Patents

Literature

137results about How to "Avoid affecting the processing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

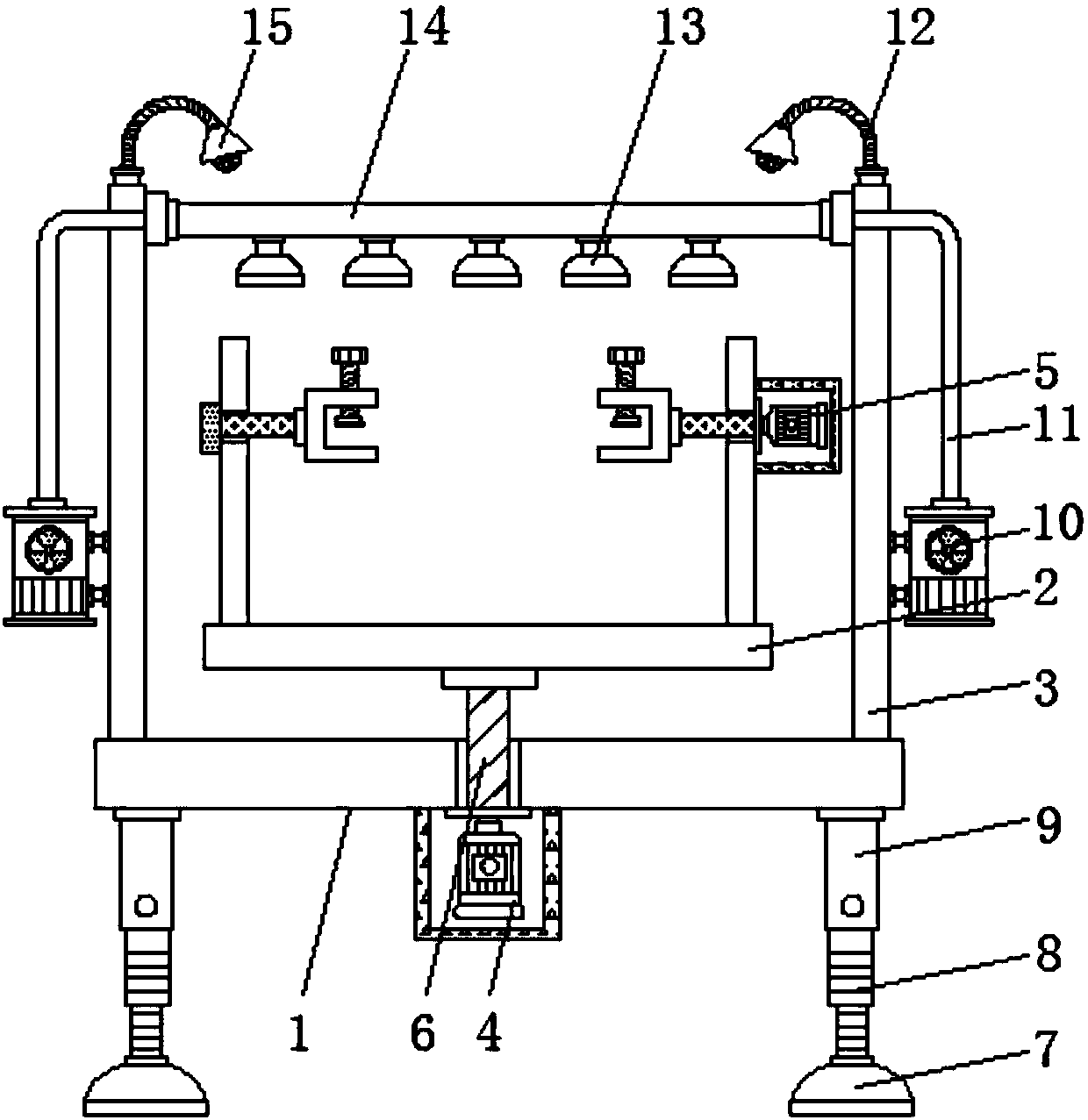

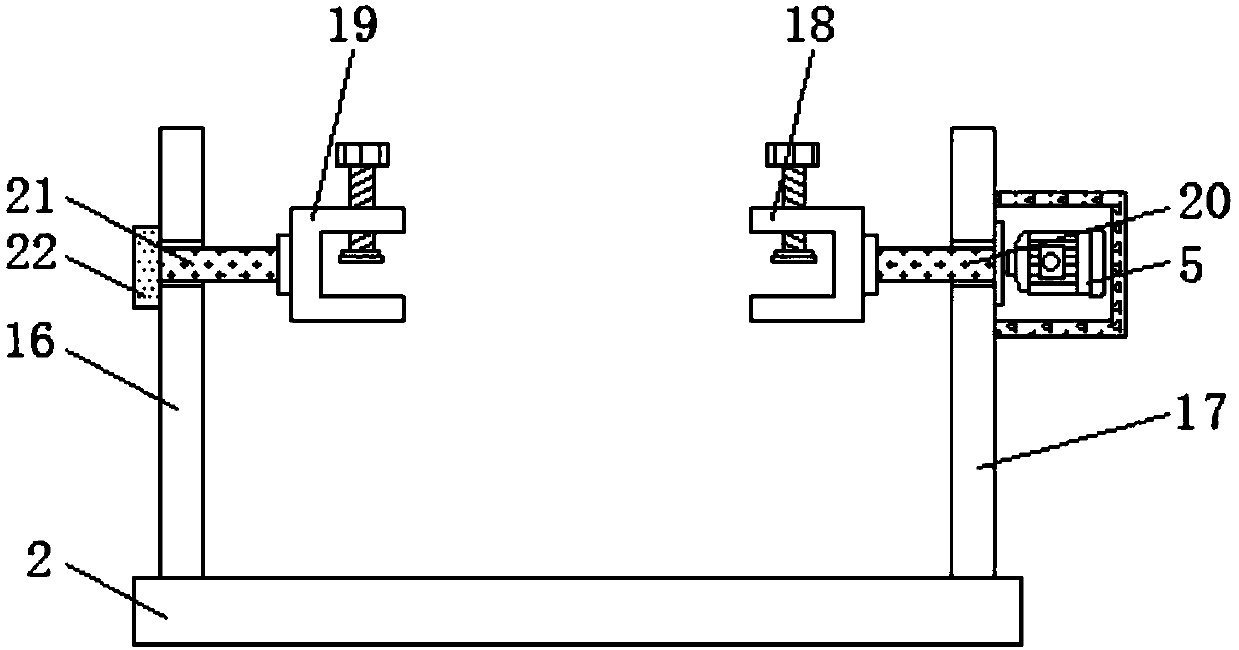

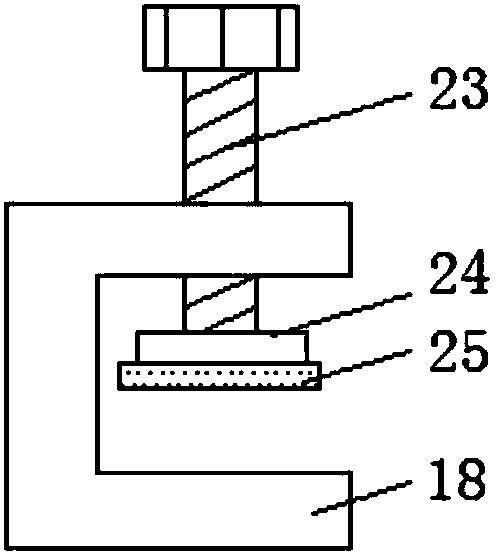

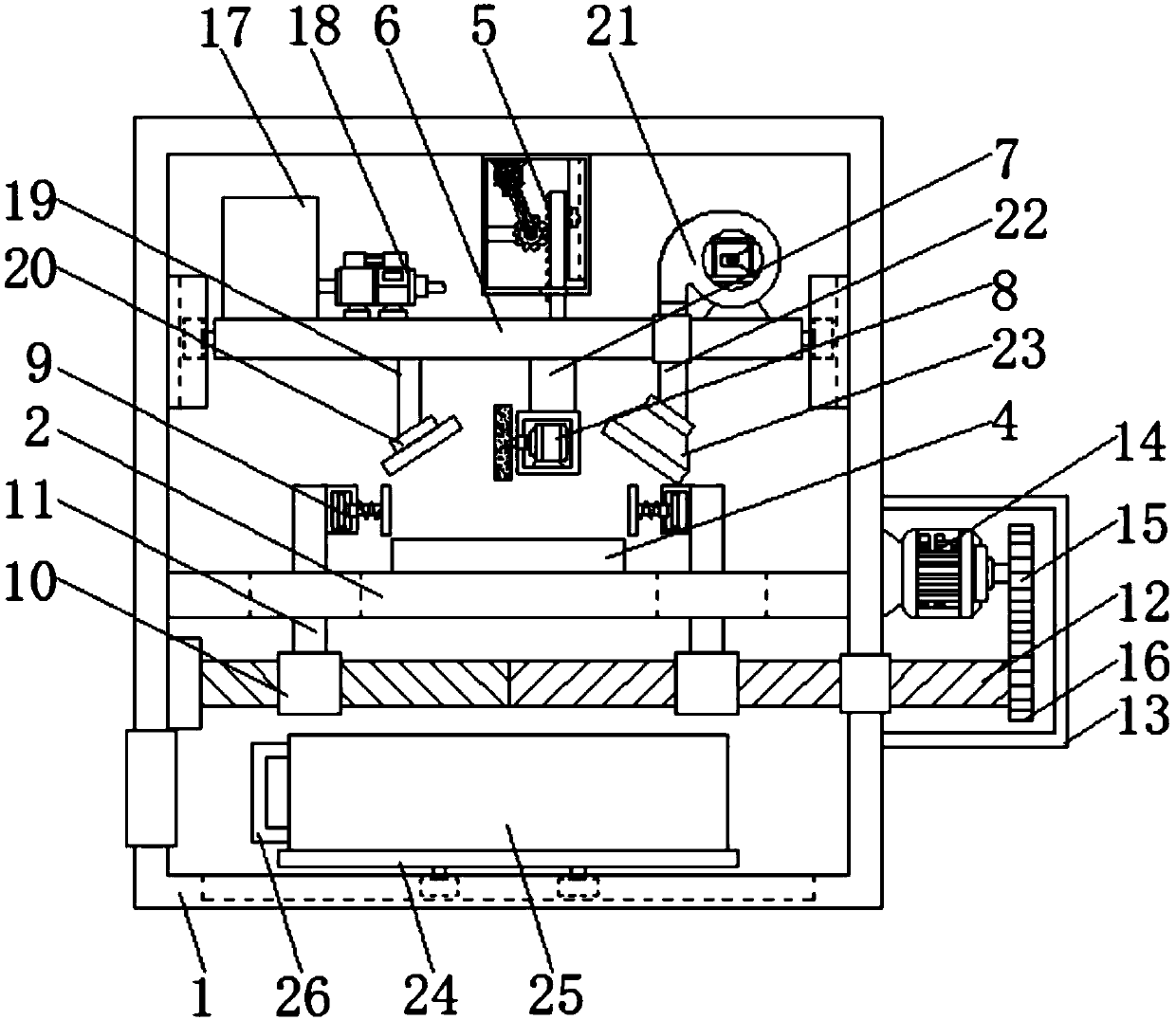

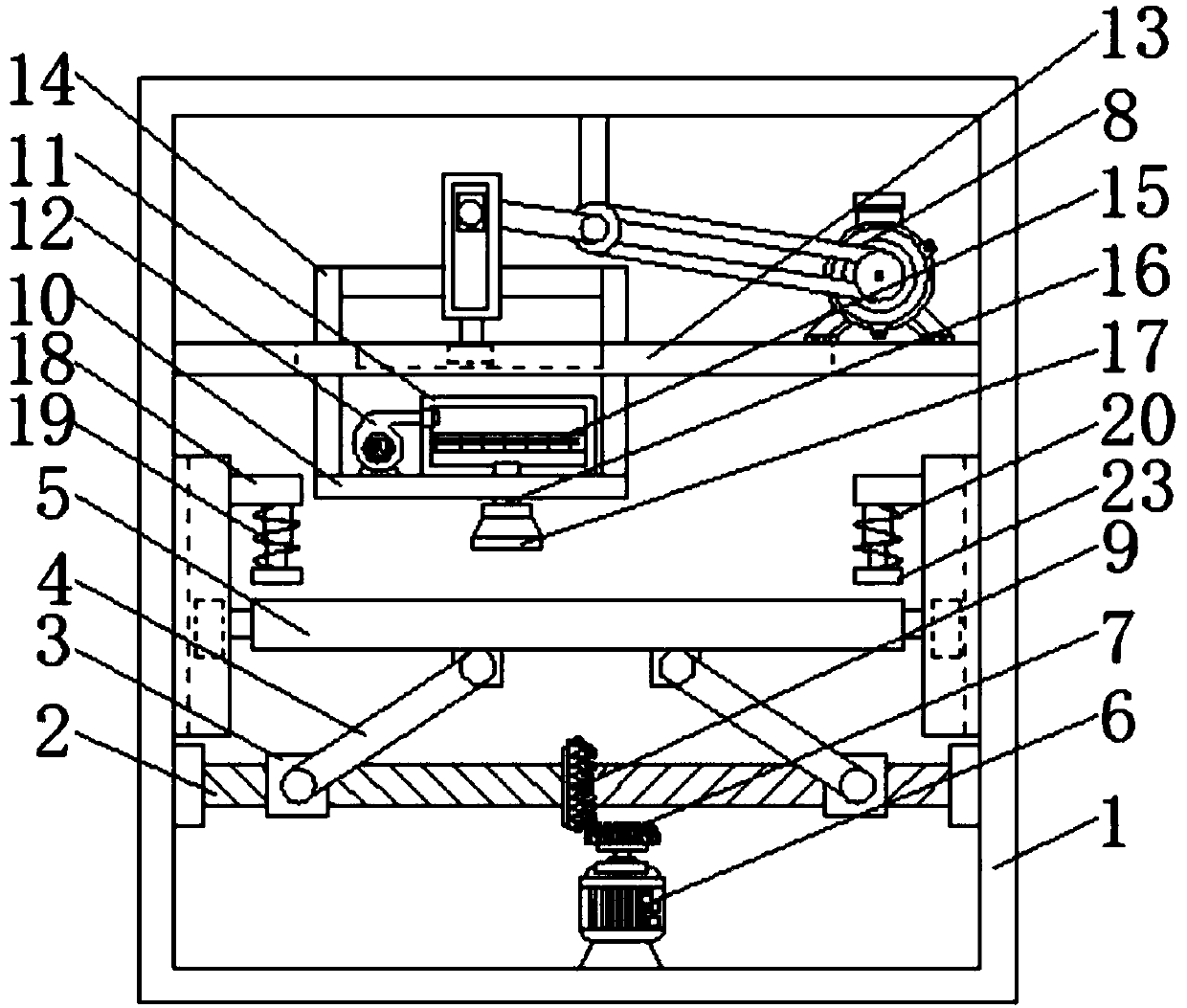

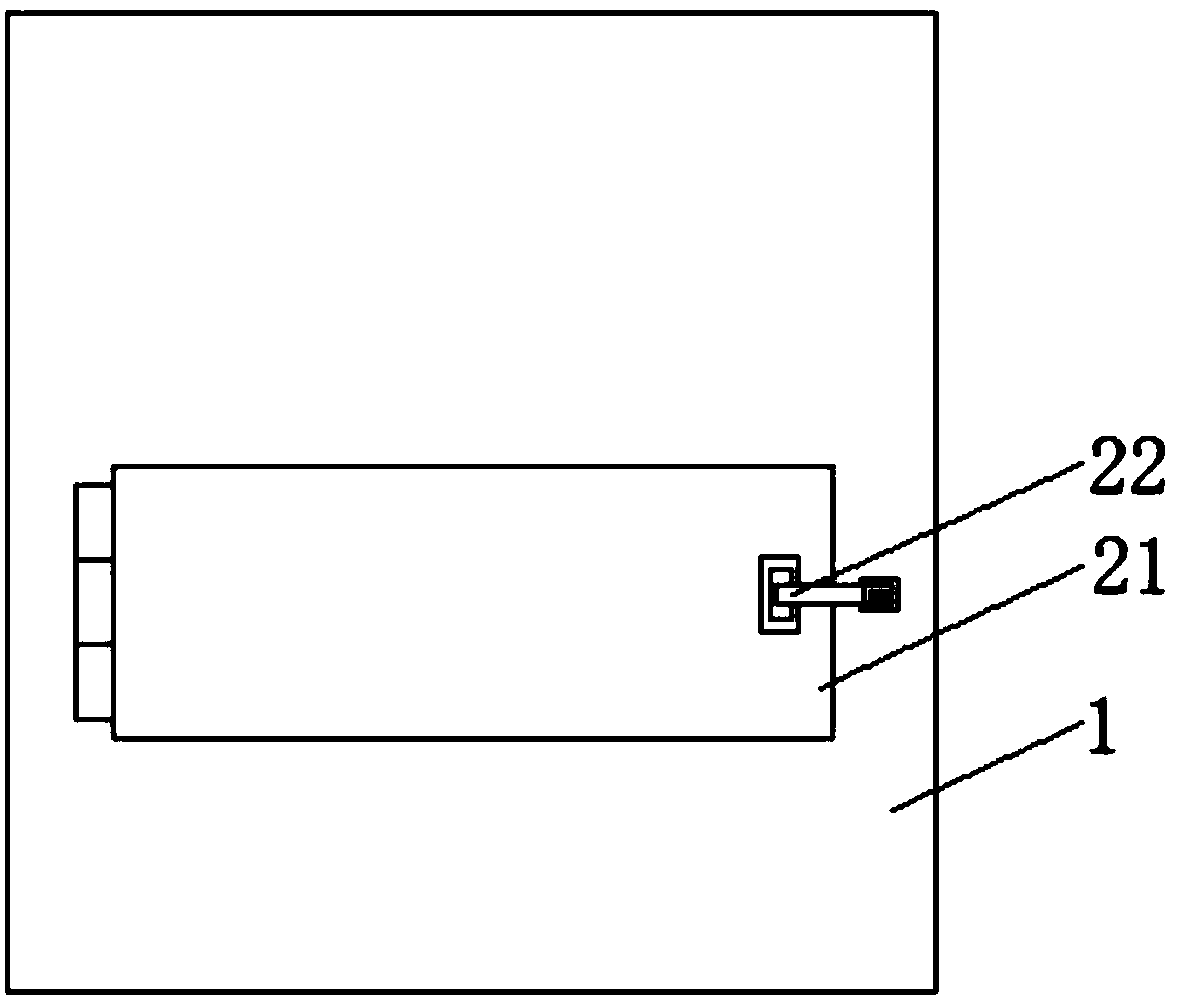

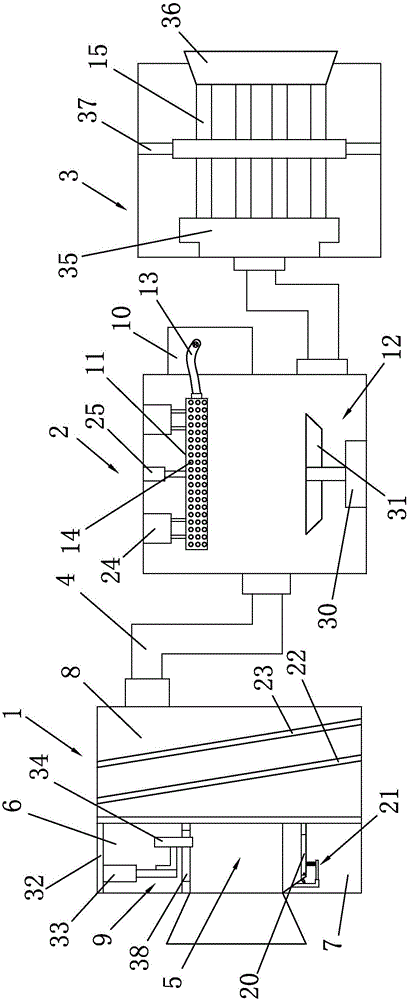

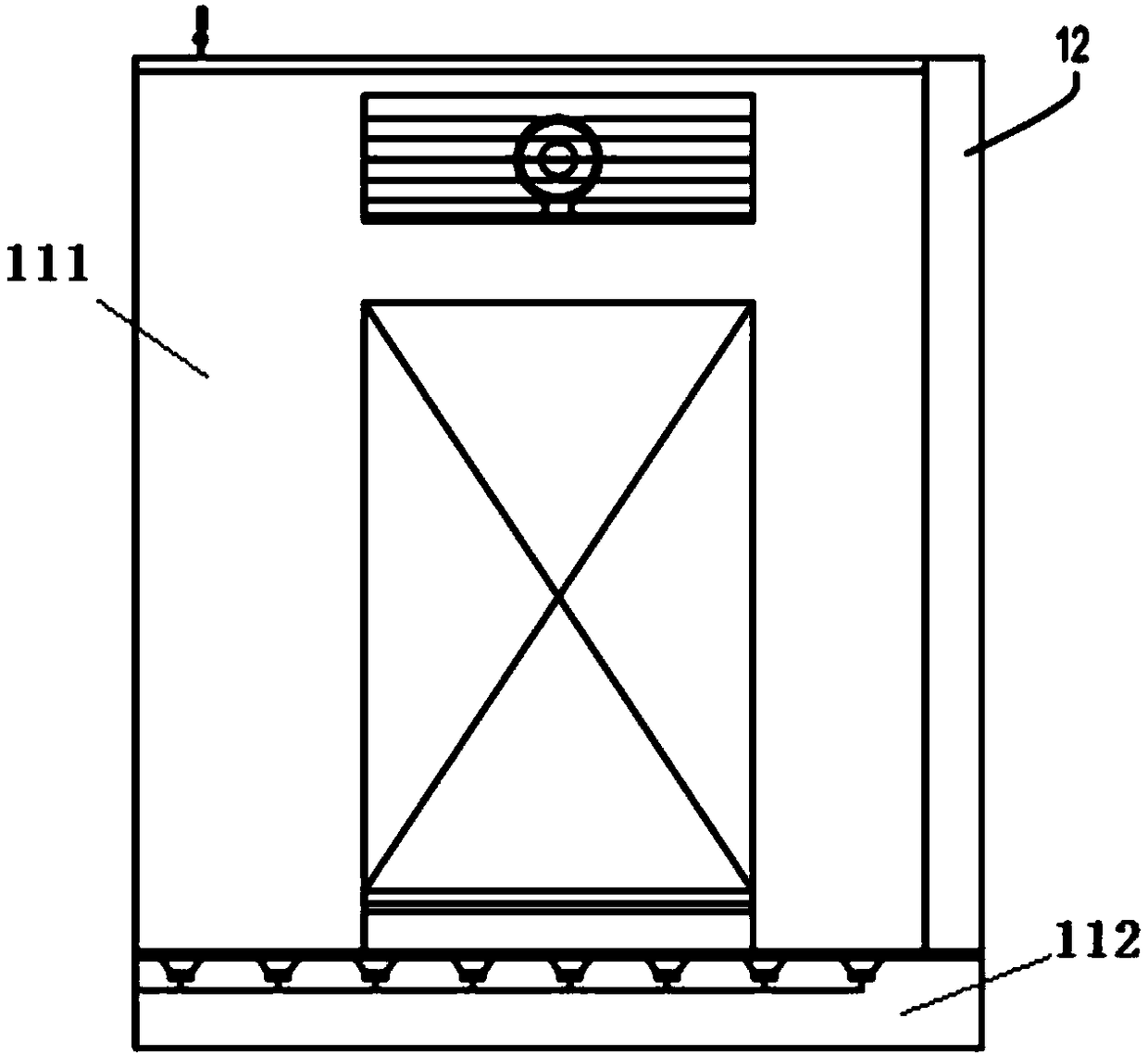

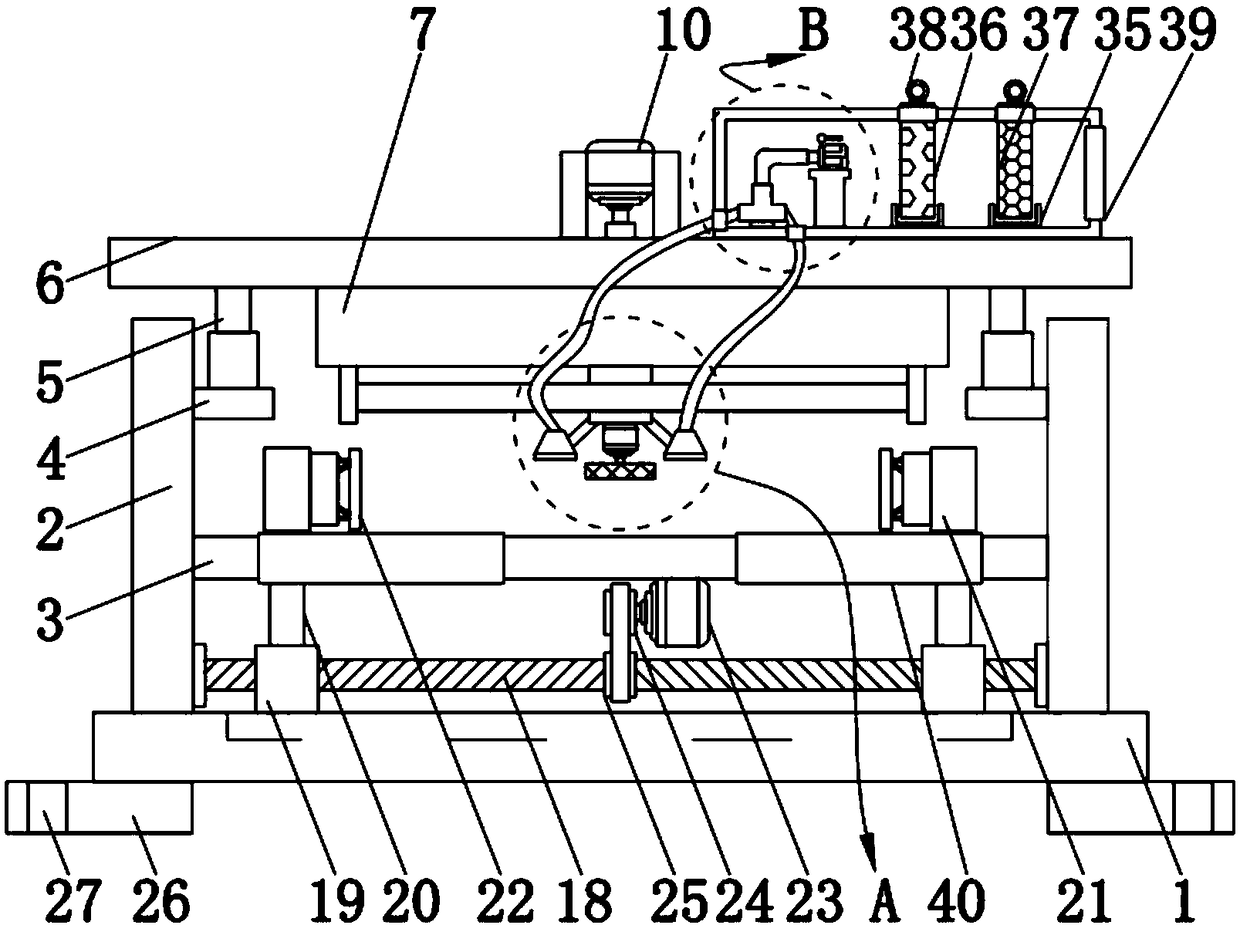

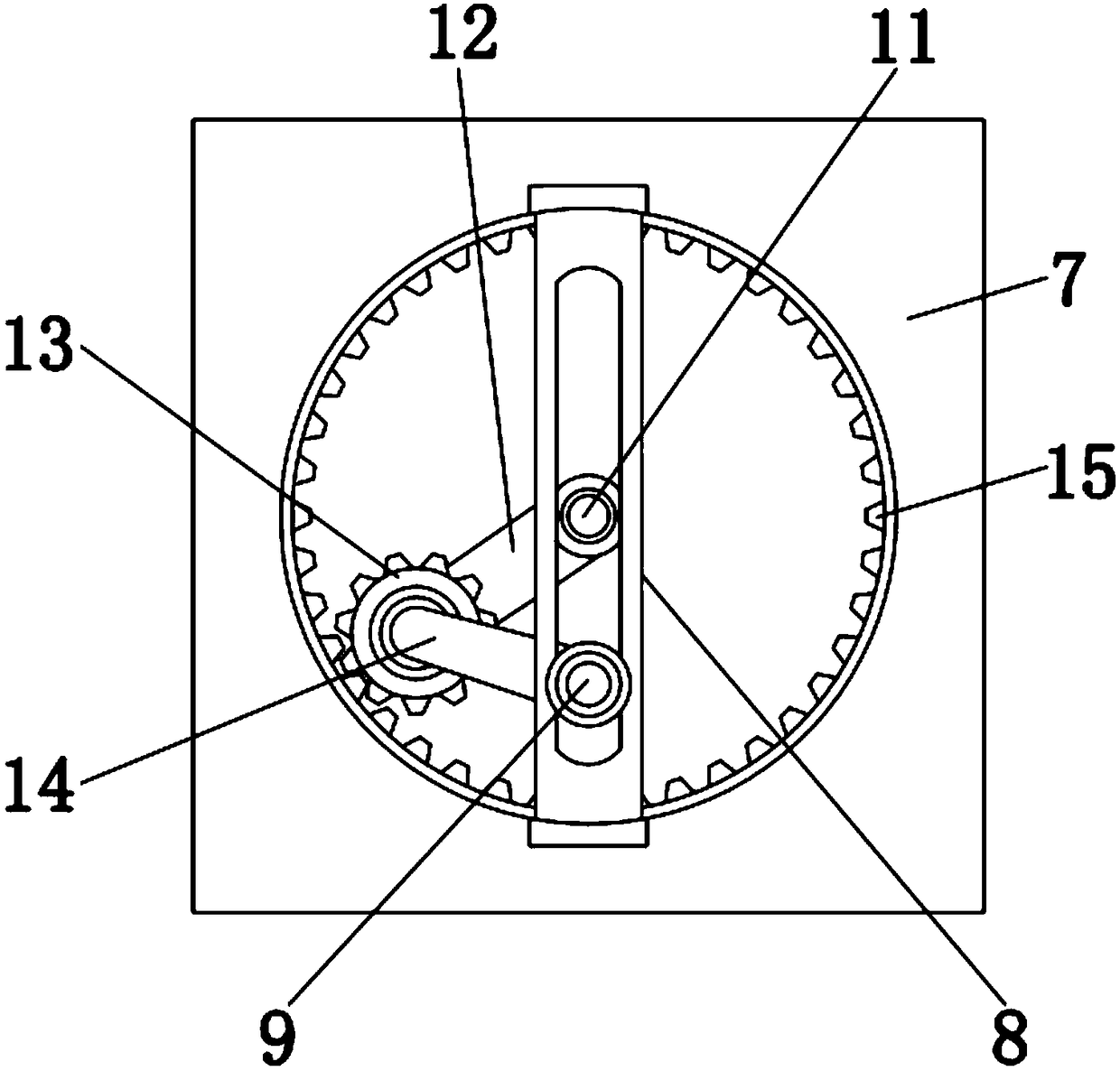

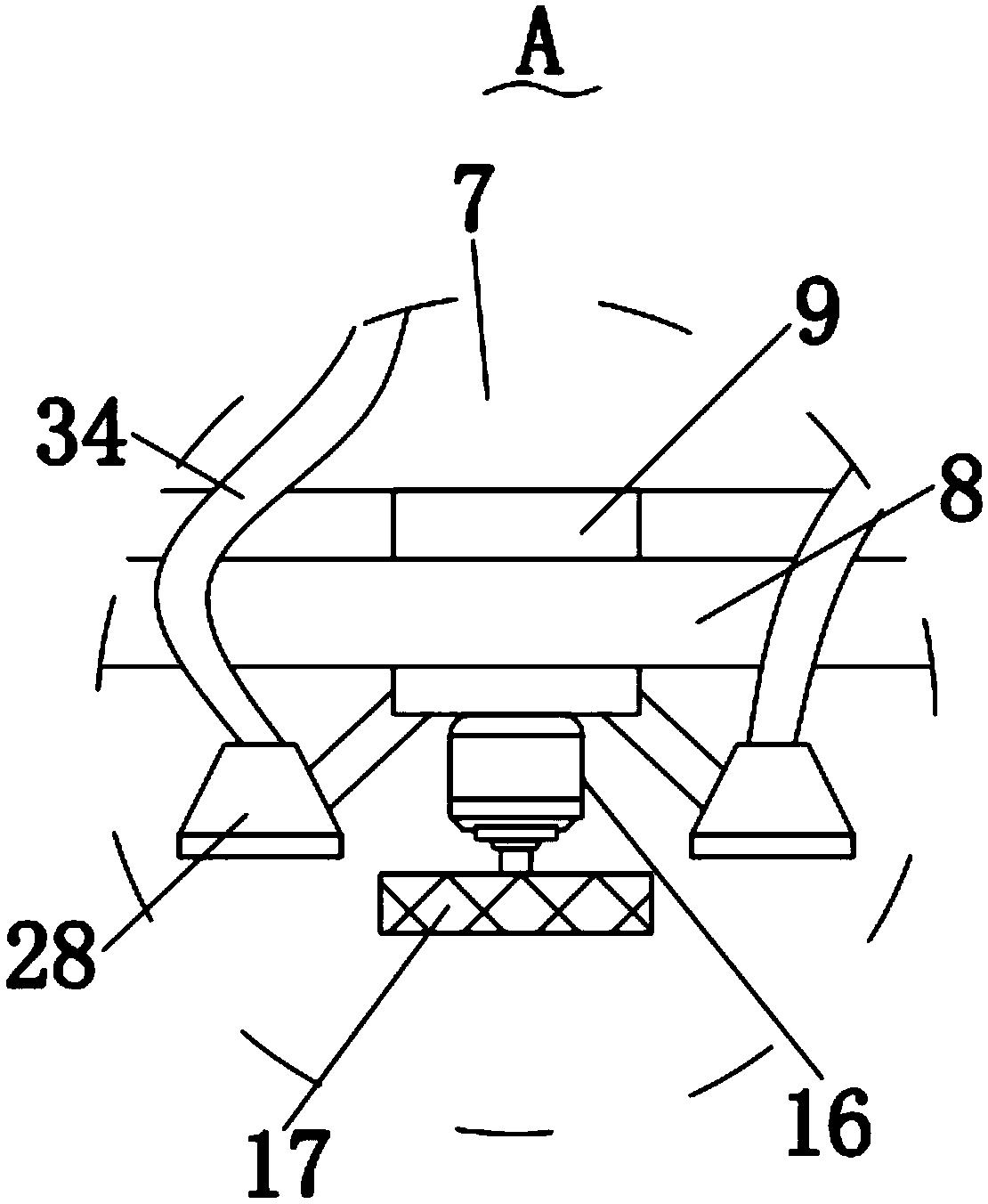

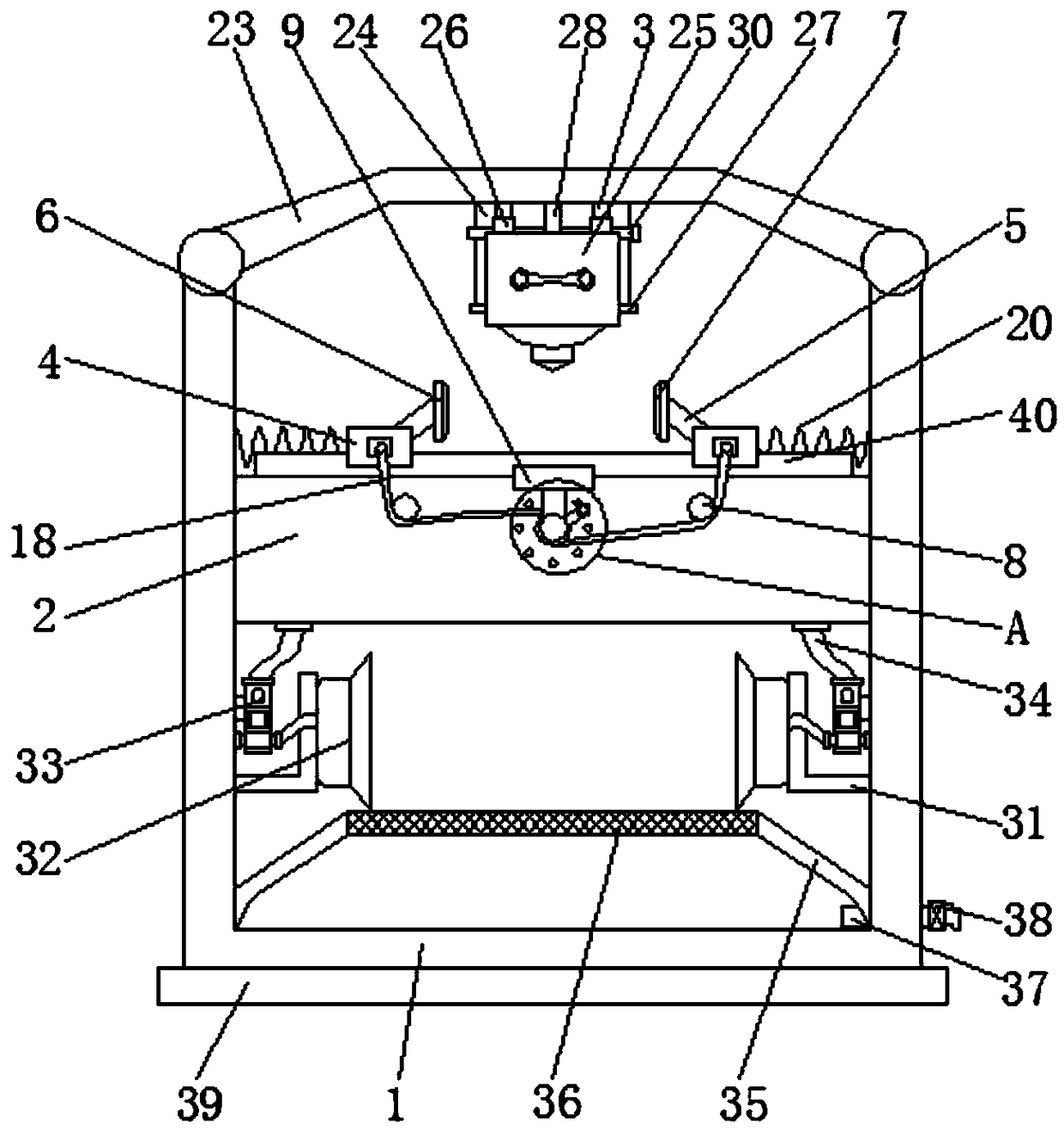

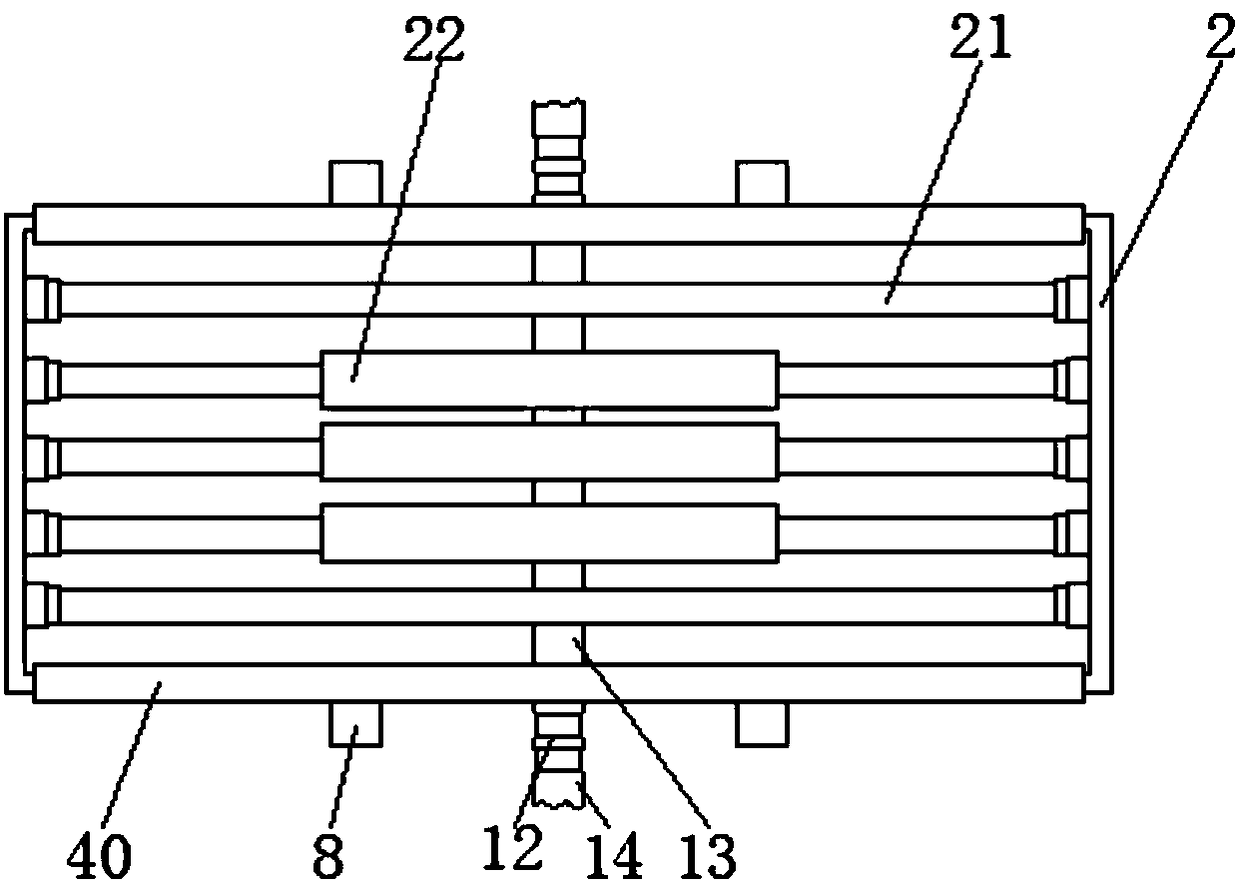

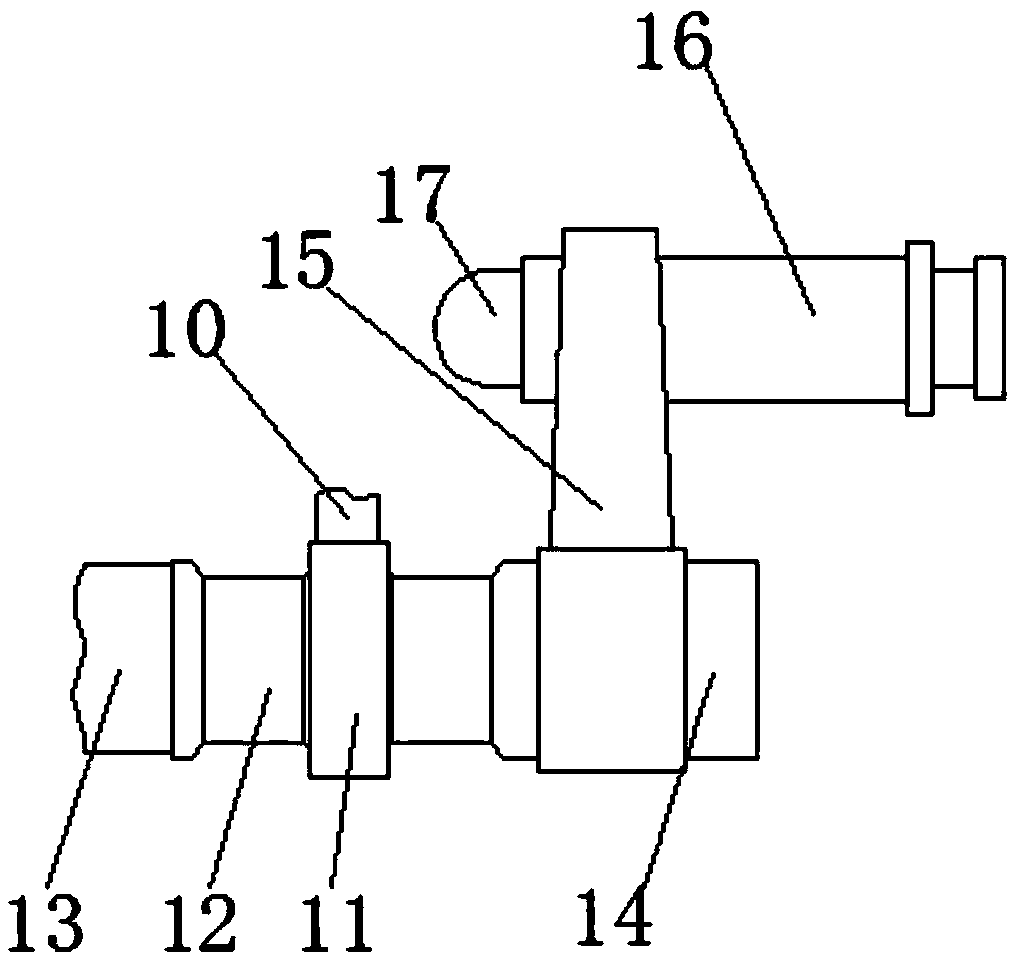

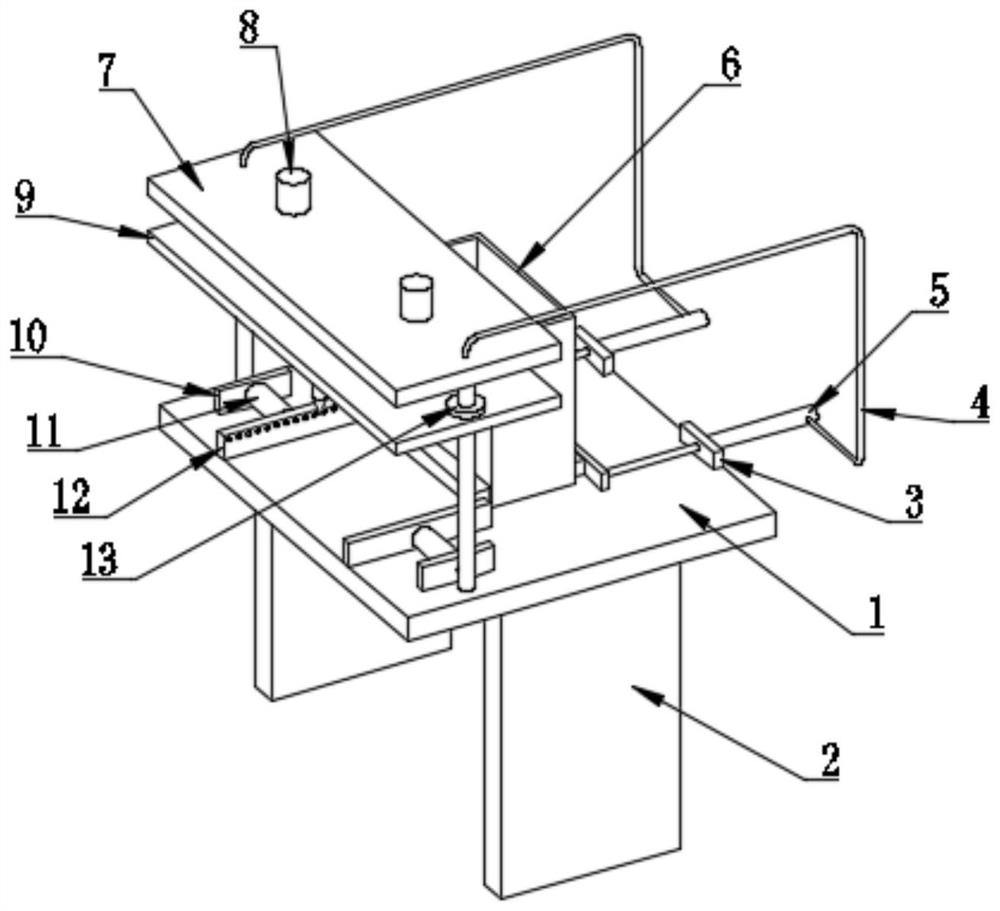

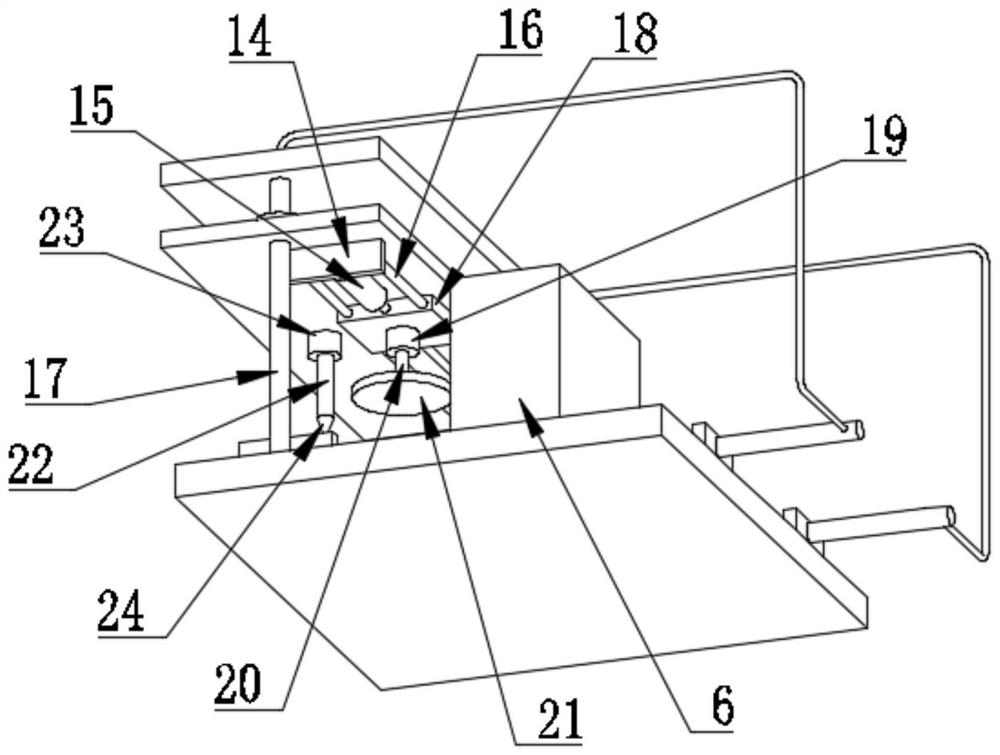

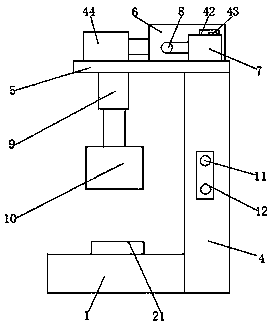

Workbench for production of decorative plates

InactiveCN107716455AConvenient for different locationsEasy to operateWork benchesCleaning using gasesElectric machineEngineering

The invention discloses a workbench for production of decorative plates. The workbench comprises a supporting base and a machining platform; a first rotating motor is mounted at the bottom of the supporting base and is connected with the machining platform through a rotating shaft; a left baffle and a right baffle are fixed on two sides of the top of the machining platform; the inner wall of the left baffle is connected with a left fixing clamp through a rotating rod; and a second rotating motor is arranged on the side wall of the right baffle and is connected with a right fixing clamp througha rotation shaft. According to the workbench, during machining, the plates can be firmly fixed through clamping by the aid of the left fixing clamp and the right fixing clamp, and thus the influenceof plate loosening during machining on the machining effect can be avoided; meanwhile, the rotating platform is driven by the first rotating motor to rotate, a worker can machine different positions of the plates conveniently, and the position of the worker is not required to be specially adjusted back and forth; and besides, the plates can be driven by the second rotating motor to be overturned for machining of different surfaces of the plates, so that the production efficiency is improved.

Owner:广东澳林板业有限公司

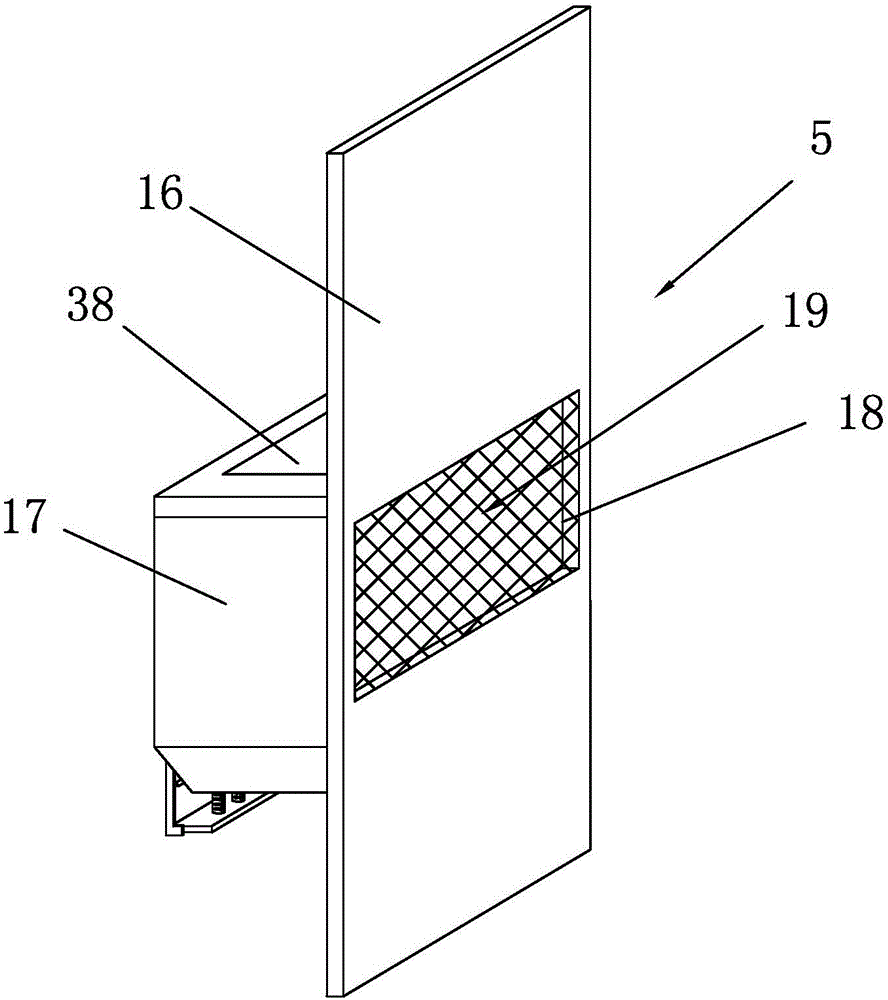

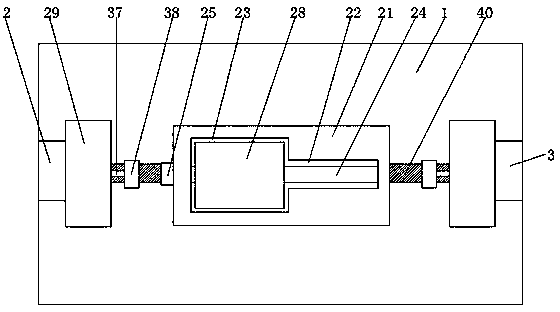

Polishing device for hardware precision machining

InactiveCN108032181AHigh precisionEasy to useGrinding machinesGrinding/polishing safety devicesPulp and paper industryMachining process

