Patents

Literature

34results about How to "Does not affect structural stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

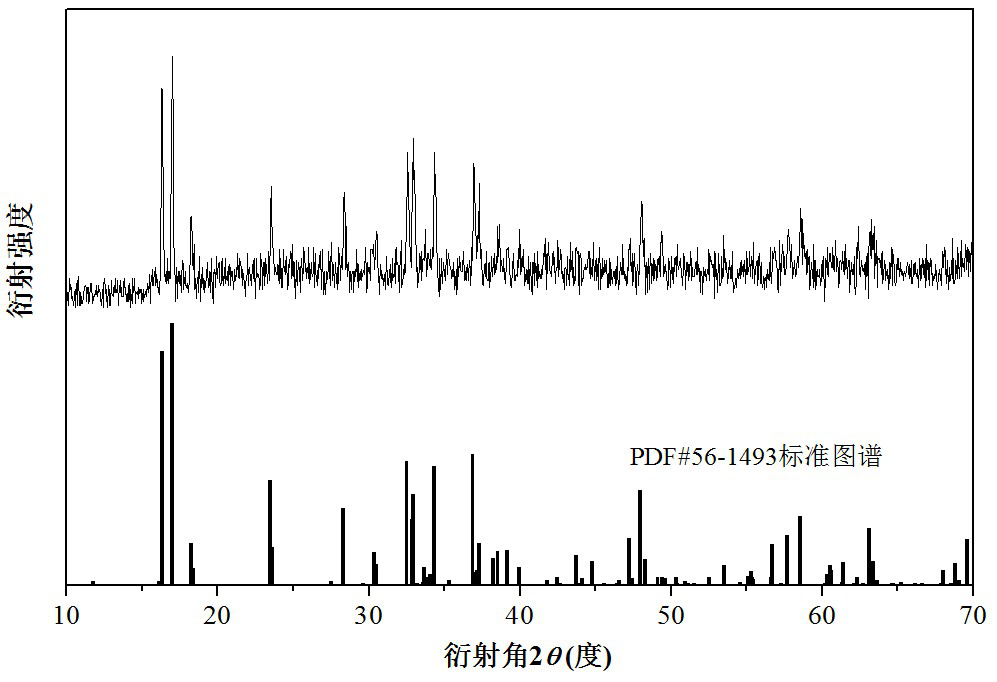

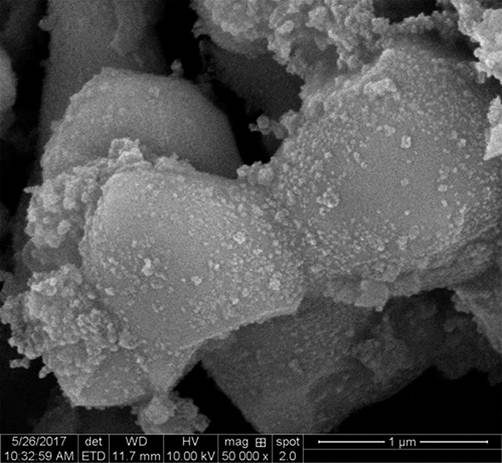

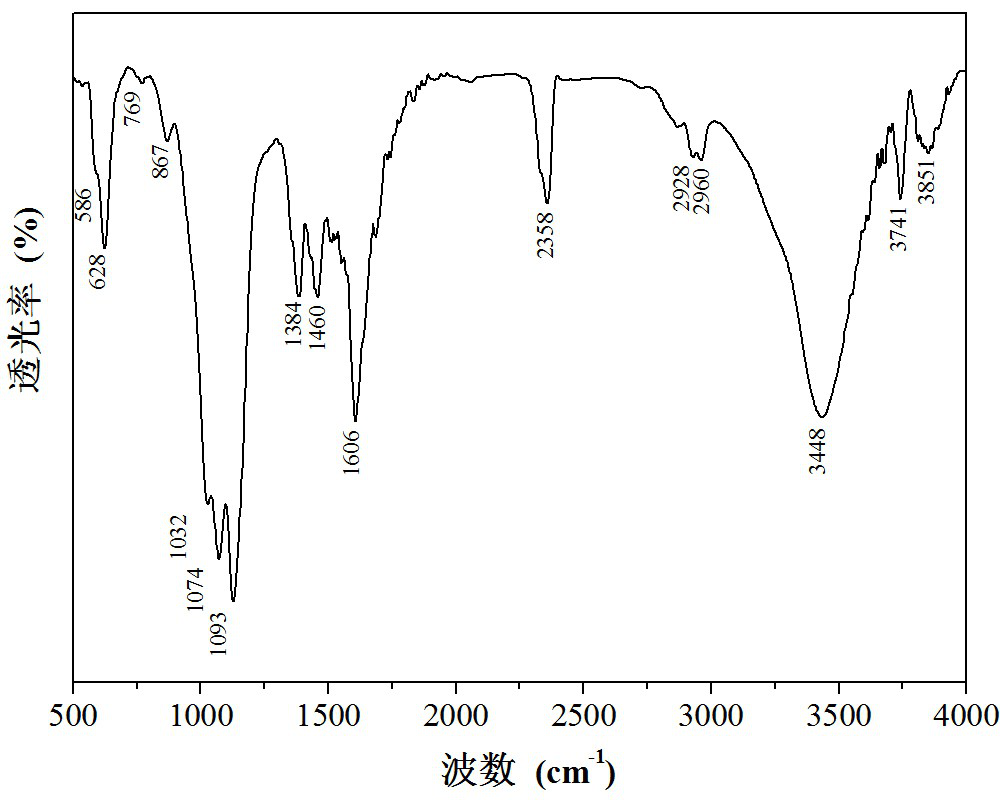

Synergistically modified cobalt lithium fluorophosphate cathode material and preparation method thereof

ActiveCN107845801AImprove electron conductivityImprove structural stabilityMaterial nanotechnologyCell electrodesCarbon sourceMetallic Nickel

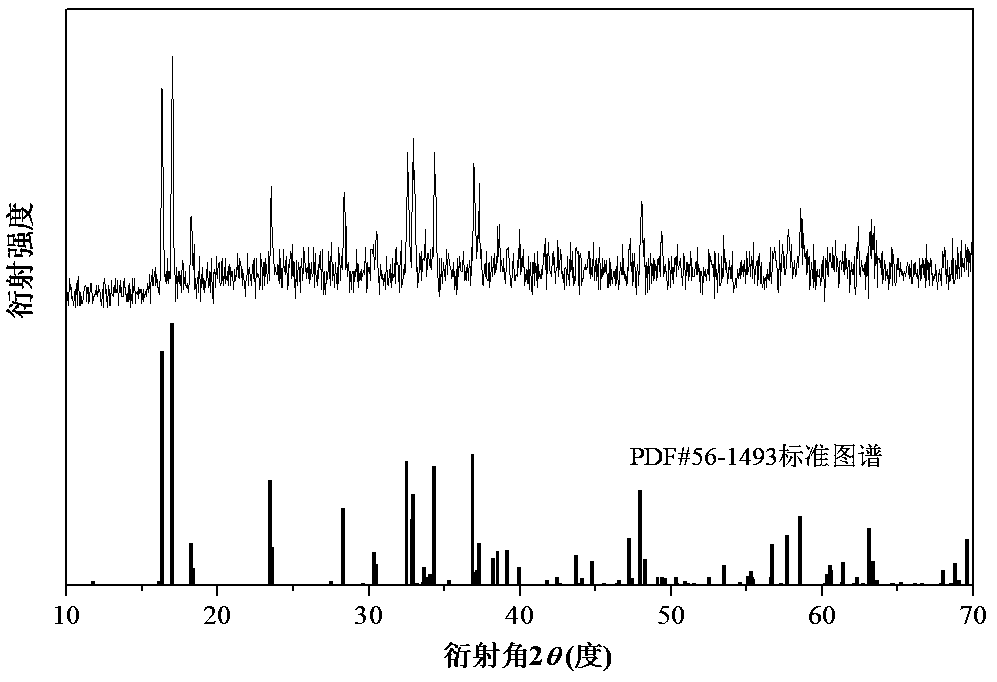

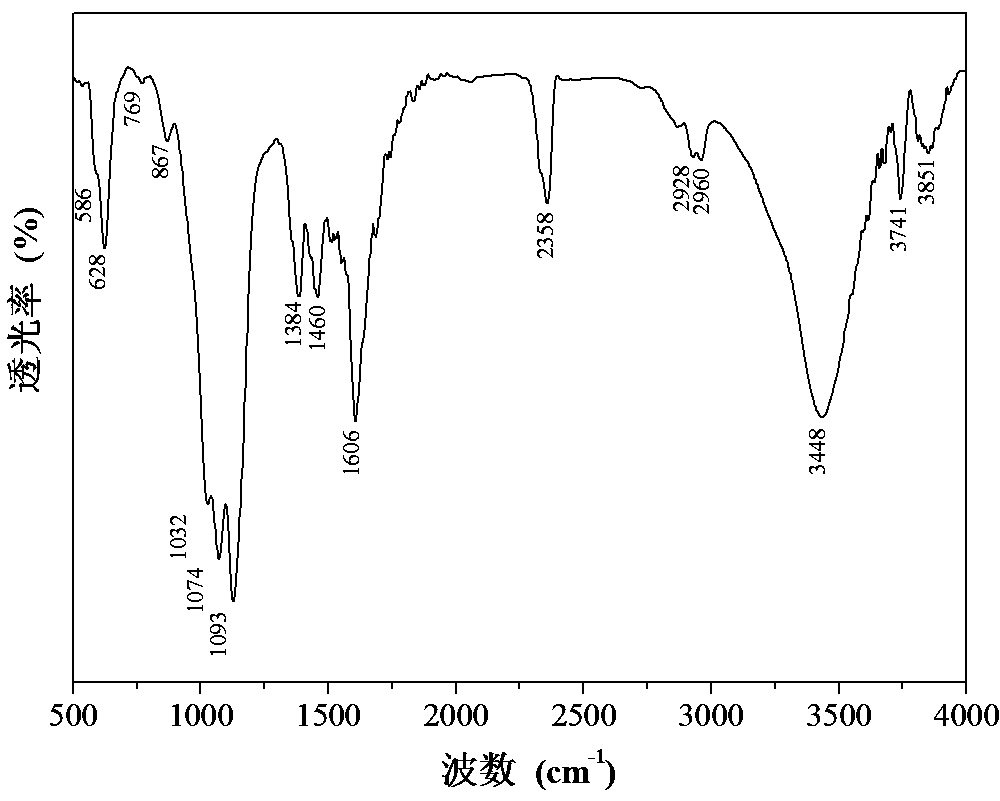

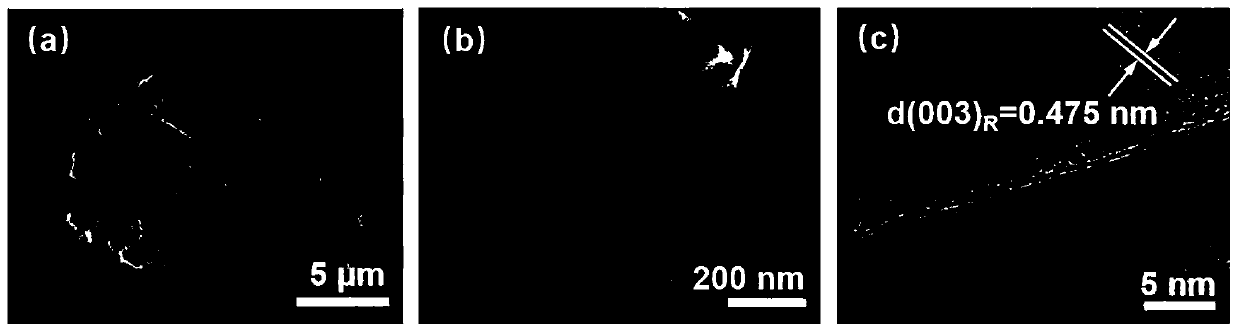

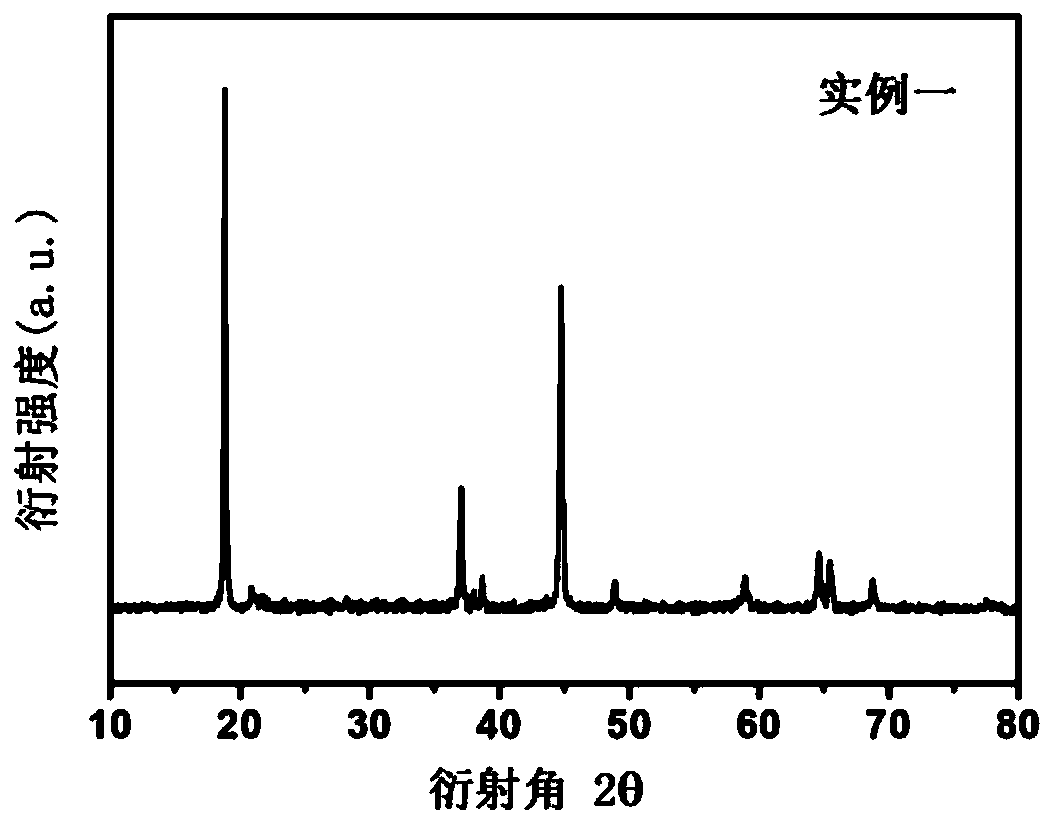

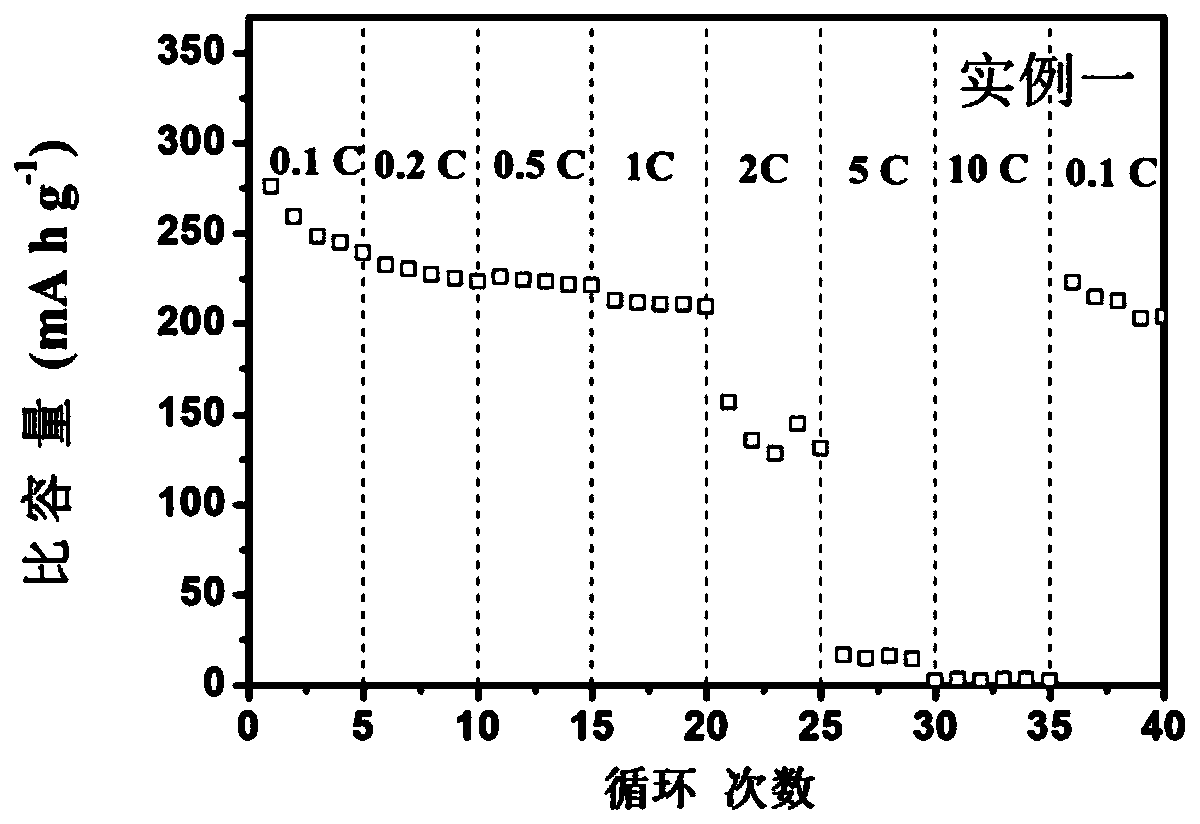

The invention relates to a nickel-doped and carbon / silica-coated synergistically modified cobalt lithium fluorophosphates cathode material and a preparation method thereof. The preparation method comprises the following steps: (1) respectively adding a lithium source, a cobalt source, a fluorine source and a nickel source compound into deionized water in a certain stoichiometric ratio, stirring, adding a certain amount of a phosphate source compound into the solution, further stirring, transferring into a high pressure reaction kettle, airtightly heating, reacting, then naturally cooling, taking out, and drying, so that a precursor is obtained; (2) mixing the obtained precursor and a carbon source compound, grinding, and calcining for two stages in inert atmosphere, so that a carbon-coatednickel-doped Li2Co1-xNixPO4F / C material is obtained; and (3) weighing a certain amount of silica, putting into a breaker, adding deionized water, carrying out ultrasonic treatment, then adding the Li2Co1-xNixPO4F / C material, stirring, drying, and grinding, so that the Li2Co1-xNixPO4F / C+SiO2 target material is obtained. The prepared material is uniform in particles and good in crystallinity and has relatively high specific capacity and good cycle performance; and meanwhile, the synthetic process is simple and easy, and the production cost is low.

Owner:UNIV OF JINAN

Degradable composite water-preserving agent for greenhouse planting and preparation method of degradable composite water-preserving agent

InactiveCN106635036AExcellent moisture control functionDoes not affect breathabilityAgriculture tools and machinesOrganic fertilisersPotassium persulfatePolyvinyl alcohol

The invention discloses a degradable composite water-preserving agent for greenhouse planting. The degradable composite water-preserving agent is prepared from the following raw materials in parts by weight: 50 to 55 parts of crop straws, 40 to 55 parts of urea, 18 to 20 parts of ammonium dihydrogen phosphate, 22 to 25 parts of potassium persulfate, 10 to 15 parts of potassium sulfate, 16 to 18 parts of potassium chloride, 24 to 36 parts of acrylic acid, 50 to 80 parts of carboxymethyl cellulose, 6 to 10 parts of N,N-methylene bisacrylamide, 9 to 12 parts of polyvinyl alcohol, 30 to 50 parts of humic acid and 70 to 100 parts of acrylamide. The water-preserving agent disclosed by the invention has an excellent water regulating and controlling function; the degradable composite water-preserving agent can continuously supply water for a greenhouse to plant and grow; after the water-preserving agent absorbs water, the water-preserving agent becomes irregular gel particles; after the water-preserving agent is blended with dry material, the air permeability, the water permeability and the structural stability of a culture material are not affected; the problem that water replenishment is difficult at the later stage of greenhouse planting is solved; the water-preserving capability of the culture material is improved, and the yield of greenhouse planting is increased; meanwhile, the water-preserving agent disclosed by the invention has degradability, no pollution to the environment and better popularization value.

