Patents

Literature

213results about How to "Increase the exposed area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

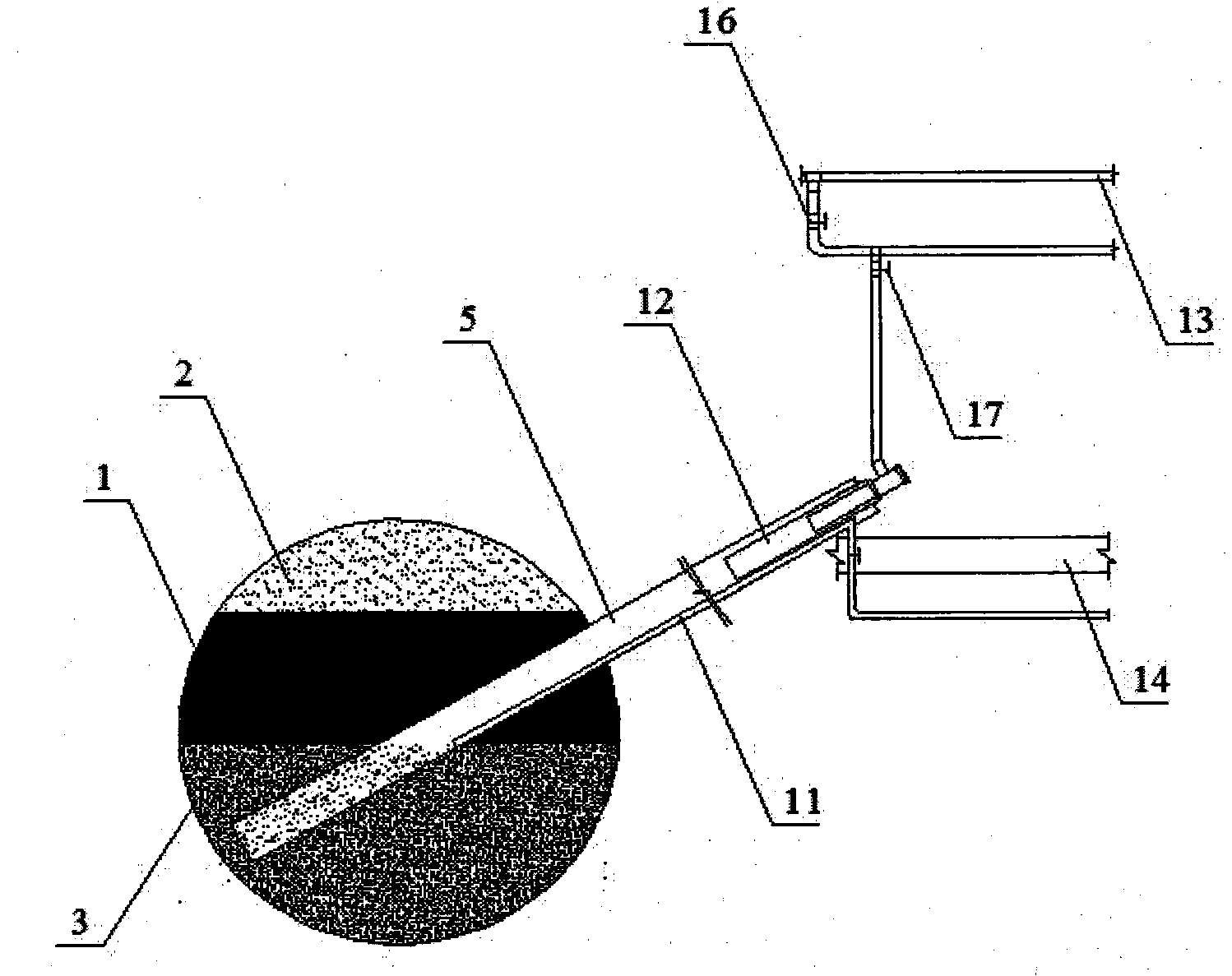

Method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing, and permeability increasing

InactiveCN101644166AImprove flow statusEasy to extractUnderground miningSurface miningHigh pressure waterHigh pressure

The invention discloses a method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing and permeability increasing, comprising the following steps: whena drill is drilled into a predetermined position of the coal seam, coal bodies at both sides of a drill hole are cut in the drill hole by high pressure water jet with a certain pressure and flow; a flat slot is formed at both sides of the drill hole; the cut coal bodies is led out the hole by the high pressure water jet. The exposed area of the coal body at the slotted part in the drill hole aregreatly increased, namely that an extremely thin protective layer is exploited with local scope of the flat slot, which enlarges effective influential range of pressure releasing, permeability increasing and gas discharging of the coal bodies in the drill hole, thus the air permeability of the coal bodies is increased about 200-300 times, the average amount of single-hole gas extraction reaches 0.3m<3> / min, the concentration of the gas extraction is 30-60%, gas drainage rate of working face of coal extraction is more than 50%, the number of drill holes for gas drainage is reduced by 10-20% after slotting, pressure releasing and permeability increasing. The method realizes the safety, high efficiency and uniform extraction of the gas from the high gas low permeability outburst coal seam, and changes high gas coal seam with outburst danger into low gas coal seam without outburst danger.

Owner:CHINA UNIV OF MINING & TECH

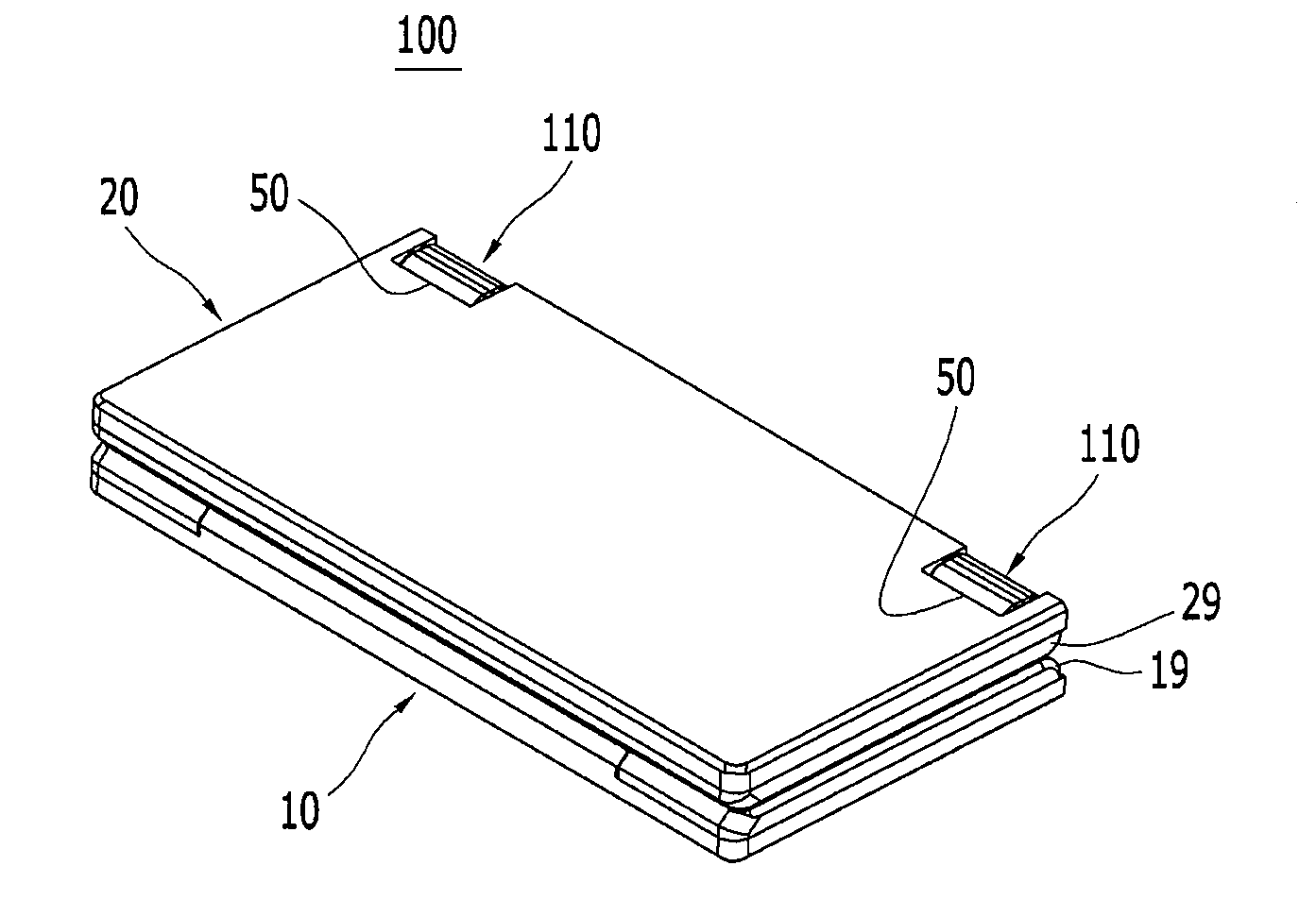

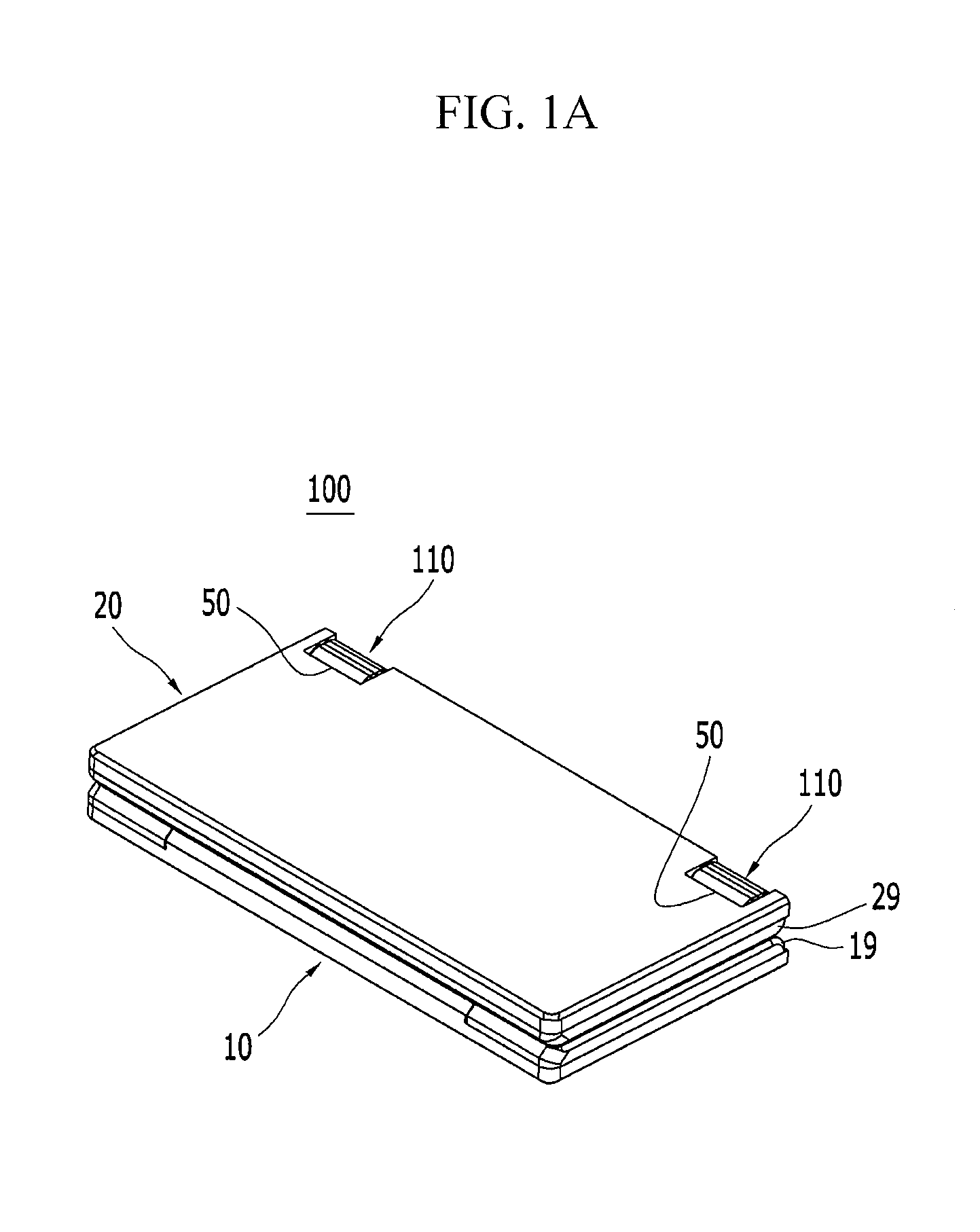

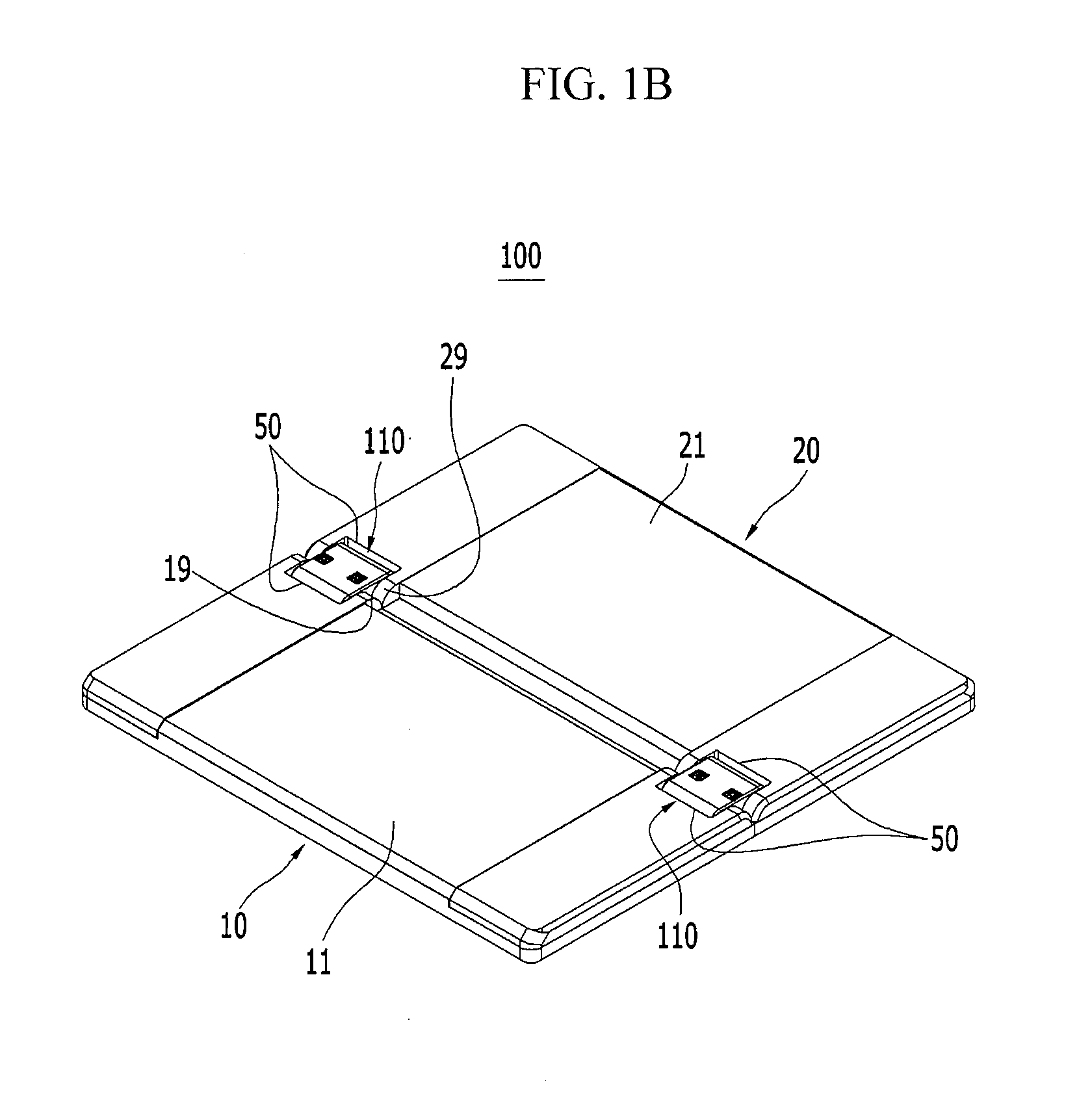

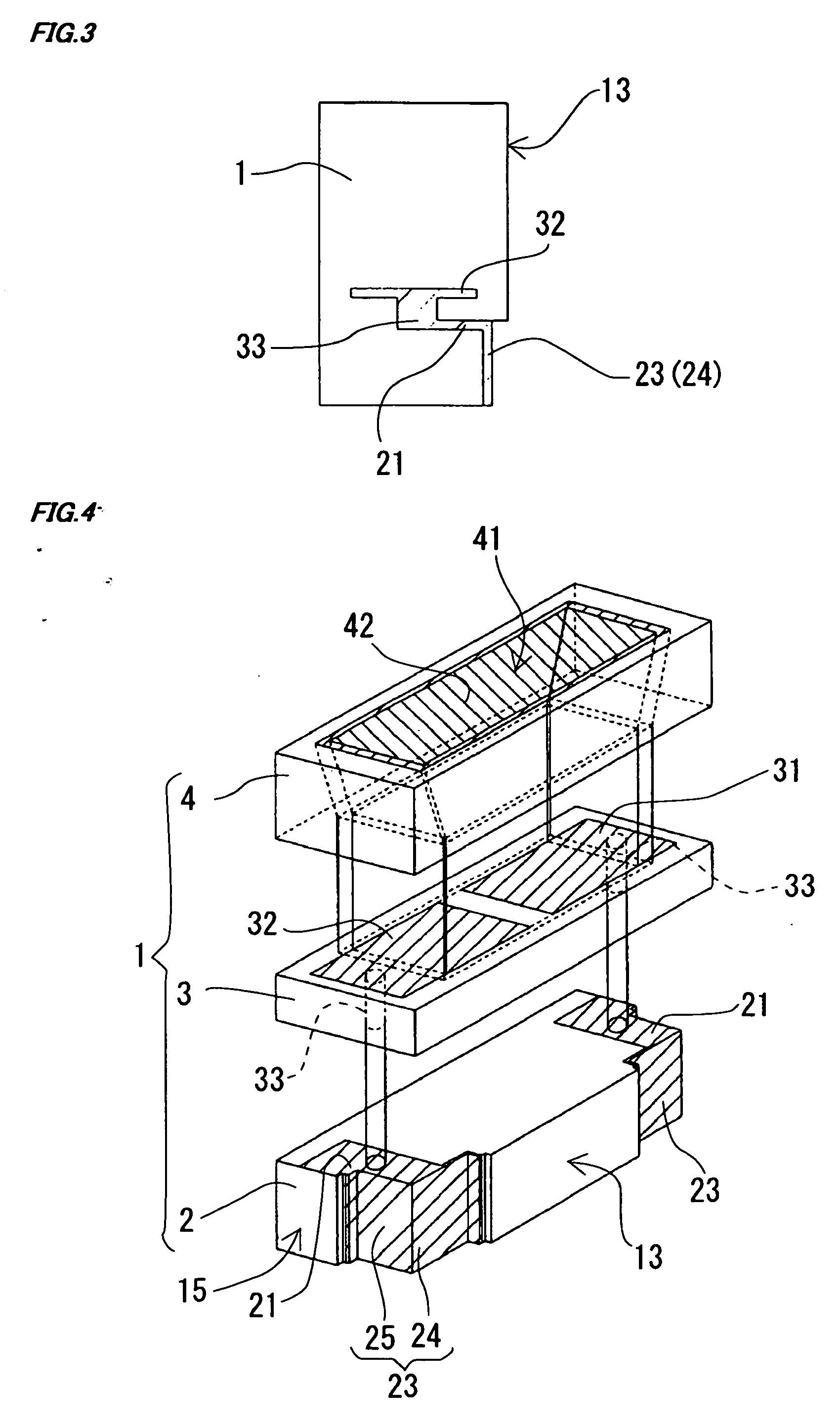

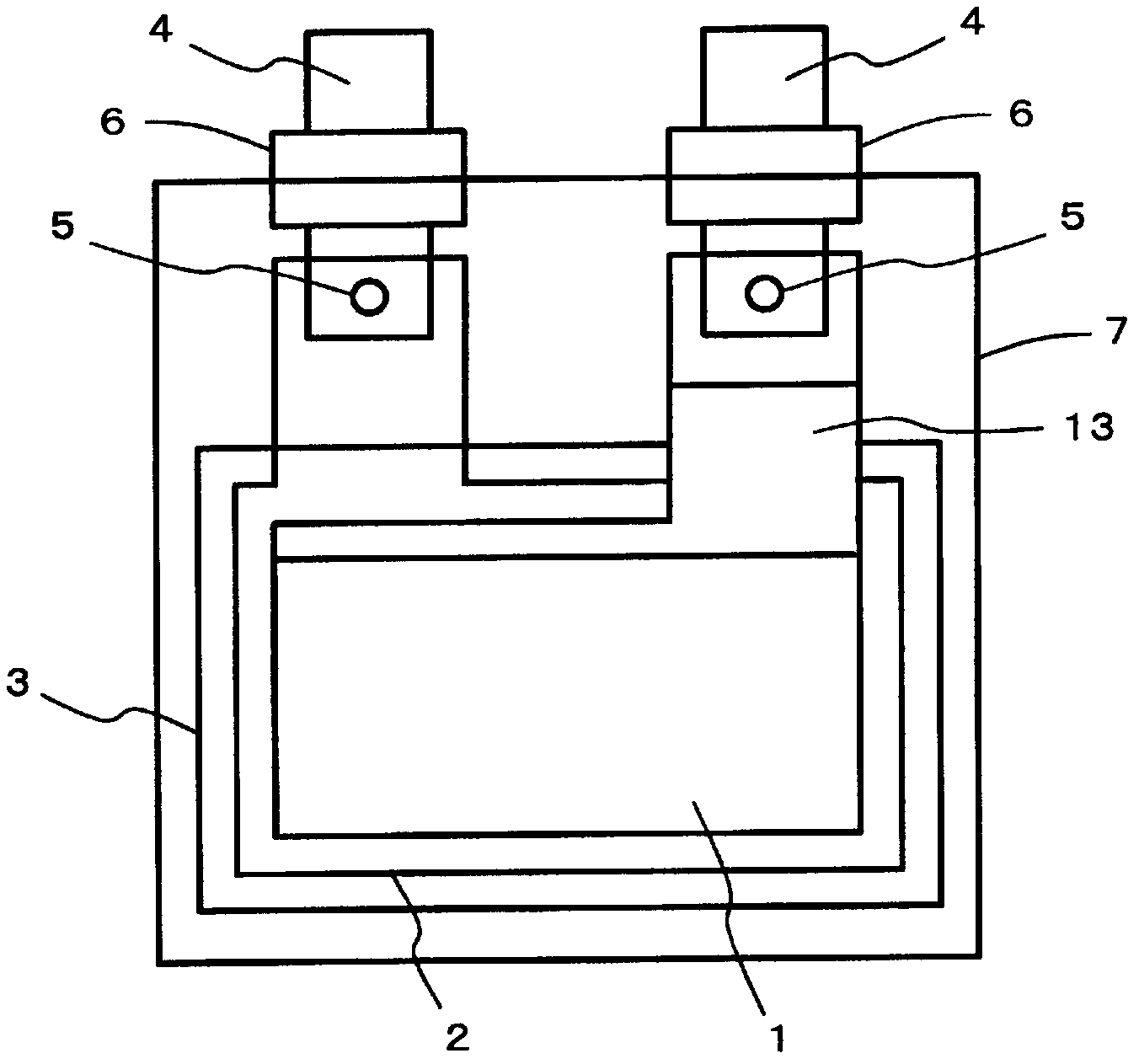

Mobile phone of folding type and hinge device of the same

InactiveUS20120149438A1Increase the exposed areaDigital data processing detailsCasings/cabinets/drawers detailsComputer moduleEngineering

A mobile phone of a folding type is disclosed. The mobile phone of a folding type according to an exemplary embodiment of the present invention may include: a first body provided with a first display portion; and a second body rotatably connected to the first body through at least one of a first hinge module and provided with a second display portion, wherein the first and second display portions form the same plane and are configured such that at least one of the first and second display portions can slide toward the other of the first and second display portions in a case that the first and second bodies are open.