The invention discloses a polishing device for hardware precision machining. The polishing device comprises a shell. A supporting plate is fixedly connected between the two sides of the inner wall ofthe shell. A transverse net is fixedly connected into the supporting plate. A working table is fixedly connected with the top of the transverse net. A movement device is fixedly connected with the topof the inner wall of the shell. A transverse plate is fixedly connected with the bottom of the movement device. A supporting column is fixedly connected with the bottom of the transverse plate. A polishing machine is fixedly connected with the bottom end of the supporting column. A lead screw is rotationally connected between the two sides of the inner wall of the shell. The invention relates tothe technical field of hardware machining. By means of the polishing device, it is avoided that scraps are attached to the surface of a workpiece in the machining process and affect the machining quality, the precision of the workpiece can be easily improved, the use effect of the workpiece is improved, the workpiece is clamped by a clamping device, and it is avoided that the workpiece deviates inthe machining process and affect the machining effect, and the product quality can be easily improved.

Owner:毕淑珍

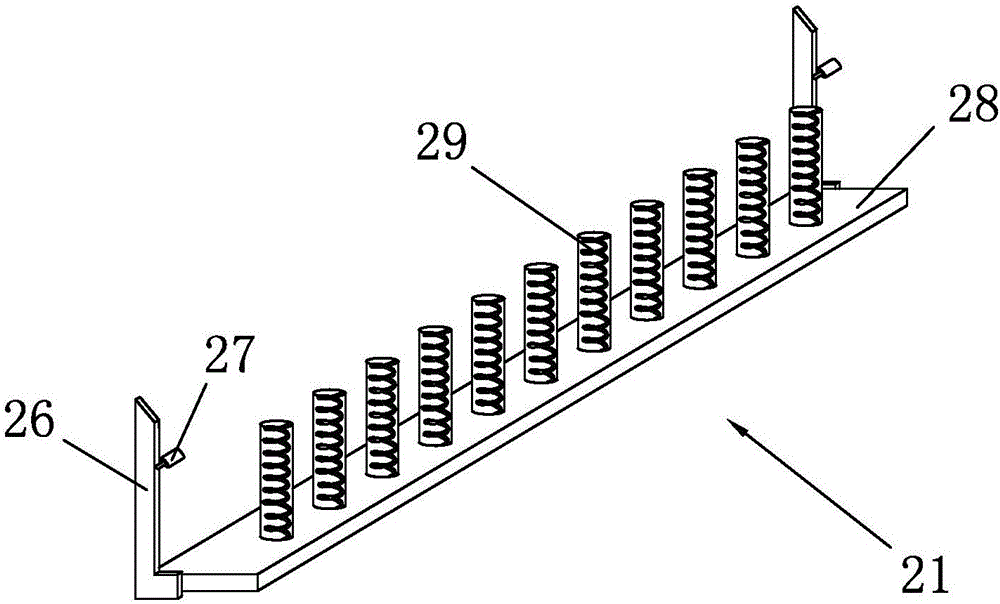

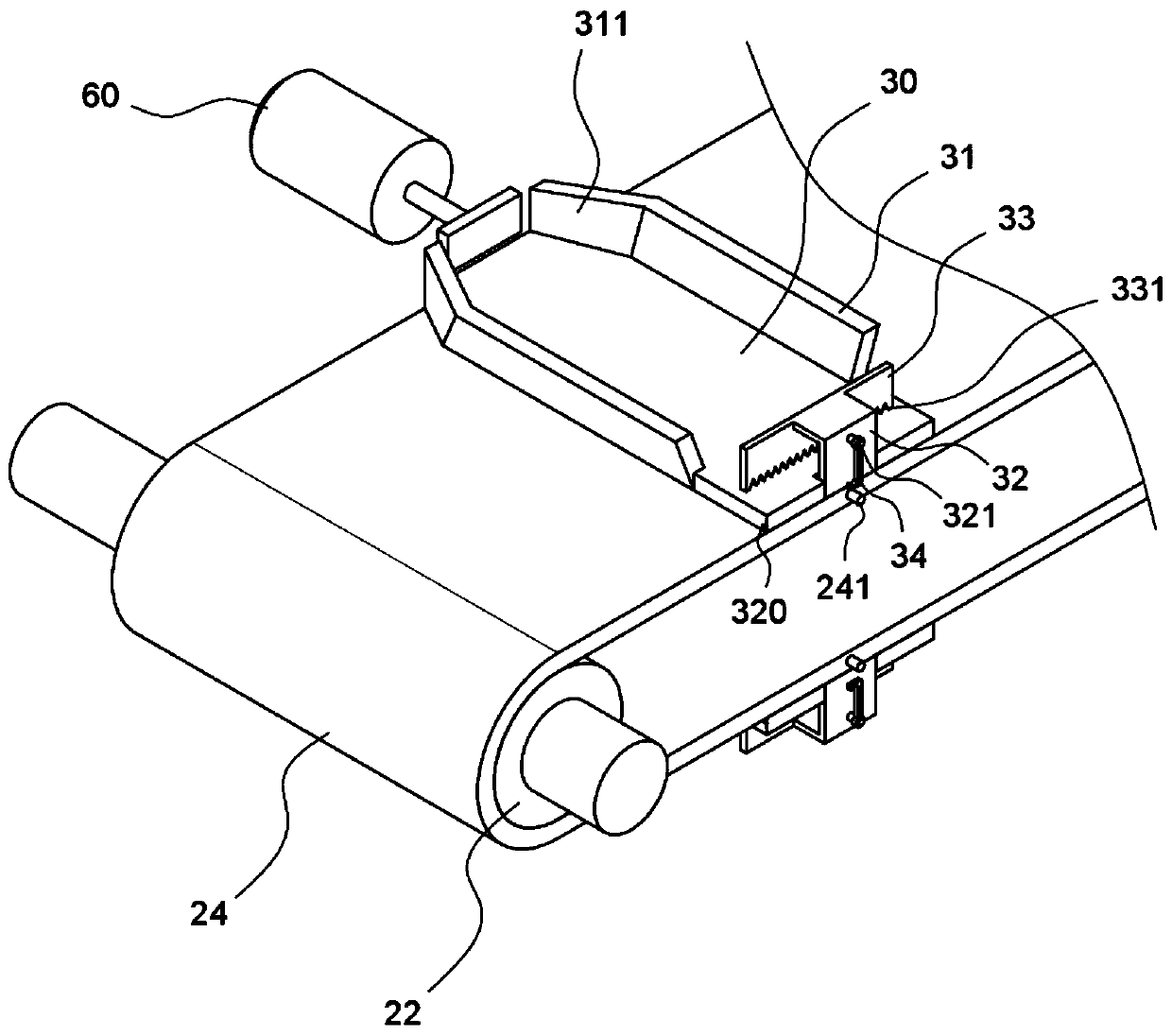

Carton folding device with size adjusting function

InactiveCN106881906ARealize the function of foldingEven by forceBox making operationsPaper-makingCartonEngineering

The invention relates to a size-adjustable carton hemming device. The pressing device includes a pressing plate, which is connected with a positioning plate, and a positioning hole is arranged on the pressing plate, and a pressing long plate and a pressing plate are fixed in the positioning hole. Pressing down the short plate, the pressing down long plate and the pressing down short plate both include a pressing down fixing plate, the two ends of the pressing down fixing plate are connected to the extension block through the extension plate, the pressing device includes a supporting plate, and the outer periphery of the supporting plate is sequentially provided with a second A pallet frame and a second pallet frame, the second pallet frame is provided with an adjustment plate on the outer periphery, and a push plate is provided on the adjustment plate, and the adjustment plate includes an adjustment plate fixing block, and the two ends of the adjustment plate fixing block are connected and adjusted by an extension plate The plate extension plate, the push plate includes a push plate fixing block, the two ends of the push plate fixing block are connected to the push plate extension plate through the extension plate, the positioning plate, the pressing plate, the adjustment plate, the push plate, the supporting plate, the first supporting plate Both the frame and the second pallet frame are connected to the cylinder through the piston rod, which is a size-adjustable carton hemming device that can meet the hemming of cartons of various sizes.

