Patents

Literature

131 results about "Japanning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Japanning is a type of finish that originated as a European imitation of Asian lacquerwork. It was first used on furniture, but was later much used on small items in metal. The word originated in the 17th century. American work is more often called toleware.

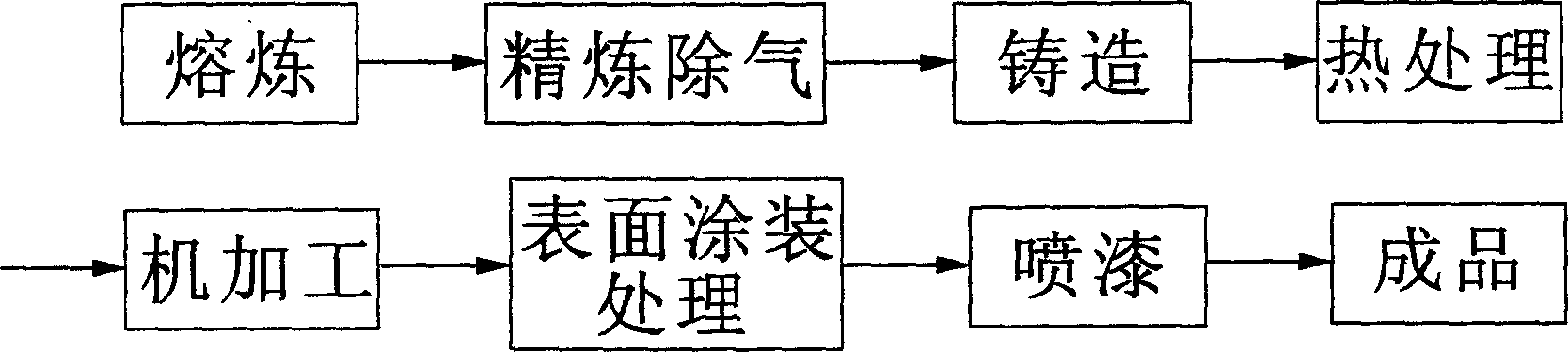

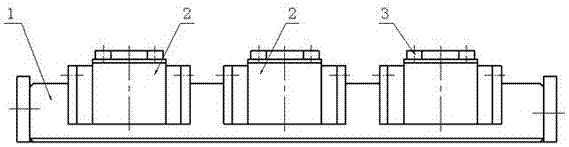

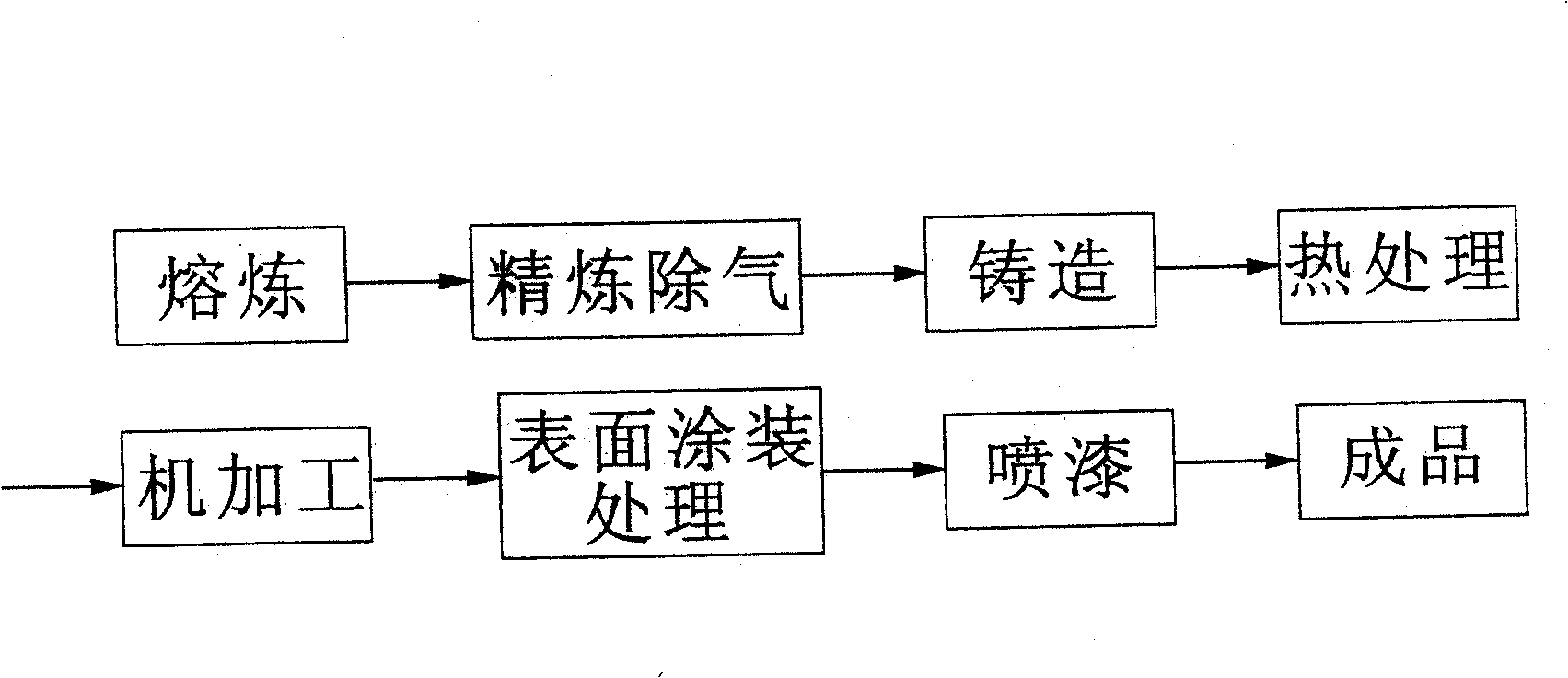

Magnesium alloy auto hub and its producing method

This invention relates to a kind of automobile hub of magnesium alloy and producing metho. It belongs to the die-casting technology of non-ferrous metal. The main raw material is magnesium alloy ingot. After preheating and drying, it is put in pot and melted under high temperature. Adding master alloy, mixing it fully. The following steps are refining and degassing, casting, heat treatment, machining, surface painting, drying, japanning. During the process, the degassing can reach standard easily. Magnesium liquid slag-removing is easy.

Owner:WUXI DAIKA WHEEL HUB MFG

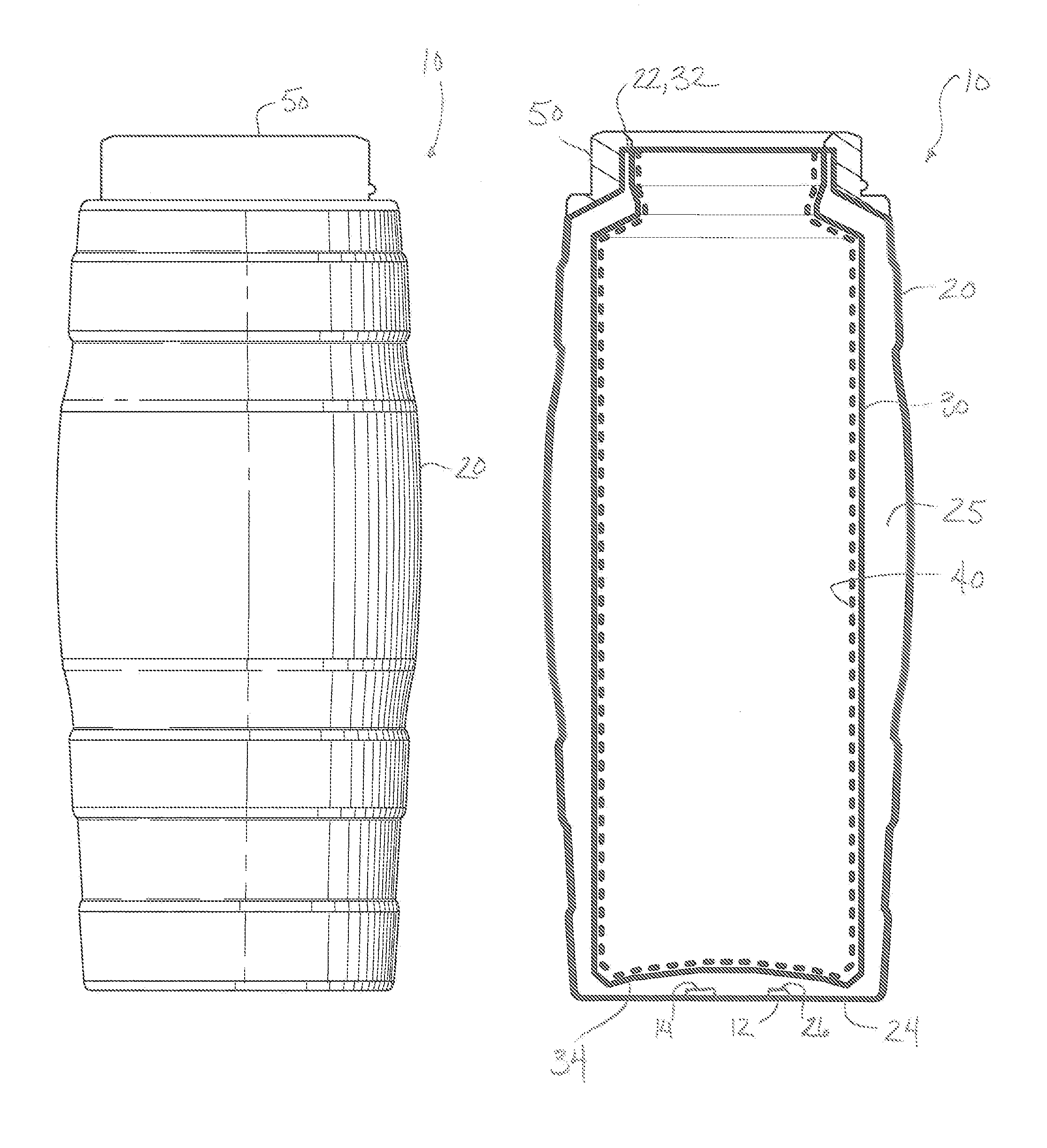

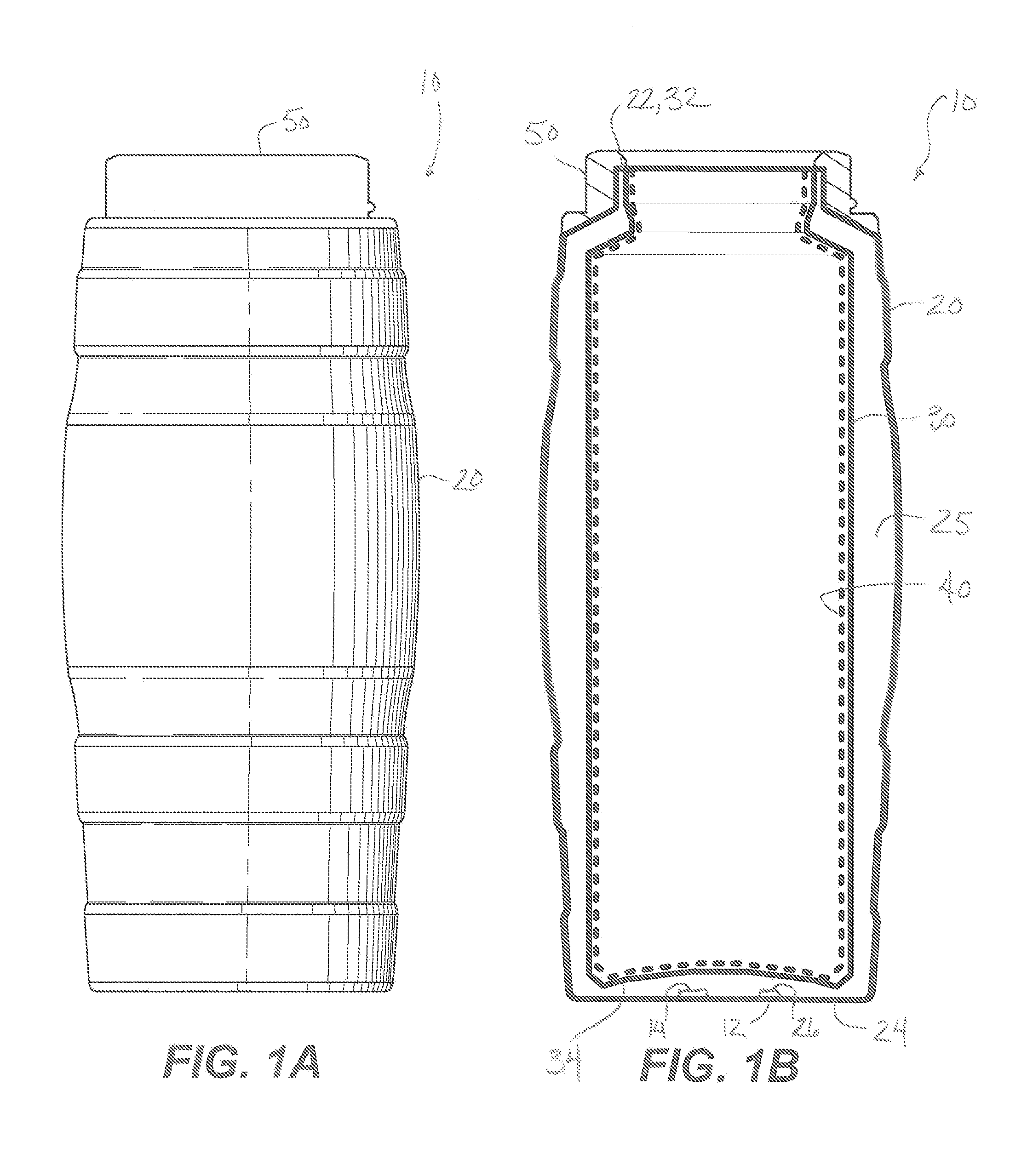

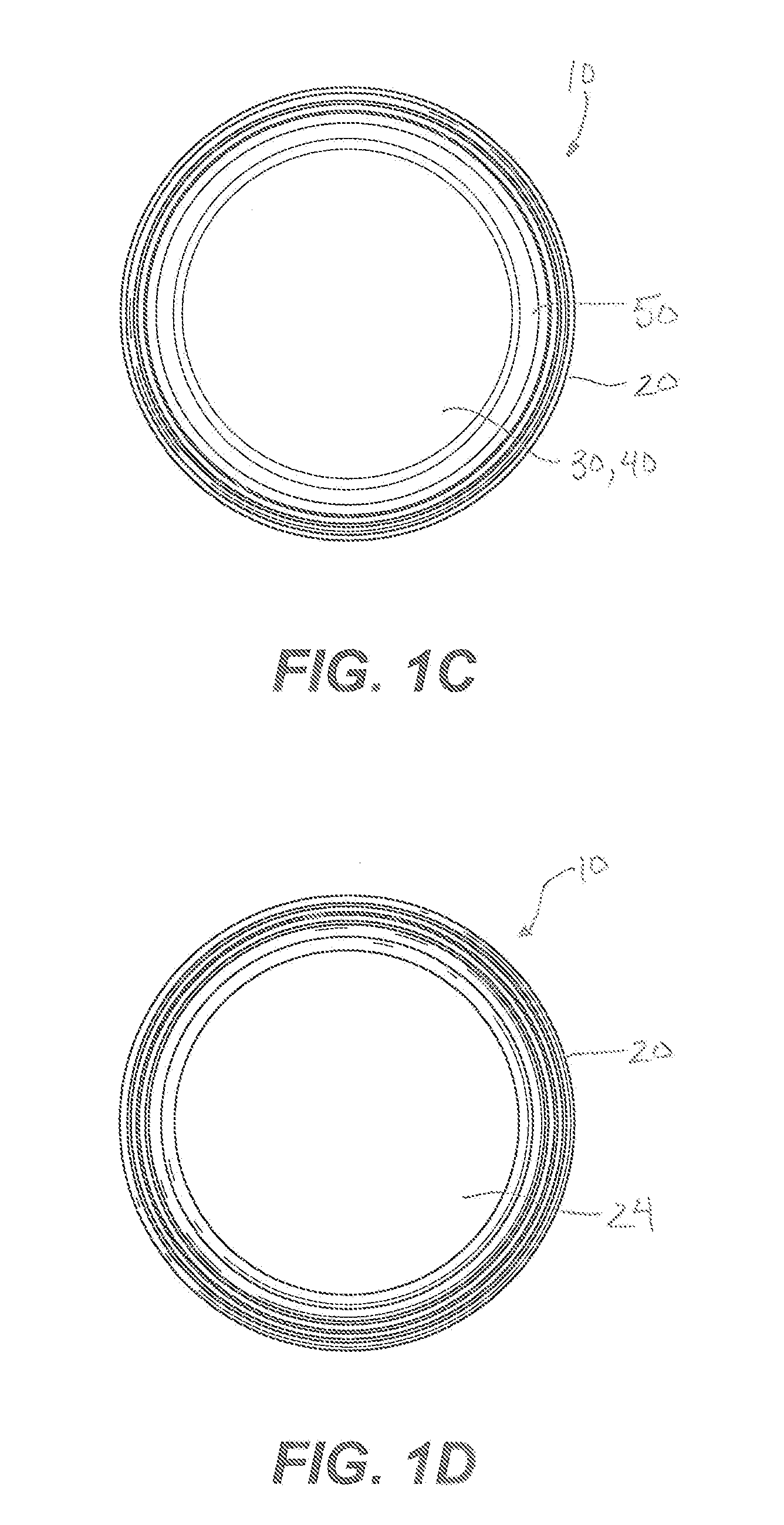

Double-walled, vacuum-insulated container having inner coating cured at high temperature

ActiveUS9555948B2Domestic cooling apparatusLighting and heating apparatusEngineeringMechanical engineering

A double-walled, vacuum-insulated container is manufactured with a cured inside coating. To form the container, an inner liner is disposed in an outer body. The inner liner has an inner sidewall, an inner bottom, and an inner lip, and the outer body has an outer sidewall and an outer lip. The inner and outer lips are affixed together with an affixation or weld having a first melt point. A plenum is enclosed between the inner liner and the outer body by affixing an outer bottom to the outer body and creating a vacuum at least partially in the plenum using a seal having a second melt point. This second melt point can be about 450° C. and 500° C. The coating is painted to an inside surface of the inner liner, and the painted coating is cured with a temperature level at least below the first and second melt points.

