Patents

Literature

51results about How to "Increase Fe content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of aluminum alloy material and preparation method thereof

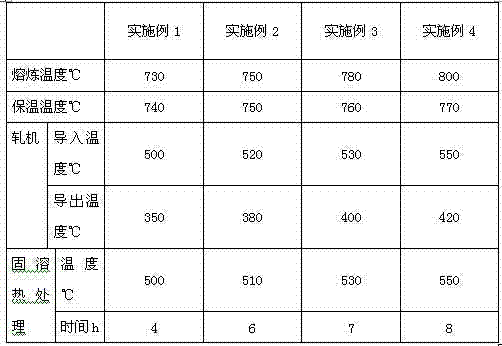

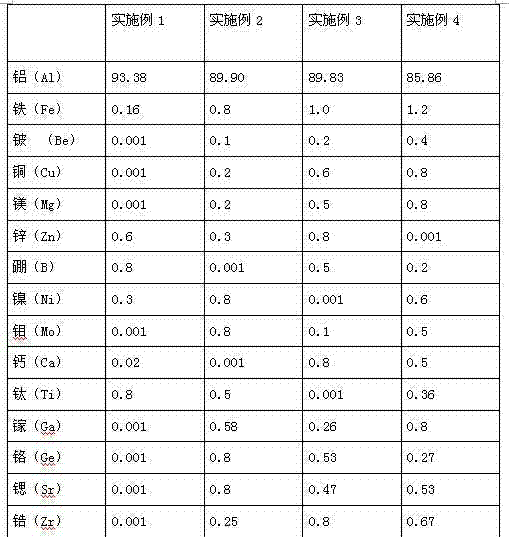

The invention relates to an aluminum alloy material which is characterized in that the aluminum alloy material comprises the following components by weight percent: 0.16-1.2% of Fe, 0.001-0.8% of Cu, 0.001-0.8% of Mg, 0.001-0.8% of Zn, 0.001-0.8% of Ca, 0.001-1.0% of rare-earth elements, a trace amount of strontium, titanium, boron, nickel, chromium, zirconium, vanadium, beryllium, cobalt, lead, tin, bismuth, molybdenum, silver, indium, niobium and barium and the balance of aluminum. The alloy has excellent mechanical strength, processing performance and corrosion resistance and is suitable for the cable armored sheath.

Owner:GUANGDONG XINYI ALUMINUM ALLOY CABLE

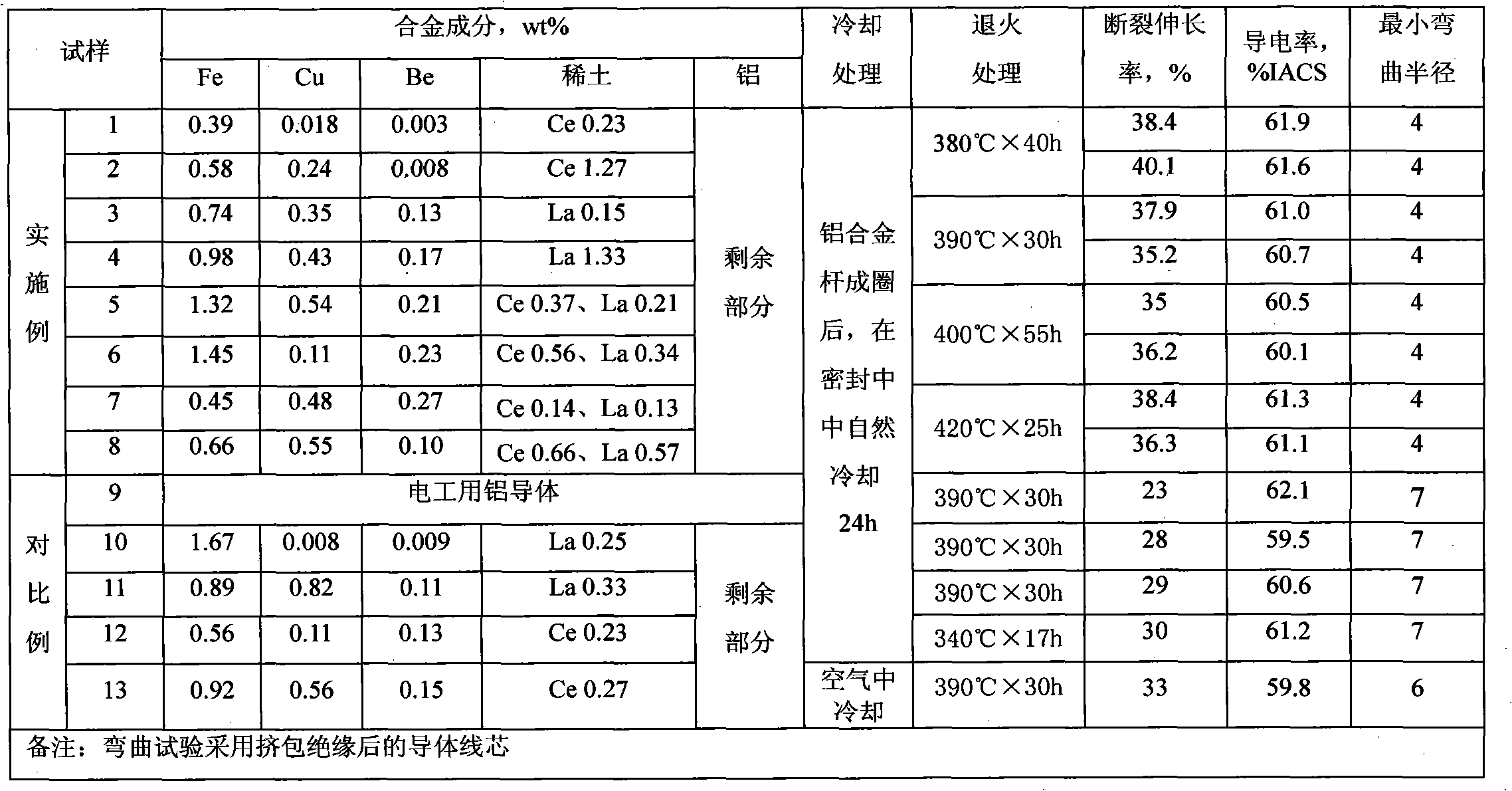

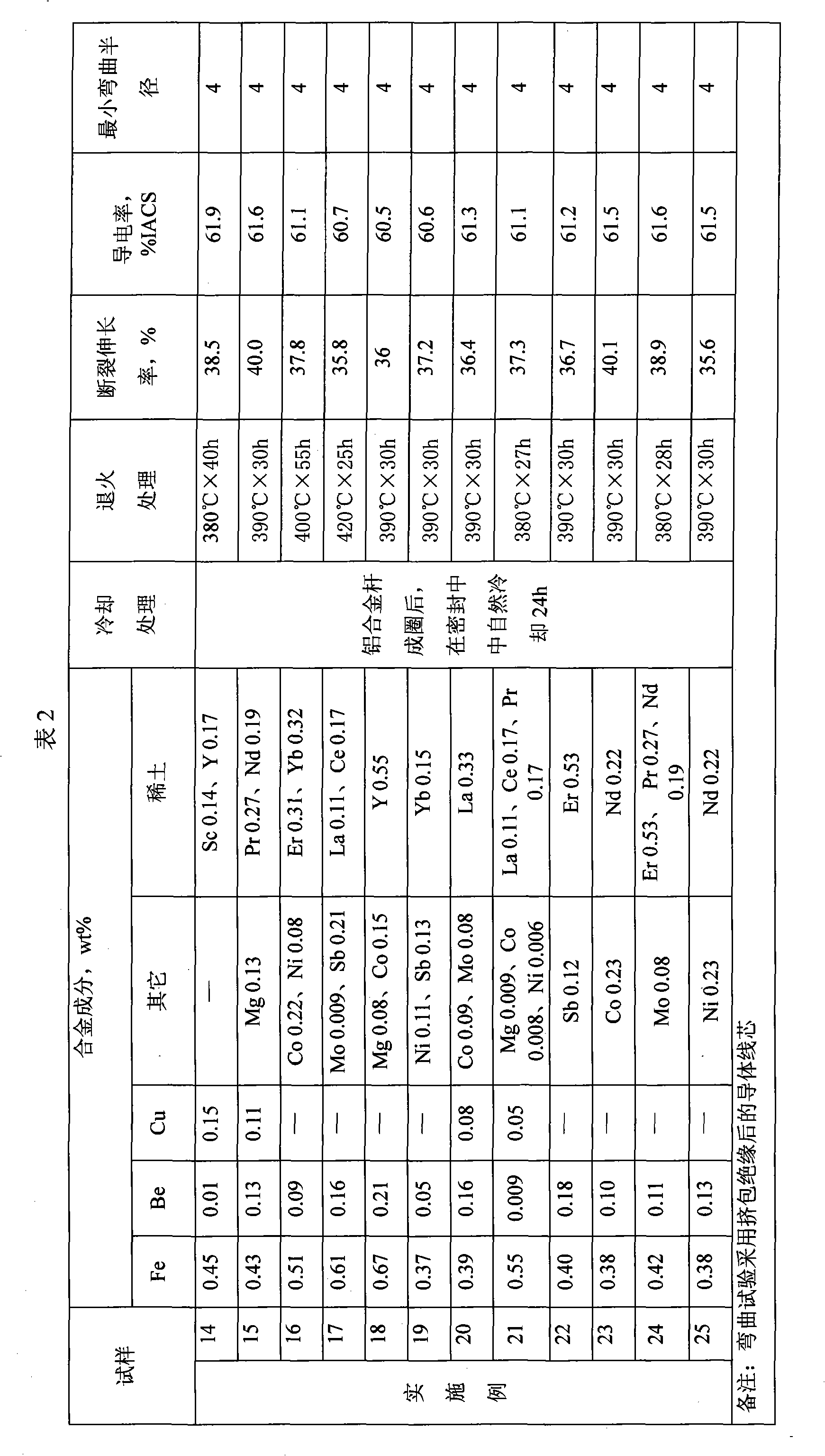

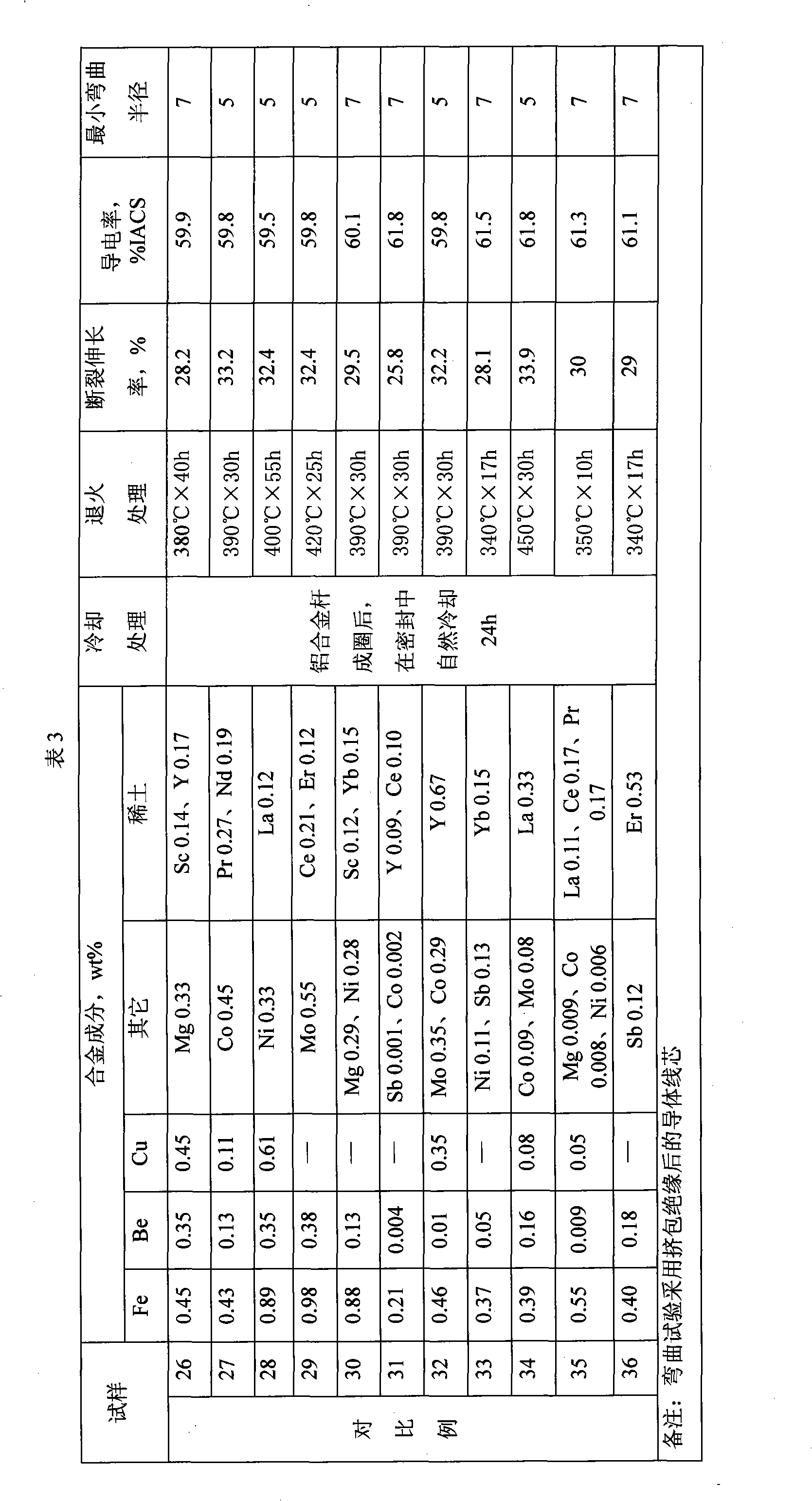

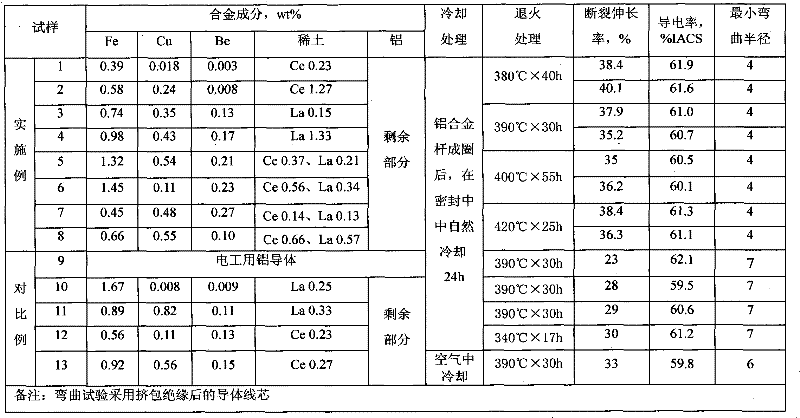

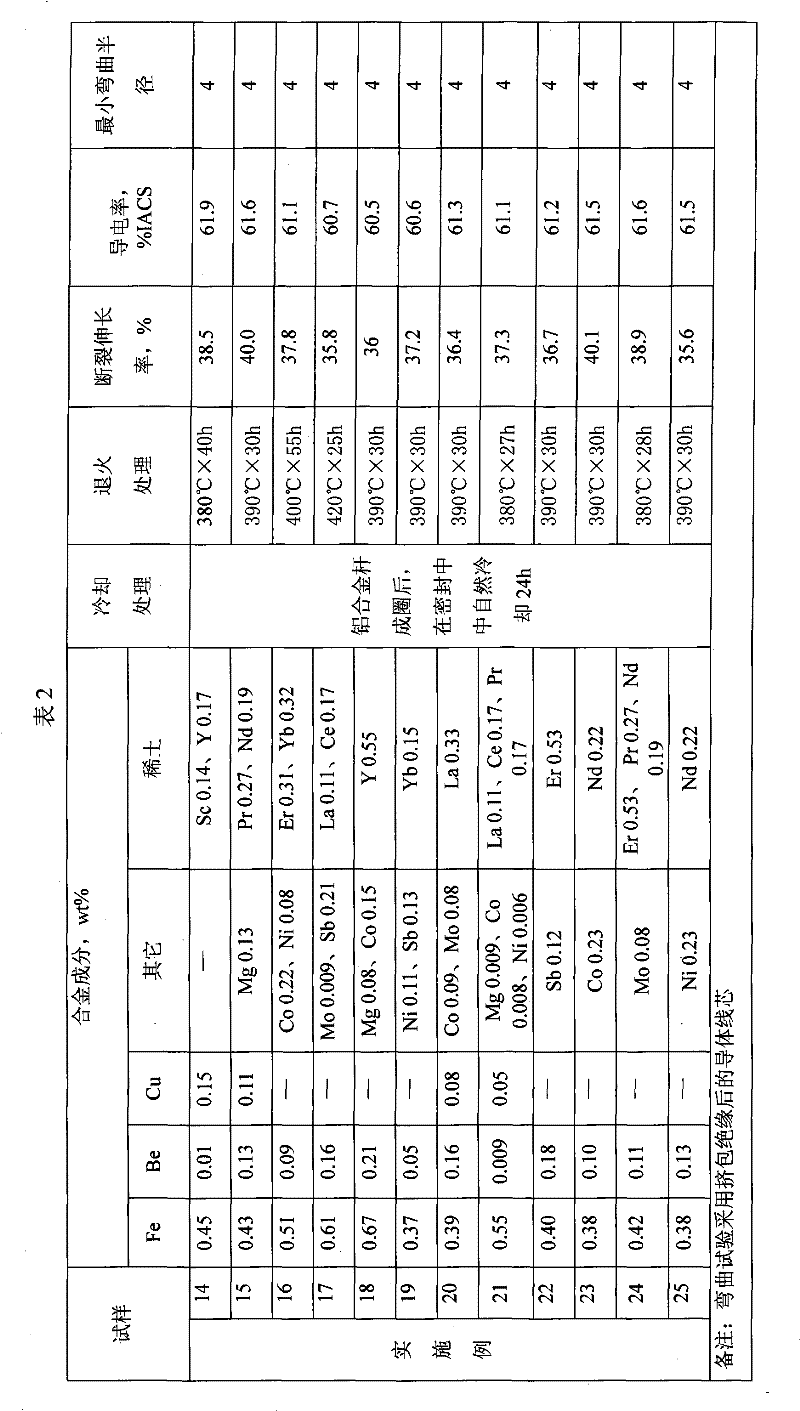

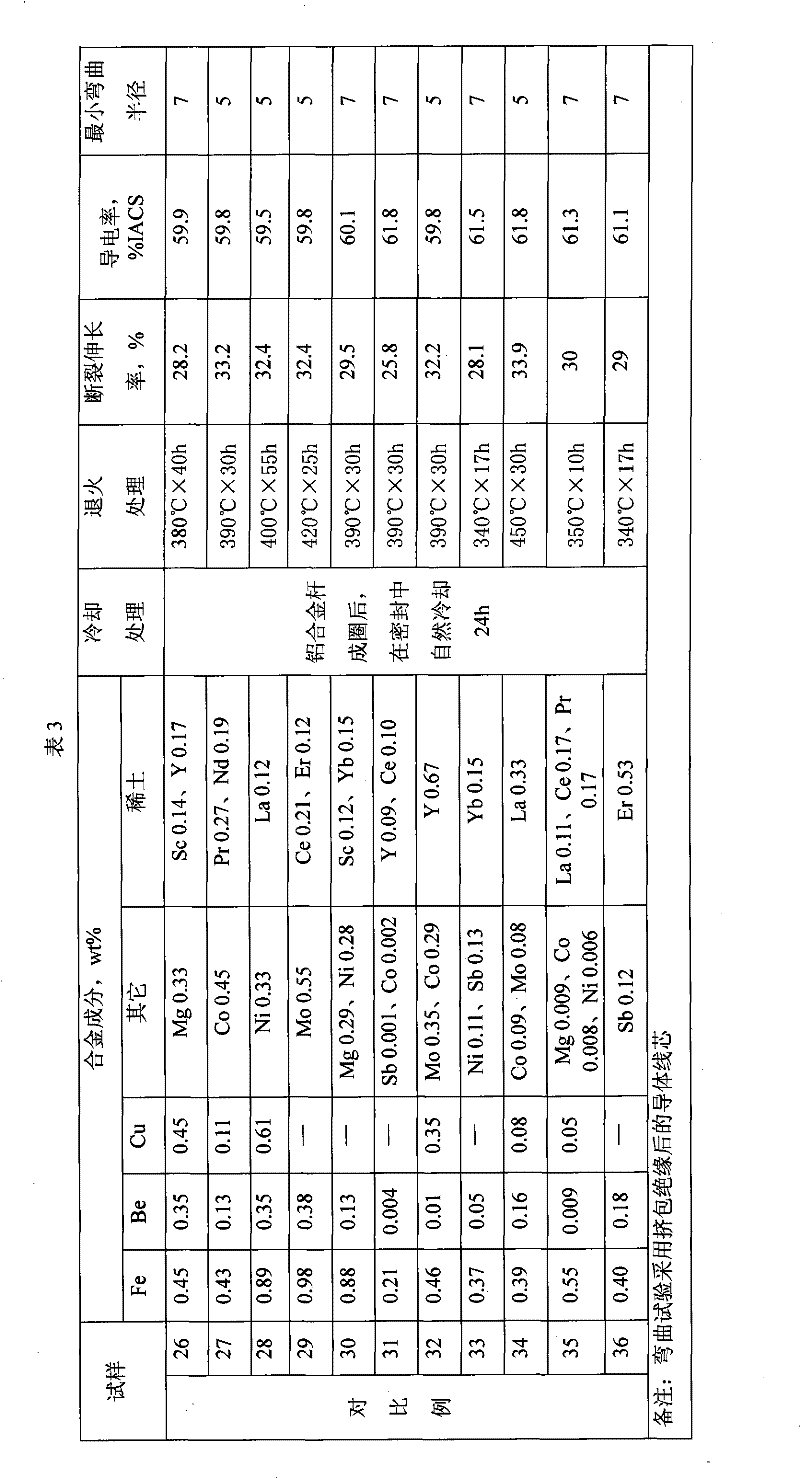

Super-soft aluminum alloy conductor and preparation method thereof

The invention provides a super-soft aluminum alloy conductor and a preparation method thereof. The aluminum alloy conductor comprises the following materials in percentage by weight: 0.3 to 1.5 percent of Fe, 0.001 to 0.3 percent of Be, 0.005 to 0.6 percent of Cu, 0.1 to 1.5 percent of rare earth, less than or equal to 0.08 percent of Si, less than or equal to 0.15 percent of total inevitable impurities, and the balance of aluminum. The aluminum alloy is drawn into an aluminum alloy wire by melting, continuous casting and continuous rolling, and the aluminum alloy wire is put into an annealing furnace and annealed for 20 to 40 hours at the temperature of between 380 and 420 DEG C to form the aluminum alloy conductor, wherein the annealing is performed in a sealed heat insulation device under the protection of nitrogen. The aluminum alloy has extremely good toughness and elongation performance, the coefficient of elongation reaches or exceeds 35 percent and even can reach 40 percent, and the electric conductivity can reach 60 percent IACS.

