Automatic production process of simulating Christmas tree

A production process and technology for Christmas trees, which are applied in spraying devices, coatings, devices for applying liquid to surfaces, etc., which can solve the problems of mutual contamination of branches, inaccuracy, and time-consuming and laborious manual painting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

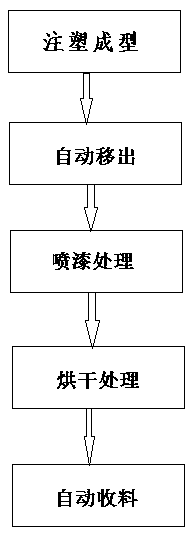

[0022] Such as figure 1 Shown, a kind of simulated Christmas tree automatic production technique, this technique comprises the steps:

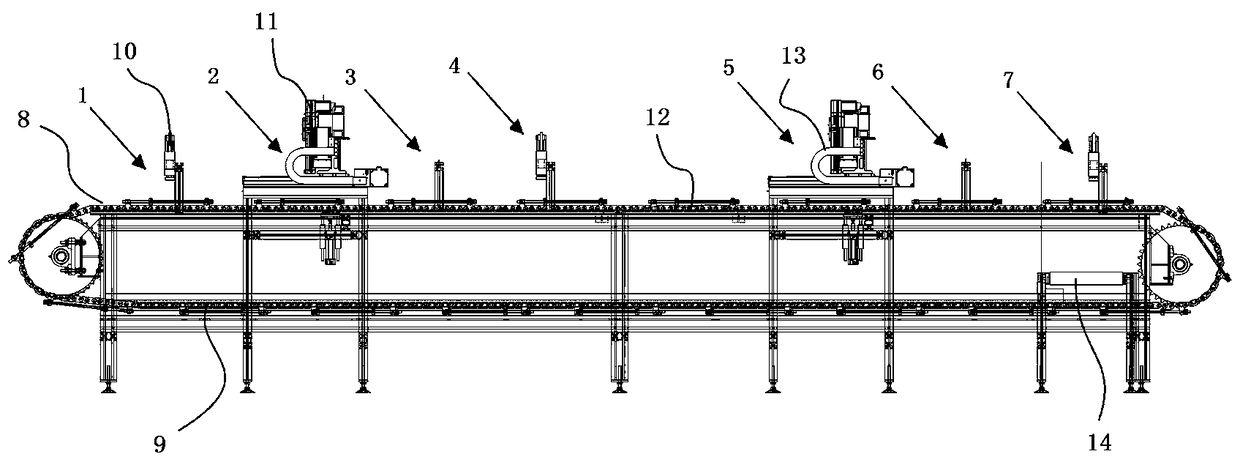

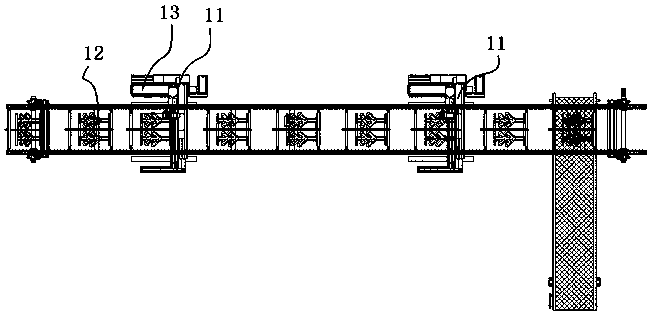

[0023] Simulation of Christmas tree injection molding machine molding and feeding; PVC raw materials are placed in the injection molding machine for injection molding, and after molding, the simulated Christmas tree branches and branches are integrated into one color, and the formed Christmas tree is placed in the painting automation system for further optimization; the first group painting treatment; such as Figure 2-4 As shown, the automation system is divided into press-in area 1, first painting area 2, first vision area 3, turning area 4, second painting area 5, second vision area 6 and extrusion area 7 according to functions. The system consists of a transmission frame 8, a transmission chain 9, a positioning cylinder module 10 and a paint spraying mechanism 11. The transmission chain 9 is located at both ends of the transmission frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com