Owner:PREXCO

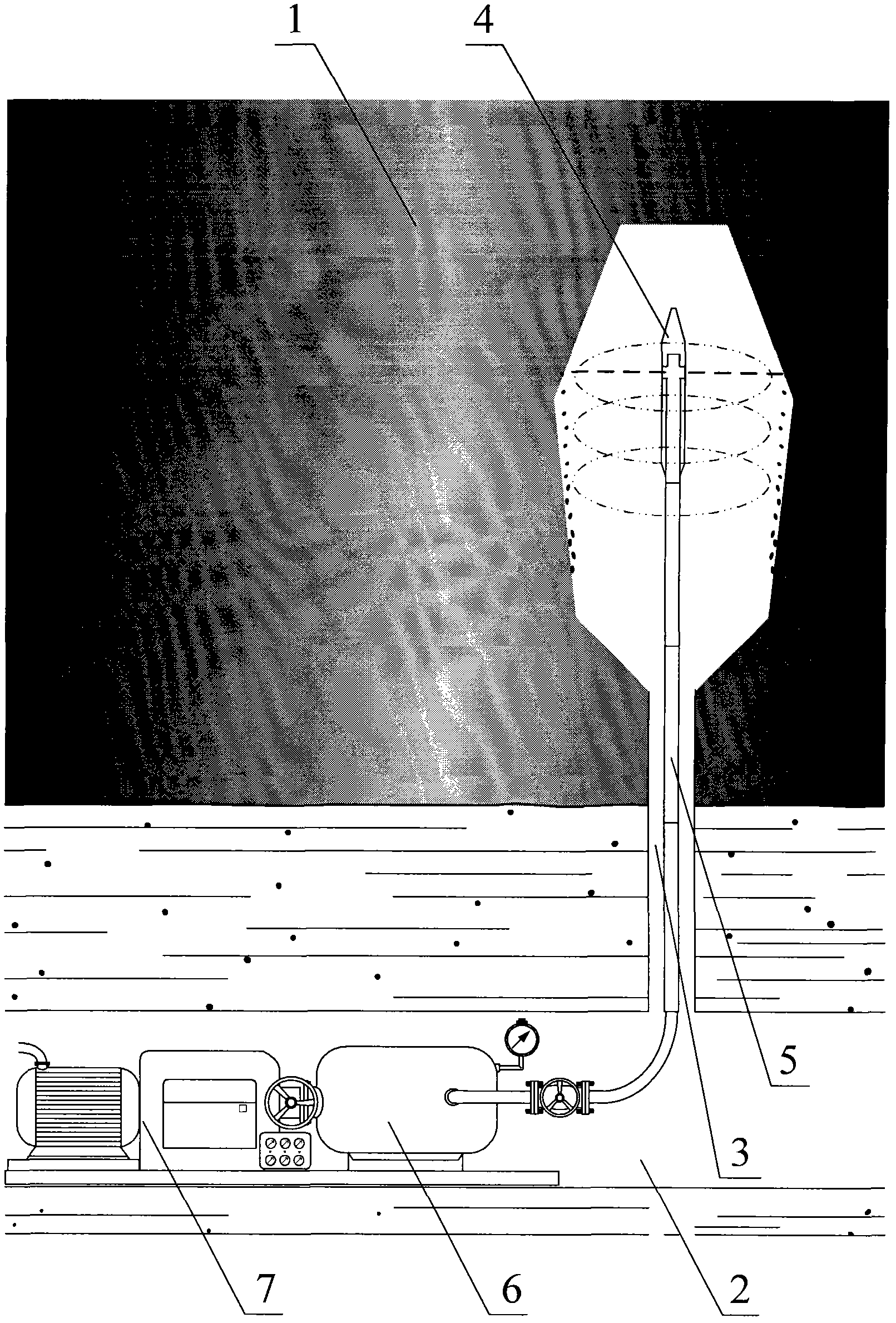

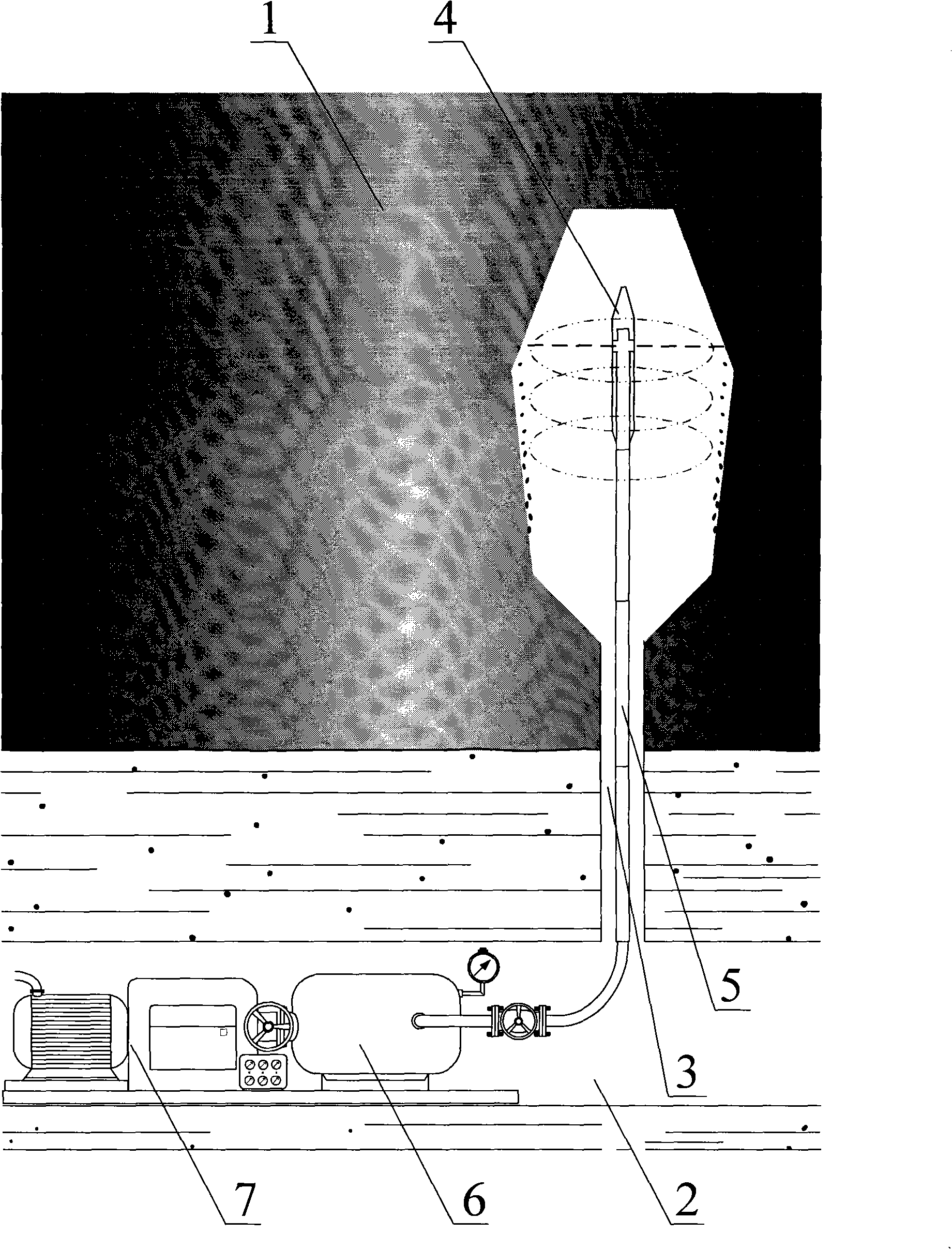

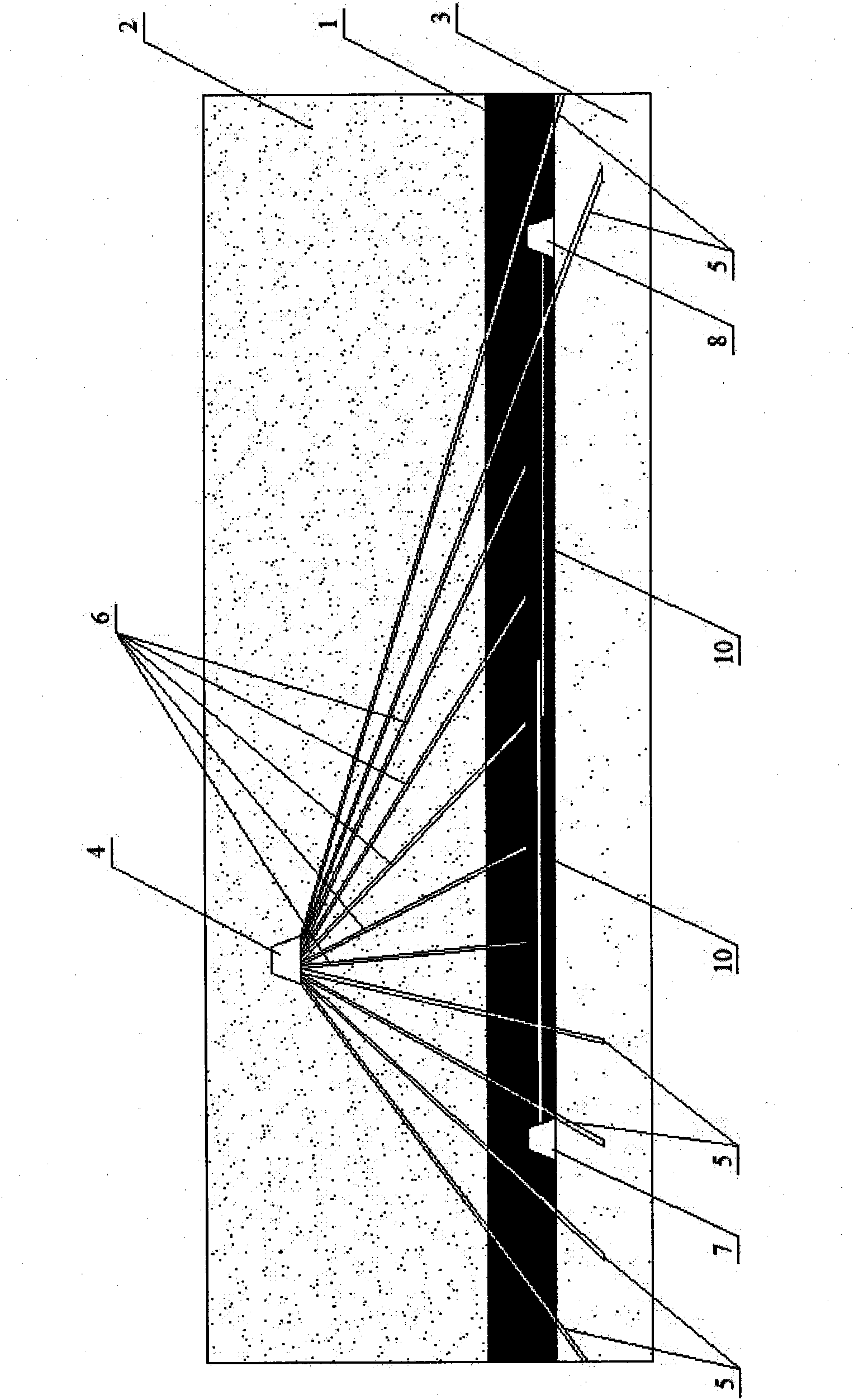

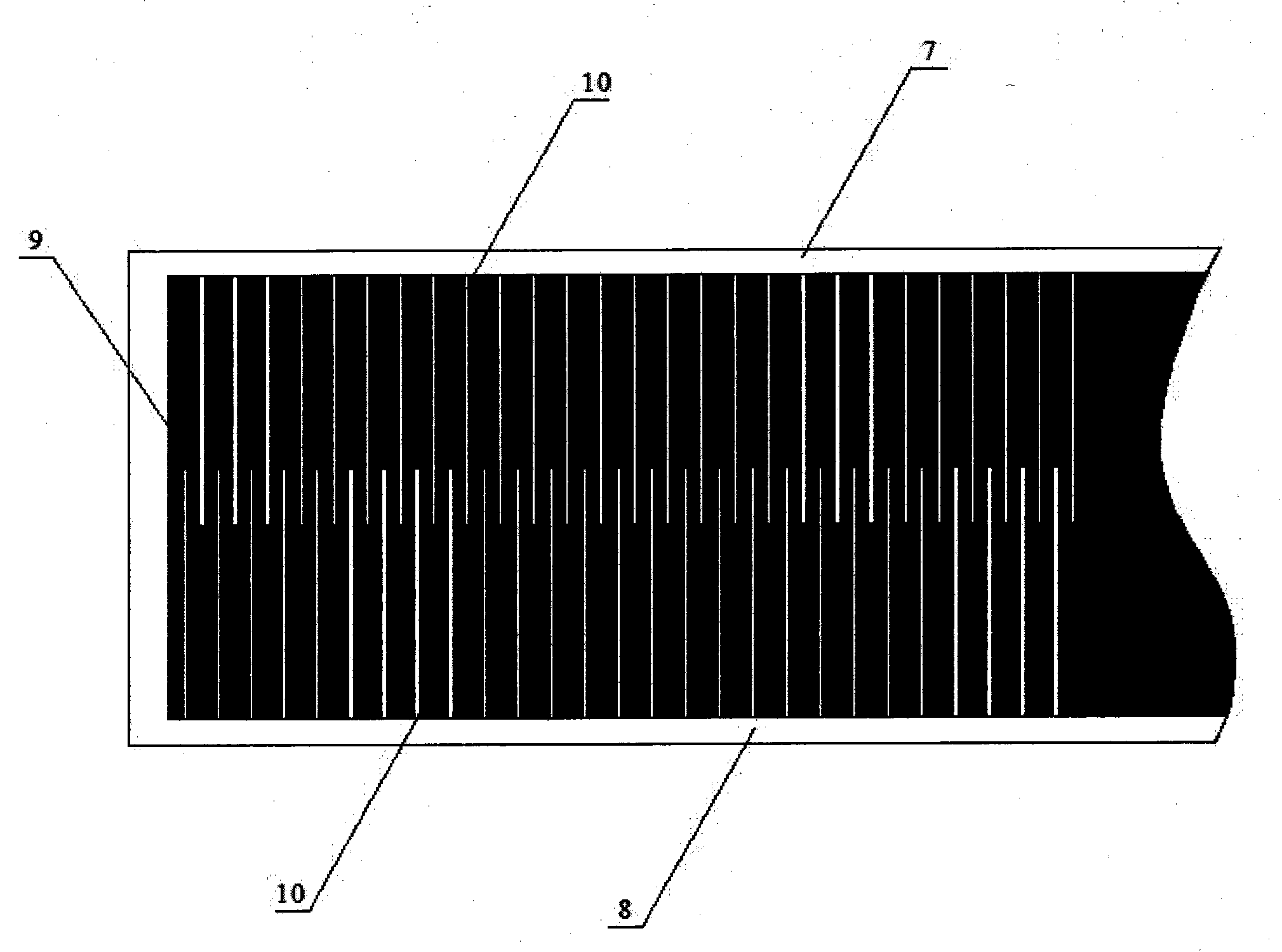

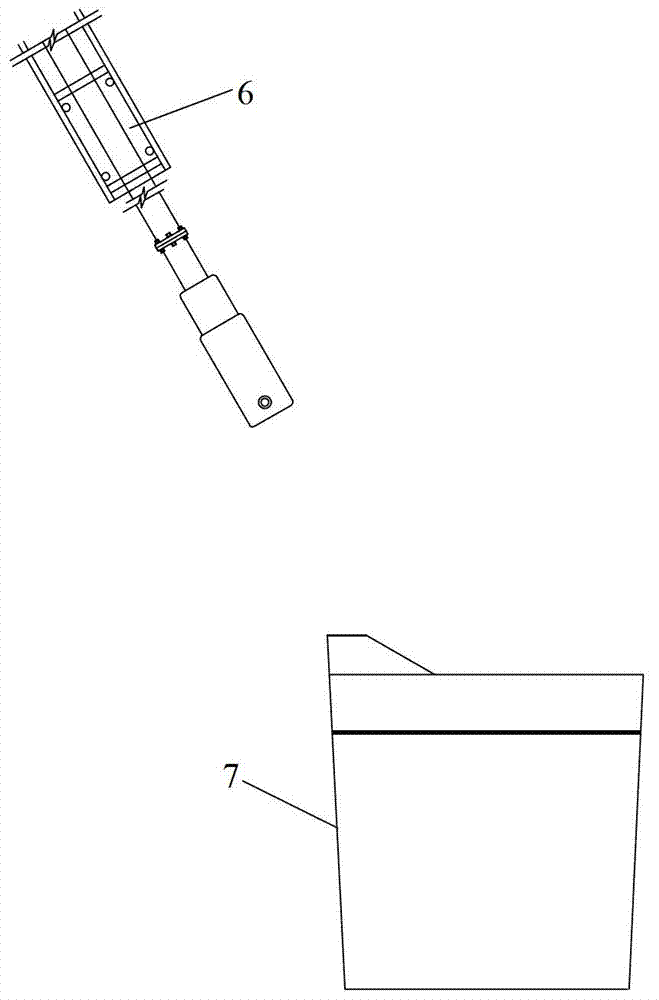

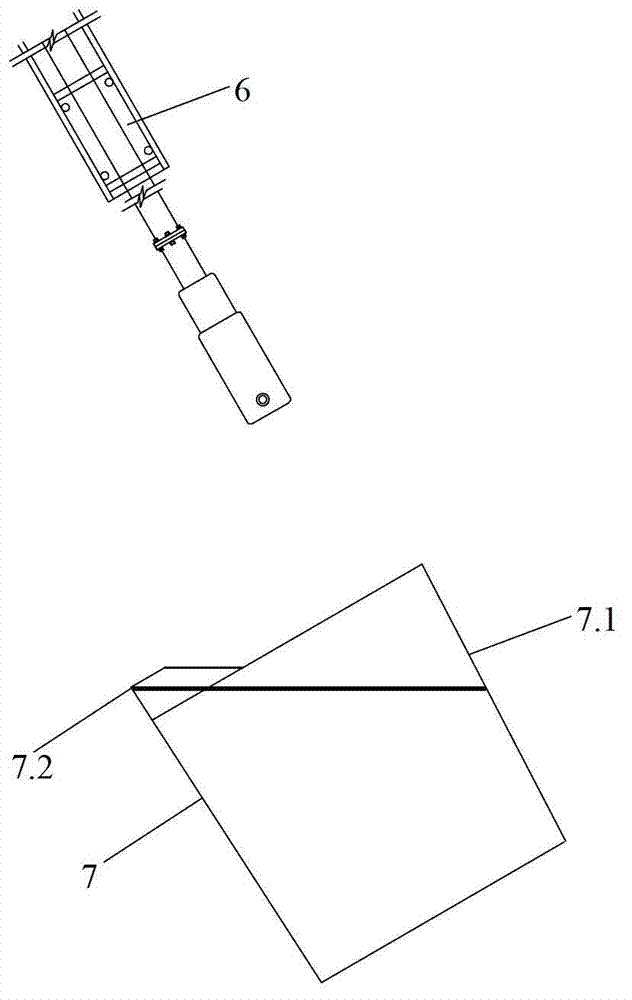

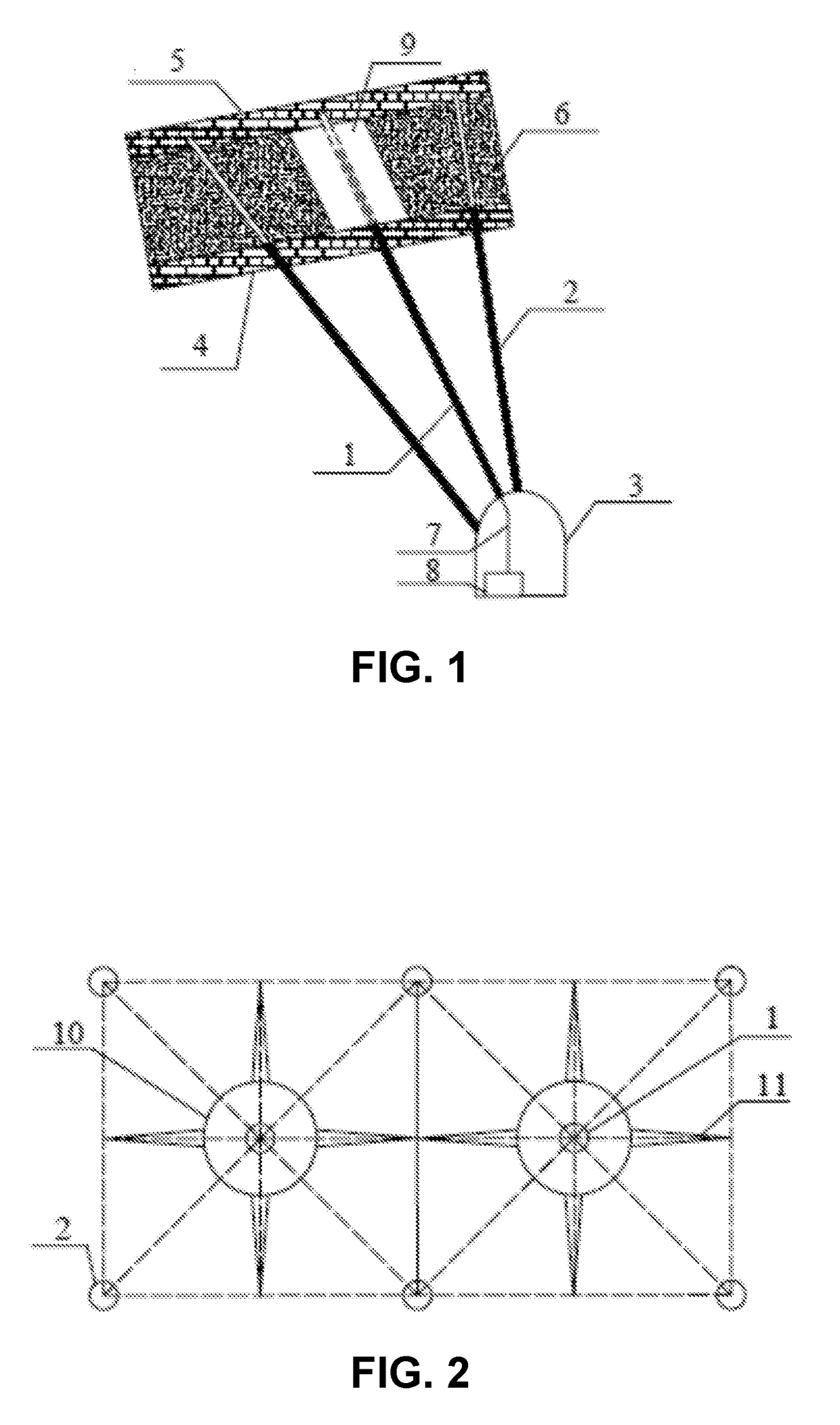

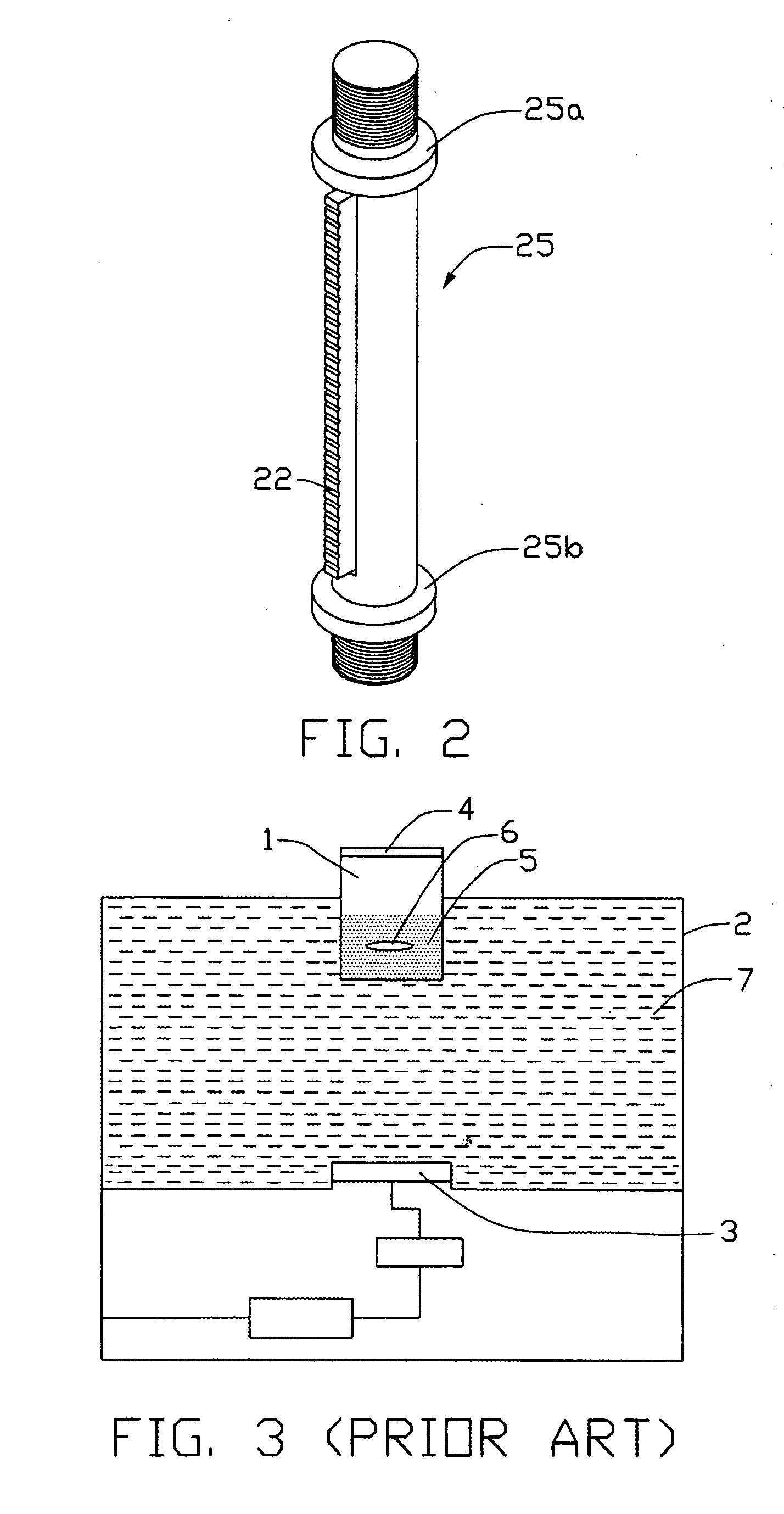

High-pressure gas injection hole-drilling pressure-releasing outburst prevention method

ActiveCN102080525AIncrease the exposed areaImprove breathabilityLiquid/gas jet drillingFluid removalEngineeringHigh pressure

The invention discloses a high-pressure gas injection hole-drilling pressure-releasing outburst prevention method which comprises the steps of: firstly, carrying out common drilling operation in a bottom plate stone drift (2) of a coal bed (1) in front of a coal mining or driving face; after a drill hole (3) enters a design depth of the coal bed, drawing back a drill, sending a jet nozzle (4) anda high-pressure drill rod (5) connected with the jet nozzle into the drill hole, and connecting a high-pressure gas-storing device (6) connected with the tail of the high-pressure drill rod (5) with a high-pressure gas compressing device (7) through a high-pressure tube; starting the high-pressure gas compressing device (7), carrying out near cylinder rotary impacting, cutting and holing on the hole wall of the drill hole in the coal bed (1) by using high-pressure impact wave as a power source through the jet nozzle (4) capable of jetting high-pressure airflow and automatically rotating to ensure that the coal body around the drill hole (3) is gradually crushed and separated from the hole wall to form pressure releasing space and subjected to the pressure balanced permeability increase through ground pressure and gas pressure action. According to the invention, the drainage efficiency of the gas in the coal bed is greatly improved and the outburst damage of the coal bed is reduced.