Owner:ANHUI JOY SENSE CABLE

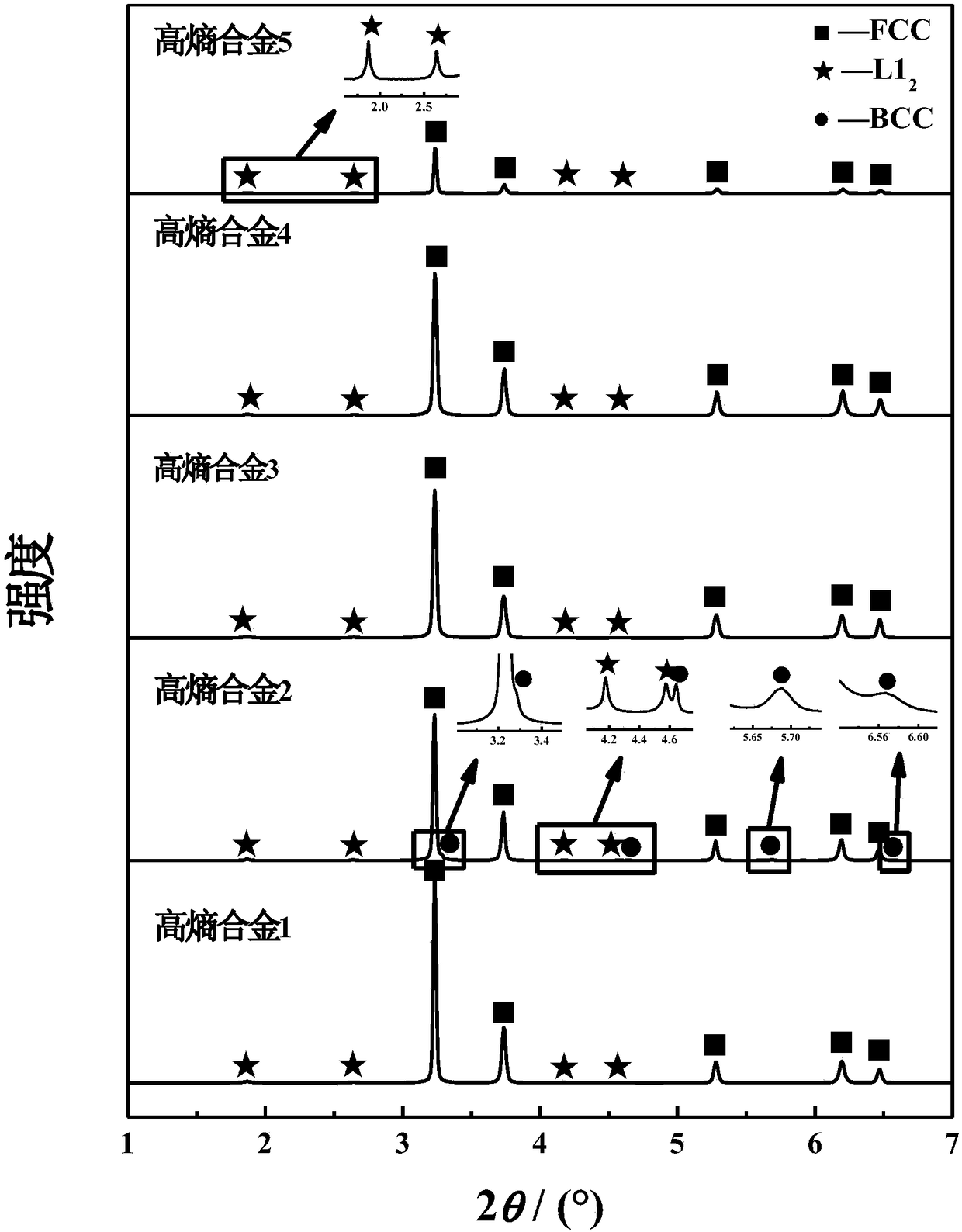

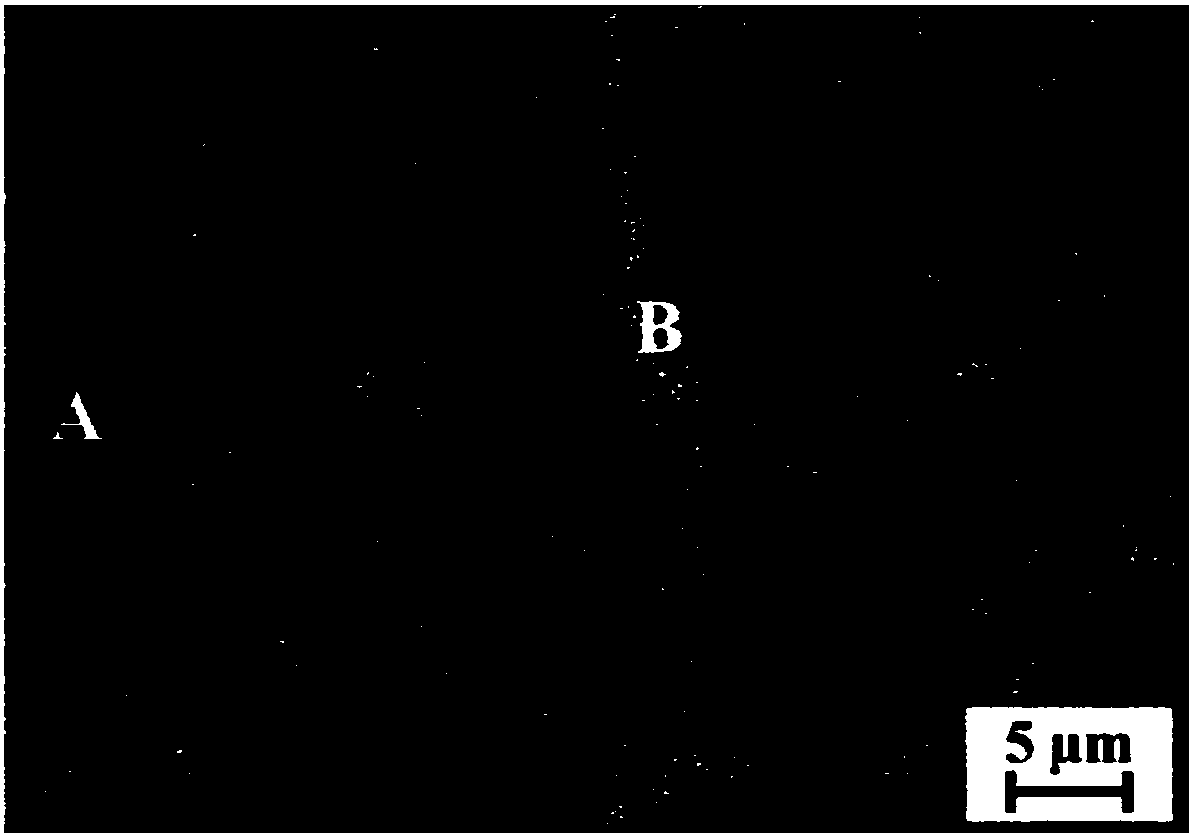

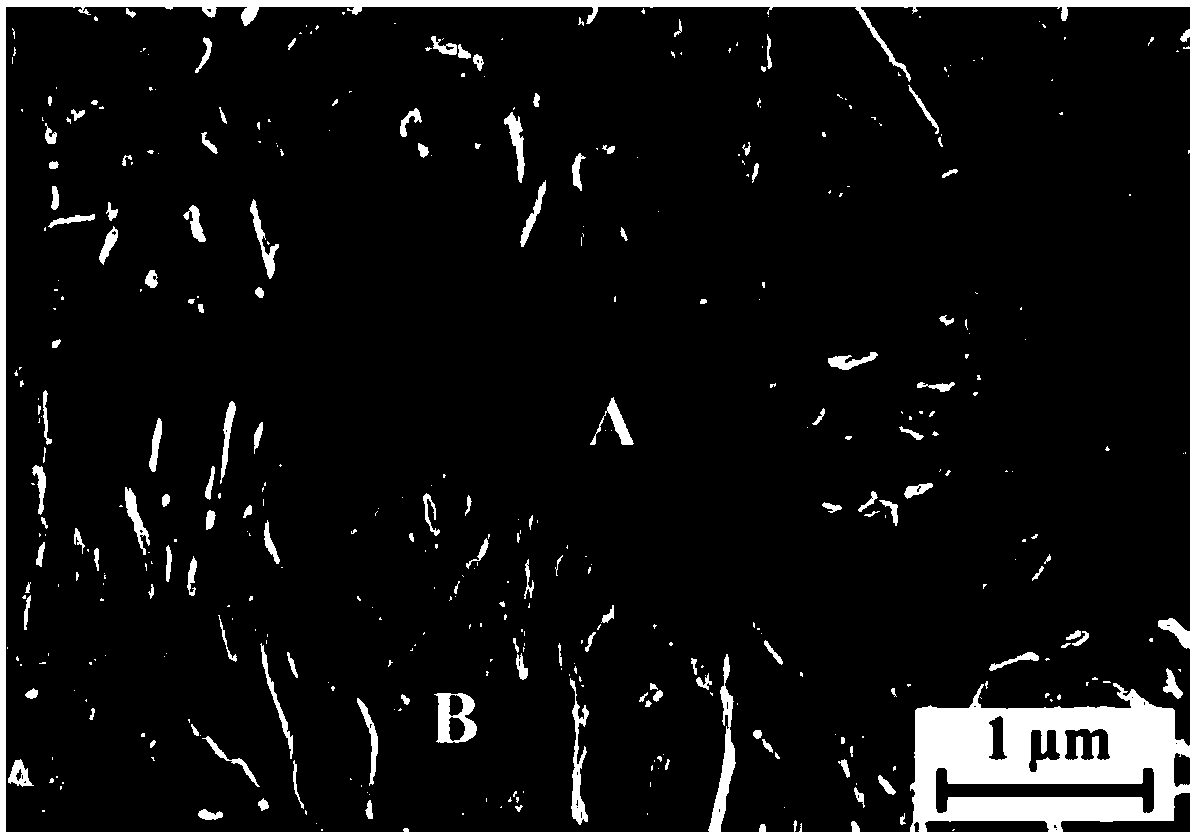

Precipitation-strengthening type AlCrFeNiV system high-entropy alloy and preparation method thereof

The invention relates to a precipitation-strengthening type AlCrFeNiV system high-entropy alloy and a preparation method thereof, and belongs to the technical field of metal materials. The high-entropy alloy comprises, by atomic weight ratio, 0.30-0.60 of Al, 0.20-0.89 of Cr, 0.60-1.20 of Fe, 1.50-3.50 of Ni and 0.10-0.30 of V; and the high-entropy alloy is prepared by a smelting molding process and a deformation heat treatment process. According to the precipitation-strengthening type AlCrFeNiV system high-entropy alloy and the preparation method thereof, the content of each element is regulated, and the synthesis process is optimized, so that a modulation structure of two-phase coherency of unordered FCC and ordered L12 is obtained; and the grain size is small, and the strength of the high-entropy alloy is significantly increased.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

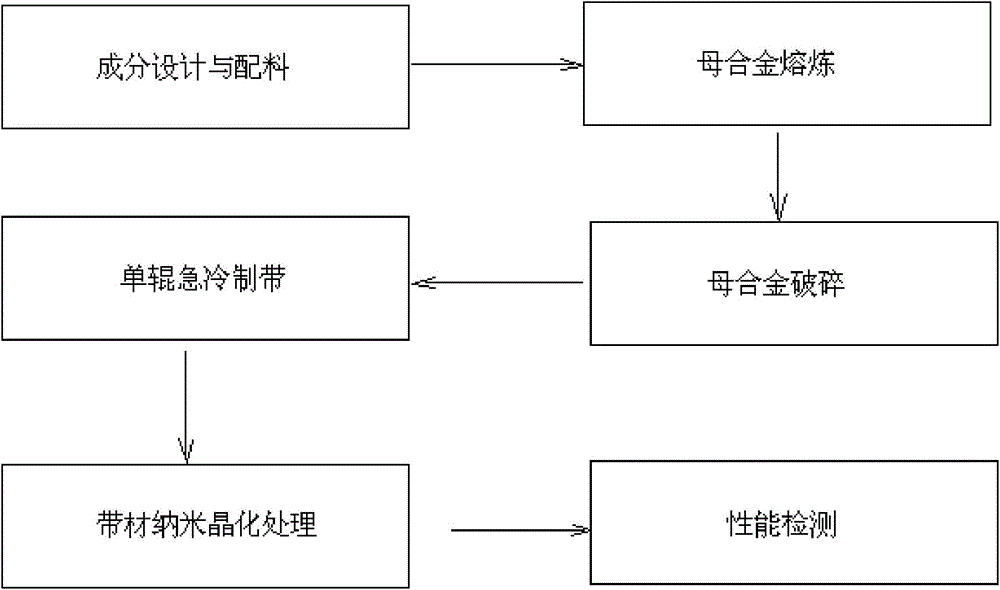

High-saturation-magnetization iron-base amorphous nanocrystal soft magnetic alloy and preparation method thereof

InactiveCN104561841ASolve the problem of low saturation magnetic inductionHigh saturation magnetizationFurnace typesMagnetic materialsMagnetization transferHigh saturation magnetization

The invention relates to a high-saturation-magnetization iron-base amorphous nanocrystal soft magnetic alloy and a preparation method thereof. The alloy is expressed as FeaMbCucSixByPz, wherein M is one or more of Al, Cr, Mn, Ti and V; and 68<=a<=90, 0<=b<=6, 0<=c<=2, 3<=x<=20, 4<=y<=20, 0<=z<=10, and a+b+c+x+y+z=100. Compared with the prior art, the product has the advantages of high saturation magnetization and the like.

