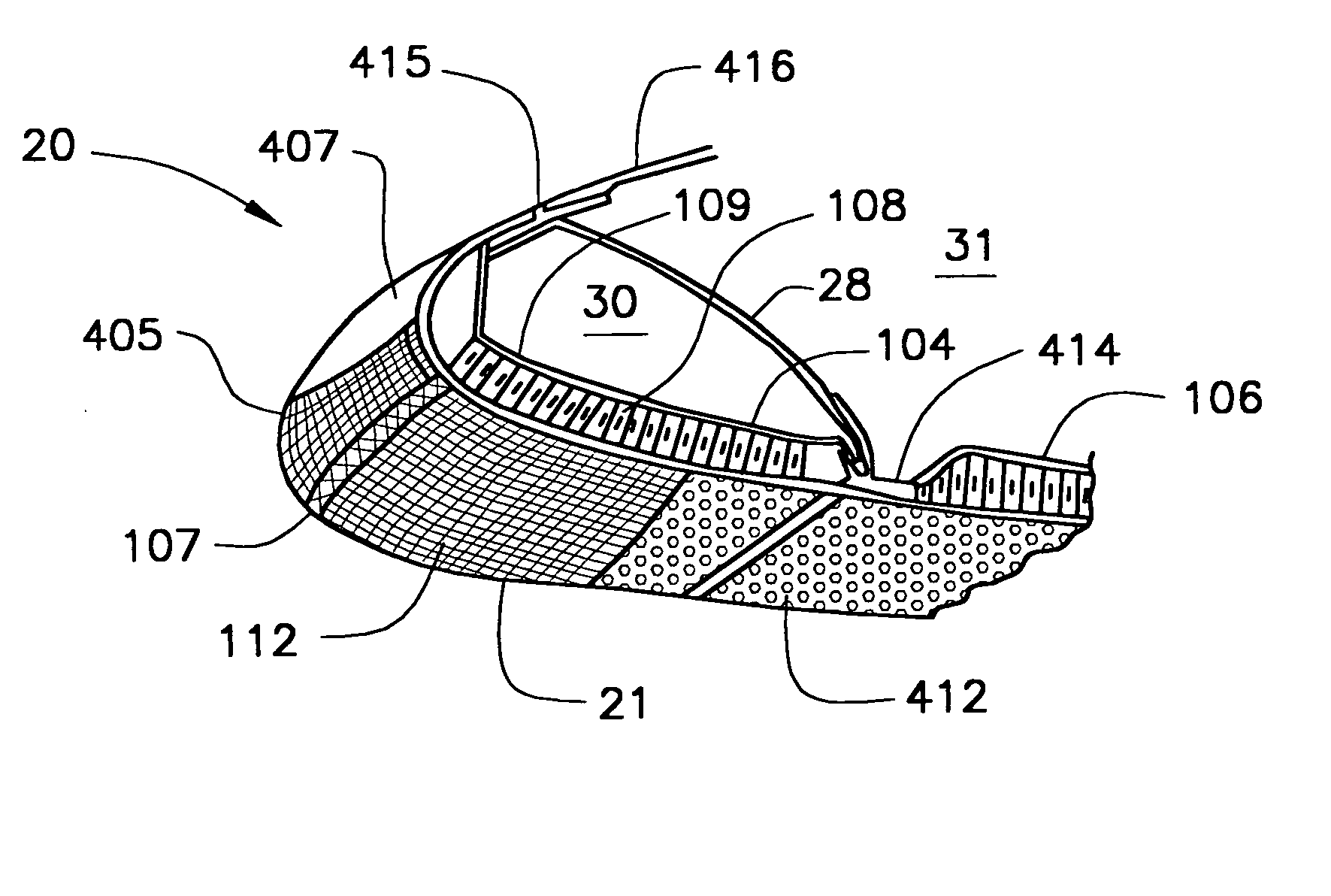

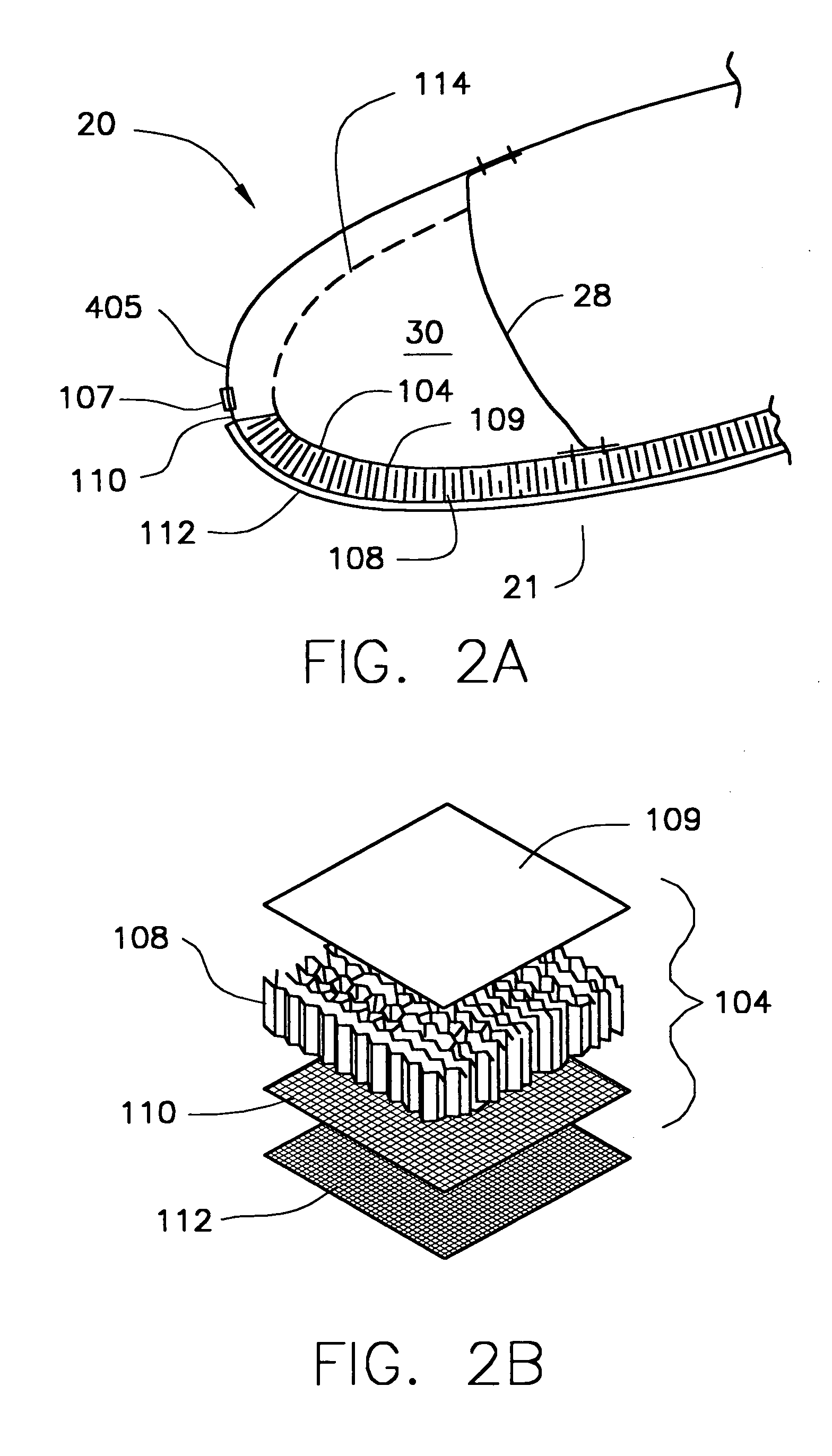

An aircraft engine nacelle comprises: (a) an inlet lip and a skin having internal and external surfaces; (b) a noise abatement structure such as an acoustic panel located on the internal surface of the nacelle skin; and (c) an electrically powered de-icing system located on the external surface of the nacelle skin and in electrical connection to a power source. A method for de-icing and abating noise from an aircraft nacelle comprises: (a) providing a noise abatement structure such as an acoustic panel located on the internal surface of the nacelle skin; (b) providing an electrically powered de-icing system on the external surface of the nacelle skin; and (c) applying an electric current to the electrically powered de-icing system. The nacelle skin may be a perforated skin, and the de-icing system comprises a wire mesh bonded to the external surface of the perforated skin. The method and nacelle permit the use of noise abatement structures such as acoustic panels for noise reduction while advantageously avoiding detrimental high temperatures associated with conventional de-icing systems.

Owner:ROHR INC

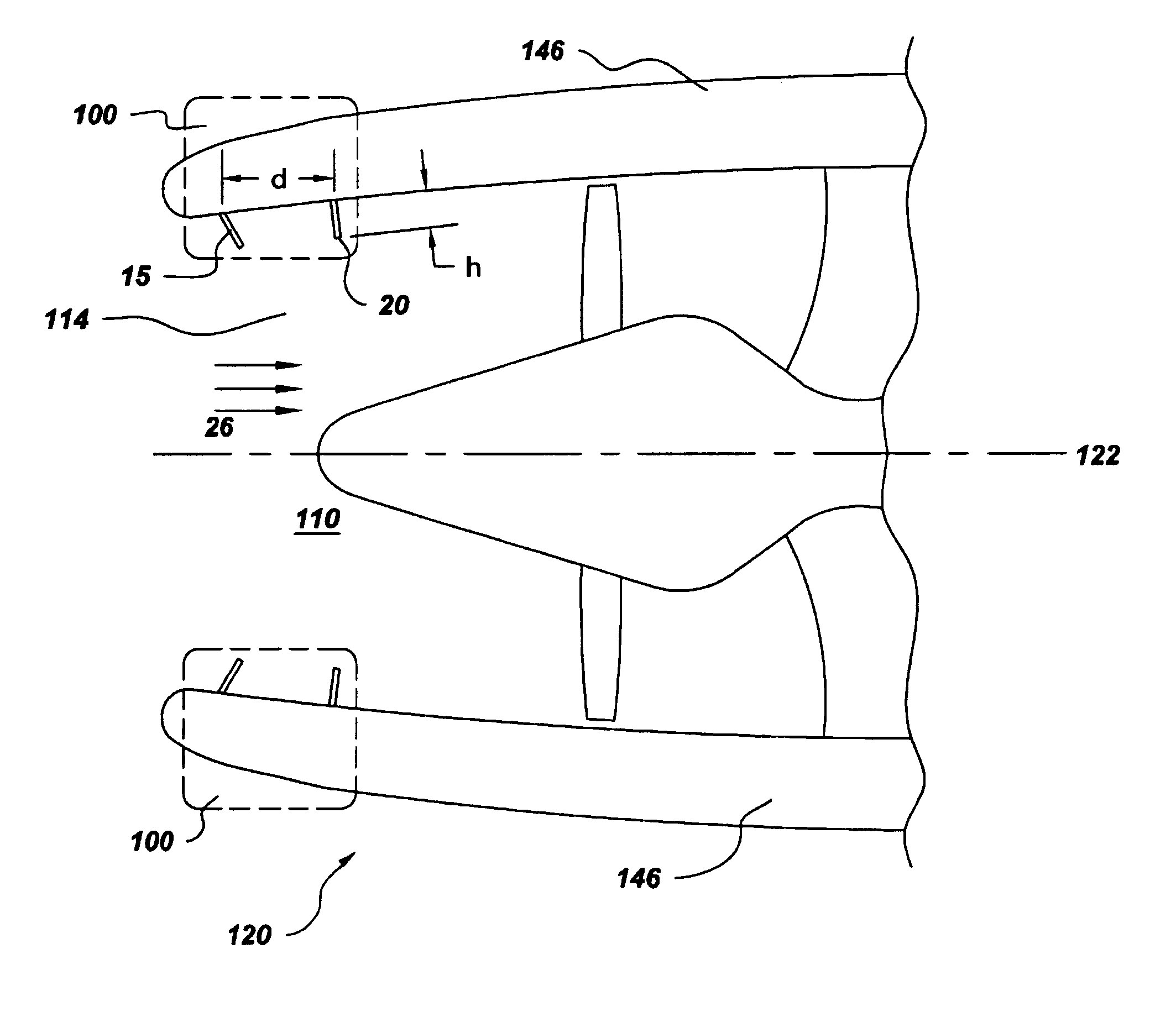

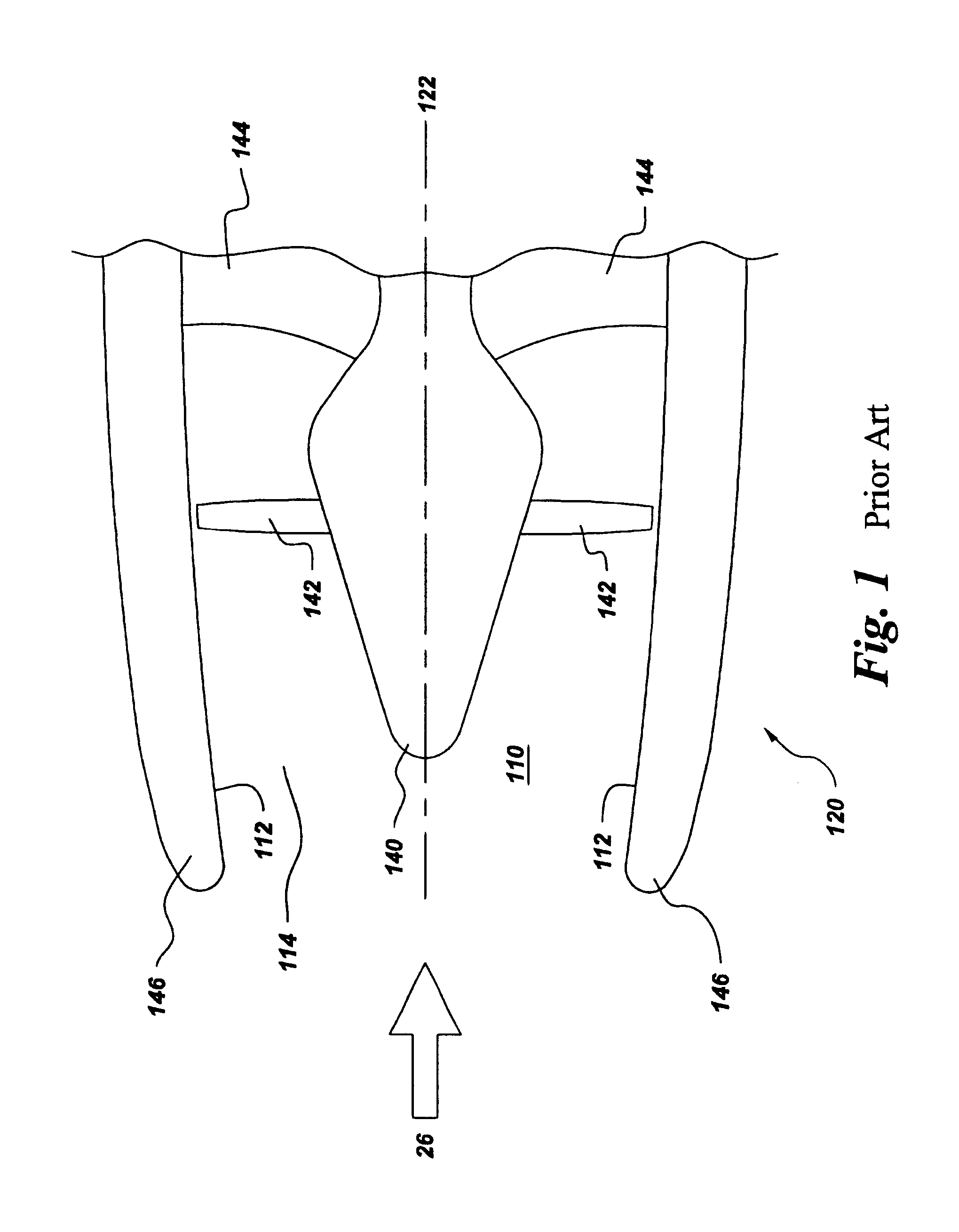

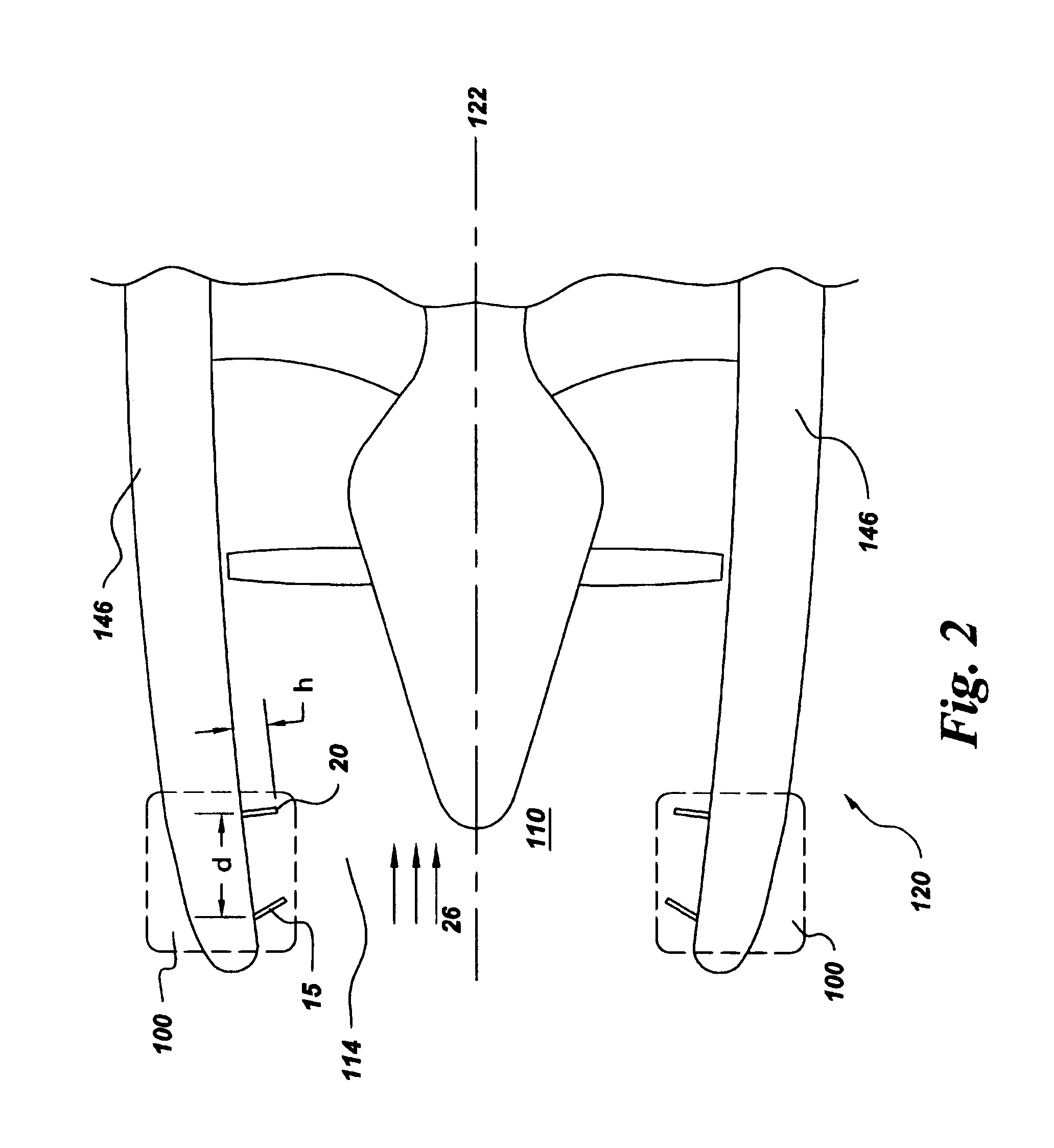

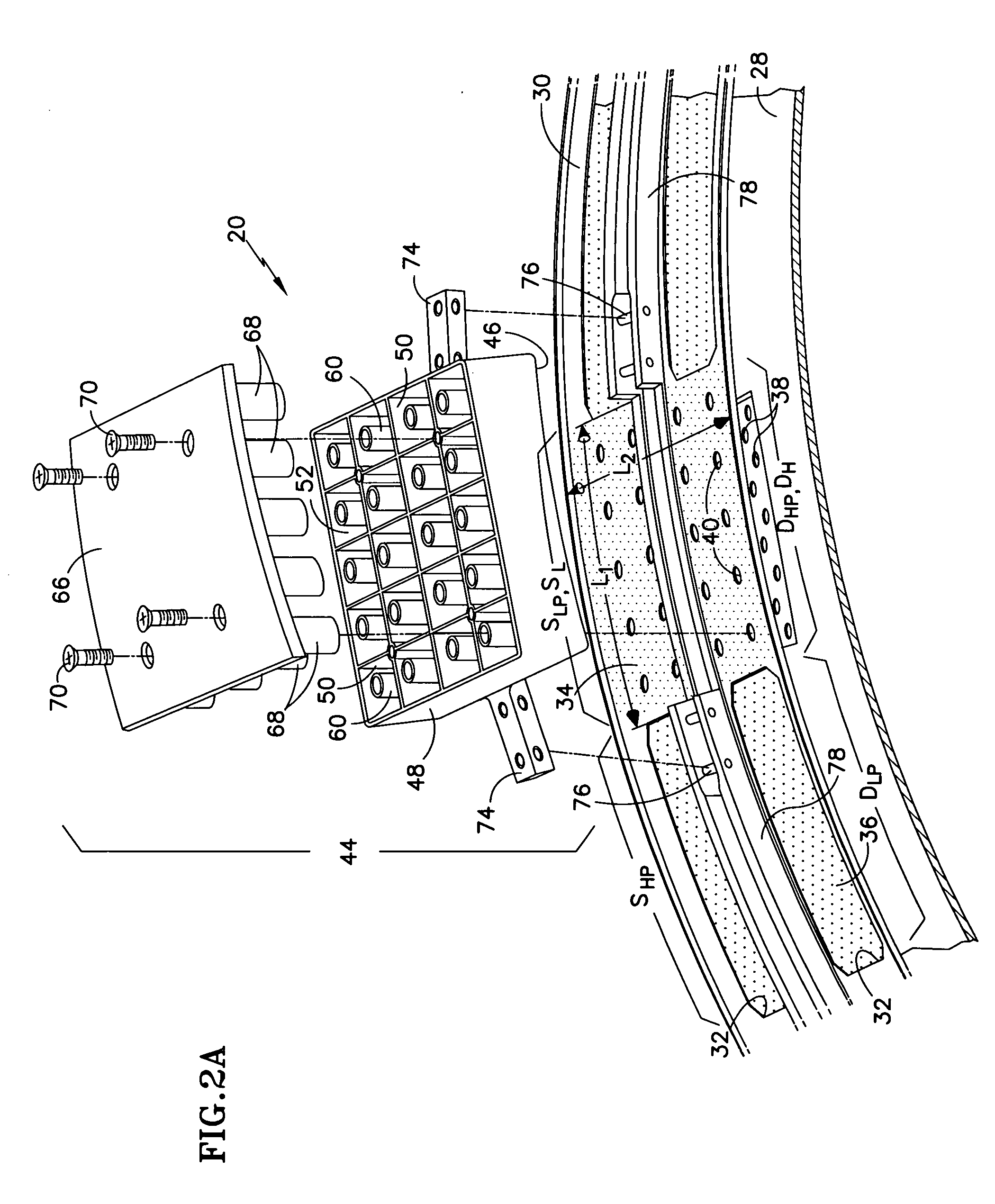

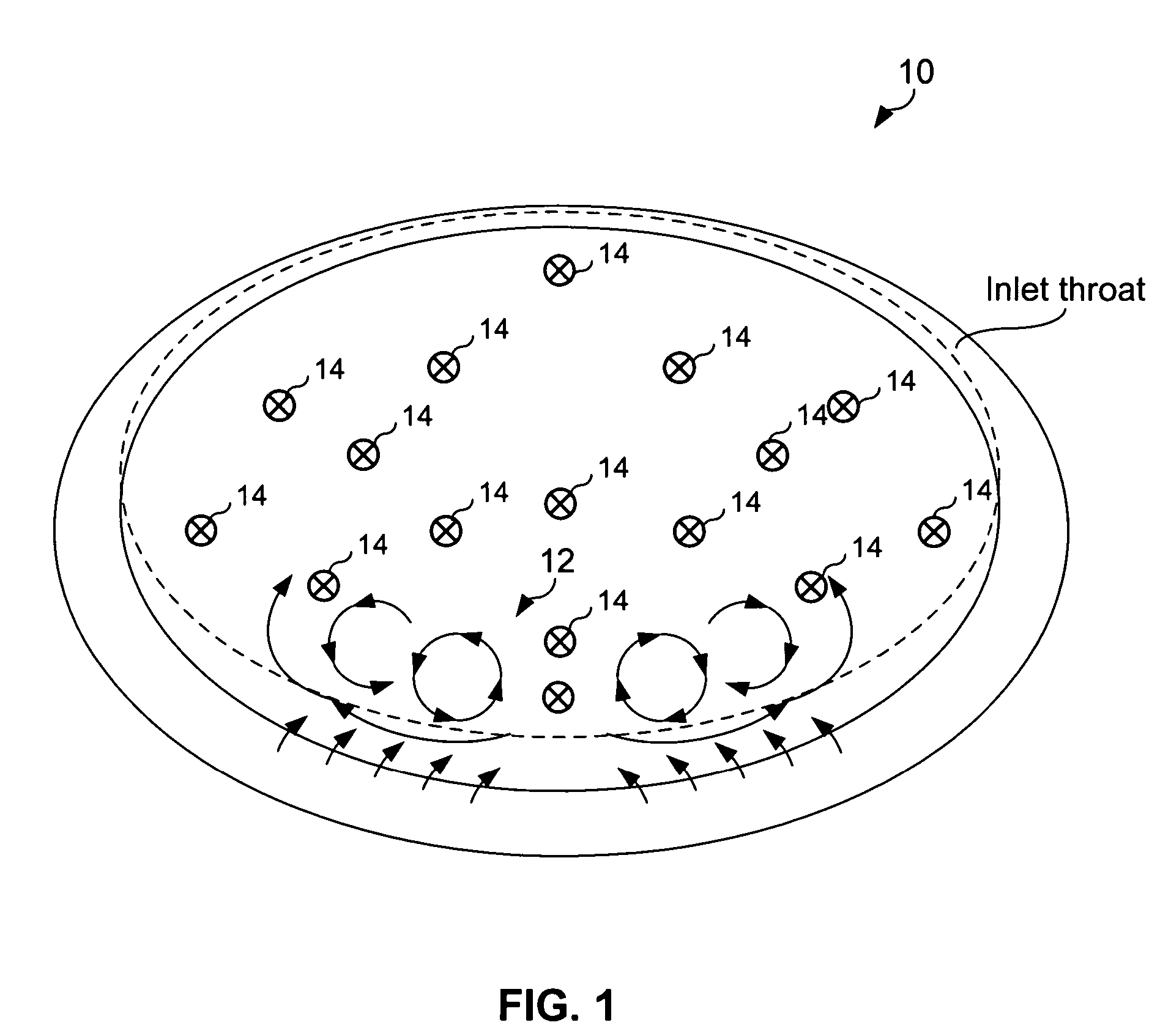

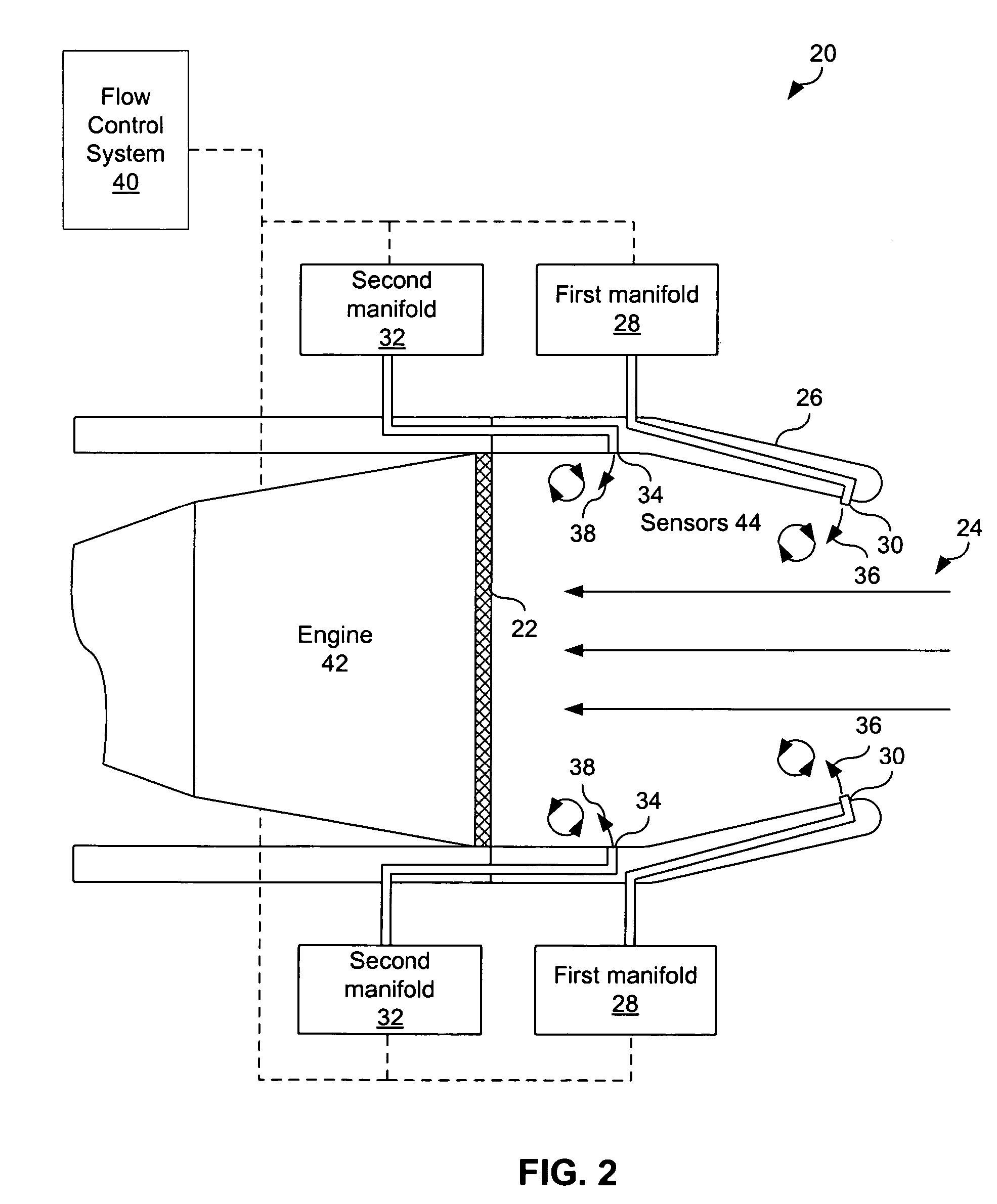

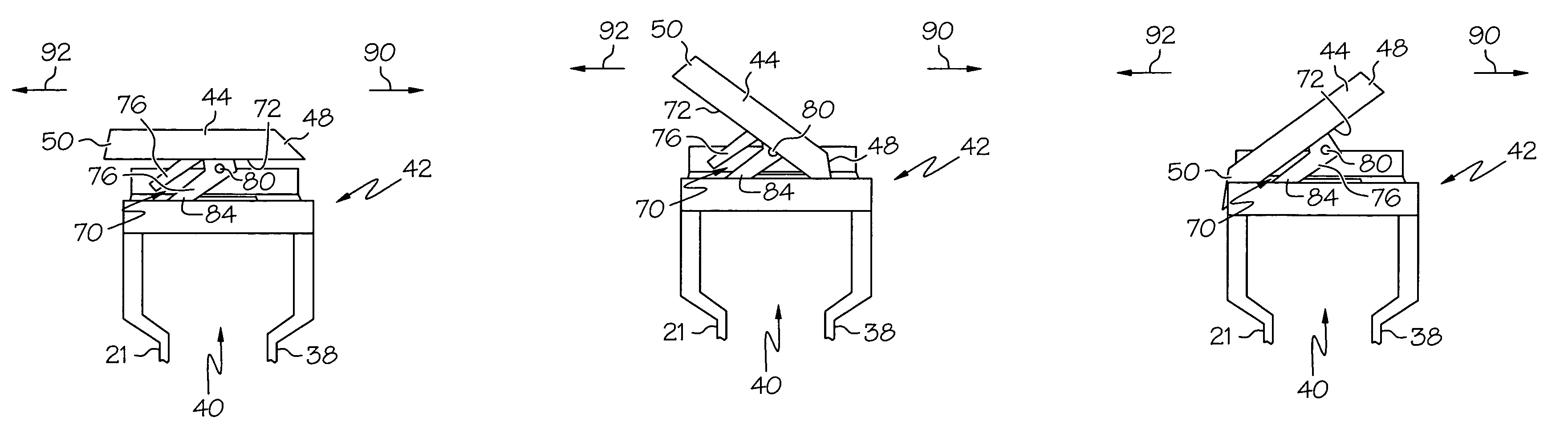

System and method for actively changing an effective flow-through area of an inlet region of an aircraft engine

An active effective flow-through area control system includes an upstream wall-flow perturber and a downstream wall-flow perturber situated in an inlet region of an aircraft engine. The downstream wall-flow perturber is positioned downstream from the upstream wall-flow perturber. The upstream and downstream wall-flow perturbers are configured to generate and trap at least one region of separated, vortical flow in the airflow through the inlet region. A method, for actively changing an effective flow-through area of an inlet region of an aircraft engine, includes creating at least one region of separated, vortical flow in an airflow passage defined by the inlet region. The method further includes trapping the region of separated, vortical flow in the airflow passage. The region of separated, vortical flow partially obstructs a main inlet airflow.

