Patents

Literature

30results about How to "Shorten the length of the runner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

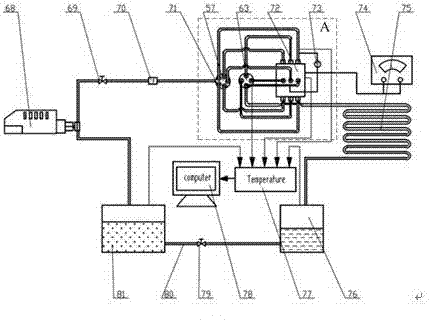

Micro-channel heat exchanger and flow heat exchange experiment device

ActiveCN106879227ABuck downUniform temperature distributionStructural/machines measurementCooling/ventilation/heating modificationsPlate heat exchangerEngineering

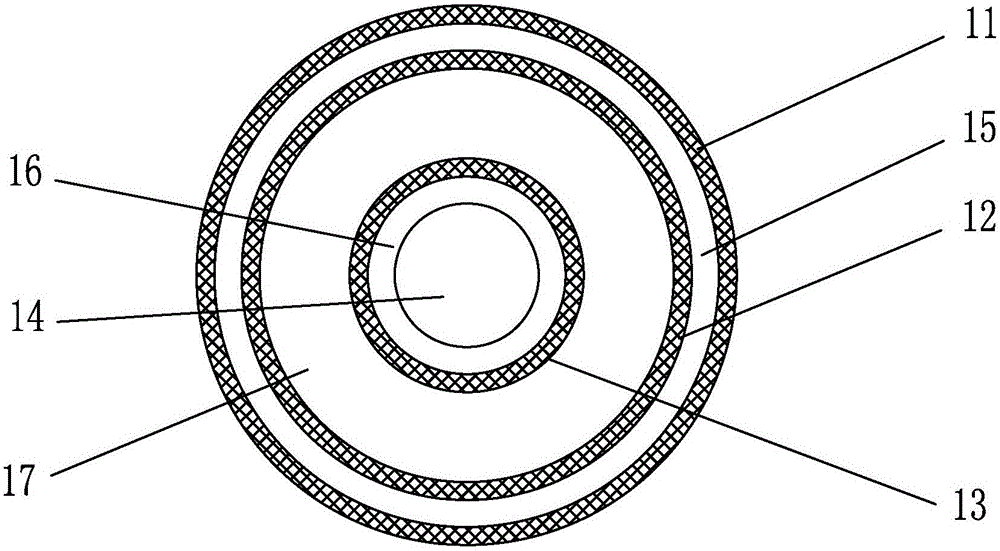

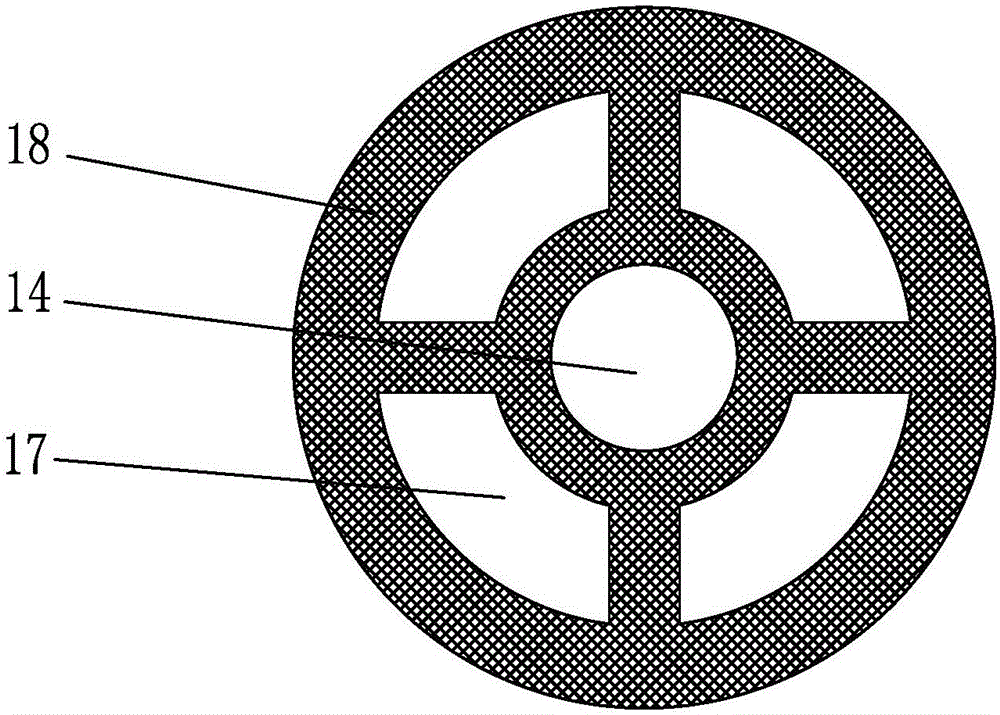

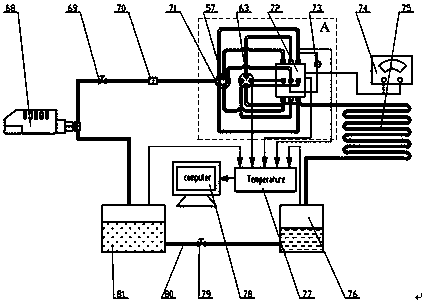

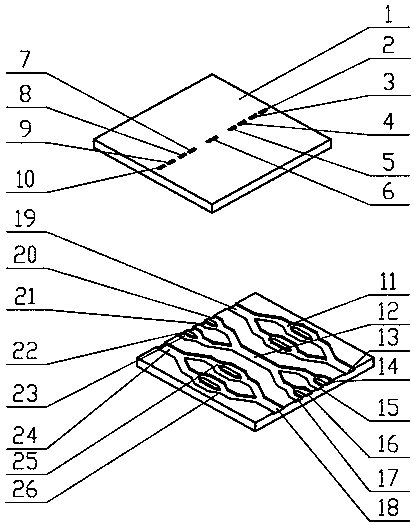

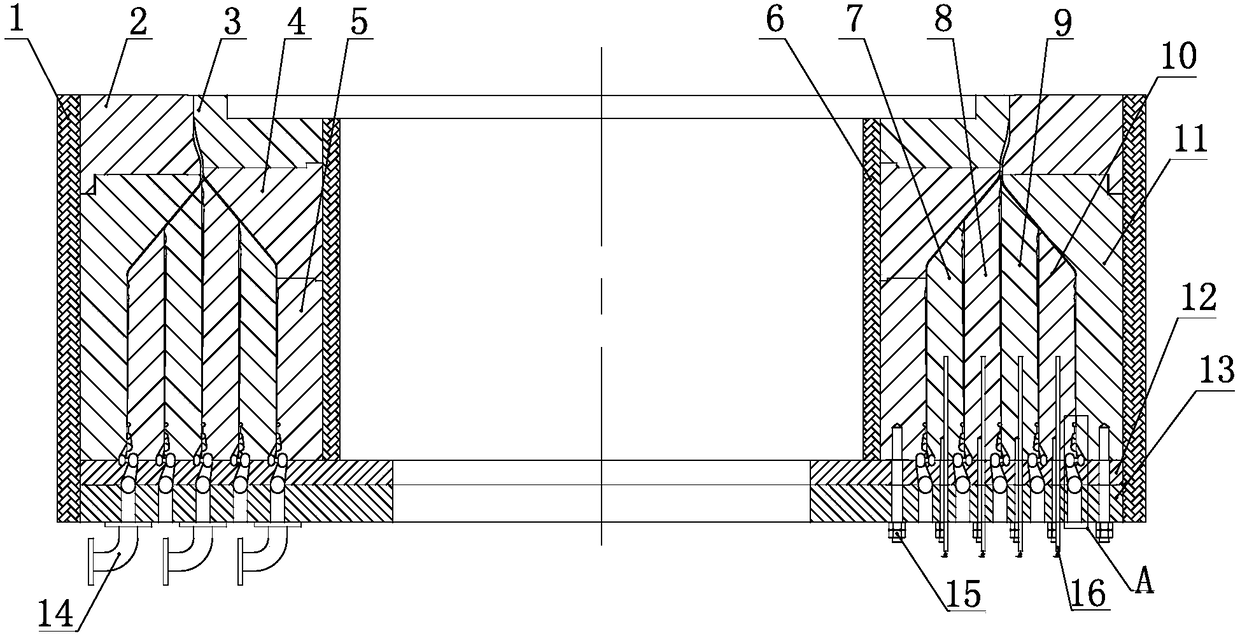

The invention relates to a micro-channel heat exchanger and a flow heat exchange experiment device. The micro-channel heat exchanger is characterized in that the heat exchanger at least comprises an upper cover plate and a lower cover plate; three flow channels, namely, a first flow channel, a second flow channel and a third flow channel, and the inlets and outlets of the three flow channels are machined on the upper cover plate and the lower cover plate respectively; the first flow channel, the second flow channel and the third flow channel are each composed of two Y-shaped flow channels; the first flow channel and the third flow channel are formed by connecting the bifurcate ends of two Y flow channels, and the second flow channel is formed by connecting the non-bifurcate ends of two Y flow channels; and when fluid flows in the first flow channel, the second flow channel and the third flow channel, the flow direction at the inlets and the flow direction at the outlets are perpendicular to each other. The heat dissipation performance is good. Electronic equipment of high heat flux density can be kept at uniform temperature.

