Packaging die and packaging method thereof

A packaging method and mold technology, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve problems such as large cavity pressure loss, increased production costs, and gold wire bending rate exceeding the standard, so as to achieve balanced injection pressure , Shorten the length of the runner, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

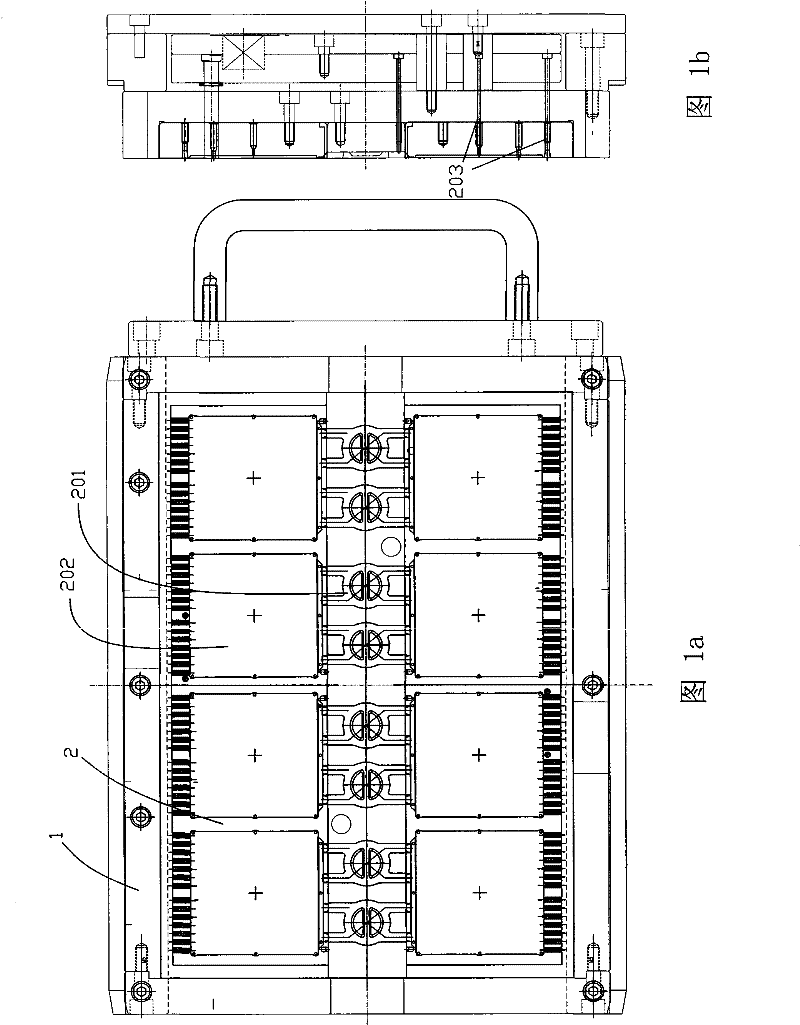

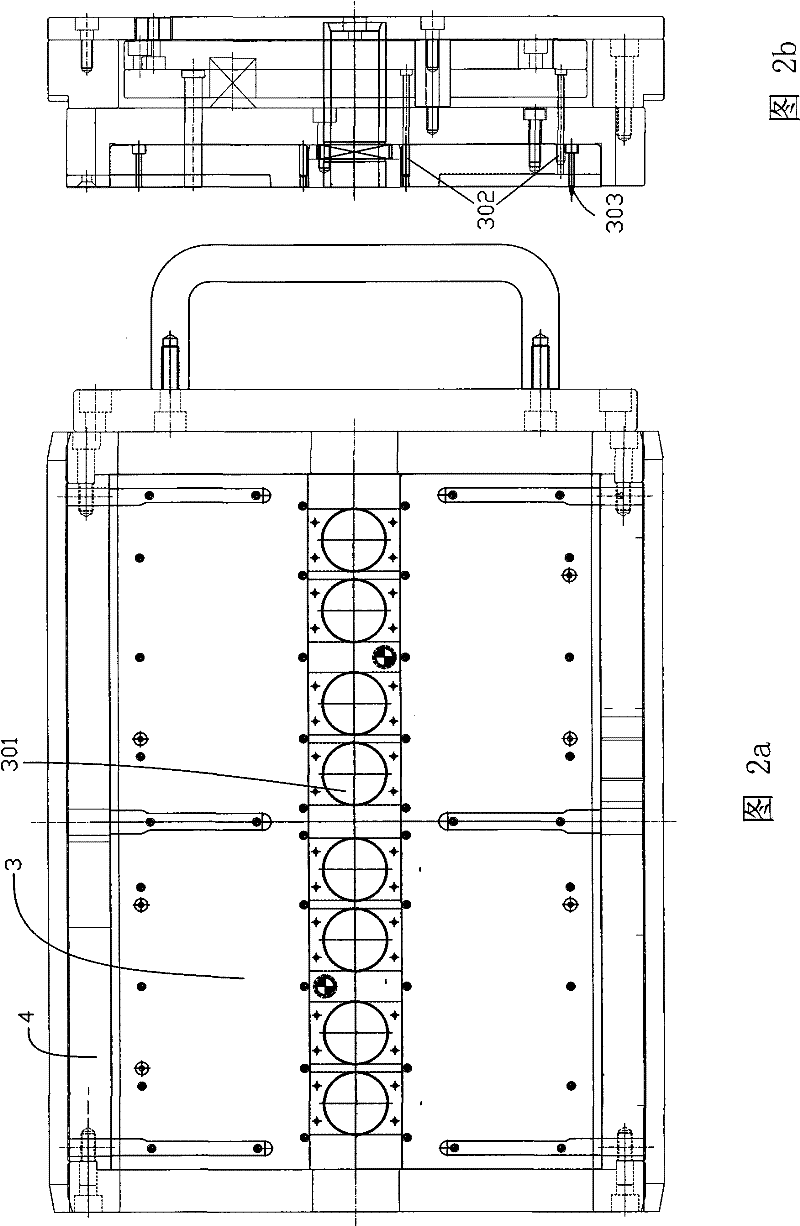

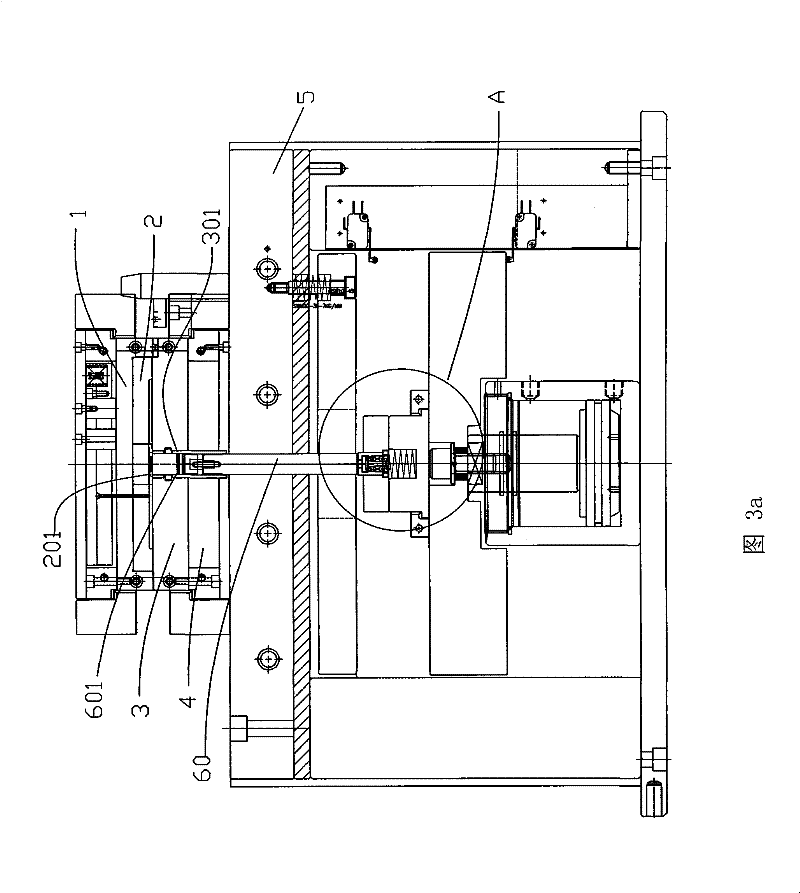

[0037] The first embodiment of packaging mold of the present invention is the packaging mold of USB memory card, as Figure 3a Said, the mold includes a patrix and a lower die; the patrix includes an upper template 1 and an upper mold core 2 fixed on the upper template; the lower mold includes a lower mold core 3, a lower mold base 4, an injection device, a lower Bottom plate 5, the lower mold core 3 is fixed on the lower mold base 4, and the injection device and the lower mold base 4 are arranged on the lower base plate 5; see Figure 1a with Figure 2a The lower mold core 3 is provided with a plurality of sleeves 301 for placing resin cakes, and the upper mold core 2 is provided with flow channels 201 corresponding to the sleeves; the injection device includes multiple 601 of the extruding rod 60, and the extruding seat 61 for installing the extruding rod 60, the extruding head 601 is matched with the sleeve 301. In order to ensure the wear resistance and precision of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com