Owner:RUBBERMAID

Method for making aluminium zipper with colorful galvanized coating

ActiveCN1666688AReduce weightExtend your lifeSlide fastenersChemical vapor deposition coatingMolding machineWorking life

Owner:东莞市瑞翔新型材料科技有限公司

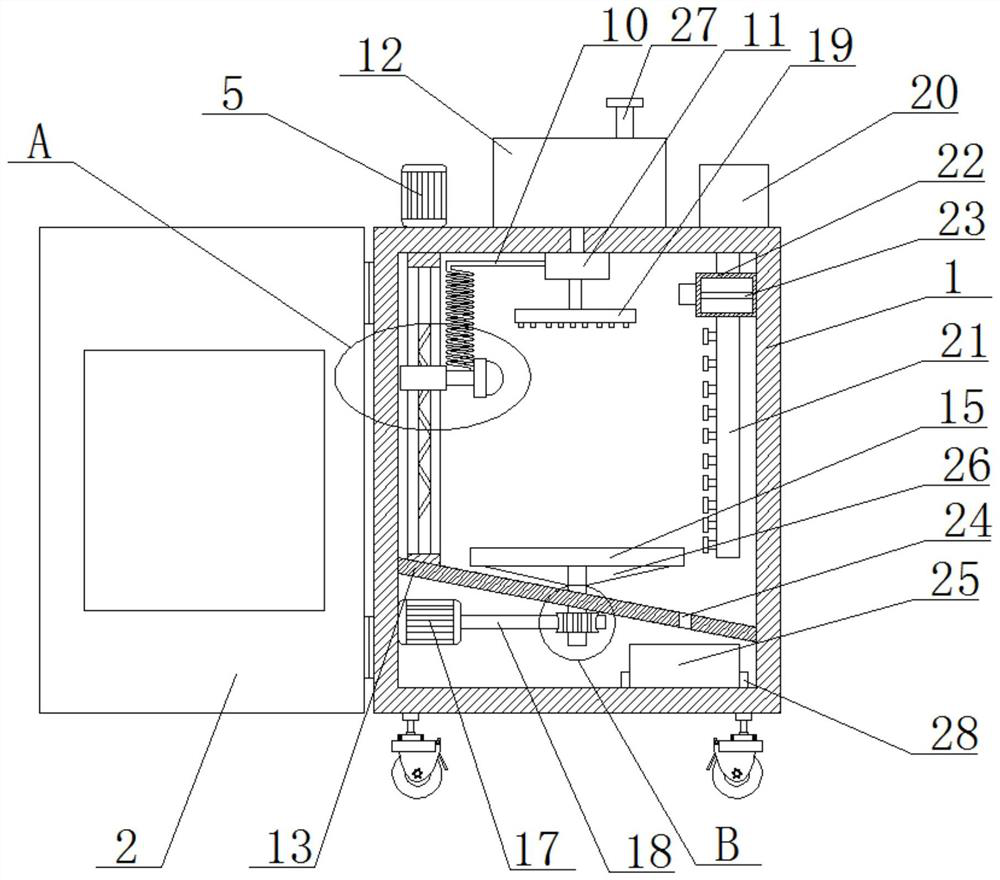

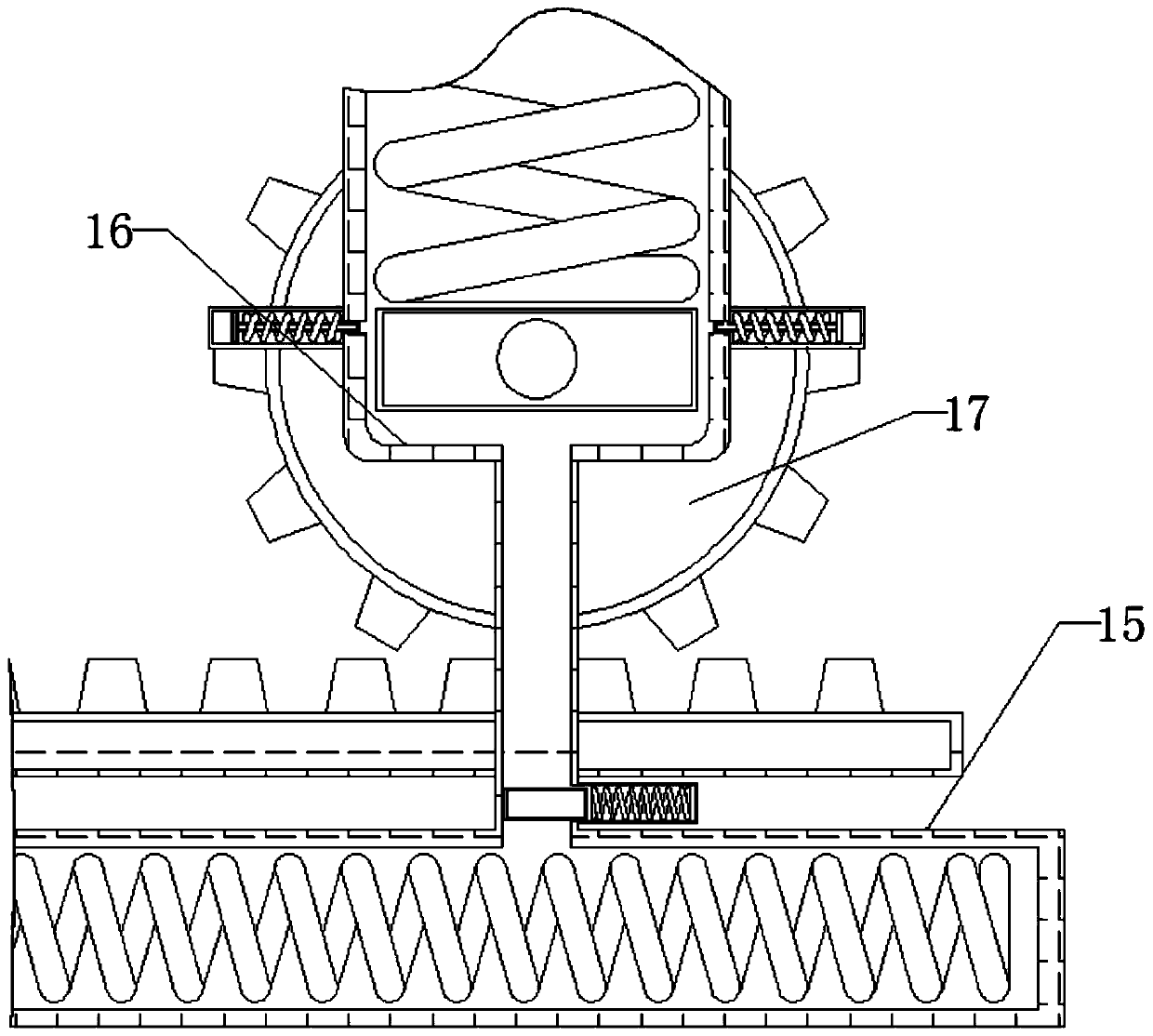

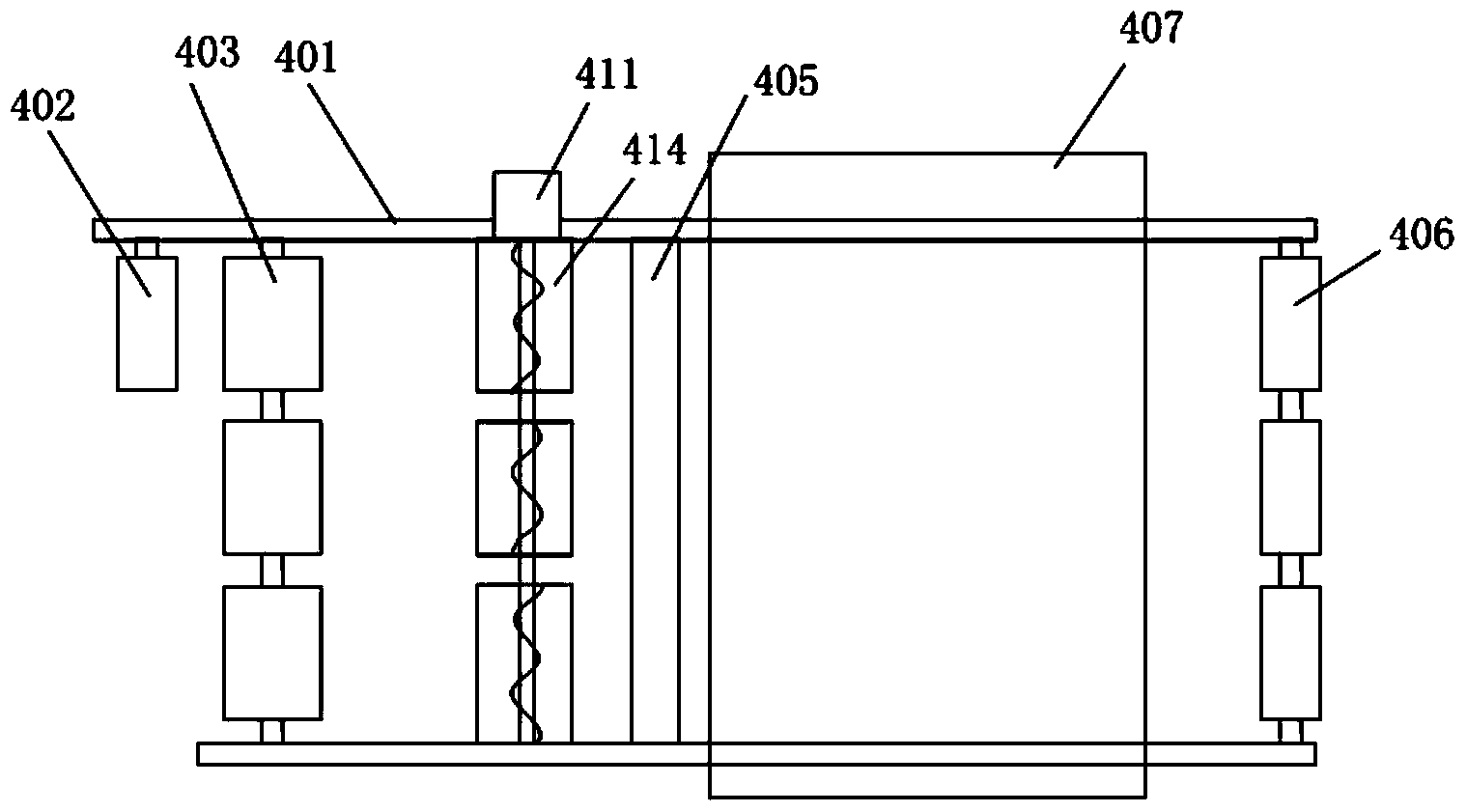

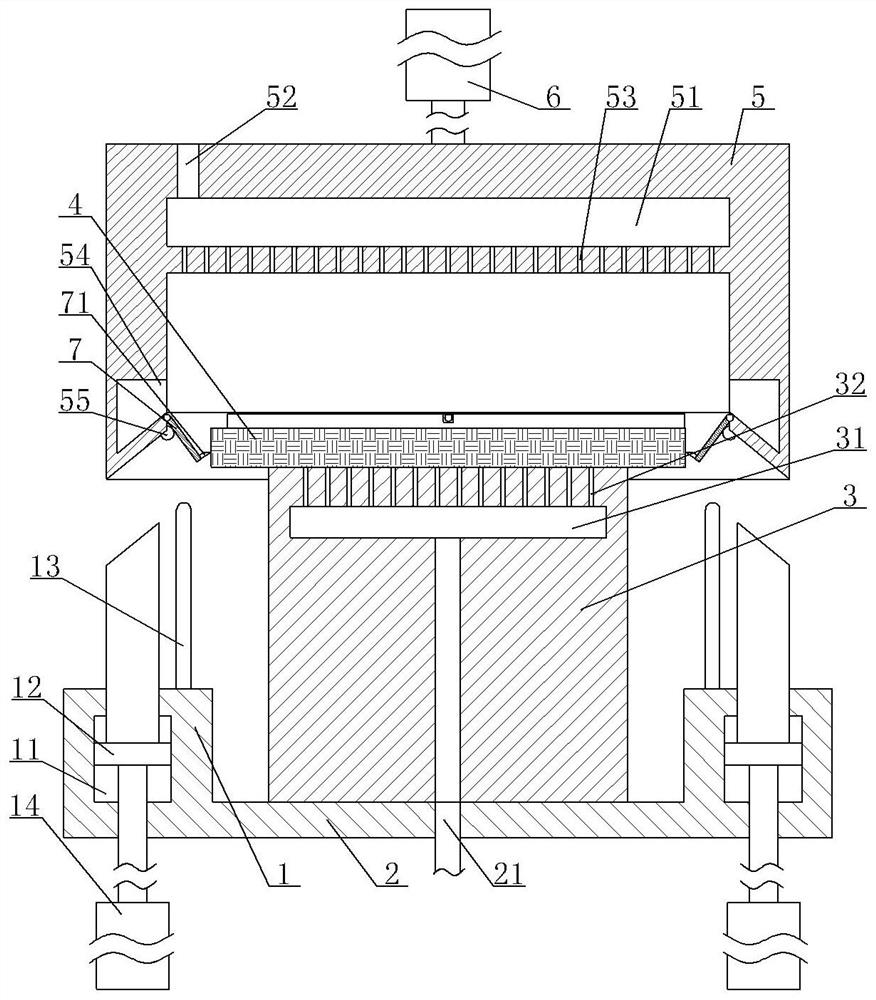

Furniture surface spraying equipment capable of uniformly spraying

InactiveCN111921753AAffect the working environmentEasy to dryPretreated surfacesCoatingsElectric machineryWorking environment

The invention relates to the technical field of furniture processing, and discloses furniture surface spraying equipment capable of uniformly spraying. The furniture surface spraying equipment capableof uniformly spraying comprises a spraying box, wherein a box door is installed at an opening of the spraying box, a limiting frame is fixedly connected to the inner box wall of the spraying box, reciprocating screw rods are rotationally connected to the opposite side walls of the limiting frame through two first bearings, a first motor is installed on the upper box wall of the spraying box, theoutput end of the first motor is connected with the upper end of the reciprocating screw rod through a coupler, a movable block is slidably connected in the limiting frame, a reciprocating threaded hole is formed in the movable block, and the movable block is in threaded connection with the reciprocating screw rod. According to the furniture surface spraying equipment capable of uniformly spraying, furniture with different heights can be uniformly sprayed, the furniture is painted in the spraying box, smell and mist spray generated by spraying are prevented from affecting the working environment of workers, and paint on the furniture can be quickly dried.

Owner:马鞍山市泰隆家具有限公司

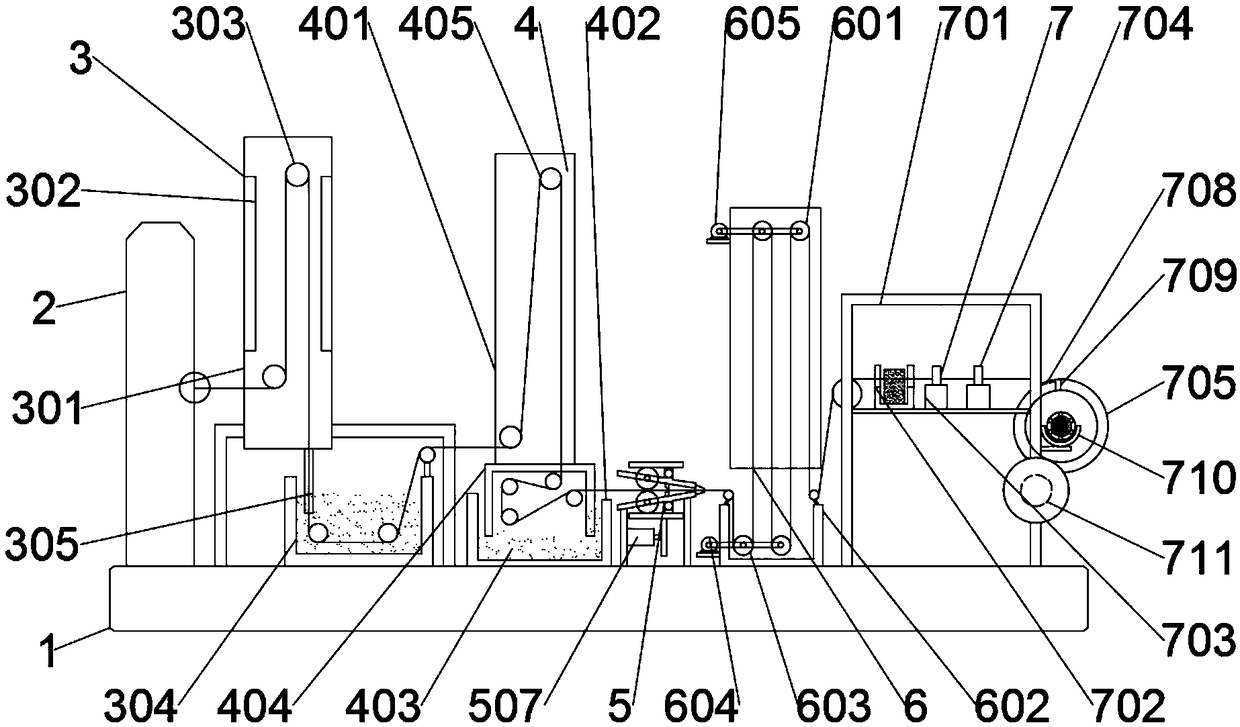

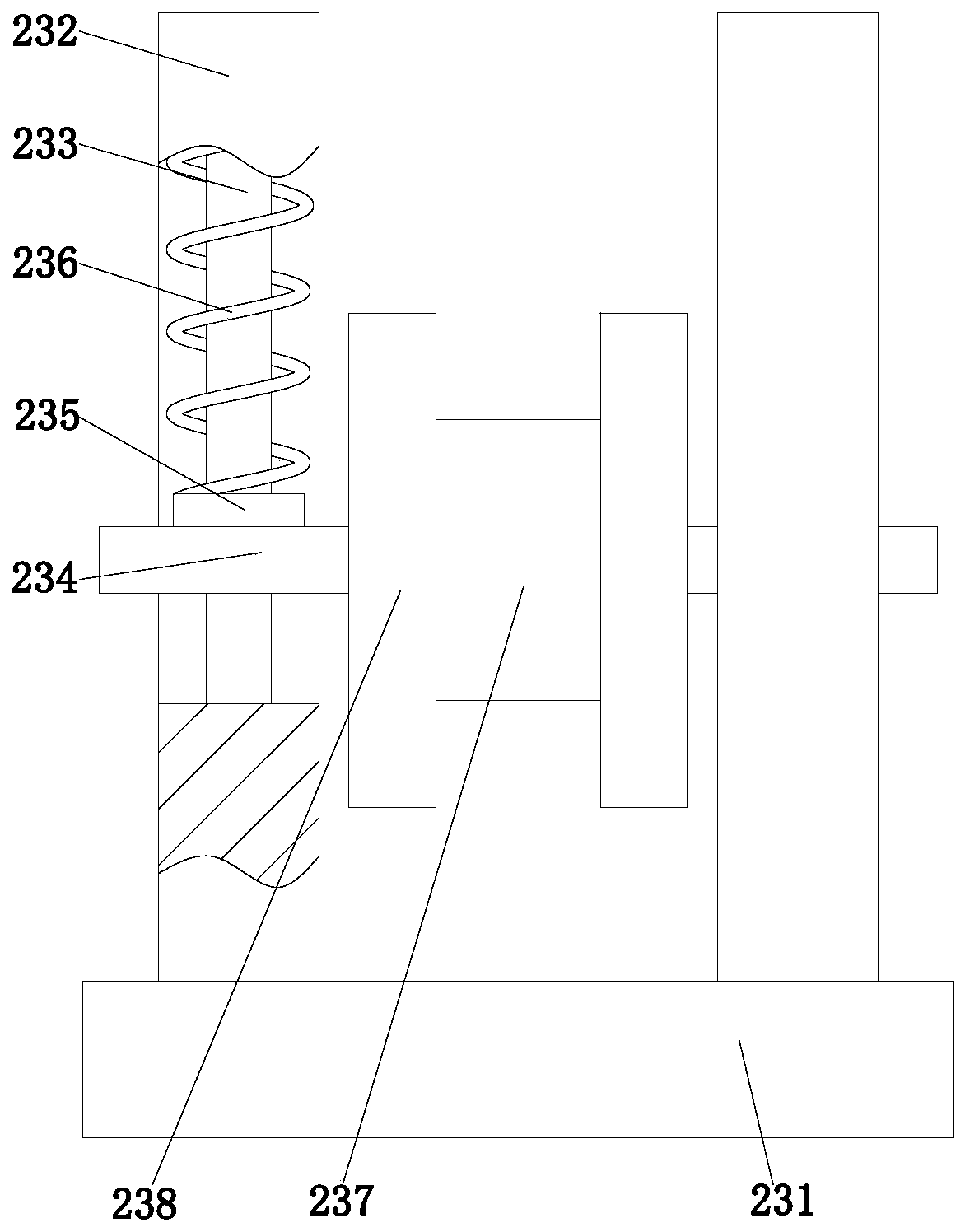

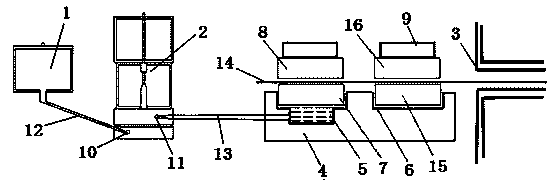

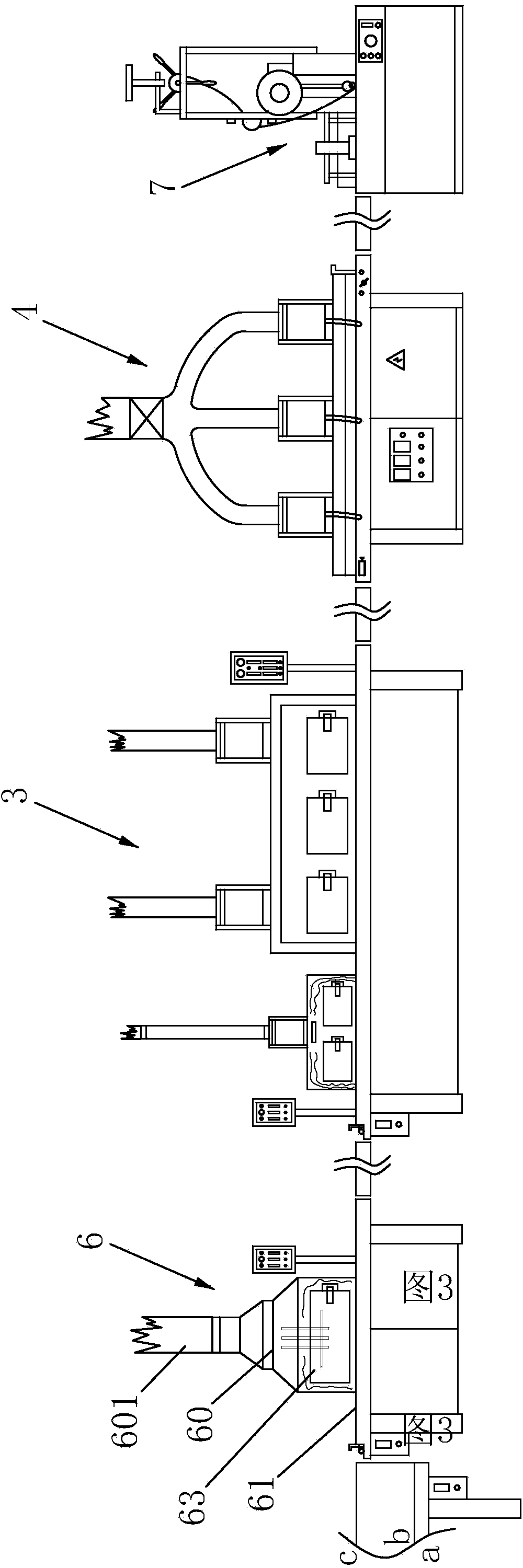

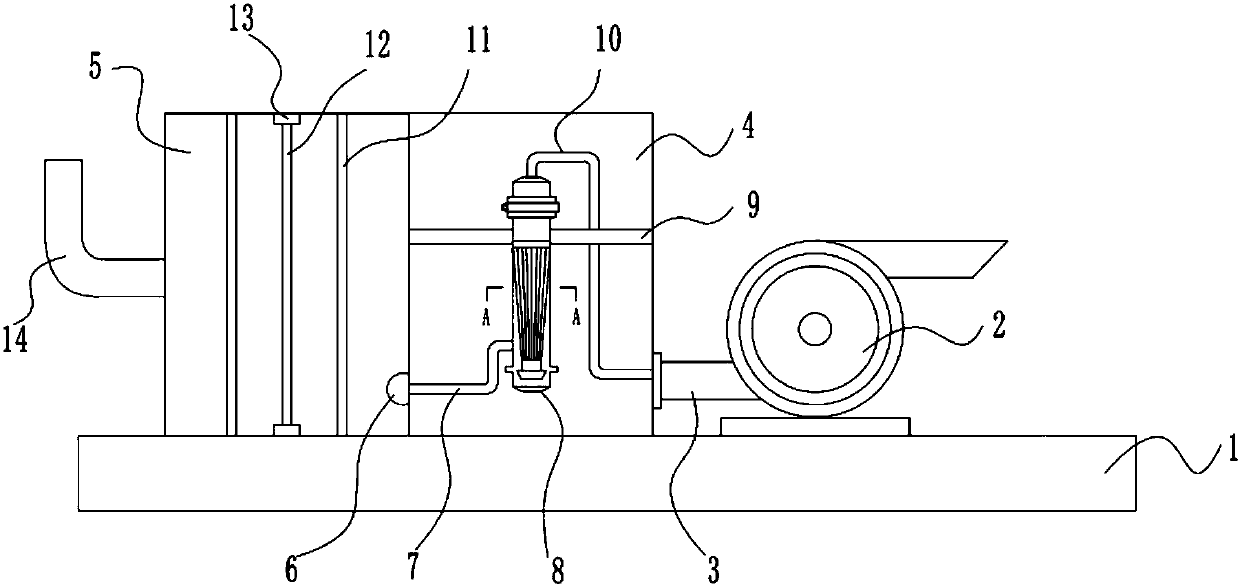

A production process of enameled wire and a production device thereof

ActiveCN109243716AQuick installationIncrease productivityInsulating conductors/cablesWork performanceLacquer

The invention discloses a production device of enameled wire, which includes a mounting base, A wire drawing machine, a quenching device, a tempering device, a cutting-coating device, a lacquer dry device and a winding packaging device are sequentially installed on the mounting base from left to right, , the invention also provides a production process of enameled wire, relying on enamelled wire production equipment to carry out wire drawing cleaning, heat treatment of conductive copper core, cuting and coating of the hybrid shield, paint drying, and on-line detection packaging. As that mix protective layer is coated and the heat treatment is carried out, The mechanical strength and toughness of the enameled wire are enhanced, cracks in the enameled wire are prevented, and the enameled wire is painted and dried by the way of soaking paint and vertical traction and baking, thus ensuring the uniformity of the thickness of the insulating paint on the enameled wire, and greatly improving the production quality and working performance of the insulating paint.