Owner:河南省迪卡尔机电设备制造有限公司

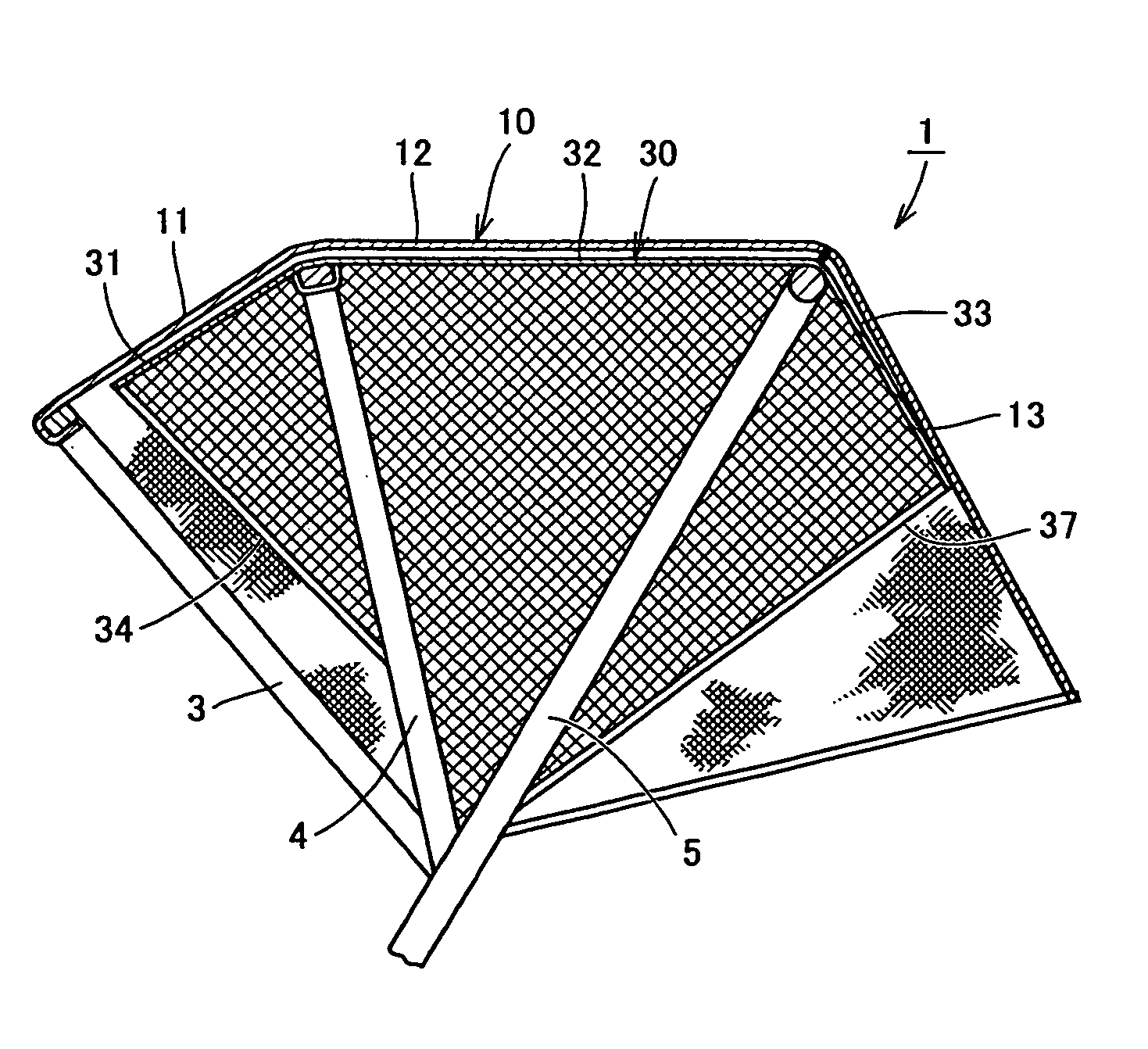

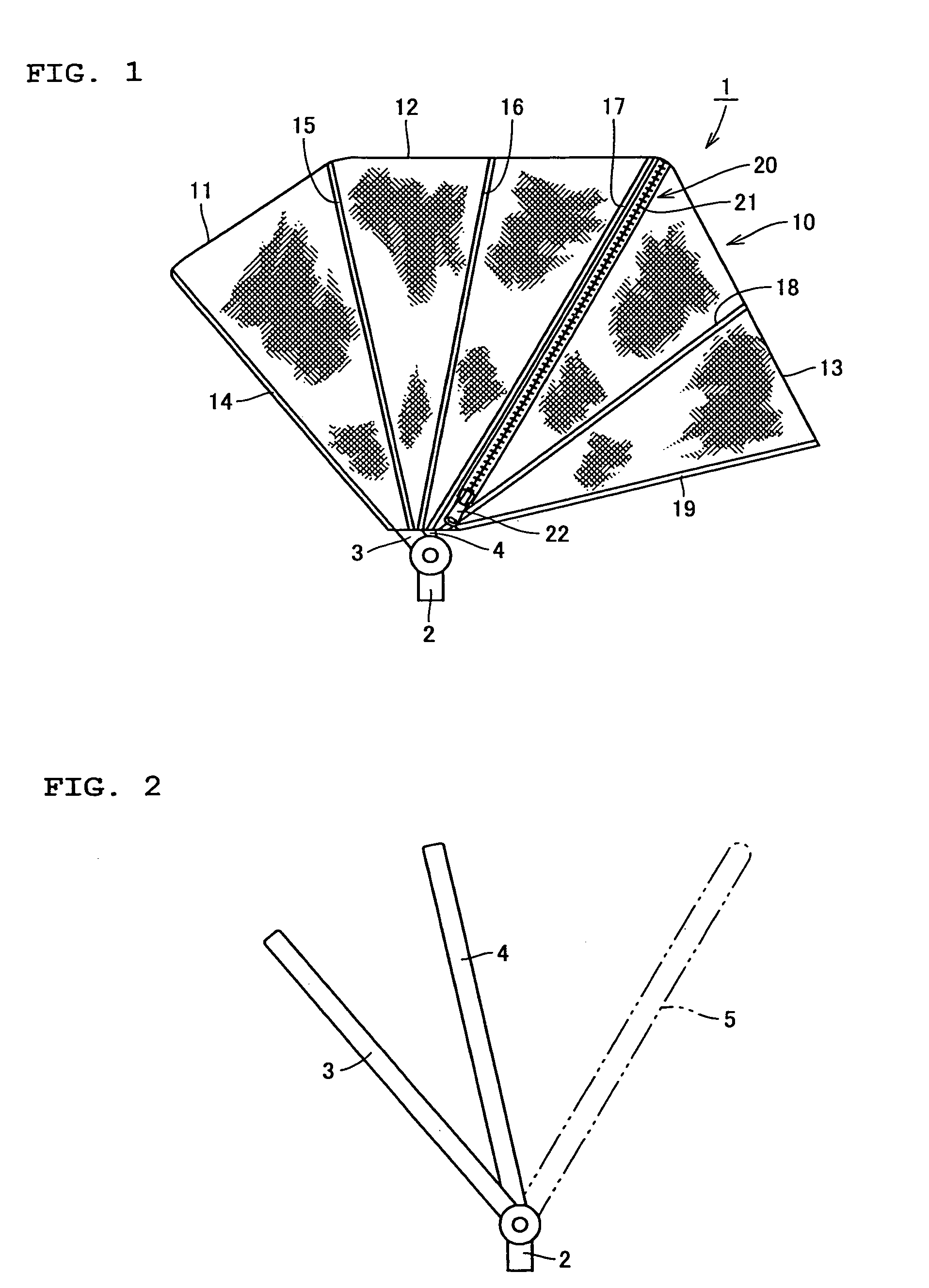

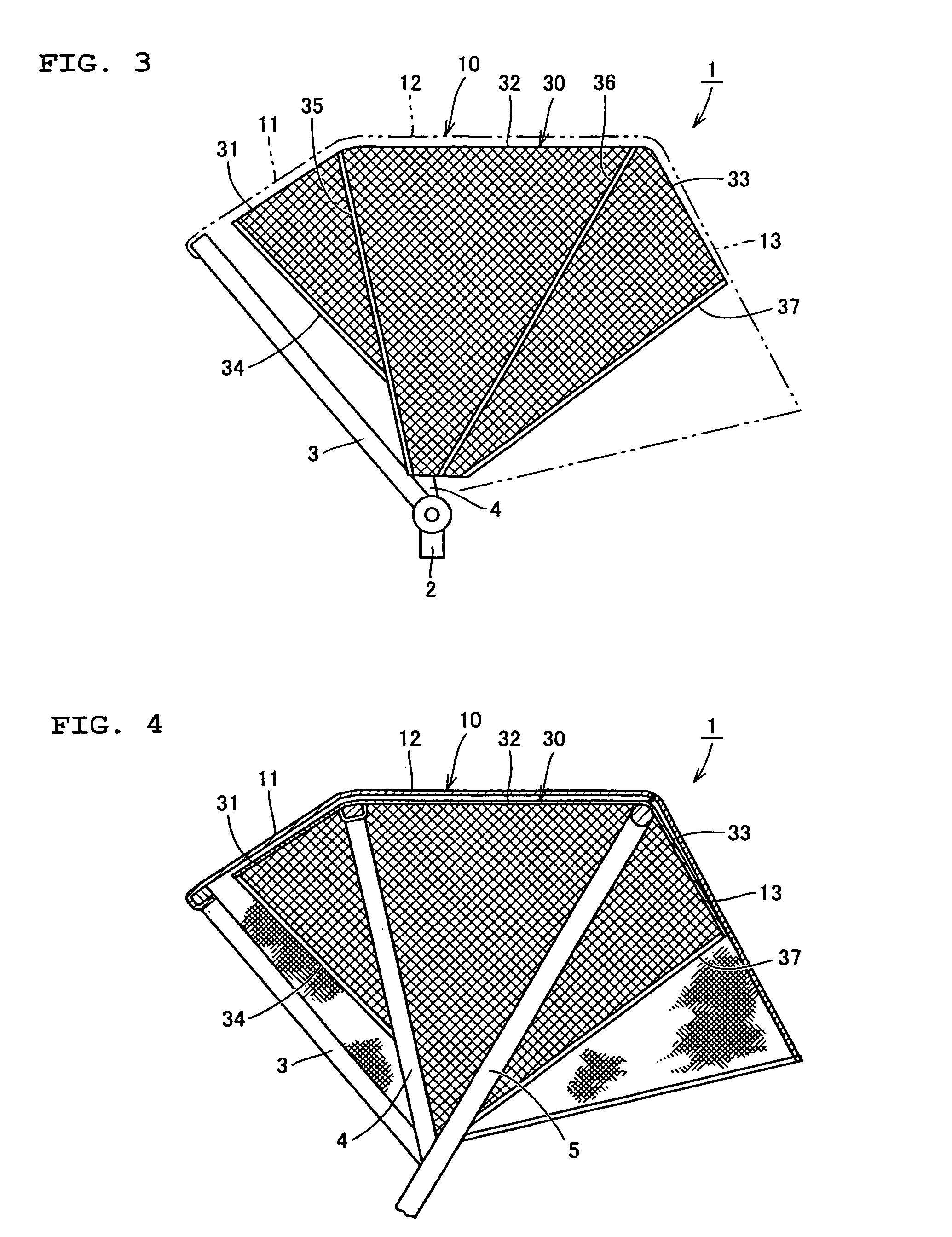

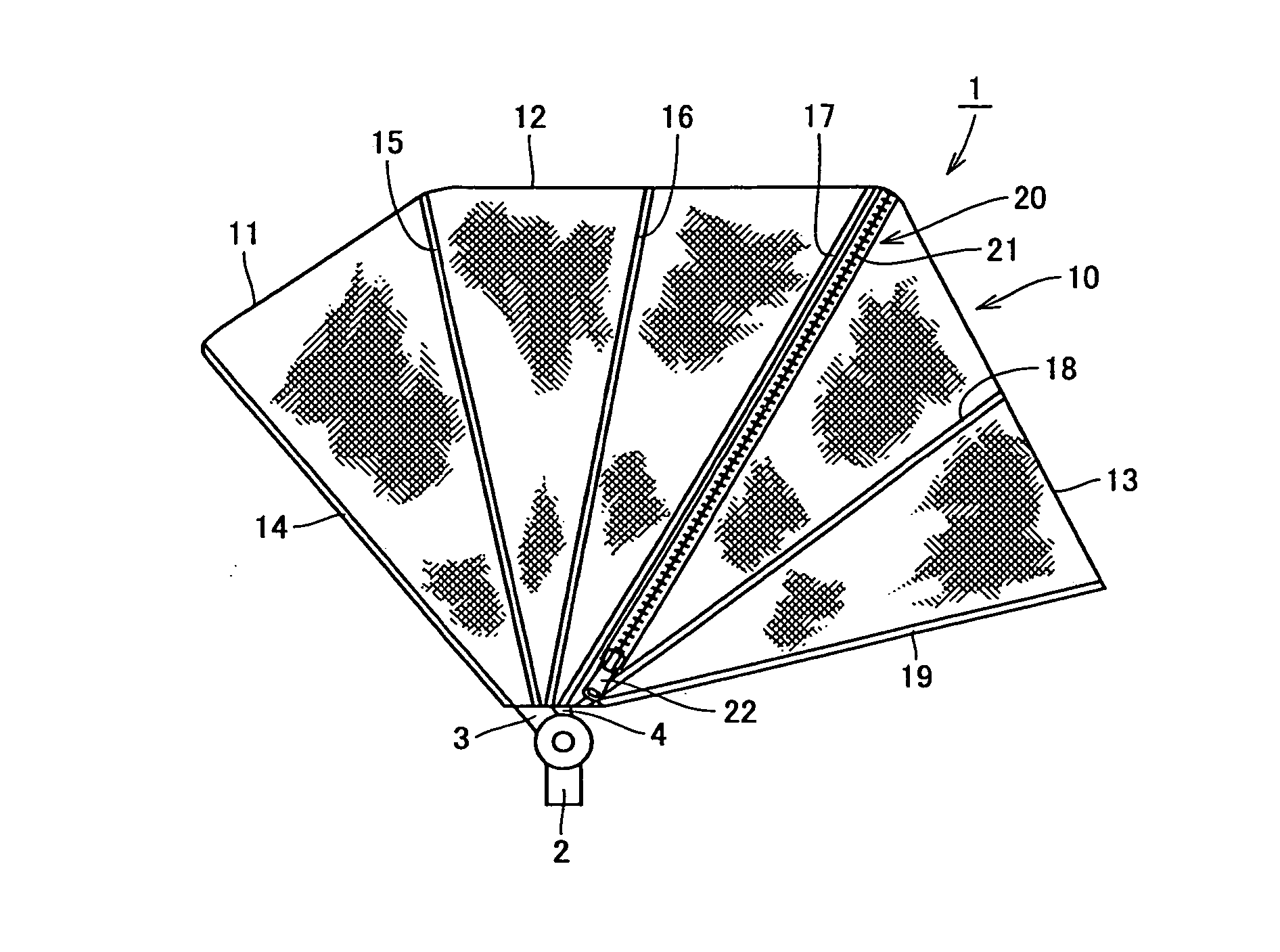

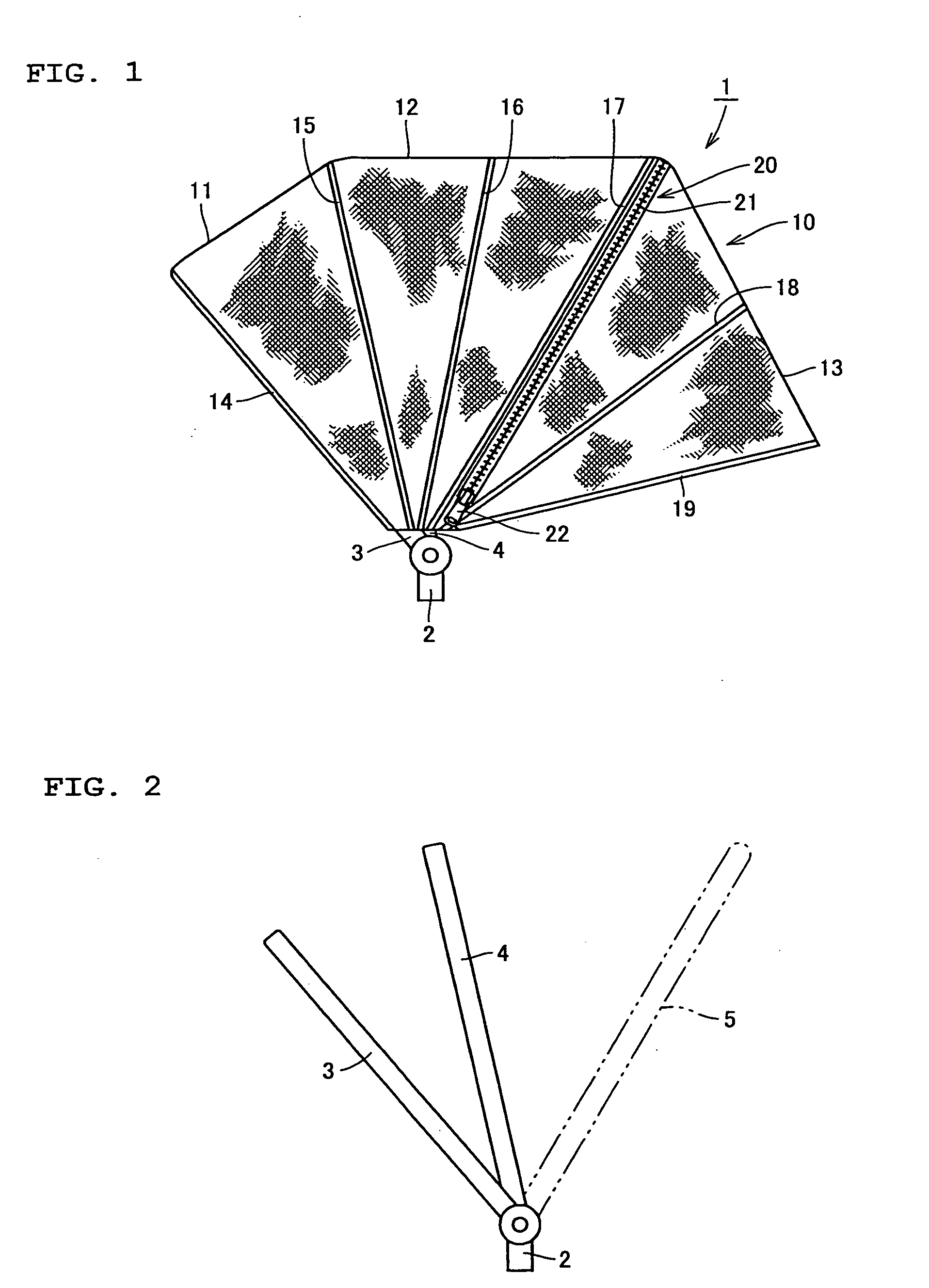

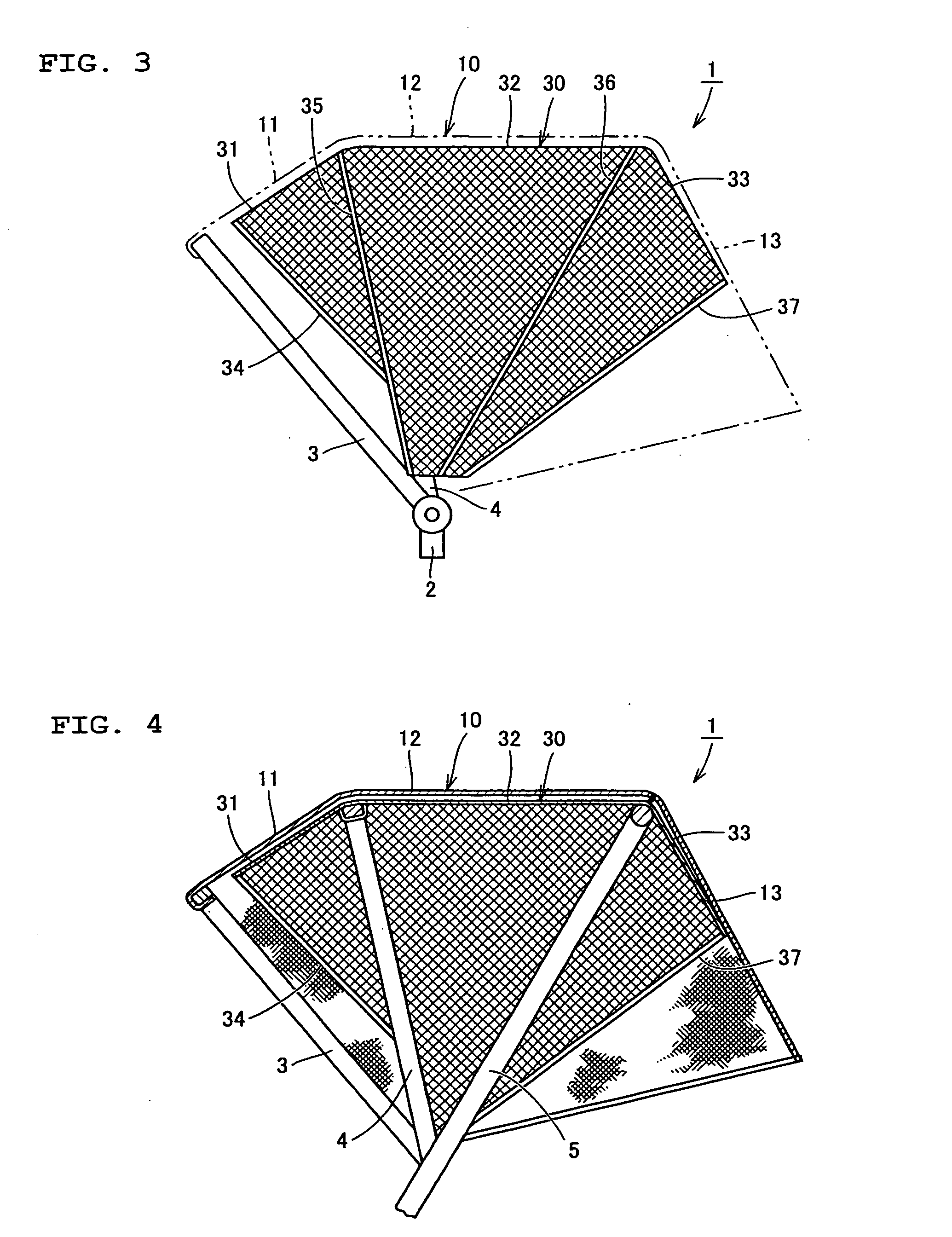

Baby-care implement provided with hood

InactiveUS7118173B2Improve shadingImprove breathabilityCarriage/perambulator accessoriesTents/canopiesEngineeringMechanical engineering

Owner:APRICA CHILDRENS PROD

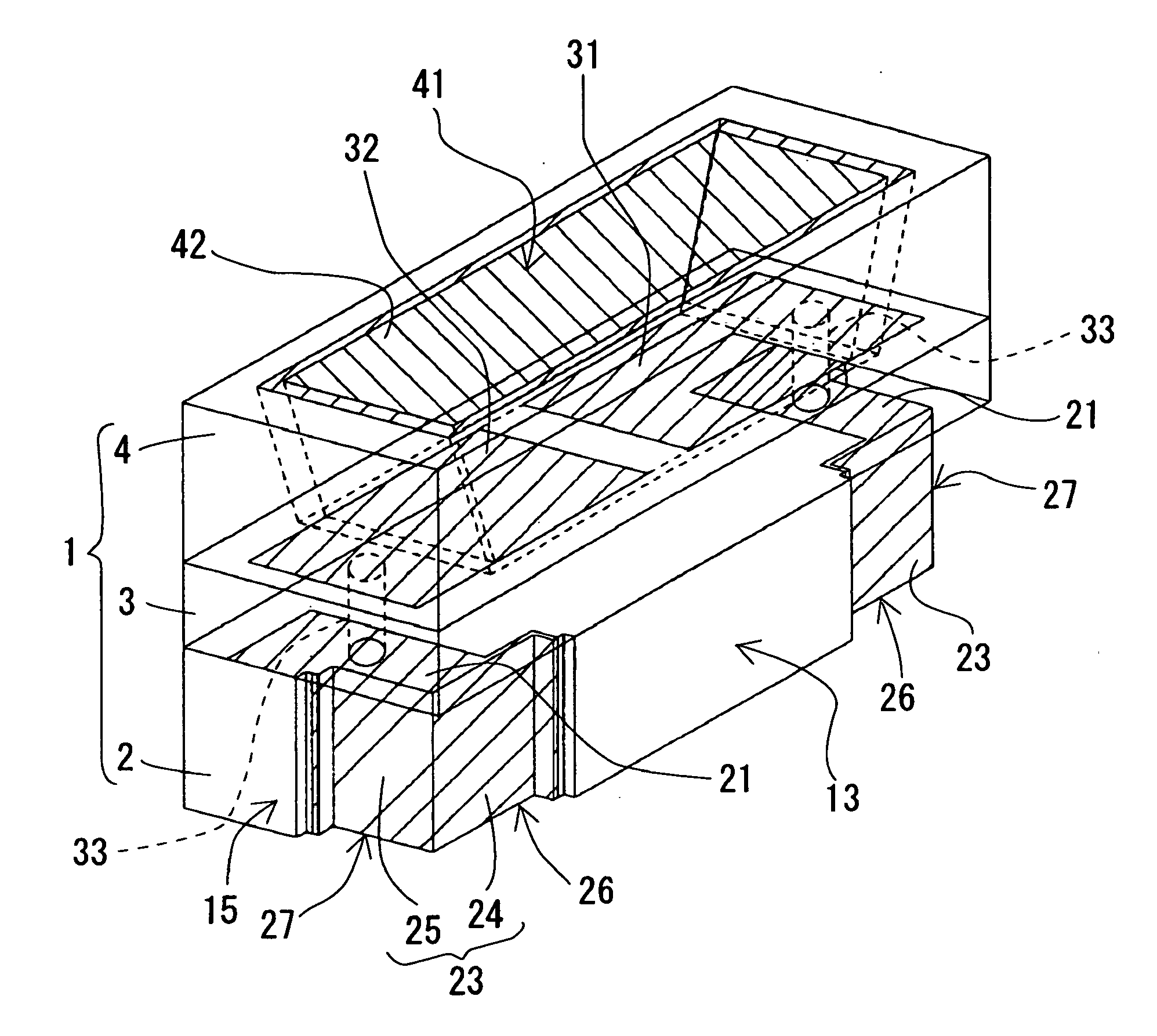

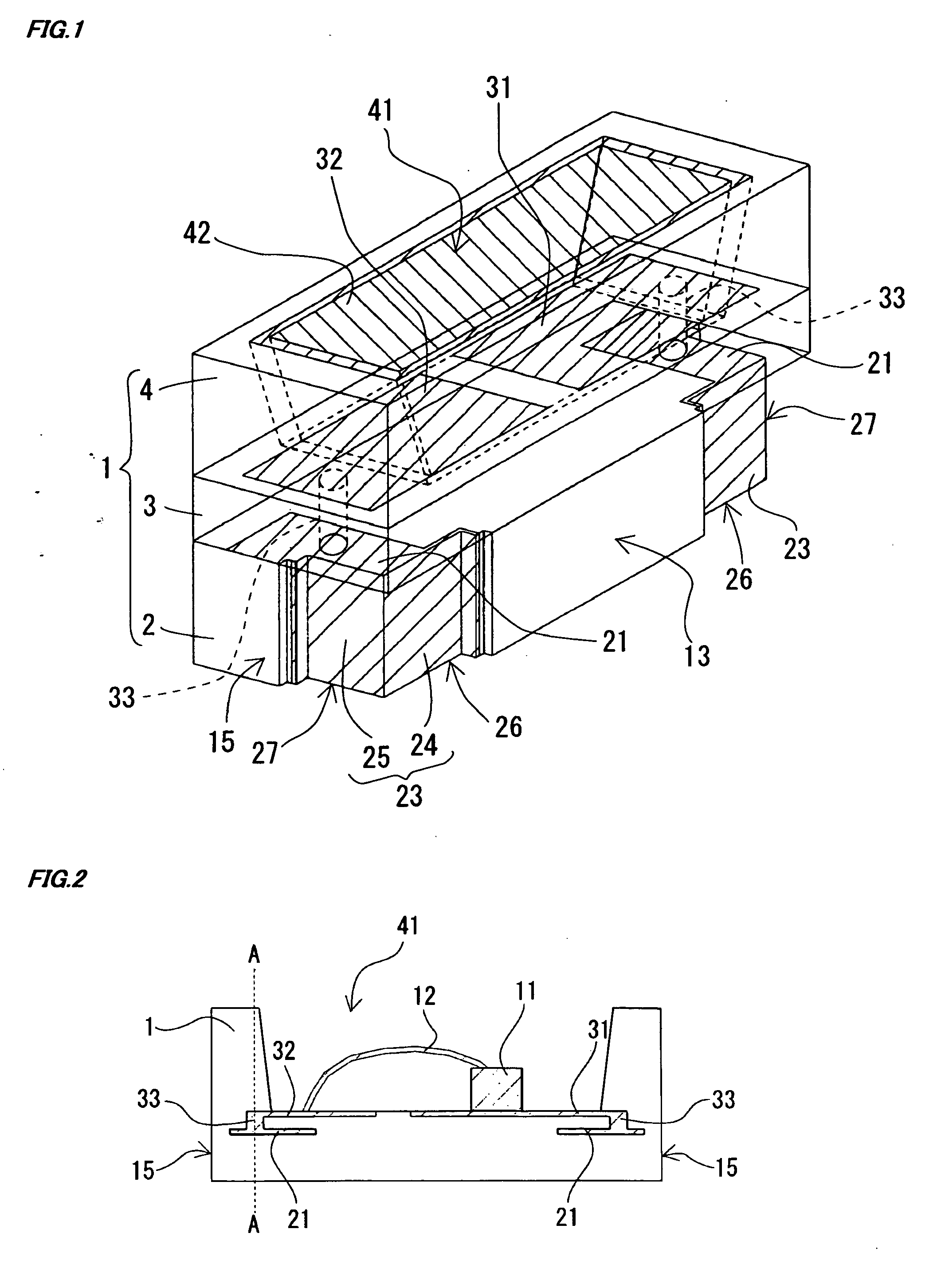

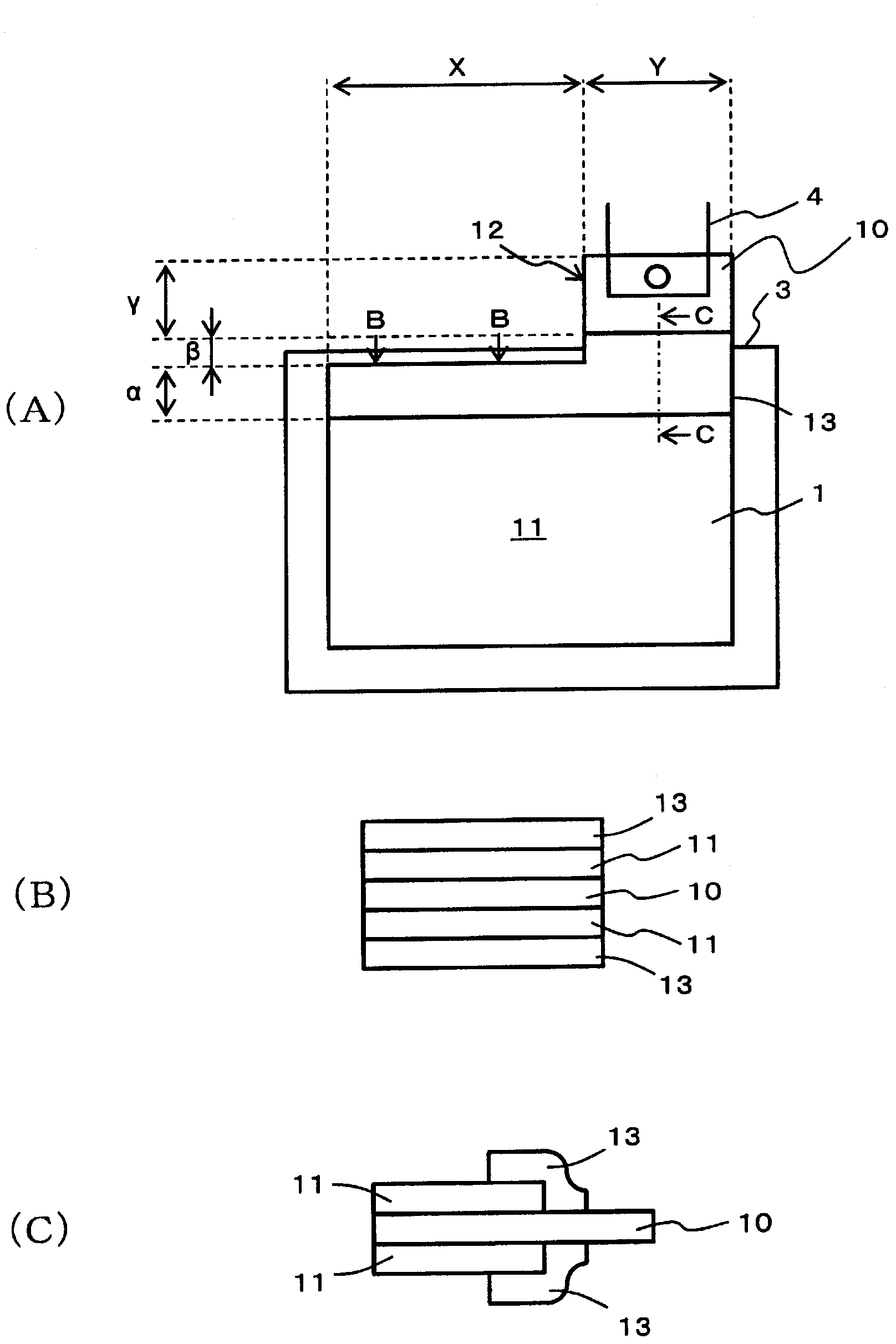

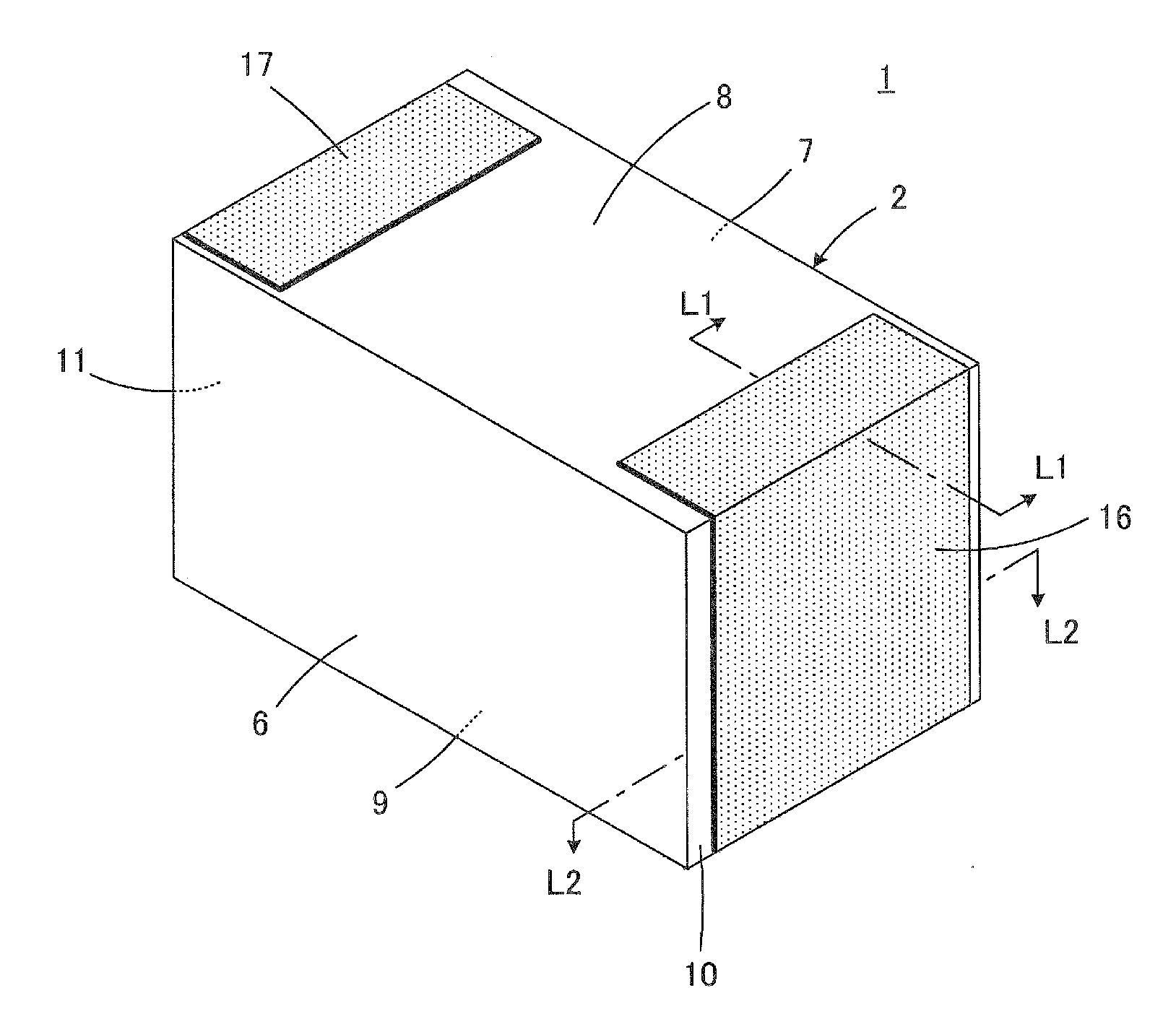

Electronic component mounting package and package assembled substrate

InactiveUS20060220205A1Large mount areaSufficient strengthSemiconductor/solid-state device detailsSolid-state devicesJoint surfaceElectronic component

A package of the present invention has a laminate structure formed by laminating a plurality of ceramic layers, and has a mount surface to be a joint surface when mounted on a mother board, defined parallel with the laminating direction. A first ceramic layer has a recess with an L-shaped cross section across the mount surface and a side surface, defined at each end thereof in a direction perpendicular to the laminating direction, and an external electrode formed on each recess, the external electrode having a surface thereof exposed to the mount surface.

