Patents

Literature

44results about How to "Reduce outflow resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

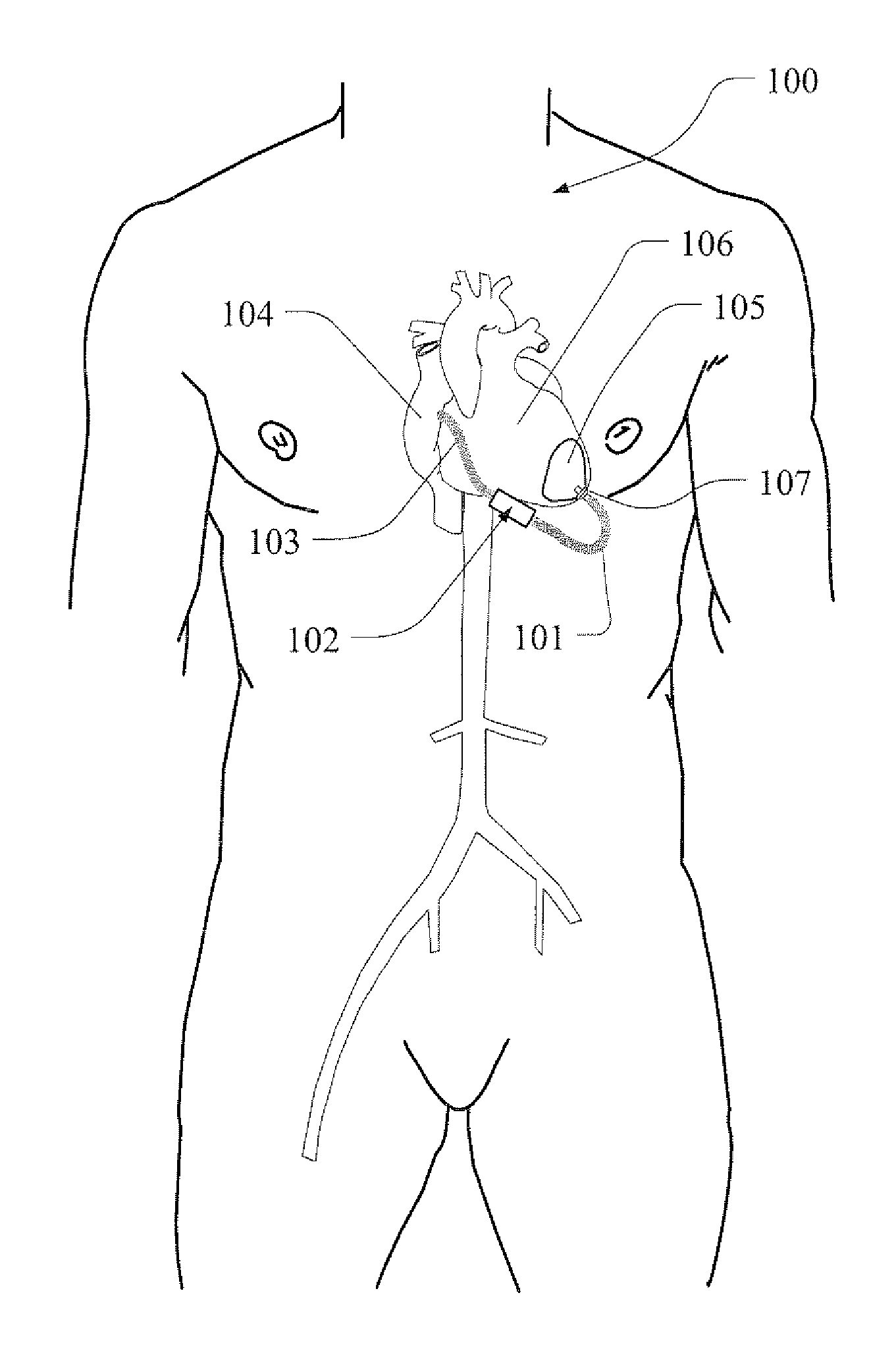

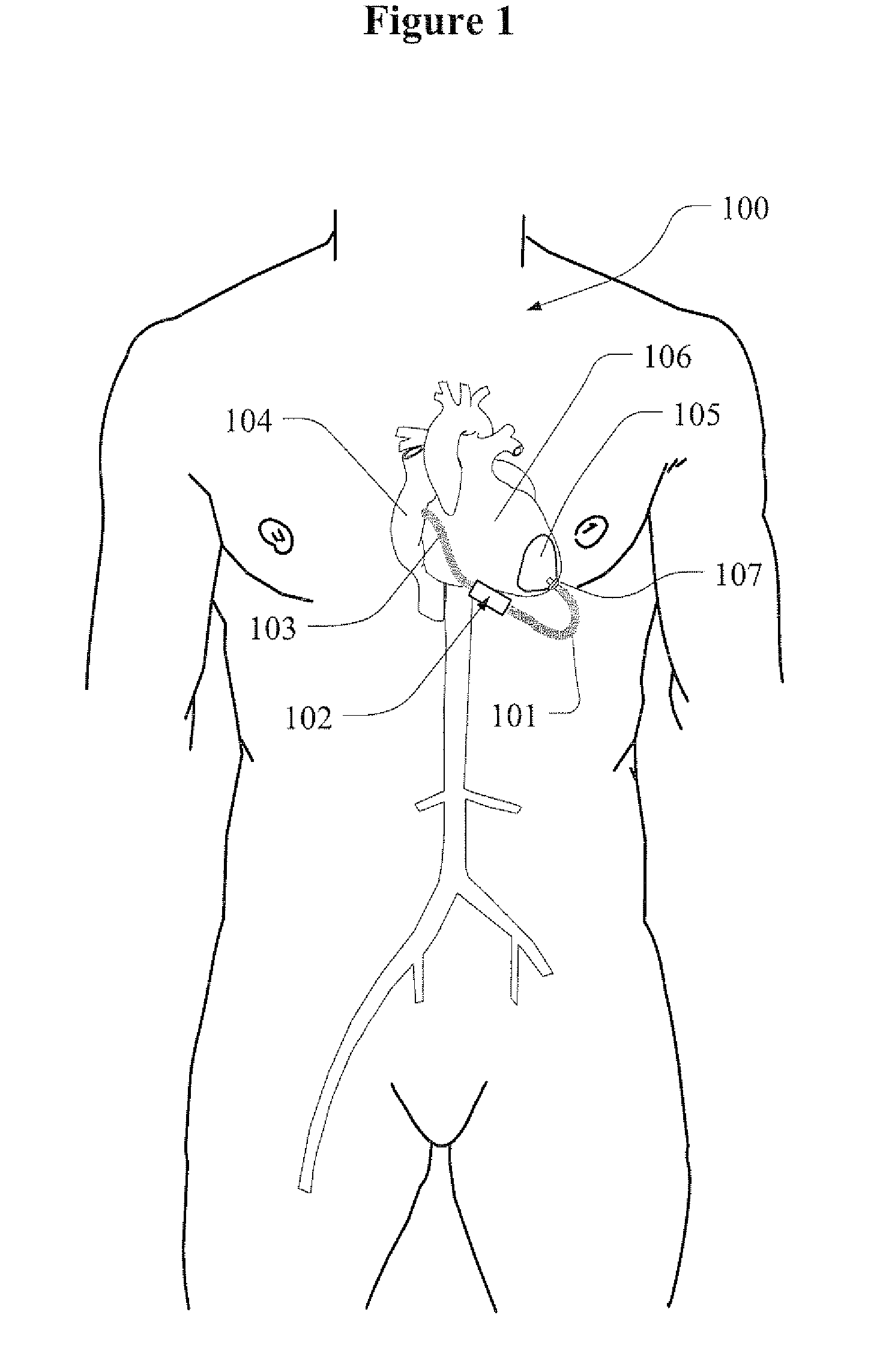

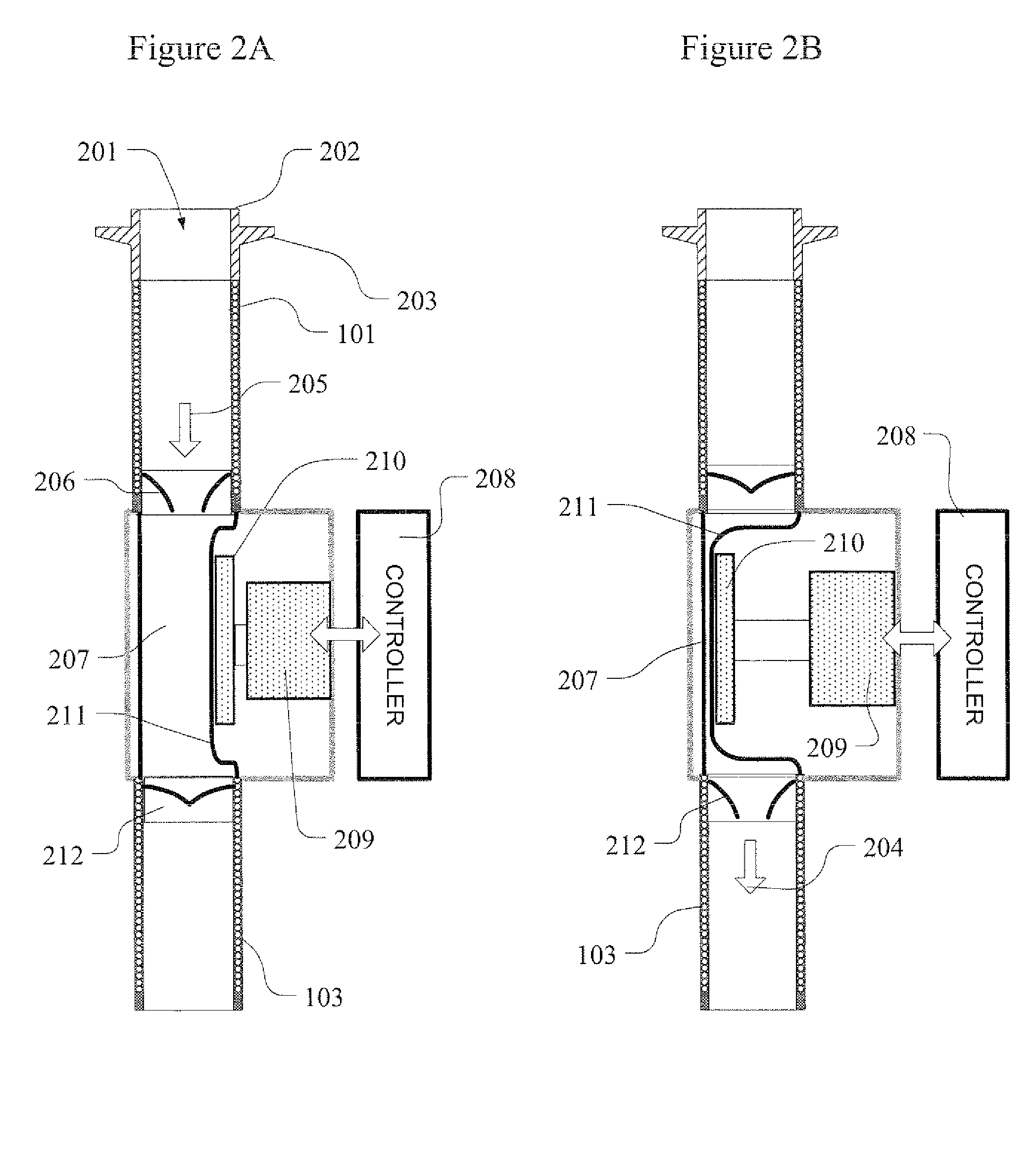

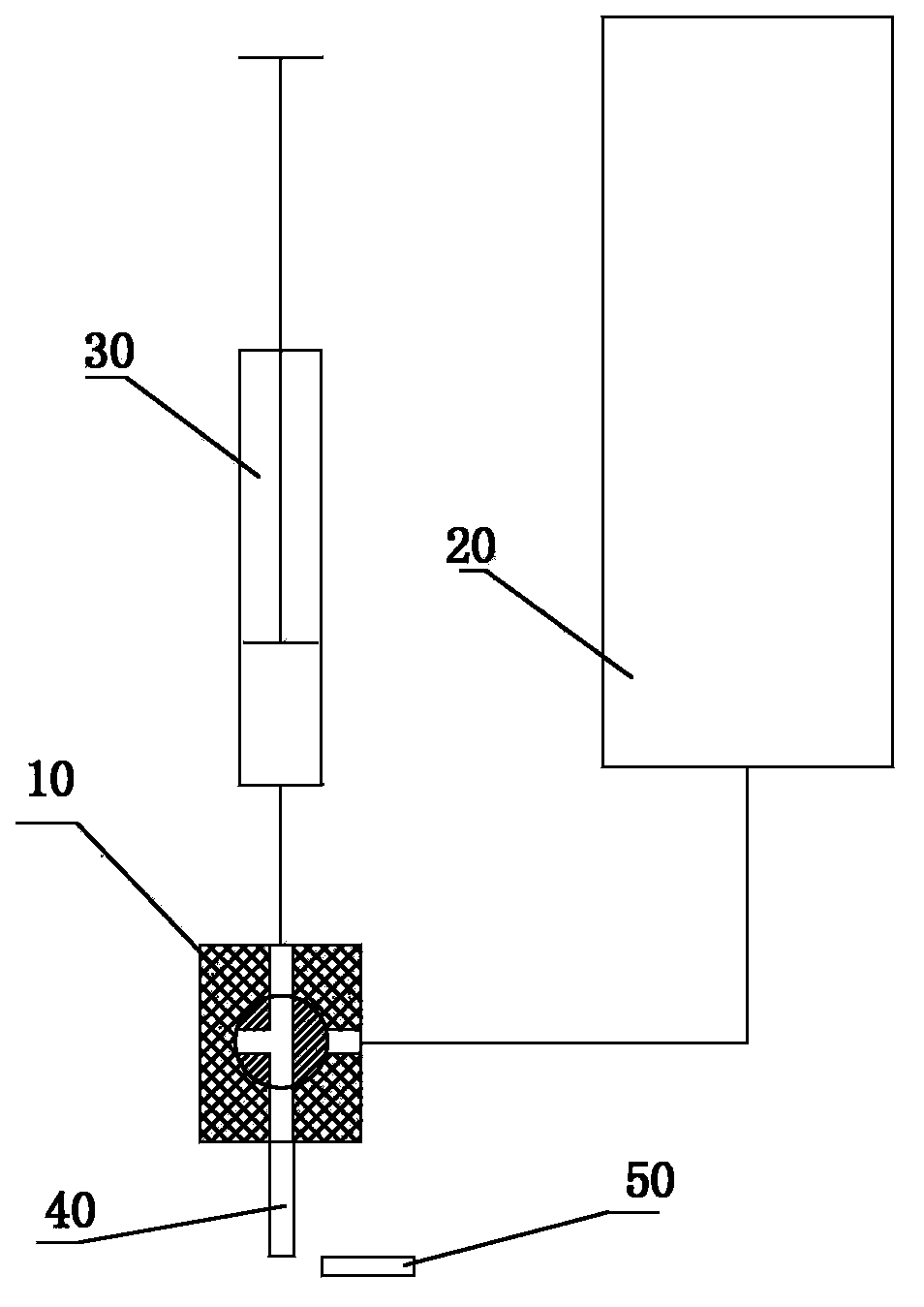

Method and apparatus to unload a failing heart

InactiveUS20070208210A1Lowering LVEDPPrevent of lung congestionElectrocardiographyHeart valvesValved conduitMedicine

A method and apparatus for treatment of heart failure by reducing LV diastolic volume and pressure by pumping blood out of the LV during diastole. A pump is synchronized to the heart cycle, connected to the apex of the LV and discharging into the right atrium of the heart. A left ventricle to aorta one-way valved conduit with added compliance decreases blood pressure in the aorta and the resistance to the ejection of blood by the heart decreases the energy requirements of the heart.

Owner:G&L CONSULTING

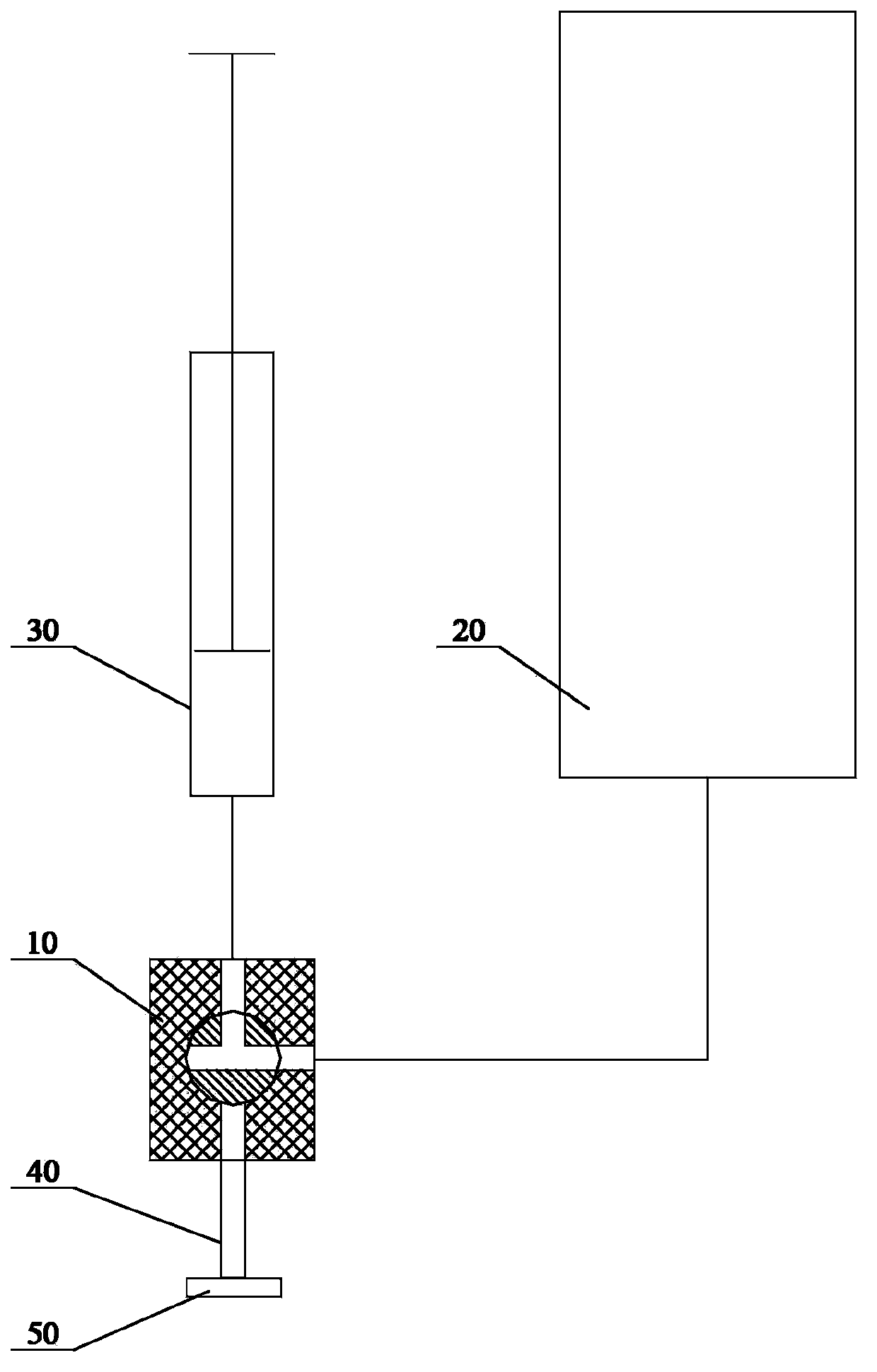

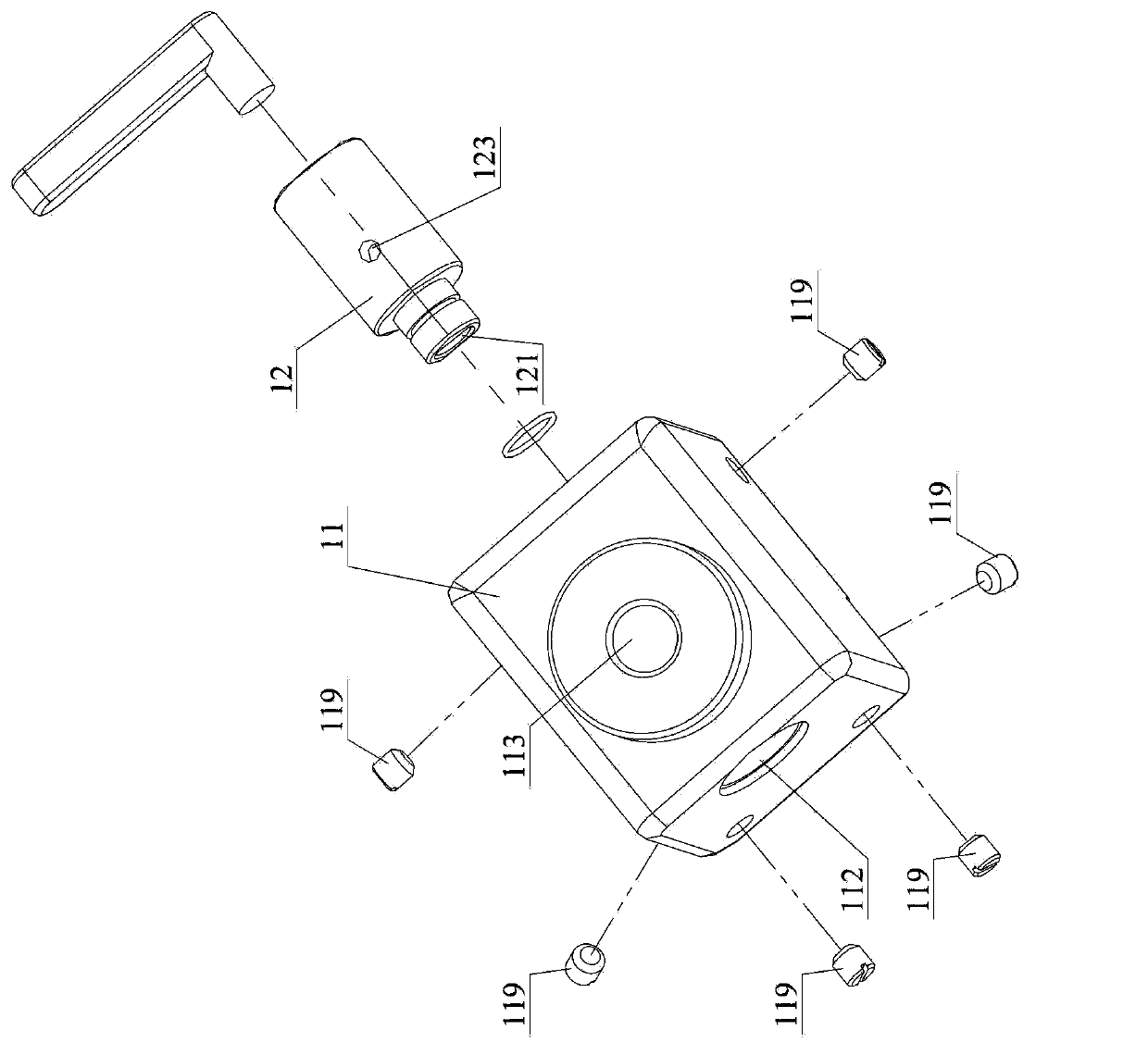

Color mixer and reversing valve device thereof

ActiveCN103968106ASolve the phenomenon of color paste dryingSolve the problem of color paste depositionPlug valvesTransportation and packagingInjection pumpPhysics

The invention discloses a reversing valve device. A first opening on a valve body is used for being communicated with a colorant container while a second opening on the same is used for being communicated with an injection pump, a valve core is arranged in an internal valve cavity of the valve body in a pivoted manner, an internal passage and a first colorant injection hole are arranged on the valve core, the internal passage is communicated with the second opening of the valve body, one end of the first colorant injection hole is communicated with the internal passage while the other end of the same is arranged on the peripheral surface of the valve core, a third opening on the valve body is formed on the inner wall of the internal valve cavity, a first passage is communicated with the first opening and the third opening, a fourth opening is formed on the lower end face of the valve body and communicated with the internal valve cavity, the first colorant injection hole can switch working positions along with rotating of the valve core, and the first colorant injection hole is exposed out of the fourth opening when being at a first colorant injection working position and communicated with the third opening when being at a non-colorant-injection position. By structural optimization, the phenomenon that colorant appears at a colorant outlet can be completely avoided. On the basis, the invention further provides a color mixer with the reversing valve device.

Owner:ZHENGZHOU SANHUA TECH & IND

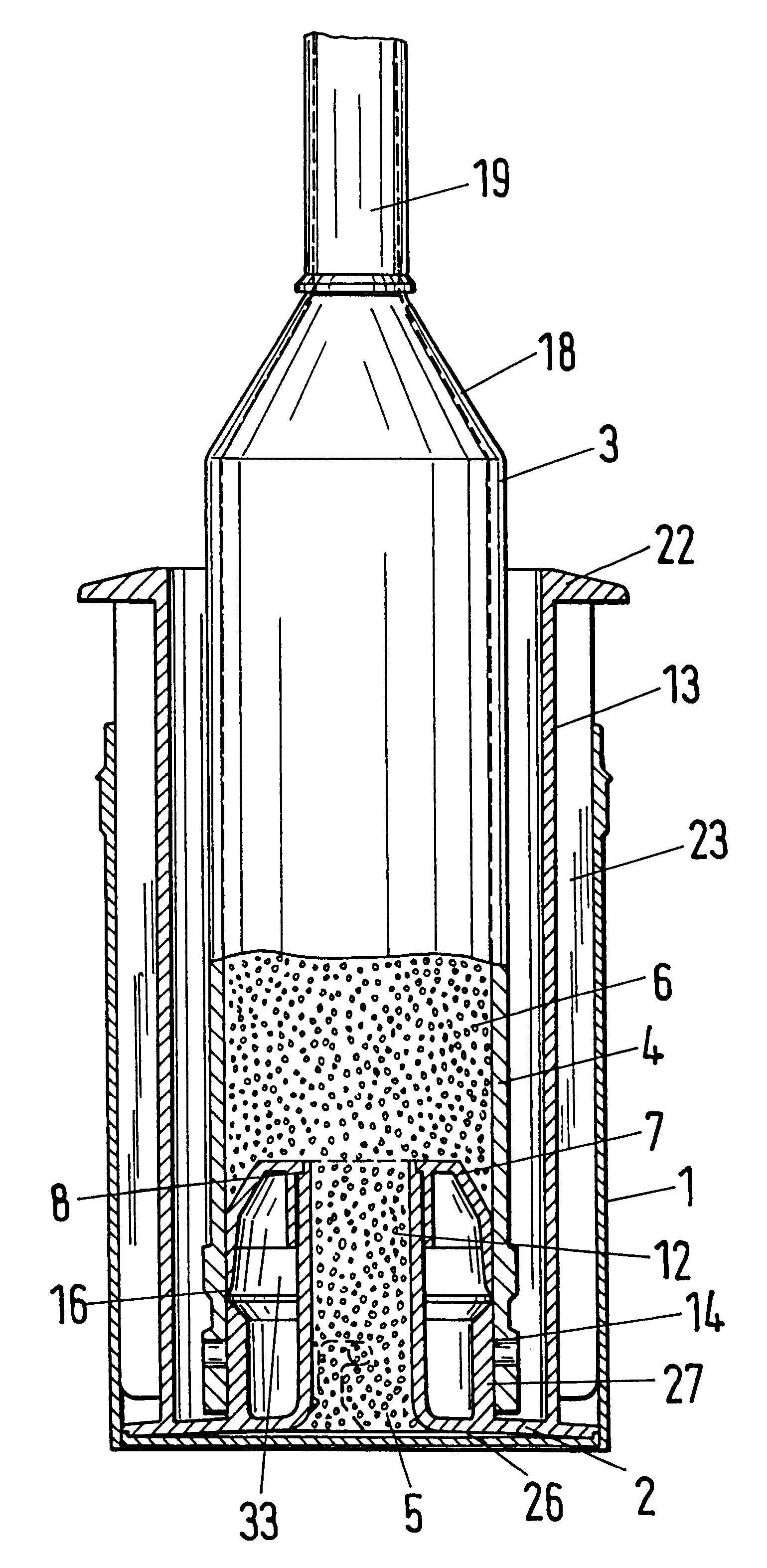

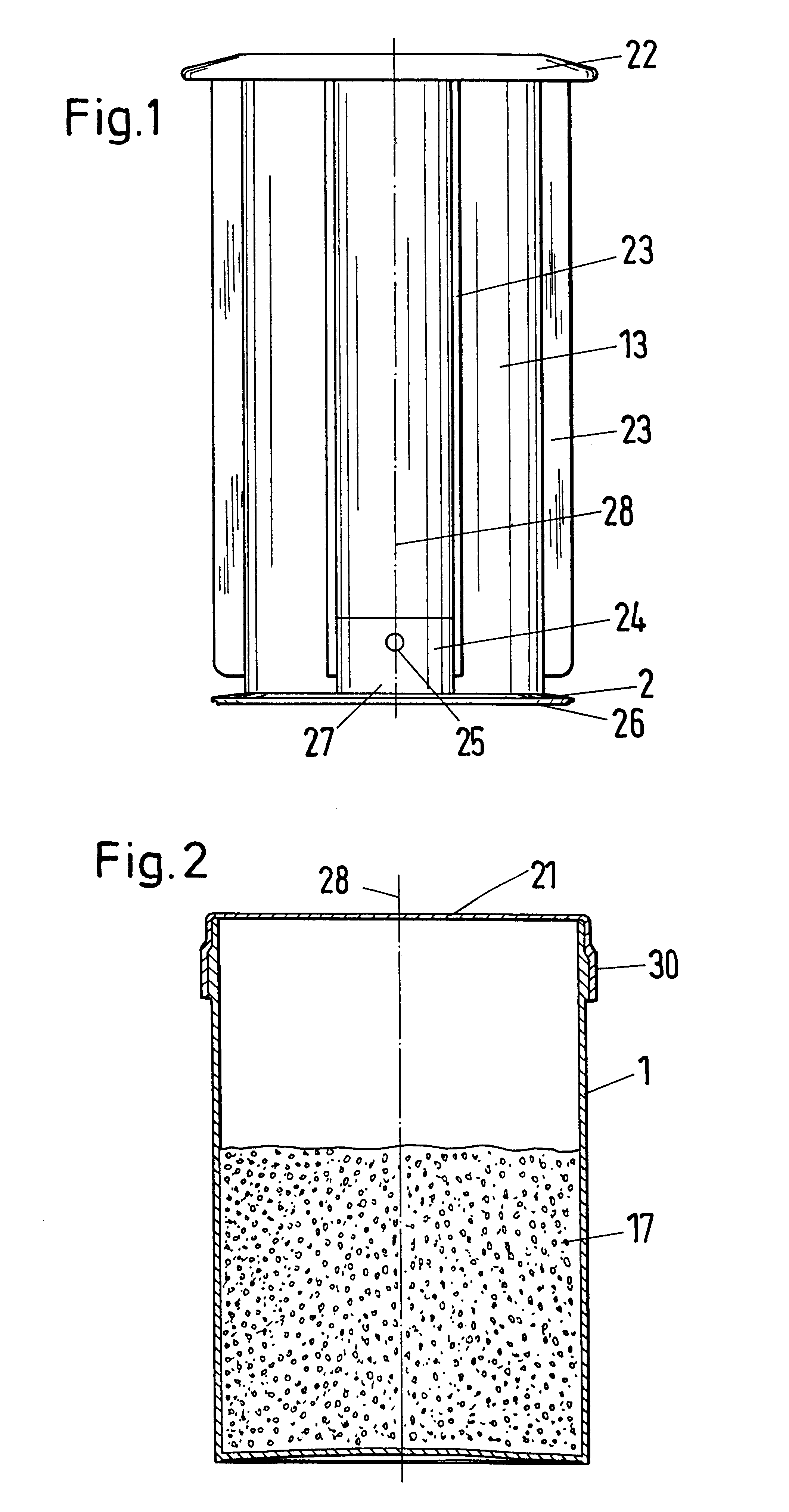

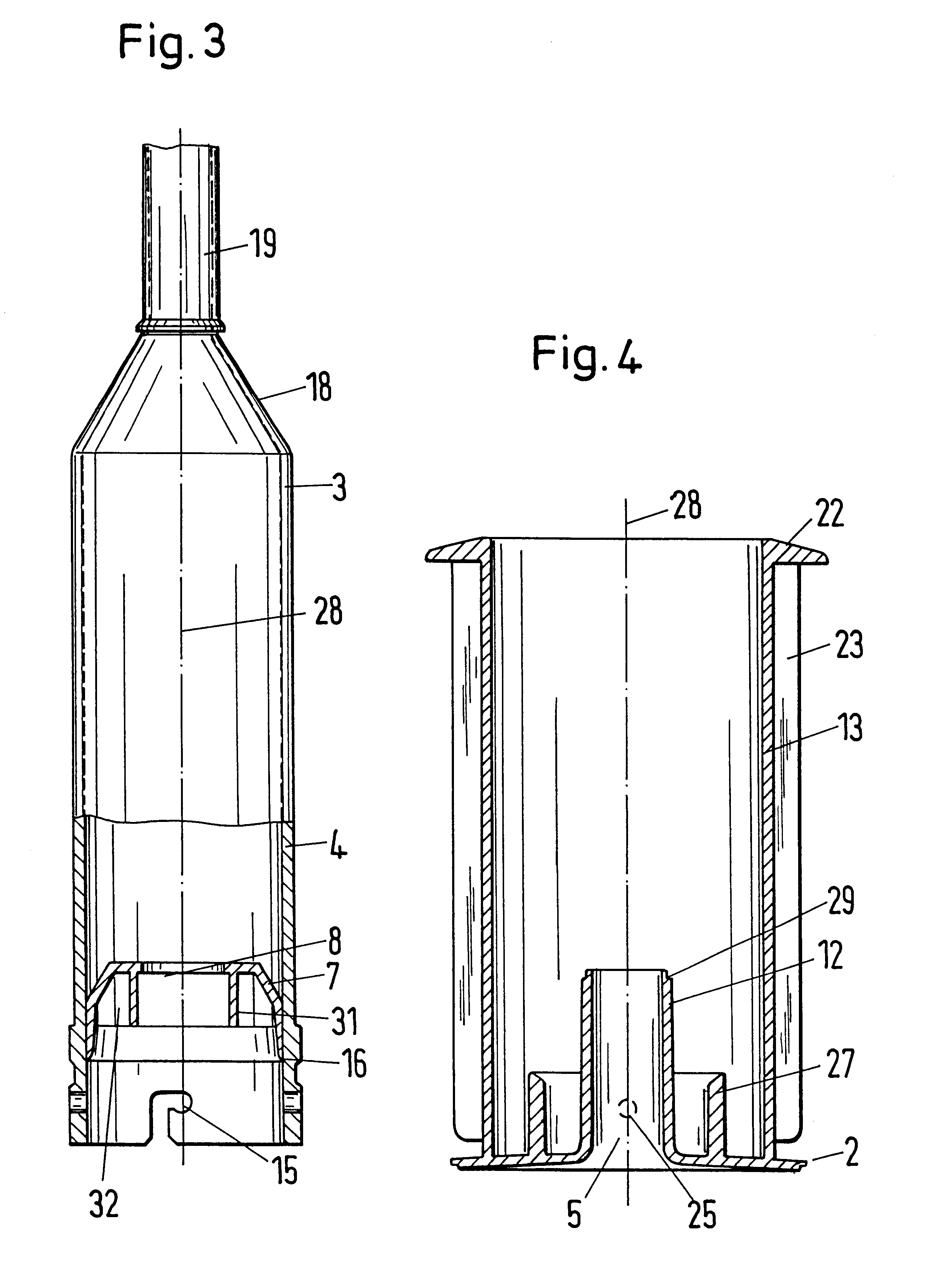

Filling transfer apparatus for bone cement

InactiveUS6238399B1Prevent wettingSmall sectionLiquid surface applicatorsSurgical furnitureBone cementPiston

The invention shows a filling transfer apparatus for bone cement with a cylindrical, upwardly open mixing container and a filling transfer piston which can be inserted therein, which is removably connected to the sleeve of a cement injector and which has an opening through which the mixed bone cement can be transferred into the sleeve through a pressing down of the filling transfer piston. In this an ejection piston is inserted in the sleeve and has an aperture in the region of the opening for the through-flowing cement which can be closed by a plug (9) after the removal of the cement injector.

