Patents

Literature

467results about How to "For quick outflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rapid coating mixing device for medical treatment package, production, and printing

InactiveCN106890595AImprove the mixing effectStirring effect is evenTransportation and packagingMixer accessoriesEngineeringMedical treatment

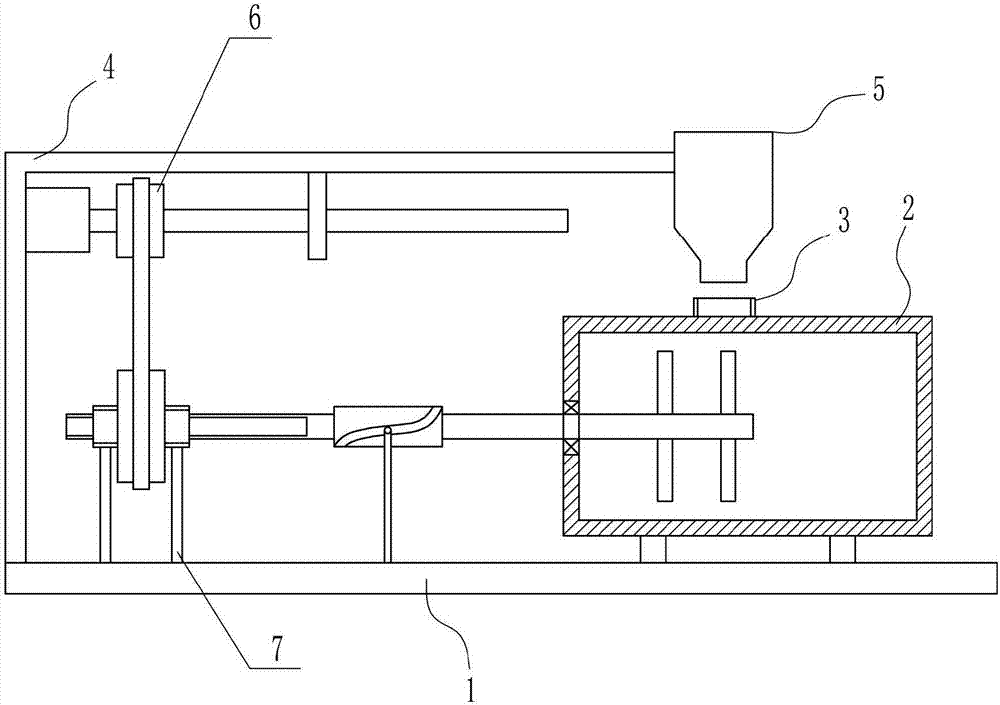

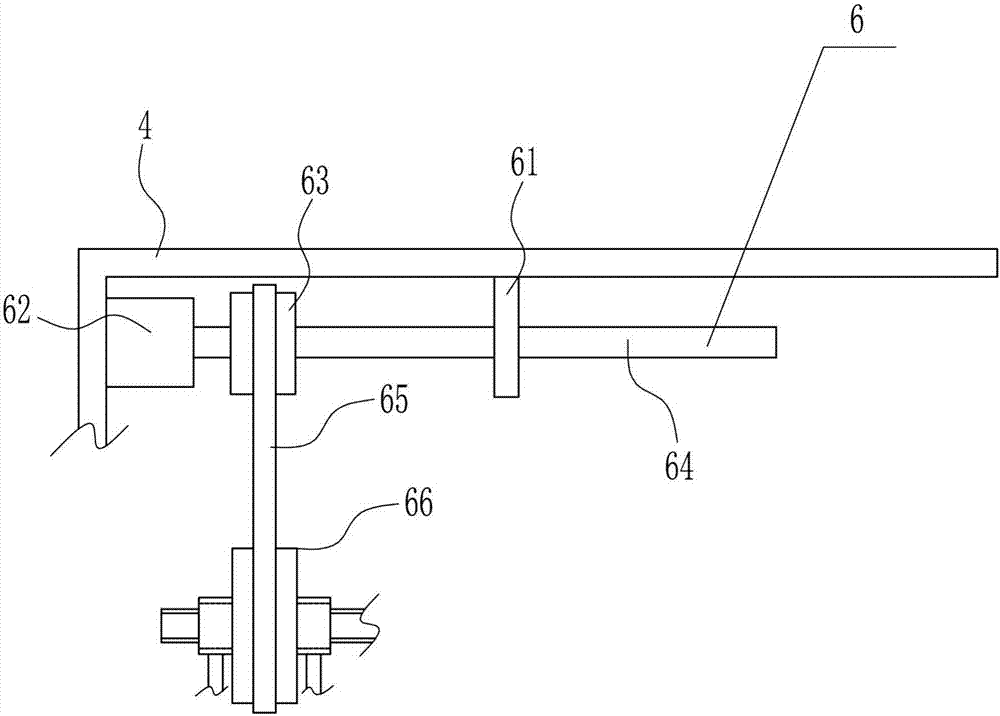

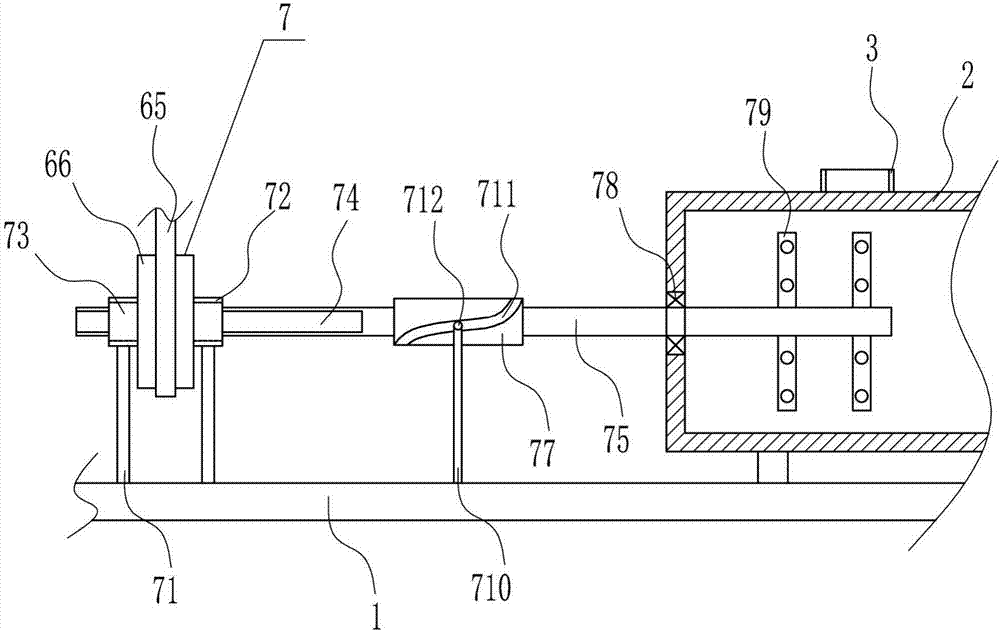

The invention relates to a coating mixer for medical treatment package, production, and printing, and particularly relates to a rapid coating mixing device for medical treatment package, production, and printing. The technical problem to be solved is to provide a rapid coating mixer with fast mixing speed and high working efficiency, capable of preventing coating from splashing and smudging people cloth and ground, and used for medical treatment package, production, and printing. In order to solve the technical problem, the invention provides the rapid coating mixing device for medical treatment package, production, and printing, comprising a bottom plate, a mixing frame, a feeding pipe, an L-type supporting plate, and a baiting hopper; the right side of the top part of the bottom plate is equipped with the mixing frame through bolt connection, and the left side of the top part of the mixing frame is connected with the feeding pipe. The mixing blade is rotated while crossly moved, so that the coating mixing is more uniform; an air outlet pipe sprays air, the coating is blown, and thus the coating mixing speed is accelerated.

Owner:滁州钰禾文具制品有限公司

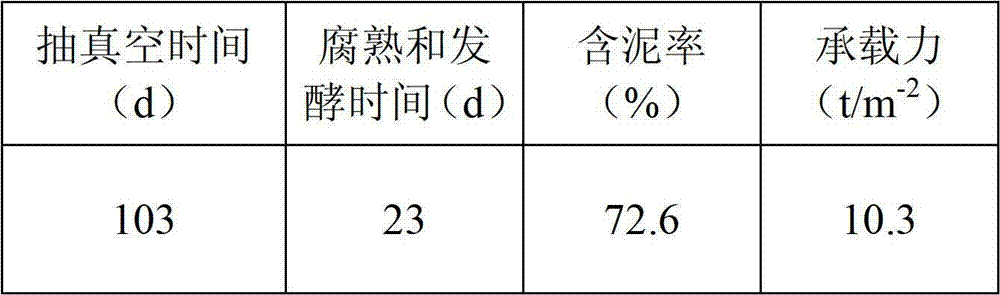

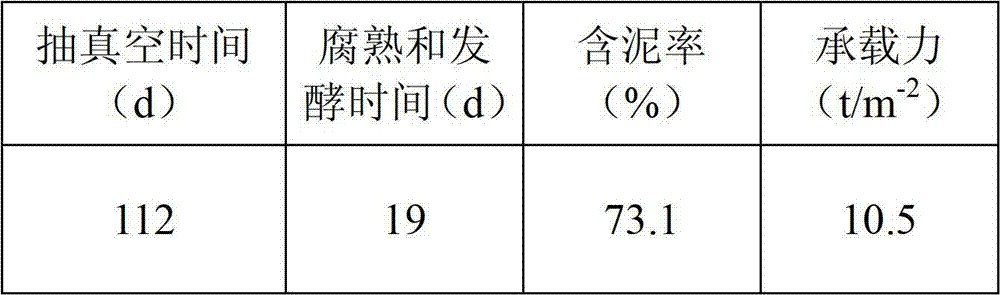

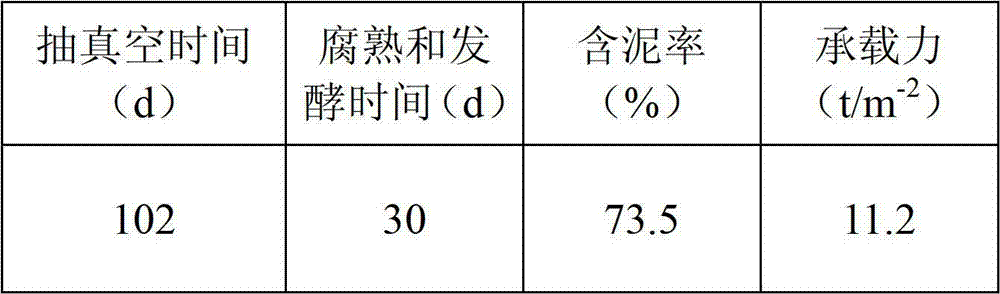

Method for promoting rapid drying of dredged silt by microorganism

ActiveCN102815854ARapid flocculation sedimentation concentrationLow costSludge treatment by de-watering/drying/thickeningBiological sludge treatmentLife activityDecomposition

The invention relates to a method for promoting rapid drying of dredged silt by a microorganism. The method includes: taking straw and other organic matters as a substrate, conducting anaerobic fermentation and decomposition, burying the substrate in a silt storage yard, pre-burying a vacuum pumping pipe network system, inputting dredged silt, and then adding a flocculant and a coagulant aid to perform initial concentration, vacuum pumping, compression and other processes. The method for promoting rapid drying of dredged silt by a microorganism makes use of life activities of the microorganism and the produced gas to change the compact silt state formed during vacuum pumping, makes the silt become loose and porous, promotes flow of moisture, thereby improving the water pumping and drainage effect of vacuum preloading, and transforming the dredged silt from a fluid state to a plastic state or semi-solid state rapidly. Thus, the method realizes rapid dewatering and drying of dredged sludge, and has the characteristics of low cost and short construction period.

Owner:JIANGSU JIANGDA ECOLOGICAL SCI & TECHCO

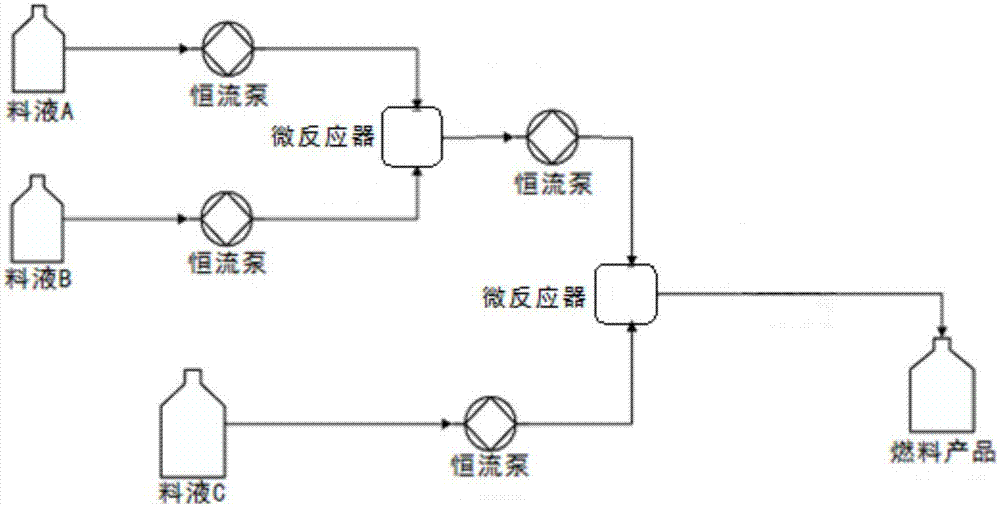

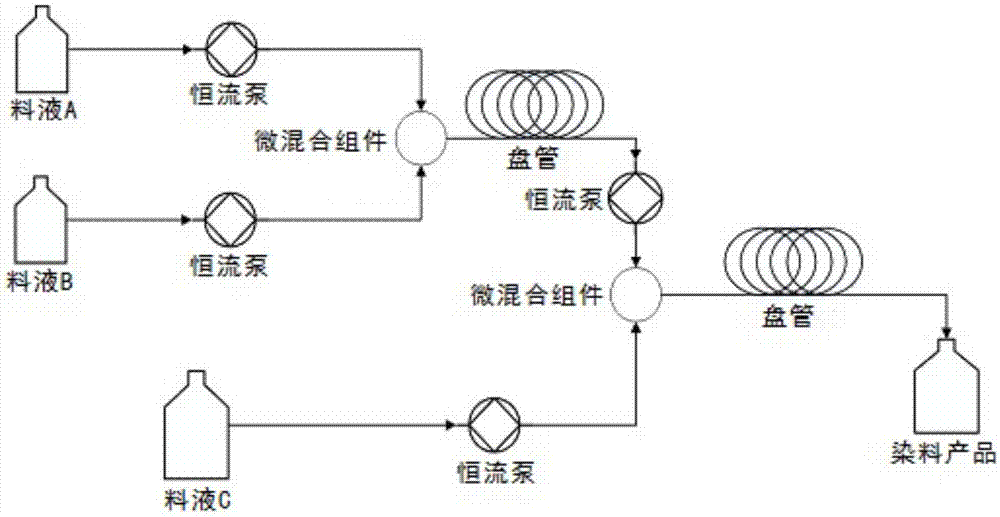

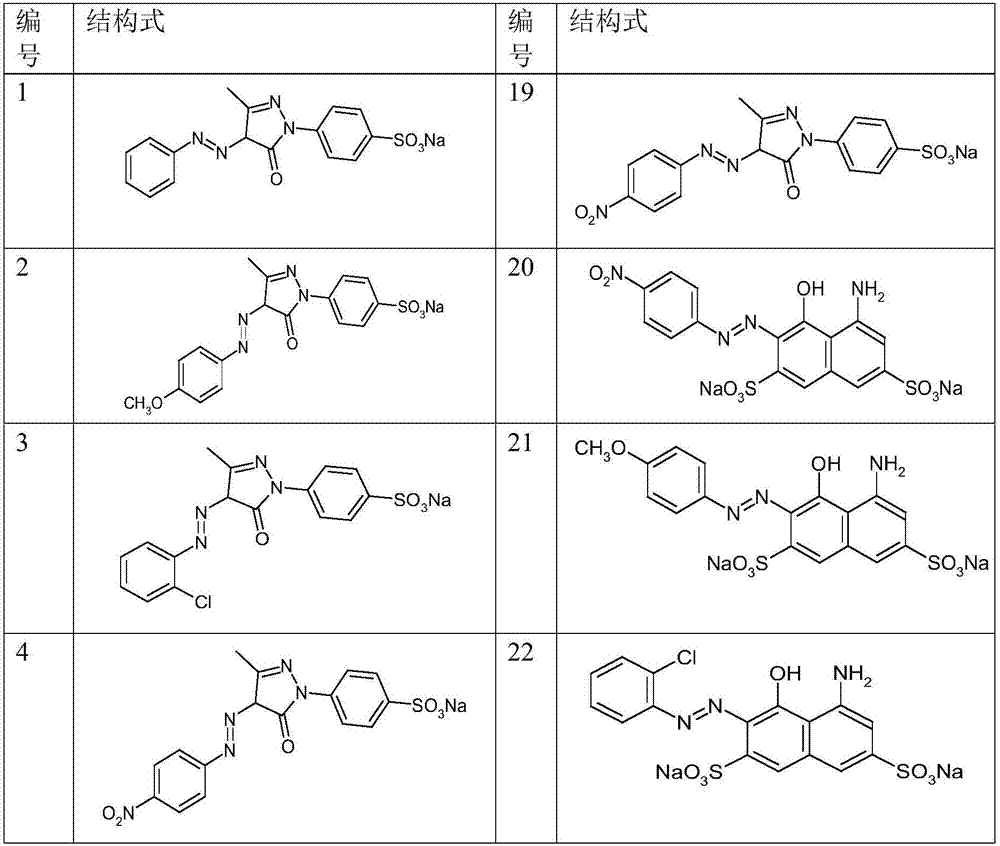

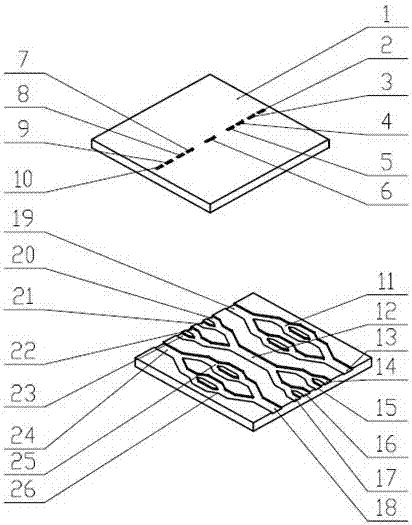

A method for continuously preparing azo dye in micro-reactors

ActiveCN107488361AImprove reaction efficiencyShort stayMonoazo dyesEnvironmentally friendlyPhotochemistry

The invention discloses a method for continuously preparing azo dye in micro-reactors in the field of dye synthesis. The azo dye is prepared by firstly subjecting a sodium nitrite solution, an aromatic primary amine and an inorganic acid to a diazotization reaction at room temperature in a first micro-reactor to generate an aromatic primary amine diazonium salt; and then subjecting the aromatic primary amine diazonium salt and a coupling component to a coupling reaction in a second micro-reactor to generate the azo dye. Continuous preparation of the azo dye is achieved by utilizing the micro-reactors, a process is simple, a reaction period is short, and a reaction process can be easily monitored and controlled. Addition of an excessive amount of the sodium nitrite and the coupling agent to increase the reaction speed is not required so that raw materials are saved and the method is environmentally friendly. Reaction liquid in the micro-reactors achieves high-speed collision mixing, a uniform reaction environment is formed immediately, the reaction efficiency is high, and the yield and quality of a reaction product are greatly improved.

Owner:深圳智微通科技有限公司

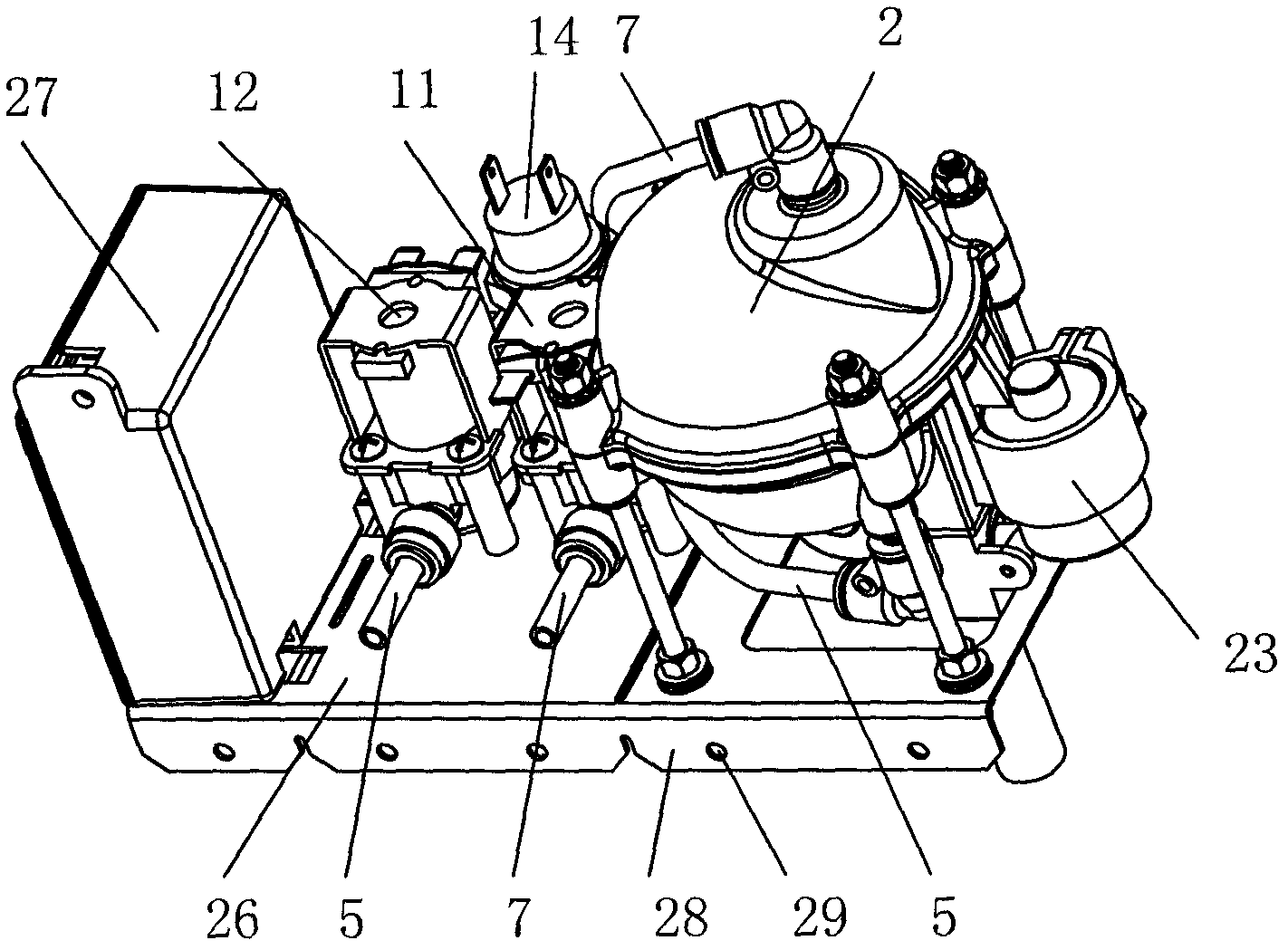

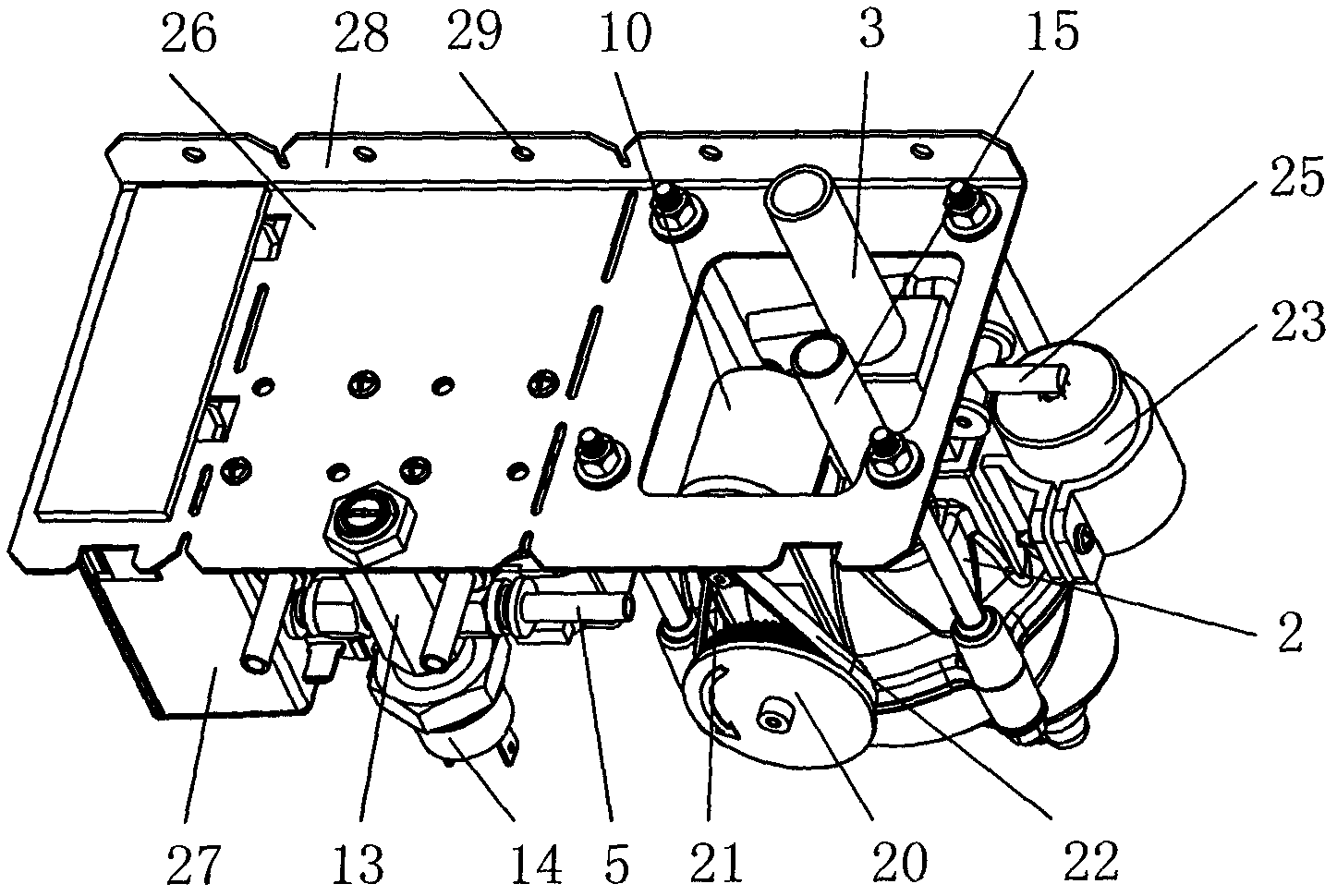

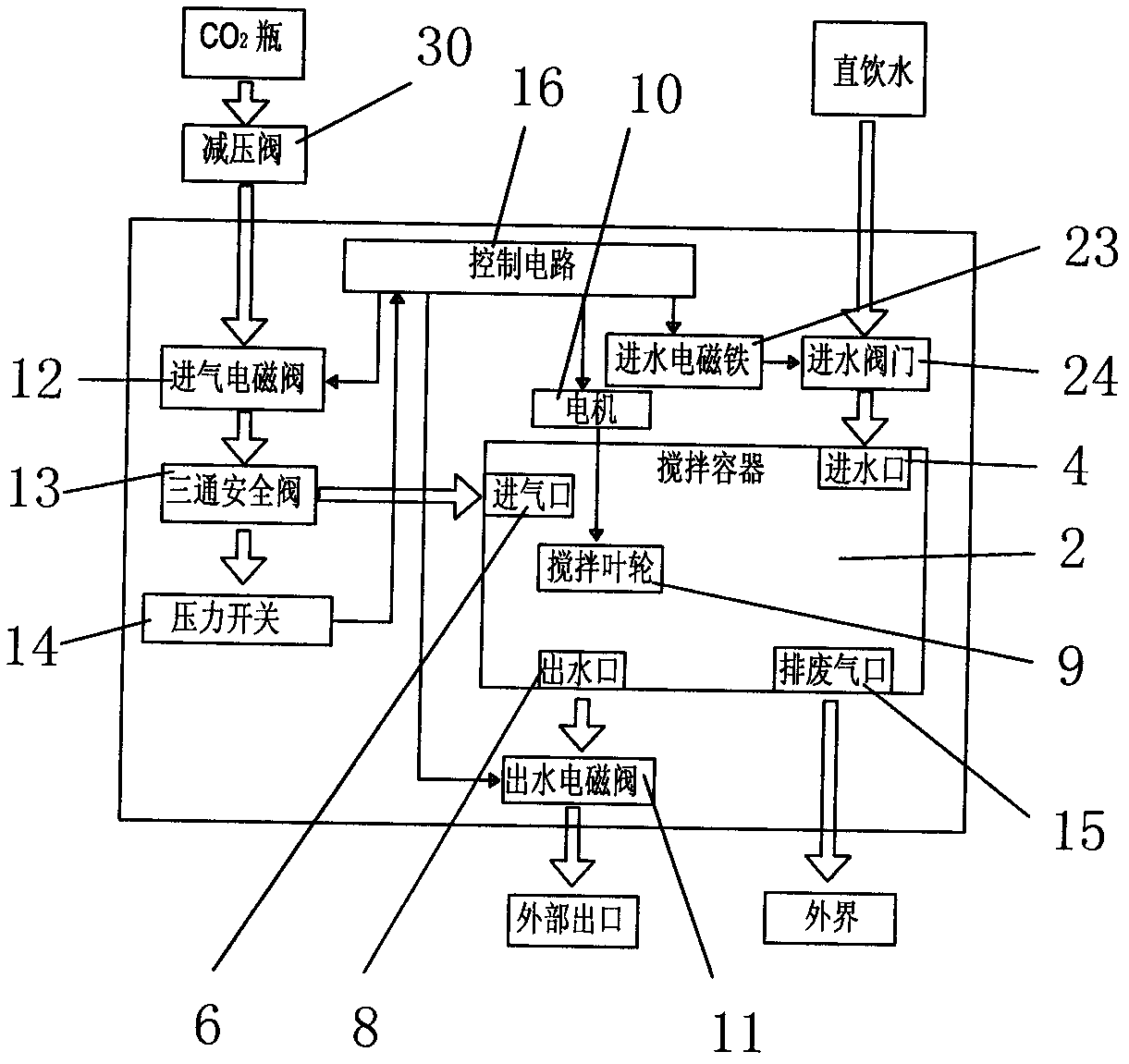

Soda water preparation device and water dispenser with same

ActiveCN102578913ALow installation requirementsFlexible installationBeverage vesselsImpellerControl circuit

The invention relates to a soda water preparation device. The soda water preparation device comprises a stirred vessel and a control circuit, wherein a water inlet connected with a water inlet pipe and an air inlet connected with an air inlet pipe are arranged at the upper part of the stirred vessel, a water outlet connected with a water outlet pipe is arranged at the lower part of the stirred vessel, paddle wheels driven by a motor are arranged in the stirred vessel, a water inlet controller is arranged on the water inlet pipe, a water outlet electromagnetic valve is arranged on the water outlet pipe, an air inlet electromagnetic valve and a three-way safety valve are arranged on the air inlet pipe, and a pressure switch is arranged on the three-way safety valve; an exhaust gas discharging port is arranged at the upper part of the stirred vessel, and a floating ball device is arranged in the stirred vessel; and the input end of the control circuit is connected with the pressure switch, the output end of the control circuit is connected with the water inlet controller, the air inlet electromagnetic valve, the motor and the water outlet electromagnetic valve. The invention also relates to a water dispenser with the soda water preparation device, and the water dispenser has the function of preparation of soda water, comprehensively promotes the functions of the existing water dispenser, and more conforms to the living demands of modern people.

