Deslagging gate valve

A gate valve and valve body technology, used in the field of short-distance slag removal gate valves, can solve the problems of frontal wear of the medium, long connection structure of the gate valve, and poor wear-resistant life of the valve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

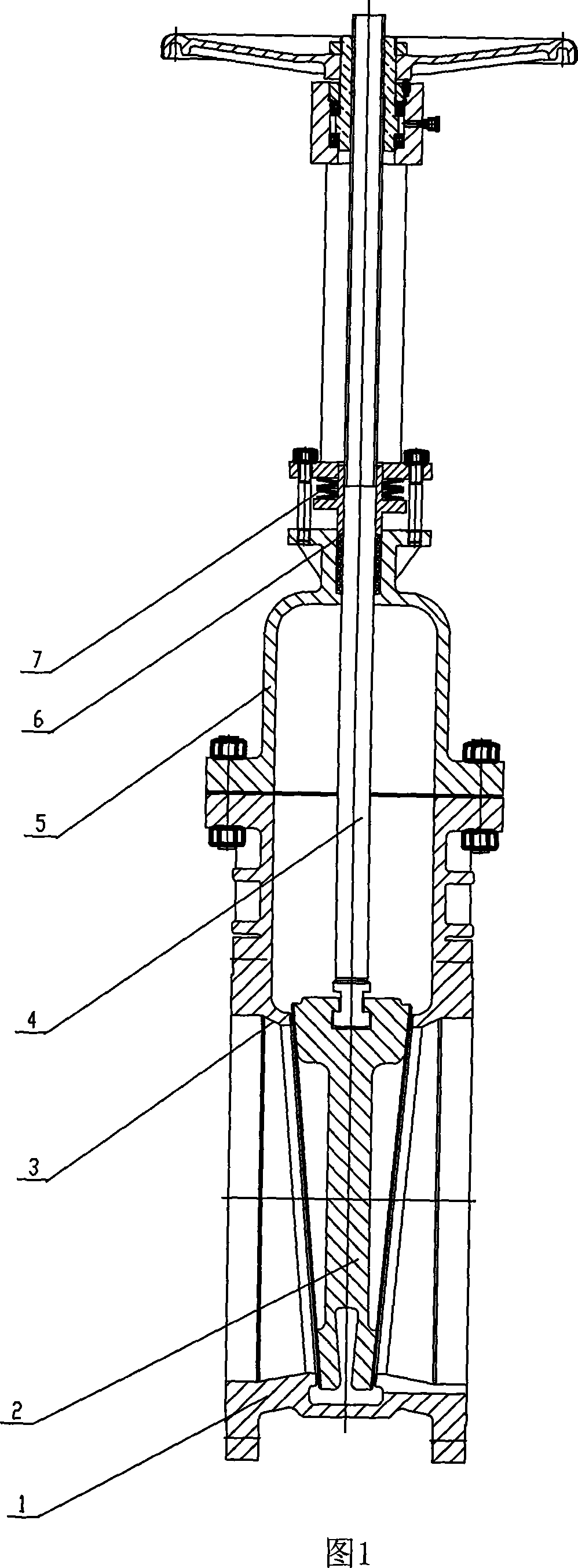

[0007] As shown in Figure 1, this embodiment includes a valve body (1), a gate plate (2), a valve stem (4), and a valve cover (5), wherein the valve body (1) is in the shape of a "butterfly valve body" to allow the gate valve to flow The channel length is greatly shortened; the channel (3) in the valve body is trumpet-shaped, and the trumpet-shaped inlet and outlet are used to create an oblique angle between the flow direction and the center of the fluid, avoiding the inner cavity of the channel from being worn by the front of the medium, and improving the overall wear life of the valve. There is a packing seal (6) between the valve stem (4) and the bonnet (5), and a pressure plate butterfly spring (7) is arranged in the stuffing box of the packing seal (6), forming a sealing and automatic compensation elastic structure, so that the valve can be used in the whole Apply compression force to the packing during use to ensure that the upper seal does not leak.

[0008] In summary,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com