Owner:XIDIAN UNIV

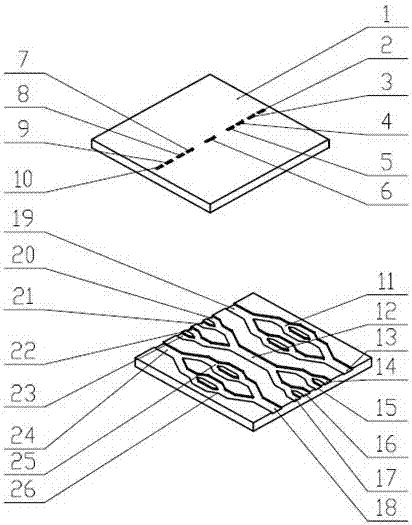

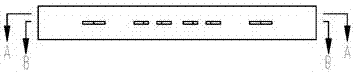

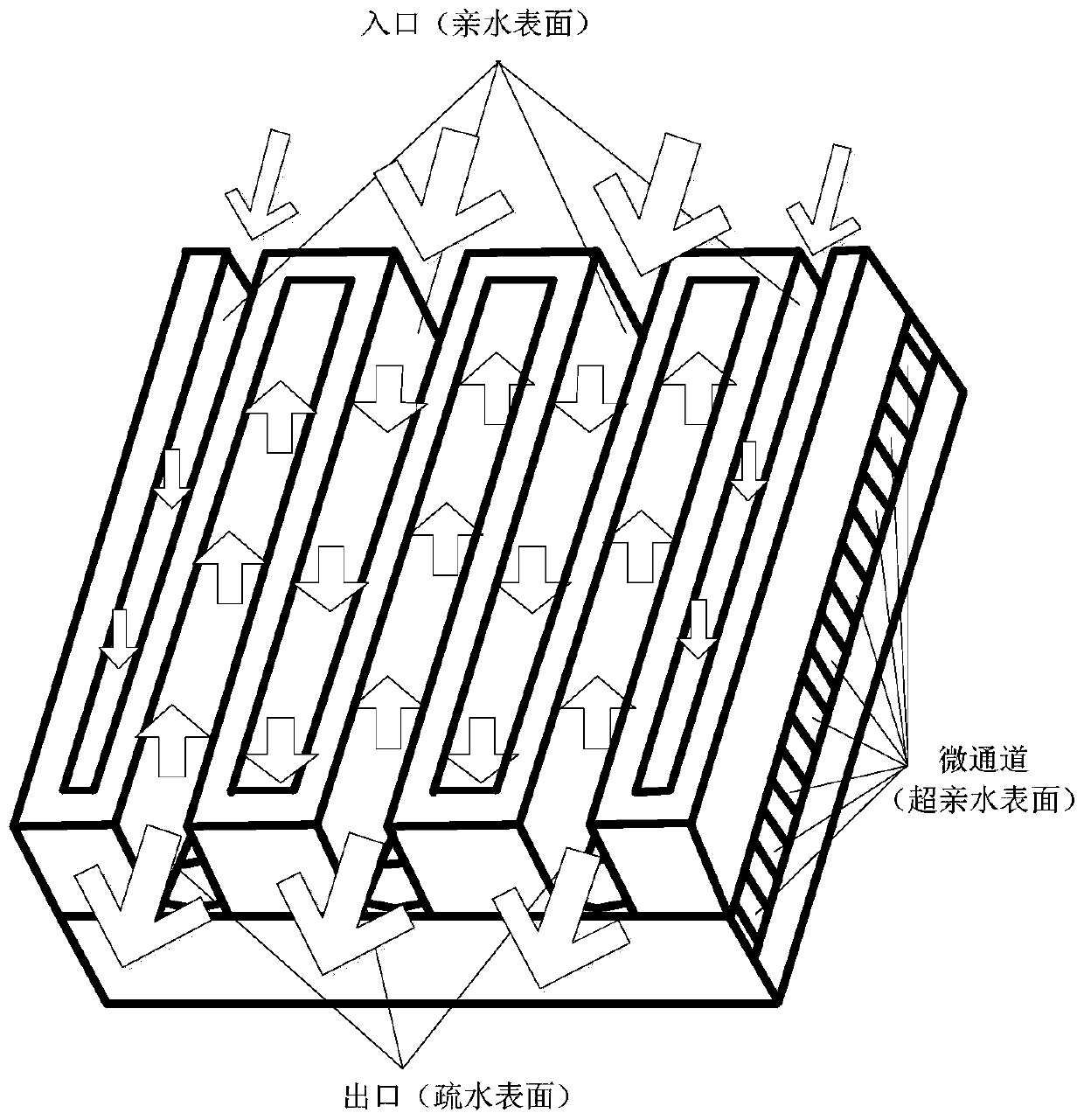

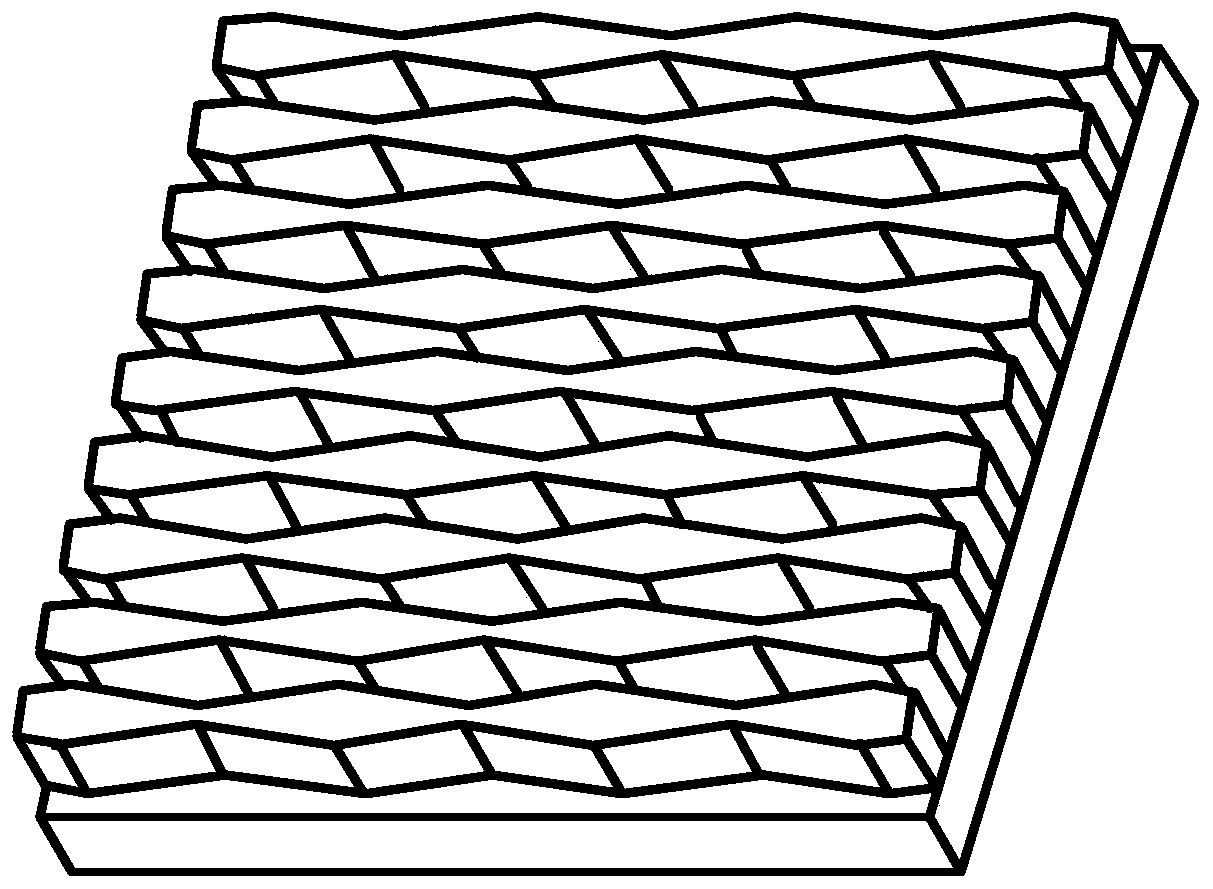

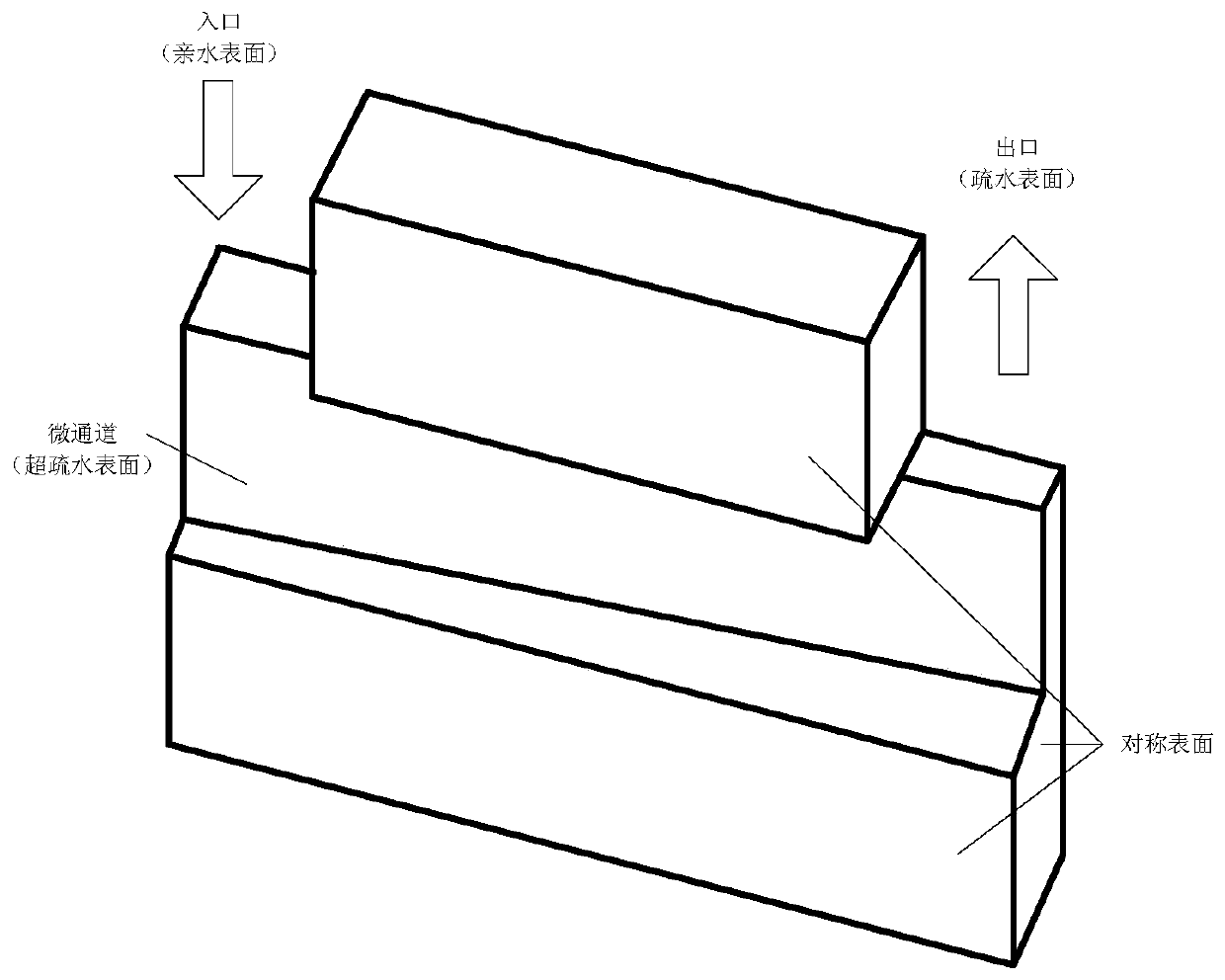

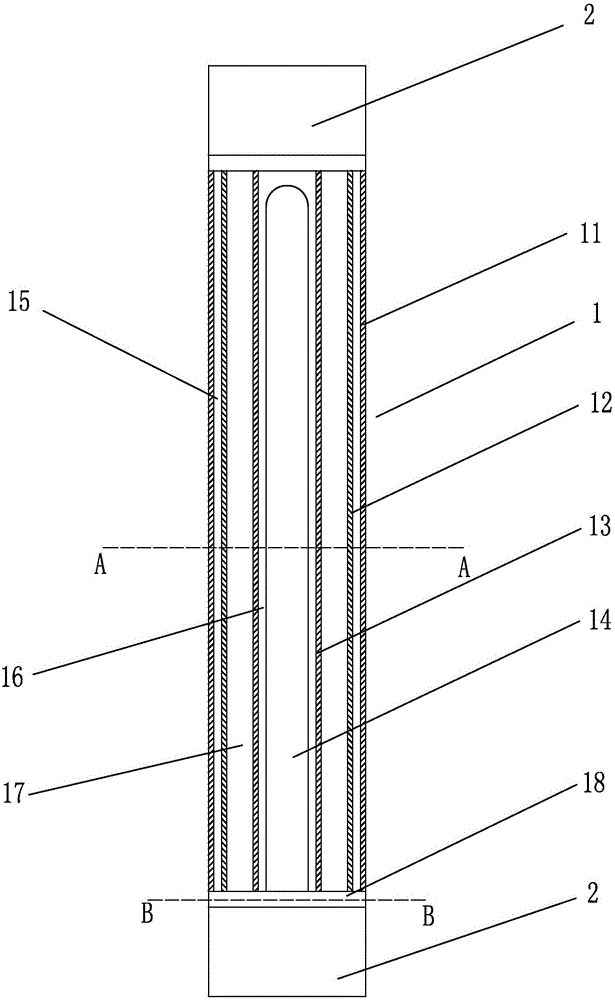

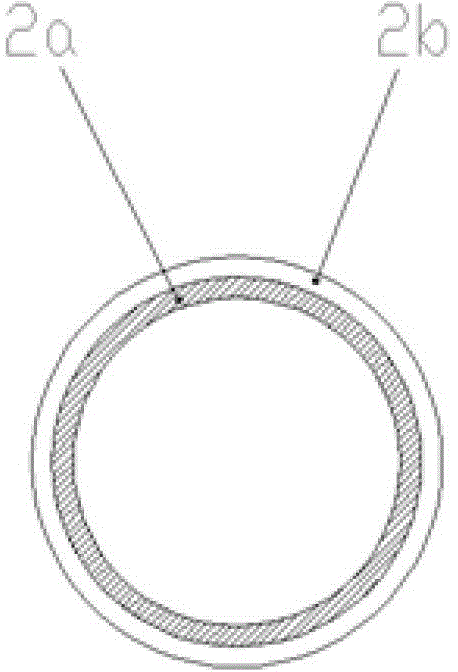

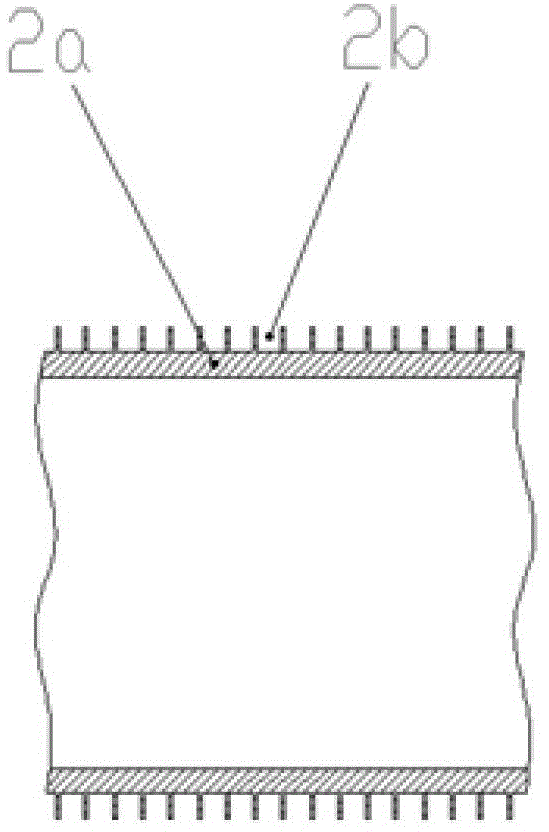

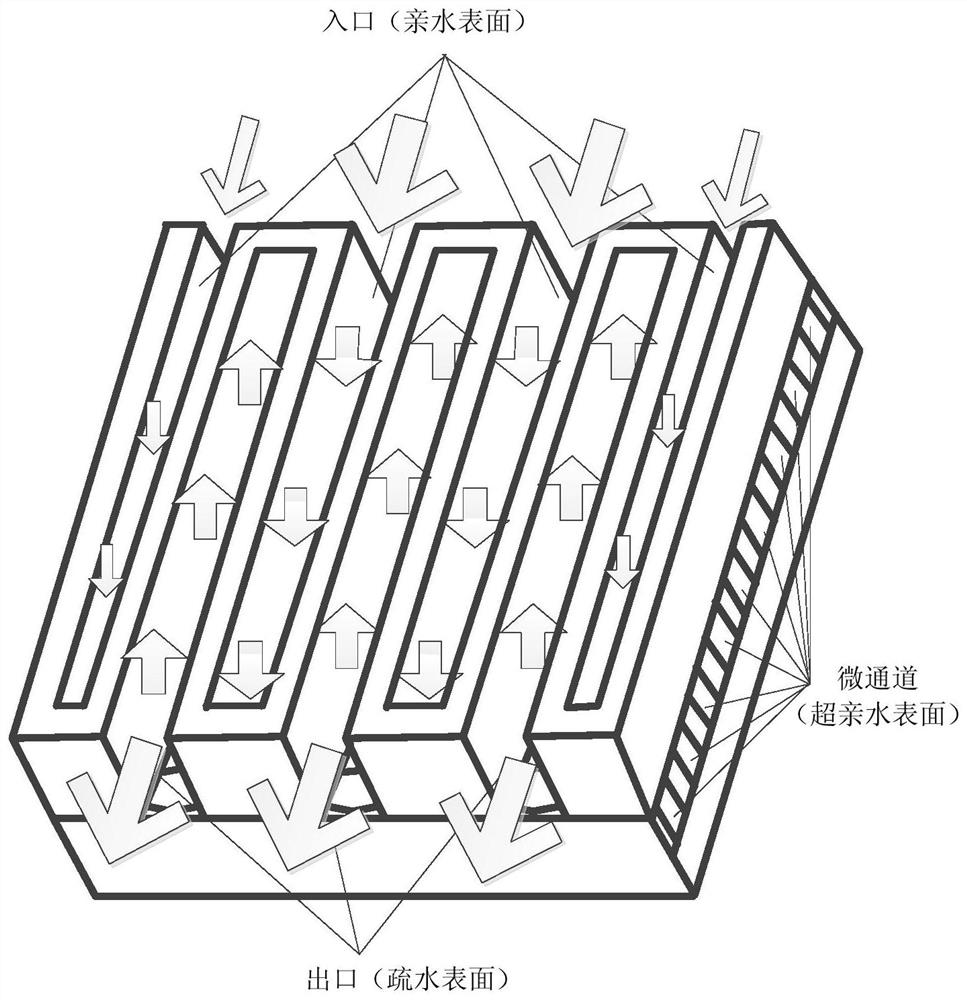

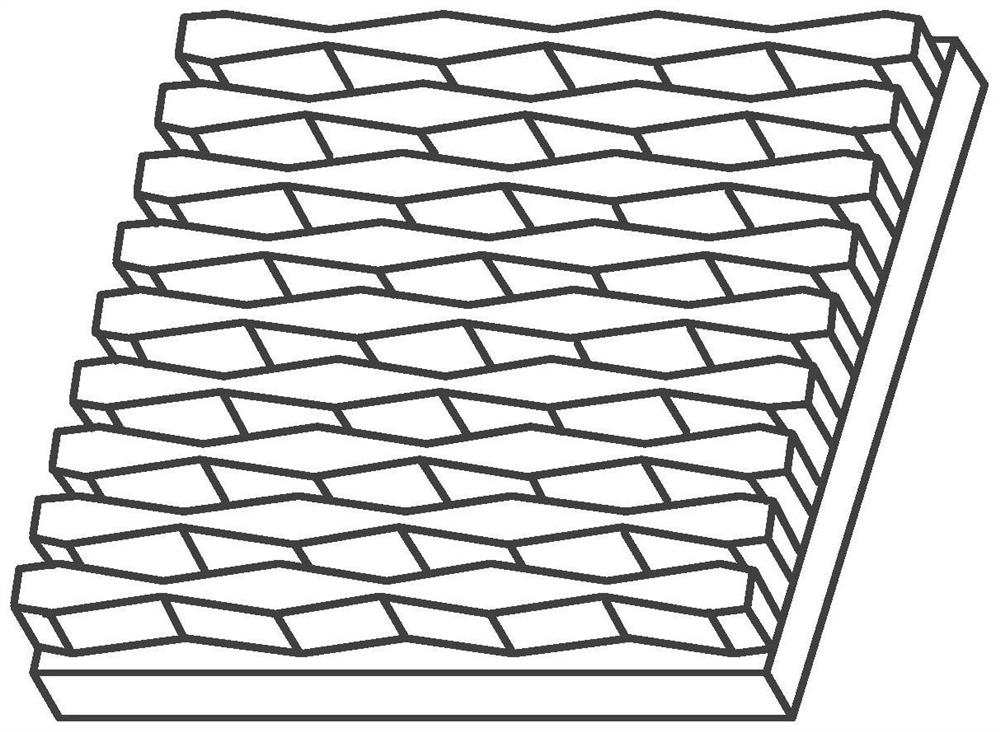

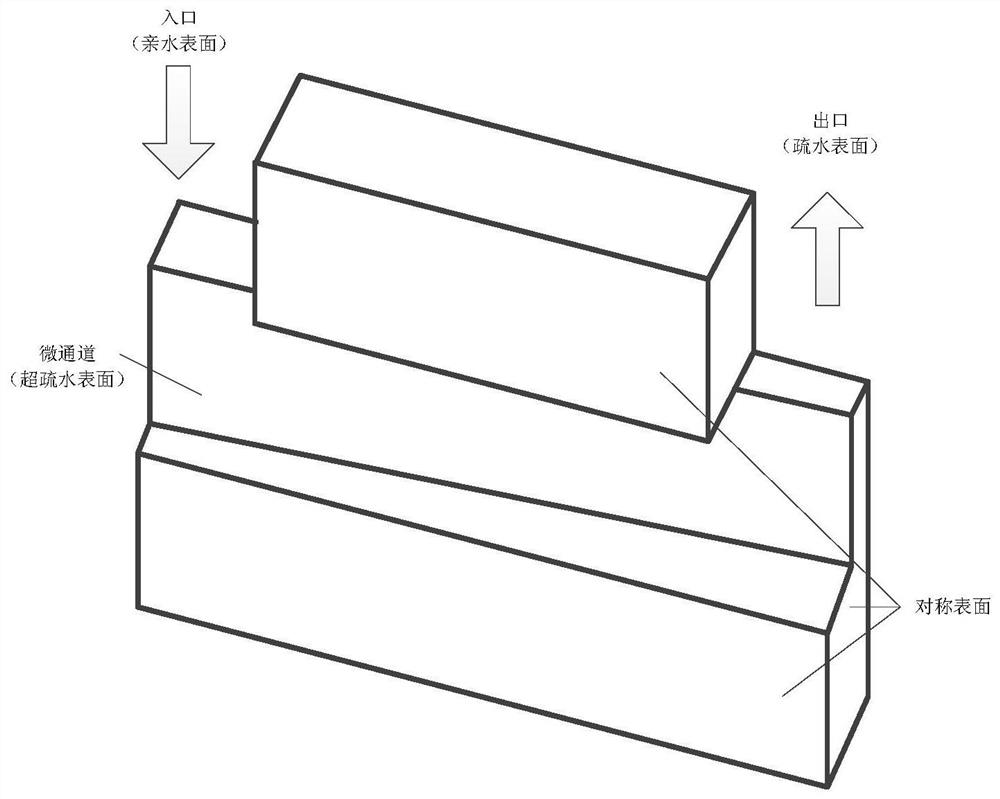

Low-resistance enhanced heat transfer structure based on nanometer super-wetting interface

ActiveCN110425914AShorten the length of the runnerReduce thicknessCoatingsModifications by conduction heat transferIsosceles trapezoidEnhanced heat transfer

The invention discloses a low-resistance enhanced heat transfer structure based on a nanometer super-wetting interface. The low-resistance enhanced heat transfer structure comprises a lower embedded microchannel layer and an upper manifold channel layer, wherein embedded microchannels are perpendicular to manifold channels; the lower embedded microchannel layer consists of a plurality of embeddedmicrochannel units; the cross section of each embedded microchannel of each unit is a rectangular divergent cross section along the flowing direction of a cooling working medium; the shape of each embedded microchannel of each unit is isosceles trapezoid; the upper manifold channel layer is composed of the S-shaped manifold channels; and two adjacent S-shaped manifold channels form inlets and outlets of the manifold channels. According to the low-resistance enhanced heat transfer structure, a microchannel radiator is constructed by utilizing a layered flow structure, the heat transfer characteristic and the resistance characteristic can be simultaneously improved by combining the microchannel radiator with the nano super-wetting interface and the divergent microchannel section, and the low-resistance enhanced heat exchange of the microchannel radiator is achieved under the condition of higher heat dissipation efficiency.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

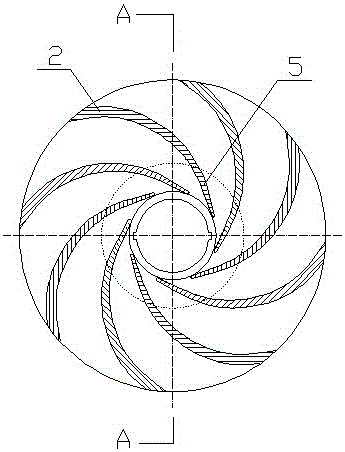

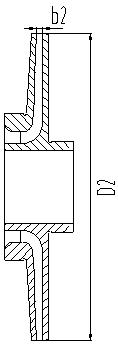

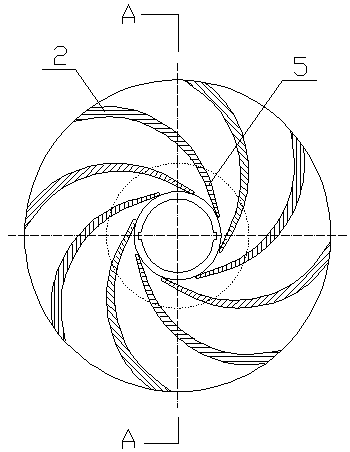

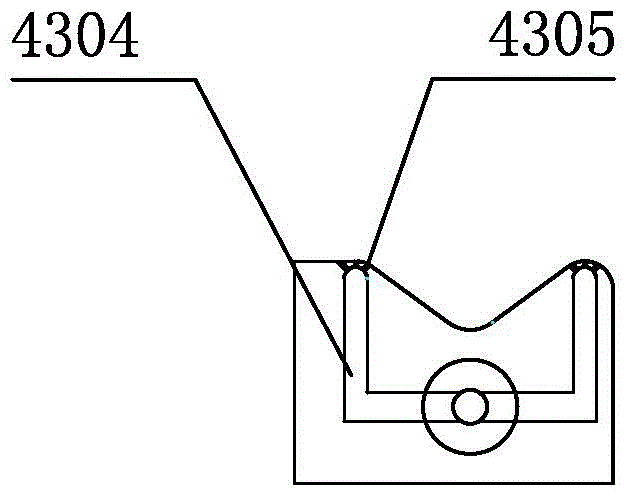

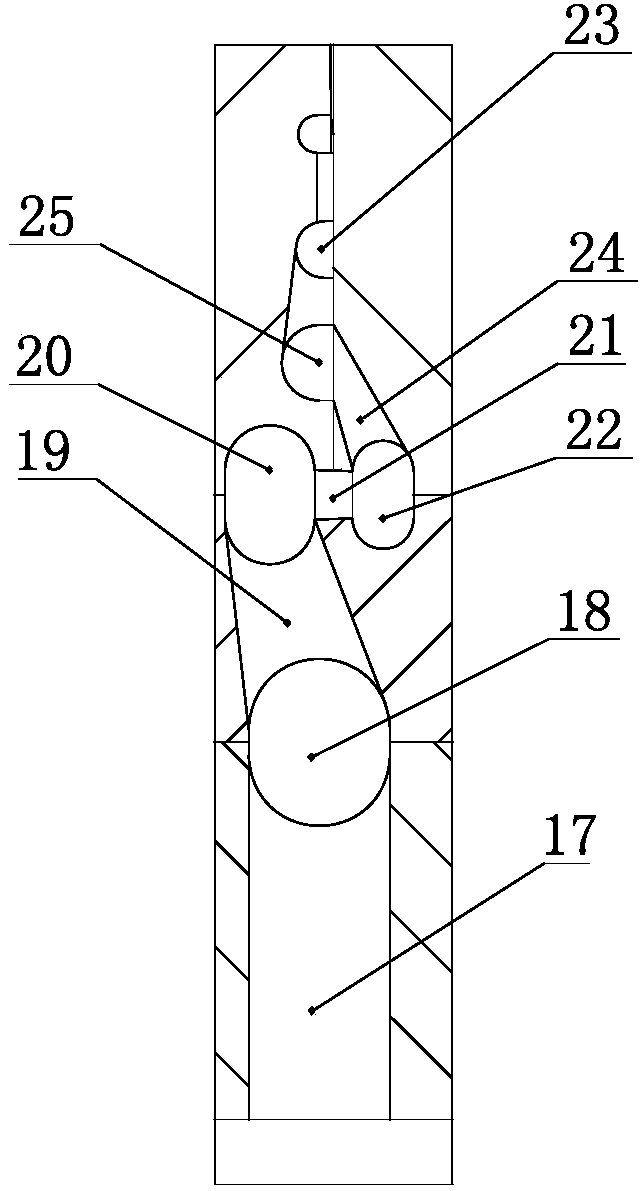

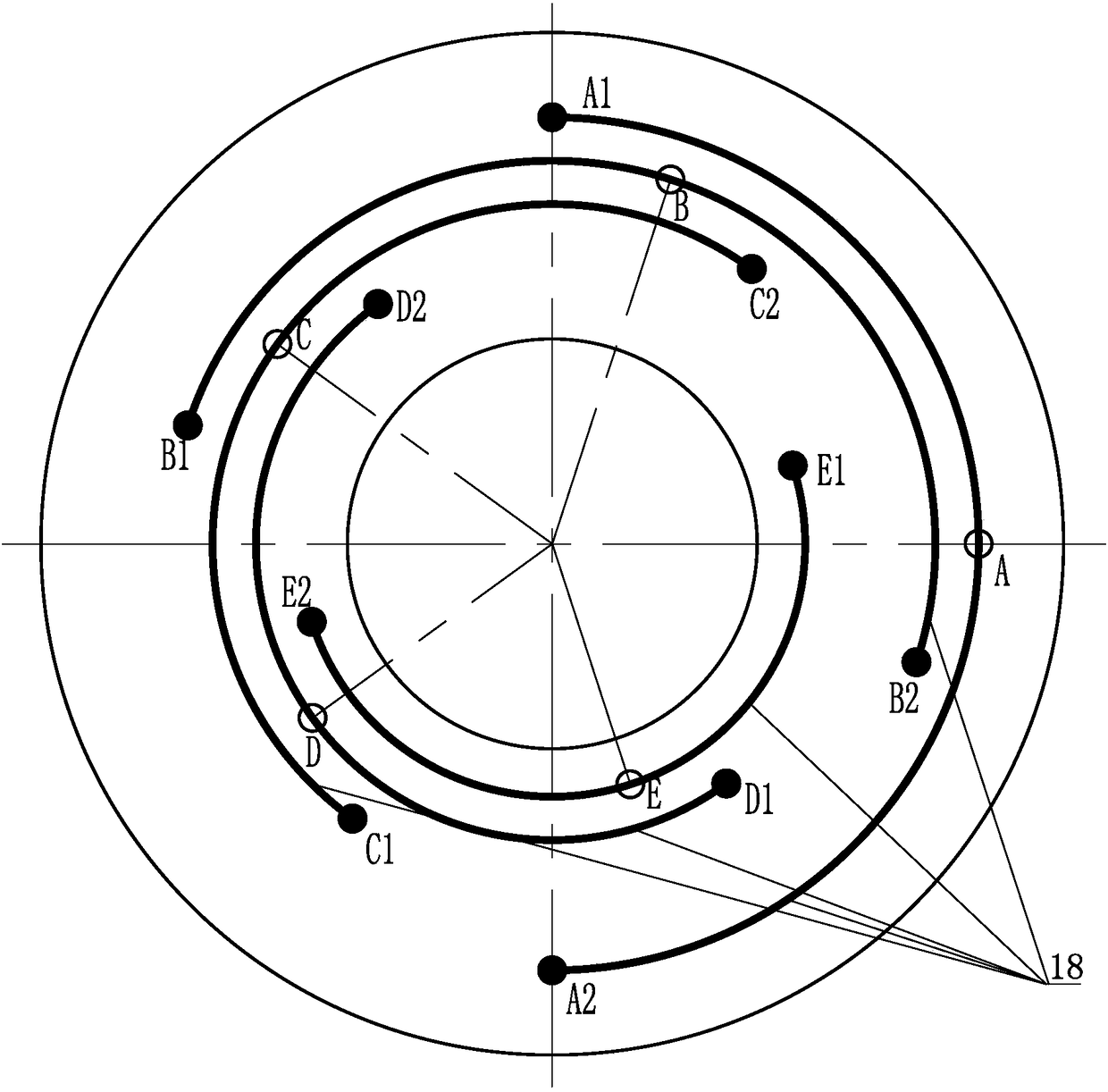

Low-specific-speed impeller structure and machining method thereof

The invention discloses a low-specific-speed impeller structure and a machining method thereof. The structure comprises an impeller body part and an impeller root part; the impeller body part includes a front cover plate, a blade body part and a back cover plate; the impeller root part includes a hub, a blade root part and a sealing ring part; the middle part of the back cover plate is downwards projected to form a sleeve; the back cover plate coats the back part of the hub through the sleeve; the front cover plate coats the sealing ring part; an annular welding line is formed between the front cover plate and the sealing ring part; and the front cover plate and the sealing ring part are tightly welded through the annular welding line. The machining method comprises the following steps: 1) the impeller body part and the impeller root part are respectively cast; 2) the impeller body part coats the impeller root part from the back end of the impeller root part; and the front cover plate coats the sealing ring part; and 3) the annular welding line between the front cover plate and the sealing ring part is tightly welded. The structure is low in machining difficulty, high in machining precision and better in total quality, improves the machining yield, is high in impeller stability, and can effectively improve the guide efficiency.