Owner:NINGBO BAINIAN ELECTRIC APPLIANCE

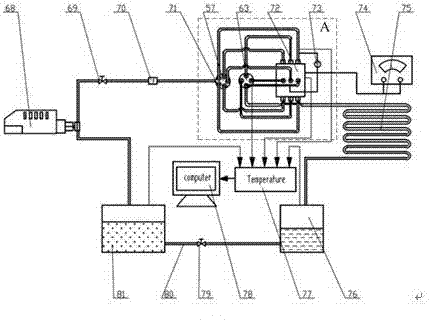

Micro-channel heat exchanger and flow heat exchange experiment device

ActiveCN106879227ABuck downUniform temperature distributionStructural/machines measurementCooling/ventilation/heating modificationsPlate heat exchangerEngineering

The invention relates to a micro-channel heat exchanger and a flow heat exchange experiment device. The micro-channel heat exchanger is characterized in that the heat exchanger at least comprises an upper cover plate and a lower cover plate; three flow channels, namely, a first flow channel, a second flow channel and a third flow channel, and the inlets and outlets of the three flow channels are machined on the upper cover plate and the lower cover plate respectively; the first flow channel, the second flow channel and the third flow channel are each composed of two Y-shaped flow channels; the first flow channel and the third flow channel are formed by connecting the bifurcate ends of two Y flow channels, and the second flow channel is formed by connecting the non-bifurcate ends of two Y flow channels; and when fluid flows in the first flow channel, the second flow channel and the third flow channel, the flow direction at the inlets and the flow direction at the outlets are perpendicular to each other. The heat dissipation performance is good. Electronic equipment of high heat flux density can be kept at uniform temperature.

Owner:XIDIAN UNIV

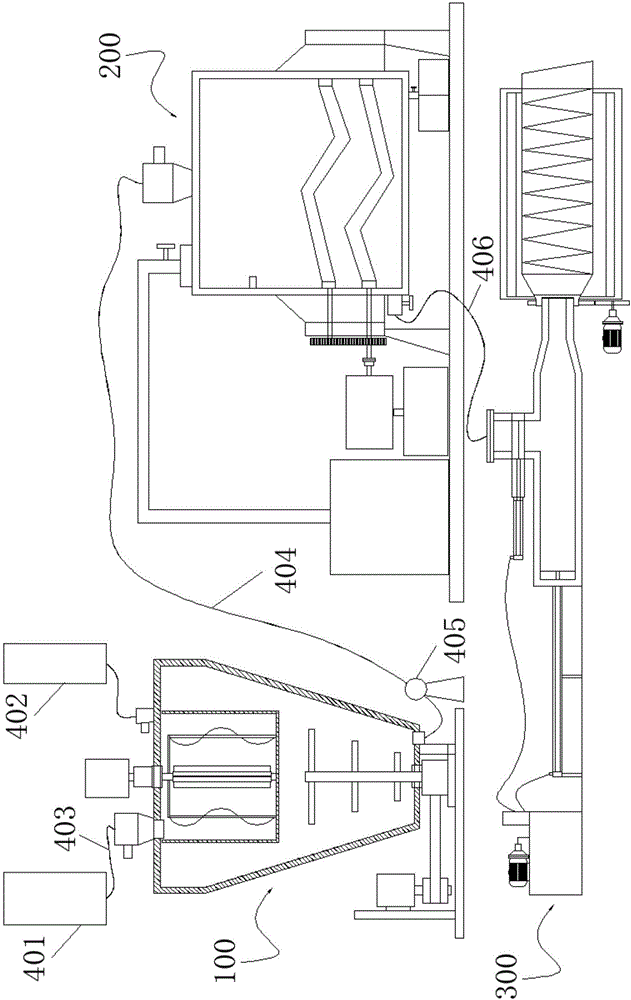

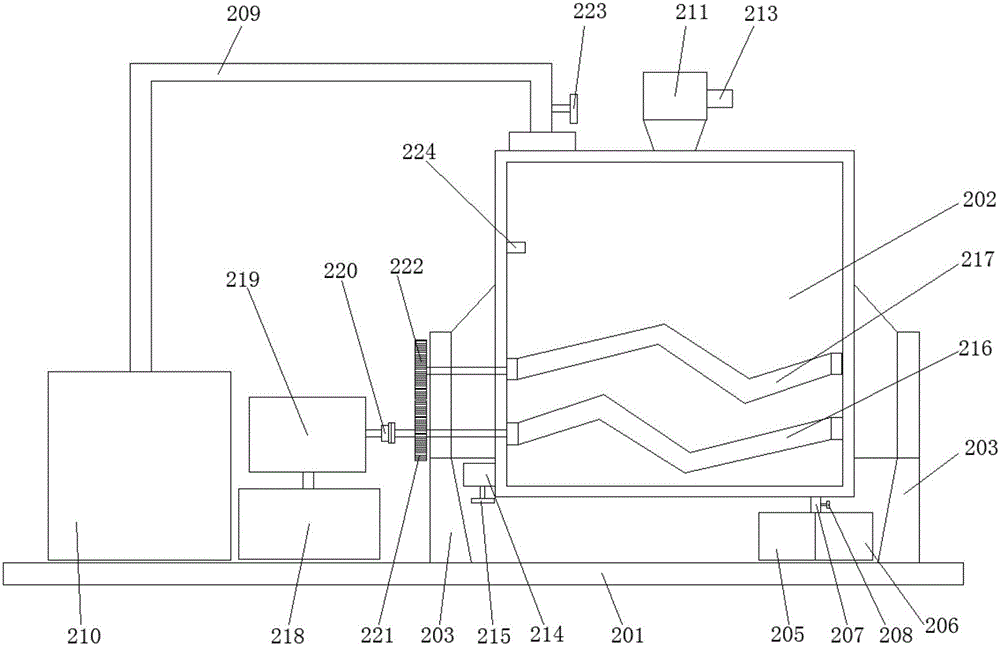

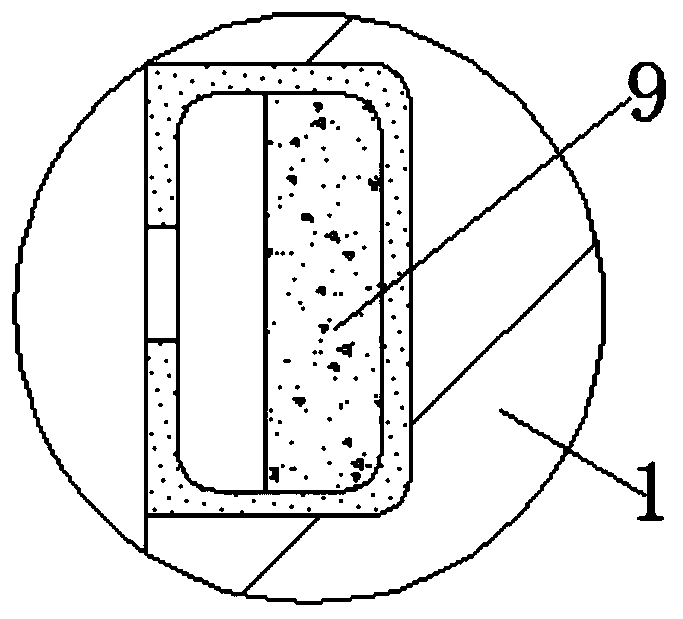

Granulation production line for composite material machining

InactiveCN106273042AAccurate and reliable measurementAccurate outputCoatingsProduction lineMixed materials

The invention discloses a granulation production line for composite material machining. The granulation production line for composite material machining comprises a mixing module for mixing materials, a kneader module for kneading the mixed materials, and a granulator module for granulating the kneaded materials; a mixing discharge port of the mixing module is connected to a kneader feed port of the kneader module through a pumping pipeline; a feeding pump is mounted on the pumping pipeline; a kneader discharge port of the kneader module is connected to a granulator feed port of the granulator module through a blanking pipeline; the mixing module includes a first feed port and a second feed port; a first weighing machine and a second weighing machine are respectively arranged on the first feed port and the second feed port; a first batching tank and a second batching tank are respectively connected to the first feed port and the second feed port through feeding pipelines; and a feed port weighing machine is arranged on the kneader feed port of the kneader module.

Owner:广东银圭新材料科技有限公司

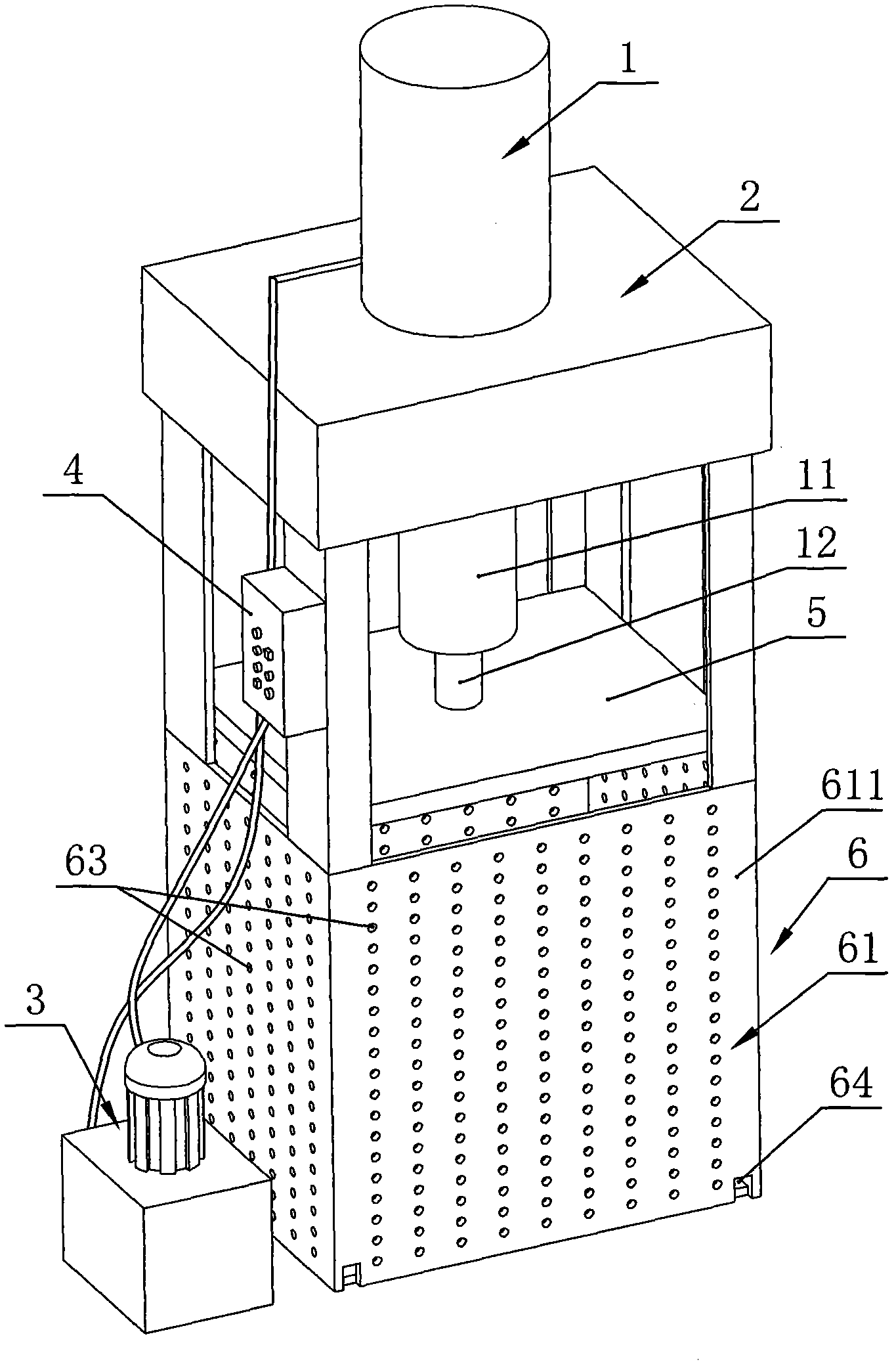

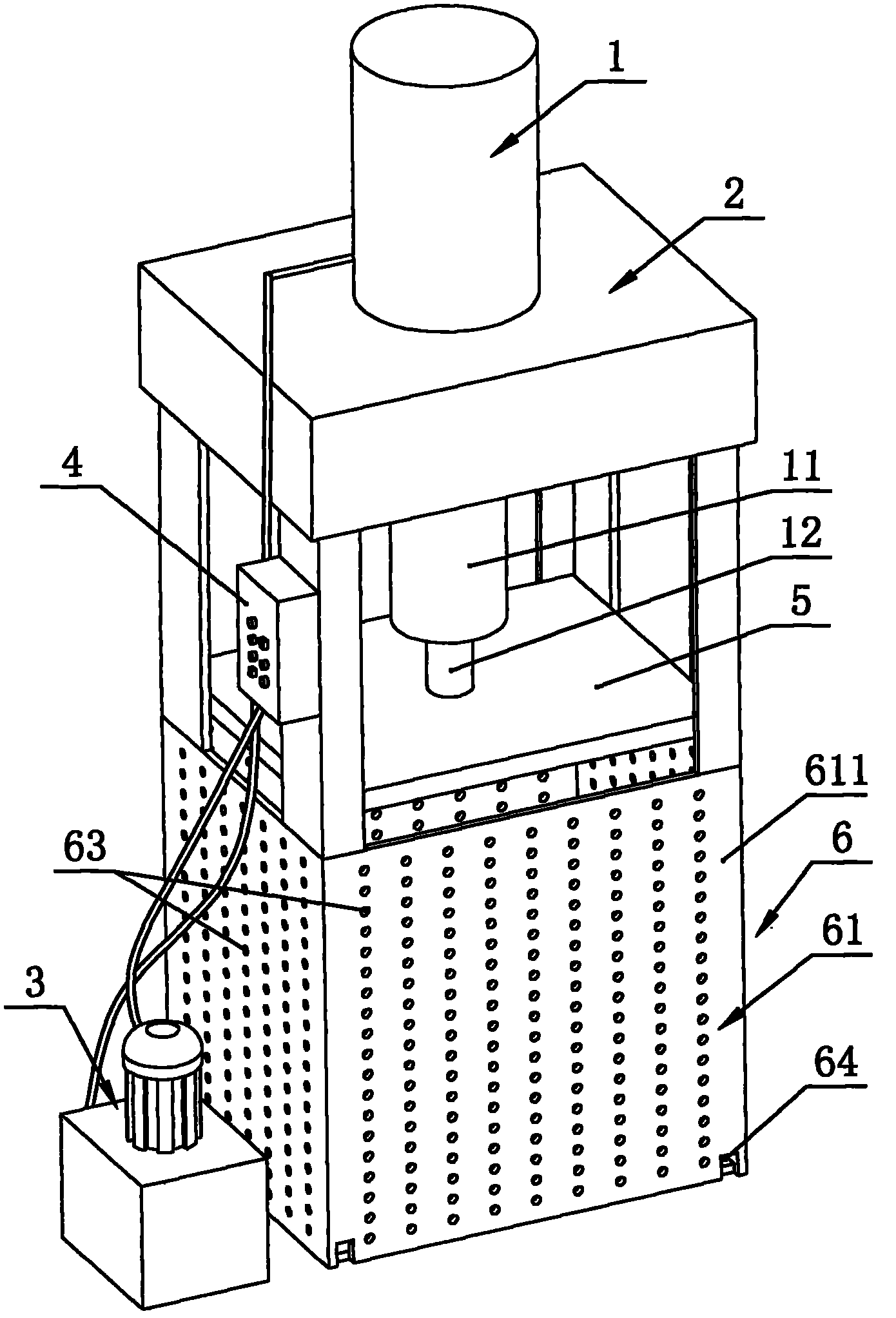

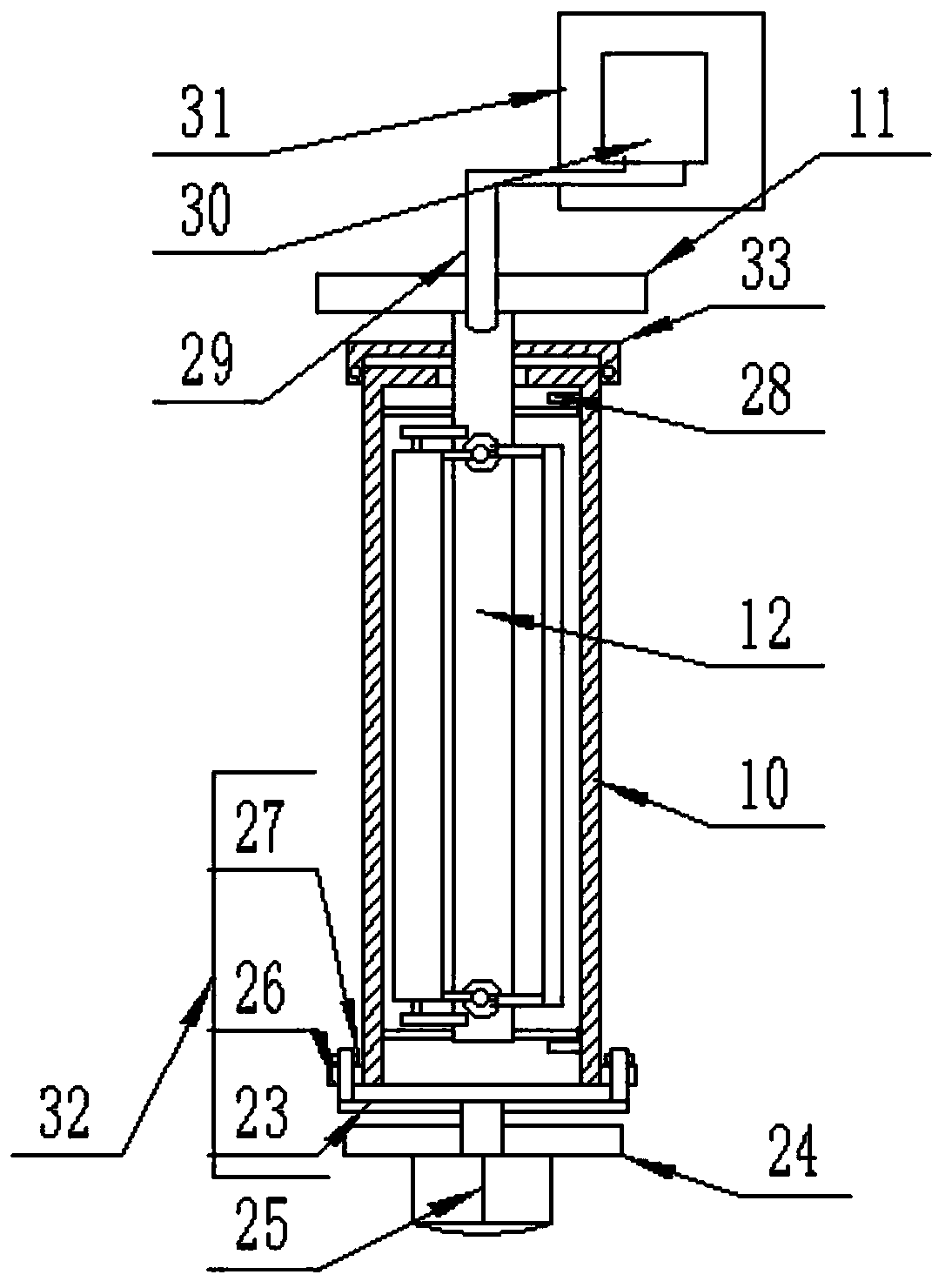

Automatic hydraulic mudjacking machine

InactiveCN102059815AThe grouting method is simplifiedEasy to placePressesHydraulic cylinderPulp and paper industry

The invention discloses an automatic hydraulic mudjacking machine which comprises a hydraulic cylinder, a hydraulic cylinder base, a hydraulic oil pump and a control device, wherein the hydraulic cylinder is fixed on the hydraulic cylinder base; the hydraulic oil pump serves as a power source of the hydraulic cylinder; the control device is arranged between the hydraulic oil pump and the hydraulic cylinder; the hydraulic cylinder comprises a cylinder body and an output shaft; and the output end of the output shaft is fixedly provided with a pressing plate, so that the automatic hydraulic mudjacking machine is suitable for extruding various pulp products, thus the water of the products can be drained quickly. Because the traditional manual mudjacking method is replaced by the fully automatic hydraulic machine, the original mudjacking mode of time and labor waste is simplified, time and labor are saved, and the quantity of extrudable pulp at one step is increased greatly compared with that of the prior art. In addition, an accommodating shell is additionally arranged below the mudjacking machine, so that bags for storing the pulp are more convenient to place; and simultaneously, a drain hole and a drain tank are additionally arranged on the accommodating shell, thus the water drained from the pulp can flow quickly out of the accommodating shell.

Owner:周毅勇

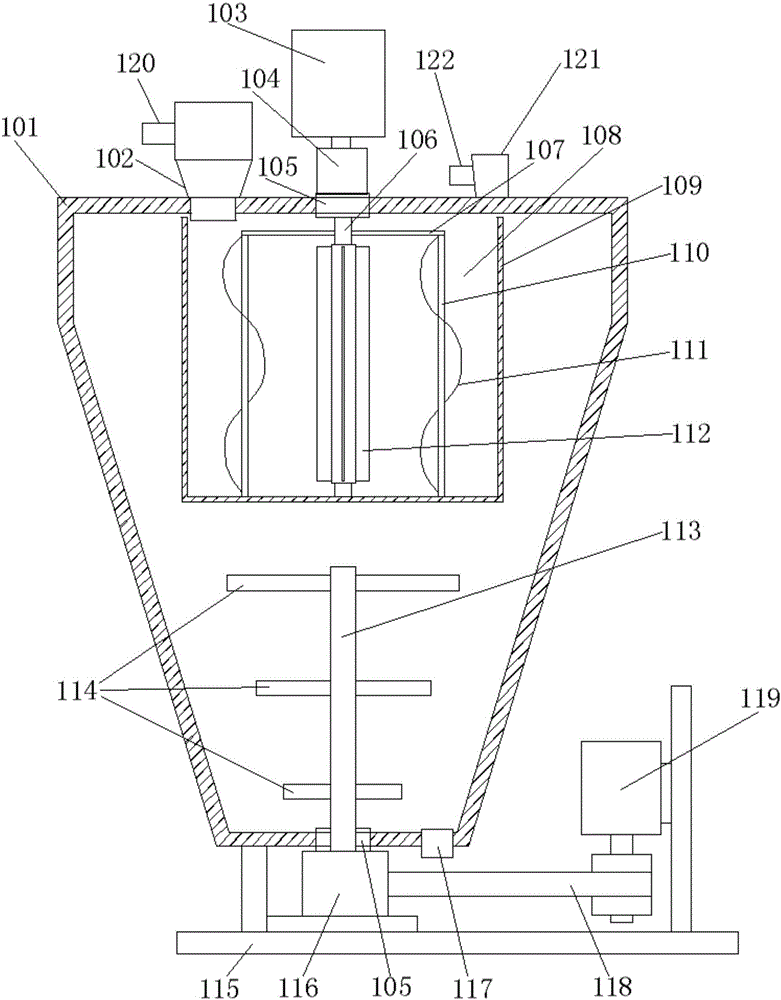

Demounting and recycling device for abandoned streetlamp shell

InactiveCN106975558ATo achieve the purpose of preliminary dismantlingAvoid spillingGrain treatmentsEngineeringSmall hole

The invention relates to a dismantling and recycling device, in particular to a dismantling and recycling device for discarded street lamp shells. The technical problem to be solved by the present invention is to provide a dismantling and recycling device for waste street lamp shells capable of multi-stage dismantling of waste street lamp shells. In order to solve the above technical problems, the present invention provides such a dismantling and recycling equipment for waste street lamp housings, which includes a crushing box, a first rotating rod, a first baffle, a driving mechanism, crushing teeth, a first bearing seat, a screw, Crushing knife, valve, feeding hopper, switch mechanism, etc.; the top center of the crushing box is connected with the feeding hopper, the top of the feeding hopper is connected with the switching mechanism, the inner wall of the crushing box is symmetrically connected with crushing teeth, the right wall of the crushing box There is a first small hole on the top. The reason why the present invention is first provided with a driving mechanism is to realize that by controlling the rotation of the first motor, the moving rod and the crushing teeth on the right side are continuously moved left and right, and the discarded street lamp housing is initially disassembled.

