Patents

Literature

149 results about "Cylinder mold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

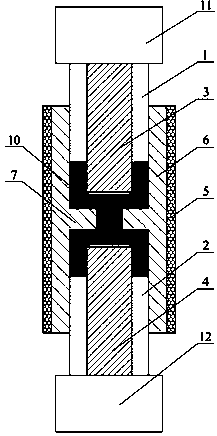

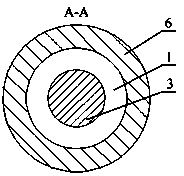

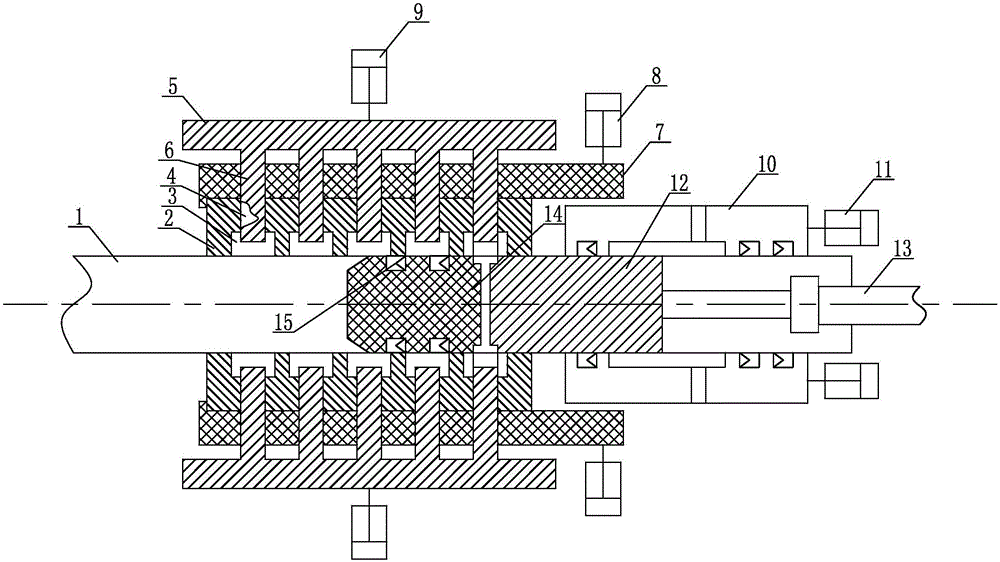

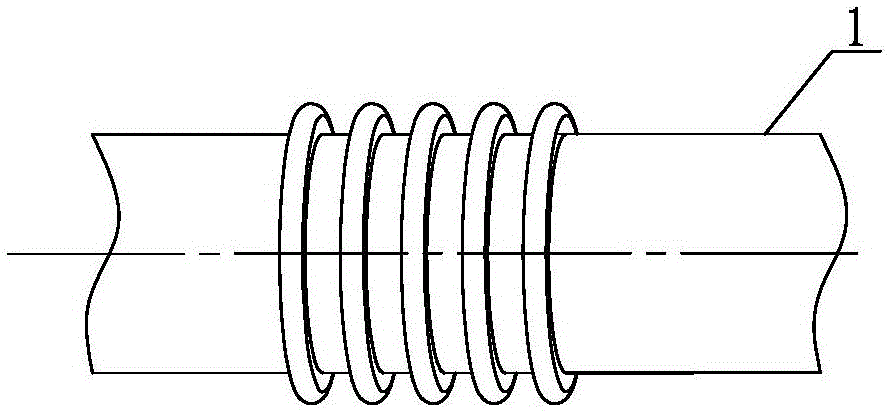

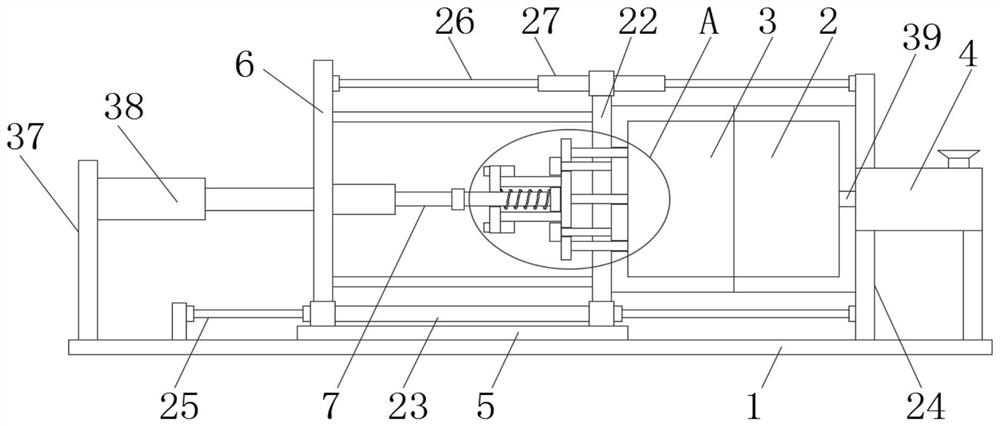

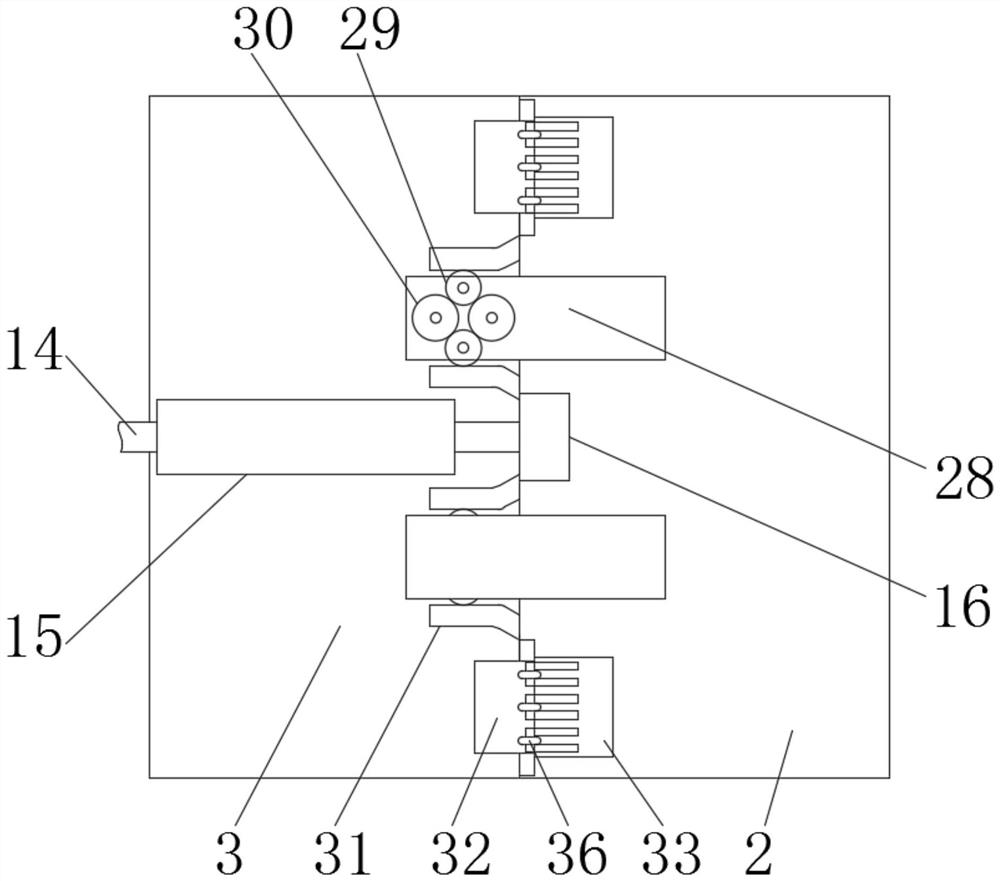

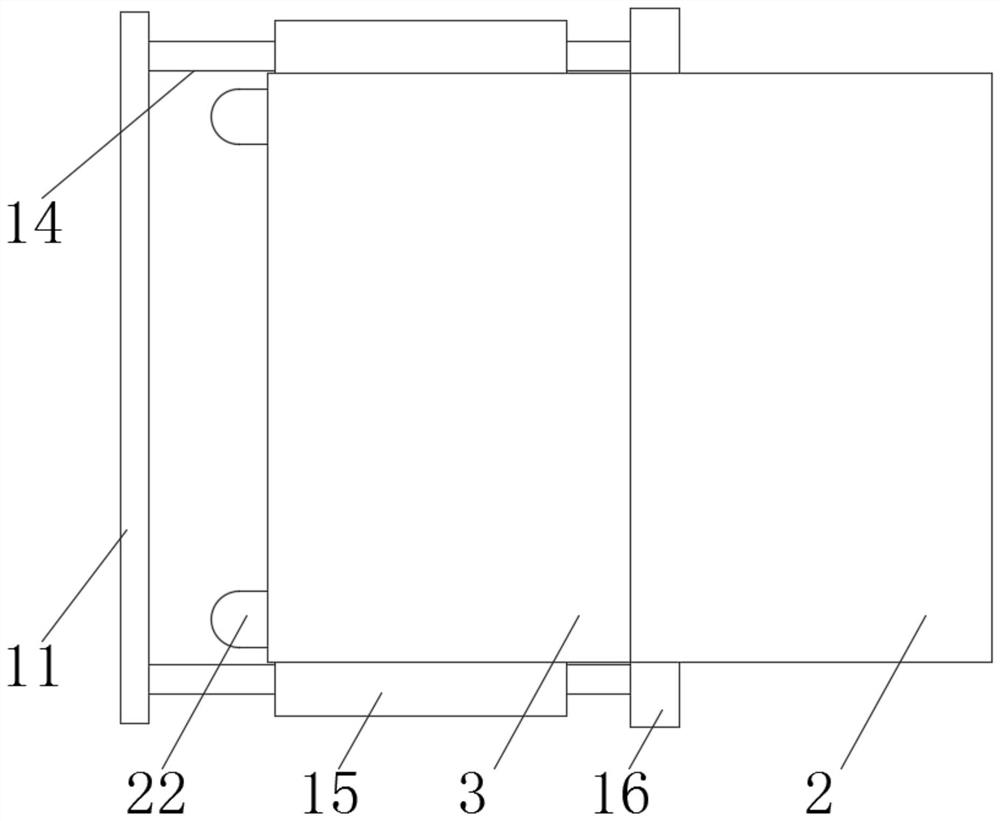

Reciprocating extruding device and machining method of reinforced magnesium alloy tube

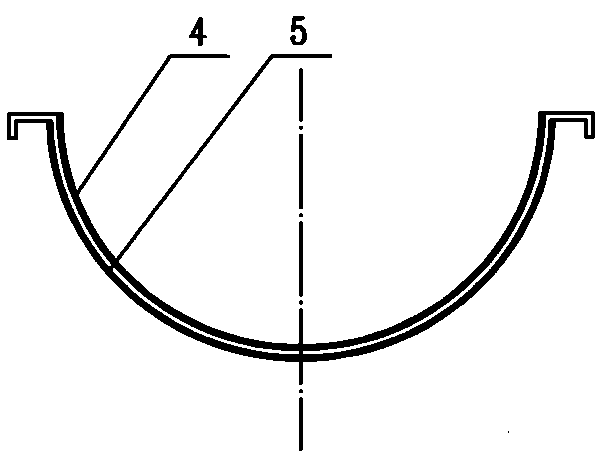

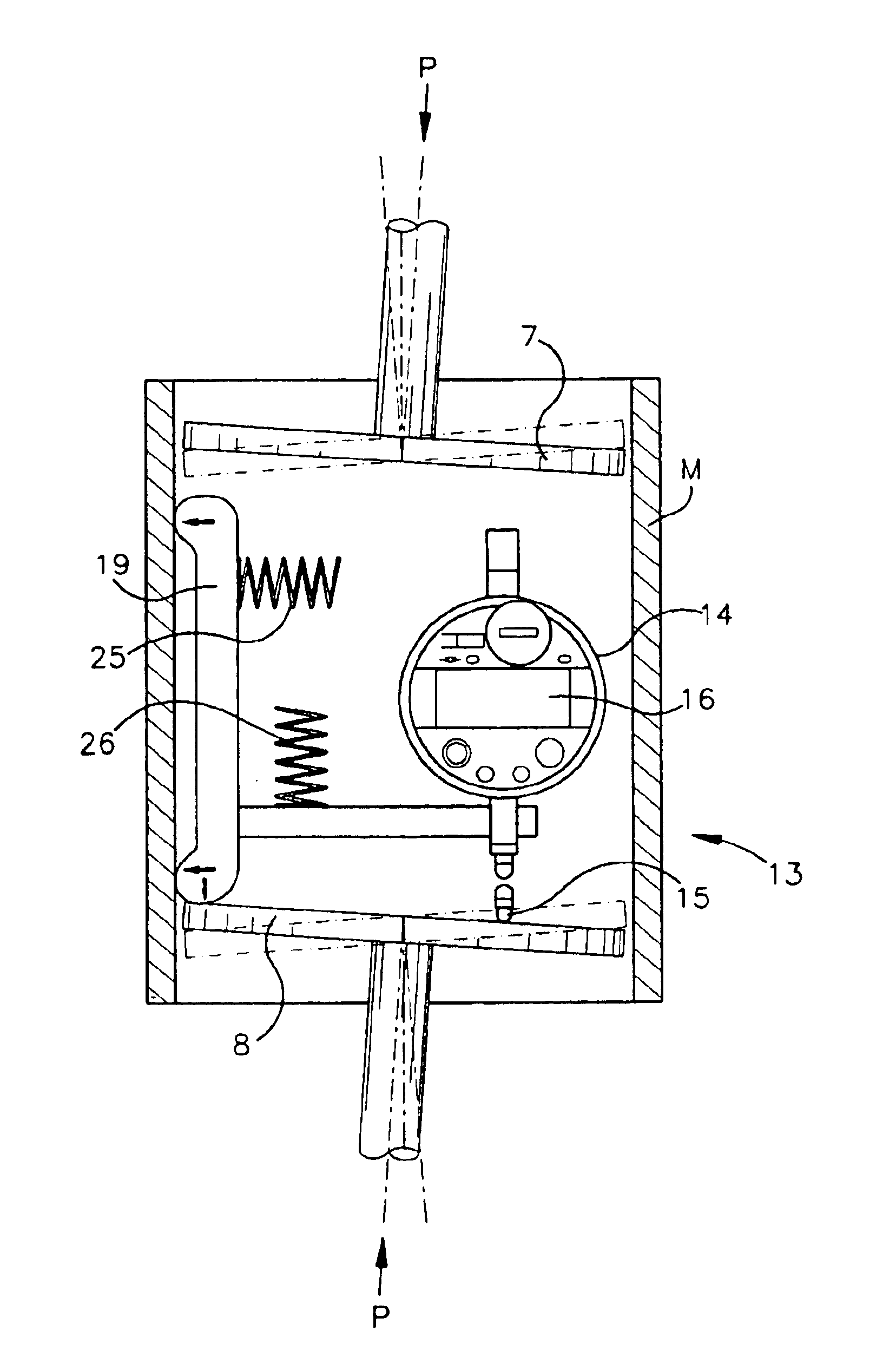

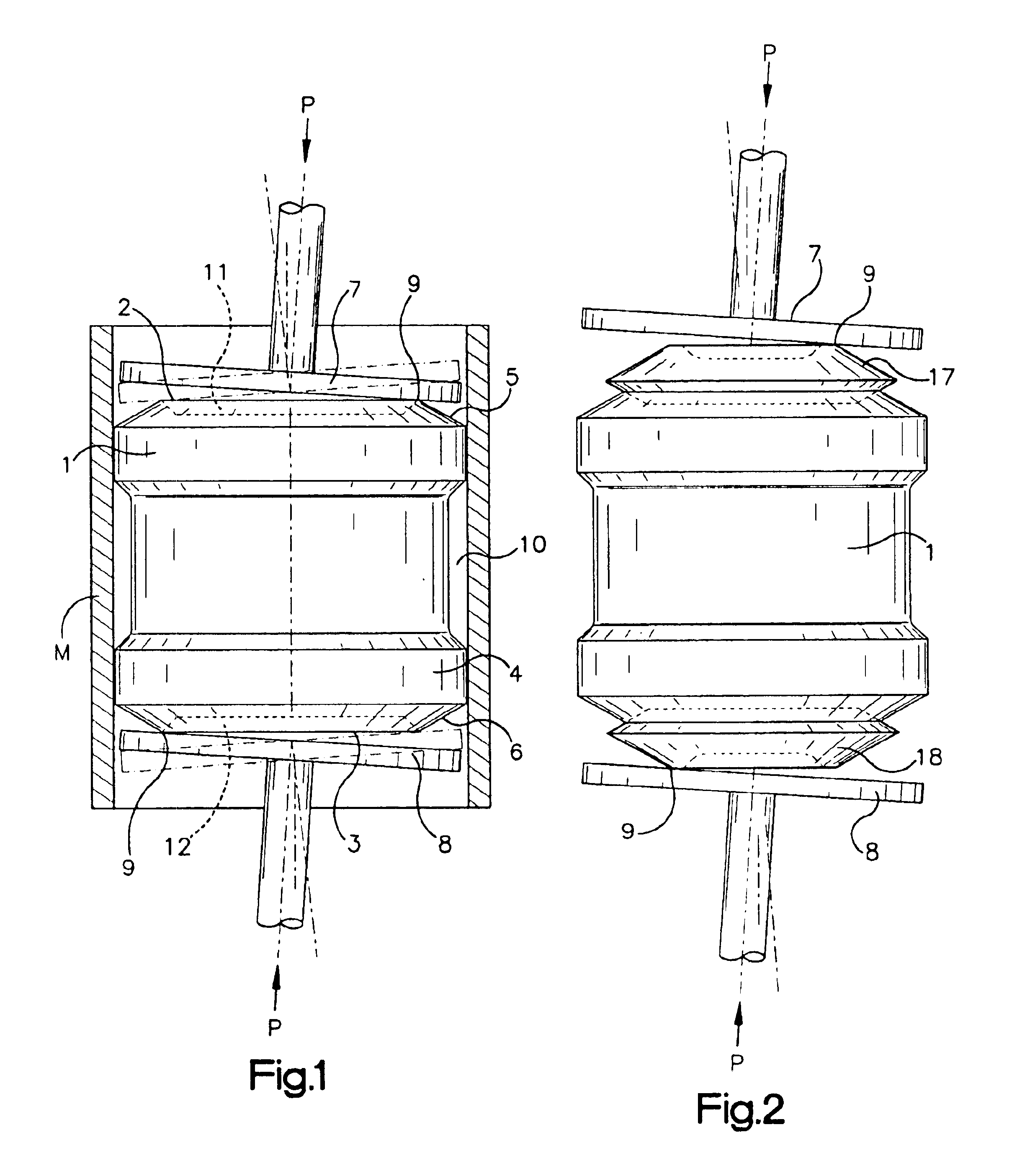

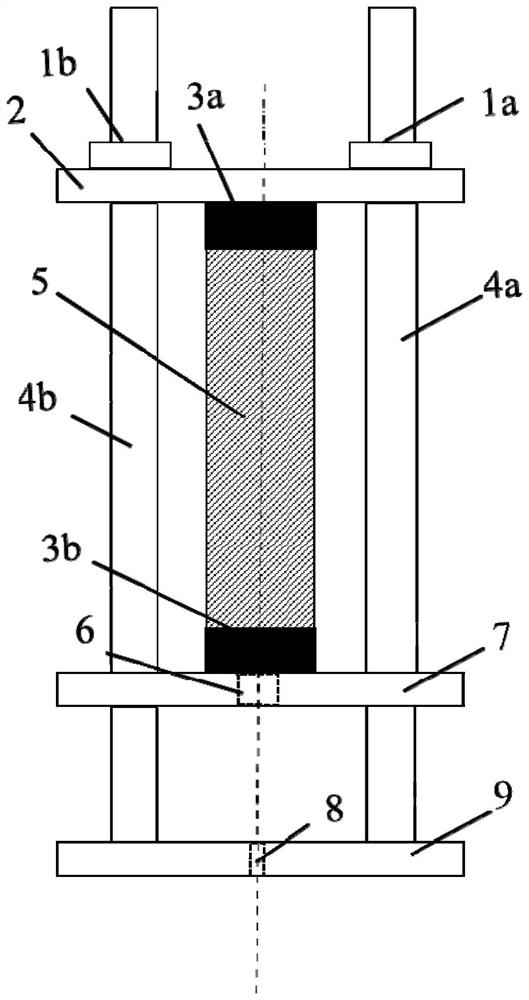

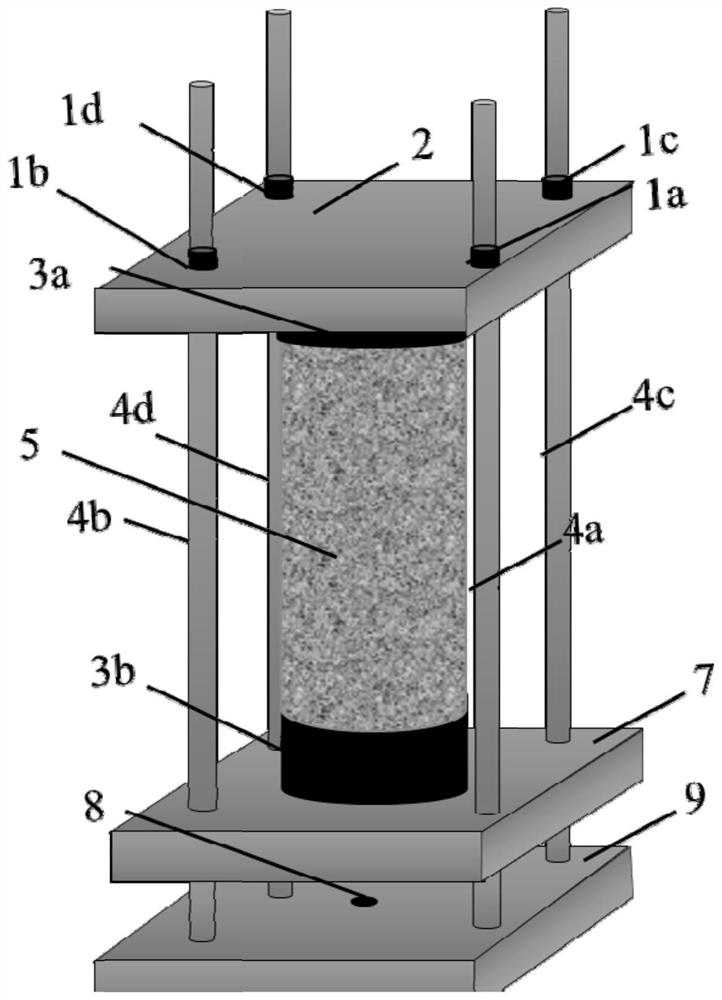

The invention relates to a reciprocating extruding device and a machining method of a reinforced magnesium alloy tube, belongs to the field of plastic machining of nonferrous metals. The reciprocating extruding device comprises an upper extruding ring, a lower extruding ring, an upper fixed extruding rod, a lower fixed extruding rod, an extruding cylinder mold and a necking region, wherein the extruding cylinder mold is divided into an upper mold cavity and a lower mold cavity by the necking region, and a heating sleeve is arranged on the outer wall of the extruding cylinder mold; the upper extruding ring and the lower extruding ring are respectively arranged at the peripheries of the upper fixed extruding rod and the lower fixed extruding rod and are respectively arranged in the upper mold cavity and the lower mold cavity, the upper extruding ring and the upper fixed extruding rod are connected with an upper hydraulic stretching cavity, and the lower extruding ring and the lower fixed extruding rod are connected with a lower hydraulic stretching cavity. The reciprocating extruding device has the beneficial effects that the tensile strength of the magnesium alloy tube machined by virtue of the reciprocating extruding device can reach 500MPa, and an extruding mold is simple in structure and strong in operability of extrusion deformation and can realize continuous extrusion deformation, so that the production cost is relatively low, and the production efficiency is high.