Owner:JIANGMEN XINHUI ZHENGYI ELECTRICAL WIRE

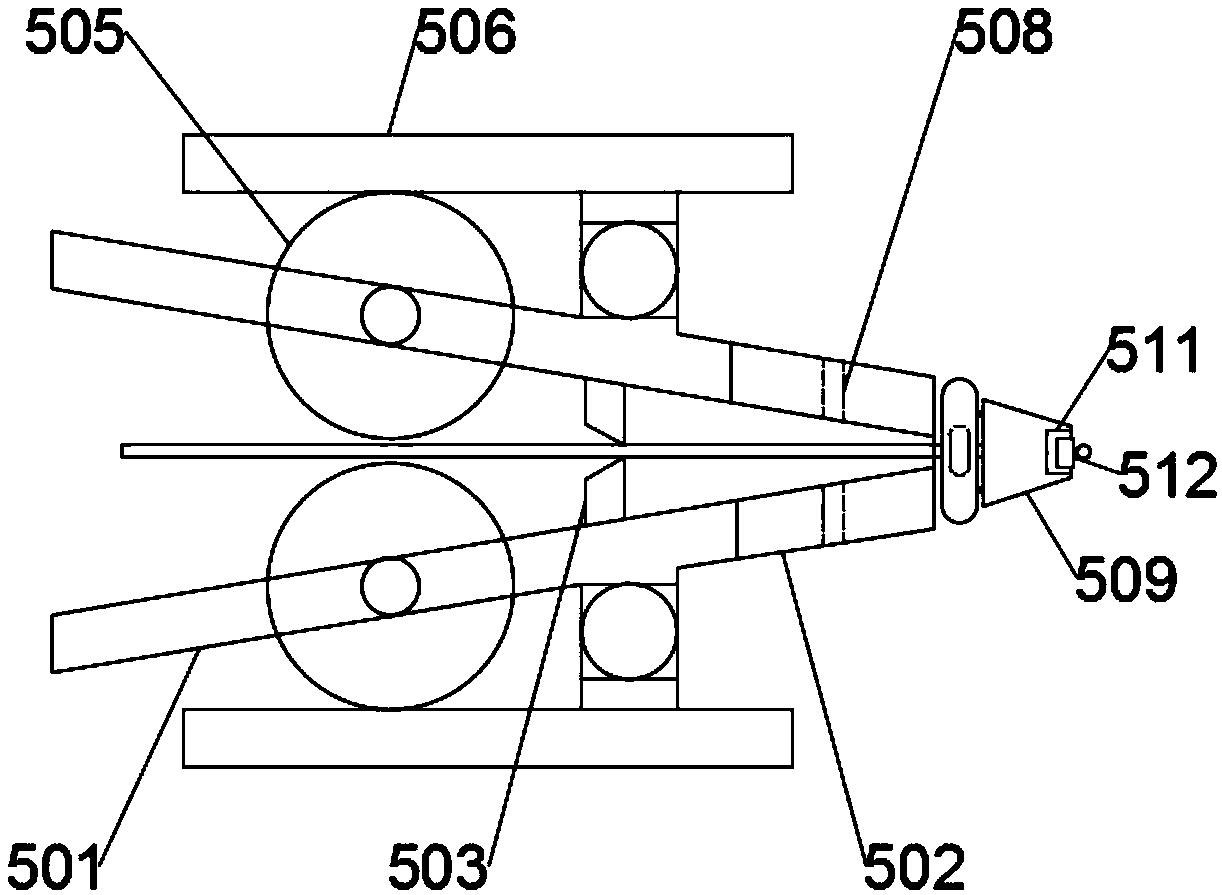

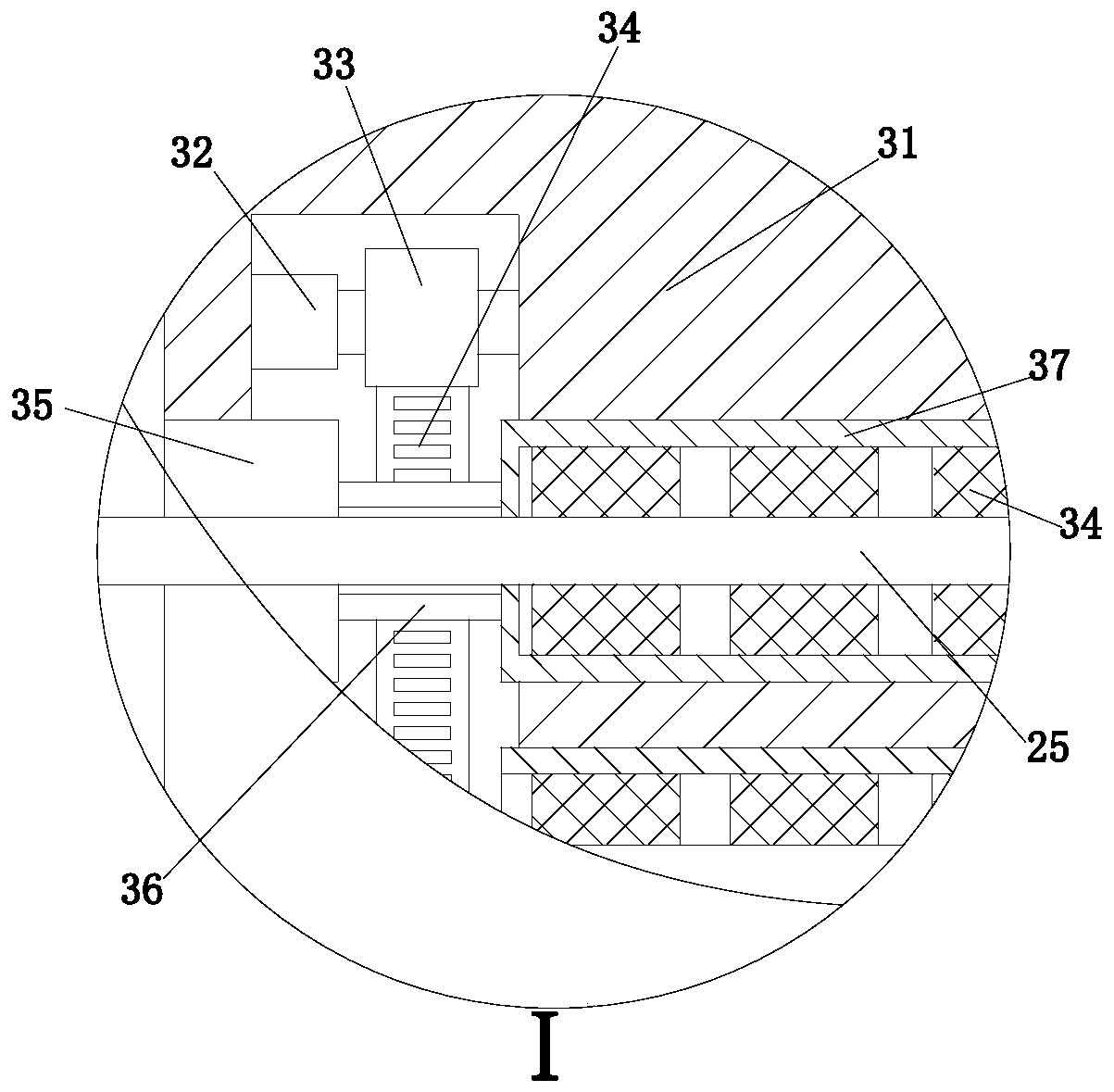

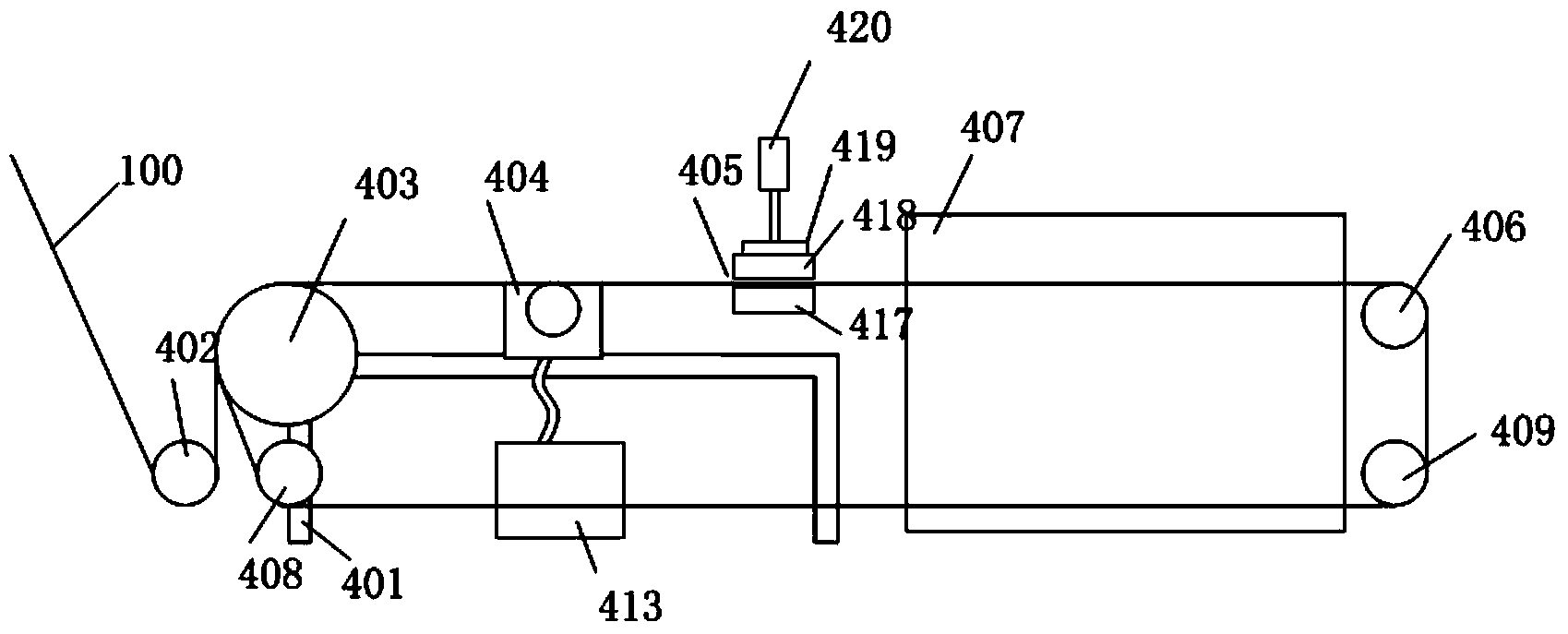

Electric appliance enameled wire manufacturing and processing system

ActiveCN110675995AReduce wasteInhibit sheddingApparatus for feeding conductors/cablesApparatus for heat treatmentMechanical engineeringIndustrial engineering

The invention relates to an electric appliance enameled wire manufacturing and processing system. The system comprises a box body, a lead unit, a painting unit and a baking unit. The lead unit is arranged in the box body, and the painting unit and the baking unit are successively arranged on an inner wall of an upper end of the box body from left to right. Through guiding of the lead unit to an enameled wire and a structural design of the painting unit, the painting unit and the baking unit carry out repeated painting treatment and baking treatment on the enameled wire so that the repeated painting treatment and baking treatment are completed by one device. A paint liquid is more uniform through repeated smearing, and wastes of the paint liquid is reduced. In the invention, through the arranged lead unit, a problem that a plurality of devices are needed to paint and bake the enameled wire is solved; a lead wheel guides the enameled wire to go in and out of the painting unit and the baking unit, a tensioning guide wheel and a wire return wheel guide the enameled wire, the enameled wire enters into a next wire inlet column, and meanwhile, the tensioning guide wheel further tensions the enameled wire.

Owner:瑞安市中德电工器材有限公司

Device for automatically controlling rapid polishing of paint by using atmospheric pressure

ActiveCN111002177AAir pressure fastIncrease air pressureGrinding carriagesGrinding drivesPolishingSprayer

The invention relates to the technical field of furniture processing, and discloses a device for automatically controlling rapid polishing of paint by using atmospheric pressure. The device comprisesa processing machine, wherein a supporting rod is movably connected to the bottom of the interior of the processing machine, a fixed plate is movably connected to the upper part of the supporting rod,an air suction pipe is movably connected to the interior of the supporting rod, a control rail is movably connected to the right side of the supporting rod, a reset spring is movably connected to theinterior of the control rail, a power wheel is movably connected to the right side of the control rail, and a transmission wheel is movably connected to the right side of the power wheel. The paint in a paint box is pressurized by an air pressure pipe and enters a sprayer through a through hole of a paint spraying sliding block to perform paint spraying on the surface of a furniture panel, so that the interior of the paint box is rapidly pressurized, the surface of the panel is rapidly subjected to paint spraying treatment in a paint spraying mode, manual treatment is not needed, and the personal safety of workers is guaranteed.