Owner:王红燕

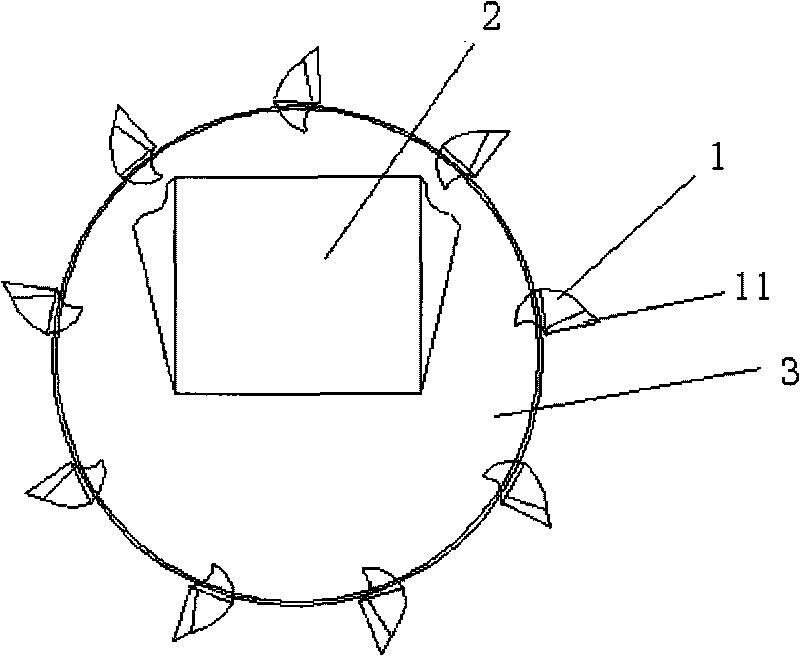

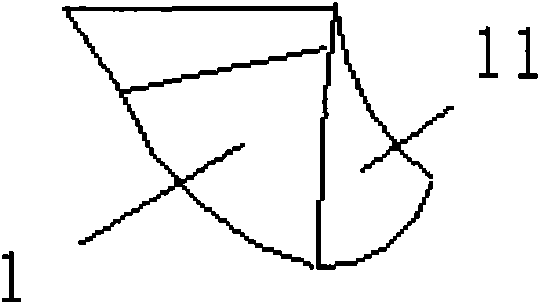

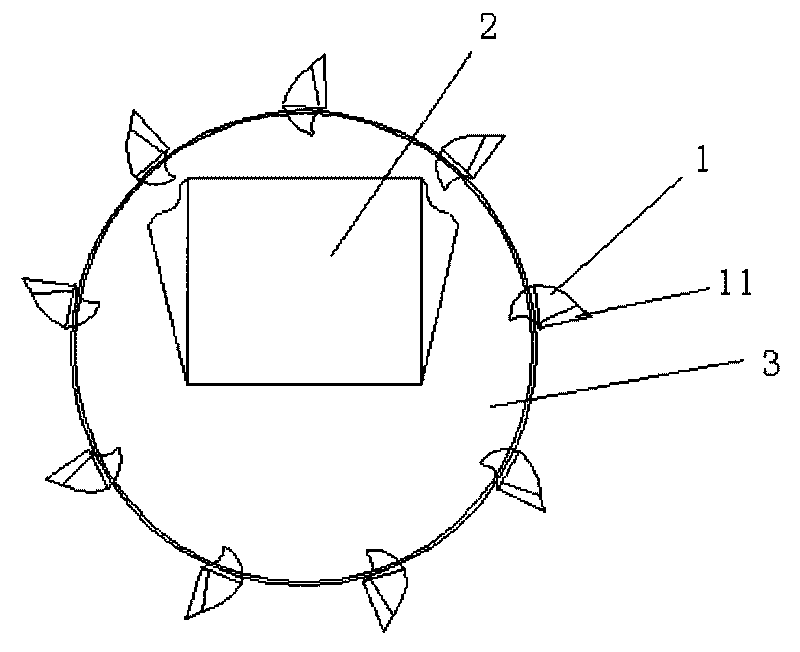

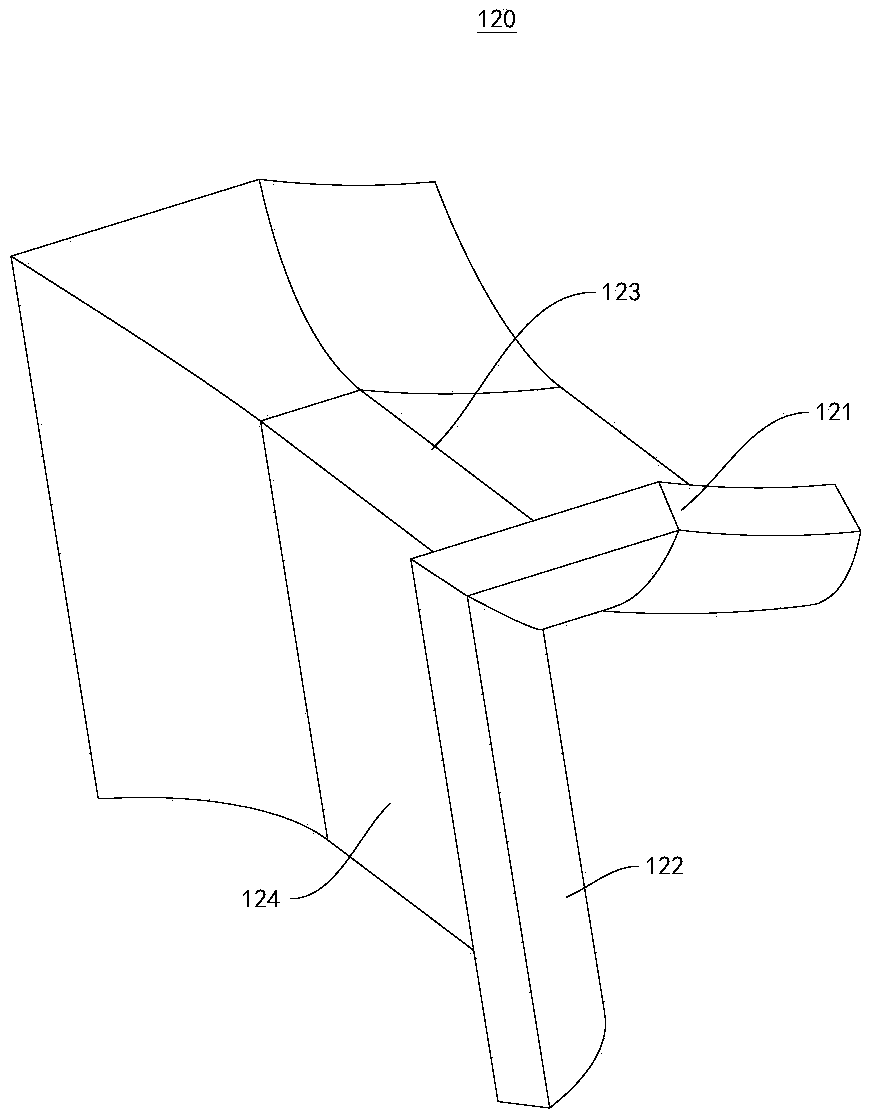

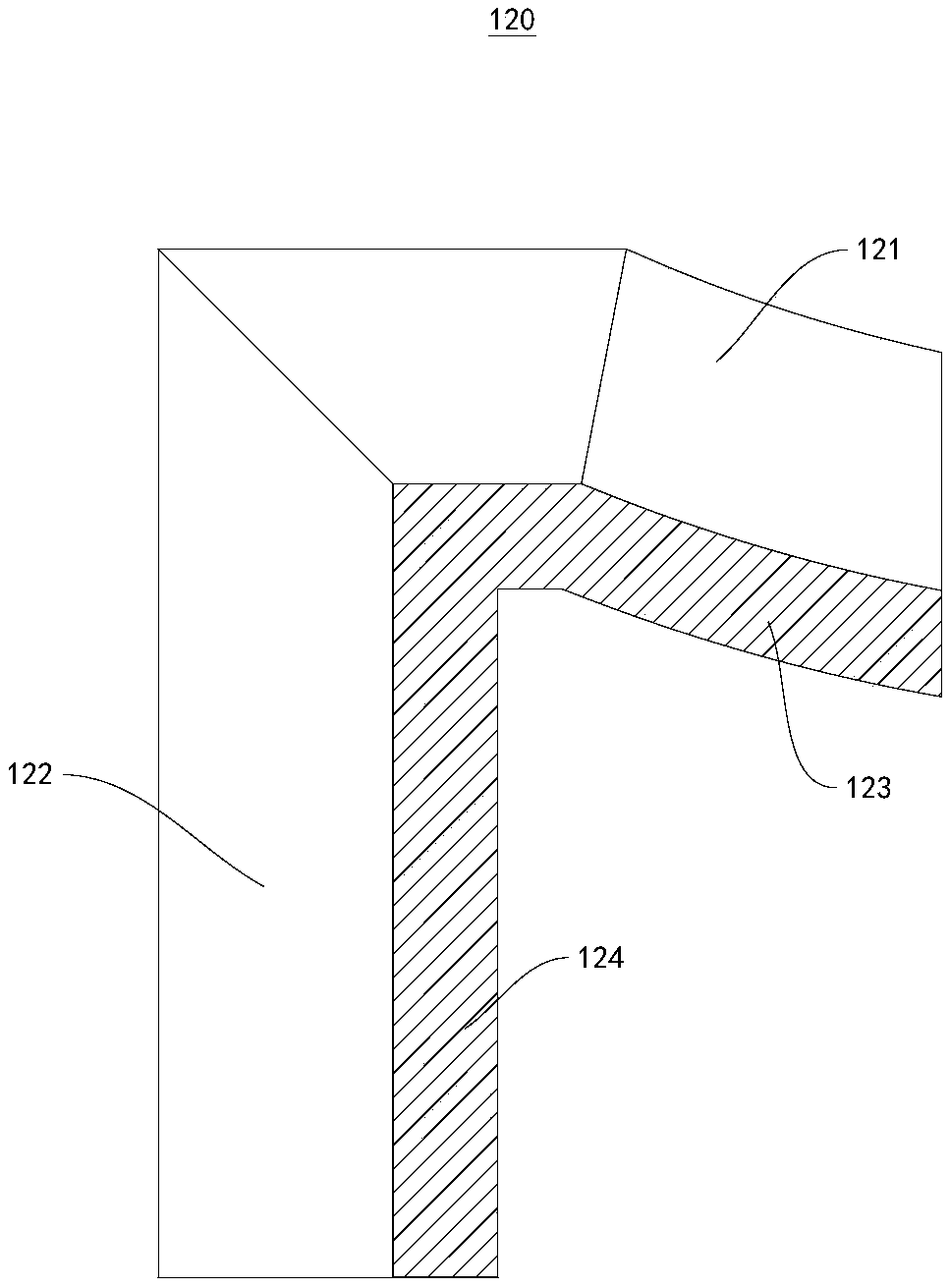

Bucket wheel mechanism suitable for lump ore stacking and taking operation

InactiveCN101693490AReduce frictionImprove work efficiencyMechanical machines/dredgersLoading/unloadingMechanical engineeringCoating

The invention discloses a bucket wheel mechanism suitable for lump ore stacking and taking operation, comprising a bucket, a material receiving trough, a bucket wheel body and a transmission mechanism of the bucket wheel. The bucket has an L-shaped appearance, special bucket teeth are arranged at a bucket opening, and a wearable coating with low affinity is sprayed at the inner side of the bucket; and the bucket wheel has different rotate speeds. By controlling the rotating speed of the bucket wheel body, the shape of the bucket and the arrangement form of the material receiving trough, the working efficiency of a bucket wheel stacking and taking machine is improved, and fast switch between lump ore and powder ore is realized.

Owner:NANJING IRON & STEEL CO LTD

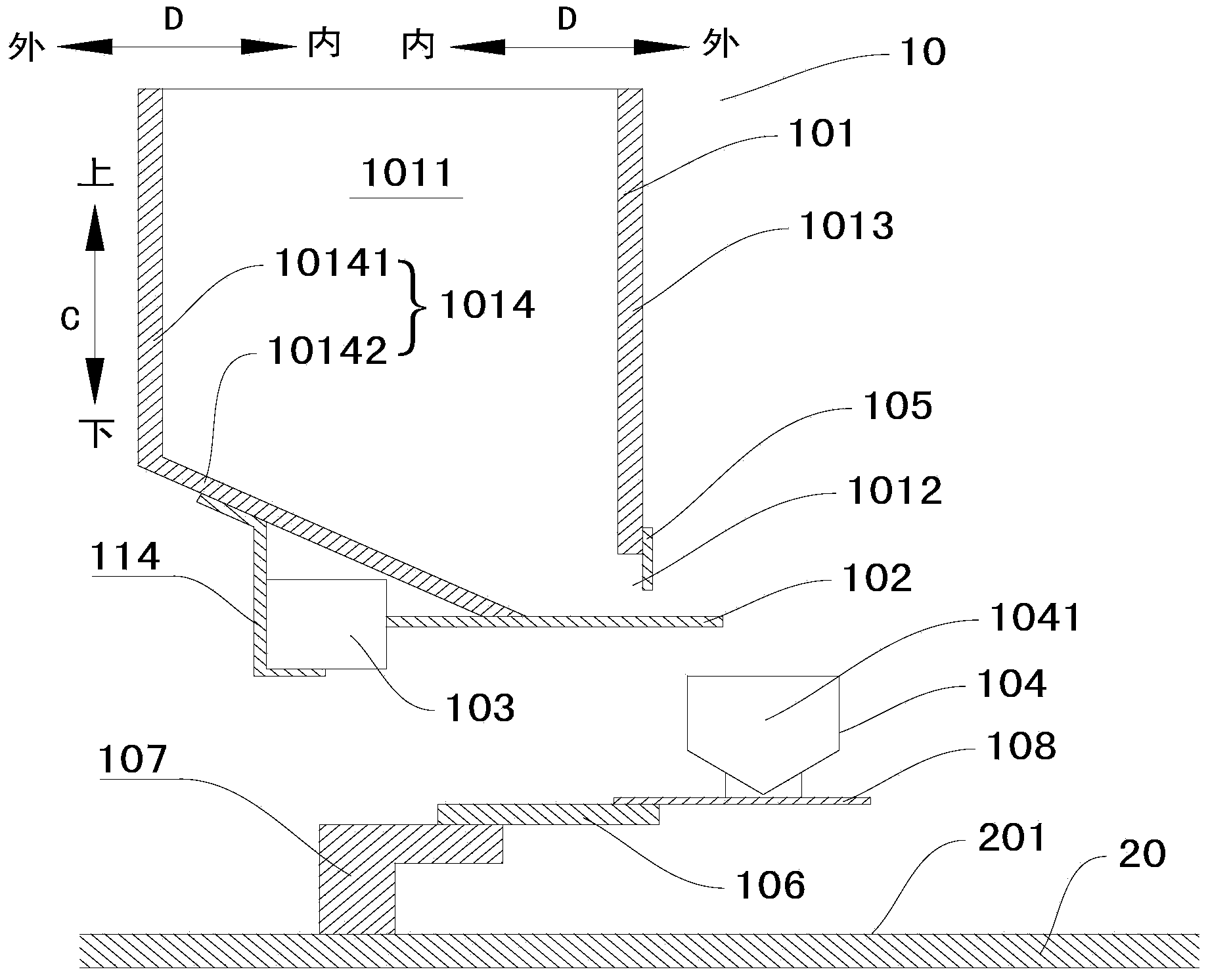

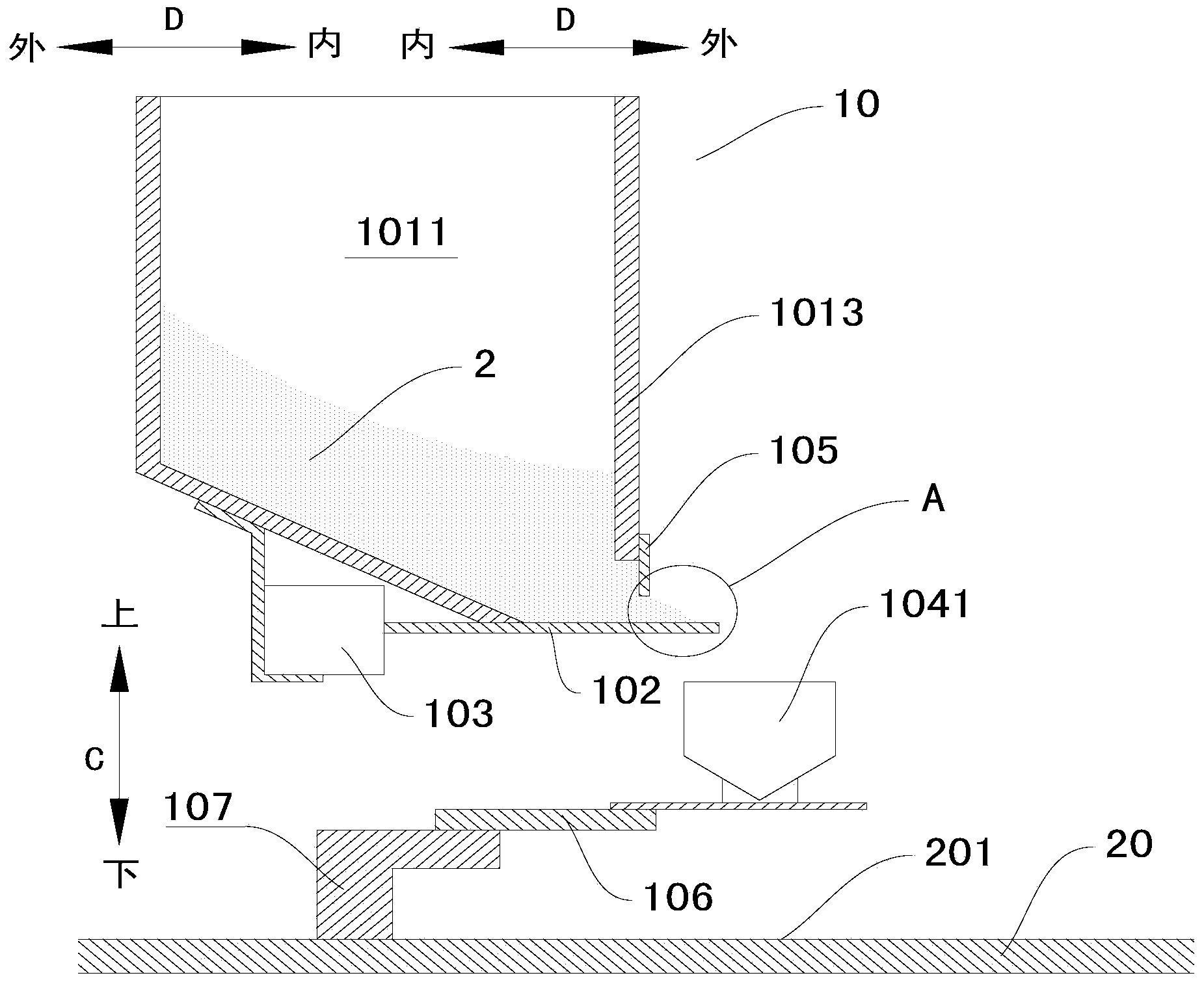

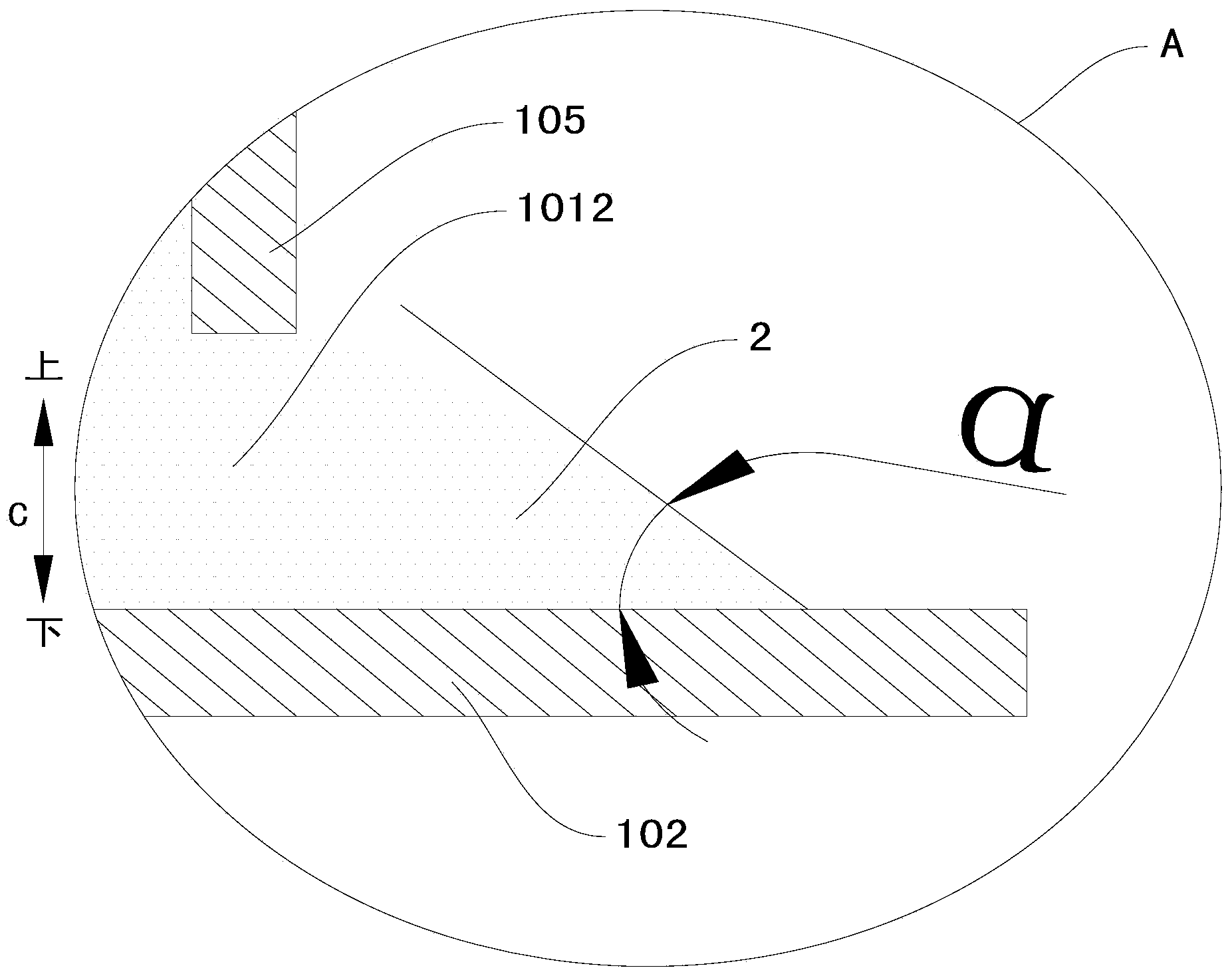

Drainage device for photovoltaic power generation panel

PendingCN109617520AWon't clogAvoid bondingPhotovoltaicsPhotovoltaic energy generationEngineeringBiomedical engineering

The invention provides a drainage device for a photovoltaic power generation panel, and belongs to the field of a device for photovoltaic power generation. The drainage device for the photovoltaic power generation panel comprises a guidance piece and a fixed piece, wherein an attachment surface and a guidance surface are arranged on the guidance piece and are connected with each other, the attachment surface comprises a first attachment part and a second attachment part, a surface where the first attachment part is located intersects with a surface where the second attachment part is located,the guidance surface comprises a first guidance part and a second guidance part, the first guidance part is connected with the first attachment part, an included angle between an extension direction of the first guidance part and the surface where the first attachment part is located is an obtuse angle, the second guidance part and the second attachment part are connected, an included angle between an extension direction of the second guidance part and the second attachment part is obtuse angle, the fixed piece is provided with a first connection part and a second connection part, and the guidance piece is made of a material with wettability.

Owner:西安金扫把光伏科技有限公司

3D printing device and method for molten metal

The invention relates to a 3D printing device and method for molten metal, and belongs to the technical field of 3D printing. The 3D printing device comprises a casing, a first nozzle, a melting-electrode welding electrode and a non-melting-electrode welding electrode, wherein the first nozzle is connected with one end of the casing; a cavity is formed in the middle part of the casing; a first sealing plate and a second sealing plate are arranged in the casing; the melting-electrode welding electrode and the non-melting-electrode welding electrode are positioned in the cavity of the casing; the melting-electrode welding electrode and the non-melting-electrode welding electrode penetrate through the two sealing plates to be arranged; the first sealing plate is provided with a gas inlet, and the second sealing plate is provided with a gas outlet; the gas inlet and the gas outlet are used for allowing noble gases to circulate. According to the 3D printing device and method disclosed by the invention, a wire material extruding hot melting forming manner and a melting forming manner based on fusion welding are creatively combined, high temperature generated by welding arcs enables high-melting-point metal wires to be melted to obtain molten metal, and under the extruding action of the inside pressure of the casing and the nozzle, the molten metal stably and quickly flows out, so that the 3D printing is realized.

