Patents

Literature

36results about How to "Extend deposition time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing powdered test sample for transmission electron microscope

InactiveCN102200497AExtend deposition timeIncrease sample preparation costPreparing sample for investigationVacuum evaporation coatingConventional transmission electron microscopeTest sample

The invention relates to a method for preparing a powdered test sample for a transmission electron microscope. The method comprises the following steps of: cutting a crystal with a flat and neat surface from a soluble monocrystalline material according to a cleavage surface of the soluble monocrystalline material; placing an electron microscope carrying net onto the cut crystal block; ultrasonically dispersing the powdered sample to be observed by using absolute ethanol, dropping a proper amount of dispersed liquid onto the carrying net and naturally drying in the air; sputtering and depositing a layer of metal thin film by adopting a magnetron sputtering technology, and wrapping and fixing particles to be analyzed onto the carrying net by using the deposited thin film; after sputtering, shearing off a sputtered thin film along the edge of the carrying net; placing the carrying net with the fixed particles to be analyzed into an ion milling for milling until leakage; and taking down the sample and placing into the electron microscope for observation after the center of the sample is punctured. By the method, the problems that a plurality of powdered samples which have large particle size and complicated structure and are hard to smash or grind are hard to prepare, and an observation area is limited and the sample is easy to pollute can be solved; and the method is a sample preparation method with high sample preparation success rate and high suitability.

Owner:CHINA NAT ACAD NANOTECH & ENG

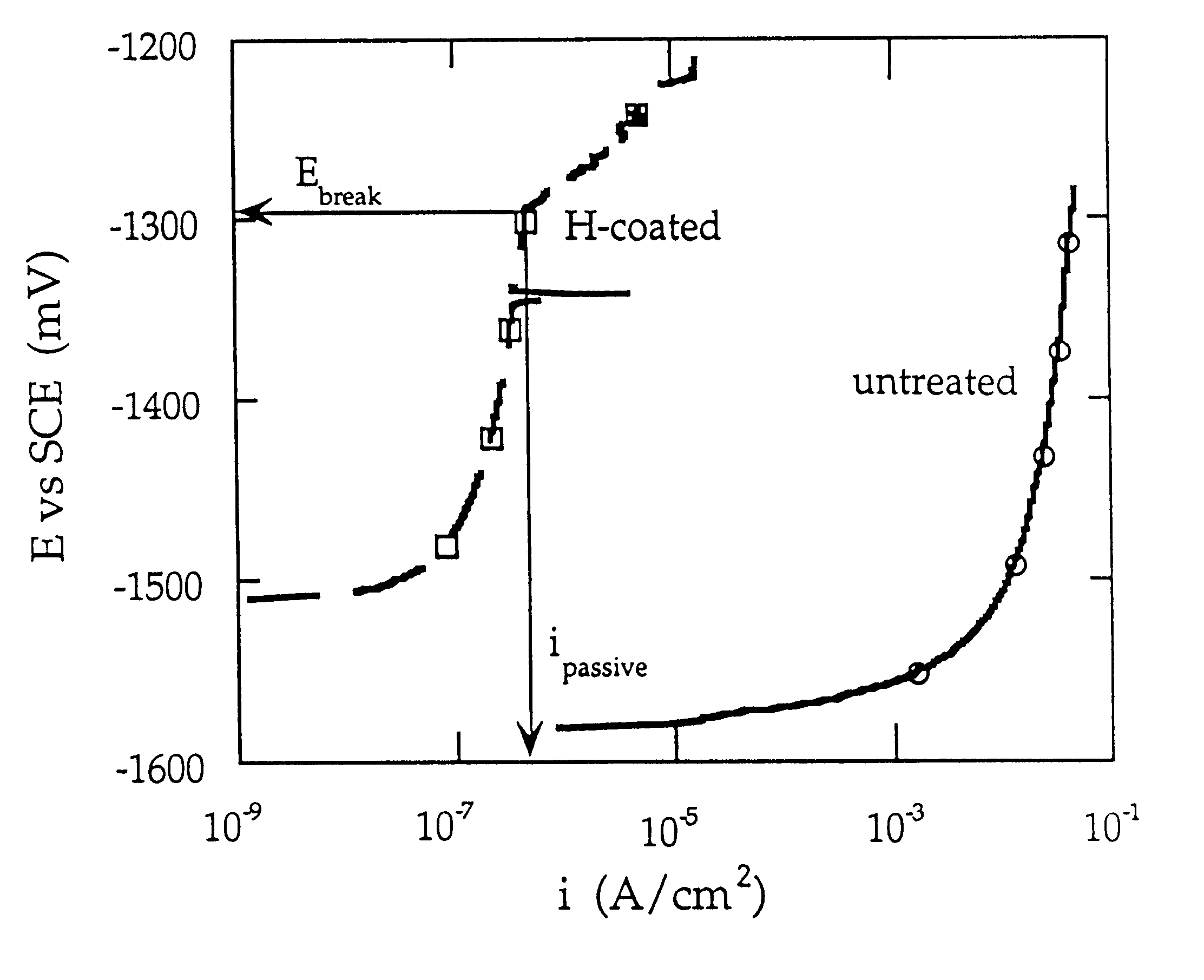

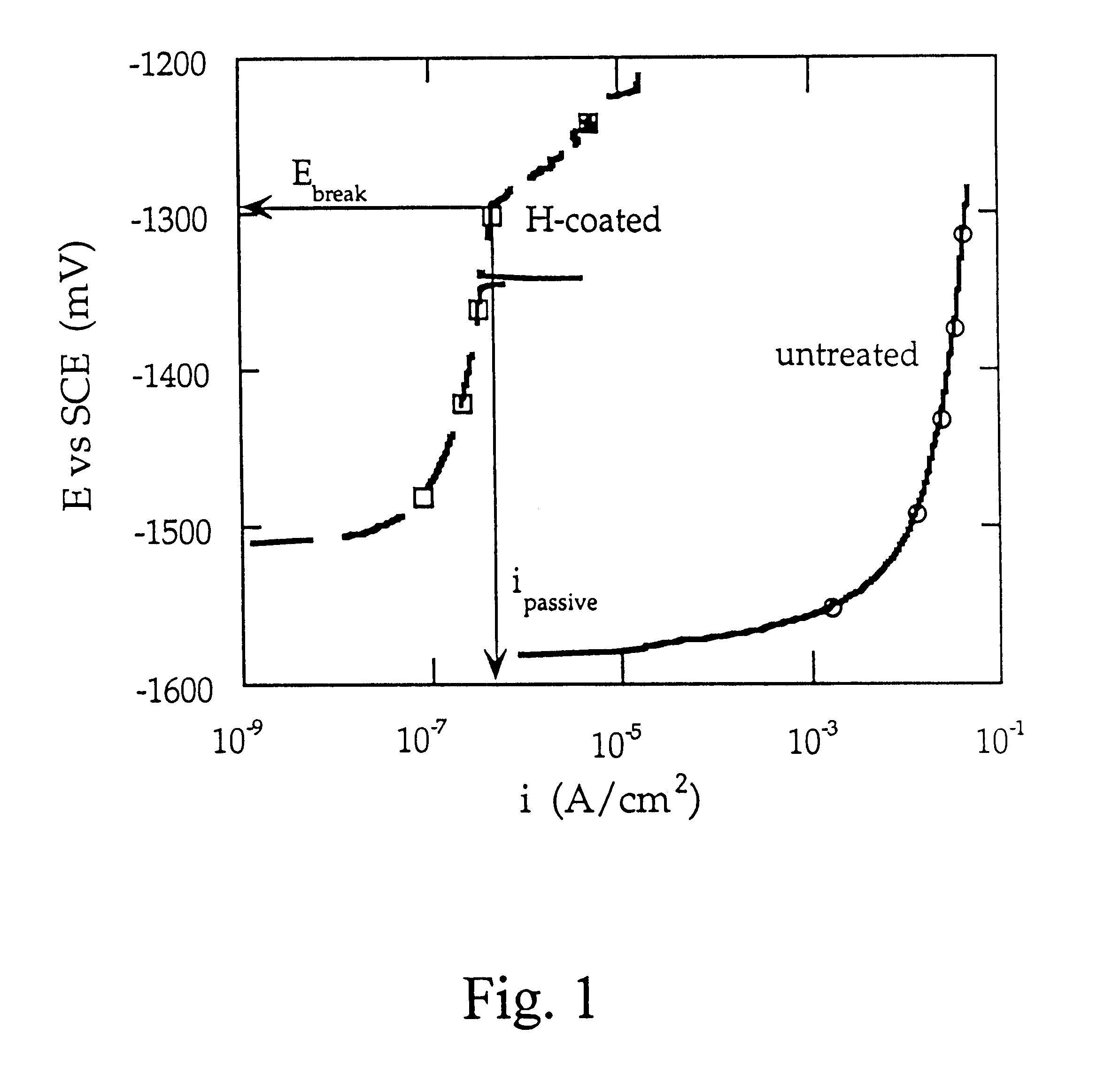

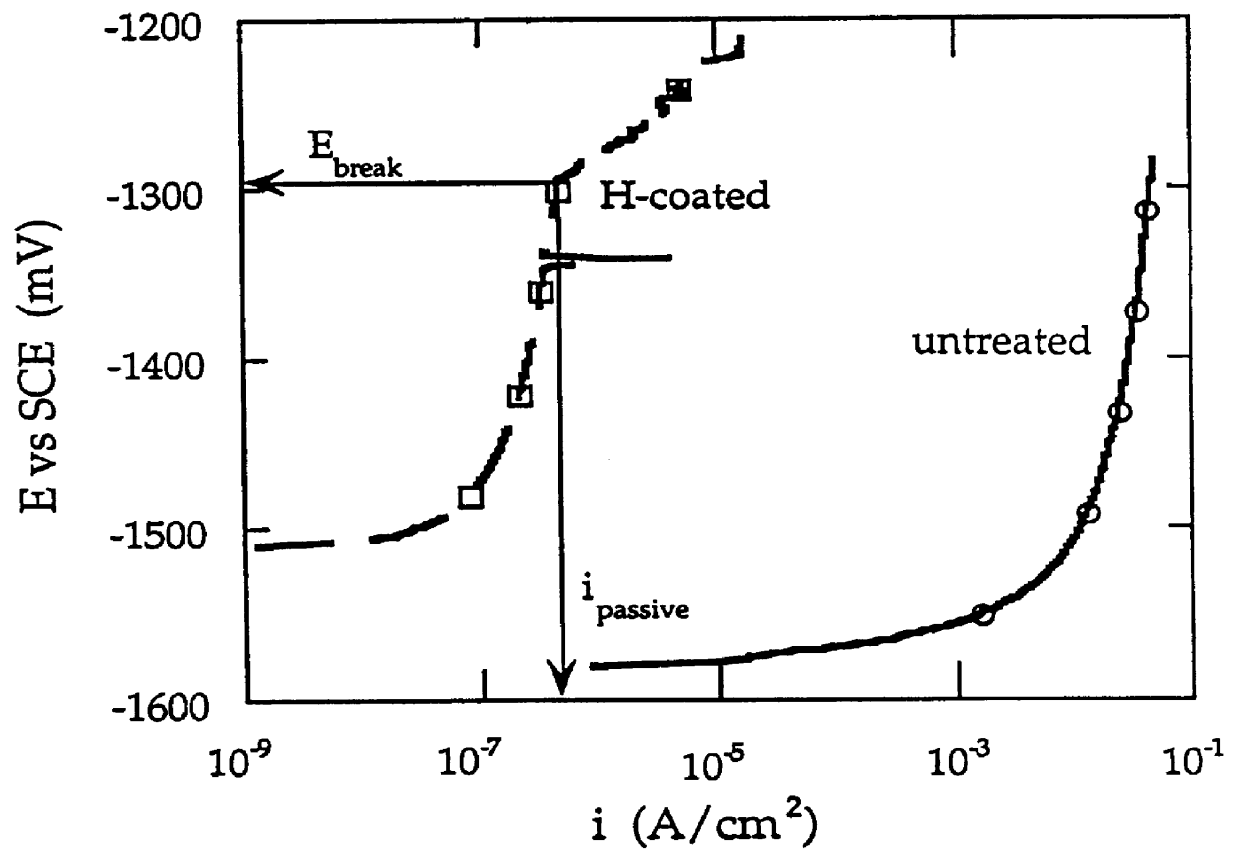

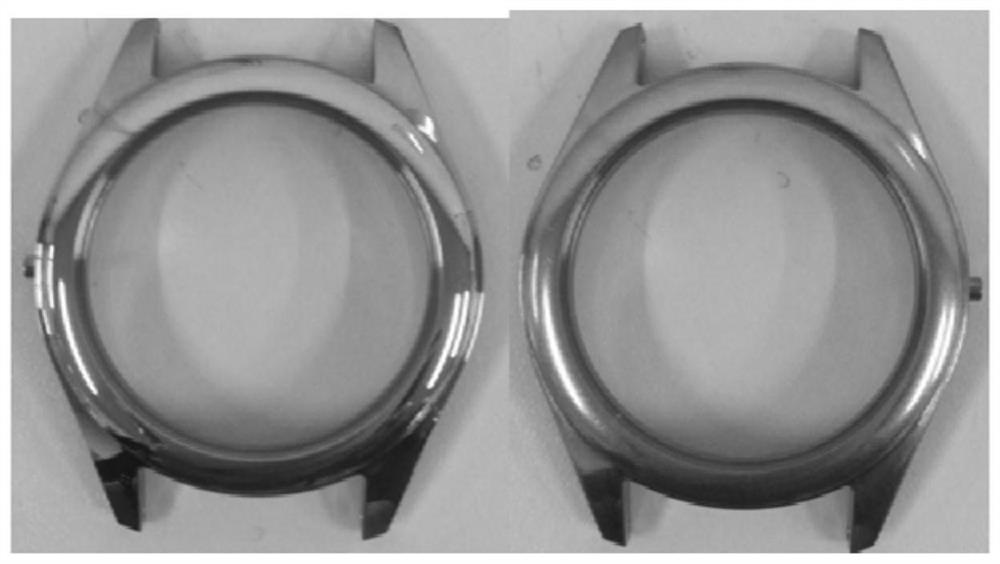

Cathodic protective coating on magnesium or its alloys

InactiveUS6291076B1Simple and efficientConvenient and economical solutionAnodisationNatural mineral layered productsHydrogenAlloy

A method is provided for treating a magnesium-containing article to form a cathodic protective coating on such article. This is done by electrochemically treating the article, acting as a cathode, in an alkaline solution, preferably at a temperature of between 40 and 80° C., with a cathodic current density of 5-200 mA / cm2. The treatment produces a magnesium-containing article having a protective coating of magnesium hydride of predetermined thickness with a high count of hydrogen particles.

Owner:INTERMAG MODELEX

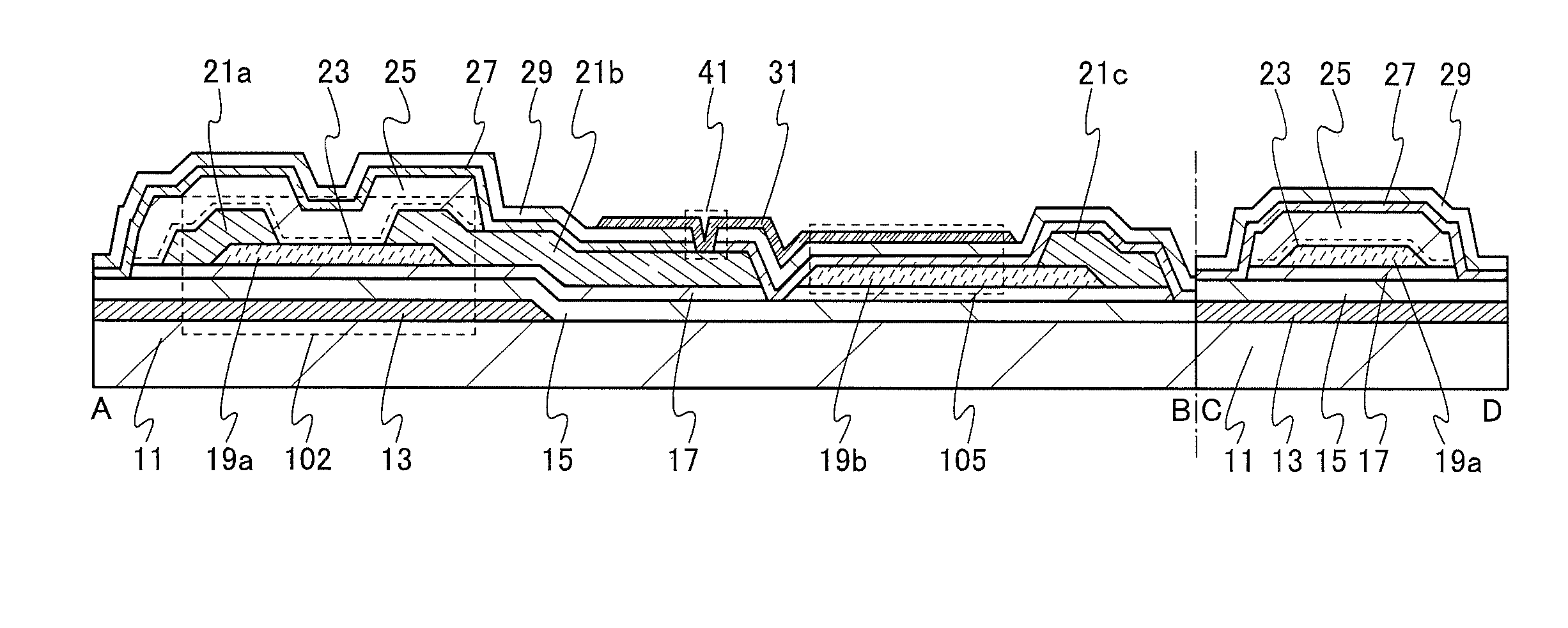

Capacitor and Semiconductor Device

ActiveUS20150053973A1Excellent electrical propertiesHigh yieldTransistorSolid-state devicesDevice materialCapacitor

A semiconductor device has an insulating surface provided with a transistor and a capacitor. The transistor includes a gate electrode, an oxide semiconductor film overlapping with the gate electrode, a gate insulating film between the gate electrode and the oxide semiconductor film, and a first conductive film serving as a pair of electrodes in contact with the oxide semiconductor film. An oxide insulating film in contact with the oxide semiconductor film, a metal oxide film over the oxide insulating film, and a second conductive film serving as a pixel electrode which is in an opening in the metal oxide film and is in contact with the first conductive film are provided. The capacitor includes a film having conductivity over the gate insulating film, the second conductive film, and the metal oxide film provided between the film having conductivity and the second conductive film.