Owner:SULZER ORTHOPAEDIC

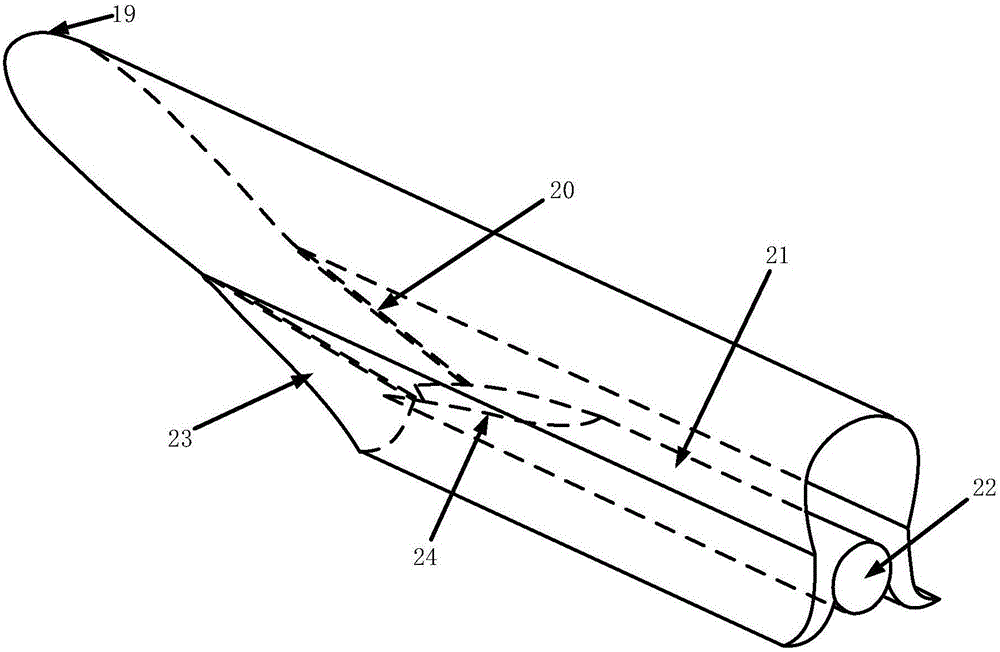

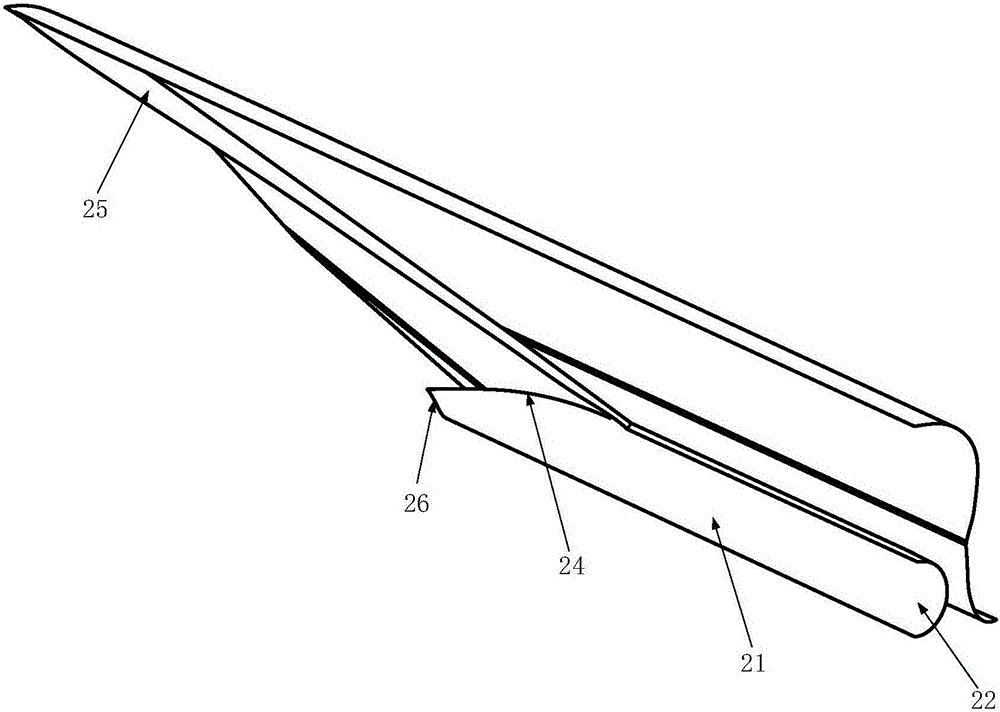

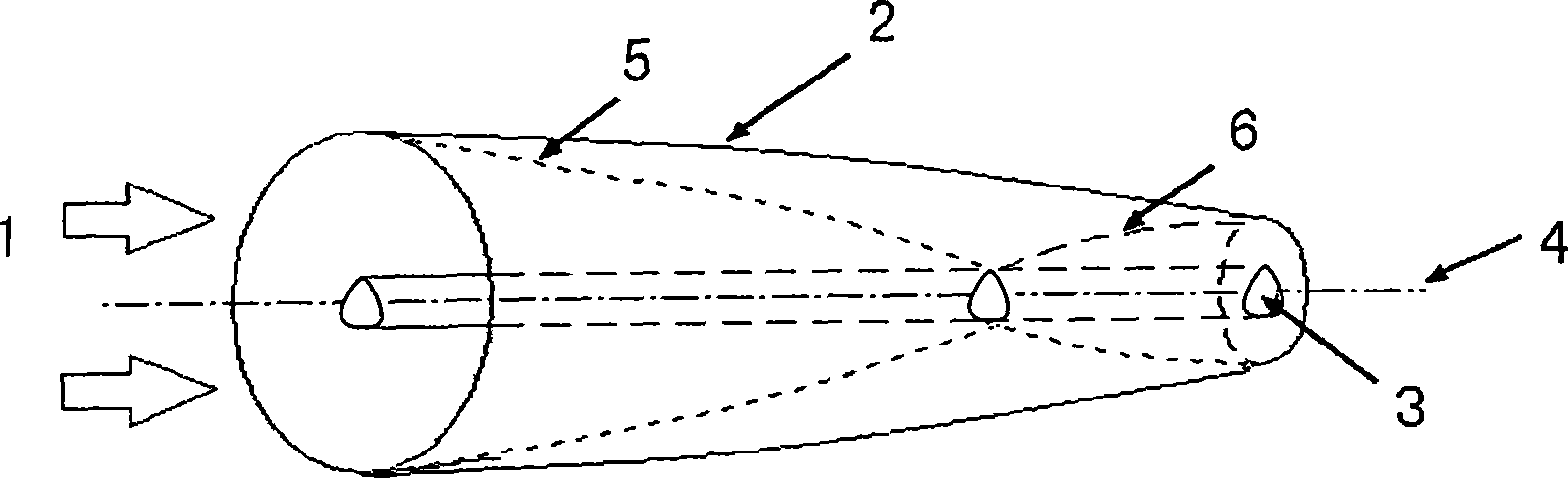

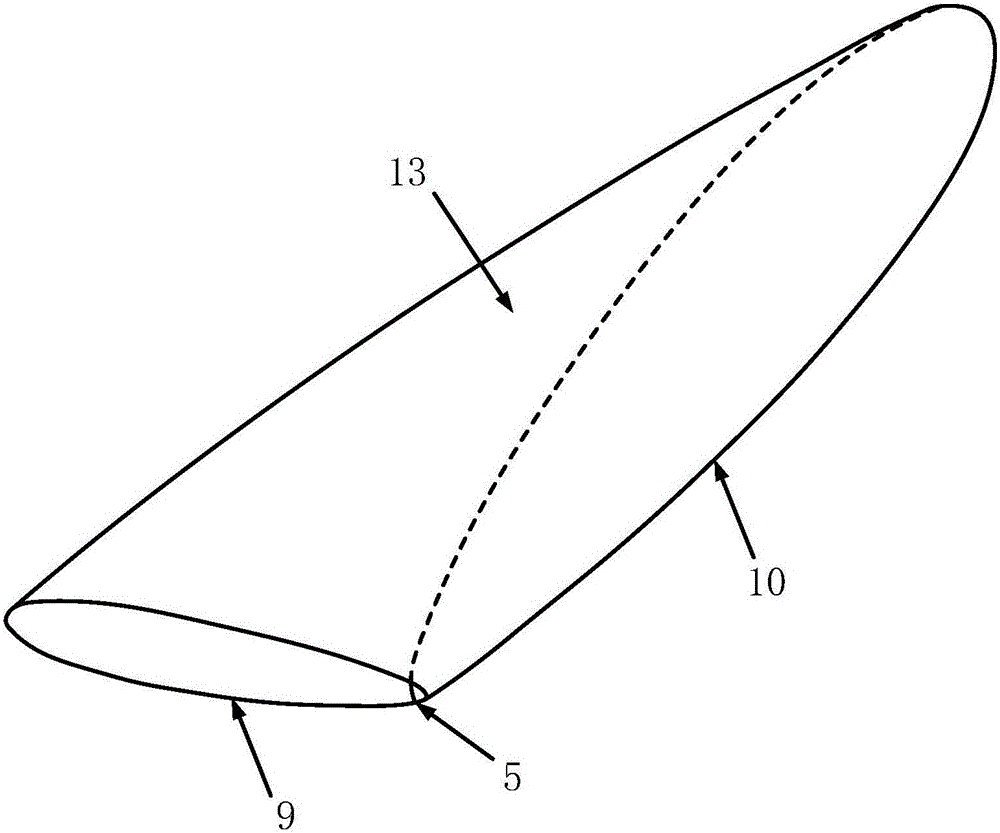

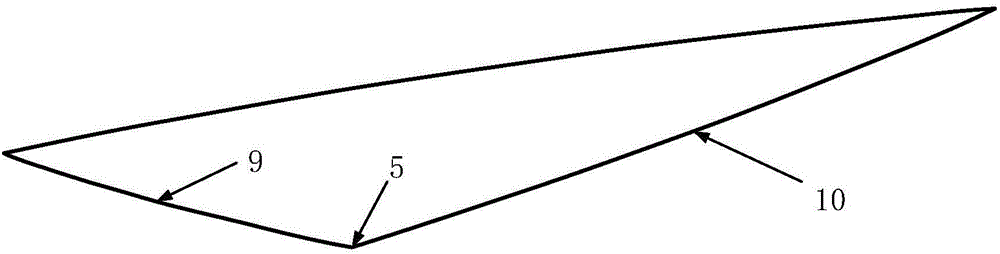

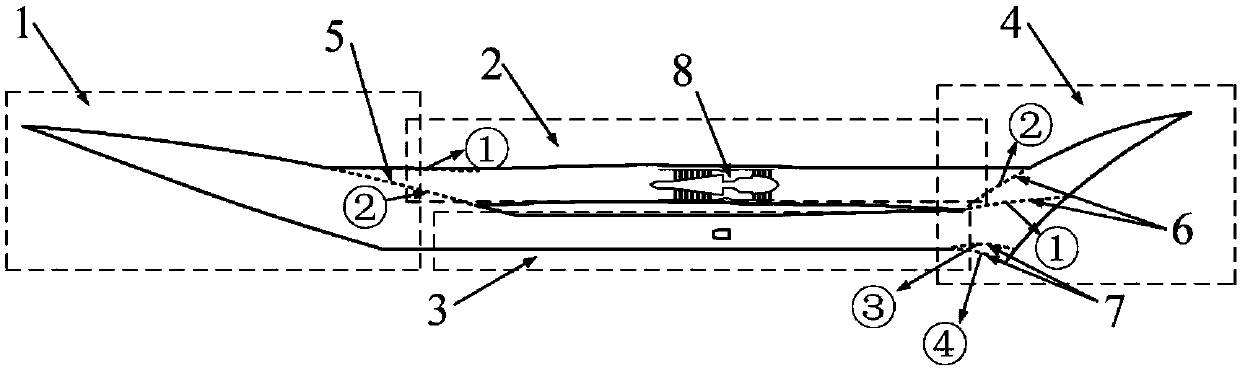

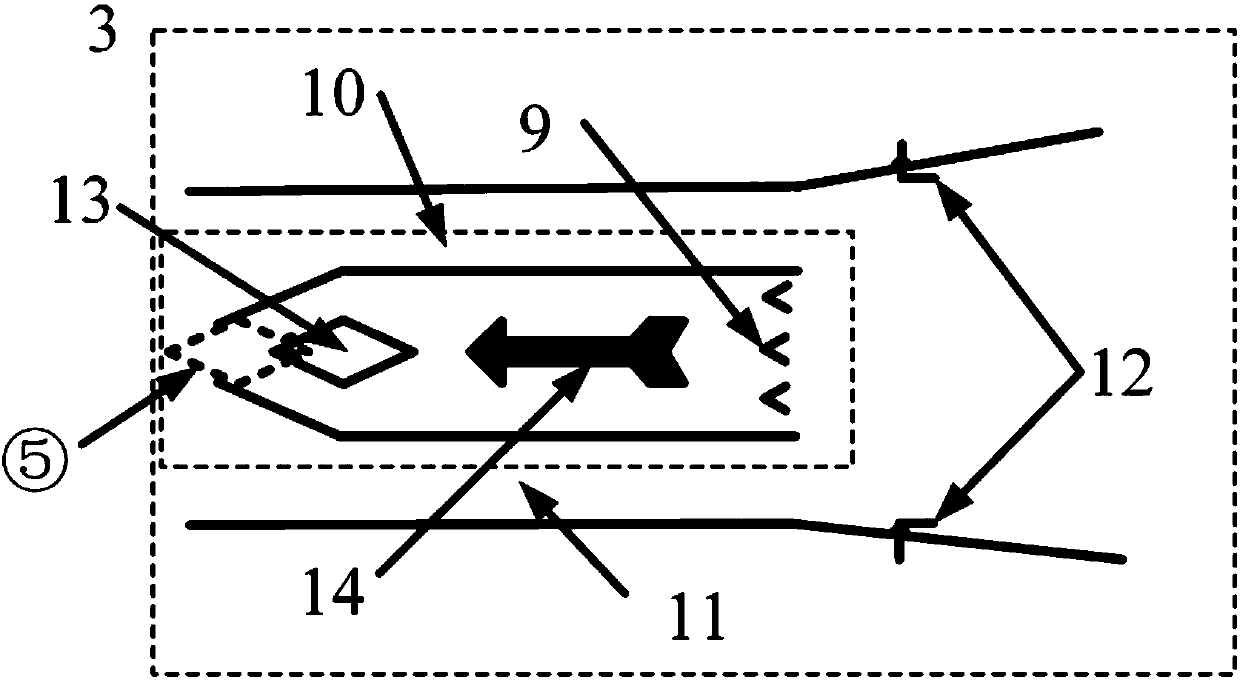

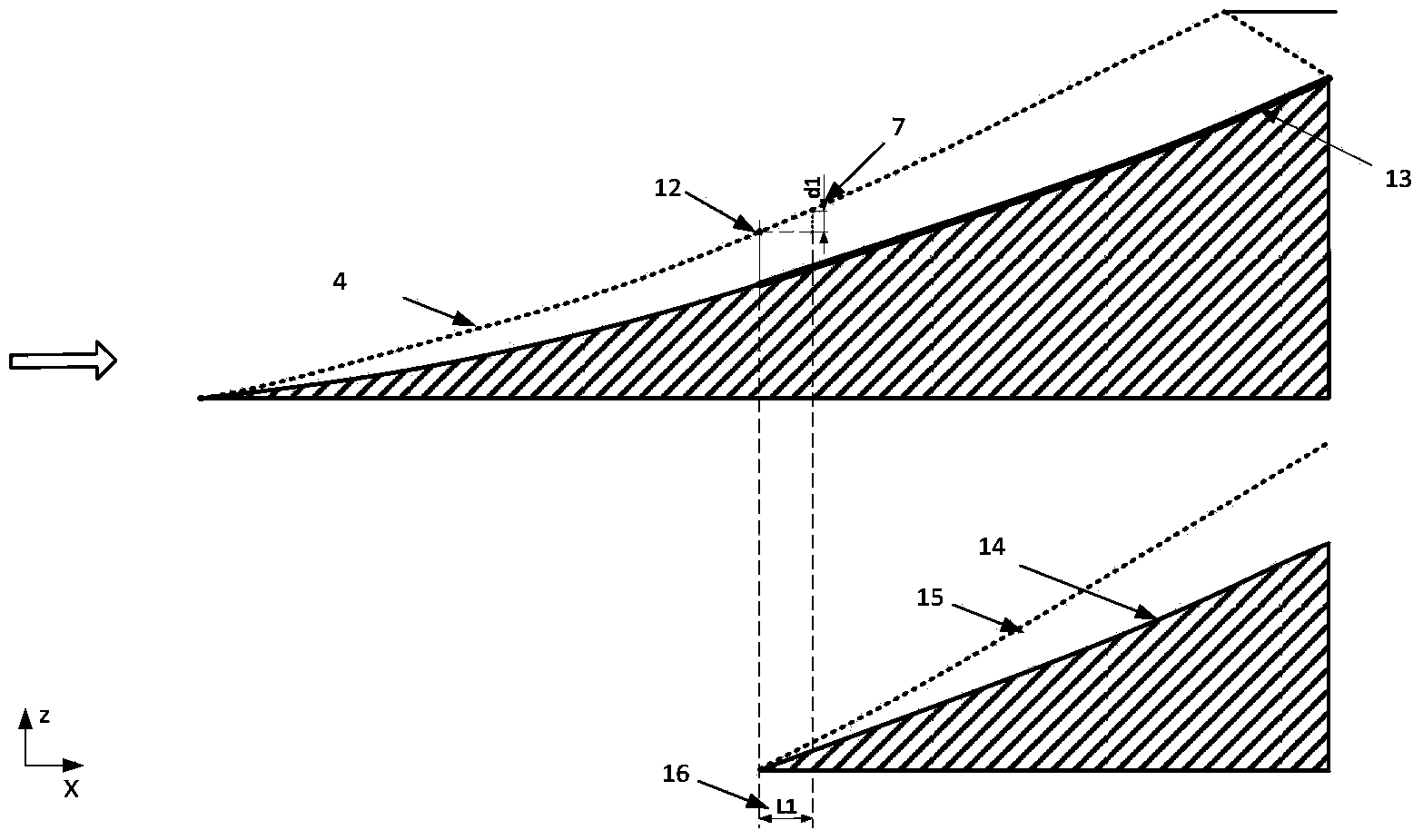

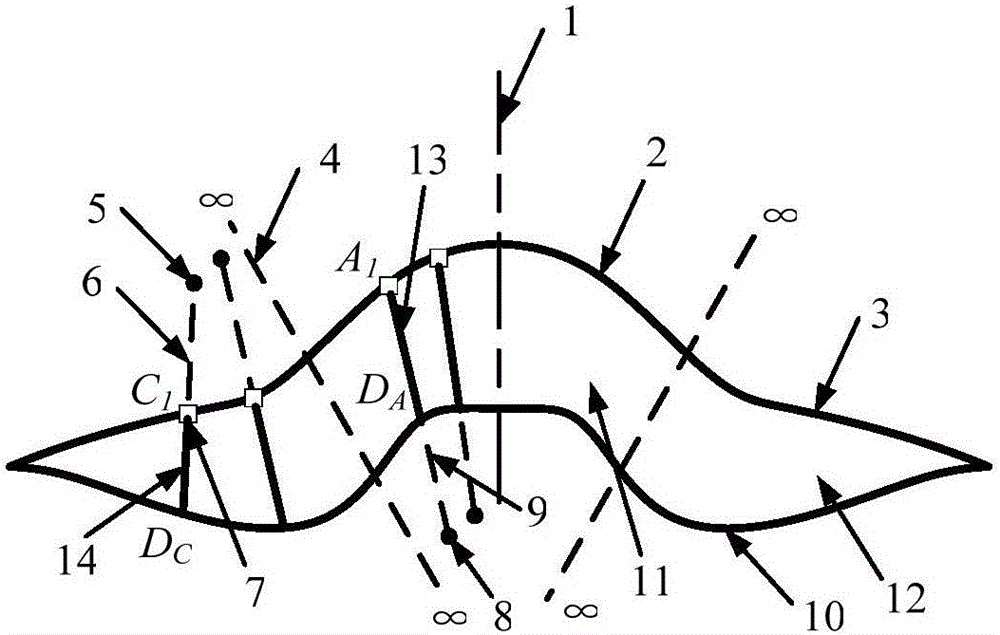

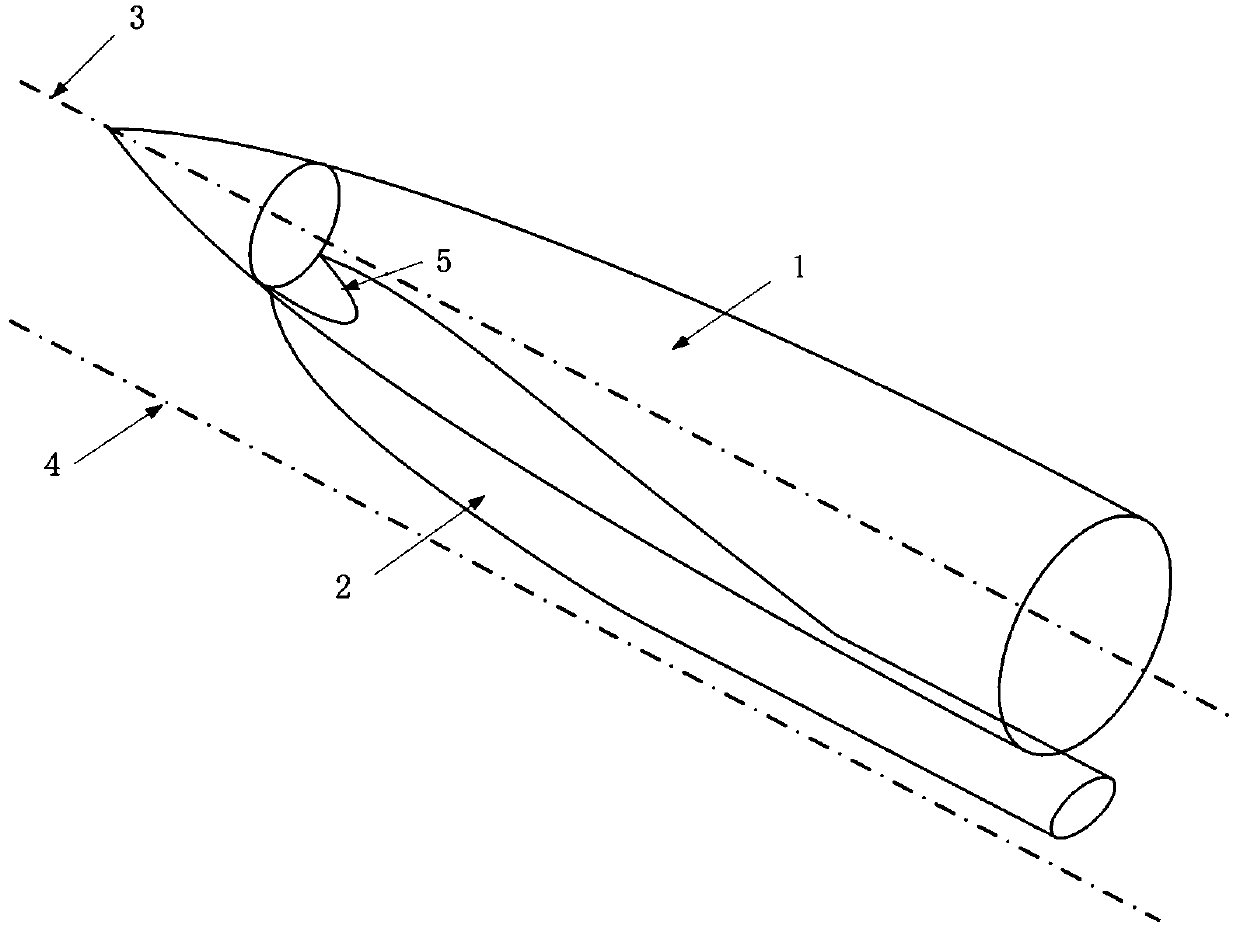

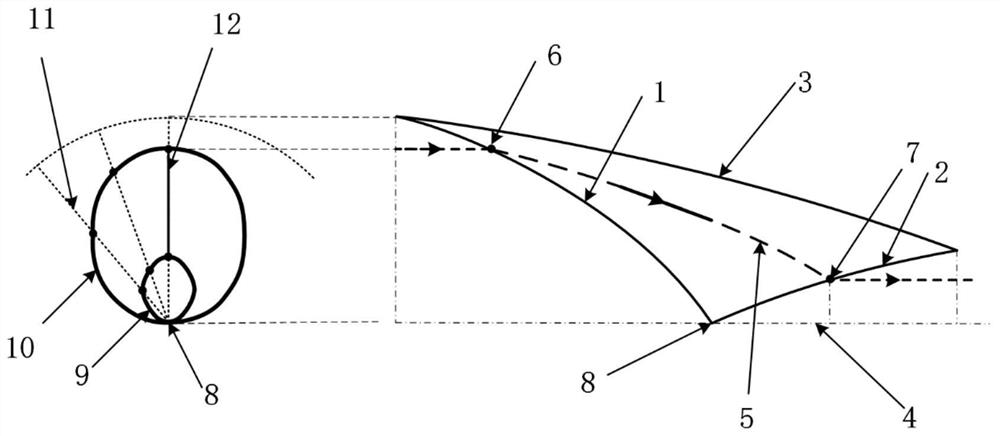

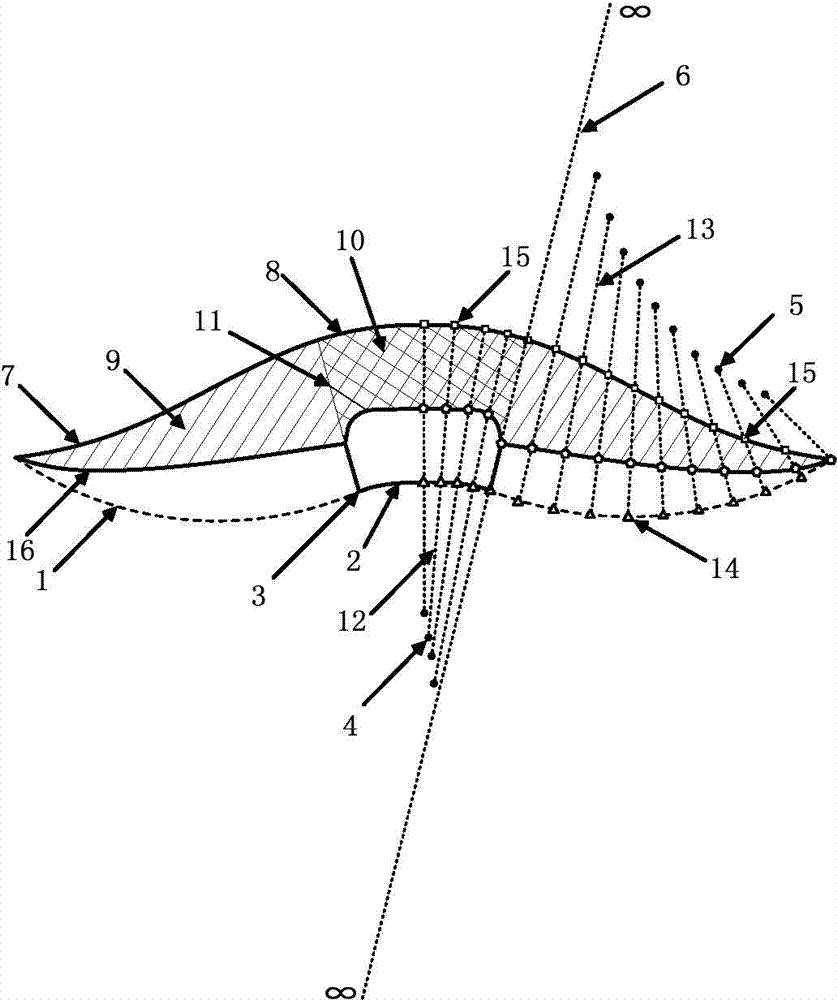

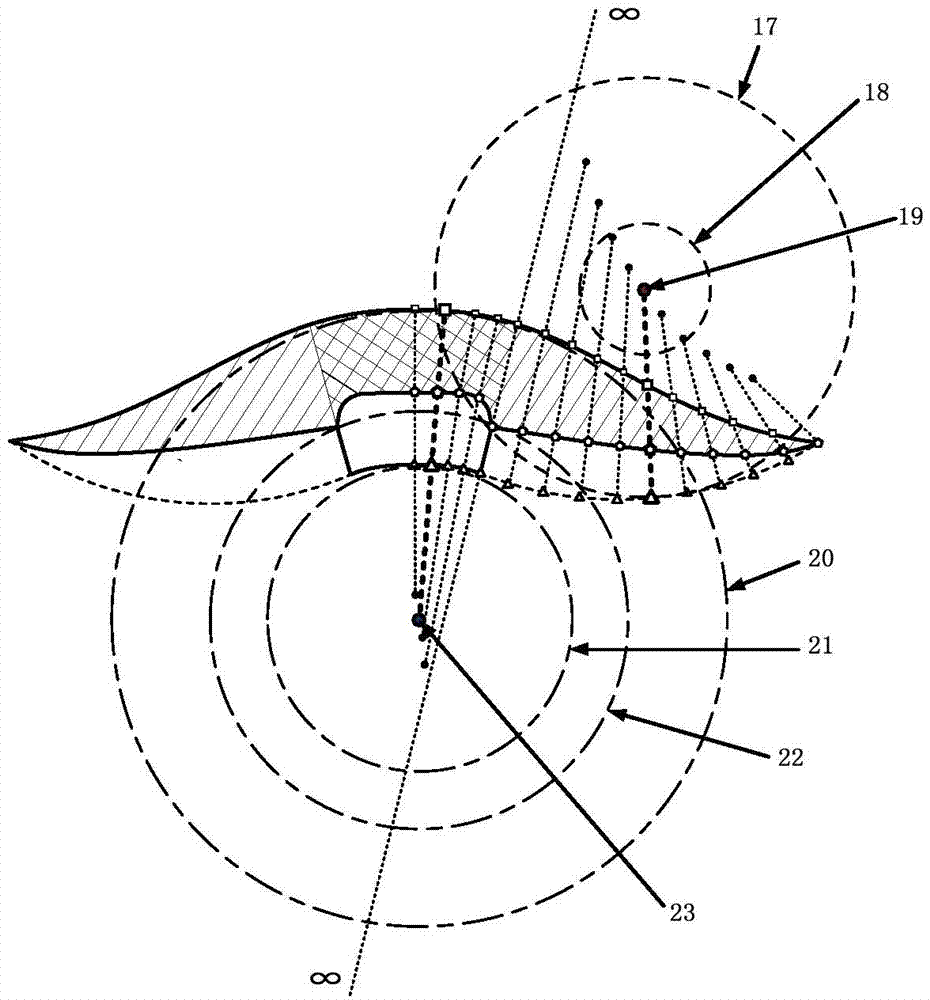

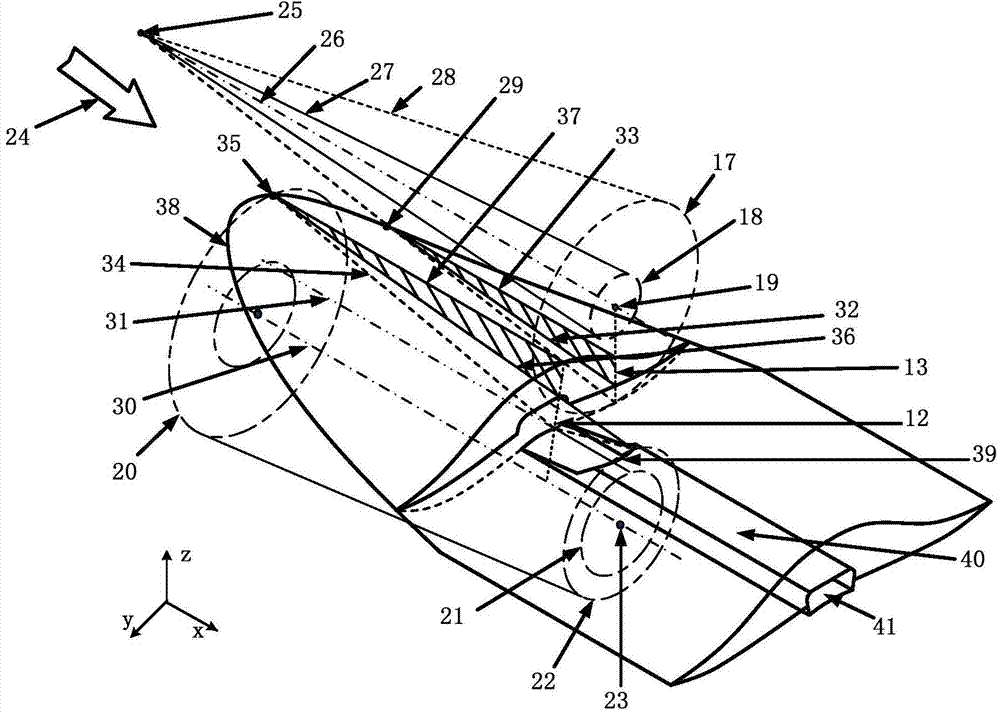

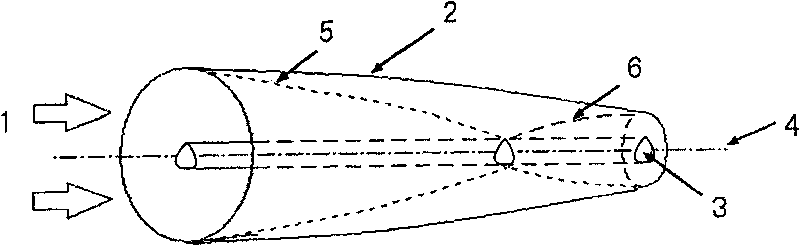

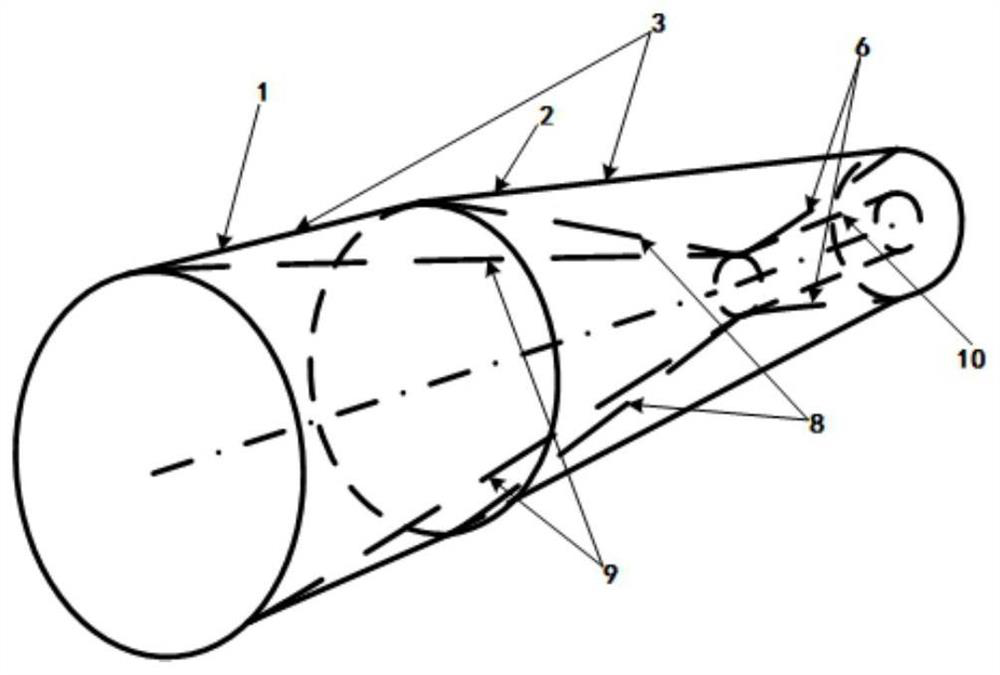

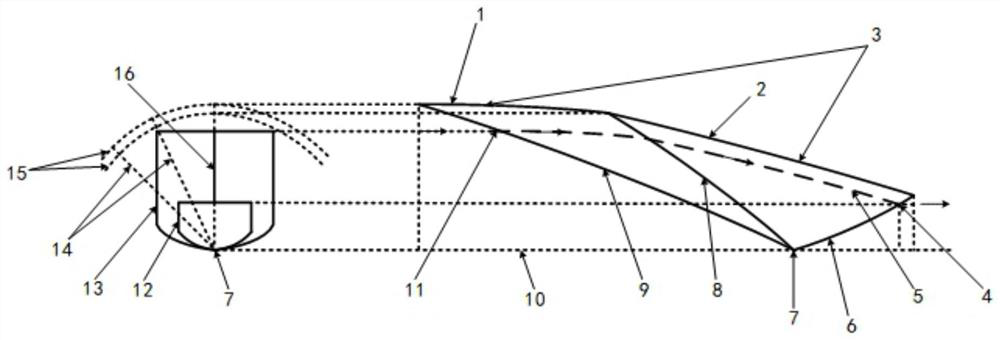

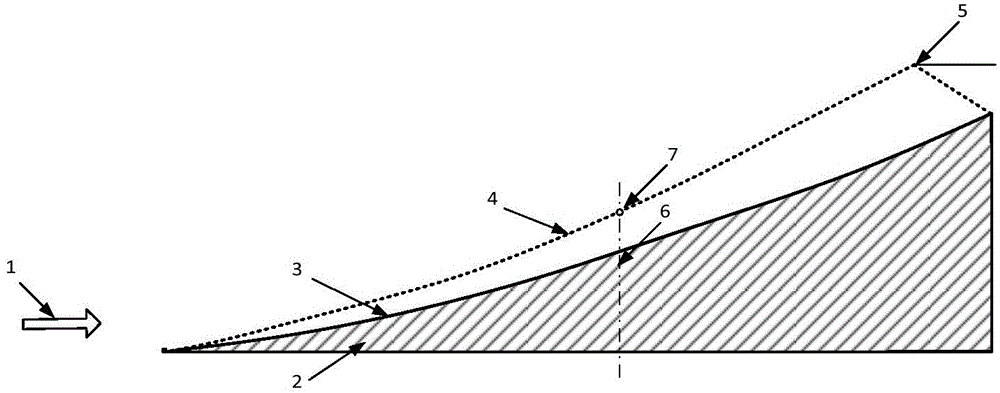

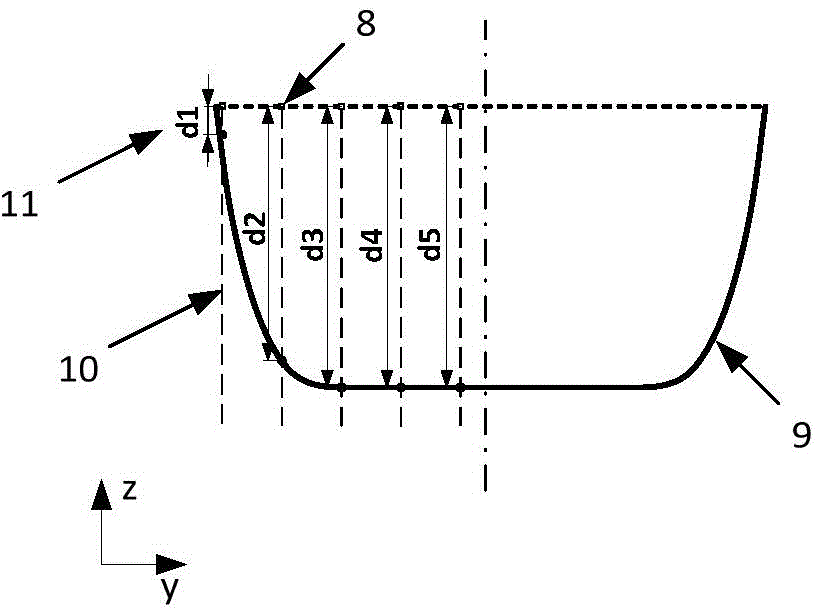

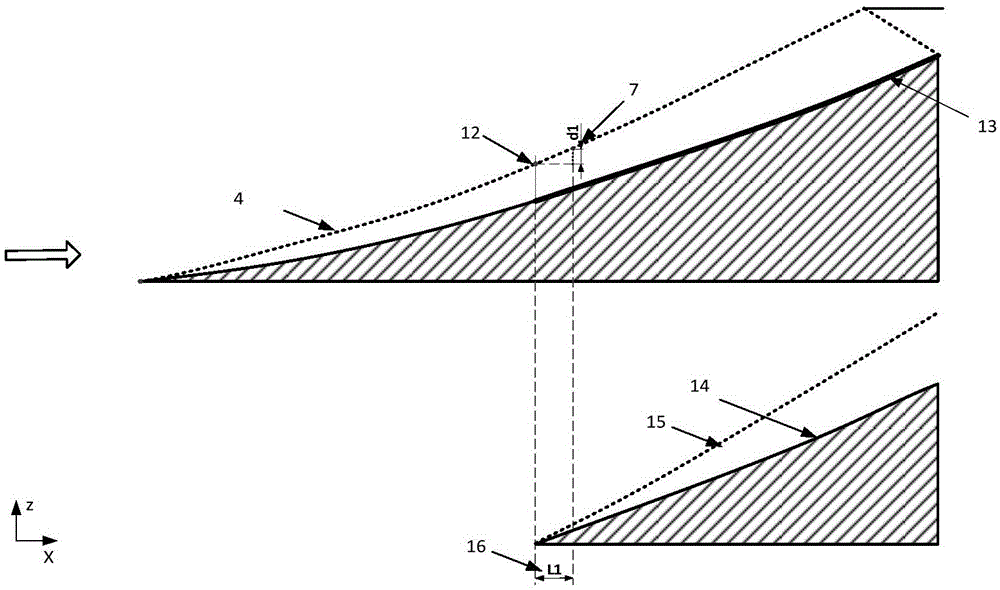

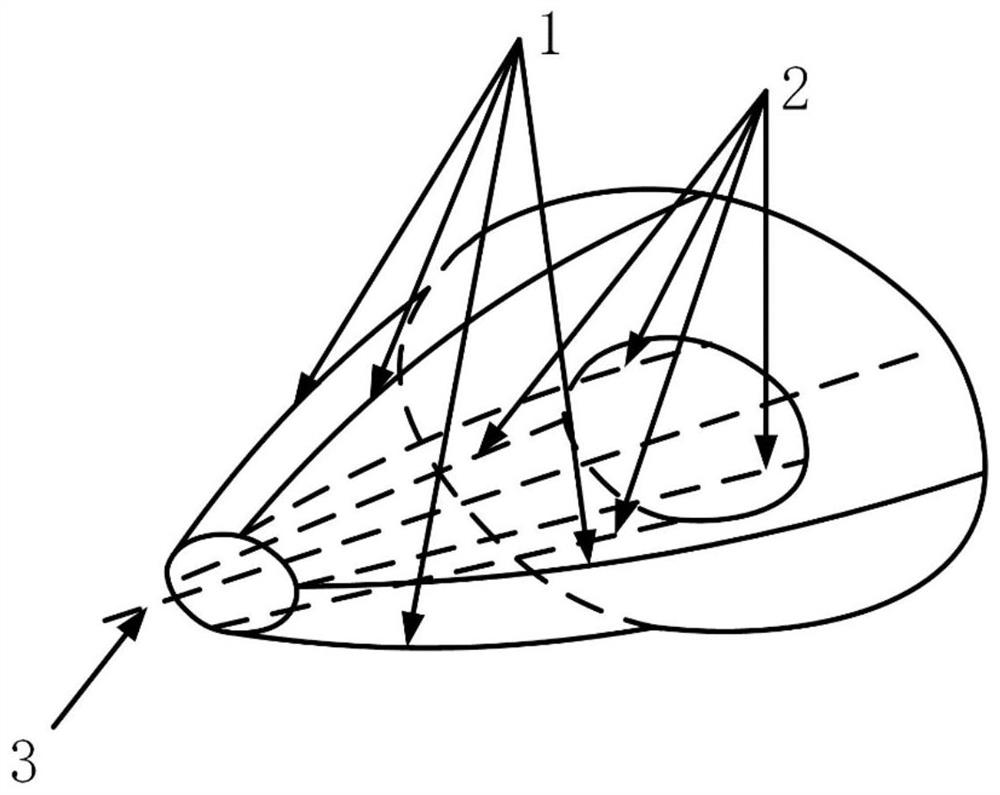

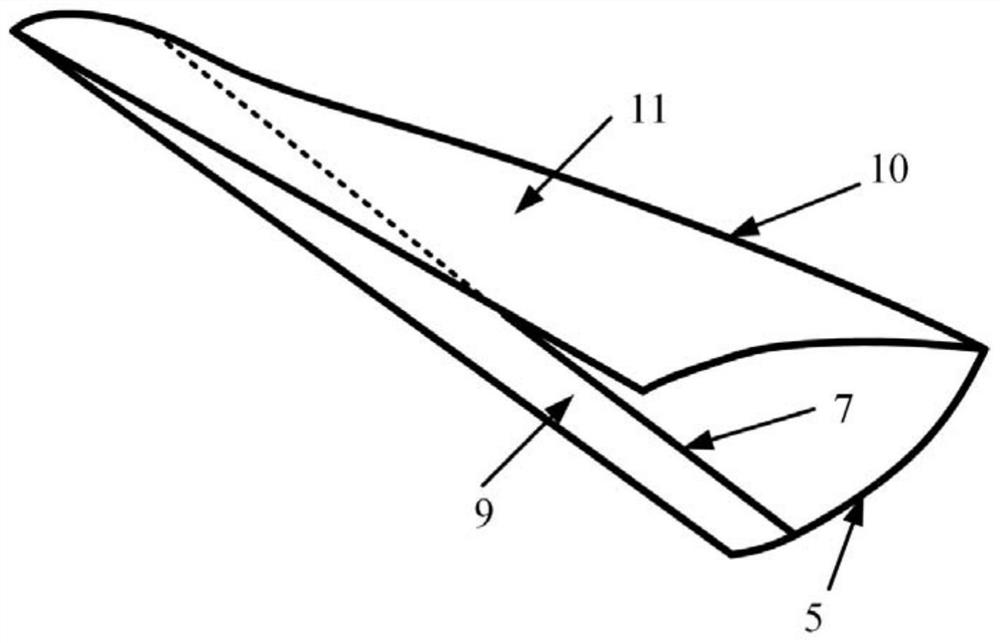

Integration design method for hypersonic slender body air vehicle and three-dimensional inward rotation air inlet channel

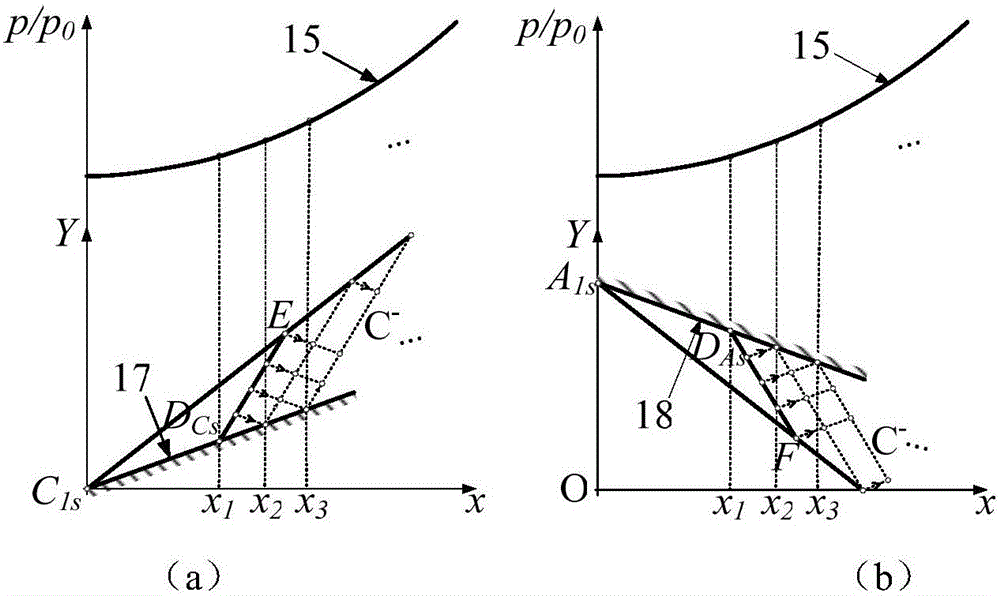

ActiveCN105775158ABroaden the working Mach number rangeLarge thrustGround installationsShock waveCounter flow

The invention discloses an integration design method for a hypersonic slender body air vehicle and a three-dimensional inward rotation air inlet channel, and relates to near space aerocrafts. The method comprises the following steps that a three-dimensional shock wave hook face is designated according to the design requirement; a series of basic flow fields are derived reversely according to the relation between the discrete shock wave curve and the curvature center; a slender waverider vehicle lower surface molded line and the outlet section of the three-dimensional inward rotation air inlet channel are designed, and streamline tracing in the counter flow direction is conducted in the basic flow fields; the two-dimensional projection shape of a lip of the three-dimensional inward rotation air inlet channel is designed, and a three-dimensional configuration of the lip of the three-dimensional inward rotation air inlet channel is obtained according to the shock wave relation; and the hypersonic slender body air vehicle is subjected to geometric construction based on a compression molded face. The performance of an outer waverider vehicle front body and the performance of the three-dimensional inward rotation air inlet channel are simultaneously considered by the generated slender body hypersonic air vehicle and the air inlet channel, the lift drag characteristic is high, full-flow incoming flow capture can be ensured, engine thrust is increased, outflow resistance is reduced, the operation Mach number range of the air inlet channel is widened, and natural transition of an inner waverider part and an outer waverider part is achieved.

