Patents

Literature

78results about How to "Affect the working environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

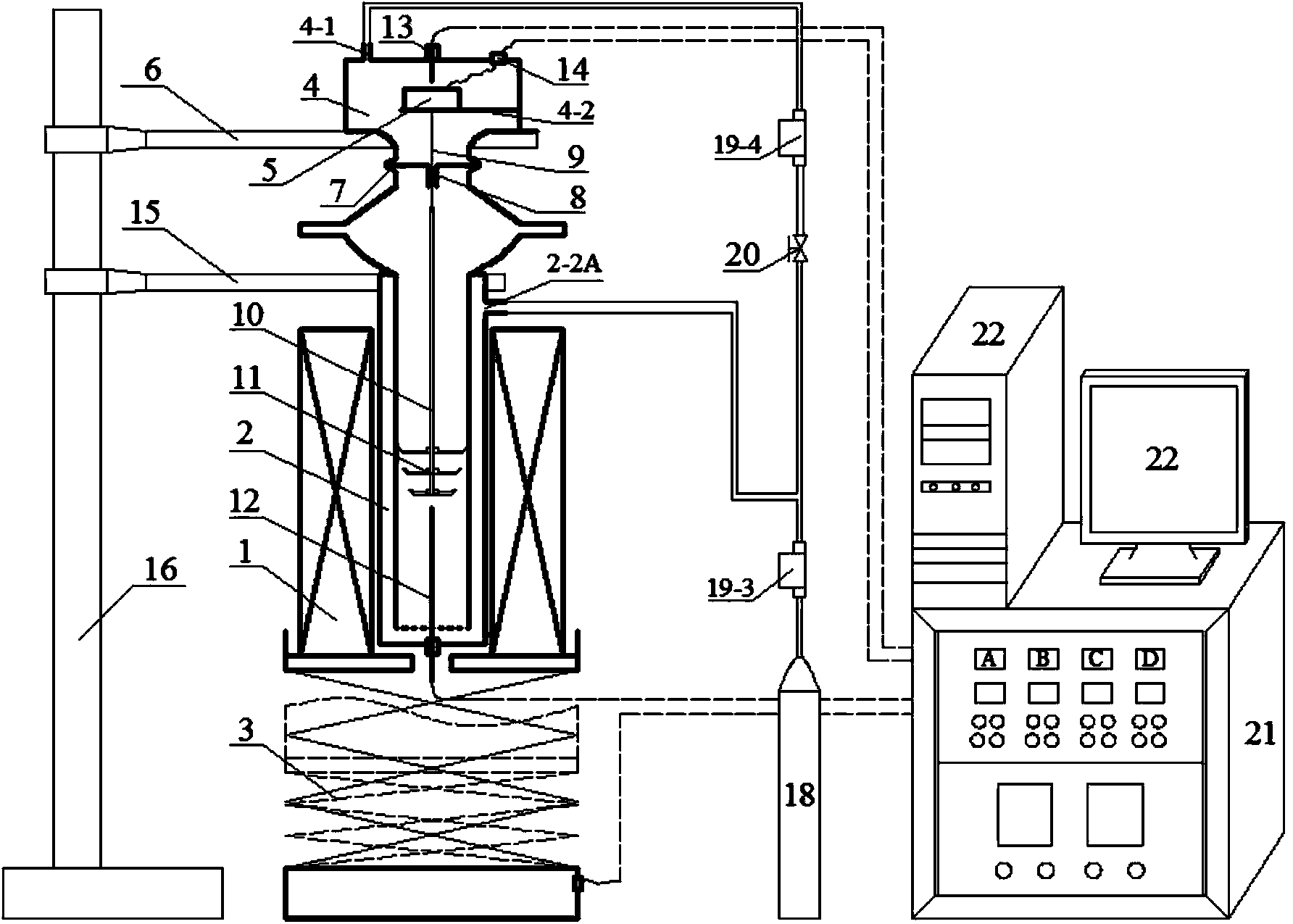

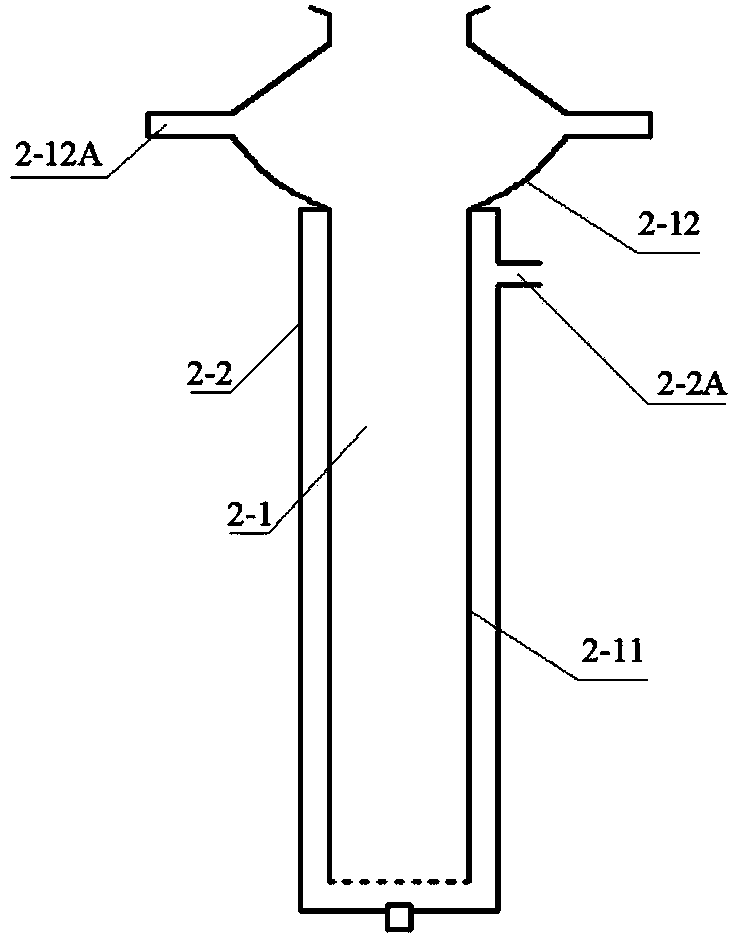

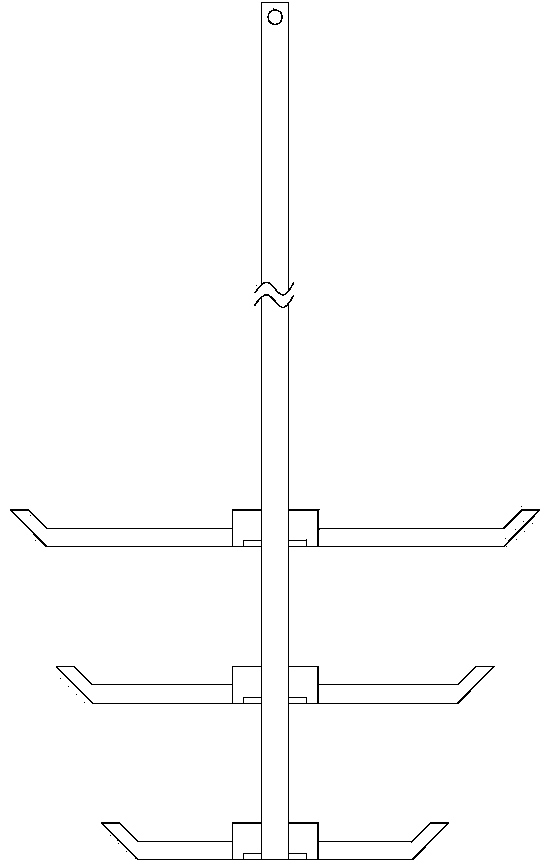

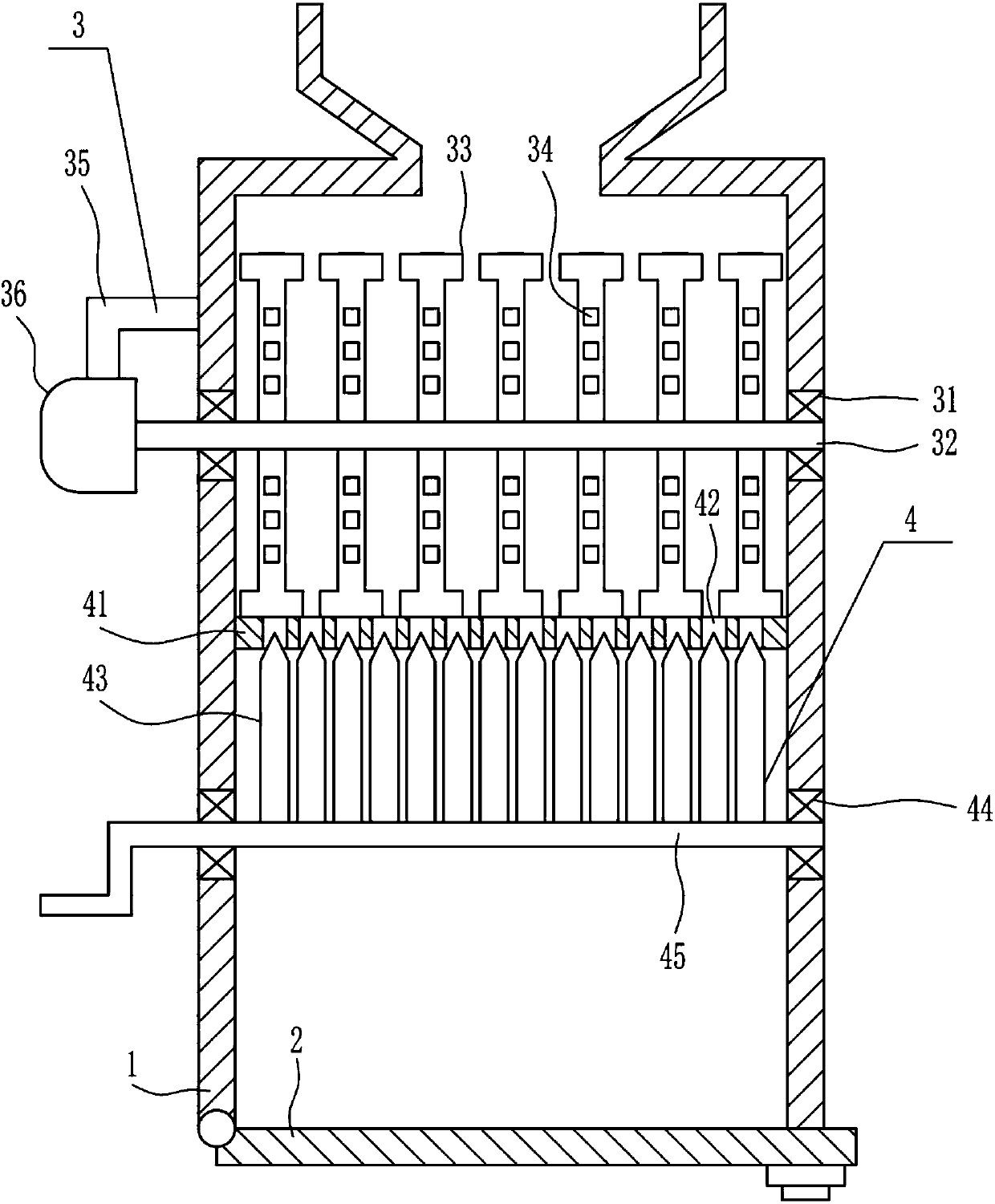

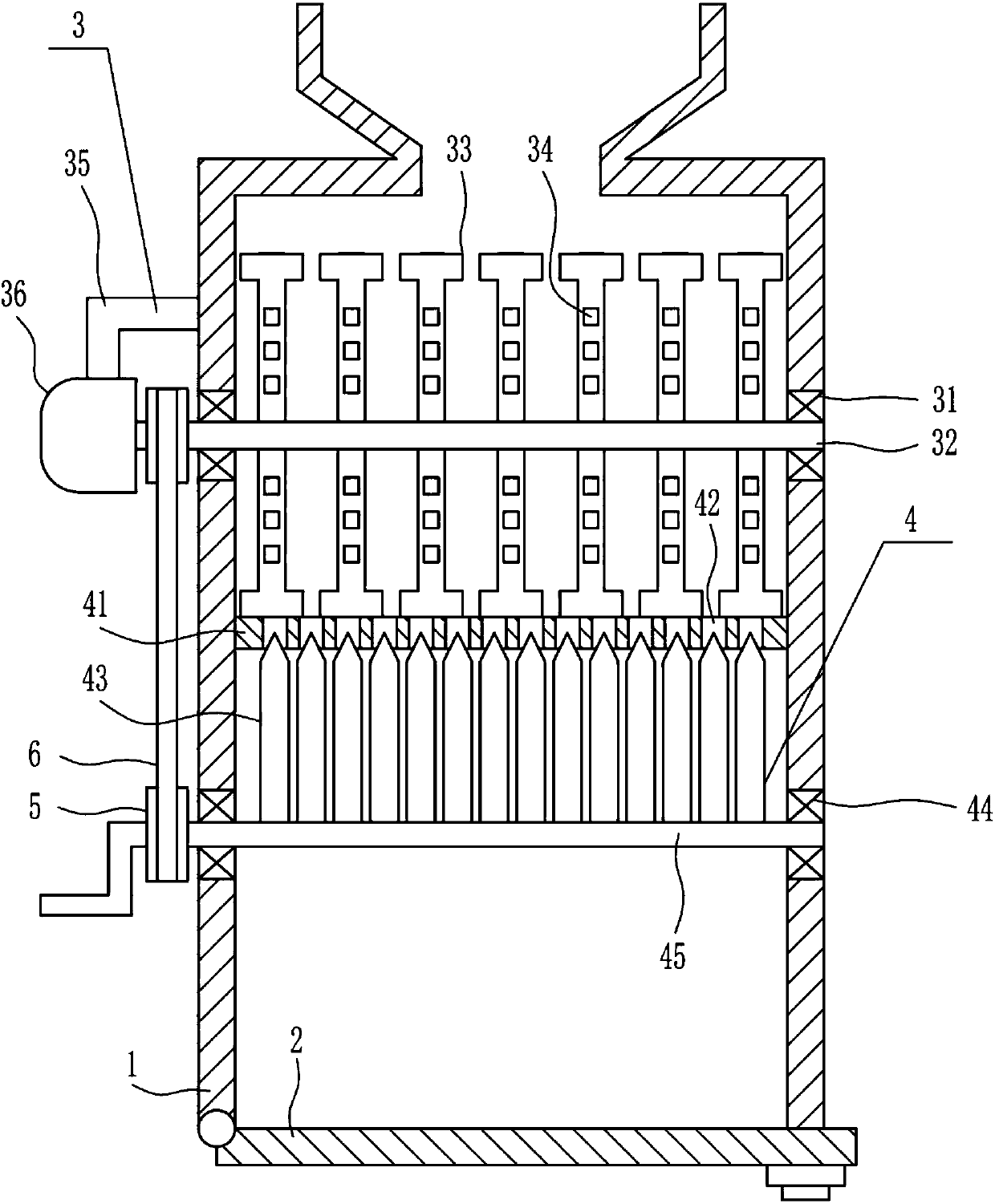

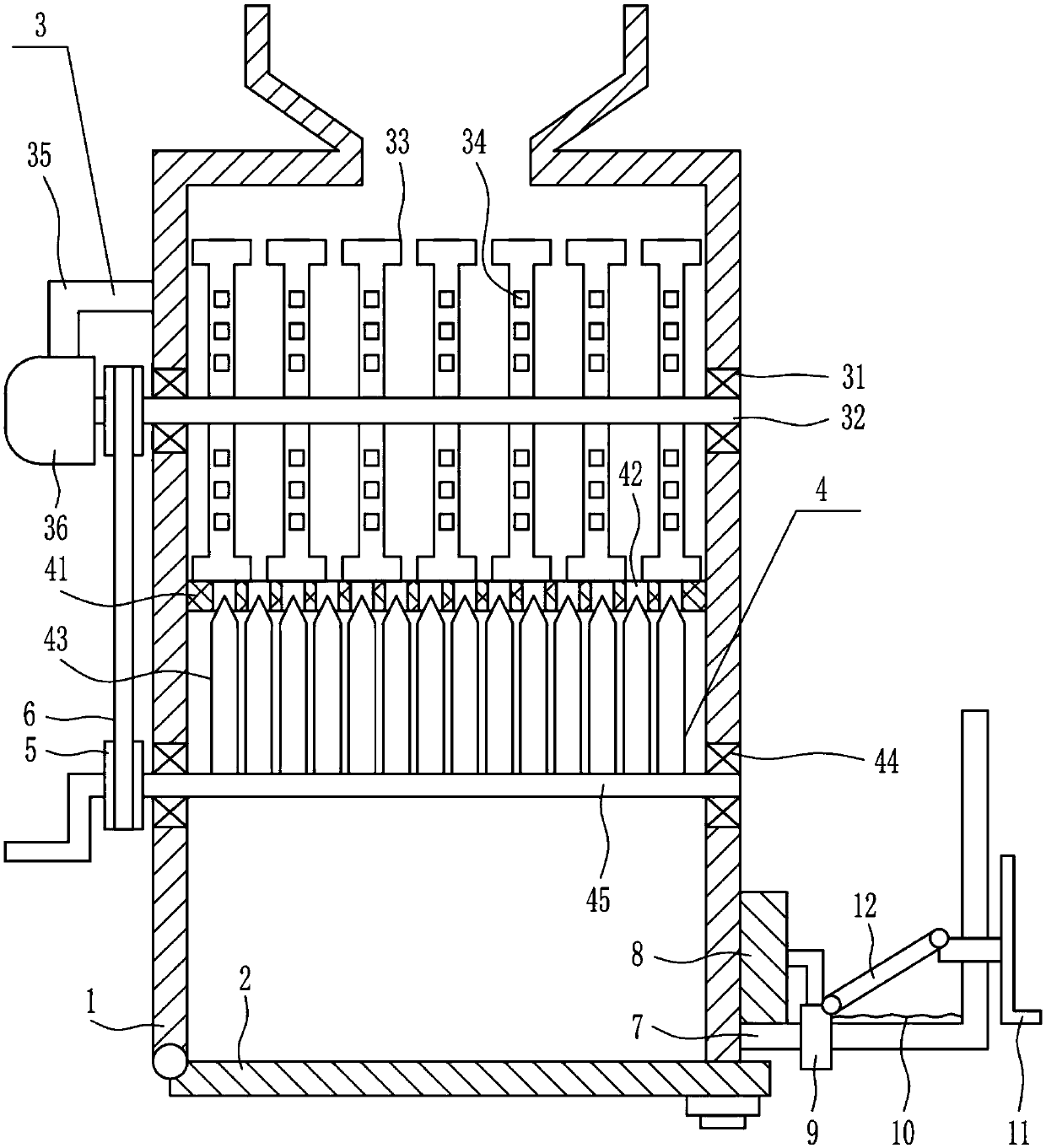

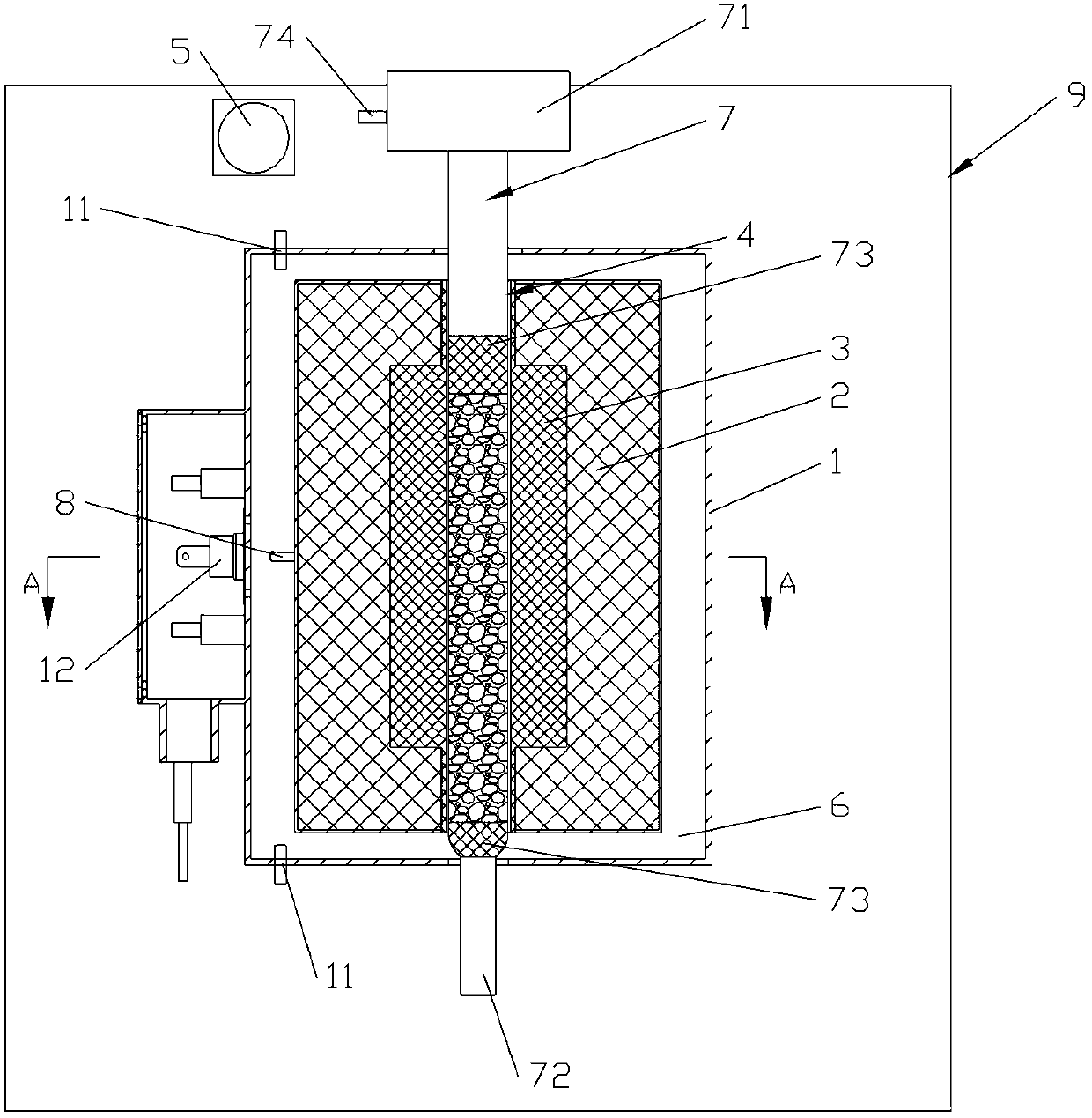

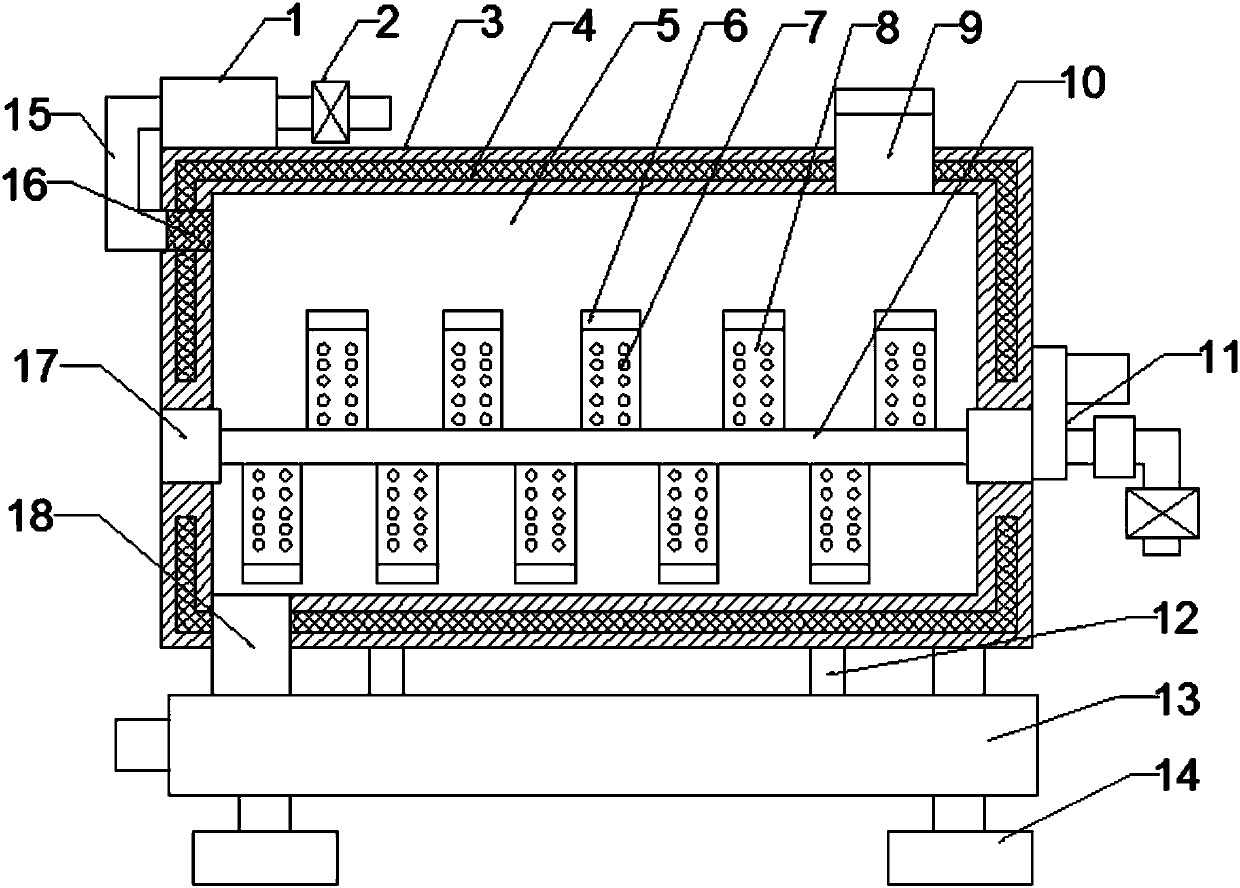

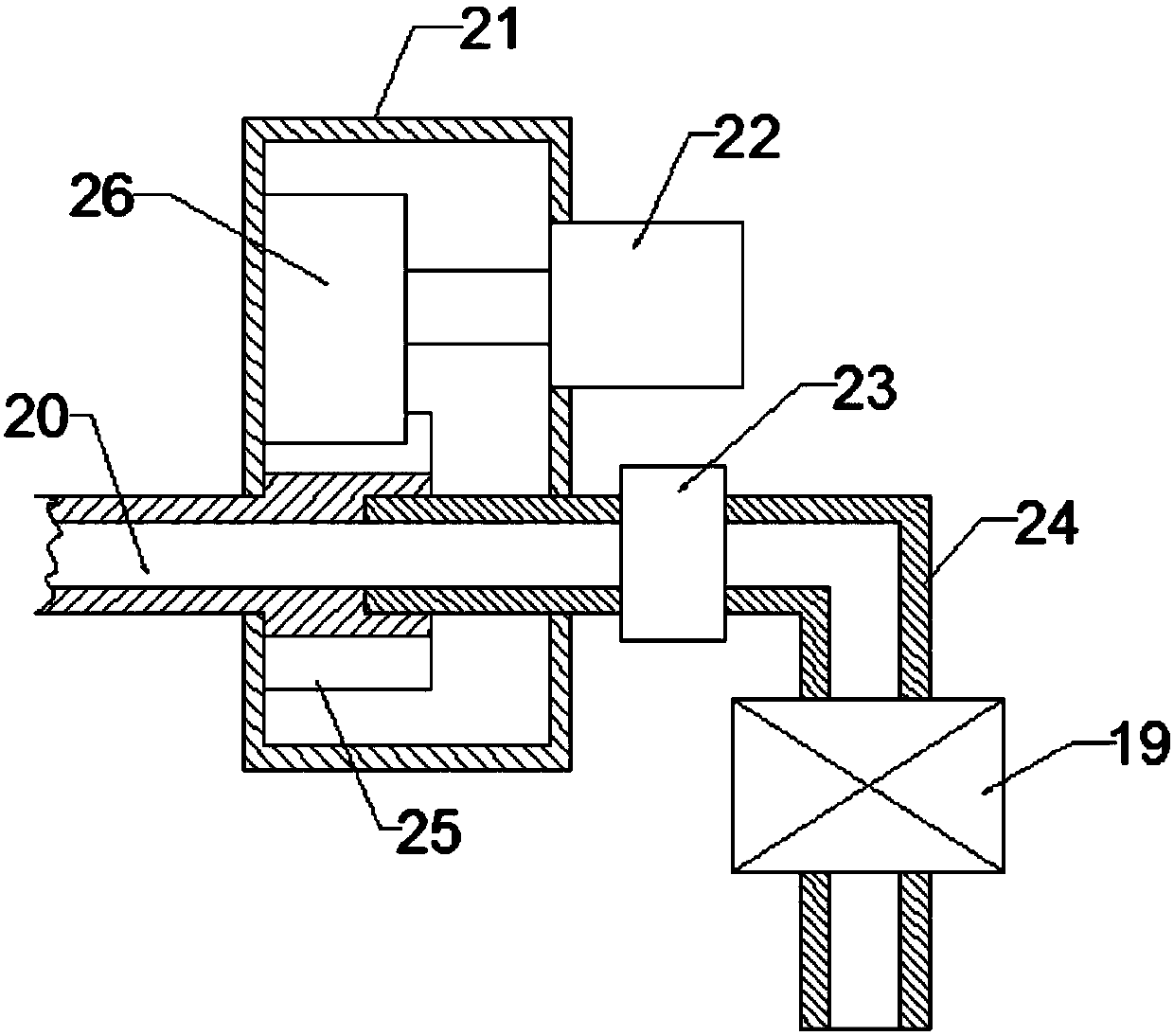

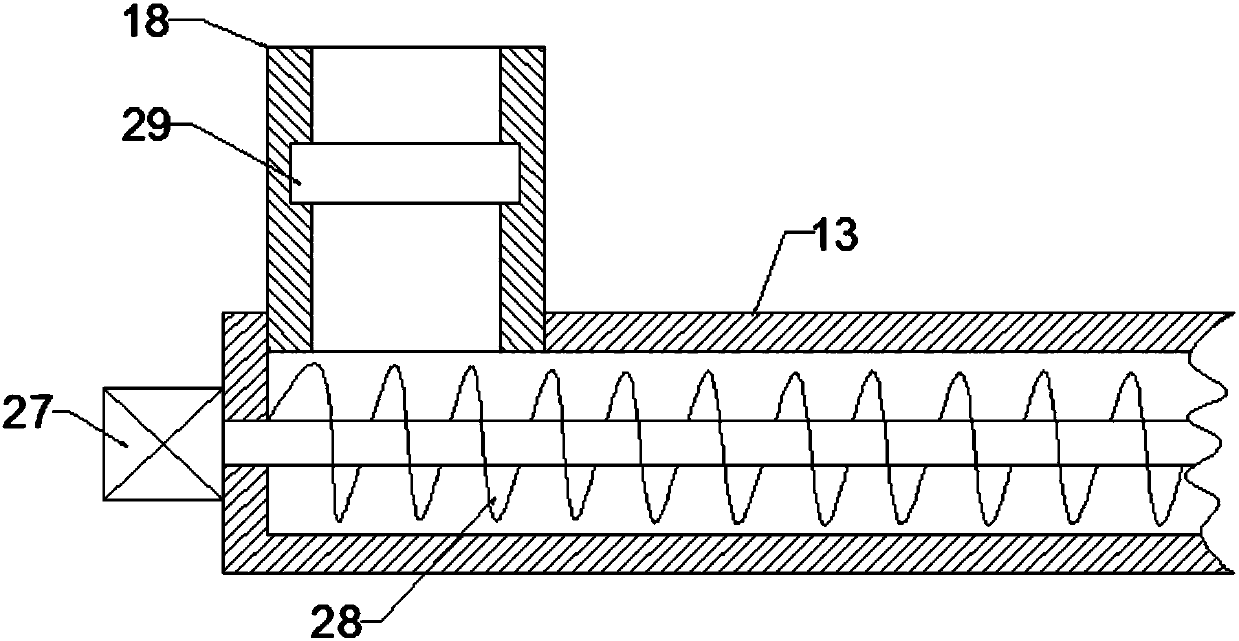

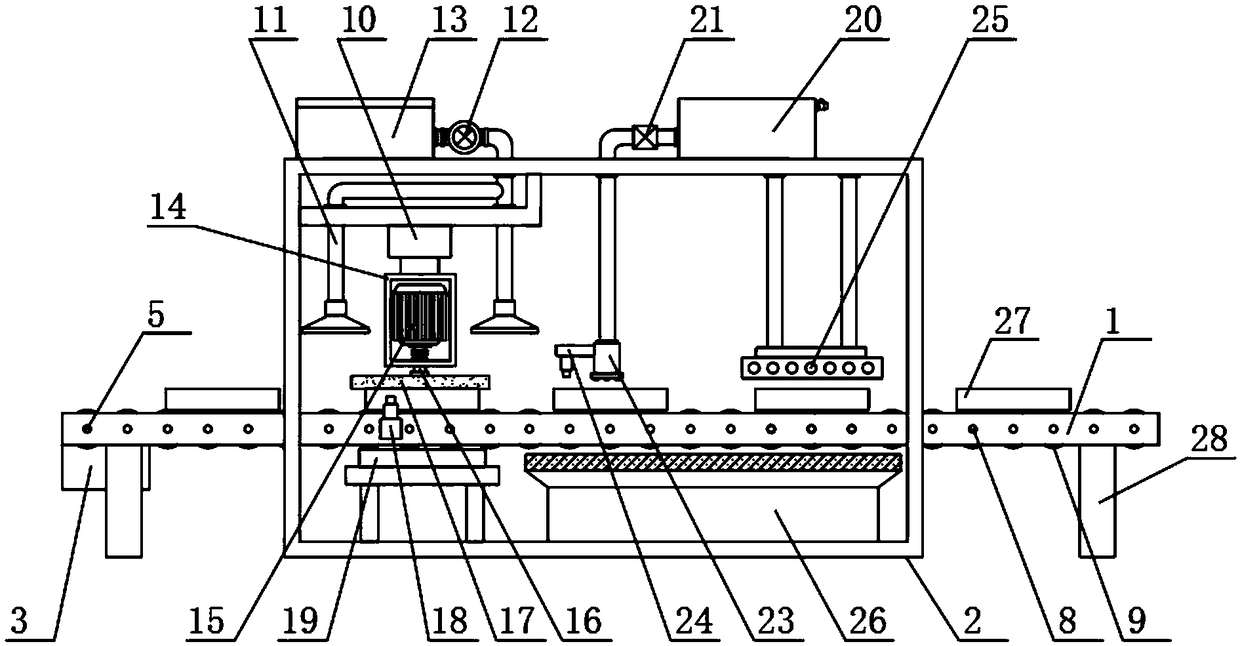

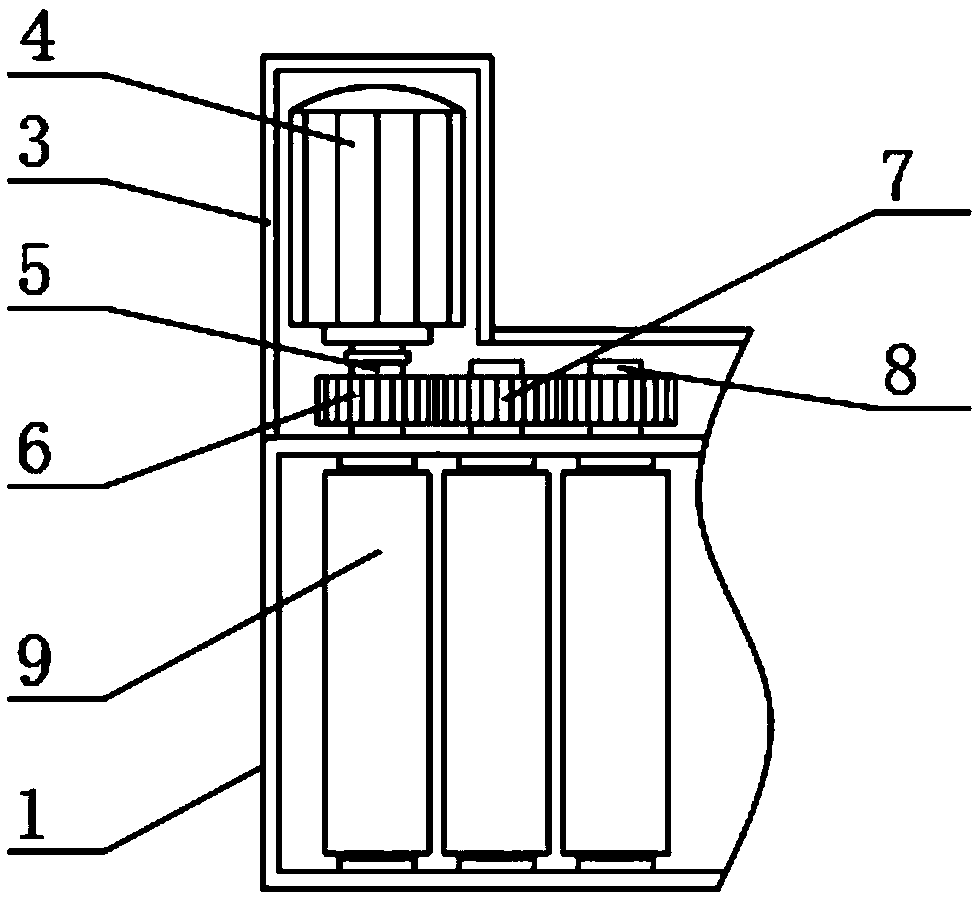

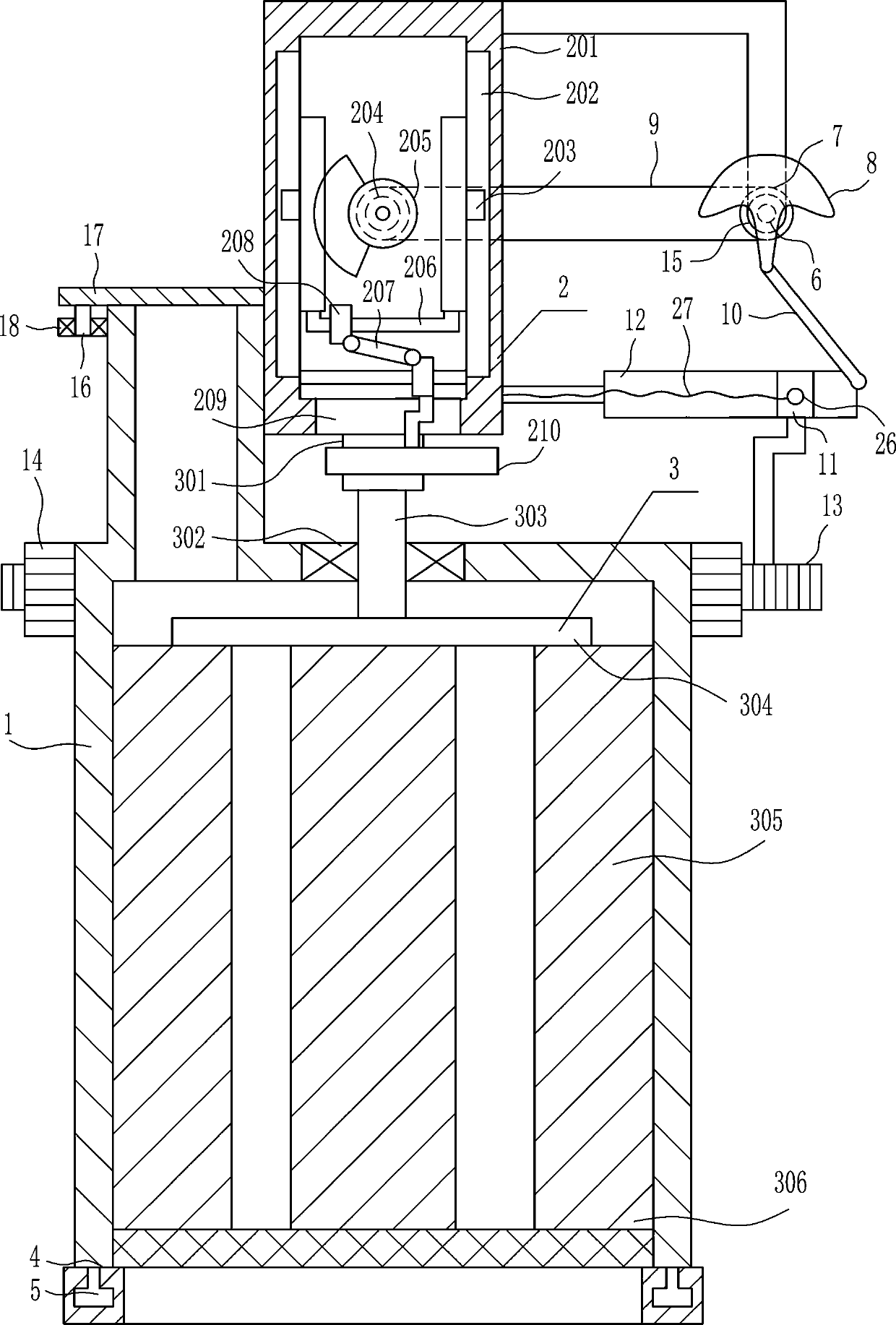

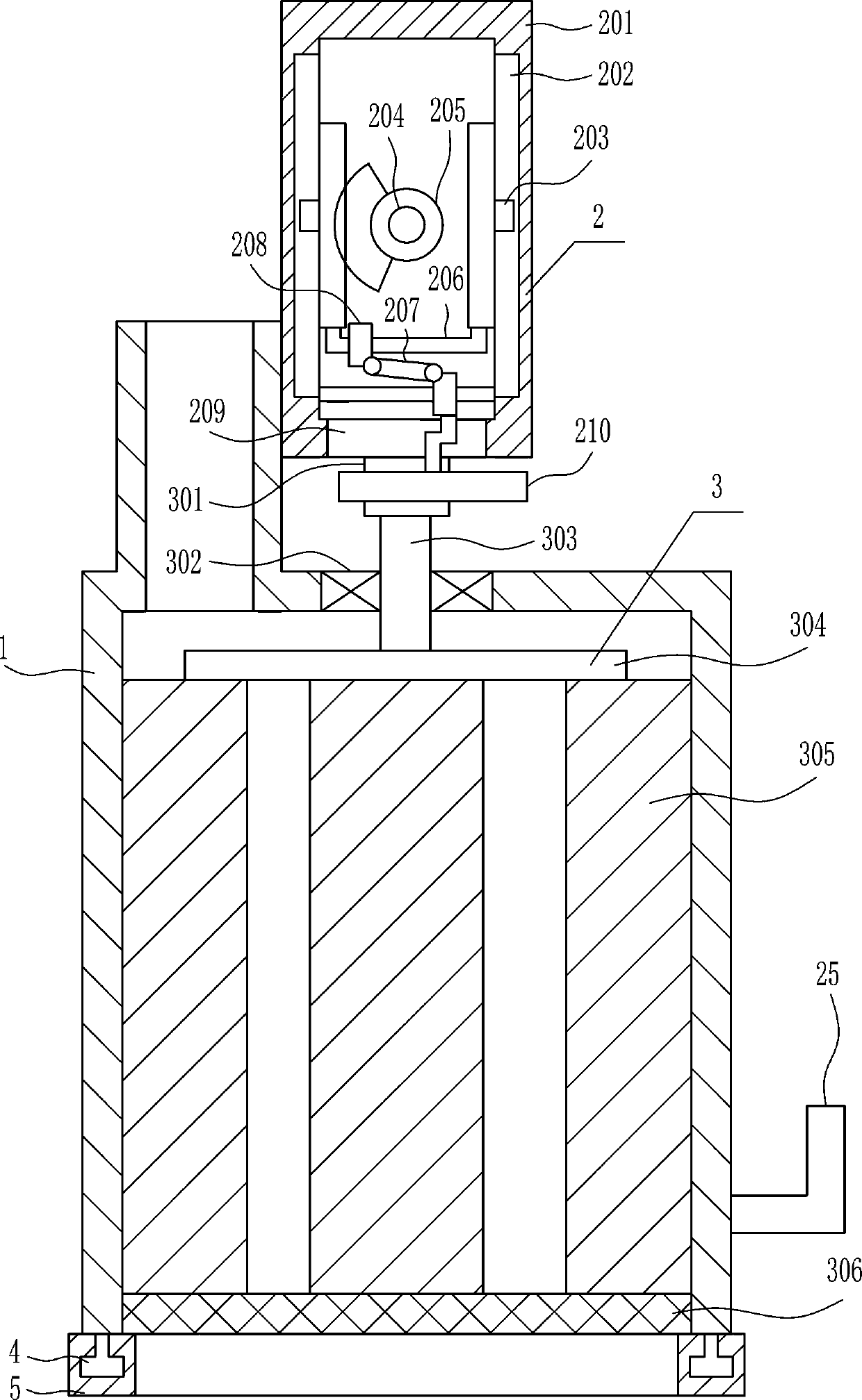

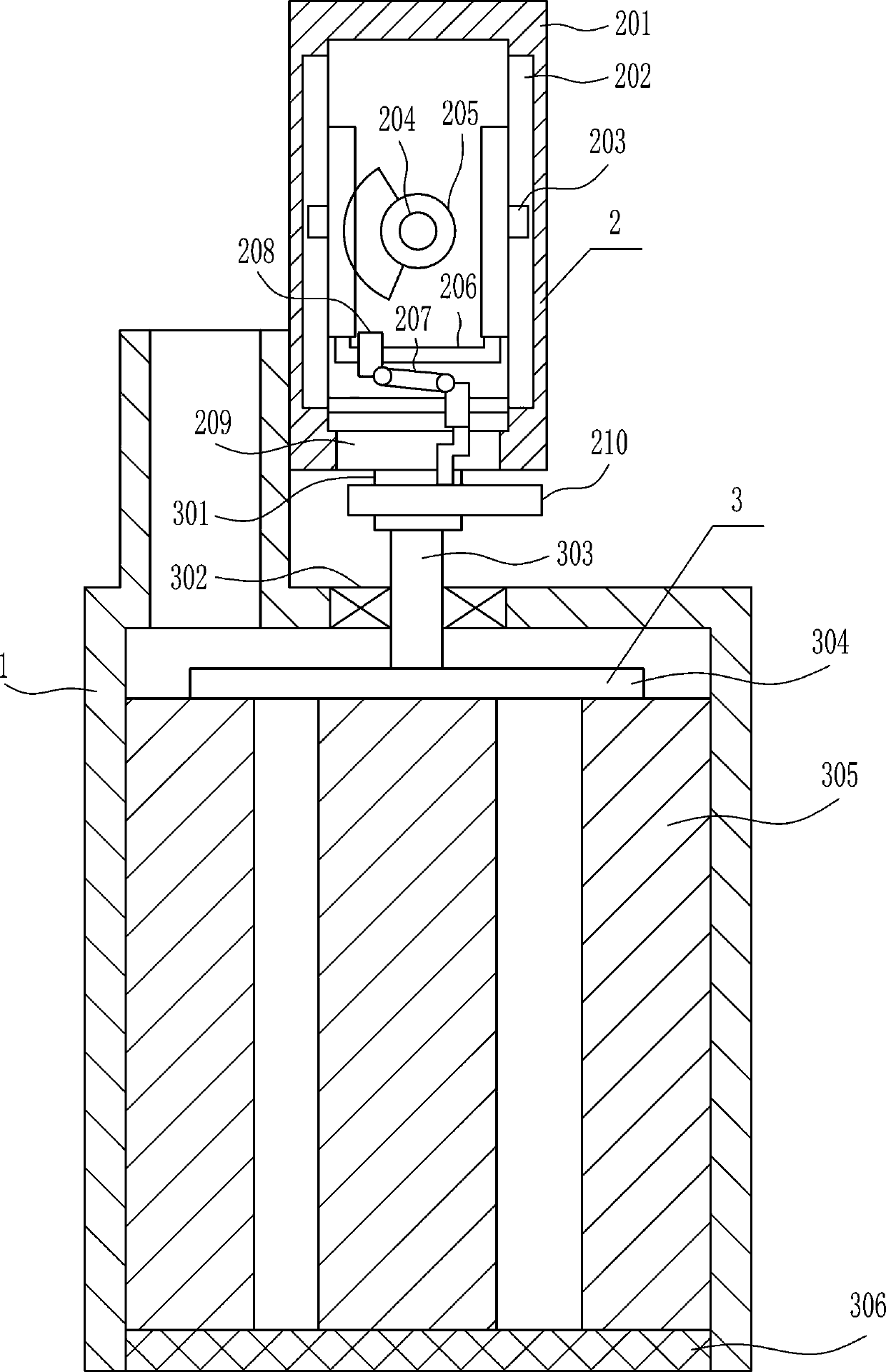

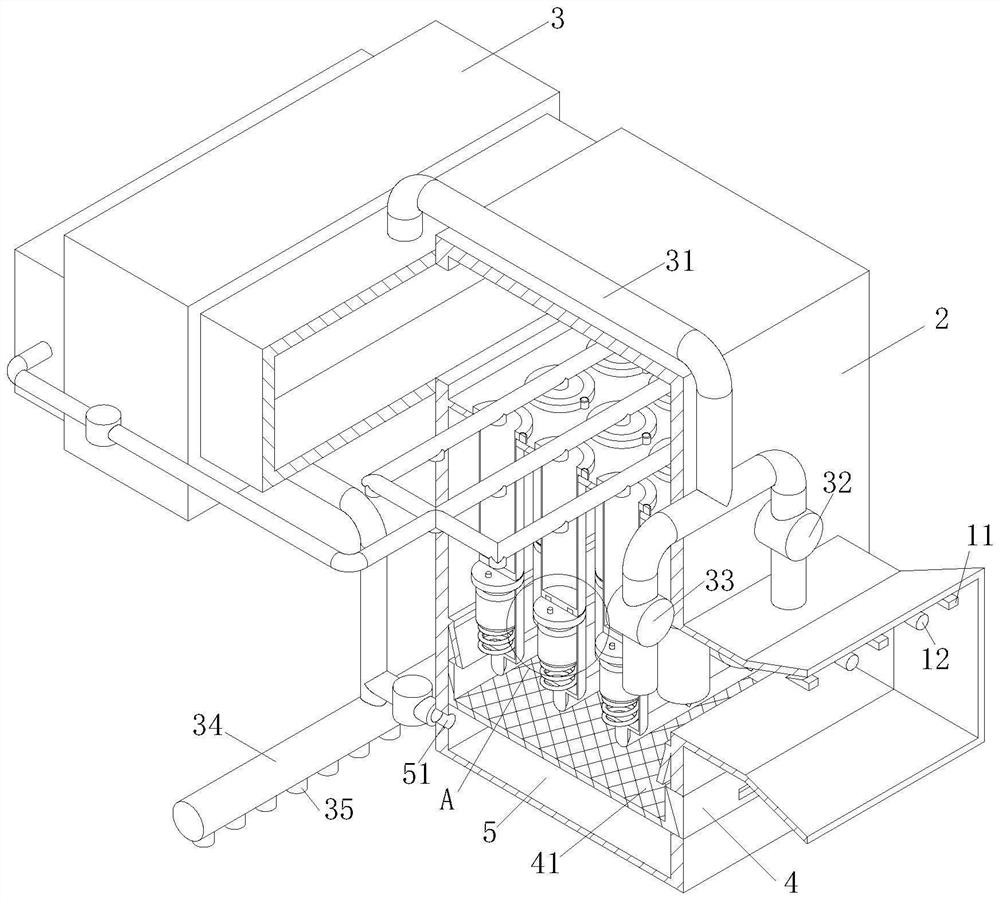

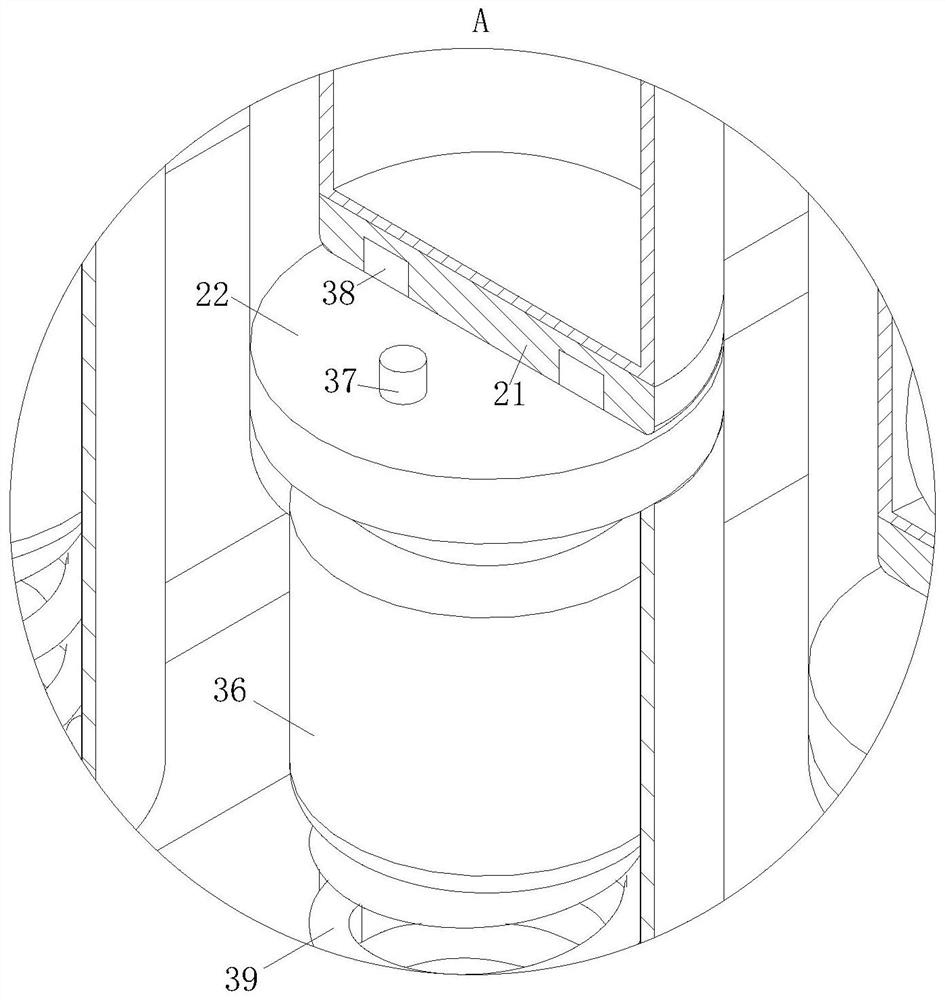

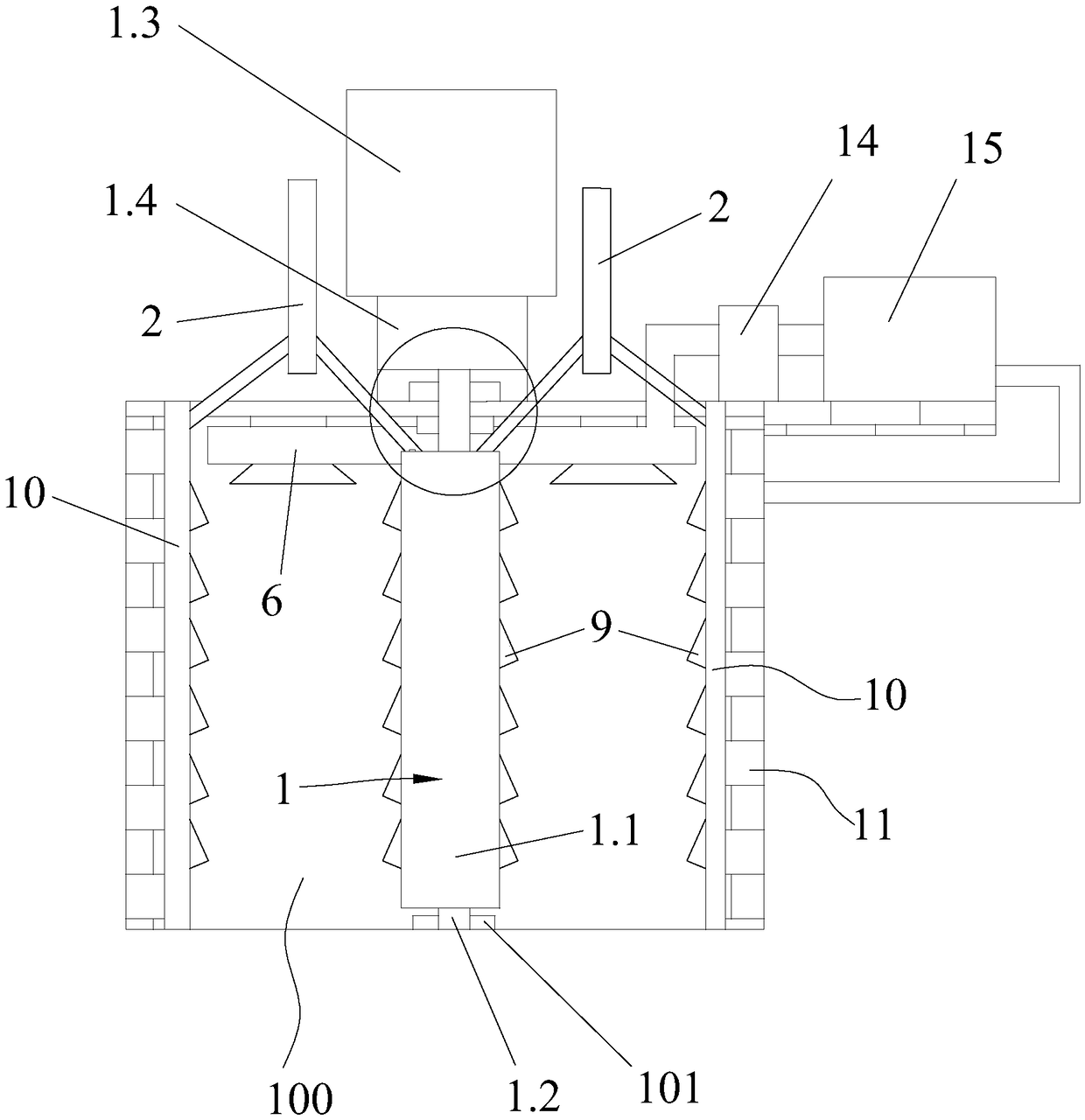

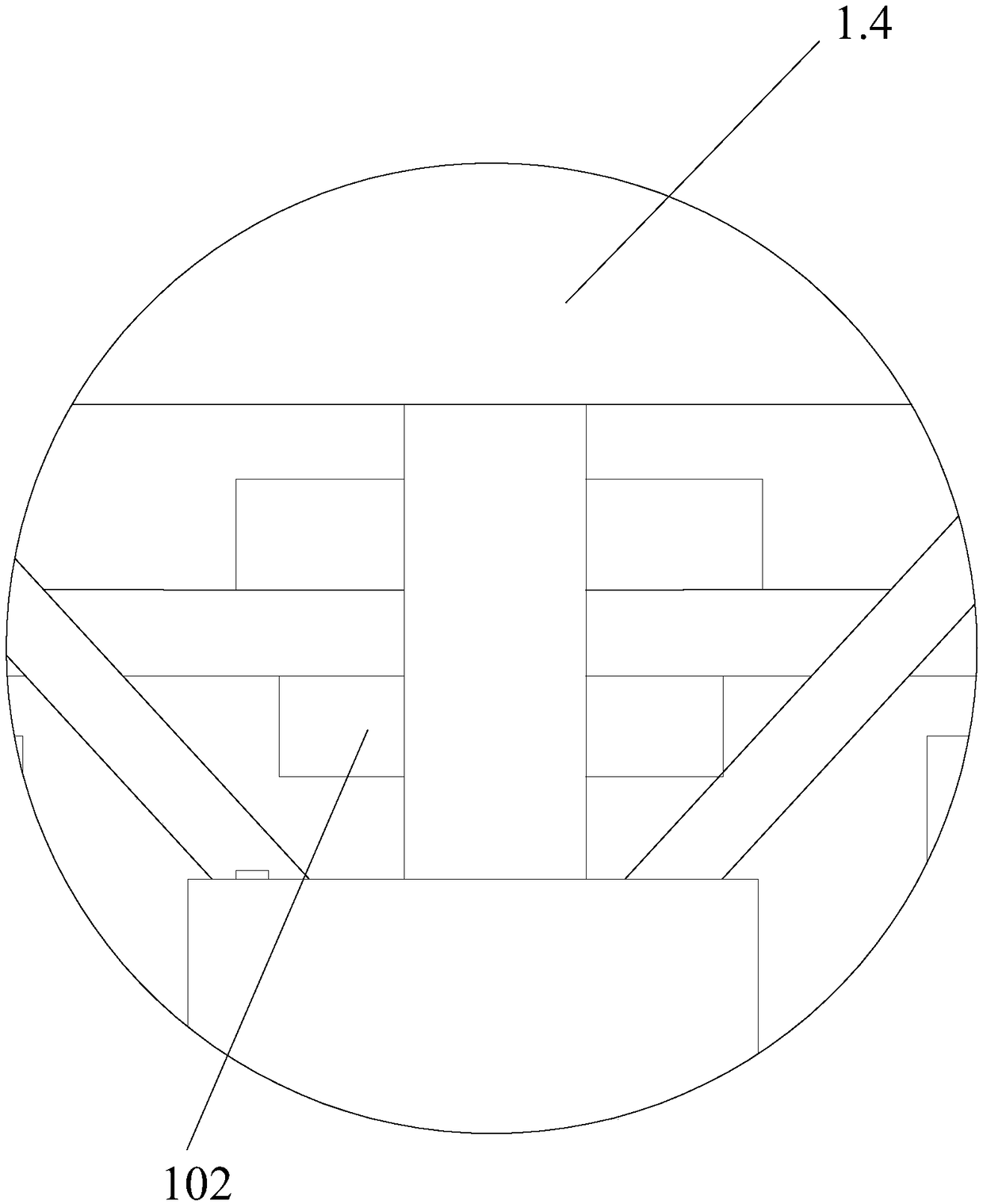

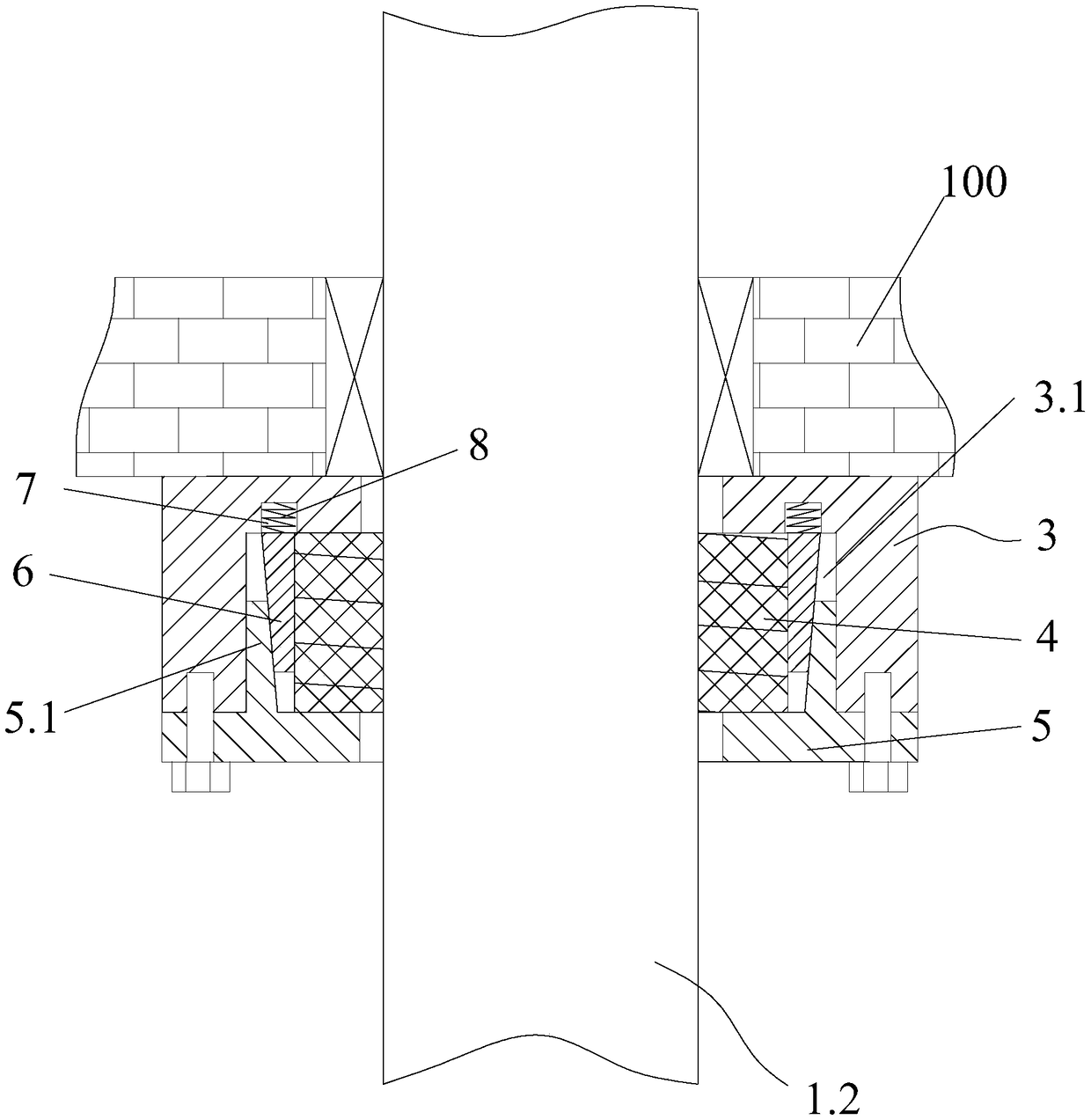

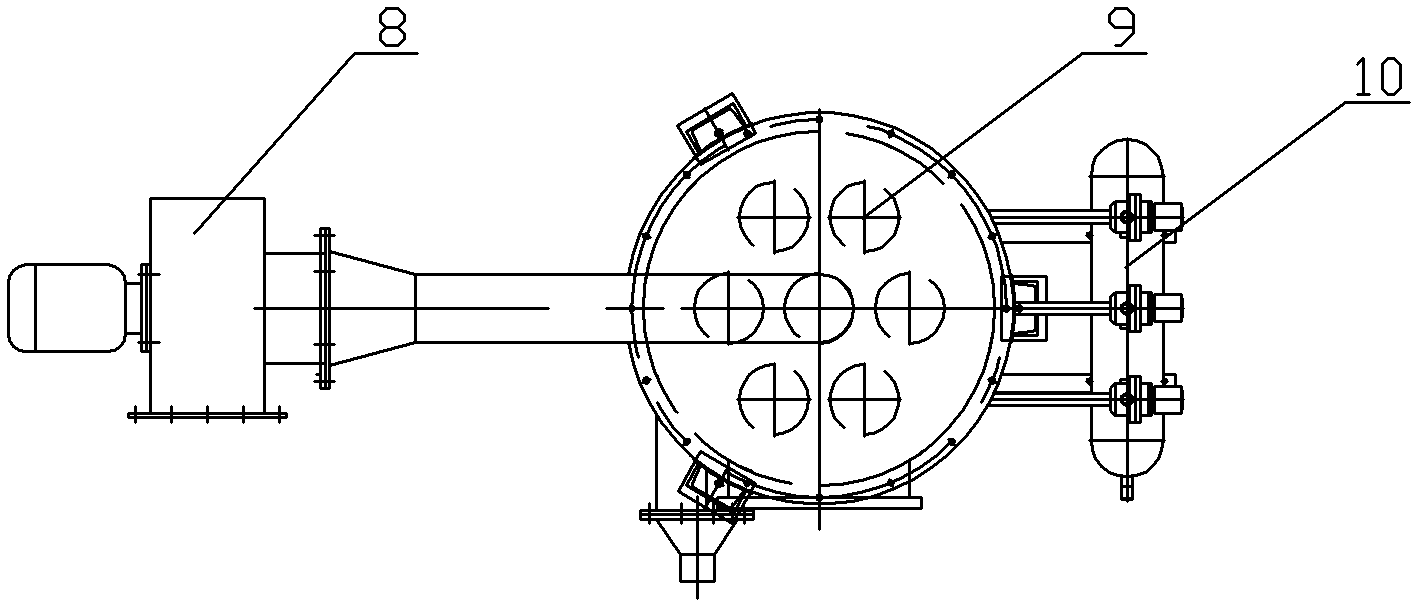

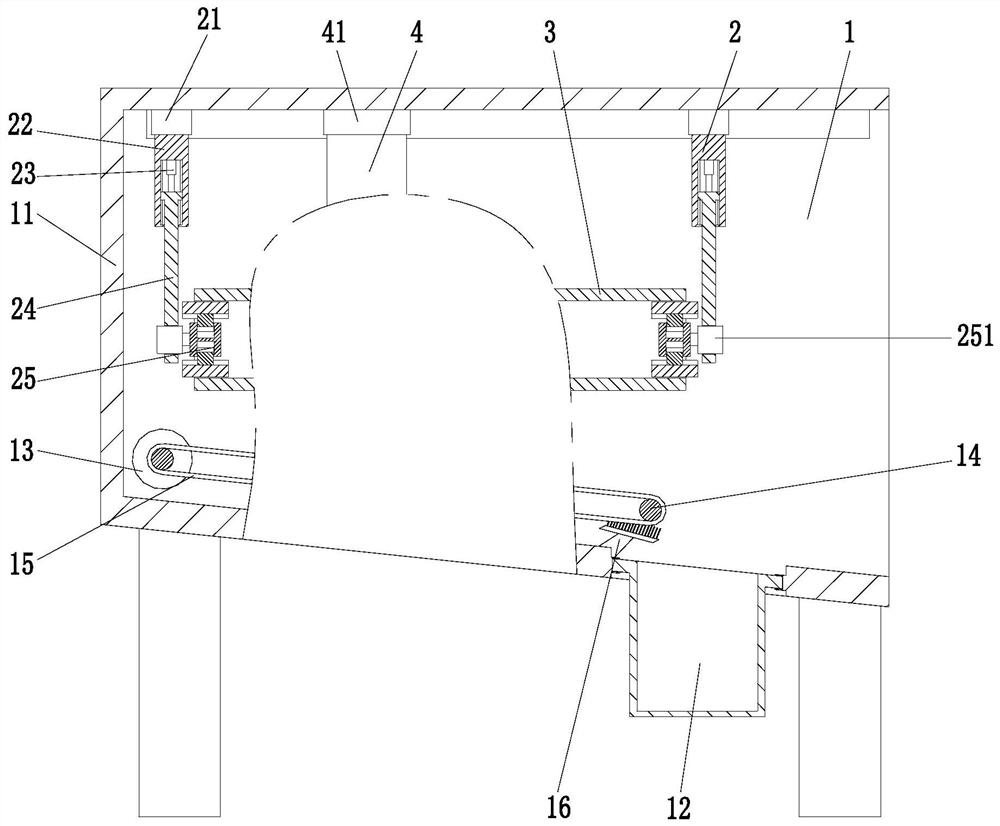

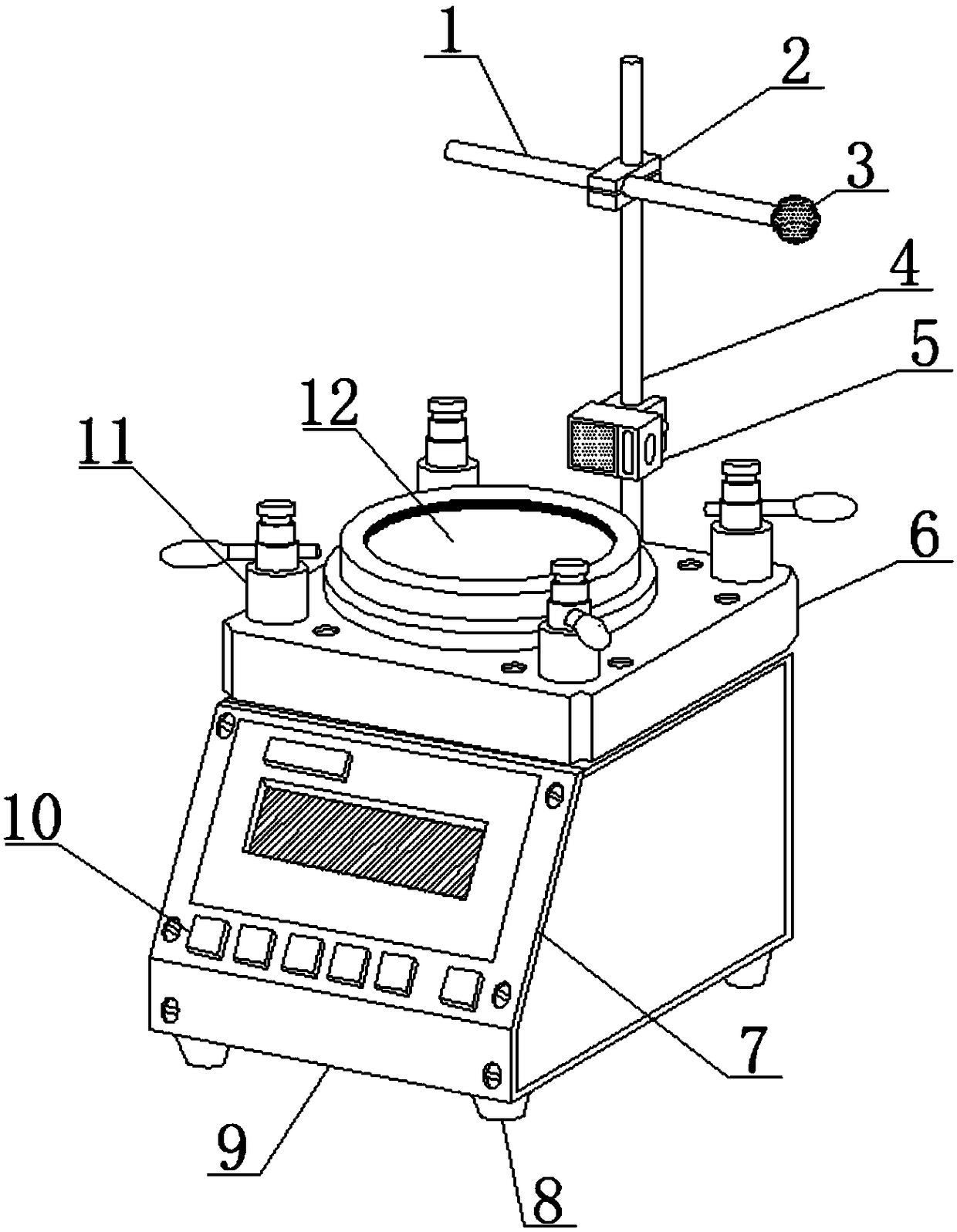

Thermal gravimetrical reactor applied to bulk specimen testing

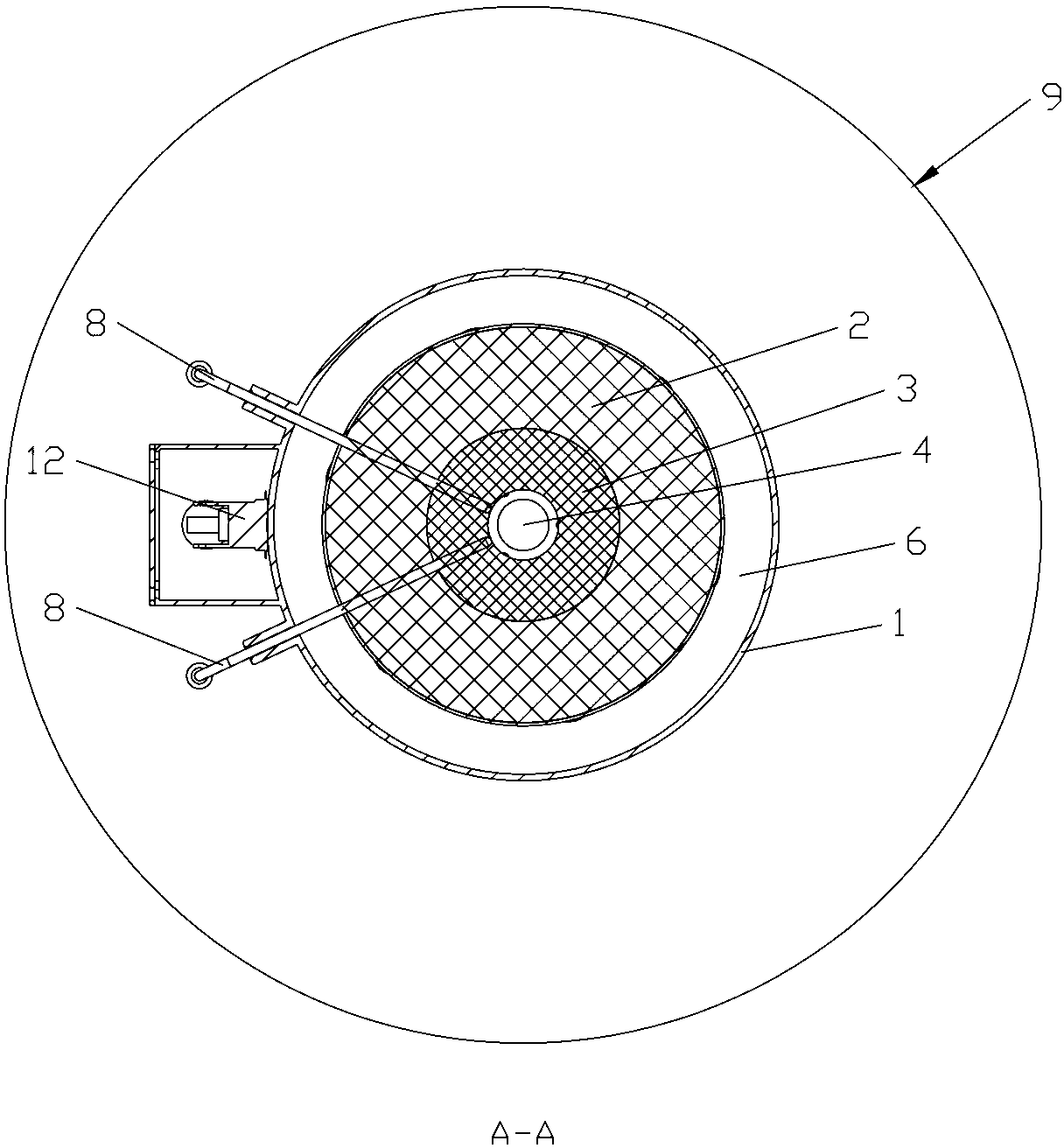