Owner:SHANDONG UNIV

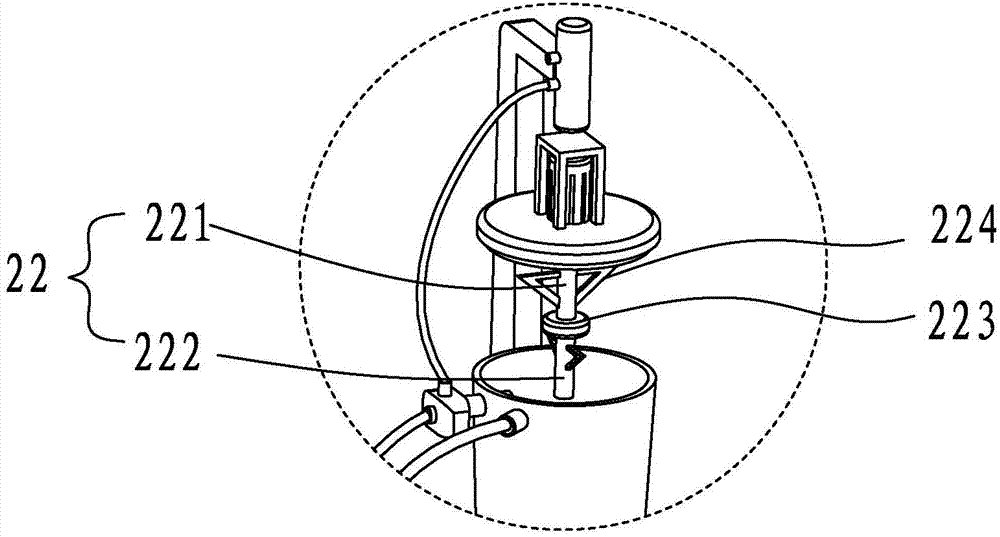

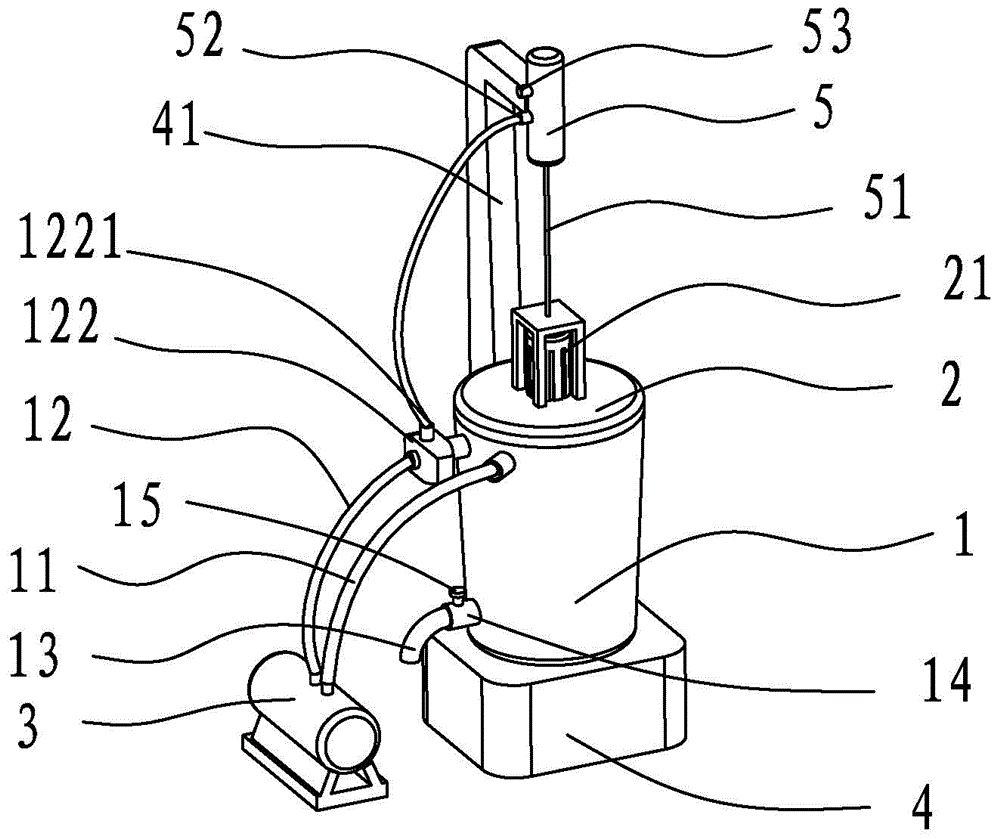

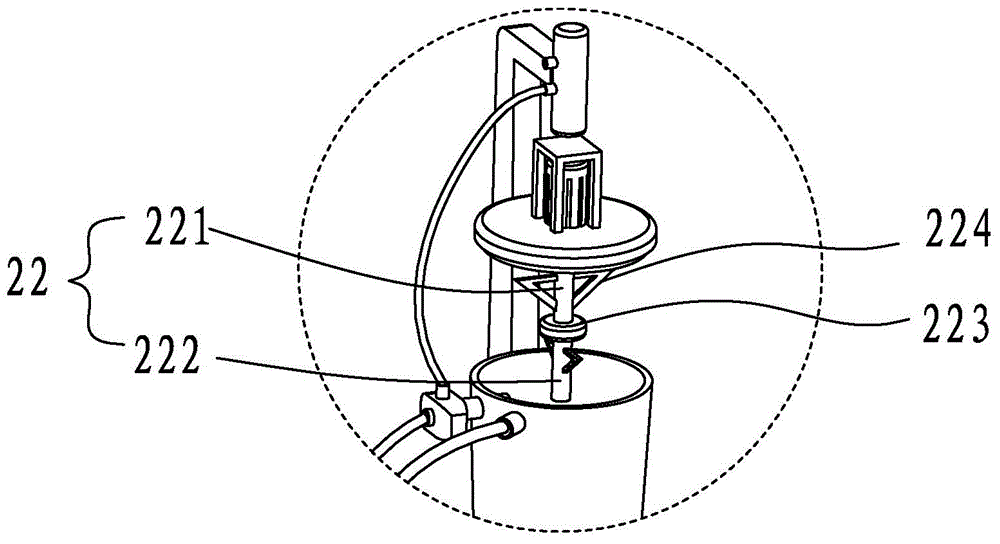

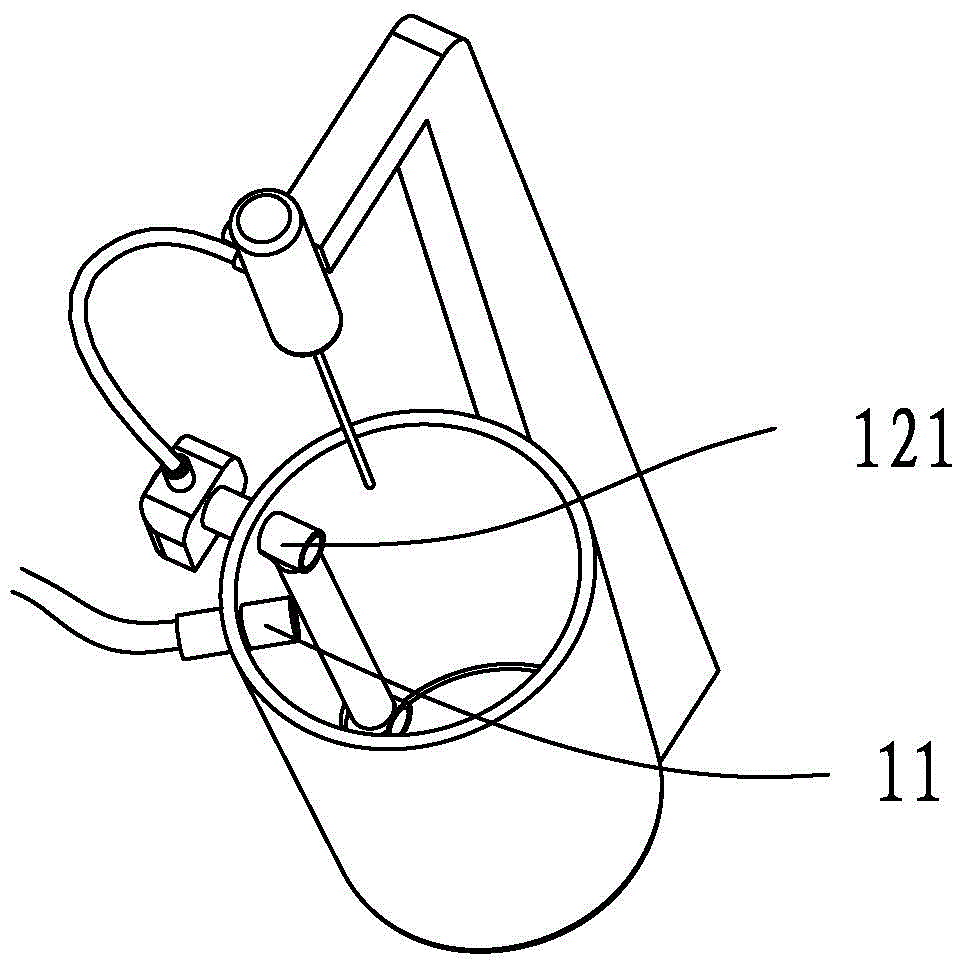

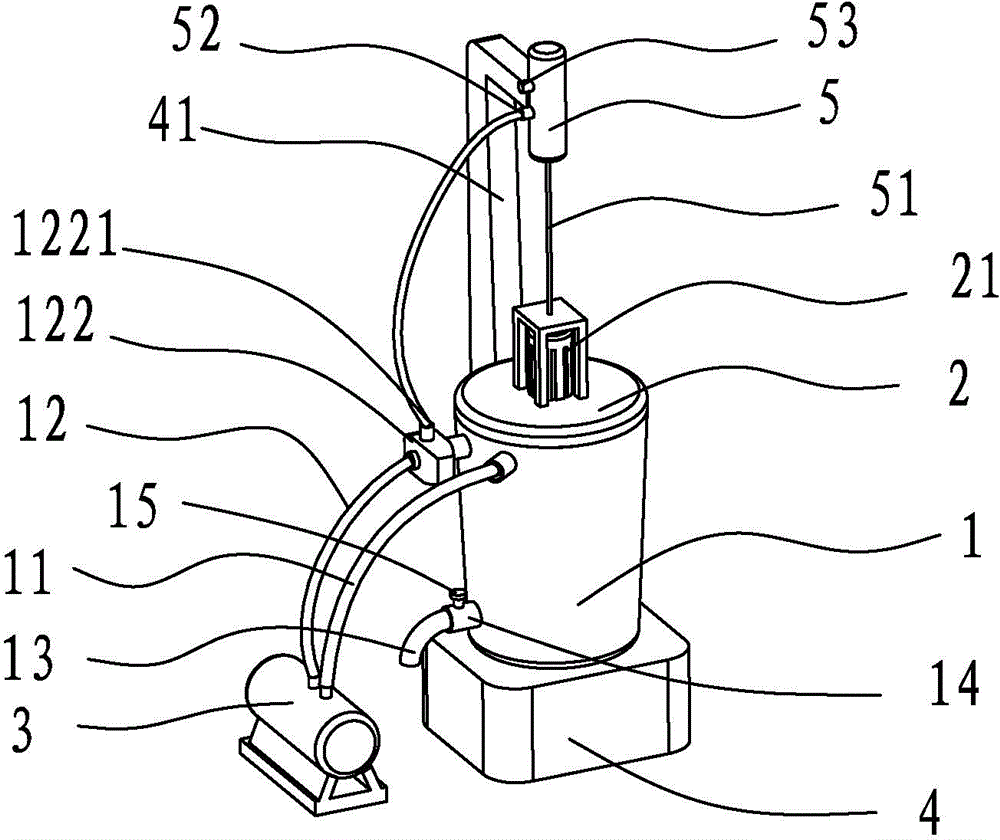

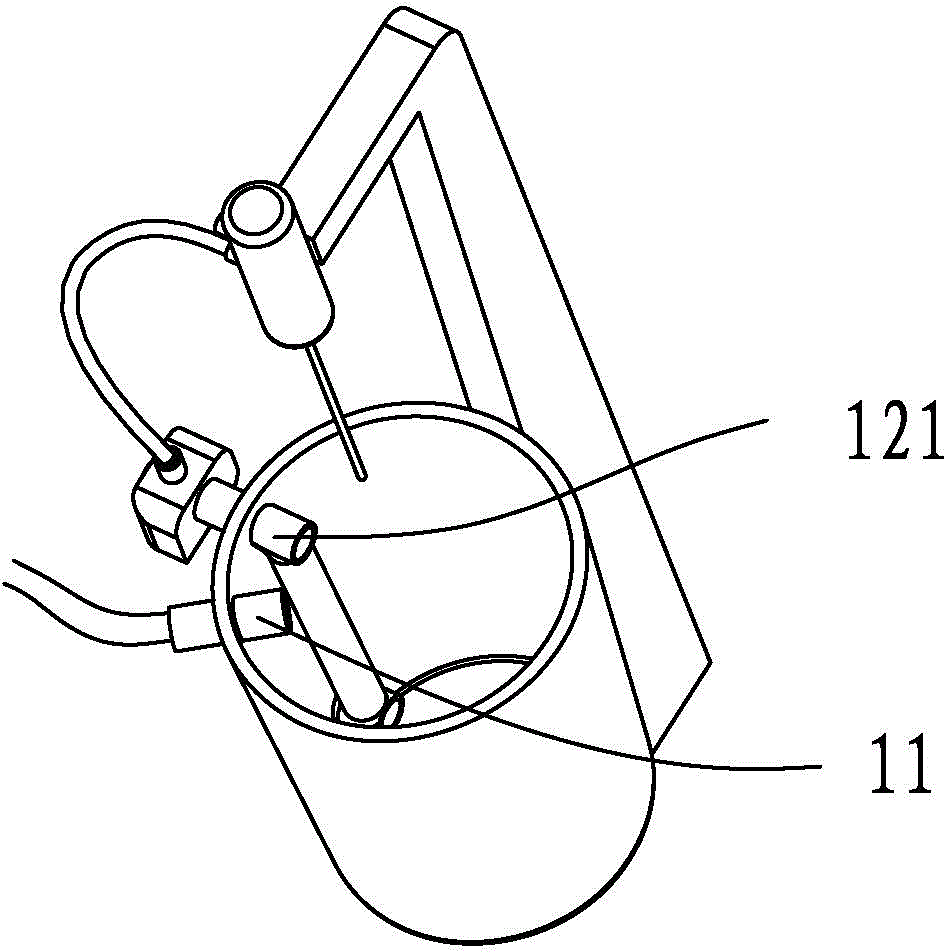

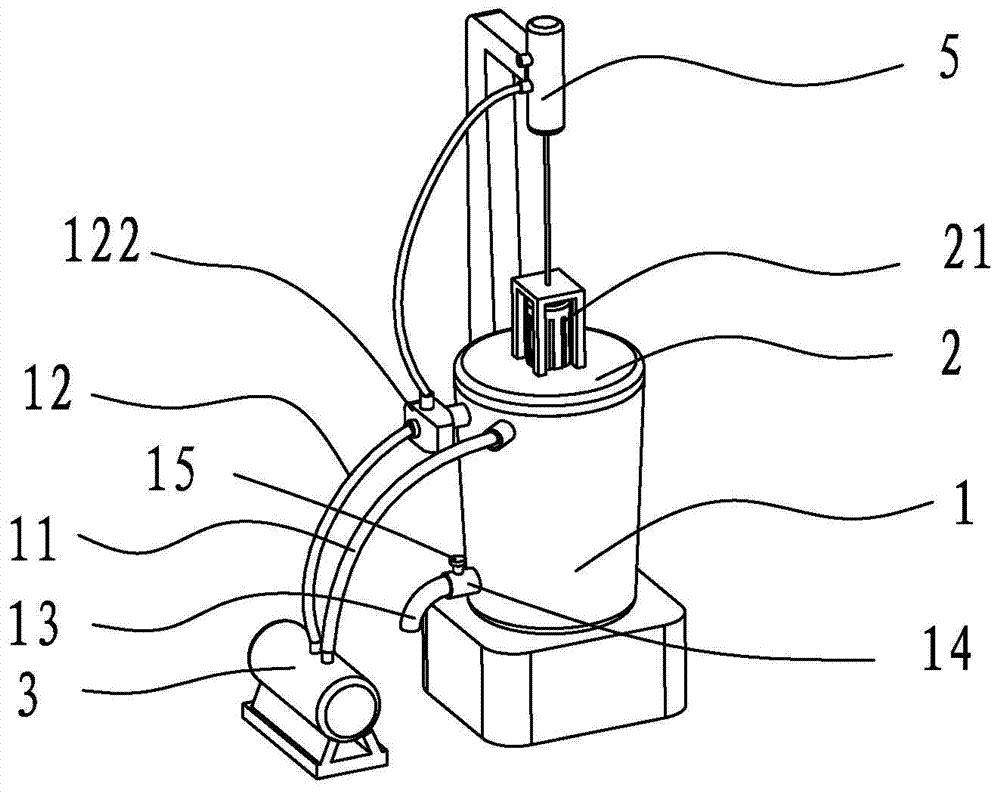

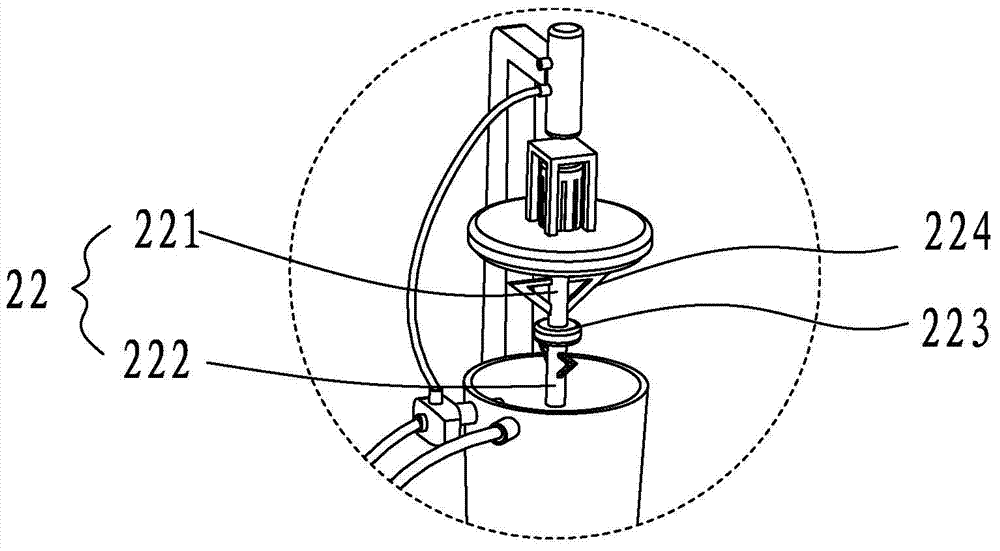

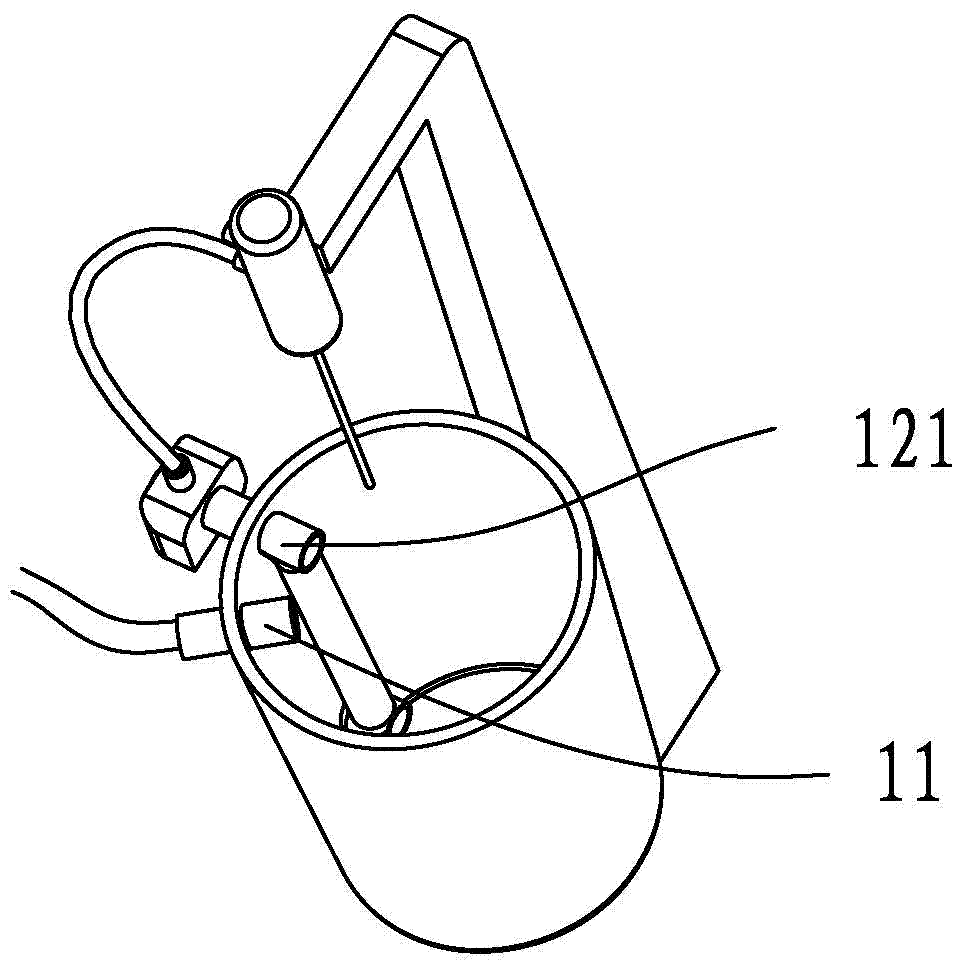

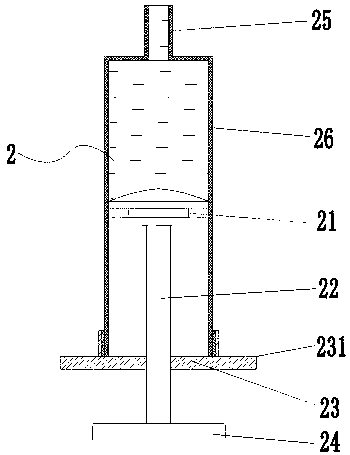

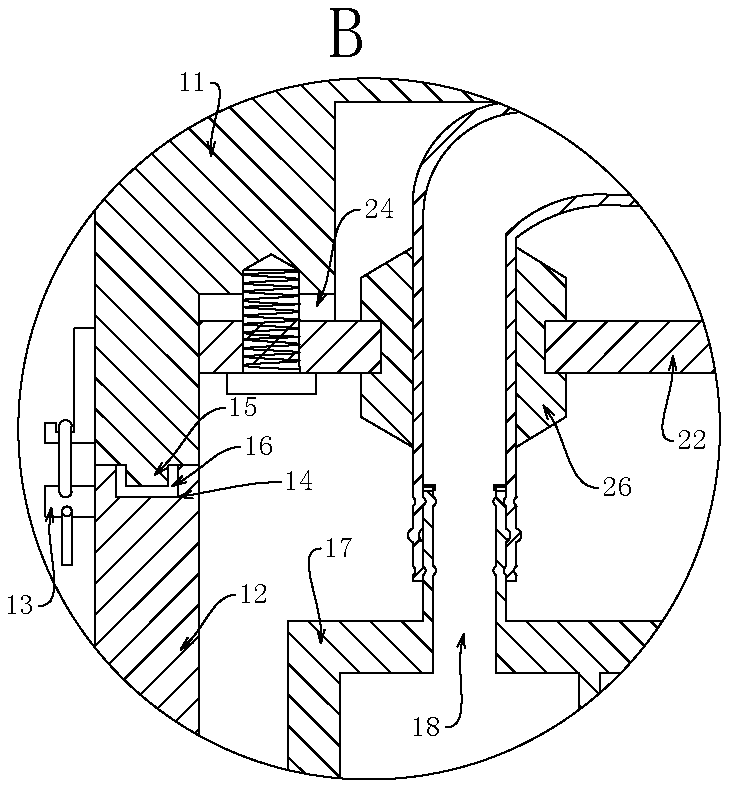

Discharging opening structure of vacuum stirring barrel

The invention discloses a discharging opening structure of a vacuum stirring barrel. The discharging opening structure of the vacuum stirring barrel comprises a stirring barrel, wherein an upper cover is arranged above the stirring barrel; a motor is arranged on the top of the upper cover; a motor bracket is arranged outside the motor; a stirring rod is arranged at the bottom of the upper cover; an air extraction pipe and an air inlet pipe are arranged on the side wall of the stirring barrel; the air extraction pipe and the air inlet pipe are connected with an air pump; a discharging opening is formed in the bottom of the stirring barrel; an air pressure valve capable of controlling circulation of materials is arranged at the discharging opening; a top two-way pipe of the air inlet pipe is arranged in the stirring barrel; one channel is directly communicated with an cavity above the stirring barrel, and the other channel is communicated with the air pressure valve; an anti-clogging touch switch is arranged on the air pressure valve. The discharging opening structure of the vacuum stirring barrel is capable of quickly discharging the materials in the stirring barrel and reducing impurities in the final stirring materials.

Owner:CHANGXING HUAQIANG ELECTRONICS

Material mixing process based on vacuum mixing drum

The invention discloses a material mixing process based on a vacuum mixing drum. The vacuum mixing drum comprises a mixing drum and an upper cover, wherein an extraction pipe and an air inlet pipe are arranged on the side wall of the mixing drum, a pneumatic cylinder used for lifting is arranged above the upper cover, and a discharge port and a pneumatic valve are formed in and arranged at the bottom of the mixing drum. Firstly, the upper cover is lifted to discharge by virtue of the pneumatic cylinder, then the upper cover is closed to exhaust, the mixing drum is vacuumized, and subsequently, air enters again after mixing for a certain time, so that air pressure in the mixing drum conforms to ambient pressure; when the air enters, the pneumatic valve is opened, materials flow out from the discharge port, and the pneumatic cylinder is driven by a part of air to lift the upper cover, so as to be convenient to discharge again. The whole process is automatically completed by air pressure, the problems of bad dust removing effect and non-uniform mixing of a traditional mixing drum are solved, the upper cover of the vacuum mixing drum can be quickly lifted with labor saving, and the working efficiency is improved.

Owner:CHANGXING HUAQIANG ELECTRONICS

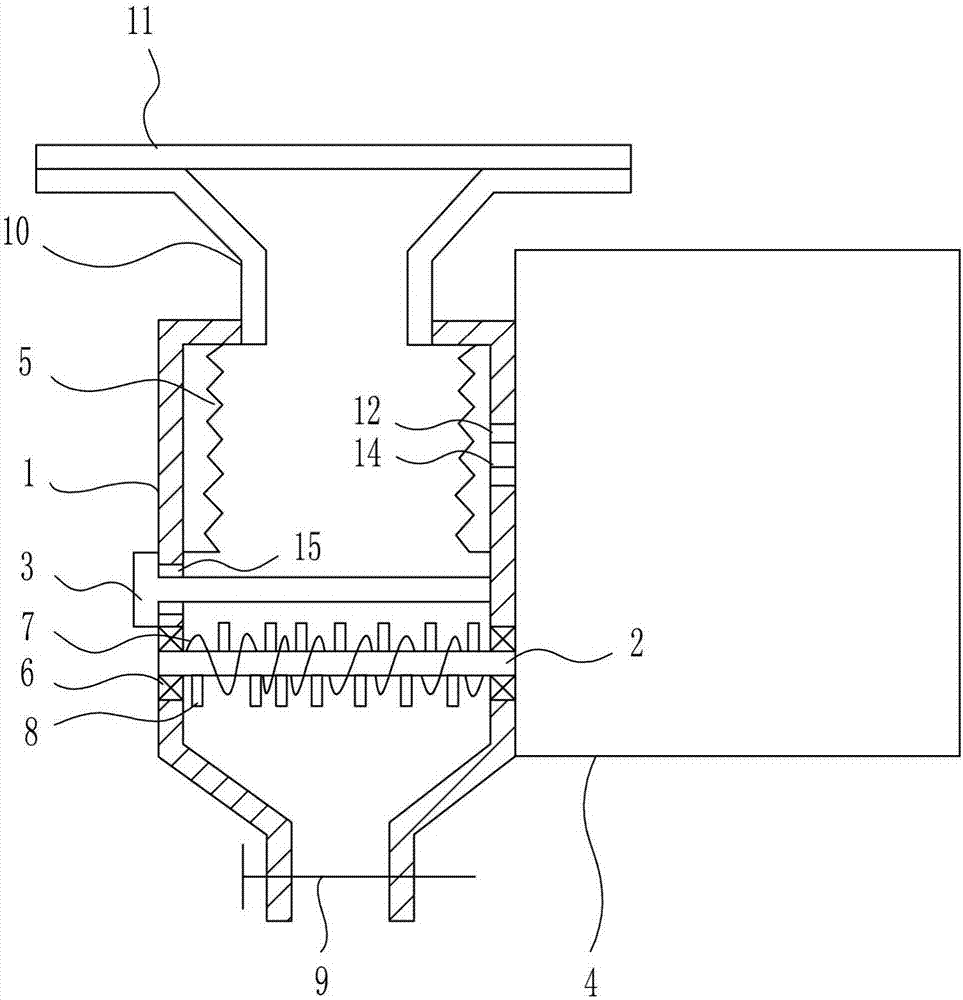

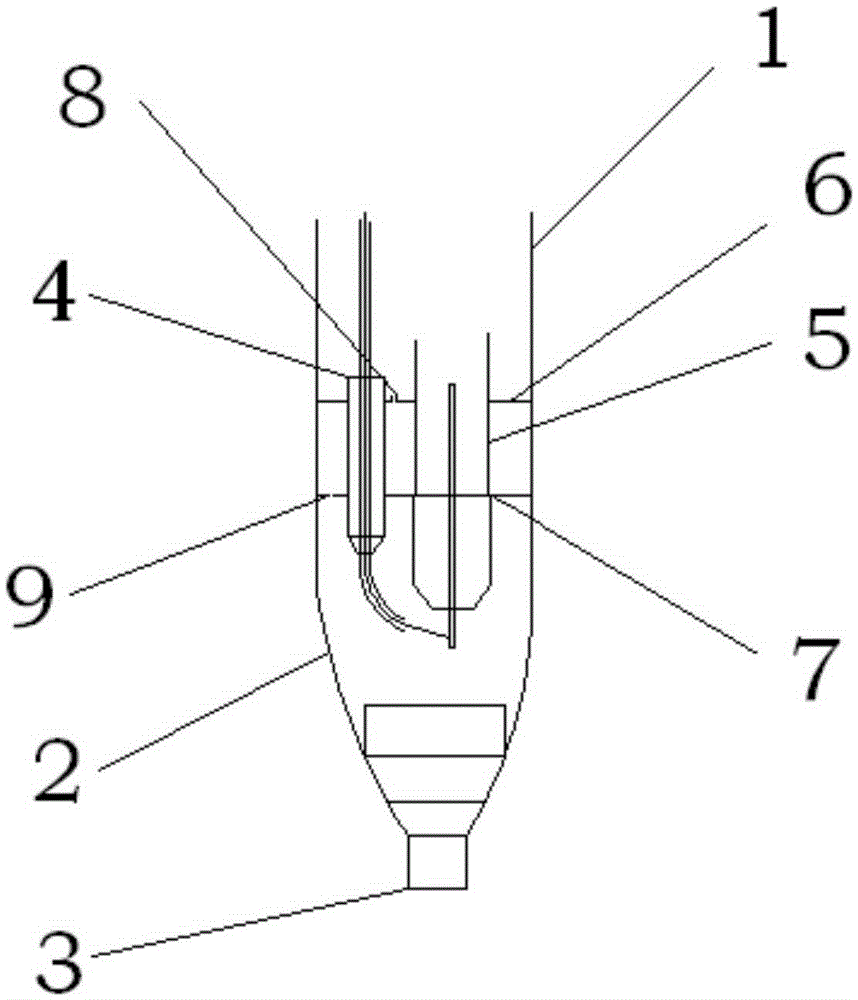

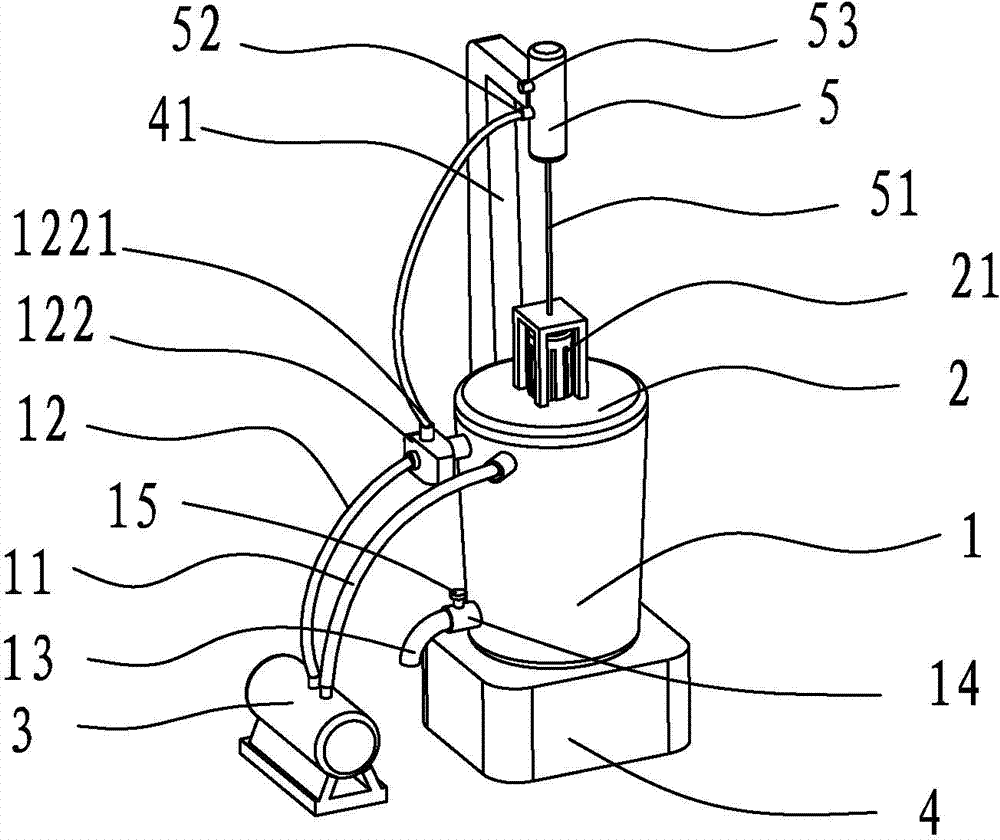

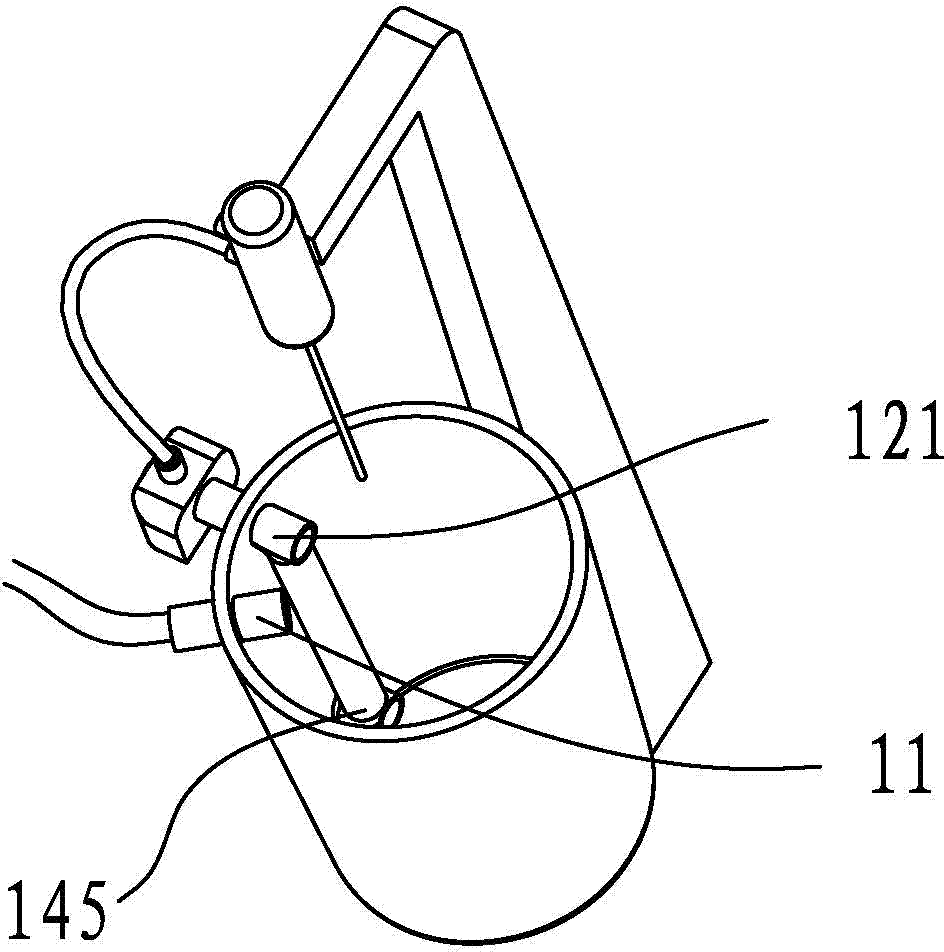

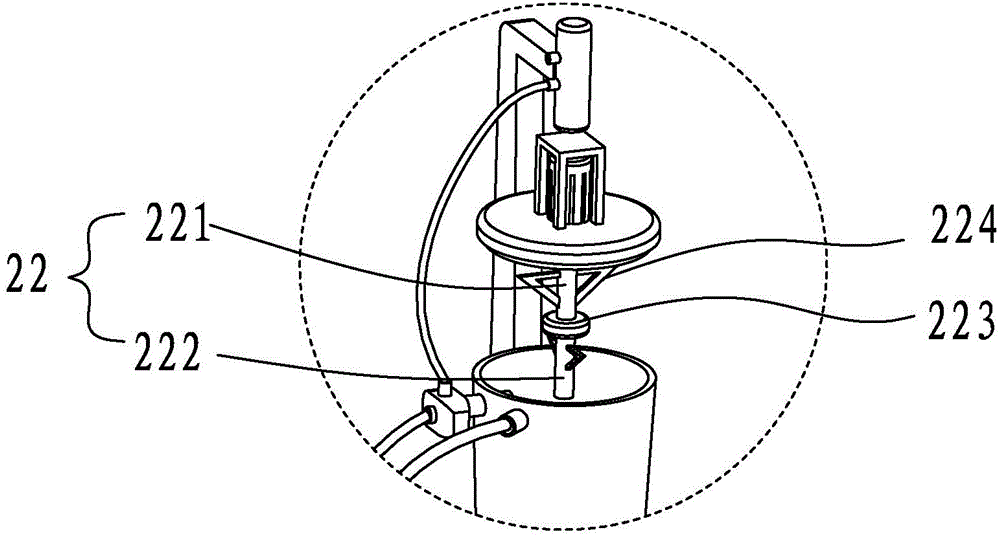

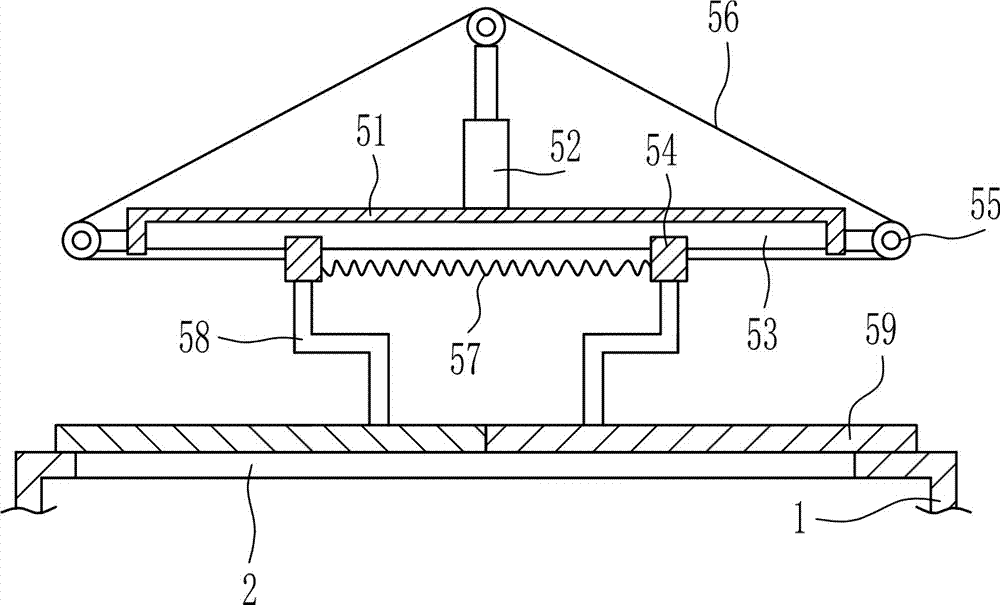

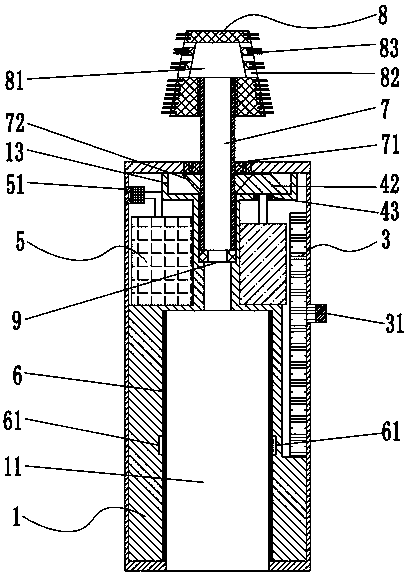

Vacuum agitating barrel

ActiveCN104128117AStir wellImprove dust removal effectMixer accessoriesPneumatic cylinderTouch switch

The invention discloses a vacuum agitating barrel. The vacuum agitating barrel comprises an agitating barrel, wherein an upper cover is arranged on the agitating barrel; a motor is arranged at the top of the upper cover; an agitating rod is arranged at the bottom of the upper cover; an exhausting pipe and an air inlet pipe are arranged on the side wall of the agitating barrel; the exhausting pipe and the air inlet pipe are connected with an air pump; a pneumatic cylinder for lifting is arranged above the upper cover; the pneumatic cylinder is connected with the air inlet pipe; the agitating rod comprises an upper rod and a lower rod; a shaft coupler is arranged between the upper rod and the lower rod; the shaft coupler is internally provided with a steering device for setting the rotation directions of the upper rod and the lower rod to be opposite; a discharge hole is formed in the bottom of the agitating barrel; a pneumatic valve is arranged at the discharge hole; a two-way pipe is arranged in the agitating barrel for the air inlet pipe; a channel is communicated with a cavity above the agitating barrel and the other channel is communicated with the pneumatic valve; an anti-blocking touch switch is arranged on the pneumatic valve. According to the vacuum agitating barrel, the problems of a traditional agitating barrel that the dust removing effect is not good and the agitation is not uniform can be solved; the upper cover of the vacuum agitating barrel can be rapidly and easily lifted so that the working efficiency is improved.