Owner:天津市腾旭工贸有限公司

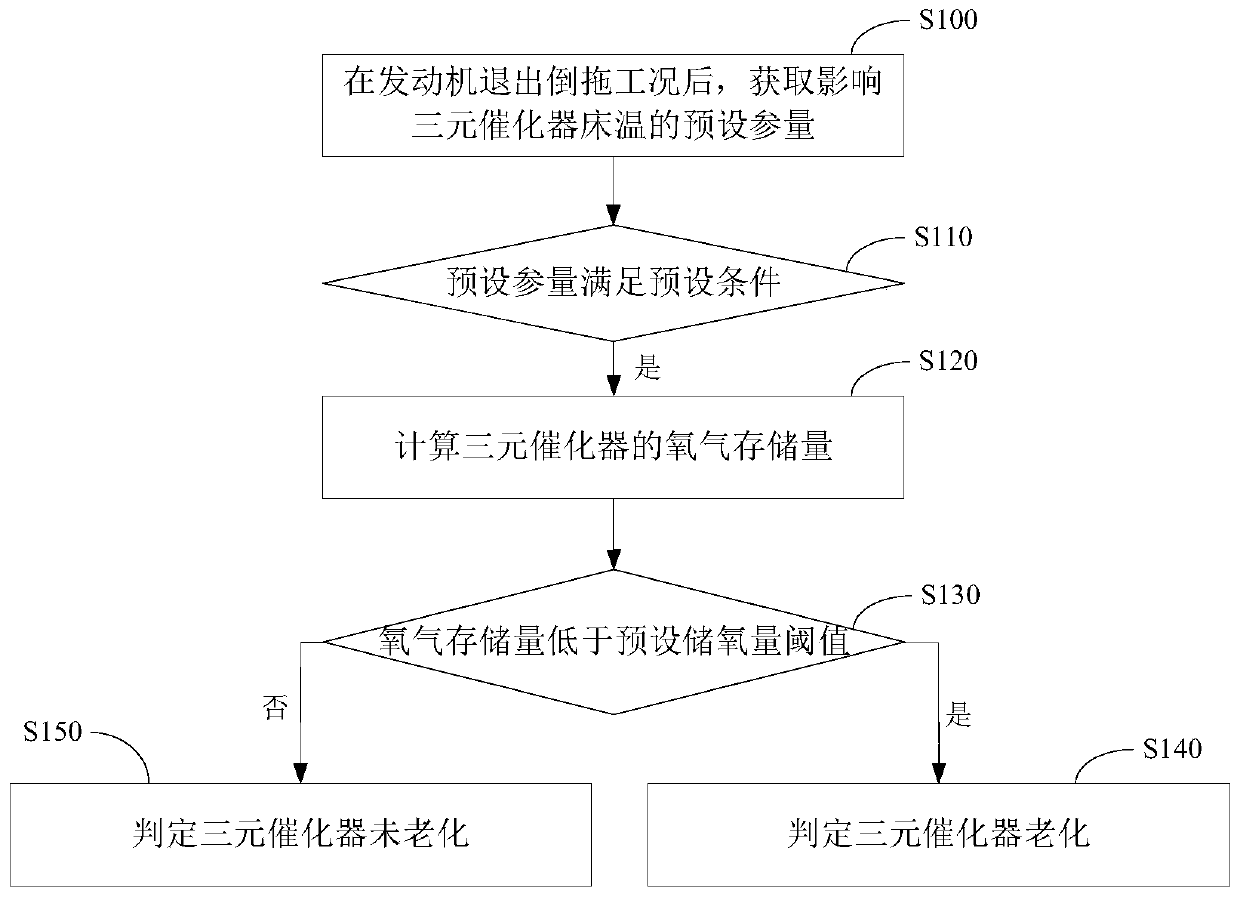

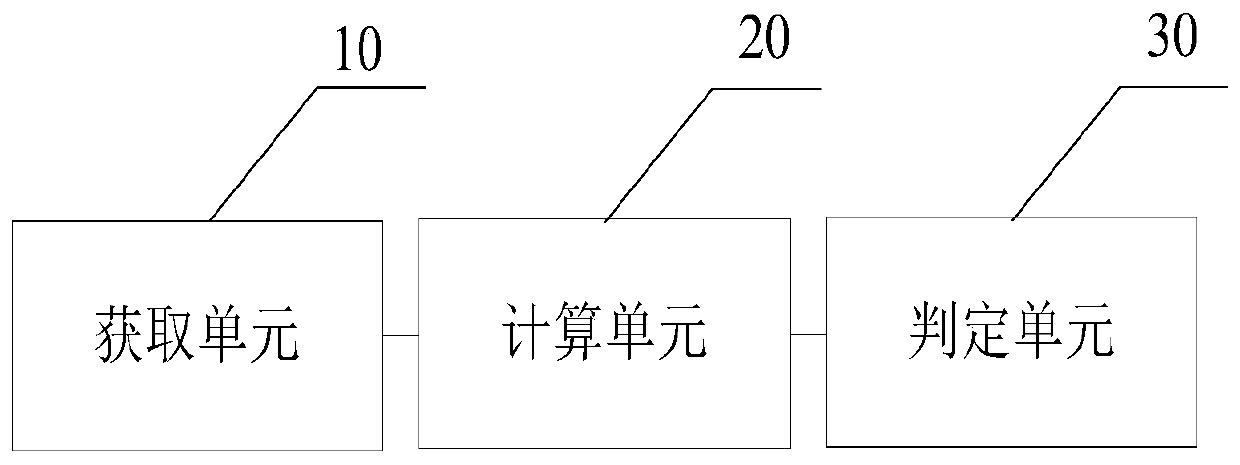

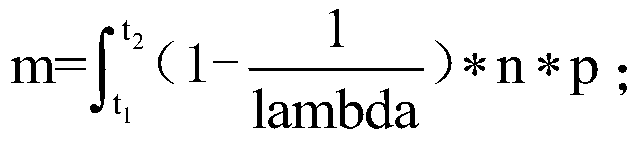

Three-way catalyst ageing detection method and device

InactiveCN110284947AAvoid affecting the processing effectInternal combustion piston enginesExhaust apparatusOxygen storageChemistry

The invention provides a three-way catalyst ageing detection method and device applied to the technical field of engines. The method includes the steps that after an engine retreats the reverse towing working condition, a preset parameter influencing the bed temperature of a three-way catalyst is obtained; if the obtained preset parameter is within the preset range, the oxygen storage amount of the three-way catalyst is calculated; the size relation between the obtained oxygen storage amount and the preset oxygen storage amount threshold value is further obtained through comparison; and if the calculated oxygen storage amount is smaller than the preset oxygen storage amount threshold value, it is judged that the three-way catalyst ages. According to the three-way catalyst ageing detection method and device, the oxygen storage amount in the normal work state of the three-way catalyst is obtained, ageing detection is conducted with the oxygen storage amount as the judgment reference, the whole detection process can be completed under the condition that the actual work state of the three-way catalyst is not influenced, and therefore it is avoided that the overall processing effect of vehicle tail gas is influenced.

Owner:WEICHAI POWER CO LTD

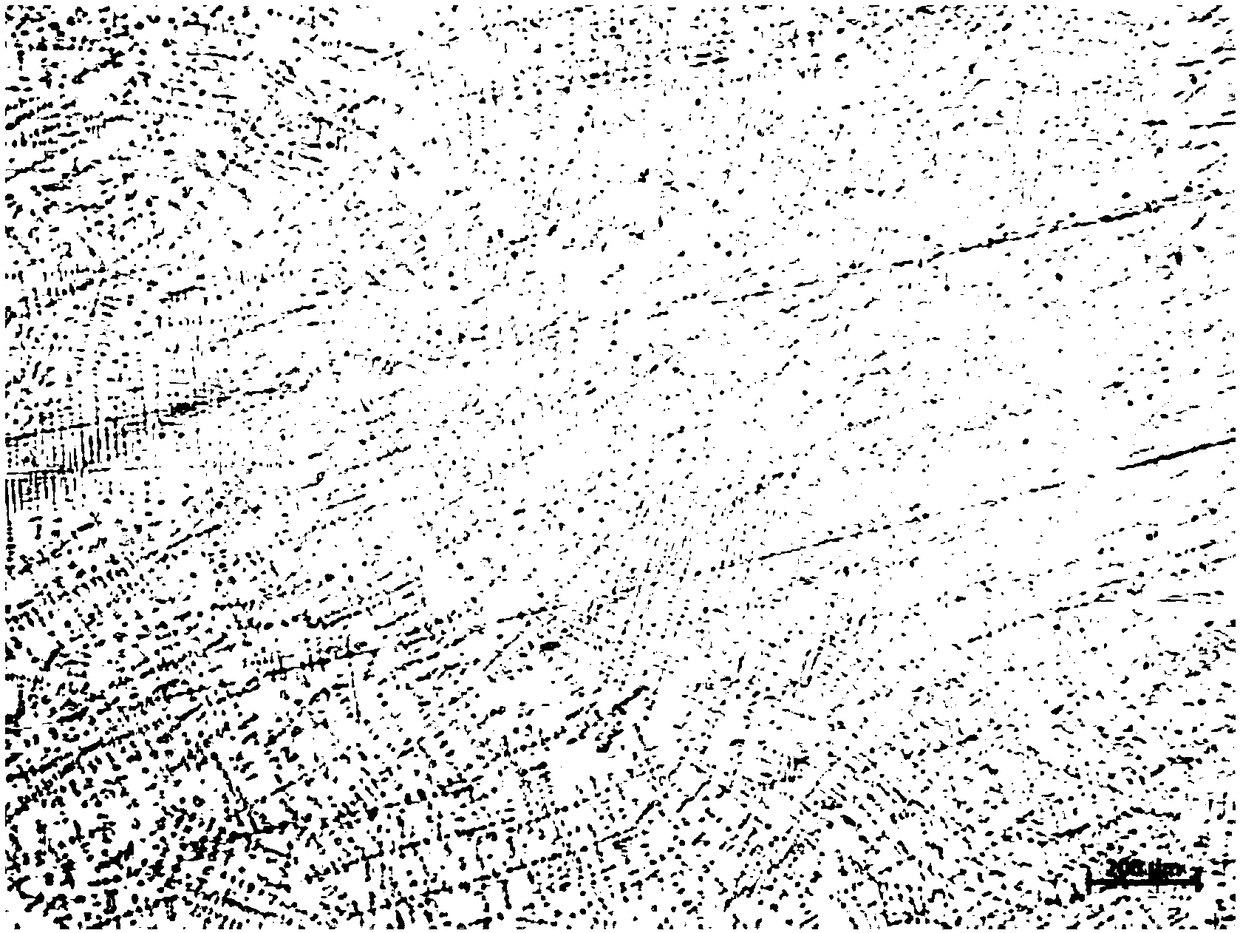

Method for preparing CuFe alloy material with different Fe contents by adopting vacuum induction smelting

ActiveCN109457167AEasy accessDense tissueFoundry mouldsFoundry coresNonferrous metalMaterials science

The invention discloses a method for preparing a CuFe alloy material with different Fe contents by adopting vacuum induction smelting, and belongs to the technical field of nonferrous metal alloys. The method mainly comprises the following steps of proportioning, charging, vacuumizing, smelting, casting and discharging from a furnace. According to the method, the CuFe alloy is prepared by adoptinga vacuum induction melting method, wherein the Fe element is added in the form of a CuFe mother alloy, the CuFe alloy prepared through the method has the advantages of compact structure, few pores and inclusion, and no macroscopic and microscopic segregation and other defects.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

Drying device uniform in heating for garment processing

InactiveCN107747200AHeating evenlyDry evenlyTextiles and paperLaundry driersEngineeringControl effect

The invention discloses a drying device uniform in heating for garment processing, and relates to the technical field garment processing. The device comprises a shell, a lead screw is rotationally connected between the two sides of the inner wall of the shell, movable blocks are rotationally connected to the two sides of the surface of the lead screw, connecting rods are rotationally connected tothe tops of the movable blocks, a movable plate is rotationally connected to the tops of the connecting rods, a transverse plate is fixedly connected between the two sides of the inner wall of the shell, a motion device is fixedly connected to the top of the transverse plate, vertical rods are fixedly connected to the two sides of the motion device, and the bottoms of the vertical rods penetrate through the transverse plate and extend to the bottom of the transverse plate. According to the drying device uniform in heating for garment processing, clothes are dried uniformly, the phenomenon thatdue to the fact that the temperature is too high or too low, the drying effect is affected is avoided, the processing quality is improved, the height of the movable plate is adjusted conveniently, the clothes drying temperature is controlled conveniently, the control effect is good, and the quality of finished clothes products is improved.

Owner:界首市永顺服饰有限公司

Tungsten carbide spraying equipment with both grinding and surface defect repair functions

ActiveCN111962003AImprove processing effectImprove flattening effectMolten spray coatingGrinding drivesGrindingDrive motor

The invention provides tungsten carbide spraying equipment with both grinding and surface defect repair functions. The equipment comprises a base, a shell, a protective cover, a collecting frame, a collecting groove, a roller shaping frame structure, a cylinder, an arc surface polishing frame structure, a guide rail, an adjustable spraying fun fixing frame structure, a machining cleaning frame structure, a Y-shaped frame, a drive motor, a driving wheel, a driven wheel and a to-be-machined roller. The shell is in bolt connection with the upper portion of the base. The protective cover is in hinged connection with the left side inside the shell. The collecting frame is in bolt connection with the middle of the upper portion of the base. The equipment has the beneficial effects that by arranging the roller, a polishing motor, a rotating roller, a brush and a polishing belt, the surface of the to-be-machined roller is polished and ground conveniently, the polishing motor drives the rollerto rotate, the surface of the to-be-machined roller is ground through the grinding belt, and meanwhile unmolten tungsten carbide powder remaining at the corners of the front and back ends of the to-be-machined roller is cleaned thoroughly through the brush.

