Sewage treatment system for aluminum plastic waste recovery production

A sewage treatment system and waste recycling technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as inability to regulate sewage flow, inconvenient replacement of filter equipment, etc., to achieve Improve the flocculation effect, improve the filtration effect and reduce the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further illustrated by the following examples.

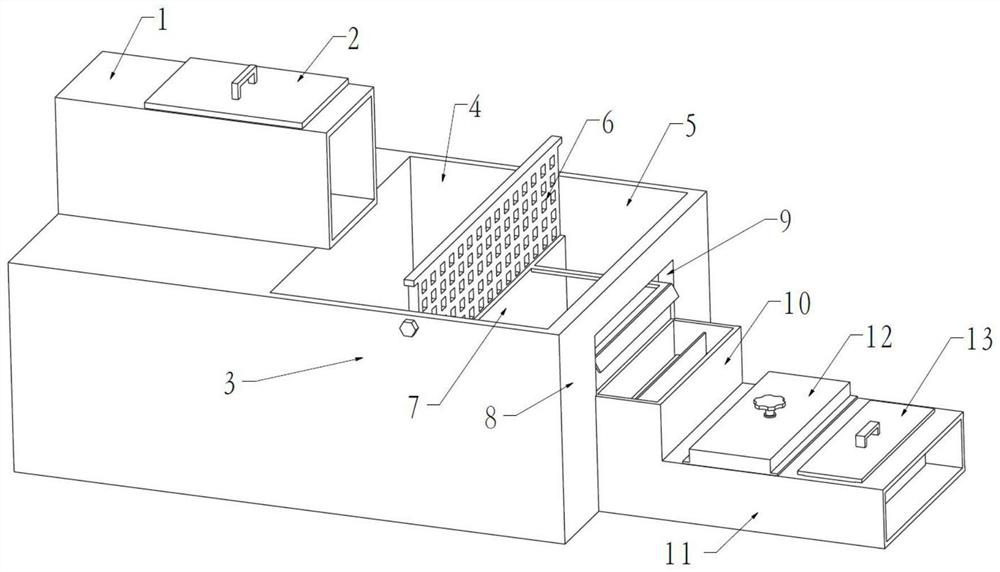

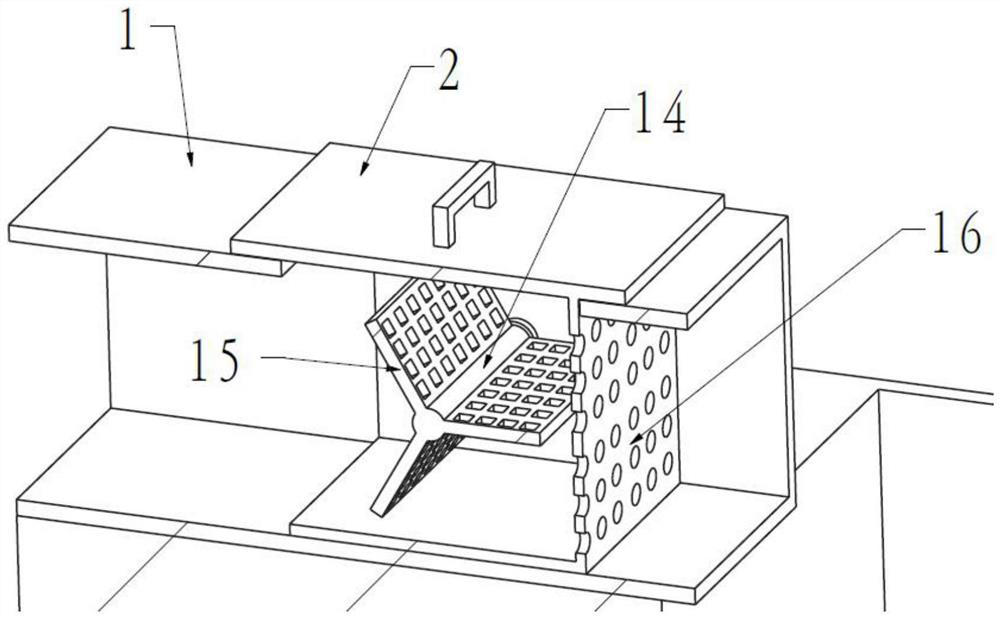

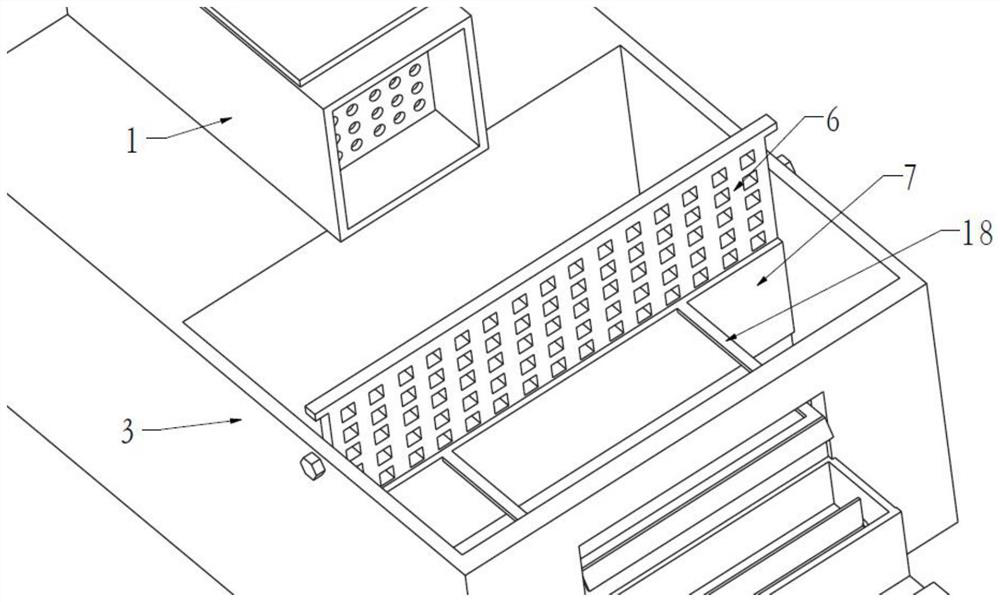

[0028] A sewage treatment system for the recycling and production of aluminum-plastic waste, comprising a water inlet channel 1 connected to a sedimentation tank 3 behind the water inlet channel 1, a first filter frame 2 is arranged in the water inlet channel 1, and the first filter frame 2 is the front end Opening rear end is provided with the structure of rear baffle plate 16, and rear baffle plate 16 is mesh plate structure; The first deposition chamber 4 and the second deposition chamber 5 are formed in the described sedimentation pool 3 by dividing plate 17, and the dividing plate 17 is provided with There is a liftable filter plate 6; the rear wall plate 8 of the second deposition chamber 5 is provided with a water outlet 9, and the water outlet 9 is provided with a liftable water outlet baffle 19, and the water outlet baffle 19 is connected with the connecting plate 18 and The filter plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com