Owner:CHANGXING HUAQIANG ELECTRONICS

Vacuum stirring barrel capable of stirring in double directions

ActiveCN104117318AStir wellImprove dust removal effectRotary stirring mixersMixer accessoriesPneumatic pressureEngineering

The invention discloses a vacuum stirring barrel capable of stirring in double directions. The vacuum stirring barrel capable of stirring in double directions comprises a stirring barrel, wherein an upper cover is arranged on the stirring barrel; a motor is arranged on the top of the upper cover; a stirring rod is arranged at the bottom of the upper cover; an air extraction pipe and an air inlet pipe are arranged on the side wall of the stirring barrel; the air extraction pipe and the air inlet pipe are connected with an air pump; the stirring rod comprises an upper rod and a lower rod; a coupler is arranged between the upper rod and the lower rod; a steering device is arranged in the coupler and used for setting reverse rotation directions of the upper rod and the lower rod; a discharging opening is formed in the bottom of the stirring barrel; an air pressure valve is arranged at the discharging opening; a two-way pipe of the air inlet pipe is arranged in the stirring barrel; one channel is directly communicated with a cavity above the stirring barrel, and the other channel is communicated with the air pressure valve. By virtue of the vacuum stirring barrel, the problems of poor dust removal effect and non-uniformity stirring of a conventional stirring barrel can be solved.

Owner:CHANGXING HUAQIANG ELECTRONICS

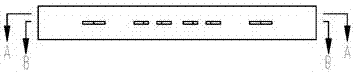

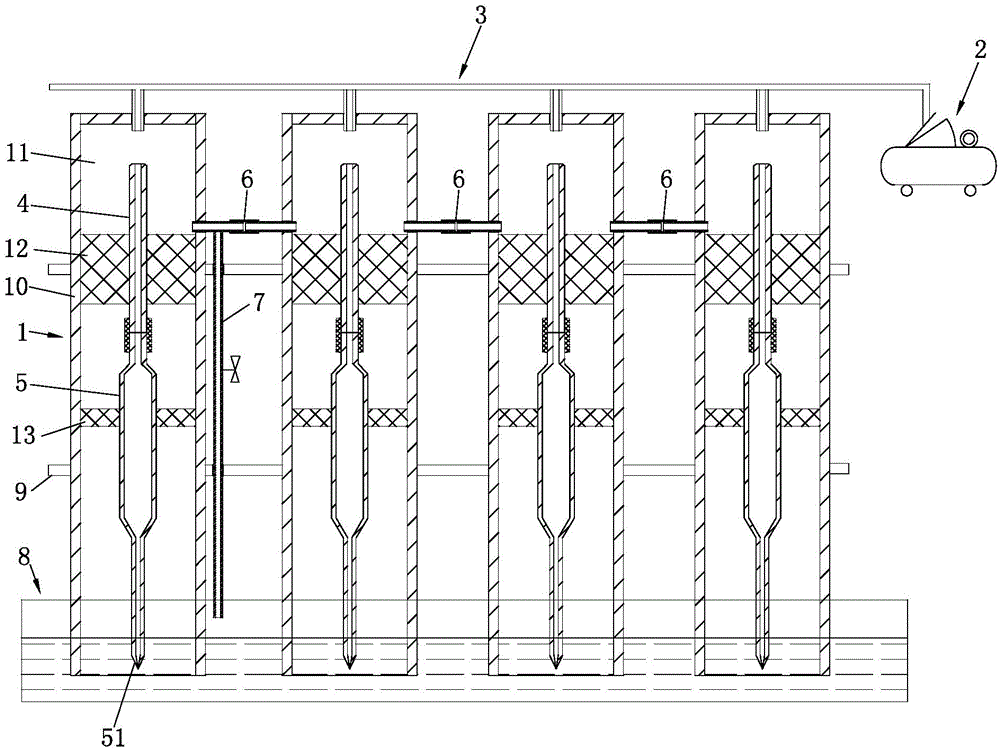

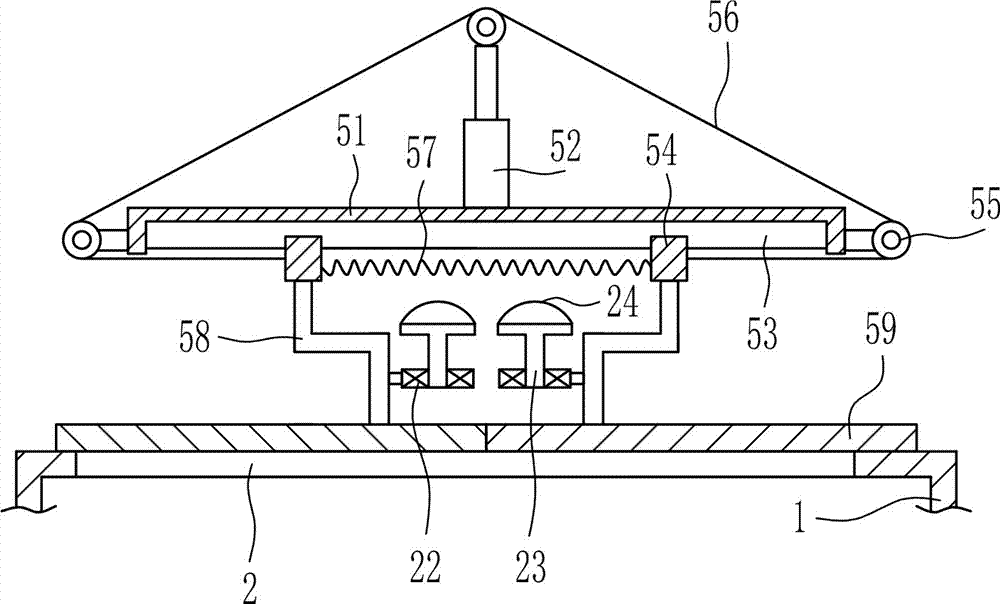

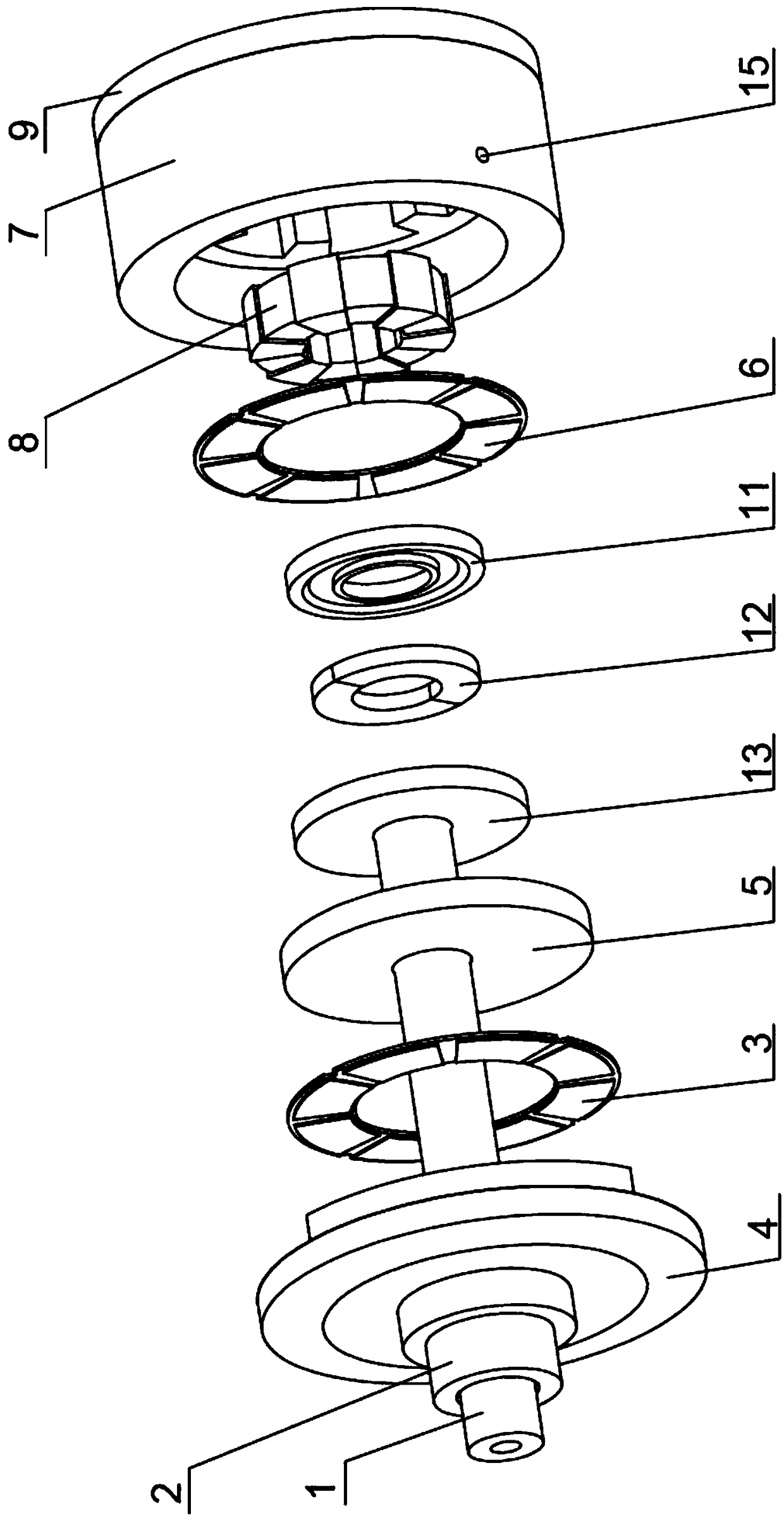

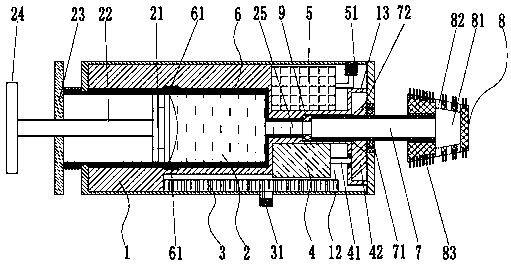

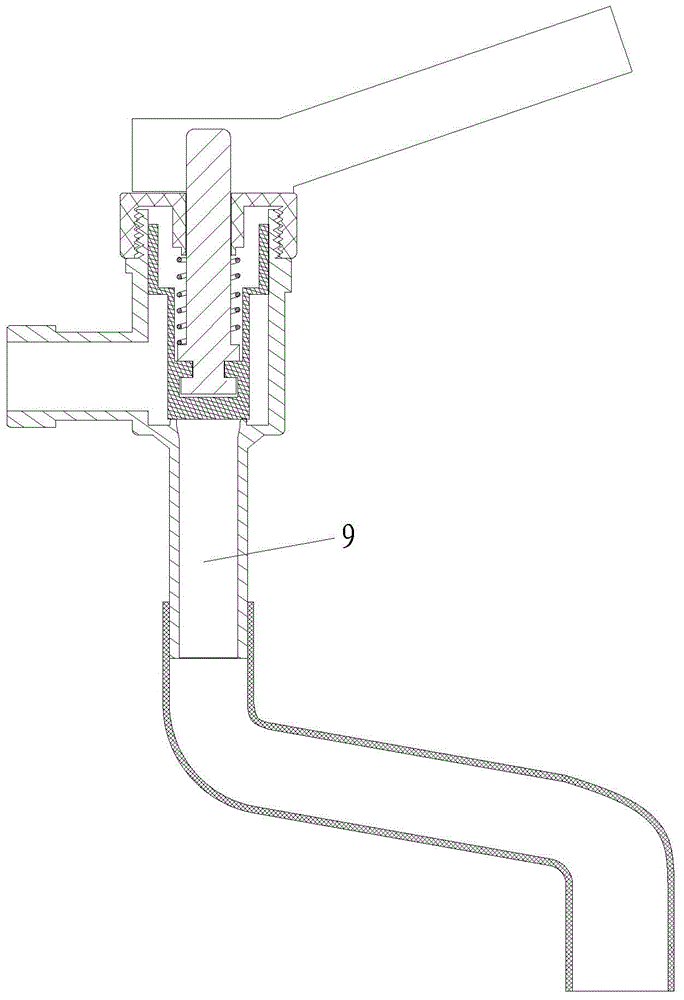

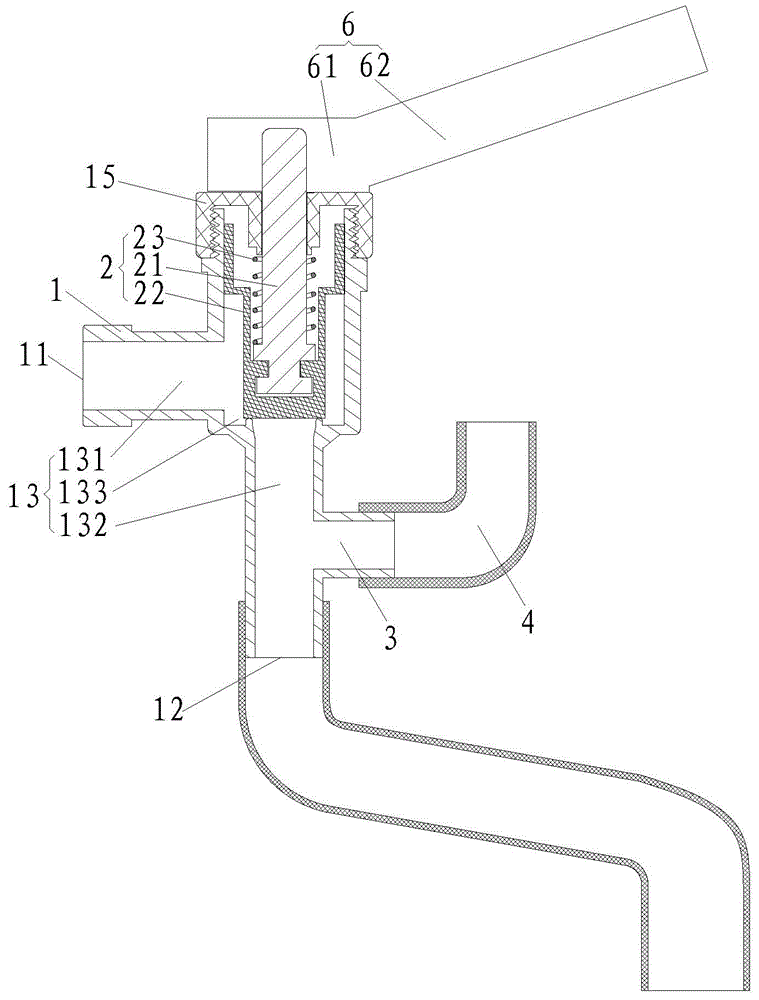

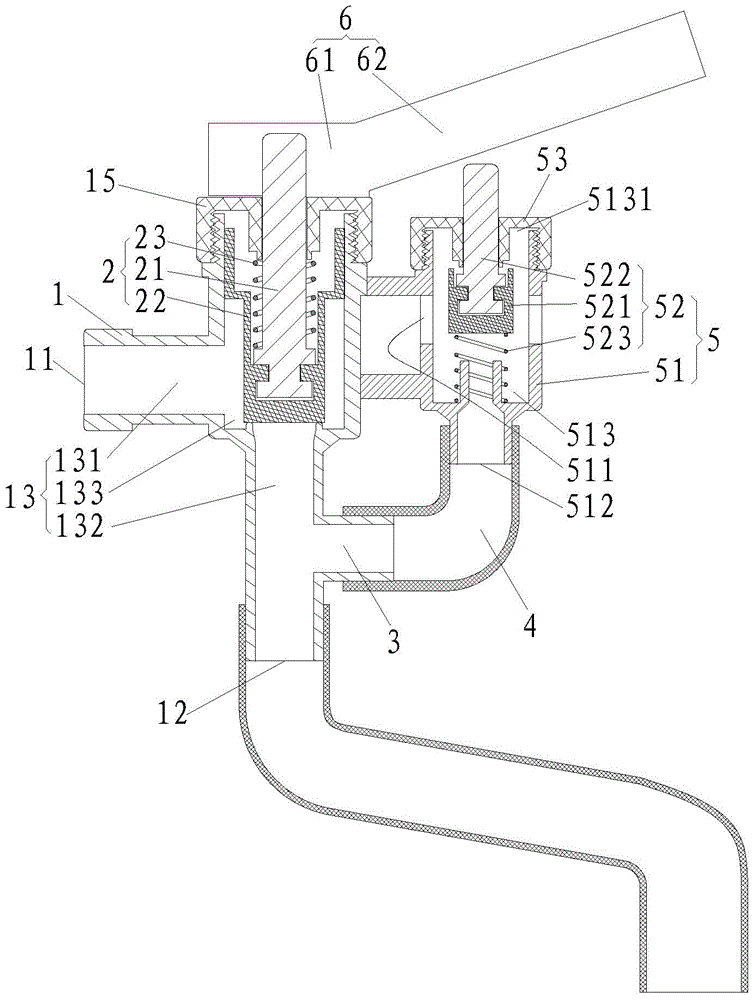

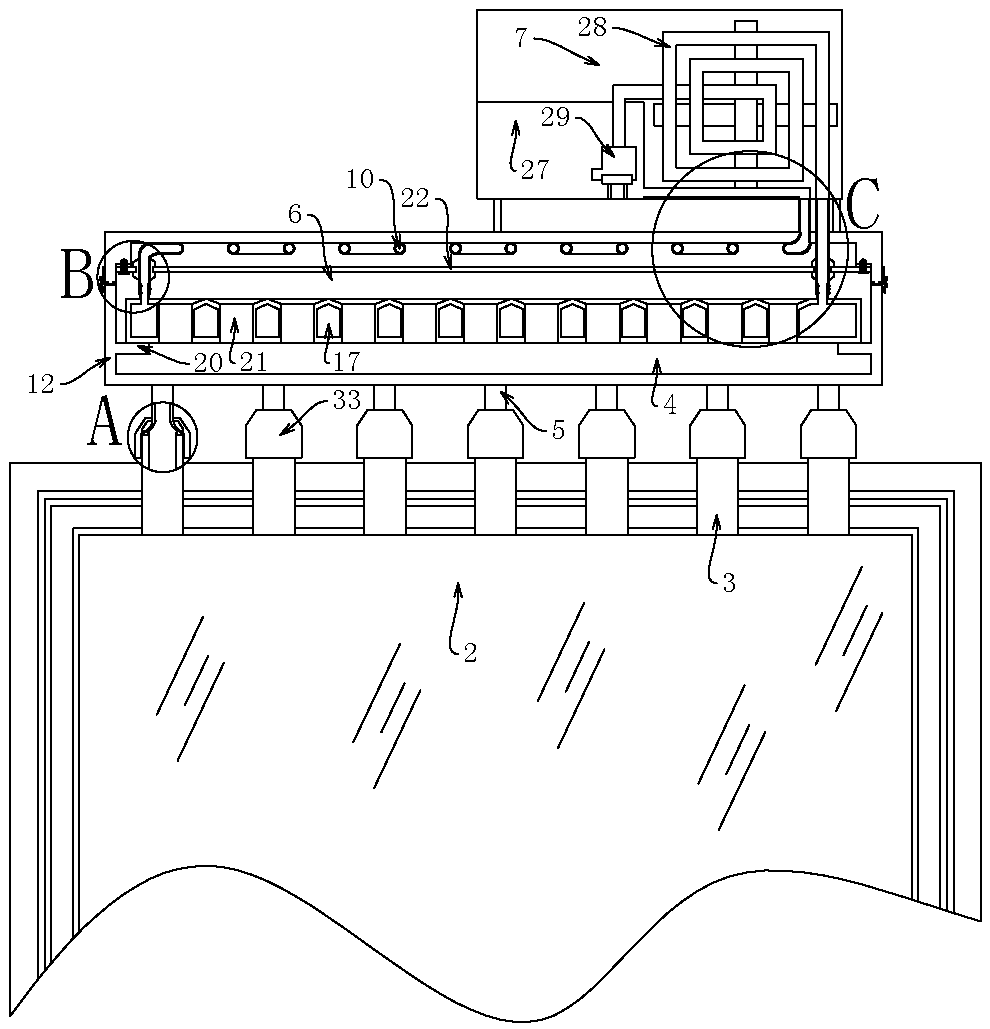

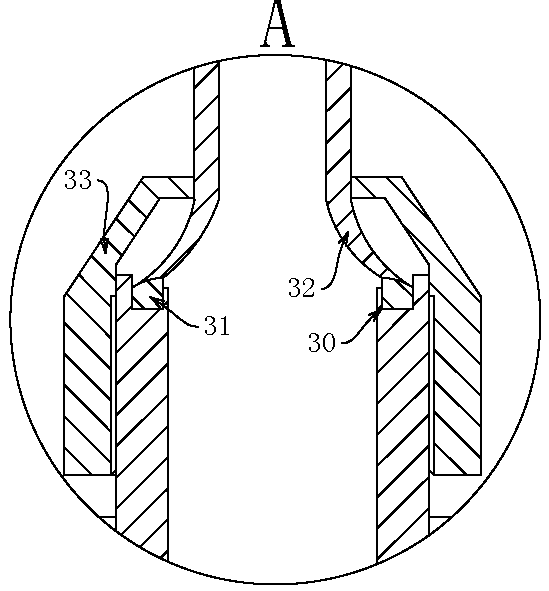

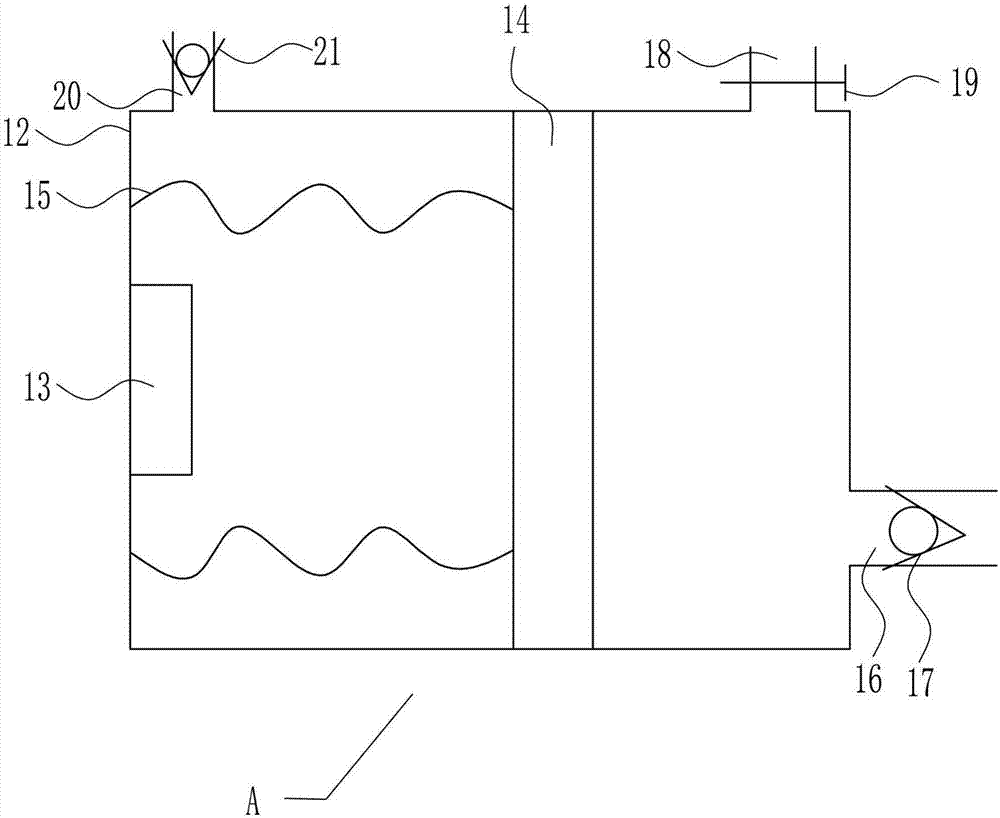

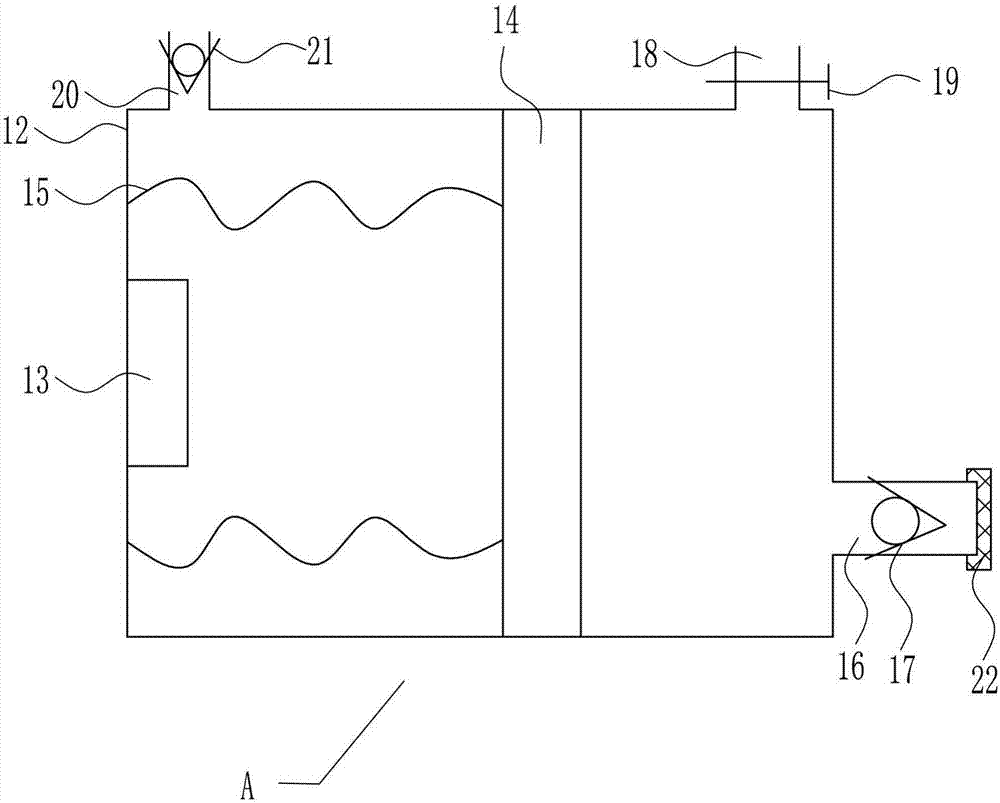

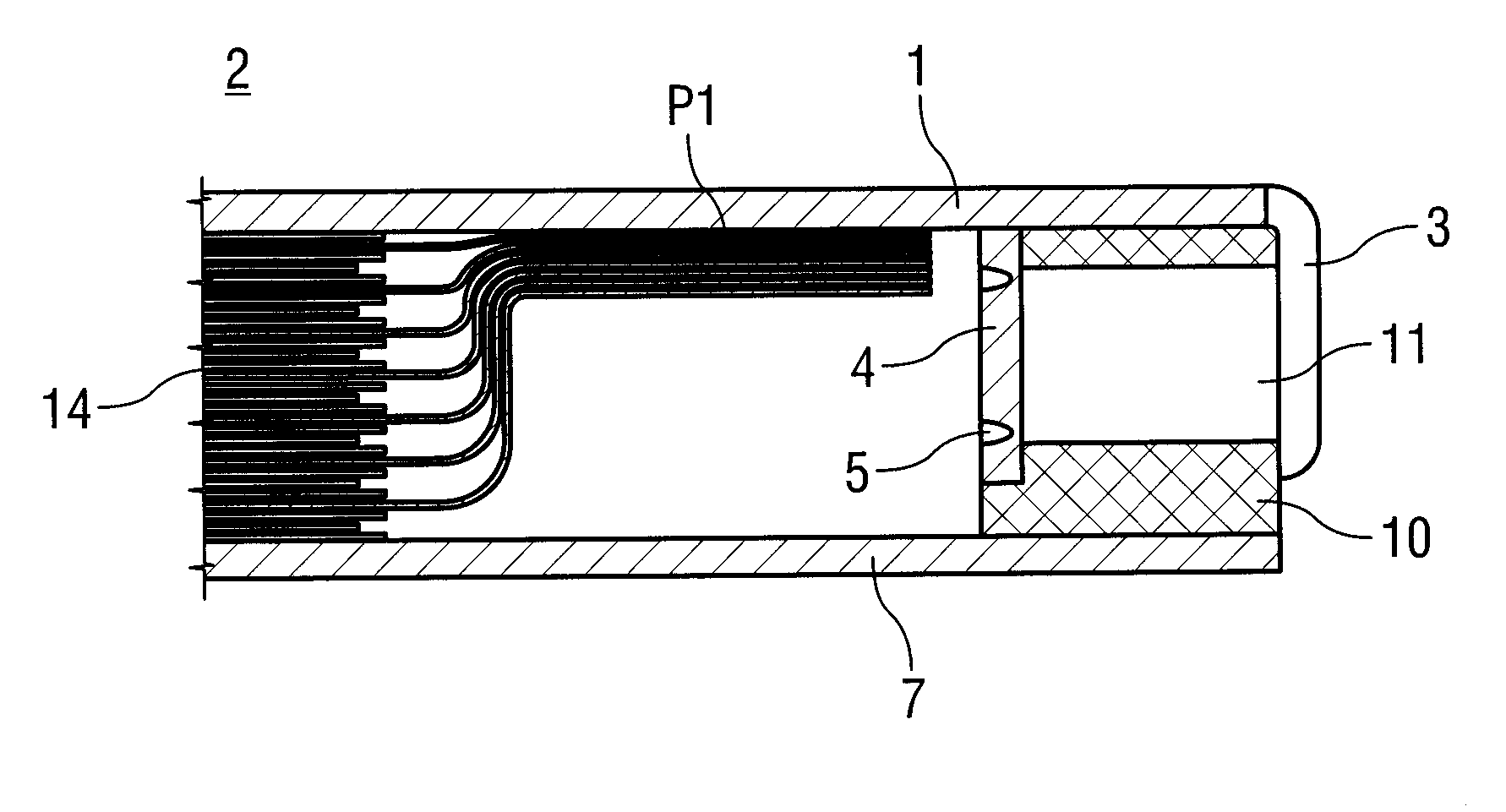

High-precision lead-acid battery acid and liquid supplementing device

ActiveCN104821388AOutflow completeFor quick outflowCell component detailsEngineeringAtmospheric pressure

The invention discloses a high-precision lead-acid battery acid and liquid supplementing device. The high-precision lead-acid battery acid and liquid supplementing device comprises a vacuumizing device and a plurality of liquid supplementing units, wherein the plurality of liquid supplementing units are sequentially connected through a positioning plate; every liquid supplementing unit is composed of a housing and a quantitative pumping and filling injector fixed inside the housing through a positioning structure, the housing is open at the lower end and closed at the upper end, a liquid storage chamber is formed between the positioning structure and the closed end of the housing, both ends of the quantitative pumping and filling injector are open at both ends, and the upper end of the quantitative pumping and filling injector extends into the liquid storage chamber; the vacuumizing device is communicated with the liquid storage chamber of every supplementing unit through a pipeline module. The high-precision lead-acid battery acid and liquid supplementing device pumps sulfuric acid electrolyte into the quantitative pumping and filling injector of every liquid supplementing unit through atmospheric pressure, and the overflow part of the sulfuric acid electrolyte can flow into the liquid storage chambers; due to the facts that the quantitative pumping and filling injectors are basically the same in volume and small in diameter, during a liquid supplementing process, acid liquid can completely and rapidly flow out and avoid hanging. Therefore, the high-precision lead-acid battery acid and liquid supplementing device can improve the production efficiency of storage batteries and is applicable to high-precision acid and liquid supplementation.

