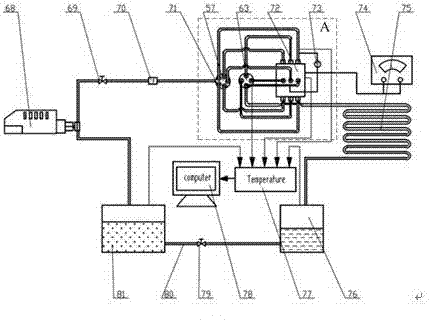

Micro-channel heat exchanger and flow heat exchange experiment device

A technology of micro-channel heat exchanger and thermal experiment, which is applied in measuring devices, cooling/ventilation/heating transformation, instruments, etc. It can solve the problems that cannot meet the heat dissipation requirements of high-load electronic devices, achieve convenient connection and shorten the length of the flow channel , the effect of reducing the number of exports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

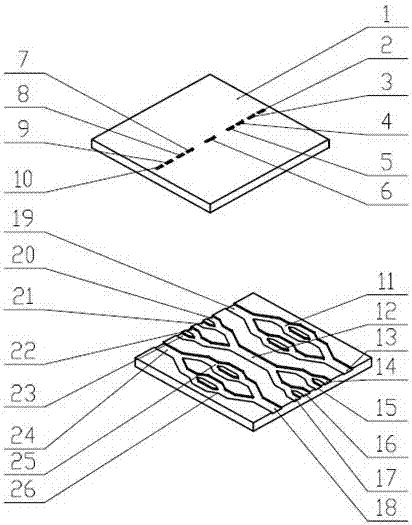

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

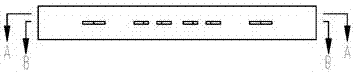

[0033] like figure 1 As shown, a microchannel heat exchanger at least includes: an upper cover plate 1, a lower cover plate 26, and the upper cover plate 1 and the lower cover plate 26 are respectively processed with 3 flow channels and 3 flow channel inlets and outlets , the first flow channel 11, the second flow channel 12 and the third flow channel 25; the first flow channel 11, the second flow channel 12 and the third flow channel 25 are composed of two Y-shaped flow channels, the flow channel 11 and the flow channel 25 is formed by connecting the Y-shaped forked ends, and the flow channel 12 is formed by connecting the unforked ends of Y. When the fluid flows in the first flow channel 11, the second flow channel 12 and the third flow channel 25 , the inlet and outlet flow directions are perpendicular.

[0034]There are four outlets of the first flow channel 11 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com