Owner:TAIYUAN UNIV OF TECH

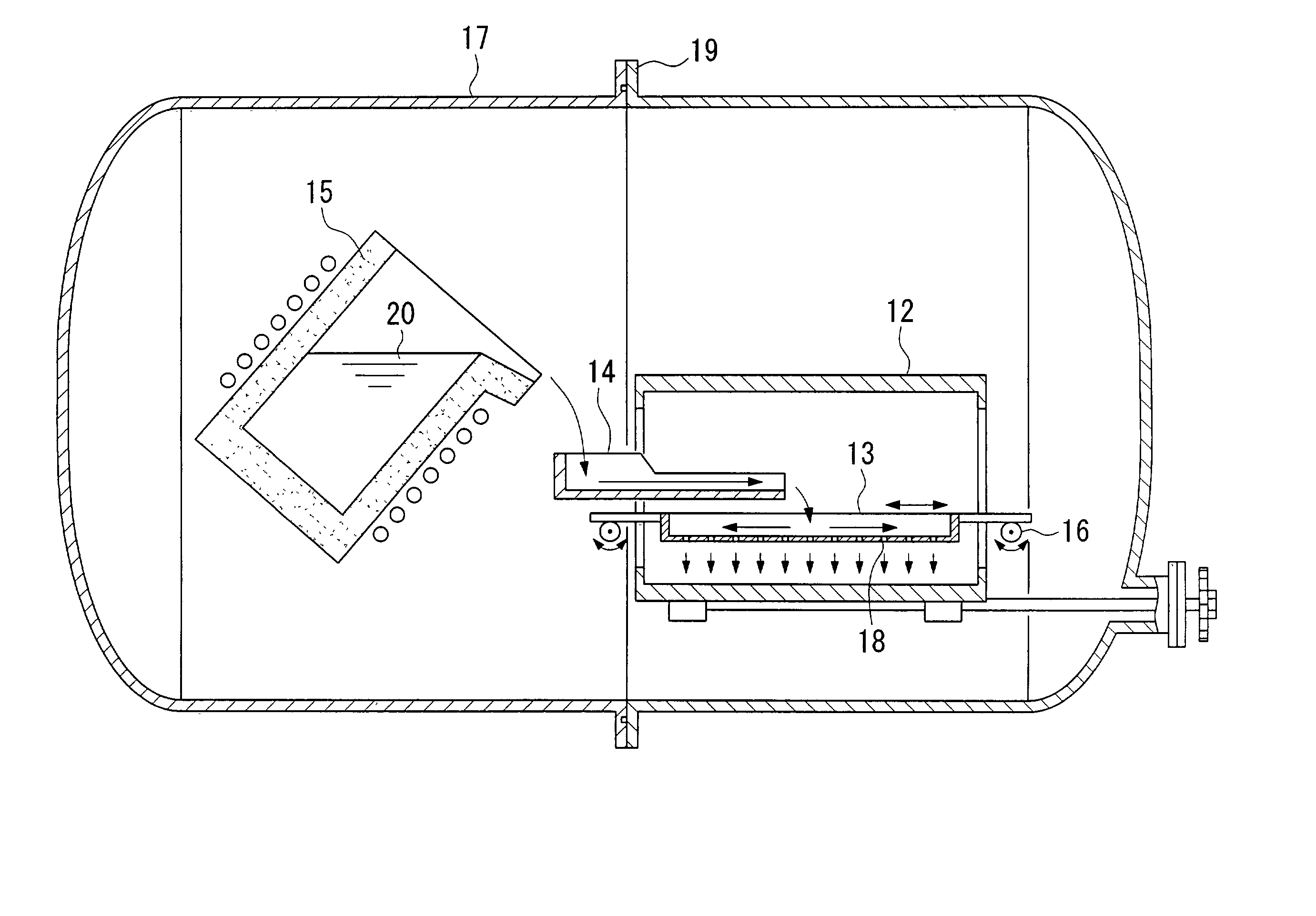

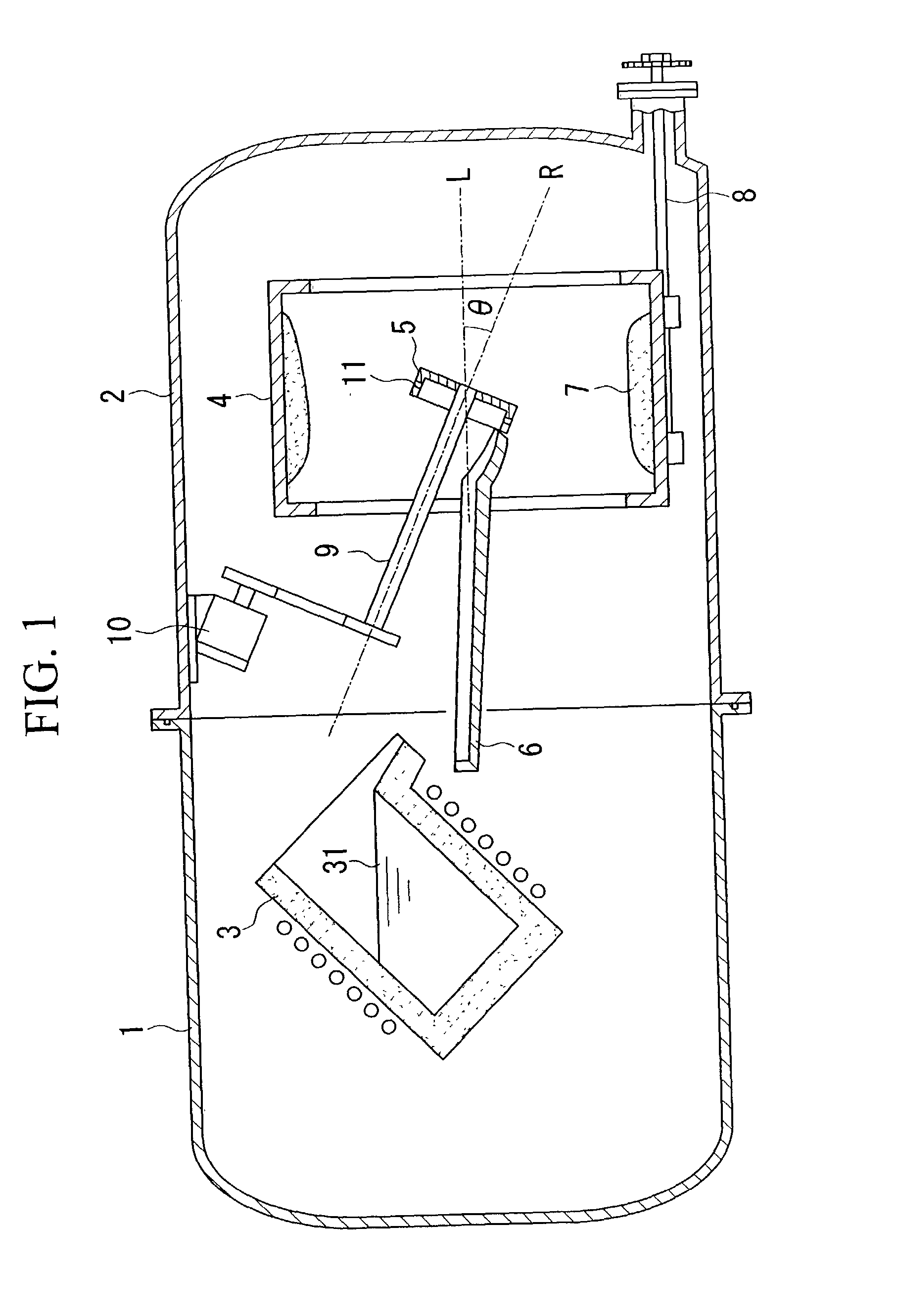

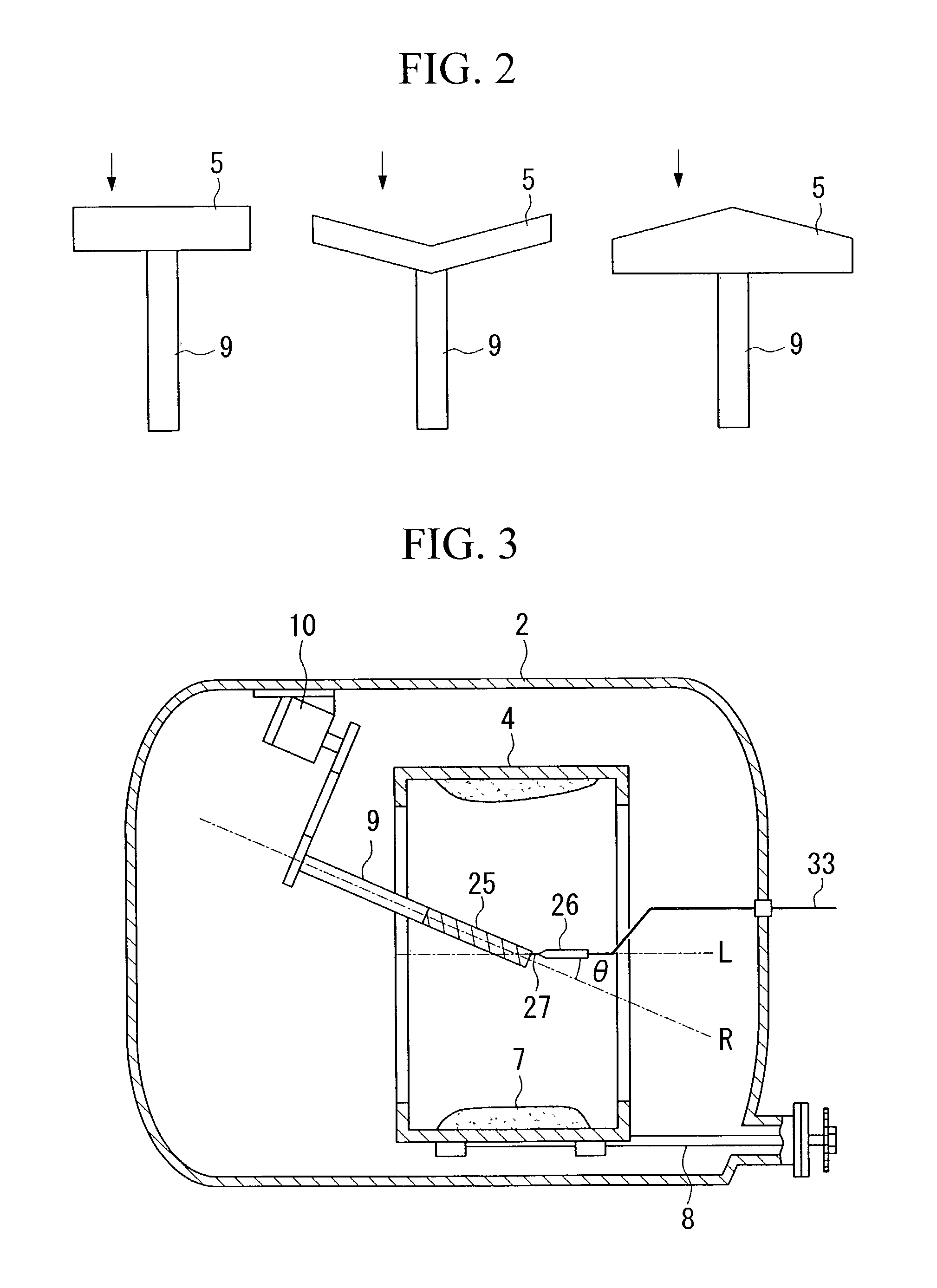

Centrifugal casting method, centrifugal casting apparatus, and cast alloy produced by same

InactiveUS20020153062A1Advantageously usableNanomagnetismInorganic material magnetismRare-earth magnetMetal

The present invention relates to a casting method which employs rapid solidification of metal, rare-earth metal or the like, as well as to a casting apparatus and a cast alloy. A centrifugal casting method includes the steps of pouring a molten material onto a rotary body; sprinkling the molten material by the effect of rotation of the rotary body; and causing the sprinkled molten material to be deposited and to solidify on the inner surface of a rotating cylindrical mold. The axis of rotation of the rotary body and the axis of rotation of the cylindrical mold are caused not to run parallel to each other. The centrifugal casting method can attain a decrease in average deposition rate. As a result, generation of the dendritic alphaFe phase or generation of a segregation phase of Mn or the like is suppressed, thereby realizing a high-performance R-T-B-type rare-earth magnet alloy.

Owner:TDK CORPARATION

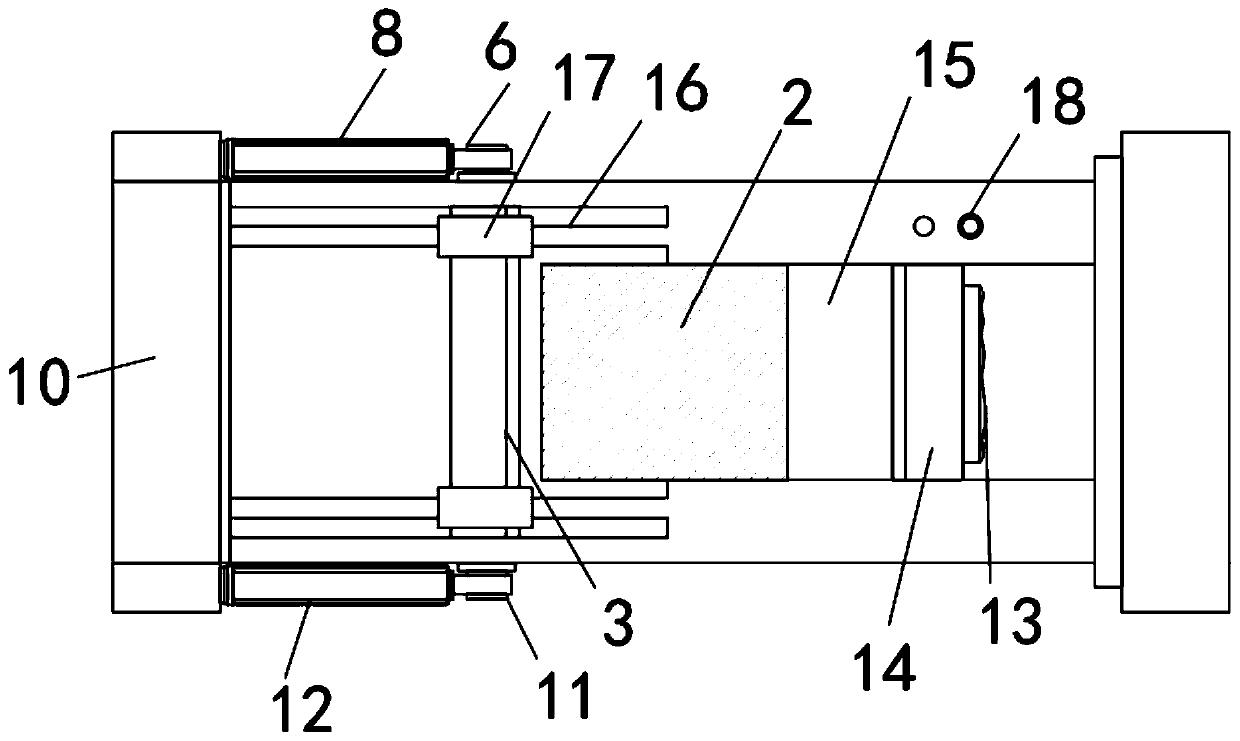

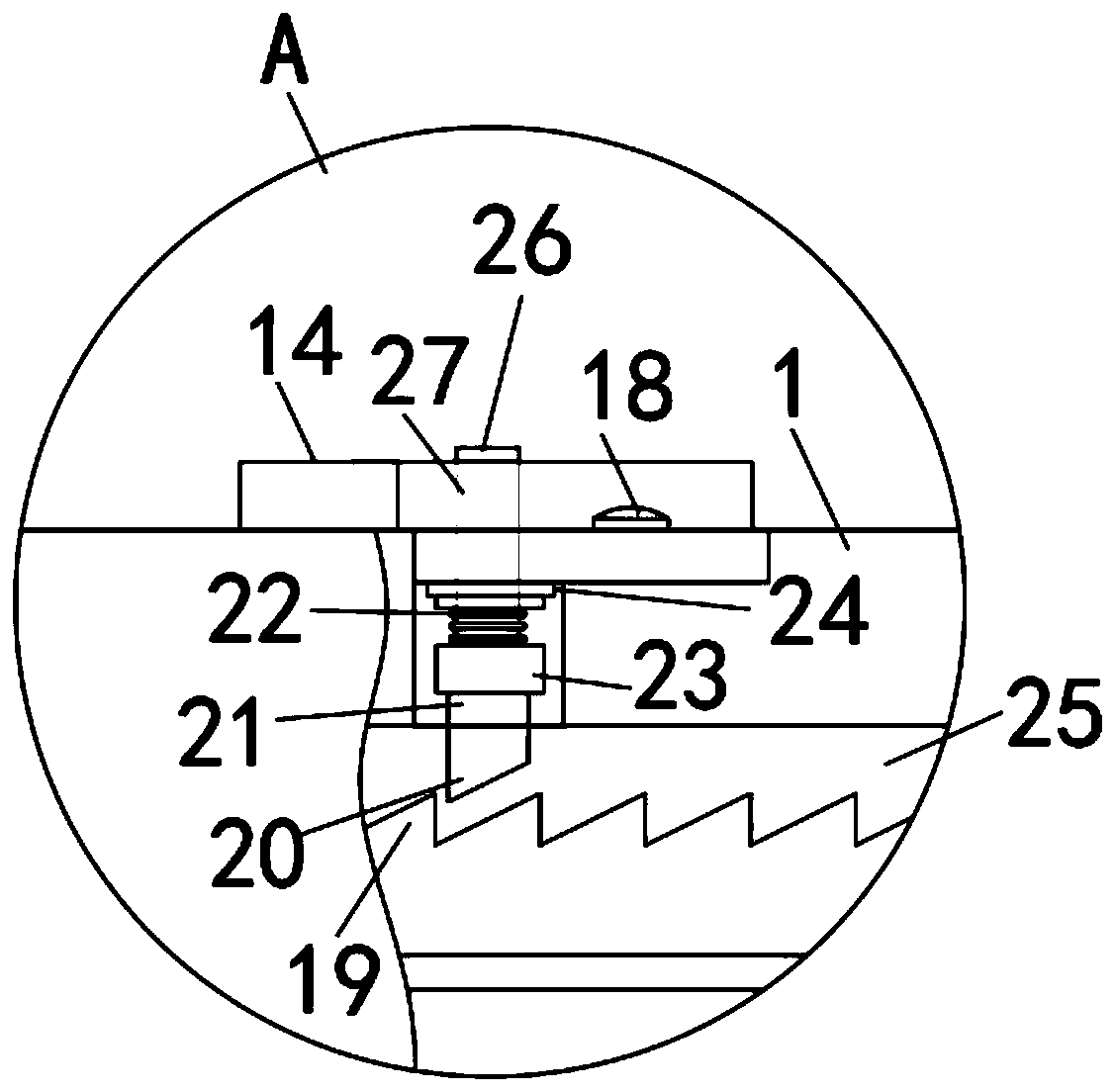

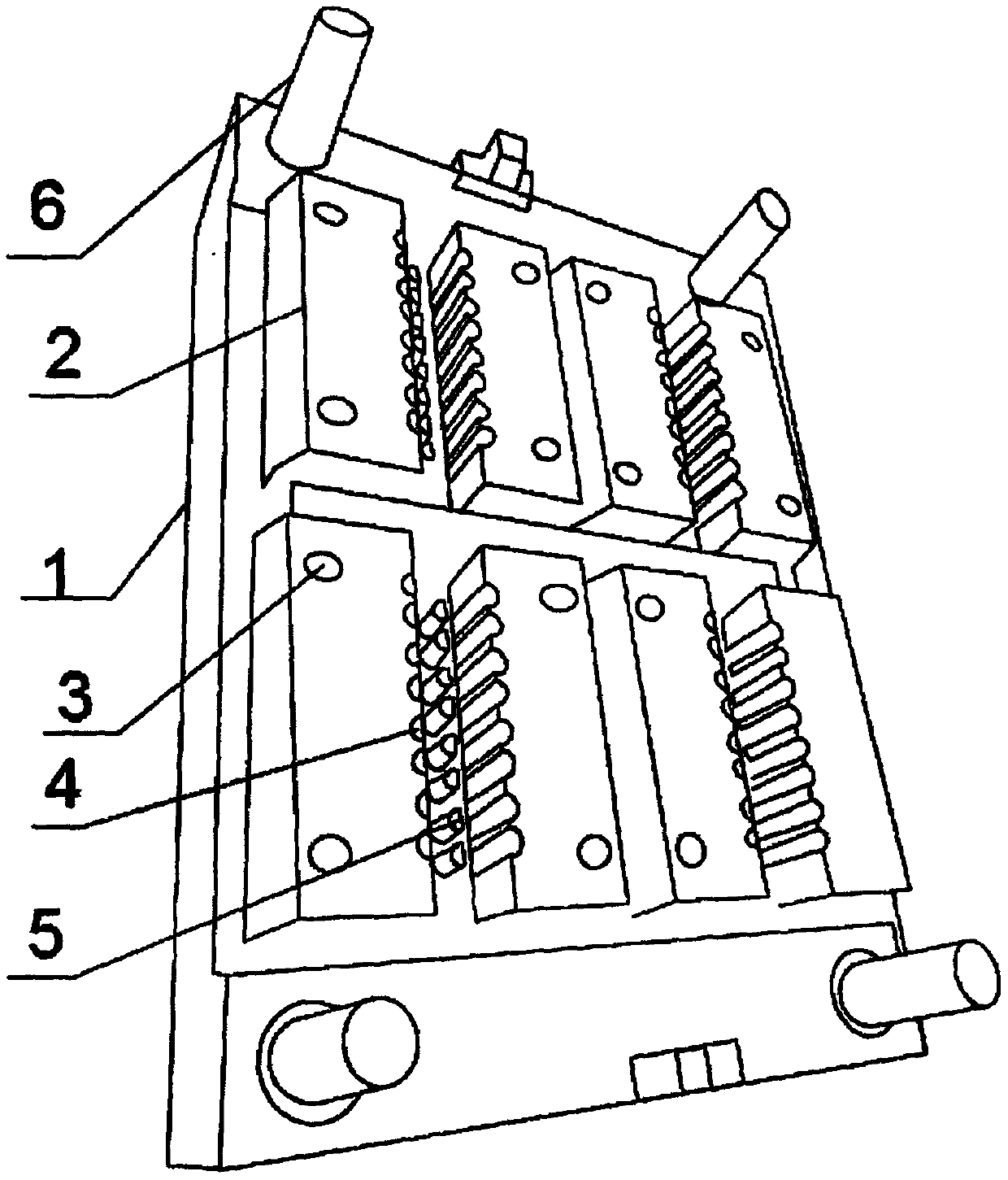

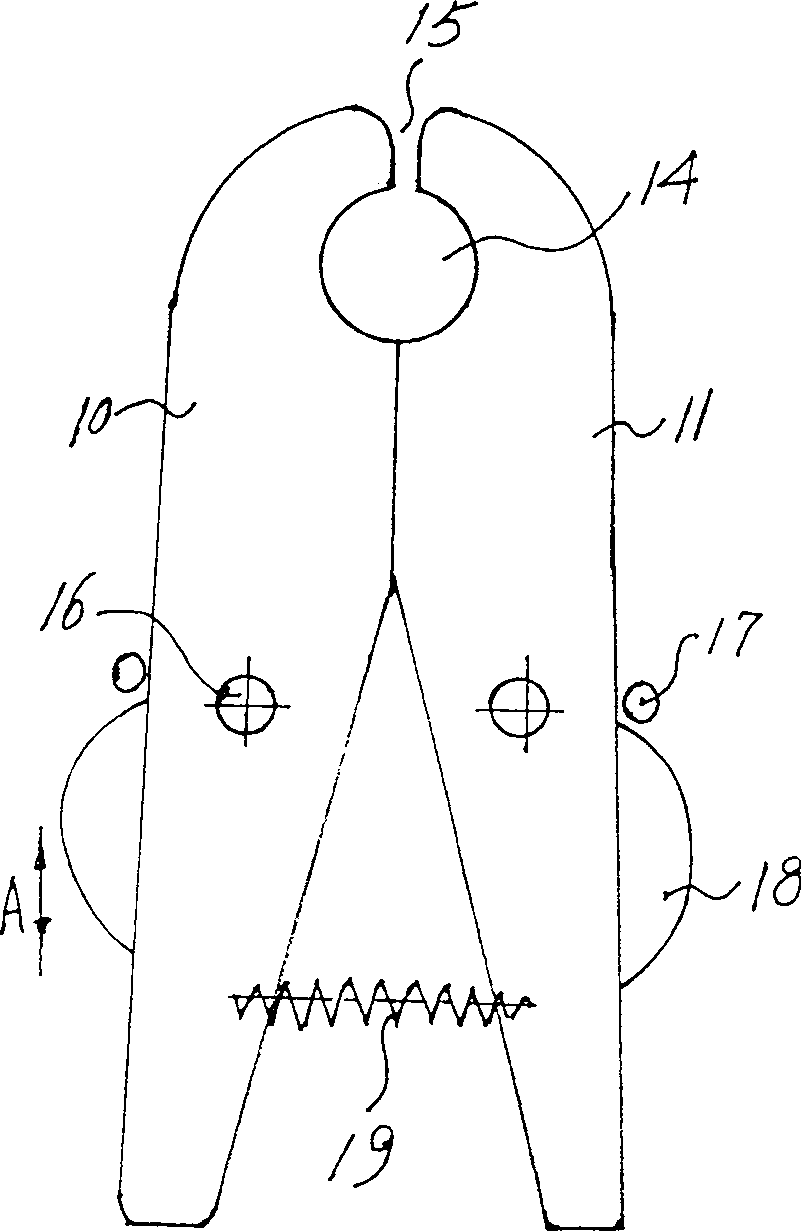

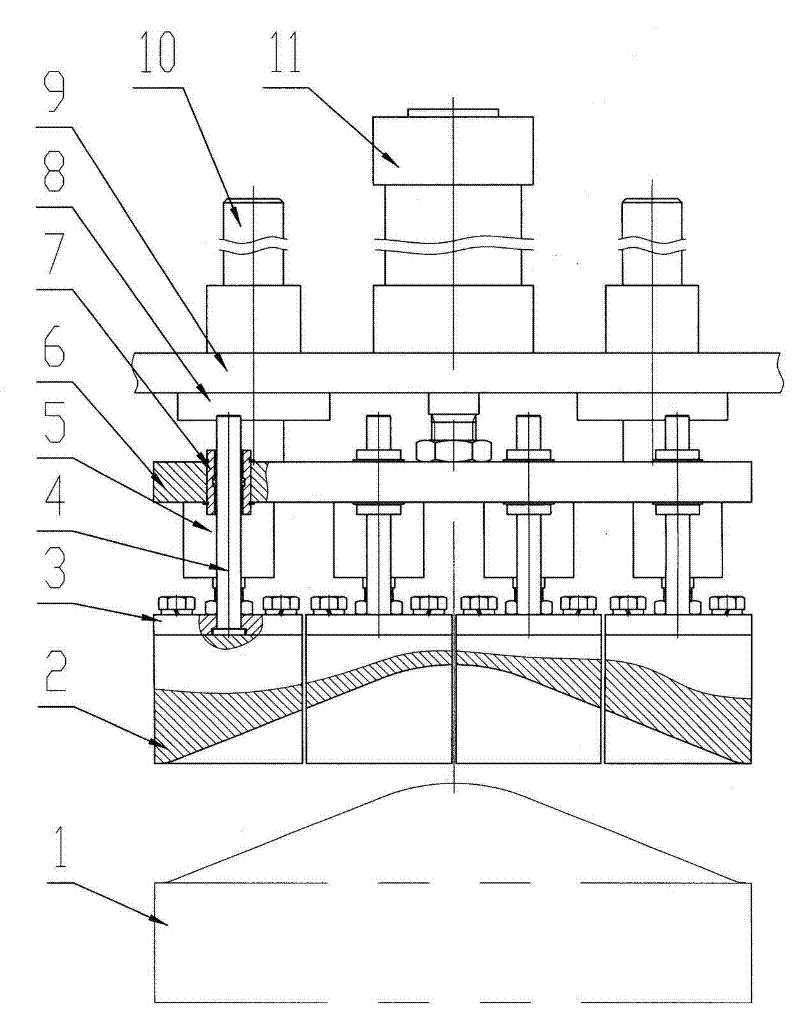

Multi-corrugation one-time forming device of EGR pipe and forming technology of multi-corrugation one-time forming device of EGR pipe

The invention discloses a multi-corrugation one-time forming device of an EGR pipe. The one-time forming device comprises two corrugation forming half cylinders surrounding the EGR pipe. The two corrugation forming half cylinders are correspondingly provided with forming half-cylinder mold combining devices respectively. Corrugation forming half grooves and corrugation top forming holes are formed in the inner walls of the two corrugation forming half cylinders. Corrugation top limiting molds are oppositely arranged on the outer sides of the corrugation forming half cylinders. Corrugation top limiting inserting pieces corresponding to the corrugation forming holes are arranged on the inner walls of the two corrugation top limiting molds respectively. The two corrugation top limiting molds are each connected with a limiting drive device. Forming half cylinder ejecting devices are arranged at the side portions of the two corrugation forming half cylinders respectively. A corrugation pressure forming device is arranged between the two corrugation forming half cylinders. One-time forming of multiple independent corrugations is achieved, consistency of the sizes such as the corrugation outer diameter, the corrugation outer outline and the length is effectively guaranteed, and the reliability of the EGR pipe is improved. Meanwhile, the production efficiency of the EGR pipe is greatly improved. The rejection rate and the assembling stress of the EGR pipe are greatly reduced.

Owner:十堰市倍力汽车管业有限公司

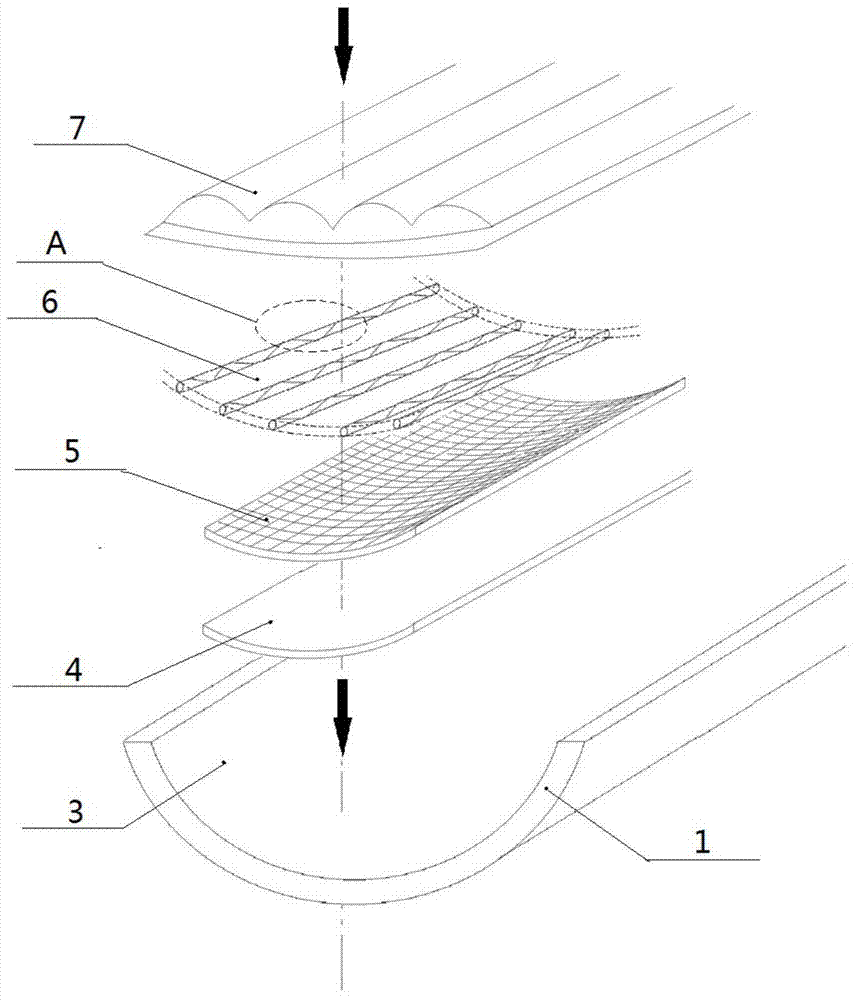

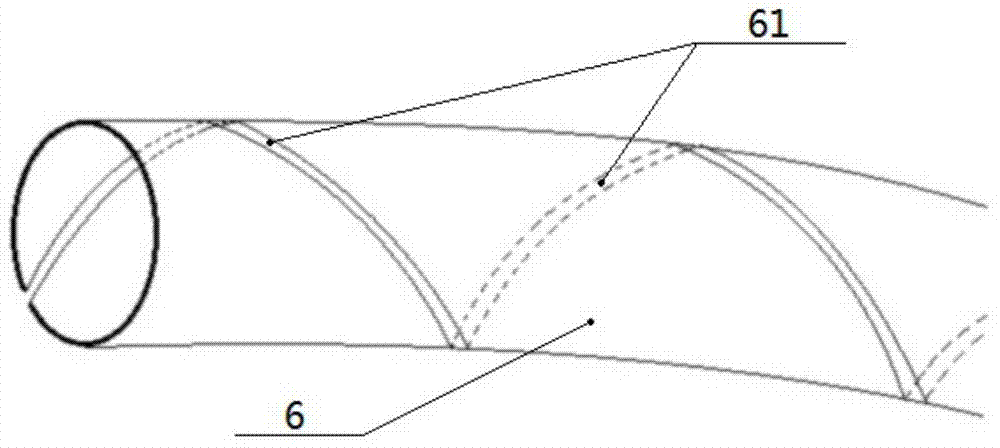

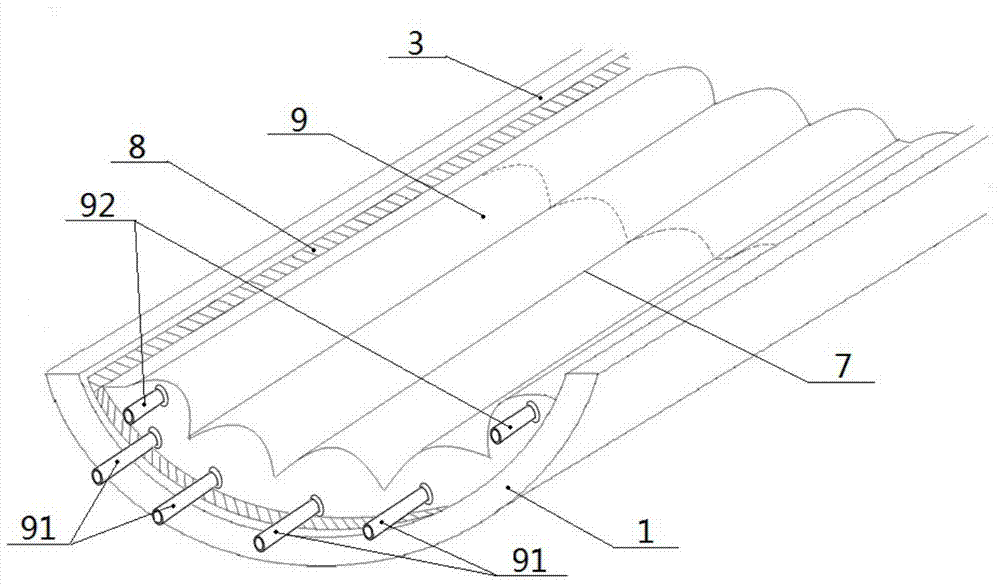

Manufacturing method of glass fiber-reinforced plastic integrated septic tank storage pot

The invention provides a manufacturing method of a glass fiber-reinforced plastic integrated septic tank storage pot. The manufacturing method is characterized in that a vacuum membrane (7), and the inner walls of a middle cylinder mold (1) and an end socket mold (2) both for the septic tank storage pot are combined to form an airtight cavity (9) isolated from outside air, the airtight cavity (9) is provided with a plurality of resin injection pipelines (91) located at different horizontal heights and a plurality of vacuum supply pipelines (92) located at the highest position, the airtight cavity (9) is kept in vacuum through air exhaust, resin is absorbed into the airtight cavity (9) through the resin injection pipelines (91), and then a glass fiber-reinforced plastic cylinder (10) and an end socket (20) are formed after solidification. After the auxiliary structure of the storage pot is fabricated completely, the cylinder (10) and the end socket (20) are assembled into the integrated glass fiber-reinforced plastic septic tank storage pot. The manufacturing method provided by the invention is capable of producing the glass fiber-reinforced plastic storage pot which is higher in compactness, higher in strength and more stable in quality, and the process of the manufacturing method is clean and has environment-friendly effect. Provided that the cylinder mold of a corrugated concave-convex structure (11) is adopted, a support in the cylinder can be further omitted, and consequently, the compressive strength and bending strength of the cylinder can be improved.

