Device and method for multi-stage plugging of surrounding rock fissure water by utilizing slurry and microbial mineralization

A microorganism and fissure water technology, applied in chemical instruments and methods, mining equipment, earthwork drilling, etc., can solve the problems that small-scale and micro-scale fissures cannot be effectively blocked, large-flow fissure water is not suitable, and slurry viscosity is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

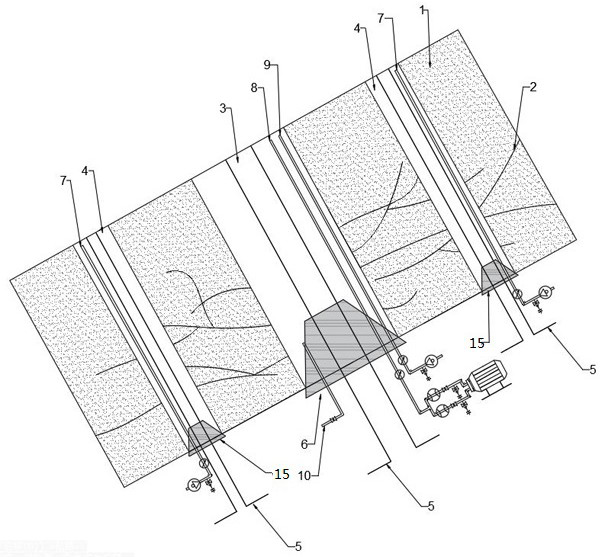

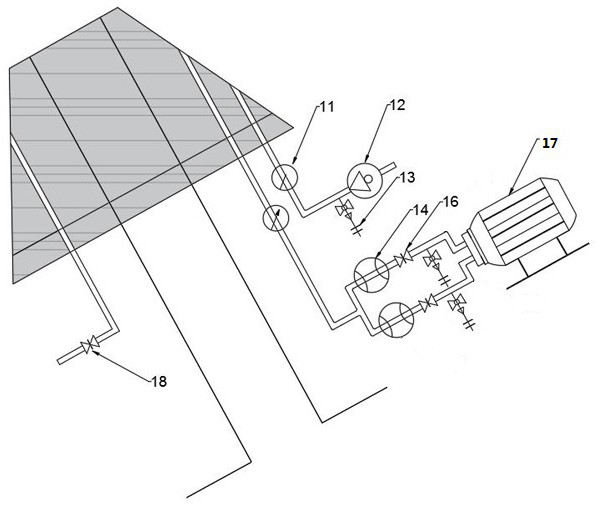

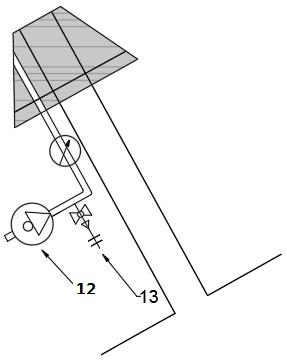

[0044] As shown in the figure, a device for multi-stage sealing of surrounding rock fissure water using grout and microbial mineralization, including a plugging component set in the key grouting hole 3 and a water-stop drilling hole respectively set in the annular water-stop curtain The second plugging component in 4, the annular water-stop curtain includes six annular water-stop boreholes 4 that are uniformly radially arranged with the key grouting hole 3 as the center and a radius of 0.8-1.5m. Blocking assembly one includes the anchor rod 5 positioned at the center of the key grouting hole 3, and the first drilling plug 6 at the opening of the key grouting hole 3 at the end of the anchor rod 5, and the first drilling plug 6 is provided with There are one 8 channels of grouting pipeline and three 9 channels of bacteria injection pipeline, the first 8 of grouting pipeline and the third 9 of bacteria injection pipeline respectively extend inwards to the bottom of key grouting ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com