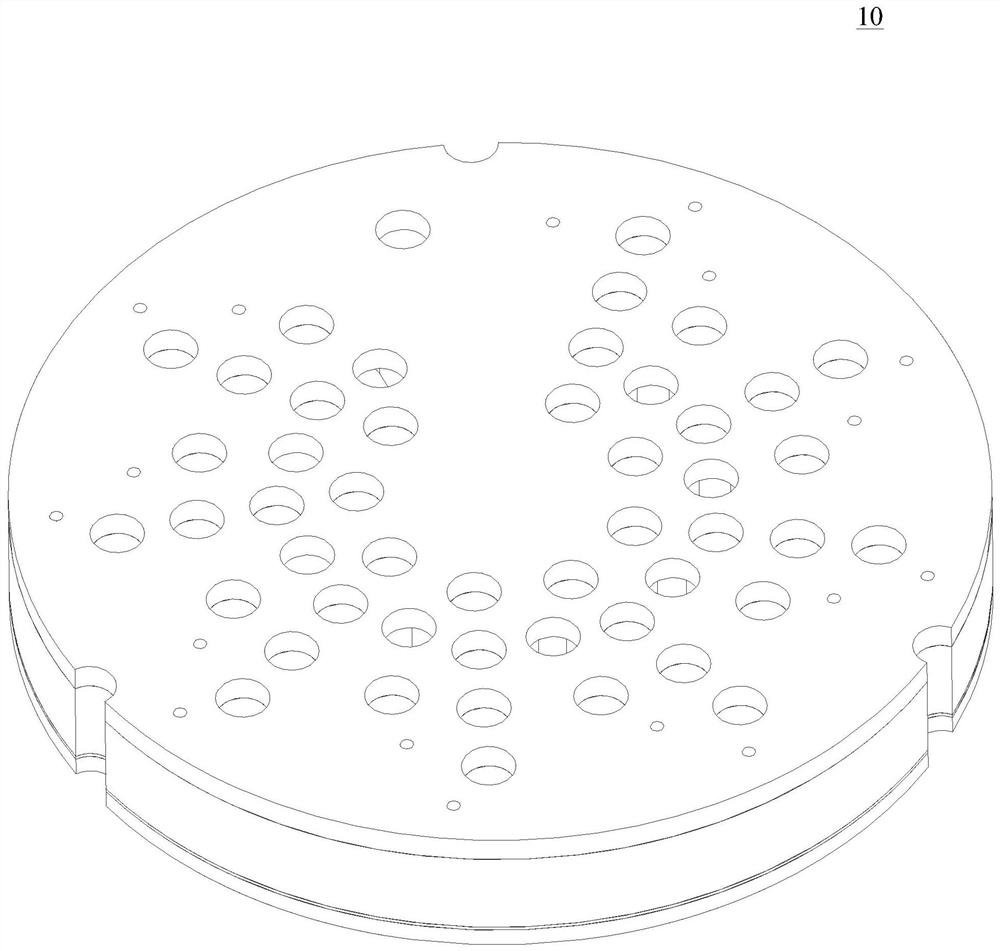

Micro-fluidic chip

A microfluidic chip and microfluidic channel technology, applied in the field of microfluidics, can solve the problems of poor repeatability and low detection accuracy of microfluidic chips, and achieve improved detection accuracy, reduced volume, and good mixing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

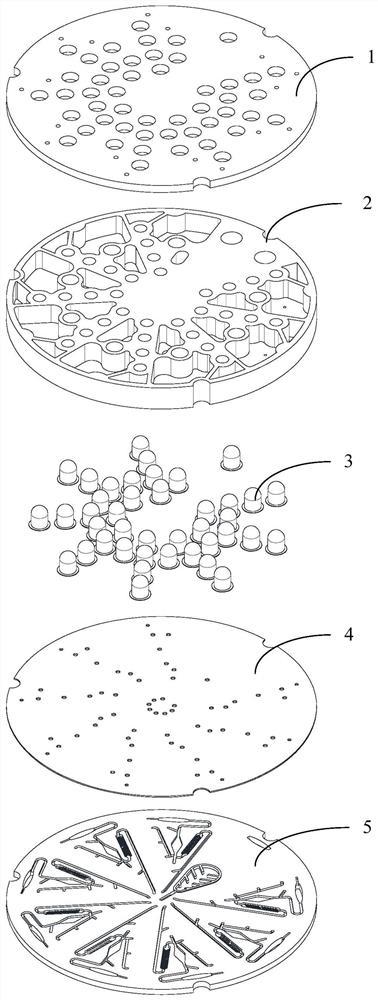

[0092] Step 1: Add the sample to be tested

[0093] Open the sealing cover of the sample inlet 101, manually add the sample to be tested into the sample chamber 201, close the sealing cover tightly, and insert the microfluidic chip 10 into the detection instrument in standby state.