Owner:重庆水泵厂有限责任公司

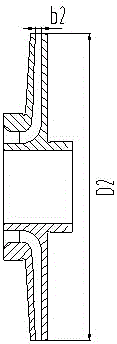

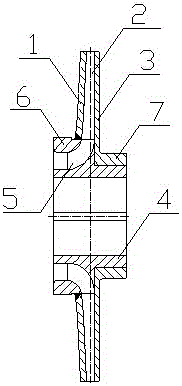

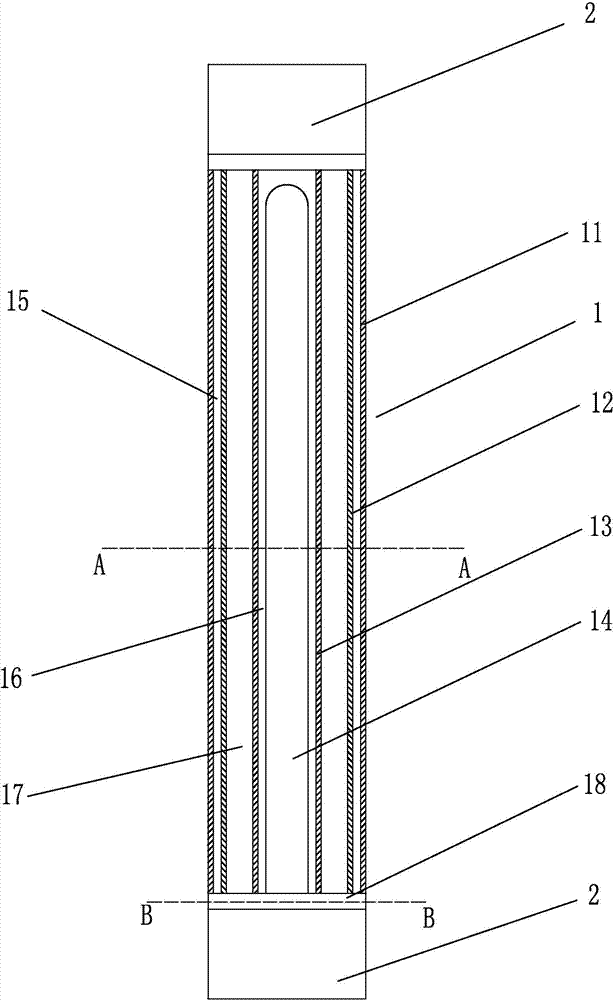

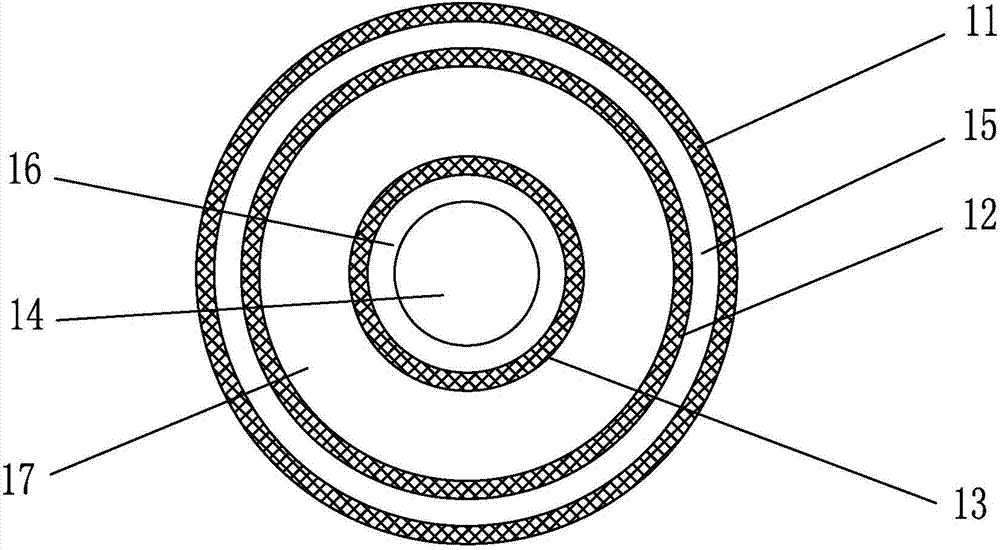

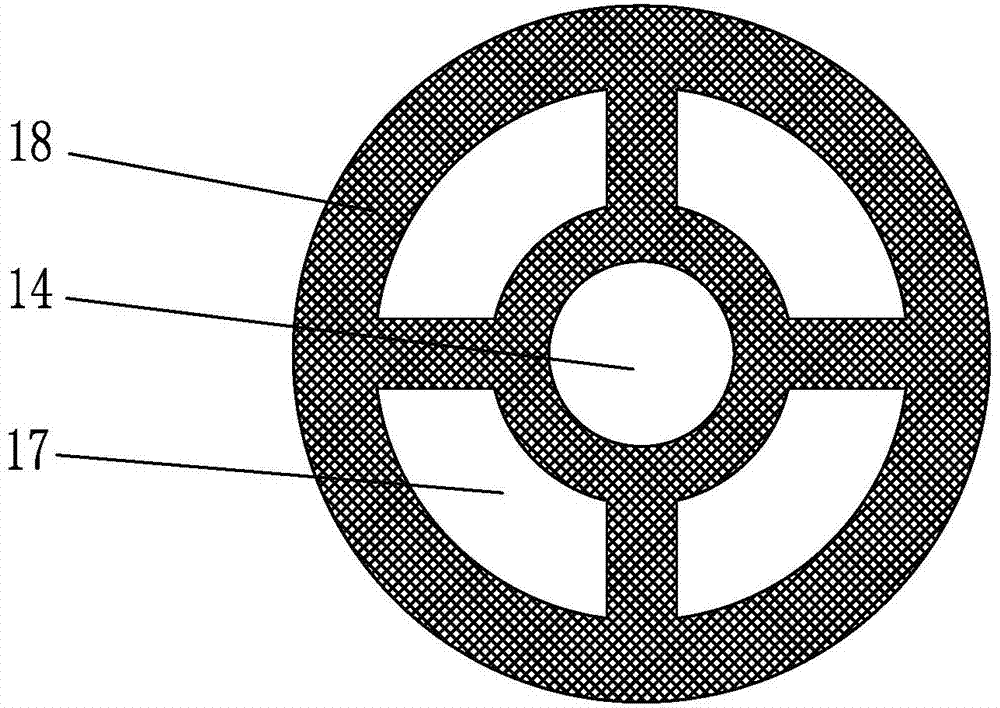

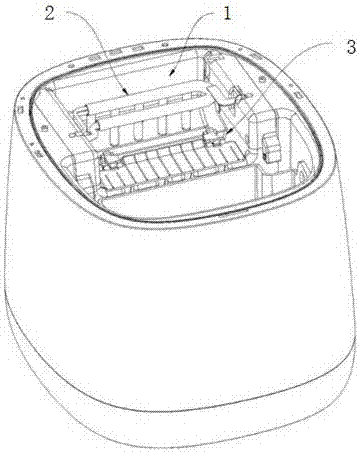

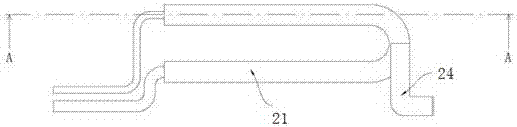

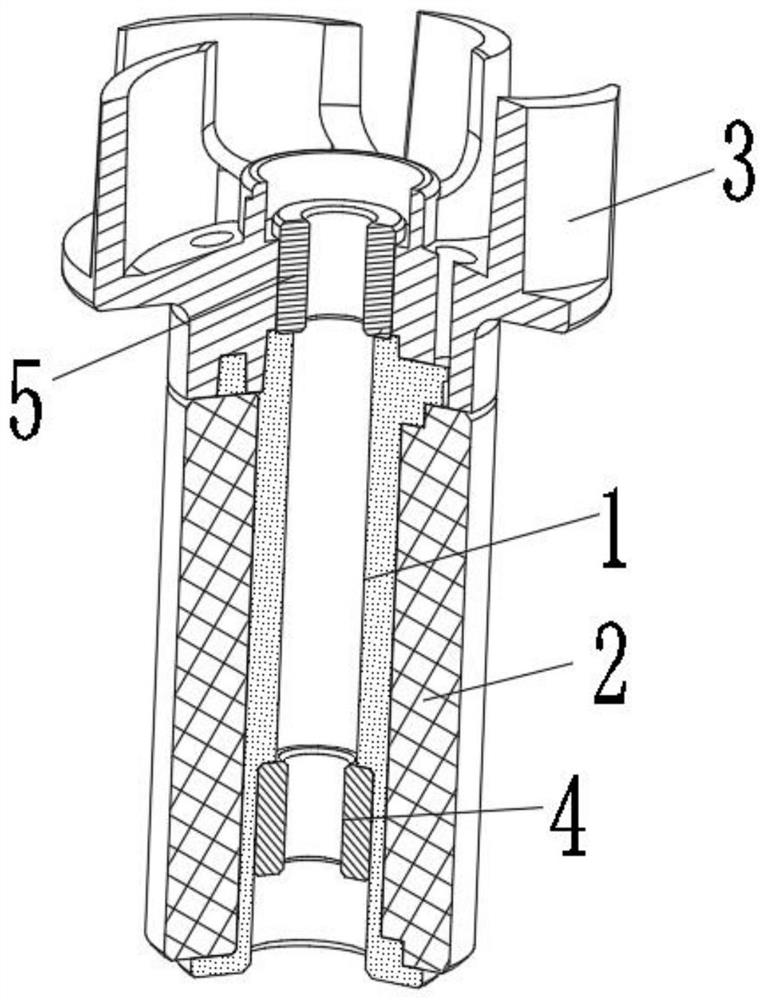

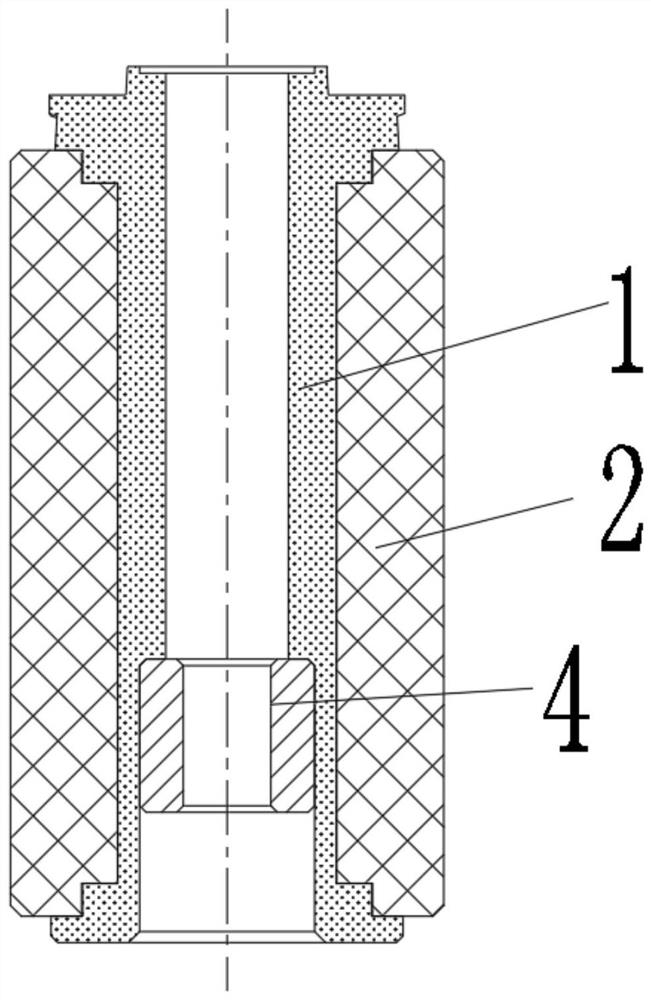

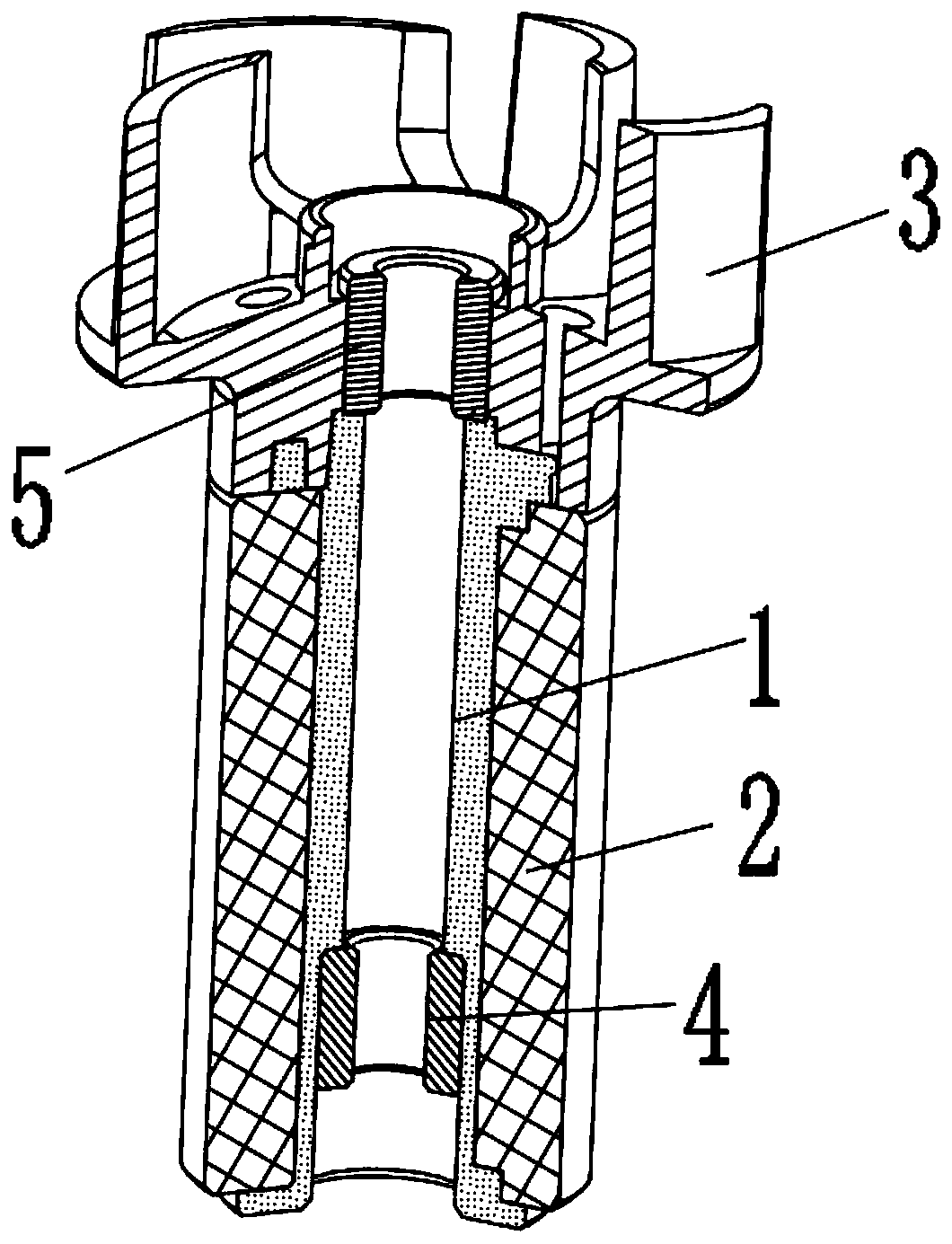

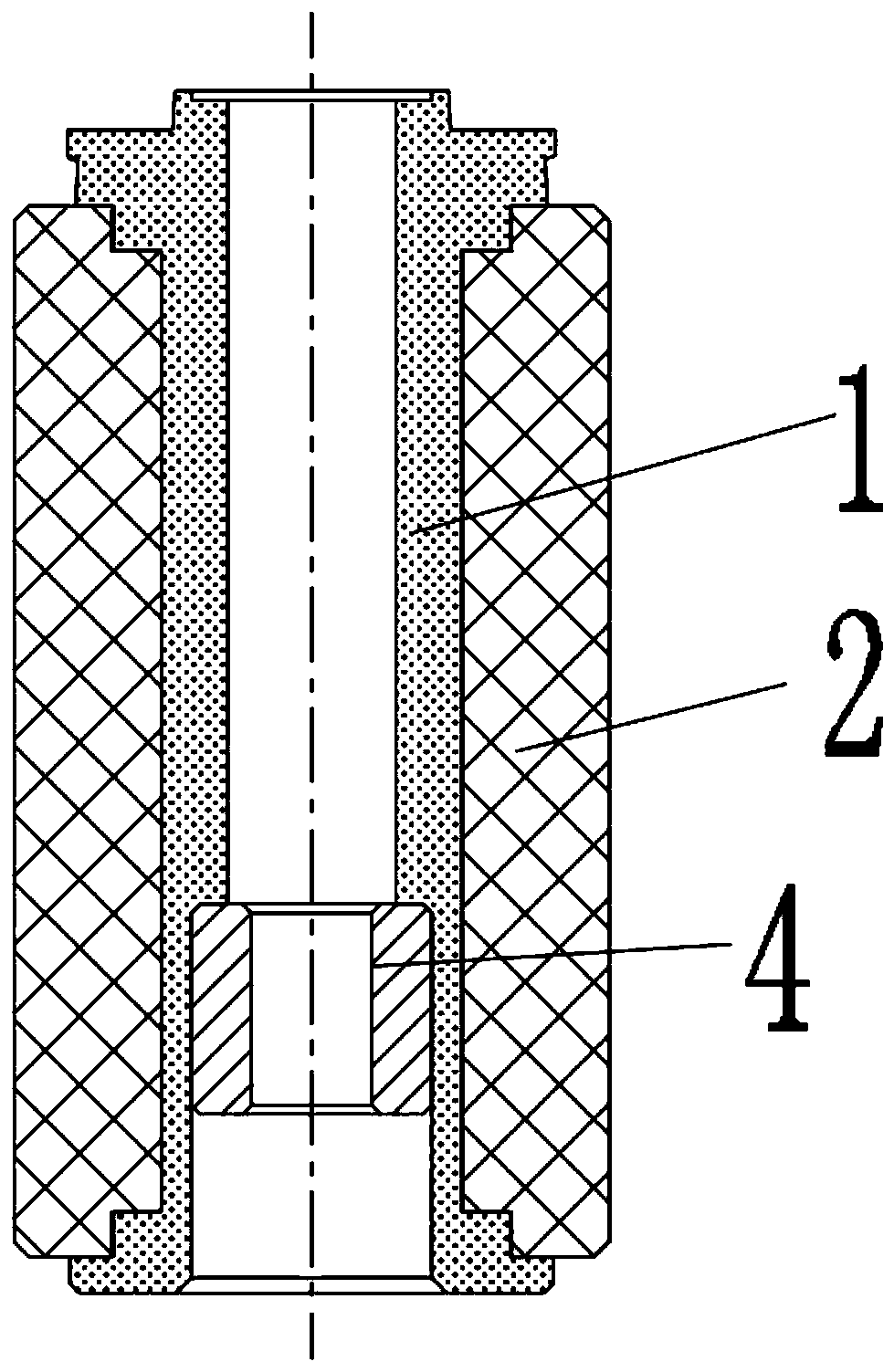

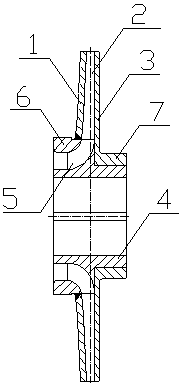

Heating pipe of instant heating faucet

ActiveCN104728510AIncrease heating rateImprove the heating effectValve members for heating/coolingWater heatersEngineeringWater heating

The invention relates to the field of structural design of electric water heater heating pipes, and discloses a heating pipe of an instant heating faucet. The heating pipe comprises a heating pipe body, electrodes and a fixing seat which are coaxial. The heating pipe body comprises an insulating shell, a first heating barrel and a second heating barrel, the first heating barrel is arranged in the insulating shell, the second heating barrel is arranged in the first heating barrel, a first heat preservation layer is arranged between the insulating shell and the first heating barrel, a water passageway is arranged between the first heating barrel and the second heating barrel, the outer wall of the first heating barrel and the inner wall of the second heating barrel are coated with resistive films, an ultraviolet lamp tube coaxial with the second heating barrel is arranged in the second heating barrel, a second heat preservation layer is arranged between the ultraviolet lamp tube and the second heating barrel, and sealing devices are arranged on a water inlet and a water outlet of the heating pipe body. The water heating efficiency is higher, the heating speed is higher, the length of the water passageway is not increased, and the water outflow speed is high. The sterilization function is achieved.