Owner:SEMICON ENERGY LAB CO LTD

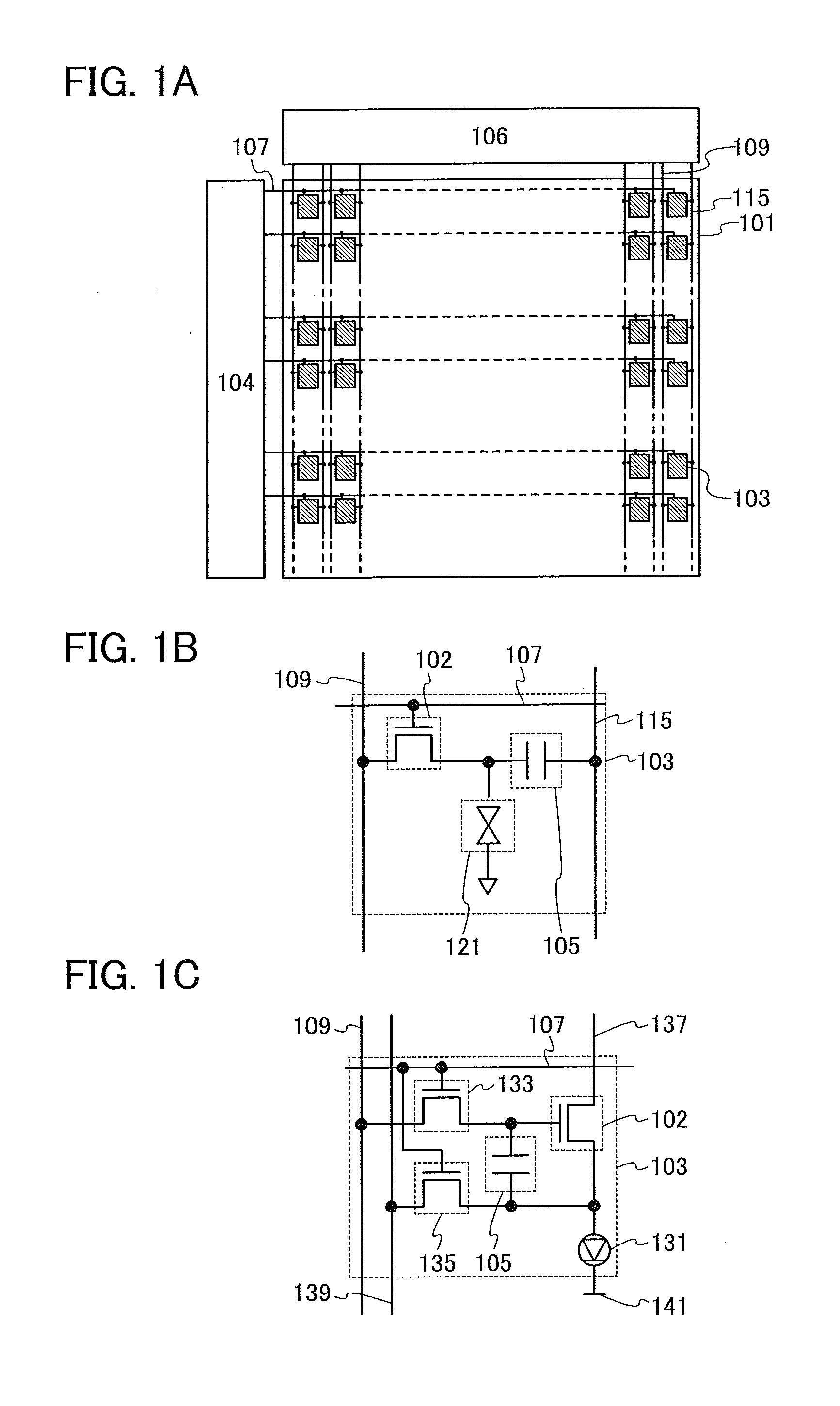

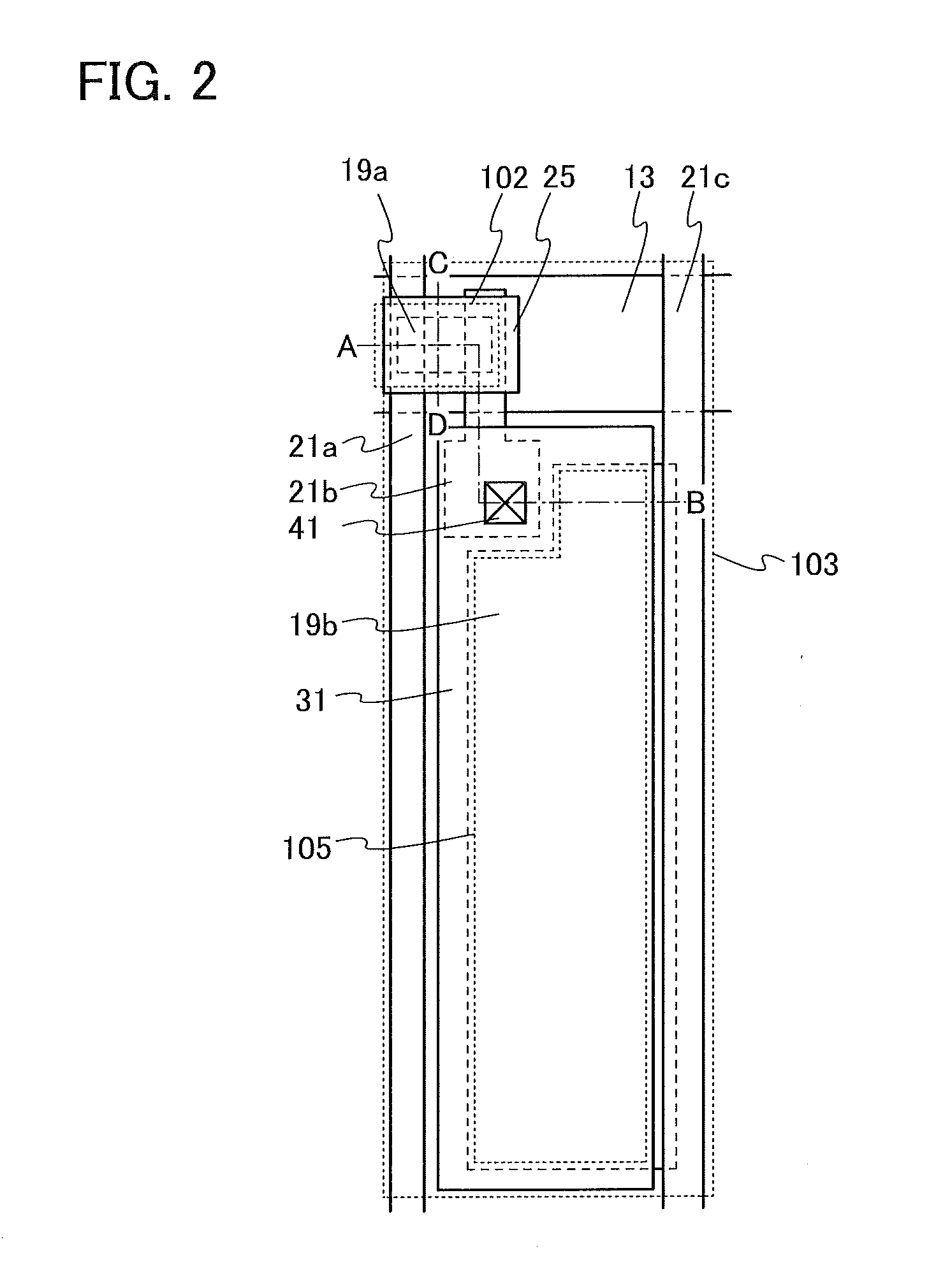

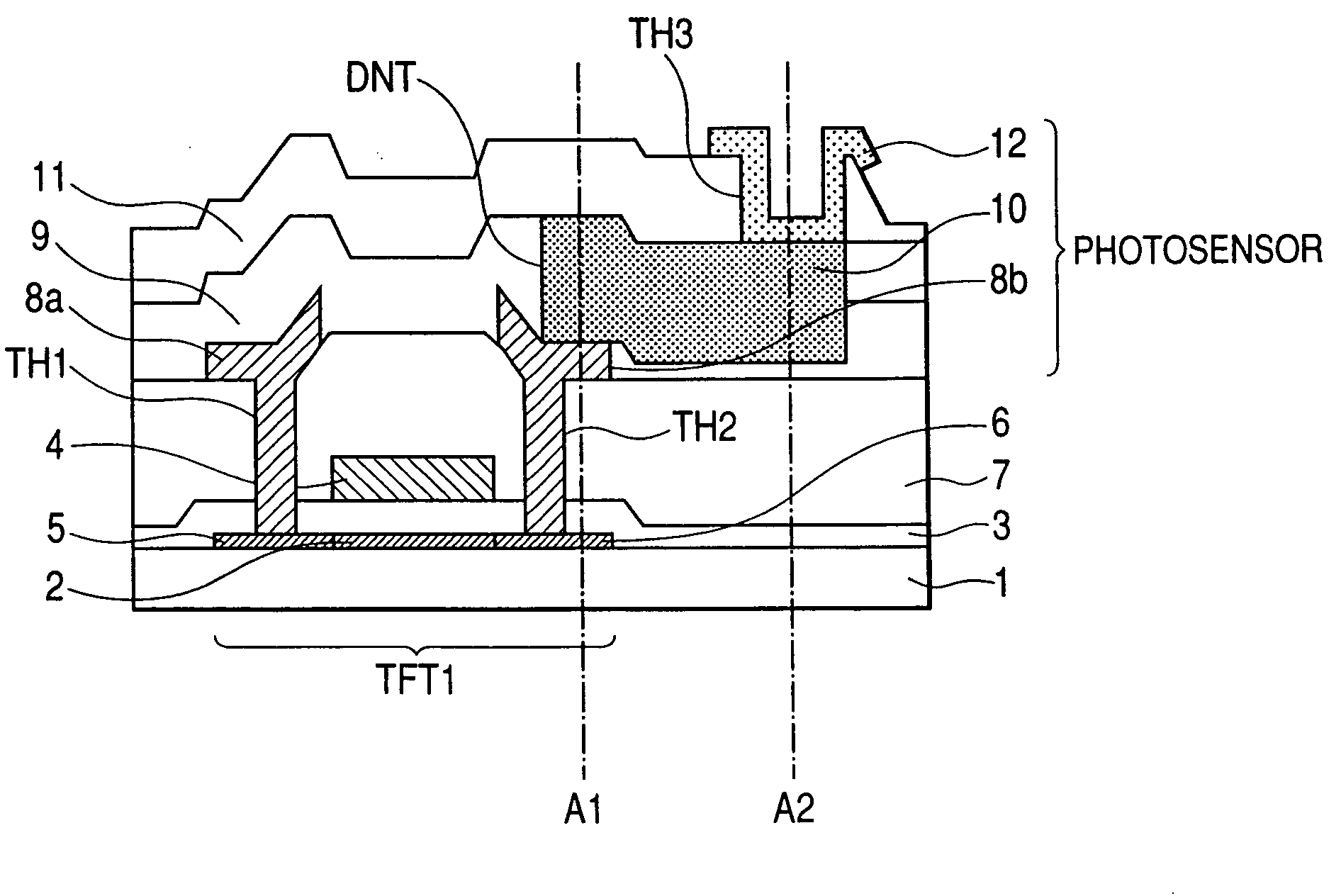

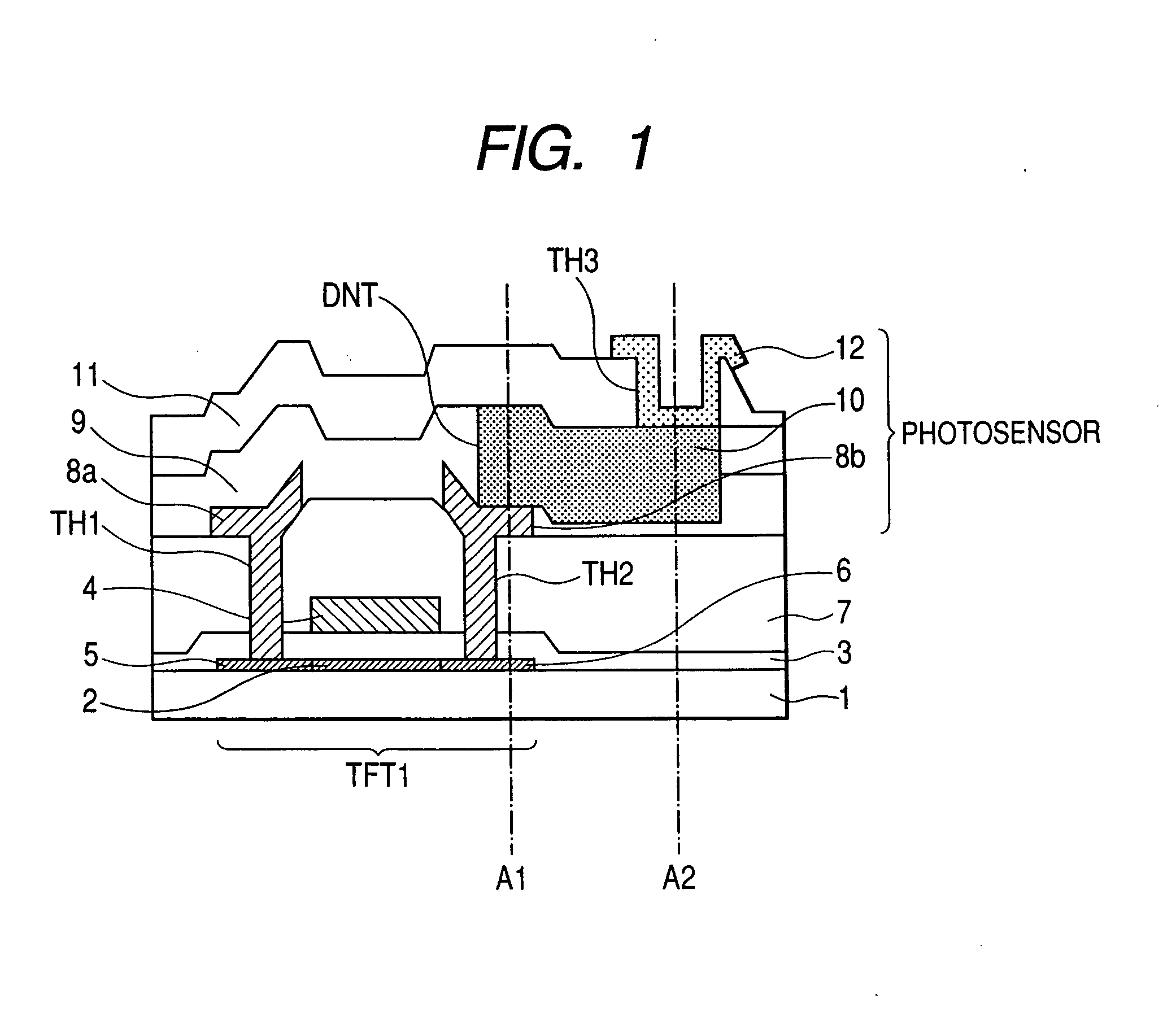

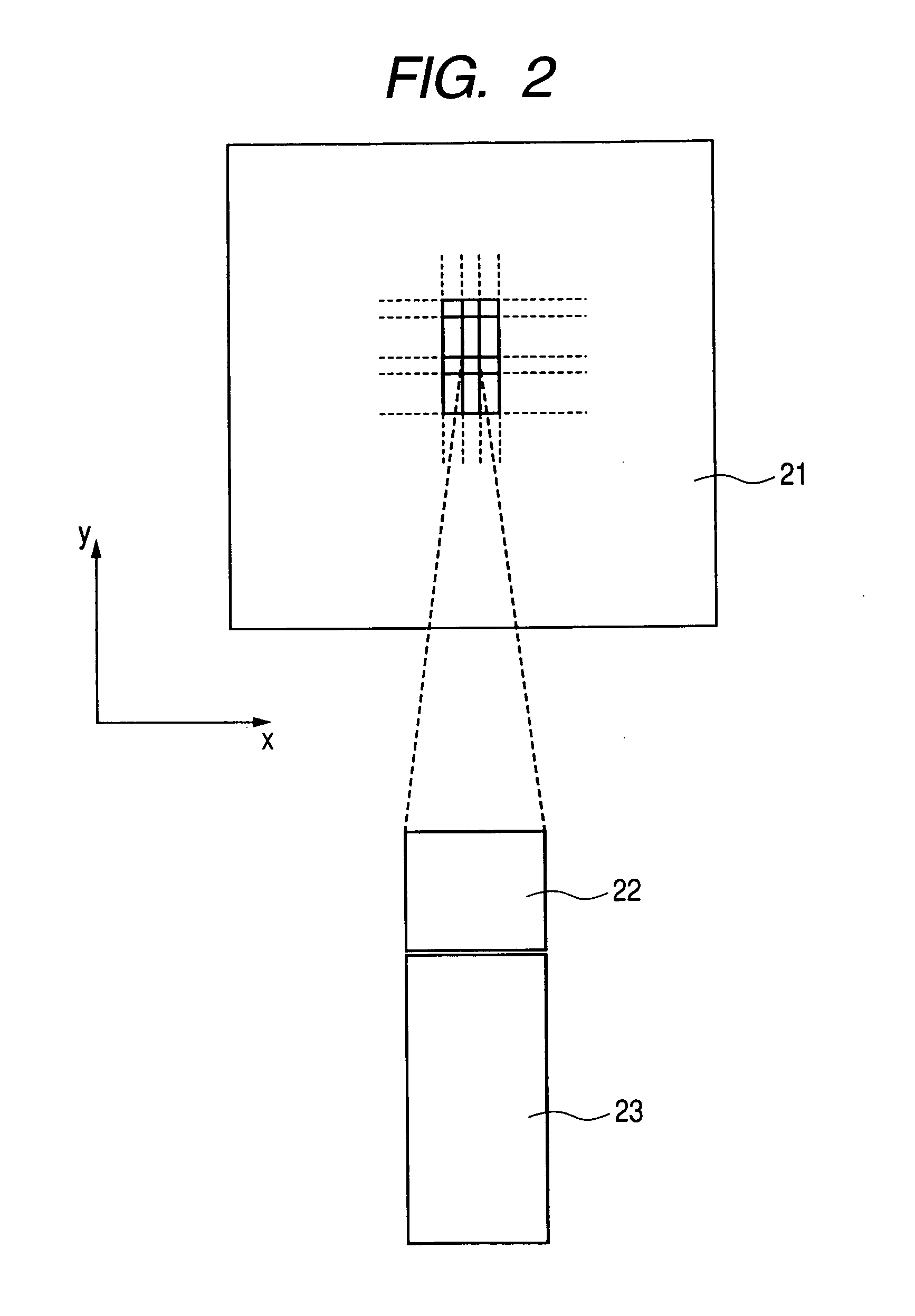

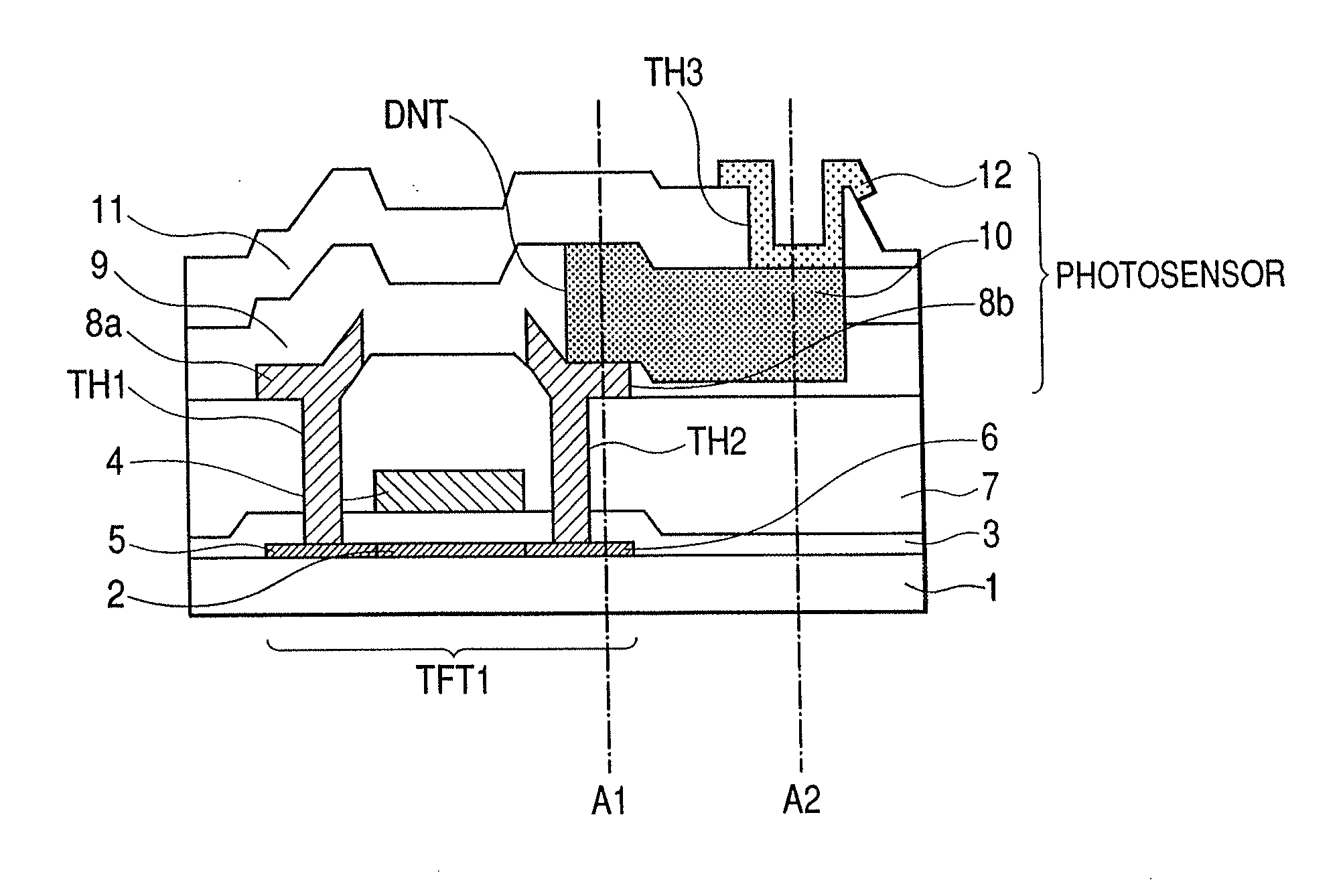

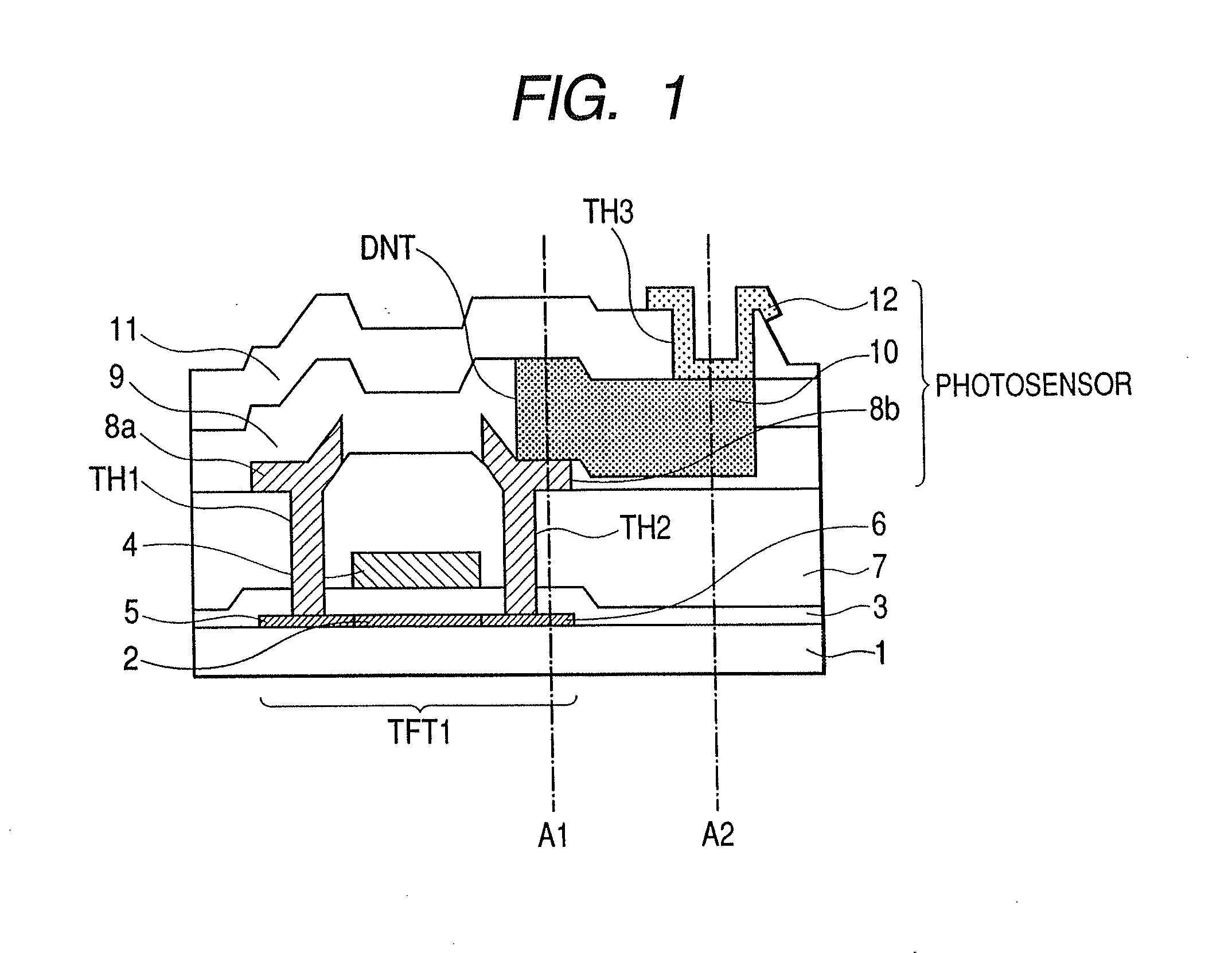

Image displaying device

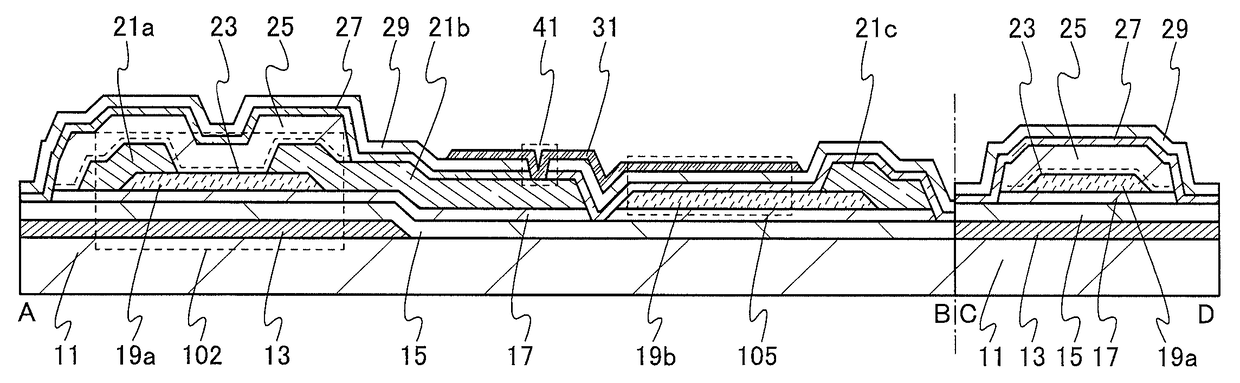

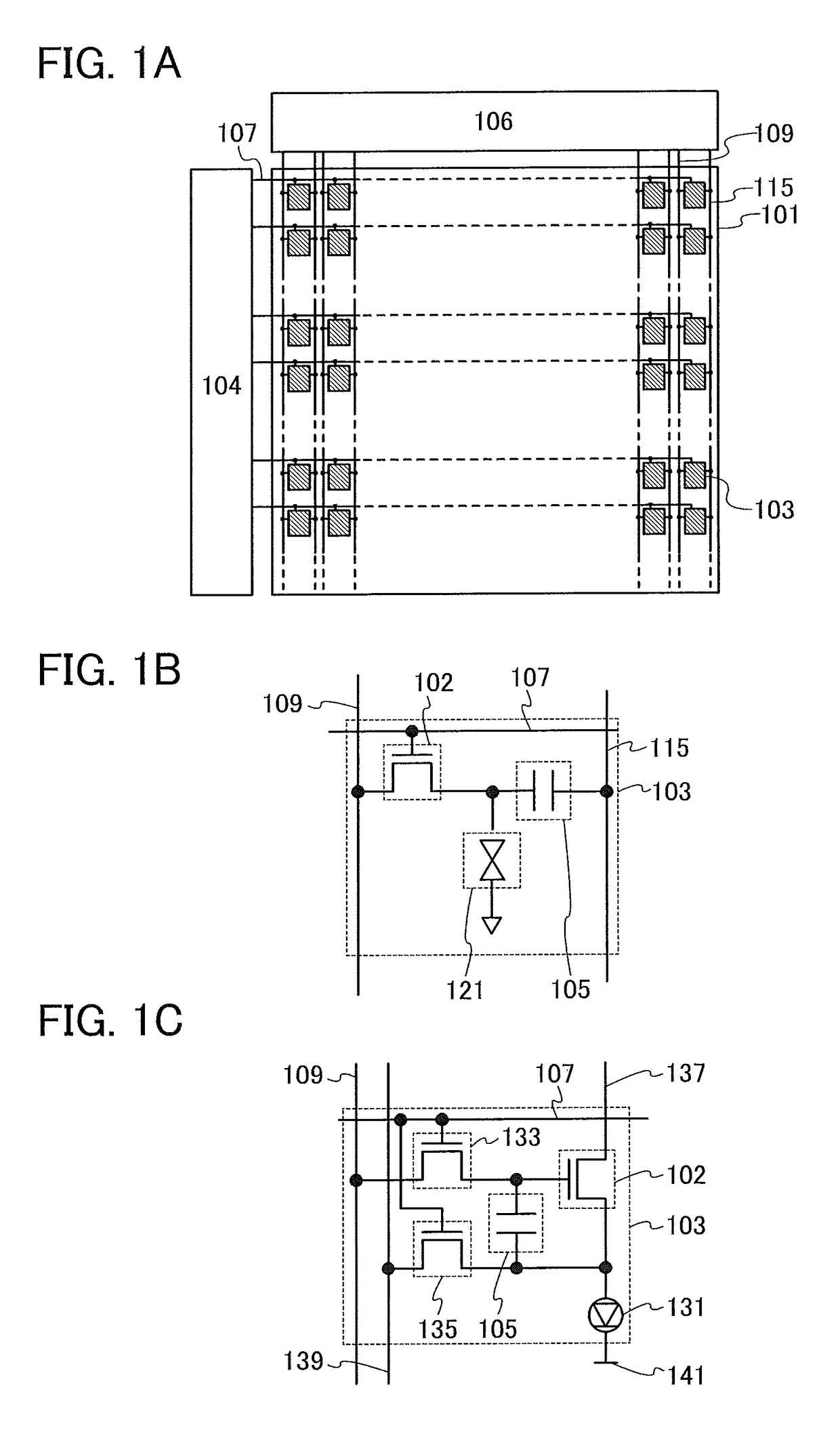

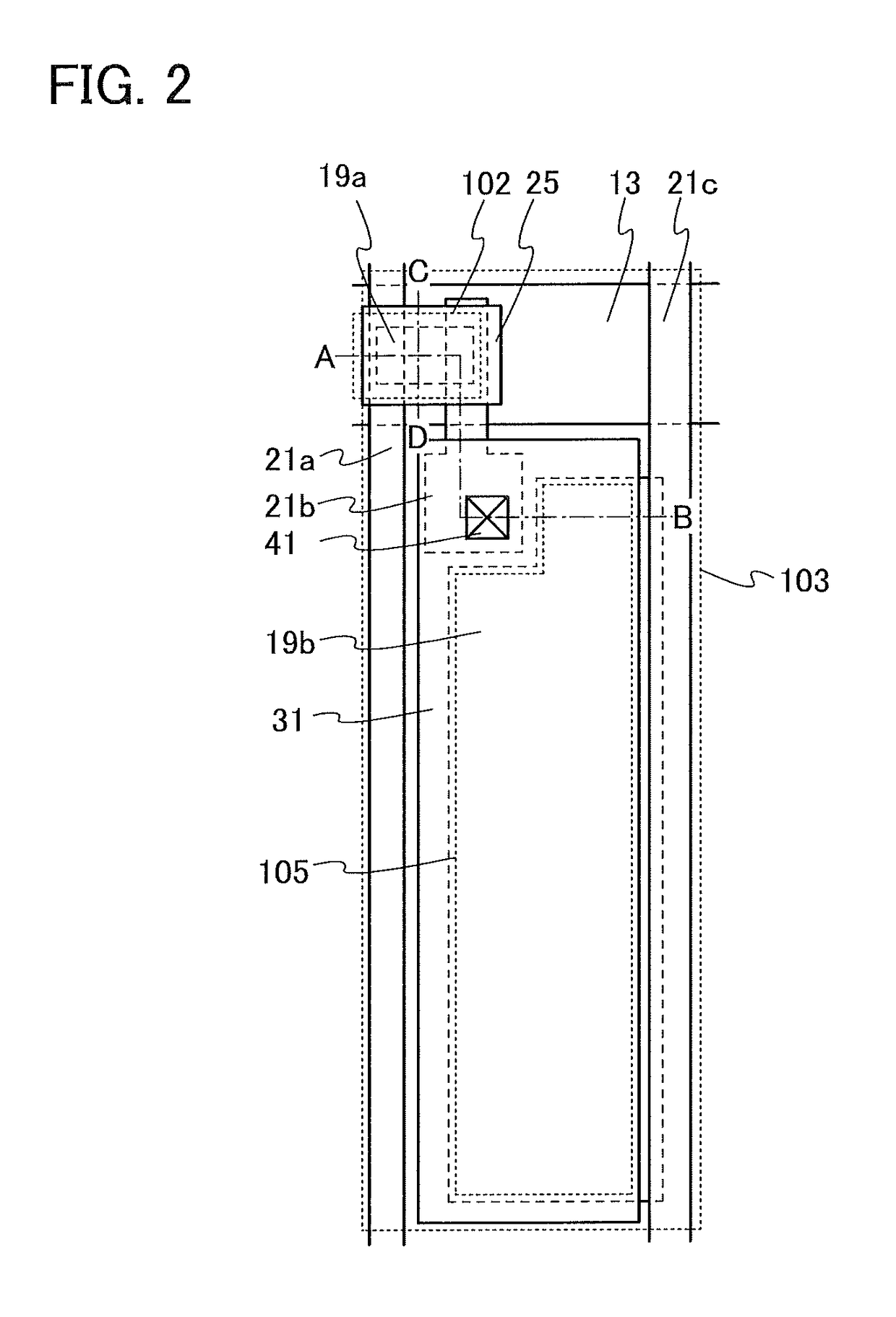

InactiveUS20090032824A1Suppress leakage currentReduce dark currentStatic indicating devicesSolid-state devicesEngineeringMatrix pattern

An image displaying device having multiple photosensing devices have successfully suppressed a leakage current from each photosensing device and improved the S / N ratio. In the image displaying device, pixels and photosensing devices are disposed as pairs in a matrix pattern on a substrate. Each of the pixels and each of the photosensing devices are driven independently. Each photosensing device includes a semiconductor layer that is a photoelectric conversion layer connected to at least a first electrode and a second electrode. The contact surfaces of the first and second electrodes with respect to the semiconductor layer are disposed so that their center axes are separated from each other.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

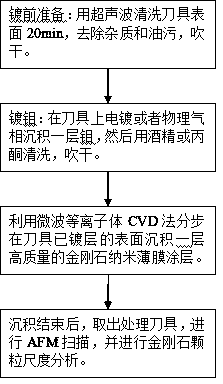

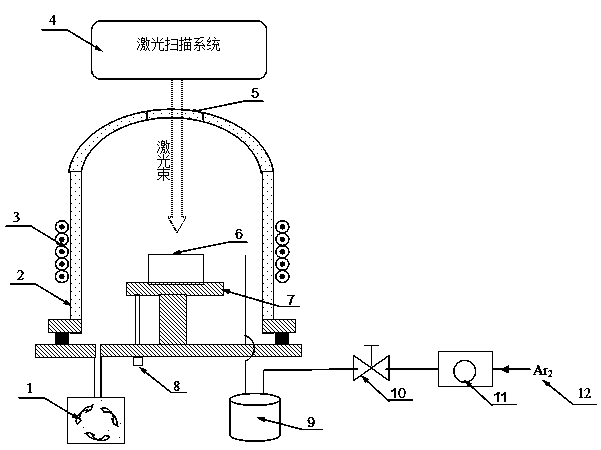

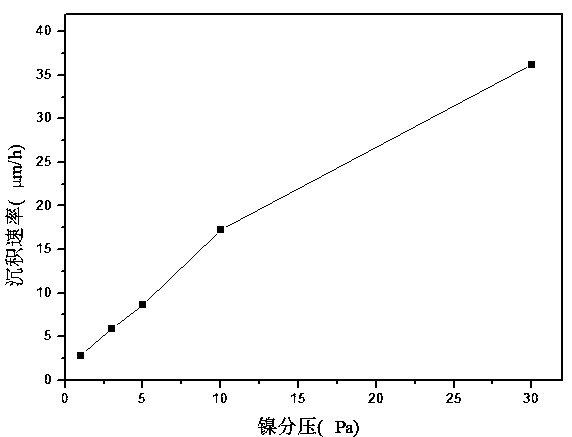

New method for preparing diamond coated cutting tool

InactiveCN104233217AEfficient removalPrevent proliferationChemical vapor deposition coatingMicrowaveAlloy

The invention belongs to the field of a material coating, and particularly provides a new method for preparing a high-quality diamond coated cutting tool by multilayered step-by-step deposition. The new method concretely comprises the following steps: firstly, plating a molybdenum layer on the surface of a hard alloy cutting tool by adopting an electroplating method or a physical vapor deposition method, wherein molybdenum is bound together with cobalt on the surface of a matrix to form a stable compound so as to form a transition layer on the surface of the matrix, so that not only can the influence of cobalt on the surface of the cutting tool to the diamond coating be reduced, but also the dispersion of cobalt towards the surface of the cutting tool from the depth position of the matrix is prevented; and then depositing a diamond coating by two steps through utilizing microwave plasma CVD (MPCVD) method, namely controlling corresponding parameters in diamond nucleation and growth stages to form a nanodiamond thin film with high quality and high stability.

Owner:JIANGSU UNIV

Ecological raising method of flavor mule ducks

InactiveCN103858826AIncrease profitIncrease the fragranceAnimal husbandryBiotechnologyThermal insulation

