Patents

Literature

45results about How to "Improve the success rate of sample preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing powdered test sample for transmission electron microscope

InactiveCN102200497AExtend deposition timeIncrease sample preparation costPreparing sample for investigationVacuum evaporation coatingConventional transmission electron microscopeTest sample

The invention relates to a method for preparing a powdered test sample for a transmission electron microscope. The method comprises the following steps of: cutting a crystal with a flat and neat surface from a soluble monocrystalline material according to a cleavage surface of the soluble monocrystalline material; placing an electron microscope carrying net onto the cut crystal block; ultrasonically dispersing the powdered sample to be observed by using absolute ethanol, dropping a proper amount of dispersed liquid onto the carrying net and naturally drying in the air; sputtering and depositing a layer of metal thin film by adopting a magnetron sputtering technology, and wrapping and fixing particles to be analyzed onto the carrying net by using the deposited thin film; after sputtering, shearing off a sputtered thin film along the edge of the carrying net; placing the carrying net with the fixed particles to be analyzed into an ion milling for milling until leakage; and taking down the sample and placing into the electron microscope for observation after the center of the sample is punctured. By the method, the problems that a plurality of powdered samples which have large particle size and complicated structure and are hard to smash or grind are hard to prepare, and an observation area is limited and the sample is easy to pollute can be solved; and the method is a sample preparation method with high sample preparation success rate and high suitability.

Owner:CHINA NAT ACAD NANOTECH & ENG

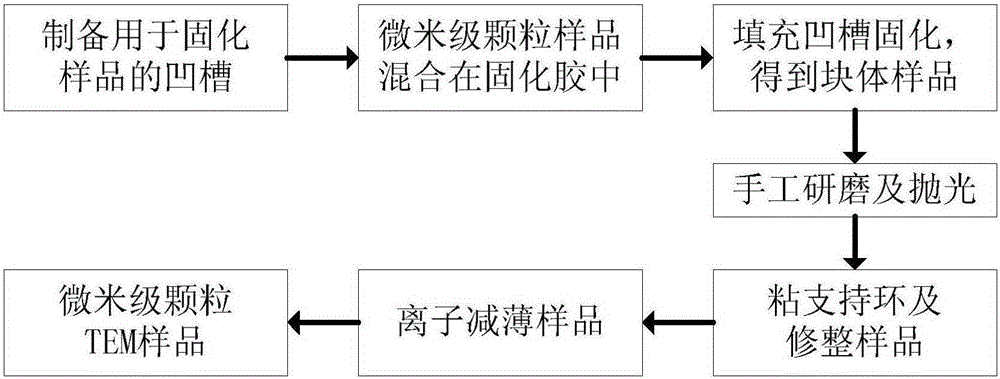

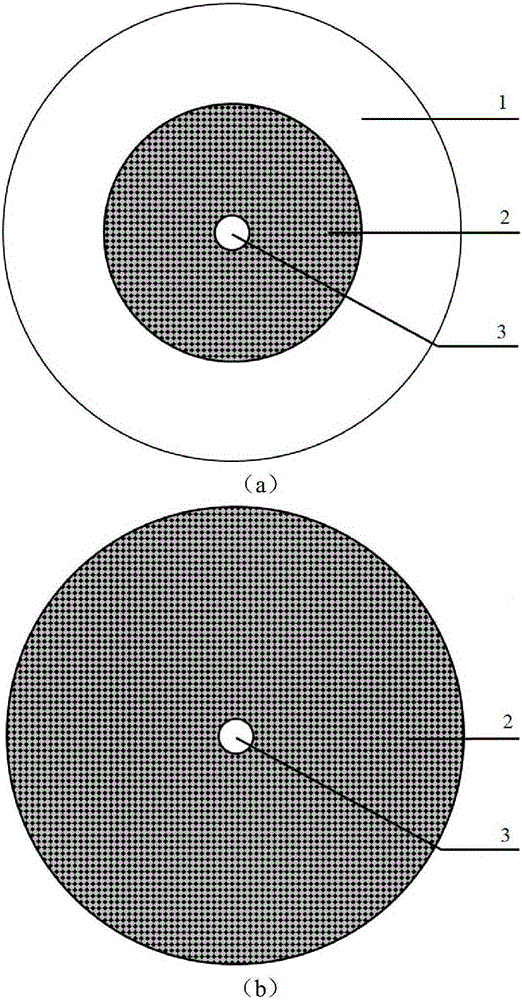

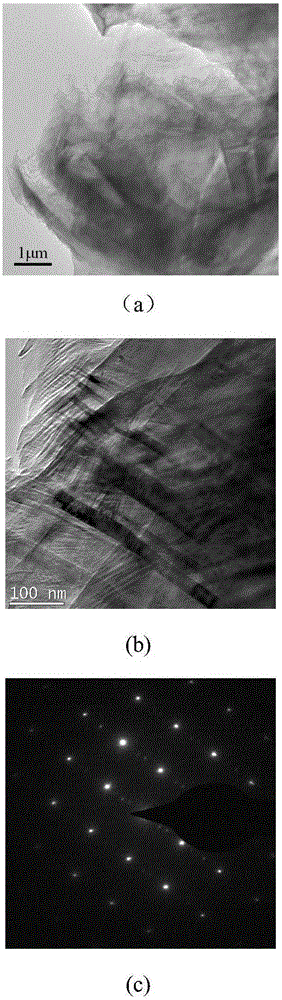

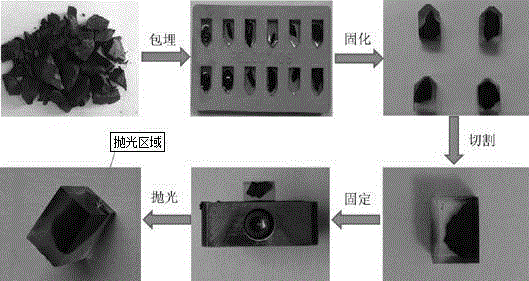

Preparing method for micron-order particle sample for transmission electron microscope (TEM)

InactiveCN105203360ASimple operation processMature sample preparation equipmentPreparing sample for investigationAdhesiveThinning

The invention discloses a preparing method for a micron-order particle sample for a TEM. The preparing method includes the steps that a groove is formed in a flat plate and then filled with curing adhesive mixed with micron-order particle sample bodies, the mixture is heated, cured, cooled and then taken out, and a sheet-shaped block sample is obtained; the two surfaces of the sheet-shaped block sample are manually grinded and polished on a sample support, and a sample sheet is obtained; then supporting rings are bound through curing and binding agents, heating is carried out, the sample support is removed, and meanwhile the supporting rings are cured and bound to the sample sheet; the sample is finished, ion thinning is finally carried out, and the micron-order particle sample for the TEM is obtained. According to the preparing method, an operation technology is simple, adopted sampling devices and adopted sampling technologies are mature, the sampling success rate is high, practicability is high, and the preparing method is suitable for preparing various micron-order particle samples.

Owner:PEKING UNIV

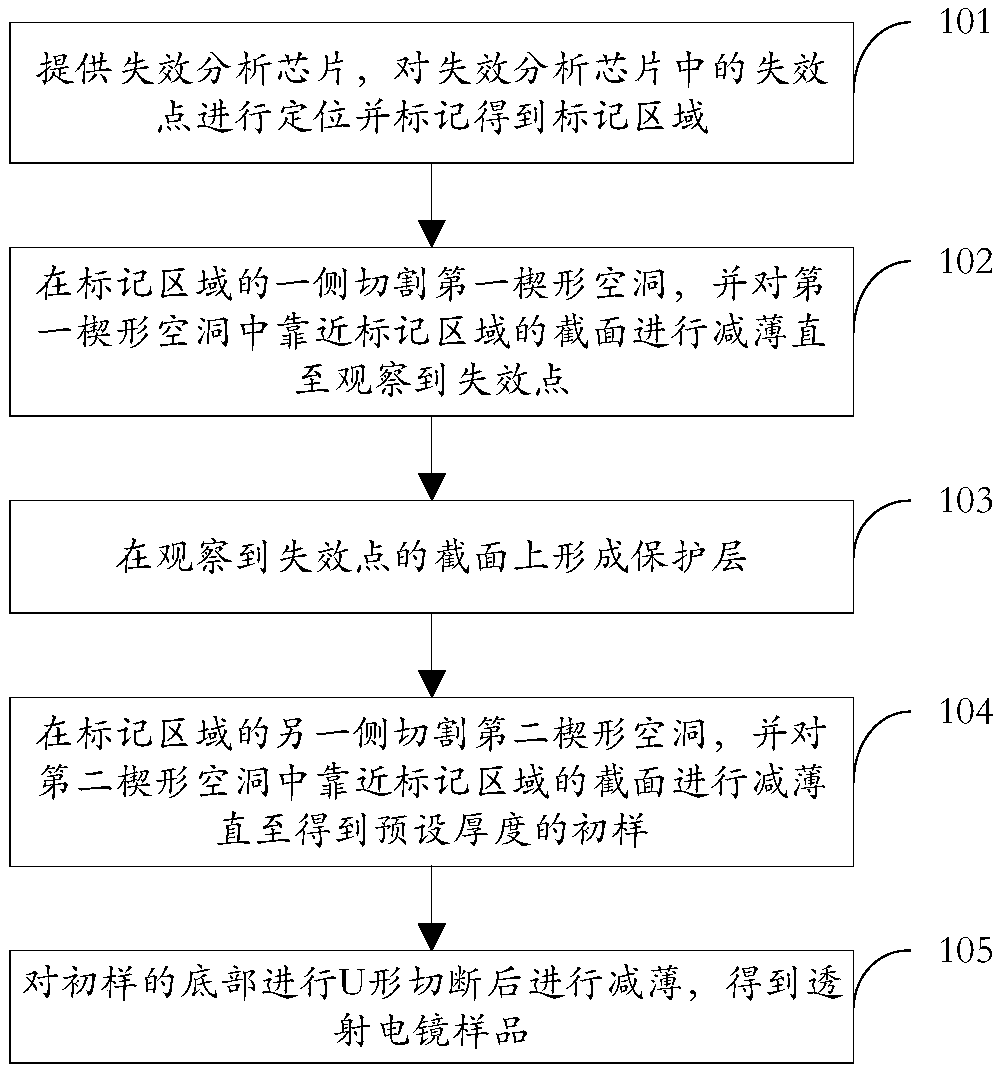

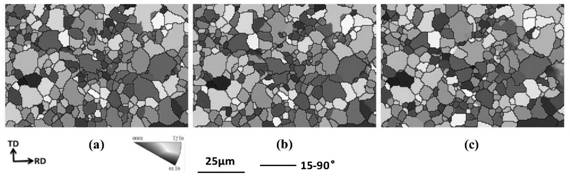

Method for preparing transmission microscope samples on basis of non-precision positioning

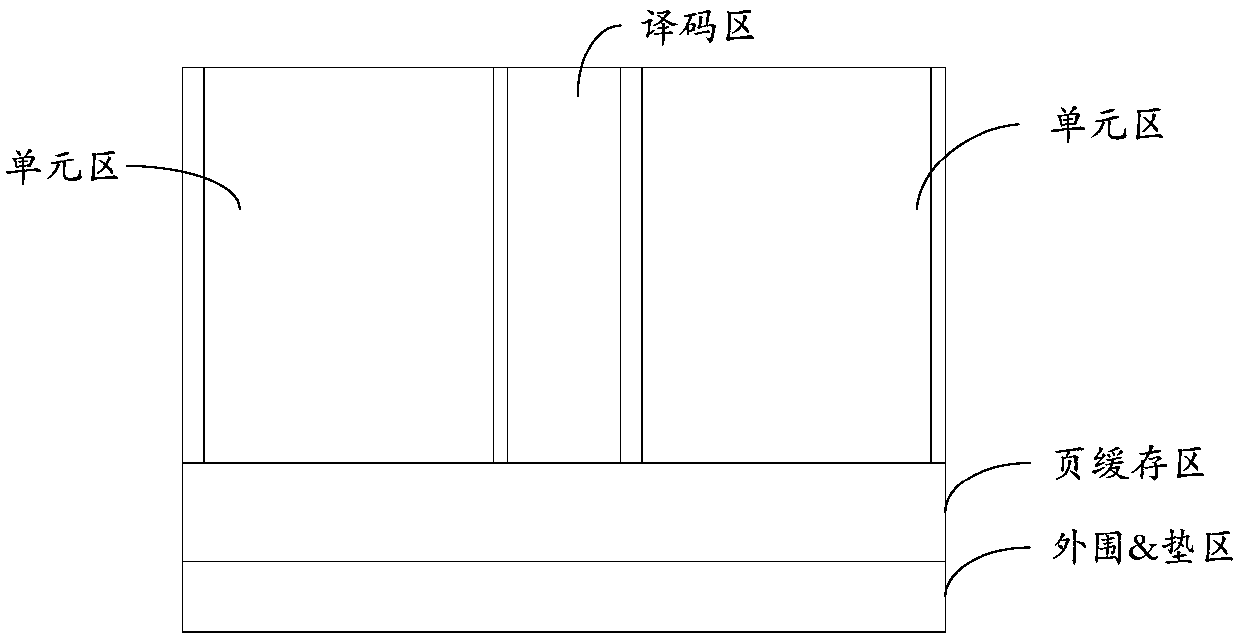

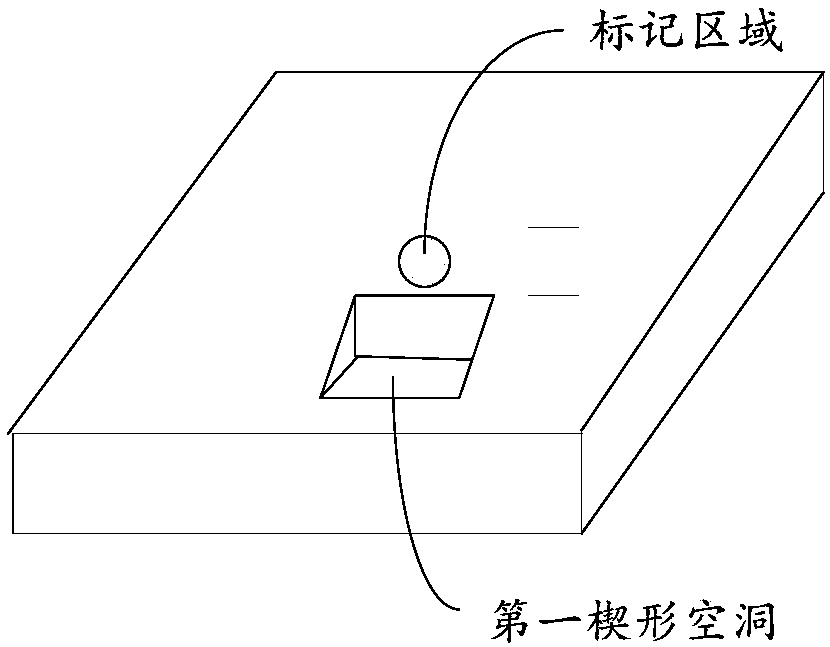

InactiveCN108037146ARapid positioningAvoid miscuttingMaterial analysis by transmitting radiationFailure analysisSemiconductor technology

The invention discloses a method for preparing transmission microscope samples on the basis of non-precision positioning, and belongs to the technical field of semiconductors. The method includes providing failure analysis chips and positioning and labeling failure points in the failure analysis chips to obtain labeled zones; cutting a side of each labeled zone to form first wedge-shaped cavitiesand thinning the sections, which are close to the labeled zones, of the first wedge-shaped cavities until the failure points can be observed; forming protective layers on the sections where the failure points are observed; cutting the other side of each labeled zone to form second wedge-shaped cavities and thinning the sections, which are close to the labeled zones, of the second wedge-shaped cavities until primary samples with preset thicknesses are obtained; carrying out U-shaped cutting-off on the bottoms of the primary samples and then thinning the primary samples to obtain the transmission microscope samples. The method has the advantages that the failure points can be effectively prevented from being cut by mistake, each cut surface with the corresponding failure points can be prevented from being damaged or stained by splashing in follow-up processes, accordingly, the sample preparation success rate can be increased, and observation results can be improved.

Owner:YANGTZE MEMORY TECH CO LTD

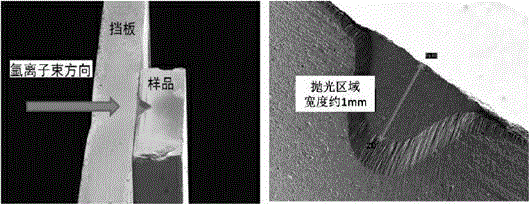

Argon ion polishing/scanning electron microscope analyzing and sampling method for shale samples

InactiveCN105067406ALower profileLower requirementPreparing sample for investigationScanning tunneling microscopeScanning electron microscope

The invention discloses an argon ion polishing / scanning electron microscope analyzing and sampling method for shale samples including fragile shale core samples and rock debris samples. The method comprises steps of embedding, curing, cutting and polishing. By comparison with a traditional argon ion polishing / scanning electron microscope analyzing and sampling method, the analysis range of the samples is widened with the method, the shale core samples which are fragile in the cutting and sampling processes and the shale rock debris samples with smaller sizes can be analyzed, and meanwhile, the success rate of sampling is increased.

Owner:CHINA PETROLEUM & CHEM CORP

Method for making sample of chemical deposited nickel fixed alloy powder for transmission electron microscope observing

InactiveCN1420349AImprove the success rate of sample preparationControllablePreparing sample for investigationIonTransmission electron microscopy

A process for preparing the specimen of chemically deposited nickel fixed alloy powder in order to observe it by transmission electron microscope includes preparing deposition solution in beaker, slowly putting the copper block coated with powder on an insulating plate in said solution, putting the beaker in water bath at 83-92 deg.C, chemical depositing for 4-6 hr, tearing the deposited film from the copper block, sticking it to frosted glass, abrasing to 30-50 microns by abrasive paper, punching to become small circular film with 3 mm of diameter, and ion thinning. Its advantages are easy control and high successful rate.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method for TEM sample

ActiveCN105699698AAvoid processing powerAvoid reactionScanning probe techniquesIon beamCombinatorial chemistry

Disclosed in the invention is a preparation method for a TEM sample. An inclined cutting opening is formed in a chip sample surface by using an ion beam and level removing and TEM sample preparation are carried out on a target area position directly, so that time for TEM sample preparation is substantially shortened; and the position and depth for level removing are controlled precisely, so that the success rate of sample preparation and the quality of the sample are improved. And the chip sample is protected from being damaged.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method for preventing TEM (Transmission Electron Microscope) chip sample from being cracked

ActiveCN105300754AObservation does not affectReduce the impactPreparing sample for investigationIon beamConductive materials

The invention provides a method for preventing a TEM (Transmission Electron Microscope) chip sample from being cracked. A displacement layer of a material needing to be replaced in a non-observation region of a sample is exposed; the displacement layer is prepared from a conductive material and an insulating material; the conductive material or the insulating material in the displacement layer is removed so that a groove is formed in the displacement layer; the groove is internally filled with a first material; when the first material and an un-removed material are cut by a focusing ion beam, the speeds are the same. The chip prepared by the method can be sequentially used for an existing flow of preparing the TEM sample; in the same displacement layer, the speeds are consistent when all the materials are cut through the focusing ion beam, and a curtain effect is avoided; the method is operated in the non-observation region, influences on an observation region are relatively small, so that the sample preparation success rate is improved and the observation of the sample is not influenced.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

