Ice making mechanism on ice making machine

An ice machine and ice chamber technology, applied in ice making, ice making, ice storage/distribution, etc., can solve problems such as low efficiency and slow ice making speed, reduce heat loss, reduce energy consumption, and shorten flow rate The effect of track length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

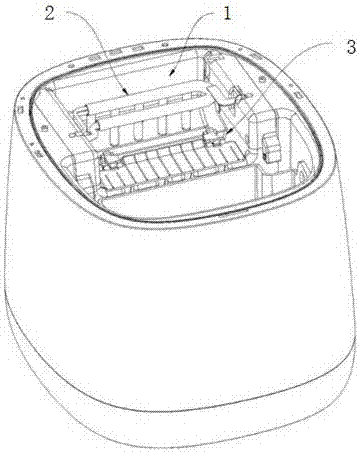

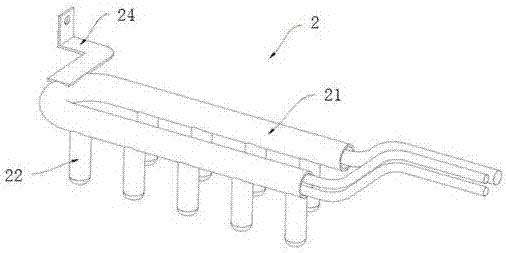

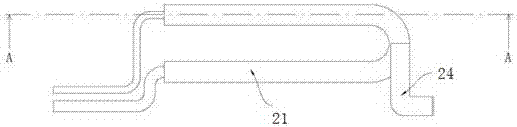

[0020] like Figure 1~4 as shown,

[0021] An ice-making mechanism on an ice-making machine includes a compressor 3 and an evaporator 2 connected to the compressor, and the evaporator is arranged in an ice-making chamber 1 of the ice-making machine.

[0022] The evaporator includes a U-shaped pipe 21 placed horizontally; the lower end of the U-shaped pipe protrudes downward to form a plurality of branch pipes; the upper end of the branch pipe 22 is connected with the U-shaped pipe, the lower end of the branch pipe is closed, and the branch pipe extends into the water in the ice chamber. A two-way electromagnetic valve is arranged between the high-pressure steam outlet of the compressor 3 and the steamer. When the compressor 3 works, the evaporator 2 cools down, ice condenses around the branch pipe 22, then the two-way solenoid valve works, the high-pressure steam output by the compressor 3 is transmitted to the evaporator, the evaporator heats up, and the ice cubes on the bra...

Embodiment 2

[0028] like Figure 1~4 As shown, when the compressor 3 works, the evaporator 2 cools down, and ice condenses around the branch pipe 22, and then the two-way solenoid valve works, and the high-pressure steam output by the compressor 3 is transmitted to the evaporator 2, and the evaporator 2 heats up, and the branch pipe 22 The ice cubes fell off. The water is directly in contact with the evaporator 2, and the ice-forming speed is fast, and ice cubes can be produced when it is refrigerated. The ice-shoveling mechanism arranged under the evaporator sends the generated ice cubes out of the ice-making chamber 1 .

[0029] The inner wall of the ice-making chamber 1 is coated with an anti-freezing and sticking coating, and the coating is composed of components A and B: the components of component A and their parts by weight are: 70-110 parts of vinyl-terminated polysiloxane, ethylene 25~45 parts of trifluoropropylpolysiloxane, 18~26 parts of silica nanoparticles, 20~30 parts of or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com