Owner:GENERAL ELECTRIC CO

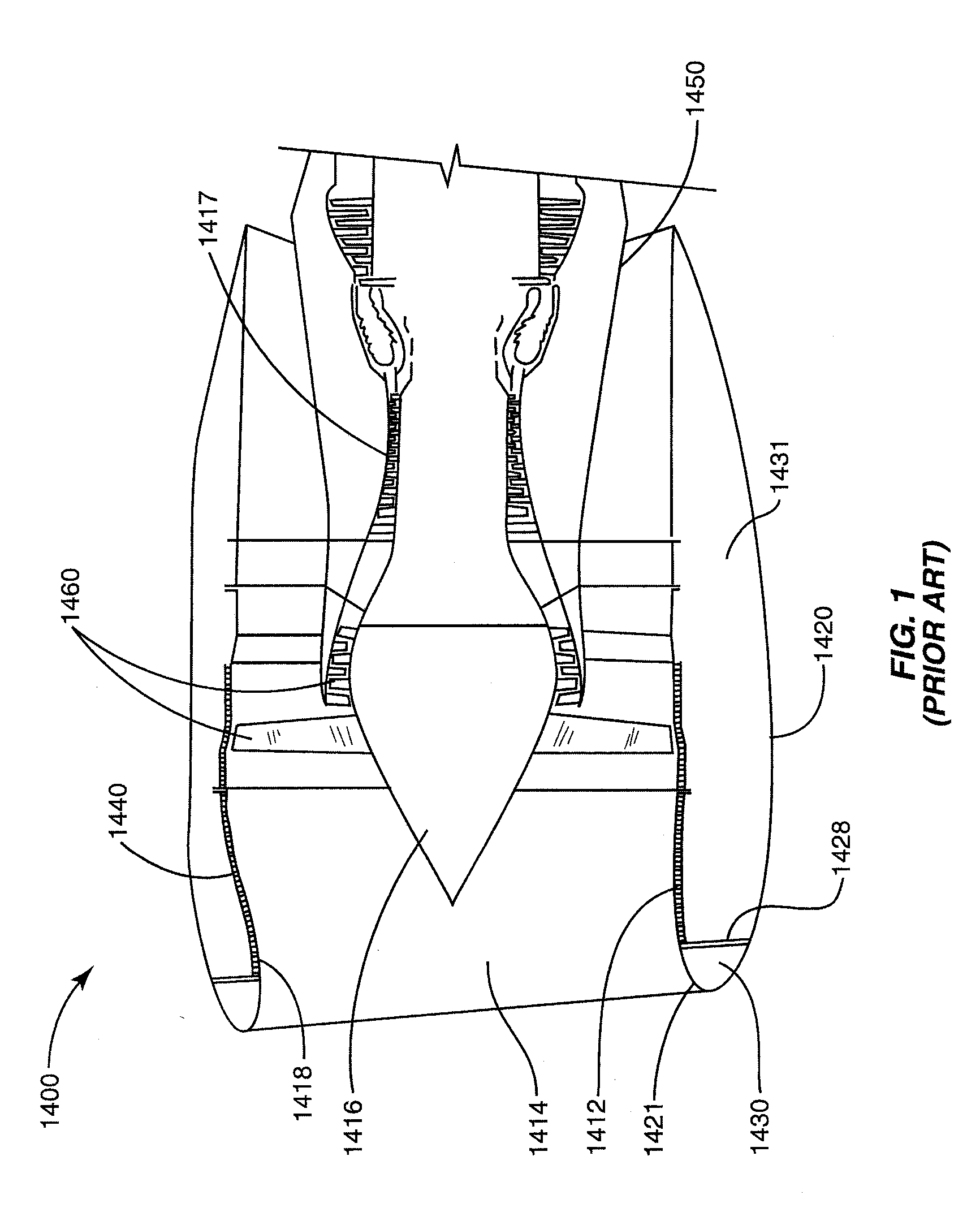

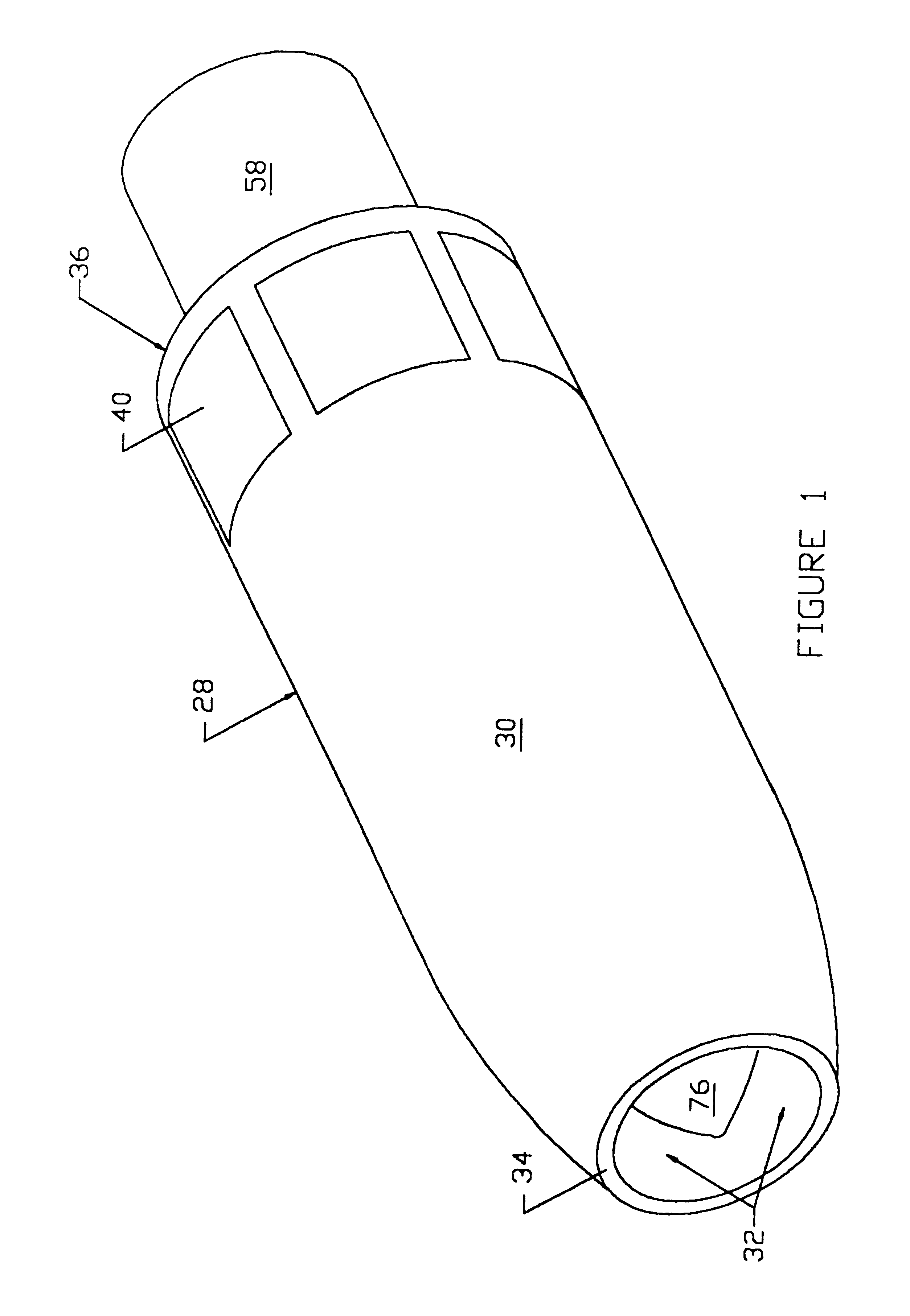

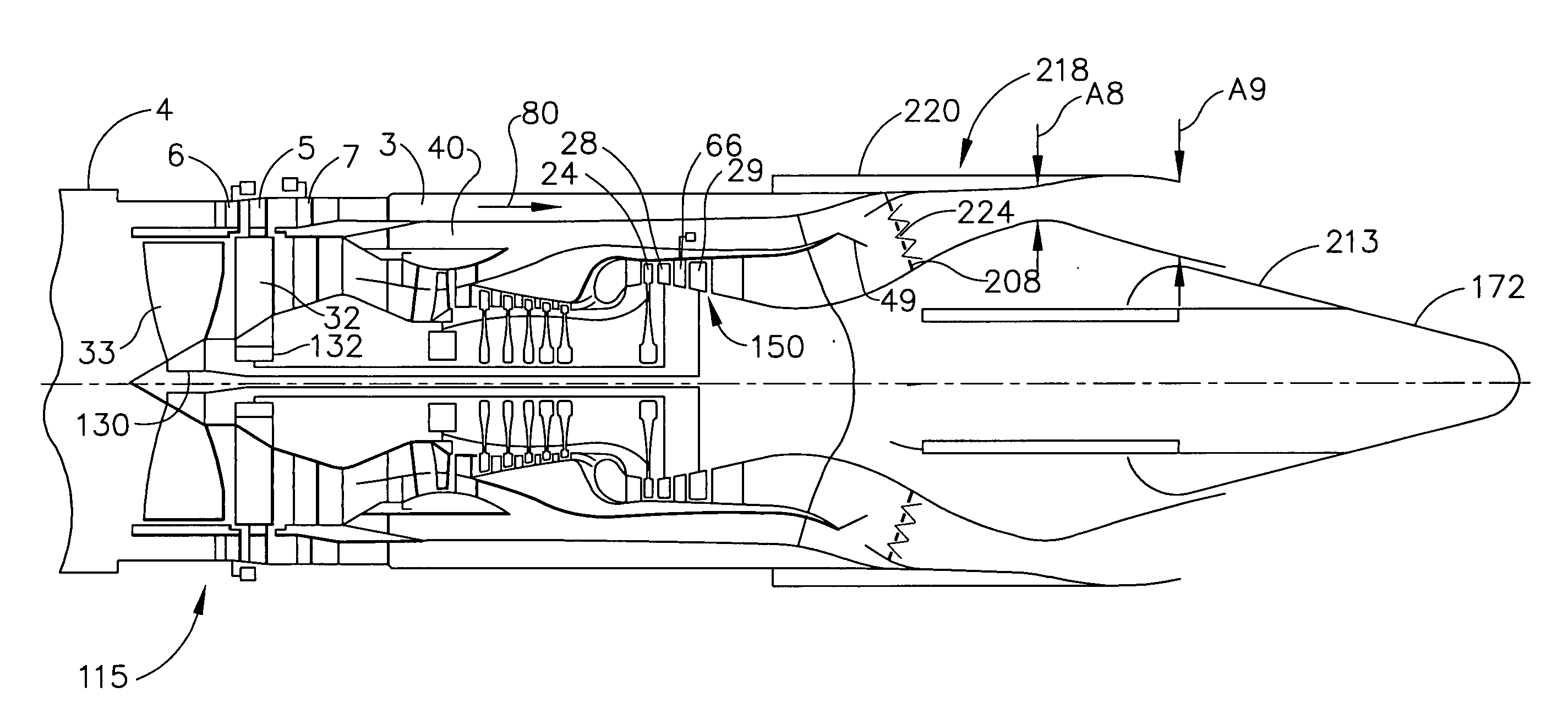

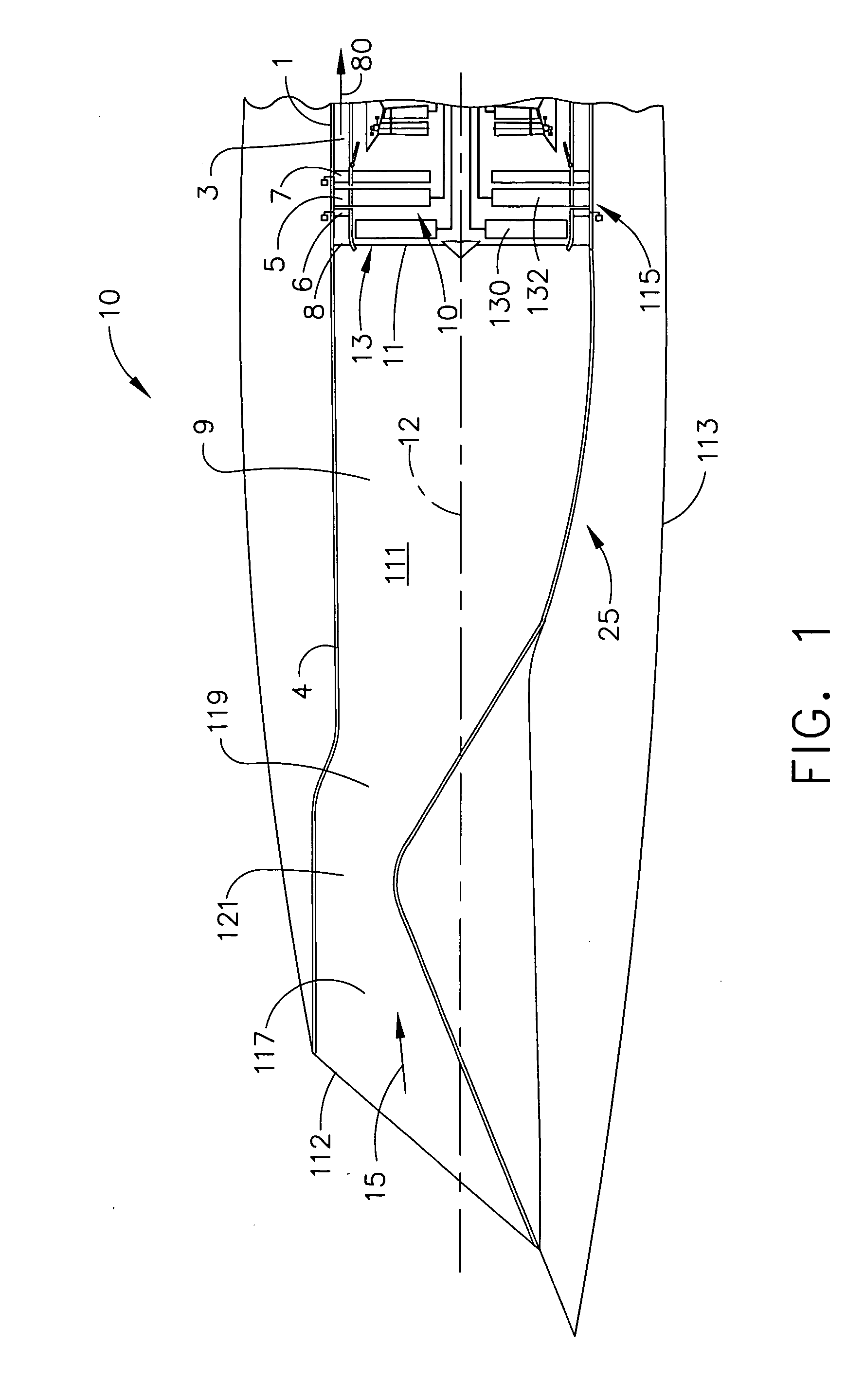

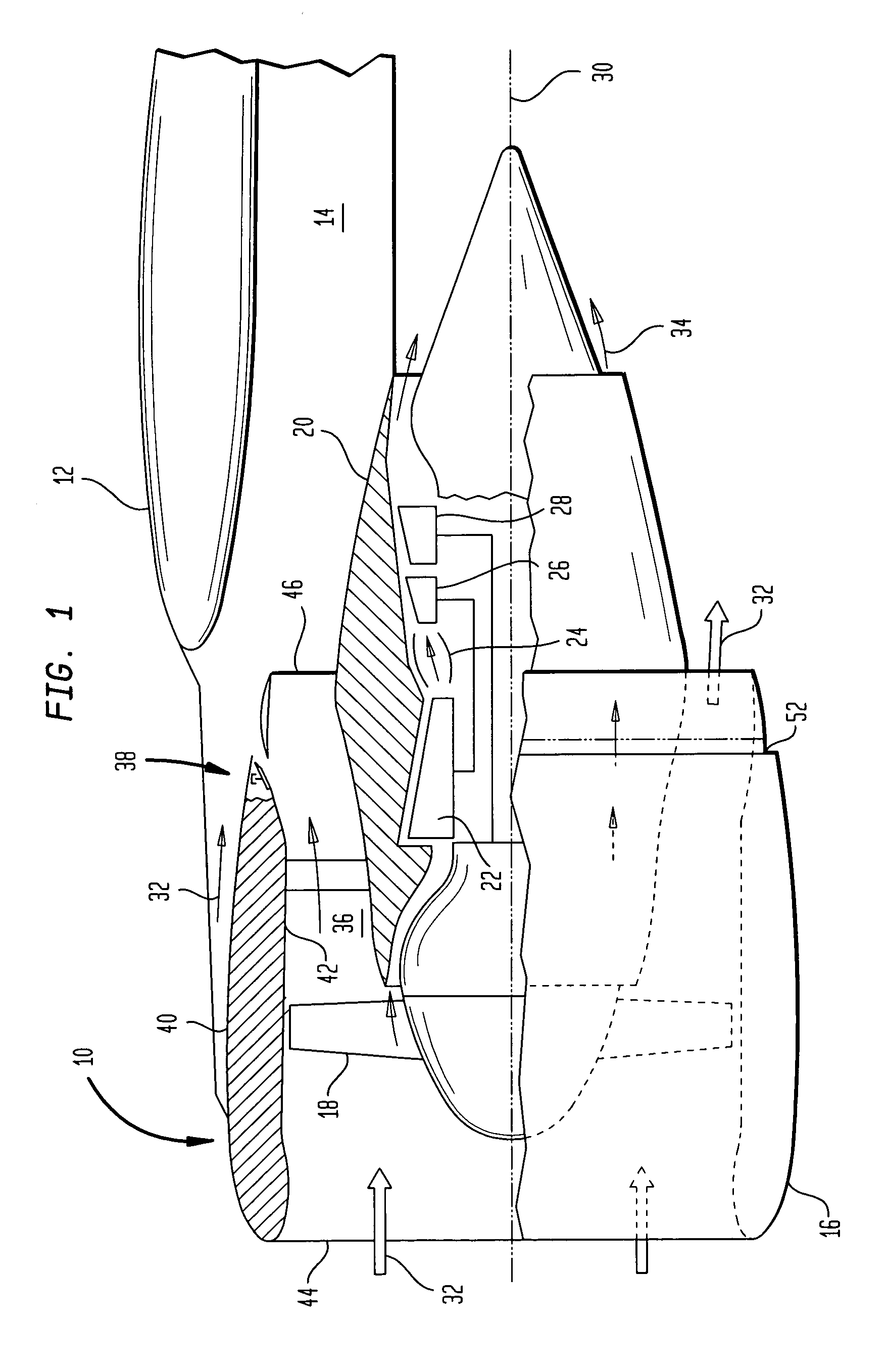

Flade gas turbine engine with fixed geometry inlet

ActiveUS20050081509A1Low costAvoid weightTurbine/propulsion engine coolingTurbine/propulsion air intakesFan bladeGas turbines

An aircraft propulsion system includes a gas turbine engine having a fan section, at least one row of FLADE fan blades disposed radially outwardly of and drivingly connected to the fan section, the row of FLADE fan blades radially extending across a FLADE duct circumscribing the fan section, an engine inlet including a fan inlet to the fan section and an annular FLADE inlet to the FLADE duct. A fixed geometry inlet duct is in direct flow communication with the engine inlet. The fan section may include only a single direction of rotation fan or alternatively axially spaced apart first and second counter-rotatable fans in which the FLADE fan blades are drivingly connected to one of the first and second counter-rotatable fans. The row of FLADE fan blades may be disposed between rows of variable first and second FLADE vanes.