Owner:SANYO ELECTRIC CO LTD

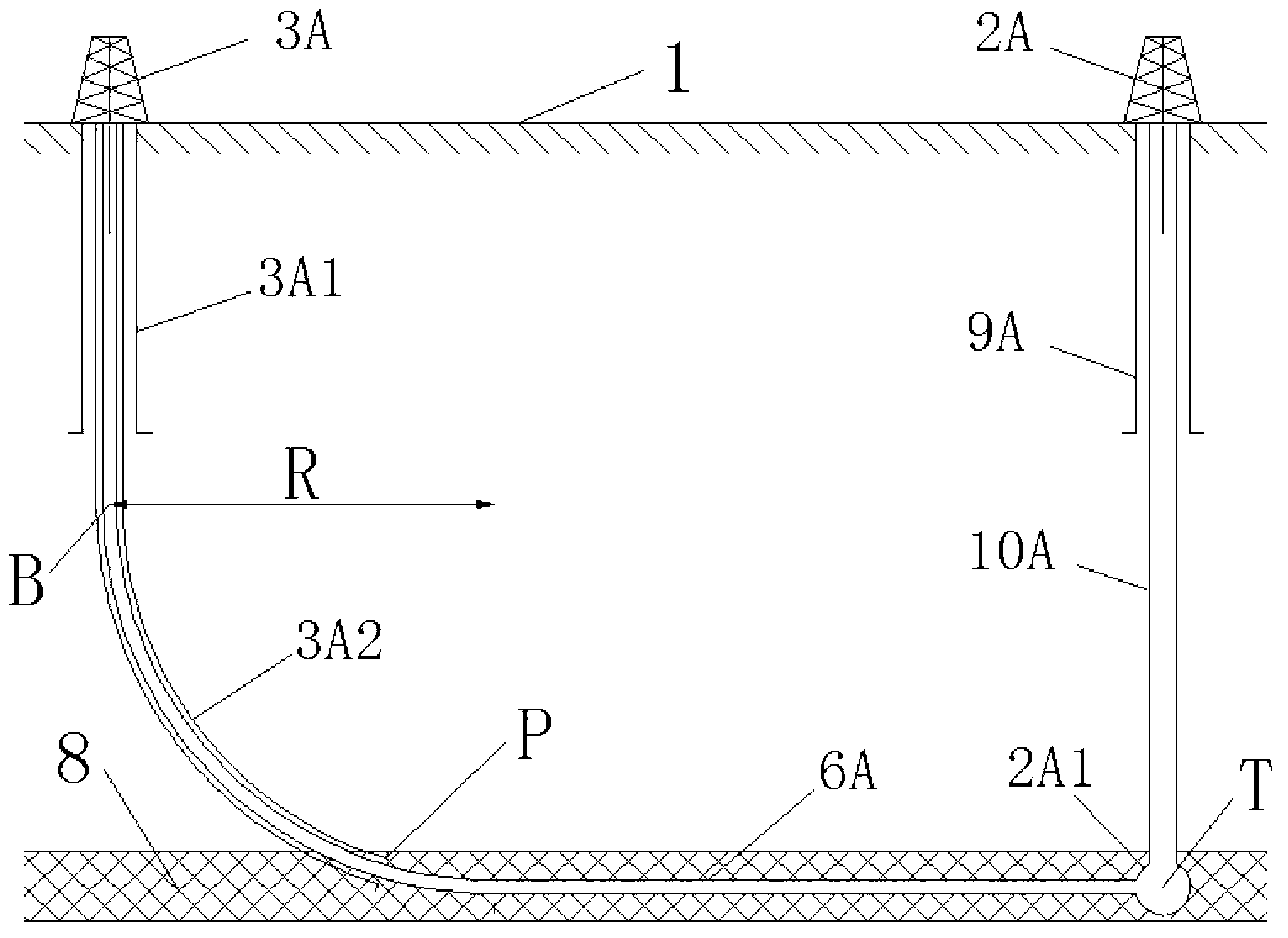

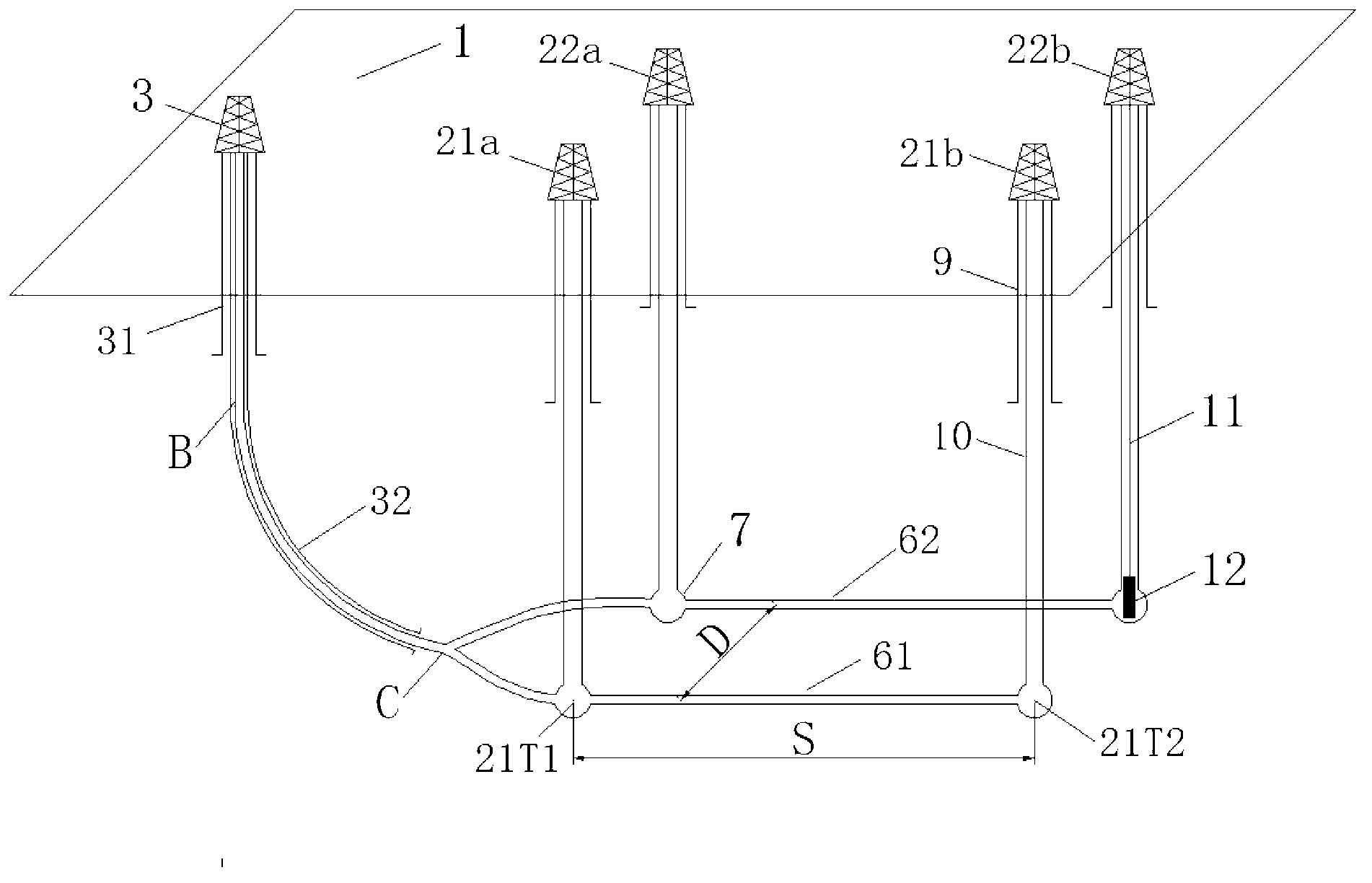

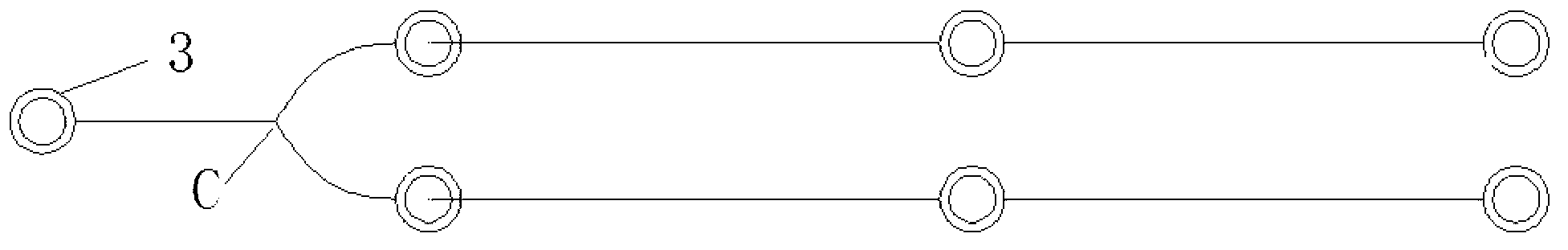

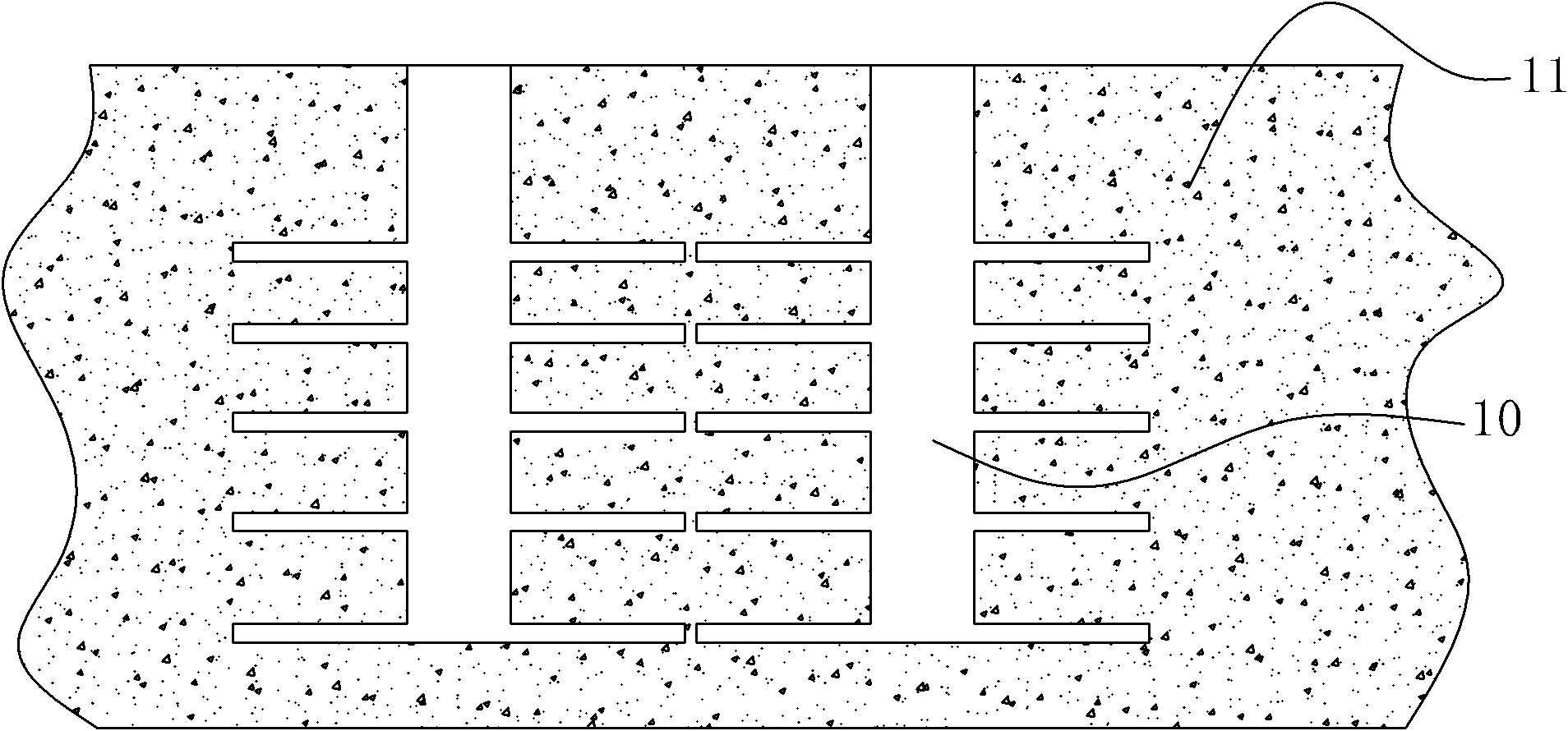

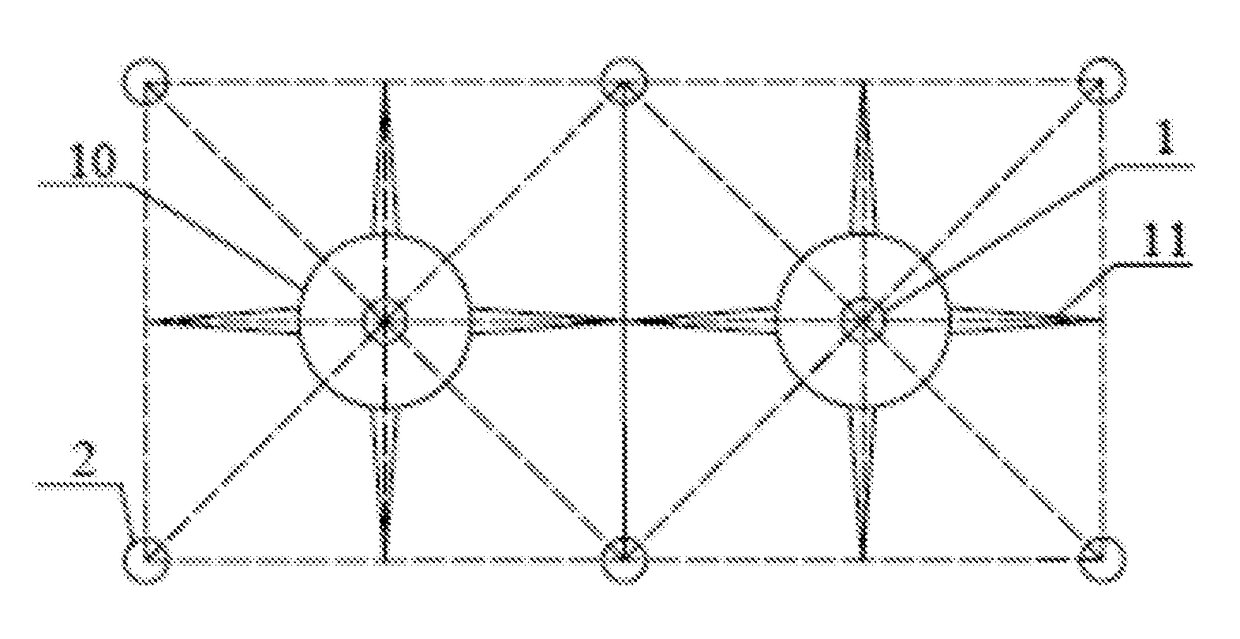

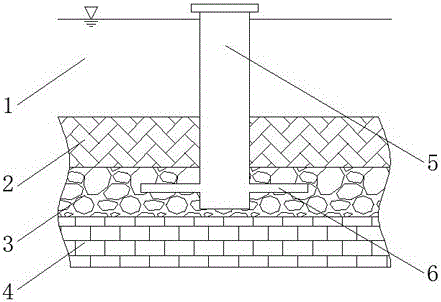

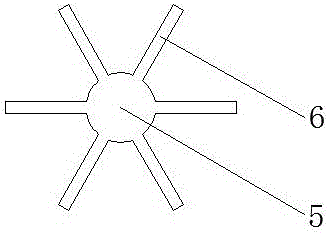

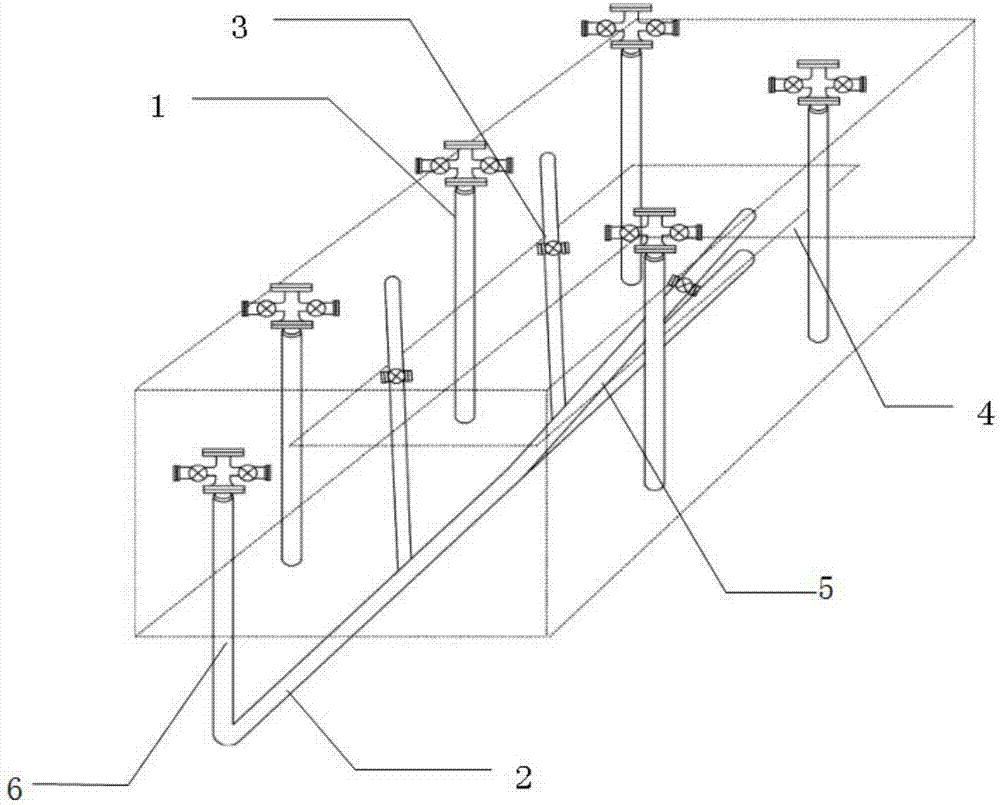

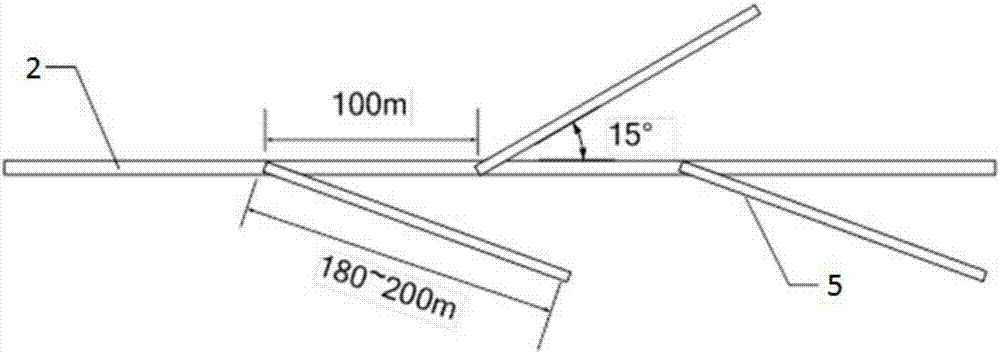

Horizontal branch multi-well-group butted well and construction method thereof

ActiveCN103216234AGuarantee normal implementationAvoid cloggingUnderground miningFluid removalWell drillingHorizontal branch

The invention discloses a horizontal branch multi-well-group butted well and a construction method thereof. The butted well adopts a distribution structure that a horizontal well corresponds to at least two vertical well groups; each vertical well group comprises at least two vertical wells; the vertical wells of each vertical well group are respectively communicated with the horizontal well at the target points respectively arranged at the bottoms of the vertical wells, so that horizontal mining channels which correspond to the vertical well groups one to one can be formed; and the target points arranged at the bottoms of the vertical wells are arranged in a target ore bed. By adopting a novel well drilling distribution form, the horizontal branch multi-well-group butted well enlarges the bare area of the ore bed, improves the mining efficiency, lowers the well drilling cost, reduces the construction period and reduces the mining risk.

Owner:EXPLORATION TECH RES INST OF CHINESE ACADEMY OF GEOLOGICAL SCI +1

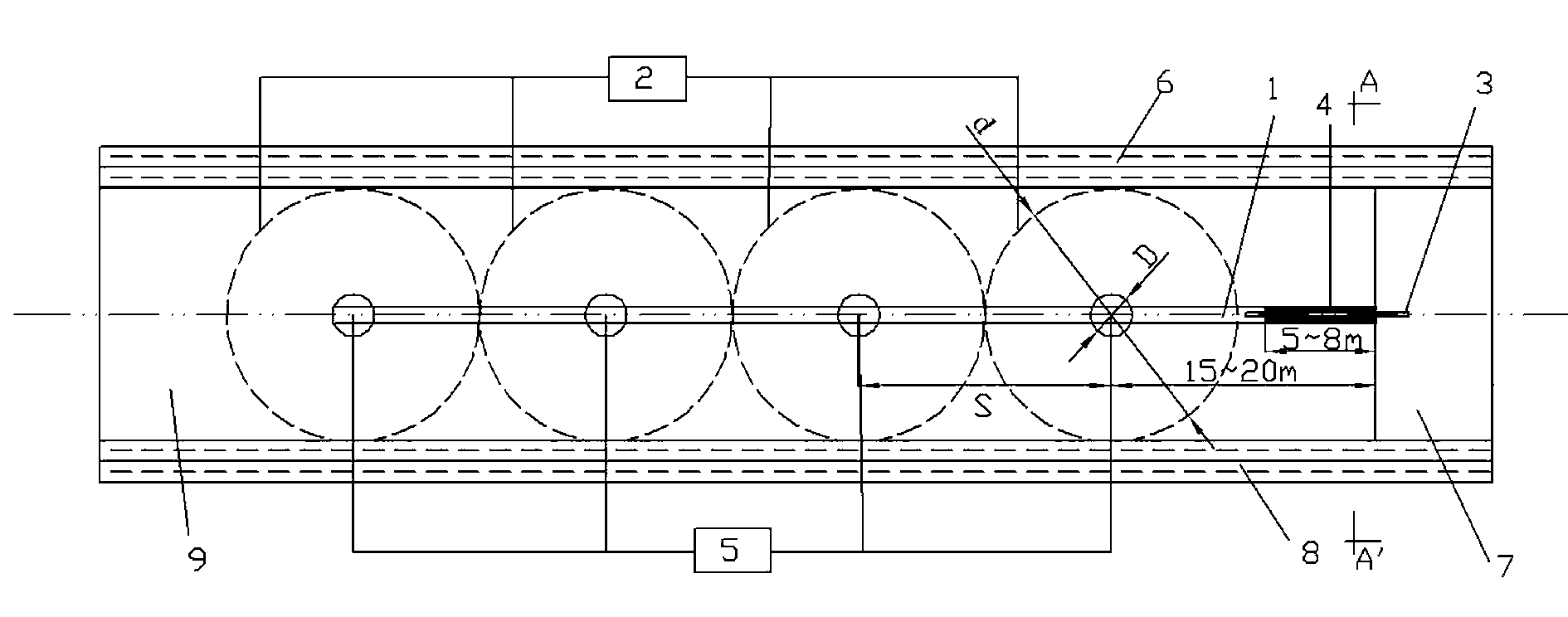

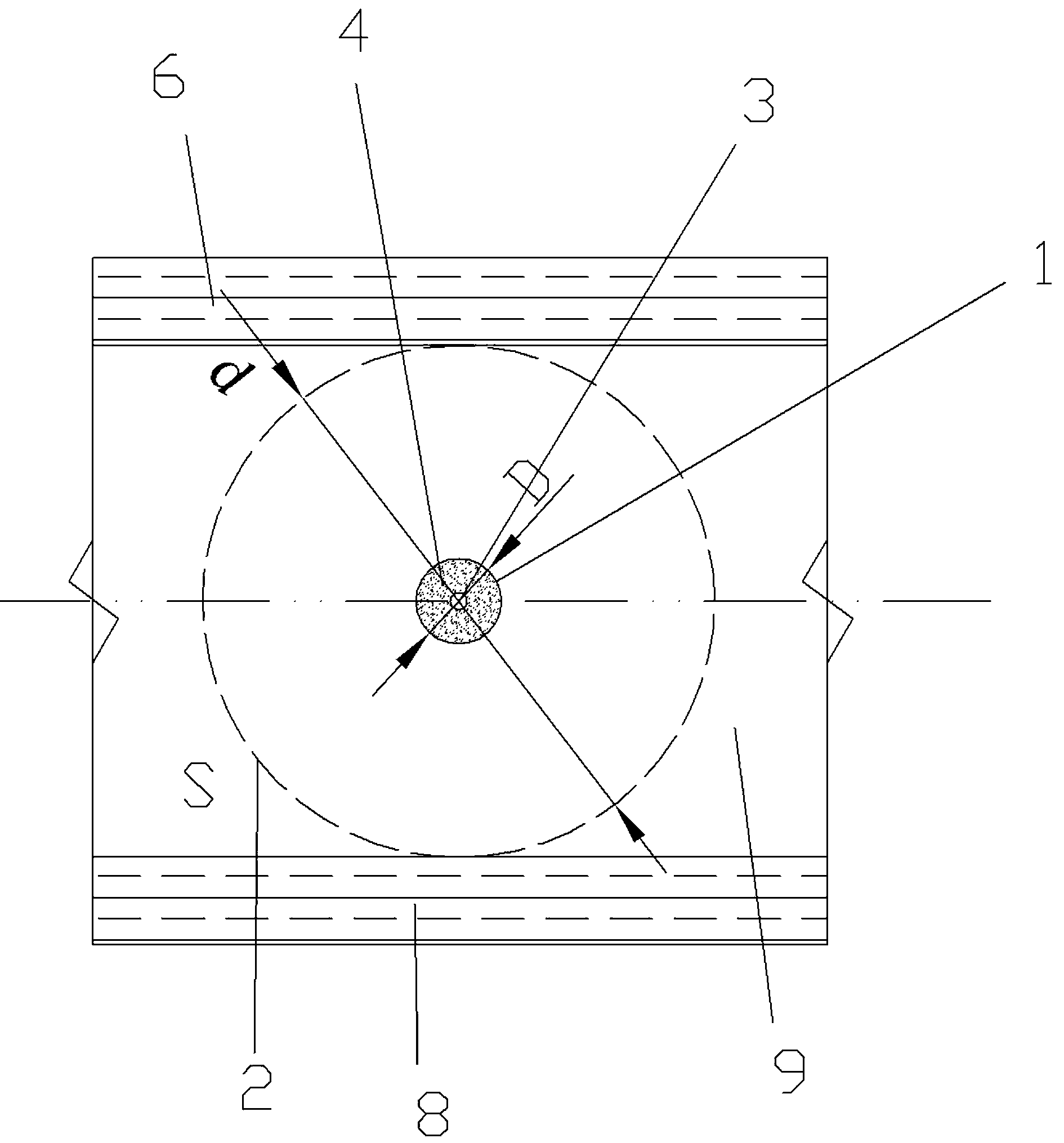

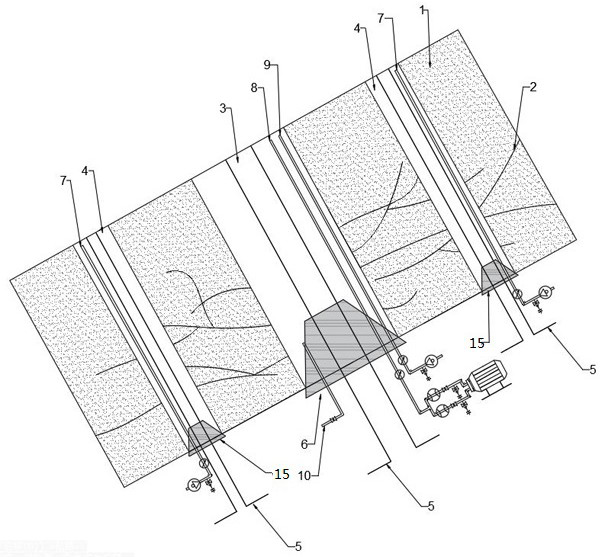

Regional forced gas extraction method for single low-permeability outburst thick coal seam

ActiveCN104100292AEliminate the problem of blank bands in extractionImprove extraction efficiencyGas removalHigh pressure waterHigh pressure

The invention provides a regional forced gas extraction method for a single low-permeability outburst thick coal seam. The regional forced gas extraction method comprises the steps of (a) excavating a rock gangway in a rock fissure zone and drilling a lower-position seam through hole downwards, (b) drilling a high-position seam through hole downwards in the rock gangway, (c) starting a high-pressure water-injection pump station, performing hole expanding operation on the coal seam through sections of the drilled holes under the conditions of the water pressure of 10-20MPa, the flow rate of 8m<3> / h and the single-hole coal output greater than 5t, (d) sealing the drilled holes and carrying out drainage strip networking extraction operation after the hole expanding operation is finished, (e) after the extraction is up to the standard, carrying out tunneling operation of an air return way and a transportation roadway, and meanwhile, drilling a bedding pre-extraction hole in the working face and carrying out the hole sealing and networking extraction operations, and (f) continuously extracting the gas of the goaf in the rock gangway during the recovery of the working face. The regional forced gas extraction method is capable of converting a high-gas outburst coal seam into a low-gas outburst risk-free coal seam, comprehensively guaranteeing safe production of the working face, and meanwhile, obviously increasing the coal roadway tunneling speed.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

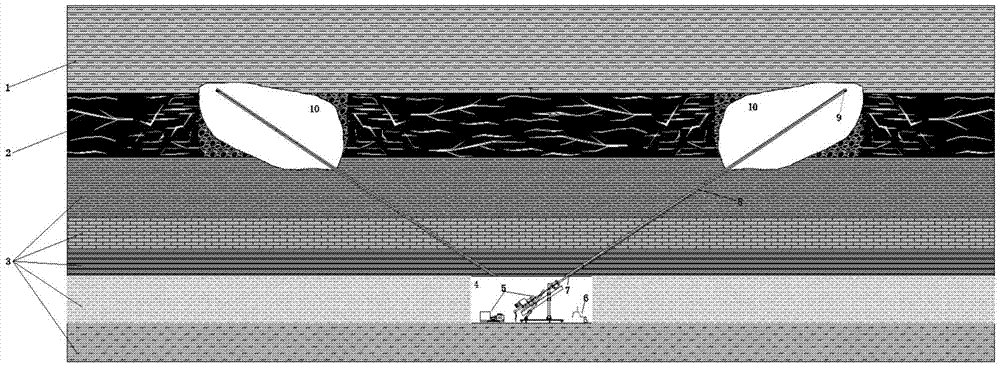

Method for extracting high-pressure hydraulic cave-manufacturing gas from rock roadway crossing hole

InactiveCN104763462AIncrease the exposed areaImprove permeabilityGas removalPunchingHydraulic fracturing

The invention discloses a method for extracting high-pressure hydraulic cave-manufacturing gas from a rock roadway crossing hole and belongs to the field of a soft high outburst seam gas extracting method. The method is characterized in that upward or downward large-diameter crossing holes are constructed into the coal seam roof or the coal seam floor by drilling and stamping integration equipment in the rock roadway of the soft high outburst seam; the cave is manufactured hydraulically by combining hydraulic fracturing with hydraulic jetting punching; a great cave is established in the coal seam and a fracture expansion region is formed around the cave, so that the coal ground stress is reduced, the bare area of the coal seam is increased, and the permeability of the coal seam, the gas extracting efficiency and the gas extracting quantity are improved. The method has the advantages that the large cave is established in the soft high outburst seam and a huge fracture expansion mesh is formed around the cave, so that the coal ground stress is reduced, the bare area of the coal seam is increased, and the permeability of the coal seam is improved; besides wide space is provided to convey and extract the gas, the gas extracting efficiency and gas extracting quality in the soft high outburst seam can be effectively improved, and a new way to treat the gas in the soft high outburst seam is provided.

Owner:CHINA UNIV OF MINING & TECH

Fish bone type branch well drilling and completing method

InactiveCN1884786AIncrease the exposed areaAvoid pitfalls that affect drillingDerricks/mastsDrilling machines and methodsWell drillingDrill

The invention relates to a herringbone branch well drilling method, belonging to the side drilling horizontal well method, wherein said invention can improve the yield; and the invention comprises: first drilling the first branch well eye; then inserting the first branch well tube post; when the main well eye drills to the second branch position, drilling into the second branch well eye, until completing all branch well eyes, then drilling into the main well eye and inserting the complete well sleeve. The invention can avoid reducing the size of main well eye, while the branch well is the same as main well eye; and the number of drilled branch wells is not limited, to increase the oil yield.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Gas-blowing and slag-gathering spray gun for assisting slag-off of molten iron and using method of spray gun

ActiveCN103114177AReduce wear rateReduce wearCharge manipulationCasting cleaning apparatusSlagEngineering

The invention discloses a gas-blowing and slag- gathering spray gun for assisting slag-off of molten iron and a using method of the spray gun. The gas-blowing and slag-gathering spray gun comprises a gun barrel, wherein the gun barrel is provided with an opening end and a closed end; spray ports are symmetrically formed on the barrel wall, close to the closed end, of the gun barrel based on the middle axis of the gun barrel; the middle axes of the spray ports are vertical to the middle axis of the gun barrel; and the ratio of the inner diameters of the spray ports to the inner diameter of the gun barrel is (0.35-0.70):1. The gas-blowing and slag-accreting spray gun has the characteristics of being simple in structure, long in service life, stable in gas-blowing and slag-accreting operation and the like. The gas-blowing and slag-gathering spray gun disclosed by the invention is combined with the using method of the spray gun, so that the molten iron slag gathering degree can be improved, the bare area of the molten iron is increased, the erosive wear to the molten iron tank wall is small, the slag-off iron loss is low and the slag-off time is short.

