Reciprocating open type equipment for fetching and sending semi-finished bottles or shaped bottles

An open type preform technology, which is applied to the pick-up and delivery device of plastic preforms, and the processing equipment of plastic hollow containers, can solve the problems that automatic production cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

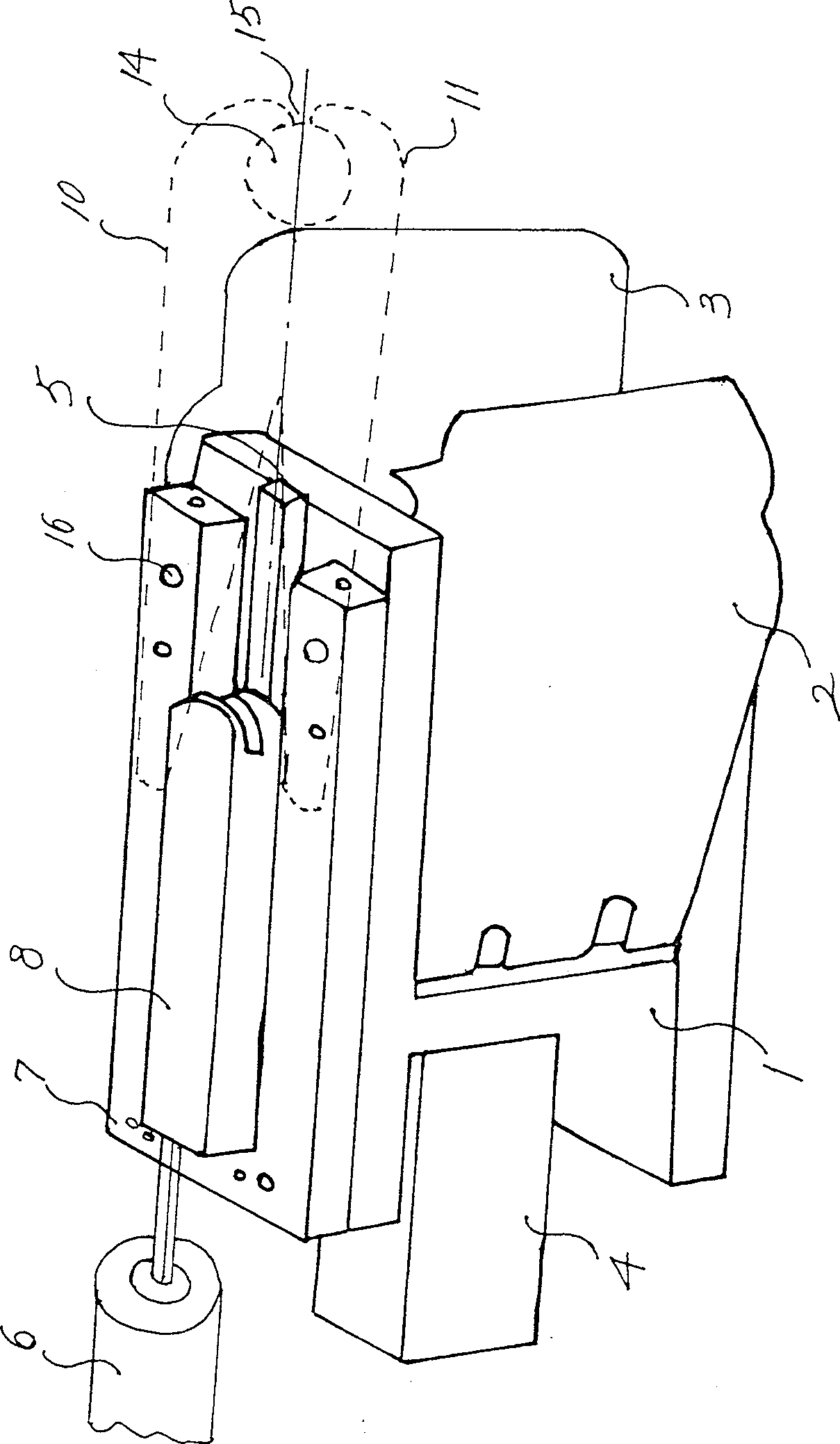

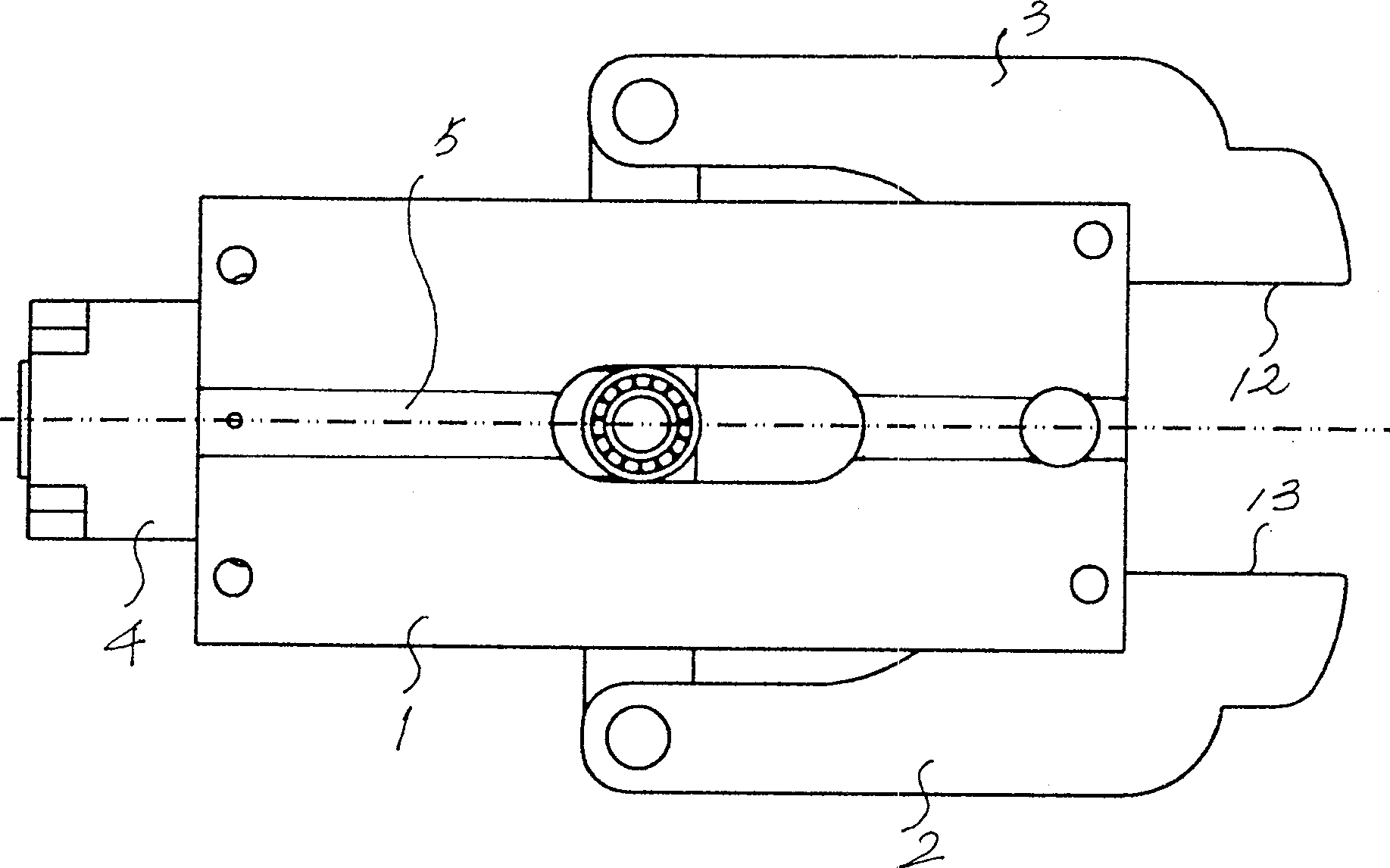

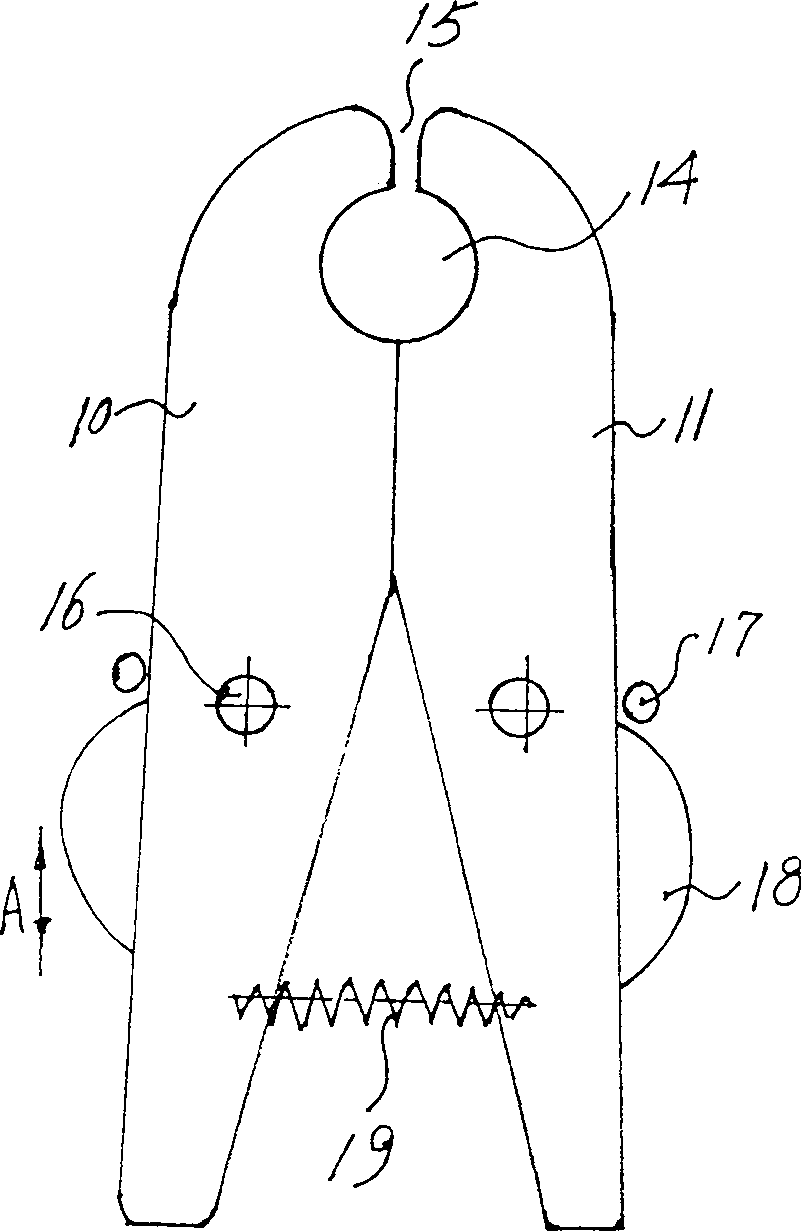

[0009] The invention discloses a pick-up and delivery device for a reciprocating opening type plastic bottle blank or a plastic molded bottle, which is matched with a clamp-type mold opening and closing mechanism of a plastic extruding and stretch blowing machine. Clamping cylinder 4, the mold opening and closing cylinder drives two templates 2 and 3 of A and B. The two templates of A and B have mold mounting surfaces 13 and 12 for installing molds. A reciprocating movable plate 8 is installed on the template seat 1 to One end of movable plate 8 is connected to power 6, and the power 6 that drives reciprocating movable plate 8 can be cylinder transmission (ideal, commonly used) or hydraulic transmission (also easy to realize) or mechanical reciprocating transmission (such as crank-link mechanism etc.), The other end of the reciprocating plate 8 is connected with an open-type plastic bottle blank or a molded bottle clamping mechanism. There are many technical solutions for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com