Preparing method for micron-order particle sample for transmission electron microscope (TEM)

An electron microscope, micron-level technology, applied in the preparation of test samples, etc., can solve the problems of complex sample preparation methods, low sample preparation success rate, complicated process, etc., to achieve mature sample preparation equipment and technology, and successful sample preparation The effect of high efficiency and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

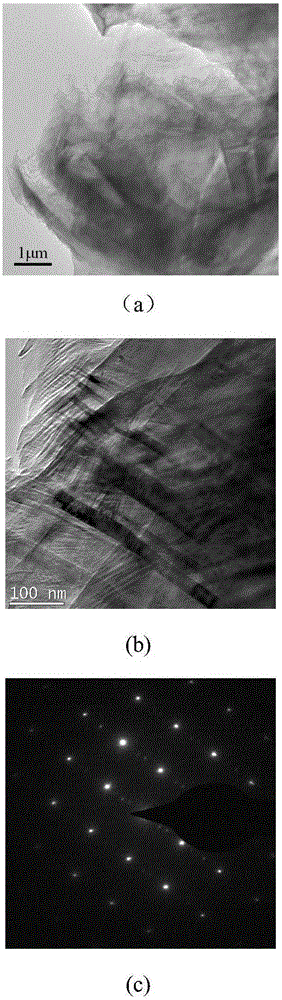

Examples

Embodiment Construction

[0025] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

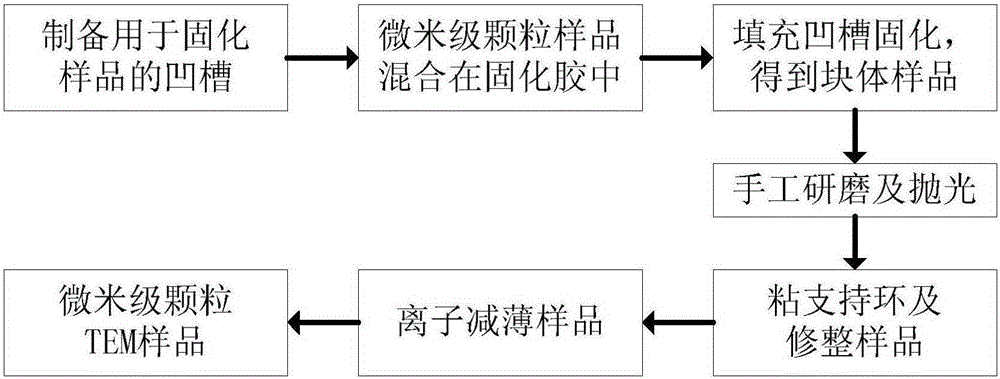

[0026] The preparation method of the micron-scale particle transmission electron microscope sample of the present embodiment, such as figure 1 shown, including the following steps:

[0027] 1) Prepare grooves for curing samples:

[0028] Process a groove for solidifying the sample on the flat plate, the flat plate adopts a polytetrafluoroethylene plate, the diameter of the groove is 10mm, and the depth is 2mm, for standby;

[0029] 2) Curing treatment of micron particle samples:

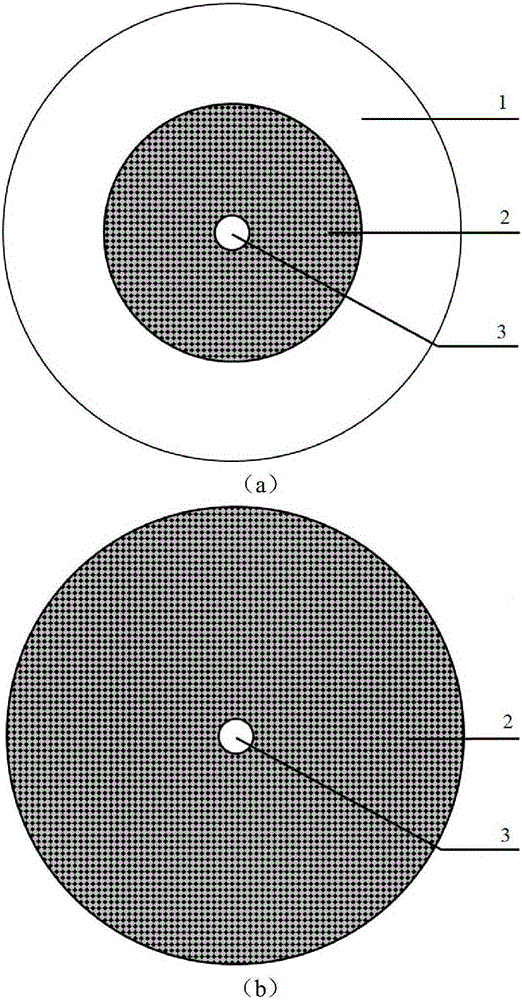

[0030] Mix the micron-sized carbon particle sample to be tested evenly in the G-1 epoxy resin curing glue, then fill it into the groove in step 1), and then put it on the heating table, and heat and cure it at 130°C for 2 hours , cooled to room temperature after solidification, and taken out from the groove to obtain a solidified disc-shaped block sample with a diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com