Owner:潜山县思迈农业科技有限公司

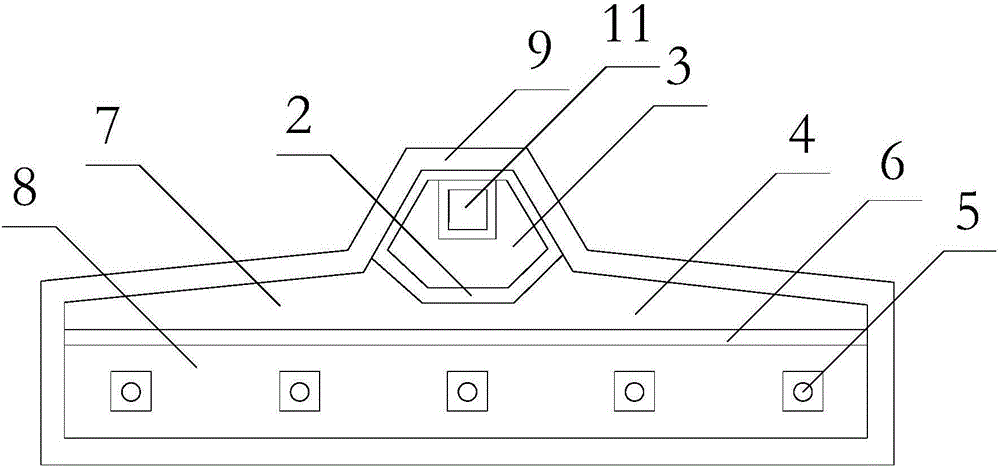

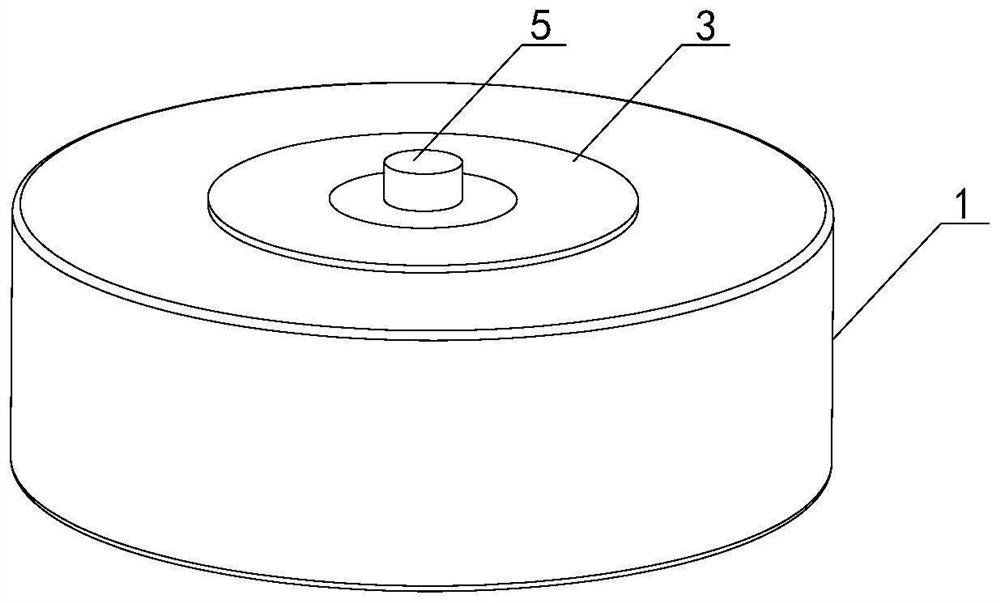

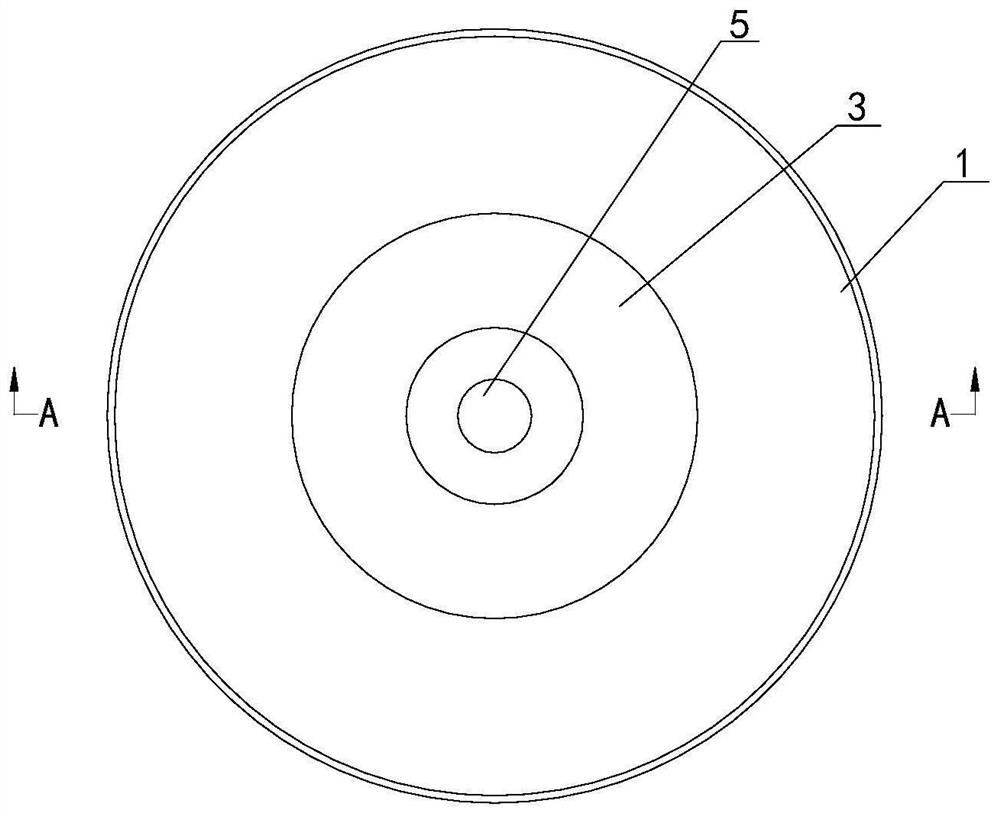

Chair

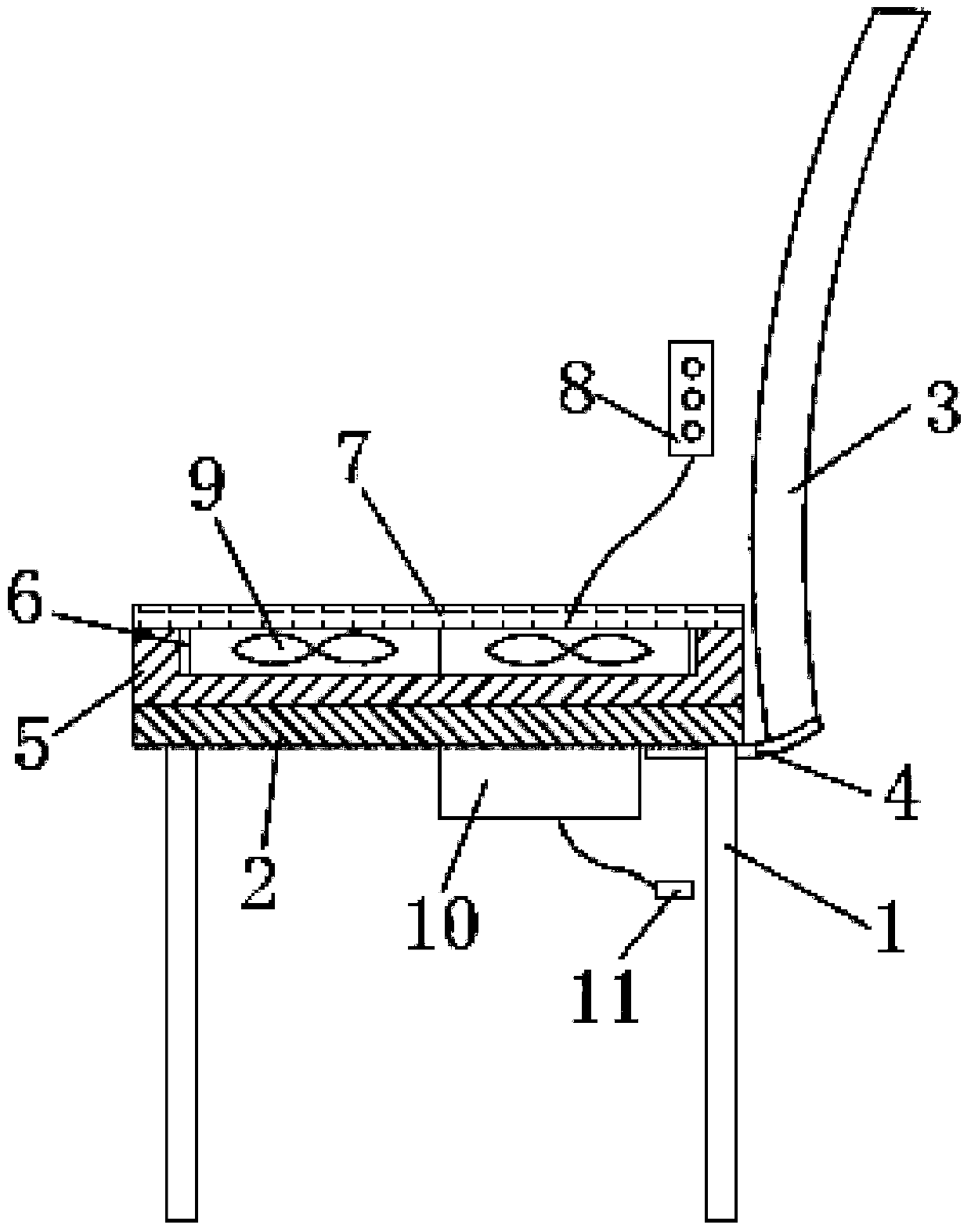

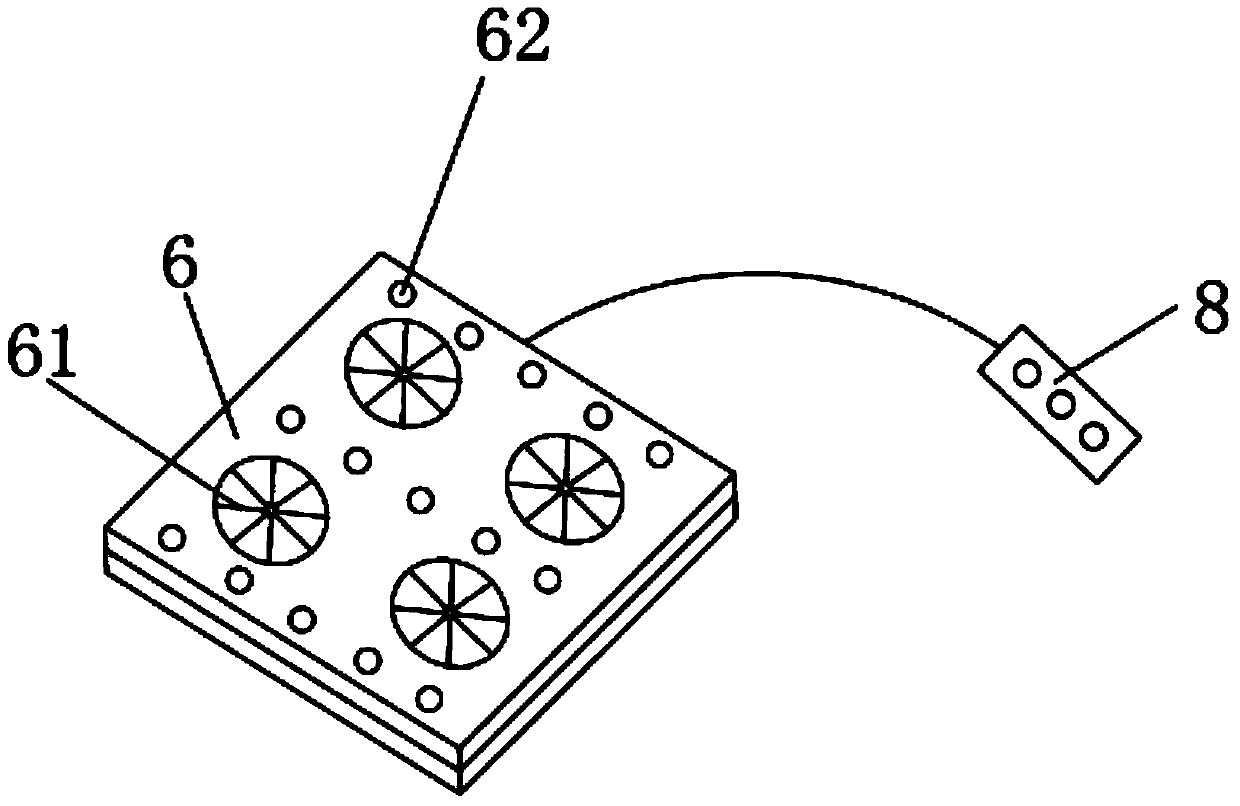

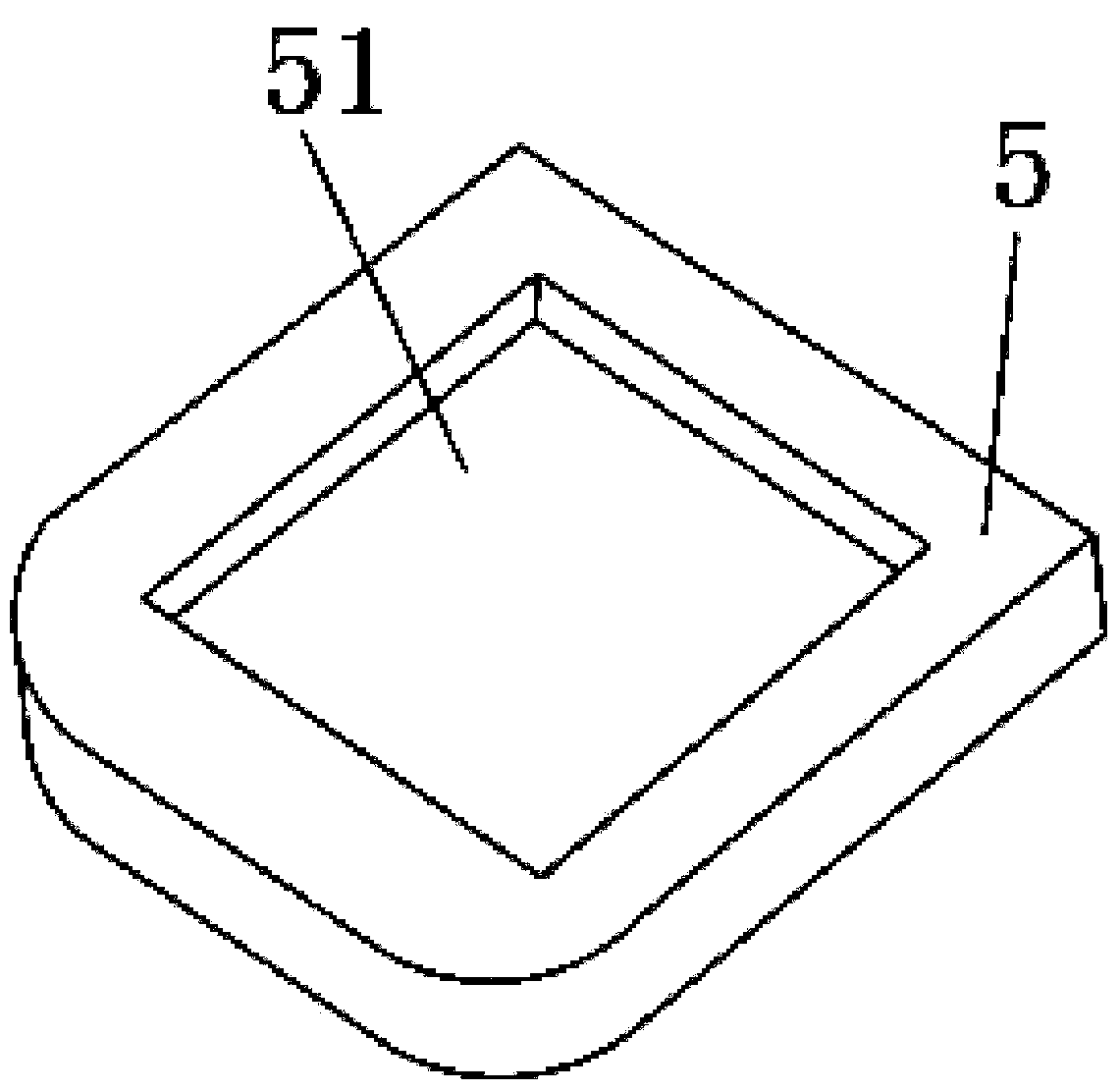

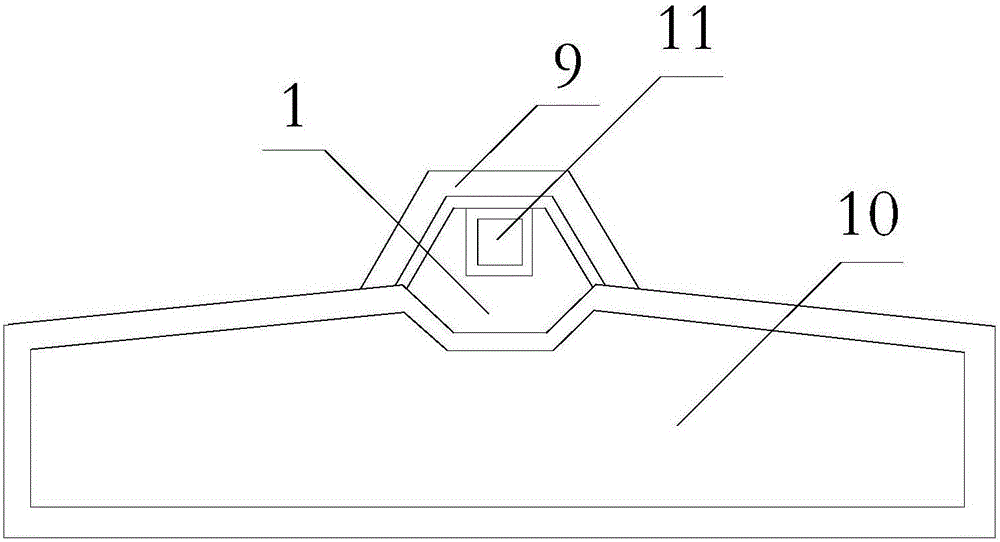

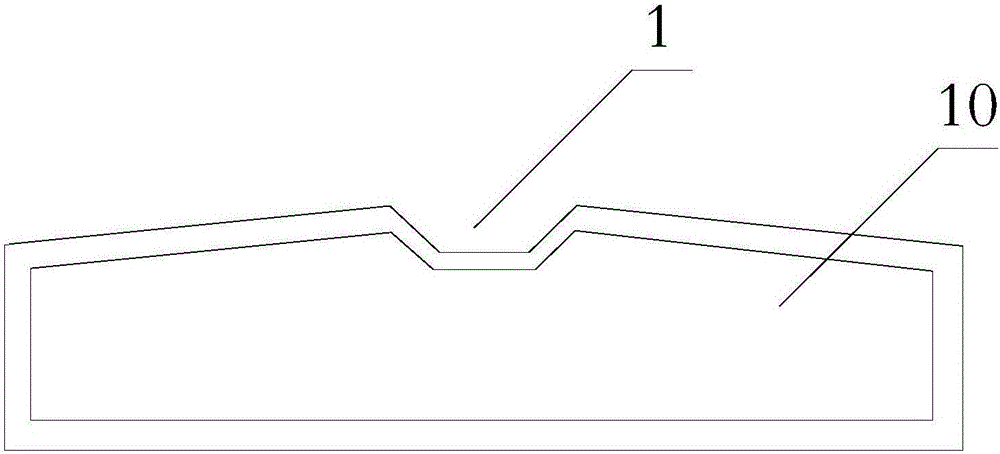

InactiveCN104188412AImprove breathabilitySimple structureStuffed mattressesSpring mattressesEngineeringCushion

The invention discloses a chair, comprising chair legs (1), a seat and a chair back (3), wherein the seat comprises a bottom plate (2) which is arranged at the bottom layer and is directly connected with the chair legs (1); the bottom plate (2) is provided with a base plate (5); a groove (61) for accommodating a heat abstractor is formed in the base plate (5); the heat abstractor comprises a fan (9) and a fan housing (6) which covers the outside of the fan; the fan (9) is connected with a controller (8); and the base plate (5) is provided with a cushion (7). The chair disclosed by the invention is simple and stable in structure, energy-saving and environmentally friendly, and can meet the cool comfort of people sitting in the chair in summer.

Owner:WUHU RUITAI AUTO PARTS

Continuous casting tundish

InactiveCN106363159AExtend your lifeEven consumptionMelt-holding vesselsThree dimensional shapeWaste management

The invention relates to a continuous casting tundish. The tundish is in a hollow three-dimensional shape. A feeding inlet is formed in the upper end of the tundish. A filter wall is vertically arranged inside the tundish. The internal space of the tundish is partitioned into a discharging region and a flow distribution region through the filter wall. The feeding inlet is located over the discharging region. A plurality of flow distribution openings are formed in the portion, located in the flow distribution region, of the bottom face of the tundish. A flow equalizing plate is vertically arranged at the portion, located in the flow distribution region, inside the tundish. The flow distribution region is partitioned into a flow storage region and a flow equalizing region through the flow equalizing plate. The flow storage region is located between the discharging region and the flow equalizing region. All the flow distribution openings are formed in the bottom of the tundish and located inside the flow equalizing region. According to the continuous casting tundish, molten steel injected from the feeding inlet can be filtered through the filter wall and subjected to flow equalizing treatment through the flow equalizing plate, the molten steel can uniformly flows to external crystallizers in a distributed mode through the multiple flow distribution openings, uniform consumption is achieved at all the flow distribution openings, the overall service life of the tundish is greatly prolonged, and the production cost is lowered.

Owner:WUHAN WINNING TECH

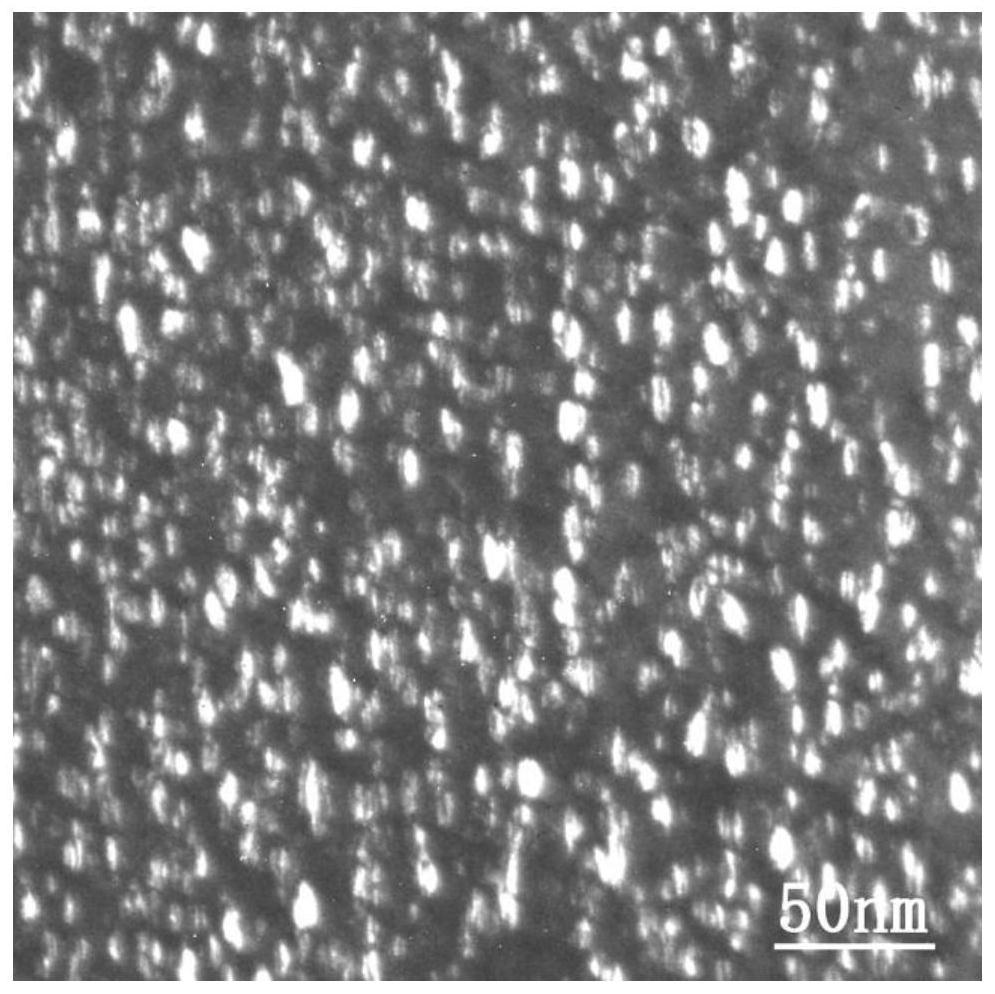

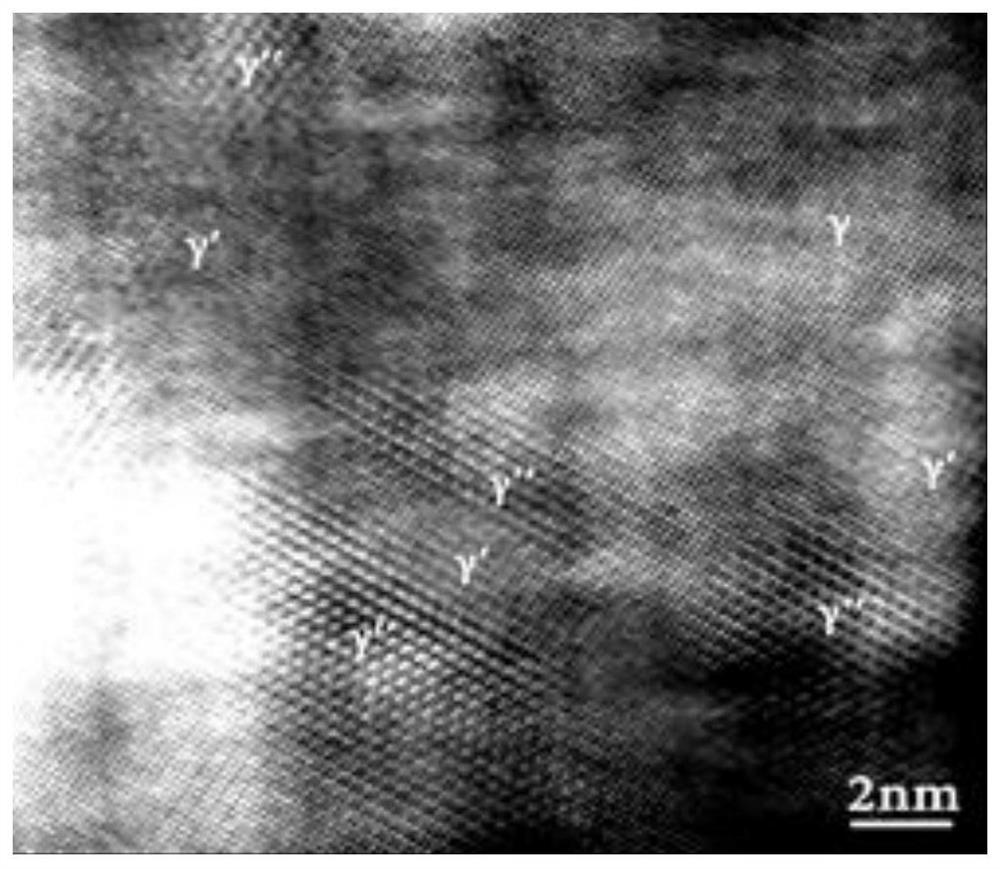

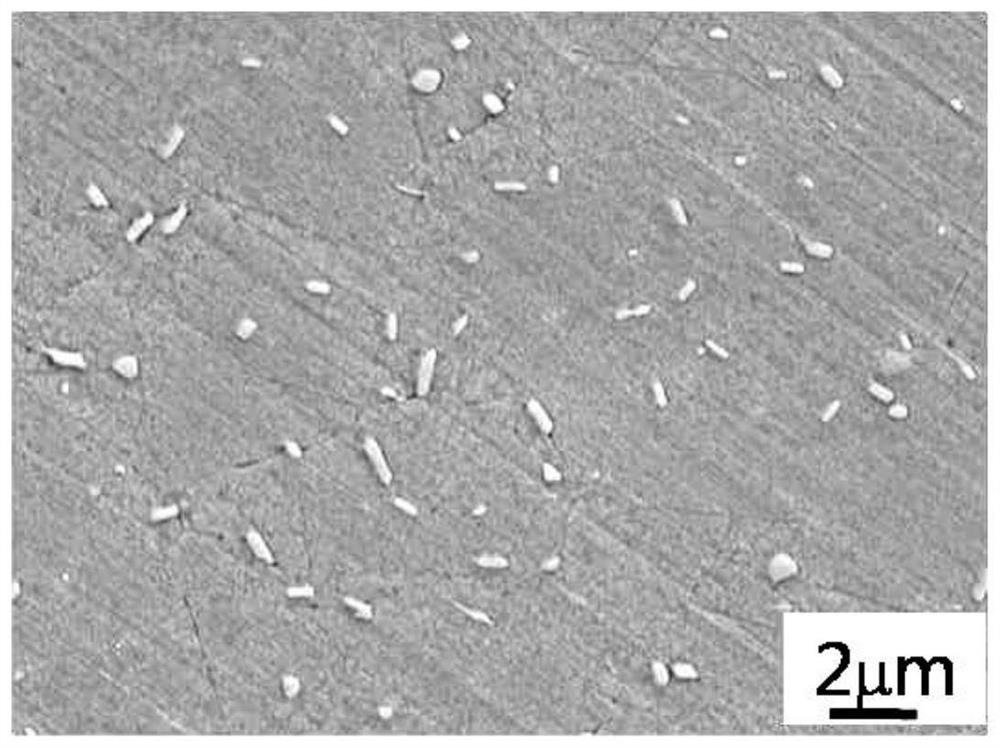

High-temperature alloy for hydrogen fuel cell air compressor bearing, and preparation method thereof

ActiveCN111733346AImprove machinabilityDoes not affect structural stabilityHydrogen fuel cellAir compressor

The invention relates to a high-temperature alloy for a hydrogen fuel cell air compressor bearing, and a preparation method thereof. The high-temperature alloy adopts austenite with a disordered face-centered structure reinforced by adopting an ordered phase L12-gamma' and a body-centered tetragonal ordered structure gamma''-(Ni3Nb); the volume fraction of a reinforcement phase ranges from 10 percent to 25 percent; and the high-temperature alloy is prepared from the components in proportion by weight: 0.02 to 0.08 percent of C, 9 to 18 percent of Fe, 12 to 18 percent of Cr, 0.85 to 1.5 percentof Al, 1.2 to 2.25 percent of Ti, 3.5 to 5 percent of Nb, 2 to 5 percent of Mo, less than or equal to 0.05 percent of B, less than 0.25 percent of Si, less than 0.25 percent of Mn, and the balance Ni, so that the alloy has excellent high-temperature strength and structure stability, and favorable machinable property and economical efficiency. According to the alloy, a TCP phase is not precipitated obviously at the temperature below 760 DEG C, the tensile strength at the temperature being 760 DEG C is larger than 1000MPa, and the alloy is particularly suitable for preparing a medium-high temperature force-bearing part including a hydrogen cell of the hydrogen fuel cell air compressor bearing.

Owner:上海康晟航材科技股份有限公司

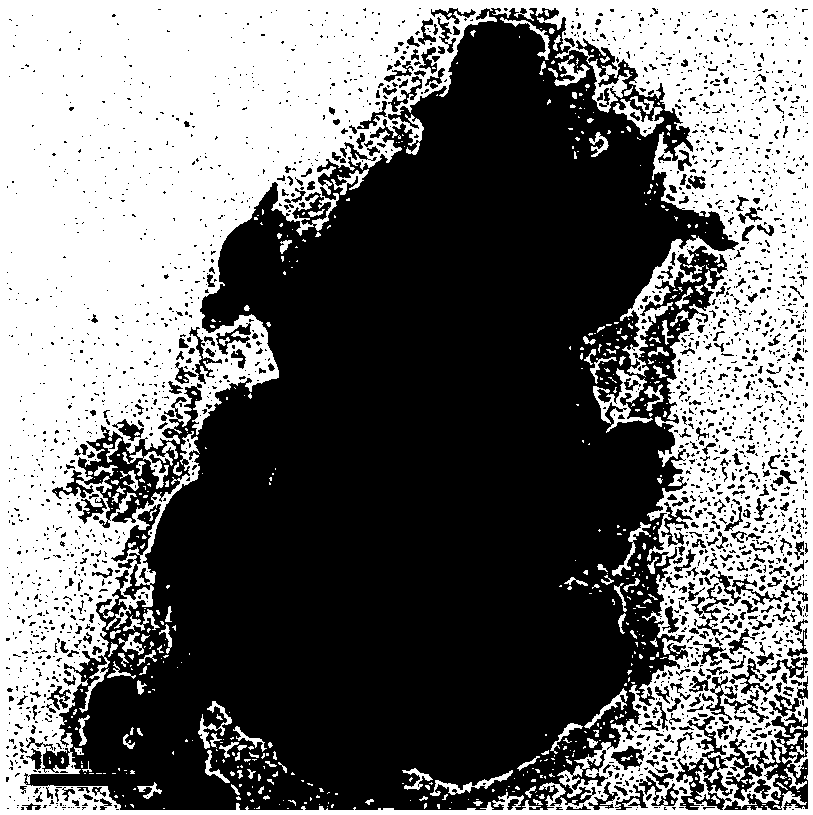

Lithium-rich manganese-based/graphene composite cathode material, preparation method thereof and application thereof

InactiveCN110165181AImprove apparent conductivityAvoid polarizationSecondary cellsPositive electrodesHigh energyManganese

The invention discloses a lithium-rich manganese-based / graphene composite cathode material, a preparation method thereof and an application thereof. The method comprises the steps of: preparing precursor powders by a coprecipitation method and by using a manganese source, a nickel source, a cobalt source, a complexing agent and a precipitating agent as raw materials; subjecting the obtained precursor powders and a lithium source to two-stage calcination to obtain a lithium-rich manganese-based cathode material; then subjecting the obtained lithium-rich manganese-based cathode material and a graphene dispersion to high-energy ball milling; and obtaining the lithium-rich manganese-based / graphene composite cathode material by drying. In the product prepared by the method, the graphene sheet can be well compounded between the surface of the lithium-rich manganese-based material particle surfaces and the particles, and form a more perfect conductive network around the particles. The cathodematerial improves the charging and discharging process and the electrical conductivity of the lithium ion battery under the premise of maintaining the structural stability, and has a simple process and good repeatability.