Owner:合力(天津)能源科技股份有限公司

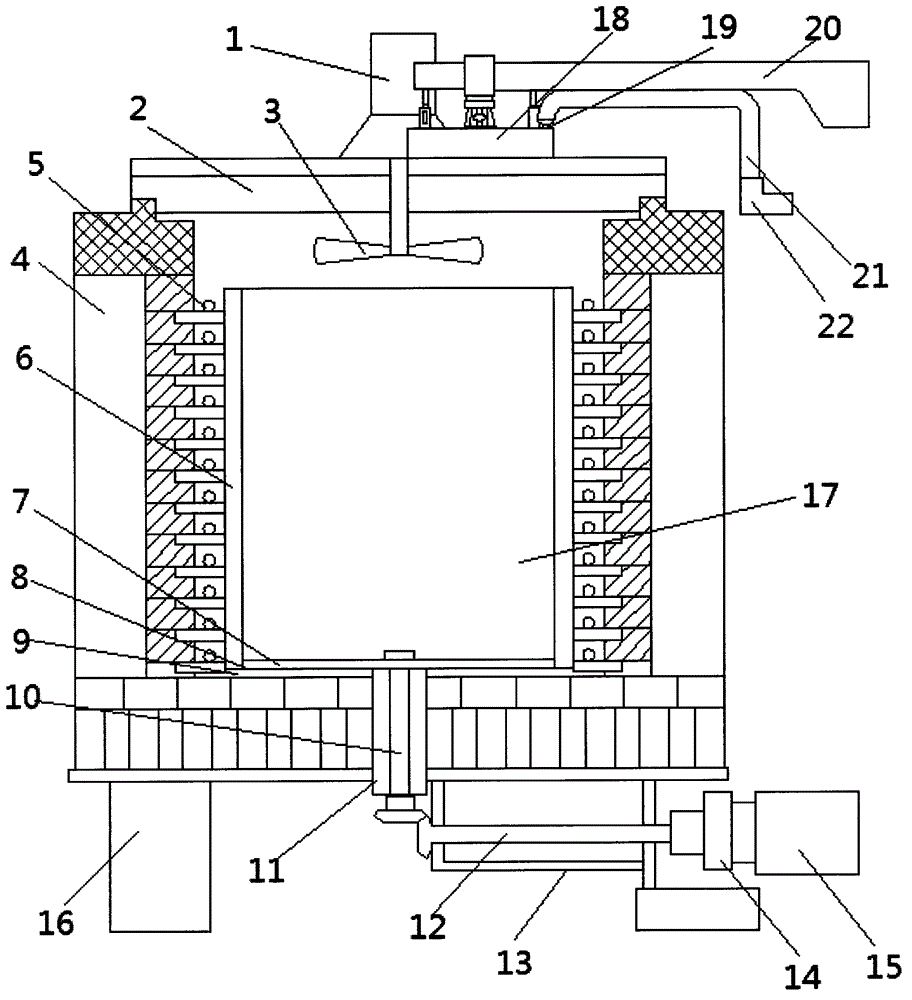

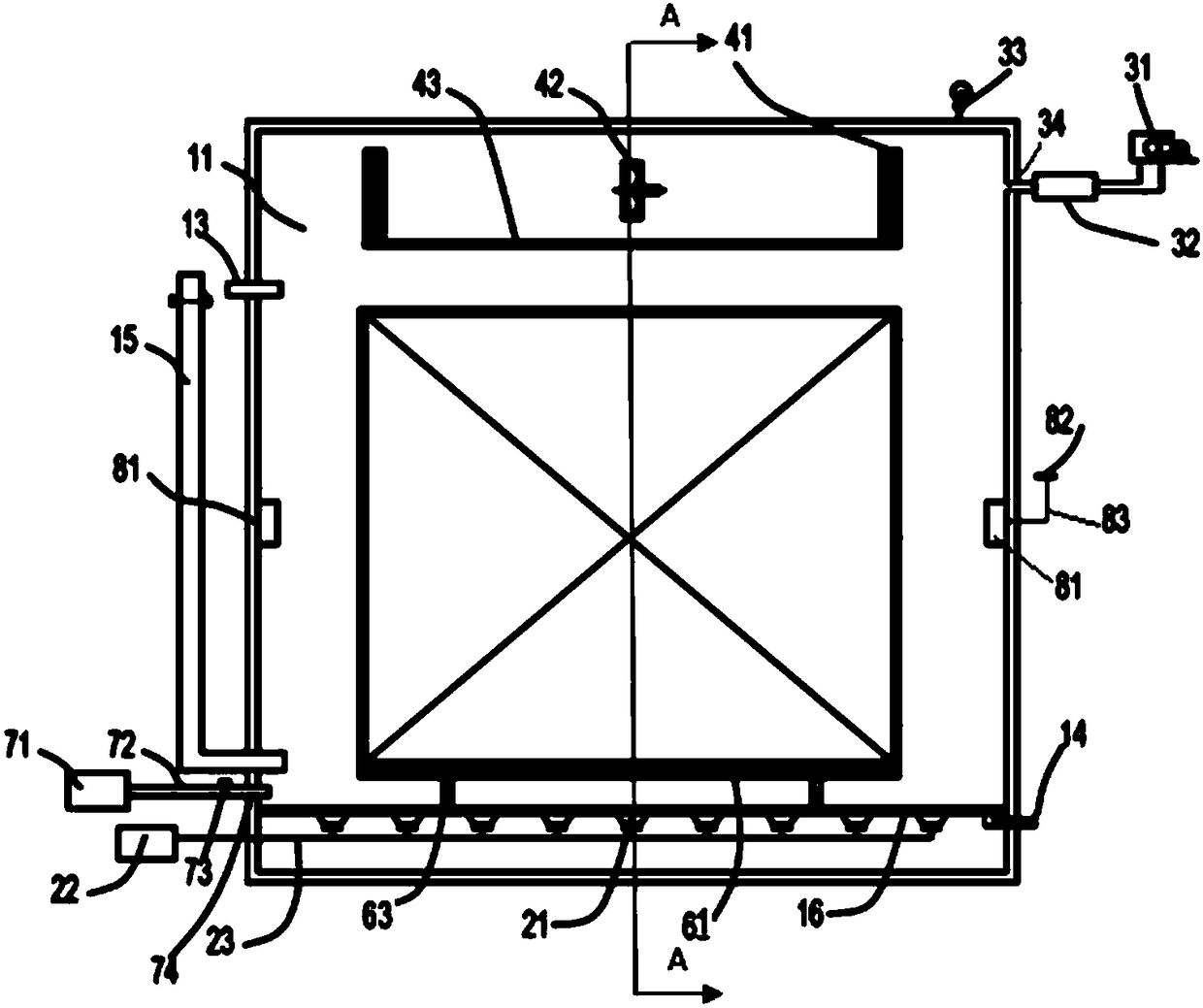

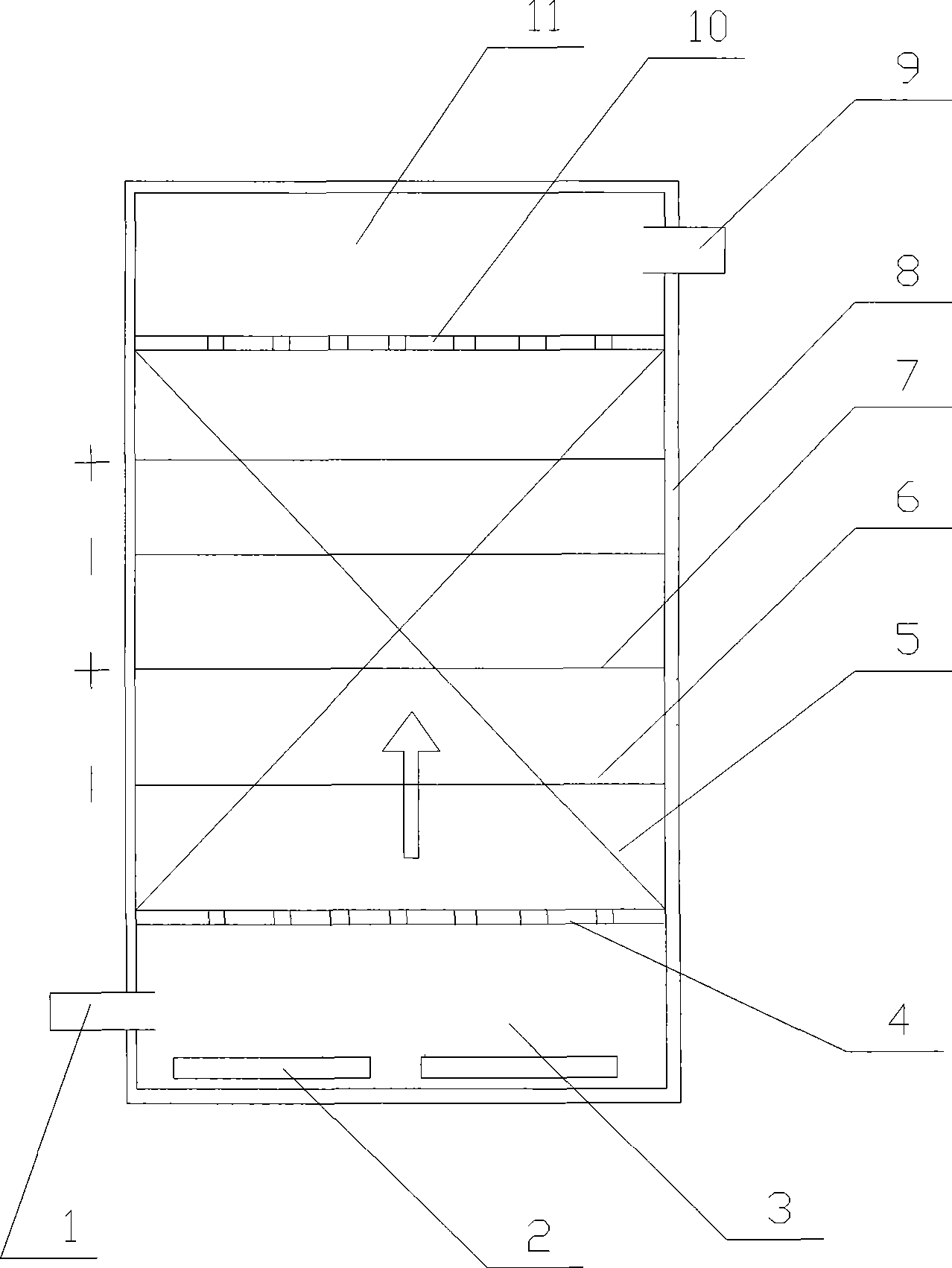

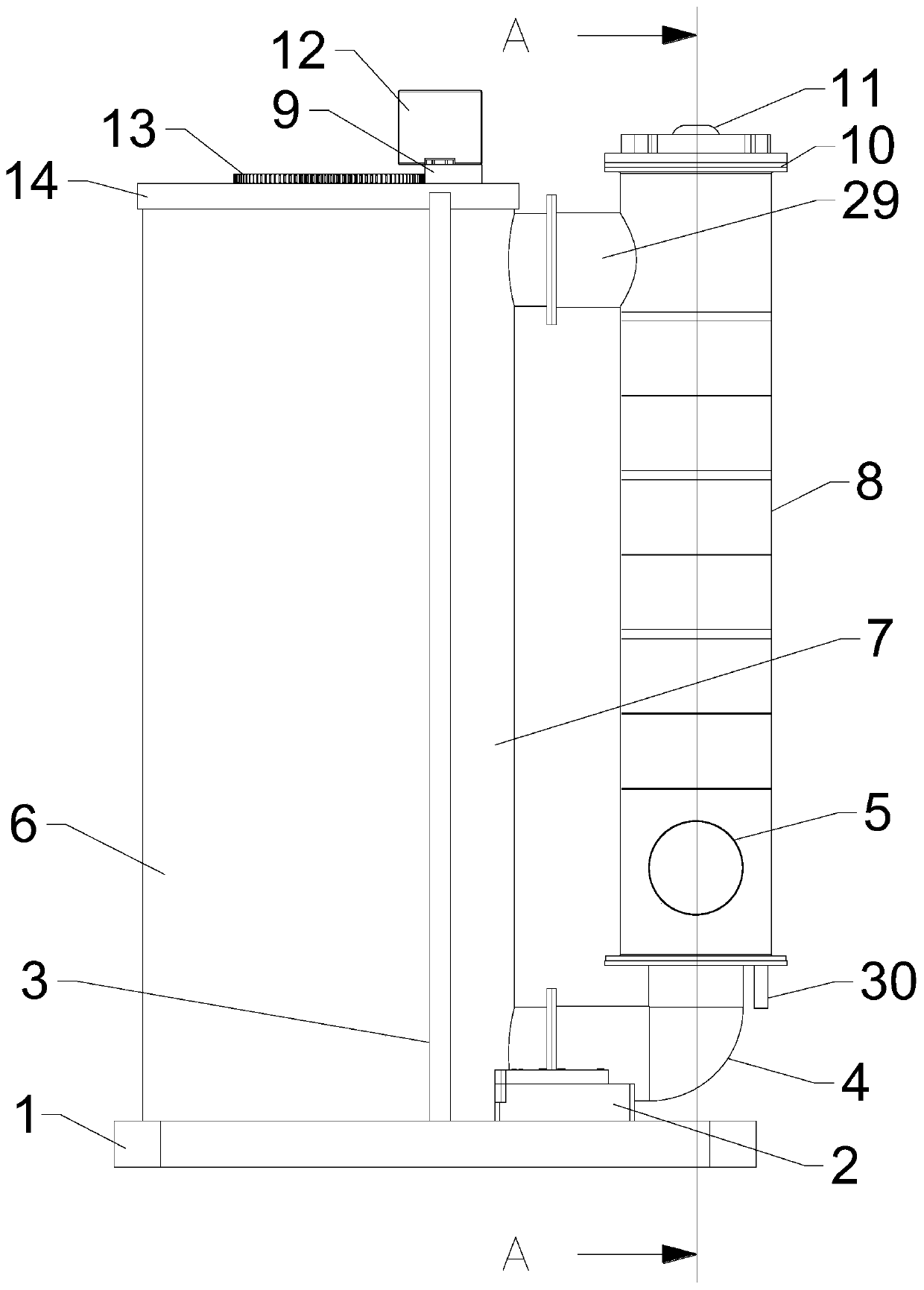

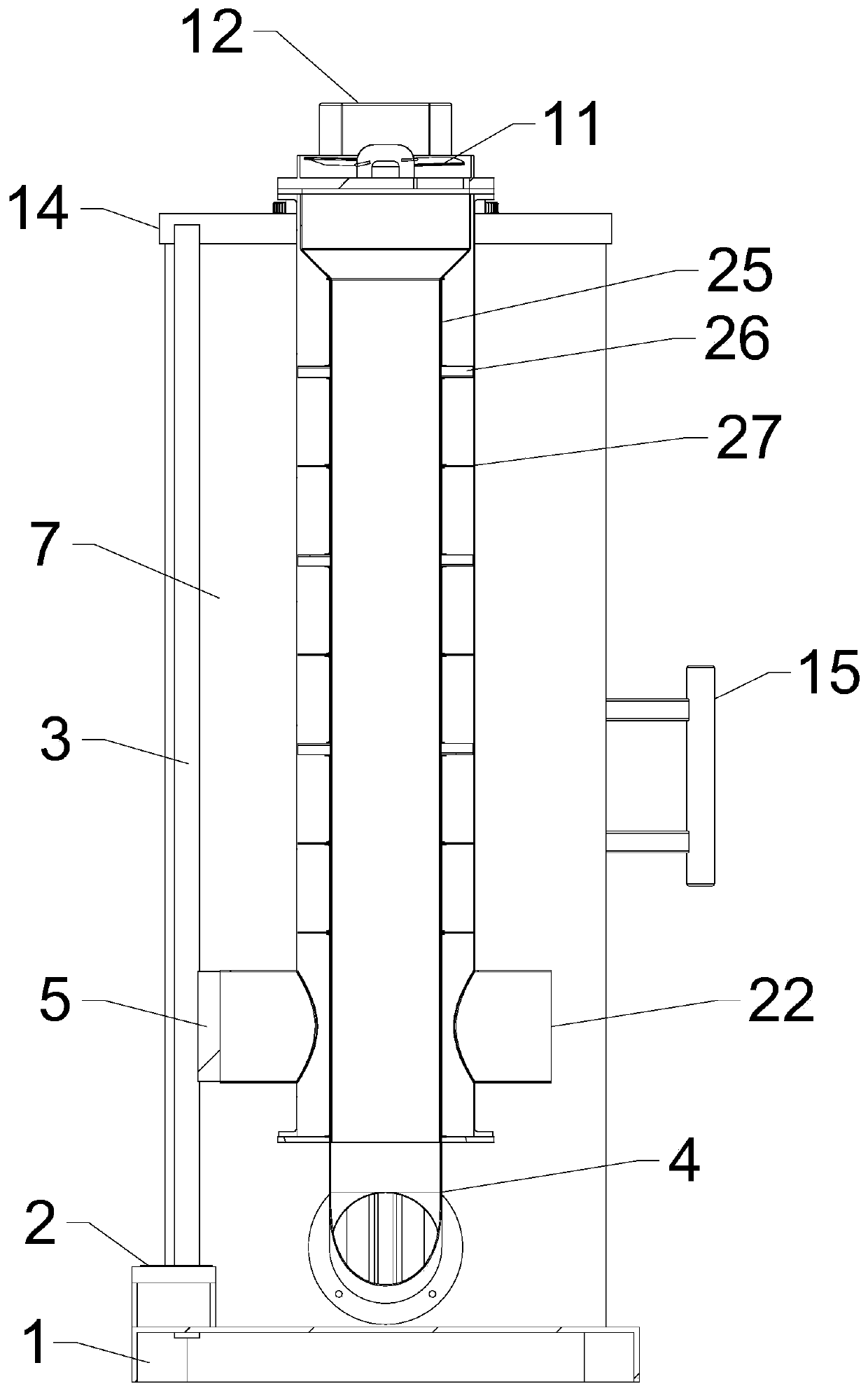

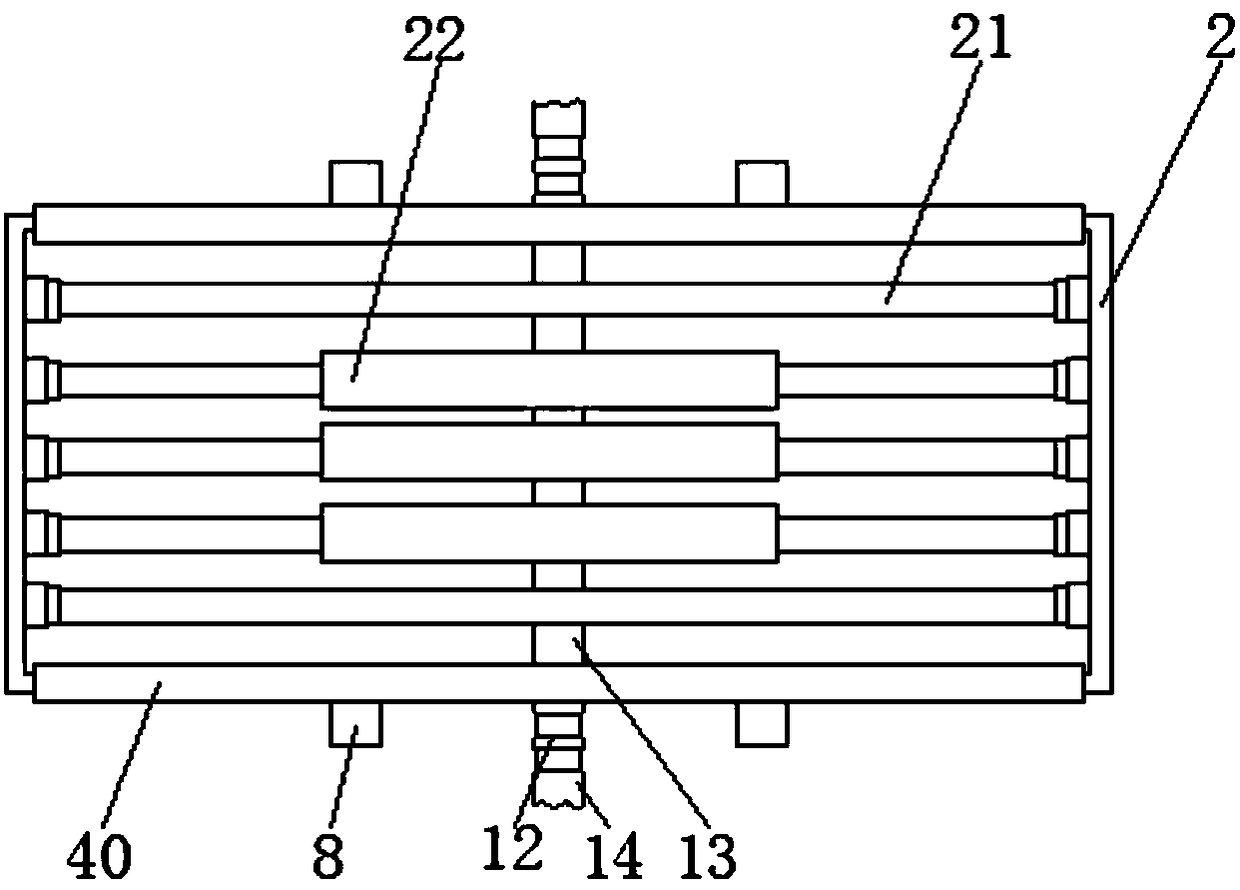

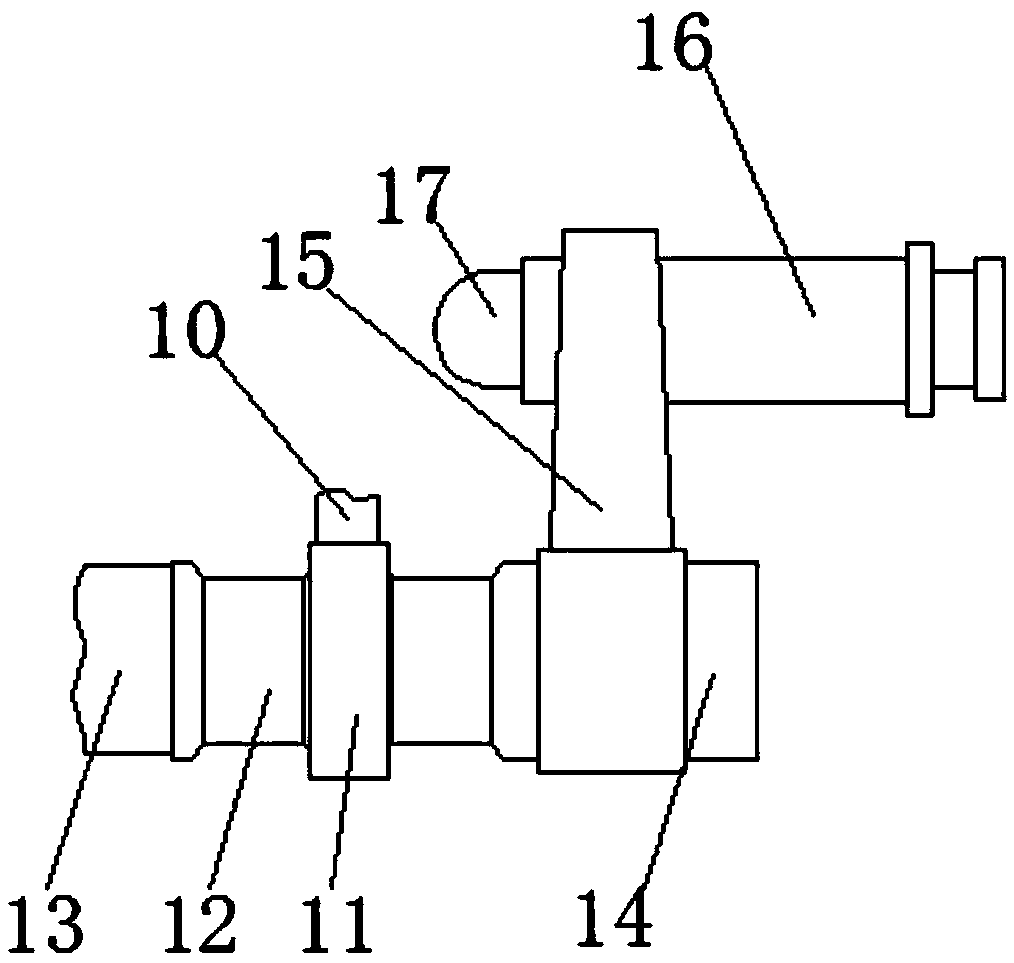

Pit-type tempering furnace with pressure control function

InactiveCN104894343AEliminate hot air circulation dead angleEvenly heatedHeat treatment process controlEngineeringInternal pressure

The invention discloses a pit-type tempering furnace with a pressure control function. The pit-type tempering furnace comprises a furnace cover and a casing, wherein the furnace cover is mounted at the upper part of the casing; heating pipes and an air duct are arranged in the casing; the air duct is covered with the multiple heating pipes; a rotating platform is arranged in a furnace body and can rotate continuously and stably; the rotating platform drives a metal casting to rotate in different directions at different speeds in a heating process, heated air circulation dead angles in the furnace body are eliminated, different areas in a tempering chamber are heated uniformly, further, the metal casting is heated uniformly, and consistent quality of finished products can be guaranteed when massive metal castings are subjected to tempering processing; a smoke exhausting system arranged on the furnace cover solves the problem that the processing effect is affected by continuous increased temperature due to overhigh pressure in the furnace body, can open an auxiliary cover in advance to reduce the pressure in the furnace body and exhausts high-temperature gas in the furnace body when the metal casting is taken out after tempering, and the metal casting is taken out conveniently.

Owner:李华良

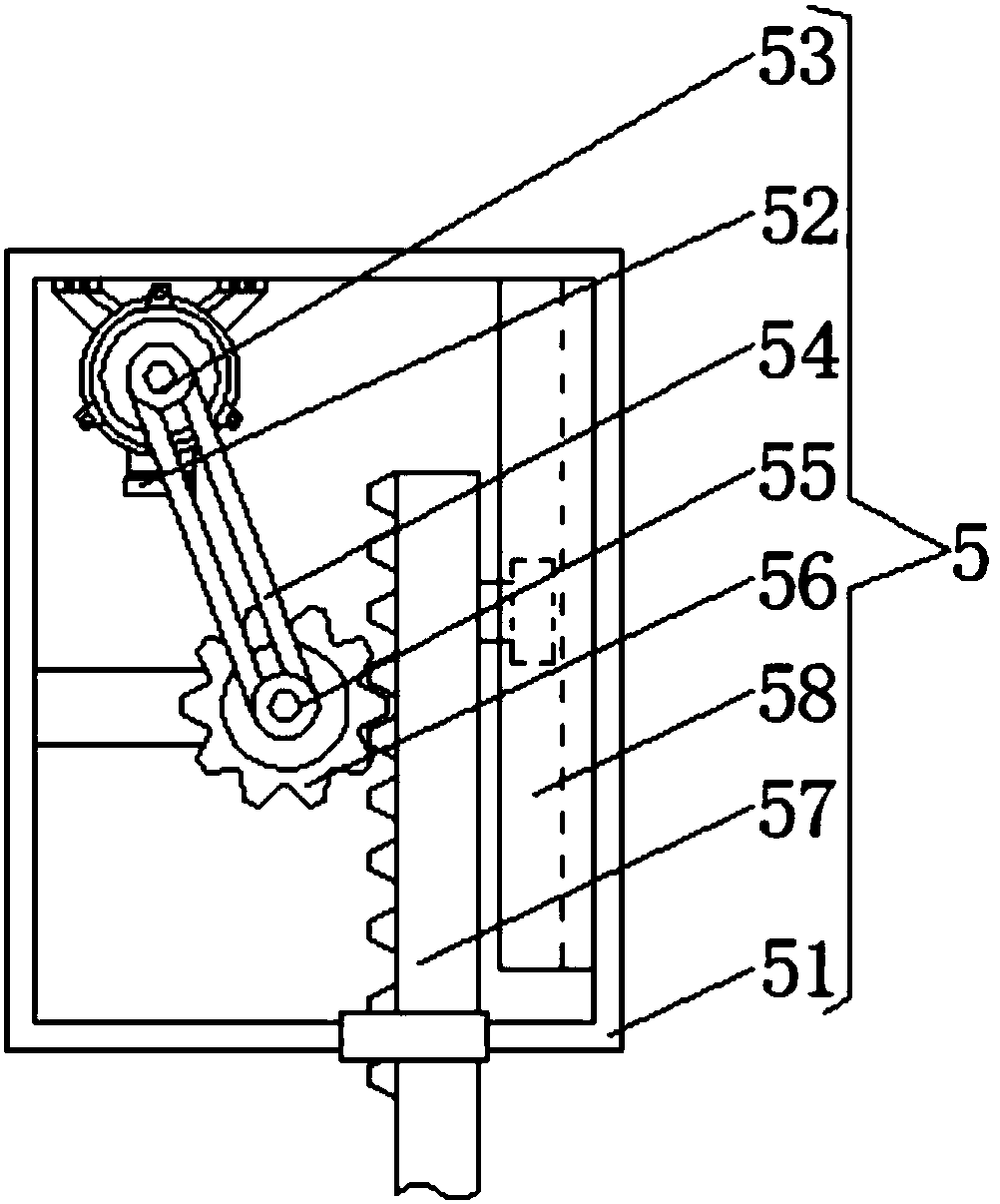

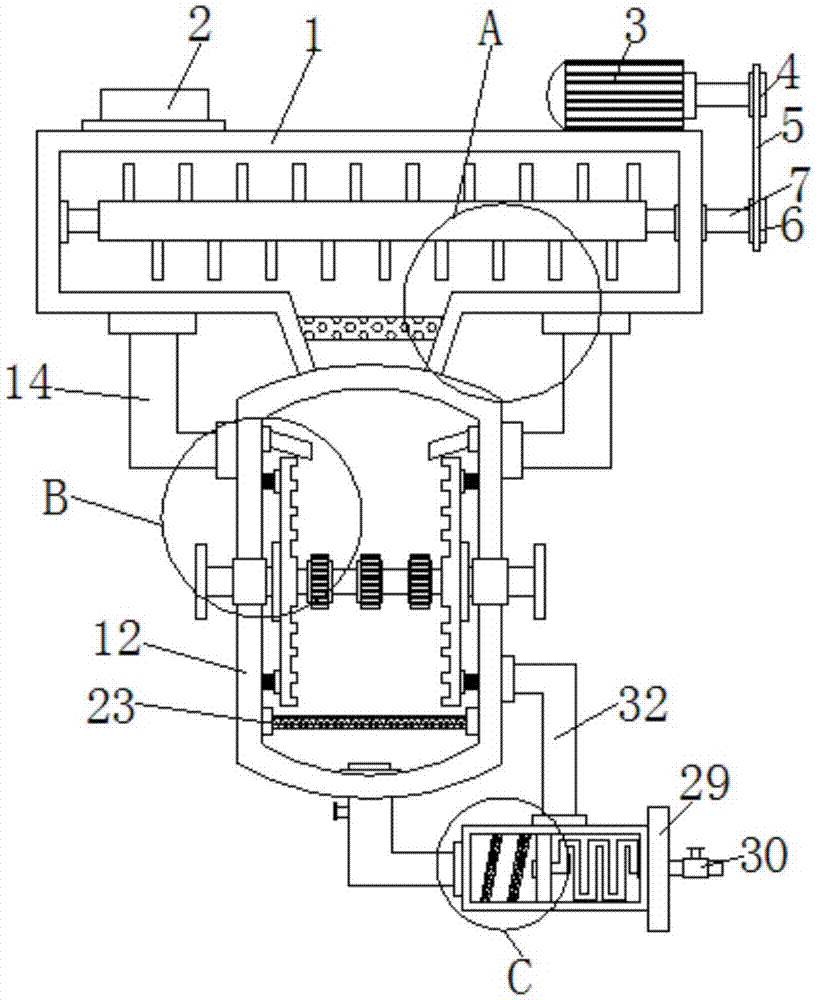

High-efficiency lubricating oil production blending device

ActiveCN107413270AAvoid accumulationAvoid affecting the processing effectTransportation and packagingMixer accessoriesDrive wheelOil production

The invention discloses a high-efficiency lubricating oil production blending device. The high-efficiency lubricating oil production blending device comprises a stirring box, a blending box and a condensation box, wherein a material inlet is formed in one side of the top of the stirring box, the other side of the top of the stirring box is fixedly connected with a motor, one end of a motor output shaft is fixedly connected with a driving wheel, the outer surface of the driving wheel is connected with the outer surface of a driven wheel in a transmission manner by virtue of a belt, the axis of the driven wheel is sleeved with a rotating shaft, one end of the rotating shaft penetrates through the stirring box and is fixedly connected with one side of the inner wall of the stirring box, the rotating shaft disposed on the outer surface, disposed in of the inner cavity of the stirring box, of the rotating shaft is sleeved with a sleeve plate, and the outer surface of the sleeve plate is fixedly connected with a stirring rods. According to the high-efficiency lubricating oil production blending device, lubricating oil to be processed is arranged into the stirring box by virtue of the material inlet, and the driving wheel, the driven wheel and the rotating shaft are driven by the motor to rotate so as to drive the sleeve plate and the stirring rods to rotate and to stir and scatter the lubricating oil, so that the accumulation of impurities contained in the lubricating oil can be prevented, and the subsequent processing effect is not influenced.