Owner:SHANGHAI HANTAO NANO TECH

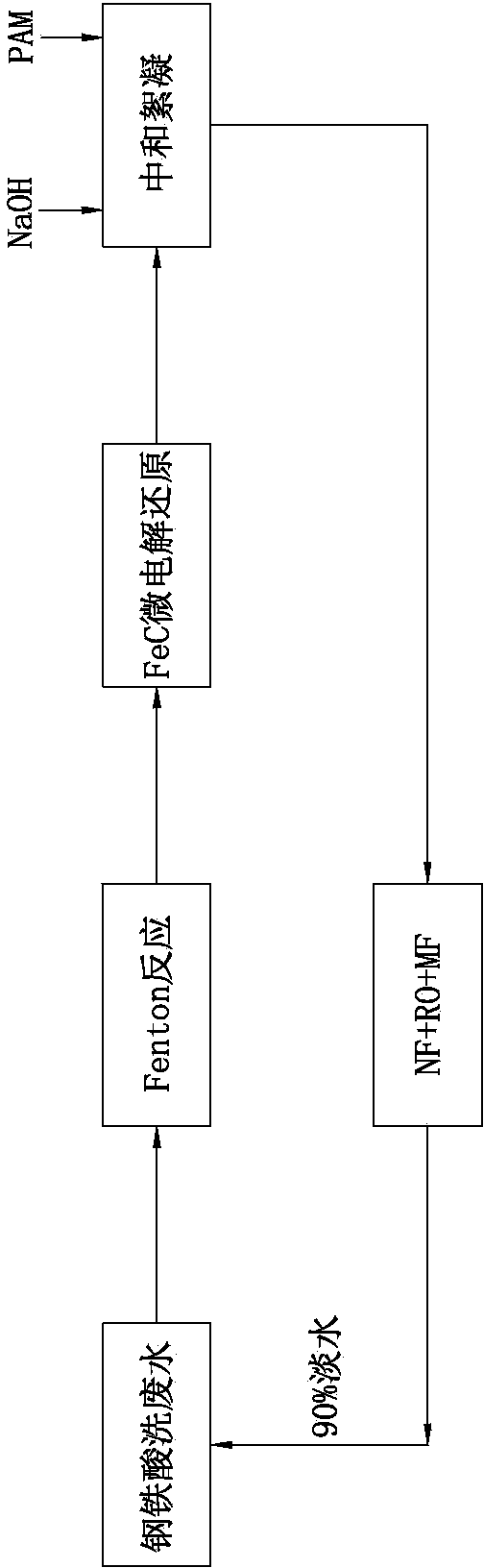

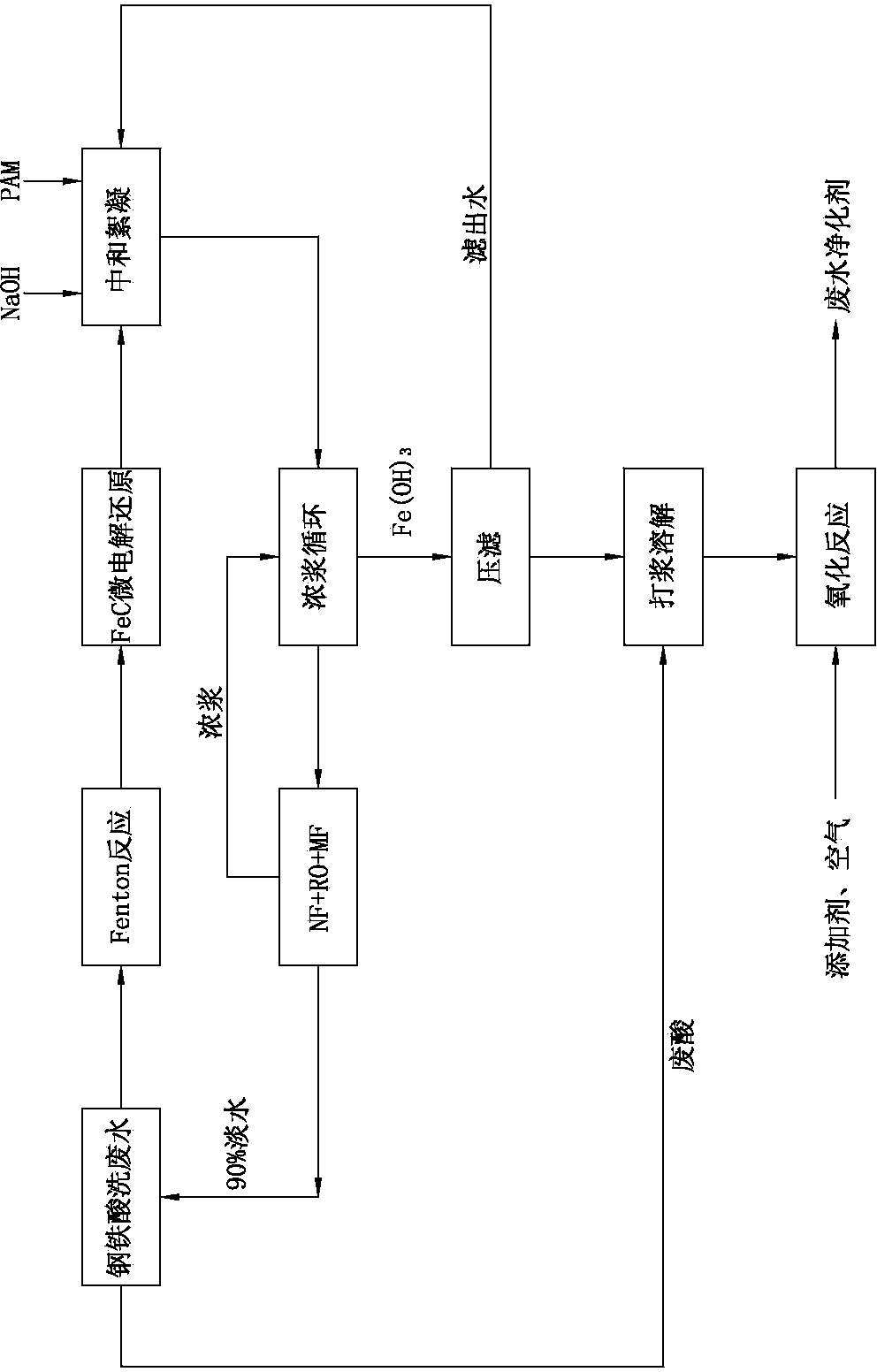

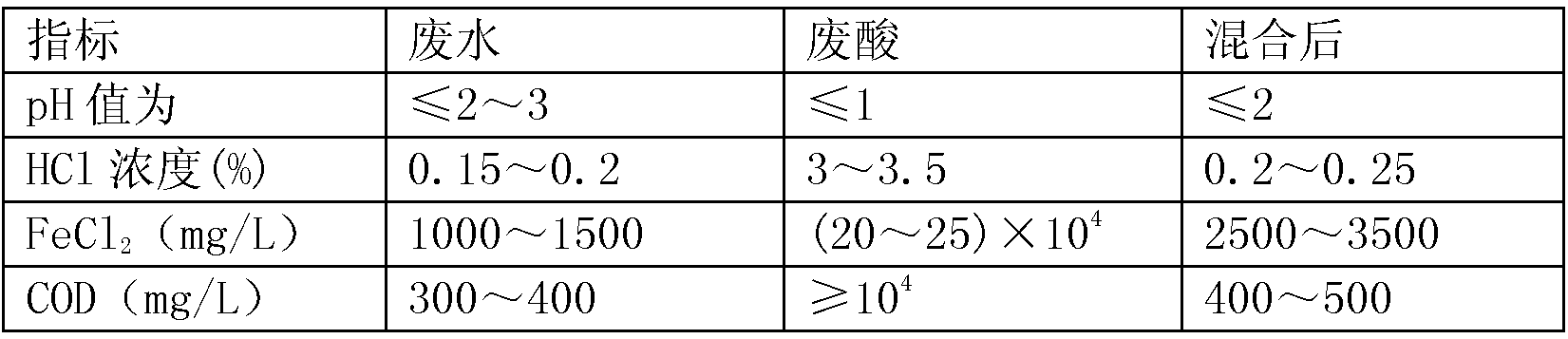

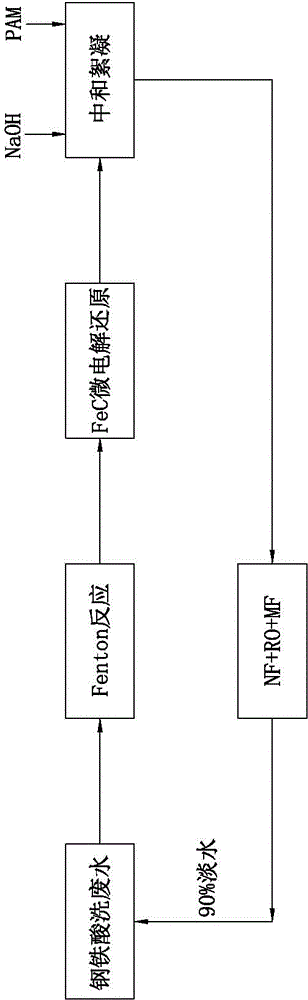

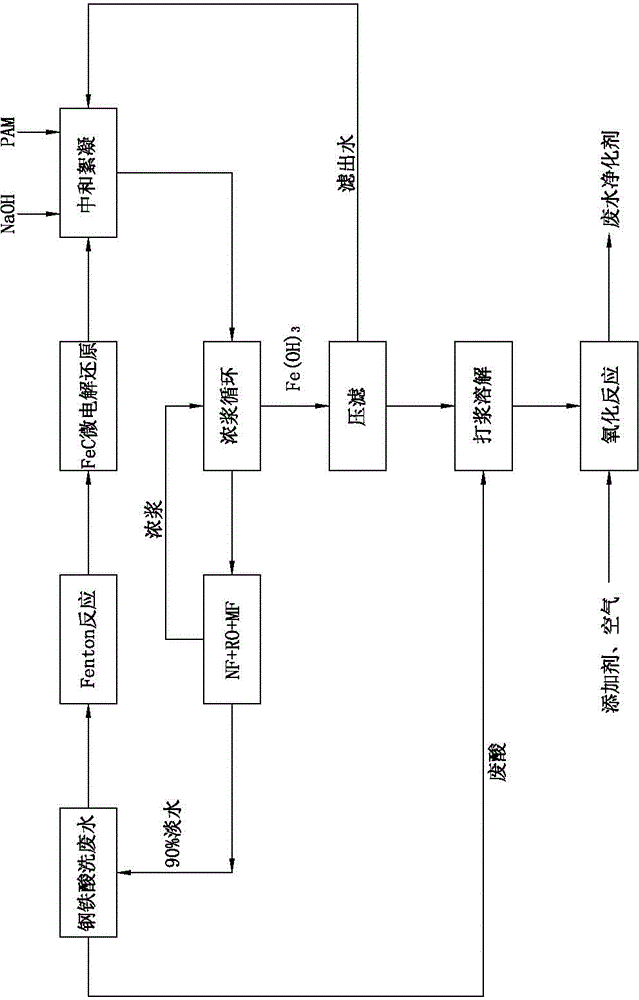

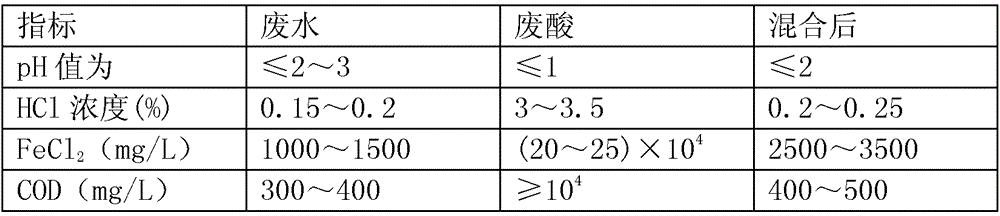

Steel pickling waste water resourcization and zero discharge process

ActiveCN104030502AIncrease Fe contentLow free acidMultistage water/sewage treatmentFenton reactionFlocculation

The invention belongs to the technical field of water treatment, and particularly relates to a steel pickling waste water resourcization and zero discharge process. The steel pickling waste water resourcization and zero discharge process comprises the following process steps of: (a) introducing steel pickling waste water; (b) carrying out Fenton reaction on the steel pickling waste water to reduce the COD (Chemical Oxygen Demand) of the steel pickling waste water to be less than or equal to 60 mg / L, convert Fe<2+> into Fe<3+> and reduce TDS (Total Dissolved Solids) to be less than or equal to 2000 mg / L; (c) carrying out FeC microelectrolysis reduction reaction on the steel pickling waste water; (d) carrying out neutralization flocculation; (e) desalting a membrane assembly to reduce the TDS of the steel pickling waste water to be less than or equal to 200 mg / L; (f) recycling effluent water. The steel pickling waste water resourcization and zero discharge process disclosed by the invention realizes the cleaning production, realizes the resourcization utilization of waste water, waste acid and iron mud, generates the benefit and realizes the zero discharge.

Owner:DONGGUAN SANRENXING ENVIRONMENTAL TECH CO LTD

Low-cost, high-strength and high-plasticity metastable beta titanium alloy and preparation method thereof

The invention discloses a low-cost, high-strength and high-plasticity metastable beta titanium alloy and a preparation method thereof. The titanium alloy comprises the following components in percentage by weight: 3-7% of Fe, 4-7.75% of Al, 3-5% of V, O not more than 0.2%, C not more than 0.08%, N not more than 0.05%, and the balance of titanium and inevitable impurities. The preparation method comprises the following steps: sponge titanium, an Al-V intermediate alloy, pure Al and pure Fe are weighed according to ratios; the raw materials are mixed to press as an electrode; a Ti-Al-Fe-V alloy cast blank is prepared by secondary smelting; the cogging and the primary forging are performed to obtain a large-scale forging; the secondary forging is performed to obtain a larger-size rod; the ternary forging is performed to obtain a small-size rod; the solid-solution treatment and the air cooling are performed; and then, the aging treatment and the air cooling are performed to obtain the low-cost, high-strength and high-plasticity metastable beta titanium alloy. The titanium alloy contains higher-content beta elements and stable elements Fe, and has such advantages as low cost, high strength and high plasticity.

Owner:CENT SOUTH UNIV

Method for reducing cadmium content of rice seedling leaves, and rice seedling nutrient solution

InactiveCN105454012AIncrease Fe contentReduced Cd contentCalcareous fertilisersMagnesium fertilisersNutrient solutionCadmium Cation

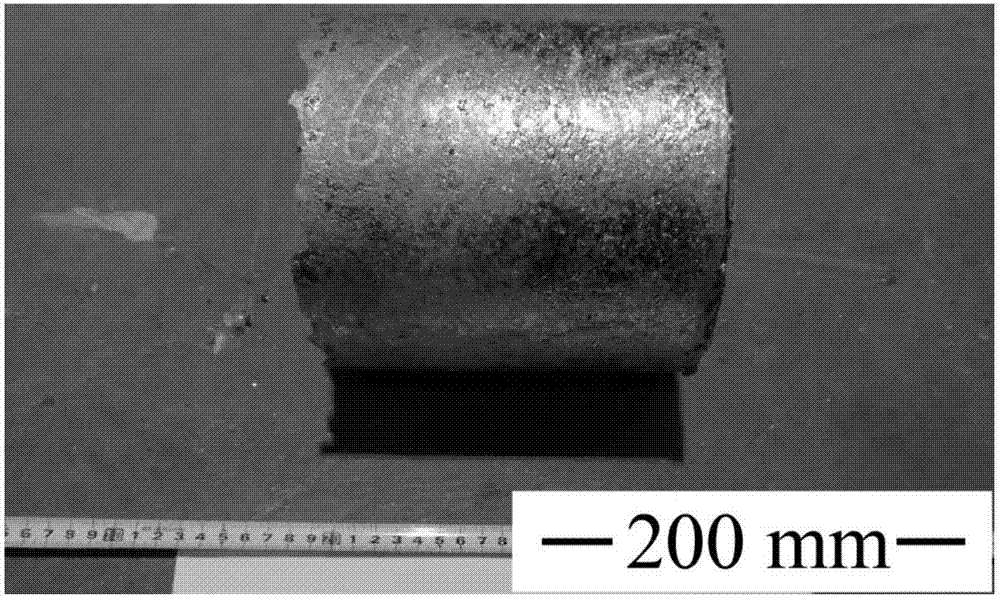

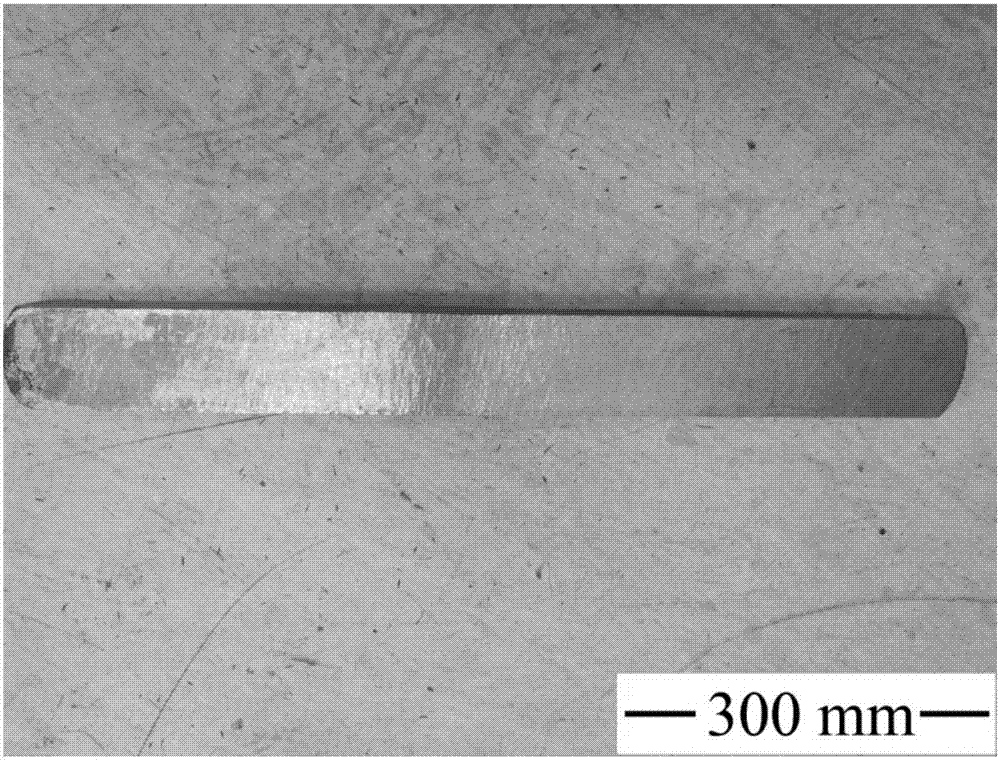

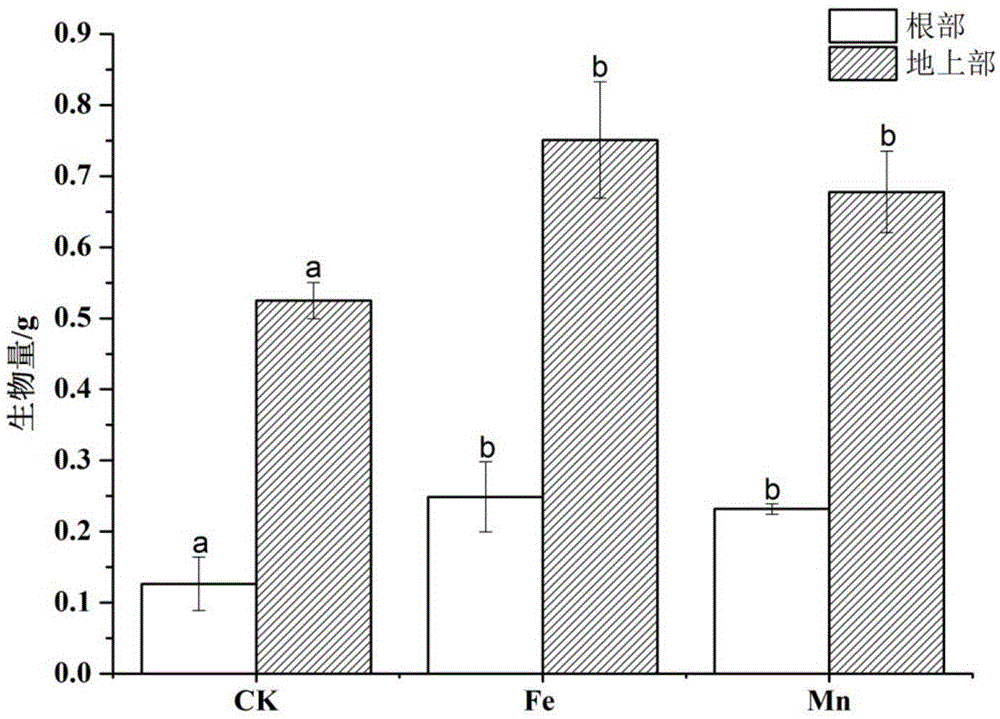

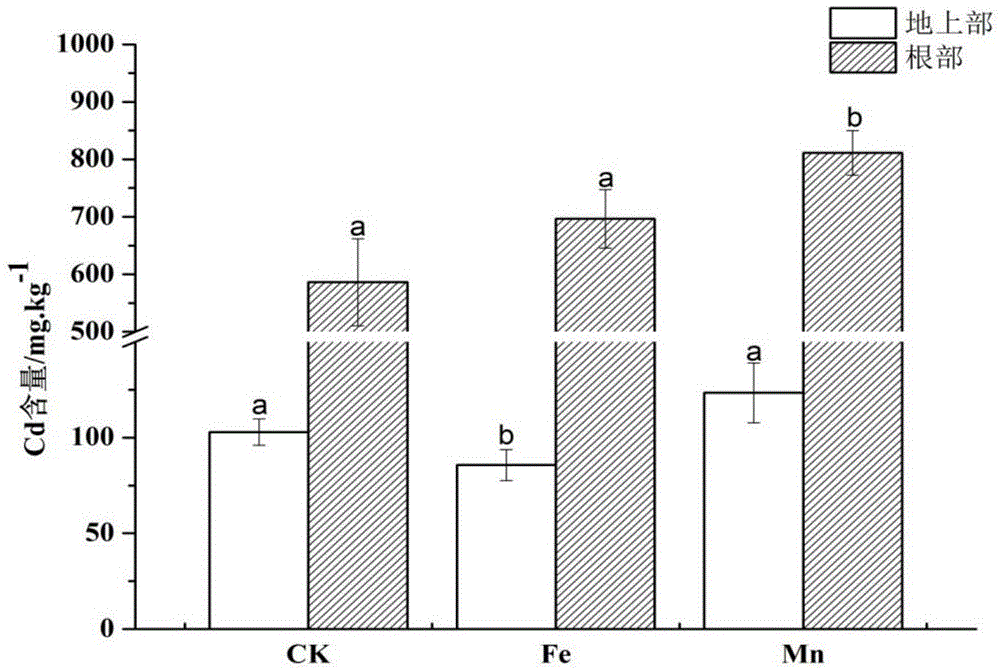

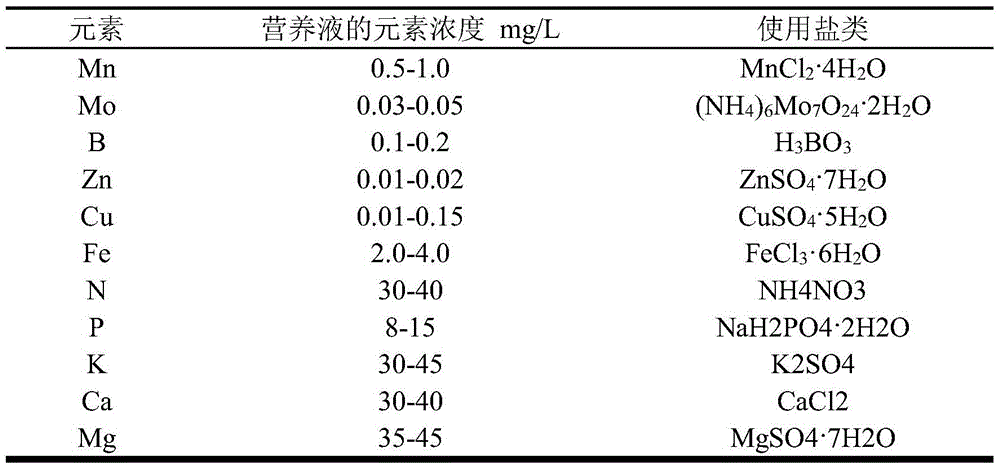

The invention relates to a method for reducing cadmium content of rice seedling leaves, and a rice seedling nutrient solution recipe. The method comprises: (1) rice variety being Yangdao 6; (2) sowing seeds whose surfaces are disinfected to plugs which use vermiculite as medium, putting the plugs in a phytotron to culture for 1-2 weeks; (3) selecting rice seedlings to transplant in cultivating pots, the nutrient solution used for water planting being international rice nutrient solution and being added with microelements. Through discussing influence of external Fe and Mn on formation of rice seedling root iron plaque and on Cd absorption and transport and on rice seedling antioxidant enzyme activities, the method provides new thoughts for rice root iron plaque research and rice safety production on Cd polluted fields.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

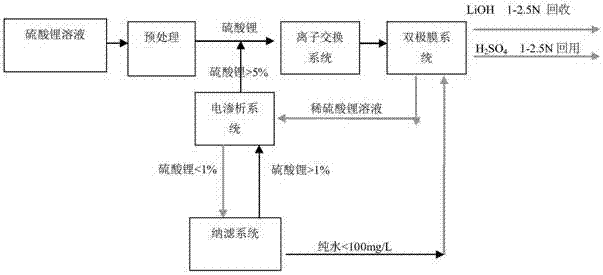

Technology for recycling lithium hydroxide from solution through bipolar membrane method

ActiveCN105154908AReduce consumptionSolve environmental problemsElectrolysis componentsLithium hydroxidePhysical chemistry