[0094] Step 2: Sample dilution and filtration

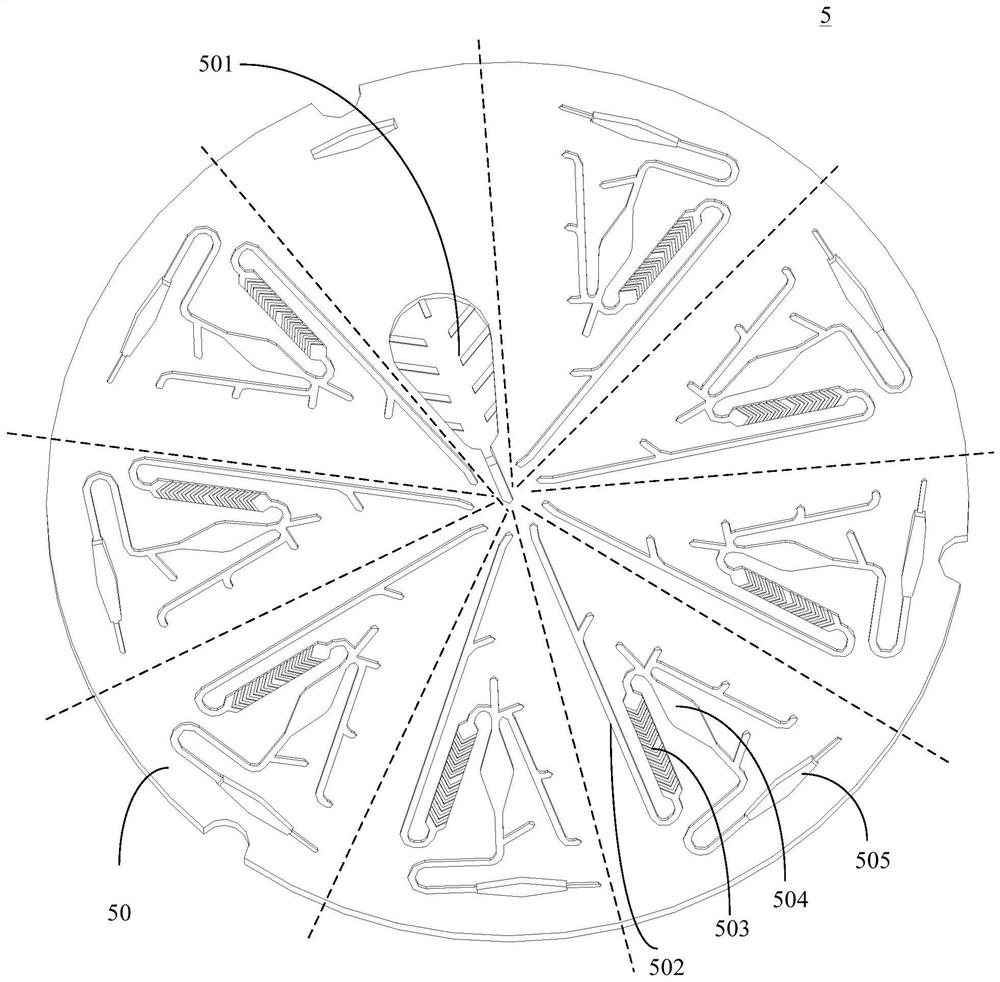

[0095] Run the instrument, open the first air outlet 103 of the reaction waste liquid storage chamber 211, close the second air outlet 105 of the detection waste liquid storage chamber 210, input a certain amount of air from the sample inlet 101 to pressurize the sample chamber 201, and drive the sample reagent From the sample chamber 201 to the sample mixing flow channel 203; at the same time, the reagent pressure rod is inserted into the reagent pressure rod inlet 102 to pressurize the diluent reagent capsule 301 in the diluent chamber 202, driving a quantitative diluent into the sample mixing flow channel 203, Mix with the sample; continue to inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com