Owner:统一石油化工有限公司

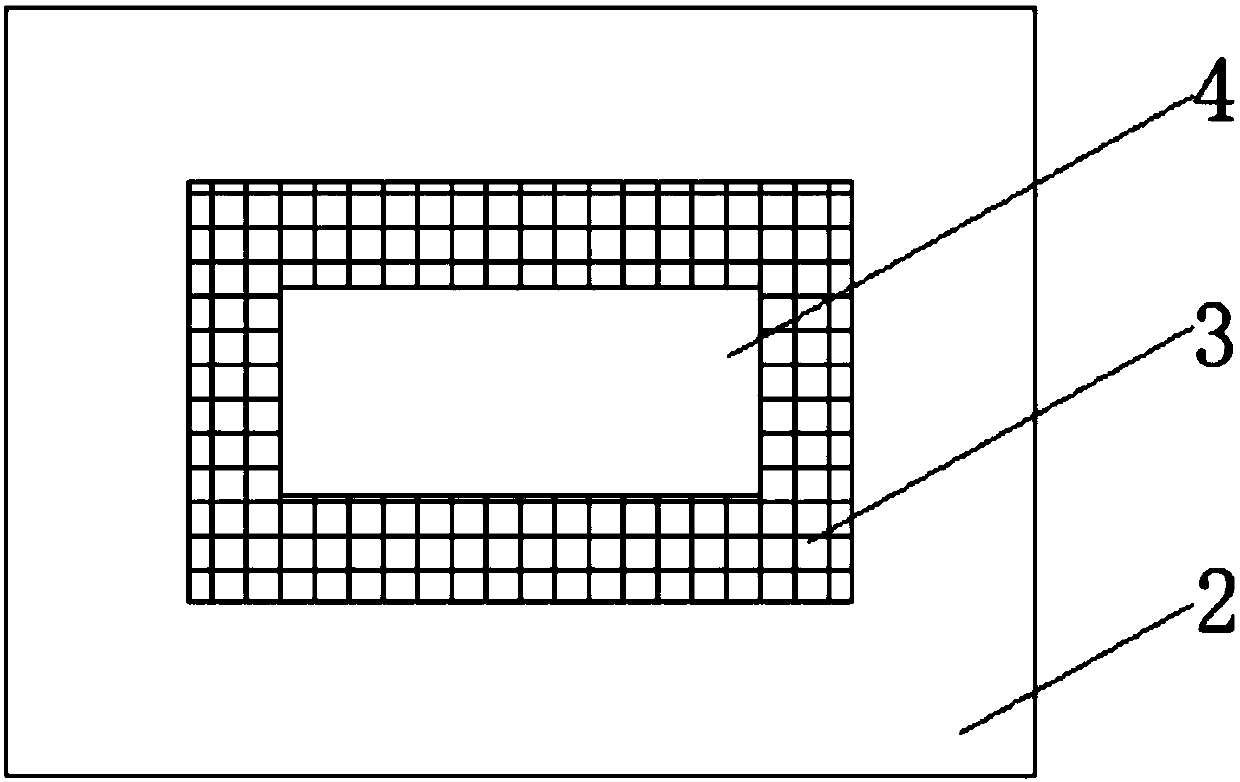

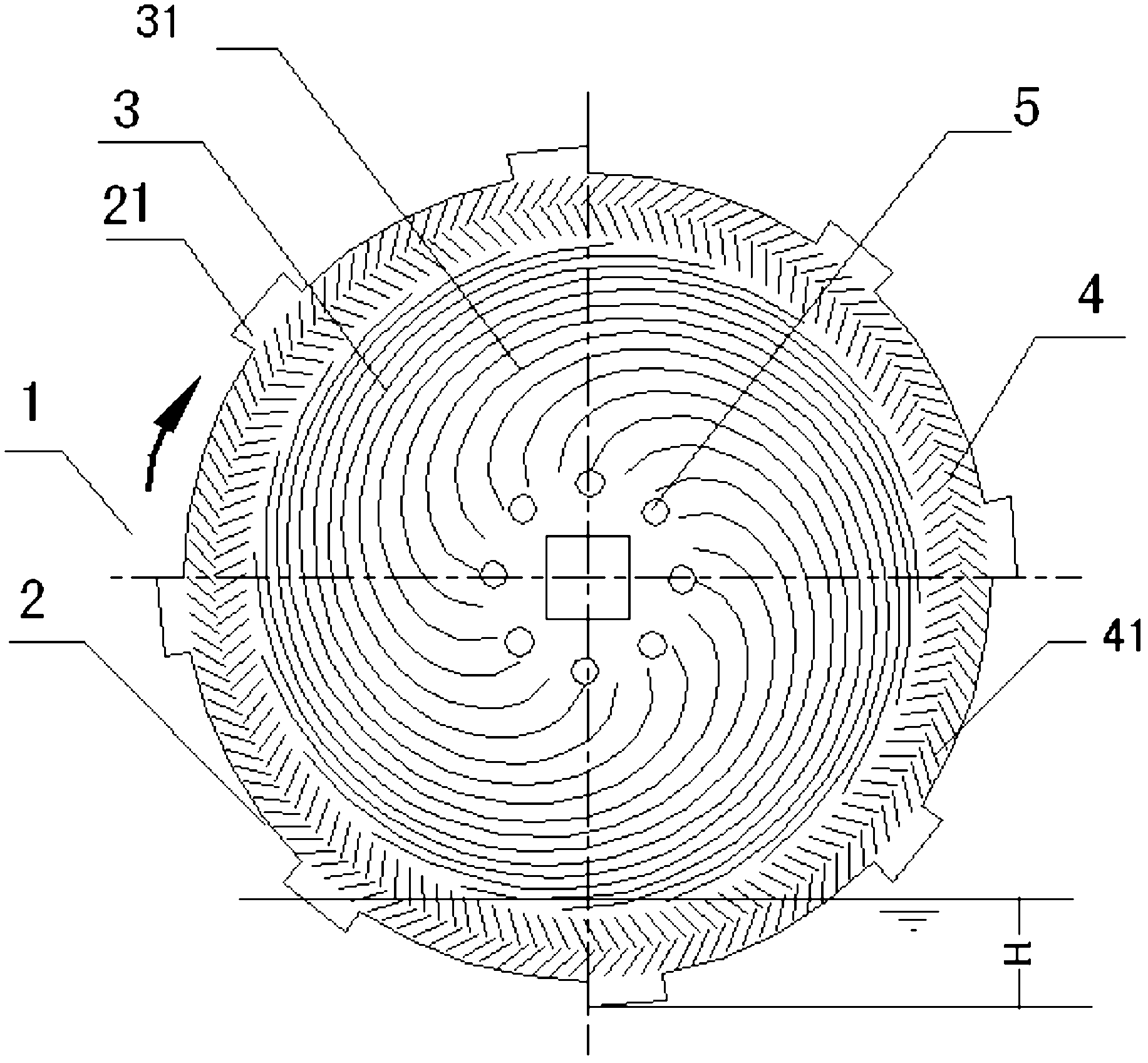

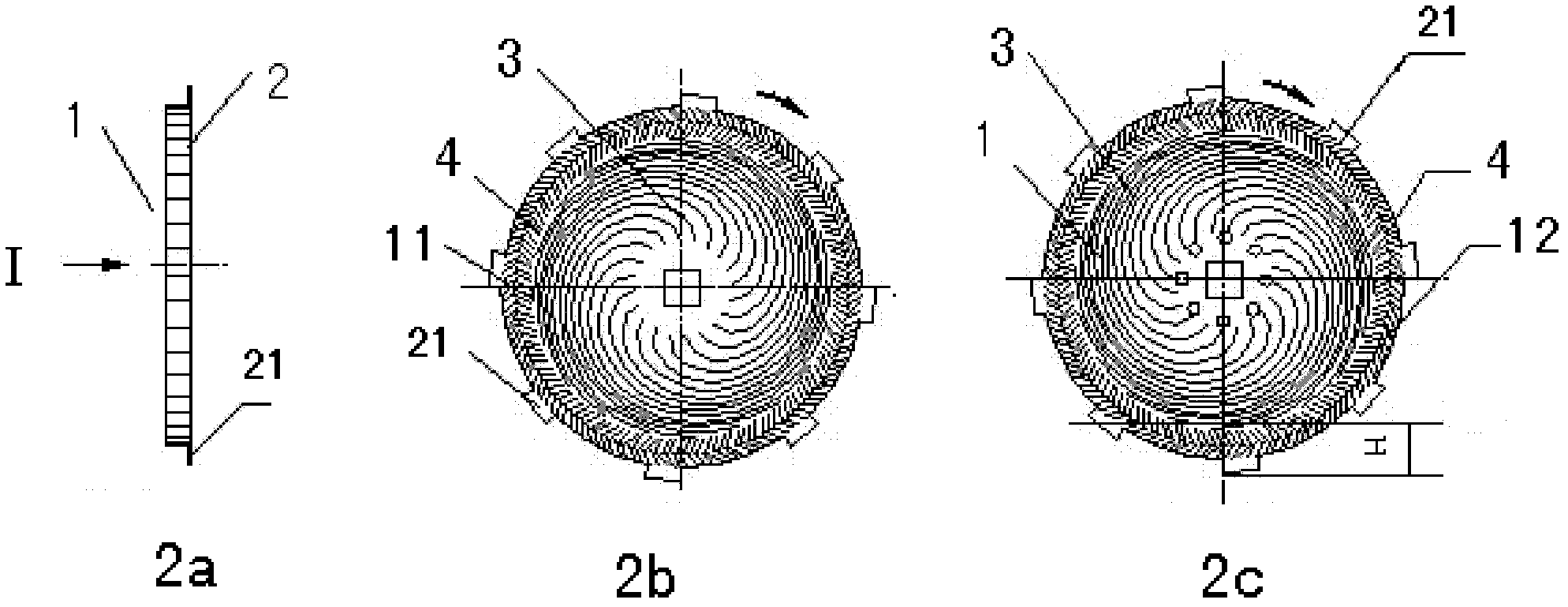

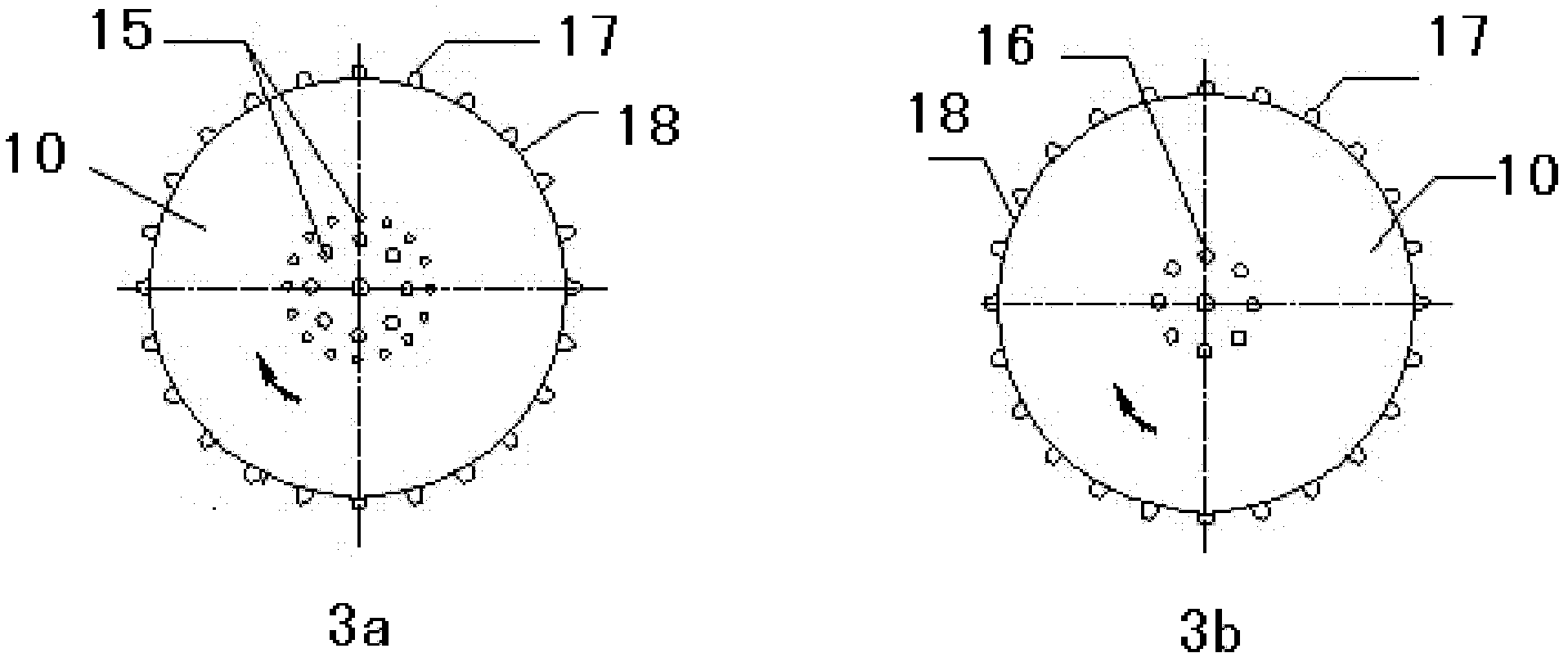

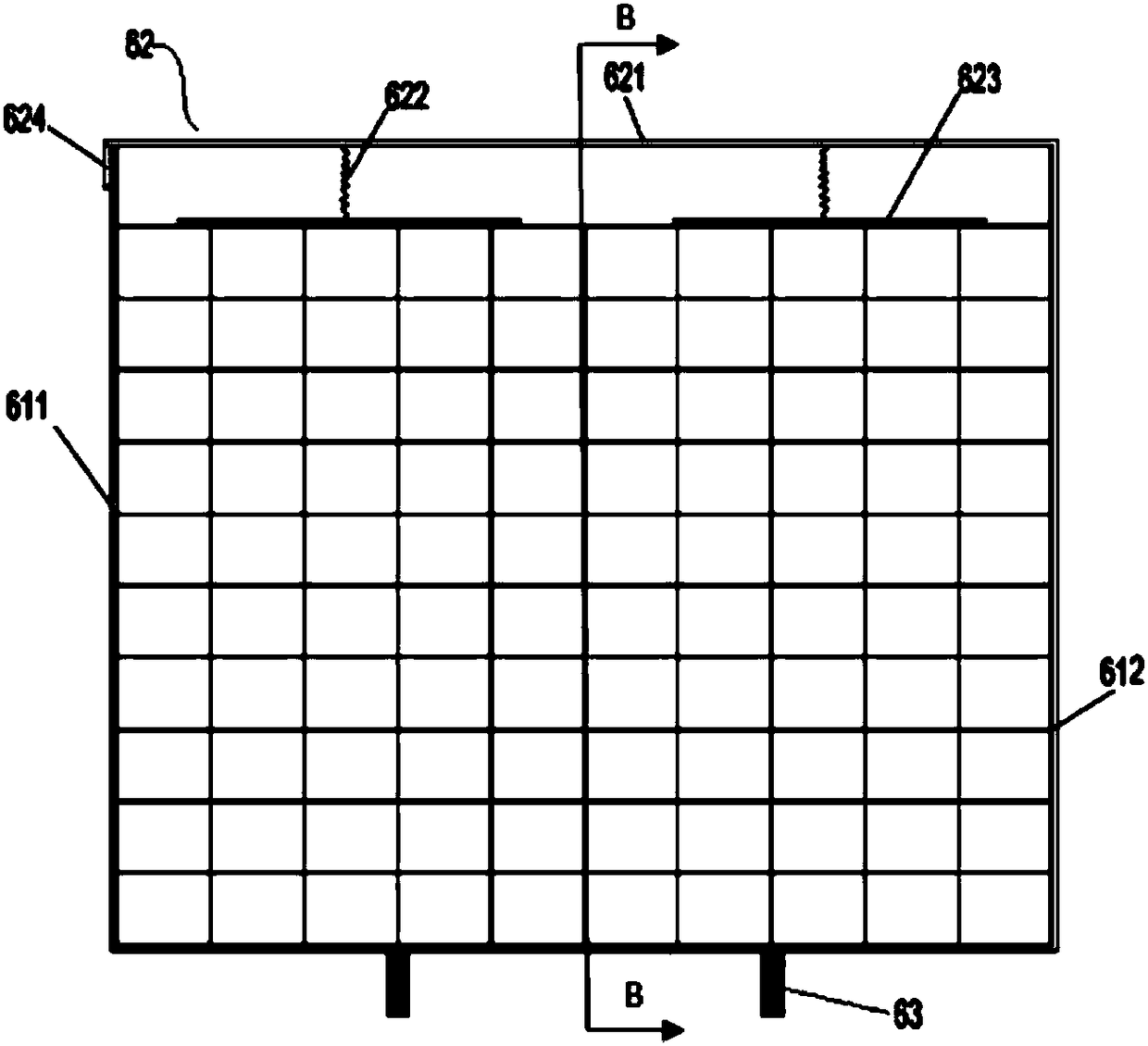

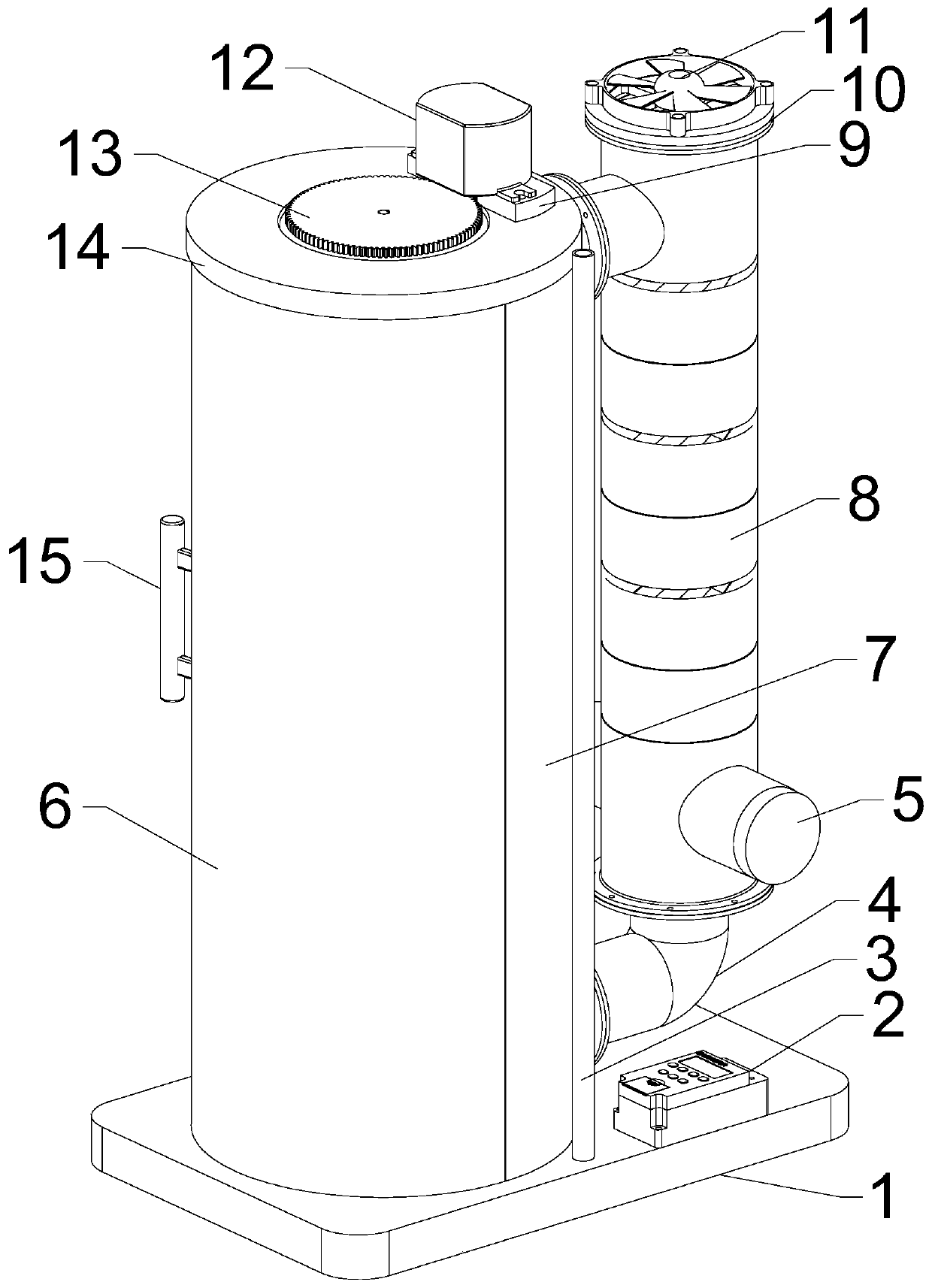

Biological disk, biological revolving drum and integrated revolving drum type domestic sewage treater

ActiveCN102633355AAvoid cloggingLifting special structuresTreatment using aerobic processesMultistage water/sewage treatmentWater flowSewage

The invention provides a biological disk, a biological revolving drum and an integrated revolving drum type domestic sewage treater. The biological disk comprises a circular support disk and blades fixed on the support disk; the blades are vertical to the support disk; an axial hole is formed in the centre of the support disk; the blades comprise lifting blades which are in a plurality of spiral structures in the same direction starting from the axial centre of the support disk; and the distance between every two spiral structures at the position close to a circle centre is more than that at the position far away from the circle centre. According to the invention, because the biological disk is provided with the lifting blades and aeration blades, the area of a turntable is greatly increased; furthermore, in the event of passing through the biological revolving drum disclosed by the invention, the water flow must flow through each disk; therefore, the superficial area contacted with sewage is greatly increased; the sewage treatment capability is greatly increased; the integrated revolving drum type domestic sewage treater is convenient for maintenance and low in intensity; and main body equipment is rustless and corrosion resistant.

Owner:苏州克莱茵环境发展有限公司

Water treatment system and treatment method applied to urban lake

ActiveCN106630384AImprove filtering effectPlay the role of interception bufferSpecific water treatment objectivesTreatment involving filtrationSuspended particlesWater treatment system

The invention discloses a water treatment system and treatment method applied to an urban lake. The water treatment system comprises a pretreatment tank, a disinfecting tank and a microbiological treatment tank, wherein a filtering device is arranged in the pretreatment tank, an agent distributing plate, a stirring device and a moving device are arranged in the disinfecting tank, the agent distributing plate is connected with a disinfecting agent box through an elastic connecting pipe, the stirring device is located at the bottom of the disinfecting tank, the moving device is connected with the upper end of the agent distributing plate, and microbiological treatment pipes are evenly arranged in the microbiological treatment tank. The treatment method comprises the following steps of device installation, sewage impurity clearing, sewage disinfecting treatment, microbiological sewage treatment and clearing, checking and repair. The water treatment system and treatment method is simple in structure, high in practicability, obvious in treatment effect and high in treatment efficiency, suspended particle impurities in sewage are cleared through the pretreatment tank and are prevented from blocking other pipes, and then the quality of treated sewage meets a certain index through treatment of the disinfecting tank and the microbiological treatment tank.

Owner:ZHEJIANG TONGJI VOCATIONAL COLLEGE OF SCI & TECH

Wood heat treatment method

ActiveCN108789718AImprove qualityLess defects in heat treatmentRadiation/waves wood treatmentWood treatment detailsPre treatmentPressure reduction

The invention provides a wood heat treatment method. The wood heat treatment method comprises the steps of sequentially carrying out ultrasonic pretreatment, ultrasonic modified treatment under the pressure reduction state and heat treatment on wood. Through the adoption of the method, the existing high-temperature treatment wood can be obtained at low heat treatment temperature; the wood treatedthrough the method achieves the size stability of the high-temperature heat treatment wood, the heat treatment efficiency and speed are increased, and energy consumption is reduced; and the prepared heat treatment wood has few defects, is high in mechanical performance and can be used for indoor furniture and floors and used for wood structures.

Owner:BEIJING FORESTRY UNIVERSITY

Electrical biological treatment apparatus for organic sewage

InactiveCN101468833AEasy to handleHigh speedTreatment using aerobic processesTreatment by combined electrochemical biological processesElectrolysisWater channel

Owner:BEIJING JINAOHUARONG TECH

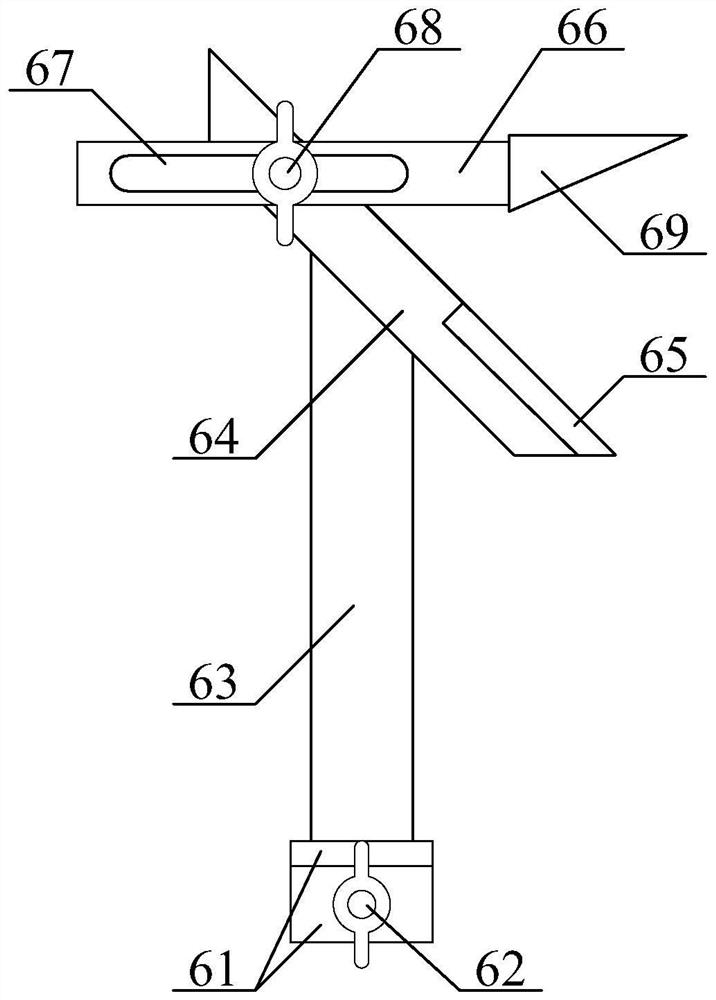

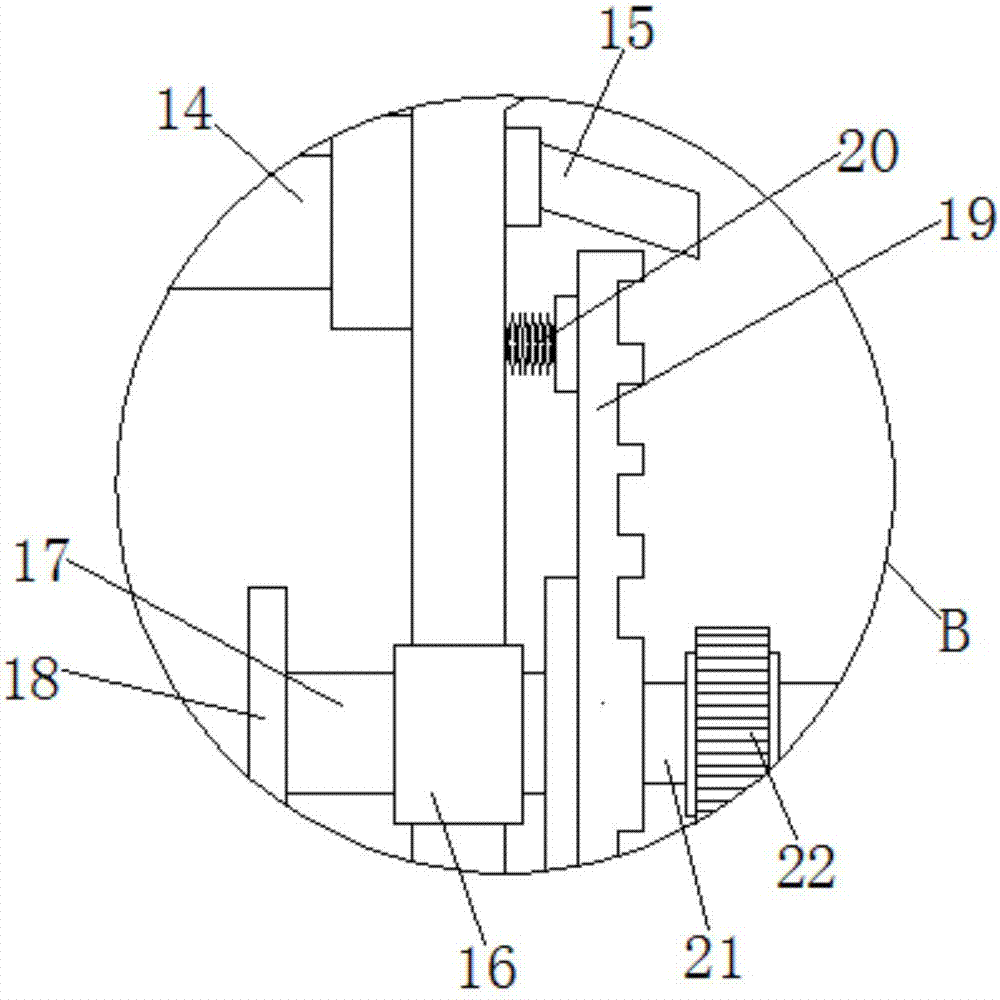

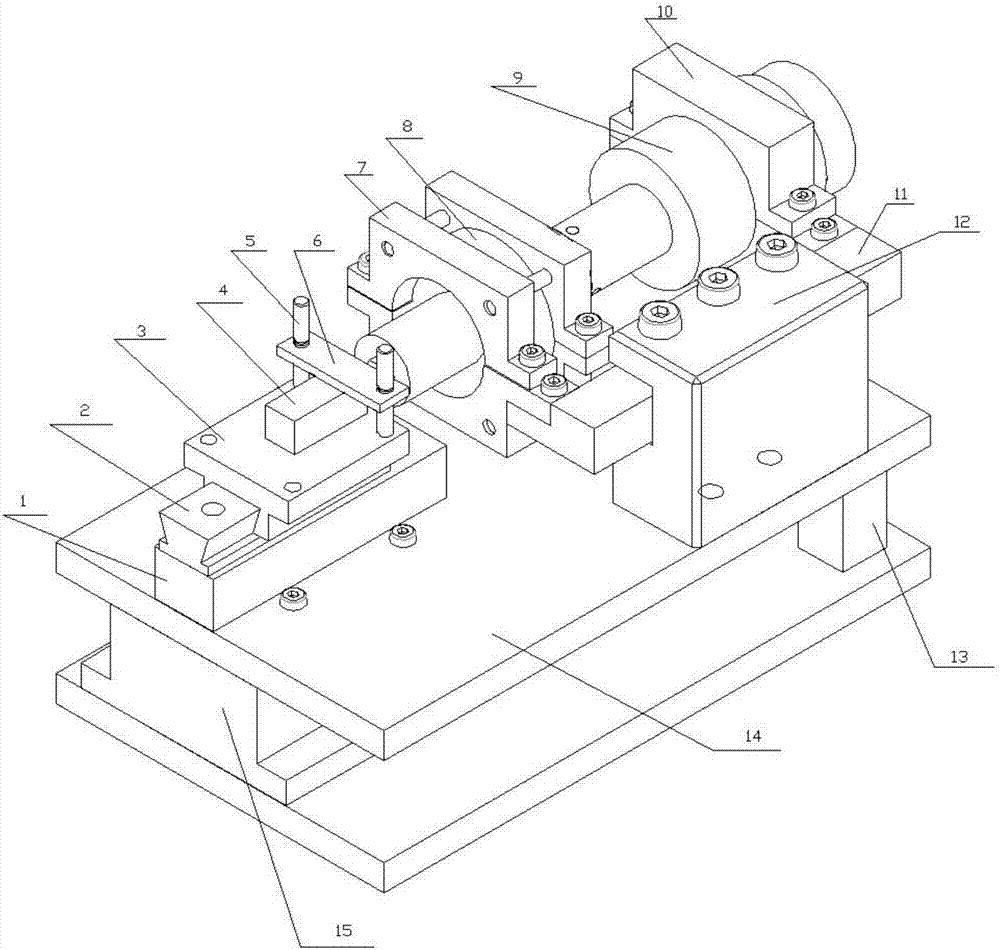

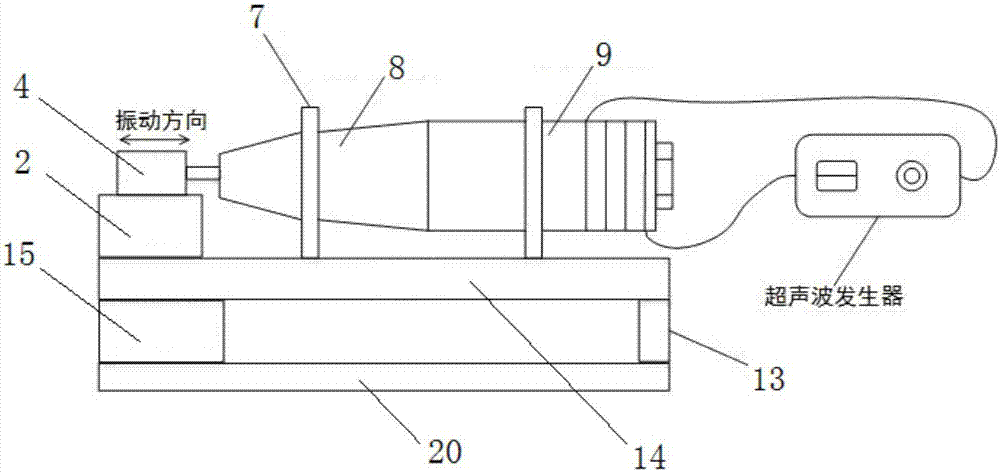

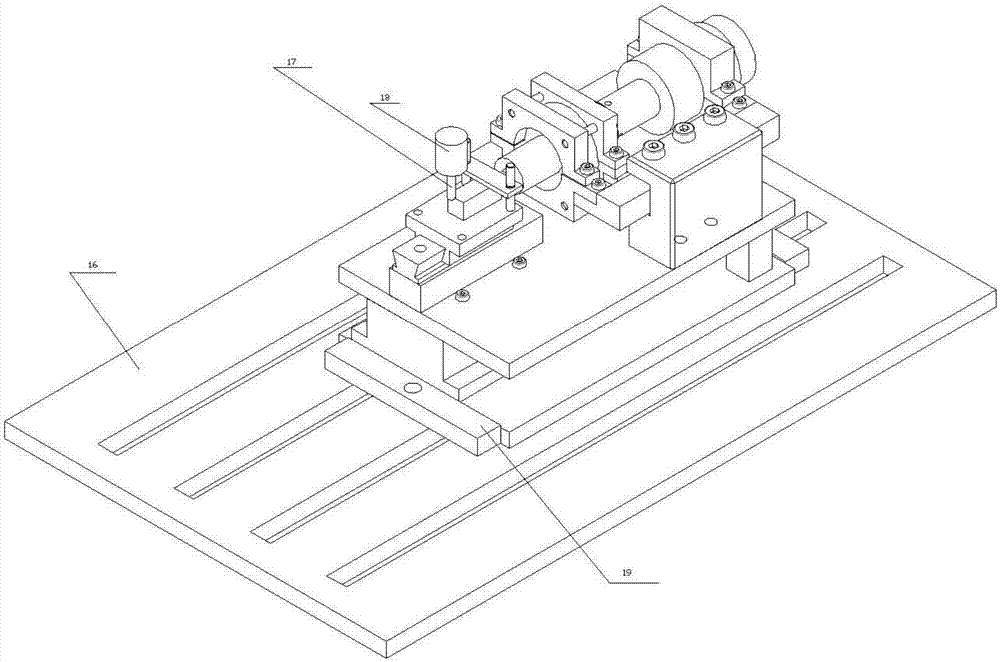

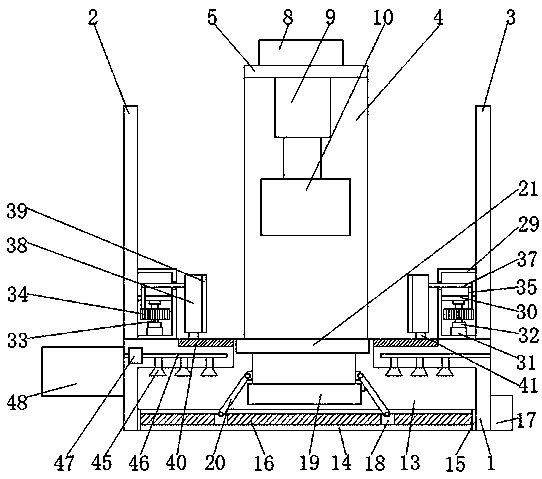

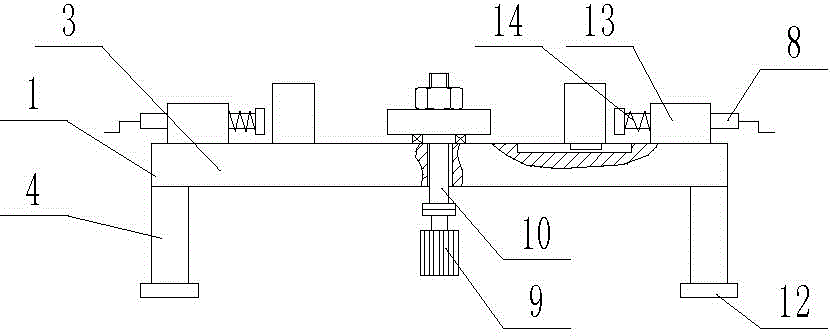

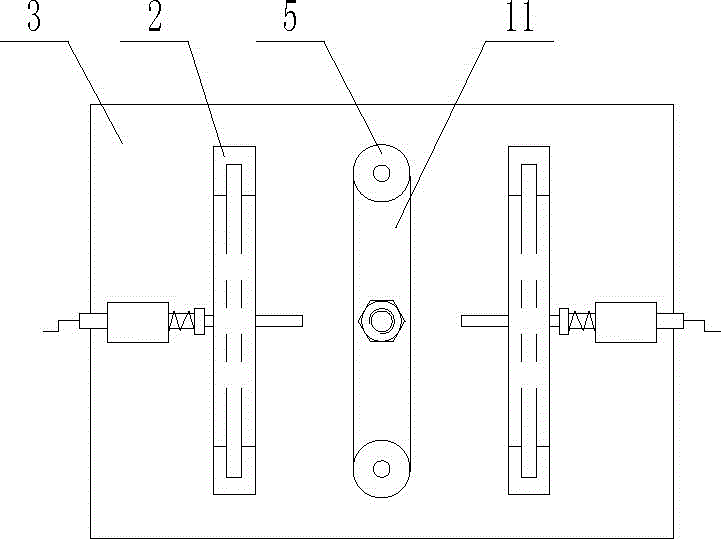

Radial ultrasonic vibration auxiliary cutting device

InactiveCN107470687AExpand the scope of processingRealize measurementMilling equipment detailsTransducerUltrasonic vibration

The invention discloses a radial ultrasonic vibration auxiliary cutting device. The radial ultrasonic vibration auxiliary cutting device comprises a first base plate and a second base plate. The first base plate is fixedly connected with the second base plate through a front support block and a rear support block. A cushion block is fixedly connected to the first base plate through bolts. A fixing block is further fixedly connected to the first base plate through bolts. A cross beam is arranged in a groove of the fixing block through fastening bolts. The cross beam and the cushion block are arranged on a central line in a corresponding manner. The cushion block is provided with a guide rail, and a slide block is in sliding fit with the guide rail. A cover plate is fixedly connected to the end of the slide block through double-end studs. A workpiece is put on the slide block and located through the cover plate. A front support is fixedly connected to the cross beam through bolts. A pore channel is formed by the front support and the cross beam, wherein the pore channel allows an amplitude-change pole to pass through. A rear support is fixedly connected to the cross beam through bolts. A transducer is fixed to the cross beam through the rear support and connected with the amplitude-change pole. The workpiece is fixedly connected to the end of the amplitude-change pole. By means of the radial ultrasonic vibration auxiliary cutting device, radial ultrasonic vibration auxiliary cutting and measurement of cutting force applied in the machining process are achieved; and the radial ultrasonic vibration auxiliary cutting device is convenient to design, easy to machine and easy and convenient to mount and demount.

Owner:NORTHEASTERN UNIV LIAONING

Polishing device for processing computer case

ActiveCN109397014AAvoid affecting the processing effectEasy to polishGrinding carriagesGrinding drivesComputer engineeringComputer case

The invention provides a polishing device for processing a computer case. The polishing device for processing the computer case comprises a bottom plate, two support plates, a transverse plate and twostabilizing blocks. The bottom parts of the two support plates are fixed on the two sides of the top of the bottom plate; the two sides of the transverse plate are fixed to the opposite sides of thetwo support plates; and the sides, far away from each other, of the two stabilizing blocks are fixed to the tops of the opposite sides of the two support plates. The polishing device for processing the computer case can comprehensively polish the surface of the case, improve the working efficiency, can process cases in different sizes, improves the practicability, and is beneficial to widespread promotion; and an air sucking pump sucks debris generated during polishing of the case into a filter box through a pipeline, a tee joint, a hose and a suction bucket, a worker is prevented from inhaling a large amount of debris, and harm to the body of the worker is avoided.

Owner:李金见

Machining device for machine

InactiveCN108817994AAvoid shakingEasy to processLarge fixed membersPositioning apparatusEngineeringSlide plate

The invention discloses a machining device for a machine. The machining device comprises a shell. The interior of the shell is fixedly connected with a cooling box. The front side and the rear side ofthe cooling box are fixedly connected with first sliding rails. The outer surfaces of the two first sliding rails are in sliding connection with sliding plates. The opposite sides of the two slidingplates are fixedly connected with supporting plates. The side, away from the corresponding sliding plate, of each supporting plate is fixedly connected with a clamp plate. One side of each clamp plateis fixedly connected with a buffer plate. The invention relates to the technical field of machines. According to the machining device for the machine, the cooling box is utilized for absorbing heat generated by machining when the machining device carries out machining, and the situation that the machining effect is influenced due to the fact that the machining environment is too high is avoided;and meanwhile, through cooperation of a wire winding column and a pull rope, the sliding plates can be driven to move on the first sliding rails, then the clamp plates are driven to clamp a machined mechanical tool, the machining device can machine the machined mechanical tool conveniently, the machined tool is prevented from offsetting, and machining is more precise.

