Hypersonic aerocraft and air inlet internal and external waverider integrated design method

A technology of hypersonic speed and design method, which is applied to the combustion of the intake port of the power plant, the intake port of the turbine/propulsion device, aircraft parts, etc., and can solve the problem of large lift-to-drag ratio and lack of integrated design of aircraft and intake port method, only 3.8 and other problems, to achieve the effect of high lift resistance characteristics and broaden the range of working Mach number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

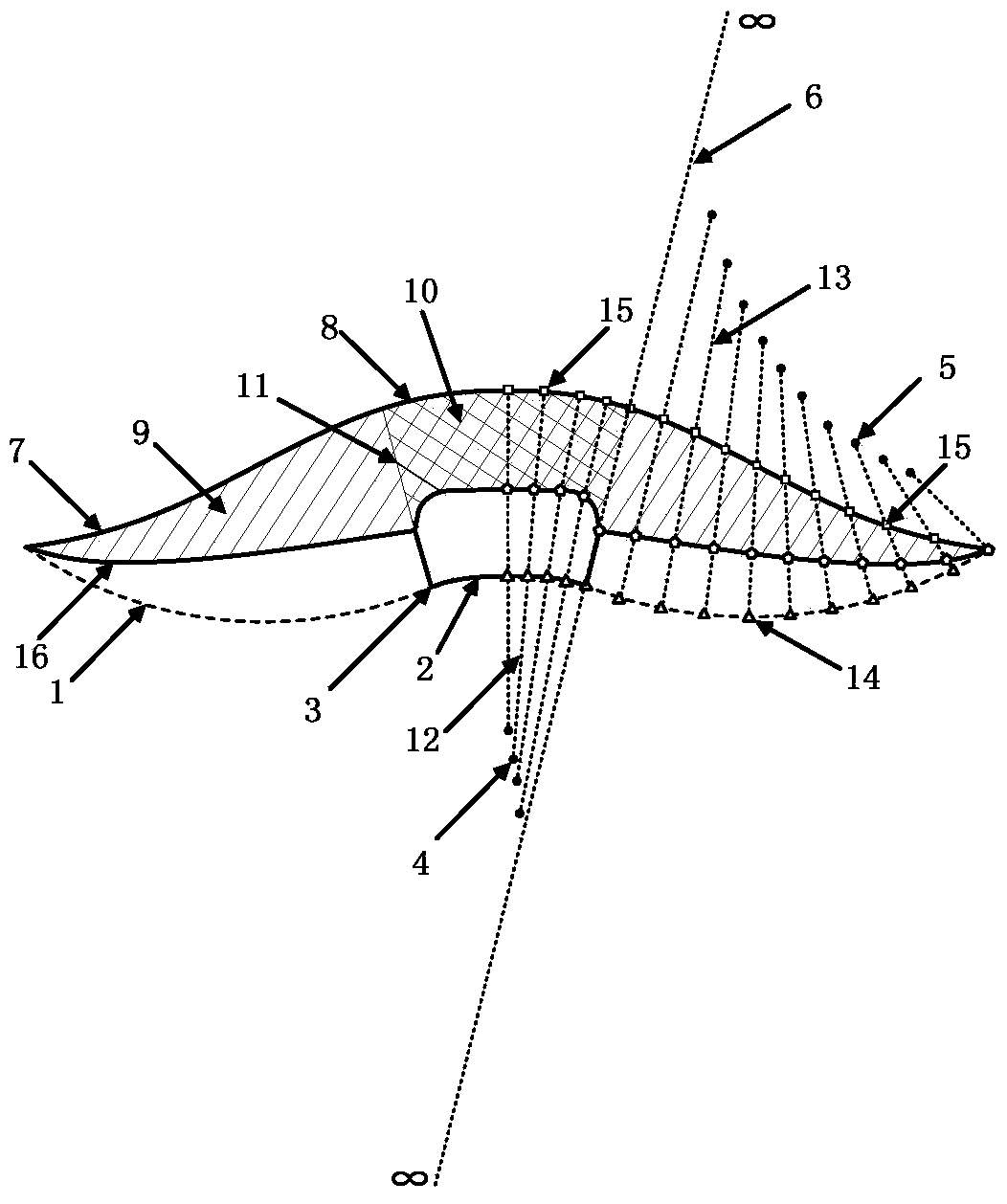

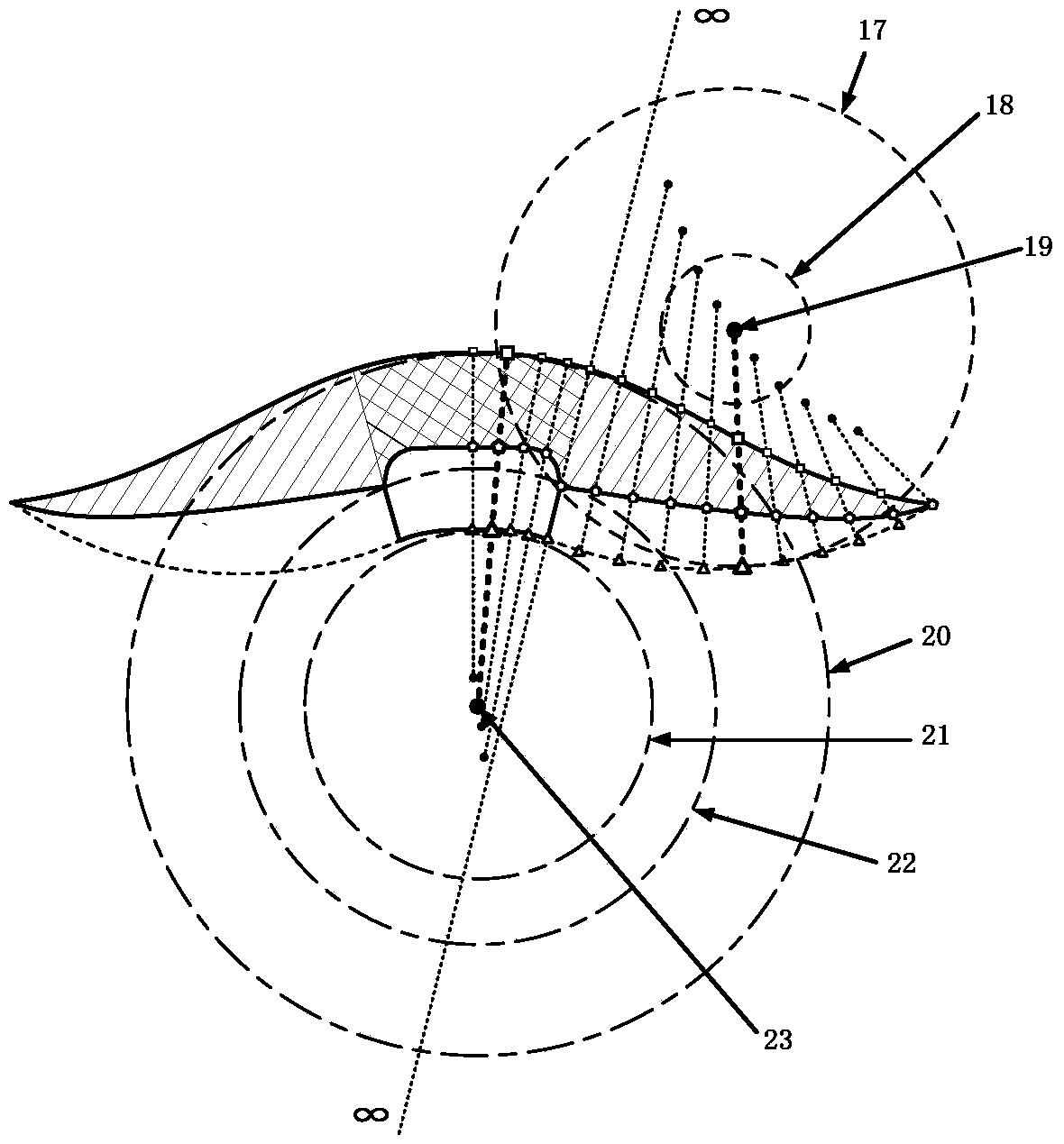

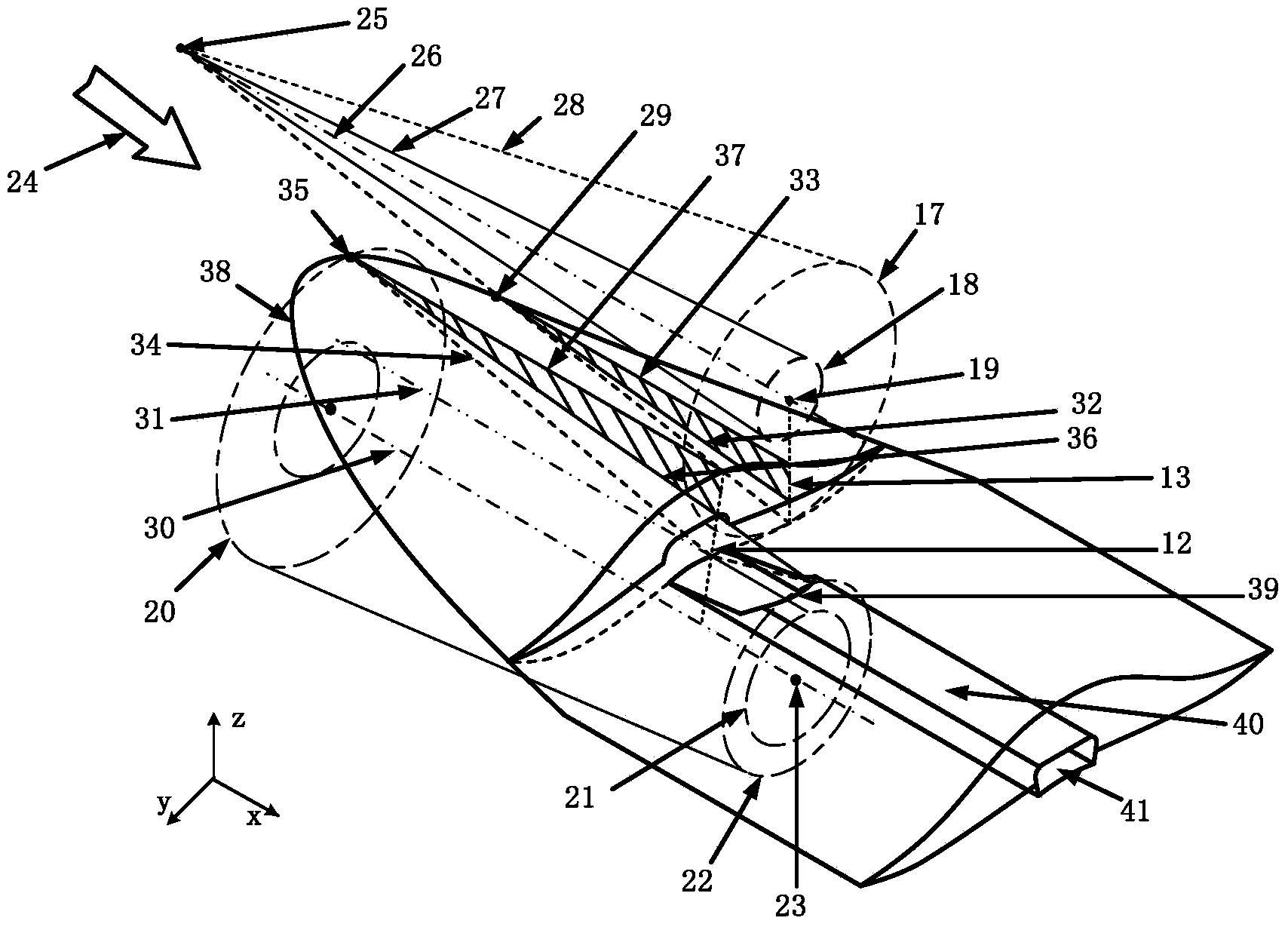

[0051] Example: The integrated design method of the hypersonic vehicle and the waveriders inside and outside the inlet. In this example, given the Mach number Ma=6.5 of the incoming flow and the incident shock wave angle β=12°, it can be designed Figure 4 All-in-one unit shown. The device is composed of an outer waverider aircraft precursor 42 and an inner waverider inlet. The inner waverider inlet includes an inner waverider inlet profile 43, an inner waverider inlet lip 44 and an inner waverider inlet. Inlet isolation section 40. The device generates an incident shock wave system under design conditions such as Figure 5 Shown in 46. Before designing the cross-section, no distinction is made between the outer wave band 1 of the shock wave curve of the hypersonic outer waverider vehicle precursor and the inner waverider inlet, and the shock wave of the hypersonic outer waverider aircraft precursor and the inner waverider inlet. The wave band 2 inside the curve is the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com