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

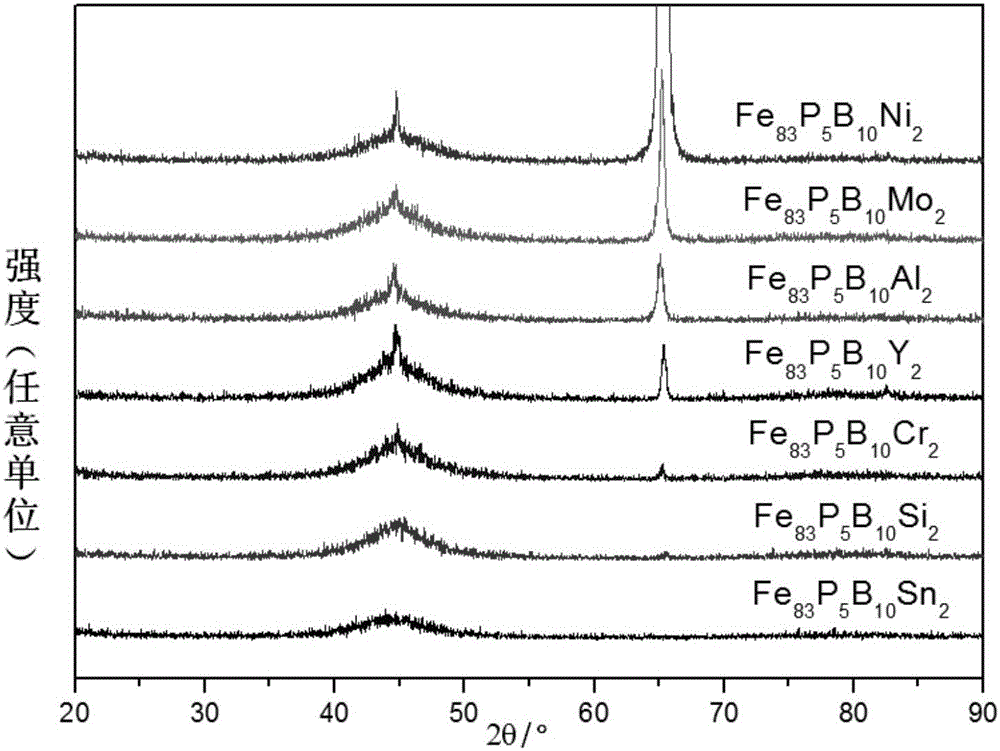

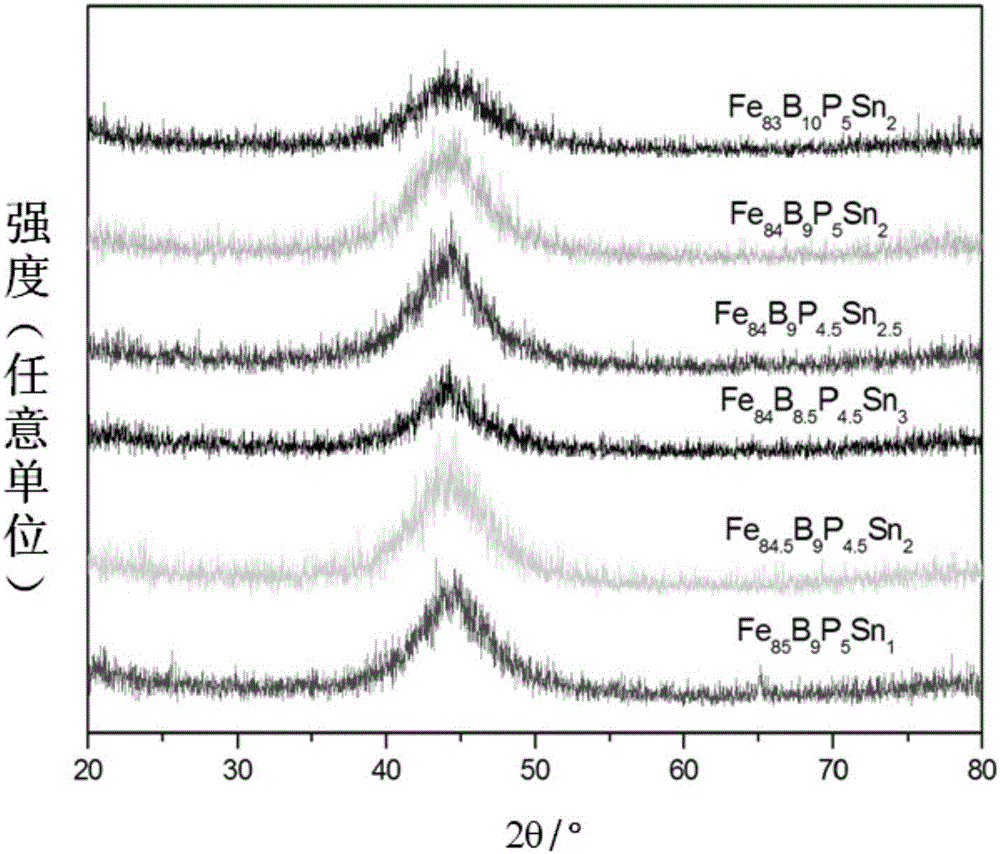

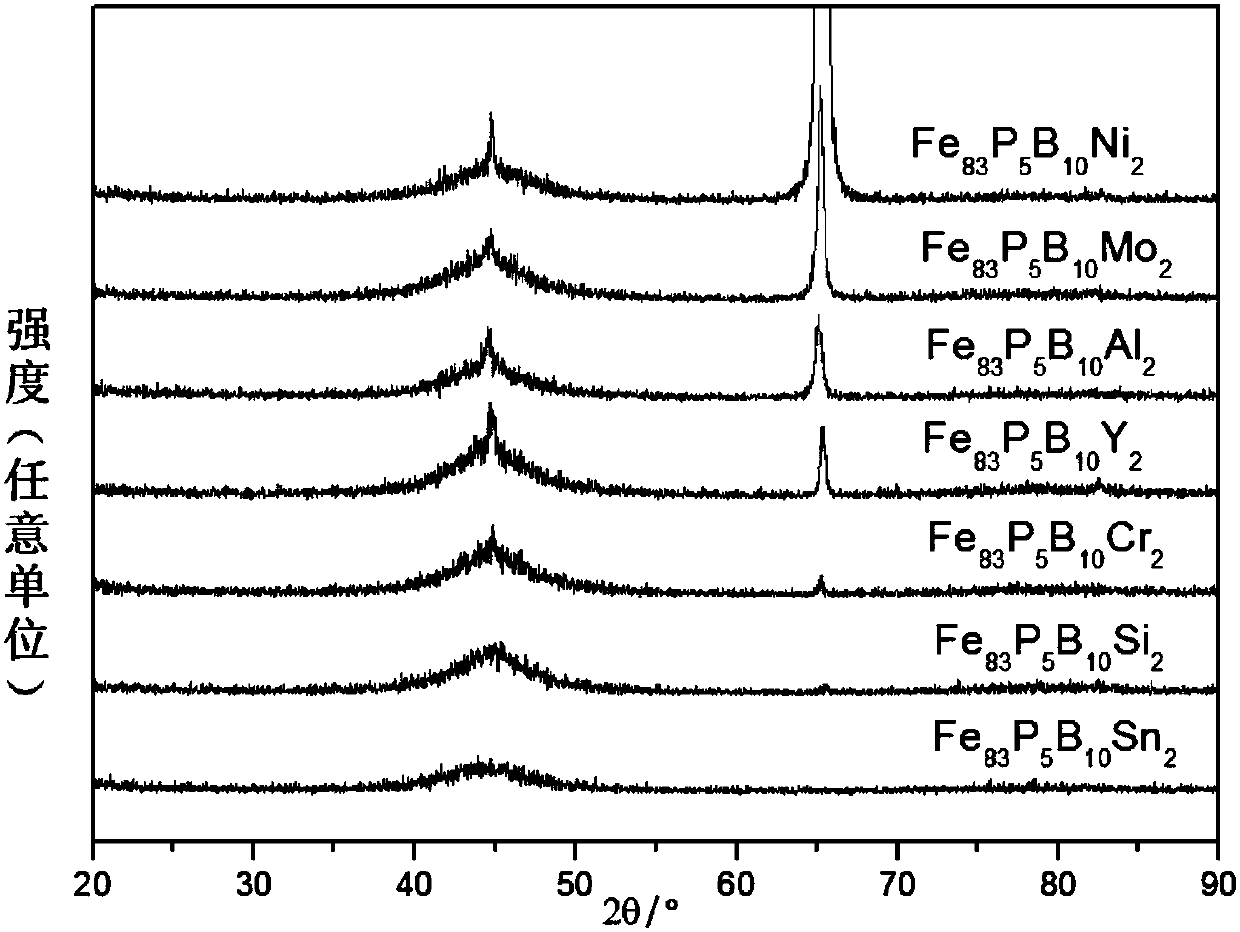

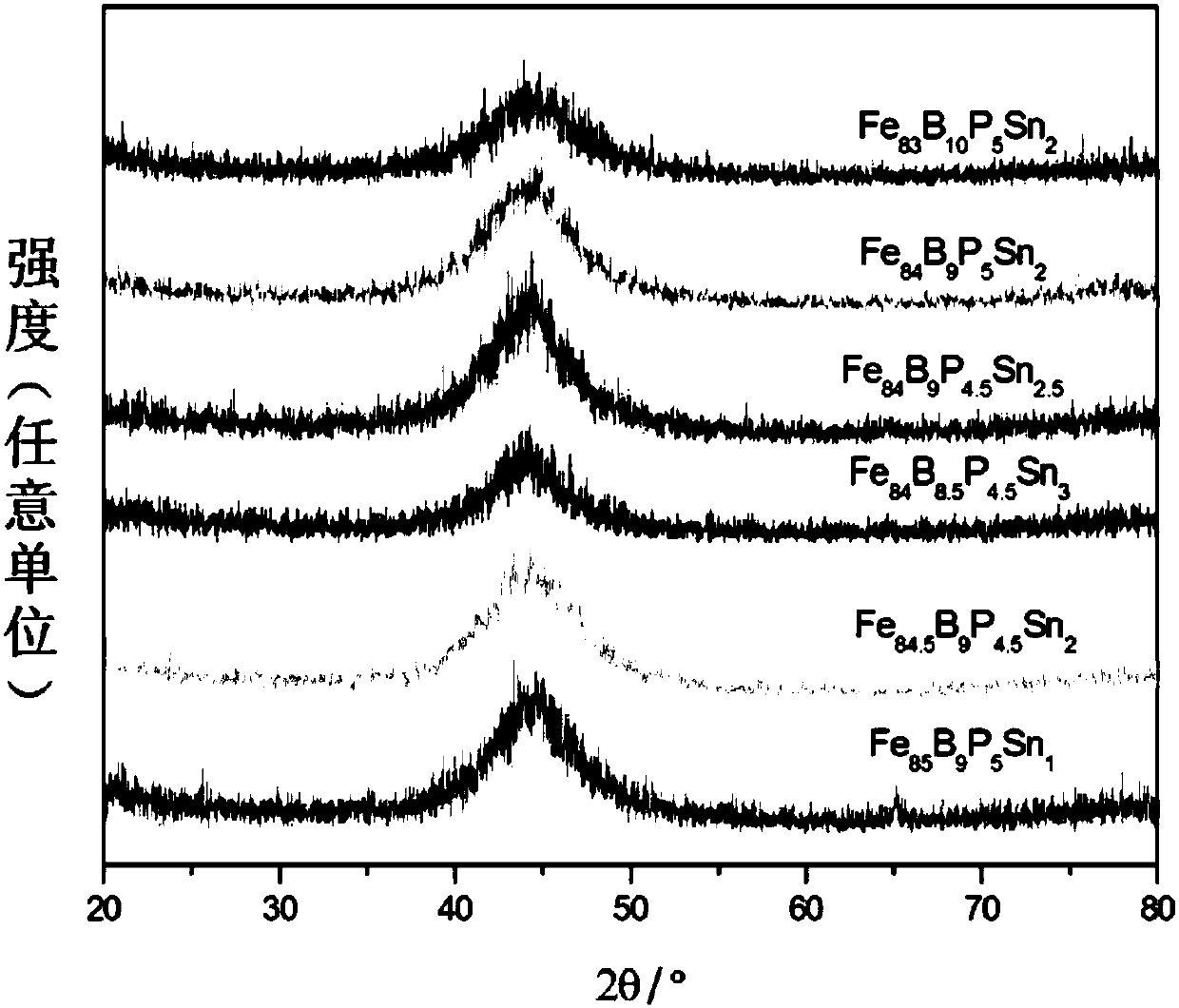

Iron-based soft-magnet amorphous alloy with less components, low cost and high saturation magnetic induction intensity and manufacturing process thereof

The invention belongs to the field of metal materials, and relates to an iron-based soft-magnet amorphous alloy with less components, low cost and high saturation magnetic induction intensity and a manufacturing process thereof. The iron-based soft-magnet amorphous alloy is prepared from the following components in atom percentage: greater than or equal to 5 percent and less than or equal to 12 percent of boron, greater than or equal to 3 percent and less than or equal to 10 percent of phosphorus, greater than or equal to 0.5 percent and less than or equal to 5 percent of tin, and greater than or equal to 80 percent and less than or equal to 84.5 percent of iron. The iron-based soft-magnet amorphous alloy is low in production cost, and is simple in process; the prepared iron-based soft-magnet amorphous alloy has the characteristics of high saturation magnetic induction intensity and low coercive force, is suitable for devices such as transformer cores, amorphous motors and the like, and is applied to the field of electric power, electronics, information, communication and the like.

Owner:SHANDONG UNIV

Super-strong high-plastic titanium alloy and preparation method thereof

The invention provides a super-strong high-plastic titanium alloy which comprises the following components in percentage by weight: 4.5 percent to 5.75 percent of Al, 3.0 percent to 5.0 percent of Mo,2.0 percent to 4.0 percent of Zr, 2.0 percent to 3.0 percent of Fe, 0.3 percent to 2.0 percent of Sn, 0.30 percent to 1.2 percent of Cr, less than or equal to 0.15 percent of O, and the balance Ti and trace impurities. The invention further provides a preparation method of the super-strong high-plastic titanium alloy. According to the super-strong high-plastic titanium alloy and the preparation method thereof provided by the invention, through simultaneously adding multiple multicomponent alloys, the tensile strength of the titanium alloy is improved to 1400MPa to 1550Mpa, meanwhile, the processing plasticity of the material is ensured, the elongation percentage is larger than 10 percent, and the reduction of cross sectional area is larger than 20 percent.

Owner:重庆金世利航空材料有限公司 +1

Method for adopting nickel or copper smelting waste slag for ferrosilicon smelting

InactiveCN103484682AHigh in ironAchieve reuseProcess efficiency improvementSmelting processFerrosilicon

The present invention relates to utilization of nickel or copper smelting waste slag, particularly to a method for adopting nickel or copper smelting waste slag for ferrosilicon smelting. The method comprises: screening, wherein nickel or copper smelting waste slag is screened, and particles with a diameter of 2-5 mm are retained; smelting, wherein the screened nickel or copper smelting waste slag, silica, semi-coke and pellet ore are poured into a furnace to smelt; and iron discharging, wherein slag iron is separated. The method has the following effects that: the nickel or copper smelting waste slag for producing ferrosilicon is a good iron product furnace material; the waste resource reuse problem is well solved with the technical scheme; the Fe content in the nickel or copper smelting waste slag is high, such that consumption of steel chips, pellet ore or oxide skin and other iron products during the ferrosilicon smelting process is reduced so as to substantially reduce production cost and expand types of iron product furnace materials in ferrosilicon production; and positive effects are provided for ferrosilicon production and even the ferroalloy industry.

Owner:内蒙古鄂尔多斯冶金有限责任公司

Heat-resistant regeneration die-cast aluminum alloy and preparation method thereof

The invention discloses a heat-resistant regeneration die-cast aluminum alloy and a preparation method thereof, and belongs to the field of regeneration die-cast aluminum alloy preparation. The invention provides the heat-resistant regeneration die-cast aluminum alloy capable of reducing the preparation cost and the preparation method of the heat-resistant regeneration die-cast aluminum alloy. Chemical components of the heat-resistant regeneration die-cast aluminum alloy include 10.0%-12.0% of Si, 0.50%-0.75% of Ni, 0.95%-1.35% of Mg, 0.9%-1.4% of Fe, 0.20%-0.30% of Mn, 0.08%-0.12% of Cr, 0.015%-0.03% of B, smaller than or equal to 0.15% of an impurity element and the balance Al. The preparation method includes the steps that smelting is conducted; sampling is conducted to adjust the alloycomponents; refining is conducted after low-melting-point alloy addition; slag removal is conducted; and casting is conducted. According to the heat-resistant regeneration die-cast aluminum alloy andthe preparation method, Ni and Cu are replaced with the low-cost impurity element Fe, and the alloy cost is effectively reduced; and by means of the compound modification technology of the Mn, the Cr, the B and the like, the size of the iron-rich phase is refined, and the high-temperature strength of the alloy is ensured.

Owner:肇庆南都再生铝业有限公司 +2

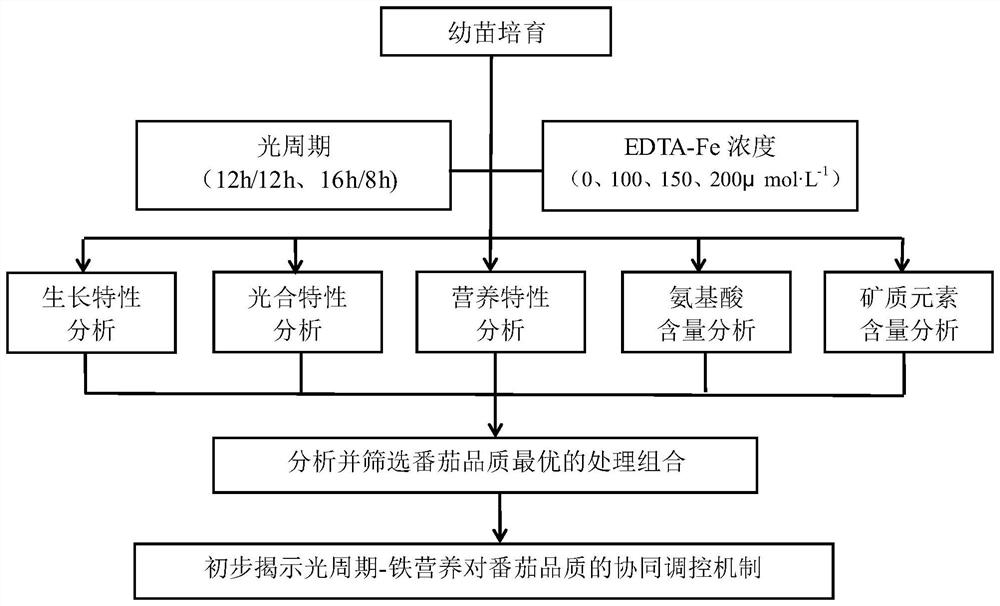

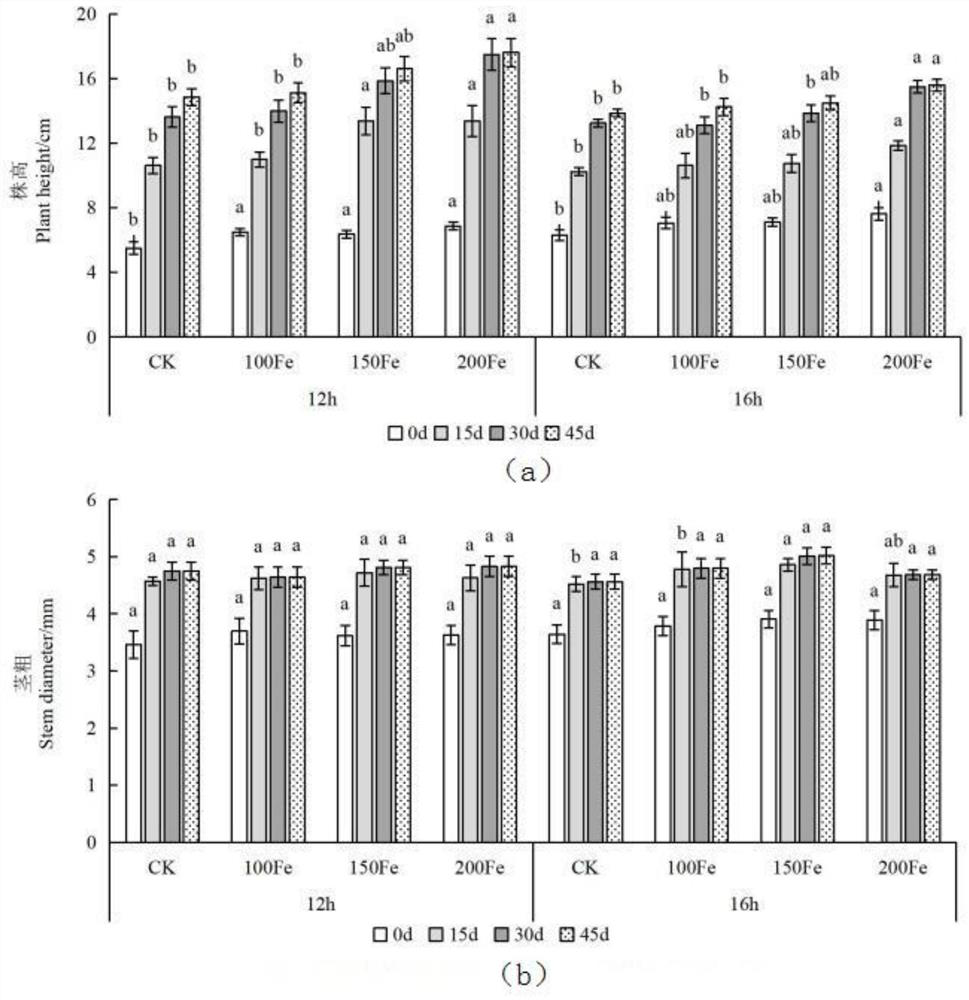

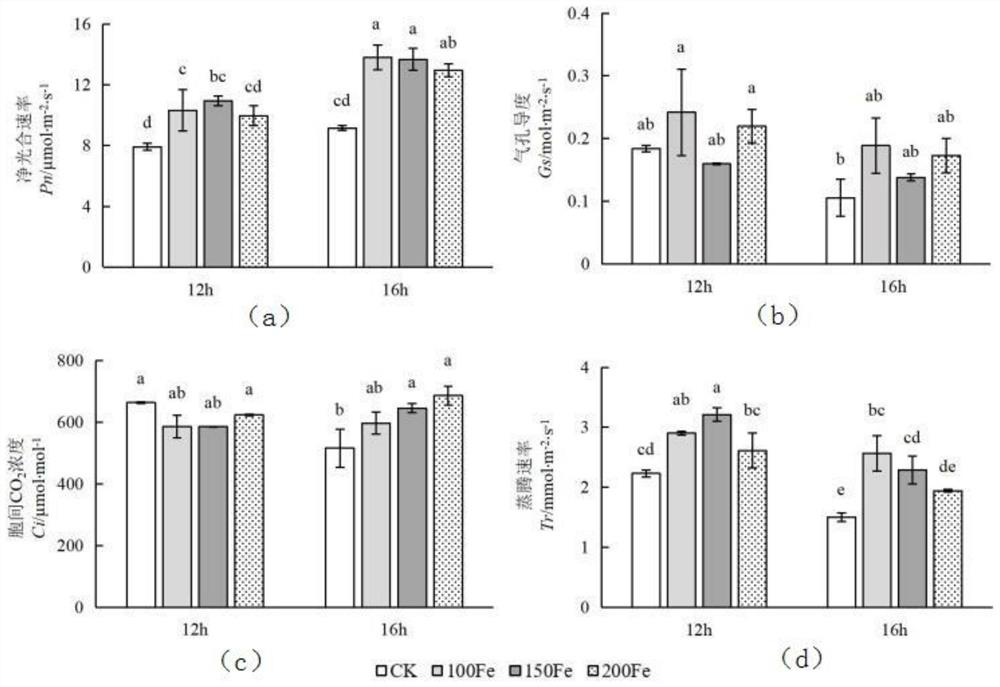

Planting method for improving growth and development and fruit quality of tomatoes

PendingCN112840973AShort internodeReduce plant heightSaving energy measuresFertilising methodsNutrient solutionPlant growth

The invention discloses a planting method for improving growth and development and fruit quality of tomatoes. The planting method comprises the steps that tomato seedlings are cultivated; LED plant growth lamps are adopted as light sources to be arranged above the tomato seedlings for irradiation, and the light period every day is set to be 12 h illumination / 12 h non-illumination or 16 h illumination / 8 h non-illumination; when the tomatoes enter the flowering stage, an EDTA-Fe aqueous solution with the concentration of 100-200 [mu] mol.L <-1 > is sprayed to tomato plants, the EDTA-Fe aqueous solution is uniformly sprayed to the front and back surfaces of leaves once a week, and the tomato plants are irrigated with a nutrient solution containing no Fe element once every other month to ensure sufficient nutrients; and after the EDTA-Fe aqueous solution is sprayed for 55-65 days, when 80% of the tomatoes on the tomato plants turn red and peels are slightly soft, spraying of the EDTA-Fe aqueous solution is stopped. According to the planting method for improving growth and development and fruit quality of the tomatoes, the tomato quality improvement effect is optimal by spraying 100 to 150 [mu] mol.L <-1 > EDTA-Fe aqueous solution on the surfaces of the leaves in the photoperiod of 16 h illumination / 8 h non-illumination.