Owner:武汉钢铁有限公司

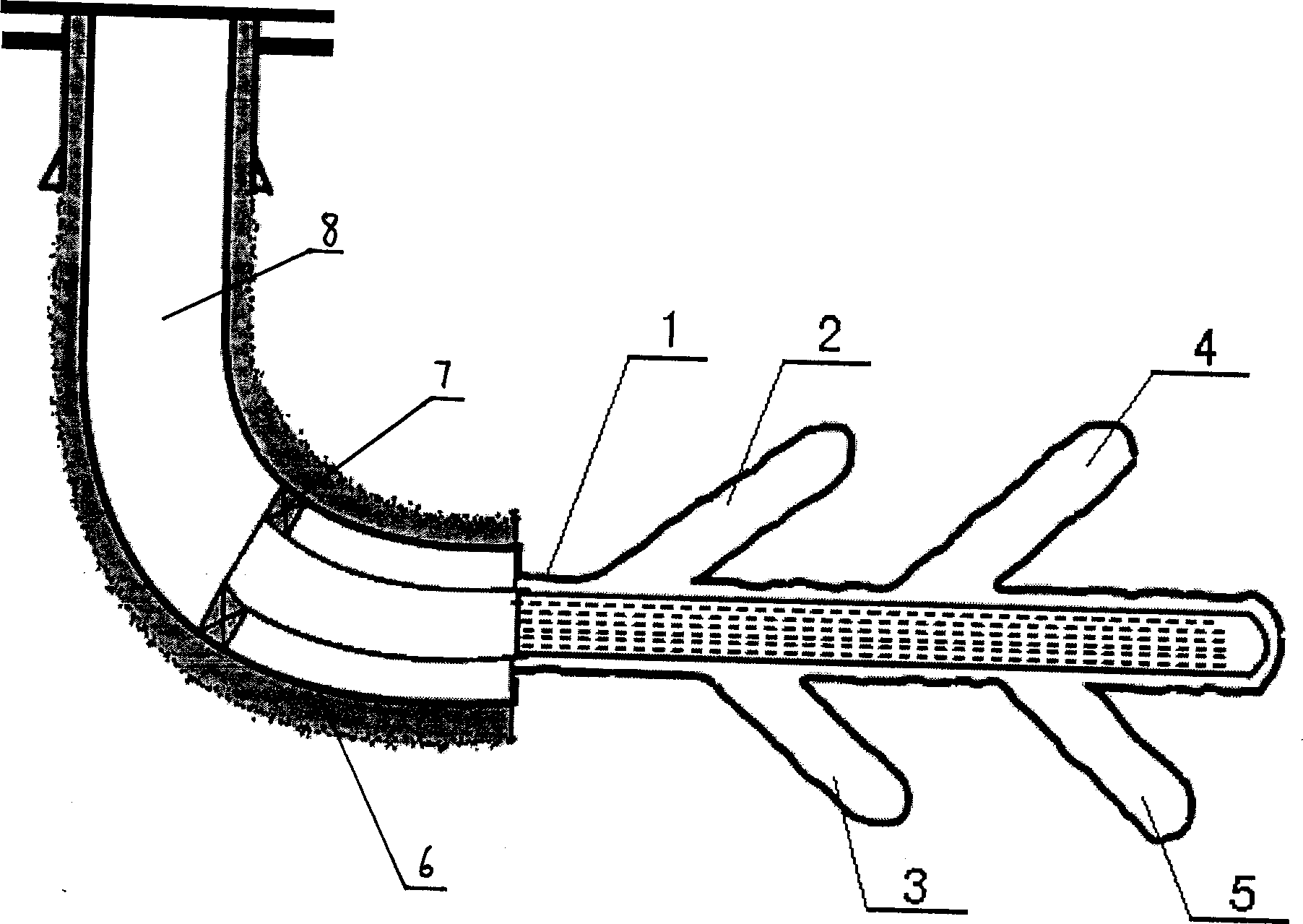

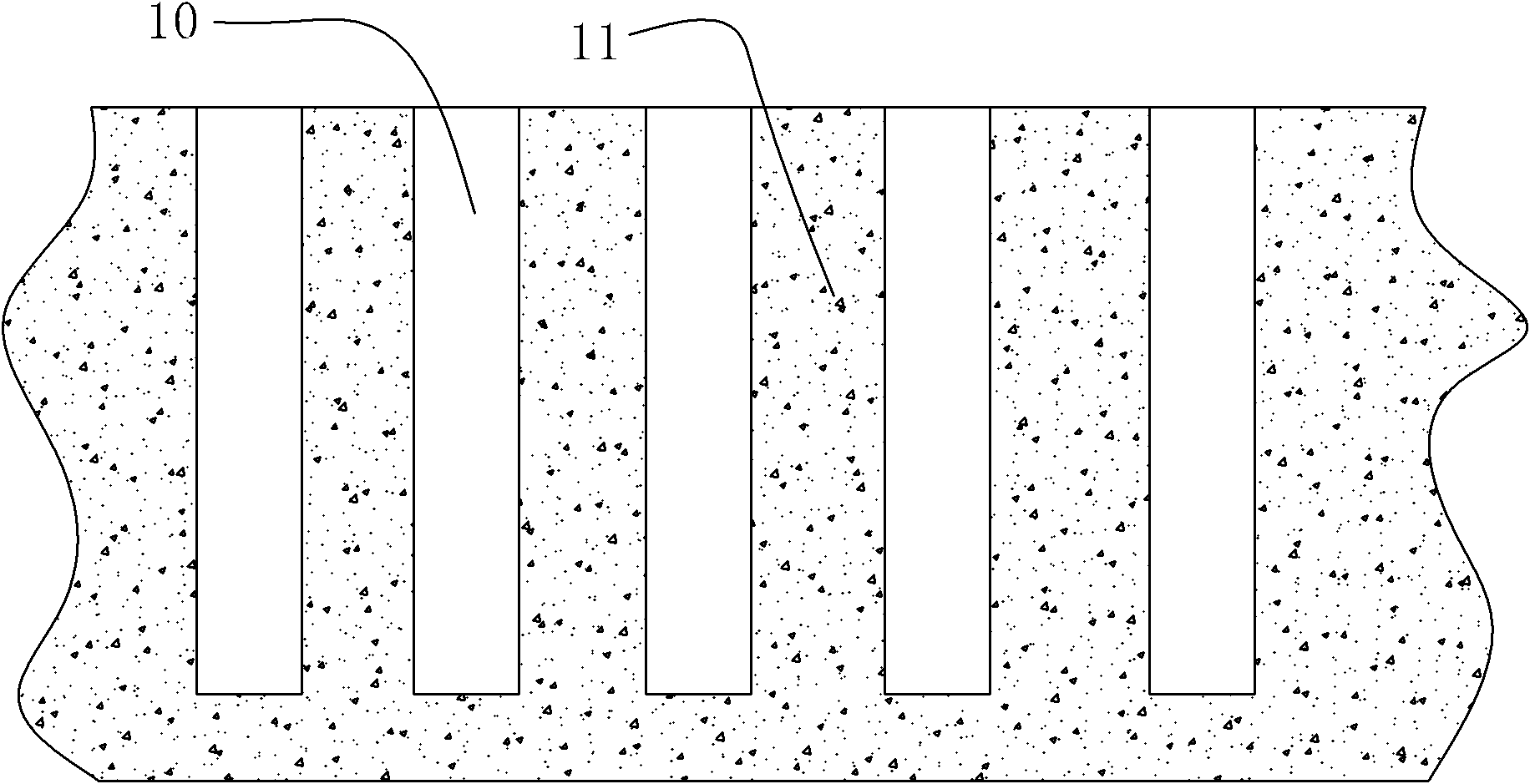

Method for extracting coal bed methane through down-hole bedding long borehole consecutive cave building

ActiveCN103061798AImprove drilling single-hole drainage production capacityImprove extraction efficiencyDrill bitsGas removalDrill siteCoal

The invention relates to a method for extracting coal bed methane through down-hole bedding long borehole consecutive cave building and a hydraulic mechanical drill with the diameter changed and enlarged while drilling. A coal bed bedding long borehole is combined with a cave building technology, and the permeability of low-permeable coal reservoirs and the coal bed borehole extraction capacity are improved. A hole is opened at 1 / 3 coal thickness or 1.5m upwards away from the coal heading floor on the extracting drill site coal wall of an underground coal mine along with the coal bed, the hydraulic mechanical drill with the diameter changed and enlarged while drilling performs cave building on the borehole from inside to outside successively after the borehole reaches the preset depth, and the cave diameters and distances can be calculated through formulas. Coal bed stresses around the cave are released and coal bed prior cracks are widened and lengthened after the caves are completed, tensional and shear failures occur to the coal bed, novel cracks are produced, and accordingly, the coal bed crack connectivity is increased, the permeability is improved, the coal bed methane can be depressurized and desorbed rapidly, the coal bed methane extracting efficiency is improved dramatically, and the coal bed methane extracting time is shortened.

Owner:ZHONGBEI UNIV +1

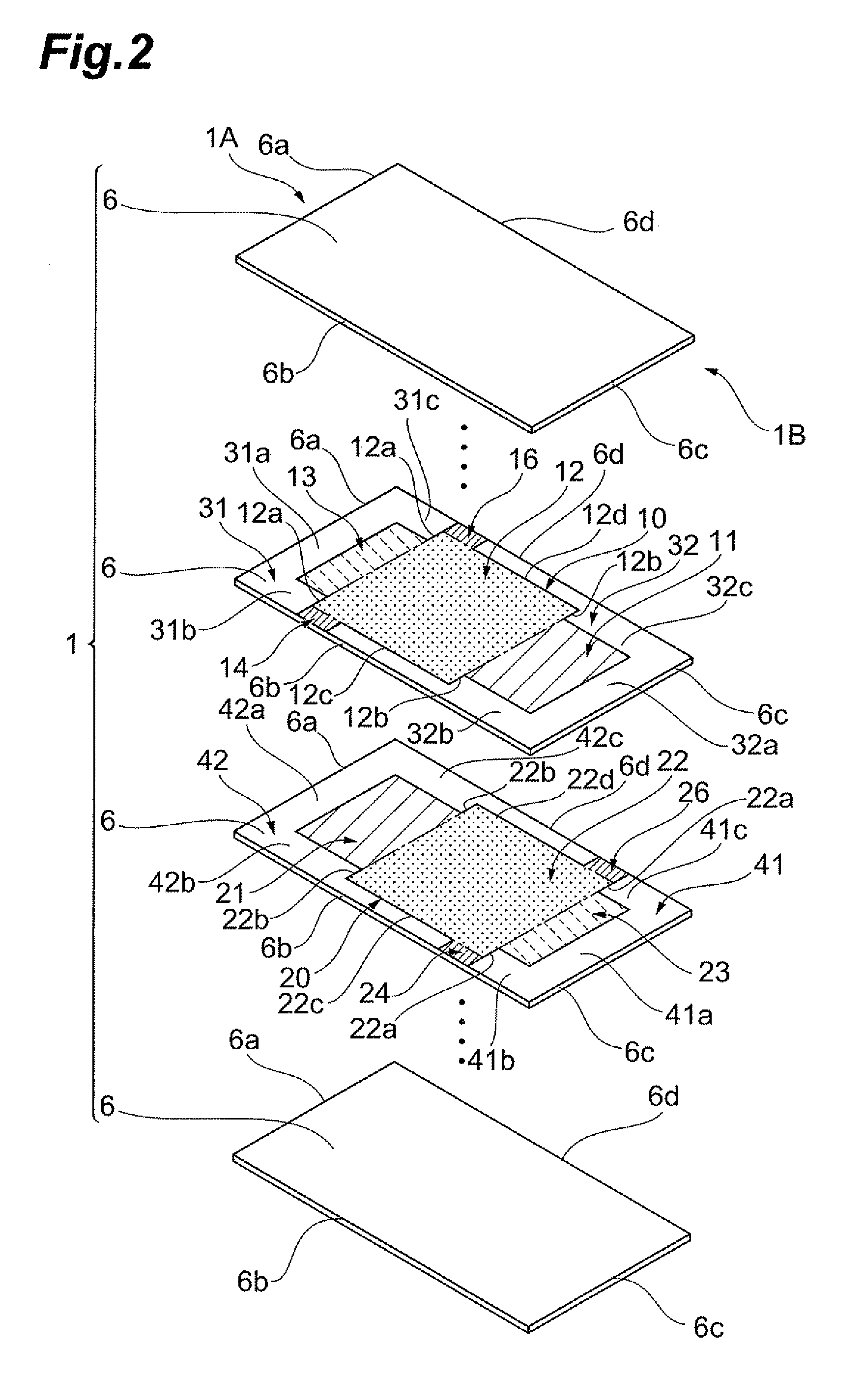

Secondary battery, method for manufacturing same, and thermal adhesive insulating film for secondary battery

ActiveCN103190028APerformance impactImprove toleranceFinal product manufactureElectrode collector coatingForeign matterPolyolefin

The secondary battery of the present invention accommodates in an outer housing an electrode body in which a positive electrode member, separator member, and negative electrode member are laminated in this order. The secondary battery is characterized by the positive electrode member and the negative electrode member each being formed from a collector and an active material layer formed so as to cover one end on the collector. The secondary battery is further characterized by an insulating body in which the insulating material does not exhibit adhesiveness at normal temperatures being applied with an adhesive force of 1 N / 15 mm or greater onto the collector constituted of the positive electrode member or negative electrode member, and the peripheral edge of the positive electrode member or negative electrode member having a cross-sectional surface containing the collector and insulating body. In addition, the thermal adhesive insulating film for a secondary battery of the present invention is characterized by having a base material layer formed from a polyolefin and an adhesive layer formed from a polyolefin modified using unsaturated carboxylic acid or a derivative thereof. A secondary battery, a method for manufacturing the same, and a thermal adhesive insulating film for a secondary battery that prevent swelling and peeling of the electrode parts and effectively prevent mixing in of foreign matter inside the battery are provided.

Owner:TORAY ADVANCED FILM CO LTD +1

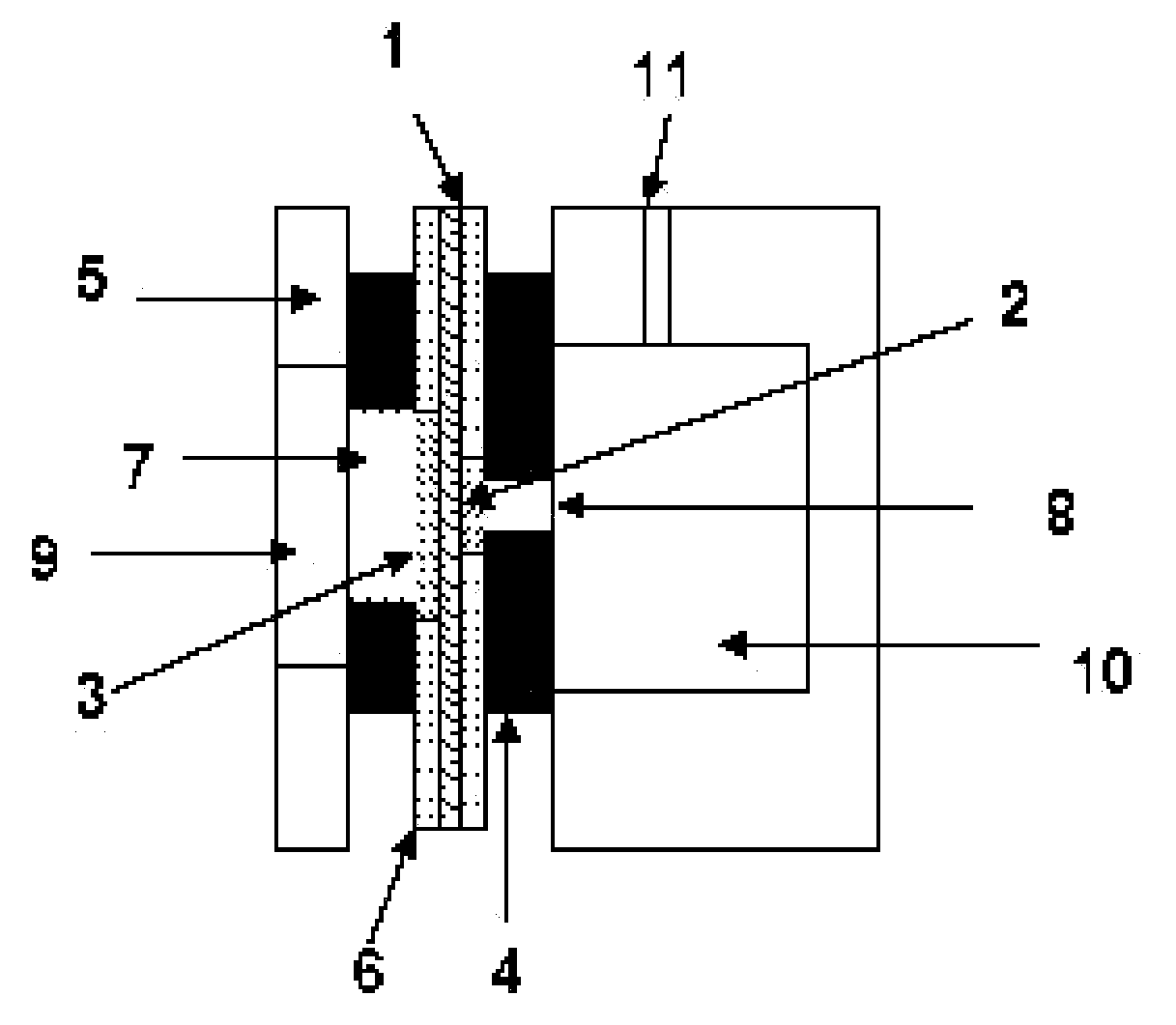

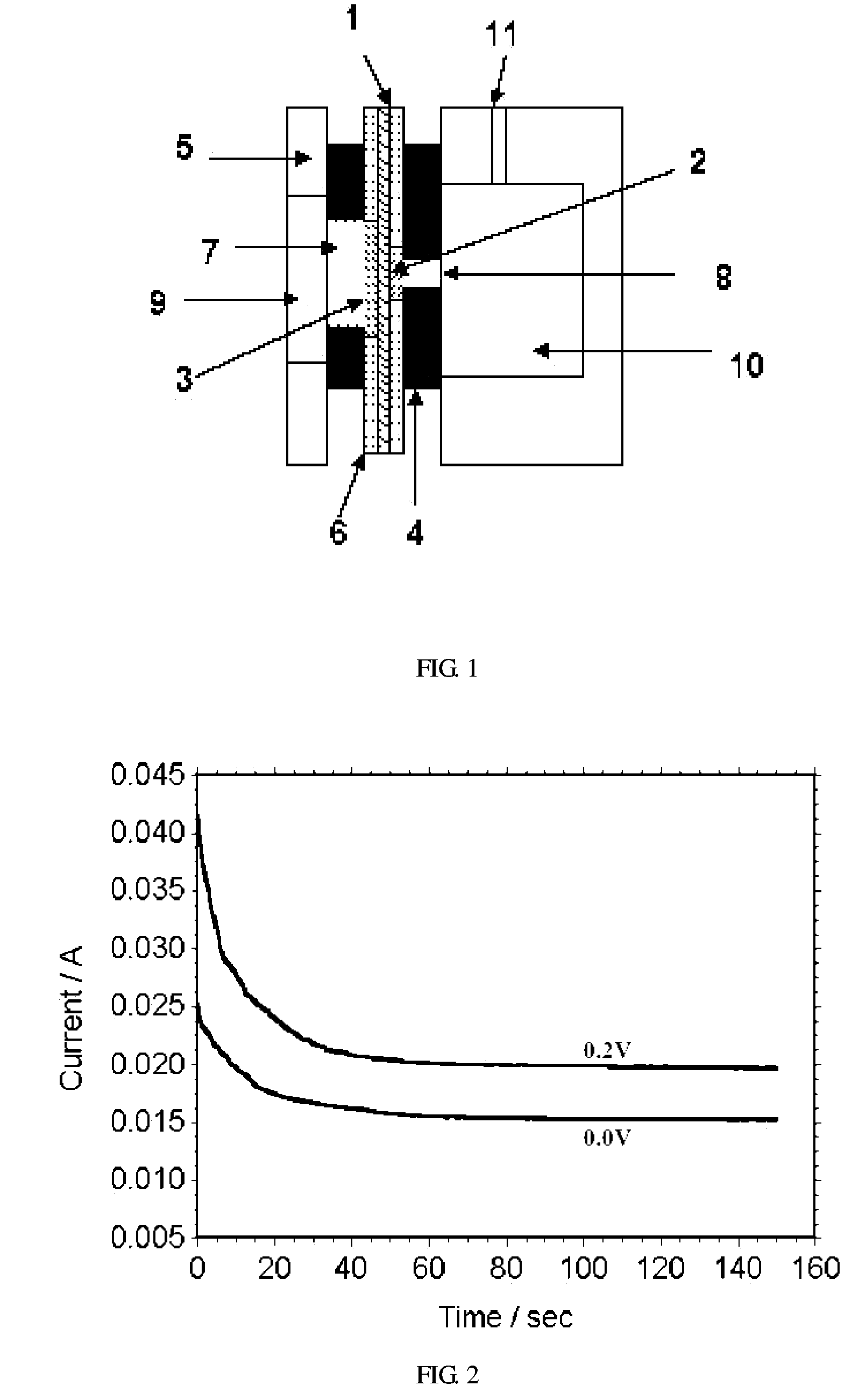

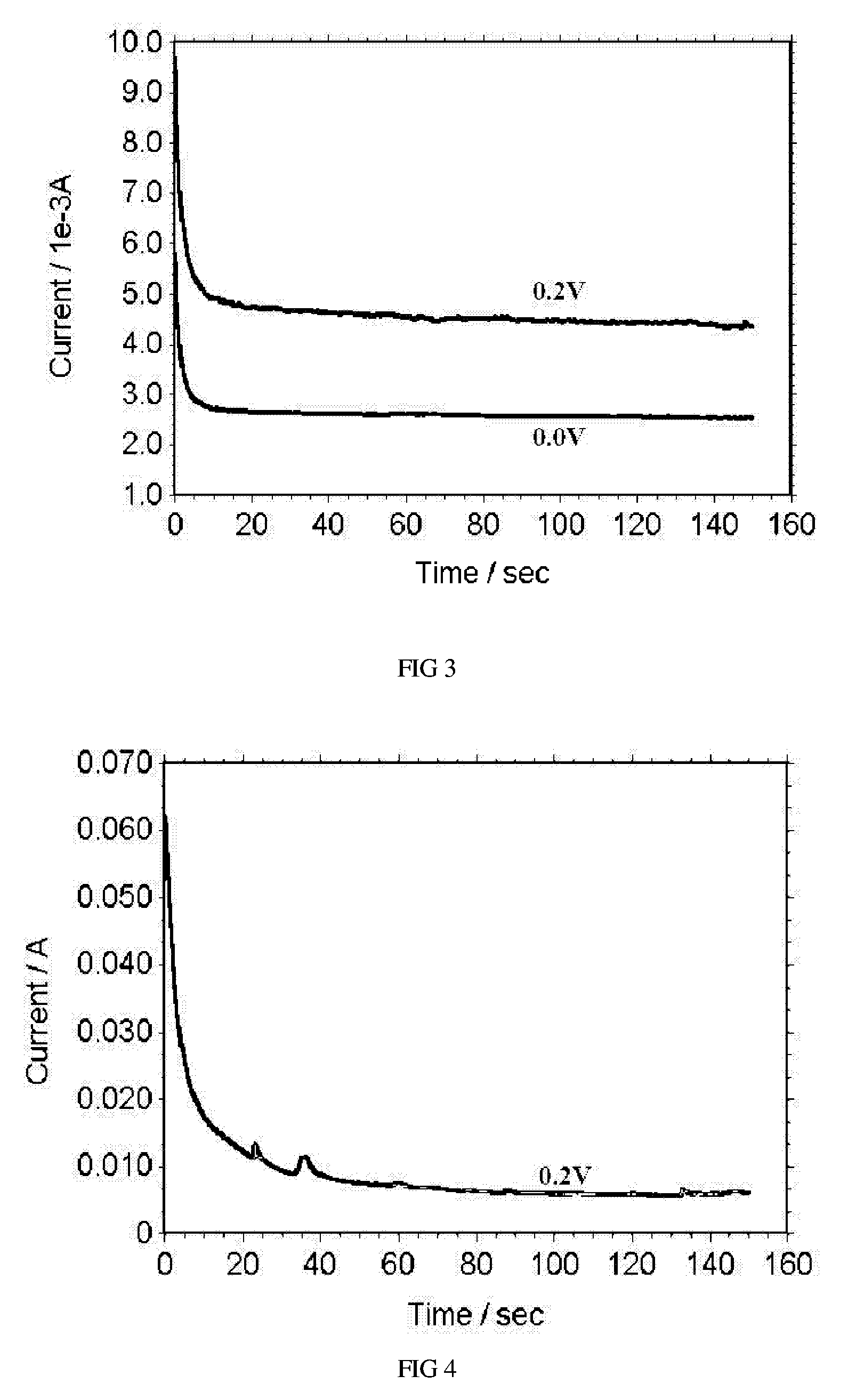

A versatile electrochemical sensor for sensing fuel concentration in an aqueous solution

InactiveUS20060272943A1Increase the exposed areaReduce exposed areaCell electrodesFuel testingCell systemMembrane electrode assembly

A simple fuel cell-type electrochemical sensor for sensing the concentration of a specific fuel, e.g., methanol, ethanol, formic acid, sodium borohydride, etc., prepared in an aqueous solution is developed. The sensor is mainly composed of a membrane electrode assembly (MEA), which is made by hot pressing a piece of electro catalytic anode and a piece of electro catalytic cathode on each side of a proton exchange membrane (PEM), such as Nafion® 117. It is uniquely designed to have an anode size much smaller than that of the cathode and utilizes ambient air as an oxidant. The innovative approach is to ensure the fuel diffused to the anode / membrane interface can be totally reacted so as to eliminate the interferences of fuel crossover and enhance output signal. Thus, the measured sensor current reflects the concentration of diffusion-limited fuel at the membrane / electrode interface, which is proportional to fuel concentration in the bulk. It can be easily operated in a passive mode as well as in an active mode with aqueous fuel solution under a stagnant or a flowing condition. The applications include uses in fuel cell systems, such as direct methanol fuel cell systems, for sensing and monitoring fuel concentration in an aqueous solution.

Owner:INST NUCLEAR ENERGY RES ROCAEC

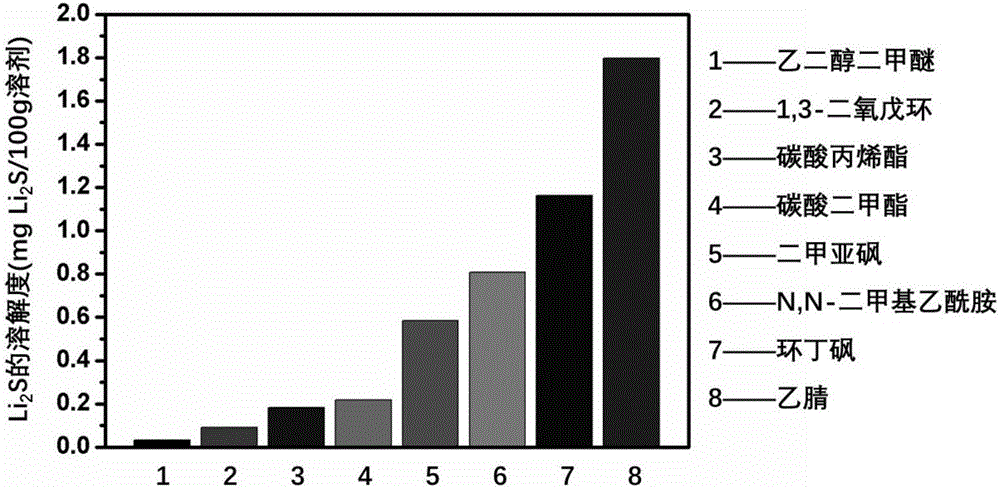

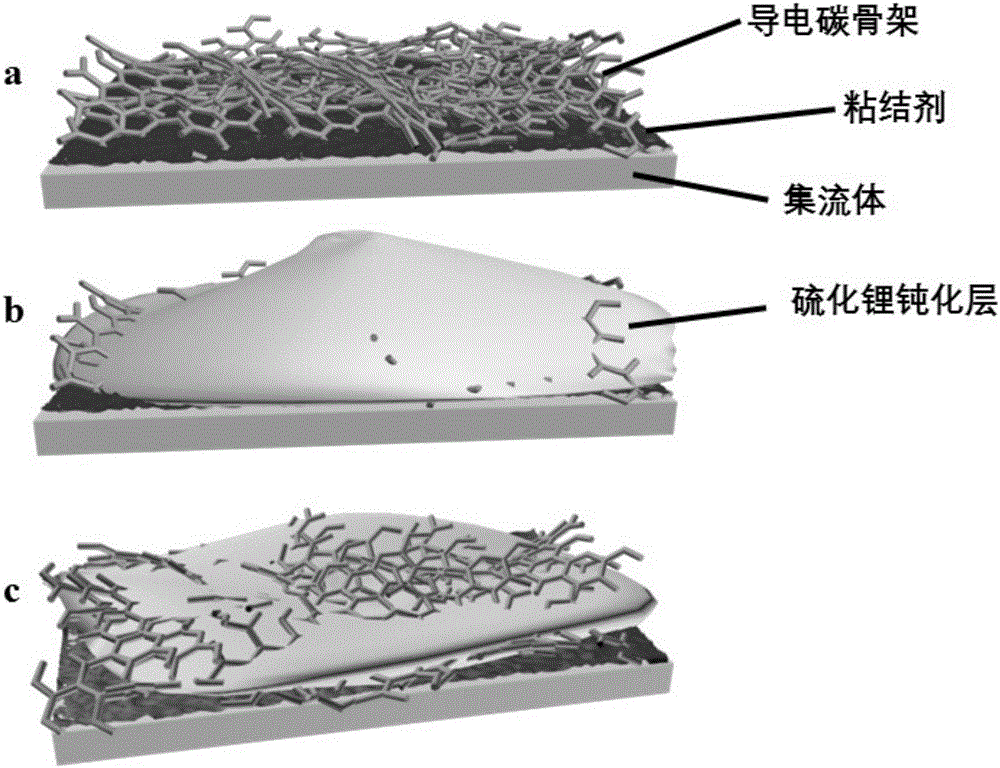

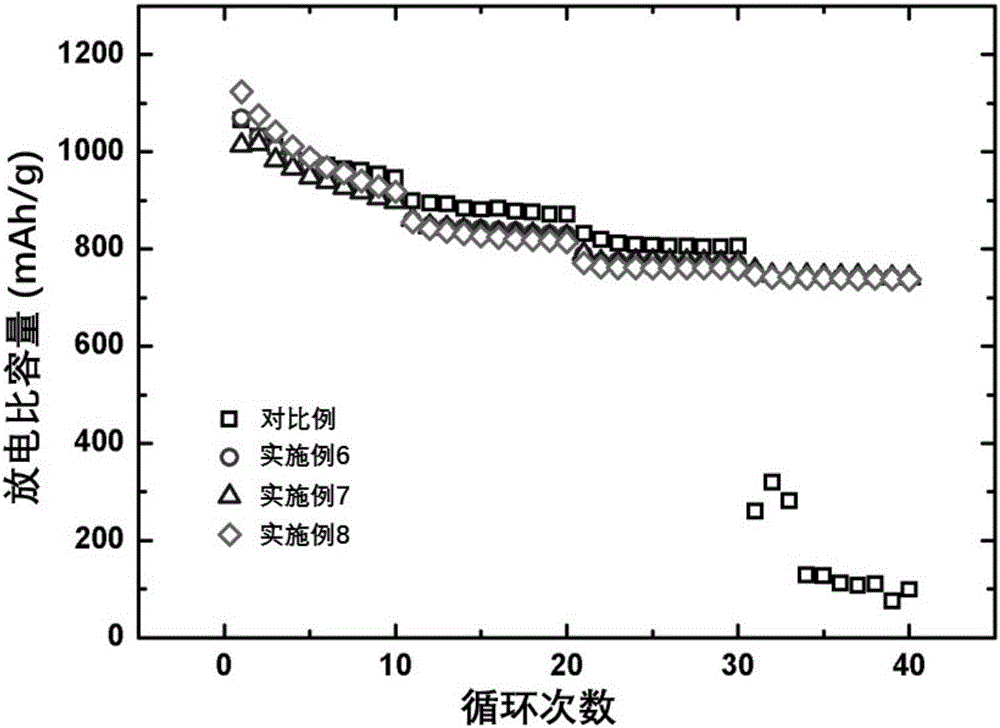

Electrolyte for lithium-sulfur battery containing sulfide solubilizer

ActiveCN106252726AUniform depositionReduce the precipitation rateLi-accumulatorsMaterial electrochemical variablesSolubilityAdhesive

The invention relates to an electrolyte for a lithium-sulfur battery containing a sulfide solubilizer. The electrolyte mainly comprises an electrolyte salt and an organic solvent, wherein the organic solvent comprises an ether organic solvent and the sulfide solubilizer. The invention discloses a determination method for the solubility of the sulfide in the organic solvent. The invention further discloses a composition method of the sulfide solubilizer. The invention provides the lithium-sulfur battery containing the electrolyte; a negative active material is a lithium metal or a lithium-containing alloy, a positive electrode is formed by alloying and ball-milling of the positive active material, a conductive agent and an adhesive at the ratio, and a positive active material is element sulfur or a sulfur-containing compound. The product provided by the invention has the advantages of being available in raw materials, simple in process and the like, and the rate capability of the lithium-sulfur battery can be improved.