The invention discloses an ecological raising method of flavor mule ducks. According to the method, hybridization is performed on France Muscovy ducks and China local ducts, healthy and lively hybrid ducklings are selected, after the ducklings are raised to 70 days without external thermal insulation, and the flavor mule ducks are obtained by prolonging gazing time and adding glutamic acid in daily ration. Sodium glutamate is sodium salt of the glutamic acid and is an important umami substance, the flavor feel of meat can be obviously enhanced through the sodium glutamate and nucleotide together, deposition of flavor substances in muscles can be increased by adding the sodium glutamate in fodder of the mule ducks, the aroma of the muscles is improved, and therefore the quality of the muscles is improved. In addition, the deposition time of the flavor substances in the muscles can be prolonged by prolonging the gazing time, and therefore the purposes of improving the flavor of the muscles of the mule ducks, improving the quality of the muscles, increasing market value of mule duck meat and increasing returns of duck farmers are achieved.

Owner:GUIZHOU UNIV

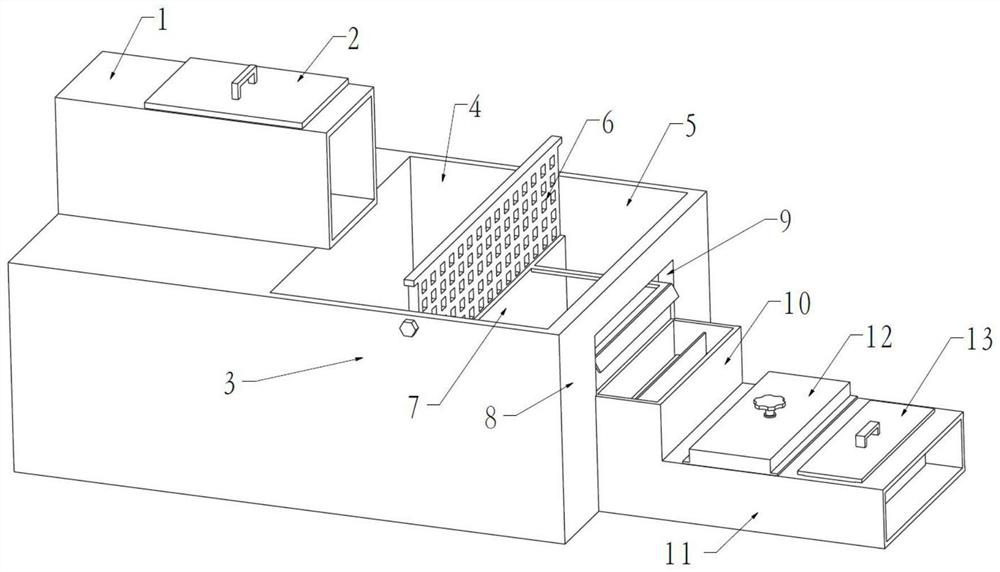

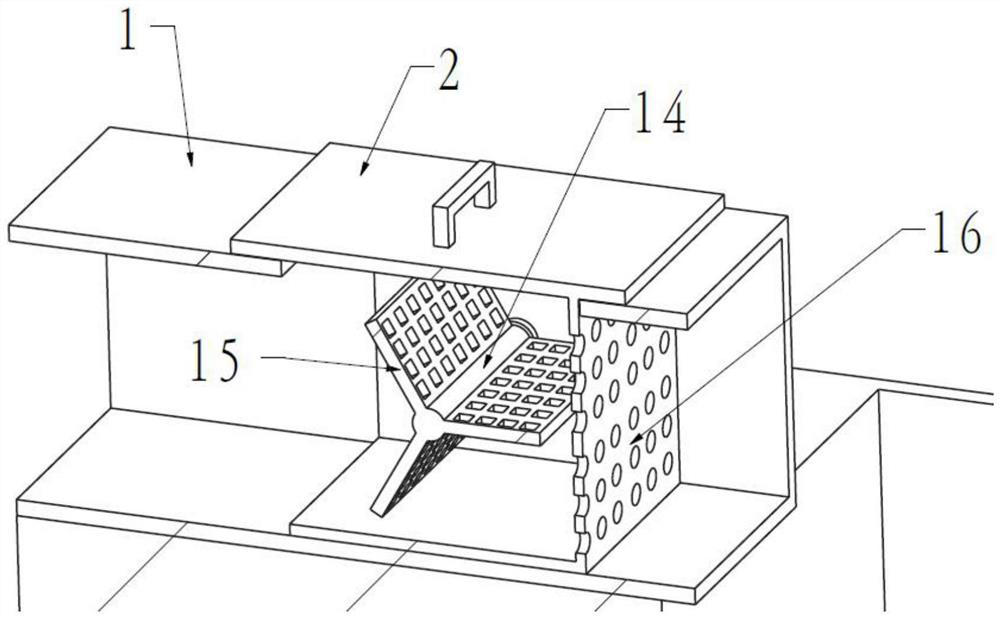

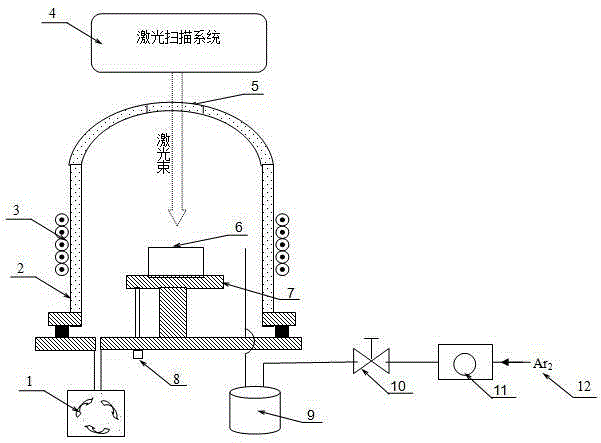

Method and device for preparing coating by using nanosecond pulse laser cladding

InactiveCN103849872AMeet processing requirementsImprove bindingChemical vapor deposition coatingNanosecond laserSurface roughness

The invention discloses a method and a device for preparing a coating by using nanosecond pulse laser cladding, belonging to the technical field of the preparation of coatings on material surfaces through laser cladding, and aiming to solve the problems existing in the present nanosecond pulse laser cladding. According to the method and the device, a metal is deposited on the surface of a workpiece through MOCVD (metal organic chemical vapor deposition), and the surface of the workpiece is scanned by nanosecond laser light at the same time, so that the metal is cladded on the surface of the workpiece, and a coating with a micron or submicron level thickness is formed on the surface of the workpiece. The method and the device disclosed by the invention do not have special requirements for a substrate material, are wide in application range, and can meet the needs of the preparation of the coatings of plane workpieces and special-shaped workpieces; a prepared thin film coating has the advantages of densification, controllable thickness (micron or submicron) and firm film-substrate adhesion; meanwhile, the surface roughness of the workpiece subjected to processing is not less than that of the workpiece before cladding; the secondary processing such as grinding and polishing is not needed, so that the production cost is reduced; meanwhile, after being processed by the method and the device, the workpiece can not be deformed and can meet the processing requirements for precision workpieces.