Owner:CHANGXING TIEYING ELECTRIC

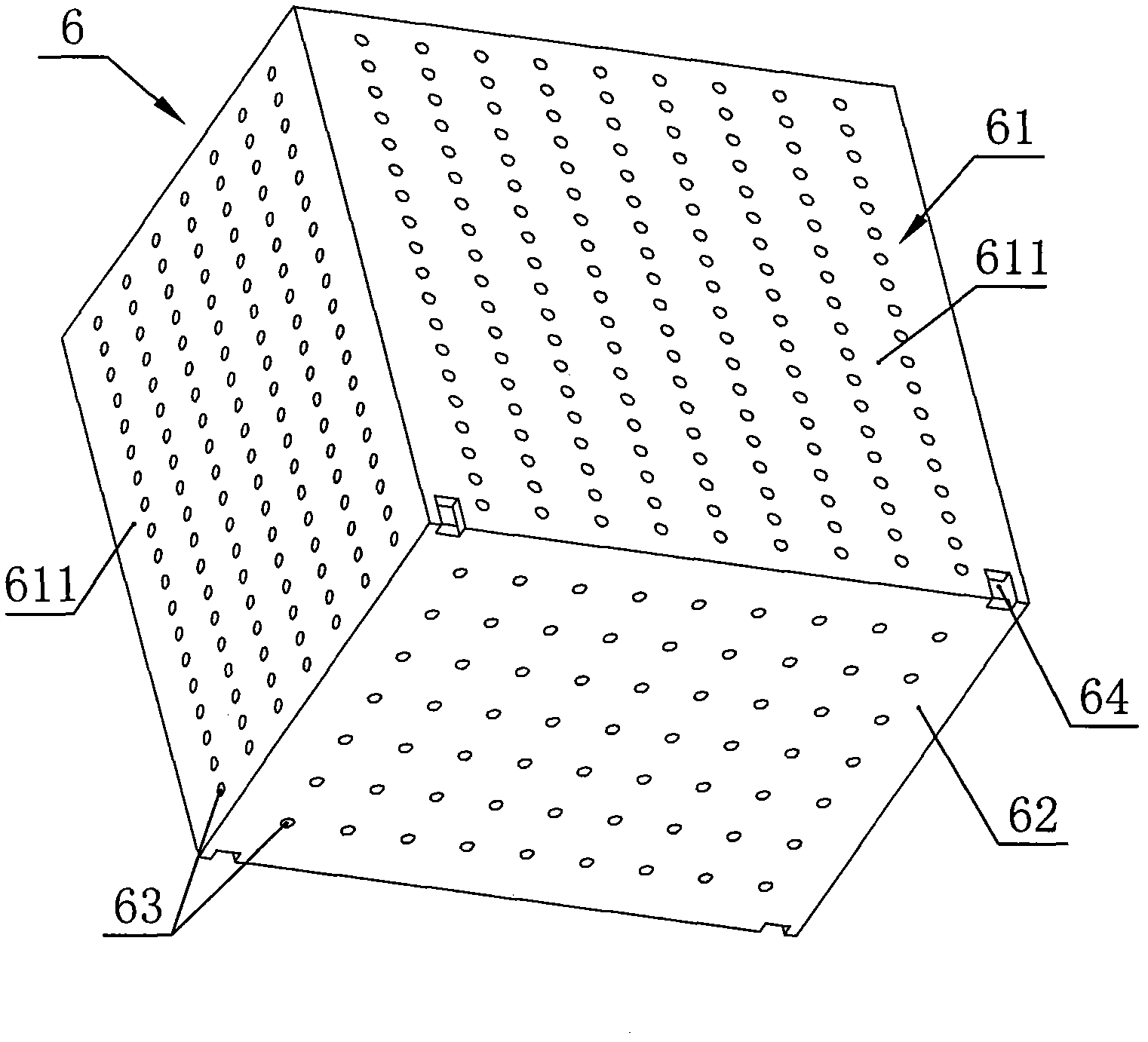

Powder feeding device for three-dimensional printing system and three-dimensional printing system

The invention discloses a power feeding device and a three-dimensional printing system with the power feeding device. The power feeding device comprises a powder storage tank, a vibration board, a vibration source, a powder receiving tank and a driving piece, wherein a containing cavity is formed in the power storage tank and a discharging port communicated with the containing cavity is formed in the powder storage tank; the vibration board is arranged below the discharging port and faces the discharging port so as to receive powder flowing out from the discharging port; the vibration source is connected with the vibration board so as to drive the vibration board to vibrate; a receiving cavity with the upper end opened is formed in the powder receiving tank, the powder receiving tank is movably arranged below the vibration board and between the receiving position and the discharging position, and the receiving cavity faces the vibration board in the receiving position so as to receive the powder fallen down through vibration of the vibration board; the driving piece is connected with the powder receiving tank so as to drive the powder receiving tank to move between the receiving position and the discharging position. The power feeding device has the advantages of being effective and stable in powder feeding and the like.

Owner:TSINGHUA UNIV

Light-sensation-control-based electricity-saving device capable of quantitatively cleaning sewage tank

InactiveCN111018231ASave electricityIncreased durabilityWater/sewage treatment by irradiationSpecific water treatment objectivesSewageSewage treatment

The invention relates to the technical field of sewage treatment equipment, and discloses a light-sensation-control-based electricity-saving device capable of quantitatively cleaning a sewage tank. The device comprises a first shell, wherein a sensor is fixedly connected to the outer portion of the first shell, the exterior of the first shell is movably connected with a driving structure, a waterinlet is fixedly connected to the top of the first shell, a flow guide plate is fixedly connected to the interior of the first shell, a filter plate is fixedly connected to the interior of the first shell, a suction pipe is fixedly connected to the interior of the first shell, a direct illuminating lamp is fixedly connected to the interior of the first shell, a photosensitive assembly is fixedly connected to the interior of the first shell, and a stirring structure is movably connected to the interior of the first shell. According to the invention, under the interaction of the rotator, the connector and the vibration block, when the rotator filters out impurities in sewage through rotary centrifugal effect, the cam impacts the vibration block to vibrate the filter plate, so that the treated sewage can flow out quickly, and accumulation of the sewage in the tank body is avoided.

Owner:卢章山

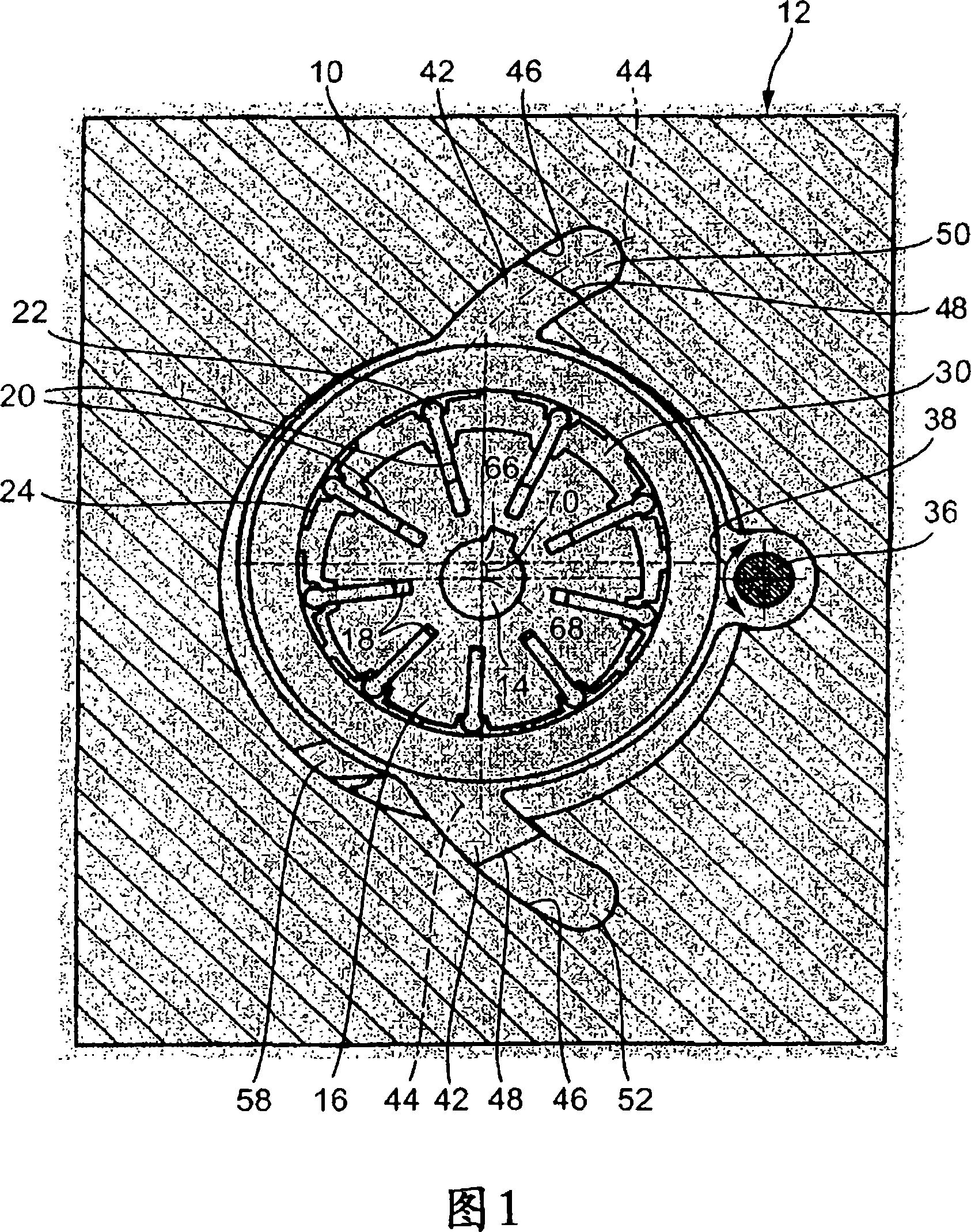

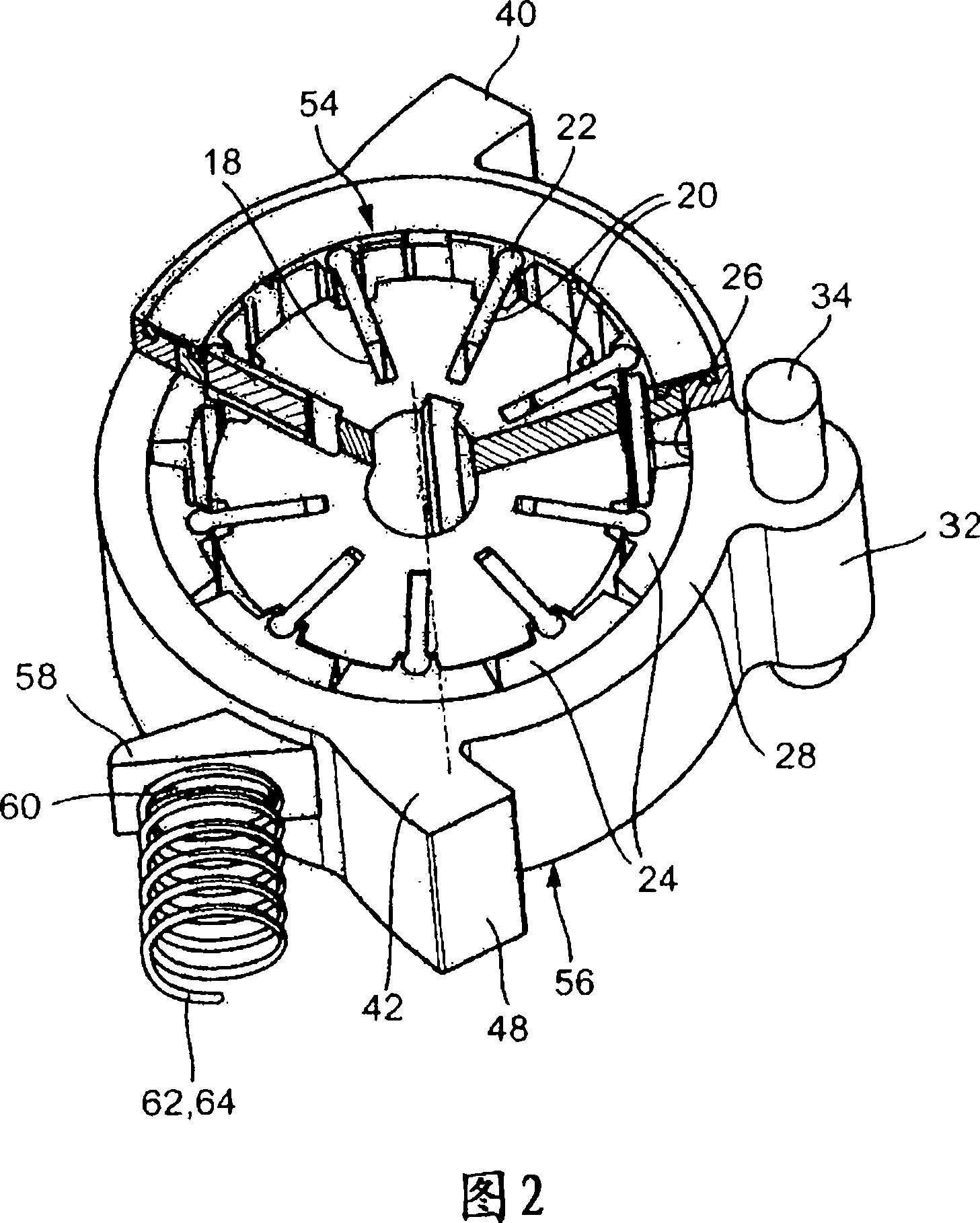

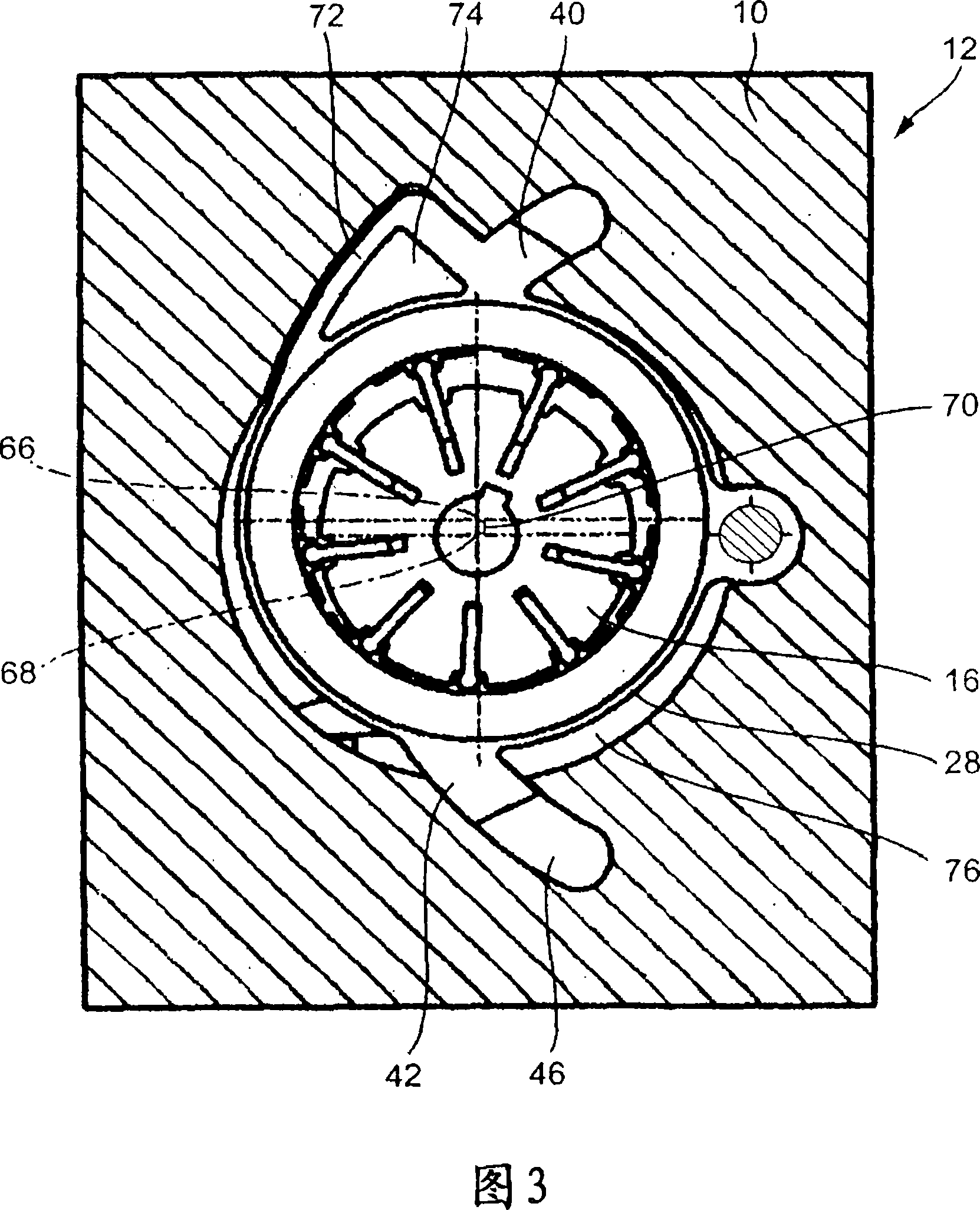

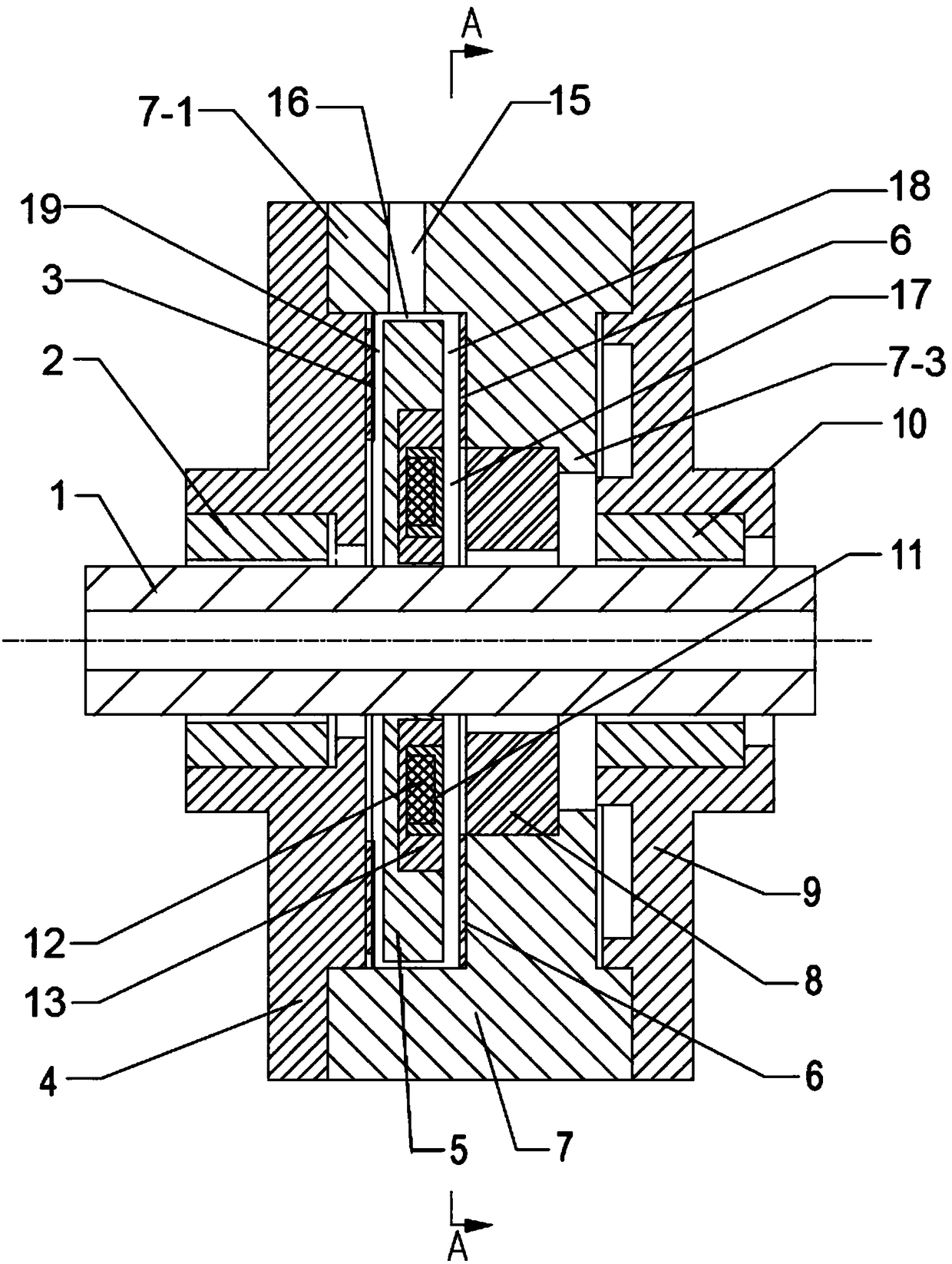

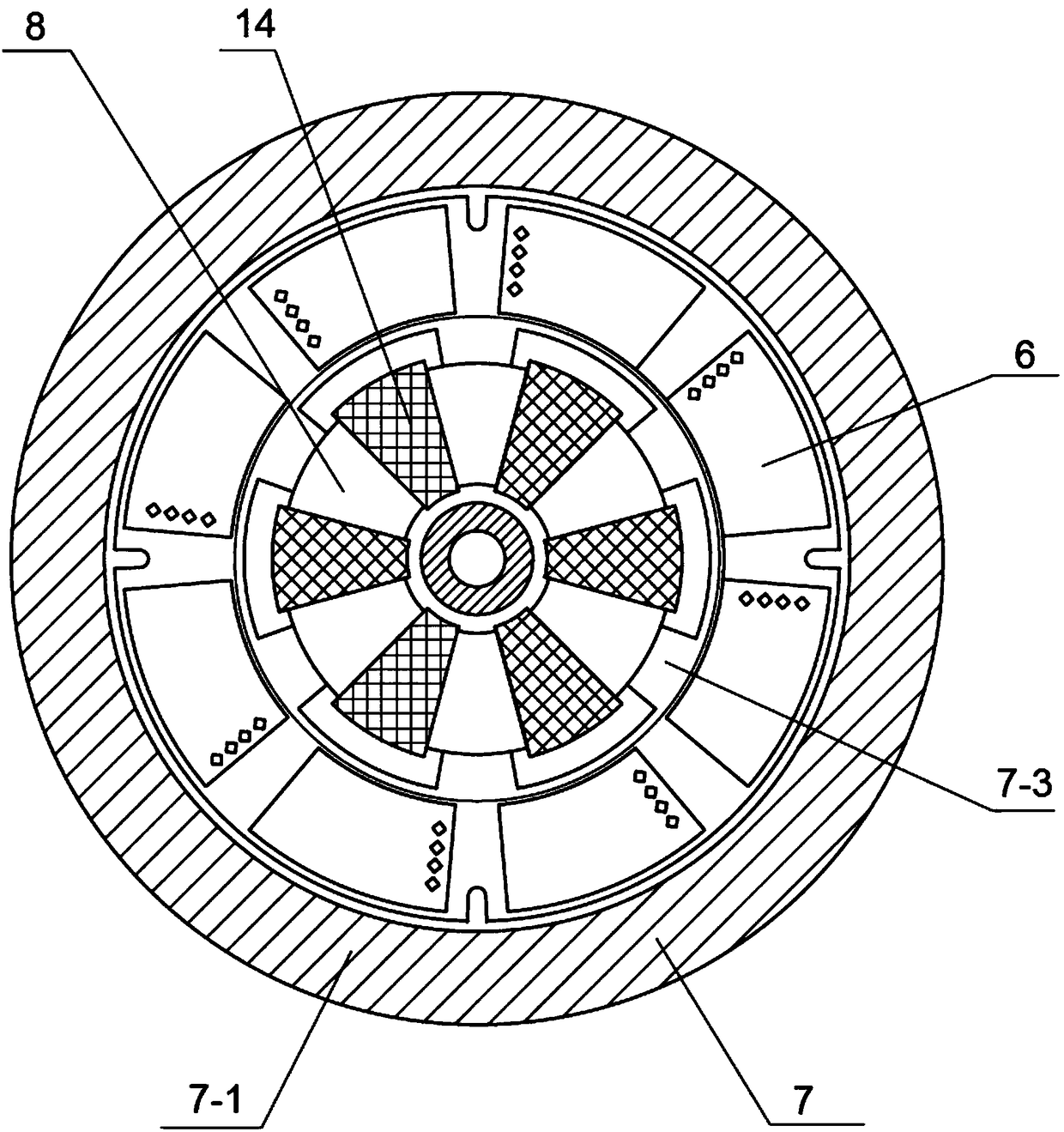

Vane cell pump

InactiveCN101147002AAccurate outputEasy to adjustRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

The invention relates to a vane pump (12) comprising an inner rotor (16) and a plurality of vanes (20) mounted substantially radially movably radially within the inner rotor in the slot (18), and directed directly or indirectly on the inner circumferential surface (26) of the stator (28). The axes of the stator and the inner rotor are offset relative to each other, and the stator (28) can be adjusted radially relative to the inner rotor (16) and thus the offset can be varied. The stator (28) includes a pivot bearing (36) disposed within the housing of the vane pump. At least one piston part (42) protrudes from the stator, whereby a piston axis (44) of said piston part extends circumferentially relative to said pivot bearing (36).