Owner:GENERAL ELECTRIC CO

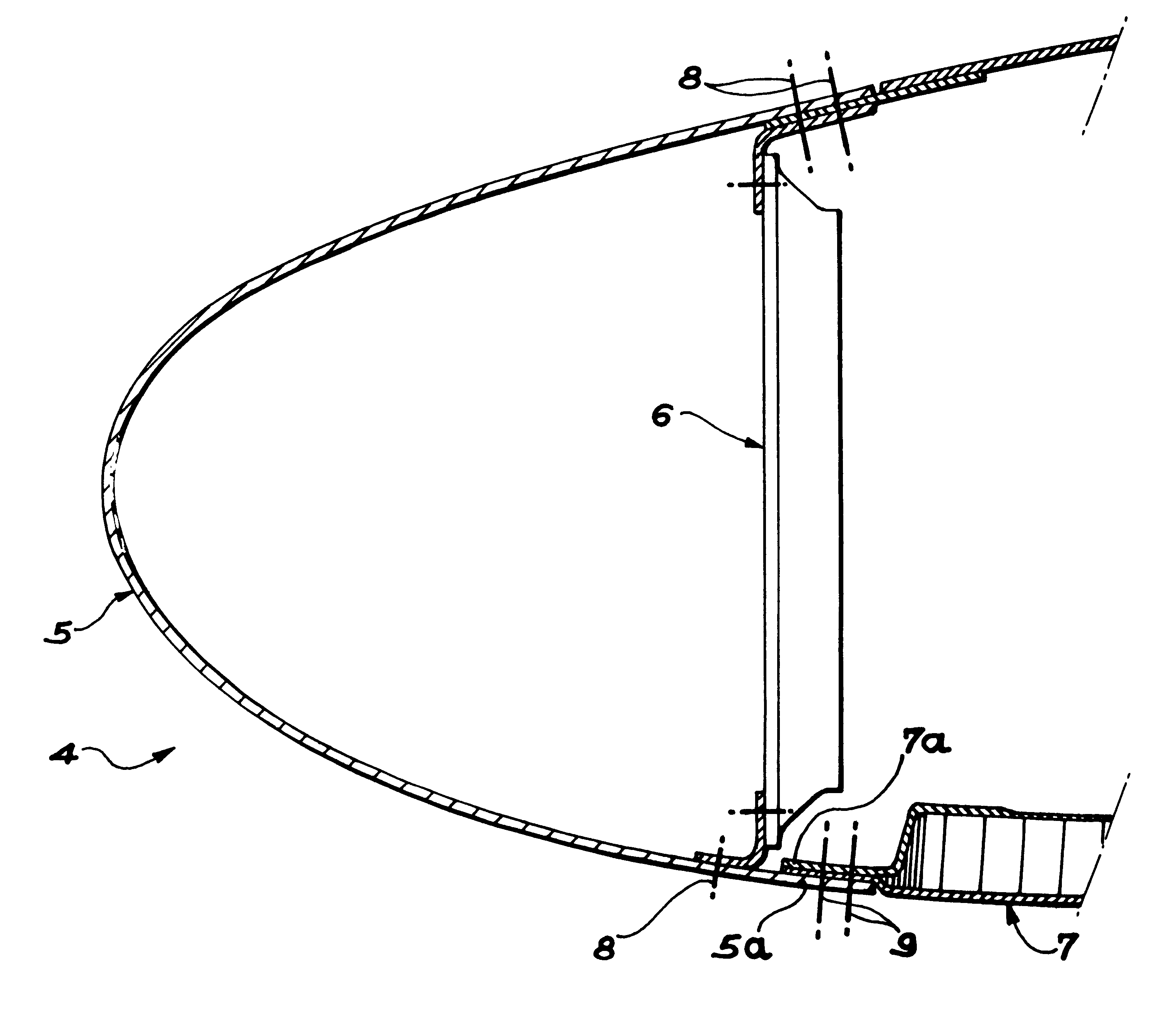

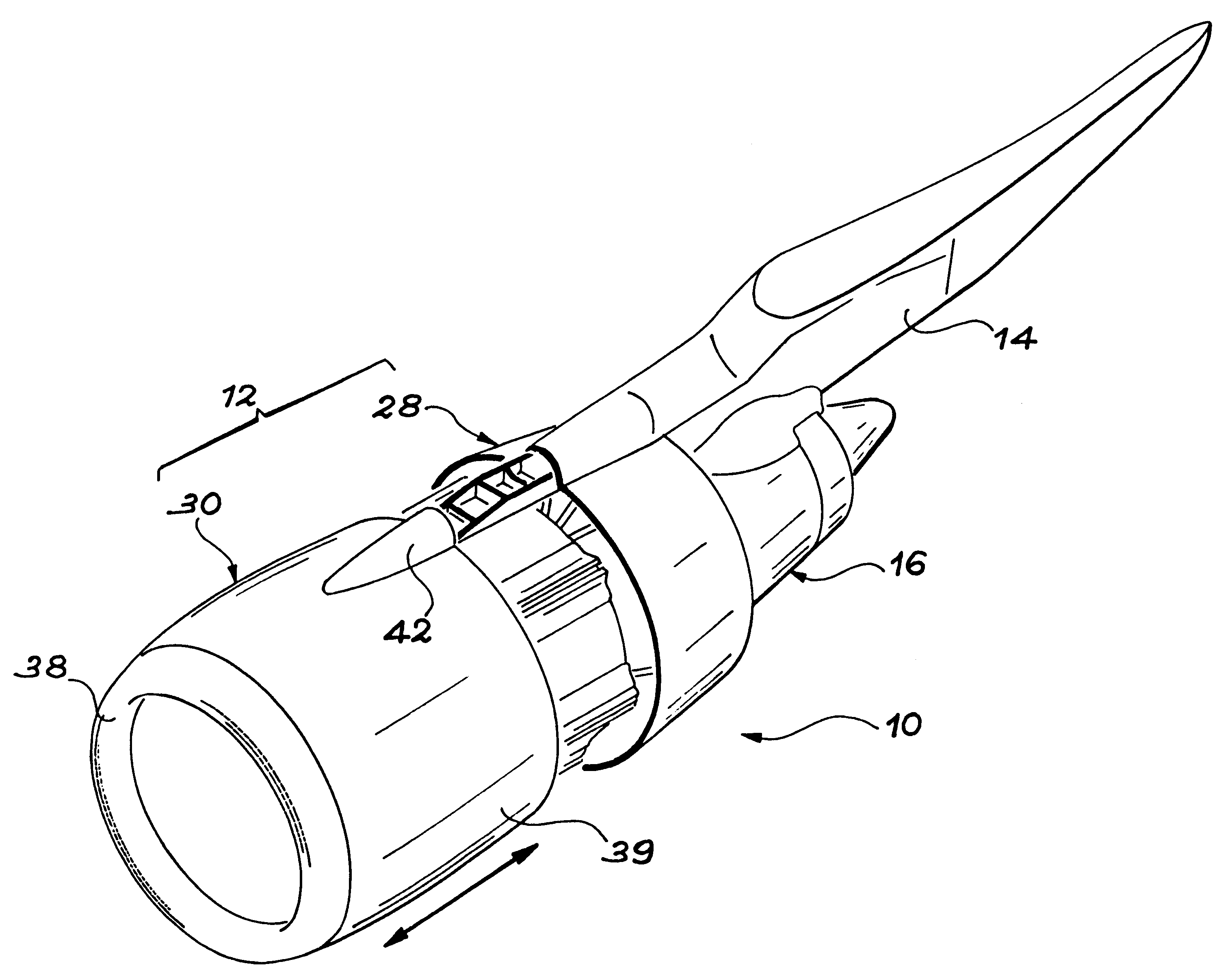

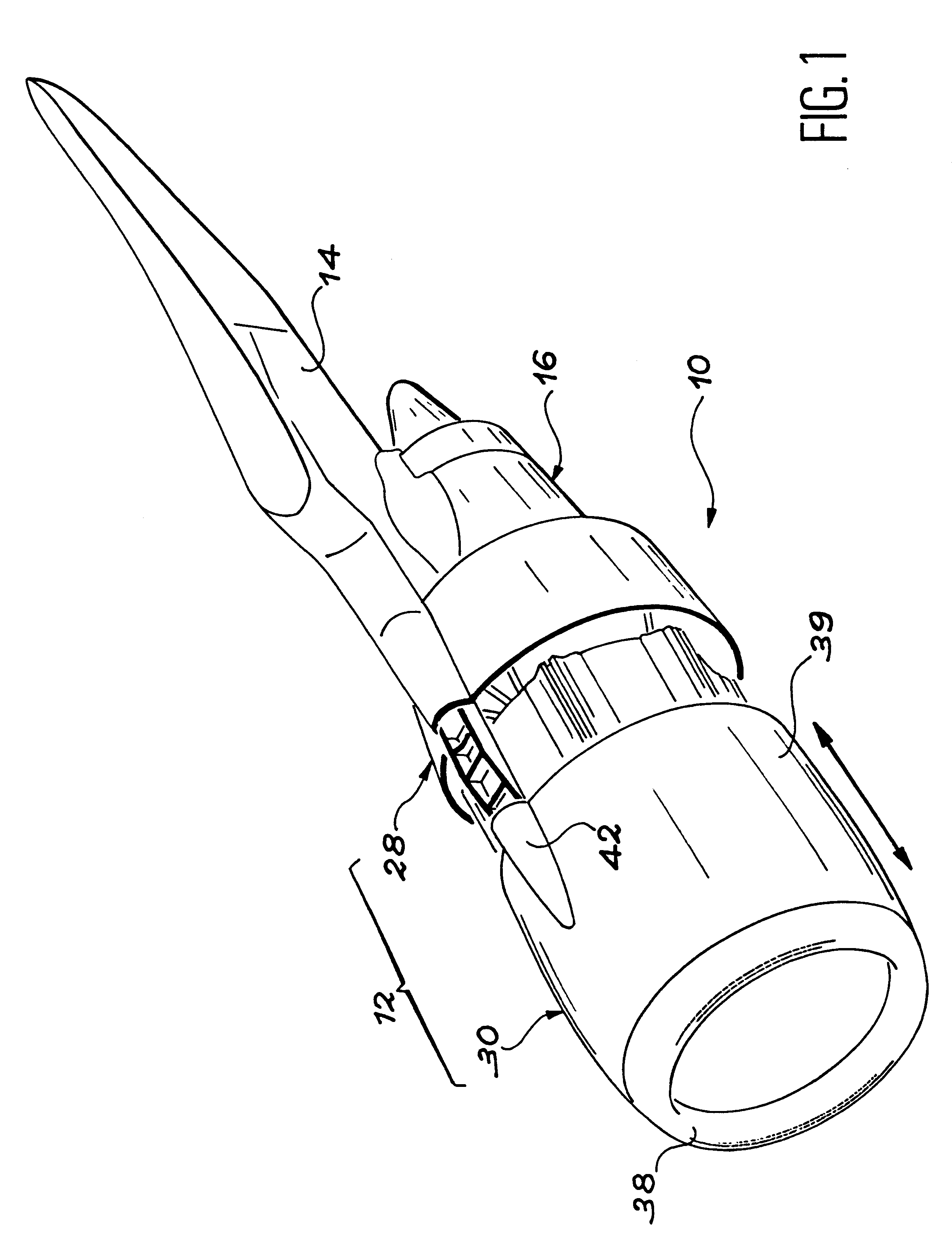

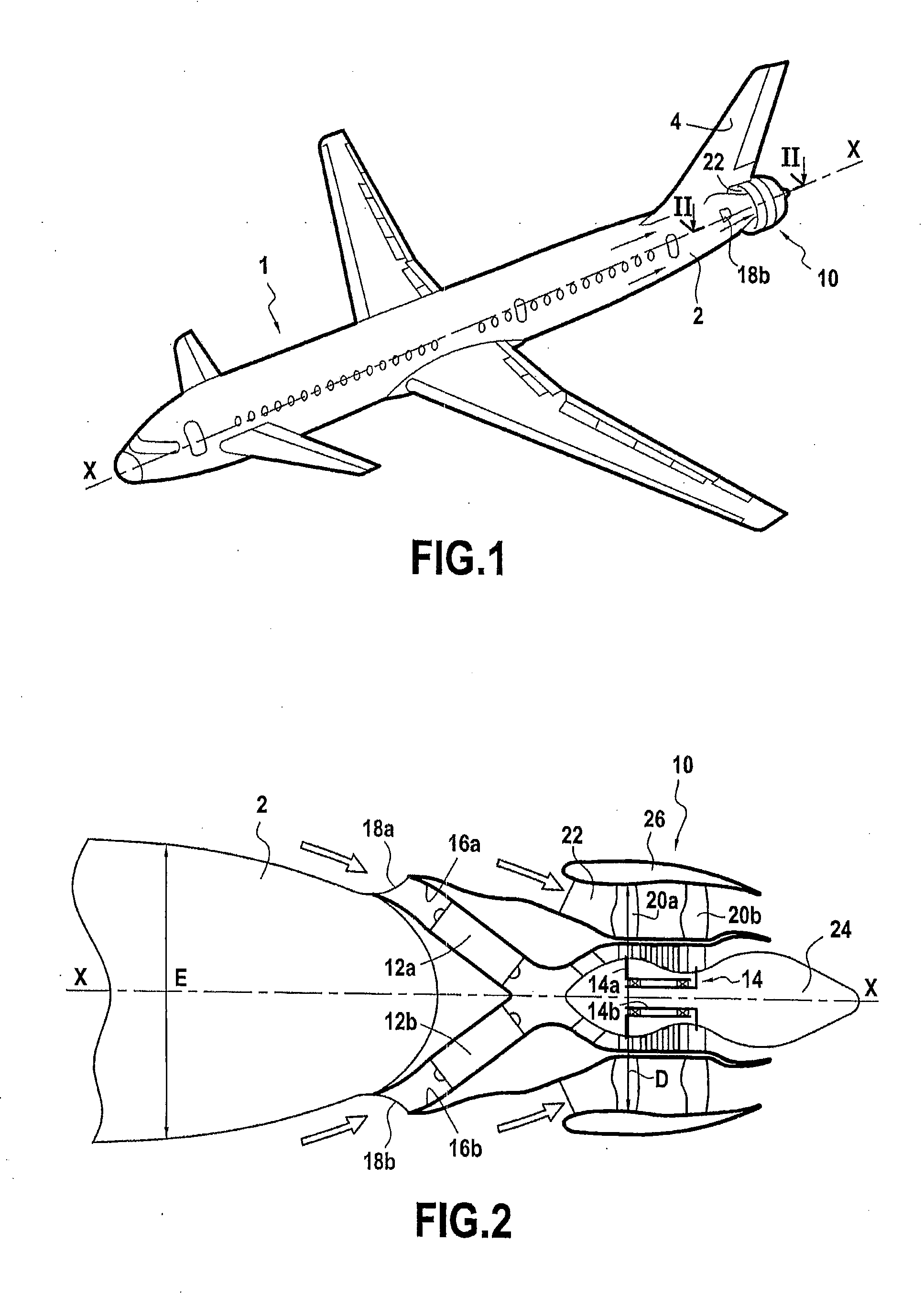

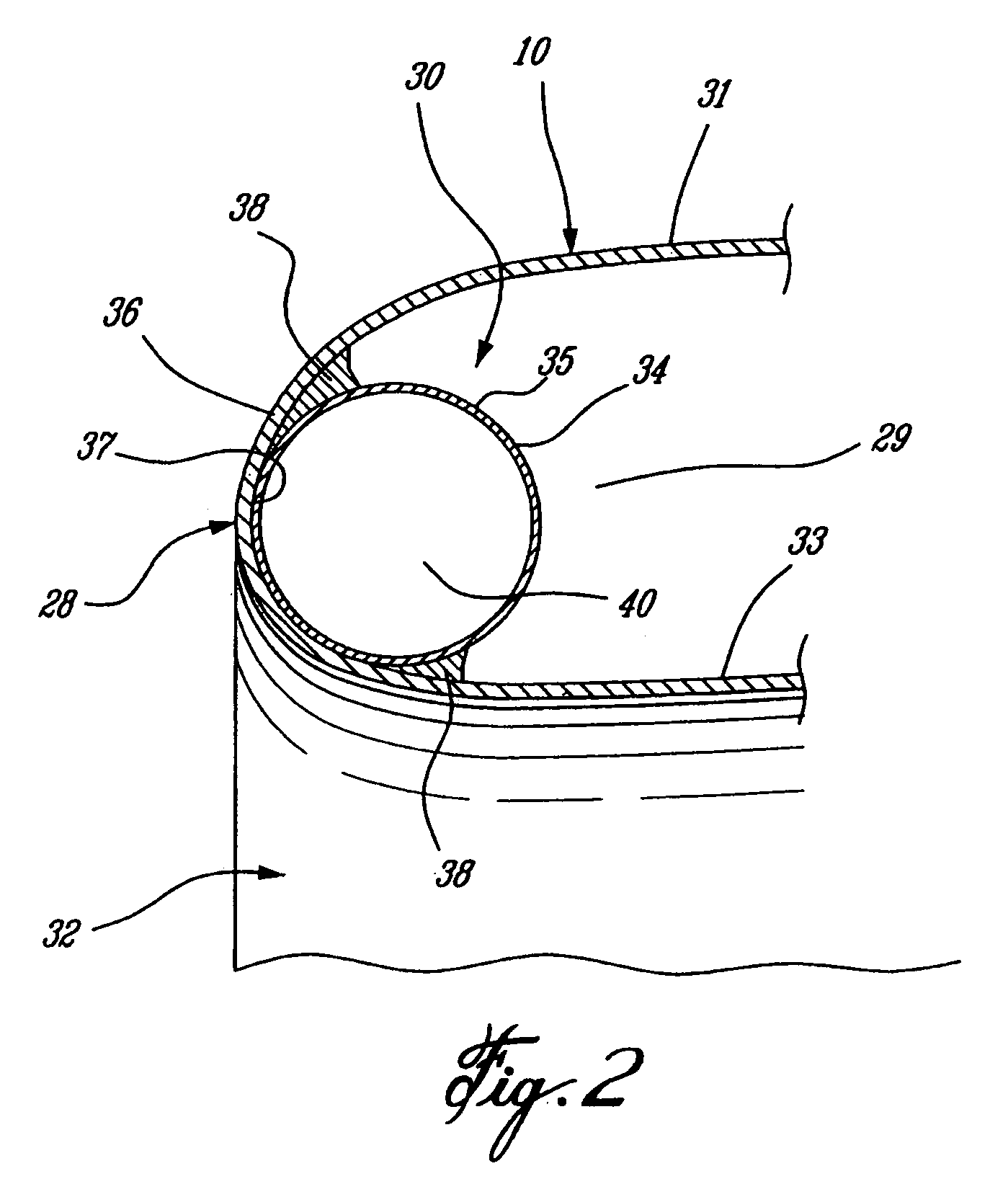

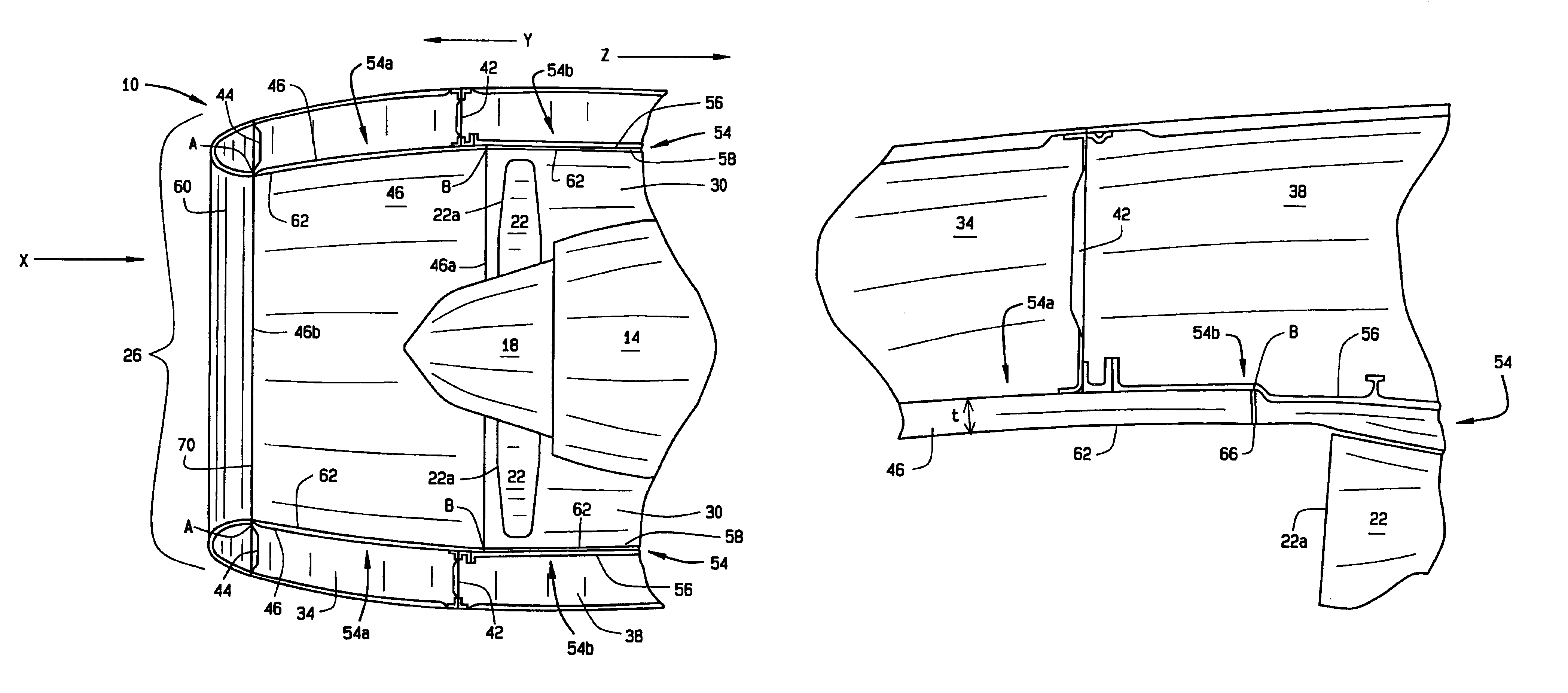

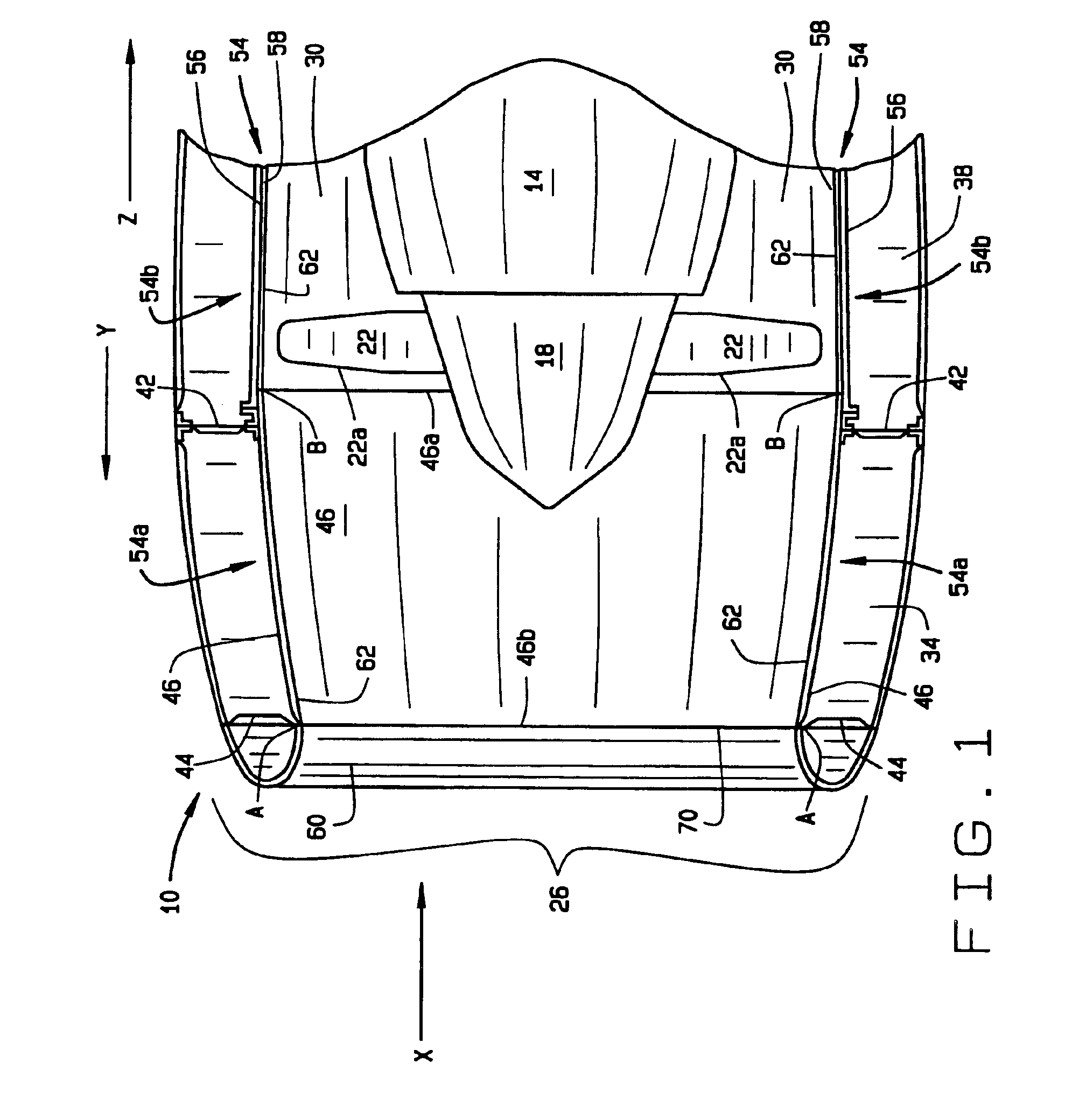

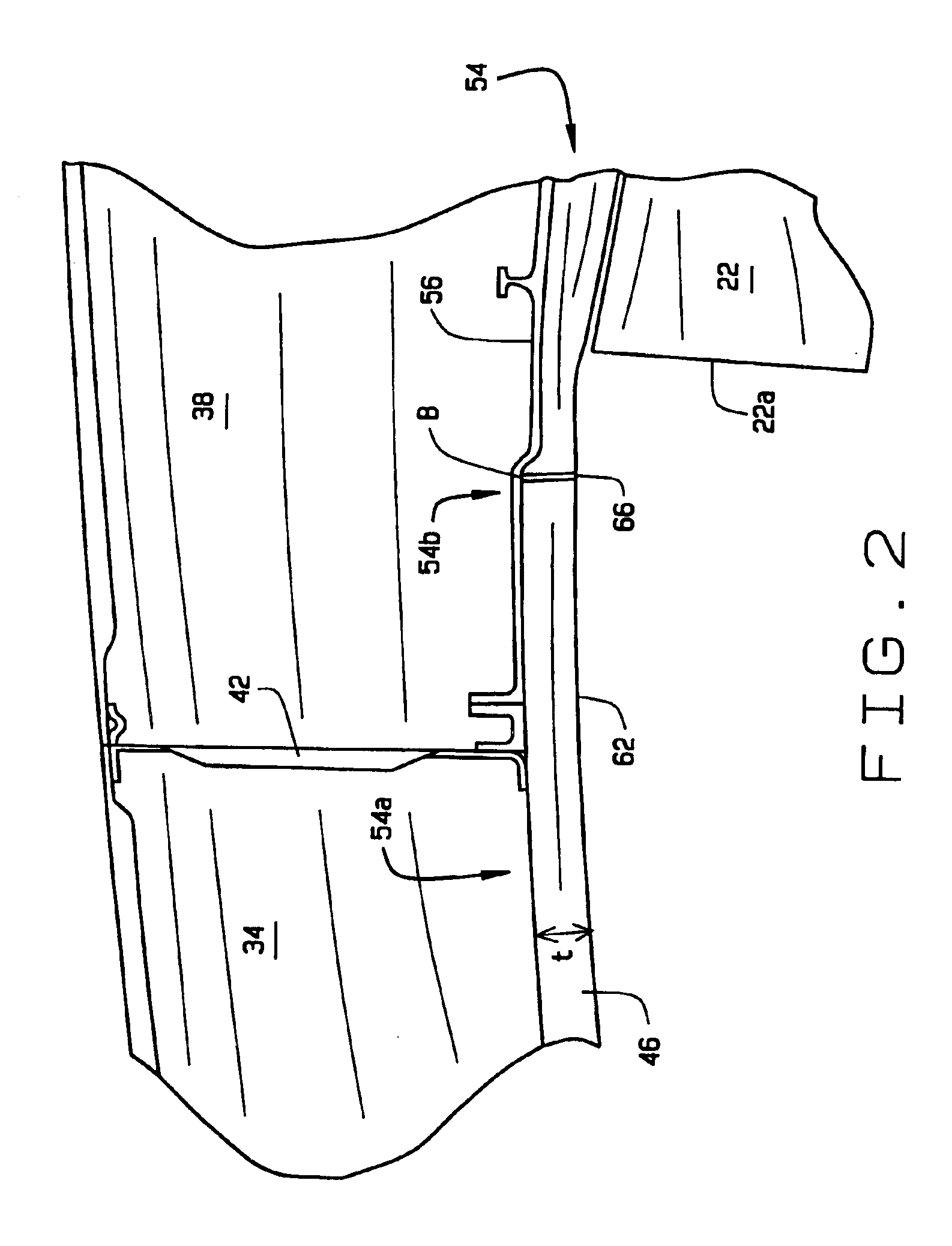

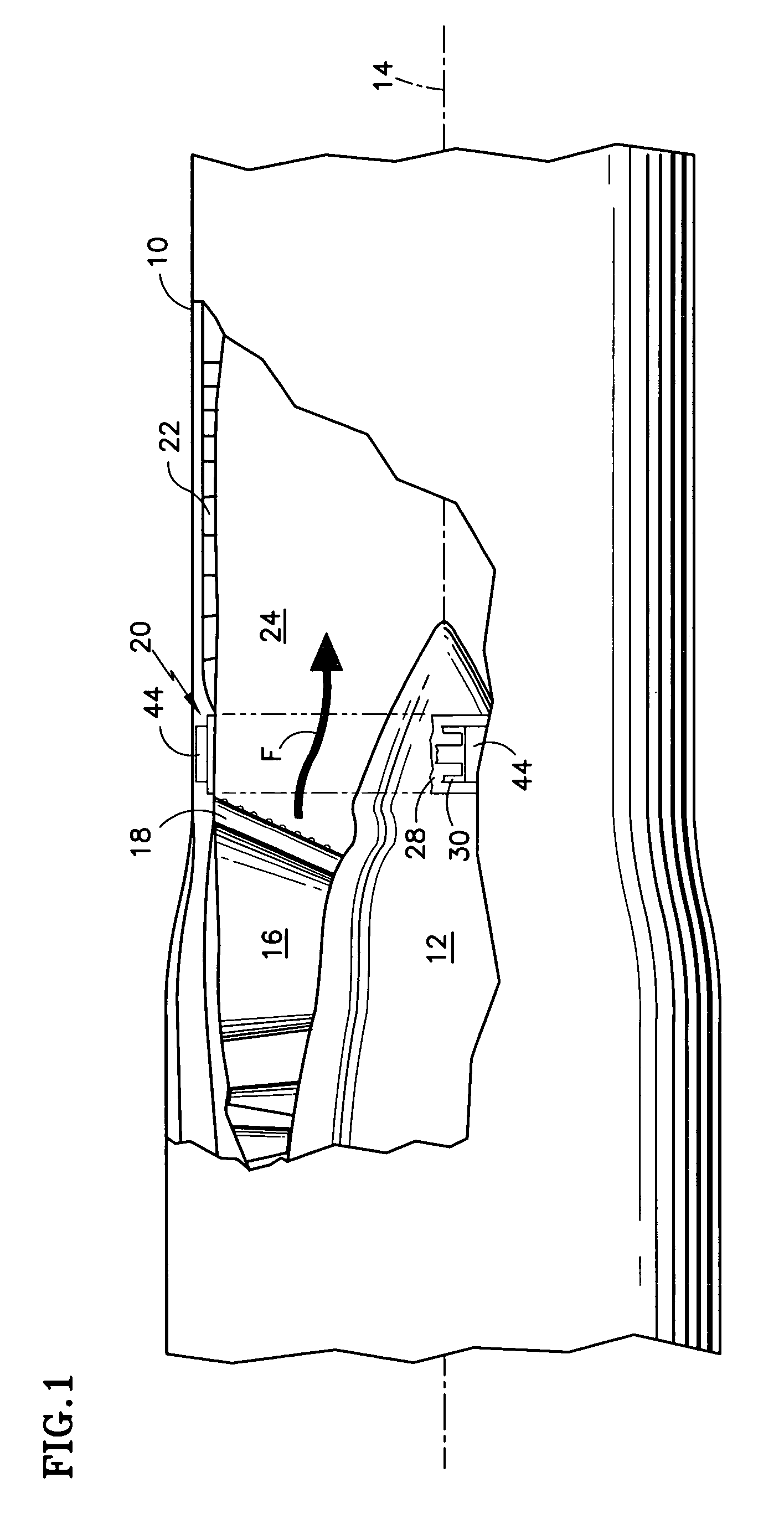

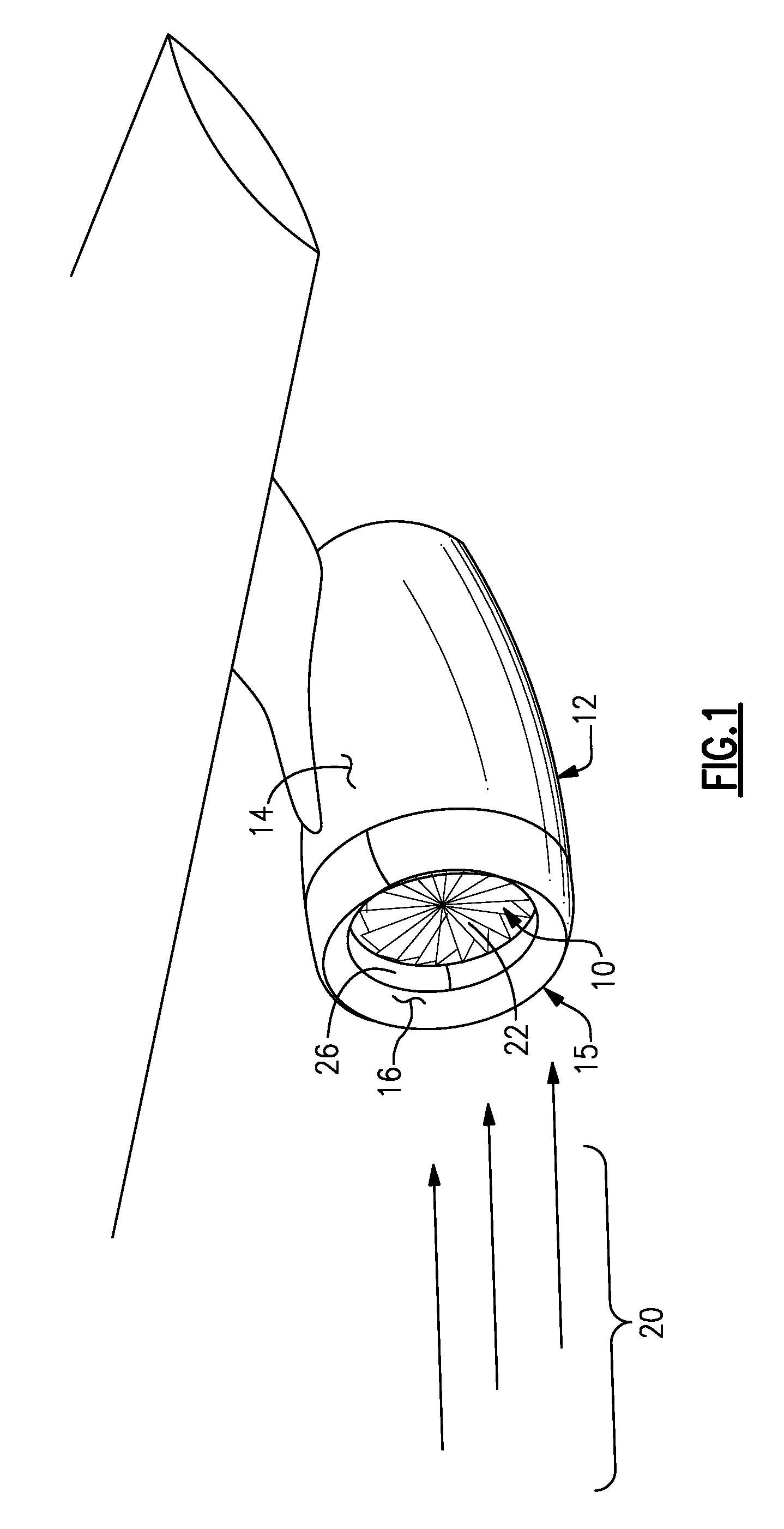

Turbojet pod with laminar flow

InactiveUS6179249B1Good aerodynamic shapeKeep shapeAircraft power plant componentsDe-icing equipmentsEngineeringTurbojet

The bay (12) of a turbofan engine (10) comprises a front structural element (30), whose external surface is continuous and extends over at least 50% of the geometrical chord of the bay. Said element (30) is installed on maintaining and guiding members (44), such as slides, which prevent a significant deformation in flight and allow a sliding to the front of the element (30) for maintenance purposes. A laminar air flow around the front half of the bay (12) is consequently ensured.

Owner:SOC NATIONALE INDUSTRIELLE AEROSPATIALE SA

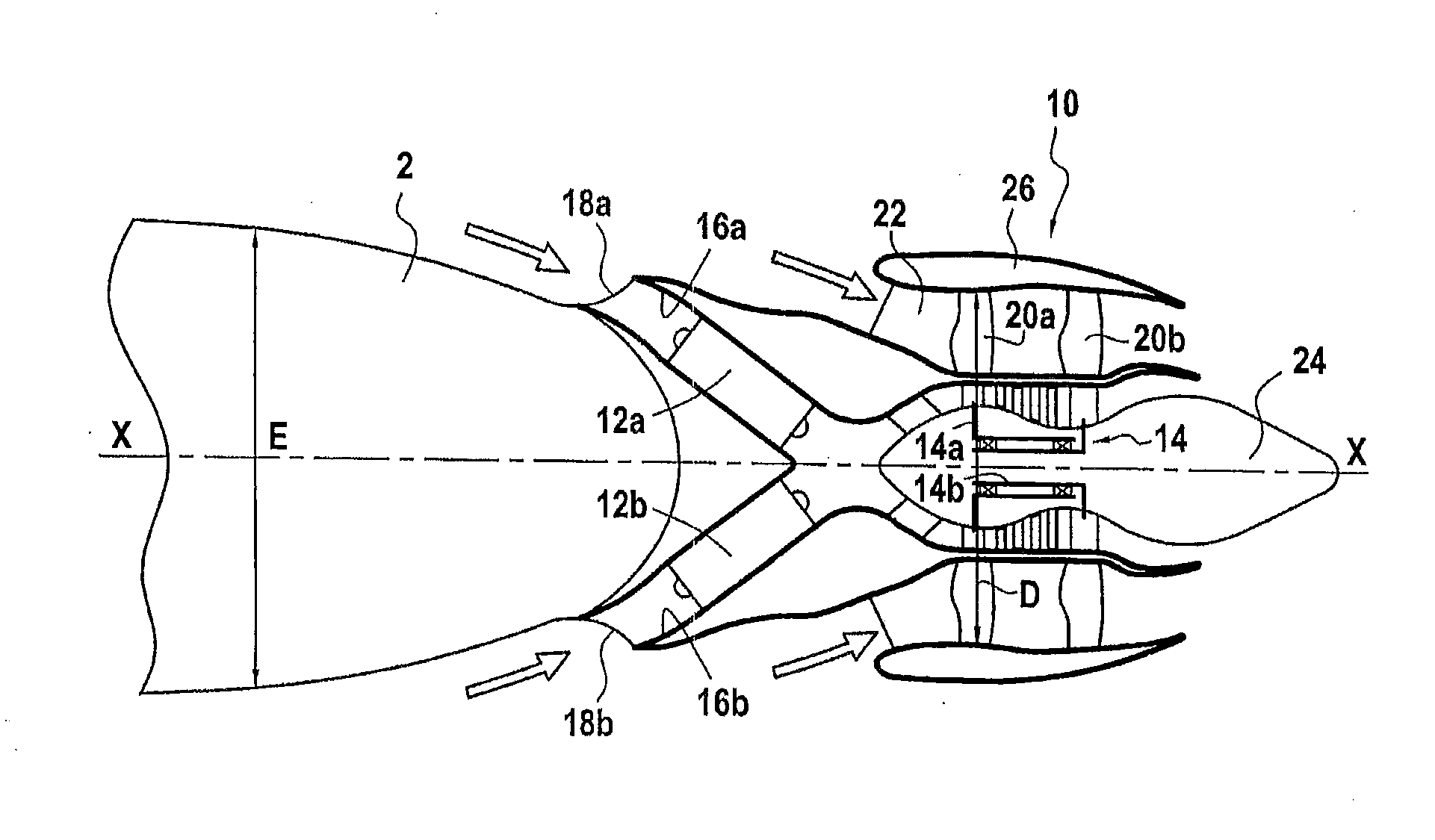

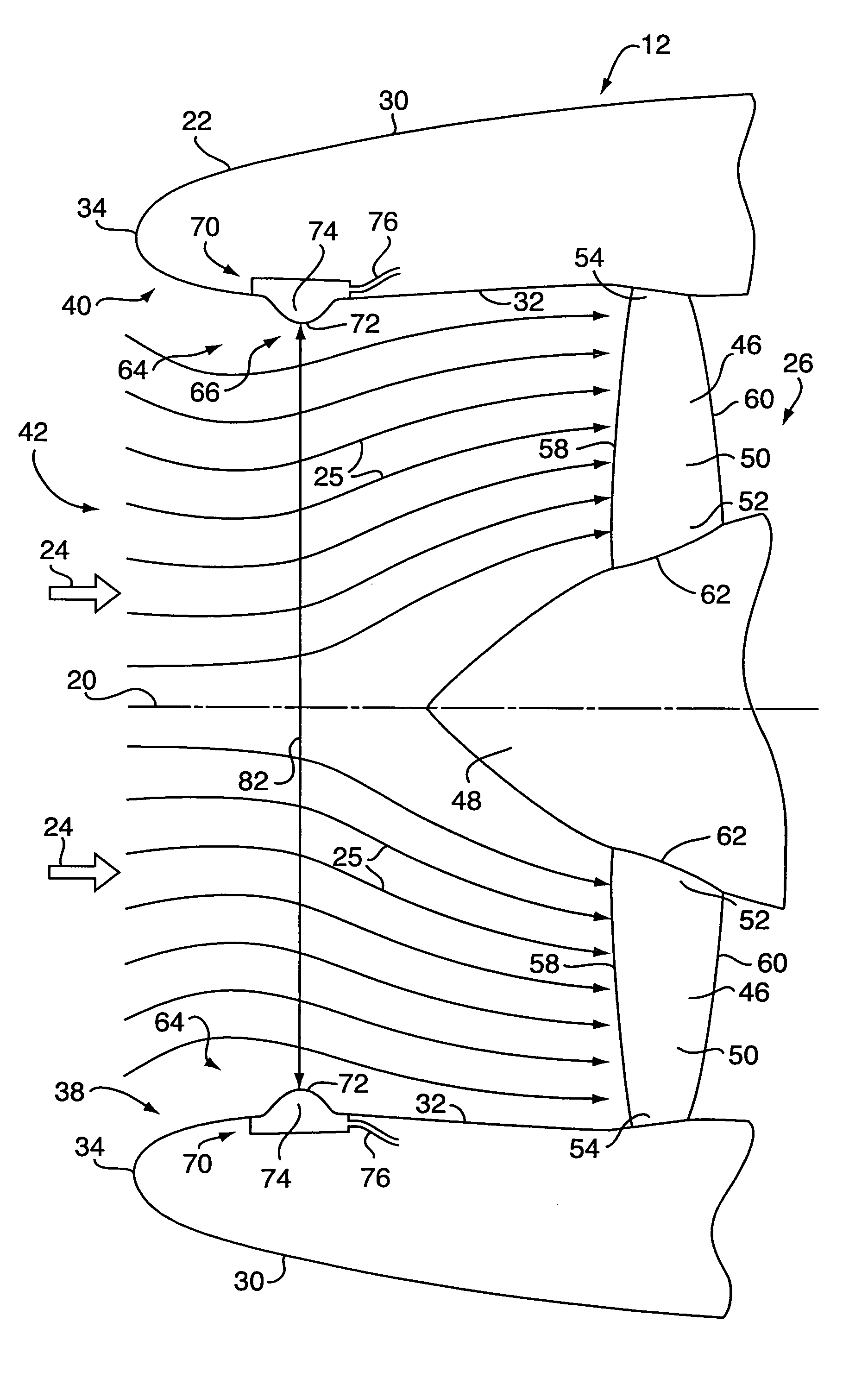

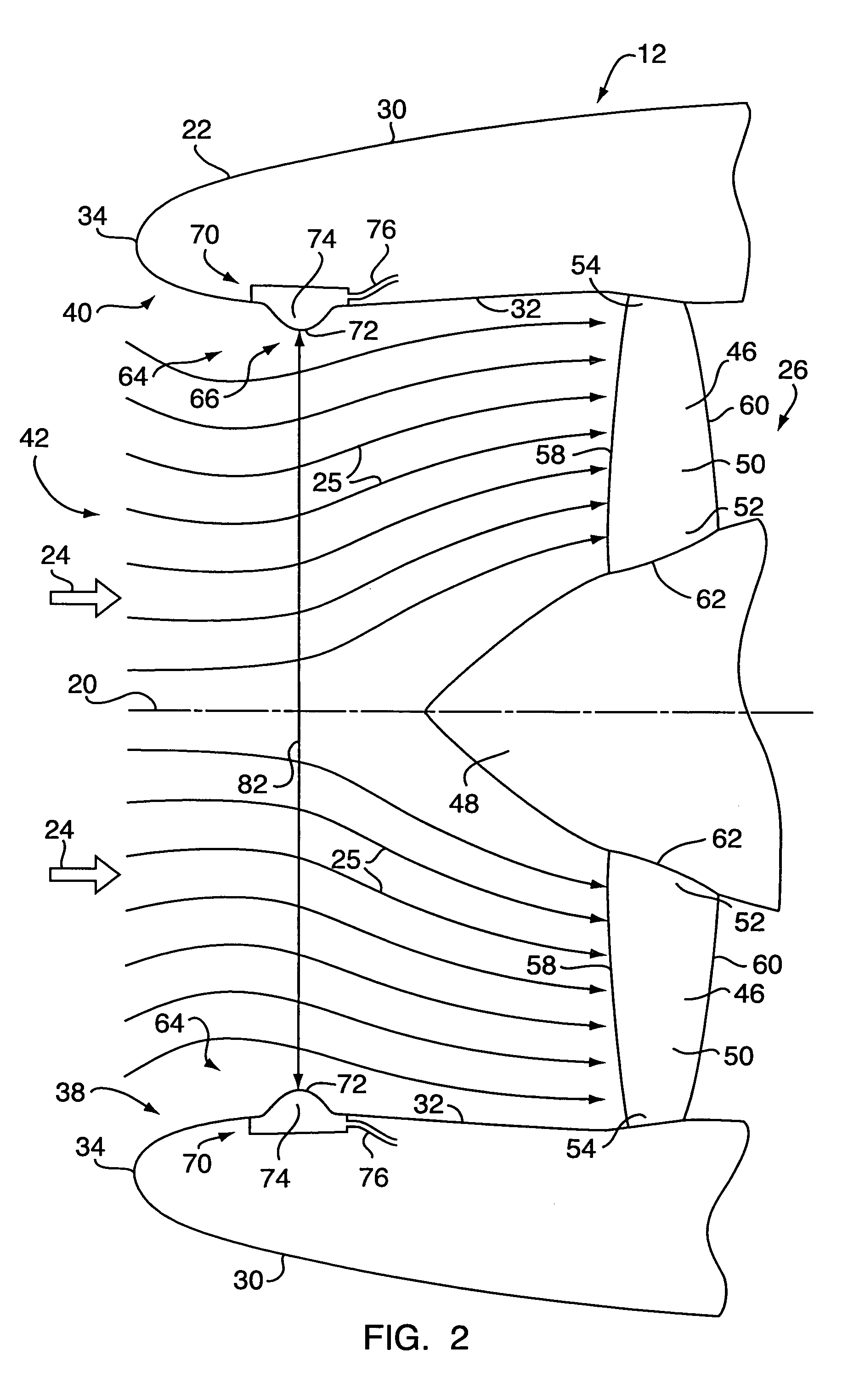

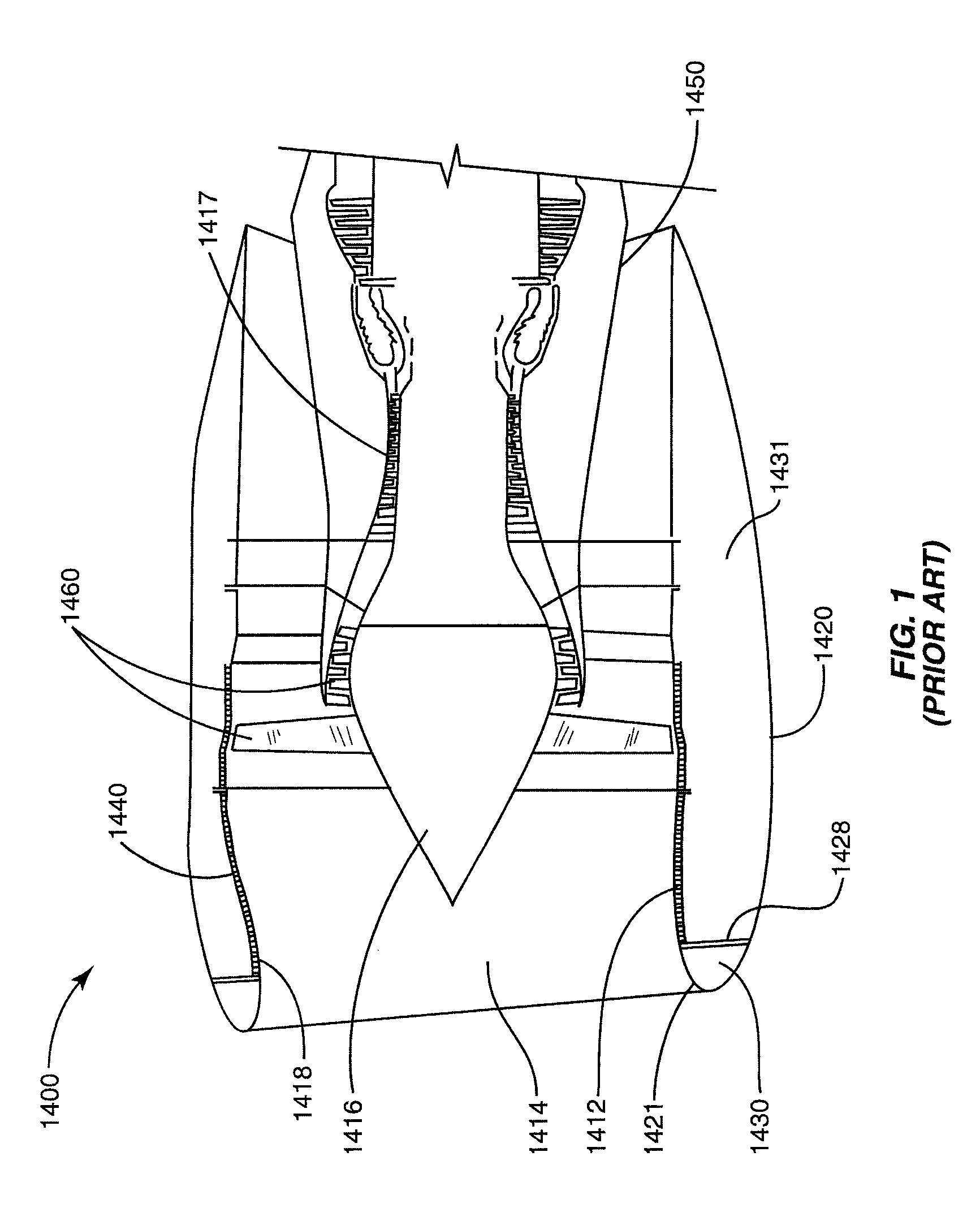

Aircraft propelled by a turbojet engine with contrarotating fans

ActiveUS20150291285A1Reduce fuel consumptionLimiting aerodynamic dragGas turbine type power plantsCombination enginesJet aeroplaneFuselage

An aircraft propelled by a turbojet having contrarotating fans, the turbojet being incorporated at the rear of a fuselage of the aircraft and in line therewith and including two gas generators that feed a working turbine having two contrarotating turbine rotors for driving two fans arranged downstream from the gas generators, and distinct air intakes for feeding each gas generator, the air intakes being connected to the fuselage of the aircraft so as to take in at least a portion of the boundary layer formed around the fuselage of the aircraft.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