Owner:SICHUAN INST OF MATERIALS & TECH

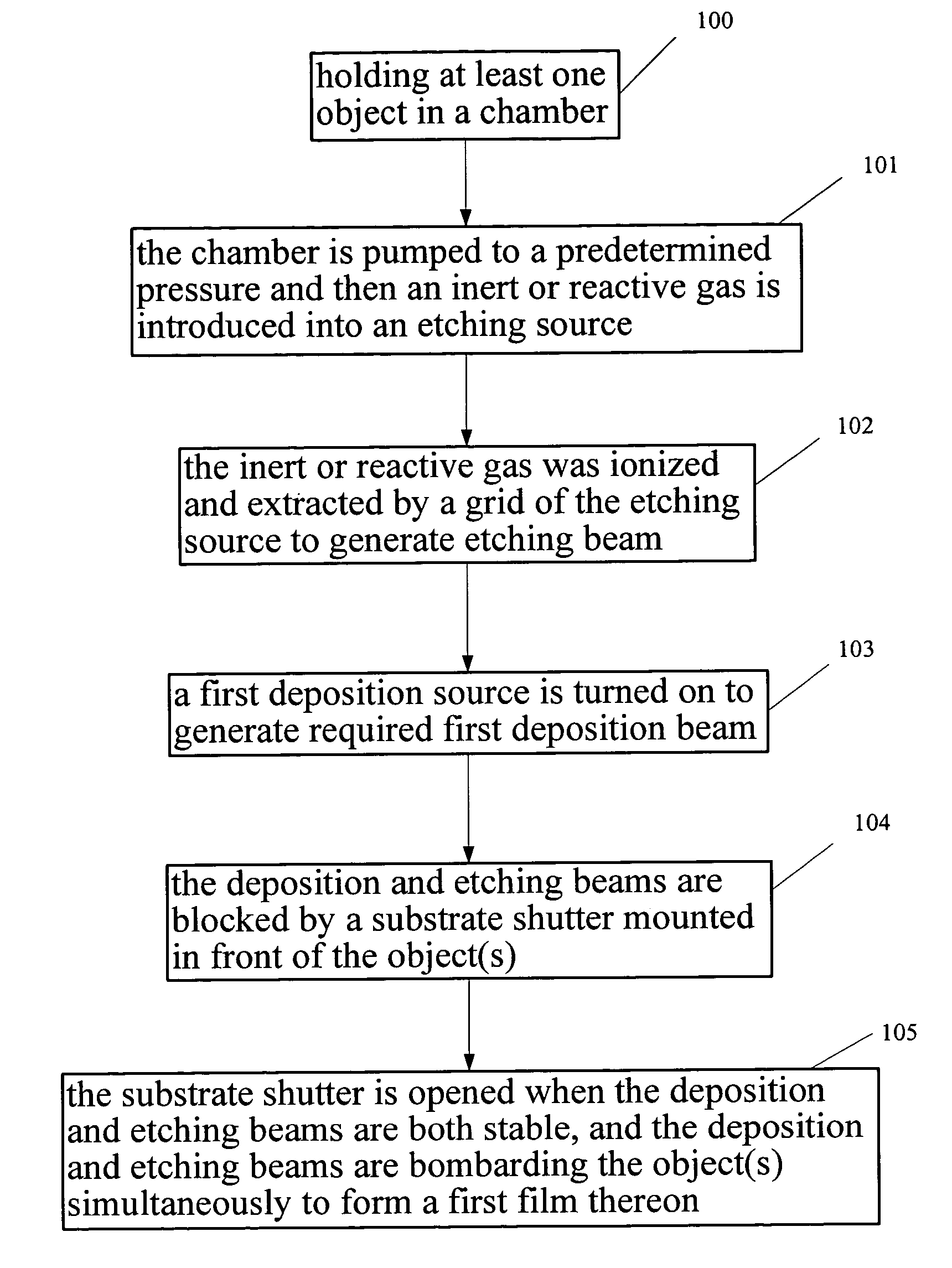

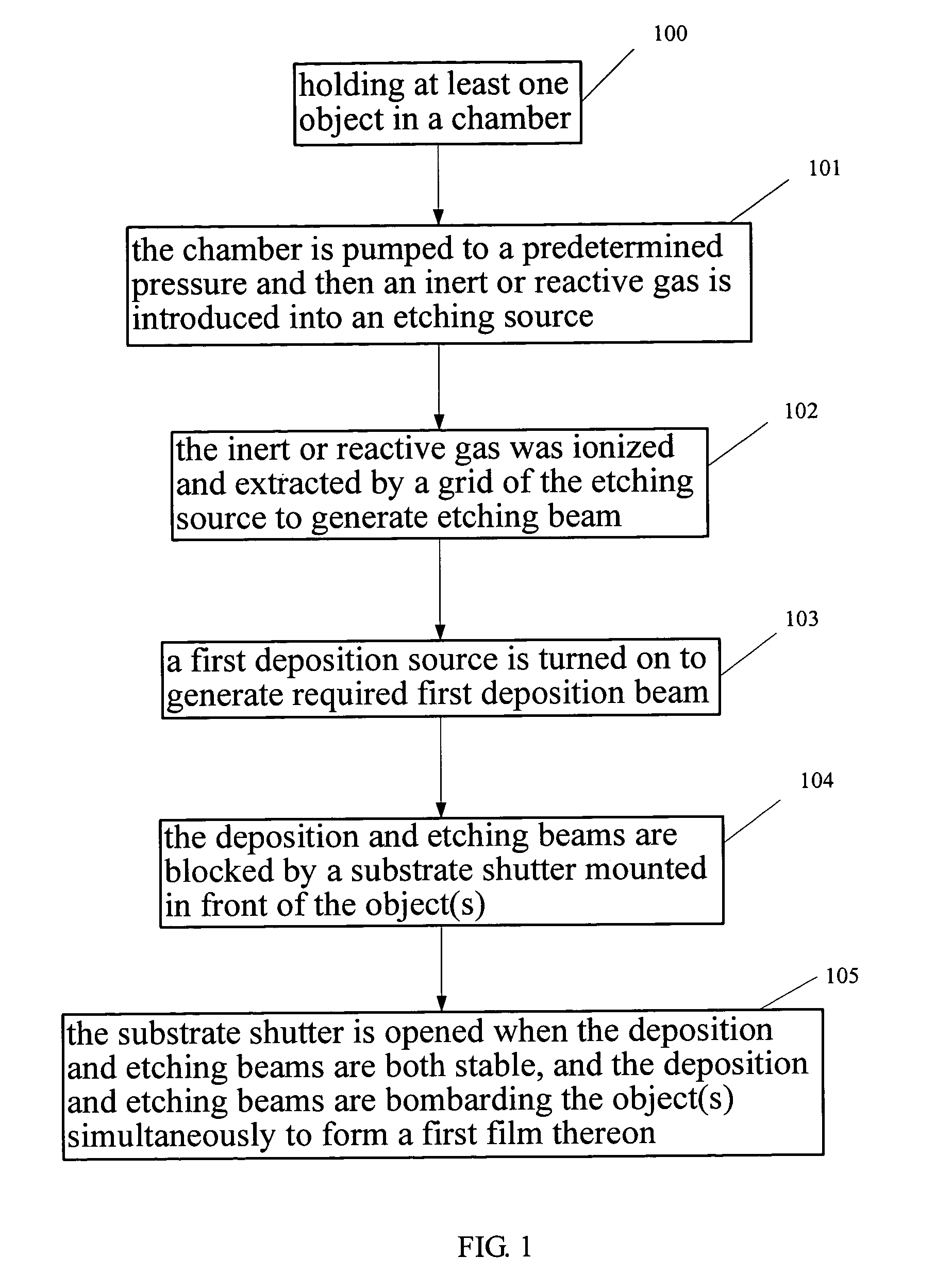

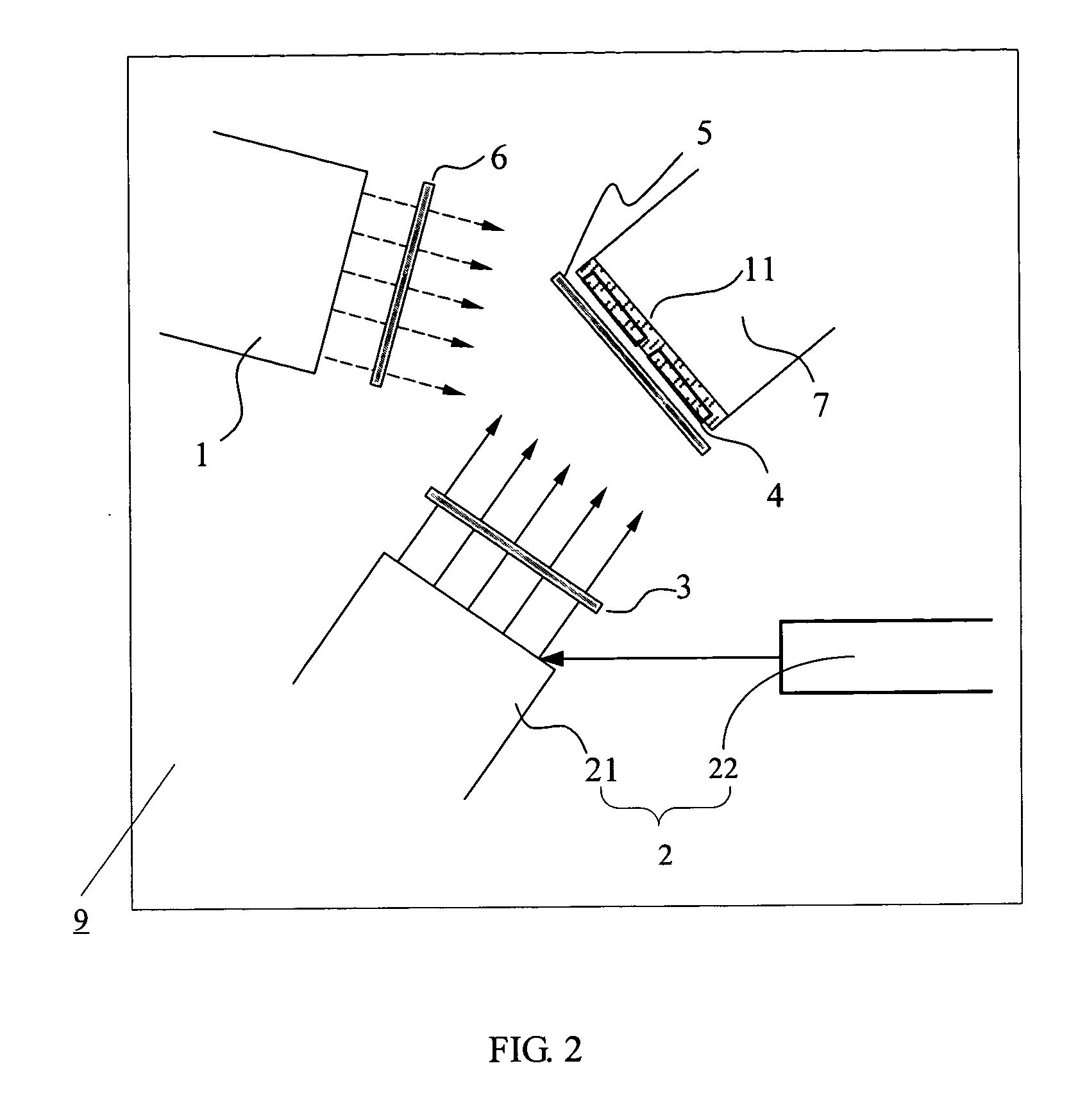

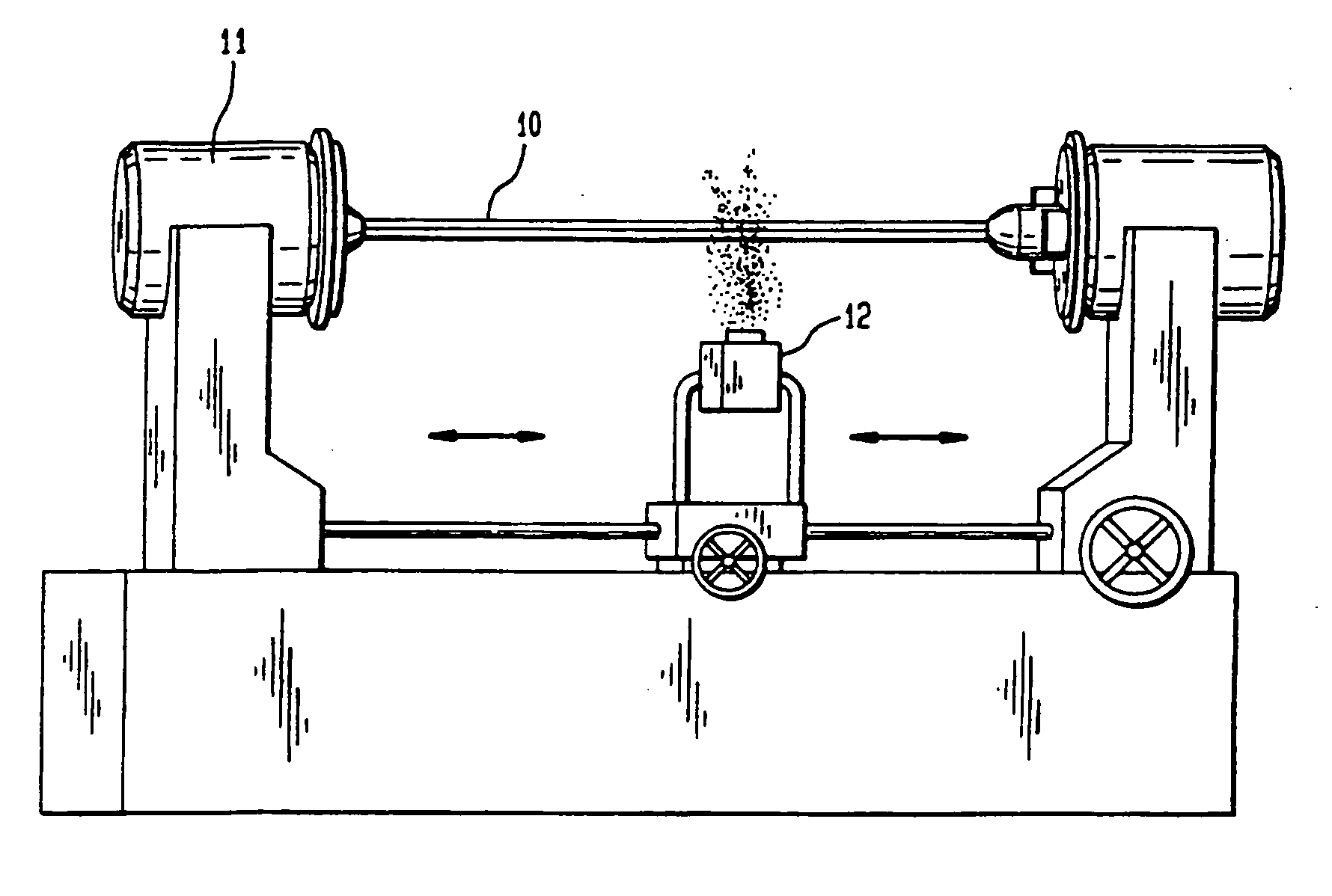

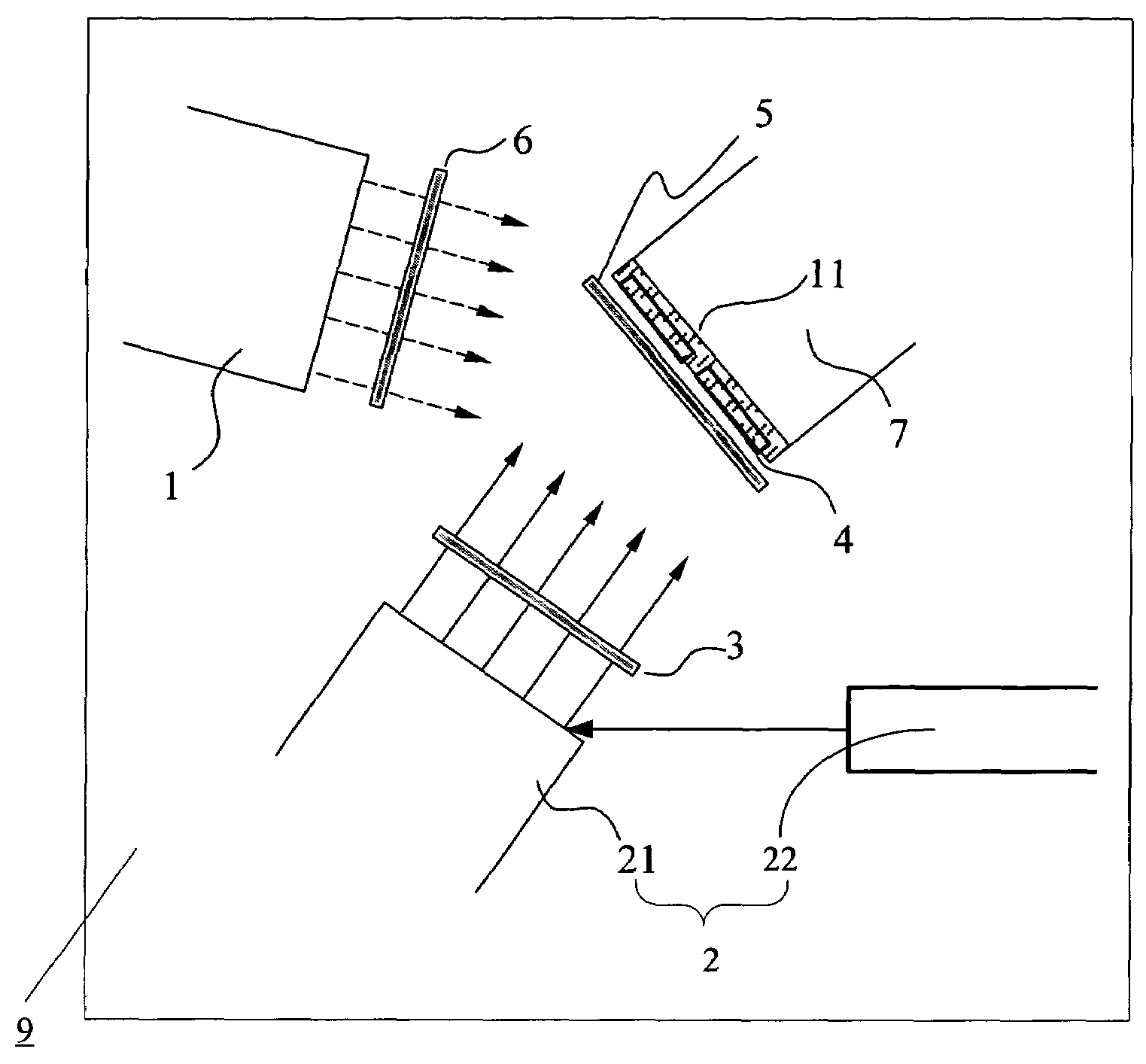

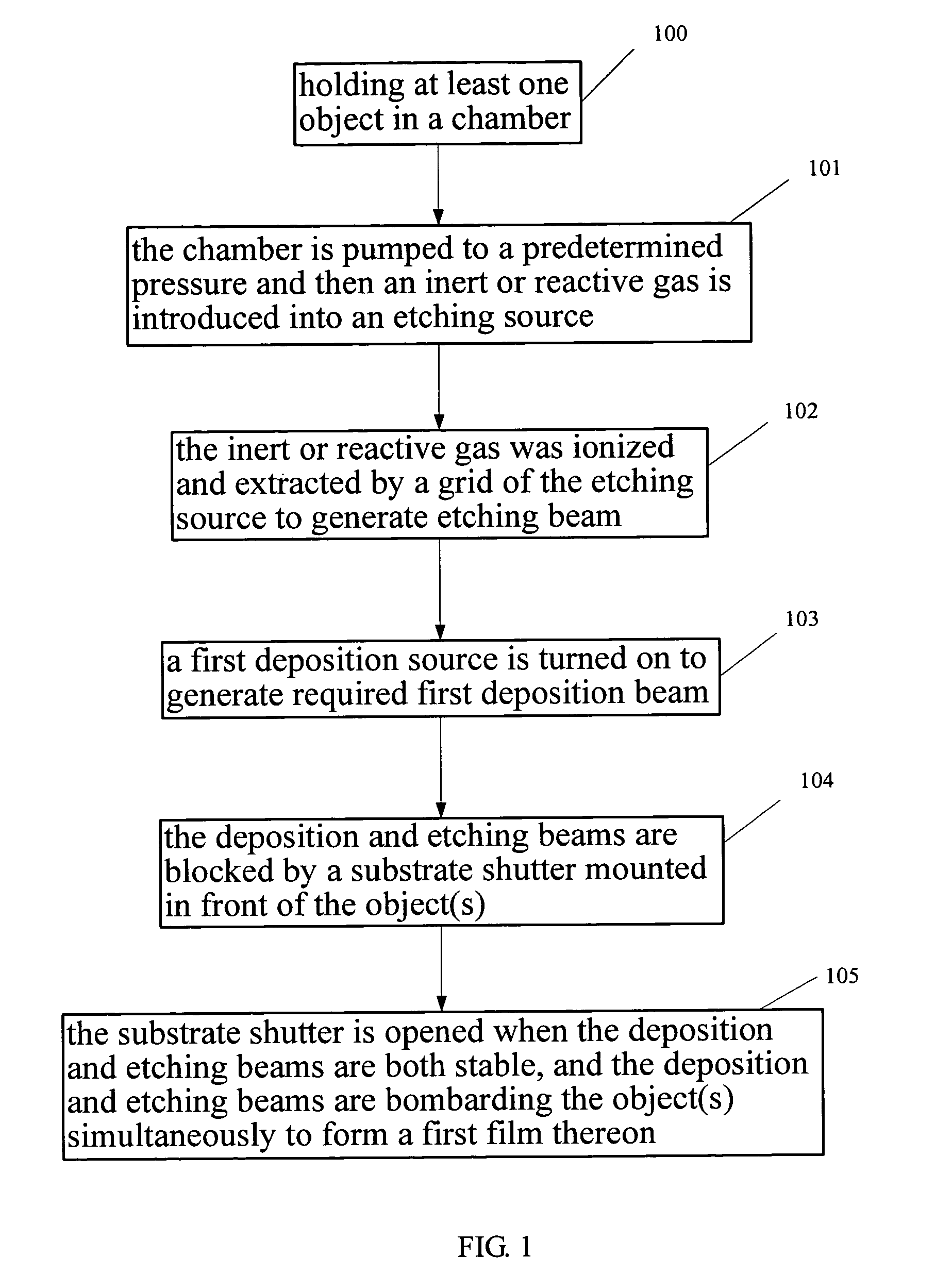

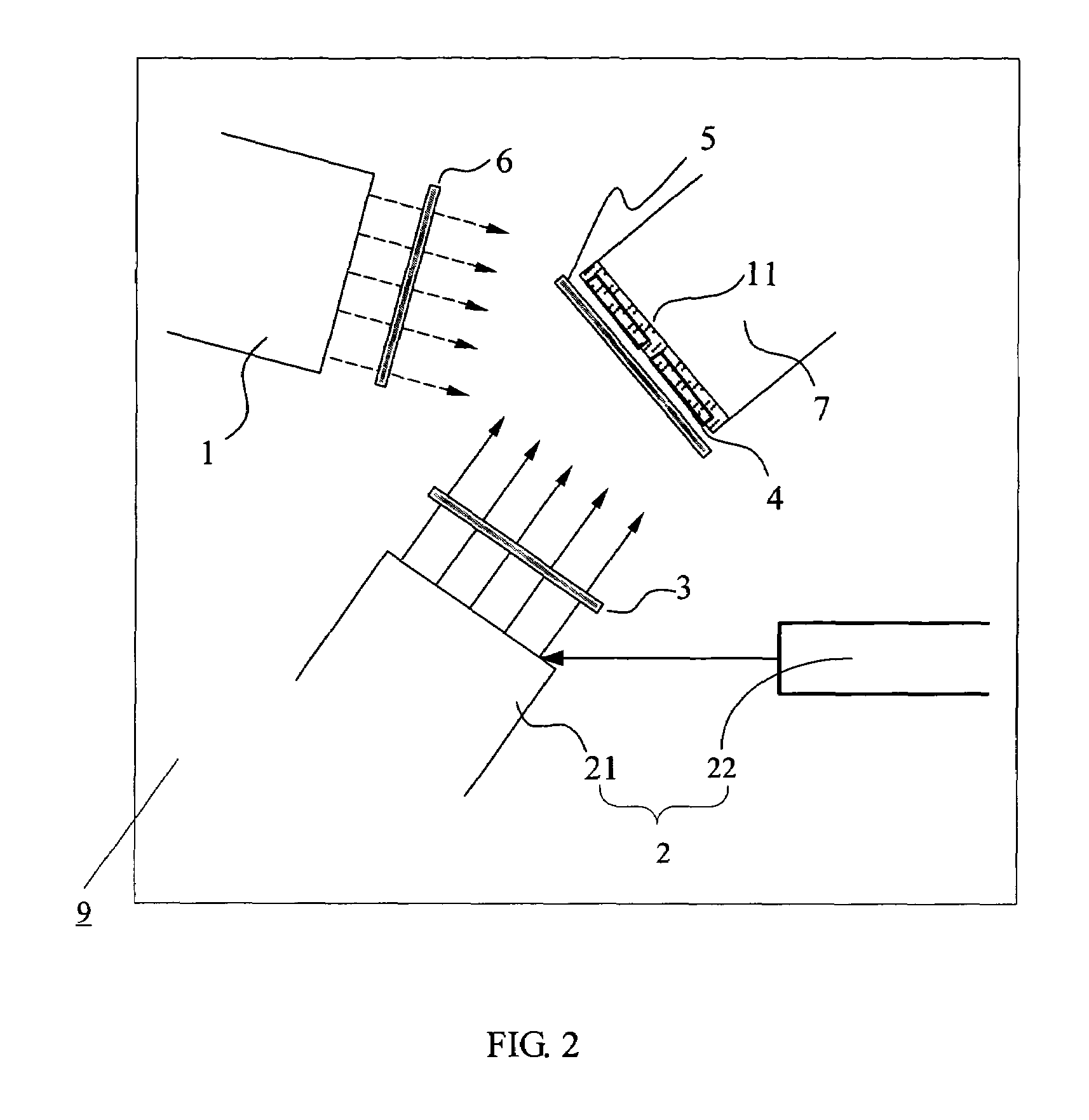

Thin film forming method and system

ActiveUS20060060559A1Improve adhesionImprove propertiesManufacture head surfaceDecorative surface effectsEtchingThin membrane

A thin-film forming method, which includes the steps of: (1) holding at least one object in a chamber; (2) depositing a film-forming material on the object; (3) etching the forming material while depositing is conducted. In the present invention, the depositing and etching are controlled to simultaneously conduct. The invention also disclose a system for performing the method.

Owner:SAE MEGNETICS H K

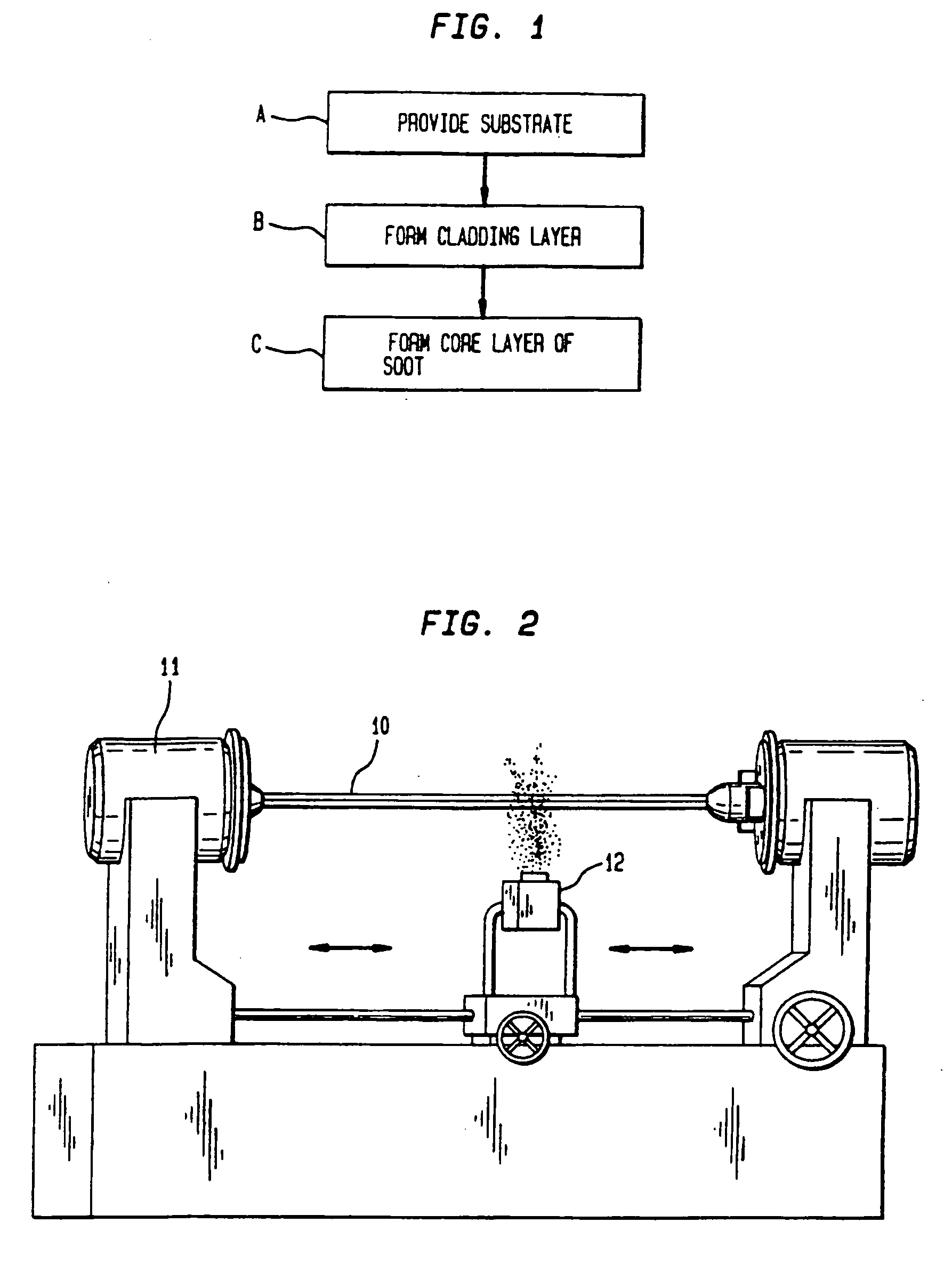

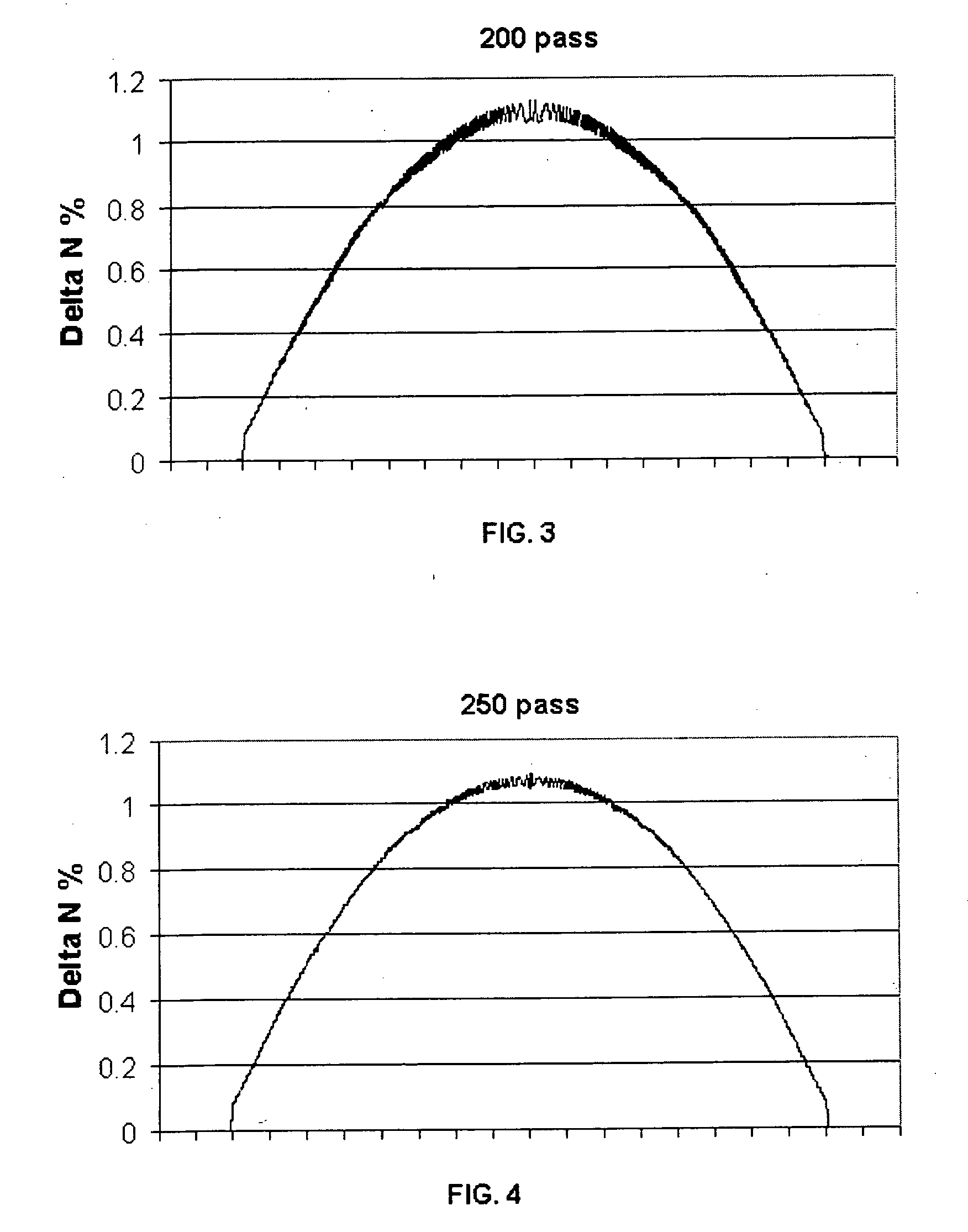

Multimode optical fiber and method for manufacturing same

InactiveUS20060185397A1Easy to controlReduce presenceGlass making apparatusCladded optical fibreFiberMaterials science

An improved MCVD process reduces a rippling structure in the refractive-index profile of a graded-index, multiple-mode optical fiber by incorporating N2O, CO, or NF3 gas in the gas stream during deposition of a soot sub-layer from which the optical fiber is formed. The soot sub-layer is sintered to form a glass sub-layer during deposition of a subsequent soot sub-layer. A dopant species is incorporated in each soot sub-layer during deposition. Fibers made from the doped glass sub-layers have a graded refractive-index profile that is near-parabolic in shape and that has significantly reduced rippling compared to profiles observed for fibers prepared conventionally.