Owner:EAST CHINA UNIV OF SCI & TECH

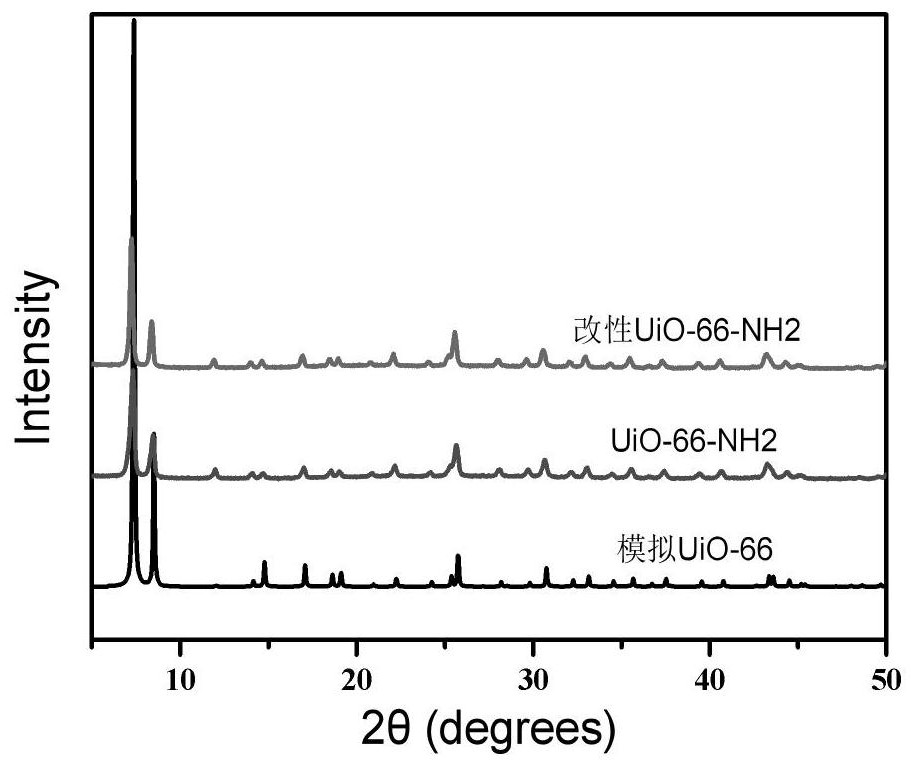

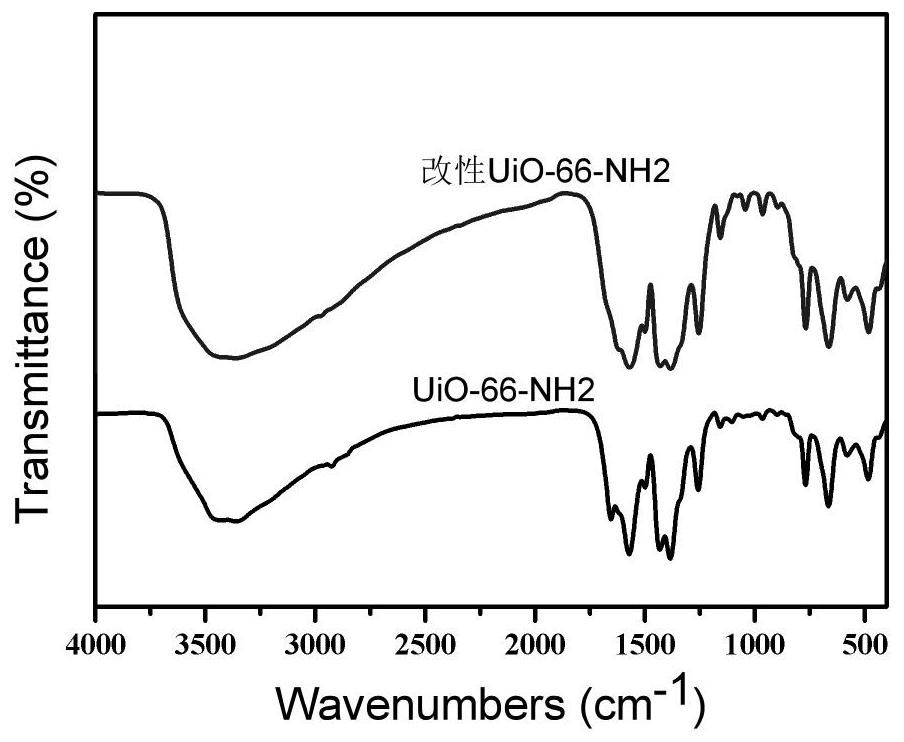

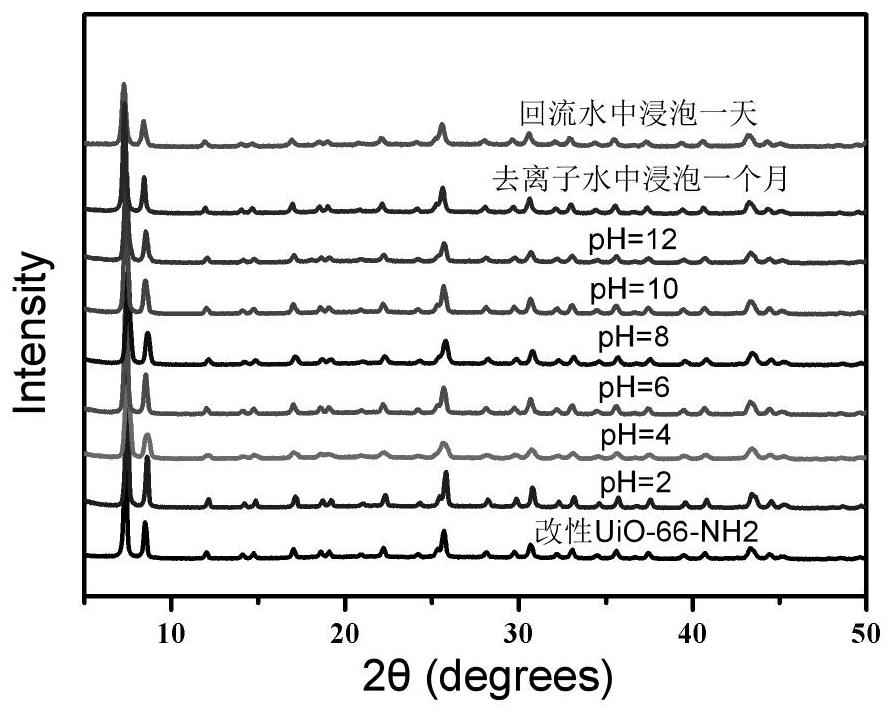

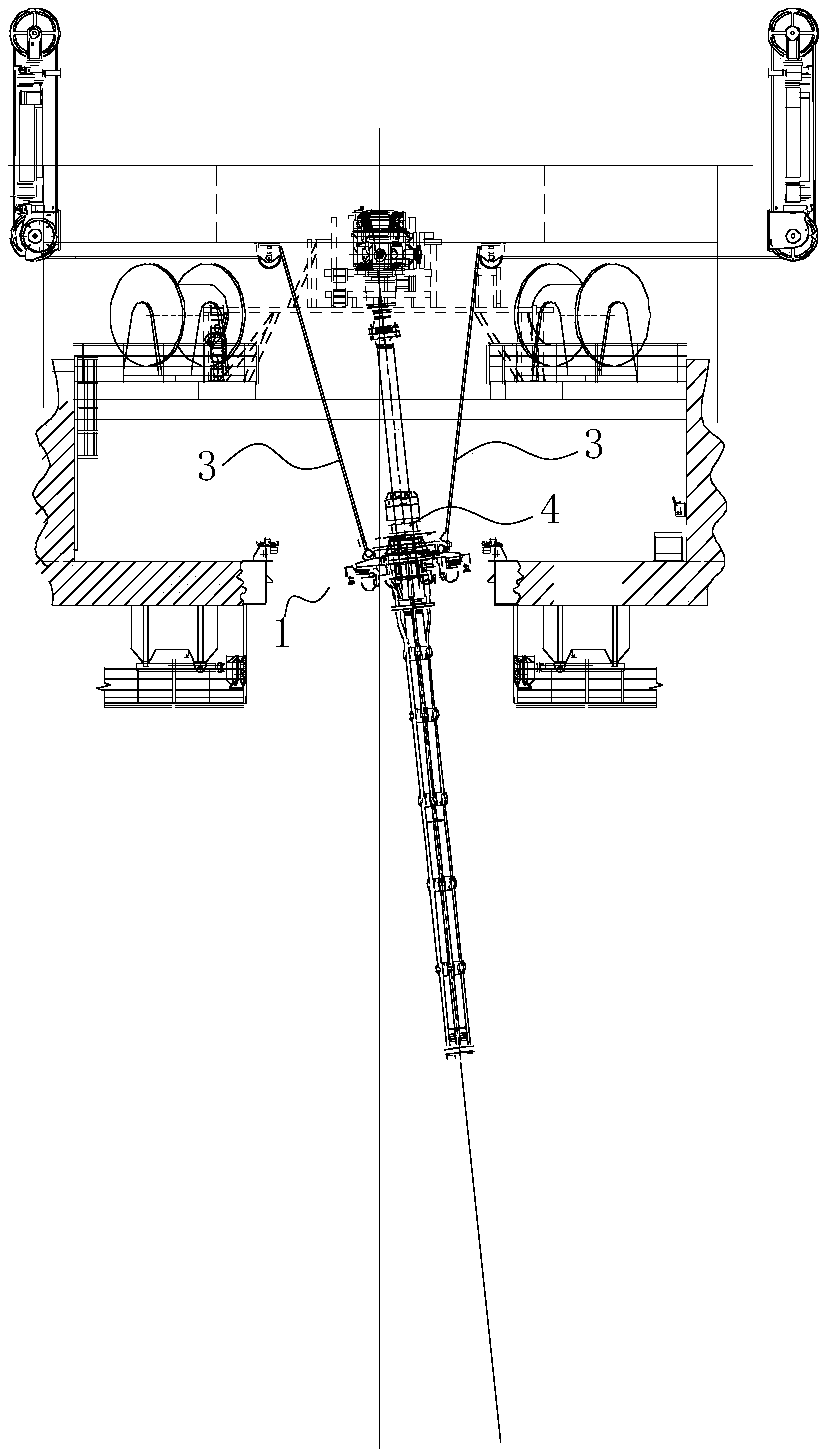

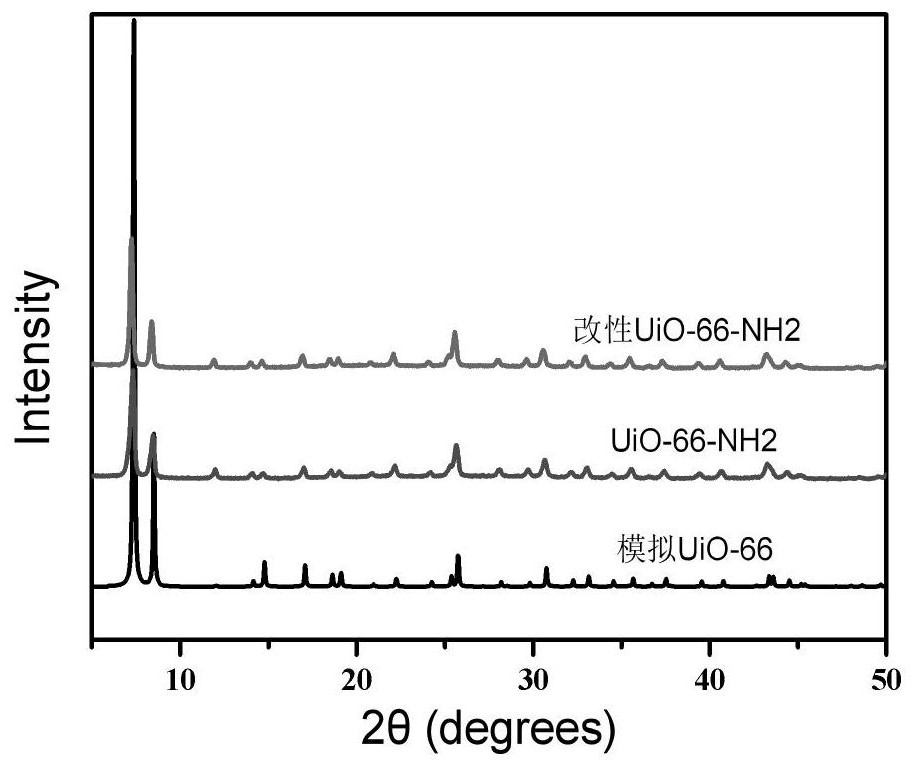

N-heterocycle molecule modified UiO-66-NH2 material with stable structure and preparation method of nitrogen heterocyclic molecule modified UiO-66-NH2 material

ActiveCN113045767AImprove stabilityAchieve multi-functionalityGroup 4/14 organic compounds without C-metal linkagesPhthalaldehydeAqueous solution

The invention discloses a N-heterocycle molecule modified UiO-66-NH2 material with a stable structure and a preparation method of the N-heterocycle molecule modified UiO-66-NH2 material, and the N-heterocycle molecule modified UiO-66-NH2 material is prepared by carrying out Schiff base reaction on m-phthalaldehyde, 3, 5-diamino-1, 2, 4-triazole and a-NH2 group on the surface of UiO-66-NH2. According to the invention, UiO-66-NH2 is synergistically modified through isophthalaldehyde and 3, 5-diamino-1, 2, 4-triazole, 3, 5-diamino-1, 2, 4-triazole molecules are introduced through a post-synthesis modification mode by taking isophthalaldehyde as a bridge based on an active-NH2 group on a skeleton, so that the number of nitrogen atoms on the surface of a modified material can be remarkably increased, the multi-functionalization of materials can be realized, the obtained modified material shows excellent stability after being soaked in an aqueous solution with the pH value of 2-12 for one week, soaked in reflux water for one day and soaked in deionized water for one month.

Owner:肇庆市武大环境技术研究院

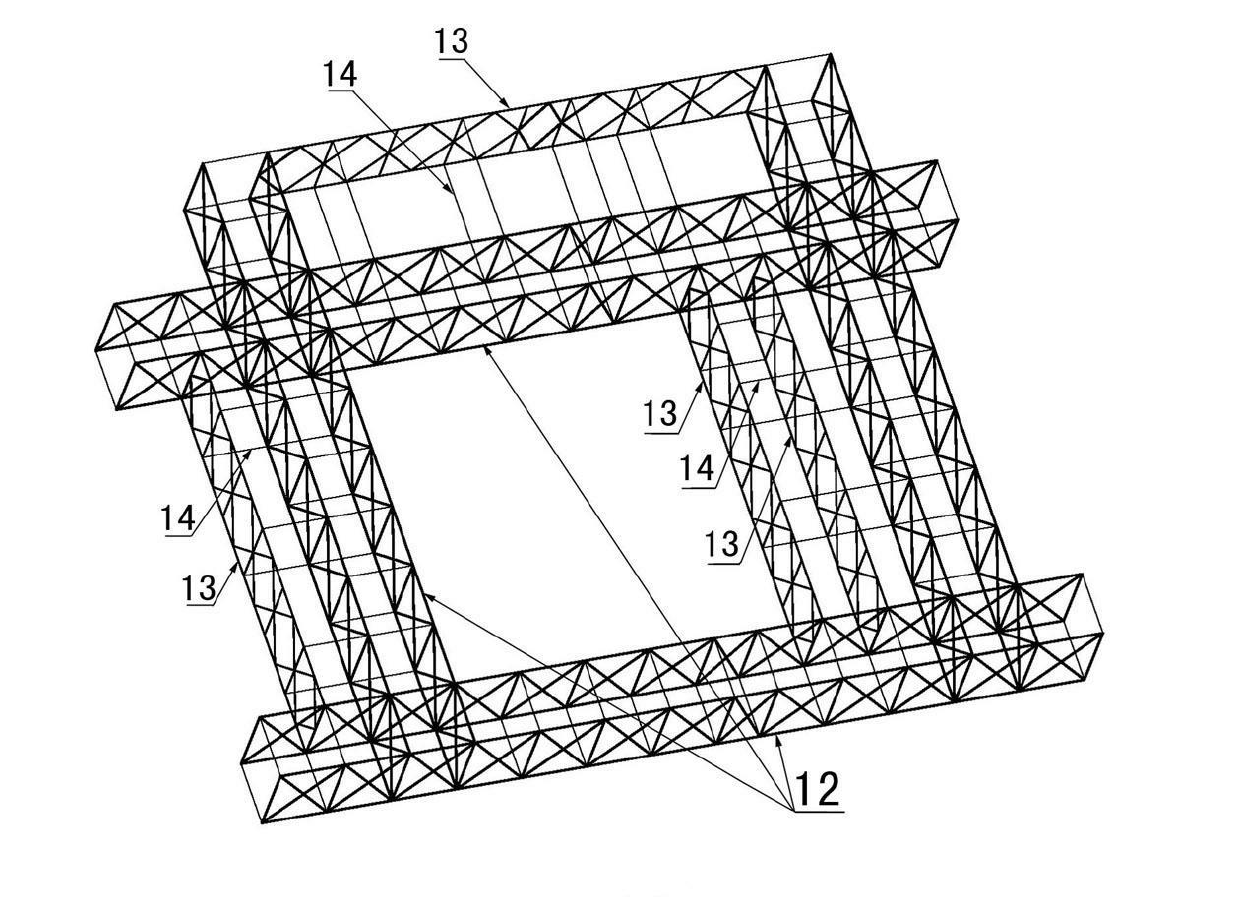

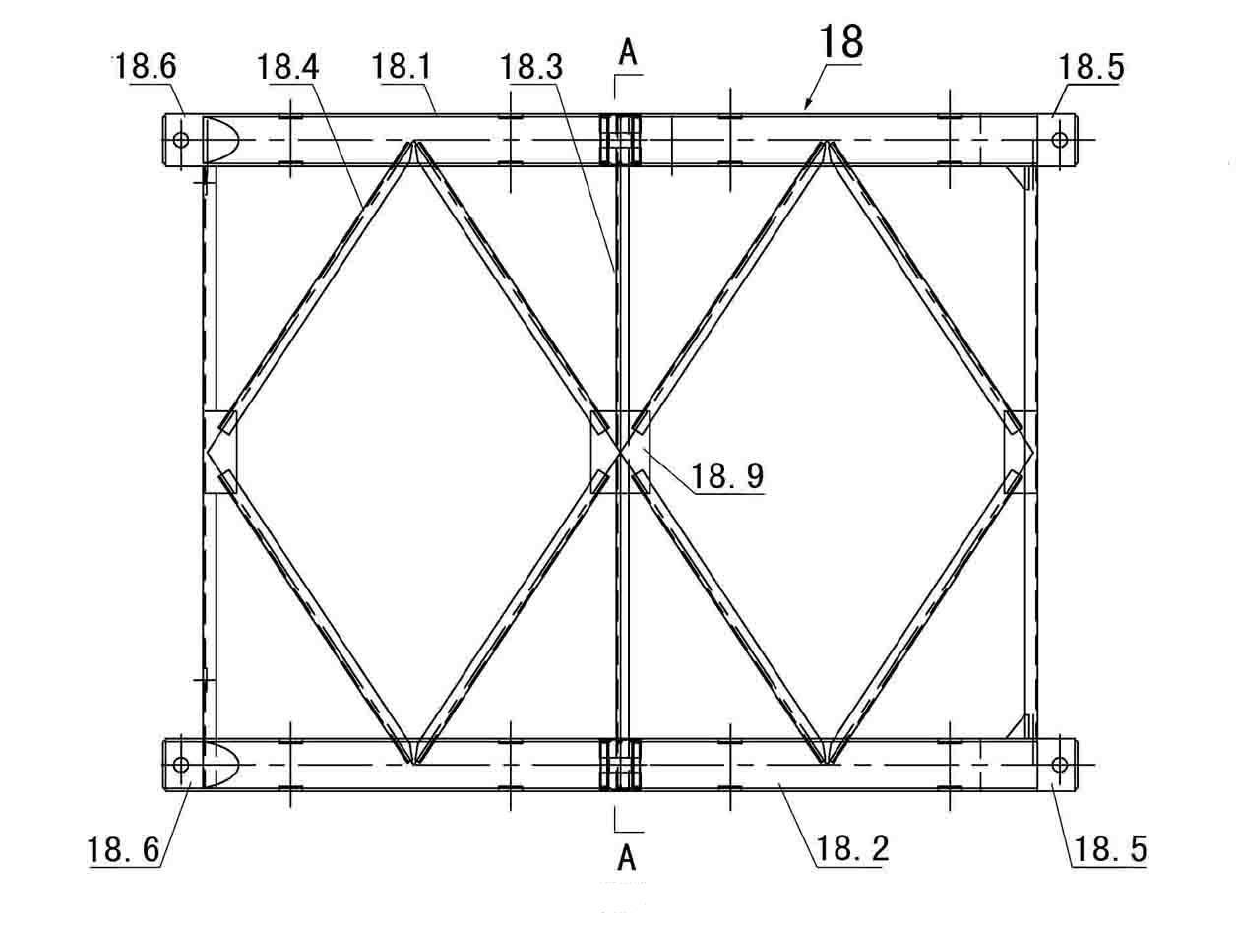

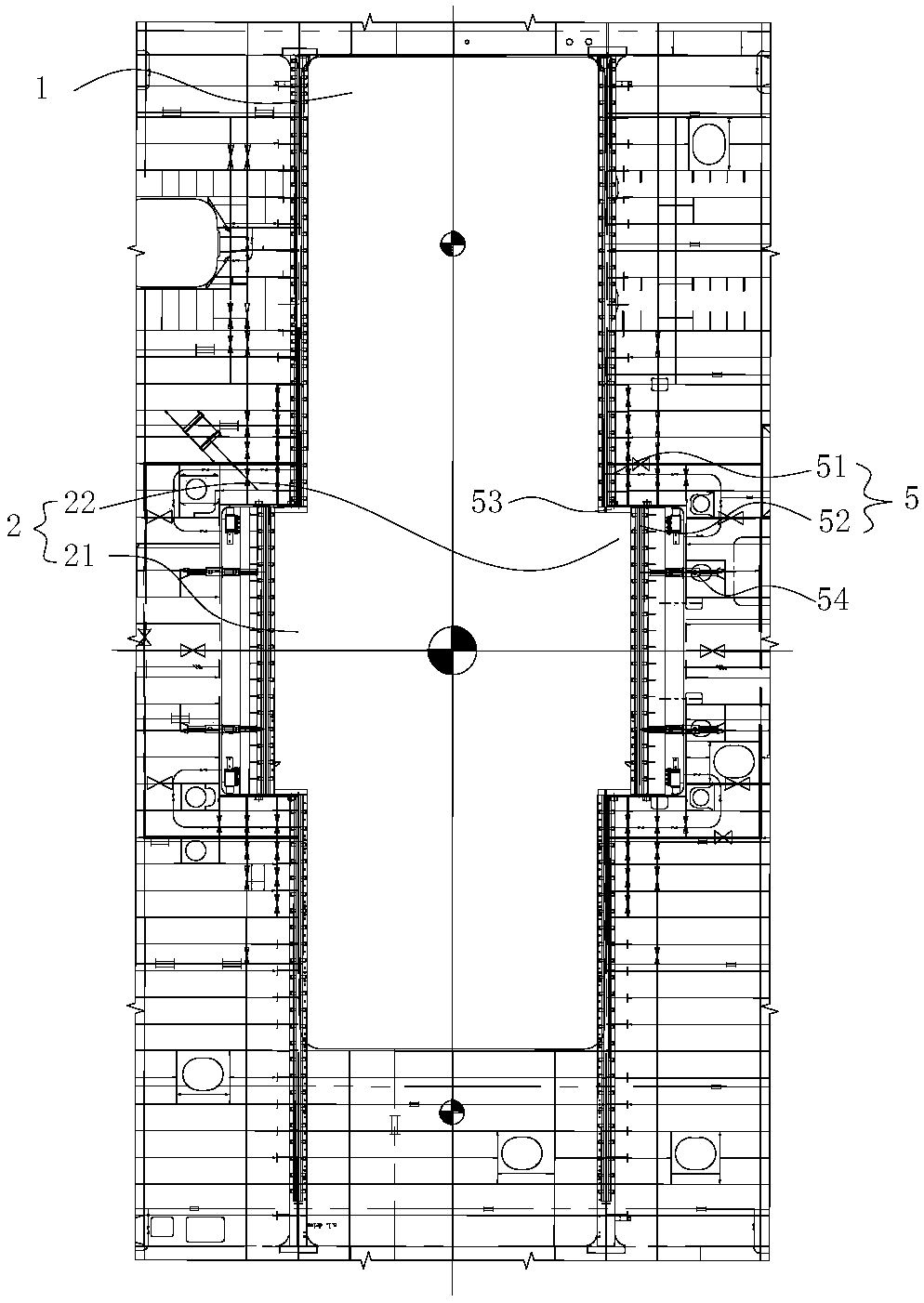

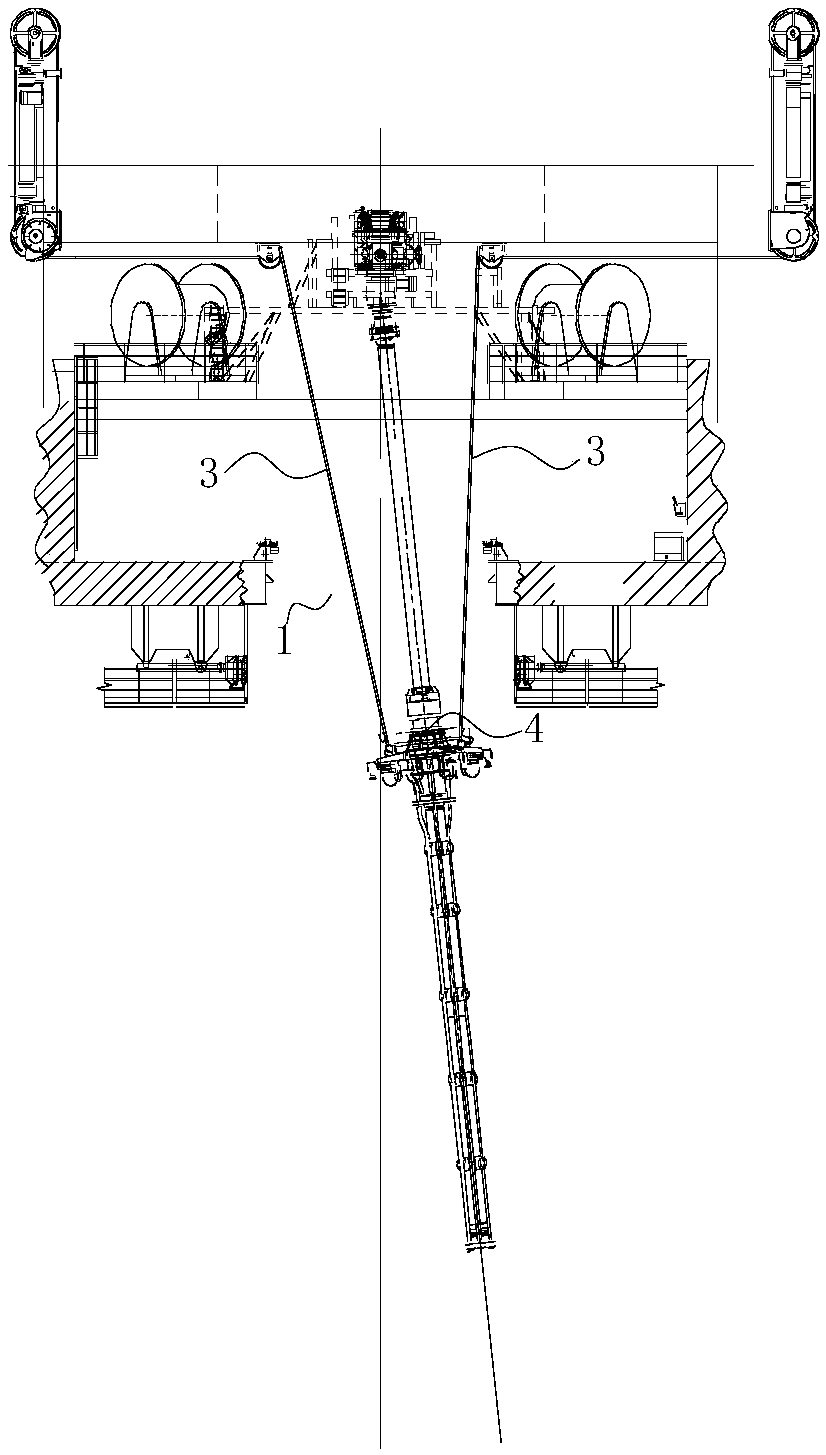

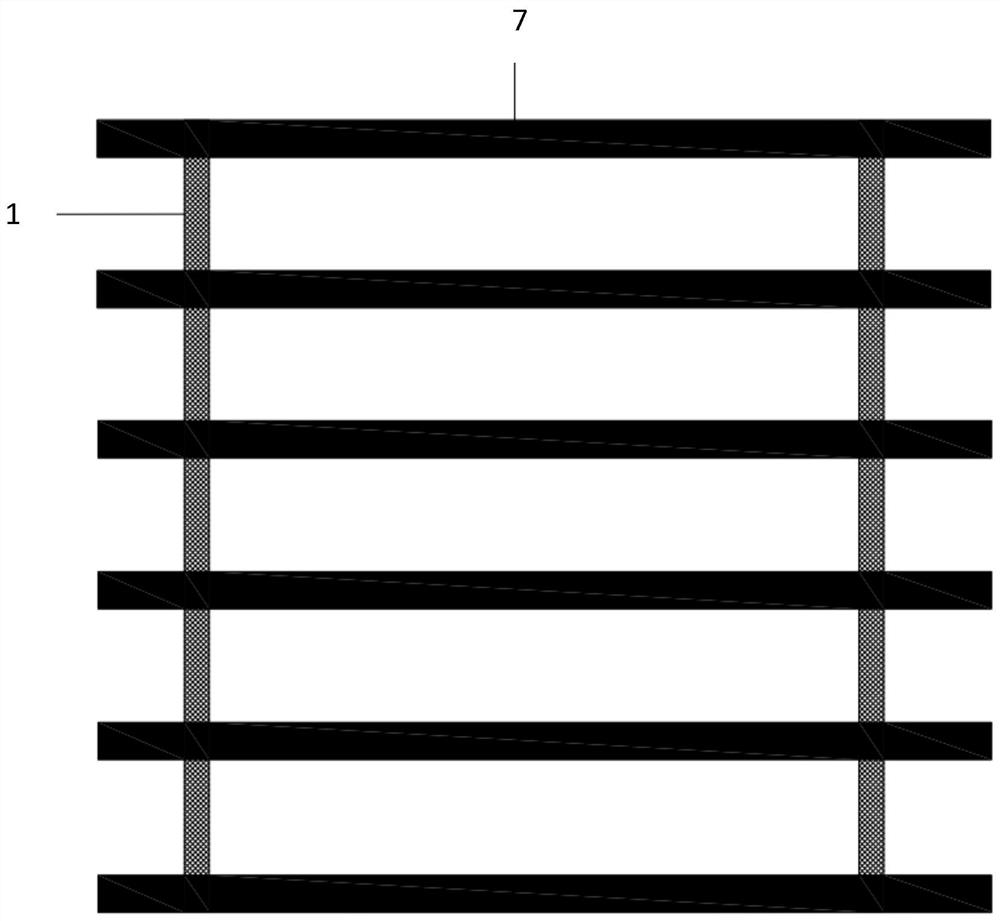

Low-position few-fulcrum modularized integral jacking steel platform formwork system