Owner:朱香芽

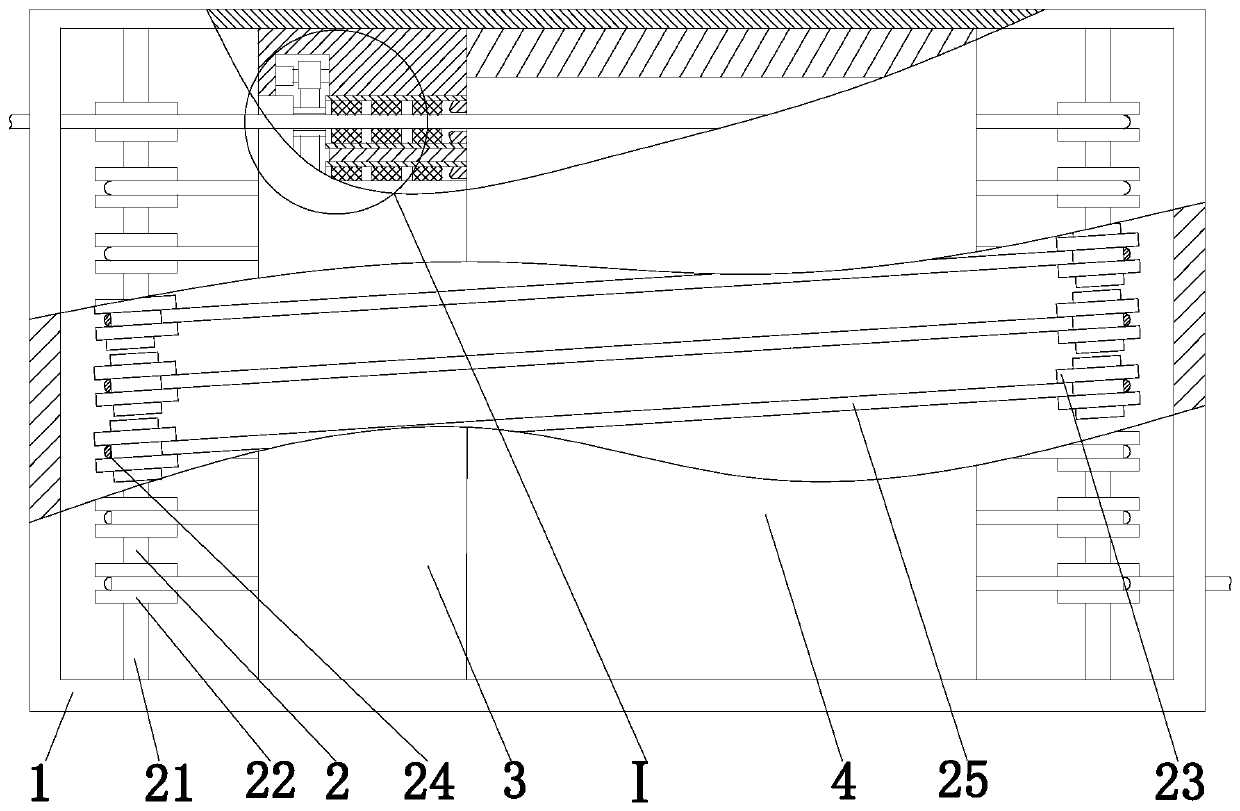

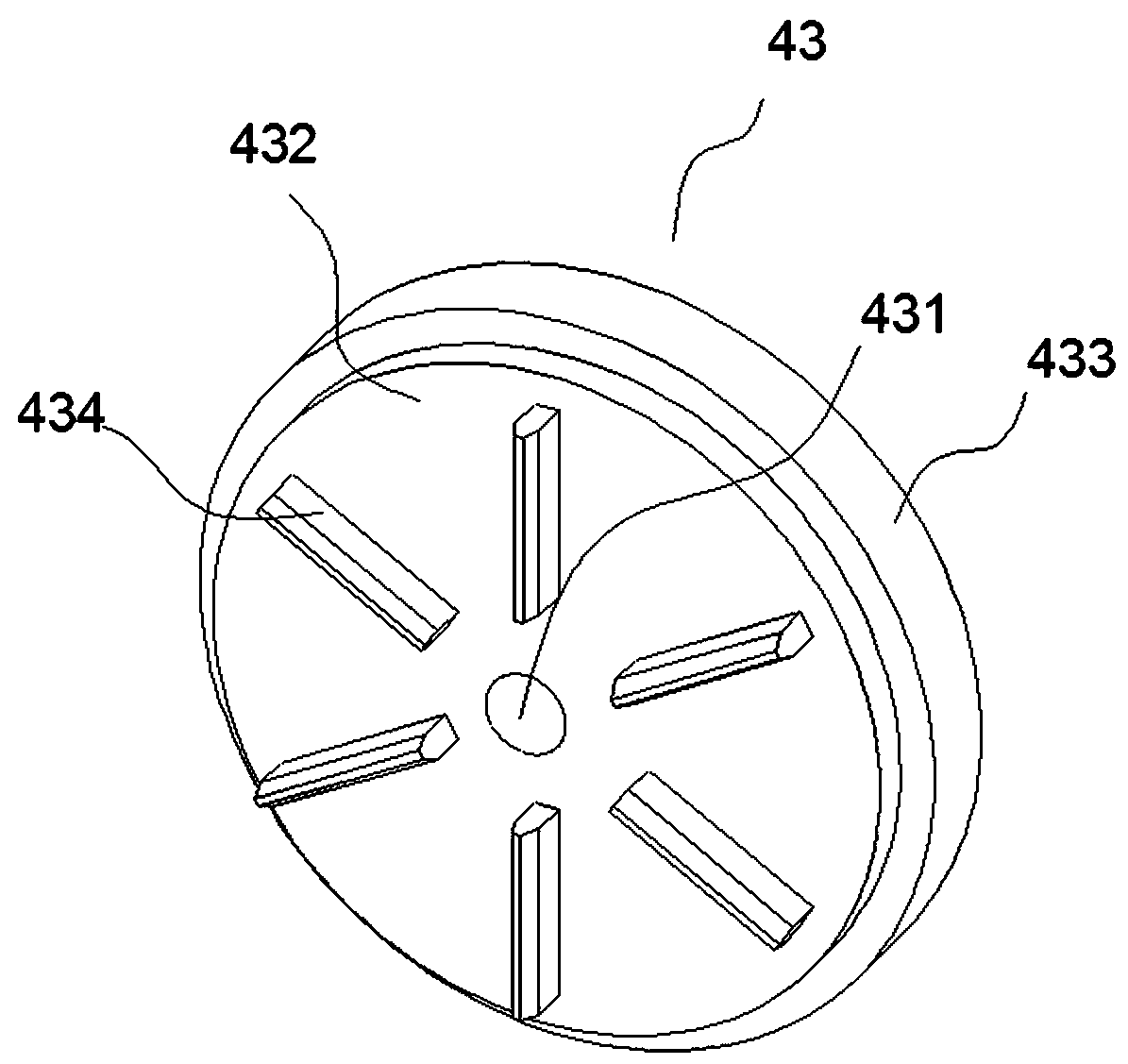

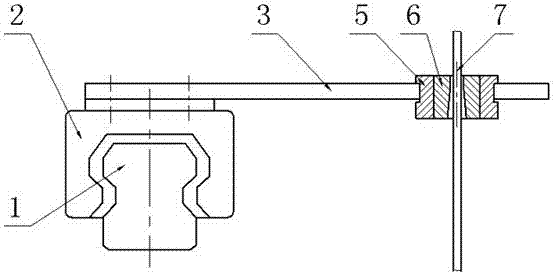

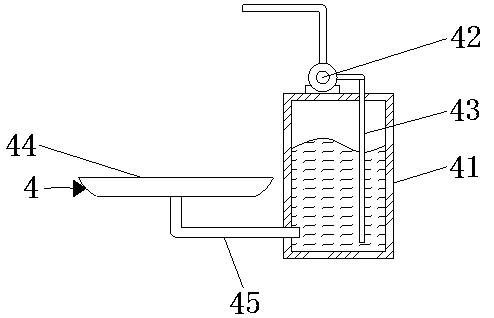

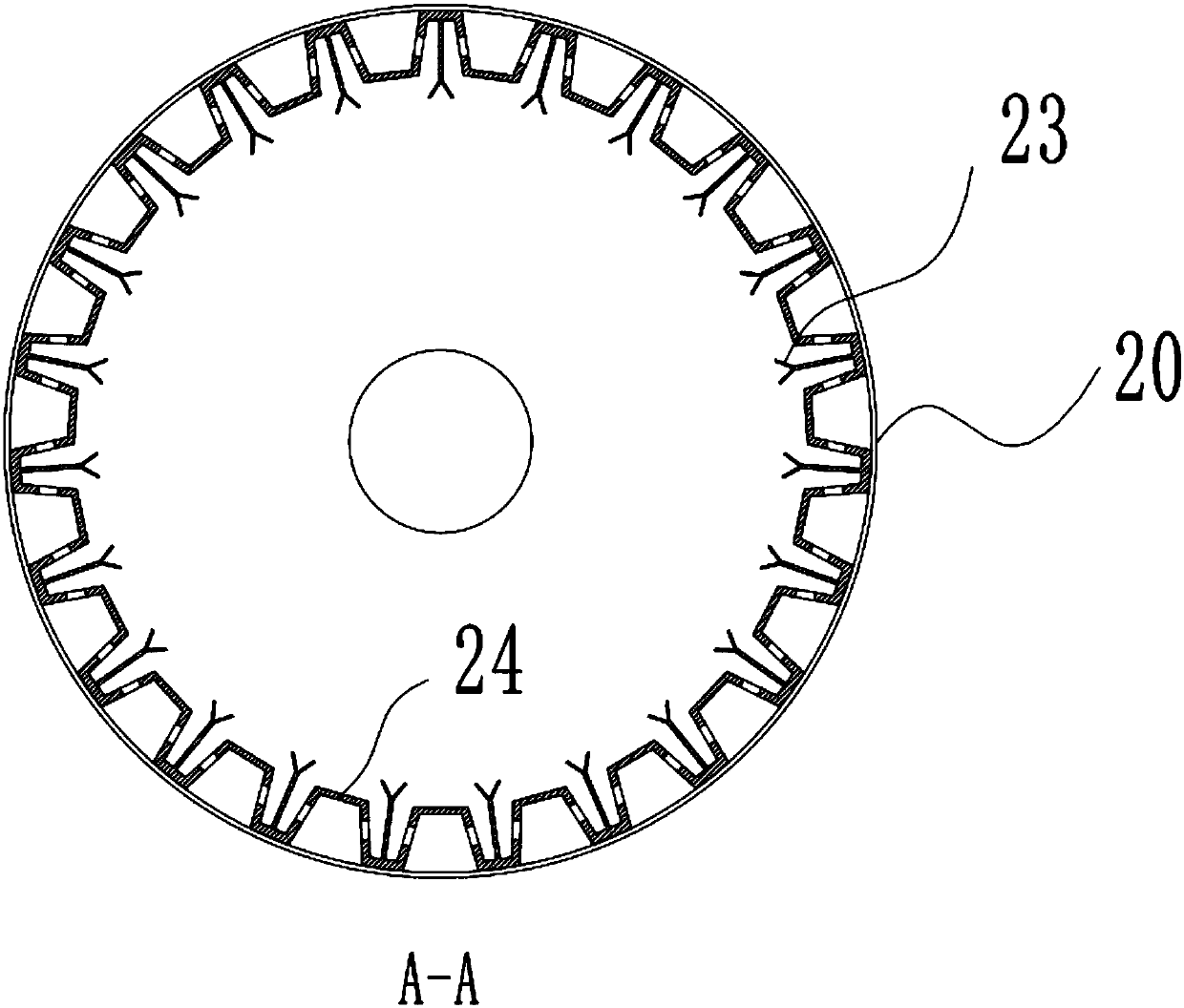

Fine enameled rectangular section conductor painting device

The invention relates to a fine enameled rectangular section conductor painting device, and belongs to a wire painting device. The fine enameled rectangular section conductor painting device comprises a paint box, a painting device and an oven. The painting device comprises a painting platform, wherein a paint groove is formed in the upper portion of the painting platform. A first painting felt is arranged above the paint groove, the lower portion of the painting platform is soaked in the paint groove and oppositely fixed to the paint groove, the upper portion of the paint groove is not lower than the upper surface of the painting platform, a second painting felt is correspondingly arranged on the upper portion of the first painting felt, a pressing plate presses and covers the upper surface of the second painting felt, and a metering pump is arranged between the paint box and the painting device. According to the fine enameled rectangular section conductor painting device, the painting felts in the painting device are arranged above paint, the painting felts are wrapped on paint and a wire into a whole, and the first painting felt and the second painting felt absorb paint in a self-absorption mode and paint and are wrapped on the wire so that the upper face and the lower face of the wire can be coated with the paint, and the paint film is uniform. In the painting process, the rotating speed is adjusted through the metering pump so that the amount of transmitted paint can be controlled, and the thickness of the paint film of the wire can be controlled in time.

Owner:烟台洛姆电子有限公司

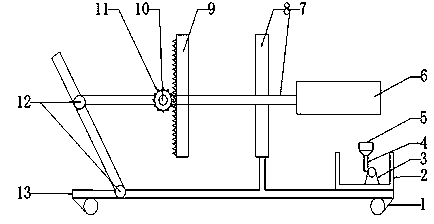

Automatic painting device and application thereof

The invention relates to an automatic painting device and belongs to the field of decorating tools. Firstly, a cart is pushed to the position of painting, then a grinding wheel plate is closed to fixthe position of the cart and a lacquer transporting pump is started. The paint of a paint box reaches to a spray lacquer head through the lacquer transporting pump and tube, and is sprayed to the surface of a paint brush under certain pressure; a speed control motor in the gear is activated by electricity; the speed control motor can stably control the rotational speed of the gear to avoid the influence of the gravitation when the gear moves up and down, thereby making the gear moving at a constant speed on the surface of a rack; the gearing of the gear drives a sliding block to move, causingthe paint brush which is connected with the sliding block to brush up and down at a constant speed, and uniformly paint the building surface. After painting a wall, the electric equipment is powered off, then a brake wheel board is opened, the cart is pushed to another position of painting, so circularly work and the work of painting is finished.

Owner:丁玉琴

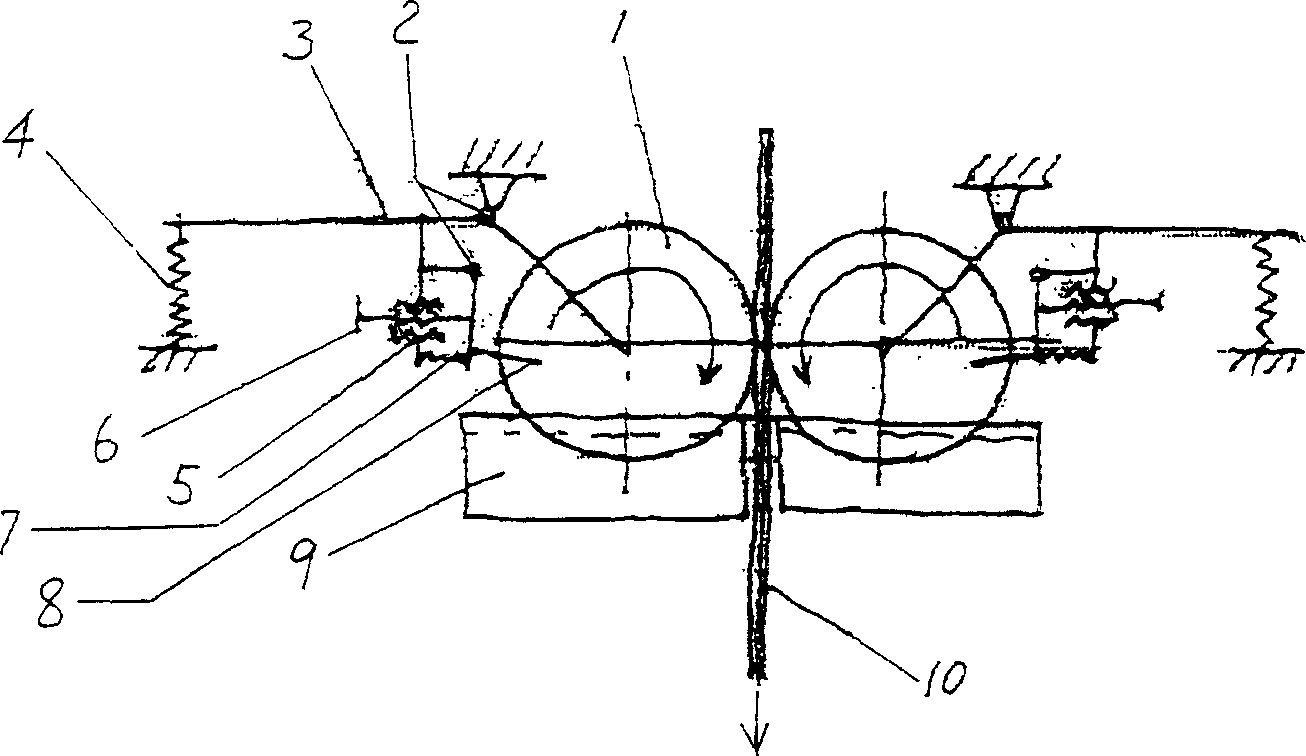

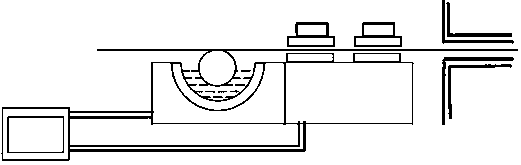

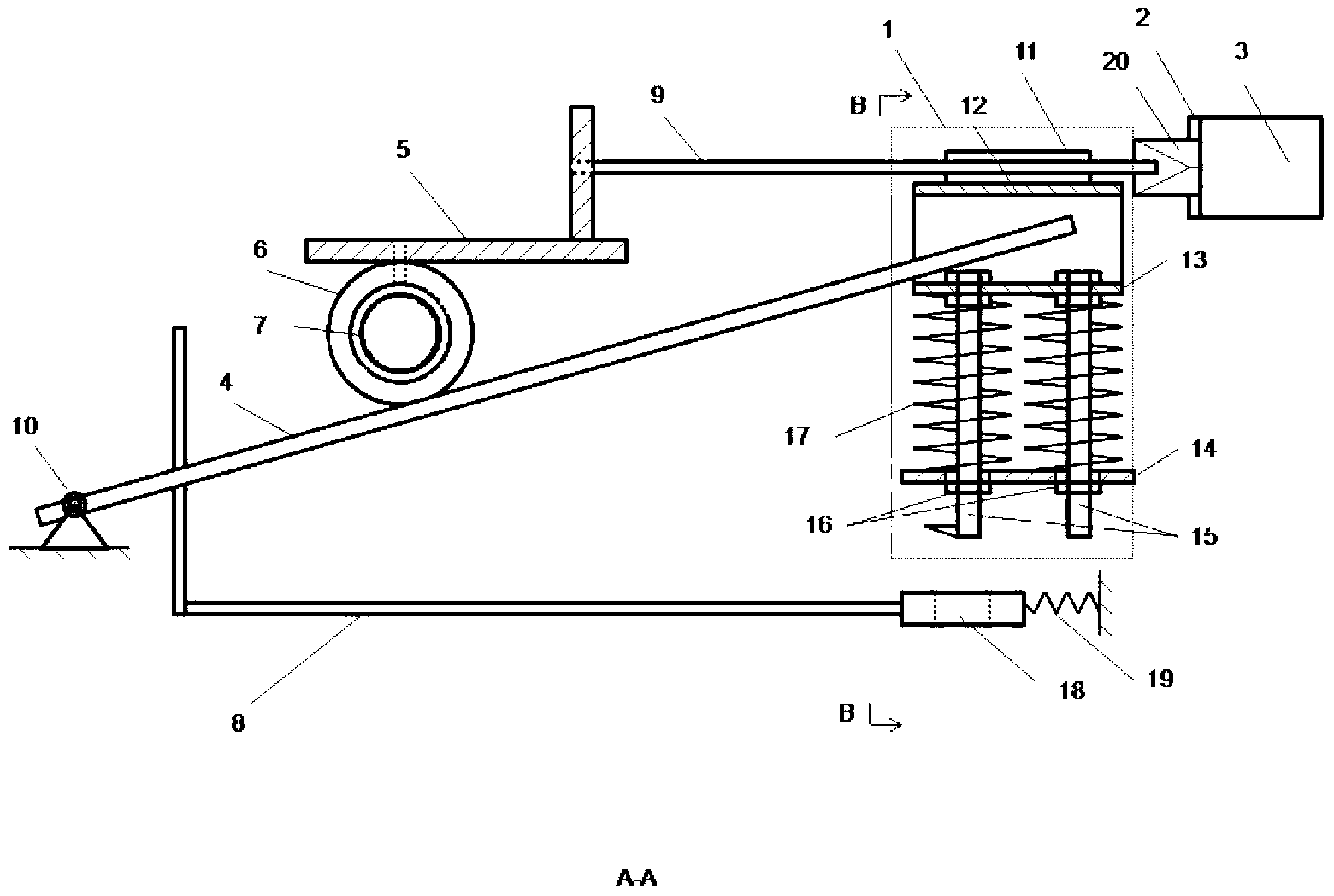

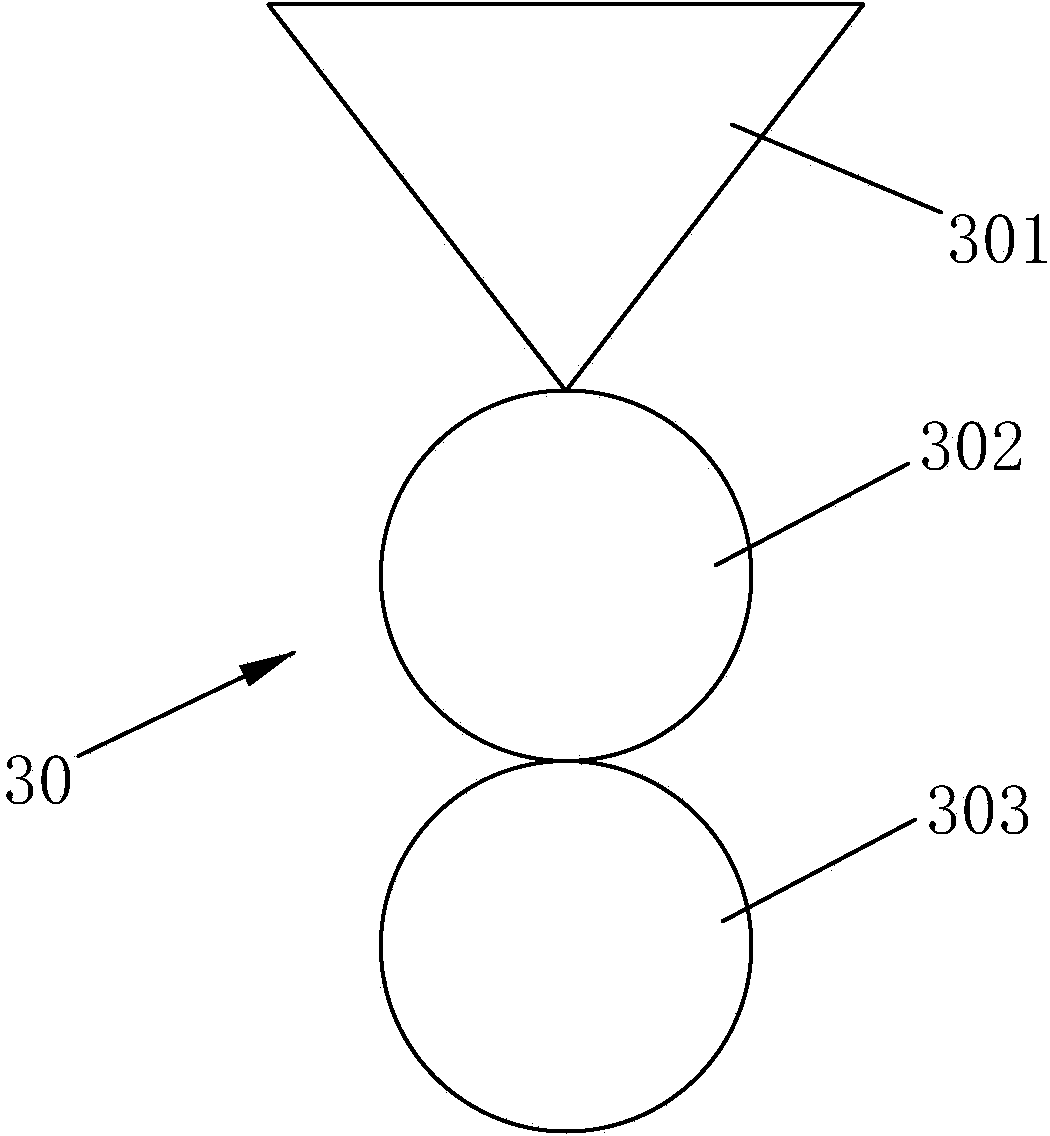

Method for propelling hole alignment and preventing paint collision in japanning process of chopstick blank machine and special device for method

InactiveCN103286037AImprove mechanical propertiesImprove the automation industryLiquid surface applicatorsCoatingsMotor driveEngineering

The invention discloses a method for propelling hole alignment and preventing paint collision in a japanning process of a chopstick blank machine and a special device of the method. The special device comprises a chopstick plate for holding chopstick blanks, a motor driving rod, a guide groove assembly, a paint box, a pressing rod and a bottom rod, wherein the chopstick plate is fixed on a sleeve and the sleeve is sleeved on the motor driving rod; the chopstick plate can rotate along the rotation of the sleeve; the guide groove assembly is arranged at an inlet end of the paint box; the bottom rod is arranged below the guide groove assembly; the pressing rod is arranged below the motor driving rod, one end of the pressing rod is fixed by a hinge and the other end of the pressing rod is overlapped on a middle baffle of the guide groove assembly; the pressing rod can realize the vertical descending of the guide groove assembly under the squeezing effect of the motor driving rod so as to realize the separation of a chopstick groove. The device disclosed by the invention is simple in design and low in manufacturing cost, has the functions of propelling the hole alignment and preventing the paint collision during mechanical and automatic japanning of the chopstick blanks, and is applicable to improvements of mechanized and automatic industries of small and medium-sized bamboo wood chopstick processing enterprises.