Owner:OFS FITEL LLC

Image displaying device

InactiveUS20130011945A1Prevented improvement of S/N ratioDark current increases easilyStatic indicating devicesSolid-state devicesPhotoelectric conversionEngineering

An image displaying device having multiple photosensing devices have successfully suppressed a leakage current from each photosensing device and improved the S / N ratio. In the image displaying device, pixels and photosensing devices are disposed as pairs in a matrix pattern on a substrate. Each of the pixels and each of the photosensing devices are driven independently. Each photosensing device includes a semiconductor layer that is a photoelectric conversion layer connected to at least a first electrode and a second electrode. The contact surfaces of the first and second electrodes with respect to the semiconductor layer are disposed so that their center axes are separated from each other.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Capacitor and semiconductor device

ActiveUS10134781B2Extend deposition timeReduce throughputSolid-state devicesSemiconductor devicesCapacitorSemiconductor

A semiconductor device has an insulating surface provided with a transistor and a capacitor. The transistor includes a gate electrode, an oxide semiconductor film overlapping with the gate electrode, a gate insulating film between the gate electrode and the oxide semiconductor film, and a first conductive film serving as a pair of electrodes in contact with the oxide semiconductor film. An oxide insulating film in contact with the oxide semiconductor film, a metal oxide film over the oxide insulating film, and a second conductive film serving as a pixel electrode which is in an opening in the metal oxide film and is in contact with the first conductive film are provided. The capacitor includes a film having conductivity over the gate insulating film, the second conductive film, and the metal oxide film provided between the film having conductivity and the second conductive film.

Owner:SEMICON ENERGY LAB CO LTD

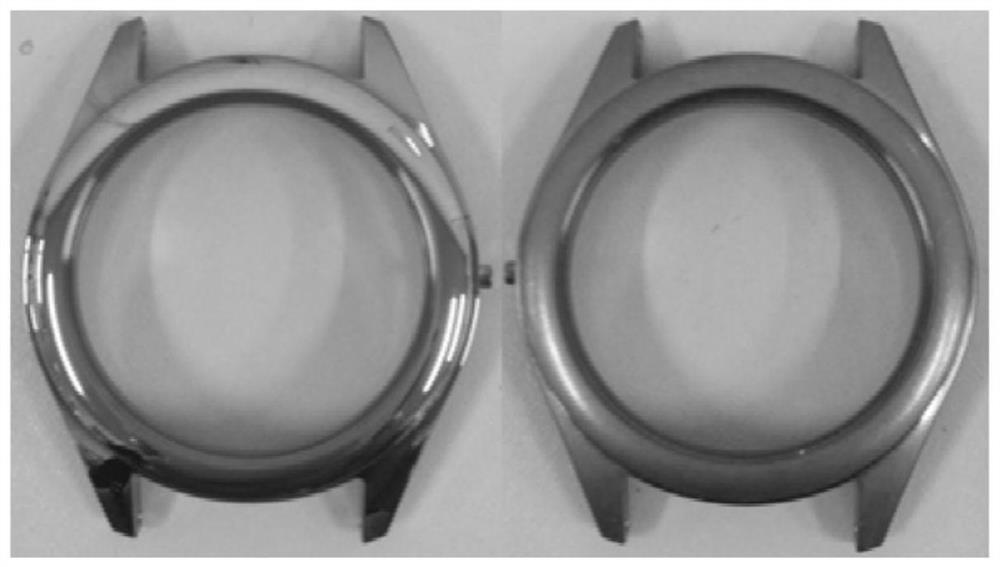

Cathodic protective coating on magnesium or its alloys and method of producing the same

A method is provided for treating a magnesium-containing article to form a cathodic protective coating on such article. This is done by electrochemically treating the article, acting as a cathode, in an alkaline solution, preferably at a temperature of between 40 and 80 DEG C., with a cathodic current density of 5-200 mA / cm2. The treatment produces a magnesium-containing article having a protective coating of magnesium hydride of predetermined thickness with a high count of hydrogen particles.

Owner:INTERMAG MODELEX

Thin film forming method and system

ActiveUS7560038B2Improve adhesionImprove propertiesManufacture head surfaceDecorative surface effectsEtchingBiomedical engineering

A thin-film forming method, which includes the steps of: (1) holding at least one object in a chamber; (2) depositing a film-forming material on the object; (3) etching the forming material while depositing is conducted. In the present invention, the depositing and etching are controlled to simultaneously conduct. The invention also disclose a system for performing the method.

Owner:SAE MEGNETICS H K

Optical colorful thin film and manufacturing method thereof

ActiveCN110373644AImprove performanceGood colorful and beautiful effectVacuum evaporation coatingSputtering coatingOptoelectronicsOptical thin film

The invention provides an optical colorful thin film and a manufacturing method. The method includes the steps that S1, a TiO2 layer is deposited on the surface of a substrate material to serve as a first layer; S2, a SiO2 layer is deposited on the first layer to serve as a second layer; S3, a TiO2 layer is deposited on the second layer to serve as a third layer; S4, a SiO2 layer is deposited on the third layer to serve as a fourth layer; S5, a TiO2 layer is deposited on the fourth layer to serve as a fifth layer; S6, a SiO2 layer is deposited on the fifth layer to serve as a sixth layer; andS7, a TiO2 layer is deposited on the sixth layer to serve as a seventh layer. The deposition process of the multi-layer film is controlled, the multi-layer film is colorful, and the seventh layer, namely the outermost layer continues to be deposited for 40-50 minutes under the state that the multi-layer film is kept colorful. According to the optical colorful thin film and the manufacturing method, the anti-abrasion performance of the optical thin film is greatly improved, and meanwhile the colorful effect of the optical thin film is guaranteed.

Owner:SHENZHEN SENFUNG VACUUM PLATING

Microwave CVD nano waterproof compound technology

InactiveCN110195218AIncrease ionization rateIncrease profitChemical vapor deposition coatingMicrowaveCurrent technology

The invention relates to a microwave CVD nano waterproof compound technology. The compound technology comprises the following steps of (1), pretreatment of a circuit board; (2) preliminary treatment of the circuit board; (3), pumping a vacuum reaction chamber till the vacuum degree is 20KPa or below, placing the vacuum reaction chamber in a microwave region with the frequency of 500-1000 GHz, introducing first gas at 0.5-2 L / min, keeping the vacuum degree in the vacuum reaction chamber at 10-30 kPa, ionizing the first gas to form an active ion monomer, and depositing a barrier insulating filmlayer on the surface of the circuit board; (4), pumping out the gas in the vacuum reaction chamber, introducing second gas to make the pressure in the vacuum reaction chamber reach 10-200 kPa, placingthe second gas at a microwave region with the frequency of 800-1200 GHz to ionize the second gas so as to form a hydrophobic oleophobic corrosion resistant coating with the thickness of 10-500 nm onthe surface of the barrier insulating film layer obtained from the step (3); and (5), post-treatment, and specifically introduced air into the vacuum reaction chamber to reach the standard atmospheric pressure, and taking out the circuit board. The microwave CVD technology has the characteristics of high efficiency, the deposition time is only half of that of a current technology in the industry,and the deposition efficiency is improved by about 2 times.

Owner:何金宁 +1

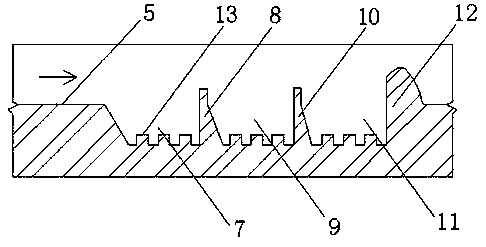

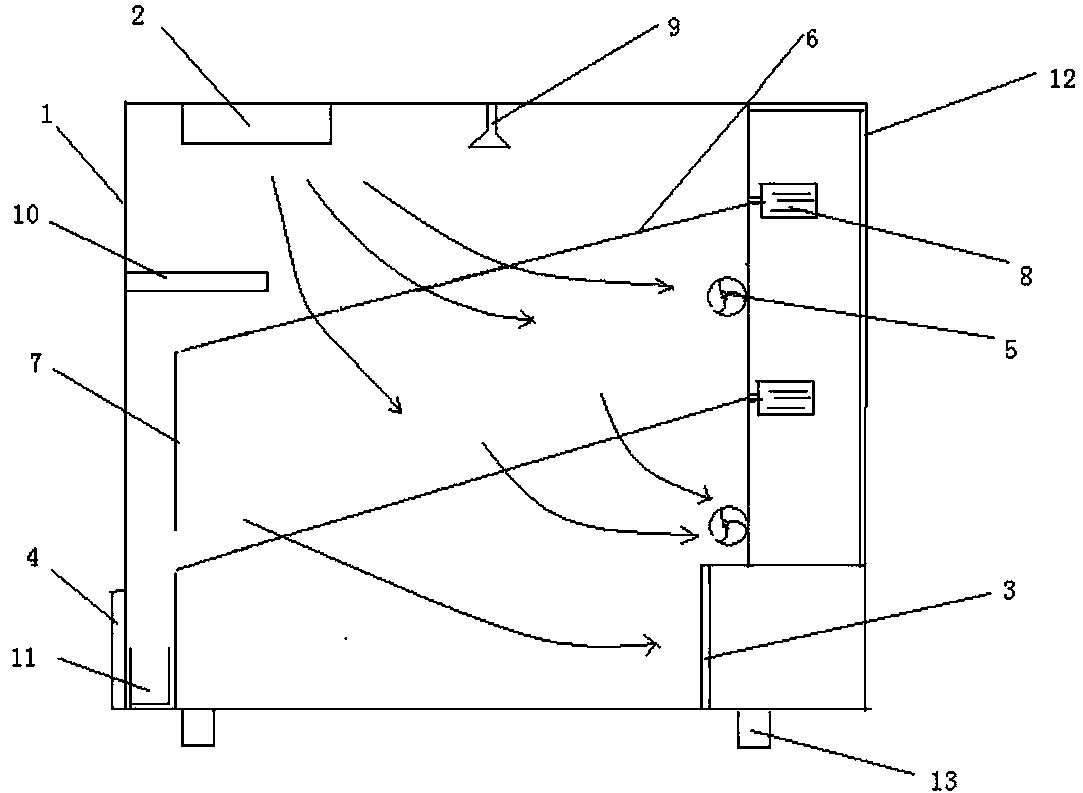

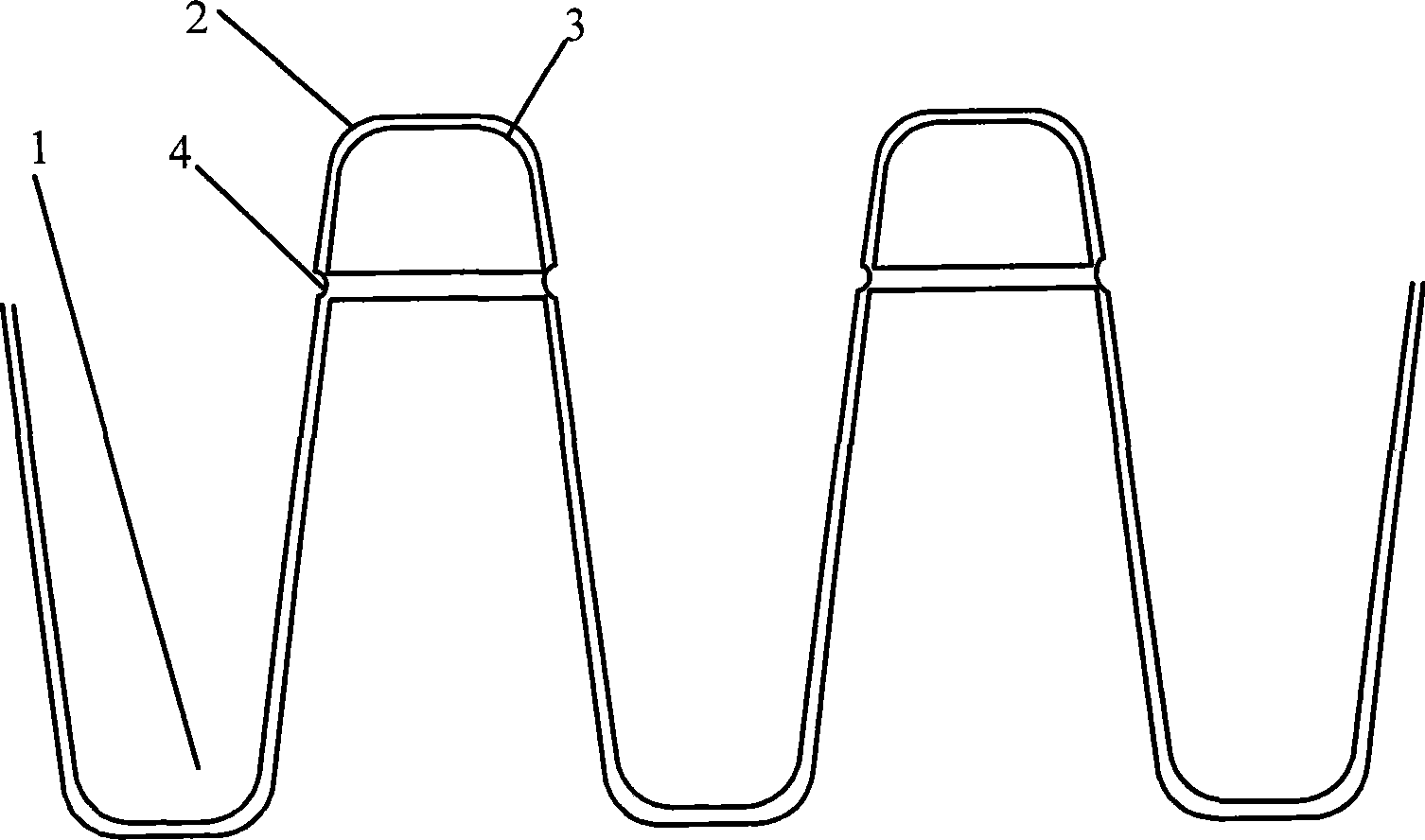

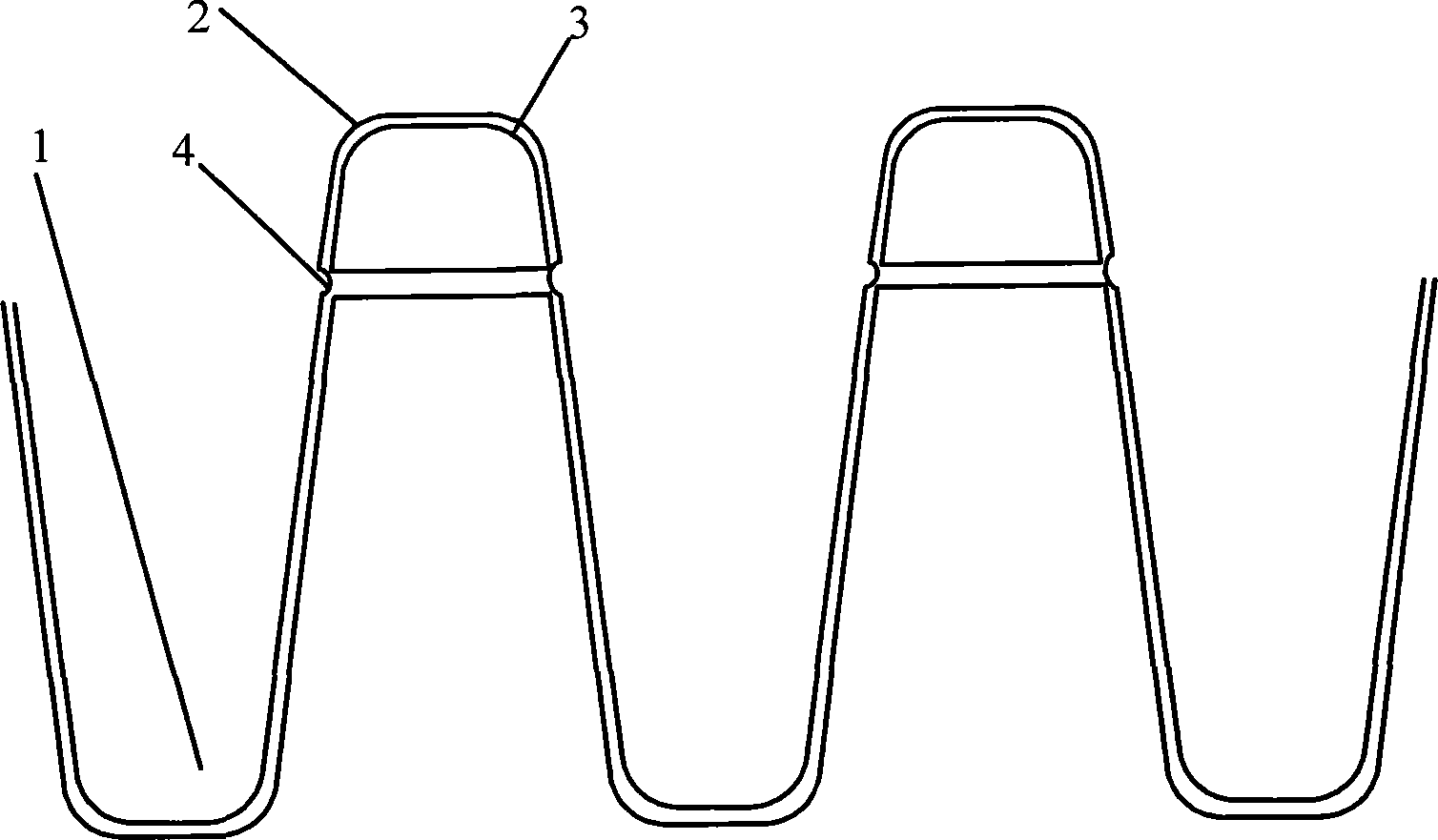

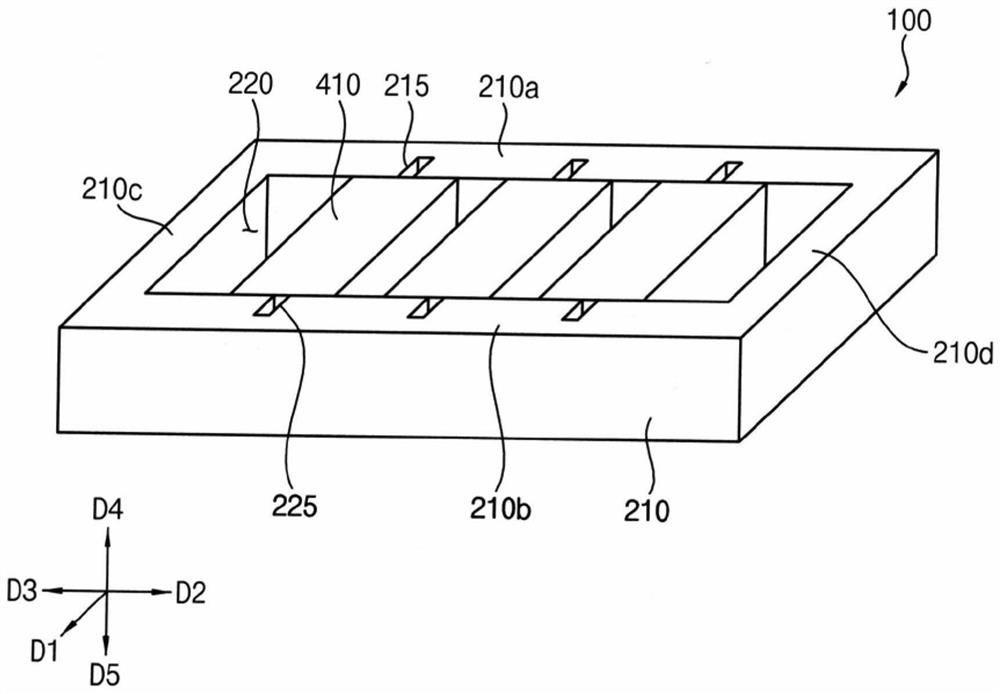

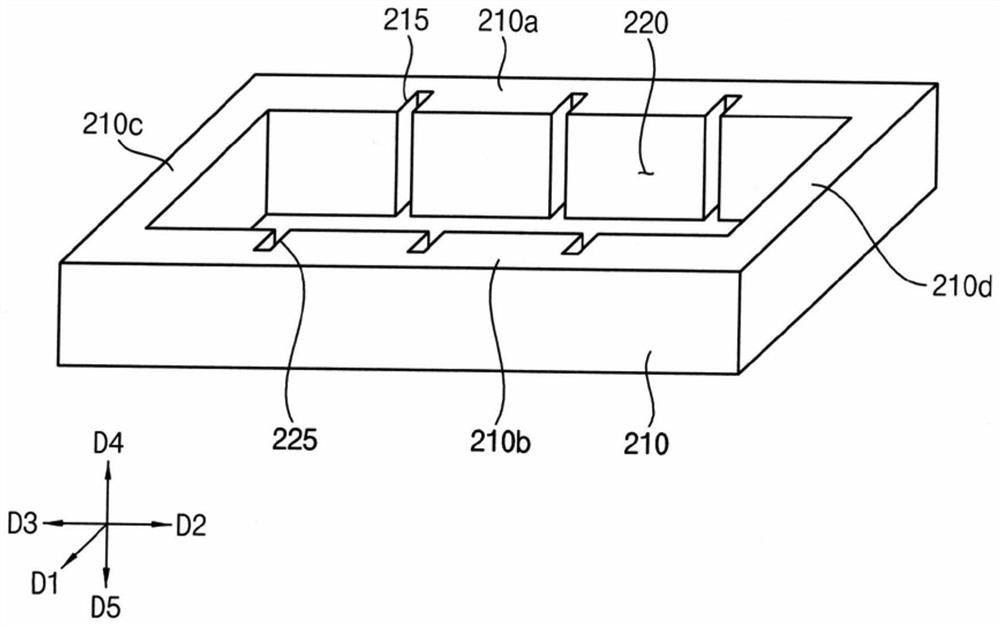

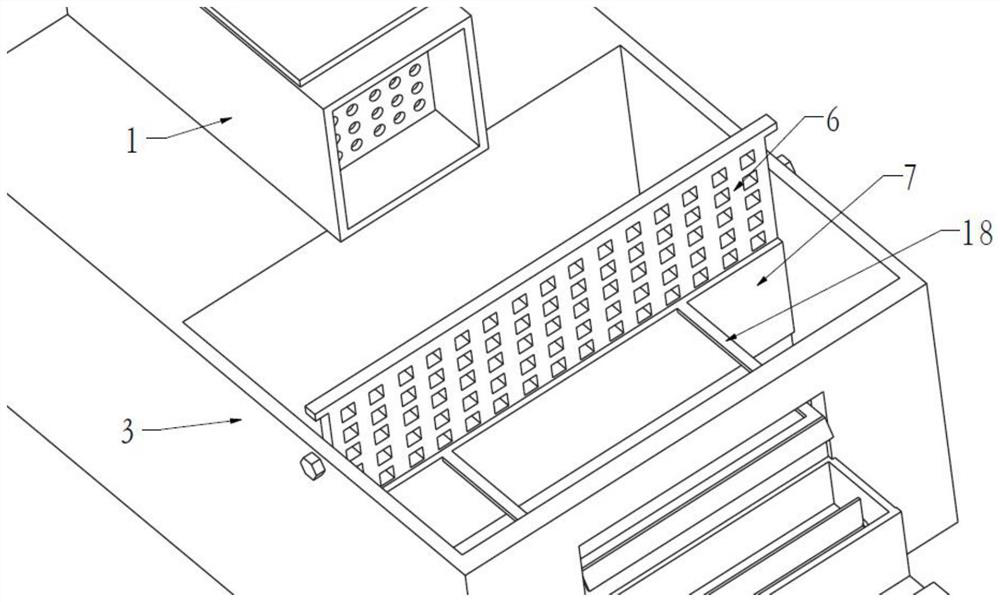

Desilting basin for alternate use in fractional precipitation

PendingCN110624280AExtended deposition timeImprove sand discharge rateSedimentation settling tanksFractional PrecipitationRiver water

The invention discloses a desilting basin for alternate use in fractional precipitation. The desilting basin comprises a partition wall, a left desilting basin, a right desilting basin and a gate. Thepartition wall is fixedly arranged at a middle position of a river channel, the left area of the partition wall is the left desilting basin, and the right area of the partition wall is the right desilting basin; a first gate is arranged at the front end of the left desilting basin, and a second gate is arranged at the front end of the right desilting basin; a first-stage desilting basin, a second-stage desilting basin and a third-stage desilting basin are sequentially arranged in the left desilting basin from left to right in order, a first baffle is arranged in the middle of the first-stagedesilting basin and the second-stage desilting basin, a second baffle is arranged in the middle of the second-stage desilting basin and the third-stage desilting basin, and an overflow weir is arranged behind the third-stage desilting basin; and the left desilting basin and the right desilting basin are arranged symmetrically. The desilting basin provided by the invention solves the problem of inconvenient dredging diversion type power stations, silt in river water is deposited and graded according to particles, thus facilitating recycling.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

