Novel on-site desorption test device for shale gas

A test device and shale gas technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of inaccurate data, inability to objectively reflect the gas-bearing properties of shale, and ineffective migration of methane gas, and reduce the measurement Error, clever design, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

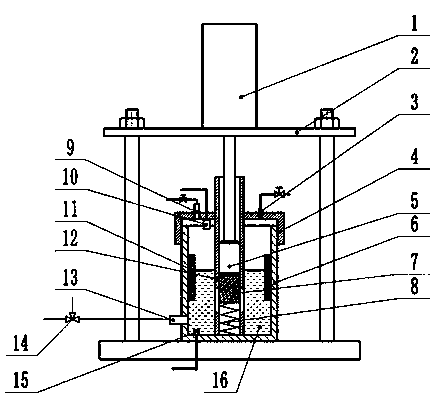

[0027] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of a novel shale gas on-site desorption test device proposed according to the present invention will be described in detail as follows.

[0028] See attached figure 1 , a new type of shale gas on-site desorption test device provided by the present invention mainly includes an air hammer 1, a desorption tank 6 and a pressure cap 4 of the desorption tank; Placed on the bottom surface of the air hammer bracket 2, the desorption tank pressure cap 4 and the desorption tank 6 are threaded for sealing fit; the hammer body 5 below the air hammer 1 is matched with the air hammer guide rail 12, and the middle and lower part of the air hammer guide rail 12 is provided with holes. Air hammer guide rail 12 bottom is provided with spring 8, and liquid level sensor 15 is installed at the bottom of desorption tank 6; There is an electric heater 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com