ActiveCN101949211BAchieve modularityLow costForms/shuttering/falseworksArchitectural engineeringStructural engineering

The invention relates to a low-position few-fulcrum modularized integral jacking steel platform formwork system. A supporting upright column of the system is a standardized lattice column and comprises an upper bearing beam connected with a steel platform, a lower bearing beam connected with an upper supporting cross beam and a lattice column main body connected between the upper bearing beam andthe lower bearing beam, the lattice column main body comprises four column limbs, and each column limb is formed by splicing standard segmented column limbs one by one in an end-to-end connection mode through bolts. A jacking cylinder of the system is inverted and penetrates through the upper supporting cross beam main body from bottom to top. The steel platform of the system is an assembly type changeable steel truss platform and comprises main stressed trusses, auxiliary stressed trusses and support bars between the trusses. A pylon of the system is an adjustable pylon and comprises a skeleton and a steel spring board fixed on the skeleton. The formwork system realizes the modularization of each assembly and the standardization of operations, can be repeatedly and circularly used on different buildings and can be adjusted along with the height of the buildings. Moreover, the formwork system can effectively reduce construction cost, reduce construction difficulty and increase workingefficiency.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD +1

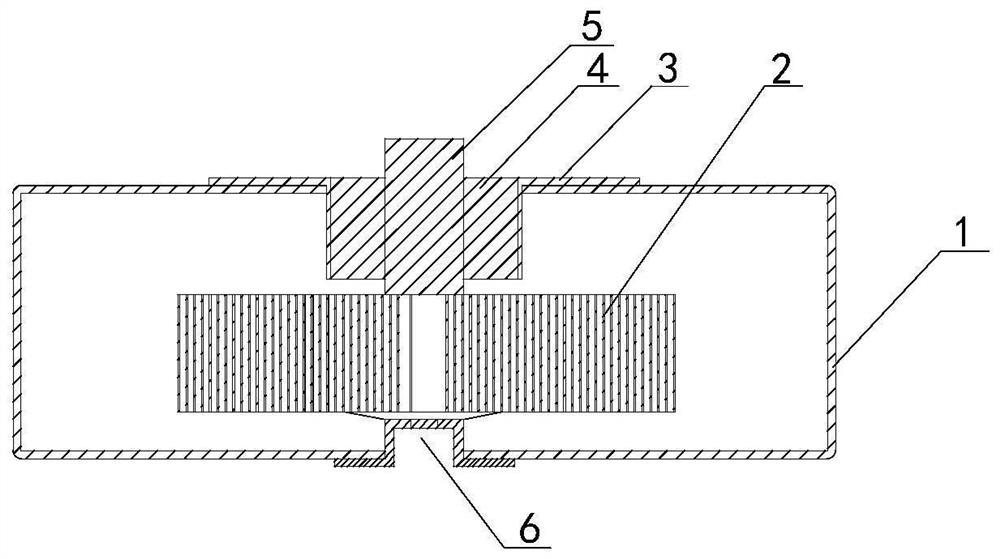

Battery structure capable of injecting liquid from bottom and battery liquid injection method

PendingCN112886155ADoes not affect structural stabilityFully infiltratedCell component detailsEngineeringMechanical engineering

The invention relates to a battery structure capable of injecting liquid from bottom. A battery cell of the battery structure is horizontally arranged on the bottom surface of a battery shell or a bottom surface support of the battery shell, and a middle space region of the battery cell is aligned to the central position of the bottom surface of the battery shell; and a liquid injection hole position of the battery is formed in the center position of the bottom surface of a battery shell, and electrolyte is injected into an inner cavity of the battery shell from bottom to top through the liquid injection hole position, so that the electrolyte is directly dispersed and guided to each region of the surface of the battery cell from the liquid injection hole position through a middle space region of the battery cell. According to the battery structure provided by the invention, the liquid injection hole is formed in the bottom part of the battery for liquid injection, and the space at the central position of the internal battery cell is ingeniously utilized and matched with the corresponding flow guide structure, so that the smoothness of liquid injection operation of the battery can be improved on the premise of not influencing the stability of the structure of the battery, and the full infiltration of the battery cell can be ensured.

Owner:GUIZHOU ZHONG RUI FENG TAI NEW ENERGY TECH CO LTD

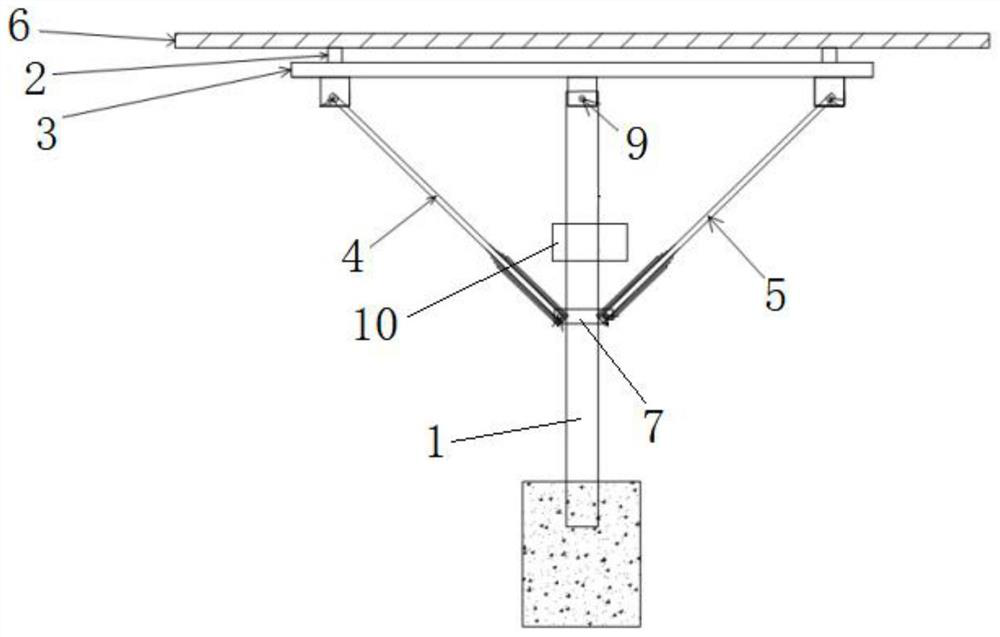

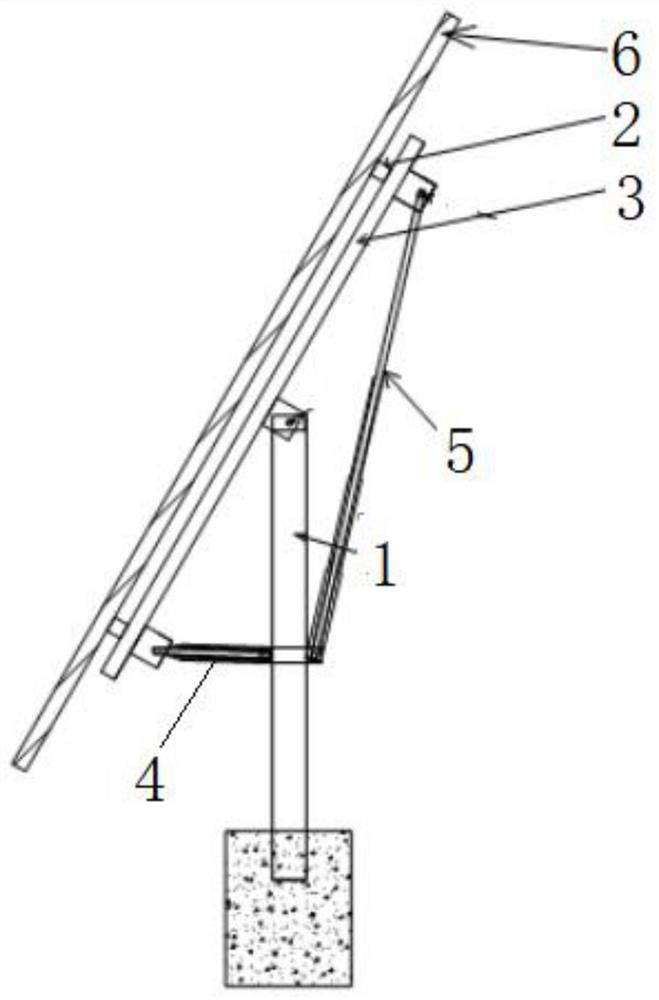

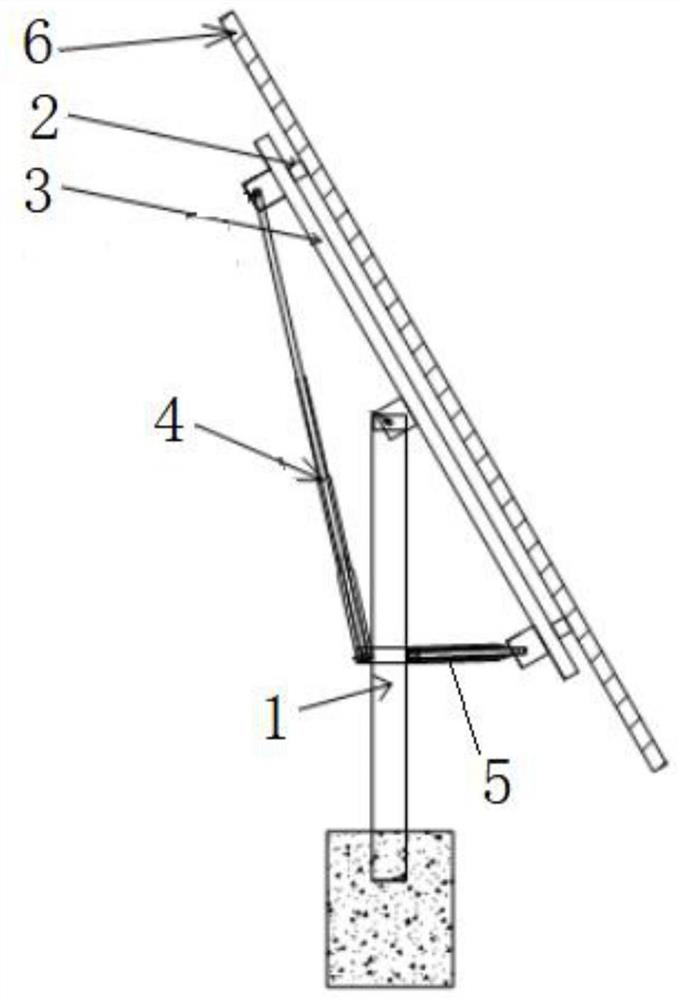

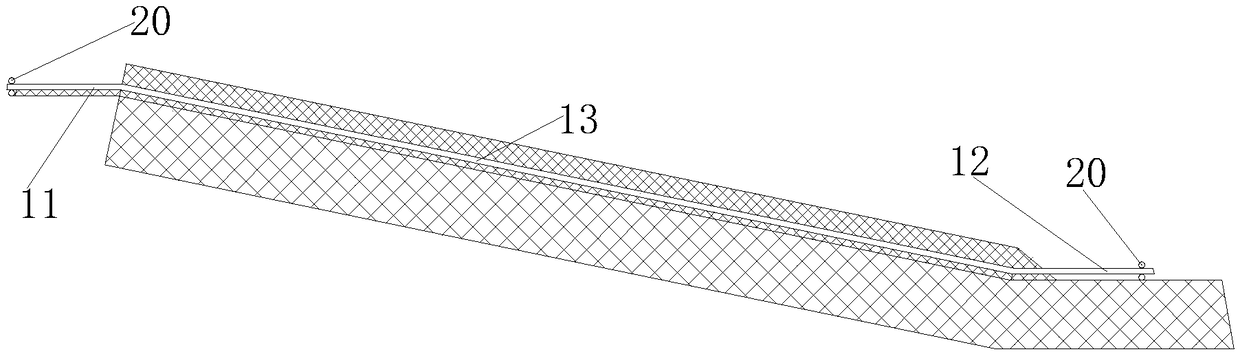

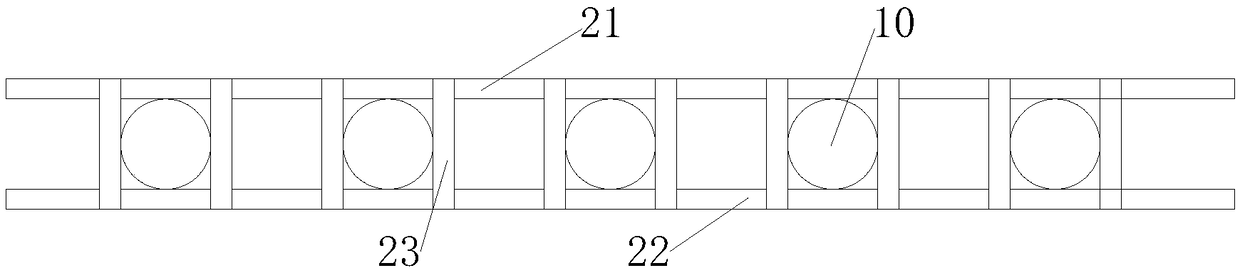

Adjustable photovoltaic support

PendingCN111697920AWide range of usesAdaptablePhotovoltaic supportsSolar heating energyUniversal jointEngineering

The invention discloses an adjustable photovoltaic support. The adjustable photovoltaic support comprises a supporting assembly, wherein the supporting assembly comprises a stand column, a cross beam,an oblique beam, a first telescopic supporting piece and a second telescopic supporting piece, the upper end of the stand column is connected with the oblique beam through a universal joint, the cross beam is connected above the oblique beam, a photovoltaic module is connected above the cross beam, the first end of the first telescopic supporting piece is movably connected to the first end of theoblique beam, the second end of the first telescopic supporting piece is movably connected to one side of the stand column, the first end of the second telescopic supporting piece is movably connected to the second end of the oblique beam, and the second end of the second telescopic supporting piece is movably connected to the other side of the stand column. The adjustable photovoltaic support aims to solve the technical problem that a photovoltaic support in the prior art is poor in wind resistance, large in adjusting difficulty and high in failure rate.

Owner:湖南三力能源科技有限公司

Moonpool, maritime device with same, and sliding device arranged on moonpool

PendingCN107672756ASmall footprintIncreased maximum operating inclinationFloating buildingsMarine equipmentStructural stability

The invention discloses a moonpool, a maritime device with the same, and a sliding device arranged on the moonpool. Through respectively correspondingly forming second spaces on two side edges of thelength direction of a first space of a moonpool, width of the moonpool is increased on the position where the second space is formed, so that a maximum operation dip angle of a water-insulating casingpipe on the moonpool of the structure is increased. A swing region of the water-insulating casing pipe when the water-insulating casing pipe works normally is increased, and probability that the water-insulating casing pipe would strike the edge of the moonpool caused by storms when the water-insulating casing pipe swings is reduced, so that the water-insulating casing pipe can be adapt to requirement of a maritime device in adverse sea conditions. Occupation area of the second space is relatively low, and stability of the integrated structure of the maritime device is not influenced. The maritime device using the moonpool is arranged on the sliding device on the moonpool, and the maritime device also has the above advantages.

Owner:YANTAI RAFFLES SHIPYARD +2

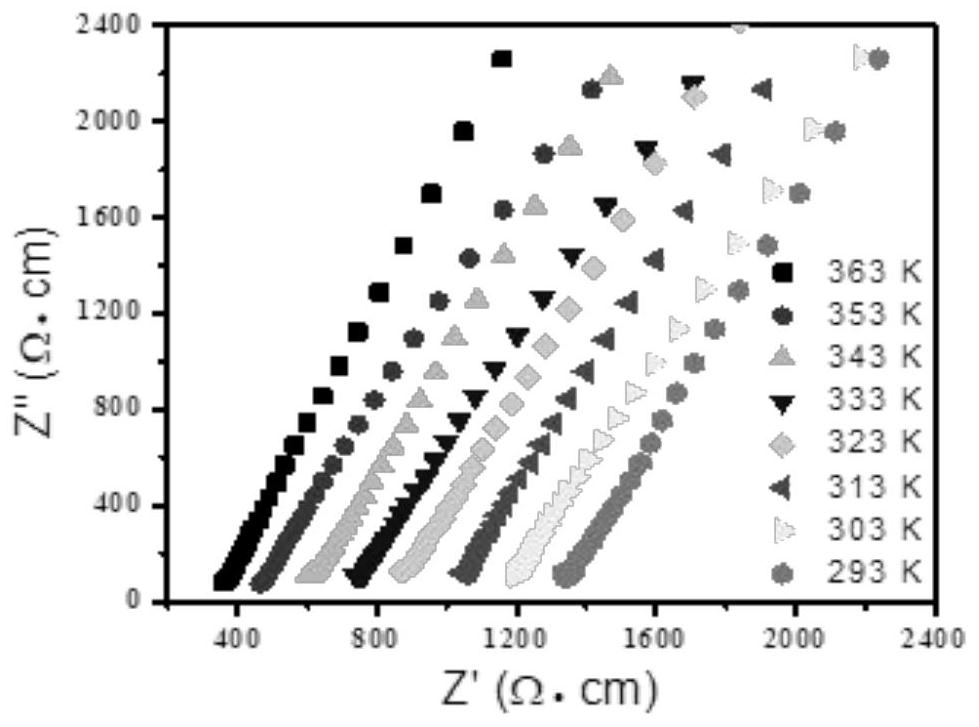

Application of modified UiO-66-NH2 material as proton conduction material

PendingCN113206279AImprove proton conductivityHigh conductivityMaterial analysis by electric/magnetic meansFuel cellsPhthalaldehydeProton conductor

The invention discloses an application of a modified UiO-66-NH2 material as a proton conduction material, and the modified UiO-66-NH2 material is obtained by carrying out a Schiff base reaction on m-phthalaldehyde, 3, 5-diamino-1, 2, 4-triazole and a -NH2 group on the surface of UiO-66-NH2. The UiO-66-NH2 is subjected to one-step modification by adopting a simple post-synthesis modification mode, the proton conductivity of the UiO-66-NH2 is improved, the modified UiO-66-NH2 material shows very high proton conductivity in a wide working temperature range, and the performance of the UiO-66-NH2 material is improved by three orders of magnitude compared with that of the unmodified UiO-66-NH2 material; the proton conductivity can still be kept almost unchanged in a long-term cycle test in a high-temperature and high-relative-humidity environment, and the material can be widely applied to electrochemical devices, sensors, fuel cells and the like as a potential proton conductor.

Owner:WUHAN UNIV

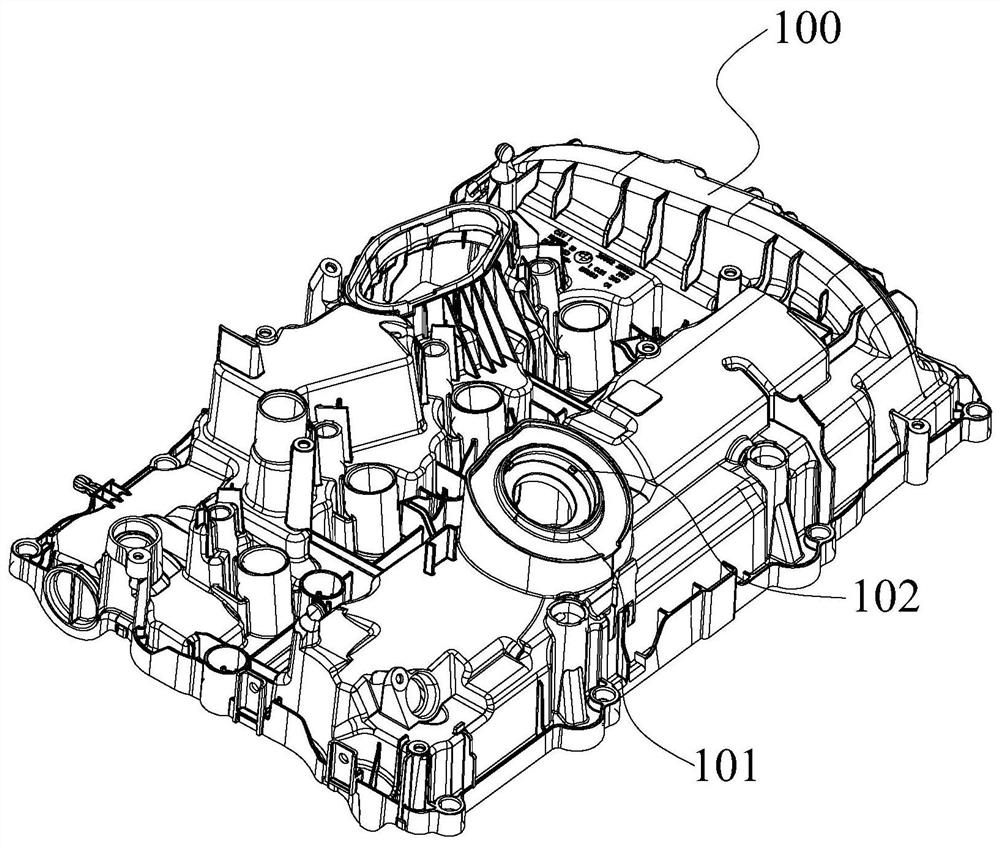

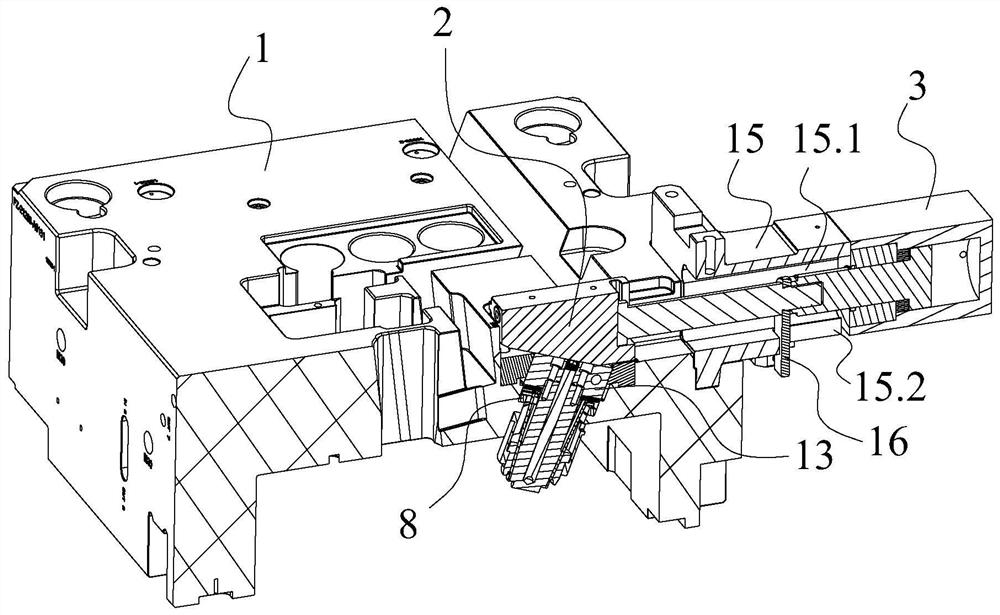

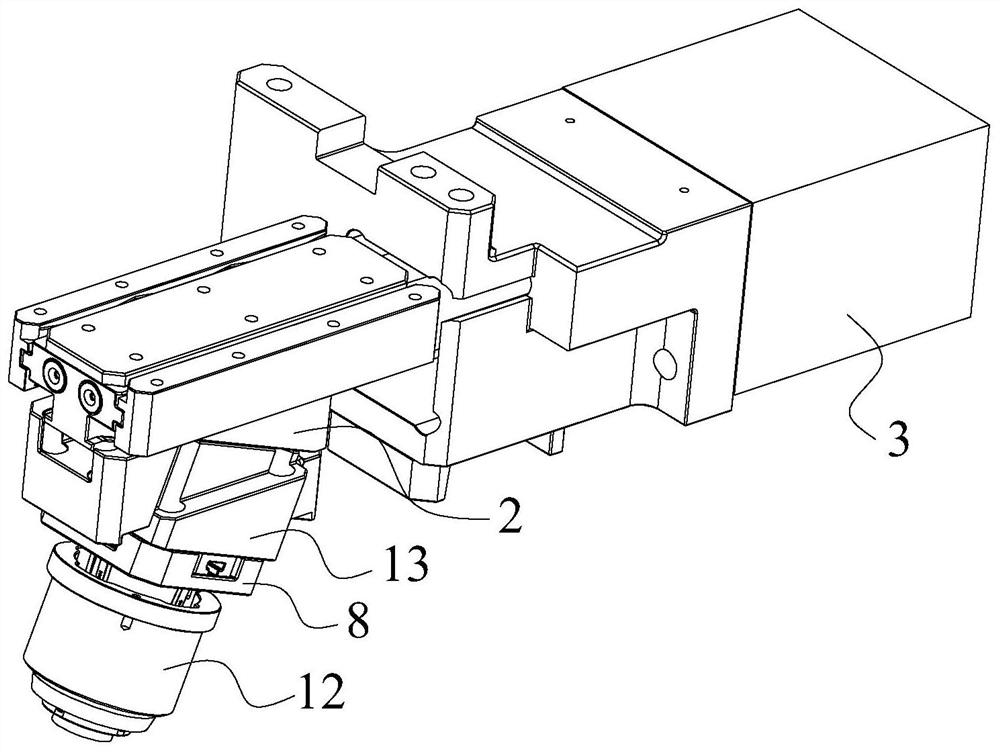

Demoulding mechanism for engine cylinder cover plate

PendingCN114311560AImprove stabilityStability does not affectDomestic articlesEngineeringStructural engineering

The invention provides an engine cylinder cover plate demolding mechanism which comprises a mold frame, a sliding block, an inclined drawing rod and a driving cylinder are arranged on the mold frame, the sliding block is in sliding fit with the mold frame, and the sliding block is in linkage fit with the inclined drawing rod. The sliding block drives the first core pulling block on the inclined pulling rod to be demolded and separated from the inner wall of an outwards-protruding inclined sleeve on the engine steel cover plate; and an inclined pulling assembly is arranged on the inclined pulling rod in a sliding mode, a second core pulling block is arranged on the inclined pulling assembly, and when the inclined pulling rod slides in a core pulling mode in the direction away from the inclined sleeve, the inclined pulling assembly moves inwards in the radial direction of the inclined pulling rod, so that demolding separation of the second core pulling block and an inverted buckle on the inner wall of the inclined sleeve is achieved. The engine cylinder cover plate demolding mechanism is simple in structure, and inclined hole demolding and inverted buckle demolding of the inner wall of an inclined hole can be conducted at the same time through one driving structure.