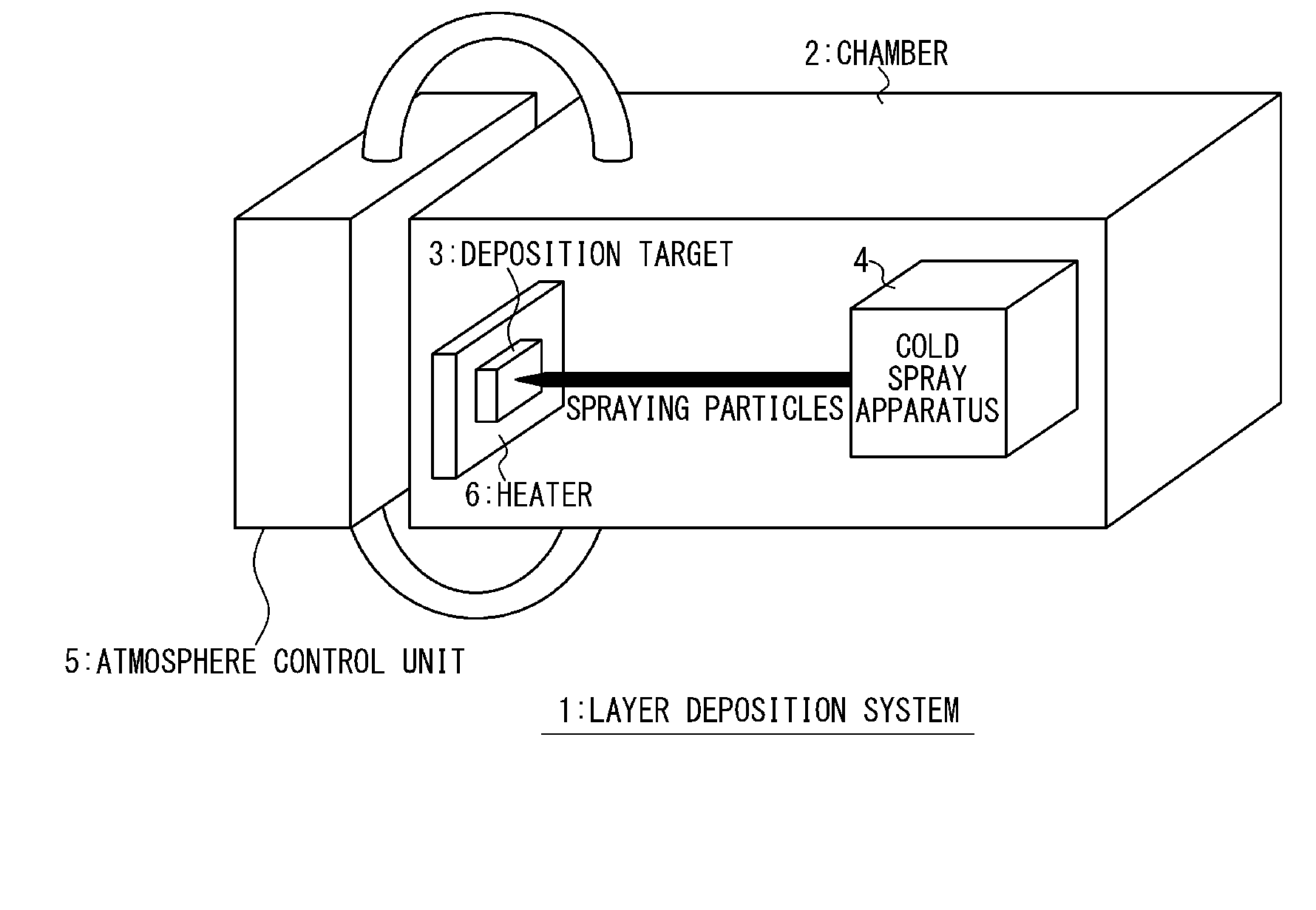

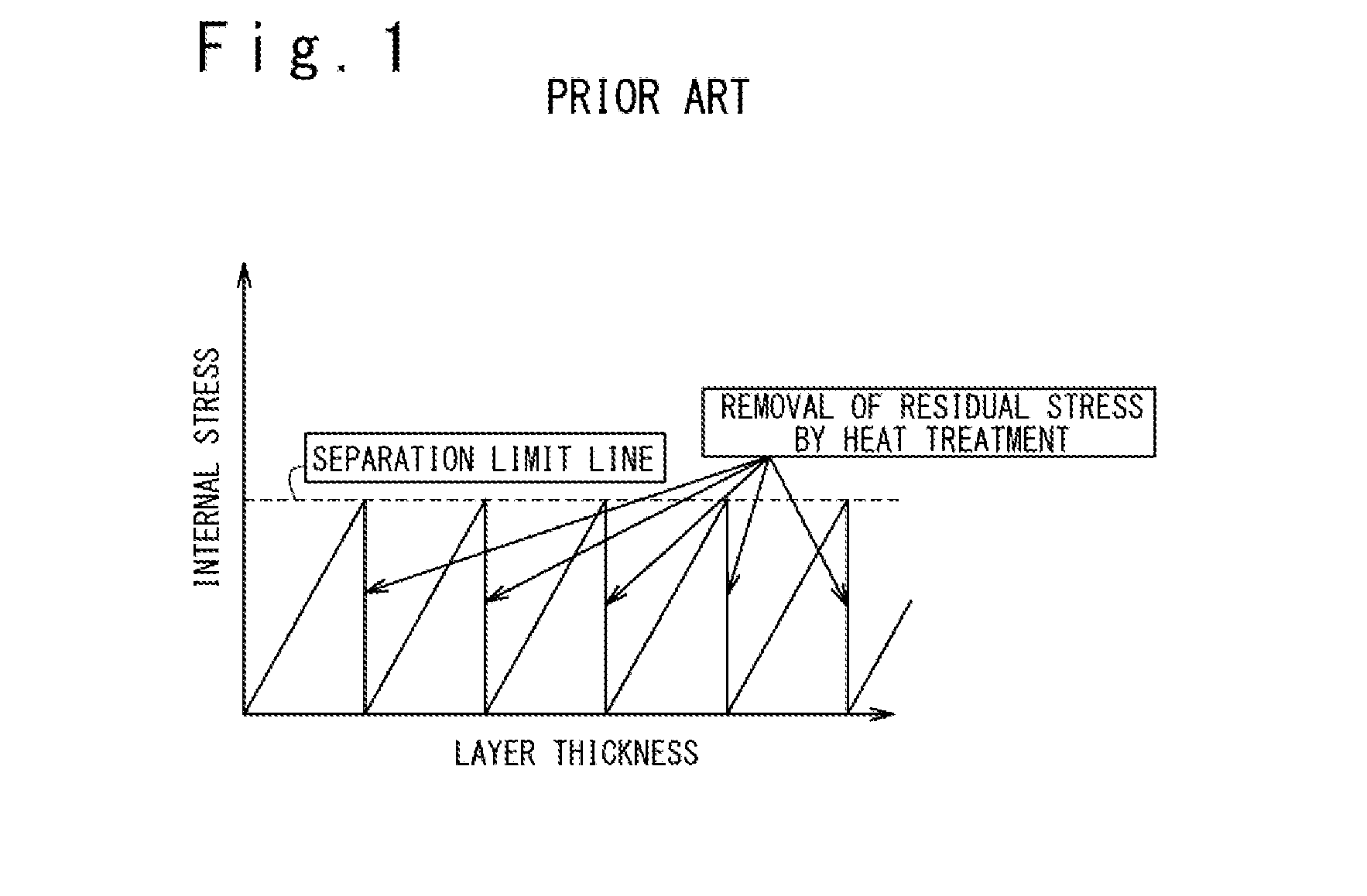

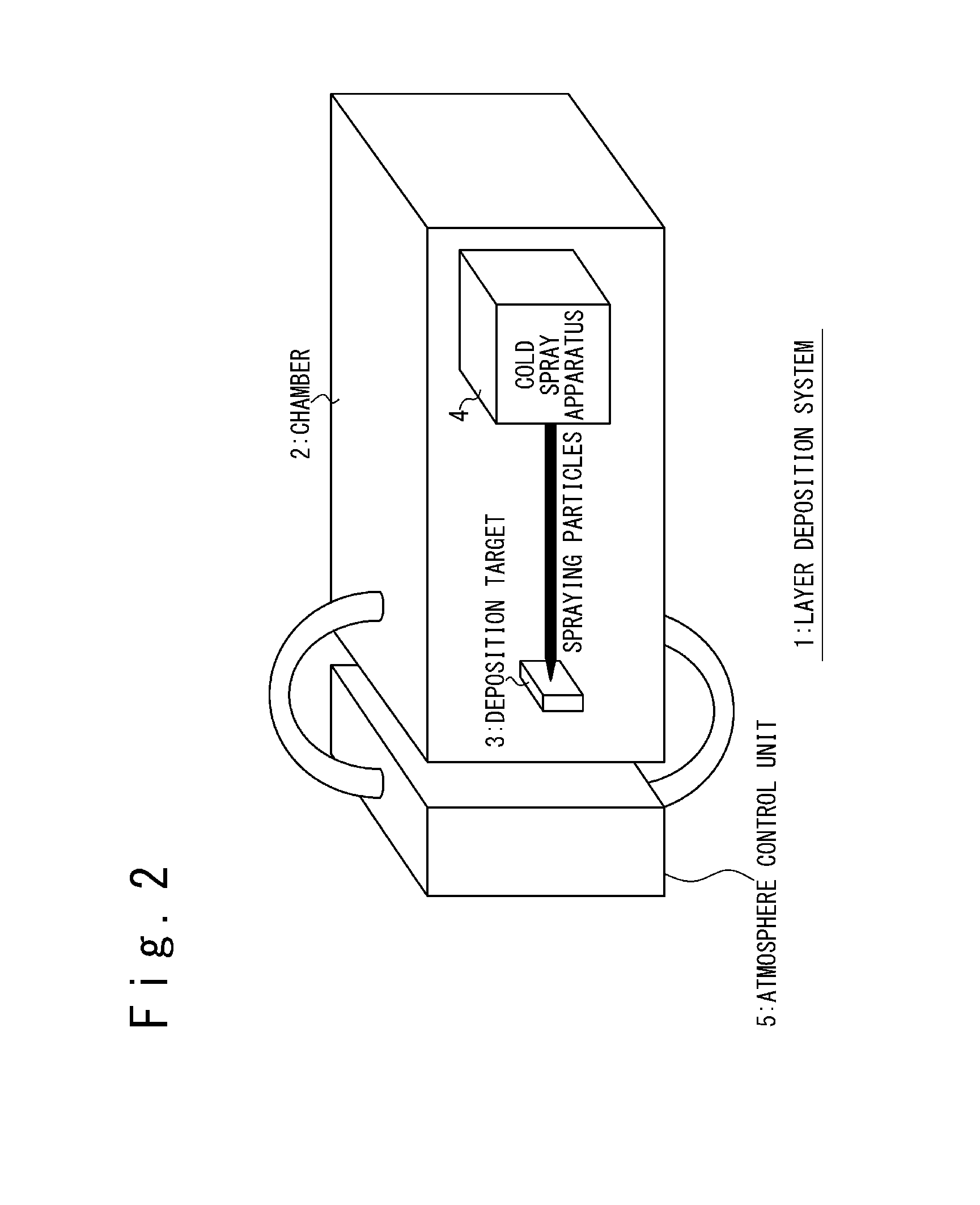

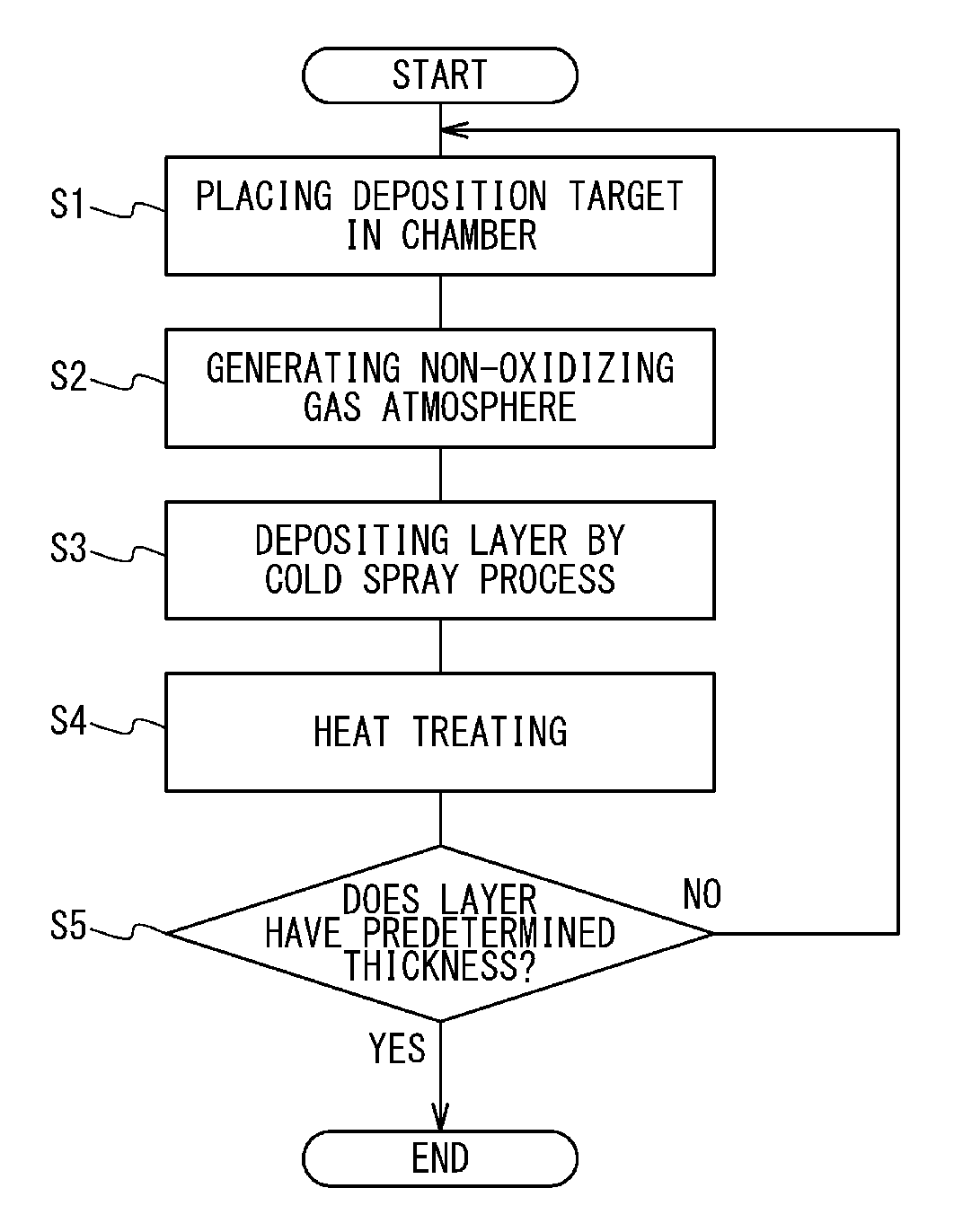

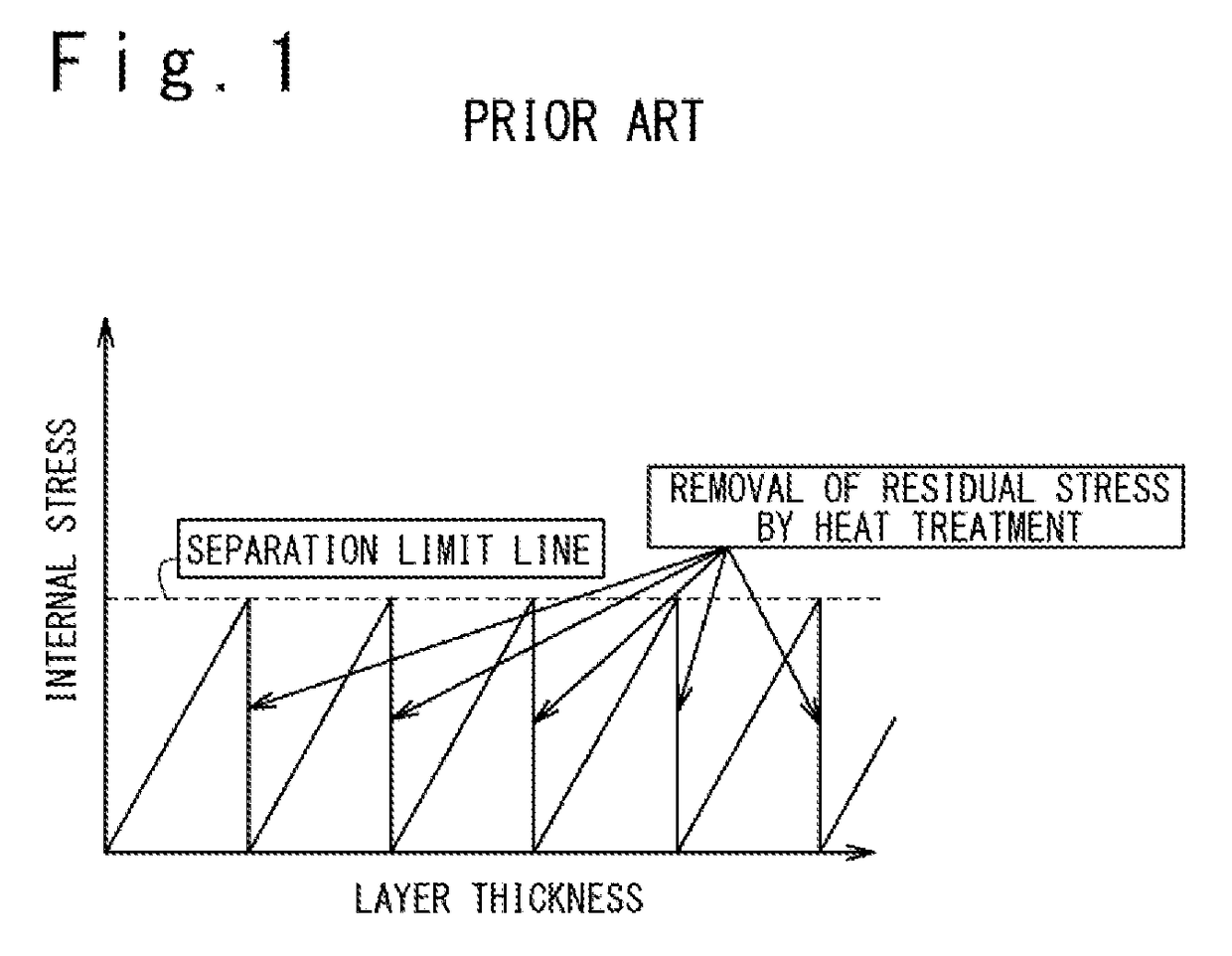

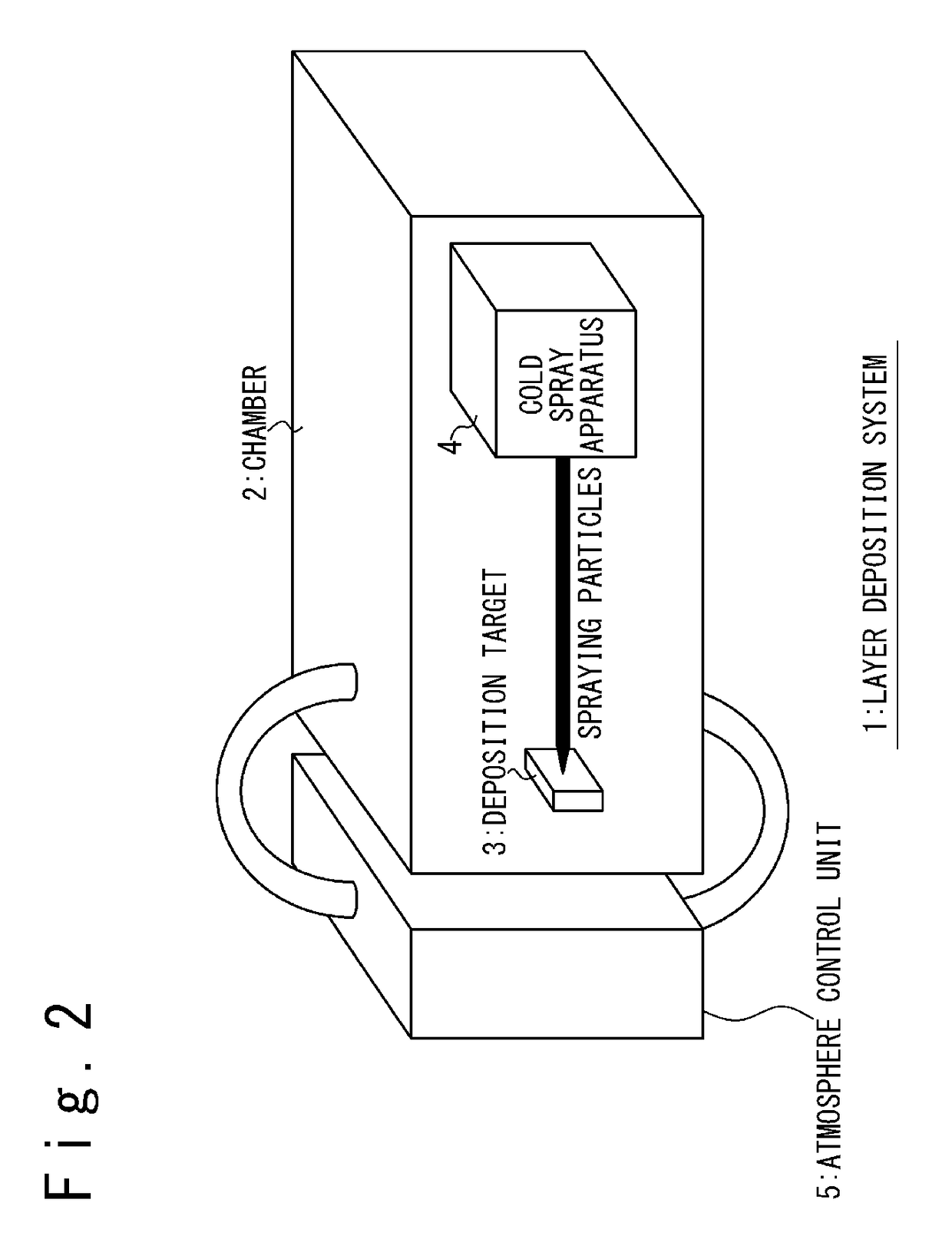

Method for depositing layer

ActiveUS20150368807A1Extend deposition timeReduce in quantityMolten spray coatingPretreated surfacesEngineeringTarget reaching

A method for depositing a layer has a step of repeatedly performing a unit deposition process until the layer on a deposition target reaches a predetermined thickness. The unit deposition process includes (A) a step of depositing the layer on the deposition target by a cold spray process while the deposition target is heated by a heater and (B) a step of heat treating the deposition target after said depositing.

Owner:MITSUBISHI HEAVY IND LTD

Environment protection dust collection equipment used in workshop

InactiveCN110215789AAccelerates the time of dust depositionEasy to cleanCombination devicesEquipment useHigh intensity

The invention discloses environment protection dust collection equipment used in a workshop. The equipment comprises a shell, wherein the shell is of a sealed structure; an air inlet, an air outlet and a dust discharge hole are formed in the shell; a dust filtering component and a fan are arranged inside the shell; the dust filtering component comprises multiple layers of filtering nets which arearranged in an inclined manner; one end part of each filtering net is fixedly arranged on a side wall of the shell through an elastic part; first partition plates are vertically arranged at the otherend parts of the filtering nets; both sides of the first partition plates are fixedly connected with two side walls of the shell; the filtering nets are connected with vibration motors; fans are arranged at bottoms of the filtering nets; the air inlet is formed in the top of the shell; a spraying device is fixedly arranged on the inner wall of the top of the shell; the air outlet is formed in thebottom of the shell; a second partition plate is arranged above the first partition plates; the filtering nets are arranged upwards in the inclined manner at the tops of the first partition plates; and the elastic parts are high-strength springs. The environment protection dust collection equipment used in the workshop, which is disclosed by the invention, is simple in structure, flexible in combination, high in dust collection efficiency, convenient in dust cleaning operation and high in working efficiency.