Owner:慈溪万陇电器有限公司

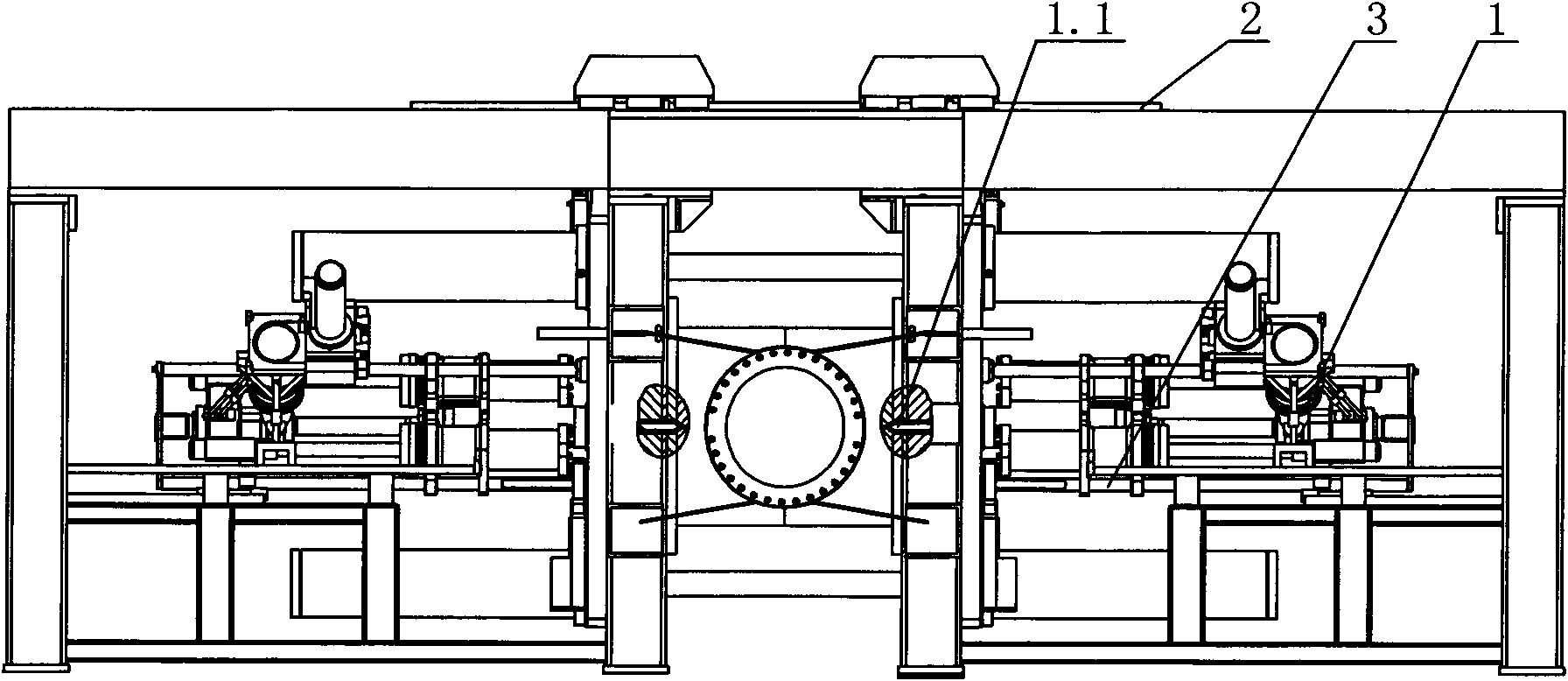

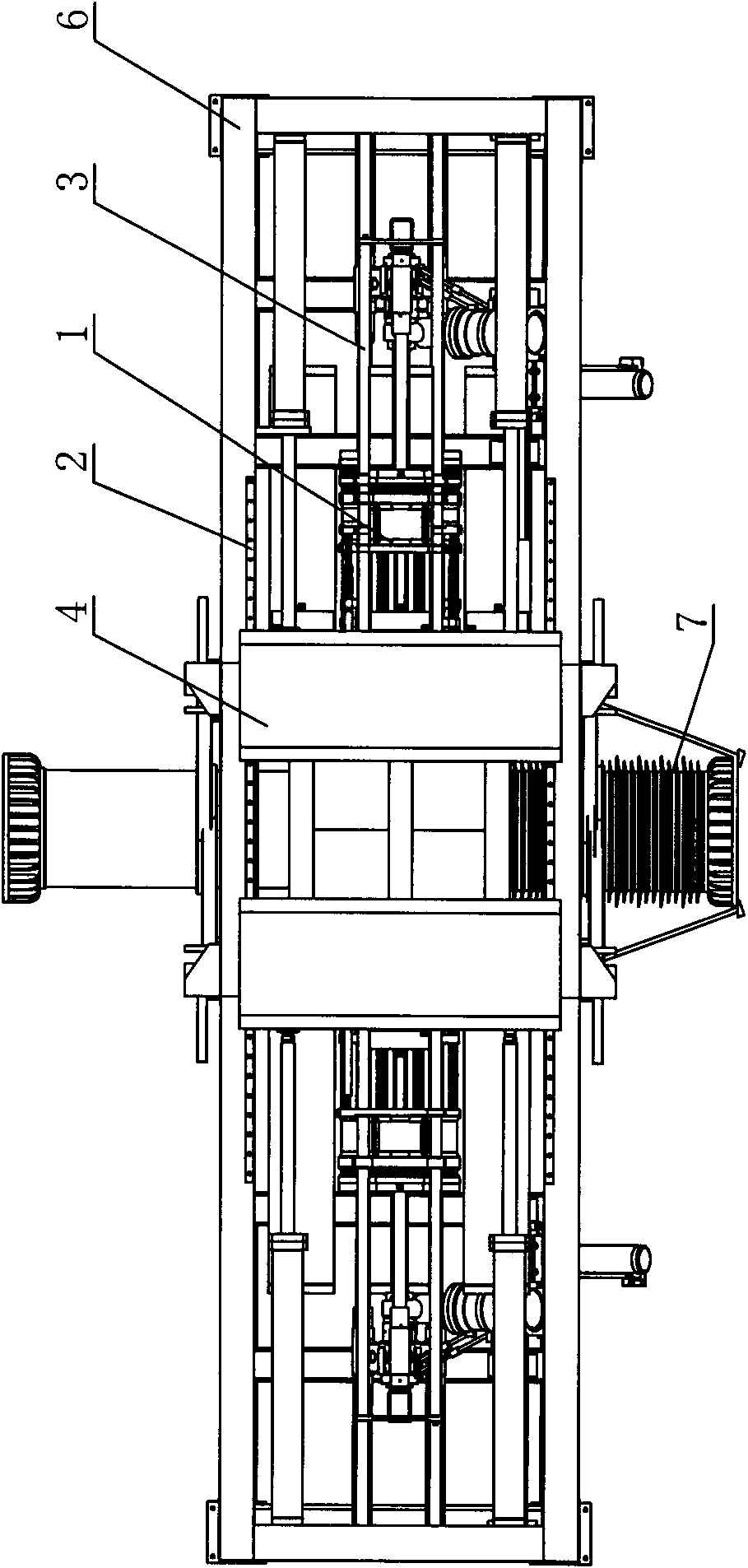

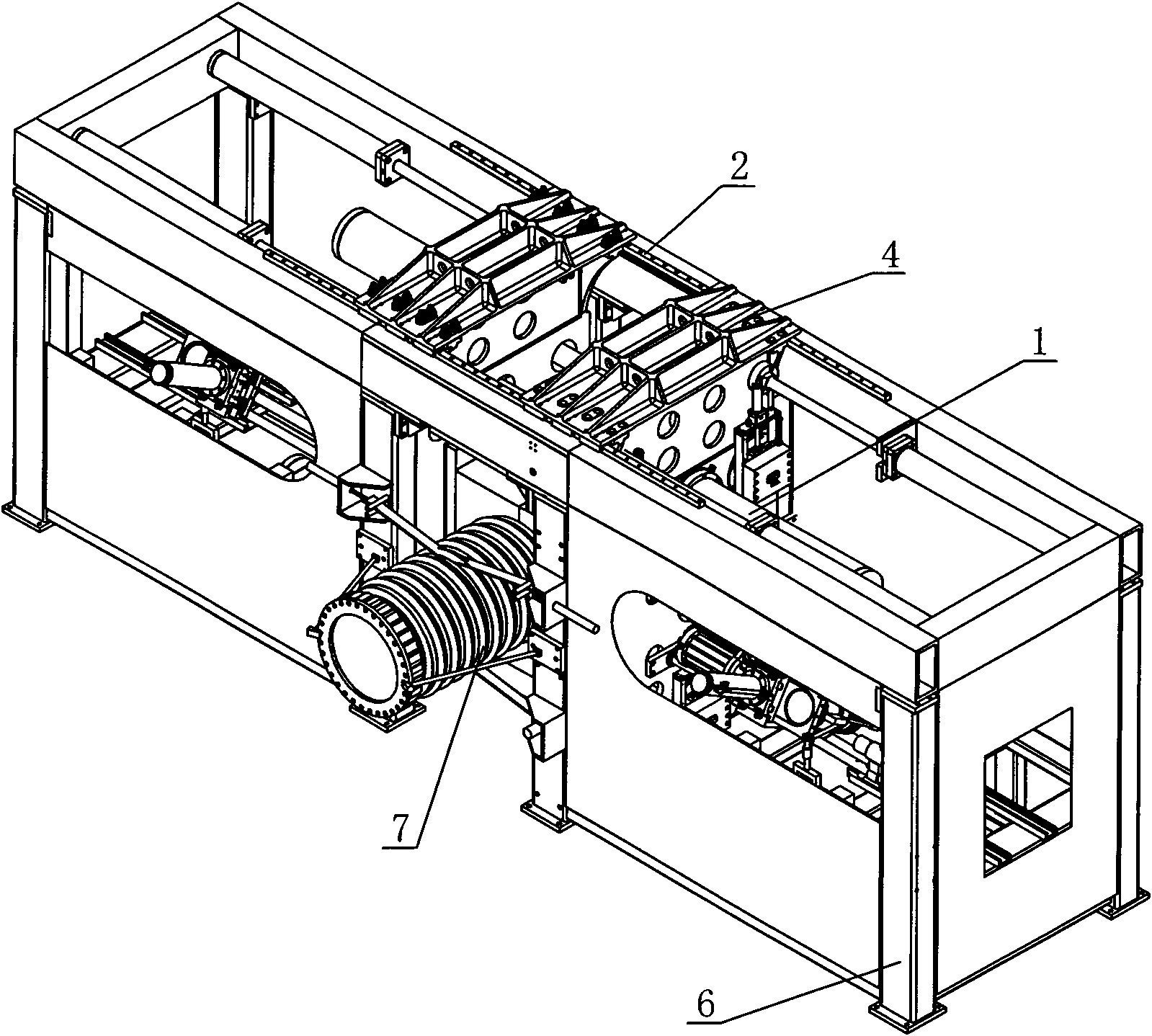

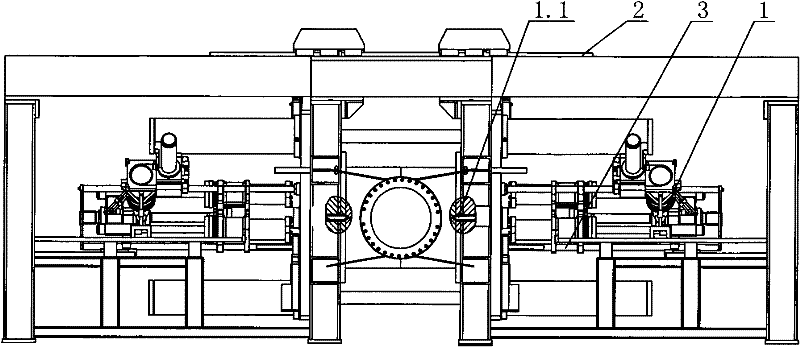

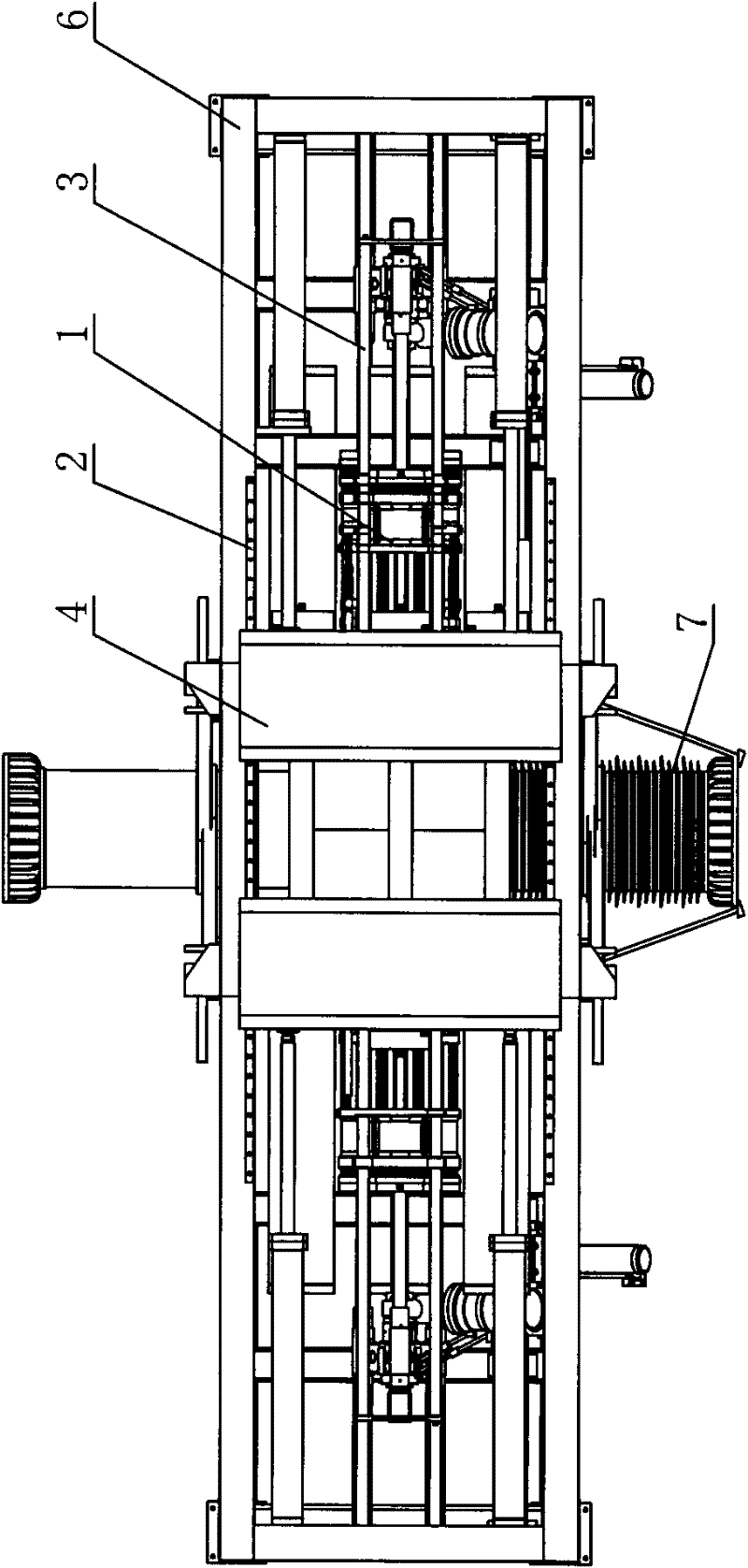

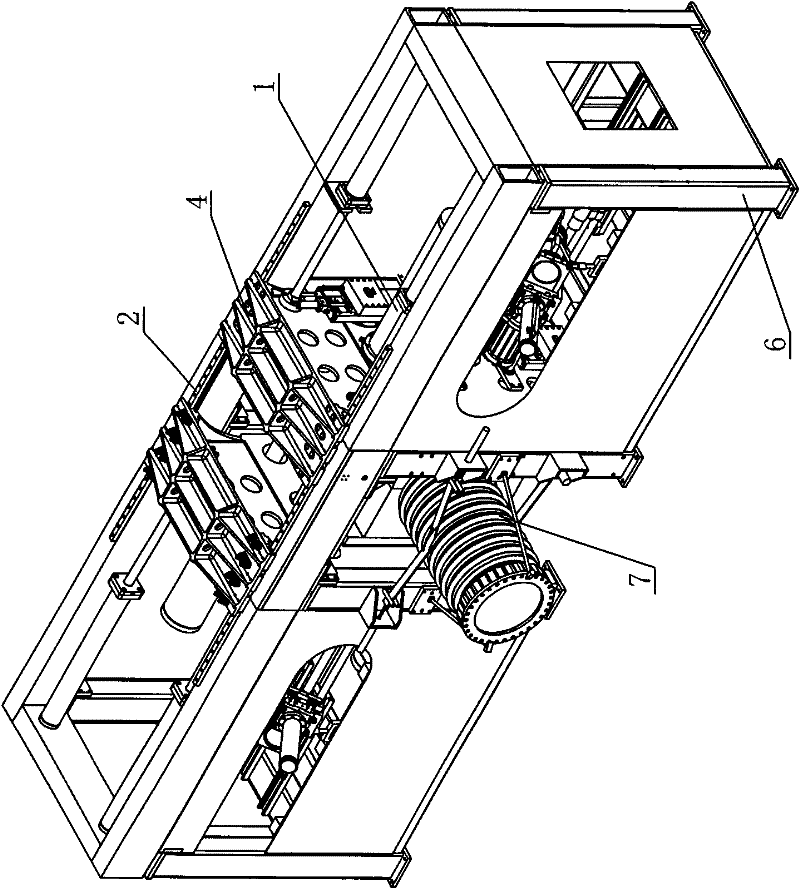

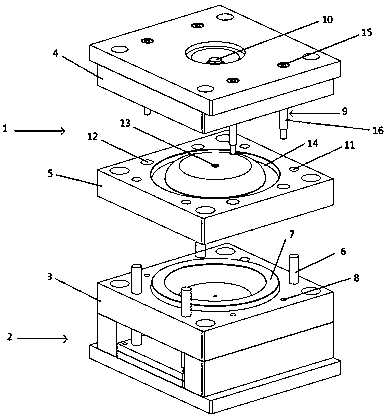

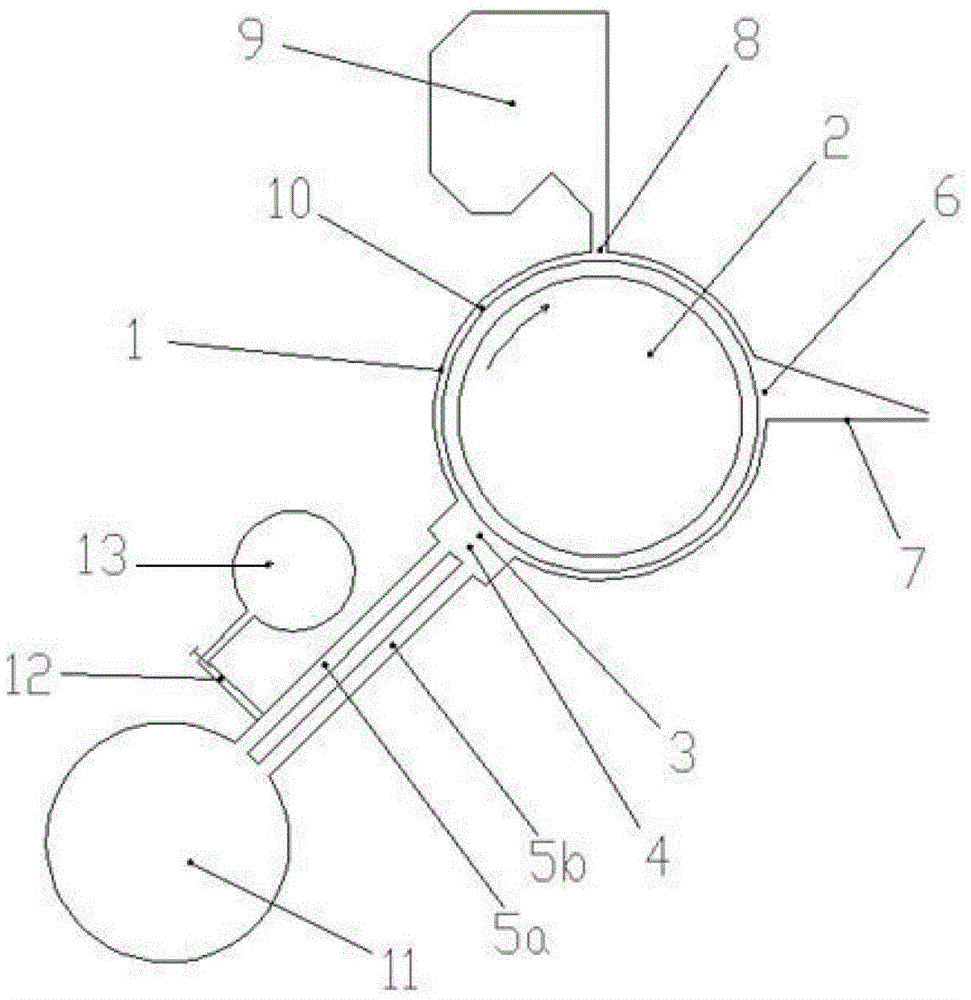

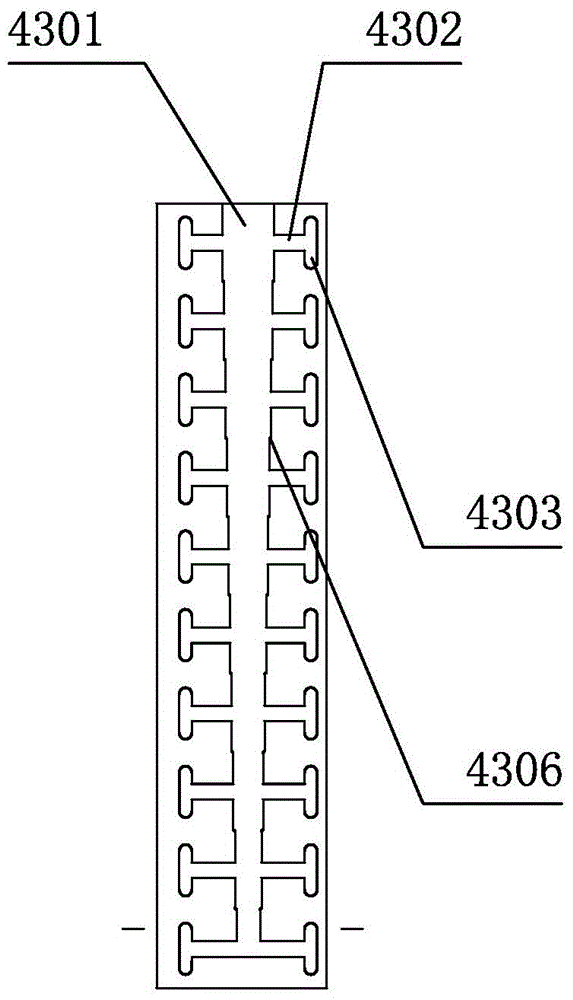

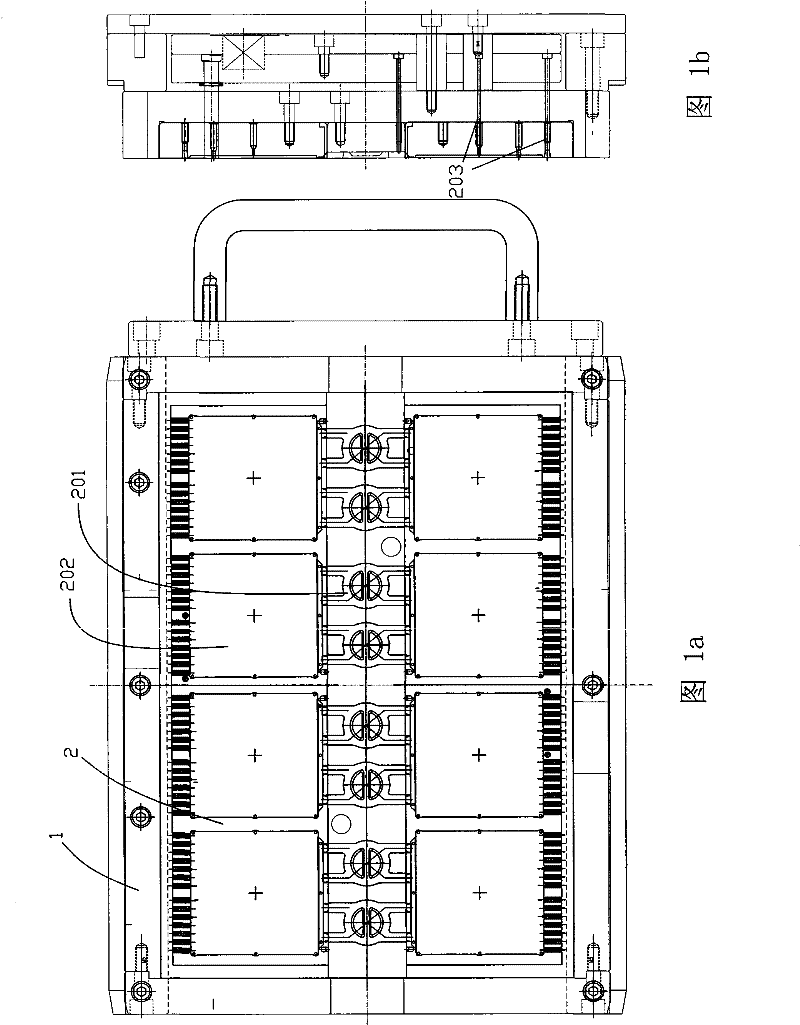

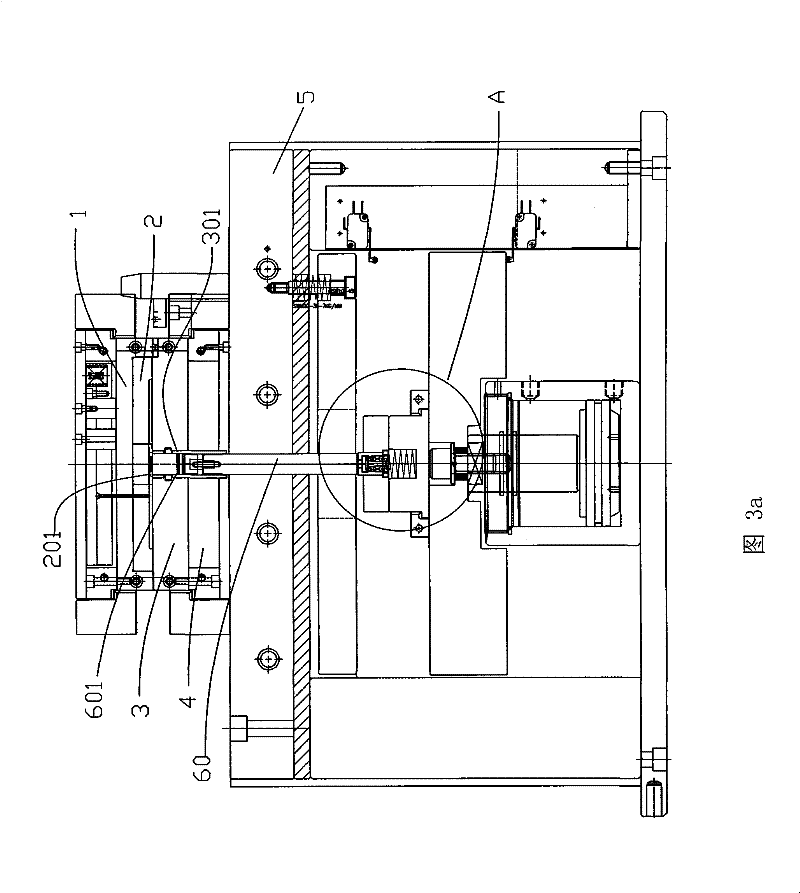

Horizontal solid-liquid dual-purpose composite insulator former

The invention discloses a horizontal solid-liquid dual-purpose composite insulator former which comprises a mold locking machine frame and injection plasticizing devices, wherein the injecting end of each injection plasticizing device is connected to movable mold plates used for fixing a mold. One or two sets of injection plasticizing devices which can slide horizontally are laterally arranged in the mold locking machine frame, and the injecting end of each injection plasticizing device is over against the inside of the mold locking machine frame. One injection plasticizing device and the movable mold plates are respectively arranged at the two ends of the mold locking machine frame, or the two ends of the mold locking machine frame are both provided with one injection plasticizing device. The movable mold plates are connected with the mold locking machine frame in a sliding way and can slide along an upper guide rail or a lower guide rail, and the two movable mold plates can move separately or together. The horizontal solid-liquid dual-purpose composite insulator former adopts a horizontal mold locking structure, single / double injection or single / double movable mold(s) can be flexibly selected according to the forming process of a product; and in forming, a core barrel and a product to be formed stay in the center of the mold locking machine frame, and an injection nozzle directly injects glue from the center of the side of a mold, thereby shortening the length of a runner, facilitating air discharge, improving the internal quality of the product and reducing energy loss.