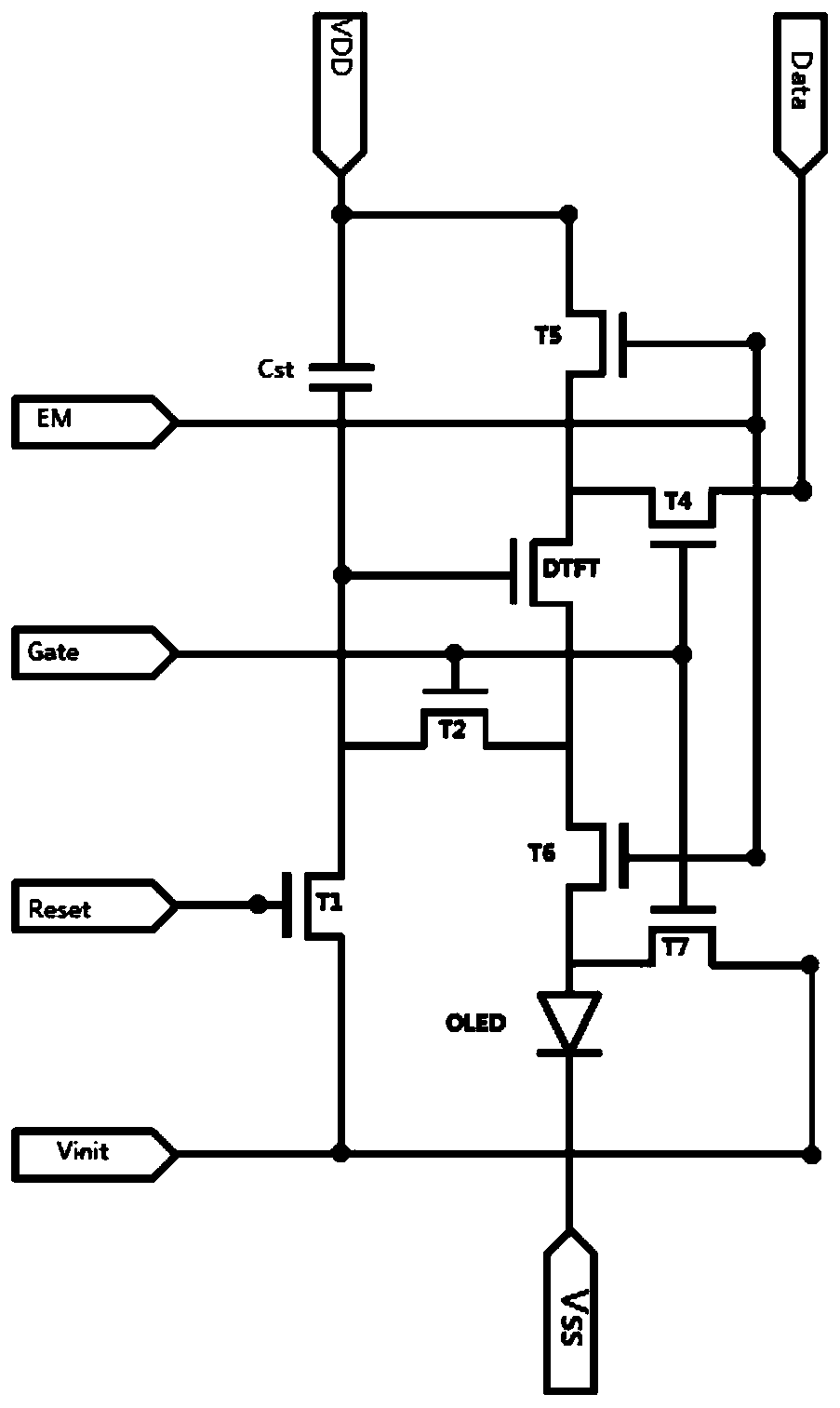

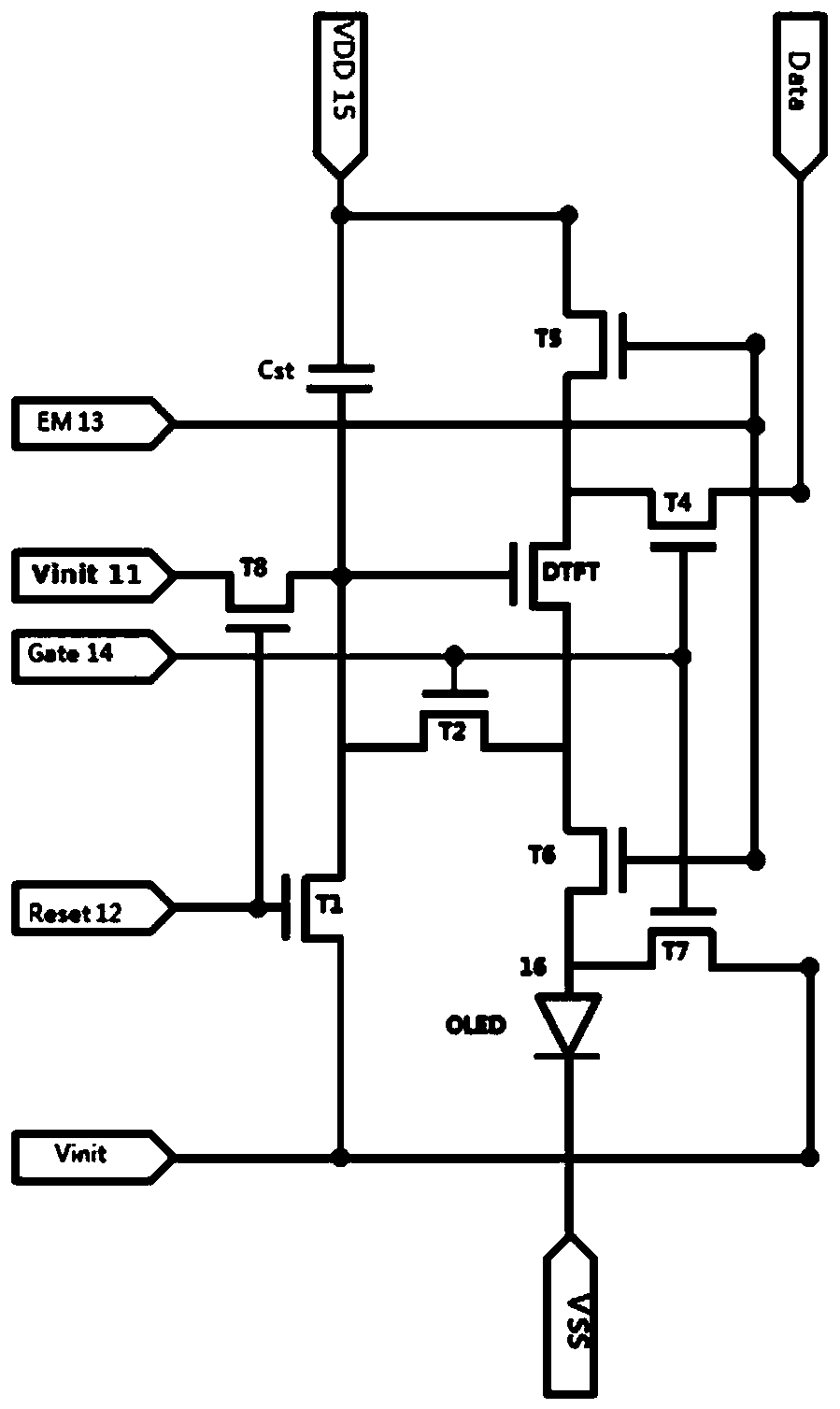

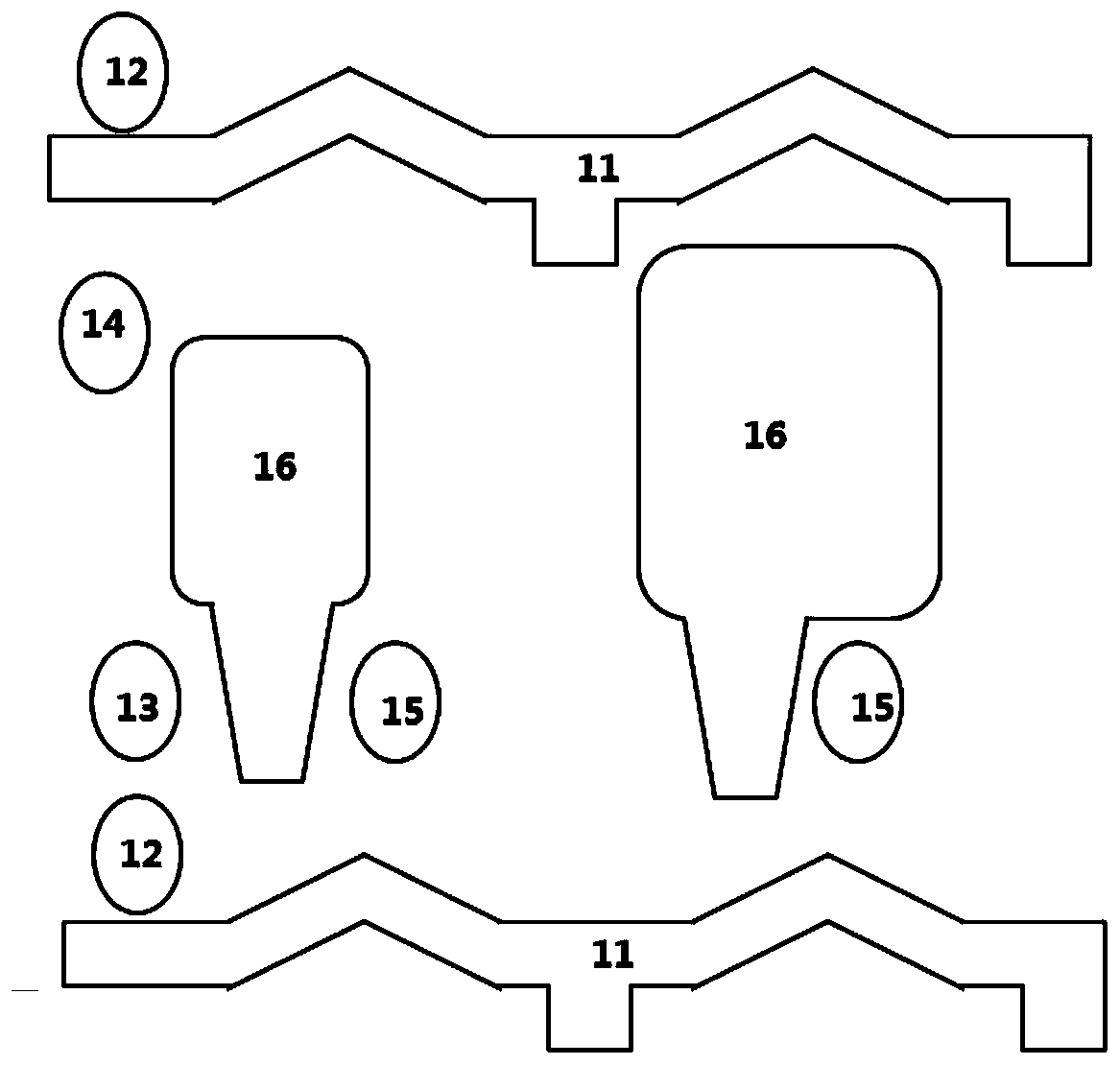

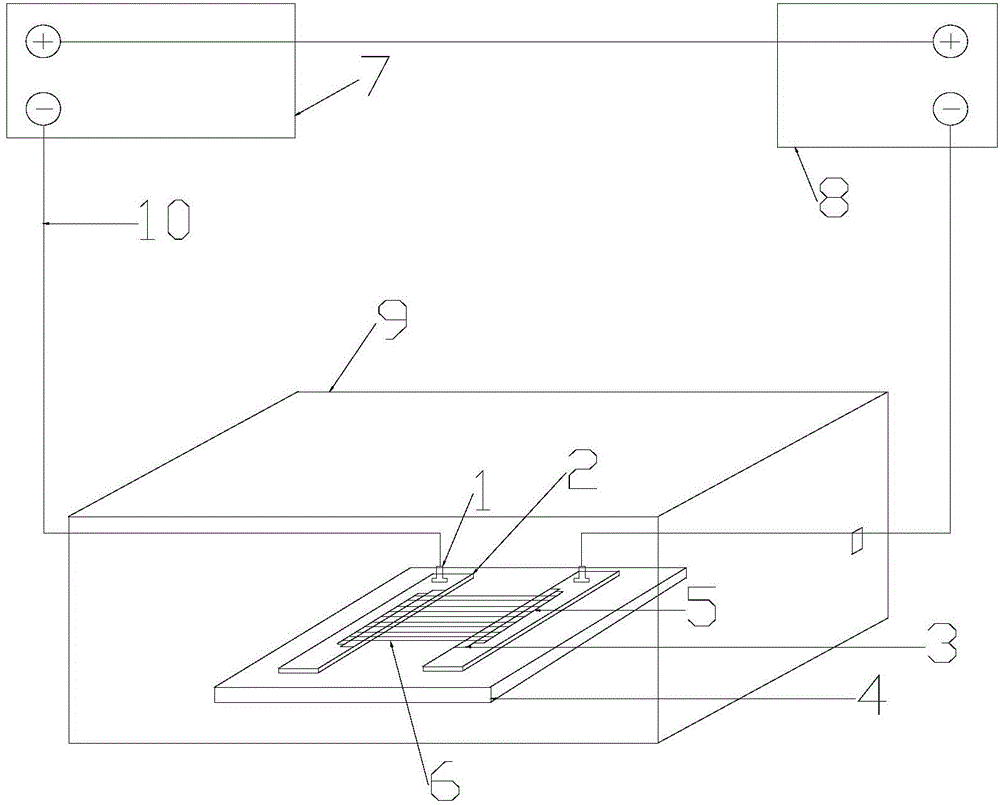

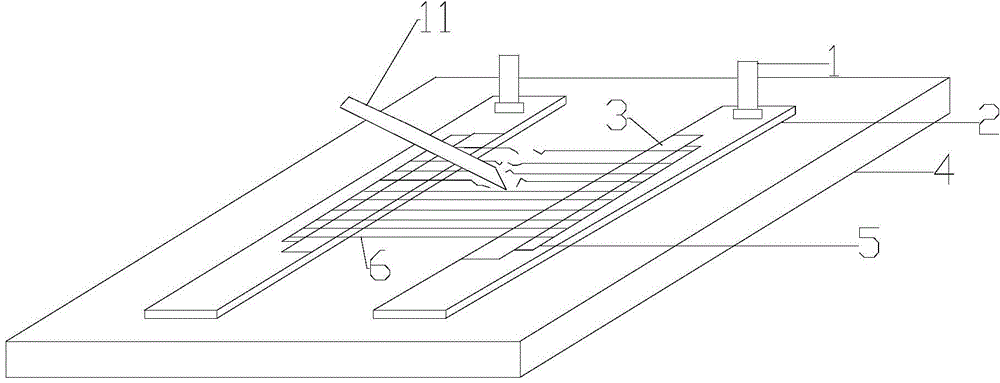

Circuit and method for detecting characteristics of transistor in pixel region of LTPSAMOLED display substrate

ActiveCN110827730AAdd initialization pathOptimize Reset effectStatic indicating devicesHemt circuitsCapacitor

The invention relates to a circuit and a method for detecting the characteristics of a transistor in a pixel region of an LTPSAMOLED display substrate. The circuit includes a drive transistor DTFT, astorage capacitor Cst, an initialization module, a write-in module and a light-emitting control module, and is characterized by further comprising a detection transistor and a plurality of detection ends, wherein the plurality of detection ends comprise a first detection end which is connected with a first electrode of the detection transistor, a second electrode of the detection transistor is connected with the grid electrode of the drive transistor DTFT, and the grid electrode of the detection transistor is connected with a reset signal line. The circuit is convenient to manufacture and hasthe higher sample preparation success rate, and meanwhile, the structural design only needs to directly overlap a probe on the metal detection end. The added detection transistor can add an initialization path for the storage capacitor Cst, so that the reset effect is optimized, and the flicker, residual images and the like can be improved.

Owner:BOE TECH GRP CO LTD +1

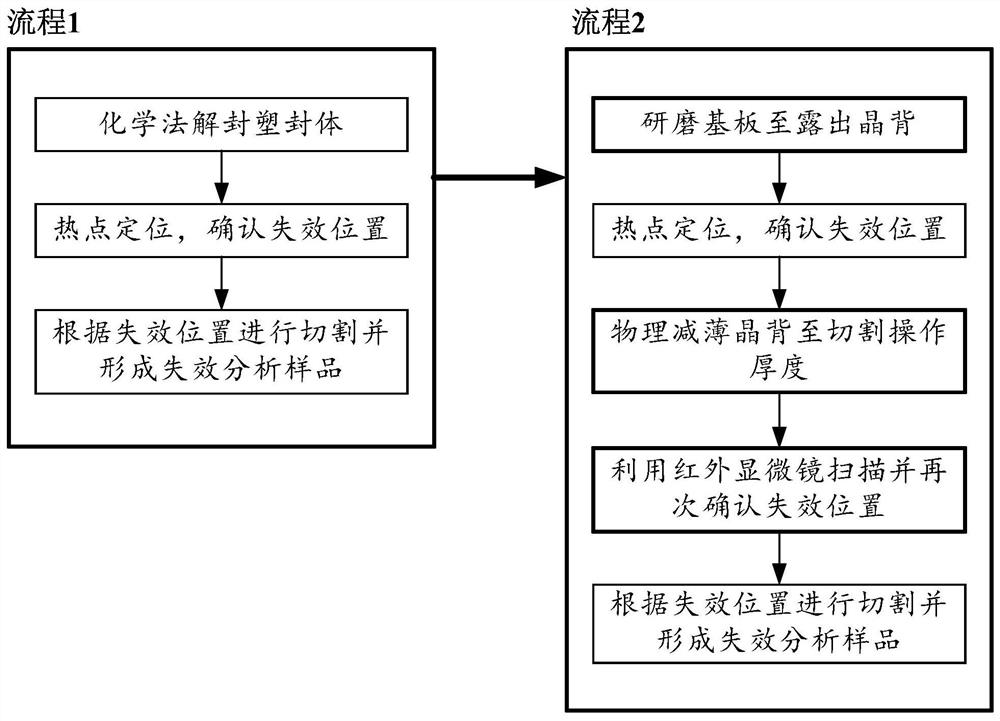

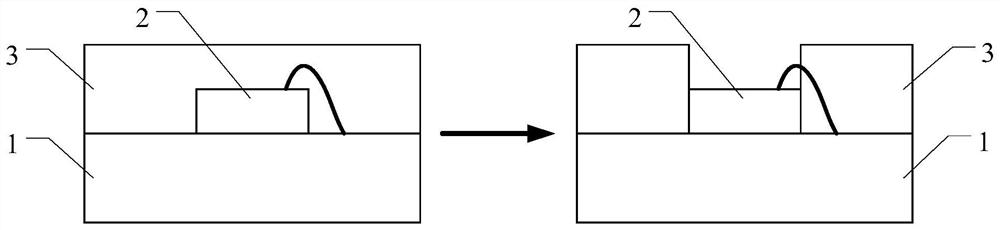

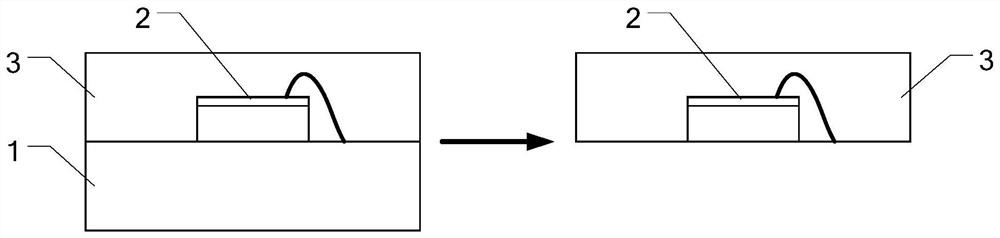

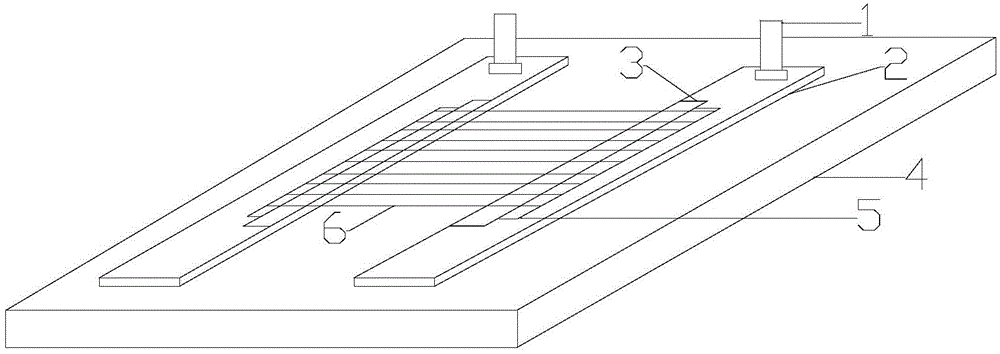

GaAs chip failure analysis sample and preparation method thereof

PendingCN113075522AAvoid destructionImprove the success rate of sample preparationIndividual semiconductor device testingOpticsSi substrate

The invention relates to a GaAs chip failure analysis sample and a preparation method thereof. The preparation method comprises the steps of: grinding a substrate of a GaAs chip to expose the crystal back of the GaAs chip; carrying out hot spot positioning on the GaAs chip with the exposed crystal back, and confirming a failure position; physically thinning the crystal back of the GaAs chip to enable the thickness after thinning to meet the cutting operation thickness; scanning the thinned GaAs chip by using an infrared microscope, and confirming the failure position again; and cutting the thinned GaAs chip according to the failure position and forming a failure analysis sample. According to the method, a traditional chemical method for unpackaging a plastic package body is canceled, damage to metal wires of the GaAs chip is avoided, the sample preparation success rate is increased, and the subsequent failure analysis effect is guaranteed.