Owner:北京潮白环保设备有限公司

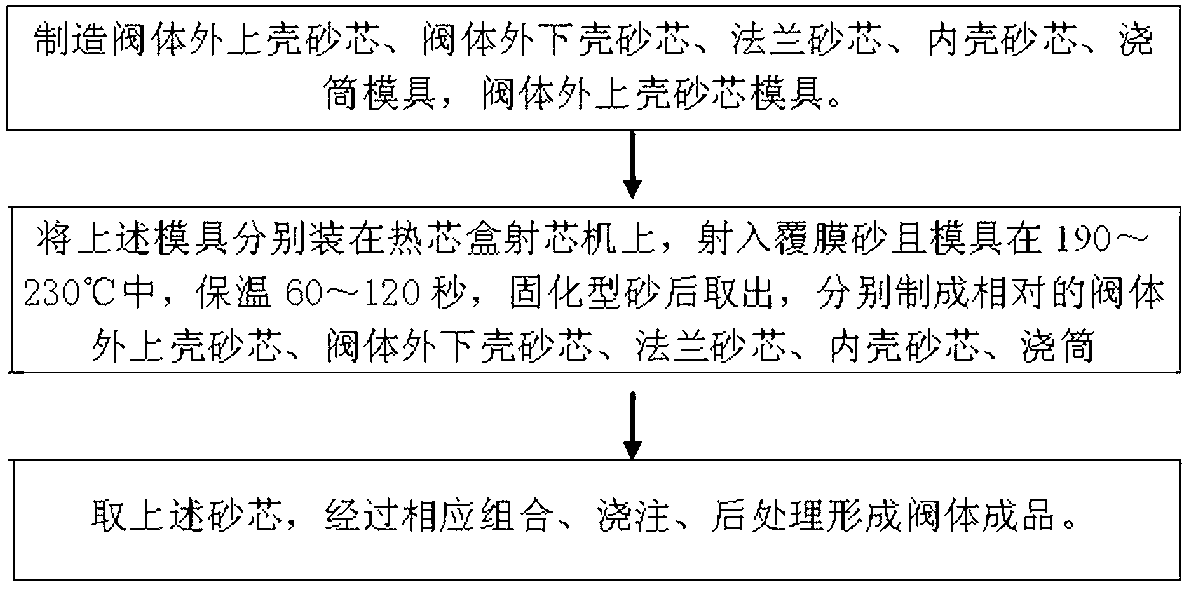

Valve body combined casting process for sluice valve with flange casting bolt hole

ActiveCN103100669AHigh surface finishHigh shape and size accuracyFoundry mouldsFoundry coresSurface finishCylinder mold

The invention discloses a valve body combined casting process for a sluice valve with flange casting with bolt hole. The process comprises steps of: first preparing a mold of an upper shell core outside the valve body, a mold of a lower shell outside the valve body, a flange core mold, an inner shell core mold, a casting cylinder mold and a mold of an upper core mould outside the valve body; respectively arranging the above molds on a hot box core shooter, injecting precoated sand and insulating the molds at 190-230 DEG C for 60-120 s, curing the casting sand, taking out, and respectively preparing into an upper shell core outside the valve body, a lower shell core outside the valve body, a flange core, an inner shell core and a casting cylinder; and finally conducting corresponding combination, casting and post treatment on the above cores to form a valve body product. The valve body produced by the above process has advantages of tightly matched and fixed components, good surface smoothness, high shape size precision, and no back-end production processing procedure; meanwhile, in the production process, procedure preparation is conducted by using cores of different shapes, so as to facilitate collaboration production by many people, improve production efficiency and save production cost. Therefore, the invention creates a novel pattern for casting process.

Owner:WUHU JINMAO FLUID TECH CO LTD

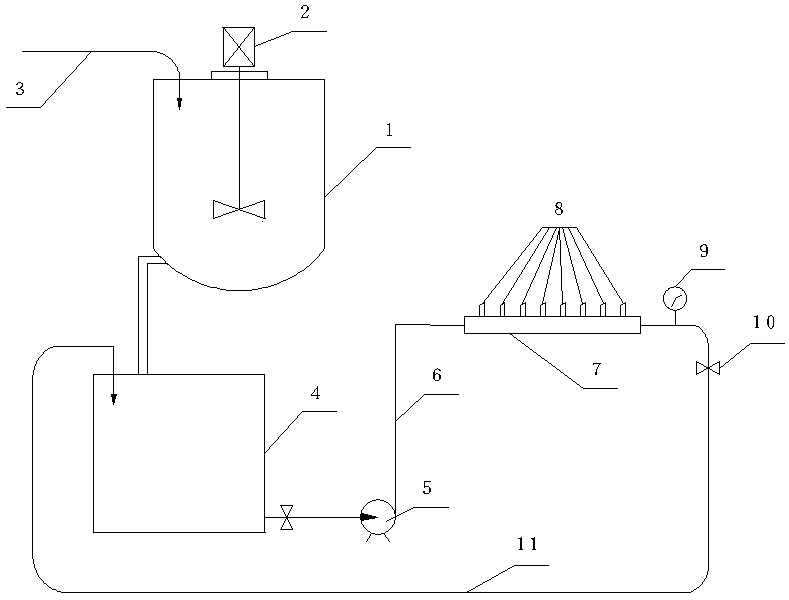

Cylinder molding part sandwiched sizing system device

InactiveCN103696322AImprove bindingIncrease the amount of sizingPaper/cardboardCylinder moldCotton cloth

The invention relates to a cylinder molding part sandwiched sizing system device. The device comprises a dissolution tank and a sizing tank which is arranged under and communicated with the dissolution tank, wherein the sizing tank is connected with a sizing pump, a glue delivery pipe and a sprayer; the sprayer is mounted at No.1 molding cylinder molding paper sheet and dragged in a crack part between the No.2 and No.3 molding cylinders by coarse cotton cloth. The cylinder molding part sandwiched sizing system device can be utilized for the multi-cylinder molding parts to strengthen the binding force between the multi-cylinder paper sheets, and improve the sizing amount according to the physical index and requirements. The product quality of a paper machine without the sizing machine can be improved by cylinder molding part sandwiched sizing, and the equipment cost investment can be further reduced, so that the purposes of saving energy, reducing consumption, reducing cost and increasing efficiency can be achieved.

Owner:MCC MEILI CLOUD COMPUTING IND INVESTMENT CO LTD

Full-sealed water, fire and explosion prevention cable joint safety box

InactiveCN101938107ALong aging resistanceFlame retardantCable junctionsAging resistanceCylinder mold

The invention discloses a full-sealed water, fire and explosion prevention cable joint safety box, comprising a shell made of a weak magnetic iron plate synthesis material. The shell is a cylinder molded from two semi cylindrical shells integrally once without welding, the two semi cylindrical shells of the shell are connected through a stock set screw at the explosion-proof inner hexagonal concave end, the diameters of both ends of the shell are reduced to form contraction openings, a section of cylinder with a small size is formed at each contraction opening, a waterproof sealing accessory made of a high-quality silicone rubber material is installed in each contraction opening, a fireproof flame-retardant insulating layer is adhered to the inner wall of the shell, and an anticorrosion and anti-ultraviolet powder is sprayed on the outer surface of the shell. The invention has the advantages that the shell is molded integrally without welding, is integrally treated by hot galvanizing and degaussing, is integrally sprayed with the anticorrosion and anti-ultraviolet material, and has the advantages of strong explosion-proof force, strong corrosion resistance and long aging resistance time. The traditional shell has common tensility and poorer explosion-proof force and is smelted to be in a carbonization state or seriously deforms for burning for a long time, and the fireproof flame-retardant insulating layer can fulfill the functions of fire prevention, flame retardancy and heat insulation.

Owner:刘金炜

Low-tightness high-strength electrolytic capacitor paper and preparation method therefor

InactiveCN108203893ALow tightnessLow tightness high tightnessHybrid capacitor separatorsPlastic/resin/waxes insulatorsElectrolysisCylinder mold

The invention relates to electrolytic capacitor paper and a preparation method therefor. According to the low-tightness high-strength electrolytic capacitor paper, raw paper pulp of the electrolytic capacitor paper is made from hemp pulp, wherein the hemp pulp has the mass concentration of 2% to 5%, the degree of beating of 30 degree SR to 60 degree SR and the wet weight of 2g to 16g; and the rawpaper pulp is subjected to molding and laminating through double cylinder molds and is subjected to squeezing and drying, then, the surface of paper is coated with coating liquid by an amount of coating of 0.1g / m<2> to 1.0g / m<2>, and the coating liquid is prepared from polycarboxylic acid and PVA which are in the mass ratio of (1: 1) to (1: 5). According to the low-tightness high-strength electrolytic capacitor paper and the preparation method therefor, the low-tightness high-strength electrolytic capacitor paper is obtained through raw paper production and in-line coating and has relatively good strength, good water absorbency, a good loss value and excellent voltage resistance, and the tensile strength is improved by 0.4kN / m or more.

Owner:ZHEJIANG KAN SPECIAL PAPER CO LTD +1

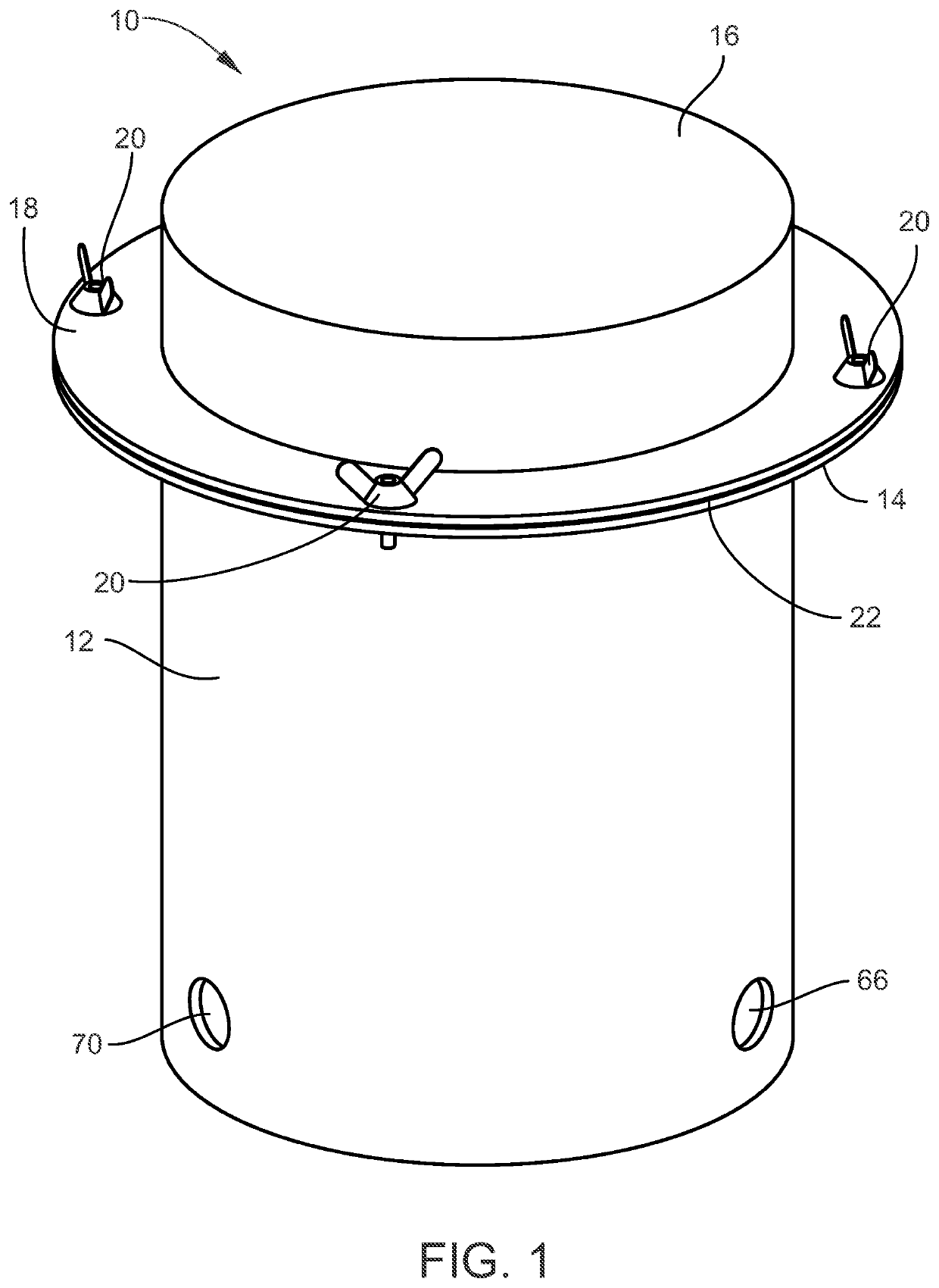

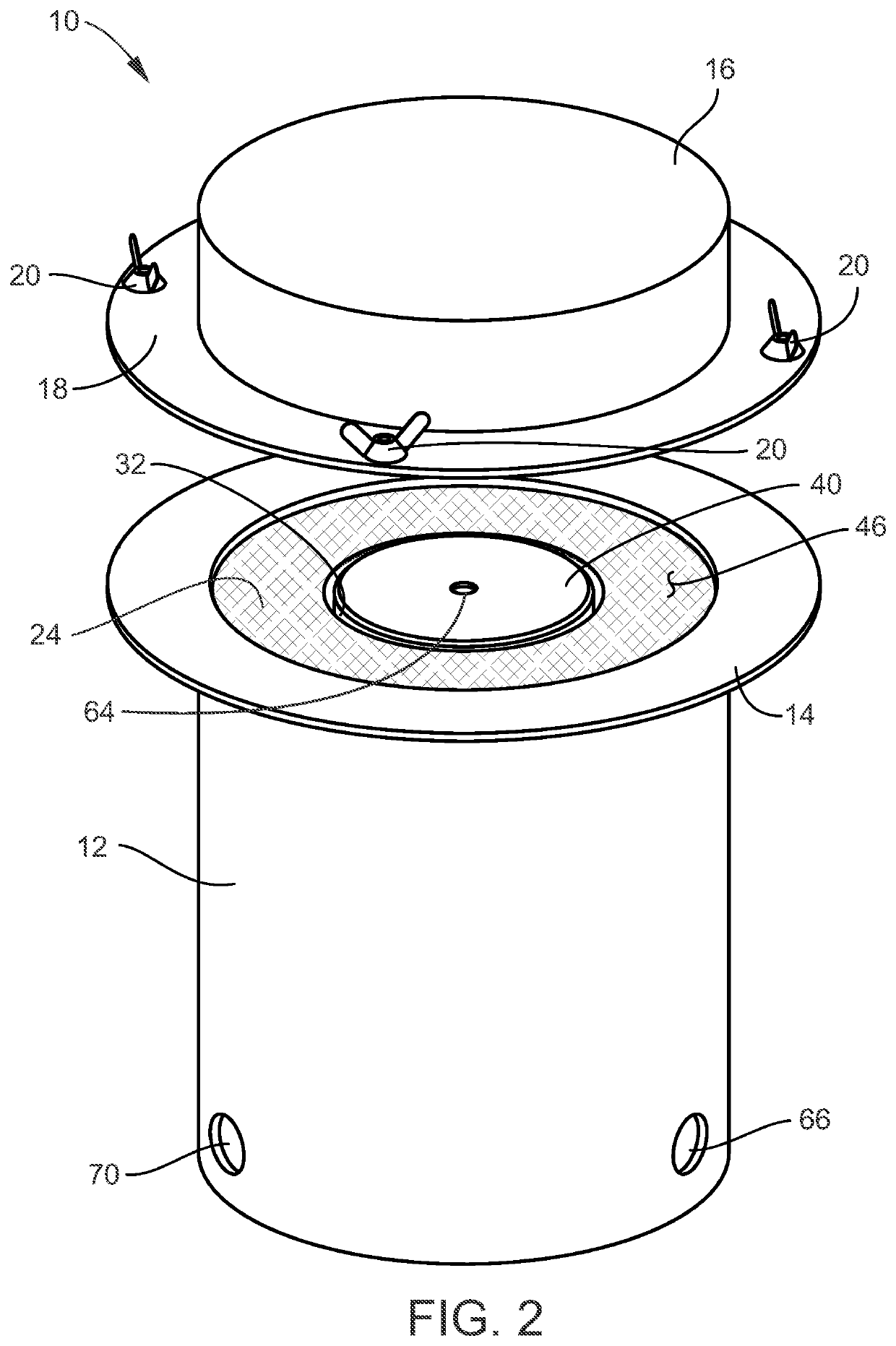

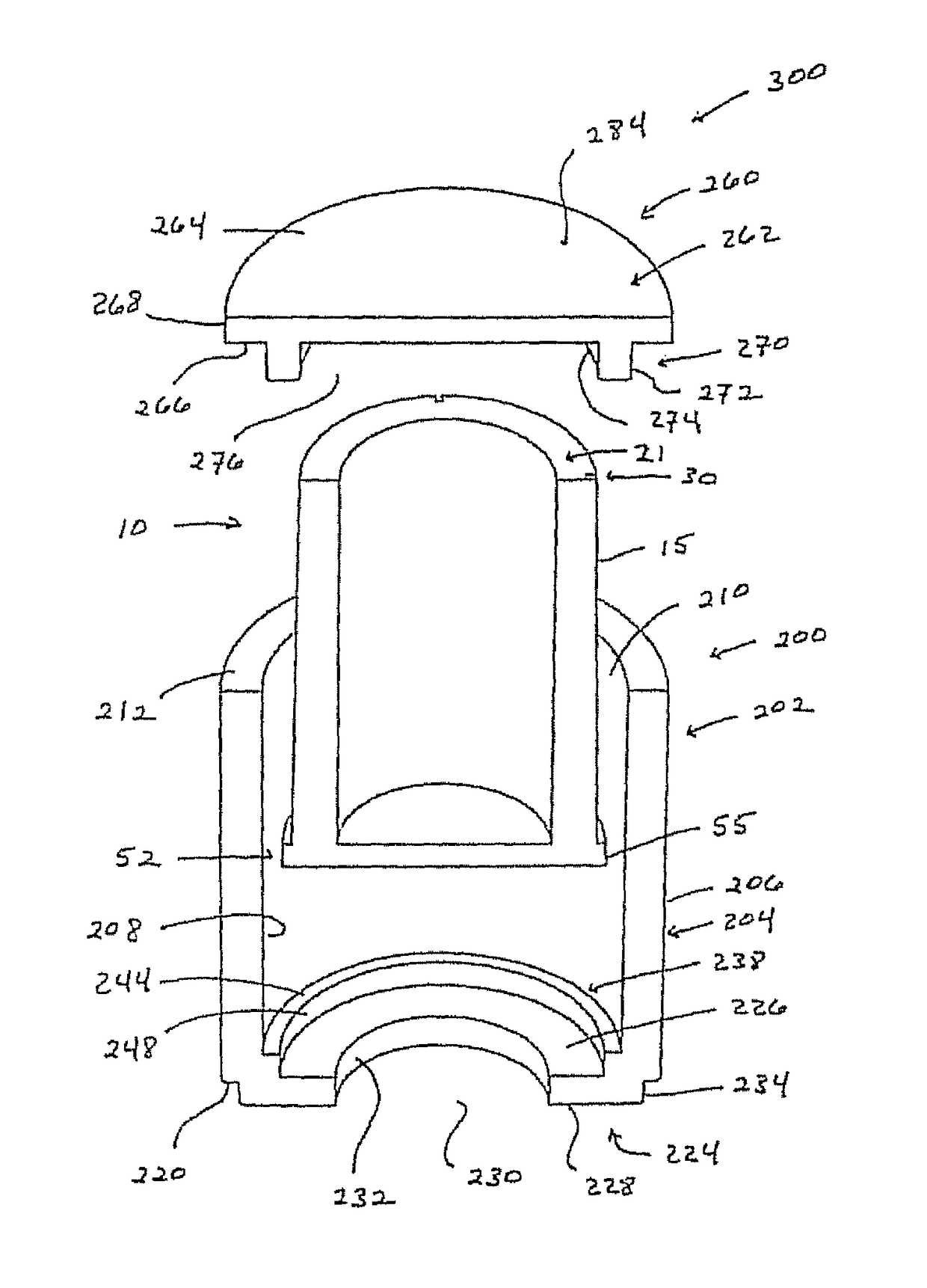

Adiabatic Concrete Calorimeter and Method

ActiveUS20200166417A1Material heat developmentMaterial testing goodsCylinder moldClassical mechanics

An adiabatic concrete calorimeter includes a thermal chamber and a heat well subassembly for being positioned in the thermal chamber. The heat well subassembly includes a test cylinder container and a test cylinder mold adapted to be positioned in the test cylinder container for defining the shape of a concrete test specimen formed in the test cylinder mold. Temperature sensors determine the temperature of the concrete test specimen, and transmit temperature data from the temperature sensors to a controller. Electrically-energized heaters are positioned on a surface of the test cylinder container for applying heat to the test cylinder container. A controller determines heat loss of the concrete test specimen and outputs data to the heaters whereby the heaters supply heat to the concrete test specimen sufficient to compensate for heat losses to an ambient environment and maintain the heat of hydration of the concrete test specimen.