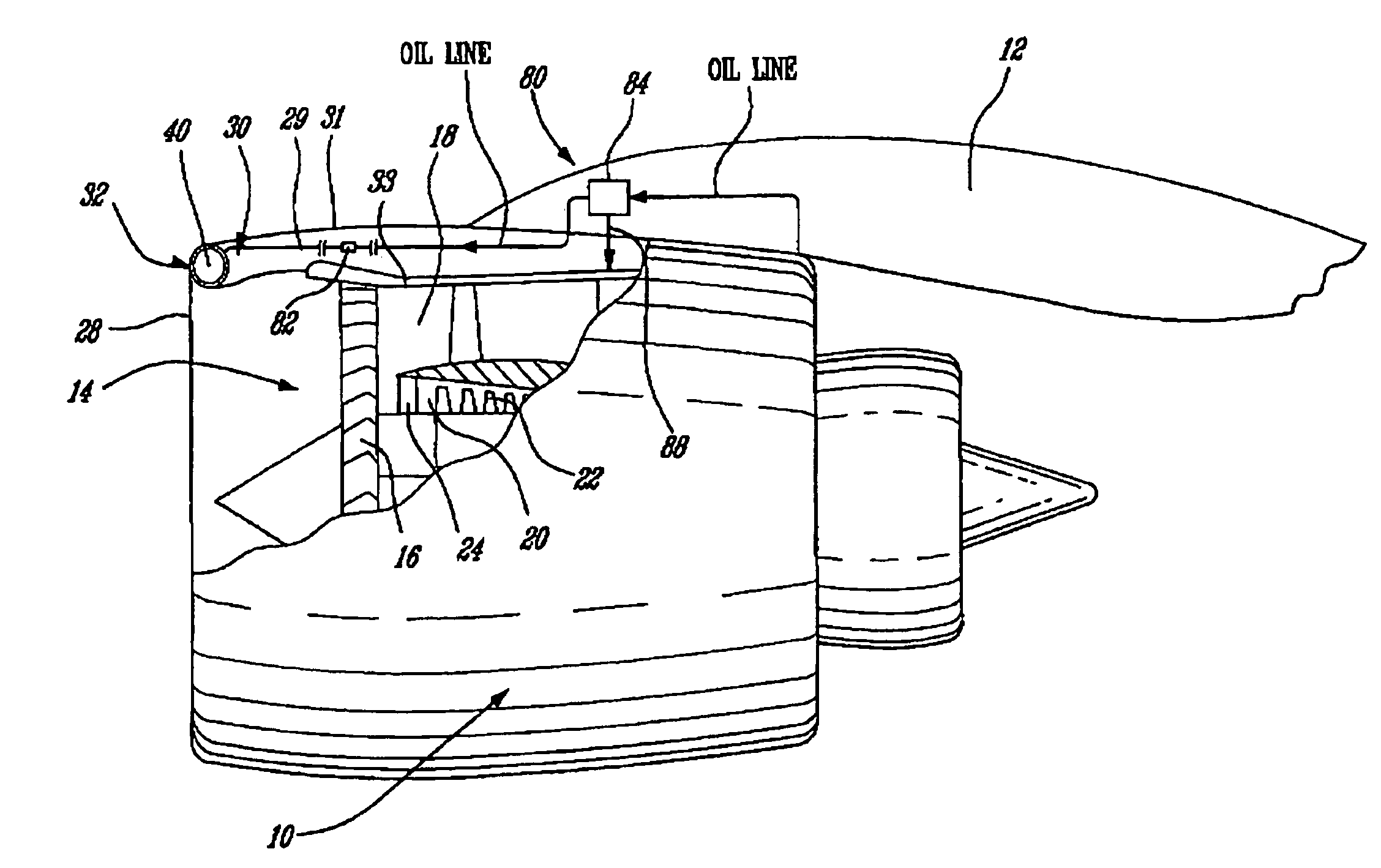

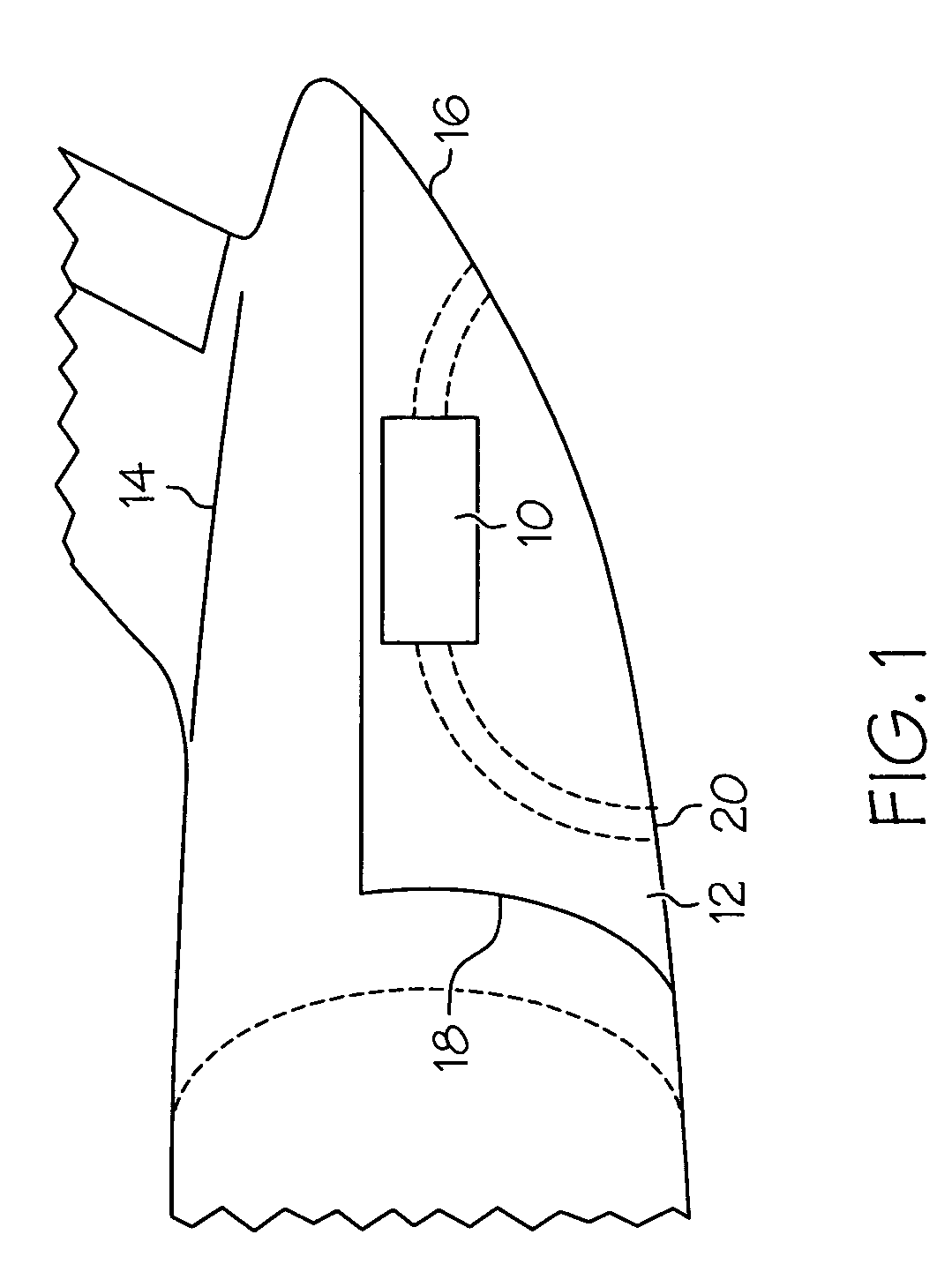

Nacelle inlet lip anti-icing with engine oil

InactiveUS7131612B2Inhibition formationPrevent freezingTurbine/propulsion engine coolingDe-icing equipmentsLeading edgeNacelle

A nacelle for housing a gas turbine engine having a pressurized oil system for lubricating components thereof comprises an inlet lip defining a leading edge of the nacelle, the inlet lip having a conduit therein in fluid flow communication with the pressurized oil system of the gas turbine engine and defining an oil passage for circulation of pressurized engine oil therethrough. The conduit is in heat transfer communication with an outer surface of the inlet lip.

Owner:PRATT & WHITNEY CANADA CORP

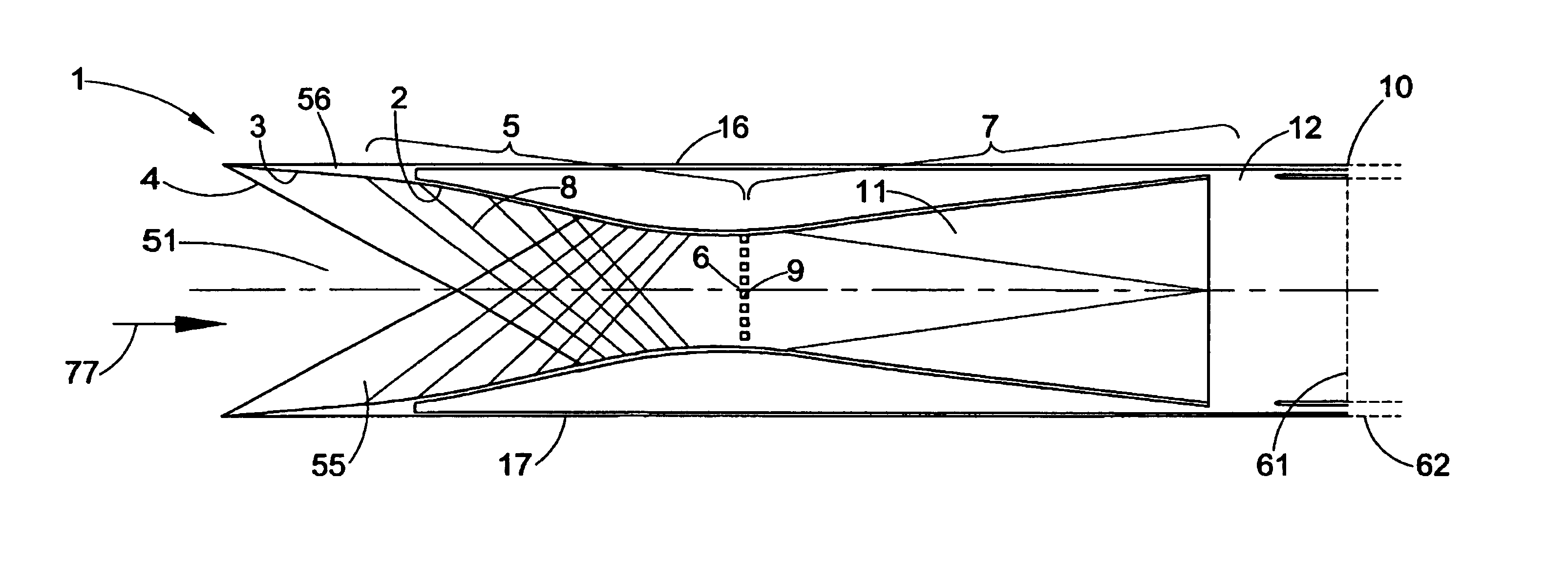

Low sonic boom inlet for supersonic aircraft

InactiveUS7048229B2Improve performanceLarge operability marginCombustion enginesEfficient propulsion technologiesThroatNacelle

All-internal compression inlets for supersonic aircraft, with variable geometry systems and shock stability bleed systems provide high performance, large operability margins, i.e. terminal shock stability that reduces the probability of inlet unstart, and contribute little or nothing to the overall sonic boom signature of the aircraft. These inlets have very high internal area contraction or compression and very low external surface angles. All shocks from the internal inlet surfaces are captured and reflected inside the inlet duct, and all of the external nacelle surfaces are substantially aligned with the external airflow. The inlet shock stability system consists of bleed regions that duct bleed airflows to variable area exits with passive or active exit area controls. This reduces the risk of inlet unstarts by removing airflow through a large open throat bleed region to compensate for reductions in diffuser (engine) corrected airflow demand. Because the stability bleed is not removed until the inlet terminal shock moves upstream over the bleed region, the necessary normal shock operability margin is provided without compromising inlet performance (total pressure recovery, and distortion).

Owner:TECHLAND RES

Gas turbine engine inlet with noise reduction features

InactiveUS20050274103A1Increase acoustic attenuationReducing inlet areaCombustion enginesGas turbine plantsNacelleCombustor

A gas turbine engine comprising a fan section, a compressor, a combustor and a turbine, includes a nacelle having an inner nacelle surface defining an inlet duct designed to reduce an inlet duct area of the inlet duct to increase acoustic attenuation. The gas turbine engine also includes a spinner, disposed forward of the fan section, that includes features to increase acoustic attenuation. In one embodiment of the present invention, the nacelle includes a nacelle contoured surface protruding radially inward from the inner nacelle surface to reduce the inlet duct area. In a further embodiment of the present invention, the spinner includes a spinner contoured surface for reducing the inlet duct area. In other embodiments, the nacelle and / or the spinner include an inflatable bladder, a SMA actuator, a fluidic actuator, or a combination thereof, selectively activated to increase acoustic attenuation during certain conditions of an aircraft.

Owner:UNITED TECH CORP

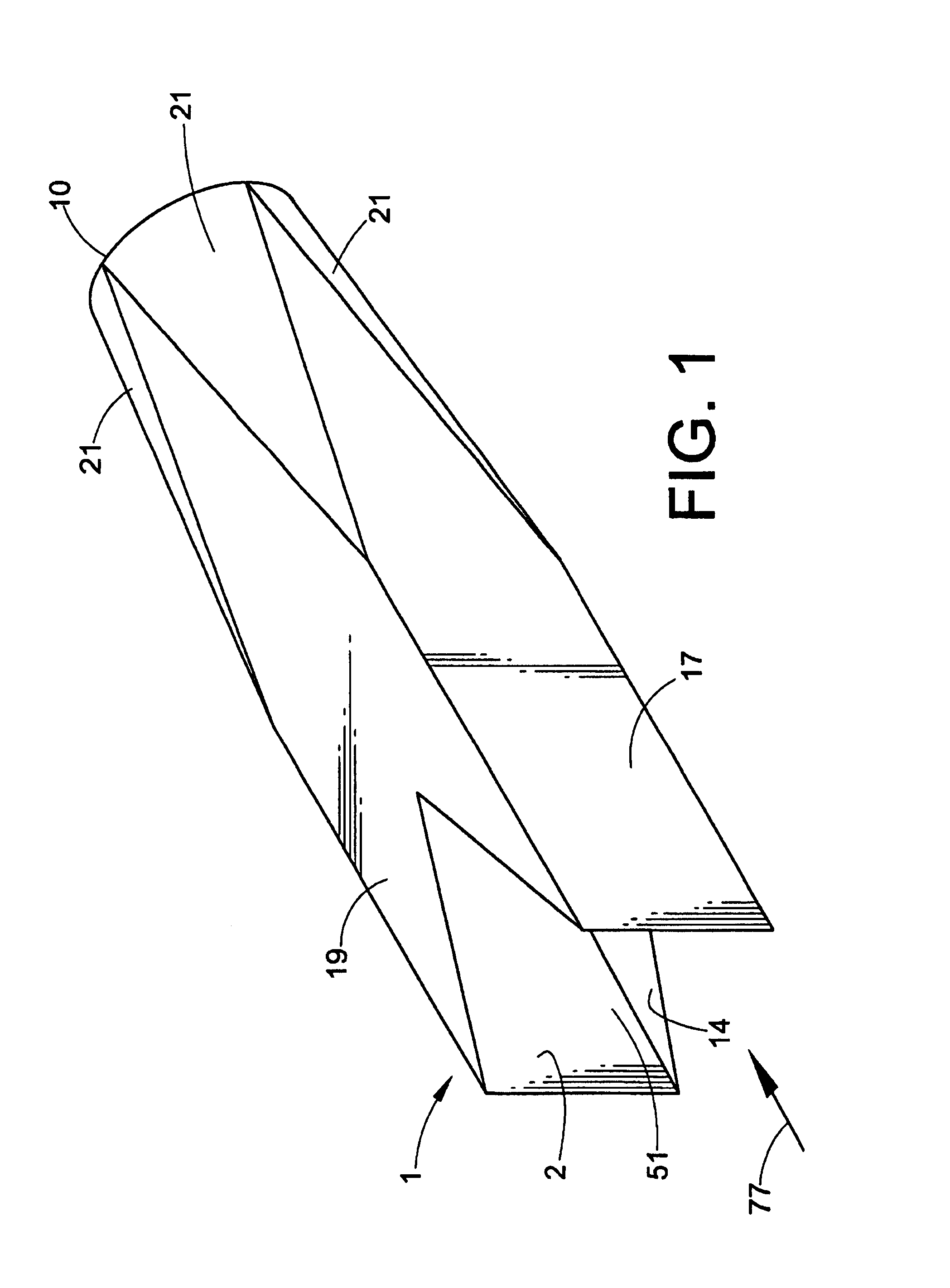

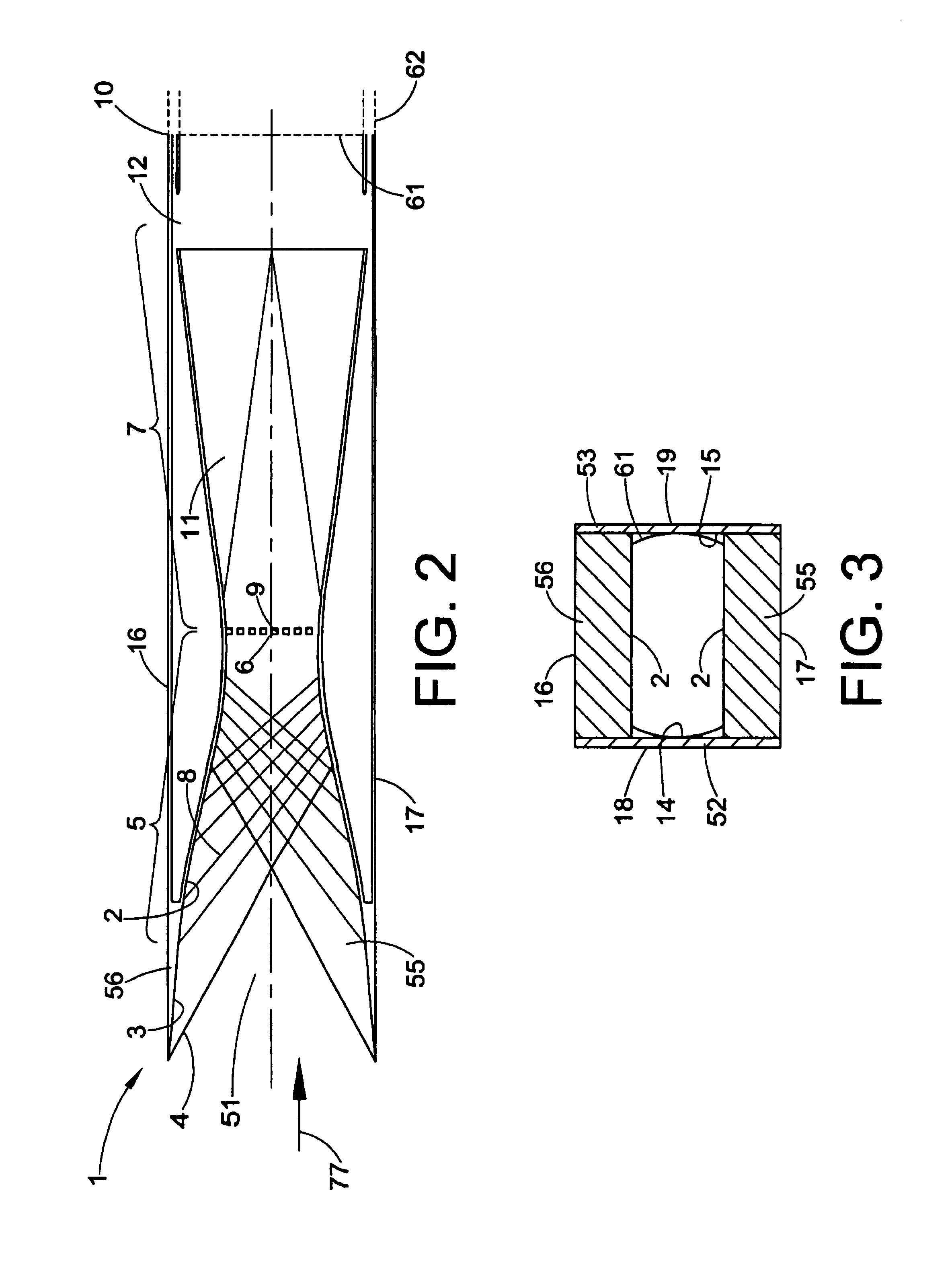

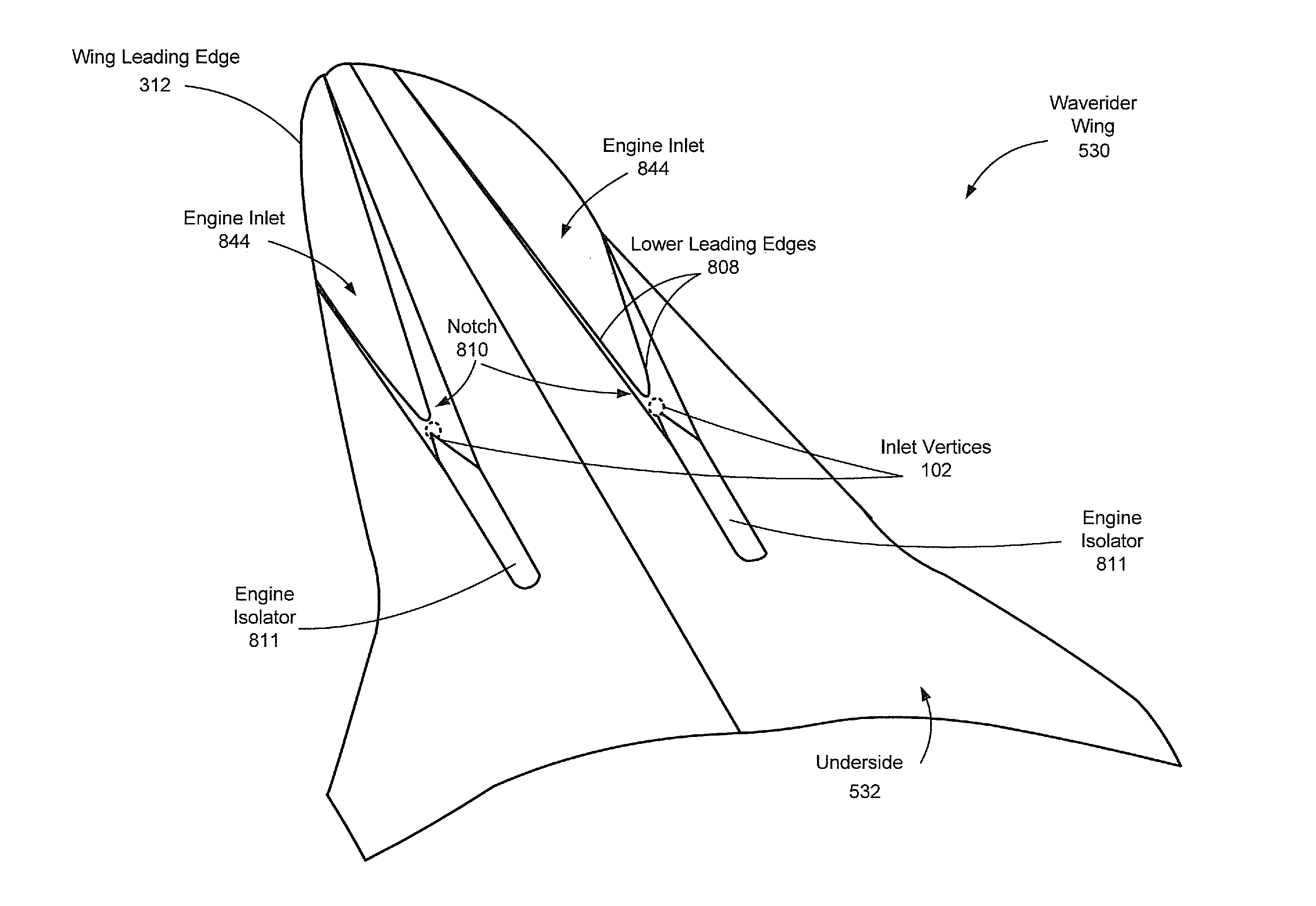

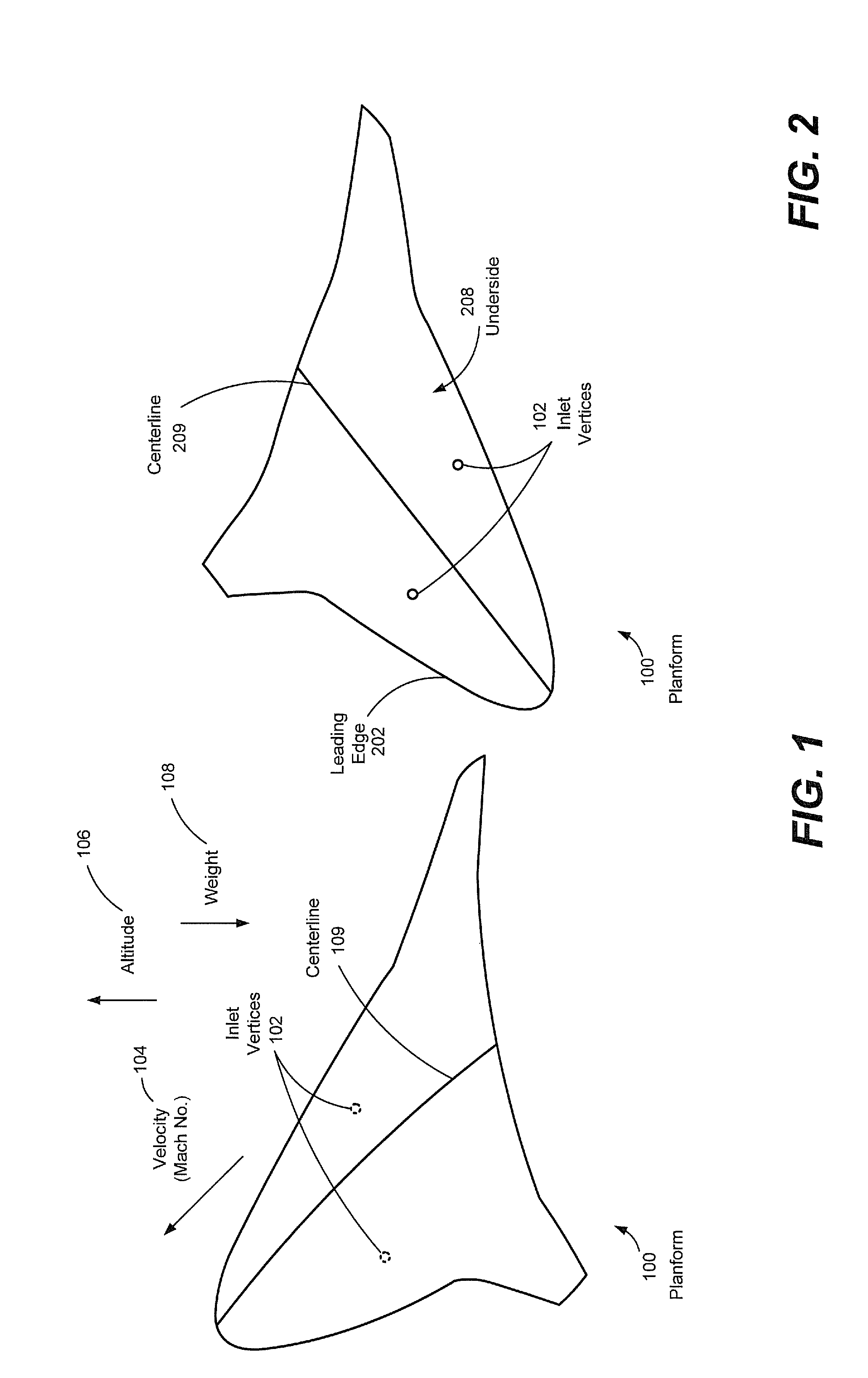

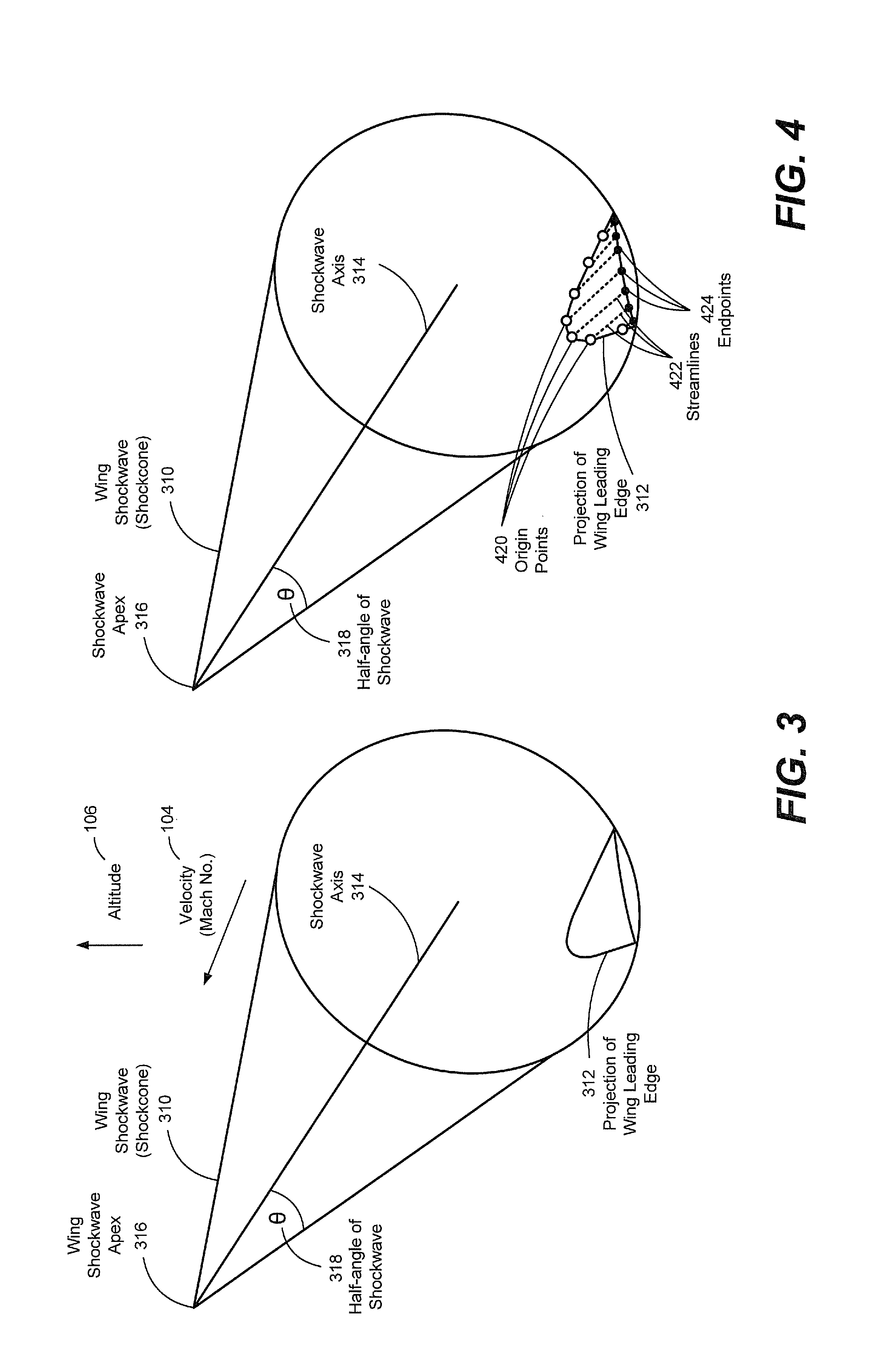

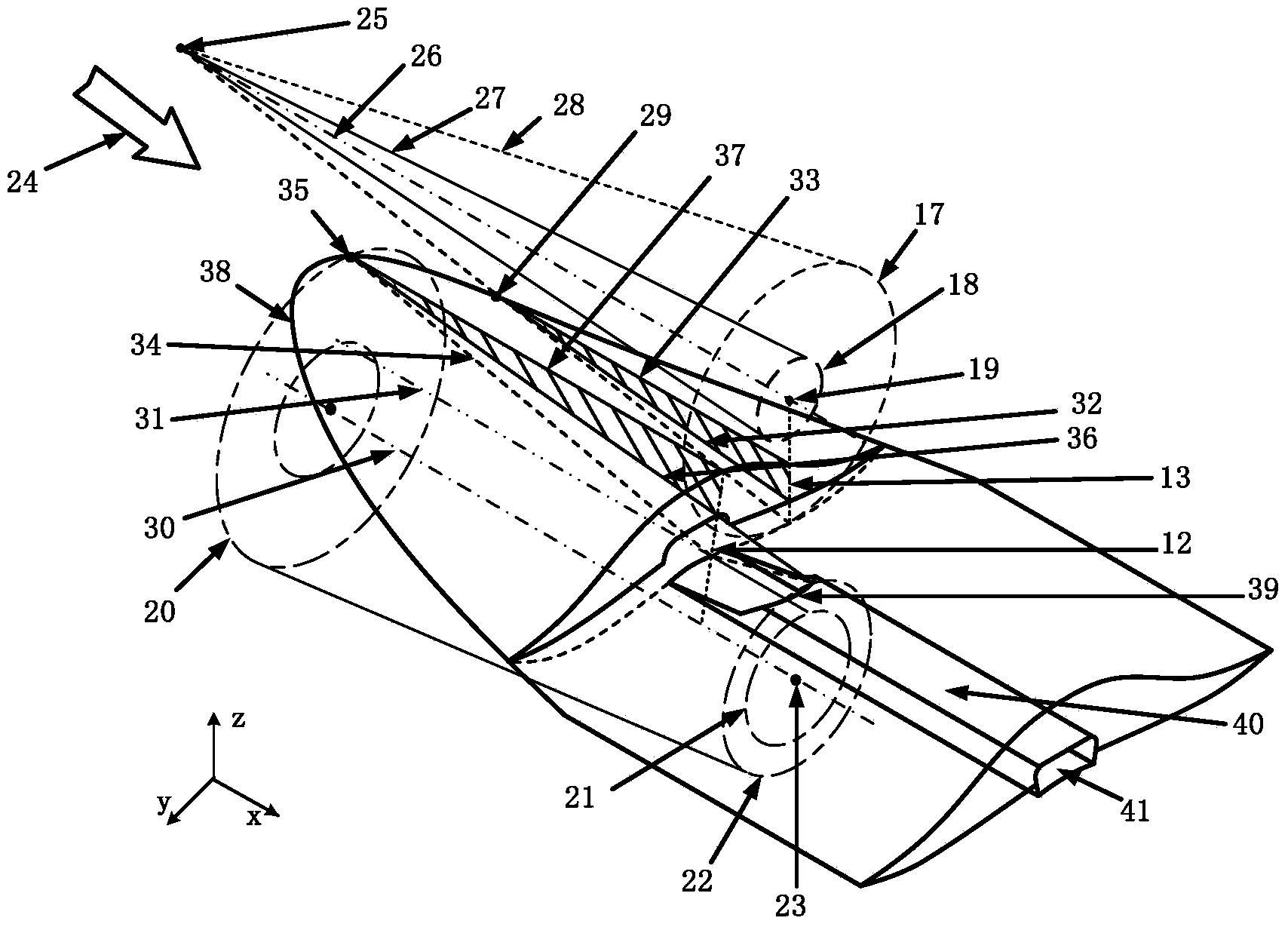

Integrated hypersonic inlet design

ActiveUS8256706B1Improve efficiencyImprove engine performanceAircraft navigation controlCombustion enginesLeading edgeNacelle

Methods, aircraft, and engine nacelles are disclosed. A wing leading edge of a planform is superimposed on a wing shockwave that extends in a first direction from a shockwave apex toward the wing leading edge. A waverider shape is streamline traced between the wing leading edge and a trailing edge of the planform to form a waverider wing. A position of an engine inlet vertex relative to the waverider wing is identified. An inlet shockwave is projected from the inlet vertex in a second direction generally opposed to the first direction. The inlet shockwave intersects the wing shockwave. An inlet leading edge of an engine inlet includes a lower leading edge including a plurality of points where the inlet shockwave intersects the wing shockwave.

