Steel bar corrosion evaluation method based on magnetic field principle

A technology for corrosion and evaluation of steel bars, applied in the fields of weather resistance/light resistance/corrosion resistance, material magnetic variables, measuring devices, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

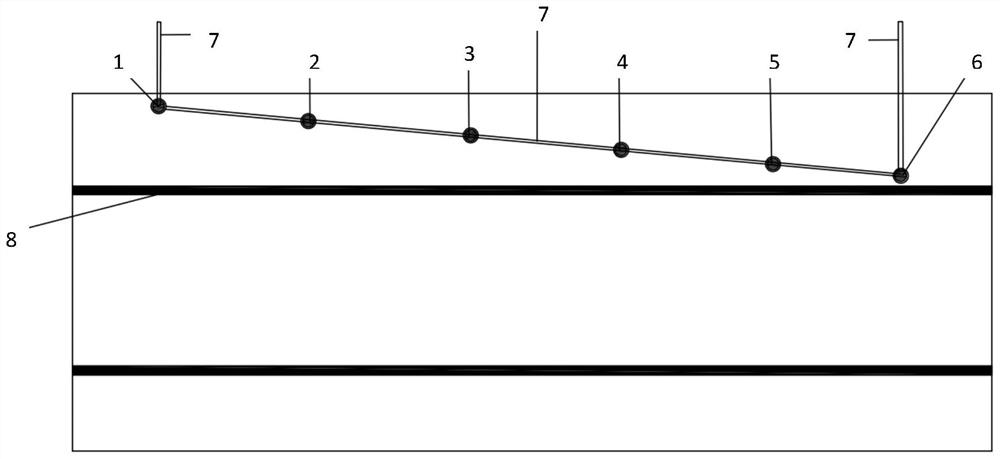

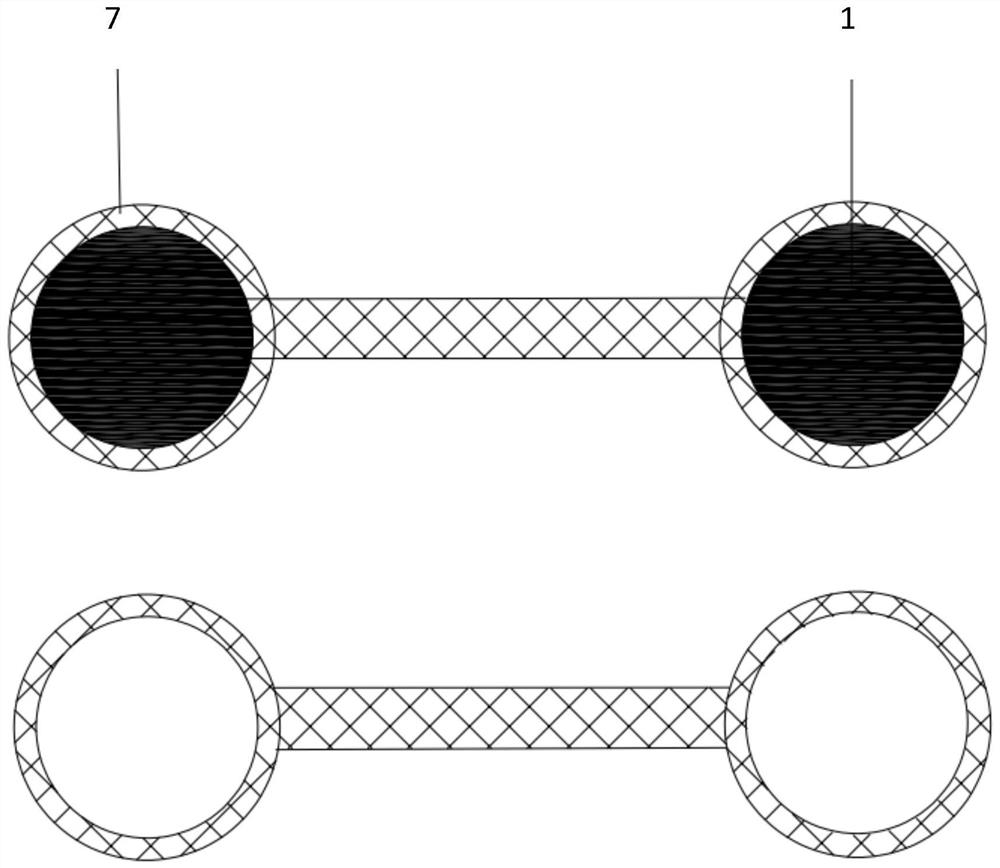

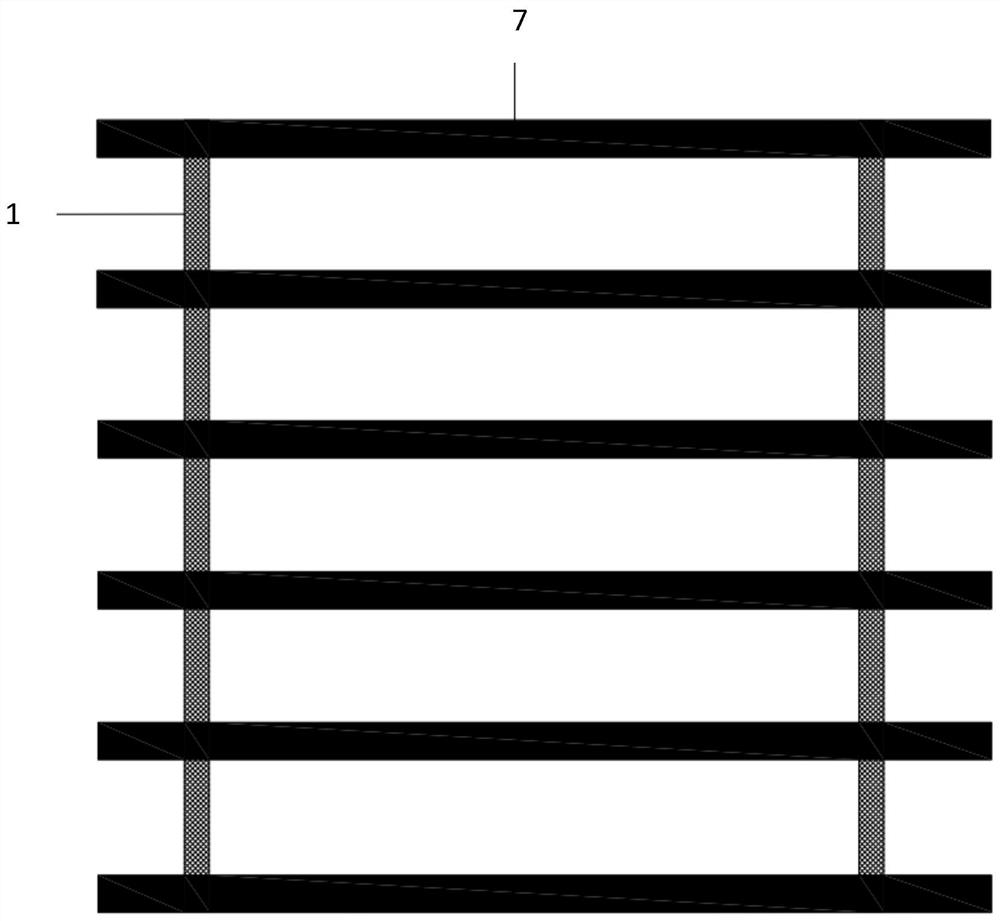

[0024] Further illustrate the present invention below in conjunction with accompanying drawing.

[0025] refer to Figure 1 ~ Figure 4 , a steel bar corrosion evaluation method based on the principle of magnetic field, using the arrangement of reference steel bars, without destroying the stability of the concrete structure, using an external sensor to test the magnetic induction intensity of the steel bars, and realizing the monitoring of the reinforced concrete specimens, according to The monitoring results and theoretical basis analysis show the corrosion of steel bars under different protective layer thicknesses, and the magnetic induction intensity of the test piece before corrosion is B 0I , the magnetic induction intensity after corrosion is B 0II , the corrosion rate of steel bars P II , the calculation formula is P II =α(B 0II -B 0I ), where α is the linear relationship coefficient.

[0026] Further, an electrified corrosion device is used to accelerate the corro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com