Owner:MCCALL W CALVIN

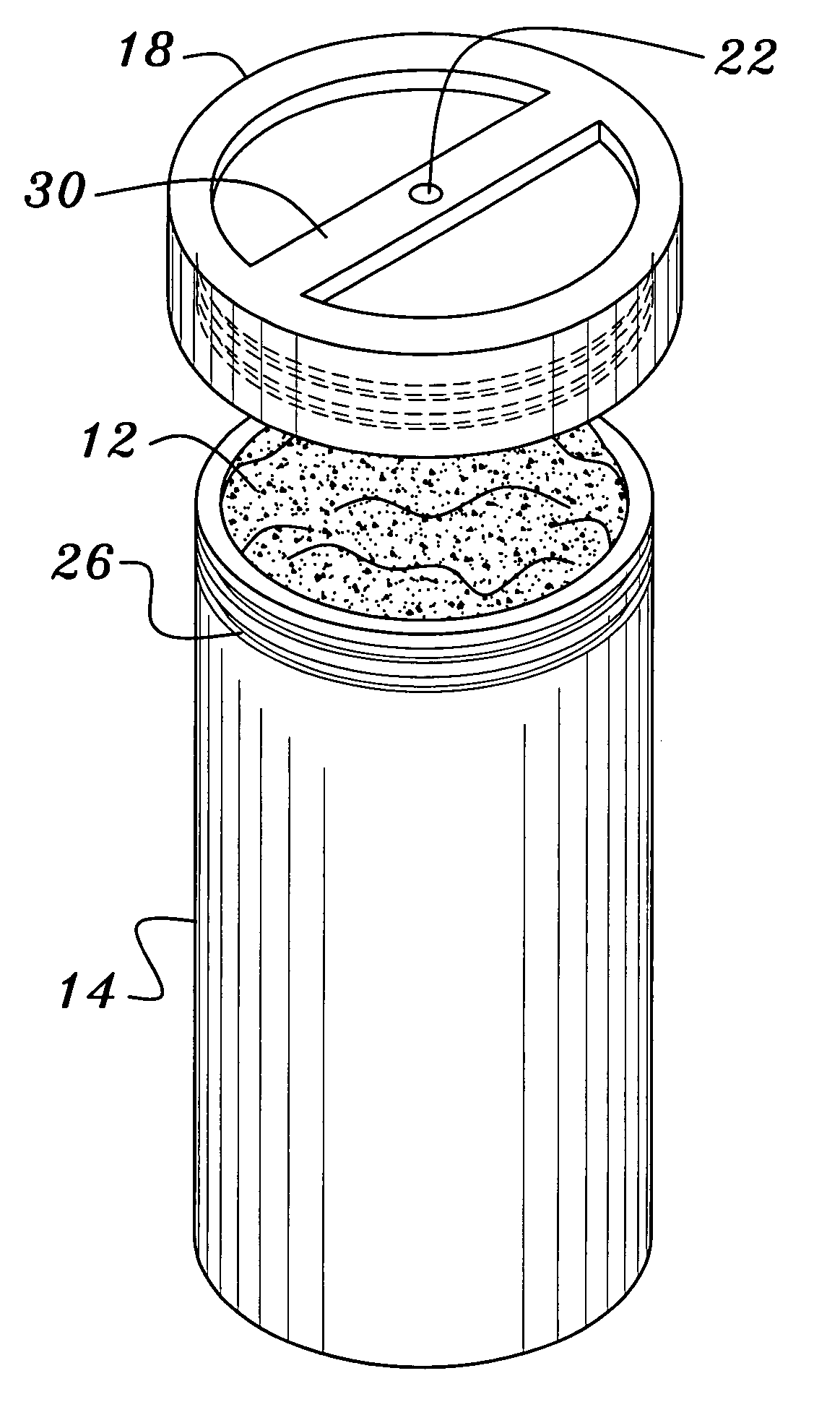

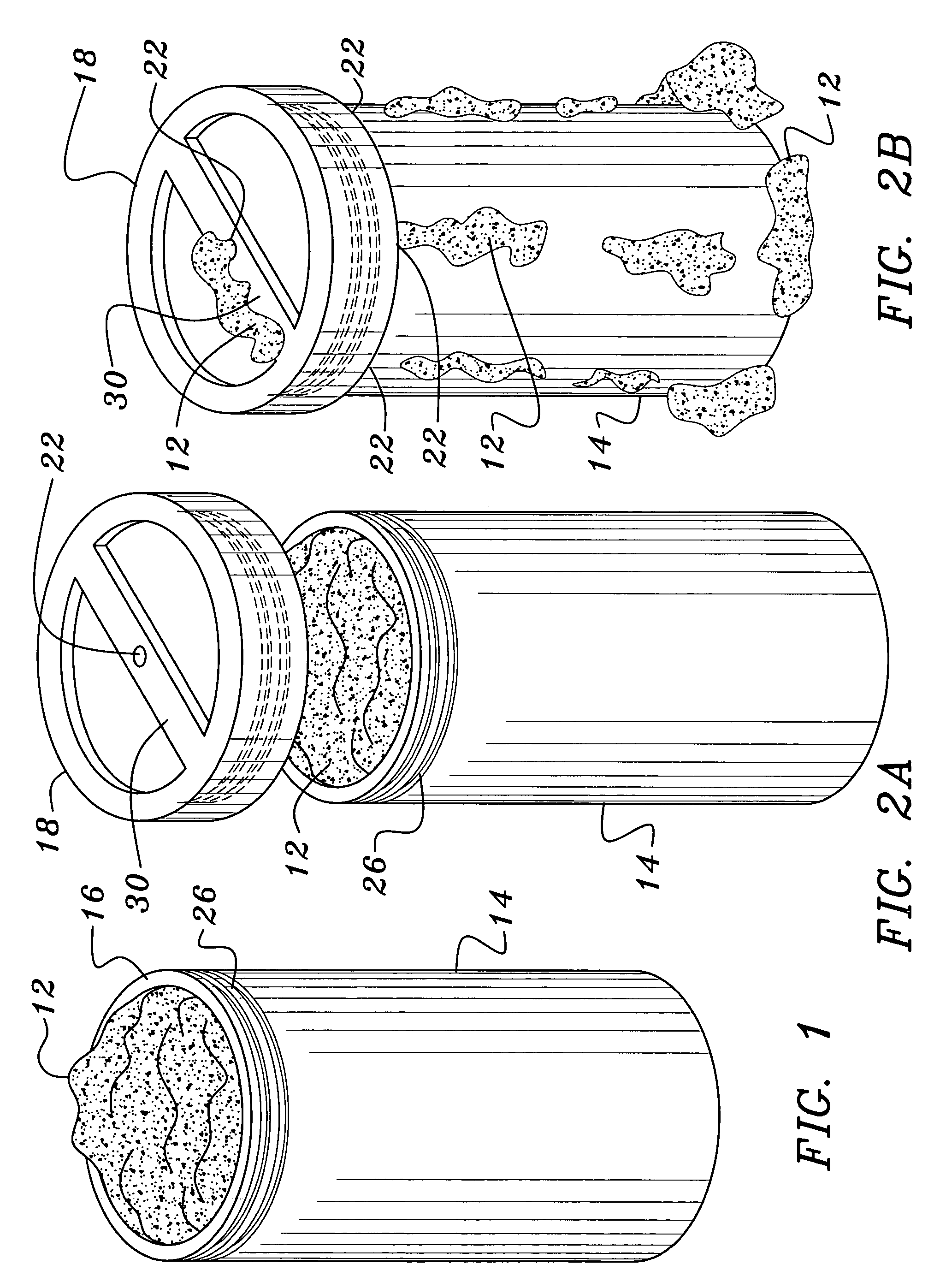

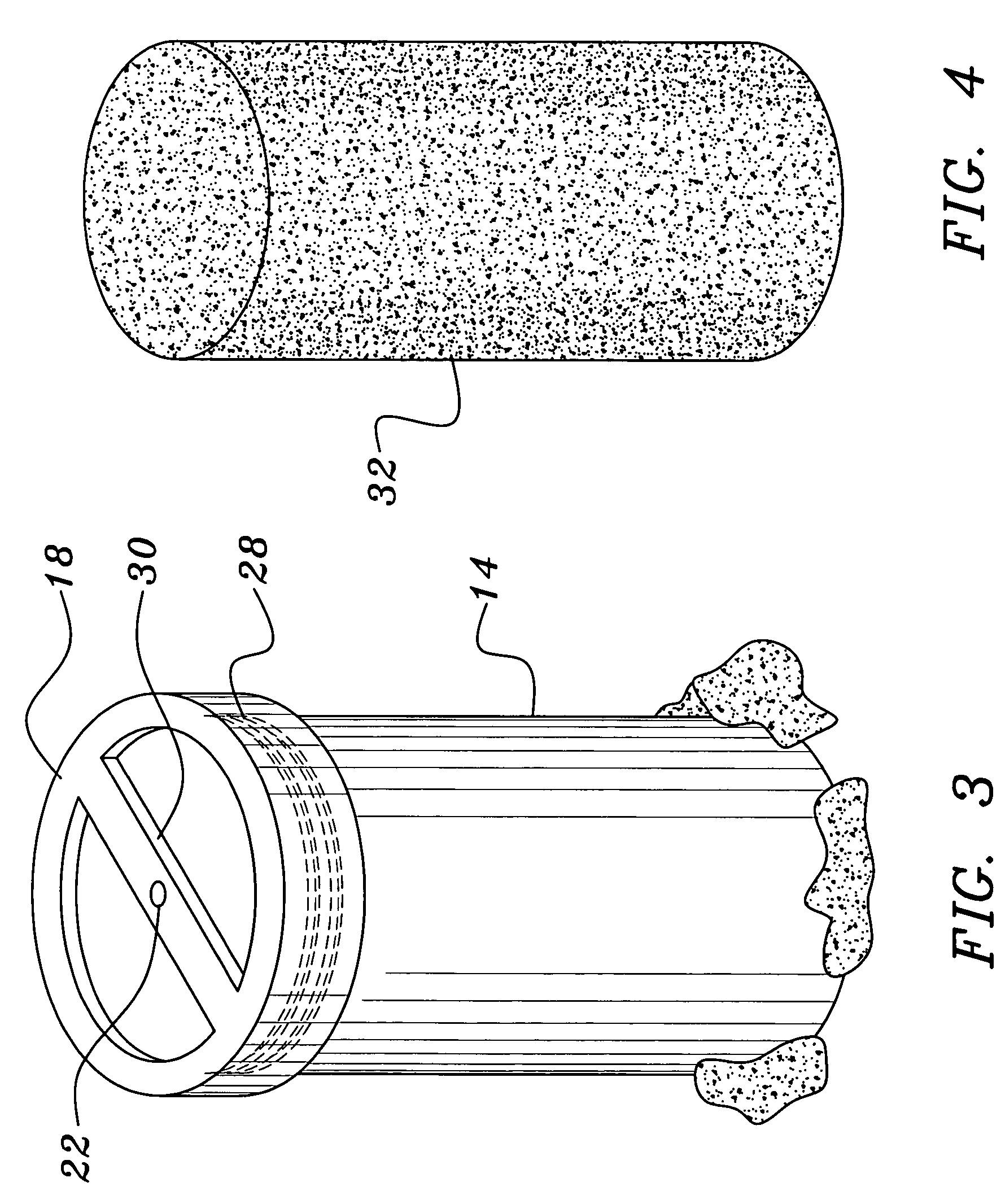

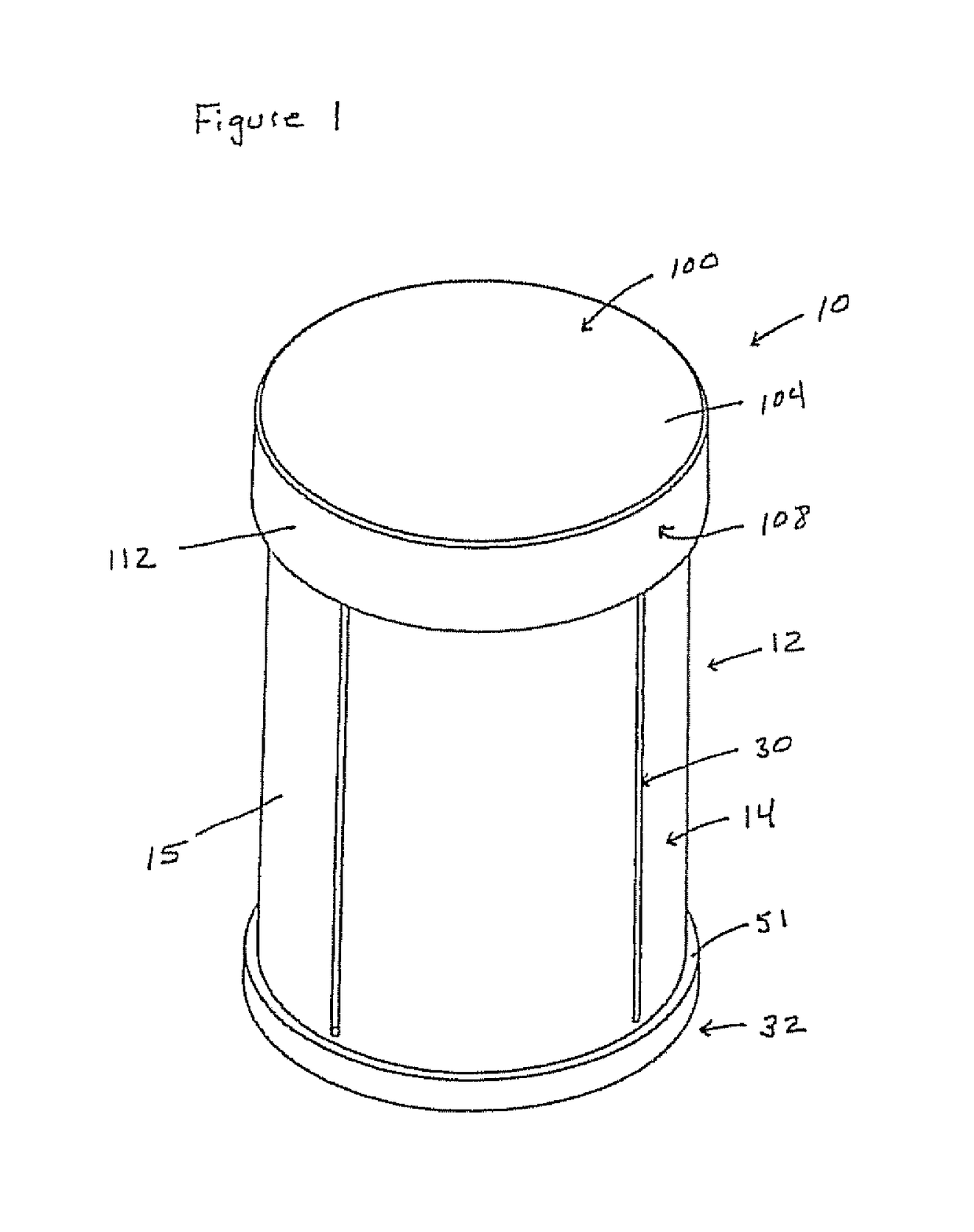

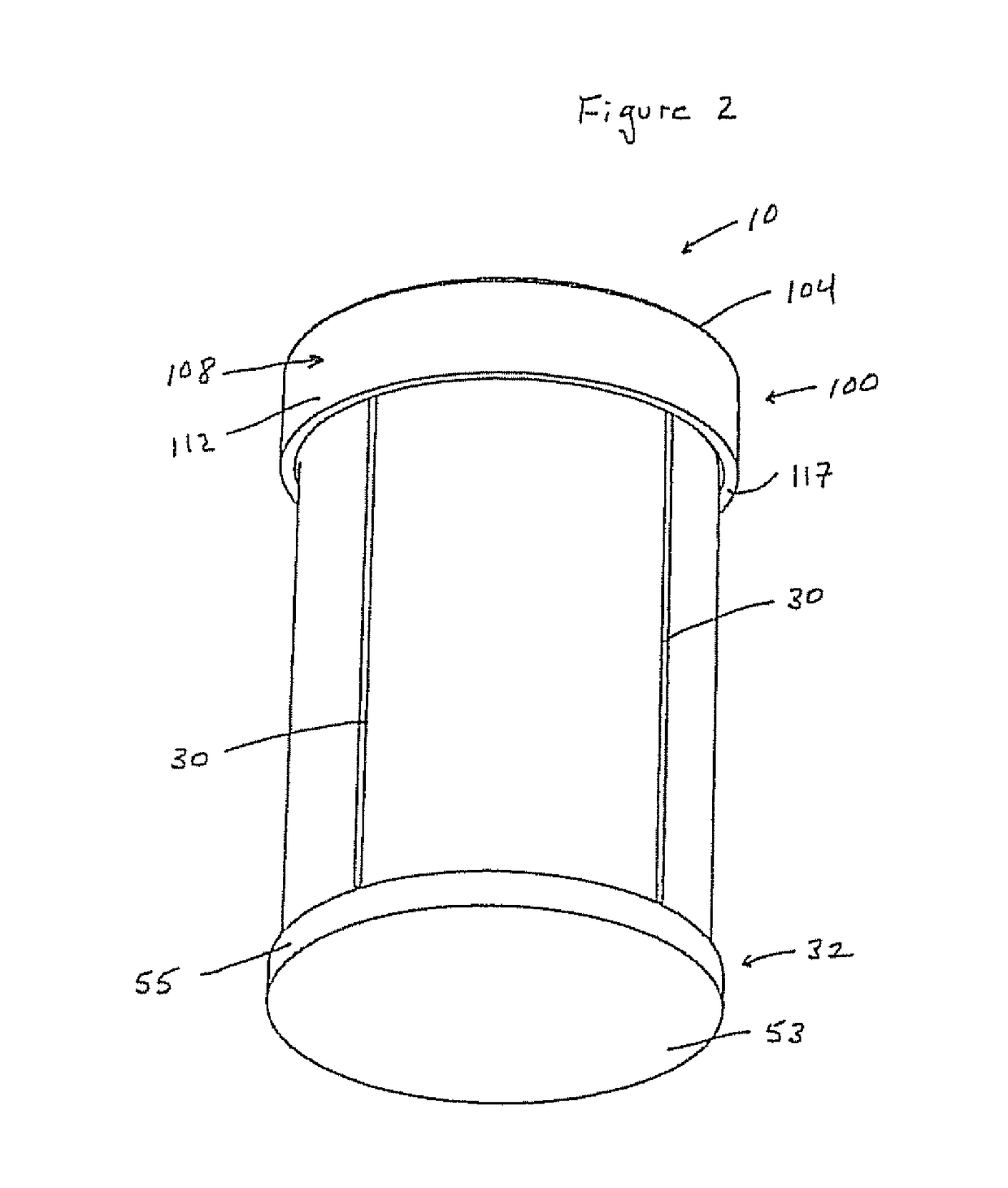

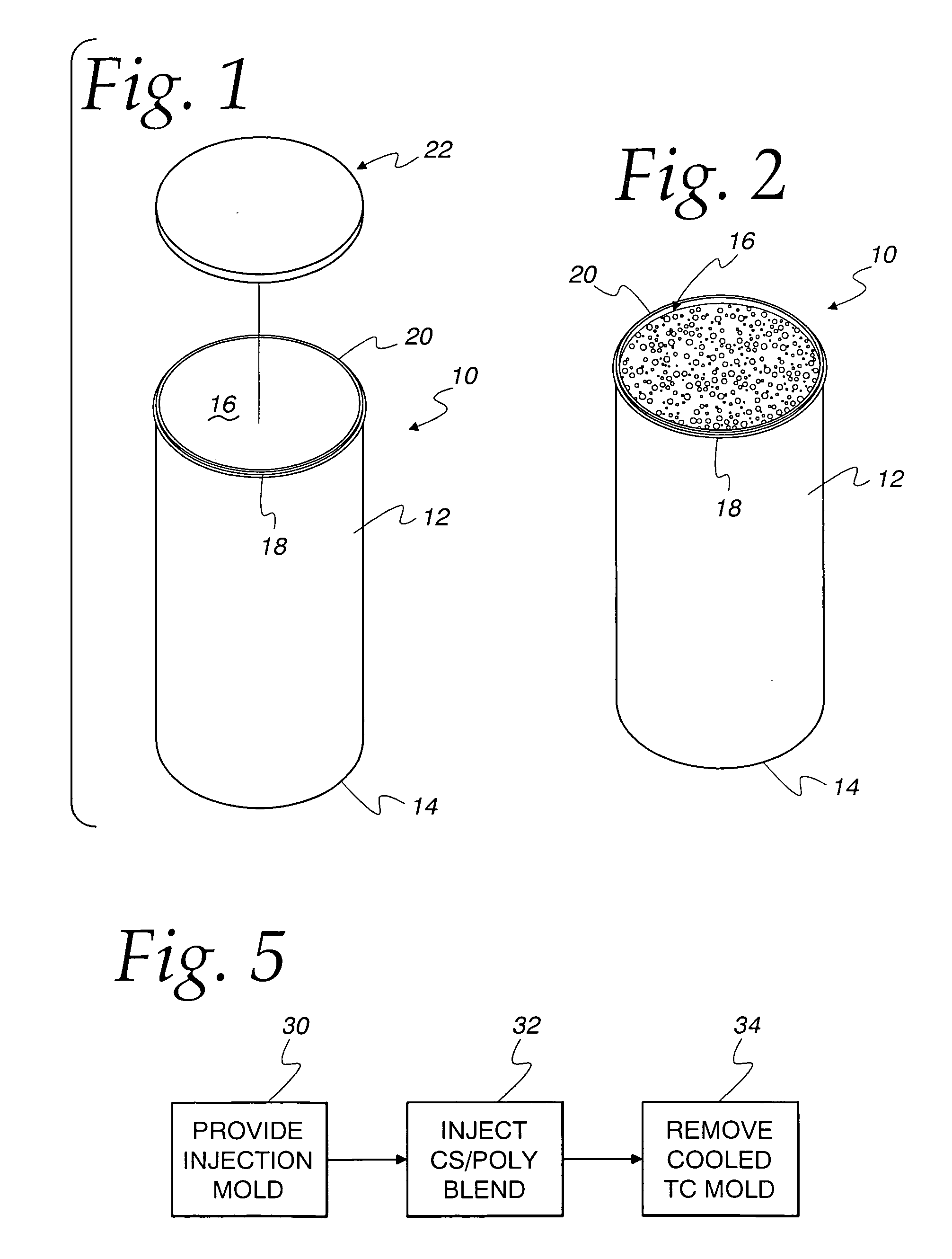

Concrete test cylinder mold cap

InactiveUS7201866B2Flat surfaceUniform diameterMould separation apparatusMouldsCylinder moldStructural engineering

A method and apparatus for molding a reproducible uniform concrete test cylinder. Concrete is poured into a concrete test cylinder mold. A cap having at least one excretion hole is placed on the top portion of the concrete test cylinder mold. The cap is pressed against the top portion of the concrete test cylinder mold thereby excreting excess concrete through the excretion hole in the cap. After the cap is separated from the poured concrete, the poured concrete is allowed to cure within the concrete test cylinder mold for a predetermined time. Then, the cured concrete is removed from the concrete test cylinder mold thereby producing a uniform and reproducible concrete test cylinder.

Owner:STALLONE DOMINICK V

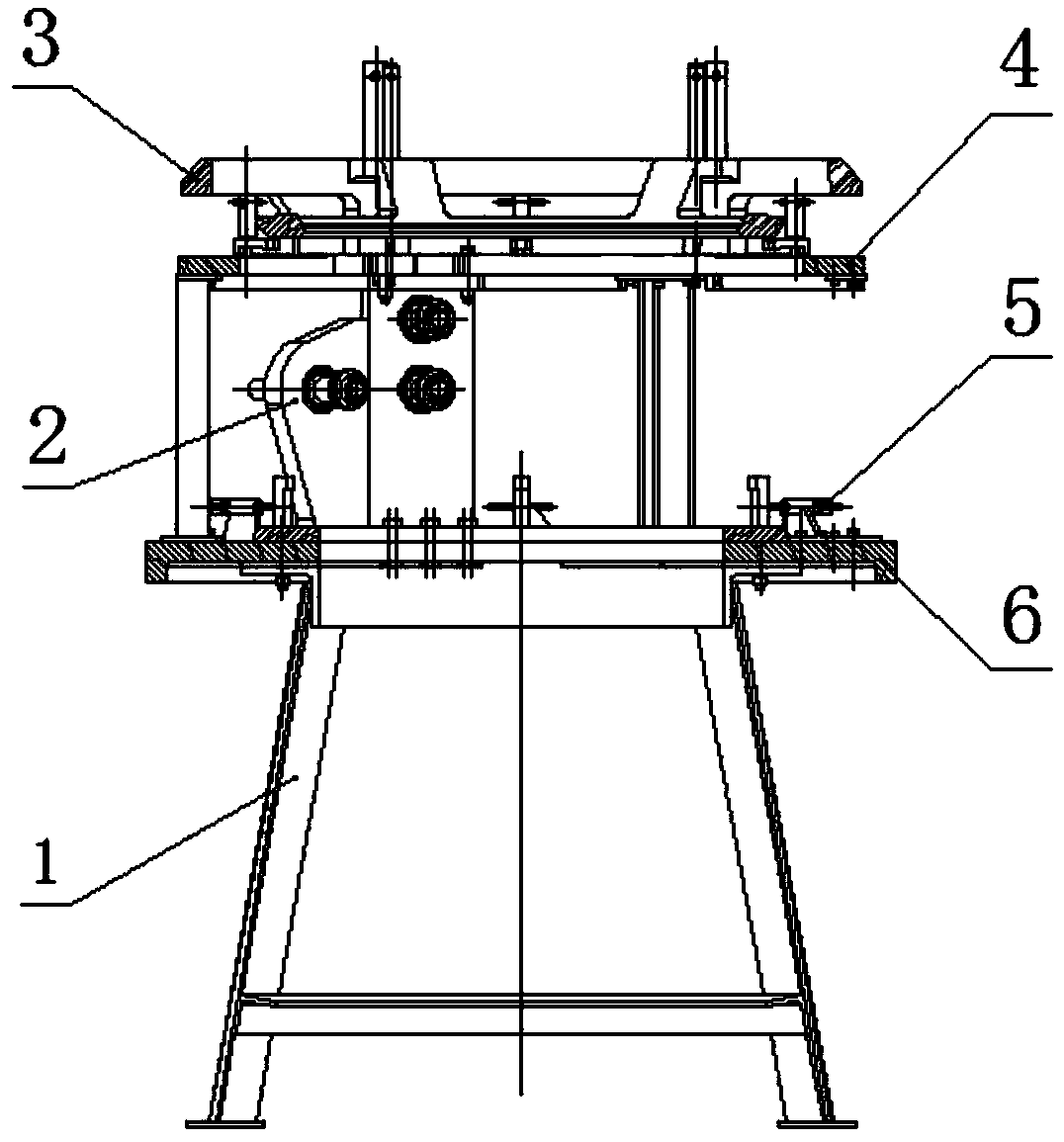

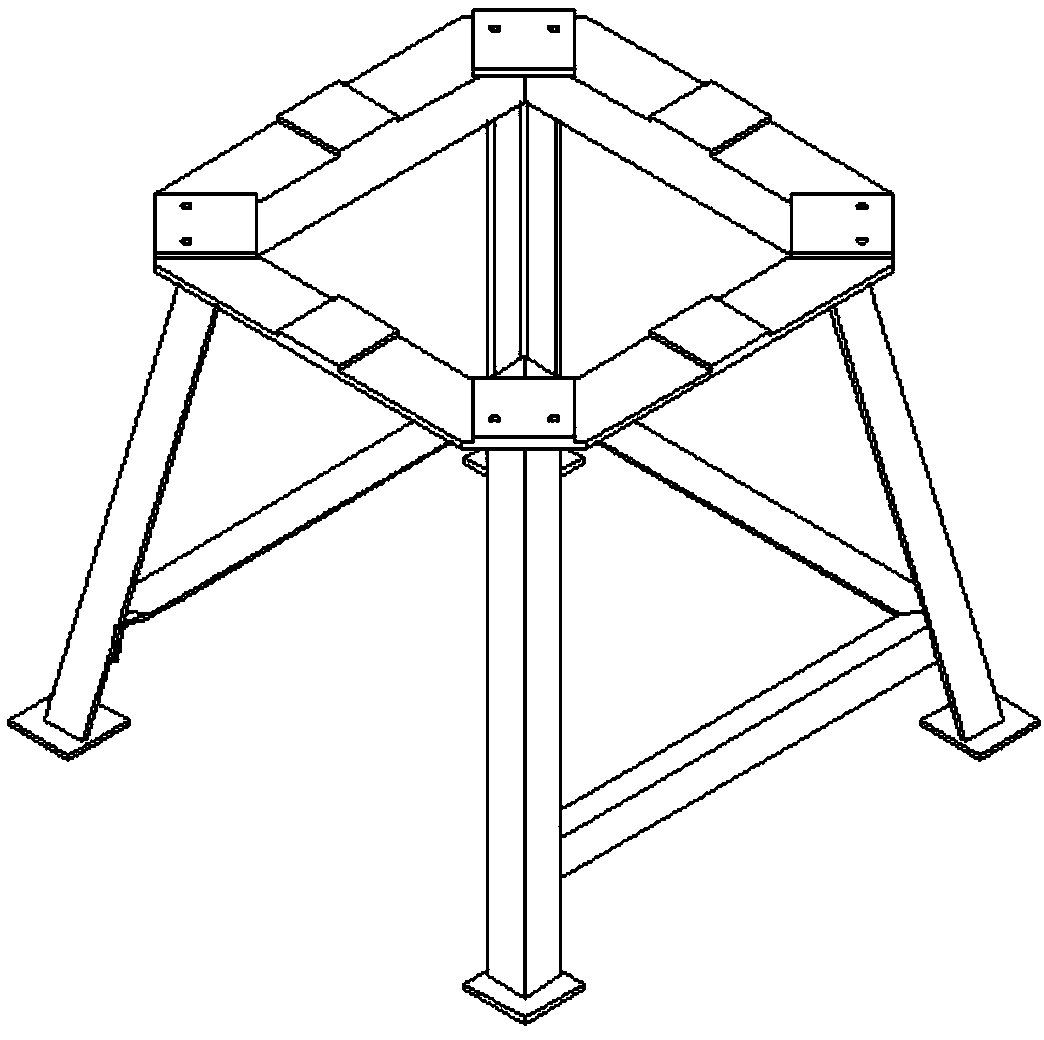

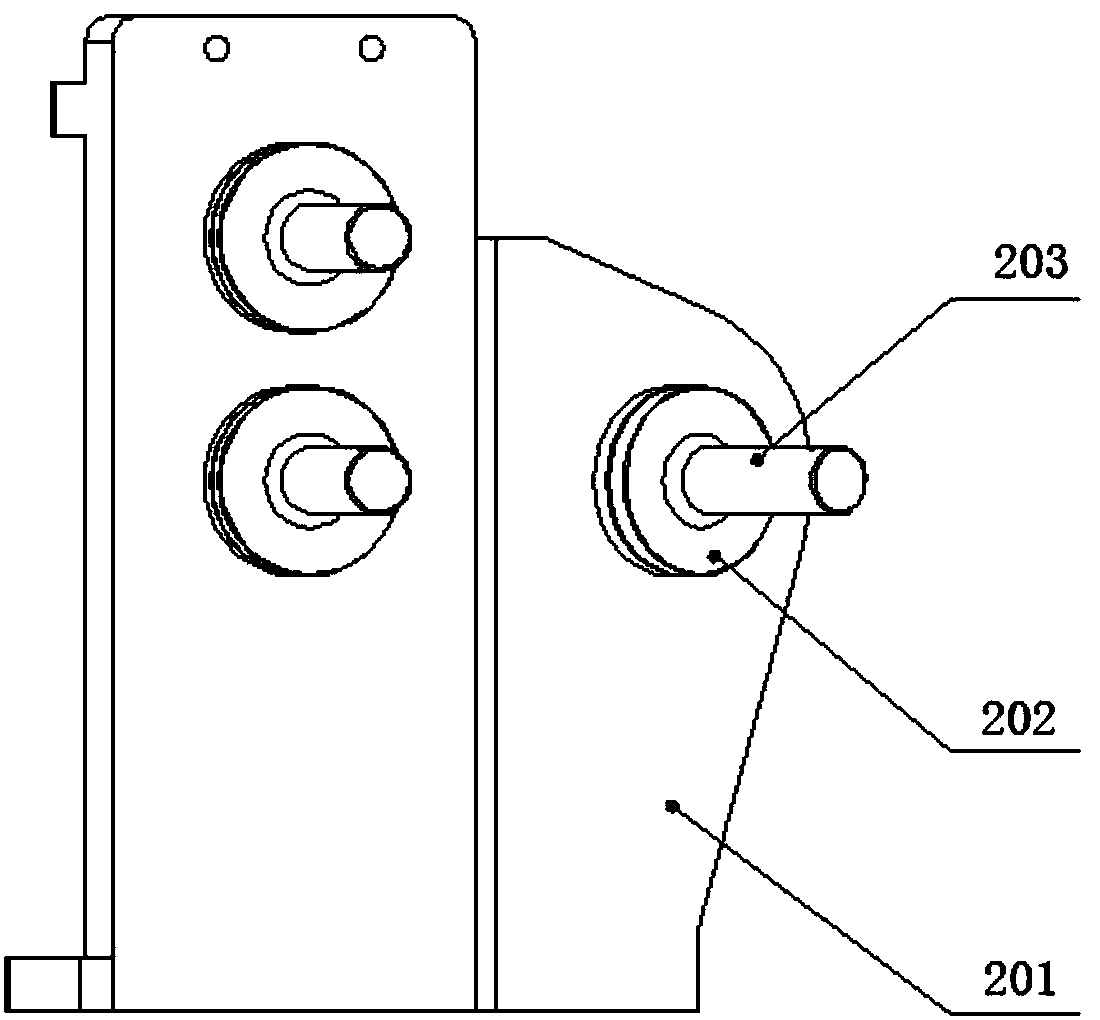

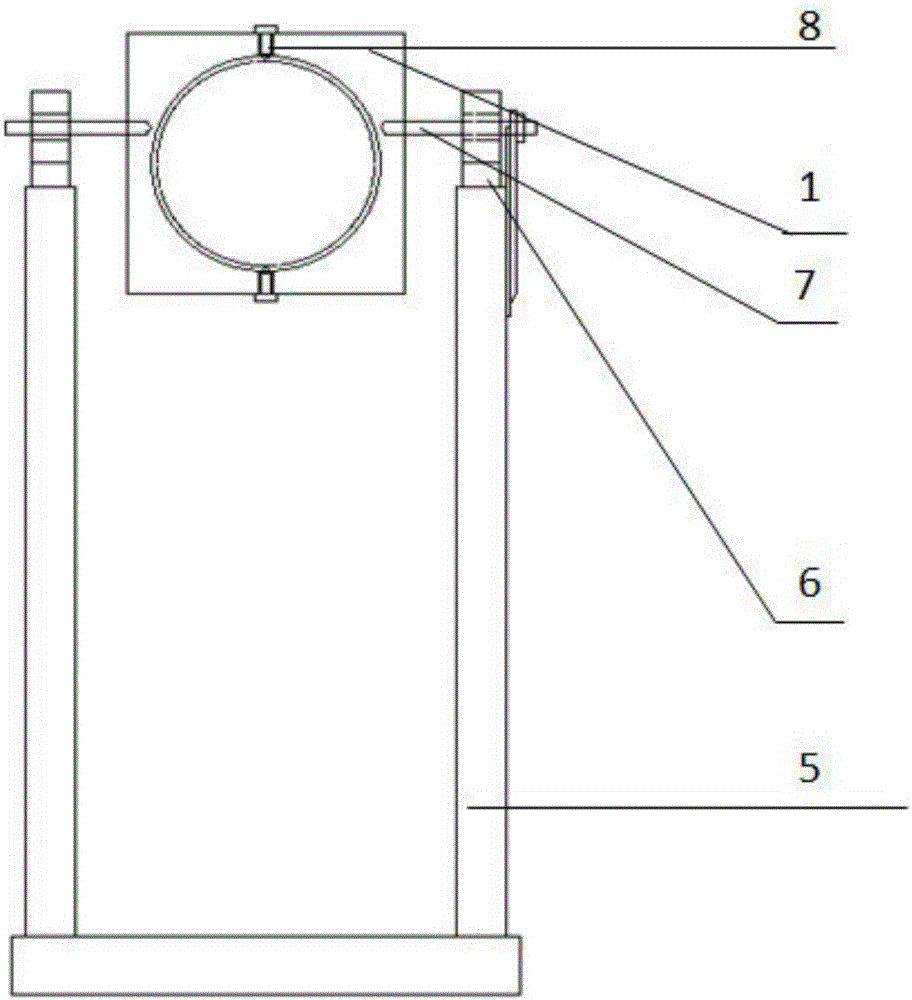

Annular heat radiator assembly fixture

ActiveCN108581875AMeet the installation requirementsImprove assembly accuracyWork holdersDrill jigsAviationCylinder mold

The invention discloses an annular heat radiator assembly fixture, which belongs to the technical field of aviation heat radiation. The annular heat radiator assembly fixture comprises a support assembly, a hot and cold pipe nozzle positioning assembly, an adapter positioning plate assembly, an upper positioning ring assembly and a lower positioning ring assembly. The lower positioning ring assembly is arranged at the upper end of the support assembly; the upper positioning ring assembly is fixed onto the lower positioning ring assembly; the hot and cold pipe nozzle positioning assembly is arranged between the lower positioning ring assembly and the upper positioning ring assembly; a plurality of presser assemblies are arranged at the upper ends of the lower positioning ring assembly and the upper positioning ring assembly; and the adapter positioning plate assembly is arranged at the upper end of the upper positioning ring assembly. According to the technical scheme, an annular heat radiator front ring assembly is positioned through the lower positioning ring assembly, a product inner cylinder molded surface and a valve ring assembly are positioned through the adapter positioningplate assembly, and various parts are preliminarily clamped and fixed through the presser assemblies, so that locking is realized after the accuracy requirement is met through adjustment, and guiding,drilling, detecting, assembling and riveting are accurately and high-efficiently accomplished.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