Owner:广东伊之密精密橡塑装备科技有限公司

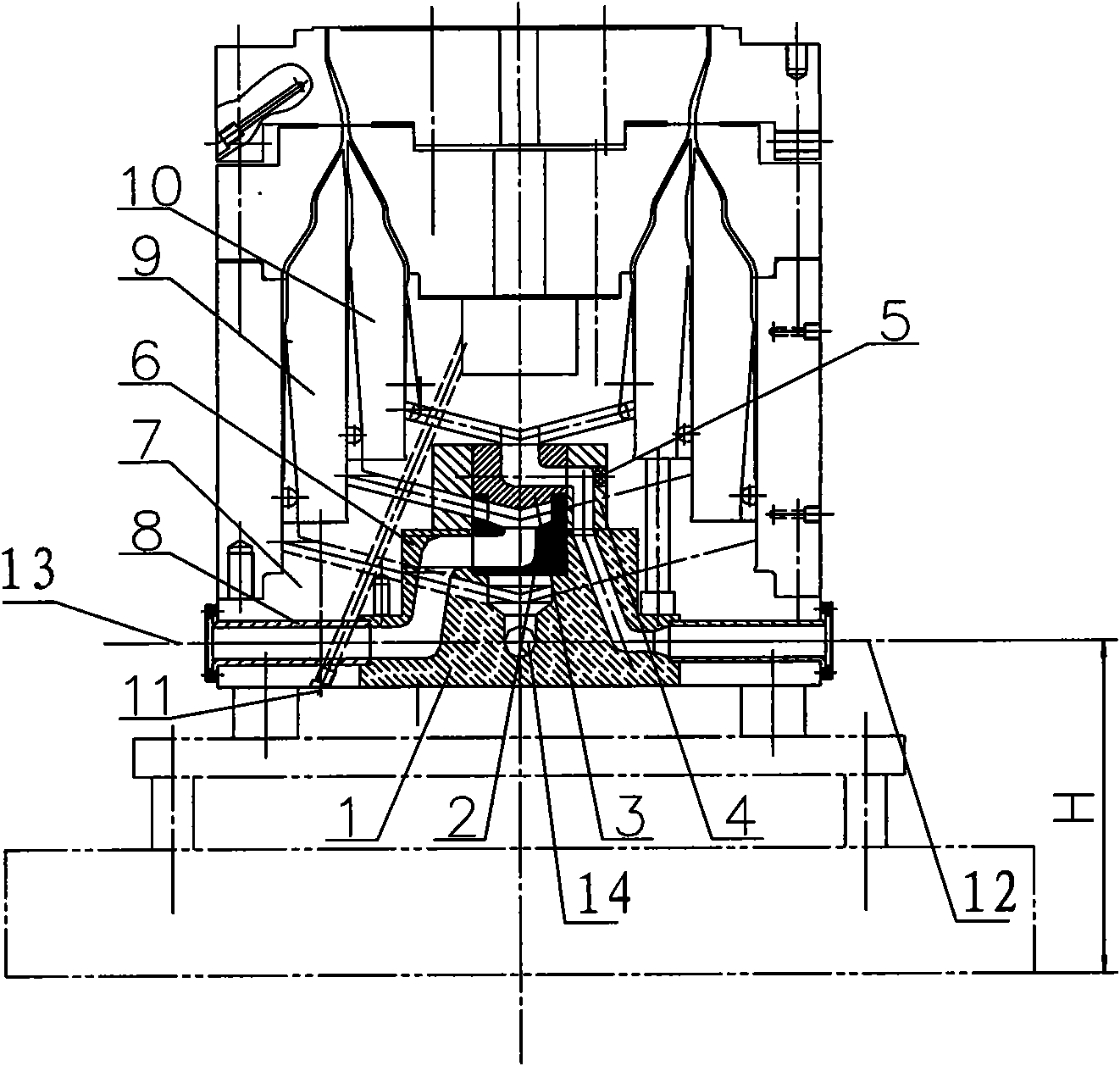

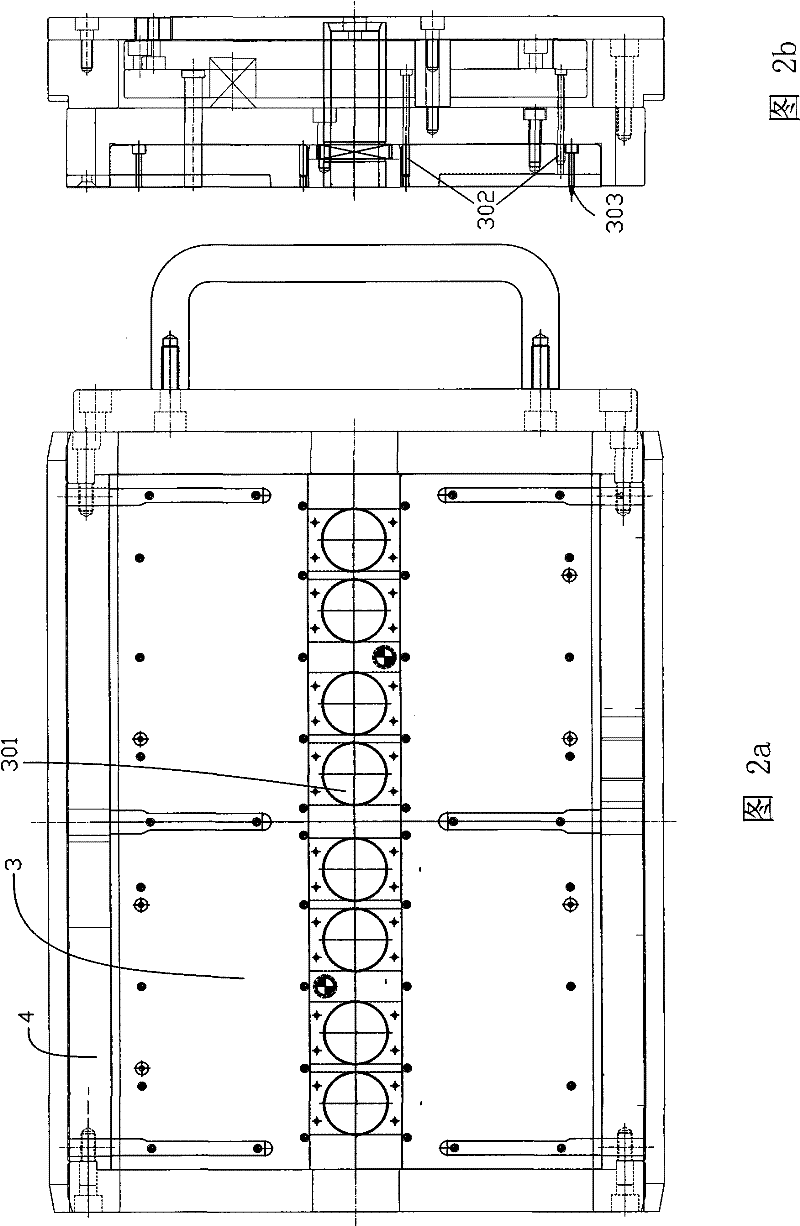

Triple extrusion die head with low center

InactiveCN101670657AReduce die heightShorten the length of the runnerEngineeringMechanical engineering

The invention discloses a triple extrusion die head with a low center, wherein, an inner layer feed inlet (12), a middle layer feed inlet (13) and an outer layer feed inlet (14) are positioned in a same plane and the center-height of which is H. The invention overcomes the defects that the runner of the existing triple extrusion die head has long length, the amount of polymer accumulated in the center of a die is large, the time needed for changing the resin or the color is long, and the cooling efficiency is low and the like. The distribution design of the invention reduces the height of thedie head, shortens the length of the runner, improves the cooling efficiency, ensures more convenient operation of the film pulling, reduces the amount of polymer accumulated in the die head, and leads the changing of the material or the color more rapid.

Owner:武汉新中德塑机股份有限公司

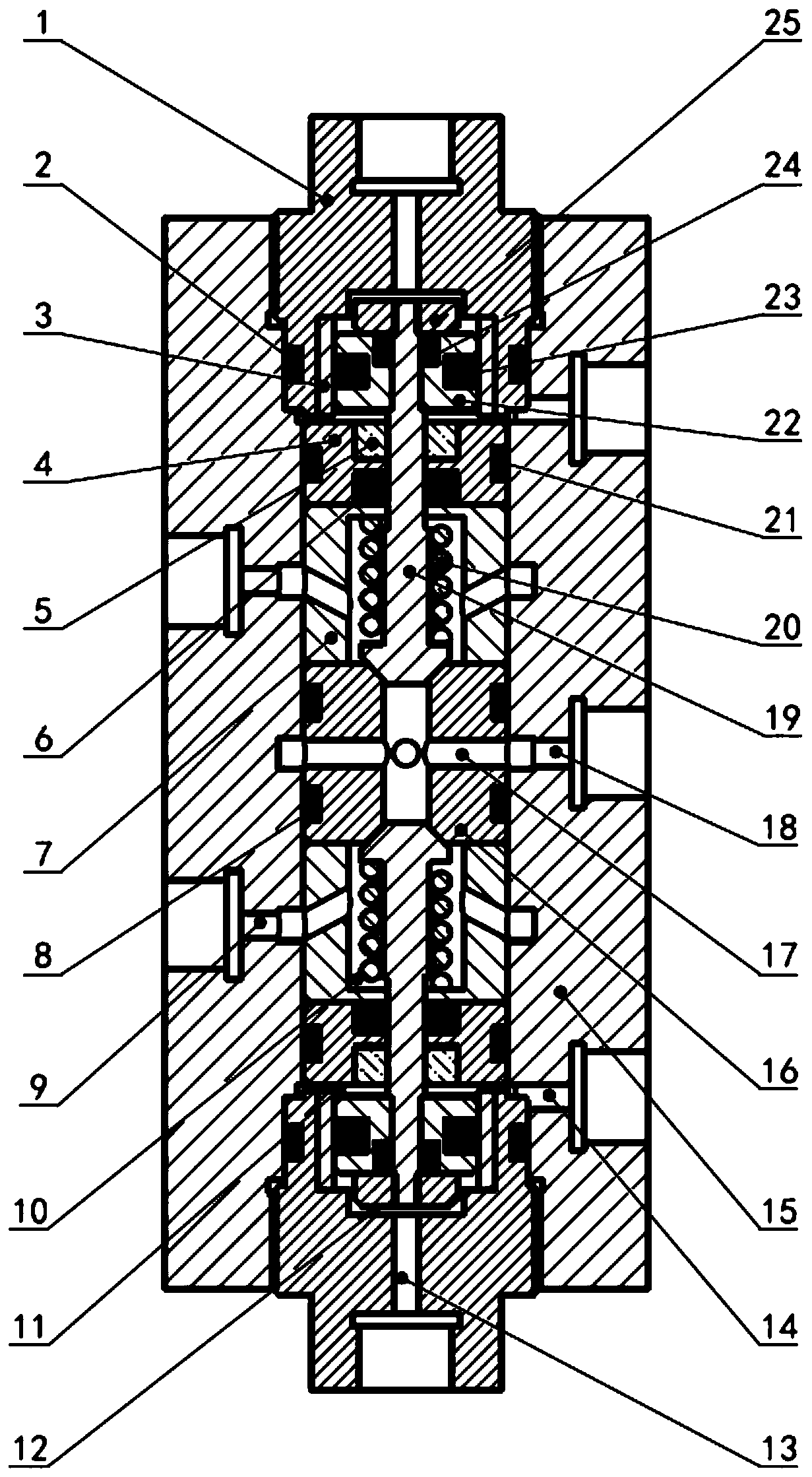

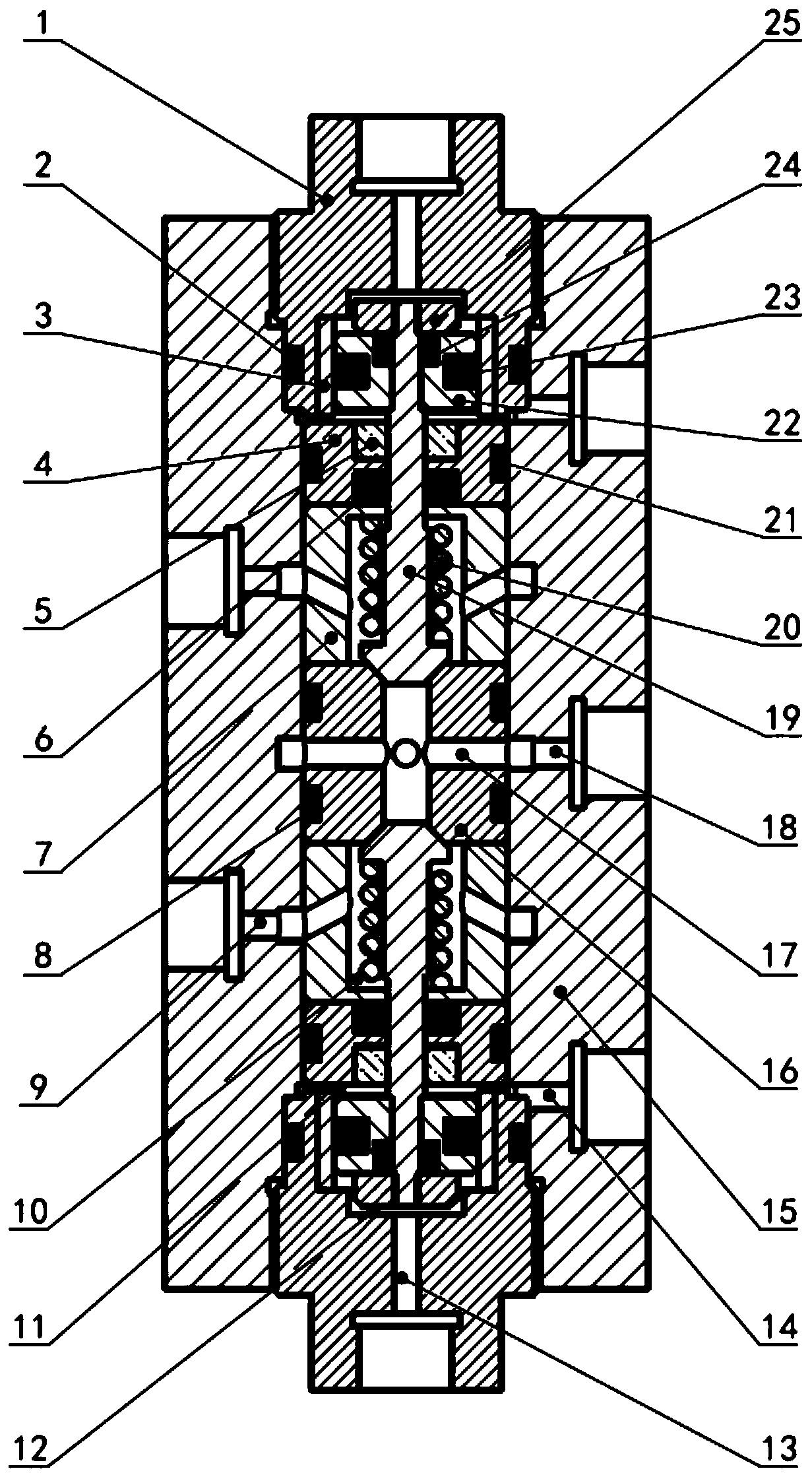

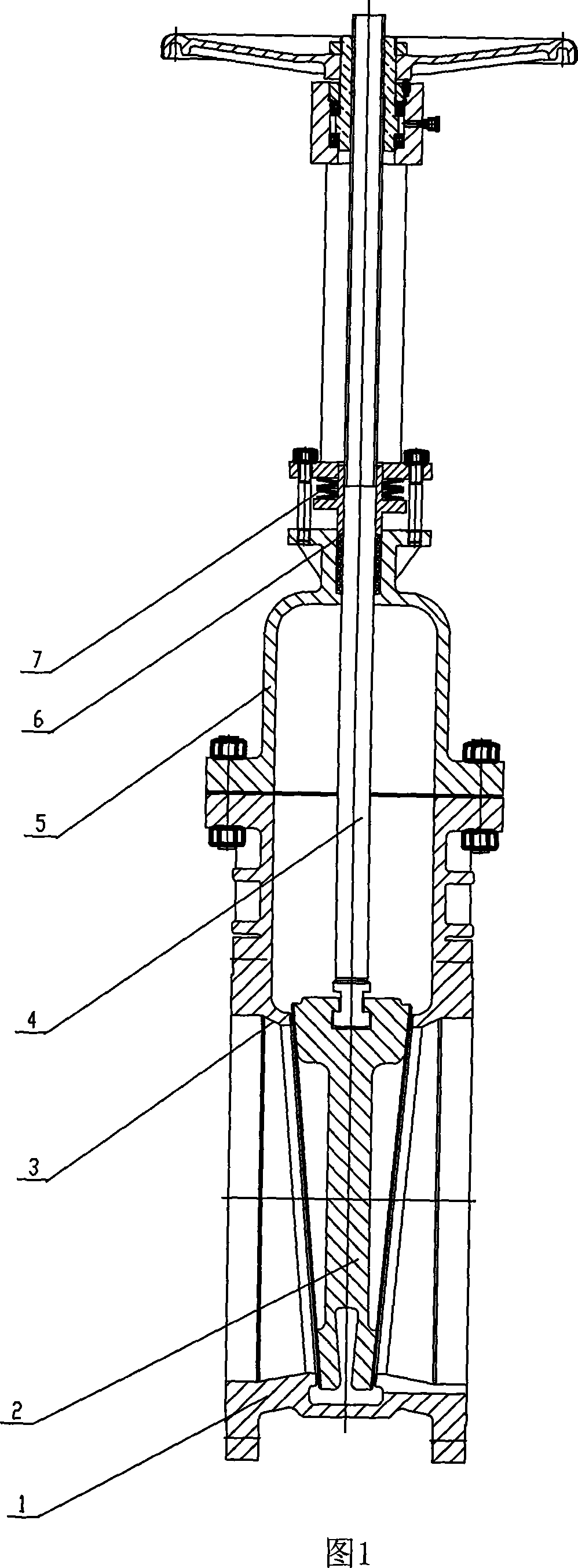

Compact pressure self-compensation total-sea-depth stop valve

ActiveCN110469698AHighly integratedSimple structureMultiple way valvesLift valveRemote controlSelf compensation

The invention discloses a compact pressure self-compensation total-sea-depth stop valve, and belongs to the relevant technical field of valve bodies. The compact pressure self-compensation total-sea-depth stop valve comprises two stop valve bodies which are oppositely arranged on the same valve body and are of the same structure. Each stop valve body comprises a stop valve screw plug assembly, a valve element assembly, an isolation pressure sheet assembly, a valve sleeve, a stop valve spring and a valve seat. The stop valve bodies are opened in a manner of being hydraulically driven, and therefore remote control can be achieved. Closing of the stop valve bodies is achieved through the force of the stop valve springs and hydraulic force generated by the area difference between the two sidesof the large end of the valve element assembly. The form of ceramic and stainless steel cooperation is adopted in cooperation between the valve element assembly and other parts, friction force in themotion process of the valve element assembly is effectively reduced, and meanwhile the possibility of jamming of the valve element assembly is reduced. The two oppositely-arranged stop valve bodies use the same valve seat in common, and the space utilization rate is increased. According to the compact pressure self-compensation total-sea-depth stop valve, the structure is simplified, the size isreduced, and then the complexity and cost of a buoyancy adjusting system of a submersible are reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

