Preparation method of carbon-coated nano-boron-lithium composite material for lithium-sulfur battery negative electrode

A composite material, lithium-sulfur battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of capacity loss, poor cycle life, lithium-sulfur battery capacity decline, etc., to reduce equipment costs and production costs, and improve electrical conductivity. security, improved safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Precursor Preparation

[0040] Glucose (6g), urea (1g), and lithium metaborate (1g) were added to 100mL deionized water, ultrasonically vibrated and mixed for 30 minutes to form a solution; after spray drying, solidify at 106°C for 6 hours to form a precursor.

Embodiment 2

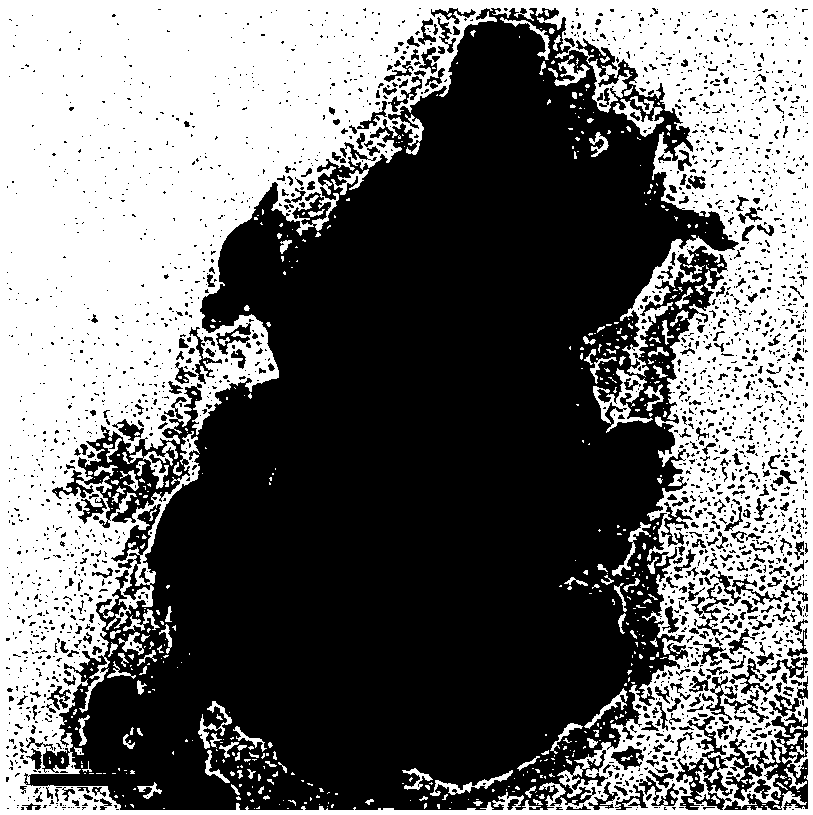

[0041] Example 2: Preparation of carbon-coated nano boron lithium

[0042] Glucose (6g), urea (1g), and lithium metaborate (2g) were added to 100mL deionized water, ultrasonically vibrated and mixed for 30 minutes to form a solution; after spray drying, solidify at 106°C for 6 hours to form a precursor. The precursor was heated to 500°C under the protection of nitrogen atmosphere for carbonization. After carbonization for 2 hours, it was heated to 900°C at a heating rate of 10°C / min, kept at a constant temperature for 10 hours, and cooled to room temperature to form a carbon-coated nano-boron-lithium composite material.

Embodiment 3

[0043] Embodiment Three: Binder Modulation

[0044] Add commercially available gum arabic powder (5 g) to 95 g of NMP, stir and heat to 90° C., stir for 2 hours to obtain a gum arabic NMP solution, and cool to room temperature for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com