Method and system for handling fracture flowback liquid

A technology for fracturing flowback fluid and treatment methods, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of reducing the aesthetic value of water bodies and cannot guarantee the degradation and removal of pollutants , Water self-purification function damage and other problems, to achieve the best pollutant degradation effect, sustainable use, and effective oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] With the treatment method and system of the present invention, the fracturing flowback fluid produced in the oil recovery process of an oil field is treated, and the total water volume designed to be treated is 360m 3 / d, designed for continuous operation 24 hours a day; the inflow flow of primary oxidation tank and advanced oxidation tank is 15m 3 / h.

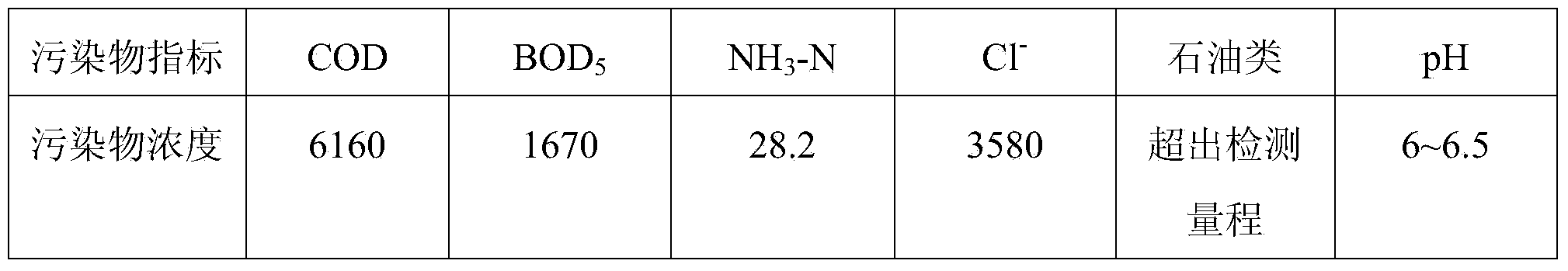

[0033] 1. Influent water quality

[0034] Table 1 Influent water quality of fracturing flowback fluid (unit: mg / L; pH value is dimensionless)

[0035]