Owner:THE BOEING CO

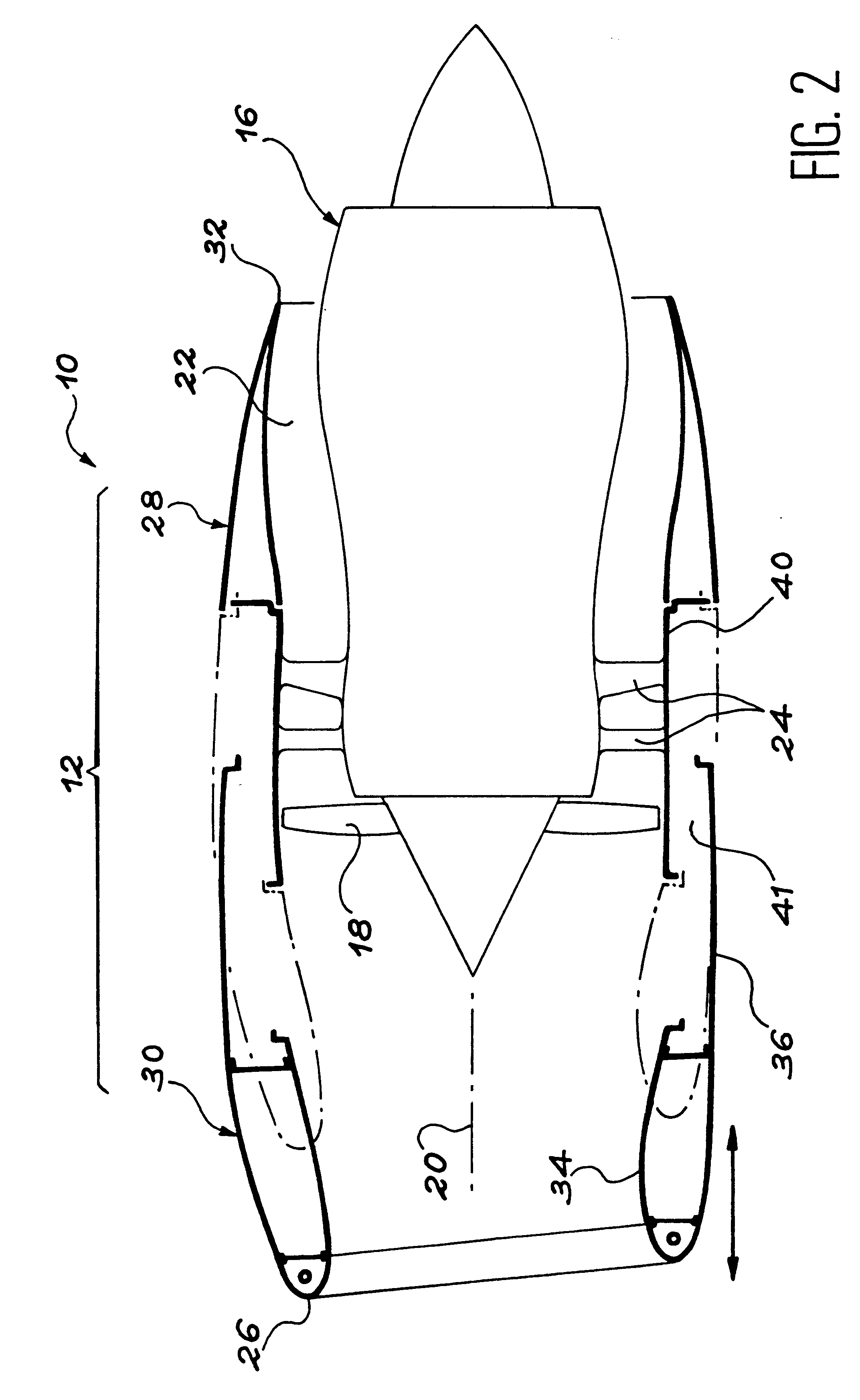

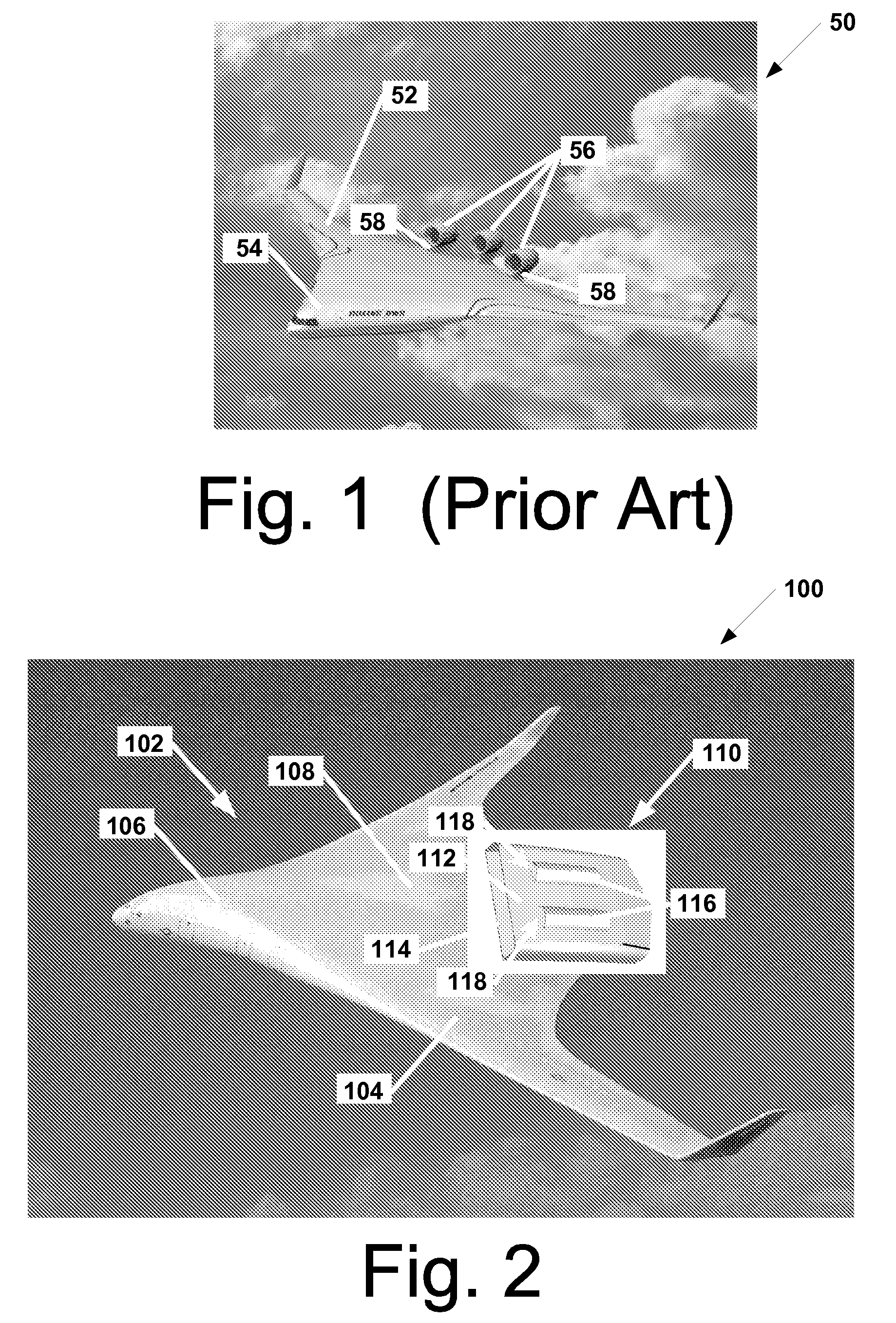

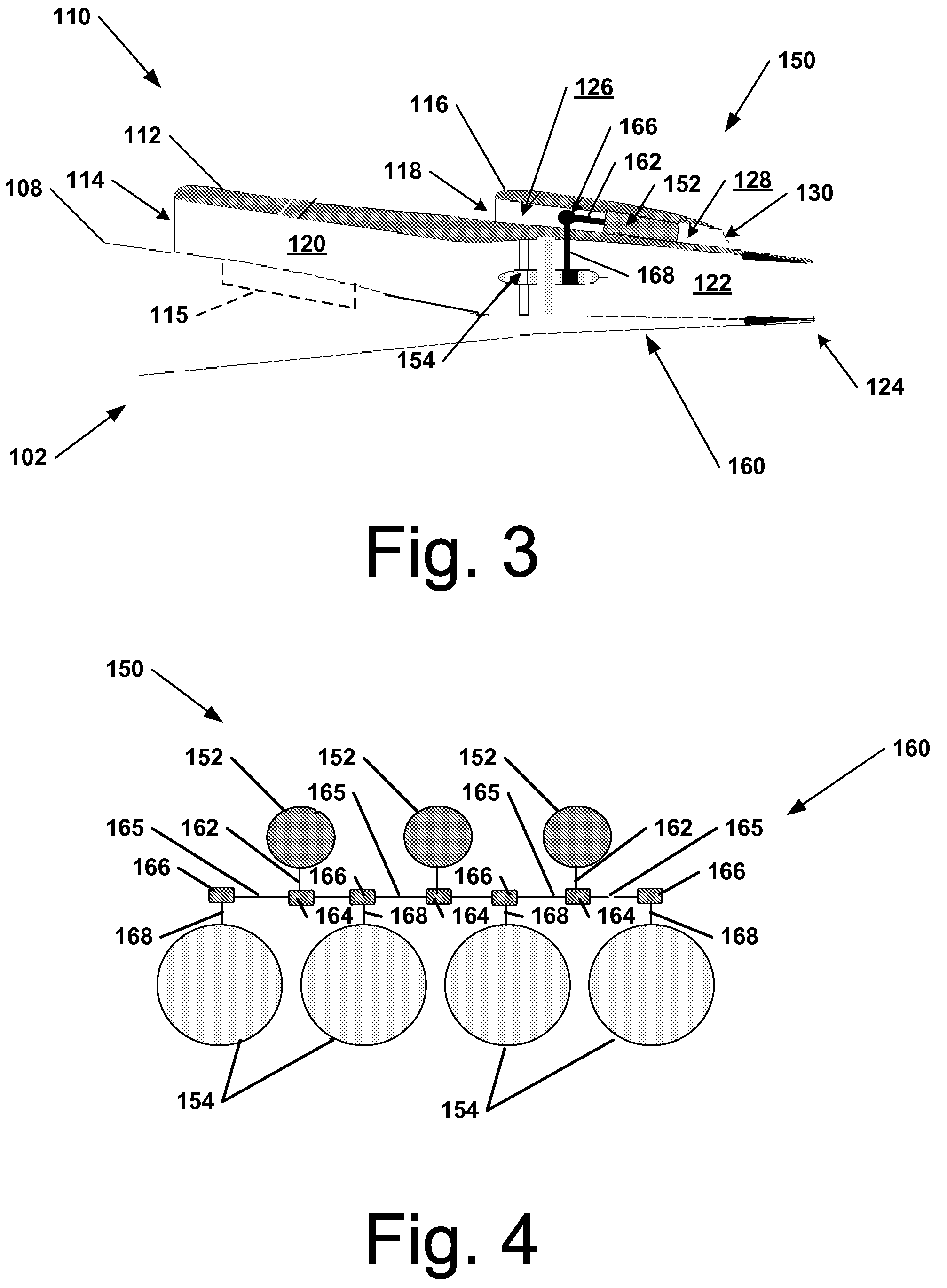

Unconventional integrated propulsion systems and methods for blended wing body aircraft

InactiveUS7665689B2Mitigate undesirable characteristicImprove balanceAircraft navigation controlGas turbine type power plantsRotational axisFlight vehicle

Integrated propulsion systems and methods for blended wing aircraft are disclosed. In one embodiment, a propulsion system at least one engine operatively disposed within an engine flow duct having an engine inlet and an engine exhaust aperture, and at least one fan operatively disposed within a fan flow duct having a fan inlet and a fan exhaust aperture. The engine and fan rotational axes extending at least approximately along a lengthwise direction of the aircraft, the fan flow duct being separate from the engine flow duct. A transmission assembly is operatively coupled between the at least one engine and the at least one fan, the transmission assembly being configured to transmit a rotary output from the at least one engine to rotate the at least one fan.

Owner:THE BOEING CO

Method and apparatus for noise abatement and ice protection of an aircraft engine nacelle inlet lip

InactiveUS7588212B2Increases amount of acoustic treatmentReduce weightDe-icing equipmentsFuselage insulationNacelleAcoustic noise reduction

Owner:ROHR INC

Acoustic nacelle inlet lip having composite construction and an integral electric ice protection heater disposed therein

An engine nacelle inlet lip includes both acoustic treatment and electric heating for ice protection. The inlet lip has a composite outer skin and a composite inner skin, with the composite outer skin having at least one integrated heater element embedded in the composite material. An acoustic cellular core positioned between the outer and inner skin acts to attenuate fan noise from the engine. Covering the outer skin and overlying the acoustic core is a perforated erosion shield having a first set of openings that pass entirely thorough its thickness. The composite outer skin includes a second set of openings such that sound waves can pass from an inner barrel portion of the inlet lip through the erosion shield, outer skin, and heater element to the underlying acoustic cellular core.

Owner:THE BF GOODRICH CO +1

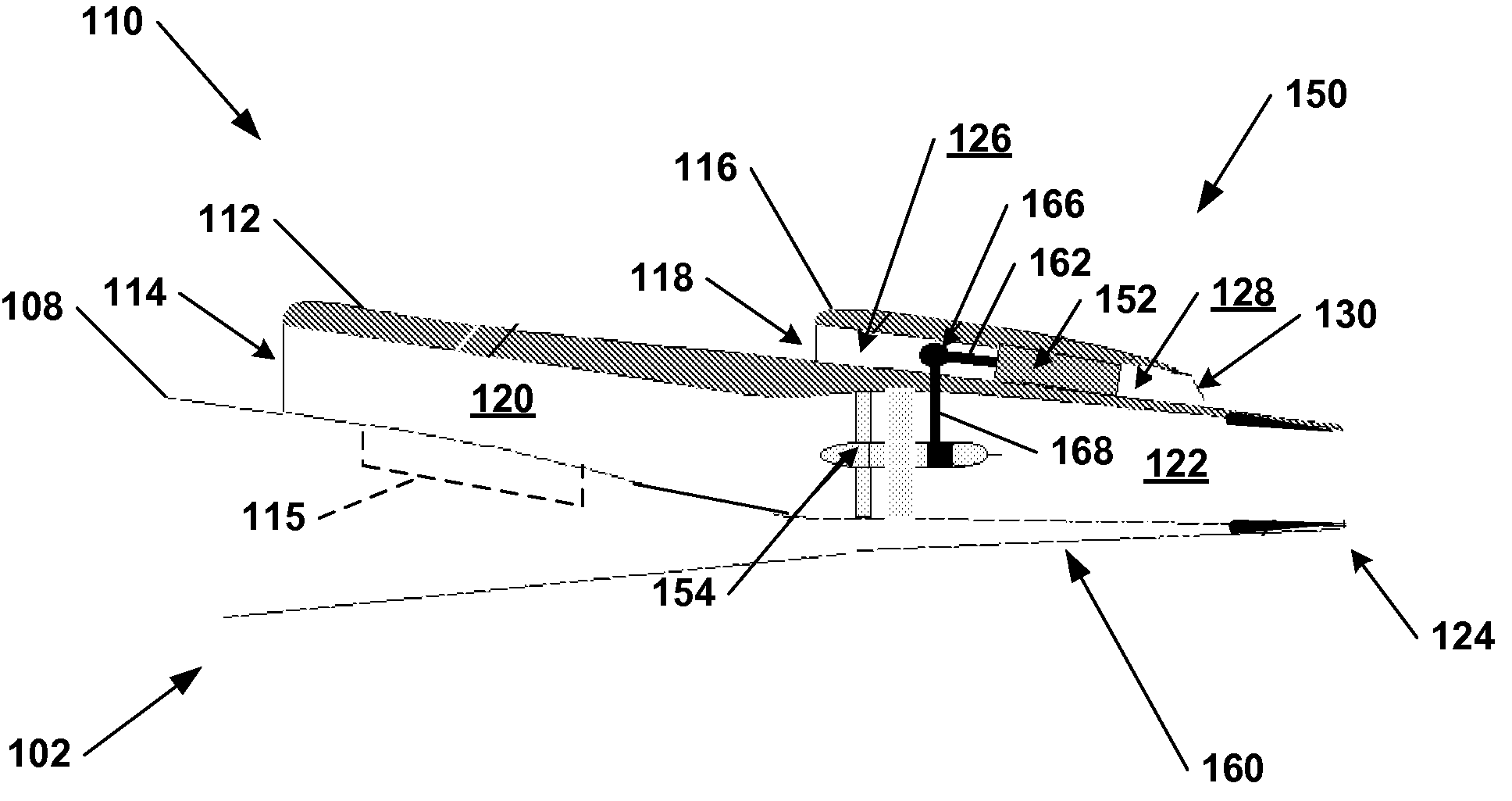

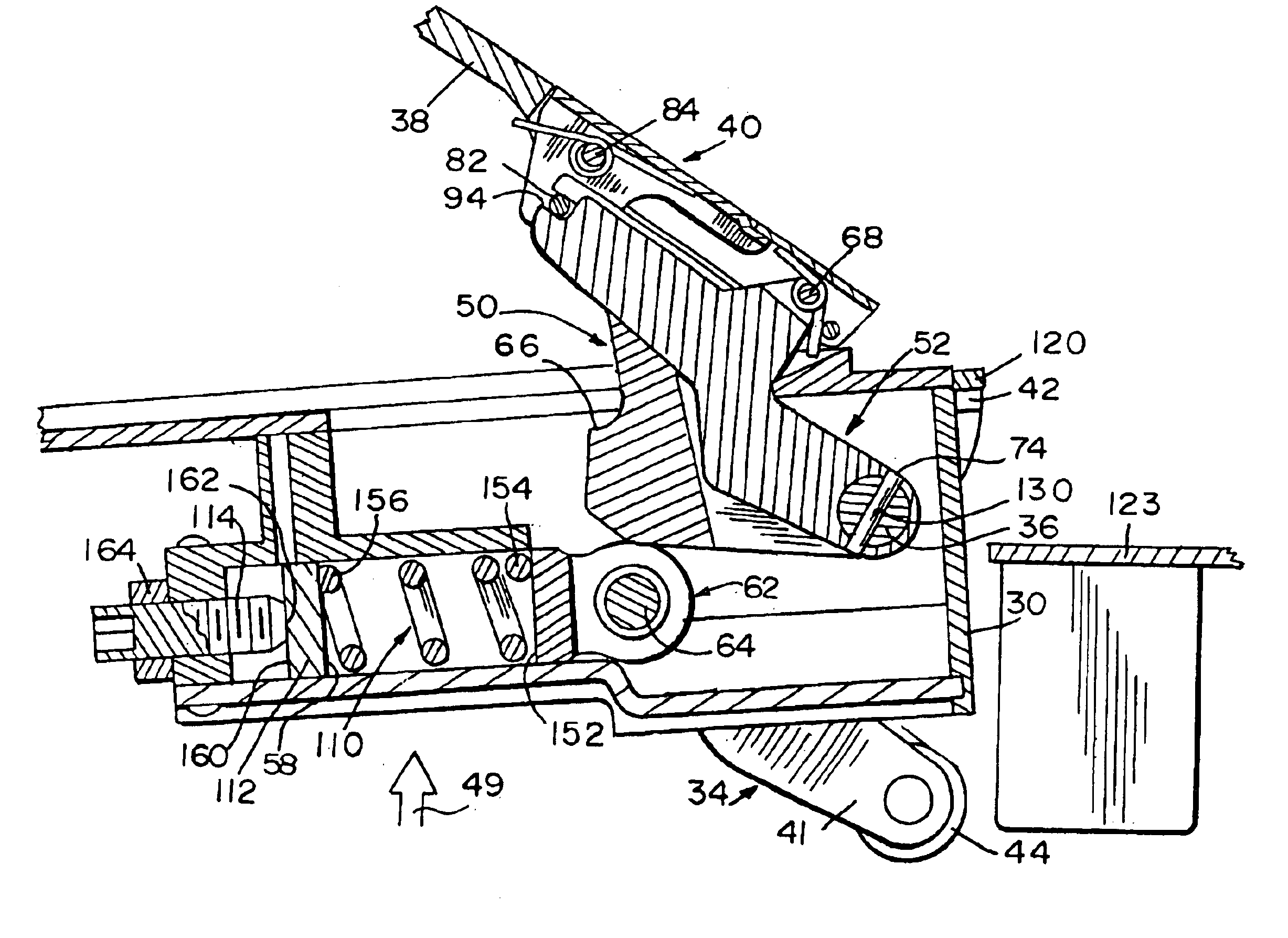

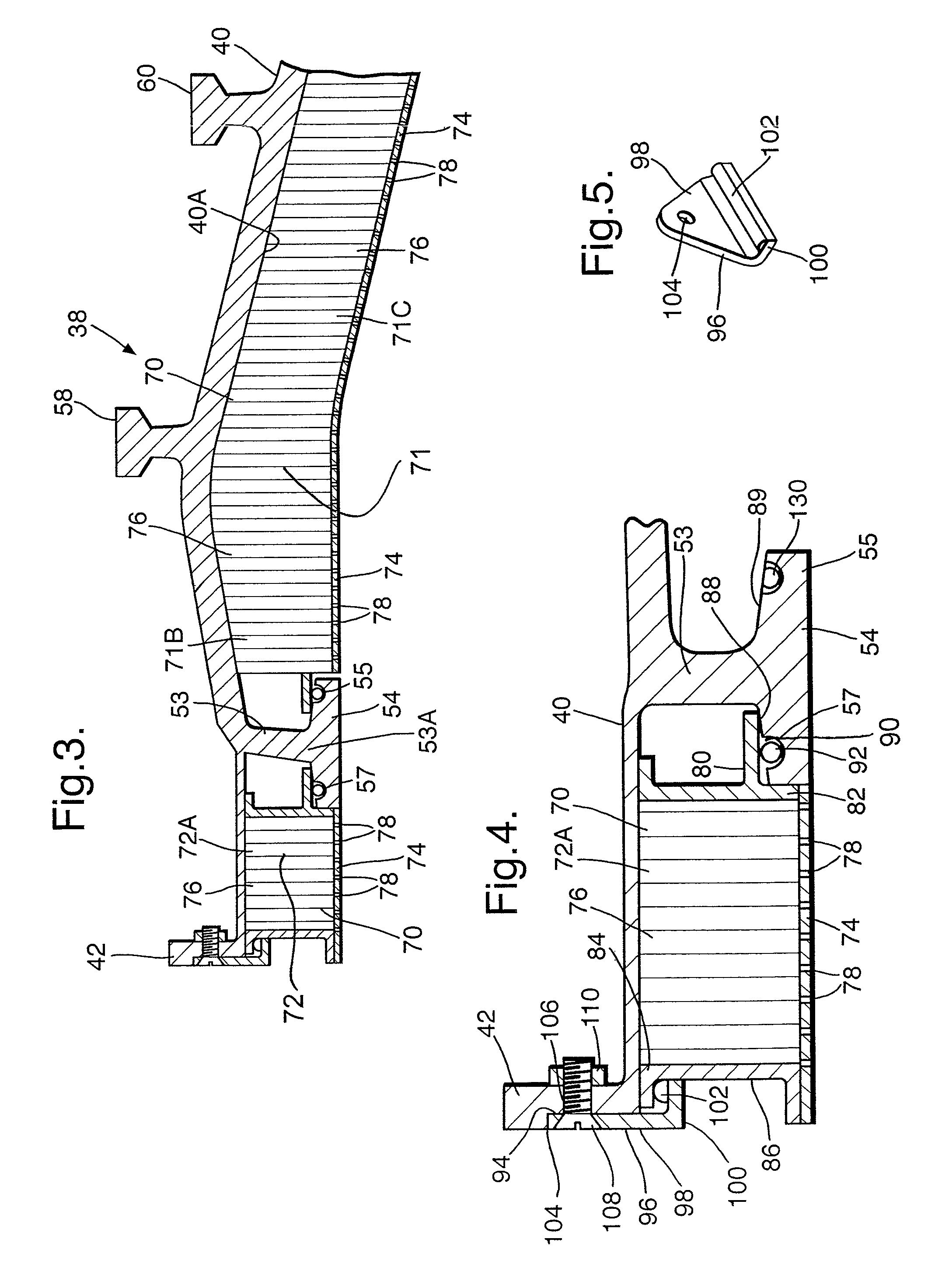

Blowout latch

A blowout latch is provided to latch a first panel to a second panel. The latch is coupled to the first panel and engaged with the second panel. The latch includes a biasing mechanism which is disengagable under pressure to move the first panel relative to the second panel. The latch may also be selectively disengaged with a lesser force than that required to overcome the biasing mechanism by bypassing the biasing mechanism. When manually disengaged, the latch maintains a biasing load on a bolt of the latch. A trigger of the latch is provided to bypass the biasing mechanism and disengage a roller assembly of the latch from the second panel.

Owner:HARTWELL

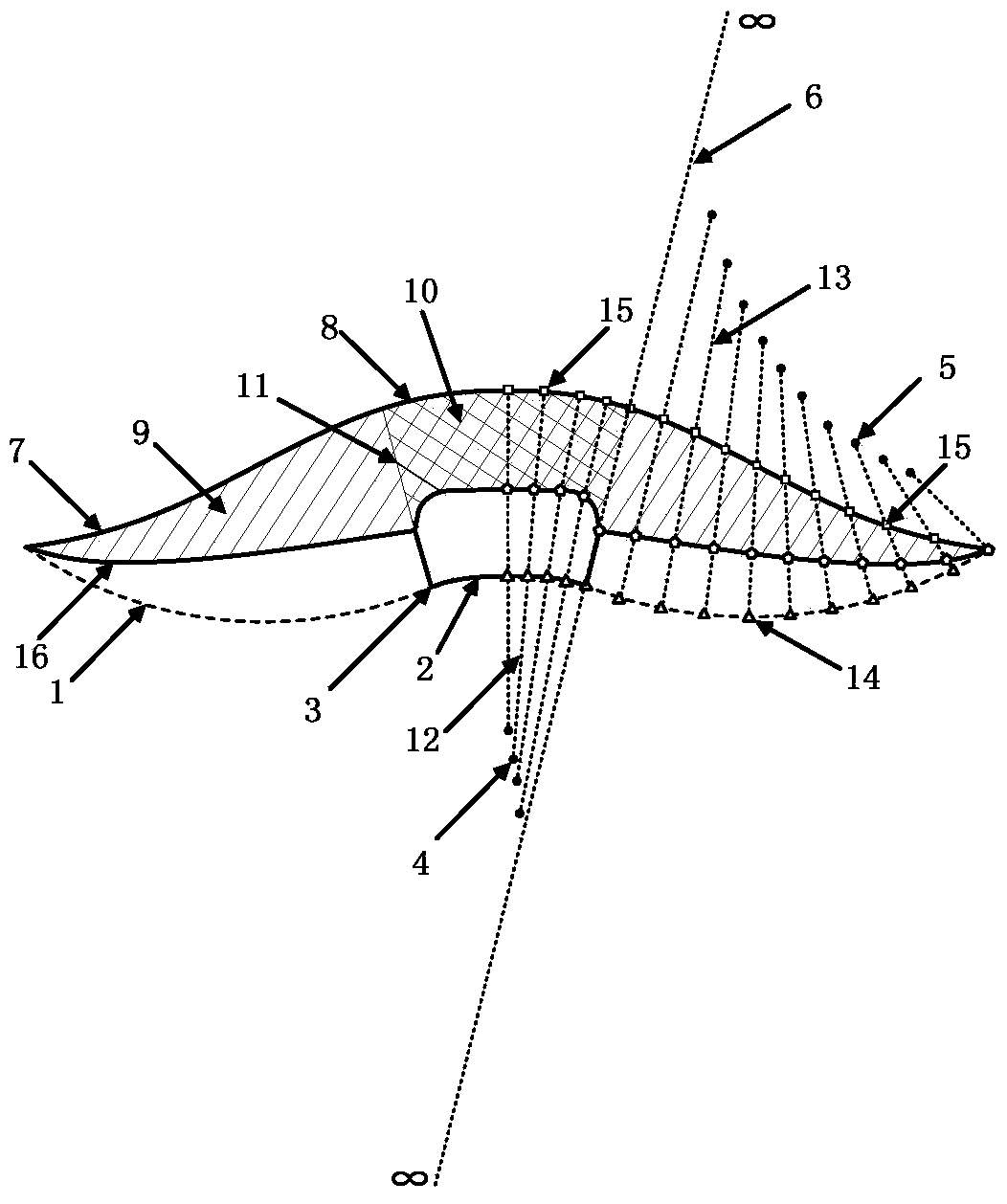

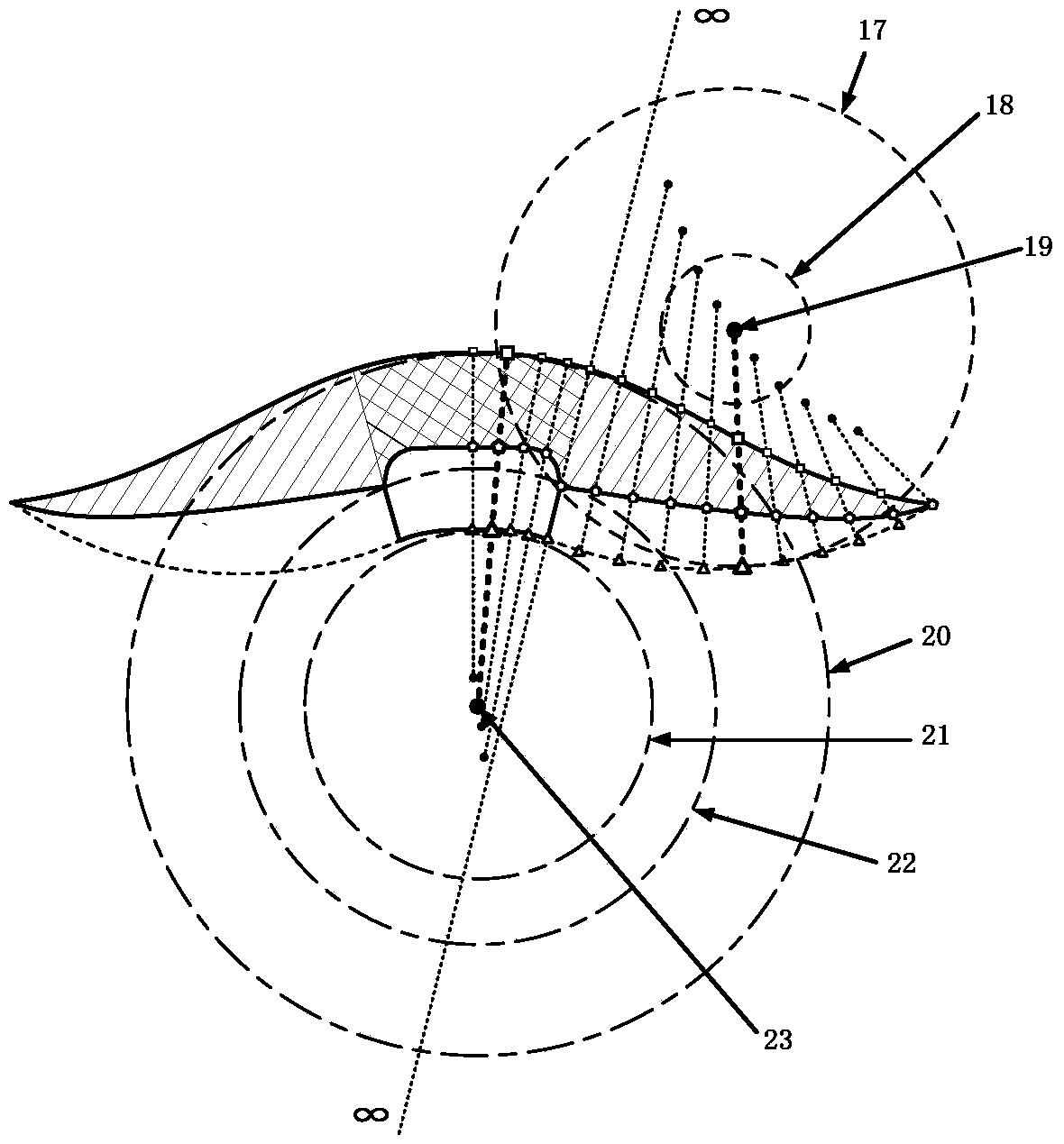

Hypersonic aerocraft and air inlet internal and external waverider integrated design method

ActiveCN103662087ARealize seamless dockingRealize integrated designTurbine/propulsion air intakesGround installationsShock waveRadial position

The invention discloses a hypersonic aerocraft and air inlet internal and external waverider integrated design method, and relates to a near space aerocraft. An aerodynamics characteristic is firstly appointed, and then a design scheme meeting the characteristic is inferred backwards; a three-dimensional shock wave curved surface in a complex shape is appointed, the change rule of the transverse curvature center is obtained, and a series of basic flow fields meeting the needs of the waverider design are inferred backwards according to the change rule; flow lines of different curvature centers and different radial positions are traced in every basic flow field in the circumferential direction; a waverider device capable of producing the appointed complex three-dimensional shock wave curved surface is obtained finally, namely the integrated design scheme is obtained. The advantages of a waveriders and an internal waverider air inlet are kept, the integrated design of the two high-performance devices is achieved, the waverider model with high lift-drag ratio and the scheme of the air inlet with full-flow capture can be obtained at the same time, and accordingly the overall performance of the aerocraft is improved.