Owner:NINGBO FANGZHENG TOOL

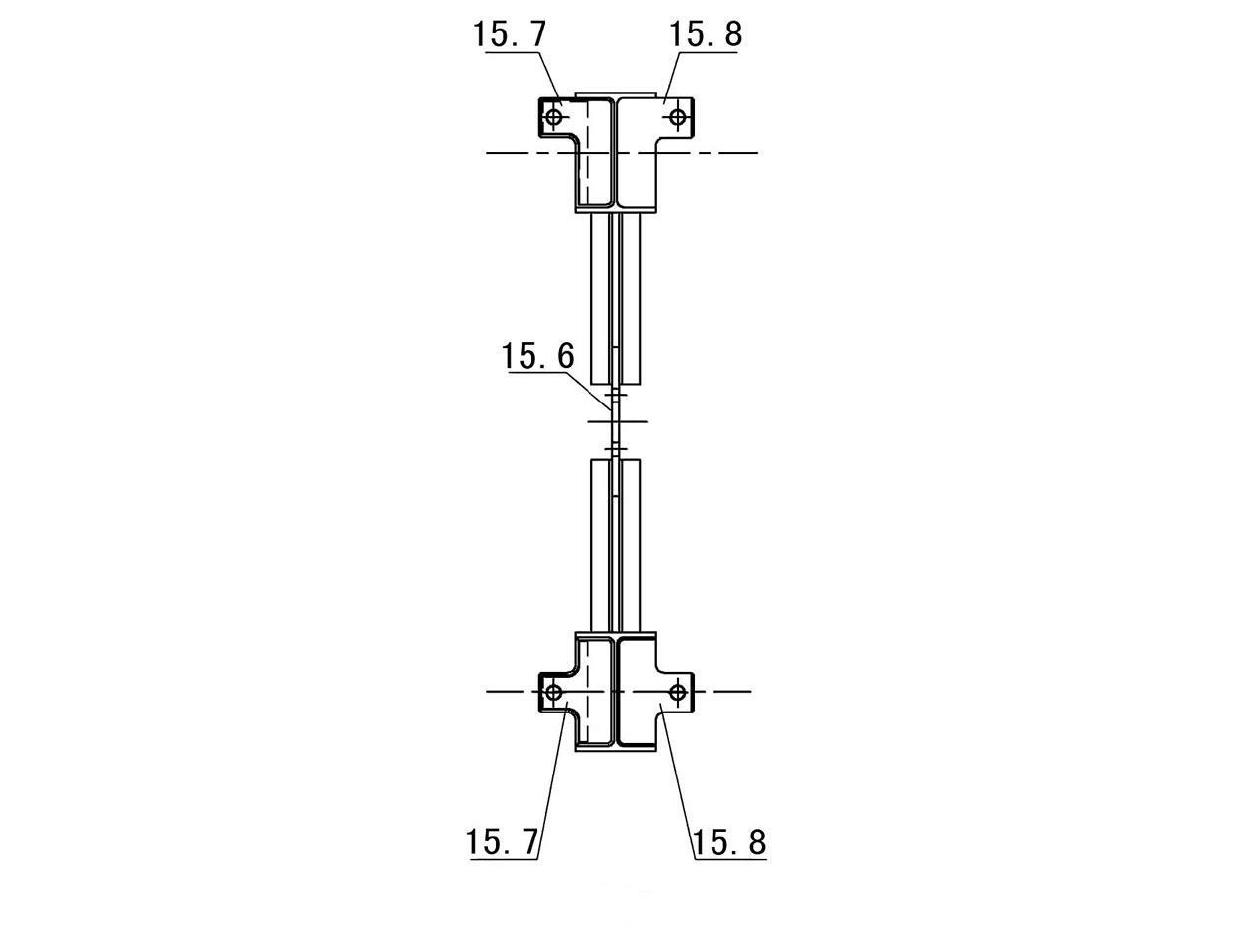

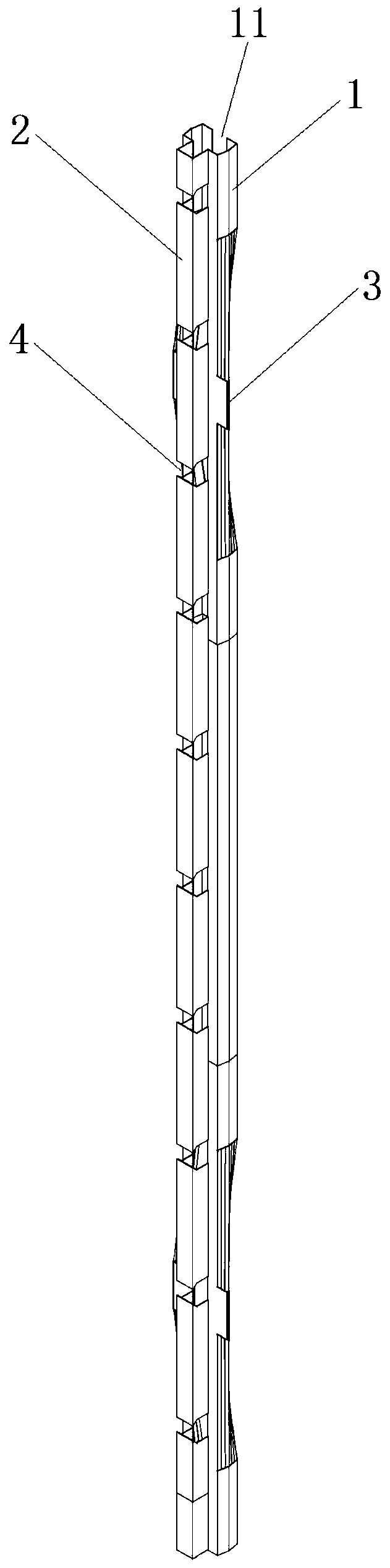

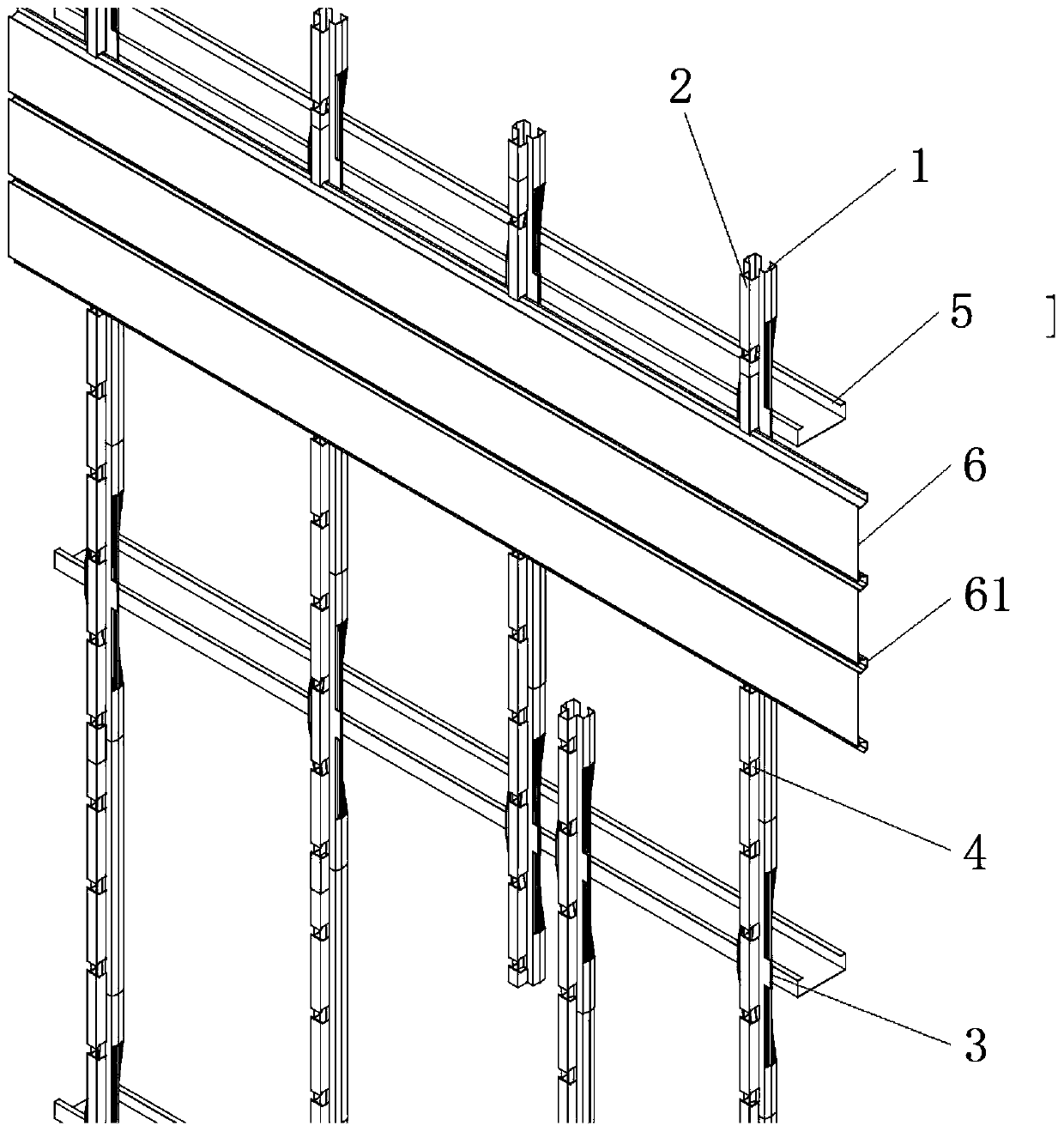

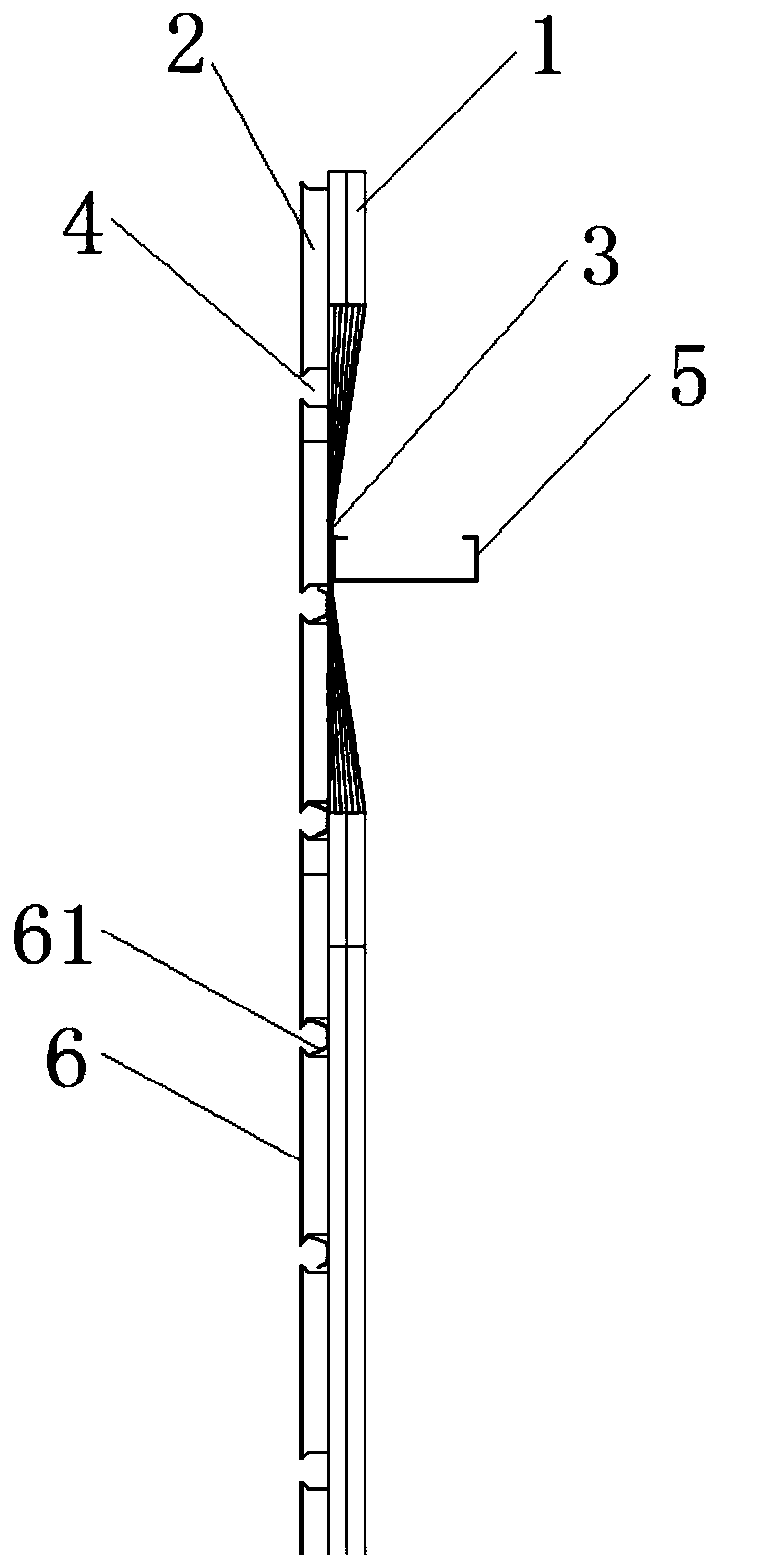

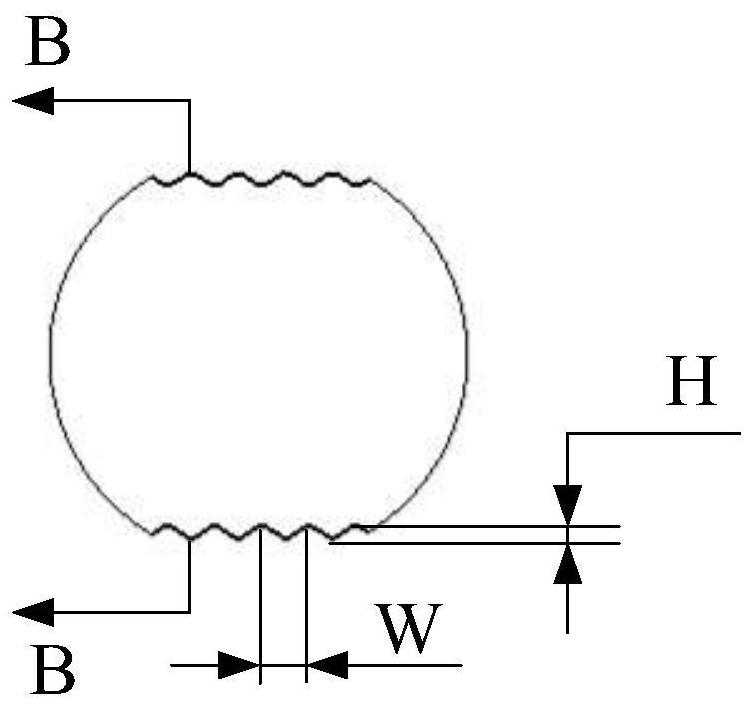

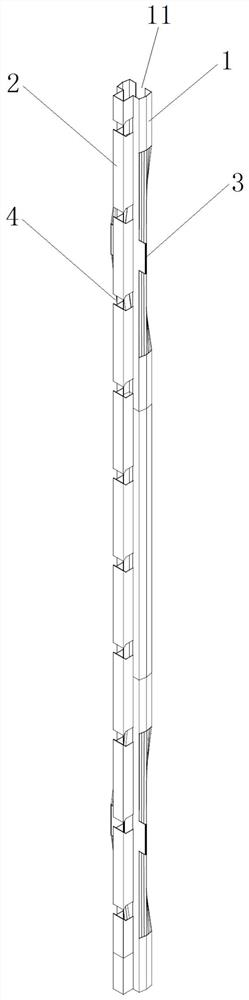

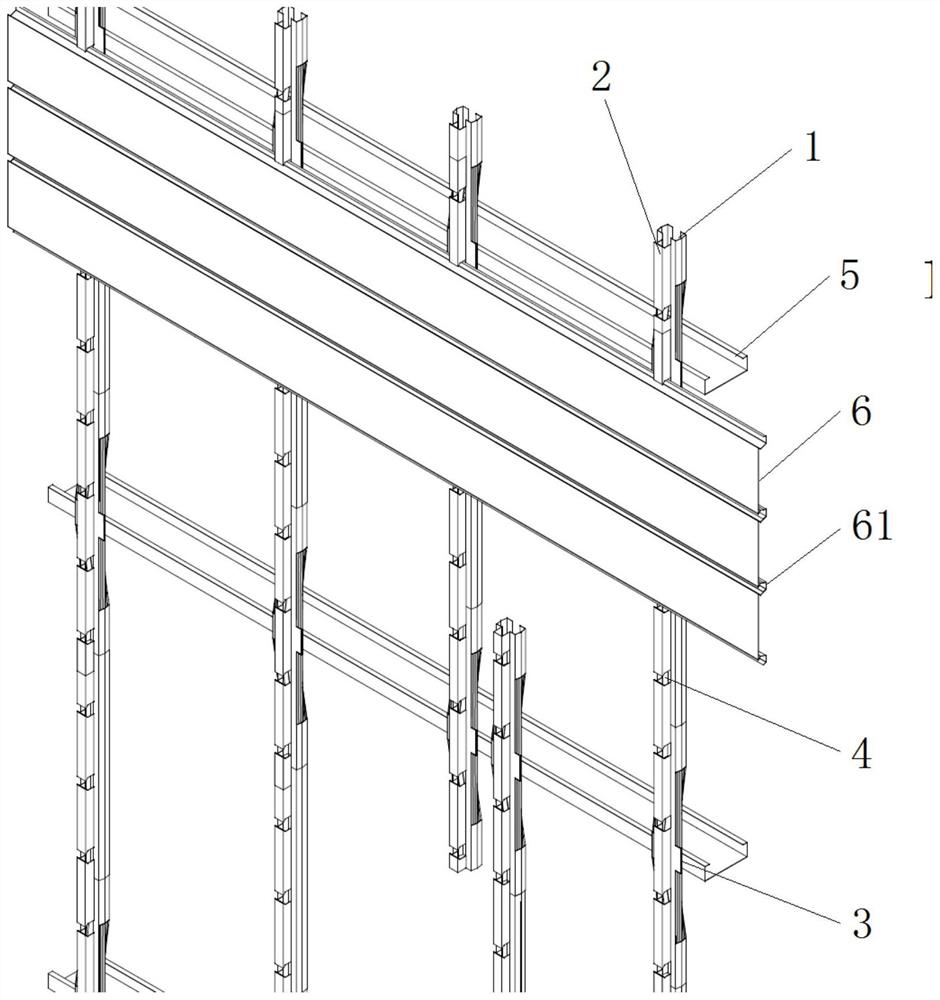

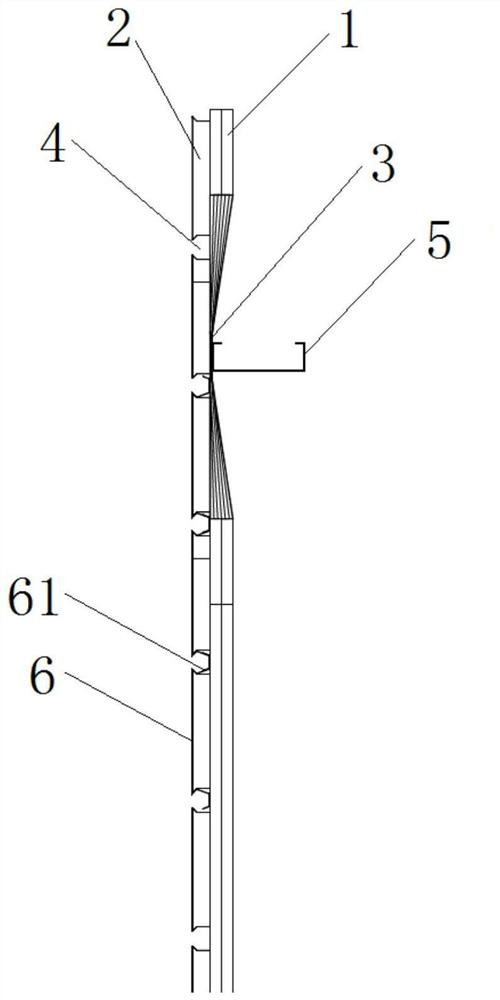

Variable-section keel

ActiveCN111255185AReduce metal usageRetains tensile and compressive propertiesCovering/liningsKeel structureMechanical engineering

The invention discloses a variable-section keel. The keel is vertically arranged on a transverse purline of a main structure, wherein the keel comprises a keel main body and a face board mounting part, the face board mounting part is arranged on one side wall of the keel main body in the length direction of the keel main body, a plurality of purline mounting parts which are arranged at intervals in the length direction of the keel main body are arranged on the other side wall, away from the face board mounting part, of the keel main body, and the purline mounting parts are concave parts whichare formed towards the direction of the face board mounting part; and a plurality of positioning clamping openings are also arranged at intervals in the length direction of the face board mounting part, wherein the positioning clamping openings are clamped to bending parts arranged on the two ends of a wall face board and is used for fixing the wall face board to the keel. According to the keel, the keel main body is pressed into the sheet-shaped purline mounting parts at the positions for connecting the purline, so that the thickness of the keel at the positions is reduced, the wall face board is inserted into the keel structure through the positioning clamping openings, the thickness of the whole wall face is reduced on the premise of not influencing the stability of the whole structure,and the metal consumption of the wall face is reduced.

Owner:CENT INT GROUP

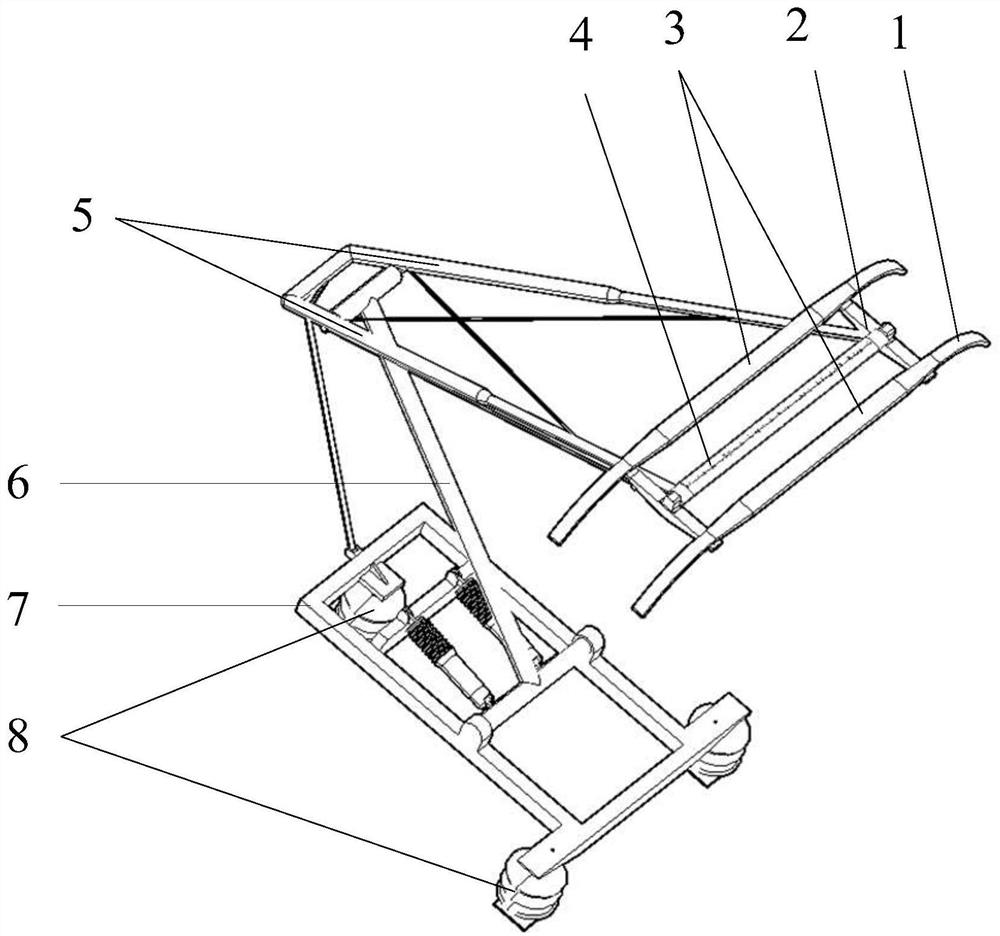

Low-noise high-speed train pantograph based on bionic structure

InactiveCN112060916AReduce noiseImprove ride comfort performanceRailway vehiclesPower current collectorsLow noiseControl engineering

The invention discloses a low-noise high-speed train pantograph based on a bionic structure. The train pantograph comprises pantograph corners, a pantograph head bracket, contact carbon sliding plates, a bracket rod, an upper arm rod, a lower arm rod, a bottom frame and an insulator, the insulator is arranged at the bottom of the bottom frame, one end of the lower arm rod is arranged on the bottomframe, and one end of the upper arm is hinged to the other end of the lower arm rod. The pantograph head support is hinged to the other end of the upper arm, the carbon sliding plates are arranged atthe two ends of the pantograph head support, the pantograph corners are fixed to the two ends of the carbon sliding plates, and the support rod is arranged on the pantograph head support and arrangedbetween the carbon sliding plates. The shape of the pantograph head rod piece of the pantograph is improved based on the bionic structure, aerodynamic noise of the pantograph head is effectively controlled, it is guaranteed that structural stability and electric power functional characteristics of the pantograph are not affected, and interference of the aerodynamic noise of the pantograph of thehigh-speed train on the surrounding environment is reduced.

Owner:NANJING UNIV OF SCI & TECH

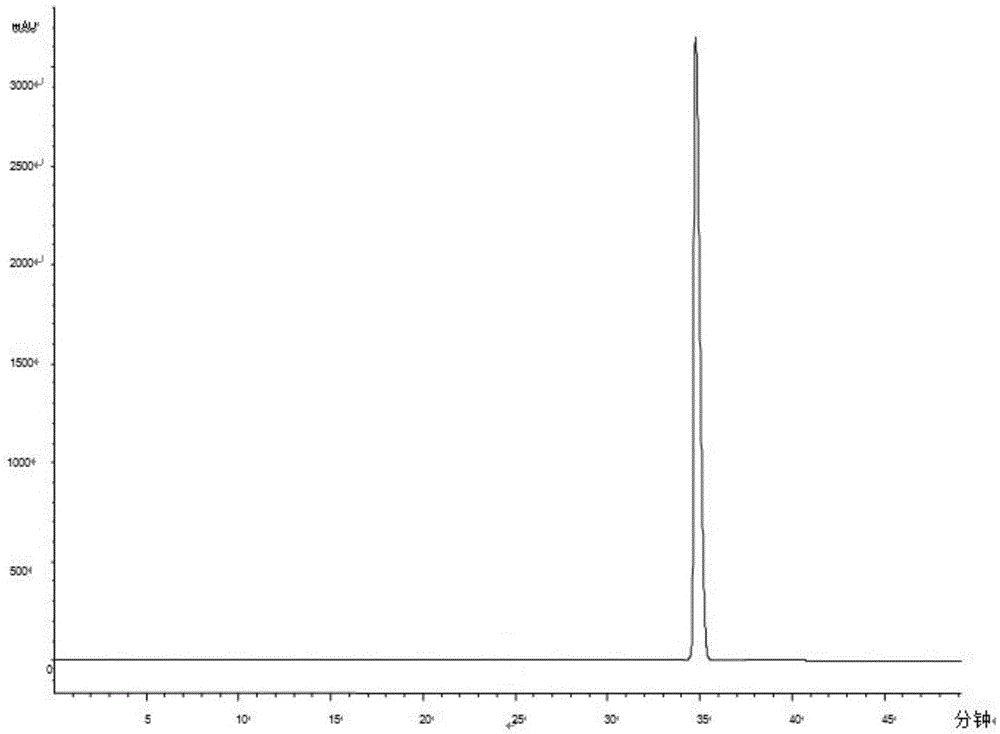

Cryptochlorogenic acid preparation method

ActiveCN105481689APoor separationDoes not affect structural stabilityOrganic compound preparationCarboxylic acid esters preparationChlorogenic acidAcid preparations

The present invention discloses a cryptochlorogenic acid preparation method comprising the following steps: taking chlorogenic acid, dissolving the chlorogenic acid in methanol, then adding 1-2mol / L hydrochloric acid for the reaction while stirring for 6-8h, using a 1-2mol / L NaOH solution for adjusting pH to be neutral, concentrating, dissolved in methanol, filtering, concentrating under reduced pressure, adding water for dissolving, and filtering to obtain a filtrate; taking the filtrate for pretreatment by a reverse phase C18 column, washing with water, collecting a water washing solution, concentrating, centrifuging, filtering, and preparing cryptochlorogenic acid by reverse phase industrial preparative chromatography. According to the cryptochlorogenic acid preparation method, best acid conversion conditions and alkali neutralization reaction conditions can be obtained by screening by system experiments, the high purity cryptochlorogenic acid can be prepared by the reverse phase industrial preparative chromatography, and the method is high in yield and suitable for large-scale preparation, and achieves good technical results.