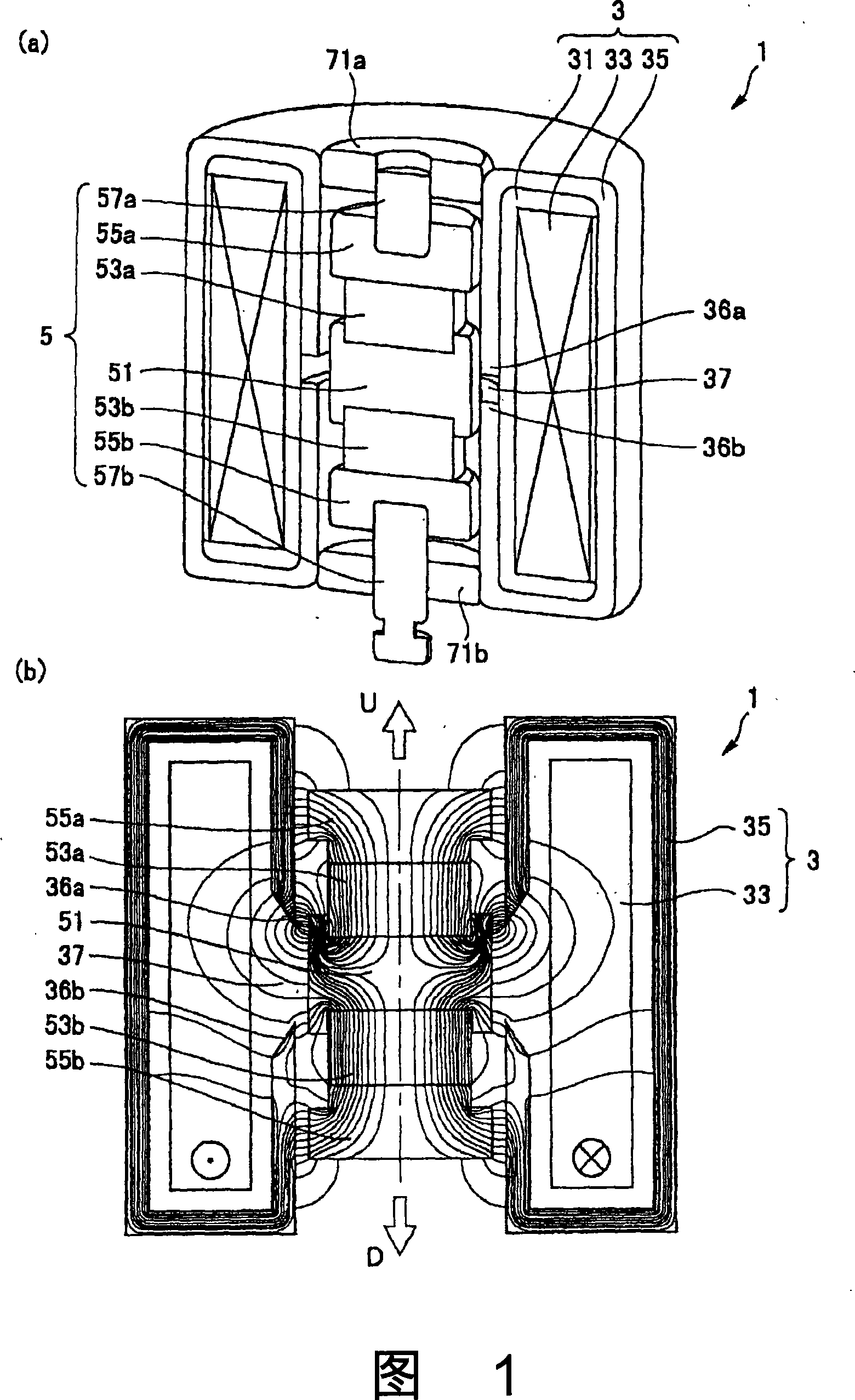

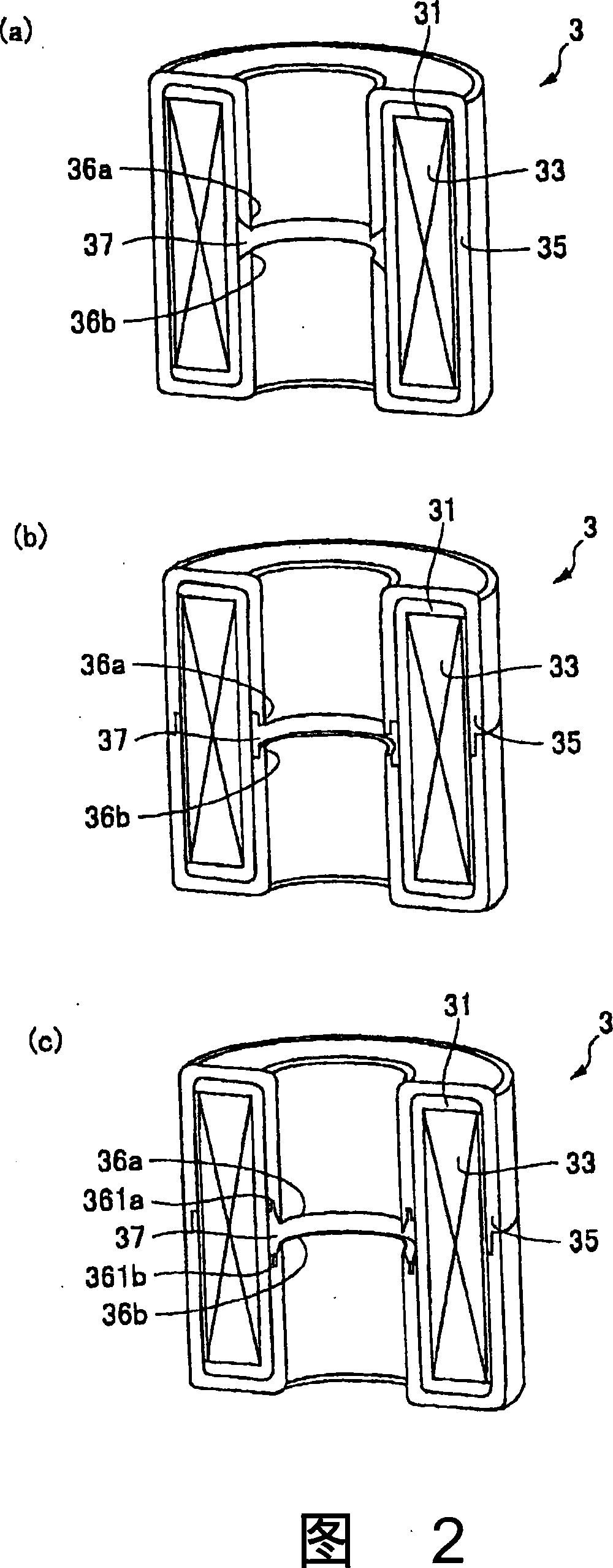

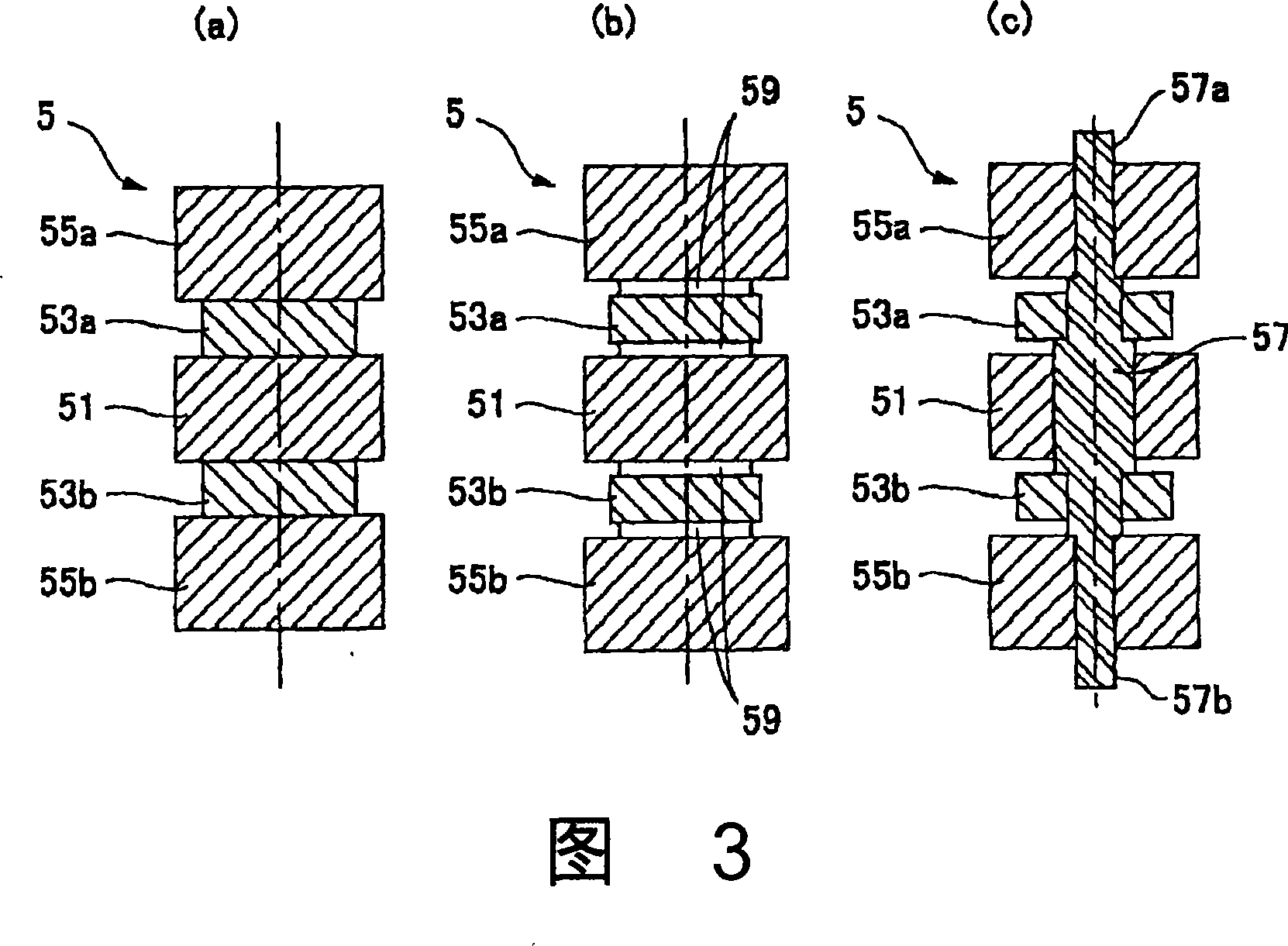

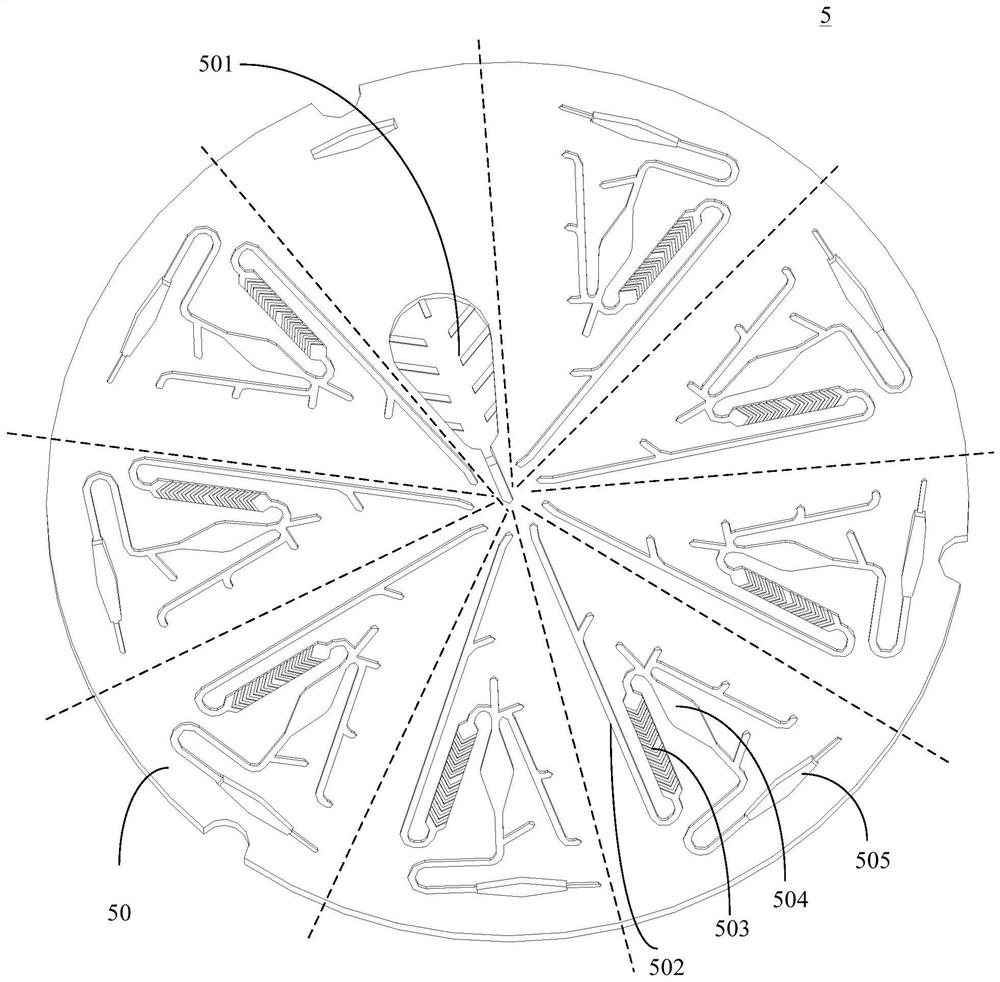

Linear actuator, valve apparatus and pump apparatus using the same

InactiveCN101240791ASimple structureEasily magnetizedPositive displacement pump componentsFlexible member pumpsPump chamberEngineering

A pump device is disclosed, characterized in that the pump device main body comprises a inflow channel communicated with a inflow hole, a inflow side active valve configured within the inflow channel, a pump chamber connected with the inflow channel, a pump mechanism configured within the pump chamber, a plurality of outflow channels which stretch from the pump chamber and are respectively communicated with a plurality of outflow holes, and outflow side active valves which are respectively configured within the plurality of outflow channels, the outflow side active valves are configured around the pump chamber in a planar shape.

Owner:SANKYO SEIKI MFG CO LTD +1

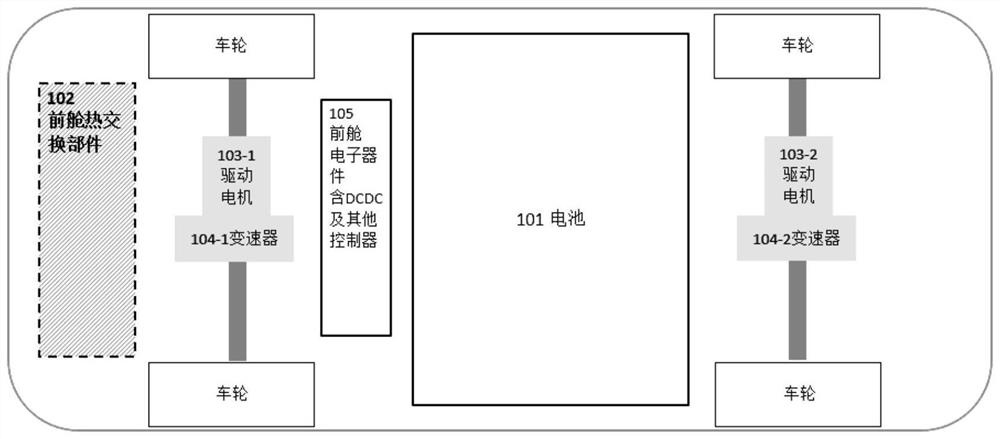

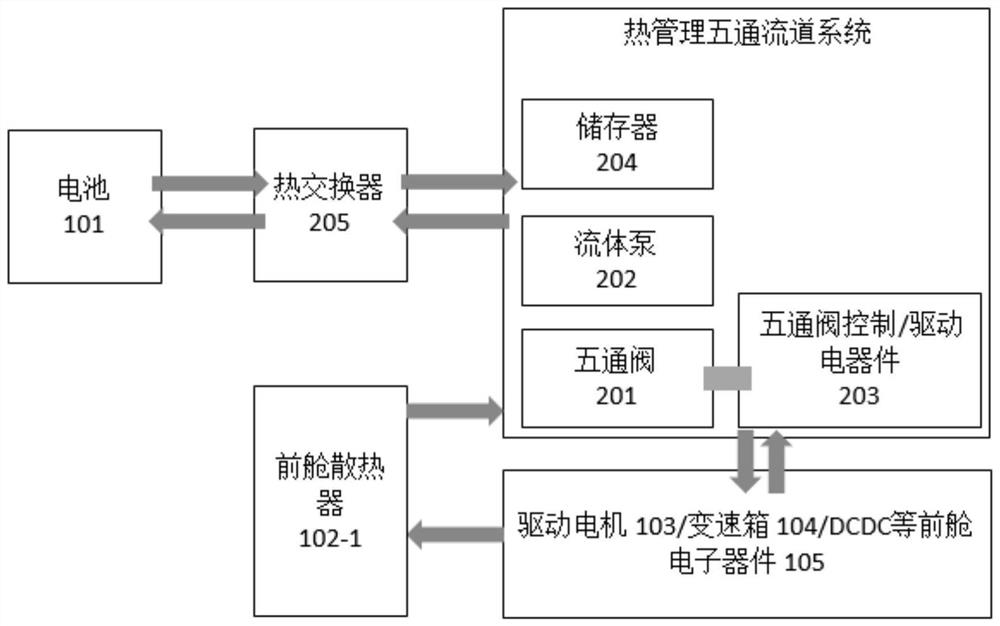

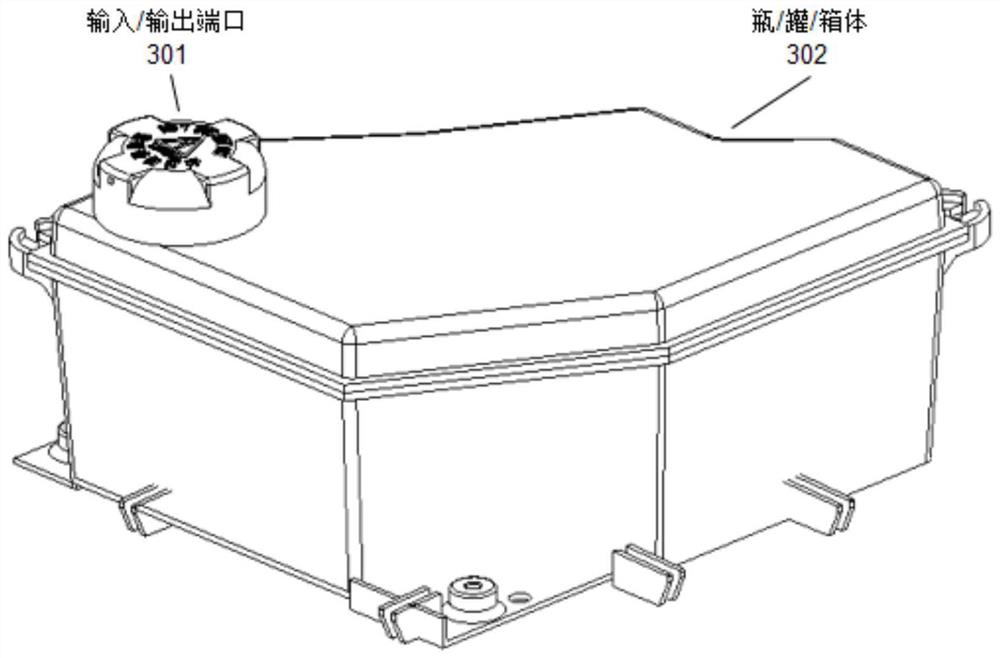

Five-way valve body assembly

PendingCN114321437AIncrease profitReduce weightOperating means/releasing devices for valvesMultiple way valvesHeat managementElectric machinery

A five-way valve integrated channel module is fixedly connected to the lower surface of a storage device of a storage medium, a five-way valve is arranged in the middle of the five-way valve integrated channel module, one connector of the five-way valve communicates with the storage device, and the other connector of the five-way valve communicates with the storage device. The other two pairs of connectors used for forming the two independent circulation loops are connected with integrated channels constructed in the five-way valve integrated channel module respectively, and the integrated channels extend to the side faces to be communicated with the hose connectors. According to the automobile heat management five-way valve body assembly, the runner driving pump, the runner switching driving motor, the runner switching valve element and other parts are integrated, a large number of pipelines and auxiliary parts (fasteners, hoops, ribbons, supports and the like) in a conventional heat management system are simplified, the weight is reduced on the whole, the runner length is shortened, and the cost is reduced. The energy utilization rate and the raw material utilization rate are improved.

Owner:BONAIRE AUTOMOTIVE ELECTRICAL SYST

A heat pipe of an instant water faucet

ActiveCN104728510BIncrease heating rateAvoid noiseValve members for heating/coolingWater heatersEngineering

The invention relates to the field of structural design of electric water heater heating pipes, and discloses a heating pipe of an instant heating faucet. The heating pipe comprises a heating pipe body, electrodes and a fixing seat which are coaxial. The heating pipe body comprises an insulating shell, a first heating barrel and a second heating barrel, the first heating barrel is arranged in the insulating shell, the second heating barrel is arranged in the first heating barrel, a first heat preservation layer is arranged between the insulating shell and the first heating barrel, a water passageway is arranged between the first heating barrel and the second heating barrel, the outer wall of the first heating barrel and the inner wall of the second heating barrel are coated with resistive films, an ultraviolet lamp tube coaxial with the second heating barrel is arranged in the second heating barrel, a second heat preservation layer is arranged between the ultraviolet lamp tube and the second heating barrel, and sealing devices are arranged on a water inlet and a water outlet of the heating pipe body. The water heating efficiency is higher, the heating speed is higher, the length of the water passageway is not increased, and the water outflow speed is high. The sterilization function is achieved.

Owner:慈溪万陇电器有限公司

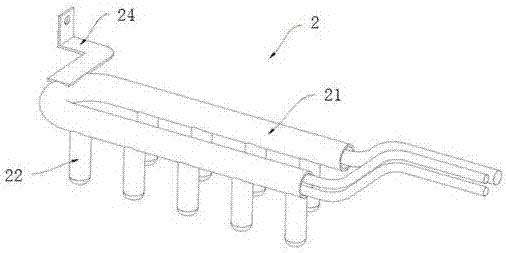

Ice making mechanism on ice making machine

InactiveCN107504735AShorten the length of the runnerShorten heat exchange lengthLighting and heating apparatusIce productionSolenoid valveEngineering

The invention discloses an ice making mechanism on an ice making machine. The ice making mechanism comprises a compressor and an evaporator connected with the compressor, and the evaporator is arranged in an ice making cavity of the ice making machine. The ice making mechanism has the beneficial effects that when the compressor works, the evaporator is cooled, ice is formed around branch pipes in a congealed manner, then a two-way solenoid valve works, high pressure steam output by the compressor is transmitted to the evaporator, the evaporator is heated, and ice blocks on the branch pipes fall. Water is directly in contact with the evaporator, the ice forming speed is high, and the ice blocks can be generated during refrigeration. The made ice blocks can be directly used, crushing and machining again are not needed; and in addition, by means of the above design, the distance between the two branch pipes can be minimum, the runner length of the evaporator is decreased, the heat exchange length is further decreased, and heat losses are reduced.

Owner:浦江县酉泽水产科技有限公司

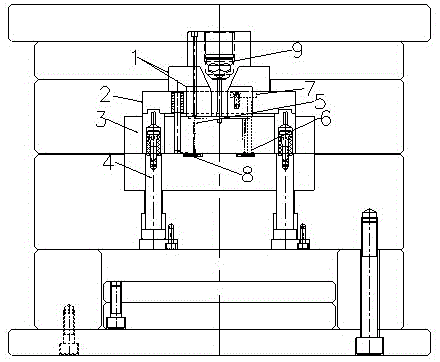

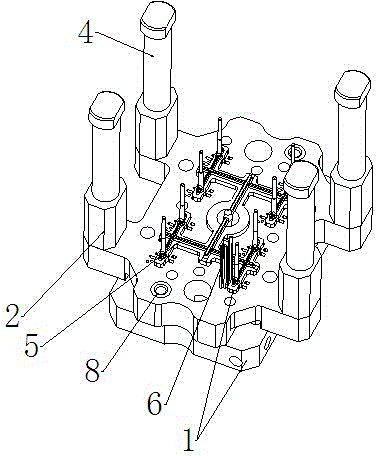

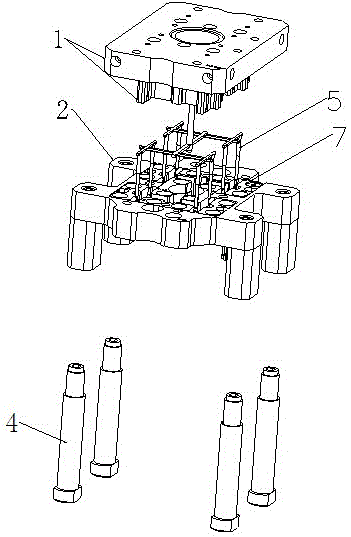

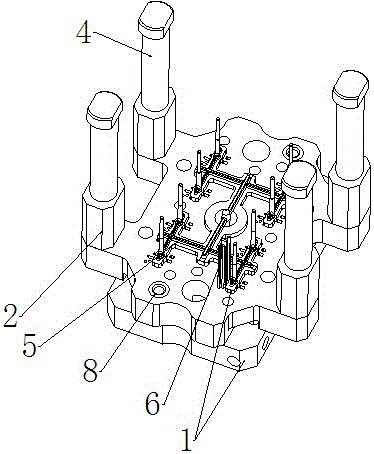

Energy-saving back-filling mechanism

The invention discloses an energy-saving back-filling mechanism. A runner system and an ejection system are designed in one assembly, wherein the runner system is designed in the ejection system; the runner system can be designed on the back of a die core; a runner plate penetrates through the ejection system and is in fit with the die core to form a runner, so that the length of the runner is reduced on the premise of no influence on the ejection mechanism; after the runner system and the ejection system are integrated to be a whole body, the advantages are characterized in that the length of the runner is reduced, the wastes are reduced, the forming period is shortened, the production cost is saved, the production efficiency is improved, and the purposes of saving energy and protecting environment are achieved.