Owner:SHANXI AGRI UNIV +1

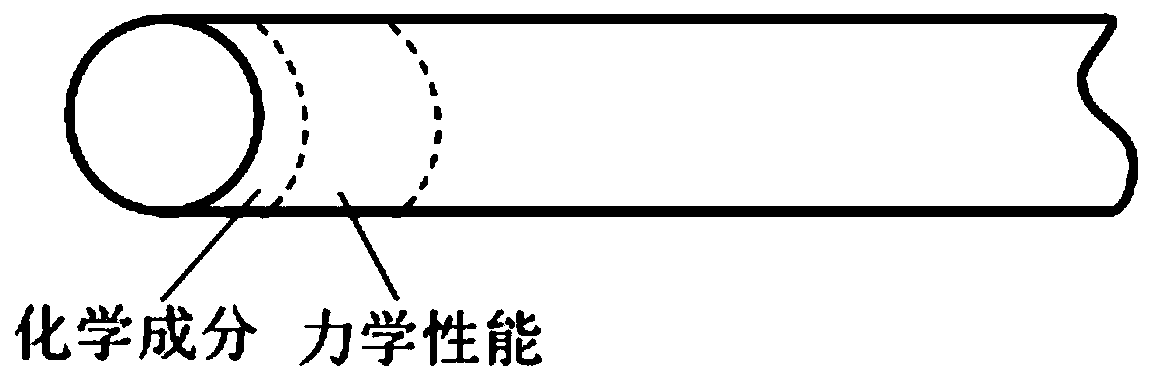

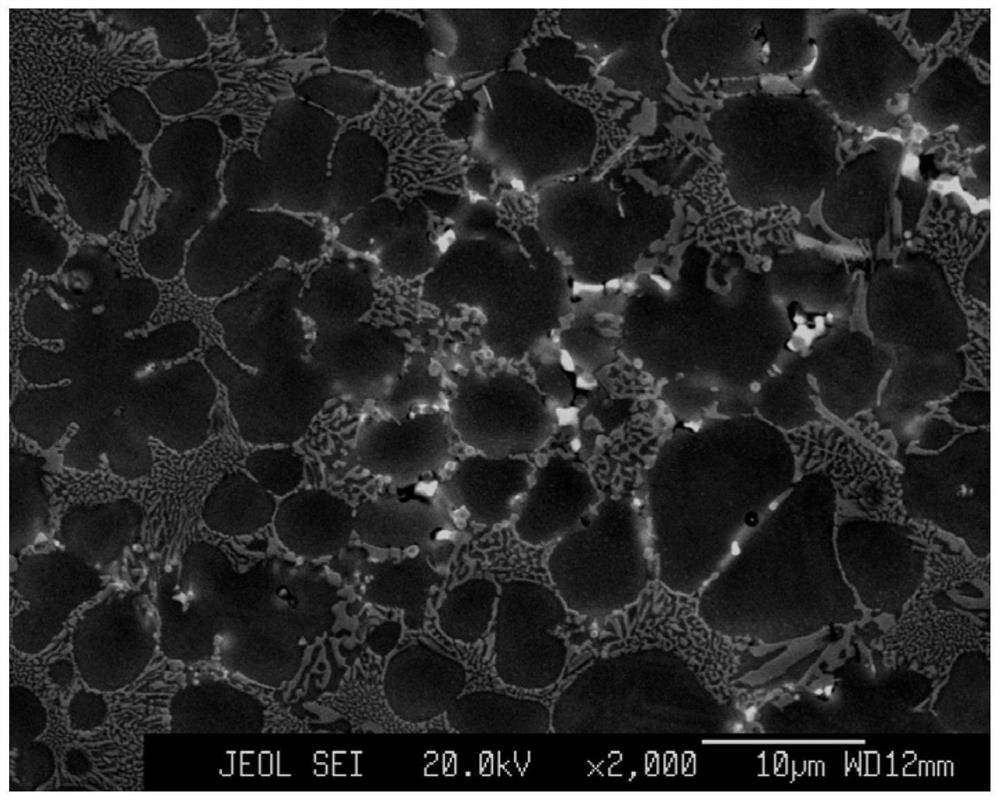

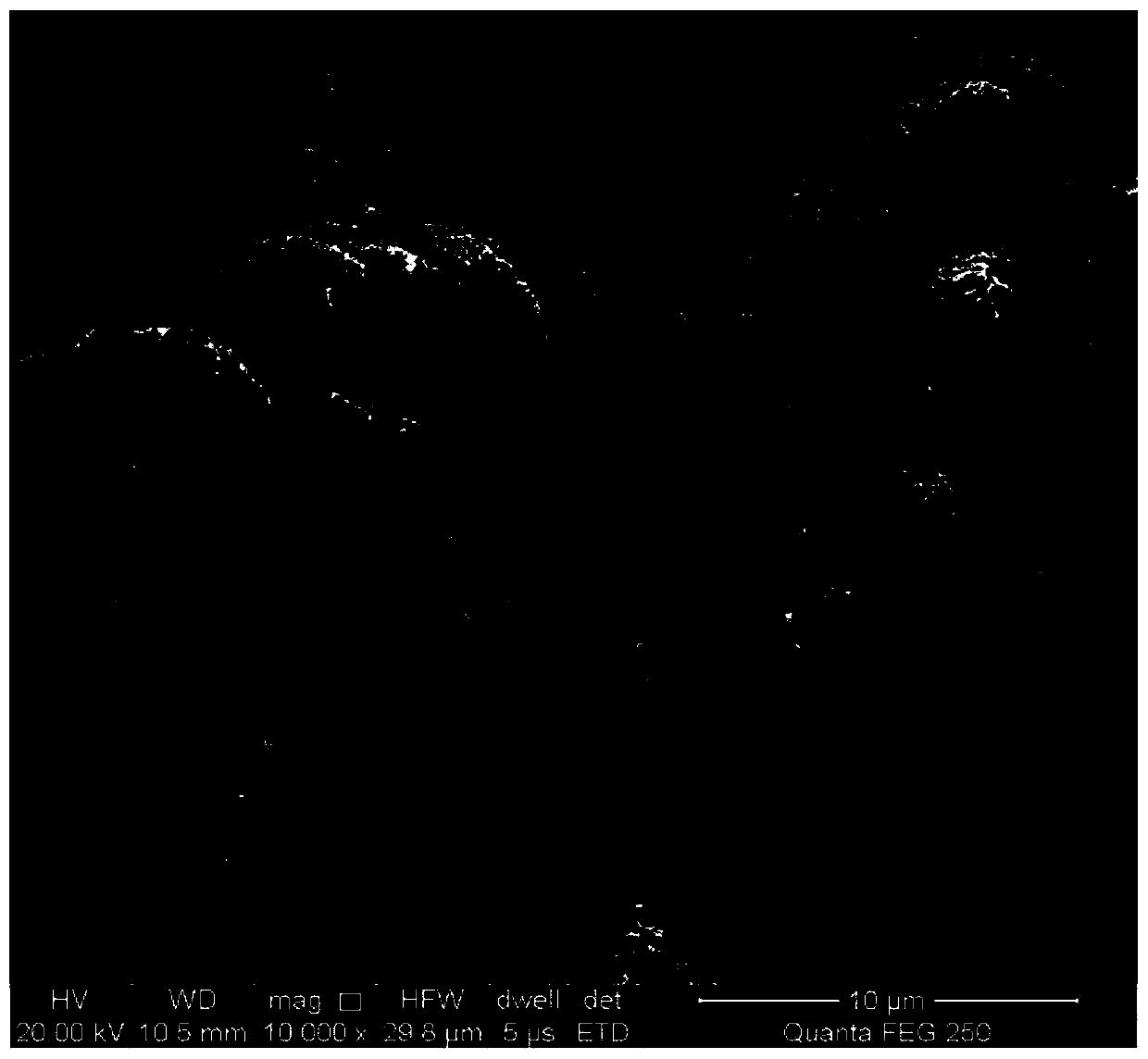

High Fe content Al-Mg2Si alloy prepared by laser selective melting and preparation method

InactiveCN110760724AEvenly distributedEvenly dispersedAdditive manufacturingIncreasing energy efficiencyMaterials scienceMetal

The invention discloses a high Fe content Al-Mg2Si alloy prepared by laser selective melting and a preparation method. The Al-Mg2Si alloy is formed by Al-Mg2Si alloy raw material powder through a laser selective melting technology, the Al-Mg2Si alloy is composed of the following components by mass percentage: 5-5.5% of Mg, 2-2.2% of Si, 0.4-0.6% of Mn, 1-3% of Fe and the balance of aluminum, and the total mass percentage is 100%. According to the invention, the high Fe content Al-Mg2Si alloy is prepared by the laser selective melting technology skillfully, through using the characteristic thatthe cooling rate in the laser selective melting technology can reach 105-108 k / s, after alloy raw material powder is melted, the alloy is in non-equilibrium solidification at an extremely fast cooling rate, alloy elements are uniformly distributed, all elements have no segregation, and (Al+Mg2Si) ultrafine eutectic structures are uniformly formed, meanwhile, the formation of coarse Fe-rich intermetallic compounds is inhibited, fine Fe-rich intermetallic compounds are uniformly dispersed, and the high Fe content Al-Mg2Si alloy with excellent mechanical properties is obtained.

Owner:CENT SOUTH UNIV

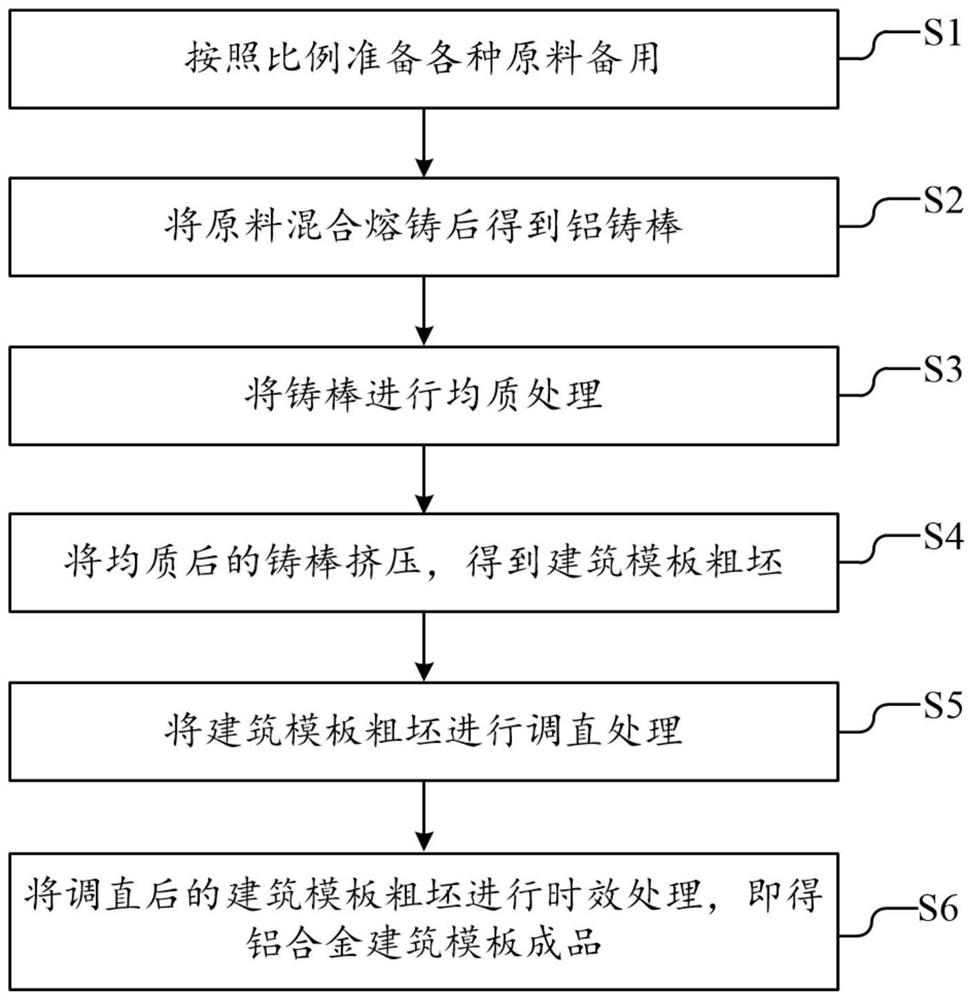

Aluminum alloy building formwork and preparation method thereof

PendingCN113234972AReduced Quench SensitivityImprove solid solubilityFurnace typesHeat treatment furnacesAluminium alloyMechanical properties of carbon nanotubes

The invention discloses an aluminum alloy building formwork mainly comprising, by mass, 0.4%-1.0% of Si, 0.8%-1.3% of Mg, 0.05%-0.2% of Cu, 0.001%-0.15% of Mn, 0.2%-0.7% of Fe, less than or equal to 0.25% of Zn, 0.001%-0.1% of Cr, 0.03%-0.15% of Ti and the balance Al and inevitable impurities. The content of the inevitable impurities is less than or equal to 0.15%. Correspondingly, the invention further discloses a preparation method of the aluminum alloy building formwork. The aluminum alloy building formwork is excellent in mechanical property, the extrusion speed can reach 8-10 m / min, and the production efficiency is high.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP +1