Owner:JIANGSU KANION PHARMA CO LTD

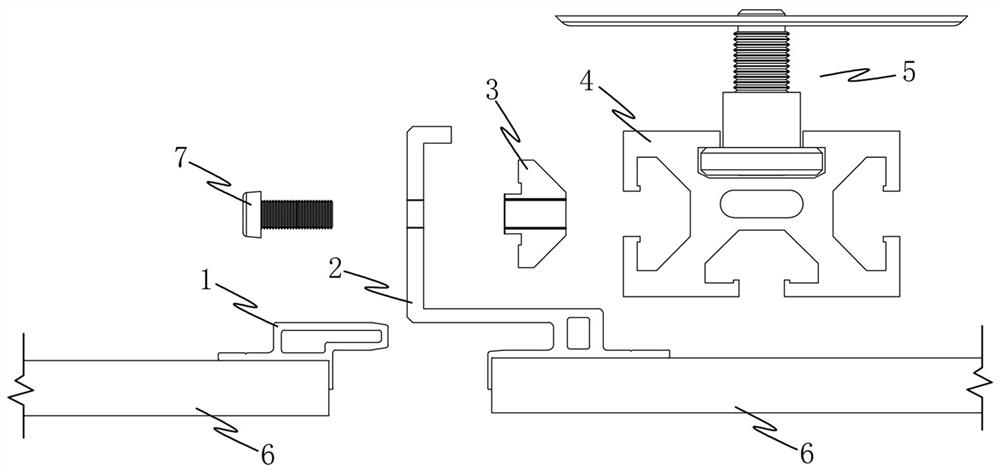

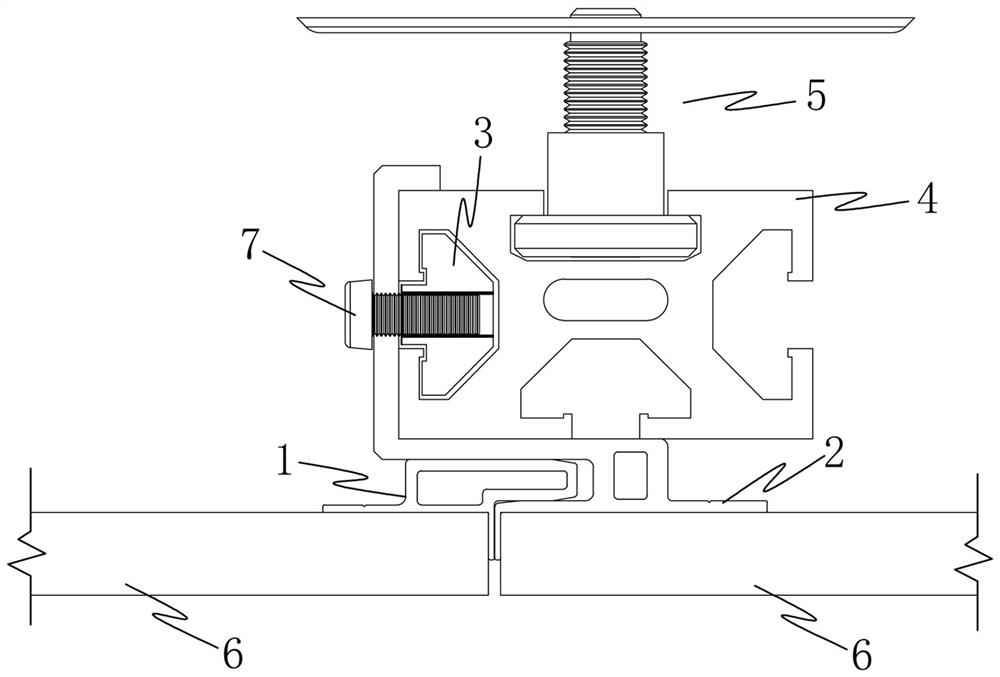

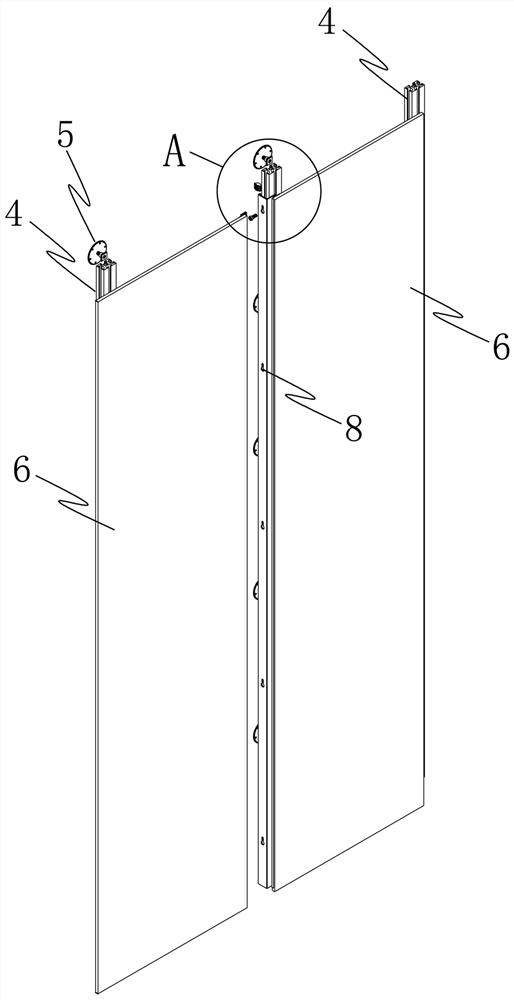

Insert-type hanging structure and installation method

PendingCN112443105AButt area reductionNo need to consider length errorCovering/liningsButt jointIndustrial engineering

The invention discloses an insert-type hanging structure and an installation method. The hanging structure comprises an inserting piece and a hanging piece, wherein the upper side of the hanging pieceis hung on a side edge structure of a sectional material, a second containing cavity used for being fixedly connected with a veneer is formed in the lower side of the hanging piece, an inserting cavity is formed in the middle structure of the hanging piece, a second splicing plate is arranged at the position, located at an end opening of the inserting cavity, of the front end of the second containing cavity, an inserting end used for being inserted into the inserting cavity is arranged at the front end of the inserting piece, a first containing cavity used for being fixedly connected with theveneer is formed in the lower side of the inserting piece, a first splicing plate is arranged at the front end of the first containing cavity, and when the inserting end is inserted into the inserting cavity, the first splicing plate and the second splicing plate abut against each other and stop the inserting end from continuing to be inserted into the inserting cavity, so that the veneer locatedin the first containing cavity and the veneer located in the second containing cavity can be assembled in a butt joint mode. According to the hanging structure, modularized assembly can be achieved,the stability of a wallboard is enhanced, a leveling structure and a hanging structure are combined and integrally assembled, and the installation efficiency is improved.

Owner:ZHEJIANG YASHA DECORATION

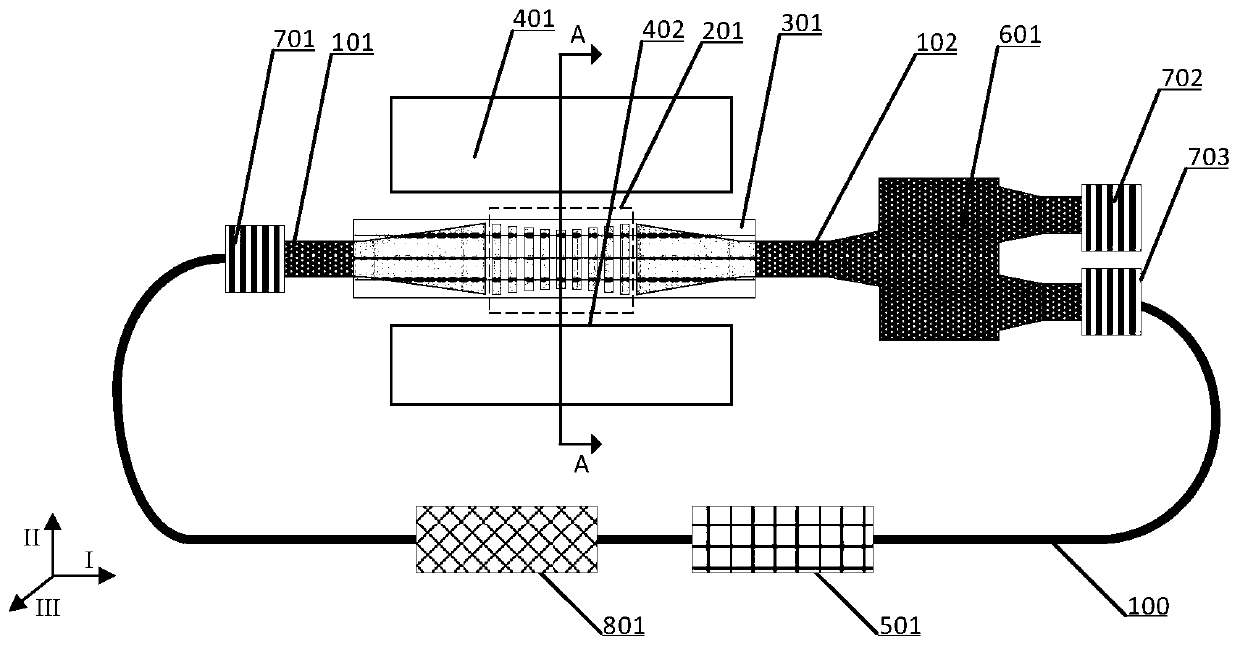

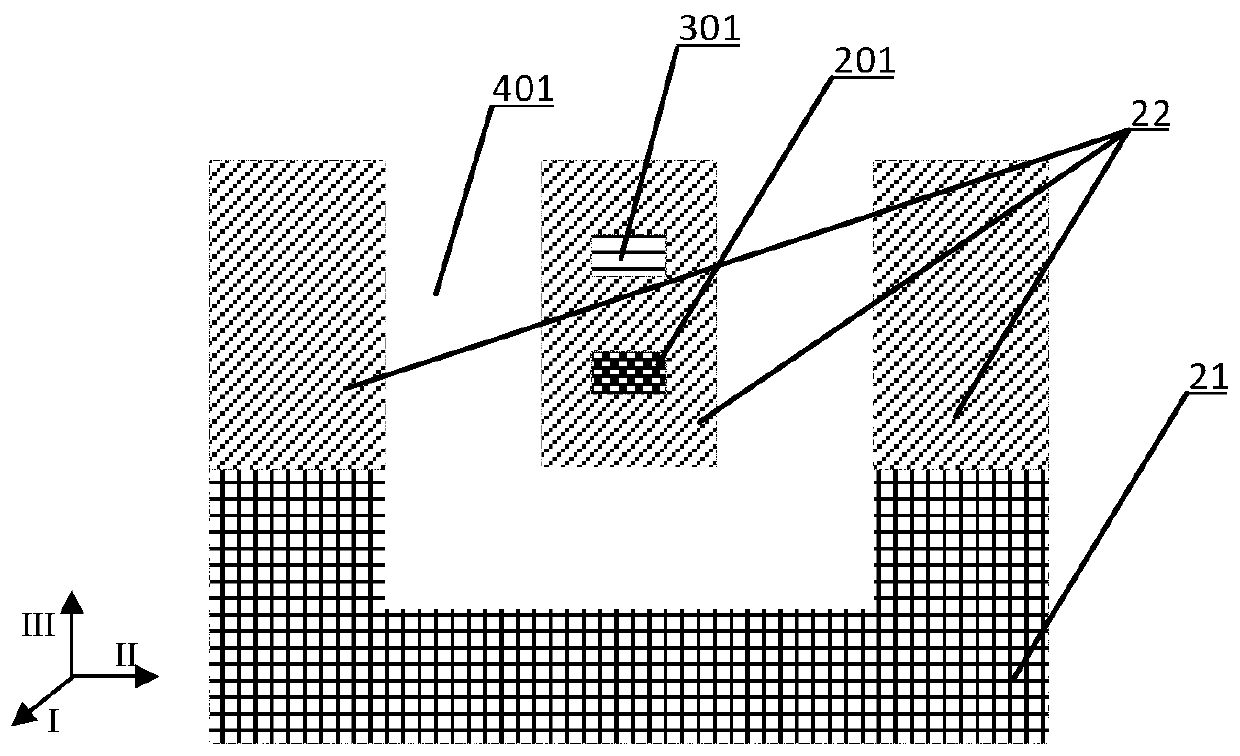

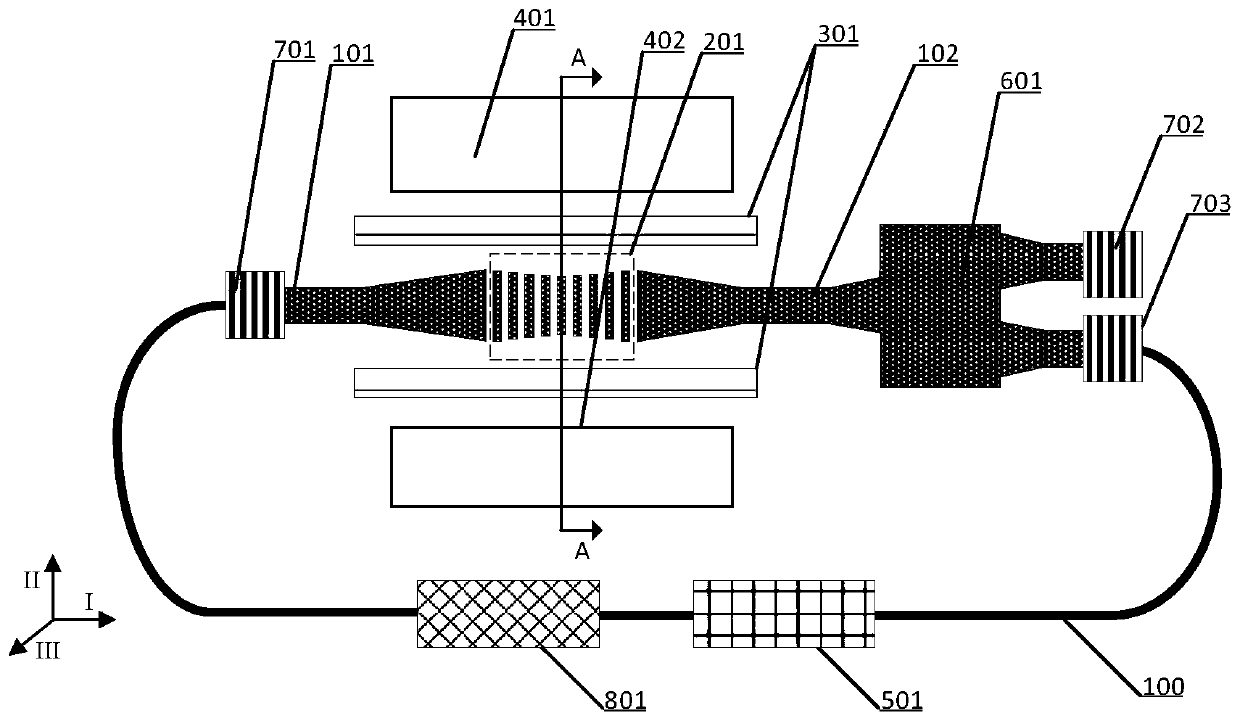

A tunable laser

ActiveCN109659805BLarge wavelength tuning rangeNo mode hoppingLaser detailsPhotonic crystal cavityGain

The invention discloses a tunable laser, and relates to the field of optical communication devices. The tunable laser includes a silicon substrate, wherein the length direction, width direction and height direction of the silicon substrate are respectively defined as a first direction, a second direction, and a third direction; an optical input port, a first optical waveguide, a photonic crystal cavity, a second optical waveguide, an optical beam splitter, an optical emission port, an optical output port and an optical gain assembly which are formed on the silicon substrate. The optical inputport and the optical output port are connected through an optical fiber link to form a loop, and the optical gain assembly is arranged on the loop. According to the tunable laser, electrodes are respectively arranged at the two sides of a photonic crystal cavity in the second direction, or electrodes are arranged above the photonic crystal cavity in the third direction. The tunable laser providedby the invention is high in adjustment efficiency, large in tuning range, stable in output wavelength, small in structural size and beneficial to large-scale integration.

Owner:WUHAN POST & TELECOMM RES INST CO LTD +1

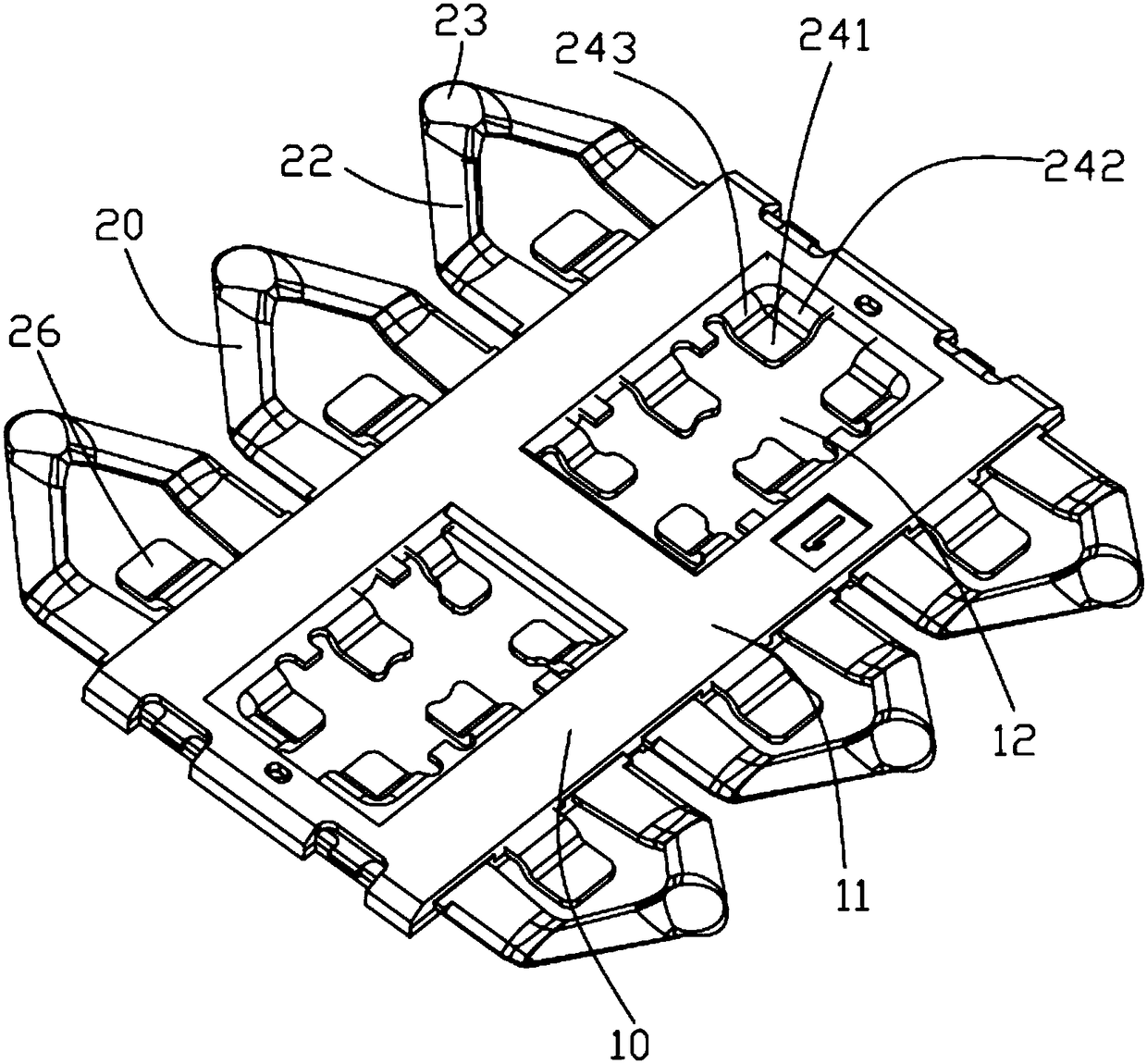

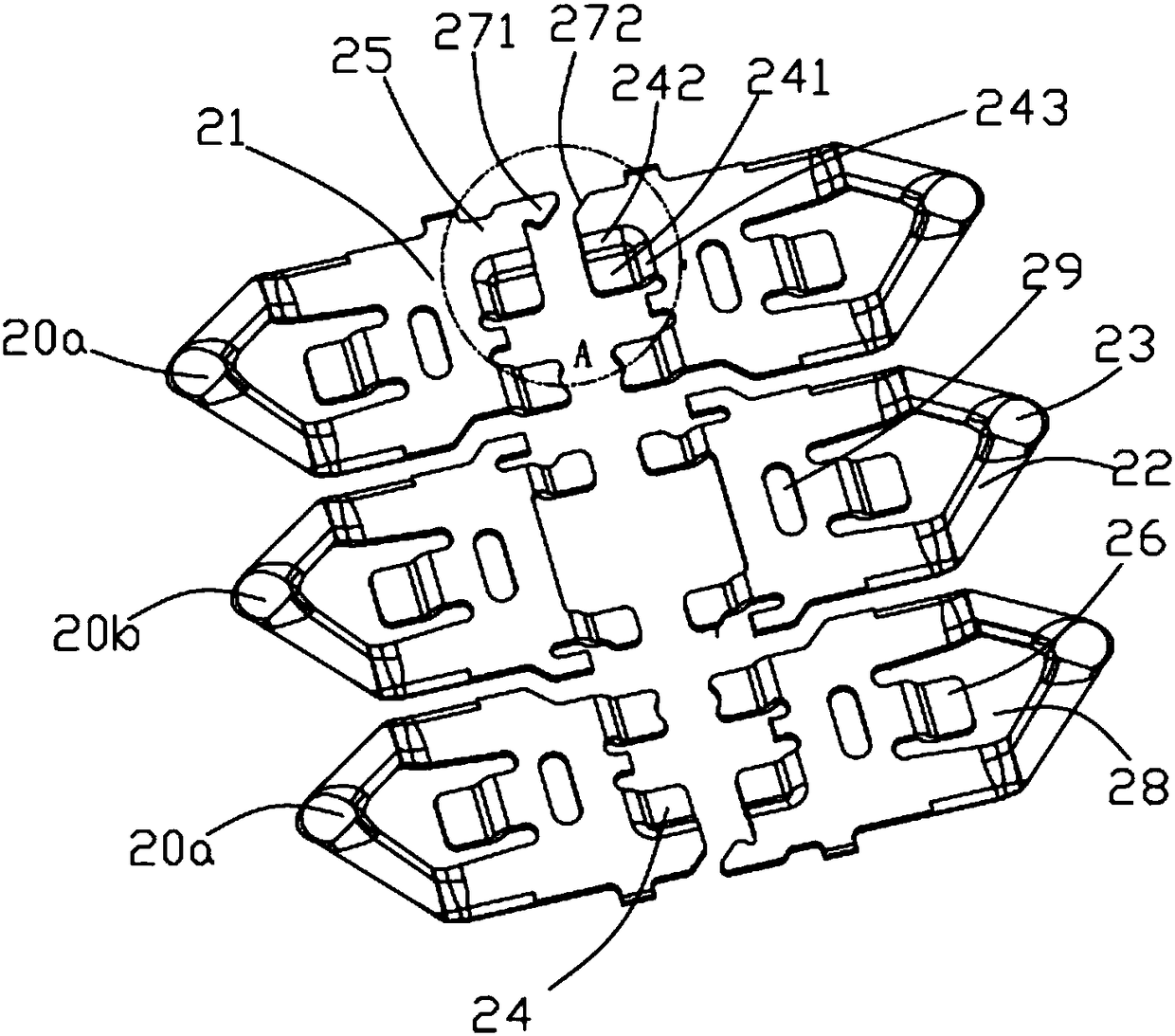

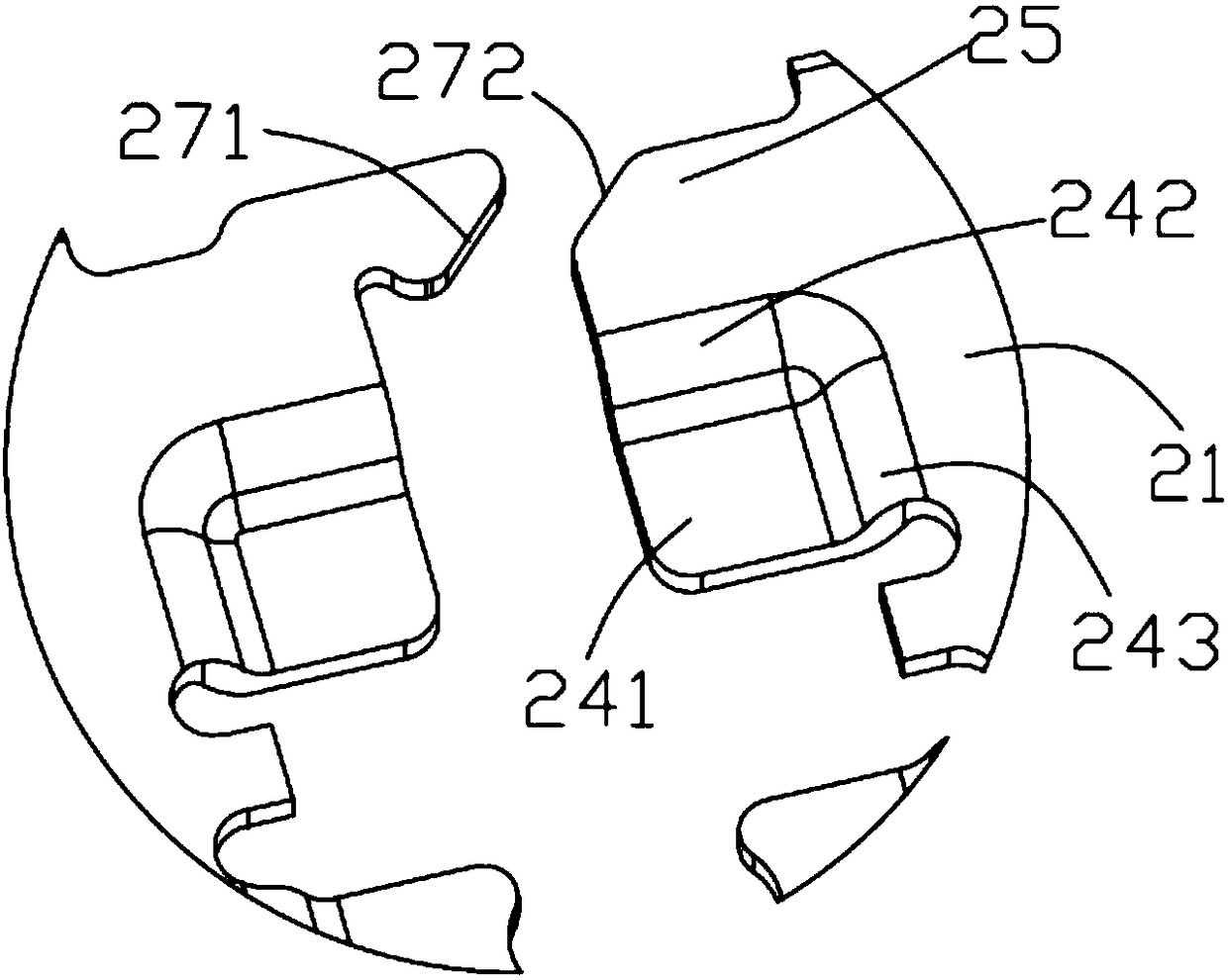

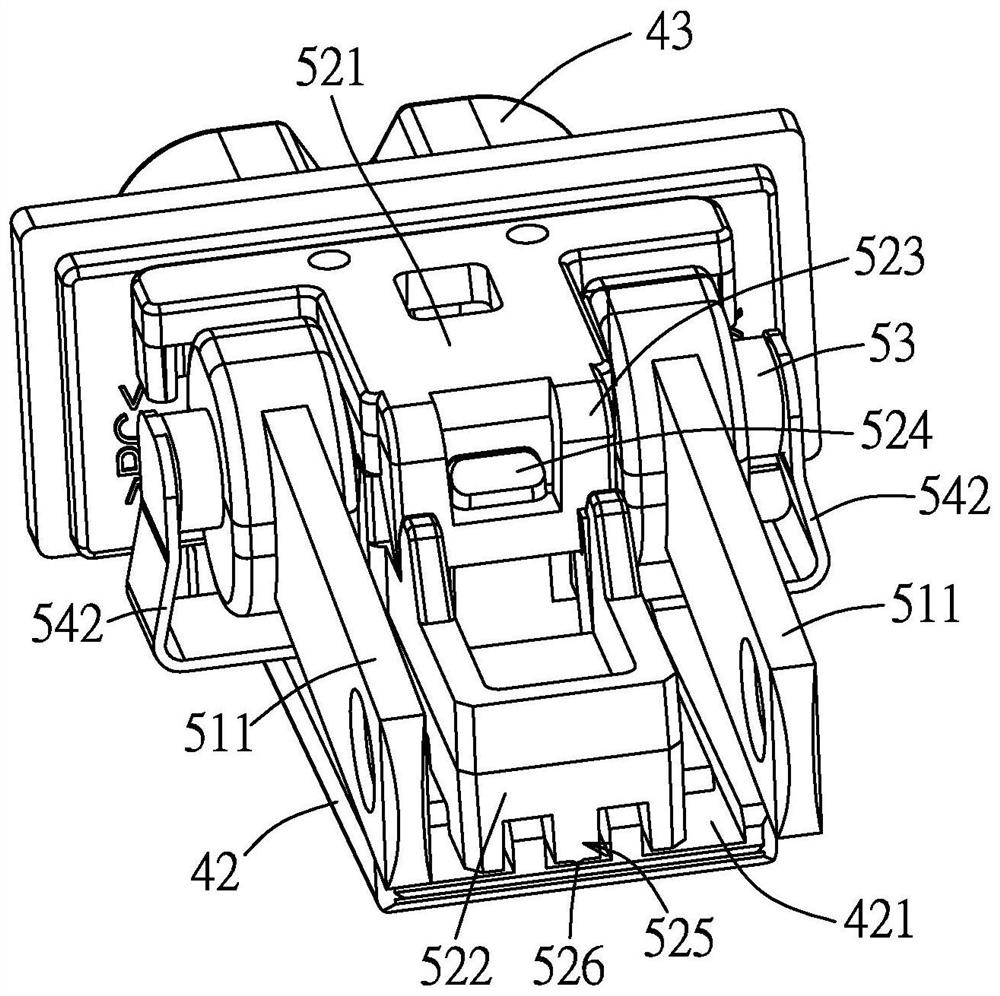

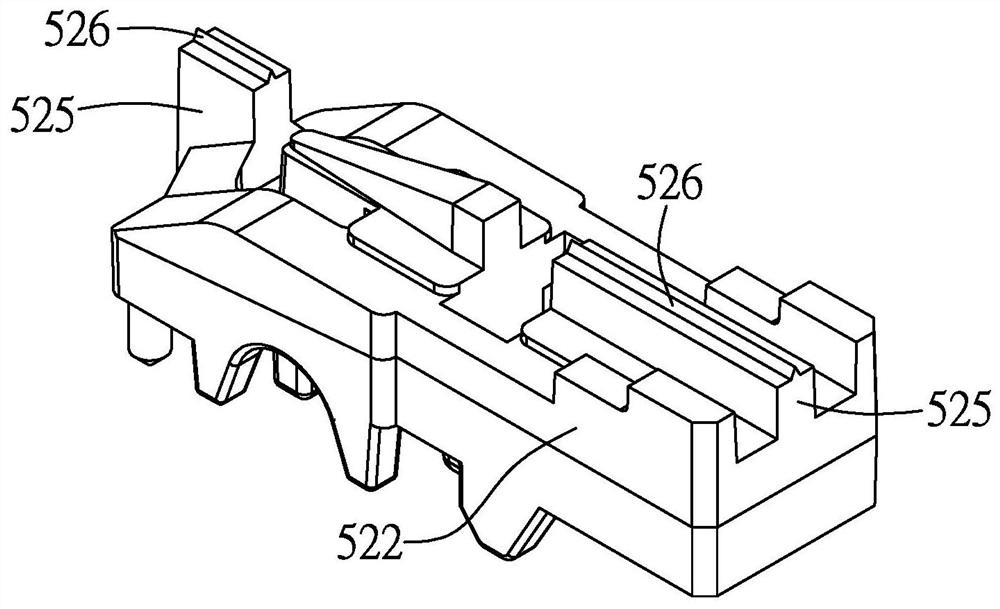

Electronic card connector

PendingCN108123245AHigh strengthDoes not affect structural stabilityCoupling contact membersCouplings bases/casesEngineeringElectrical and Electronics engineering

An electronic card connector comprises a plurality of conductive terminals and an insulator which integrally forms the plurality of conductive terminals. The conductive terminals are arranged in two opposite rows in the longitudinal direction of card insertion. The insulator comprises a frame body portion and a welding pin accommodating portion formed in the middle of the frame body portion. Eachrow of the conductive terminals comprises two outer side conductive terminals arranged at two ends in the longitudinal direction, and inner conductive terminals arranged between the two outer side conductive terminals. Each conductive terminal comprises a holding portion which is integrally formed in the insulator, two extending arms formed by extending upwardly and obliquely from one lateral sideof the holding portion toward a direction away from the insulator, a contact portion formed by intersecting the two extending arms at a high point, and welding pins extending into the welding pin accommodating portion from the other lateral side of the holding portion. Outer sides of the outer side conductive terminals in the longitudinal direction extend relatively to form reinforcing portions embedded in the insulator. The electronic card connector can effectively strengthen the overall strength and stability of products.