Owner:INTEGRA TED SERVICE TECH SHANGHAI CO LTD

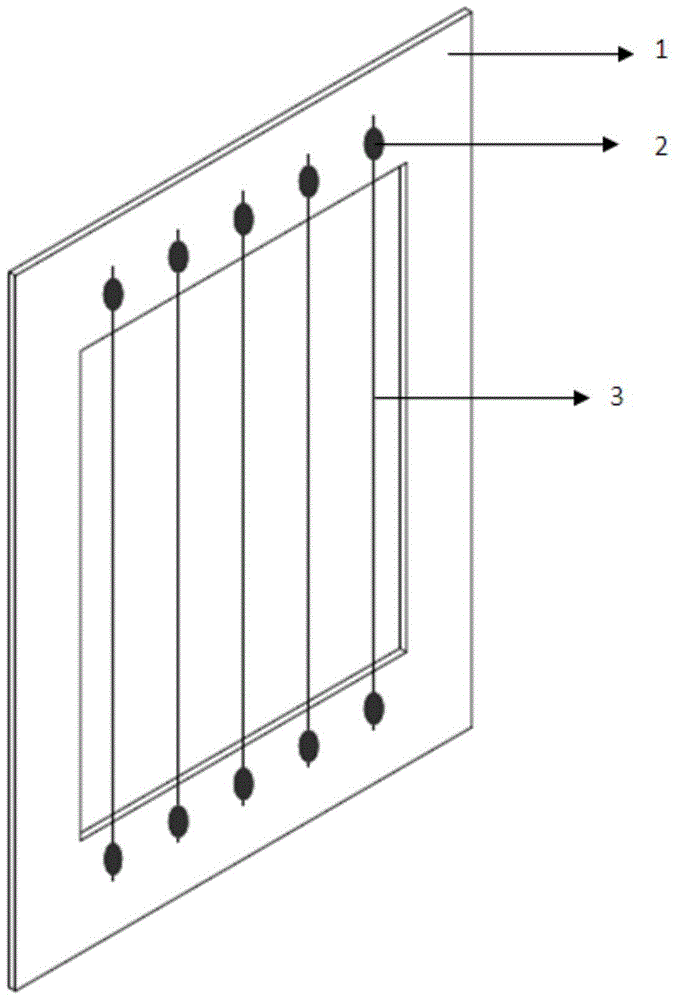

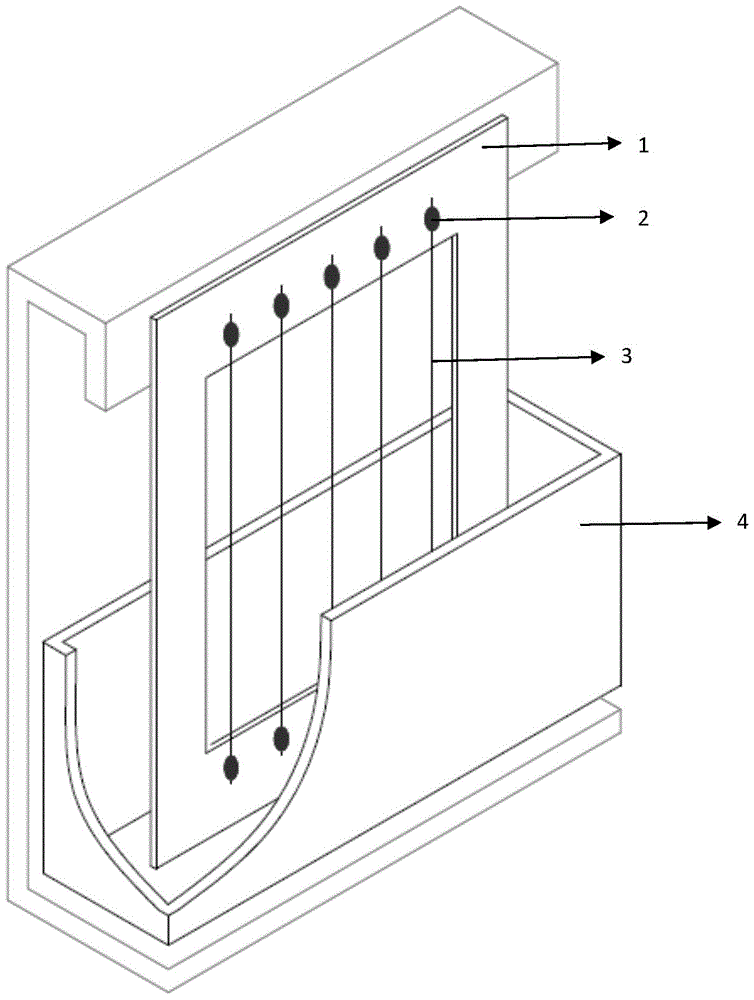

Ceramic fiber resistivity testing method

ActiveCN104597327AAccurate measurementEfficient measurementResistance/reactance/impedenceFiberHigh resistance

The invention relates to ceramic fibers, in particular to a ceramic fiber resistivity testing method. Multiple ceramic fibers are parallelly bonded to a metal plate sample table through double-sided adhesive tapes; the fibers are parallelly connected through silver conductive adhesive; after the silver conductive adhesive solidifies, a fiber sample and the metal plate sample table are put in a metal electromagnetic shielding box; the metal plate sample table, an electrometer for testing circuit current and a digital source meter providing test voltage are connected in series; under the constant-temperature constant-humidity condition, a micro current test is performed; after one current value is measured, voltage output of the digital source meter is closed; the metal electromagnetic shielding box is opened, one fiber is torn off, and corresponding micro current of the remaining parallel fibers is continually measured until that the current of the different fibers is all tested; resistivity values of the multiple groups of fibers different in quantity are solved according to the ohm law and a volume resistivity formula, and a statistical average is acquired. The problem that high resistance of the fine-diameter ceramic fibers cannot be accurately measured can be effectively solved.

Owner:XIAMEN UNIV

Test method for interfacial bonding strength of ceramic fiber reinforced resin matrix composites

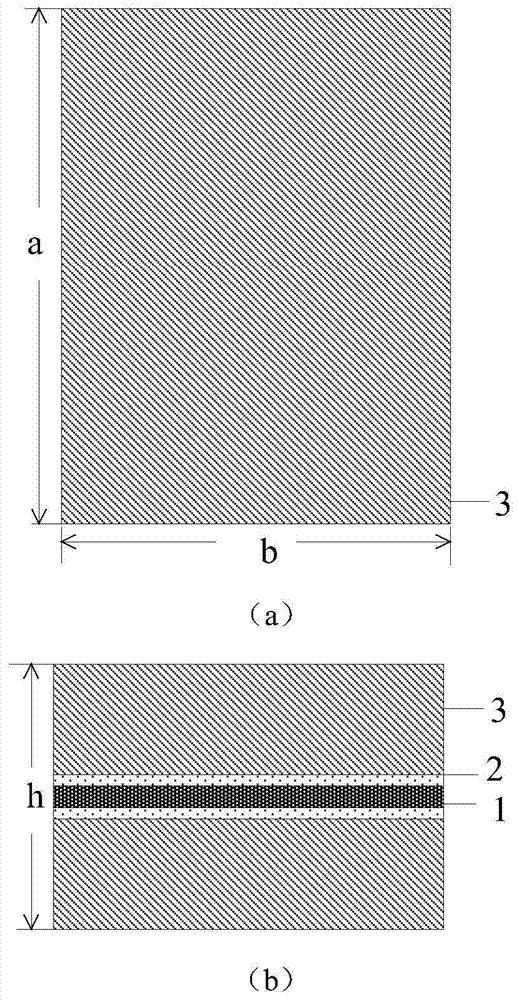

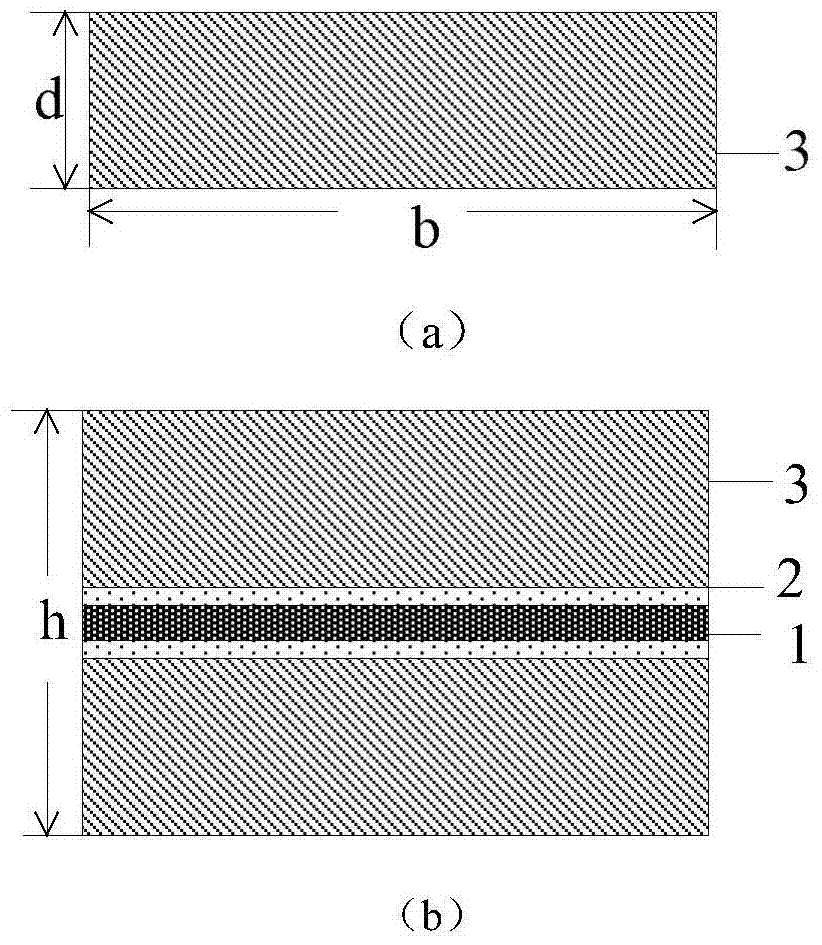

ActiveCN104122202BImplement statistical measurementsSolve the fragileUsing mechanical meansMaterial analysisAdhesiveResin matrix

Owner:XIAMEN UNIV

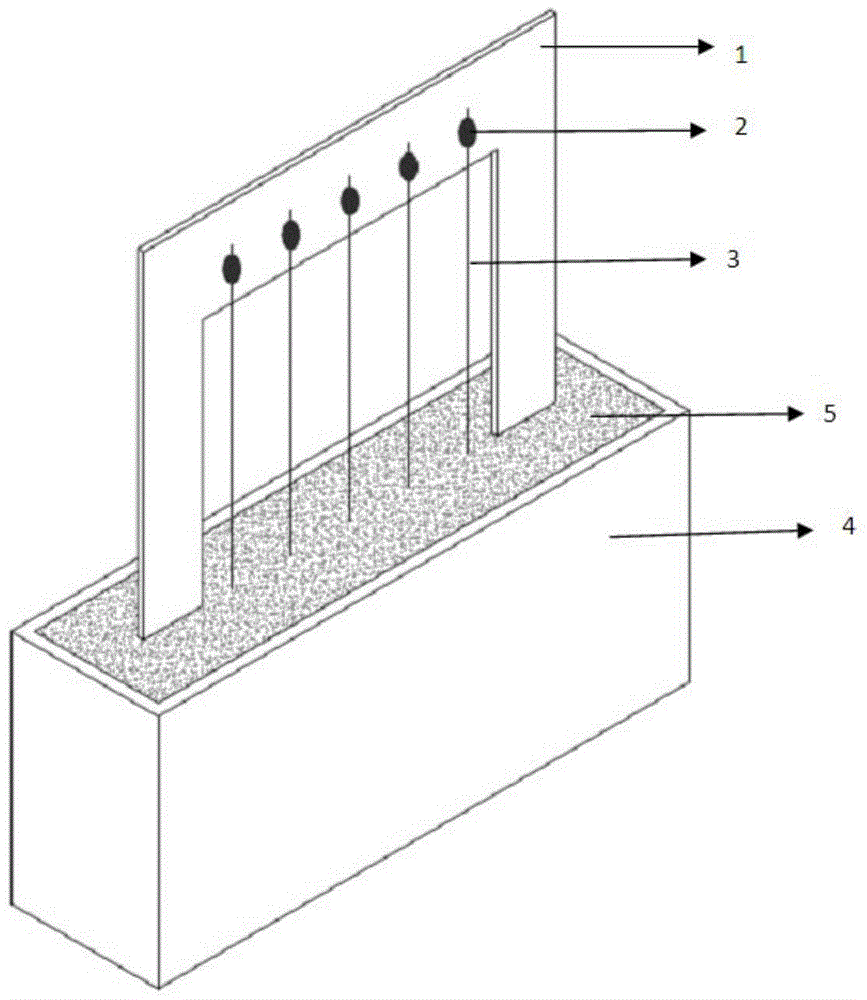

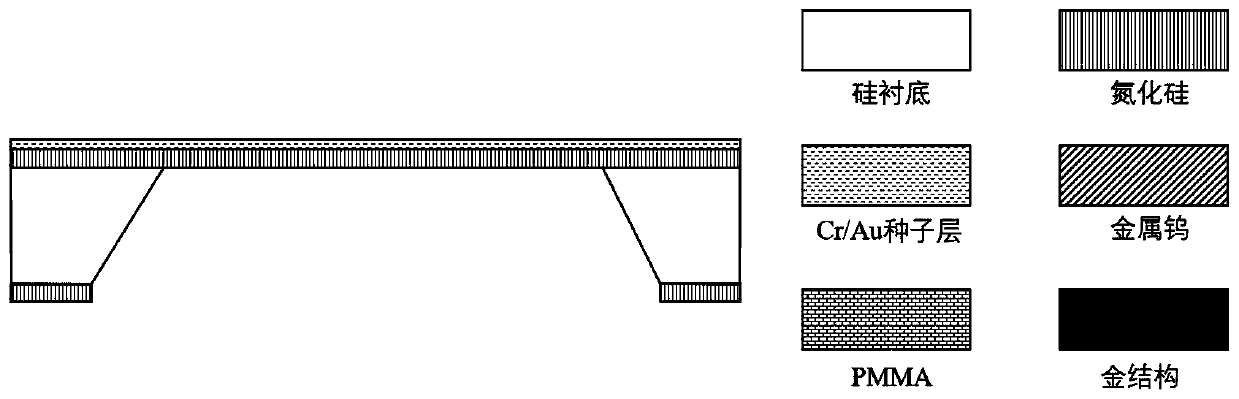

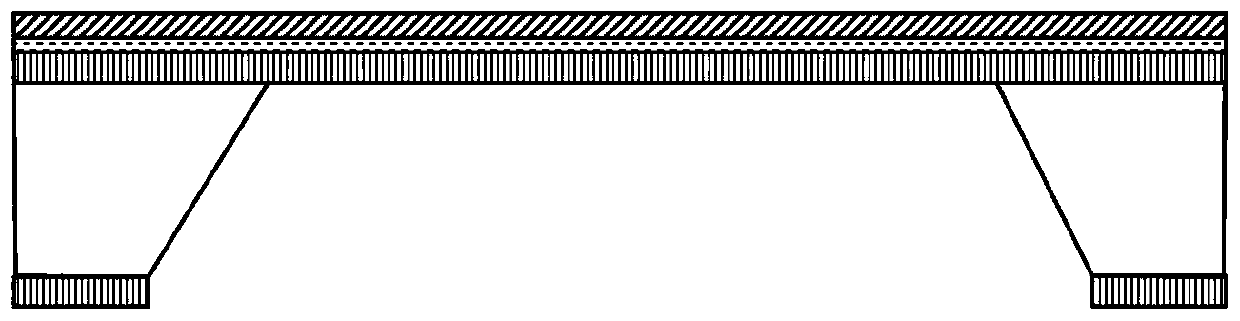

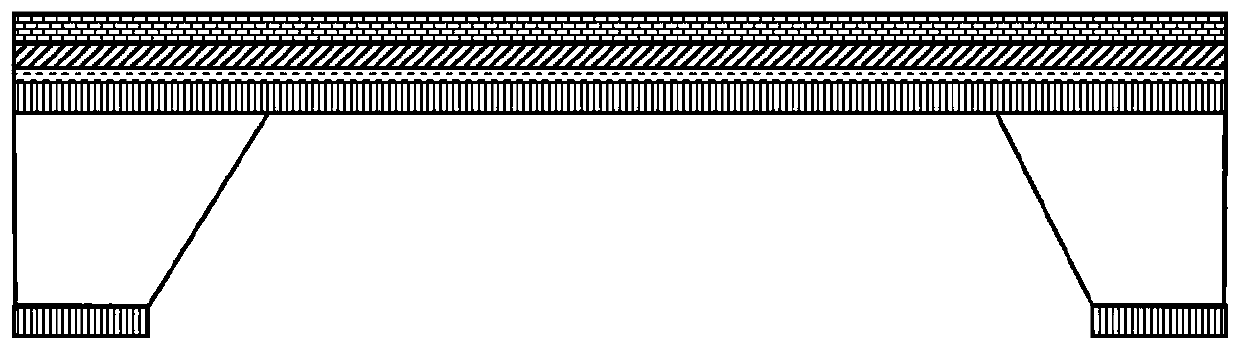

High-resolution hard X-ray tungsten/gold Fresnel zone plate and preparation method thereof

ActiveCN110970147AHigh resolutionStructural morphology controllableHandling using diffraction/refraction/reflectionNanotechnologyReactive-ion etchingElectron-beam lithography

Belonging to the technical field of X-ray imaging, the invention particularly relates to a high-resolution hard X-ray tungsten / gold Fresnel zone plate and a preparation method thereof. The method includes the steps of: growing a chromium / gold electroplated seed layer on a silicon nitride substrate; growing metal tungsten on the electroplated seed layer; conducting spin-coating of a PMMA positive photoresist on the substrate, and performing baking and curing; utilizing an electron beam lithography machine to perform exposure; conducting developing, and then performing rinsing with IPA to obtaina photoresist zone plate structure; taking the photoresist as a mask, and carrying out nano gold electroplating on the upper layer to obtain an upper-layer gold zone plate; and putting the upper-layer gold zone plate into a reactive ion etching machine, taking the gold zone plate as a mask to etch metal tungsten, and transferring the pattern to obtain the tungsten / gold Fresnel zone plate. The zone plate has a high resolution with large aspect ratio (greater than 20 / 1). The method can also be used for preparation of a Fresnel zone plate lens for soft X-ray to hard X-ray detection, the obtainednano-pattern structure is controllable in morphology, and the method is compatible with the existing semiconductor process.