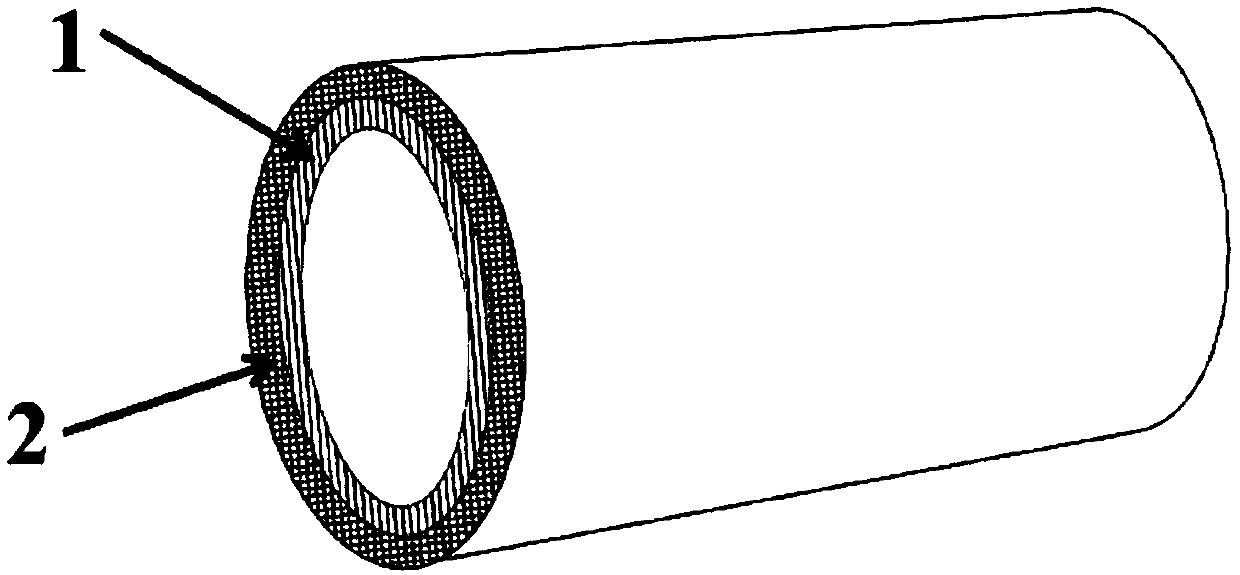

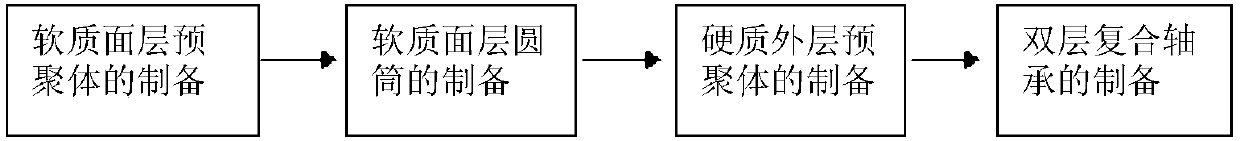

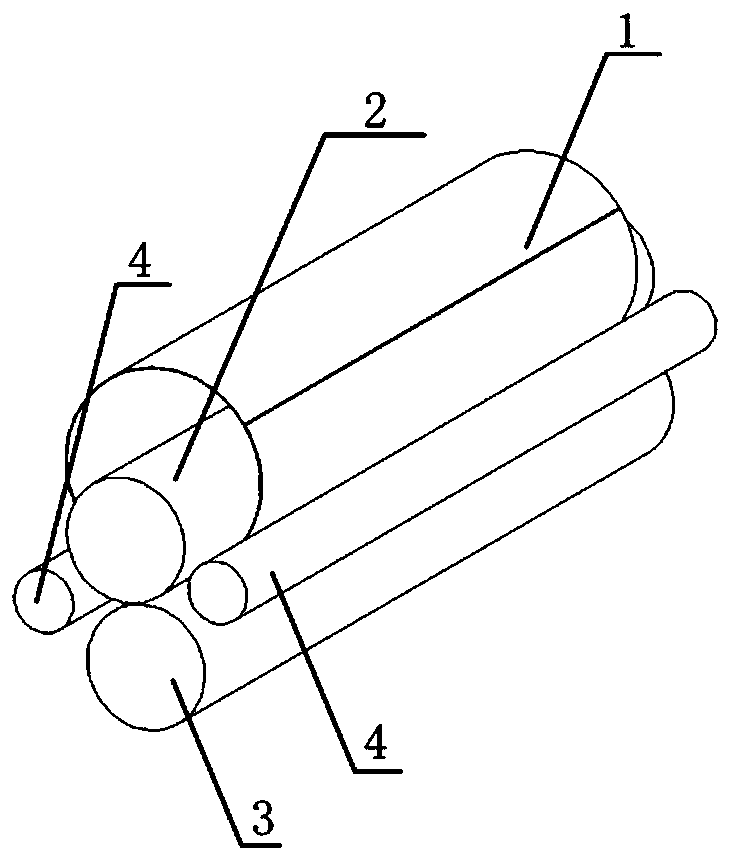

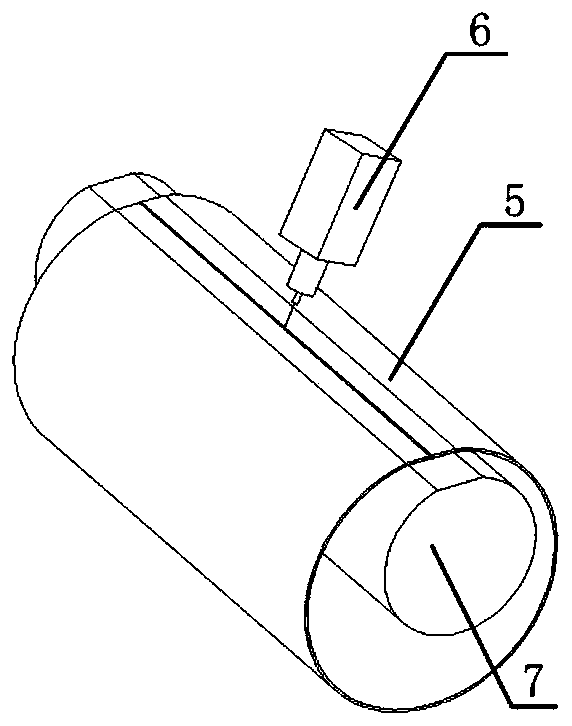

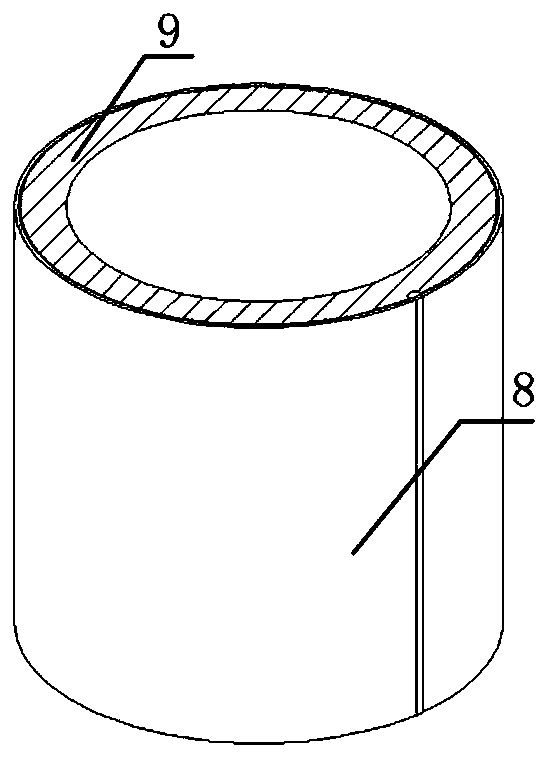

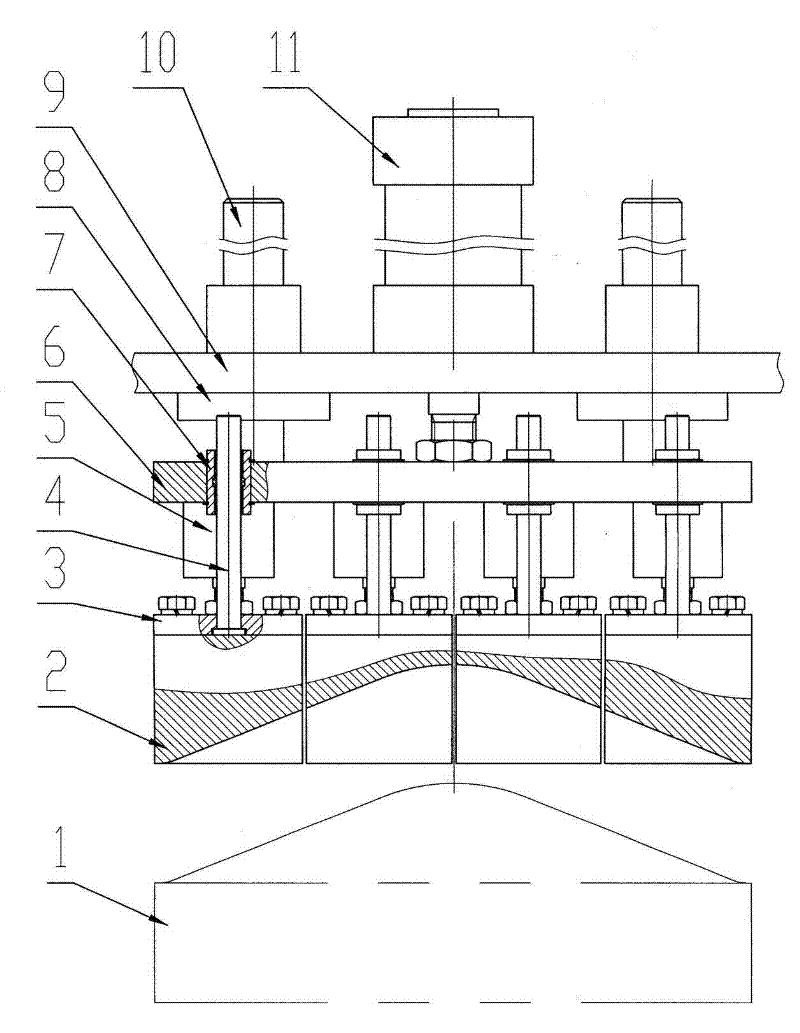

Preparation method of polyurethane composite bearing of double-layer structure

ActiveCN107725601APlay a supporting roleImprove impact resistanceShaftsBearing componentsSurface layerCylinder mold

The invention discloses a preparation method of a polyurethane composite bearing of a double-layer structure and belongs to the technical field of sliding bearings. The polyurethane composite bearingis composed of a hard polyurethane outer layer (2) achieving the supporting and bearing effects and a soft polyurethane surface layer (1) with the self-lubricating and anti-abrasion functions. Firstly, a cylinder mold is adopted, the soft surface layer is cast through a centrifugal casting method, and the outer surface of the surface layer is ground, cleaned, dried, and then coated with an adhesion agent to serve as a mold core; and then the hard outer layer is cast on the outer surface of the surface layer, and the bearing is formed by adhering and composing the layers through the adhesion agent. According to the preparation method of the polyurethane composite bearing of the double-layer structure, the bearing has the technical characteristics of being high in bearing, capable of achieving water-breaking operation within a short time, resistant to silt, easy to machine, low in cost and the like, and the domestic market vacancy is made up; and a composite material integrally has the excellent properties of being resistant to changing of the high and low temperature and hydrolysis and the like, the service life is long, and the polyurethane composite bearing can be widely applied to the rotary or swing sliding portions of water pumps, propeller stern bearings, rudder bearings and the like.

Owner:BEIHUA UNIV

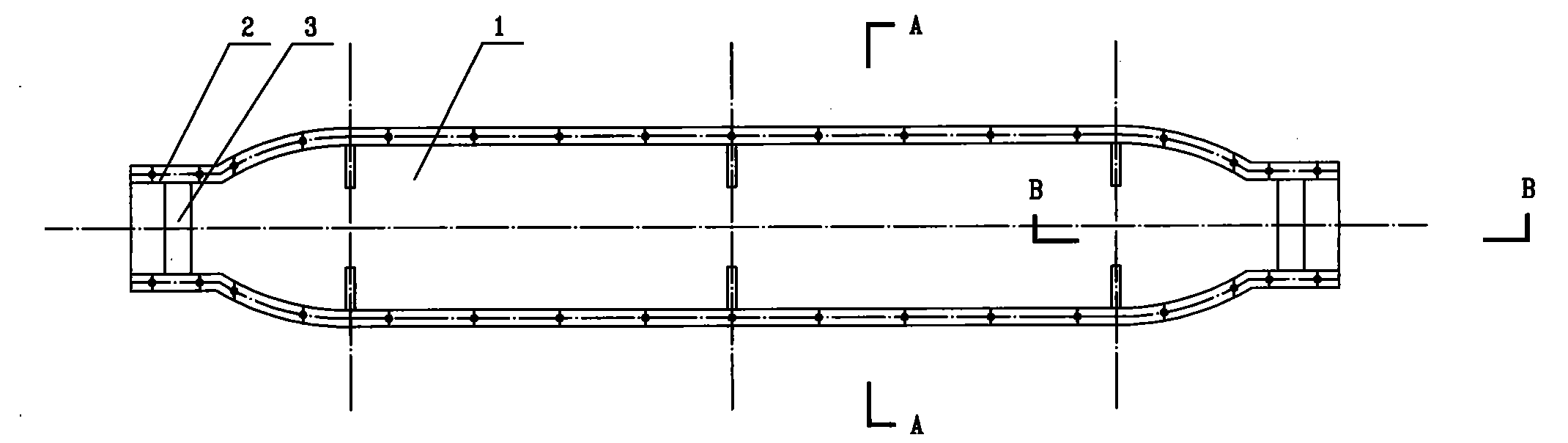

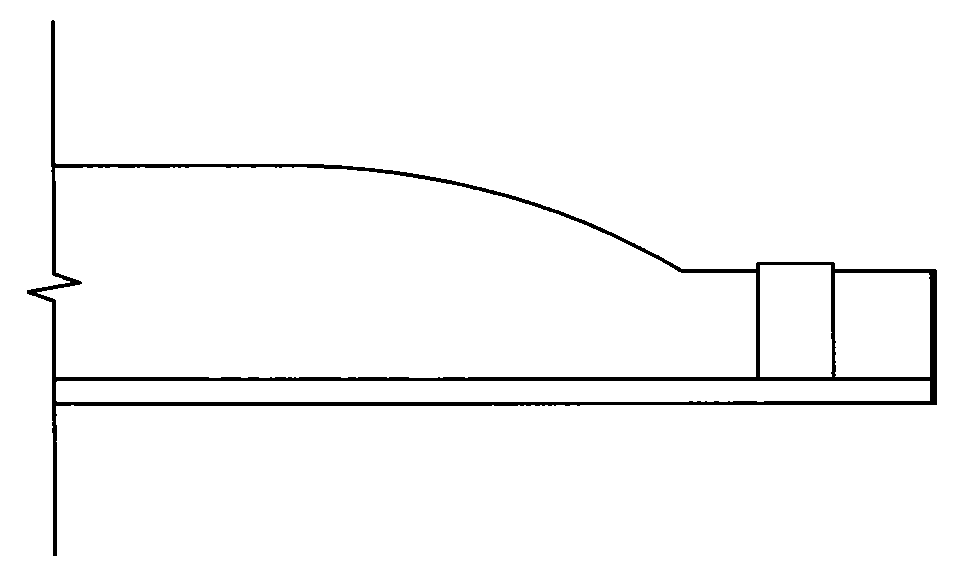

Preparation method of large-diameter thin-wall titanium alloy annular pipe

InactiveCN110480260AReduce the number of weldsReduce the difficulty of assemblyCylinder moldWelding residual stress

The invention provides a preparation method of a large-diameter thin-wall titanium alloy annular pipe. The preparation method of the large-diameter thin-wall titanium alloy annular pipe comprises thefollowing steps of 1) flat plate winding cylinder; 2) longitudinal seam welding; 3) cylinder section shape correcting; and 4) liquid pouring and bending; a titanium alloy is cut by utilizing a cuttingdevice to obtain a titanium alloy blank, and the cut titanium alloy blank is rolled into an open type cylinder section by virtue of the roll bending forming equipment; the open type cylinder sectionobtained in the step 1) is put on a welding workbench, and then the open type cylinder section is welded through a welding device, and a closed type cylinder section is obtained after the open type cylinder section is welded through the welding device; the closed cylinder section obtained in the step 2) is assembled on a high-temperature-resistant stainless steel creep correcting cylinder mold, then the closed cylinder section is integrally placed in a vacuum thermal creep furnace, vacuumizing and heating treatment are carried out, so that the titanium alloy cylinder is corrected under the action of the vacuumizing and the heating treatment; and the two ends of the titanium alloy cylinder obtained in the step 3) are clamped through a bending clamp. The preparation method has the advantagesthat the number of welding lines is reduced, the welding difficulty is remarkably reduced, and the welding residual stress is released.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

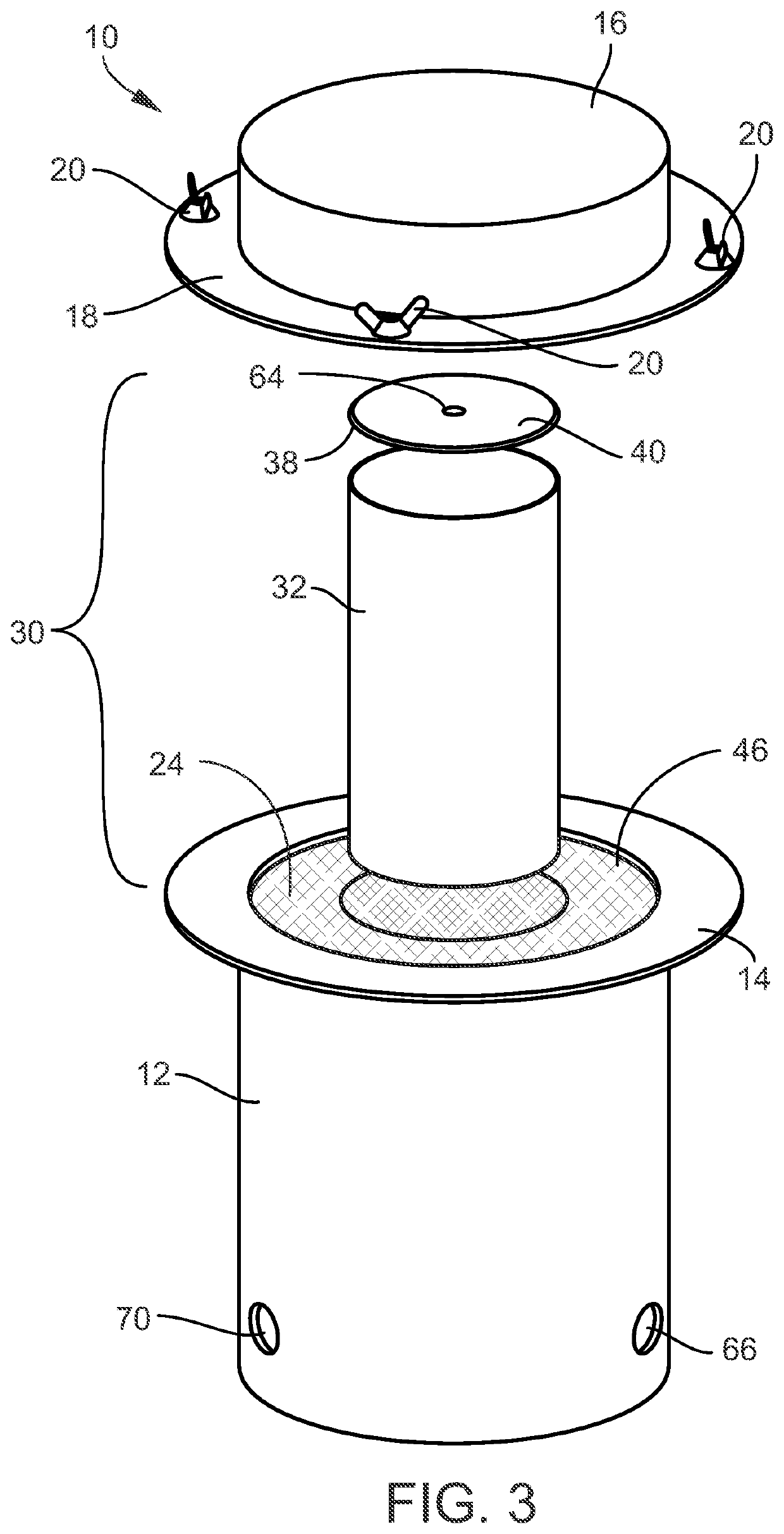

Concrete test cylinder mold, system, and method of use

ActiveUS9689861B1Minimum compressive strengthMaintain curing temperatureDischarging arrangementMouldsCylinder moldPolystyrene

A concrete test cylinder mold formed of expandable polystyrene and which is used to form geometrically uniform concrete test cylinders that accurately reflect the structural properties of the concrete mix used to form the test cylinders despite fluctuations in temperature to which the test cylinder may be exposed during formation within the mold. The mold is constructed and configured such that compression testing of the concrete test cylinder may be conducted while the cylinder is still in the mold. A specially designed heat shield may be used in unison with the concrete test mold to form, at least in part, a system by which heat further may be retained within the system during formation of the concrete test cylinder.