Owner:熊飞燕

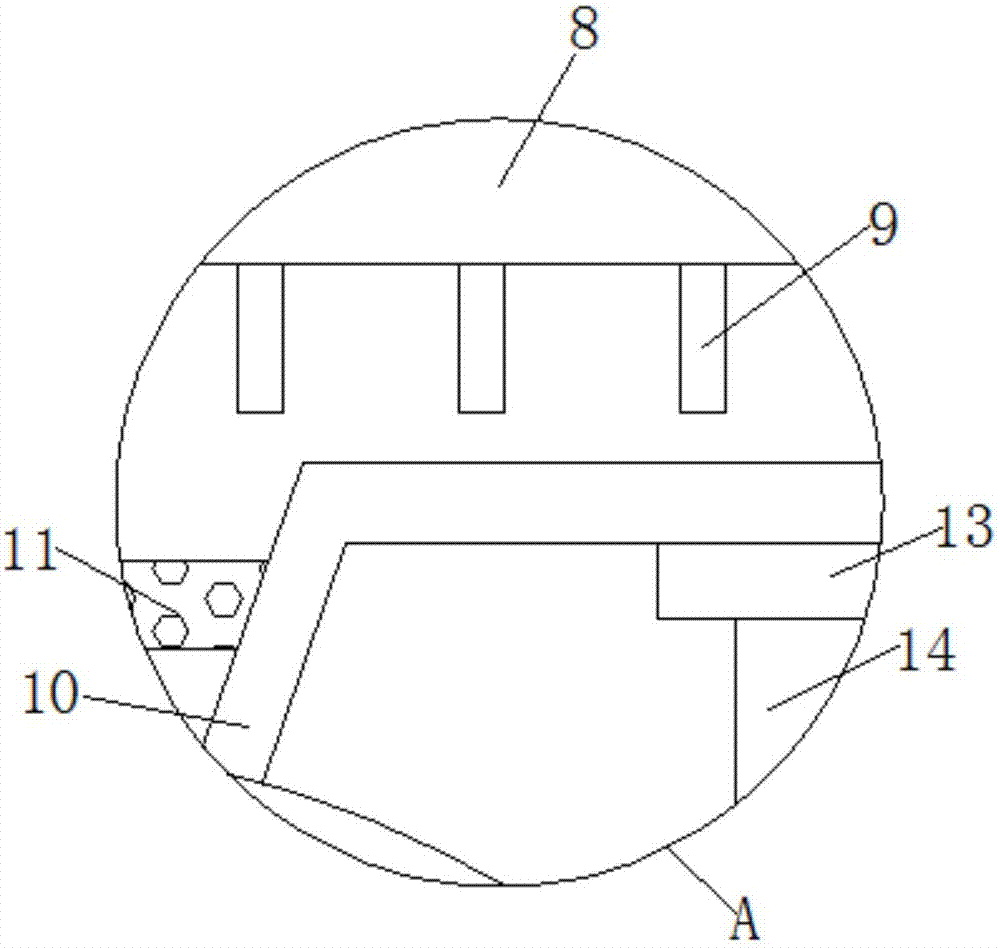

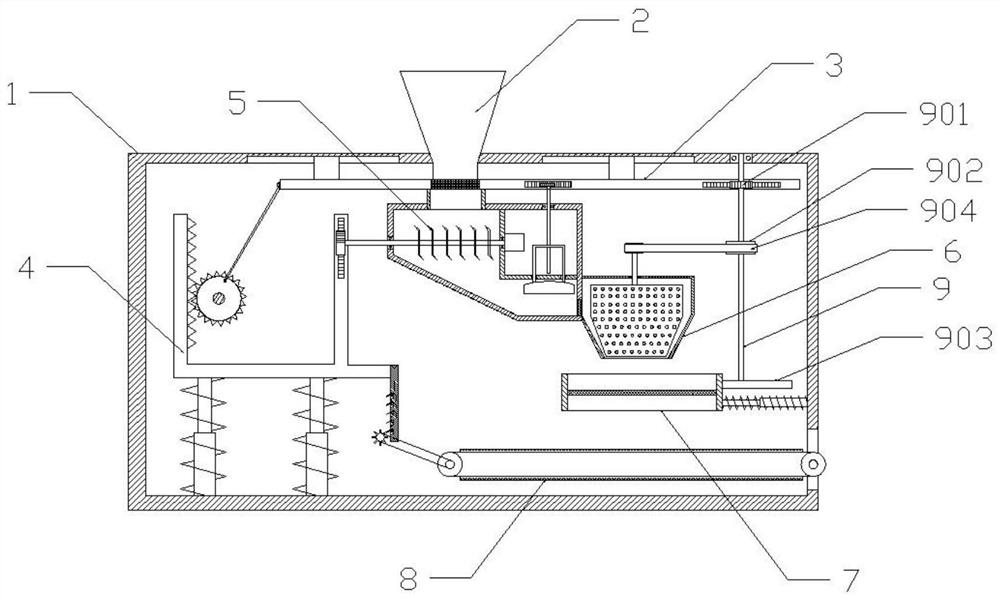

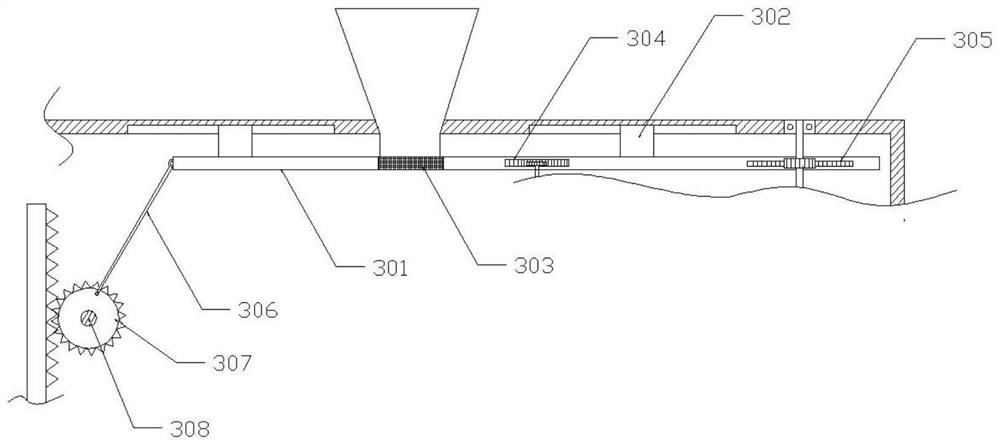

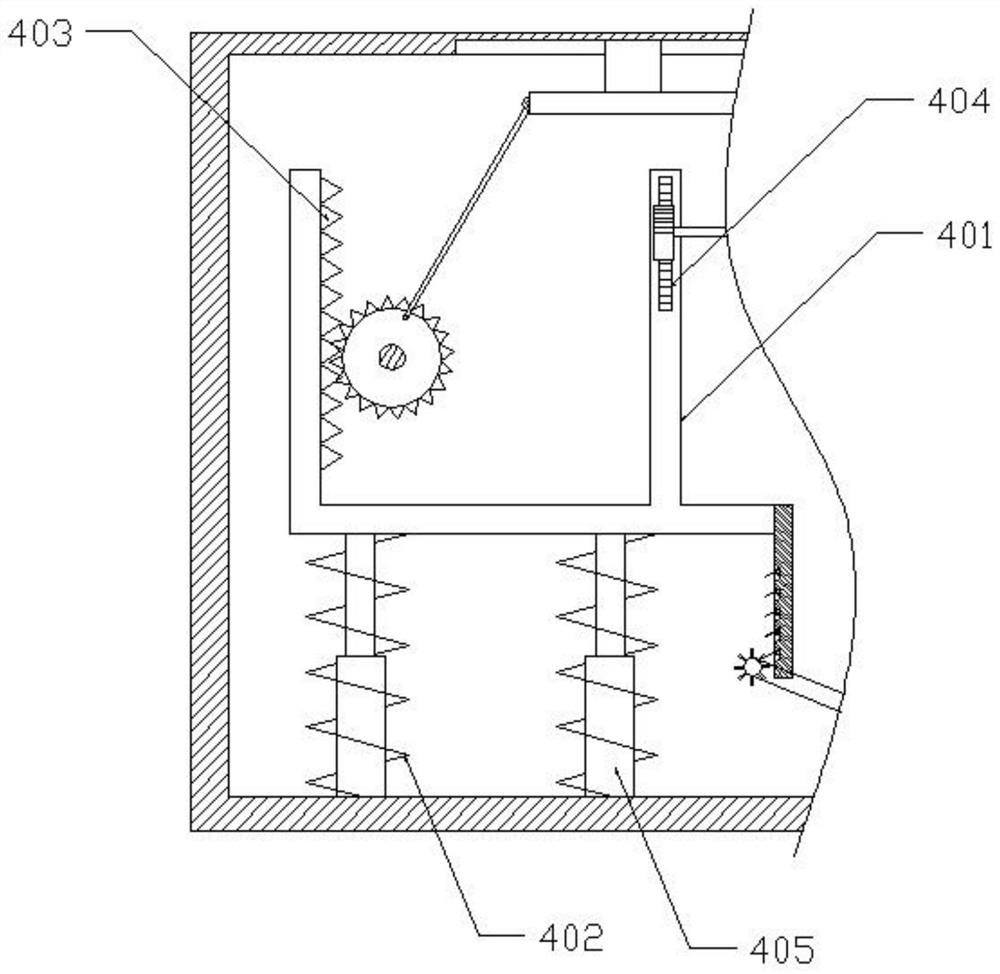

Mineral pigment grinding device for art pigment preparation

ActiveCN112076876AAvoid affecting the processing effectReasonable structural designGrain treatmentsLoading/unloadingMetallurgyPhysical chemistry

The invention discloses a mineral pigment grinding device for art pigment preparation. The mineral pigment grinding device comprises a vertical frame. A feeding hopper is connected to the center of the top of the vertical frame. A material blocking mechanism is arranged at the top of an inner cavity of the vertical frame. A transmission mechanism is arranged on the left side of the inner cavity ofthe vertical frame. A smashing mechanism is arranged in the middle of the inner cavity of the vertical frame. A grinding mechanism is connected to the right end of the smashing mechanism. A materialscreening mechanism is arranged below the grinding mechanism. A discharging mechanism is arranged below the material screening mechanism. The right end of the discharging mechanism extends out of thevertical frame. The mineral pigment grinding device is reasonable in structural design, an intermittent feeding function is achieved, the situation that the processing effect is affected due to the fact that excessive raw materials are fed at a time is avoided, the effect of smashing and refining pigment raw materials is achieved, follow-up grinding operation is facilitated, the grinding effect isfurther improved through evenly-distributed wear-resisting protruding blocks, the product quality of the pigment preparation is improved, pigment meeting the specification is effectively screened out, and qualified pigment can be conveniently conveyed out of the vertical frame.

Owner:ANYANG NORMAL UNIV

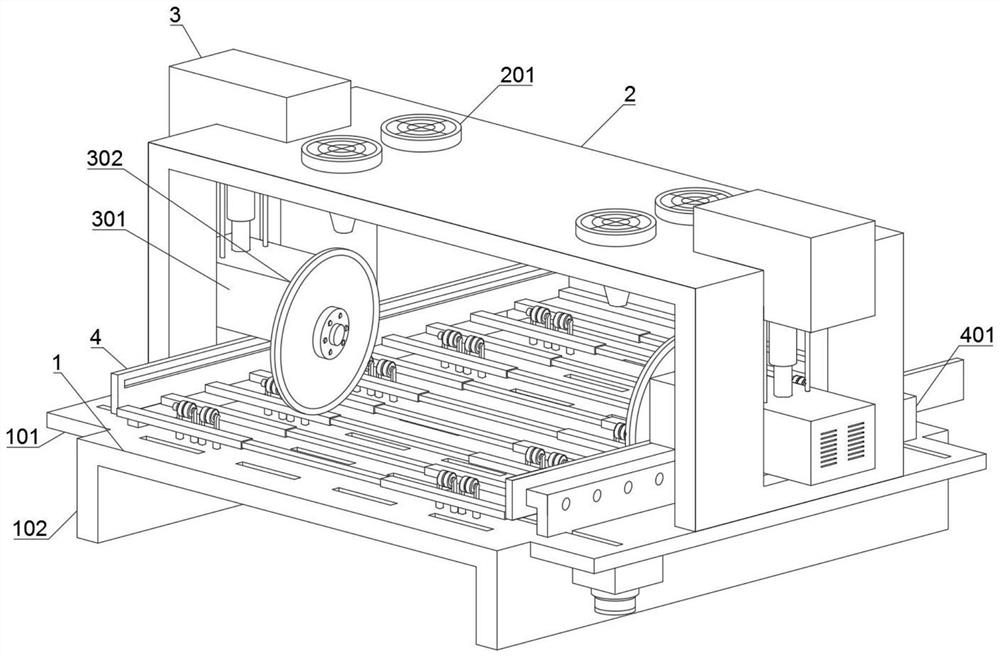

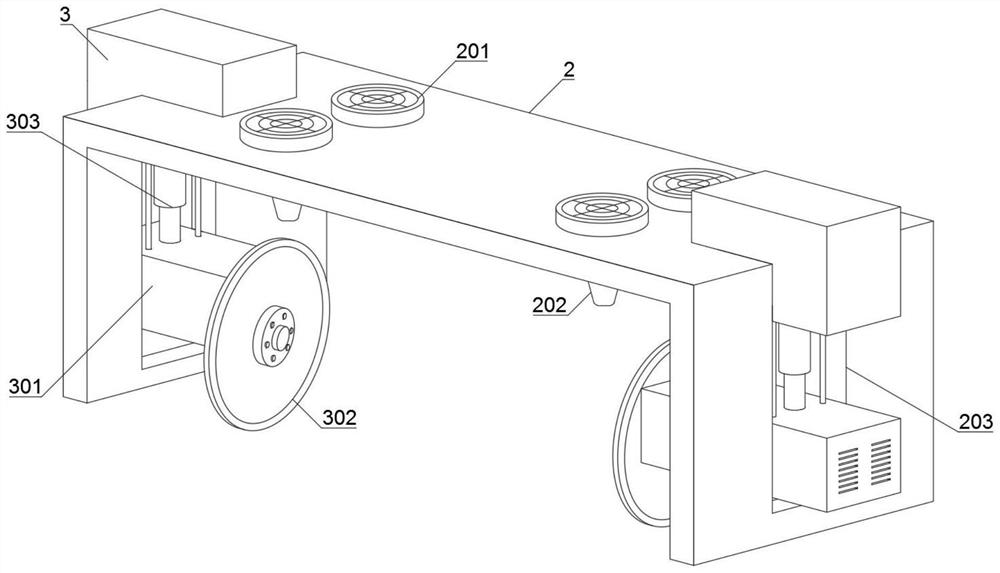

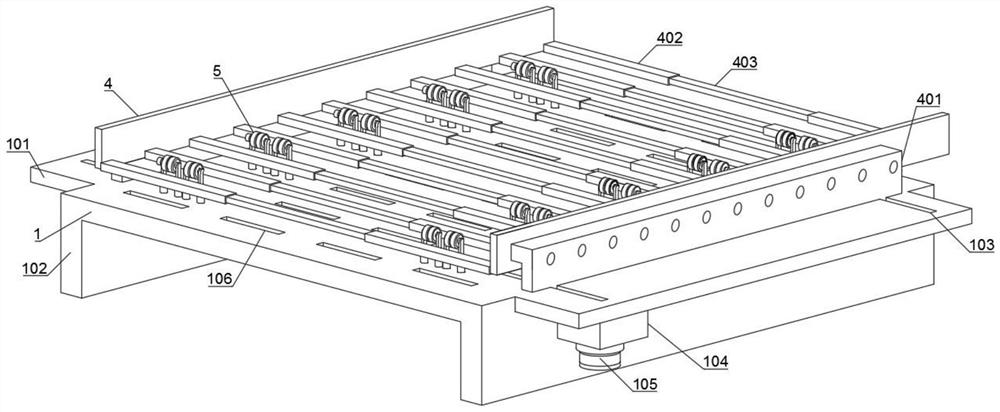

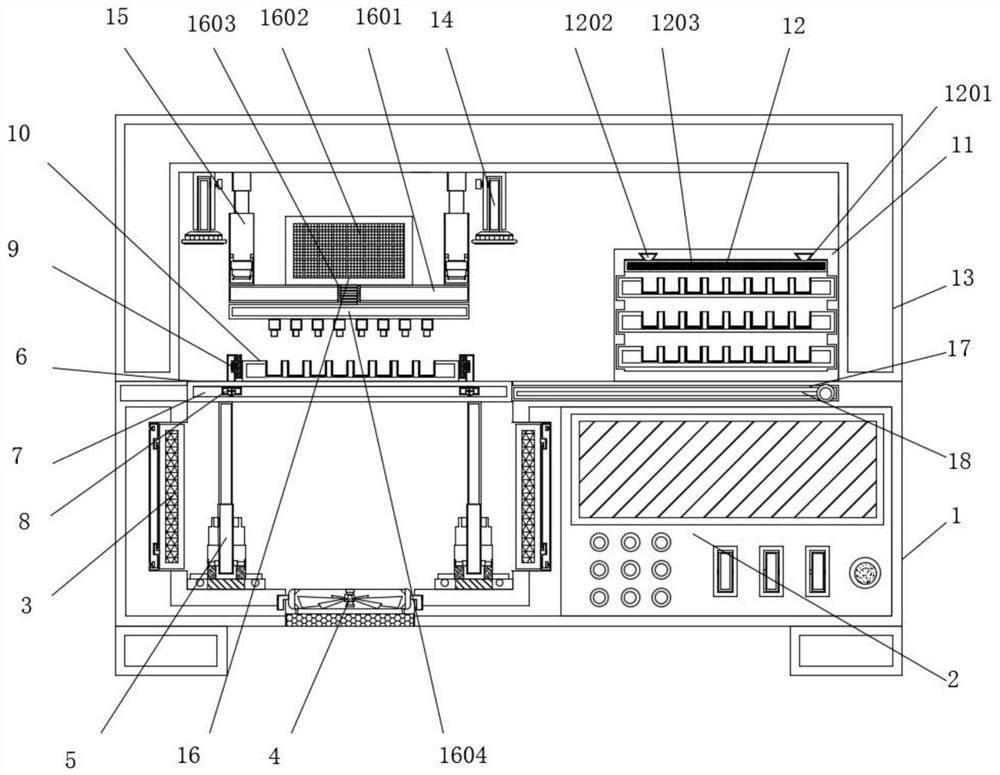

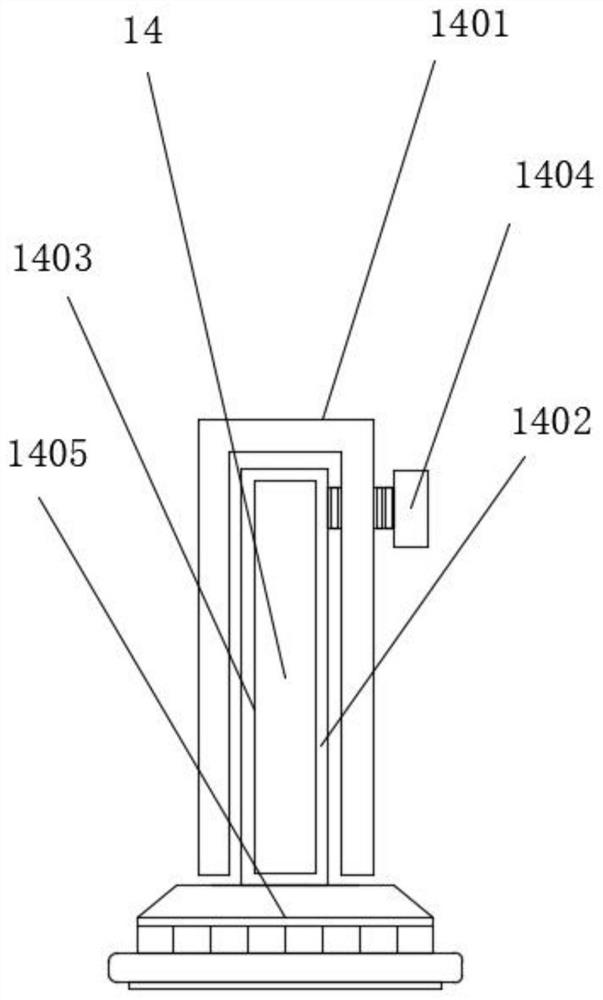

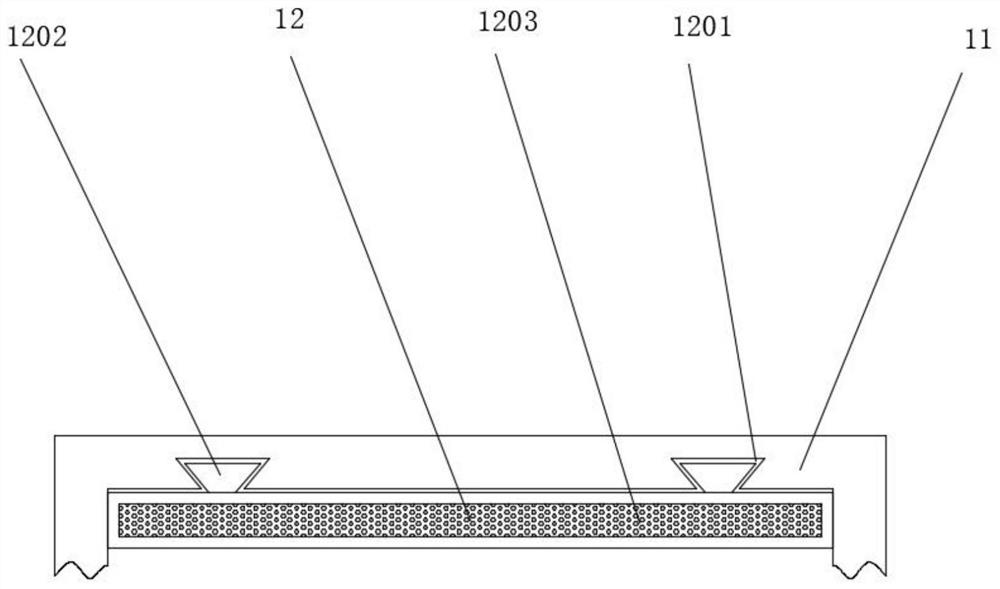

Graphene integrated circuit board polishing and drilling equipment

PendingCN114179162ARealize automatic loading and unloadingImprove work efficiencyGrinding carriagesGrinding drivesEngineeringSlide plate

The graphene integrated circuit board polishing and drilling equipment comprises a machining platform, two hollow sliding rods which are symmetrically arranged are fixedly installed at the top of the machining platform, a same fixing plate is fixedly installed at the tops of the two hollow sliding rods, and two lifting air cylinders are symmetrically arranged at the top of the fixing plate; the two hollow sliding rods are slidably sleeved with the same sliding plate, and the telescopic ends of the two lifting air cylinders penetrate through the top of the fixing plate and are fixedly connected to the top of the sliding plate. According to the automatic feeding and discharging device, automatic feeding and discharging of the circuit board can be achieved, the working efficiency is improved, use is convenient, meanwhile, the circuit board pushed to the position below the sliding plate can be automatically clamped and fixed, manual operation is not needed, the working efficiency is further improved, waste on the surface of the polished and drilled circuit board can be automatically blown away, and the production efficiency is improved. Cleaning of the surface of the circuit board after polishing and drilling is achieved, and the machining effect is prevented from being affected.

Owner:陈让吉

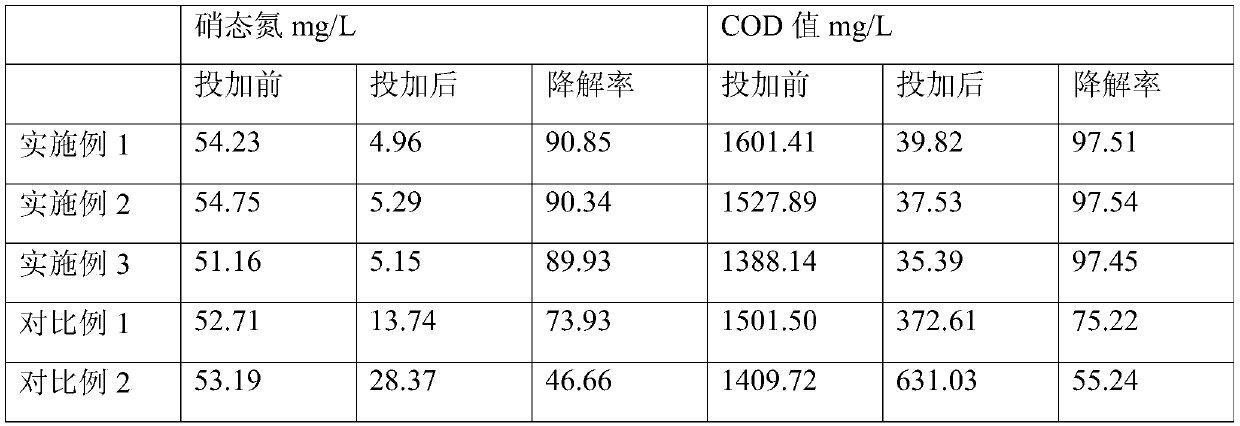

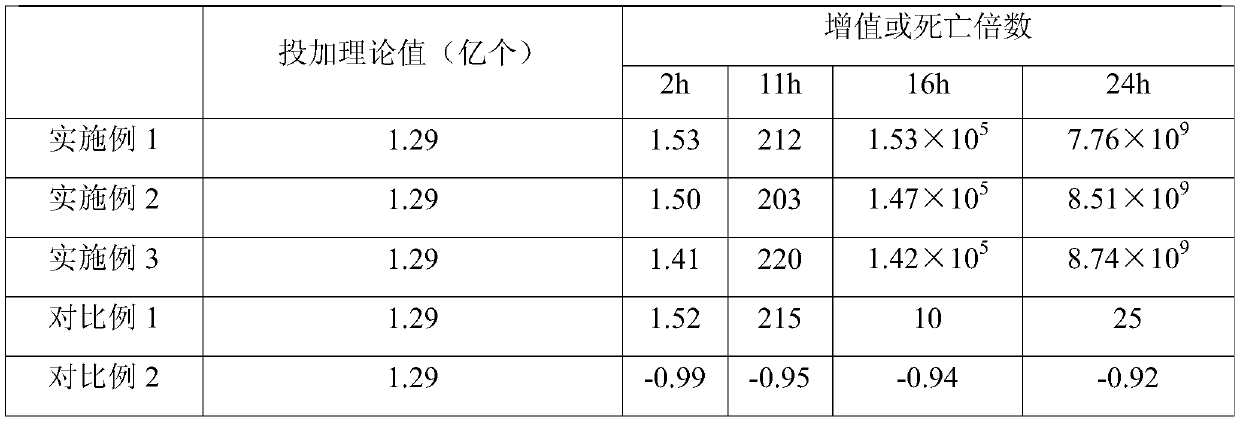

Embedded immobilized microorganism particles, preparation method and sewage treatment method

ActiveCN111333200AImprove purification effectReduce dosageSustainable biological treatmentBiological water/sewage treatmentEnvironmental chemistryOrganosilicon

The invention relates to embedded immobilized microorganism particles, a preparation method and a sewage treatment method. The preparation method comprises the following steps: 1, suspending microorganisms in a liquid culture medium to obtain a microorganism suspension solution; slowly pouring into an adsorbent, stirring, standing for 2 hours, and centrifuging after the adsorbent fully adsorbs themicroorganism suspension solution to obtain an adsorbent adsorbed with microorganisms; 2, dissolving polyvinyl alcohol and agar in water, adding an adsorbent adsorbed with microorganisms, stirring uniformly, cooling, and cutting into particles to obtain immobilized microorganism particles; and step 3, uniformly mixing the cement, the porous ore, the porous carbon fiber and the organic silicon cross-linking agent, adding water into the mixture, continuously stirring until the mixture is uniformly mixed, spraying the mixture on the surfaces of the immobilized microorganism particles, and curing. After the microorganisms are embedded and immobilized by adopting the method, the survival rate of the microorganisms in sewage is high, and the sewage treatment effect is good.

Owner:YUNCHENG UNIVERISTY

Forging and pressing equipment for aluminum metal machining

InactiveCN108787973AAchieve clampingImprove stabilityDirt cleaningForging/hammering/pressing machinesCouplingFuel tank

The invention provides forging and pressing equipment for aluminum metal machining. The forging and pressing equipment comprises a worktable. A light projector and a light receptor are fixedly mountedon the left side and the right side of the worktable correspondingly. A supporting column is fixedly mounted on the right side of the worktable. A supporting plate is fixedly mounted at the top of the supporting column. An oil tank is fixedly mounted at the top of the supporting plate. A motor and an oil pump are arranged inside the oil tank, and the motor is in transmission connection with the oil pump through a coupling. According to the forging and pressing equipment for aluminum metal machining, through an arranged speed controller, when the pressure needs to be adjusted, a forging and pressing strength knob is turned, the speed of a transmission is adjusted, the rotating speed of the motor is controlled by the transmission, the pressure of a forging and pressing hammer can be changedaccording to the need, and thus the machining efficiency is improved; and a gear is driven to rotate by a second motor and drives a supporting rod to move in the left-right direction on the worktable, aluminum metal is clamped tightly, and a sliding rail is arranged on the worktable.

Owner:芜湖市涵润智能科技有限公司

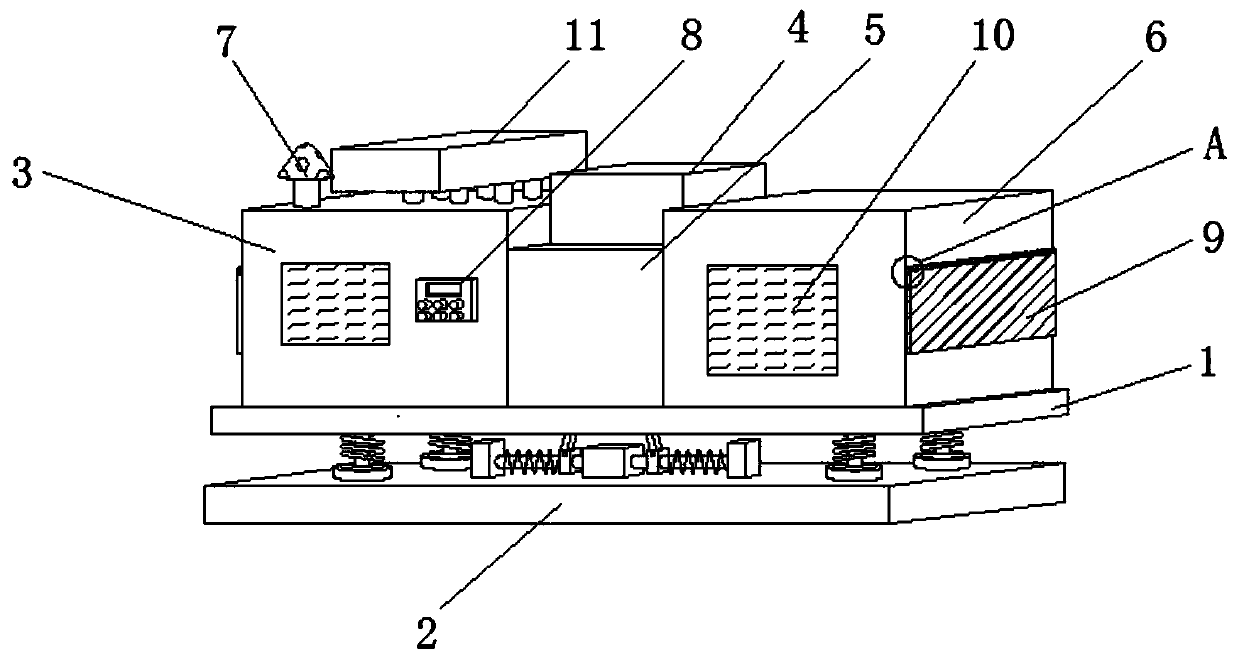

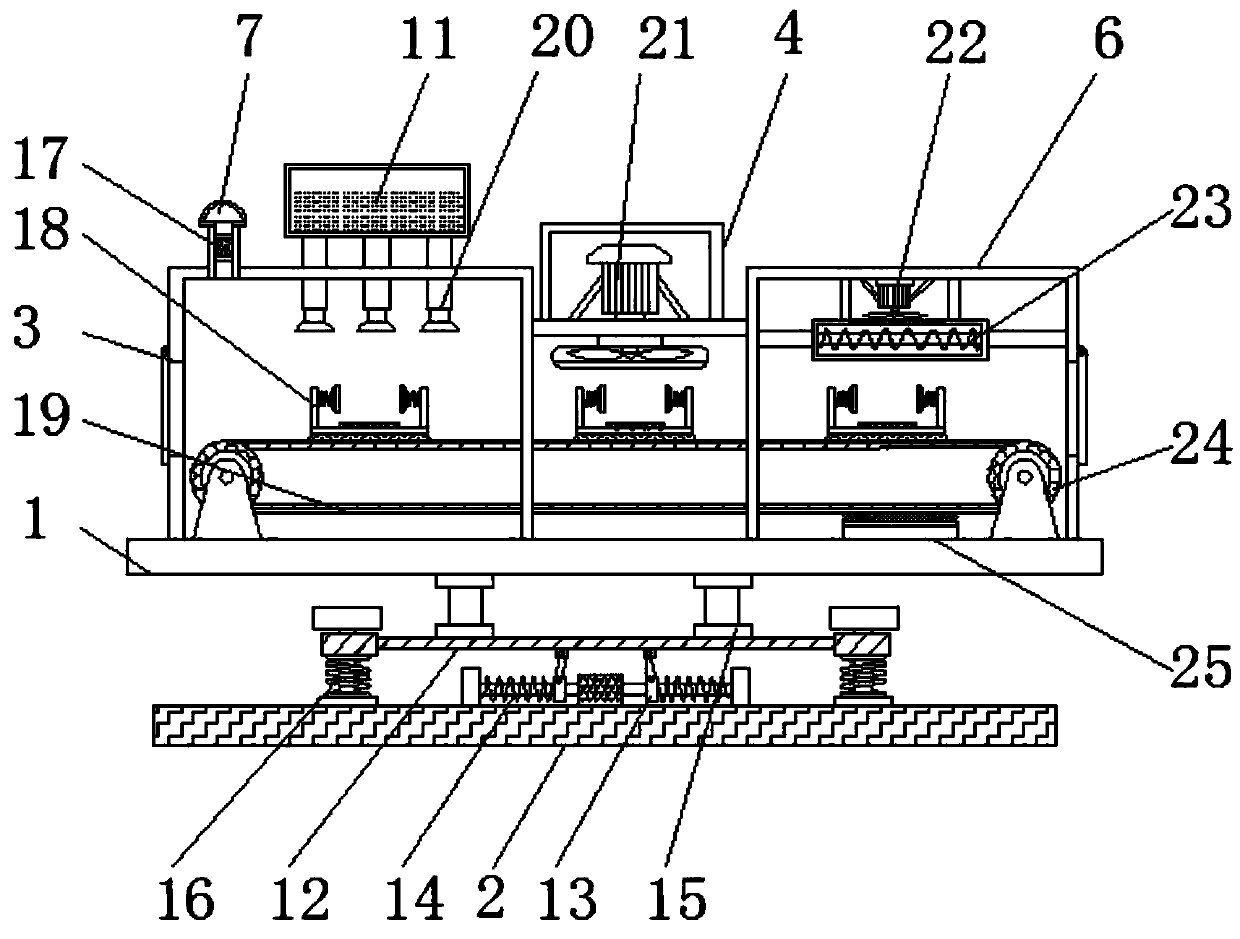

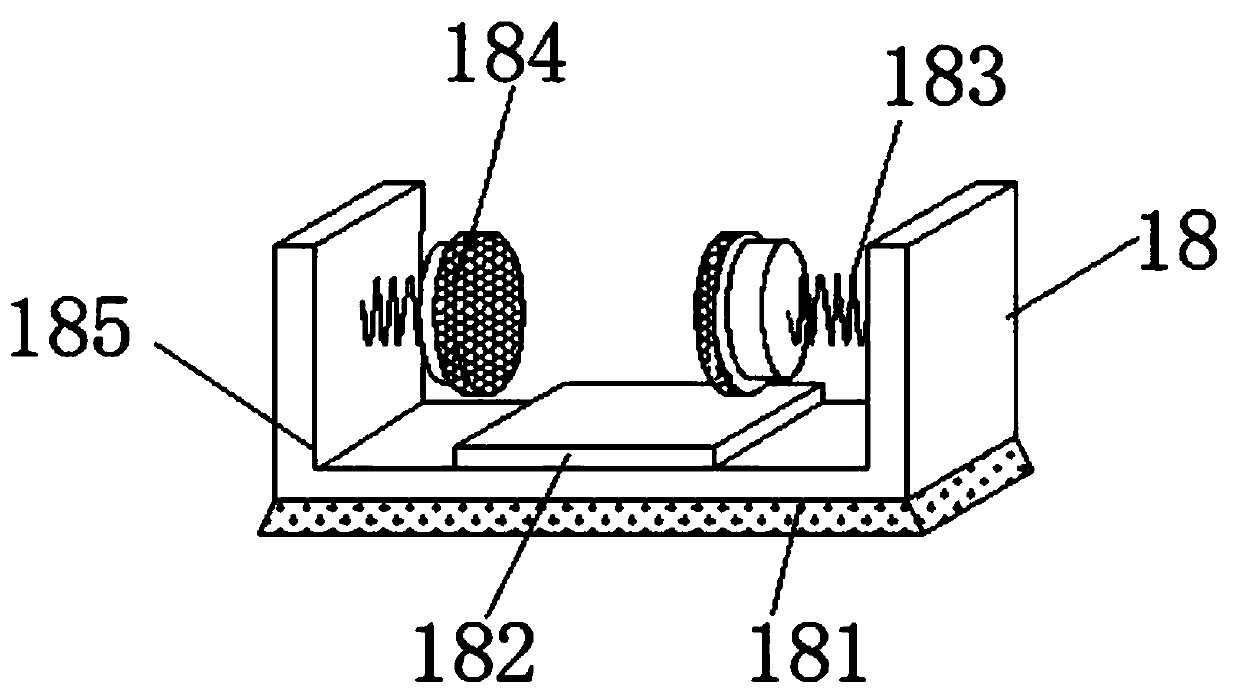

Electrophoresis spraying machine device for automobile accessories

InactiveCN110548633AEasy to compressEasy to disassemble and useSpray boothsElectrophoresisEngineering

The invention discloses an electrophoresis spraying machine device for automobile accessories. The device comprises a supporting plate, wherein a base is arranged at the lower end of the supporting plate, and a painting chamber is arranged at the upper end of the supporting plate; an air blowing chamber is arranged at one side of the painting chamber, and a control panel is arranged on the front surface of the painting chamber; a vent hole is formed in the upper end of the painting chamber, and a fixing device is arranged in the painting chamber; and an electric spray gun is arranged at the upper end of the fixing device, and a conveying belt is arranged at the lower end of the fixing device. According to the device, a damping spring and a compression spring are arranged, and the damping spring can be conveniently compressed through an adjusting rod, so that the vibration of the device in use is buffered; and meanwhile, the adjusting rod is capable of compressing the compression springwhile a transverse slide connection sleeve forwards and backwards swings, and thus the device in use can be buffered again; double-buffer reduces the loss of inner original parts in work, and thus the service life of the device is greatly prolonged.