Owner:浙江安迅电气股份有限公司

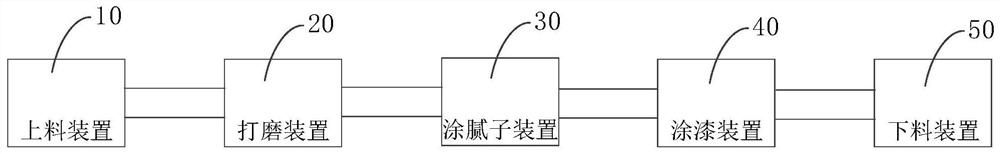

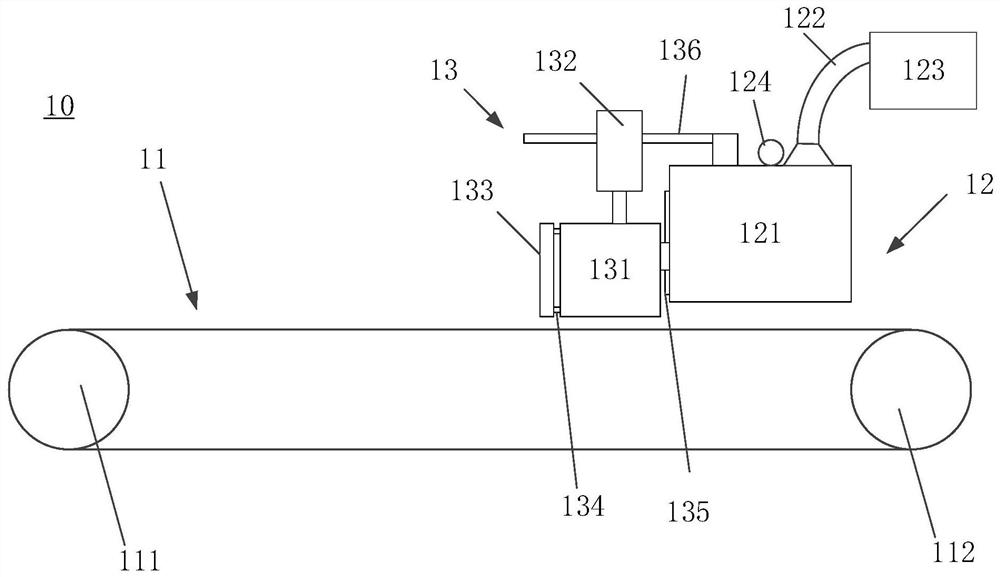

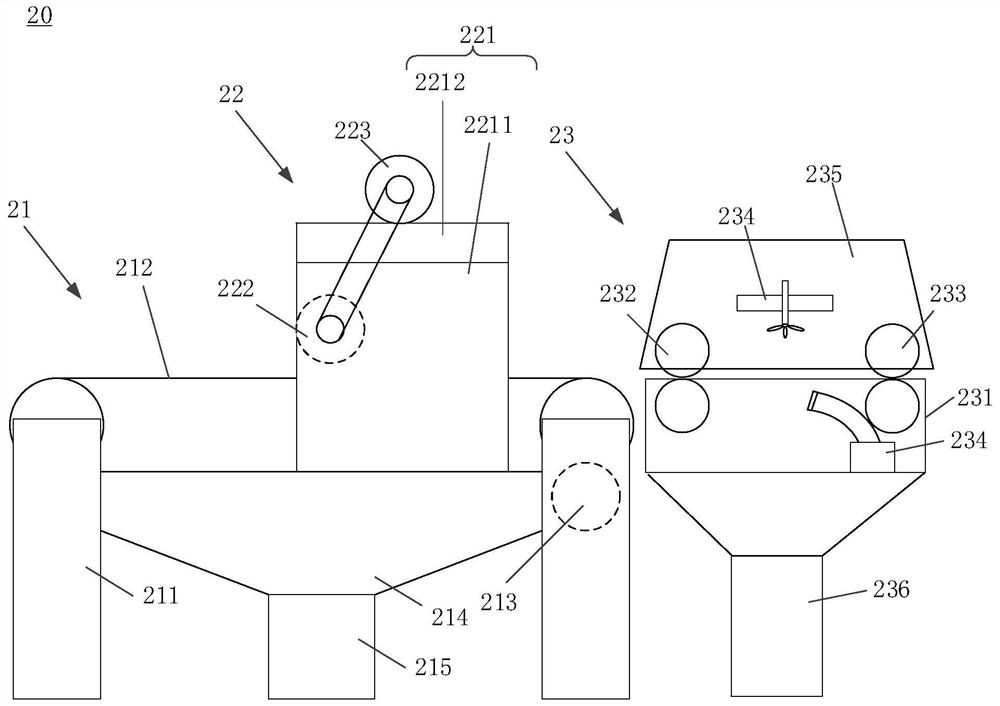

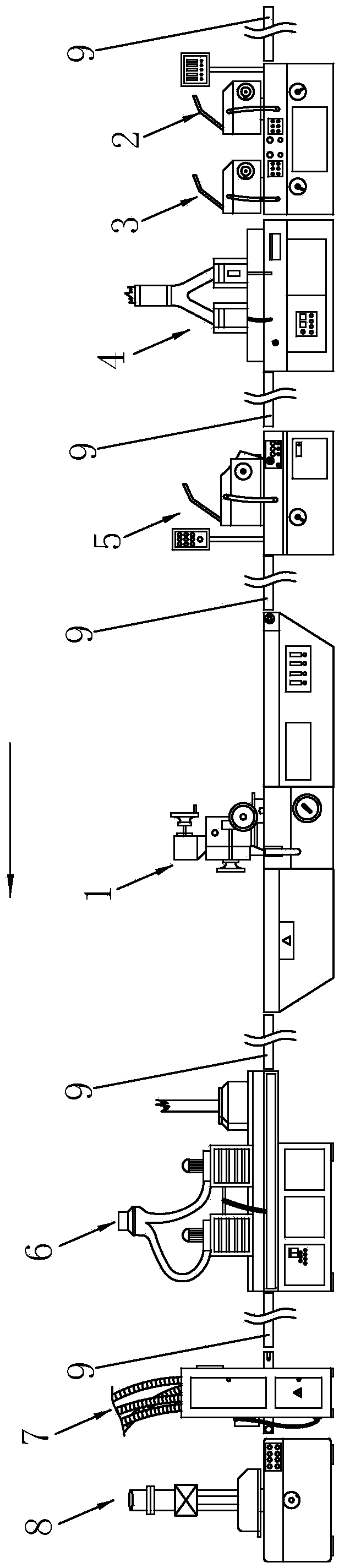

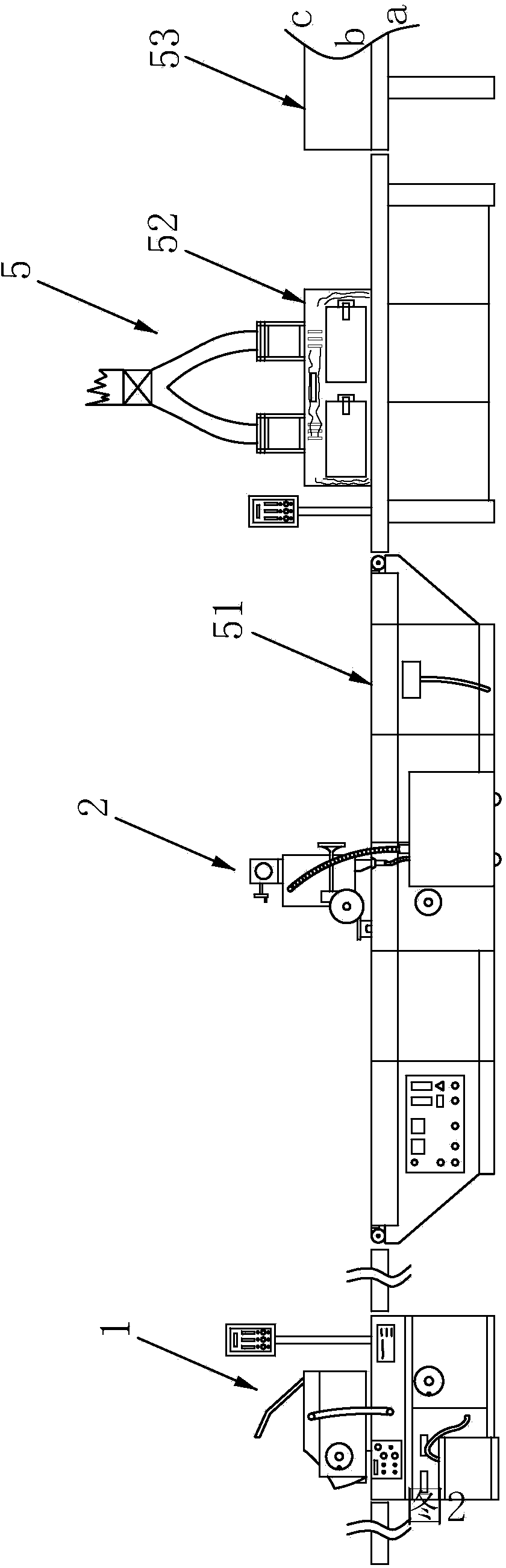

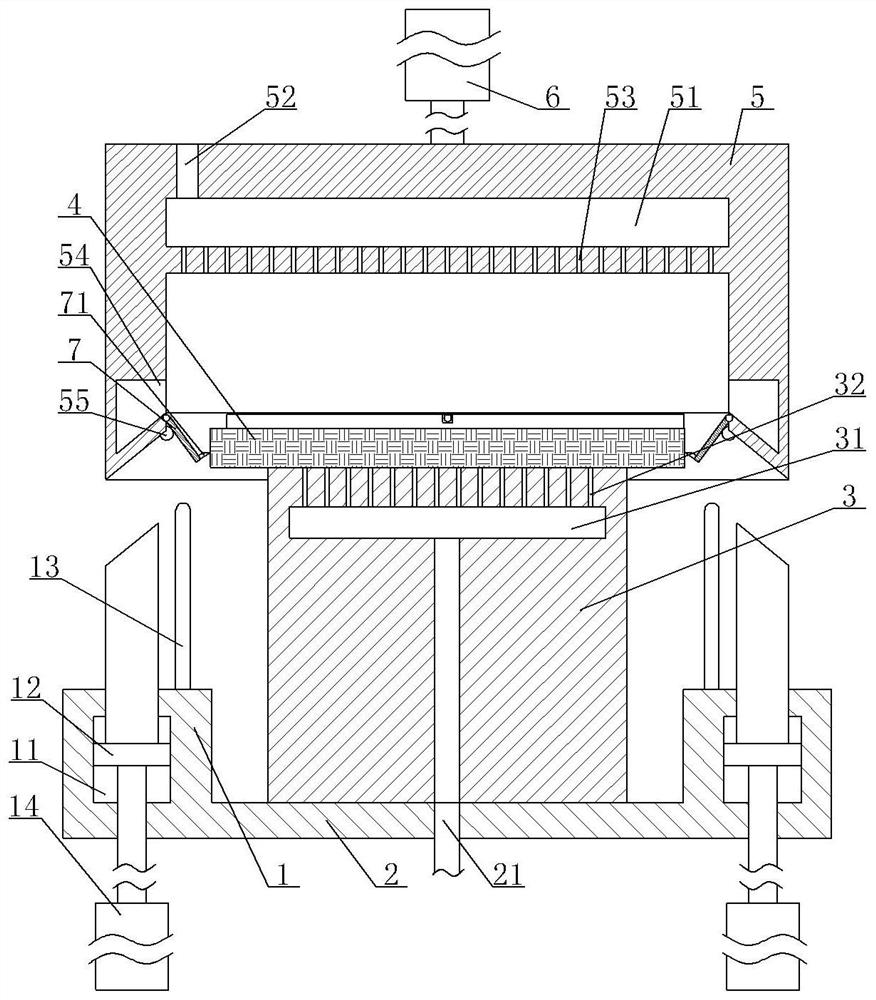

Plate painting production line

PendingCN111974630AImprove surface integrityIncrease profitPretreated surfacesDirt cleaningProduction lineSingle plate

The invention discloses a plate painting production line. The plate painting production line comprises a feeding device, a polishing device, a putty coating device, at least one painting device and adischarging device, wherein the feeding device comprises a feeding conveying line, a dust suction mechanism arranged on the feeding conveying line and a material blocking mechanism arranged at an inlet of the dust suction mechanism; the material blocking mechanism is configured to only allow a single plate to pass; and the polishing device comprises a polishing conveying line, a grinding mechanismarranged on the polishing conveying line and a rotary air blowing mechanism. After the plate is fed, the surface of the plate is polished through the polishing device, the surface of the plate is filled and leveled up through the putty coating device, then the plate with the surface filled and leveled up is subjected to paint spraying treatment through the painting device, and finally the paintedplate is discharged through the discharging device.

Owner:宜兴慕森智能家居有限公司

Processing technology of copper enameled wire with high painting fastness

ActiveCN113223777ADry fastGood adhesionApparatus for feeding conductors/cablesApparatus for heat treatmentCopper wireSurface roughness

The invention belongs to the technical field of enameled wire production technologies, and particularly relates to a processing technology of a copper enameled wire with high painting fastness. The processing technology specifically comprises the steps of wire drawing, paying off, annealing, cleaning, painting, baking and curing, and taking up. Wire drawing and paying off are carried out for many times to obtain a copper wire, then the cooper is annealed, and the annealed copper ispolished and cleaned to remove surface burrs of the copper wire and increase the surface roughness, so paint adhesion is facilitated; and the paint and the surface of the copper wire are tightly and uniformly bonded through multiple times of painting and two times of pressurization, meanwhile, drying of the surface of the paint is accelerated by increasing the temperature in a pressurization machine, and finally the paint is more stable through baking and curing, so the prepared enameled copper wire is uniform and stable in paint layer, high in fastness, not easy to fall off and high in breakdown strength.

Owner:江西泰和百盛实业有限公司

Processing technology for solid wood floor of balanced health care

InactiveCN111452171AAvoid breakingImprove wear resistanceLiquid surface applicatorsDrying gas arrangementsSolid woodAdhesive

The invention relates to a processing technology for a solid wood floor of balanced health care. The solid wood technology from a material to packaging at many aspects is improved, the stability, uniformity, smoothness and flatness of the paint surface are ensured, the penetration, sealing, flatness, adhesion and clarity of the floor are ensured, paint is made to penetrate into the floor, the clear texture of the floor is ensured, wear resistance is high, and full luster of the floor is achieved; drying and dedusting treatment is carried out after each coating step, so that impurities do not exist among the multi-layer paints, and the adhesion is high; and meanwhile, the treatment of formaldehyde and other harmful chemicals is conducted, formaldehyde can be quickly removed, and a water-based adhesive and an oil-based adhesive are used in a painting process to form guarantee of the double adhesion.

Owner:浙江林昌木业有限公司

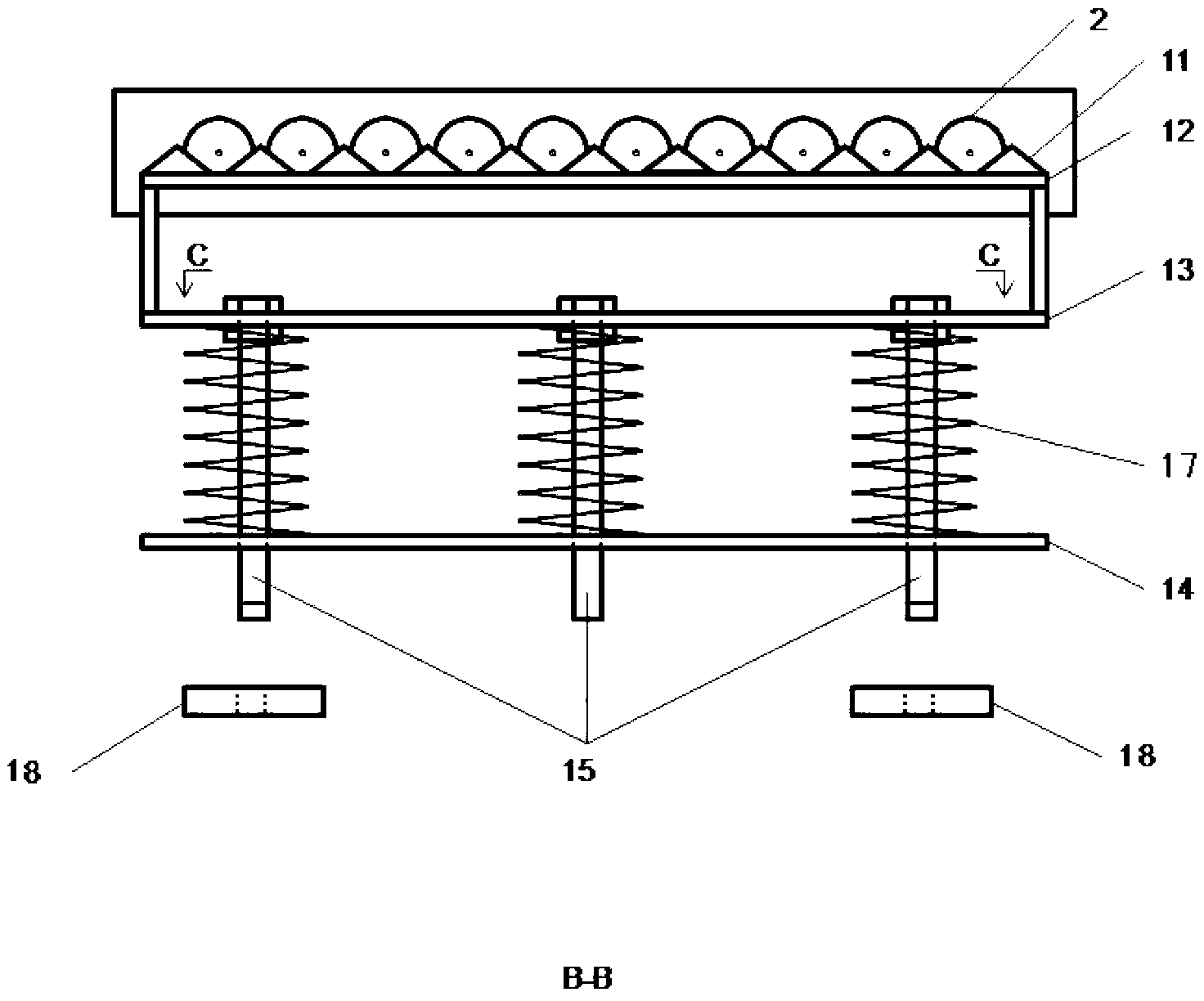

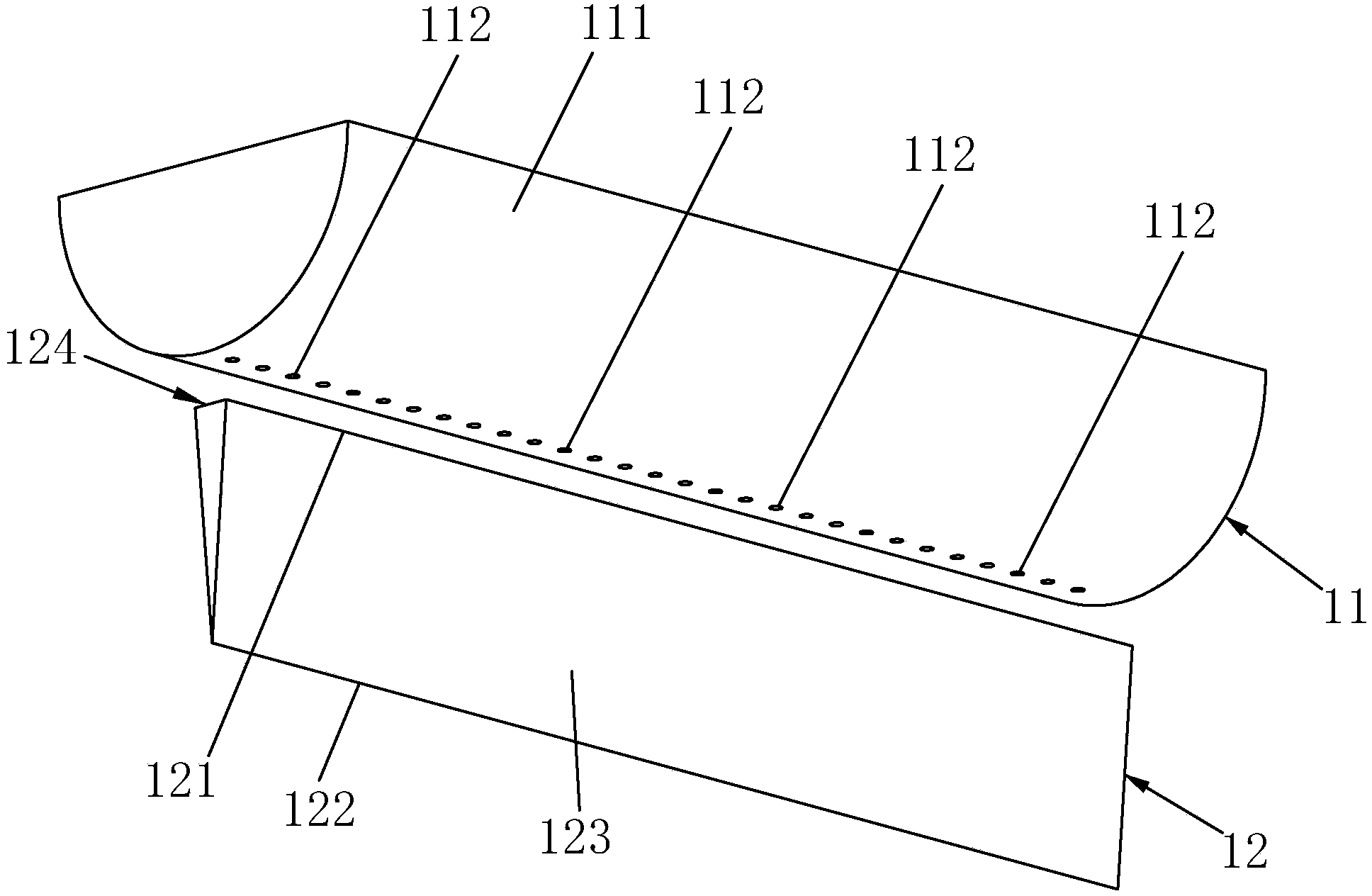

Panel sprinkling curtain coating japanning equipment

InactiveCN104069988AUniform thicknessPrecise control of thicknessPretreated surfacesCoatingsEngineeringConveyor belt

The invention discloses panel sprinkling curtain coating japanning equipment which comprises a sprinkling curtain coating mechanism, wherein the sprinkling curtain coating mechanism is sequentially provided with a paint dropping tank, a sprinkling curtain coating knife and a panel conveyor belt from top to bottom, the top of the sprinkling curtain coating knife is a long and narrow receiving platform, the bottom of the sprinkling curtain coating knife is shrunk into a linear second sharp edge, a plurality of japanning through holes are formed in the bottom of a tank body of the paint dropping tank, and are located above the receiving platform, and a paint sprinkling curtain is formed by the sprinkling curtain coating knife. The panel sprinkling curtain coating japanning equipment is simple in structure and uniform in japanning to ensure that a paint layer is free from gaps; a paint layer is uniform in thickness, and high in precision; and the thickness of the paint layer is accurately controlled.