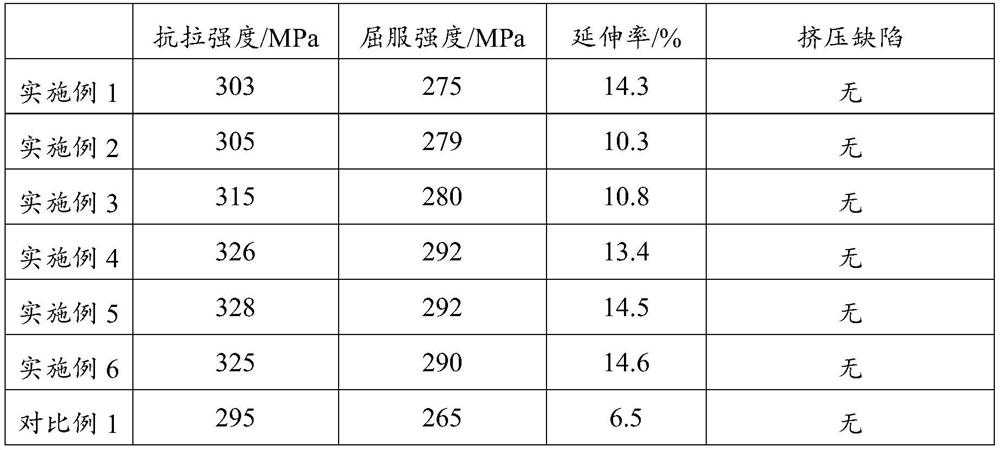

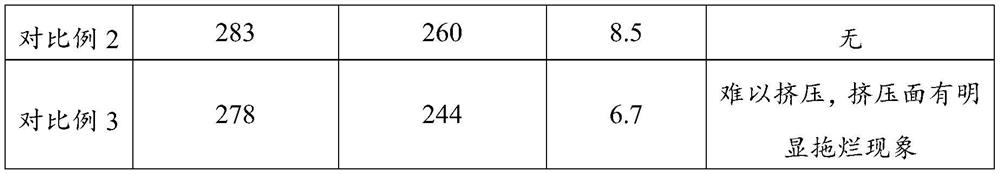

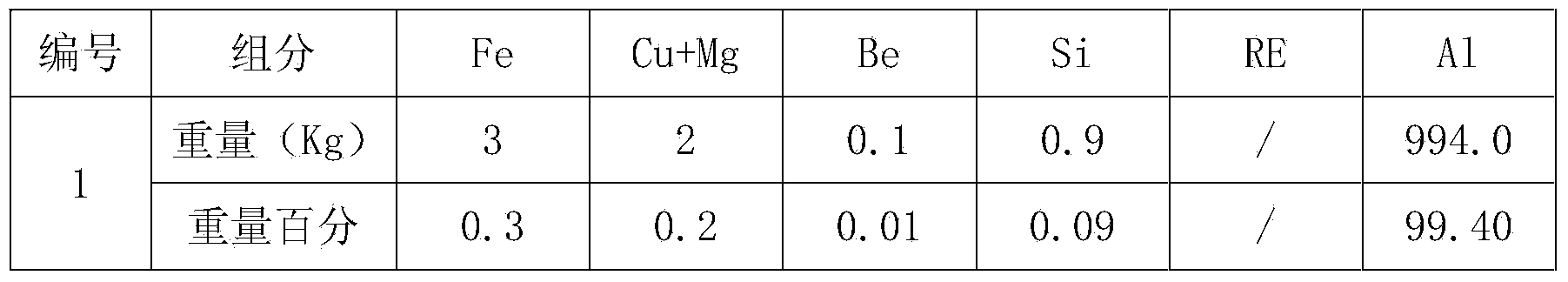

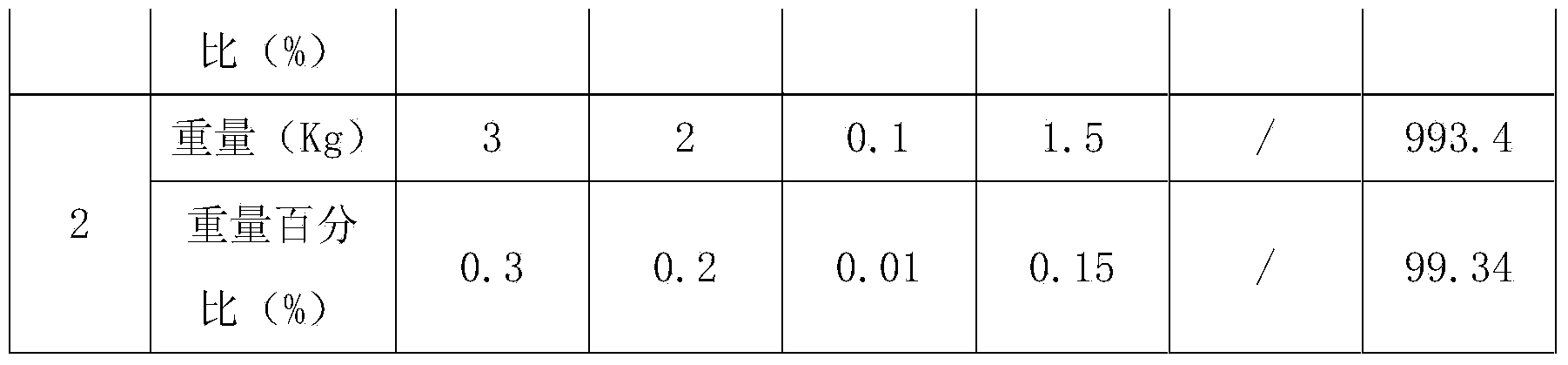

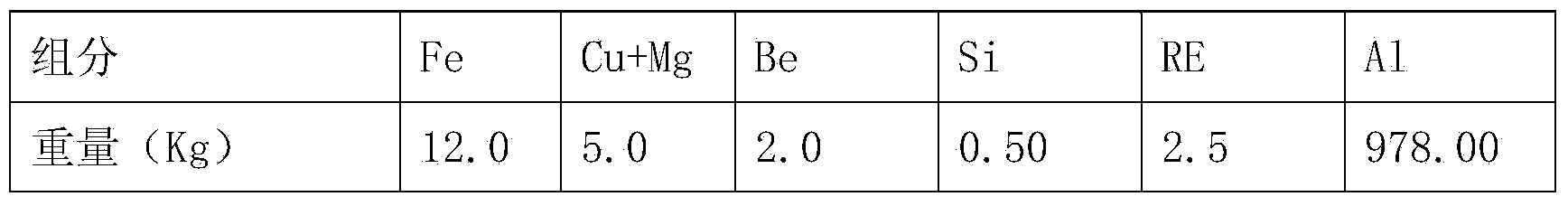

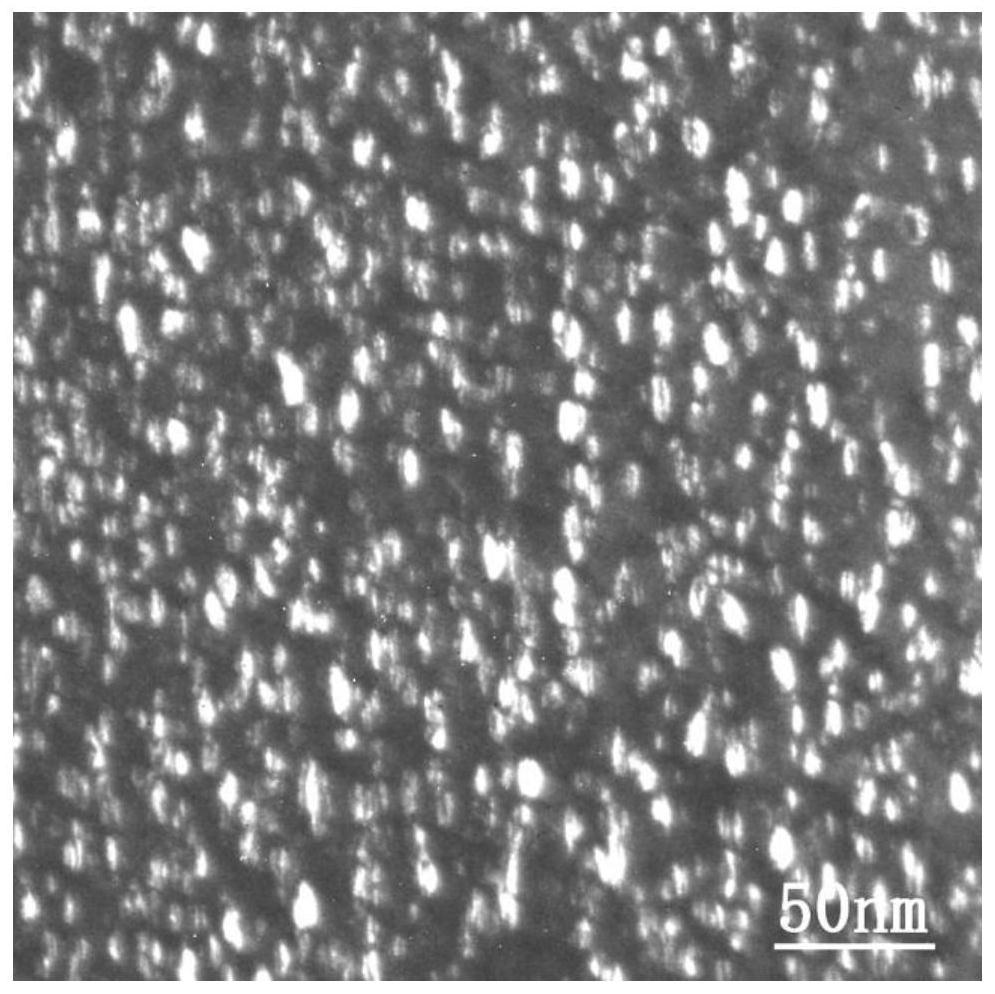

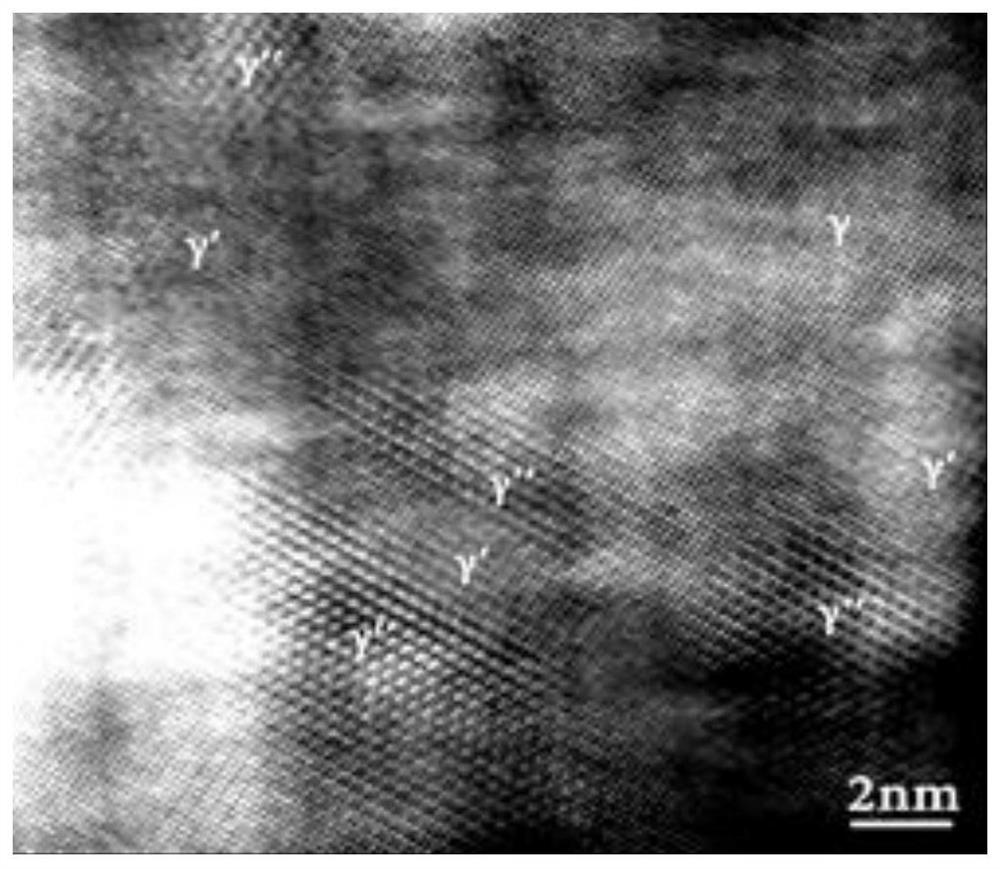

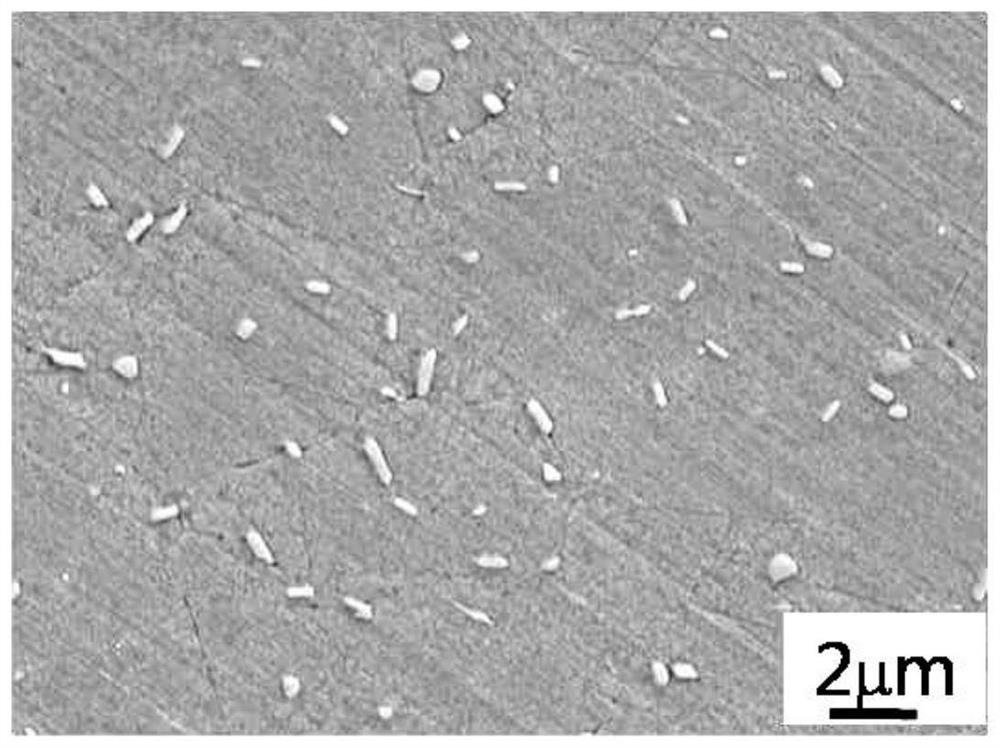

Al-Fe-Cu-Mg-Be alumium alloy for automobile wire and wiring harness therefore

PendingCN103725930AHigh mechanical strengthImprove tensile propertiesNon-insulated conductorsMetal/alloy conductorsSurface finishUltimate tensile strength

The invention discloses an Al-Fe-Cu-Mg-Be alumium alloy for an automobile wire and a preparation method thereof, and an automobile wiring harness prepared by the preparation method. The Al-Fe-Cu-Mg-Be alumium alloy for the automobile wire comprises the following components: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Cu+Mg, 0.001-0.2wt% of Be, and the balance of Al and inevitable impurities. According to the invention, Fe element is added so that the mechanical strength and the tensile property of the alloy can be improved; Fe is also capable of obviously improving the high-temperature creep resistance and the fatigue resistance of the alloy; the addition of Cu+Mg is capable of improving the strength and the high-temperature creep property and the fatigue resistance of the alloy; Be is capable of improving the smelting quality of the alloy and the compactness of the surface oxide film, so that good-quality castings good in surface smoothness, high in strength and improved in ductility can be obtained; Be is also capable of improving the fluidity of the alloy so that the fluidity of the melt is improved, and can further improve the tensile strength and the limit of yielding of the alloy.

Owner:ANHUI JOY SENSE CABLE

High-temperature alloy for hydrogen fuel cell air compressor bearing, and preparation method thereof

ActiveCN111733346AImprove machinabilityDoes not affect structural stabilityHydrogen fuel cellAir compressor

The invention relates to a high-temperature alloy for a hydrogen fuel cell air compressor bearing, and a preparation method thereof. The high-temperature alloy adopts austenite with a disordered face-centered structure reinforced by adopting an ordered phase L12-gamma' and a body-centered tetragonal ordered structure gamma''-(Ni3Nb); the volume fraction of a reinforcement phase ranges from 10 percent to 25 percent; and the high-temperature alloy is prepared from the components in proportion by weight: 0.02 to 0.08 percent of C, 9 to 18 percent of Fe, 12 to 18 percent of Cr, 0.85 to 1.5 percentof Al, 1.2 to 2.25 percent of Ti, 3.5 to 5 percent of Nb, 2 to 5 percent of Mo, less than or equal to 0.05 percent of B, less than 0.25 percent of Si, less than 0.25 percent of Mn, and the balance Ni, so that the alloy has excellent high-temperature strength and structure stability, and favorable machinable property and economical efficiency. According to the alloy, a TCP phase is not precipitated obviously at the temperature below 760 DEG C, the tensile strength at the temperature being 760 DEG C is larger than 1000MPa, and the alloy is particularly suitable for preparing a medium-high temperature force-bearing part including a hydrogen cell of the hydrogen fuel cell air compressor bearing.

Owner:上海康晟航材科技股份有限公司

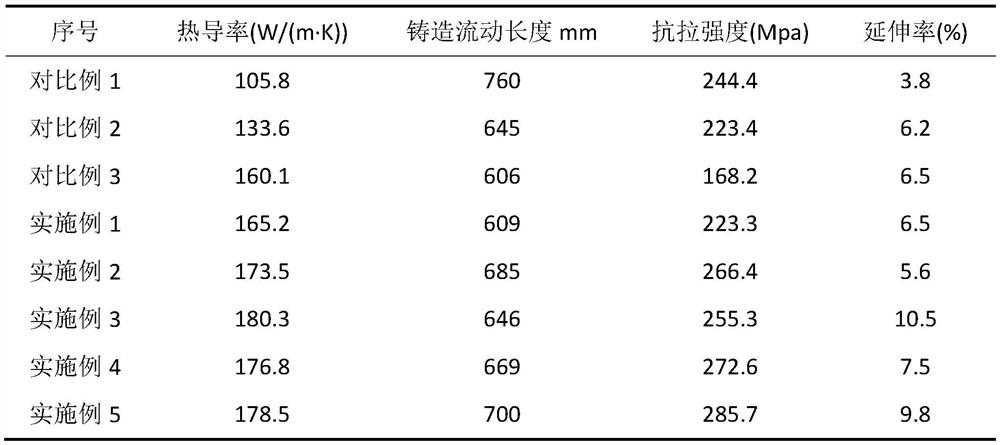

A kind of cast aluminum alloy with high thermal conductivity, high strength and low Si and preparation method thereof

ActiveCN111485146BGood casting fluidityMeet casting performance requirementsCo elementThermal conductivity

The invention discloses a cast aluminum alloy with high thermal conductivity, high strength and low Si and a preparation method thereof; the raw material components are: 2.5-4.5% Si; 2.0-3.0% Zn; 0.8-1.2% Fe; 0.2-0.4% Mg; 0.1-0.3% Co; 0.03-0.1% Sr; 0.02%-0.05% B; 0.05-0.15% RE; the balance is Al; the preparation method includes high-temperature melting aluminum alloy, supplementary elements and trace elements multi-component alloying treatment, Refining slag removal, casting molding. The invention makes full use of the composite synergistic effect of auxiliary alloying of Mg and Co elements and microalloying of Sr, B and RE elements, solves the problem of mutual restriction between the strengthening of the alloy and the improvement of the thermal conductivity of the material, and realizes the thermal conductivity and high thermal conductivity of the cast aluminum alloy. With the synchronous improvement of mechanical properties, a low-Si cast aluminum alloy material for communication and heat dissipation devices with high thermal conductivity and high strength has been obtained.