Owner:XIAMEN UNIV

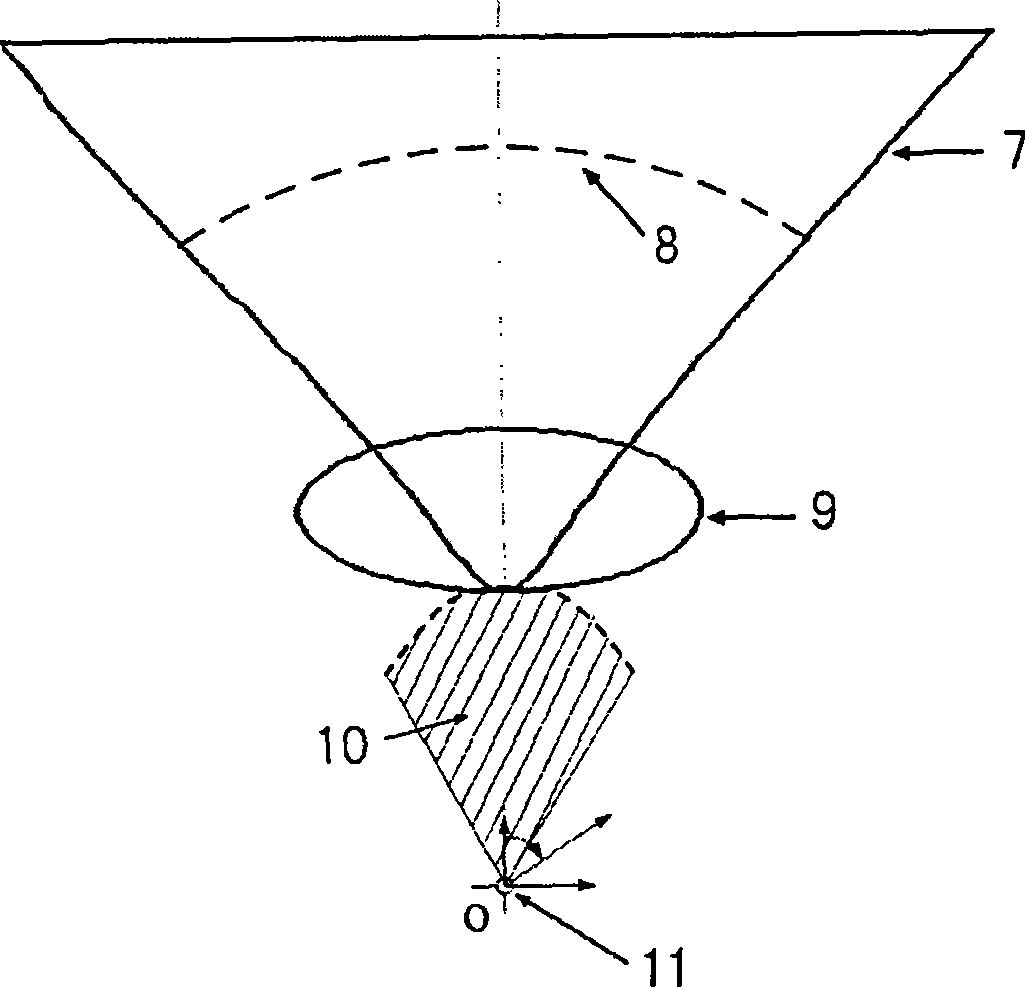

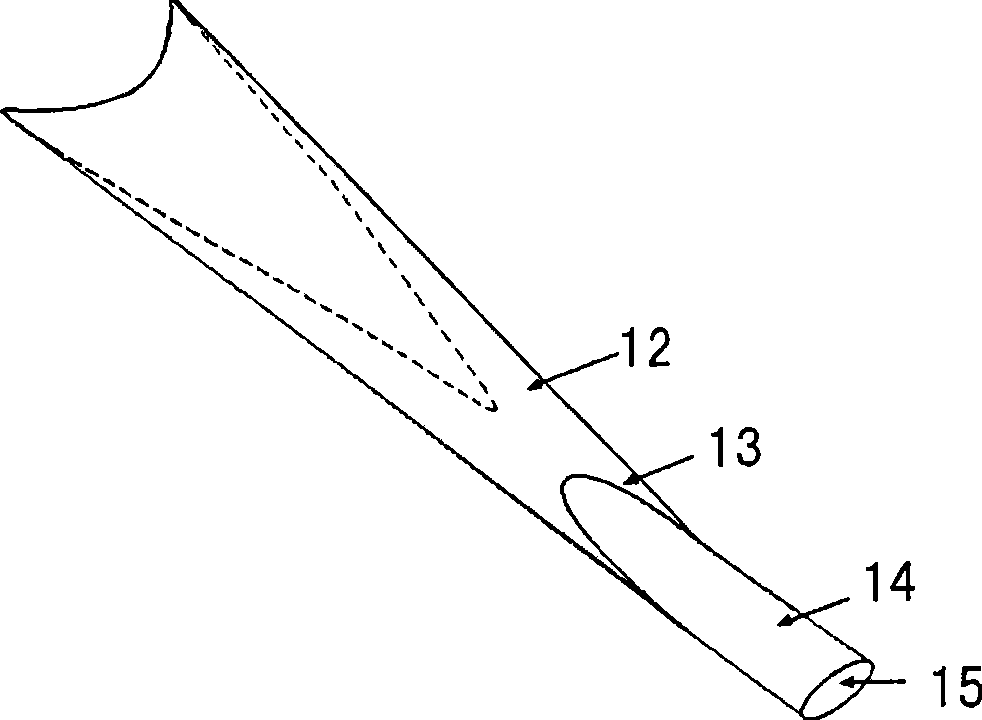

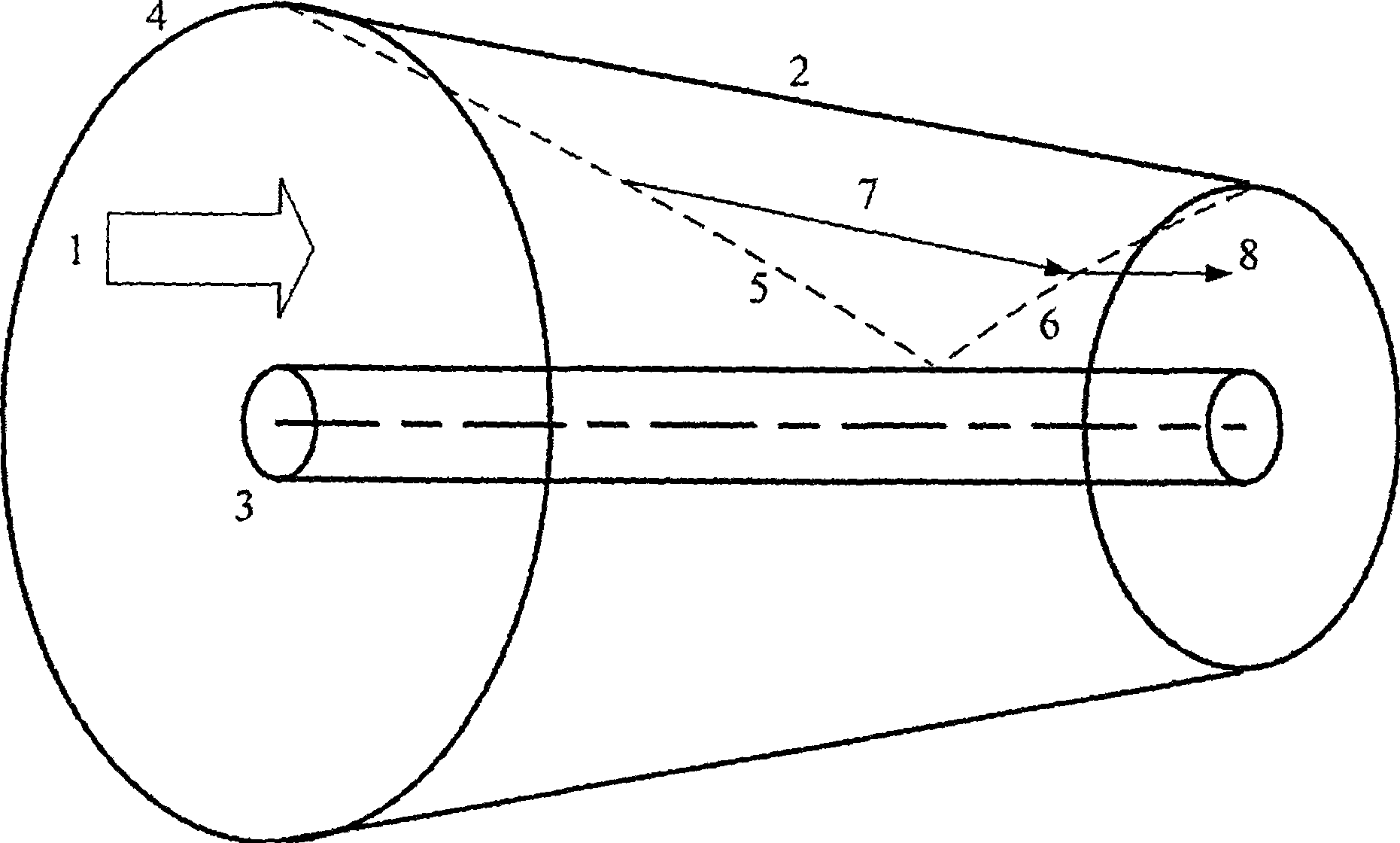

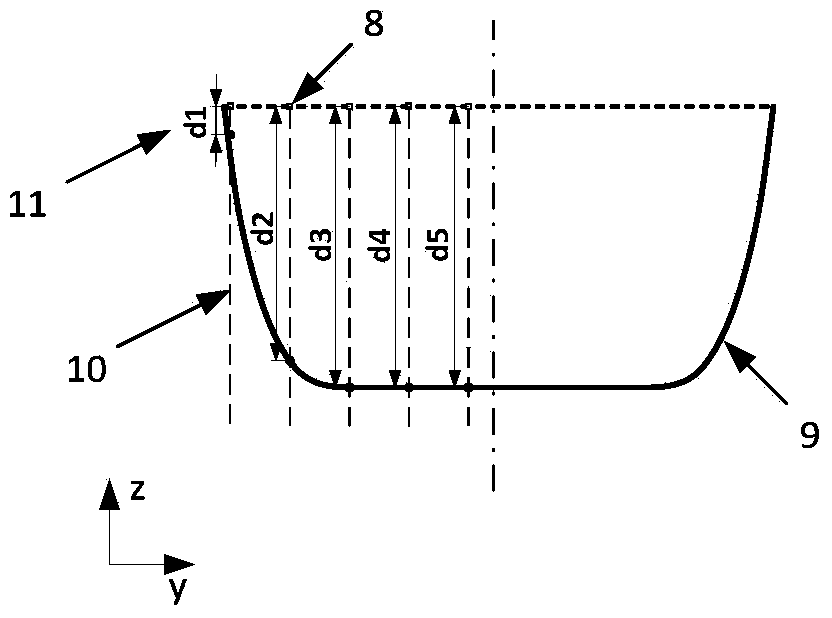

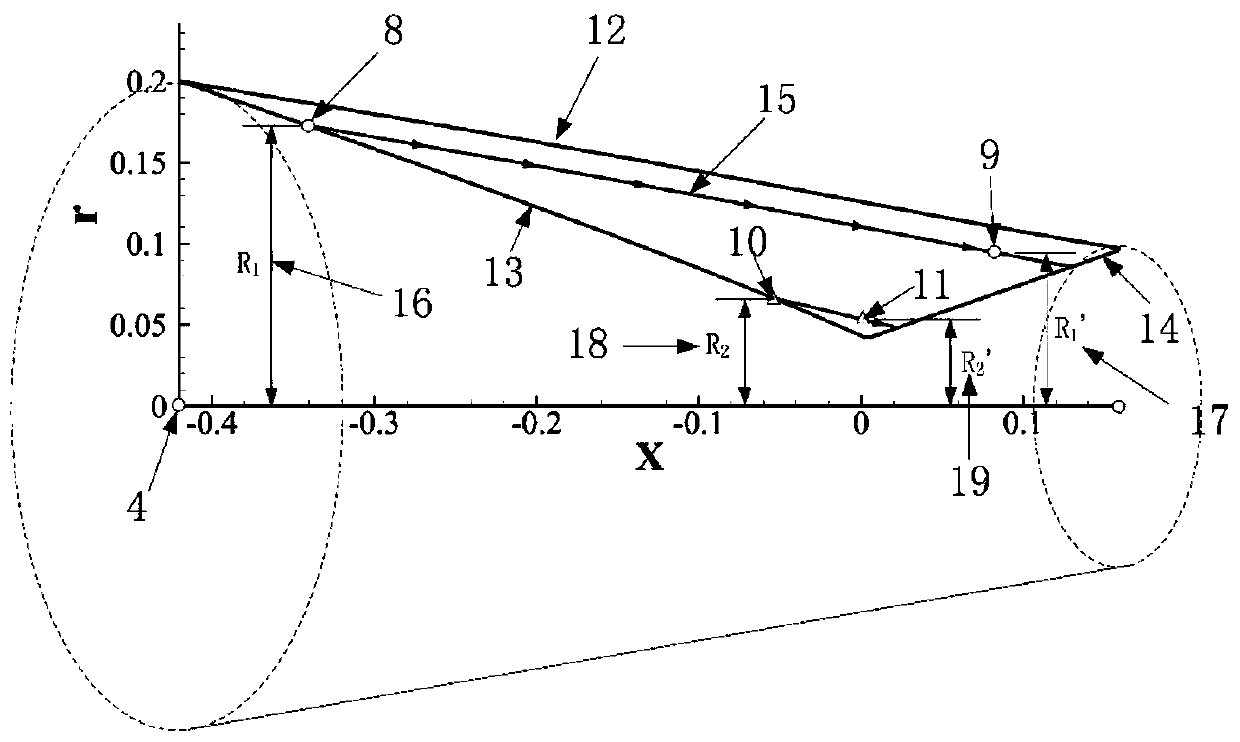

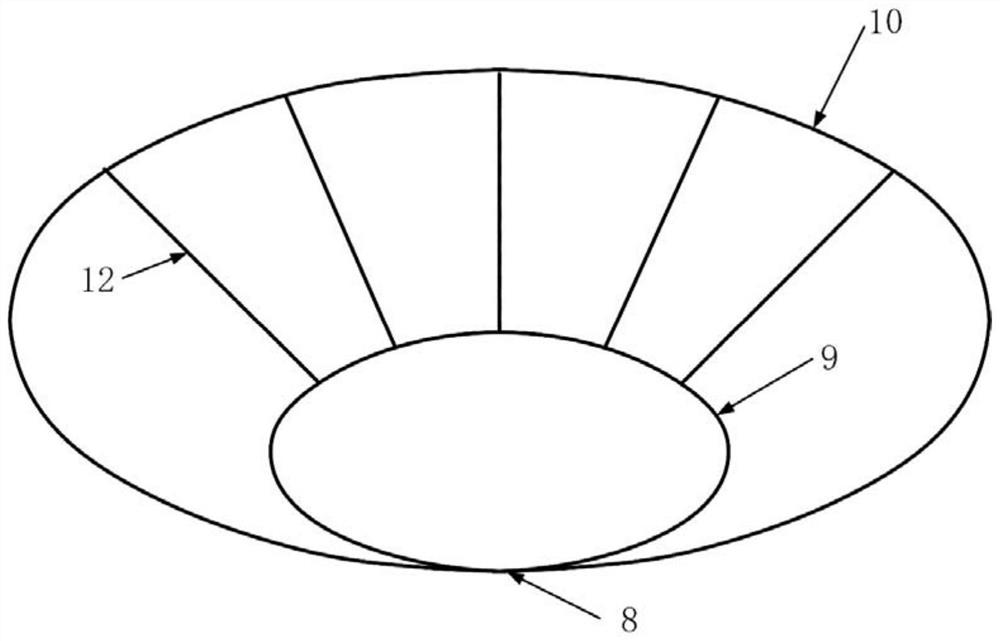

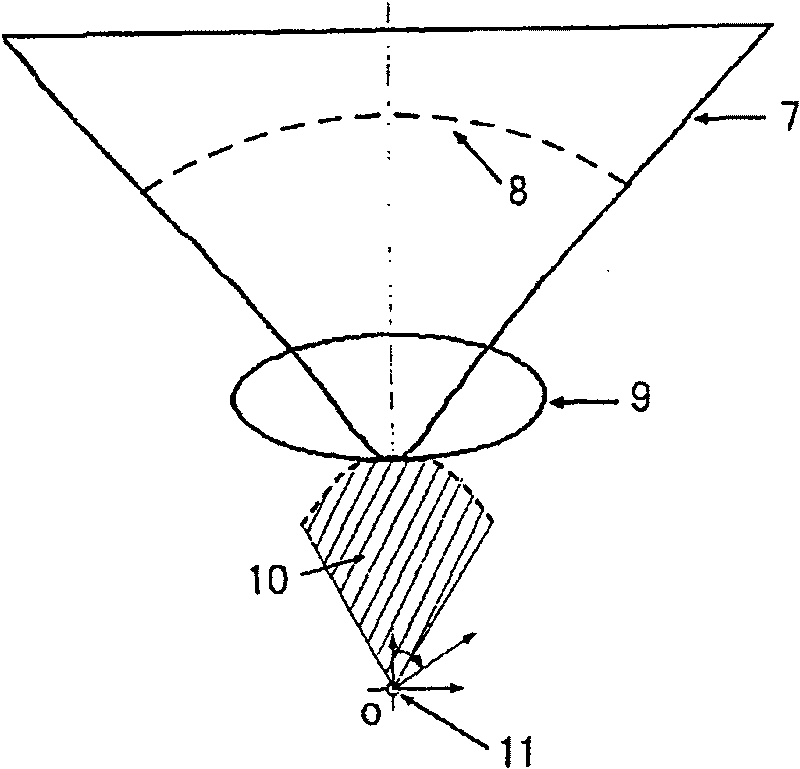

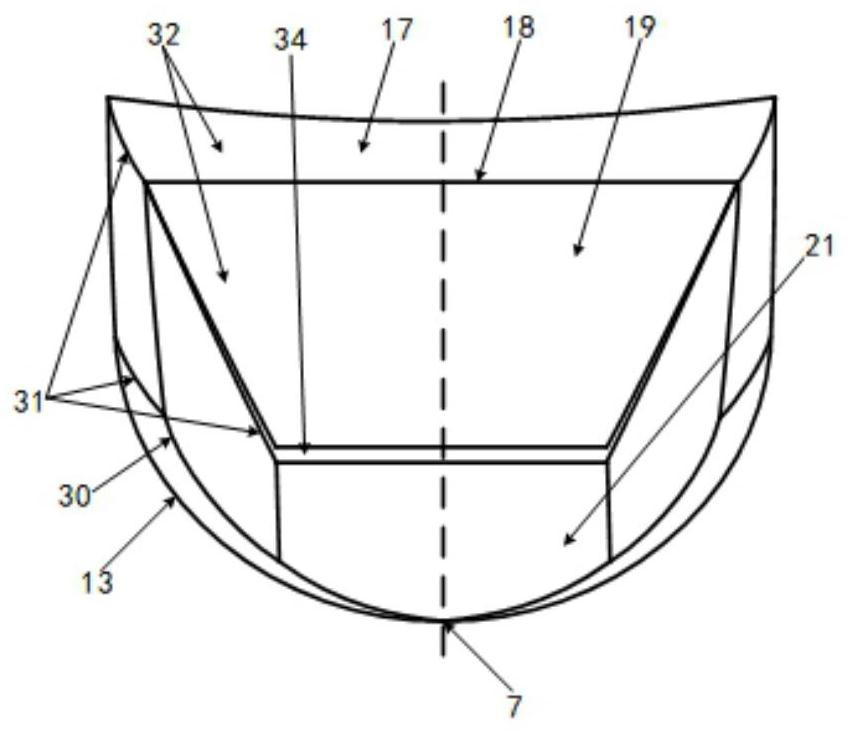

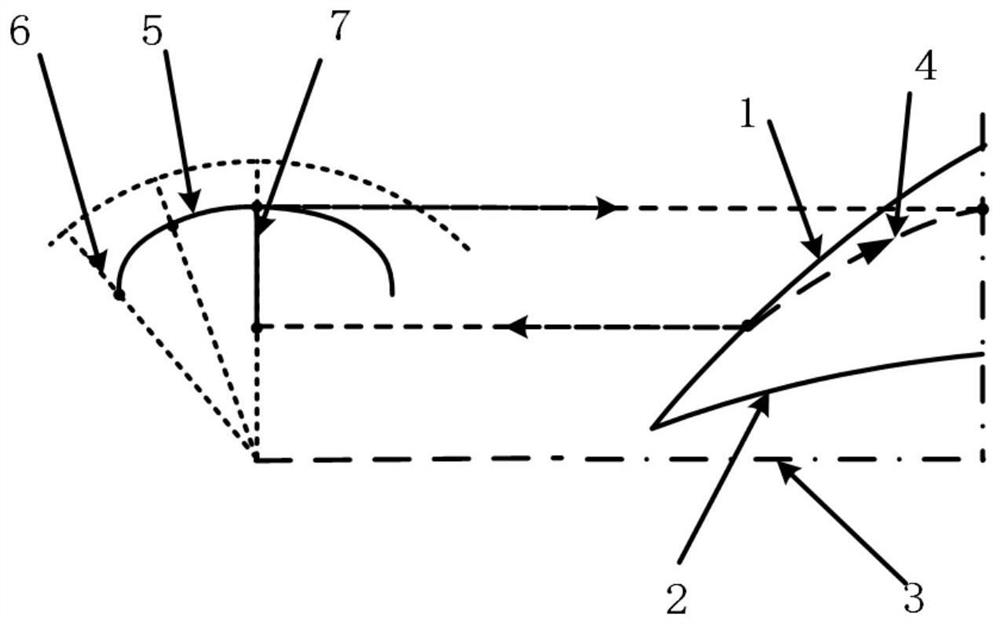

Internal waverider-derived hypersonic inlet with ordered inlet and outlet shape and design method

InactiveCN101418723ABroaden the working Mach number rangeLarge thrustTurbine/propulsion air intakesEngineeringIntegrated design

The invention discloses an internal waverider-derived high supersonic inlet duct, the shapes of the inlet and outlet of which can be customized, and a design method thereof. The structure of the internal waverider-derived high supersonic inlet duct comprises an inlet duct contraction section and an isolated section, wherein the shape of the inlet duct contraction section is in three dimensional inward contraction. The design method is that a non-axisymmetric internal contraction basic flow field is taken as the base, the non-axisymmetric internal contraction basic flow field comprises an axisymmetric internal contraction rotary wall surface and a non-axisymmetric variable radius central body, wherein the axisymmetric internal contraction rotary wall surface keeps no changing, and the radius of the central body is adjustable. The invention has the advantages that the internal waverider-derived high supersonic inlet duct can capture the inflow by full flow and has low Mach number automatic overflow; the shapes of the inlet and the outlet can be customized according to the layout requirement, and the parallel module installation or the integrated design with various aircrafts can be easily realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Design method for three-dimensional internal rotary inlet based on complete flow direction suction

ActiveCN106250597AImprove self-starting performanceExcellent self-startGeometric CADTurbine/propulsion air intakesLow speedMethod of characteristics

The invention discloses a design method for a three-dimensional internal rotary inlet based on complete flow direction suction, and relates to inlet boundary layer suction. The method comprises the following steps of solving an axial symmetric basic flow field by adopting a characteristic line method according to design requirements; generating a three-dimensional internal rotary inlet compression profile by applying a streamline tracing method; calculating displacement thicknesses of conical sections of different positions of the shoulder of the three-dimensional internal rotary inlet according to a displacement thickness formula; designing a complete flow direction suction opening based on the inlet compression profile and the displacement thicknesses; constructing a new inlet exit shape by the complete flow direction suction opening, and performing unidiameter backward stretching to obtain a three-dimensional internal rotary inlet separation section; and obtaining the three-dimensional internal rotary inlet which is capable of eliminating low-speed and low-energy airflow of a boundary layer completely in a flow direction and does not influence flowing characteristics of high-speed and high-energy airflow in the inlet. The self-opening performance of the three-dimensional internal rotary inlet can be remarkably improved. The low-energy flow of the boundary layer can be completely eliminated and the flowing characteristics in the inlet are not influenced.

Owner:XIAMEN UNIV

Design method of three-power combined engine with coexisting of supersonic combustion combustor and subsonic combustion combustor

ActiveCN108561244AReduce complexityBridging the thrust gapRam jet enginesComposite engine plantsCombustion chamberCombustor

The invention discloses a design method of a three-power combined engine with coexisting of supersonic combustion combustor and a subsonic combustion combustor, and relates to a combined engine. According to the flight mission, the overall performance requirement is formulated, a basic flow field is designed based on the overall performance requirement, and then a three-dimensional internal turning air passage is obtained by streamline tracing. In a three-dimensional internal turning air passage outlet, according to the overall performance of the engine, the inlet and outlet parameters of thesupersonic combustion combustor are obtained, and the supersonic combustion combustor is designed. In front of a supersonic combustion combustor inlet, an ejection rocket passage of corresponding sizes are arranged based on a thrust requirement of the Ma2-5 engine, and a central cone, a rocket engine and the subsonic combustion combustor are included. According to the flow requirement of the engine in a Ma0-2 stage, the area of a turbine passage inlet is calculated by using the flow formula shown in the specification, an opening is formed in the wall surface of the three-dimensional internal turning air passage, and the turbine passage is arranged. A common tail spraying pipe with an adjustable geometric area is arranged at a supersonic combustion combustor outlet and the turbine passage outlet, and a spreader plate is designed according to the different working conditions of the tail spraying pipe.

Owner:XIAMEN UNIV

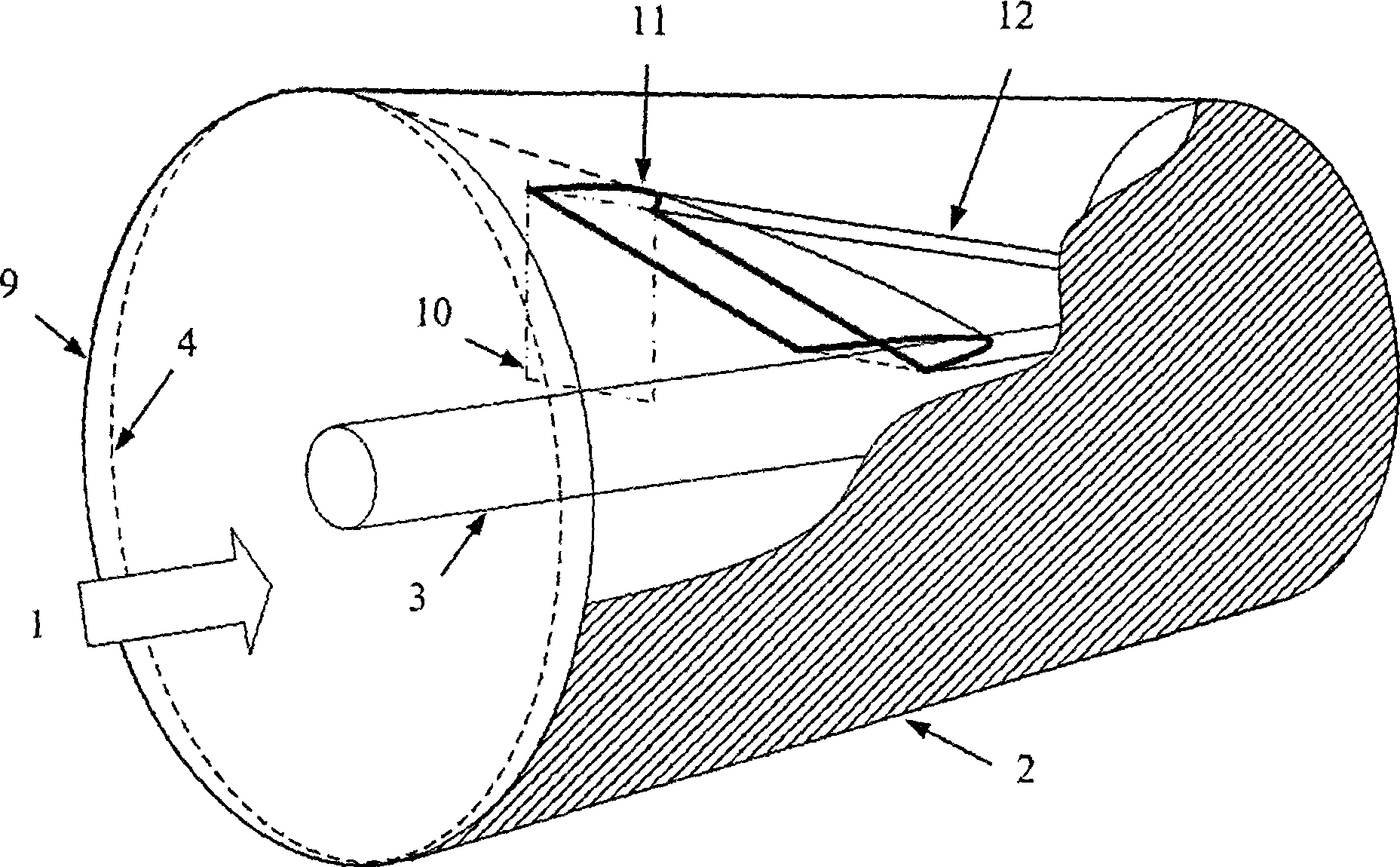

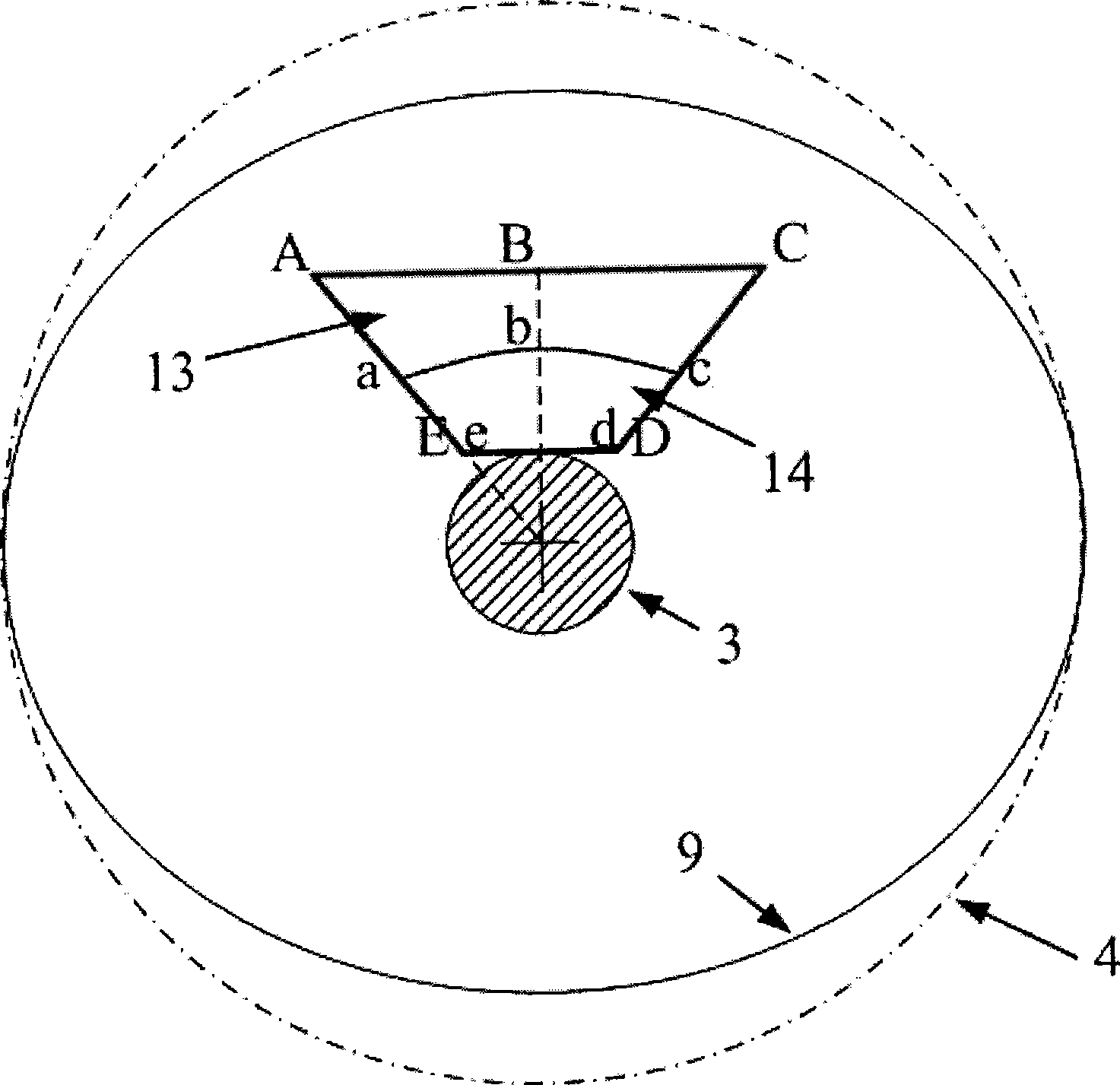

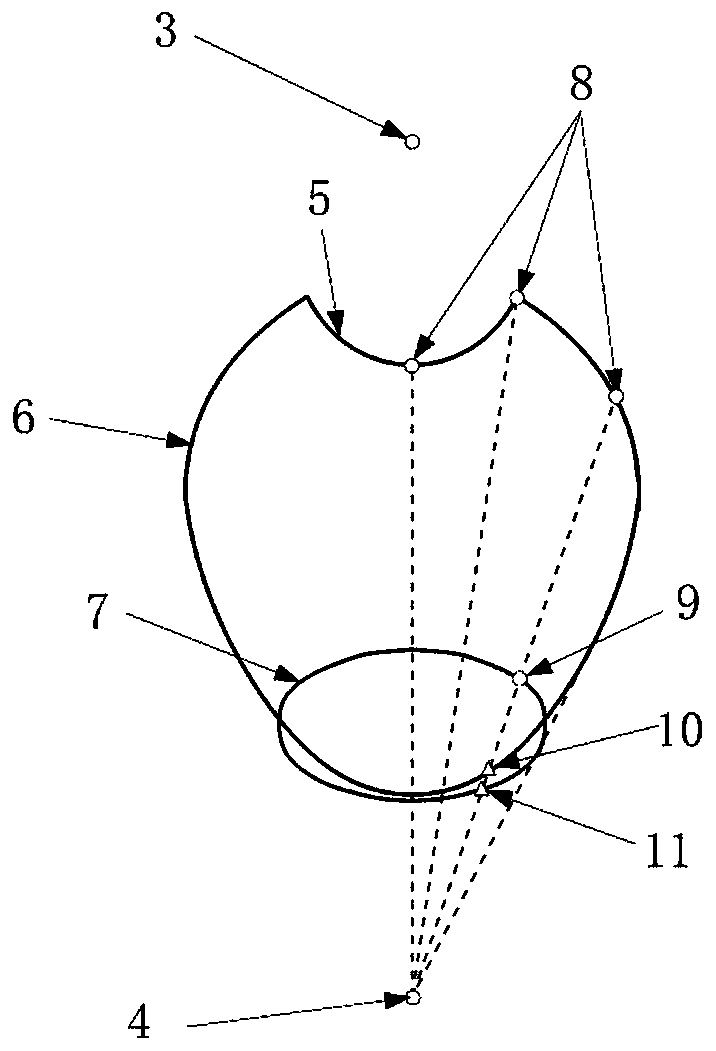

Internal waverider hypersonic inlet and design method for giving attention to internal and external flow performance

InactiveCN101392686AHigh operating Mach number rangeReduce overflowTurbine/propulsion air intakesShock waveCounter pressure

The invention provides an internal waverider-derived high speed inlet considering both internal flow performance and external flow performance and a design method thereof. The structure of the high speed inlet consists of a contraction section, an insulation section or an expansion section, wherein the contraction section of the high speed inlet is characterized by adopting three-dimensional inward contraction of a smooth curved surface. High speed incoming flow forms a curved surface shockwave at the inlet to close the inlet completely so as to realize that the inlet 'rides' on shockwave without overflow completely. The design method is to carry out flow line tracing by using a specific non-axisymmetric internally contracted basic flow field as a base to obtain downstream flow surface according to the given inlet shape, thereby obtaining a three-dimensional moulding surface of the internal waverider-derived high speed inlet. The non-axisymmetric internally contracted basic flow field can be obtained through performing gradual change based on the prior revolution surface along a circumferential contracting surface, and arranging a cylinder with specific radius on the axes. The internal waverider-derived high speed inlet and the method have the advantages that external flow resistance can be reduced more while ensuring high quality of internal flow, wide range of working mach number, strong counter pressure resistance and other performances of the internal flow.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

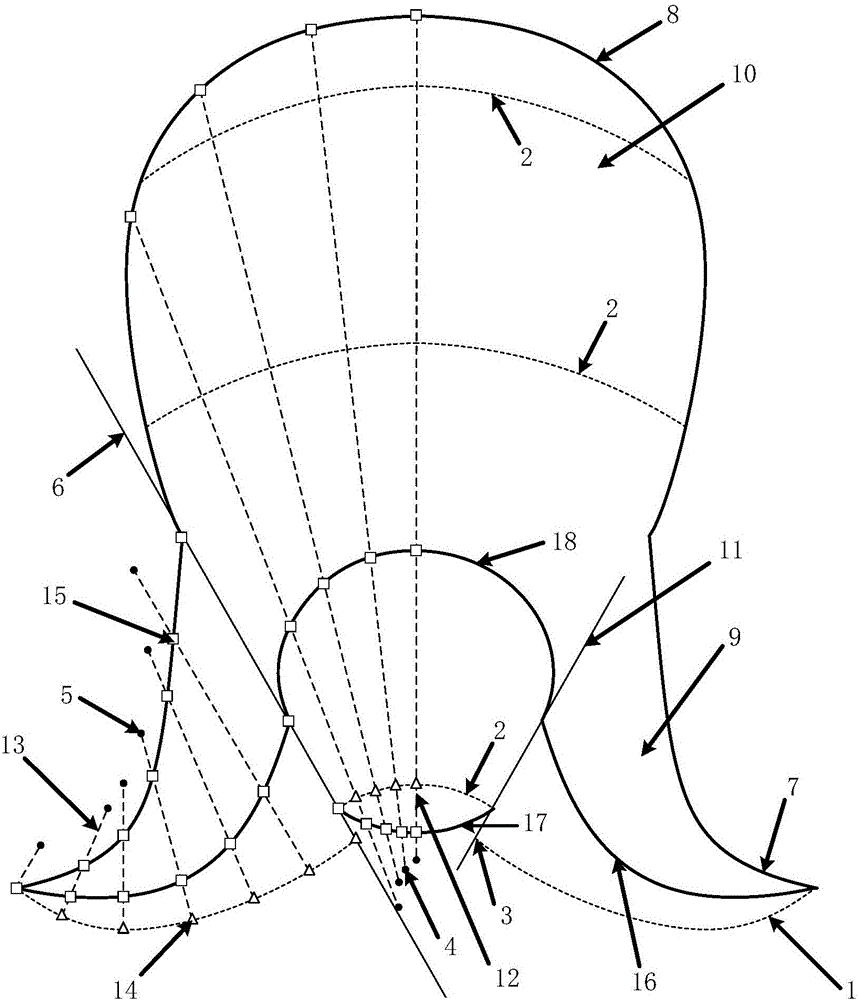

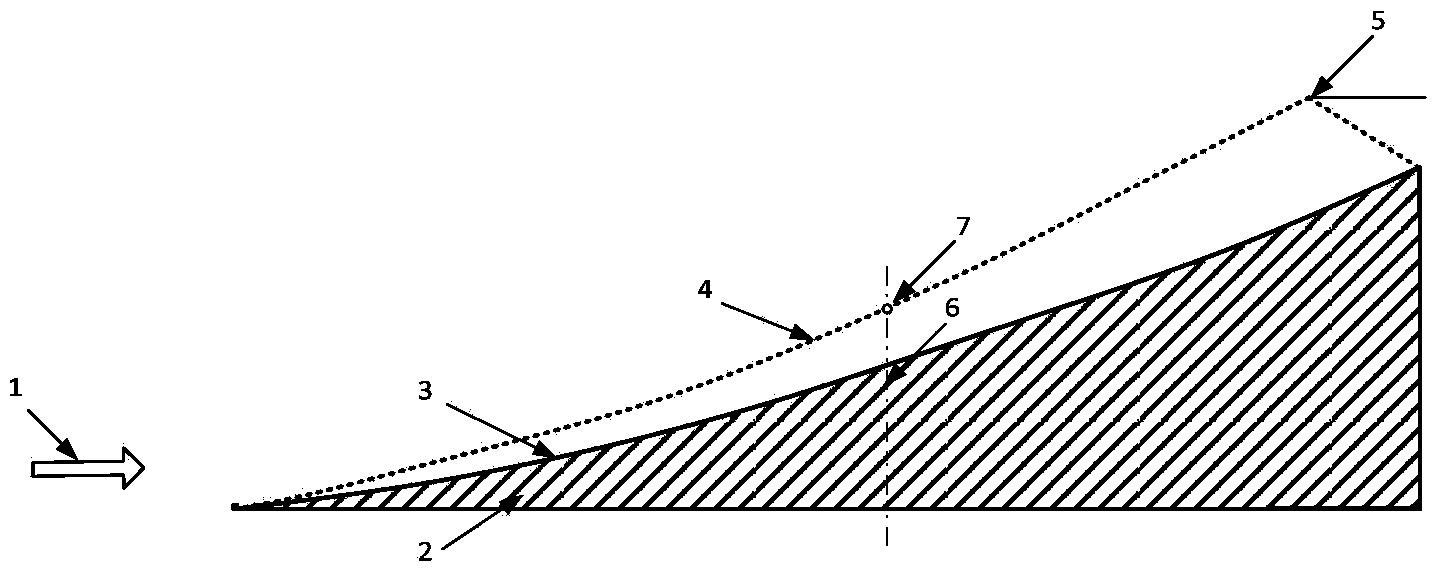

Transverse pressure gradient controlled ride wave forebody and air inlet channel integrated designing method

ActiveCN103963996AHigh lift and drag characteristicsLarge thrustGround installationsPower plant air intake arrangementsShock waveInlet channel

The invention provides a transverse pressure gradient controlled ride wave forebody and air inlet channel integrated designing method and relates to a near space hypersonic flight vehicle. The method comprises the steps of designing a basic flow field required by a two-dimensional air inlet channel; confirming the position where a designed cross section is located; designing projection of front edge capture molded lines in the designed cross section according the working condition requirements and calculating projection distances from front edge points in wedge tangent planes to shock wave points in z-direction; obtaining pressure distribution of compression molded lines at the positions of the wedge tangent planes corresponding to disperse shock wave points; obtaining newly-generated two-dimensional air inlet channel compression molded lines by applying two-dimensional characteristic line method according to calculated pressure distribution; arranging the two-dimensional air inlet channel compression molded lines at the positions of the corresponding front edge capture molded lines to form a complete air inlet channel compression profile, obtaining a ride wave forebody and air inlet channel integrated device after three-dimensional modeling and finishing the transverse pressure gradient controlled ride wave forebody and air inlet channel integrated design. By adopting the method, the device can have high lifting drag characteristic, external flow resistance is reduced while engine thrust is increased.

Owner:XIAMEN UNIV

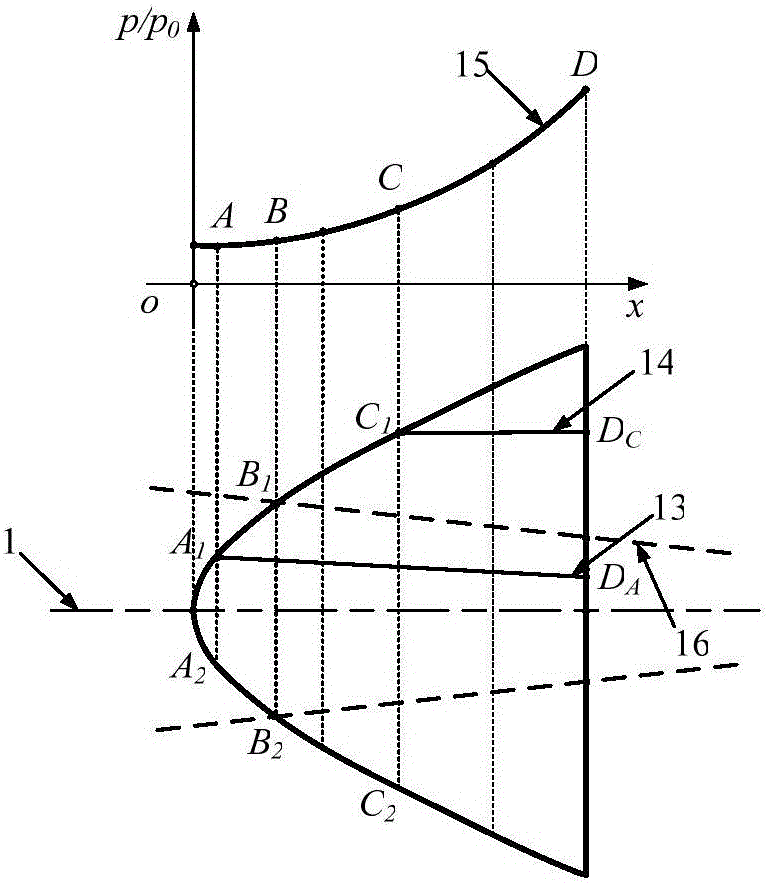

Wall-pressure-controllable internal and external wave rider integrated design method

ActiveCN106777828AHigh lift resistanceHigh lift and drag characteristicsGeometric CADSustainable transportationShock waveInlet channel

The invention relates to a near space hypersonic flight vehicle, in particular to a wall-pressure-controllable internal and external wave rider integrated design method. The projection and needed pressure distribution of a front edge capture molded line on a design section are specified according to design requirements. The projection of the front edge capture molded line on a top view is designed, and according to given pressure distribution, a reverse characteristic line method is utilized for solving a corresponding compression molded line. According to the compression molded line and the included angle between an osculating plane and a symmetry plane, an internal and external wave rider integrated compression molded surface is obtained in a corresponding axial symmetry external compressive flow field or an axial symmetry internal contraction flow field through coordinate transformation. The projection of a three-dimensional internal rotating air inlet channel outlet section and a three-dimensional internal rotating air inlet channel lip on the design section is designed, and a three-dimensional structure of the three-dimensional internal rotating air inlet channel lip is obtained according to the shock wave relation. The compression molded surface is adopted as a foundation for carrying out geometric construction on internal and external wave rider integrated aircrafts.