Owner:FUDAN UNIV

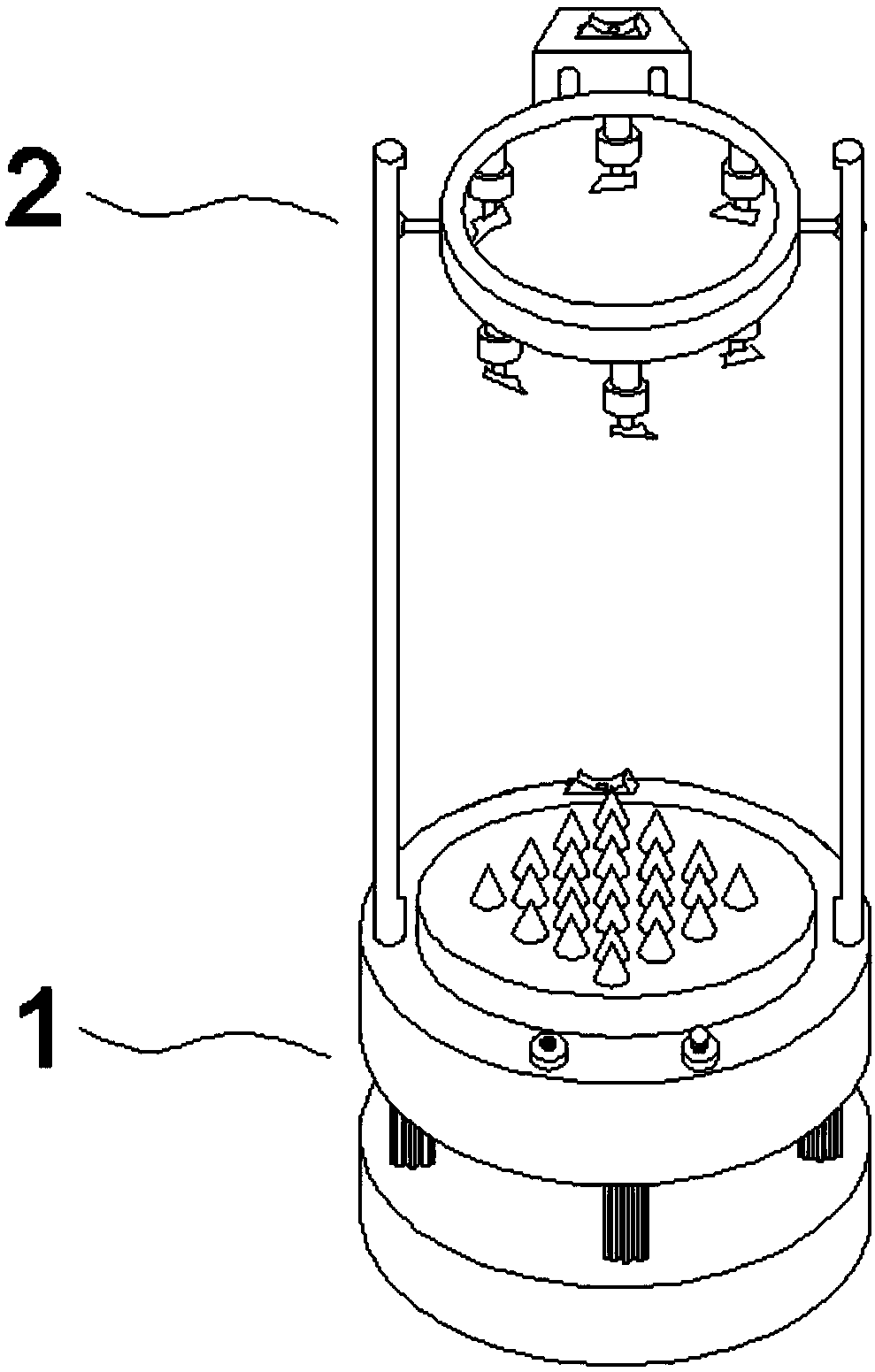

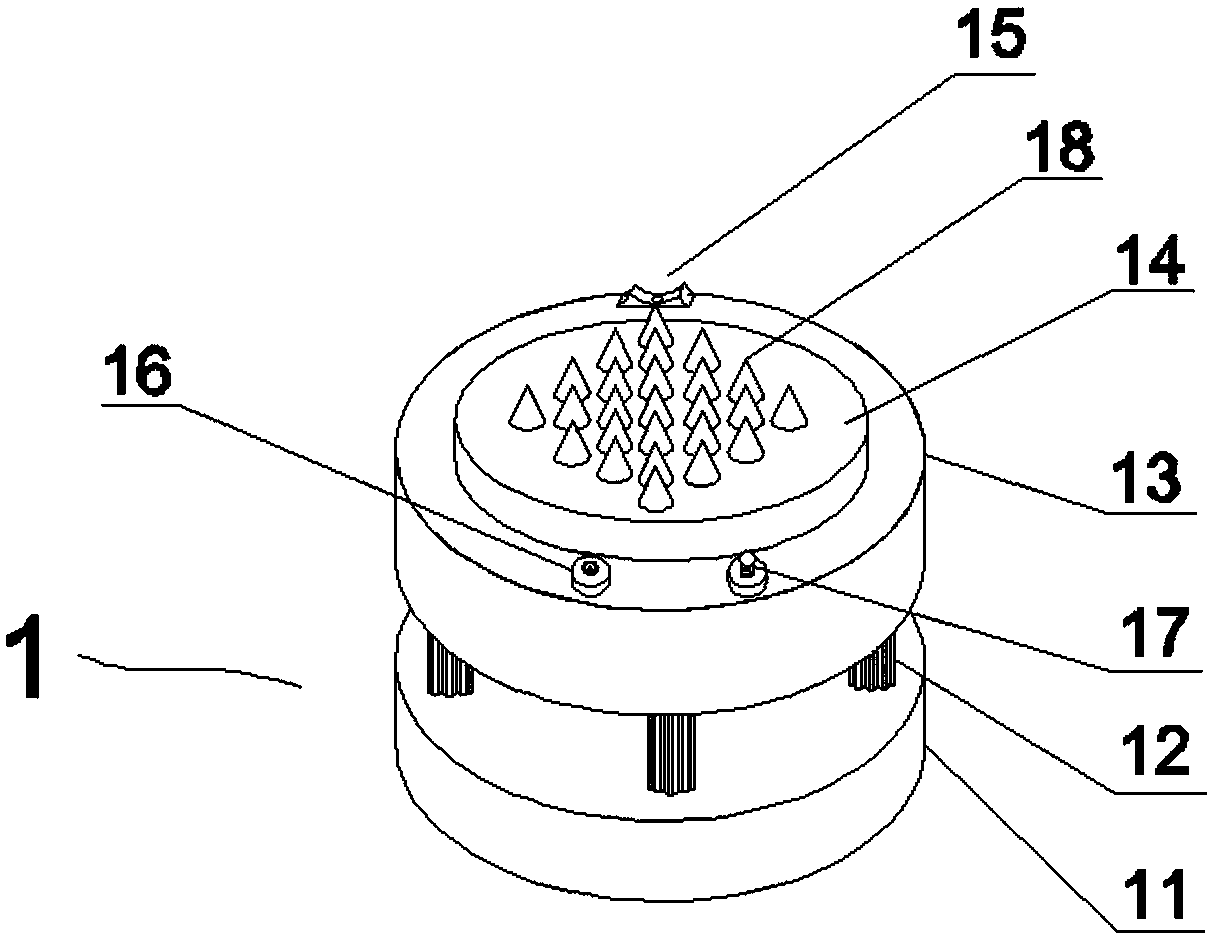

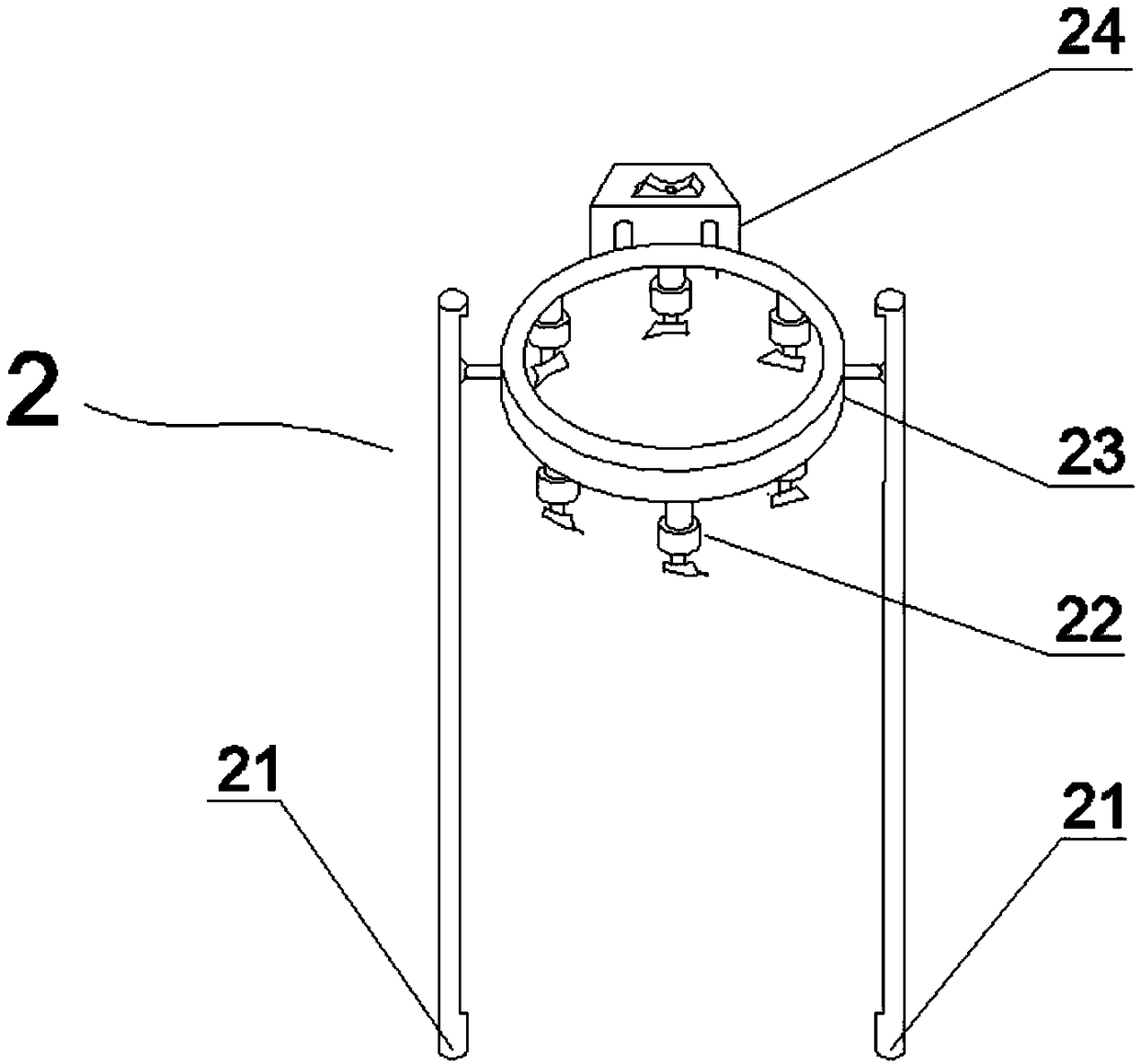

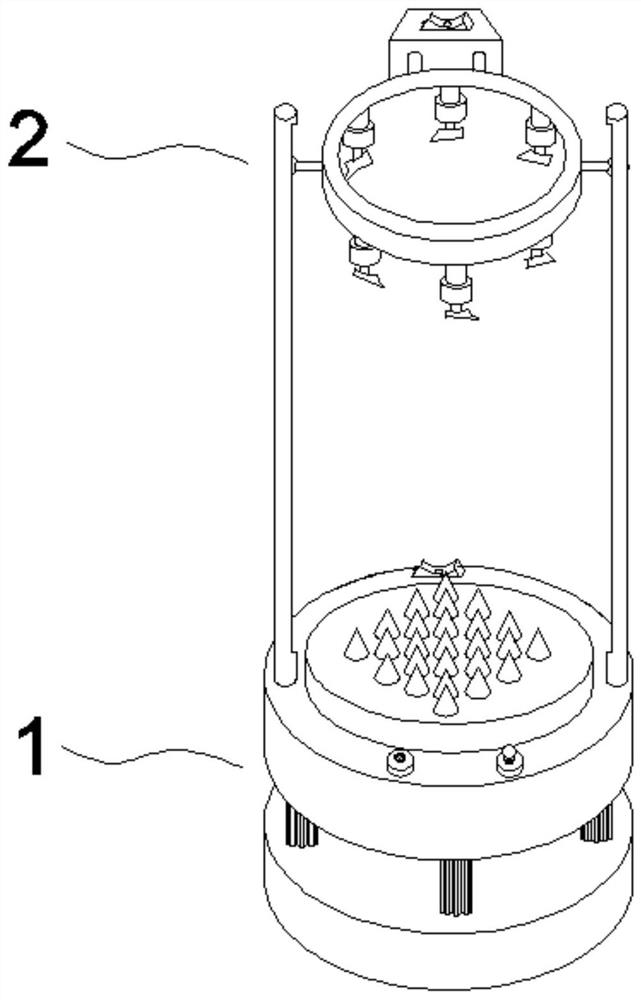

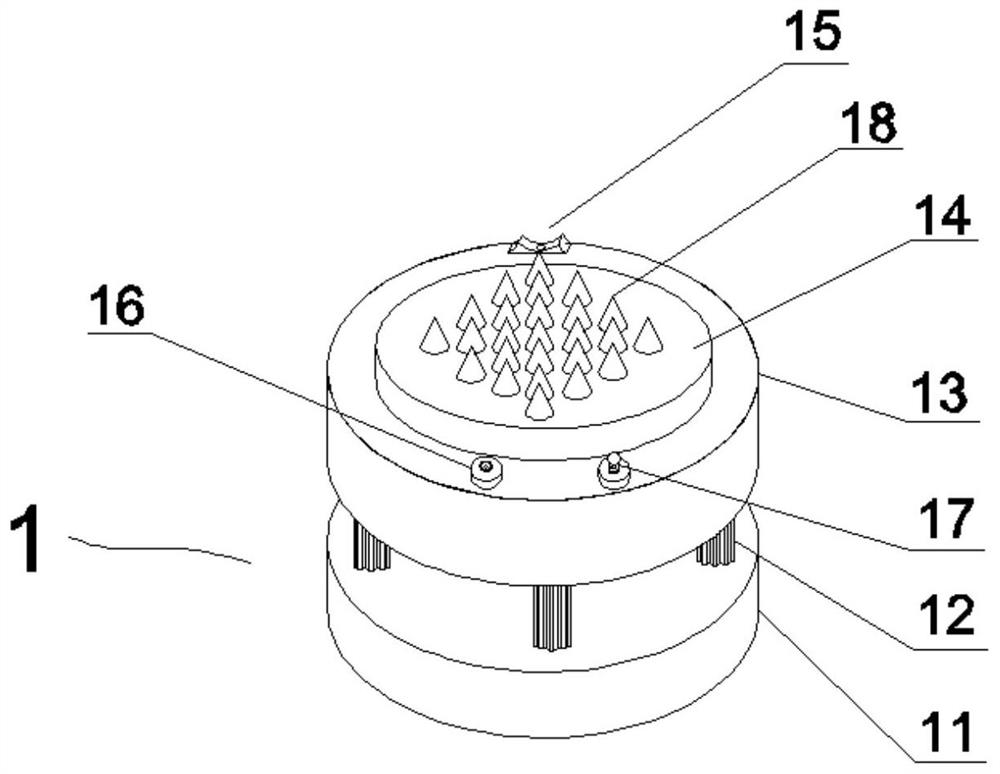

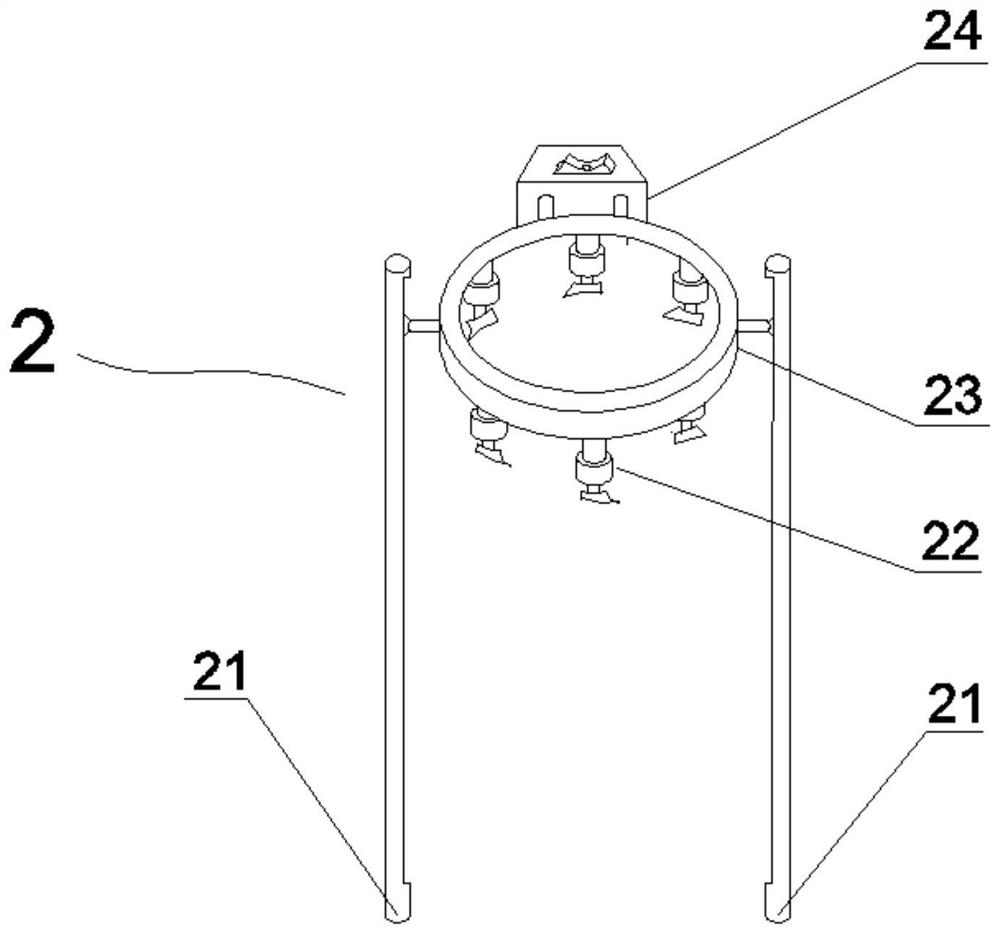

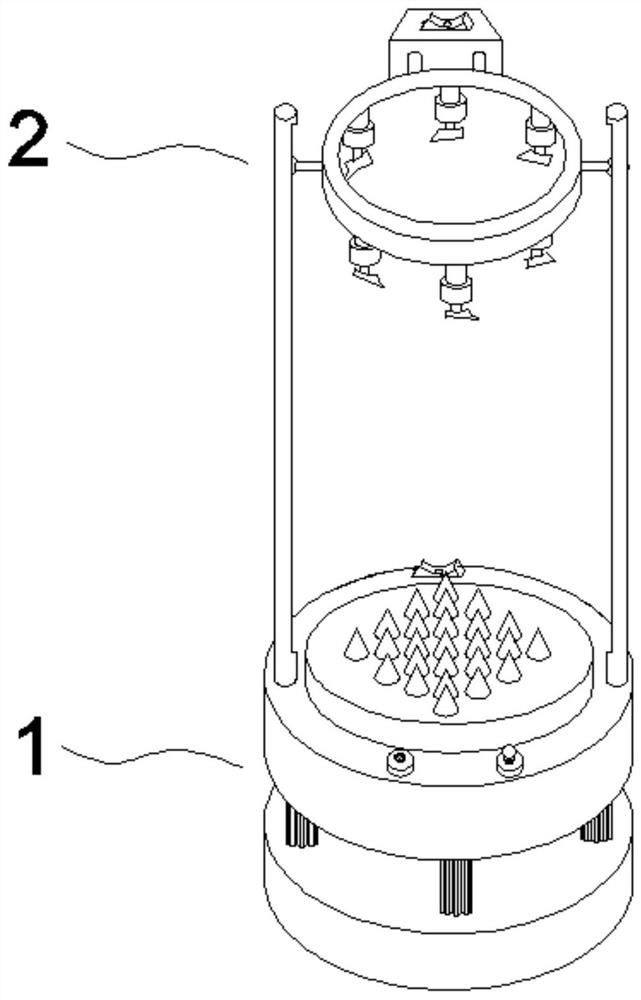

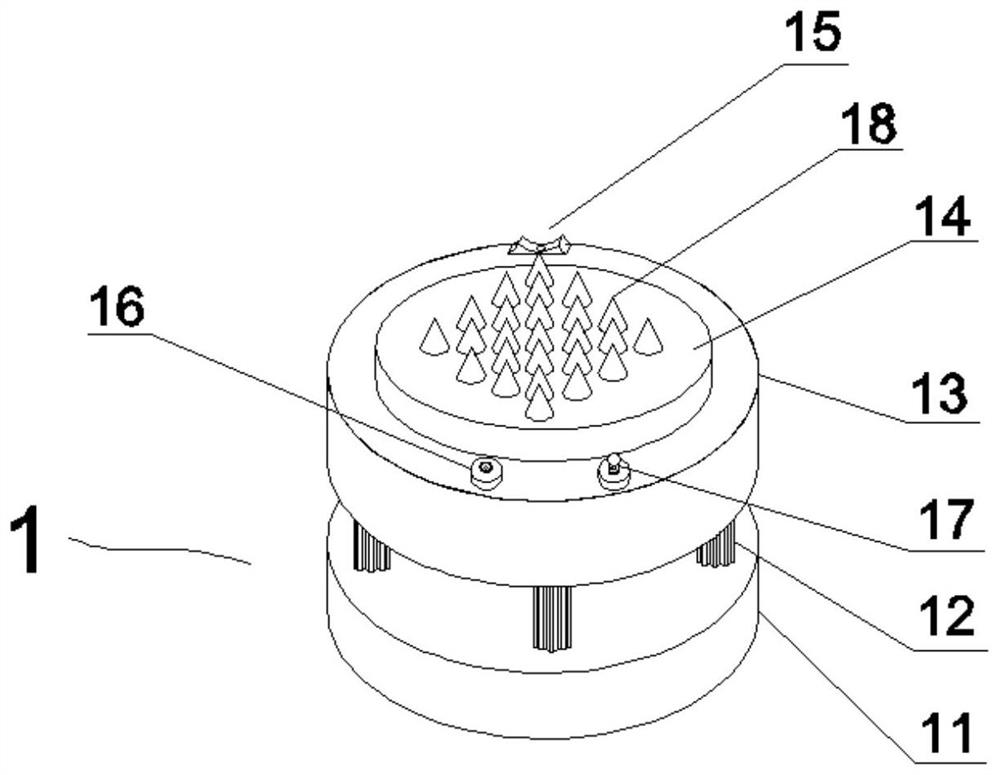

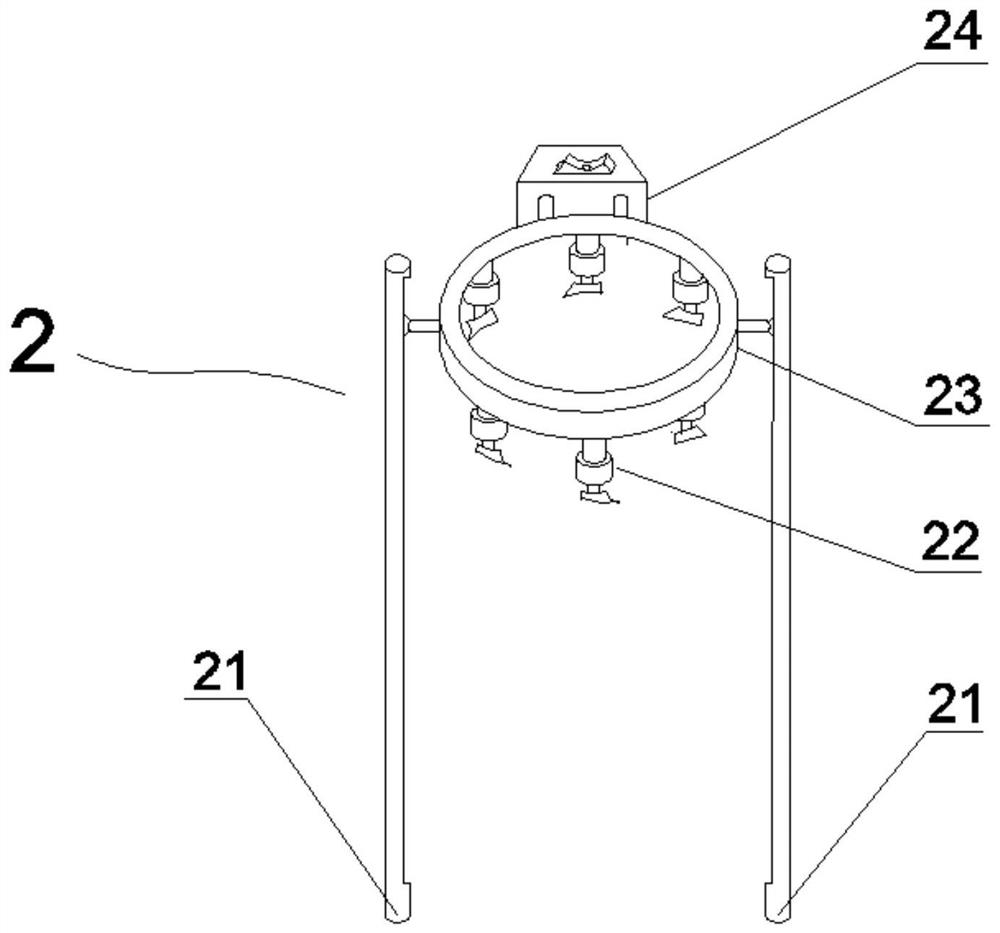

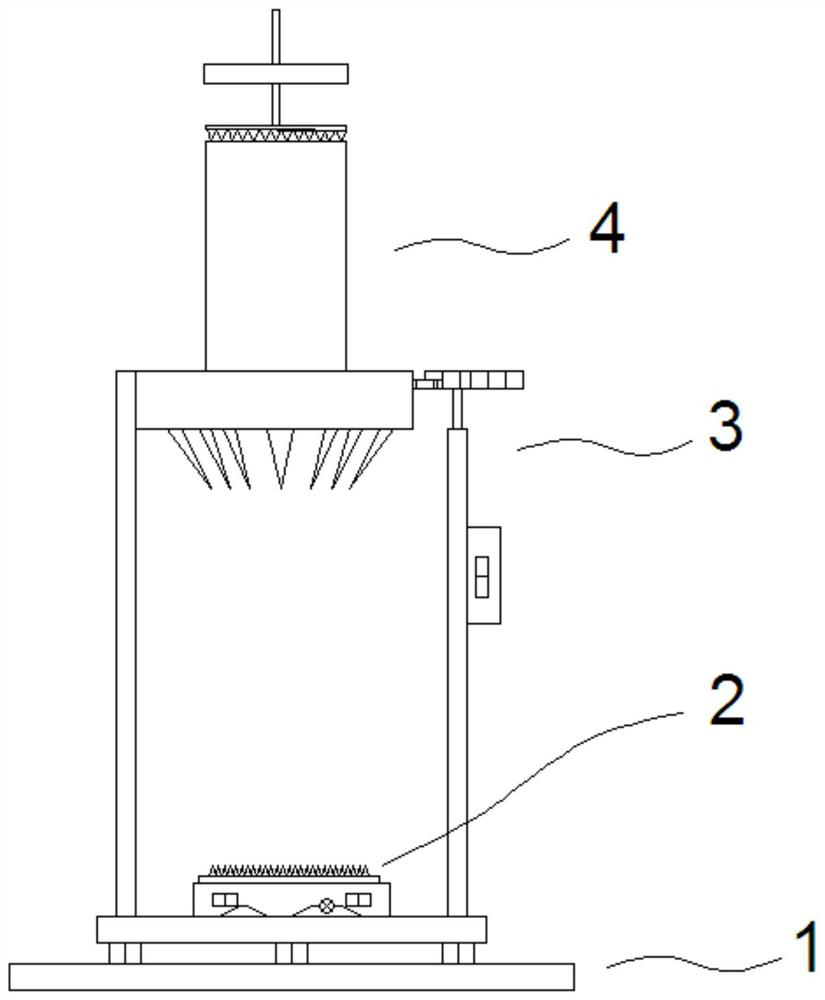

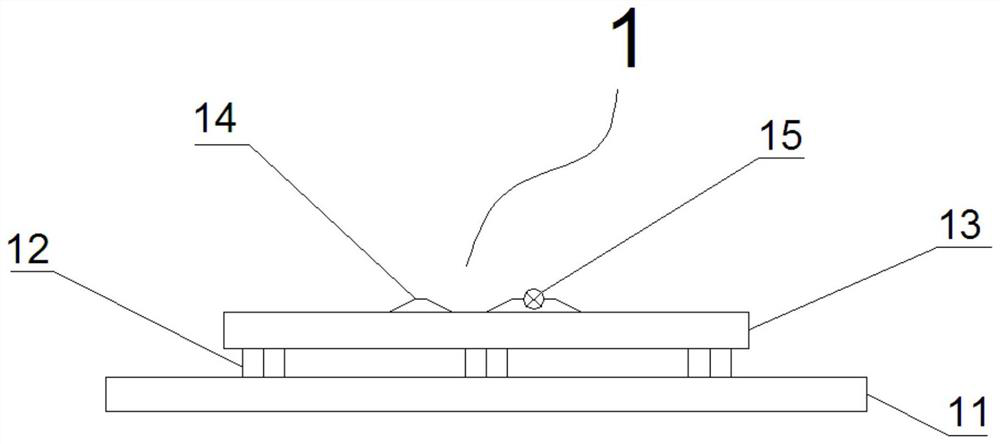

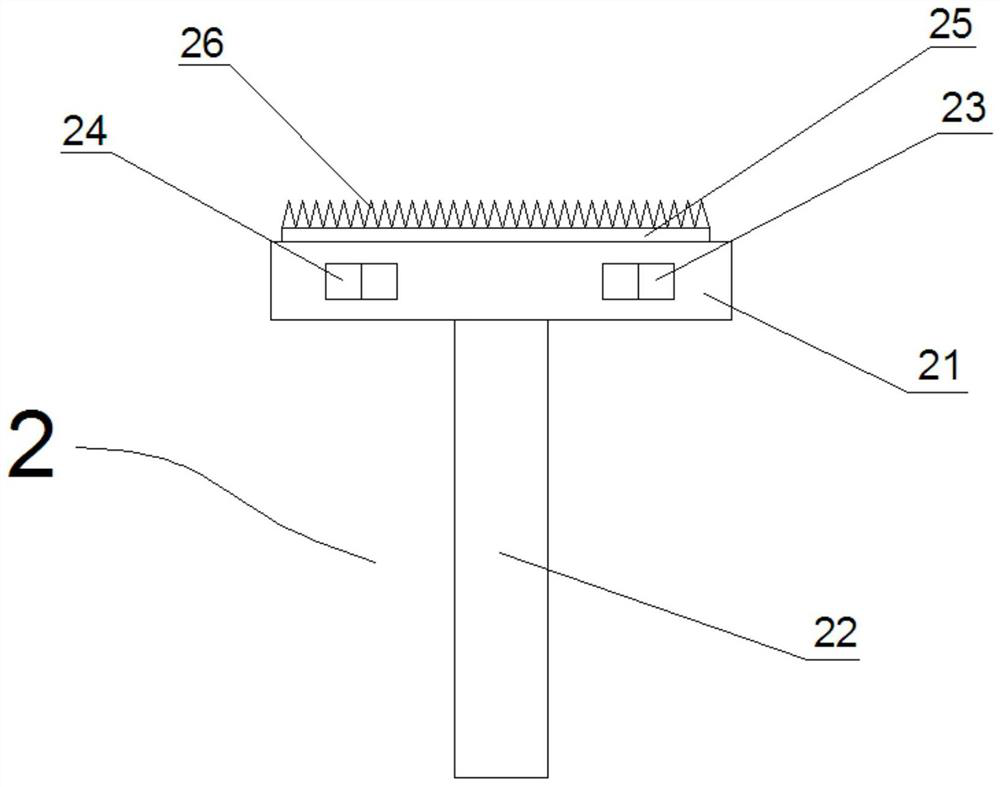

Spiral-downward undisturbed soil triaxial sample maker

ActiveCN109030135APrevent tilting deformationAvoid huge disturbancesPreparing sample for investigationEngineeringLaboratory facility

The application relates to a spiral-downward undisturbed soil triaxial sample maker, and belongs to the technical field of the indoor soil engineering testing of the civil engineering subject. The sample maker comprises a support mechanism, a cutting mechanism, and a sample bearing mechanism; the lifting of the cutting mechanism is driven by two lifting shafts, two wedge-shaped detachable cuttingblades replace the manual cutting, the cutting blades with two different diameters are used for cutting the soil sample into the cylinder samples required by the test in twice; a cutting speed switchis turned off after the sample making is accomplished, a cutting turntable is ascended to take out the made sample. The undisturbed soil cannot be disturbed in the cutting process, the influences of uncertain factors and artificial factors in the soil cutting process are avoided, and the sample making can be precisely and efficiently accomplished; compared with a soil cutter of undisturbed soil inthe existing laboratory, the sample making efficiency is doubled, and the sample making time is about 15min.

Owner:SHAOXING UNIVERSITY

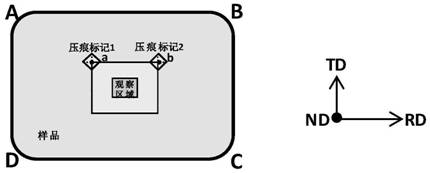

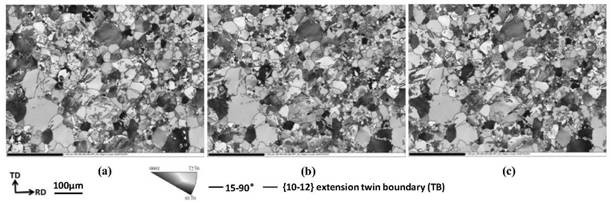

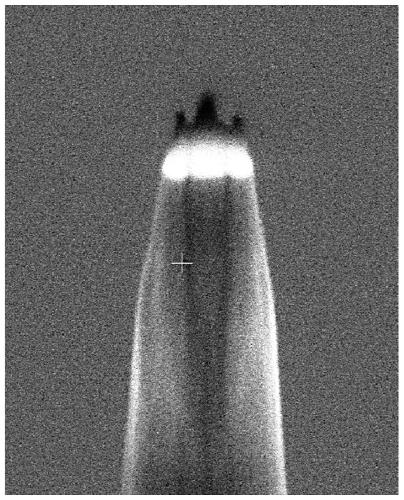

In-situ EBSD observation method for microscopic orientation evolution of recrystallized grains of magnesium alloy

InactiveCN111999323AImprove the success rate of sample preparationGuaranteed follow-up observationMaterial analysis using radiation diffractionEtchingMetallic materials

The invention belongs to the field of metal material structure analysis sample preparation and structure observation characterization, and particularly relates to an in-situ EBSD observation method for microcosmic orientation evolution of recrystallized grains of magnesium alloy. The method comprises the steps of firstly, carrying out mechanical polishing on a magnesium alloy sample, then preparing indentation mark points on the surface to be detected, and conducting EBSD observation for the first time on a target area after ion etching; and taking out the sample, carrying out recrystallization annealing heat treatment and ion etching, finding the same area according to the indentation mark points, carrying out EBSD observation for the second time, and similarly, completing subsequent required in-situ EBSD observation. According to the method, in-situ tracking characterization of recrystallization nucleation, grain growth and microscopic orientation evolution in the same area in the recrystallization annealing process of the magnesium alloy is achieved, and the problems that the magnesium alloy is low in calibration rate due to a surface stress layer, an oxide layer and pollutants,accurate positioning cannot be achieved, and in-situ EBSD observation is difficult to achieve are solved. The process is simple and controllable, the technical requirements on sample preparation of experimenters are low, and the experiment success rate is high.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

X-luminoscope fusion sample preparation method

InactiveCN103808559AChemically stableNot easy to absorb moistureMaterial analysis using wave/particle radiationPreparing sample for investigationCrucibleFree cooling