Owner:SOUTH CHINA UNIV OF TECH

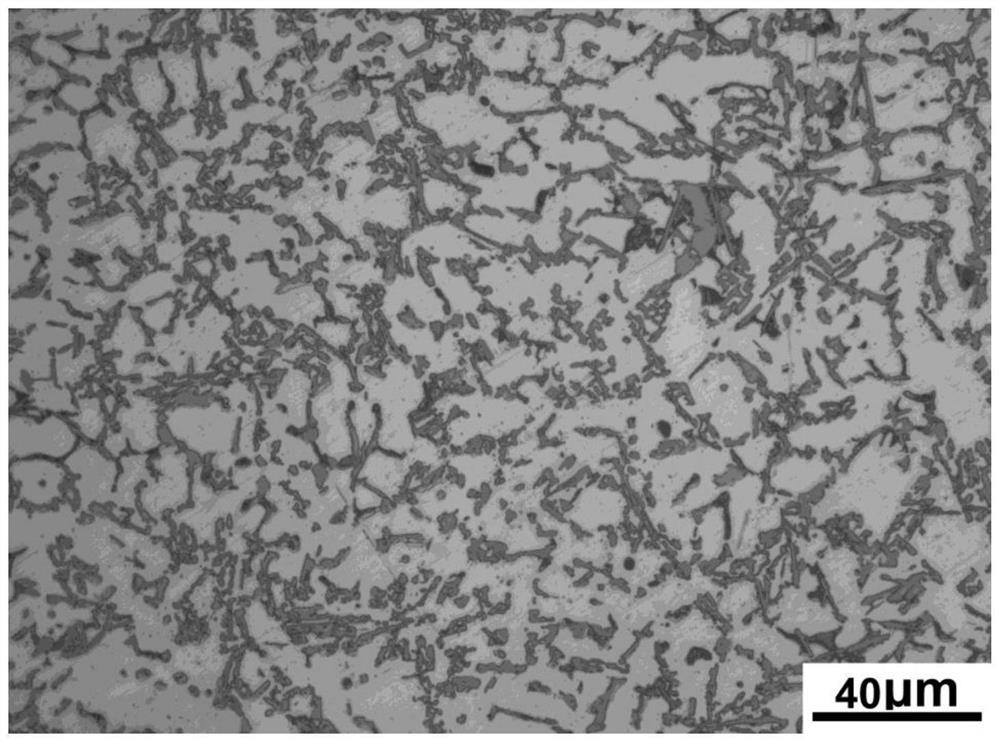

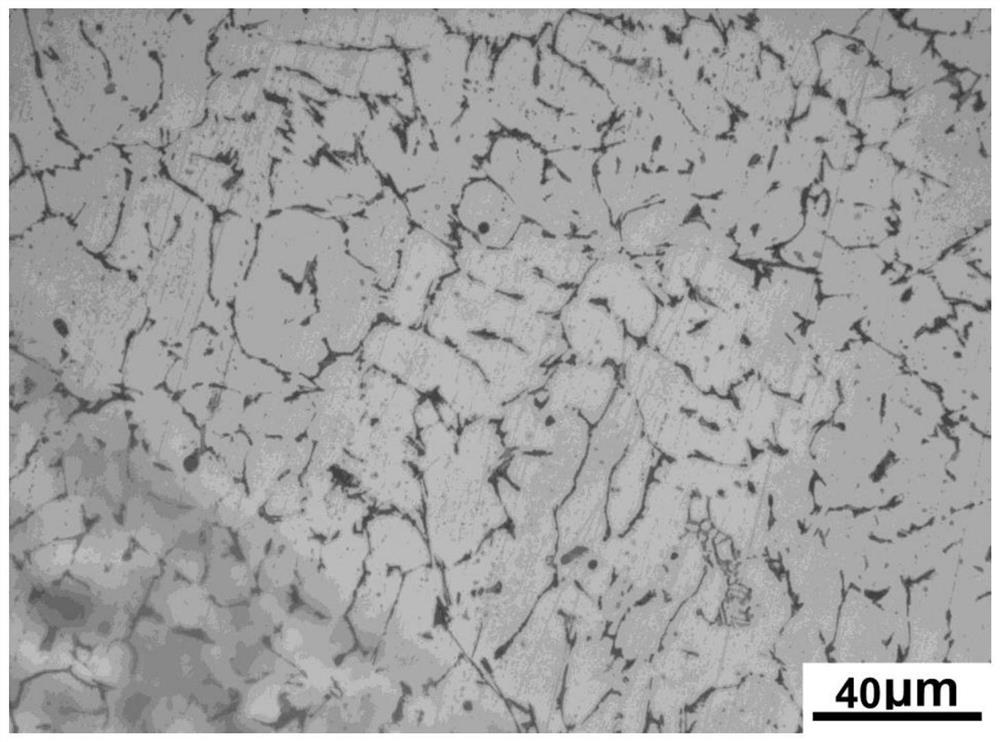

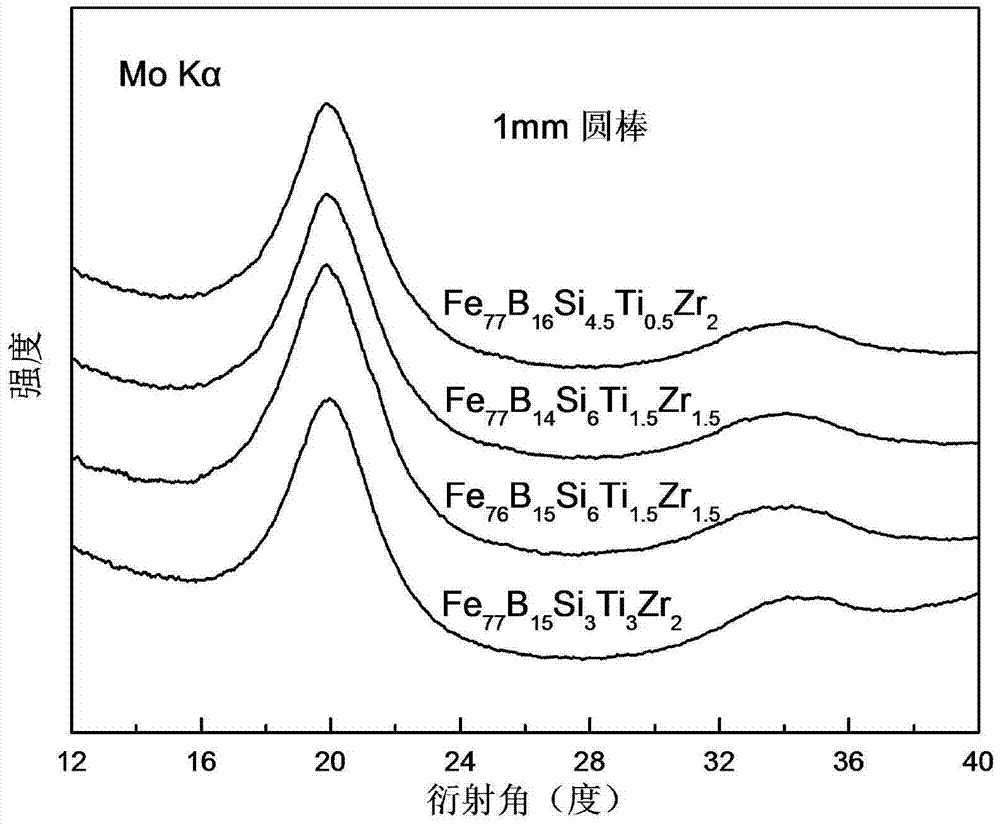

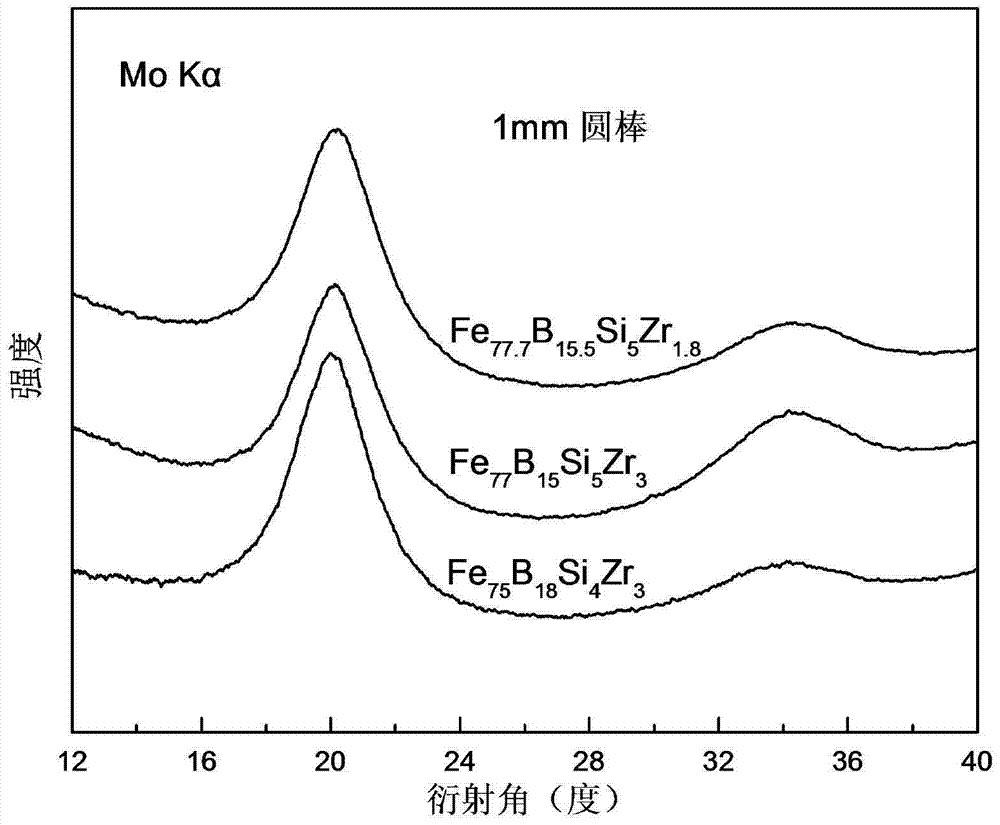

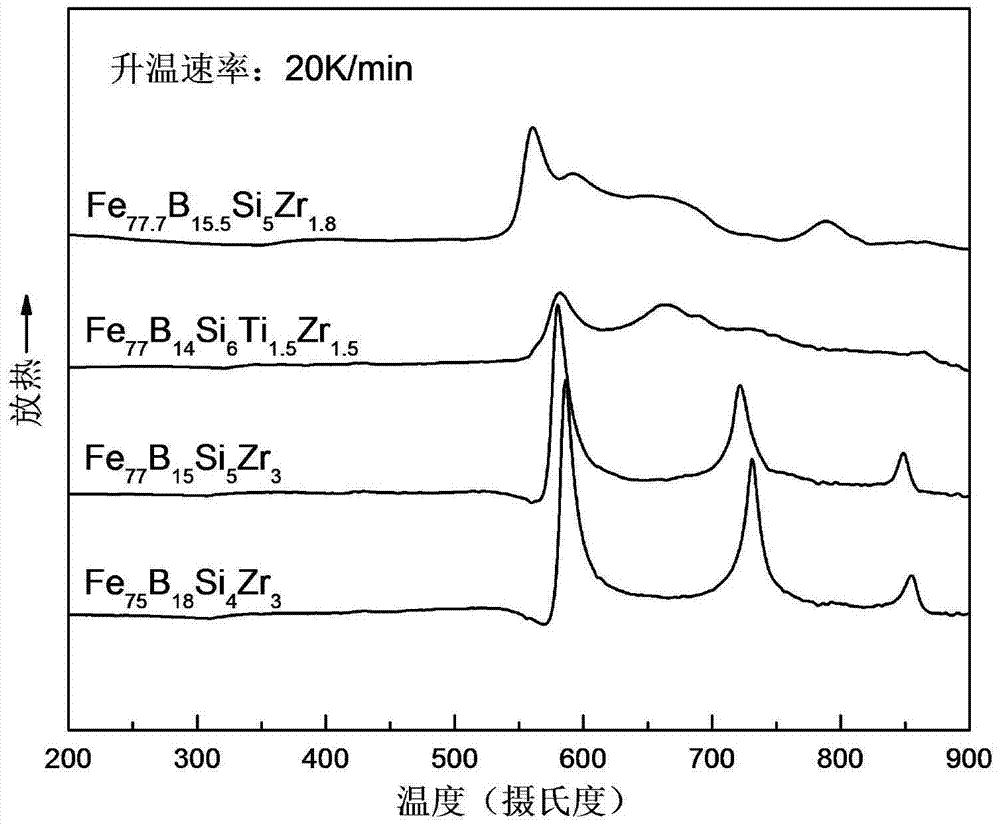

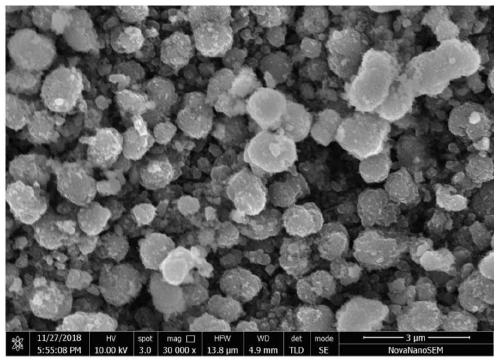

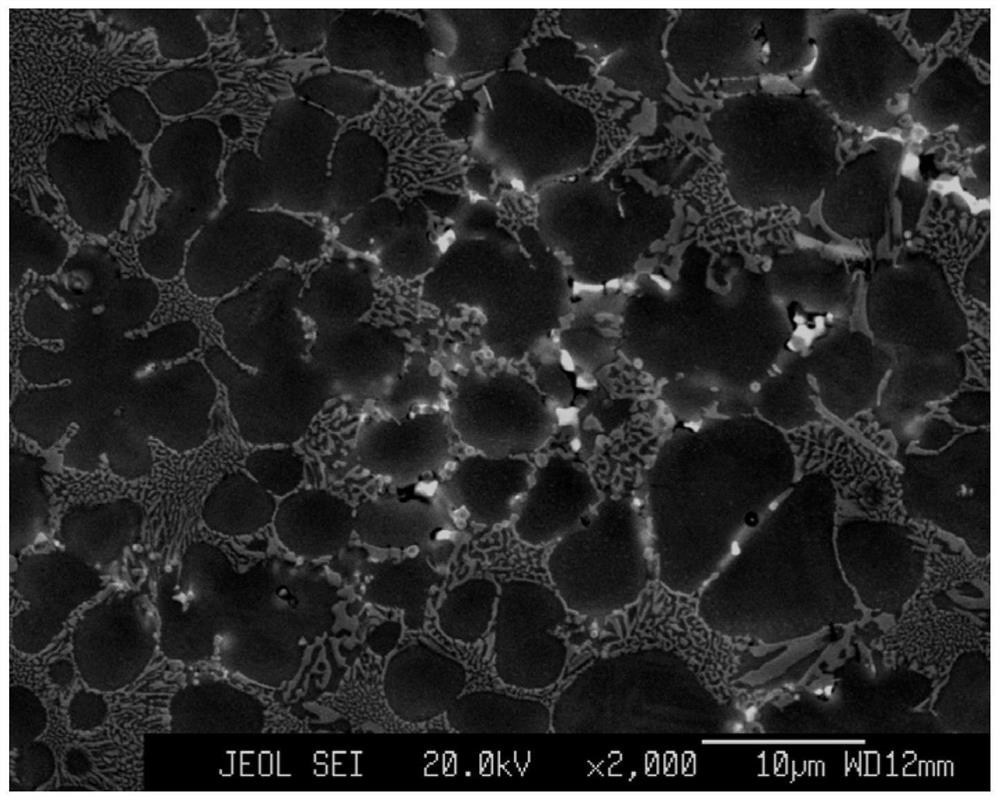

A fe-b-si-based bulk amorphous alloy with high saturation magnetization

ActiveCN105420641BHigh saturation magnetizationEnhanced Amorphous Formation AbilityMagnetic materialsChemical compositionUltimate tensile strength

The invention discloses a Fe-B-Si iron-based bulk amorphous alloy and belongs to the field of amorphous alloys. The chemical components of the amorphous alloy are designed to be FeaBbSicTidZre according to the atomic ratio. The component features include: a is larger than or equal to 75 but smaller than or equal to 79; b is larger than or equal to 12 but smaller than or equal to 19; c is larger than or equal to 2 but smaller than or equal to 9; d is larger than or equal to 0 but smaller than or equal to 5; e is larger than or equal to 1 but smaller than or equal to 3.5; d+e is larger than or equal to 1 but smaller than or equal to 6; a+b+c+d+e is equal to 100. The Fe-based amorphous alloy has the characteristics that high Fe content and good amorphous forming ability are achieved. High saturation magnetization of the alloy is guaranteed by the aid of high Fe content, and meanwhile low coercive force of the alloy is guaranteed through the alloy amorphous characteristic. Accordingly, the Fe-B-Si bulk amorphous alloy is good in the application prospect in the field of soft magnetic materials.

Owner:UNIV OF SCI & TECH BEIJING

Low-pressure casting process of aluminum alloy turbine

The invention discloses a low-pressure casting process of an aluminum alloy turbine. A metal mold is preheated to a temperature of 380 DEG C for keeping 2 hours; a resin sand core is heated to a temperature of 100 DEG C by a far infrared heating furnace for keeping 60 minutes, and is discharged from the furnace before the casting to perform the mold assembly; an aluminum alloy is molten by a steel plate furnace lined with a resistance furnace, and is cast at a temperature of 700-710 DEG C; the mold filling time is 15-20 S; the pressure keeping time is 10-12 min; and the mold filling pressure is 0.08 MPa. Asbestos cloth is adopted to seal so as to effectively prevent the problem of greater gas generation quantity due to the sealing by a sealing gasket in a traditional production process; and the proper casting temperature of 700-710 DEG C is selected, so that the time of the aluminum alloy in a crucible is shortened, the increment of the Fe content is reduced, the working efficiency is improved, the service life of a liquid rising pipe is prolonged, and the production cost is reduced.

Owner:QINGDAO YUGUANG PRECISION CASTING FACTORY

Novel biomass-based catalyst as well as preparation method thereof and application of catalyst in coal pyrolysis

ActiveCN109847755AImprove catalytic performanceActive component with high Fe contentCatalyst activation/preparationSpecial form destructive distillationBrown coalActive component

The invention belongs to the technical field of coal dry distillation engineering, and particularly relates to a method for depolymerizing coal by utilizing a novel biomass-based catalyst. Specifically, brown coal is pyrolyzed by using the novel Fe-Ni / Humus catalyst. The novel biomass-based catalyst Fe-Ni / Humus provided by the invention has the advantages of a high content of active component Fe,good thermal stability and oxidation resistance, better catalytic activity, cheapness and accessibility; and when the novel biomass-based catalyst is used for pyrolysis of the brown coal, the conversion rate of coal coke cracking can be improved, the catalyst can be regenerated, and a recycling pollution-free production conception is realized.

Owner:ZHENGZHOU UNIV

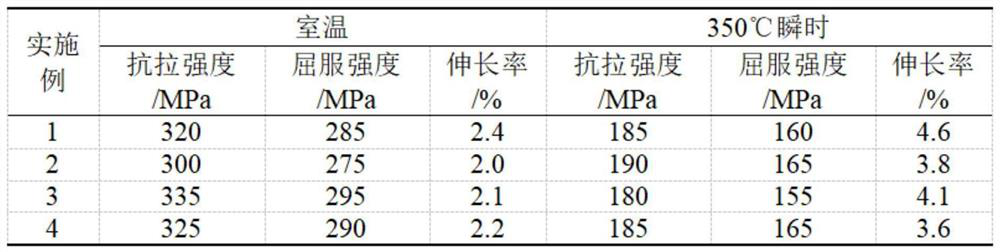

A heat-resistant recycled die-casting aluminum alloy and its preparation method

The invention discloses a heat-resistant recycled die-casting aluminum alloy and a preparation method thereof, belonging to the field of preparation of recycled die-casted aluminum alloys. The invention includes a method for providing a heat-resistant recycled die-casting aluminum alloy and a preparation method for reducing the preparation cost; the chemical composition of the heat-resistant recycled die-casted aluminum alloy is as follows: the content of Si is 10.0-12.0%, and the content of Ni is 0.50-0.75%. , the content of Mg is 0.95-1.35%, the content of Fe is 0.9-1.4%, the content of Mn is 0.20-0.30%, the content of Cr is 0.08-0.12%, the content of B is 0.015-0.03%, and the content of impurity elements is ≤ 0.15%, and the rest is Al; the preparation method is as follows: smelting, sampling to adjust the alloy composition, refining after adding low-melting point alloy, slag removal, and casting; the present invention effectively reduces the alloy content by replacing Ni and Cu with cheap impurity element Fe. Cost, and through the compound modification technology of Mn, Cr, B, etc., the size of the iron-rich phase is refined to ensure the high temperature strength of the alloy.

Owner:肇庆南都再生铝业有限公司 +2

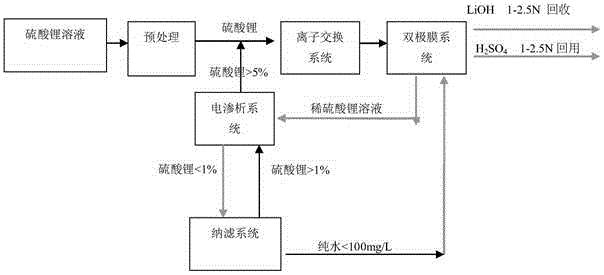

Lithium Hydroxide Recovery Technology from Solution by Bipolar Membrane Method

ActiveCN105154908BReduce consumptionSolve environmental problemsElectrolysis componentsLithium sulphateEnvironmental issue

The invention provides a bipolar membrane method for recovering lithium hydroxide from a solution. The lithium sulfate solution is treated with a bipolar membrane system, and the produced water after the bipolar membrane system treatment is lithium hydroxide and sulfuric acid. The invention not only solves the problem of environmental protection, but also reduces the consumption of alkali and acid, realizes clean production, saves energy and reduces emissions, and reduces operating costs.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

Super-soft aluminum alloy conductor and preparation method thereof

ActiveCN101974709BLittle change in performanceReduce solid solutionMetal/alloy conductorsElectrical conductorRare earth

Owner:ANHUI JOY SENSE CABLE

An iron-based soft magnetic amorphous alloy with few components, low cost and high saturation magnetic induction and its preparation process

The invention belongs to the field of metal materials, and relates to an iron-based soft magnetic amorphous alloy with few components, low cost and high saturation magnetic induction intensity and a preparation process thereof. The iron-based soft magnetic amorphous alloy of the present invention, the atomic percentage of each element in the alloy is as follows: 5%≤boron≤12%, 3%≤phosphorus≤10%, 0.5%≤tin≤5%, 80%≤iron ≤84.5%. The invention has low production cost and simple process; the prepared soft magnetic amorphous alloy has the characteristics of high saturation magnetization and low coercive force, and is suitable for transformer cores, amorphous motors and other devices, and is applied in electric power, electronics, information, communications and other fields.

Owner:SHANDONG UNIV

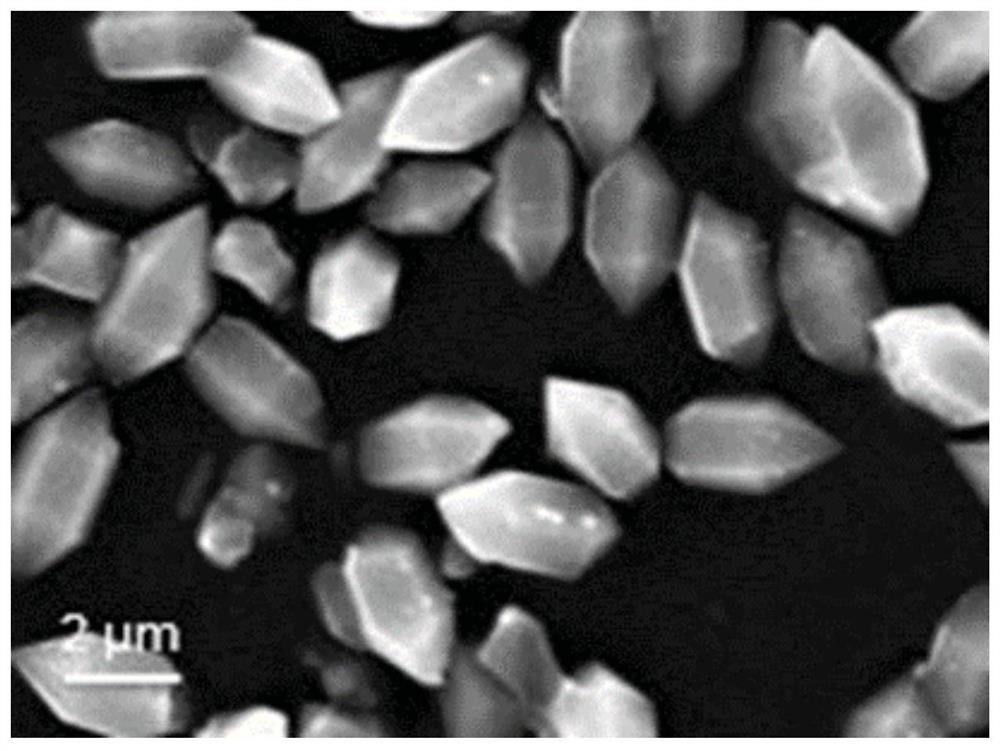

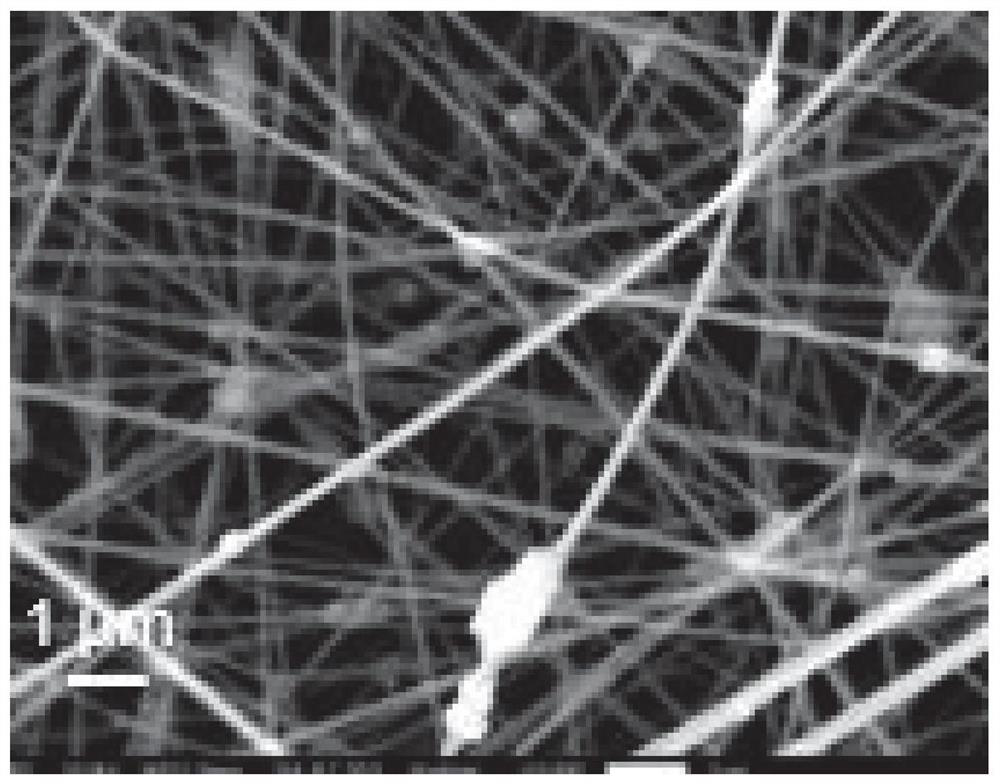

Preparation and application of Fe-N-CNFs catalyst based on Fe-MIL

PendingCN113889628AHigh in ironHigh quality conversion efficiencyCell electrodesPtru catalystSynthetic materials

The invention provides preparation and application of a Fe-N-CNFs (Carbon Nanofibers) catalyst based on Fe-MIL, and the method is as follows: firstly, ferric chloride hexahydrate and terephthalic acid react in N, N-dimethylformamide to generate a Fe-MIL precursor, then the Fe-MIL precursor and a nitrogen-containing binder are mixed in N, N-dimethylformamide for electrostatic spinning to prepare nanofibers, and then the nanofibers are prepared into the Fe-N-CNFs catalyst based on Fe-MIL, and the Fe-N-CNFs (Carbon Nanofibers) catalyst is prepared after the Fe-N-CNFs catalyst is subjected to pre-sintering and pyrolysis. The catalyst is large in active area, high in electron transfer capability and high in mass transmission capability, so that the capability of catalyzing the oxygen reduction reaction is relatively high. In addition, the synthetic material is low in price, and the cost of the catalyst can be reduced, so that the catalyst has a relatively great application prospect in the aspect of proton exchange membrane fuel cells.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Iron and Steel Pickling Wastewater Recycling and Zero Discharge Process

ActiveCN104030502BIncrease Fe contentLow free acidMultistage water/sewage treatmentFenton reactionFlocculation

The invention belongs to the technical field of water treatment, and particularly relates to a steel pickling waste water resourcization and zero discharge process. The steel pickling waste water resourcization and zero discharge process comprises the following process steps of: (a) introducing steel pickling waste water; (b) carrying out Fenton reaction on the steel pickling waste water to reduce the COD (Chemical Oxygen Demand) of the steel pickling waste water to be less than or equal to 60 mg / L, convert Fe<2+> into Fe<3+> and reduce TDS (Total Dissolved Solids) to be less than or equal to 2000 mg / L; (c) carrying out FeC microelectrolysis reduction reaction on the steel pickling waste water; (d) carrying out neutralization flocculation; (e) desalting a membrane assembly to reduce the TDS of the steel pickling waste water to be less than or equal to 200 mg / L; (f) recycling effluent water. The steel pickling waste water resourcization and zero discharge process disclosed by the invention realizes the cleaning production, realizes the resourcization utilization of waste water, waste acid and iron mud, generates the benefit and realizes the zero discharge.