Owner:XIAMEN UNIV

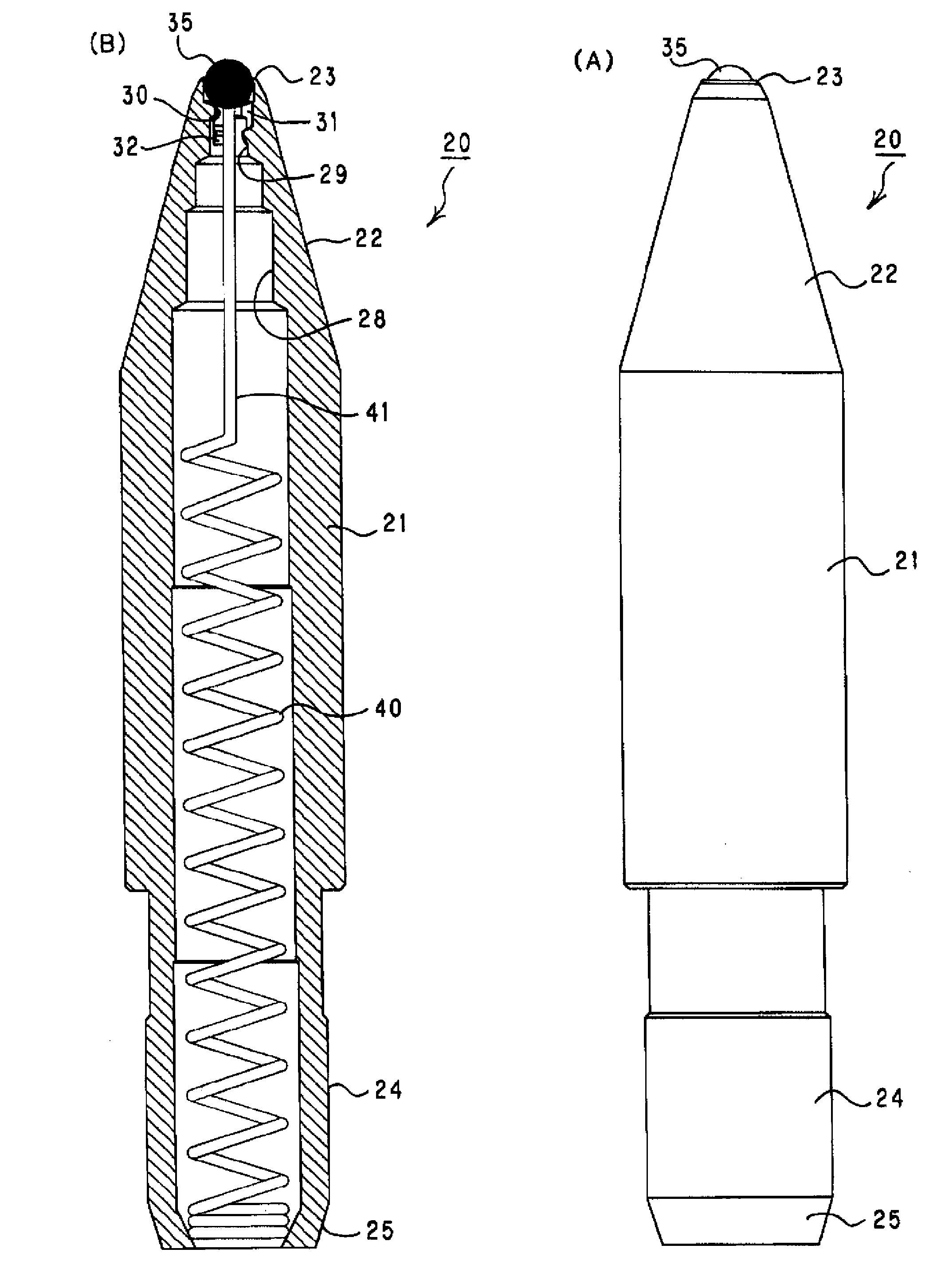

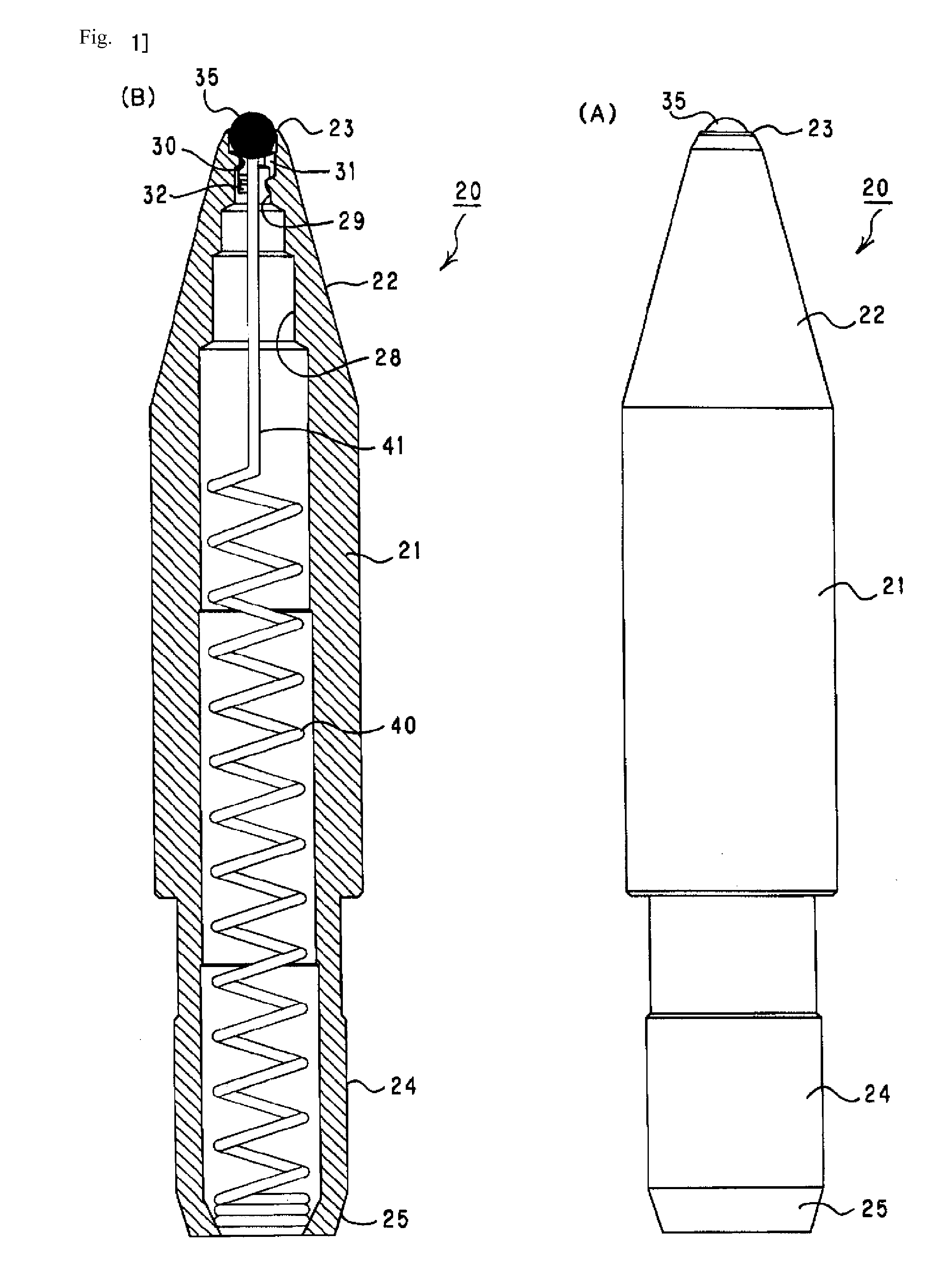

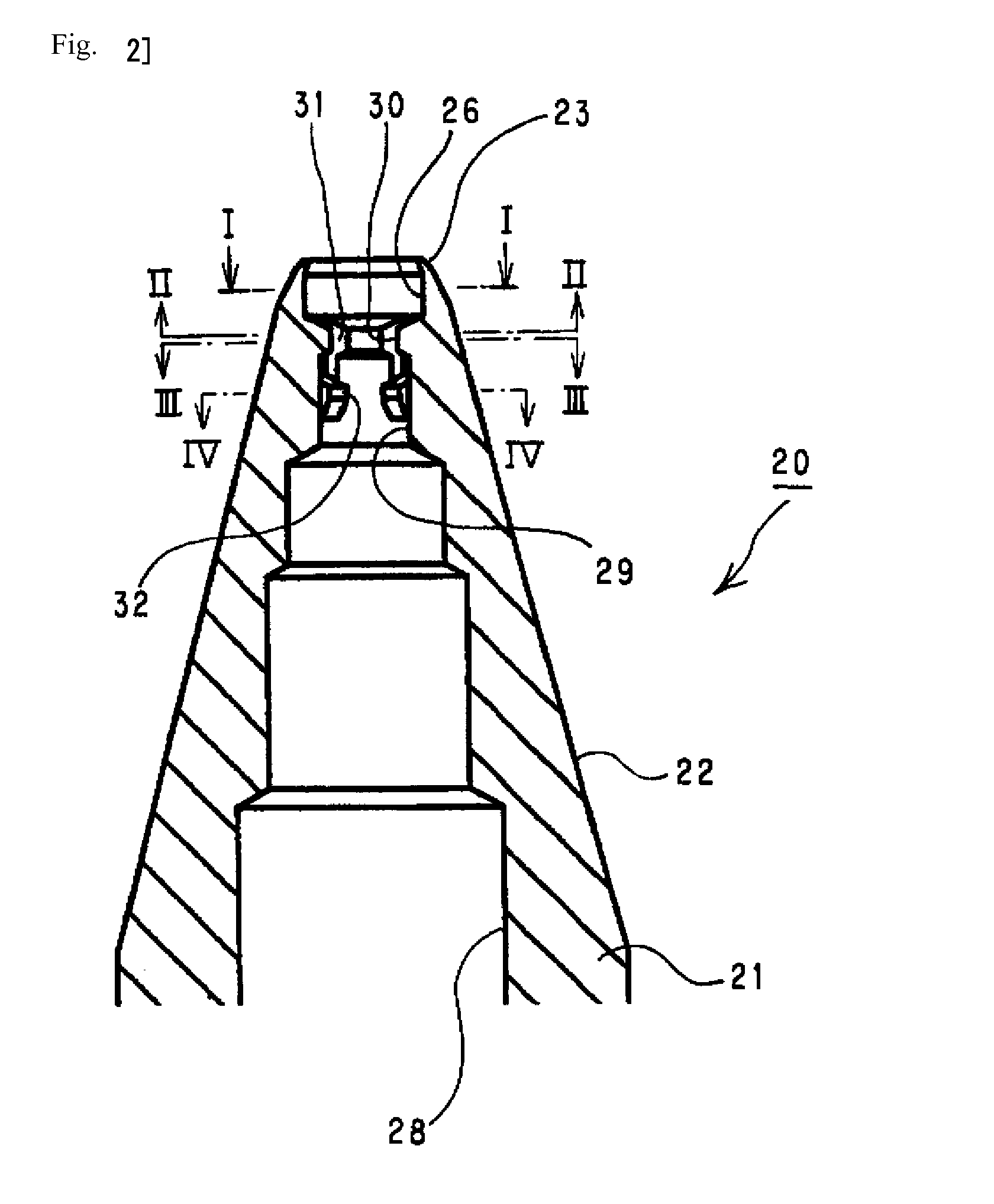

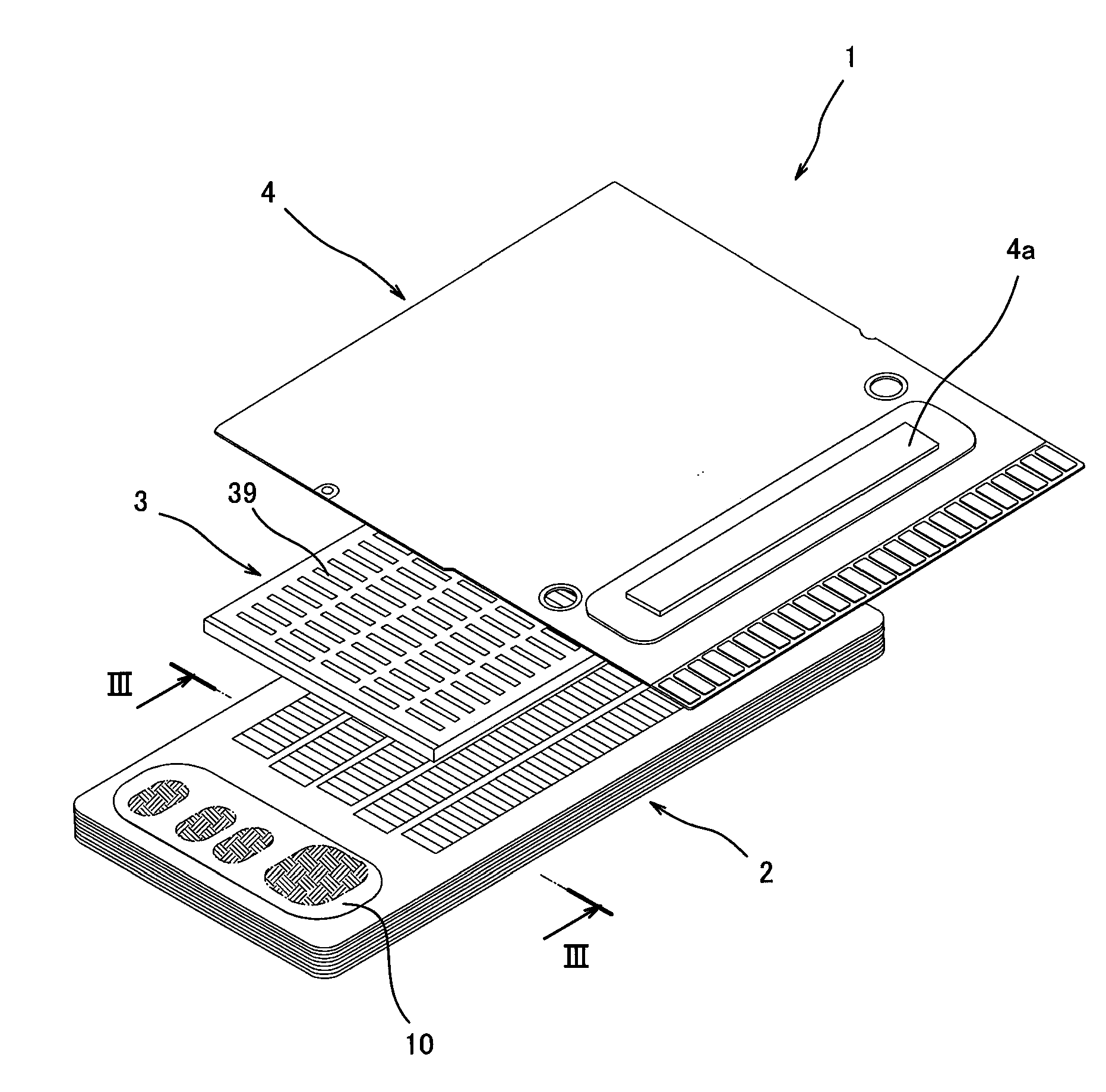

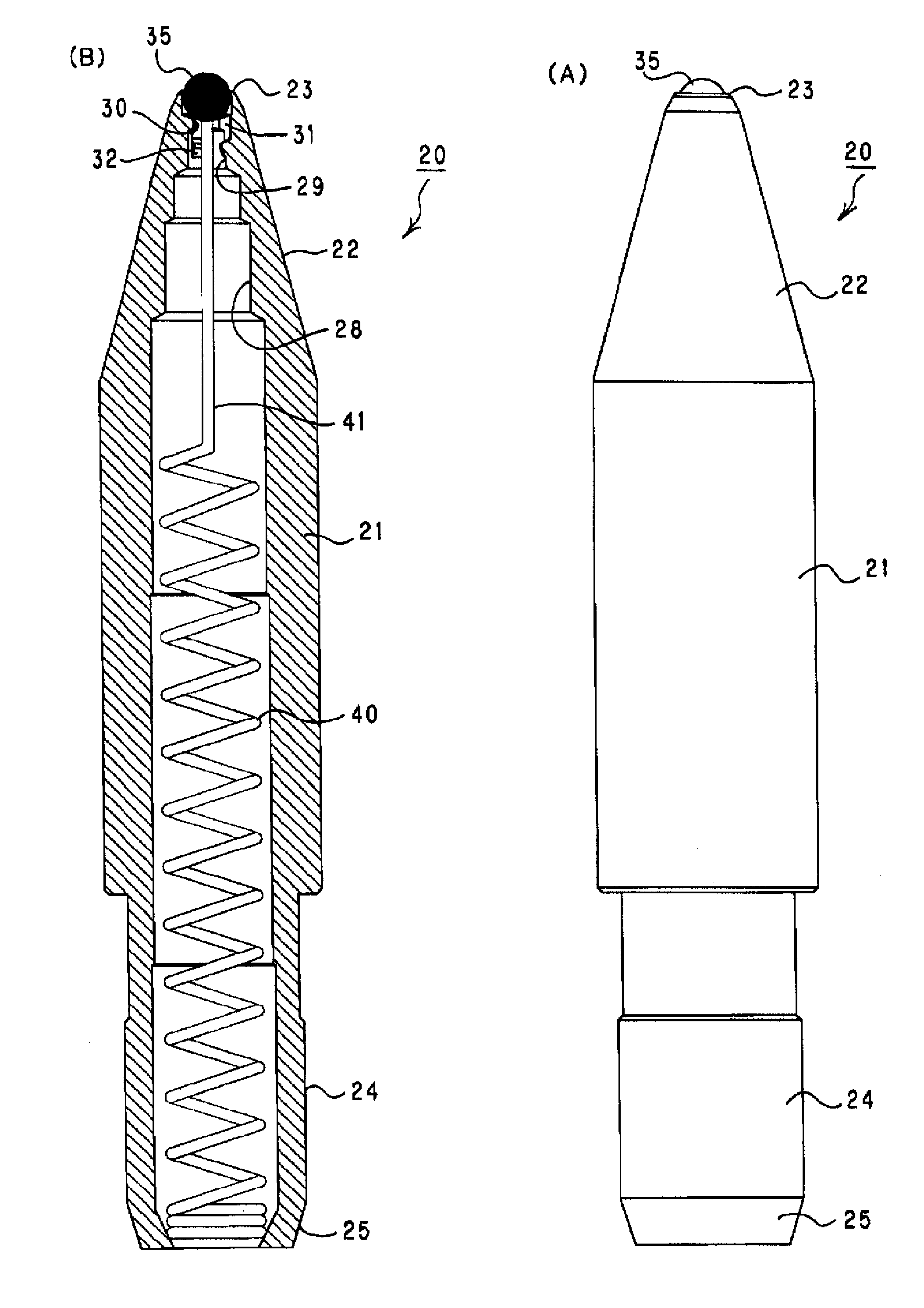

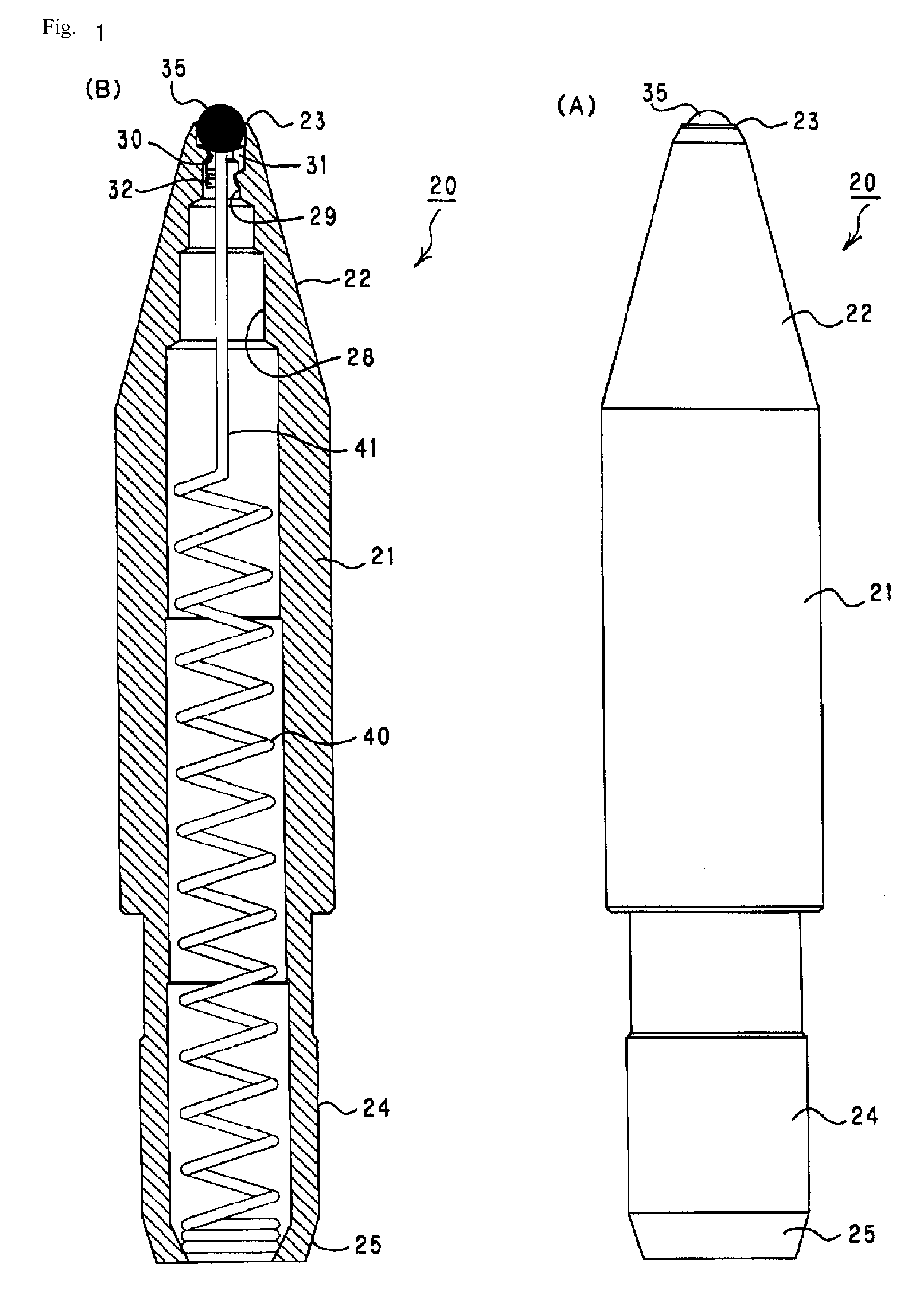

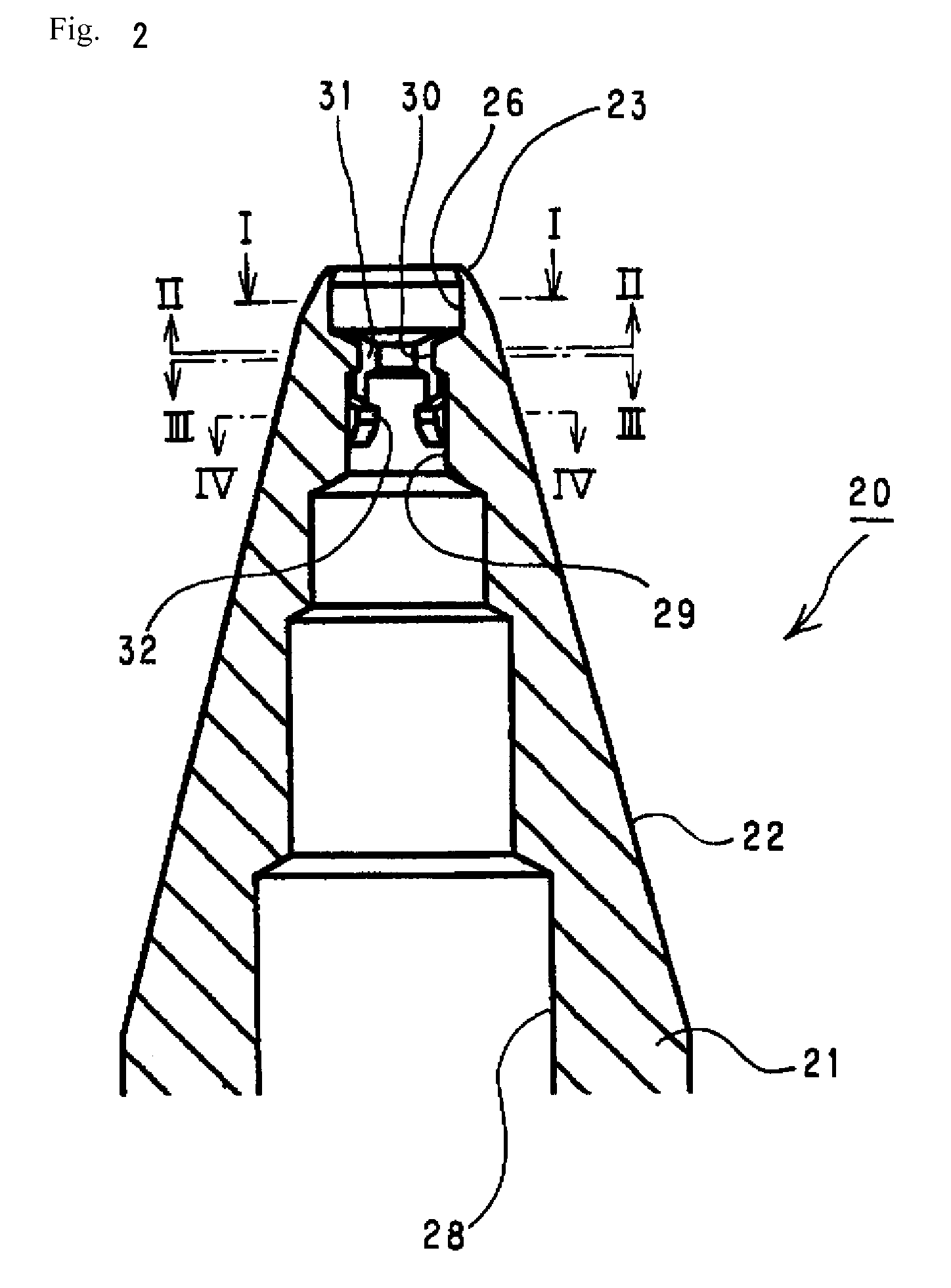

Ballpoint pen tip, ballpoint pen refill, and ballpoint pen

InactiveUS20120328356A1Reduce outflow resistancePreventing defective writingPen repairingBall-point pensMechanical engineeringEngineering

A ballpoint pen tip in which ink grooves are formed around an ink guide hole at equally distributed places, the ink guide hole connecting a ball house and a back hole of a holder for holding the writing ball, and the ink grooves radially penetrate through from the ball house side to the front end portion of the back hole. Inward protrusions are formed at positions which are respectively in contact with the rear ends of the ink grooves. If the inner diameter of the ink guide hole is A, the inner diameter of the front end portion of the back hole is B, the diameter of the circle circumscribing the ink grooves is C, and the diameter of the circle inscribing the inward protrusions is D, their relationships are A<B<C, and D<B.

Owner:MITSUBISHI PENCIL CO LTD

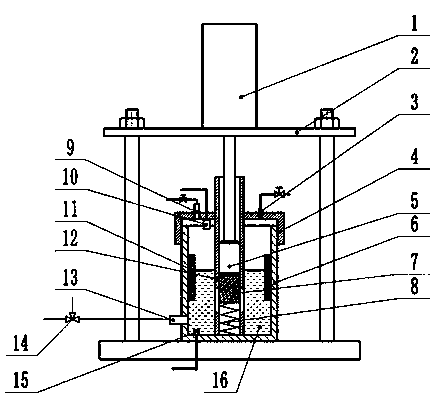

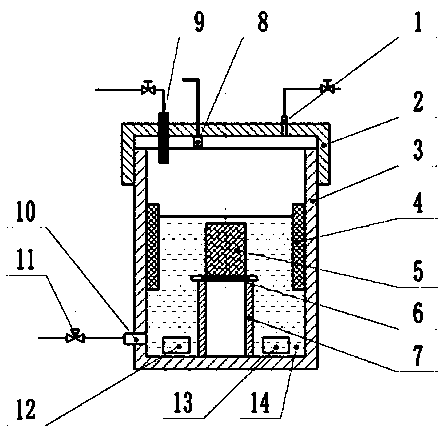

Novel on-site desorption test device for shale gas

The invention discloses a novel on-site desorption test device for shale gas, relates to the technical field of measurement, and is characterized in that an air hammer (1) is fixed by an air hammer support (2), a desorption tank (6) is placed on the bottom surface of the air hammer support (2), and a desorption tank press cap (4) and the desorption tank (6) are in seal fit in a threaded manner; aspring (8) is arranged at the bottom of an air hammer guide rail (12), and a rock core (7) is placed on the spring (8); a liquid level sensor (15) is arranged at the bottom of the desorption tank (6);an oil feed hole (13) is arranged at the lower part of the side face of the desorption tank (6); an electric heater (11) is arranged at the inner side face of the desorption tank (6); the top surfaceof the desorption tank press cap (4) is provided with a sampling port (9), an oil drain hole (3) and a pressure sensor (10). The novel on-site desorption test device for shale gas has the advantagesof simple structure and ingenious design, and can effectively reduce measurement errors caused by a low pressure coefficient in the rock core and obtain real gas content data.

Owner:龚大建

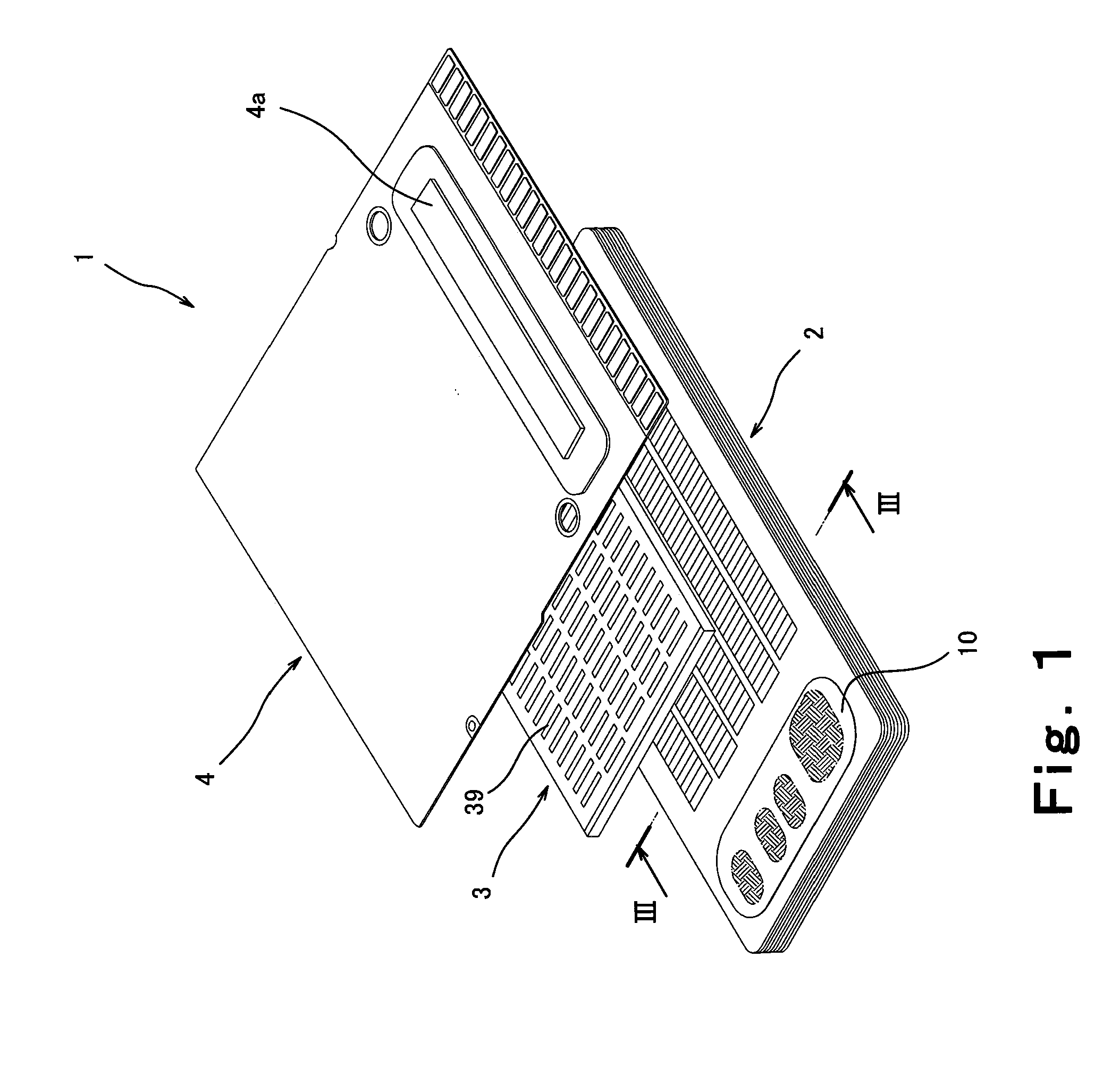

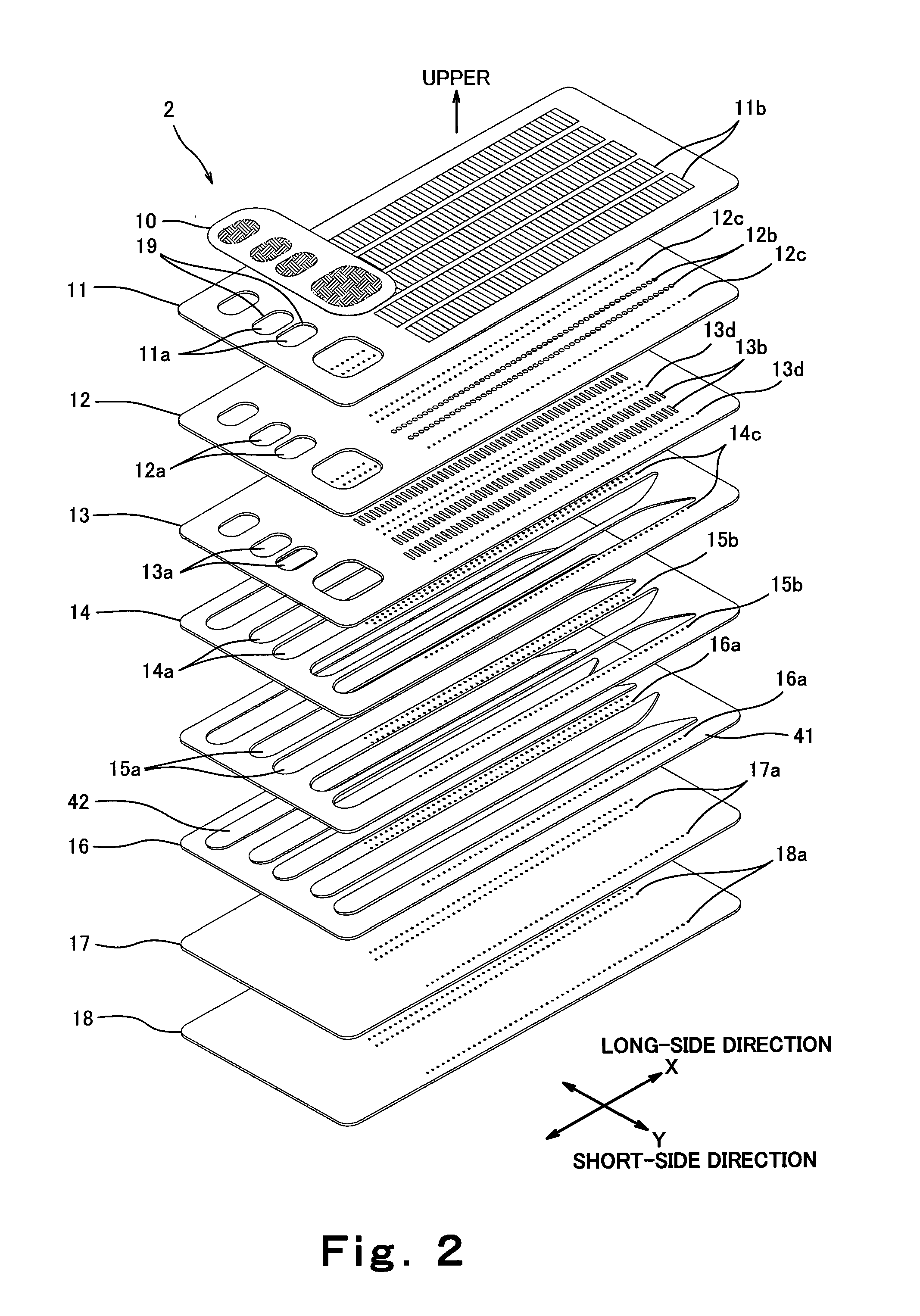

Liquid droplet ejection head and method for manufacturing the same

ActiveUS20090244188A1Increase flexibilityImprove damping performanceWriting implementsMetal-working apparatusEngineeringControl theory

An object of the present invention is to provide a liquid droplet ejection head capable of securing sealing of a common liquid chamber and realizing a high damper effect while suppressing a driving energy of the liquid droplet ejection head. A passage unit includes manifold plates, and a damper plate which is stacked on the manifold plates and has a damper wall facing a common liquid chamber. The damper plate is constituted by a base portion having a damping space at a position corresponding to the manifold holes in plan view, and a resin portion stacked on the base portion. The resin portion is formed to cover at least a portion above and around the damping space to constitute the damper wall, be smaller in a contour shape than the common liquid chamber in plan view, and be stored in the manifold holes.