The invention discloses an X-luminoscope fusion sample preparation method, comprising the following steps: grinding a solid sample into powder of not less than 200 meshes for later use, wiping a crucible, a stirrer and a medicine spoon to be clean by using alcohol, placing in an oven for drying for 30min and more, taking out and placing on a tray, wiping the inner wall of a die to be clean by using alcohol, naturally withering for later use; weighing a certain mass of PE material to be put into a crucible, heating until the solvent is completely fused; weighing a certain mass of sample powder in S1 to place in a crucible in the S4, turning on the stirrer, stirring while heating, stopping stirring and heating after 30min; fetching melt at the upper layer in the crucible in S5 with a medicine spoon in a die in the S3, wherein the melt is about 2 / 3 of the height of the die, naturally cooling to completely solidify to obtain the sample sheet. The borate flux is replaced by the PE material, the manufactured sample sheet is hard to break, crack and pollute, easy to de-mold and store, the sample preparation time is effectively shortened, and the sample preparation cost is greatly reduced.

Owner:南京大展机电技术研究所

Sample preparation toolkit for determining curing temperature of high-solid-content propellant powder and use method of sample preparation toolkit

ActiveCN114112584AReduce lossEasy to splitAmmunition testingPreparing sample for investigationPhysical chemistrySolid content

The invention discloses a sample preparation toolkit for determining the curing temperature of a high-solid-content propellant powder and a use method of the sample preparation toolkit. The high-solid-content propellant powder is cylindrical propellant powder with the solid filler mass fraction of 54%, the diameter of 14 mm and the height of 15 mm, and the sample preparation tool kit comprises a sample preparation knife, a sample preparation cover, a sample preparation disc and a hammer. Each propellant grain is split into two halves along the axis by using a sample preparation toolkit, the two halves are cured for 0-5 days at 80 DEG C, 90 DEG C and 100 DEG C respectively, an elastic modulus average value E and a standard deviation delta are calculated through multi-point detection by using a nanoindentor, and alpha = E * 4 + delta * 6; recording corresponding time tmin when alpha reaches the minimum value at the same temperature, and enabling delta to be equal to tmin-3; delta at the three temperatures of 80 DEG C, 90 DEG C and 100 DEG C is compared, and the temperature corresponding to the minimum value of delta is the optimal curing temperature. When the sample preparation toolkit is used for sample preparation, the loss is small, the potential safety hazard is small, the sample preparation time is short, the sample preparation repeatability is good, and the influence on a detection result is small.

Owner:XIAN MODERN CHEM RES INST

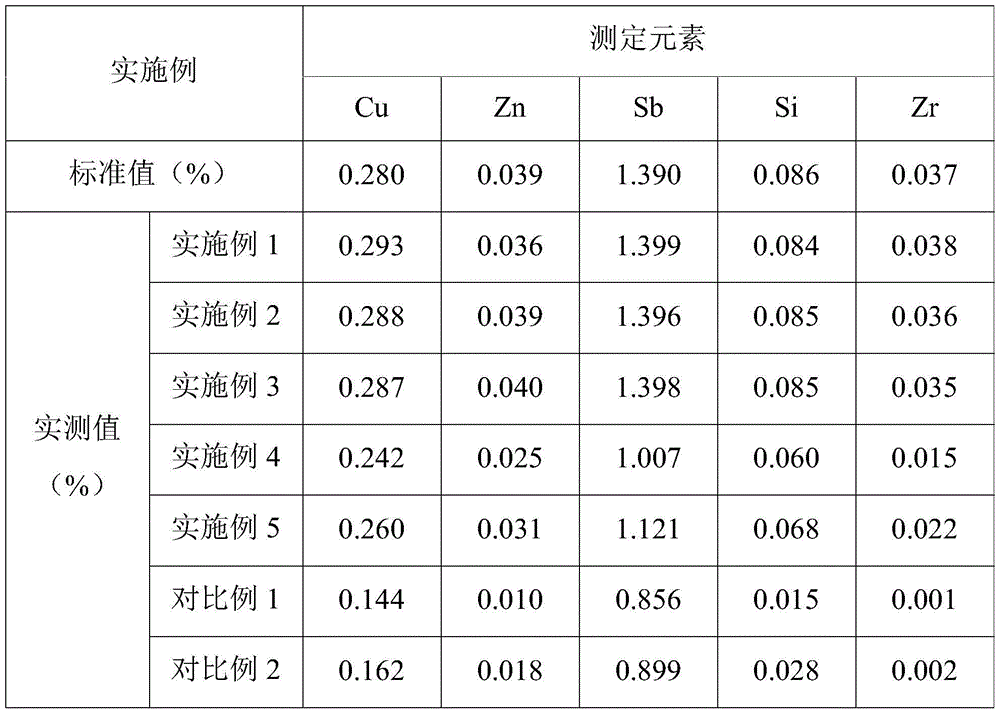

Method determining impurity content in stannic oxide electrode material

InactiveCN105628683AEasy to handleImprove the success rate of sample preparationPreparing sample for investigationAnalysis by thermal excitationLithium metaborateStrong acids

The invention discloses a method determining impurity content in a stannic oxide electrode material. The method comprises: adding the stannic oxide electrode into lithium tetraborate and lithium metaborate serving as a flux and mixed proportionally for melting, taking a fuse piece after cooling, adding water and inorganic strong acid to dissolve to obtain a solution to be determined, and then determining the solution to be determined by adopting an inductive coupling plasma emission spectrometer. By adopting the method disclosed by the invention, the high compactness stannic oxide electrode material can be fully dissolved, sampling is simple, various impurity elements in the stannic oxide electrode can be determined, a determined result is accurate and an analysis error is small.