Owner:KUNSHAN XINTAILI PRECISION COMPONENTS CO LTD

Unmanned aerial vehicle with night cruise mode and lamp holder thereof

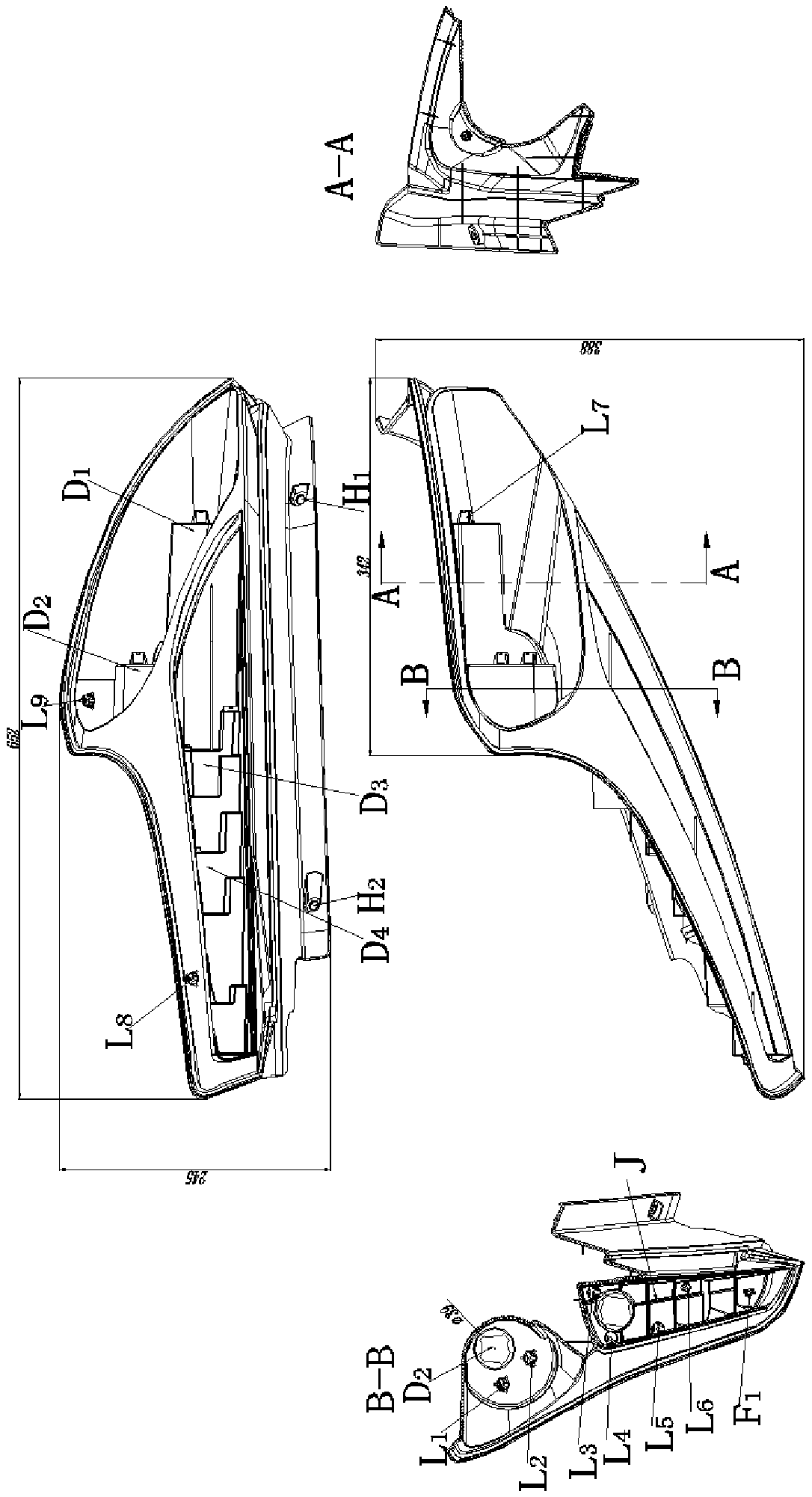

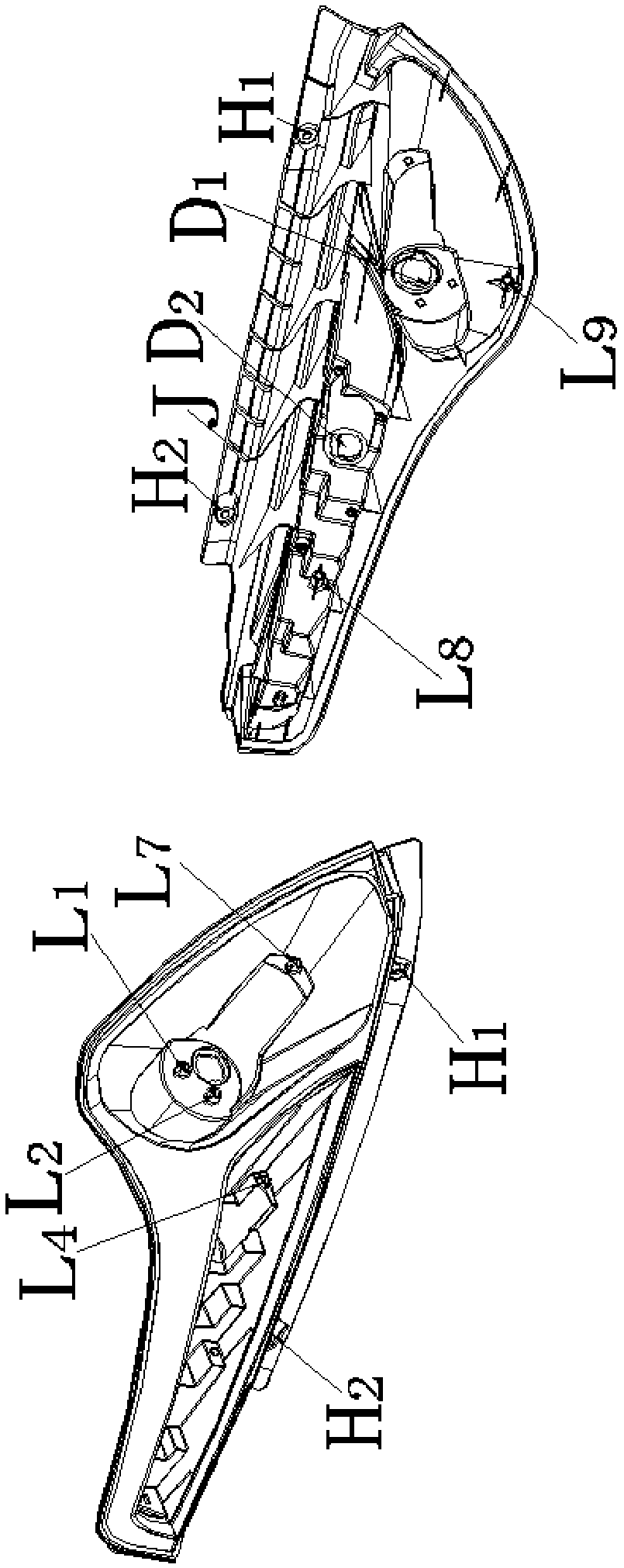

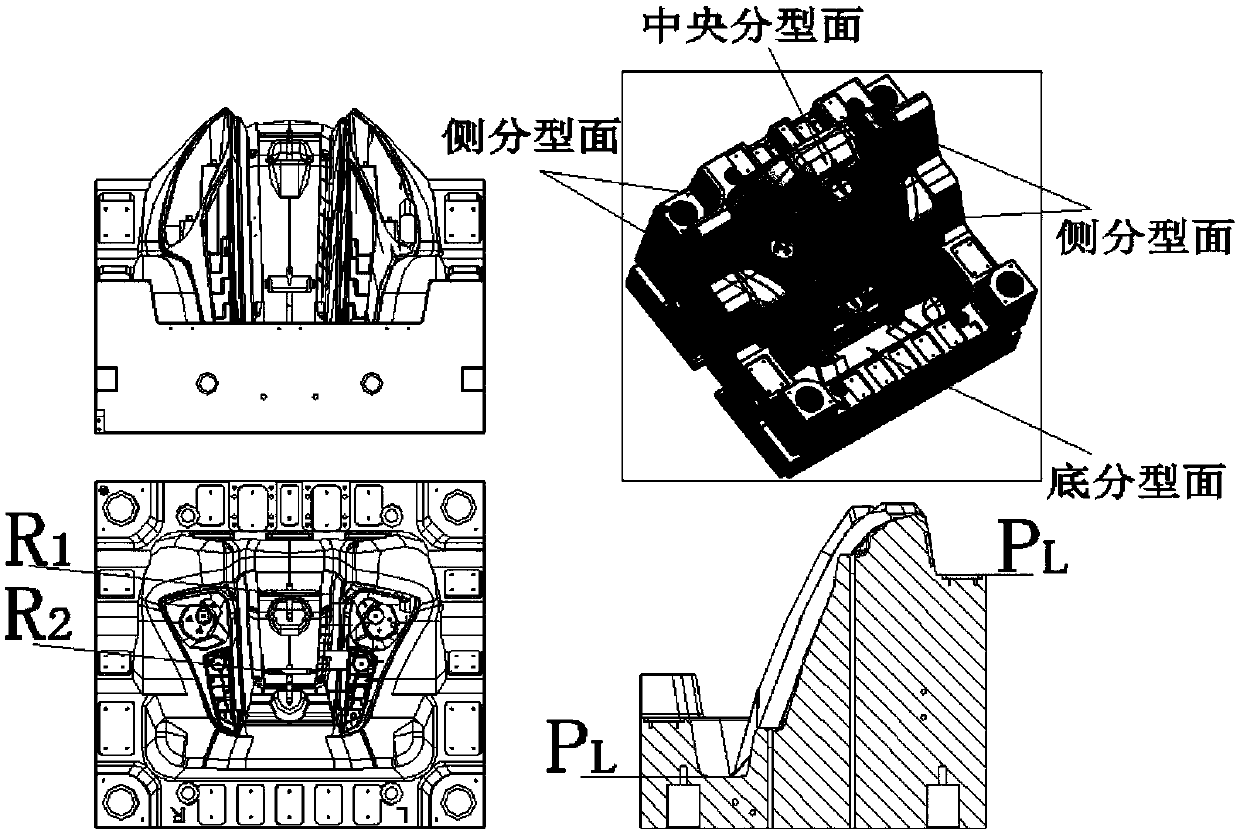

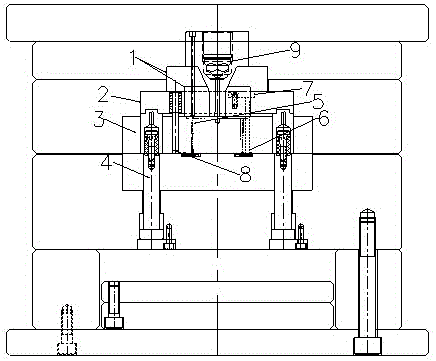

InactiveCN109895324ARaise the front temperatureGuaranteed fullnessDomestic articlesUncrewed vehicleEngineering

The invention relates to the field of unmanned aerial vehicle design, in particular to an unmanned aerial vehicle with a night cruise mode and a lamp holder thereof. The technical problems that one side of a movable mold core has more oblique side core pulling requirements, the structure size of a mold is certainly increased if more oil cylinder driving mechanisms are adopted, the using requirements for an injection molding machine are increased, and the mold cost is sharply increased are solved in the mode that a mold frame structure adopts a two-plate-mold two-time mold opening mode. The unmanned aerial vehicle with the night cruise mode and the lamp holder thereof achieve the beneficial effects that core pulling demolding is effectively driven through opening and closing power of mold plates, the mold manufacture cost is effectively reduced, and the mechanism design is simplified.

Owner:张剑箫

Energy-saving pouring mechanism

Owner:KUNSHAN XINTAILI PRECISION COMPONENTS CO LTD

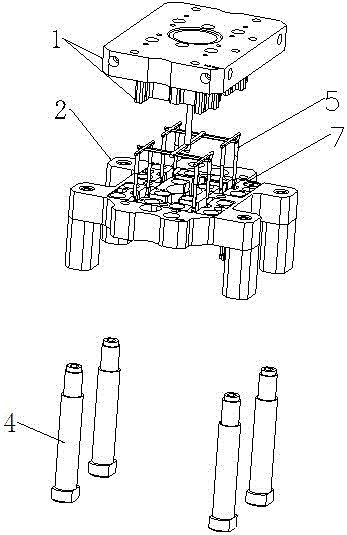

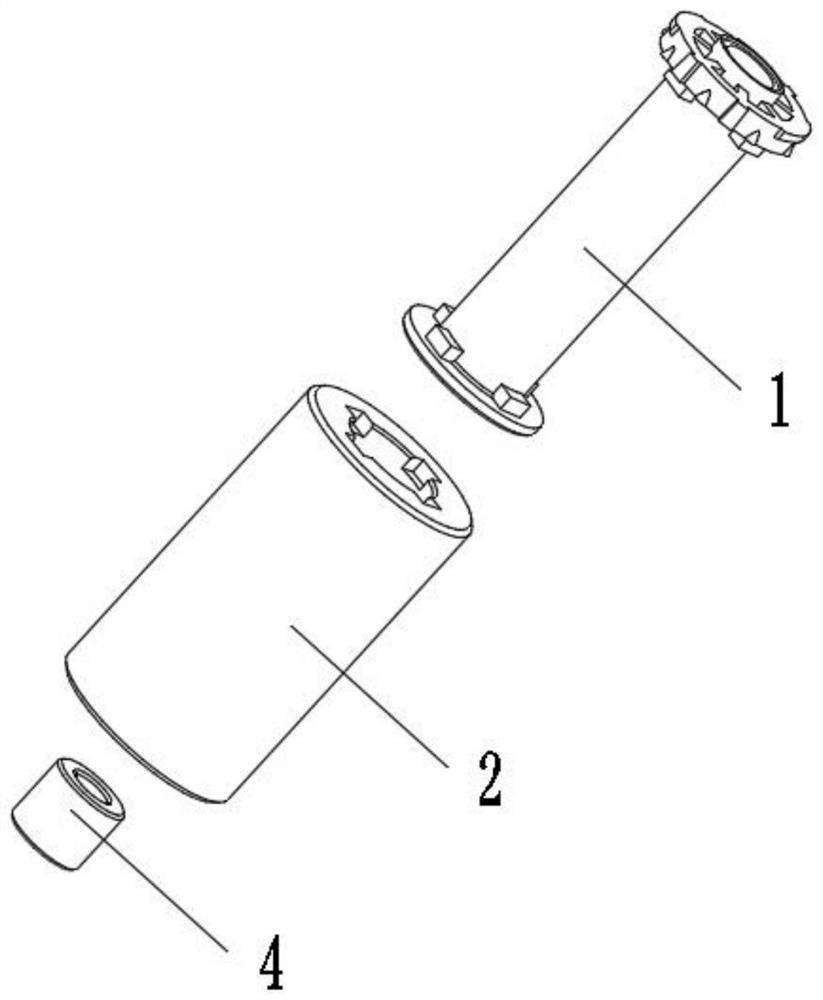

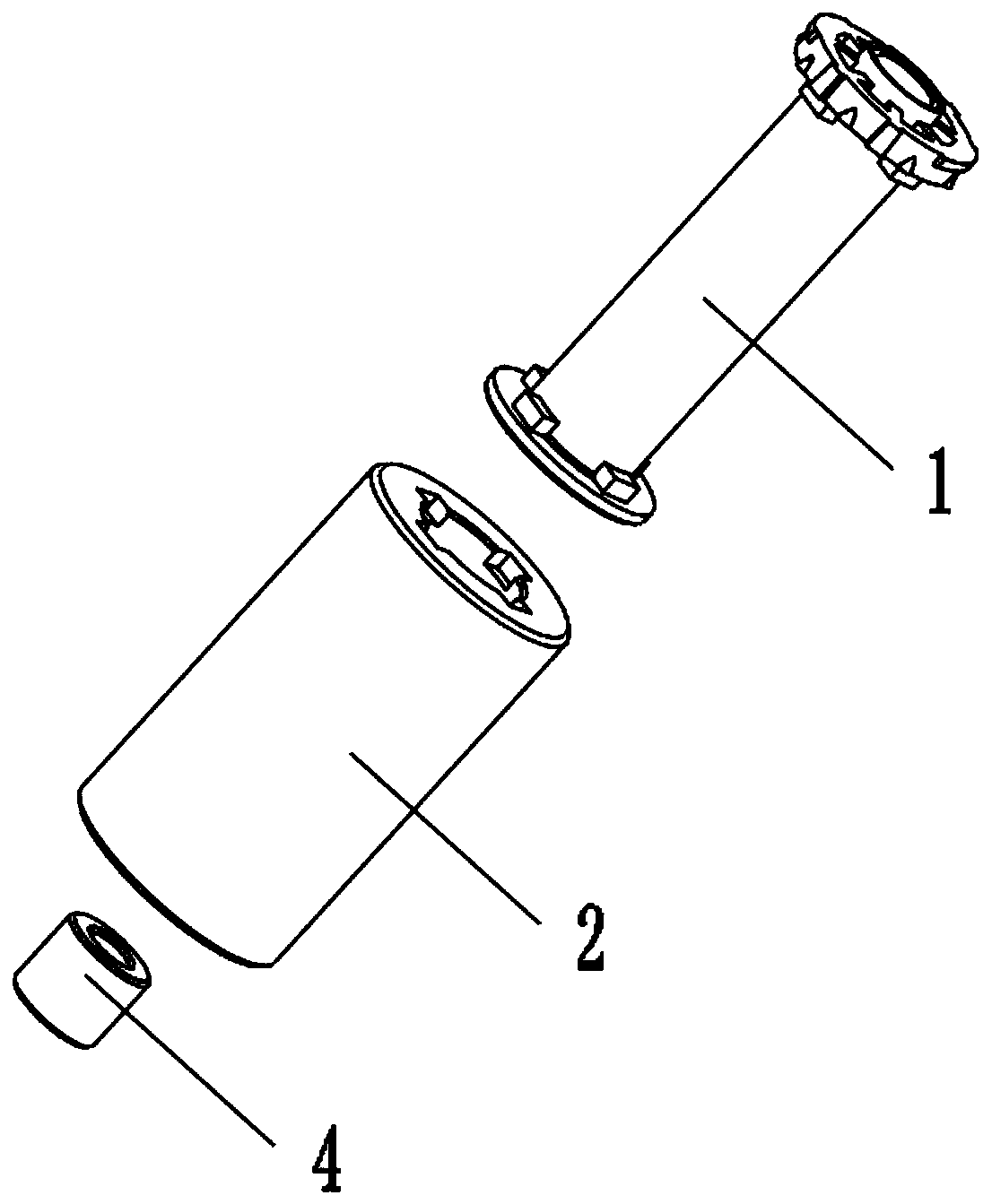

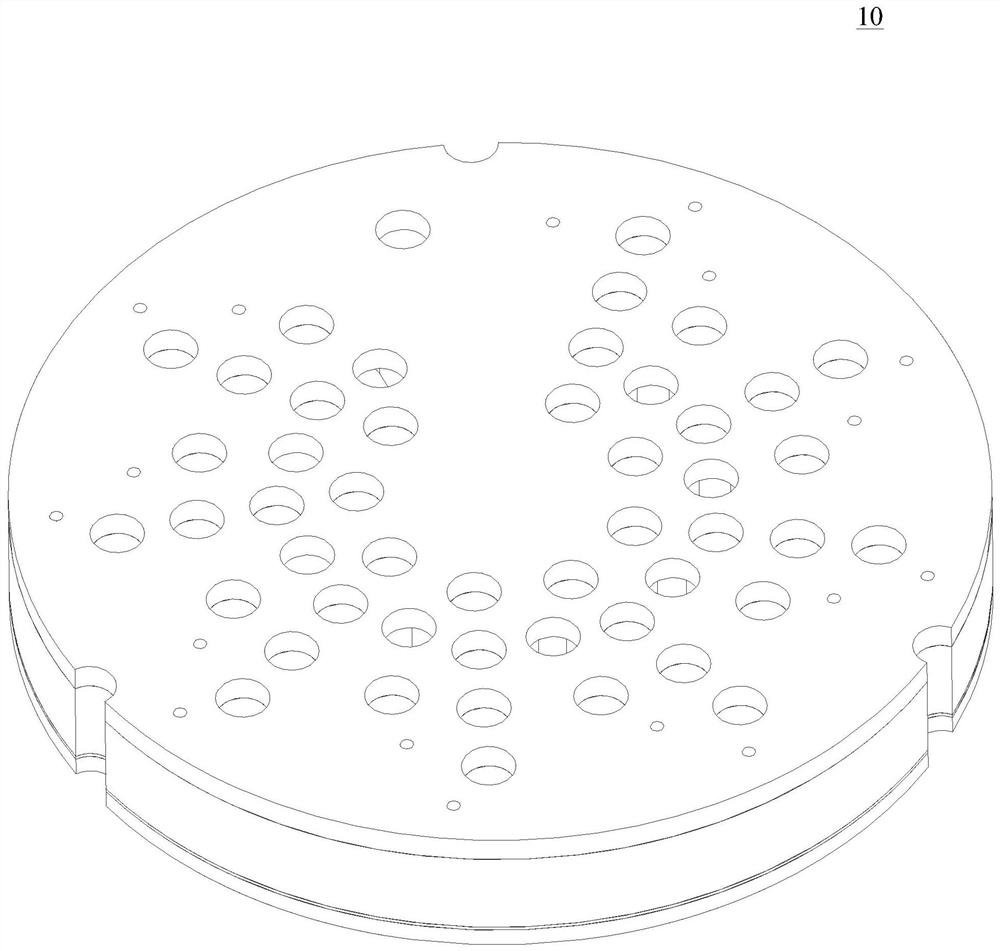

A water pump rotor forming method

The invention provides a method for forming a water pump rotor, which includes a magnetic ring, a long cylindrical rotor frame and an impeller cover, the magnetic ring is sleeved on the outer surface of the rotor frame, and the impeller cover is arranged on the rotor frame Above, the inner cavity of the rotor frame is provided with a first bearing, and the center hole of the impeller cover is provided with a second bearing, which is molded in two steps. In the first molding, the first bearing and the magnetic ring are coated with glue Molded on the rotor frame to form a semi-finished product; in the second molding, the impeller is formed by injection molding on the semi-finished product, and the second bearing is glued in the impeller cover, and the two bearings are positioned with the same insert pin when they are molded twice, which can be better. The concentricity is perfectly guaranteed, no reaming is required after injection molding, saving man-hours, the material cost of the two short bearings is low, the bearings are overmolded, this structure has better resistance to mechanical shock and temperature shock, and the molding is divided into two, Then the length of the runners of the two moldings is greatly reduced, which can realize faster and better filling in the mold.