Owner:BROTHER KOGYO KK

Novel shale gas on-site desorption testing device and testing method for atmospheric pressure stratum

PendingCN108663285ASolve Air Impact ProblemsSimple structureMaterial analysisDesorptionMegasonic cleaning

The invention discloses a novel shale gas on-site desorption testing device and a testing method for an atmospheric pressure stratum and relates to the technical field of measurement. The testing device is characterized in that a liquid level sensor (12) and an electric heater (13) are fixedly mounted at the bottom in a desorption tank (3) through screws; a filter screen bracket (7) is placed in the middle of the bottom in the desorption tank (3); a filter screen (6) is placed above the filter screen bracket (7); a desorption tank pressure cap (2) is mounted above the desorption tank in a threaded connection manner; an oil draining hole (1) and a pressure sensor (8) are formed in and mounted on the desorption tank pressure cap (2); an oil inlet hole (10) is formed at the bottom of the sideface of the desorption tank (3); and a three-way valve (11) is mounted outside the oil inlet hole (10). The device is simple in structure and ingenious in design, solves the problem of difficult testing of a gas content of a core of the atmospheric pressure stratum, and has important significance on shale gas resource evaluation of the atmospheric pressure stratum.

Owner:上海瑞达峰致能源科技股份有限公司

Design method of variable cross-section three-dimensional internal contraction air inlet channel matched with curved cone projectile body

ActiveCN110210096ABroaden the working Mach number rangeLarge thrustGeometric CADSpecial data processing applicationsCombustion chamberInlet channel

The invention discloses a design method of a variable cross-section three-dimensional internal contraction air inlet channel matched with a curved cone projectile body, which comprises the curved coneprojectile body and the variable cross-section three-dimensional internal contraction air inlet channel and comprises the following steps: 1) designing the inlet shape of the variable cross-section three-dimensional internal contraction air inlet channel and the shoulder profile shape of the air inlet channel according to the geometric shape of the curved cone projectile body and the combustion chamber inlet shape requirement; 2) dispersing the inlet molded line of the air inlet channel and the shoulder molded line of the air inlet channel; 3) solving the axisymmetric basic flow field, and performing streamline tracking in the basic flow field according to the shape of the variable cross-section three-dimensional internal contraction air inlet to obtain a corresponding streamline; 4) cutting off the streamline according to the relative position of the inlet and outlet shapes of the variable cross-section three-dimensional internal contraction air inlet channel, and performing three-dimensional arrangement on the obtained streamline to obtain a variable cross-section three-dimensional internal contraction air inlet channel compression molded surface; and 5) on the basis of the variable-cross-section three-dimensional internal contraction air inlet channel compression molded surface, carrying out geometric construction on the variable-cross-section three-dimensional internal contraction air inlet channel matched with the curved cone projectile body.

Owner:NANCHANG HANGKONG UNIVERSITY

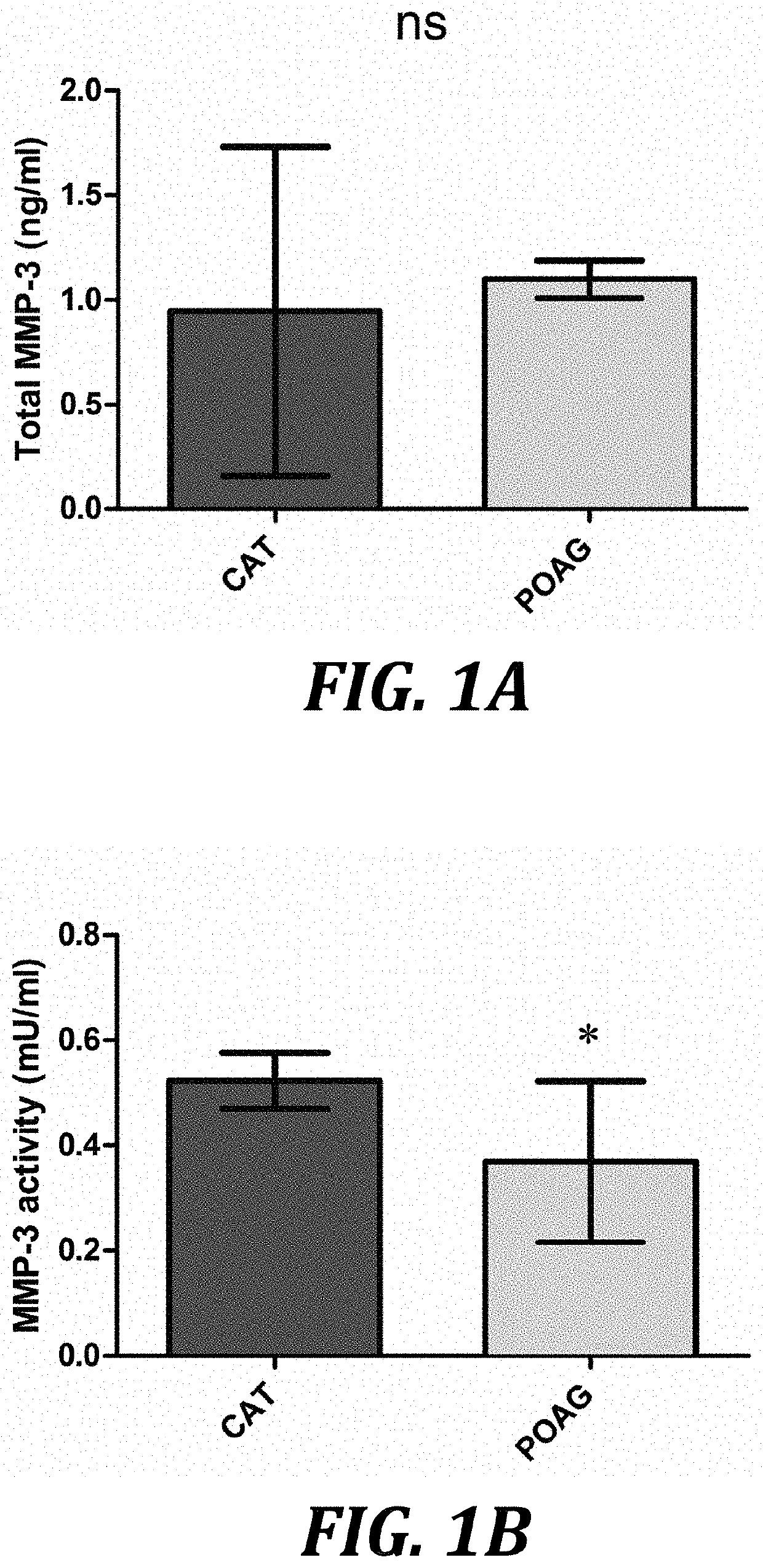

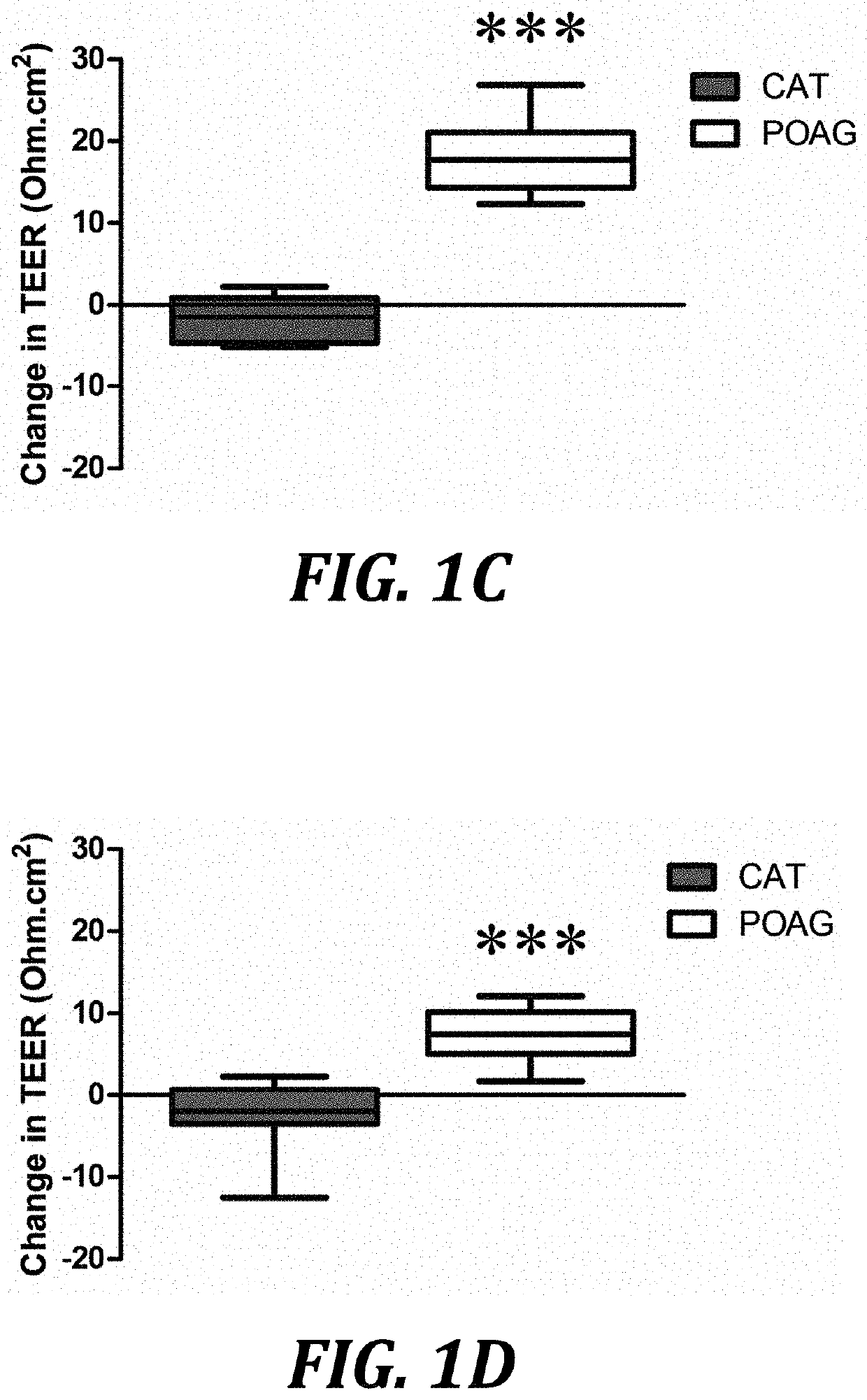

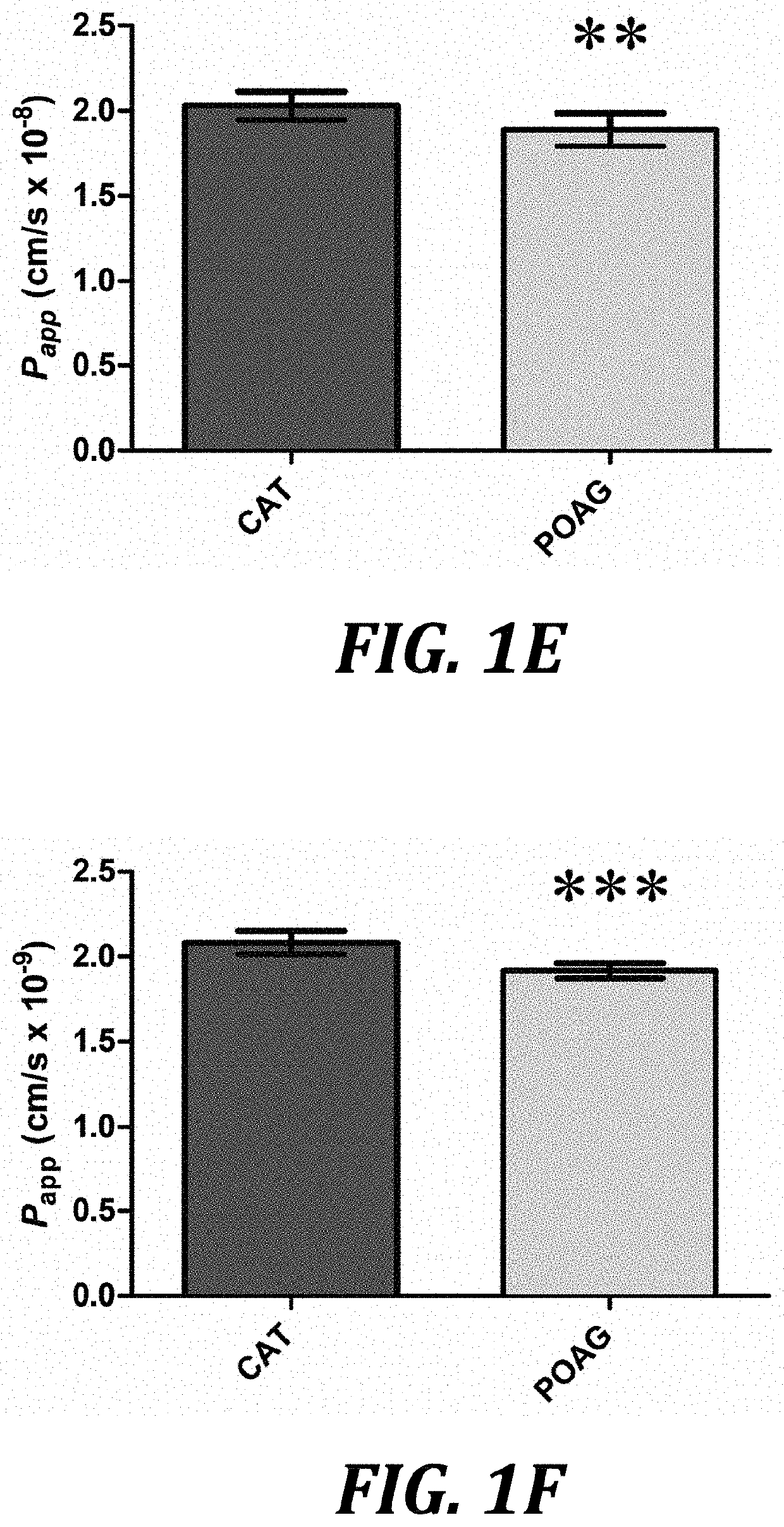

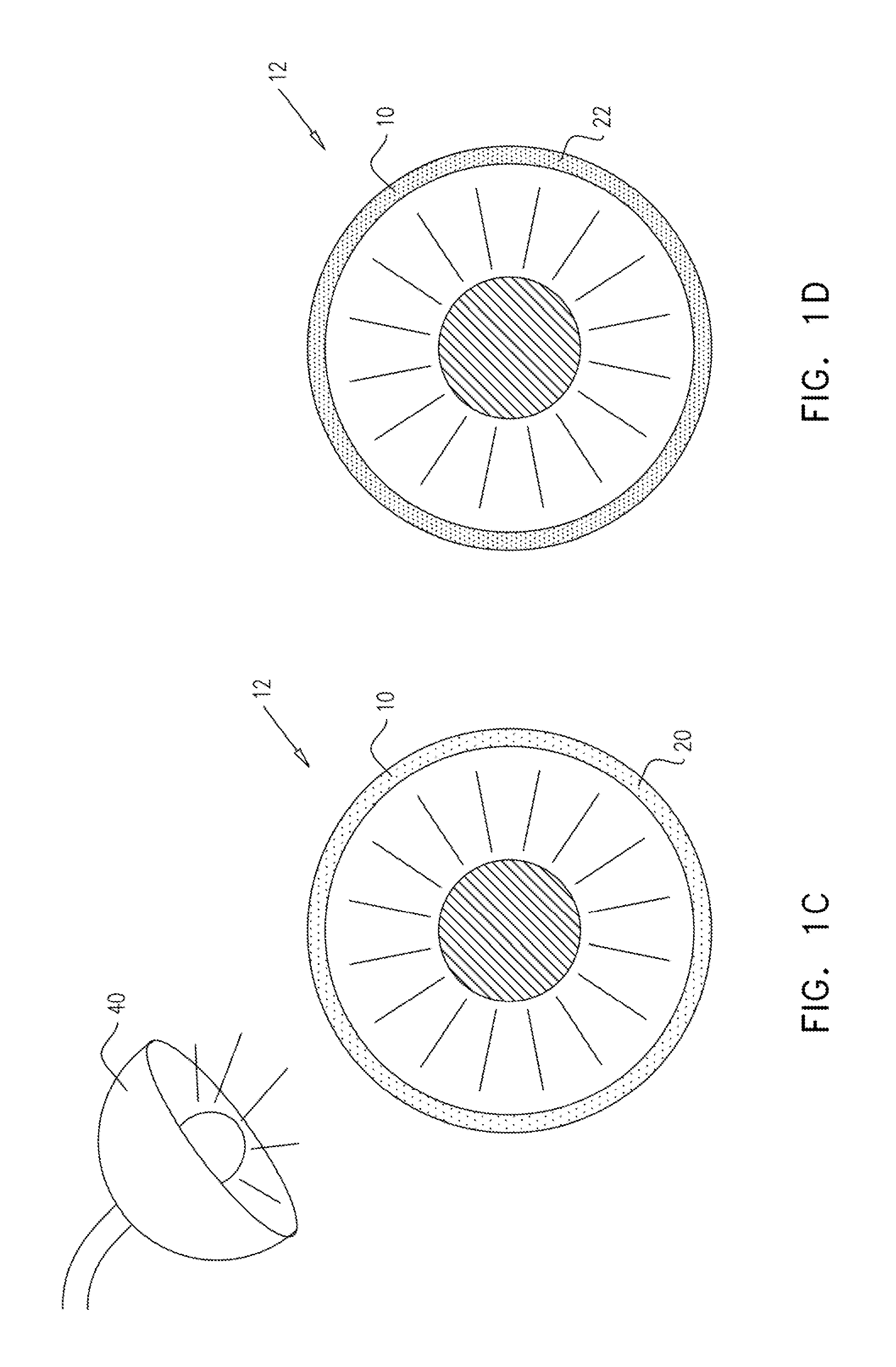

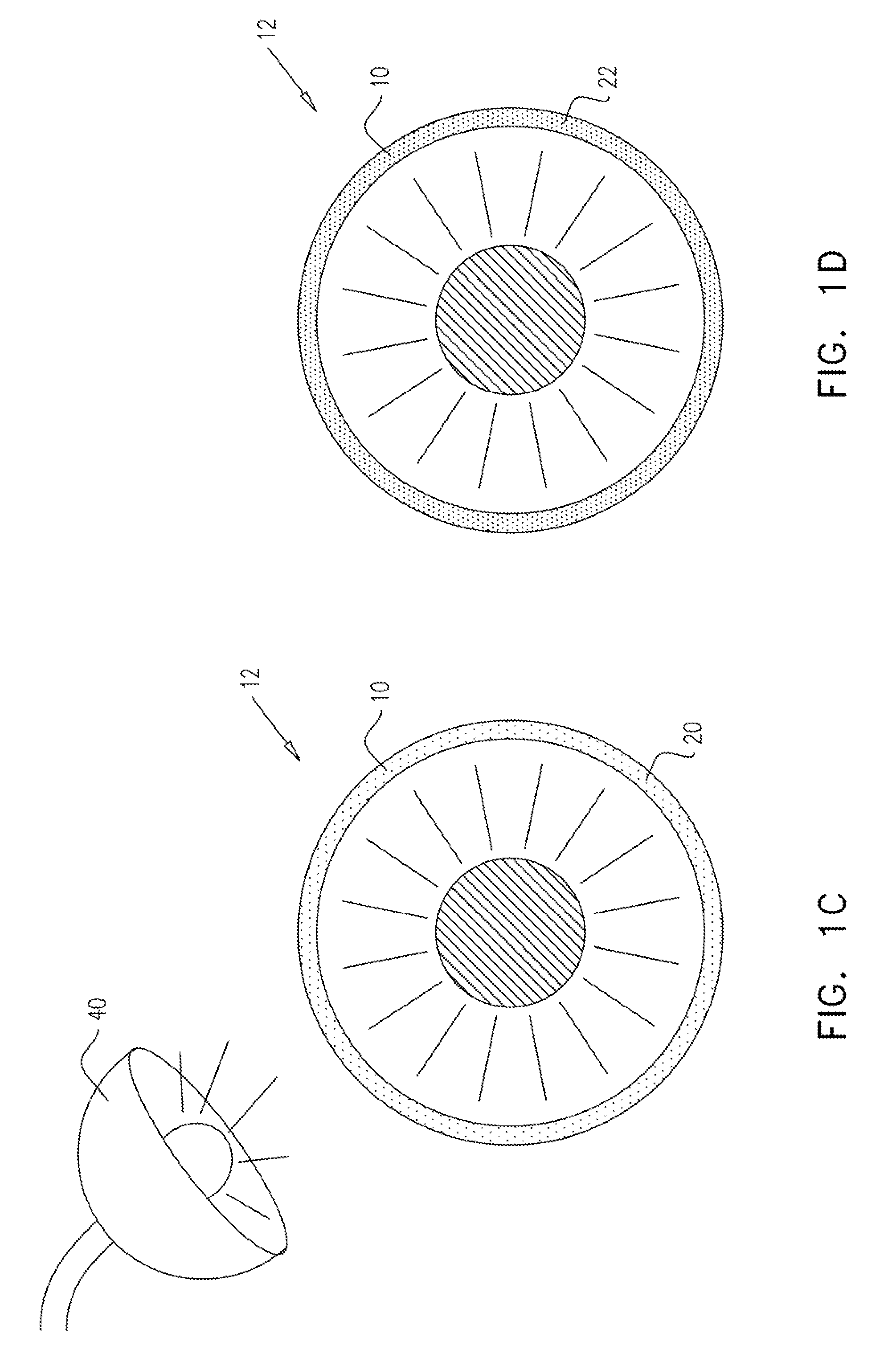

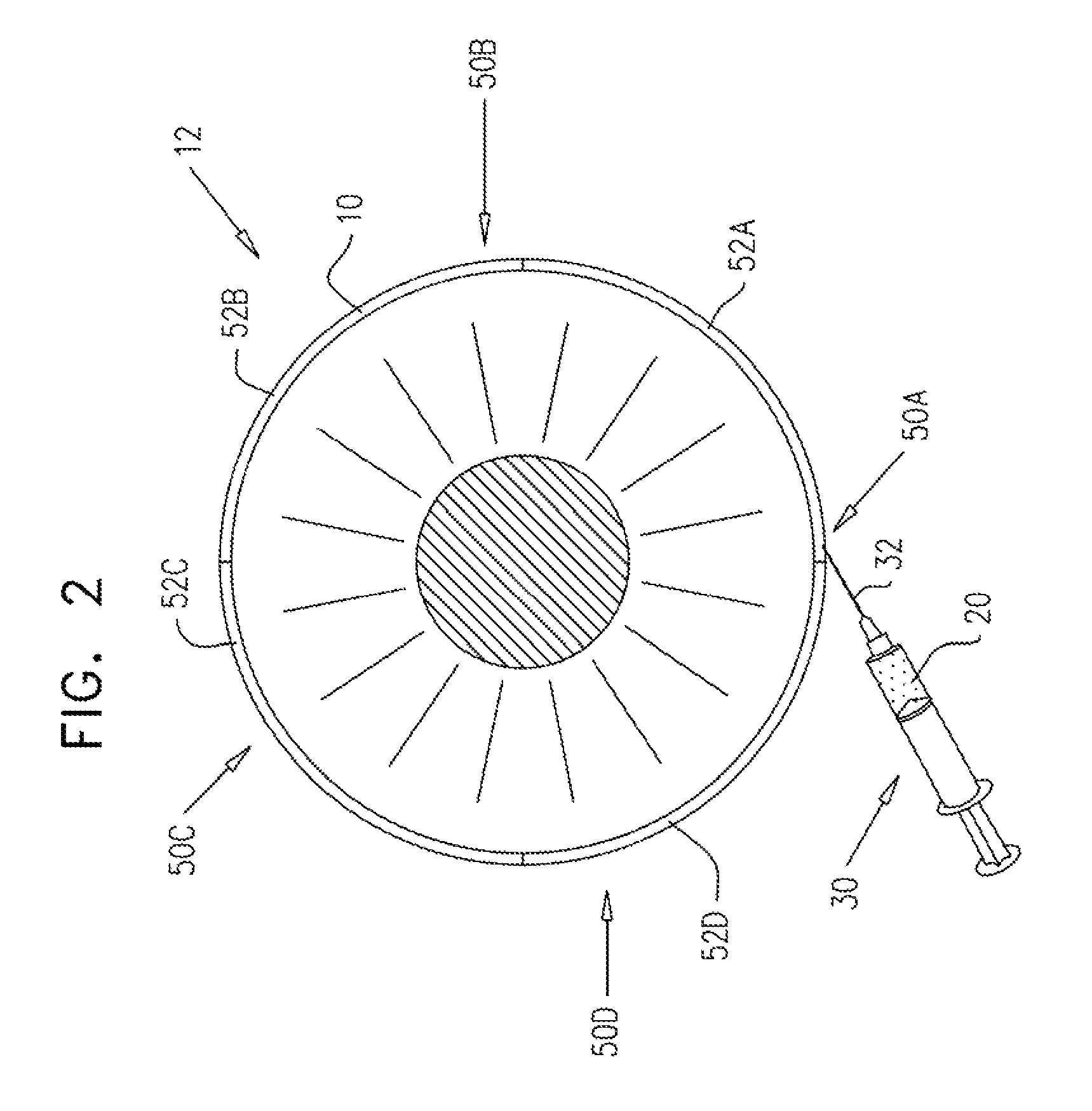

Aav-based gene therapy for glaucoma

PendingUS20190358305A1Increase ratingsReduce resistanceSenses disorderPeptide/protein ingredientsCell-Extracellular MatrixTherapeutic protein

The disclosure provides compositions and methods useful for treating glaucoma. In particular, the invention provides an adeno-associated viral (AAV)-mediated gene therapy for glaucoma in which transduced cells of the eye secrete a therapeutic protein (for example, a matrix metalloproteinase) resulting in remodeling of the extracellular matrix of the trabecular meshwork of said eye.

Owner:TRINITY COLLEGE DUBLIN

Full-three-dimensional inward turning air inlet channel reverse design method based on curved shock wave theory

ActiveCN112324572AExpand the scope of the designBroaden the working Mach number rangeTurbine/propulsion air intakesShock waveInlet channel

A full-three-dimensional inward turning air inlet channel reverse design method based on the curved shock wave theory comprises the following steps of: 1) specifying full-three-dimensional incident shock waves in a full-three-dimensional reference flow field according to design requirements; 2) dispersing the full-three-dimensional incident shock waves into a series of reference planes, and solving a corresponding full-three-dimensional internal contraction basic flow field by utilizing a curved shock wave theory according to a full-three-dimensional incident shock wave angle, a shock wave curvature and a wave back parameter; 3) designing a full-three-dimensional inward turning air inlet channel outlet section, and performing streamline tracking in the full-three-dimensional internal contraction basic flow field in the step 2) to obtain a hypersonic speed full-three-dimensional inward turning air inlet channel compression profile, wherein the cross section is elliptical or quasi-rectangular; and 4) geometrically constructing a hypersonic speed full-three-dimensional inward turning air inlet channel on the basis of the full-three-dimensional inward turning air inlet channel compression profile in the step 3): according to the outlet area requirement, equally straightening or expanding and stretching a shoulder molded line to obtain a full-three-dimensional inward turning air inlet channel isolation section, and obtaining the full-three-dimensional inward turning air inlet channel based on the curved shock wave theory in the designed flight state.