Owner:SHENZHEN EVERWIN PRECISION TECH

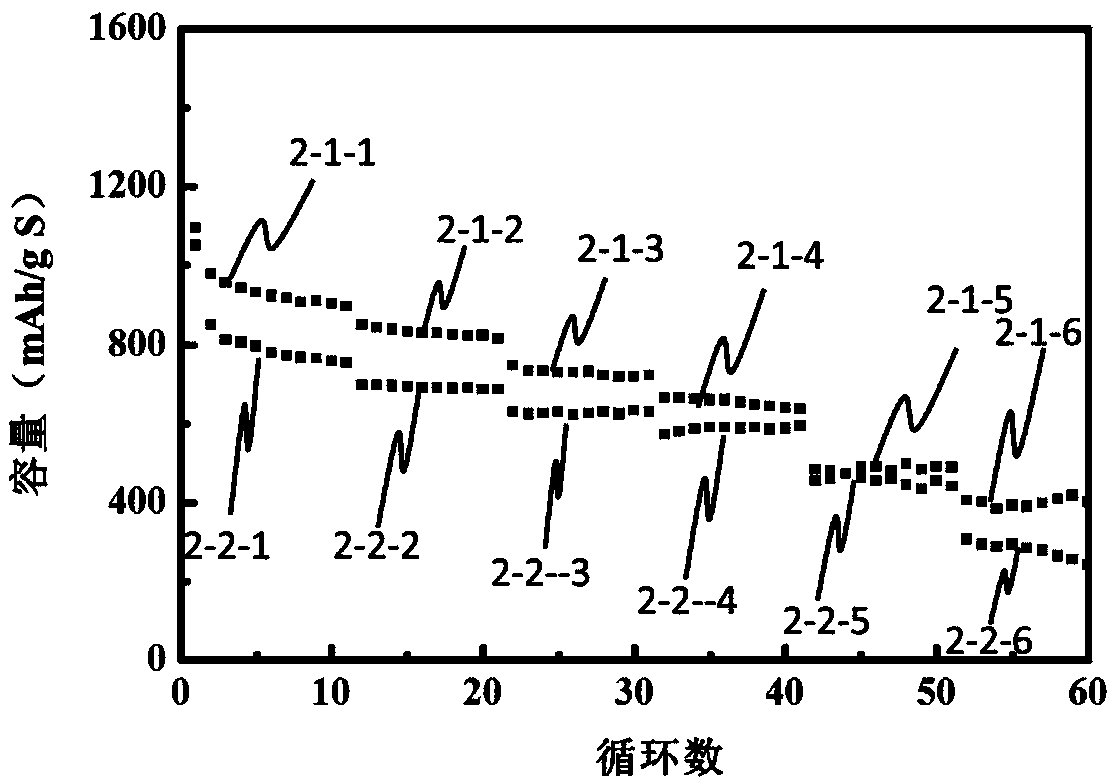

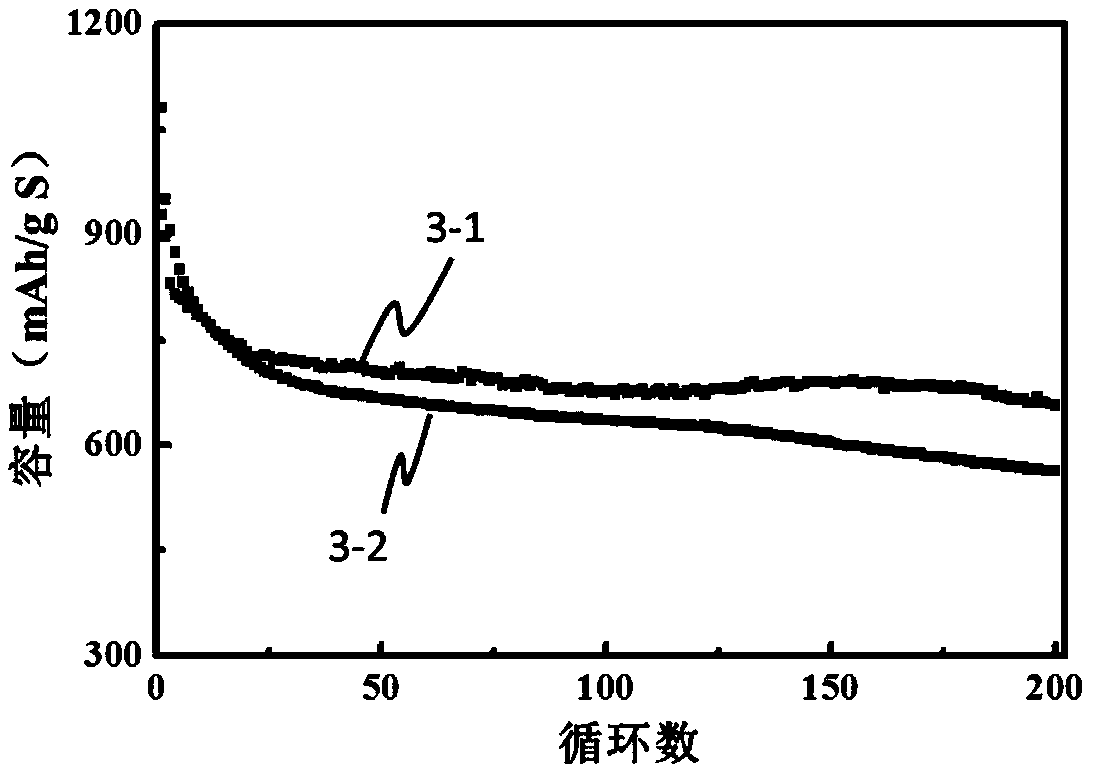

A synergistically modified cobalt lithium fluorophosphate positive electrode material and preparation method thereof

ActiveCN107845801BImprove conductivityIncreased effective discharge capacityMaterial nanotechnologyCell electrodesPhysical chemistryPhosphoric acid

The invention relates to a nickel-doped and carbon / silica-coated synergistically modified cobalt lithium fluorophosphates cathode material and a preparation method thereof. The preparation method comprises the following steps: (1) respectively adding a lithium source, a cobalt source, a fluorine source and a nickel source compound into deionized water in a certain stoichiometric ratio, stirring, adding a certain amount of a phosphate source compound into the solution, further stirring, transferring into a high pressure reaction kettle, airtightly heating, reacting, then naturally cooling, taking out, and drying, so that a precursor is obtained; (2) mixing the obtained precursor and a carbon source compound, grinding, and calcining for two stages in inert atmosphere, so that a carbon-coatednickel-doped Li2Co1-xNixPO4F / C material is obtained; and (3) weighing a certain amount of silica, putting into a breaker, adding deionized water, carrying out ultrasonic treatment, then adding the Li2Co1-xNixPO4F / C material, stirring, drying, and grinding, so that the Li2Co1-xNixPO4F / C+SiO2 target material is obtained. The prepared material is uniform in particles and good in crystallinity and has relatively high specific capacity and good cycle performance; and meanwhile, the synthetic process is simple and easy, and the production cost is low.

Owner:UNIV OF JINAN

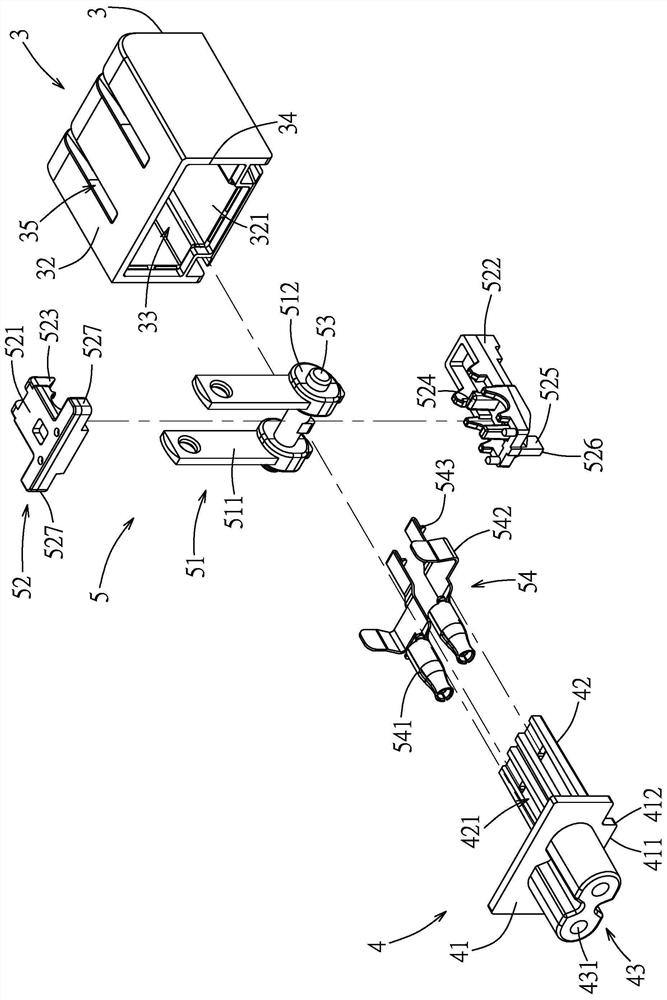

Plug device

ActiveCN109411939BExtended service lifeDoes not affect structural stabilityCoupling contact membersTwo-part coupling devicesStructural engineeringMechanical engineering

Owner:CONNTEK INTEGRATED SOLUTIONS

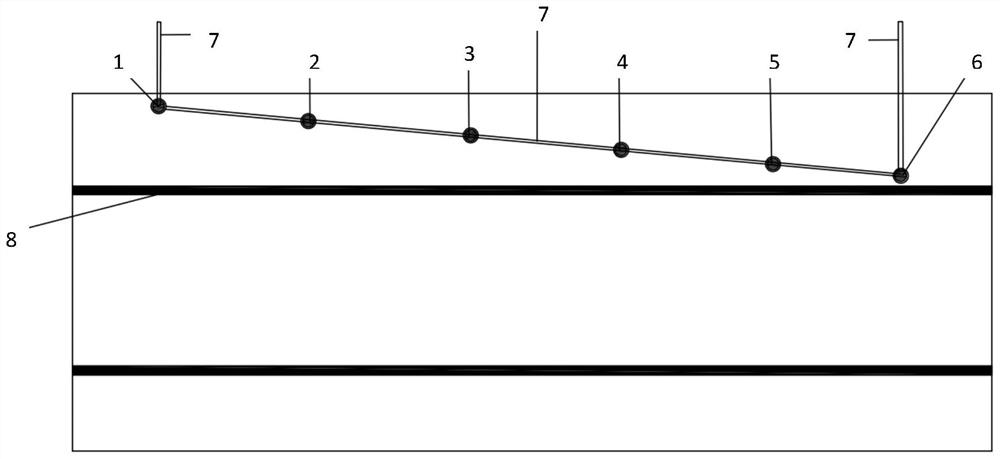

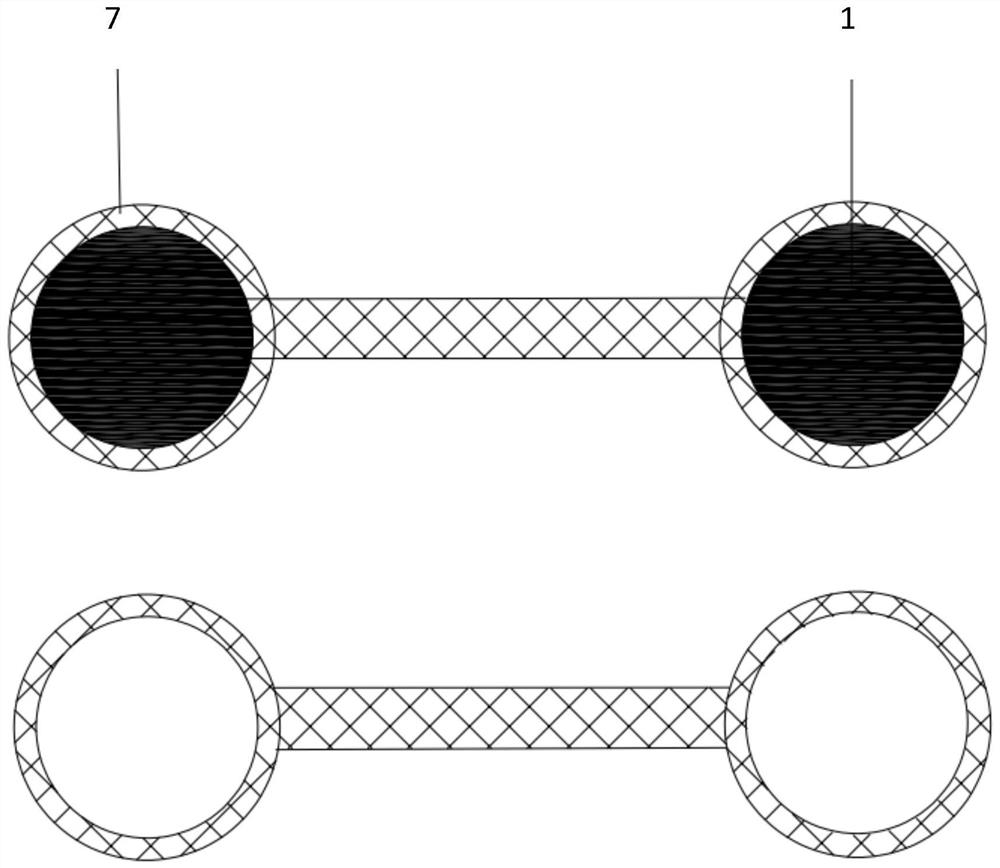

Steel bar corrosion evaluation method based on magnetic field principle

PendingCN113866077ADoes not affect structural stabilityImprove efficiencyWeather/light/corrosion resistanceMaterial magnetic variablesRebar corrosionClassical mechanics

The invention relates to a steel bar corrosion evaluation method based on a magnetic field principle, which comprises the following steps: arranging a reference steel bar, testing the magnetic induction intensity of the steel bar by using an external sensor on the basis of not damaging the stability of a concrete structure, and monitoring a reinforced concrete test piece. The corrosion conditions of the reinforcing steel bars under different protective layer thicknesses are obtained according to monitoring results and theoretical basis analysis, the magnetic induction intensity of the test piece before corrosion is set to be B0I, the magnetic induction intensity of the test piece after corrosion is set to be B0II, the corrosion rate of the reinforcing steel bars is set to be PII, the calculation formula is PI = alpha (B0II-B0I), and alpha is a linear relation coefficient. The method is an evaluation method which does not influence the stability of a concrete structure and accurately tracks and tests steel bar corrosion at different protective layer thicknesses in a concrete sample for a long time on the basis of a magnetic field principle, the efficiency of a steel bar corrosion test in a laboratory can be greatly improved, and smooth research is helped.

Owner:ZHEJIANG UNIV OF TECH

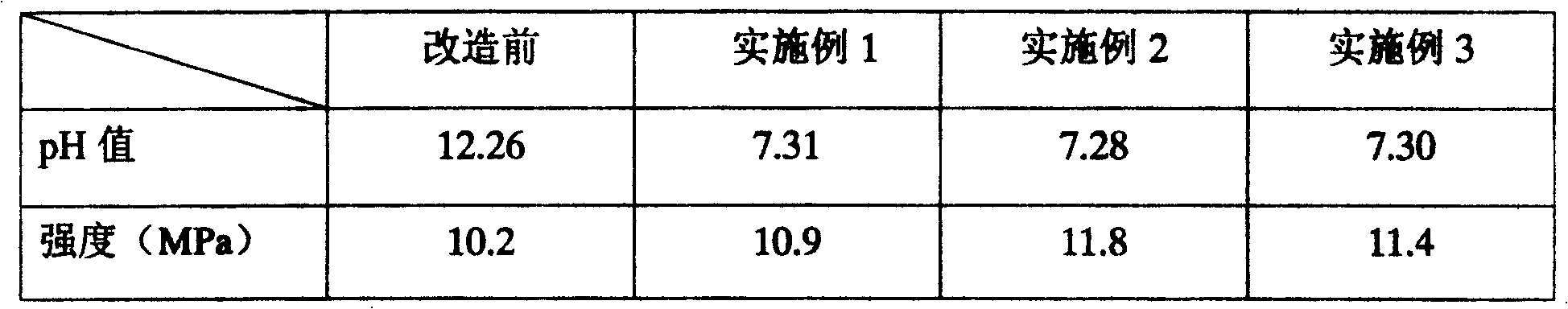

Method of modifying porous vegetation concrete pore alkalinity

InactiveCN100445239CDoes not affect structural stabilityDoes not affect strengthCeramicwareVegetationAlkalinity

This invention relates to a reform method for alkalinity of holes for porous vegetation concrete, which confects spraying solution, carries out filming by spraying and film solidification to form a densed macromolecular film layer on the surfaces of the holes, so that the filled soil in the holes is not basified and keeps neutral for a long time, which is suitable for the growing of vegetable roots and does not influence the strength of porous concrete.

Owner:CHONGQING UNIV

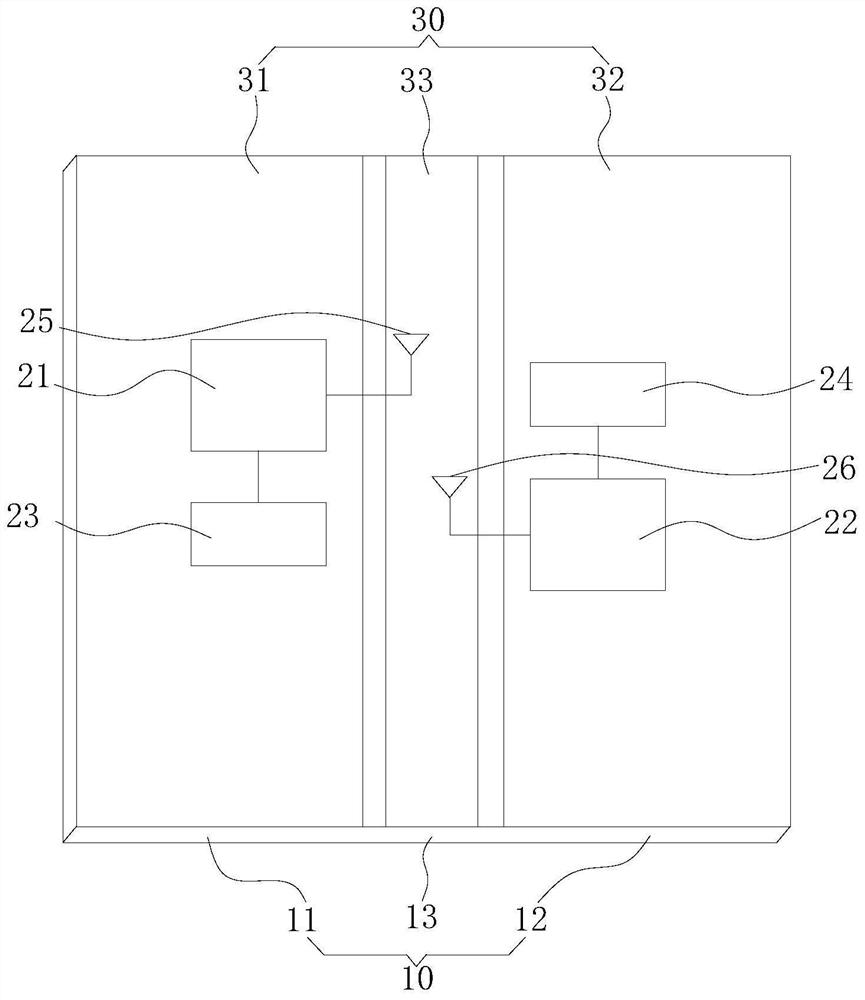

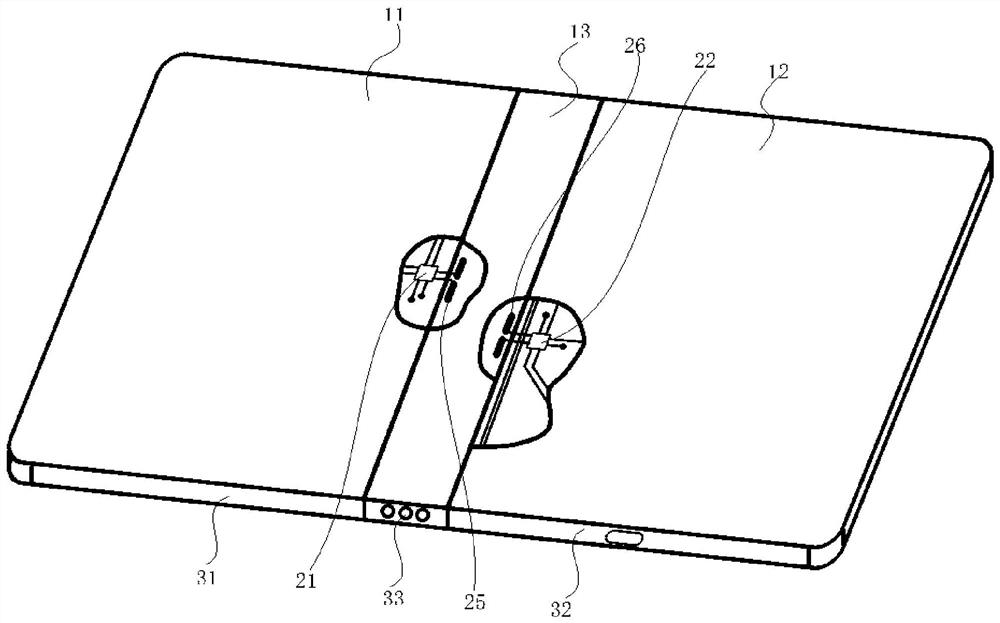

Folding device and terminal equipment

ActiveCN112995370BReduce lossGuaranteed transmission performanceRadiating elements structural formsDetails for portable computersTerminal equipmentTransmission performance

The present application provides a folding device and a terminal device. The folding device includes a folding body, and the folding body includes a first folding part, an intermediate bending part and a second folding part which are connected in sequence. The first folding part and the second folding part are connected in sequence. The folding part can be relatively rotated based on the middle bending part; the first folding part is provided with a first wireless communication chip, the second folding part is provided with a second wireless communication chip, the first folding part and the The second folding part performs wireless communication through the first wireless communication chip and the second wireless communication chip. The folding device replaces the traditional physical wiring used for internal signal transmission through wireless communication. When the folding body performs frequent bending operations, the wireless communication method reduces the loss of the communication carrier and ensures that the first folding part and the second folding part are connected to each other. There is always stable transmission performance between the two folded parts.