Owner:GUANGDONG HULUBAO CULTURE TECH CO LTD

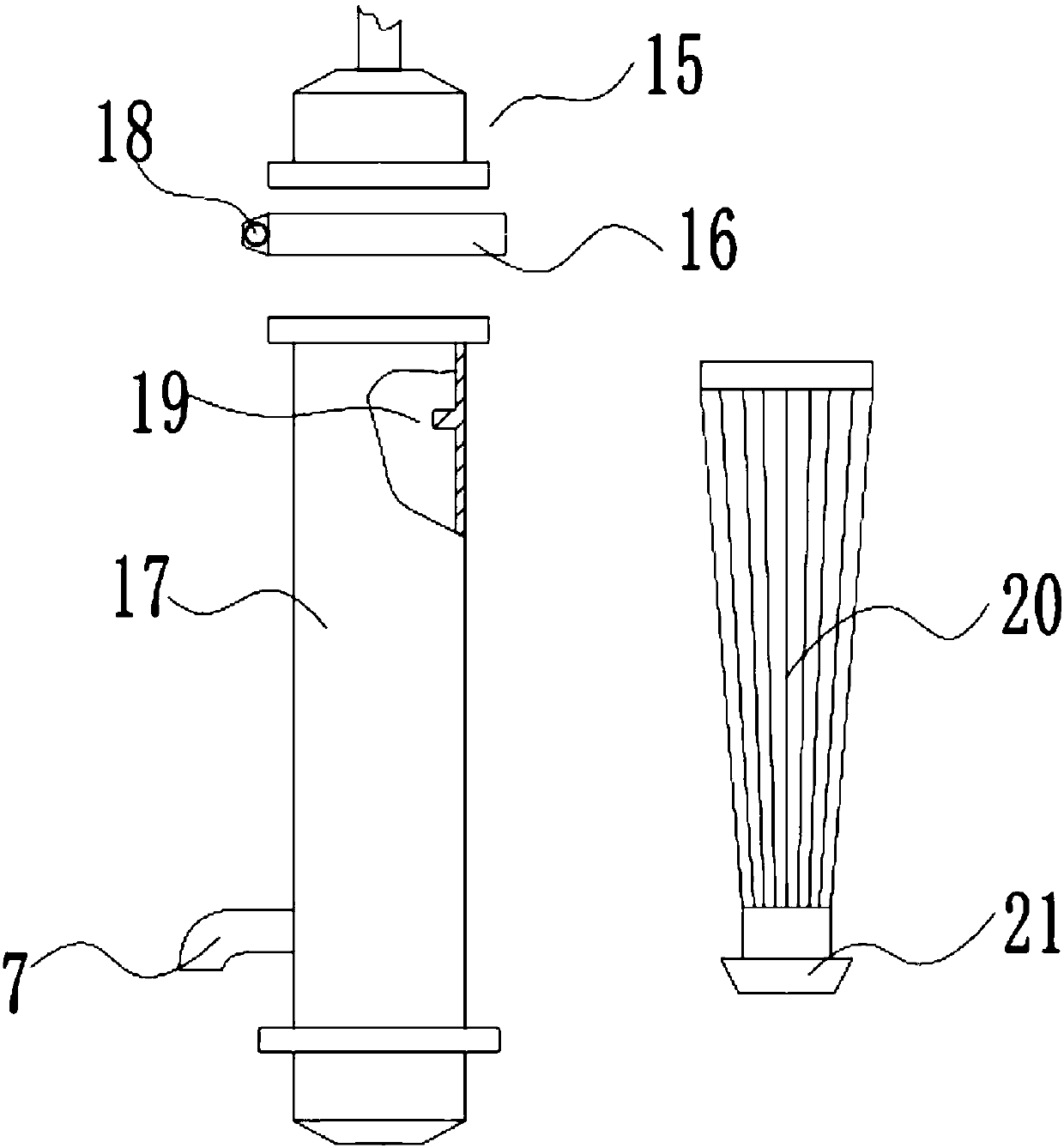

Lacquering method and lacquering device of enameling machine

ActiveCN104036882ANumber of coats achievedRealize the number of layersInsulating conductors/cablesComputer scienceVarnish

The invention discloses a lacquering method and a lacquering device of an enameling machine. The lacquering method includes that an annealed aluminum wire is repeatedly lacquered and dried, the number of times of lacquering and the number of layers of lacquering of an enameled wire are realized, and a function of lacquering of multiple lines at the same time through one machine is realized. By the lacquering method and the lacquering device, composite lacquering of insulating varnish of different varieties can be performed, so that product quality and working efficiency are improved. In addition, the lacquering method and the lacquering device have the advantages that varnish films different in thickness can be coated at the same time, and multifunctionality is realized.

Owner:汕头市深港电工实业有限公司

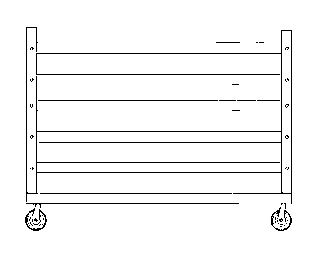

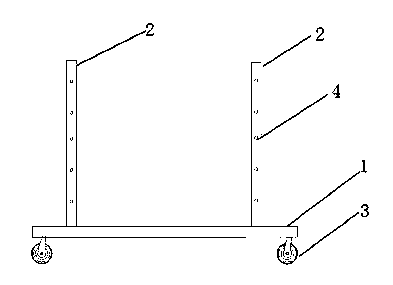

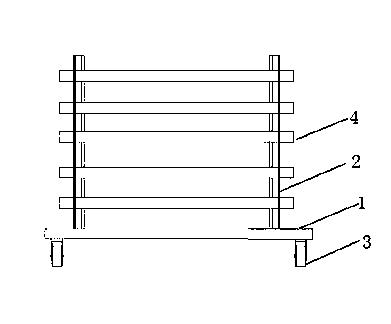

Furniture plate placing rack

InactiveCN103769354ASmall footprintReduce contact surfacePretreated surfacesCoatingsEpoxyRubber material

The invention relates to the field of furniture production, in particular to a furniture plate placing rack which comprises a base support and lateral supports connected with the left side and the right side of the base support. Rollers are installed on the lower portion of the base support, and a plurality of cross bars are symmetrically arranged on the left lateral support and the right lateral support and are wrapped by a rubber material. The placing rack can be used for placing a plurality of plates, the plates subjected to painting or gluing can be arranged on the placing rack in a layering mode, and the plate storage occupation area is greatly reduced. Meanwhile, the plates are supported by two cross bars, the contact face between the plates and the placing rack is reduced, the paint drying speed of the upper surfaces and the lower surfaces of the plates is increased, the cross bars are wrapped by the rubber material, and abrasion of the cross bars to the surfaces of the plates is reduced. Due to the fact that the four rubber anti-skidding rollers are installed on the lower portion of the base support, the placing rack can move conveniently on the smooth epoxy resin ground.

Owner:SHIFANG MIDEE WOOD IND

Wood japanning apparatus for uniform japanning

ActiveCN108816636AEasy to overlapEvenly paintedLiquid surface applicatorsCoatingsEngineeringAtmospheric pressure

The invention discloses a wood japanning apparatus for uniform japanning. The structure of the apparatus comprises a gas pressure conveying pipe, a uniform japanning mechanism, a housing and a threaded rod. The invention has the following beneficial effects: through an air-liquid damping cylinder, an L-shaped drive rod is slowly driven at constant speed to move, and then a roller rolls for japanning slowly at constant speed, thus avoiding overlapping of the japanning track and achieving uniform japanning; with the static electricity, the paint is adsorbed on the inner wall of a conductive walllayer and flows down along the inner wall, thus effectively avoiding the paint from dripping on the roller and making more uniform dipping of the paint for the roller; according to the graph 6, whenthe roller rolls clockwise, an opening exists between a movable plate and the inner wall of a paint placement cavity, and the paint flows out of the opening and rolls with the rolling of the roller, thus making uniform dipping of the paint for the roller.

Owner:ANHUI JINDUN PAINT

Enameled wire painting, drying and cooling device

PendingCN107705931ASmall temperature fluctuationsReduce the impactInsulating conductors/cablesEngineeringCooling pipe

The invention provides an enameled wire painting, drying and cooling device, which comprises a feeding pipe, a drying furnace and a cooling pipe. A painting piece is arranged between the feeding pipeand the drying furnace, and the painting piece comprises a baffle plate, a painting felt located at the upper end of the baffle plate, and a heat insulation plate between the painting felt and the drying furnace. A through hole is formed in the middle of the heat insulation plate, and a material inlet of the drying furnace is disposed opposite to the heat insulation plate. The cooling pipe is located at one end of a material outlet of the drying furnace, a sleeve is disposed on the cooling pipe, and a partition plate is disposed between the sleeve and the cooling pipe. The partition plate, thesleeve and the cooling pipe form a cavity opening to the side of the drying furnace, and an air inlet hole is formed in a side of the cooling pipe near the drying furnace. There is a fan in the cavity, and the air outlet of the fan faces the side of the partition plate.

Owner:湖州中洲电磁线有限公司

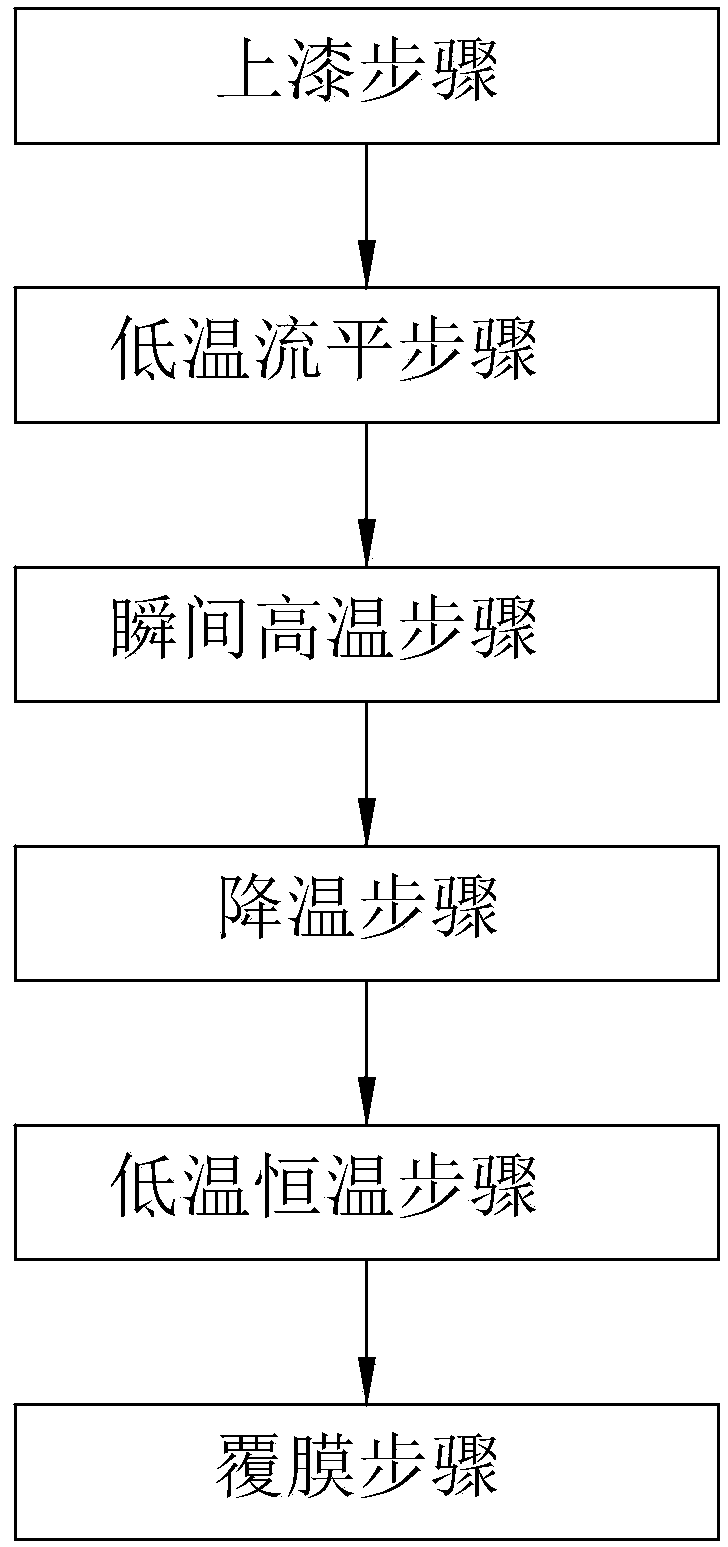

Sheet material environment protection japanning technology free of formaldehyde

InactiveCN104069993AIncrease productivitySo as not to damagePretreated surfacesCoatingsBenzeneEngineering

The invention discloses a sheet material environment protection japanning technology free of formaldehyde. The sheet material environment protection japanning technology free of the formaldehyde includes a japanning step, a low temperature leveling step, an instant high temperature step, a cooling step and a low temperature keeping step. The sheet material environment protection japanning technology free of the formaldehyde enables sheet materials to rapidly pass through an instant high temperature heating area, not only can solidify and dry oil paint, but also can not damage the sheet materials, can not ignite the oil paint, can rapidly volatilize formaldehyde, ammonia, benzene and volatile harmful matter in the oil paint, enables no formaldehyde, no ammonia, no benzene and no volatile harmful matter to remain in the sheet materials and the oil paint, rapidly removes the formaldehyde, the ammonia, the benzene and the volatile harmful matter, which remain in the sheet materials, and saves energy and protects environment.