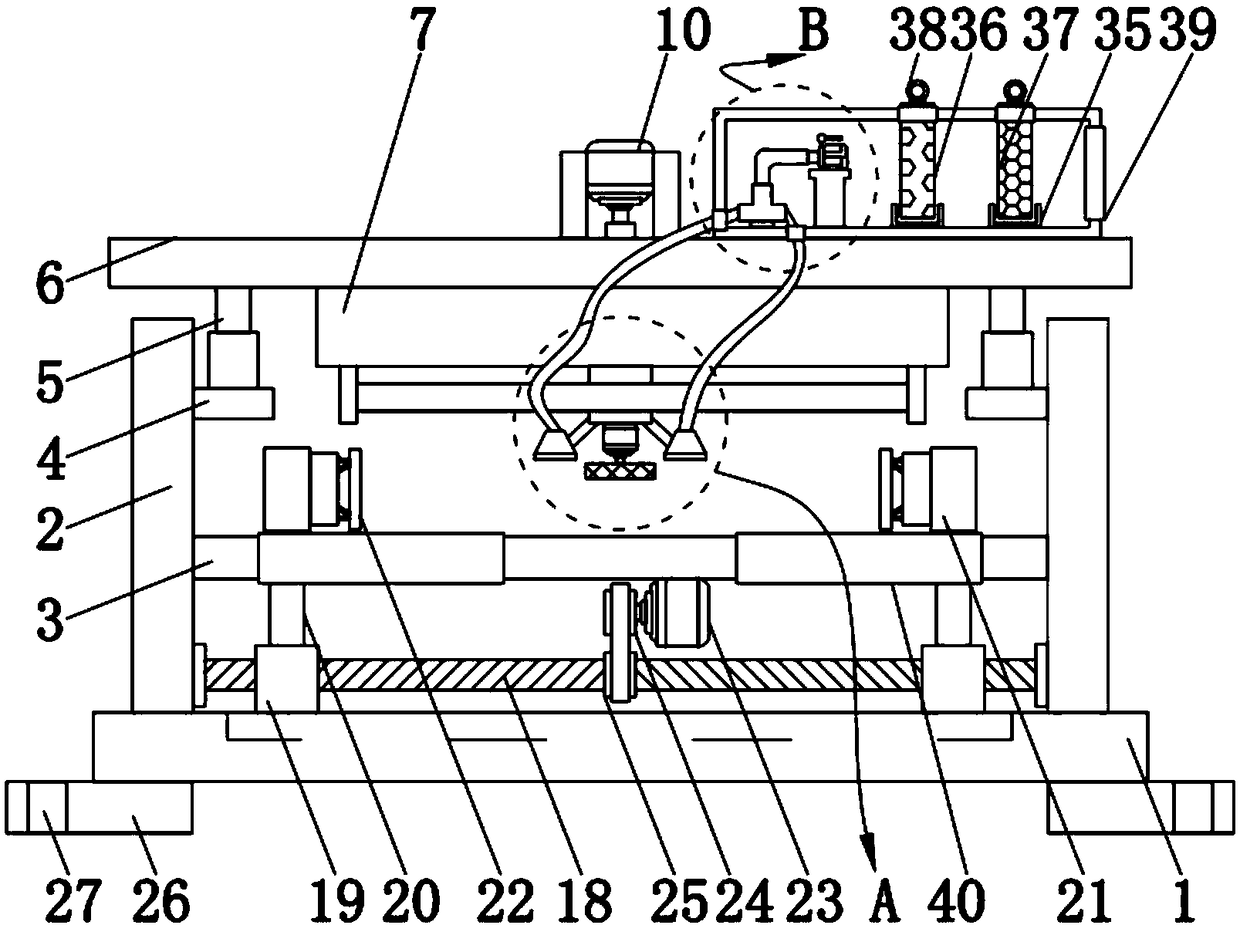

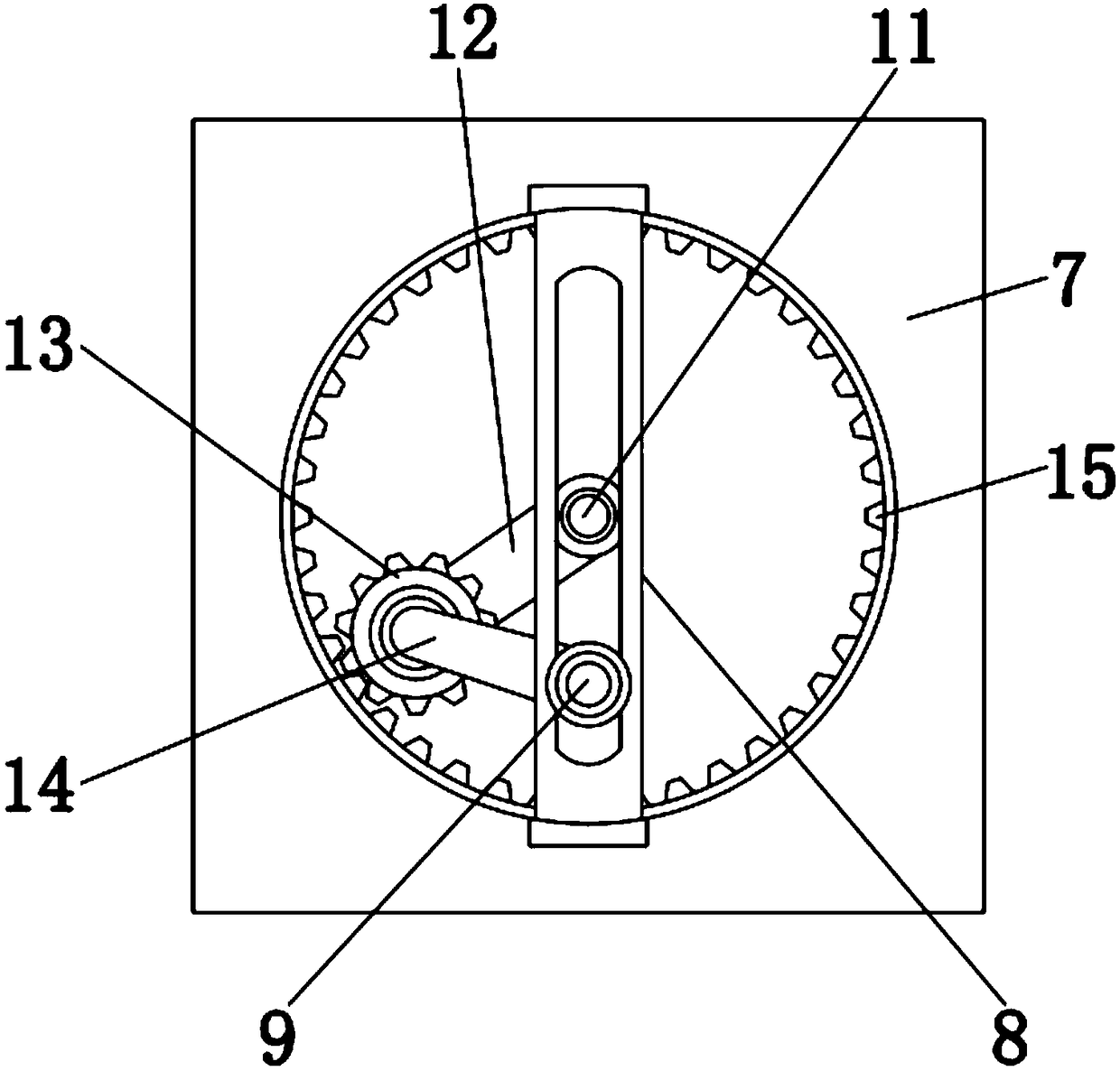

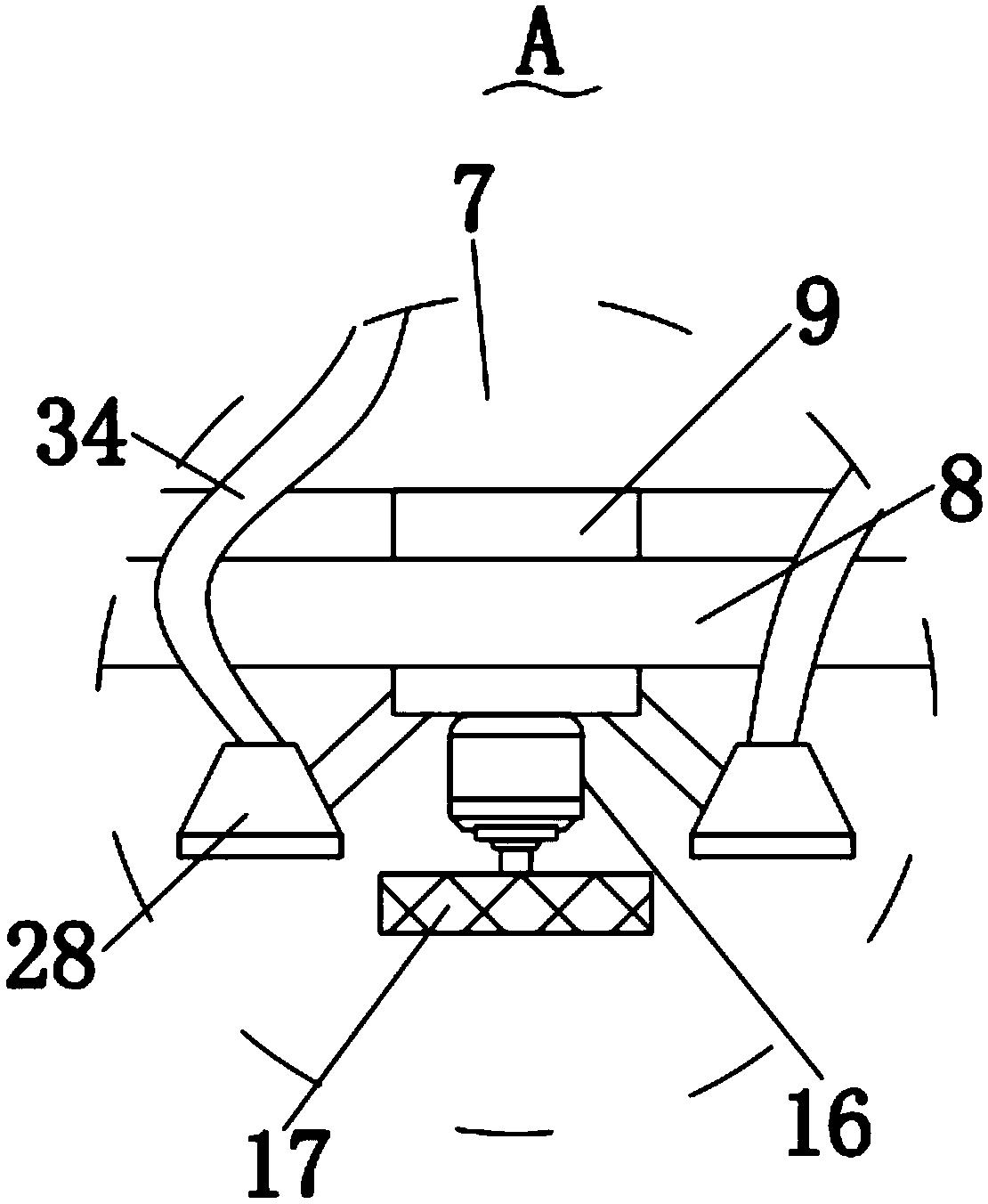

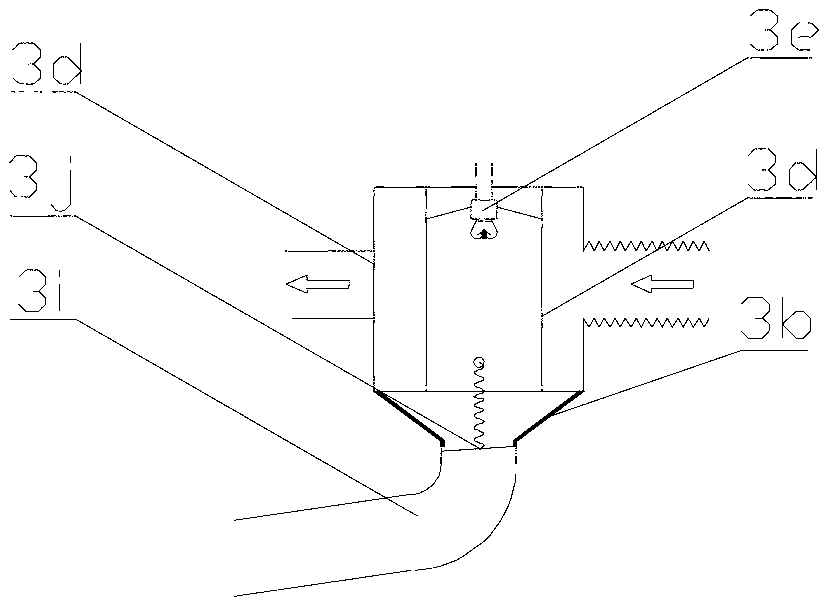

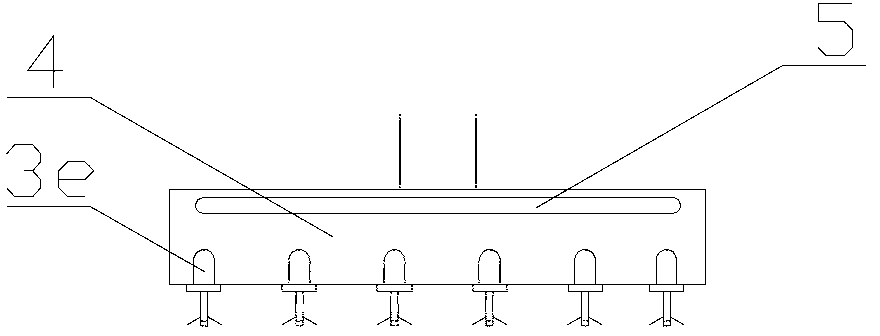

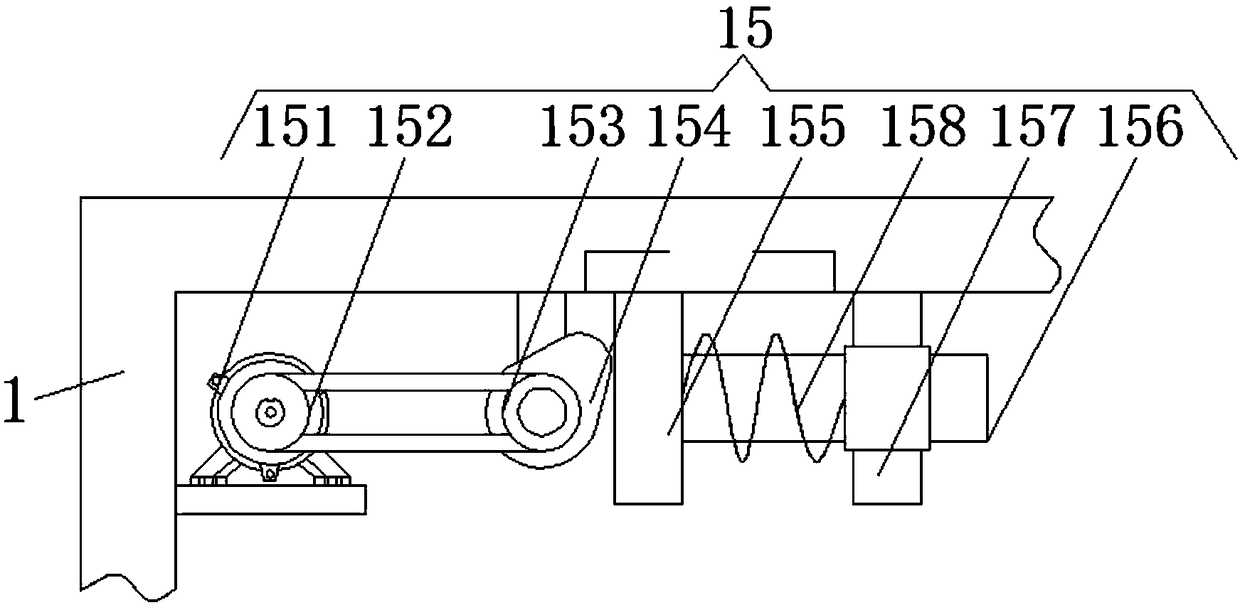

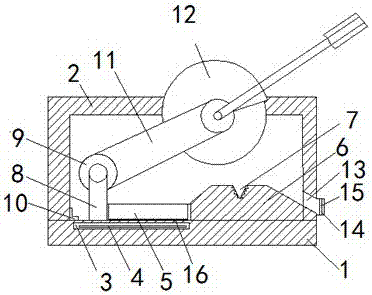

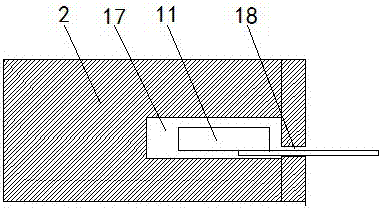

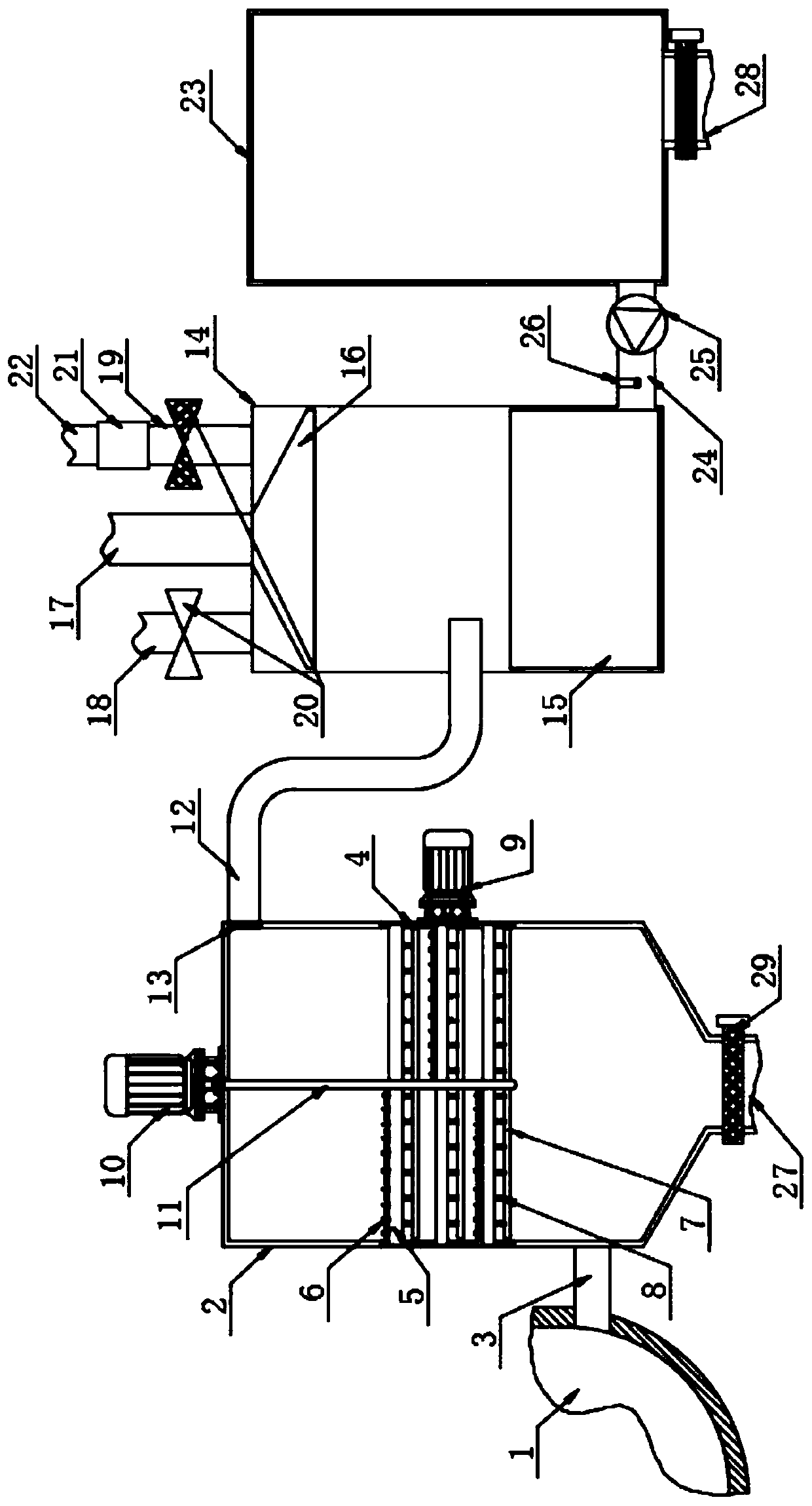

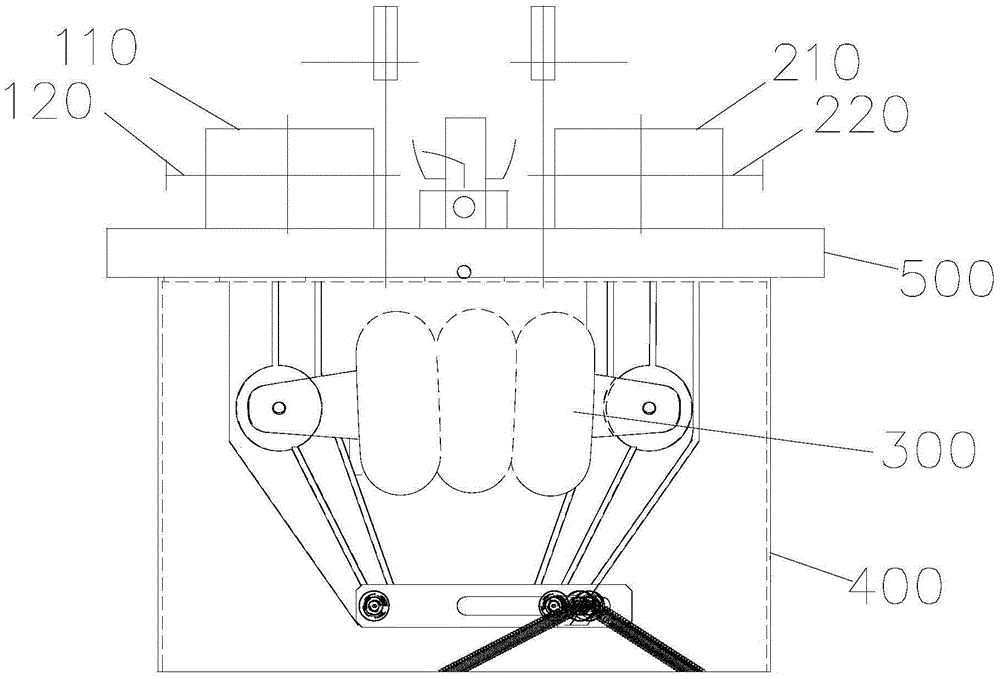

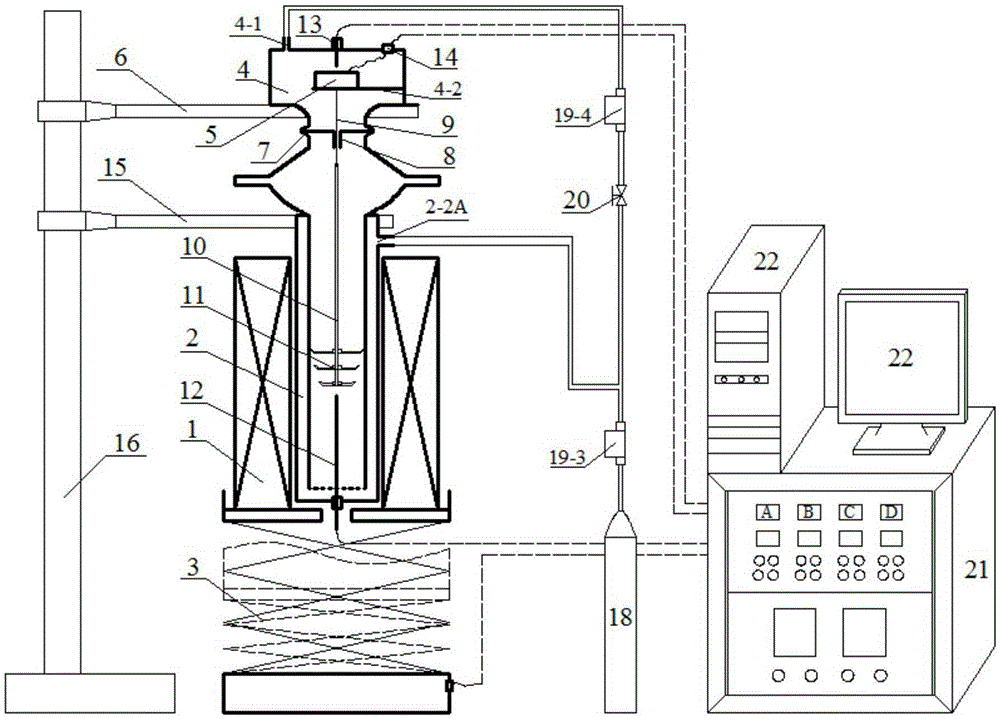

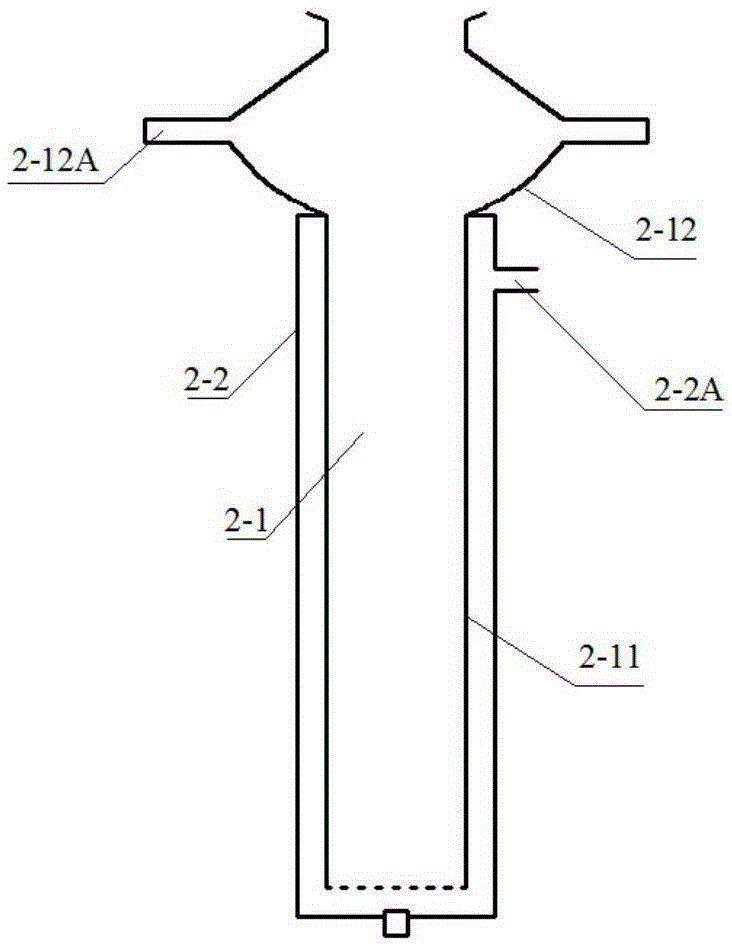

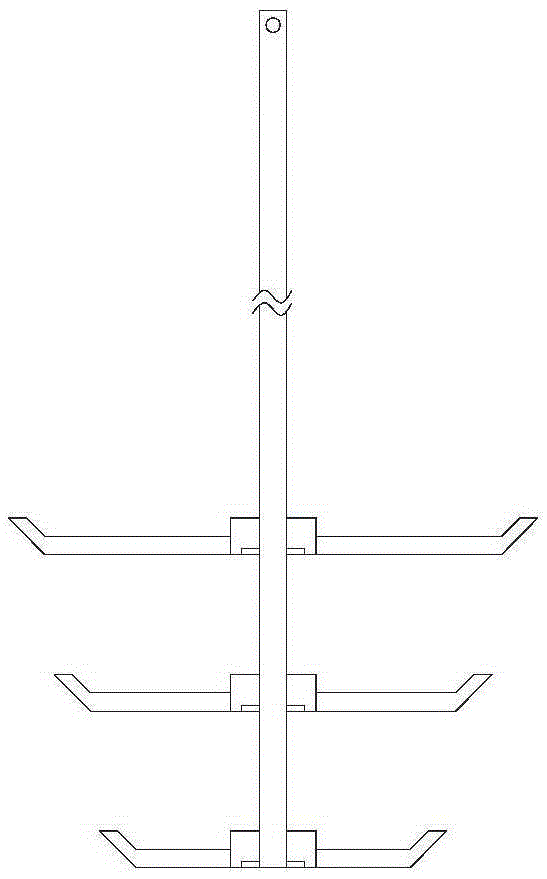

The invention discloses a thermal gravimetrical reactor applied to bulk specimen testing, belonging to testing equipment for performing thermo gravimetric analysis on specimens and aiming to solve the problems that small-mass and small-sized specimens are required and a sample vessel is unbeneficial to gas-solid reactions in the conventional thermo gravimetric analyzer. Through a high-temperature reactor, reaction gas is preheated fully, so that mass measuring errors caused by temperature change of the reaction atmosphere are avoided; two types of hanging baskets are specific to different specimens respectively, so that the diffusion resistance during the reactions of bulk