Owner:NAT UNIV OF DEFENSE TECH

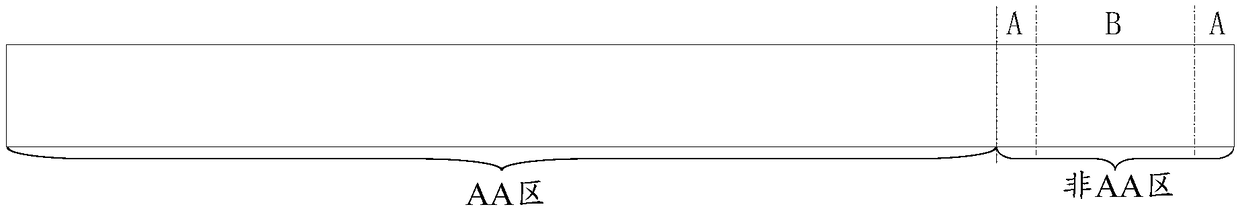

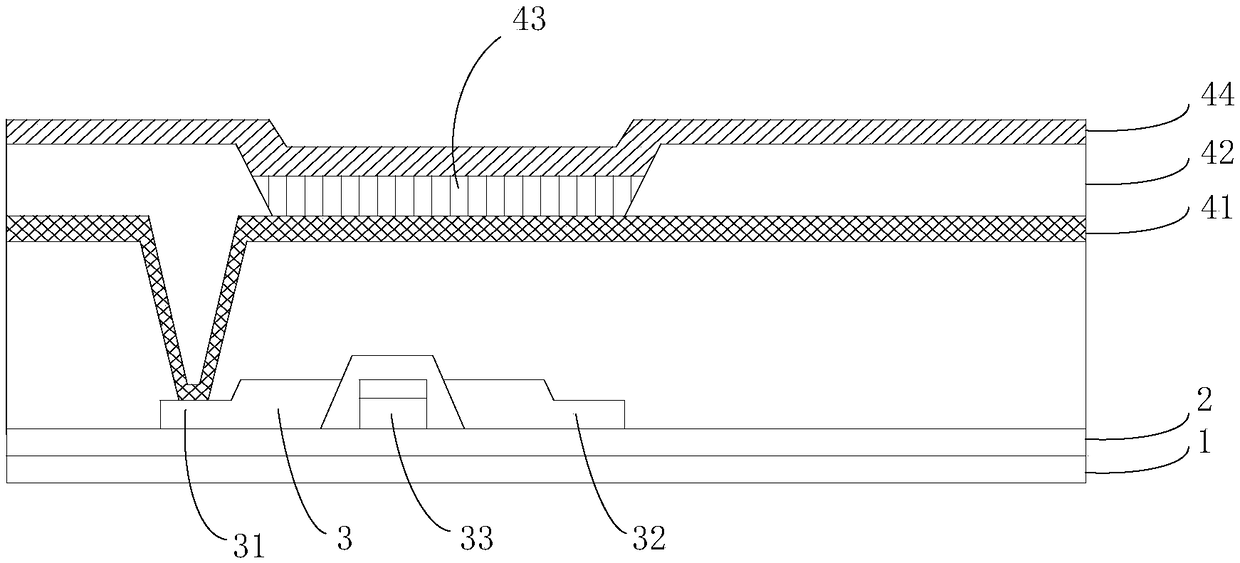

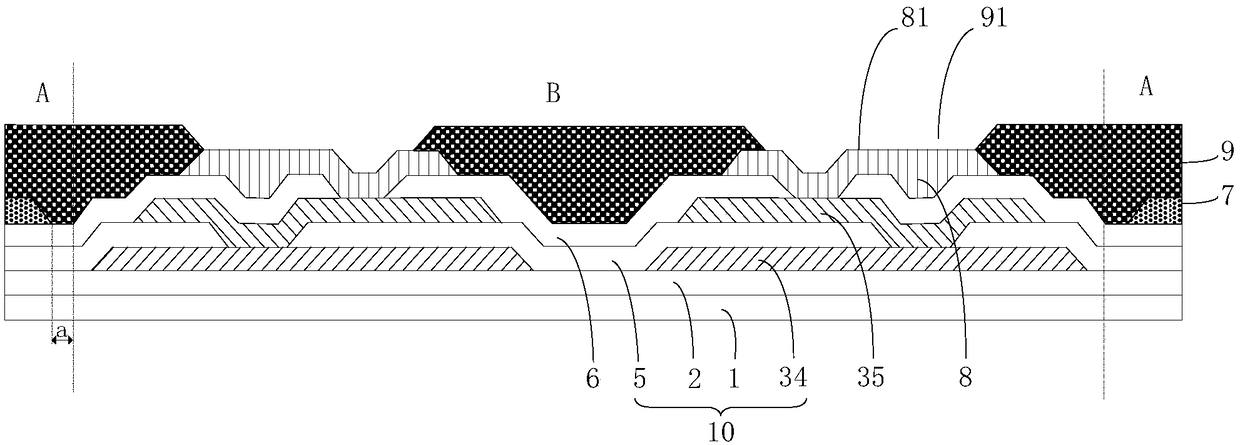

Display panel and display device

ActiveCN109309101AIncrease the exposed areaIncrease the number ofSolid-state devicesSemiconductor devicesDisplay deviceOrganic layer

The invention provides a display panel and display device. The display panel includes a display area and a bonding area connected to the display area; the bonding area includes a substrate layer set,first metal layers formed on the substrate layer set, passivation layers formed on the first metal layers, second metal layers formed on the passivation layers, and protective layers formed on the second metal layers; the second metal layers are electrically connected to the first metal layers through the contact holes in the passivation layers; the protective layers have multiple through holes; and the parts of the second metal layers corresponding to the through holes are exposed to form multiple contact electrodes. Through the large area etching on first organic layers, third connection electrodes can have larger bare areas, and therefore, bonding areas can be enlarged, the number of ACF particles can be increased, bonding resistance can be reduced, and the yield rate of bonding can beimproved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

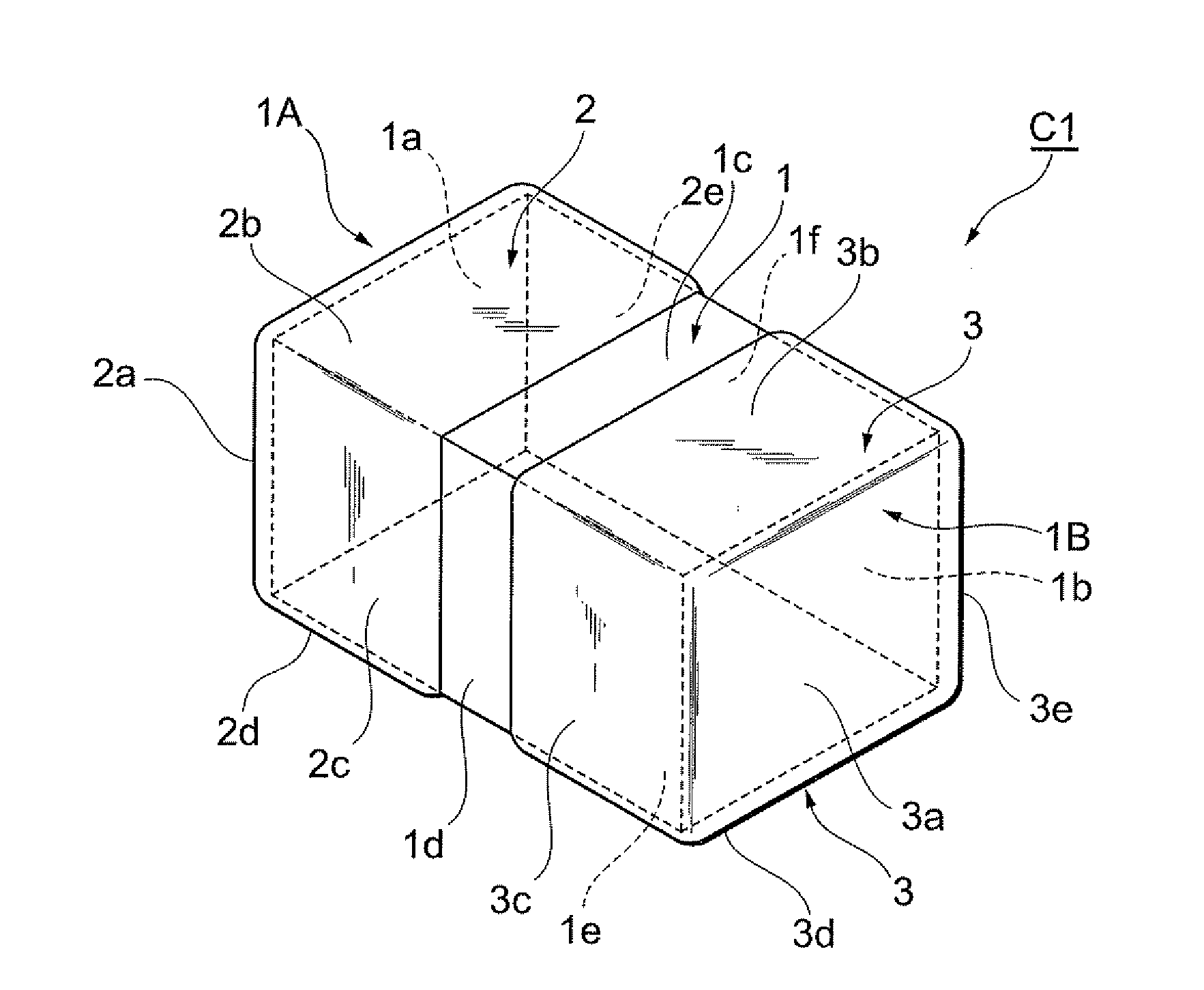

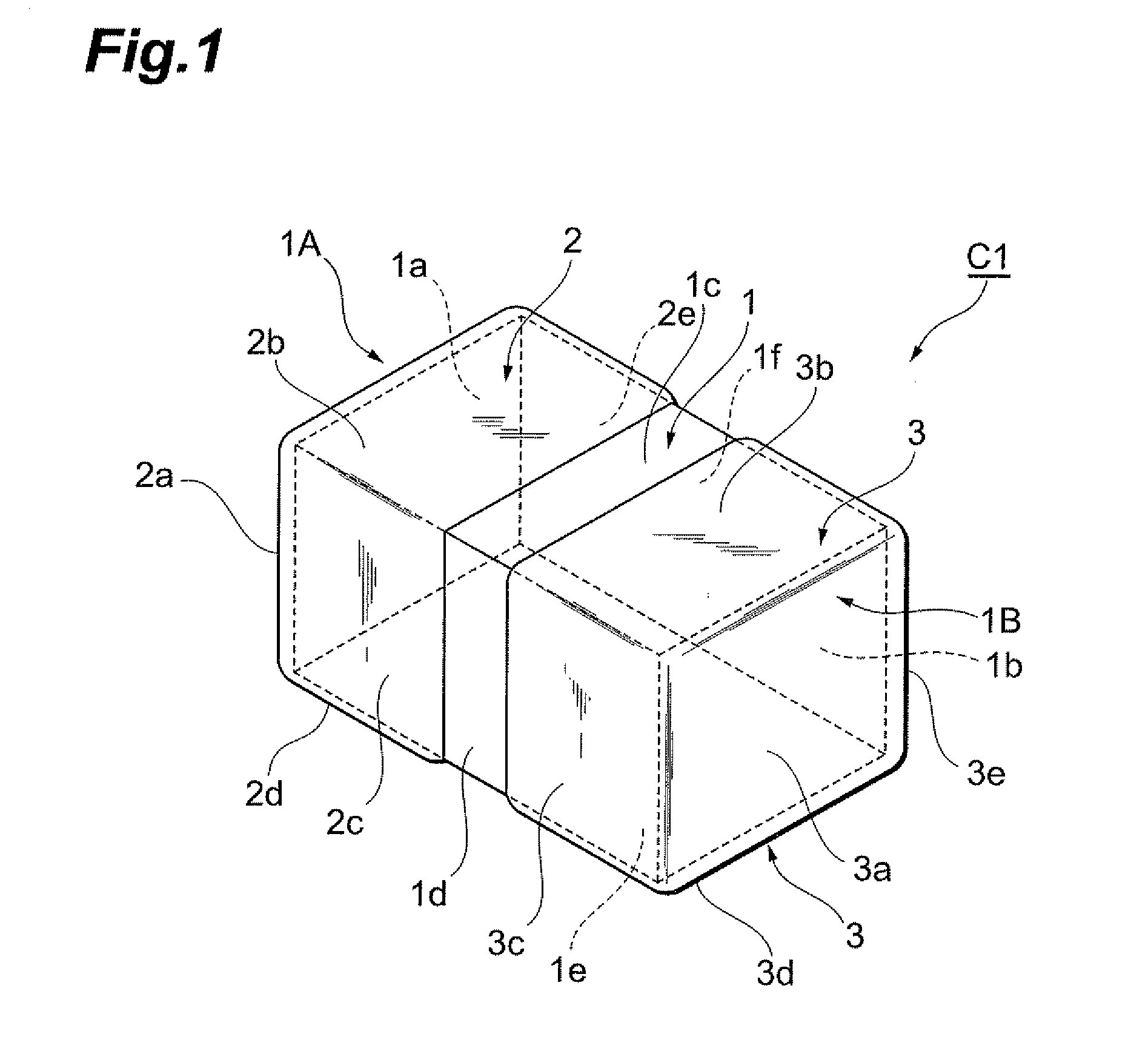

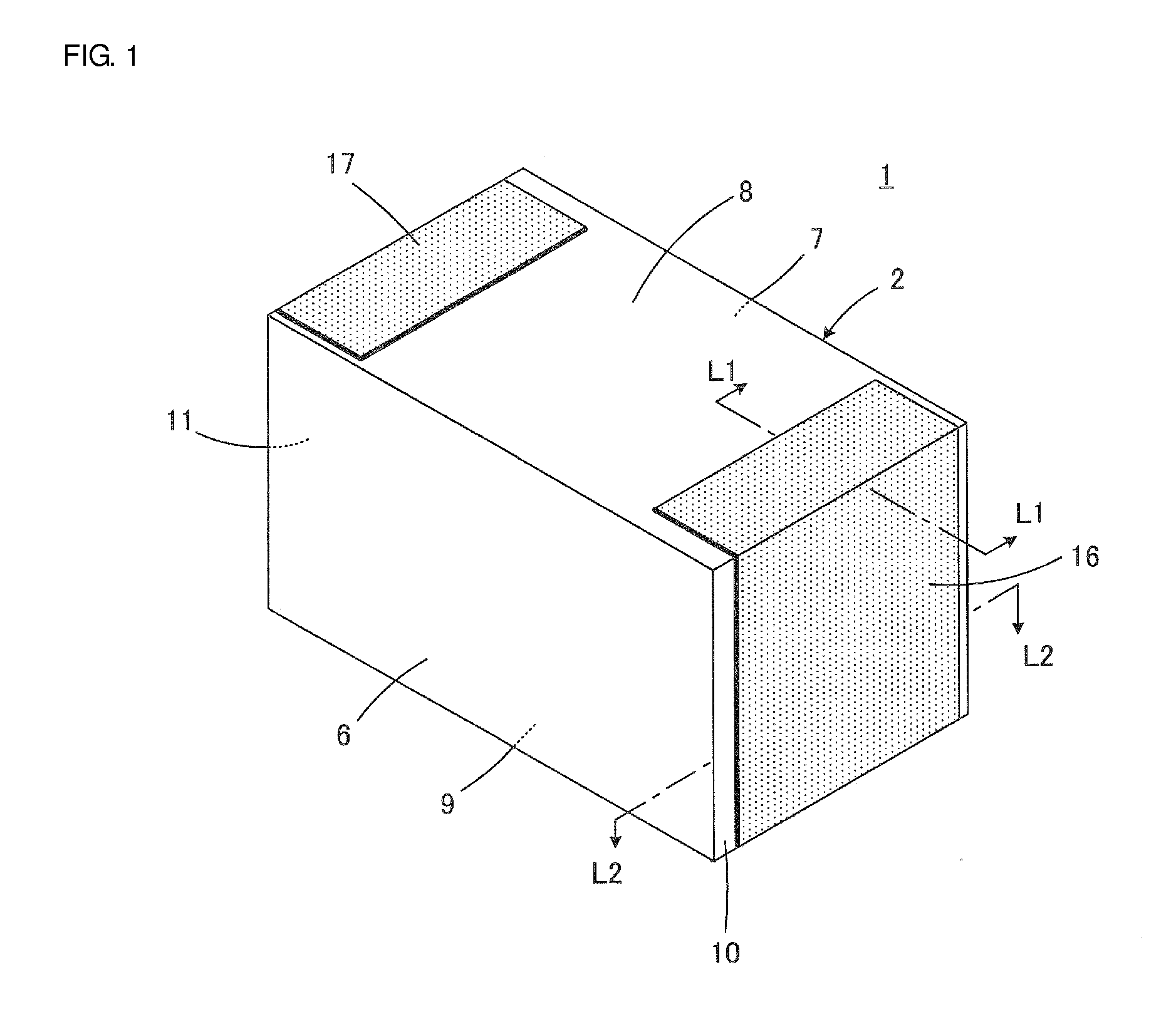

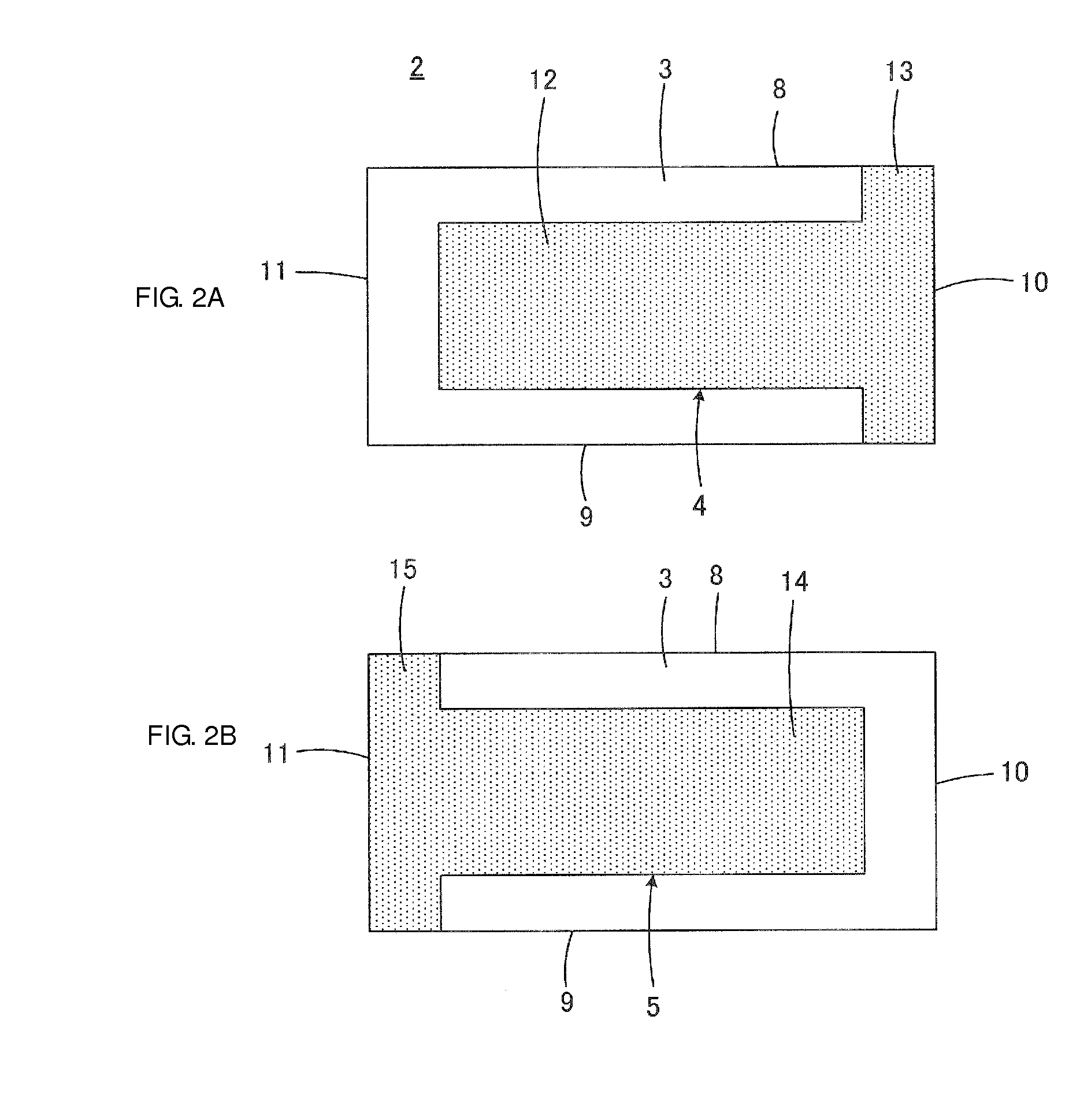

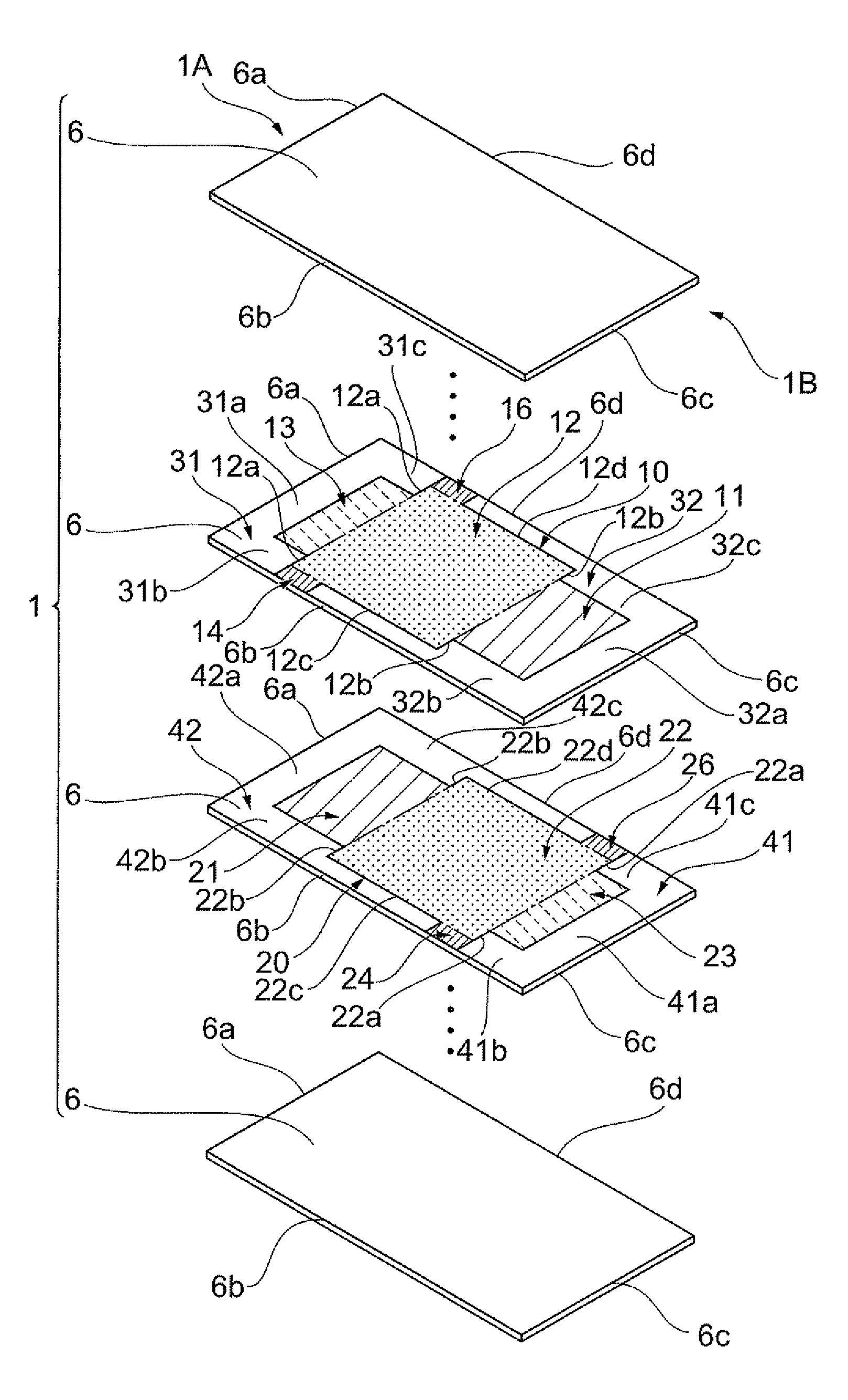

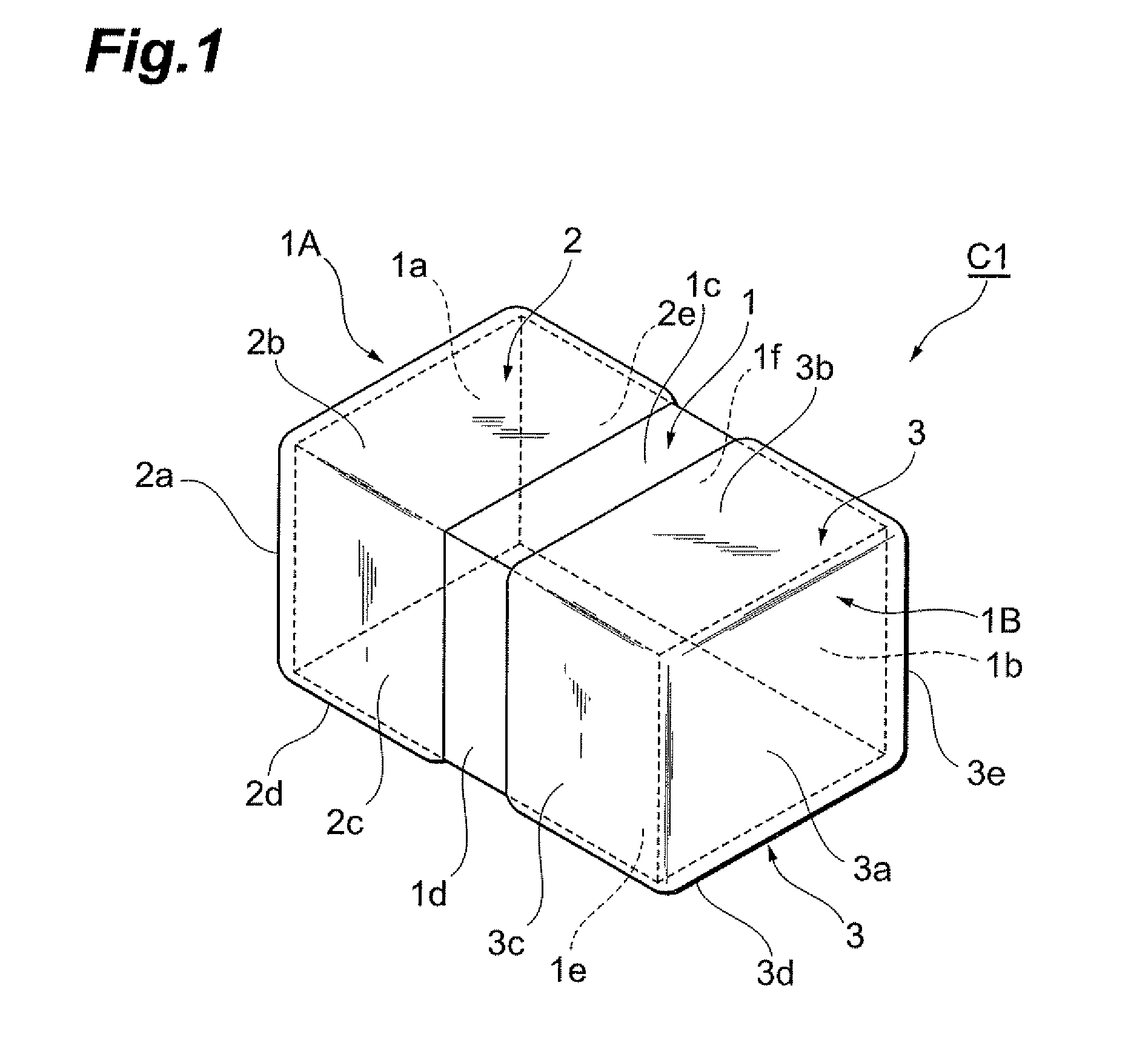

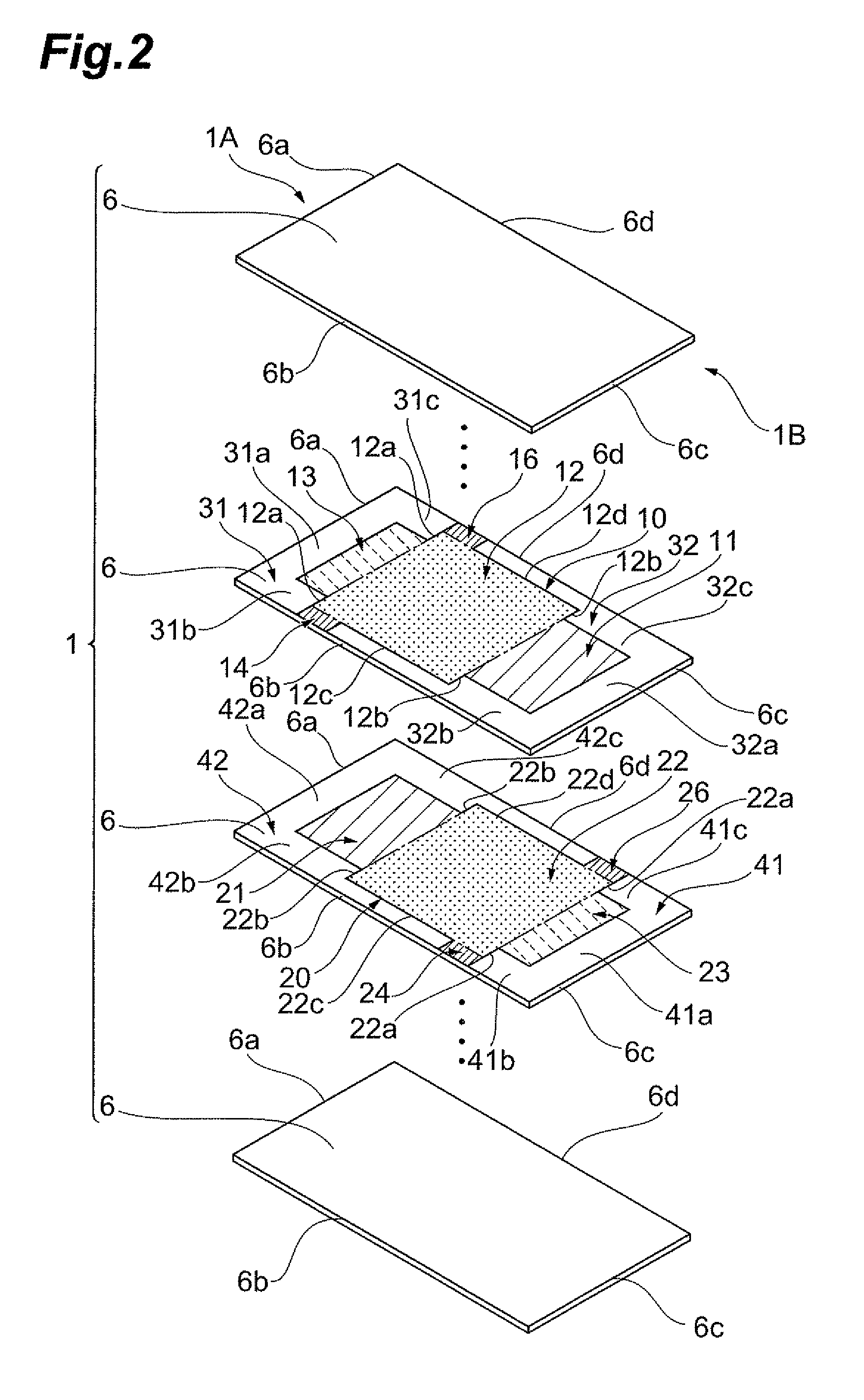

Multilayer capacitor

Disclosed is a multilayer capacitor capable of improving reliability and further reducing ESL. In a width direction, a second principal-surface electrode portion is greater than a first principal-surface electrode portion, and a fifth principal-surface electrode portion is greater than a fourth principal-surface electrode portion. When viewed from a lamination direction, an outer edge of the second principal-surface electrode portion at the other end side is arranged near the other end side more than outer edge of the fifth principal-surface electrode portion at one end side. First lead portions are connected to the second principal-surface electrode portion, and second lead portions are connected to the fifth principal-surface electrode portion. Thus, portions of the second principal-surface electrode portion greater than the first principal-surface electrode portion and portions of the fifth principal-surface electrode portion greater than the fourth principal-surface electrode portion function as current paths between the first lead portions and the second lead portions. Therefore, the current paths are shortened.