Owner:GUANGDONG HULUBAO CULTURE TECH CO LTD

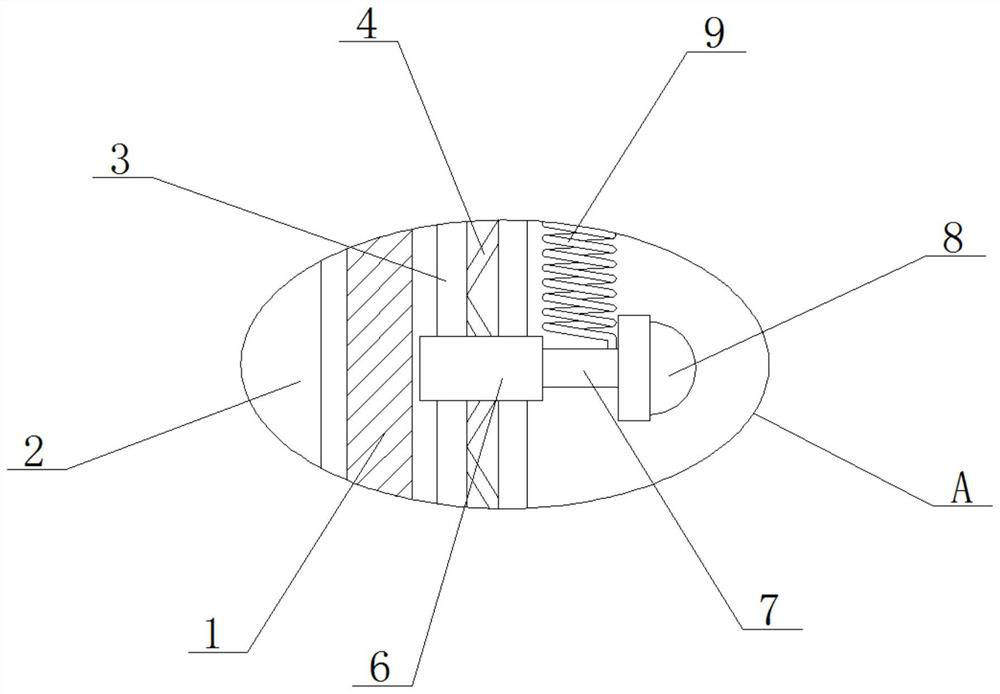

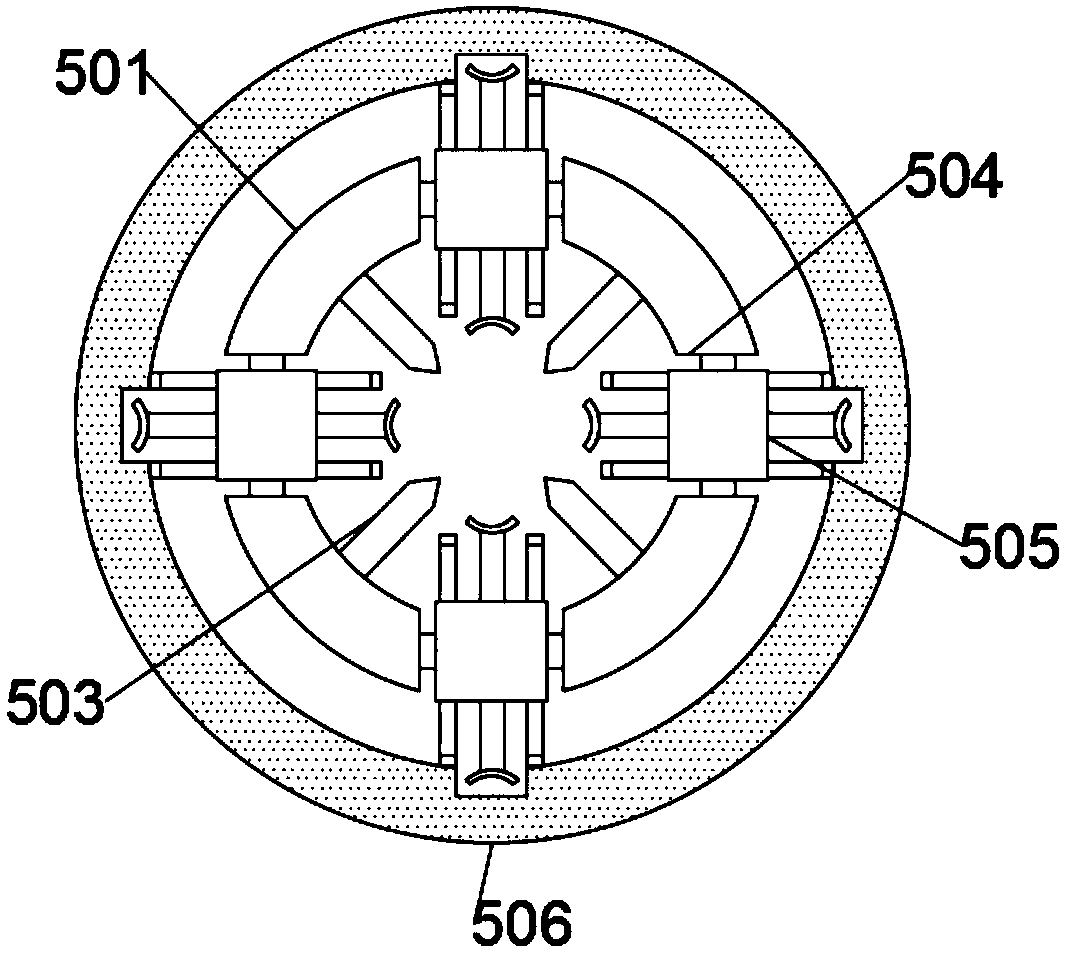

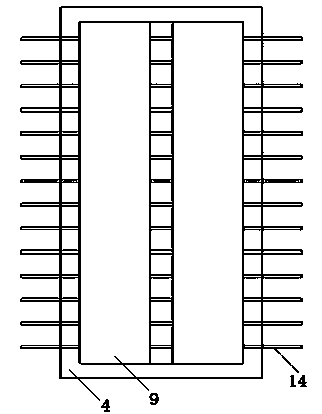

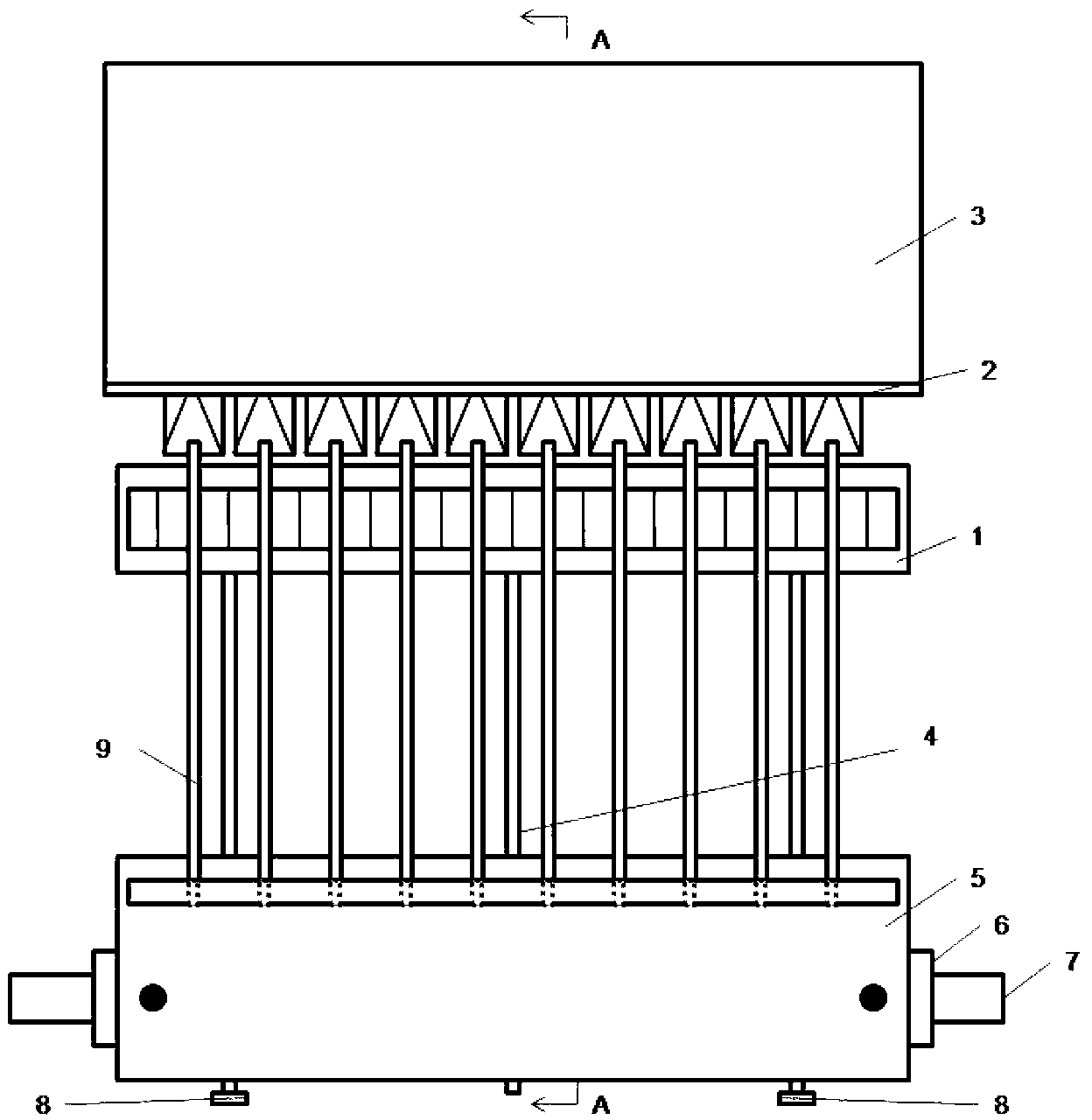

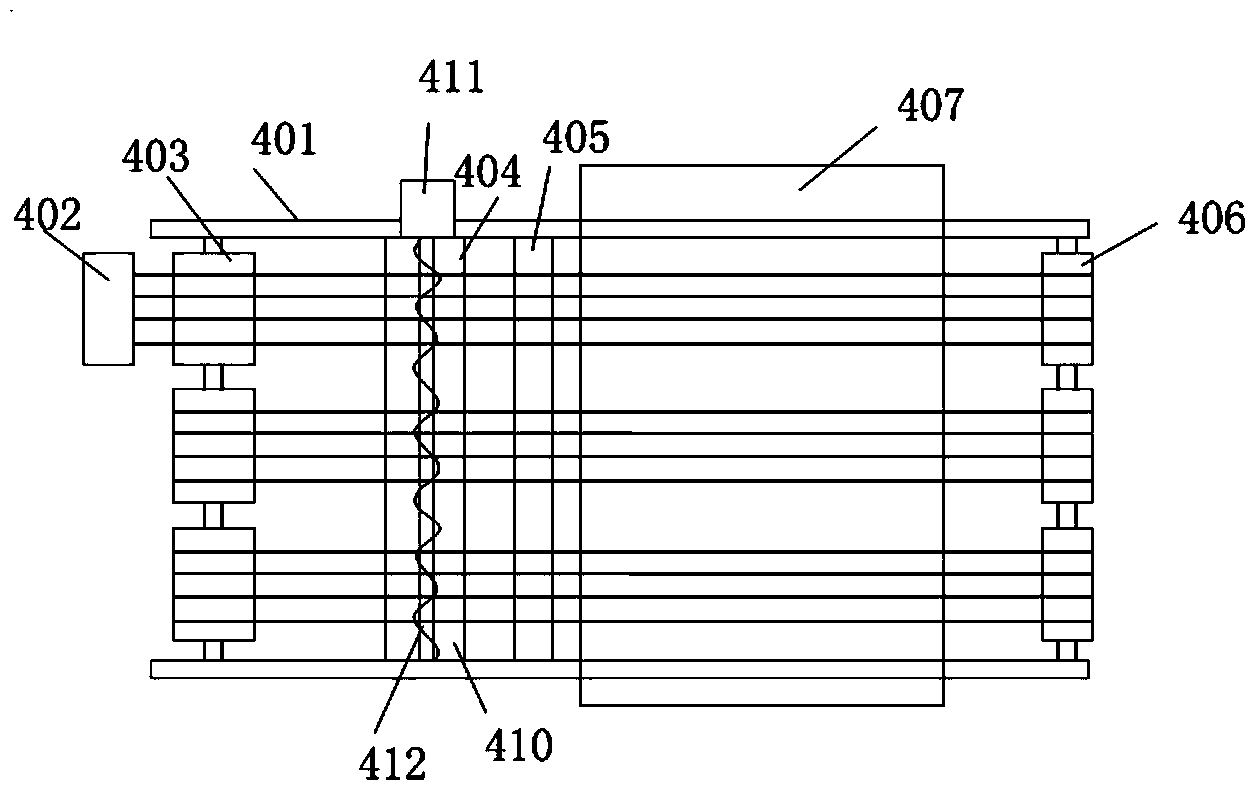

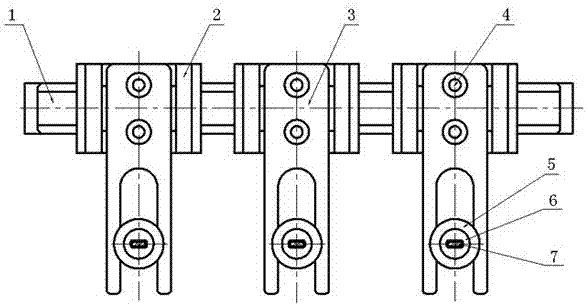

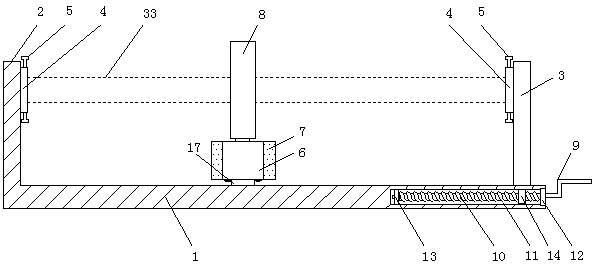

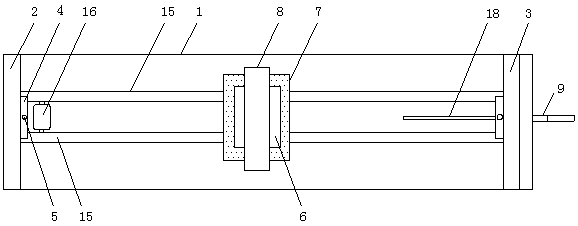

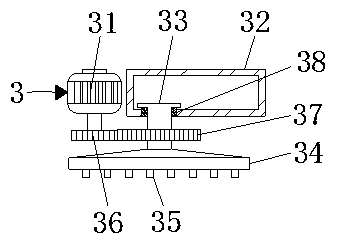

Painting mold frame capable of moving transversely and longitudinally and using method thereof

ActiveCN107958751AKeep a reasonable gapGuaranteed uniformityInsulating conductors/cablesStructural engineeringMechanical engineering

The invention relates to a painting mold frame capable of moving transversely and longitudinally and a using method thereof, which belong to the technical field of transformer winding wire equipment.The painting mold frame comprises a linear sliding rail (1), sliding blocks (2), U-shaped mold positioning frames (3), fixing bolts (4) and painting molds (5), wherein the number of the sliding blocks(2) ranges from 10 to 12, and the sliding blocks (2) are movably arranged on the linear sliding rail (1); the number of the U-shaped mold positioning frames (3) matches that of the sliding blocks (2), the U-shaped mold positioning frames (3) are fixedly connected with the sliding blocks (2) by means of the fixing bolts (4); and the painting molds (5) are movably arranged in U-shaped grooves of the U-shaped mold positioning frames (3). According to the painting mold frame, mold bases are fixed onto the sliding blocks in the linear sliding rail, paint scraping molds are squeezed by a lead wirewhen the large-scale lead wire is produced, a transverse free moving space of the mold sliding rail in the horizontal plane has great advantages compared with an original fixed mold frame, a reasonable clearance between the paint scraping molds and the lead wire is kept, the uniformity of paint film coating is guaranteed, and the produced products fully meet the standard requirements of State Grid.

Owner:BAODING TIANWEI WIRE MFG

Magnesium alloy auto hub and its producing method

ActiveCN100447270CReduce pollutionEasy to remove slagWheel protectionMaterials scienceEnergy conservation

This invention relates to a kind of automobile hub of magnesium alloy and producing metho. It belongs to the die-casting technology of non-ferrous metal. The main raw material is magnesium alloy ingot. After preheating and drying, it is put in pot and melted under high temperature. Adding master alloy, mixing it fully. The following steps are refining and degassing, casting, heat treatment, machining, surface painting, drying, japanning. During the process, the degassing can reach standard easily. Magnesium liquid slag-removing is easy.

Owner:WUXI DAIKA WHEEL HUB MFG

Control method for painting shrinkage cavity defect of tin-plated plate

PendingCN114086222AEasy to controlReduced incidence of shrinkageLiquid surface applicatorsChromatisationTinningSurface oxidation

The invention belongs to the technical field of coating layers, and discloses a method for controlling the painting shrinkage cavity defect of a tin-plated plate. According to the method, a layer of surface structure with good coating property is formed on the surface of the tin-plated plate by controlling a leveling process of the surface structure of the tin-plated plate and controlling a passivation and drying process of a passivation film layer on the surface of the tin-plated plate; the surface structure is composed of a passive film and an oil film, the surface roughness Ra is 0.4-0.6 [mu] m, and the surface peak density RPc is 70-90 pieces / cm; and the surface oxidation degree is reduced by controlling the storage environment of the tin-plated plate after shearing and before printing and coating, so that good wettability is kept, it is ensured that the surface of the tin-plated plate has good coating performance before coating, and the problem of painting shrinkage of the tin-plated plate is solved fundamentally. The control method disclosed by the invention is simple and easy to implement, can meet the requirements of coating the tin-plated plate with coatings such as white coating and golden yellow base oil and can be used in factories in southern humid and hot environments, and the occurrence rate of shrinkage cavities is greatly reduced to 0.02% or below from 0.5% compared with that of a traditional process.

Owner:SHAGANG GROUP +2

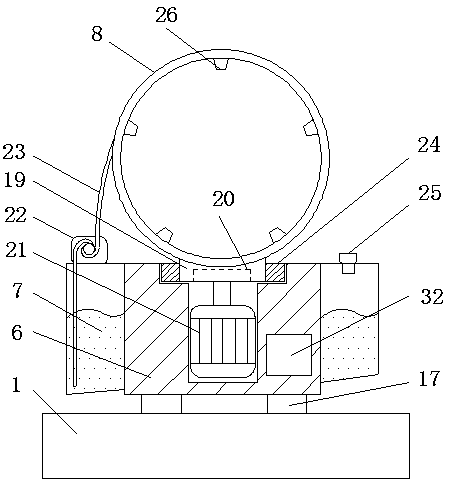

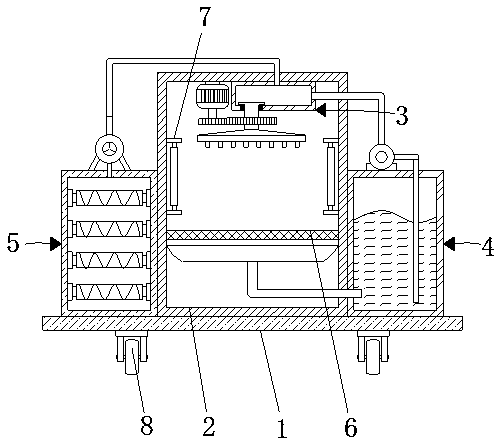

Building component japanning device

The invention relates to a building component japanning device. The building component japanning device comprises a base. A fixed plate is arranged on the left side of the base. A movable plate is arranged on the right side of the base. The fixed plate and the movable plate are both provided with fixed rings. The top and bottom of each fixed ring are provided with fastening bolts. A mounting baseis arranged above the base. A motor B is fixedly mounted in the mounting base. An external gear is arranged at the rotary output end of the upper portion of the motor B. The external gear is engaged with an internal gear. The internal gear is arranged on a rotary part. A japanning device body is fixedly arranged on the upper portion of the rotary part. The inner side of the japanning device body is provided with a paint spray gun head. The rotary part is fixed to the upper portion of the mounting base through a bearing A. A paint storage tank is arranged on the outer side of the mounting base.A booster pump and a tank plug are arranged on the upper portion of the paint storage tank. The booster pump is connected with the paint spray gun head of the japanning device body through a guide pipe. The lower end of the guide pipe is arranged n the paint storage tank. Sliding blocks are arranged at the bottom of the mounting base. The sliding blocks are arranged on electric sliding rails. Thebuilding component japanning device has the advantages of being stable in japanning effect, wide in japanning range and uniform in japanning.

Owner:NANYANG LINGYU MACHINERY CO LTD

Wooden door surface plate sealing type painting device and method

PendingCN111617950AEasy to handleAvoid inhalationLiquid surface applicatorsCleaning using toolsMechanical engineeringIndustrial engineering

The invention relates to the field of furniture processing, and particularly discloses a wooden door surface plate sealing type painting method. The method comprises the following steps that 1, a doorplate is cleaned; 2, the sheet-shaped paint film is placed on the door plate; and 3, the paint film is heated until the paint film is molten and covers the door plate, meanwhile gas around the paintfilm is exhausted, and then the door plate is cooled until the paint on the door plate is solidified. According to the wooden door surface plate sealing type painting method, painting efficiency can be improved, and meanwhile workers are prevented from inhaling a large amount of paint particles and toxic and harmful gas in paint.