specimens is reduced effectively, and complete reactions and measuring accuracy are ensured; the height of an electric heating furnace is adjusted through a hydraulic lifting platform, so that samples can be heated at constant temperature under a high-accuracy condition. The thermal gravimetrical reactor can be used for dynamically measuring the mass changes of bulk specimens at various heating rates or under a constant-temperature condition, and is more consistent with the requirements of scientific research production than the conventional thermal gravimetrical analyzer.

Owner:HUAZHONG UNIV OF SCI & TECH

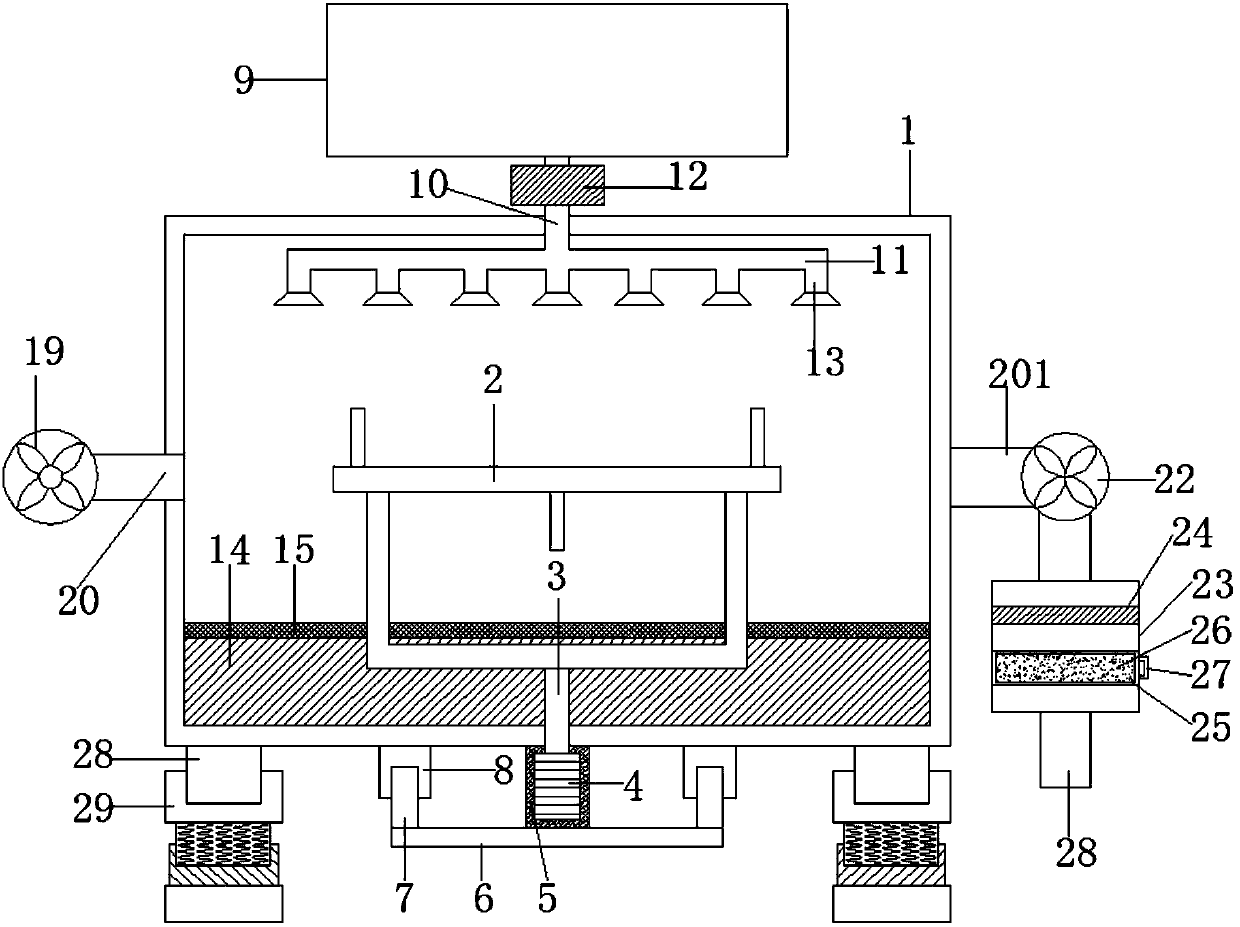

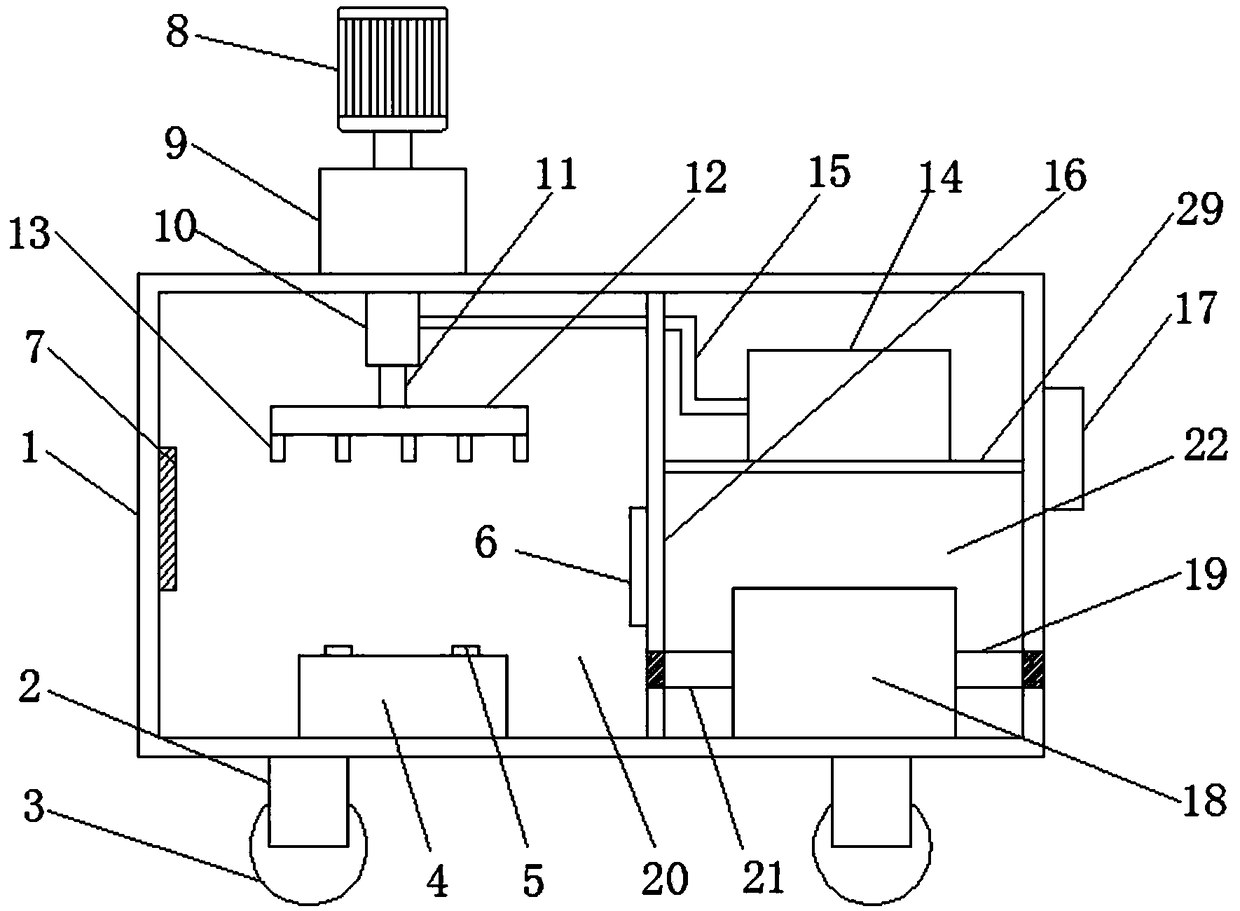

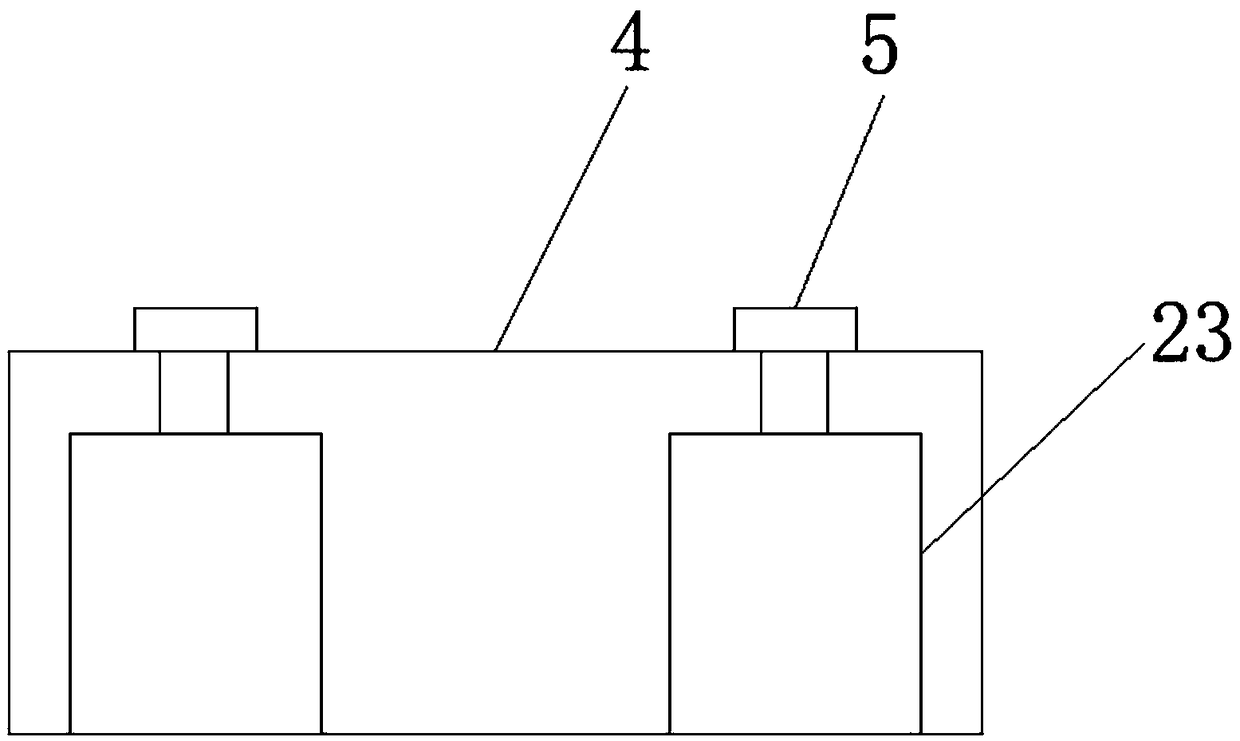

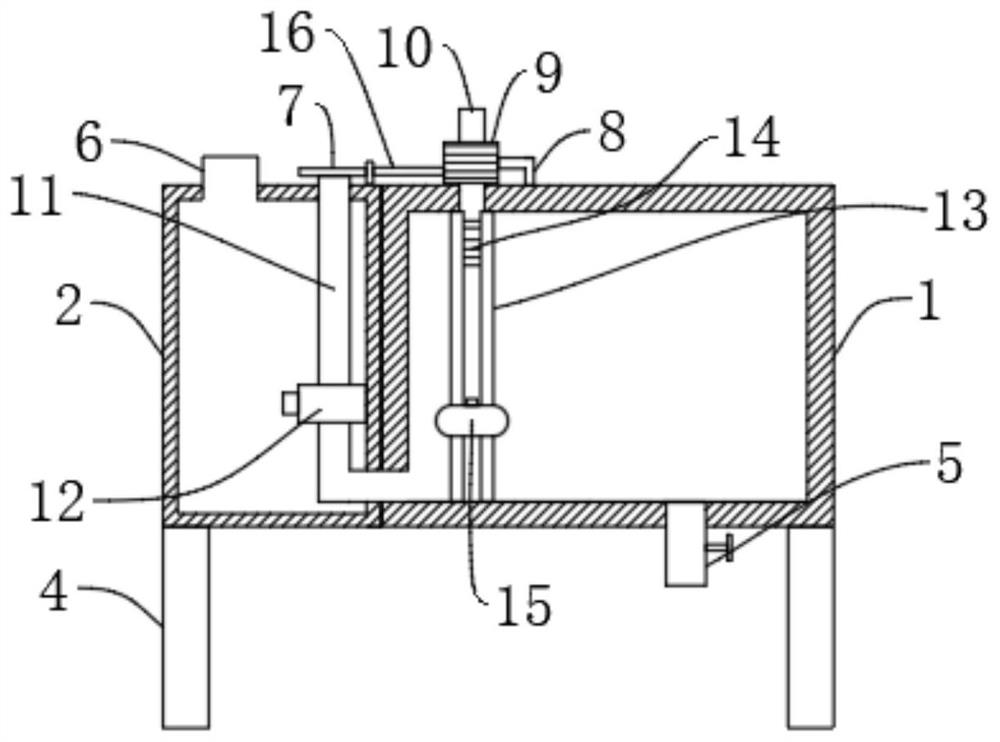

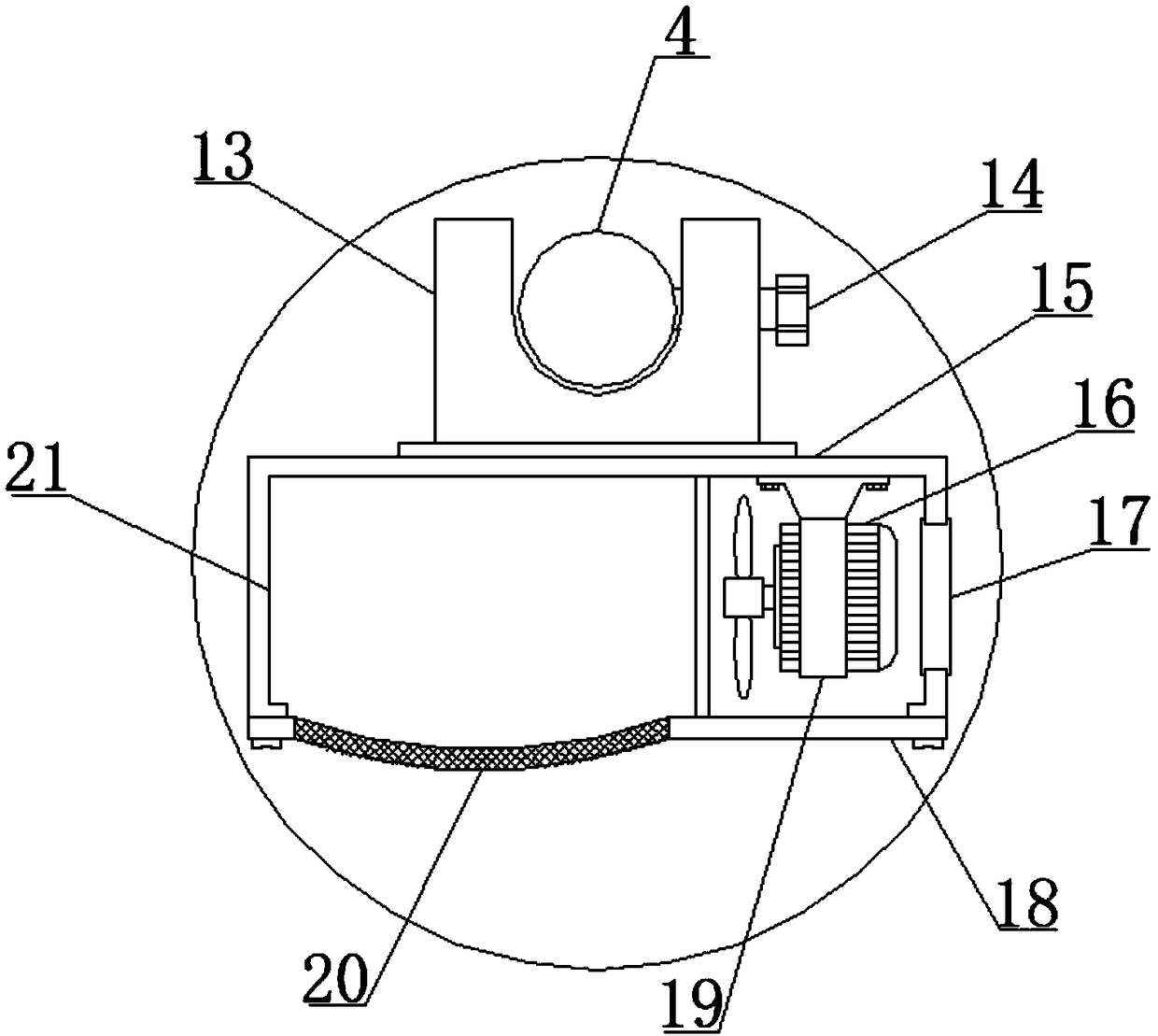

Paint spraying device for electrical equipment machining

InactiveCN107661836APrevent leakageImprove working environmentPretreated surfacesLiquid spraying apparatusActivated carbonElectric machinery

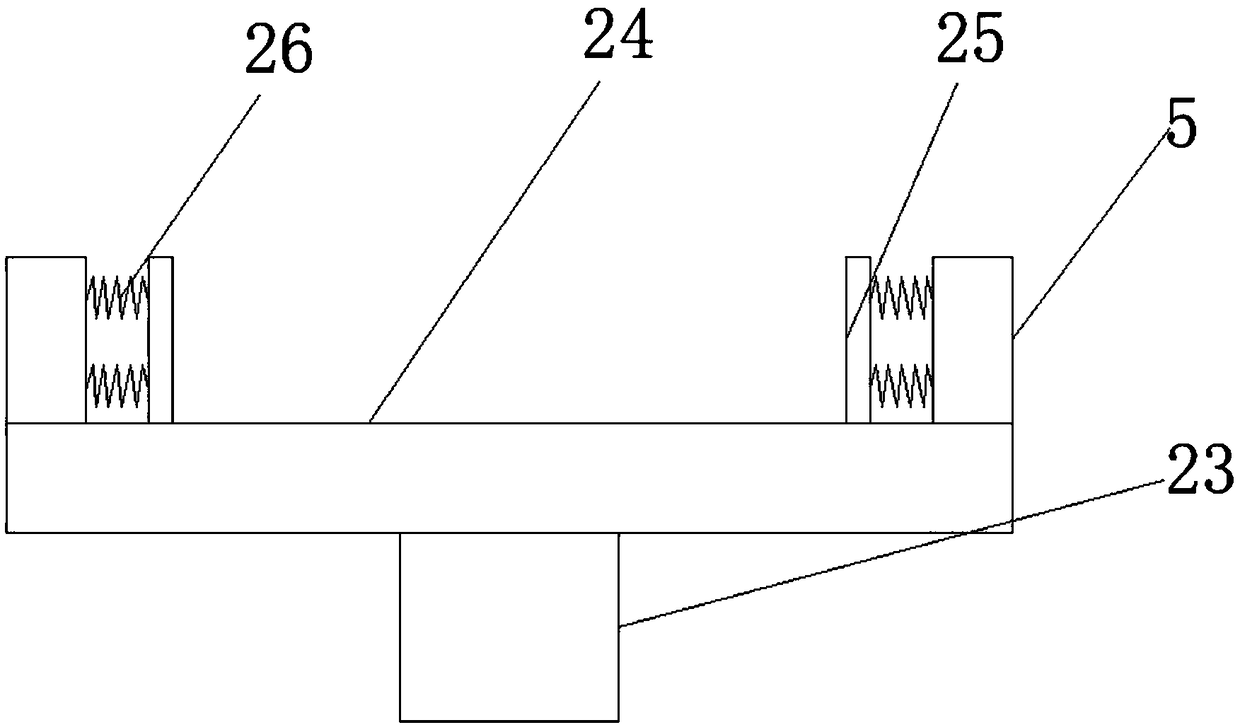

The invention discloses a paint spraying device for electrical equipment machining. The paint spraying device comprises a machine body, a paint spraying support is arranged in the center in the machine body, a rotary shaft is connected with the center of the bottom of the paint spraying support, and the bottom of the rotary shaft stretches outside of the machine body and is connected with a rotating motor. A noise-reduction cover is arranged on the outer side of the rotating motor, a horizontal supporting plate is arranged on the lower side of the rotating motor, and lifting rods are connectedwith the left and right ends on the upper side of the supporting plate respectively. According to the paint spraying device for electrical equipment machining, a part is driven by the rotating motorrotate and rise in the paint spraying process, convenience is brought to paint spraying, and the work efficiency is improved. Extra paint in the paint spraying process enters a water tank along with awater curtain and collected by a gauze layer, the paint can be filtered, the paint smell can be adsorbed, and the working environment of operators is improved; activated carbon particles are easily taken out and replaced, and convenience is brought to use; besides, damping can be effectively conducted, the device can more smoothly work, and the safety is improved.