Owner:JOMA POLYTEC

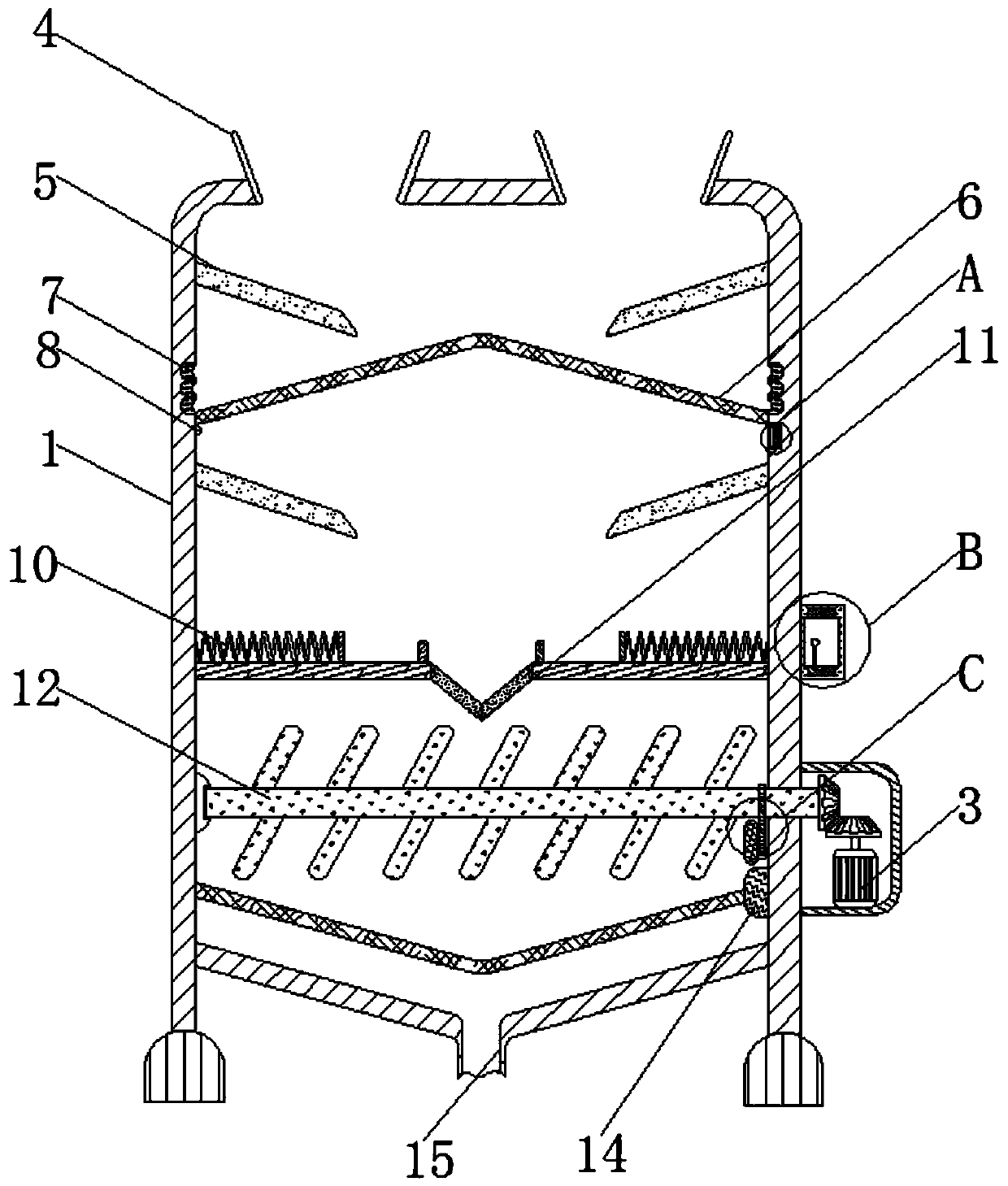

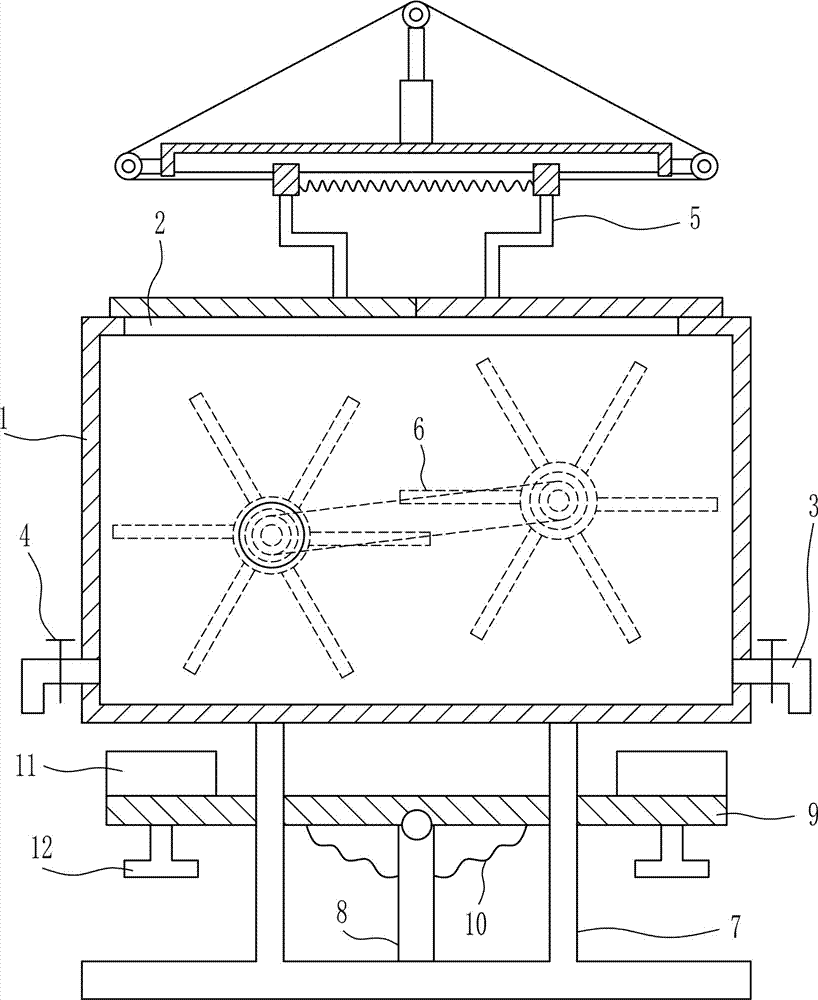

Preparation equipment of antirust agent for electric power engineering construction

InactiveCN107297167AEasy to prepareFor quick outflowRotary stirring mixersTransportation and packagingMulti directionalArchitectural engineering

The invention relates to preparation equipment, in particular to preparation equipment of an antirust agent for electric power engineering construction. The technical problem to be solved by the invention is to provide the preparation equipment of the antirust agent for electric power engineering construction, which can perform multi-directional rotating and stirring preparation and can perform preparation under an airtight condition. In order to solve the technical scheme, the invention provides the preparation equipment of the antirust agent for electric power engineering construction. The preparation equipment of the antirust agent for electric power engineering construction comprises a preparation box and the like; a through hole is formed in a top wall of the preparation box; lower parts of the left side and the right side of the preparation box are connected with liquid outlet pipes; valves are arranged on the liquid outlet pipes; a preparation mechanism is arranged in the preparation box; and a switching mechanism is arranged over the preparation box. The switching mechanism and the preparation mechanism are provided, so that the aim of performing preparation under the airtight condition can be fulfilled; and a worker pulls a second handle to move outwards, so that the aim that the antirust agent prepared in the preparation box is prepared perfectly is achieved.

Owner:喻杨凯

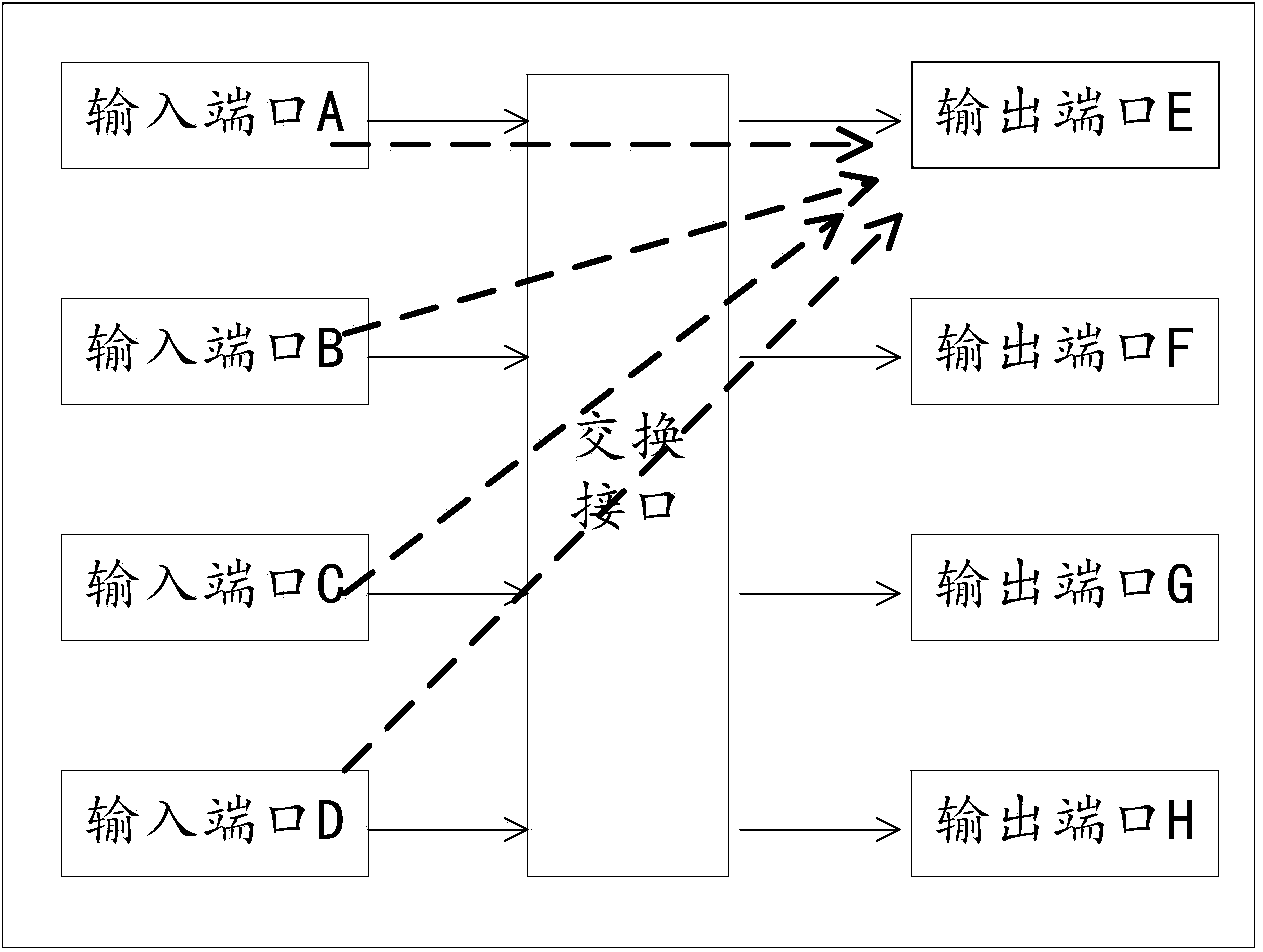

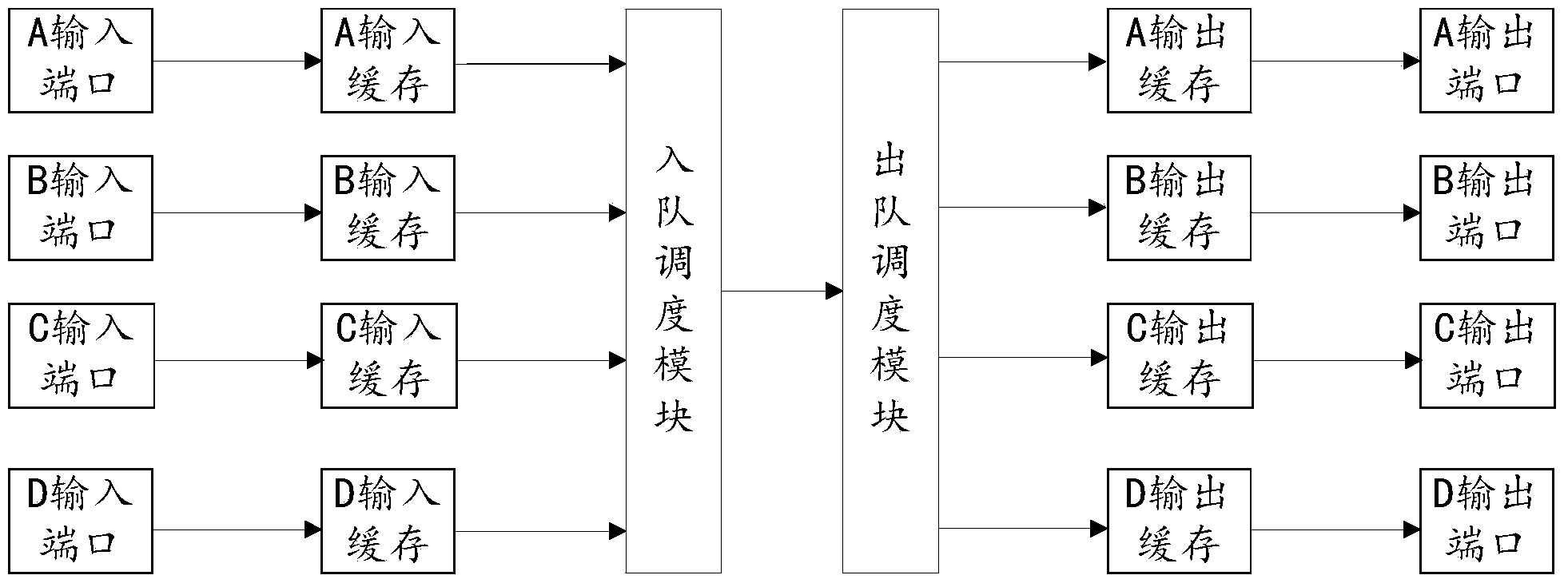

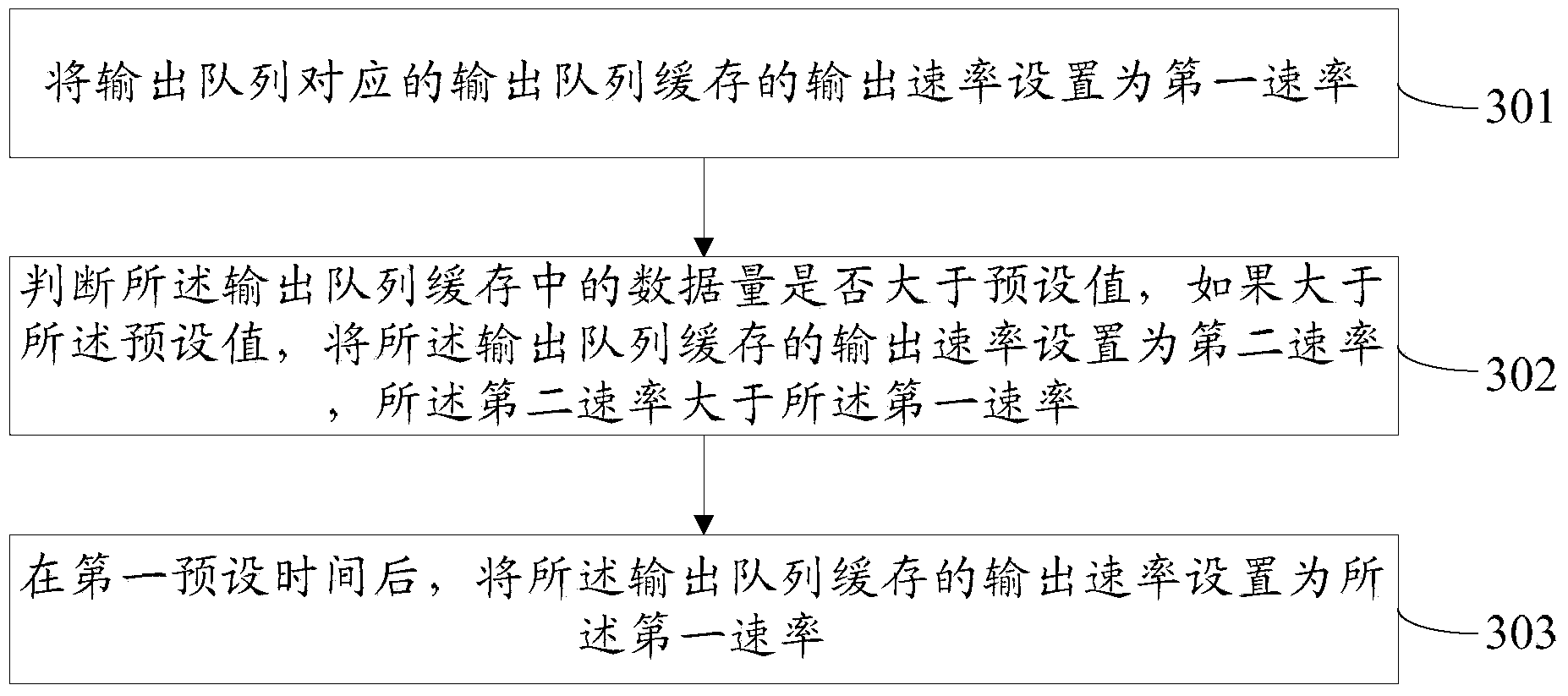

Message dequeue scheduling method and equipment thereof

The invention provides a message dequeue scheduling method and equipment thereof. According to the invention, the problem of packet loss caused by traffic burst can be solved. The method comprises the following steps: output rate which is cached by an output queue and is corresponding to the output queue is set as a first rate; whether data size in the output queue cache is greater than a preset value is judged; if the data size is greater than the preset value, the output rate cached by the output queue is set as a second rate which is greater than the first rate; and after a first preset time, the output rate cached by the output queue is set as the first rate. The method is suitable for the field of communication technology.

Owner:XFUSION DIGITAL TECH CO LTD

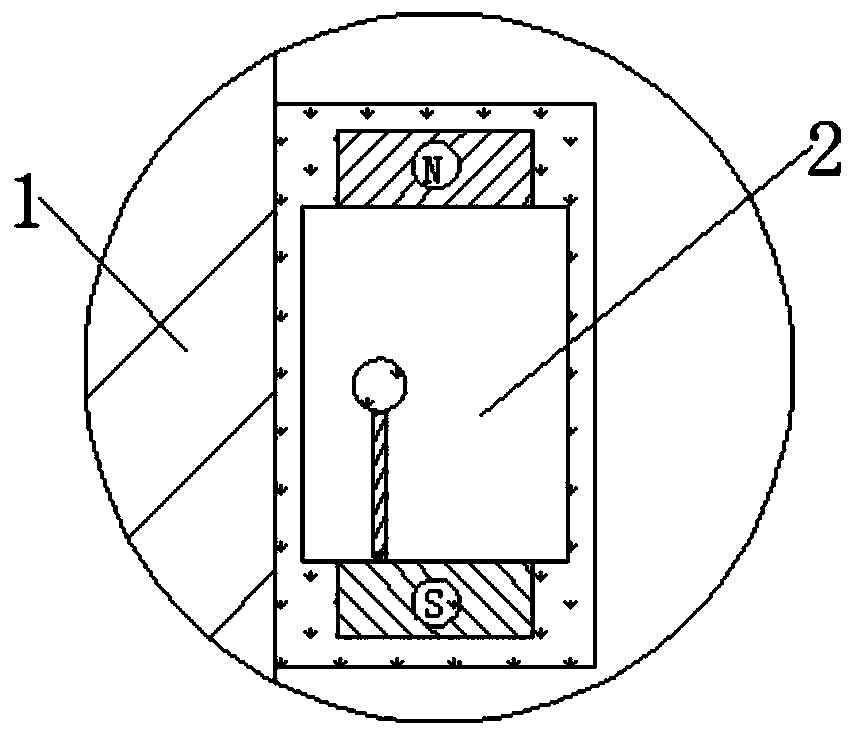

Ultrahigh-speed disc type permanent magnet synchronous motor

PendingCN108233656AIncrease the critical speedShorten the axial lengthSupports/enclosures/casingsSynchronous machines with stationary armatures and rotating magnetsUltra high speedPermanent magnet synchronous motor

The invention provides an ultrahigh-speed disc type permanent magnet synchronous motor. The motor comprises a rotor, a stator, a thrust disc and a case, wherein the rotor consists of a rotary shaft and a rotor disc; the rotor disc consists of an aluminum sheath, a permanent magnet and a protection jacket; the rotary shaft is sleeved with the thrust disc and in clearance fit with the thrust disc; afirst annular groove is formed in the thrust disc, the aluminum sheath is embedded in the first annular groove, a second annular groove is formed in the aluminum sheath, and the permanent magnet is embedded in the second annular groove; the stator consists of a stator core and a coil winding which winds around the stator core, and the rotary shaft is sleeved with the stator core in a hollow manner. The rotor disc adopts a disc structure and is embedded on the thrust disc, the axial length of the motor is greatly reduced, so that the size of the whole motor is reduced, the clearance between the rotator disc and the thrust disc which are combined together and surrounding parts is increased, and the cooling effect is improved remarkably; the stator adopts the annularly concentrated winding,the stator core is inlaid in the case, and the size of the whole motor is reduced greatly.

Owner:XIAN UNIV OF SCI & TECH

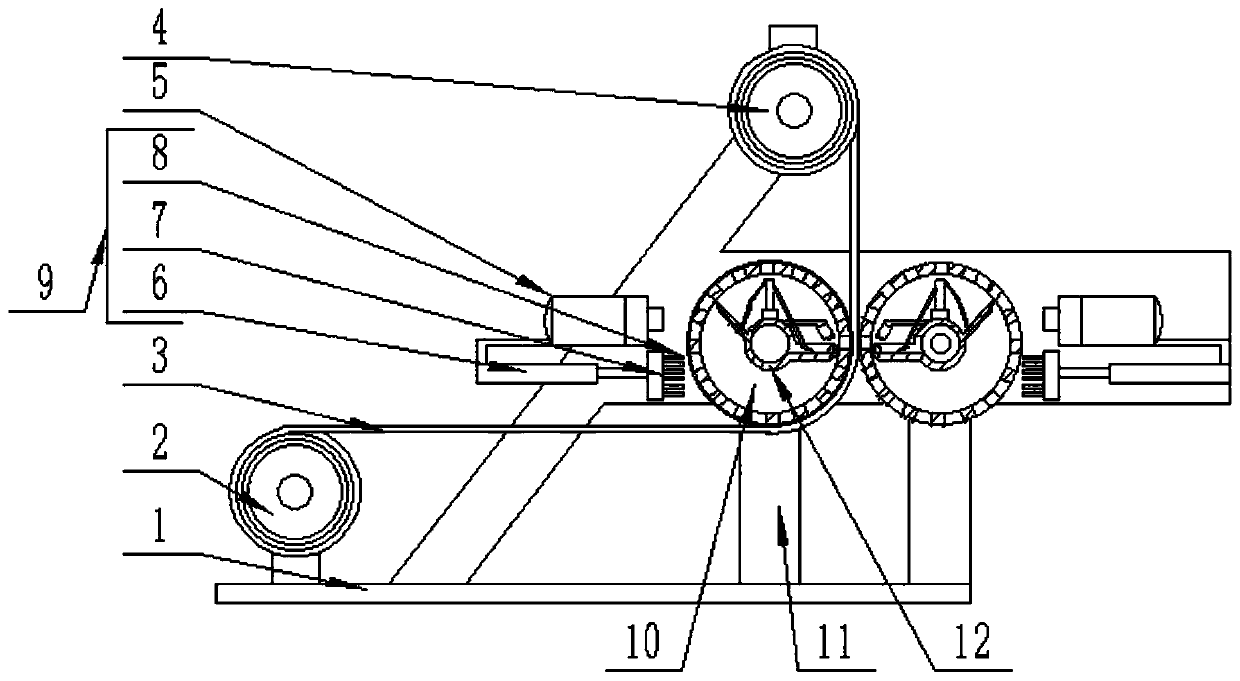

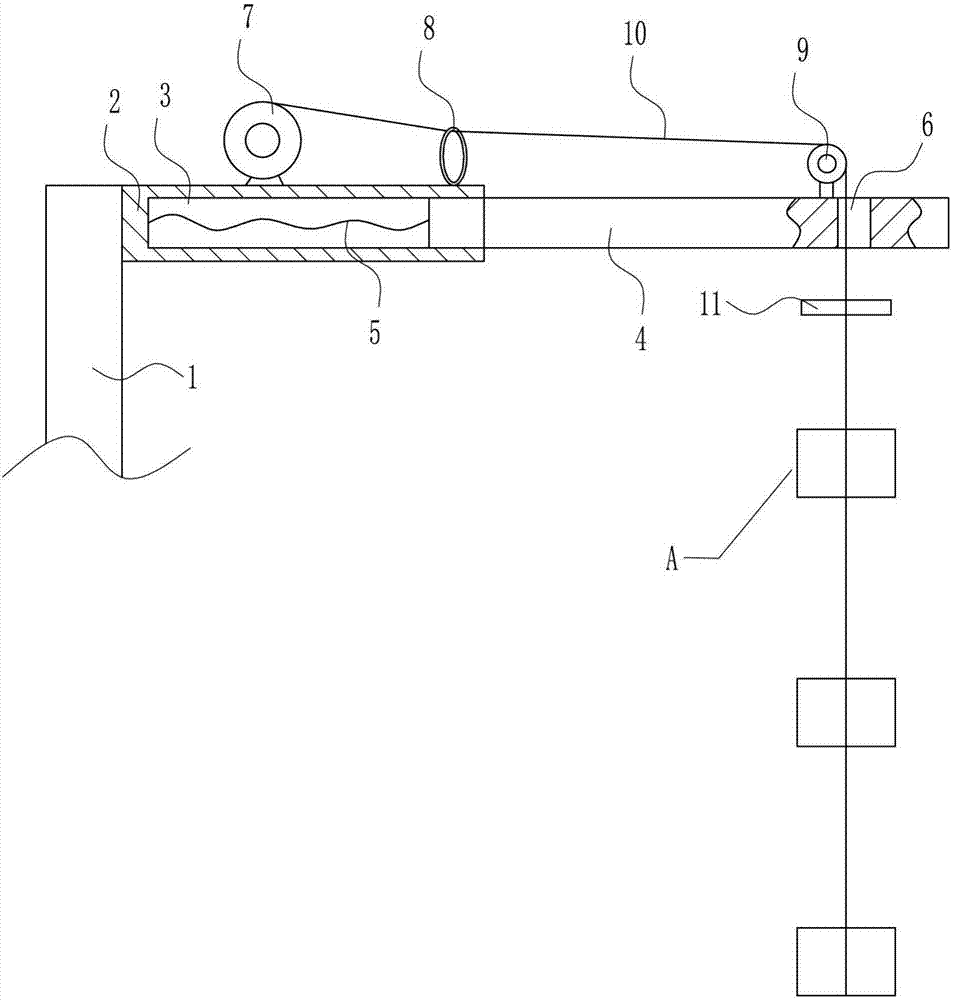

Glass-fiber wall cloth coating device with heat insulation and fire protection functions and process

PendingCN110756398AFor quick outflowImprove flowLiquid surface applicatorsCoatingsFiberMechanical engineering

The invention discloses a glass-fiber wall cloth coating device with heat insulation and fire protection functions and a process. The glass-fiber wall cloth coating device comprises a bottom plate; acloth unwinding rotary drum is fixedly arranged on the left side of the upper end surface of the bottom plate; glass-fiber wall cloth is wound around the cloth unwinding rotary drum; a cloth winding rotary drum is fixedly arranged above the right of the bottom plate; the tail end of the glass-fiber wall cloth is fixedly wound on the side wall of the cloth winding rotary drum; and coating rollers are horizontally arranged below the cloth winding rotary drum in a pair left and right; and the glass-fiber wall cloth penetrates through a gap between the coating rollers arranged in a pair left and right. When the cloth unwinding rotary and the cloth winding rotary drum are started to rotate, the glass-fiber wall cloth penetrates through the gap between the coating rollers continuously, meanwhile, a servo motor connected with the coating rollers drive the coating rollers to rotate, and a coating pump is started, and is used for conducting fireproof non-combustible coating in a coating box ina guide pipe, and the coating transported in the guide pipe flows out from a discharge guide plate, and is quickly sprayed from spray holes toward the passing glass-fiber wall cloth to realize the coating.

Owner:天津方元绿洲新材料科技有限公司

Portable nasal cavity cleaning device for pediatric nursing

InactiveCN108210308AAvoid risk of aspiration into lungsAutomate the processBathing devicesNasal cavityPediatric nursing

The invention discloses a portable nasal cavity cleaning device for pediatric nursing. The nasal cavity cleaning device comprises a device body, a controller, a built-in power supply, a syringe, a micro motor, a liquid guide tube and a cleaning head. Through coordinated linkage of the syringe, the micro motor and the liquid guide tube, the micro motor drives the liquid guide tube to rotate, so thecleaning head can clean the nasal cavity through bristles, cleaning liquid can be safely and reliably injected into the nasal cavity through the syringe for further cleaning, and thus the effect andreliability of nasal cavity nursing are greatly improved; besides, a heating jacket is arranged in the device body, so the cleaning liquid in the syringe can be kept at a suitable use temperature, therejection reaction of the nasal cavity is relieved, and the use experience is improved; moreover, the nasal cavity cleaning device is compact in structure, small in size, suitable for carrying, low in use environment requirement and convenient to use for home life or medical institutions.