Owner:QINGDAO HUANGHAI UNIV

Lining insulating layer high-density ionic depositing method

ActiveCN101546725BExtend deposition timeEliminate notchSemiconductor/solid-state device manufacturingHydrogenHigh density

The invention provides a lining insulating layer high-density ionic depositing method, wherein insulating layer high-density ionic depositing is in a sealed reaction cavity; the top and the side edge of a sealed reaction cavity are connected with a conveying pipe of a reaction medium and a guiding medium capable of generating an insulating layer; lining insulating layer high-density ionic depositing makes use of radio frequency sputtering to realize insulating layer deposition; the radio frequency sputtering comprises two parameters, namely the decomposition power of the reaction medium and the sputtering power of the guiding medium used for guiding an insulator to grow; moreover, the sputtering power of the guiding medium ranges between 2.5 and 6.5 KW, and the deposition time of the entire insulating layer is between 3 and 15 seconds. Meanwhile, the method reduces the generation speed of the insulator by reducing the feeding speed and the amount of the reaction medium in the reactioncavity and adopts micromolecular hydrogen as a main guiding medium to increase the generating uniformity of the insulator. The depositing method can effectively eliminate notches existing in the prior insulating layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP

A kind of optical dazzling thin film and preparation method thereof

ActiveCN110373644BImprove performanceGood colorful and beautiful effectVacuum evaporation coatingSputtering coatingMultilayer membranePhysical chemistry

Owner:SHENZHEN SENFUNG VACUUM PLATING

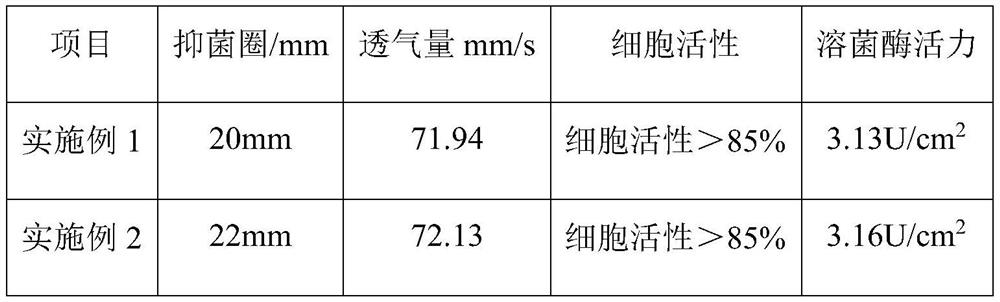

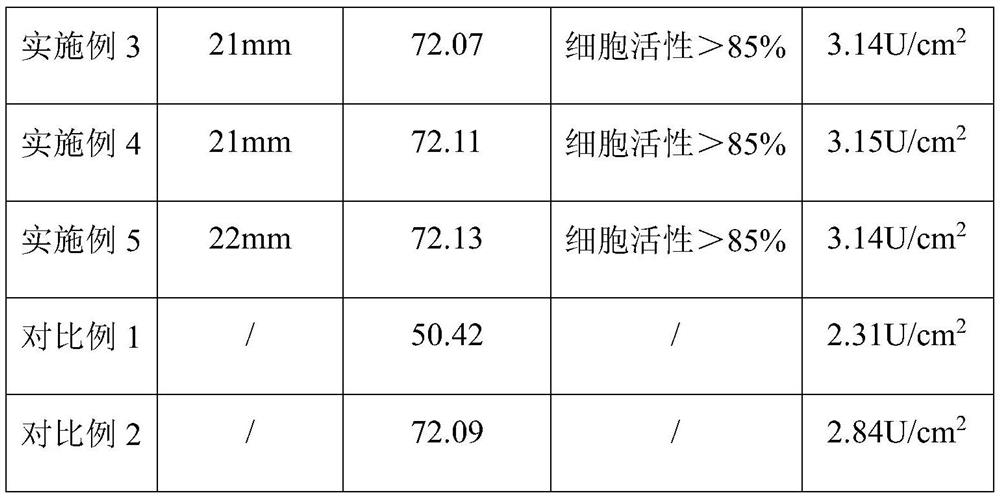

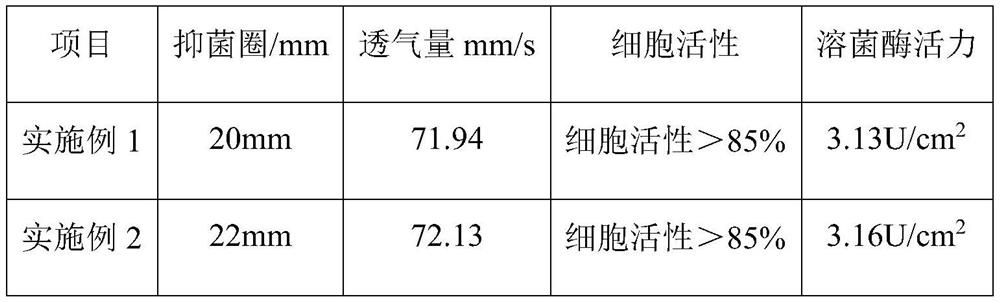

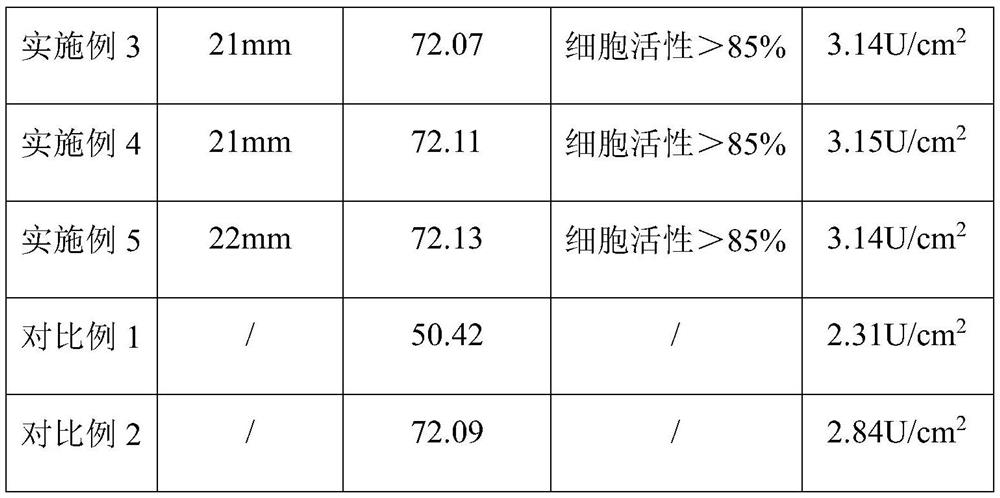

A kind of plant extract combined dressing based on ginseng extract and preparation method thereof

ActiveCN113456878BLow antigenicityNon-irritatingAbsorbent padsBandagesBiotechnologyPolyethylene oxide

The invention discloses a plant extract combined dressing based on ginseng extract and a preparation method thereof. During preparation, the application first uses chitosan and polyoxyethylene as raw materials to prepare a chitosan film by electrospinning to obtain The chitosan film is used as the dressing base film. Because chitosan has the characteristics of non-toxicity, broad-spectrum antibacterial property, hemostasis, scar reduction and good biocompatibility, chitosan is selected as the main raw material, and Introduce plant extracts. The plant extracts of this application are ginseng extract + Ophiopogon japonicus extract, ginseng extract + chrysanthemum extract and ginseng extract + Artemisia annua extract. You can choose to mix and match at will. The invention has reasonable process design and simple operation, and the prepared combined dressing not only has excellent antibacterial performance, but also is non-toxic to human body, has good biocompatibility, and can promote skin surface wound healing when used, and has high practicability.

Owner:吉林省蓝浦浩业科技有限公司

Plant extract combined dressing based on ginseng extract and preparation method thereof

The invention discloses a plant extract combined dressing based on ginseng extract and a preparation method thereof. During preparation, chitosan and polyoxyethylene serve as raw materials, a chitosan film is prepared through electrostatic spinning, the chitosan film serves as a dressing base film, chitosan has the characteristics of no toxicity, broad-spectrum antibacterial property, hemostasis, scar reduction, good biocompatibility and the like, so that chitosan is selected as a main raw material, and plant extracts are introduced; the plant extract is compounded by three combination modes of the ginseng extract and the radix ophiopogonis extract, the ginseng extract and the chrysanthemum extract and the ginseng extract and the artemisia apiacea extract, and matching and selection can be randomly carried out in actual operation. The process is reasonable in design and simple to operate, and the prepared combined dressing not only has excellent antibacterial performance, but also is non-toxic to a human body and good in biocompatibility, can promote healing of wounds on the skin surface during use, and has relatively high practicability.

Owner:吉林省蓝浦浩业科技有限公司

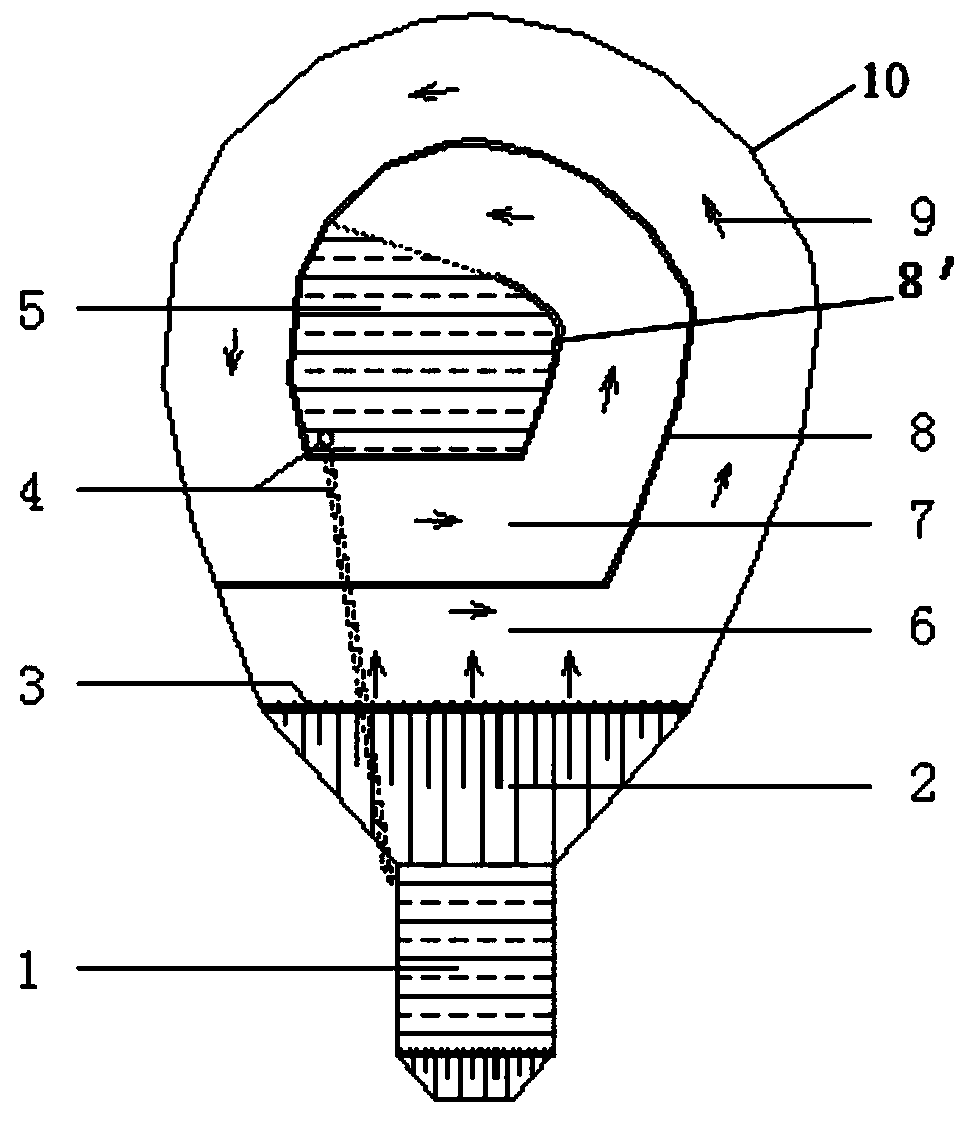

A safe and environmentally friendly stacking method for a valley-type phosphogypsum storage

The invention discloses a safe and environment-friendly piling method for a valley-type phosphogypsum warehouse. According to the safe and environment-friendly piling method, a minimum dry beach separation dam (8) is arranged around the interior of the valley-type phosphogypsum warehouse in a circle at the preset spacing away from the front of a phosphogypsum dam (2) and a mountain slope (10); a flood regulation dry beach separation dam (8') is arranged around the interior of the valley-type phosphogypsum warehouse in 0.45 to 0.55 of a circle at the preset spacing away from the minimum dry beach separation dam (8), and starts from the end of the minimum dry beach separation dam (8); after being discharged from a slurry discharging pipe (3), phosphogypsum slurry is guided by a spiral linearseparation dam to form a spiral alluvial beach surface; water in the phosphogypsum slurry finally gathers in a clarification area (5) inside the valley-type phosphogypsum warehouse; and the average slope of a minimum dry beach (6) and a flood regulation dry beach (7) reaches 0.26% to 0.42%. The safe and environment-friendly piling method disclosed by the invention has the beneficial effects thatthrough the guide by the spiral linear separation dam, the alluviation of phosphogypsum around a filling warehouse and the spiral rise can be achieved, thereby greatly prolonging the deposition time,guaranteeing the high clarity of water in the clarification area (5) inside the valley-type phosphogypsum warehouse, and reducing the running cost of the valley-type phosphogypsum warehouse.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD +1

Method for depositing layer

ActiveUS9932660B2Extend deposition timeReduce in quantityMolten spray coatingPressure inorganic powder coatingTarget reachingDeposition process

A method for depositing a layer includes repeatedly performing a unit deposition process until the layer on a deposition target reaches a predetermined thickness. The unit deposition process includes (A) placing the deposition target in a chamber, (B) providing a non-oxidizing gas atmosphere or a vacuum atmosphere in the chamber, (C) depositing the layer on the deposition target by a cold spray process in the non-oxidizing gas atmosphere or the vacuum atmosphere, and (D) heat treating the deposition target after the depositing.

Owner:MITSUBISHI HEAVY IND LTD

Crucible

PendingCN113930726AShorten heating timeIncrease contact areaVacuum evaporation coatingSputtering coatingCrucibleMetal

The present invention relates to a crucible, which may include: a main body storing a deposited substance, and including a first tank; and a first metal member fastened to the first groove, extending in a first direction, and fixing the deposited substance. Accordingly, the crucible comprises the metal part for fixing the deposition substance in the solid state, so that the deposition substance can be completely melted, and the temperature rise time of the deposition substance can be relatively shortened.

Owner:SAMSUNG DISPLAY CO LTD

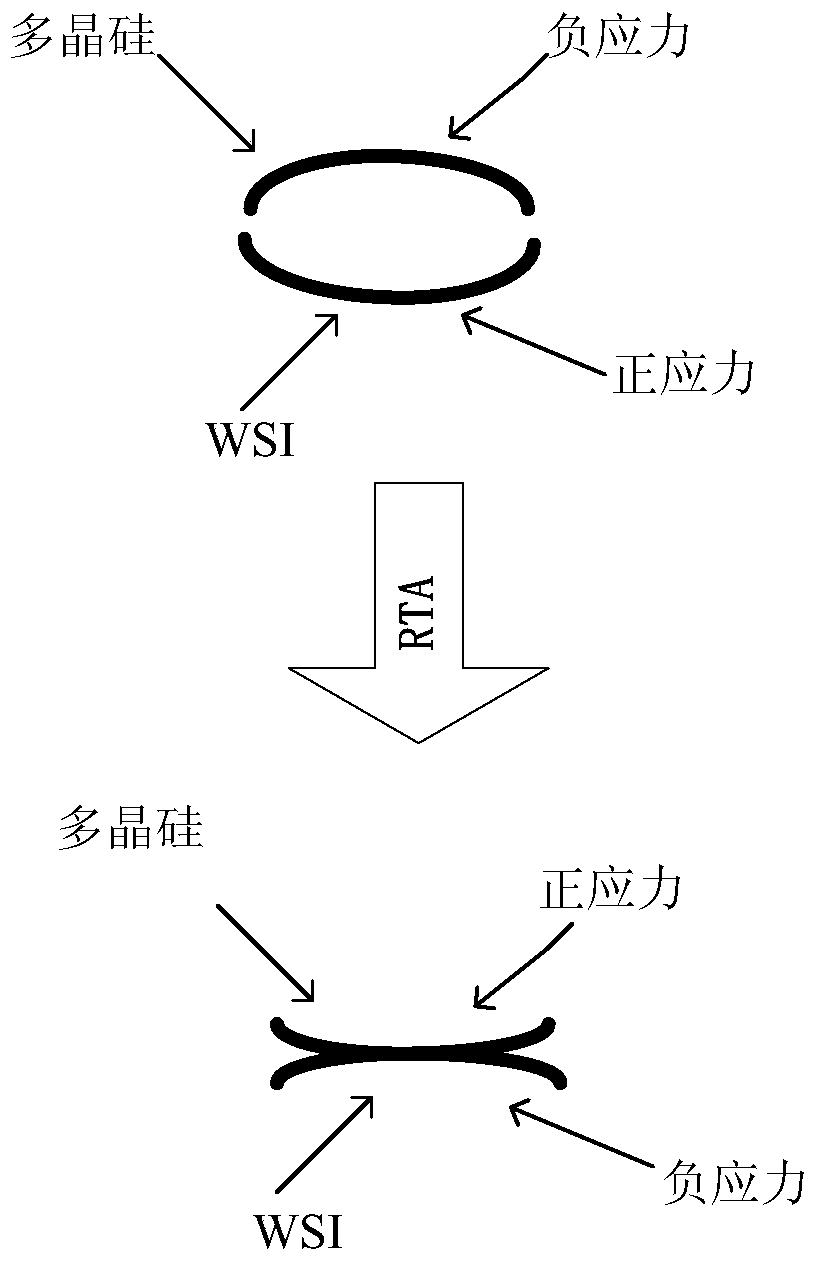

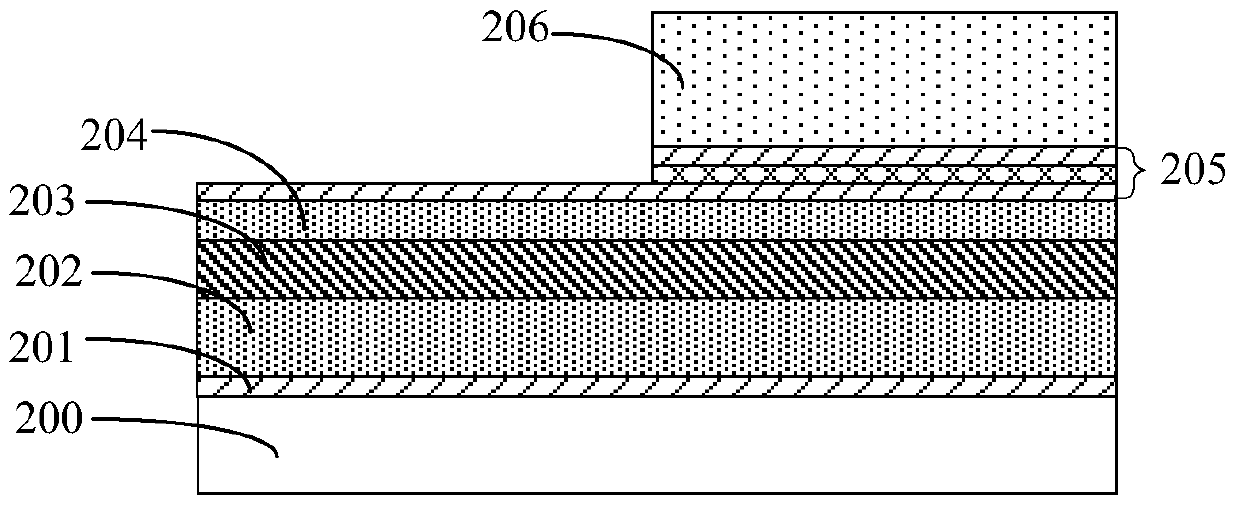

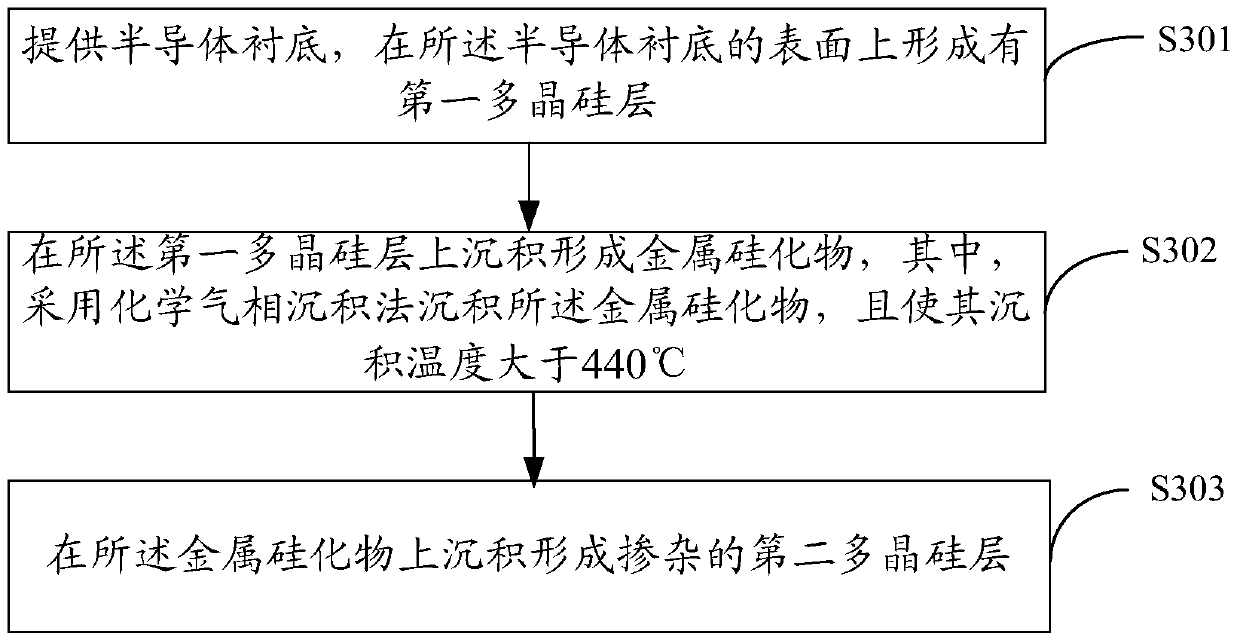

A method of manufacturing a semiconductor device

ActiveCN106816370BIncrease deposition temperatureExtend deposition timeSemiconductor/solid-state device manufacturingPower semiconductor deviceSalicide

The invention provides a method for manufacturing a semiconductor device and relates to the technical field of a semiconductor. The method comprises steps that a semiconductor substrate is provided, and a first polysilicon layer is formed on the surface of the semiconductor substrate; metal silicide is formed on the first polysilicon layer through deposition, the metal silicide is deposited in an chemical vapor deposition method, and deposition temperature is made to be greater than 440 DEG C; a second doped polysilicon layer is formed on the metal silicide through deposition. According to the manufacturing method, through enhancing the deposition temperature of the metal silicide and prolonging the deposition time non-doped polysilicon in the polysilicon layer on the metal silicide, stress of corresponding material layers is reduced, a problem of peeling of the metal silicide and the upper-layer polysilicon layer caused by change of stress generated in a later annealing process can be avoided, and thereby the yield and performance of devices are improved.

Owner:CSMC TECH FAB2 CO LTD

Sewage treatment system for aluminum plastic waste recovery production

PendingCN114455746AEasy to cleanReduce flow rateTreatment involving filtrationMultistage water/sewage treatmentActivated carbonPlastic waste

The invention discloses a sewage treatment system for aluminum-plastic waste recovery production, and belongs to the technical field of aluminum-plastic waste recovery production, the sewage treatment system comprises a water inlet channel, a sedimentation tank is connected behind the water inlet channel, a first filter frame is arranged in the water inlet channel, the first filter frame is of a structure with an opening at the front end and a rear baffle at the rear end, and the rear baffle is of a net plate structure; the interior of the sedimentation tank is divided into a first sedimentation chamber and a second sedimentation chamber through a partition plate, and a liftable filter plate is arranged on the partition plate; a water outlet is formed in a rear wall plate of the second deposition chamber, a liftable water outlet baffle is arranged at the water outlet, and the water outlet baffle is connected with the filter plate through a connecting plate; a water inlet pipe with a top opening is connected behind the second deposition chamber, the lower end of the water inlet pipe is communicated with a horizontally arranged water outlet pipe, a second filter frame and an activated carbon frame are sequentially arranged in the water outlet pipe, and filter plate assemblies are arranged at the bottom of the second filter frame in an array mode.