Owner:ZHENJIANG QILONG TECH CO LTD

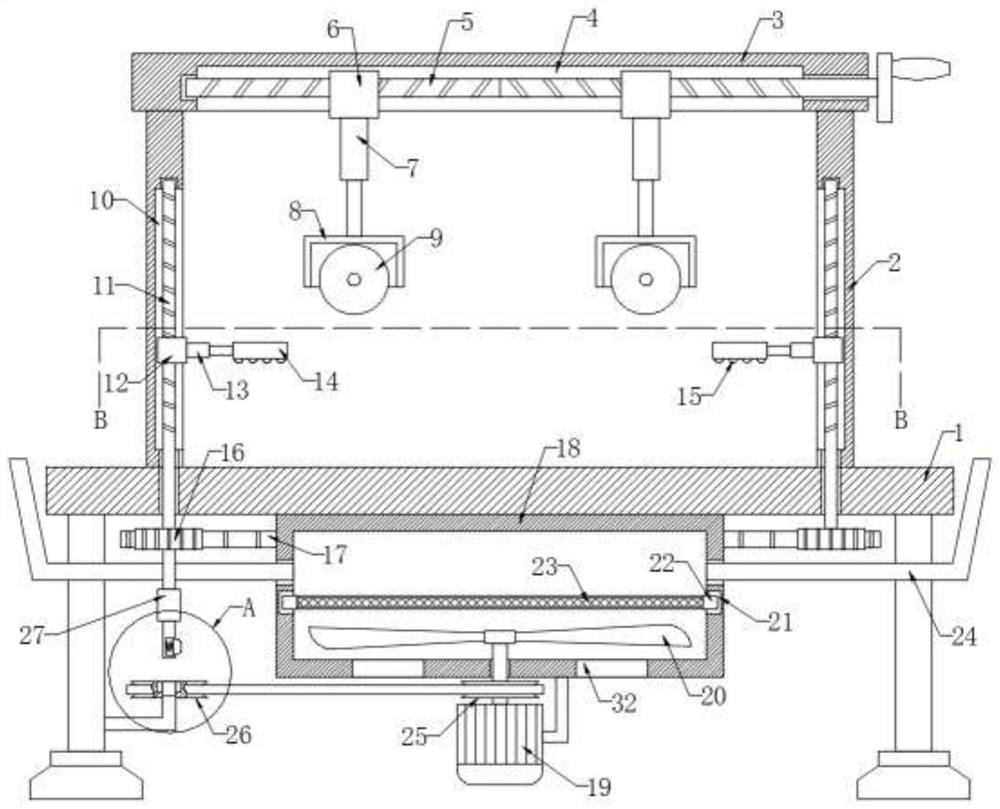

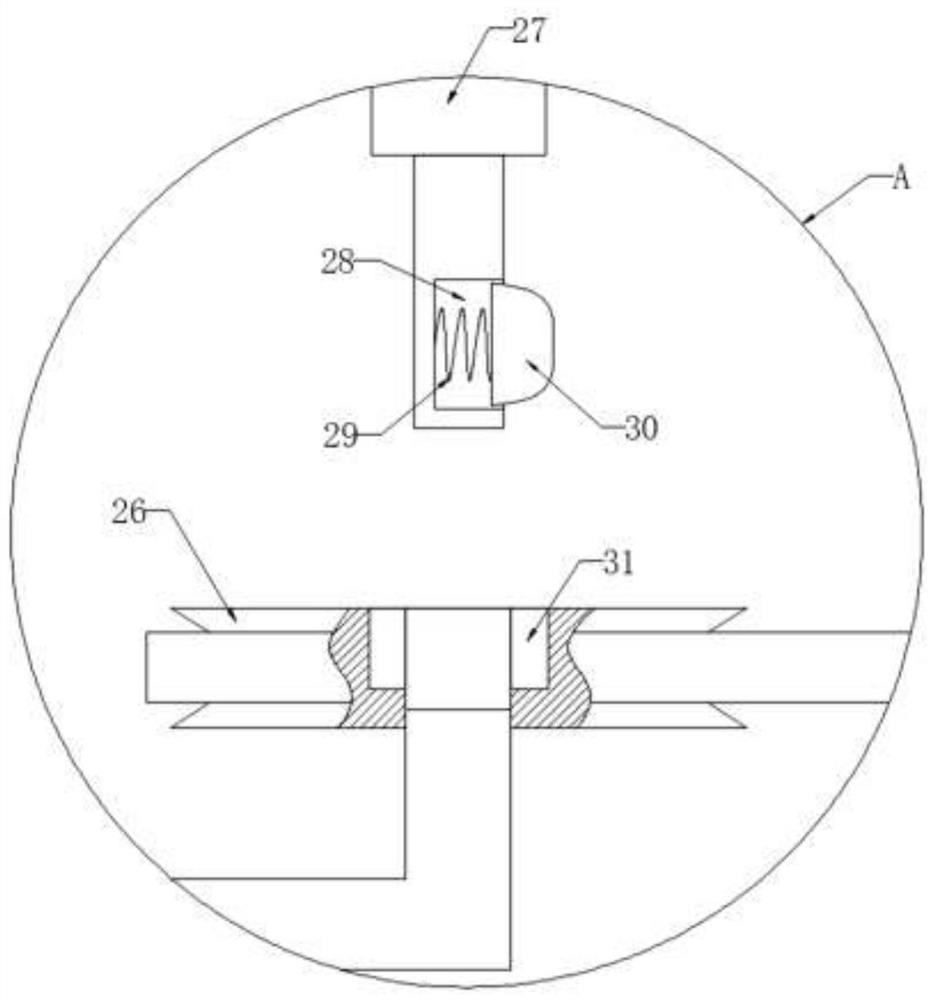

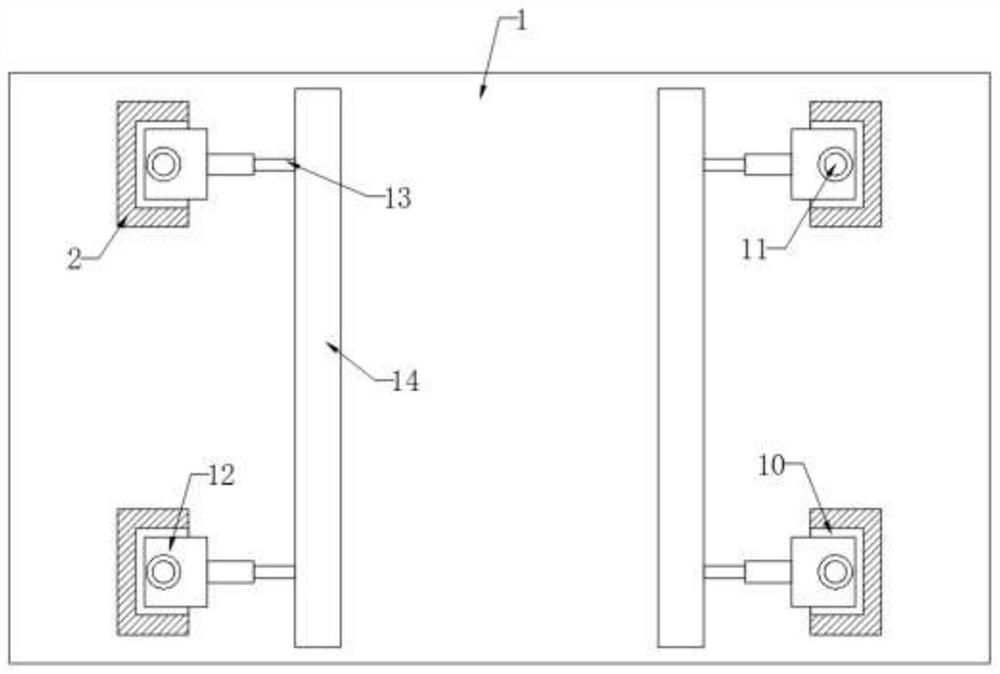

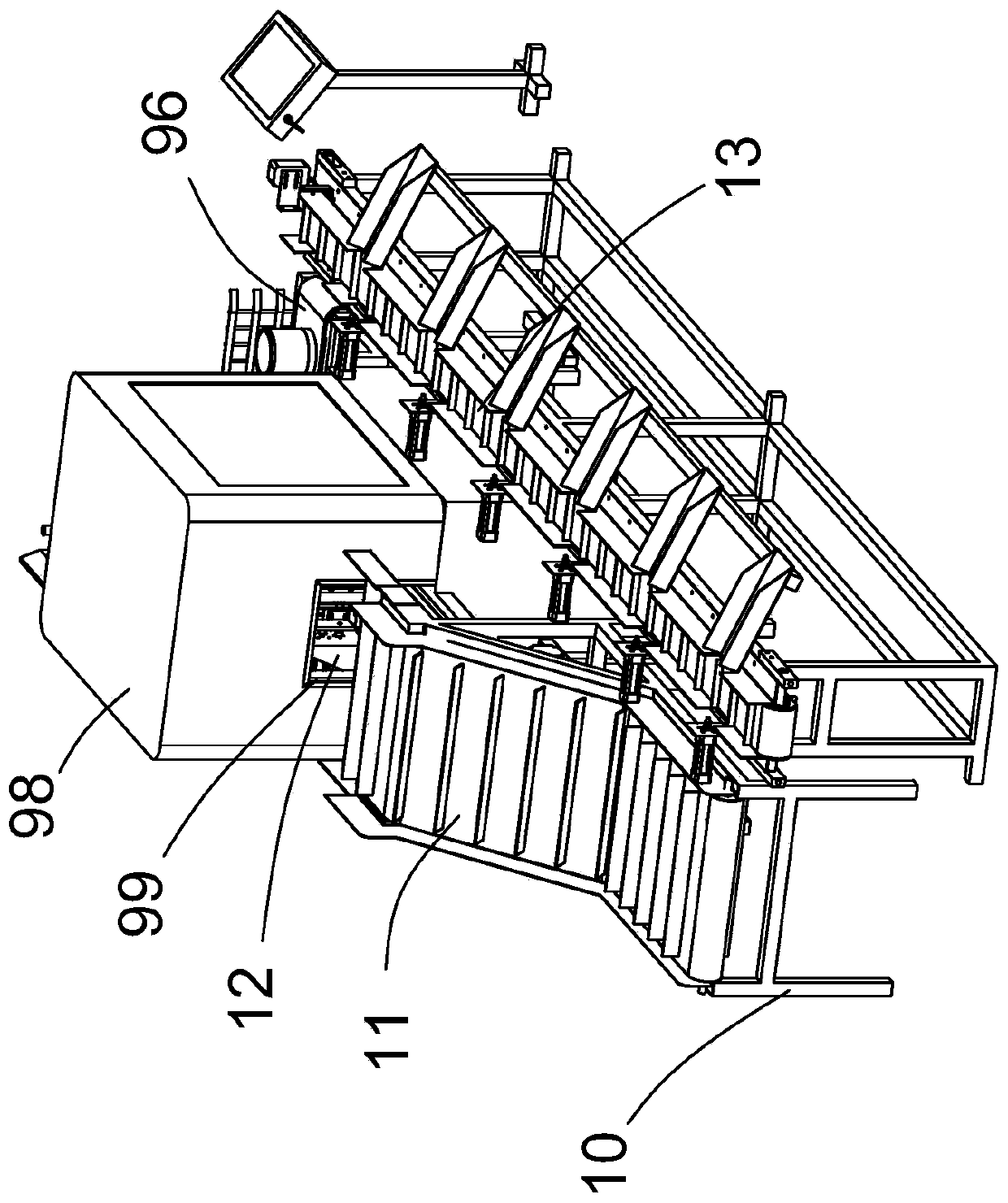

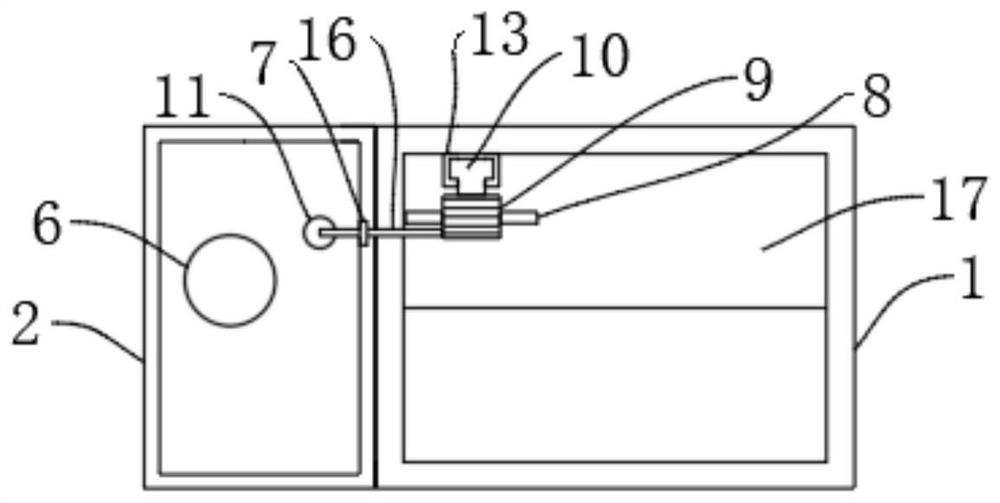

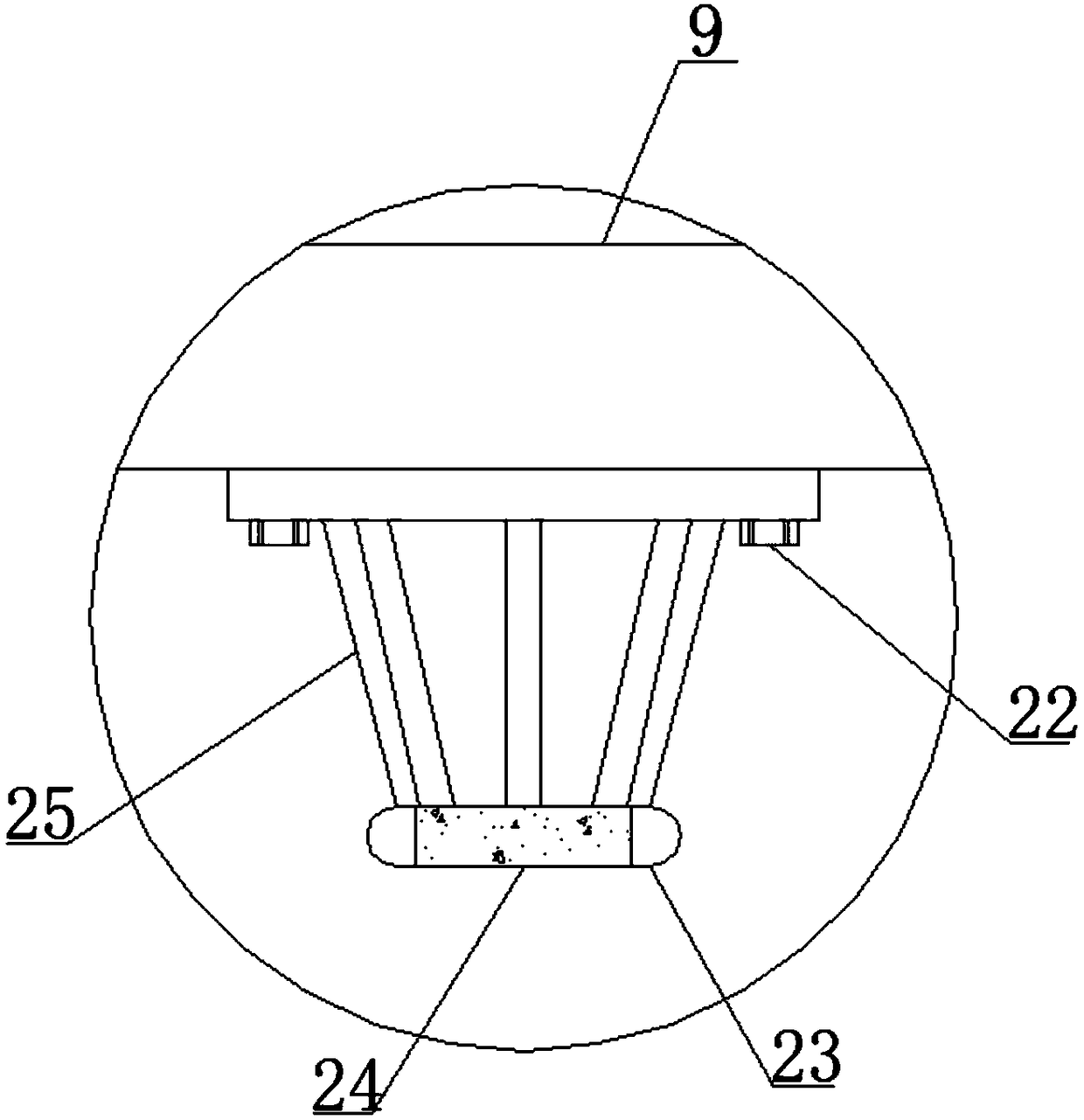

Pattern making device convenient for quick cutting and used for garment production processing

InactiveCN111607953AAvoid wrinklesEasy to compressMechanical cleaningPressure cleaningFiberWorking environment

The invention discloses a pattern making device convenient for quick cutting and used for garment production processing, the pattern making device comprises a pedestal, an upper end of the pedestal issymmetrically and fixedly connected with four vertical plates, the upper ends of the four vertical plates are jointly and fixedly connected with a transverse plate, a lower end of the transverse plate is provided with a first groove, an inner wall of the first groove is rotationally connected with a double-headed threaded rod, and a flattening mechanism for flattening a cloth is mounted on the double-headed threaded rod. According to the pattern making device provided by the invention, a sliding block is driven by rotation of the double-headed threaded rod to drive a roller to roll at the upper end of the cloth so as to flatten the cloth, thus, the cloth is prevented from generating wrinkles after being paved for many layers and causing ununiform size of the cut cloth, a motor rotates todrive a negative pressure impeller to rotate quickly, thus, a dust absorption box collects fibers drifting away in a cloth cutting process through a dust absorption tube, and the fibers on the cloth is prevented from massively drifting away in the air, affecting a work environment of workers and harming body health of the workers.

Owner:金溪县金三龙服饰有限公司

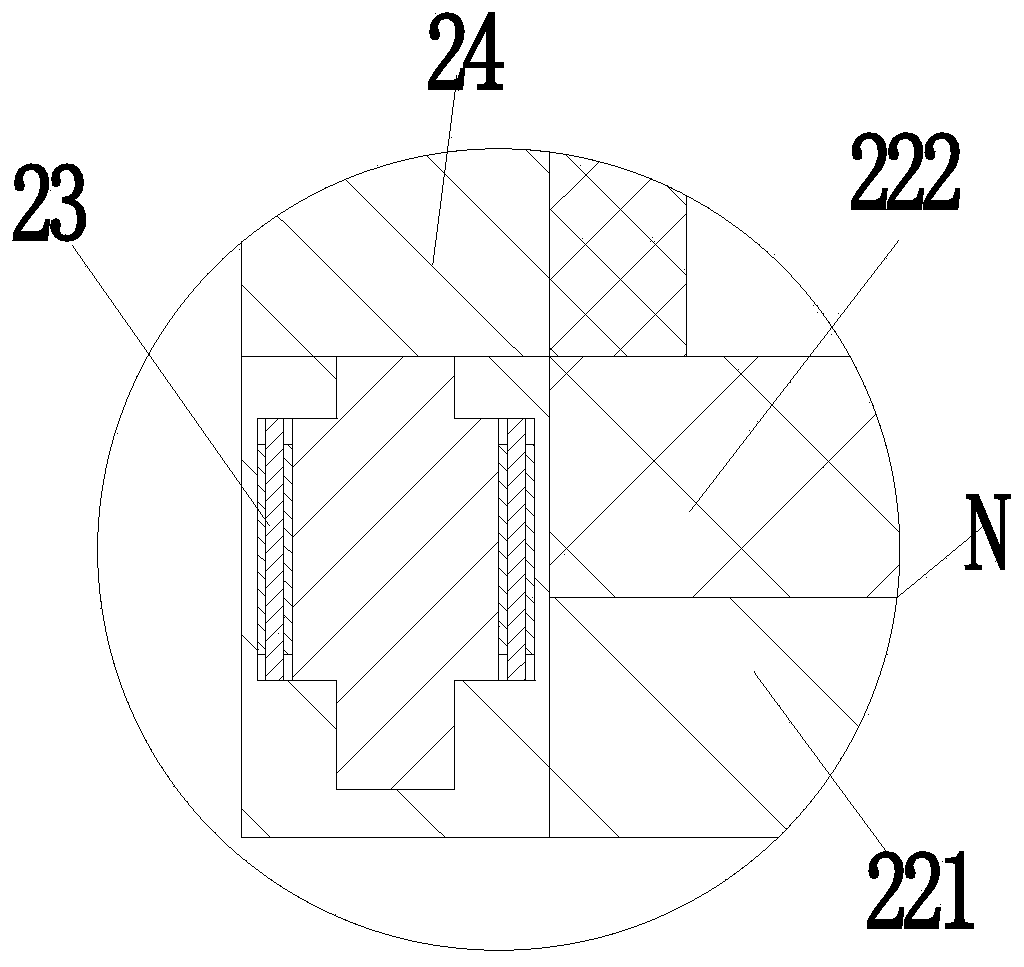

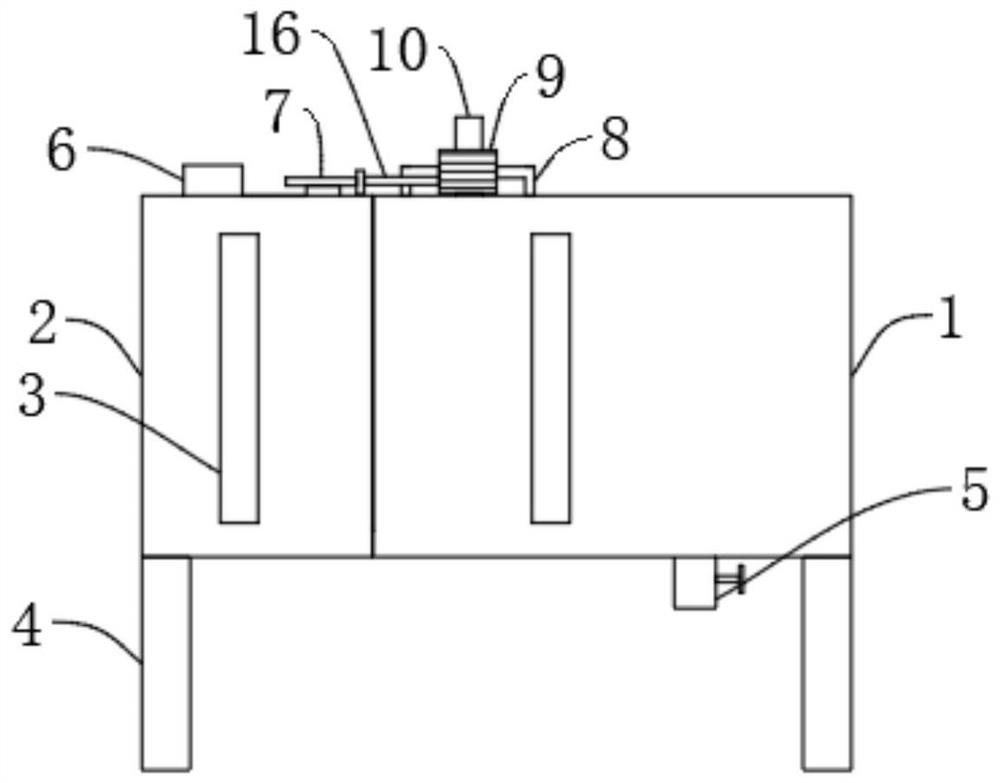

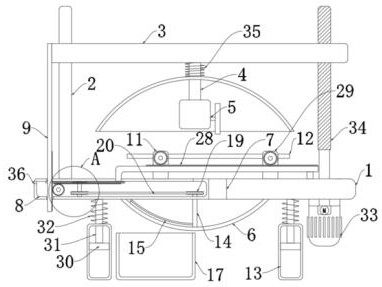

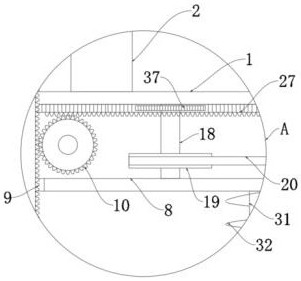

Cement deblocking device for building monitoring

InactiveCN107617471AAffect the working environmentAvoid cloggingSievingScreeningMaterials scienceLeft wall

The invention relates to cement deblocking devices for building monitoring, in particular to a cement deblocking device for building monitoring. According to the cement deblocking device for buildingmonitoring, the clogging phenomenon can be prevented, the deblocking time is short, and deblocking can be completed under the airtight condition. The cement deblocking device for building monitoring comprises a deblocking box and the like; a deblocking mechanism is connected to the upper portion of the deblocking box; a dredging mechanism is connected to the lower portion of the deblocking box; abaffle is rotatably connected to the bottom end of the left wall of the deblocking box; and the right side of the bottom of the baffle is fixed to the right wall of the deblocking box in a bolted connection mode. By arranging the deblocking mechanism and the dredging mechanism, blocked cement is deblocked, and clogging can be prevented; and by pushing a lifting rod continuously, a knocking block moves leftwards and rightwards continuously to knock the deblocking box.

Owner:查宇

Combustion furnace for total organic carbon determination

ActiveCN102944454AAvoid harmAffect the working environmentPreparing sample for investigationFurnace typesInjection portCombustion

The present invention relates to the field of total organic carbon detection, and discloses a combustion furnace for total organic carbon determination. The combustion furnace comprises a barrier layer housing, a thermal insulation layer positioned inside the barrier layer housing, a heating apparatus inside the thermal insulation layer, a furnace core through hole and a heat conduction fan, wherein the barrier layer housing is positioned inside a sealed combustion furnace chamber, an air outlet is arranged above the side wall of the combustion furnace chamber, the heat conduction fan is arranged on the air outlet, the bottom of the combustion furnace chamber is provided with an air inlet, an air barrier layer for air flowing is formed between the thermal insulation layer and the barrier layer housing, the furnace core through hole penetrates through the barrier layer housing, the thermal insulation layer and the heating apparatus, a combustion pipe is arranged inside the furnace core through hole, both ends of the combustion pipe are respectively provided with an injection port and an air exhaust port, the side wall of the injection port is provided with a carrier gas inlet, and the injection port penetrates through the top wall of the combustion furnace chamber and is positioned outside the combustion furnace chamber. The combustion furnace has the following advantages that: an oxidation rate is high, continuous detection can be achieved, and a high temperature region inside the combustion furnace and an external environment can be separated.

Owner:浙江泰林分析仪器有限公司

Polishing device for processing computer case

ActiveCN109397014AAvoid affecting the processing effectEasy to polishGrinding carriagesGrinding drivesComputer engineeringComputer case

The invention provides a polishing device for processing a computer case. The polishing device for processing the computer case comprises a bottom plate, two support plates, a transverse plate and twostabilizing blocks. The bottom parts of the two support plates are fixed on the two sides of the top of the bottom plate; the two sides of the transverse plate are fixed to the opposite sides of thetwo support plates; and the sides, far away from each other, of the two stabilizing blocks are fixed to the tops of the opposite sides of the two support plates. The polishing device for processing the computer case can comprehensively polish the surface of the case, improve the working efficiency, can process cases in different sizes, improves the practicability, and is beneficial to widespread promotion; and an air sucking pump sucks debris generated during polishing of the case into a filter box through a pipeline, a tee joint, a hose and a suction bucket, a worker is prevented from inhaling a large amount of debris, and harm to the body of the worker is avoided.

Owner:李金见

Feed drying device facilitating material discharge

InactiveCN108036610ADry evenlyEasy to storeDrying gas arrangementsDrying machines with non-progressive movementsThermal insulationEngineering

The invention discloses a feed drying device facilitating material discharge, and belongs to the technical field of feed processing. The feed drying device comprises a blending tank, a scrapper plate,stirring pieces, a feed tank, a stirring shaft, a driving and drying device, a material discharge pipe, support legs and a dehumidification pipe; the feed drying device is characterized in that the blending tank is a hollow cylinder arranged horizontally, and made of stainless steel materials; the inner wall of the blending tank is provided with a thermal insulation layer, and the blending tank is internally provided with a mixing chamber; the feed tank is arranged on the right side of the top end of the blending tank, and communicates with the mixing chamber; the stirring pieces are fixed tothe same cross section of the stirring shaft, and divided into an upper row and a lower row, and the two rows of the stirring pieces are staggered; and the surfaces of the stirring pieces are evenlyprovided with a plurality of blowholes, and the stirring pieces and the stirring shaft are internally provided with gas channels. The feed drying device disclosed by the invention is rational in structure and high in drying efficiency, and feed is stirred by a stirring device; and the feed adhering to the inner wall of the tank is scrapped by the scrapper plate, and the feed drying device is uniform in drying, and facilitates material discharge.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

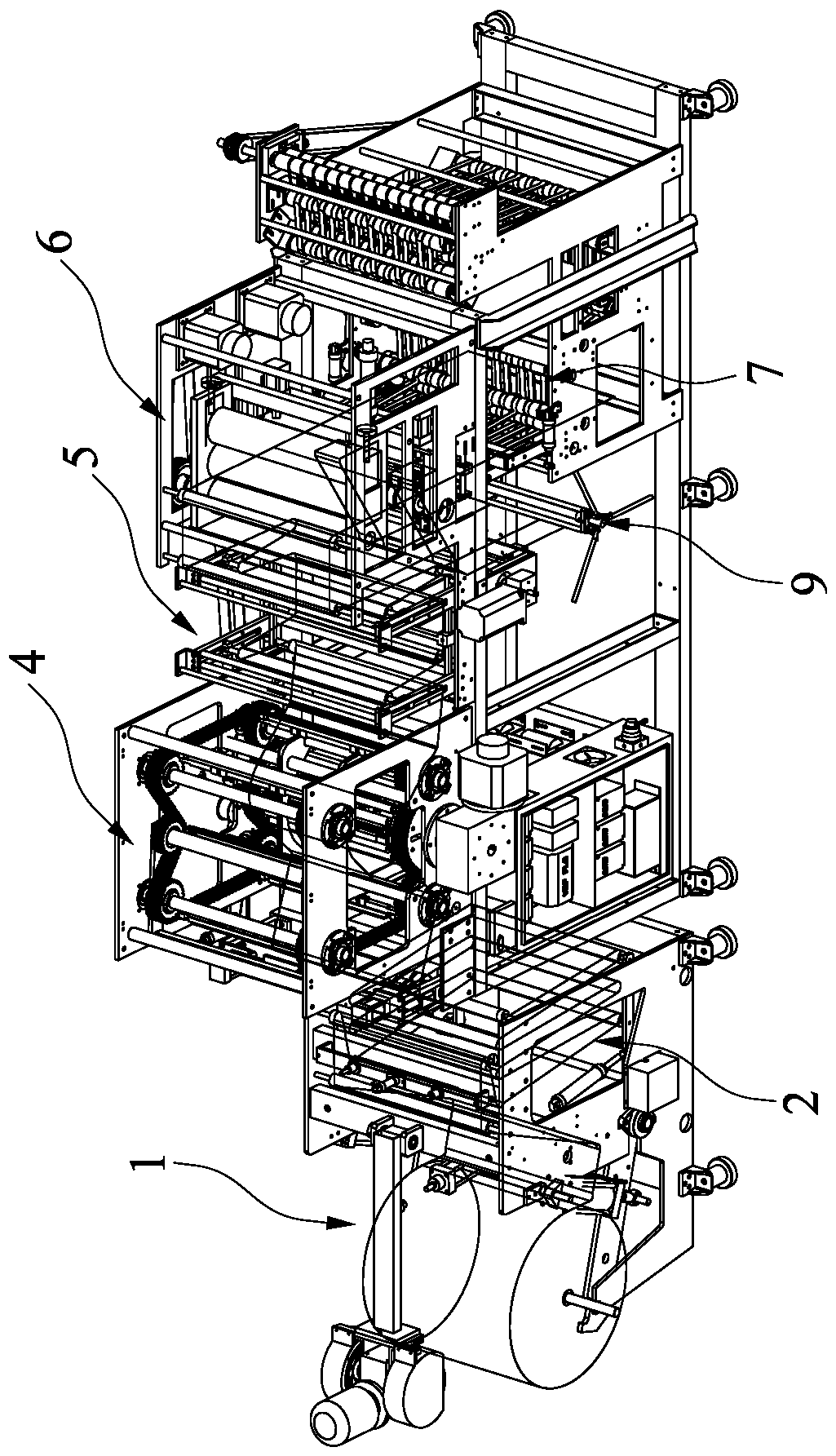

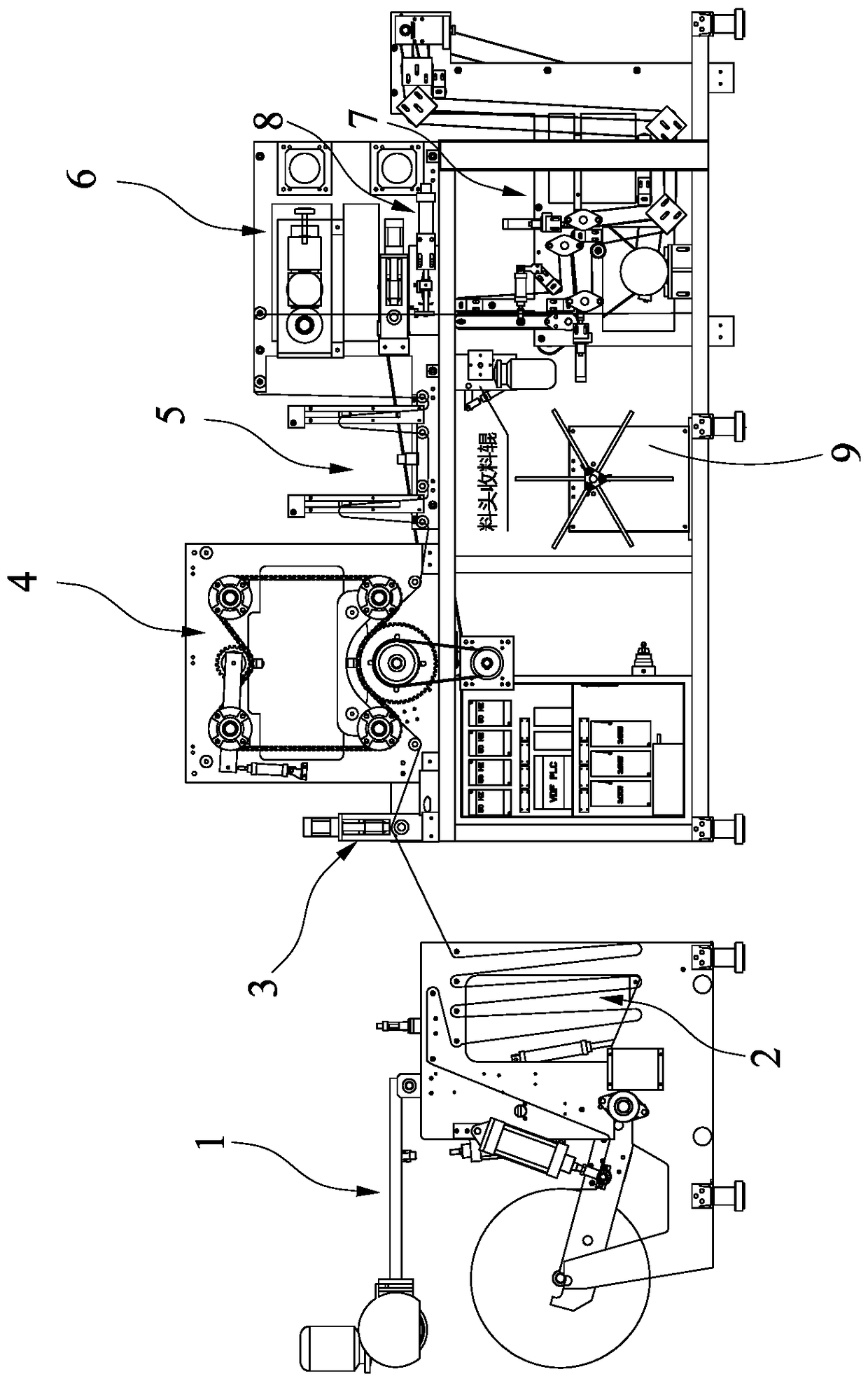

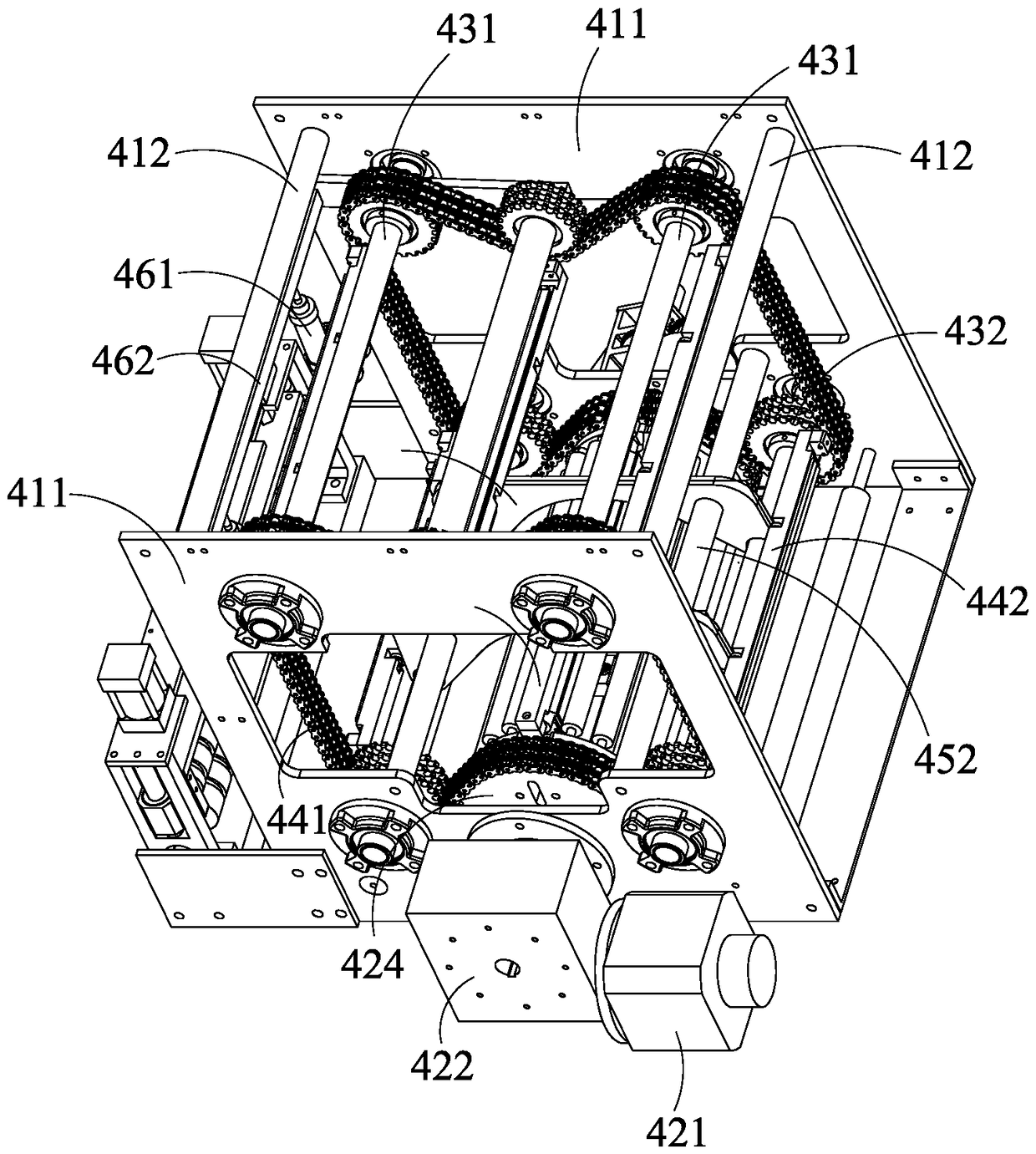

Plastic vest bag production device

PendingCN108099267AIncrease productivityAvoid pouringBag making operationsPaper-makingDrive shaftActive component

The invention relates to a plastic vest bag production device which mainly comprises an active placing mechanism, a feeding mechanism, a synchronous heat sealing mechanism, a die cutting mechanism anda bag folding mechanism. The synchronous heat sealing mechanism comprises a driving shaft and a chain group, a heat sealing knife is arranged on the driving shaft, and a heat sealing base matched with the heat sealing knife is arranged on the chain group. When plastic films pass the synchronous heat sealing mechanism, a motor of an active component drives the driving shaft to rotate through a gearbox, the driving shaft drives the chain group to rotate through a driving chain wheel and a driven chain wheel, the heat sealing knife and the heat sealing seat on the driving shaft and the chain group gradually approach and are pressed below a sliding seat top block in the transmission process of the driving shaft and the chain group, so that the conveyed plastic films are sealed in a heating manner, and the heat sealing knife and the heat sealing seat are gradually separated after heat sealing. According to the plastic vest bag production device, heat sealing, feeding and conveying can be synchronously performed, so that the production efficiency of plastic vest bags is improved.