Owner:张洪娟

Faucet and water dispenser

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG +1

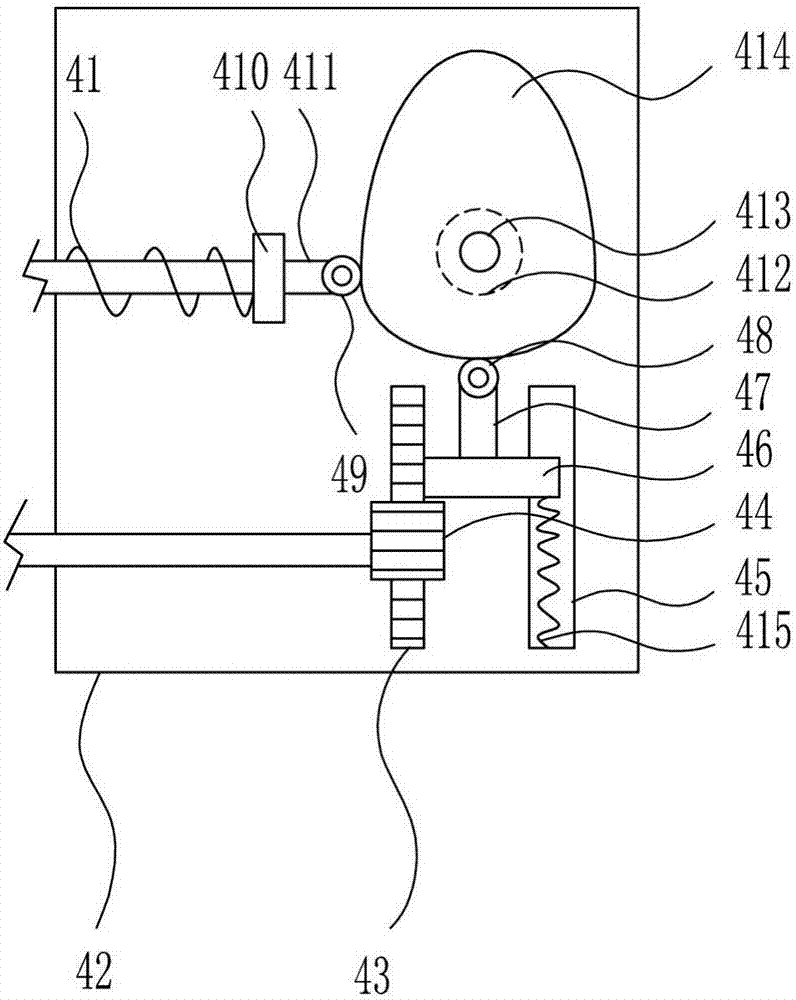

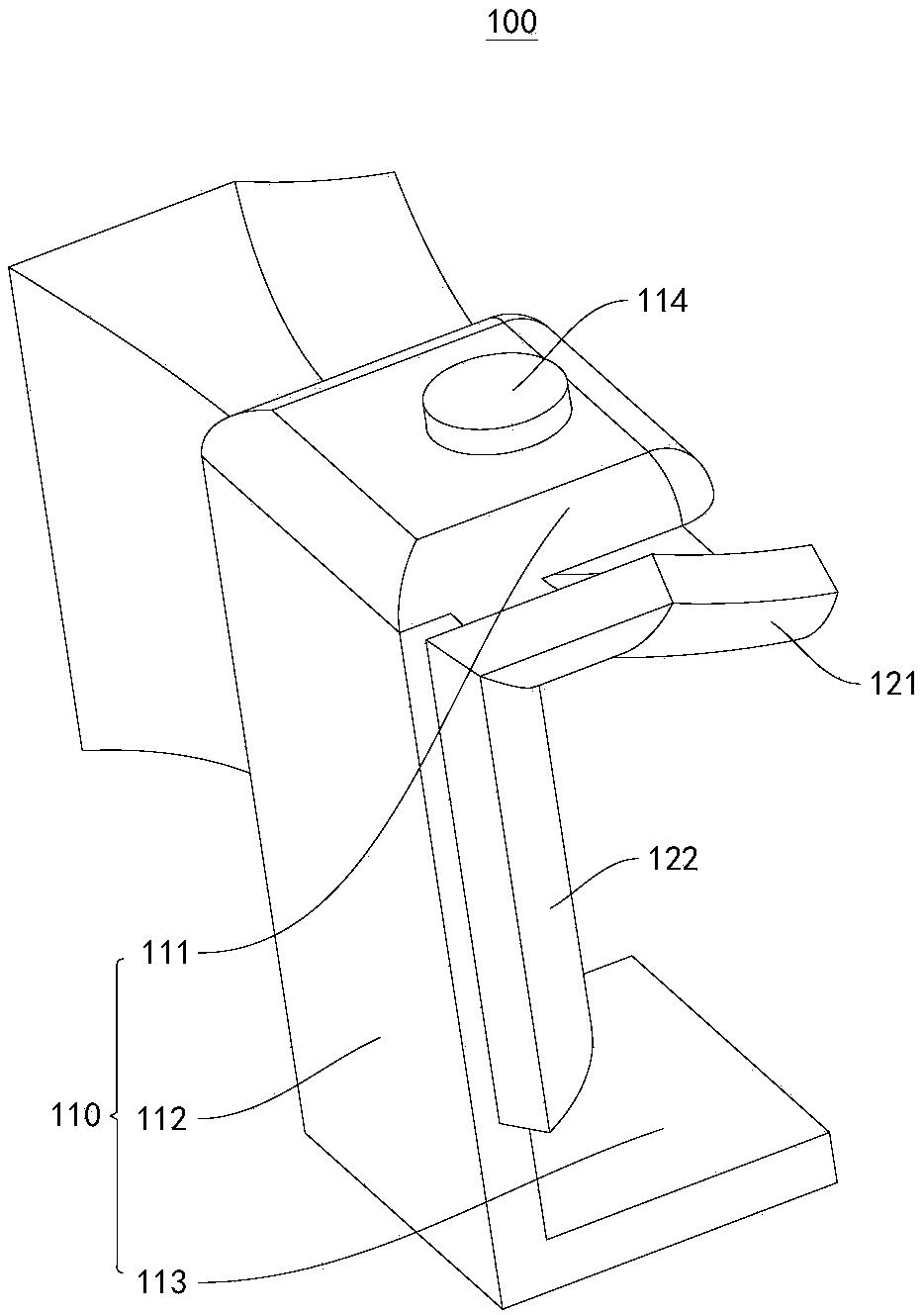

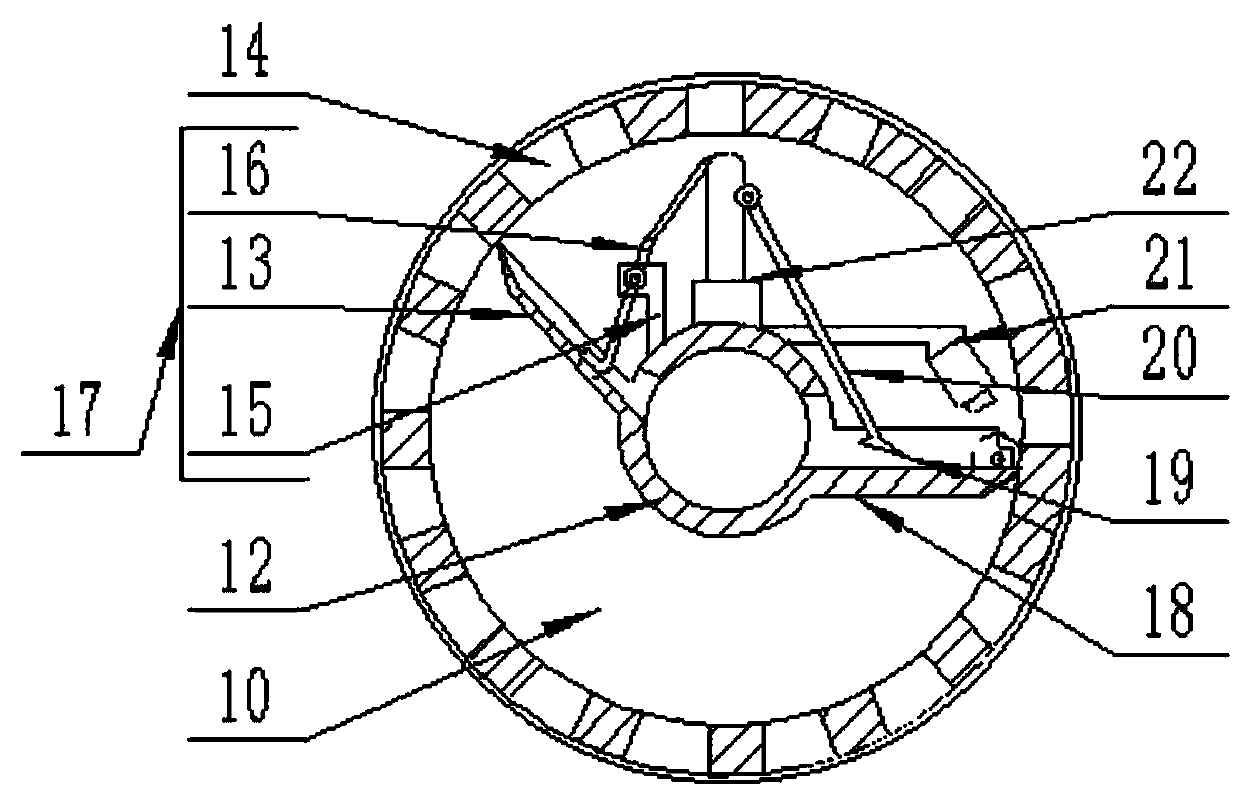

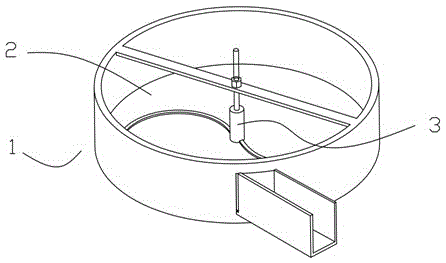

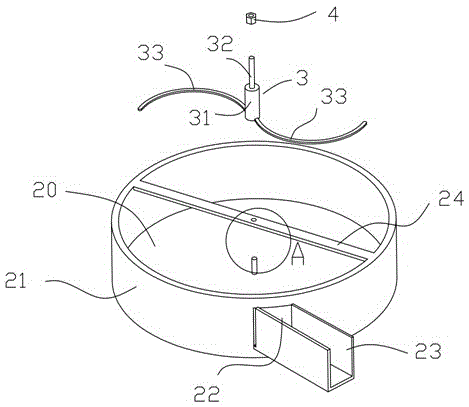

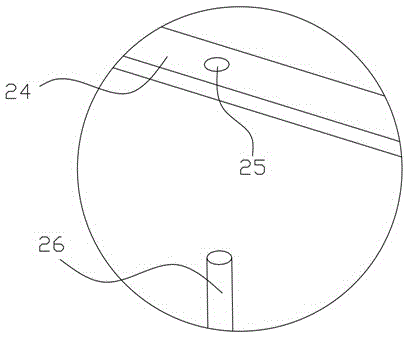

An automatic vibration feeding device

InactiveCN106315138AImprove the efficiency of vibration feedingFor quick outflowJigging conveyorsConveyor partsDrive shaftElectric machinery

The invention provides an automatic vibration feeding device which comprises a vibration cavity. The vibration cavity contains a disk-like vibration bottom plate; an annular barrier is arranged in the circumferential direction of the vibration bottom plate and is provided with a discharging opening; the discharging opening is provided with a discharging groove rack; the top of the annular barrier is provided with a fixed cross bar in the shape of a long strip; the center of the fixed cross bar is provided with a fixing round hole; the vibration bottom plate is provided with a locating pillar head at the center; a rotatable feeding support is arranged between the locating pillar head and the fixing round hole. During use, a drive shaft rod of the feeding support is connected with an external drive motor; when multiple chain wheel blanks are placed in the vibration cavity for vibration feeding, a material pushing arc strip pushes the chain wheel blanks to the edge of the vibration cavity directly, so that the chain wheel blanks can flow out of the discharging groove rack rapidly and thus the vibration feeding efficiency of blanks is greatly increased.

Owner:TAIZHOU HONGXIANG POWER MACHINERY

Frequency converter shell convenient for heat dissipation of frequency converter

InactiveCN110350764ADoes not cause dust accumulationPromote absorptionModifications for power electronicsPower conversion systemsFrequency changerPartial filling

The invention relates to the technical field of frequency converters, and particularly relates to a frequency converter shell convenient for heat dissipation of a frequency converter. The frequency converter shell comprises a shell covering the outer side of the frequency converter body. At least one side surface of the interior of the shell is provided with a liquid storage chamber laying and extending along the surface. A cavity is arranged inside the liquid storage chamber. The liquid storage chamber is provided with a pipeline which is integrated with the liquid storage chamber and extendsout of the shell. The liquid storage chamber is partially filled with a heat absorbing medium capable of absorbing heat and gasifying within the set temperature. A sealed liquefaction chamber is connected directly above the shell through a fixed column integrated with the shell. A cooling device for cooling gas after heat adsorbing and gasifying of the liquid of the heat absorbing medium in the liquid storage chamber is connected with the liquefaction chamber. The liquefaction chamber is sealed and communicated with the pipeline through the connecting pipe having the integral structure with the liquefaction chamber so that the problems of poor heat dissipation effect and dust liquefaction chamber caused by using the heat dissipation holes for heat dissipation of the frequency converter inthe prior art can be solved. The frequency converter shell has good prospect in the technical field of the frequency converter.

Owner:HENAN YUQIAN TECH TRANSFER CENT CO LTD

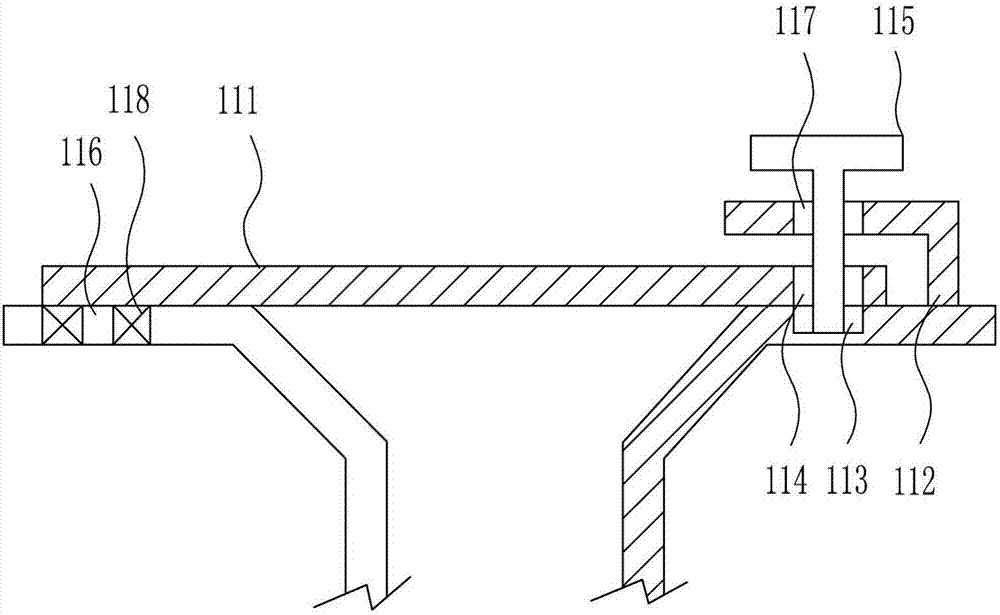

Extracting device for water bodies with different depths and production and use methods of extracting device

InactiveCN108007727AWill not flowFor quick outflowWithdrawing sample devicesWater qualityEngineering

The invention relates to an extracting device for water bodies with different depths. The device comprises a support, a top plate, a telescopic rod, a first spring, an electric winding wheel, a guidering, a fixed pulley, a stay cord, a floating plate, a water collector, an electromagnet, an iron piston and the like, wherein the top plate is horizontally connected to the right side of the top of the support; a sliding chute is formed in the top plate. The extracting device disclosed by the invention achieves simple structure and convenience in operation, and can simultaneously sample differentdeep water segments at the same position, so that the result of water quality detection is more accurate and high precision is realized.

Owner:NANJING CUIZHI WATER CONSERVANCY TECH CO LTD

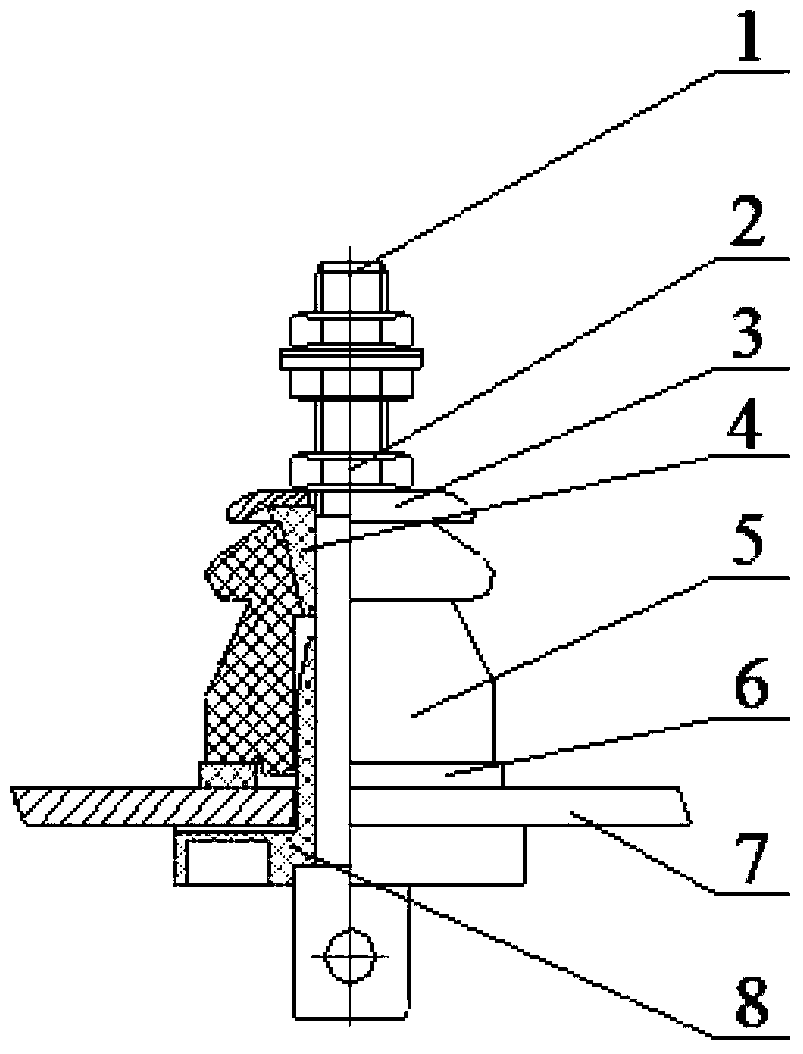

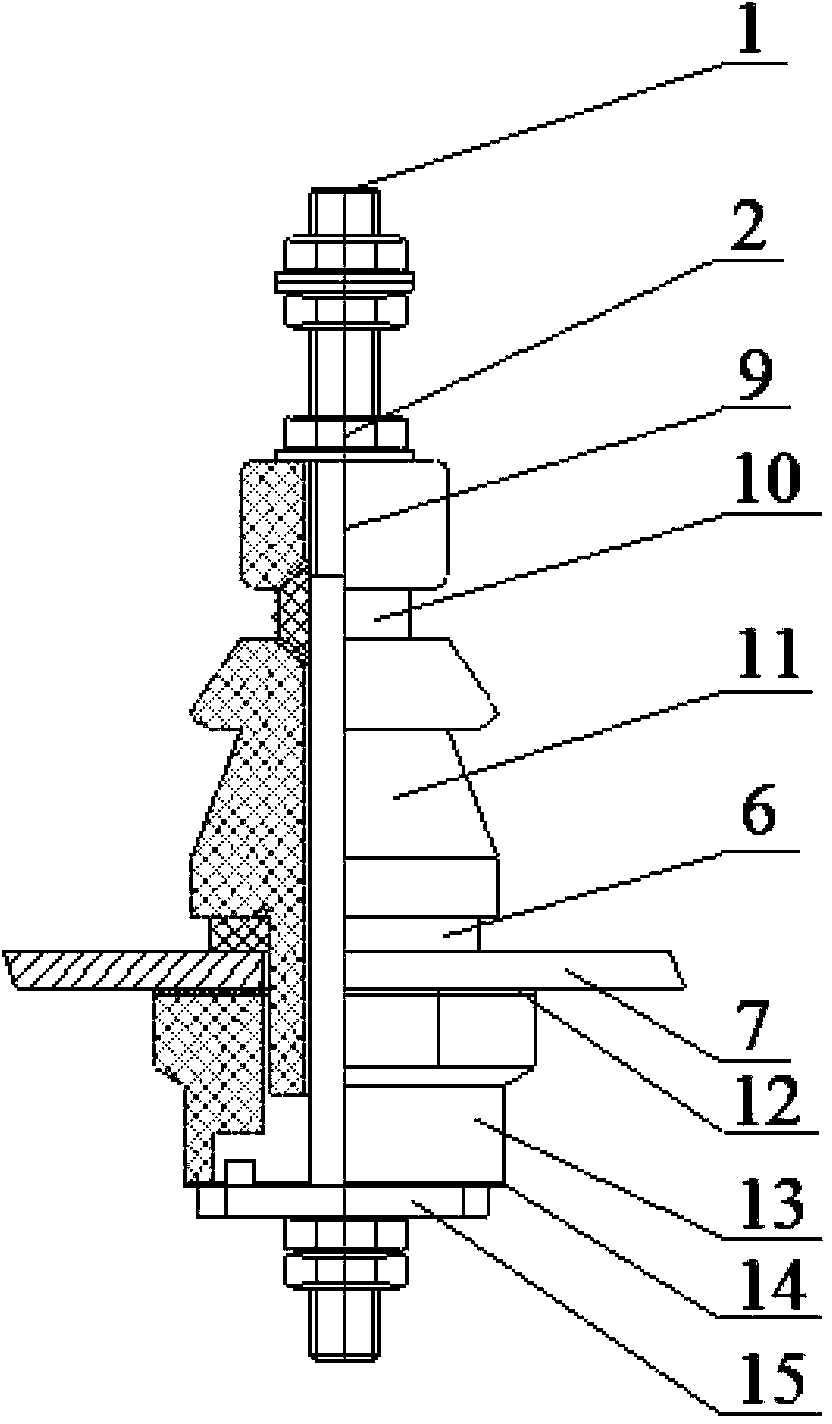

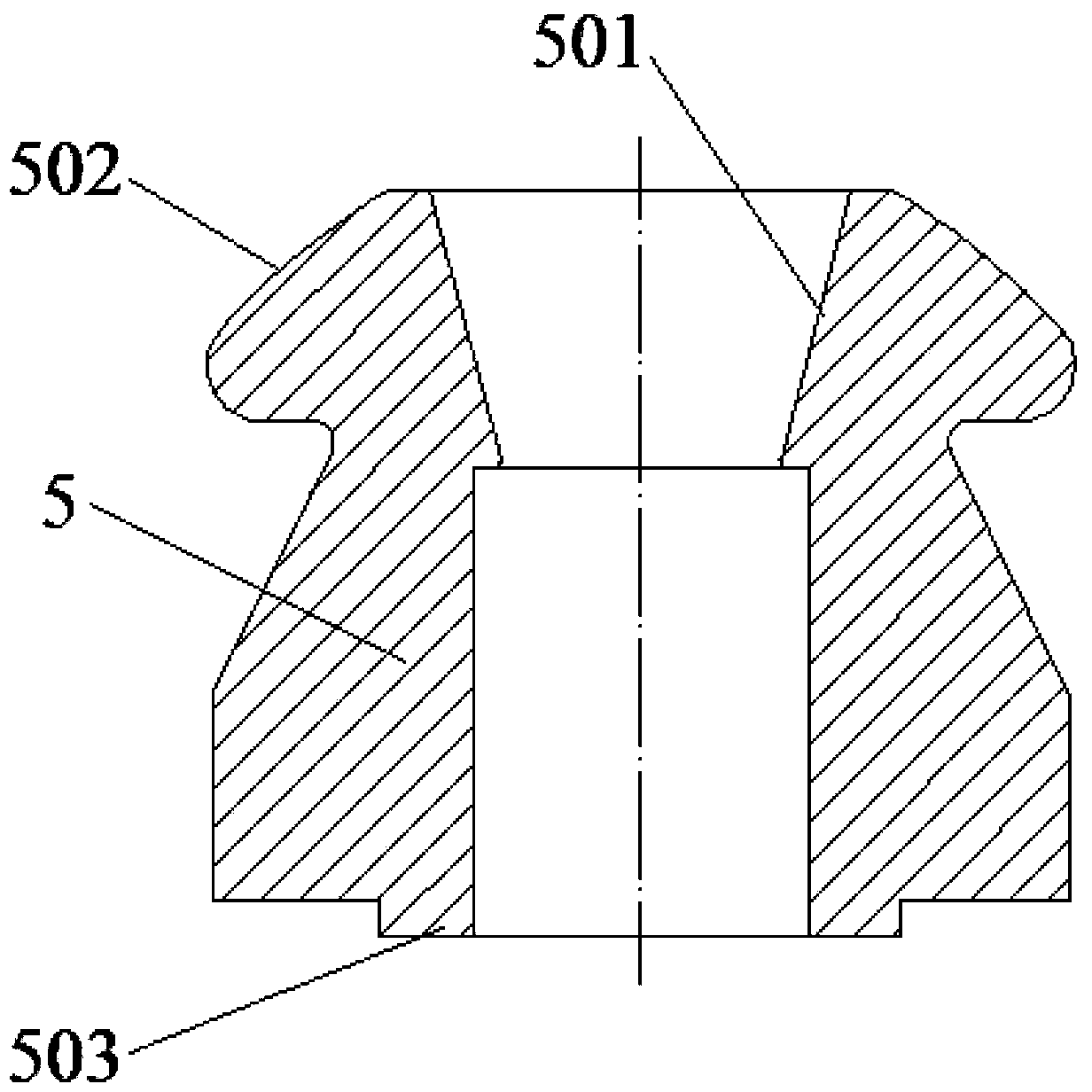

Combined type 1-KV level transformer bushing

ActiveCN103413659AImprove reliabilityEasy to install and operateTransformers/inductances coils/windings/connectionsInsulating bodiesEngineeringWedge shape

The invention discloses a combined type 1-KV level transformer bushing, and belongs to the technical field of transformer bushings. The combined type 1-KV level transformer bushing comprises a conductive rod, a nut, a porcelain bushing, a sealing flat gasket, a metal gland, a wedge-shaped sealing leather ball and a base, wherein an external thread is formed at one end of the conductive rod, and a flat wiring terminal is arranged at the other end of the conductive rod; the base is an insulation casting body and is combined with one end, which is close to the flat wiring terminal, of the conductive rod to form an integrated structure; the sealing flat gasket, the porcelain bushing, the wedge-shaped sealing leather ball and the metal gland are sequentially sleeved on the conductive rod; the nut is matched with the external thread on the conductive rod and is arranged at the upper end of the metal gland. The combined type 1-KV level transformer bushing is simple in structure, convenient to mount and high in sealing property; the number of constituent accessories of the bushing is small; therefore the manufacturing cost is greatly reduced.

Owner:江苏金诺电气科技有限公司

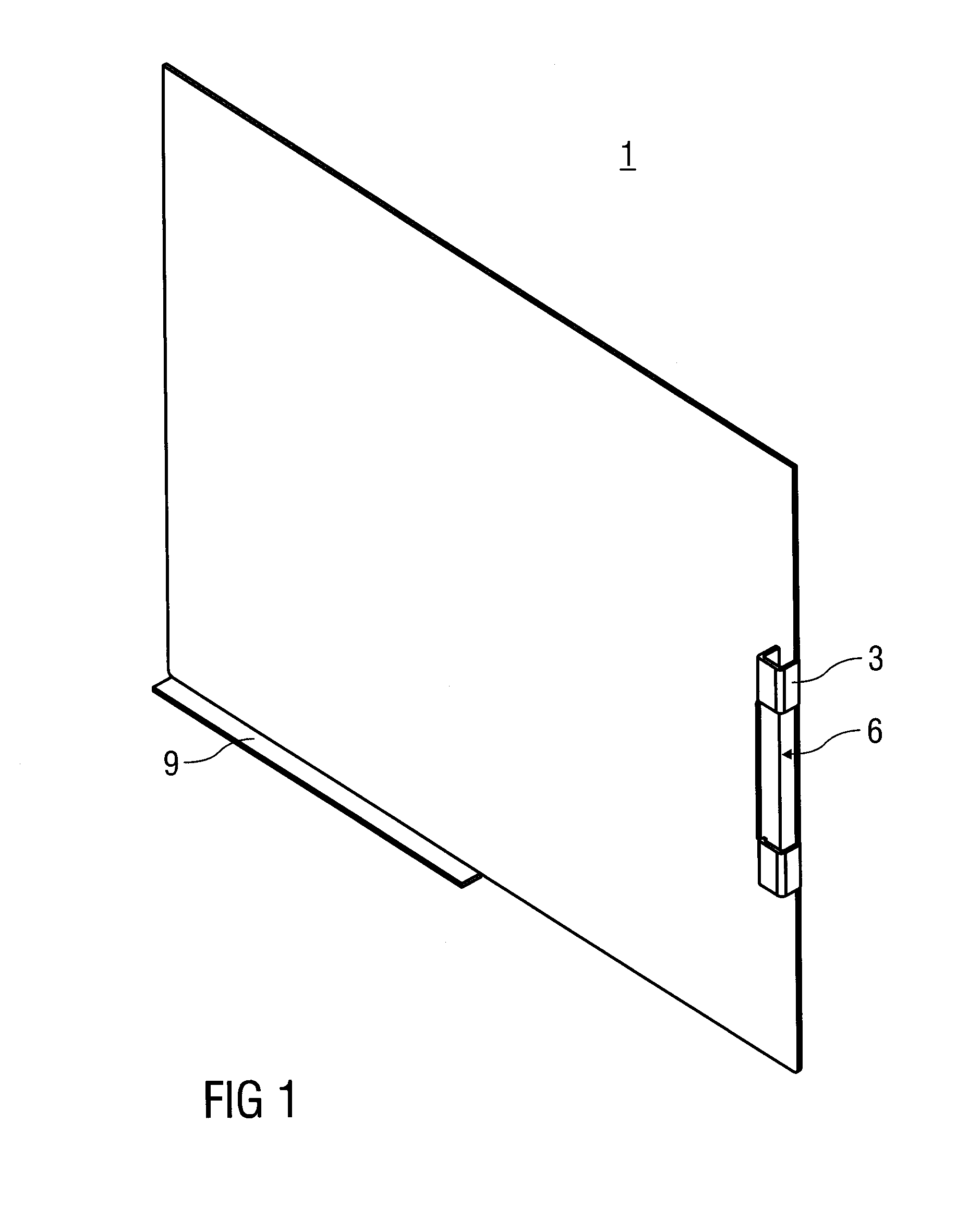

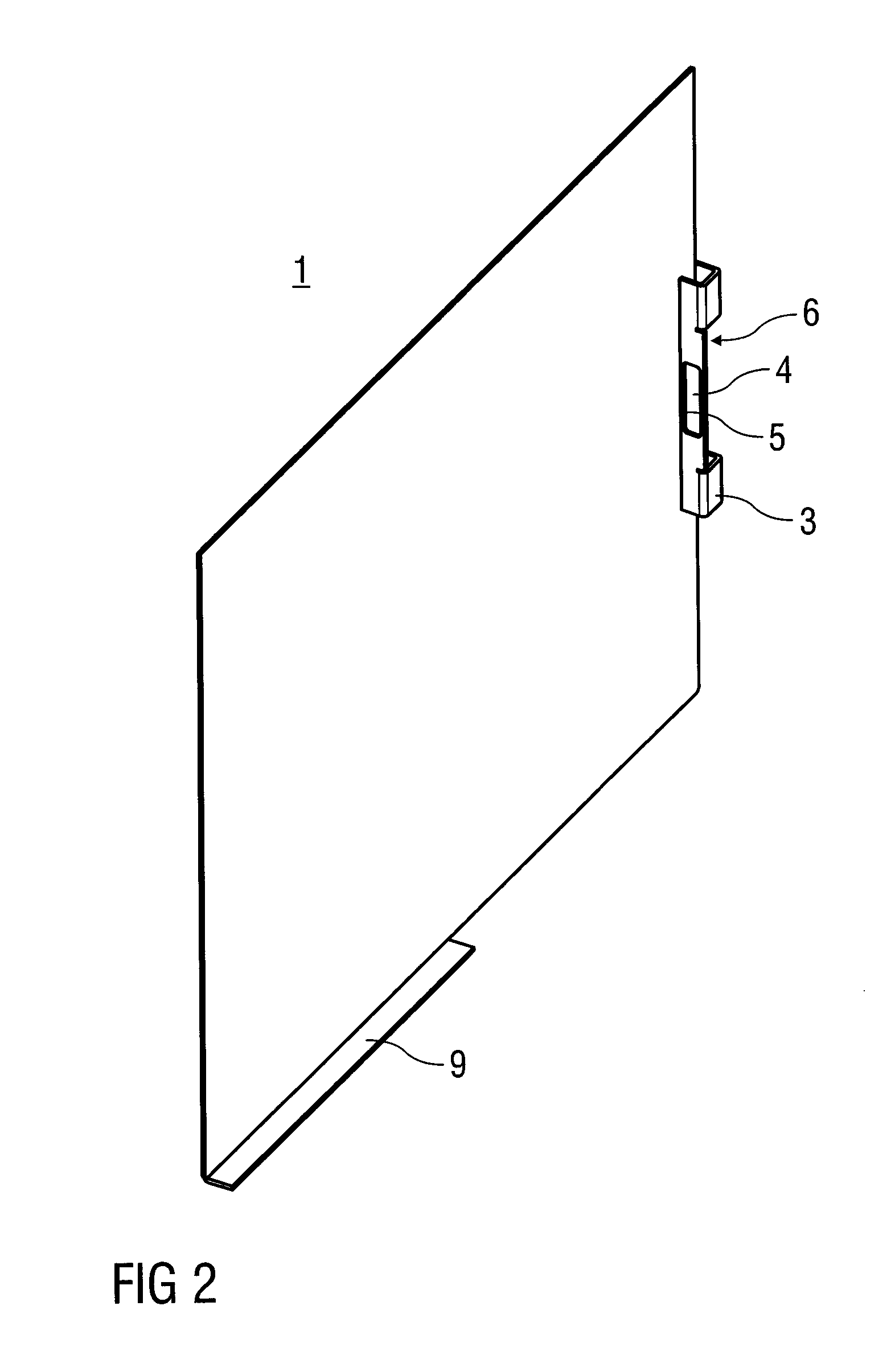

Galvanic Cell Having Overpressure Protection

InactiveUS20120141844A1Save construction spacePromote productionSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringElectrolyte

A single cell having a casing formed from a first casing side part, a second casing side part and a casing frame, in which casing an electrolyte and an electrochemically active electrode foil unit are arranged, wherein the casing comprises an overpressure protection. The first casing side part includes a casing side part segment going at least sectionally over a length of the single cell, which casing side part segment is angled down in relation to the first casing side part in the direction of the cell interior and in which the overpressure protection is arranged and a venting opening is incorporated into the casing frame in a region of the overpressure protection.

Owner:DAIMLER AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com