Owner:XIAMEN UNIV

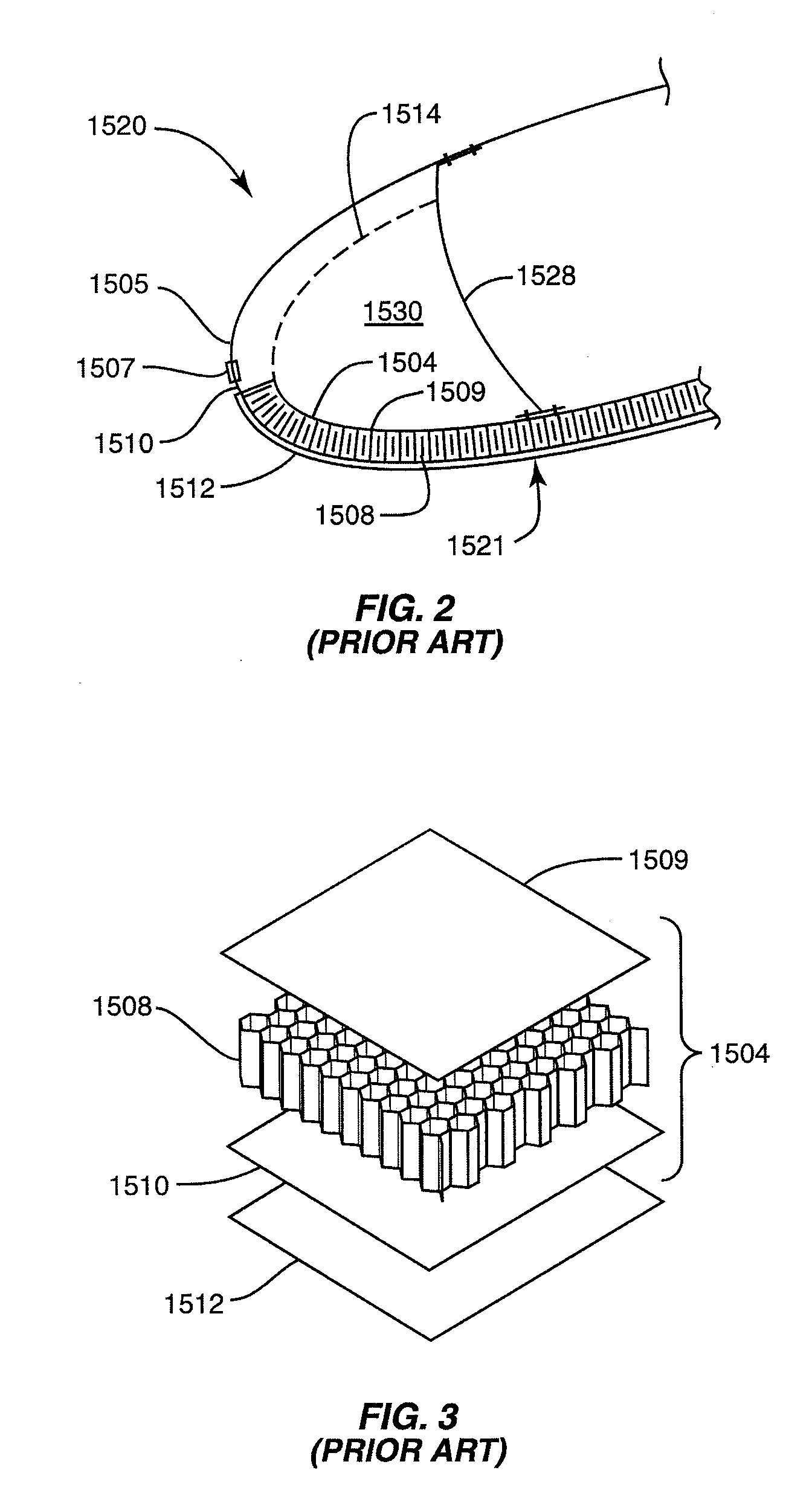

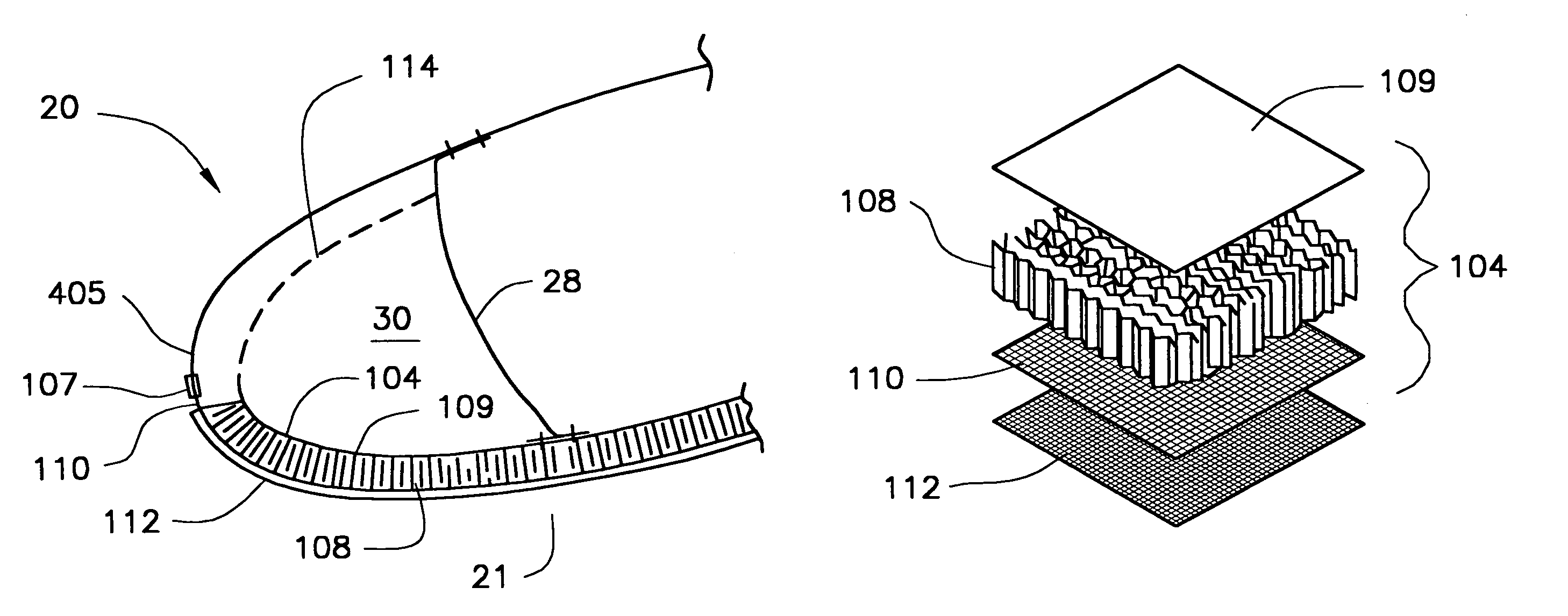

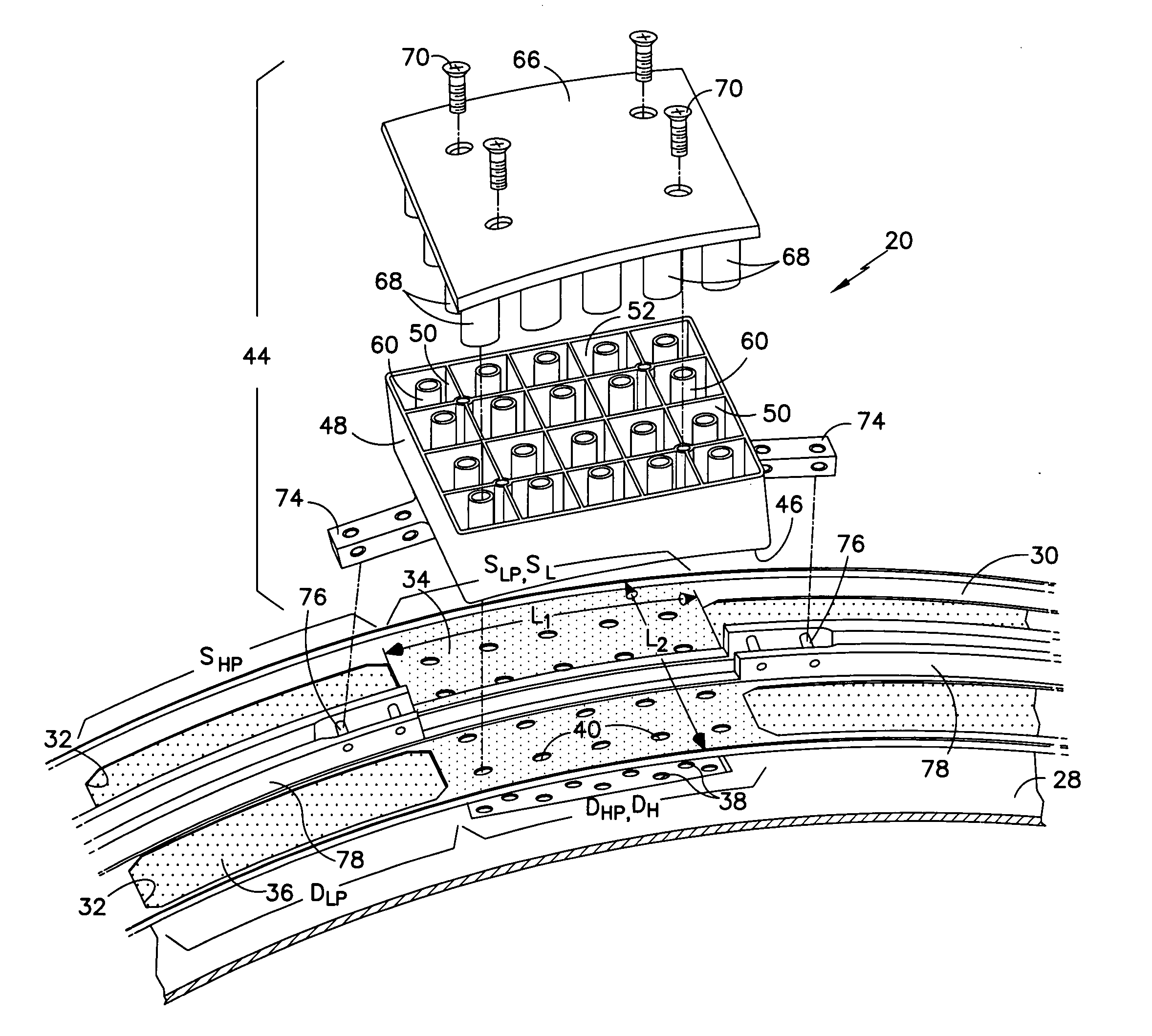

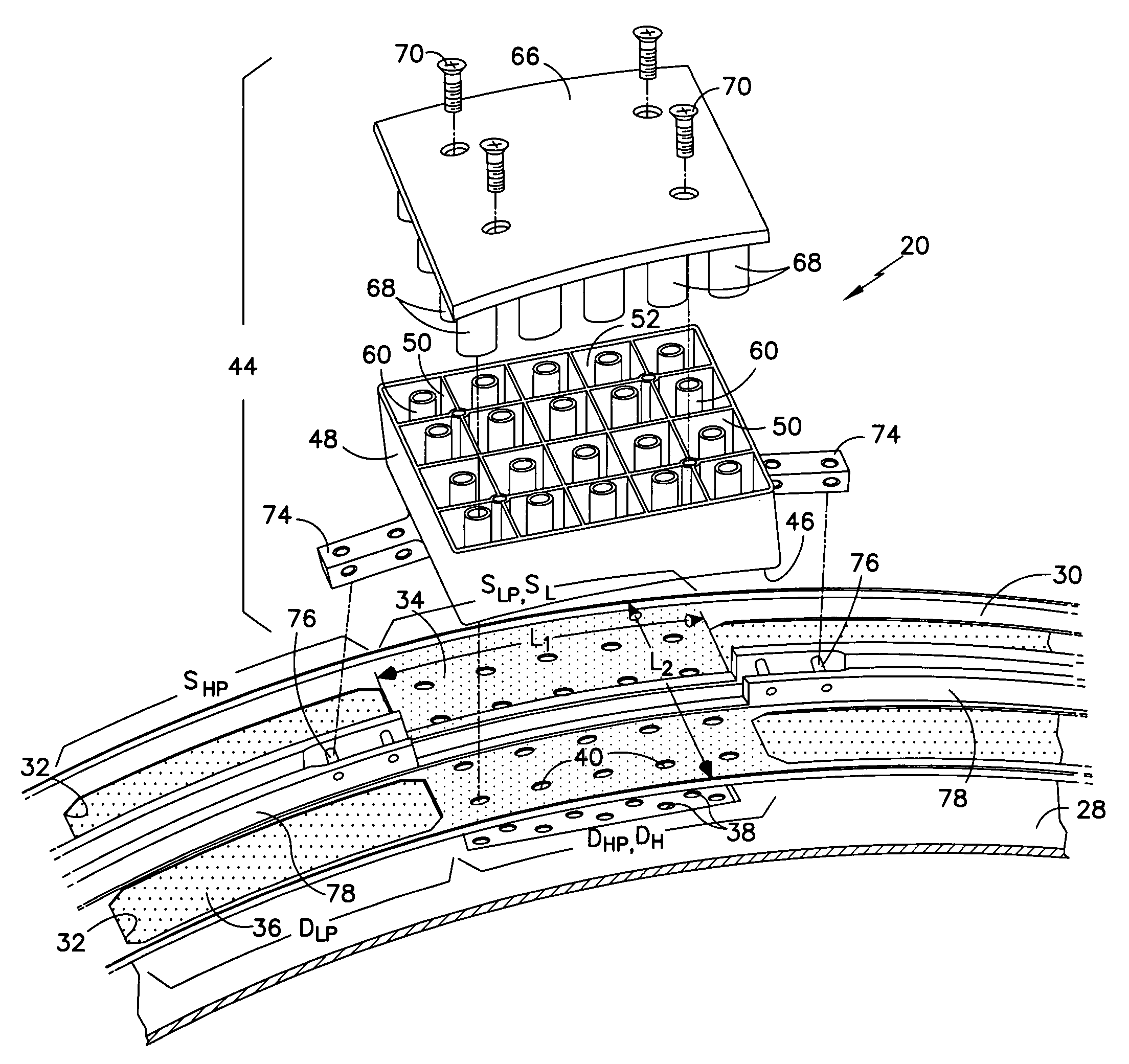

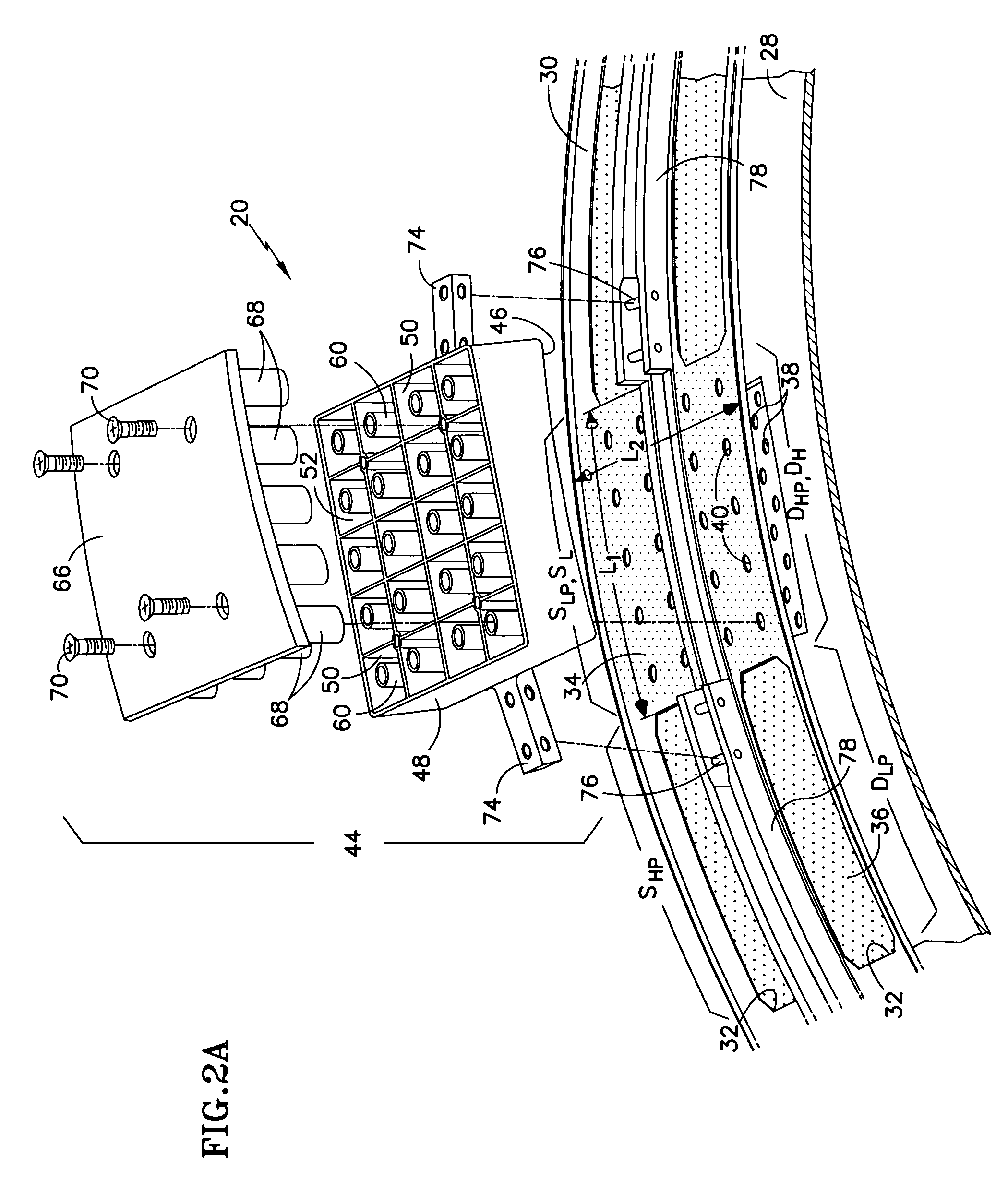

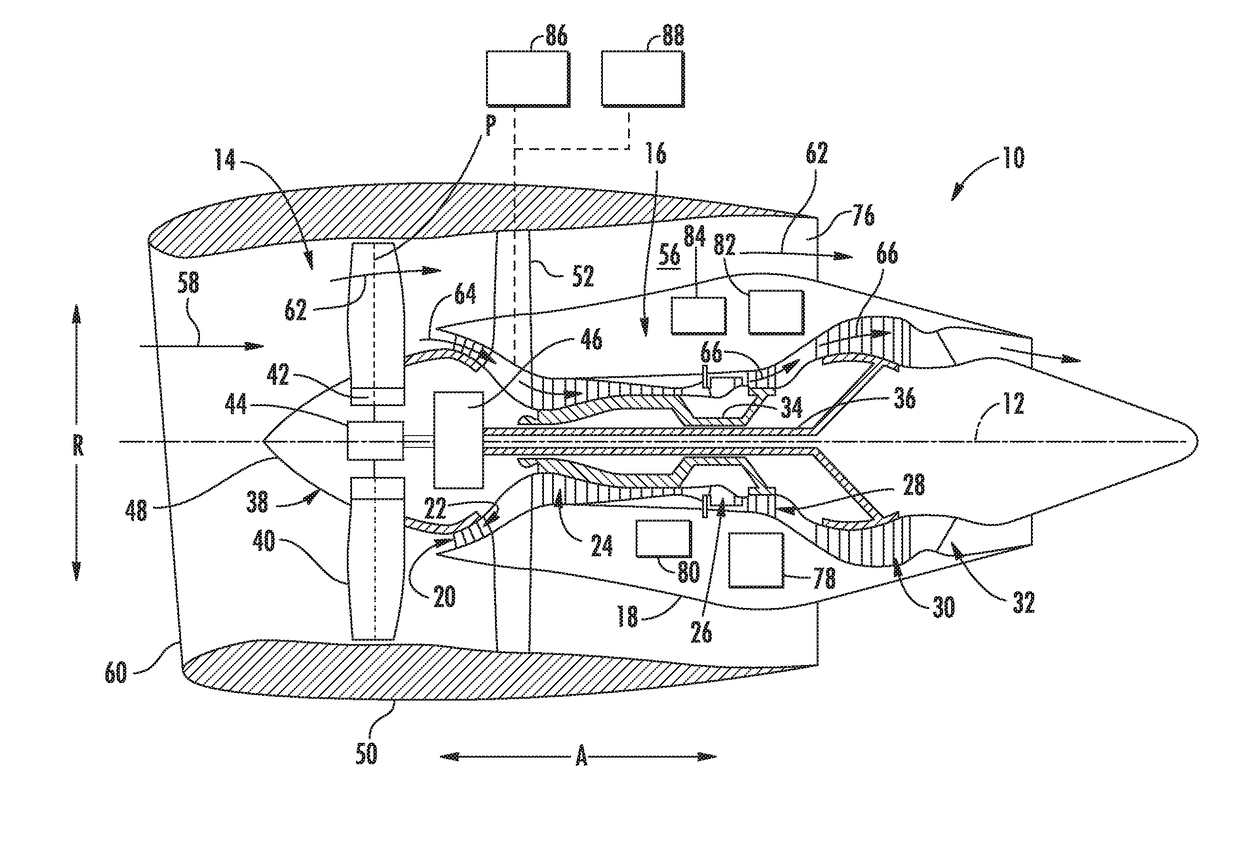

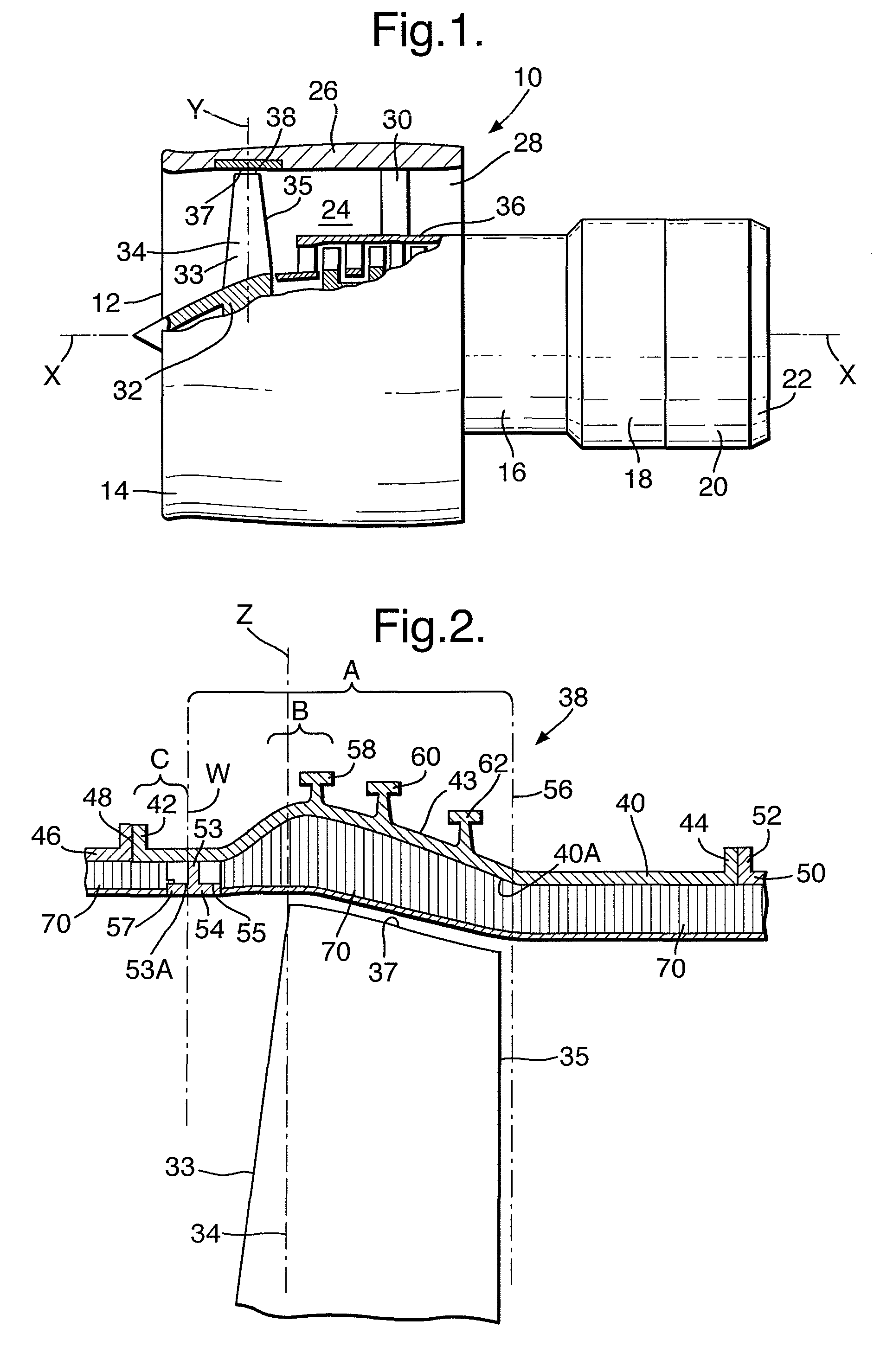

High admittance acoustic liner

ActiveUS20050284690A1High admittanceImproved acoustic admittanceNoise reduction installationsWallsPorosityCoolant flow

A cooled acoustic liner useful in a fluid handling duct includes a resonator chamber 52 with a neck 56, a face sheet 86, and a coolant plenum 80 residing between the face sheet and the chamber. Coolant bypasses the resonator chamber, rather than flowing through it, resulting in better acoustic admittance than in liners in which coolant flows through the resonator chamber and neck. In one embodiment, the liner also includes a graze shield 88. Openings 40, 38 penetrate both the face sheet and the shield to establish a relatively low face sheet porosity and a relatively high shield porosity. The shielded embodiment of the invention helps prevent a loss of acoustic admittance due to fluid grazing past the liner. Another embodiment that is not necessarily cooled, includes the resonator chamber, low porosity face sheet and high porosity shield, but no coolant plenum for bypassing coolant around the resonator chamber. An associated method of retrofitting an acoustic treatment into a fluid handling module includes installing openings in the module and mounting a resonator box 44 on the module so that the inlets to the resonator necks register with the installed openings.

Owner:RAYTHEON TECH CORP

Variable cam exhaust nozzle

Owner:THE NORDAM GRP

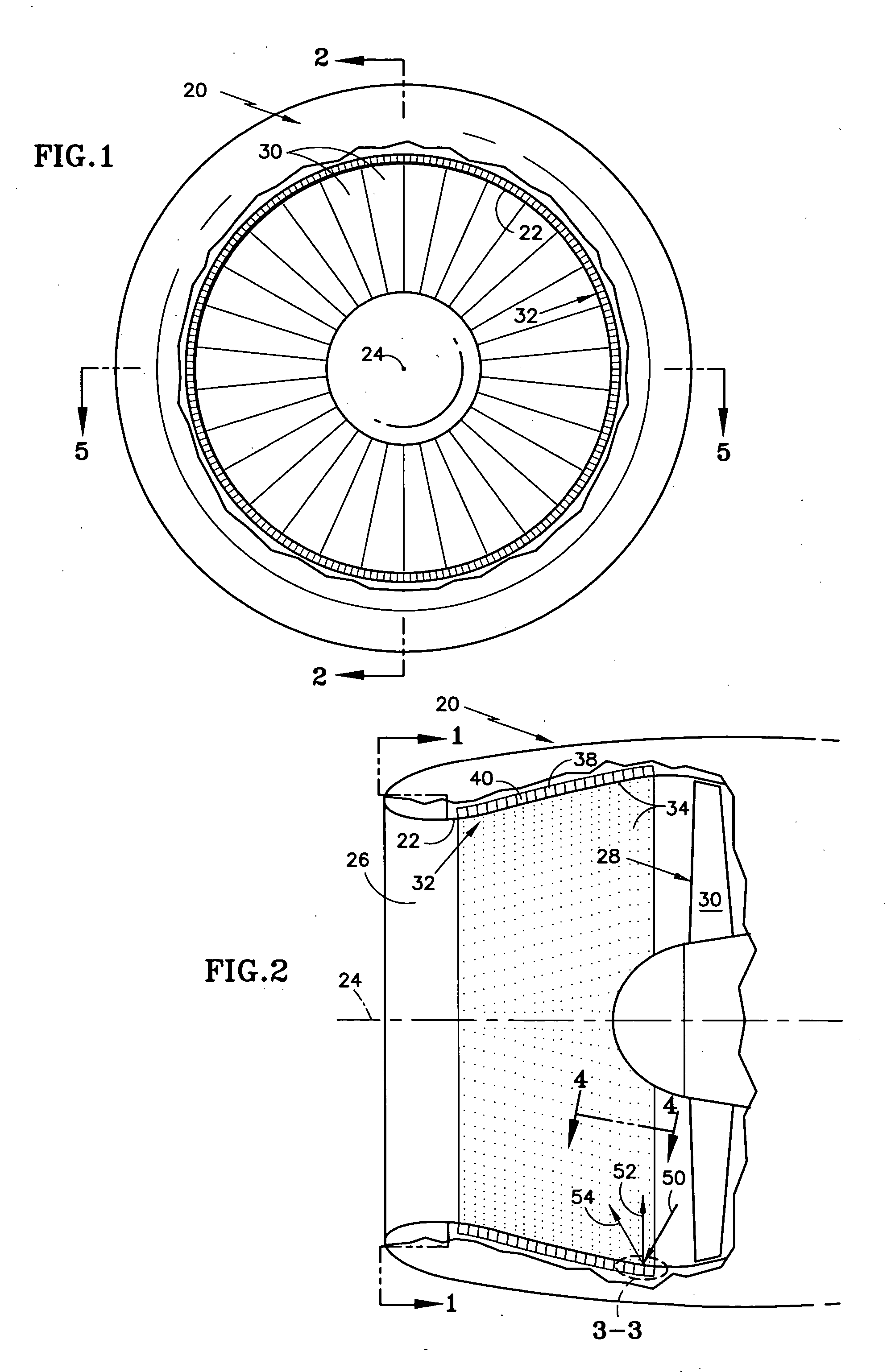

Annular acoustic panel

InactiveUS6920958B2Reduce noiseIncreasing noise absorption qualityNoise reduction installationsEngine fuctionsNacelleEngineering

An aircraft engine assembly is provided that is adapted to reduce noise produced by an engine included in the engine assembly. The engine assembly includes a nacelle having an inlet section and a main section that is houses the engine and fan assembly associated with the engine. The inlet section is coupled to the main section at a main bulkhead junction between the inlet section and the main section. A one piece annular acoustic panel is located within a recess in an internal wall of the nacelle. The annular acoustic panel extends from a forward portion of the inlet section to a forward portion of the main section such that the bulkhead is covered by the annular acoustic panel.

Owner:THE BOEING CO

High admittance acoustic liner

ActiveUS7337875B2High admittanceImproved acoustic admittanceNoise reduction installationsWallsPorosityCoolant flow

A cooled acoustic liner useful in a fluid handling duct includes a resonator chamber 52 with a neck 56, a face sheet 86, and a coolant plenum 80 residing between the face sheet and the chamber. Coolant bypasses the resonator chamber, rather than flowing through it, resulting in better acoustic admittance than in liners in which coolant flows through the resonator chamber and neck. In one embodiment, the liner also includes a graze shield 88. Openings 40, 38 penetrate both the face sheet and the shield to establish a relatively low face sheet porosity and a relatively high shield porosity. The shielded embodiment of the invention helps prevent a loss of acoustic admittance due to fluid grazing past the liner. Another embodiment that is not necessarily cooled, includes the resonator chamber, low porosity face sheet and high porosity shield, but no coolant plenum for bypassing coolant around the resonator chamber. An associated method of retrofitting an acoustic treatment into a fluid handling module includes installing openings in the module and mounting a resonator box 44 on the module so that the inlets to the resonator necks register with the installed openings.

Owner:RTX CORP

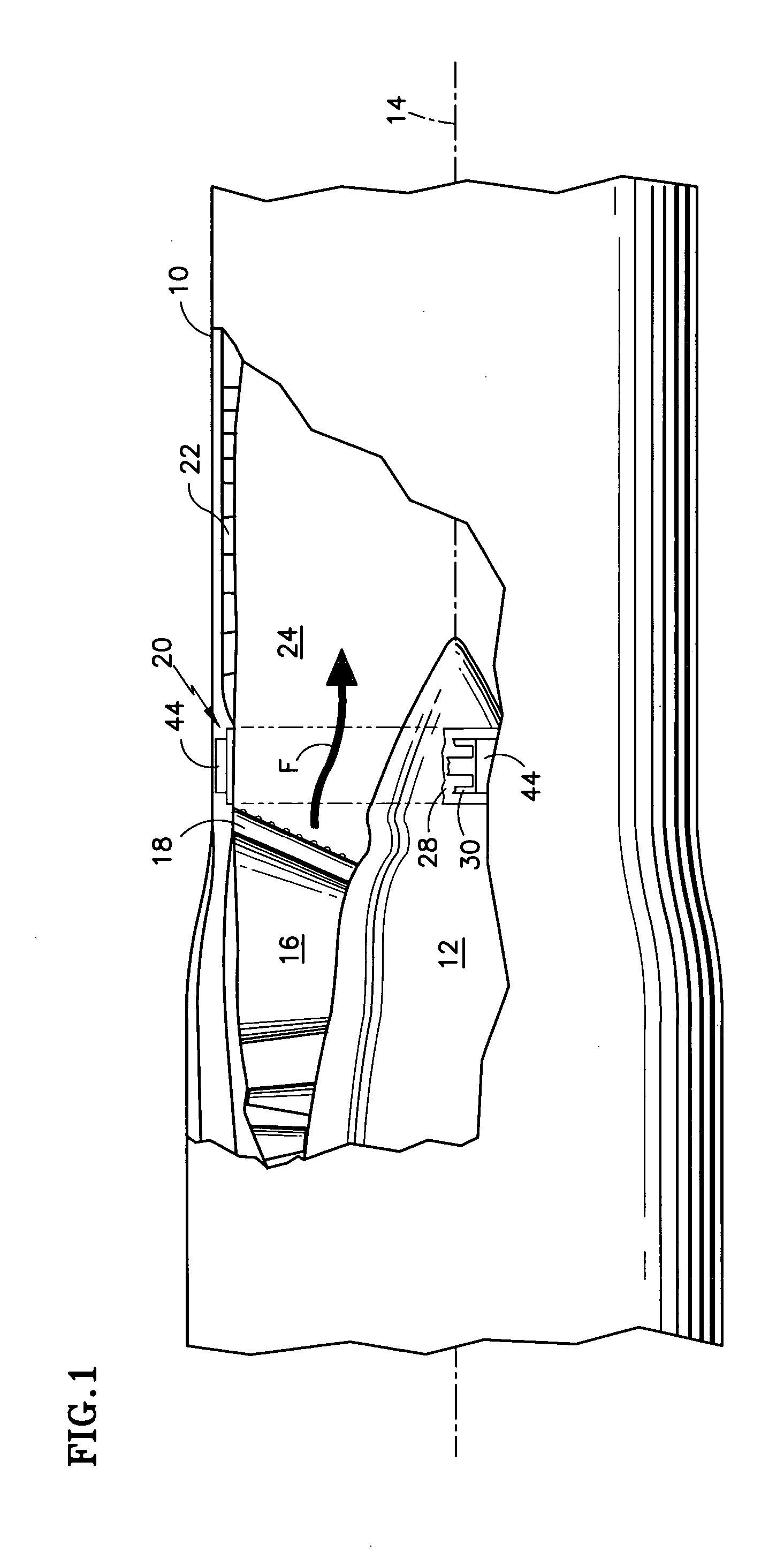

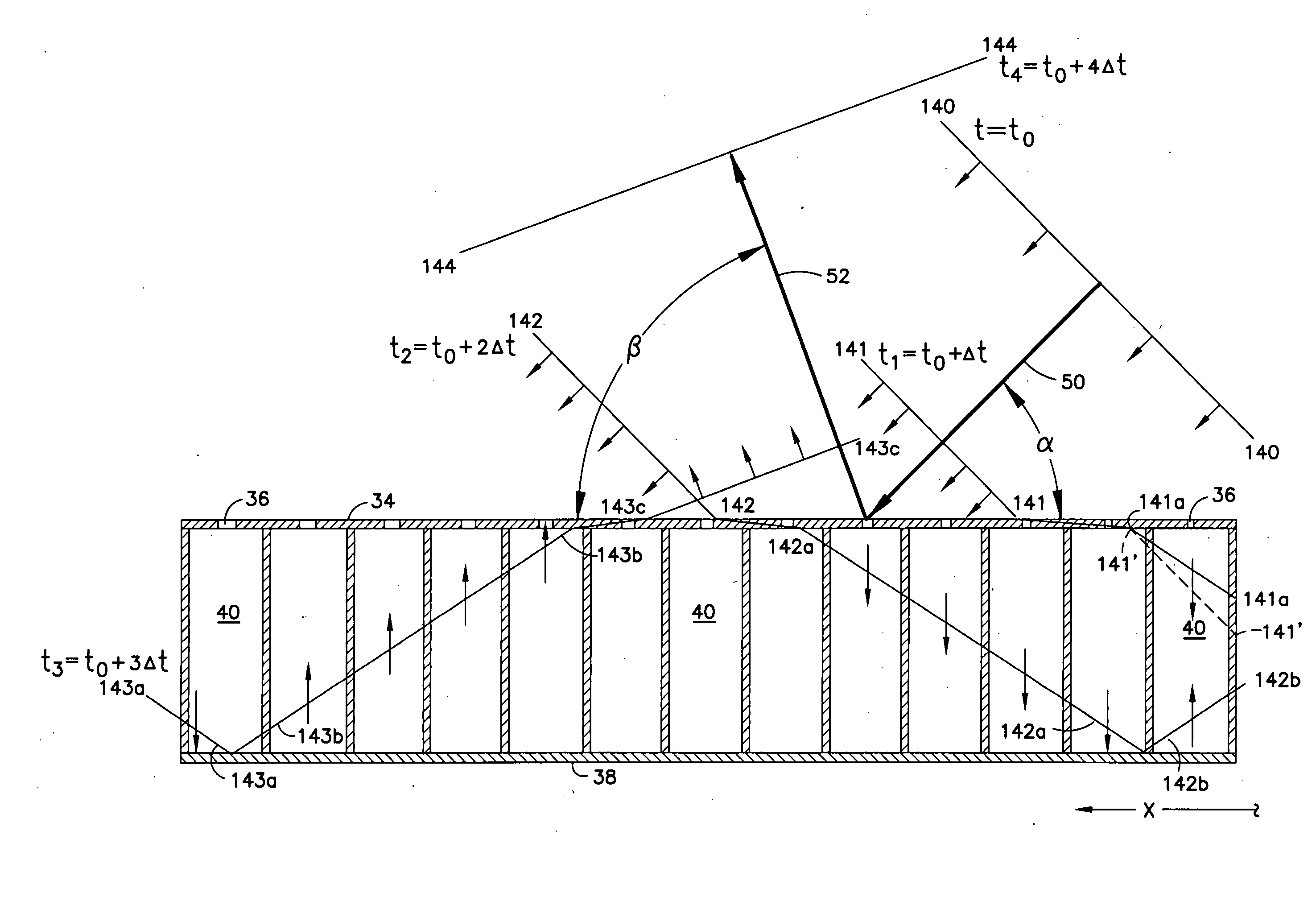

Acoustic liner with nonuniform impedance

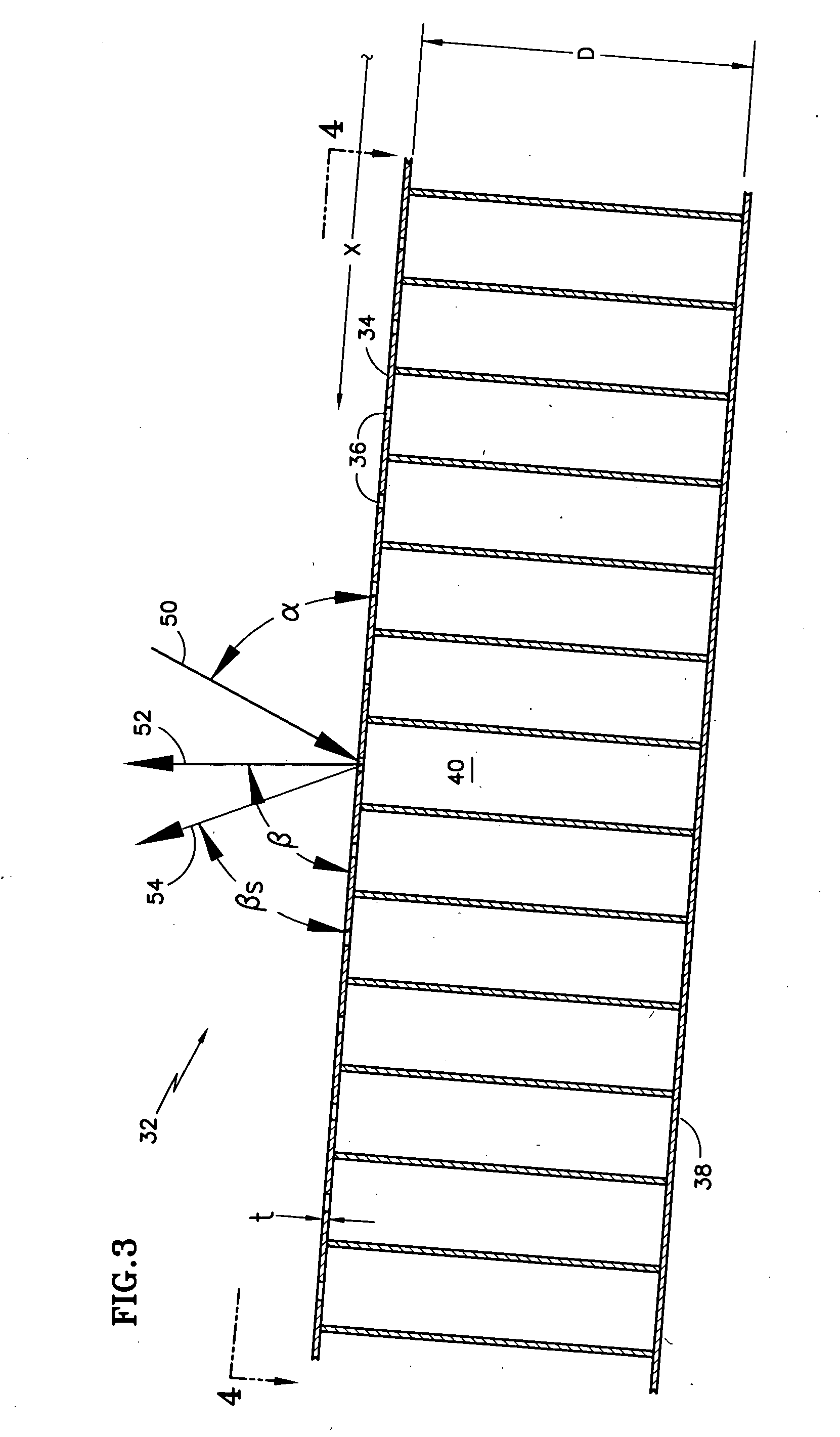

InactiveUS20060169532A1Without jeopardizing aerodynamic performanceNoise reduction installationsPump componentsEngineeringAcoustic wave