Owner:厦门亚太创新机器有限公司

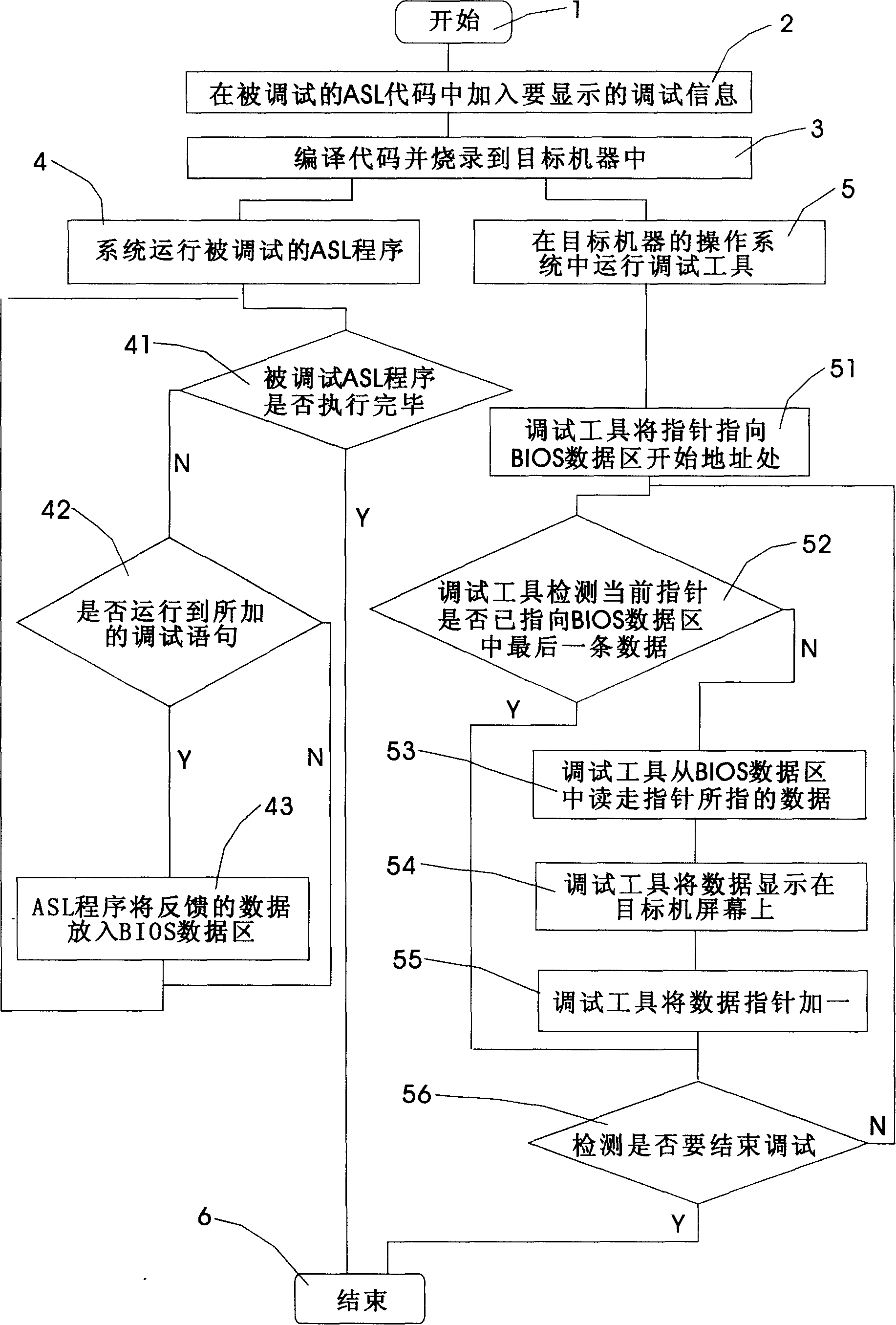

Method for debugging high configuration and power supply interface module in basic inputting and outputting system

InactiveCN1848093AAffect the working environmentPerform synchronizationSoftware testing/debuggingEmbedded systemInput/output

The present invention discloses a debugging method of high-level configuration and power supply interface module in basic input / output system. Said method includes the following steps: adding debugging information into the high-level configuration and power supply interface module code to be debugged; compiling the code containing debugging information and reading it into object machine; on the object machine operating debugging tool; after the debagging tool is operated, utilizing said debugging information displayed on object machine to make debugging work.

Owner:SHENZHEN TOPSTAR DIGITAL TECH

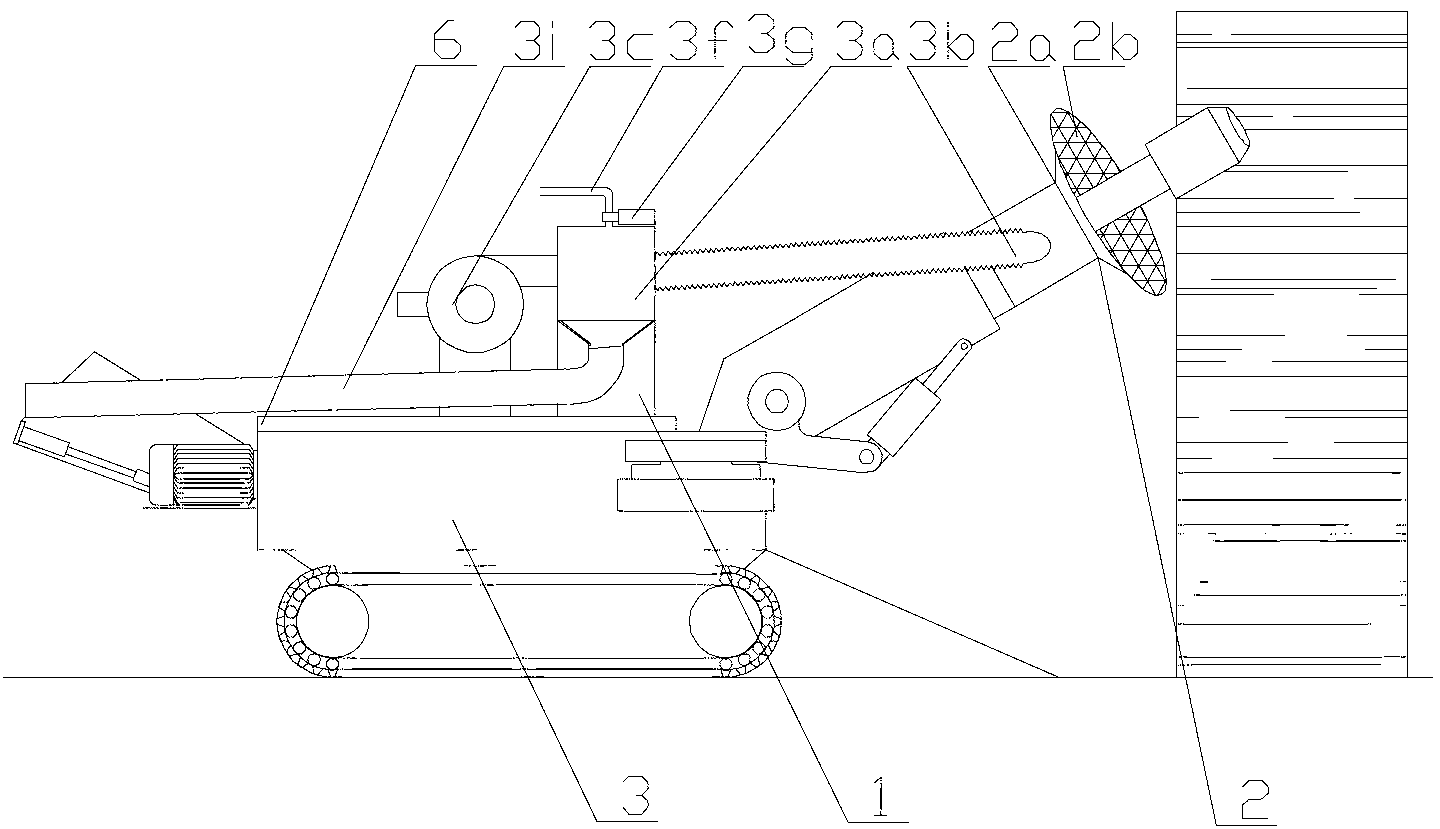

Dust fall system for cantilever type heading machine

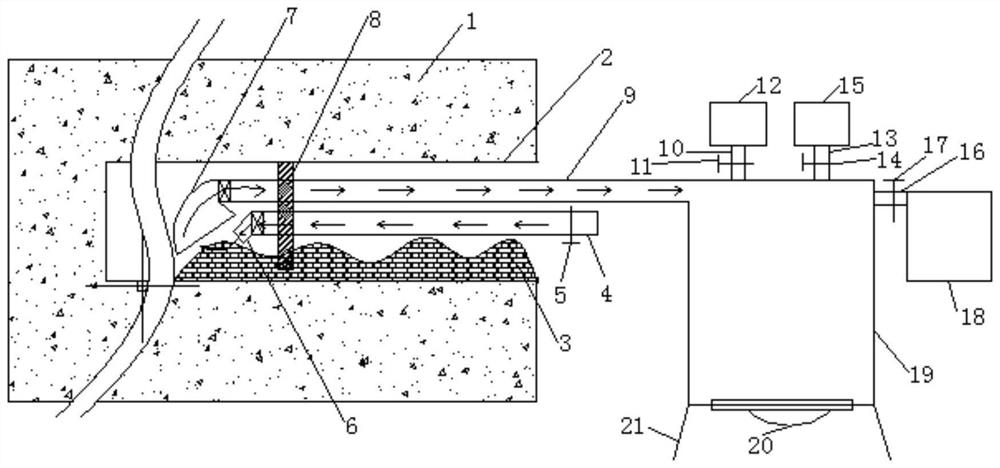

InactiveCN103291298AWill not affect the working environmentAffect the working environmentSlitting machinesEngineeringSewage

The invention discloses a dust fall system for a cantilever type heading machine, which comprises a mine dust collection mechanism and a mine dust treatment mechanism, wherein the mine dust collection mechanism comprises a suction hood sleeved on a cutting arm of a heading machine; the mine dust treatment mechanism comprises a dust fall box; the middle part of the dust fall box transversely penetrates through a dust suction pipeline communicated with the dust fall box; dust filtering nets are respectively arranged on the part of an inner cavity of the dust fall box, which is close to the dust suction pipeline; a water mist nozzle is arranged on the top of the inner cavity of the dust fall box between the dust filtering nets; a water inlet pipe and a water suction pump are arranged on the water mist nozzle; an inverted frustum-shaped sewage collection cavity is formed in the bottom of the dust fall box; the bottom of the sewage collection cavity is connected to a drainage pipeline; a rotating clapboard is arranged between the sewage collection cavity and the drainage pipeline at an interval; the rotating clapboard is connected to the bottom of the dust fall box through an elastic part. The dust fall system can move along with the heading machine, excessive external matched equipment is not required, excessive manual operations are not required, the heading operation is not influenced, and the cost is low.

Owner:ANHUI UNIV OF SCI & TECH

Drying device for shoe processing

PendingCN108851368AImprove heating uniformityEmission reductionShoemaking devicesReduction driveAgricultural engineering

Owner:郑新

Method for cleaning coal powder at sealing section of gas extraction drill hole

ActiveCN111734475AEasy to cleanCongeal fastConstructionsGas removalPetroleum engineeringStorage tank

The invention discloses a method for cleaning coal powder at a sealing section of a gas extraction drill hole. A coal mine underground compressed air system is utilized and connected with a gas injection pipe, so that the gas injection pipe can better blow the coal powder in a sealing area; a gas inlet of a gas suction pipe is matched with a nozzle of the gas injection pipe, the blown coal powdercan be sucked to the maximum extent, the coal powder enters a coal powder storage tank through the gas suction pipe, and water mist can be in contact with the coal powder quickly and wrap the surfaceof the coal powder; meanwhile, under the action of liquid nitrogen mist, the water mist on the surface of the coal powder is condensed quickly, the descending speed of the coal powder is increased, and the coal powder is enabled to settle to the bottom of the coal powder storage tank quickly; and a device for cleaning residual coal powder in the sealing section of the gas extraction drill hole canmove in the gas extraction drill hole, so that the coal powder at all positions in the drill hole is cleaned. Therefore, the method has the advantages of being good in coal powder cleaning effect andhigh in efficiency; and meanwhile, in the cleaning process, the dust cannot affect the roadway operation environment, air leakage after drill hole sealing can be reduced, the gas extraction effect isimproved, and wide practicability is achieved.

Owner:XUZHOU UNIV OF TECH

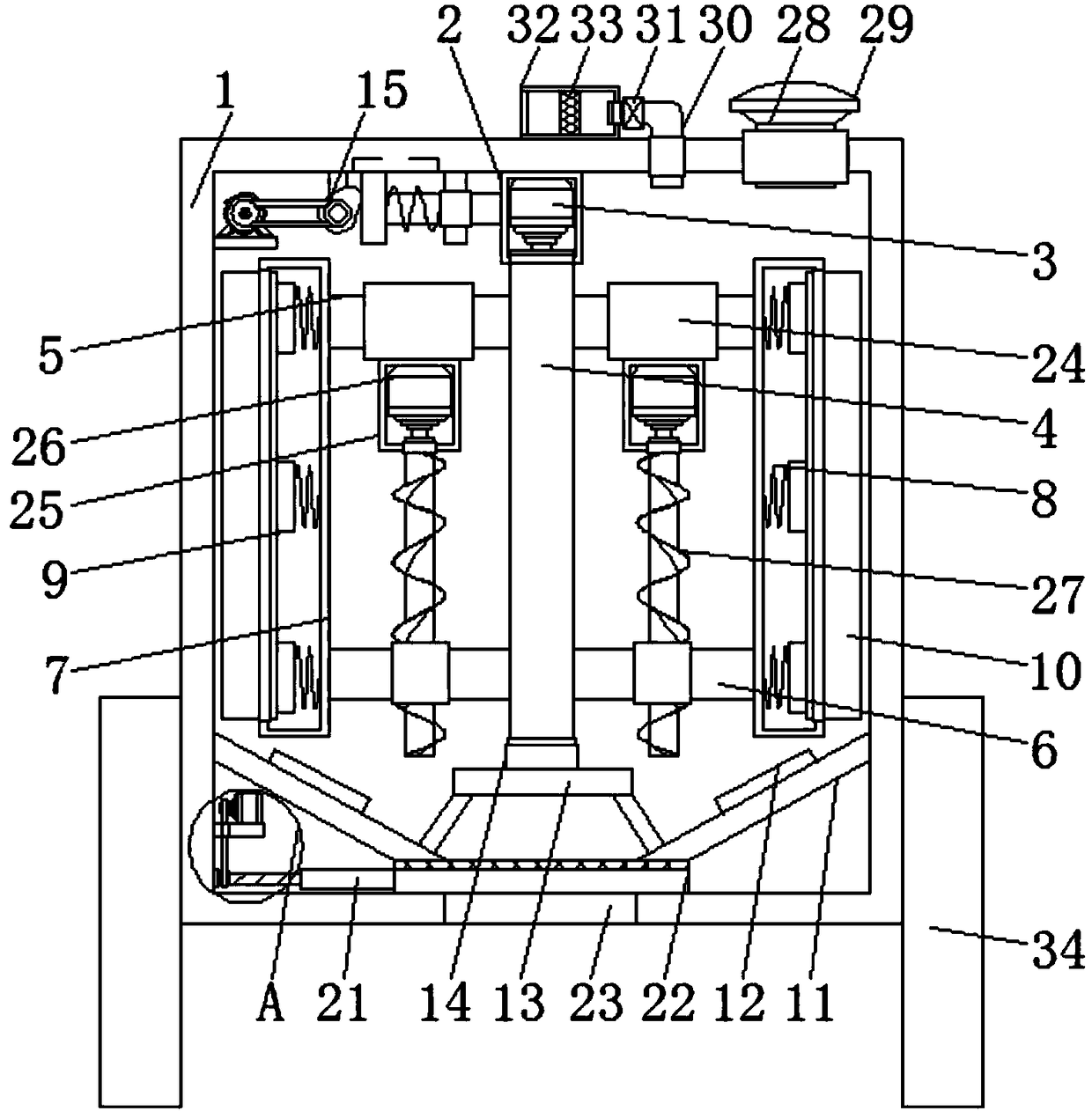

Preparation method and processing device for Chinese medicine agricultural medicinal fertilizer

PendingCN108546188ANo pollution in the processStrong disease resistanceNitrogenous fertilisersOrganic fertilisersDiseaseDisease injury

The invention discloses a preparation method and a processing device for Chinese medicine agricultural medicinal fertilizer, relating to the technical field of medicinal fertilizer processing devices.The processing device comprises a box body, wherein the top of the inner wall of the box body is slidably connected with a first chassis, and a first motor is fixedly connected to the top of the inner wall of the first chassis. The preparation method and the processing device for Chinese medicine agricultural medicinal fertilizer have the advantages that raw materials are easy to obtain, all of the raw materials are pure natural substances of traditional Chinese medicine and are safe and environmentally friendly in the production process and after application, the production cost is low, theapplication range is large, various kinds of crops can realize production increase and income increase, moreover, various pests and diseases can be prevented and controlled, and therefore, without using chemical fertilizers and pesticides, farmers can grow high-yield good-harvest vegetables, fruits and cereals having perfect combination of color, aroma and taste without any heavy metals or any harmful residues; when the processing device is in use, materials are quickly mixed to reduce the mixing time, so as to prevent a subsequent normal use effect, and to prevent excessive local heating anduneven heating.

Owner:山东罗纳朗克生物农化有限公司

Reinforcing steel bar cutting machine capable of recovering scrap iron

InactiveCN107999671AAffect the working environmentProtect life safetyFouling preventionArchitectural engineeringRebar

The invention relates to the technical field of construction and discloses a reinforcing steel bar cutting machine capable of recovering scrap iron. The machine comprises a mounting base; two ends ofthe top of the mounting base are fixedly connected with a protecting shell; a magnet groove is formed in the front surface of the mounting base; the inner wall of the magnet groove is movably connected with a magnet piece; the top of the mounting base is movably connected with a scrap iron box; the bottom of the inner wall of the scrap iron box is movably connected with a felt net; the top of themounting base is movably connected with a cutting platform located on the right side of the scrap iron box; a cutting groove is formed in the top of the cutting platform; a supporting rod located on the left side of the scrap iron box is fixedly mounted at the top of the mounting base; and a motor is fixedly mounted at the top of the supporting rod. The reinforcing steel bar cutting machine capable of recovering the scrap iron is stable to use, the scrap iron cannot fly all over the place in the use process, the life safety of a user is protected, more convenient and quick sweeping is realized, and use by the user is facilitated.

Owner:孝昌县宝德智能科技有限公司

Gas boiler with tail gas heat convenient to absorb and store

PendingCN110006064AAchieve cleanupAchieve absorptionSteam generation using hot heat carriersCombustionSolid particle

The invention discloses a gas boiler with tail gas heat convenient to absorb and store, and particularly relates to the technical field of boiler combustion. The gas boiler comprises a gas boiler body, wherein a filter box is arranged on one side of the gas boiler body, a first gas delivery pipe is arranged between the gas boiler body and the filter box, and communicate with each other through a first gas delivery pipe, a lantern ring is fixedly arranged in the middle of the filter box, filter screens are fixedly arranged on the inner wall of the circumferential side of the lantern ring, brushrods are arranged at the tops of the filter screens, and vibration transfer rods are arranged at the bottoms of the filter screens. According to the gas boiler, the multistage filter screens are usedfor grading intercepting of solid particles in the tail gas, a driving motor is used for driving the brush rods to rotate, meanwhile, a vibration motor is combined to drive the vibration transfer rods to generate vibration, the vibration generated by the vibration transfer rods is transferred to the filter screens through contact rods so as to clear the solid particles left in holes of the filterscreens, and in addition, drying treatment can be carried out on the discharged wet tail gas through a drying layer.

Owner:YANTAI VOCATIONAL COLLEGE

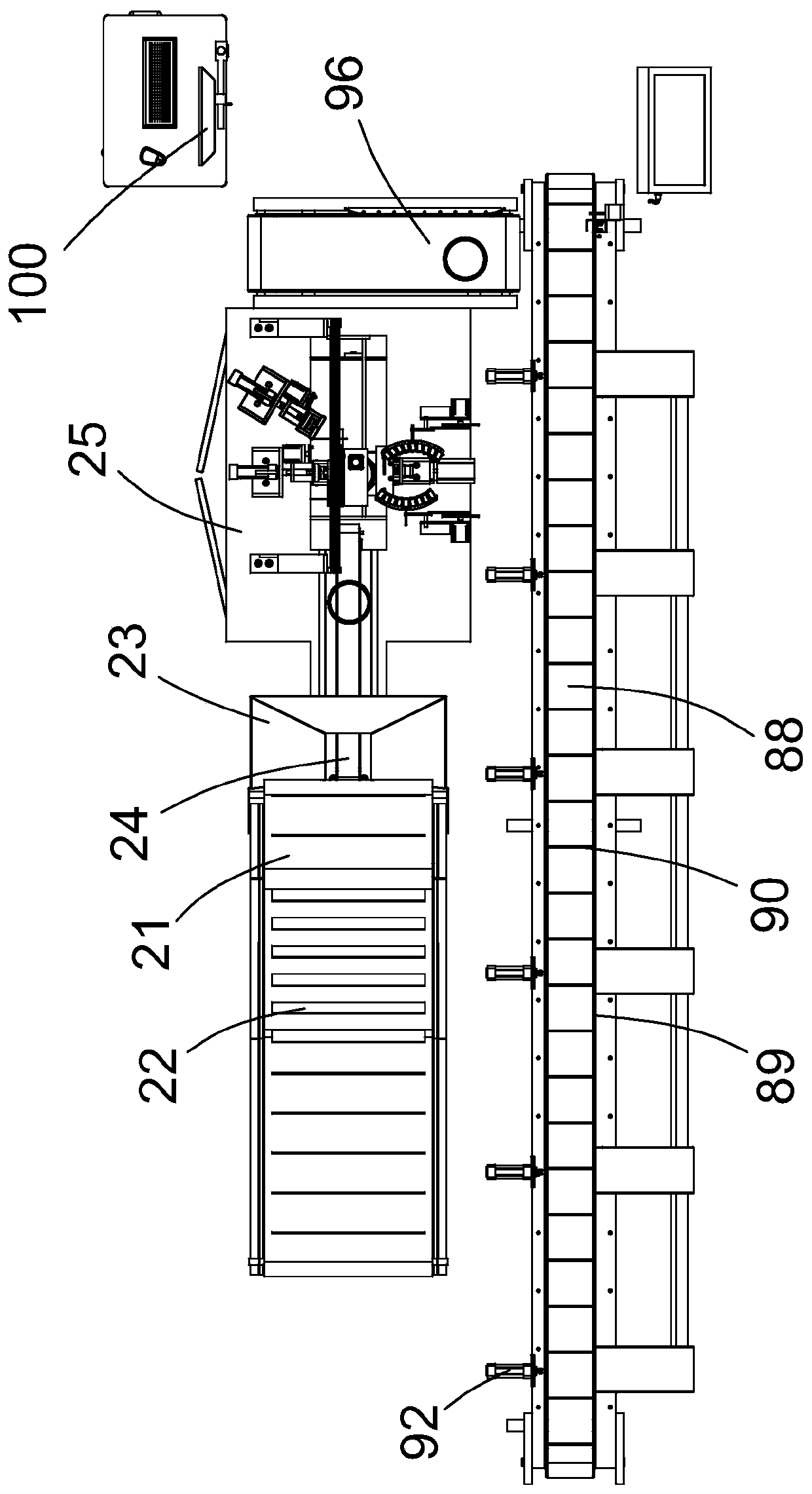

Integrated processing device for concrete tubular pile end plate without manual operation

PendingCN109382746AReduce labor intensityAvoid wastingGrinding machinesAutomatic grinding controlEngineeringIntegrated processing

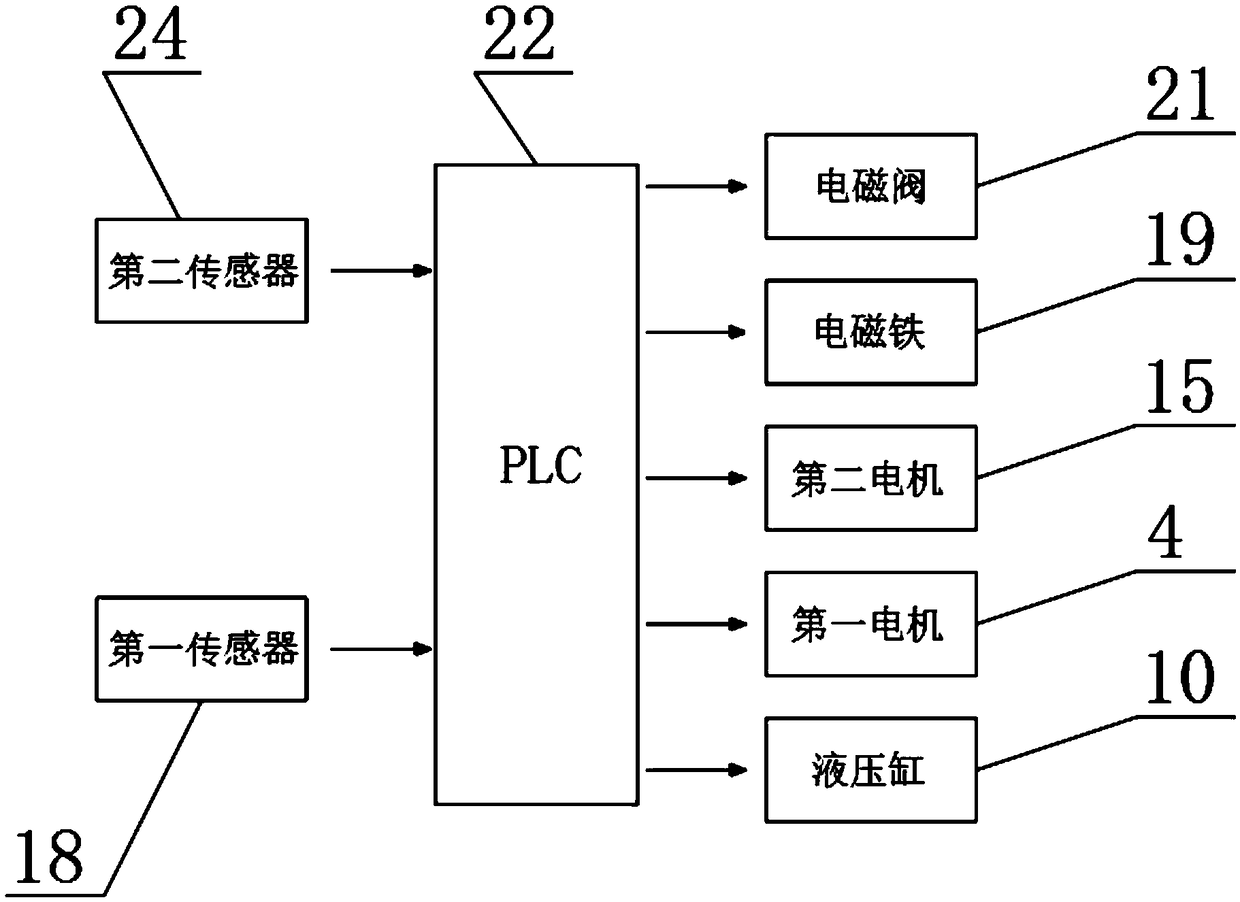

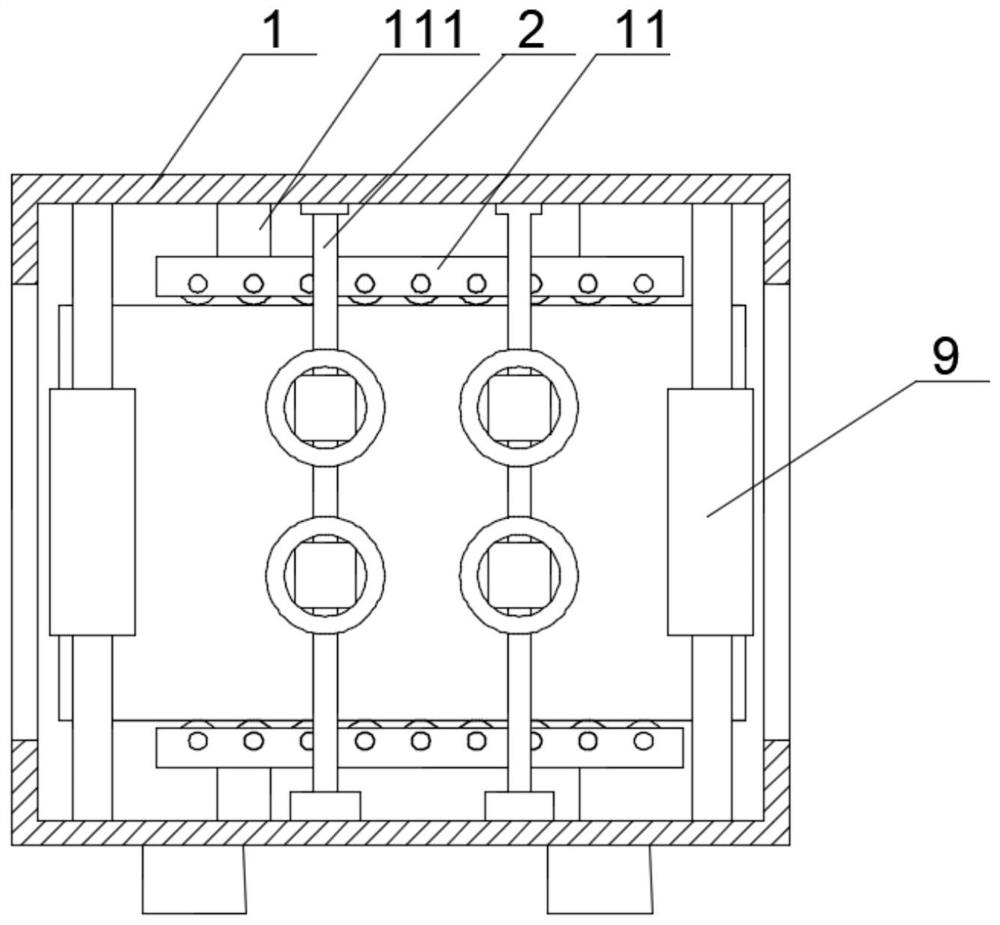

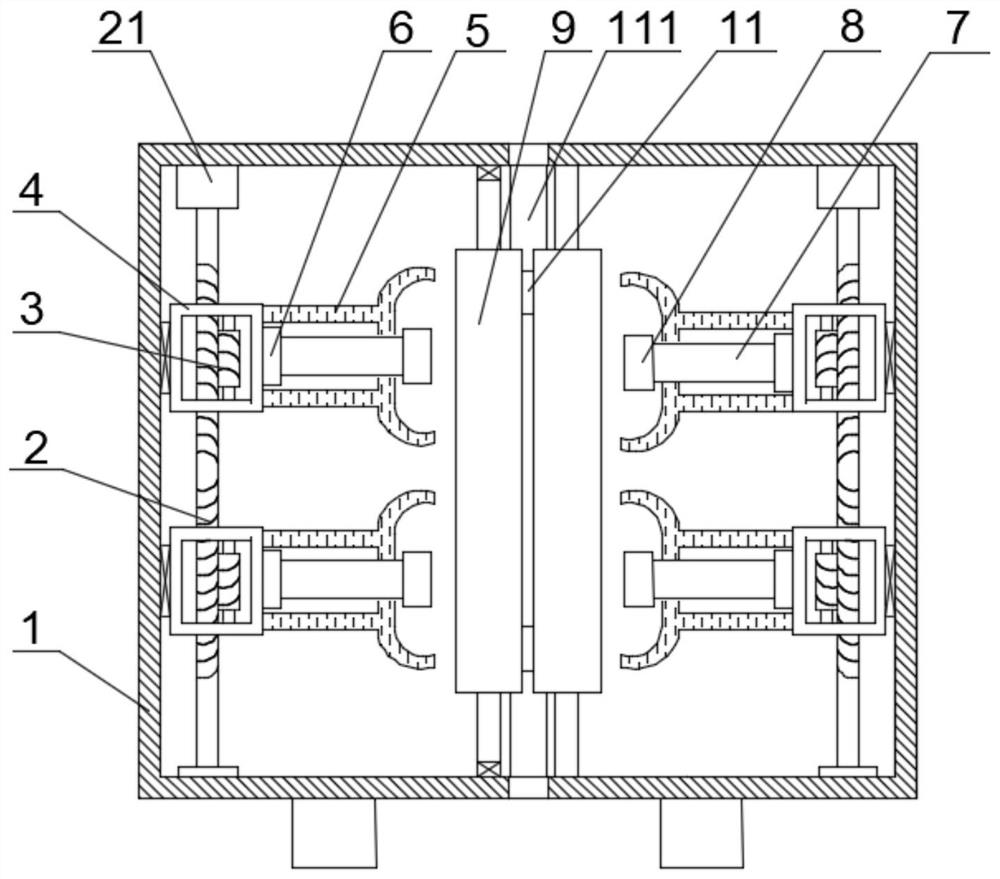

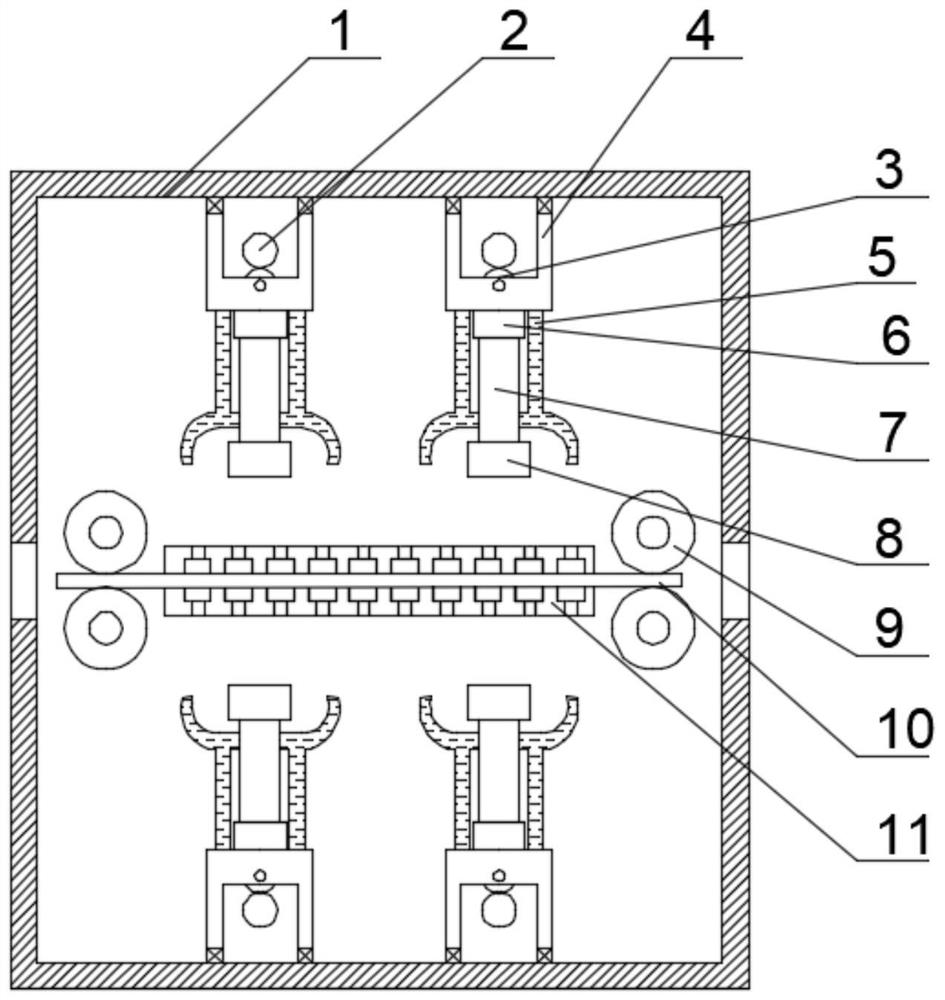

The invention relates to the technical field of tubular pile end plate processing devices and discloses an integrated processing device for a concrete tubular pile end plate without manual operation.The device comprises a support frame and a PLC, a protection box is arranged in the middle of the support frame, a protection cover disposed on the left side of the protection box is fixedly mounted on the back face of the support frame, a first motor is fixedly mounted in the protection cover, an output shaft of the first motor is fixedly connected with a driving shaft, a mother gear located in the protection cover fixedly sleeves the driving shaft, and the right end of the mother gear is meshed with child gears. According to the integrated processing device for the concrete tubular pile endplate without manual operation, through arrangement of the PLC, the PLC is adopted for controlling the first motor, a hydraulic cylinder, a second motor, an electromagnet and a solenoid valve, integration and automation of processing processes without manual work are achieved, and the labor intensity of workers is reduced.