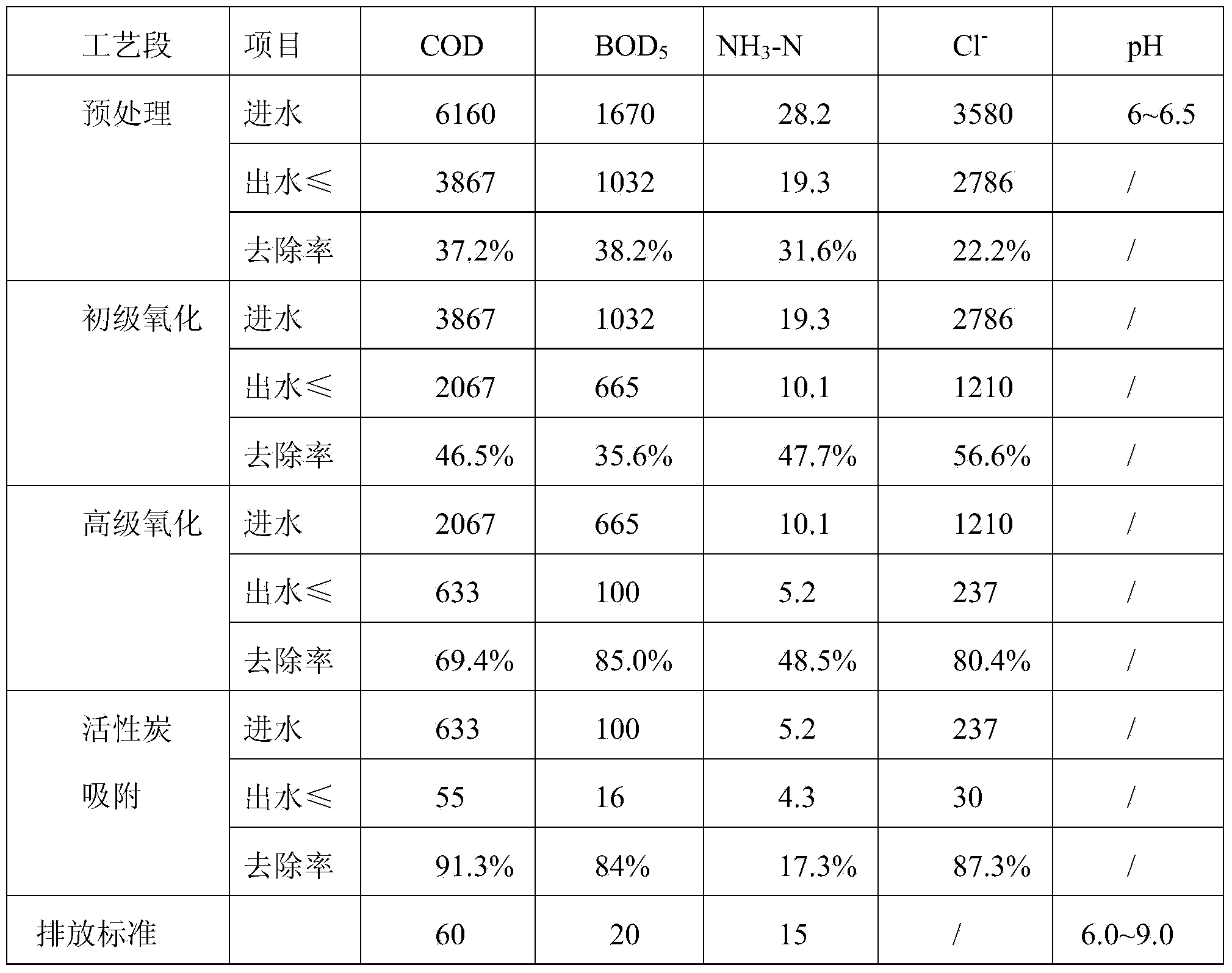

[0036] 2. Process parameter design

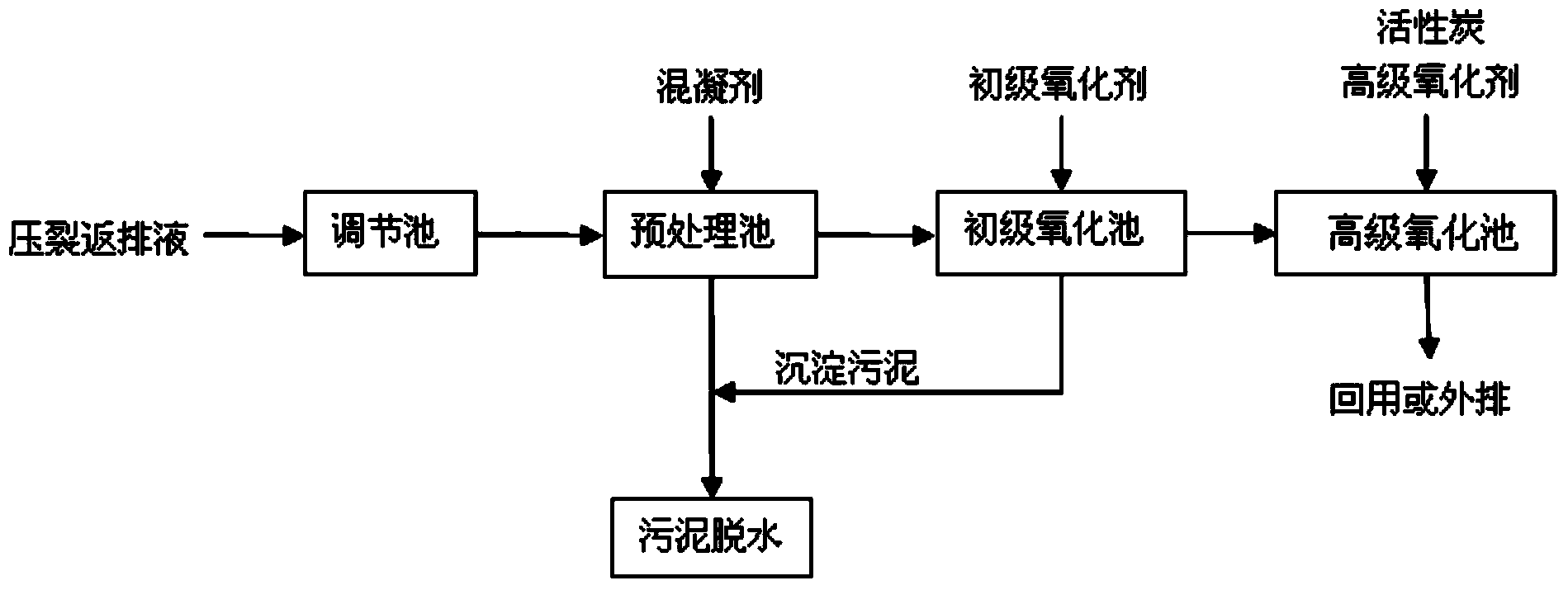

[0037] 360m 3 / d The fracturing flowback fluid is treated by pretreatment, primary oxidation, and advanced adsorption oxidation in sequence, of which:

[0038]Pretreatment step: under stirring conditions, add potassium ferrate (analytical pure) to the fracturing flowback fluid at a treatment dose of 0.5g / L (wastewater), and then treat with 9.0g / L (wastewater) after stirring for 0.5 hours Dosage Add quicklime (analytically pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com