Owner:东莞市力诚泵业有限公司

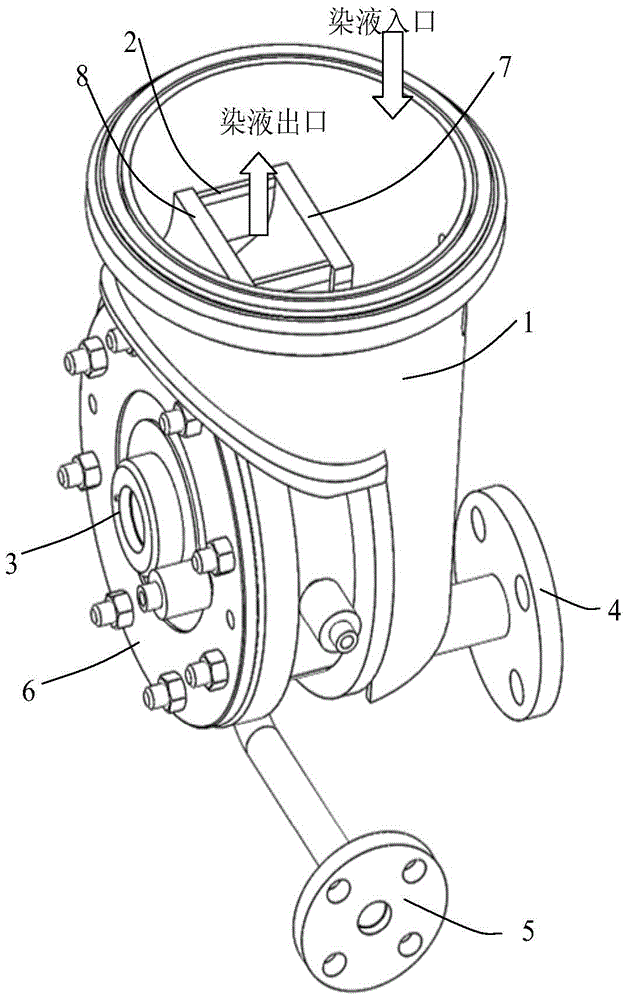

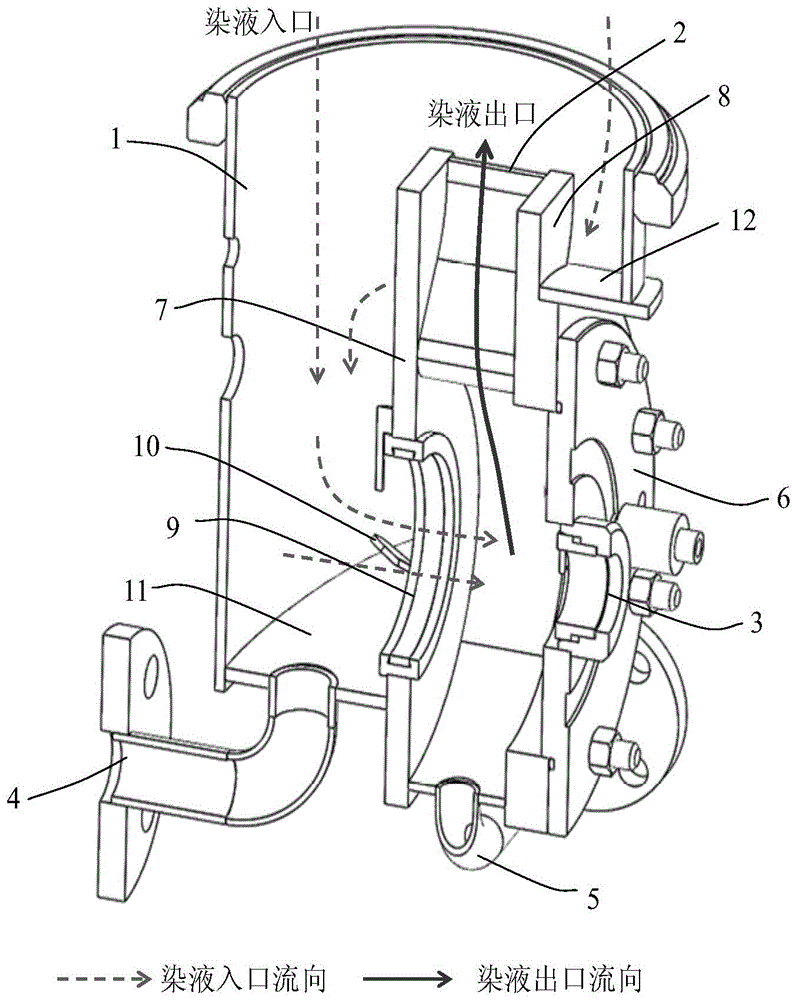

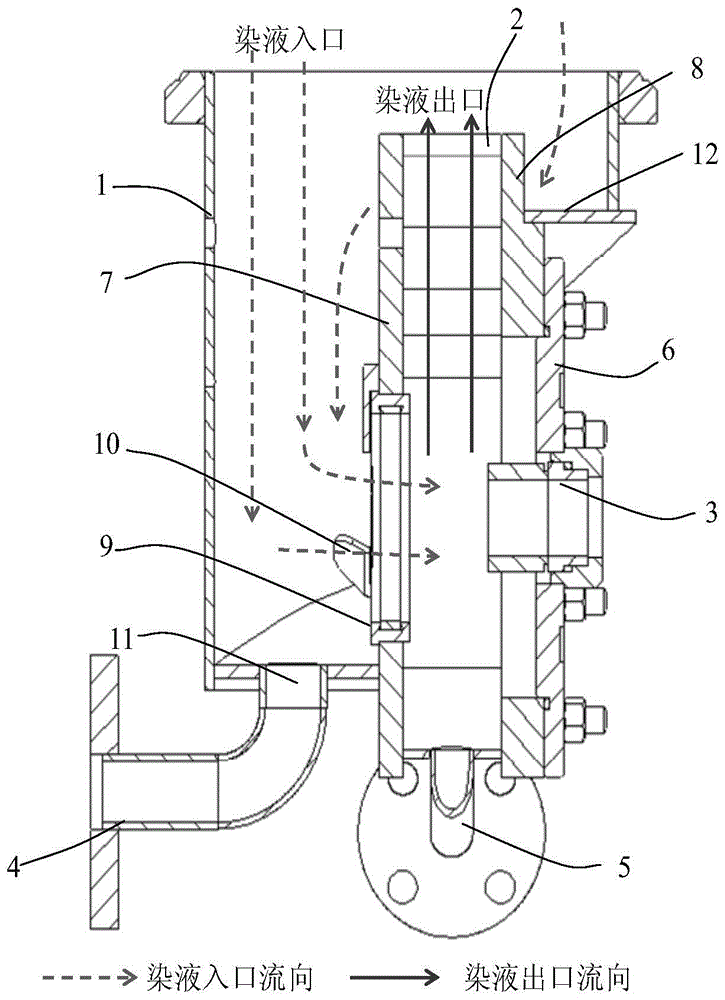

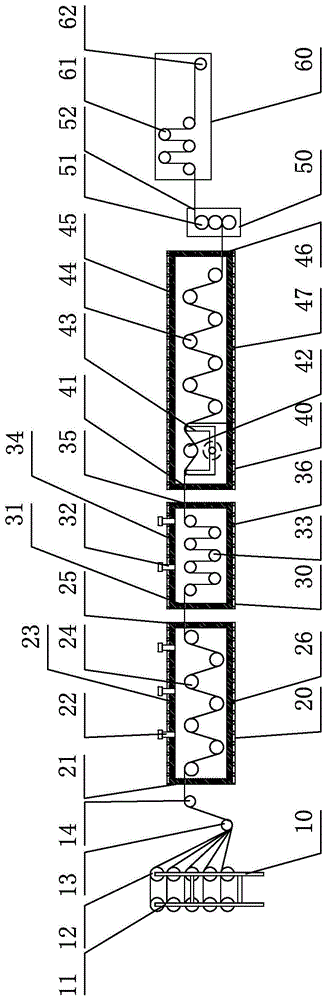

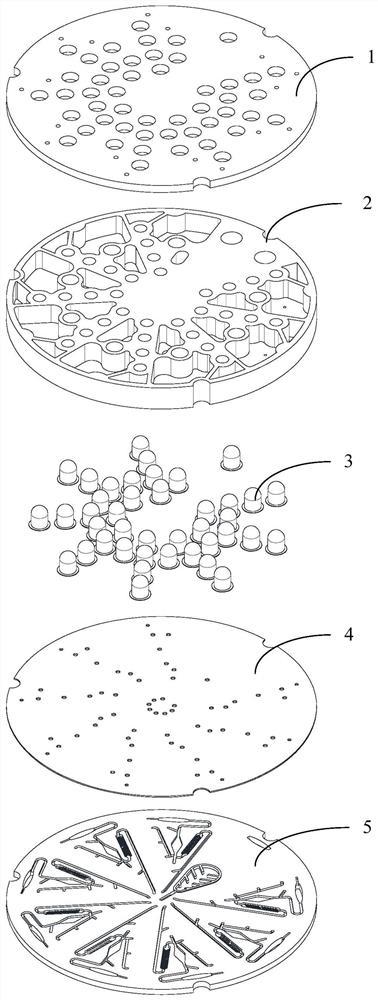

A Dye Liquor Circulation System of a 1:2 Extremely Low Liquor Ratio Yarn Dyeing Machine

ActiveCN104846579BImprove energy efficiencyReduce volumeTextile treatment machine arrangementsYarnPulp and paper industry

The invention provides a dye liquor circulating system of a yarn dyeing machine with extremely-low bath ratio of 1:2. The dye liquor circulating system mainly comprises a cylinder, a guide plate, a flange central seat, a liquor feeding and discharging pipe, a flange cover, a front plate, a rear plate, a pump supporting seat, a water retaining plate, a sealing plate, a cover plate and the like. The dye liquor circulating system has the advantages that the system tightly fuses with a pump body structure by the aid of ingenious runner arrangement, the size of the circulating system is reduced greatly, and the yarn dyeing machine is allowed to have the ultimate extremely-low bath ratio of 1:2; the runner length of the circulating system is also shortened greatly, and pump energy efficiency is increased effectively.

Owner:高勋绿色智能装备(佛山)有限公司

Forming method of water pump rotor

The invention provides a forming method of a water pump rotor. The device for realizing the method comprises a magnetic ring, a long-cylinder-shaped rotor frame and a vane wheel cover, wherein the magnetic ring is connected to the outer surface of the rotor frame in a sleeving manner; the vane wheel cover is arranged on the rotor frame; a first bearing is arranged in an inner cavity of the rotor frame; and a second bearing is arranged on a center hole of the vane wheel cover. The water pump rotor is shaped in two times, during the first-time shaping, the first bearing and the magnetic ring aresubjected to encapsulization, and are shaped on the rotor frame to form a semi-finished product; during second-time shaping, injection molding is performed on the semi-finished product to form a vanewheel, and the second bearing is subjected to encapsulization in the vane wheel cover; during shaping in two times of the two bearings, positioning is performed by the same inserting pin, so that theconcentricity can be well guaranteed; after injection molding, reaming is not needed, so that man-hour is saved; the material cost of the two short bearings is low; the bearings are shaped through encapsulization and injection molding, so that the capacity of resisting mechanical shock and temperature shock of the structure of the water pump rotor is better; and shaping is performed into two times, so that the length of the flow channels shaped in two times is greatly reduced, and rubber filling in a mold can be quicker and better realized.

Owner:东莞市力诚泵业有限公司

Horizontal solid-liquid dual-purpose composite insulator former

The invention discloses a horizontal solid-liquid dual-purpose composite insulator former which comprises a mold locking machine frame and injection plasticizing devices, wherein the injecting end of each injection plasticizing device is connected to movable mold plates used for fixing a mold. A sled movable slide rail is horizontally arranged in the mold locking machine frame corresponding to the injection plasticizing device, and one injection plasticizing device is slidely connected with the corresponding sled movable slide rail. The movable mold plates are connected with the mold locking machine frame in a sliding way and can slide along an upper guide rail or a lower guide rail, and the two movable mold plates can move separately or together. The horizontal solid-liquid dual-purpose composite insulator former adopts a horizontal mold locking structure, single / double injection or single / double movable mold(s) can be flexibly selected according to the forming process of a product; and in forming, a core barrel and a product to be formed stay in the center of the mold locking machine frame, and an injection nozzle directly injects glue from the center of the side of a mold, thereby shortening the length of a runner, facilitating air discharge, improving the internal quality of the product and reducing energy loss.

Owner:广东伊之密精密橡塑装备科技有限公司

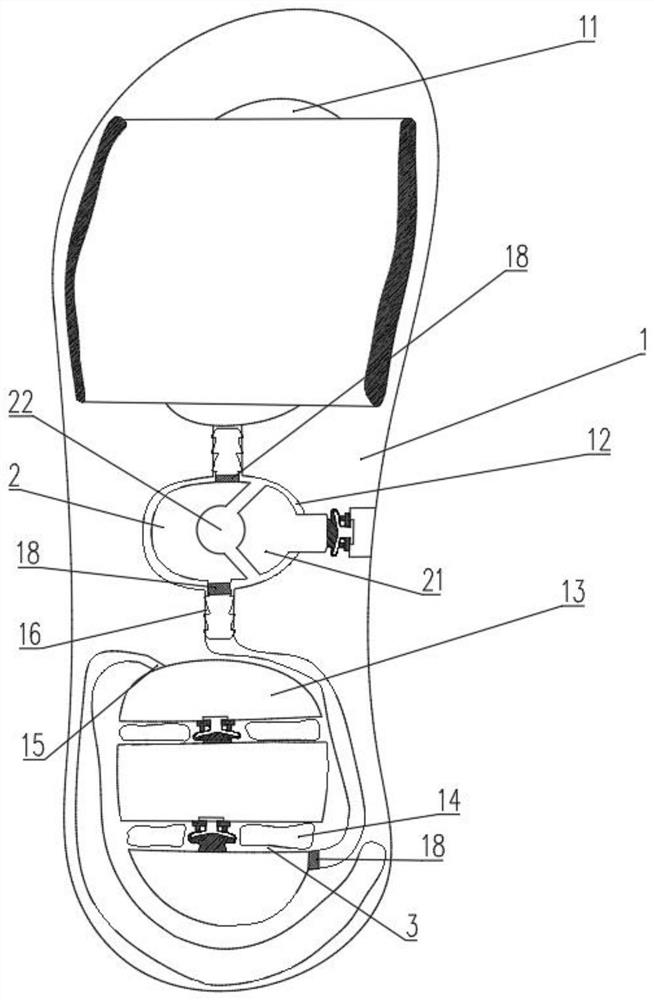

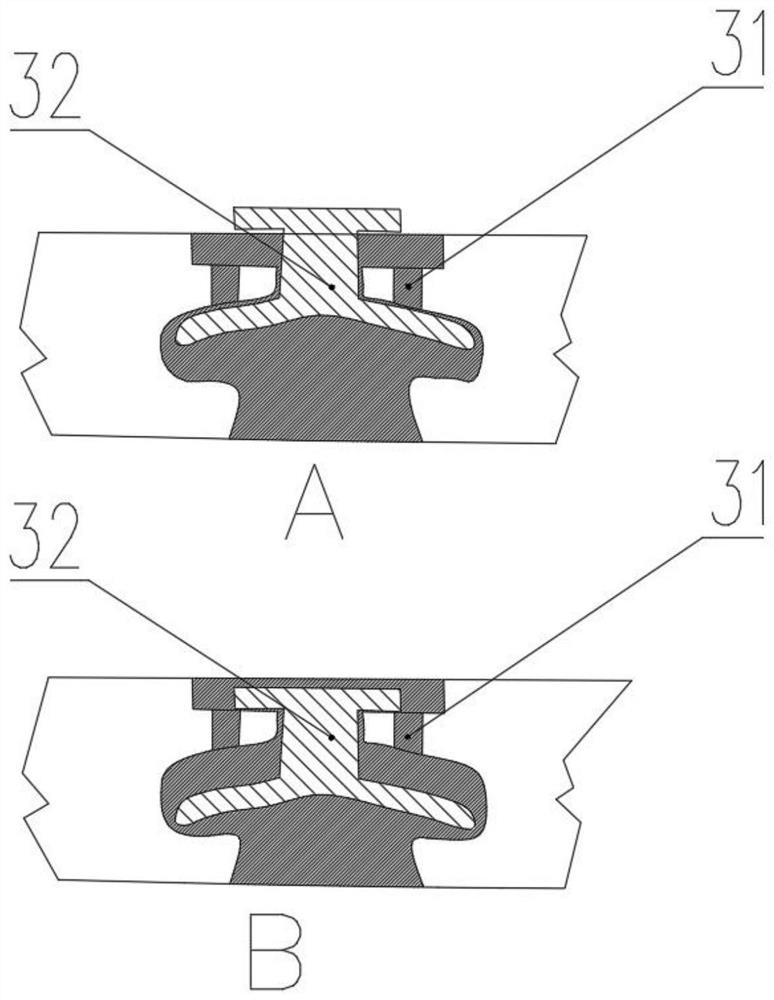

Comfortable foaming EVA slipper and manufacturing process

PendingCN113317584AImprove ventilation efficiencyStrong comfortSolesShoe gluingAir springManufacturing engineering

The invention discloses a comfortable foaming EVA slipper and manufacturing process. The comfortable foaming EVA slipper comprises a vamp and a sole, and is characterized in that the sole is provided with a first air cushion cavity located below the foot sole and a second air cushion cavity located below the heel, and a third storage cavity is formed between the first air cushion cavity and the second air cushion cavity; the first air cushion cavity and the second air cushion cavity are internally provided with a plurality of sealed air bags, an air outlet channel located in the side wall and an air inlet channel connected with the third storage cavity, air passes through the air outlet channel and the air inlet channel in a one-way guiding mode, and the third storage cavity is internally provided with a storage bag capable of being detached relative to the shoe sole. According to the slipper, the sealed air bags are arranged to form the air springs, the double air cushion cavities of the sole and the heel and the layer-by-layer progressive partition type air passing channels, the gravity center change in the walking process is reasonably utilized in the walking process of a user every time, the air output is large through pressure air supply, and the comfort level is higher.

Owner:晋江富峰鞋业有限公司

Injection molding die and application method thereof

Owner:苏州市海豚塑胶模具有限公司

A low specific speed impeller structure and its processing method

Owner:重庆水泵厂有限责任公司

Flow box

The invention discloses a flow box, and belongs to the field of paper-making mechanical equipment. The flow box comprises a cylindrical shell, wherein a pulp inlet and a pulp outlet are formed on the cylindrical shell; a pulp applying device is arranged at the pulp outlet; the pulp inlet is communicated with a pulp distributing device; a roller capable of rotating around the axis thereof is coaxially sleeved inside the cylindrical shell; a clearance is formed between the outer roll surface of the roller and the inner surface of the cylindrical shell. According to the invention, the roller is coaxially sleeved inside the cylindrical shell and the roller can rotate around the axis thereof, so that when the roller rotates at a high speed, under the driving of the pressure difference and the roll surface, pulp flows along with the roll surface in the clearance formed between the roll surface and the cylindrical shell; the flowing speed of the pulp is smaller than the motional speed of the roll surface, so that friction is generated, a turbulent flow is generated in a pulp flow, flocculated fiber clusters in the pulp flow can be dispersed, and thus the evenness of a paper sheet is improved; and the flow box is simple in structure and convenient to manufacture and is applicable to paper-making machines with high, medium and low speeds.

Owner:SHAANXI UNIV OF SCI & TECH

A compact pressure self-compensating full sea depth stop valve

ActiveCN110469698BHighly integratedSimple structureMultiple way valvesLift valveEngineeringFriction force

The invention discloses a compact pressure self-compensation total-sea-depth stop valve, and belongs to the relevant technical field of valve bodies. The compact pressure self-compensation total-sea-depth stop valve comprises two stop valve bodies which are oppositely arranged on the same valve body and are of the same structure. Each stop valve body comprises a stop valve screw plug assembly, a valve element assembly, an isolation pressure sheet assembly, a valve sleeve, a stop valve spring and a valve seat. The stop valve bodies are opened in a manner of being hydraulically driven, and therefore remote control can be achieved. Closing of the stop valve bodies is achieved through the force of the stop valve springs and hydraulic force generated by the area difference between the two sidesof the large end of the valve element assembly. The form of ceramic and stainless steel cooperation is adopted in cooperation between the valve element assembly and other parts, friction force in themotion process of the valve element assembly is effectively reduced, and meanwhile the possibility of jamming of the valve element assembly is reduced. The two oppositely-arranged stop valve bodies use the same valve seat in common, and the space utilization rate is increased. According to the compact pressure self-compensation total-sea-depth stop valve, the structure is simplified, the size isreduced, and then the complexity and cost of a buoyancy adjusting system of a submersible are reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

A microchannel heat exchanger and flow heat transfer experimental device

ActiveCN106879227BBuck downUniform temperature distributionStructural/machines measurementCooling/ventilation/heating modificationsEngineeringElectron

The invention relates to a micro-channel heat exchanger and a flow heat exchange experiment device. The micro-channel heat exchanger is characterized in that the heat exchanger at least comprises an upper cover plate and a lower cover plate; three flow channels, namely, a first flow channel, a second flow channel and a third flow channel, and the inlets and outlets of the three flow channels are machined on the upper cover plate and the lower cover plate respectively; the first flow channel, the second flow channel and the third flow channel are each composed of two Y-shaped flow channels; the first flow channel and the third flow channel are formed by connecting the bifurcate ends of two Y flow channels, and the second flow channel is formed by connecting the non-bifurcate ends of two Y flow channels; and when fluid flows in the first flow channel, the second flow channel and the third flow channel, the flow direction at the inlets and the flow direction at the outlets are perpendicular to each other. The heat dissipation performance is good. Electronic equipment of high heat flux density can be kept at uniform temperature.

Owner:XIDIAN UNIV

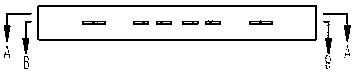

Melt feeding device, continuous fiber reinforced thermoplastic impregnated belt molding device and method

ActiveCN104441323BShorten the length of the runnerReduce resistanceCoatingsThermoplasticPolymer science

The invention relates to a melt feeding device, and a device and a method for forming continuous fiber reinforced thermoplastic impregnated belts, and belongs to the technical field of the preparation of continuous fiber reinforced thermoplastic resin composites. The melt feeding device comprises a main runner which is orderly communicated with primary sub-runners, secondary sub-runners and third-stage sub-runners; the primary sub-runners are divided from the main runner and distributed in parallel in parallel with one another along the main runner; the device for forming the continuous fiber reinforced thermoplastic impregnated belts comprises an impregnation unit in which the melt feeding device and impregnation rollers are arranged, wherein the first pushing impregnation roller in the feeding direction is arranged right above the main runner of the melt feeding device; the method for forming the continuous fiber reinforced thermoplastic impregnated belt comprises the steps of preheating pre-dispersing, preheating tensioning, impregnating, lustering, cooling, collecting and the like. The melt feeding device and the device for forming the continuous fiber reinforced thermoplastic impregnated belts are simple in structure; besides, the fiber preheating speed is high, the fiber preheating efficiency is high, the melt flowing resistance and the melt heating time are reduced, and the fiber wetting effect of the impregnated belts is excellent.

Owner:谭洪生

Micro-fluidic chip

ActiveCN112495456AReduce volumeImprove the mixing effectLaboratory glasswaresBiological testingEngineeringComputational physics

The invention provides a micro-fluidic chip which comprises a sample cavity and at least one reaction detection unit communicated with the sample cavity, the at least one reaction detection unit is arranged on a bottom plate, and reagents required by the at least one reaction detection unit are stored in a storage cavity of a reagent storage cavity plate. The storage cavity is communicated with the at least one reaction detection unit through a first one-way through hole; the first power source is used for driving the sample to flow to the reaction detection unit, and the second power source is used for driving the reagent in the storage cavity to flow to the reaction detection unit. According to the technical scheme, the micro-fluidic chip is of a multi-layer structure, the reagents required by the reaction detection unit and the reaction detection unit are designed on different layers, and the sample and the reaction reagent are added into the reaction detection unit through different power sources respectively, so that the mixing effect of the sample and the reaction reagent is better, the detection precision is improved, and the length of the flow channel can be reduced, the size of the micro-fluidic chip is reduced, and the cost is saved.

Owner:合肥中科国腾生物科技有限公司

Deslagging gate valve

InactiveCN101033806ASmall space required for installationShorten the length of the runnerSpindle sealingsSlide valveState of artSlag

The invention relates a technology of the valve especially a kind of short-range slag-off valve. It includes a valve body, a shutter, a valve handle, a valve cap and between the valve handle and the valve cap installs filling material seal and the valve body with the shape of 'butterfly valve body'. The purpose of it is that in orders to design a kind of short-range and installment space with few requirements slag-off valve. Comparing with the modern technology it has the merits as follows: the total of valve with high wearing life and the line piping with light weight and saving material and well seal performance and so on.

Owner:曹剑钢

Packaging die and packaging method thereof

ActiveCN101866865BShorten the length of the runnerReduce wasteSemiconductor/solid-state device manufacturingMemory cardsInjection device

The invention relates to a packaging die and a packaging method. The die is used for packaging a memory card and comprises an upper die and a lower die. The upper die comprises an upper die plate and an upper die core fixed on the upper die plate. The lower die comprises a lower die core, a lower die holder, an injection device and a lower bottom plate. The lower die core is fixed on the lower die holder. The injection device and the lower die holder are arranged on the lower bottom plate. The lower die core is provided with a plurality of sleeves for placing resin material cakes. The positions on the upper die core corresponding to the sleeves are provided with runners. The injection device comprises a plurality of adhesive extruding rods with adhesive extruding heads and an adhesive extruding seat for installing the adhesive extruding rods. The adhesive extruding heads are in fit with the sleeves. The method uses the die to package the memory card. The packaging die of the inventionadopts a plurality of material barrels and a plurality of adhesive extruding rods matched with the material barrels, shortens the length of the runners of the die and avoids conditions that the resingenerates bubbles, pores, is not full filled and the like in the flowing process.

Owner:深圳市劲升迪龙科技发展有限公司

A low-resistance enhanced heat transfer structure based on nano-superwetting interface

ActiveCN110425914BShorten the length of the runnerReduce thicknessCoatingsModifications by conduction heat transferEnhanced heat transferEngineering

The invention discloses a low-resistance enhanced heat transfer structure based on a nano-superwetting interface, which includes a lower embedded microchannel layer and an upper manifold channel layer, the embedded microchannel and the manifold channel are vertically arranged, and the lower embedded microchannel The layer is composed of several embedded microchannel units. The cross section of the embedded microchannel of each unit is a rectangular gradually expanding section along the flow direction of the cooling medium. The shape of the embedded microchannel of each unit is isosceles trapezoidal. The tube channel layer is composed of serpentine manifold channels, and two adjacent serpentine channels constitute the inlet and outlet of the manifold channel. The present invention utilizes a hierarchical flow structure to construct a microchannel heat sink. By combining the microchannel heat sink with a nano-superwetting interface and a gradually expanding microchannel section, the heat transfer characteristics and resistance characteristics can be improved at the same time. In the case of high efficiency, the low resistance of the micro-channel heat sink can be realized to enhance heat transfer.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Blow molding machine head

The invention is mainly applied to the field of blow molding of blow molding machines, and particularly relates to a blow molding machine head which comprises a machine head. Annular spiral channels are distributed inside the machine head, distribution plates are arranged at the bottoms of the spiral channels, an inlet runner which is communicated with a corresponding feed inlet is vertically arranged inside each distribution plate, a one-to-two runner is communicated with the top of each inlet runner, two ends of each one-to-two runner are communicated with the bottoms of vertical communication holes, two-to-four runners are communicated with the tops of the vertical communication holes, each of two ends of each two-to-four runner is communicated with an end of a horizontal communicationhole, the other end of each horizontal communication hole is communicated with a four-to-eight runner, two ends of each four-to-eight runner are positioned on two sides of the corresponding horizontalcommunication holes, the tail end of each four-to-eight runner is upwardly connected with an eight-to-sixteen runner, the tail ends of the eight-to-sixteen runners are communicated with annular channels, and each spiral channel is communicated with the corresponding annular channel. The blow molding machine head has the advantages that the lengths of runners can be shortened to a great extent, material burning conditions can be reduced, and accordingly the product quality can be enhanced; intermediate cavities are reserved, and accordingly dies can be conveniently replaced at any time.

Owner:SHANDONG QINGTIAN PLASTIC IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com