Owner:CONCRETE BLOCK INSULATING SYST INC

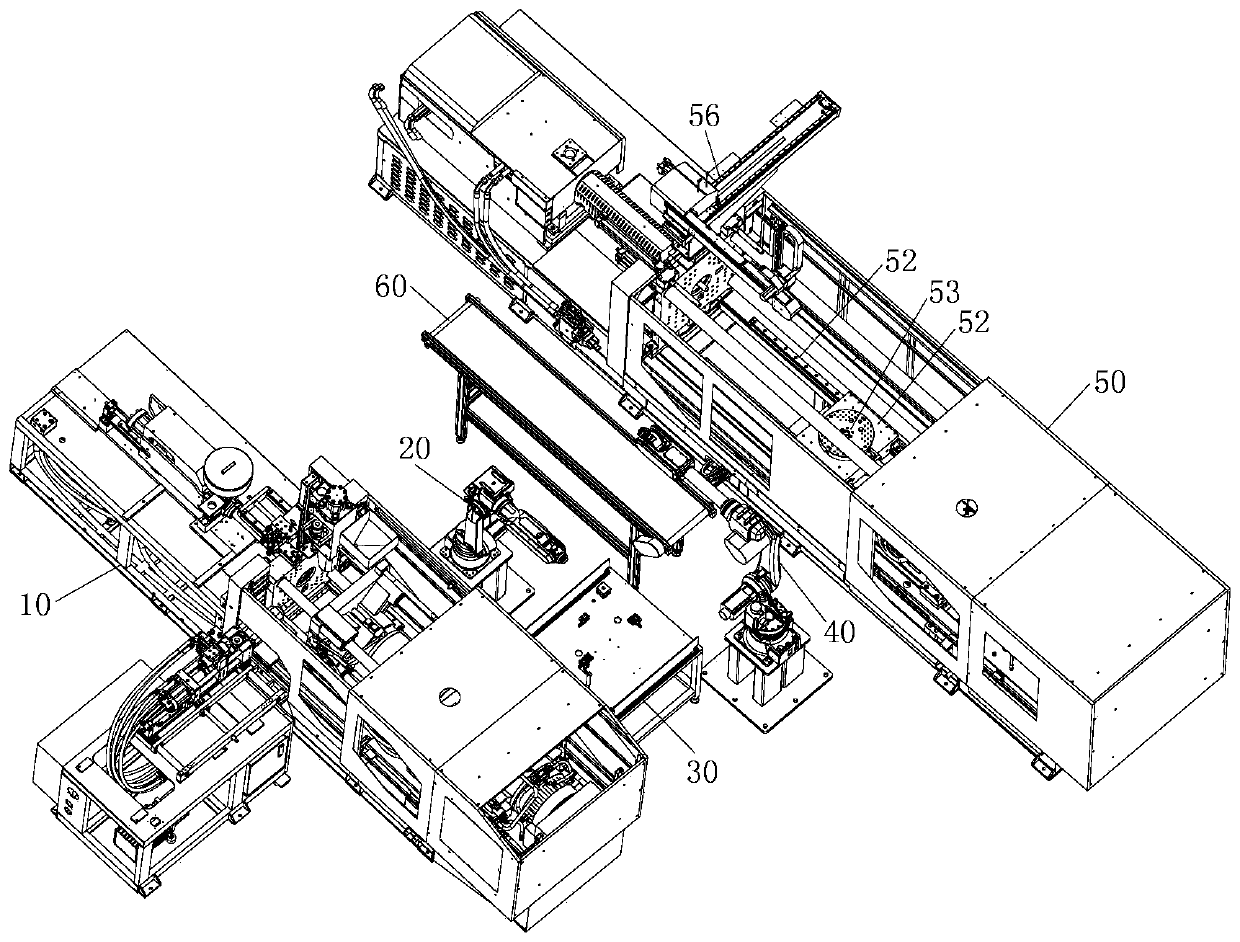

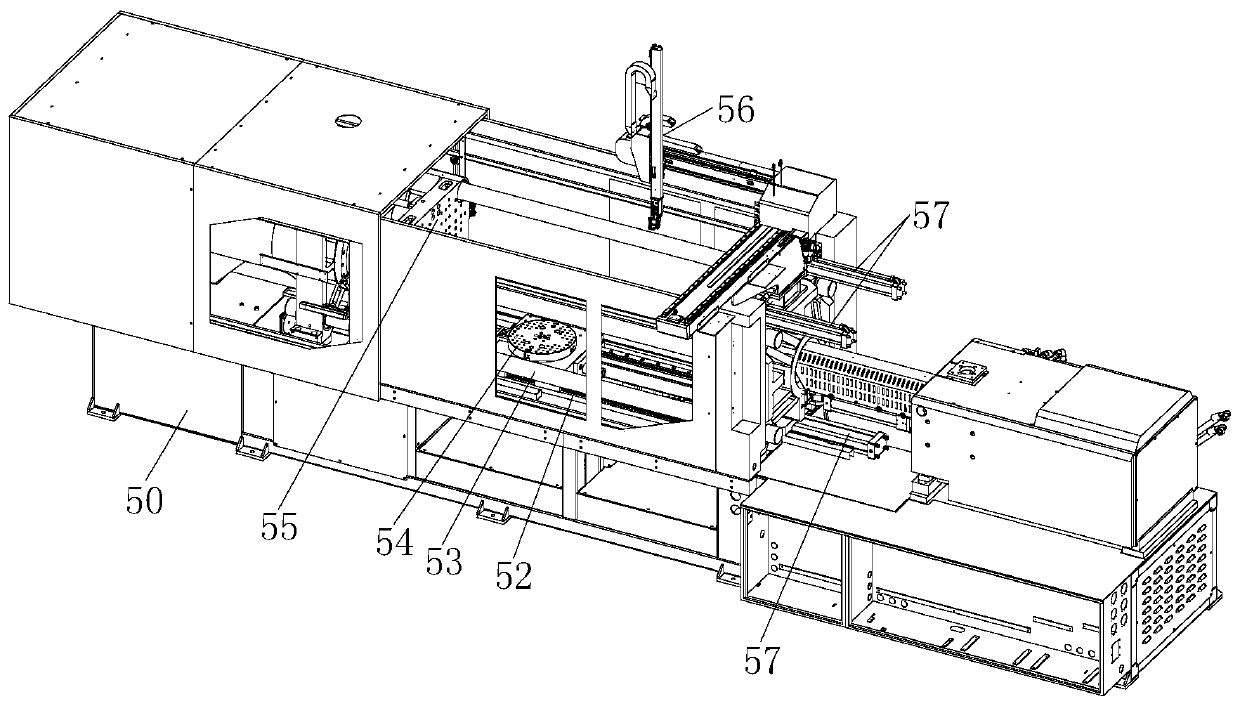

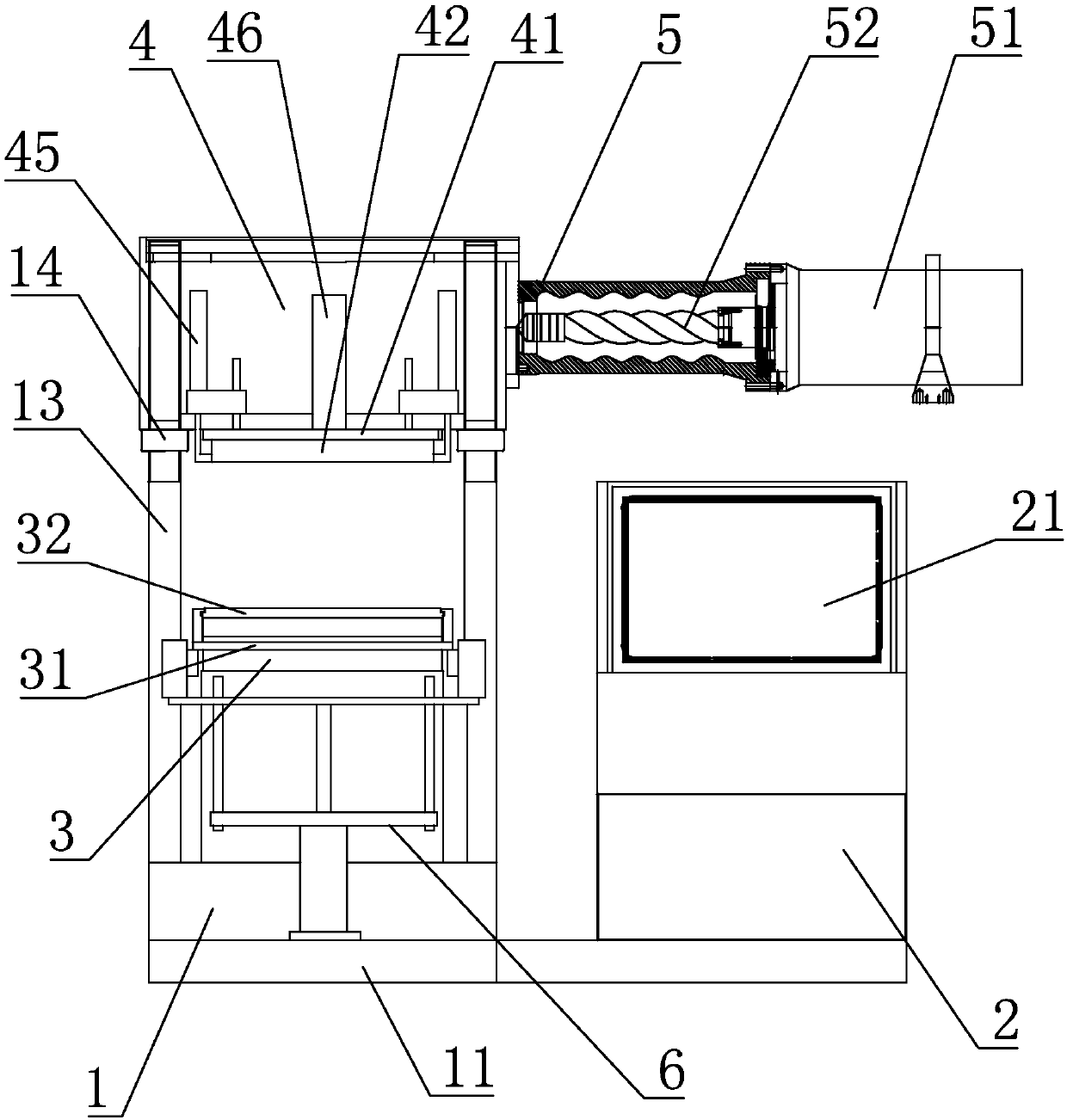

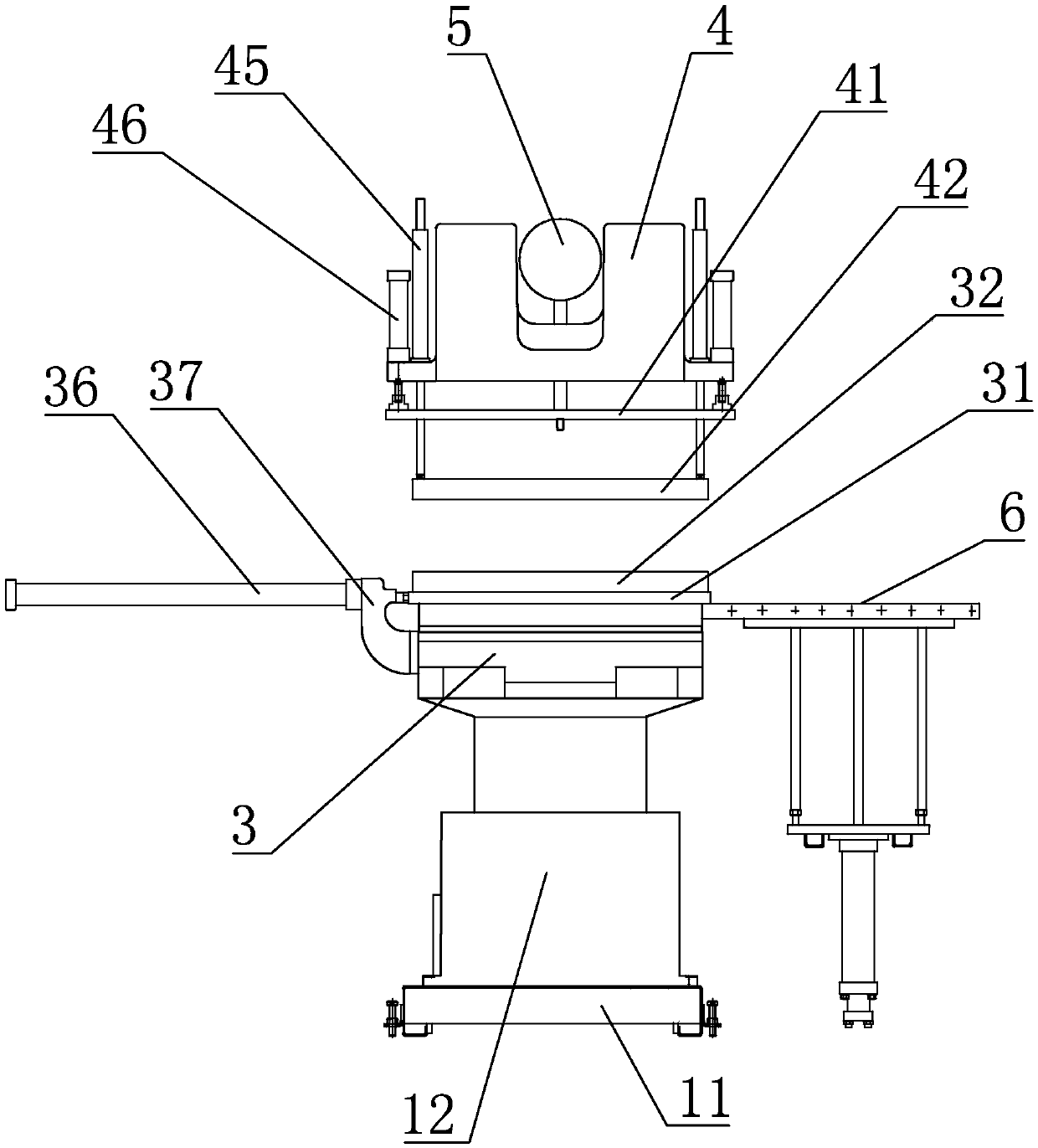

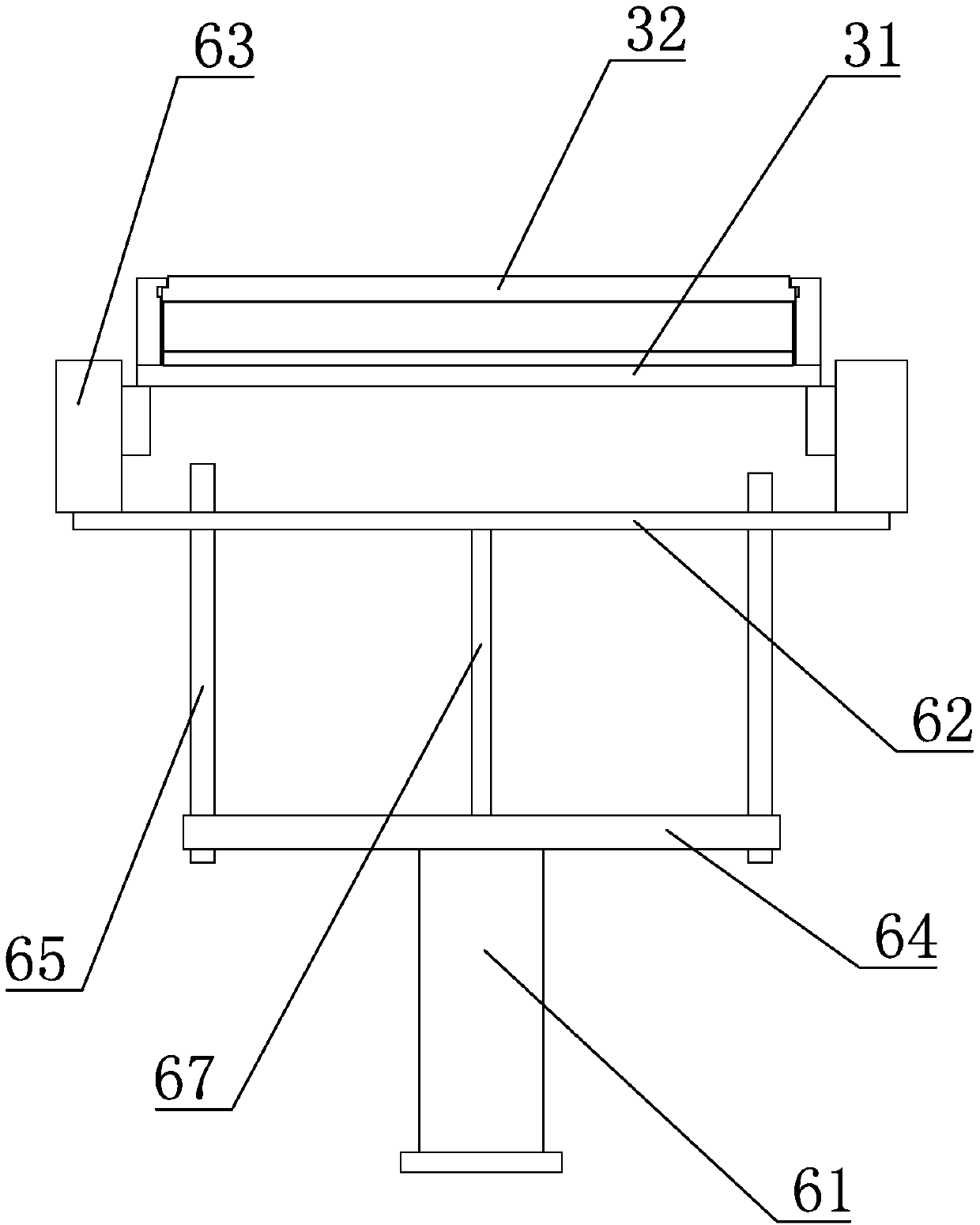

High-pressure needle cylinder production line

InactiveCN110962289AIncrease productivityReduce labor costsDomestic articlesCylinder moldInjection moulding

Owner:东莞亿东机器有限公司

Quantitative concrete workability testing device and method

The invention discloses a concrete workability quantitative testing device and testing method. The test device of the present invention is composed of a bracket, a dial, a pointer, a chuck, and a detachable sealed cylinder mold, wherein a bearing seat is installed on the bracket, an eccentric shaft is arranged on the chuck, and the dial is fixed on the bracket; The eccentric shaft and the support form a rotational connection through bearings, the pointer is fixedly connected to the eccentric shaft of the chuck, the detachable sealed cylinder mold is fixed by fastening bolts on the chuck, and the detachable sealed cylinder mold is connected to the eccentric shaft of the chuck. The chuck and the pointer rotate synchronously. The test device and test method of the invention can realize fast and accurate measurement of the workability of fresh concrete, thereby guiding the construction of pumped concrete, and the invention can also be used for evaluating the influence of admixtures on the workability of concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

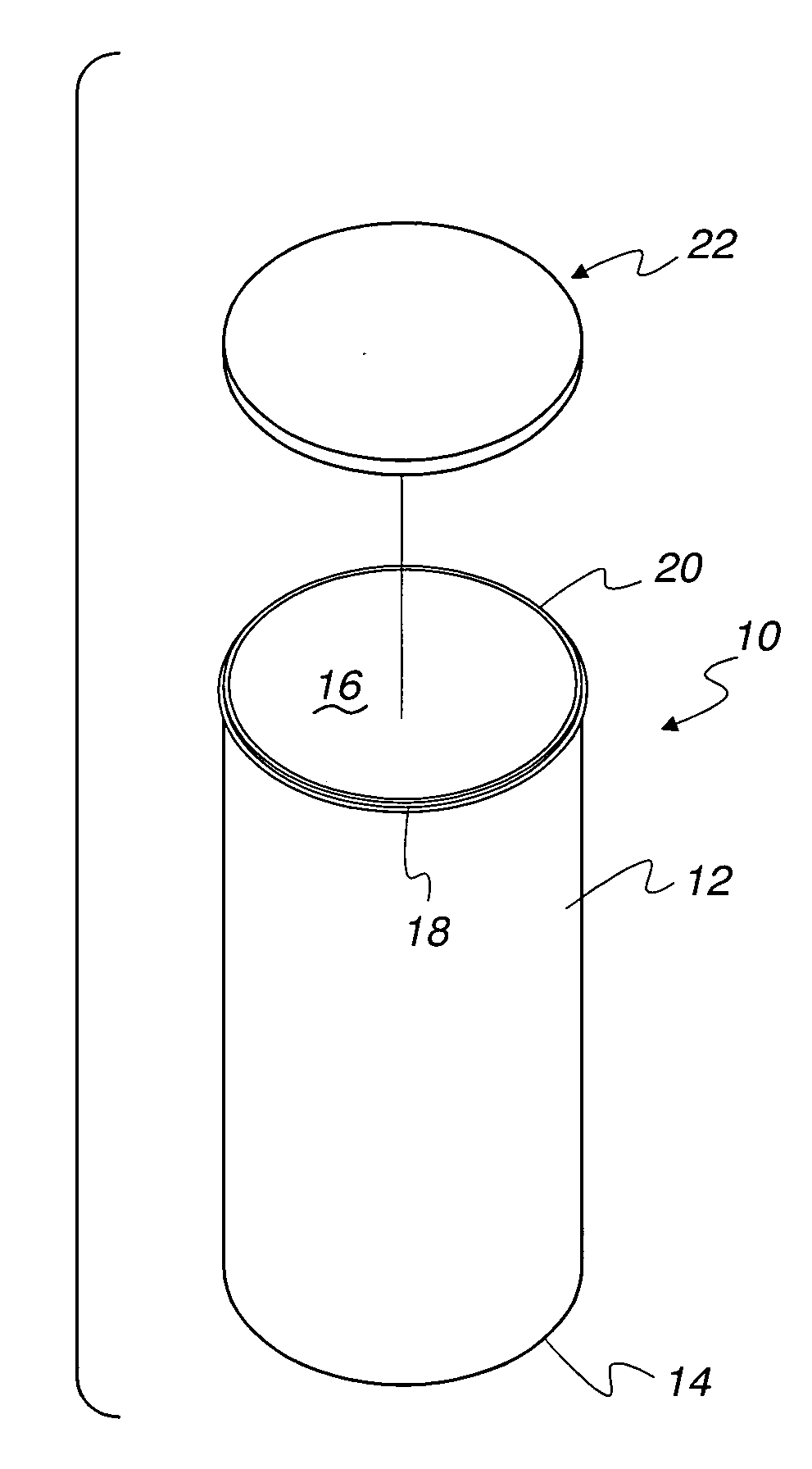

Biodegradable test cylinder mold

A biodegradable test cylinder mold is used for testing concrete specimens. The mold comprises a cylindrical wall connected to a bottom wall to define a hollow, unitary cylindrical container for receiving concrete to form a test specimen. The cylindrical container is formed of a biodegradable material comprising corn starch or a blend of corn starch and plastic.

Owner:DESLAURIERS

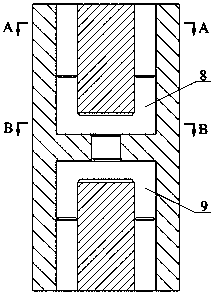

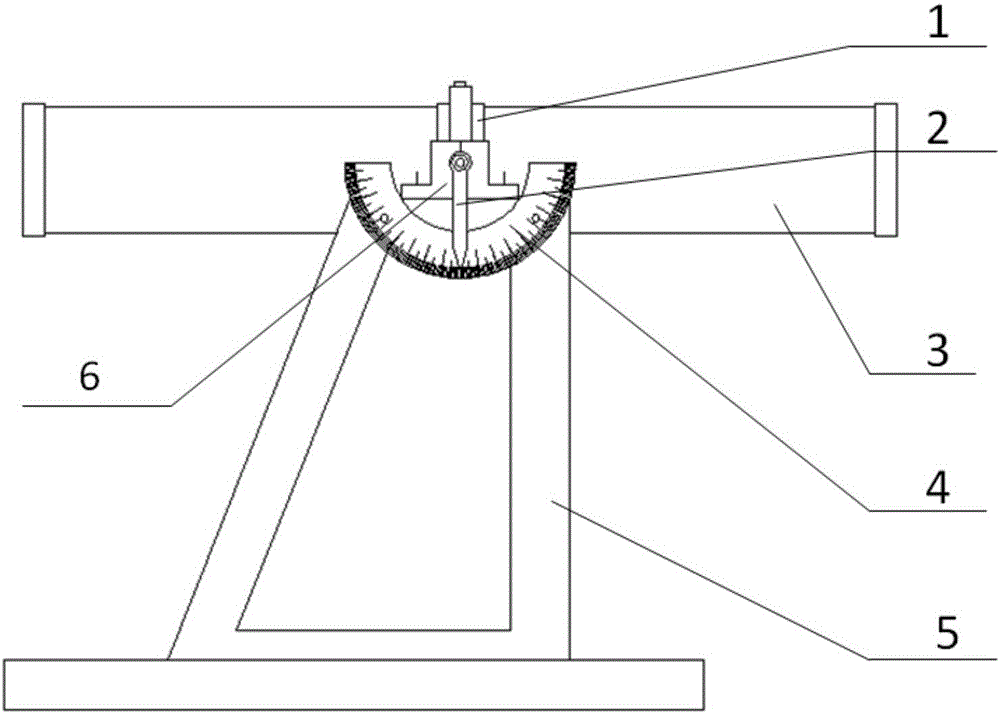

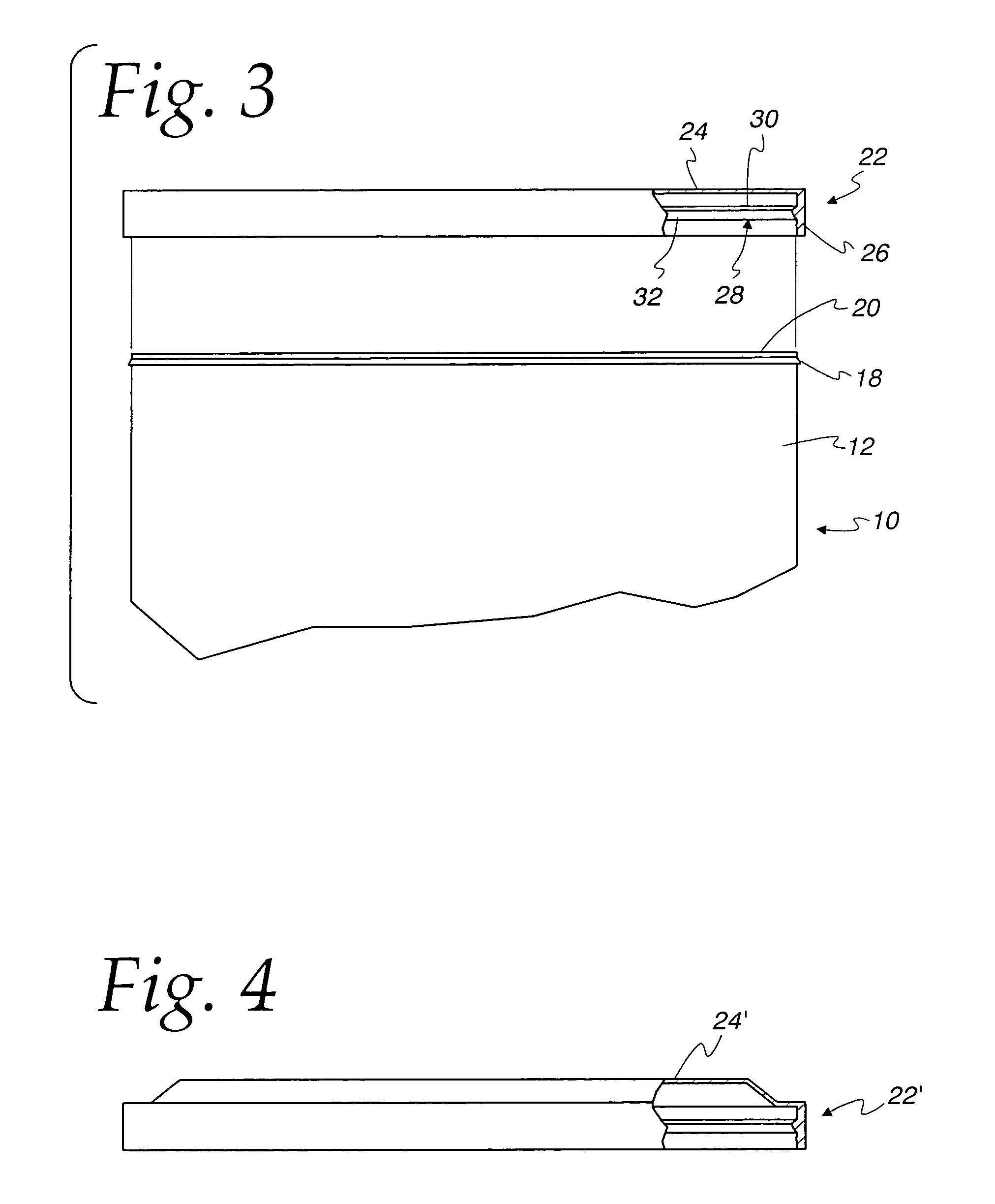

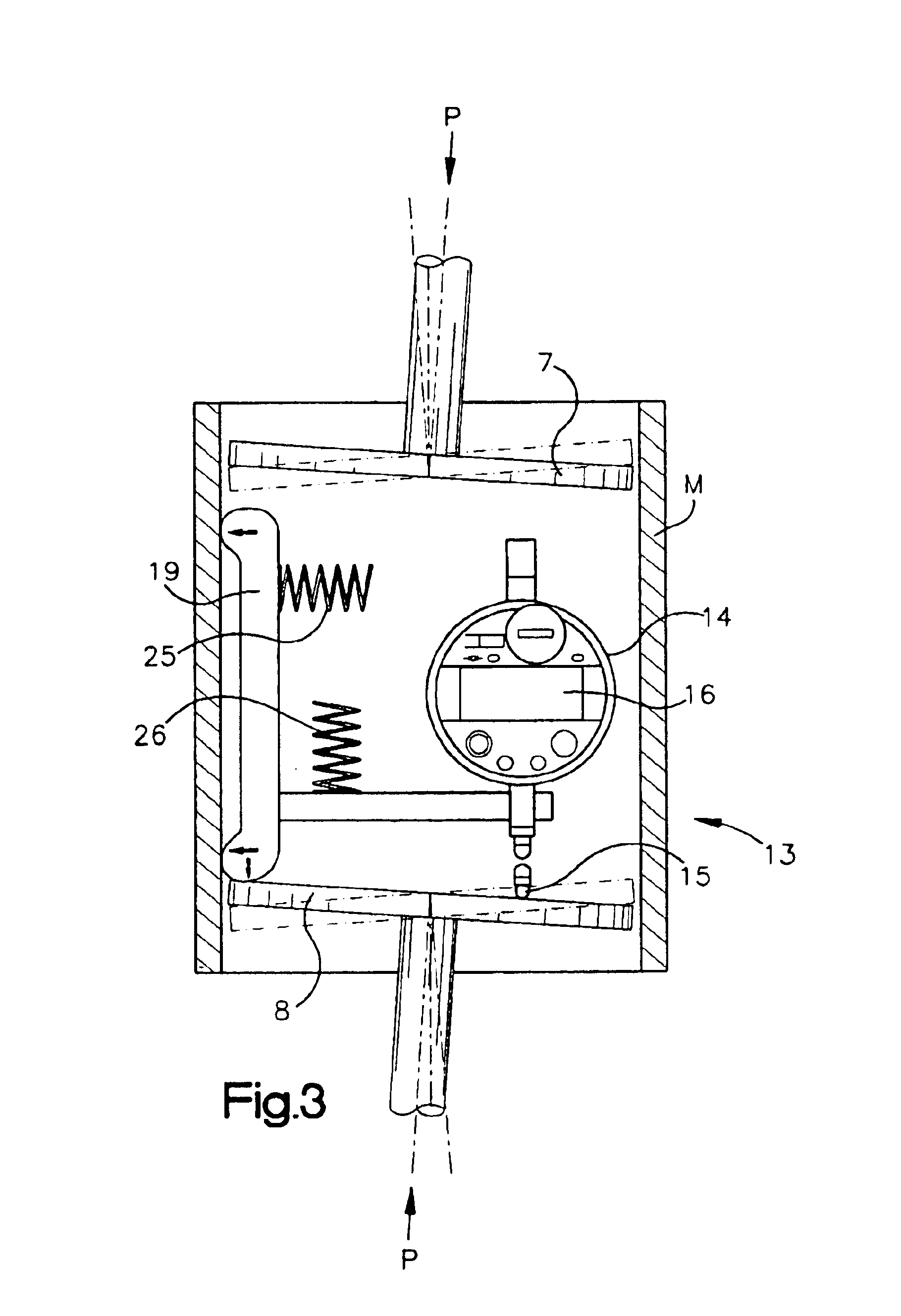

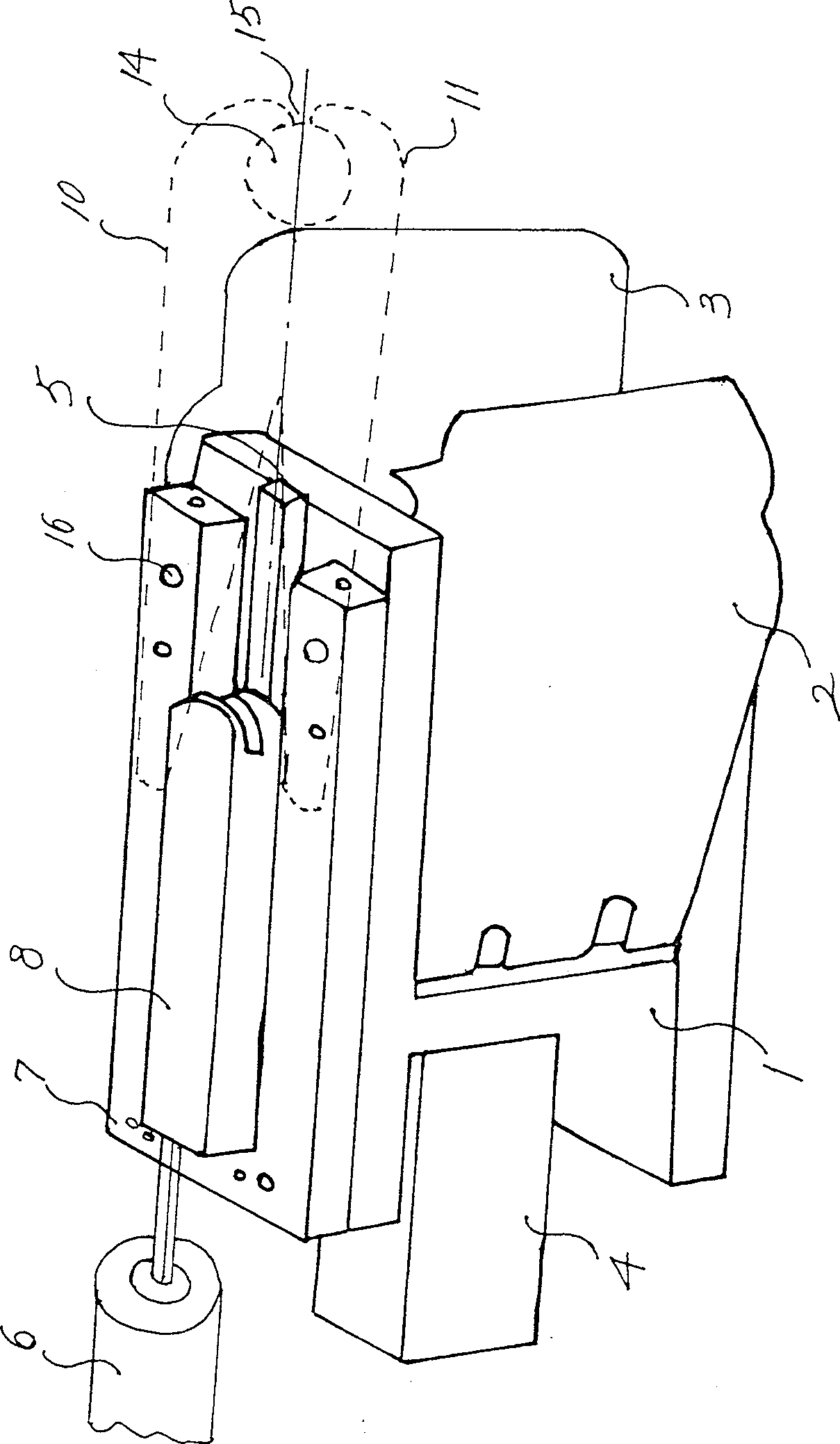

Method and device for defining elastic deformations and internal angle of a gyratory compactor

InactiveUS6904693B2Quick to useAccurate and reliable processMechanical counters/curvatures measurementsPreparing sample for investigationCylinder moldEngineering

The object of the invention is a method for defining elastic deformations and integral angle between of the most important parts of a gyratory compactor, in which method the angle of gyration of a gyratory compactor is measured during the use of the gyratory compactor. The object of the invention is also a device in accordance with the claim 1, which device includes measuring elements (13, 20, 27, 28) for measuring the angle of gyration of a gyratory compactor. Characteristic to the method in accordance with the invention is the fact that a loading device (1) is adjusted in the place of mass specimen, the loading of which on the gyratory compactor is earlier known and that the gyratory compactor will be in use while the loading device (1) is inside the gyratory compactor. Characteristic to the device in accordance with the invention is the fact that the device includes at least one loading device which can be placed inside the specimen cylinder mold of the gyratory compactor.

Owner:PINE INSTR

Direct-pressing mode locking device for mechanical equipment

The invention discloses a direct-pressing mold locking device for mechanical equipment. The direct-pressing mold locking device for mechanical equipment comprises a mold locking mechanism, an air cylinder mold locking push plate and a fine adjustment push plate, wherein the two sides of the mold locking mechanism are respectively provided with a mold locking mechanism side plate, and the two sidesof the mold locking mechanism side plate are respectively connected with an air cylinder extension plate. By placing a detachable direct-pressing mold in a limiting groove of the mold locking mechanism, the detachable direct-pressing mold can be pushed through a first push air cylinder and a second push air cylinder to be touched with the fine adjustment push plate. By adjusting the position of the fine adjustment push plate through a push plate pad, the detachable direct-pressing mold can be clamped and locked by the mold locking push plate for air cylinders and the fine adjustment push plate for air cylinders, so that a mold installation is achieved. Replacing of the mold has reverse operations. By resetting the first push cylinder and the second push cylinder and pressing an electromagnetic switch, a second electromagnetic ring is electrified to attract a first electromagnetic ring to drive a limiting gear block to ascend, and the position of the fine-adjustment push plate can be adjusted at will. The direct-pressing mold locking device for mechanical equipment has the advantages of simple and convenient operation, convenient die locking and die changing, and improved work efficiency of die locking and die changing in direct pressure production.