A fluid handling duct such as a turbine engine inlet duct 20 includes an acoustic liner 32 comprising a face sheet 34 and a backwall 38 laterally spaced from the face sheet. The liner has a nonuniformly distributed acoustic impedance to direct sound waves incident on the backwall in a prescribed direction relative to the face sheet. The nonuniform impedance is spatially distributed to regulate the direction in which noise signals reflect from the backwall, thereby reducing noise propagation from the duct to the surrounding environment.

Owner:RAYTHEON TECH CORP

Integral suction device with acoustic panel

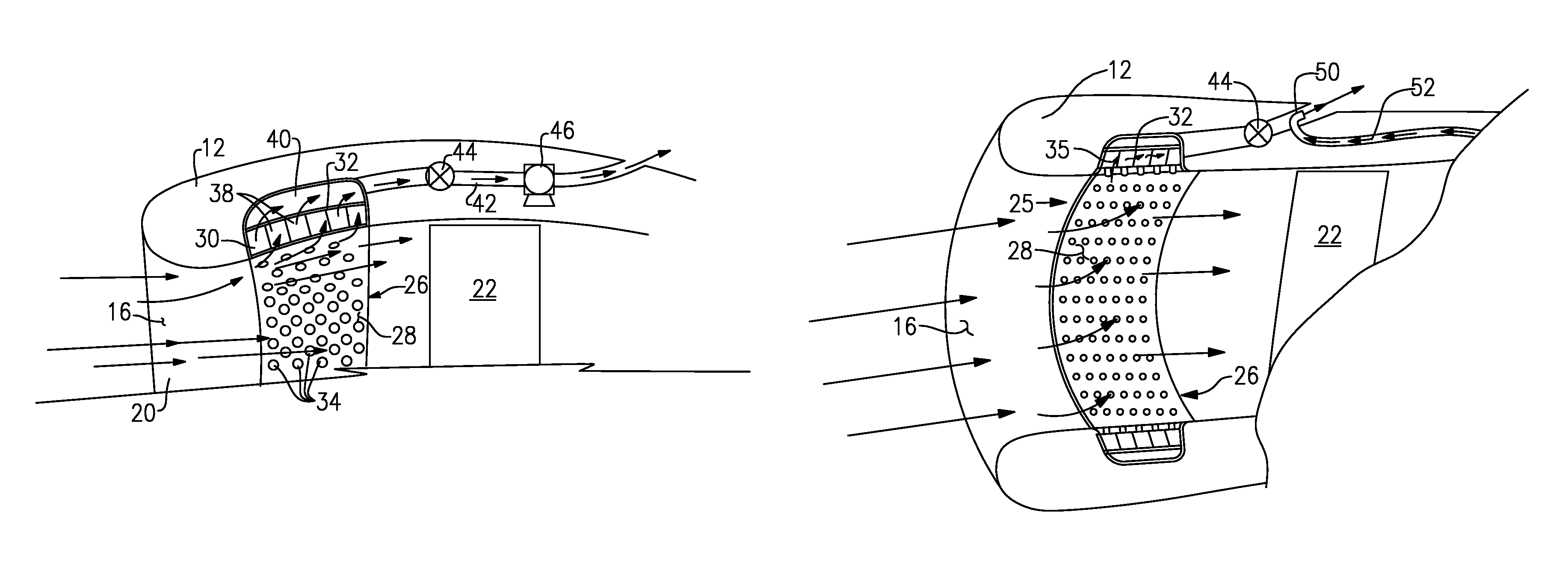

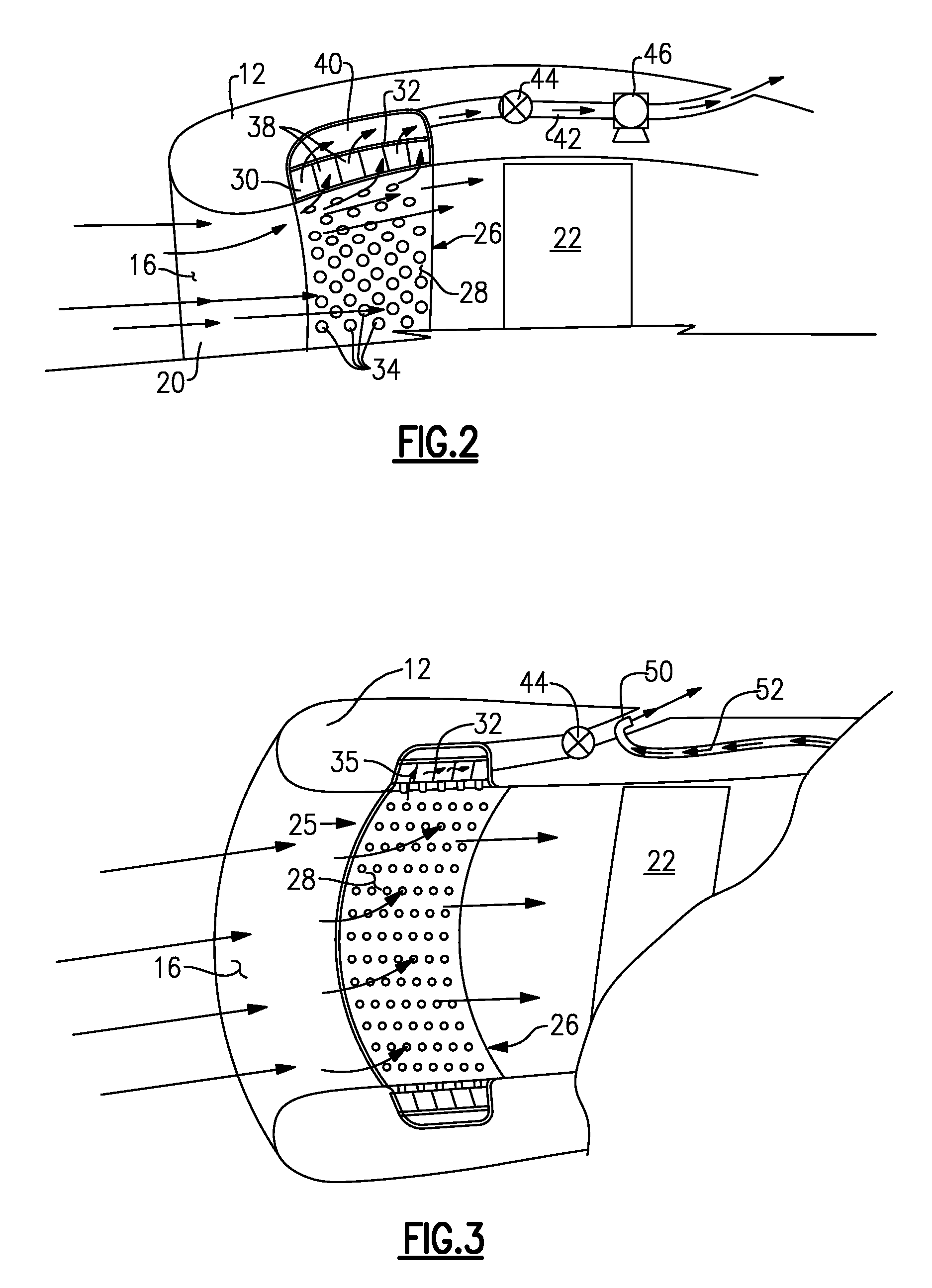

InactiveUS7766280B2Avoid separationLower performance requirementsEngine fuctionsWingsNacelleControl system

An inlet flow control system disposed within a nacelle includes a panel on an inner surface of that nacelle. The panel includes a noise attenuation layer that dissipates noise energy. A vacuum source generates a pressure differential across the noise attenuation layer for drawing airflow through the panel and away from an inner surface of the nacelle.

Owner:RAYTHEON TECH CORP

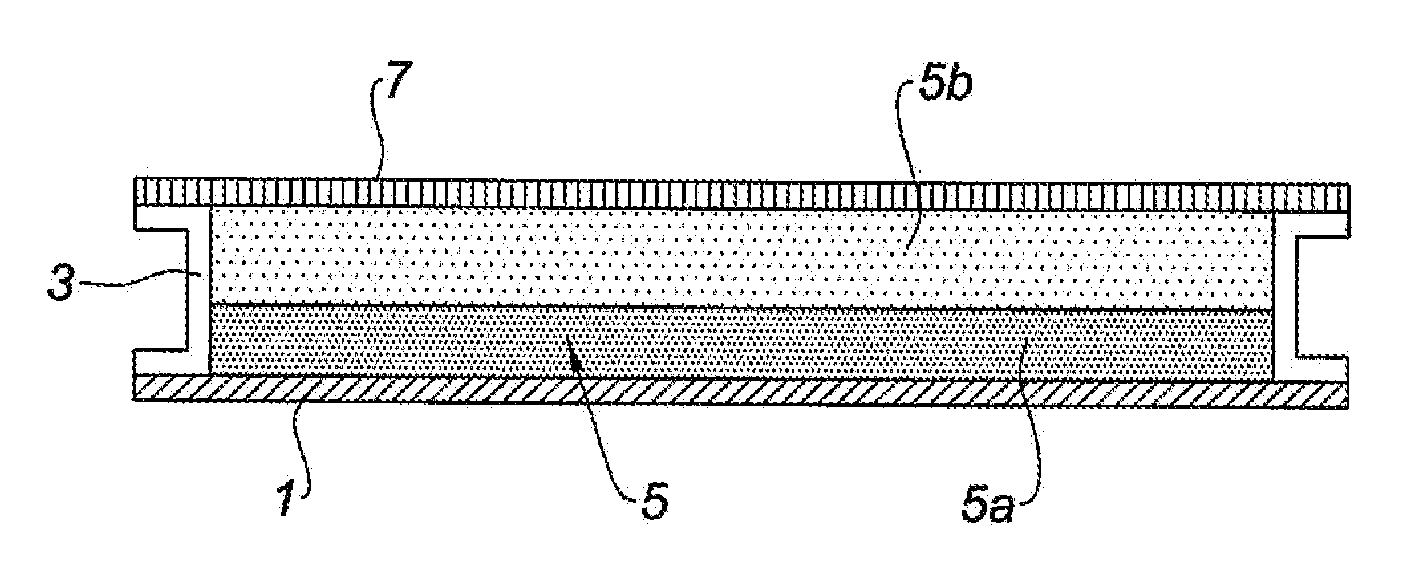

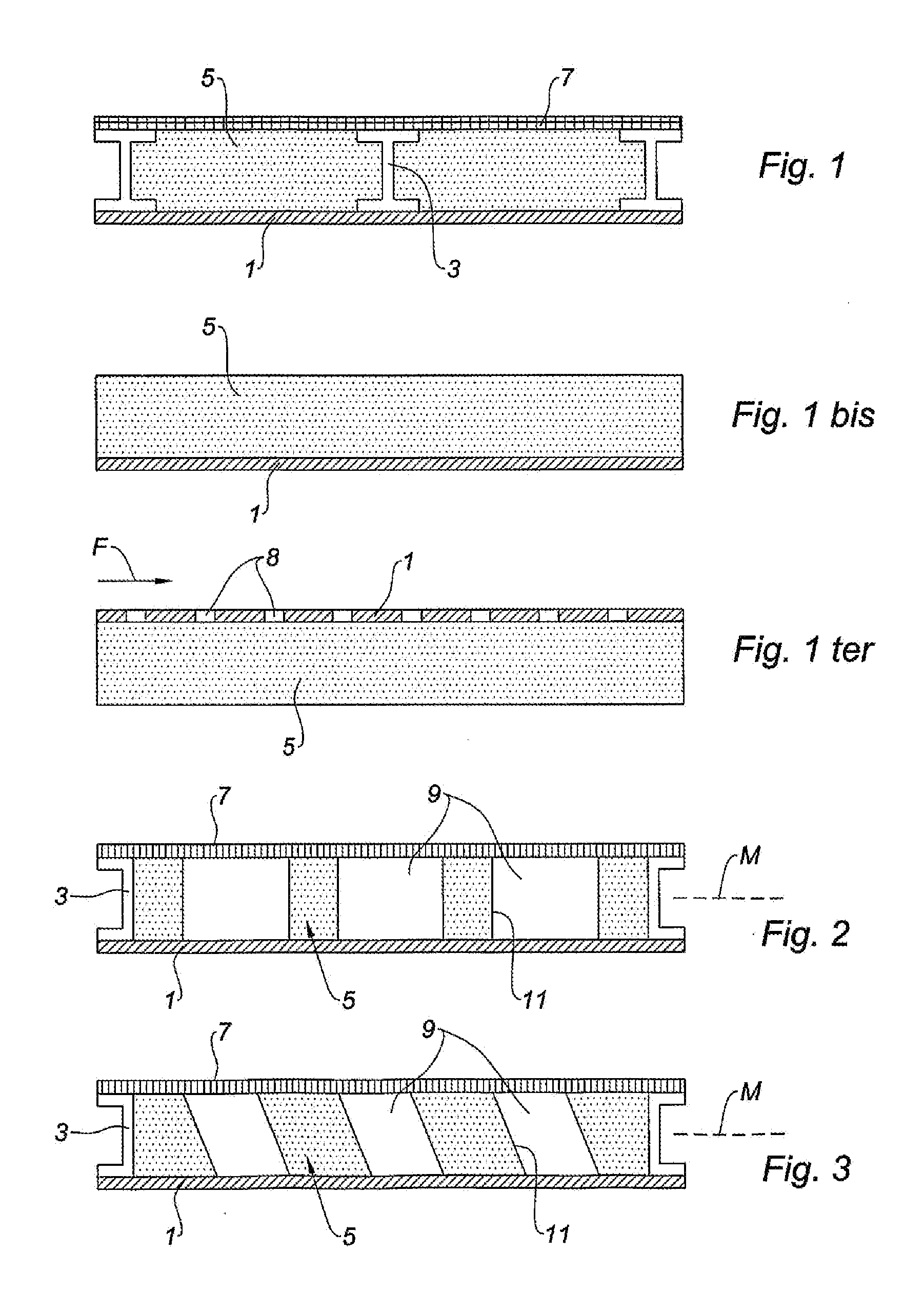

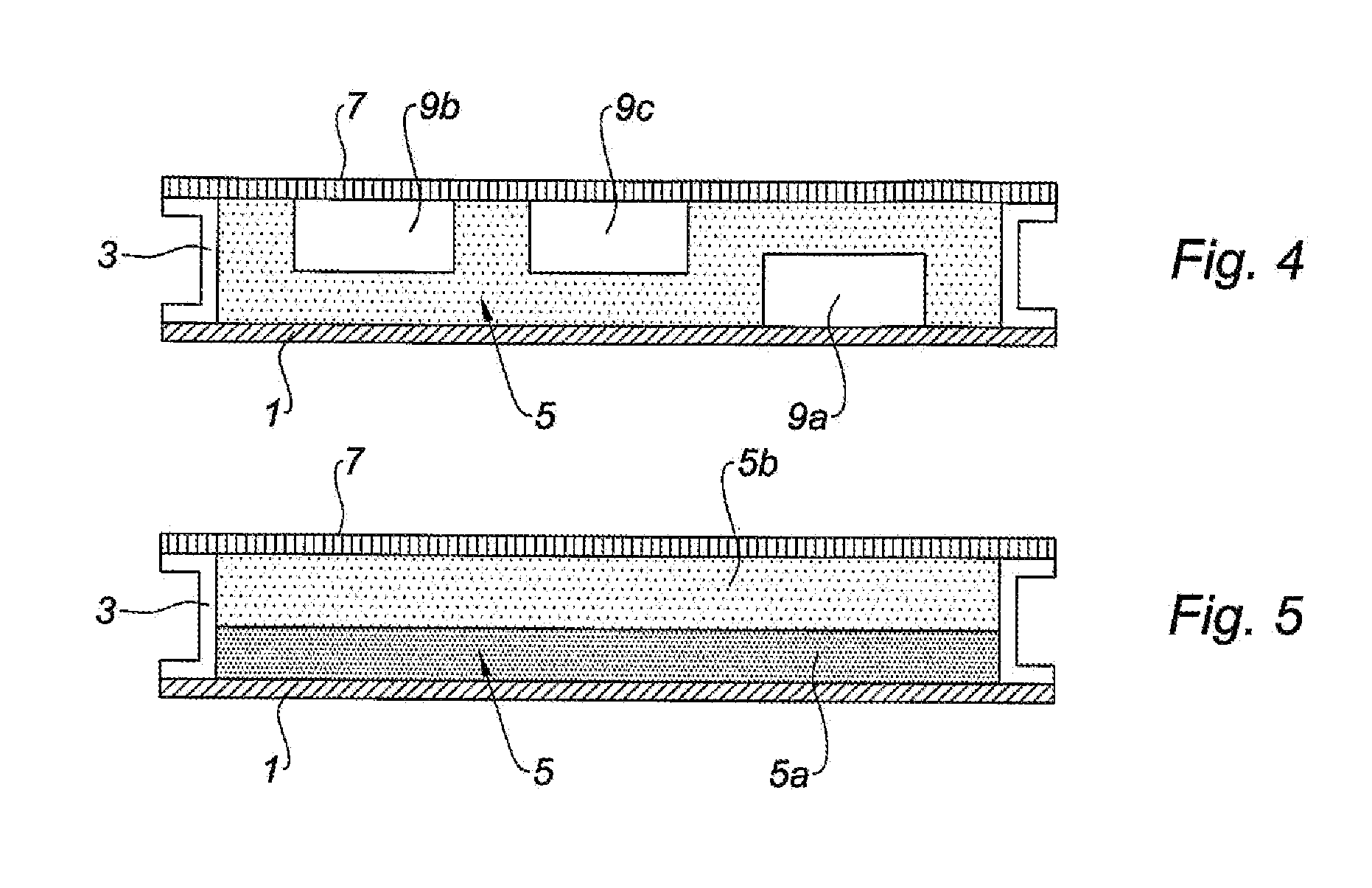

Acoustic attenuation panel for aircraft for engine nacelle

InactiveUS20110133025A1Weight optimizationOptimize sound absorption characteristicDe-icing equipmentsEfficient propulsion technologiesNacelleAcoustic absorption

This acoustic attenuation panel for an aircraft engine nacelle comprises a structuring skin (1) and, by way of acoustic absorption material, a porous material (5) attached to this skin (1).

Owner:SAFRAN NACELLES

Thermal Management System

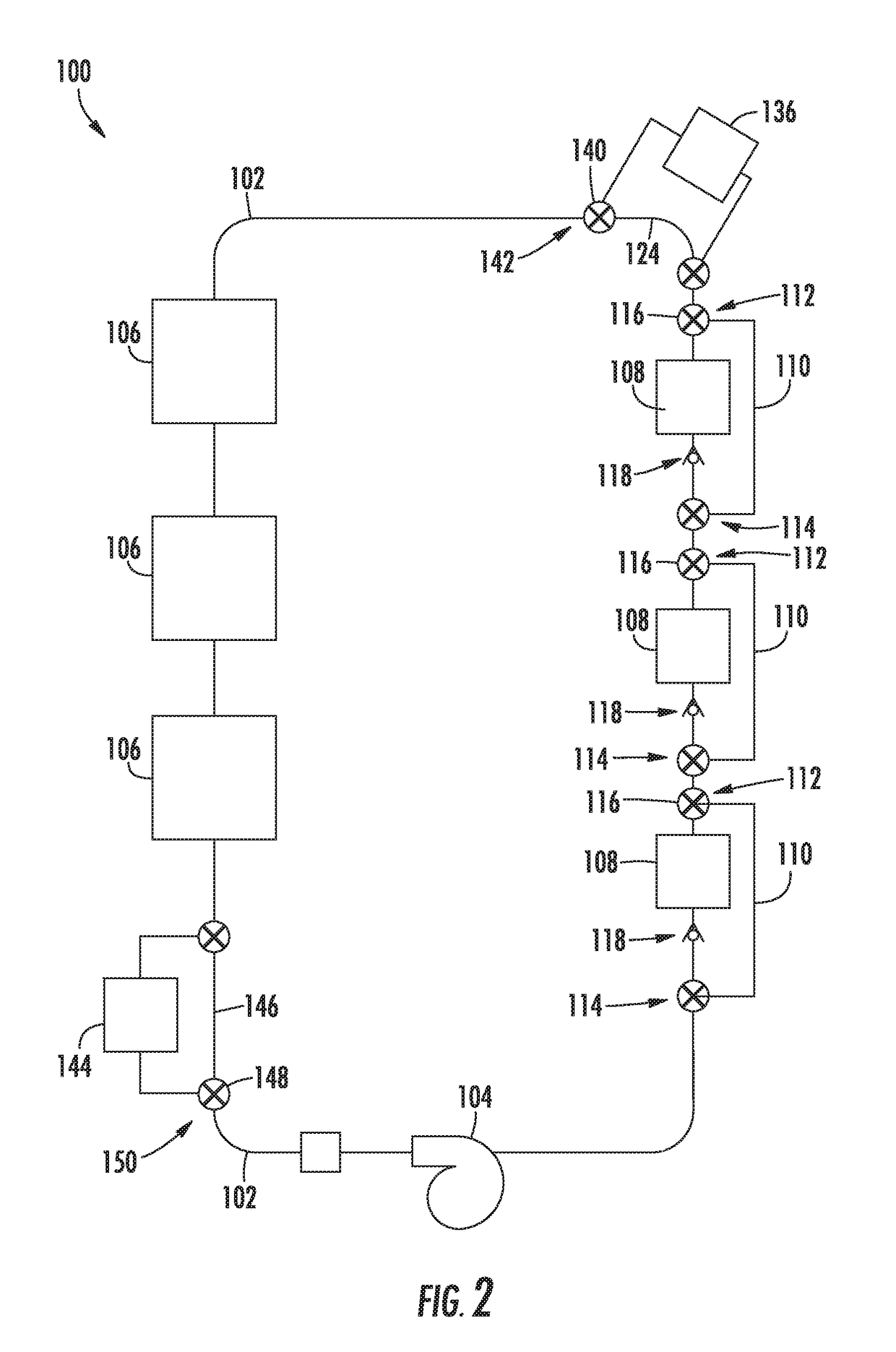

ActiveUS20170167382A1Engine fuctionsTurbine/propulsion engine coolingEngineeringThermal management system

A thermal management system for a gas turbine engine and / or an aircraft is provided including a thermal transport bus having a heat exchange fluid flowing therethrough. The thermal management system also includes one or more heat source exchangers and a deicing module. The one or more heat source exchangers and the deicing module are each in thermal communication with the heat exchange fluid in the thermal transport bus. The one or more heat source exchangers are configured to transfer heat from one or more accessory systems to the heat exchange fluid, and the deicing module is located downstream of the one or more heat source exchangers for transferring heat from the thermal transfer fluid to a surface of one or more components of the gas turbine engine and / or the aircraft.