Owner:TDK CORPARATION

Baby-care implement provided with hood

InactiveUS20050258673A1Block effectReduce coverage areaCarriage/perambulator accessoriesTents/canopiesEngineeringMechanical engineering

Owner:APRICA CHILDRENS PROD

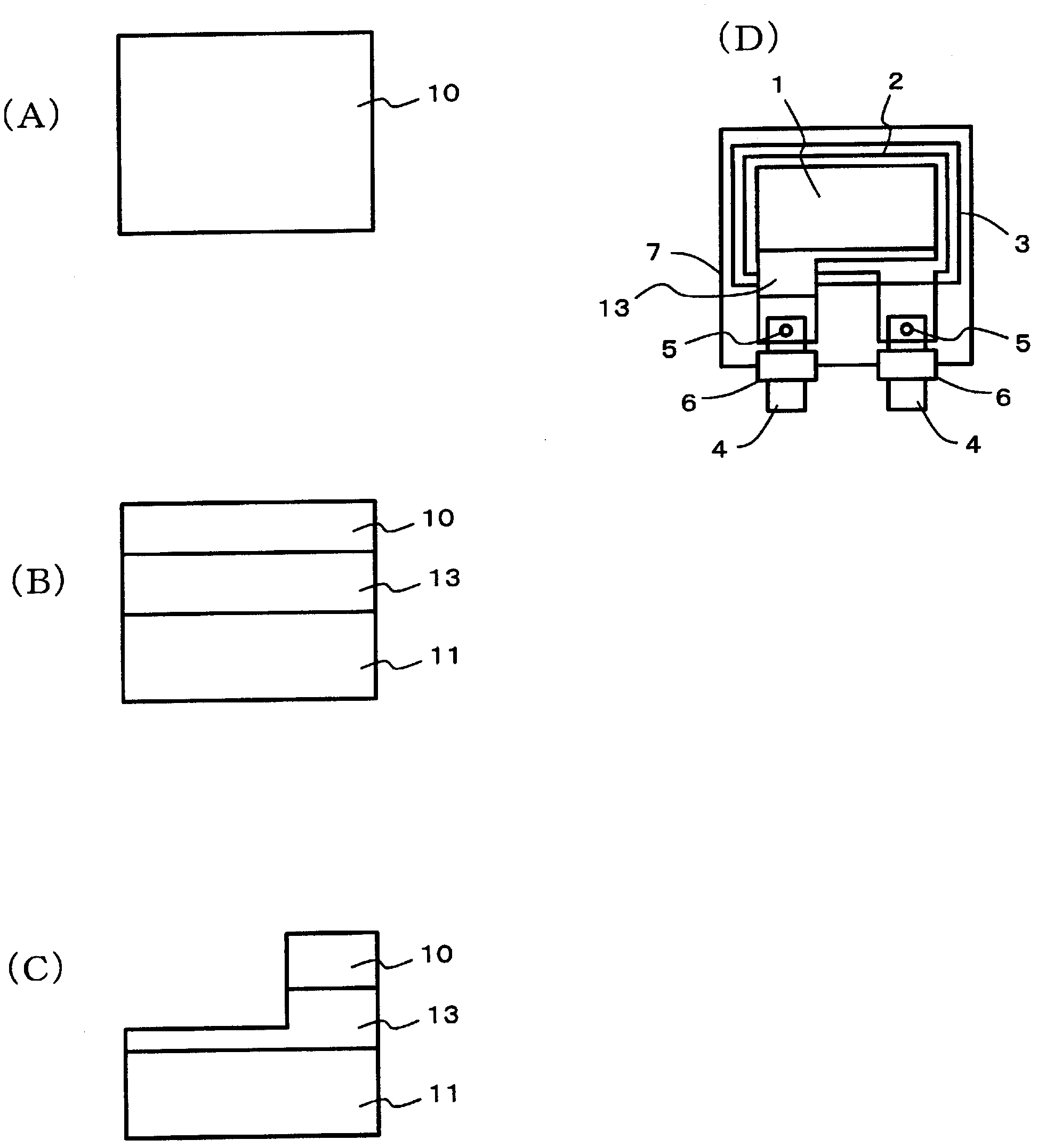

Monolithic ceramic electronic component

ActiveUS20140293503A1High strengthIncrease the exposed areaFixed capacitor electrodesStacked capacitorsElectronic componentElectroplating

A monolithic ceramic electronic component includes an outer electrode including a first plating layer formed directly on a component body by electroless plating so as to cover an exposed portion distribution region including exposed portions of a plurality of inner electrodes and a second plating layer formed by electrolytic plating so as to cover the first plating layer. An amount of extension of the first plating E1 and an amount of extension of the second plating E2 satisfy the relationship E1 / (E1+E2)≦20%, where E1 represents a distance from an edge of the exposed portion distribution region to an edge of the first plating layer, and E2 represents a distance from the edge of the first plating layer to an edge of the second plating layer.

Owner:MURATA MFG CO LTD

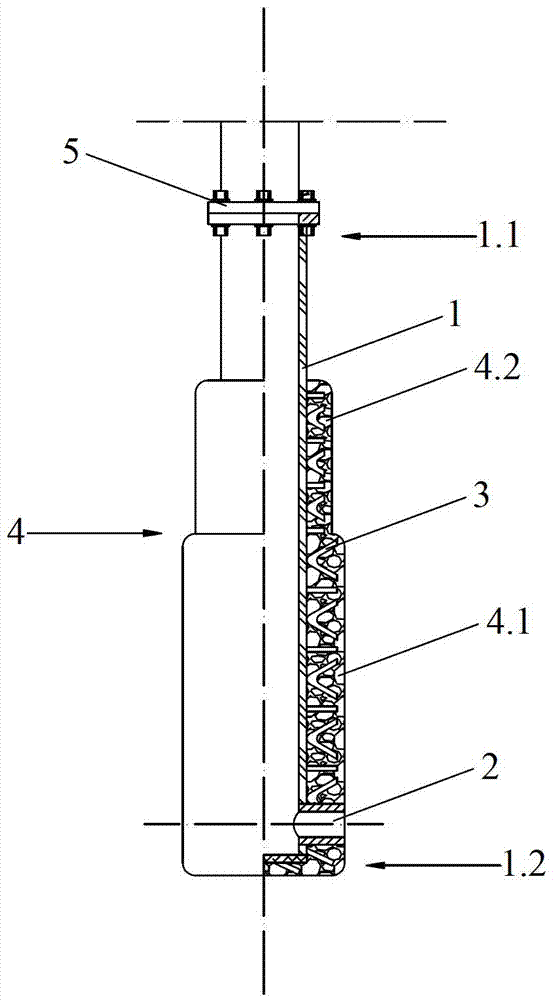

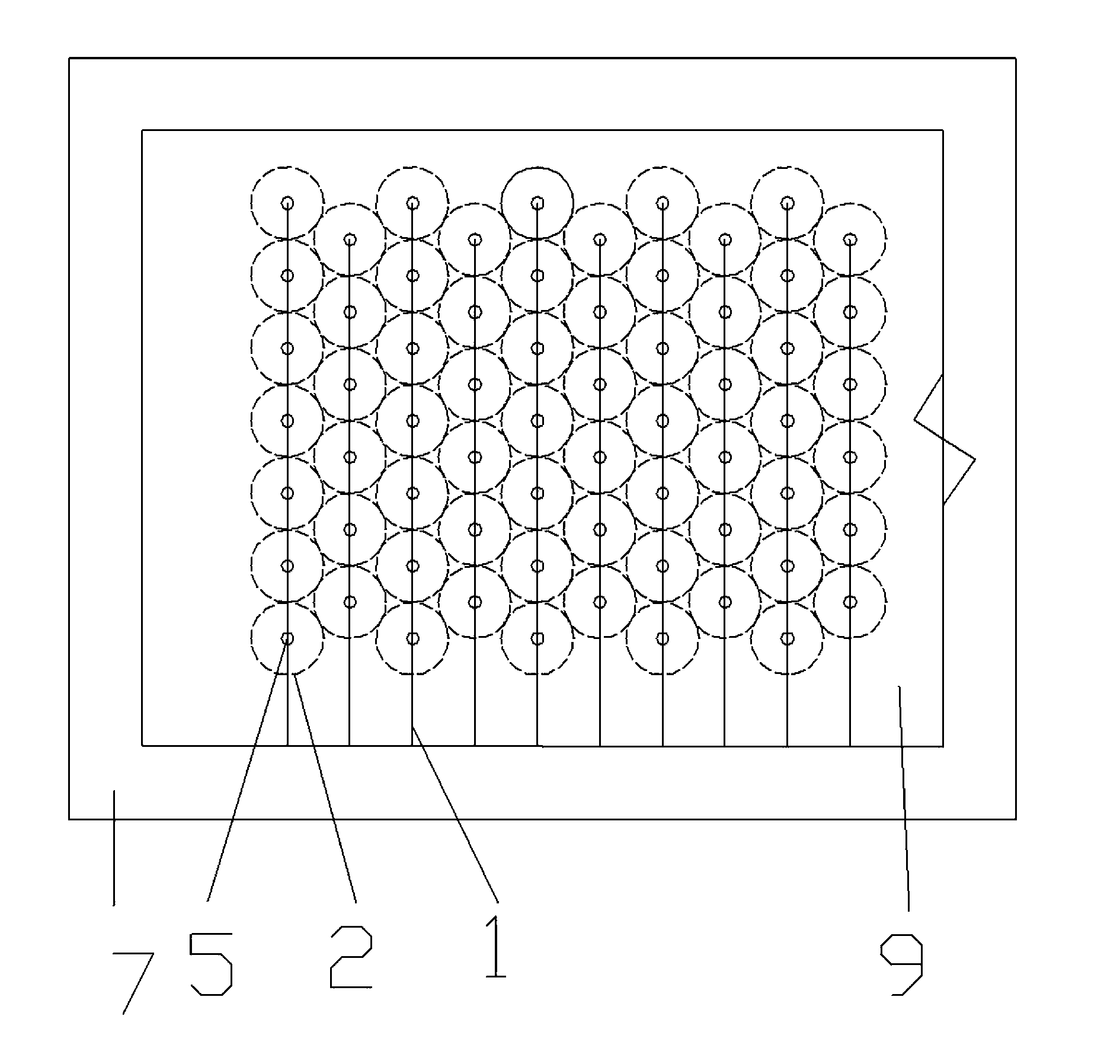

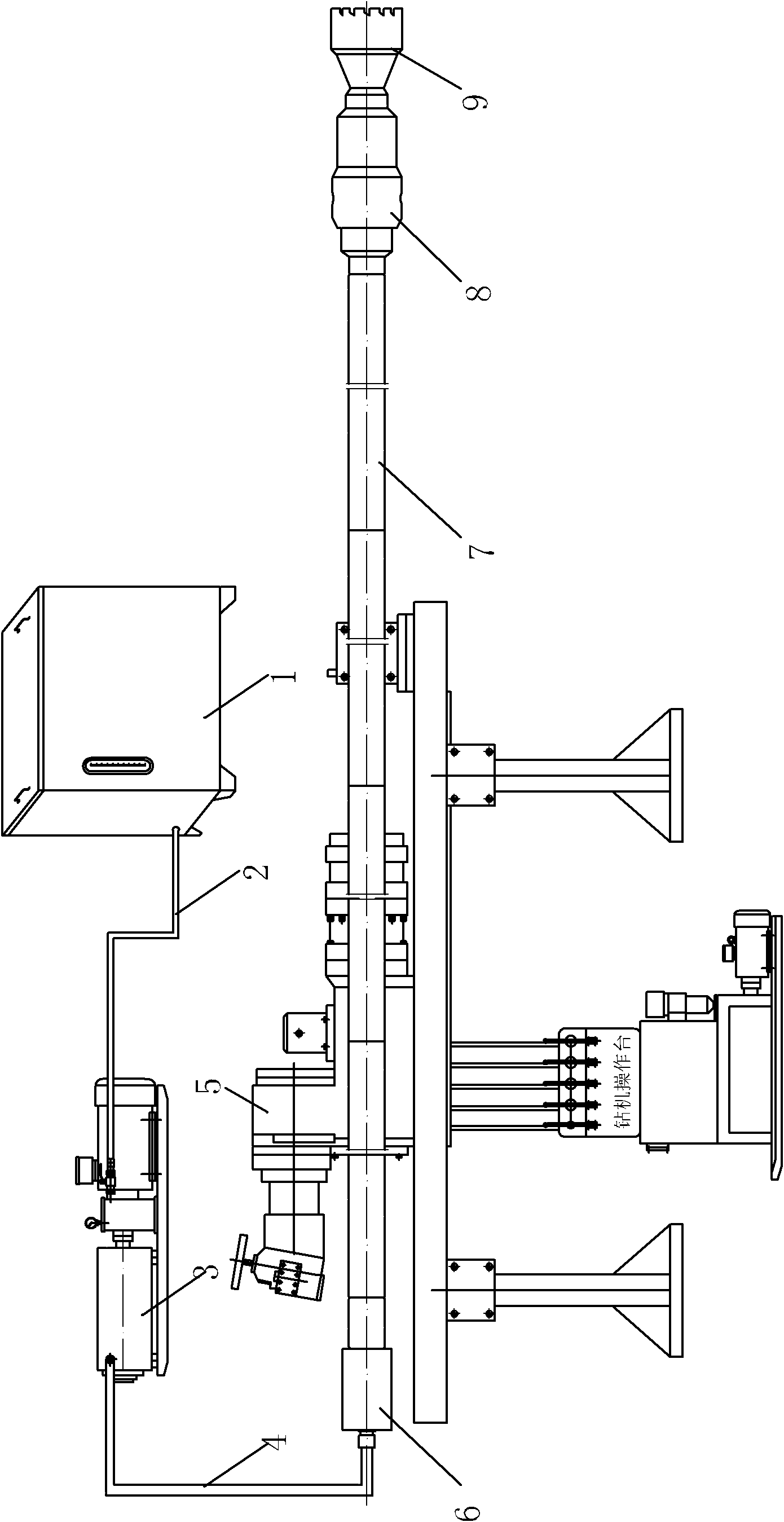

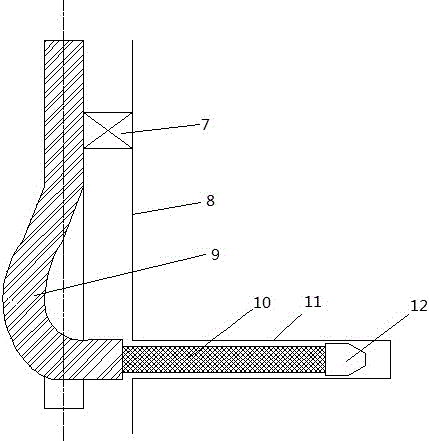

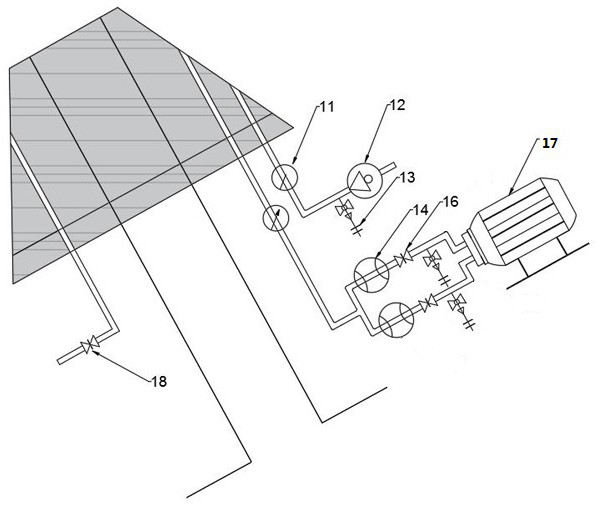

Drilling-cutting-linked coal layer gas drainage and outburst prevention system and method based on ultra-long drilling and high-pressure water jetting

InactiveCN102465712AIncrease the exposed areaExpand the scope of the releaseOperating means/releasing devices for valvesMultiple way valvesPressure senseHigh pressure water

The invention discloses a drilling-cutting-linked coal layer gas drainage and outburst prevention system and method based on ultra-long drilling and high-pressure water jetting. The system comprises a drill bit, a pressure sensing valve, a drill stem, a drill machine, a high / low-pressure water delivery and rotation device, a high-pressure pump and a water tank, wherein the pressure sensing valve is mounted at the front end of the drill stem; the drill bit is mounted at the front end of the pressure sensing valve; a nozzle is mounted at the outer side of the pressure sensing valve; the drill machine drives the drill stem to rotate; and water in the water tank is delivered to the high / low-pressure water delivery and rotation device through the high-pressure pump, input to the drill stem through the high / low-pressure water delivery and rotation device and delivered to the pressure sensing valve through the drill stem. In the drill withdrawing process, the coal layer is cut by the high-pressure water, thereby realizing the drilling-cutting linkage and improving the working efficiency. The invention is simple and delicate in structure; and by using the invention, the cutting diameter can be up to 3 meters or above, thereby increasing the gas exposure area to more than 6 times of the traditional gas exposure area and effectively widening the gas release range by more than 3 times. Thus, the invention solves the drainage and outburst prevention problems of coal mine gas.

Owner:湖南汉寿中煤科技有限公司

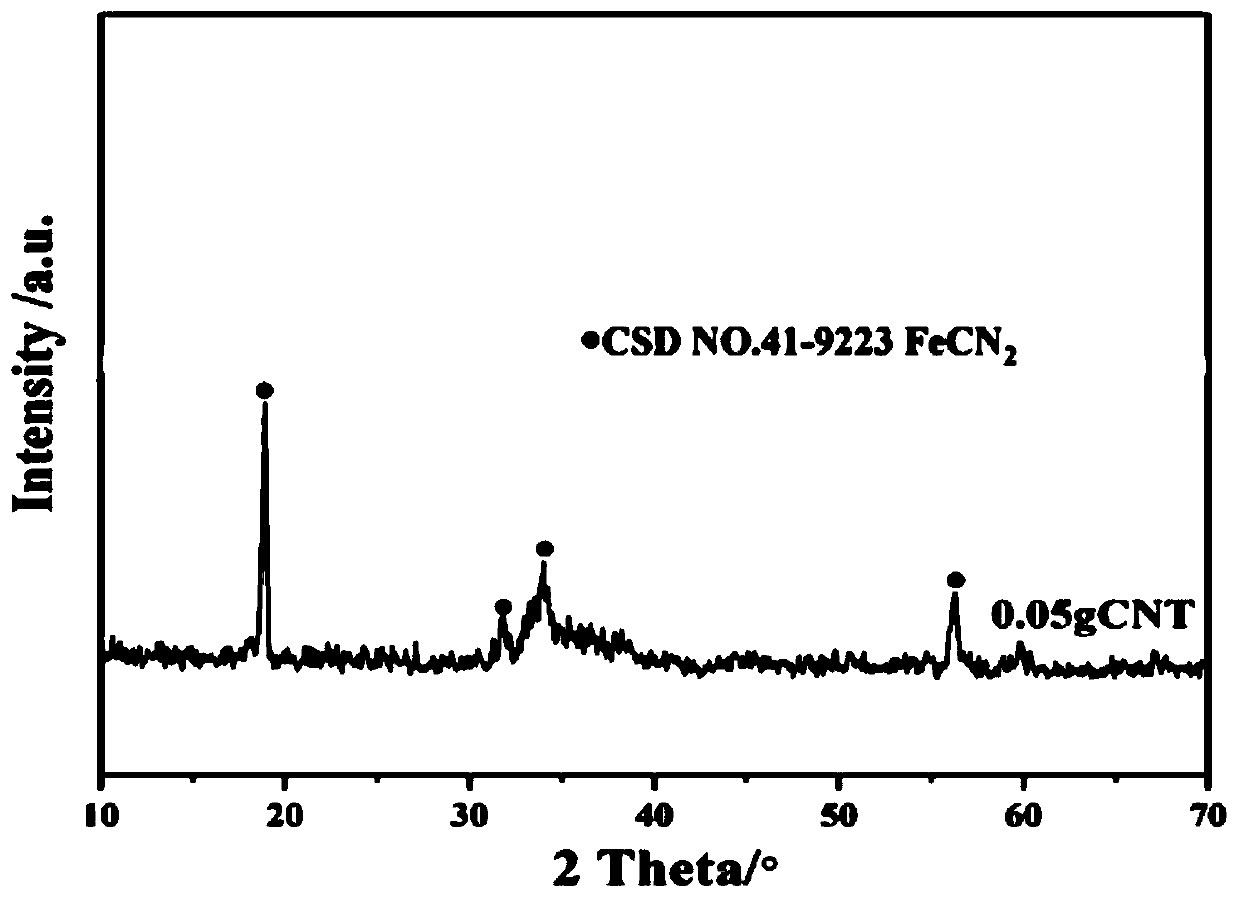

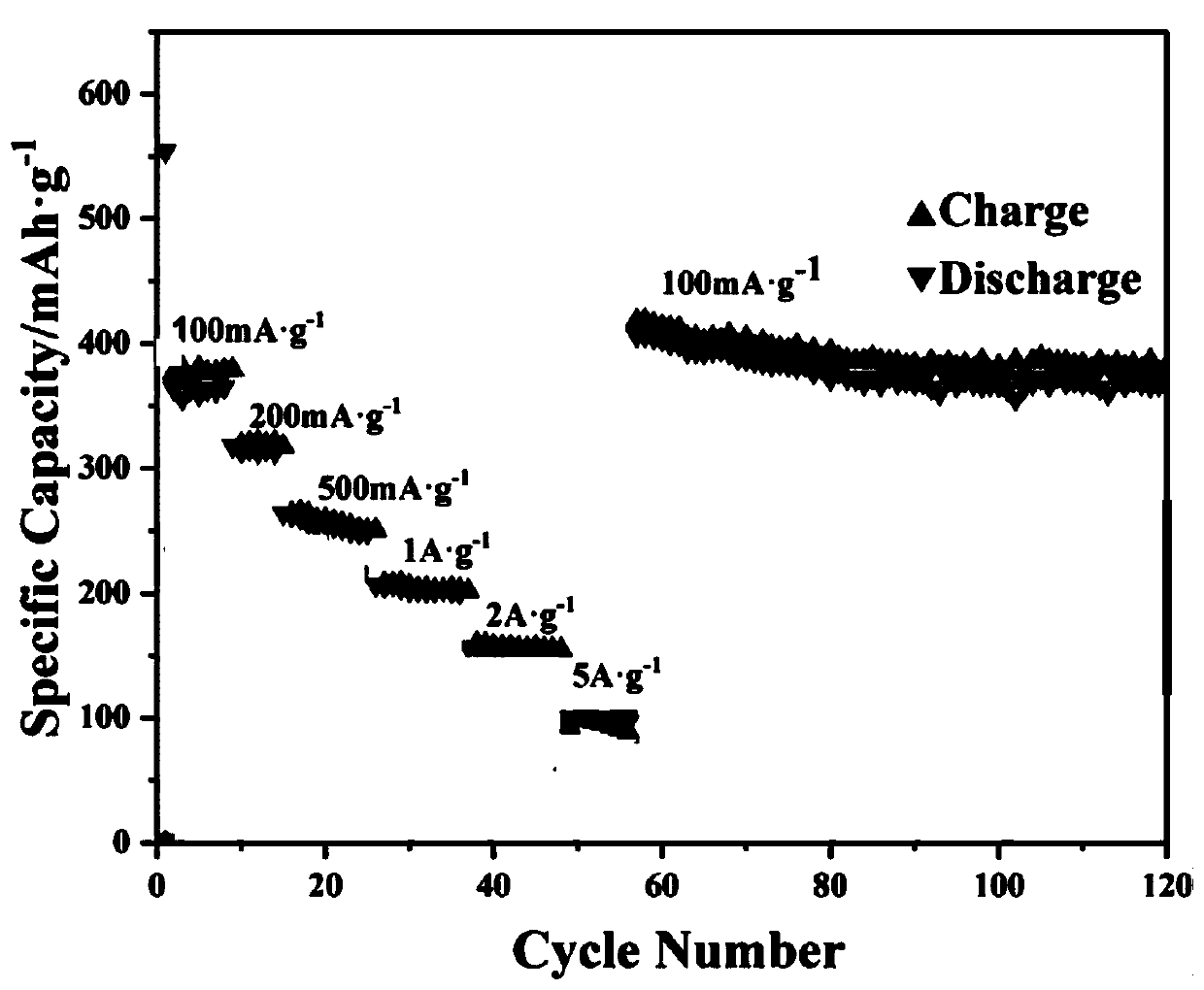

Carbon-based composite iron cyanamide material and preparation method thereof, and sodium ion battery adopting carbon-based composite iron cyanamide material as negative electrode material

ActiveCN109817933AImprove conductivityGood dispersionCell electrodesSecondary cellsFreeze-dryingMass ratio

The invention discloses a preparation method of a carbon-based composite iron cyanamide material, which comprises the following steps: firstly, respectively taking ferramine oxalate, urea and conductive carbon according to a mass ratio of 1:2:(0.1-1), fully grinding and mixing to obtain uniform mixture powder, and marking the product as A; adding a surfactant into the product A, dissolving in water, dispersing, and freeze-drying to obtain a black product marked as B; and pyrolyzing the product B in a protective atmosphere to obtain a product C, namely the carbon-based composite iron cyanamidematerial. The obtained carbon-based composite iron cyanamide material is taken as a negative electrode material of the sodium ion battery. According to the invention, FeCN2 and conductive carbon are compounded by adopting a high-temperature pyrolysis and nitridation method; the synthetic product carbon-coated iron cyanamide active material is used as a negative electrode material of a sodium ion battery, a new material system is constructed by adding a conductive carbon material, the conductivity of the material is enhanced, and the preparation method is simple to operate, low in cost, safe and non-toxic, and is expected to realize industrial production.

Owner:SHAANXI UNIV OF SCI & TECH

Method for integrated drilling, flushing, slotting and thermal injection for coalbed gas extraction

ActiveUS20170145794A1Speed up the extraction processEasy to operateFluid removalGas removalDesorptionEngineering

A method for combining integrated drilling, flushing and slotting with thermal injection to enhance coalbed gas extraction, applicable to managing gas extraction from microporous, low-permeability, high-adsorption coalbed areas. A gas extraction borehole is drilled within a certain distance of a predetermined drilling, flushing and slotting borehole, and, once sealed, is used for gas extraction. An integrated drilling, flushing and slotting drill bit is used to sink the borehole, which is then sealed. Concentration variation in the gas extraction borehole is monitored in real time, and when concentration is below 30%, borehole is opened and high-temperature steam is injected by means of a steam generator, after which the borehole is again closed. Drilling a drilling, flushing and slotting borehole increases pressure relief space and the surface of exposed coal, relieves stress on the coal body, and increases gas permeability of the coalbed, while the injection of high-temperature steam promotes gas desorption in the coal body, promotes crack propagation around the borehole, and increases channels for gas flow, thus achieving highly efficient extraction of gas from the coalbed.

Owner:CHINA UNIV OF MINING & TECH

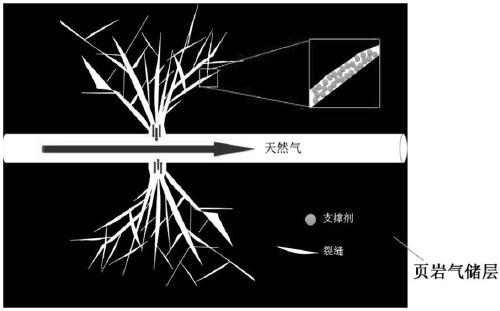

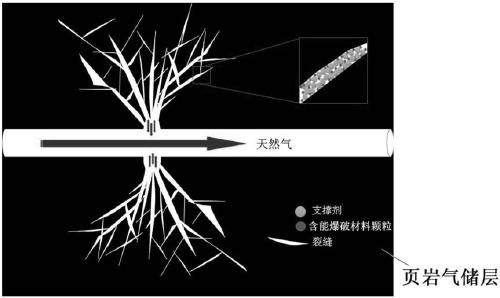

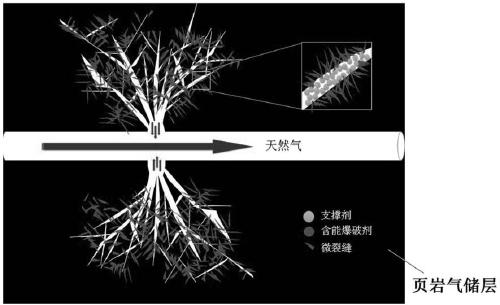

Method and application of secondary fracturing of compact oil and gas reservoir

ActiveCN109025945ARich varietyImplement injectionFluid removalDrilling compositionLithologyMicro nano

The invention provides a method and an application of the secondary fracturing of a compact oil and gas reservoir. The invention is mainly applied to the secondary fracturing field of shale gas and shale oil reservoirs. The method comprises the steps of injecting micro-nano-sized and energy-contained blasting material particles in the graded manner on the basis of primary hydraulic fracturing, transmitting blasting material particles to the wall surface of a primary fracture, and realizing the secondary fracturing by using the pulse current detonation mode. According to the method, a dense seam network capable of communicating matrix pores with one another can be formed. Based on the dense seam network, the exposed area of the pore walls of matrix pores is greatly increased. The total discharge area of an oil-gas desorption and migration pathway is increased and the recovery efficiency is further improved. Selectable energy-contained materials are rich in variety, wherein the materialregulation and material combination are carried out through the physical and chemical means. A secondary fracturing scheme is designed according to the characteristics of different reservoir lithology, physical properties and the like. Adopted energy-contained blasting materials can be compounded with high-strength and micro-size propping agents, and the injection of a fracturing agent and a propping agent can be realized at one time. The invention provides a new idea for further improving the shale gas and shale oil yield.

Owner:PETROCHINA CO LTD

Natural gas horizontal well completion method

ActiveCN106285617AIncrease the number ofAvoid or reduce downhole complicationsConstructionsLiquid/gas jet drillingSoil scienceCement slurry

The invention relates to a natural gas horizontal well completion method. According to the technical scheme, the natural gas horizontal well completion method comprises the steps that the target well depth is drilled at a time with a large-size drill bit, and a large hole is formed; a plurality of horizontal branch holes are drilled out in a natural gas hydrate reservoir through the horizontal well technology; and the contact surface area between the reservoir and the holes is increased to the greatest extent. The natural gas horizontal well completion method has the beneficial effects that the downhole complex conditions in the exploitation process is avoided or decreased; the number of the holes can be greatly increased; the bare area and the depth of the natural gas hydrate reservoir are increased to the greatest extent by the holes; the recovery ratio is greatly increased; the well spacing number and the development investment are decreased; and a window sealant is adopted, thus, a cement slurry system is stable, strength development is rapid, the thickening time is adjustable, hydrate layer sealing shallow water-gas channeling can be effectively prevented, and the construction performance is good.