Owner:TAIZHOU RUNWEI MACHINERY

Device for grinding and cleaning building plates

InactiveCN112428073AAffect the working environmentDecrease productivityEdge grinding machinesGrinding drivesDust controlWorking environment

The invention relates to the field of building material processing, and specifically relates to a device for grinding and cleaning building plates. The device for grinding and cleaning the building plates comprises a grinding structure and a spraying structure, wherein the grinding structure is driven to move through rotation of a lead screw; the grinding structure telescopes through a telescopicstructure in the grinding structure to be attached to the plates for grinding; the spraying structure is connected to the grinding structure, and completes grinding operation by cooperating with the grinding structure; a screw rod is arranged on the grinding structure, and meshed with a lead screw structure connected to the inner wall of the box body; the grinding structure is driven to move through rotation of the lead screw structure; conveying rollers convey the plates at a constant speed, and the plates are evenly ground; the spraying structure sprays liquid to grinding positions to precipitate dust generated by grinding, so that the problems that in the actual treatment process for the building plates, due to the lack of a dust removal structure in the grinding device, a large numberof grinding chippings enter air in the grinding process, and the working environment of workers is affected, and meanwhile, due to the fact that a single-face grinding mode is usually adopted, the working efficiency is reduced, and the working time and the production cost are increased, are avoided.

Owner:王书娟

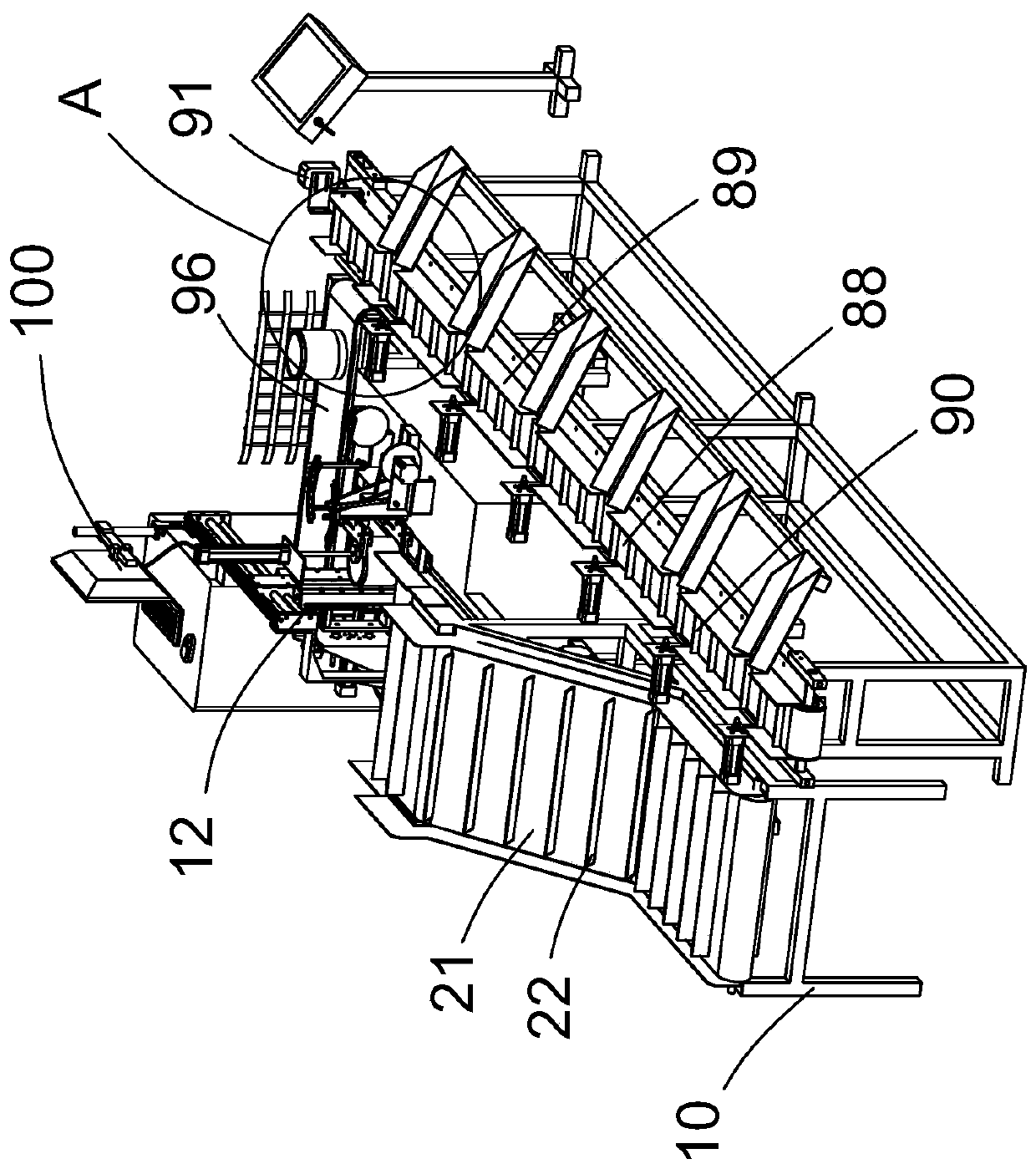

Yarn bobbin automatic cleaning and recycling equipment

PendingCN111002355AClean up quickly and efficientlyReduce spendingSevering textilesCleaning using toolsYarnBobbin

The invention provides yarn bobbin automatic cleaning and recycling equipment which is reasonable in structural design, simple and easy to operate and capable of achieving full-automatic cleaning andrecycling of yarn bobbins. The equipment comprises a machine frame, wherein a feeding mechanism, a cleaning mechanism, a sorting mechanism are arranged on the machine frame in sequence, the cleaning mechanism comprises a workbench arranged on the machine frame, a first conveyor belt is arranged on the workbench, the first conveyor belt is arranged on the machine frame, an opening is formed in position, behind the conveying of the first conveying belt, of the workbench, a sliding rail is arranged in the opening, the sliding rail is arranged on the workbench, and a first driving mechanism is arranged above the sliding rail. Positioning devices, one group of cutting devices or above and cleaning devices are arranged on the workbench on the two sides of the sliding rail correspondingly, and arecycling device used for collecting fallen yarns and a first driving device used for driving the first conveying belt to transmit are arranged at the position, below the opening, of the machine frame.

Owner:漳浦金盛智能科技有限公司

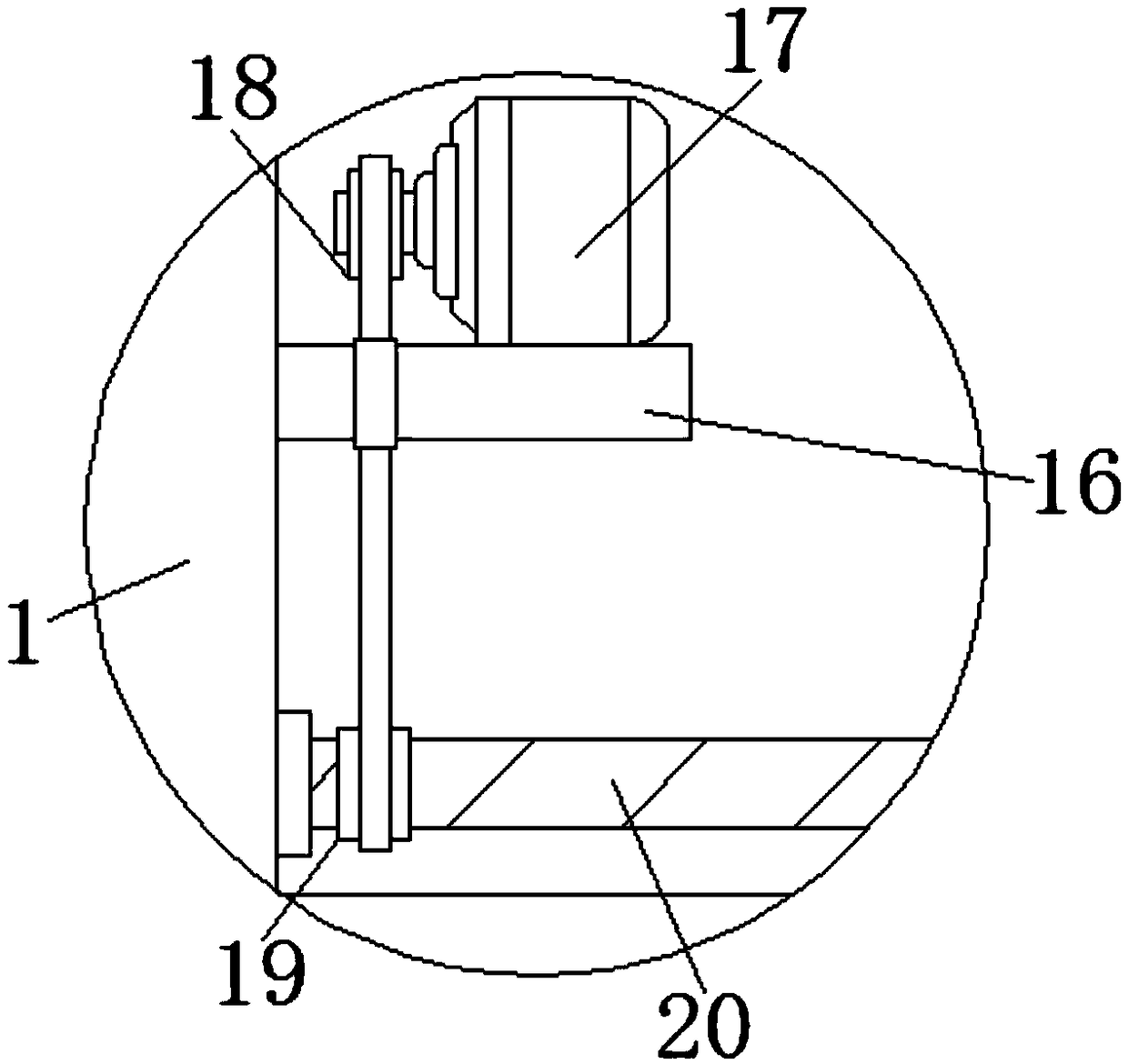

Waste gypsum grinding and recovering equipment for orthopedics department

InactiveCN107694678ATo achieve the purpose of grindingAchieve rotationDirt cleaningGrain treatmentsOrthopedic departmentGypsum

The invention relates to grinding and recovering equipment, in particular to waste gypsum grinding and recovering equipment for the orthopedics department. The invention aims to solve the technical problem so as to provide the waste gypsum grinding and recovering equipment for the orthopedics department, which can be used for grinding sufficiently, is labor-saving and can prevent ground powdered gypsum powder from flying at the same time. In order to solve the technical problem, the invention provides the waste gypsum grinding and recovering equipment for the orthopedics department, which comprises a grinding tank and the like. A driving mechanism is connected to the uppermost part of the right side of the grinding tank; and a grinding mechanism is arranged in the grinding tank and is connected with the driving mechanism. According to the waste gypsum grinding and recovering equipment for the orthopedics department provided by the invention, the driving mechanism and the grinding mechanism are arranged, so that the aim of grinding gypsum is achieved; a handle is held to rotate so as to drive the grinding tank to rotate through a third slide block, so that the aim of more sufficientgrinding is achieved; and an outer gearing ring drives the grinding tank to rotate through the third slide block, so that the aim of more sufficient grinding is achieved, and meanwhile, the manpowercan be saved.

Owner:姚鲁兰 +1

Coal mine gas explosion early warning protection device

ActiveCN114060091AImprove ventilationAvoid stickingMining devicesDispersed particle filtrationThermodynamicsGas detector

The invention belongs to the technical field of coal mine gas safety equipment and particularly relates to a coal mine gas explosion early warning protection device. The device comprises a detection module, a bag-type dust collector, a fan and a controller, wherein the detection module comprises a gas detector and a dust detector. In the prior art, when a coal mine is exploited, gas is attached to pulverized coal, the gas and the pulverized coal are discharged together through a ventilation system, the pulverized coal outside a mine overflows, the environment outside the mine is affected, humidity in the mine is high, adhesion of the pulverized coal is high, unsmooth ventilation or blockage of the ventilation system is easily caused, the concentration of the gas is easily caused to exceed the limit, and danger is easily caused. By arranging the bag-type dust collector, pulverized coal is convenient to collect, on one hand, the situation that excessive pulverized coal is discharged to pollute the environment and affect the working environment of workers on the ground is avoided, on the other hand, the situation that the pulverized coal is attached to a pipeline passing through the system is avoided, good ventilation of a mine is guaranteed, and safety of the workers under the mine is guaranteed.

Owner:ANHUI UNIV OF SCI & TECH

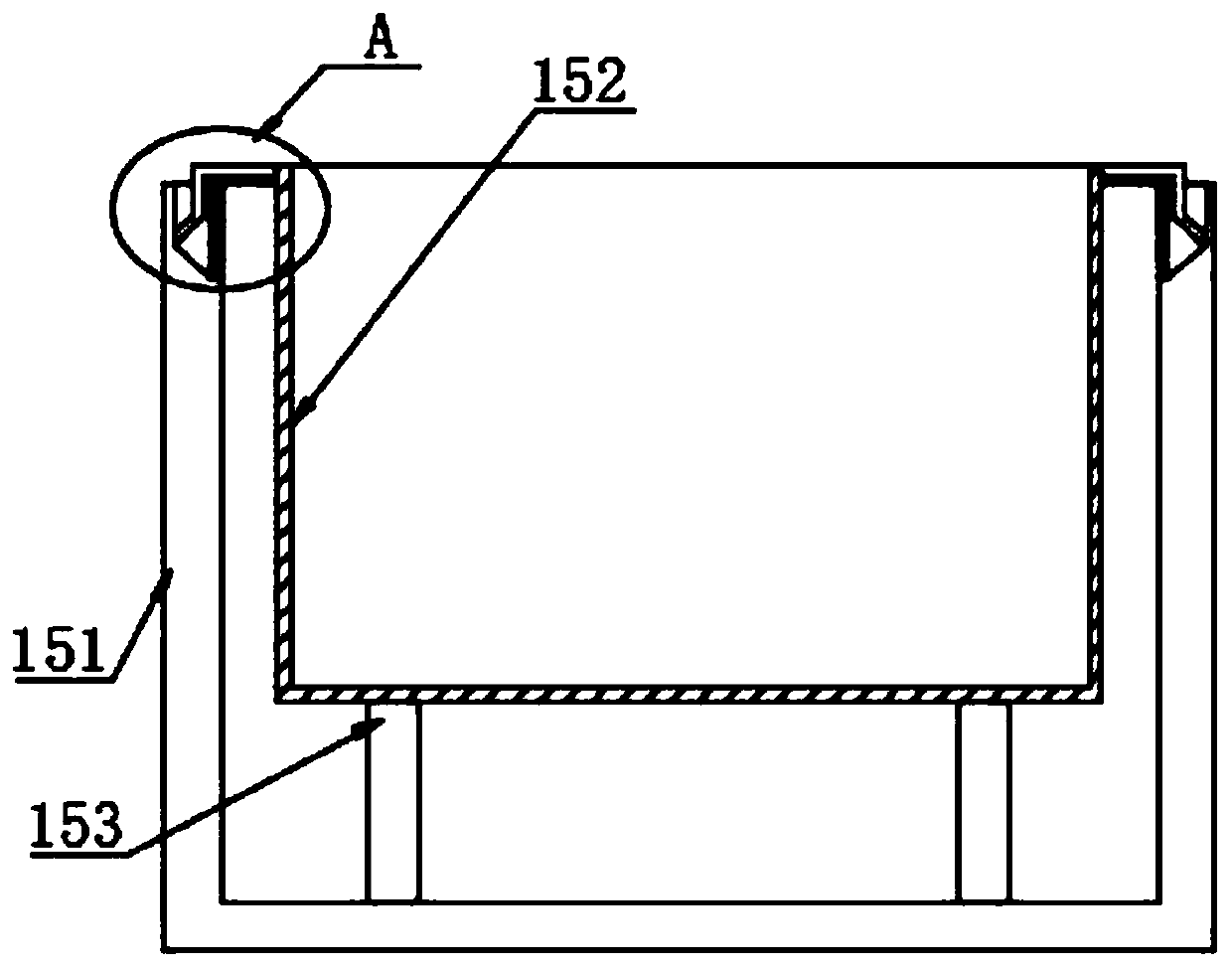

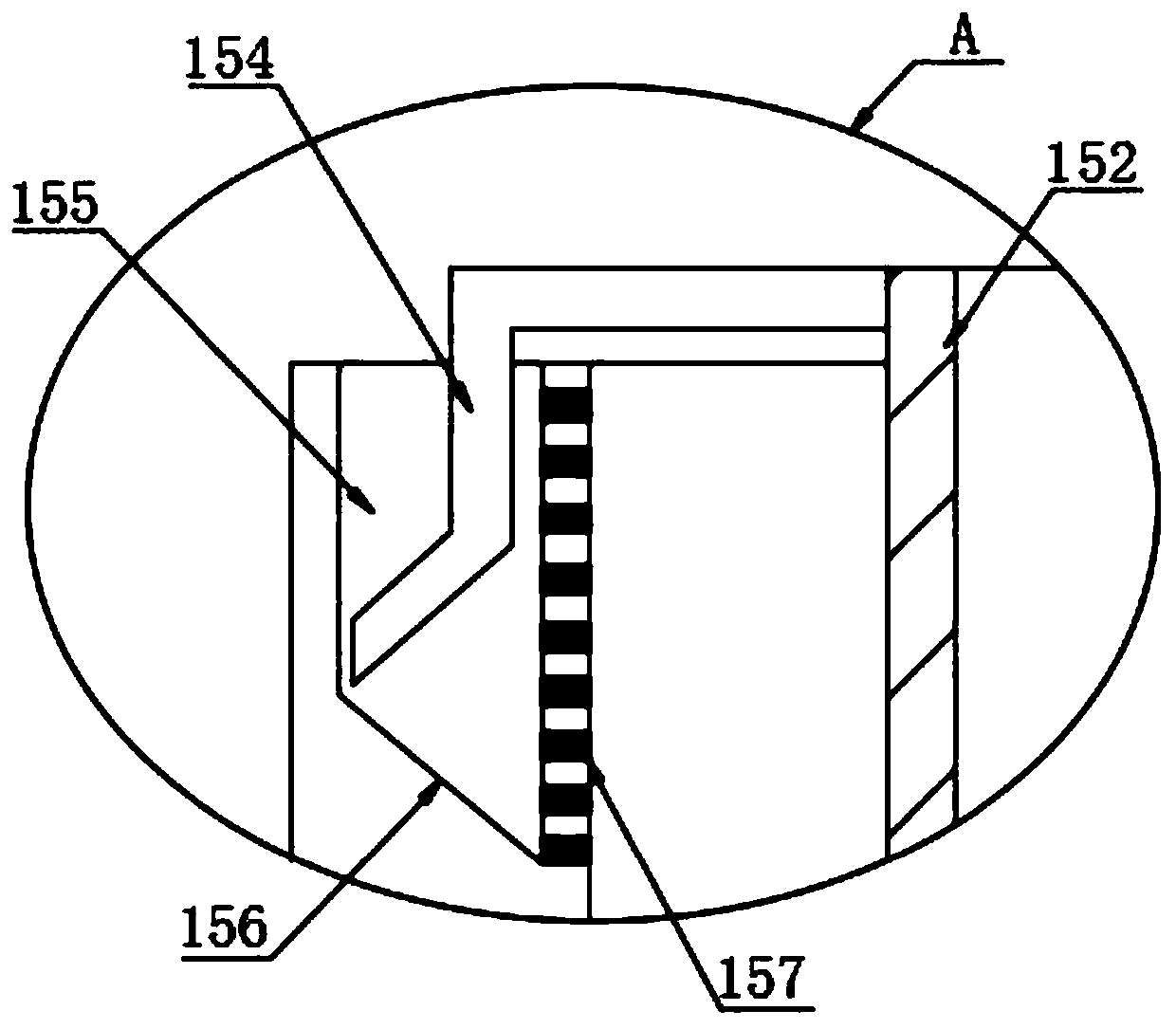

Ceramic packing air drying room

InactiveCN109163513AAffect the working environmentExtended service lifeDrying gas arrangementsDrying chambers/containersReducerAir drying

The invention discloses a ceramic packing air drying room. The ceramic packing air drying room comprises an air drying room main body, a rotary air outlet device with the top communicating with an airinlet pipeline is arranged in the air drying room main body, the rotary air outlet device comprises an air outlet pipe, a rotary shaft, a motor and a speed reducer, the rotary shaft is arranged in the middle of the air drying room main body in a rotating mode in the vertical direction, a plane bearing is arranged on the bottom surface of the air drying room main body, the lower end of the rotaryshaft is connected to the plane bearing in a rotating mode, the motor and the speed reducer are both arranged at the top of the air drying room main body, one end of the speed reducer is connected with an output shaft of the motor, the other end of the speed reducer is connected with the upper end of the rotary shaft, and an air sealing mechanism is arranged between the rotary shaft and the top ofan inner cavity of the air drying room main body. According to the disclosed ceramic packing air drying room, air drying hot air is provided for the interior of an air drying room cavity through therotary air outlet device, the hot air is continuously and uniformly conveyed through the rotating device, so that the air drying efficiency is effectively improved, moreover, the sealing performance of the top of the rotary air outlet device is good, air leakage of a rotary portion is avoided.

Owner:李亿明

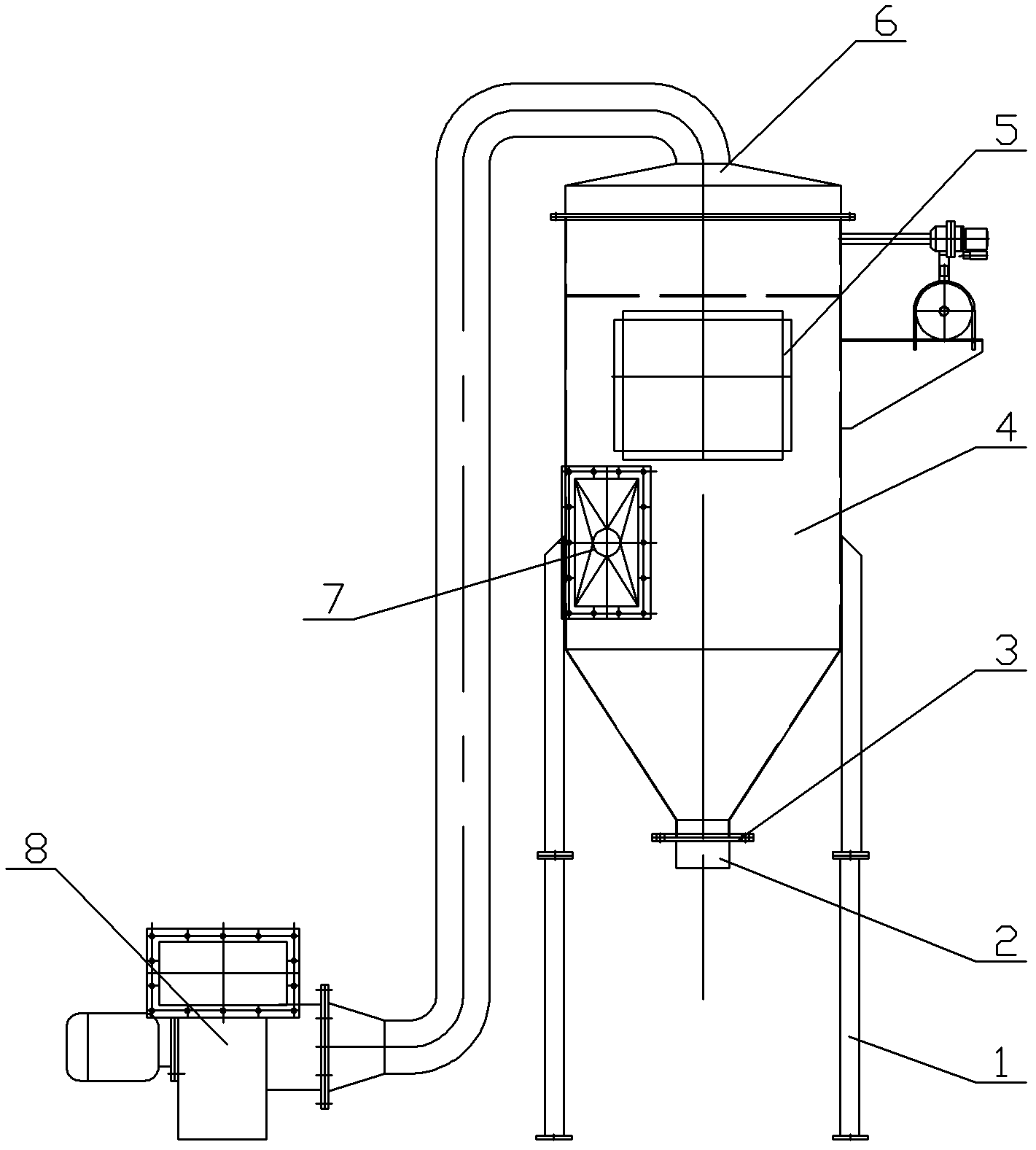

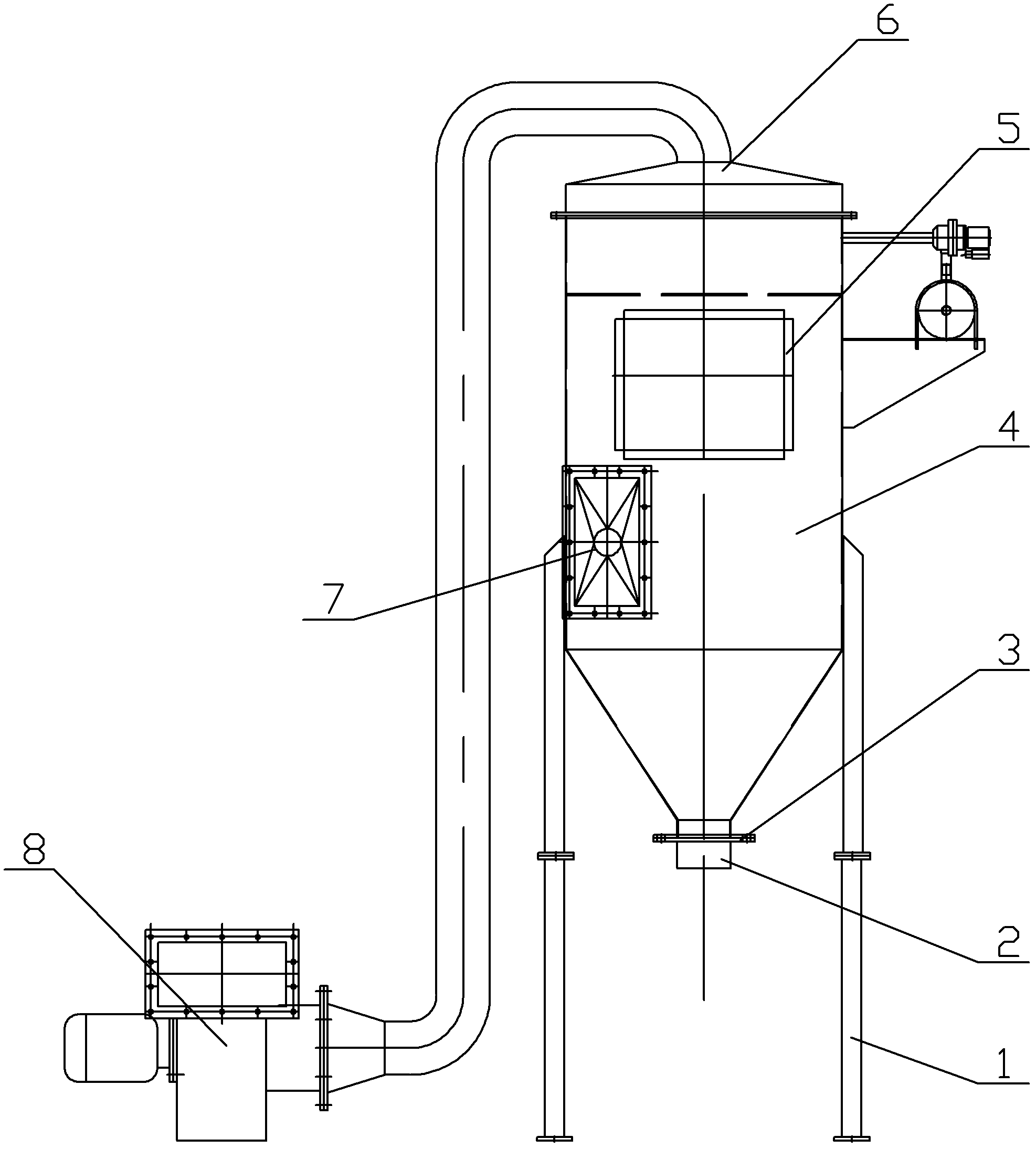

Cyclone dust collector

The invention discloses a cyclone dust collector, which comprises a cyclone dust collection main body and a supporting frame for supporting the cyclone dust collection main body, wherein an air outlet is formed at the upper end of the cyclone dust collection main body; an air inlet is formed in the middle of the cyclone dust collection main body; a dust outlet is formed at the bottom of the cyclone dust collection main body; a cyclone device for rotating dust-containing air is arranged at the air inlet of the cyclone dust collection main body; a filter is arranged at the air outlet of the cyclone dust collection main body and connected with an air exhaust fan through a pipeline; dust particles in air flow in the cyclone dust collector are separated out from the air flow under the action of a centrifugal force, so that the dust and the air flow are separated; the air flow in the cyclone dust collector rotates repeatedly; the rotation speed of the air flow is higher, the centrifugal force on the particles in the rotating air flow is larger, so that the dust and the air flow are separated completely; furthermore, the filter arranged at the air outlet filters out the dust; a backflushing cylinder can clear away the dust adsorbed on the filter conveniently; and the phenomenon that the filter is blocked by much dust and influence caused by mildew, escherichia colion and the like which grow in the filter on the working environment are avoided.