Owner:TUNGHSU TECH GRP CO LTD +1

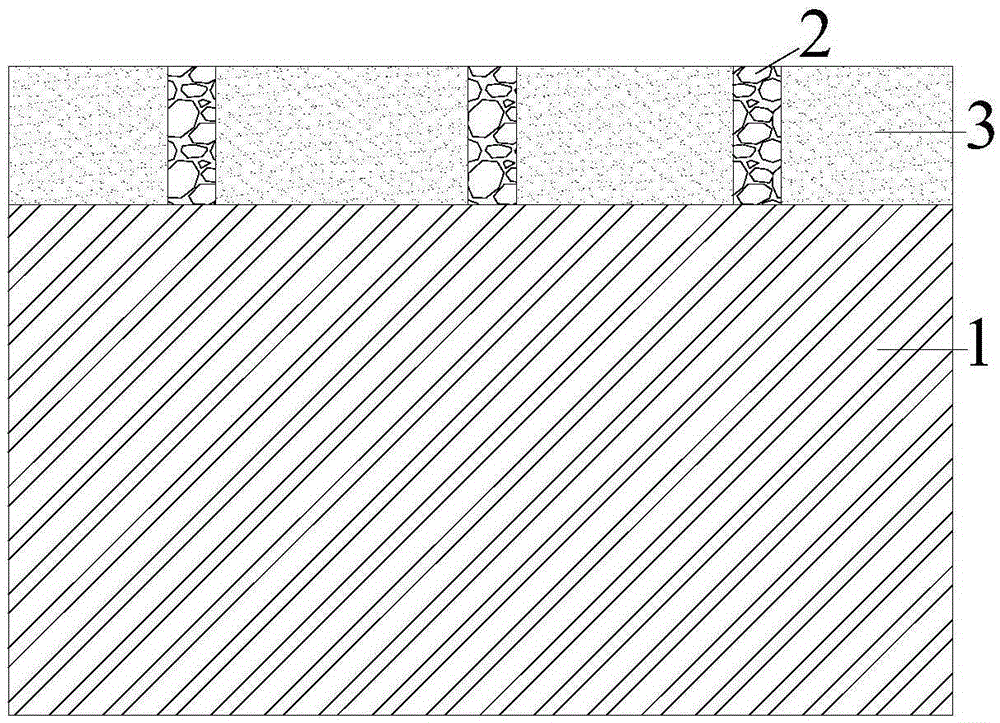

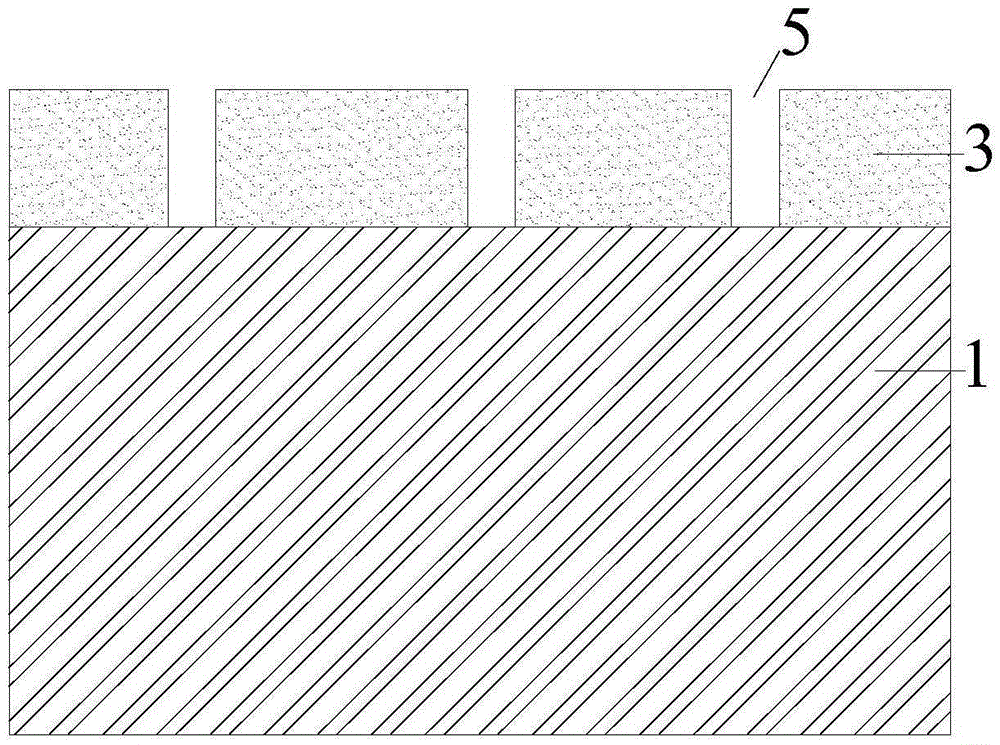

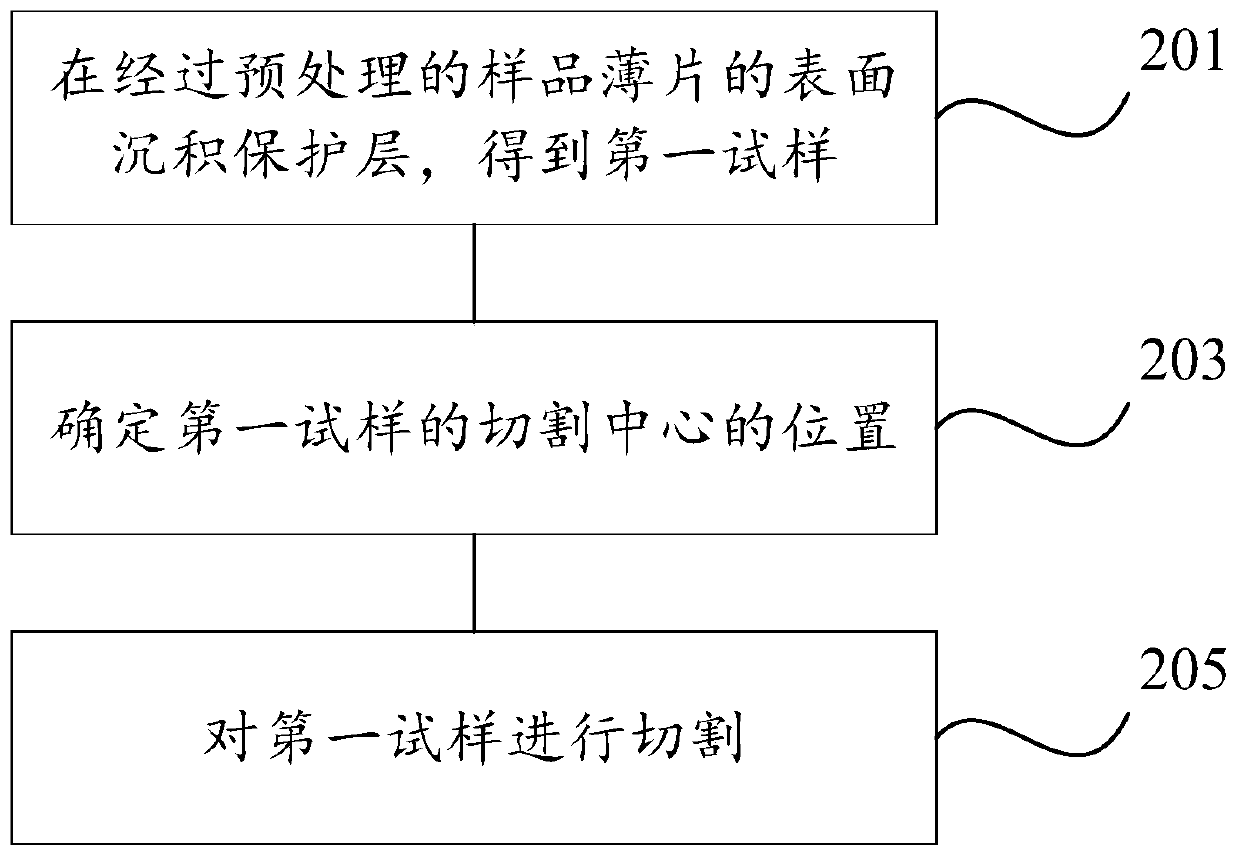

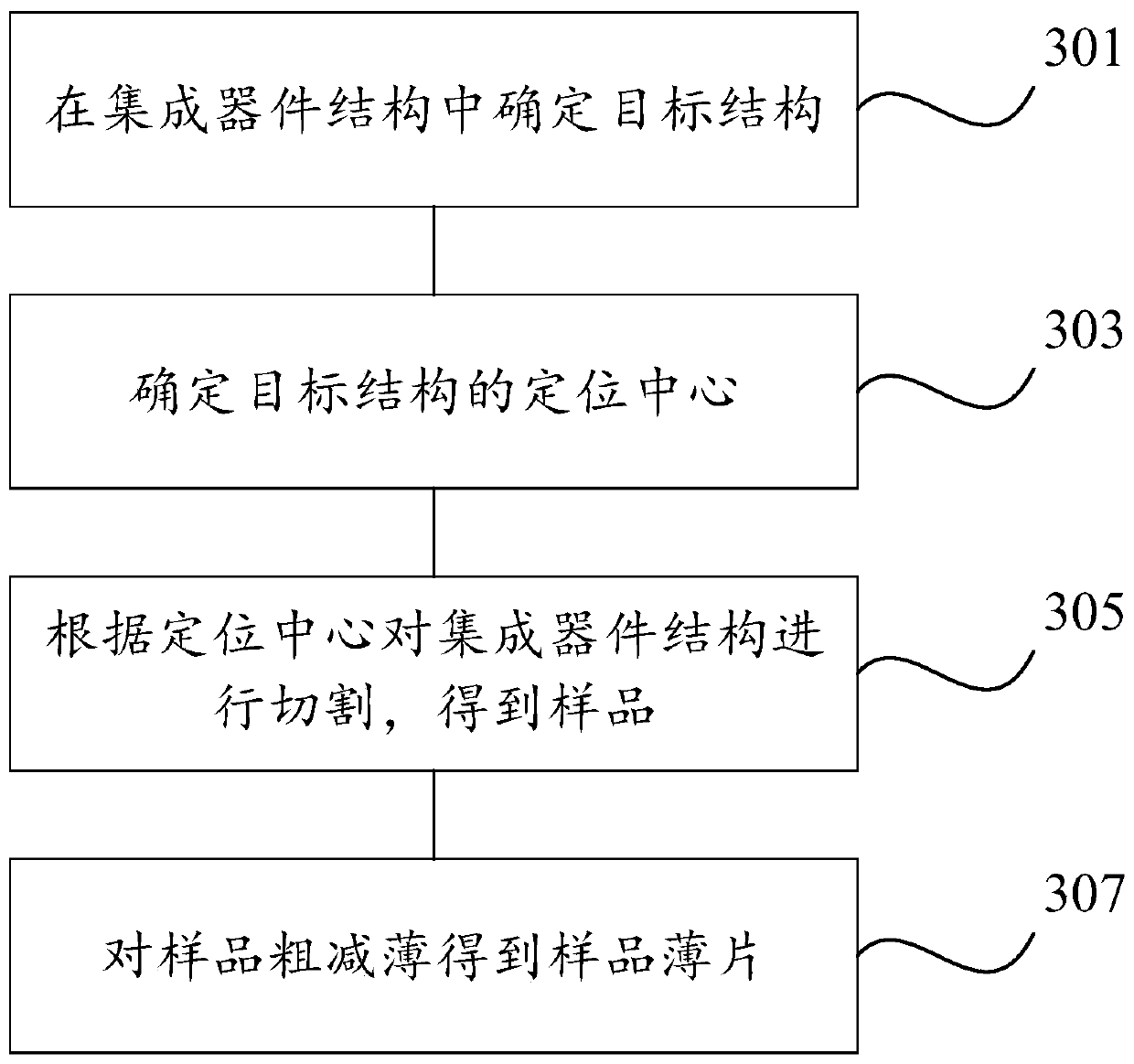

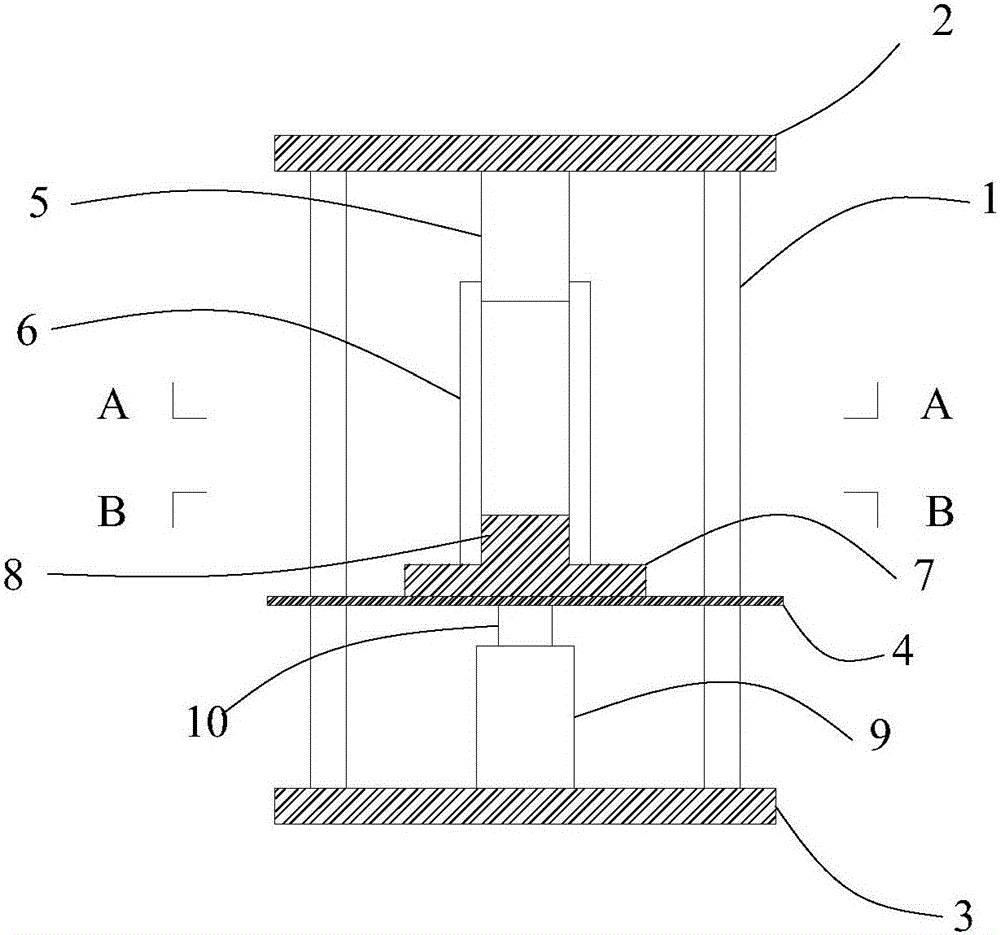

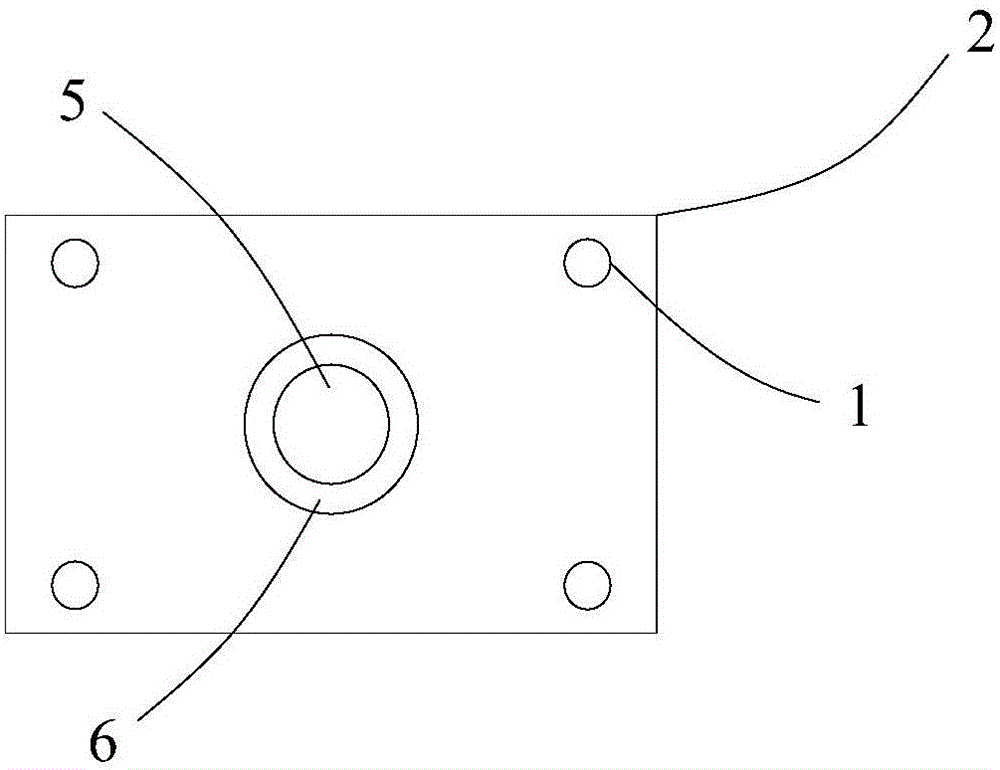

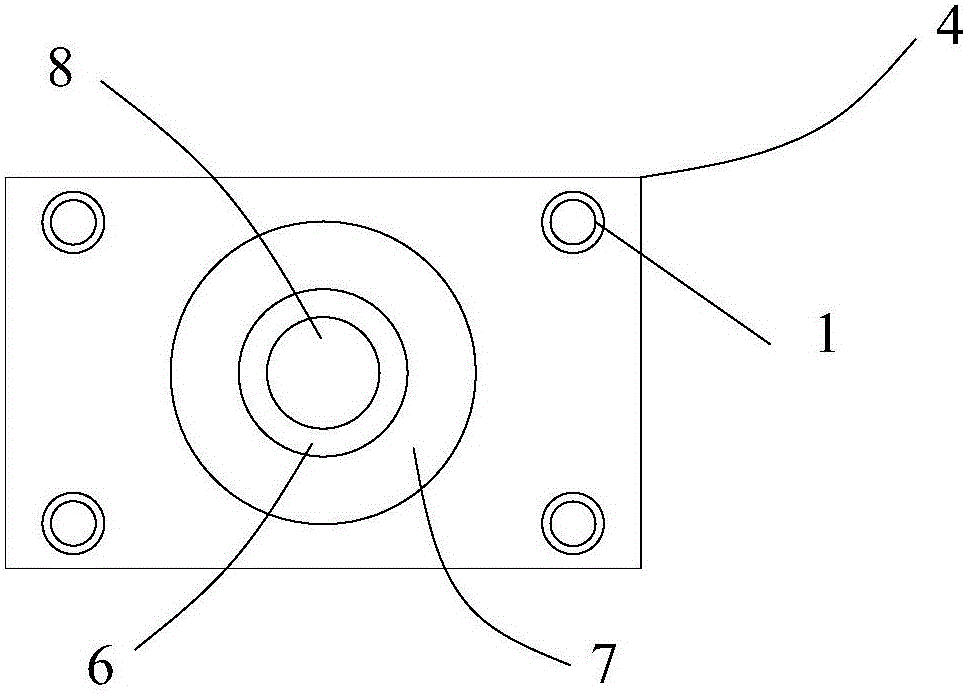

Focused ion beam cutting sample preparation method

ActiveCN111220819AImprove integrityImprove the success rate of sample preparationScanning probe techniquesThin sheetFocused ion beam

The invention relates to the technical field of material sample preparation, in particular to a focused ion beam cutting sample preparation method. The focused ion beam cutting sample preparation method comprises the following steps of: depositing a protective layer on the surface of a pretreated sample sheet to obtain a first sample; determining the position of a cutting center of the first sample, wherein the cutting center is a positioning center of a target structure; and cutting the first sample. According to the focused ion beam cutting sample preparation method provided by the embodiment of the invention, the protective layer is deposited on the surface of the sample sheet, so that the integrity of the target structure is protected in the sample preparation process, the positioningcenter of the target structure is determined as the cutting center to ensure that the finally obtained sample contains the target structure, and the sample preparation success rate is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Briquette coal sample preparation device

InactiveCN105738178ASimple and fast operationReduce laborPreparing sample for investigationEngineeringBriquette

A briquette sample preparation device, characterized in that it includes a column, an upper panel, a lower panel, a middle panel, a pad, a hollow cylinder, a lower part of the chassis, an upper part of the chassis, a jack, and a jack piston rod; the lower part of the chassis and the upper part of the chassis Consolidation into one body; the inner surface of the hollow cylinder is smooth; the pads can be fully extended into the cylinder and are in close contact with the inner wall of the cylinder; there are four columns in total, the columns penetrate the middle panel, and the two ends are respectively fixed On the upper and lower panels; the jack is placed in the center of the lower panel. The briquette sample preparation device can independently complete sample preparation, is easy to operate, requires less labor, and has a high success rate of sample preparation.

Owner:ANHUI UNIV OF SCI & TECH

A spin-down undisturbed soil triaxial sample preparation device

ActiveCN109030135BPrevent tilting deformationAvoid huge disturbancesPreparing sample for investigationSoil scienceKnife blades

The application relates to a spin-down type undisturbed soil triaxial sample preparation device, which belongs to the technical field of indoor geotechnical testing in the discipline of civil engineering. It includes a support mechanism, a cutting mechanism, and a sample-holding mechanism; the present invention drives the cutting mechanism up and down through two lifting shafts, six wedge-shaped detachable cutting blades replace manual cutting, and uses two kinds of cutting blades with different diameters to divide the soil sample Cut the cylindrical sample required for the test twice. After the sample preparation is completed, turn off the cutting speed switch, raise the cutting turntable, and take out the prepared sample. The present invention will not disturb the undisturbed soil during the cutting process, avoiding Influenced by uncertain factors and human factors in the soil cutting process, the sample preparation can be completed accurately and efficiently. Compared with the undisturbed soil cutter in the existing laboratory, the sample preparation efficiency is increased by 2 times, and the sample preparation time is about 15 minute.