Owner:桃江县博强再生资源有限公司

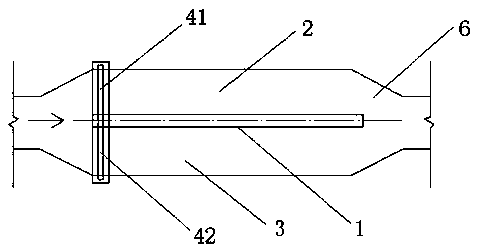

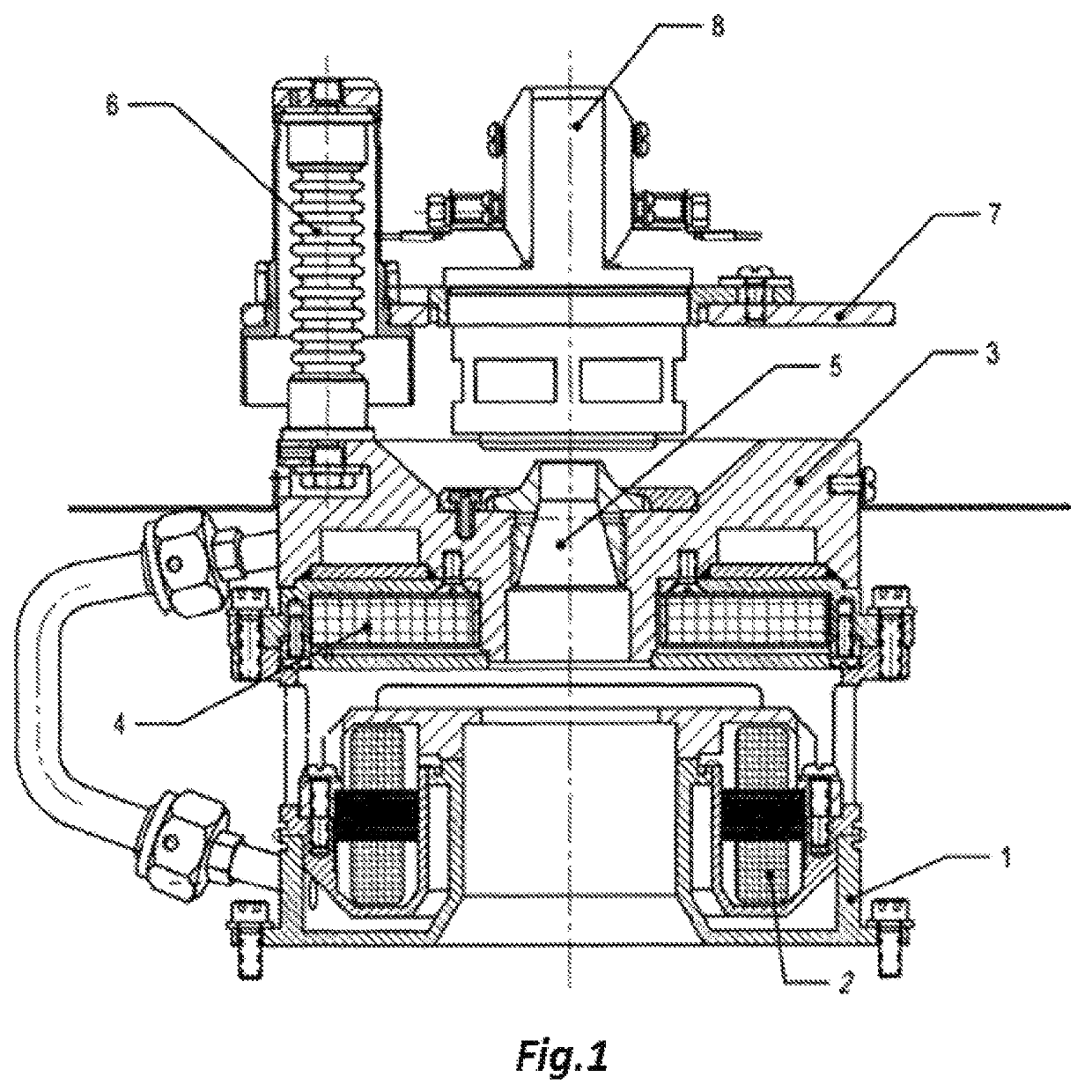

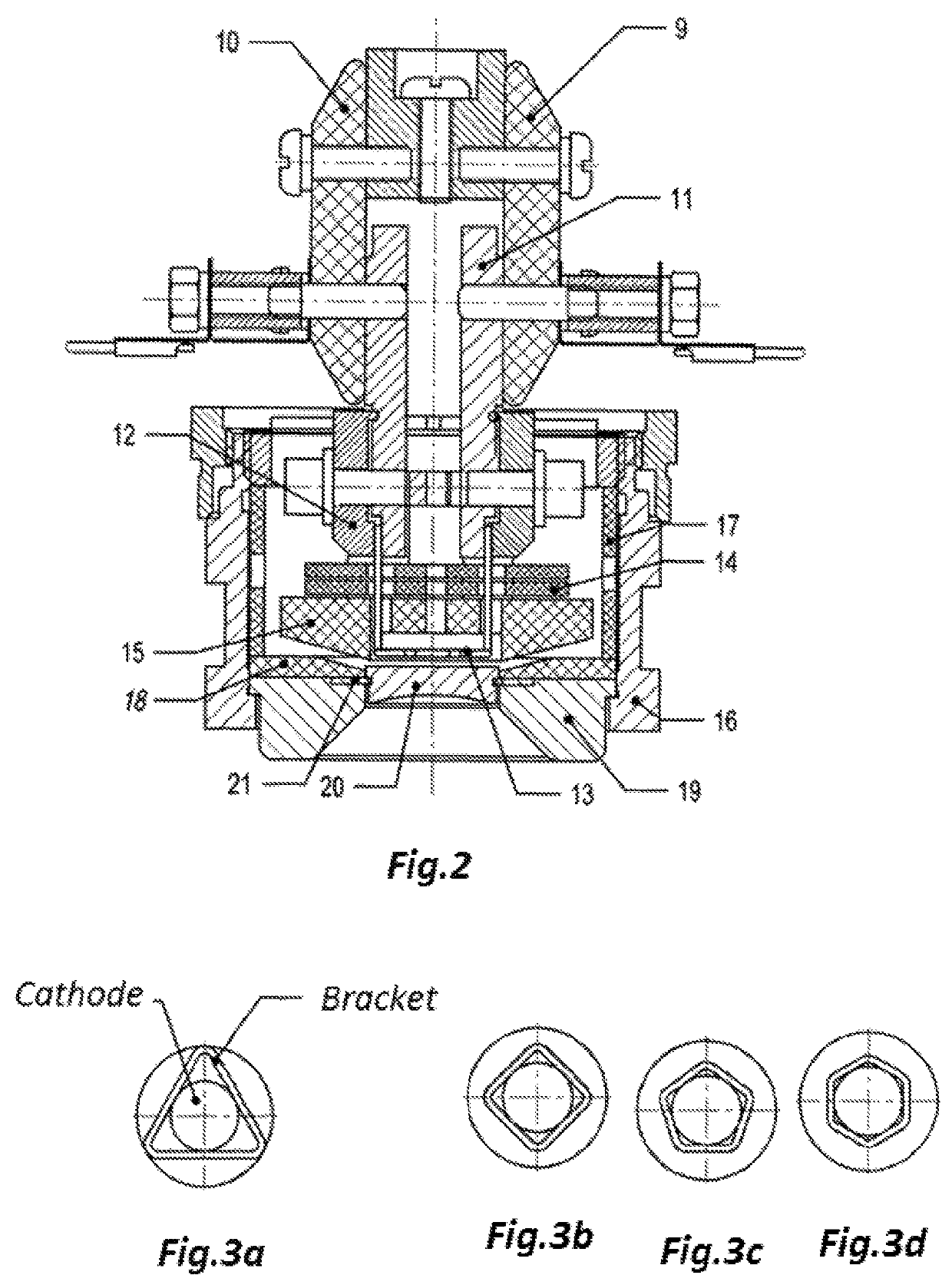

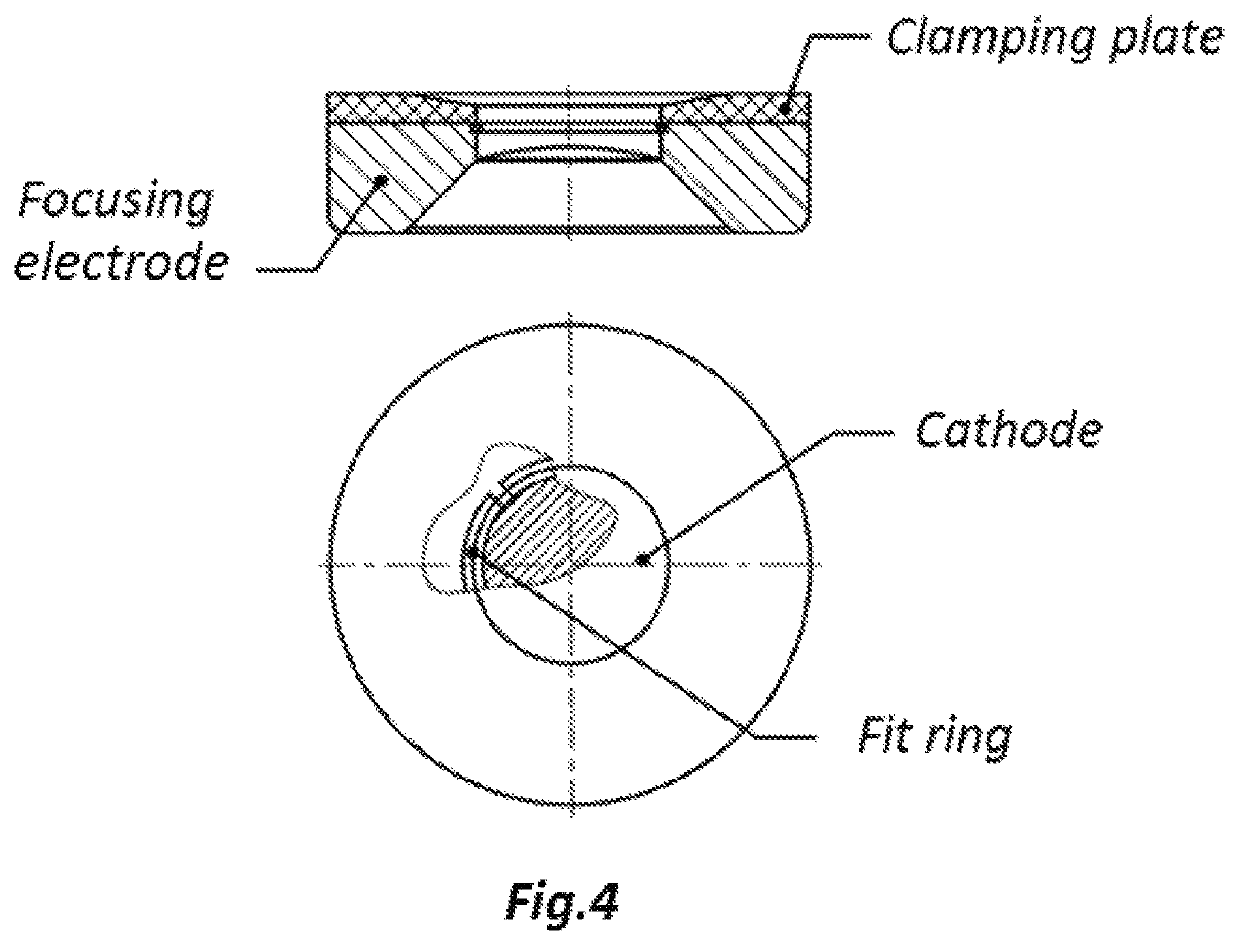

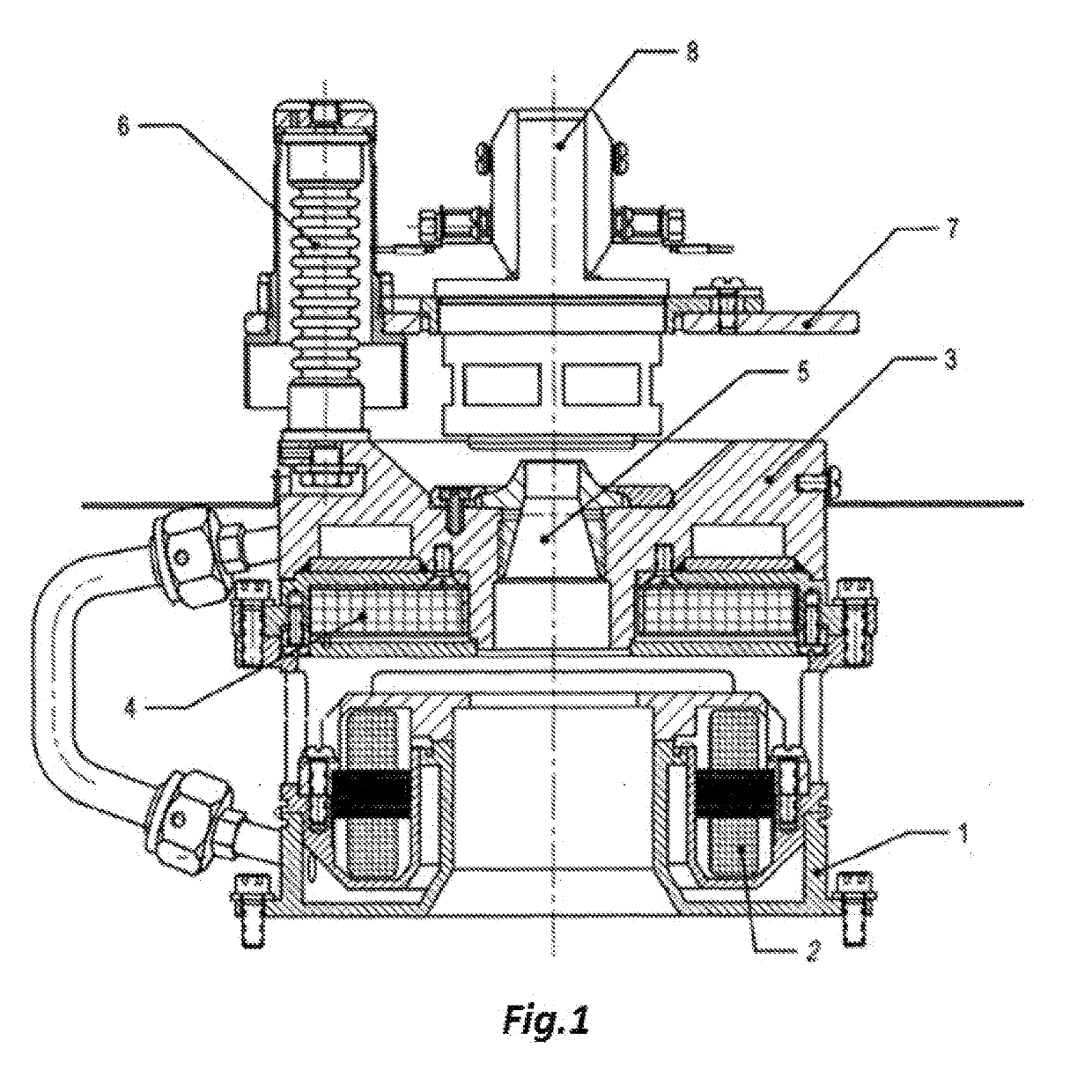

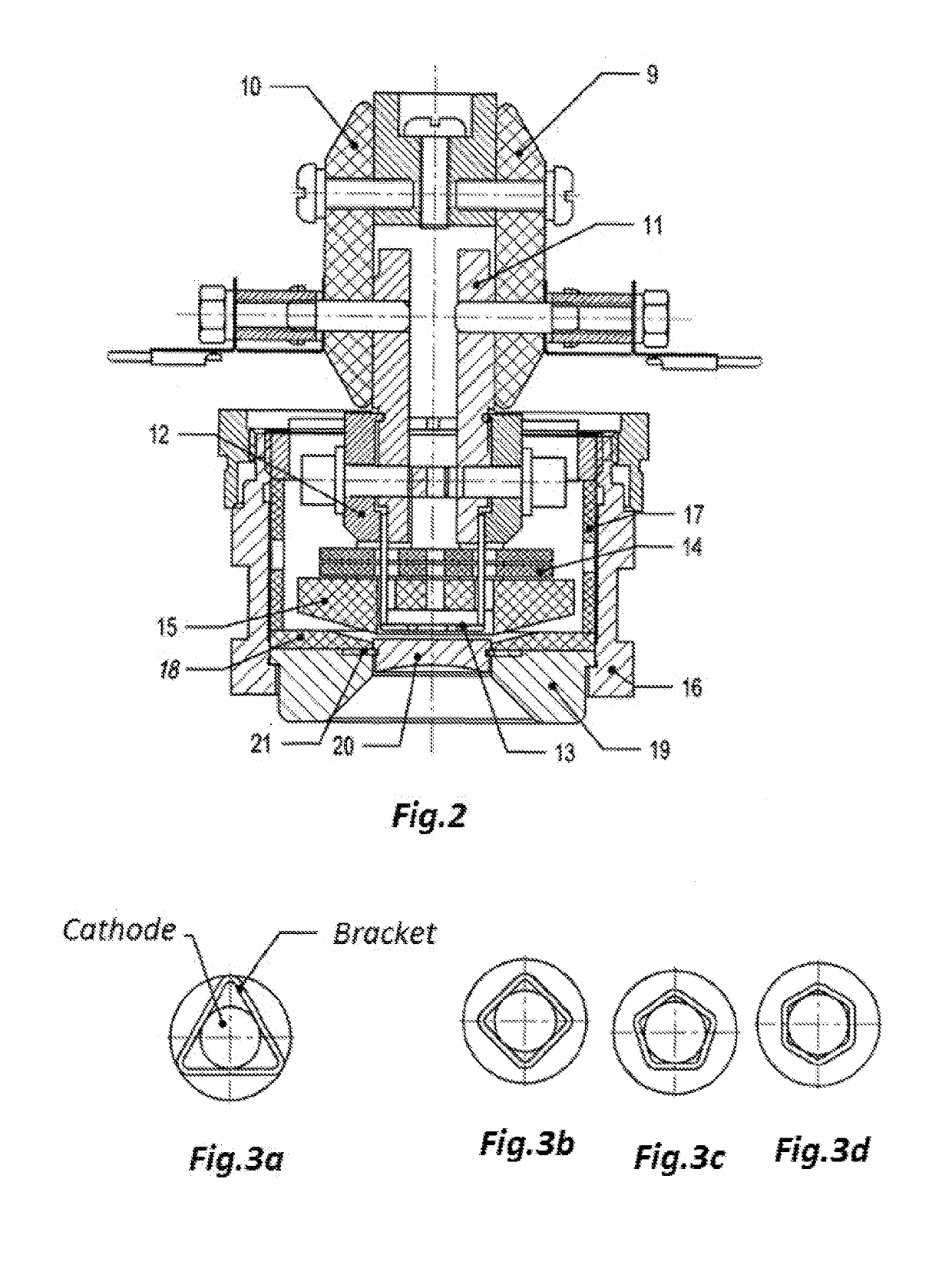

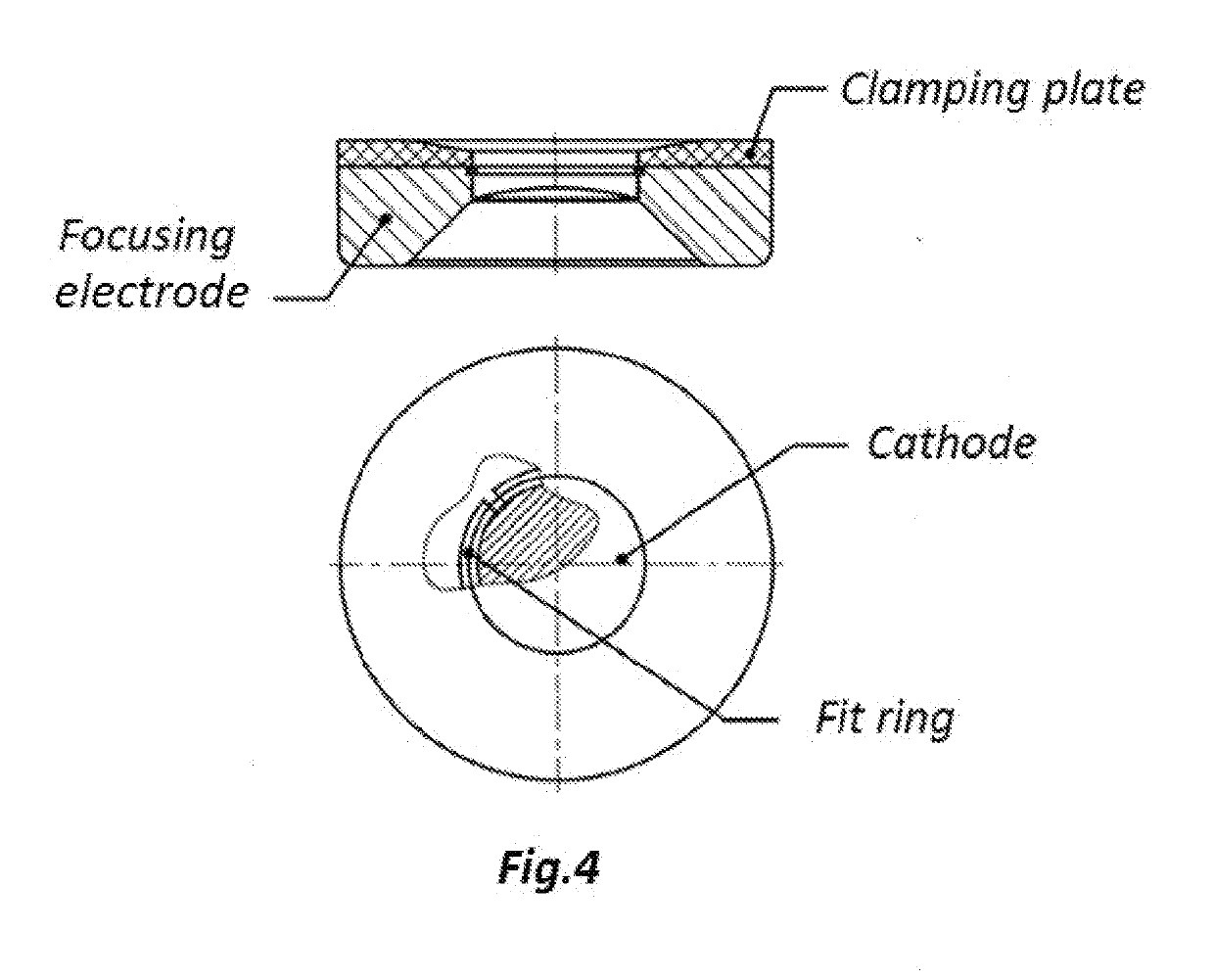

Axial electron gun

ActiveUS10636617B2Compensation changesMaintain positionElectric discharge tubesDischarge tube solid thermionic cathodesReactive gasElectron bombardment

The invention relates to the field of fabrication of new materials and coatings and may be used in plants designed for electron-beam heating, melting and evaporating of materials in vacuum or reactive gas atmosphere. The disclosed axial electron gun that comprises, in particular, the primary and secondary cathodes and features the figure-shaped holder used for maintaining a stable position of the secondary cathode relative to the electron-beam axis of the axial gun and the pulsed voltage that is applied between the cathodes for electron bombardment of the secondary cathode. The invention ensures an improved stability of process parameters and operation of the electron gun.

Owner:PATON TURBINE TECH LLC

Axial electron gun

ActiveUS20190214220A1Compensation changesMaintain positionElectric discharge tubesDischarge tube solid thermionic cathodesPulse voltageNew materials

The invention relates to the field of fabrication of new materials and coatings and may be used in plants designed for electron-beam heating, melting and evaporating of materials in vacuum or reactive gas atmosphere. The disclosed axial electron gun that comprises, in particular, the primary and secondary cathodes and features the figure-shaped holder used for maintaining a stable position of the secondary cathode relative to the electron-beam axis of the axial gun and the pulsed voltage that is applied between the cathodes for electron bombardment of the secondary cathode. The invention ensures an improved stability of process parameters and operation of the electron gun.

Owner:PATON TURBINE TECH LLC

A method and device for preparing a coating by nanosecond pulse laser cladding

InactiveCN103849872BImprove bindingEasy to processChemical vapor deposition coatingNanosecond laserPhysical chemistry

The invention discloses a method and a device for preparing a coating by using nanosecond pulse laser cladding, belonging to the technical field of the preparation of coatings on material surfaces through laser cladding, and aiming to solve the problems existing in the present nanosecond pulse laser cladding. According to the method and the device, a metal is deposited on the surface of a workpiece through MOCVD (metal organic chemical vapor deposition), and the surface of the workpiece is scanned by nanosecond laser light at the same time, so that the metal is cladded on the surface of the workpiece, and a coating with a micron or submicron level thickness is formed on the surface of the workpiece. The method and the device disclosed by the invention do not have special requirements for a substrate material, are wide in application range, and can meet the needs of the preparation of the coatings of plane workpieces and special-shaped workpieces; a prepared thin film coating has the advantages of densification, controllable thickness (micron or submicron) and firm film-substrate adhesion; meanwhile, the surface roughness of the workpiece subjected to processing is not less than that of the workpiece before cladding; the secondary processing such as grinding and polishing is not needed, so that the production cost is reduced; meanwhile, after being processed by the method and the device, the workpiece can not be deformed and can meet the processing requirements for precision workpieces.

Owner:SICHUAN INST OF MATERIALS & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com