Owner:XIAMEN UNIV

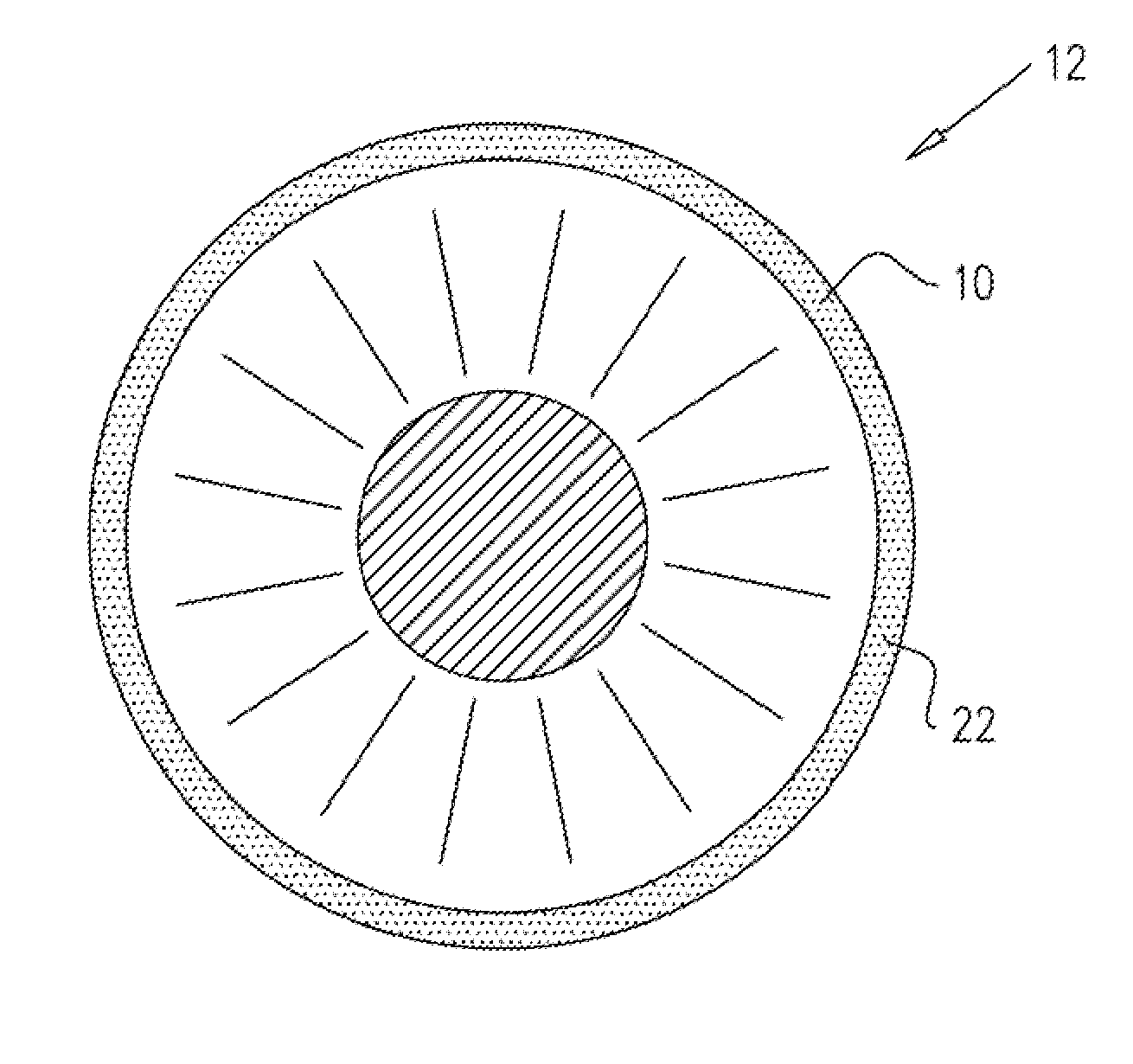

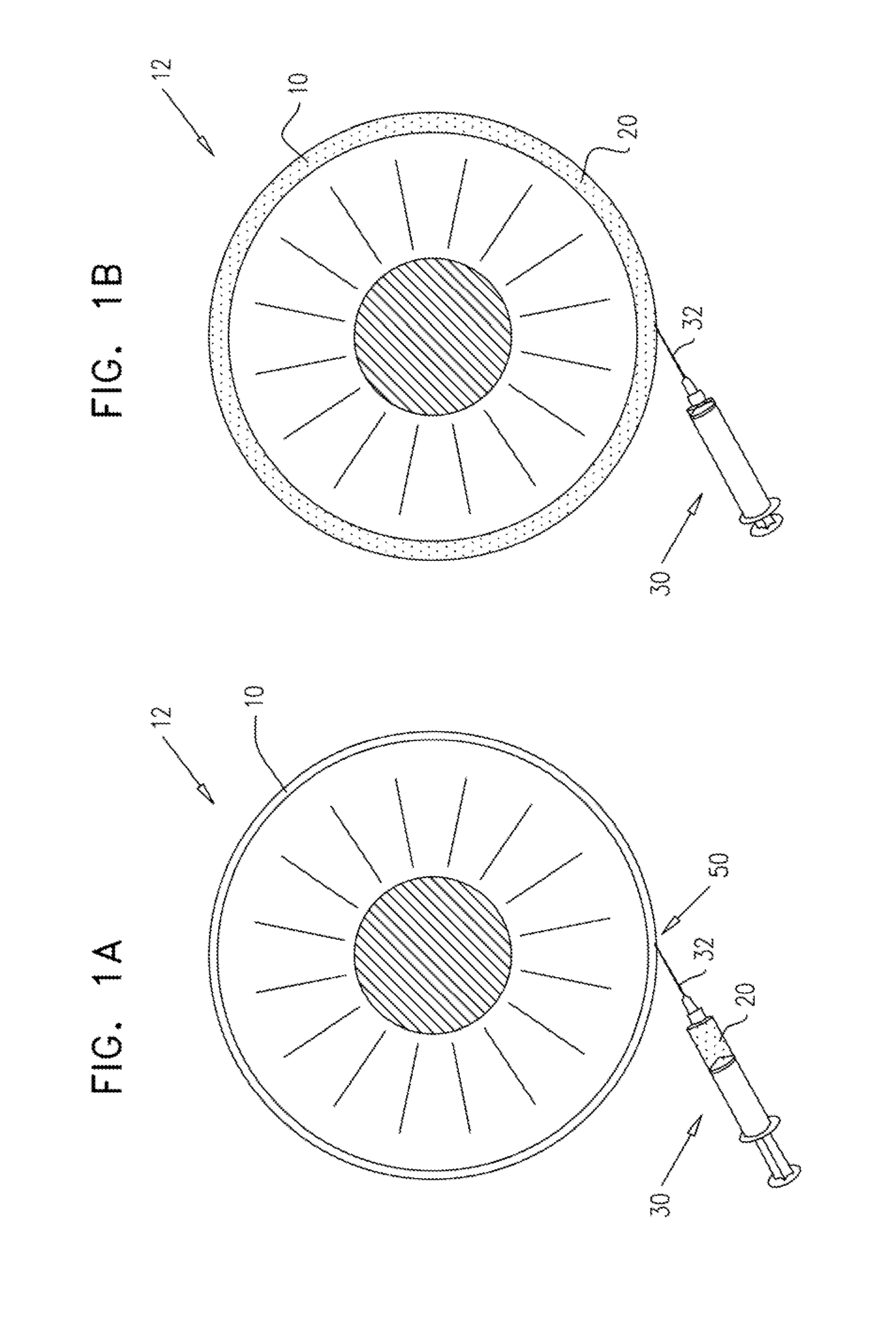

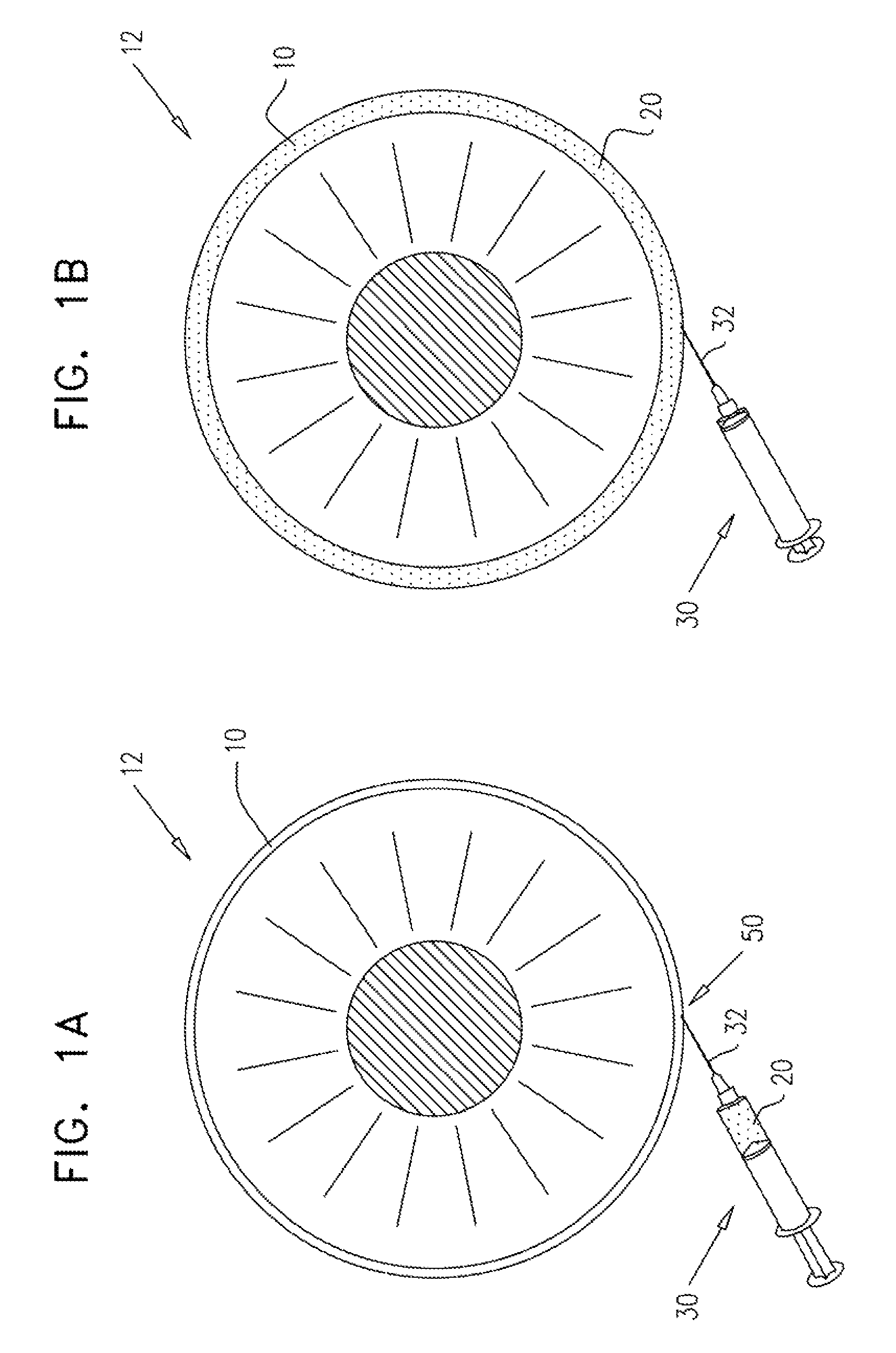

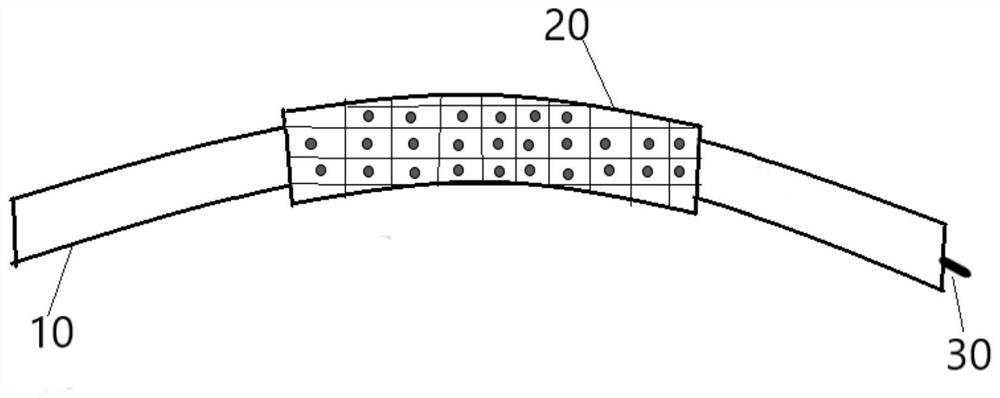

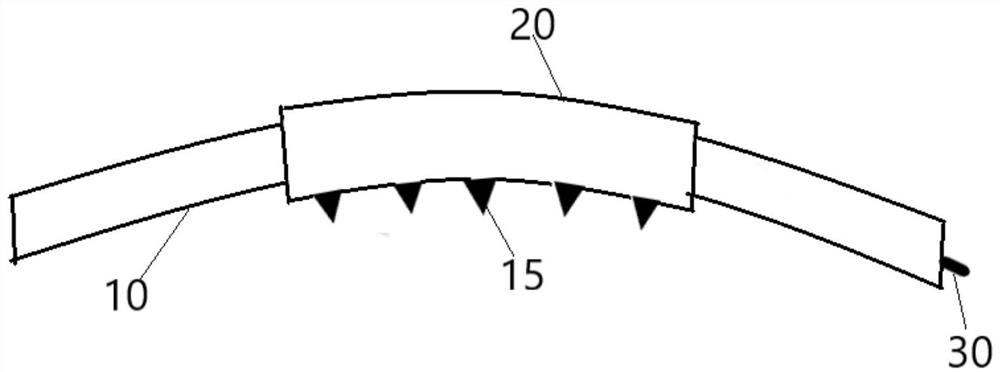

Injectable hydrogel implant for treating glaucoma

ActiveUS20150190554A1Good fluid permeabilityReduce outflow resistanceBiocideEye surgerySchlemm's canalAqueous outflow

A method is provided for increasing the aqueous outflow of fluid through a trabecular meshwork and into a Schlemm's canal of an eye. A liquid hydrogel precursor solution is introduced into the Schlemm's canal, during a medical procedure. The liquid hydrogel precursor solution is crosslinked to form a water-permeable flexible semi-solid hydrogel in the Schlemm's canal, during the medical procedure. The hydrogel is left in the Schlemm's canal upon conclusion of the medical procedure. Other embodiments are also described.

Owner:RAINBOW MEDICAL LTD

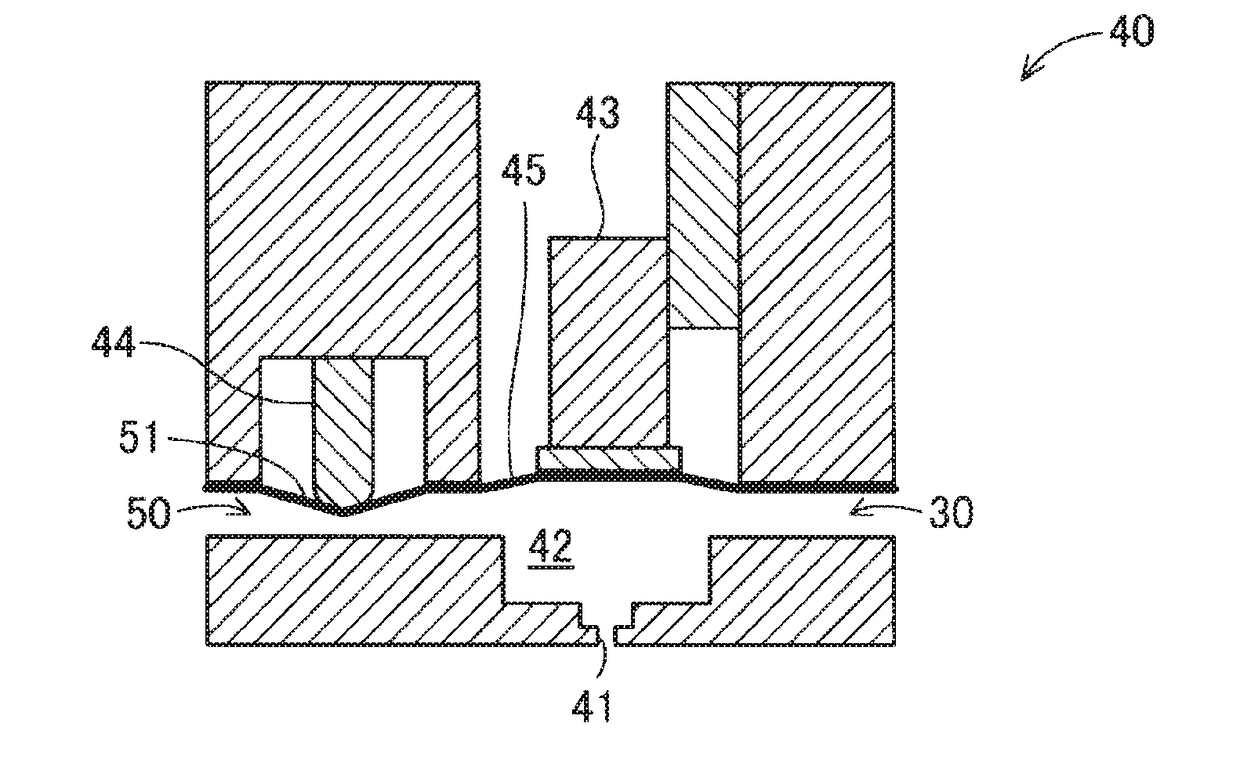

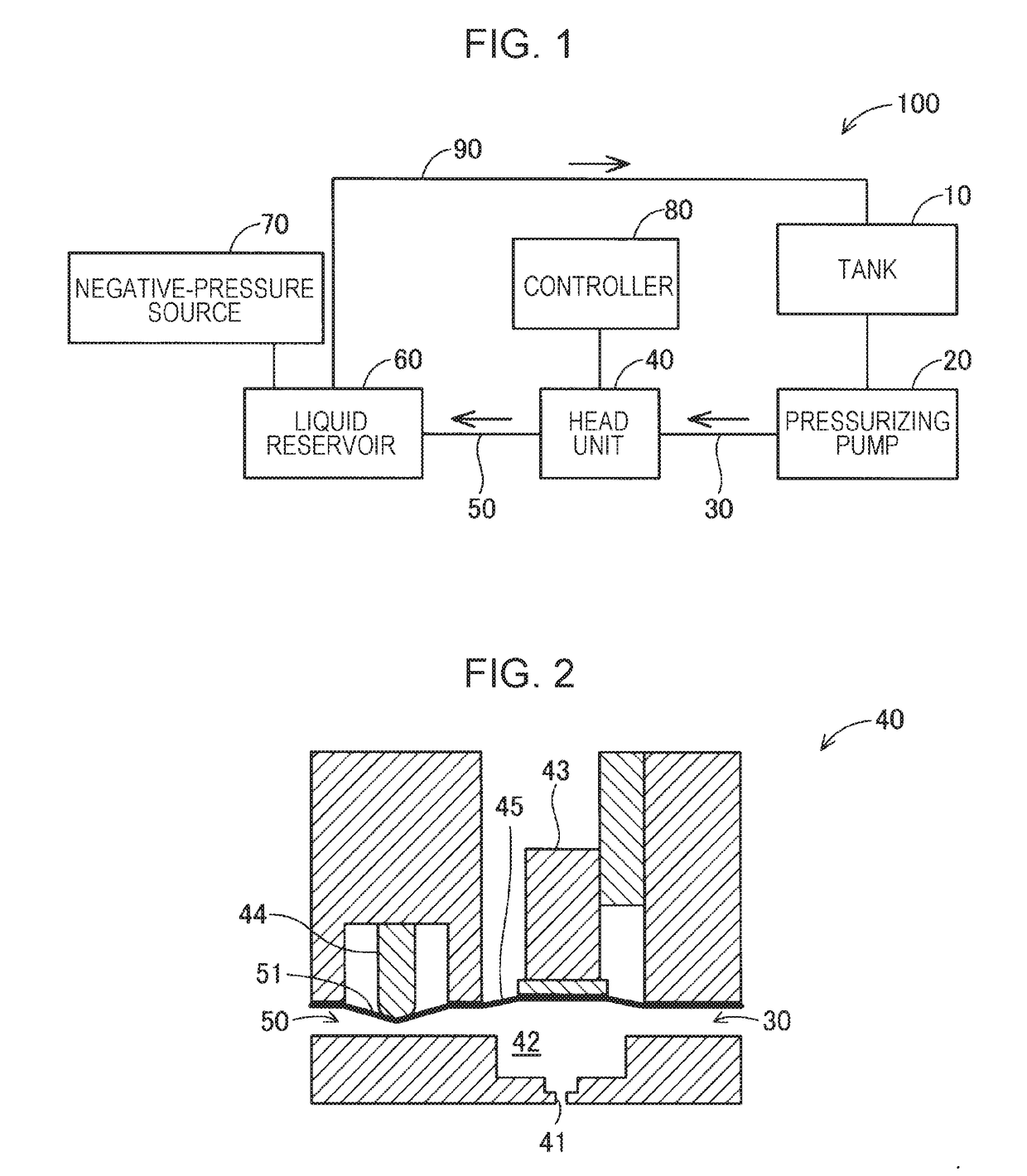

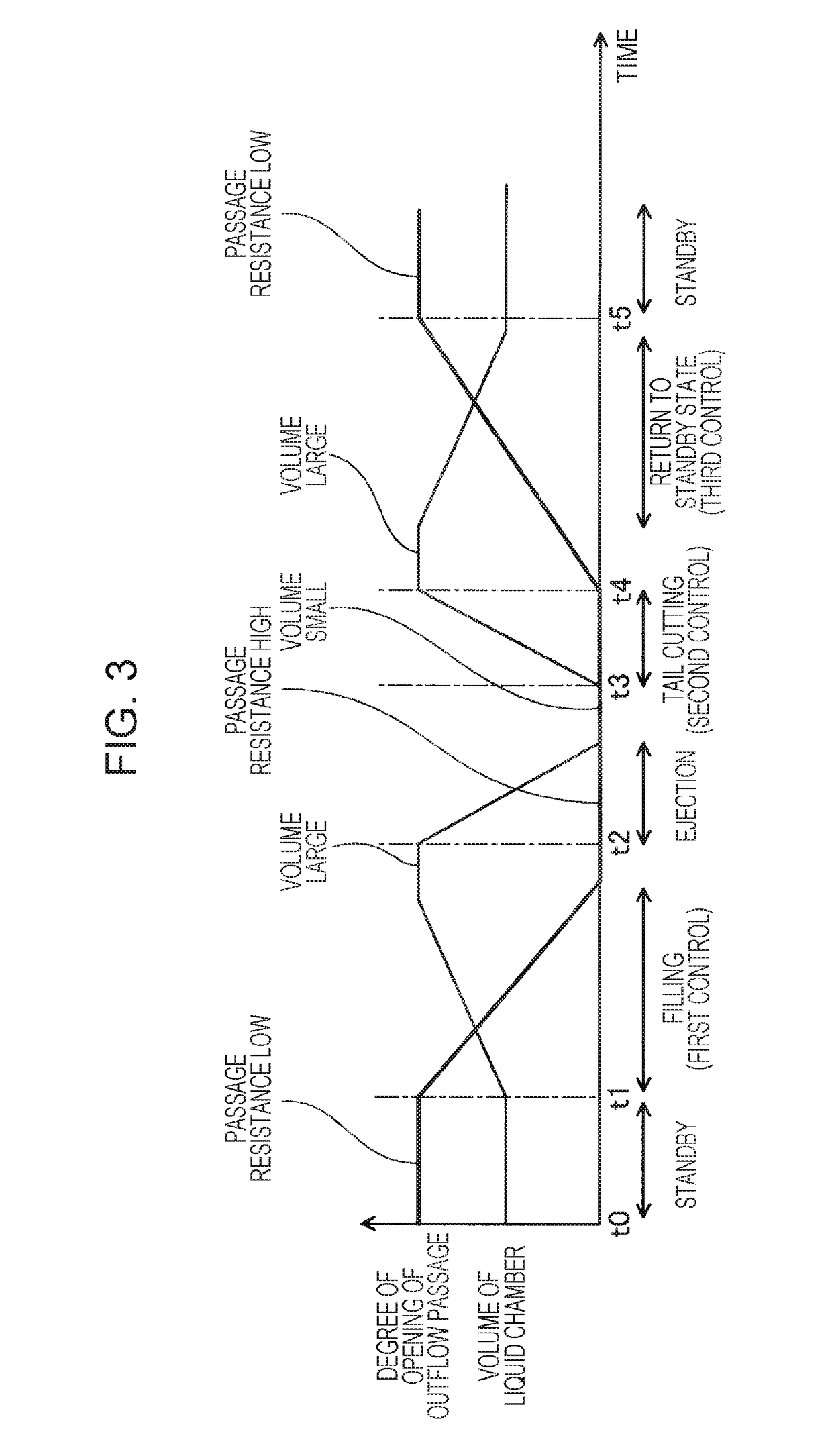

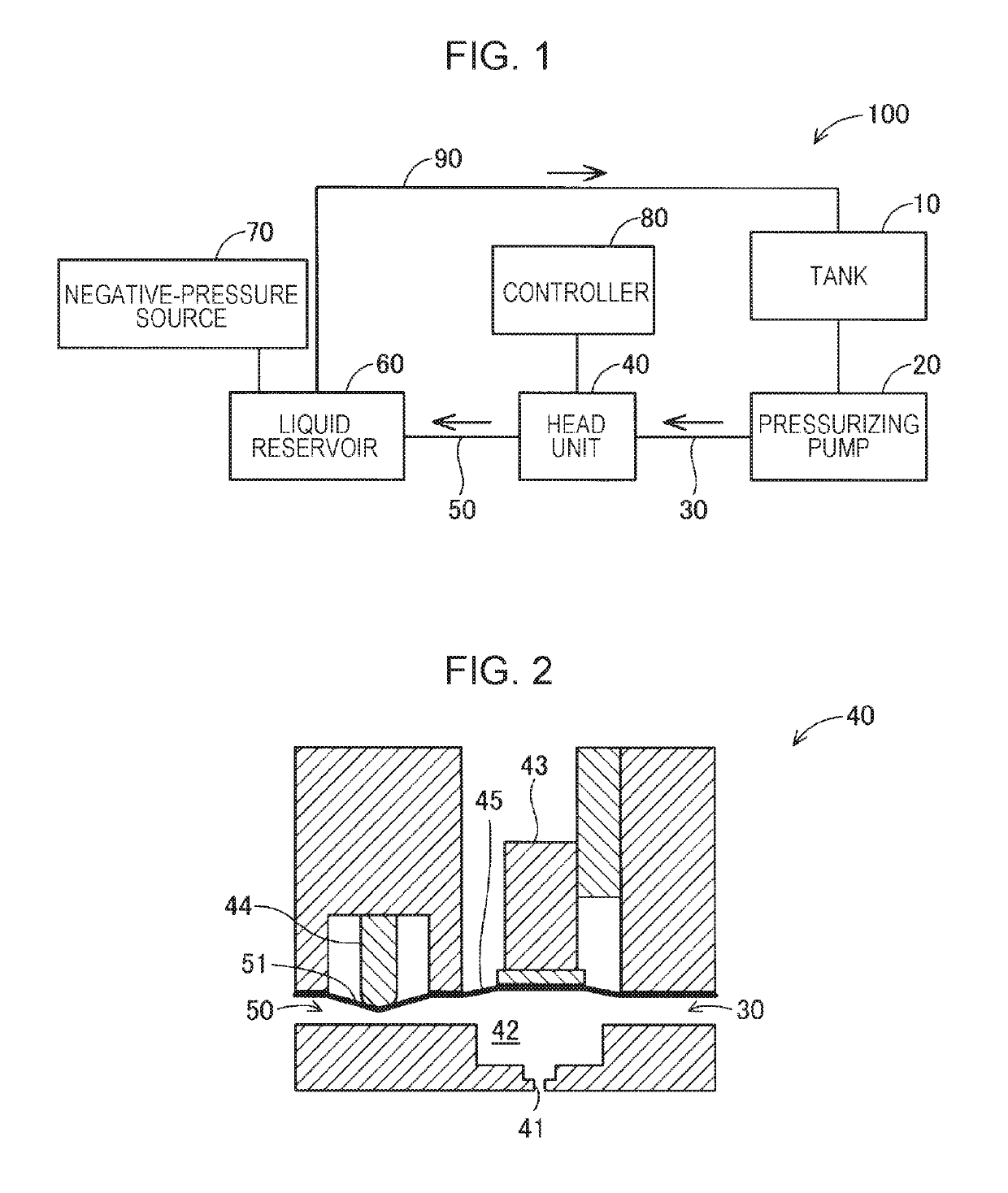

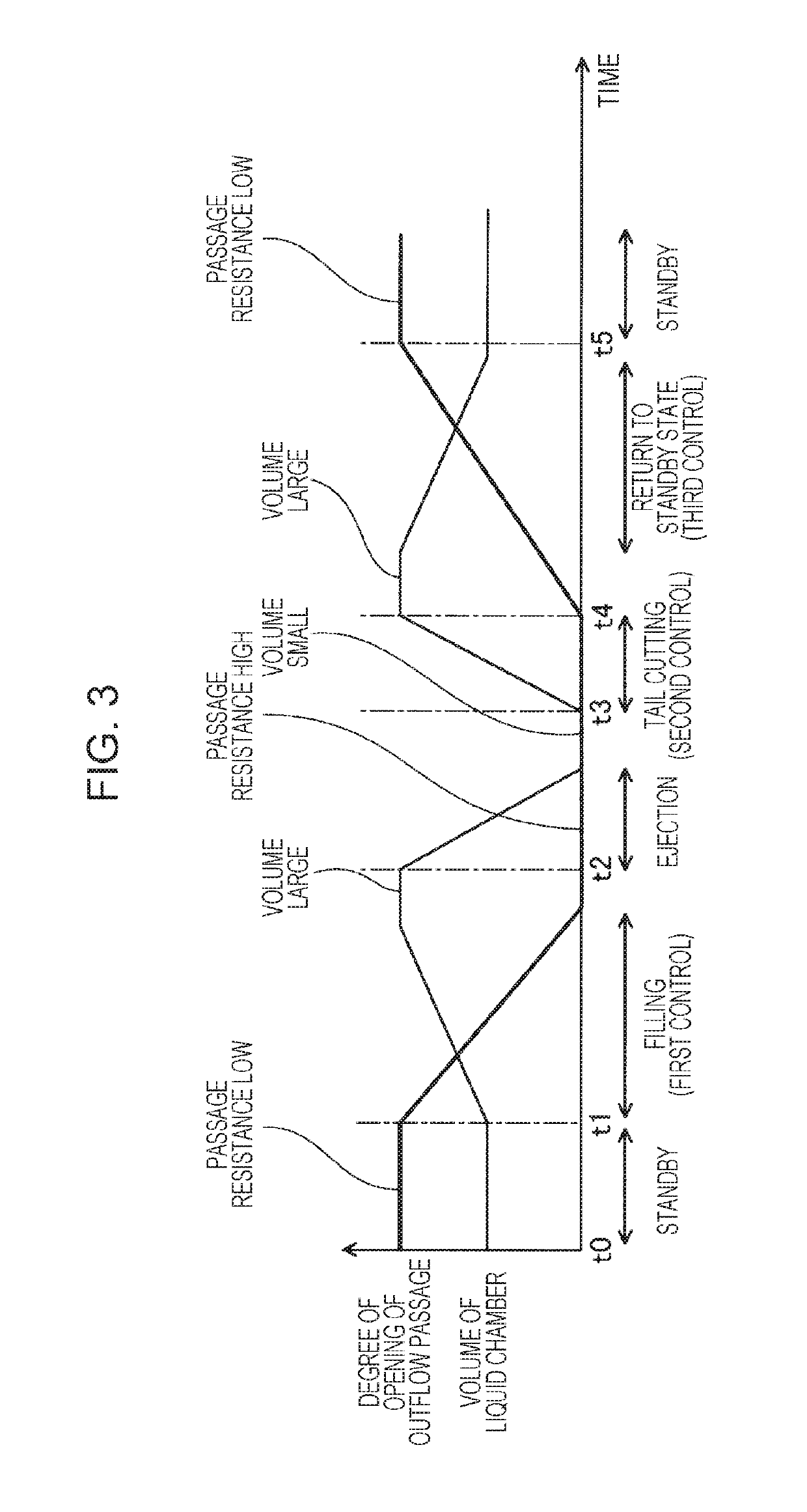

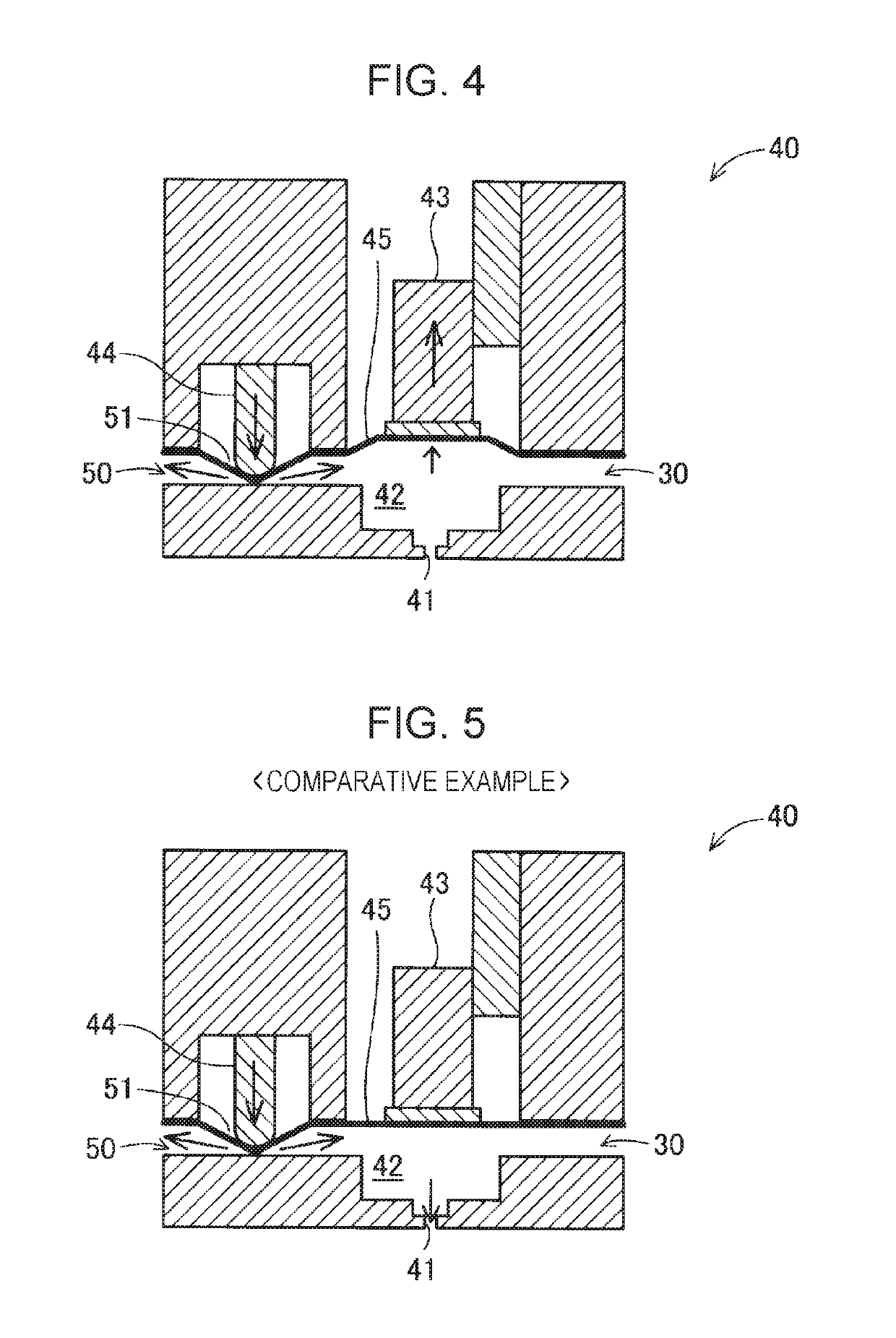

Liquid ejecting apparatus and liquid ejection method

A liquid ejecting apparatus includes a liquid chamber in communication with a nozzle, a volume changing unit configured to change a volume of the liquid chamber, an inflow passage through which the liquid flows into the liquid chamber, an outflow passage through which the liquid flows out of the liquid chamber, a passage resistance changing unit configured to change a passage resistance of the outflow passage, and a controller configured to control the volume changing unit to reduce the volume of the liquid chamber so as to cause the liquid to be ejected through the nozzle. In filling the liquid chamber with the liquid for ejection of the liquid through the nozzle, the controller controls the passage resistance changing unit to change the passage resistance of the outflow passage to an increased passage resistance and controls the volume changing unit to increase the volume of the liquid chamber.

Owner:SEIKO EPSON CORP

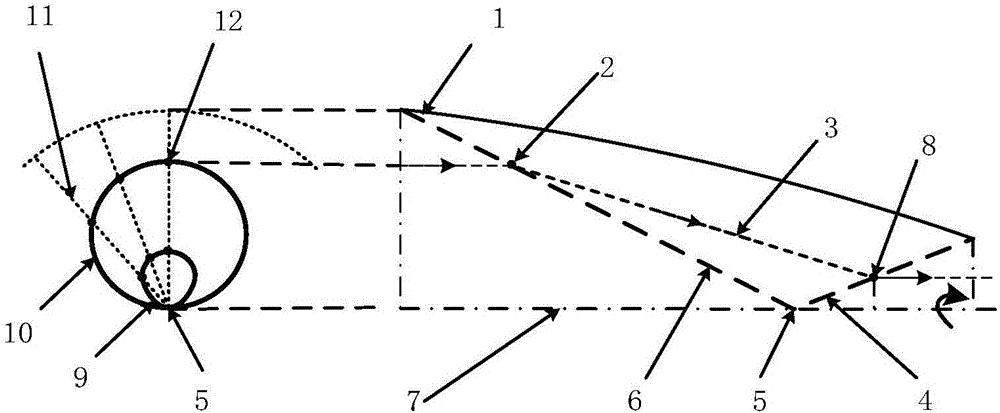

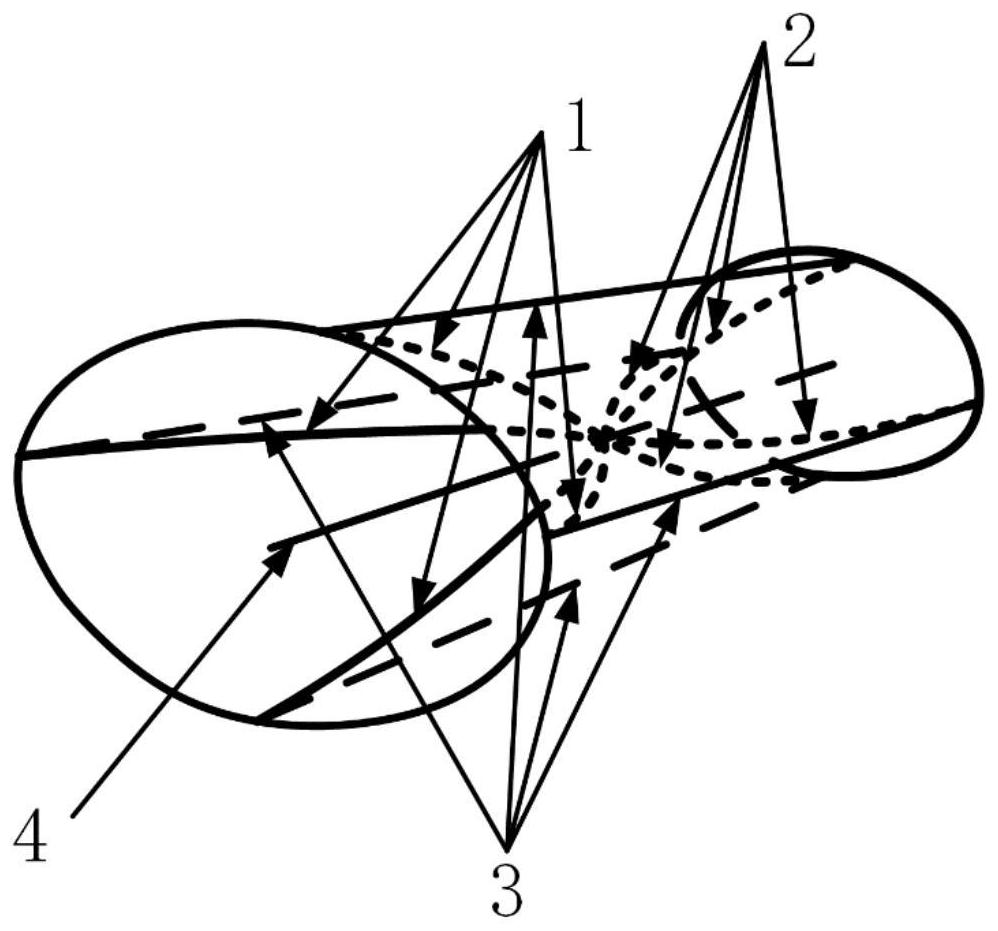

Hypersonic aerocraft and air inlet internal and external waverider integrated design method

ActiveCN103662087BBroaden the working Mach number rangeLarge thrustTurbine/propulsion air intakesGround installationsShock waveRadial position

The invention discloses a hypersonic aerocraft and air inlet internal and external waverider integrated design method, and relates to a near space aerocraft. An aerodynamics characteristic is firstly appointed, and then a design scheme meeting the characteristic is inferred backwards; a three-dimensional shock wave curved surface in a complex shape is appointed, the change rule of the transverse curvature center is obtained, and a series of basic flow fields meeting the needs of the waverider design are inferred backwards according to the change rule; flow lines of different curvature centers and different radial positions are traced in every basic flow field in the circumferential direction; a waverider device capable of producing the appointed complex three-dimensional shock wave curved surface is obtained finally, namely the integrated design scheme is obtained. The advantages of a waveriders and an internal waverider air inlet are kept, the integrated design of the two high-performance devices is achieved, the waverider model with high lift-drag ratio and the scheme of the air inlet with full-flow capture can be obtained at the same time, and accordingly the overall performance of the aerocraft is improved.