Owner:SHAOXING UNIVERSITY

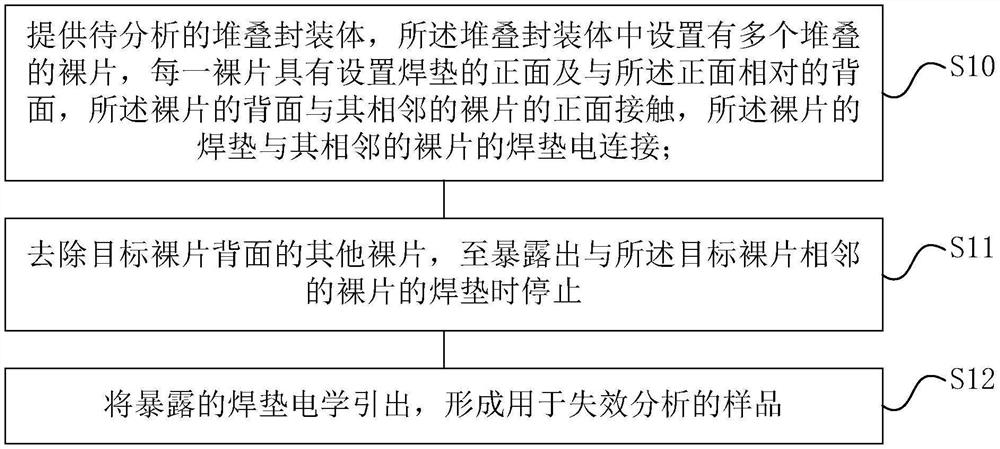

Failure analysis sample preparation method and failure analysis sample

ActiveCN111812487BAvoid removalImprove the success rate of sample preparationElectronic circuit testingHemt circuitsElectrical connection

Owner:YANGTZE MEMORY TECH CO LTD

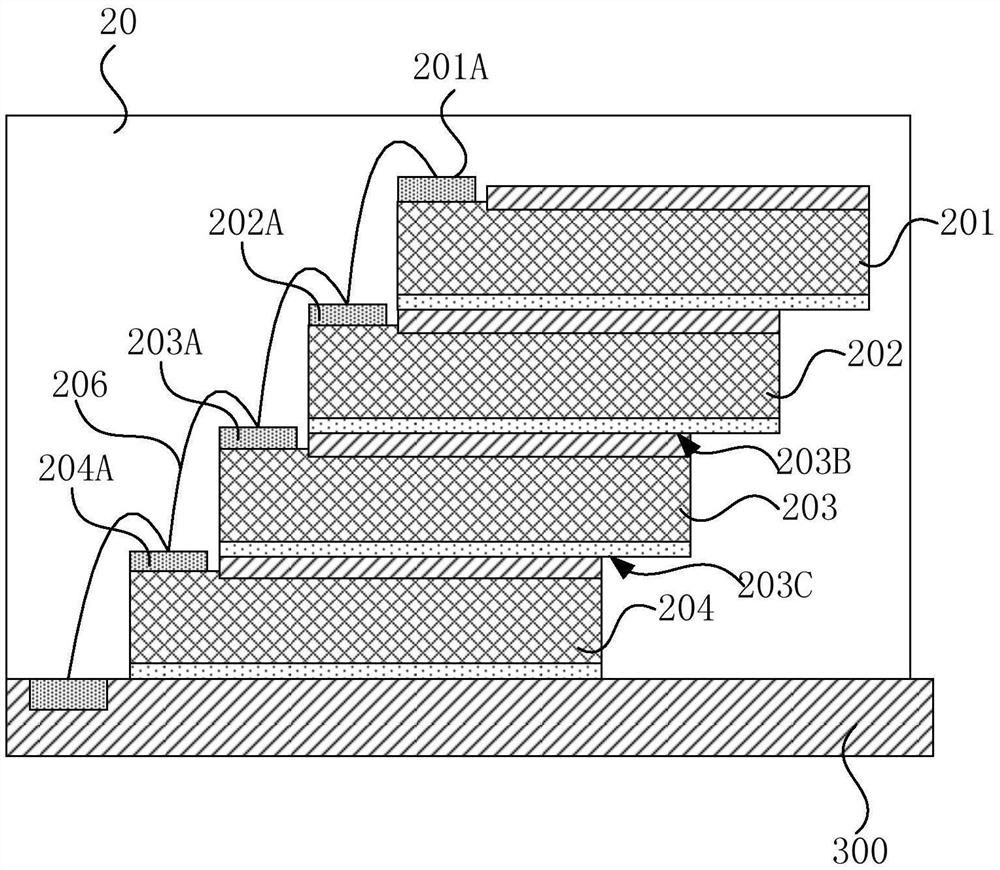

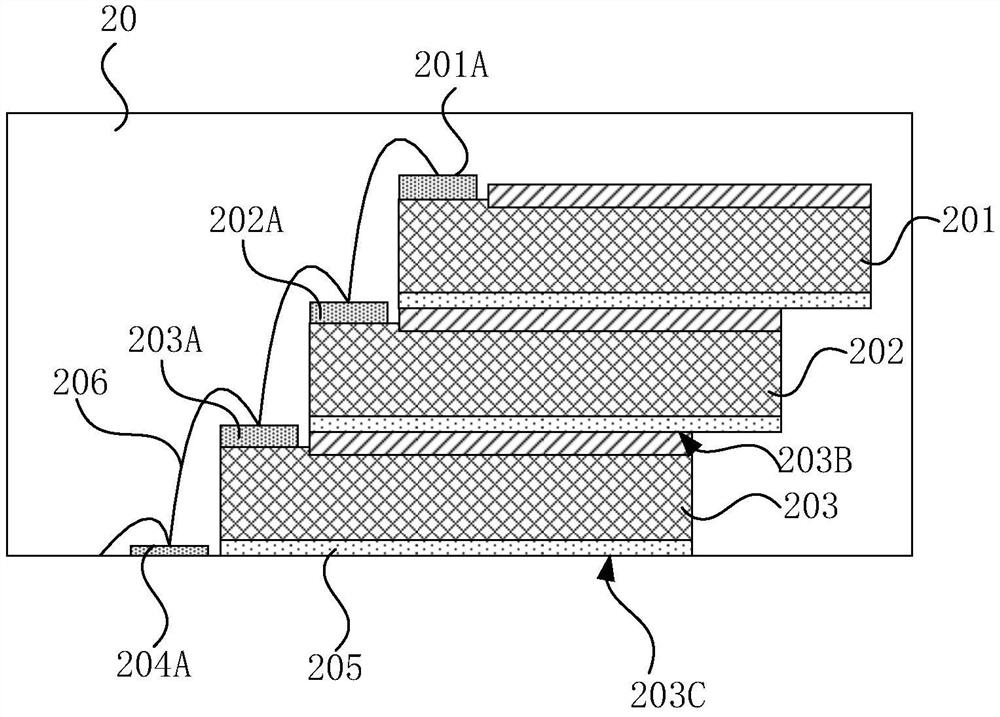

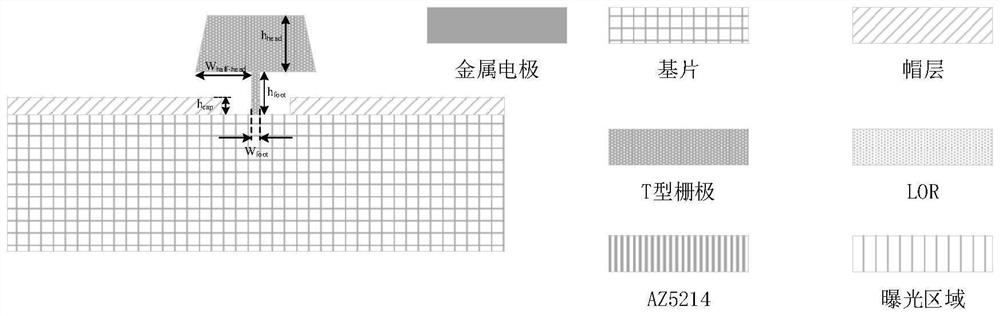

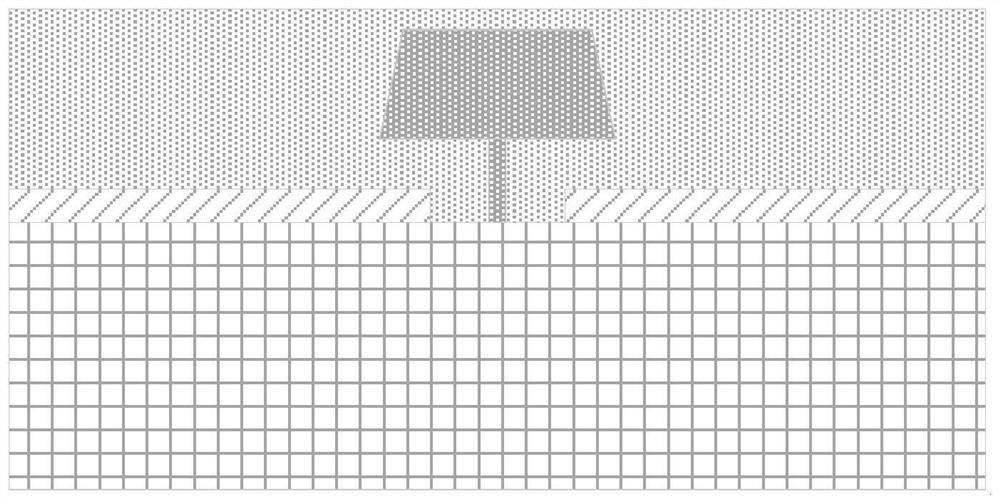

Preparation method of source and drain electrodes of high-electron-mobility transistor

ActiveCN112687531AImprove the success rate of sample preparationLow costSemiconductor devicesPhysical chemistryEngineering

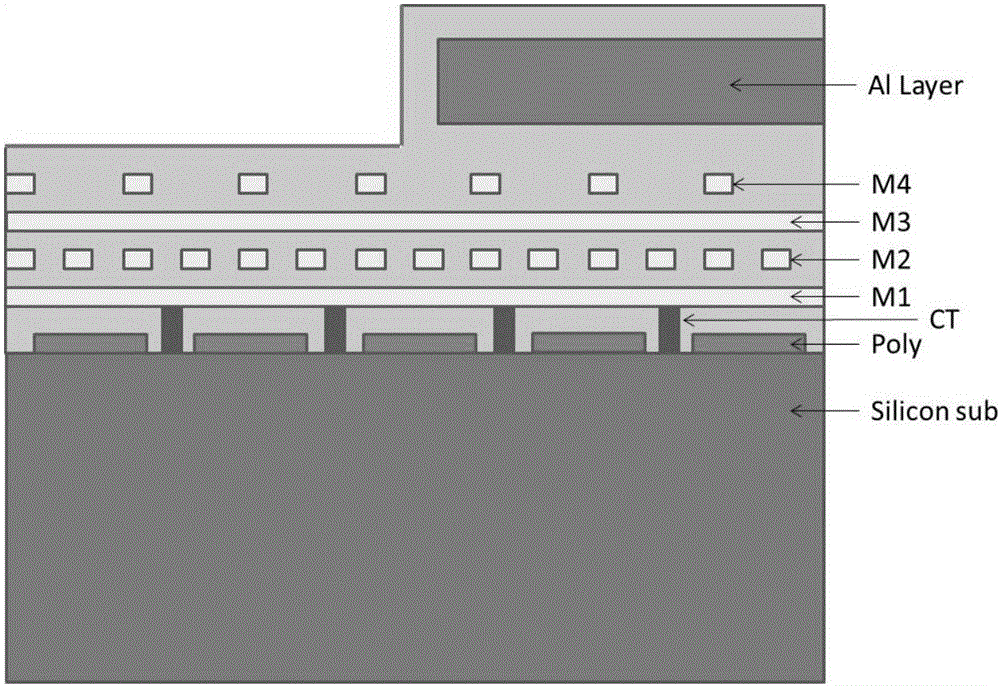

The invention belongs to the technical field of transistor preparation, and particularly relates to a preparation method of source and drain electrodes of a high-electron-mobility transistor. The preparation method provided by the invention adopts an angular evaporation self-alignment process, and basically comprises the following steps: on the basis of a T-shaped gate growth process, accurately controlling the distance between a source electrode and a gate electrode and the distance between a drain electrode and the gate electrode of a high-electron-mobility transistor device in an angular evaporation manner by utilizing a unique T-shaped structure of the gate electrode of the high-electron-mobility transistor; therefore, the positions of the source electrode, the drain electrode and the T-shaped gate of the high-electron-mobility transistor device achieve the purpose of position-controllable self-alignment, and finally, a new adjustable geometrical parameter freedom degree is provided for improving the performance of the device. The method provided by the invention can be used for preparing a high-electron-mobility transistor device with a T-shaped gate structure to obtain a symmetrical or asymmetrical distance between a source and a gate and a distance between a drain and the gate, and is compatible with the existing semiconductor process at the same time.

Owner:FUDAN UNIV

A kind of preparation method of nanoscale carbide transmission electron microscope extraction replica sample

ActiveCN104897454BEasy to break awayQuality improvementPreparing sample for investigationScanning probe techniquesCarbon filmVacuum coating

The invention discloses a method for preparing a replica sample extracted by a nanoscale carbide transmission electron microscope. The steps are: mechanically grinding and polishing the sample until the surface is smooth and free of scratches; into alcohol for cleaning, and then take it out for drying; wherein, the corrosion solution is a mixed solution of picric acid, bromic acid and methanol; use a vacuum coating instrument to spray a layer of carbon film on the surface of the sample; the carbon film on the surface of the sample Divided into a grid shape, electrolyzed in the electrolyte, the surface of the sample is inclined, so that the carbon film is separated from the surface of the sample; wherein, the electrolyte is a mixed solution of nitric acid, bromic acid, and absolute ethanol; The membrane was removed from the electrolyte, rinsed in alcohol, and dried on filter paper or air-dried. The carbon extraction replica sample produced by the invention has good carbon film shape and high sample preparation success rate, and is suitable for observing very small nanoscale carbides with a transmission electron microscope.

Owner:SOUTHEAST UNIV

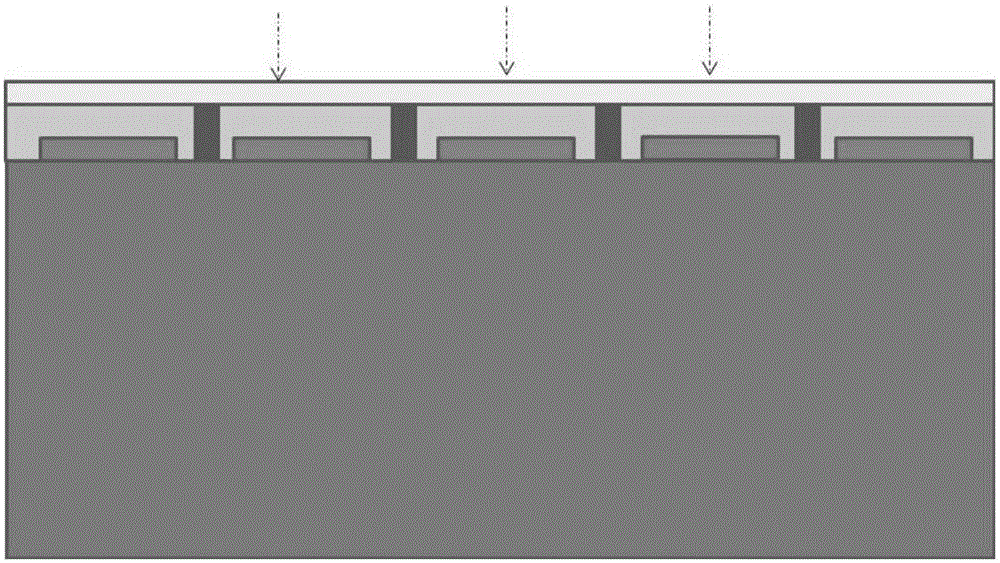

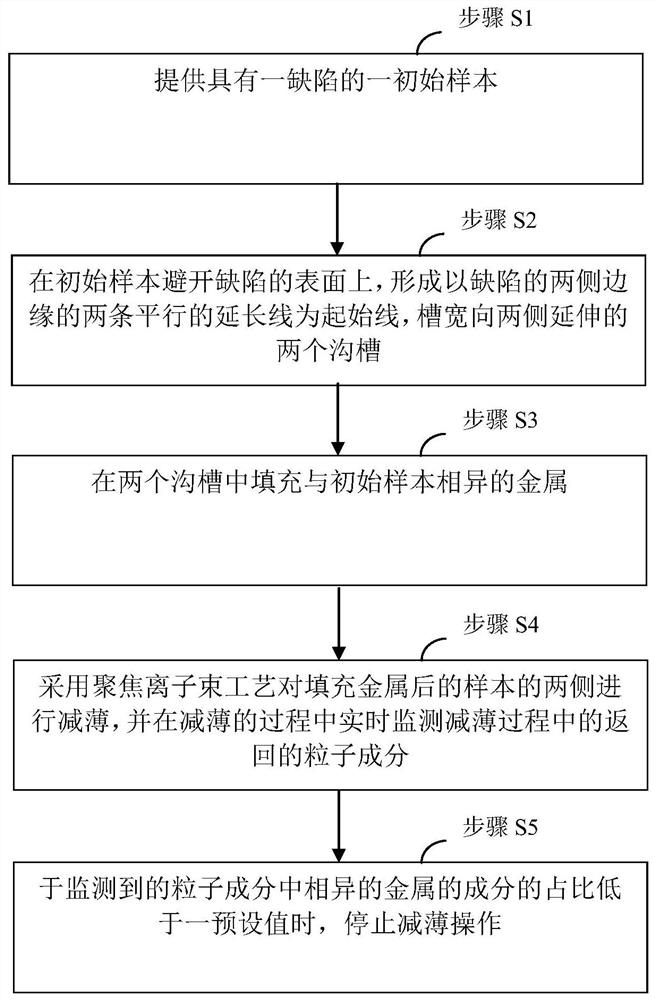

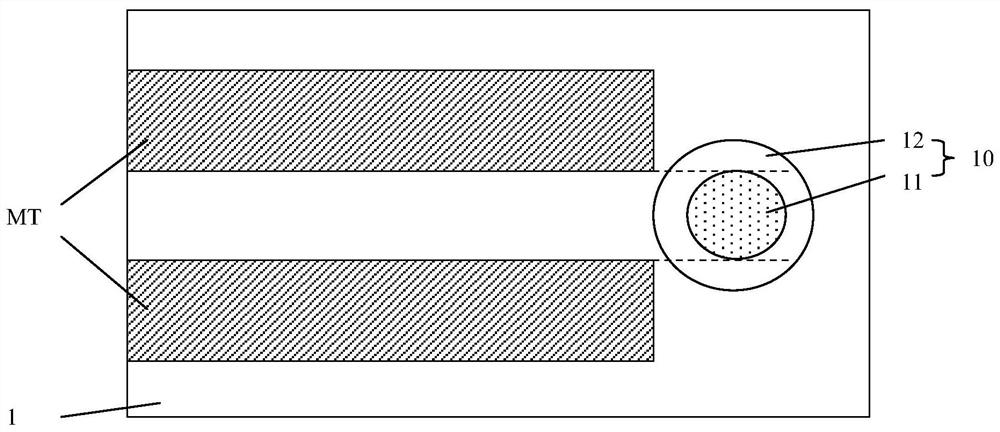

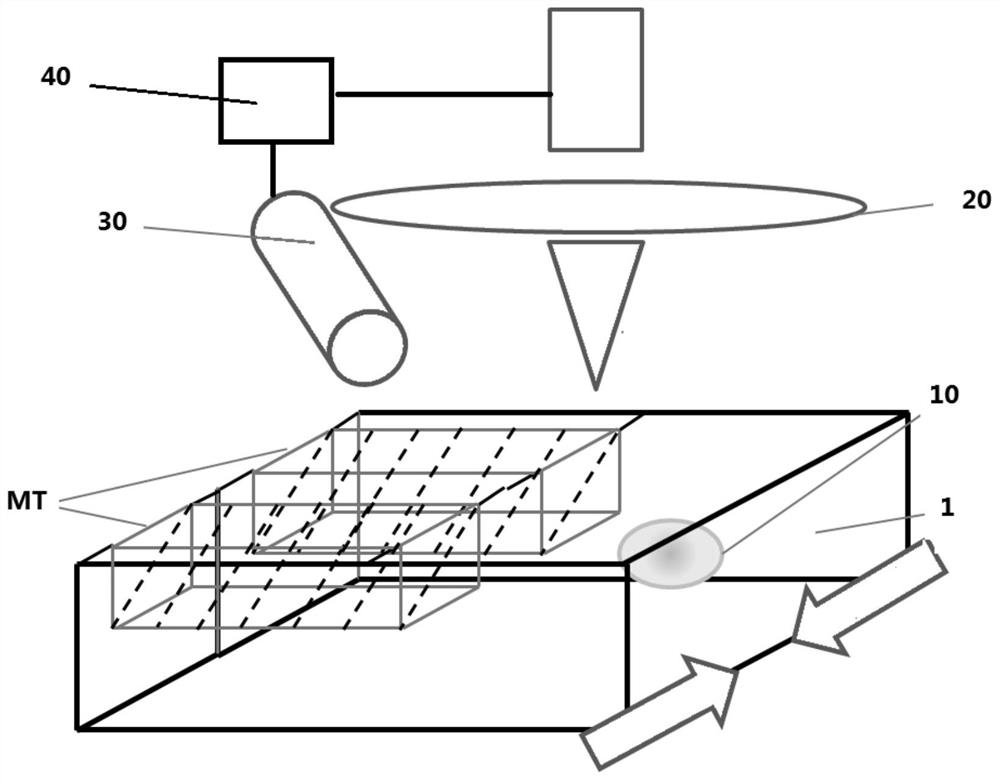

An automated method for sample thinning

ActiveCN107894357BPrecise control of cutting positionImprove Slicing AccuracyPreparing sample for investigationIon beamEngineering