Owner:希格玛智家(重庆)科技有限公司

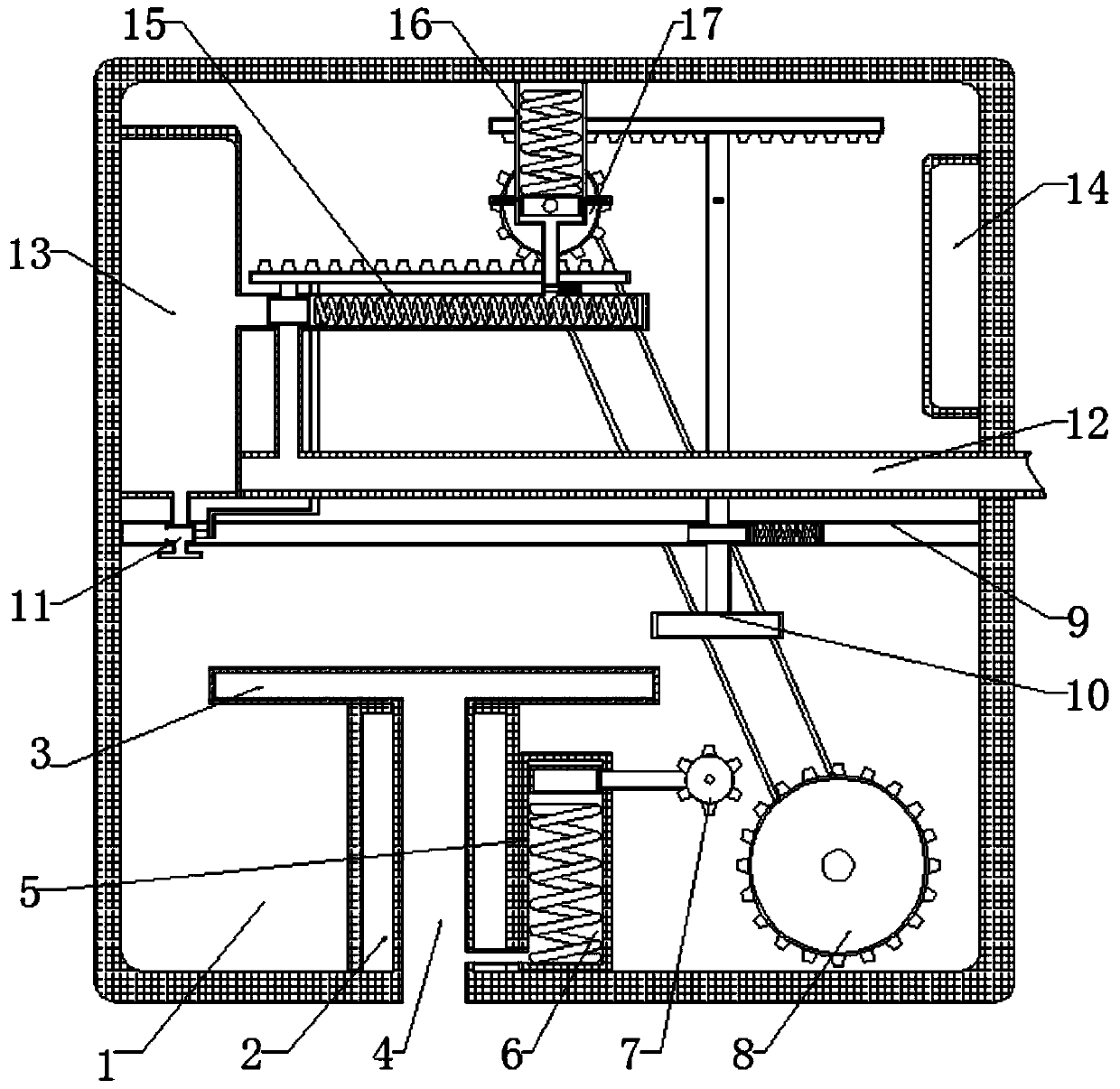

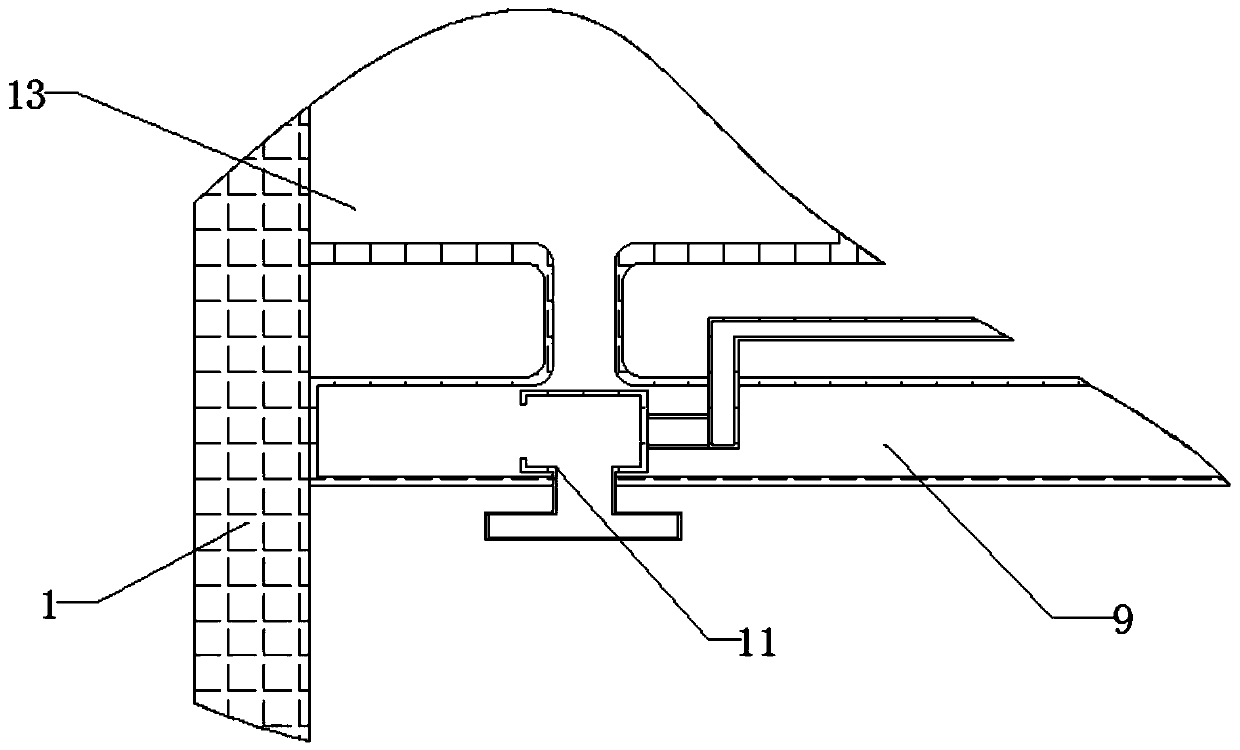

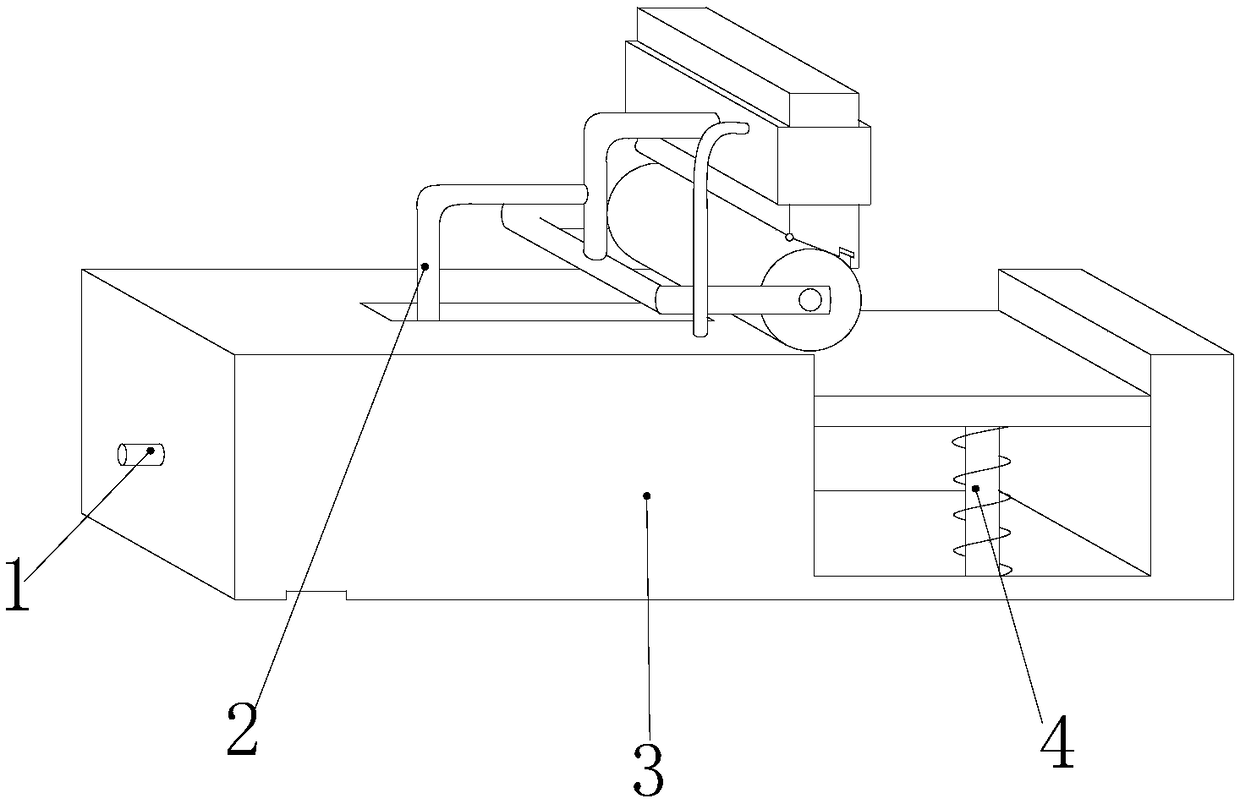

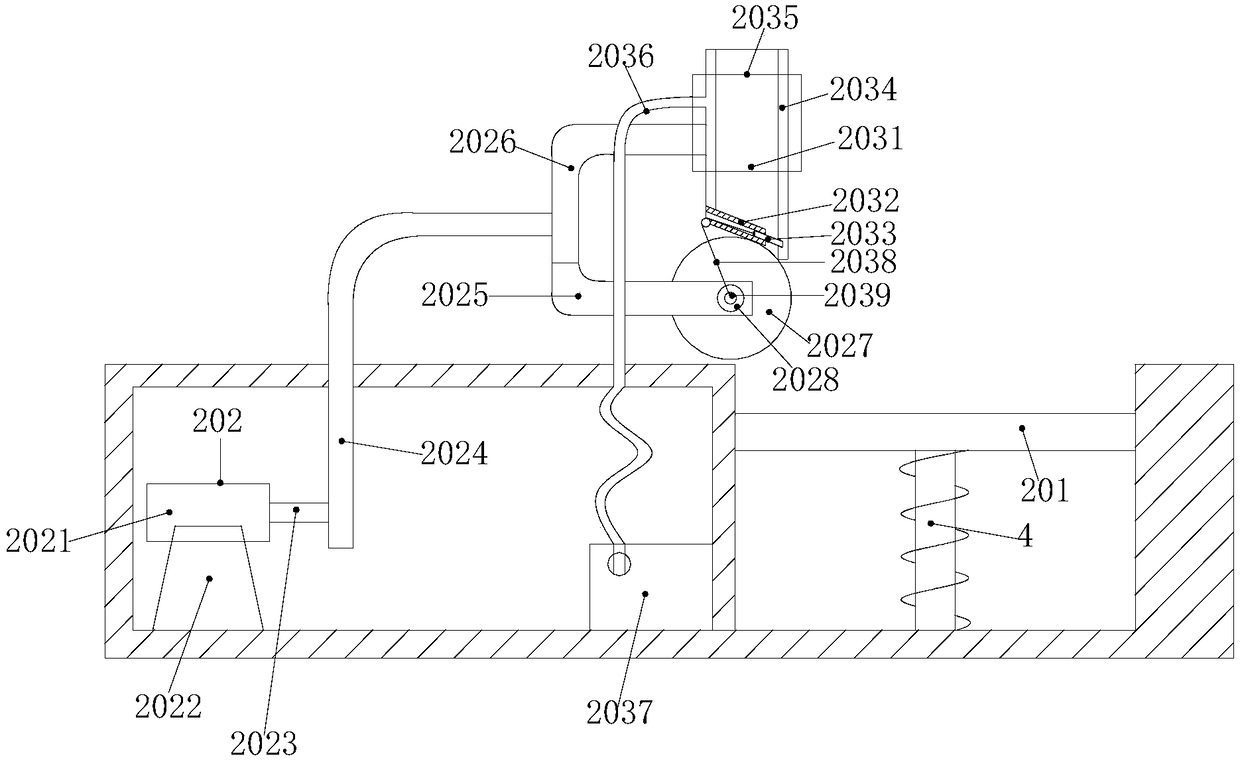

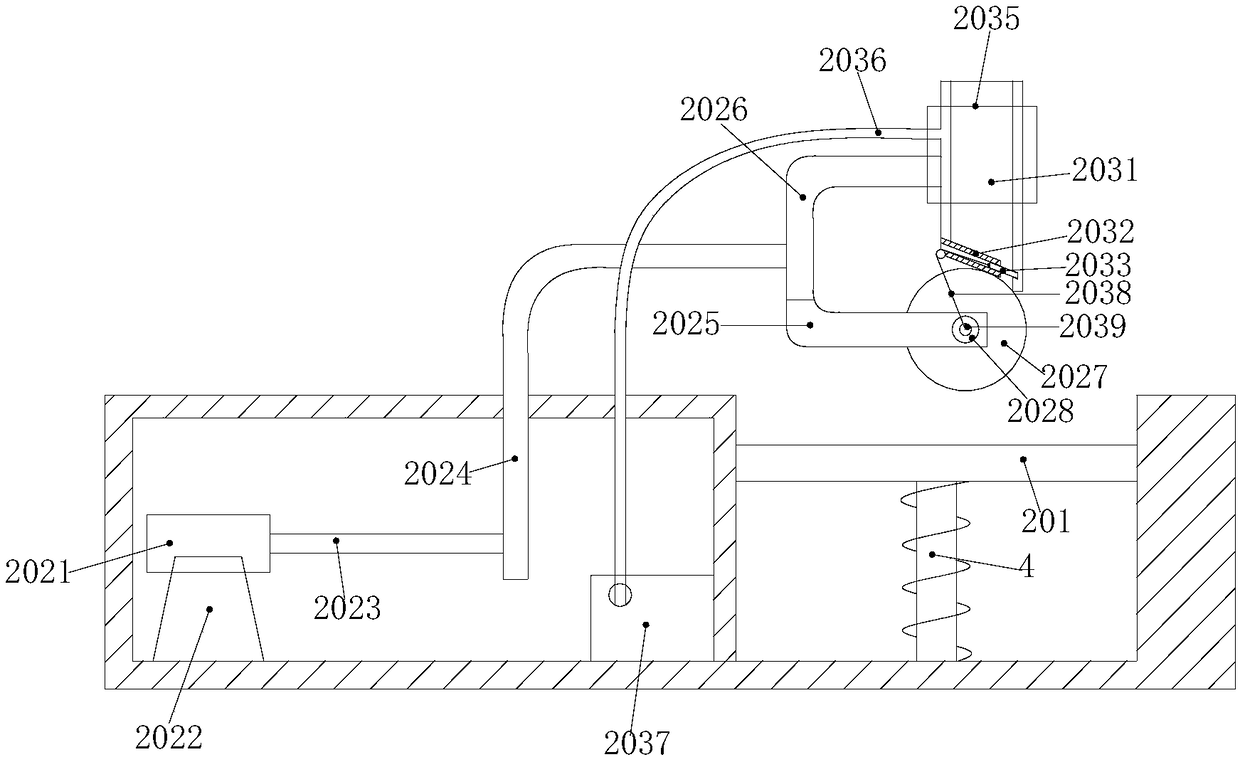

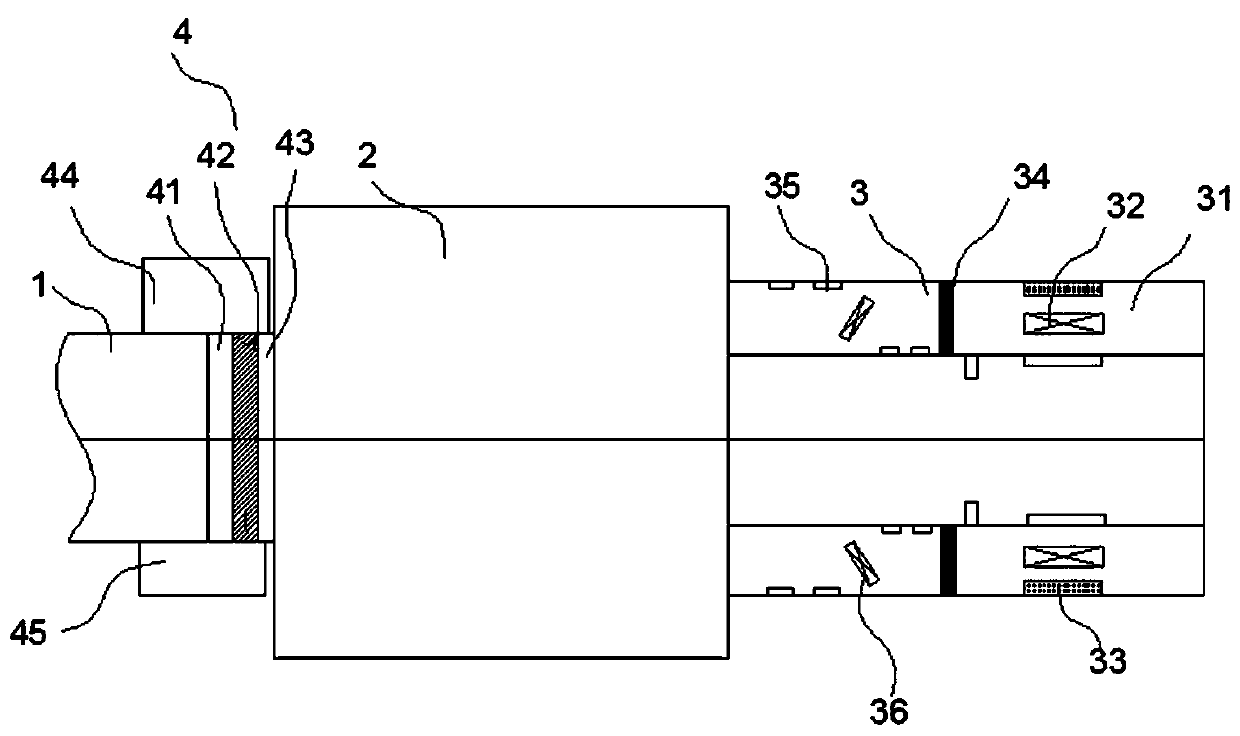

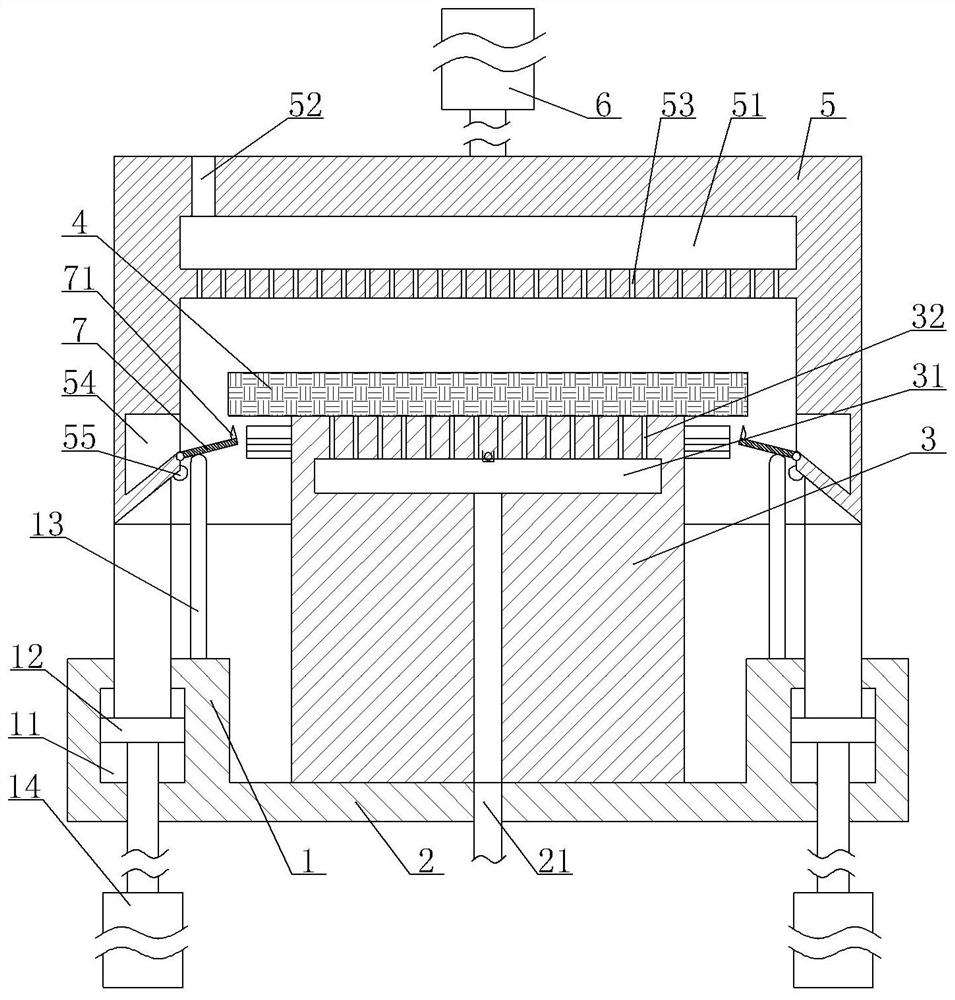

Japanning equipment for processing of bamboo chopsticks

InactiveCN109261383AEvenly paintedEasy to useMovable spraying apparatusPretreated surfacesHuman bodyEngineering

The invention discloses japanning equipment for processing of bamboo chopsticks. The equipment includes a base, a transmission mechanism, a paint circulating mechanism and a drying mechanism; a box body is fixedly connected to the top of the base, the transmission mechanism is arranged on the top of an inner cavity of the box body, the paint circulating mechanism is disposed on the right side of the top of the base, and the drying mechanism is arranged on the left side of the top of the base. Since the transmission mechanism is arranged, the chopsticks can be more uniformly japanned with paintor more uniformly dried through hot wind; through arrangement of the paint circulating mechanism, the effects of circularly using the paint and reducing the cost are achieved; through arrangement ofthe drying mechanism, the chopsticks are dried conveniently without automatic air-drying, the work efficiency is improved, and therefore the problems are solved that under a manual japanning mode, notonly is the efficiency extremely low, but also the distance between people and paint is short, correspondingly some volatilizing harmful gas can be absorbed by the human body, the health of the humanbody is terribly damaged, and the efficiency is too low.

Owner:耒阳市马王塘林业有限公司

Wooden furniture surface japanning method

The invention relates to a wooden furniture surface japanning method which comprises a step (1) of coating of water-borne putty; a step (2) of secondary coating of water-borne putty after refrigeration; a step (3) of uniform baking; and a step (4) of drying after japanning. Through experiments, the wooden furniture surface japanning method further improves adhesive force of paint, and when normally used, the paint is not subjected to phenomena of bubbling and dropping.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

Heat insulation break bridge aluminum profile electrophoresis japanning process

InactiveCN107699936AHeat resistantStain resistantAnodisationElectrophoretic coatingsThermal insulationElectrophoresis

The invention discloses a heat insulation break bridge aluminum profile electrophoresis japanning process. A heat insulation break bridge aluminum profile comprises an aluminum alloy profile on the inner side, a heat insulation aluminum alloy profile on the outer side, and heat insulation clamping grooves formed in the aluminum alloy profile on the inner side and the heat insulation aluminum alloyprofile on the outer side; and the aluminum alloy profile on the inner side and the heat insulation aluminum alloy profile on the outer side are spliced together through the heat insulation clampinggrooves. The heat insulation break bridge aluminum profile electrophoresis japanning process specifically comprises the steps of nanometer treatment, anodic oxidation, electrophoresis japanning, drying solidification and the like. Through the heat insulation break bridge aluminum profile electrophoresis japanning process, a formed paint film is about 12-15 [mu]m, the heat insulation effect of theheat insulation break bridge aluminum profile can be enhanced as the paint film has the properties of resisting heat, contamination, ageing and the like, and meanwhile, as the nanometer treatment andother treatment are conducted before electrophoresis japanning, the paint film is more even and compact, and the quality of products is improved.

Owner:湖南金牛铝业有限公司

Method for manufacturing bamboo louver pieces

InactiveCN1799798AWill not deformExtended service lifeWood working apparatusFlat articlesPunchingEngineering

The invention relates to a method for producing bamboo leaves of louver, which is characterized in following producing steps: sizing the former bamboo; rough plane and layered; softening, hot-pressed molding, rough burnishing shaping, chamfering finished burnishing, punching, japanning, and mounting. The invention can shape the bamboo via layer, softening, high-temperature braising, and hot-pressed shaping, without the deformation caused by irradiation, while the inventive louver has lower cost, long service life and reduced material.

Owner:姜伟

Protection method applicable to chaste tree twig woven products

InactiveCN107053412ASolve usabilitySolve the problem of longevityLiquid surface applicatorsWood treatment detailsPlasma depositionInstability

The invention relates to the technical field of processing of woven articles, and discloses a protection method applicable to chaste tree twig woven products. The protection method comprises the following steps that 1, new-made chaste tree twig woven products are treated at the high temperature and the low temperature alternately, on one hand, the weather resistance of the chaste tree twig woven products can be improved, on the other hand, kinetic energy of molecular movement is reduced, the instability problem caused by thermal expansion and contraction to the woven products is reduced, and the mechanical property is improved; 2, the surfaces of the chaste tree twig woven products are wetted by base solution spray before lacquering, the anti-penetrability performance and the antibacterial insect-proof antiseptic performance of the woven products can be improved, the binding force of paint can be improved, and the problems that japanning performance of the surfaces of chaste tree twigs is poor and disengagement is likely to be caused are solved; 3, the speed and environmental temperature are controlled in the japanning process, japanning is uniform, and the drying speed is increased; and 4, the chaste tree twig woven products are coated with polytetrafluoroethylene powder through a plasma deposition rapid curing method, the chemical stability, corrosion resistance and good aging resistance of the products are further improved, and the service life is prolonged.

Owner:阜南县环宇柳木工艺制品有限公司

Paint mist purification recovery device applied to japanning room

InactiveCN107649004AAchieve reuseLow costGas treatmentDispersed particle filtrationFixed frameJapanning

The invention discloses a paint mist purification recovery device applied to a japanning room. The paint mist purification recovery device comprises an air suction fan, a paint mist recovery box and acatalytic cracking box, wherein the air suction fan, the paint mist recovery box and the catalytic cracking box are arranged on a base, a plurality of paint mist recovery barrels are arranged in thepaint mist recovery box through fixing frames, air inlet pipes of the paint mist recovery barrels are connected with a fan air outlet pipe, the fan air outlet pipe is arranged at the output end of theair suction fan, machine cores for recovering the paint mist are arranged in the paint mist recovery barrels, paint cups are fixed to the bottoms of the machine cores, air outlet pipes are arranged at the bottoms of the paint mist recovery barrels, the catalytic cracking box is tightly attached to the paint mist recovery box, and end openings of the air outlet pipes are connected with openings ona lateral wall of the paint mist recovery box. The paint mist purification recovery device disclosed by the invention has the beneficial effects that paint particles in the paint mist can be attachedto the machine cores, gathered into drops and finally gathered into the paint cups, recovery of the paint in the paint mist can be recovered, resource reutilization is achieved, and more cost is saved compared with utilizing a water curtain to absorb the paint.

Owner:山东古润环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com