Owner:HUAWEI TECH CO LTD

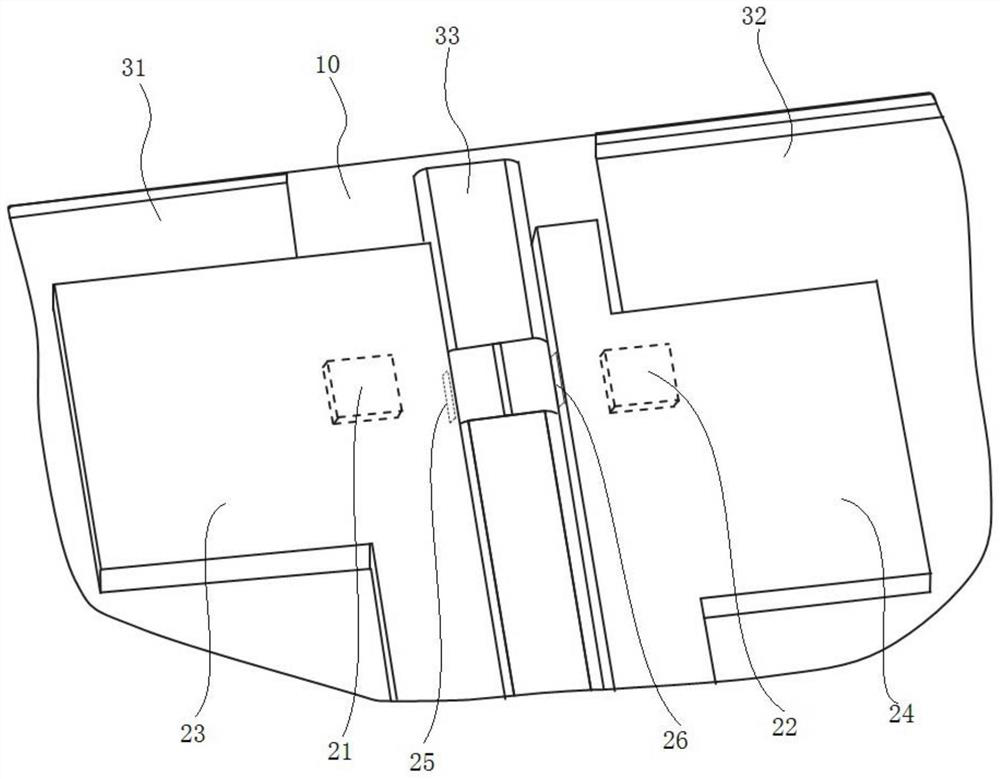

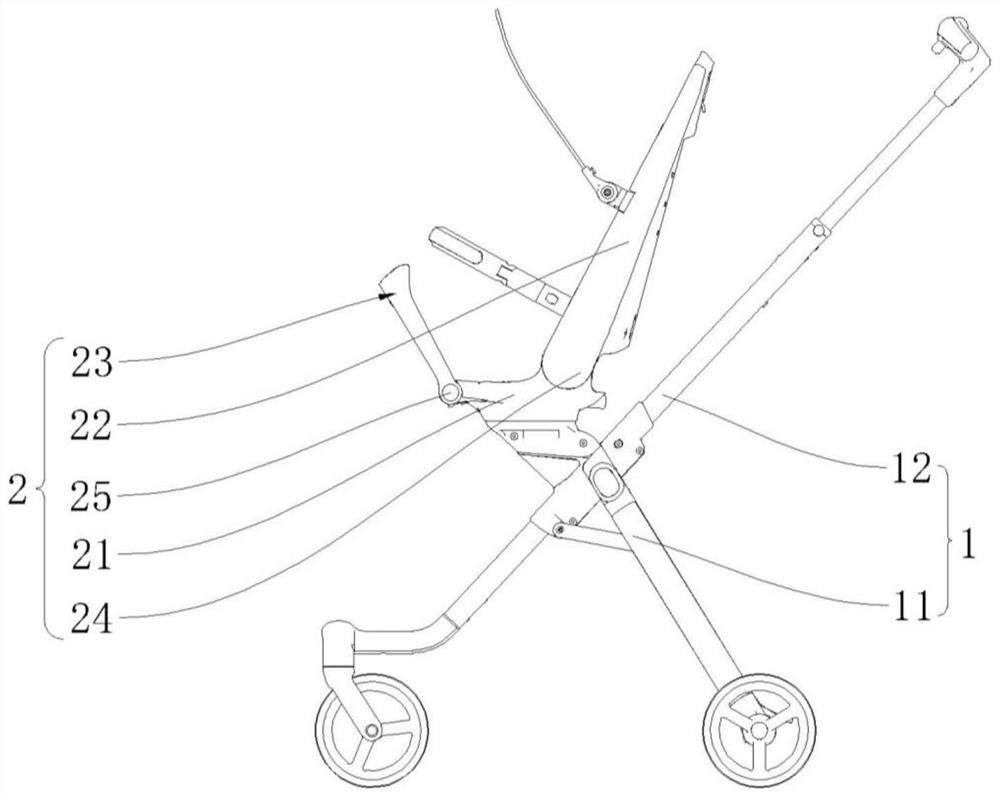

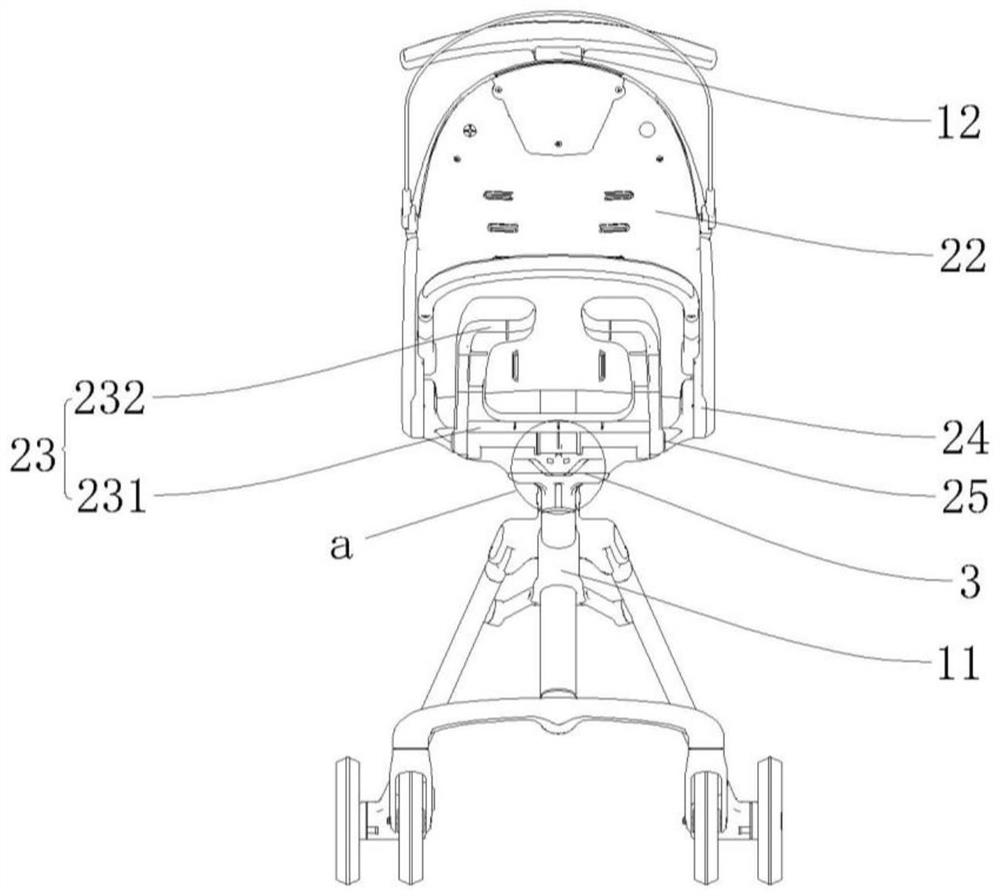

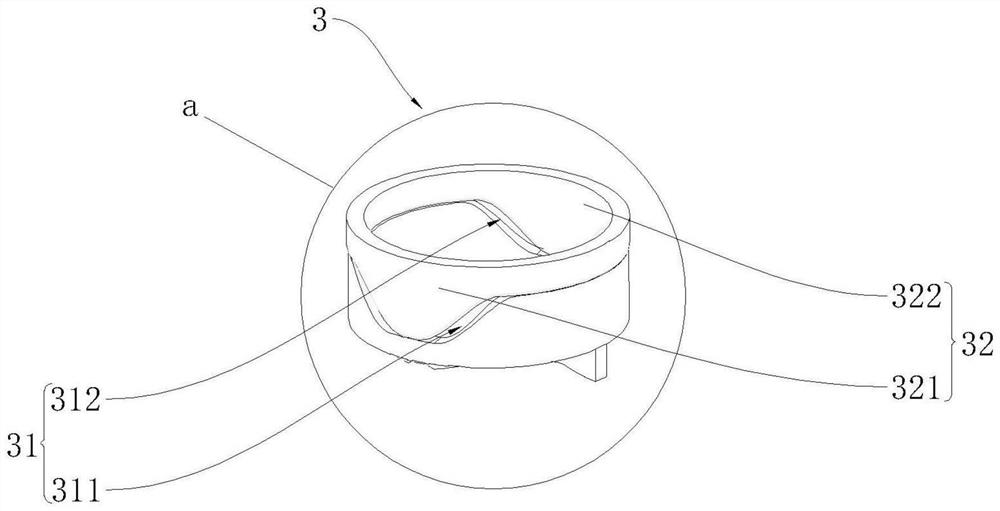

Baby stroller

InactiveCN114104072AAvoid interferenceEasy to viewCarriage/perambulator accessoriesCarriage/perambulator with multiple axesPhysical medicine and rehabilitationPhysical therapy

The invention belongs to the technical field of products for children, and discloses a stroller. The baby stroller comprises a stroller frame assembly, a seat pocket assembly and a connecting assembly. The seat pocket assembly rotates and reverses so that the sitting child can face a caregiver, and the state of the child can be checked conveniently. The connecting assembly comprises a first connecting piece arranged on the frame assembly and a second connecting piece arranged on the seat pocket assembly, the first connecting piece is located below the second connecting piece, the first connecting piece is rotationally connected with the second connecting piece, and the connecting assembly is used for upwards lifting or downwards lowering the seat pocket assembly by a certain height in the reversing process; the height of the seat pocket assembly is consistent before and after rotation reversing, the interference problem of the seat pocket assembly and the stroller frame assembly in the rotation reversing process of the stroller is solved, the use experience is not affected, and the structural stability of the stroller is not affected.

Owner:跃石(上海)婴童用品有限公司

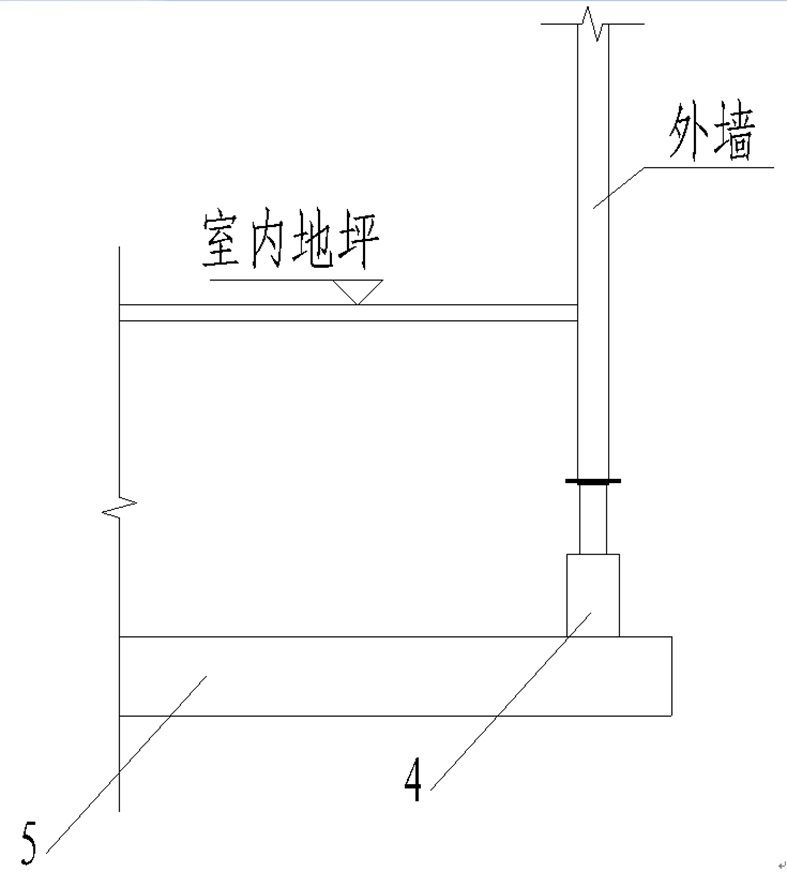

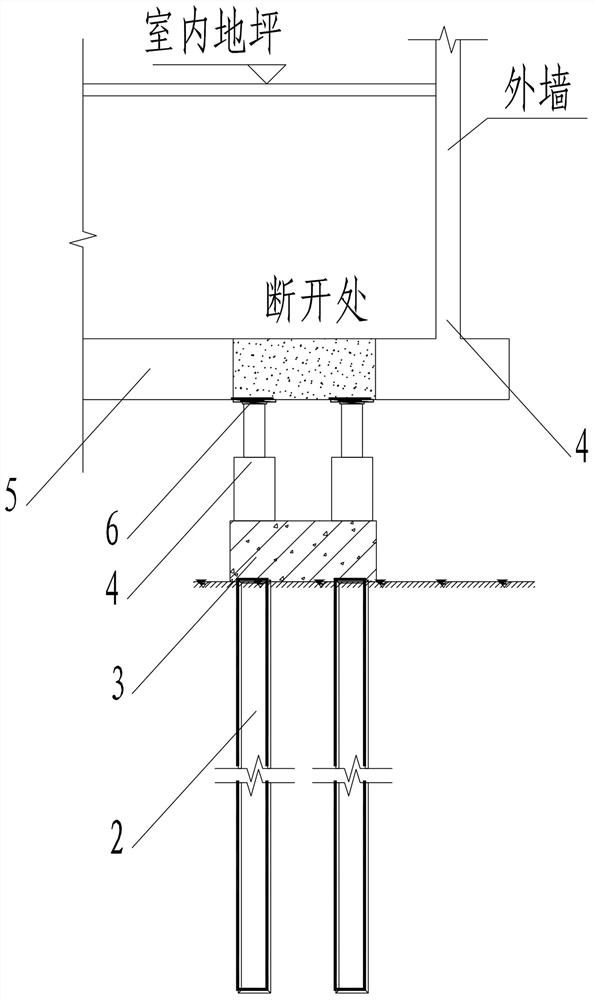

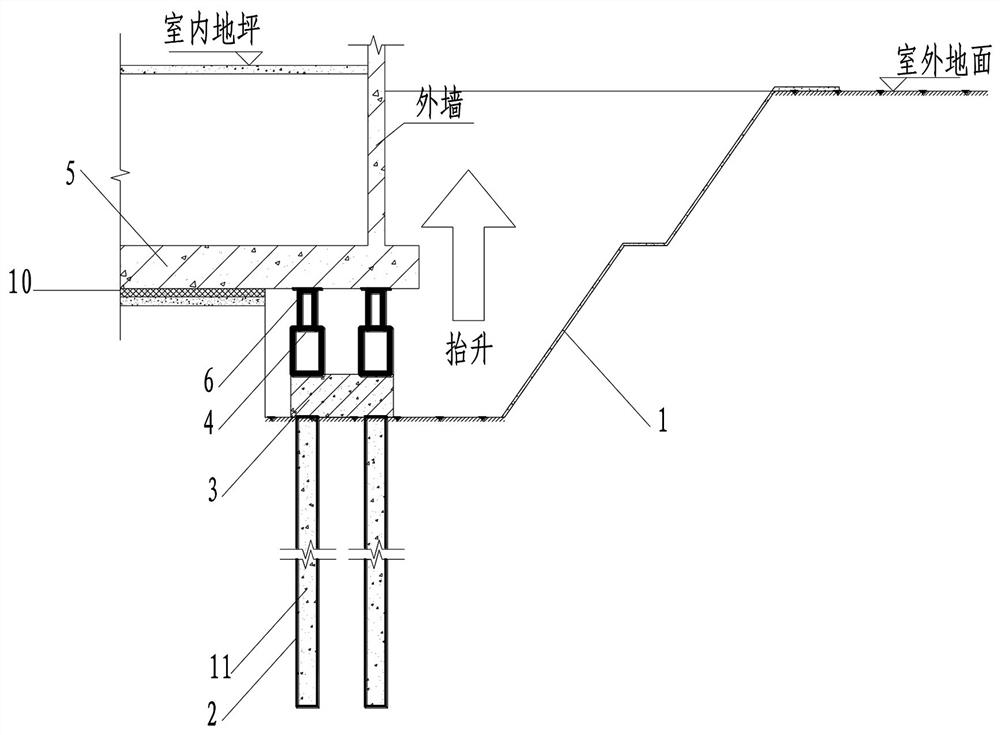

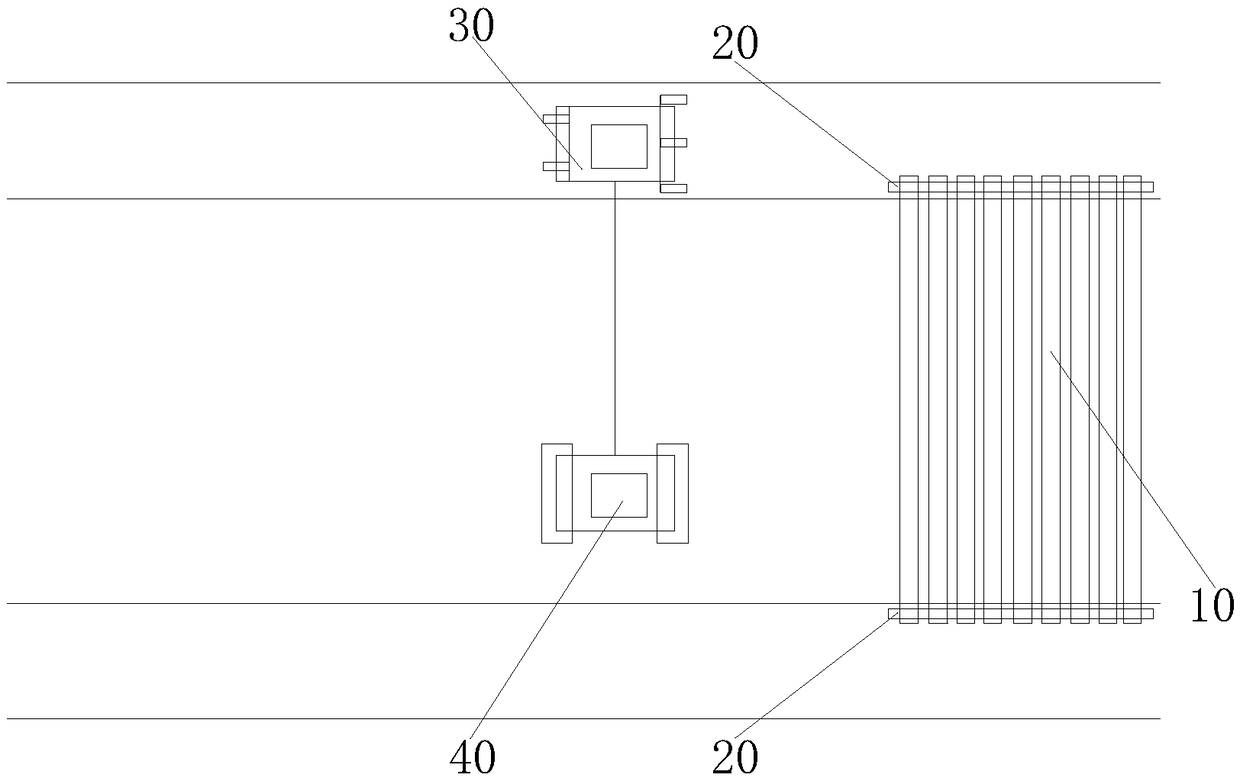

Building grading jacking deviation rectifying method

PendingCN114439059AAvoid crackingImprove securityFoundation engineeringInterior spaceArchitectural engineering

The invention relates to the technical field of building deviation rectification engineering, in particular to a building grading jacking deviation rectification method which comprises the steps that (1) a building needing deviation rectification is analyzed, and the position of a building jacking point is determined; (2) determining the optimal jacking force and the maximum jacking height of each jacking point according to the overall load and the gravity center of the building and the setting positions of the jacking points; (3) according to the maximum jacking height of each jacking point and counter force provided by soil body springback, the grading jacking grade number of each jacking point and the jacking height of each grade are calculated; 4) excavating a construction operation pit and an operation surface, and then arranging a jacking system at each jacking point; 5, after the jacking system is arranged, the building foundation is jacked according to the jacking grade number and the jacking height of each grade. According to the method, the foundation on the settlement side of the building is jacked in a grading jacking and grouting mode, the internal space and the overall structure of the building are not damaged, and the structural integrity and safety of the building are guaranteed.

Owner:HUANGHUAI UNIV

Joint construction method of inclined surface of ring road in test yard

ActiveCN109235205ADoes not affect structural stabilityImprove flatnessPaving detailsRoads maintainenceCrushed stoneCement slurry

The invention discloses a joint construction method of an inclined surface of a ring road in a test yard. The method comprises the following steps: A, according to the design requirements of the inclined surface of the ring road, laying an inclined surface base layer in advance, and then laying a graded crushed stone mixture on the inclined surface base layer; B, laying the graded crushed stone mixture on the inclined surface base layer; B, star to spread that asphalt layer section by section along the length direction of the inclined surface of the extension ring road, laying a stainless steel pipe in front of the truncation of the asphalt lay, and laying the stainless steel pipe along the slope surface of the inclined surface of the extension ring road from the top to the bottom; C, starfrom that truncated surface of the asphalt lay, adopting a paver to continuously lay a new asphalt layer on the stainless steel pipe; D, arrange a roller to roll that new asphalt lay along the lengthdirection of the inclined surface of the ring road, continuously supplying wat from the upper end to the lower end of the stainless steel pipe by adopting a water injection pipe, and cooling the joints of the new asphalt layer and the paved asphalt layer; E, aft meeting that joint temperature of the new asphalt lay and the paved asphalt layer, the water injection pipe stops the wat supply and thestainless steel pipe is plugged with cement slurry.

Owner:THE FIRST ENG CO LTD OF CTCE GRP +1

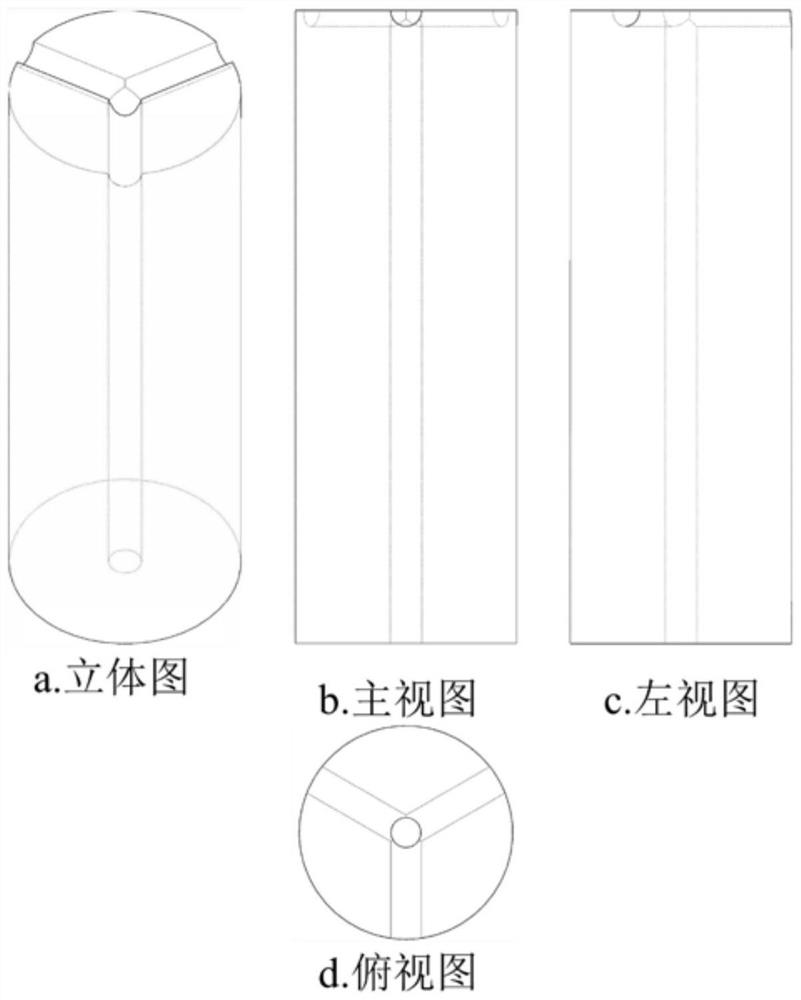

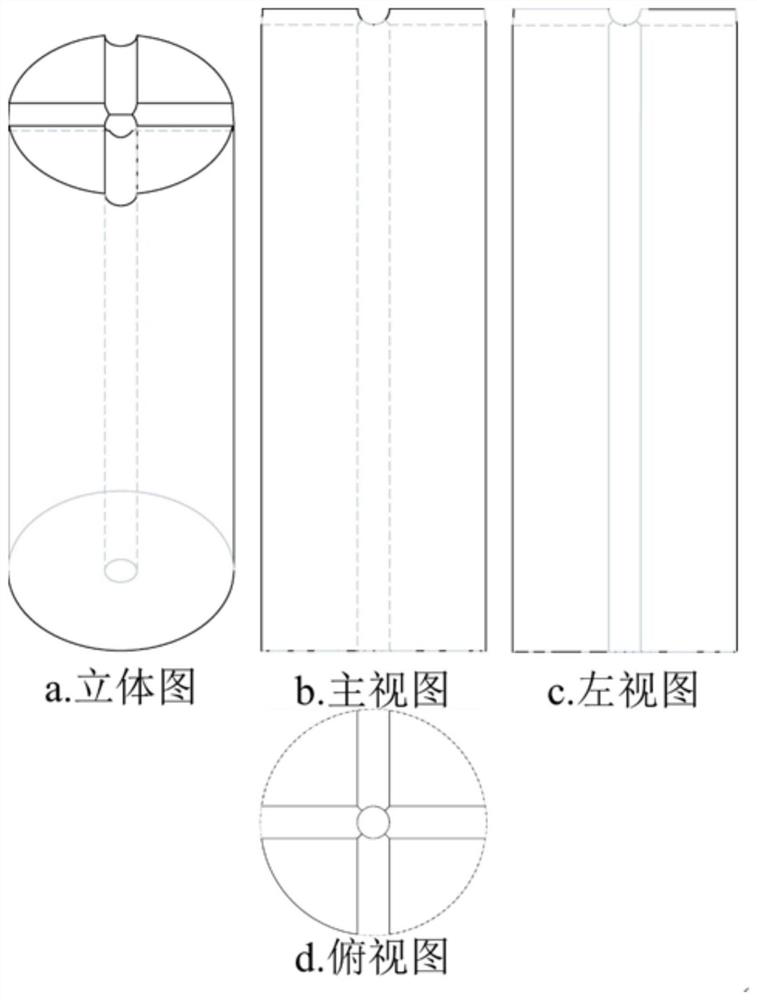

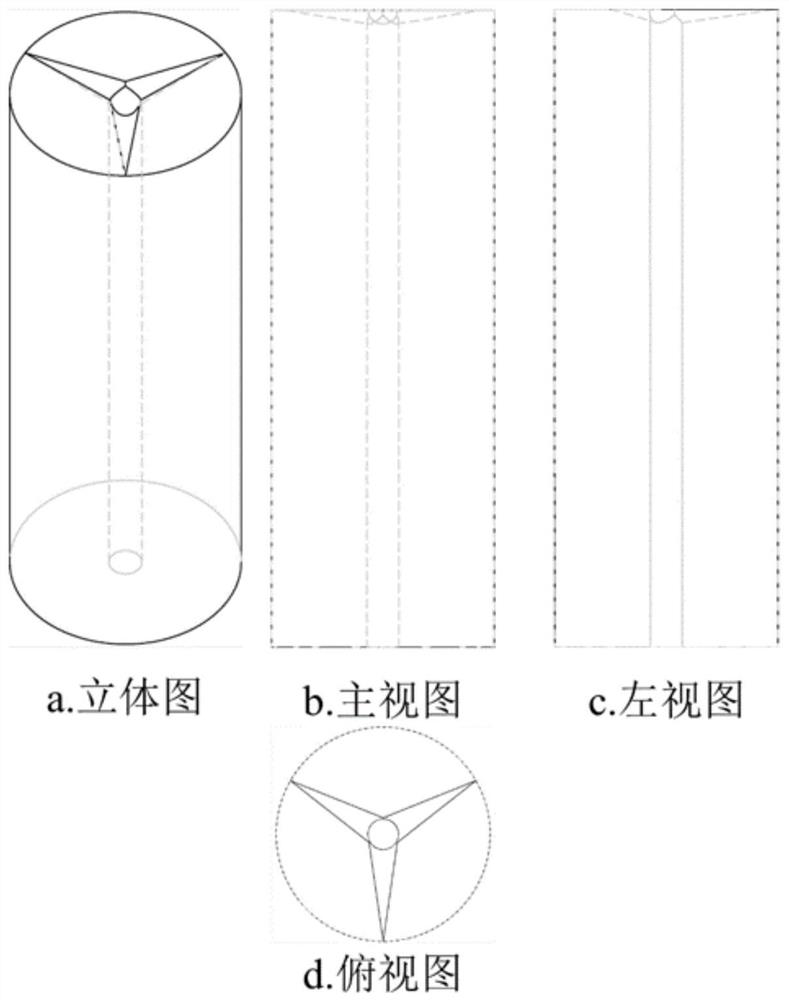

Method for improving gas circulation uniformity of vertical tubular furnace

PendingCN113587641AImprove uniformityImprove accuracyMaintainance of heating chambersCrucible furnacesTube furnaceMechanical engineering

The invention discloses a method for improving gas circulation uniformity of a vertical tubular furnace.The method comprises the steps of: (1) punching a hole with the diameter of 5-10 mm in the circle center position of a solid cylindrical plug, and enabling the hole to penetrate through the whole plug; and (2) vertically placing the plug punched with the through holes in the step (1), and punching 3-4 uniformly-distributed channels with the diameters of 5-10mm from the circumference to the circle center along the radius direction at the top. The method can obviously improve the uniformity of circulating gas. The plug is modified, so that the circulation path of the circulating gas is adjusted, the uniformity of the circulating gas is improved, and then the accuracy in an experiment process is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A variable section keel

The invention discloses a keel with variable cross-section, which is vertically arranged on the transverse purlin of the main body structure. The keel includes a keel main body and a panel installation part, and the panel installation part is arranged on a side wall of the keel main body along the length direction of the keel main body. , the other side wall of the keel body away from the panel installation part is provided with a plurality of purlin installation parts arranged at intervals along its length direction, and the purlin installation part is a concave part formed toward the direction of the panel installation part; A plurality of positioning bayonets are provided, and the positioning bayonets are engaged with the bending parts provided at both ends of the wall panel, and are used to fix the wall panel on the keel. In the present invention, the main body of the keel is pressed into a sheet-like purlin installation part at the connection with the purlin, so that the thickness of the keel at this position is reduced, and the wall panel is inserted into the keel structure through the positioning bayonet, so that the entire structure is not affected. The thickness of the wall is reduced, reducing the amount of metal used on the wall.

Owner:CENT INT GROUP

Preparation method of carbon-coated nano-boron-lithium composite material for lithium-sulfur battery negative electrode

InactiveCN106784666BHigh specific capacity for lithium deintercalationAvoiding defects in the battery production processCell electrodesLithium metaborateHigh rate

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com