Owner:陈忠信

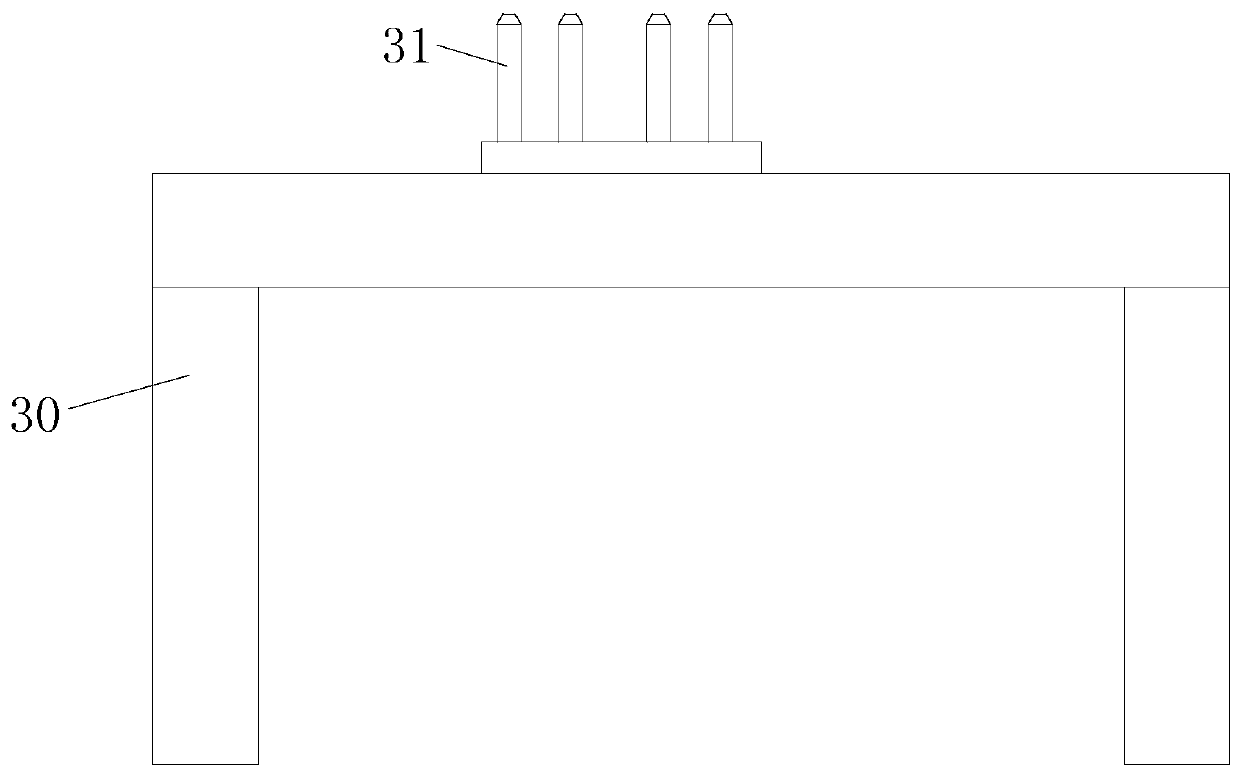

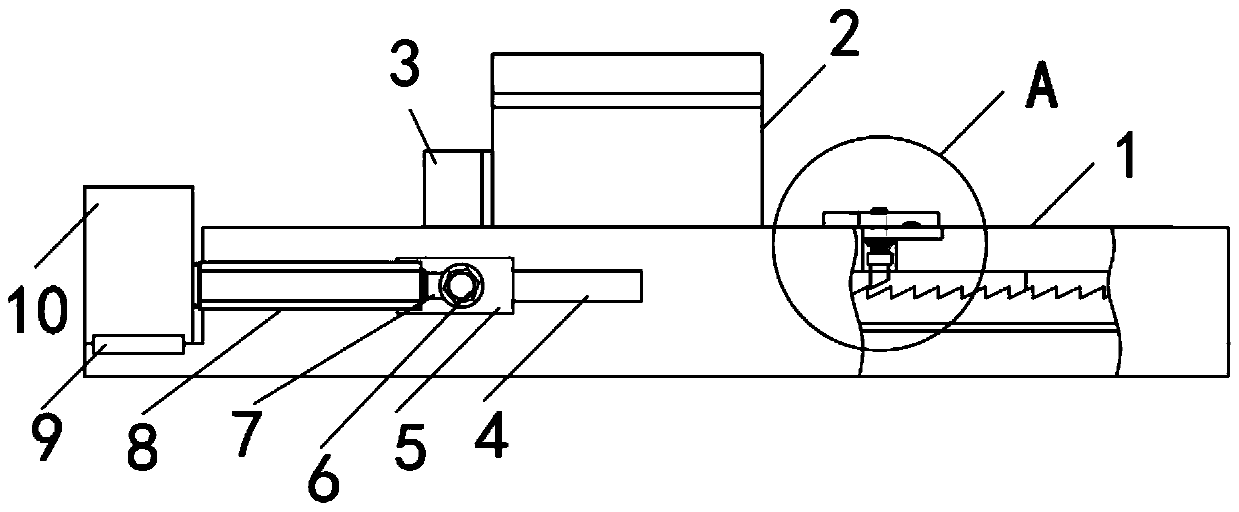

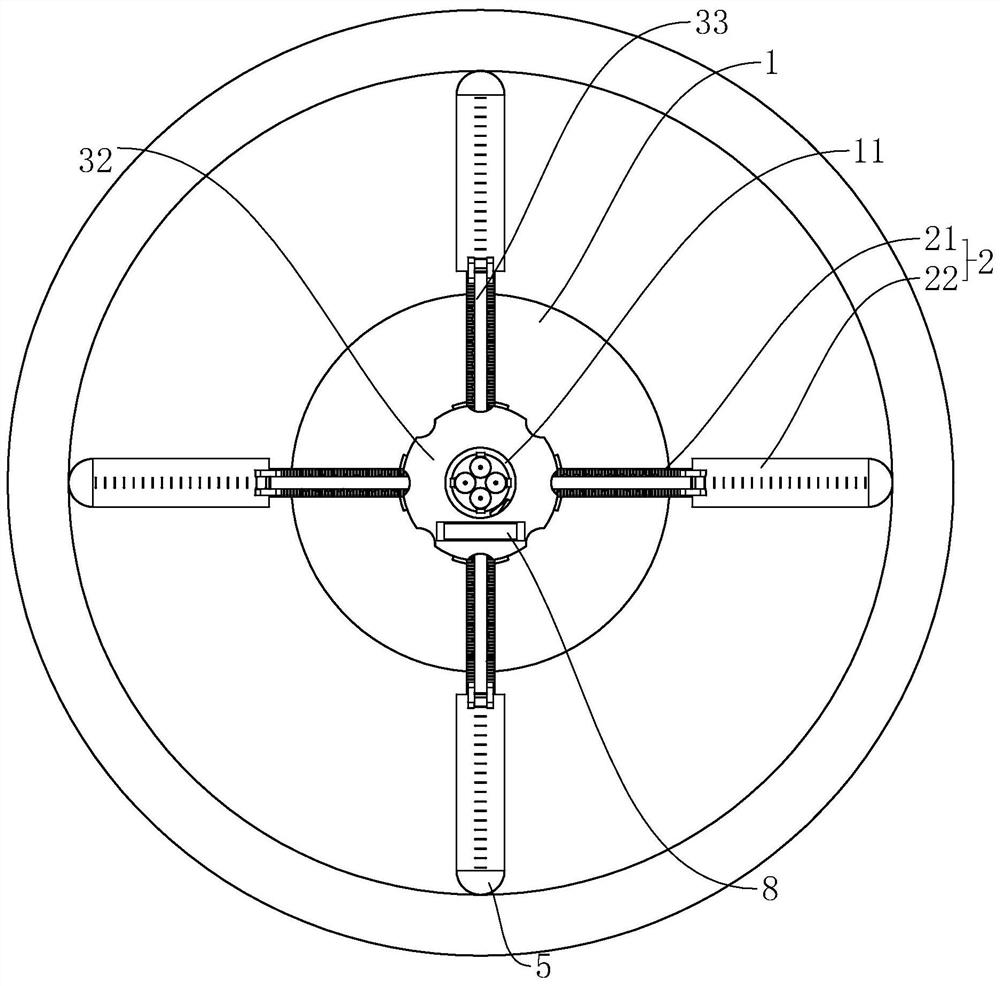

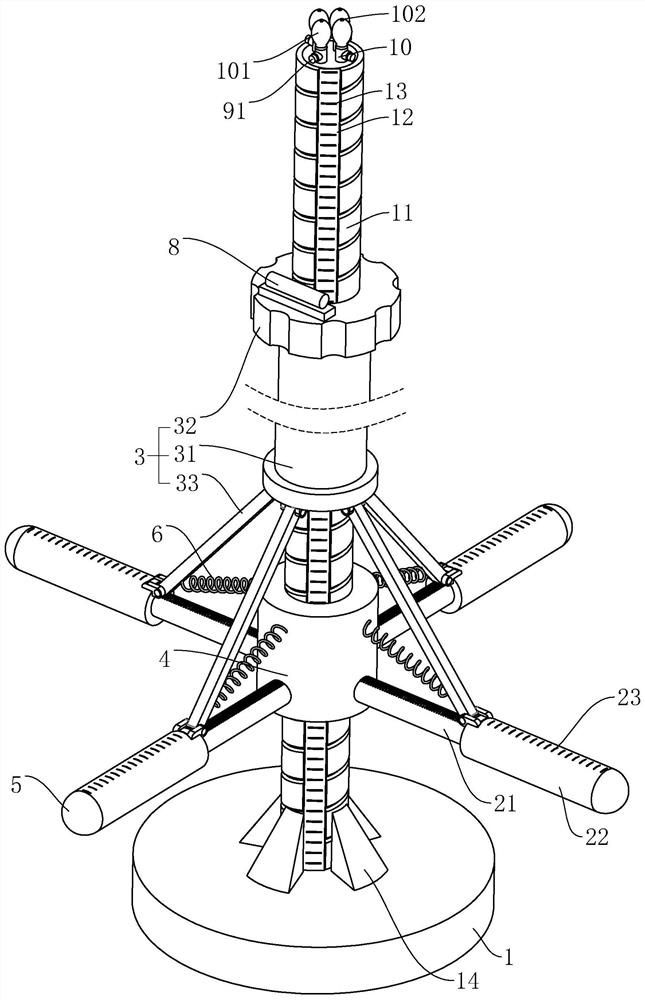

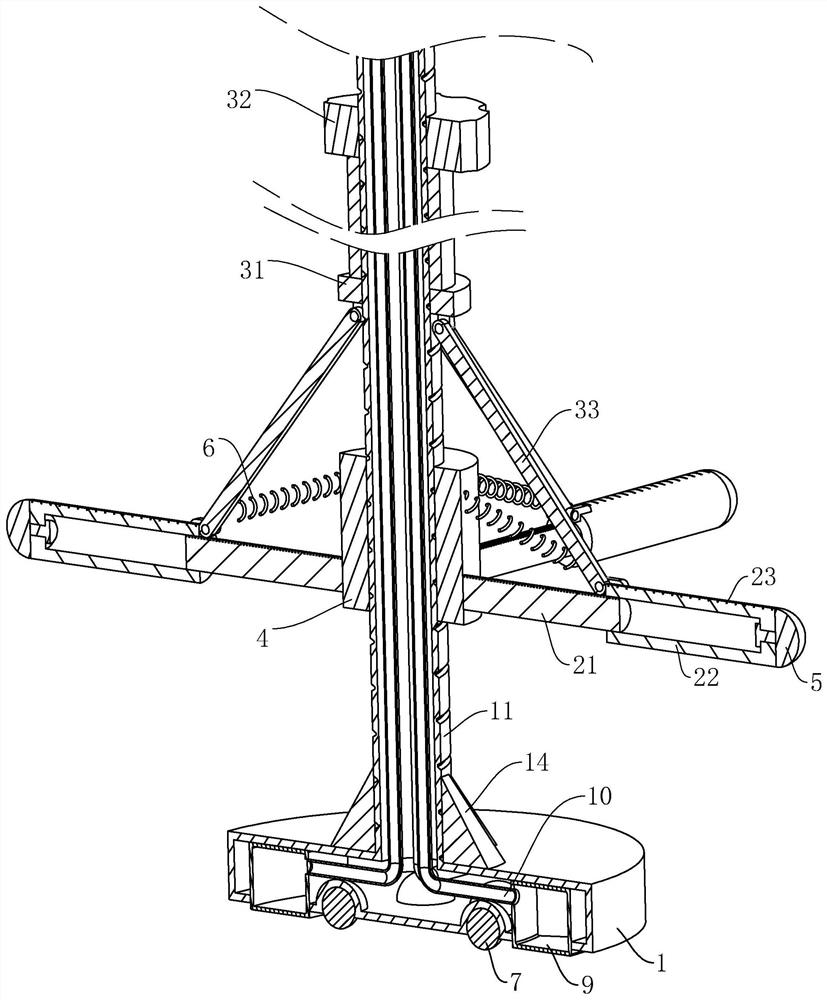

Large-scale container circular cylinder molding inner wall dimension form and position combination measuring device

ActiveCN112665484AQuick calculationReduce measurement errorMechanical diameter measurementsMeasurement deviceCylinder mold

The invention relates to the technical field of measuring equipment, and relates to a large-scale container circular cylinder forming inner wall size, shape and position combined measuring device which comprises a supporting seat and a center rod fixedly connected to the upper side of the supporting seat, wherein a plurality of telescopic pieces used for measuring the inner diameter of a cylinder are arranged in the circumferential direction of the center rod, and each telescopic piece comprises a first telescopic rod, and a second telescopic rod, wherein the first telescopic rod is sleeved with the second telescopic rod, hemispheres are arranged at the ends, away from the center rod, of the second telescopic rods, and the center rod is further provided with driving pieces for driving the multiple second telescopic rods to slide relative to the corresponding first telescopic rods. The first telescopic rod and the second telescopic rod are each provided with a first scale groove. The measuring device has the advantages that measuring errors can be effectively reduced by the aid of the measuring device, and accordingly the measuring precision can be improved.

Owner:九江检安石化工程有限公司

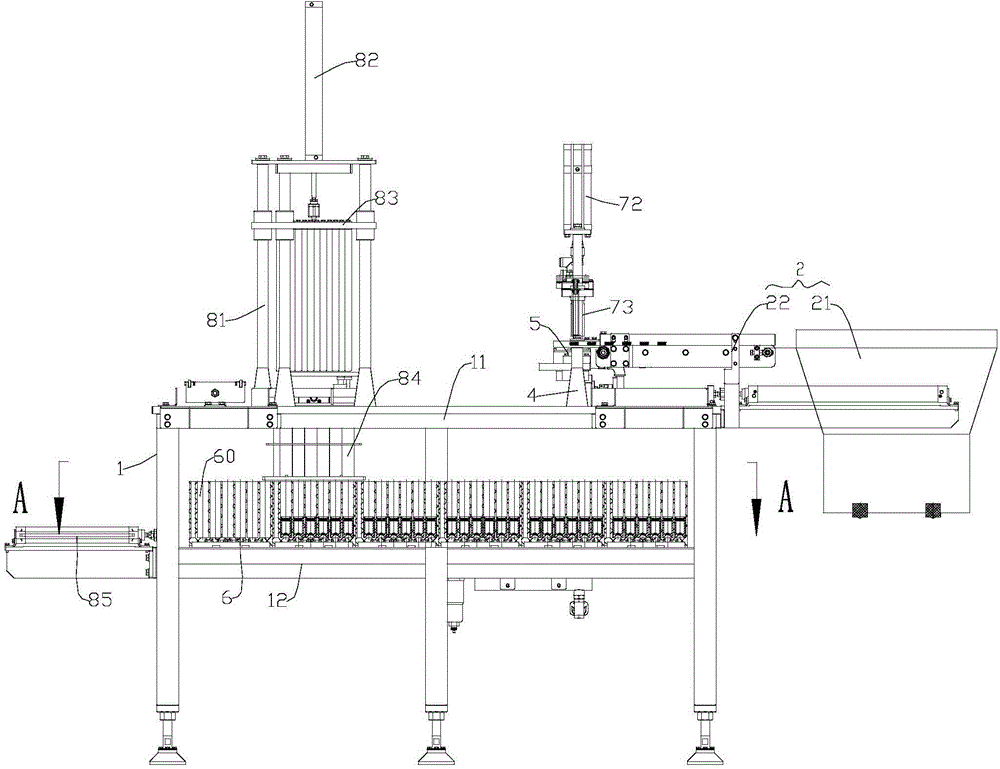

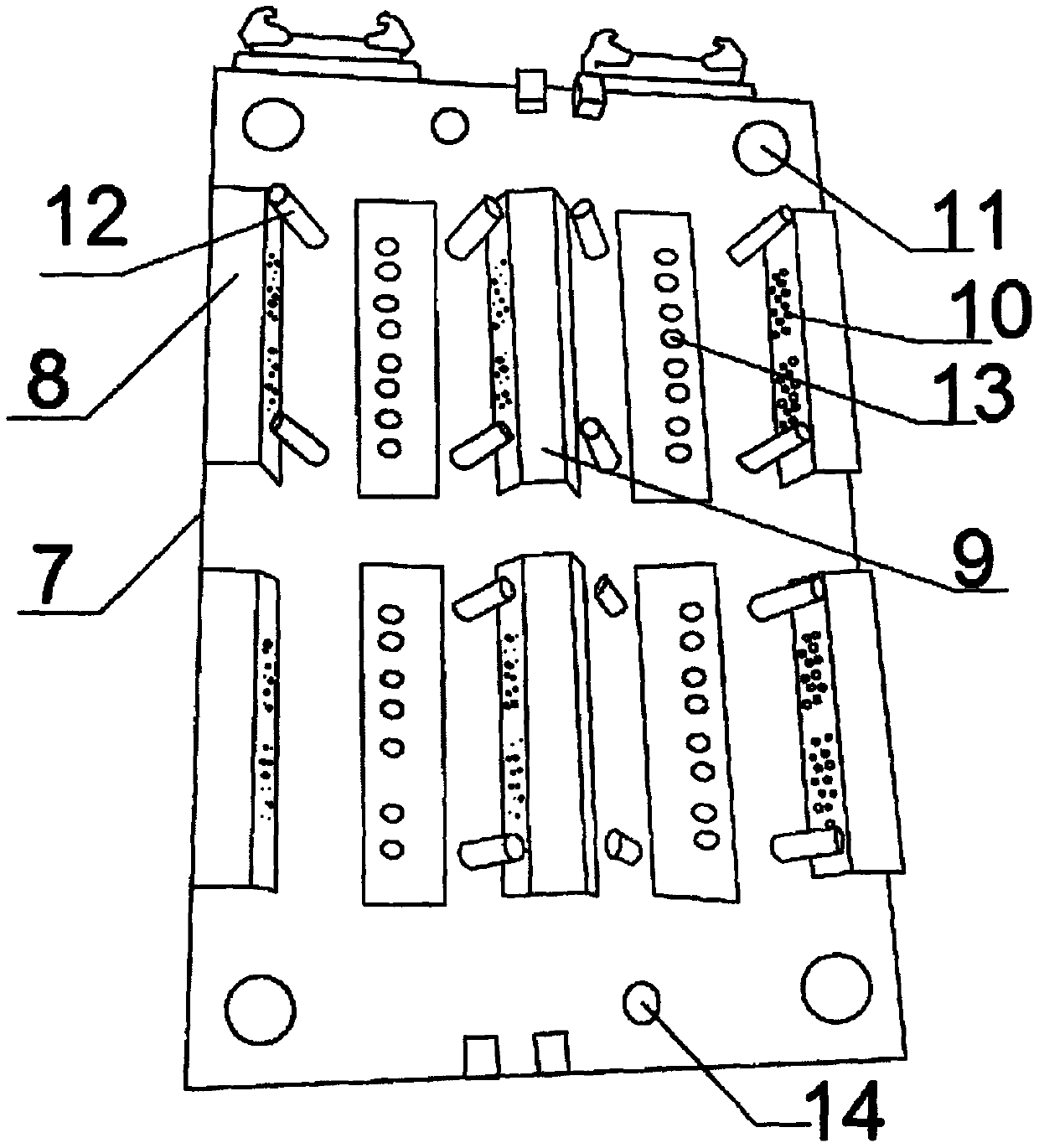

Firework cylinder assembling device

ActiveCN104457437AReduce labor intensityIncrease productivityFireworksCylinder moldAgricultural engineering

The invention discloses a firework cylinder assembling device. The firework cylinder assembling device comprises a workbench, an upper cover subassembly, a coating gland subassembly, and a material basin-feeding subassembly, wherein the workbench is arranged on the ground and comprises an upper platen and a lower platen; an upper cover station, a coating gland station and a material basin-feeding station are sequentially arranged on the upper platen in the length direction; the upper cover subassembly is arranged on the upper cover station and comprises a cover tidying bucket and a cover fetching seat; the coating gland subassembly comprises an internal cylinder mold and a coating gland component; the internal cylinder mold can be moved along the upper cover station, the coating gland station and the material basin-inputting station in sequence; the coating gland component is movably arranged on the coating gland station and used for fetching the inner cover on the cover fetching seat and pressing the coated inner cover into the internal cylinder; the material basin-inputting subassembly comprises a firework pedestal and a material pushing component arranged on the material basin-inputting station. The firework cylinder assembling device disclosed by the invention is low in labor intensity of workers, high in production efficiency and high in qualification rate of the firework cylinder.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

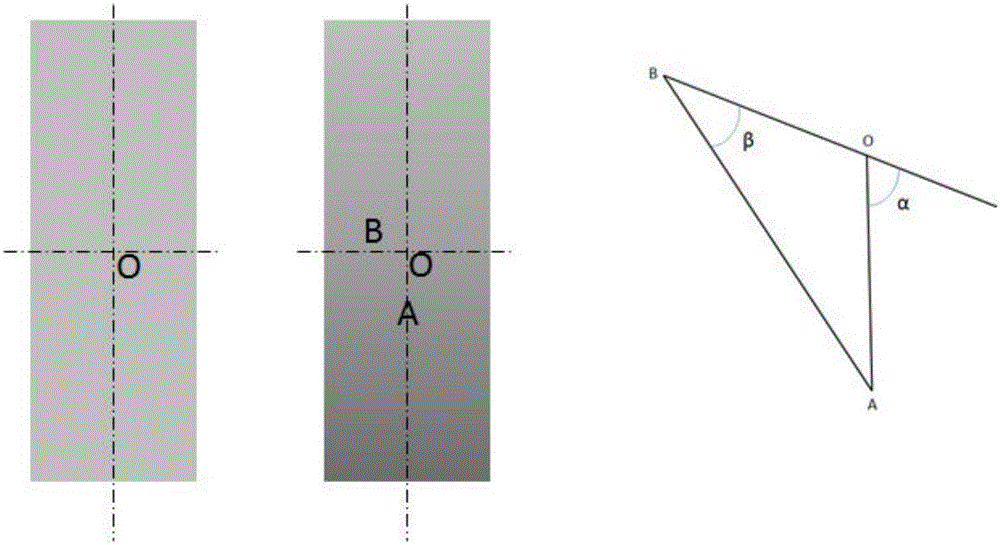

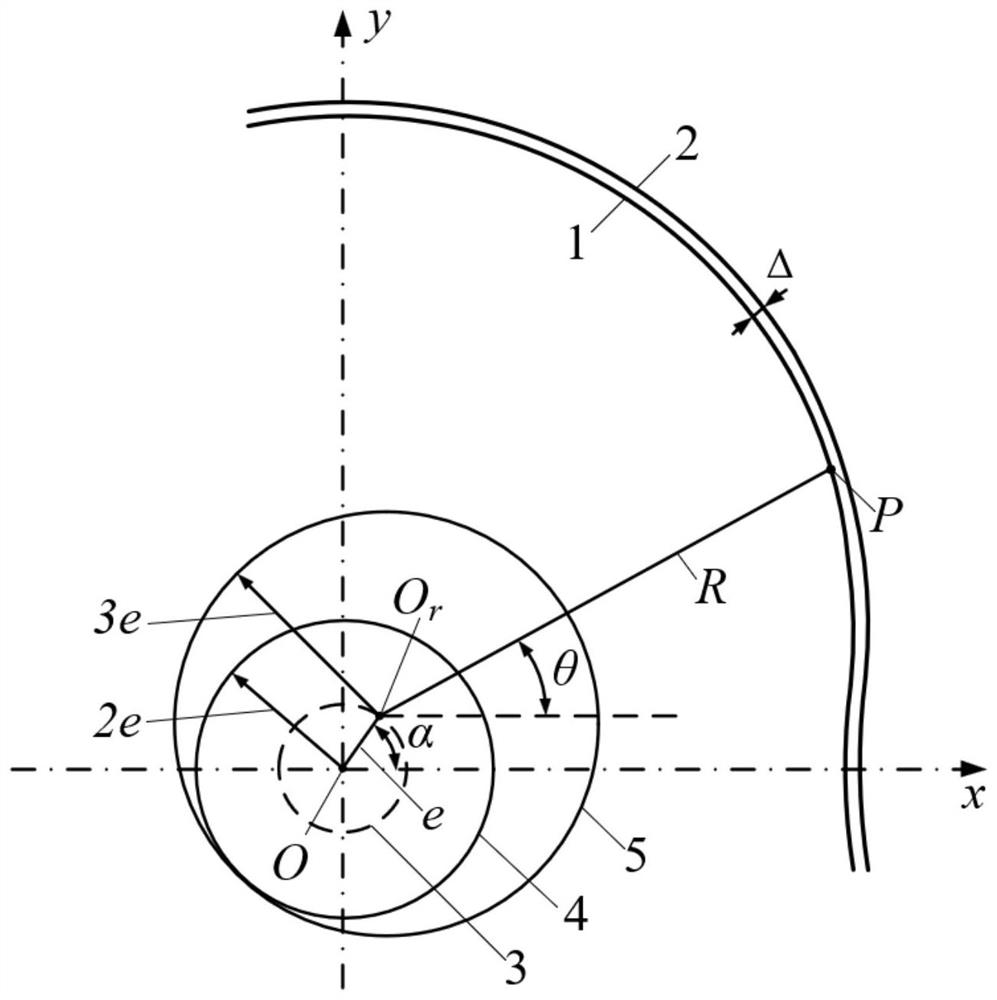

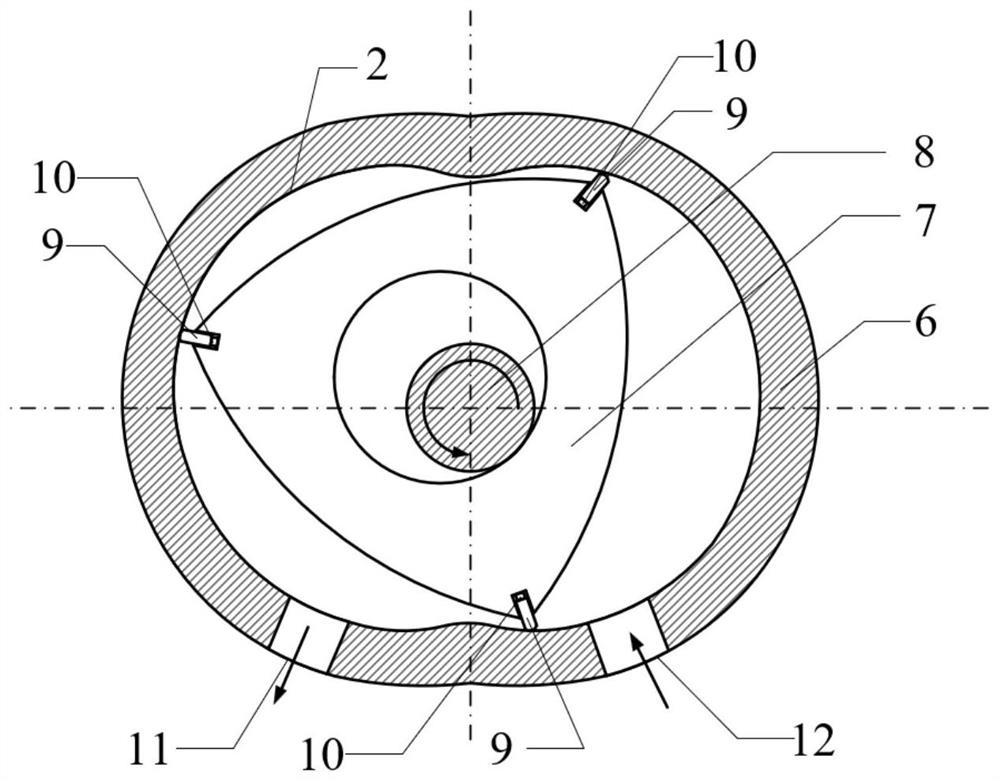

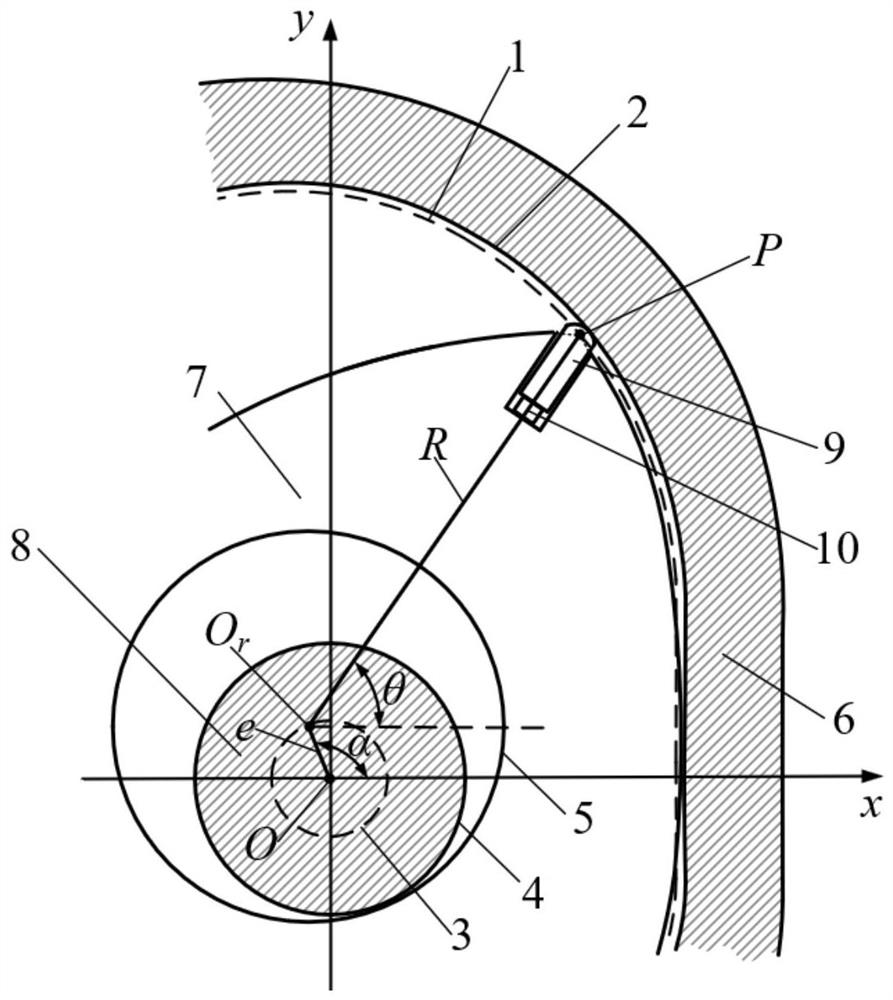

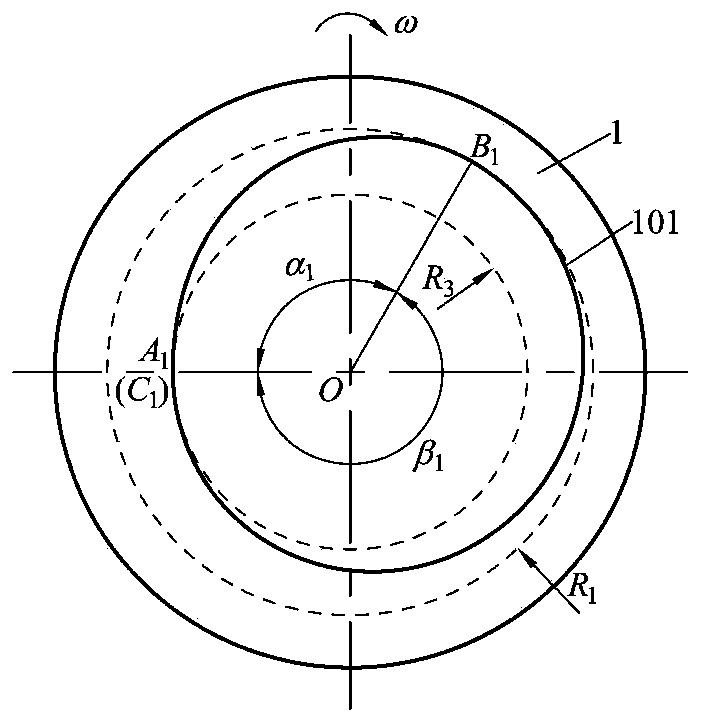

A triangular rotor engine combined cylinder molded line design method

PendingCN113836687AImprove flutterImprove sealingGeometric CADInternal combustion piston enginesCylinder moldEngineering

The invention discloses a triangular rotor engine combined cylinder molded line design method, and belongs to the field of rotor engines. The method comprises the following steps: determining three double-arc long-short-amplitude epicycloids, and establishing the three double-arc long-short-amplitude epicycloids in a Cartesian coordinate system by utilizing an eccentric distance and different generated radiuses; selecting a specified eccentric shaft rotation angle to determine three control points A, B and C; drawing inscribed circular arcs of the epicycloid at the three control points A, B and C, and connecting the three double-arc long-short epicycloid; selecting local curves of three double-arc long-short-amplitude extrochoids to be combined with four inscribed circular arcs, so that a combined type air cylinder theoretical molded line of the rotor engine can be drawn, and the combined type air cylinder theoretical molded line is deviated outwards by a certain distance to obtain a combined type air cylinder actual molded line. The influence of gas pressure on the radial sealing fin in the compression and combustion stages of the rotor engine is reduced, and the chatter condition of the radial sealing fin and the abrasion condition between the radial sealing fin and the molded surface of the air cylinder are improved; the combustion performance of the rotor engine is improved.