The present invention relates to the field of semiconductor technology, in particular to an automatic sample thinning method; including: step S1, providing an initial sample with a defect; step S2, forming two defects on the surface of the initial sample avoiding the defect The two parallel extension lines on the side edge are the starting lines, and the groove width extends to both sides of the two grooves; step S3, filling the two grooves with a metal different from the initial sample; step S4, using focused ion Beam technology thins both sides of the sample filled with metal, and monitors the returned particle composition in the thinning process in real time during the thinning process; step S5, the composition of the different metals in the monitored particle composition When the ratio is lower than a preset value, the thinning operation will be stopped; the cutting position of the focused ion can be precisely controlled, and the sectioning accuracy can be improved. At the same time, the degree of automation is high, the efficiency is high, the labor cost is low, and the success rate of sample preparation is high.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Nano-film transmission electron microscope in-situ heating chip sample preparation method

InactiveCN110926899AAchieve precise titrationReduce sample preparation costsPreparing sample for investigationMaterial analysis by transmitting radiationCopper wireThin membrane

The invention discloses a nano-film transmission electron microscope in-situ heating chip sample preparation method. The method comprises the following steps: (1) selecting a liquid injection device;(2) cleaning and fixing the liquid injection device; (3) bending one end of a copper wire into a copper ring; (4) moving the copper ring to a position near the thin film sample, and fishing up the thin film sample to the copper ring; (5) extruding a liquid drop from the liquid in the microsyringe; (6) moving the copper ring to a position near the liquid drop at the tip of the microsyringe, so thatthe film sample is adsorbed on the liquid drop; (7) accurately adsorbing the liquid drops in a sample observation area, and then moving away the microsyringe; (8) naturally drying the chip; and (9) heating and baking the naturally dried chip. Accurate titration of the nano-film in the Si3N4 film observation area in the transmission electron microscope in-situ heating chip can be realized, hydrophilic treatment on the Si substrate is not needed, the cost is reduced, the influence of surface tension on the film is avoided, the sample preparation success rate is improved, and the risk of damageto a chip electrode is reduced.

Owner:GUANGXI UNIV

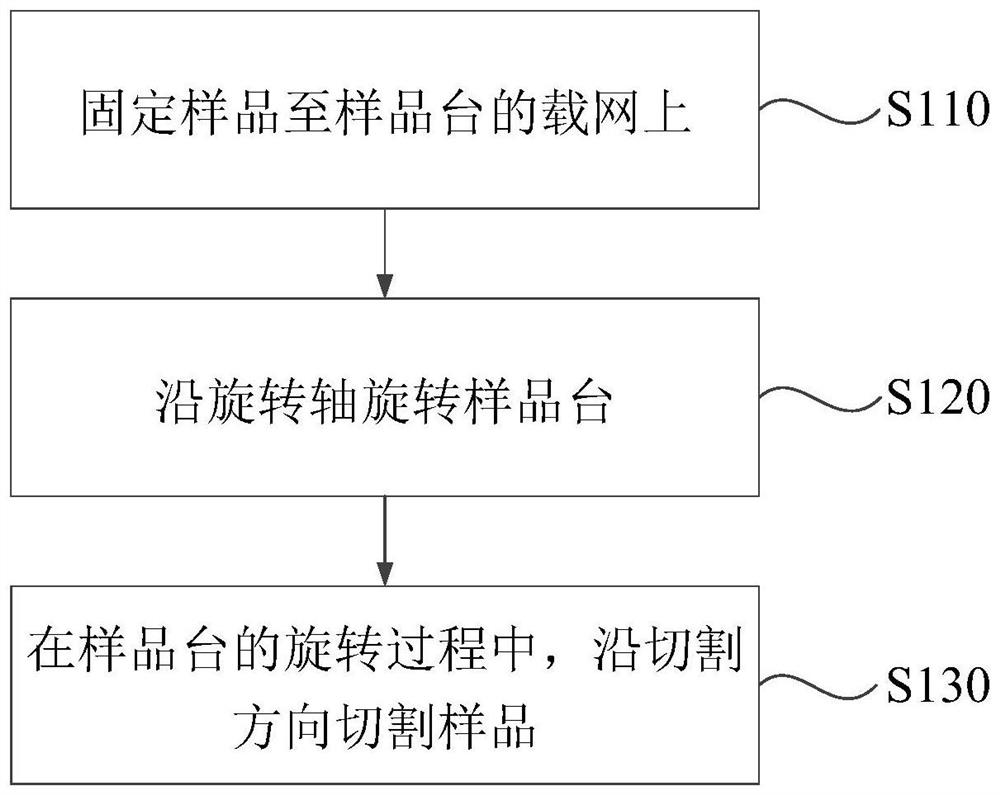

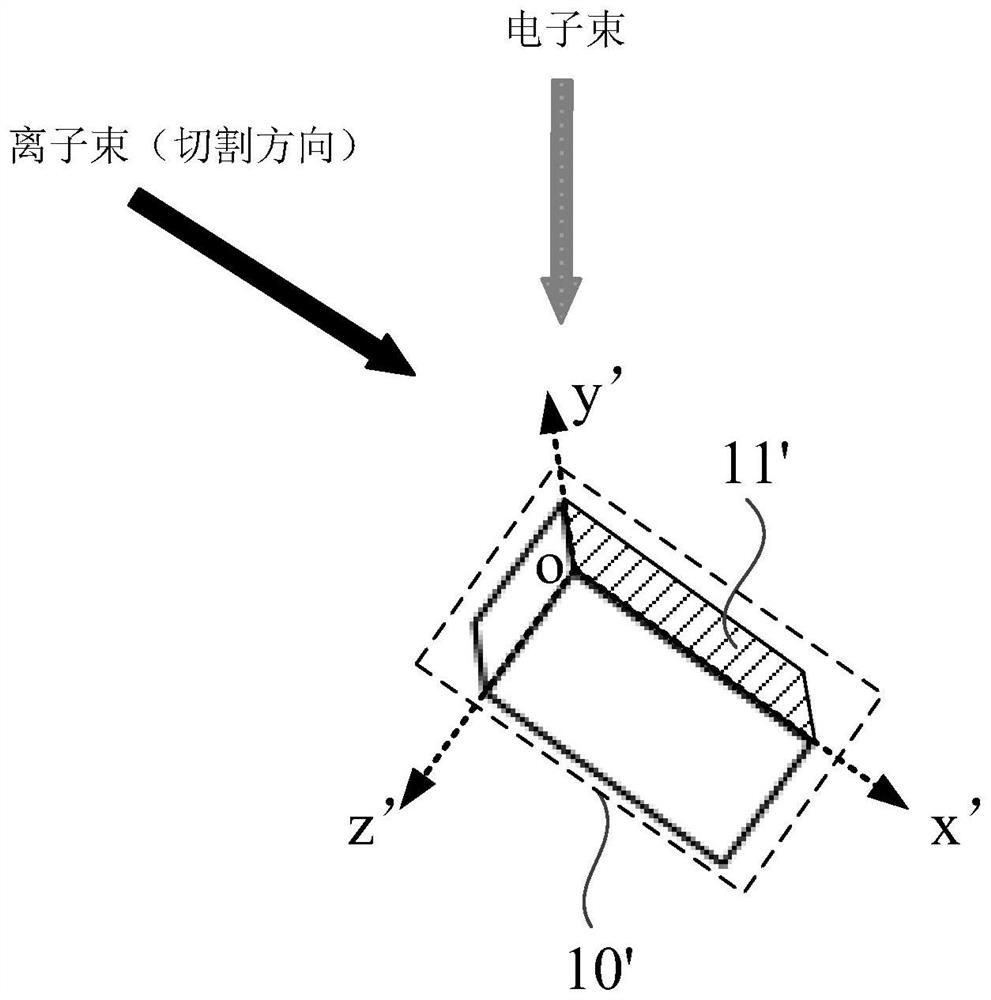

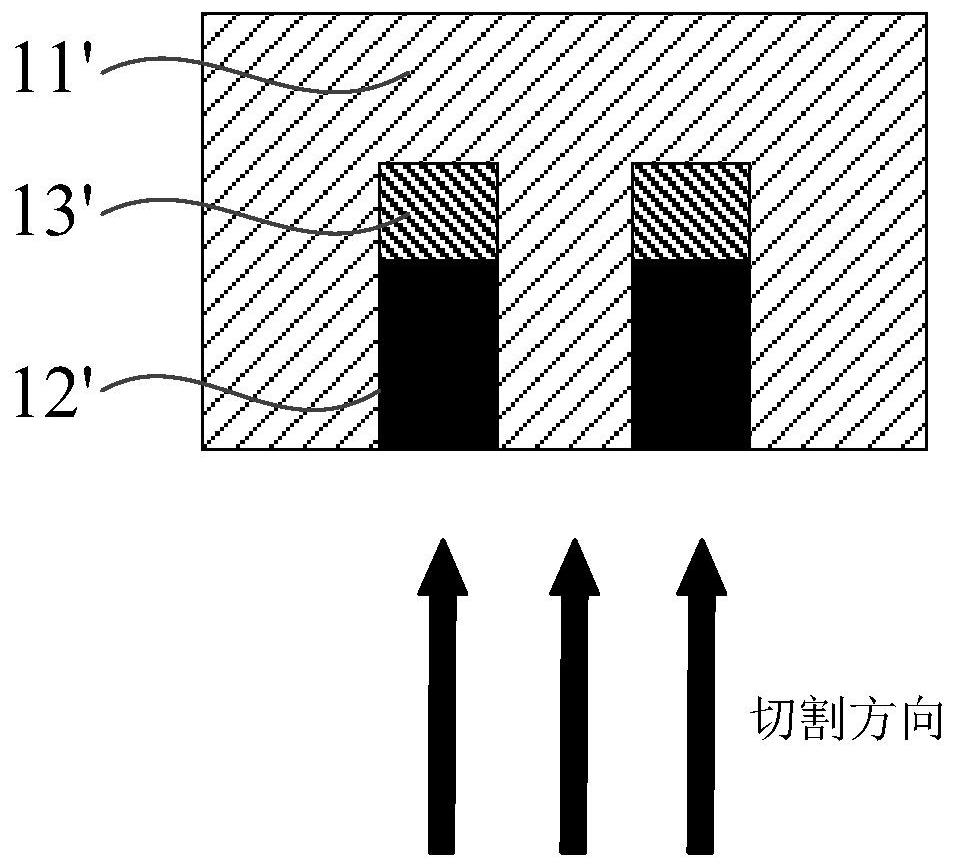

Preparation method of transmission electron microscope sample

PendingCN114486324AUniform thicknessUniform cutting thicknessWithdrawing sample devicesPreparing sample for investigationLight beamElectron microscope

The invention discloses a preparation method of a transmission electron microscope sample. The method comprises the following steps: fixing the sample to a carrying net of a sample table; rotating the sample table along a rotating shaft, wherein the extending direction of the rotating shaft is parallel to the normal direction of the to-be-thinned surface of the sample; in the rotating process of the sample table, the sample is cut in the cutting direction, and the cutting direction is parallel to the plane where the surface to be thinned is located. According to the technical scheme, in the sample cutting process, the cutting direction is always parallel to the plane where the to-be-thinned surface is located, by changing the rotating angle of the sample table, the cutting light beam can directly cut part of the area behind the component difficult to cut at a certain angle, drawing marks are reduced, and the cutting efficiency is improved. The cutting thickness of the surface to be thinned is more uniform, the thickness of the prepared transmission electron microscope sample is more uniform, and the success rate of sample preparation is improved; and the thickness of the prepared transmission electron microscope sample is relatively uniform, so that convenience can be provided for subsequent observation and analysis.

Owner:GIGA FORCE ELECTRONICS CO LTD

A preparation method of a micron-scale sheet transmission electron microscope section sample

InactiveCN105115795BSimple operation processMature technologyPreparing sample for investigationEnergy filtered transmission electron microscopyPhysics

The invention discloses a method for preparing a section sample of a micron-scale sheet transmission electron microscope. In the present invention, the micron-scale thin slice sample is first cut into rectangular sample strips and clamped in the solidified sample sheet to form a block sample, and then cut into a cross-sectional sample thin slice, a sample holder is attached to the surface of a cross-sectional direction, and the two surfaces are manually ground. The other surface is bonded to the support ring by a curing adhesive, and then heated to remove the sample holder, and at the same time the support ring is cured and bonded to the cross-section sample sheet, and then the sample is trimmed, and finally ion thinning is carried out to obtain a TEM cross-section sample; the preparation of the present invention The method has the advantages of simple operation process, mature sample preparation equipment and technology, high sample preparation success rate, strong practicability, and is suitable for the preparation of various micron-scale flake-shaped TEM cross-sectional samples.

Owner:PEKING UNIV

A sample preparation process of undisturbed triaxial sample of spin-down type soil

ActiveCN108593389BPrevent tilting deformationAvoid huge disturbancesPreparing sample for investigationSoil scienceStructural engineering

The application relates to a sample preparation process of a spin-down type undisturbed soil triaxial sample, which belongs to the technical field of indoor geotechnical testing of the civil engineering discipline. The rotary cutting method is used for sample preparation. First, calculate the liquid index of the soil according to the soil data, and then select the corresponding cutting blade speed, and then place the soil sample on the nail plate, and control the lifting switch and cutting speed. switch to make the cutting blade complete lifting and rotating. When the cutting blade rotates, a circle with a larger diameter is formed at the cutting edge, and the original soil sample is cut through the self-rotation and lifting of the cutting blade to complete the production of the sample; The invention greatly simplifies the operation steps, does not disturb the undisturbed soil during the cutting process, avoids the influence of uncertain factors and human factors in the cutting process, and completes the sample preparation accurately and efficiently; compared with the existing laboratory The undisturbed soil cutter, its sample preparation efficiency is increased by 2 times, and the sample preparation time is about 15 minutes.

Owner:SHAOXING UNIVERSITY +1

A Lifting and Undisturbed Soil Triaxial Sample Preparation Technology

ActiveCN108844792BPrevent tilting deformationAvoid huge disturbancesPreparing sample for investigationSoil scienceStructural engineering

Owner:SHAOXING UNIVERSITY +1

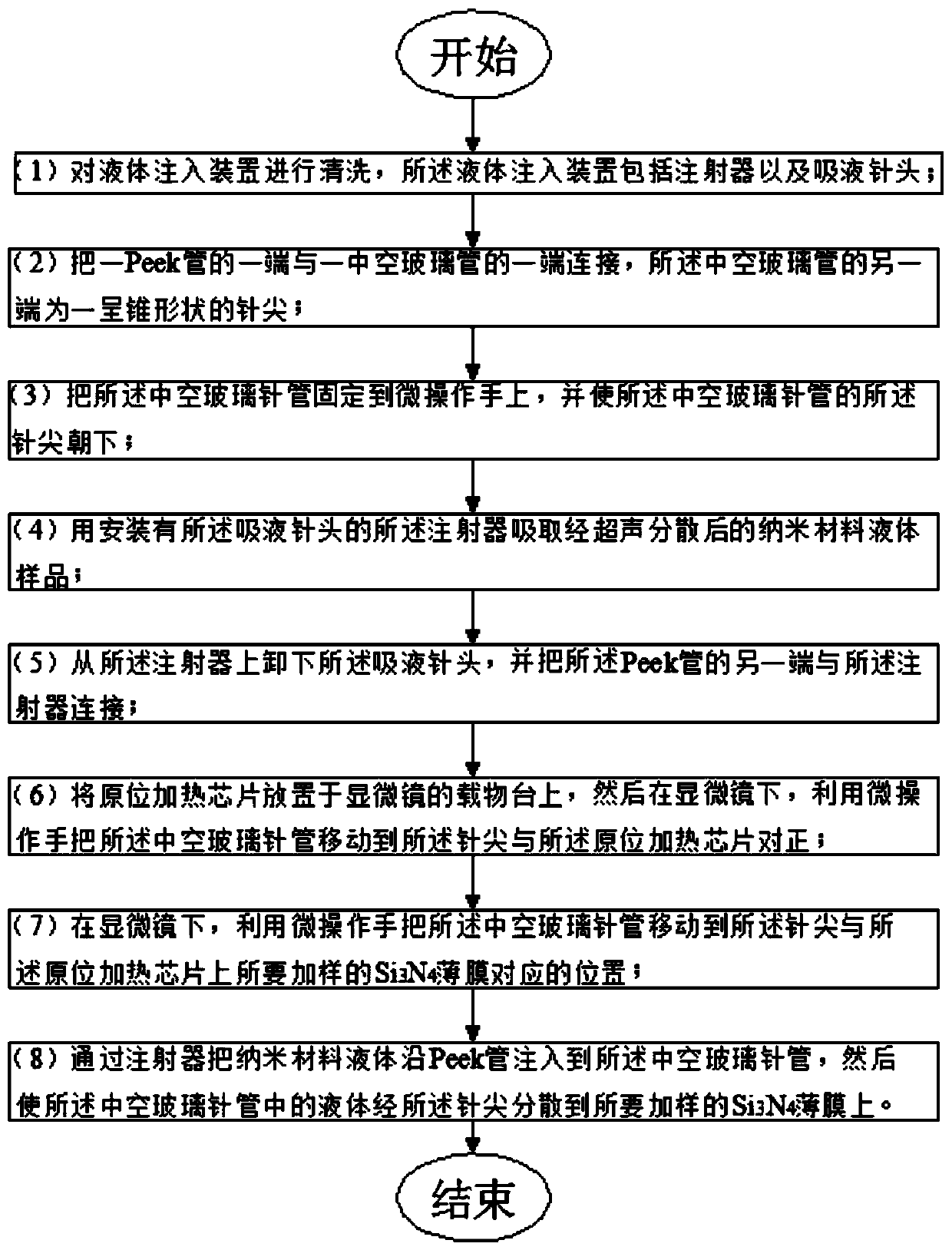

A kind of sample preparation method of in-situ heating chip for transmission electron microscope of nanomaterials

ActiveCN107505174BNon-destructiveHigh precisionPreparing sample for investigationElectron microscopeBiomedical engineering

The present invention discloses a sample preparation method of a nano-material transmission electron microscope in-situ heating chip, and the method comprises the following steps: (1) cleaning a liquid injection device; (2) connecting one end of a Peek tube with one end of a hollow glass needle tube; (3) fixing the hollow glass needle tube to a micromanipulator; (4) drawing a liquid sample with a syringe; (5) removing a liquid suction needle and connecting the other end of the Peek tube with the syringe; (6) putting an in-situ heating chip on an objective table of a microscope; (7) moving the hollow glass needle tube until the position of a tip needle corresponds to a Si3N4 film to be loaded; and (8) injecting, along the Peek tube, a nano material liquid into the hollow glass needle tube by the syringe, and dispersing the nano material liquid through the tip needle onto the Si3N4 film to be loaded. The method can accurately titrate a sample solution, simple preparation is sample, cost can be reduced, comparative experiments on one chip are facilitated, and the usage rate of the chip is improved.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com