Owner:HUAXIN TANGSHAN PETROLEUM EQUIP CO LTD

Well network structure for extra-heavy oil reservoir and oil extraction method

ActiveCN107975357AEfficient developmentFlexible adjustmentFluid removalProduction effectNetwork structure

The invention discloses a steam-flooding well network structure for an extra-heavy oil reservoir and an oil extraction method. The well network structure comprises a herringbone horizontal well, at least one straight well and layered steam injection mechanisms. The herringbone horizontal well comprises a vertical section, a horizontal section communicating with the lower end of the vertical section and located on the lower portion of an interlayer, and a plurality of branch sections; one ends of the branch sections communicate with the horizontal section, and the other end of at least one of the branch sections is located above the interlayer; sectioned plugging devices are arranged in the positions, in the interlayer, of the branch sections; the herringbone horizontal well serves as an oil extraction well; the straight wells are arranged close to the horizontal section, serve as steam injection wells and are provided with at least two perforations located on the upper portion and thelower portion of the interlayer correspondingly; and the layered steam injection mechanisms are arranged in the straight wells and enable the perforations to be opened in a perforated mode. Accordingto the steam-flooding well network structure for the extra-heavy oil reservoir and the oil extraction method, the influence of formation heterogeneity on the production effect is avoided, the oil extraction speed and the crude oil recovery ratio are increased, and comprehensive benefits of heavy oil extraction are improved further.

Owner:PETROCHINA CO LTD

Device and method for multi-stage plugging of surrounding rock fissure water by utilizing slurry and microbial mineralization

ActiveCN112855072AImprove precipitation effectGood flocculation effectDrilling compositionSealing/packingMicroorganismSoil science

The invention belongs to the technical field of underground engineering plugging, and particularly discloses a device and a method for multi-stage plugging of surrounding rock fissure water by utilizing slurry and microbial mineralization. According to the device, microbial dry powder is activated and then induced to generate calcium carbonate deposition with cementing property so as to plug rock stratum fissures, the flow of the fissure water is controlled, and the stability of surrounding rock is enhanced. The device is composed of annular waterproof curtain plugging and key hole grouting plugging, wherein annular waterproof curtains are circularly and uniformly distributed on the periphery of key holes, the flow speed and the flow of the fissure water are reduced by injecting cement-water glass slurry into annular grouting holes, and primary plugging of centimeter-level surrounding rock fissures is carried out; and the key hole grouting plugging adopts coarse aggregate and microbial-induced calcium carbonate precipitation to carry out secondary plugging on millimeter-level fissures in the surrounding rock fissures, the microbial dry powder is activated and then induces the calcium carbonate precipitation to plug micron-level fissures in the surrounding rock so as to carry out third-level plugging, and the plugging effect of the surrounding rock fissures and the curing effect of the surrounding rock are enhanced step by step.

Owner:HENAN POLYTECHNIC UNIV +1

Multilayer capacitor having reduced equivalent series inductance

ActiveUS8659871B2Improve reliabilityLower ESLFixed capacitor electrodesFixed capacitor dielectricEquivalent series inductanceReducing equivalent

A multilayer capacitor is provided with improved reliability and reduced ESL. In a width direction, a second principal-surface electrode portion is greater than a first principal-surface electrode portion, and a fifth principal-surface electrode portion is greater than a fourth principal-surface electrode portion. When viewed from a lamination direction, an outer edge of the second principal-surface electrode portion at the other end side is arranged near the other end side more than outer edge of the fifth principal-surface electrode portion at one end side. First lead portions are connected to the second principal-surface electrode portion, and second lead portions are connected to the fifth principal-surface electrode portion. Thus, portions of the second principal-surface electrode portion greater than the first principal-surface electrode portion and portions of the fifth principal-surface electrode portion greater than the fourth principal-surface electrode portion function as current paths between the first lead portions and the second lead portions.

Owner:TDK CORPARATION

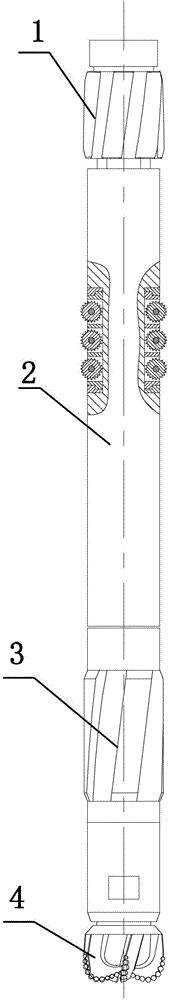

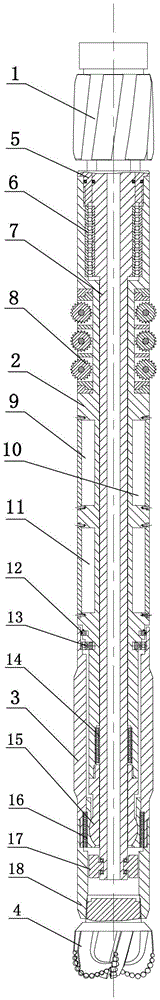

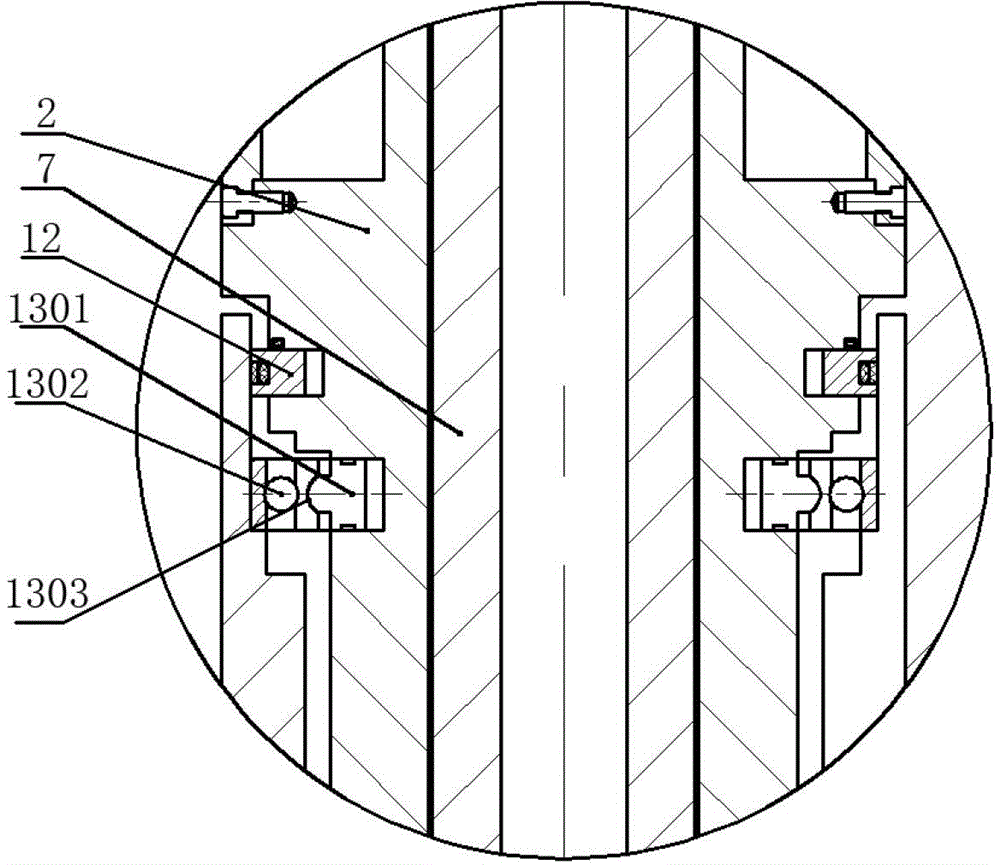

Push-to-point rotary steerable drilling device

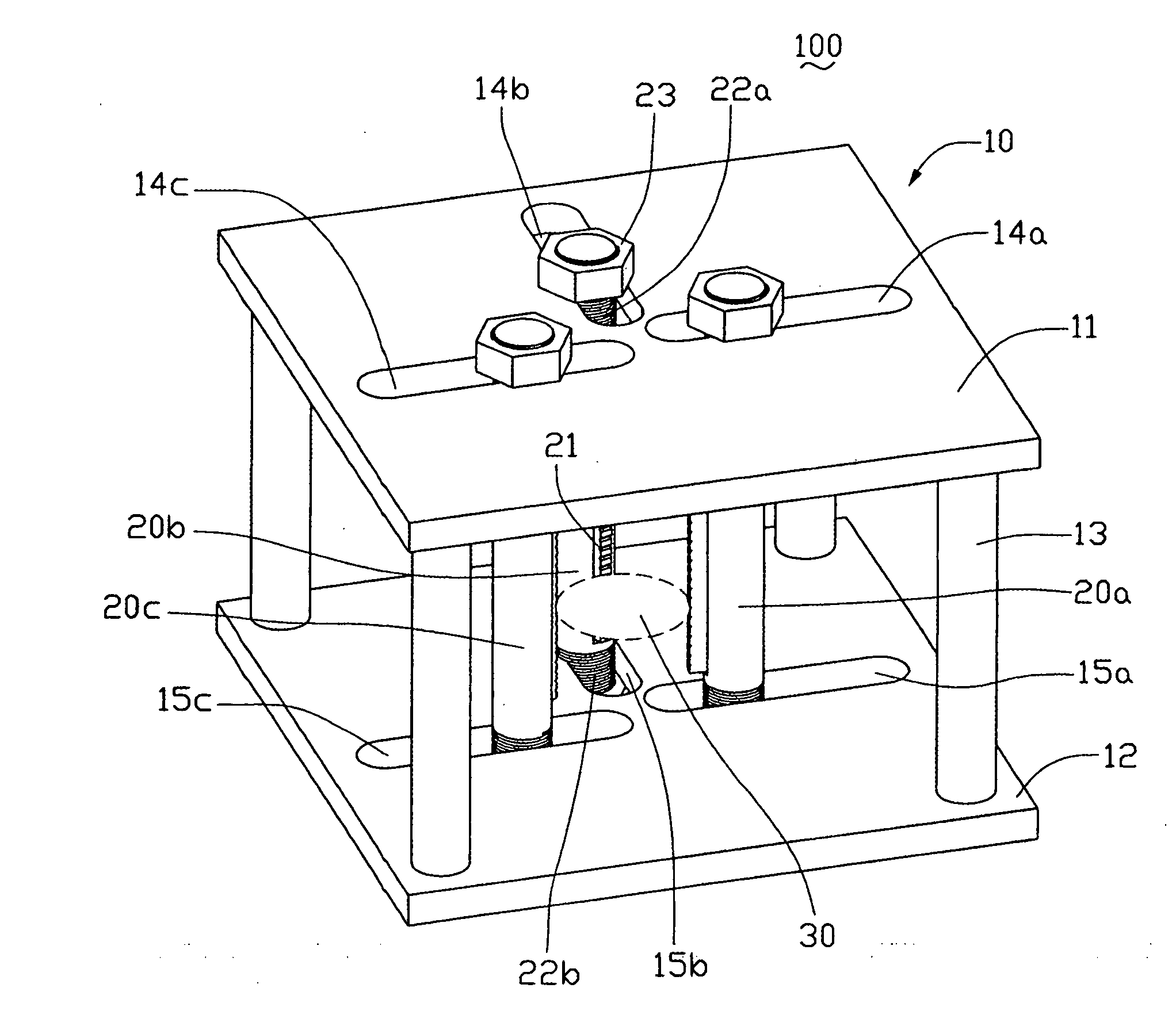

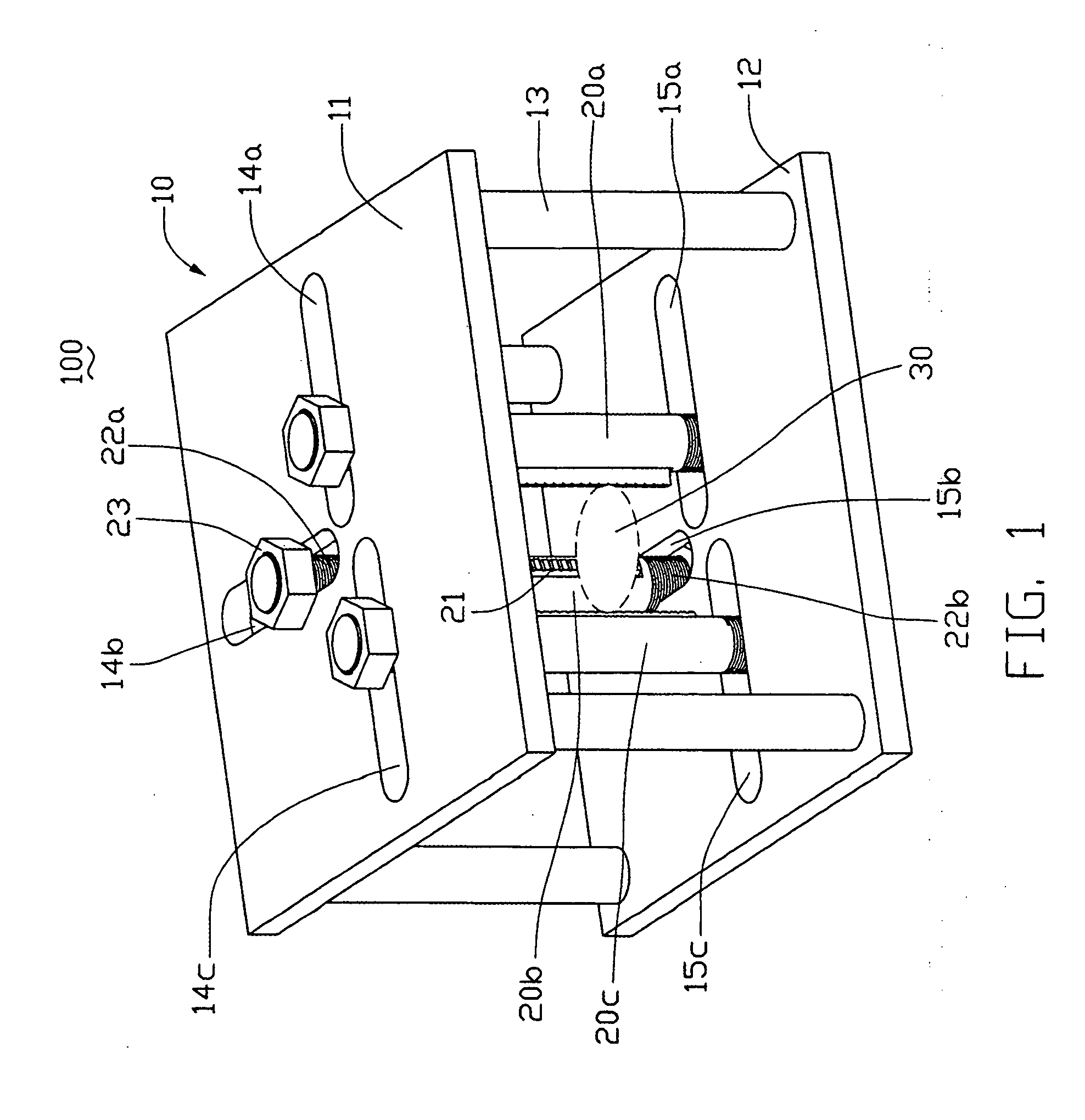

ActiveCN103437704BIncrease the exposed areaExpand production potentialDirectional drillingAutomatic control for drillingControl systemEngineering

The invention relates to a push-and-point rotary steerable drilling device, which comprises an upper stabilizer (1), a central shaft (7), a control nipple (2), a stabilizer sleeve (3) and a drill bit (4), and the stabilizer The sleeve (3) is connected to the control nipple (2) through a ball joint (15), the stabilizer sleeve (3) is fixedly connected to the drill bit (4), and the control nipple (2) is equipped with a control system (9) and The hydraulic system (11) guides the hydraulic cylinder (13), and the hydraulic eccentric device (13) is installed between the upper part of the stabilizer sleeve (3) and the control nipple (2), and the hydraulic system (11) drives the hydraulic eccentric device (13) action, the hydraulic eccentric device (13) drives the stabilizer sleeve (3) to rotate around the ball joint (15). The drilling device of the present invention has a simple structure, can complete high build-up rate, builds deeper in the exploitation of shale gas, maximizes the exposed area of oil layers, reduces development risks, and improves oil and gas production potential.

Owner:SINOPEC OILFIELD EQUIP CORP +1

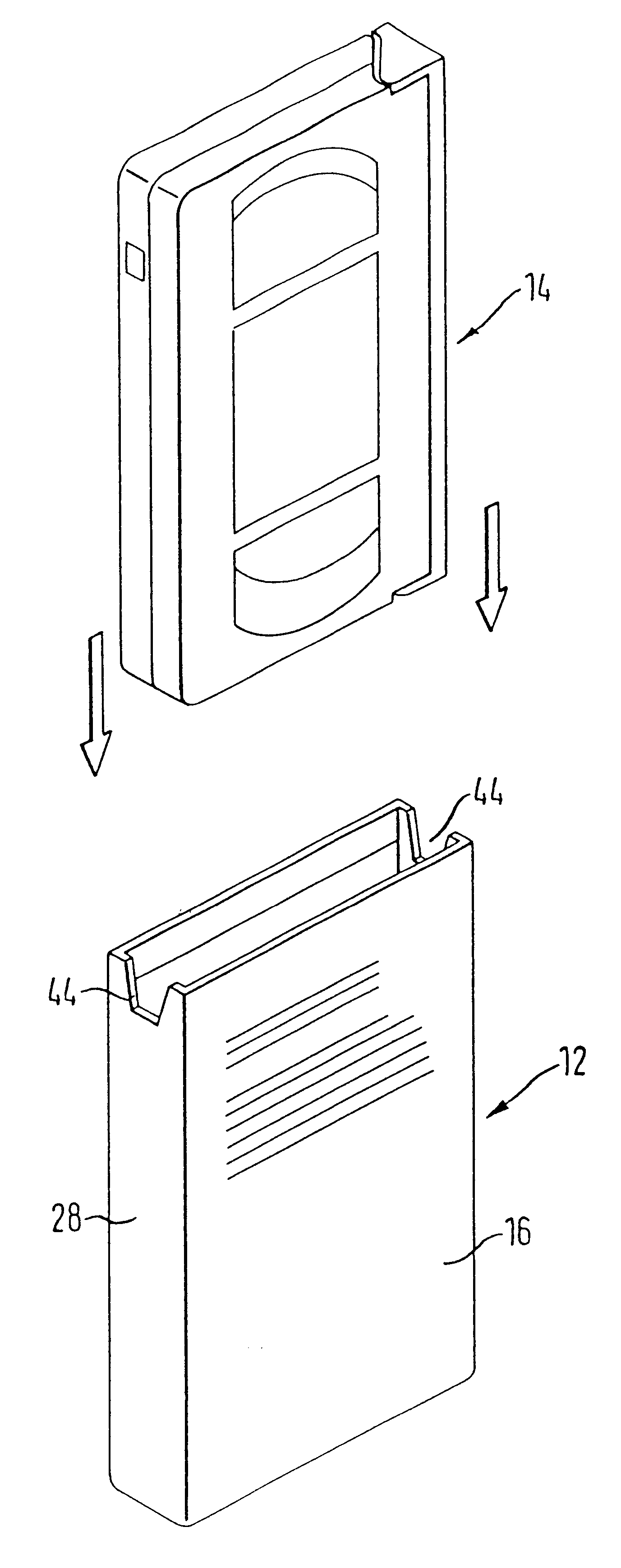

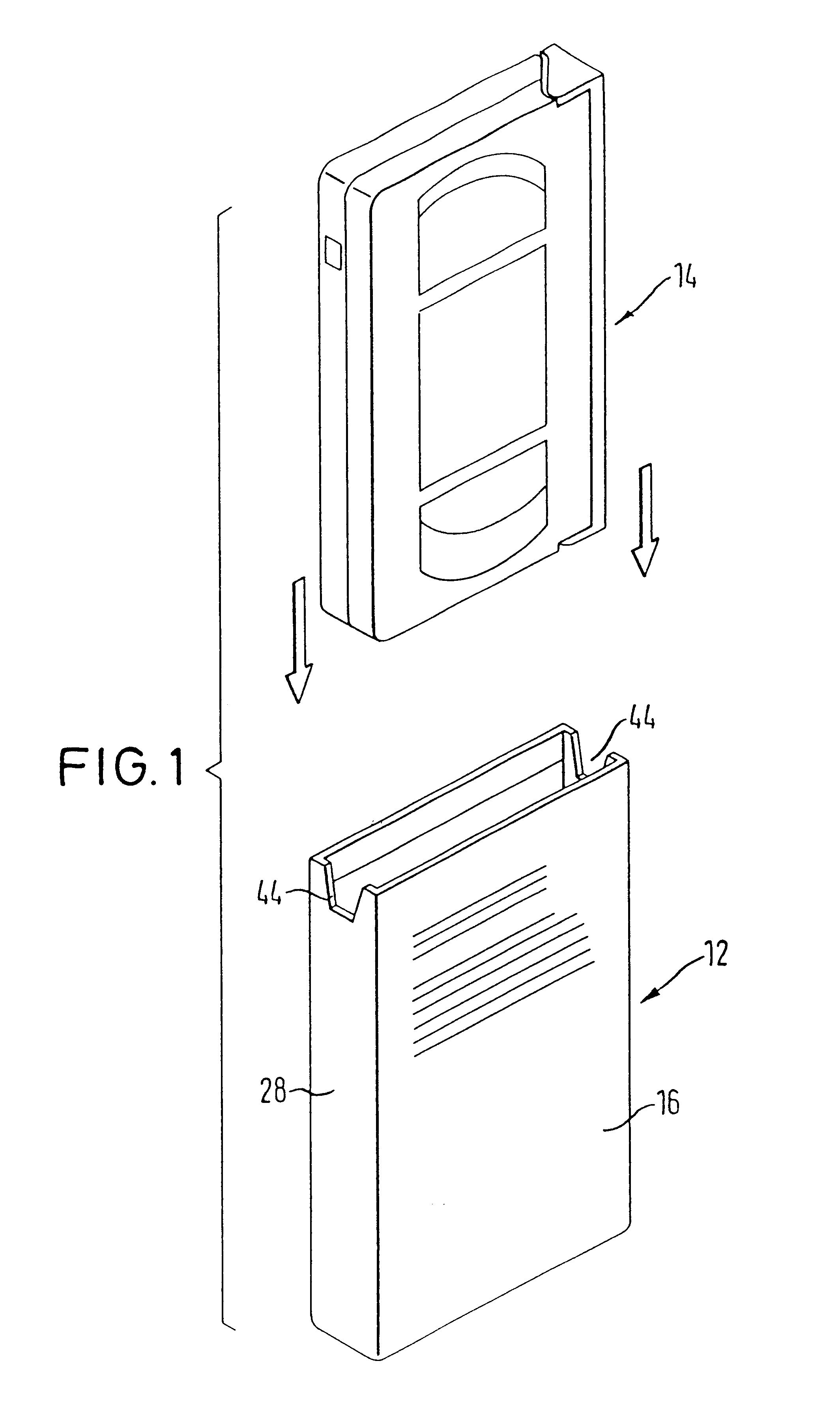

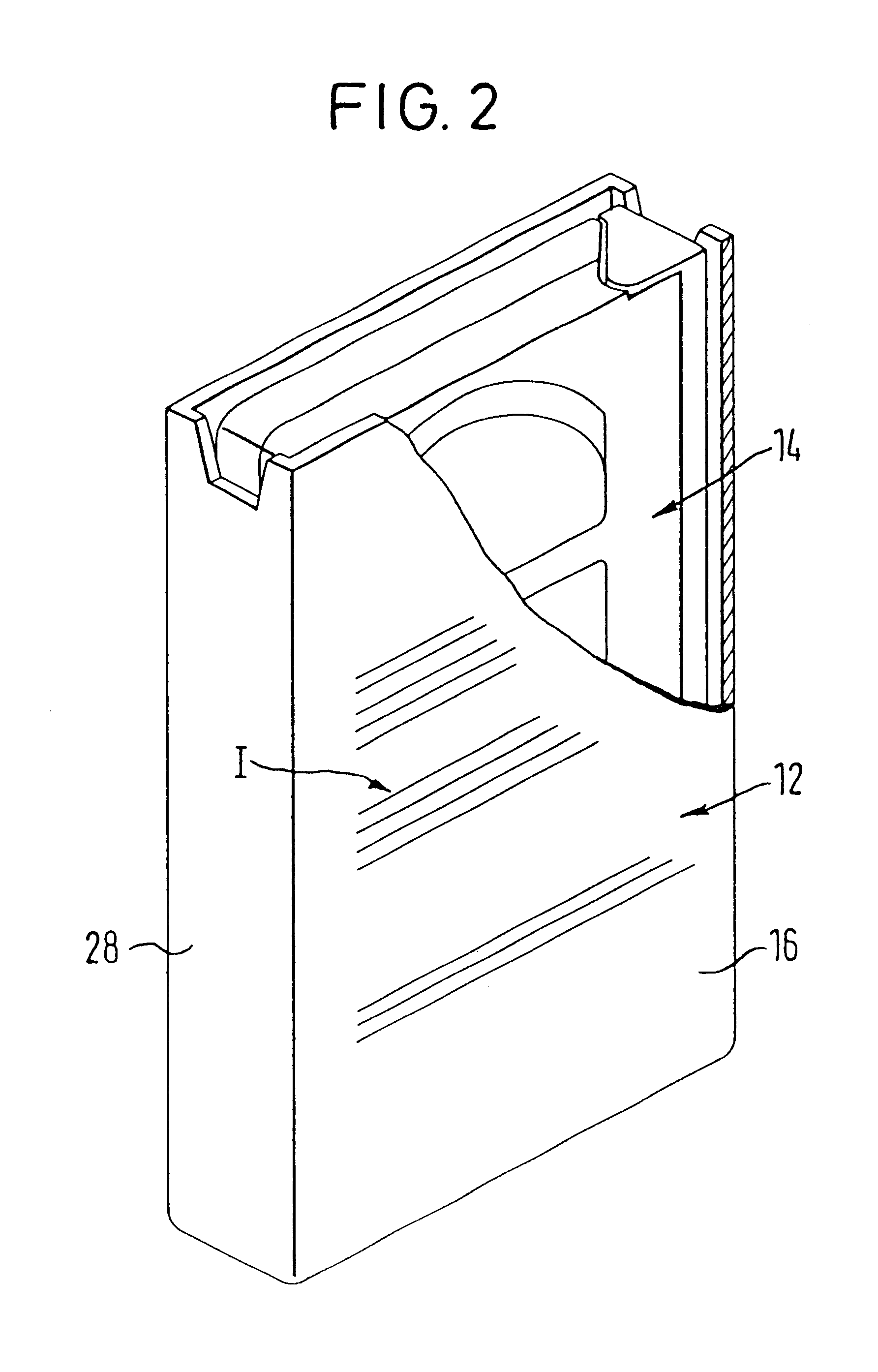

Printable blank of improved durability for forming video cassette boxes

InactiveUS6257404B1Increasing the thicknessIncreased durabilityBoxes/cartons making machineryBox making operationsEngineeringMechanical engineering

A blank having a defined pattern of reduced strength, allowing separation along said defined pattern, the pattern defining a video cassette box from a single sheet having first and second face portions, one or more side flaps for forming a parallelepiped, one or more reinforcing tabs for increasing the durability of the box and one or more top tabs for forming an enclosure at one end of the box.

Owner:FELLOWES INC

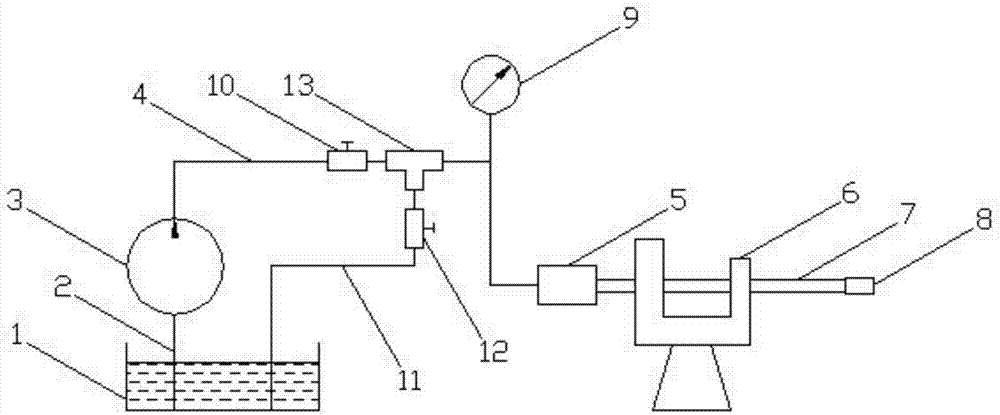

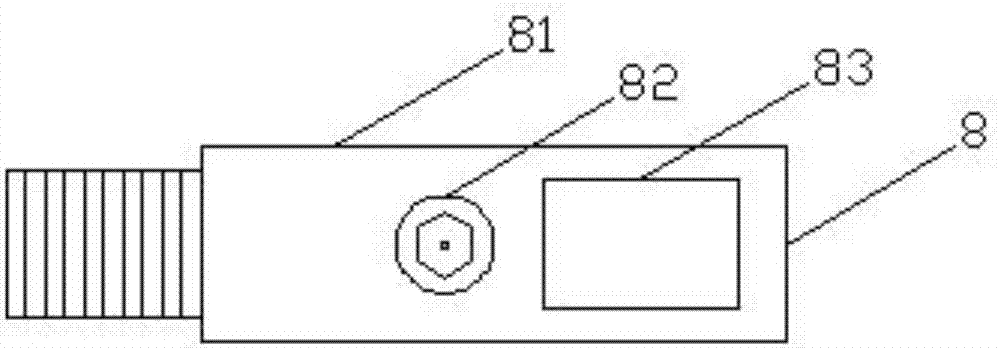

Hydraulic cutting device and hydraulic cutting method for drilling through bed

PendingCN107201892AIncrease the exposed areaImprove breathabilityLiquid/gas jet drillingFluid removalHigh pressure waterCoal

The invention discloses a hydraulic cutting device and a hydraulic cutting method for drilling through a bed. The hydraulic cutting device for drilling through the bed comprises a water tank, a water inlet pipe, a water pump, a water outlet pipe, a rotating water tail, a drilling machine, a drilling rod and a hydraulic cutting drill; one end of the water inlet pipe extends into the water tank, and the other end of the water inlet pipe is connected with a water inlet of the water pump; one end of the water outlet pipe is connected with a water outlet of the water pump, the other end of the water outlet pipe is connected with one end of the drilling rod through the rotating water tail, the other end of the drilling rod is connected with the hydraulic cutting drill, and the drilling rod is arranged on the drilling machine and is driven by the drilling machine to rotate; and a pressure gage is arranged on the water outlet pipe, and a pressure regulating valve is arranged on the water outlet pipe between the pressure gage and the water outlet of the water pump. The hydraulic cutting device for drilling through the bed has the advantages that a drilling coal section is reamed by using the cutting action of high pressure water jet, the area of a coal body exposed in the hole is increased, a fracture is manufactured, the gas permeability of the coal bed is improved, so that the gas extraction effect is improved.

Owner:HUAINAN MINING IND GRP

Optical element washing apparatus

InactiveUS20060181773A1Improve washing efficiencyIncrease the exposed areaOptical elementsEngineeringMechanical engineering

Owner:HON HAI PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com