Owner:TIANJIN CITY XINLIHUA COLOR MATERIAL

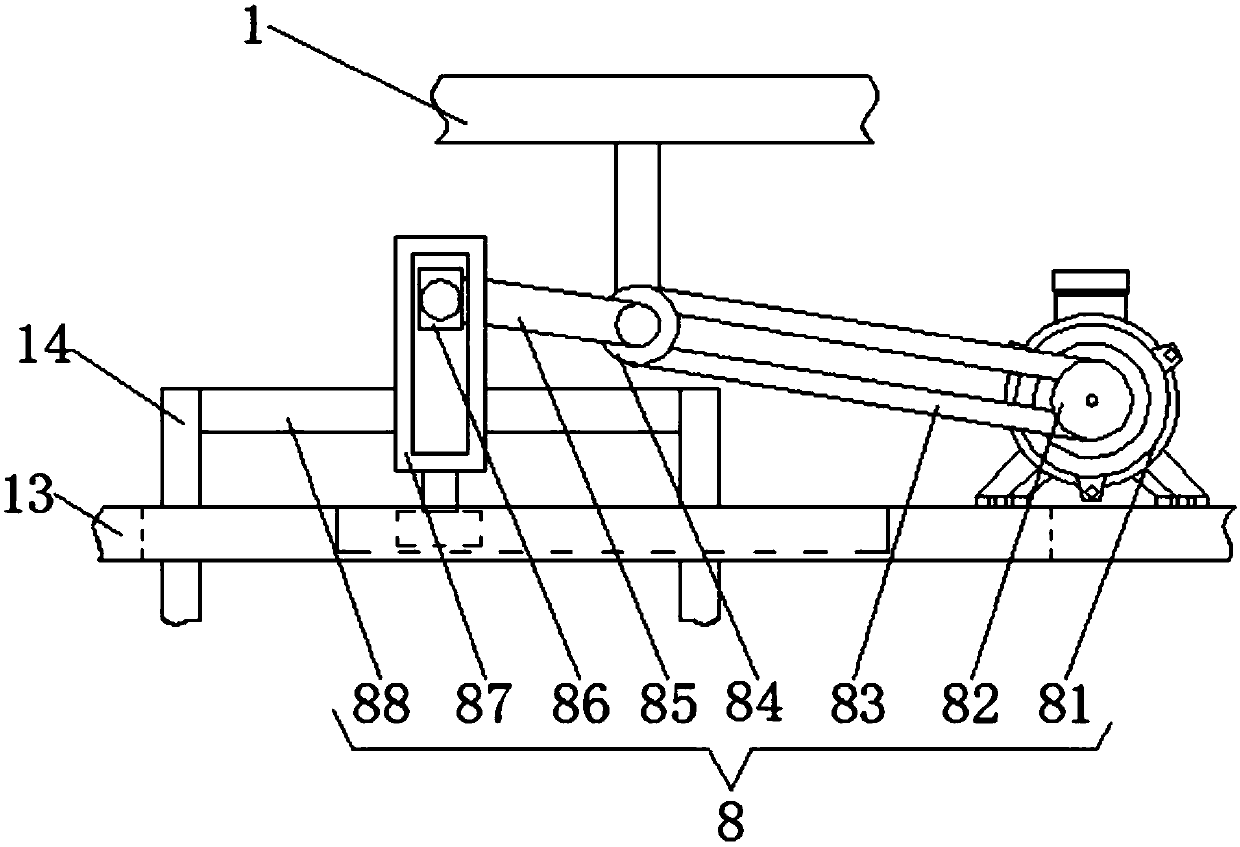

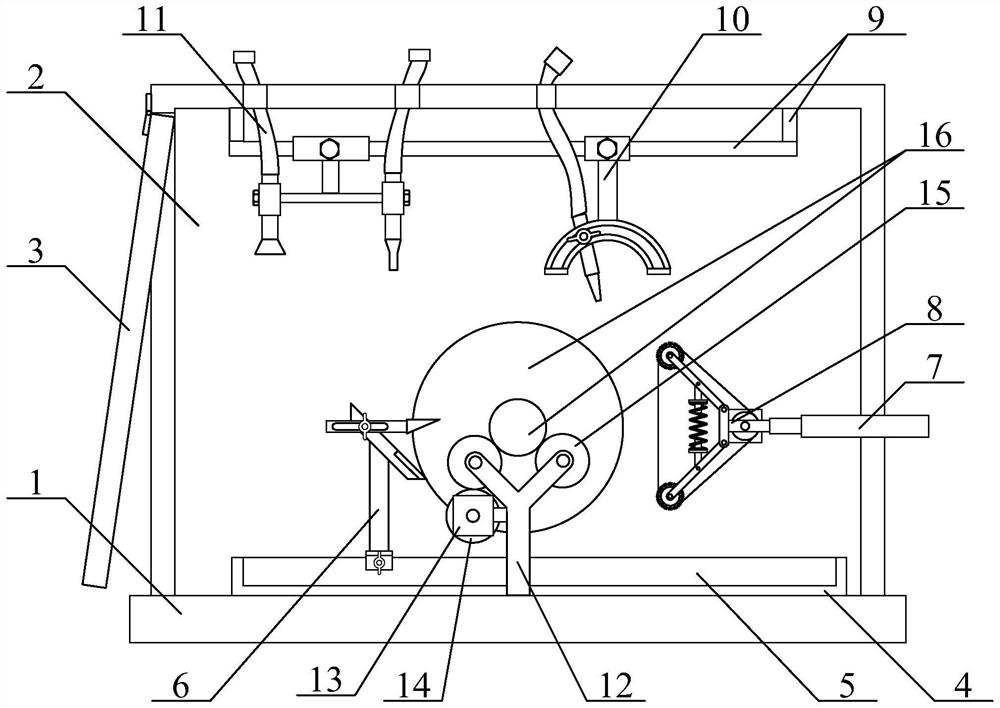

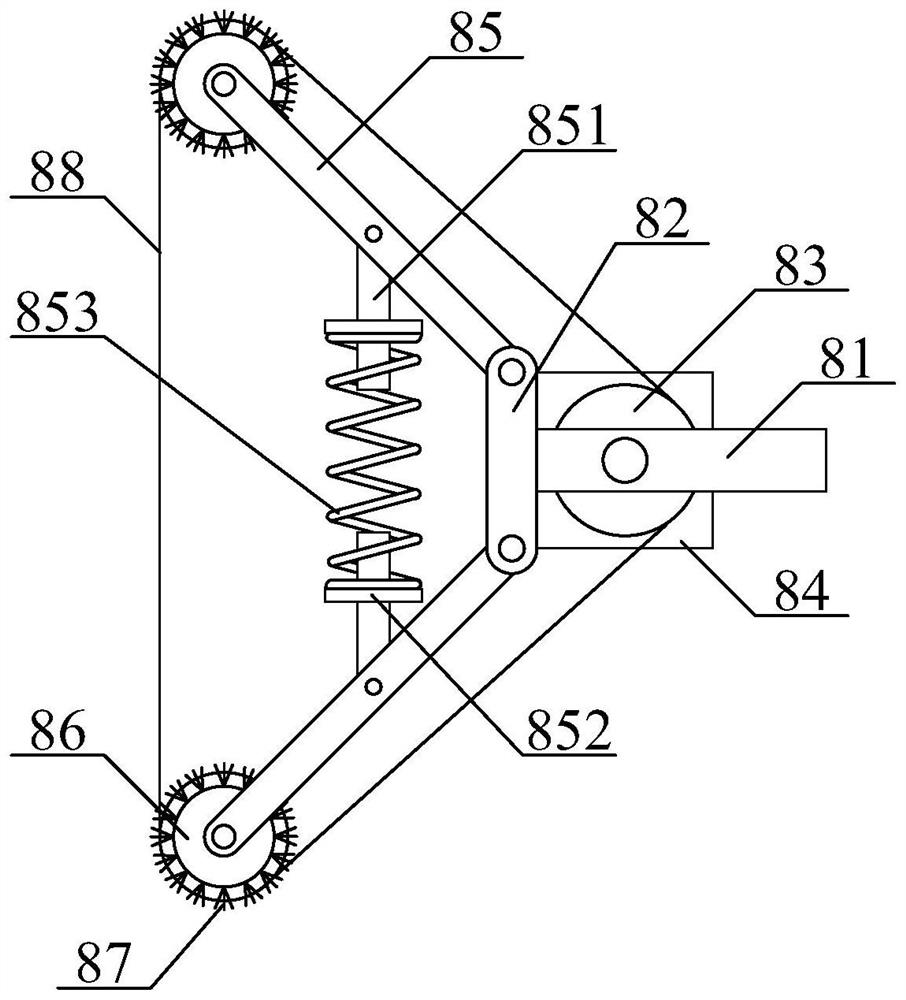

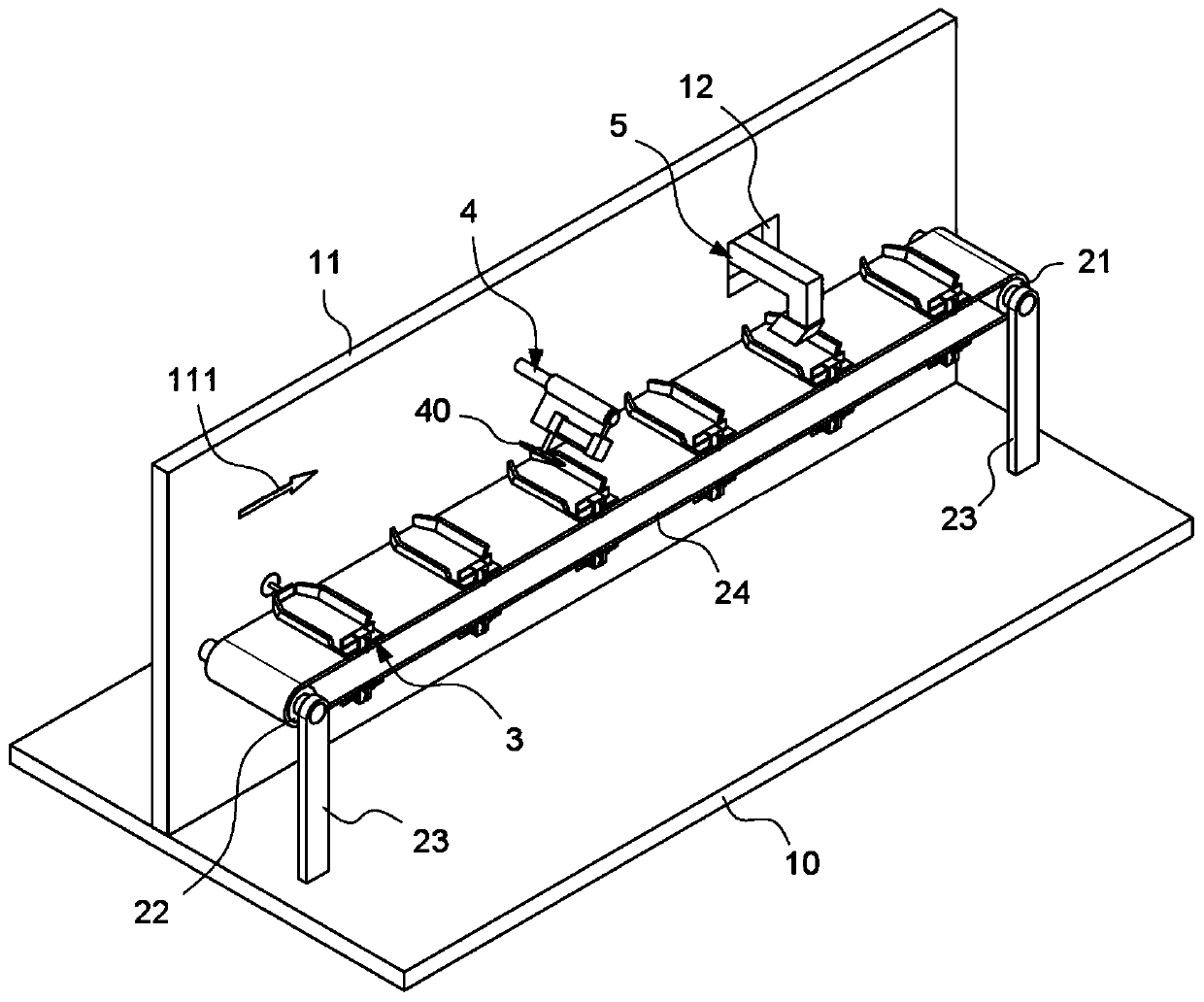

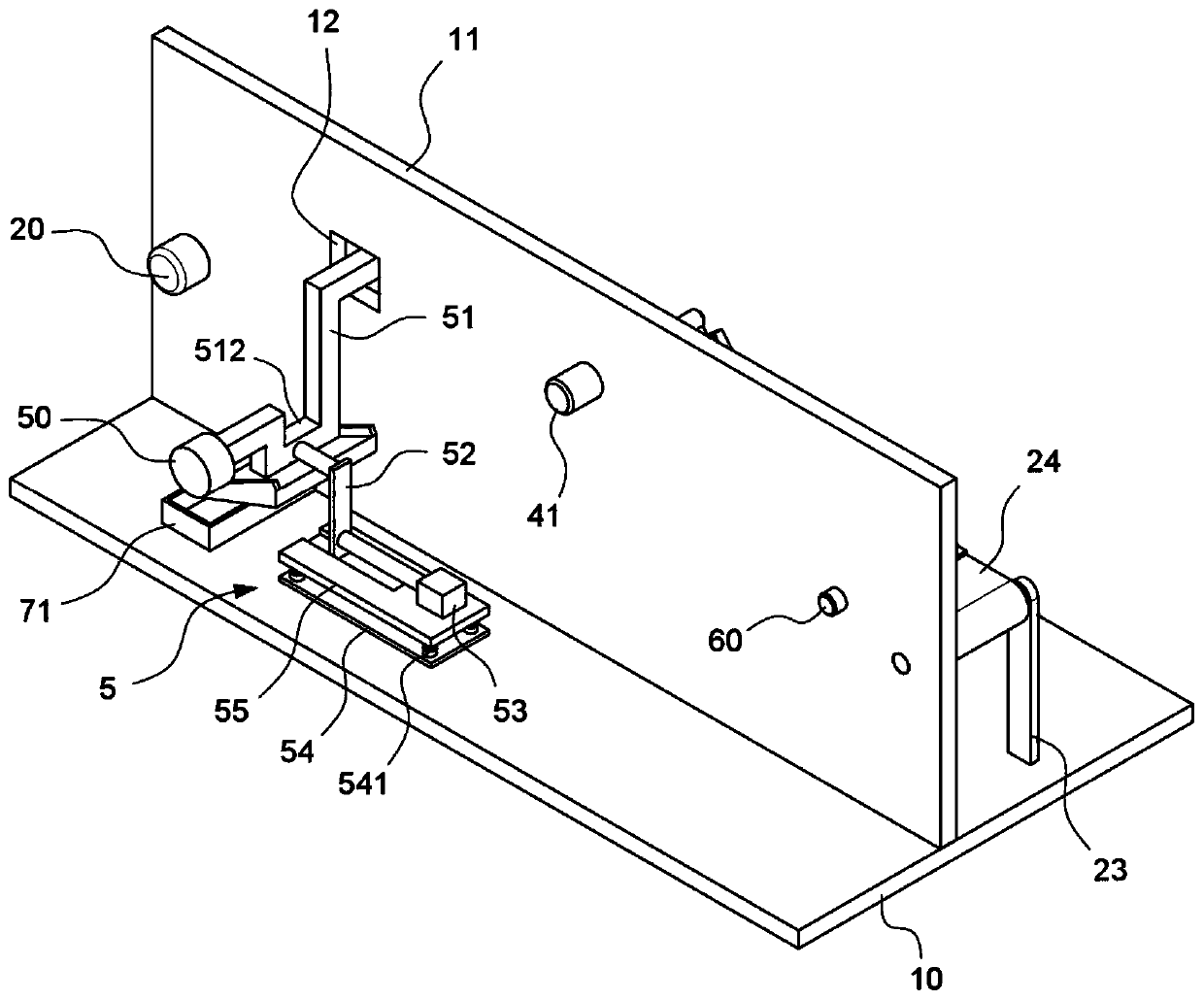

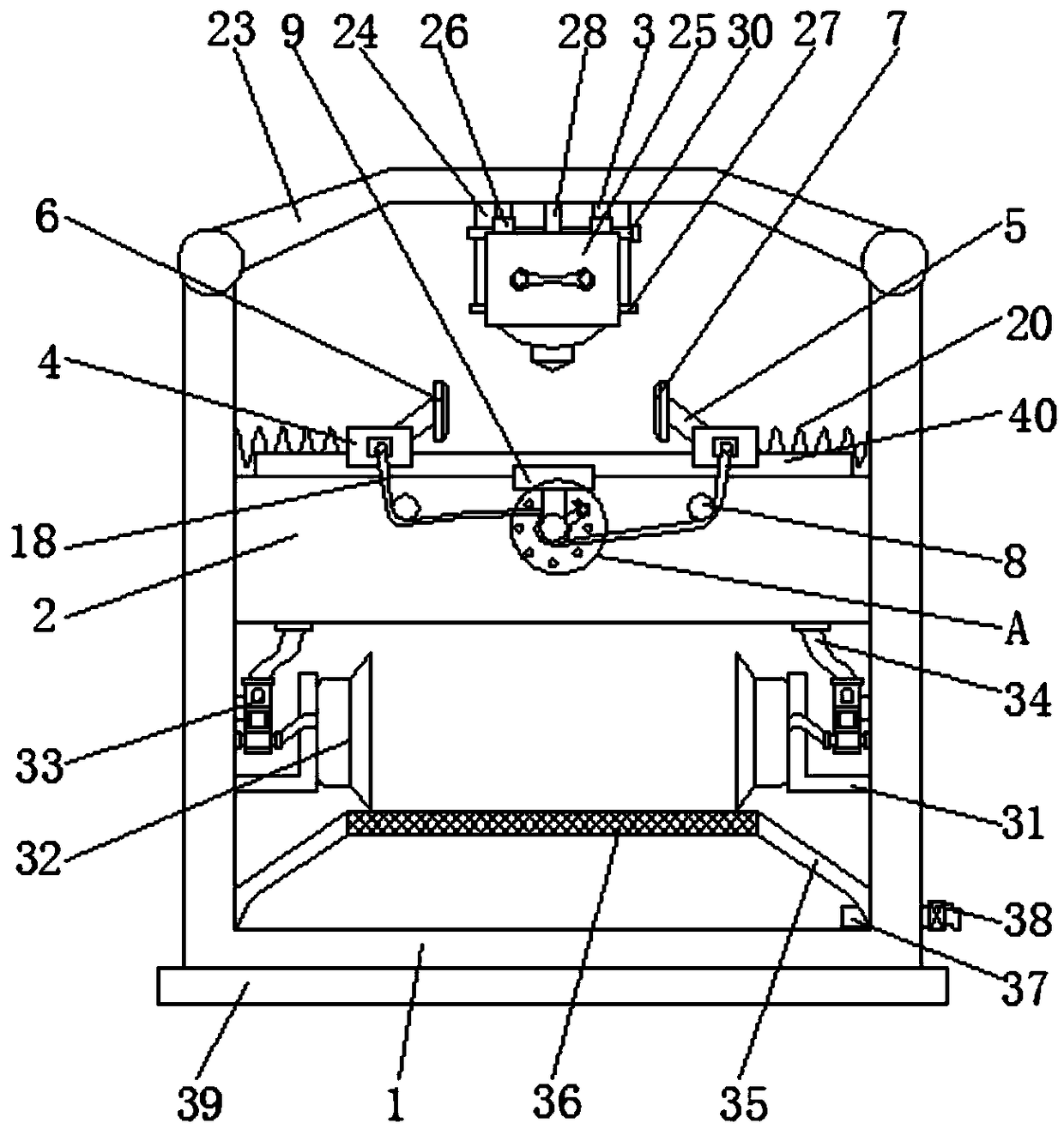

Fish belly dissecting and viscera removing machine

The invention discloses a fish belly dissecting and viscera removing machine. The fish belly dissecting and viscera removing machine comprises a rack, a guiding and feeding unit, a plurality of fish body fixing units, a fish belly dissecting unit and a viscera sucking-out unit, wherein the rack comprises a bottom rack seated on an operation bottom surface and a supporting rack fixed on the top ofthe bottom rack; the guiding and feeding unit is used for conveying processed fish bodies; the fish body fixing units are used for fixing the processed fish bodies; the fish belly dissecting unit is used for cutting the processed fish bodies fixed on the fish body fixing unit; and the viscera sucking-out unit is used for removing the viscera of the fish bodies. According to the fish belly dissecting and viscera removing machine provided by the invention, the processed fish bodies can be fixed and dissected, viscera are removed and the fish bodies are released in a programmed mode, while the processing quality is guaranteed, the labor intensity of operators is greatly reduced, the viscera of the fish bodies are separated from the processed fish bodies under the action of an adsorption fan,and are guided to a viscera receiving disc to be recovered in time, so that a large amount of fishy smell is prevented, and pollution to the environment is avoided.

Owner:WUHAN POLYTECHNIC UNIVERSITY

PTA wastewater sectionalizing separating and cobalt-manganese recycling method

InactiveCN104058514AInfluence activityReduce loadMultistage water/sewage treatmentProcess efficiency improvementManganeseWastewater

The invention relates to a PTA wastewater sectionalizing separating and cobalt-manganese recycling method. The method comprises three independent reaction steps, wherein the first step is a PTA wastewater fine particle foreign material filtering step comprising removing a fine particle foreign material through a solid-liquid separation device and adjusting the pH value to recycling PA and PT acids with the pH value of 3-5; the second step is a pH value-adjusting and iron-removing step comprising introducing the wastewater into a first-section regulating tank and carrying out oxidation coagulation with the pH value of 6-6.5; and the third step is a pH value-adjusting and cobalt-manganese removing step comprising introducing the wastewater into a second-section regulating tank and carrying out oxidation coagulation with the pH value of 9-9.5. The steps are simple and are independently separately performed, the PA and PT acids are recycled, cobalt and manganese ions in the wastewater are greatly reduced, the load of wastewater treatment is reduced, and the cost is saved.