Owner:GENERAL ELECTRIC CO

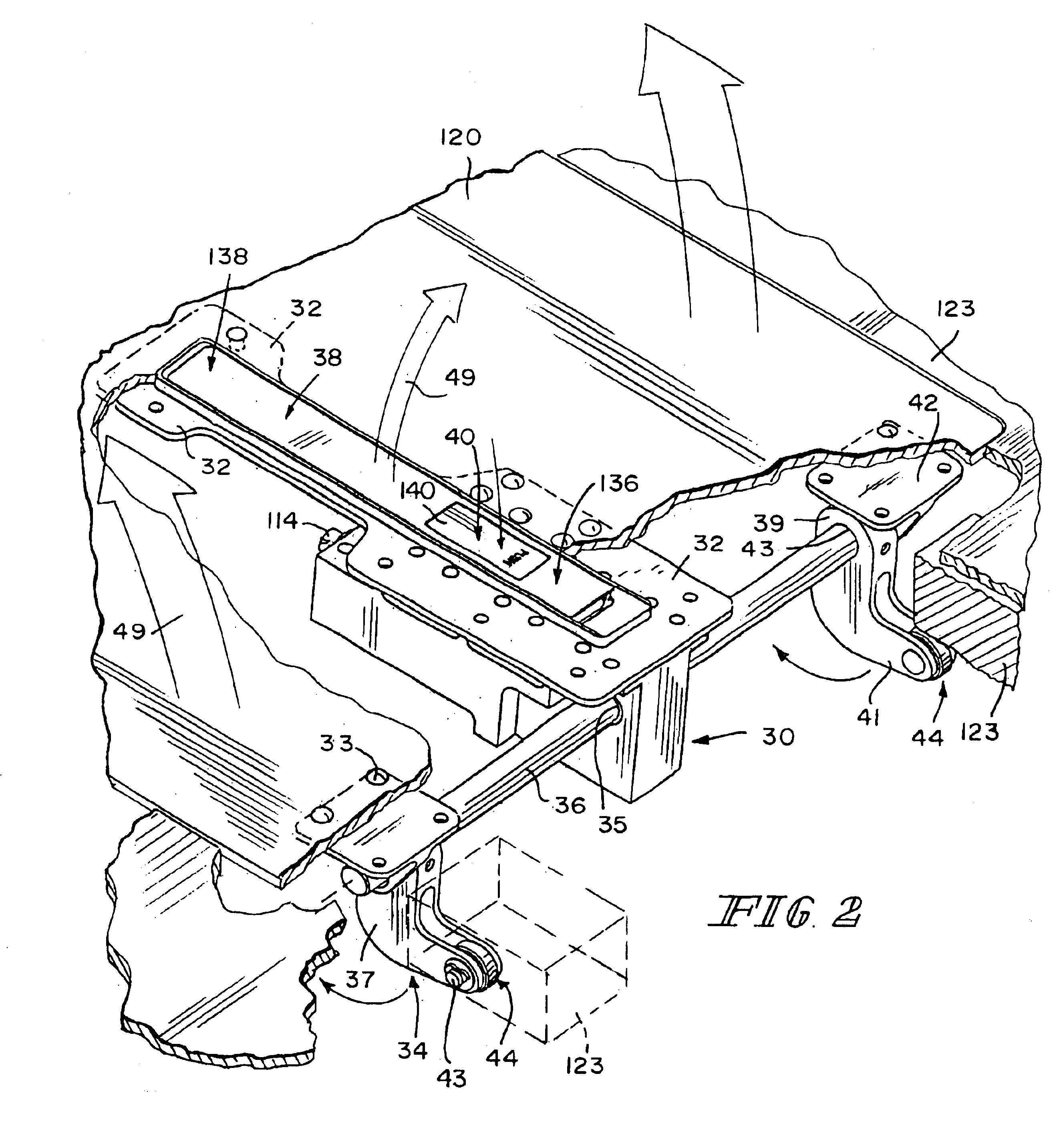

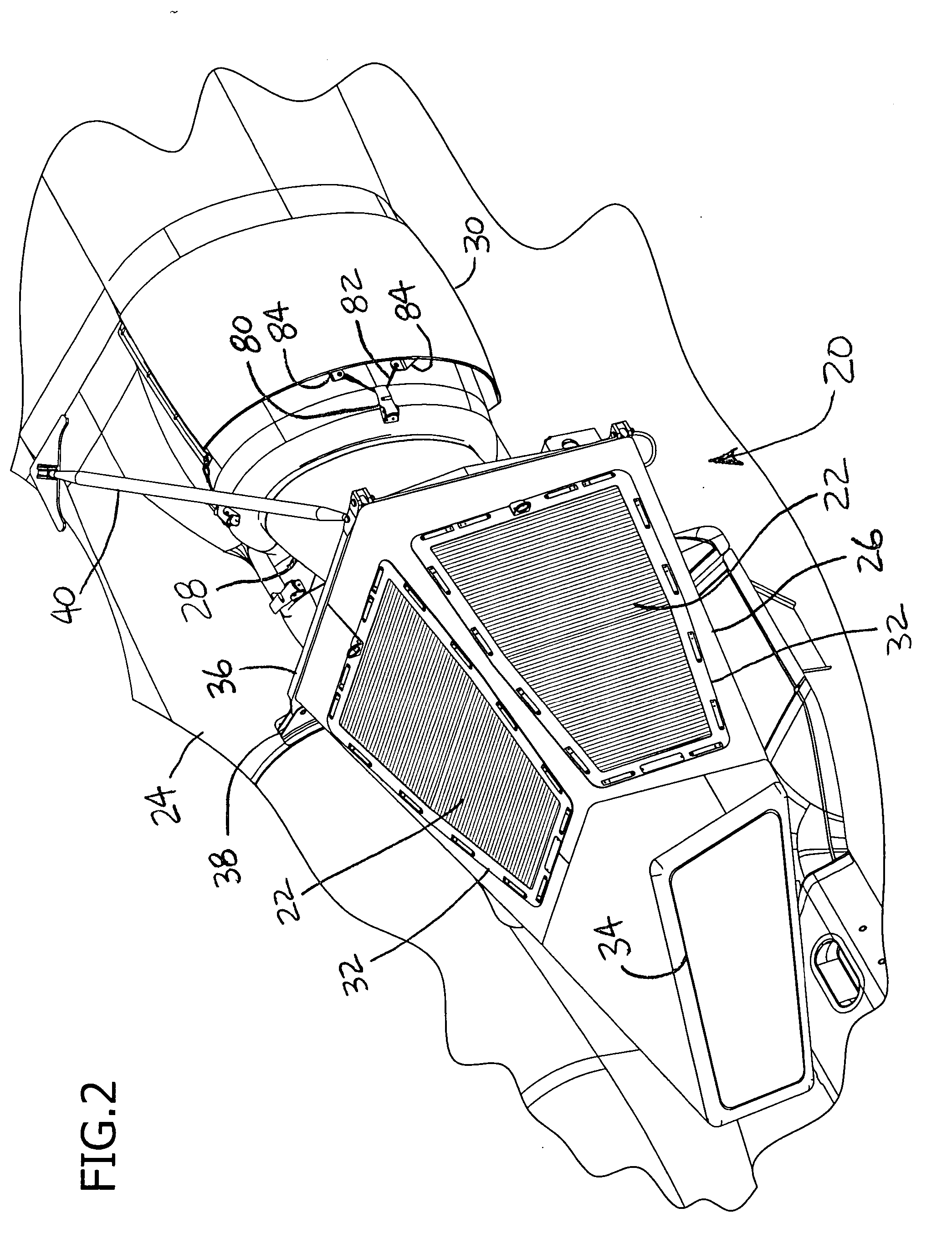

Engine air filter and sealing system

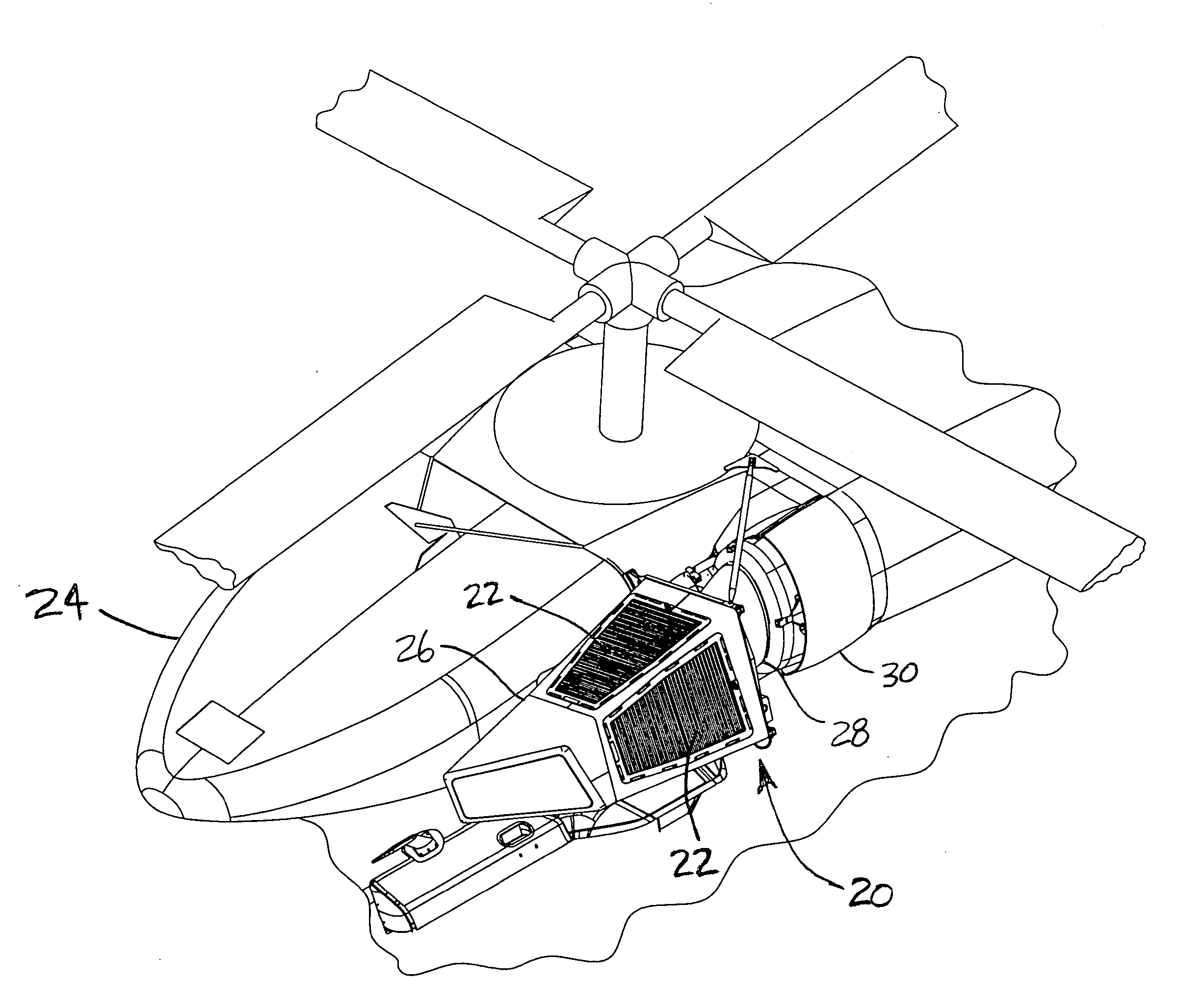

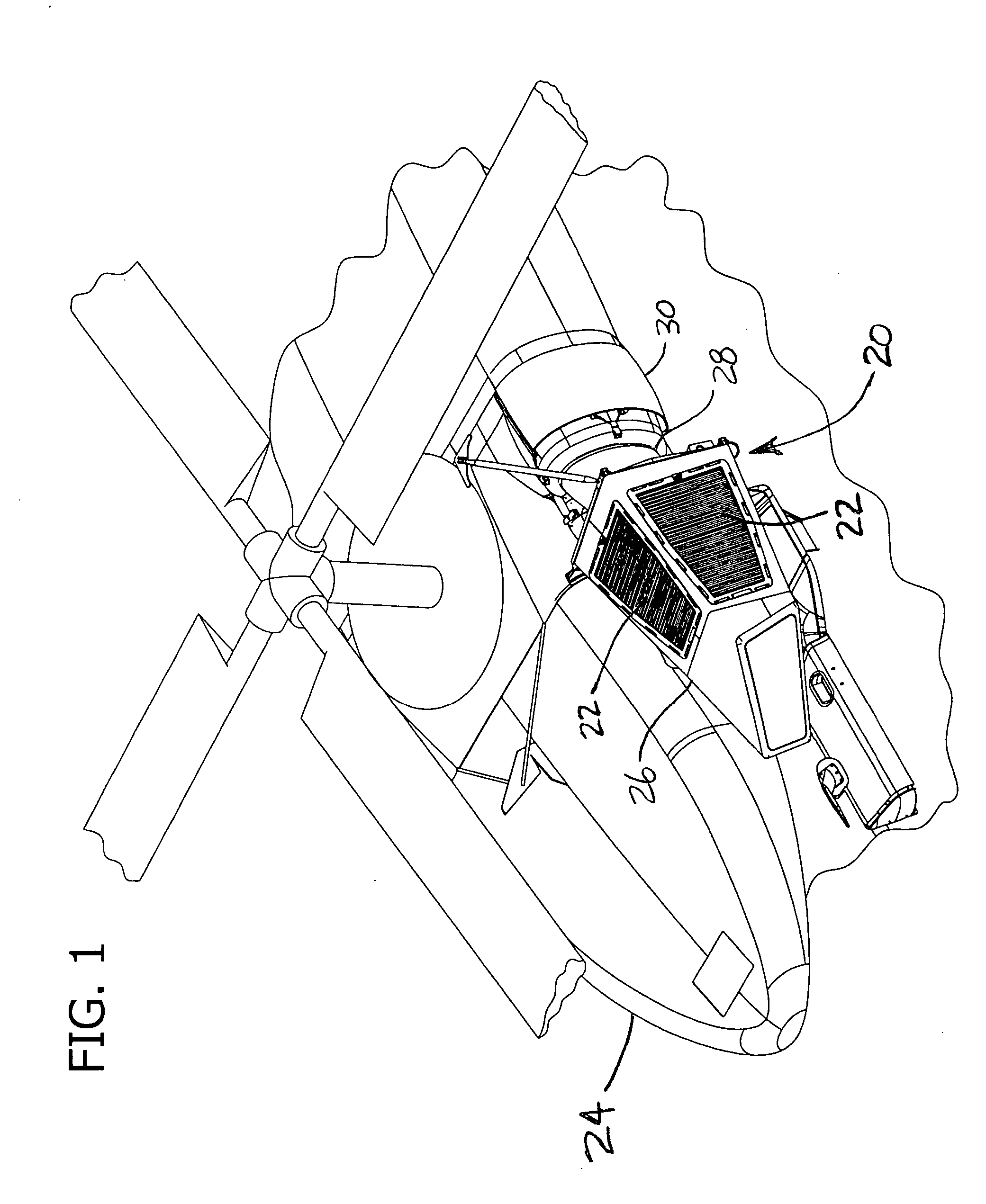

ActiveUS20050229558A1Efficient removalMinimize total lossCombination devicesDispersed particle filtrationAir filterEngineering

An air induction system for an engine to remove contaminants from intake air prior to delivery to the engine. The system includes an assembly for filtering air which is mounted in advance of the engine, and a duct for delivering air from the assembly to the engine. A sealing system is provided which prevents entry of unfiltered air while simultaneously permitting movement of the engine relative to adjacent parts of the airframe as engine power setting varies. The seal is protected from high pressures in the duct which can occur in operation of the engine.

Owner:DONALDSON CO INC

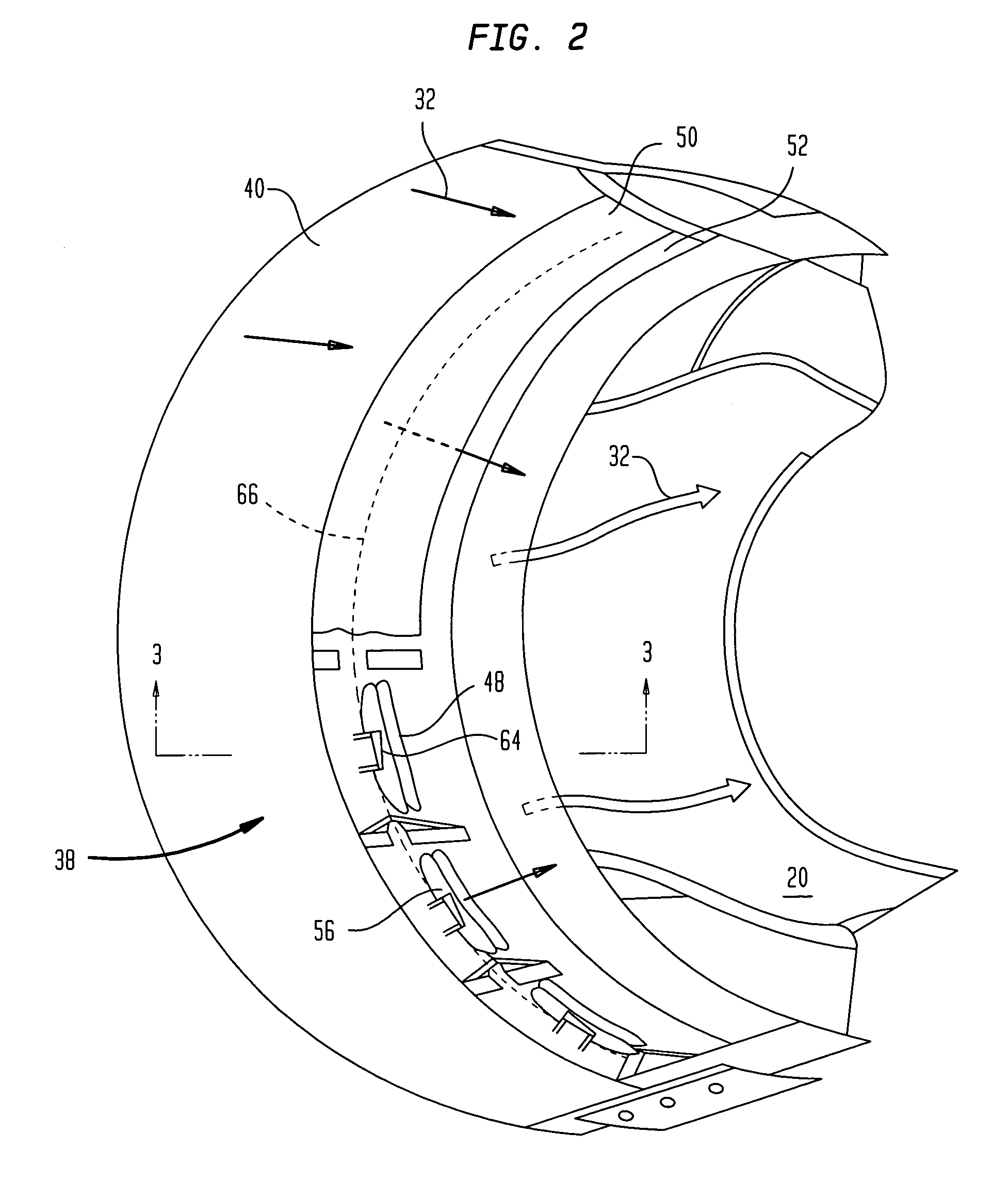

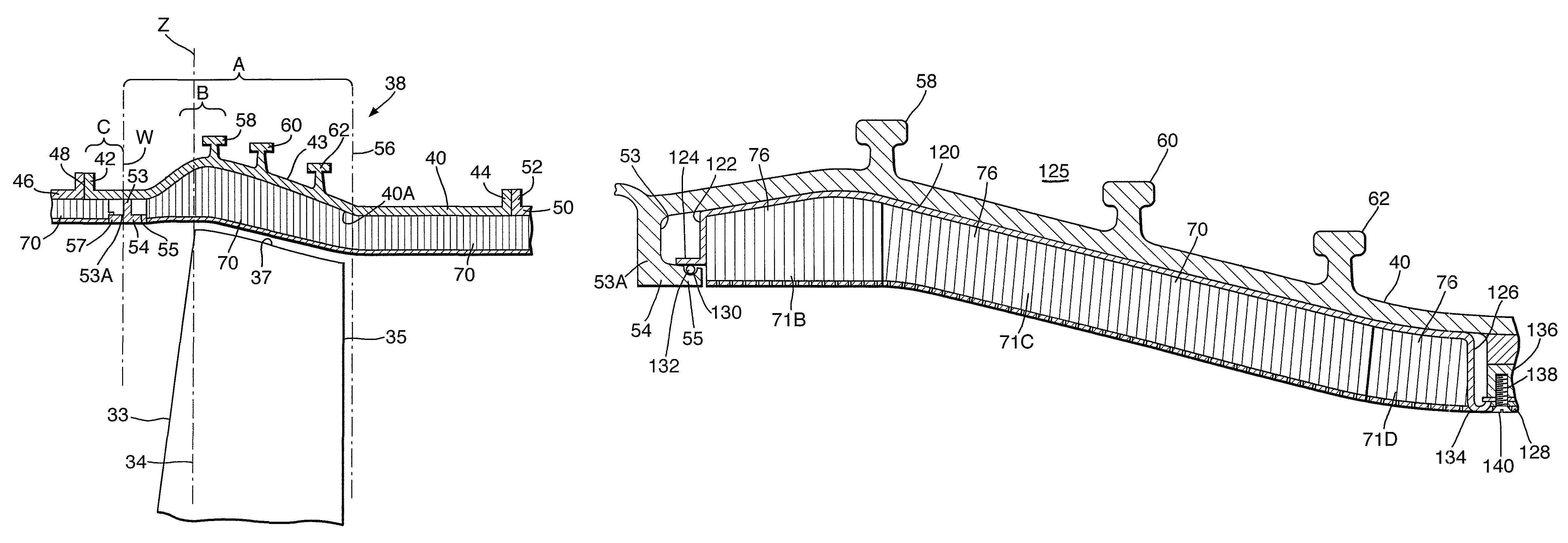

Liner for a gas turbine engine casing

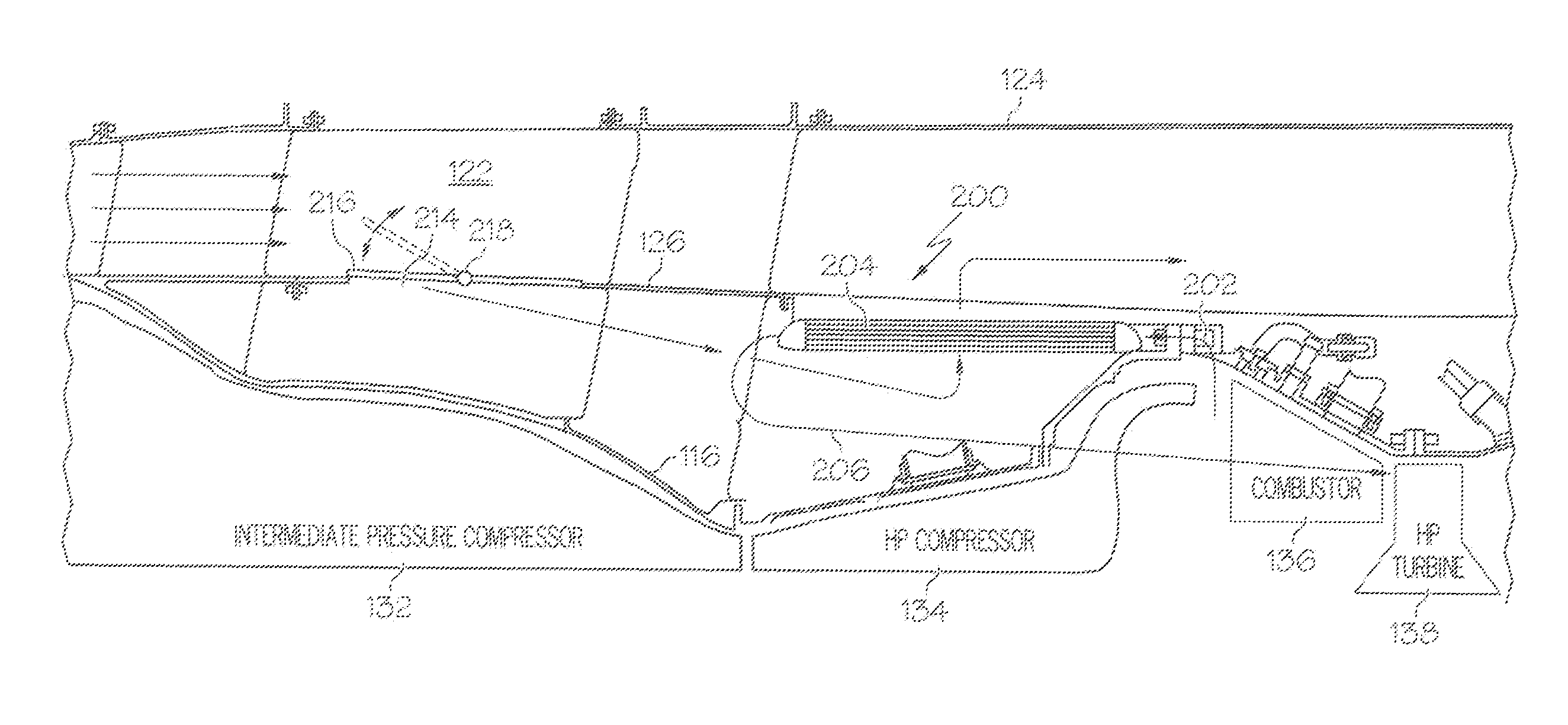

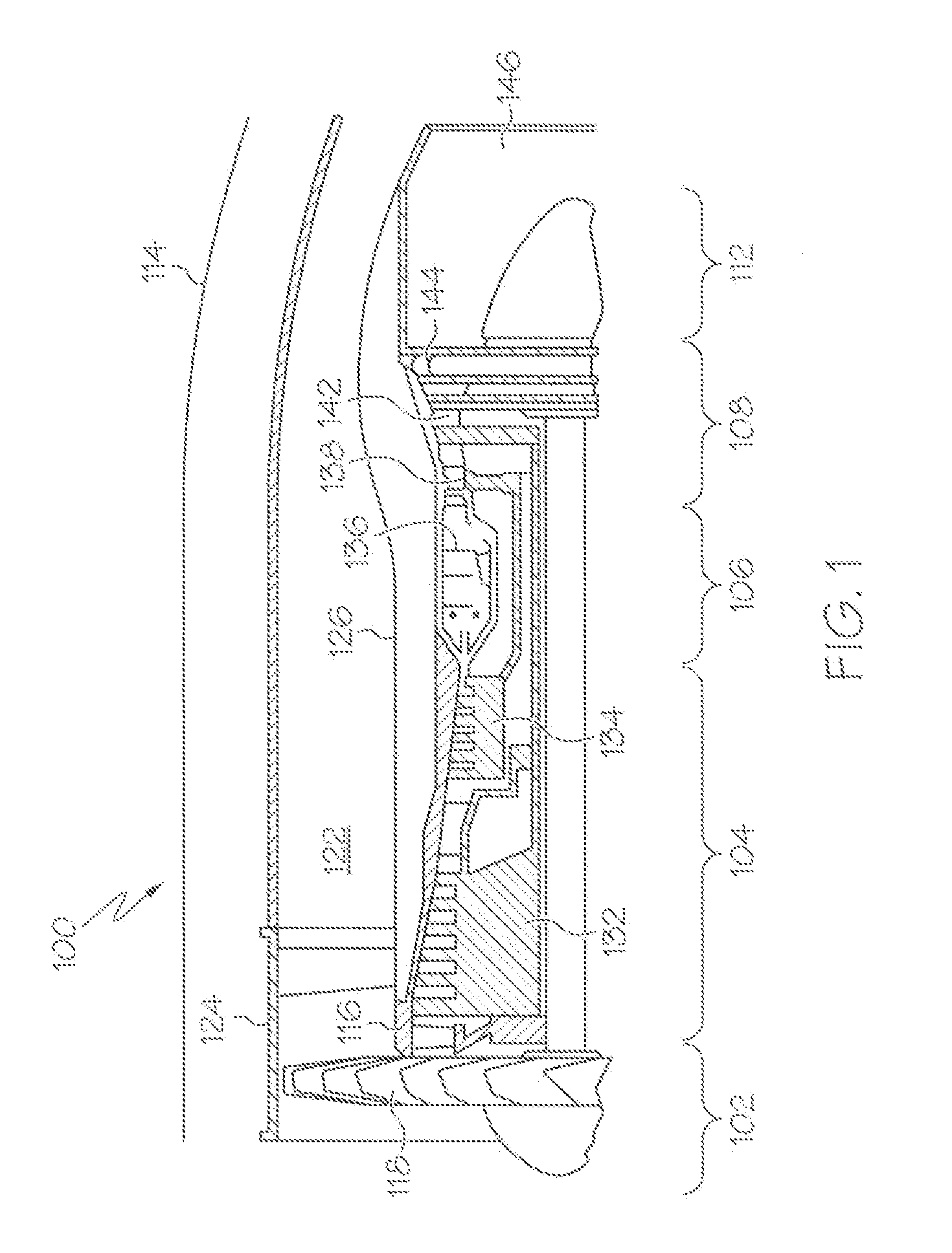

A turbofan gas turbine engine (10) comprises a fan rotor (32) carrying a plurality of radially extending fan blades (34). A fan blade containment assembly (38) surrounds the fan blades (34) and the fan blade containment assembly (38) comprises a generally cylindrical, or frustoconical, metal casing (40). The casing (40) comprises an annular member (54) positioned axially upstream of the tip (37) of the fan blade (34). The annular member (54) extends in a radially inwardly and axially downstream direction from the metal casing (40) towards the tip (37) of the fan blade. A set of cassettes (120) carries fan blade track panels (71B, 71C, 71D). The cassettes (120) are secured to the metal casing (40) by axially extending members (124, 128) on the upstream and downstream ends (122, 126) of the cassettes (120) which locate on the annular member (54) and are secured to inserts (136) on the inner face of the casing (40).

Owner:ROLLS ROYCE PLC

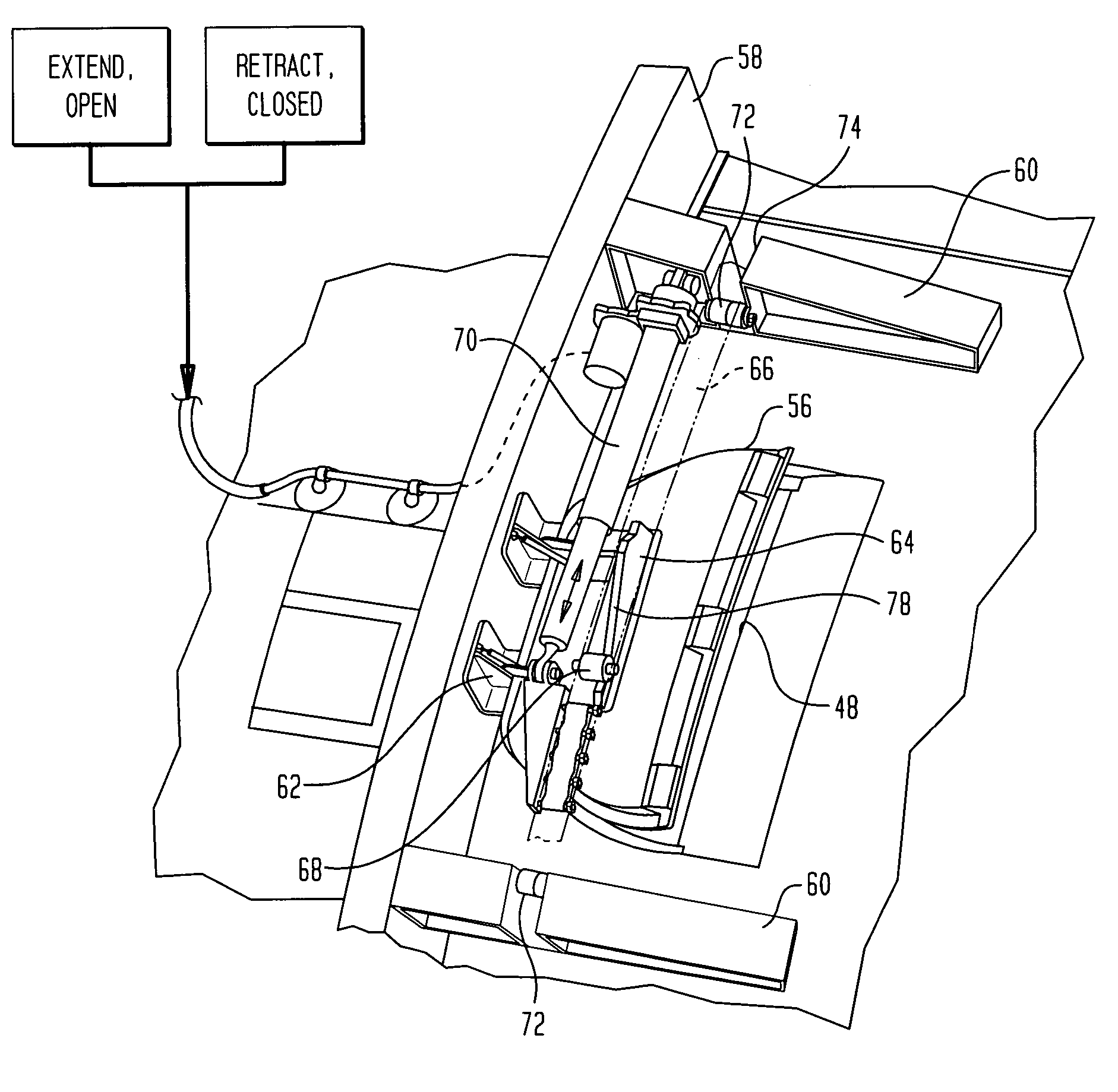

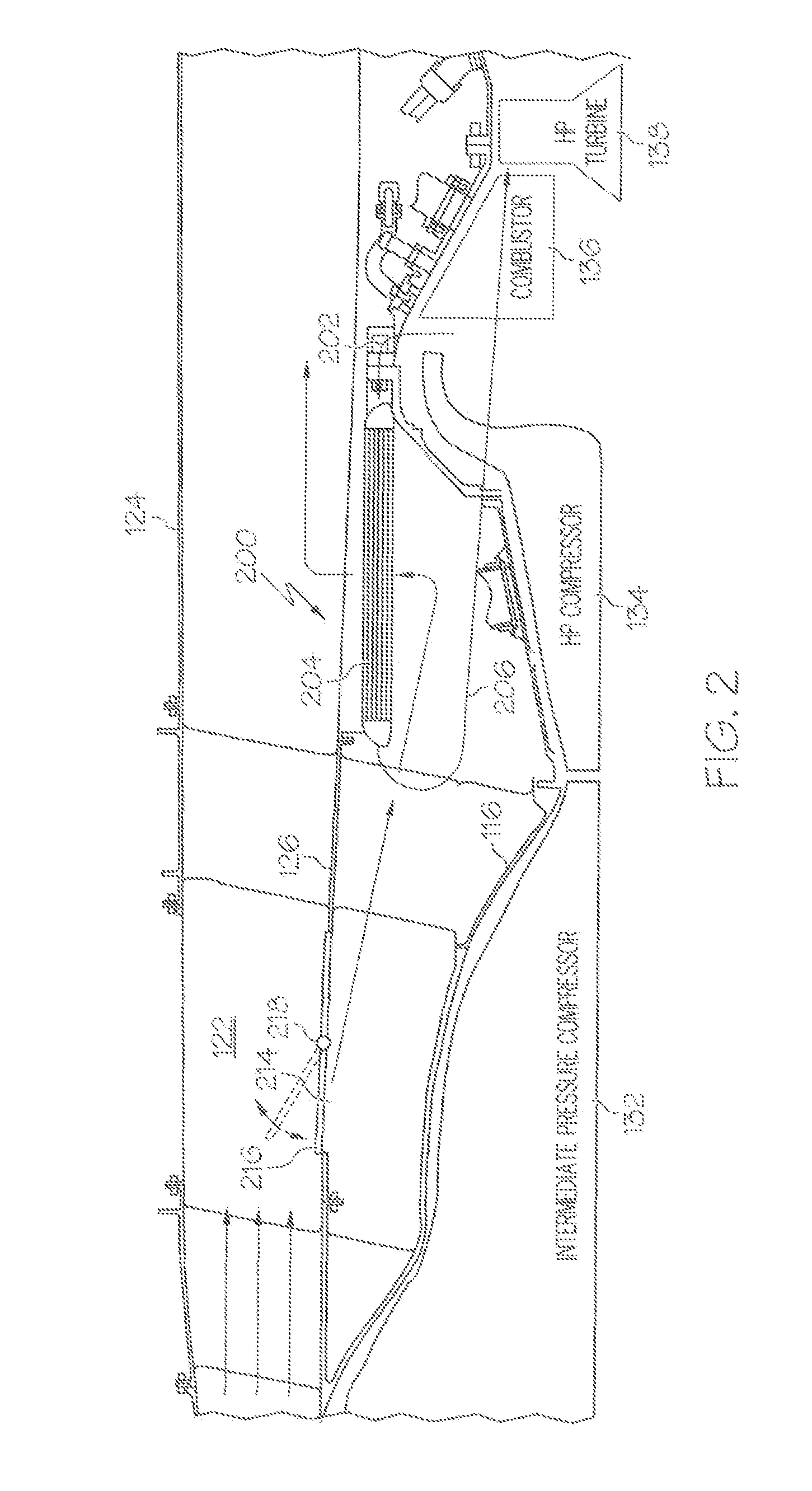

Gas turbine engine in-board cooled cooling air system

A system for supplying turbine cooling air flow includes a turbofan engine, a heat exchanger, and a door. The turbofan engine includes an engine case that has an inner volume within which at least a gas turbine engine is mounted, and a bypass flow passage that is defined by an outer fan duct and an inner fan duct and that is configured to direct fan air flow therethrough. The heat exchanger is disposed within the turbofan engine, is coupled to receive fluid and cooling air from the bypass flow passage, and is configured to transfer heat between fluid and the cooling air. The door is movably mounted in the turbofan engine and is movable between a closed position, in which the cooling air will not flow through the heat exchanger, and an open position, in which the cooling air may flow through the heat exchanger.

Owner:HONEYWELL INT INC

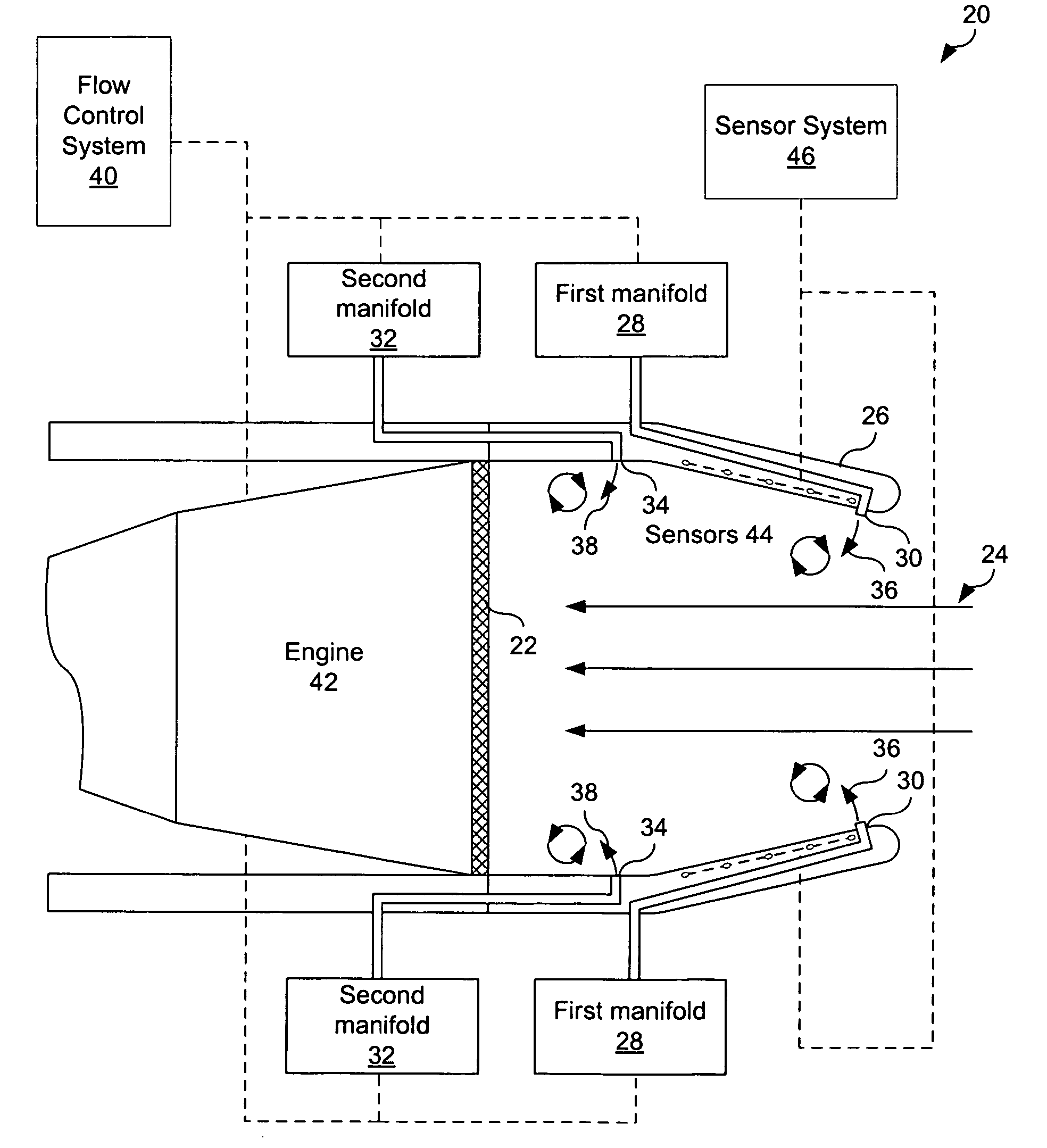

Flow control redistribution to mitigate high cycle fatigue

ActiveUS7617670B2Improve distortionPromote recoveryCombustion enginesGas turbine plantsEngineeringLow-cycle fatigue

A method operable to improve pressure recovery and / or distortion within engine inlet is disclosed. A first fluid flow is provided to primary jet vortex generator(s) operable to inject fluid at a first injection rate into a boundary layer of a primary fluid flow within the inlet. A secondary fluid flow is injected by secondary jet vortex generator(s) at a second injection rate into the boundary layer of the primary fluid flow, The fluid injected at the first injection rate and second injection rate is operable to induce secondary flow structures within the boundary layer. These secondary close structures are then operable to improve or manipulate the pressure recovery of the inlet. At specific engine conditions, this method may redistribute the ratio of the first injection rate and second injection rate in order to improve pressure recovery and / or distortion of the inlet when the particular engine conditions.

Owner:LOCKHEED MARTIN CORP

Dual action inlet door and method for use thereof

InactiveUS7014144B2Reduce noiseReducing APU noisePower installationsEngine fuctionsDual actionEngineering

An inlet door assembly and method for reducing noise from an auxiliary power unit (APU) contained within an aircraft housing is provided. The inlet assembly includes an inlet duct, an actuator, and a door. The inlet duct is configured to extend from the auxiliary power unit to the aircraft housing and has a sidewall that defines a flow passage through which APU noise propagates. The actuator is disposed at least partially within the inlet duct. The door coupled to the actuator. The actuator is also configured to selectively rotate the door between at least a first position, in which at least a portion of the door deflects APU noise in a first direction, and a second position, in which at least a portion of the door deflects the APU noise in a second direction.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com