Owner:无锡超科食品有限公司

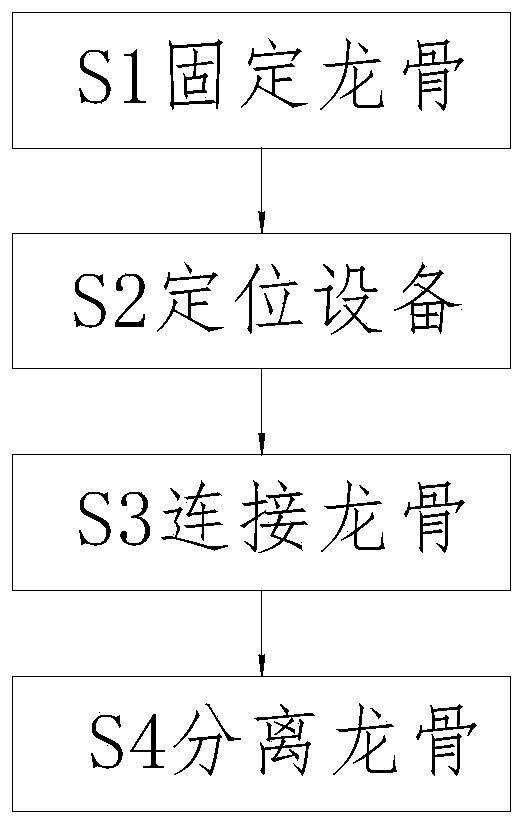

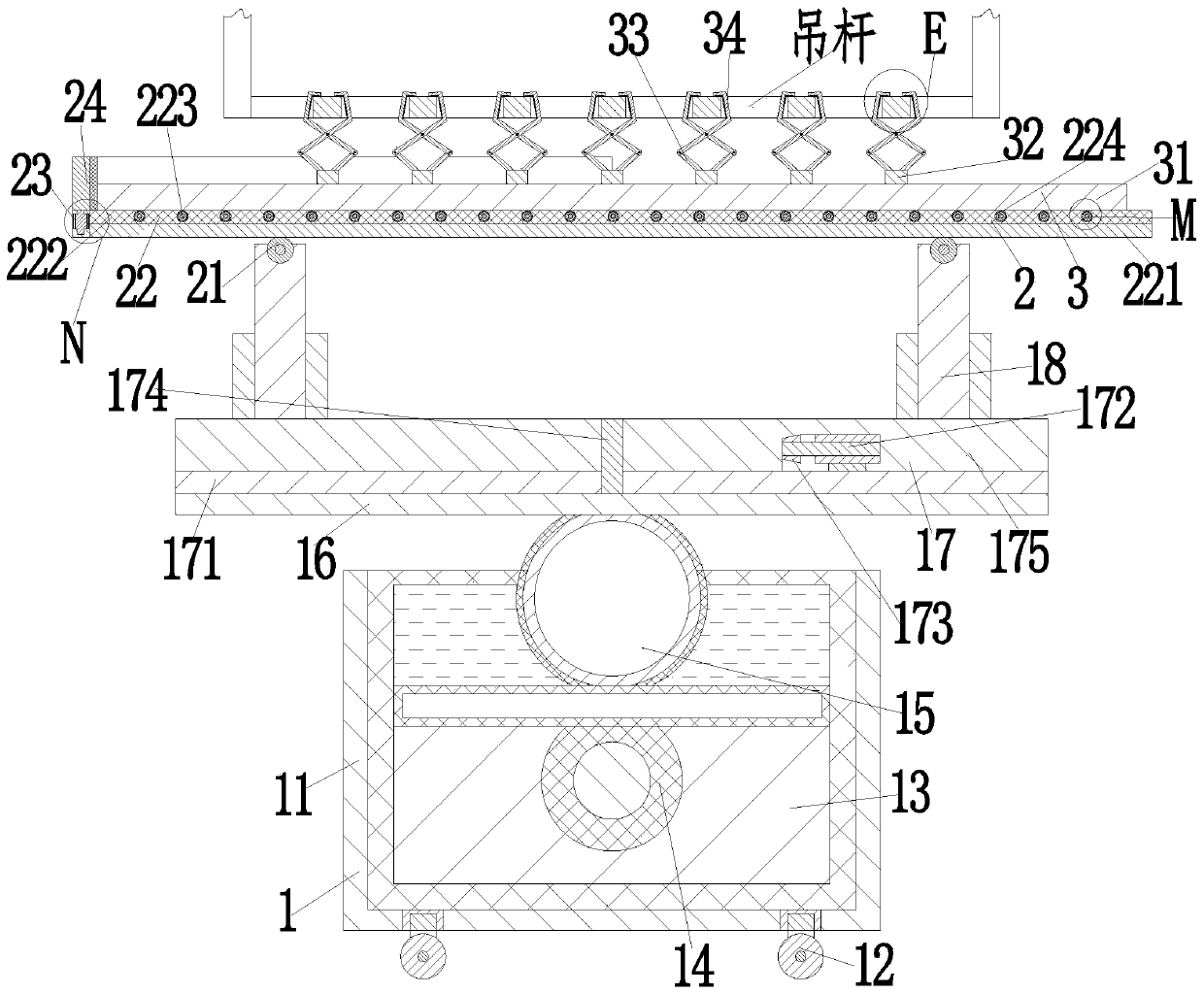

Building indoor keel installation construction method

ActiveCN111550000AInstallation impactReduce installation difficultyCovering/liningsBuilding material handlingKeelArchitectural engineering

The invention relates to a building indoor keel installation construction method. A device comprises a positioning device, an installation device and a connecting device, the installation device is installed at the upper end of the positioning device, the connecting device is installed at the upper end of the installation device, the positioning device comprises a cylindrical box, universal wheels, mercury, a rotating column, a hollow ball, a circular plate, a rotating frame and a telescopic bracket, and the installation device comprises an arc-shaped long plate, a supporting plate, rollers and a fixed plate. According to the building indoor keel installation construction method, a keel is always in a state parallel to a horizontal plane without being limited by an installation site through the positioning device, so that the influence of the installation site on keel installation in the installation process is prevented, the installation difficulty is reduced, the keel is installed and positioned through the installation device, the keel is connected with a suspension rod through the connecting device, and the keel is fixedly installed with the suspension rod under the action of gravity.

Owner:JIANGSU JIANGZHONG GROUP

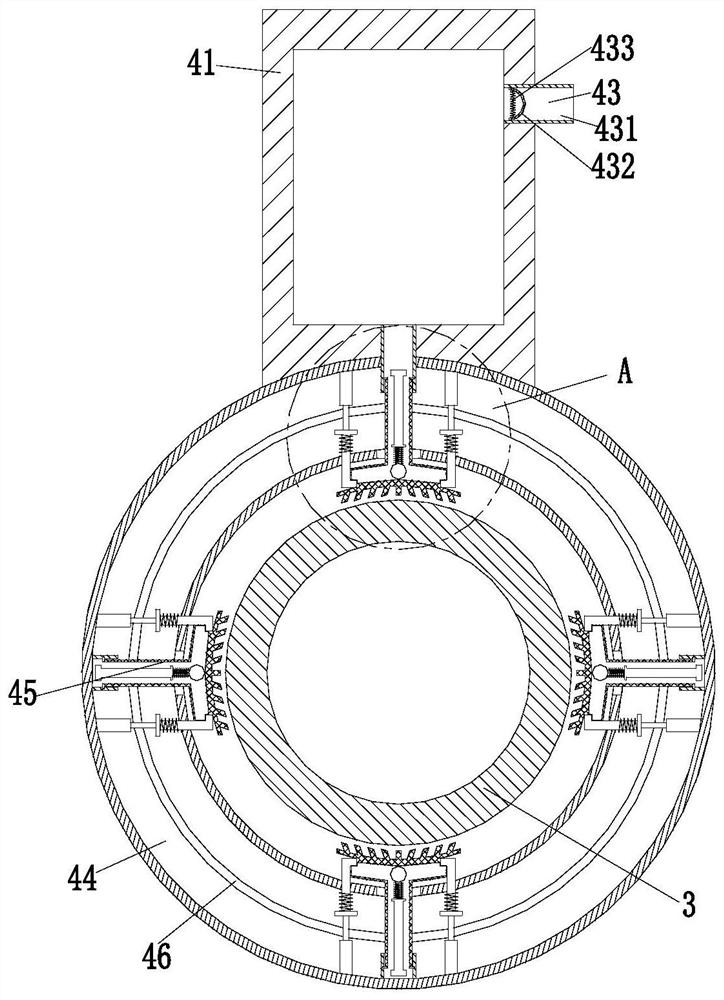

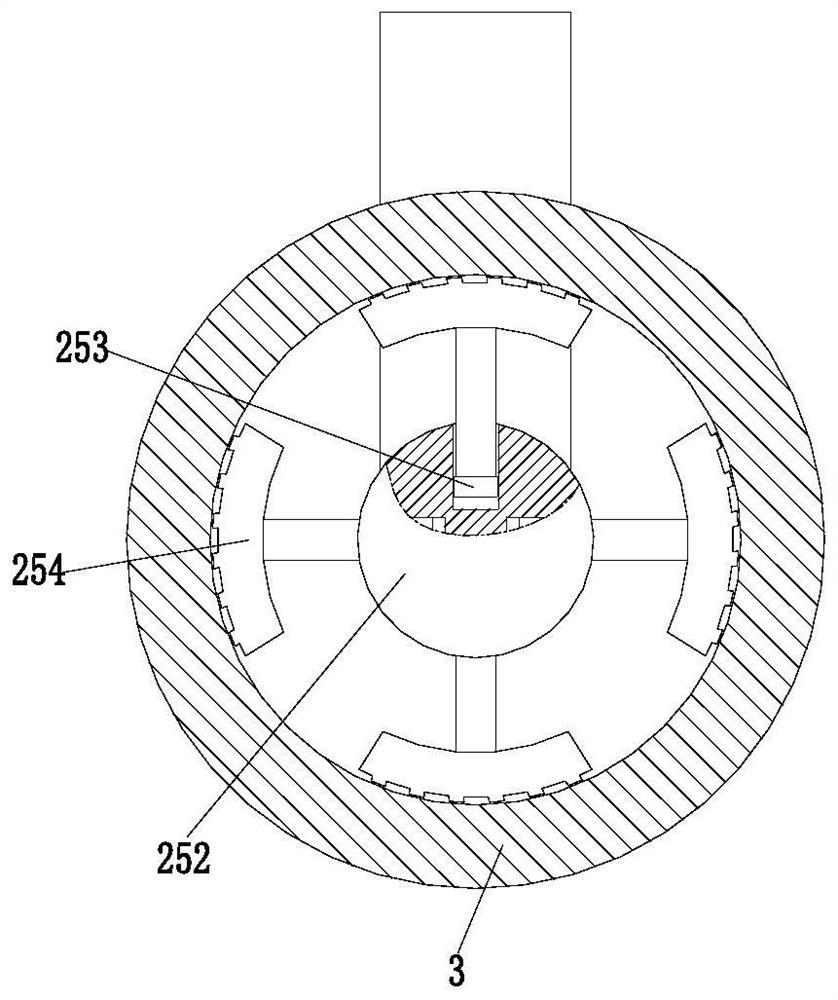

CNC machine tool for processing metal pipe fittings

The invention provides a numerically controlled machine tool for processing metal pipes. The numerically controlled machine tool comprises a box body module, fixed devices, a steel pipe and a sprayingdevice. The invention can solve the problems that the spraying efficiency is low as the ranges of spray heads cannot be adjusted according to the diameters of large-diameter metal pipes with different diameters by existing spraying equipment in the current spraying process; meanwhile, as the diameters of the pipelines are inconsistent during spraying, the distances between the spray heads and thepipes are varied, the spraying strength is not uniform, a spraying agent cannot spray on the outer walls of the pipelines and further the spraying efficiency is affected; and in addition, a large amount of particulate matters are produced in the spraying process and are not attached to the outer walls of the pipes, so that the particulate matters disperse in air to influence the working environment of a workshop, or even body health of workers is affected in a serious situation, and the like.

Owner:王利华

Automatic electrolytic cell liquid level adjusting device

PendingCN112159991AAffect the working environmentNo pollutionElectrolysis componentsPhotography auxillary processesElectrolytic agentThermodynamics

The invention relates to the technical field of electrolytic cells, and discloses an automatic electrolytic cell liquid level adjusting device. The automatic electrolytic cell liquid level adjusting device comprises an electrolytic cell. A replenishing liquid tank is fixedly connected to the left side of the electrolytic cell, a water pipe is fixedly connected to an inner cavity of the replenishing liquid tank and communicates with the electrolytic cell, a water pump is clamped to the surface of the water pipe, and a switch is fixedly connected to the top of the water pipe. A telescopic plateis slidably connected to the surface of the rear side of the inner wall of the electrolytic cell, a rack is fixedly connected to the surface of the telescopic plate, a buoy is clamped to the bottom ofthe telescopic plate, a gear is arranged at the top of the electrolytic cell, the gear is meshed with the rack, and a connecting rod is fixedly connected to the left side of the gear. When the liquidlevel of electrolyte descends, the electrolyte is supplemented in time, waste of an anode is avoided, the concentration of the electrolyte can be kept, the electrolyte does not need to be checked andsupplemented manually all the time, the manual labor amount is reduced, and the working efficiency is improved.

Owner:宁夏鼎辉科技有限公司

Grinding machine for optical fiber cable manufacturing

InactiveCN108637890AEasy to GrindAdjust the relative height at any timeLapping machinesCoupling light guidesEngineeringControl switch

The invention discloses a grinding machine for optical fiber cable manufacturing. The grinding machine comprises a magnetic bracket; the magnetic bracket is mounted at four corners of the lower end ofa machine body; an end surface is fixedly arranged in front of the machine body through a nut; a control switch is arranged on the other surface, corresponding to the end surface, of the machine body; a grinding table is arranged at the upper end of the machine body; a grinding turntable is arranged in the center position of the upper end of the grinding table; fixing devices are arranged at fourcorners of the upper end of the grinding table and positioned around the grinding turntable; stand rods are arranged behind the machine body and the grinding table, and are fixed on the machine body;dust sucking devices are buckled in the middle positions of the stand rods; cross bars are arranged in the front positions of the upper ends of the stand rods; the stand rods and the cross bars are fixedly connected through connecting heads; and spherical sleeves sleeve the right ends of the cross bars. The grinding machine prevents movement of an optical fiber grinding machine during working, isconvenient for the optical fiber grinding machine to grind optical fibers, and improves the use performance of the optical fiber grinding machine.

Owner:YICHANG HONGQI ZHONGTAI CABLE CO LTD

Auxiliary supporting and adjusting equipment for rotor shaft machining and use method thereof

InactiveCN113275909AAffect the working environmentRealize automatic fixationPositioning apparatusMaintainance and safety accessoriesStructural engineeringMachining

The invention discloses auxiliary supporting and adjusting equipment for rotor shaft machining, comprising a supporting plate. A sliding rod is fixedly connected to the supporting plate; a lifting plate is slidably connected to the sliding rod; a connecting column is fixedly connected to the lifting plate; a cutting machine is fixedly connected to the lower end of the connecting column; protective covers are arranged on the supporting plate and the connecting column; a cleaning mechanism used for removing scrap iron generated during cutting is arranged in the protective cover at the lower end; a moving mechanism used for moving the lifting plate is arranged at the right end of the supporting plate; a guide opening matched with a cutting machine is formed in the supporting plate; and a cavity is formed in the supporting plate. The invention further discloses a use method of the auxiliary supporting and adjusting equipment for rotor shaft machining, comprising steps of S1, S2 and S3. The equipment is reasonable in structure, a rotor shaft can be automatically fixed before cutting, and meanwhile, cuttings can be collected to avoid splashing of the cuttings.

Owner:南通捷越机电有限公司

Chemical raw material turning circulating drying device

InactiveCN108131927AExpand the spraying areaFully dryDrying gas arrangementsDrying machines with progressive movementsWorking environmentFeeding tube

The invention provides a chemical raw material tuning circulating drying device. The device comprises a tank body; the tank body is designed as a hollow cylinder of which both ends are communicated, atop cover is arranged at the opening of the top of the tank body, and the opening of the bottom of the tank body is provided with a bottom cover; a feeding tube is fixedly welded to the left side ofthe top cover; a bracket and a discharge tube are fixedly welded on the bottom surface of the bottom cover; a drying device and a feeding and turning device are arranged inside the tank body; an exhaust gas filtering device is arranged on the outer wall of the top of the tank body; according to the device, the spraying area of hot air is expanded through the drying device, convenience is providedfor full contact between the hot air and chemical raw materials, and the drying uniformity of the raw materials is improved; the circulating turning of the raw materials in the tank body is achieved through the feeding and turning device, and the turned raw materials are rotated to be evenly distributed to facilitate sufficient drying of the raw materials; exhaust gas generated by drying process is adsorbed and filtered by the exhaust gas filtering device to prevent raw material dust and irritating odor in the exhaust gas from diffusing into air to affect the working environment of workers.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

Novel corner crimping machine

InactiveCN105478604AStable working performanceGood fatigue resistanceMetal-working apparatusPower unitEngineering

The invention discloses a novel corner crimping machine comprising a left corner crimping sliding plate, a left piercing-riveting shaft, a left corner crimping tool, a right corner crimping sliding plate, a right piercing-riveting shaft and a right corner crimping tool, wherein the left piercing-riveting shaft is arranged on the left corner crimping sliding plate; the left corner crimping tool is arranged on the left piercing-riveting shaft; the right piercing-riveting shaft is arranged on the right corner crimping sliding plate; the right corner crimping tool is arranged on the right piercing-riveting shaft; and the left corner crimping sliding plate and the right corner crimping sliding plate are respectively connected with an air-sac-type power unit by which the left corner crimping sliding plate is driven to be close to or separated from the right corner crimping sliding plate. According to the novel corner crimping machine, the air-sac-type power unit is arranged to drive the corner crimping tools to realize 90-DEG connection of aluminum doors and windows; the air-sac-type power unit has the various advantages of zero friction during working, no maintenance need and stable working performance; the actions of the corner crimping tools are driven by the air-sac-type power unit instead of an oil cylinder / an air cylinder, so that the stability of each corner crimping tool in working and the workpiece machining quality are ensured.

Owner:广东欧亚特机械设备有限公司

A Thermogravimetric Reactor for Large Sample Testing

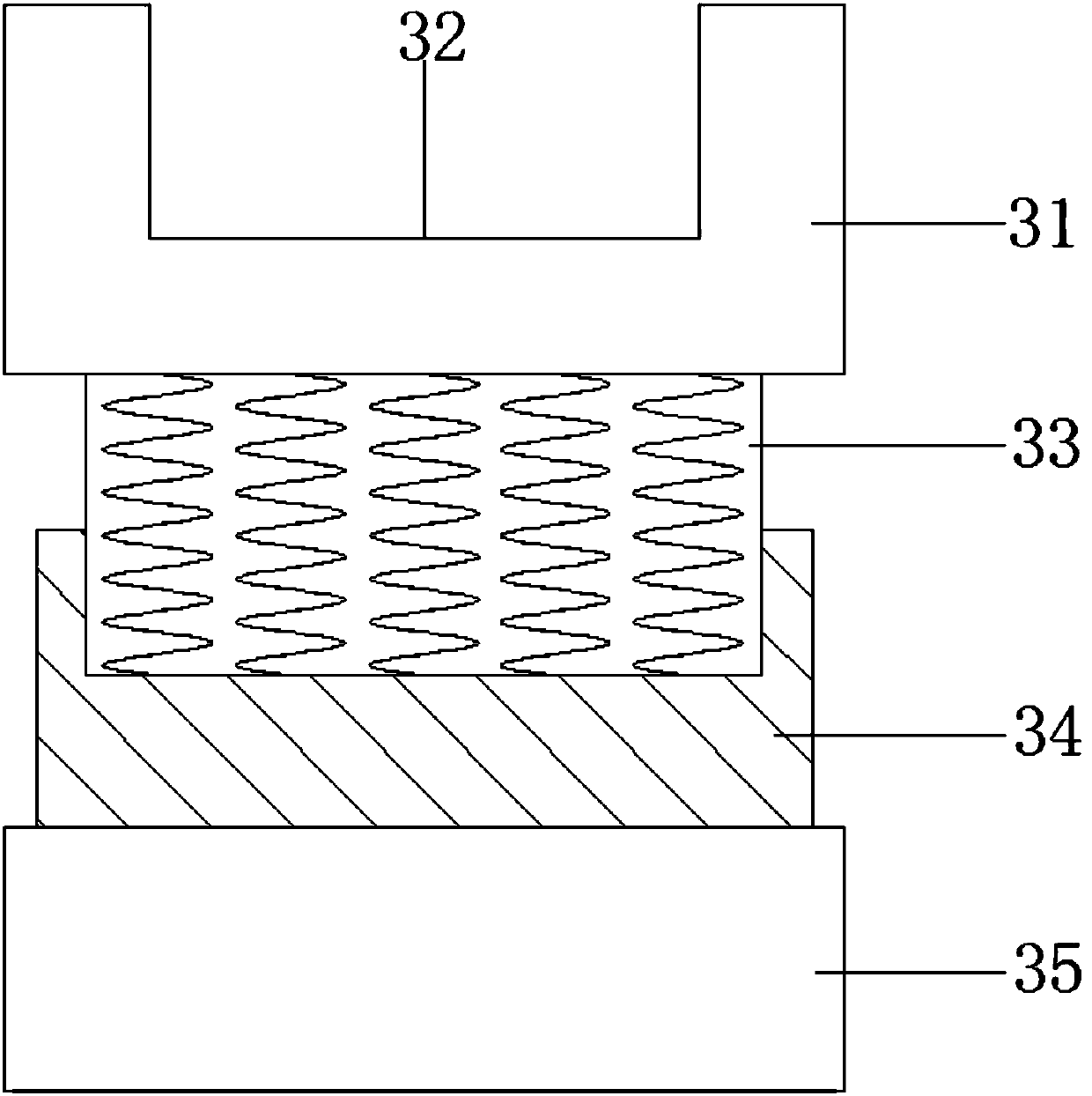

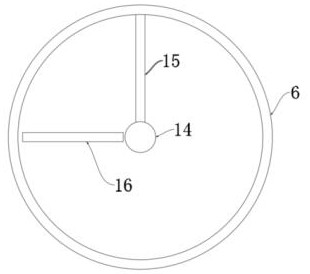

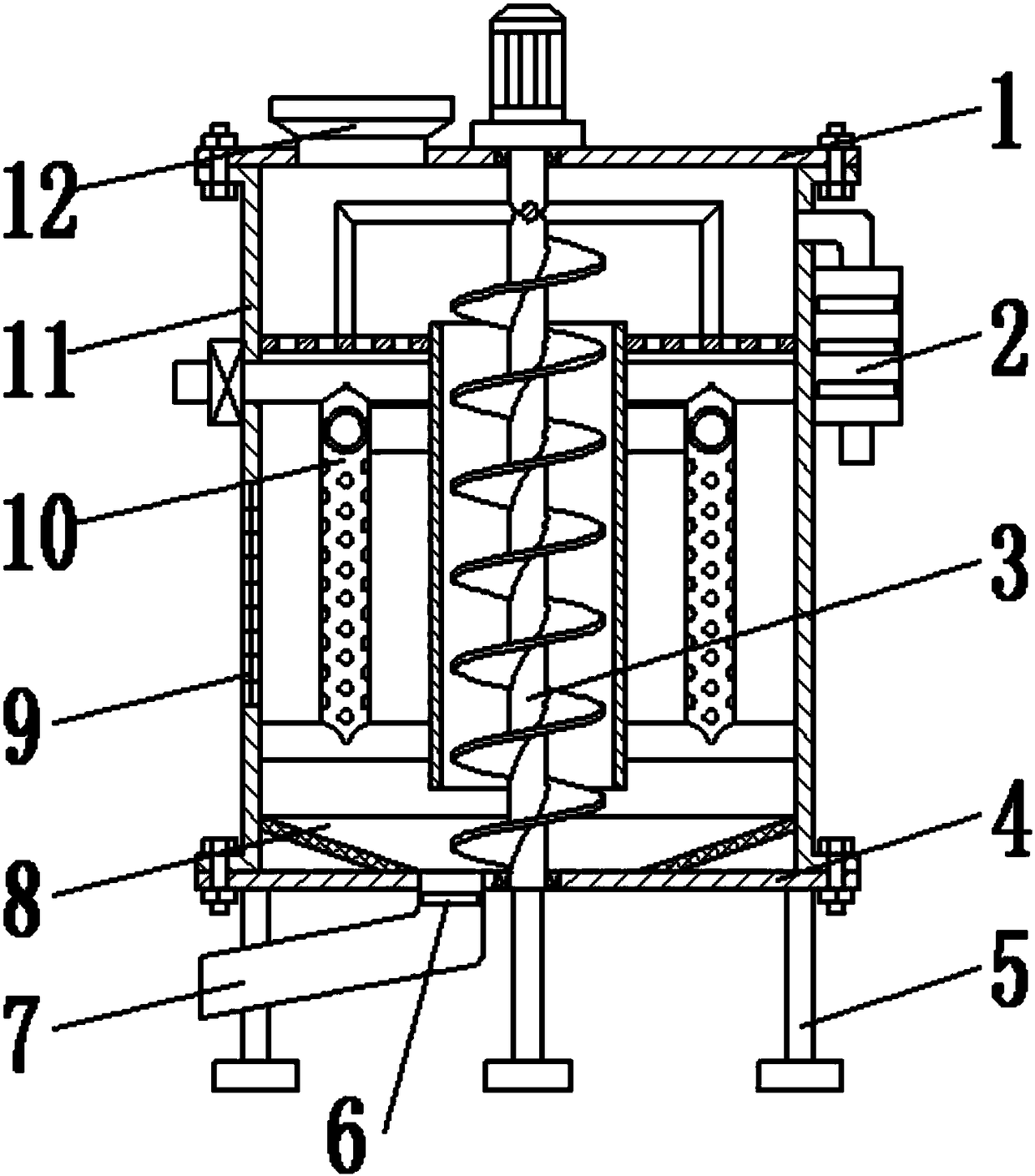

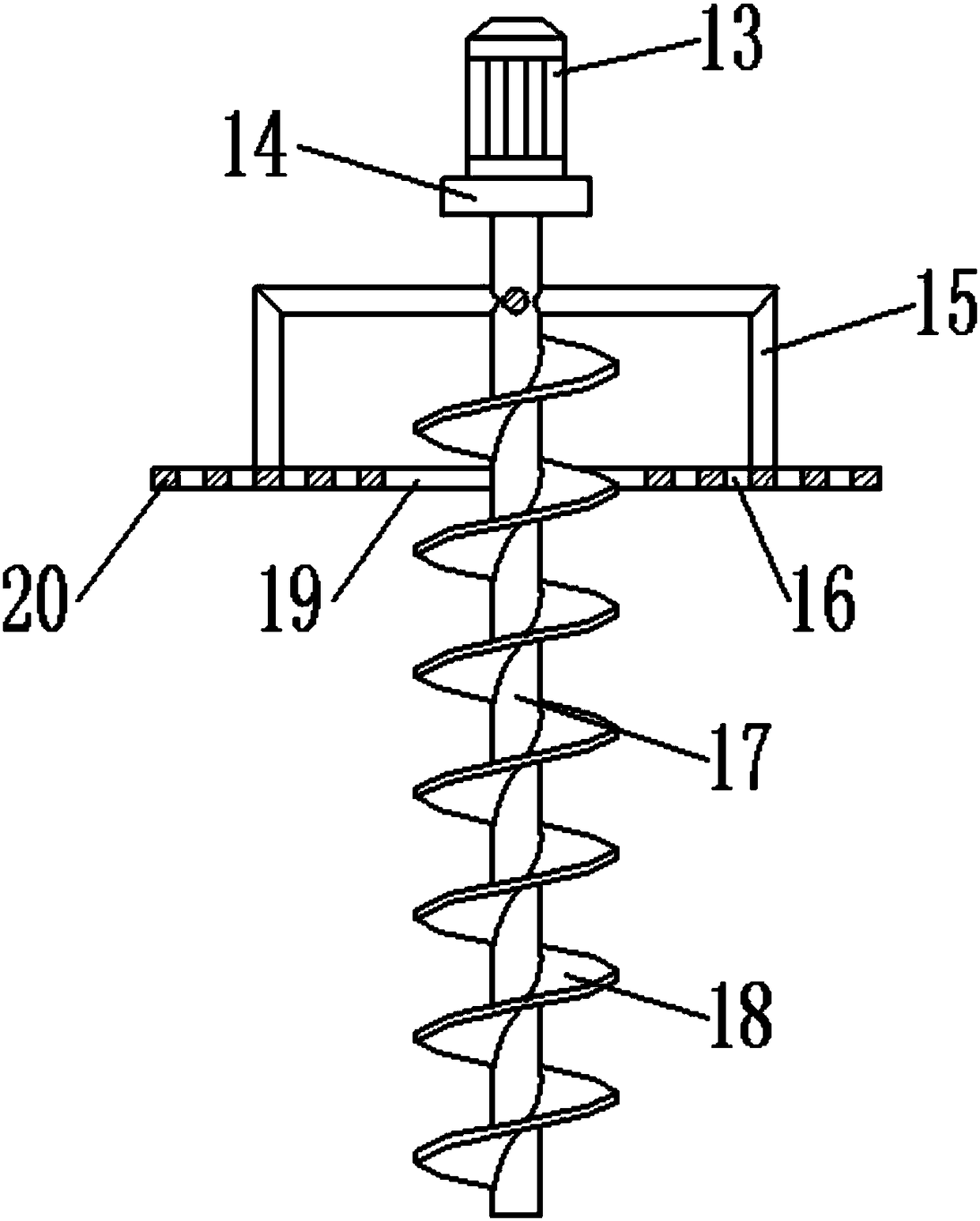

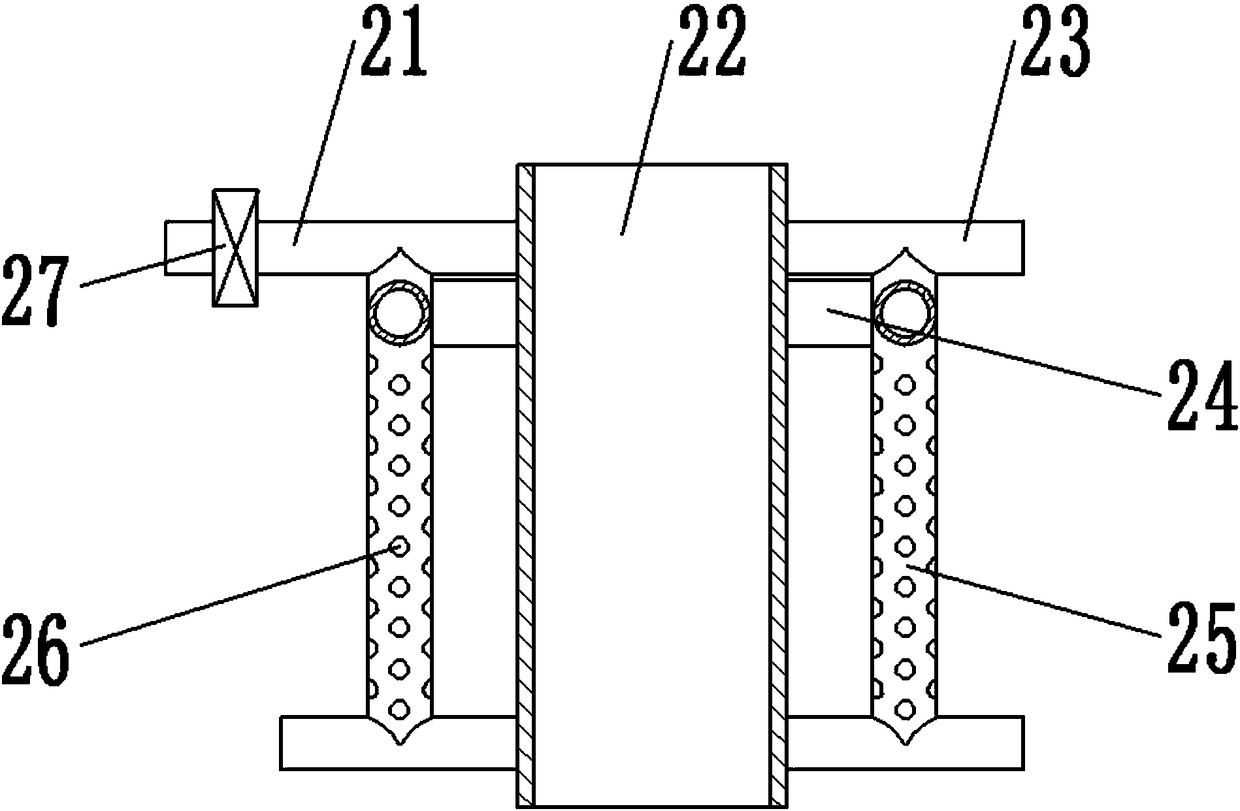

InactiveCN103760054BReduced Diffusion ResistanceGuaranteed accuracyMaterial weighingGas solidDiffusion resistance

The invention discloses a thermal gravimetrical reactor applied to bulk specimen testing, belonging to testing equipment for performing thermo gravimetric analysis on specimens and aiming to solve the problems that small-mass and small-sized specimens are required and a sample vessel is unbeneficial to gas-solid reactions in the conventional thermo gravimetric analyzer. Through a high-temperature reactor, reaction gas is preheated fully, so that mass measuring errors caused by temperature change of the reaction atmosphere are avoided; two types of hanging baskets are specific to different specimens respectively, so that the diffusion resistance during the reactions of bulk specimens is reduced effectively, and complete reactions and measuring accuracy are ensured; the height of an electric heating furnace is adjusted through a hydraulic lifting platform, so that samples can be heated at constant temperature under a high-accuracy condition. The thermal gravimetrical reactor can be used for dynamically measuring the mass changes of bulk specimens at various heating rates or under a constant-temperature condition, and is more consistent with the requirements of scientific research production than the conventional thermal gravimetrical analyzer.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com