Owner:DONGGUAN SANRENXING ENVIRONMENTAL TECH CO LTD

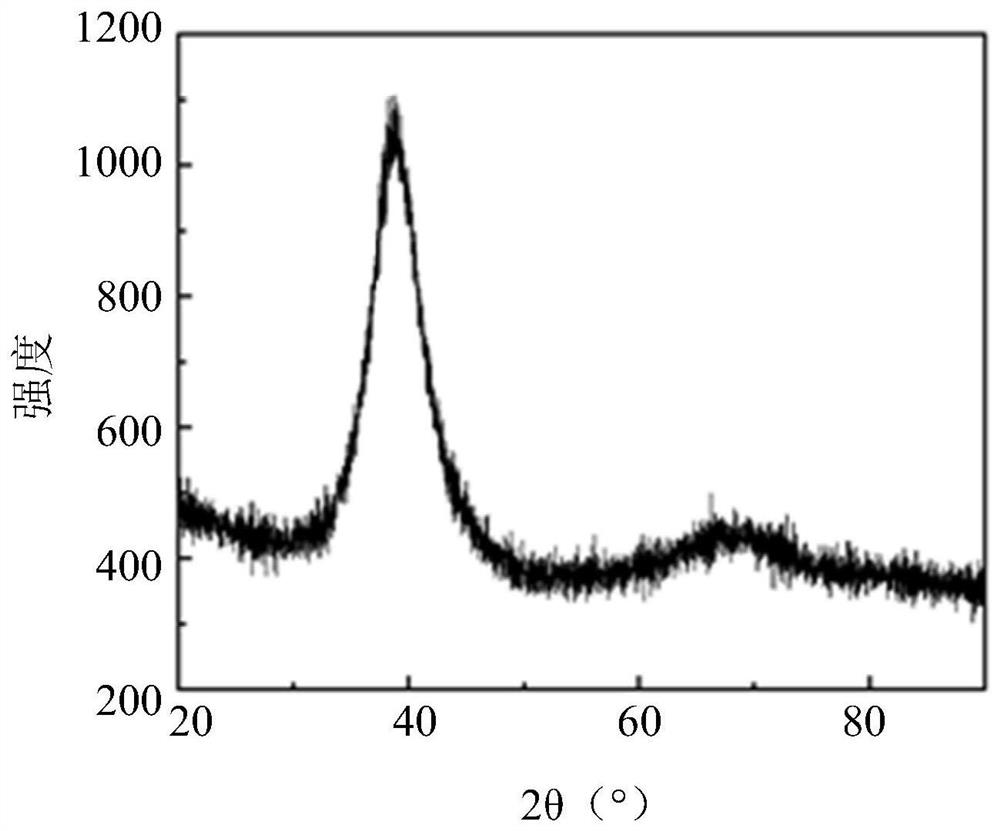

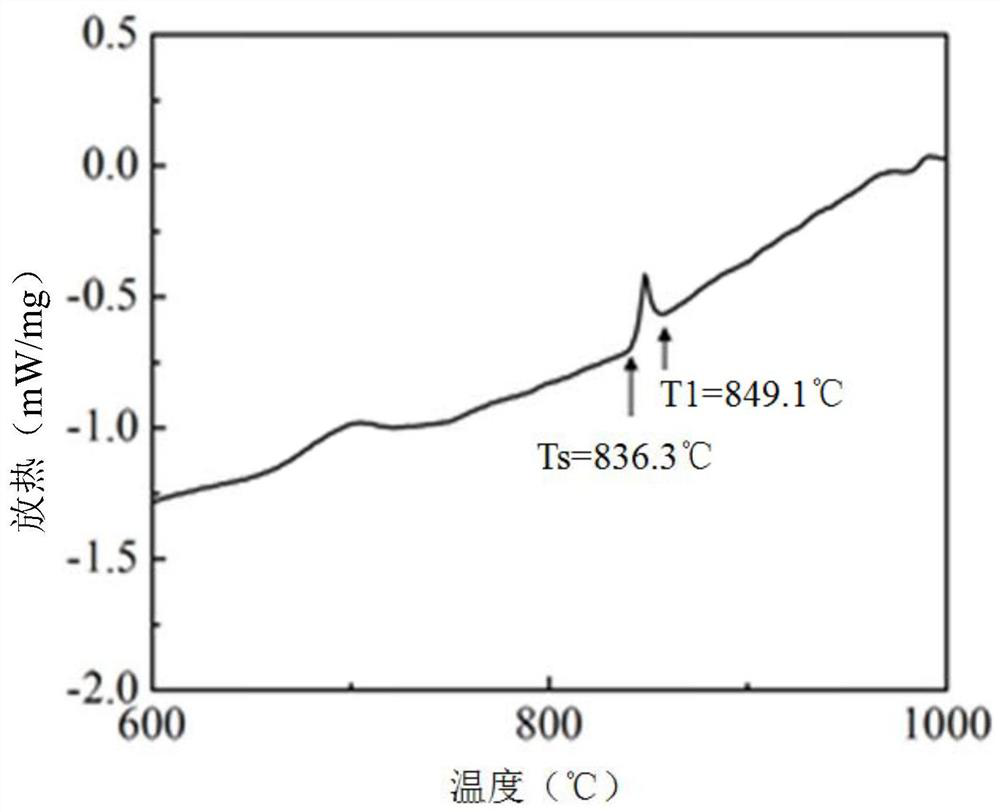

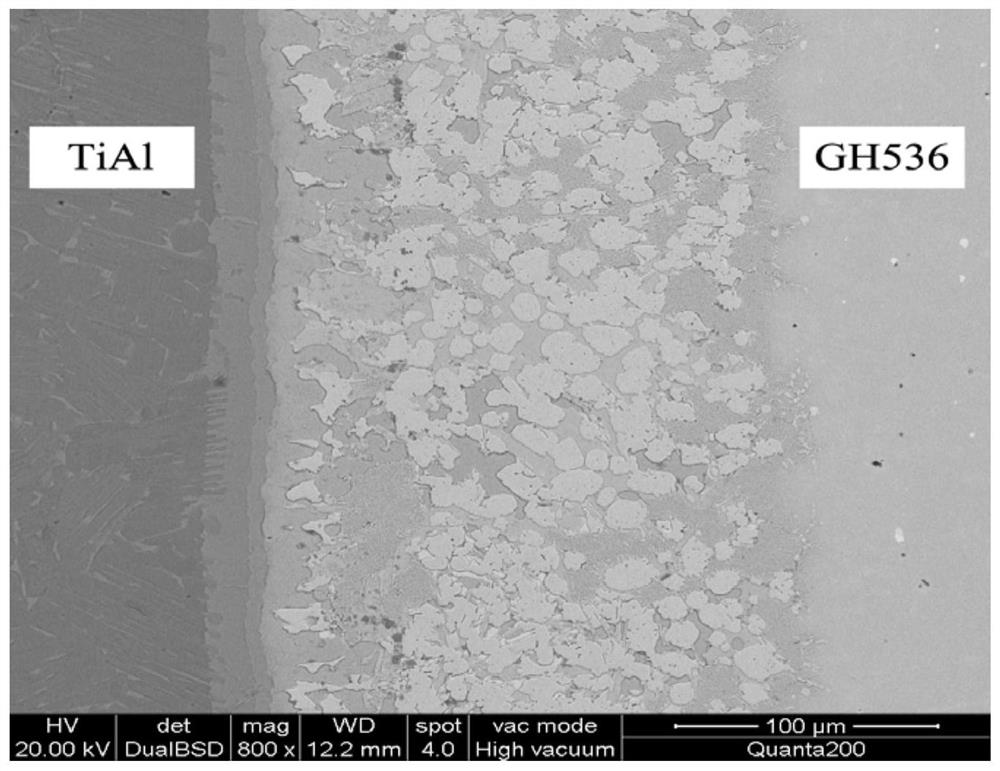

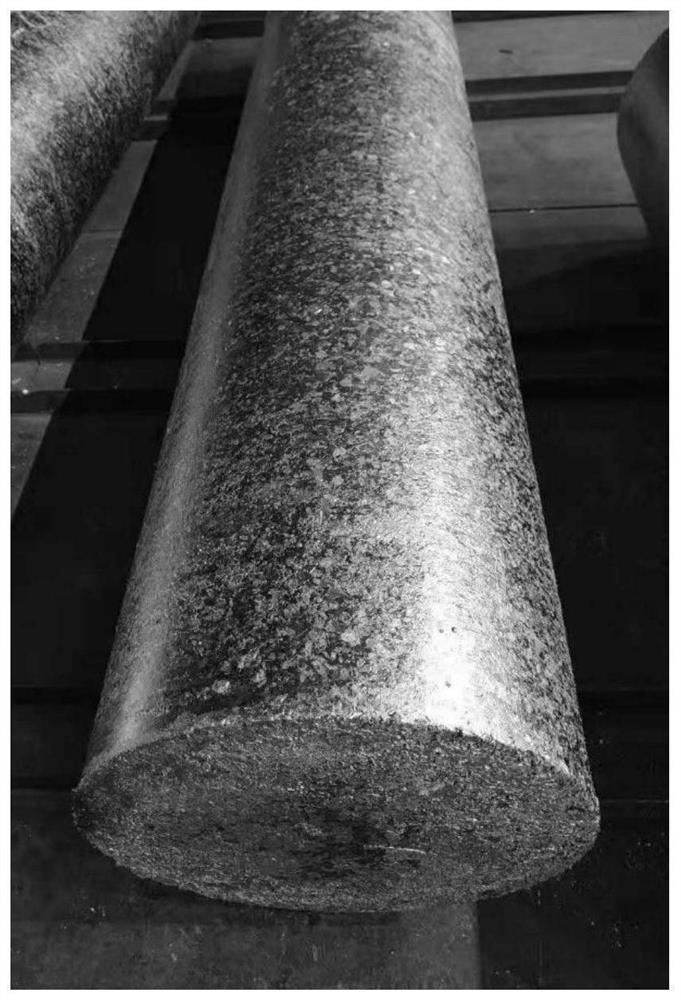

A kind of ti-zr-ni-fe-cu-co-mo-b solder and its preparation method and application

ActiveCN108971801BLow melting pointReduce manufacturing costWelding/cutting media/materialsSoldering mediaMetallurgyIngot

The invention belongs to the technical field of welding materials, and discloses Ti-Zr-Ni-Fe-Cu-Co-Mo-B brazing filler metal and a preparing method and application thereof. The brazing filler metal comprises the following components including, by mass, 29%-32% of Zr, 3.4%-7% of Fe, 7.5%-13% of Ni, 3%-5% of Cu, 2%-4% of Co, 1%-3% of Mo, 0.2%-0.6% of B and the balance Ti. According to the brazing filler metal, the preparing method and application, burdening is carried out according to the contents of the above components; and an electric arc melting method is adopted for preparing a brazing filler metal alloy ingot, the alloy ingot is smashed into small particles to be heated and melted, and a rapid set technology is adopted for preparing the Ti-Zr-Ni-Fe-Cu-Co-Mo-B foil brazing filler metal.The brazing filler metal has the advantages that the belt forming performance is high, the cost is low, and the braze TiAl and Ni based high temperature alloy connector connecting strength is high.

Owner:SOUTH CHINA UNIV OF TECH

A kind of super strong high plasticity titanium alloy and preparation method thereof

The invention provides a super-strong high-plastic titanium alloy, which comprises the following composition by weight percentage: Al: 4.5% to 5.75%, Mo: 3.0% to 5.0%, Zr: 2.0% to 4.0%, Fe: 2.0% to 3.0%, Sn: 0.3%-2.0%, Cr: 0.30%-1.2%, O≤0.15%, and the rest are Ti and trace impurities. The invention also provides a preparation method of the super-strong high-plastic titanium alloy. The invention increases the tensile strength of the titanium alloy to 1400MPa-1550MPa through the simultaneous addition of multiple multi-element alloys, while ensuring the processing plasticity of the material, making the elongation greater than 10% and the reduction of area greater than 20%.

Owner:重庆金世利航空材料有限公司 +1

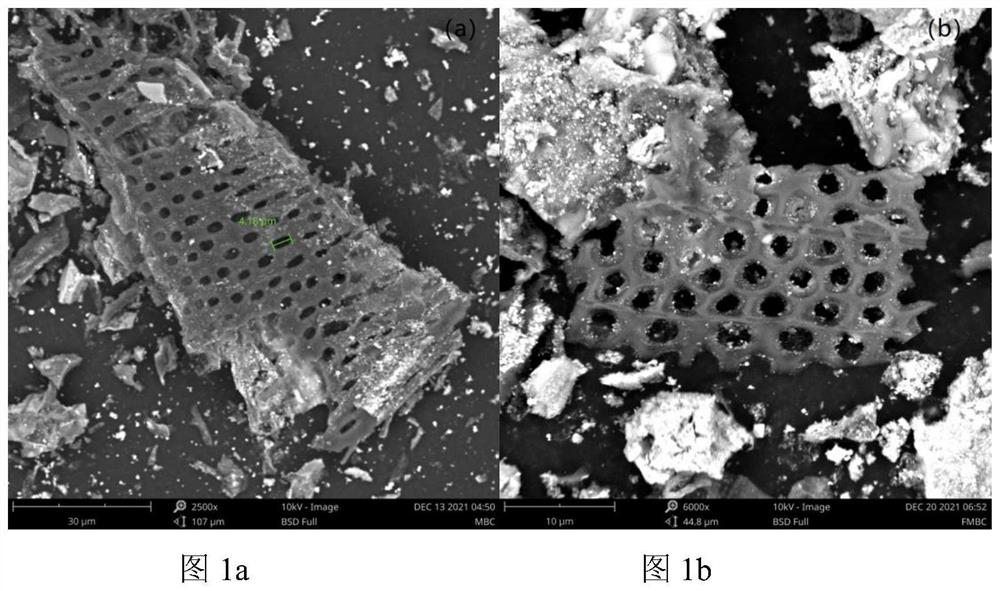

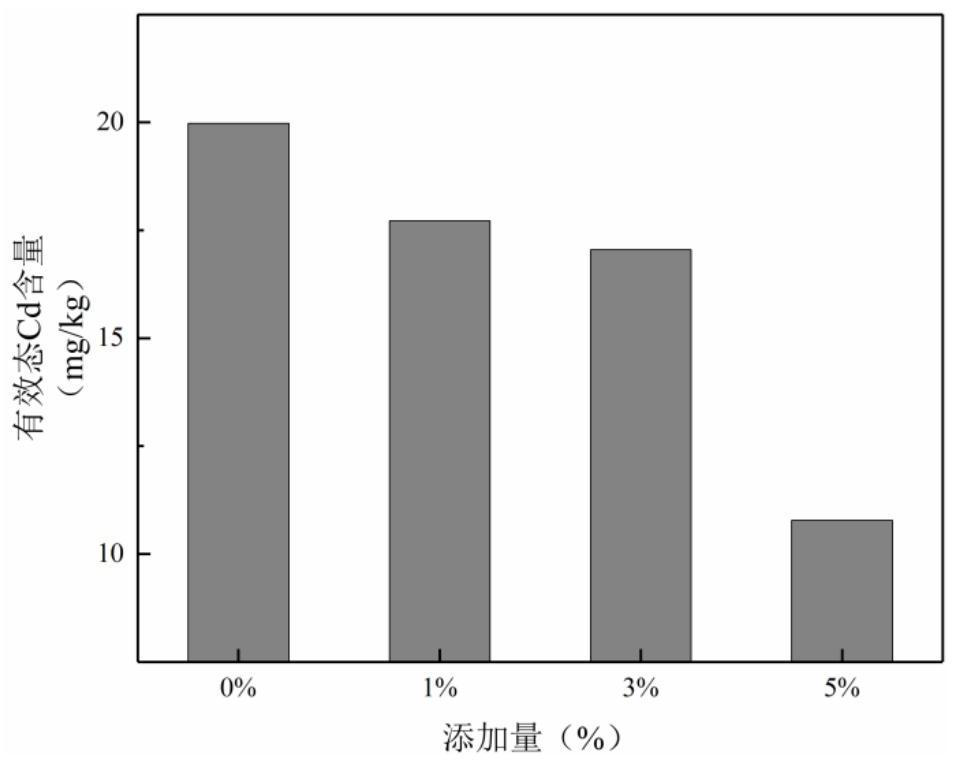

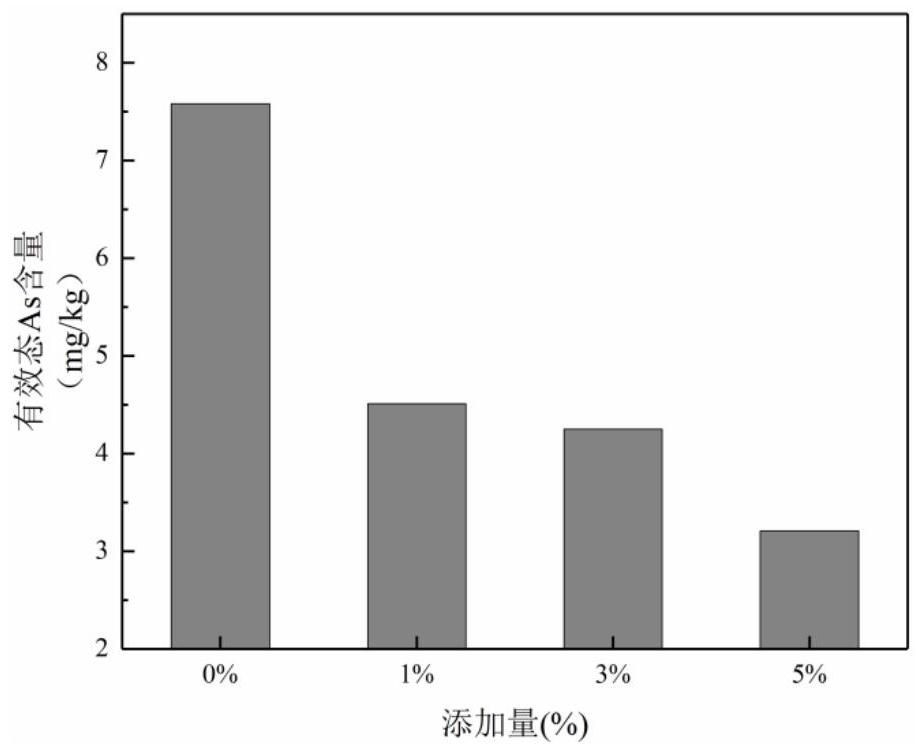

Preparation method and application of ferromagnetism-rich biochar for synchronously treating cadmium and arsenic in freeze-thaw environment

PendingCN114682216AIncrease Fe contentLow priceOther chemical processesContaminated soil reclamationFreeze thawingSoil science

The invention relates to the technical field of biochar preparation, in particular to a preparation method of ferromagnetism-rich biochar and application of the ferromagnetism-rich biochar in adsorption of heavy metal pollution. And immersing the magnetic biochar in a FeCl3 solution, adjusting the pH value of the system to 7-12 under a stirring condition, standing at room temperature for 24-36 hours, filtering, and drying to obtain the ferromagnetism-rich biochar. The modified biochar provided by the invention can realize synchronous and stable remediation of soil heavy metal Cd-As combined pollution. The modified biochar is higher in applicability, and the ferromagnetism-rich biochar still has a better stabilizing effect on Cd-As under the condition of different water contents of soil; after freezing and thawing, the effective state content of Cd-As in the soil can still be reduced by more than 30%.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com