Owner:XIAMEN UNIV

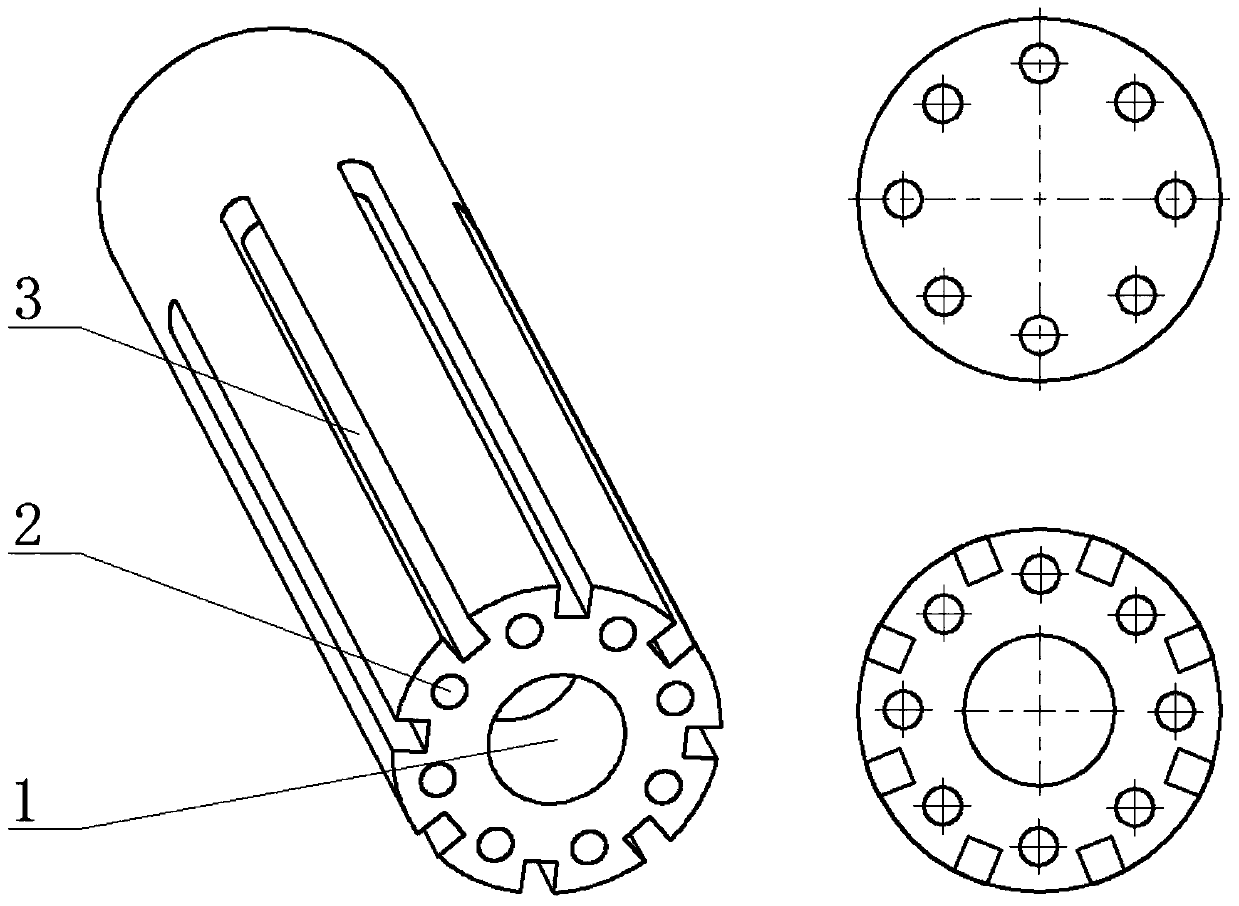

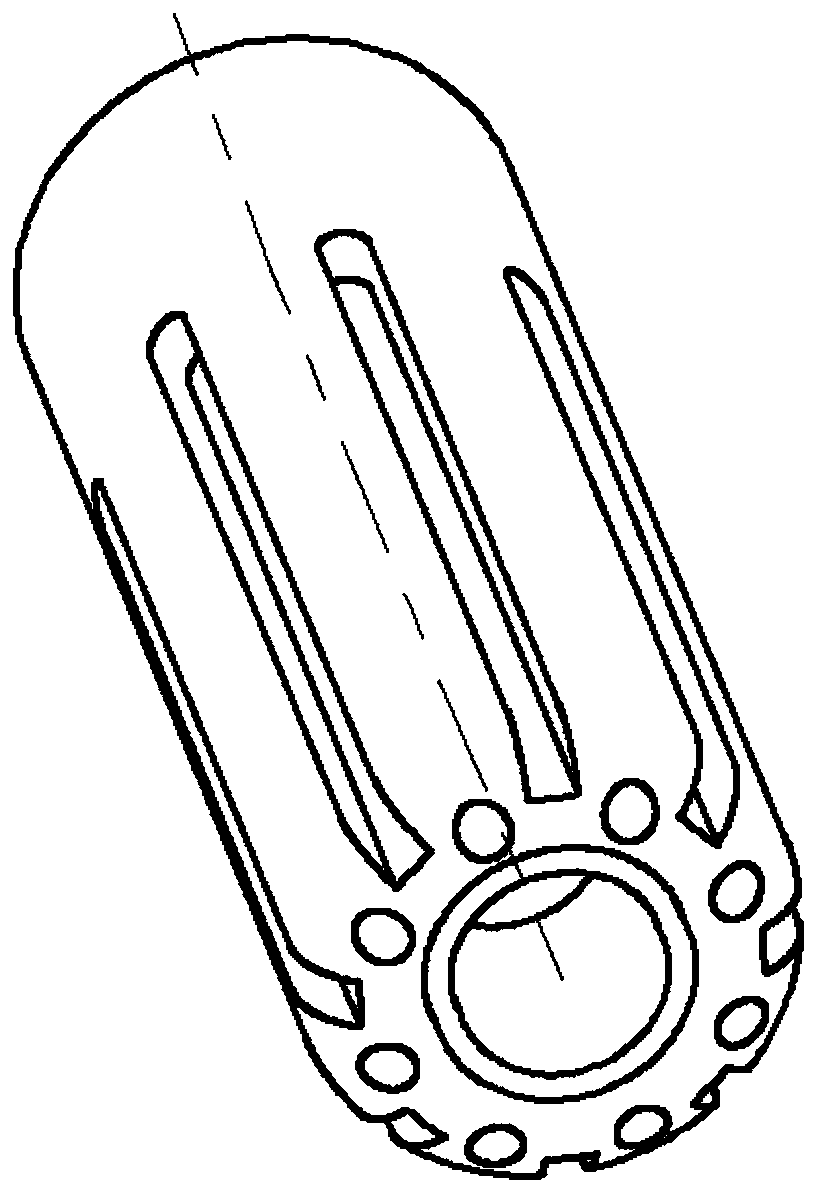

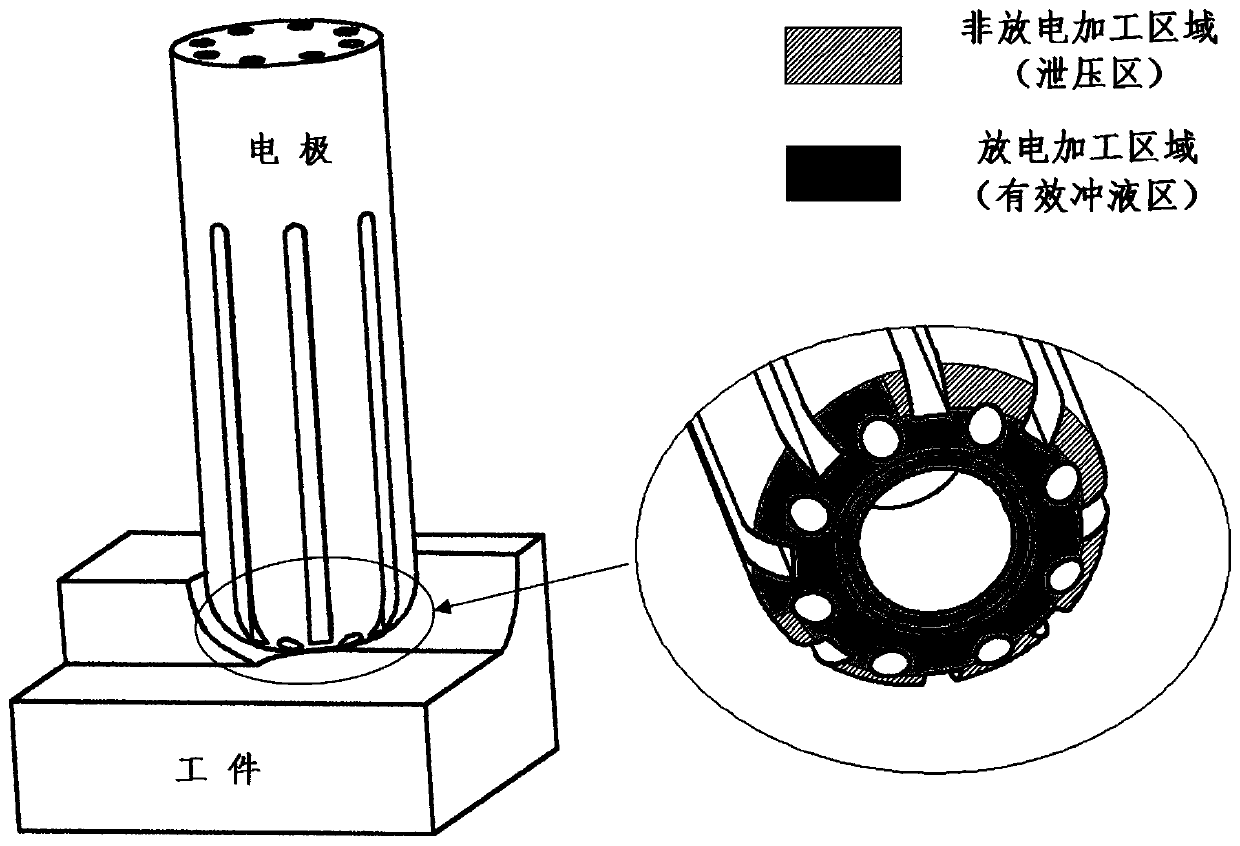

Anti-short-circuit porous high-efficiency flushing electrode for arc discharge machining

ActiveCN108620699BEasy to passRealize strong flushingElectrical-based machining electrodesMachined surfaceEngineering

A short circuit prevention porous efficient liquid flushing electrode for arc discharge machining is characterized in that the electrode is cylindrical; the central area of the bottom of the electrodeis provided with a blind hole along the electrode axis; a plurality of inner liquid flushing through holes are distributed in one periphery of the outer side area of the bottom of the electrode in the axial direction; the side face of the electrode is provided with a plurality of liquid flushing chip discharge grooves, so that the side face of the electrode forms a discontinuous surface; each liquid flushing chip discharge groove is open in the bottom face of the electrode; and the openings of the liquid flushing chip discharge grooves and the inner liquid flushing through holes are formed ina staggered mode. According to the electrode, the decompression effect on work liquid from a non-discharge machining area can be reduced effectively, strong inner liquid flushing of the discharge machining area is maintained, a short circuit phenomenon is prevented, the quality of the machined surface is promoted, the machining rejection rate is lowered, and uniformity of electrode loss and the precision of the machining size are improved.

Owner:SHANGHAI JIAO TONG UNIV

Internal waverider-derived hypersonic inlet with ordered inlet and outlet shape and design method

InactiveCN101418723BBroaden the working Mach number rangeLarge thrustTurbine/propulsion air intakesEngineeringIntegrated design

The invention discloses an internal waverider-derived high supersonic inlet duct, the shapes of the inlet and outlet of which can be customized, and a design method thereof. The structure of the internal waverider-derived high supersonic inlet duct comprises an inlet duct contraction section and an isolated section, wherein the shape of the inlet duct contraction section is in three dimensional inward contraction. The design method is that a non-axisymmetric internal contraction basic flow field is taken as the base, the non-axisymmetric internal contraction basic flow field comprises an axisymmetric internal contraction rotary wall surface and a non-axisymmetric variable radius central body, wherein the axisymmetric internal contraction rotary wall surface keeps no changing, and the radius of the central body is adjustable. The invention has the advantages that the internal waverider-derived high supersonic inlet duct can capture the inflow by full flow and has low Mach number automatic overflow; the shapes of the inlet and the outlet can be customized according to the layout requirement, and the parallel module installation or the integrated design with various aircrafts can be easily realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Liquid ejecting apparatus having outflow passage resistance changing member and liquid ejection method thereof

A liquid ejecting apparatus includes a liquid chamber in communication with a nozzle, a volume changing unit configured to change a volume of the liquid chamber, an inflow passage through which the liquid flows into the liquid chamber, an outflow passage through which the liquid flows out of the liquid chamber, a passage resistance changing unit configured to change a passage resistance of the outflow passage, and a controller configured to control the volume changing unit to reduce the volume of the liquid chamber so as to cause the liquid to be ejected through the nozzle. In filling the liquid chamber with the liquid for ejection of the liquid through the nozzle, the controller controls the passage resistance changing unit to change the passage resistance of the outflow passage to an increased passage resistance and controls the volume changing unit to increase the volume of the liquid chamber.

Owner:SEIKO EPSON CORP

Wide-speed-range air inlet channel design method based on double-incidence bending shock waves

ActiveCN113153529AFeature length shortenedGuaranteed performanceSustainable transportationGas turbine plantsInlet channelEngineering

The invention discloses a wide-speed-range air inlet channel design method based on double-incidence bending shock waves. The method comprises the following steps of designing a double-incidence bending shock wave reference flow field based on the bending shock wave theory; designing an air inlet channel initial throat section molded line, and performing reverse flow streamline tracking in the reference flow field to obtain an initial air inlet channel compression molded surface; designing an air inlet channel isolation section outlet section, expanding an air inlet channel initial throat section in a double-S-bend form, and stretching in an equal-straight manner to obtain a three-dimensional inward-turning wide-speed-range air inlet channel isolation section; carrying out wall surface fairing and viscosity correction; taking the tail end of a first-stage compression molded surface of an air inlet channel as the rotating shaft position of a first-stage splitter plate, and taking the length of a second-stage compression molded surface as the length of the first-stage splitter plate; taking the position where the second derivative of an upper wall curve of the air inlet isolation section is zero, taking the position as the position of a second-stage splitter plate rotating shaft, and taking the length from the second-stage splitter plate rotating shaft to the air inlet channel initial throat section as the length of the second-stage splitter plate; and designing a discharge port area under the Mach number and a throat area under the Mach number. Expansion waves at the position of the rotating shaft can be eliminated; and performance requirements are met.

Owner:XIAMEN UNIV

Injectable hydrogel implant for treating glaucoma

ActiveUS9205181B2Improve permeabilityReduce outflow resistanceEye surgerySurgerySchlemm's canalAqueous outflow

A method is provided for increasing the aqueous outflow of fluid through a trabecular meshwork and into a Schlemm's canal of an eye. A liquid hydrogel precursor solution is introduced into the Schlemm's canal, during a medical procedure. The liquid hydrogel precursor solution is crosslinked to form a water-permeable flexible semi-solid hydrogel in the Schlemm's canal, during the medical procedure. The hydrogel is left in the Schlemm's canal upon conclusion of the medical procedure. Other embodiments are also described.

Owner:RAINBOW MEDICAL LTD

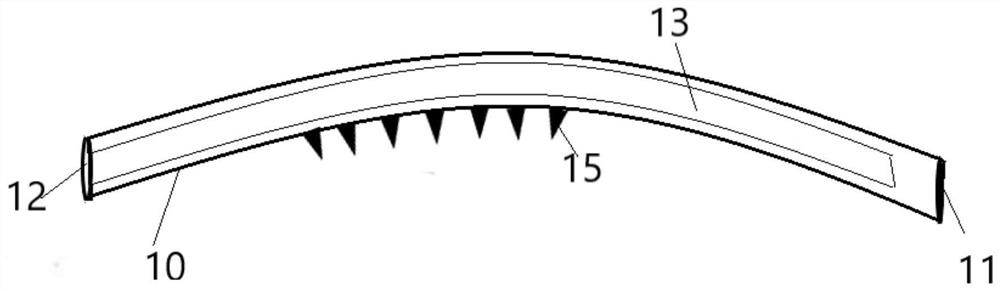

Schlemm canal dilatation stent and dilatation method

The invention discloses a schlemm canal dilatation stent. The dilatation stent comprises a catheter, a stent body and a guide head, wherein the radian of the catheter is the same as that of a schlemmcanal; the outer side of the catheter is sleeved with the stent body, and the curvature radius of the stent body is the same as that of the catheter; the guide head is arranged at a first end of the catheter; the diameter of the catheter is smaller than the inner diameter of the schlemm canal; and the catheter is made of an elastic material, and the stent body is made of a plastic material. The dilatation effect of the schlemm canal dilatation stent on the schlemm canal is flexible and controllable; and a new aqueous humor outflow channel is formed in a trabecular meshwork, so that the aqueoushumor outflow resistance is reduced, damage to the trabecular meshwork is reduced, bleeding is reduced, related complications are reduced, and intraocular pressure is stably reduced.

Owner:PEKING UNIV THIRD HOSPITAL

Ballpoint pen tip, ballpoint pen refill, and ballpoint pen

InactiveUS9056518B2Preventing defective writingWider widthPen repairingBall-point pensStructural engineeringMechanical engineering

A ballpoint pen tip in which ink grooves are formed around an ink guide hole at equally distributed places, the ink guide hole connecting a ball house and a back hole of a holder for holding the writing ball, and the ink grooves radially penetrate through from the ball house side to the front end portion of the back hole. Inward protrusions are formed at positions which are respectively in contact with the rear ends of the ink grooves. If the inner diameter of the ink guide hole is A, the inner diameter of the front end portion of the back hole is B, the diameter of the circle circumscribing the ink grooves is C, and the diameter of the circle inscribing the inward protrusions is D, their relationships are A<B<C, and D<B.

Owner:MITSUBISHI PENCIL CO LTD

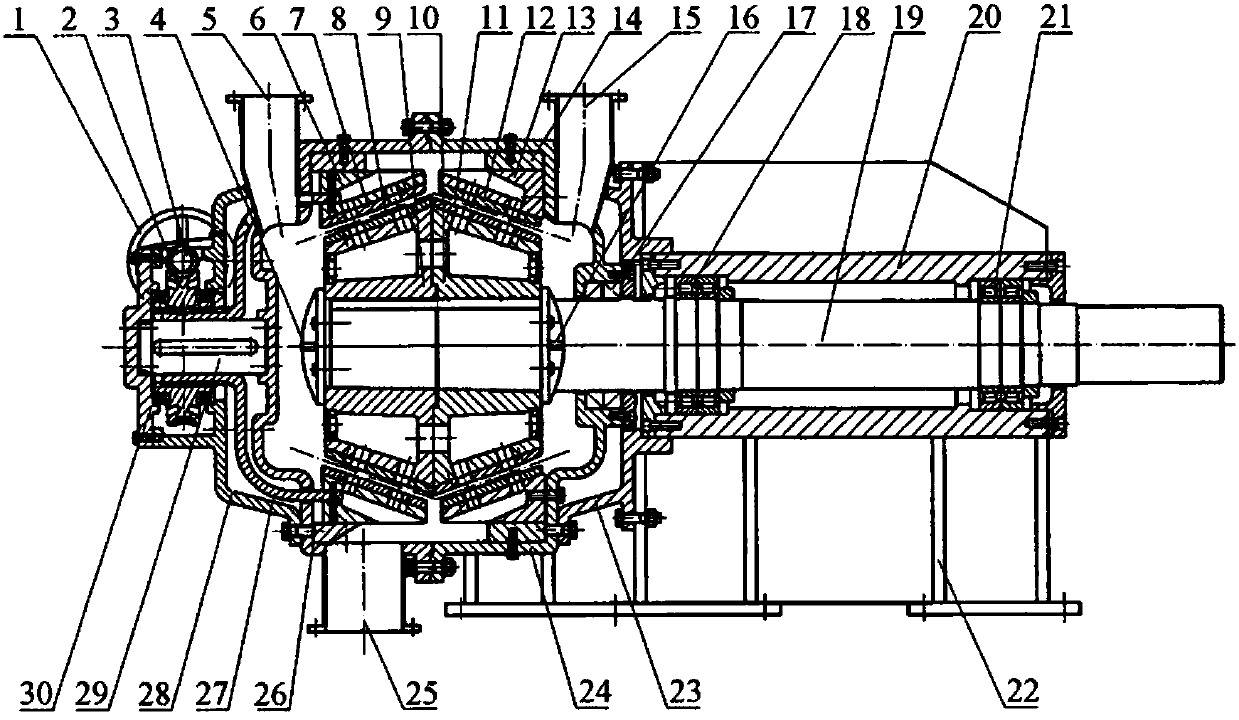

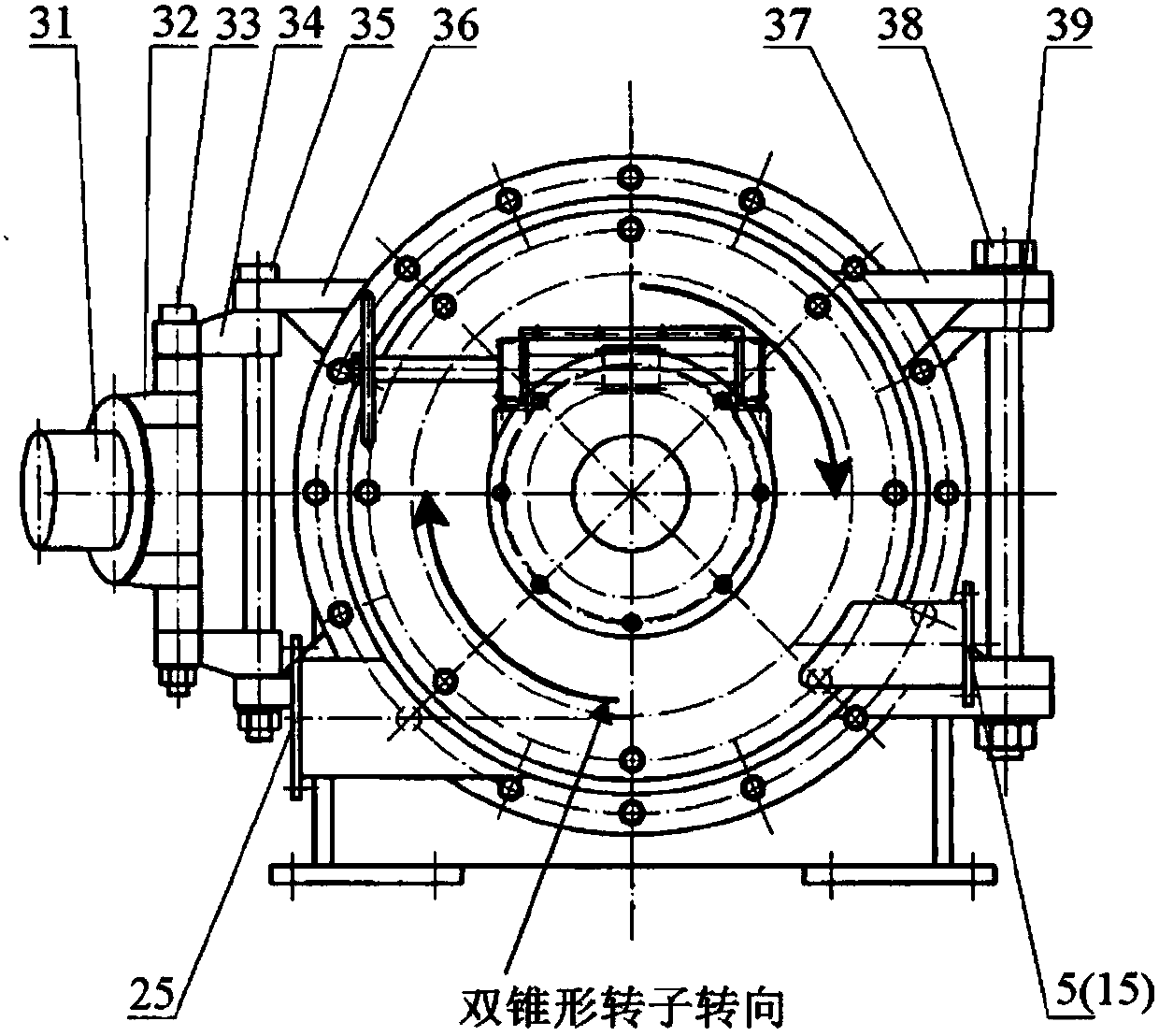

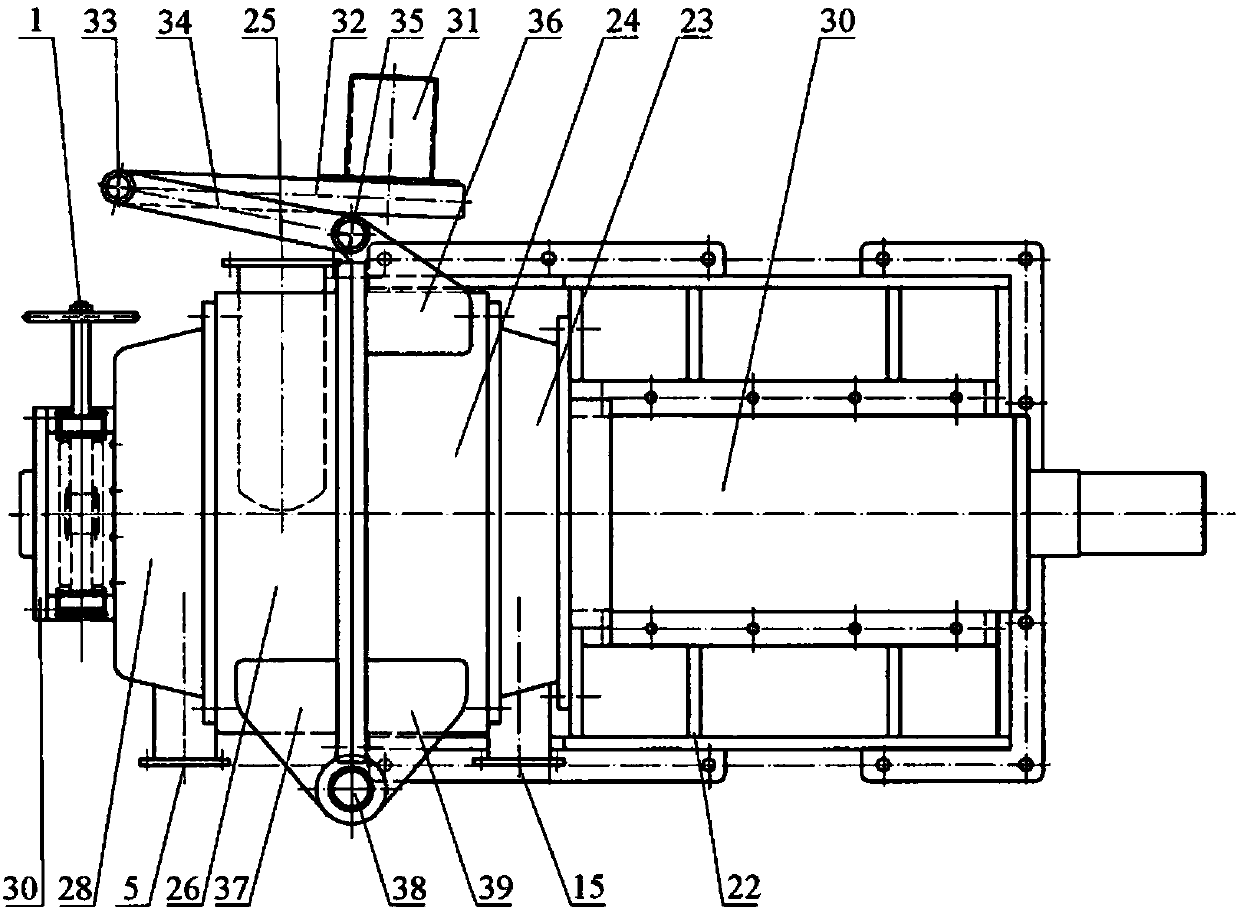

A double-cone refiner with internal flow guide channels

InactiveCN106192524BIncrease throughput per unit timeImprove refining efficiencyPulp beating/refining methodsEngineeringPower consumption

The invention relates to a biconical refiner with an internal diversion channel. The biconical refiner comprises an engine base, a grinding chamber base, a main shaft, a biconical rotor and a biconical stator; the interior of a left conical rotor body and the interior of a right conical rotor body are each provided with a rotor diversion cavity, the rotor diversion cavities are communicated with a grinding chamber cover and a grinding chamber feeding cavity, and the external conical surface of the left conical rotor body and the external conical surface of the right conical rotor body are each provided with a rotor diversion hole perpendicular to the direction of the grinding surface; the interior of a left conical stator body and the interior of a right conical stator body are each provided with a stator diversion cavity, the stator diversion cavities are communicated with a grinding chamber cover discharge cavity, the external conical surface of the left conical stator body and the external conical surface of the right conical stator body are each provided with a stator diversion hole perpendicular to the direction of the refining surface, the rotor diversion cavities, the rotor diversion holes, the stator diversion holes and the stator diversion cavities from the internal diversion channel. According to the biconical refiner with the internal diversion channel, channel design is scientific and reasonable, throughput of the biconical refiner in unit time is increased, the refining efficiency of the middle and the big end of the conical rotor is exerted, and refining power consumption is further reduced.

Owner:TIANJIN UNIV OF SCI & TECH

Integrated Design Method of Waverider Precursor and Inlet with Controllable Transverse Pressure Gradient

ActiveCN103963996BHigh lift and drag characteristicsLarge thrustGround installationsPower plant air intake arrangementsShock waveInlet channel

The invention provides a transverse pressure gradient controlled ride wave forebody and air inlet channel integrated designing method and relates to a near space hypersonic flight vehicle. The method comprises the steps of designing a basic flow field required by a two-dimensional air inlet channel; confirming the position where a designed cross section is located; designing projection of front edge capture molded lines in the designed cross section according the working condition requirements and calculating projection distances from front edge points in wedge tangent planes to shock wave points in z-direction; obtaining pressure distribution of compression molded lines at the positions of the wedge tangent planes corresponding to disperse shock wave points; obtaining newly-generated two-dimensional air inlet channel compression molded lines by applying two-dimensional characteristic line method according to calculated pressure distribution; arranging the two-dimensional air inlet channel compression molded lines at the positions of the corresponding front edge capture molded lines to form a complete air inlet channel compression profile, obtaining a ride wave forebody and air inlet channel integrated device after three-dimensional modeling and finishing the transverse pressure gradient controlled ride wave forebody and air inlet channel integrated design. By adopting the method, the device can have high lifting drag characteristic, external flow resistance is reduced while engine thrust is increased.

Owner:XIAMEN UNIV

Inverse Design Method of Full 3D Waverider Based on Bending Shock Wave Theory

ActiveCN112298599BImprove computing efficiencyHigh precisionGround installationsSupersonic aircraftShock waveMechanical engineering

The full three-dimensional waverider inverse design method based on the bending shock wave theory, 1) specify the three-dimensional external flow shock wave in the full three-dimensional reference flow field according to the design requirements, and the full three-dimensional external flow shock wave adopts an elliptical or non-axisymmetric shape design; The three-dimensional outflow shock wave is discretized into a series of reference planes, and according to the full three-dimensional outflow shock angle, shock curvature and wave parameters, the corresponding full three-dimensional external compression basic flow field is solved by using the bending shock theory; 3) the full three-dimensional waverider is designed The body captures the profile and performs streamline tracking in the full three-dimensional external compression basic flow field in step 2) to obtain the compression profile of the lower surface of the hypersonic full three-dimensional waverider, and the profile adopts an elliptic curve or a non-axisymmetric shape; 4 ) geometrically construct the hypersonic full three-dimensional waverider based on the following surface compression profile: according to the volume ratio requirements, the upper surface of the waverider is constructed as a plane or a convex surface, and the full Three-dimensional waverider.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com