Owner:WUXI XINGSHENG ENVIRONMENTAL PROTECTION EQUIPCO

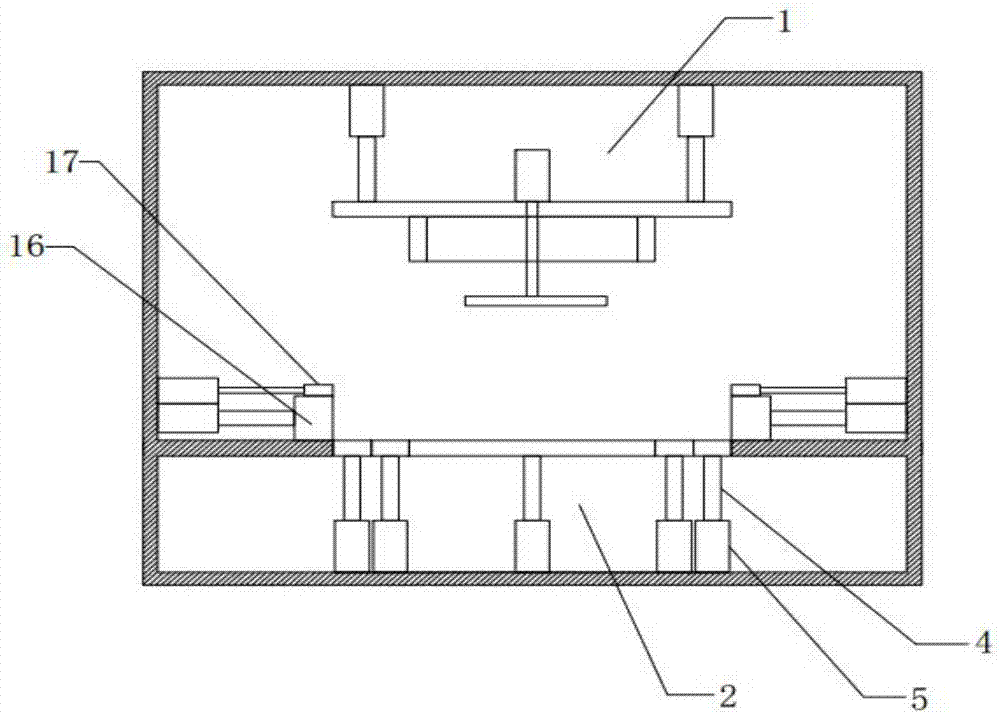

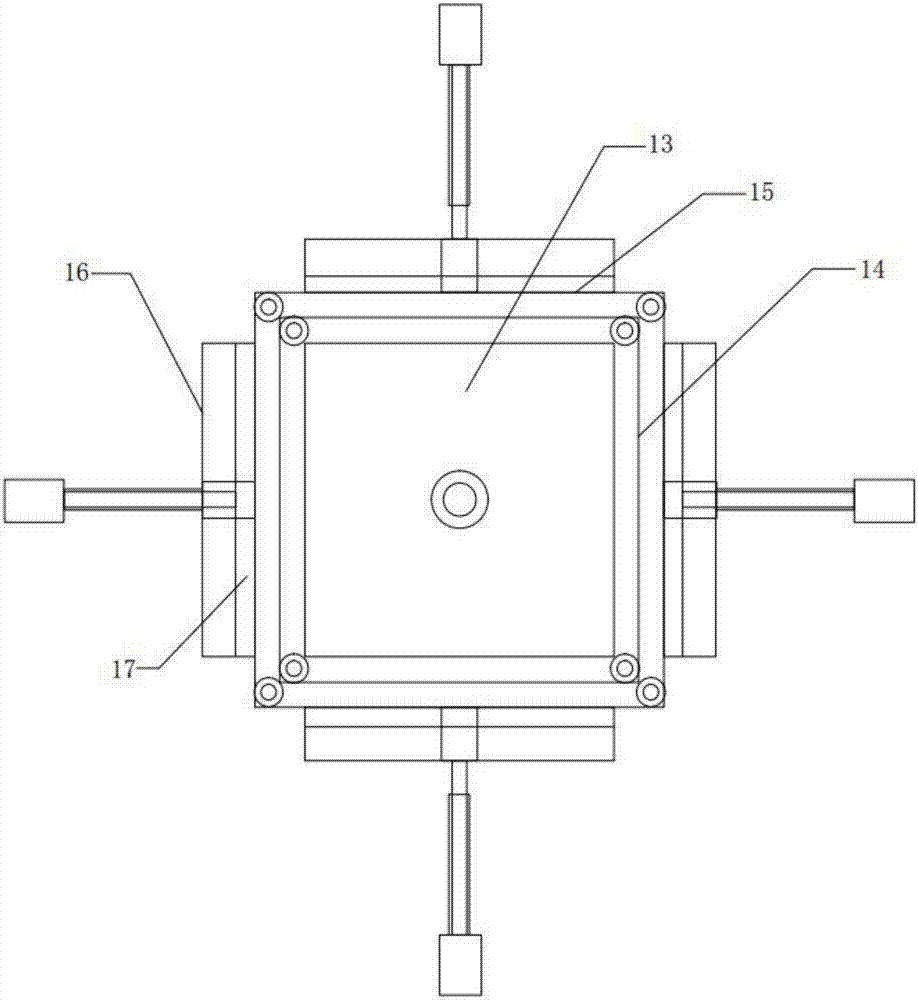

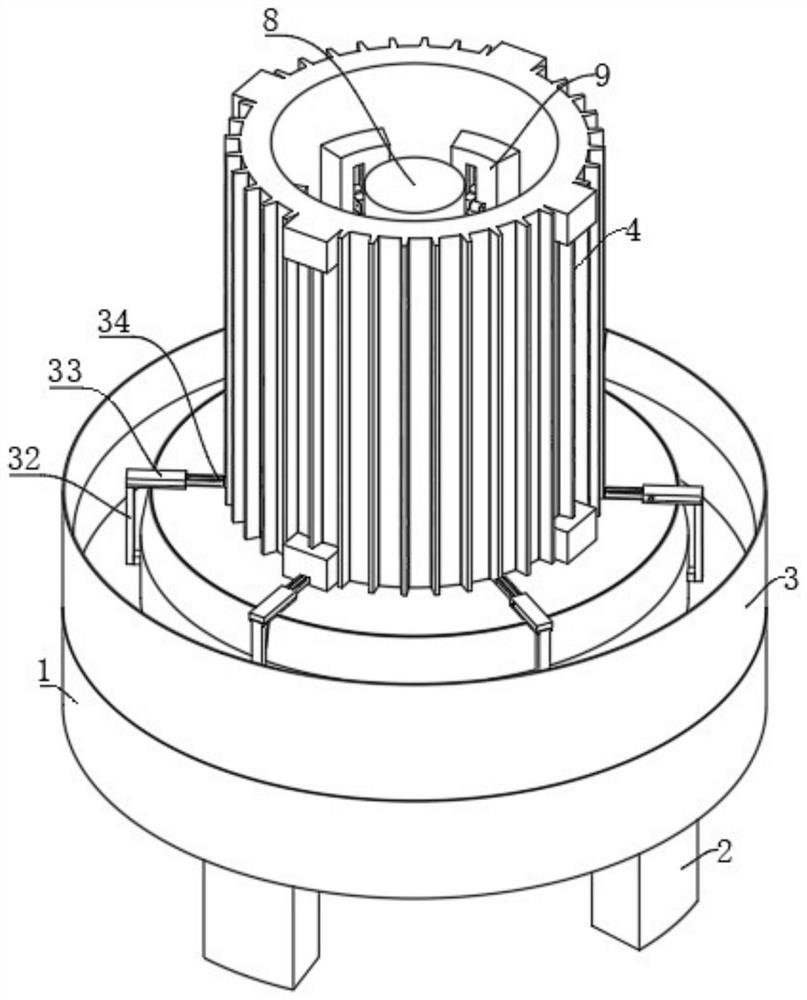

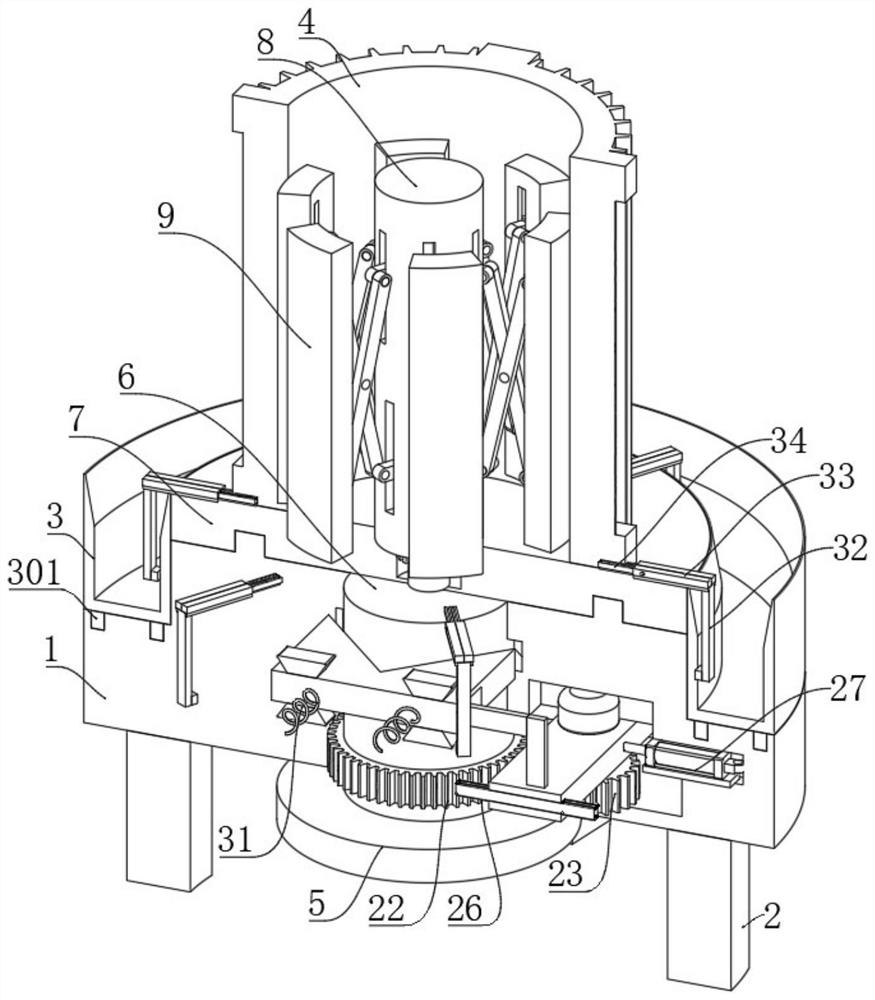

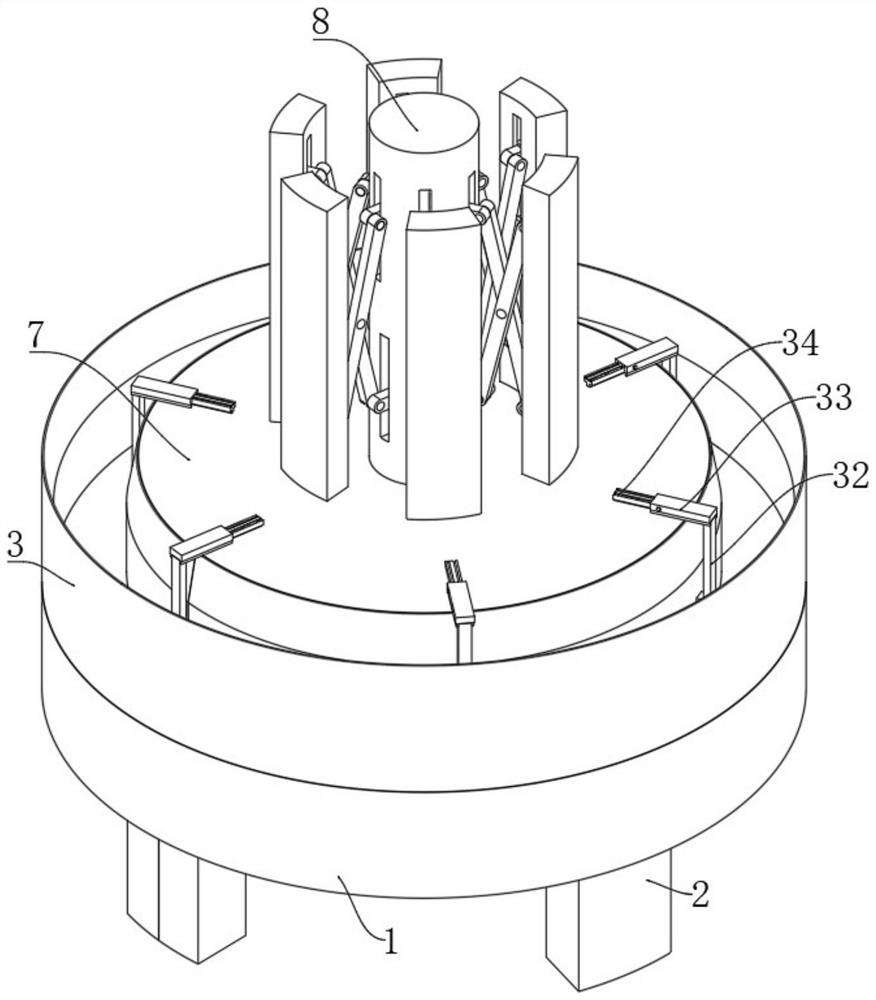

Numerical control machining equipment for producing motor shell for new energy vehicle

ActiveCN114248131ARealize axial rotation adjustmentAxial rotation adjustment is normalWork clamping meansPositioning apparatusNumerical controlNew energy

The new energy vehicle motor shell production numerical control machining equipment comprises a machining platform and a motor shell assembling assembly arranged on the machining platform, the motor shell assembling assembly sequentially comprises a stand column, an upper limiting table, a center column and a lower limiting disc from top to bottom, and the upper limiting table is rotationally installed on the upper end face of the machining platform; the center column is driven by a first driving device to rotate, a center column axial limiting mechanism is arranged in the machining platform, a motor shell is placed at the upper end of the upper limiting table, a motor shell clamping mechanism is arranged on the stand column and mainly comprises a plurality of inner pressing strips, each inner pressing strip is movably connected with a set of X-shaped hinge pieces, and the inner pressing strips are movably connected with the motor shell clamping mechanism. And the plurality of X-shaped hinging pieces are driven by a second driving device to do telescopic motion. While the motor shell is stably clamped, the position of the motor shell can be correspondingly adjusted according to requirements, and the production efficiency of the motor shell is effectively improved.

Owner:深圳市金卓五金塑胶制品有限公司

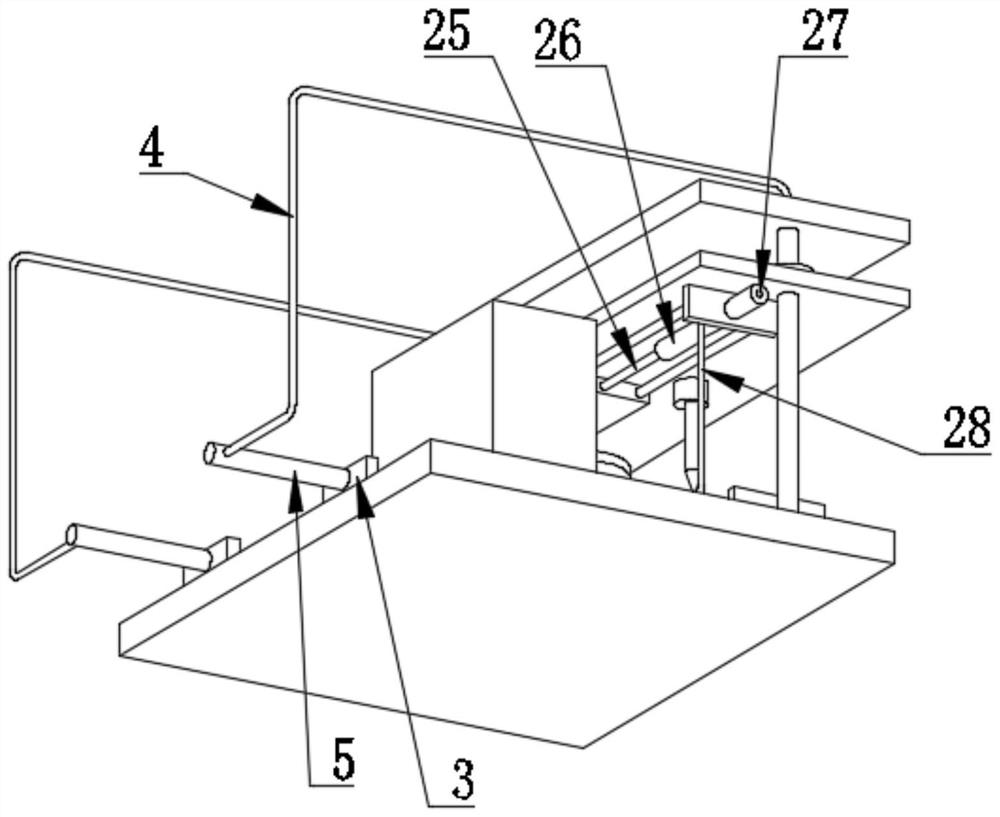

Decorative plate positioning and cutting device and method capable of measuring edge distance

ActiveCN114453949AGuaranteed stabilitySimple structureProfiling/shaping machinesMeasurement/indication equipmentsLaser transmitterLaser ranging

The invention discloses a decorative plate positioning and cutting device and method capable of measuring the edge distance, and belongs to the technical field of decorative plate machining. In order to solve the problems that a decorative plate is inconvenient to fix, the positioning effect is poor, and a cutting device cannot be rapidly adjusted according to the edge distance requirement of the plate, the decorative plate needing to be positioned and cut is placed above a workbench and is supported through a fixing sleeve plate above the workbench, and a servo motor below the workbench is started according to the length required by machining; a servo motor drives a threaded rod to rotate, so that a movable baffle and a movable limiting frame move, the position of a telescopic sliding rod in a fixed sleeve plate is adjusted, the two sides of a decorative plate are attached and extruded, positioning work is conducted, and therefore the position of the decorative plate can be limited, the stable effect is kept, and a laser transmitter is turned on; the position between the decorative plate and the movable baffle is sensed through the laser distance measuring sensor, the pressure sensor in the fixed sleeve plate is matched for sensing, and the two sides of the decorative plate are measured.

Owner:江苏索亚建筑装饰新材料有限公司

Smoke-free grill

PendingCN110123150AUniform temperatureNo smoke effectDispersed particle filtrationRoasting apparatusExhaust gas emissionsEngineering

The invention relates to a smoke-free grill, and belongs to the field of kitchen supplies. The smoke-free grill comprises a grill body, a grill body upper cover, a front door, a rotary hanging frame,a gas inlet inner pipe, an exhaust gas emission cylinder and a filtering part; one side of the grill body is provided with an opening for dishes to be placed on; the grill body upper cover is fixedlyconnected to the top of the grill body; the bottom of the grill body upper cover is provided with a first sliding groove, and the top of the front door is slidably formed in the first sliding groove;the rotary hanging frame is located in the grill body; one end of the gas inlet inner pipe is connected with the outer wall of the grill body; the exhaust gas emission cylinder fixedly sleeves the gasinlet inner pipe, and one end of the exhaust gas emission cylinder is connected with the grill body; the filtering part is fixedly arranged between the exhaust gas emission cylinder and the gas inletinner pipe. The smoke-free grill has the advantages that exhaust gas can be treated, and particles in the exhaust gas are filtered out, so that emitted exhaust gas does not contain the particles.

Owner:GUIZHOU MINZU UNIV

Device for processing flat steel

The invention discloses a device for processing flat steel. The device comprises a supporting base, a power system and a clamping plate, wherein the clamping plate is connected with the supporting base; the supporting base comprises a supporting plate and a supporting pillar; a through hole is formed on the middle part of the supporting plate; two slide slots are formed on the supporting plate; the clamping plate comprises a base plate and two clamping bases; the base plate is fixedly connected with the clamping bases; U-shaped slots are formed on the clamping bases; slide blocks corresponding to the slide slots are arranged at the bottom of the clamping bases; openings of the U-shaped slots on the two clamping bases are opposite to each other; two sleeves are arranged on the supporting base; thread holes are arranged as inner holes of the sleeves; a screw rod is arranged in the thread holes; a baffle is arranged on an end part of the screw rod close to the clamping plate; the power system comprises a motor, a rotating shaft and a rotating rod; idler wheels are arranged at the two ends of the rotating rod; the rotating shaft is connected with the motor through a flange; a thrust bearing is arranged at the through hole on the supporting plate; the rotating shaft passes through the through hole on the supporting plate. The device for processing flat steel overcomes the defect of low working efficiency during the process of bending the flat steel in the processing of flat steel spring in the prior art.

Owner:CHONGQING ANTAI SPRING IND

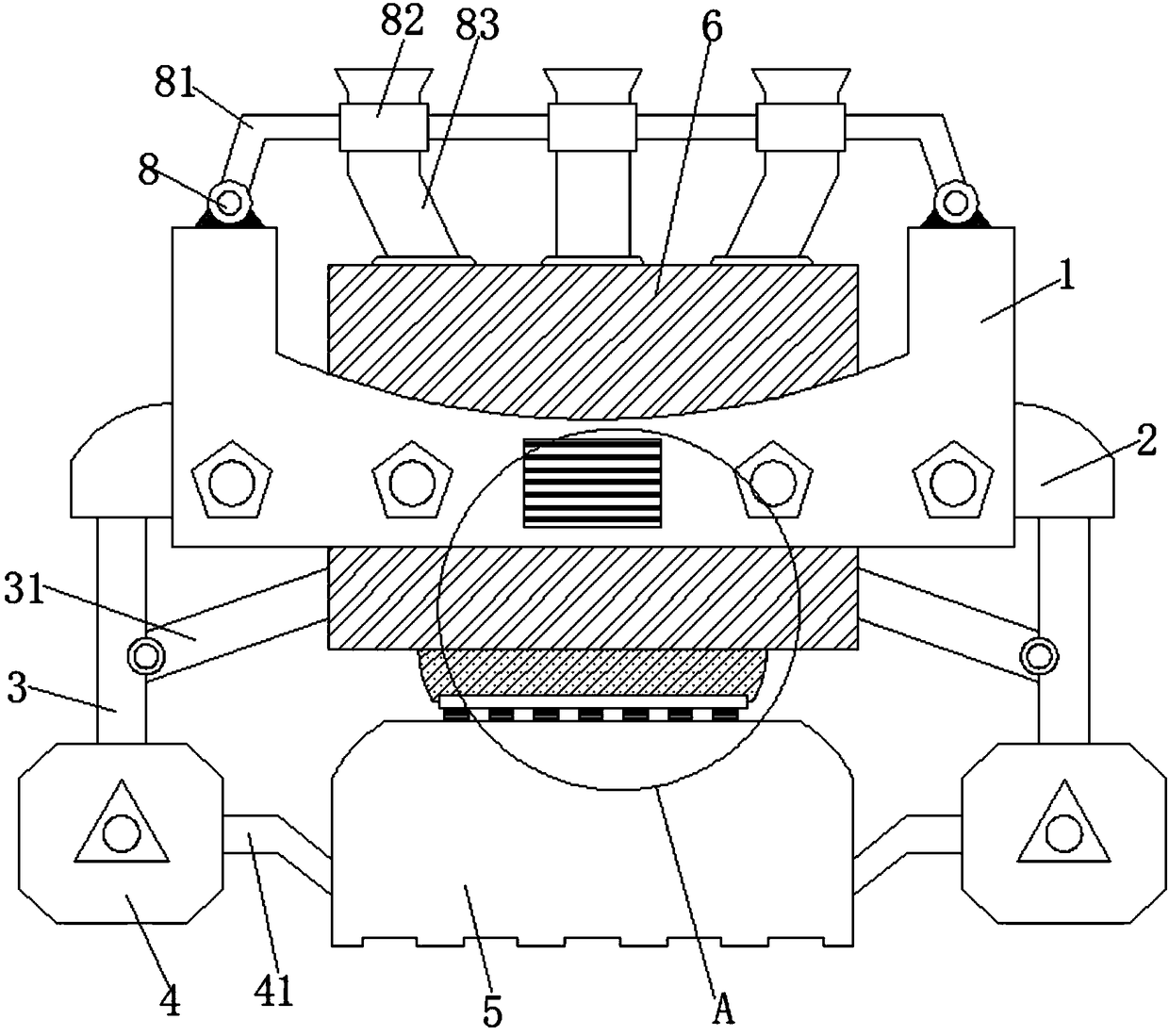

Blanking type environment-friendly papermaking raw material processing and pulping equipment based on three-pipe channel

InactiveCN108411670AReduce deliveryEasy to processRaw material divisionRaw material pretreatmentMotor drivePulp and paper industry

The invention relates to the technical field of environmental protection and discloses blanking type environment-friendly papermaking raw material processing and pulping device based on a three-pipe channel. The equipment comprises a mechanical positioning frame; fixing convex blocks are protruded on the two sides, located on the outer surface, of the mechanical positioning frame respectively; supporting frames are inserted into the bottoms of the inner sides of the two fixing convex blocks respectively; one ends of the bottoms of the two supporting frames penetrate through and extend to the middles of inner cavities of two octagonal supporting bases respectively, and connecting protection frames are welded to one sides of the two octagonal supporting bases respectively; one ends of the two connecting protection frames are welded to the two sides of a material receiving box respectively, and a processing device penetrates through and is connected to the middle of an inner cavity of themechanical positioning frame. According to the blanking type environment-friendly papermaking raw material processing and pulping equipment based on the three-pipe channel, a motor drives a materialstirring device to rotate so that not only can raw materials for pulping be processed, but also impurities attached to the raw materials can be precipitated through a centrifugal force during pulpingto prevent the situation that environmental pollution is caused when the impurities are discharged to the outside.

Owner:闫光

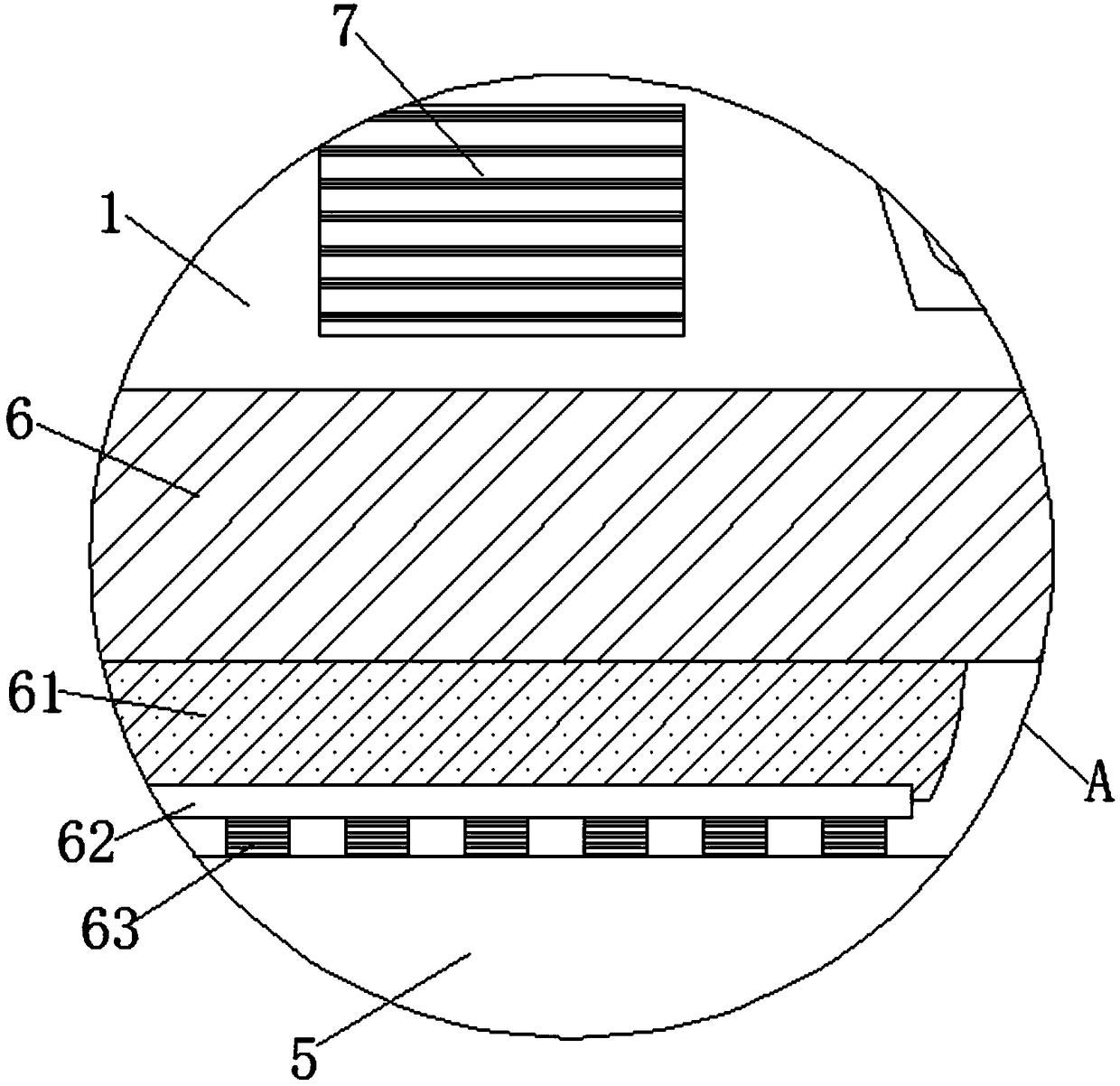

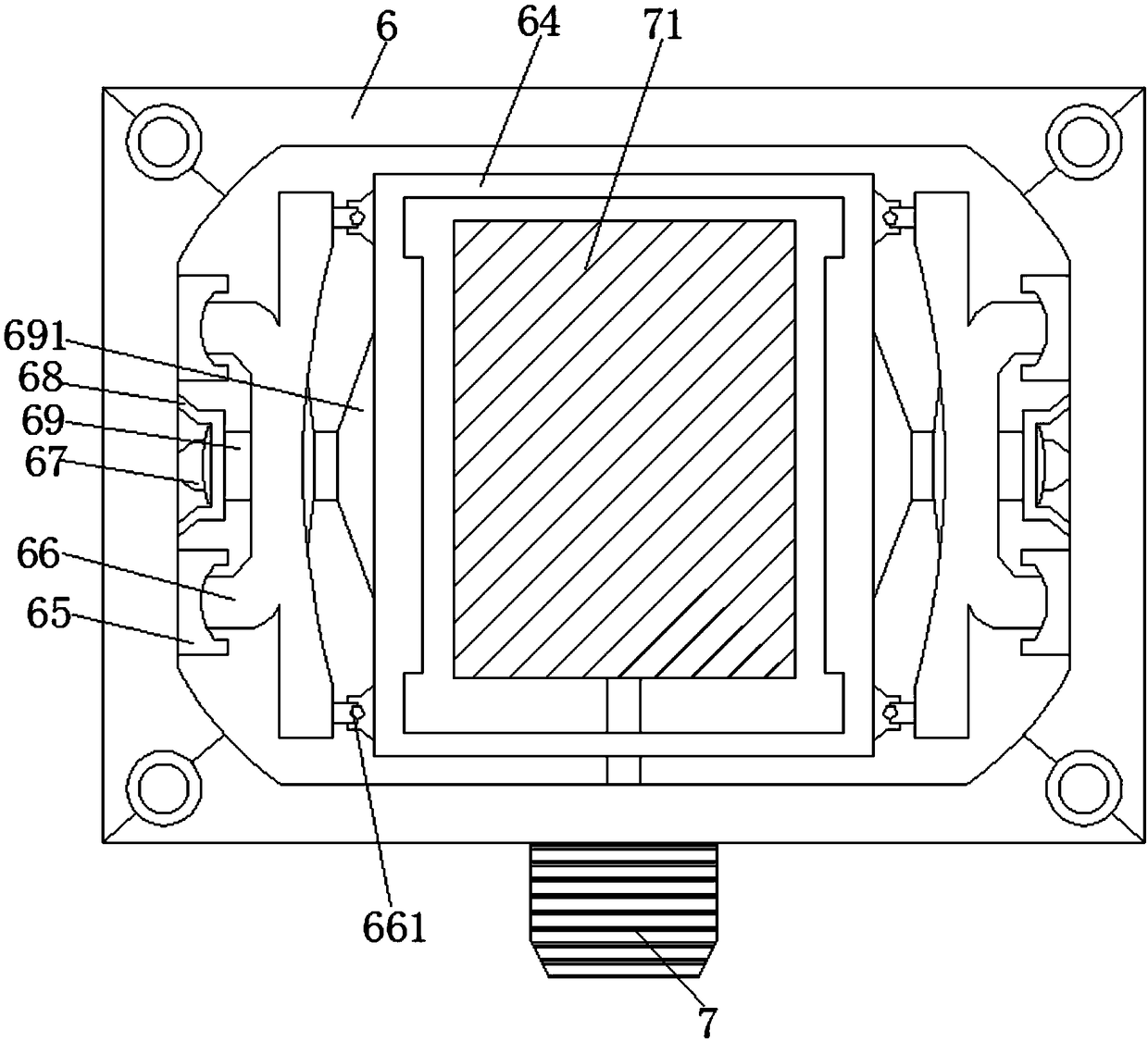

Glue pouring and packaging equipment for lamp production and technological method thereof

PendingCN112354784AFast drying operationImprove work efficiencyPretreated surfacesCoatingsFixed frameEngineering

The invention belongs to the related technical field of lamp production, and particularly relates to glue pouring and packaging equipment for lamp production and a technological method thereof. The glue pouring and packaging equipment for lamp production comprises a bottom box, an electric appliance box is in threaded connection with the inner side of the bottom box, a heating mechanism is installed on the inner side wall of the bottom box, a heat dissipation mechanism is installed below the inner side of the bottom box, and electric telescopic rods are welded to the upper portion of the outerside of the bottom box; sliding blocks are arranged on the inner side of a sliding groove; a fixing frame is in threaded connection with the upper portion of the outer side of the bottom box, and a lighting mechanism is arranged above the inner side of the fixing frame; electric lifting rods are welded to the upper portion of the inner side of the fixing frame, and a glue pouring mechanism is installed on the outer sides of the electric lifting rods; and a sliding groove is formed in the upper portion of the inner side wall of the bottom box, and a sealing plate is arranged on the inner sideof the sliding groove. According to the glue pouring and packaging equipment for lamp production, the heating mechanism is arranged, the heating and drying effects can be provided for the device through the heating mechanism, lamp materials can be conveniently and rapidly dried after glue pouring machining is conducted on the device, and the working efficiency of the device is effectively improved.

Owner:KUNSHAN ENDO LIGHTING

Cooling treatment equipment for machining

InactiveCN109114854AAvoid shakingEasy to processDomestic cooling apparatusLighting and heating apparatusEngineeringSlide plate

The invention discloses cooling treatment equipment for machining. The cooling treatment equipment comprises a housing, wherein a cooling box is fixedly connected to the interior of the housing, firstsliding rails are fixedly connected to the front and back sides of the cooling box, sliding plates are connected to the outer surfaces of the two first sliding rails in a sliding mode, support platesare fixedly connected to the opposite sides of the two sliding plates, clamping plates are fixedly connected to one side, which is far from the sliding plates, of the support plates, and buffer plates are fixedly connected to one side of the clamping plates. The cooling treatment equipment relates to the technical field of machinery. According to the processing device for machinery, heat generated by processing can be absorbed by utilizing the cooling box when the processing device is used for processing, so that the processing effect cannot be influenced by the overhigh processing environment; additionally, the sliding plates can be driven to move on the first sliding rails by utilizing the matching between a wrapping post and a pull rope, so that the clamping plates are driven to clampa to-be-processed mechanical tool, the mechanical tool is convenient to process by the processing device, the to-be-processed mechanical tool is prevented from deflecting, and the processing is accurate.

Owner:熊飞燕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com