Owner:BEIJING UNIV OF TECH

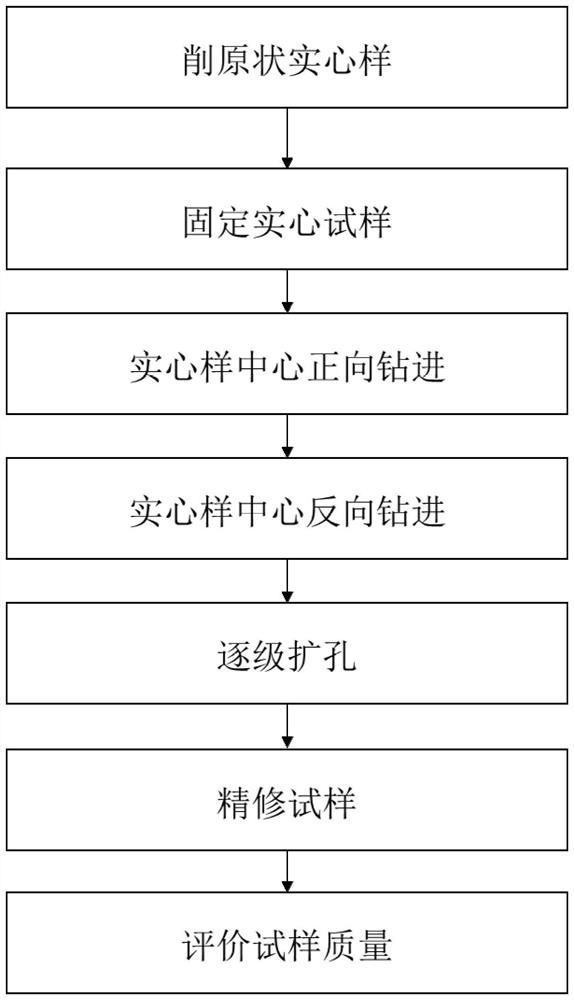

Preparation method of original-state sample for hollow torsional shear test of strong-weathered rock and residual soil

ActiveCN112362441ASolve problems that are difficult to prepare successfullyGuaranteed integrityPreparing sample for investigationStrength propertiesRubber membraneSoil science

The invention discloses a preparation method of an original-state sample for a hollow torsional shear test of strong-weathered rock and residual soil. The method comprises the following steps: (1) cutting an original-state solid sample: taking an original-state soil block, and cutting the soil block to a height higher than a standard height by using a soil cutter; (2) fixing the solid sample: sleeving the soil sample with a preservative film, and putting the soil sample into a split cylinder mold; (3) forward drilling of the center of the solid sample: adjusting the extension length of a forcetransmission guide rod of an inner cavity cutter, and withdrawing the inner cavity cutter according to an original path; (4) reversely drilling the center of the solid sample: taking out the cylindermold filled with the soil sample and a fixed clamping ring, detaching a rotary lower chassis with a groove from the device, and re-fixing the rotary lower chassis on the chassis; (5) carrying out step-by-step chambering: reinstalling the test sample; (6) finely trimming the sample; and (7) evaluating the quality of the test sample: wrapping the prepared test sample with a rubber membrane, and mounting the test sample on a hollow torsional shear apparatus. The method has the characteristics of simplicity, low cost, low material consumption, low in-situ sampling requirement, high sample preparation success rate and the like.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

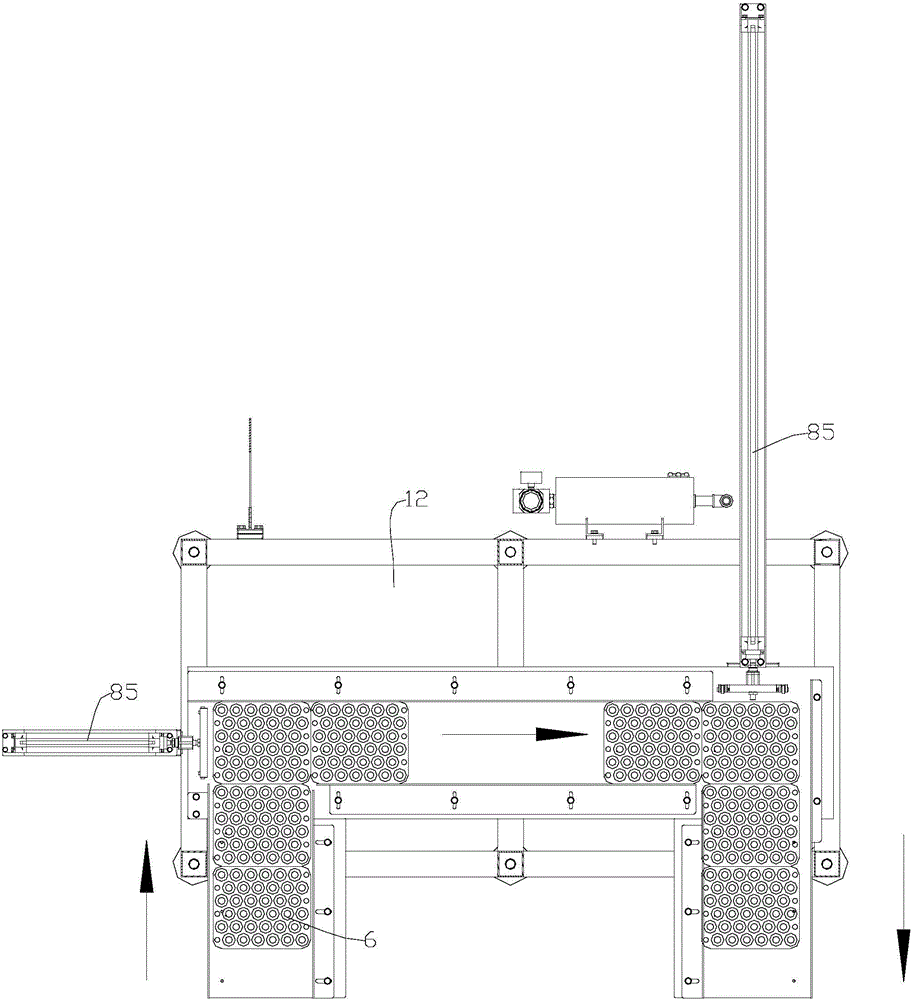

Hot pressing forming machine with die collecting device

The invention discloses a thermocompression molding machine with a mold retracting device, which includes a main machine and an operating table. The machine base is provided with a lower mold base and an injection molding part. The lower mold is fixed on the bottom plate of the mold; the lower side of the injection part is provided with a upper mold top plate, and the upper part is provided with a feeding pipe, and the lower side of the upper mold top plate is fixed with the upper mold, and the outlet of the feeding pipe is connected with the pouring interface of the upper mold top plate; The rear side of the mold base is provided with a horizontal and longitudinal mold pushing cylinder, and the end of the output rod of the mold pushing cylinder is detachably fixed on the rear side of the bottom plate of the lower mold through a latch; the front side of the lower mold base is provided with a mold retracting device, which includes a fixed In the vertical mold retracting cylinder in the middle of the front side of the machine base, a positioning plate is fixed on the top of the cylinder rod of the mold retracting cylinder, and two horizontal and vertical guide rails are respectively fixed on both sides of the positioning plate. The distance between the two guide rails is the same as that of the lower The width of the base plate is adapted.

Owner:李俊强

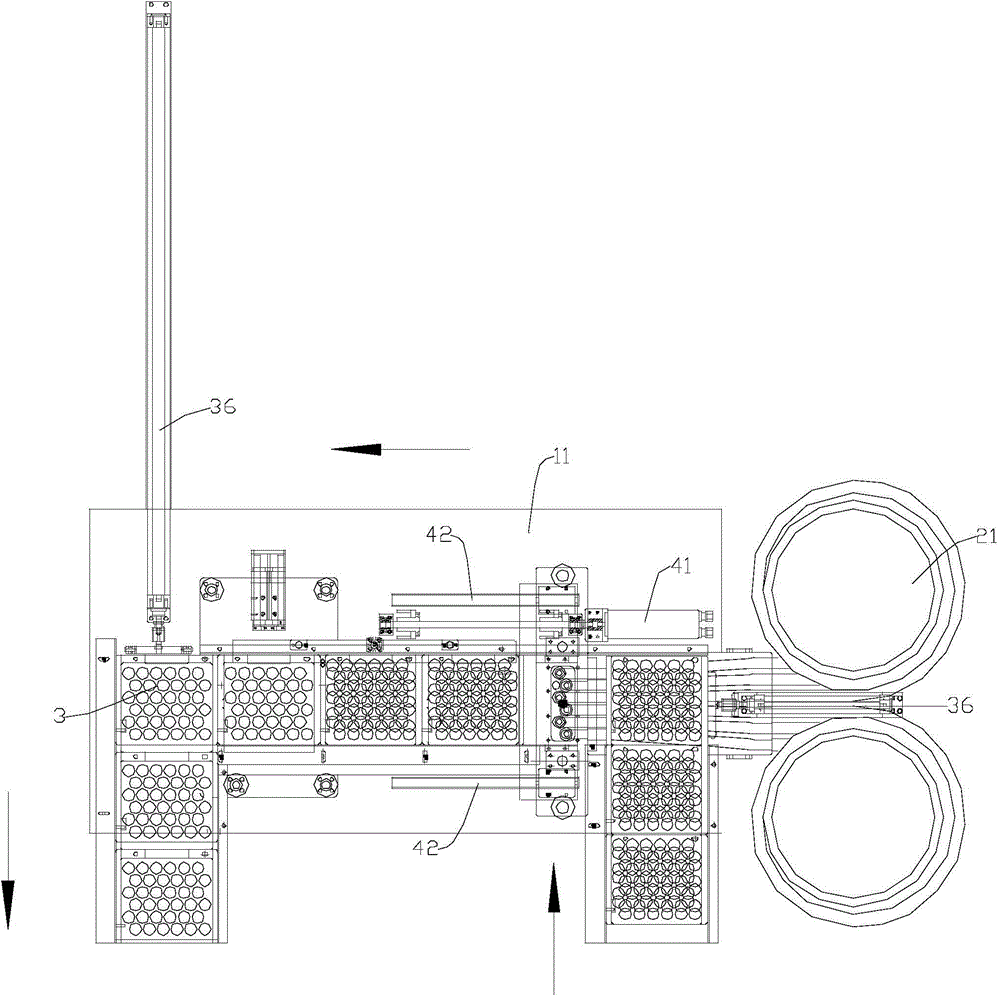

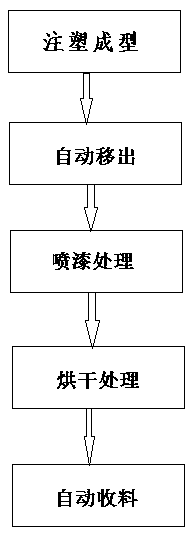

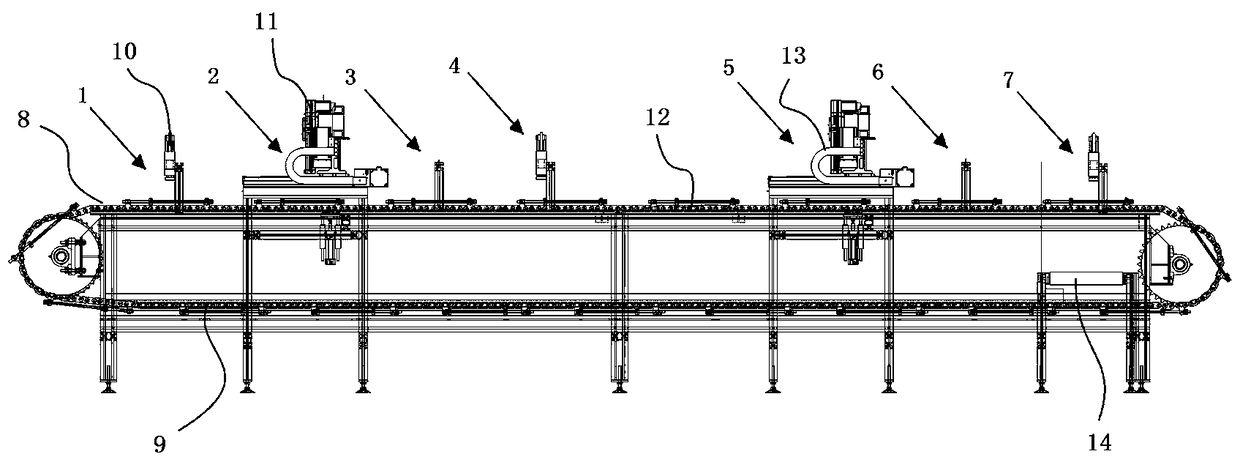

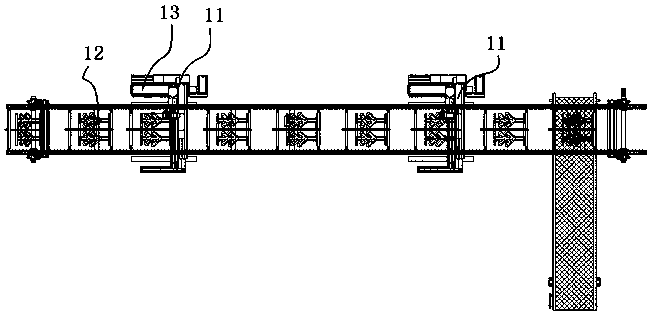

Automatic production process of simulating Christmas tree

InactiveCN109396000AImprovement of painting processEfficient paintingLiquid surface applicatorsSpraying apparatusButt jointCylinder mold

The invention discloses an automatic production process of a simulating Christmas tree. The formed Christmas tree is placed in an automatic japanning system to be further subjected to optimizing treatment; pine twigs of the Christmas tree are automatically placed into five-fork pine twig mold jigs; the automatic japanning system is sequentially provided with the five-fork pine twig mold jigs, positioning cylinder mold sets and a paint spraying mechanism; the first set of five-fork pine twig mold jig is conveyed to the paint spraying mechanism and stops; a three-shaft arm drives a spraying headto do the paint spraying action; after spraying of a main rod, transposition moving is performed, and pine twig branches are sprayed in a V shape; then the pine twig branches are subjected to position moving repeated spraying, automatic turn-over is performed to perform the reverse side pine twig spraying action, and forward conveying to a drying area is performed; the paint spraying action is repeated by parity of reasoning; and the rear of a novel cup making machine formed after improvement of the paint spraying technological process is directly connected to automatic japanning production so that carrying can be omitted online, direct positioning, conveying and painting are performed, automatic moving for turn-over is achieved, efficient japanning is performed, direct butt joint with automatic baking online is also achieved, manual carrying is avoided, time and labor are saved, and an unmanned automatic production mode is achieved.

Owner:江苏谐丰自动化科技有限公司

Mold for water dropper forming

The invention discloses a mold for water dropper forming. An A mold body and a B mold body which can be buckled are included; the A mold body comprises an A base and four sets of independent mold cores installed above the A base in a protruding manner; the four sets of mold cores are arranged into two rows, and two sets of mold cores are arranged in each row; each set of mold core comprises two oblong core bodies side by side in a left-right spaced manner, and the two opposite side edges of every two core bodies are each provided with eight up-down through water dropper mold cavities with semicircular cross sections; the water dropper mold cavities on the two side edges are opposite left and right, and a cylinder mold core is arranged between every two opposite water dropper mold cavities;each core body is provided with two positioning small holes, and four positioning large columns are arranged at the four corners of the A base; and the B mold body comprises a B base and six positioning sealing bases fixed to the B base. The mold cost is saved, it is avoided that after whole plate structure mold core abrasion, a mold core is replaced as a whole, and the production efficiency is improved.

Owner:LAIWU SPRING RAIN DRIP IRRIGATION TECH

Reciprocating open type equipment for fetching and sending semi-finished bottles or shaped bottles

The reciprocating opening type preform or molded bottle pick-up and delivery device has a pair of template seats, and the mold opening and closing cylinder is installed in the template seat. One end of the plate is connected to power, and the other end of the reciprocating plate is connected to an open-type plastic preform or molded bottle clamping mechanism, which is characterized in that the open-type plastic preform or molded bottle clamping mechanism includes a There are cams on both sides of the left and right retrieving pliers, fixed clips are installed on the template seat, and a support spring is installed at one end of the two pliers. The other end of the pliers is formed with an opening for feeding and clamping.

Owner:蔡桂森

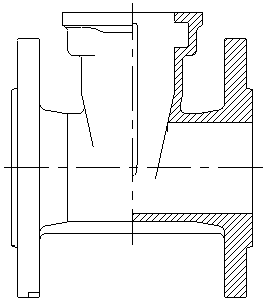

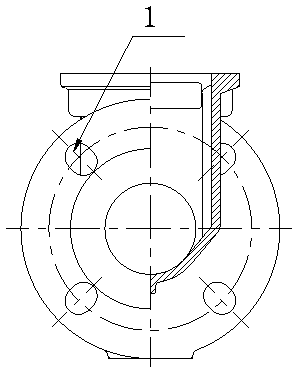

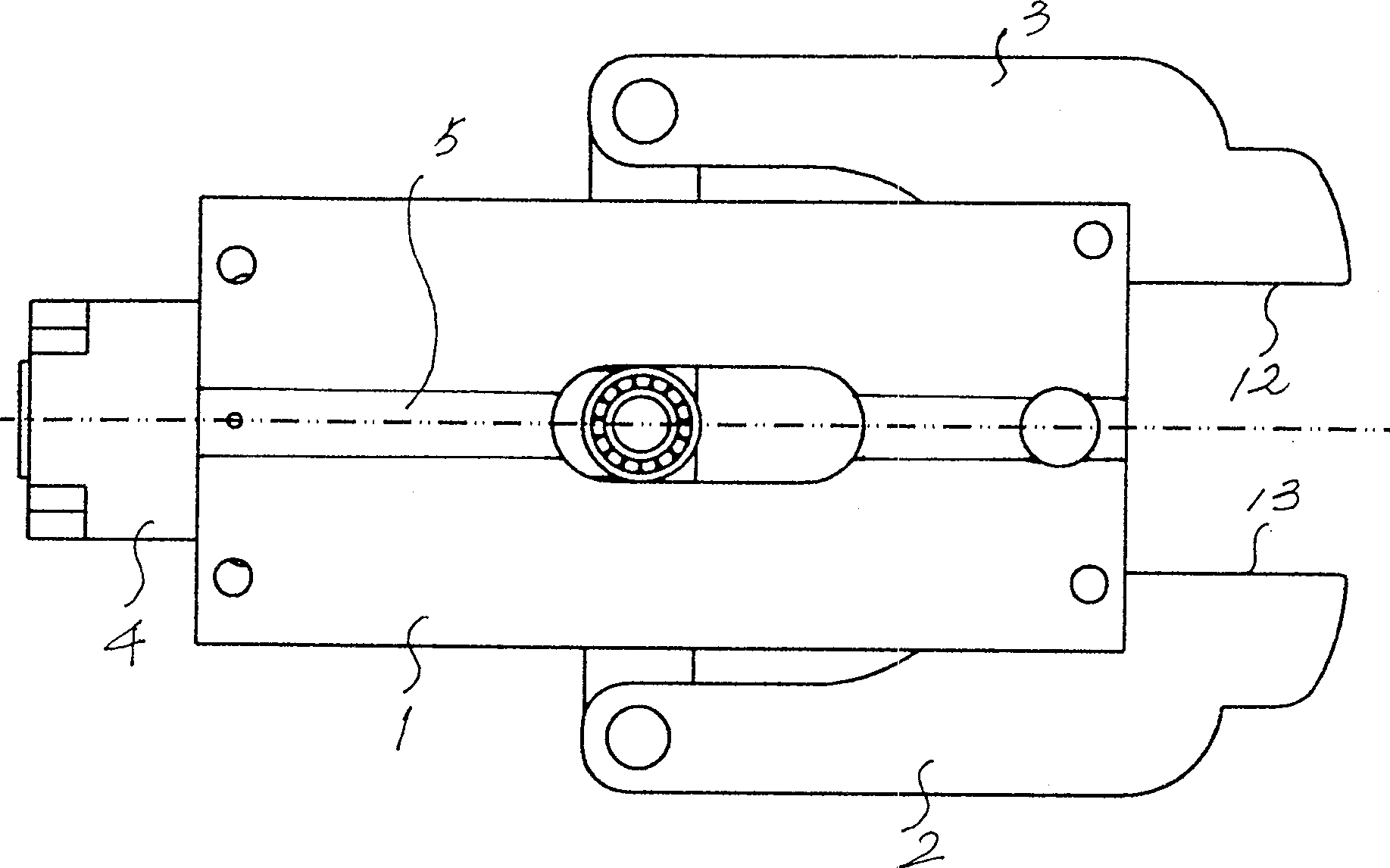

Double-cylinder mold opening device of injection molding machine and working method thereof

The invention discloses a double-cylinder mold opening device of an injection molding machine. The double-cylinder mold opening device comprises a supporting plate, a fixed mold, a movable mold and aninjection molding box. The invention relates to the technical field of garment materials. According to the double-cylinder mold opening device of the injection molding machine, a first hydraulic telescopic rod is fixedly connected with a push rod, an ejector rod is fixedly connected with a sliding cylinder through a push plate, the push rod is movably connected with the sliding cylinder through aspring, the push rod can drive the sliding cylinder to move through the cooperation of a sliding plate, the spring and a cylinder cover, the ejector rod can move within a certain range while the first hydraulic telescopic rod can adjust the position of the ejector rod, it is guaranteed that the position of the ejector rod is not affected by the first hydraulic telescopic rod when accurately positioned, a positioning block limits the position of a positioning rod from the right side of the positioning rod, a limiting column and a limiting plate limit the position of the push plate from the left side of the push plate, and therefore the accuracy of the positions of the push plate and the positioning rod is guaranteed, and then the accuracy of the position of the ejector rod is guaranteed.

Owner:HANGZHOU JIATONG MACHINERY

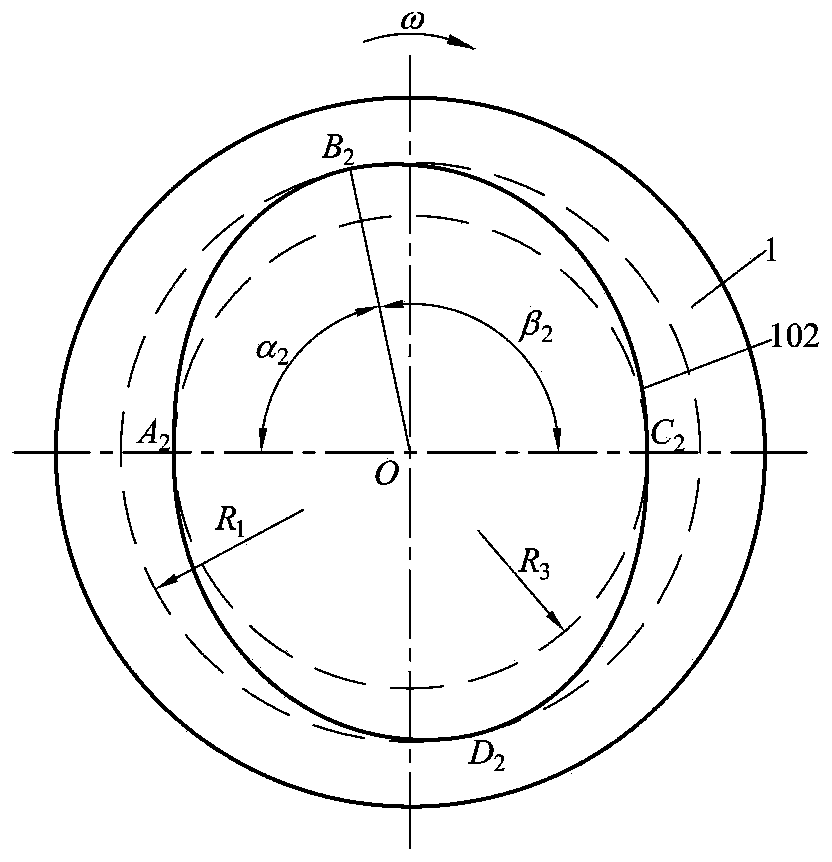

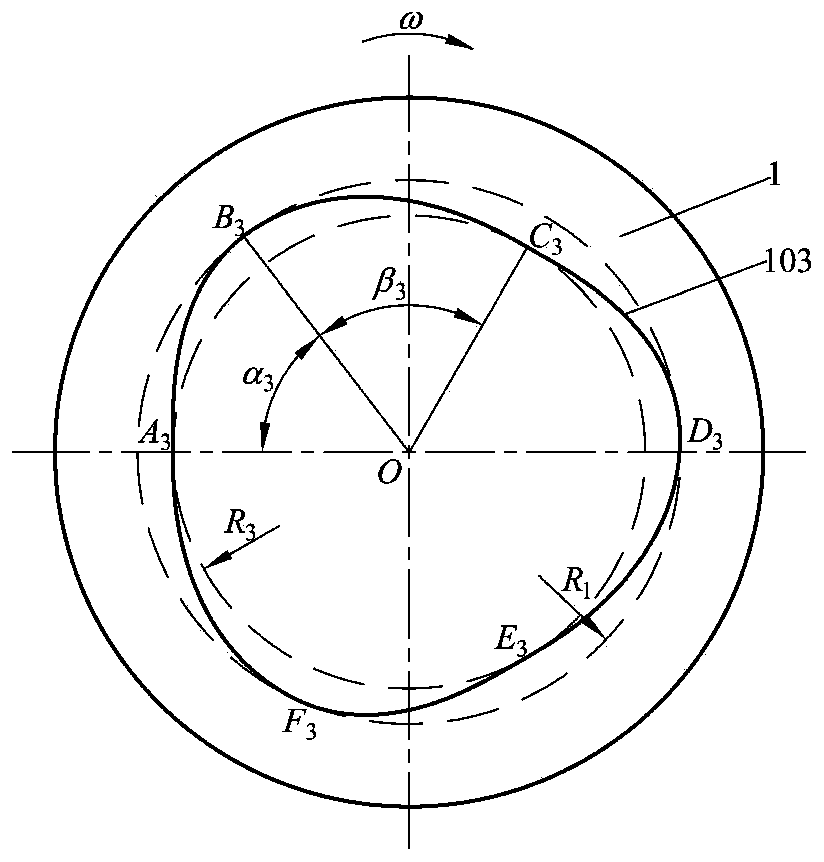

Asymmetric sliding vane type compressor air cylinder molded line design method

ActiveCN109854507AImprove stress conditionReduce vibrationRotary piston pumpsRotary piston liquid enginesCylinder moldEngineering

The invention discloses an asymmetric sliding vane type compressor air cylinder molded line design method. The method is suitable for design of single-cavity, double-cavity and three-cavity asymmetricsliding vane type compressor air cylinder molded lines, an air cylinder molded line on an air cylinder is composed of a secondary spiral line including suction section curves and exhausting section curves; all the sections of curves are completely and smoothly connected, the first derivative is continuous and smooth, and the second derivative is continuous; the degree of the central angle corresponding to the suction section curves is alpha<n>, the degree of the central angle corresponding to the exhausting section curves is beta<n>, the beta<n> is larger than the alpha<n>, and alpha<n>+beta<n>=2pi / n. An asymmetric working cavity is formed between the air cylinder molded line and a rotor, the situation that a center line passing through a rotation center enables the asymmetric working cavity to be symmetrical about the axis of the working cavity does not exist, the exhausting volume is decreased, the exhausting pressure is improved, the pressure ratio of a sliding vane type compressorcan be effectively increased, and the central angles corresponding to the suction section curves and the exhausting section curves can be adjusted according to the design working condition.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Yeast pressing mechanism

ActiveCN102220203AMeet the quality requirements of extraction pulpQuality improvementAlcoholic beverage preparationYeastCylinder mold

The invention relates to a yeast pressing mechanism, comprising a hydraulic oil cylinder and pressing molds. The yeast pressing mechanism is characterized in that: between the hydraulic oil cylinder and the pressing molds are provided cylinders and cylinder mold connection boards; there are 4 to 16 cylinders; the amount of pressing molds and cylinder mold connection boards are in accordance with the amount of the cylinders; each cylinder drives a corresponding pressing mold and a cylinder mold connection board. The beneficial effects of the invention are as follows: with the above-mentioned structure and characteristics, the yeast pressing mechanism can simulate the artificial process of purifying syrup, satisfy the traditional technology requirement for quality of purified syrup from thesurface of yeast blocks in wine brewing industry, and improve quality of wine brewed with mechanically pressed yeast.

Owner:四川宜宾岷江机械制造有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com